Ricoh SR5060, SR5050 Field Service Manual

Booklet Finisher SR5060

Finisher SR5050

Machine Code: D734/D735

Field Service Manual

V1.1

May 2015

Revision History

This is the Revision History for the Booklet Finisher SR5050/SR5060 service manual.

Version Date Changes

Text, Illustrations. In procedures the order of the text and

Ver. 1.1 31 Mar 2015

illustrations has been reversed. For each step, the text description

(action) is followed by the relevant illustration. The callouts [A], [B],

[C] in text refer to the illustration below, not above.

1

Symbols, Abbreviations and Trademarks

Conventions

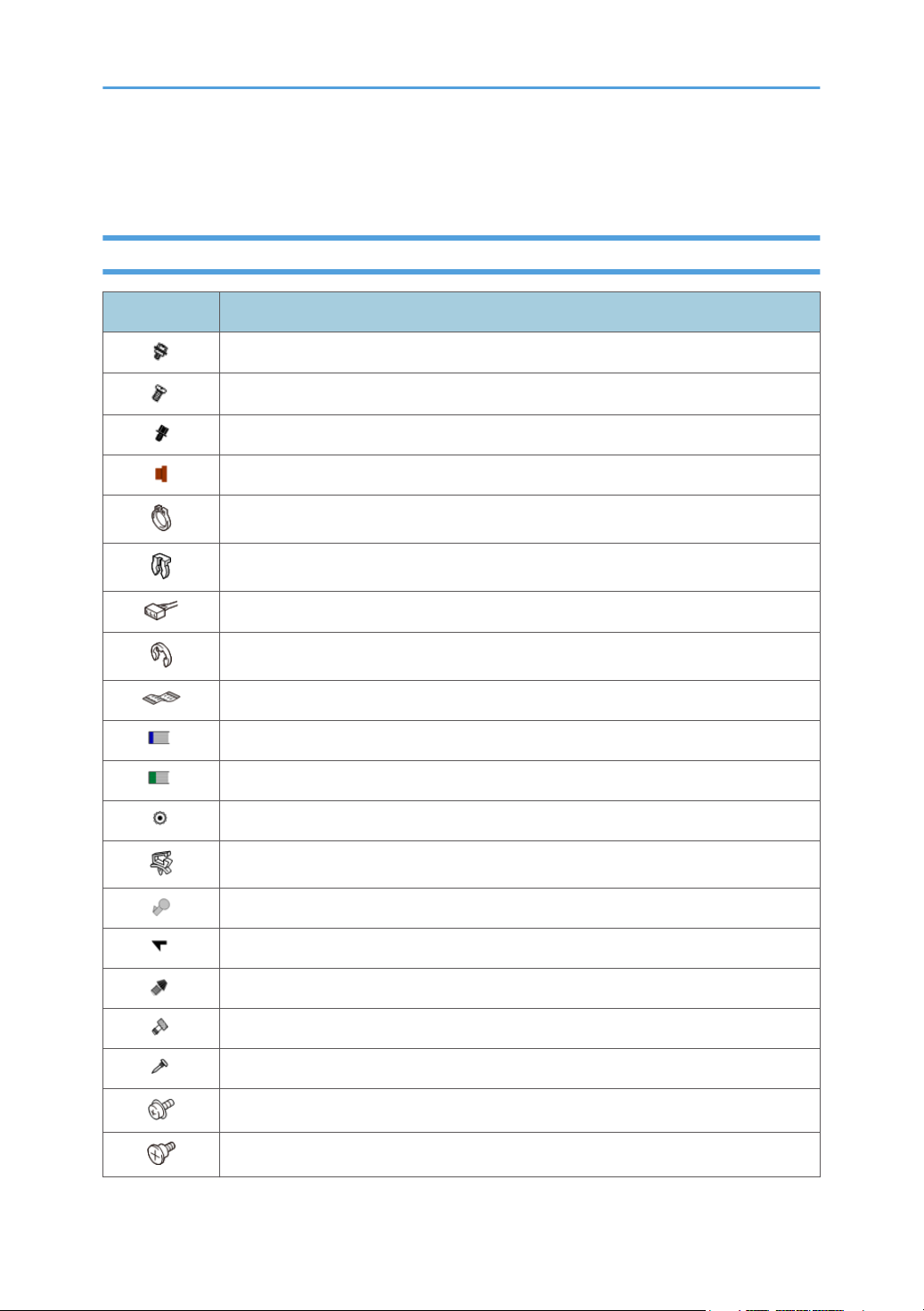

Symbol What it means

Binding screw (shoulder hexagonal head)

Binding screw (round flathead)

Black screw (heavy, fusing unit, TCRU)

Bushing

C-ring

Clip

Connector

E-ring

FFC (Flat Film Connector)

FFC (Flat Film Connector)

FFC (Flat Film Connector)

Gear

Harness clamp

Harness clamp: metal: fusing unit

Hook (or tab release: sensors)

Knob screw (black)

Knob screw (sliver)

Pivot screw

Screw: most common: silver

Shoulder screw

2

Symbol What it means

Shoulder screw (black)

Spring

Standoff

Stud screw

Tapping screw (for plastic)

Timing belt

Washer

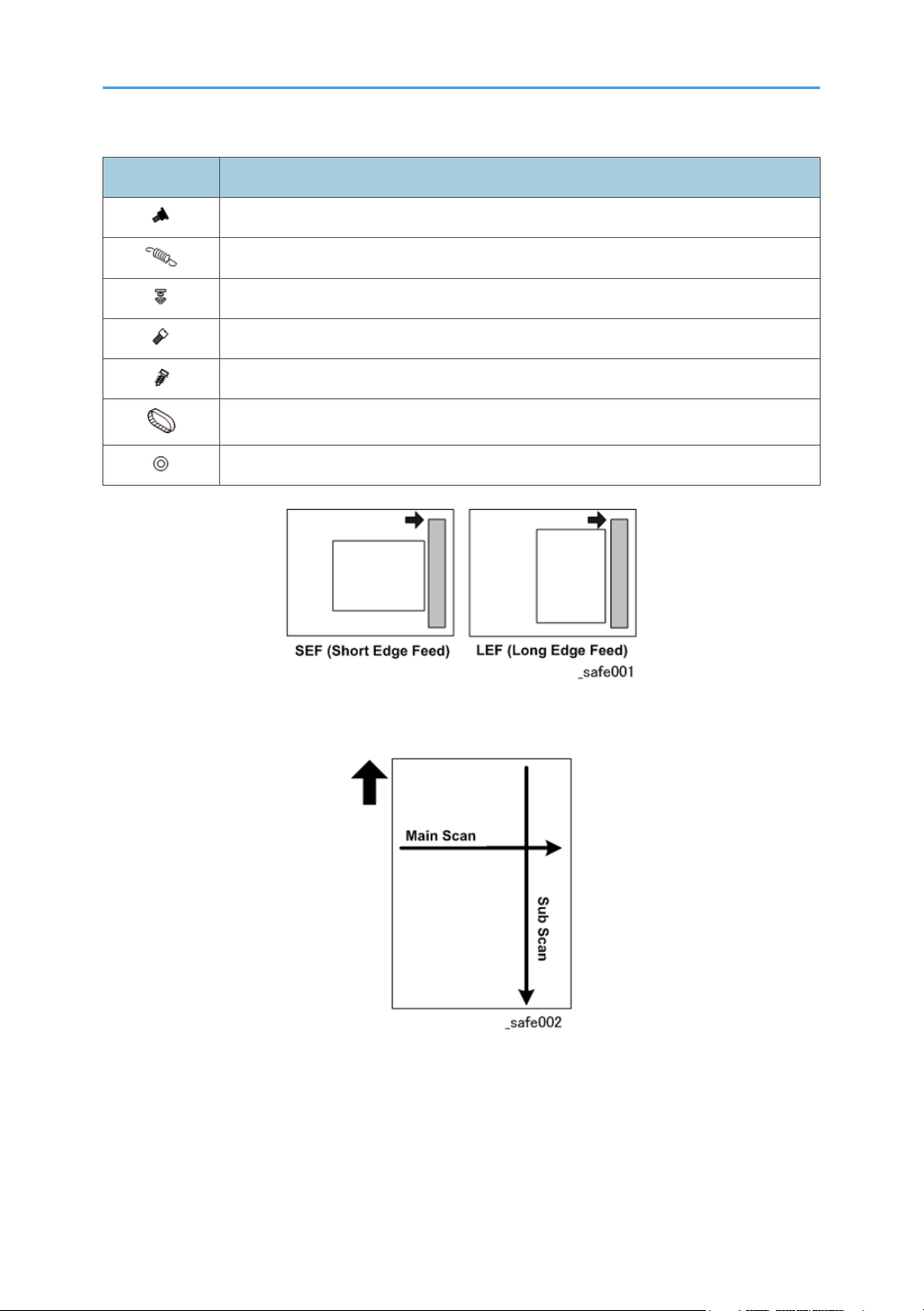

The notations "SEF" and "LEF" describe the direction of paper feed. The arrows indicate the direction of

paper feed.

In this manual "Main Scan" means "Horizontal" and "Sub Scan" means "Vertical", both relative to the

direction of paper feed.

3

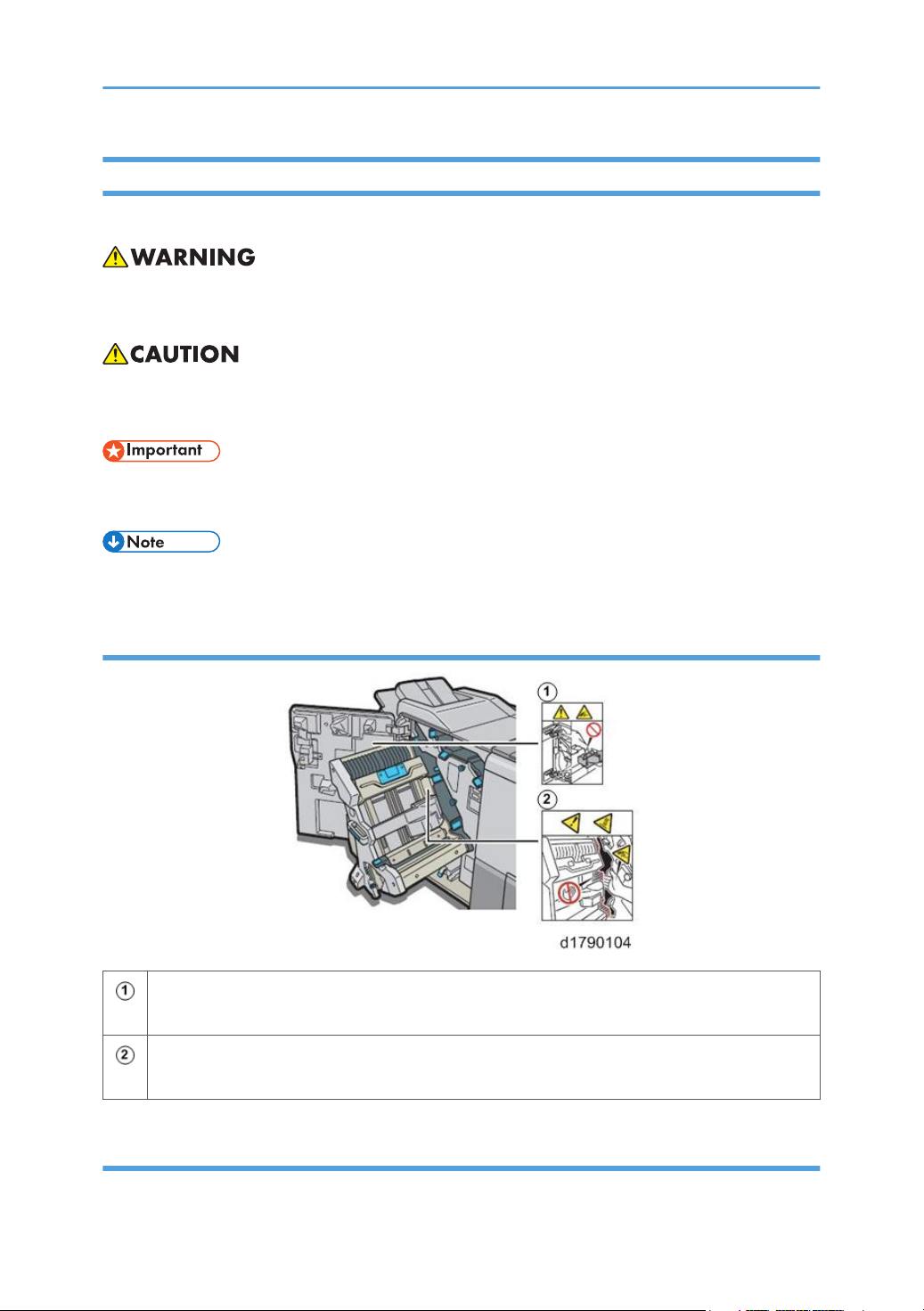

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

• A Warning indicates a potentially hazardous situation. Failure to obey a Warning could result in

death or serious injury.

• A Caution indicates a potentially hazardous situation. Failure to obey a Caution could result in

minor or moderate injury or damage to the machine or other property.

• Obey these guidelines to avoid problems such as misfeeds, damage to originals, loss of valuable

data and to prevent damage to the machine.

• This information provides tips and advice about how to best service the machine.

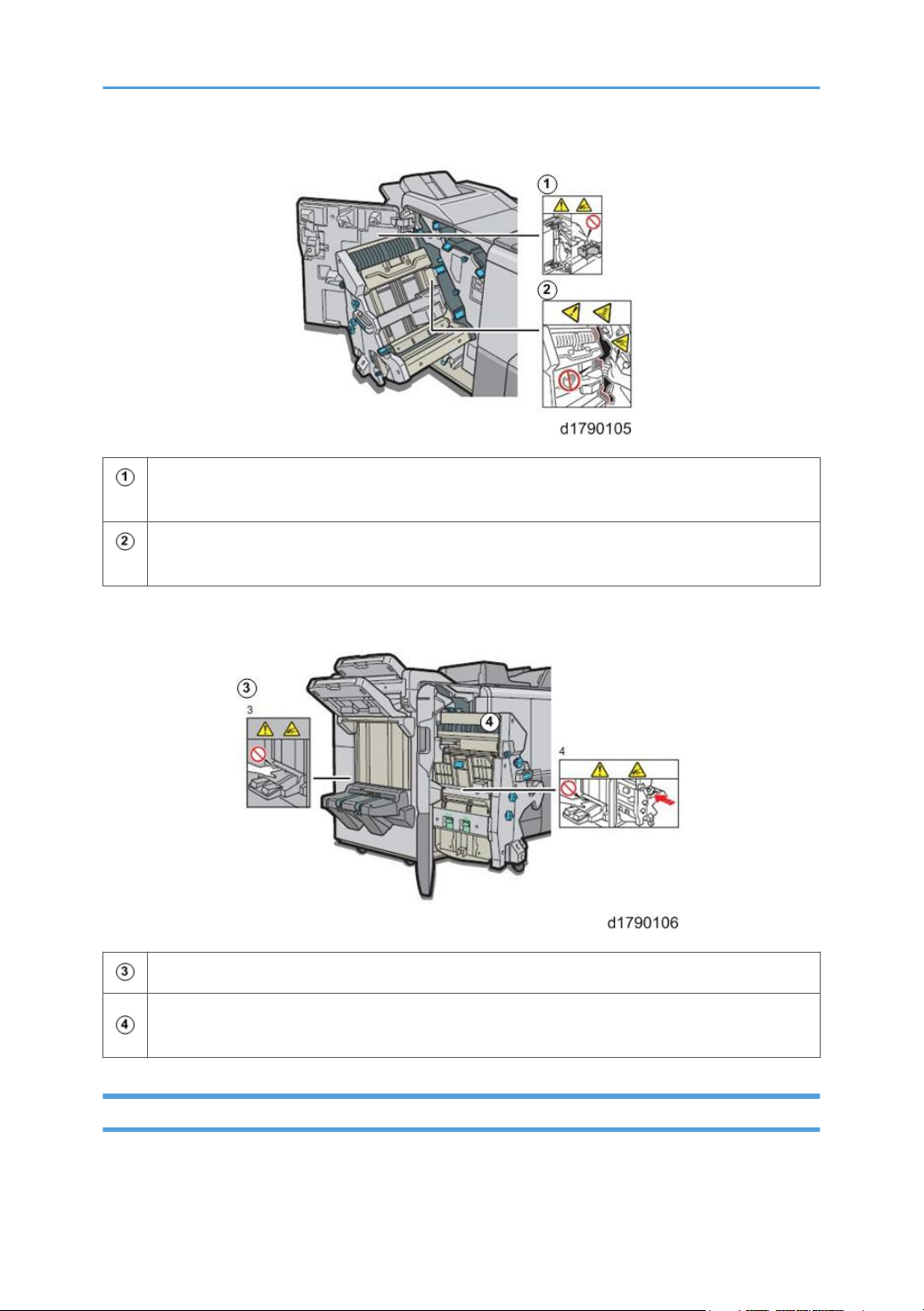

Finisher SR5050

To avoid injury, keep your hands clear of the hinges when opening and closing the finisher

door.

To avoid injury, avoid the indicated parts that become hot during operation and locations

where you could pinch your hand or fingers.

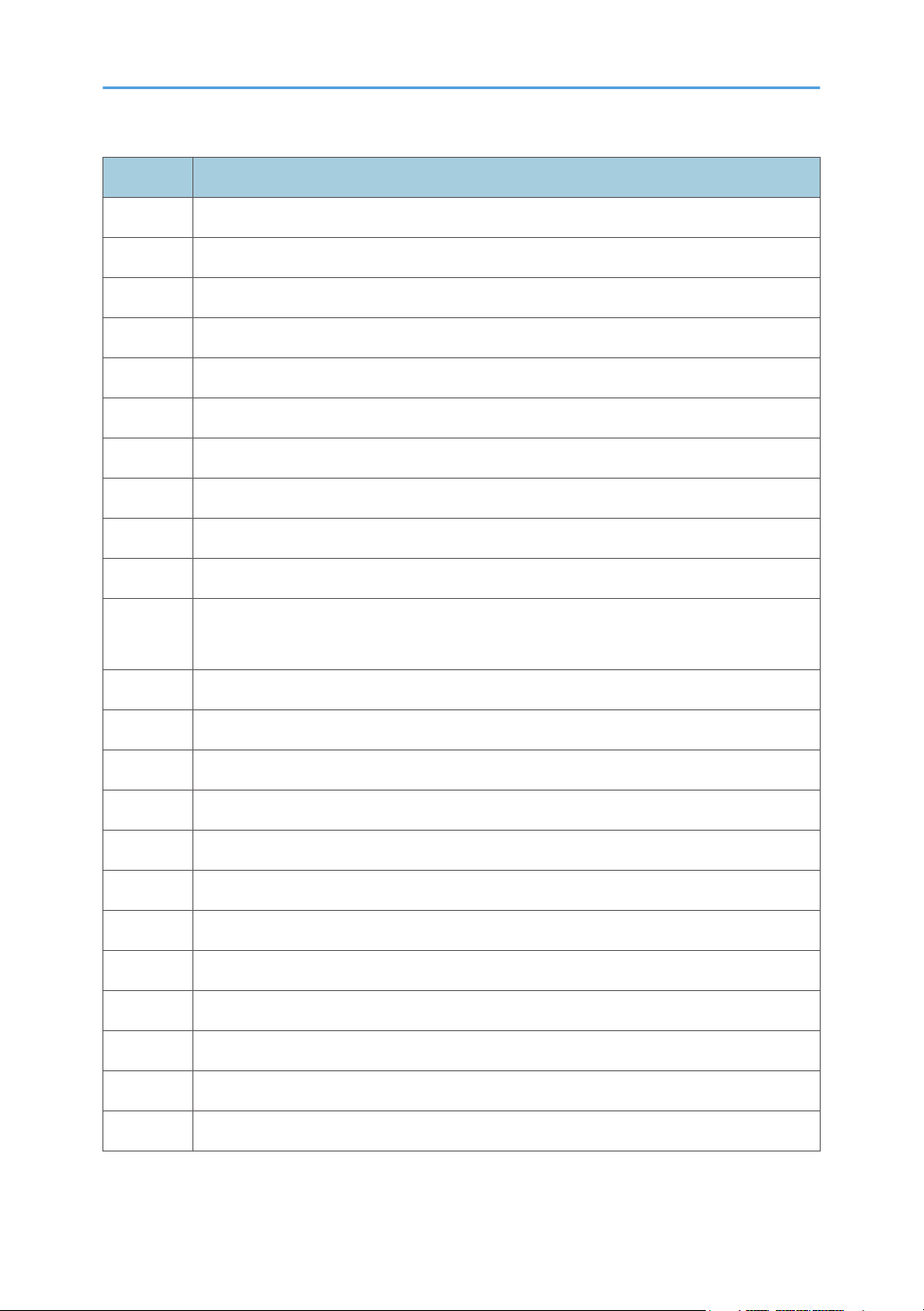

Booklet Finisher SR5060

Front

4

To avoid injury, keep your hands clear of the hinges when opening and closing the finisher

door.

To avoid injury, avoid the indicated parts that become hot during operation and locations

where you could pinch your hand or fingers.

Left Side

To avoid injury, never touch the booklet tray during operation.

To avoid injury, never touch the booklet tray when removing a paper jam, or when pulling out

or pushing in the stacker/stapler unit.

Commonly Used Terms and Abbreviations

Here is a list of commonly used terms and abbreviations that are used throughout the Field Service

Manual and Appendices.

5

Terms Meaning

(ccw) Counter-clockwise rotation of a drum, roller, gear, etc.

(cw) Clockwise rotation of a drum, roller, gear, etc.

BF Booklet Finisher SR5060 (D734)*

1

BW Black and white (monochrome) copying or printing

Bank Paper Bank (1st, 2nd, 3rd Tray of the main machine)

CIT Cover Interposer Tray CI5030 (D738)*

1

CIT-PB Cover Interposer Tray for Perfect Binder Type S1 (D736-2)*

FIN Finisher SR5050 (D735) (corner staple only, no booklets)*

ITB Image Transfer Belt

JG Junction Gate

LCIT Large Capacity Input Tray.

LCIT RT5080 (D732) or LCIT RT5070 (D733)*

1

LD Laser Diode (Laser Unit)

LE Leading Edge

LSDB Laser Synchronization Detection Board (Laser Unit)

MFU Multi Folding Unit FD5020 (D740)*

1

1

1

PCDU Photoconductor Development Unit

PB Perfect Binder GB5010 (D736)*

1

PFU Paper Feed Unit (Tray 1, Tray 2, Tray 3)

PTB Paper Transport Belt (between PTR and fusing unit)

PTR Paper Transfer Roller

RB Ring Binder RB5020 (D737)

TCRU Trained Customer Replacement Units

TE Trailing Edge

6

Terms Meaning

TM/P ID sensor. "ID sensor" is used in this manual. However, you may see "TM/P" in the SP

codes on the operation panel.

TPU Transit Path Unit for Perfect Binder Type S1 (D736)*

TRM Trimmer Unit 5040 (D520)*

1

1

VTU Vertical Transport Unit

*1Optional peripheral devices.

Trademarks

• Microsoft®, and Windows® are registered trademarks of Microsoft Corporation in the United

States and /or other countries.

• PostScript® is a registered trademark of Adobe Systems, Incorporated.

• PCL® is a registered trademark of Hewlett-Packard Company.

• Ethernet® is a registered trademark of Xerox Corporation.

• PowerPC® is a registered trademark of International Business Machines Corporation.

• Other product names used herein are for identification purposes only and may be trademarks of

their respective companies. We disclaim any and all rights involved with those marks.

7

TABLE OF CONTENTS

Revision History...................................................................................................................................................1

Symbols, Abbreviations and Trademarks ........................................................................................................2

Conventions.................................................................................................................................................... 2

Warnings, Cautions, Notes...........................................................................................................................4

Finisher SR5050.................................................................................................................................... 4

Booklet Finisher SR5060...................................................................................................................... 4

Commonly Used Terms and Abbreviations..................................................................................................5

Trademarks..................................................................................................................................................... 7

1. Replacement and Adjustment

Common Procedures........................................................................................................................................13

Overview...................................................................................................................................................... 13

Covers...........................................................................................................................................................15

Rear Upper Cover...............................................................................................................................15

Rear Lower Cover............................................................................................................................... 16

Lower Inner Cover: Rb10, Rb11....................................................................................................... 17

Center Inner Cover: Rb14, Rb16...................................................................................................... 18

Upper Inner Cover: Rb2, Rb8............................................................................................................19

Front Door............................................................................................................................................19

Proof Tray.............................................................................................................................................20

Corner Strip Cover..............................................................................................................................20

Top Right Cover...................................................................................................................................21

Top Rear Cover................................................................................................................................... 22

Shift Tray Jogger Unit..........................................................................................................................22

Left Upper Cover................................................................................................................................. 23

Upper, Lower Right Panels................................................................................................................. 24

Shift Tray.............................................................................................................................................. 25

Booklet Tray.........................................................................................................................................26

Booklet Unit.................................................................................................................................................. 28

Booklet Stapler.................................................................................................................................... 28

Booklet Unit Removal..........................................................................................................................29

Handling and Moving the Booklet Unit.............................................................................................32

End Fence..................................................................................................................................................... 33

Exit Roller Cover..................................................................................................................................33

8

Shift Tray.............................................................................................................................................. 34

Shift Tray Base.....................................................................................................................................35

Left Lower Cover..................................................................................................................................38

End Fence............................................................................................................................................ 39

Drag Roller Unit............................................................................................................................................41

Horizontal Paper Feed.....................................................................................................................................45

Entrance........................................................................................................................................................45

Entrance Roller Motor(........................................................................................................................45

Entrance Sensor...................................................................................................................................49

Registration...................................................................................................................................................50

Registration Motor...............................................................................................................................50

Horizontal Transport Motor............................................................................................................... 52

Proof Tray..........................................................................................................................................................54

Proof Tray Motors........................................................................................................................................ 54

Proof Tray JG Motor........................................................................................................................... 54

Proof Tray Vertical Transport Motor.................................................................................................. 55

Proof Tray Exit Motor..........................................................................................................................57

Proof Tray Sensors....................................................................................................................................... 58

Proof Tray JG HP Sensor.................................................................................................................... 58

Proof Tray Exit Sensor, Proof Tray Full Sensor..................................................................................60

Shift Tray........................................................................................................................................................... 63

Shift Tray Side-to-Side Movement..............................................................................................................63

Shift Motor........................................................................................................................................... 63

Shift Tray HP Sensors (Front, Rear)....................................................................................................64

Shift Tray Exit................................................................................................................................................65

Shift Tray Exit Motor............................................................................................................................65

Shift Tray Exit Sensors (Long and Short)............................................................................................66

Drag Roller Motors, Sensors.......................................................................................................................70

Preparation.......................................................................................................................................... 70

Drag Roller Motor...............................................................................................................................71

Drag Roller Drive Motor.....................................................................................................................72

Drag Roller HP Sensor........................................................................................................................ 73

Shift Tray Jogger Unit...................................................................................................................................74

9

Shift Jogger Motor.............................................................................................................................. 74

Shift Tray Jogger Fence HP Sensor....................................................................................................76

Shift Jogger Retraction Motor............................................................................................................ 76

Shift Jogger Fence Retract HP Sensor................................................................................................78

Shift Tray Operation.................................................................................................................................... 78

Shift Tray Lift Motor............................................................................................................................. 78

Paper Height Sensors 1, 2, 3 (Shift, Staple, Z-Fold)....................................................................... 80

Paper Height Sensor (TE), Shift Tray Upper Limit Switch................................................................. 81

Shift Tray Full Sensors 1, 2, 3, 4 (500).............................................................................................85

Pre-Stacker........................................................................................................................................................88

Pre-Stack Motors..........................................................................................................................................88

Pre-Stack Motor.................................................................................................................................. 88

Pre-Stack Release Motor, Pre-Stack Roller HP Sensor.....................................................................91

Corner Stapler Unit.......................................................................................................................................... 97

Corner Stapler Unit Entrance...................................................................................................................... 97

Stapler JG Motor.................................................................................................................................97

Stapler JG HP Sensor..........................................................................................................................98

Stapling Tray Entrance Sensor........................................................................................................... 99

Stapling Tray Entrance Motor..........................................................................................................100

Corner Stapler Side-to-Side Jogging.......................................................................................................102

Front Jogger Fence Motor................................................................................................................102

Jogger Fence HP Sensor (Front)...................................................................................................... 104

Rear Jogger Fence Motor................................................................................................................ 104

Jogger Fence HP Sensor (Rear).......................................................................................................107

Corner Stapling Bottom, Top Jogging..................................................................................................... 108

Positioning Roller Rotation Motor....................................................................................................108

Positioning Roller Motor...................................................................................................................109

Positioning Roller HP Sensor............................................................................................................110

Leading Edge Stopper HP Sensor, Staple Tray Paper Sensor......................................................111

Top Fence HP Sensor....................................................................................................................... 112

Corner Stapling......................................................................................................................................... 114

Corner Stapler.................................................................................................................................. 114

Corner Stapler Movement Motor....................................................................................................116

10

Stapler Rotation Motor.....................................................................................................................118

Staple Trimmings Hopper Full, Hopper Set Sensor....................................................................... 119

Stapler Movement Sensors..............................................................................................................121

Corner Stapled Stack Feed Out...............................................................................................................124

Stack Transport Motor......................................................................................................................124

Stack Transport Unit HP Sensor.......................................................................................................125

Stack Feed-Out Belt Motor.............................................................................................................. 126

Stack Feed-Out Belt HP Sensor....................................................................................................... 128

Stack Junction Gate Motor.............................................................................................................. 129

Stack JG HP Sensor..........................................................................................................................130

Corner Stapled Stack Exit to Shift Tray....................................................................................................131

Exit Guide Motor.............................................................................................................................. 131

Exit Guide HP Sensor....................................................................................................................... 134

Booklet Unit.................................................................................................................................................... 135

Booklet Stapler.......................................................................................................................................... 135

Booklet Unit Transport, Entrance..............................................................................................................136

Fold Unit Entrance Sensor................................................................................................................136

Booklet Side-to-Side Jogging...................................................................................................................136

Booklet Stapler Side Fence Motor.................................................................................................. 136

Booklet Stapler Side Fence HP Sensor (Front)............................................................................... 138

Booklet Stapler Jogger HP Sensor (Rear).......................................................................................138

Booklet Bottom, Top Jogging................................................................................................................... 139

Booklet Stapler Bottom Fence Motor..............................................................................................139

Booklet Stapler Bottom Fence HP Sensor....................................................................................... 140

Booklet Stapler Top Fence Motor................................................................................................... 142

Booklet Top Fence HP Sensor..........................................................................................................143

Booklet Press for Stapling......................................................................................................................... 143

Booklet Stapler Clamp Roller Motor, Booklet Stapler Exit Sensor............................................... 143

Booklet Stapler Clamp Roller HP Sensor........................................................................................151

Booklet Folding..........................................................................................................................................153

Fold Roller Motor..............................................................................................................................153

Fold Plate Cam HP Sensor............................................................................................................... 154

Fold Plate HP Sensor........................................................................................................................ 155

11

Booklet Exit.................................................................................................................................................156

Fold Roller Motor..............................................................................................................................156

Boards............................................................................................................................................................ 159

Main Board................................................................................................................................................159

Punch Unit PCB.......................................................................................................................................... 161

Shift Tray Jogger Unit PCB........................................................................................................................161

PSU............................................................................................................................................................. 162

Switches..........................................................................................................................................................166

Front Door Switch......................................................................................................................................166

Emergency Shift Tray Stop Switch............................................................................................................167

Rollers and Brushes........................................................................................................................................168

Rollers.........................................................................................................................................................168

Drag Roller........................................................................................................................................ 168

Positioning Roller...............................................................................................................................168

Alignment Brush Roller..................................................................................................................... 169

Discharge Brushes..................................................................................................................................... 171

Shift Tray Exit.....................................................................................................................................171

Corner Stapler Entrance...................................................................................................................172

Booklet Unit Exit................................................................................................................................ 173

Special Adjustments.......................................................................................................................................174

Horizontal Skew Adjustment.................................................................................................................... 174

[A] Adjustment: Rear Fence Low......................................................................................................175

[B] Adjustment: Front Fence Low......................................................................................................176

Vertical Skew Adjustment..........................................................................................................................177

Base Fence Replacement..........................................................................................................................178

12

1. Replacement and Adjustment

Common Procedures

Overview

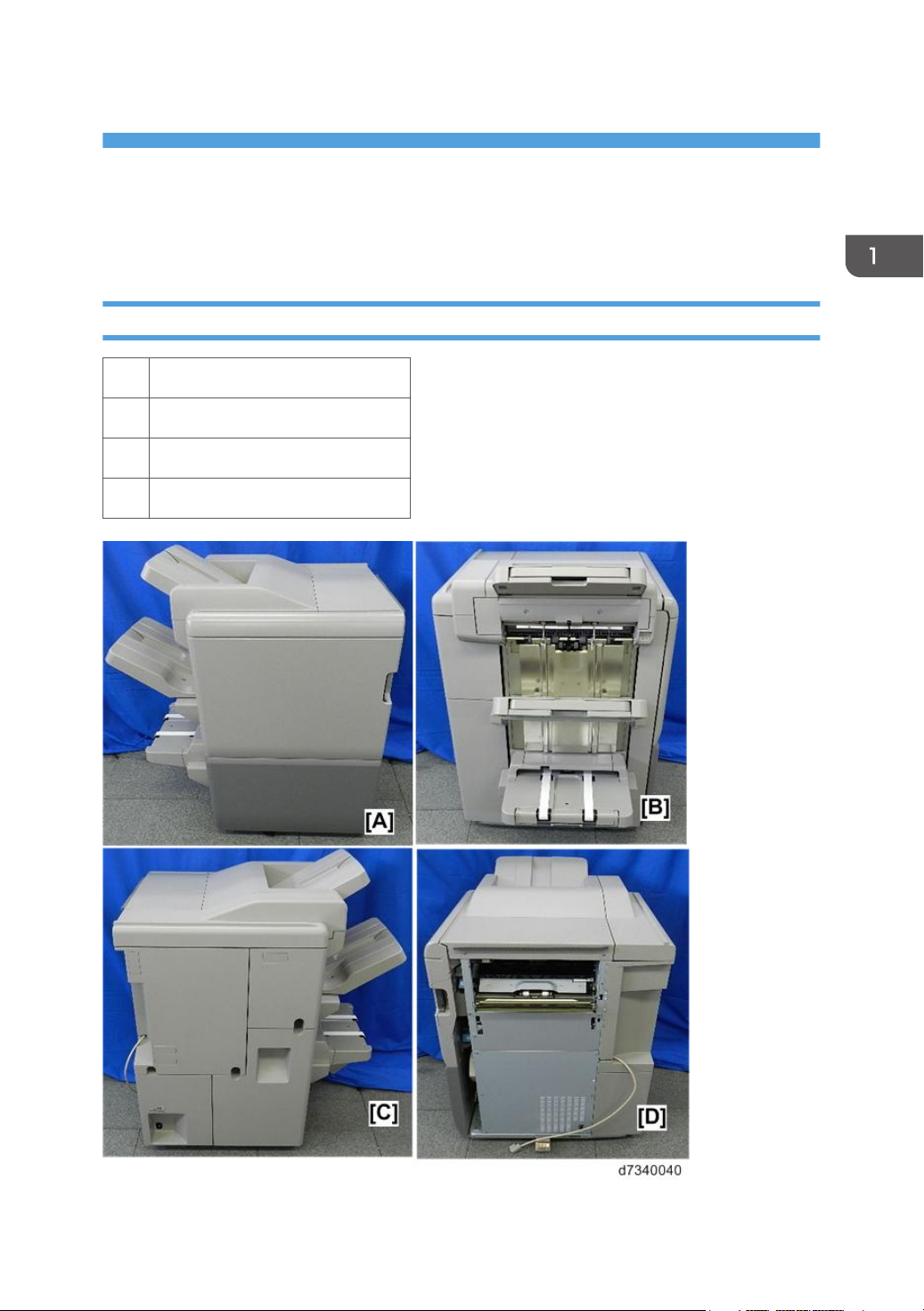

[A] Front

[B] Left

[C] Rear

[D] Right

13

1. Replacement and Adjustment

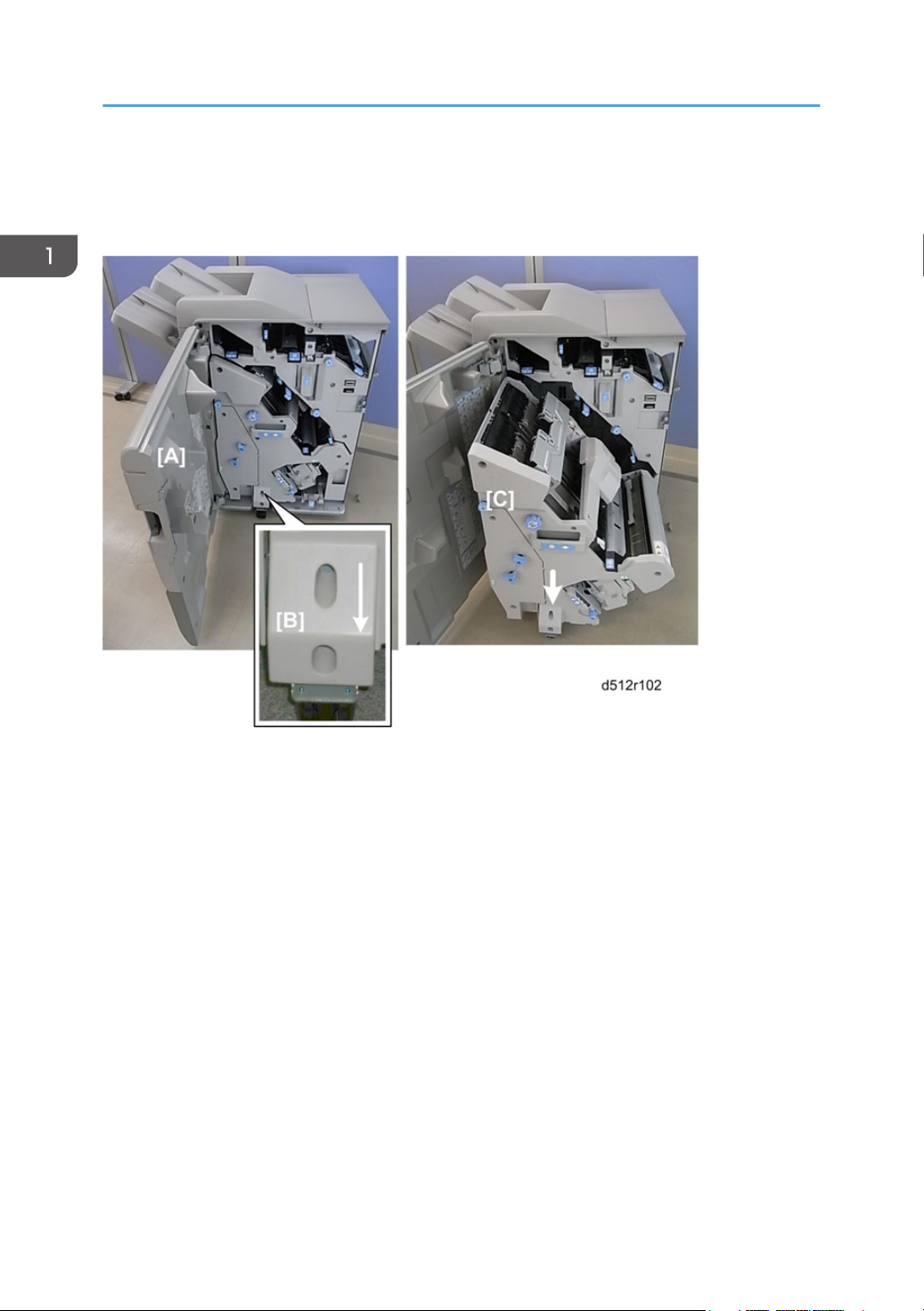

[A] Open the front door.

[B] Adjustable caster

[C] Pull the stack/stapler unit out (pull handle Rb12).

14

• Inner covers:

[A] Upper: Rb2, Rb8

[B] Center: Rb14, Rb16

[C] Lower Rb10, Rb11

Common Procedures

Covers

Rear Upper Cover

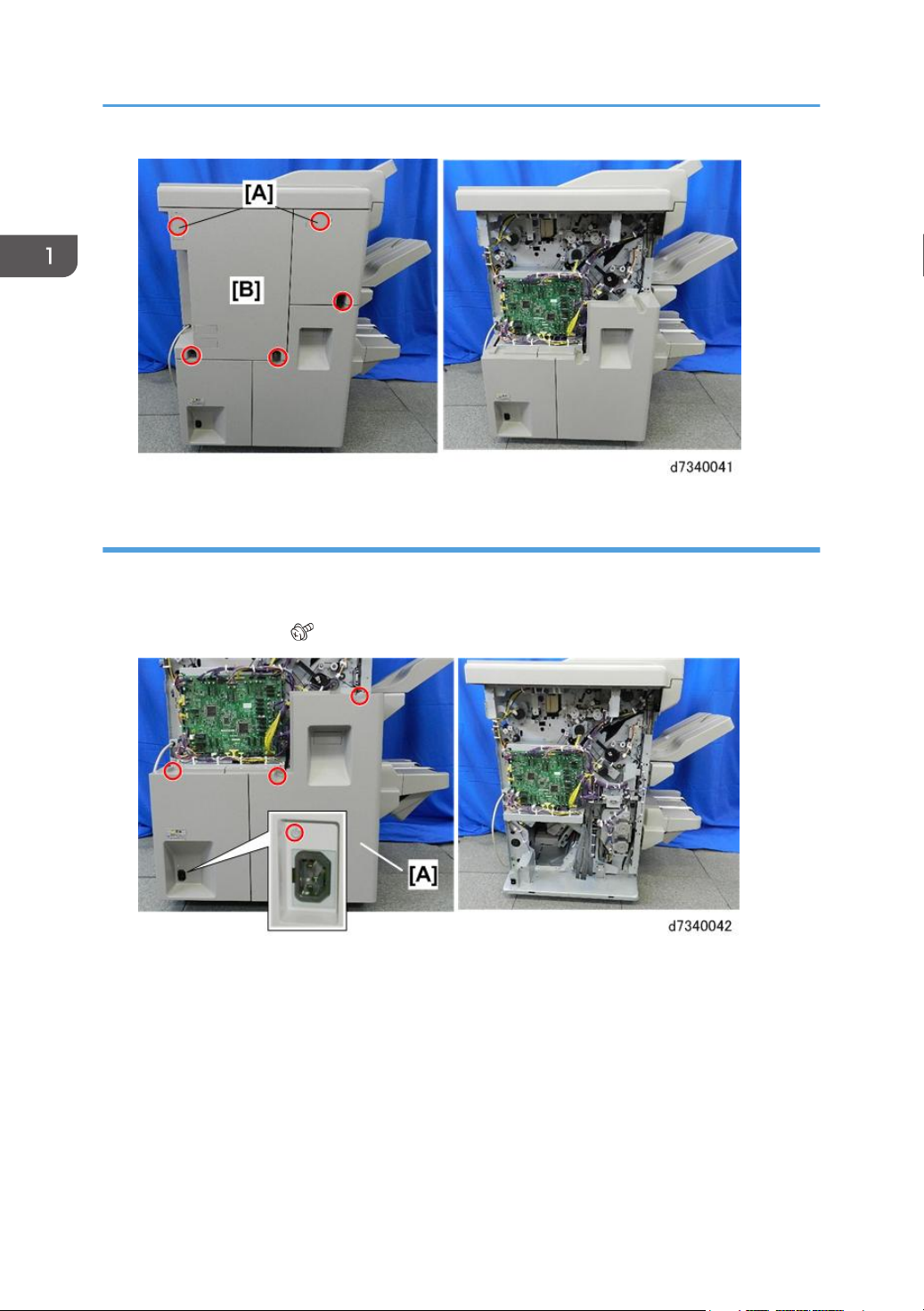

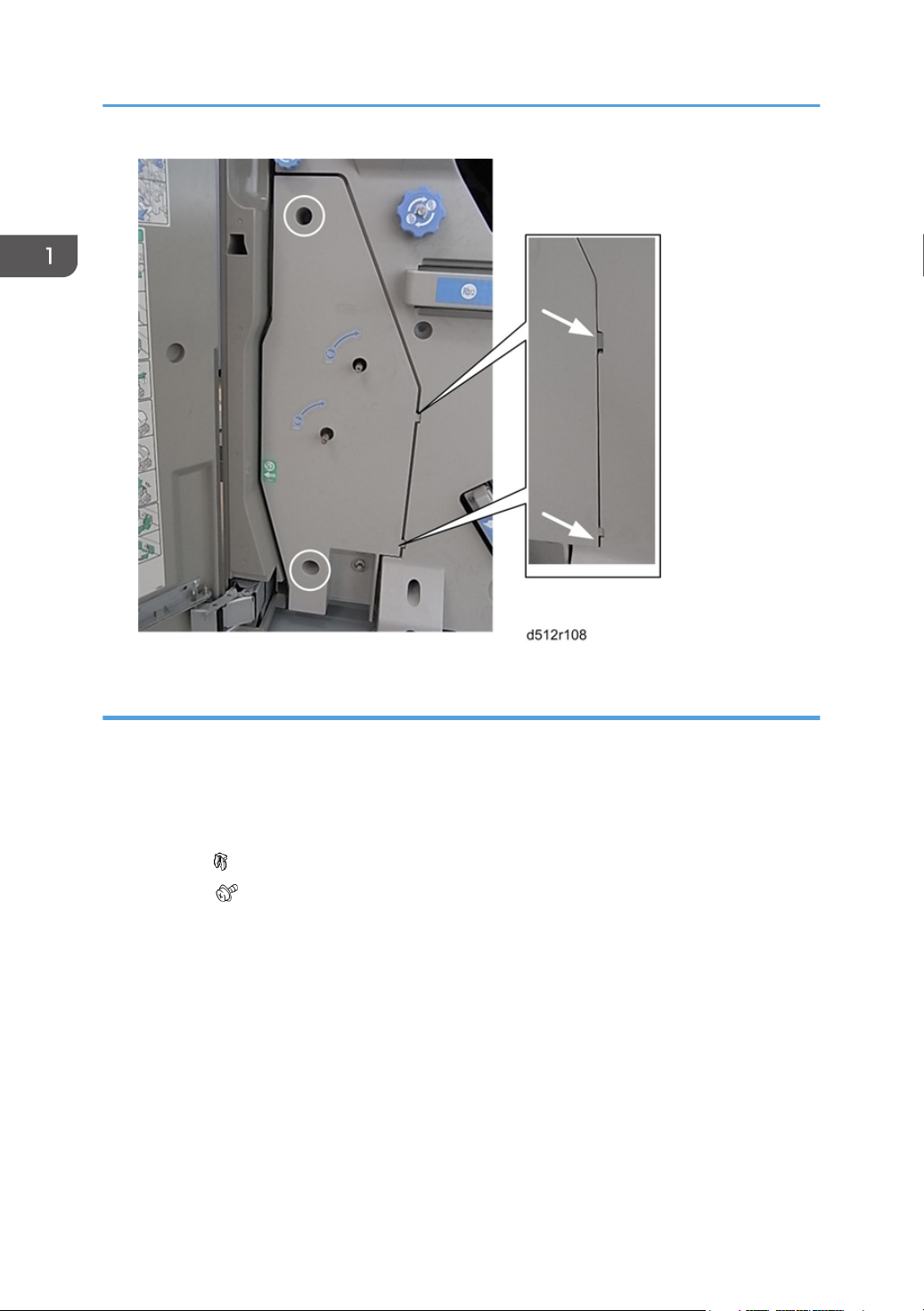

1. Screw covers [A] (hooks)

2. Rear upper cover [B] ( x5)

• The rear upper cover must be removed before the rear lower cover.

15

1. Replacement and Adjustment

Rear Lower Cover

Preparation

• Rear upper cover

1. Rear lower cover [A] ( x4). The screw near the power connection point is difficult to see.

Re-installation

1. Engage both tabs on the bottom of the rear lower cover before fastening the screws.

16

Lower Inner Cover: Rb10, Rb11

1. Remove handles Rb11, Rb12 ( x1 each, Pin x1 each).

2. Make sure that the pins [A] are removed and stored with the screws.

Common Procedures

3. Remove the cover ( x2, Tabs x2).

17

1. Replacement and Adjustment

Center Inner Cover: Rb14, Rb16

Preparation

• Lower inner cover

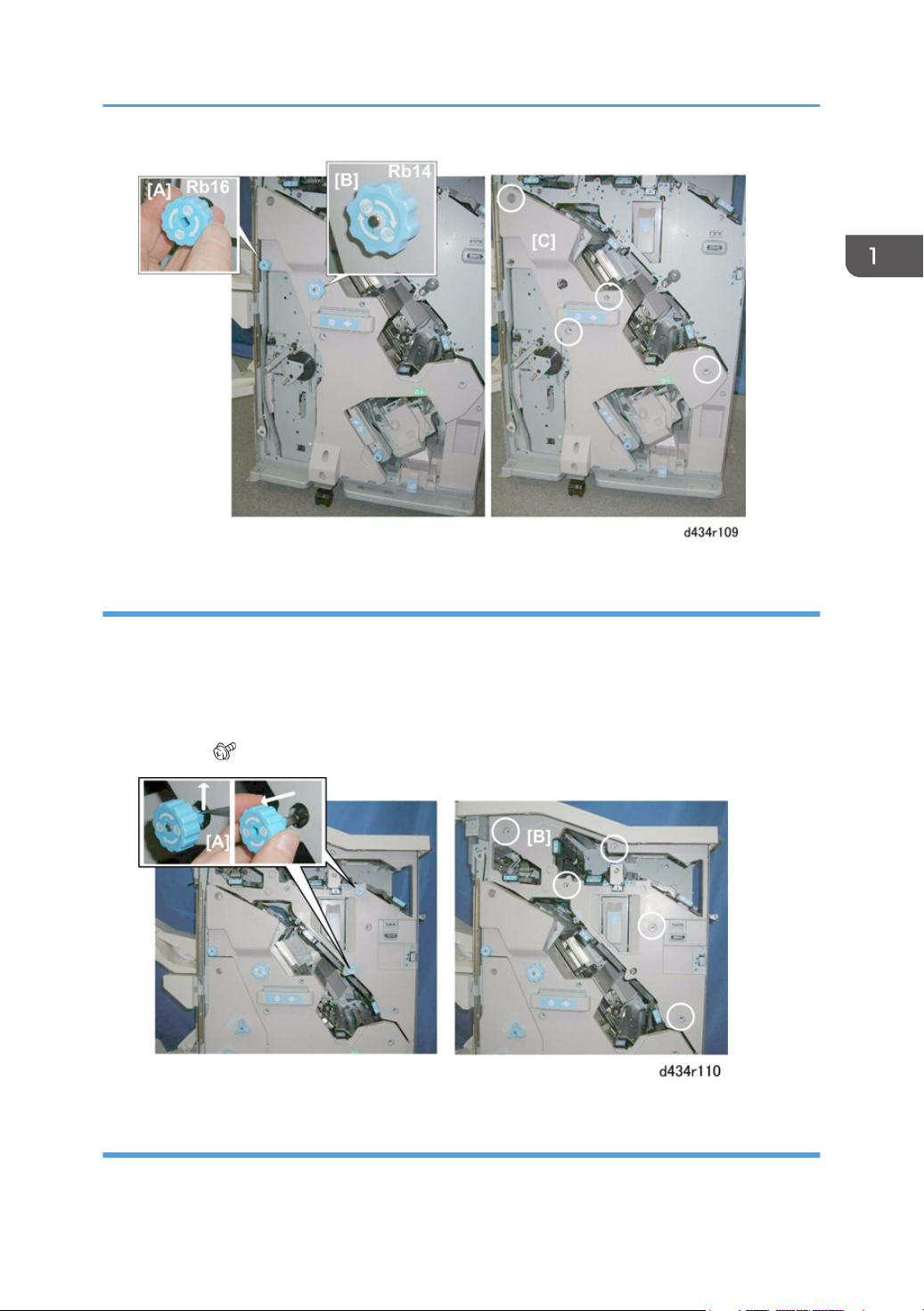

1. Remove:

[A] Rb16

[B] Rb 14 ( x1)

[C] Cover ( x4)

18

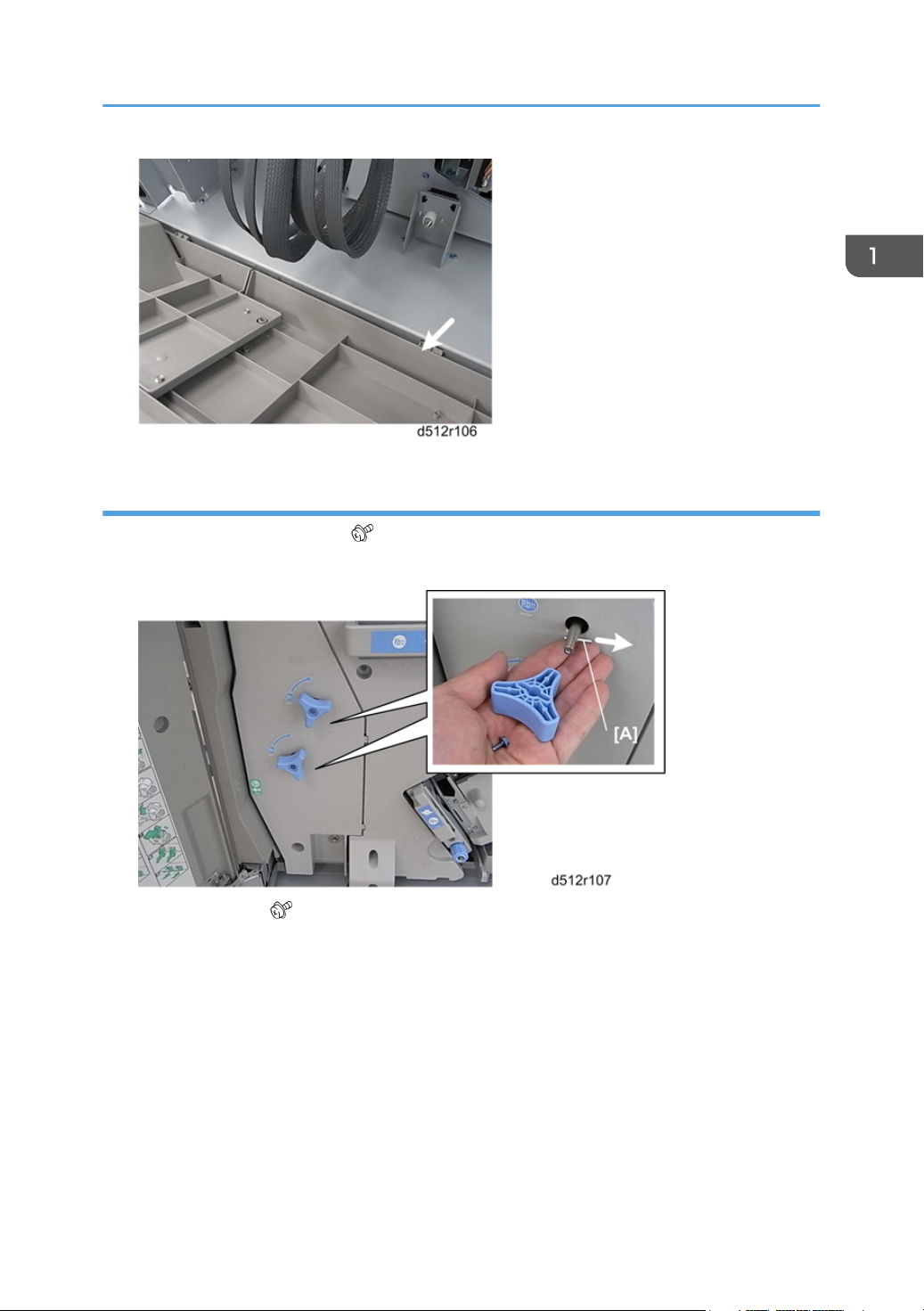

Upper Inner Cover: Rb2, Rb8

Common Procedures

1. Remove:

[A] Rb2, Rb8.

If these tab releases are stiff, use the point of a sharp tool to release these knobs, then pull them off.

Work carefully to avoid breaking the tab releases.

[B] Cover ( x5)

Front Door

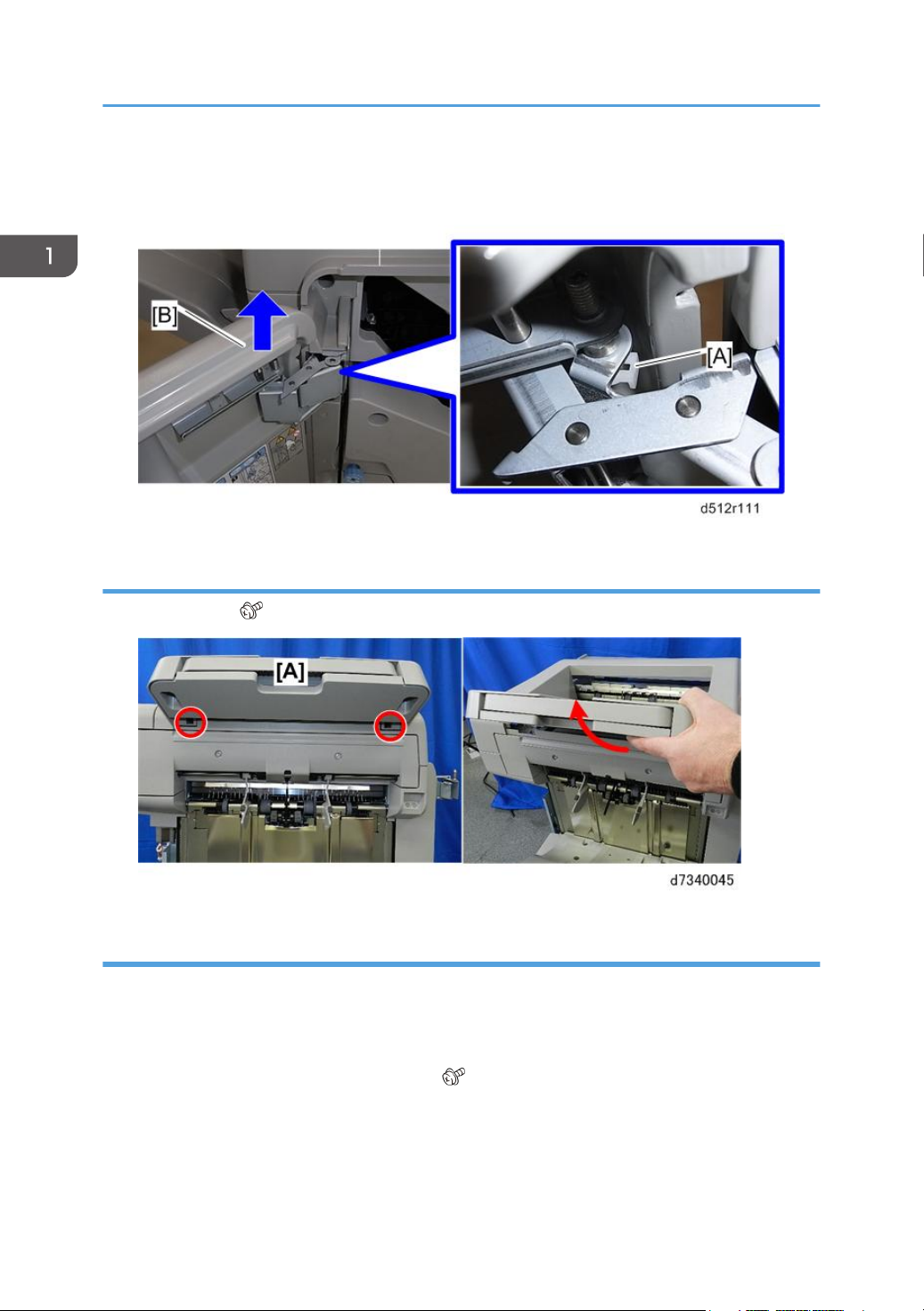

1. Open the front door.

19

1. Replacement and Adjustment

2. Remove the clip [A].

3. Lift off the door [B] from its bottom post.

Proof Tray

1. Proof tray [A] ( x2)

Corner Strip Cover

Preparation

• Front door page 19)

• Proof tray page 20)

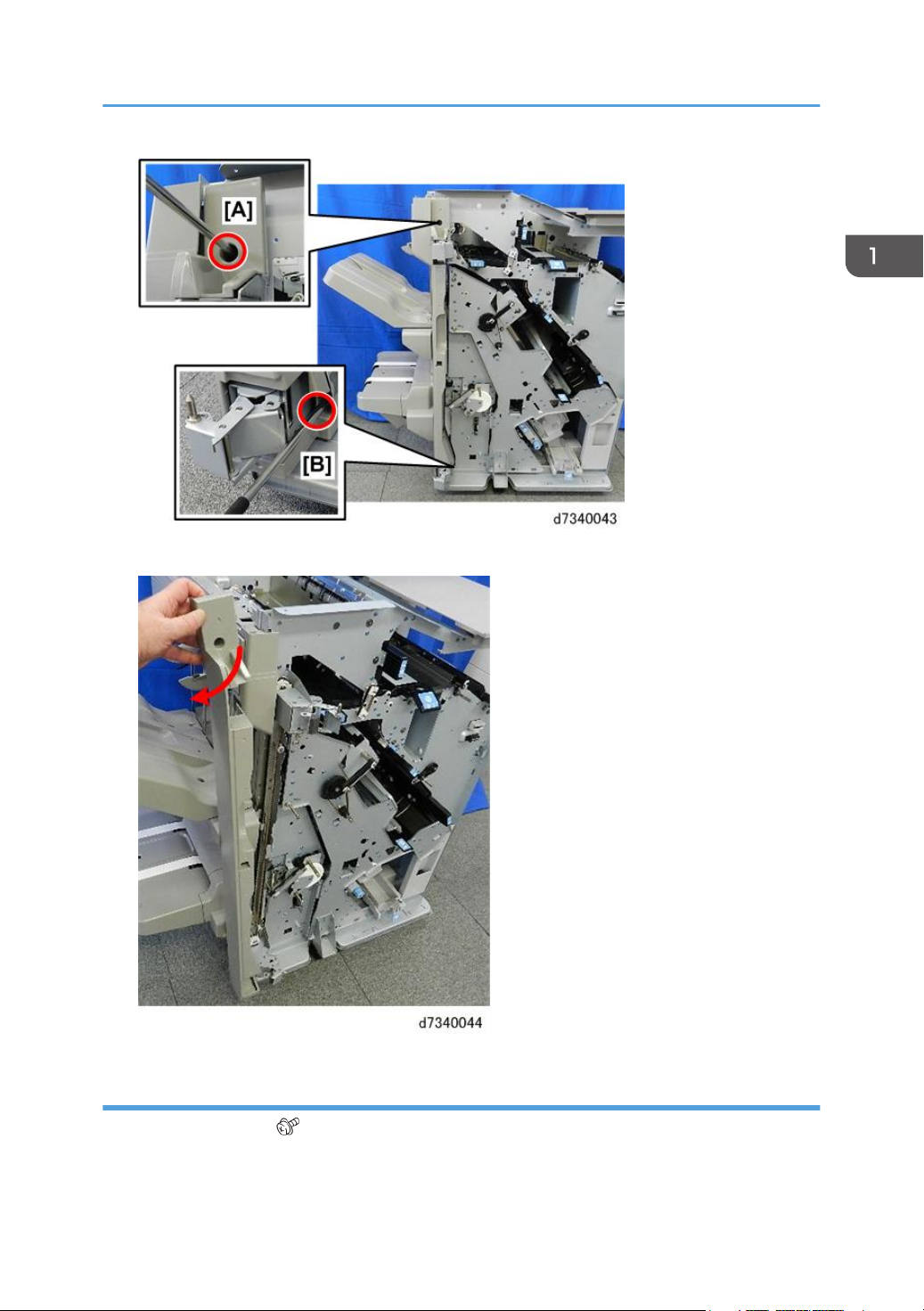

1. Remove the top and bottom screws [A], [B] ( x2).

2. Disconnect the tabs at the top and bottom.

20

3. Twist the cover away from the corner.

Common Procedures

Top Right Cover

1. Top right cover [A] ( x2)

21

1. Replacement and Adjustment

Top Rear Cover

Preparation

Remove:

• Proof tray (page 20)

• Top right cover (page 21)

• Rear upper cover (page 15)

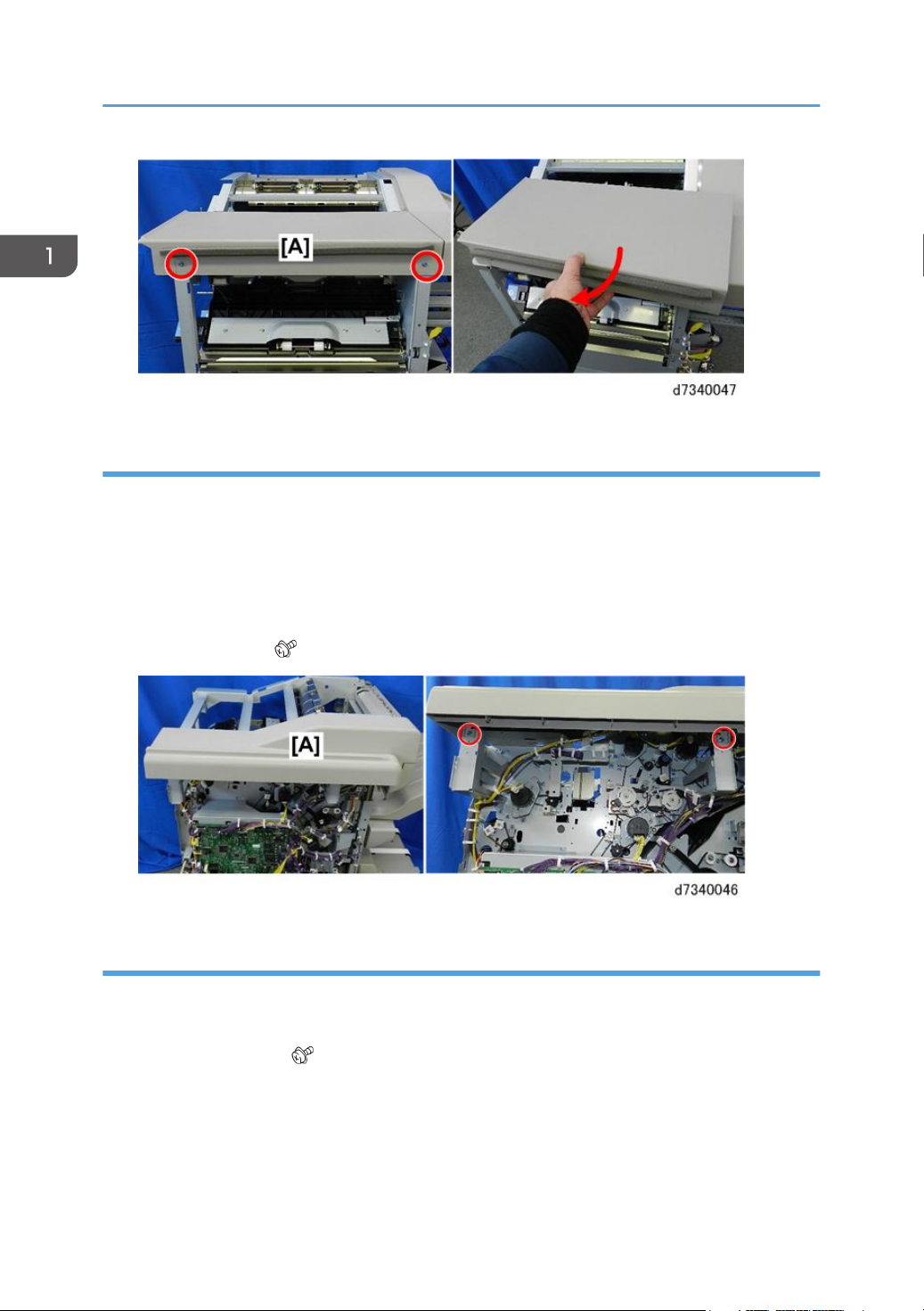

1. Top rear cover [A] (

Shift Tray Jogger Unit

1. Top rear cover page 22)

2. Remove:

[A] Jogger unit cover ( x2)

x2).

22

3. Lift the jogger unit [A] off ( x2, x2, x1).

Common Procedures

Left Upper Cover

Preparation

Remove:

• Proof tray (page 20

• Shift tray jogger unit (page 22)

1. Remove the left upper cover [B] ( x2, x1, x2).

23

1. Replacement and Adjustment

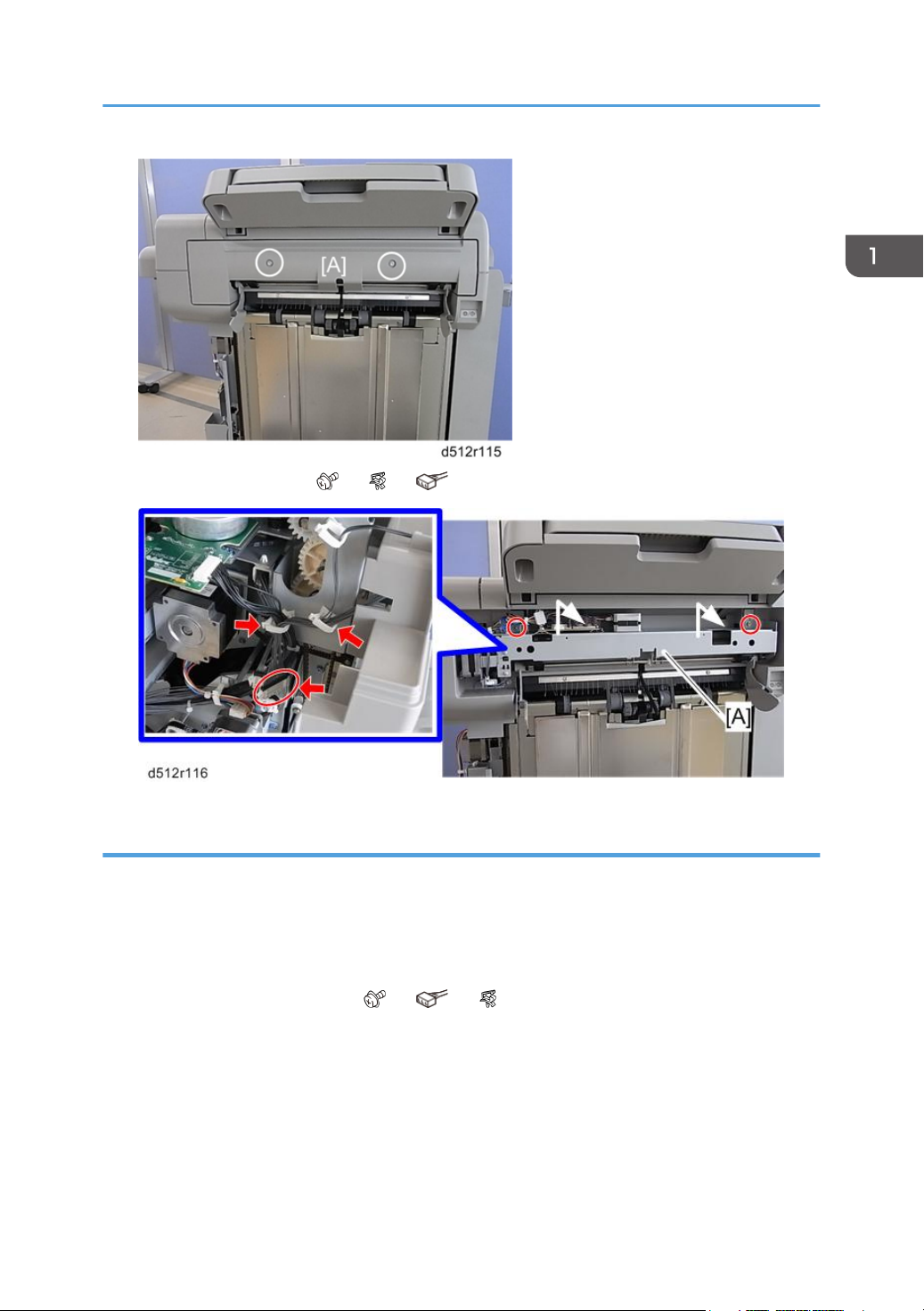

Upper, Lower Right Panels

• The lower right panel covers the PSU, which retains residual voltage after the system is switched off.

• Before removing the right panel for any procedure, switch the machine off and wait 30 min. for the

charge on the PSU to dissipate.

24

1. Remove upper right panel [A] ( x4).

2. Remove lower right panel [B] ( x6).

Common Procedures

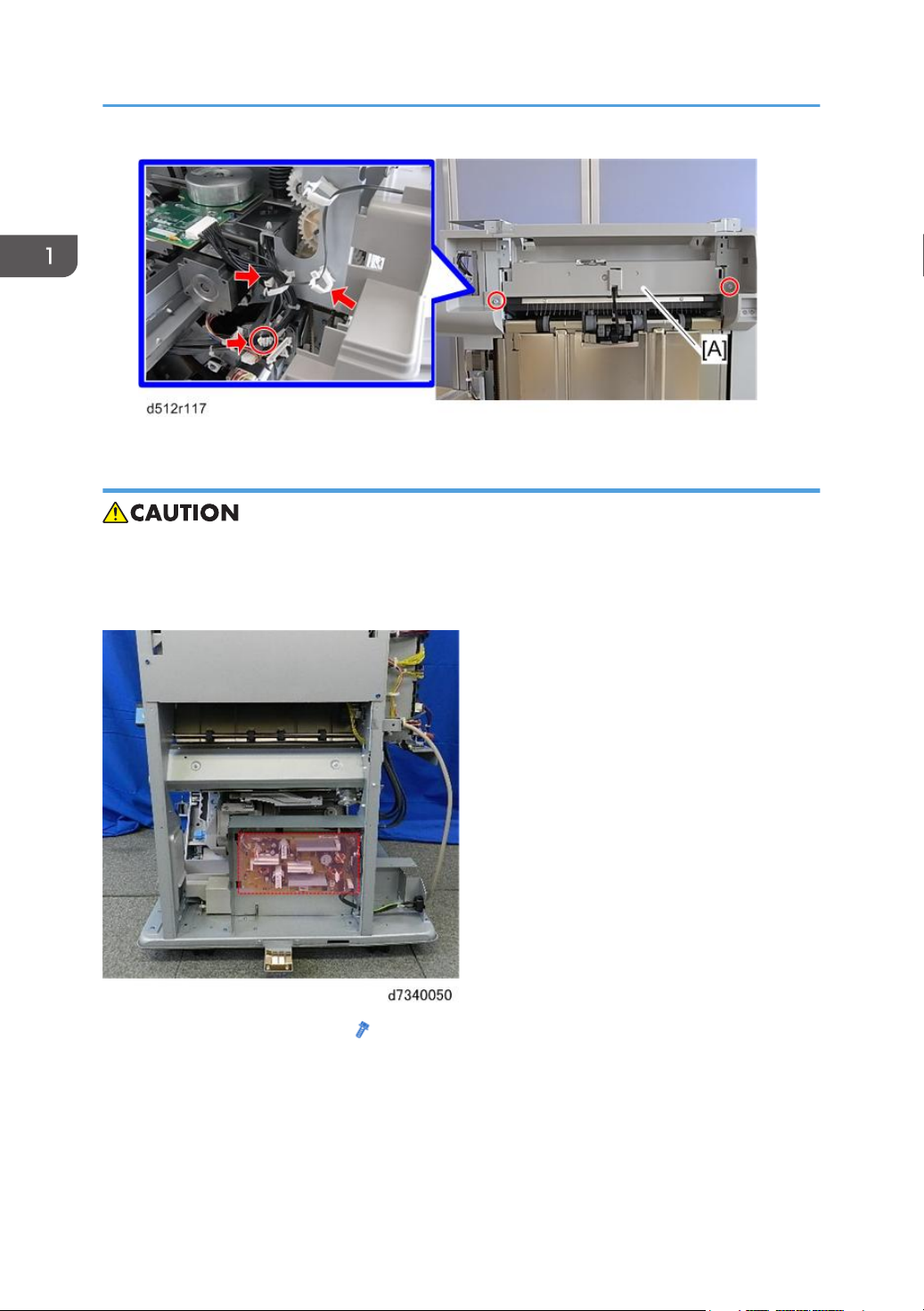

Shift Tray

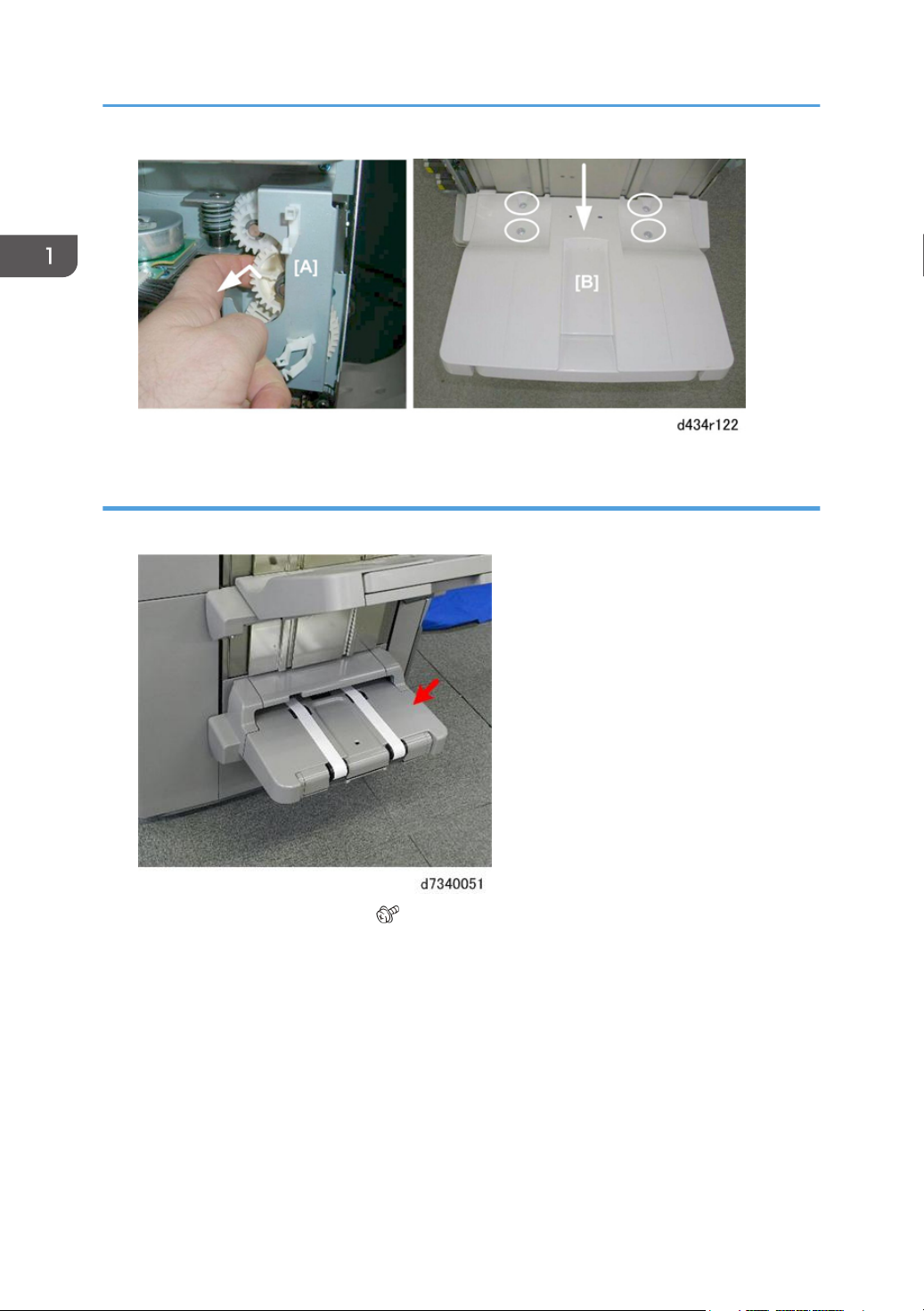

1. While supporting the tray with one hand, pull gear [A] toward you to release the tray.

2. Lower the tray [B] slowly until it stops, then remove it. ( x4)

25

1. Replacement and Adjustment

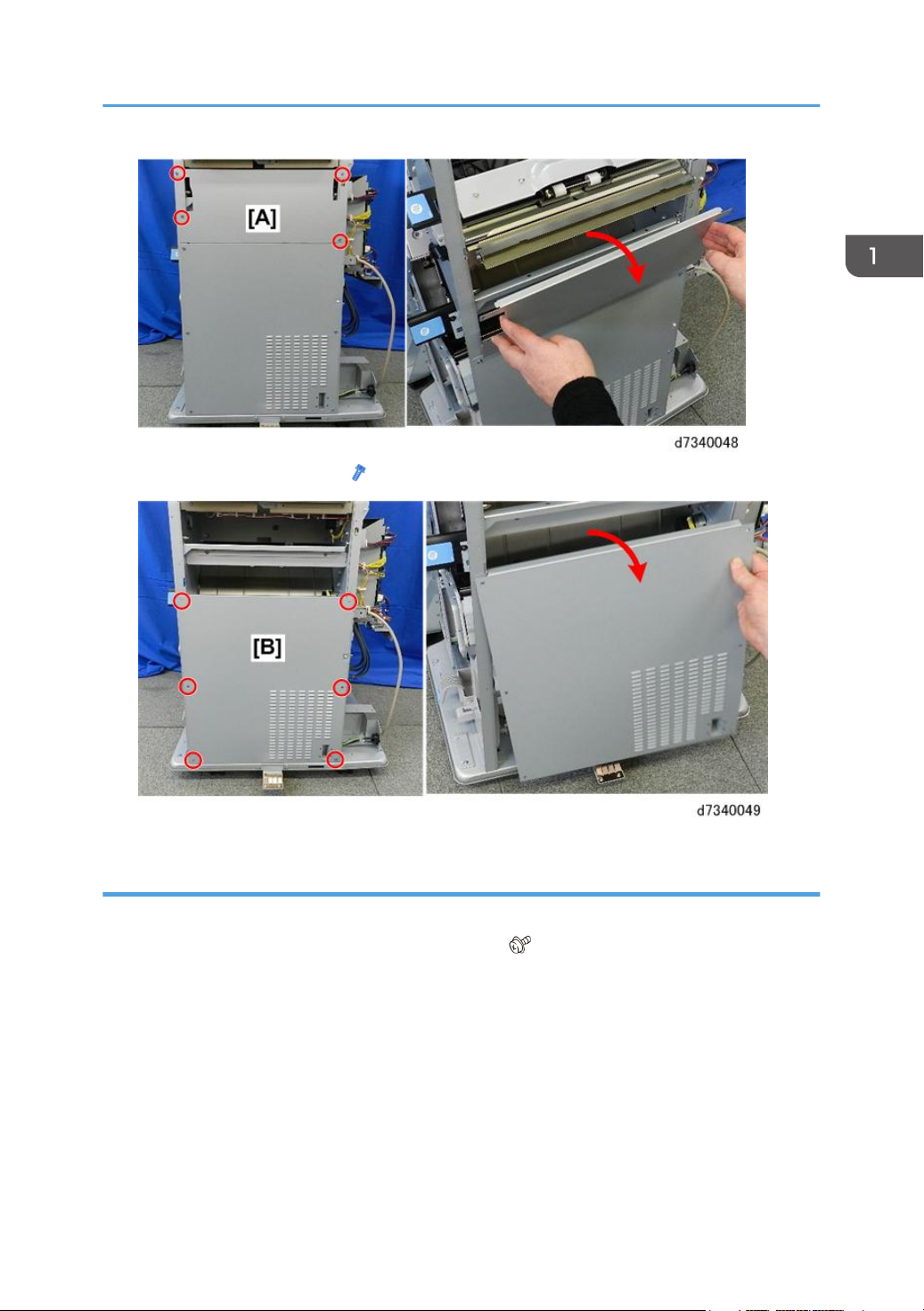

Booklet Tray

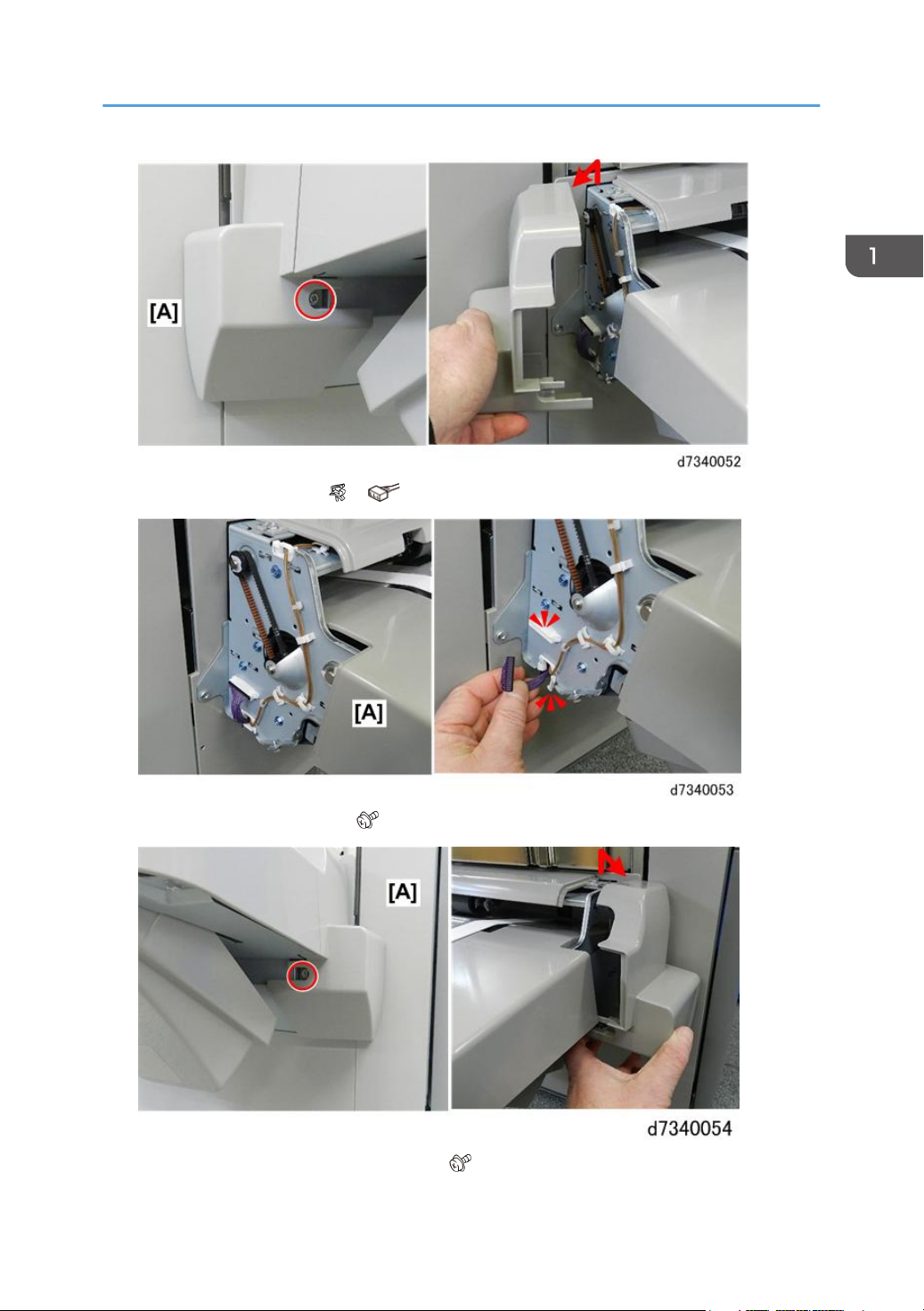

1. The booklet tray is the lower tray.

26

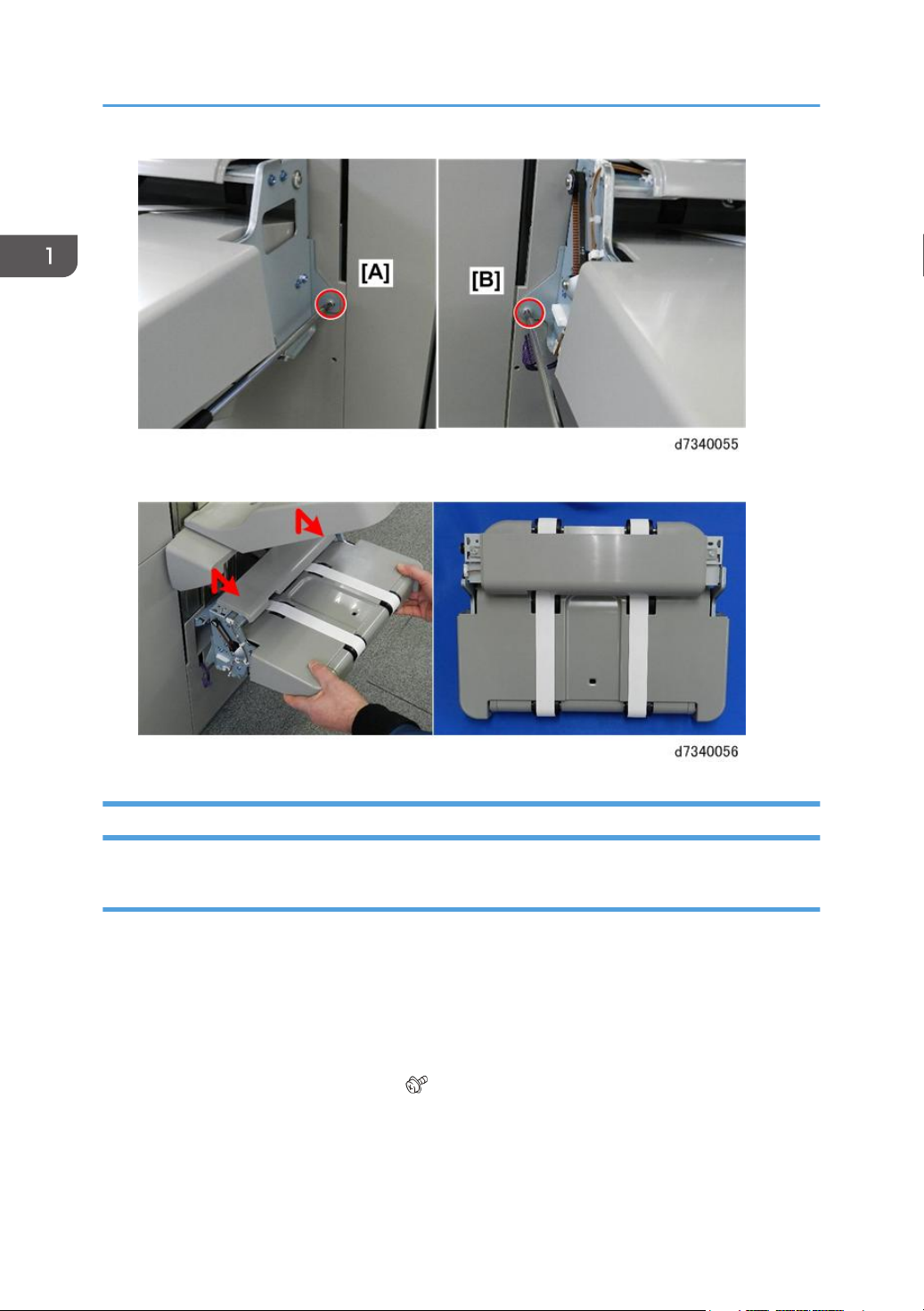

2. At the rear [A] remove rear cover ( x1).

3. At rear [A] disconnect tray ( x1, x1).

Common Procedures

4. At front [A] remove front cover ( x1).

5. Disconnect tray bracket at front [A], rear [B] ( x2).

27

1. Replacement and Adjustment

6. Lift tray off the side of the machine.

Booklet Unit

Booklet Stapler

The booklet stapler weighs about 3 kg (6.6 lb.)

Preparation

• Open the front door.

• Pull stack/stapler unit out with Rb12.

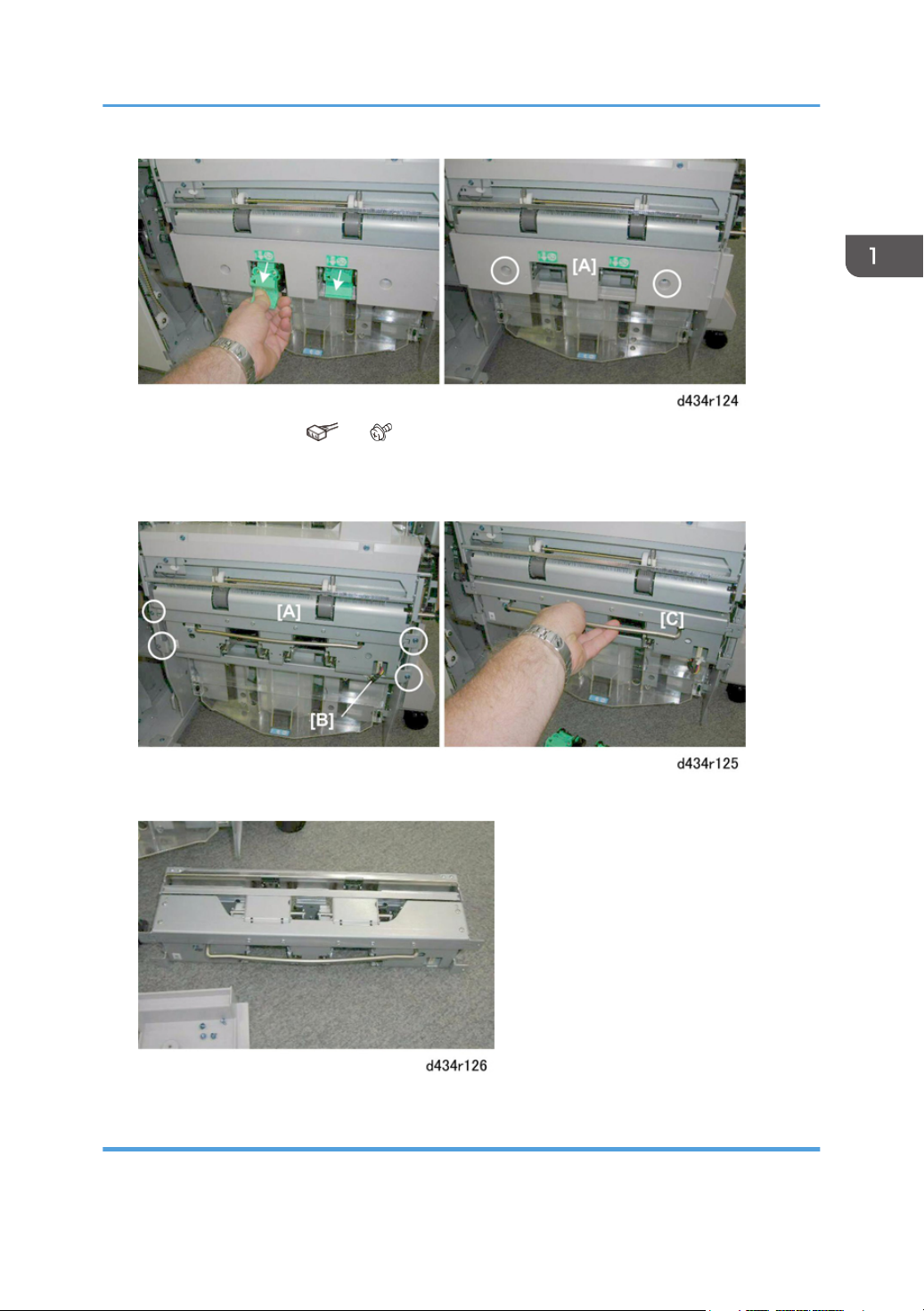

1. Remove both booklet staplers.

2. Remove booklet stapler unit cover [A] ( x2)

28

3. Remove stapler unit [A] ( x1, x4)

4. Make sure connector [B] is disconnected.

5. Remove the stapler unit with its handle [C].

Common Procedures

6. Lay the unit on a flat, clean surface.

Booklet Unit Removal

Preparation

29

Loading...

Loading...