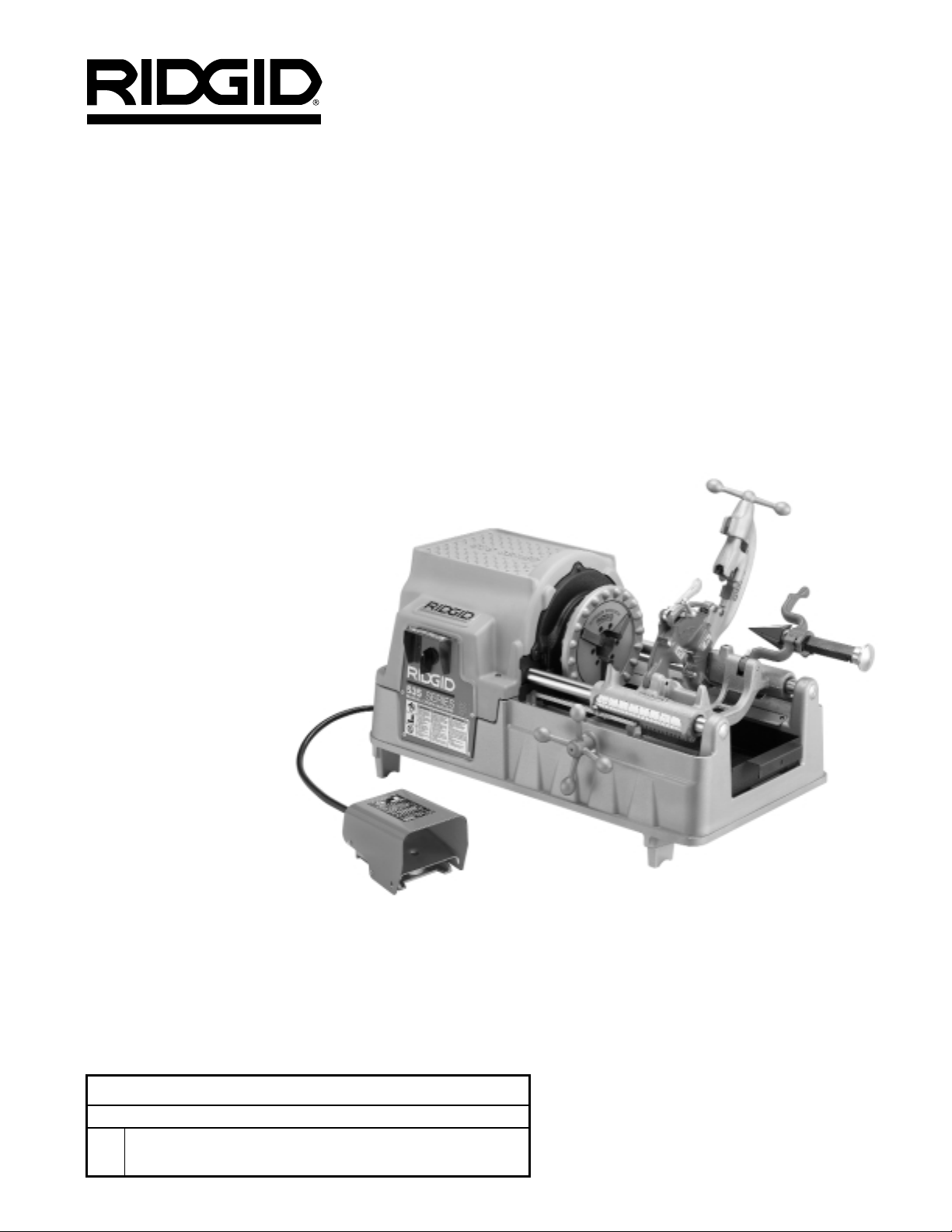

Page 1

Manual

Pipe and Bolt

Threading Machine

OPERATOR’S

MANUAL

535

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of this

manual may result in electrical shock, fire and/or serious

personal injury.

• Français – 19

• Castellano – pág. 43

Page 2

535 Manual Pipe and Bolt Threading Machine

Ridge Tool Company

ii

Table of Contents

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service........................................................................................................................................................................3

Specific Safety Information

Foot Switch Safety......................................................................................................................................................3

Machine Safety ..........................................................................................................................................................3

Description, Specifications and Standard Equipment

Description..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Standard Equipment ..................................................................................................................................................4

Machine Assembly

Mounting Machine to Stand........................................................................................................................................5

Mounting Machine to Bench ......................................................................................................................................5

Machine Inspection ......................................................................................................................................................6

Machine and Work Area Set-Up ..................................................................................................................................6

Operation Using Machine-Mounted Tools

Installing Pipe In Threading Machine..........................................................................................................................7

Cutting Pipe with No. 820 Cutter ................................................................................................................................8

Reaming Pipe with No. 341 Reamer ..........................................................................................................................8

Threading Pipe or Rod with Quick-Opening, Self-Opening or Semi-Automatic Die Head..........................................9

Removing Pipe From the Threading Machine............................................................................................................9

Left Hand Threading ..................................................................................................................................................9

Installing Dies in Quick-Opening Die Head (Right Hand & Left Hand) ......................................................................9

Installing Dies in Self-Opening Die Head (Right Hand Only)....................................................................................10

Installing Dies in Model 816/817 Die Heads ............................................................................................................11

Checking Thread Length ..........................................................................................................................................11

Priming Oil Pump......................................................................................................................................................11

Operation Instructions Using Geared Threaders

Adjusting Nos. 141 & 161 Geared Threaders ..........................................................................................................12

Thread Size Adjustment Procedure..........................................................................................................................12

Changing Posts for Straight or Tapered Threads ....................................................................................................12

Changing Die Set......................................................................................................................................................13

Installing No. 141 Geared Threader (Closed-Coupled Method) ..............................................................................13

Threading Pipe Using No. 141 Geared Threader (Close Coupled Method) ............................................................15

Installing Nos. 141 &161 Geared Threaders Using No. 840A Universal Drive Shaft ..............................................15

Threading Pipe Using Nos. 141 & 161 Geared Threaders with No. 840A Universal Drive Shaft ............................16

No. 819 Nipple Chuck

Short or Close Nipple Threading Procedure ............................................................................................................16

Accessories

Accessories For Threading Machine........................................................................................................................17

Die Heads and Dies..................................................................................................................................................18

Maintenance Instructions

Lubrication................................................................................................................................................................18

Oil System Maintenance ..........................................................................................................................................18

Jaw Insert Replacement ..........................................................................................................................................19

Motor Brush Replacement........................................................................................................................................19

Machine Storage ......................................................................................................................................................19

Service and Repair......................................................................................................................................................19

Wiring Diagrams ........................................................................................................................................................20

Lifetime Warranty ........................................................................................................................................Back Cover

Page 3

535 Manual Pipe and Bolt Threading Machine

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

535 Manual

Pipe and Bolt

Threading Machine

Page 4

535 Manual Pipe and Bolt Threading Machine

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a power tool outside, use an out-

door extension cord marked “W-A” or “W”. These

cords are rated for outdoor use and reduce the risk of

electrical shock.

• Use only three-wire extension cords which have

three-prong grounding plugs and three-pole receptacles which accept the tool’s plug. Use of other

extension cords will not ground the tool and increase

the risk of electrical shock.

• Use proper extension cords. (See chart.) Insufficient conductor size will cause excessive voltage

drop and loss of power.

• Keep all electric connections dry and off the

ground. Do not touch plugs or tool with wet hands.

Reduces the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medications. A moment of inat-

tention while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch ON

invites accidents.

• Remove adjusting keys before turning the tool

ON. A wrench or a key that is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and bal-

Ridge Tool Company

2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate power tools in explosive atmos-

pheres, such as in the presence of flammable liquids, gases, or dust. Tools create sparks which may

ignite the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a tool. Distractions can cause you to lose

control.

• Keep floors dry and free of slippery materials

such as oil. Slippery floors invite accidents.

• Guard or barricade the area when work piece

extends beyond machine. A guard or barricade that

provides a minimum of three (3) feet clearance around

the work piece will reduce the risk of entanglement.

Electrical Safety

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether the

outlet is properly grounded. If the tool should elec-

trically malfunction or break down, grounding provides a low resistance path to carry electricity away

from the user.

• Avoid body contact with grounded surfaces. There

is an increased risk of electrical shock if your body is

grounded.

• Don’t expose electrical tools to rain or wet condi-

tions. Water entering a tool will increase the risk of

electrical shock.

Grounding prong

Cover of

grounded

outlet box

Grounding prong

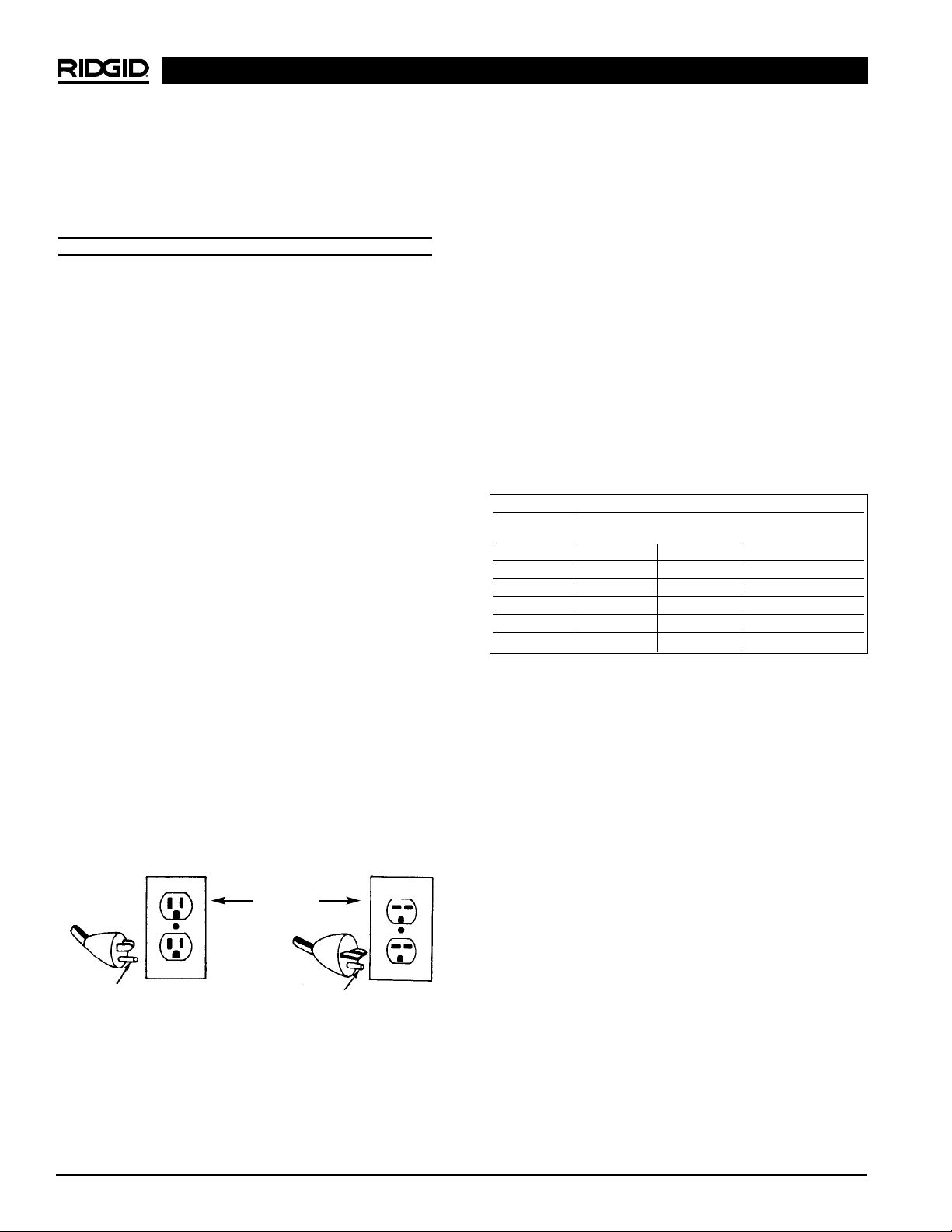

Minimum Wire Gauge for Extension Cord

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG NOT RECOMMENDED

16 – 20 12 AWG 10 AWG

NOT RECOMMENDED

Page 5

Ridge Tool Company

3

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Tool Use and Care

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Disconnect the plug from the power source before

making any adjustments, changing accessories,

or storing the tool. Such preventive safety mea-

sures reduce the risk of starting the tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool's operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

• Use only accessories that are recommended for

your tool. Accessories that may be suitable for one tool

may become hazardous when used on another tool.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the 535 Threading Machine. Failure to understand

and follow the contents of this manual may result in

electrical shock, fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service

Department at (800) 519-3456 if you have any questions.

Foot Switch Safety

Using a threading machine without a foot switch

increases the risk of serious injury. A foot switch

provides better control by letting you shut off the

motor by removing your foot. If clothing should

become caught in the machine, it will continue to

wind up, pulling you into the machine. Because the

machine has high torque, the clothing itself can bind

around your arm or other body parts with enough

force to crush or break bones.

Machine Safety

• Threading Machine is made to thread and cut

pipe or bolt and to power roll grooving equipment. Follow instructions on proper use of this

machine. Do not use for other purposes such

as drilling holes or turning winches. Other uses or

modifying this power drive for other applications may

increase the risk of serious injury.

• Secure machine to bench or stand. Support long

heavy pipe with pipe supports. This practice will

prevent tipping.

• Do not wear gloves or loose clothing when oper-

ating machine. Keep sleeves and jackets buttoned.

Do not reach across the machine or pipe. Clothing

can be caught by the pipe or machine resulting in

entanglement and serious injury.

• Operate machine from side with REV/OFF/FOR

switch. Eliminates need to reach over the machine.

• Do not use this machine if the foot switch is bro-

ken or missing. Foot switch is a safety device to

prevent serious injury.

• Keep hands away from rotating pipe and fittings.

Stop the machine before wiping pipe threads or

screwing on fittings. Allow the machine to come to

a complete stop before touching the pipe or

machine chucks. This practice will prevent entan-

glement and serious injury.

• Do not use this machine to make or break fittings.

This practice is not an intended use of the machine and

can result in serious injury.

• Tighten chuck handwheel and engage rear cen-

tering device on the pipe before turning on the

machine. Prevents oscillation of the pipe.

• Keep covers in place. Do not operate the machine

with covers removed. Exposure to moving parts may

result in entanglement and serious injury.

• Lock foot switch when machine is not in use

(Figure 1). Avoids accidental starting.

535 Manual Pipe and Bolt Threading Machine

WARNING

Page 6

Ridge Tool Company

4

Figure 1 – Locked Foot Switch

Description, Specifications and

Standard Equipment

Description

The RIDGID Model 535 Threading Machine is an electric motor-driven machine which centers and chucks

pipe, conduit and rod (bolt stock) and rotates it while

threading, cutting and reaming operations are performed. Left-hand or right-hand rotation can be selected

with the FOR/OFF/REV switch. Threading dies are

mounted in self-opening or quick-opening die heads.An

automatic oiling system is provided to flood the work with

thread cutting oil during threading operations. Geared

Threaders can also be used with the Threading Machine

to thread larger diameter pipe.

The RIDGID Model 535 Threading Machine can also be

used as a power source for roll grooving equipment.

Designed to attach to the carriage rail of the Threading

Machine, the roll grooving equipment forms standard roll

grooves on a variety of pipe sizes and materials.

Specifications

Threading Capacity.......Pipe 1/8″ through 2″

Bolt 1/4″ through 2″

Geared Threaders:

Pipe 21/2″ through 6″

Chuck............................Speed Grip Chuck with

Replaceable Jaw Inserts

Rear Centering Device....Scroll Operated, Rotates with

Chuck

Operating Speed ............36 RPM or 54 RPM

Motor:

Type............................Universal

Horsepower.................1/2HP

Volts............................120V Single Phase AC

25-60 Hz

(230V Available On Request)

Amps...........................15 Amps (36 RPM)

18 Amps (54 RPM)

Controls.........................Rotary Type FOR/OFF/REV

Switch & ON/OFF Foot Switch

Pump.............................Gerotor-Type

Cutter ............................No. 820 - Roll-Type Cut-Off,

Self-Centering, Full Floating,

Pipe –

1

/8″ through 2″,

Bolt – 1/4″ through 1″

or

No. 821 - Blade-Type Cut-Off,

Self-Centering, Full Floating,

Pipe – 1/2″ through 2″,

Dovetail-Type Cut-Off and

Chamfering Tool.

Reamer..........................No. 341 - Positive-Locking,

5-Flute Cone, Right Hand,

1

/8″ through 2″

Weight............................260 lbs. (Less Die Head &

Dies)

Standard Equipment

Model No. 535 Manual Threading Machine with Foot

Switch

1 - No. 811-A Universal Quick-Opening Die Head

1 - No. 341 Reamer

1 - No. 820 Cutter

1 - Set 1/2″ - 3/4″ Universal Alloy Dies

1 - Set 1″ - 2″ Universal Alloy Dies

1 - Gallon Premium Oil

4 - Hex Wrenches

1 - Spare E-1032 Cutter Wheel

Machines listed as 1/2″ - 2″ include Standard Equipment. Machine

Only includes Standard Equipment less all Die Heads and Dies. All

machines have 25-60 Hz Universal 1/2 HP single-phase motors.

NOTE! NPT Dies are for NPT Die heads only. BSPT

Dies are for BSPT Die Heads only. Please use

Catalog Item Nos. when ordering. High-Speed

Dies are recommended for use with machines

having an RPM of 54 or more.

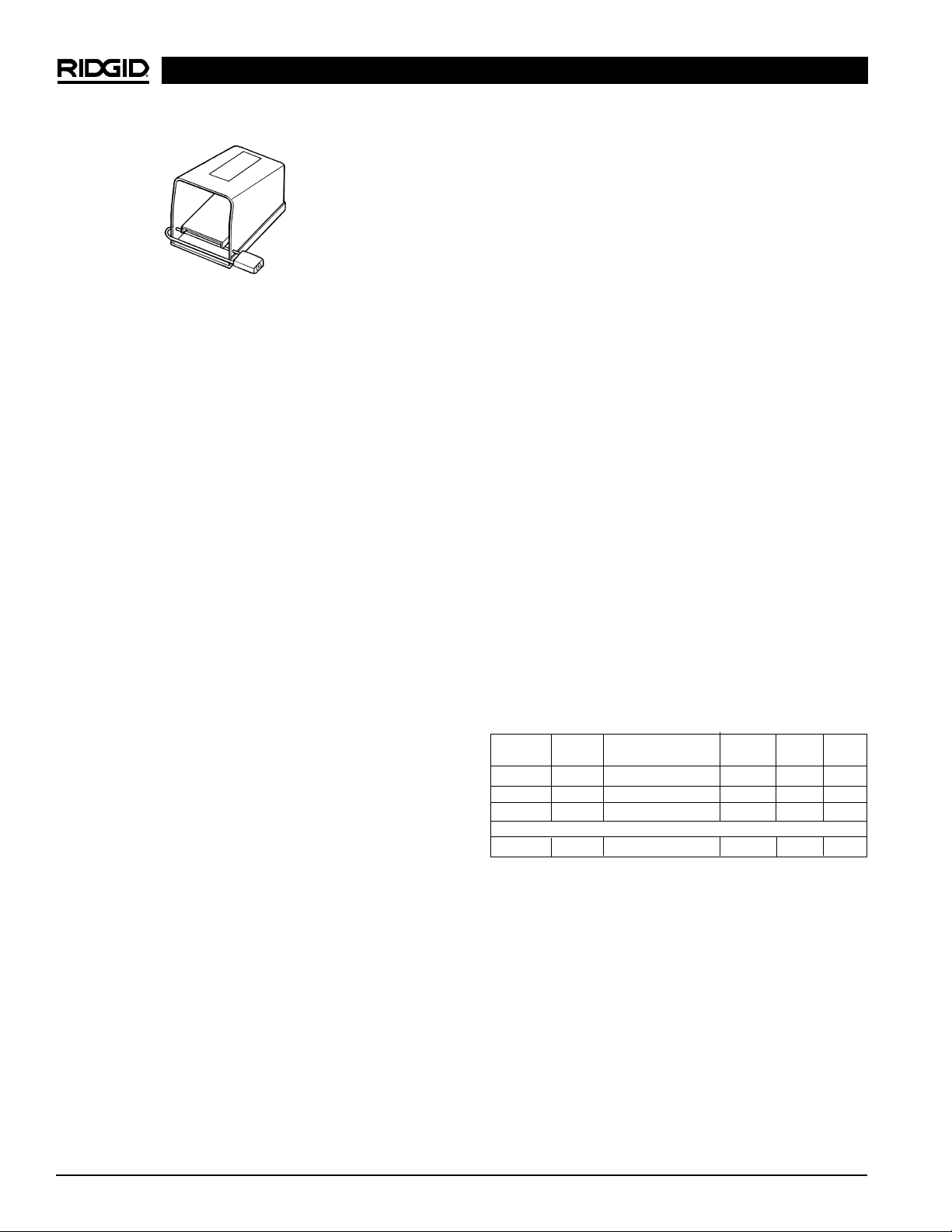

535 Manual Pipe and Bolt Threading Machine

Standard Machines

Catalog Model Description Cutter

No. No. 115V 25-60 Hz Model RPM Volt

93787 535 1/2″ - 2″ NPT 820 36 115V

96497 535 Machine Only 820 36 115V

96502 535 1/2″ - 2″ NPT 820 54 115V

230V 25-60 Hz

96507 535 1/2″ - 2″ NPT 820 36 230V

Page 7

Ridge Tool Company

5

Figure 2 – No. 535 Machine Dimensions

Machine Assembly

WARNING

To prevent serious injury, proper assembly of the

Threading Machine is required. The following procedures should be followed:

Mounting Machine To Stand

1. The machine is designed to mount on the three universal stands listed below.

Figure 3

NOTE: To attach a pre-1996 Model 535 Threading

Machine to a Model 100, 150 or 200 Stand, a

58007 Adapter Kit must be used.

2. Parts diagram and parts list for the stands are includ-

ed in the 535 Parts List.

3. Assemble stand with “inside” decals located towards

the inside of the stand (Figure 4).

4. Insert stand stop tabs into bottom of the legs as

shown in the detail drawing. Use the four (4) 3/8″ - 16

x 21/2″ hex bolts to secure the legs to the cross-member. Adjust the two halves of the stand stop to the

proper distance to fit into the rear legs on the stand.

The stand stop bracket is not required or supplied with

the No. 100 Leg and Tray Stand.

Figure 4 – Stand Assembly

5. Insert axle into frame and secure it with a 1/2″ lock

washer and nut. Position stand stop bracket so that

the end of the bracket is held in place by the axle

shaft. Slide a wheel onto the axle. Slide a flat washer over the axle and install a cotter pin to hold the

wheel on the axle.

6. Mount machine to the stand using four (4) bolts that

mount into each corner of the base.

For proper balance and operation, RIDGID

machines must be mounted through the appropriate

holes in the legs (Figure 4).

Mounting Machine To Bench

1. If a stand is not used, the machine should be mounted to a stable bench. To mount the unit on a bench,

use four (4) 5/16″ bolts in holes provided at each corner

of machine base. Base dimensions are shown in

Figure 2.

Failure to mount the threading machine

to a stable stand or bench may result in tipping and

serious injury.

535 Manual Pipe and Bolt Threading Machine

CAUTION

WARNING

Machine Stands

Model No. Cat. No. Description

100A 92457 Universal Leg & Tray Stand

150A 92467 Universal Wheel & Tray Stand

200A 92462 Universal Wheel & Cabinet Stand

1224

(Front)

535 (Front)

Pre-2001

Detail Section

300 Compact

1233, 1822 (Rear)

300 Compact

1233, 1822

(Front)

3

/8″ - 16 x 21/2″ Bolt

4 Required

535-A/535

Manual - 2001

535-A/535

Manual - 2001

20.8″

38.1″

20.5″

535 (Rear)

Pre-2001

Page 8

7. Lubricate the Threading Machine if necessary according to the Maintenance Instructions.

8. Use tools and accessories that are designed for your

Threading Machine and meet the needs of your

application. The correct tools and accessories allow

you to do the job successfully and safely. Accessories

designed for use with other equipment may be hazardous when used with this Threading Machine.

9. Clean any oil, grease or dirt from all handles and

controls. This reduces the risk of injury due to a tool or

control slipping from your grip.

Inspect the cutting edges of your tools and dies. If

necessary, have them replaced prior to using the

Threading Machine. Dull or damaged cutting tools and

dies can lead to binding, tool breakage and poor

quality threads.

10. Clean metal shavings and other debris from the chip

tray of the Threading Machine. Check the level and

quality of the thread cutting oil. Replace or add oil if

necessary. Reservoir in the base will hold approximately seven (7) quarts of thread cutting oil.

NOTE! Thread cutting oil lubricates and cools the threads

during the threading operation. A dirty or poor

grade cutting oil can result in poor thread quality.

NOTE! To drain dirty oil and properly maintain the oil

system, refer to the “Maintenance Instructions”.

Machine and Work Area Set-Up

WARNING

To prevent serious injury, proper set-up of the machine

and work area is required. The following procedures

should be followed to set-up the machine:

1. Locate a work area that has the following:

• Adequate lighting.

• No flammable liquids, vapors or dust that may ignite.

• Grounded electrical outlet.

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for machine and operator. Do not use

the machine while standing in water.

• Level ground.

Ridge Tool Company

6

Machine Inspection

WARNING

To prevent serious injury, inspect your Threading

Machine. The following inspection procedures

should be performed on a daily basis:

1. Make sure Threading Machine is unplugged and the

directional switch is set to the OFF position (Figure 5).

Figure 5 – No. 535 Pipe and Bolt Threading Machine

2. Clean the speed chuck jaws with a wire brush.

3. Inspect the jaw inserts for excessive wear. Refer to the

Maintenance Instructions if they need to be replaced.

4. Make sure the foot switch is present and attached to

the Threading Machine (Figure 5).

Do not operate the Threading Machine

without a foot switch.

5. Inspect the power cord and plug for damage. If the

plug has been modified, is missing the grounding

pin or if the cord is damaged, do not use the

Threading Machine until the cord has been replaced.

6. Inspect the Threading Machine for any broken, missing, misaligned or binding parts as well as any other

conditions which may affect the safe and normal

operation of the machine. If any of these conditions

are present, do not use the Threading Machine until

any problem has been repaired.

535 Manual Pipe and Bolt Threading Machine

Centering

Device

(Not Shown)

Chuck Handwheel

Quick or

Self-Opening

Die Head

No. 820

Cutter

(Standard)

No. 341

Reamer

Chip

Pan

REV/OFF/FOR

Switch

Foot Switch

Carriage Handwheel

Length Gauge

WARNING

Page 9

9. Check the Threading Machine to insure it is operating

properly.

• Flip the directional switch to FOR (Forward). Press

and release the foot switch. Check that the

Threading Machine rotates in a counterclockwise

direction as you are facing the front chuck. Have the

Threading Machine serviced if it rotates in the

wrong direction or if the foot switch does not control

its stopping or starting.

• Depress and hold the foot switch. Inspect the mov-

ing parts for misalignment, binding, odd noises or

any other unusual conditions that may affect the safe

and normal operation of the machine. If such conditions are present, have the power drive serviced.

• Flip the directional switch to REV (Reverse). Press

and release the foot switch. Check that that Threading Machine rotates in a clockwise direction as

you are facing the chuck.

• Release the foot switch and flip the directional

switch to OFF.

Operation Using

Machine-Mounted Tools

WARNING

Do not wear gloves or loose clothing when operating Threading Machine. Keep sleeves and jackets

buttoned. Do not reach across the machine or pipe.

Do not use this Threading Machine if the foot switch

is broken or missing. Always wear eye protection to

protect eyes from dirt and other foreign objects.

Keep hands away from rotating pipe and fittings.

Stop the machine before wiping pipe threads or

screwing on fittings. Allow the machine to come to

a complete stop before touching the pipe or

machine chucks.

Do not use this machine to “make-on” or “break

off” fittings. This practice is not an intended use of

this Threading Machine.

Installing Pipe In Threading Machine:

1. Check to insure the cutter, reamer and die head are

swung to UP position.

2. Mark the pipe at the desired length if it is being cut to

length.

3. Insert the pipe into the Threading Machine so that the

Ridge Tool Company

7

2. Clean up the work area prior to setting up any equipment. Always wipe up any oil that may have splashed

or dripped from the machine to prevent slips and falls.

3. If the workpiece extends more than four (4) feet beyond

the Threading Machine, use one or more pipe stands

to prevent tipping and the oscillation of the pipe.

4. If the workpiece extends beyond the Threading

Machine, set-up guards or barricades to create a minimum of three (3) feet of clearance around the

Threading Machine and workpiece. This “safety zone”

prevents others from accidentally contacting the

machine or workpiece and either causing the equipment to tip or becoming entangled in the rotating parts.

5. If necessary, fill the reservoir with RIDGID Thread

Cutting Oil.

6. Make sure FOR/OFF/REV switch is in the OFF position.

7. Position the foot switch so that the operator can

safely control the machine, tools and workpiece. It

should allow the operator to do the following:

• Stand facing the directional switch.

• Use the foot switch with his left foot.

• Have convenient access to the directional switch,

tools and chucks without reaching across the

machine.

Machine is designed for one person operation.

8. Plug the Threading Machine into the electrical outlet

making sure to position the power cord along the clear

path selected earlier. If the power cord does not reach

the outlet, use an extension cord in good condition.

WARNING

To avoid electrical shock and electrical fires, never use

an extension cord that is damaged or does not meet the

following requirements:

• The cord has a three-prong plug similar to shown

in Electrical Safety section.

• The cord is rated as “W” or “W-A” if being used

outdoors.

• The cord has sufficient wire thickness (14 AWG

below 25′/12 AWG 25′ - 50′). If the wire thickness is

too small, the cord may overheat, melting the cord’s

insulation or causing nearby objects to ignite.

To reduce risk of electrical shock, keep

all electrical connections dry and off the ground. Do

not touch plug with wet hands.

535 Manual Pipe and Bolt Threading Machine

WARNING

Page 10

Ridge Tool Company

8

end to be worked or the cutting mark is located about

12 inches to the front of the speed chuck jaws.

4. Insert workpieces less than 2 feet long from the front

of the machine. Insert longer pipes through either

end so that the longer section extends out beyond the

rear of the Threading Machine.

To avoid equipment tip-overs, position

the pipe supports under the workpiece.

NOTE! For plastic and coated work pieces, special jaw

inserts (No. 97365) should be used to prevent

damaging the workpiece.

5. Tighten the rear centering device around the pipe by

using a counterclockwise rotation of the handwheel at

the rear of the Threading Machine. This prevents movement of the pipe that can result in poor thread quality.

6. Secure the pipe by using repeated and forceful counterclockwise spins of the speed chuck handwheel

at the front of the Threading Machine. This action

“hammers” the jaws tightly around the pipe.

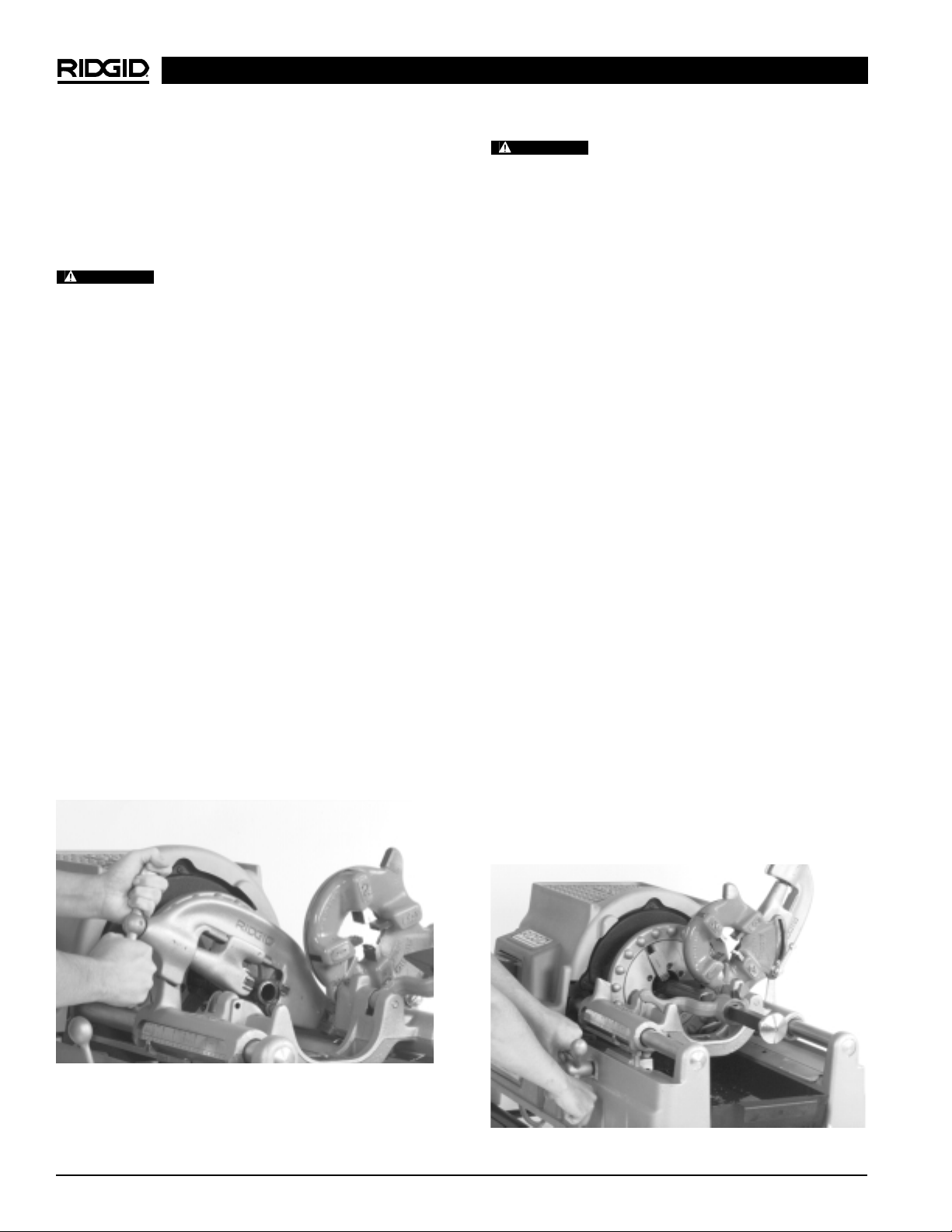

Cutting Pipe with No. 820 Cutter

1. Swing reamer and die head to UP position.

2. Move pipe cutter DOWN onto pipe and move carriage with handwheel to line up cutter wheel with

mark on pipe.

NOTE! If using length gauge on machine carriage, place

cutter wheel against end of stock and set point to

“0”. Raise cutter to clear stock and turn carriage

handwheel until pointer is at length desired.

3. Tighten cutter feed screw handle on pipe keeping

wheel aligned with the pipe. (Figure 6)

Figure 6 – Cutting Pipe with 820 Cutter

4. Assume the correct operating posture.

This will allow you to maintain proper bal-

ance and to safely keep control of the machine and tools.

• Be sure you can quickly remove your foot from

the foot switch.

• Stand facing the directional switch.

• Be sure you have convenient access to directional

switch, tools and chucks.

• Do not reach across the machine or workpiece.

5. Flip the directional switch to FOR (Forward).

6. Grasp the pipe cutter’s feedscrew handle with both

hands.

7. Depress and hold down the foot switch with the left foot.

8. Tighten the feedscrew handle slowly and continuously

until the pipe is cut. Do not force the cutter into the

workpiece.

9. Release the foot switch and remove your foot from

the housing.

10. Swing pipe cutter back to the UP position.

Reaming Pipe with No. 341 Reamer

1. Move reamer arm into DOWN position.

2. Extend reamer by pressing latch and sliding knob

toward pipe until latch engages bar.

3. Check the directional switch to insure it is in the

FOR (Forward) position. Depress and hold the foot

switch down with left foot.

4. Position reamer into pipe and complete reaming by

exerting pressure on handwheel. (Figure 7)

5. Retract reamer bar and return reamer to UP position.

6. Release foot switch and remove your foot from the

housing.

Figure 7 – Reaming with 341 Reamer

535 Manual Pipe and Bolt Threading Machine

WARNING

WARNING

Page 11

Ridge Tool Company

9

Threading Pipe or Rod with

Quick-Opening, Self-Opening or

Semi-Automatic Die Head

1. Install die set. Refer to die installation procedure.

2. Swing cutter and reamer to UP position.

3. Swing die head to DOWN position with throwout

lever set to CLOSE position.

4. Check directional switch to insure it is in the FOR

(Forward) position. Depress and hold the foot switch

down with left foot.

NOTE! Current 535 Machines have an automatic oiling

system that brings oil to the work through the die

head. Machines made prior to June 1, 1996

have an oil spout which must be swung to the

down position to flood dies with oil.

5. Turn carriage handwheel to bring dies against end of

pipe. Slight pressure on handwheel will start dies.

(Figure 8)

Figure 8 – Threading with 535 Manual Threading Machine

6. Quick-Opening 811A Die Head (Figure 9) – When

thread is completed, rotate throwout lever to OPEN

position, retracting dies.

Self-Opening 815A Die Head (Figure 10) – When die

head trigger contacts end of pipe, throwout lever is

automatically opened.

Semi-Automatic Die Head (Figure 11) – When the end

of the pipe being threaded is flush with the end of the

number 1 die, tap the handle for the dies to release

the pipe.

7. Turn carriage handwheel to back die head off pipe.

8. Release the foot switch and remove your foot from

the housing.

9. Swing die head back to UP position.

Removing Pipe From The Threading

Machine

1. Use repeated and forceful clockwise spins of the

speed chuck handwheel at the front of the Threading

Machine to release the workpiece from the speed

chuck jaws.

2. If necessary, loosen the rear centering device using

a clockwise rotation of the handwheel at the rear of

the Threading Machine.

3. Slide the workpiece out of the Threading Machine,

keeping a firm grip on the workpiece as it clears the

Threading Machine.

To avoid injury from falling parts or equipment tip-overs when handling long workpieces, make

sure that the end farthest from the Threading Machine is

supported prior to removal.

4. Clean up any oil spills or splatter on the ground surrounding the Threading Machine.

Left Hand Threading

An optional pump kit along with a special pipe or bolt die

head is required for left hand threading. These optional

accessories consists of the following:

Pump Kit:

Model MJ-1 Pump

Bracket Fitting

Model 842 Quick-Opening NPT Die Head

Model 531 and 532 Quick-Opening Bolt Die Head

NOTE! Pump Kit not required on all pre-2001 535

machines.

Installing Dies in Quick-Opening Die

Head (Right Hand and Left Hand)

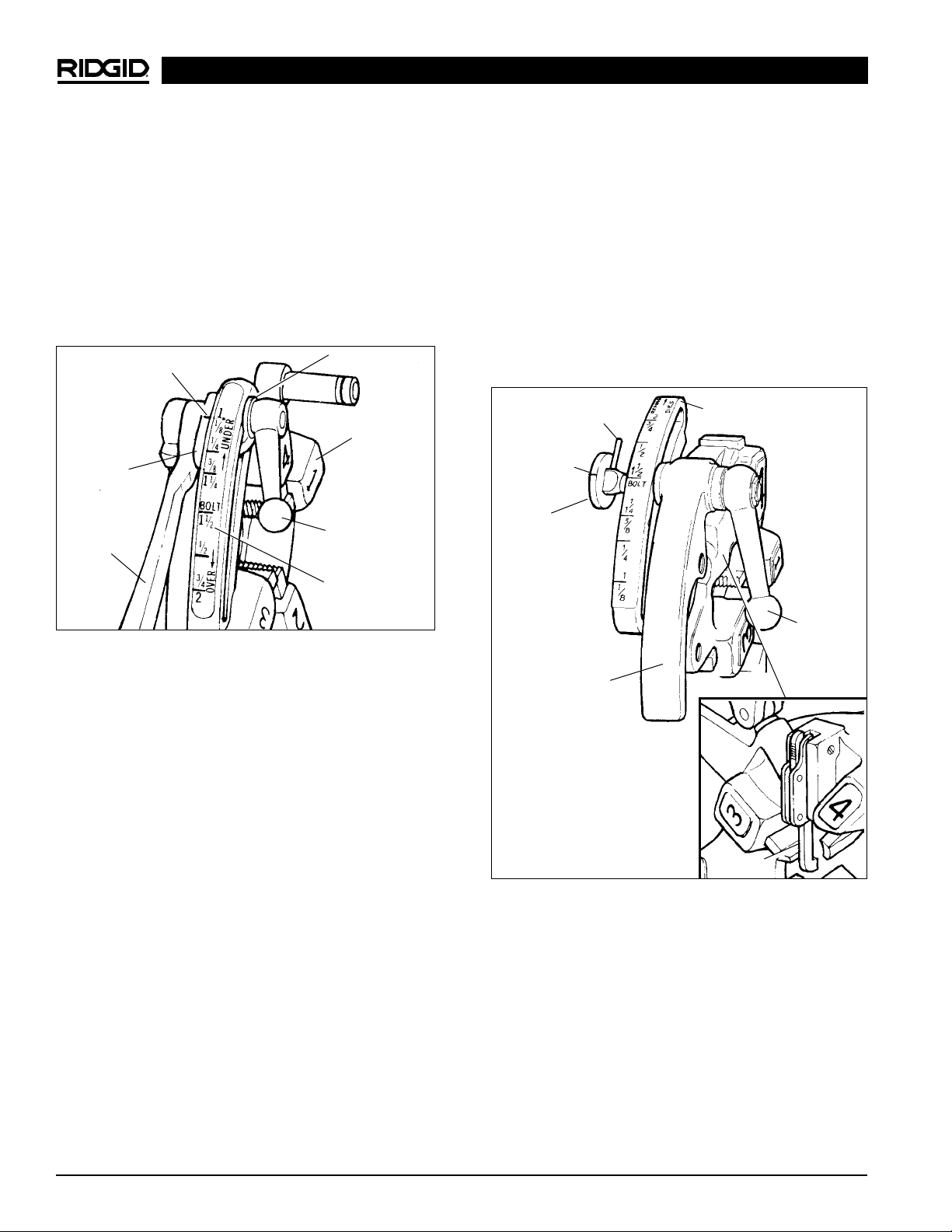

The No. 811A Universal Die Head (Figure 9) for right

hand threads requires four sets of dies to thread pipe

ranging from 1/8″ through 2″. One set of dies is required

for each of the following pipe size ranges: (1/8″), (1/4″

and 3/8″), (1/2″ and 3/4″) and (1″ through 2″). Bolt threading

requires a separate set of dies for each bolt size. No bolt

dies are available for left hand universal die heads.

1. Lay die head on bench with numbers face up.

2. Flip throwout lever to OPEN position.

3. Loosen clamp lever approximately three turns.

4. Lift tongue of clamp washer up and out of slot under

size bar. Slide throwout lever all the way to end of slot

in the change die direction indicated on cam plate.

5. Remove dies from die head.

535 Manual Pipe and Bolt Threading Machine

WARNING

Page 12

6. Insert new dies to mark on side of dies. Numbers 1

through 4 on the dies must match numbers on the

die head.

7. Slide throwout lever back so that tongue of clamp

lever washer will drop in slot under size bar.

8. Adjust die head size bar until index line on link is

aligned with proper size mark on size bar. For bolt

threads, align underline with bolt line on size bar.

9. Tighten clamp lever.

Figure 9 – Universal Quick-Opening Die Head

10. If oversize or undersize threads are required, set

the index line in direction of OVER or UNDER size

mark on size bar.

Installing Dies in Self-Opening Die Head

(Right Hand Only)

The No. 815A Self-Opening Die Head (Figure 10) for

right-hand threads requires four sets of dies to thread

pipe ranging from 1/8″ - 2″. One set of dies is required for

each of the following pipe size ranges: (1/8″), (1/4″ - 3/8″), (1/2″

- 3/4″), and (1″ - 2″). Bolt threading requires a separate set

of dies for each bolt size.

1. Place self-opening die head on bench in vertical

position.

2. Make sure trigger assembly is released.

3. Loosen clamp lever approximately six full turns.

4. Pull lock screw out of slot under size bar so that roll

pin in lock screw will bypass slot. Position size bar so

that index line on lock screw is aligned with the end of

REMOVE DIES position.

5. Lay head down with numbers up.

6. Remove dies from die head.

Ridge Tool Company

10

7. Insert new dies to mark on side of dies. Numbers 1

through 4 on the dies must match numbers on the

die head.

8. Move throwout lever back to lock in dies.

9. With head in vertical position, rotate cam plate until roll

pin on lock screw can be positioned in slot under size

bar. In this position dies will lock in die head. Make

sure roll pin points toward end of size bar marked

REMOVE DIES.

10. Adjust die head size bar until index line on lock screw

or link is aligned with proper size mark on size bar.

Figure 10 – Universal Self-Opening Die Head

11. Tighten clamp lever.

12. If oversize or undersize threads are required, set

the index line in direction of OVER or UNDER size

mark on size bar.

535 Manual Pipe and Bolt Threading Machine

Roll Pin

Index Line

Size Bar

Lock Screw

Throwout

Lever

Clamp

Lever

Trigger

Assembly

Index Line

Link

Throwout

Lever

Washer

Head

Clamp Lever

Size Bar

Page 13

Installing Dies in

Model 816/817 Die Heads

The Semi-Automatic Die Head (Figure 11) for right hand

threads requires four sets of dies to thread pipe ranging

from 1/8″ through 2″. One set of dies is required for each

of the following pipe size ranges: (1/8″), (1/4″ and 3/8″), (1/2″

and 3/4″) and (1″ through 2″). Bolt threading requires a

separate set of of dies for each bolt size.

1. Depress handle so that camplate rests (Figure 8 –

Model 816/817 Die Head) against the stop. (As

shown).

2. Lay the Die Head down flat on a table or bench

with the numbers facing up.

3. Pull up on the plunger knob and push the handle all

the way to the left.

4. Select the correct dies for the size desired. (Size

marked on the back end or face of the dies.)

5. Numbers on the Dies must correspond with those on

the Die Head Slots. Insert Dies to the line marked on

the Dies – numbered edge up.

6. Rotate the handle back to the right so that the plunger

knob pops back down flush against the Die Head.

7. To set or adjust for desired depth of cut, loosen

the screw for the desired position block size, move

the block to the right to make it Under-Size and to

the left to make it Over- Sized. When setting blocks

for new dies start with the position block on the

middle mark and adjust from there.

Figure 11 – Semi-Automatic Die Head

Ridge Tool Company

11

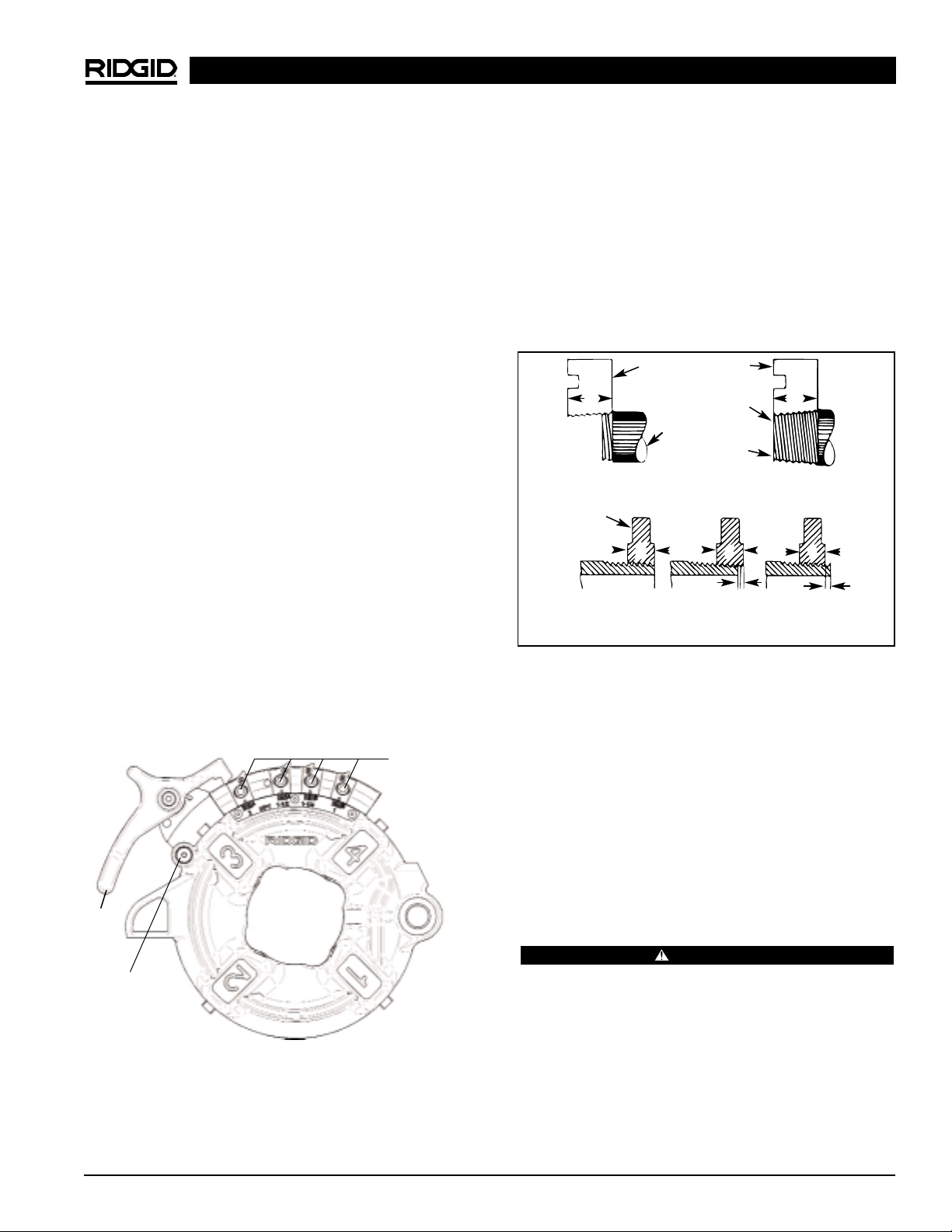

Checking Thread Length

(Figure 12)

1. Thread is cut to proper length when end of pipe is

flush with edge of dies (Figure 12).

2. Die head is adjustable to obtain proper thread diameter. If possible, threads should be checked with a

thread ring gage (Figure 12). A proper thread is cut

when end of pipe is plus or minus one turn of being

flush with face of ring gage.

Figure 12 – Checking Thread Length

NOTE! If a ring gage is not available, a fitting can be

used. This fitting should be representative of

those being used on the job. The pipe thread

should be cut to obtain 2 or 3 turns hand tight

engagement with fitting. If pipe thread is not proper diameter the index line should be moved in the

direction of the OVER or UNDER size mark on

size bar. (Refer to “Installing Dies In Die Heads”).

Priming Oil Pump

Current 535 Machines have a self-priming gerotor-type

pump. Machines made prior to June 1, 1996 have a

Model A vane-type pump that may require priming.

WARNING

All 535 Threading Machines made prior to June 1, 1996

should have a tube extension on the oil pump priming

port, as well as a top cover access hole, so the pump can

be primed without removing the top cover of the machine.

This will prevent the operator from contacting the internal

gearing of the machine which could result in serious injury.

If your older-style machine has a Model A Vane-Type pump

and does not have a priming port, contact the Ridge Tool

Company at 1-800-519-3456 or e-mail techservices@ridgid.com regarding a retrofit policy.

535 Manual Pipe and Bolt Threading Machine

WW

D

D

D

Die

Pipe

Die

Pipe

A - Full Width Die Thread

Starting to Cut Thread

Flush

(Basic Size)

One Turn Large

(Maximum Size)

One Turn Small

(Minimum Size)

Thin Ring

Gage

Completed Thread

Die Flush

With End

of Pipe

B - Checking Threads Within Pipe Gage

Handle

Plunger Knob

Size Block

Page 14

Ridge Tool Company

12

To prime the Model A Pump, the following procedure

should be followed:

1. Remove button plug located on cover.

2. Remove primer screw through opening with allen

wrench.

3. Fill pump with oil.

4. Replace primer screw and button plug before starting

machine or pump will drain itself immediately.

NOTE! If machine must be primed on a frequent basis,

it is an indication the pump is in need of repair.

Operation Instructions Using

Geared Threaders

WARNING

Do not wear gloves or loose clothing when operating Threading Machine. Keep sleeves and jackets buttoned. Do not reach across the machine,

geared threader or drive shaft.

Do not use this Threading Machine if the foot switch

is broken or missing. Always wear eye protection to

protect eyes from dirt and other foreign objects.

To prevent tipping, proper set-up of the Threading

Machine and Geared Threader is required. Follow

instructions carefully.

Geared Threaders weigh 95 to 160 pounds. Two (2)

persons should be used to lift these threaders.

Adjusting Nos. 141 and 161 Geared

Threaders

Cam Plate (Pipe Size) Adjustment Procedure

1. Place threader on floor or workbench with drive

shaft up.

2. Pull knobs (Figure 13) of cam plate and rotate cam

plate to desired pipe size marking on top of die head.

Release knobs when locating pins drop into hole in

selector plate.

Thread Size Adjustment Procedure

Grasp workholder and turn square end of drive shaft or

turn gear case by hand to respective reference lines on

guide post (Figure 13).

Standard Size Thread - Either one of the following two

(2) reference lines may be used.

Reference Line 1: Set bottom surface of die head at

red STANDARD line on pinion sleeve.

Reference Line 2: Set upper surface of die head

which houses guide post even with STANDARD line

at top end of guide post.

Oversize Thread: For oversize (shallow thread) set head

at bottom line on guide post. This line is marked (2T

OVER).

Undersize Thread: For undersize (deep thread) set head

at top line on guide post. This line is marked (2T UNDER).

Changing Posts For Straight Or Tapered

Threads

1. Adjust threader to cut standard size threads using

“STANDARD” reference line.

2. Remove screw from gear case at base of guide

post.

3. Pull guide post up until guide block attached to selector plate is disengaged from angle slot in guide post.

4. Turn guide post until straight slot faces inward for

535 Manual Pipe and Bolt Threading Machine

Guide Post

Head

Drive Shaft

Clamp Screw

Cam Plate

Knob (2)

Reference

Lines (3)

Figure 13 – No. 141 Geared Threader with Drive Shaft

Up (No. 161 Threader Similar).

Page 15

535 Manual Pipe and Bolt Threading Machine

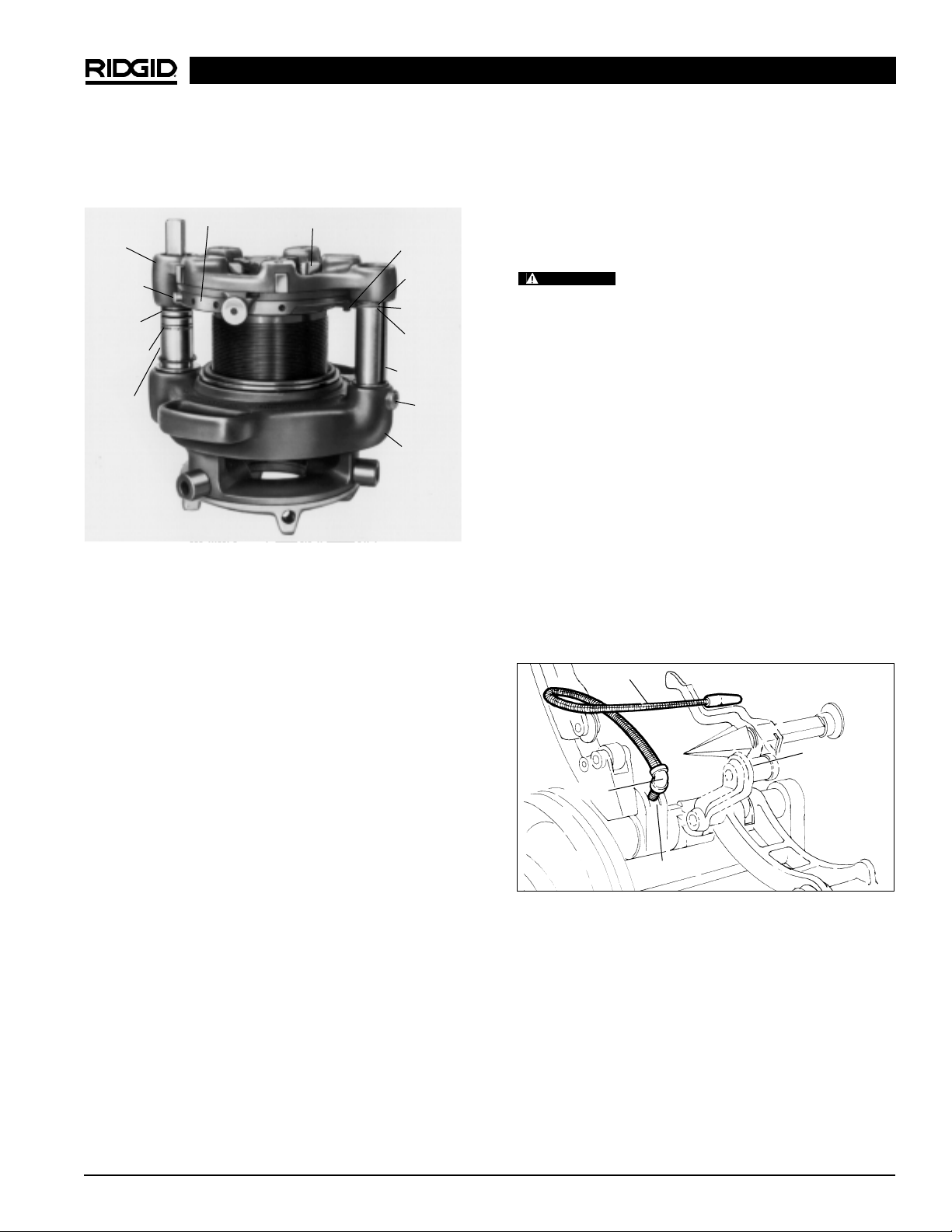

Installing No. 141 Geared Threader

(Close-Coupled Method)

Threading pipe with a No. 141 Geared Threader (closedcoupled method) requires a No. 768 Drive Link Assembly,

No. 844 Drive Bar saddle adapter for high clearance carriage and a RIDGID Support Stand.

The REV/OFF/FOR switch should be in

the OFF position until geared threader is installed and

ready to thread.

1. Remove die head from machine.

2. Raise cutter and reamer out of way and move carriage to front.

3. Open front chuck jaws and workholder jaws.

4. Old-style 535: Install replacement oil spout (Figure 15)

which includes pipe nipple E-811, 90 degree elbow E812 and coolant nozzle E-810 and 44340 pivot plug

and o-rings.

New style 535: Multi-position oil spout is attached to

E-814-X Drive Link (Figures 17A, B).

NOTE! No. 768 Drive Link Assembly includes: E-814-X

Drive Link, E-810 Coolant Nozzle, E-811 Pipe

Nipple, E-812 90 Degree Elbow E-1178-X Pipe

With Coupling, E-2978 Set Screw, 44340 Pivot

Plug and 44470 O-Rings.

Figure 15 – Oil Spout Used With Geared Threader

Close-Coupled Method (Old Style 535)

5. Install No. 844 Drive Bar (Figure 16) onto 141 Geared

Threader Drive Shaft and tighten two (2) set screws

using 5/16″ socket head wrench.

Ridge Tool Company

13

straight thread, or tapered slot inward for tapered

thread. Figure 14 shows guide post set to cut tapered

thread.

5. Engage guide block in slot and push guide post

down into position.

6. Replace guide post screw.

Unit is now set to cut straight threads (NPSM or BSPP)

or taper threads (NPT or BSPT).

Changing Die Set

1. Remove stop screw (Figure 14) from selector plate.

2. Pull Knobs (Figure 13) and rotate cam plate to CD

mark on top of die head.

3. Remove worn die set (Figure 14) and insert new die set.

IMPORTANT: Be sure to replace complete die set.

Die numbers must correspond with slot

numbers.

4. Rotate cam plate to original position and replace

stop screw.

NOTE! If it becomes necessary to remove or replace

the guide block, the stamped number E-1997 on

guide block must be AGAINST selector plate. If

stamped number is visible you will cut an

UNDERSIZE thread.

Figure 14 – No. 141 Geared Threader showing Pinion

Sleeve and Guide Post Reference Lines

Die (Set of 5)

Guide

Block

2T Under

Line

Standard

LIne

2T Over

Line

Screw

Guide Post

Gear Case

Selector

Plate

Die Head

Stop

Screw

Red Stop

Line

Standard

Line

Pinion

Sleeve

Coolant Nozzle

Drive Link

(Do not Install)

Elbow

Pipe Nipple

WARNING

Page 16

535 Manual Pipe and Bolt Threading Machine

Figure 16 – No. 844 Drive Bar and Drive Link Installed

6. Insert E-814-X Drive Link into loop hole on 141

Geared Threader. Using a 1/4″ socket head wrench,

tighten E-2978 Set Screw only enough to retain E814-X Drive Link, allowing it to swing freely.

NOTE! On 535s with high clearance carriage a leveling

saddle must be used in conjunction with Model

141 Geared Threader. (Figure 18)

7. Using two persons, Raise 141 Geared Threader and set

on carriage. Resting 141 Geared Threader on carriage, move carriage rearward and engage No. 844

Drive Bar in 535 front chuck and rear centering device.

8. Align grooves on No. 844 Drive Bar with front chuck

jaws and grip securely using chuck handwheel and

workholder centering head.

Be sure that No. 844 Drive Bar is prop-

erly engaged and secured.

9. Supporting 141 Geared Threader, move carriage

and fully engage E-814-X Drive Link Assembly in

die head mounting hole on carriage. Tighten E-2978

Set Screw.

If pipe extends beyond machine bed, it

should have a pipe support. Be sure that adjusting collar on pipe support stand is locked securely.

10. Support pipe with a pipe support. Position support

approximately 21/2feet from threader.

11. Insert pipe in threader and center end of pipe in

throat of dies. Tighten workholder with socket wrench.

12. Tighten clamp screw securely with socket wrench.

Ridge Tool Company

14

Figure 17A – 141 Geared Threader Close-Coupled To

New-Style 535 using 768 Drive Link. Note

Oil Spout Attached To E-814-X Link.

Figure 17B – 141 Geared Threader Closed-Coupled to

New-Style 535 Showing Position Of Oil

Spout On Workpiece.

Figure 18A – Geared Threader Saddle Adapter

WARNING

WARNING

141 Geared Threader

Set Screw (2)

No. 844 Drive Bar

Drive Shaft

Set Screw E-2978

Drive LInk

Page 17

Ridge Tool Company

15

535 Manual Pipe and Bolt Threading Machine

Figure 18B – Saddle Adapted Mounted on 535 Carriage

Threading Using No. 141 Geared

Threader (Close-Coupled Method)

1. Install geared threader and pipe.

2. Turn Threading Machine REV/OFF/FOR switch to

FOR (Forward) position.

3. Step on foot switch.

4. Flood dies with RIDGID Thread Cutting Oil during

threading operation to assure long die life.

5. Release foot switch when red STOP line appears on

pinion sleeve (Figure 14).

NOTE! RIDGID Geared Threaders have a jam-proof

design so pinion shaft will automatically disengage if threader is accidentally run on pipe past

a full thread length.

6. Turn REV/OFF/FOR switch to REV (Reverse) position. Step on foot switch and back threader off of

pipe.

IMPORTANT: Do not loosen workholder until dies have

been disengaged from pipe.

7. Using the socket wrench, loosen clamp screw, turn

workholder to OPEN position and remove pipe.

NOTE!: Before threading next piece of pipe, run thread-

er head beyond STANDARD line on pinion

sleeve and then back to STANDARD line. This

movement takes up slack in gearing for immediate response when cutting next thread.

8. Turn REV/OFF/FOR switch to OFF position.

IMPORTANT: If, by accident, a RIDGID Geared Thread-

er is backed off too far and threaded barrel becomes disengaged from workholder, the threader must be removed from

the Threading Machine and put on a

bench. Re-engage the threads carefully

by hand. Do not attempt this by power.

Installing Nos. 141 and 161 Geared

Threaders Using No. 840A Universal

Drive Shaft

WARNING

Chain vise must be securely anchored with jack

screw assembly and post to ceiling or bolted to

floor. Failure to follow these instructions could

result in the Vise tipping and causing serious injury.

When threading pipe up to 5 inches nominal, the

450 Tristand Vise can be used. However, when

threading 6 inch nominal pipe, a BC-610, BC-810

Top Screw Bench Chain Vise or a 460 Tristand

Vise must be used.

Only use 535 machines that operate at 36 RPM

when threading with a geared threader using the

No. 840A Universal Drive Shaft. Higher speeds

may result in tipping.

Refer to Figure 19.

1. Adjust threader being used.

The REV/OFF/FOR switch should be in

the OFF position until geared threader is set up and

ready to thread.

2. Slide long hexagon end of the universal drive shaft

into rear centering device head and through to front

chuck of No. 535 Machine.

3. Make certain that universal drive shaft is centered in

centering device head and front chuck jaws; tighten

securely.

4. Locate chain vise in line, on same level, and approx-

imately length of universal drive shaft away from

centering head device.

5. Tightly secure pipe in No. 460 Tristand Chain Vise.

6. Support long piece of pipe with Pipe Support.

7. Using two persons, position workholder so that a

jaw is on top center and slide threader onto pipe.

Carefully center end of pipe in throat of dies.

8. Using socket wrench, tighten workholder clamp screw

(Figure 13) securely.

9. Slip square socket of No. 840A Universal Drive Shaft

over square end of threader drive shaft and tighten

two (2) set screws.

WARNING

Page 18

Figure 19 – Threading Pipe using No. 840A Universal

Drive Shaft

No. 819 Nipple Chuck

The RIDGID No. 819 Nipple Chuck is a quick and easy

tool for holding short and close nipples or studs for

threading.

Capacity:1/8″ to 2″Standard Pipe (NPT)

1

/4″ to 2″ Bolts or Studs UNC or UNF

Short or Close Nipple Threading

Procedure

The REV/OFF/FOR switch should be in

the OFF position until nipple chuck is set up and ready

to thread.

1. Grip pipe in machine chuck. Thread and ream one

end and cut nipple to desired length.

2. Place nipple chuck body (Figure 20) in Threading

Machine chuck, gripping jaw grooves. Tighten chuck

with snap spin of handwheel.

3. Position insert with small end toward chuck body for

1

/8″ to 3/4″ pipe; large end toward chuck body for 1″

pipe; no insert required for 11/4″ pipe and up.

4. Select proper size nipple chuck adapter and screw

Ridge Tool Company

16

535 Manual Pipe and Bolt Threading Machine

IMPORTANT: When properly positioned, sliding shank

of universal drive shaft should be approximately centered to allow movement in

either direction.

10. Position No. 418 Oiler directly under threader.

Threading Pipe Using Nos. 141 & 161

Geared Threaders with No. 840A

Universal Drive Shaft

1. Install geared threader and pipe.

2. With REV/OFF/FOR switch in REV position, step on

foot switch.

3. Flood dies with RIDGID Thread Cutting Oil using

RIDGID 418 Oiler during threading operation to assure

long die life. 141 and 161 – Release foot switch when

red stop line appears on pinion sleeve. (Figure 14)

NOTE! RIDGID geared threaders are jam proof designed

so that pinion shaft will automatically disengage

if threader is accidentally run on pipe past a full

thread length.

4. Turn REV/OFF/FOR switch to FOR (forward) position

to back geared threader off pipe.

NOTE! Do not loosen workholder until dies have been

disengaged from pipe.

141 and 161 – Step on foot switch and reverse

threader one or two revolutions. Pull knobs (Figure

13) and rotate cam plate as far as it will go towards

CD mark on head to disengage dies.

5. Turn REV/OFF/FOR switch to OFF position.

6. Loosen two (2) set screws (Figure 19) and remove

universal drive shaft from threader.

NOTE! Do not loosen workholder until dies have been

disengaged from pipe.

141 and 161 – Loosen jaw clamp screw (Figure 13)

and turn workholder to OPEN position. Remove

threader.

7. Loosen chain vise and remove pipe.

8. Open centering device head to release No. 840A

Universal Drive Shaft.

NOTE! If by accident, a RIDGID Geared Threader is

backed off too far and threaded barrel becomes

disengaged from workholder, the threader must

be put on a bench and the threads re-engaged

carefully by hand. Do not attempt this by power.

WARNING

Pipe Adapters Stud Adapters

1

/8″, 1/4″, 3/8″, 1/2″,

1

/4″ to 2″ UNC

3

/4″, 1″, 11/4″, 11/2″

1

/4″ to 11/2″ UNF

No. 418 Oiler

No. 141

Geared Threader

No. 840A

Drive Shaft

No. 460 Tristand

Chain Vise

Set

Screw (2)

Foot Switch

Centering Head

Page 19

Ridge Tool Company

17

Accessories

Only the following RIDGID products have

been designed to function with the 535 Threading

Machine. Other accessories designed for use with other

tools may become hazardous when used on this

Threading Machine. To prevent serious injury, use only

the accessories listed below.

Accessories For Threading Machine

Die Head Racks:

4U...........................holds 4 heads

6U...........................holds 6 heads

Stands:

No. 100A.................4 legs w/tray

No. 150A.................2 wheels w/tray

No. 200A...................2 wheels w/enclosed cabinet

Pipe Supports:

VJ-99......................281/4″ – 521/2″

RJ-99......................301/2″ – 543/4″

No. 819 Nipple Chuck (Right Hand only):

Pipe Adapters...........1/8″ through 11/2″

Stud Adapters..........1/4″ through 2″ UNC

1

/4″ through 11/2″ UNF

Model MJ-1 Pump Kit for Left Hand Threading

Accessories for Threading By Close-Coupled

Method

No. 768 Drive Link Assembly & No. 844 Drive Bar

for No. 141 Geared Threader

Saddle Adapter for Model 141

No. 141 Geared Threader for 21/2″ – 4″ Threading

VJ-99/RJ-99 Pipe Support Stand

Accessories for Threading with Drive Shaft

No. 840A Universal Drive Shaft (41″ closed, 50″

extended)

No. 460 Tristand Chain Vise

No. 418 Oiler

VJ-99/RJ-99 Adjustable Pipe Support

Nos. 141 Geared Threader 2

1

/2″ to 4″ Threading

No. 161 Geared Threader 4″ to 6″ Threading

NOTE! See Ridge Tool catalog for complete list of pipe

supports, thread cutting oil and dies.

535 Manual Pipe and Bolt Threading Machine

into nipple chuck (Figure 20) by hand. Tighten with

wrench provided with nipple chuck.

To prevent injury, remove wrench before

turning on machine.

5. Screw nipple (Figure 21) threaded on one end into

adapter by hand. Turn directional switch to ON and

press down on foot switch. Ream and thread other

end.

6. Insert pin on end of wrench (Figure 21) into one of

holes in nipple chuck release collar and turn. Remove

threaded nipple by hand.

To prevent injury, remove wrench before

turning on machine.

Figure 20 – Installing Nipple Chuck Body

Figure 21 – Installing Unfinished Nipple and Releasing

Finished Nipple with Wrench

Nipple

Release

Collar

Wrench

WARNING

Adapter

Wrench

WARNING

WARNING

Page 20

Ridge Tool Company

18

535 Manual Pipe and Bolt Threading Machine

Maintenance Instructions

WARNING

Make sure machine is unplugged from power

source before performing maintenance or making any adjustment.

Lubrication

Proper lubrication is essential to trouble-free operation

and long life of Power Drive.

1. Remove four (4) cover mounting screws and remove

the cover.

2. Use grease gun to apply grease to the shaft bearing

grease fittings every 2 to 6 months, depending upon

frequency of machine use.

3. Apply moderate coat of lubricating grease on large

gear each time bearings are lubricated.

Do not operate the threading machine

with cover off. Always replace cover immediately after

lubricating machine.

Oil System Maintenance

To help assure proper operation of threading machine,

keep oil system clean, as follows:

1. Replace thread cutting oil when it becomes dirty or

contaminated. To drain the oil, position a container

under drain plug and remove plug.

2. Keep oil filter screen clean to assure proper flow or

clean oil to work. Oil filter screen is located in the bottom of oil reservoir. To clean filter screen, loosen

the screw that secures filter to base and pull filter from

Die Heads and Dies

Pipe Bolt

Model Capacity Capacity Dies Opening Operation

811A NPT

1

/8″ - 2″

1

/4″ - 2″ Universal Quick R.H.

815A NPT

1

/8″ - 2″

1

/4″ - 2″ Universal Self R.H.

842 NPT

1

/4″ - 2″ — Universal Quick L.H.

816 NPT

1

/8″ - 3/4″

1

/4″ - 2″ Universal TAP R.H.

817 NPT 1″ - 2″

1

/4″ - 2″ Universal TAP R.H.

811A BSPT

1

/8″ - 2″

1

/4″ - 2″ Universal Quick R.H.

815A BSPT

1

/8″ - 2″

1

/4″ - 2″ Universal Self R.H.

531 Bolt —

1

/4″ - 1″ 500B Quick R.H./L.H.

532 Bolt — 1

1

/8″ - 2″ 500B Quick R.H./L.H.

Universal Pipe Die

NPT NPSM

(Catalog Numbers)

1

/8″

1

/4″ - 3/8″

1

/2″ - 3/4″ 1″ - 2″

1

/8″

1

/4″ - 3/8″1/2″ - 3/4″ 1″ - 2″

H.S. R.H. 47755 47760 47765 47770 47845 47850 47855 47860

H.S. L.H. — 47810 47815 47820 ———70775

H.S. for S.S. R.H. 47775 47780 47785 47790 ————

H.S. for C.I. R.H. ———70740 ————

H.S. for PVC R.H. ——70745 70750 ————

H.S. for Coated R.H. ———31822 ————

Universal Pipe Die

BSPT BSPP

(Catalog Numbers)

1

/8″

1

/4″ - 3/8″

1

/2″ - 3/4″ 1″ - 2″

1

/8″

1

/4″ - 3/8″1/2″ - 3 /4″ 1″ - 2″

H.S. R.H. 66750 66755 66760 66765 66795 66800 66805 66810

H.S. L.H.

—

66840 66845 66850

——

66870 66875

H.S. for S.S. R.H. 66770 66775 66780 66785 66815 66820 66825 66830

H.S. for S.S. L.H.

—

66855 66860 66865

————

H.S. for PVC R.H.

——

70755 70760

——

70765 70770

H.S. for Coated R.H.

———

31837

————

Note: BSPT and BSPP Dies require a British Model Die Head

Note: L.H. operation of the 1822-I requires special set up

Note: High Speed Dies are recommended for threading 1″ - 2″ pipe at 45 RPM

Universal Bolt Dies for 811A, 815A, 816 and 817 Die Heads

Over 90 sets available from 1/4″ to 2″, Alloy or High Speed.

Right Hand only in UNC, UNF and BSW thread forms.

500B Bolt Dies for 531 and 532 Die Heads

Over 200 sets for the 531 Bolt Die Head

Over 150 sets for the 532 Bolt Die Head

Mono Dies for Mono (A Series) Die Heads

WARNING

Page 21

Service and Repair

WARNING

Service and repair work on this Threading Machine

must be performed by qualified repair personnel.

Machine should be taken to a RIDGID Independent

Authorized Service Center or returned to the factory. All

repairs made by Ridge service facilities are warranted

against defects in material and workmanship.

When servicing this machine, only identical replacement parts should be used. Failure to follow these

instructions may create a risk of electrical shock or

other serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-Mail: techservices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool

Company at (800) 519-3456 or http://www.ridgid.com

oil line. Clean filter screen in solvent and blow out with

compressed air if available. Do not operate machine

with oil filter screen removed.

NOTE! RIDGID Thread Cutting Oil produces high quality

threads and maximizes die life. For information

concerning its use and handling, refer to the labels

on the oil containers. Disposal of the oil should be

in accordance with government regulations.

Jaw Insert Replacement

NOTE! When teeth on jaw inserts become worn and fail

to hold pipe or rod during operation, replace

entire set of jaw inserts. Clean teeth of jaw inserts daily with wire brush.

1. Place screwdriver in insert slot and turn 90 degrees

in either direction.

2. Place insert sideways on locking pin and press

down as far as possible.

3. Hold insert down firmly with screwdriver, turn so teeth

face up.

Figure 18 – Jaw Insert Replacement

Motor Brush Replacement

Check motor brushes every six (6) months and replace

brushes when they are worn to less than 1/2″. If commutator is worn, turn outer dimensions of commutator

and undercut mica before replacing brushes.

Machine Storage

Motor-driven equipment must be kept

indoors or well covered in rainy weather. Store the

machine in a locked area that is out of reach of children

and people unfamiliar with threading machines. This

machine can cause serious injury in the hands of

untrained users.

Ridge Tool Company

19

535 Manual Pipe and Bolt Threading Machine

WARNING

To Remove

To Replace

Screw Driver

Insert

Locking

Pin

Teeth

PRESS

DOWN

➔

Page 22

Ridge Tool Company

20

535 Manual Pipe and Bolt Threading Machine

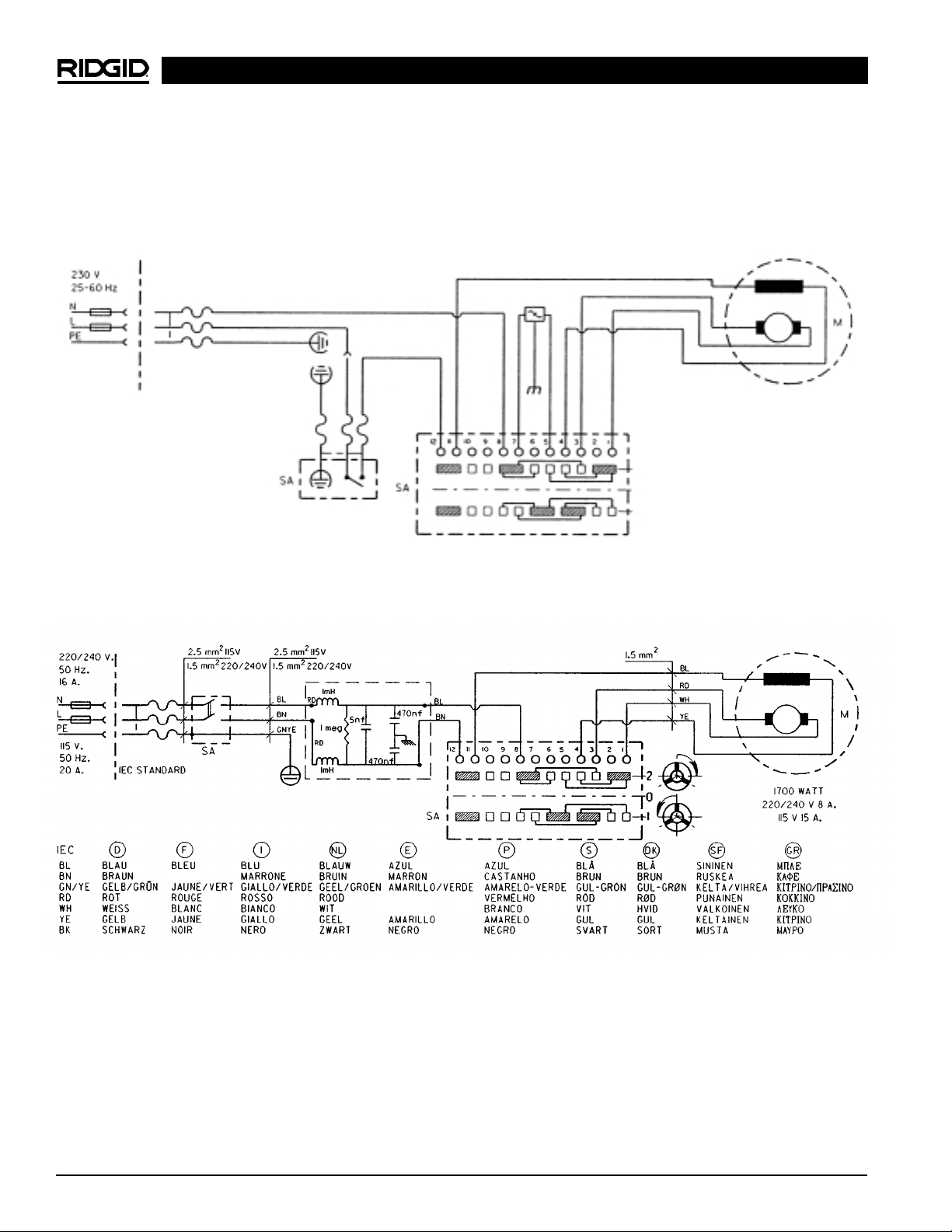

1101 Motor (115V)

2301 Motor (230V)

1101A Motor (115V)

European Wiring Diagram

White (Blue)

Black (Brown)

Green (Green/Yellow)

115V

25-60 Hz

IEC Standard

Black

Green

White

Black

Green/Yellow

Black

Suppressor

Yellow

White

Red

Blue

OFF

FWD

REV

Foot Switch

Wiring Diagrams

MARRON

ROJO

BLANCO

Page 23

Machine à fileter manuelle

Modèle 535 pour tuyaux

et boulons

Machine à fileter manuelle Modèle 535 pour tuyaux

et boulons

Inscrivez ci-dessous le numéro de série de la plaque signalétique l’appareil pour future référence.

N° de

série :

Page 24

Machine à fileter manuelle Modèle 535 pour tuyaux et boulons

Ridge Tool Company

22

Table des matières

Consignes générales de sécurité

Sécurité du chantier..................................................................................................................................................23

Sécurité électrique....................................................................................................................................................23

Sécurité personnelle.................................................................................................................................................23

Utilisation et entretien de l’appareil...........................................................................................................................24

Service après-vente..................................................................................................................................................24

Consignes de sécurité particulières

Sécurité de la pédale de commande ........................................................................................................................24

Sécurité de la machine .............................................................................................................................................25

Description, spécification et équipements de base

Description................................................................................................................................................................25

Spécifications............................................................................................................................................................25

Equipements de base...............................................................................................................................................26

Assemblage de la machine

Montage de la machine sur support..........................................................................................................................26

Montage de la machine sur établi.............................................................................................................................27

Inspection de la machine............................................................................................................................................27

Préparation de la machine et du chantier.................................................................................................................28

Utilisation de la machine et des outils à montage direct

Installation des tuyaux sur la machine à fileter.........................................................................................................29

Coupe des tuyaux à l’aide du coupe-tubes N° 820...................................................................................................30

Alésage des tuyaux à l’aide de l’alésoir N° 341........................................................................................................30

Filetage des tuyaux et tiges à l’aide des filières à ouverture rapide, ouverture automatique ou

ouverture semi-automatique..................................................................................................................................31

Retrait des tuyaux de la machine à fileter.................................................................................................................31

Filetages à gauche....................................................................................................................................................31

Installation des filières sur la tête de filière à ouverture rapide (filetages à droite et à gauche) ...............................32

Installation des filières sur la tête de filière à ouverture automatique (filetage à droite uniquement) .......................32

Installation des filières sur les têtes de filière N° 816 et N° 817................................................................................33

Vérification de la longueur de filetage.......................................................................................................................33

Amorçage de la pompe à huile.................................................................................................................................34

Utilisation des filières démultipliées

Réglage des filières démultipliées N° 141 et N° 161................................................................................................34

Réglage des dimensions de filets.............................................................................................................................35

Positionnement des poteaux pour filetages droits et coniques.................................................................................35

Remplacement des filières........................................................................................................................................35

Installation de la filière démultipliée N° 141 (entraînement direct)............................................................................36

Filetage des tuyaux avec la filière démultiplié N° 141 (entraînement direct) ............................................................38

Installation des filières démultipliées N° 141 et N° 161 à l’aide de l’arbre d’entraînement universel N° 840A .........38

Filetage des tuyaux avec les filières N° 141 et N° 161 montées sur l’arbre d’entraînement universel N° 840A ......39

Mandrin à raccords N° 819

Filetage des manchons et raccords..........................................................................................................................40

Accessoires

Accessoires de la machine à fileter ..........................................................................................................................40

Têtes de filière et filières...........................................................................................................................................41

Entretien

Lubrification...............................................................................................................................................................41

Entretien du système de lubrification........................................................................................................................42

Remplacement des mâchoires .................................................................................................................................42

Remplacement des balais du moteur .......................................................................................................................42

Stockage de la machine............................................................................................................................................42

Service après-vente et réparations............................................................................................................................43

Schémas électriques...................................................................................................................................................44

Garantie à vie...........................................................................................................................................Page de garde

Page 25

Ridge Tool Company

23

Machine à fileter manuelle Modèle 535 pour tuyaux et boulons

• Evitez tout contact avec les surfaces mises à la

terre. Le contact avec des masses augmente les

risques de choc électrique.

• N’exposez pas les appareils électriques aux intem-

péries ou à l’eau. Toute pénétration d’eau à l’intérieur

de l’appareil augmente les risques de choc électrique.

• Ne maltraitez pas le cordon électrique de l’appareil.

Ne jamais porter l’appareil par son cordon électrique, ni tirer sur celui-ci pour débrancher

l’appareil. Gardez le cordon à l’abri des sources de