Page 1

SHIFT TRAY UNIT

(Machine Code: B313)

Page 2

20 September 1999 SPECIFICATIONS

1 OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size: Standard Size:

A5 lengthwise to A3

HLT lengthwise to DLT

Non-standard Size:

Paper Width: 90 ~ 297 mm

Paper Length:148 ~ 432 mm

Paper Weight: 60 ~ 105 g/m², 16 ~ 28 lbs.

Tray Capacity: 125 sheets (80 g/m², 20 lbs.)

Power Source: 5 VDC, 24 VDC (from the copier)

Power Consumption: 17 W

Weight: 1.1 kg

Size (W x D x H):

530 mm x 410 mm x 120 mm

B313-1

Options

Page 3

COMPONENT LAYOUT 20 September 1999

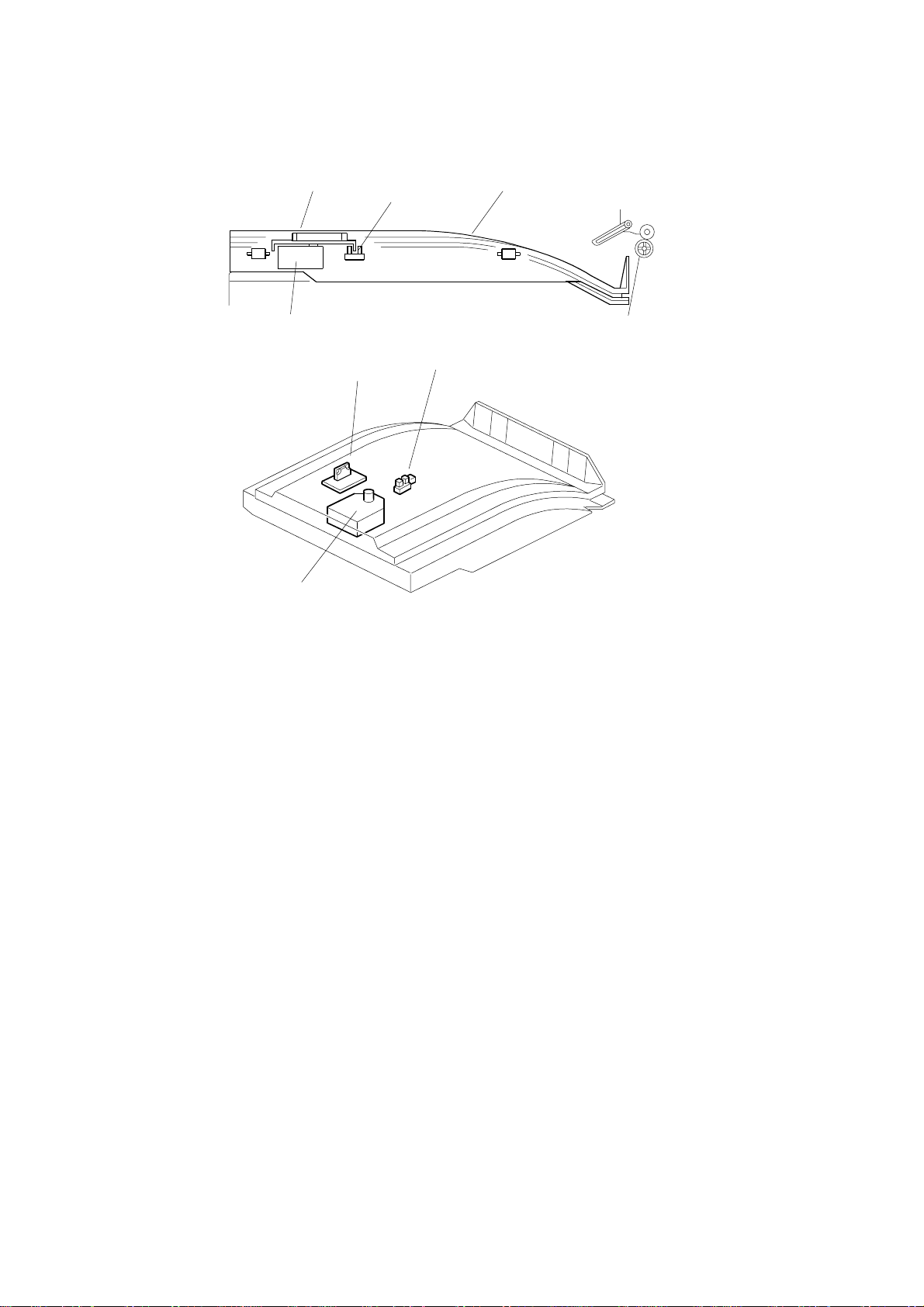

1.2 COMPONENT LAYOUT

1

23

4

B313D101.WMF

5

1

4

B313D102.WMF

1. Half Turn Sensor

2. Tray Cover

3. Slip Disc

4. Tray Motor

5. Driver PCB

B313-2

Page 4

20 September 1999 BASIC OPERATION

2. DETAILED SECTION DESCRIPTIONS

2.1 BASIC OPERATION

[A]

B313D500.WMF

The shift tray allows copies to be sorted into separate piles on one tray.

From the left-right movement of the tray cover [A], the piles of copies are offset into

two positions, slightly overlapping one another.

Options

B313-3

Page 5

PRIMARY MECHANISMS 20 September 1999

2.2 PRIMARY MECHANISMS

2.2.1 TRAY SHIFT

[A]

[C]

[B]

[D]

B313D103.WMF

As stated above, the shift tray cover [A] moves from left to right to create two

possible positions for the copies to stack up. This motion is driven by the tray motor

[B], which connects to the slip disc [C] via a small shaft. The shaft is connected at

the rotational center of the disc. However, there is an off-centered white square

attached to the top surface of the disc. When the tray cover is attached to the unit,

this square fits into a groove [D] (approximately equal to its width) that runs

lengthwise along the underside of the tray

When the motor is running, the disc rotation causes the off-centered white square

to change position. Since the square only has freedom of movement along the

groove [D], the only net motion of the tray is from left to right.

B313-4

Page 6

20 September 1999 PRIMARY MECHANISMS

2.2.2 HALF TURN DETECTION

[C]

[A]

[B]

B313D103.WMF

Half turn detection is performed through a combination of two components: the slip

disc [A] and half turn sensor [C].

The slip disc has a rim extending below the top surface. However, the rim only

extends 180° around the disc. The half turn sensor is below the edge of the disc,

opposite the tray motor. The sensor is positioned so that the rim of the disc passes

between the LED and photo diode when the disc turns.

While the motor [B] is rotating the disc and moving the tray cover, the disc rim is

not between the diode and LED. After the disc has turn ed its max i mum 18 0°, the

rim passes between these two parts and blocks the signal to the LED, stopping the

motor. The tray stays in place until the motor is activated again to move the tray

across to receive another copy of the original.

B313-5

Options

Page 7

TRAY COVER REPLACEMENT 20 September 1999

3. REPLACEMENT AND ADJUSTMENT

3.1 TRAY COVER REPLACEMENT

[A]

[C]

[B]

[D]

[E]

B313R101.WMF

3.1.1 TRAY COVER REMOVAL

1. Remove the tray cover [A] by pressing on the two pawls [B] on the left side of

the cover.

3.1.2 TRAY COVER ATTACHMENT

NOTE:

1. Fit the pawls [C] (just below the cover fin) around the thin bar [D] on the shift

2. Align the square [E] so that it fits into the groove in the underside of the tray

3. Complete the attachment by inserting the left side pawls [B] into place.

The right side of the tray cover should be attached first.

tray.

cover and does not interfere with the attachment of the cover.

B313-6

Page 8

20 September 1999 TRAY MOTOR AND HALF TURN SENSOR REPLACEMENT

3.2 TRAY MOTOR AND HALF TURN SENSOR

REPLACEMENT

[A]

[B]

[C]

B313R102.WMF

3.2.1 REPLACING THE TRAY MOTOR

1. Remove the slip disc [A].

2. Remove the tray motor [B] from the motor holder (1 connector).

3.2.2 REPLACING THE HALF TURN SENSOR:

1. Remove the half turn sensor [C] (1 connector).

B313-7

Options

Loading...

Loading...