Ricoh Provence-P2W Service Manual

Provence-P2W

(Machine Code: J006)

Service Manual

(Insert Version)

15 July 2005

Subject to Change

Conventions Used in this Manual

This manual uses several symbols.

Symbol What it means

Refer to section number

See Core Tech Manual for

details

Screw

Connector

E-ring

Clip ring

Clamp

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

WARNING

A Warning indicates a potentially hazardous situation. Failure to obey a Warning

could result in death or serious injury.

CAUTION

A Caution indicates a potentially hazardous situation. Failure to obey a Caution

could result in minor or moderate injury or damage to the machine or other

property.

Important

• Obey these guidelines to avoid problems such as misfeeds, damage to originals,

loss of valuable data and to prevent damage to the machine.

NOTE: This information provides tips and advice about how to best service the

machine.

Lengthwise, SEF

(Short Edge Feed)

Sideways, LEF

(Long Edge Feed)

Safety Instructions

For your safety, please read this manual carefully before you service this product.

Always keep this manual handy for future reference.

Safety Information

Always obey the these safety precautions when using this product.

Switches and Symbols

Where symbols are used on or near switches on machines for Europe and other

areas, the meaning of each symbol conforms with IEC60417.

Responsibilities of the Customer Engineer

Maintenance

Maintenance shall be done only by trained customer engineers who have

completed service training for the machine and all optional devices designed for

use with the machine.

Installation

The main machine and options can be installed by either the customer or customer

engineer. The customer or customer engineer must follow the installation

instructions described in the operating instructions.

Reference Material for Maintenance

Maintenance shall be done with the special tools and the procedures prescribed for

maintenance of the machine described in the reference materials (service manuals,

technical bulletins, operating instructions, and safety guidelines for customer

engineers).

Use only consumable supplies and replacement parts designed for use with the

machine.

SAFE-SYM.WMF

ON

OFF

Push ON/Push OFF

STANDBY

Before Installation, Maintenance

Shipping and Moving the Machine

CAUTION

1. Work carefully when lifting or moving the machine. If the machine is heavy,

two or more customer engineers may be required to prevent injuries (muscle

strains, spinal injuries, etc.) or damage to the machine if it is dropped or

tipped over.

2. Personnel moving or working around the machine should always wear proper

clothing and footwear. Never wear loose fitting clothing or accessories

(neckties, loose sweaters, bracelets, etc. ) or casual footwear (slippers,

sandals, etc.) when lifting or moving the machine.

3. Always unplug the power cord from the power source before you move the

machine. Before you move the machine, arrange the power cord so it will not

fall under the machine.

Power

Warning

1. Always turn the machine off and disconnect the power plug before doing any

maintenance procedure. After turning the machine off, power is still supplied

to the main machine and other devices. To prevent electrical shock, switch

the machine off, wait for a few seconds, then unplug the machine from the

power source.

2. Before you do any checks or adjustments after turning the machine off, work

carefully to avoid injury. After removing covers or opening the machine to do

checks or adjustments, avoid touching electrical components or moving parts

(gears, timing belts, etc.).

3. After turning the machine on with any cover removed, keep your hands away

from electrical components and moving parts. Never touch the cover of the

fusing unit, gears, timing belts, etc.

Installation, Disassembly, and Adjustments

CAUTION

1. After installation, maintenance, or adjustment, always check the operation of

the machine to make sure that it is operating normally. This ensures that all

shipping materials, protective materials, wires and tags, metal brackets, etc.,

(attached to protect the machine during shipping), have been removed and

that no tools remain inside the machine.

2. Never use your fingers to check moving parts that are causing spurious

noise. Never use your fingers to lubricate moving parts while the machine is

operating.

Special Tools

CAUTION

1. Use only standard tools approved for machine maintenance.

2. For special adjustments, use only the special tools and lubricants described

in the service manual. Using tools incorrectly, or using tools that could

damage parts, could damage the machine or cause injuries.

During Maintenance

General

CAUTION

1. Before you begin a maintenance procedure, always:

• Switch the machine off.

• Disconnect the power plug from the power source.

• Allow the machine to cool for at least 10 minutes.

2. Avoid touching the components inside the machine that are labeled as hot

surfaces.

Safety Devices

WARNING

1. Never remove any safety device (a fuse, thermistor, etc.) unless it requires

replacement. Always replace a safety device immediately.

2. Never do any procedure that defeats the function of any safety device.

Modification or removal of a safety device (fuse, thermistor, etc.) could cause

a fire and personal injury. After removal and replacement of any safety

device, always test the operation of the machine to ensure that it is operating

normally and safely.

3. For replacement parts use only the correct fuses, thermistors, circuit

breakers, etc. rated for use with the machine. Using replacement devices not

designed for use with the machine could cause a fire and personal injuries.

Organic Cleaners

CAUTION

1. During preventive maintenance, never use any organic cleaners (alcohol,

etc.) other than those described in the service manual. (Refer the “2.

Preventive Maintenance” in the Service Manual.)

2. Make sure the room is well ventilated before using any organic cleaner.

Always use organic solvents in small amounts to avoid breathing the fumes

and becoming nauseous.

3. Switch the machine off, unplug it, and allow it to cool before doing preventive

maintenance. To avoid fire or explosion, never use an organic cleaner near

any component that generates heat.

4. Wash your hands thoroughly after cleaning parts with an organic cleaner to

avoid contamination of food, drinks, etc. which could cause illness.

Power Plug and Power Cord

WARNING

1. Before servicing the machine (especially when responding to a service call),

always make sure that the power plug has been inserted completely into the

power source. A partially inserted plug could lead to heat generation (due to

a power surge caused by high resistance) and cause a fire or other problems.

2. Always check the power plug and make sure that it is free of dust and lint.

Clean it if necessary. A dirty plug can generate heat and cause a fire.

3. Inspect the entire length of the power cord for cuts or other damage. Replace

the power cord if necessary. A frayed or otherwise damaged power cord can

cause a short circuit which could lead to a fire or personal injury from

electrical shock.

4. Check the length of the power cord between the machine and power supply.

Make sure the power cord is not coiled or wrapped around any object such

as a table leg. Coiling the power cord can cause excessive heat to build up

and could cause a fire.

5. Make sure that the area around the power source is free of obstacles so the

power cord can be removed quickly in case of an emergency.

6. Make sure that the power cord is grounded (earthed) at the power source

with the ground wire on the plug.

7. Connect the power cord directly into the power source. Never use an

extension cord.

8. When you disconnect the power plug from the power source, always pull the

plug, not the cable.

After Installation, Servicing

Disposal of Used Items

WARNING

Ink is flammable. Never attempt to incinerate empty cartridges.

CAUTION

1. Always dispose of used items in accordance with the local laws and

regulations regarding the disposal of such items.

2. To protect the environment, never dispose of this product or any kind of

waste from consumables at a household waste collection point. Dispose of

these items at one of our dealers or at an authorized collection site.

Points to Confirm with Operators

At the end of installation or a service call, instruct the user about use of the

machine. Emphasize the following points.

• Show operators how to remove jammed paper and troubleshoot other minor

problems by following the procedures described in the operating instructions.

• Point out the parts inside the machine that they should never touch or attempt to

remove.

• Confirm that operators know how to store and dispose of consumables such as

cartridges, ammonia water, paper, etc..

• Make sure that all operators have access to an operating instruction manual for

the machine.

• Confirm that operators have read and understand all the safety instructions

described in the operating instructions.

• Demonstrate how to turn off the power and disconnect the power plug (by pulling

the plug, not the cord) if any of the following events occur:

1) Something has spilled into the product.

2) Service or repair of the product is necessary.

3) The product cover has been damaged.

• Caution operators about removing paper fasteners around the machine. They

should never allow paper clips, staples, or any other small metallic objects to fall

into the product.

Important: Make sure the operators understand the following points:

• The operator must lift the output tray to release the paper cassette before

loading paper.

• Paper is loaded in the standard paper cassette without removing it from the

printer.

• The operator should never attempt to remove the paper cassette from the

printer.

Special Safety Instructions For Cartridges

Accidental Physical Exposure To Ink

CAUTION

1. If ink gets on the skin, wash the affected area immediately with soap and cold

running water.

2. If ink gets into the eyes, immediately flush the eyes with cold running water. If

there are signs of irritation or other problems, seek medical attention.

3. If ink is swallowed, drink a strong solution of cold water and table salt to

induce vomiting. Seek medical attention immediately.

4. Ink is difficult to remove from fabric. Work carefully to avoid staining clothing

when performing routine maintenance or replacing cartridges.

Handling and Storing Cartridges

WARNING

Ink is flammable. Never store cartridges in a location where they will be exposed

to high temperature or an open flame.

CAUTION

1. Always store cartridges out of the reach of children.

2. Always store cartridges in a cool, dry location that is not exposed to direct

sunlight.

Cartridge Disposal

CAUTION

1. Attach the caps to empty ink containers for temporary storage to avoid

accidental spillage.

2. Return empty cartridges to a local dealer who can accept such items for

collection and recycling or disposal.

3. If the customer decides to dispose of empty cartridges, make sure that they

are disposed of in accordance with local laws and regulations.

1

Contents

OVERVIEW OF MAIN NEW FEATURES........................................................................................... 2

1. INSTALLATION ........................................................................................................................... 3

2. PREVENTIVE MAINTENANCE................................................................................................... 3

2.1 FRICTION PAD....................................................................................................................... 3

3. REPLACEMENT AND ADJUSTMENT ....................................................................................... 4

3.1 OUTPUT TRAY....................................................................................................................... 4

3.2 PAPER FEED CASSETTE ..................................................................................................... 4

3.3 MAINTENANCE UNIT, WASTE INK UNIT ............................................................................. 5

4. TROUBLESHOOTING.................................................................................................................8

4.1 OPERATION PANEL LED DISPLAY...................................................................................... 8

4.2 STATUS MONITOR MESSAGES ........................................................................................ 10

4.2.1 SC ERROR CODE TABLE ........................................................................................ 14

5. SERVICE INFORMATION ......................................................................................................... 16

5.1 OPERATION PANEL FUNCTIONS...................................................................................... 16

5.1.1 MAIN FUNCTIONS.................................................................................................... 17

5.1.2 TO SELECT USB 1.1................................................................................................. 17

5.1.3 TO SELECT USB AUTO SELECT MODE................................................................. 18

5.1.4 TO FEED 3 CLEAN SHEETS.................................................................................... 18

5.1.5 TO PREPARE THE PRINTER FOR TRANSPORT................................................... 18

6. DETAILS .................................................................................................................................... 19

6.1 PRINT CARTRIDGES........................................................................................................... 19

6.2 PRINT CARTRIDGE SET DETECTION ............................................................................... 20

6.3 WASTE INK TANK FULL SENSOR ..................................................................................... 21

6.4 CASSETTE LOCK/RELEASE............................................................................................... 22

6.5 ELECTRICAL COMPONENTS............................................................................................. 23

6.5.1 MAIN BOARDS.......................................................................................................... 23

6.5.2 CONTROL BOARD.................................................................................................... 25

6.5.3 INK CARTRIDGE BOARD......................................................................................... 26

6.5.4 DRV BOARD.............................................................................................................. 27

6.5.5 SUB ENCODER (DC RELAY) BOARD ..................................................................... 28

6.5.6 CONNECTOR LIST ................................................................................................... 29

7. SPECIFICATIONS ..................................................................................................................... 31

7.1 PRINTER ENGINE BASE SPECIFICATIONS...................................................................... 31

7.2 J006 PAPER SPECIFICATIONS.......................................................................................... 36

7.3 MAIN UNIT AND OPTION DESCRIPTIONS ........................................................................ 37

7.4 CONFIGURATION................................................................................................................ 38

7.4.1 PRINTER ................................................................................................................... 38

7.4.2 DUPLEXER................................................................................................................ 39

7.4.3 PAPER TRAY (OPTION)........................................................................................... 40

OVERVIEW OF MAIN NEW FEATURES 15 July 2005

2

OVERVIEW OF MAIN NEW FEATURES

This document describes the new features and changes of the Provence-P2W

(hereafter "J006"), compared to the earlier models Alsace-P1 and Provence-P1

(hereafter "previous models" or respectively "J001" and "J003").

Here is a summary of the important new features of this printer.

• Black ink improvement

The adherence of the black ink has been improved to the equivalent of

permanent marker pen.

• Each ink cartridge provided with an ID chip

Each ink cartridge is equipped with a new ID chip that allows greater accuracy in

displaying the amount of ink remaining (5 steps), enables detection to determine

whether an individual cartridges is set properly, and provides other useful

information about the cartridge.

• Duplex unit

The lock mechanism on the duplex unit and the bypass feed operation have

been improved.

• Secondary count function

The counts for PM parts are based on the length of A4-size paper.

• Print compatibility with used paper and punched paper

Printer driver settings allow the printer to ignore paper width detection to

improve the compatibility of the printer with used punched paper.

NOTE: The section numbers of this document (Sections 1-7) correspond to the

section numbers of the Alsace/Provence (Machine Code: J001/J003)

Service Manual, 17 September 2004.

15 July 2005 INSTALLATION

3

1. INSTALLATION

Like the previous models, the J006 can be fully installed by the user.

2. PREVENTIVE MAINTENANCE

2.1 FRICTION PAD

Reference Comment

None New Feature

1. Position the bottom of the printer over the edge

of a table.

NOTE: To prevent spilling ink from the

maintenance unit, keep the printer level.

2. Remove the friction pad [A] from the bottom of

the printer (x2).

3. Use a damp cloth to wipe clean the surface of

the friction pad [B].

P2W-2-5A.BMP

P2W-2-5B.BMP

[A]

[B]

REPLACEMENT AND ADJUSTMENT 15 July 2005

4

3. REPLACEMENT AND ADJUSTMENT

3.1 OUTPUT TRAY

J001/J003 Manual Reference

3.2.2 Detaching and Reattaching Output Tray

Comment

The detachment and reattachment of the output tray is much

easier.

1. Raise the exit tray [A].

2. Push up the exit tray to release the

shaft of the lock, then pull the exit tray

toward you.

3. To set the exit tray again, reverse this

procedure by pushing in the tray to lock

the shaft and then lowering the exit tray.

3.2 PAPER FEED CASSETTE

J001/J003 Manual Reference

3.2.3 Paper Feed Cassette

Comment

The standard paper feed cassette (Tray 1) pulls easily out of

the printer. There are no pawls to release under the cassette.

Just pull the feed cassette [A] out of the

printer to remove it.

P2W-3-2.BMP

P2W-3-3.BMP

[A]

[A]

15 July 2005 REPLACEMENT AND ADJUSTMENT

5

3.3 MAINTENANCE UNIT, WASTE INK UNIT

J001/J003 Manual Reference

The section numbers referenced in Step 1 are in the

J001/J003 Service Manual.

Comment

Procedure change due to slight modifications in the structure

of the printer.

1. Remove:

• Output tray (3.2.2)

• Paper feed cassette (3.2.3)

• Top cover (3.2.4)

• Front cover, right cover (3.2.7)

• Right front door (3.2.6)

2. Remove:

• Front cover

• Right cover

NOTE: You can remove the right cover by first removing the two screws of the

rear cover and then releasing the upper pawls of the right cover.

3. Remove the lock screws , , of

the ink supply unit (x3).

P2W-3-7A.BMP

REPLACEMENT AND ADJUSTMENT 15 July 2005

6

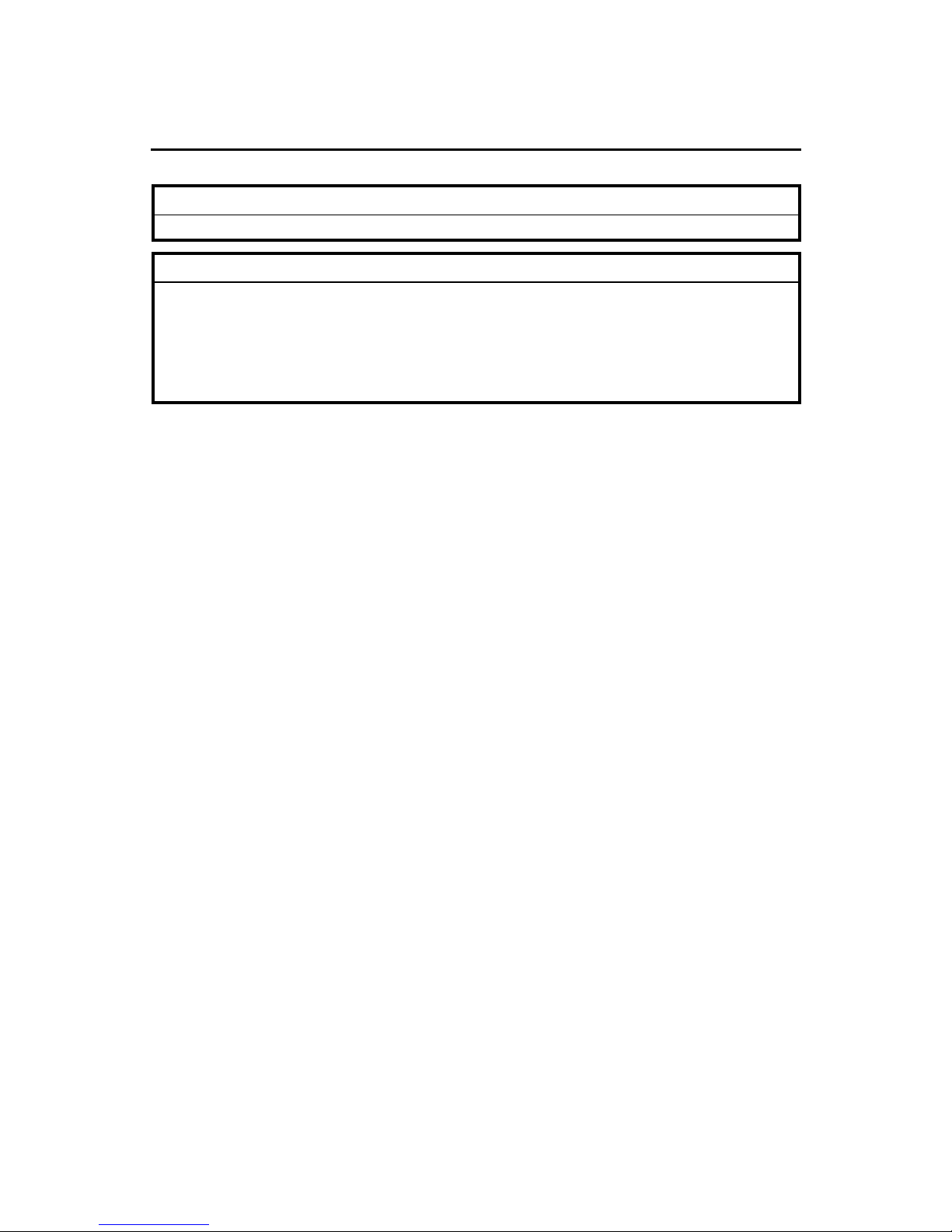

4. On the maintenance unit use a plus

(+) screwdriver to turn the screw at [A]

counter-clockwise until the tip of the

upper triangle [B] aligns with the tip of

the lower triangle [C]. This unlocks the

carriage.

Important: Be sure to rotate screw [A]

counter-clockwise.

5. Push the unlocked carriage to the

middle of the platen above the

transport belt.

6. Remove the lock screw [A] ( x1) and

bracket [B] ( x2).

7. Disconnect the maintenance HP

sensor [C] ( x1).

8. While pressing down on the blade [A],

pull the maintenance unit toward you to

remove it.

G707R914.BMP

P2W-3-8A.BMP

P2W-3-8B.BMP

[A]

[B]

[C]

Unlock

[A]

[B]

[C]

[A]

15 July 2005 REPLACEMENT AND ADJUSTMENT

7

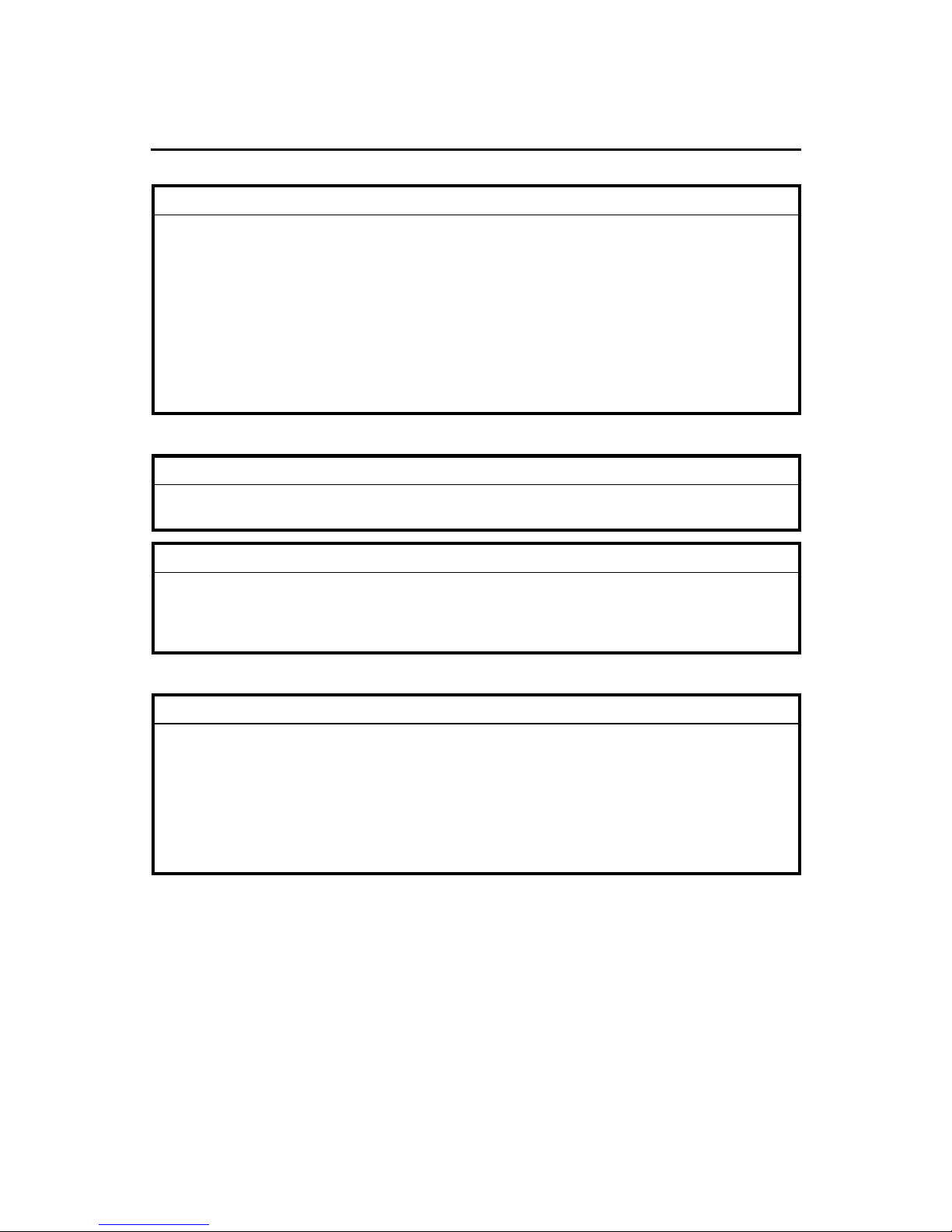

9. Release the ink supply tubes [A] from

the clamps on the back of the ink

supply unit.

Important: Reconnect the tubes in

order from left to right: K, C, M, Y

10. Pull out the ink supply unit [A].

11. Remove the screw [B] of the waste ink

collection unit.

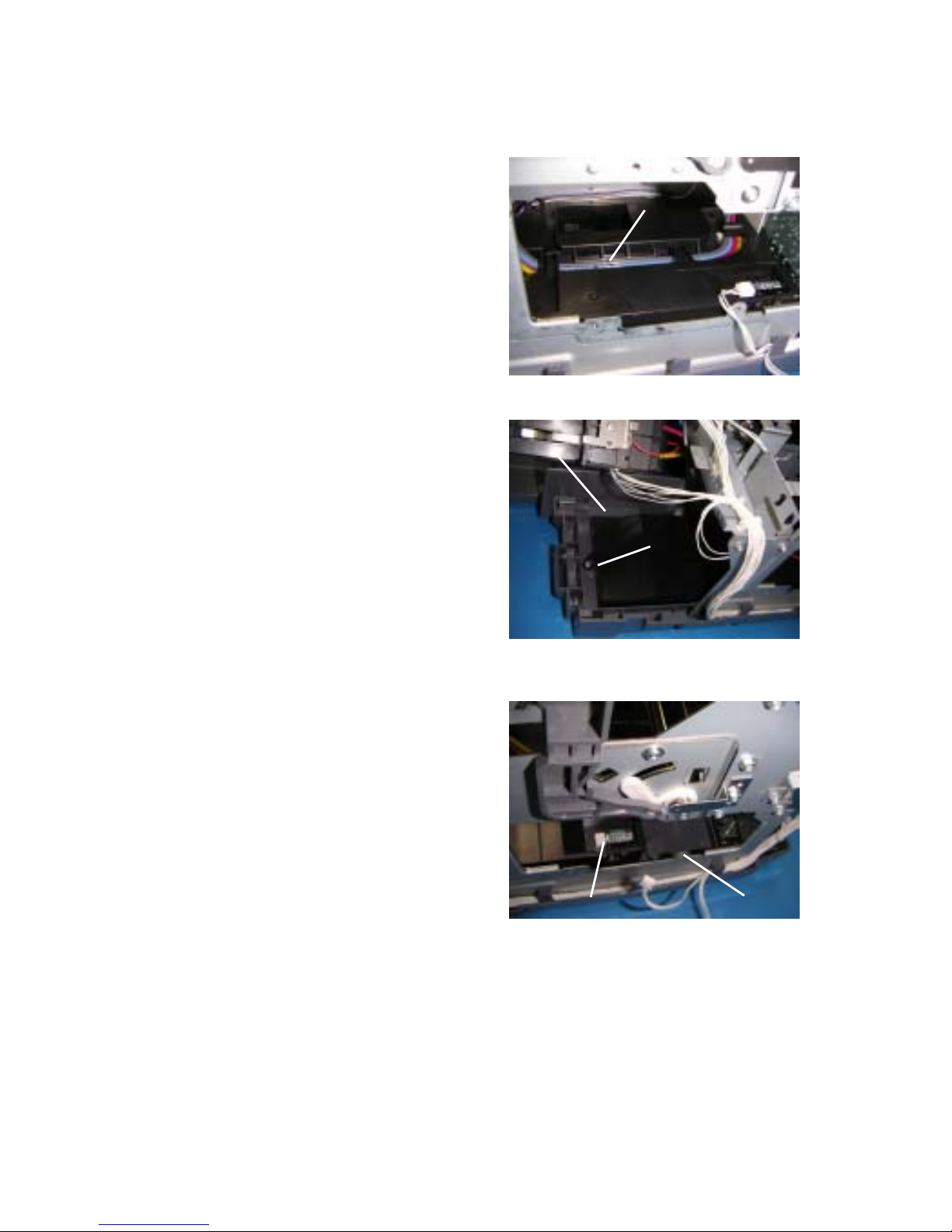

12. Disconnect the full sensor [A] of the

waste ink tank.

13. Raise the waste ink suction unit above

the boss [B] on the frame. Then pull it

out of the printer.

P2W-3-8C.BMP

P2W-3-8D.BMP

P2W-3-9A.BMP

[A]

[A]

[B]

[A]

[B]

Loading...

Loading...