Ricoh ST23 SPECIFICATIONS

RICOH ST23

SERVICE MANUAL

OVERALL MACHINE INFORMATION 6 March 1992

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration: Console

Number of Bins: 20 + proof tray

Paper for Proof Tray: Size: Maximum: A3, 11" x 17"

Minimum: A5, 51/2" x 81/2" (sideways)

Weight: 52 g/m2 ~ 160 g/m2, 14 ~ 43 lb

Paper for Bins: Sort/Stack Mode:

Size Maximum: A3, 11" x 17"

Minimum: A5, 51/2" x 81/2" (sideways)

Weight 52 g/m2 ~ 160 g/m2, 14 lb ~ 43 lb

Staple Mode:

Size Maximum: A3, 11" x 17"

Minimum: A4, 81/2" x 11"

Weight 64 g/m2 ~ 80 g/m2, 17 lb ~ 21 lb

Stapler Capacity: From 2 to 50 sheets (80 g/m2, 20 lb)

Bin Capacity:

1 sided copies 2 sided copies

Sort mode 70 sheets 50 sheets

Stack mode 50 sheets 35 sheets

(80 g/m

2

, 20 lb)

Proof Tray Capacity: 250 sheets (80 g/m2, 20 lb)

20 sheets (translucent paper)

Staple Position: a = b = 5 ± 2 mm

b

a

Staple Time: Within 1.5 seconds/staple

Staple Replenishment: Cartridge exchange (5,000 pieces/cartridge)

Power Source: 1st sorter: 100 V (from copier)

2nd sorter:120 V (for U.S.A.)

220/230/240 V (for Europe)

1

Sorter Stapler

6 March 1992 OVERALL MACHINE INFORMATION

Power Consumption: Maximum: 0.2 kW

Dimensions: (1st sorter only) 580 x 828 x 1063 mm

(22.8" x 32.6" x 41.8")

(1st and 2nd sorter) 1120 x 828 x 1063 mm

(44.1" x 32.6" x 41.8")

Weight: 1st sorter: 98 kg, 216 lb

2nd sorter:90 kg, 198 lb

2

OVERALL MACHINE INFORMATION 6 March 1992

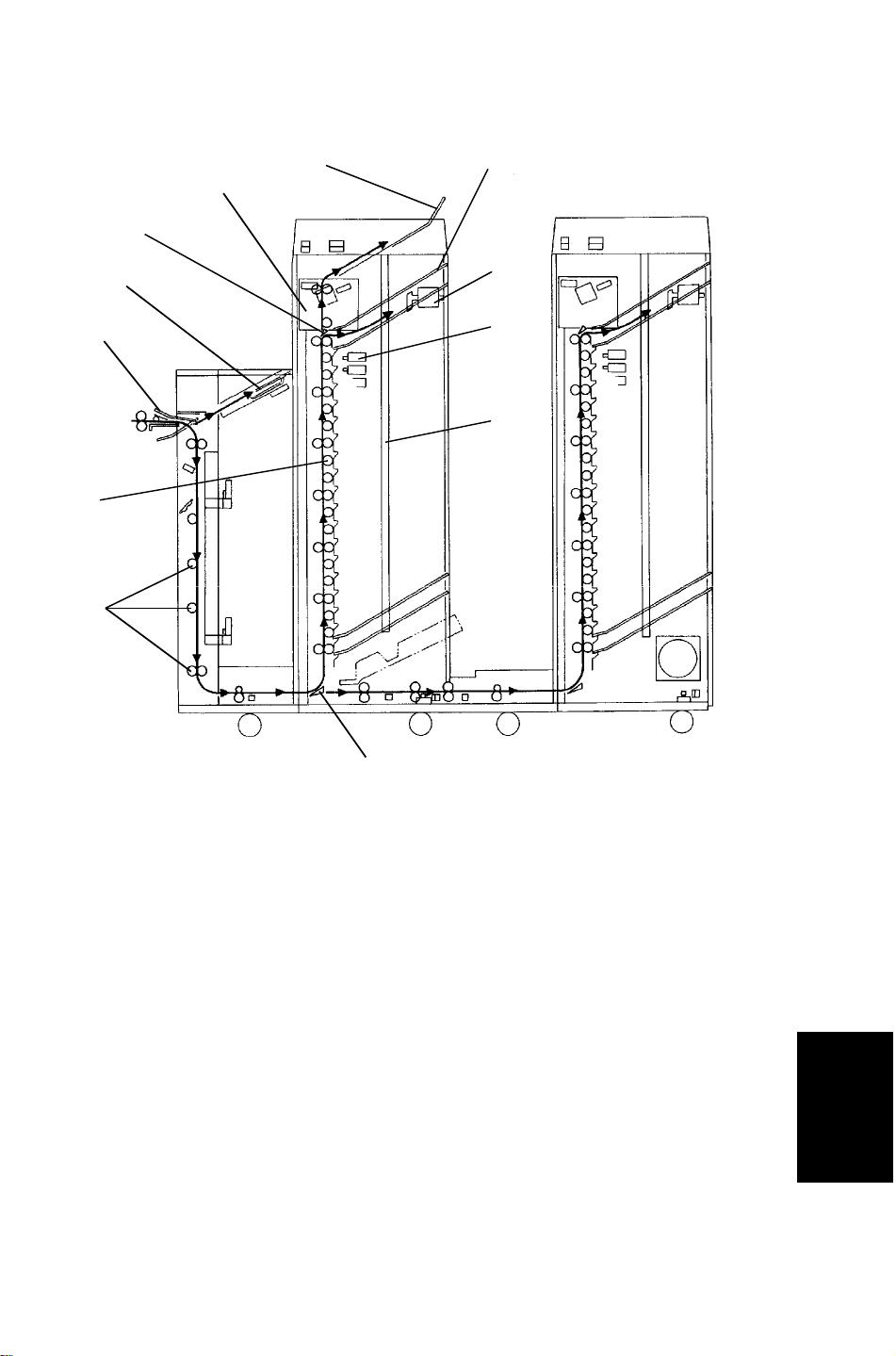

1.2 MECHANICAL COMPONENT LAYOUT

1

2

12

3

11

10

4

5

6

9

8

7

1. Staple Unit

7. Relay Gate

2. Proof Tray

3. Bins

4. Jogger

5. Bin Solenoids

6. Side Bar

8. Diagonal Transport Rollers

9. Distribution Rollers

10. By-pass Tray Gate

11. By-pass Tray

12. Bin Gate

Sorter Stapler

3

6 March 1992 OVERALL MACHINE INFORMATION

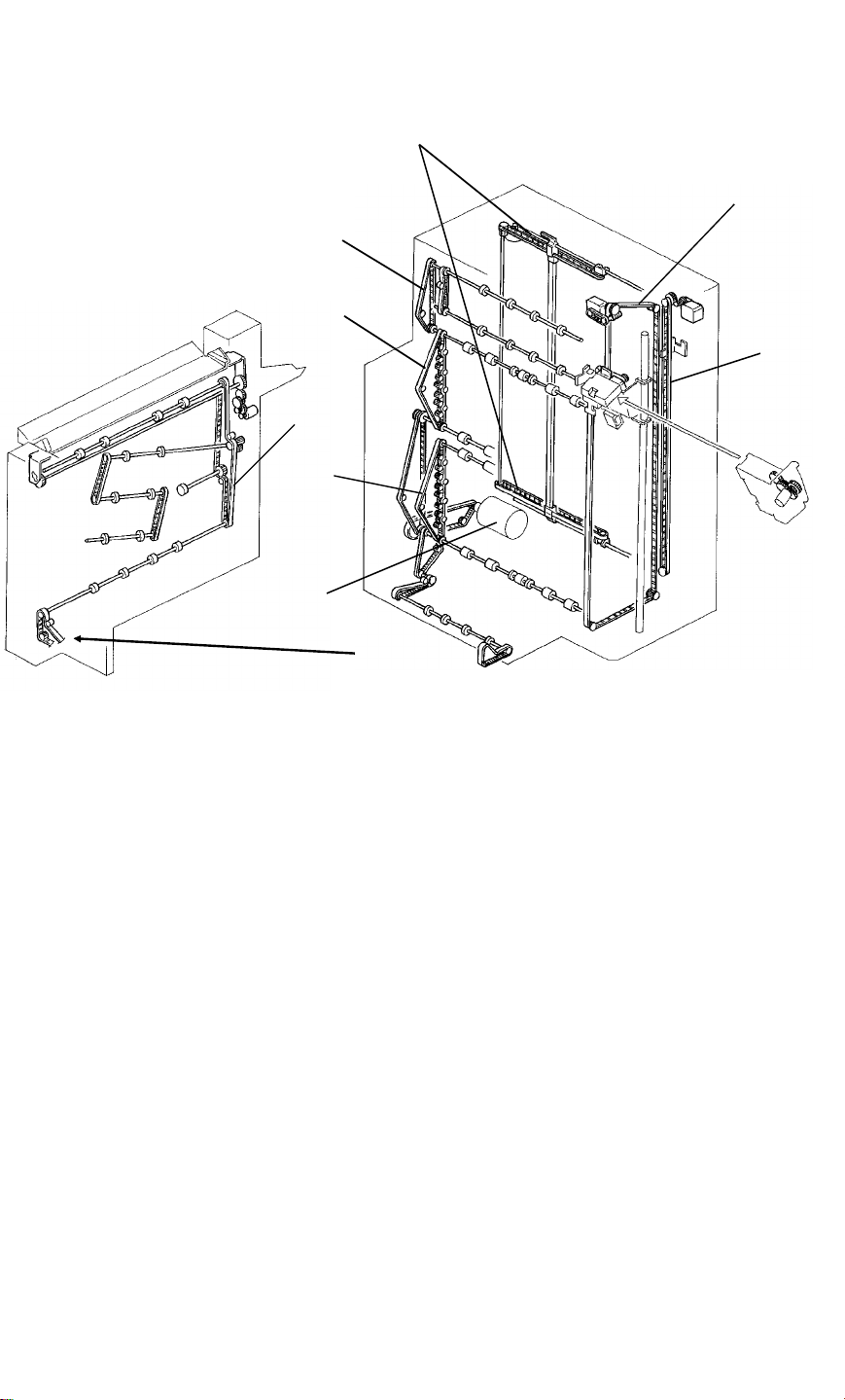

1.3 DRIVE LAYOUT

6

5

7

8

4

1

2

3

1. Diagonal Transport Drive Belt

2. Bin Drive Belt (1st to 10th)

3. Main Motor

4. Jogger Unit Drive Belt

5. Staple Unit

6. Side Bar Drive Belt

7. Proof Tray Exit Roller Drive Belt

8. Bin Drive Belt (11th to 20th)

4

OVERALL MACHINE INFORMATION 6 March 1992

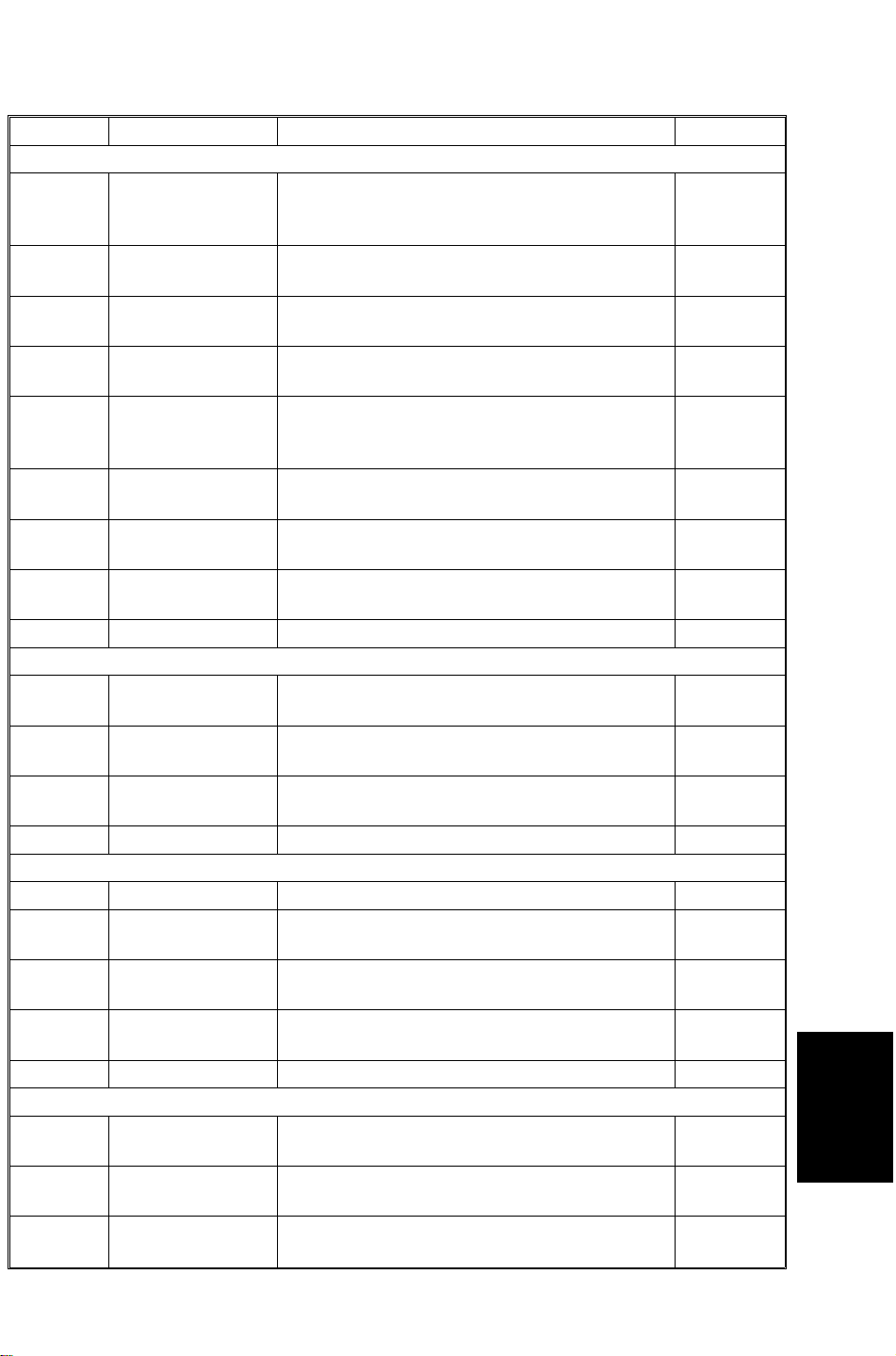

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

Main Drives the diagonal transport unit, horizontal

M1

M2

M3

M4

M5

M6

M7

M8

transport unit, and distribution unit through

timing belts.

Staple Unit

Positioning

Jogger Unit

Positioning

Side bar Drives the side bar side to side according to

Grip Drives the gripper forward into the bin to grip

Staple Feeds the staples and drives the stapler

Jogger Drives the jogger arm to align the copy. (dc

By-pass Tray Gate Drives the by-pass tray gate up or down to

Drives the staple unit up or down to the

appropriate bin. (dc stepper)

Drives the jogger unit up or down to the

appropriate bin. (dc stepper)

the paper size. (dc stepper)

the copies and bring them to the stapling

position. (dc brush)

hammer. (dc brush)

stepper)

switch the paper delivery tray.

22

5

9

1

12

15

18

36

Switches

SW1

SW2

SW3

Circuit Boards

PCB1 Main Controls overall sorter stapler functions. 31

PCB2

PCB3

PCB4

Solenoids

SOL1~20

SOL21

SOL22

Front Door De-energize the main motor and cuts 24 V

line when the front door is open.

Vertical Transport

Door

Horizontal

Transport Door

DC Power Supply Convert ac voltage to 5 V dc and 24 V dc to

Bin Solenoid

Control 1

Bin Solenoid

Control 2

Bin Opens and closes the bin gate to direct the

Grip Opens and closes the bin gate to drive the

Pressure Release Releases pressure of the brake roller when

De-energize the main motor when the vertical

transport door is open.

Informs the main board if the cover is open.

supply power to all dc components.

Interfaces between the bin solenoids 1 ~ 10

and the main board.

Interfaces between the bin solenoids 11 ~ 20

and the main board.

copies into the appropriate bin.

grippers to grip copies on the bins.

the paper is fed lengthwise.

8

6

20

26

28

30

27

Sorter Stapler

14

38

5

6 March 1992 OVERALL MACHINE INFORMATION

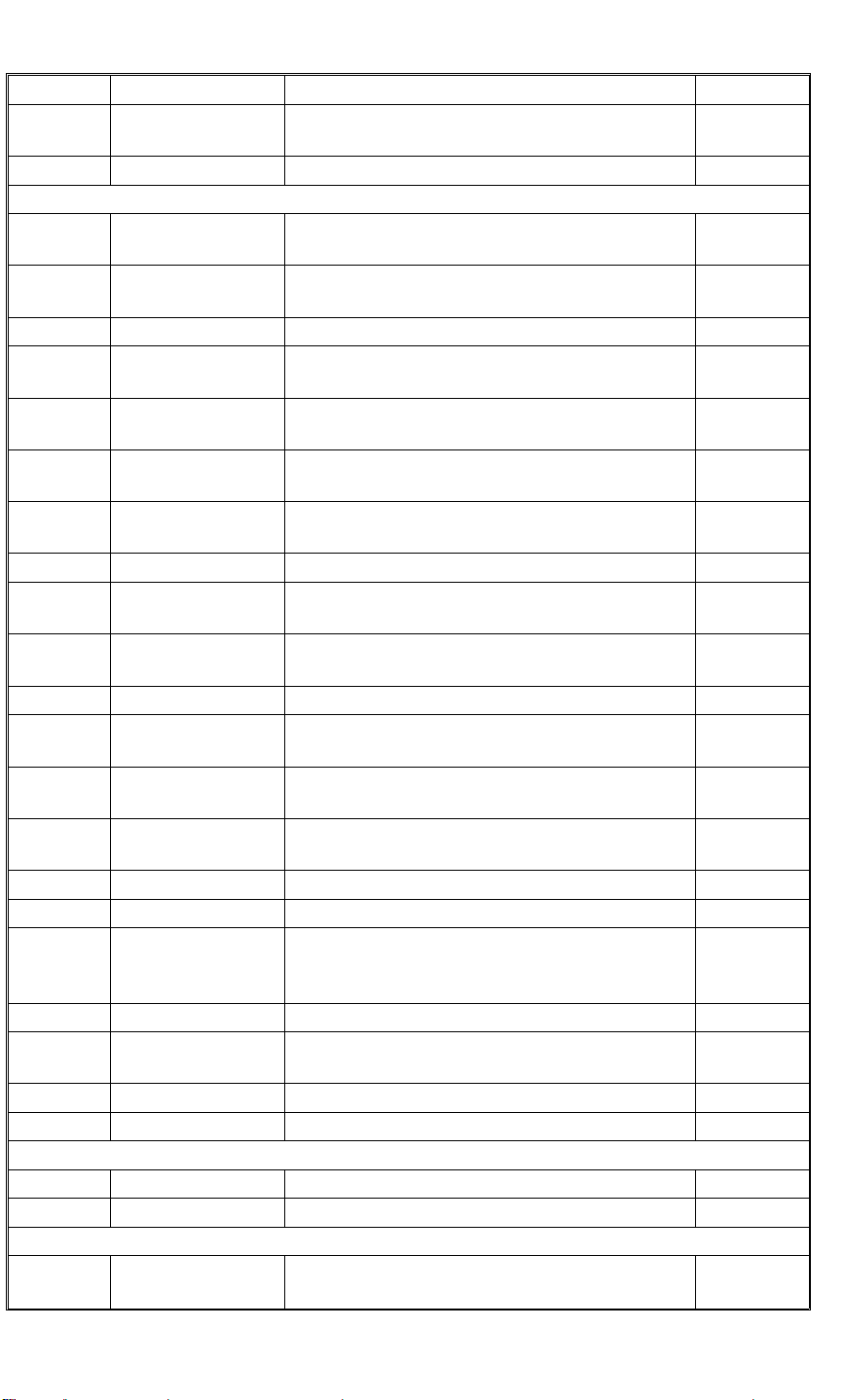

Symbol Name Function Index No.

SOL23

Relay Solenoid Turn the relay gate to transport the copy to

the 2nd sorter.

43

Sensors

S1

S2

Entrance Detects paper jams at the entrance of the

diagonal transport unit.

Registration Detects paper jams at the horizontal transport

unit.

37

21

S3 Proof Tray Exit Detects paper jams at the proof tray exit. 2

S4

S5

S6

S7

Bin/Jam (LED) Detects if paper is in the bin.

Detects paper jams at the bin.

Bin/Jam (Photo Tr) Detects if paper is in the bin.

Detects paper jams at the bin.

Staple Unit H.P. Detects if the staple unit is in the home

position.

Jogger Unit H.P. Detects if the jogger unit is in the home

position.

3

19

4

10

S8 Grip H.P. Detects if the gripper is in the home position. 11

S9

S10

Hammer H.P. Detects if the staple hammer is in the home

position.

Jogger H.P. Detects if the jogger arm is in the home

position.

13

17

S11 Side Bar H.P. Detects if the side bar is in the home position. 33

S12

S13

S14

Tray Gate H.P. Detects if the by-pass tray gate is in the home

position.

Tray Gate Upper

Position

Staple Unit

Detects if the by-pass tray gate is in the upper

position.

Detects the position of the staple unit.

Position

34

35

32

S15 Paper Detect if copies are under the hammer. 7

S16 Staple End Detects if the staple is present. 16

S17

Diagonal

Transport Door

Detects if the diagonal transport door is open.

39

Open

S18 Timing Supplies timing pulses to the main board. 29

S19

Relay Unit Cover

Open

Detects if the relay unit cover is open.

41

S20 Relay Sensor Detects paper jam at the relay unit. 42

Capacitor

C1 Main Motor Protects the PCB’s from induced current. 23

Noise Filter

NF1

Noise Filter Removes electrical noise generated by the

copier and the sorter stapler.

6

25

OVERALL MACHINE INFORMATION 6 March 1992

Symbol Name Function Index No.

Relay

RA1 Main Controls main power. 24

Transformer

TF1 2nd Sensor Detects paper jam at the relay unit. 42

Sorter Stapler

7

6 March 1992 OVERALL MACHINE INFORMATION

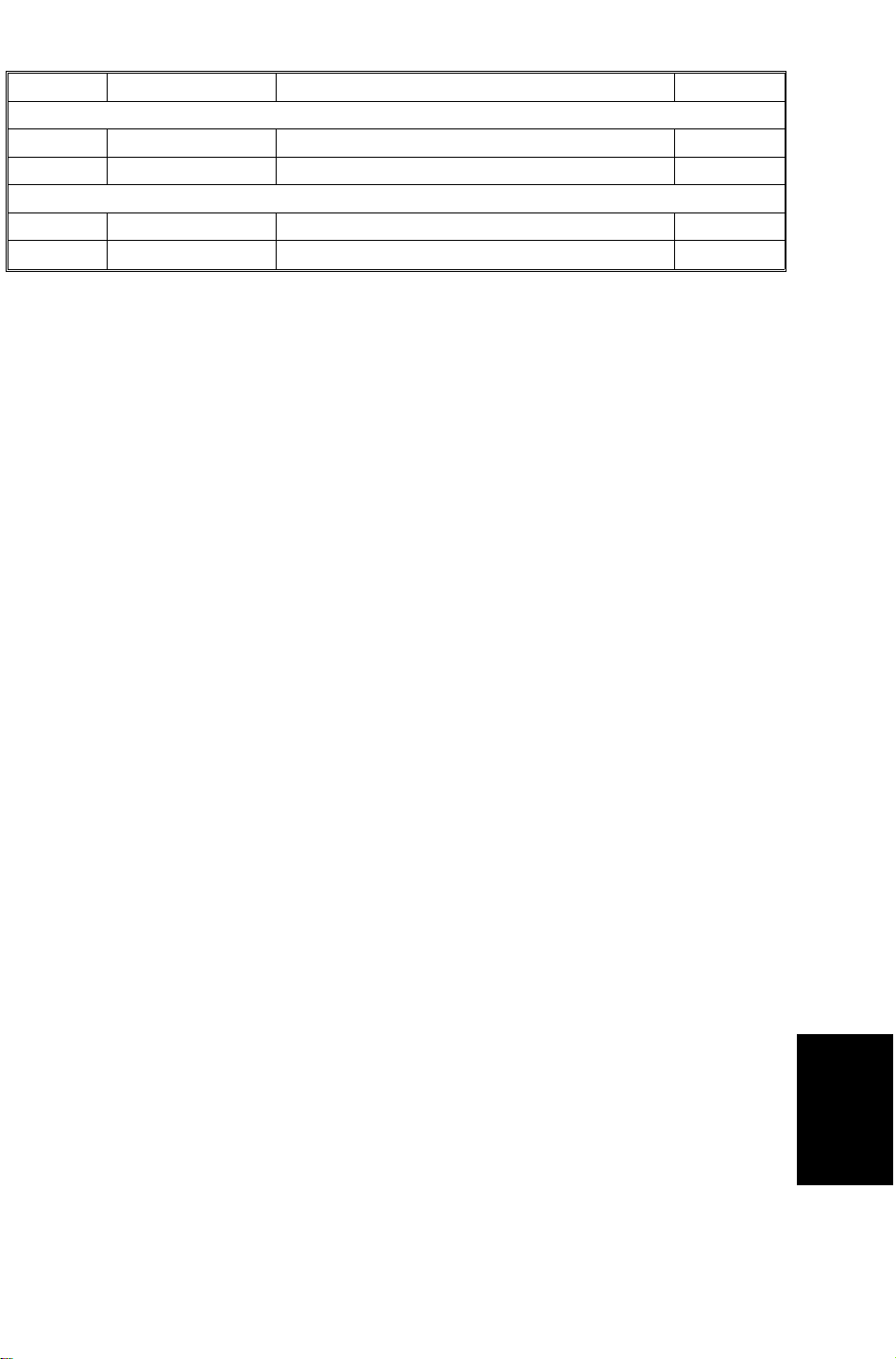

1.5 BASIC OPERATION

[C]

[G]

[I]

[A]

[B]

[H]

[F]

[D]

[E]

[J]

Copies exiting the copier enter the sorter or the by-pass tray [A] depending

on the by-pass tray gate [B] position. In normal operation, copies are sent to

the sorter, if paper jams occur in the sorter, the remaining papers in the

copier are fed to the by-pass tray.

If sort/stack mode is not selected, copies are delivered to the proof tray [C]

through the diagonal transport unit [D], the horizontal transport unit [E], and

the distribution unit [F].

When sort/stack mode is selected, copies are delivered to the bins [G] in

order.

The copies in the bins are arranged by the jogger arm [H].

If staple mode is selected, when the last page of the original is delivered to

the 1st bin, the staple unit [I] starts stapling the copies in each bin.

The 1st sorter has capacity to hold 20 sorted copies.

If the 2nd sorter is installed next to the 1st sorter, an additional 20 sorted

copies can be sorted.

After the 20th copy is fed to the distribution unit of the 1st sorter, the relay

gate [J] moves to the upper position and the 21st copy is transported to the

2nd sorter. After the final copy of the designated number has passed under

the relay gate, the relay gate moves down to transport copies to the bins of

the 1st sorter again.

8

SECTIONAL DESCRIPTION 6 March 1992

2. SECTIONAL DESCRIPTION

2.1 PAPER DELIVERY SWITCHING

[D]

[F]

[C]

[A]

[E]

Depending on the by-pass tray gate [A] position, paper fed from the copier

enters either the sorter or the by-pass tray [B].

The by-pass tray gate is driven by the by-pass tray gate motor [C]. Under

normal operating conditions, the by-pass tray gate is in the home position

(H.P. sensor [D] is actuated) to deliver copies to the sorter. If a sorter paper

jam occurs, the gate rotates on its shaft [E] until the upper tray gate position

sensor [F] is actuated and stops.

[B]

[F]

Sorter Stapler

9

6 March 1992 SECTIONAL DESCRIPTION

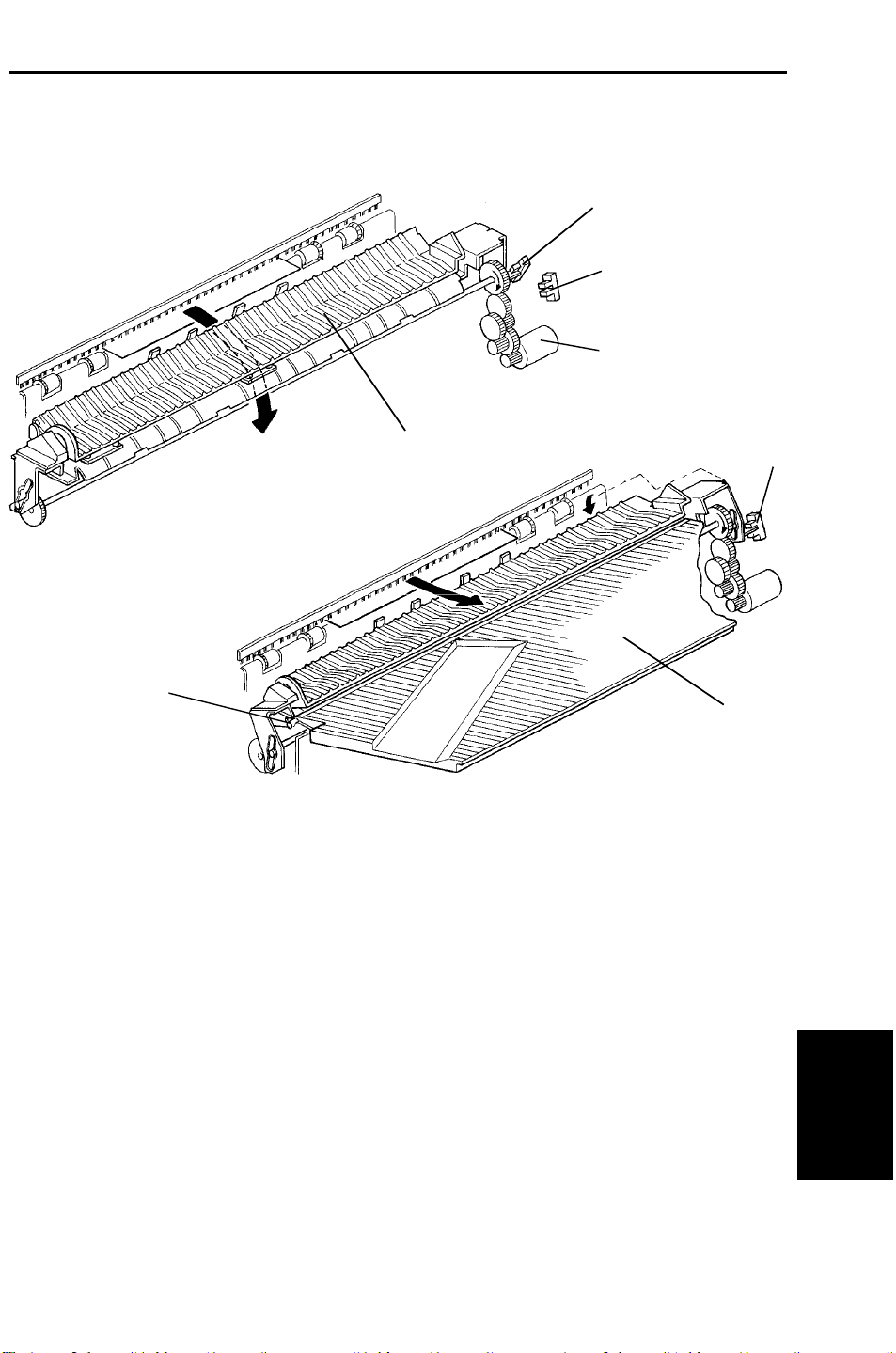

2.2 DIAGONAL TRANSPORT

[A]

[B]

[E]

[D]

[C]

[E]

Paper entering the diagonal transport unit is transported down to the

horizontal transport unit. The front side of the paper advances more than the

back side due to the front transport roller [A] being larger than the back

rollers. This causes the paper to skew as it enters the diagonal transport unit.

This skew prevents the diagonal transport guide [B] from catching the edge of

the copies.

The paper is then moved to the front by the diagonal transport rollers [C].

Where it is aligned as it is guided by the diagonal transport guide [B].

The brake roller [D] prevents the rear side of the paper from falling forward.

If the paper is traveling lengthwise, the pressure release solenoid [E] turns on

to prevent over skewing.

10

SECTIONAL DESCRIPTION 6 March 1992

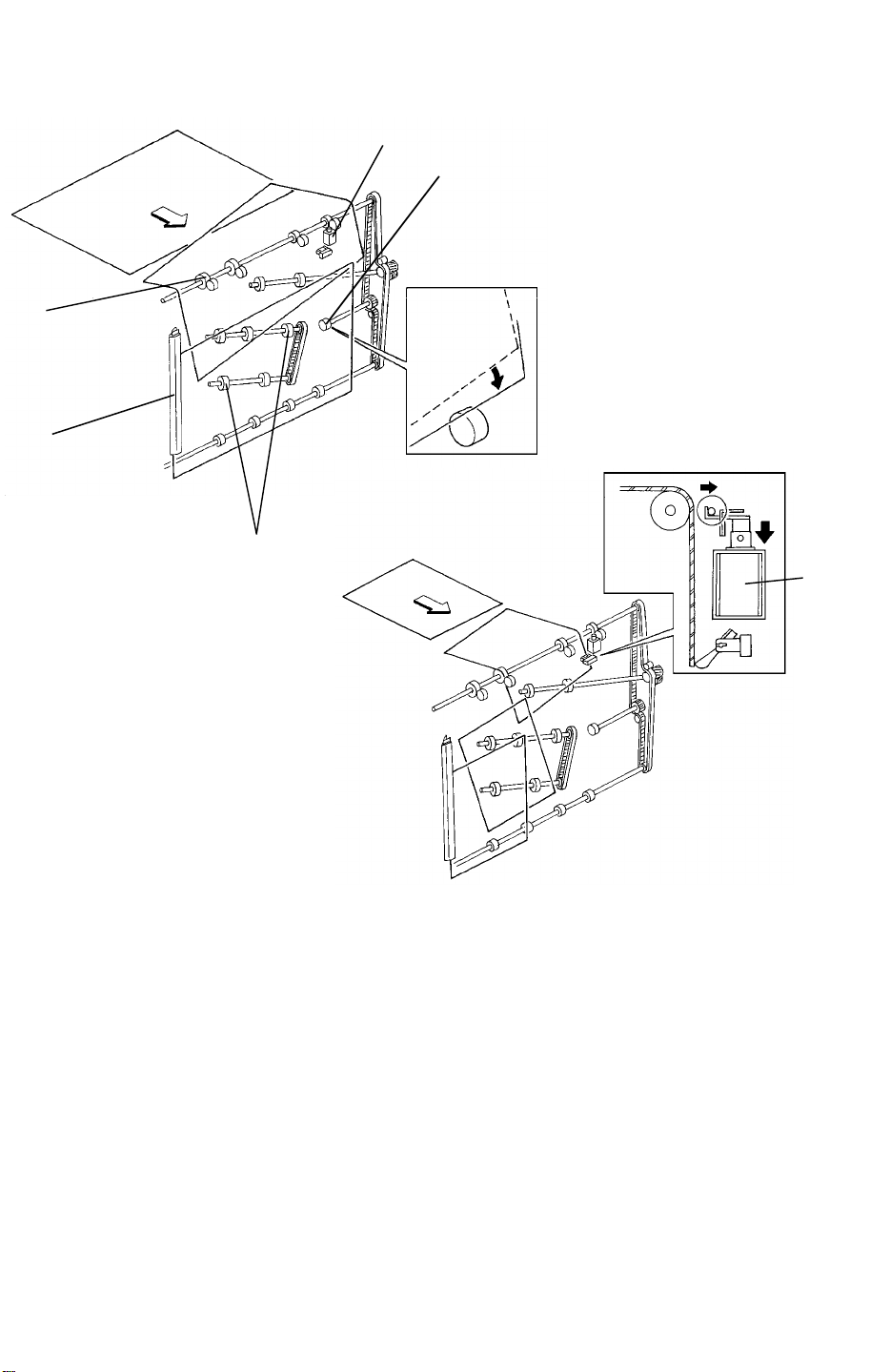

2.3 SORTING

[D]

[B]

[E]

[C][A]

The distribution section has the distribution rollers [A], 20 bin gates, and 20

bin solenoids.

When a bin gate solenoid [B] is off, the return spring [C] holds the bin gate [D]

out of the paper path, allowing the copies to pass to the upper bin.

The appropriate bin gate solenoid turns on and opens the bin gate. The other

solenoids are off. The copies go to the bin [E] through the gate.

11

Sorter Stapler

6 March 1992 SECTIONAL DESCRIPTION

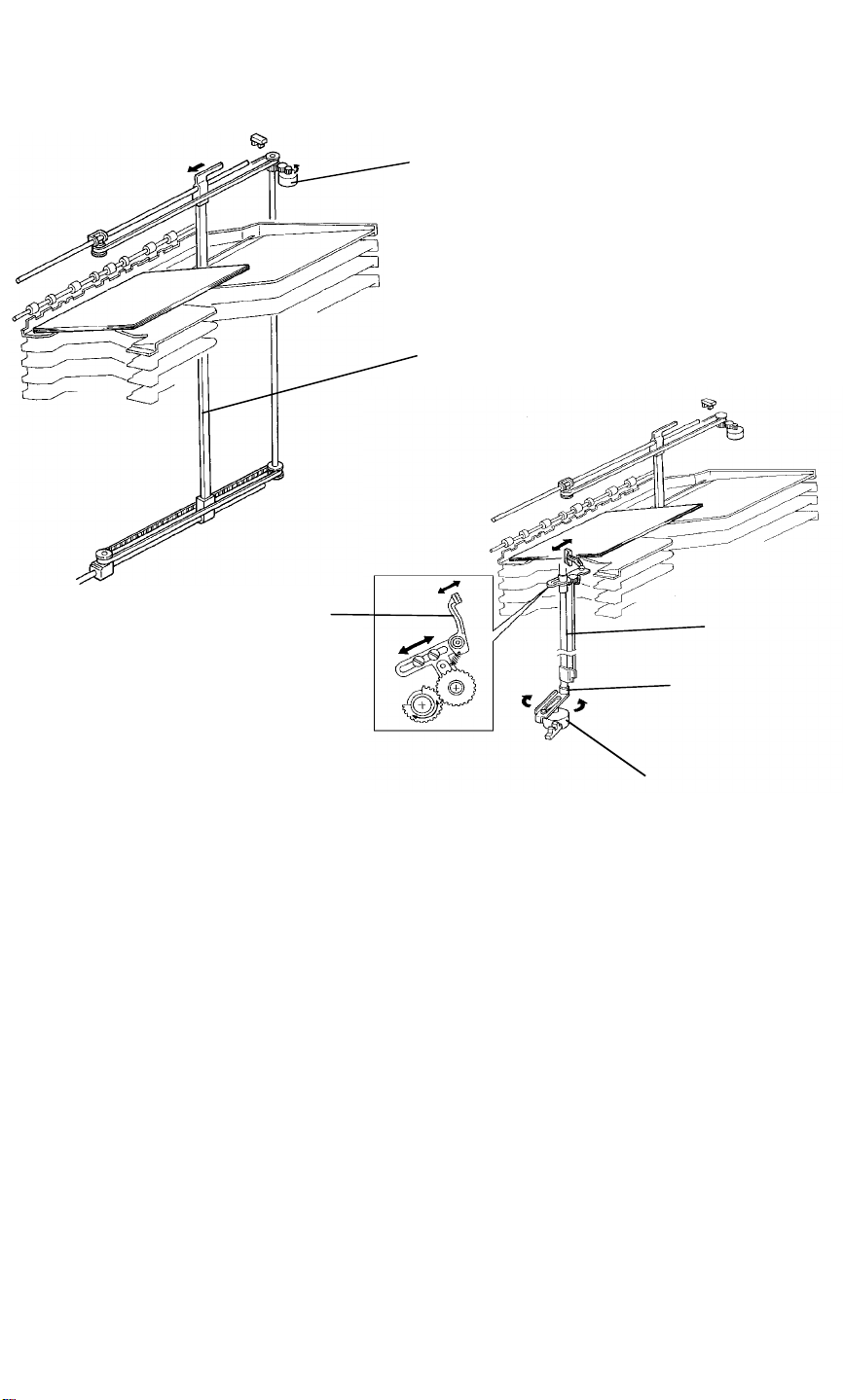

2.4 PAPER JOGGING

[B]

[A]

[C]

[F]

[E]

[ D]

Ordinarily, the side bar [A] is in the home position. It moves to within 10 mm

of the rear of the selected paper size. The side bar is driven by the side bar

motor [B] through the gears and a timing belt.

The jogger arm [C] home position is 10 mm in front of the paper.

After the paper passes the jam sensor, the jogger arm moves twice due to

the forward and reverse rotation of the jogger motor [D]. Jogger arm

movement is controlled through the link [E] and jogger bar [F].

The reverse rotation of the jogger motor prevents motor lock caused by an

overly stiff paper stack. Even if the overly stiff paper interferes with the jogger

arm movement, the arm returns to its home position via the reverse rotation

of the jogger motor.

12

SECTIONAL DESCRIPTION 6 March 1992

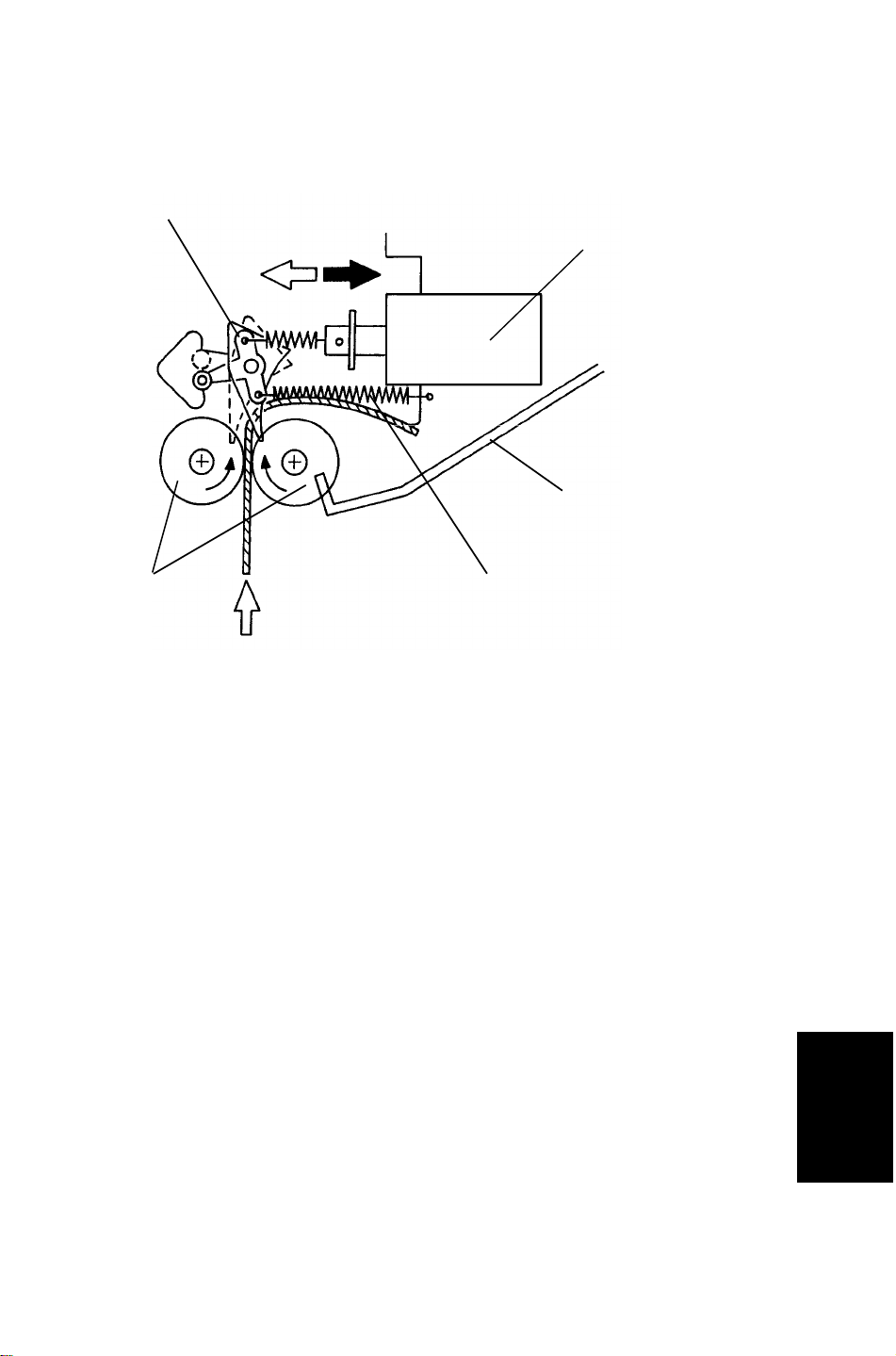

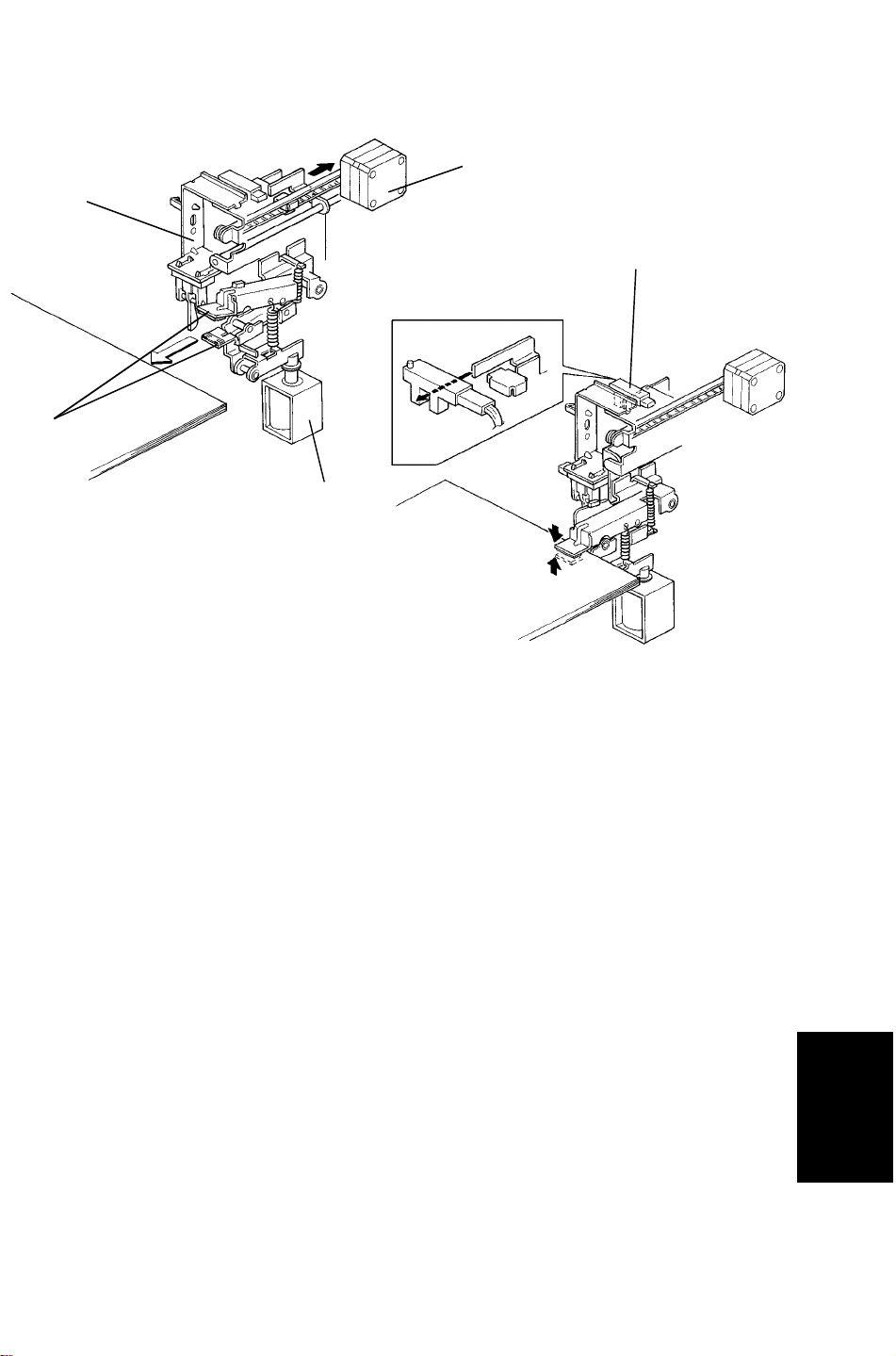

2.5 STAPLING

[C]

[A]

[E]

[D]

[B]

2.5.1 Gripper

The grip unit [A] grips and moves the jogged paper to the staple position and

returns the stapled paper to the bin.

The grip solenoid [B] and grip motor [C] are built into the grip unit. The motor

moves the grippers [D] back and forth, and the solenoid [B] controls paper

clamping.

When the grippers reach the paper in the bin, the grip solenoid turns on and

the grippers grasp the paper.

The lower gripper arm has a shorter stroke to prevent it from disturbing the

jogged paper in the bin.

Paper gripped by the grippers is moved by the grip motor into stapling

position.

Resetting the main PCB DIP SW101-1 to 101-4 adjusts the stapling position

(0.5 mm increments).

The stapled paper (held by the gripper arms throughout stapling) is returned

to its original position. The grip solenoid turns off to release the stapled

paper, and the gripper arms return to their original position.

The grip H.P. sensor [E] confirms that the grip unit has returned to its home

position.

Sorter Stapler

13

Loading...

Loading...