Page 1

Pipe Thawing

Units

OPERATOR’S

MANUAL

• Castellano – pág. 11

KT-190

KT-200

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of this

manual may result in electrical shock, fire and/or serious

personal injury.

Page 2

Table of Contents

Recording Form for Machine Serial Number ..............................................................................................................1

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Tool Safety..................................................................................................................................................................3

Description and Specifications

Description ..................................................................................................................................................................3

Specifications..............................................................................................................................................................3

Standard Equipment....................................................................................................................................................4

Accessories.................................................................................................................................................................4

Cables and Clamps.....................................................................................................................................................4

Problem Diagnostics

Main Service Lines......................................................................................................................................................4

Tap Water Lines..........................................................................................................................................................4

Tool Assembly...............................................................................................................................................................5

Tool Inspection..............................................................................................................................................................5

Tool Set-Up ....................................................................................................................................................................5

Operating Instructions

Thawing Tap Water Lines ...........................................................................................................................................6

Tool Removal..............................................................................................................................................................7

Thawing Frozen Hydronic Systems.............................................................................................................................7

Single Zone System..................................................................................................................................................7

Multi-Zone System ....................................................................................................................................................8

Isolating Multi-Zone Systems....................................................................................................................................8

Special Applications Procedure

Increasing Thawing Capacity on KT-200 Only............................................................................................................8

Series Operation .....................................................................................................................................................8

Parallel Operation....................................................................................................................................................9

Maintenance Instructions .............................................................................................................................................9

Tool Storage...................................................................................................................................................................9

Service and Repair ........................................................................................................................................................9

Electrical Schematics..................................................................................................................................................10

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

Model KT-190 and KT-200 Pipe Thawing Units

Page 3

KT-190 and KT-200 Pipe Thawing Units

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

KT-190 and KT-200

Pipe Thawing Units

Page 4

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate these tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Electrical switches may create

sparks which may ignite dust or fumes.

• Keep bystanders, children, and visitors away while

operating a Pipe Thawing Unit. Distractions can

cause you to lose control.

Electrical Safety

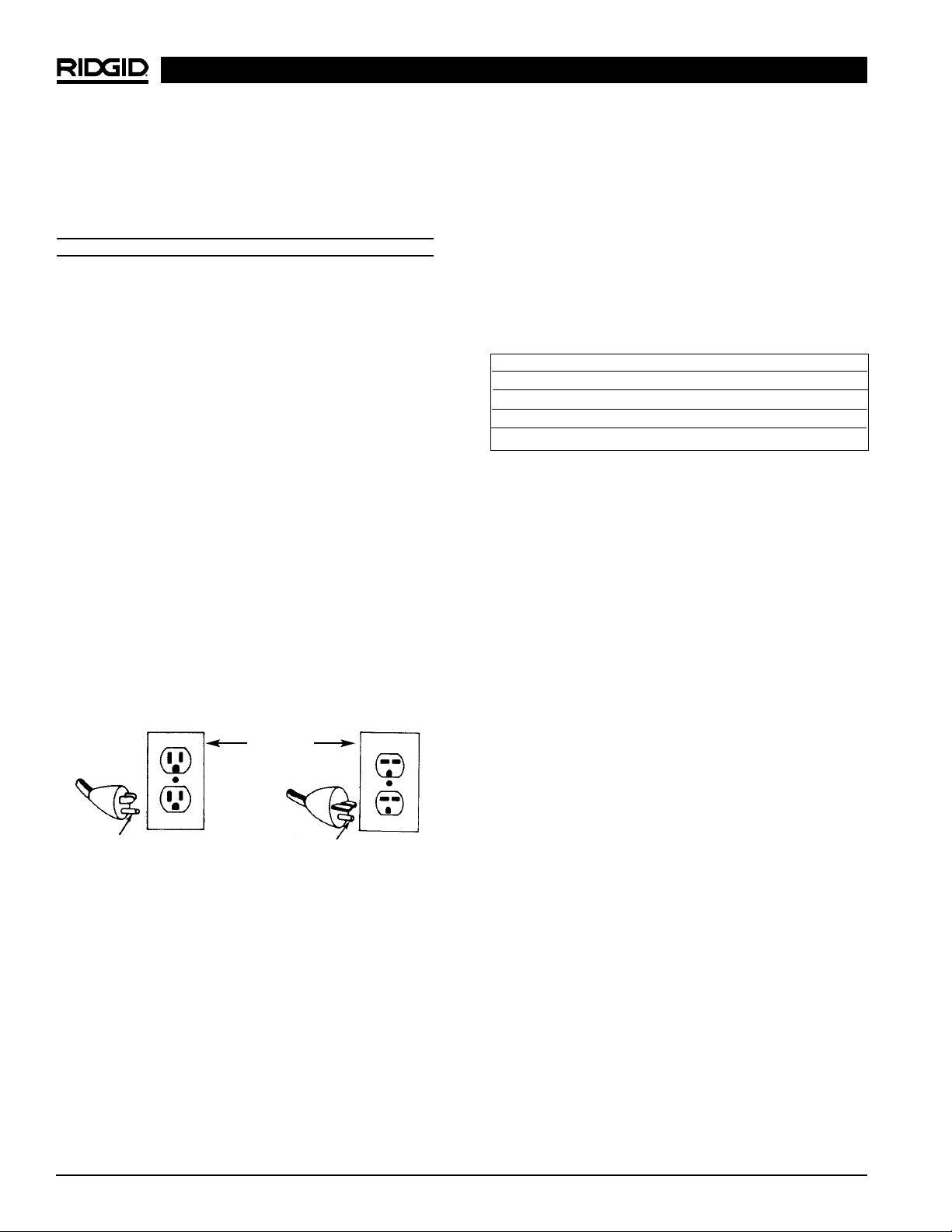

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the tool should electrically

malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering an electrical tool will increase the

risk of electrical shock.

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges, or moving parts.

Replace damaged cords immediately. Damaged cords

increase the risk of electrical shock.

• When operating an electrical tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce

the risk of electrical shock.

• Use only three-wire extension cords which have

three-prong grounding plugs, and three-pole receptacles which accept the tools plug. Use of other

extension cords will not ground the tool and increases

the risk of electrical shock.

• Use proper extension cords. (See chart.) Insufficient

conductor size will cause excessive voltage drop, loss

of power, and overheating.

• Keep all electric connections dry and off the

ground. Do not touch plugs or tool with wet hands.

Reduces the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a tool. Do not use tool

while tired or under the influence of drugs, alcohol

or medications. A moment of inattention while oper-

ating tools may result in serious personal injury.

• Avoid accidental starting. Be sure switch is OFF

before plugging in. Plugging in machines that have

the switch ON invites accidents.

• Do not over-reach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Properly maintained tools

are less likely to cause injury.

• Check for breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

Grounding prong

Cover of

grounded

outlet box

Grounding prong

Minimum Wire Gauge for Cord Set

Total Length (in feet)

0 – 25 14 AWG

26 – 50 12 AWG

Over 50 ft.

NOT RECOMMENDED

Page 5

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company 3

• Use only accessories that are recommended by the

manufacturer for your tool. Accessories that may be

suitable for one tool may become hazardous when

used on another tool.

• Inspect tool and extension cords periodically and

replace if damaged. Damaged cords increase the risk

of electrical shock.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

• Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the unit. These preventative safety measures

reduce the risk of accidentally starting the unit.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

• Disconnect all power from the unit before servicing. Eliminates the risk of electrical shock and

accidental starting.

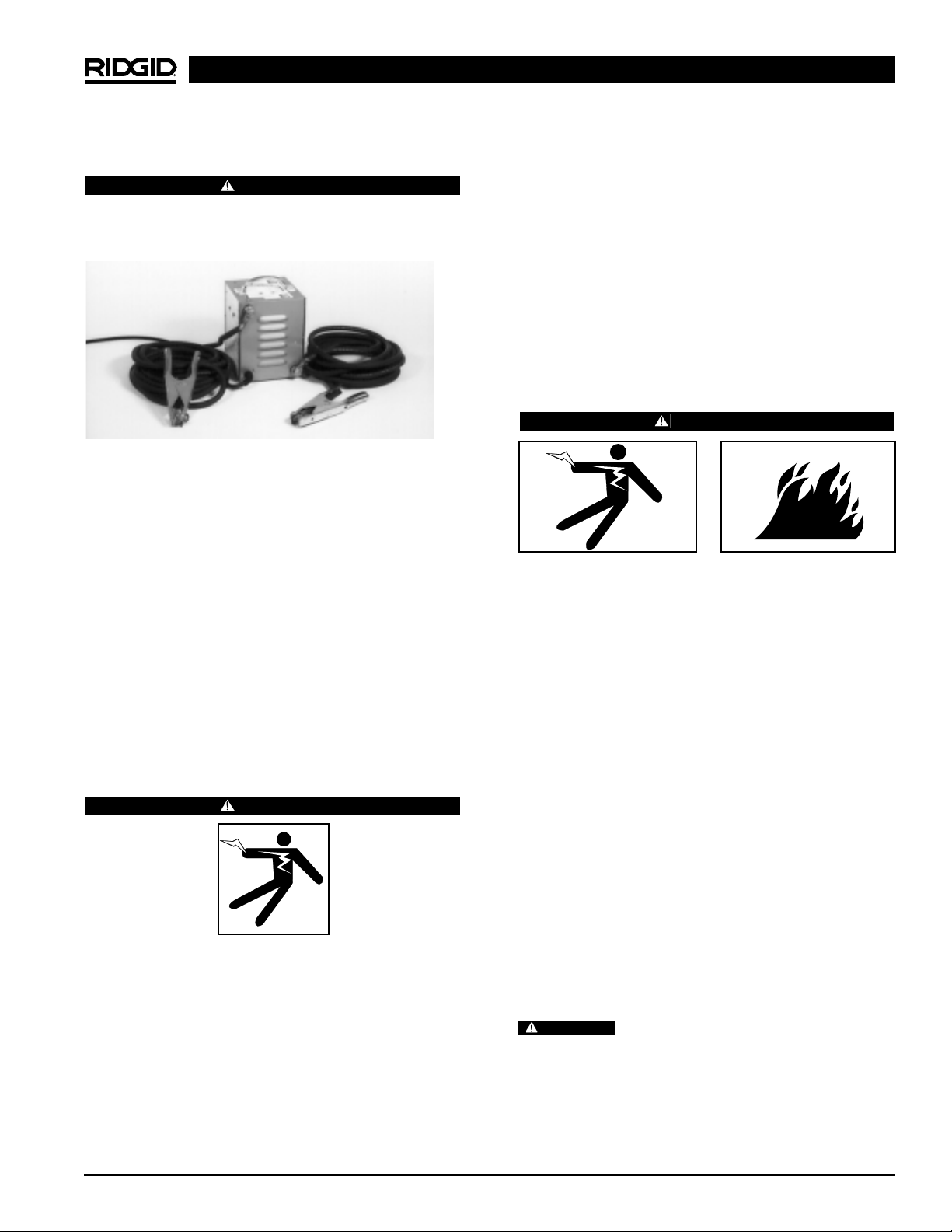

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the Pipe Thawing Tools. Failure to understand and

follow the contents of this manual may result in

electrical shock, fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service Department at (800) 519-3456 if you have any questions.

Tool Safety

• Tool is made to thaw frozen iron or copper water

pipes. Follow the instructions on proper use. Other

uses may increase the risk of injury.

• Do not leave the unit unattended while thawing.

Such preventive measures reduce the risk of injury or

fire.

• Do not touch the clamp tips or cable connections.

Reduces the risk of burns.

• Do not operate unit with housing removed.

Exposure to internal parts may result in injury.

• Make both pipe connections before plugging in

unit. Prevents electrical arcing between the clamps and

the pipe.

• Use cable and clamps provided with unit. Incorrect

cables may result in overheating of the wires.

• Keep clamps away from combustible materials or

articles that can be damaged by heat. Clamp tips be-

come hot during use.

Description and Specifications:

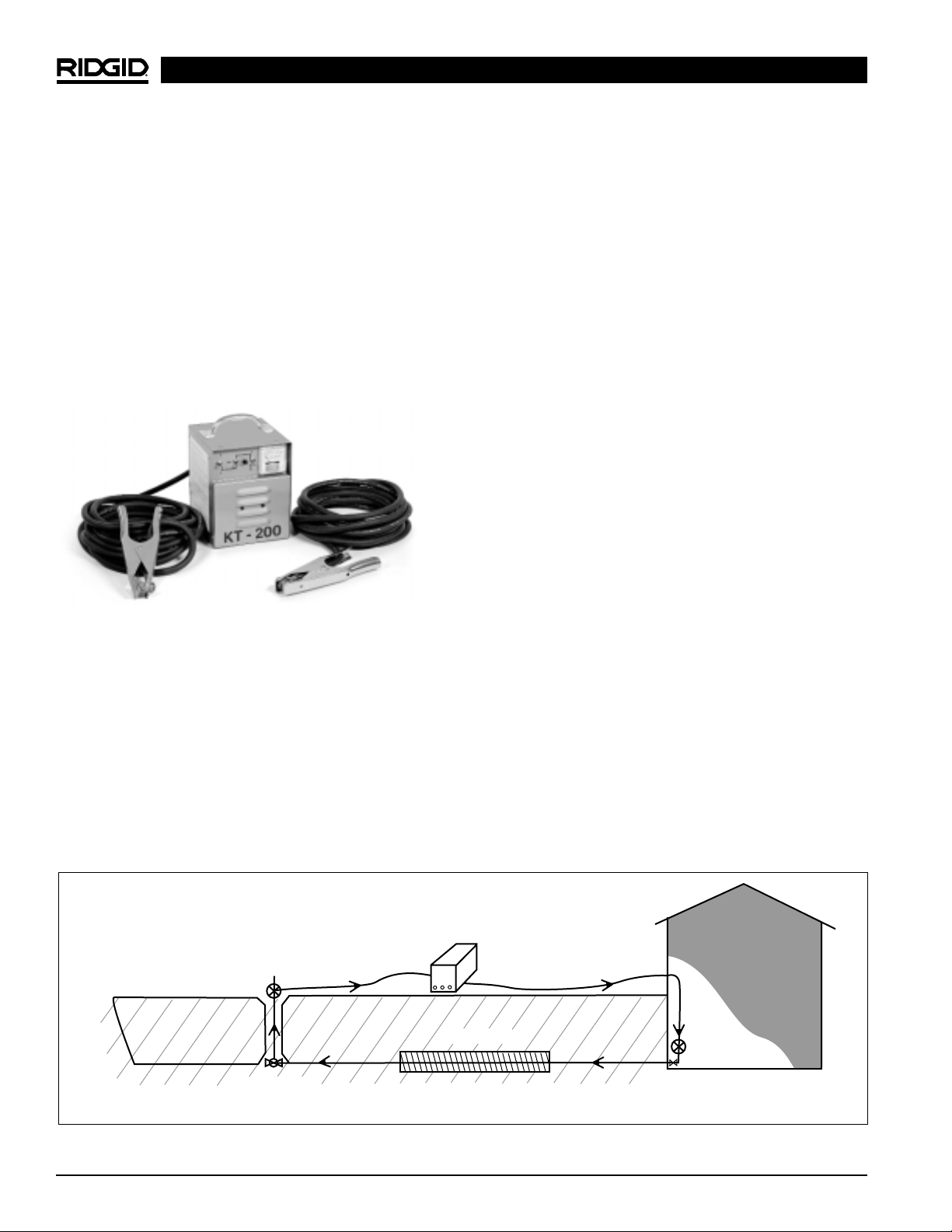

Description

The RIDGID Pipe Thawing Machines are easy-to-use,

and versatile for thawing 1/2″ to 11/2″ copper or steel/iron

pipe up to 150 feet (KT-200). Both the KT-190 and KT-200

use low voltage and high amperage to quickly thaw frozen

tap water lines and frozen heating systems.

This method does not require that you know exactly

where the frozen section is nor do you have to have direct

access to the area. The KT-190 and KT-200 will thaw copper or steel pipe that is underground, beneath the floor or

behind walls. Multiple voltage settings on the KT-200

allow for maximum amperage to provide the shortest

thawing time. Vinyl coated clamps with 25 foot cables,

standard with both units, permit thawing of a 50′ section of

pipe. Additional 25′ cable extensions are available for

longer runs.

Specifications

Line Capacity:

Primarily recommended for all indoor copper or steel

pipes from 1/2″ to 11/2″. Thawing units will not work with

plastic pipe or lines containing plastic or rubber couplings.

Thawing Unit:

Input ..............................115 Volts, 15 Amps

KT-190 KT-200

Output............................6.0 Volts 4.5 - 7.6 Volts

Output............................300 Amps 300 Amps

Minimum Reach ............15′ 4′

Maximum Reach ..........75′ 150′

Weight ..........................25 lbs 29 lbs

Weight ..........................11.4 kgs 13.2 kgs

Page 6

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company4

Problem Diagnostics

Main Service Lines

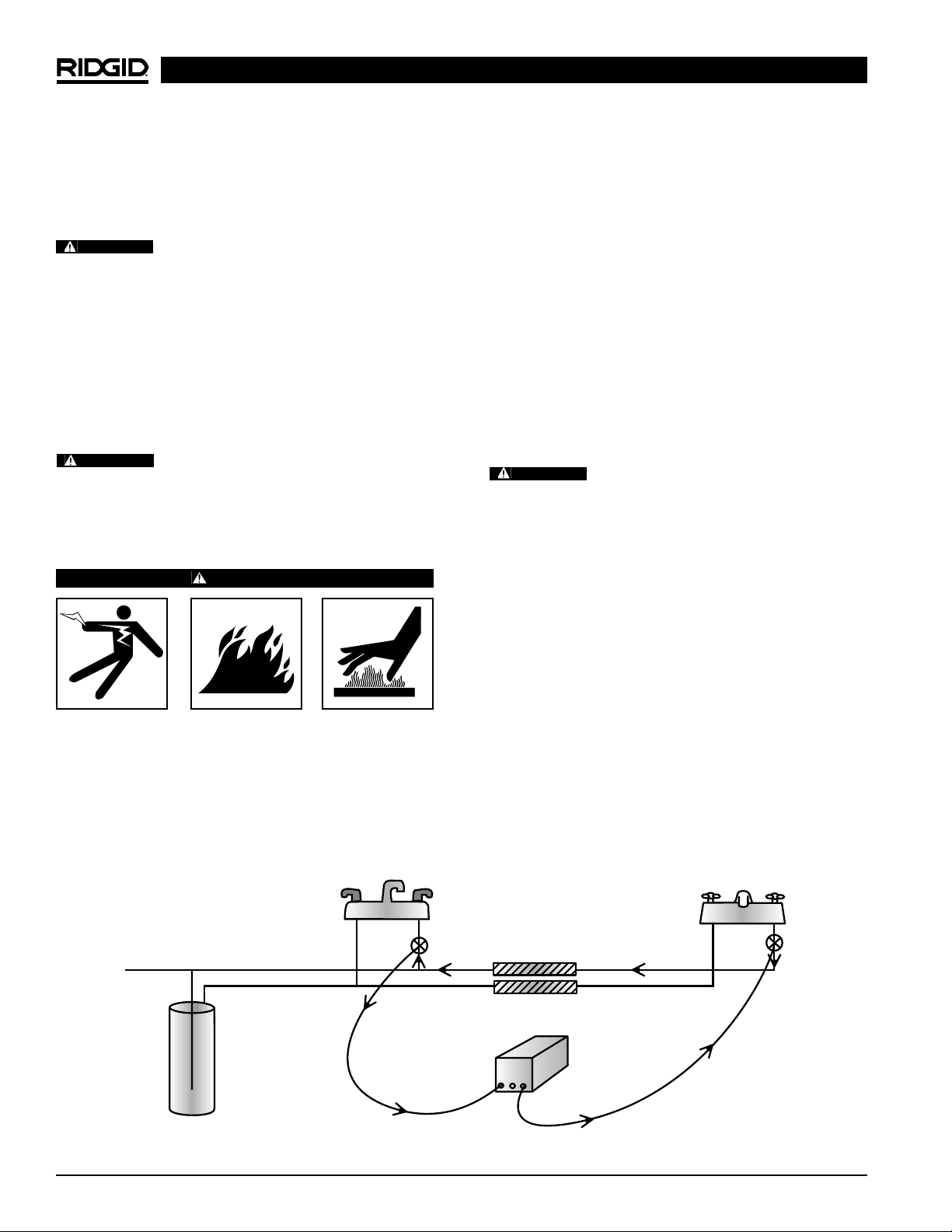

If there is no running water anywhere in the house, the

main service from the curb valve to the house is frozen.

The service can be thawed by placing one clamp on a tap

water line in the basement and the other on the curb key

attached to the curb valve. Make sure there is contact between the curb key and valve. Extension Cables are

required if runs exceed 50 feet. Additional thawing units

may be required to reduce thawing time. Refer to Special

Application Procedure for Series Set-Up.

Tap Water Lines

Locate the frozen line by opening faucets and checking for

water flow. The frozen section will normally be in an outside wall or in a crawl space with poor insulation. If one

faucet does not have running water and the next faucet

does, frozen section is between faucets. Place clamps on

either hot or cold water lines, not on faucets.

Refer to Thawing Tap Water Lines for procedure.

Standard Equipment

Qty. Item

1........Thawing Unit, Model KT-190 or KT-200. 115

volts, 15 Amps.

2........Cables, 25 feet in length, with a vinyl coated

spring clamp on one end and a mounting loop

on the other.

Accessories

• Extension Cable, 25 feet, # 1/0 AWG c/w nut & bolt.

Catalog No. 62772

• Series Cable, 3 feet, # 1/0 AWG Catalog No. 62812

Figure 1 – KT-200 Pipe Thawing Tool

Cables and Clamps

25 feet in length with vinyl coated clamp.

KT-190 KT-200

Size ....................#2 AWG #1/0 AWG

Weight ................19 lbs/Pair 23 lbs/Pair

(8.6 kgs) (10.5 kgs)

Pipe Thawer

Frozen Section

Earth

Street Valve

Curb Shut

Off Rod

Figure 2 – Thawing Main Service Lines

Page 7

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company 5

Tool Assembly

WARNING

To prevent serious injury, proper assembly of the

Thawing Tool is required. The following procedures should be followed:

Figure 3 – Thawing Tool with Cables Installed

Installing Cables with Clamps

1. Remove retaining nut from one of the lugs on back of

unit.

2. Slip looped end of cable onto lug bolt with flat side towards unit.

3. Reinstall lug nut and secure tightly.

4. Ensure looped end of cable does not contact housing.

5. Repeat steps 1 and 2 for remaining lug.

NOTE! If cable leads are not securely fastened to thaw-

ing unit, thawing time may be extended and/or

unit may not function properly.

Tool Inspection

WARNING

To prevent serious injury, inspect your Pipe

Thawing Tool. The following procedures should

be followed.

1. Make sure Pipe Thawing Tool is unplugged and the

control switches are in the OFF position.

2. Inspect the power cord and plug for damage. If the

plug has been modified, is missing the grounding

prong or if the cord is damaged, do not use the

Thawing Tool until the cord has been replaced.

3. Inspect the cables and clamps for damage. Be sure

cable leads are securely fastened to thawing unit. If

cable or clamps are damaged, do not use the

Thawing Tool until they are replaced. Only use cable

and clamps provided with the unit.

4. Clean any oil, grease or dirt from handles, controls

and clamps.

5. Inspect the Thawing Tool for any broken or missing

parts as well as damage to the metal enclosure. If any

of these conditions are present, do not use the Thawing Tool until any problem has been repaired.

Tool Set-Up

WARNING

To prevent serious injury, proper set-up of the tool

and work area is required. The following procedures should be followed to set-up the Pipe Thawing

Tool.

1. Check work area for:

• Adequate lighting

• 15 Amp grounded electrical outlet

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for tool and operator. Do not use the

tool while standing in water.

• Flammable liquids, vapors or dust that may ignite.

2. Position KT-190 or KT-200 Pipe Thawer near the

area suspected of having a frozen section of pipe.

3. Make sure unit is unplugged and turned OFF. (Switch

on KT-190 is in the down (OFF) position. Center

switch on KT-200 is in the middle (OFF) position).

4. Uncoil both cables completely and insure they are not

overlapping or in contact.

5. Follow instructions on proper placement of clamps.

Making pipe connections before plug-

ging in unit prevents arcing between clamp and pipe.

NOTE! Whenever making connections, clean pipe of

paint, scale rust, etc. to ensure good amperage

flow from the clamps to the pipe. Poor connections will cause the clamps to get much hotter

than normal.

WARNING

Page 8

Ridge Tool Company6

6. When plugging the Pipe Thawing Tool into the electrical outlet, making sure to position the power cord

along the clear path selected earlier. If the power

cord does not reach the outlet, use an extension cord

in good condition.

To avoid electric shock and electrical

fires, never use an extension cord that is damaged or

does not meet the following requirements:

• The cord has a three-prong plug similar to shown in

Electrical Safety section.

• The cord is rated as “W” or “W-A” if being used out-

doors.

• The cord has sufficient wire thickness (14 AWG below

25′/12 AWG 25′ - 50′). If the wire thickness is too small,

the cord may overheat, melting the cord’s insulation

or causing nearby objects to ignite.

To reduce risk of electrical shock, keep all

electrical connections dry and off the ground. Do not

touch plug with wet hands.

Operating Instructions

WARNING

To reduce risk of electrical shock, keep all electrical connections dry and off the ground. Do not

touch plug with wet hands.

Be very careful when thawing frozen pipes. Clamp

tips and cable connections become hot during use.

Avoid contact with skin as burns can result.

Keep clamps away from combustible materials or

articles that can be damaged by heat.

Do not leave the unit unattended while thawing.

Thawing Tap Water Lines

NOTE! It is recommended that there be standard water

pressure on one side of the frozen section of

pipe and an open faucet on the other side of the

frozen section (Figure 4). As the pipe warms to

above freezing point, the water, with pressure

behind it, will seep along the inside walls melting

and flushing the remaining ice out of the faucet.

1. Make sure unit is unplugged and turned OFF and

cables are completely uncoiled.

2. Place one clamp on each side of the frozen section of

pipe. Open the faucet where no water flows.

Making pipe connections before plug-

ging in unit prevents arcing between clamps and pipe.

3. Plug unit into a grounded 15 amp outlet making sure

to position the power cord along the clear path selected earlier.

4. Move switch to ON (up position on KT-190. Center

switch down to low position, left switch to A on KT-200).

5. If current is below 15 amps on KT-200, switch to B. If

current is still below 15 amps, switch to high position

on center switch and right switch up to C.

6. Continue until 15 amps is reached but not exceeded,

D switch setting is used with long runs.

Thawing time may vary from a few seconds to several

hours depending on length and diameter of pipe being

thawed. If time seems unreasonable, check clamps for

proper placement.

Model KT-190 and KT-200 Pipe Thawing Units

Figure 4 – Thawing Tap Water Lines

Kitchen Sink

Bathroom Sink

Frozen Section

WARNING

WARNING

WARNING

Page 9

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company 7

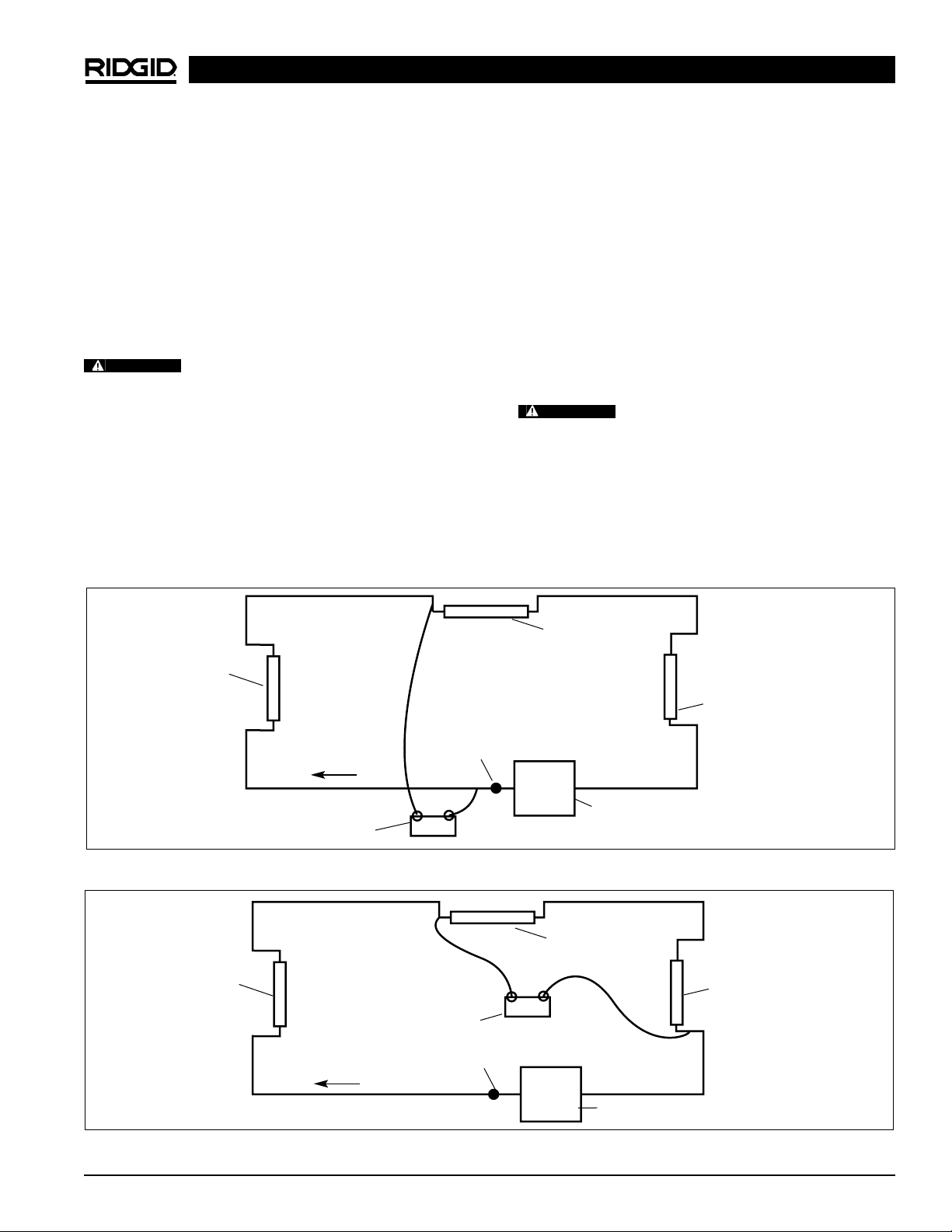

NOTE! The electrical output current of both the KT-190

and KT-200 can take two paths. The shortest

distance between the clamps, or the long path

around the pipe loop. Therefore, in some systems it is required to break the pipe to eliminate

the short path (Figure 7).

Single Zone System

1. Circulating pump must be operating.

2. Make sure unit is unplugged and OFF and cables

are completely uncoiled.

3. Place one clamp near the furnace and the second

clamp next to a radiator.

Making pipe connections before plug-

ging in unit prevents arcing between clamps and pipe.

4. Plug unit into a grounded 15 amp outlet, making

sure to position the power cord along the clear path

selected earlier.

5. Position switch to ON. (Up position on KT-190. Center

switch down to low and left switch to lower A position

on KT-200).

NOTE! This tool is equipped with a thermal overload for

added safety. If thawing for long periods of time at

maximum current, the unit may shut down automatically. Unit will resume operations automatically after approximately 3 minutes.

Tool Removal

1. When water lines have thawed, turn switch to the

OFF position and unplug power cord from the electrical outlet.

2. Remove clamps from the pipe.

Clamp tips are hot and can cause burns.

3. Allow clamps to cool before coiling cables and placing

the unit in storage. While the clamps are hot, keep

them away from combustible materials or articles

that can be damaged by heat.

Thawing Frozen Hydronic Systems

NOTE! Hydronic systems are harder to thaw due to the

lower pressure produced by the circulating pump

and the greater lengths of pipe required in a single or multi-zone system.

Figure 5 – Single Zone System

Figure 6 – Single Zone System

Pipe Thawer

Radiator

Radiator

Furnace

Circulating

Pump

Water

Flow

Radiator

Pipe Thawer

Radiator

Radiator

Furnace

Circulating

Pump

Water

Flow

Radiator

WARNING

WARNING

Page 10

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company8

6. If current is below 15 amps on KT-200, switch to B. If

current is still below 15 amps, switch to high position

on center switch and right switch up to C.

7. Continue until 15 amps is reached but not exceeded;

D switch setting is used with long runs.

Multi-Zone System

If you are dealing with multi-zones it will be necessary to

break the electric current flow to specific zones.

1. Make sure unit is unplugged and switch is in the OFF

position and cables are completely uncoiled.

2. Place the pipe clamps several feet apart.

Making pipe connections before plug-

ging in unit prevents arcing between clamp and pipe.

3. Maintain a minimum of 15 feet between clamps when

using the KT-190, 4 feet for KT-200, to prevent excessive amp draw.

4. Plug unit into a grounded 15 amp outlet making sure

to position the power cord along the clear path selected earlier.

5. Move switch to ON (Up position on KT-190. Center

switch to low and left switch down to A on KT-200.) If

current draw is below 15 amps, select switch B, C, or

D to maximize amp draw and reduce thaw time. (Do

not exceed 15 amps)

NOTE! If the heat is not restored to piping in 10 minutes,

change the location of the clamps to heat a different section of the system. If the above steps

have been tried without success, the entire zone

is frozen and will need to be thawed by following

the Isolating Multi-Zone Steps.

Isolating Multi-Zone Systems

1. Break and cap pipe at point B. This prevents current flow through the second zone and allows for

100% of the current to be used in Zone #1. Do not let

pipe ends contact one another.

2. Break the pipe at Point A and place pipe clamps as

shown in Figure 7. This forces the current to flow

through Zone #1. Use a container to collect the water.

3. Once Zone #1 is thawed, turn the unit and circulating

pump OFF. If Zone #2 is frozen, cap the pipe at Point

A Remove the cap from Point B and place a container

at Point B to collect the water.

4. Place the clamps of the opposites sides of the break

at Point B. Once Zone #2 is thawed, turn circulating

pump and thawing unit OFF.

5. Reconnect all pipes and check both Zone #1 and #2

for heat.

Special Applications Procedure

Increasing Thawing Capacity on KT-200

Only

Failure to follow the procedures below for

parallel and series operation of the thawing units can result in electrical shock or damage to the equipment.

Series Operation

Units arranged in series work best for long pipe lengths.

1. Position units near the frozen section of pipe and next

to one another such that cable lugs are toward pipe.

2. Make sure the units are unplugged and center switch

is in the OFF position.

Figure 7 – Multi Zoned System

Pipe Thawer

Radiator

Radiator

Furnace

Circulating Pump

Water

flow

Radiator

Zone #2

Zone #1

Radiator

B Break

Break

A

WARNING

WARNING

Page 11

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company 9

3. Connect one end of the pigtail (Ridge Catalog #62812)

on the right lug of the left unit, and the other end on the

left lug of the right unit.

4. Attach pipe thawing leads to remaining lugs.

5. Place one clamp on either side of the frozen section of

pipe.

Making pipe connections before plug-

ging in unit prevents arcing between clamps and pipe.

6. Plug the units into outlets that are NOT on the same

circuit. (Protected by separate fuses).

Both thawing units must be plugged into

electrical outlets before switching unit ON. Failure to

follow the procedure can result in electrical shock.

7. With two units connected in series, seven power settings are available with the KT-200 by using the

switches on both units. The combinations are AA,

AB, BB, BC, CC, CD, DD.

NOTE! A circuit will not be completed until the switch of

both units is in the ON position.

Figure 8 – Series Set-Up

Parallel Operation

Units arranged in parallel work best for larger pipes diameters.

Figure 9 – Parallel Set-Up

1. Position units near frozen section of pipe.

2. Make sure units are unplugged and switches are in

the OFF position and cables are completely uncoiled.

3. Attach cables and clamps to lugs.

4. Place clamps on either side of the frozen section of

pipe.

Making pipe connections before plug-

ging in unit prevents arcing between clamp and pipe.

5. Plug units into outlets that are NOT on the same circuit. (protected by different fuses).

Both thawing units must be plugged into

electrical outlets before switching unit ON. Failure to follow the procedure can result in electrical shock.

6. The power settings available are AA, BB, CC, and DD

with the KT-200.

NOTE! With both units on the same setting both KT-200

amp. meters should read approximately the

same. If this does not occur, turn both units OFF

and exchange the cables on one unit. The correct

polarity is achieved by the cable hook-up that produces the lowest amp. meter reading.

IMPORTANT: Failure to follow above set-up will result

in most current flowing through the adjacent clamps and not the pipe.

Maintenance Instructions

WARNING

Make sure unit is unplugged from power source before performing maintenance or repairs.

Tool Maintenance

1. Replace damaged, frayed, broken or worn cables.

2. Periodically clean lugs with steel wool and emery

cloth.

3. Replace damaged, frayed, broken or worn cords.

4. Keep clamps dry and clean.

Tool Storage

Electrical equipment must be kept indoors

or well covered in rainy weather. Store the tool in a locked

area that is out of reach of children and people unfamiliar

with Pipe Thawing tools. This tool can cause serious injury

in the hands of untrained users.

Unit #1

Frozen Section

Frozen Section

Unit

#1

Unit #2

Unit

#2

WARNING

WARNING

WARNING

WARNING

WARNING

Page 12

Model KT-190 and KT-200 Pipe Thawing Units

Ridge Tool Company10

Electrical Schematics

KT-190 Thawer

115V/60Hz

OUTPUT

TERMINALS

KT-200 Thawer

115V/60Hz

OUTPUT

TERMINALS

Service and Repair

WARNING

Service and repair work on this tool must be performed by

qualified repair personnel. Thawing unit should be taken

to a RIDGID Independent Authorized Service Center or returned to the factory. All repairs made by Ridge service

facilities are warranted against defects in material and

workmanship.

When servicing this tool, only identical replacement parts

should be used. Failure to follow these instructions may

create a risk of electrical shock or other serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Company at (800) 519-3456 or http://www.ridgid.com

Page 13

Descongeladoras de tuberías

KT-190 y KT-200

Limpiadoras de desagües K-60SP

A continuación apunte y retenga el número de serie de la máquina, que se encuentra en

su placa de características.

No. de

serie

Page 14

Índice

Ficha para apuntar el Modelo y Número de Serie de la máquina ...........................................................................11

Información general de seguridad

Seguridad en la zona de trabajo ...............................................................................................................................13

Seguridad eléctrica....................................................................................................................................................13

Seguridad personal...................................................................................................................................................13

Uso y cuidado de la máquina....................................................................................................................................14

Servicio......................................................................................................................................................................14

Información específica de seguridad

Seguridad de la Descongeladora de tuberías...........................................................................................................14

Descripción y especificaciones

Descripción................................................................................................................................................................15

Especificaciones........................................................................................................................................................15

Equipo estándar........................................................................................................................................................15

Accesorios.................................................................................................................................................................15

Cables y pinzas.........................................................................................................................................................15

Diagnóstico de problemas

En tuberías principales de servicio público...............................................................................................................15

En tuberías domiciliarias de agua potable ................................................................................................................16

Ensamblaje de la máquina..........................................................................................................................................16

Inspección de la máquina...........................................................................................................................................17

Preparación de la máquina.........................................................................................................................................17

Instrucciones de funcionamiento

Descongelación de tuberías domiciliarias de agua potable......................................................................................18

Extracción de la Descongeladora..............................................................................................................................19

Descongelación de redes hidrónicas congeladas.....................................................................................................19

Red de zona única ..................................................................................................................................................19

Red multizona .........................................................................................................................................................20

Cómo aislar una red multizonal...............................................................................................................................20

Procedimientos para métodos especiales

Aumento de la capacidad de descongelación de la KT-200 solamente....................................................................21

Funcionamiento en serie.......................................................................................................................................21

Funcionamiento en paralelo..................................................................................................................................21

Instrucciones de mantenimiento ...............................................................................................................................22

Almacenamiento de la máquina.................................................................................................................................22

Mantenimiento y reparaciones...................................................................................................................................22

Esquemas eléctricos...................................................................................................................................................23

Garantía vitalicia..................................................................................................................................carátula posterior

Ridge Tool Company12

Descongeladoras de tuberías KT-190 y KT-200

Page 15

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company 13

Información general de seguridad

¡

ADVERTENCIA! Lea y comprenda todas las instrucciones.

Pueden ocurrir golpes eléctricos, incendios y/o lesiones corporales graves si

no se siguen todas las instrucciones detalladas a continuación.

¡

GUARDE ESTAS INSTRUCCIONES!

Seguridad en la zona de trabajo

• Mantenga su área de trabajo limpia y bien alumbrada. Los bancos de trabajo desordenados y las

zonas oscuras provocan accidentes.

• No haga funcionar estos aparatos eléctricos en

ambientes explosivos, como por ejemplo, en la

presencia de líquidos, gases o polvos inflamables.

Estos aparatos generan chispas que pueden encender

el polvo o los gases.

• Al hacer funcionar una Descongeladora de tuberías, mantenga apartados a los espectadores,

niños y visitantes. Las distracciones pueden hac-

erlo perder el control del aparato.

Seguridad eléctrica

• Las máquinas provistas de conexión a tierra deben

ser enchufadas a un tomacorriente debidamente

instalado y conectado a tierra de acuerdo con

todos los códigos y reglamentos. Jamás extraiga

del enchufe del aparato la tercera clavija que conduce a tierra ni lo modifique de manera alguna. No

use ningún tipo de enchufe adaptador. Consulte

con un electricista calificado si no puede determinar acaso el tomacorriente está debidamente

conectado a tierra. En la eventualidad de que el

aparato sufra una avería eléctrica o de otro tipo, la

conexión a tierra proporciona una vía de baja resistencia para conducir la electricidad lejos del operario.

• Evite que su cuerpo haga contacto con superficies

conectadas a tierra tales como radiadores, tuberías, cocinas o refrigeradores. Si su cuerpo queda

conectado a tierra, aumenta el riesgo de que sufra un

choque eléctrico.

• No exponga las máquinas eléctricas a la lluvia o a

condiciones mojadas. Si agua penetra en una

máquina eléctrica, aumenta el riesgo de que se produzca un choque eléctrico.

• No maltrate el cordón. Nunca use el cordón para

sacar el enchufe del tomacorriente. Mantenga el

cordón lejos de fuentes de calor, aceite, bordes

cortantes o piezas movibles. Recambie los cor-

dones dañados de inmediato. Los cordones en mal

estado aumentan los riesgos de que se produzca un

choque eléctrico.

• Al hacer funcionar un aparato eléctrico a la in-

temperie, emplee un cordón de extensión fabricado

para uso exterior y rotulado “W-A” o “W”. Estos

cordones han sido diseñados para su empleo al aire

libre y reducen el riesgo de que se produzca un choque

eléctrico.

• Sólo use un cordón de extensión de tres alambres

equipado con un enchufe de tres clavijas para

conexión a tierra, y un tomacorriente tripolar que

acoja a las tres clavijas del enchufe del aparato.

Otros alargadores no conectarán el aparato a tierra y

aumentarán el riesgo de que se produzca un choque

eléctrico.

• Use cordones de extensión apropiados. (Vea la

tabla). Una dimensión insuficiente del conductor

causará una caída excesiva del voltaje, pérdida de po-

tencia y el recalentamiento del aparato.

• Mantenga todas las conexiones eléctricas secas y

levantadas del suelo. No toque el aparato o el

enchufe con las manos mojadas. De esta manera se

evita un choque eléctrico.

Seguridad personal

• Manténgase alerta, preste atención a lo que está

haciendo y use sentido común cuando trabaje

con un aparato a motor. No la use si está cansado

o se encuentra bajo la influencia de drogas, alcohol

o medicamentos. Sólo un breve descuido mientras

hace funcionar una máquina motorizada puede resultar en lesiones personales graves.

• Evite echar a andar el aparato sin querer. Antes de

enchufarlo, asegure que su interruptor se encuentre en la posición OFF (apagado). Se producen

accidentes cuando se enchufan aparatos que tienen su

interruptor en la posición de encendido (ON).

Dimensión mínima de alambre para cordones de extensión

Longitud total (en pies)

0 – 25 14 AWG

26 – 50 12 AWG

Sobre 50 pies

NO SE RECOMIENDA

Clavija para la

conexión a tierra

Tapa del

enchufe conectado

a tierra

Clavija para la

conexión a tierra

Page 16

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company14

• No trate de extender su cuerpo para alcanzar algo.

Mantenga sus pies firmes en tierra y un buen equilibrio en todo momento. Al mantener el equilibrio y los

pies firmes, tendrá mejor control sobre el aparato en

situaciones inesperadas.

• Use equipo de seguridad. Siempre lleve protección

para los ojos. Cuando las condiciones lo requieran,

debe usar mascarilla para el polvo, calzado de seguridad antideslizante, casco duro o protección para los

oídos.

Uso y cuidado de la máquina

• Si el interruptor de la máquina no la enciende o

apaga, no la use. Cualquier aparato que no pueda ser

controlado mediante su interruptor es peligroso y debe

ser reparado.

• Almacene las máquinas que no estén en uso fuera

del alcance de los niños y de otras personas sin

entrenamiento. Las máquinas son peligrosas en las

manos de usuarios no capacitados.

• Efectúele cuidadoso mantenimiento a su aparato.

Es menos probable que un aparato bien mantenido lo

lesione.

• Verifique si hay piezas quebradas y si existe cualquiera otra condición que pueda afectar el funcionamiento del aparato. En el caso de estar dañado,

antes de usar el aparato, hágalo componer. Nume-

rosos accidentes son causados por aparatos que no

han recibido un mantenimiento adecuado.

• Emplee únicamente los accesorios recomendados por el fabricante de su máquina. Los accesorios

que son los adecuados para una máquina pueden

ser peligrosos acoplados a otro aparato.

• Revise la máquina y los cordones de extensión

periódicamente. Cámbielos si están dañados. Los

cordones en mal estado aumentan el riesgo de que se

produzca un choque eléctrico.

• Mantenga los mangos limpios y secos, libres de

aceite y grasa. Esto permite un mejor control del

aparato.

• Desenchufe el aparato de todas sus fuentes de

suministro antes de hacerle cualquier ajuste, de

cambiarle accesorios o de almacenarlo. Esta me-

dida preventiva evita los choques eléctricos y la puesta

en marcha involuntaria del aparato.

Servicio

• El aparato sólo debe ser reparado por técnicos

de reparación calificados. El mantenimiento o repara-

ciones practicados por personal no calificado puede

ocasionar lesiones.

• Cuando se le hagan mantenimiento o reparaciones

al aparato, deben usarse únicamente repuestos o

piezas de recambio idénticas. Siga las instrucciones en la sección de Mantenimiento en este

manual. Pueden producirse choques eléctricos o le-

siones si no se emplean piezas y partes autorizadas o

si no se siguen las instrucciones de mantenimiento.

• Desconecte el aparato de toda fuente de suministro

antes de efectuarle mantenimiento. Así se evitan los

choques eléctricos y que el aparato se ponga en marcha sin querer.

Información específica

de seguridad

ADVERTENCIA

Lea este Manual del Operario detenidamente antes

de poner en funcionamiento una de estas Descongeladoras. Si no se siguen o no se comprenden las

instrucciones de este manual, es posible que ocurran choques eléctricos, incendios y/o lesiones

personales graves.

Si tiene cualquier pregunta, llame al Departamento de

Servicio Técnico de Ridge Tool Company al (800) 519-

3456.

Seguridad de la Descongeladora

de tuberías

• Esta unidad fue hecha para descongelar tuberías de

agua, fabricadas de hierro o cobre. Siga las instrucciones para emplearla correctamente. Se corre

el riesgo de sufrir lesiones si se le dan otros usos.

• No deje la unidad sin supervisión mientras está

descongelando. Este tipo de medida preventiva reduce

el riesgo de que se produzcan lesiones o incendios.

• No toque las puntas de las pinzas ni las conexiones del cable. Así reducirá el riesgo de que sufra

quemaduras.

• No haga funcionar la unidad sin su carcasa. Las

piezas internas del aparato que queden expuestas

pueden lesionarlo.

• Antes de enchufar la unidad monte ambas pinzas

sobre el tubo. Esto evita que se forme un arco eléc-

trico o voltaico entre el tubo y las pinzas.

• Use el cable y las pinzas que vienen con la máquina. El uso de cables incorrectos puede causar el

recalentamiento de los alambres.

Page 17

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company 15

Equipo Estándar

Cantidad Piezas

1 ..........Descongeladora modelo KT-190 ó KT-200,

115 voltios, 15 amperios

2 ..........Cable de 25 pies de largo que en uno de

sus extremos lleva una pinza a resorte recubierta en vinilo y, en el otro, un bucle de

montaje.

Accesorios

• Cable de extensión, 25 pies, N° 1/0 AWG, incluye

perno y tuerca. N° en el catálogo 62772.

• Cable en serie, 3 pies, N° 1/0 AWG, N° en el

catálogo 62812

Figura 1 – Descongeladora KT-200

Cables y pinzas

Cable de 25 pies de longitud con pinza recubierta en

vinilo.

KT-190 KT-200

Tamaño...............N° 2 AWG N° 1/0 AWG

Peso....................19 lbs/el par 23lbs/el par

(8,6 kgs) (10,5 kgs)

Diagnóstico de problemas

En tuberías principales del servicio

público

Si no sale agua por ningún grifo de la casa, se ha congelado la tubería principal del servicio público: entre la

válvula en la calle (acera) y la casa. Esta tubería puede

descongelarse colocando una pinza sobre un tubo de

agua potable en el sótano de la casa y la otra pinza

sobre la llave que se encuentra acoplada a la válvula

en la calle. Asegúrese de que la llave y la válvula en la

calle estén haciendo contacto. Si las longitudes exceden los 50 pies, se requerirán cables de extensión. Para

• Mantenga las pinzas apartadas de materiales com-

bustibles o de artículos que pueden dañarse con el

calor. Durante el uso, las puntas de las pinzas se

calientan.

Descripción y especificaciones

Descripción

Las máquinas descongeladoras de tuberías marca

RIDGID son versátiles y fáciles de usar para descongelar

tuberías de cobre o de hierro/acero de 1/2a 11/2pulgadas

de diámetro de hasta 150 pies de longitud (KT-200).

Ambos modelos, KT-190 y KT-200, emplean bajo voltaje

y alto amperaje para rápidamente descongelar tuberías

domiciliarias de agua potable y sistemas de calefacción

que se encuentren congelados.

Este método no requiere que se conozca con exactitud el

lugar en que se ubica la sección congelada y tampoco es

necesario que se disponga de un acceso directo a la

zona congelada. Ambas unidades descongelan tubos de

acero o de cobre situados bajo tierra, debajo del piso, o

detrás de paredes. La KT-200 posee múltiples posiciones

de voltaje para lograr el máximo de amperaje y así garantizar un tiempo mínimo de descongelación. Las pinzas

recubiertas de vinilo y con 25 pies de cable, estándar en

ambas unidades, permiten descongelar una sección de tubería de 50 pies de longitud. Para longitudes mayores hay

disponibles extensiones de cable de 25 pies.

Especificaciones

Capacidad

Principalmente recomendados para todo tipo de tubería de

cobre o acero de 1/2a 11/2pulgada. Las descongeladoras

no funcionan con tubos de plástico ni con tuberías que

contienen acoplamientos de plástico o goma.

Descongeladoras

Entrada .......................115 voltios,........15 amperios

KT-190 KT-200

Salida..........................6,0 voltios,.........4,5 a 7,6 voltios

Salida..........................300 amperios ...300 amperios

Alcance mínimo ..........15 pies...............4 pies

Alcance máximo..........75 pies...............150 pies

Peso............................25 lbs.................29 lbs

Peso............................11,4 kg ..............13,2 kg

Page 18

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company16

reducir el tiempo de descongelación, es posible que se

haga necesario emplear varias unidades descongeladoras a la vez. Consulte la sección de “Procedimientos

para métodos especiales” en este manual para conocer

los métodos de instalación en serie.

En tuberías domiciliarias de agua

potable

Localice la tubería que se encuentra congelada dentro del

inmueble abriendo los grifos o llaves de agua. Fíjese en

el flujo de agua. La sección de tubería congelada normalmente se encontrará en una pared exterior de la

casa o edificio o en algún espacio debajo del inmueble

con insuficiente aislamiento. Si de un grifo no sale agua y

del siguiente sí, la sección congelada se encuentra entre

estos dos grifos. Monte las pinzas sobre tubos ya sea de

agua caliente o fría, pero no sobre los grifos mismos.

Consulte la sección “Descongelación de tuberías domiciliarias de agua potable” para conocer los procedimientos

a seguir.

Ensamblaje de la máquina

ADVERTENCIA

Para evitar lesiones de gravedad se requiere ensamblar la Descongeladora correctamente. Deben

seguirse los siguientes procedimientos:

Figura 3 – Descongeladora con los cables acoplados

Instalación del cable con pinza

1. Extraiga la tuerca de retención de una de las orejetas

ubicadas en la parte trasera de la unidad.

2. Meta el extremo del cable que lleva el bucle en el

perno de la orejeta, con su parte plana apuntando

hacia la máquina.

3. Vuelva a instalar la tuerca de la orejeta y apriétela

firmemente.

4. Asegure que el bucle del cable no haga contacto

con la carcasa de la máquina.

5. Siga los pasos 1 y 2 para acoplar el otro cable a la

otra orejeta.

¡

NOTA! Si los cables no quedan acoplados firmemente a

la Descongeladora, ésta tardará más en des-

congelar o puede que no funcione debidamente.

Descongeladora de tuberías

Sección congelada

Tierra

Válvula en la calle

Varilla de

desconexión en la calle

Figura 2 – Descongelación de tuberías principales de servicio público

Page 19

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company 17

Inspección de la

Descongeladora

ADVERTENCIA

Revise la Descongeladora para evitar lesiones

graves. Deben realizarse los procedimientos de

inspección siguientes:

1. Asegure que la Descongeladora esté desenchufada

y que su interruptor de encendido/apagado se encuentre en la posición de OFF (apagado).

2. Revise que el cord ón de suministro y el enchufe

estén en buenas condiciones. Si el enchufe ha sido

modificado o no tiene su clavija de conexión a tierra,

o si el cordón está dañado, no use la Descongeladora

hasta que se haya cambiado el cordón.

3. Revise los cables y pinzas por si están dañados.

Asegure que los cables estén bien conectados a la

Descongeladora. Si los cables o las pinzas están

dañados, no use la Descongeladora. Emplee únicamente los cables y pinzas provistos con la unidad.

4. Limpie el aceite, grasa o mugre de todos los mangos,

controles y pinzas.

5. Revise la Descongeladora para asegurar que no le faltan piezas, que no tiene partes quebradas, o por si la

carcasa metálica está dañada. Si detecta cualquier

defecto, no use la Descongeladora hasta que no

haya sido reparada.

Preparación de la máquina

ADVERTENCIA

Se requiere una adecuada preparación de la

máquina y de la zona de trabajo para evitar que

ocurran lesiones de gravedad. Deben seguirse los

siguientes procedimientos para preparar la

Descongeladora:

1. Elija una zona de trabajo donde:

• haya suficiente luz;

• exista un tomacorriente eléctrico conectado a

tierra de 15 amperios;

• haya una senda directa hasta el tomacorriente,

libre de fuentes de calor, aceites, bordes afilados o

cortantes o piezas movibles que puedan dañar al

cordón eléctrico;

• haya un lugar seco para situar la máquina y al

operario. No use la máquina si se encontrará

parado sobre agua. Y,

• no hayan líquidos, vapores o gases inflamables.

2. Coloque la Descongeladora KT-190 ó la KT-200

cerca de la sección de la tubería donde se sospecha

que se ha congelado.

3. Asegure que la unidad se encuentra apagada y desenchufada. El interruptor en la KT-190 debe estar

en la posición inferior de OFF. En el interruptor central

de la KT-200, la posición de OFF (apagado) se encuentra en el medio.

4. Desenrolle ambos cables por completo y asegure

que no queden sobrepuestos ni en contacto el uno

con el otro.

5. Siga las instrucciones sobre cómo deben colocarse

las pinzas.

Para evitar la formación de chispas

entre las pinzas y la tubería, acople las pinzas a la tubería antes de enchufar la Descongeladora.

¡

NOTA! Antes de efectuar una conexión, siempre limpie

el tubo para quitarle las escamas de pintura,

óxido u otros materiales que impidan un buen

flujo de amperios desde la pinza al tubo. Cuando

la conexión es mala, las pinzas se calientan

más de lo debido.

6. Enchufe la Descongeladora al tomacorriente ubicado

al final de la senda despejada elegida con anterioridad. Si el cordón de la máquina no alcanza el tomacorriente, use un cordón de extensión en buenas

condiciones.

Para evitar choques e incendios eléctricos, nunca use un cordón de extensión dañado o que

no cumpla con los siguientes requisitos:

• tener un enchufe de tres clavijas similar al que se

muestra en la sección Seguridad eléctrica.

• estar clasificado como “W” ó “W-A”, si será usado a la

intemperie.

• tener el grosor suficiente (14 AWG si mide menos

de 25 pies de largo, 12 AWG si mide entre 25 y 50

pies). Si el grosor del cable es insuficiente, el cordón

puede recalentarse y derretirse su material aislante, o

prender fuego a objetos cercanos.

ADVERTENCIA

ADVERTENCIA

Page 20

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company18

punto de congelación, el agua, empujada por la

presión, comenzará a colarse a lo largo de las

paredes interiores del tubo, derritiendo y desalojando el hielo a través del grifo abierto.

1. Asegure que la unidad se encuentre desenchufada y

apagada y que los cables estén completamente desenrollados.

2. Coloque una pinza a cada lado de la sección congelada del tubo.

Para evitar la formación de chispas

entre las pinzas y la tubería, acople las pinzas a la tubería antes de enchufar la Descongeladora.

3. Enchufe la Descongeladora a un tomacorriente conectado a tierra de 15 amperios y asegure que el cordón

de suministro vaya extendido por la senda despejada

elegida con anterioridad.

4. Mueva el interruptor a la posición de ON (en la KT190, posición superior. En la KT-200, posición LOW

(abajo) en el interruptor central y posición A en el interruptor izquierdo).

5. Si la corriente es menor a 15 amperios en la KT200, cambie el interruptor a la posición B. Si la

corriente sigue por debajo de 15 amperios, cambie a

la posición arriba en el interruptor central y, el interruptor de la derecha, a C.

6. Continúe hasta que se alcancen, pero no excedan, los

15 amperios. La posición D en el interruptor se usa

para tramos largos de tubería.

Las descongelaciones pueden demorar entre algunos segundos y hasta varias horas, todo depende del largo y el

diámetro de la tubería que se intenta descongelar. Si el

tiempo transcurrido sin que se logre una descongelación

pareciera excesivo, revise que las pinzas estén bien

colocadas.

Para reducir el riesgo de ocasionar

choques eléctricos, mantenga todas las conexiones

eléctricas secas y levantadas del suelo. No toque el

enchufe con las manos mojadas.

Instrucciones de

funcionamiento

ADVERTENCIA

Para reducir el riesgo de ocasionar choques eléc-

tricos, mantenga todas las conexiones eléctricas

secas y levantadas del suelo. No toque el enchufe

con las manos mojadas.

Tenga mucho cuidado cuando descongele tuberías.

Durante la descongelación, las puntas de la pinza y

las conexiones del cable se calientan. Debido a

que puede sufrir quemaduras, evite el contacto de

su piel con los materiales.

Mantenga las pinzas apartadas de materiales combustibles o de artículos que puedan dañarse con el

calor.

No se aleje de la unidad mientras descongela.

Obsérvela.

Descongelación de tuberías domiciliarias

de agua potable

¡

NOTA! Se recomienda que exista una presión de agua

normal a un lado de la sección congelada del

tubo y un grifo abierto en el otro lado de la

sección congelada (Figura 4). A medida que el

tubo se calienta a temperaturas superiores al

Figure 4 – Descongelación de tuberías domiciliarias de agua potable

Fregadero o lavaplatos de la cocina

Lavabo en el baño

Sección congelada

ADVERTENCIA

ADVERTENCIA

Page 21

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company 19

¡

NOTA! Esta máquina viene equipada con una protección

de sobrecarga térmica. Al efectuar una descongelación por un largo período de tiempo a

corriente máxima, la unidad puede apagarse

automáticamente. La unidad reanudará su marcha en forma automática después de unos 3

minutos.

Extracción de la Descongeladora

1. Cuando las cañerías de agua se hayan descongelado,

mueva el interruptor a la posición de OFF (apagado)

y desenchufe el cordón de suministro.

2. Desmonte las pinzas que estaban puestas sobre la tubería.

Las puntas de las pinzas estarán ca-

lientes y pueden quemarlo.

3. Permita que las pinzas se enfríen antes de enrollar los

cables y de almacenar la máquina. Mientras las pinzas estén calientes, no permita que estén cerca de

materiales combustibles o artículos que pueden dañarse con el calor.

Descongelación de redes hidrónicas

congeladas

¡

NOTA! Una red hidrónica es más difícil de descongelar

debido a que su bomba de circulación genera

presiones más bajas y porque su tubería, ya

sea sencilla o multizonal, recorre mayores distancias.

¡

NOTA! La corriente eléctrica de salida, tanto de la

KT-190 como de la KT-200, puede seguir dos

trayectorias: una corta distancia entre las pinzas,

o la trayectoria más larga, a lo largo del circuito

de la tubería. Por lo tanto, en algunas redes se

requiere cortar la tubería para eliminar la trayectoria corta (Figura 7).

Red de zona única

1. La bomba de circulación debe estar funcionando.

2. Asegure que unidad se encuentre desenchufada, su

interruptor en la posición de OFF (apagado) y los

cables completamente desenrollados.

3. Coloque una pinza cerca de la caldera y la otra próx-

ima a un radiador.

Figura 5 – Red de zona única

Figura 6 – Red de zona única

Descongeladora de tubería

Radiador

Radiador

Caldera

Bomba de

circulación

Flujo

del

agua

Radiador

Descongeladora de tubería

Radiador

Radiador

Caldera

Bomba de

circulación

Flujo

del

agua

Radiador

ADVERTENCIA

Page 22

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company20

Para evitar la formación de chispas

entre las pinzas y la tubería, acople las pinzas a la tubería

antes de enchufar la Descongeladora.

4. Enchufe la Descongeladora a un tomacorriente conectado a tierra de 15 amperios y asegure que el cordón

de suministro vaya extendido por la senda despejada

elegida con anterioridad.

5. Mueva el interruptor a la posición de ON (en la KT-190,

posición superior. En la KT-200, posición LOW (abajo)

en el interruptor central y posición A en el interruptor

izquierdo).

6. Si la corriente es menor a 15 amperios en la KT-200,

cambie el interruptor a la posición B. Si la corriente

sigue por debajo de 15 amperios, cambie a la posición

arriba en el interruptor central y el interruptor de la

derecha a C.

7. Continúe hasta que se alcancen, pero no excedan, los

15 amperios. La posición D en el interruptor se usa

para tramos largos de tubería.

Red multizonal

Si la red consta de varias zonas se hará necesario interrumpir el flujo de corriente eléctrica a zonas específicas.

1. Asegure que unidad se encuentre desenchufada, su

interruptor en la posición de OFF (apagado) y los

cables completamente desenrollados.

2. Coloque las pinzas separadas por varios pies la una

de la otra.

Para evitar la formación de chispas

entre las pinzas y la tubería, acople las pinzas a la tubería

antes de enchufar la Descongeladora.

3. Cuando emplee la KT-190, mantenga un mínimo de

15 pies de separación entre las pinzas, 4 pies en el

caso de la KT-200, para evitar una toma excesiva de

amperios.

4. Enchufe la Descongeladora a un tomacorriente

conectado a tierra de 15 amperios y asegure que el

cordón de suministro vaya extendido por la senda despejada elegida con anterioridad.

5. Mueva el interruptor a la posición de ON (en la KT-190

posición UP (arriba). En la KT-200, posición LOW

(abajo) en el interruptor central y posición A en el interruptor izquierdo). Si la corriente es menor a 15

amperios en la KT-200, cambie el interruptor a la

posición B, C ó D para potenciar al máximo la toma de

amperios y reducir el tiempo de descongelación. (No

sobrepase los 15 amperios.)

¡

NOTA! Si la tubería no se ha calentado en 10 minutos,

cambie la ubicación de las pinzas para calentar

otra sección de la red. Si se han hecho varios

intentos siguiendo los pasos descritos anteriormente y no se han logrado resultados, toda la

zona está congelada y deberá descongelársela

con el método de aislamiento multizonal que se

describe a continuación.

Cómo aislar una red multizonal

1. Corte la tubería y tápela en el punto B. Esto interrumpe el flujo de corriente a través de la segunda

zona y permite que el 100 por ciento de la corriente

se use en la Zona No. 1. No permita que los extremos cortados del tubo se toquen entre ellos.

2. Corte la tubería en el Punto A y coloque las pinzas

Figura 7 – Red multizonal

Descongeladora

Radiador

Radiador

Caldera

Bomba de circulación

Flujo

del

agua

Radiador

Zona No. 2

Zona No. 1

Radiador

B Corte en la tubería

Corte en la tubería

A

ADVERTENCIA

ADVERTENCIA

Page 23

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company 21

como se muestra en la Figura 7. Así se fuerza la corriente por la Zona No. 1. Use un recipiente para

recoger el agua.

3. Una vez que se haya descongelado la Zona No. 1,

apague la Descongeladora y la bomba de circulación.

Si la Zona No. 2 está congelada, tape los tubos en el

Punto A. Extraiga la tapa del Punto B y coloque en el

Punto B un recipiente para recoger el agua.

4. Coloque las pinzas ubicadas a cada lado del corte en

el Punto B. Una vez descongelada la Zona No. 2,

apague la bomba de circulación y la Descongeladora.

5. Vuelva a conectar todos los tubos cortados anteriormente y compruebe si las zonas 1 y 2 reciben calor.

Procedimiento para métodos

especiales

Aumento de la capacidad de descongelación de la KT-200 solamente

Pueden ocurrir choques eléctricos o

daños en los equipos si no se siguen los procedimientos

correctos para efectuar operaciones en serie o en paralelo con las descongeladoras.

Funcionamiento en serie

Las unidades descongeladoras colocadas en serie forman la mejor configuración para descongelar largas

extensiones de tubería.

1. Coloque las Descongeladoras cerca de la sección de

tubería que se encuentra congelada y próximas unas

de otras. Las orejetas o terminales de los cables

deben quedar apuntando hacia la tubería.

2. Asegure que todas las unidades estén desenchufadas y que el interruptor central de cada una esté en

la posición de OFF (apagado).

3. Conecte un extremo de la colita de cerdo (No. 62812

en el Catálogo RIDGID) en la orejeta derecha de la

Descongeladora situada a la izquierda, y el otro extremo en la orejeta izquierda de la Descongeladora

situada a la derecha.

4. Acople los cables descongeladores a las orejetas

restantes.

5. Coloque una pinza a cada lado de la sección de tubería que se encuentra congelada.

Se evita la producción de chispas

entre las pinzas y la tubería si las pinzas se montan

antes de enchufar la descongeladora.

6. Enchufe las Descongeladoras a tomacorrientes que

NO se encuentren en el mismo circuito (protegidos

por distintos fusibles).

AMBAS descongeladoras deben

estar enchufadas a un tomacorriente ANTES de encenderlas para evitar choques eléctricos.

7. Cuando se emplean dos Descongeladoras conectadas en serie, en el caso de las KT-200, se

dispondrá en conjunto de siete regulaciones de potencia si se emplean los interruptores de las dos

unidades. Las combinaciones son: AA, AB, BB, BC,

CC, CD, DD.

¡

NOTA! No se armará un circuito hasta que los inte-

rruptores de ambas unidades se hayan colocado

en la posición ON (encendido).

Figura 8 – Instalación en serie

Funcionamiento en paralelo

Unidades descongeladoras colocadas paralelamente

forman la mejor configuración para descongelar tuberías de mayor diámetro.

Figura 9 – Instalación en paralelo

1. Coloque ambas descongeladoras próximas a la sección de tubería que se encuentra congelada.

2. Asegure que las unidades se encuentren desenchufadas, sus interruptores en la posición de OFF (apagado) y los cables completamente desenrollados.

3. Acople los cables y pinzas a las orejetas en la parte

trasera de las unidades.

Unidad No. 1

Sección congelada

Sección congelada

Unidad

No. 1

Unidad No. 2

Unidad

No. 2

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Page 24

Descongeladoras de tuberías KT-190 y KT-200

Almacenamiento de la máquina

Los equipos eléctricos deben guardarse dentro, bajo

techo, o bien cubiertos para guarecerlos de la lluvia.

Almacene la máquina bajo llave, fuera del alcance de

los niños y personas que no conocen el manejo de estas

Descongeladoras. Esta máquina puede causar graves

lesiones en manos de usuarios sin entrenamiento.

Servicio y reparaciones

ADVERTENCIA

Los trabajos de mantenimiento y reparaciones de esta

máquina deben realizarlos técnicos calificados. La

Descongeladora debe llevarse a un Servicentro Autorizado Independiente RIDGID o devuelta a la fábrica.

Todas las reparaciones efectuadas por un servicentro

RIDGID están garantizadas contra defectos en los materiales y de la mano de obra.

Sólo deben usarse piezas de recambio idénticas cuando

se le hace servicio a esta máquina. El incumplimiento de

estas instrucciones puede ocasionar choques eléctricos

y otras lesiones graves.

Si tiene cualquier pregunta relativa al servicio o reparación

de esta máquina, llame o escriba a:

Ridge Tool Company

Departamento de Servicio Técnico

400 Clark Street

Elyria, Ohio 44035-6001

Teléfono: (800) 519-3456

E-mail: TechServices@ridgid.com

Para información sobre el nombre y dirección del Servicentro Autorizado Independiente más cercano, llame a

Ridge Tool Company al (800) 519-3456 o visítenos

http://www.ridgid.com

Ridge Tool Company22

4. Coloque las pinzas a ambos lados de la sección

congelada de la tubería.

Para evitar la formación de chispas

entre las pinzas y la tubería, acople las pinzas a la tubería antes de enchufar la Descongeladora.

5. Enchufe las descongeladoras a tomacorrientes que

NO estén en el mismo circuito (protegidos por distintos fusibles).

Para evitar choques eléctricos, AMBAS descongeladoras deben estar enchufadas a un

tomacorriente ANTES de encenderlas.

6. En la unidad KT-200, las regulaciones de corriente

disponibles son: AA, BB, CC y DD.

¡

NOTA! Si ambas unidades tienen fijadas las mismas

regulaciones, los dos amperímetros en las KT200 deben mostrar aproximadamente el mismo

valor. Si no es así, apague ambas unidades e intercambie los cables de una de las descongeladoras. La polaridad correcta se logra con la

disposición de cables que genere la lectura más

baja de amperios.

IMPORTANTE: Si no se siguen las instrucciones de ins-

talación anteriores la mayor parte de la

corriente fluirá a través de las pinzas

adyacentes y no a través del tubo.

Instrucciones de mantenimiento

ADVERTENCIA

Asegure que la unidad esté desenchufada de la

fuente de suministro antes de efectuarle mantenimiento o reparaciones.

Mantenimiento de la máquina

1. Recambie los cables dañados, pelados, rotos o desgastados.

2. Periódicamente limpie las orejetas con lana de acero

y papel de lija.

3. Recambie los cordones dañados, pelados, rotos o

desgastados.

4. Mantenga las pinzas limpias y secas.

ADVERTENCIA

ADVERTENCIA

Page 25

Descongeladoras de tuberías KT-190 y KT-200

Ridge Tool Company 23

Esquemas eléctricos

Descongeladora KT-190

115V/60Hz

TERMINALES

DE SALIDA

Descongeladora KT-200

115V/60Hz

TERMINALES

DE SALIDA

ON/OFF

(encendido/apagado)

Sobrecarga

térmica

Amperímetro

Interruptor de

alimentación

Sobrecarga

térmica

Negro

Blanco

Verde

Negro

Blanco

Verde

Page 26

Ridge Tool Company24

Descongeladoras de tuberías KT-190 y KT-200

Page 27

Printed in U.S.A. 6/05 999-998-752.10

Rev. A

What is covered

RIDGID®tools are warranted to be free of defects in workmanship and material.

How long coverage lasts

This warranty lasts for the lifetime of the RIDGID

®

tool. Warranty coverage ends when the prod-

uct becomes unusable for reasons other than defects in workmanship or material.

How you can get service

To obtain the benefit of this warranty, deliver via prepaid transportation the complete product

to RIDGE TOOL COMPANY, Elyria, Ohio, or any authorized RIDGID

®

INDEPENDENT SERVICE

CENTER. Pipe wrenches and other hand tools should be returned to the place of purchase.

What we will do to correct problems

Warranted products will be repaired or replaced, at RIDGE TOOL’S option, and returned at no

charge; or, if after three attempts to repair or replace during the warranty period the product

is still defective, you can elect to receive a full refund of your purchase price.

What is not covered

Failures due to misuse, abuse or normal wear and tear are not covered by this warranty. RIDGE

TOOL shall not be responsible for any incidental or consequential damages.

How local law relates to the warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty gives you specific

rights, and you may also have other rights, which vary, from state to state, province to

province, or country to country.

No other express warranty applies

This FULL LIFETIME WARRANTY is the sole and exclusive warranty for RIDGID

®

products. No

employee, agent, dealer, or other person is authorized to alter this warranty or make any other

warranty on behalf of the RIDGE TOOL COMPANY.

FULL LIFETIME

Qué cubre

Las herramientas RIDGID están garantizadas contra defectos de la mano de obra y de los

materiales empleados en su fabricación.

Duración de la cobertura

Esta garantía cubre a la herramienta RIDGID durante toda su vida útil. La cobertura de la

garantía caduca cuando el producto se torna inservible por razones distintas a las de defectos

en la mano de obra o en los materiales.

Cómo obtener servicio

Para obtener los beneficios de esta garantía, envíe mediante porte pagado, la totalidad del producto a RIDGE TOOL COMPANY, en Elyria, Ohio, o a cualquier Servicentro Independiente

RIDGID. Las llaves para tubos y demás herramientas de mano deben devolverse a la tienda donde

se adquirieron.

Lo que hacemos para corregir el problema

El producto bajo garantía será reparado o reemplazado por otro, a discreción de RIDGE TOOL,

y devuelto sin costo; o, si aún resulta defectuoso después de haber sido reparado o sustituido

tres veces durante el período de su garantía, Ud. puede optar por recibir un reembolso por el valor

total de su compra.

Lo que no está cubierto

Esta garantía no cubre fallas debido al mal uso, abuso o desgaste normal. RIDGE TOOL no se

hace responsable de daño incidental o consiguiente alguno.

Relación entre la garantía y las leyes locales

Algunos estados de los EE.UU. no permiten la exclusión o restricción referente a daños incidentales o consiguientes. Por lo tanto, puede que la limitación o restricción mencionada

anteriormente no rija para Ud. Esta garantía le otorga derechos específicos, y puede que,

además, Ud tenga otros derechos, los cuales varían de estado a estado, provincia a provincia o

país a país.

No rige ninguna otra garantía expresa

Esta GARANTIA VITALICIA es la única y exclusiva garantía para los productos RIDGID. Ningún

empleado, agente, distribuidor u otra persona está autorizado para modificar esta garantía u ofrecer cualquier otra garantía en nombre de RIDGE TOOL COMPANY.

Ridge Tool Company

400 Clark Street

Elyria, Ohio 44035-6001

WARRANTY

Against Material Defects

& Workmanship

FULL LIFETIME

WARRANTY

Against Material Defects

& Workmanship

Loading...

Loading...