Ricoh Pro C9200, Pro C9210 Operating Instructions Manual

Operating Instructions

Advanced Settings for Custom Paper

For safe and correct use, be sure to read Safety Information before using

the machine.

TABLE OF CONTENTS

1. Introduction

Basic Procedure.................................................................................................................................................. 3

Advanced Settings..............................................................................................................................................4

2. Printing Process

Overview.............................................................................................................................................................5

Laser Exposure....................................................................................................................................................7

Laser Unit (Exposure)..................................................................................................................................... 7

Development....................................................................................................................................................... 8

Development...................................................................................................................................................8

Drum-to-Belt Transfer....................................................................................................................................... 10

Drum-to-Belt Transfer...................................................................................................................................10

Belt-to-Paper Transfer...................................................................................................................................... 11

Belt-to-Paper Transfer..................................................................................................................................11

PTR Rotation Speed......................................................................................................................................13

Fusing................................................................................................................................................................ 14

Fusing Unit.................................................................................................................................................... 14

Fusing Nip Width Adjustment..................................................................................................................... 15

Fusing Cleaning Unit....................................................................................................................................15

Fusing Belt Smoothing Roller.......................................................................................................................16

Paper Delivery..................................................................................................................................................18

Mainframe....................................................................................................................................................18

Decurl Unit....................................................................................................................................................21

Vacuum Feed LCIT....................................................................................................................................... 22

3. Details of Advanced Settings

Overview.......................................................................................................................................................... 25

Print Mode....................................................................................................................................................25

Registration....................................................................................................................................................... 26

Image Position/Magnification....................................................................................................................26

Image Quality...................................................................................................................................................27

Maximum Image Density............................................................................................................................ 27

Drum-to-belt Transfer Current..................................................................................................................... 27

Belt-to-paper Transfer..................................................................................................................................28

Fusing............................................................................................................................................................30

1

Paper Feed/Delivery....................................................................................................................................... 35

Main Tray/Vacuum Feed LCIT...................................................................................................................35

Adjusting the Machine’s Paper Delivery and Output............................................................................... 40

2

1. Introduction

This chapter provides an overview of the Media Library.

Basic Procedure

ProC9200/C9210 Series is capable of printing on a wide variety of media using the latest

technologies in digital printing such as the AC transfer and elastic fusing belt.

In addition to these technologies, support of various media is also made possible by the Media Library

database, which is registered with tested and proved media and programmed with optimized print

parameters by media type/weight.

How to use the Media Library:

1. Select a media from the library and associate the media to a tray.

2. Set the media on the associated tray.

3. Specify the media in Job Properties of the color controller.

3

DZH310

1. Introduction

Advanced Settings

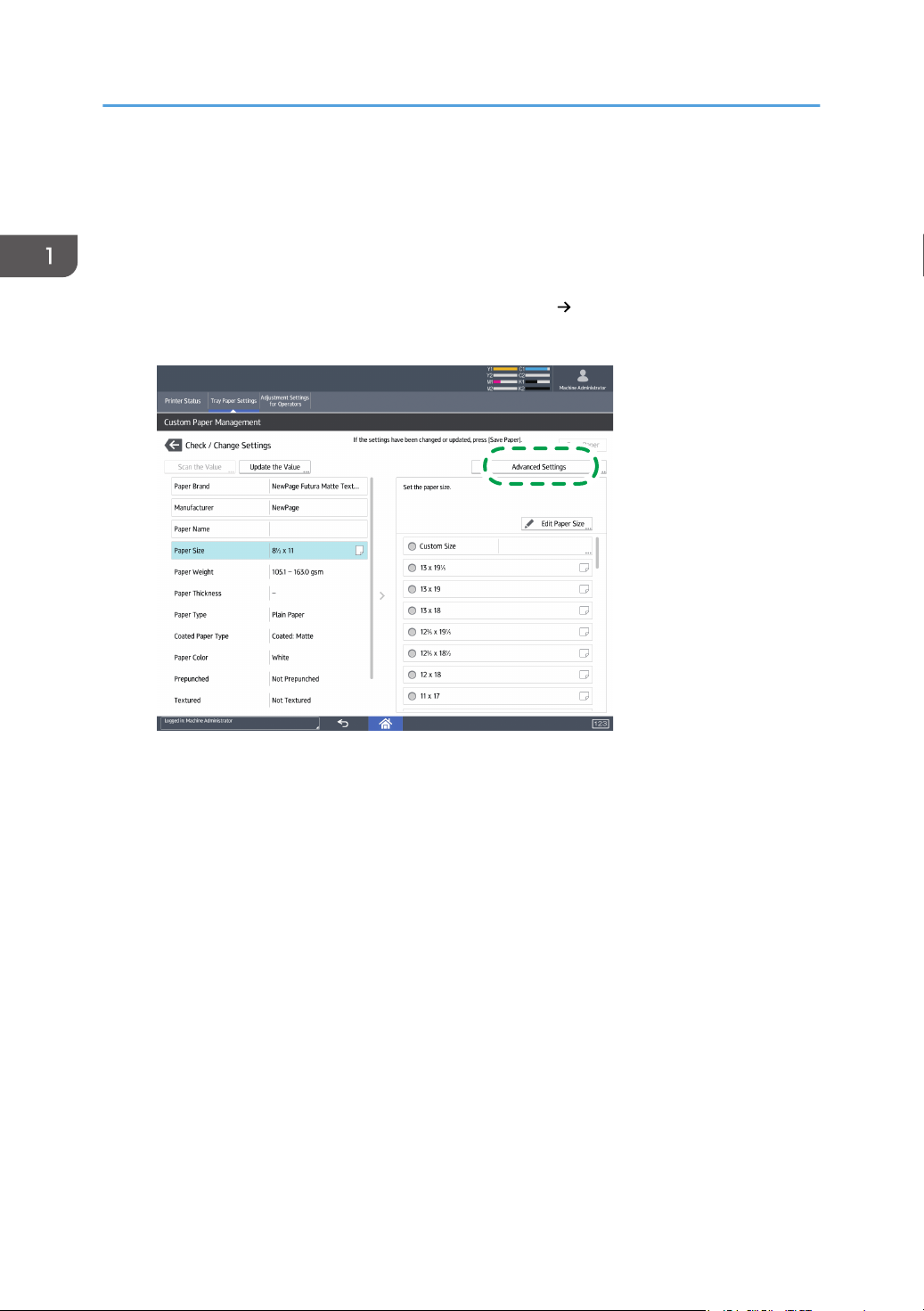

Printing from the Media Library is possible with a simple procedure, however, precise adjustments (such

as the transfer and fusing conditions) may be required depending upon the media attributes, which differ

by each and every media.

Such precise adjustments can be made from [Tray Paper Settings] [Advanced Settings].

In this menu, the followings can be adjusted:

• Machine: Image Position

• Machine: Image Quality

• Machine: Paper Feed / Output

To effectively adjust the above, it is important to have a basic understanding of how the printer works.

4

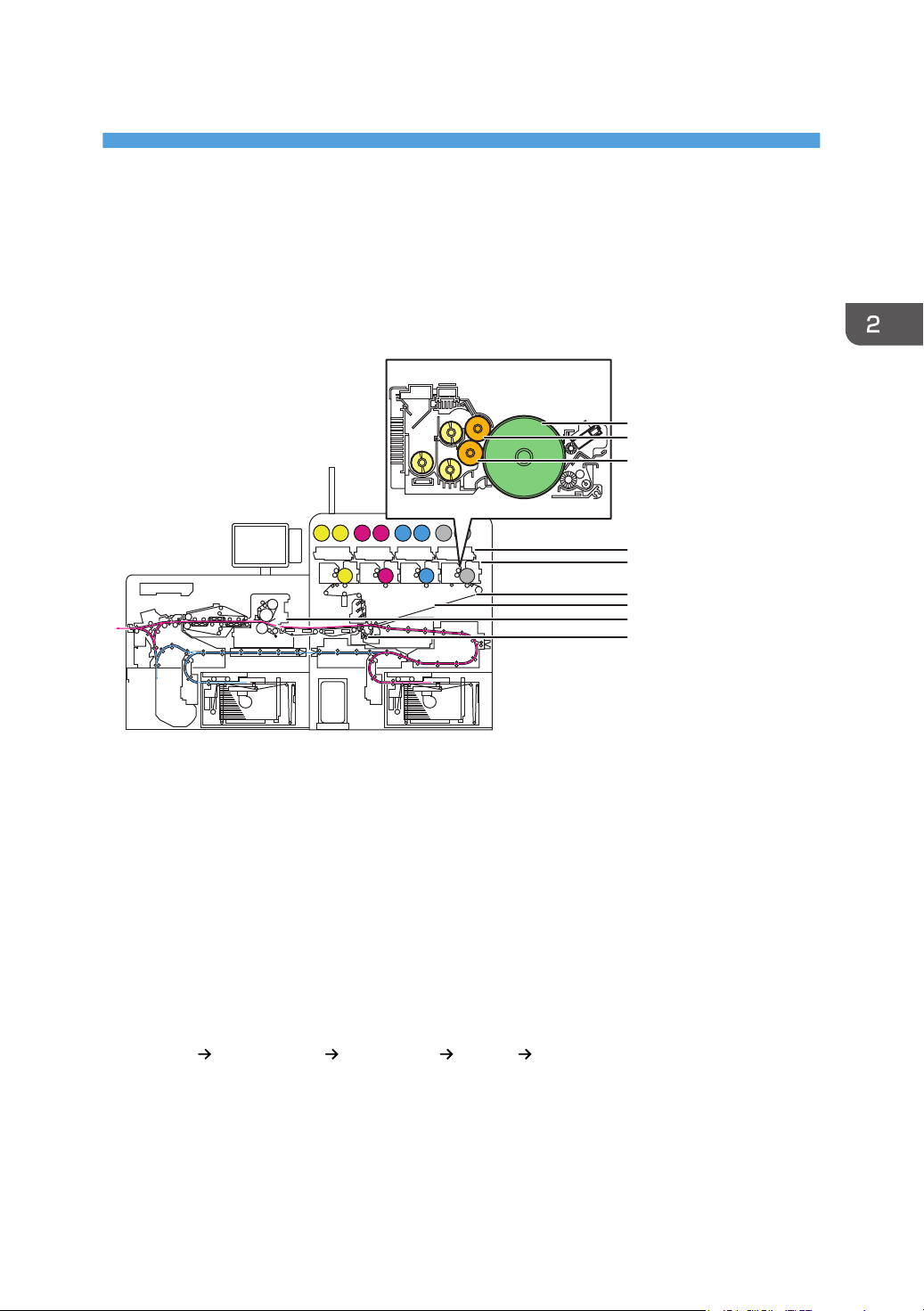

2. Printing Process

YMCK

DZH300

1

2

2

3

4

5

7

6

8

This chapter provides explanation on the basic Xerographic process of the engine by referring to the

items of the Advanced Settings.

Overview

1. OPC drum

2. Development roller

3. Laser unit

4. Charge roller

5. Intermediary transfer belt(ITB)

6. Image transfer roller

7. Fusing unit

8. Paper transfer roller(PTR)

The printing process consists of the following steps:

Drum charge Laser exposure Development Transfer Fusing

• Drum charge …… The charge roller [4] gives an equal charge across the surface of the OPC drum

[1].

• Laser exposure …… Laser unit [3] creates an electrostatic latent image on the OPC drum [1].

5

2. Printing Process

• Development …… The development roller [2] carries toner to the latent image on the OPC drum

[1].

• Image transfer

Drum-to-belt transfer …… Toner images created on each OPC drum [1] are transferred sequentially

to the ITB [5].

Belt-to-paper transfer …… Toner image on the ITB [5] is transferred onto the paper when the paper

passes through the PTR [8].

• Fusing …… The fusing unit [7] applies heat and pressure to fuse the toner image onto the paper.

6

1

2

3

4

DZH003

Laser Exposure

Laser Exposure

Laser Unit (Exposure)

The laser unit is equipped with the Vertical Cavity Surface Emitting Laser (VCSEL) technology.

40 laser beams are emitted to produce 2400dpi×4800dpi.

Laser beams are reflected on the polygon mirror and lenses to create a latent image on each of the

photoconductive drums by imparting static electricity on the surface of the drum.

1. VCSEL

2. Polygon mirror

3. OPC drum

4. Laser beam

Adjusting the start timing and frequency of this latent image creation process in both main and sub scan

directions enables registration, masking and scaling of the image.

Main scan direction ... Across the paper feed direction

Sub scan direction ... Along the paper feed direction

Related Advanced Settings

page 26 "Image Position/Magnification"

page 32 "Erase margin: leading/trailing edge"

7

1

2

1

DZH301

[A]

6

5

4

3

2

1

DZH302

2. Printing Process

Development

Development

The development system employs the dual-component*1 development method.

The developer is pre-mixed*2 to prevent image quality degradation caused by deterioration of the

developer that occurs over time.

Electrostatic latent image areas of the drum attract negatively charged toner particles from the

development roller [1].

To maintain consistent amount of toner attraction from the development roller [1] to the drum [2] for

stable image quality(toner density), image quality adjustment process runs automatically when turning

on the machine power and at optimum timings.

The developer consists of positively charged carrier (+) and negatively charged toner (-).

*1

The carrier is pre-mixed with the toner in the toner bottle and the mixture is supplied to the development unit to

*2

constantly refresh old developer in the development unit with new developer.

During the image quality adjustment process, toner patterns in 10 gradients are created on the ITB for

each toner color, which are read by the toner mark sensors. Xerographic conditions are adjusted

according to the sensor readings, maintaining consistent development (maximum image density).

8

Related Advanced Settings

page 27 "Maximum Image Density"

Development

9

12 3

BW

FC

Print

mode

Engine status

(Stations greyed out are inactive.)

Paper

Paper

YMC

Y M

C

K

K

DZH308

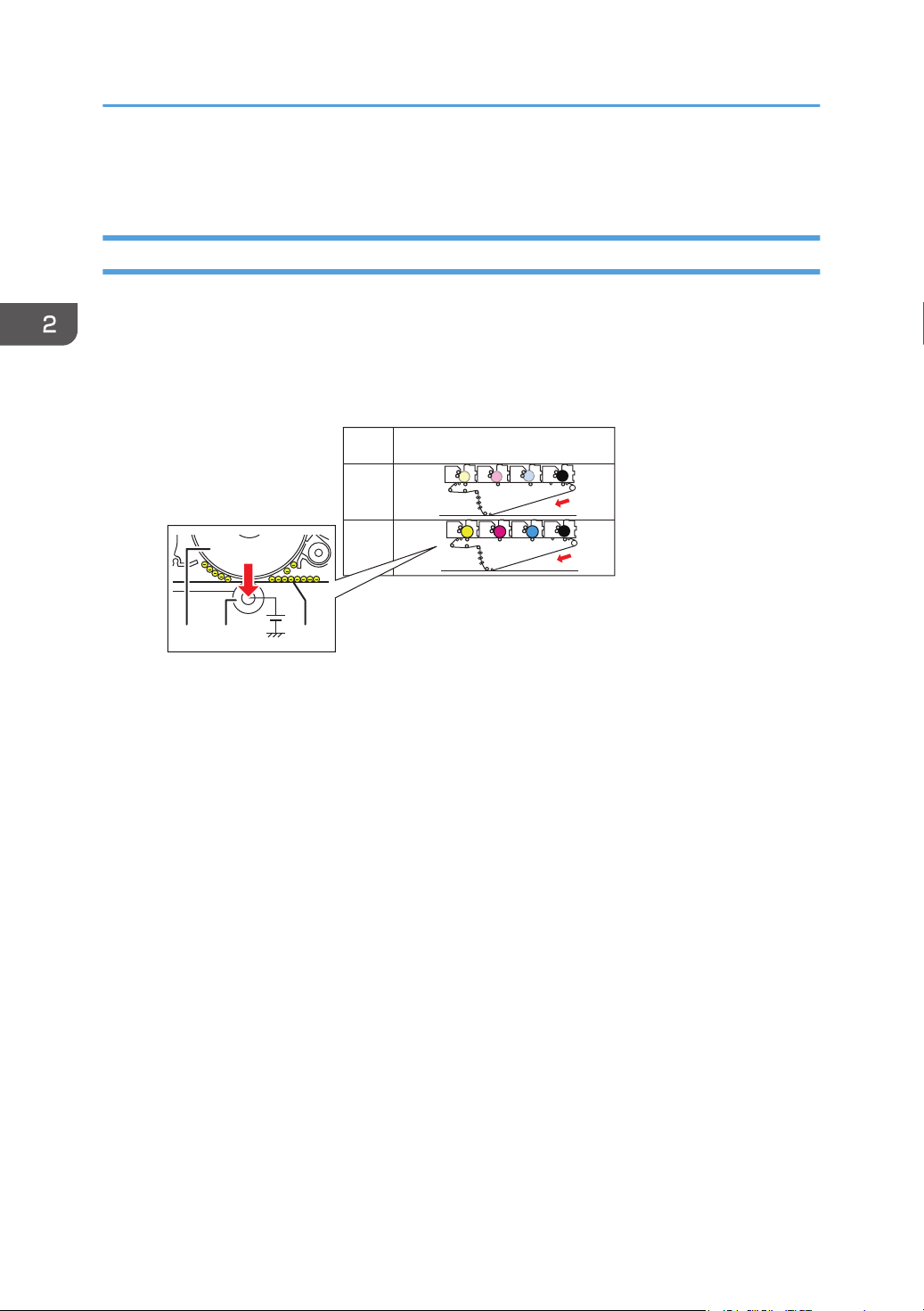

2. Printing Process

Drum-to-Belt Transfer

Drum-to-Belt Transfer

Among the following two print modes, the correct mode is selected automatically according to the print

data sent from the printer controller.

• BW mode: Job contains only black data.

• FC mode: Job contains color data.

1. OPC drum

2. Image transfer roller

3. Intermediary transfer belt(ITB)

By applying a positive (+) bias (transfer current) to the image transfer roller, negatively charged toner (-)

on the drum is attracted to the ITB that positions between the roller and the belt. Any remaining toner on

the drum is cleaned by the drum cleaning unit.

Related Advanced Settings

page 27 "Drum-to-belt Transfer Current"

10

DZH307

1

2

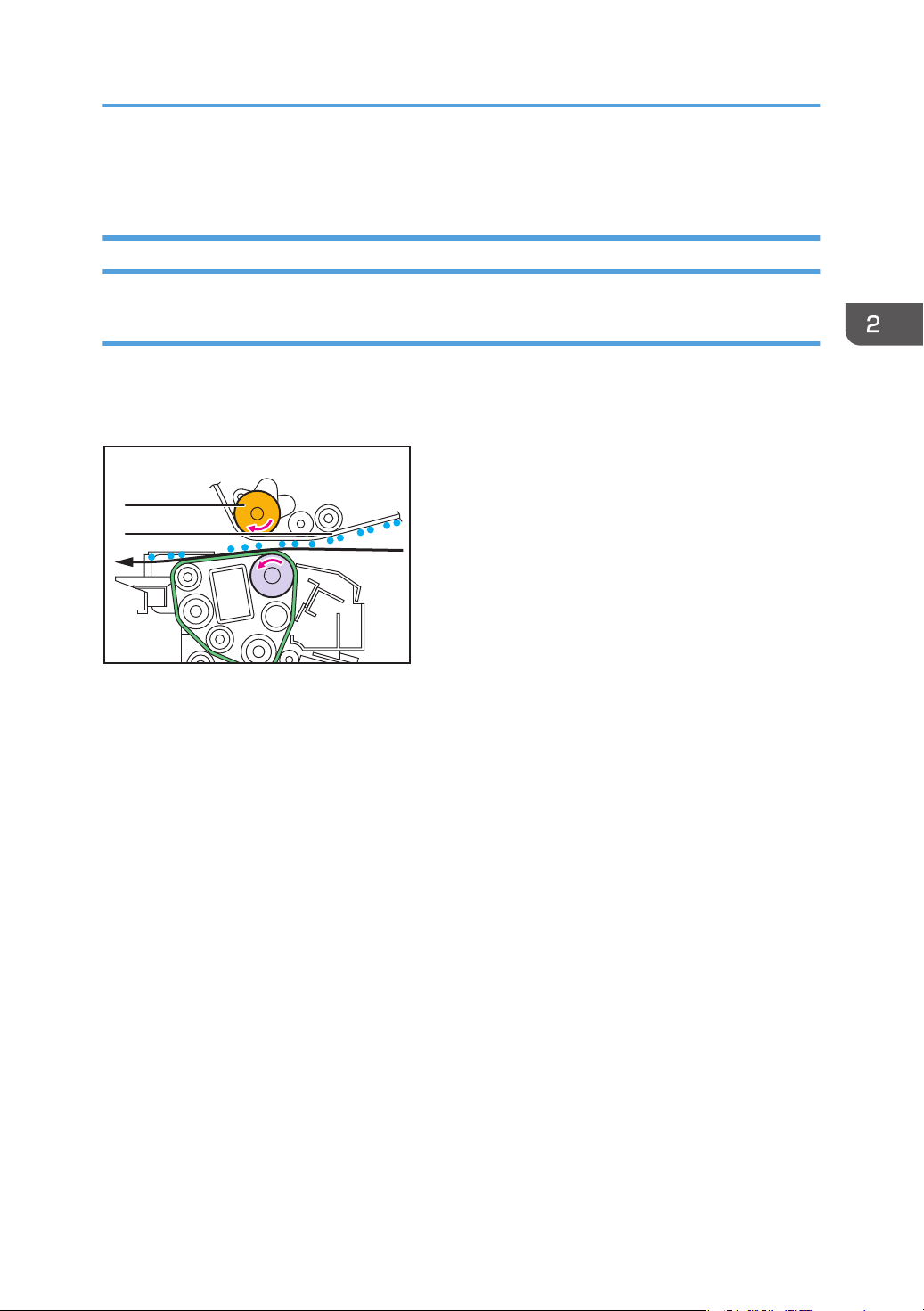

Belt-to-Paper Transfer

Belt-to-Paper Transfer

Belt-to-Paper Transfer

Applied voltage

The paper transfer roller features AC transfer technology.

Negatively charged toner image (-) on the ITB [2] is transferred to the paper by applying a negative

bias (-) to the paper transfer bias roller [1].

Following are the three types of negative bias applied to the paper transfer bias roller:

• DC bias: For all media types

• AC bias (Standard): For media other than metallic pearl and textured paper

• AC bias (Textured): For textured paper

* At low temperature and humidity, only DC bias is applied.

Bias is adjustable by print mode because the optimum bias level is dependent on the amount of toner

transfer.

(Bias is higher for FC than for BW due to the greater amount of transferred toner.)

By nature of AC, in which the current flows in an alternating up-and-down movement, toner particles

sync with this movement. Toner transferred to the media is pulled back to the ITB to gain further

transferability, enabling toner particles to fall into the indentations on rough surfaced media.

11

1

2345

DZH009

DZH010

12

2. Printing Process

Textured paper mode

1. ITB

2. Textured paper

3. Toner is partially transferred.

4. Toner transferred to the paper returns to the belt and combines with toner remaining on the belt.

5. Toner is transferred to the indentations on the surface of the paper.

1. AC transfer inactive

2. AC transfer active

Related Advanced Settings

• DC bias

page 28 "Paper transfer current"

Leading/Trailing edge correction

To prevent image quality problems owing to the instability of the leading/trailing edges of the paper

when entering the nip of the PTR, the belt-to-paper transfer bias is adjusted for the leading/trailing

edges.

• Belt-to-paper transfer: Leading edge correction

12

• Belt-to-paper transfer: Trailing edge correction

DZH304

1

• Belt-to-paper transfer: Length of area to apply correction at leading edge of paper

• Belt-to-paper transfer: Length of area to apply correction at trailing edge of paper

• Current vs. Voltage

• Bias is applied using 'constant current' for drum-to-belt and belt-to-paper transfer, as this

method is resilient to changes in operational environment and thickness of the media.

• On the other hand, 'constant voltage' is used for AC bias and as this method does not require

adjustments according to paper width.

Related Advanced Settings

page 29 "Belt-to-paper transfer correction: LE/TE"

PTR Rotation Speed

The PTR [1] has the function to deliver the paper from the paper transfer timing roller.

Belt-to-Paper Transfer

Since the paper transport speed is controlled by the PTR, if the PTR rotation speed is slower than the

target the image will shrink, if faster than the target the image will stretch.

A problem such as side-to-side image magnification misalignment and mottling on black half-tone parts

may occur in the printed image because of the speed difference relative to the image transfer belt. To

solve this problem, it is necessary to adjust the PTR rotation speed.

Since the paper is simultaneously gripped by the PTR and the paper transfer timing roller, uneven density

and banding problems may occur, if the speed differs between these rollers. To prevent this problem,

you can adjust the PTR rotation speed.

Related Advanced Settings

page 42 "Paper transfer roller speed"

page 42 "Transfer timing roller feed speed"

13

Loading...

Loading...