Page 1

Double Insulated Variable Speed Dual Action

Reciprocating Saw

OPERATOR’S

MANUAL

• Pour français voire page 9

• Para el castellano vea la

página 19

5228

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of this

manual may result in electrical shock, fire and/or serious

personal injury.

Page 2

Table of Contents

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Tool Safety..................................................................................................................................................................4

Description, Specifications and Equipment

Description ..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Accessories.................................................................................................................................................................4

Machine Operation Instructions

Blade Selection ...........................................................................................................................................................4

Blade Installation.........................................................................................................................................................4

Dual Motion.................................................................................................................................................................5

Start/Stop Switch.........................................................................................................................................................5

Gripping Saw Properly ................................................................................................................................................5

Pivoting Guide Shoe....................................................................................................................................................6

Using the Saw

Preparation..................................................................................................................................................................6

Sawing Wood..............................................................................................................................................................6

Plunge Cutting Wood ..................................................................................................................................................6

Edge Cutting Metal......................................................................................................................................................7

Maintenance Instructions

Failure to Start.............................................................................................................................................................7

Ventilation....................................................................................................................................................................7

Lubrication...................................................................................................................................................................7

Service and Repairs....................................................................................................................................................7

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Page 3

5228 Recipr ocating Saw

5228 Variable Speed Reciprocating Saw

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Page 4

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate power tools in explosive atmos-

pheres, such as in the presence of flammable

liquids, gases, or dust. Tools create sparks which

may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a tool. Distractions can cause you to lose

control.

• Do not let visitors contact the tool or extension

cord. Such preventative measures reduce the risk of

injury.

Electrical Safety

• Double Insulated tools are equipped with a polarized plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates

the need for the three wire grounded power cord and

grounded supply system.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Don’t expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a power tool outside, use an out-

door extension cord marked “W-A” or “W”. These

cords are rated for outdoor use and reduce the risk of

electrical shock.

• Connect the tool to an AC power supply that

matches the name plate specifications. Incorrect

voltage supply can cause electrical shock or burns.

• Use proper extension cords. (See chart.) Insufficient

conductor size will cause excessive voltage drop and

loss of power.

• Keep all electrical connections dry and off the

ground. Do not touch plug with wet hands. Reduces

the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is OFF be-

fore plugging in. Carrying tools with your finger on the

switch or plugging tools in that have the switch ON in-

vites accidents.

• Remove adjusting keys or switches before turning

the tool ON. A wrench or a key that is left attached to

a rotating part of the tool may result in personal injury.

• Do not over-reach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other

masonry products

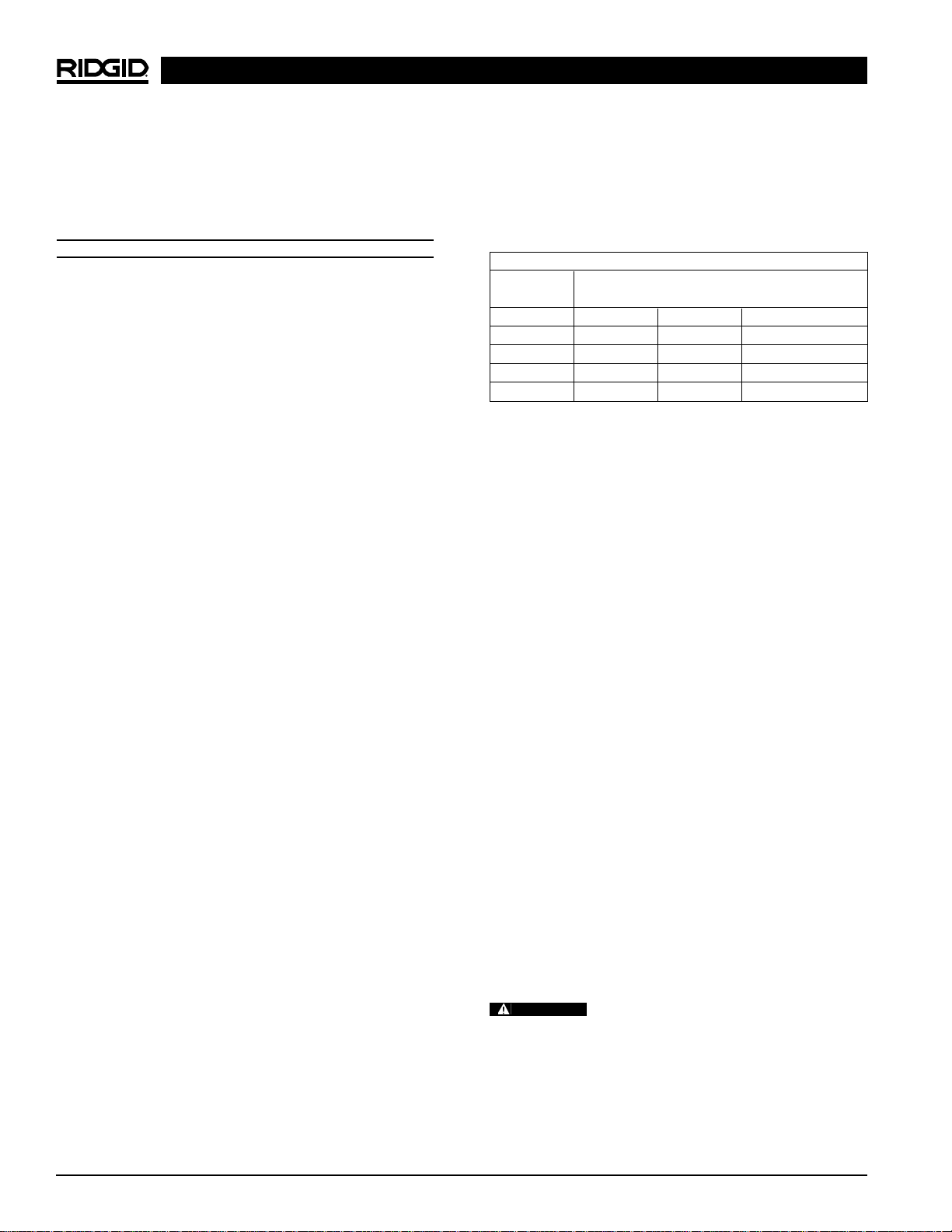

Minimum Wire Gauge for Cord Set

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

WARNING

Page 5

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Ridge Tool Company 3

• Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as

those dust masks that are specially designed to filter out

microscopic particles.

• Wear hearing protectors, ear plugs or muffs when

using tool. Noise level may affect hearing with pro-

longed use.

Tool Use and Care

• Use clamp or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable

and may lead to loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Disconnect plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures re-

duce risk of starting tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that

may affect the tools operation. If damaged, have the

tool serviced before using. Many accidents are

caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool may become hazardous when

used on another tool.

• Inspect tool and extension cords periodically and

replace if damaged. Damaged cords increase the

risk of electrical shock.

• Keep handles dry and clean; free from oil and

grease. This allows for better control of the tool.

• Store tools in dry place. Such measures reduce the

risk of electrical shock.

Service

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

• Follow instructions for lubricating and changing

accessories. Accidents are caused by poorly main-

tained tools.

Specific Safety Information

The Operator’s Manual contains specific safety information and instructions for your protection against serious

injuries including:

• Electrical shock or burns from contact with wires,

motor or other power drive parts;

• Eye injuries, including being blinded by the workpiece

or workpiece chips.

Read this operator’s manual carefully before using

the machine. Failure to understand and follow the

contents of this manual may result in electrical

shock, fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service

Department at (800) 519-3456 if you have any questions.

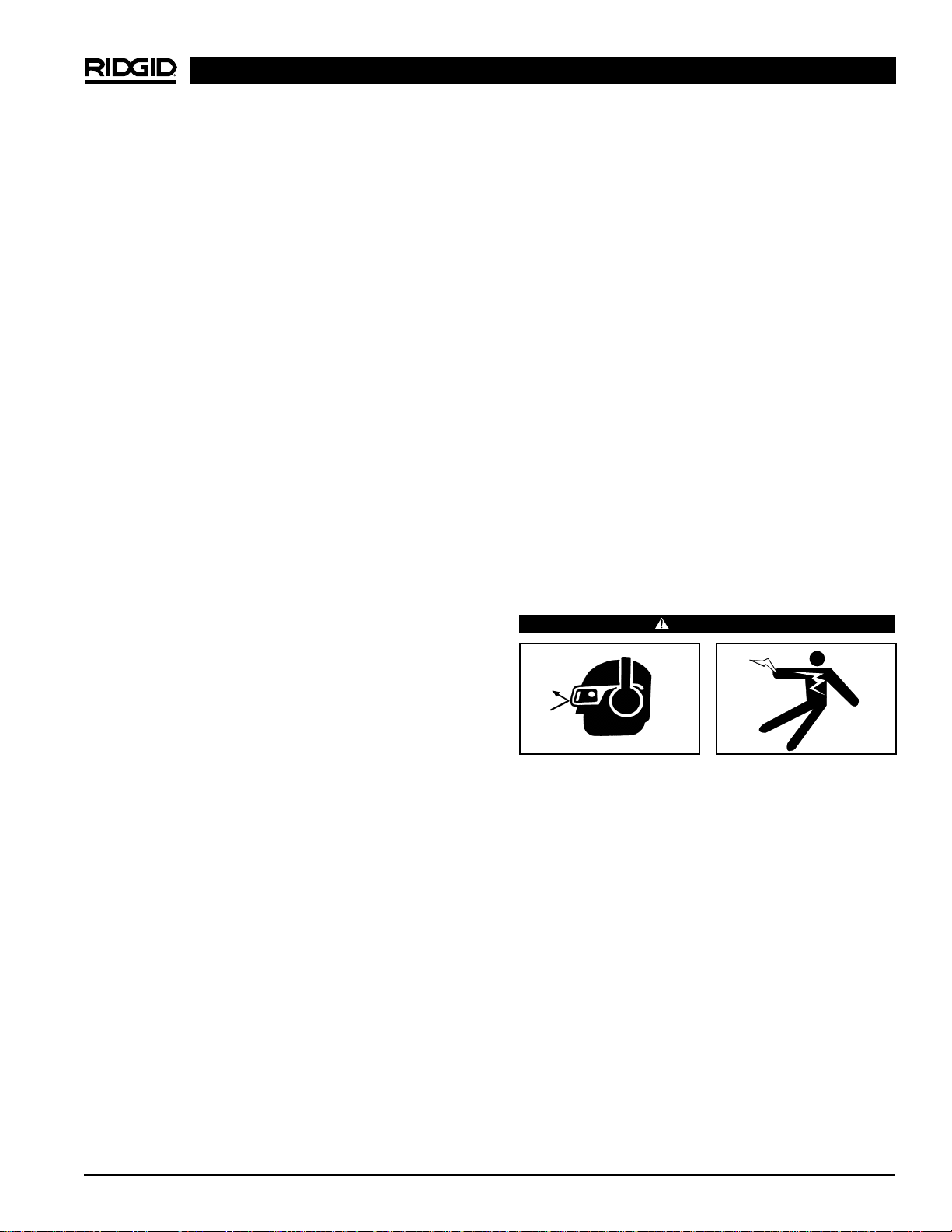

WARNING

Eye injuries can occur from thrown workpiece chips.

• Wear safety glasses or safety shield.

• Keep switch in working order.

• Do not use tool with damaged or worn electrical

cords.

• Do not use damaged saw blades.

Page 6

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Ridge Tool Company4

Specifications

Maximum Material Thickness

Metal Cutting.............3/

4

″

Wood Cutting ............12″

Blade Stroke..................11/

8

″

Motor

Type ..........................Universal

Rating........................115V, 25-60Hz., AC/DC

9.6A, 0-2600 Strokes/Min.

Switch

OFF/ON.....................Spring-return type

High Speed/

Low Speed ................Manual position

Length ...........................17″

Weight...........................9.0 Lbs.

Accessories

Carbon Steel

Saw Blade.................(1) D-999 6TPI

Blade Wrench............3/

16

″

(Hex Key Type)

Operating Instructions

WARNING

Before attempting to use this tool, read complete

operating instructions to become familiar with all

functions. As this tool was designed for specific applications, we strongly recommend that it NOT

be modified and/or used for any application other

than for which it was designed.

Blade Selection

A wide assortment of RIDGID blades is listed in the

RIDGID catalog. For maximum efficiency, long blade

life and smooth cutting, select the proper blade for work

being done. When cutting metal, always select blade

which will allow at least three teeth to be in contact with

the thickness of the material.

Blade Installation

No. 5228 Type II

The reciprocating shaft must be fully extended to permit

access to the blade release collar. If necessary, gently

squeeze the trigger switch to move the reciprocating

shaft to its outermost position. Pivot the guide shoe

FORWARD to improve access to the blade clamp.

Tool Safety

• Do not alter or misuse tool. Other uses may in-

crease the risk of injury.

• Position electric cord clear of saw blade. Damaged

cord can cause electrical shock.

• Do not reach across the saw or wear loose cloth

gloves. May become entangled in the tool causing

serious injury.

• Do not use dull or damaged saw blades. Less likely

to bind and lose control.

• Keep fingers and hands away from the saw blade.

Reduces the risk of being cut.

• Keep hands and feet clear of work pieces that may

fall after being cut. Reduces the risk of injury.

• Always use the blade recommended for the material being cut. Less likely to bind and lose control.

• Always hold saw as shown in Figure 4. Have the

rubber front housing cover properly installed and

not damaged. Prevents electrical shock resulting

from cutting a live wire when sawing into a wall or other

blind area.

• Do not operate with guide shoe removed. Can result

in blade breakage or losing control of the tool.

• Some wood contains preservatives which can be

toxic. Take extra care to prevent inhalation and skin

contact when working with these materials. Request,

and follow, any safety information available from your

material supplier.

SAVE THESE INSTRUCTIONS!

Description, Specifications and

Accessories

Description

The RIDGID No. 5228 Double Insulated Variable Speed,

Dual Action Reciprocating Saw is a professional quality,

extra heavy duty tool. This saw operates at variable

speeds and features a dual blade motion for efficient cutting of wood or metal. It is designed for cutting wood up to

12 inches thick, metal up to 3/4inches thick and various

other materials including hard rubber, laminates, fiberglass and plastics. The motor will operate on single-phase

25 to 60 Hertz AC current with voltage within plus or

minus 5% of that shown on the specification plate. Double

insulation of the tool provides protection equivalent to a

properly grounded three-conductor cord.

Page 7

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Ridge Tool Company 5

Always Disconnect Saw From Power

Source Before Installing or Removing Blades.

To open the blade clamp:

Rotate and hold the blade release collar, counter clockwise (as viewed from the front of the saw). Insert the

blade into the clamp until it bottoms. Allow the release

collar to rotate clockwise to secure the blade in place.

To remove a blade:

Rotate collar counter clockwise and hold it in the open

position. Carefully remove the blade from the clamp.

NOTE! If the blade clamp collar resists rotation to remove

a blade, work the blade up and down while rotating the clamp (in a counterclockwise direction).

If the blade breaks leaving nothing to grasp (to

pull it from the clamp), it may be necessary to

use another blade as a tool to aid in removing

the broken piece. While holding the release

collar in the open position, use the tip of another

blade to hook the broken piece and pull lit from

the clamp. (A thin, fine-toothed, metal-cutting

blade works best.)

Periodically clean the blade clamp with dry

compressed air. DO NOT lubricate the blade

clamp. Lubricant can attract contamination.

Wear safety glasses while using com-

pressed air.

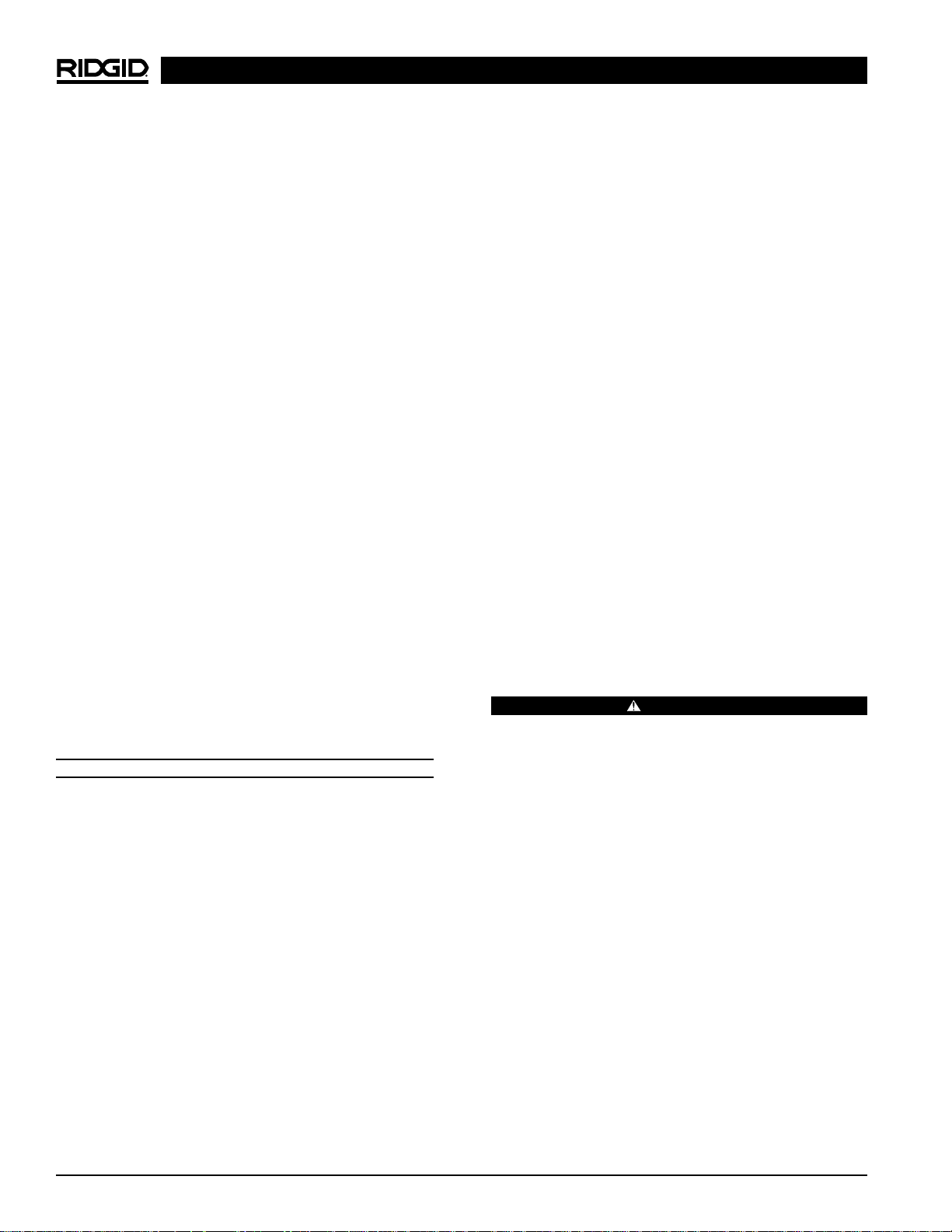

Dual Motion

The dual motion feature of the RIDGID Reciprocating

Saw provides cutting efficiency for both wood and metal.

When selector lever (Figure 1) is in the metal position

pointing up, the blade moves in a straight reciprocating

motion. When the lever is in the wood position pointing

toward front of saw, the blade moves in an orbital motion. (Figure 2)

Figure 1 – Saw motion when lever points up

Figure 2 – Saw motion when lever points to left

Figure 3 – Trigger Switch

Start/Stop Switch

The saw is operated by use of the trigger switch B

(Figure 3) in front of the handle. To start saw, depress

switch. To stop saw, RELEASE switch. Switch cannot

be locked into the ON position.

Gripping Saw Properly

For safe operation, the saw must be held as shown

(Figure 4). The plastic front housing cover must be

properly installed and not damaged. Always grip saw

firmly with two hands to prevent accidental slipping.

If the blade cuts into live wiring within a

wall, the blade and pivoting guide shoe may be made

electrically live.

Figure 4 – Proper way to hold Reciprocating Saw

UP

TO FRONT

OF SAW

SWITCH

WARNING

CAUTION

WARNING

Page 8

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Ridge Tool Company6

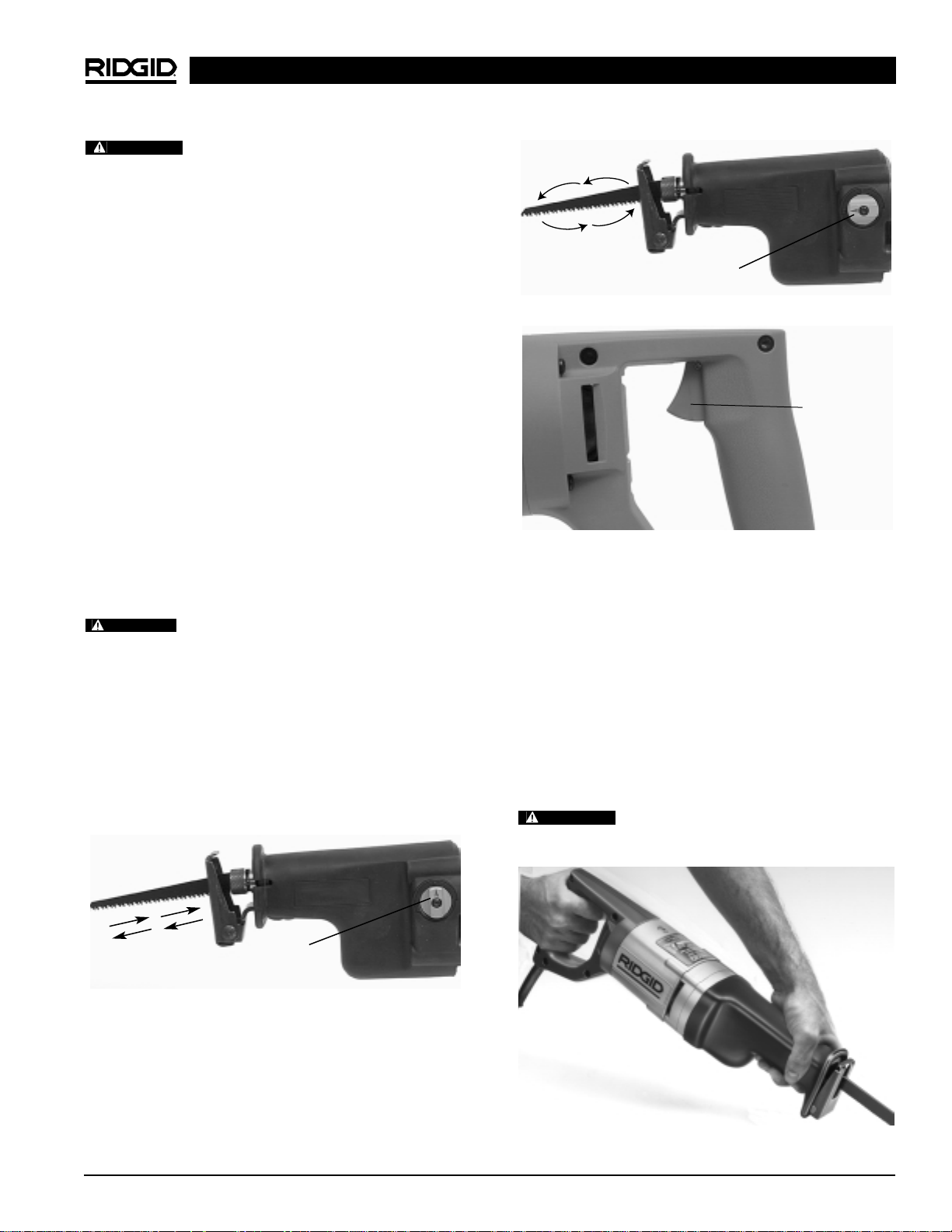

Pivoting Guide Shoe

The guide shoe (Figure 5) is designed to serve as a tool

rest while making a cut. The shoe pivots to allow the

saw to be raised to a position perpendicular to the work as

the saw is brought toward the operator while making a cut.

Figure 5 – Using pivoting guide shoe

Using the Saw

Preparation

Use the blade selector guide in the RIDGID catalog to

select the proper blade for the job to be done. For

greatest economy, use the shortest blade suitable for the

thickness of material to be cut. Set the blade speed

and motion most appropriate for the material to be cut.

Material to be cut should be firm and supported properly.

Clamp small work pieces to the worktable or clamp them

securely in a bench vise. Do not force the saw into the

work. The saw will cut freely with only slight feed pressure.

Sawing Wood

The RIDGID Reciprocating Saw makes its cut similar to

a hand saw in that it is moved toward the operator during the cutting operation. However, since the blade

makes its cut on the upstroke, the finished side of the

wood should face down during the cutting operation.

Plunge Cutting Wood

The RIDGID Reciprocating Saw can be used for plunge

cutting wood, plywood, wall board and plastic materials.

It is not recommended for plunge cutting metals. Grasp

front housing with one hand and rear handle with

other hand. To make plunge cut into wood or comparable material, start by holding saw parallel to material

(Figure 6). Rest shoe bracket of saw firmly against

material, start saw and pivot saw handle upward bringing blade in contact with material.

Keeping shoe bracket in firm contact with material, continue to raise handle until blade has cut through the

work and saw is perpendicular to the work surface

(Figure 7). With saw in perpendicular position, continue

to move blade along line of cut.

WARNING

When blind cutting into existing construction, exercise extreme caution to be certain that there is

no obstructions, such as electrical wires, conduit, plumbing, etc. that may come in contact

with the blade. For safe operation, the plastic

front housing cover must be properly in place and

undamaged. Hold saw only by plastic front housing

and handle.

Figure 6 – Starting plunge cut

Figure 7 – Proper way to hold saw when wood cutting

Guide Shoe

Page 9

Edge Cutting Metal

To cut metal from an edge, start the cut on the surface

where the greatest number of teeth will contact the work.

To avoid vibration of metal and blade chatter, hold saw

firmly against materiel while making cut.

To make a pocket cut in metal, first drill a starting hole

large enough for the blade to enter. To extend blade life

and facilitate better cutting, apply cutting oil to the work

surface along the line of the cut. Forcing saw into work

should be avoided. Allow saw blade to do the work

while guiding saw at moderate rate.

Maintenance Instructions

WARNING

Always unplug power cord before performing any

service on this tool.

Failure to Start

If the tool should fail to operate, confirm that the prongs

on the power cord are making good contact in the outlet.

Check for blown fuses or open circuit breakers in the line.

Ventilation

Keep air inlet passages clear to insure a cool running

motor. Periodically blow out all air passages with an air

jet. Wear safety glasses when performing this operation.

Never use solvents when cleaning plastic parts as this

could damage the finish.

Lubrication

After approximately 100 hours of operation, the saw

should be taken to a RIDGID Authorized Service Center

to be relubricated. At that time, the tool will be thoroughly cleaned and inspected and worn parts replaced

when necessary.

Ridge Tool Company 7

Service & Repairs

If any maintenance or repair is required other than that

outlined above, the tool should be sent to a RIDGID

Authorized Service Center or returned to the factory.

All repairs made by Ridge service facilities are warranted against defects in material and workmanship.

If you have any questions regarding the service or repair

of this saw, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool

Company at (800) 519-3456 or http://www.ridgid.com

In any correspondence, please give all information shown

on the Nameplate of your tool including Model Number,

Voltage and Serial Number.

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Page 10

5228 Double Insulated Variable Speed, Dual Action Reciprocating Saw

Ridge Tool Company8

Page 11

Scie alternative à vitesse variable modèle 5228

Notez ci-dessous le numéro de série qui parait sur la fiche signalétique du produit.

N° de

Série

Le Scie Alternative

Modèle 5228

Page 12

Table des Matières

Fiche d’enregistrement des numéros de modèle et de série de la machine ...........................................................9

Consignes de Sécurité Générales

Sécurité du chantier ..................................................................................................................................................11

Sécurité électrique.....................................................................................................................................................11

Sécurité personnelle..................................................................................................................................................11

Utilisation et entretien de l’appareil ...........................................................................................................................12

Réparations...............................................................................................................................................................12

Consignes de Sécurité Particulières

Sécurité de l’appareil.................................................................................................................................................13

Description, Spécifications et Equipements

Description ................................................................................................................................................................13

Spécifications............................................................................................................................................................14

Accessoires...............................................................................................................................................................14

Fonctionnement de l’Appareil

Sélection des lames..................................................................................................................................................14

Montage des lames...................................................................................................................................................14

Mouvement va-et-vient..............................................................................................................................................14

Interrupteur marche/arrêt ..........................................................................................................................................15

Prise en main de l’appareil........................................................................................................................................15

Sabot de guidage orientable .....................................................................................................................................15

Consignes d’utilisation

Préparation................................................................................................................................................................15

Coupe du bois...........................................................................................................................................................16

Coupe du bois en plongée ........................................................................................................................................16

Coupe des métaux....................................................................................................................................................16

Consignes d’Entretien

En cas de non démarrage.........................................................................................................................................17

Ventilation..................................................................................................................................................................17

Lubrification...............................................................................................................................................................17

Entretien et réparations.............................................................................................................................................17

Garantie à vie ...........................................................................................................................................Page de garde

Ridge Tool Company10

5228 – Scie alternative double isolement, double action, deux vitesses

Page 13

5228 – Scie alternative double isolement, double action, deux vitesses

Ridge Tool Company 11

Consignes générales de sécurité

MISE EN GARDE ! Familiarisez-vous avec l’ensemble des

instructions. Le respect des consignes

suivantes vous permettra d’éviter les

risques de choc électrique, d’incendie

et de blessure corporelle grave.

CONSERVEZ CES INSTRUCTIONS !

Sécurité du chantier

• Gardez le chantier propre et bien éclairé. Les établis encombrés et les locaux mal éclairés sont une

invitation aux accidents.

• N’utilisez pas d’appareils électriques dans un milieu explosif tel qu’en présence de liquides, de

gaz ou de poussière inflammable. Les appareils

électriques produisent des étincelles qui pourraient

causer la poussière ou les vapeurs de s’enflammer.

• Gardez les tiers, les enfants et les visiteurs à l’écart

lorsque vous utilisez un appareil électrique. Les dis-

tractions peuvent vous faire perdre le contrôle de

l’appareil.

• Ne laissez pas les visiteurs toucher la machine

ou ses rallonges électriques. De telles mesures

préventives réduisent les risques de blessure.

Sécurité électrique

• Les appareils à double isolement sont équipés

d’une fiche polarisée (une lame plus large que

l’autre). Cette fiche ne peut être introduite dans

un réceptacle polarisé que dans un sens. Si la

fiche ne s’enfonce pas complètement dans le réceptacle, inversez-la. Si elle ne s’enfonce toujours

pas complètement, confiez l’installation d’un réceptacle polarisé à un électricien qualifié. Ne tentez

pas de modifier la fiche d’une manière quelconque.

Le double isolement élimine le besoin d’un cordon

d’alimentation avec terre et d’un réseau d’alimentation

relié à la terre.

• Evitez tout contact de votre corps avec des surfaces reliées à la terre telles que les canalisations

métalliques, les radiateurs, les cuisinières et les

réfrigérateurs. Les risques de choc électrique aug-

mentent lorsque votre corps est mis à la terre.

• N’exposez pas les appareils électriques aux in-

tempéries ou aux endroits mouillés. La pénétration

de l’eau à l’intérieur de l’appareil augmente les risques

de choc électrique.

• Ne maltraitez pas le cordon électrique de l’appareil. Ne jamais porter l’appareil par son cordon

électrique, ni tirer sur celui-ci pour débrancher

l’appareil. Gardez le cordon à l’abri des sources de

chaleur, de l’huile, des angles tranchants et des

pièces mobiles. Remplacez immédiatement tout

cordon endommagé. Les cordons endommagés aug-

mentent les risques de choc électrique.

• Lorsqu’à l’extérieur, utilisez une rallonge élec-

trique marquée “W-A” ou “W”. Ce type de cordon est

prévu pour être utilisé à l’extérieur et réduit les risques

de choc électrique.

• Branchez l’appareil sur une source d’alimenta-

tion à courant alternatif qui correspond aux

indications portées sur la plaque signalétique.

Une tension incorrecte peut entraîner des chocs ou

des brûlures électriques.

• Utilisez les rallonges électriques appropriées.

(Consultez le tableau ci-dessous.) Une section de

conducteur insuffisante entraînera une chute de tension

excessive qui nuira aux performances de l’appareil.

• Maintenez toutes les connexions électriques au

sec et surélevées. Ne touchez pas la fiche avec vos

mains mouillées afin de limiter les risques de choc

électrique.

Sécurité personnelle

• Restez alerte, faites attention à ce que vous faites

et faites preuve de bon sens lorsque vous utilisez

un appareil électrique. N’utilisez pas ce type d’appareil lorsque vous êtes fatigués, ou lorsque vous

prenez des médicaments, de l’alcool ou des produits pharmaceutiques. Un instant d’inattention peut

entraîner de graves blessures lorsque l’on utilise un appareil électrique.

• Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ni de bijoux. Attachez les

cheveux longs. Gardez vos cheveux, vos vêtements

et vos gants à l’écart des pièces mécaniques. Les

vêtements amples, les bijoux et les cheveux longs peuvent s’entraver dans les pièces mobiles.

• Evitez les risques de démarrage accidentel.

Assurez-vous que l’interrupteur marche/arrêt est

éteint avant de brancher l’appareil. Porter l’appareil

avec un doigt sur la gâchette, ou le brancher lorsque

Section minimale des fils conducteurs des rallonges

Ampères indiqués

sur la plaque Longueur totale (en pieds)

signalétique

0 à 25 26 à 50 51 à 100

0 à 6 18 AWG 16 AWG 16 AWG

6 à 10 18 AWG 16 AWG 14 AWG

10 à 12 16 AWG 16 AWG 14 AWG

12 à 16 14 AWG 12 AWG

Déconseillé

Page 14

5228 – Scie alternative double isolement, double action, deux vitesses

Ridge Tool Company12

son interrupteur est en position de marche sont des invitations aux accidents.

• Enlevez les clés de réglage et autres outils avant de

mettre l’appareil en marche. Une clé laissée sur

une partie rotative de l’appareil peut entraîner des

blessures corporelles.

• Ne vous mettez pas en porte-à-faux. Gardez une

bonne assise et un bon équilibre à tous moments.

Une bonne assise et un bon équilibre vous assurent un

meilleur contrôle l’appareil en cas d’imprévu.

• Utilisez les équipements de sécurité nécessaires.

Portez systématiquement une protection oculaire.

Prévoyez, selon les conditions d’utilisation, un masque

à poussière, des chaussures de sécurité antidéra-

pantes, le casque et/ou une protection auditive.

Selon l’état de la Californie, certains

types de poussières résultant du ponçage, du sciage, du

meulage, du perçage ou d’autres activités de construction

mécanisées contiennent des produits chimiques responsables du cancer, de malformations congénitales et autres

lésions du système reproductif. Parmi ces substances

se trouvent :

• Le plomb contenu dans les peintures à base de

plomb

• La silice cristalline contenue dans les briques, le ciment et autres matériaux de construction

• L’arsenic et le chrome contenu dans le bois chimiquement traité.

Les risques associés à ces substances varient selon la

fréquence d’exposition. Afin de limiter votre exposition à

ces substances, travaillez dans un local suffisamment

bien ventilé et servez-vous des équipements de sécurité

prévus, tels que les masques à poussière à filtration microscopique.

• Protégez vos oreilles avec des bouchons ou un

casque antibruit lorsque vous utilisez cet appareil.

Le niveau sonore élevé de l’appareil peut nuire à votre

acuité auditive suite à une utilisation prolongée.

Utilisation et entretien de l’appareil

• Utilisez un serre-joint ou autre moyen approprié

pour arrimer l’ouvrage sur une plate-forme stable. Tenir l’ouvrage à la main ou contre le corps peut

vous mettre en position d’instabilité et vous faire perdre

le contrôle de l’appareil.

• Ne forcez pas l’appareil. Utilisez un appareil qui soit

adapté au travail prévu. L’outil approprié assurera un

meilleur travail et une meilleure sécurité s’il est utilisé au

régime prévu.

• N’utilisez pas un appareil si son interrupteur ne

permet pas de le mettre en marche ou de l’arrêter.

Tout appareil qui ne peut pas être contrôlé par son in-

terrupteur est dangereux et doit être réparé.

• Débranchez le cordon électrique de l’appareil

avant le réglage, le changement d’accessoires,

ou le rangement de celui-ci. De telles mesures

préventives réduisent le risque de démarrage accidentel de l’appareil.

• Rangez les appareils non utilisés hors de la portée

des enfants et des amateurs. Ces appareils sont

dangereux entre les mains de personnes non initiées.

• Entretenez les appareils consciencieusement.

Maintenez les outils de coupe bien affûtés et en

bon état de propreté. Les outils bien entretenus et af-

fûtés réduisent les risques de grippage et sont plus

faciles à contrôler.

• Assurez-vous qu’il n’y a pas de désalignement ou

de grippage des pièces mécaniques, ou d’autres

conditions qui pourraient entraver le bon fonctionnement de l’appareil. Le cas échéant, faites

réparer l’appareil avant de vous en servir. De

nombreux accidents sont le résultat d’un appareil

mal entretenu.

• Utilisez exclusivement les accessoires recommandés par le fabricant pour votre modèle

d’appareil particulier. Des accessoires prévus pour un

certain type d’appareil peuvent être dangereux lorsqu’ils

sont montés sur un autre.

• Vérifiez régulièrement l’état du cordon d’alimentation de l’appareil et des rallonges électriques et

remplacez tout élément endommagé. Les cordons et

rallonges endommagés augmentent les risques de

choc électrique.

• Gardez les poignées de la machine propres,

sèches et dépourvues d’huile ou de graisse. Cela

vous permettra de mieux contrôler l’appareil.

• Rangez l’appareil dans un endroit sec. De telles

mesures préventives réduisent les risques de choc

électrique.

Réparations

• Toutes réparations de l’appareil doivent être confiées à un réparateur qualifié. La réparation ou

l’entretien de l’appareil par du personnel non qualifié

peut entraîner des blessures.

• Lors de la réparation de l’appareil, utilisez exclusivement des pièces de rechange identiques à

celles d’origine. Suivez les instructions de la section “Entretien” du mode d’emploi. L’utilisation de

pièces de rechange non homologuées et le non re-

MISE EN GARDE

Page 15

5228 – Scie alternative double isolement, double action, deux vitesses

• Eloignez le cordon électrique de la lame de l’appareil. Les cordons électriques endommagés peuvent

provoquer des chocs électriques.

• Ne vous penchez pas sur la scie et ne portez pas

de gants en toile trop grands. Ceux-ci risquent de

s’enchevêtrer dans l’appareil et provoquer de graves

blessures.

• N’utilisez pas de lames émoussées ou endommagées. Cela réduira les risques de grippage et de

perte de contrôle.

• Ecartez vos doigts et vos mains de la lame de

scie. Cela réduira les risques de coupure.

• Ecartez vos mains et vos pieds de tout ouvrage

susceptible de tomber en fin de coupe. Cela réduira

les risques de blessure.

• Utilisez exclusivement le type de lame prévue pour

le type de matériau à couper. Cela réduira les risques

de grippage et de perte de contrôle.

• Tenez la scie uniquement de la manière indiquée à

la Figure 4. Assurez-vous que la protection en

caoutchouc en tête de l’appareil soit correctement

installée et en bon état. Celle-ci protège contre les

risques de choc électrique en cas de coupe d’un fil

sous tension lors de la découpe d’une cloison ou autre

paroi aveugle.

• N’utilisez pas l’appareil sans son sabot de guidage.

Cela pourrait causer la lame de se briser ou vous

faire perdre le contrôle de l’appareil.

• Certains bois sont traités avec des produits de

conservation potentiellement toxiques. Prenez soin

d’éviter l’inhalation et le contact avec la peau lorsque

vous travailler avec de tels matériaux. Demandez,

puis respectez, les consignes de sécurité applicables

disponibles chez votre fournisseur de matériaux.

CONSERVEZ CES INSTRUCTIONS!

Description, Spécifications et

Accessoires

Description

La scie alternative à double isolement, vitesse variable et

double action RIDGID No5228 est une scie de qualité industrielle particulièrement robuste. Cette scie fonctionne

à des vitesses variables et est équipée d’une lame à dou-

ble action assurant une grande efficacité de coupe dans

le bois ou les métaux. Elle est prévue pour la coupe de

pièces de bois d’une épaisseur maximale de 12″, de

pièces métalliques d’une épaisseur maximale de 3/4″ et de

spect des consignes d’entretien peut créer un risque de

choc électrique ou de blessure corporelle.

• Suivez les instructions de lubrification et de

changement des accessoires. Les accidents sont

souvent le résultat d’appareils mal entretenus.

Consignes de Sécurité

Particulières

Le mode d’emploi contient des consignes de sécurité et in-

structions visant spécifiquement cet appareil en vue de vous

protéger contre d’éventuelles blessures graves telles que:

• les chocs ou brûlures électriques provenant du contact avec les fils, le moteur ou autres éléments du

système d’entraînement ;

• les blessures oculaires, y compris l’aveuglement par

la projection de copeaux ou de l’ouvrage lui-même.

Familiarisez-vous complètement avec le mode

d’emploi avant d’utiliser cet appareil. Le manque de

compréhension ou de respect des consignes contenues dans ce manuel vous met à risque de choc

électrique, d’incendie et/ou de grave blessure corporelle.

En cas de questions, veuillez consulter les services

techniques de la Ridge Tool Company en composant le

(800) 519-3456.

Sécurité de l’appareil

• Ne tentez pas de modifier l’appareil ou de l’utiliser

pour une application non prévue. Les applications

non prévues peuvent augmenter les risques de

blessure corporelle.

MISE EN GARDE !

La projection de copeaux peut entraîner des

blessures oculaires.

• Utilisez des lunettes ou un bouclier de sécurité.

• Assurez-vous de bon fonctionnement de l’interrup-

teur.

• N’utilisez pas cet appareil avec des cordons électriques endommagés ou usés.

• N’utilisez pas de lames endommagées.

Ridge Tool Company 13

Page 16

5228 – Scie alternative double isolement, double action, deux vitesses

Ridge Tool Company14

divers autres matériaux, y compris le caoutchouc dur, les

stratifiés, la fibre de verre et les matières plastiques. Son

moteur monophasé fonctionne à entre 25 et 60 Hz de

courant alternatif et à une tension d’alimentation de plus ou

moins cinq pour cent de celle indiquée sur la plaque signalétique de l’appareil. Le double isolement de l’appareil

assure une protection équivalente à celle offerte par un cordon d’alimentation avec terre correctement relié.

Spécifications

Epaisseur maximale des matériaux

Coupe des métaux....3/

4

″

Coupe du bois...........12″

Trajet de lame ...............11/

8

″

Moteur

Type ..........................Universal

Consommation /

Puissance..................115V, 25-60 Hz, CA/CC,

9,6A, 0 à 2600 coups/minute

Interrupteur

Marche/Arrêt............Gâchette à retour automatique

Haute vitesse/

Basse vitesse ...........Sélecteur manuel

Longueur ......................17″

Poids .............................9,0 lbs.

Accessoires

Lame en acier

au carbone ................(1) D-999 (6 dents par pouce)

Clé à lame.................3/

16

″

(type clé Allen)

Fonctionnement de l’Aparreil

MISE EN GARDE !

Lisez le mode d’emploi complètement avant de

tenter d’utiliser cet appareil afin de vous familiariser avec l’ensemble de ses fonctions. Dans la

mesure où cet appareil a été conçu pour des applications particulières, nous conseillons fortement

qu’il ne soit PAS modifié et/ou utilisé pour d’autres

applications non prévues quelles qu’elles soient.

Sélection des lames

Il existe une grande variété de lames dans le catalogue

RIDGID. Pour assurer un maximum d’efficacité de coupe

et de longévité des lames, sélectionnez celle qui soit

adaptée à l’application prévue. Lors de la coupe des mé-

taux, assurez-vous que la lame sélectionnée soit

suffisamment fine pour permettre un contact d’au moins

trois dents sur l’épaisseur du matériau.

Montage des lames

No5228 Type II

L’arbre alternatif doit être complètement déployé pour

donner accès au collier de verrouillage des lames. Si

nécessaire, appuyez doucement sur la gâchette afin

de faire avancer l’arbre complètement. Tournez le sabot

de guidage vers l’avant pour faciliter l’accès au collier de

verrouillage des lames.

MISE EN GARDE !

Débranchez l’appareil avant tout montage ou retrait des lames.

Ouverture du collier de verrouillage des lames :

Tournez le collier de verrouillage à gauche (vu de face)

et tenez-le. Introduisez la lame dans le porte-lame

jusqu’à ce qu’elle bute au fond de celui-ci. Laissez le collier revenir à sa position initiale pour verrouiller la lame

en place.

Pour enlever une lame:

Tournez le collier à gauche et tenez-le en position ouverte. Retirez soigneusement la lame du porte-lame.

NOTA ! Si le collier de verrouillage résiste lorsque vous

essayez de le tourner pour enlever une lame, gigotez la lame tout en tournant le collier à gauche.

Si la lame se casse au raz du porte-lame, sans

laisser de prise permettant son retrait, il se

peut qu’il soit nécessaire d’utiliser une seconde lame en tant qu’outil pour retirer la lame

cassée. Tout en tenant le collier de verrouillage

en position ouverte, servez-vous du bout de

la seconde lame pour accrocher et retirer la

partie encastrée de la lame cassée. (Une lame

à métaux mince à dents fines marche le mieux.)

Nettoyez le porte-lame régulièrement à l’air com-

primé. NE PAS lubrifier le porte-lame. Sa

lubrification risque d’accélérer son encrassement.

Portez des lunettes de sécurité

lorsque vous utilisez de l’air comprimé.

Double action

La double action de la scie alternative RIDGID assure

une grande efficacité de coupe, qu’il s’agisse de la

coupe du bois ou du métal. Lorsque le sélecteur de

mode (Figure 1) est orienté vers le haut (position Métal),

la lame effectue un va-et-vient rectiligne. Lorsque le

sélecteur est orienté vers l’avant de la scie (position

Bois), la lame effectue un mouvement orbital. (Figure 2)

AVERTISSEMENT

Page 17

5228 – Scie alternative double isolement, double action, deux vitesses

Ridge Tool Company 15

Figure 1 – Déplacement de la lame lorsque le sélecteur

est orienté vers le haut

Figure 2 – Déplacement de la lame lorsque le sélecteur

est orienté vers la gauche

Figure 3 – Interrupteur à gâchette

Interrupteur Marche/Arrêt

Le fonctionnement de la scie est commandé par un interrupteur à gâchette (B) (Figure 3) situé à l’avant de sa

poignée. Pour activer la scie, appuyez sur la gâchette.

Pour arrêter la scie, lâchez la gâchette. La gâchette ne

peut pas être verrouillée en position marche.

Prise en main de la scie

Pour raisons de sécurité, la scie doit être tenue comme

indiqué à la Figure 4. La protection en caoutchouc

avant doit être correctement installé et en bon état.

Tenez la scie systématiquement des deux mains afin de

l’empêcher de s’échapper.

Si la lame coupe un fil sous tension

derrière une paroi, la lame et le sabot orientable risquent

d’être mis sous tension également.

Figure 4 – Prise en main appropriée de la scie alternative

Sabot de guidage orientable

Le sabot de guidage (Figure 5) sert d’appui pour l’appareil lors de son utilisation. Le sabot pivote afin de

permettre à la scie d’être amenée en position perpendiculaire à l’ouvrage lorsque l’utilisateur la ramène vers

lui durant la coupe.

Figure 5 – Utilisation du sabot de guidage orientable

Consignes d’Utilisation

Préparation

Utilisez le guide de sélection des lames du catalogue

RIDGID pour sélectionner la lame appropriée en fonction

du travail prévu. Par souci d’économie, utilisez la lame

la plus courte prévue pour l’épaisseur du matériau à

couper. Réglez la vitesse et le mode de déplacement de

la lame en fonction du matériau à couper.

Le matériau à couper devrait être rigide et correctement soutenu. Utilisez des serre-joints pour tenir les

pièces de faible importance sur la surface de travail, ou

bien tenez-les dans un étau. Ne forcez pas la scie contre l’ouvrage. Elle coupera d’elle-même avec un

minimum de pression.

Sabot de

guidage

HAUT

Vers l’avant

de la scie

Gâchette

MISE EN GARDE

Page 18

5228 – Scie alternative double isolement, double action, deux vitesses

Ridge Tool Company16

Coupe du bois

La scie alternative RIDGID est semblable à une scie à

main dans la mesure où elle est ramenée vers l’utilisateur

durant la coupe. Cependant, vue que la coupe s’ef-

fectue lorsque la lame remonte, la face finie de l’ouvrage

doit être tournée vers le bas durant l’opération.

Coupe du bois en plongée

La scie alternative RIDGID peut servir pour effectuer

des coupes en plongée dans le bois, le contre-plaqué, les

cloisons sèches et la matière plastique. Elle n’est pas

recommandée pour la coupe en plongée des métaux.

Tenez la partie avant de l’appareil d’une main et sa

poignée de l’autre. Lors de la coupe en plongée du bois

ou d’un matériau comparable, commencez en tenant

la scie parallèle à la surface (Figure 6). Appuyez le

sabot de la scie fermement contre le matériau, démarrez la scie, puis ramenez la poignée vers le haut jusqu’à

ce que la lame entre en contact avec le matériau.

Tout en gardant le sabot fermement appuyé contre le

matériau, continuez à lever la poignée jusqu’à ce que la

lame ait traversé l’ouvrage et qu’elle se trouve perpendiculaire à sa surface (Figure 7). Une fois la scie en

position perpendiculaire, continuez à faire avancer la

lame le long de la ligne de coupe.

MISE EN GARDE !

Soyez particulièrement prudent lors de la coupe

d’une paroi aveugle dans un bâtiment existant et

assurez-vous qu’il n’y ait pas de fils sous tension,

de gaines, de canalisations, etc. qui risqueraient

d’entrer en contact avec la lame. Par soucis de

sécurité, le couvercle avant en matière plastique

doit être correctement installé et en bon état.

Tenez la scie exclusivement par sa partie avant en

matière plastique et par sa poignée.

Figure 6 – Début de coupe en plongée

Figure 7 – Manière appropriée de tenir la scie lors de la

coupe du bois

Coupe des métaux

Pour couper le métal à partir d’un bord, entamez la

coupe sur la surface où le plus grand nombre de dents

peuvent venir en contact avec l’ouvrage. Afin d’éviter les

vibrations du métal et le tremblement de la lame, tenez

la scie fermement contre le matériau lors de la coupe.

Pour effectuer une coupe intérieure dans le métal, commencez par percer un trou suffisamment large pour

permettre le passage de la lame. Pour prolonger la vie

utile de la lame et faciliter la coupe, appliquez de l’huile

de coupe le long de la ligne de coupe. Evitez de forcer la

scie contre le matériau. Laissez la lame couper d’ellemême pendant que vous guidez la scie avec une

pression modérée.

Consignes d’Entretien

MISE EN GARDE!

Débranchez l’appareil avant toute intervention.

En cas de non démarrage

Si l’appareil refuse de démarrer, vérifiez d’abord que

les barrettes de la fiche fassent bien contact avec le

réceptacle, puis examinez les fusibles ou le coupe-circuit

du réseau d’alimentation.

Page 19

5228 – Scie alternative double isolement, double action, deux vitesses

Ridge Tool Company 17

Ventilation

Gardez les orifices de ventilation de l’appareil bien dé-

gagés afin d’assurer le refroidissement du moteur.

Passez régulièrement l’ensemble des orifices de ventilation à l’air comprimé. Portez des lunettes de sécurité

lors de cette opération. N’utilisez jamais de solvants

pour le nettoyage des éléments en matière plastique, car

cela risque de les endommager.

Lubrification

Au bout d’environ 100 heures d’utilisation, la scie doit être

confié à un Centre de Service RIDGID agréé pour y

être lubrifiée. L’appareil sera alors complètement nettoyé

et contrôlé, avec remplacement éventuel de ses composants usés.

Entretien et réparations

Pour toute intervention autre que celles indiquées plus

haut, l’appareil doit être confié à un Centre de Service

RIDGID agréé, ou bien renvoyé à l’usine. Toutes réparations effectuées par les services techniques de Ridge

sont garanties contre les vices de matériaux et de main

d’oeuvre.

Veuillez adresser toutes questions éventuelles concernant l’utilisation ou le fonctionnement de cet appareil

par écrit à :

The Ridge Tool Company

Attention: Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

ou par téléphone en composant le

800/519-3456

Lors de toute correspondance, veuillez indiquer l’ensem-

ble des informations portées sur la plaque signalétique de

votre appareil, notamment le numéro de modèle, la tension

d’alimentation et le numéro de série.

Page 20

5228 – Scie alternative double isolement, double action, deux vitesses

Ridge Tool Company18

Page 21

No. 5228 Sierra de Vaivén de velocidad variable

A continuación apunte y retenga el número de serie del producto que se encuentra en la

placa de características.

No. de

Serie

Sierra de Vaivén No. 5228

Page 22

Índice

Formulario para Apuntar el Modelo y Número de Serie de la Máquina ................................................................19

Información General de Seguridad

Seguridad en la Zona de Trabajo..............................................................................................................................21

Seguridad Eléctrica...................................................................................................................................................21

Seguridad Personal...................................................................................................................................................21

Uso y Cuidado de la Herramienta.............................................................................................................................22

Servicio......................................................................................................................................................................22

Información Específica de Seguridad

Seguridad en el Uso de la Herramienta....................................................................................................................23

Descripción, Especificaciones y Accesorios

Descripción................................................................................................................................................................23

Especificaciones........................................................................................................................................................24

Accesorios.................................................................................................................................................................24

Instrucciones para el Funcionamiento de la Máquina

Selección de las Hojas de Sierra ..............................................................................................................................24

Instalación de las Hojas de Sierra.............................................................................................................................24

Movimiento Doble......................................................................................................................................................25

Interruptor de Arranque/Detención............................................................................................................................25

Cómo Sostener la Sierra Debidamente.....................................................................................................................25

Zapata Guía de Giro..................................................................................................................................................25

Uso de la Sierra

Preparación...............................................................................................................................................................26

Cortes en Madera......................................................................................................................................................26

Cortes de Inmersión en Madera................................................................................................................................26

Cortes de Bordes en Metales....................................................................................................................................27

Instrucciones para el Mantenimiento

No Arranca................................................................................................................................................................27

Ventilación.................................................................................................................................................................27

Lubricación................................................................................................................................................................27

Servicio y Reparaciones............................................................................................................................................27

Garantía de por Vida..........................................................................................................................Carátula Posterior

Ridge Tool Company20

No. 5228 Sierra de Vaivén de Velocidad Variable

Page 23

No. 5228 Sierra de Vaivén de Velocidad Variable

Ridge Tool Company 21

Información general

de seguridad

¡

ADVERTENCIA! Lea y comprenda todas las instrucciones.

Pueden ocurrir golpes eléctricos, incendios y/o lesiones corporales graves si

no se siguen todas las instrucciones detalladas a continuación.

¡

GUARDE ESTAS INSTRUCCIONES!

Seguridad en la zona de trabajo

• Mantenga su área de trabajo limpia y bien alumbrada. Los bancos de trabajo desordenados y las

zonas oscuras invitan a que se produzcan accidentes.

• No haga funcionar herramientas autopropulsadas

en atmósferas explosivas, como por ejemplo en la

presencia de líquidos, gases o polvos inflamables.

Las herramientas autopropulsadas generan chispas

que pueden encender el polvo o los gases.

• Al hacer funcionar una herramienta autopropulsada, mantenga apartados a los espectadores,

niños y visitantes. Las distracciones pueden causar

que pierda el control.

• No permita que los visitantes se pongan en contacto con la herramienta o el cordón de extensión.

Este tipo de medida preventiva reduce el riesgo de que

se produzcan lesiones.

Seguridad eléctrica

• Las herramientas con aislación doble van provistas

de un enchufe polarizado (una clavija es más ancha

que la otra). Este enchufe entrará en un receptáculo de salida de corriente de una sola manera. Si

el enchufe no entra totalmente en el receptáculo

hembra, invierta el enchufe. Si todavía no cabe,

llame a un electricista calificado para que instale

una salida polarizada de suministro de corriente. No

modifique el enchufe de la máquina de ninguna

manera. La aislación doble elimina la necesidad de que

la herramienta cuente con un cordón de tres alambres con protección a tierra y que deba enchufarse a un

suministro de corriente conectado a tierra.

• Evite el contacto del cuerpo con superficies conectadas a tierra tales como cañerías, radiadores,

estufas o cocinas y refrigeradores. Si su cuerpo

ofrece conducción a tierra, existe un riesgo aumentado

de que se produzca un choque eléctrico.

• No exponga las herramientas autopropulsadas a la

lluvia o a condiciones mojadas. Si agua penetra

en una herramienta a motor, aumenta el riesgo de

que se produzca un golpe eléctrico.

• No abuse del cordón. Nunca use el cordón para

transportar herramientas o para tirar el enchufe del

receptáculo de salida de corriente. Mantenga el

cordón lejos del calor, aceite, bordes cortantes o

piezas movibles. Recambie los cordones dañados inmediatamente. Los cordones en mal estado

aumentan los riesgos de que se produzca un choque

eléctrico.

• Al hacer funcionar una herramienta autopropul-

sada a la intemperie, emplee un cordón de

extensión fabricado para uso exterior y rotulado

“W-A” o “W”. Estos cordones han sido diseñados

para su empleo al aire libre y reducen el riesgo de que

se produzca un choque eléctrico.

• Enchufe la herramienta a una fuente de sumin-

istro de corriente alterna igual a la especificada en

la placa de características de la herramienta. El

suministro con corriente de voltaje incorrecto puede

producir un choque eléctrico o quemaduras.

• Use cordones de extensión apropiados. (Vea la

tabla.) Una dimensión insuficiente del conductor

causará una caída excesiva del voltaje y una pérdida

de potencia.

• Mantenga todas las conexiones eléctricas secas y

levantadas del suelo. No toque el enchufe con

manos mojadas. Ello reduce los riesgos de un choque

eléctrico.

Seguridad Personal

• Manténgase alerta, preste atención a lo que está

haciendo y use sentido común cuando trabaje

con una herramienta autopropulsada. No la use si

está cansado o se encuentra bajo la influencia de

drogas, alcohol o medicamentos. Sólo un breve

descuido mientras hace funcionar una herramienta a

motor puede resultar en lesiones personales graves.

• Vístase adecuadamente. No lleve ropa suelta ni

joyas. Contenga el cabello largo. Mantenga cabello, ropa y guantes apartados de las piezas en

movimiento. La ropa suelta, las joyas o el pelo largo

pueden engancharse en la piezas móviles.

• Evite la puesta en marcha no intencional. Antes de

Dimensión Mínima de Alambre para Cordones de Extensión

Amperios en

la Placa de Longitud Total (en pies)

Características

0-25 26-50 51-100

0-6 18 AWG 16 AWG 16 AWG

6-10 18 AWG 16 AWG 14 AWG

10-12 16 AWG 16 AWG 14 AWG

12-16 14 AWG 12 AWG

NO SE RECOMIENDA

Page 24

No. 5228 Sierra de Vaivén de Velocidad Variable

Ridge Tool Company22

enchufar la herramienta, asegure que el interruptor

se encuentre en la posición OFF (APAGADO).

Cargar las herramientas con el dedo sobre el interruptor o enchufarlas cuando su interruptor está en la

posición de encendido constituyen una invitación a

que se produzcan accidentes.

• Antes de poner en marcha la herramienta, extraiga

las llaves de ajuste o regulación. Una llave mecánica

o una llave que se ha dejado acoplada a una pieza giratoria de la herramienta puede resultar en lesiones

personales.

• No trate de sobreextender su cuerpo. Mantenga

sus pies firmes en tierra y un buen equilibrio en todo

momento. Al mantener el equilibrio y los pies firmes,

tendrá mejor control sobre la herramienta en situaciones inesperadas.

• Use equipo de seguridad. Siempre lleve protección

para la vista. Cuando las condiciones lo requieran,

debe usar mascarilla para el polvo, calzado de seguridad antideslizante, casco duro o protección para

los oídos.

Puede que parte del polvo que se

desprende cuando se lija, serrucha, corta, taladra, pule o

afila, o durante otras tareas de construcción, contenga sustancias químicas que el estado de California considera

cancerígenas, causantes de defectos congénitos u otros

daños al sistema reproductor. Algunos de estos productos

químicos son:

• plomo, en pinturas a base de plomo

• sílice cristalino en ladrillos y cemento y otros pro-

ductos usados en mampostería

• arsénico y cromo, en maderas tratadas con sustan-

cias químicas

Los riesgos a la salud que implica la exposición o contacto

con estos materiales varían según la frecuencia con que

Ud. realiza este tipo de trabajo. Para reducir el contacto

con estas sustancias químicas, trabaje siempre en una

zona bien ventilada y vistiendo equipos de seguridad autorizados, tales como mascarillas contra el polvo diseñadas

para impedir el paso de partículas microscópicas.

• Use protección para los oídos, tapones o amortiguadores de sonido. El uso prolongado de

herramientas que producen altos niveles de ruido

pueden afectar su audición.

Uso y Cuidado de la Herramienta

• Use un tornillo de presión u otro medio práctico

para asegurar la pieza de trabajo a una plataforma

estable. El sostener la pieza de trabajo a mano o

contra su cuerpo es inestable y puede causar la pérdida del control.

• No fuerce la herramienta. Use la herramienta correcta para su aplicación. La herramienta correcta

hará el trabajo mejor y de manera más segura a la velocidad para la cual fue diseñada.

• Si el interruptor de la herramienta no la enciende ni

la apaga, no use la herramienta. Cualquier he-

rramienta que no pueda ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

• Antes de efectuar trabajos de regulación, de cambiar accesorios o de almacenar la herramienta,

desconecte el enchufe de la fuente de corriente

eléctrica. Este tipo de seguridad preventiva reduce el

riesgo de poner la herramienta en marcha involuntariamente.

• Almacene las herramientas que no estén en uso

fuera del alcance de los niños y de otras personas

sin entrenamiento. Las herramientas son peligrosas

en las manos de usuarios no capacitados.

• Las herramientas deben ser mantenidas cuidadosamente. Mantenga las herramientas de corte

limpias y bien afiladas. Las herramientas con filos

de corte agudos mantenidas debidamente tienen menos

tendencia a agarrotarse y son más fáciles de controlar.

• Verifique si las piezas movibles están desalineadas o agarrotadas, si hay piezas quebradas y

si existe cualquiera otra condición que pueda

afectar el funcionamiento de la herramienta. En

caso de estar dañada, antes de usar la herramienta,

hágala componer. Numerosos accidentes son causados por herramientas que no han recibido un

mantenimiento adecuado.

• Solamente use accesorios y cordones de extensión recomendados por el fabricante para su

modelo. Los accesorios que pueden ser adecuados

para una herramienta pueden ser peligrosos al usárselos en otra herramienta.

• Inspeccione las herramientas y los cordones de extensión periódicamente y recámbielos si están

dañados. Los cordones dañados aumentan el riesgo

de que se produzca un choque eléctrico.

• Mantenga los mangos limpios y secos, libres de

aceite y grasa. Esto permite disponer de un mejor

control sobre la herramienta.

• Si se hace necesario cambiar el cordón, ocupe

sólo repuestos idénticos que incluyan protección

GFCI a tierra. La protección GFCI a tierra debe con-

servarse para reducir el riesgo de un choque eléctrico.

ADVERTENCIA

Page 25

No. 5228 Sierra de Vaivén de Velocidad Variable

Ridge Tool Company 23

Lea este manual del operador con detención antes

de hacer funcionar esta máquina. Si no se comprenden y siguen las instrucciones de este manual,

pueden ocurrir choques eléctricos, incendios y/o lesiones personales graves.

Llame al Departamento de Servicio Técnico de Ridge

Tool Company, al (800) 519-3456, si tiene cualquier

pregunta.

Seguridad en el Uso de la Herramienta

• No altere o mal use la herramienta. Darle otros usos

aumenta el riesgo de que se produzcan lesiones.

• Aparte el cordón eléctrico de la hoja de la sierra. Un

cordón dañado puede producir un choque eléctrico.

• No se extienda por sobre la sierra o use guantes de

tela que le queden sueltos. Ellos pueden engan-

charse en la herramienta y provocarle lesiones serias.

• No use hojas de sierra desafiladas o dañadas. Así es

menos posible que se traben y se pierda el control.

• Mantenga dedos y manos apartados de la hoja o

cuchilla de la sierra. Ello reduce el riesgo de cor-

tarse.

• Mantenga manos y pies alejados de las piezas de

trabajo que puedan caer después de haber sido

cortadas. Ello reduce el riesgo de lesiones.

• Siempre use la hoja recomendada para el material

que va a cortar. Es menos probable que se trabe y se

pierda el control.

• Siempre sostenga la sierra de la manera como se

muestra en la Figura 4. Tenga la cubierta de goma

delantera de la carcasa instalada debidamente.

Asegure que no esté dañada. Así se evitan los

choques eléctricos que ocurren cuando se corta un

alambre eléctrico al aserrar hacia adentro de una

pared u otro lugar ciego.

• No haga funcionar la sierra sin su zapata guía.

Ello puede provocar el rompimiento de la hoja y la pér-

dida del control de la herramienta.

• Algunas maderas contienen preservativos que

pueden ser tóxicos. Cuando trabaje con estos ma-

teriales, tenga especial cuidado en prevenir la

inhalación y el contacto de la piel con ellos. Solicite de

su proveedor todas las indicaciones de seguridad que

tenga disponibles y sígalas.

¡

GUARDE ESTAS INSTRUCCIONES!

Servicio

• El servicio a la herramienta sólo debe ser efectuado por personal de reparación calificado. El servicio

o mantenimiento practicado por personal de reparaciones no calificado puede resultar en lesiones.

• Cuande repare una herramienta debe usar únicamente repuestos o piezas de recambio idénticas.

Siga las instrucciones en la sección de

Mantenimiento de este manual. El uso de piezas

no autorizadas o el no seguir las instrucciones para el

mantenimiento, pueden crear el riesgo de que se produzca un choque eléctrico o lesiones.

• Siga las instrucciones para la lubricación y el

reemplazo de accesorios. Ocurren accidentes cuando

las herramientas no están bien mantenidas.

Información Específica de

Seguridad

El Manual del Operador contiene información específica

de seguridad e instrucciones para proteger al operador

de lesiones graves, incluídas:

• Choque eléctrico o quemaduras debido al contacto

con cables, el motor u otras piezas del accionamiento

autopropulsado;

• Lesiones a la vista, incluso ceguera, causadas por

los materiales con que se está trabajando o desechos que salen despedidos.

ADVERTENCIA

Los desechos que salen despedidos pueden dañar

sus ojos.

• Use anteojos protectores o viseras de seguridad

para la cara.

• Mantenga el interruptor en buenas condiciones de

funcionamiento.

• No use la herramienta si el cordón eléctrico está

gastado o dañado.

• No use hojas de sierra que estén dañadas.

Page 26

No. 5228 Sierra de Vaivén de Velocidad Variable

Ridge Tool Company24

Descripción, Especificaciones

y Accesorios

Descripción

La Sierra de Vaivén de doble acción, de velocidad variable con aislación doble Ridgid No. 5228 es una

herramienta de calidad profesional para servicio extrapesado. Esta sierra funciona a varias velocidades y

dispone de un movimiento doble para la hoja para

garantizar un corte eficiente en maderra o metal. Ha sido

diseñada para cortar maderas de hasta 12 pulgadas de

espesor, metales de hasta 3/4de pulgada y varios otros

materiales, incluso goma dura, laminados, fibra de vidrio

y plásticos. El motor funciona con corriente alterna de

fase única de 25 a 60 Hertz, con un voltaje que se encuentre dentro de la gama más/menos 5 por ciento de lo

que indica la placa de características. La aislación doble

de la herramienta proporciona una protección equivalente a la de un cordón de tres conductores debidamente

conectado a tierra.

Especificaciones

Espesor máximo del material

Corte de metales.......3/

4

″

Corte de madera .......12″

Carrera de la hoja..........11/

8

″

Motor

Tipo ...........................Universal

Características ..........115V, 25-60Hz.,AC/DC 9,6A,

0-2600 carreras/minuto

Interruptor

OFF/ON (ENCENDIDO/

APAGADO) ...............de retorno con resorte

Alta velocidad//

baja velocidad ...........posición manual

Longitud.........................17″

Peso..............................9,0 libras

Accesorios

Hoja de sierra en acero

de carbono ................(1) D-999 6TPI

Llave para la hoja o

cuchilla de la sierra ...3/

16

″

(llave tipo hexagonal)

Instrucciones para el

Funcionamiento

ADVERTENCIA

Antes de intentar trabajar con esta herramienta,

lea por completo las instrucciones del funcionamiento para familiarizarse con todas sus

funciones. Como esta herramienta está diseñada

para realizar tareas específicas, recomendamos

enfáticamente que NO se la modifique y/o se la

emplee en tareas que no sean aquéllas para las

cuales fue diseñada.

Selección de las Hojas

En el catálogo RIDGID se lista una amplia variedad

de hojas RIDGID para sierras. Para obtener una máxima

eficiencia, una larga vida de la hoja, y para cortar

suavemente, seleccione la hoja apropiada para el trabajo que efectuará. Al cortar metal, elija siempre una

hoja que permita que por lo menos tres dientes se encuentren en contacto con el espesor del material.

Instalación de la Hoja de Sierra

No. 5228 Tipo II

El árbol de vaivén debe estar totalmente extendido

para permitir el acceso al collar de desenganche de la

hoja. Si es necesario, apriete suavemente el interruptor

de gatillo para mover el árbol de vaivén hasta su posición más saliente. Gire la zapata guía hacia ADELANTE

(FORWARD) para mejorar el acceso a la abrazadera de

la hoja.

Siempre desenchufe la sierra de la

salida de corriente antes de instalar o extraer las hojas.

Cómo abrir la abrazadera para la hoja:

Gire y sostenga el collar de desenganche de la hoja, en

sentido contrario a las manecillas del reloj (mirando la