Page 1

SERVICE MANUAL

(Machine code: C229)

Page 2

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals, make

sure that the power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drops or flush

with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down your

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those models.

CAUTION

I

The RAM has a lithium battery which can explode if handled incorrectly.

Replace only with the same type of RAM. Do not recharge or burn this

battery. Used RAM's must be handled in accordance with local regulations.

ATTENTION

I

La carte RAM comporte une pile au lithium qui présente un risque

d'explosion en cas de mauvaise manipulation. Remplacer la pile

uniquement par une carte RAM identique. Ne pas recharger ni brûler cette

pile. Les cartes RAM usagées doivent être éliminées conformément aux

réglementations locales.

1

Page 3

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an environmentally safe

manner and in accordance with local regulations.

3. When keeping used lithium batteries (from the main processing units) in order

to dispose of them later, do not store more than 100 batteries (from the main

processing units) per sealed box. Storing larger numbers or not sealing them

apart may lead to chemical reactions and heat build-up.

2

Page 4

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals, make

sure that the power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drops or flush

with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down your

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those models.

CAUTION

I

The RAM has a lithium battery which can explode if handled incorrectly.

Replace only with the same type of RAM. Do not recharge or burn this

battery. Used RAM's must be handled in accordance with local regulations.

ATTENTION

I

La carte RAM comporte une pile au lithium qui présente un risque

d'explosion en cas de mauvaise manipulation. Remplacer la pile

uniquement par une carte RAM identique. Ne pas recharger ni brûler cette

pile. Les cartes RAM usagées doivent être éliminées conformément aux

réglementations locales.

1

Page 5

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an environmentally safe

manner and in accordance with local regulations.

3. When keeping used lithium batteries (from the main processing units) in order

to dispose of them later, do not store more than 100 batteries (from the main

processing units) per sealed box. Storing larger numbers or not sealing them

apart may lead to chemical reactions and heat build-up.

2

Page 6

1 July, 1998 SPECIFICATIONS

1. OVERALL INFORMATION

1.1 SPECIFICATIONS

Configuration: Desktop

Master Processing: Digital with 400 dpi thermal head

Scanning (Pixel Density): 400 dpi CCD

Printing Process: Fully automatic stencil system, with one drum and

pressure cylinder system

Original Type: Sheet/Book

In Platen Mode: Document size:

Maximum 304.8 x 432 mm [12.0" x 17.0"]

Thickness: Less than 30 mm

Weight: Less than 10 kg

In ADF Mode: Document size:

Maximum 297 x 864 mm [11.6" x 33.8"]

Minimum 105 x 128 mm [4.2" x 5.1"]

Document weight:

52.3 - 104.7 g/m2[14 - 28 lb]

Overall

Information

ADF capacity:

30 sheets (using 20 lb or 80 g/m2 paper)

Reproduction Ratios: Inch versions Others

Full Size: 100% 100%

Reduction: 65% 71%

74% 82%

77% 87%

93% 93%

Enlargement: 121% 115%

129% 122%

155% 141%

Zoom: 50 - 200% (by 1%) in Platen mode

50 - 155% (by 1%) in ADF mode

Directional Magnification:

50 - 200% (by 1%)

Image Modes: Letter, Photo, Letter/Photo, Pencil, Tint

1-1

Page 7

SPECIFICATIONS 1 July, 1998

Printing Area:

(At 20 °C/ 65 % RH)

Metric size version models:

290 mm x 409 mm

Inch size version models:

290 mm x 419 mm [11.4" x 16.4"]

With optional A4 drum:

290 mm x 204 mm [11.4" x 8.0"]

Edge Margins: Leading edge:

10 mm (At the "0" position of Image Shift mode)

Trailing edge:

2 mm

Print Paper Size: Minimum: 70 mm x 148 mm [2.8" x 5.9"]

Maximum: 325 mm x 447 mm [12.7" x 17.6"]

Print Paper Weight: 47.1 g/m2 to 209.3 g/m2 [12.5 lb to 55.6 lb]

Printing Speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

Master Process Time: Platen mode:

Less than 15.5 seconds (A3 paper)

Less than 12 seconds (A4 paper)

ADF mode:

Less than 19.5 seconds (A3 paper)

Less than 16 seconds (A4 paper)

Master Eject Box Capacity: 60 masters / A3 size (Normal conditions)

Side Registration Adjustable

± 10 mm

Range:

Vertical Registration Adjustable

Range:

Inch size version models:

± 10 mm

Metric size version models:

± 15 mm

Paper Feed Table Capacity: 1000 sheets (80 g/m2 / 20 lb)

Paper Delivery Table Capacity: 1000 sheets (80 g/m2 / 20 lb)

Power Source: 110/120 V, 50/60 Hz: 2.7 A

220 - 240 V, 50/60 Hz: 1.5 A

Maximum Power Consumption: 110/120 V version: 285 W

220 - 240 V version: 280 W

1-2

Page 8

1 July, 1998 SPECIFICATIONS

Noise Emission:

(At operation position)

At 60 rpm printing speed: 57 dB

At 90 rpm printing speed: 60 dB

At 120 rpm printing speed: 64 dB

Weight: 94 kg [207 lb]

101 kg [222.7 lb] with ADF

Dimensions:

(Width x Depth x Height)

Trays closed: 625 mm x 650 mm x 574 mm

With ADF:

625 mm x 650 mm x 684 mm

Trays open: 1405 mm x 650 mm x 574 mm

With ADF:

1405 mm x 650 mm x 684 mm

Master Type: Thermal master roll type:

420 mm width, 110 m / roll

Yield:

200 masters/roll (at A3 size)

Max run length per master:

2,000 prints

Master Storage Conditions: Temperature:

-10 °C to 40 °C

Overall

Information

Humidity:

10% to 95% RH

Recommended maximum storage period:

One year after production date

* Avoid locations exposed to direct sunlight.

Ink Type 1000 ml cartridge type

Available colors:

Black, Red, Blue, Green, Brown

Ink Storage Conditions: Temperature:

-5 °C to 40 °C

(Optimum conditions: 15 °C to 25 °C)

Humidity:

10% to 95% RH

(Optimum conditions: 20% to 70% RH)

Recommended maximum storage period:

One year after production date

* Avoid locations exposed to direct sunlight.

1-3

Page 9

SPECIFICATIONS 1 July, 1998

Available Options

· A3 Drum

· A4 Drum

· Document Feeder

· Key Counter

· Memory Board (Editing Function)

· PC Controller

· Interface Board (Standard for the U.S.A and

European versions)

1-4

Page 10

1 July, 1998 GUIDE TO COMPONENTS AND THEIR FUNCTION

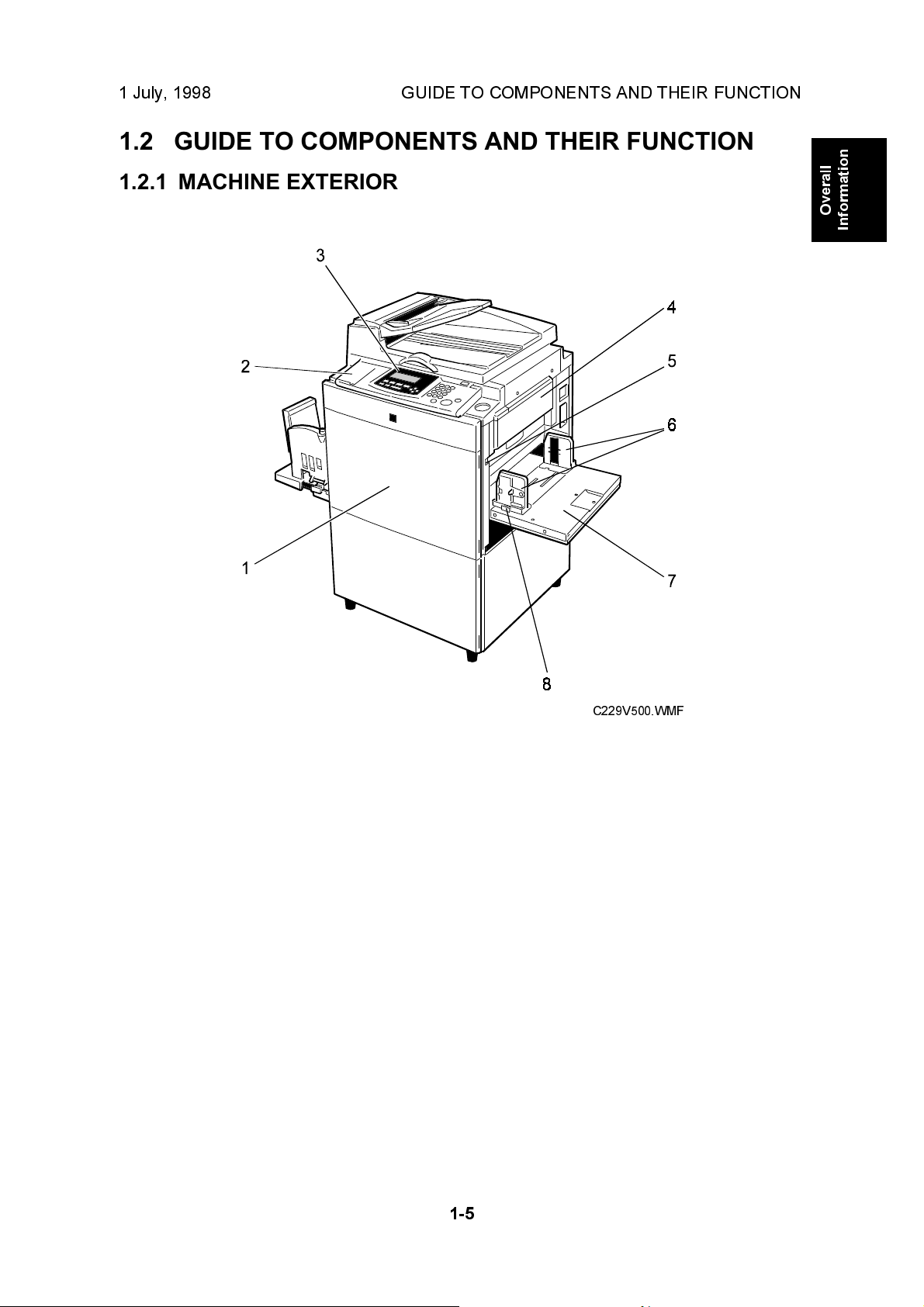

1.2 GUIDE TO COMPONENTS AND THEIR FUNCTION

1.2.1 MACHINE EXTERIOR

Overall

Information

1. Front Door

2. Flip-up Cover

3. Operation Panel

4. Master Feed Unit

5. Paper Feed Tray Down key

6. Paper Feed Side/End

Plates

7. Paper Feed Tray

8. Paper Feed Side/End Plate

Knob

C229V500.WMF

Open for access to the inside of the

machine.

Open to access the Image Density key and

so on.

Operator controls and indicators are

located here.

Open the master feed unit when installing

the master.

Press to lower the paper feed tray.

Use to prevent paper skew.

Set paper on this tray for printing.

Use to move the side/end plates.

1-5

Page 11

MACHINE INTERIOR 1 July, 1998

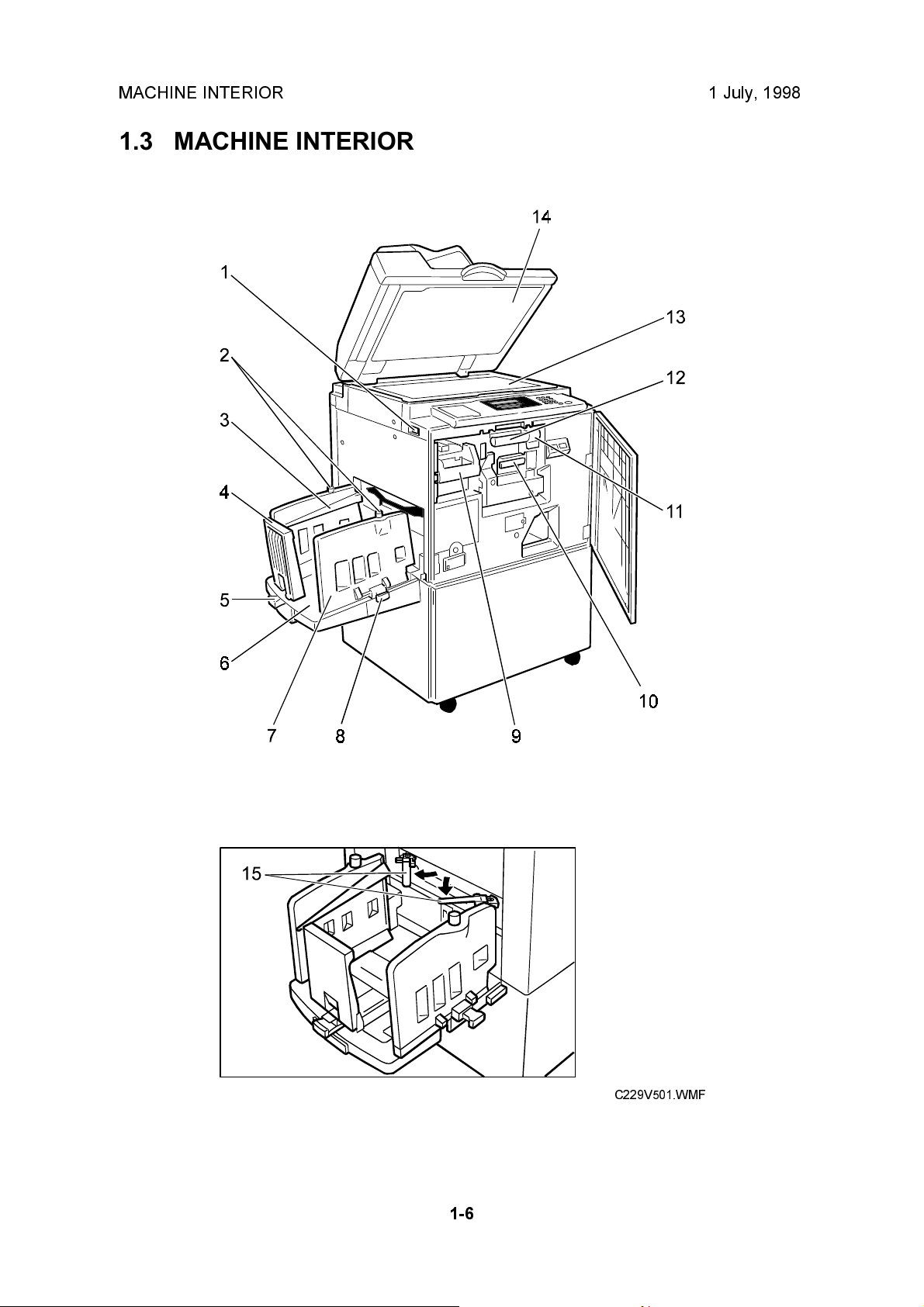

1.3 MACHINE INTERIOR

1-6

C229V501.WMF

Page 12

1 July, 1998 MACHINE INTERIOR

1. Main Switch

2. Paper Alignment Wing

Knobs

3. Paper Alignment Wings

4. Paper Delivery End Plate

5. Paper Delivery End Plate

Knob

6. Paper Delivery Tray

7. Paper Delivery Side Plates

8. Paper Delivery Side Plate

Knobs

9. Master Eject Unit Front

Handle E1

10. Ink Holder

11. Drum Unit Lock Lever B1

Use to turn the power on or off.

Use to lift or lower the paper alignment

wings.

Lift or lower the wings depending on the

paper type you use.

This plate aligns the leading edge of prints.

Use to move the end plate.

Completed prints are delivered here.

These plates align the prints on the paper

delivery tray.

Use to move the side plates.

Use to pull out the master eject unit.

Set the ink cartridge in this holder.

Lower to unlock and pull out the drum unit.

Overall

Information

12. Drum Unit

13. Exposure Glass (Contact

Glass)

14. Platen Cover

15. Trailing Edge Guides

The master is wrapped around this unit.

Position originals here face down for

printing.

Lower this cover over an original before

printing.

Swing out these guides when you use A4,

8

1/2

" x 11" sideways, or B5 lengthwise

paper.

1-7

Page 13

MACHINE INTERIOR 1 July, 1998

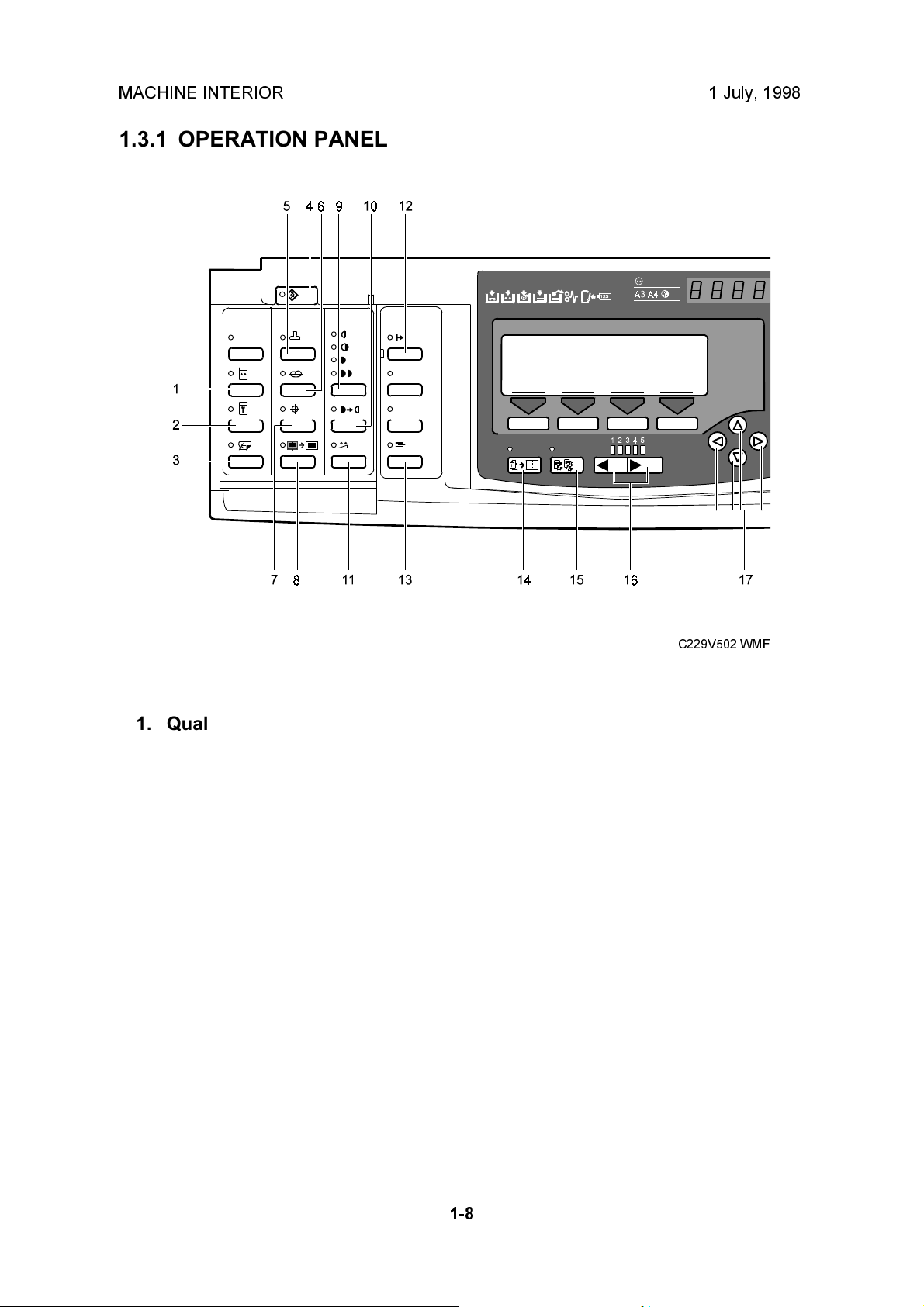

1.3.1 OPERATION PANEL

1. Quality Start key

2. Security key

3. Skip Feed key

4. User Tools key

Press to change the default

settings and conditions to meet

your requirements.

5. Stamp key

6. Make-up key

7. Overlay key

8. Edge Erase key

9. Image Density key

Press to make prints darker or

lighter.

C229V502.WMF

11. Economy Mode key

12. On Line key

13. Job Separator key

14. Combine key

Press to combine originals onto

one print.

15. Class key

Press to select All Class, Auto

Class, Manual Class, or Class

mode.

16. Speed keys

17. Scroll keys

Press to shift the image forward,

backward, right, or left.

10. Tint key

1-8

Page 14

1 July, 1998 MACHINE INTERIOR

Overall

Information

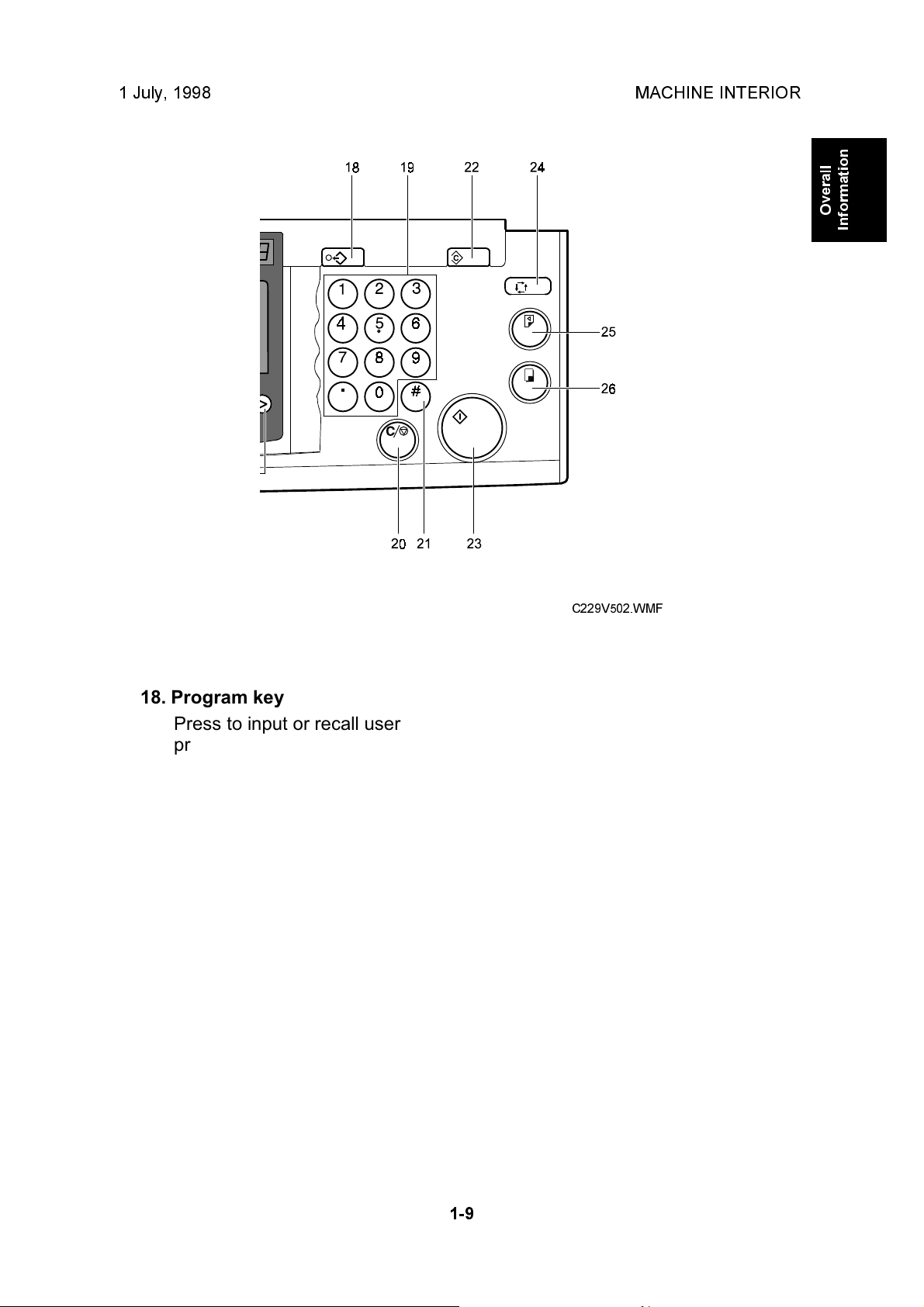

18. Program key

Press to input or recall user

programs.

19. Number keys

20. Clear/Stop key

While printing, press to stop the

machine.

21. Enter key

Use to enter data in selected

modes.

22. Clear Modes key

Press to clear the previously

entered job settings.

C229V502.WMF

23. Start key

Press to make a master.

24. Auto Cycle key

Use to process the master and

make prints at one stroke.

25. Proof key

Press to make a proof print.

26. Print key

Press to start printing.

1-9

Page 15

MACHINE INTERIOR 1 July, 1998

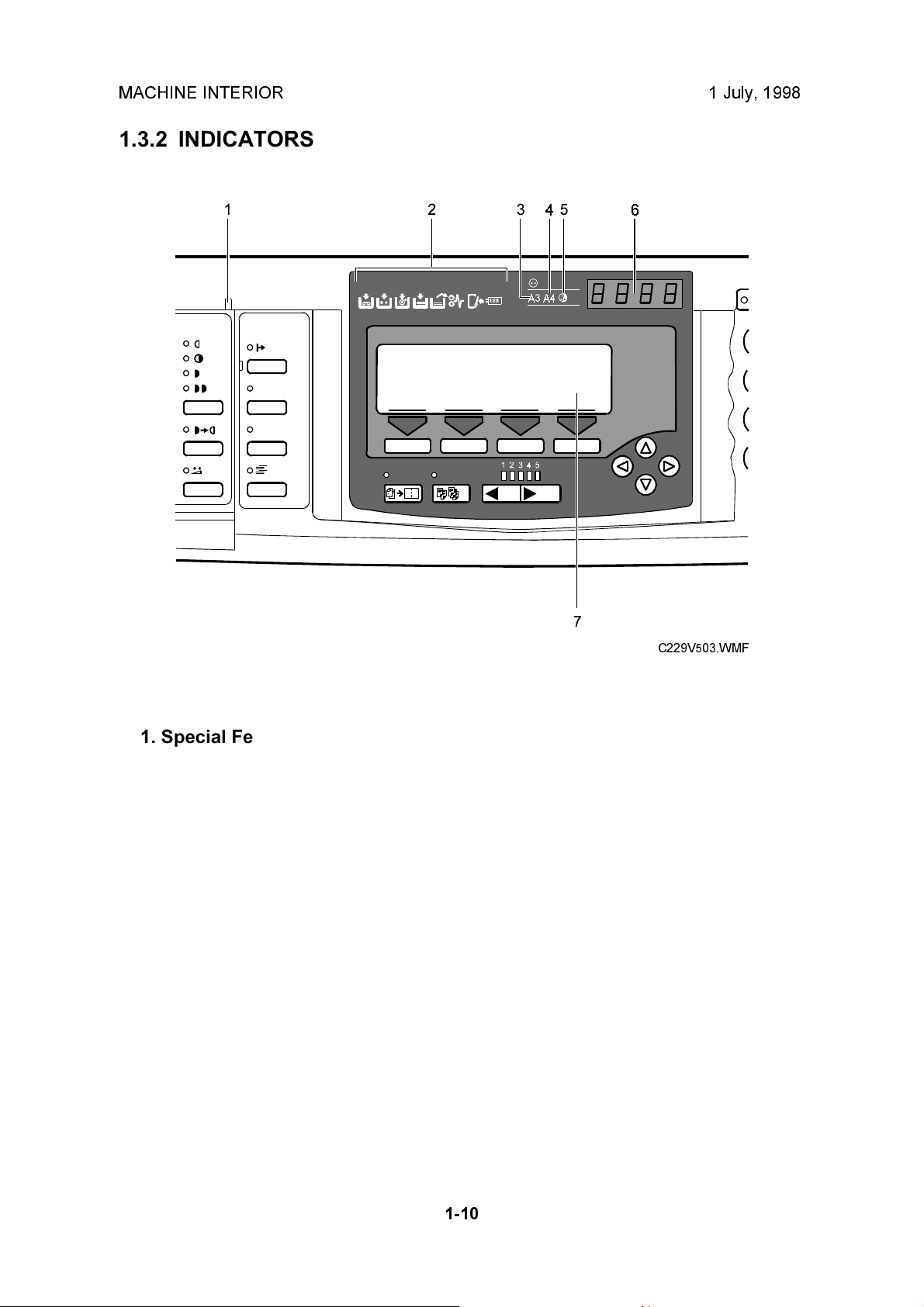

1.3.2 INDICATORS

1. Special Feature indicator

This indicator is lit when you

press keys under the flip-up

cover.

2. Monitors

The monitors light up when a

non-standard condition occurs

within the machine.

3. A3/11" x 17" Drum indicator

This indicator is lit when the A3,

11" x 17" drum unit is installed.

4. A4/81/2" x 11" Drum indicator

This indicator is lit when the A4,

81/2" x 11" drum unit is installed.

C229V503.WMF

5. Color Drum indicator

This indicator is lit when the color

drum unit is installed.

6. Counter

Displays the number of prints

entered. While printing, it shows

the number of prints remaining.

7. Panel Display

1-10

Page 16

1 July, 1998 PRINTING PROCESS OVERVIEW

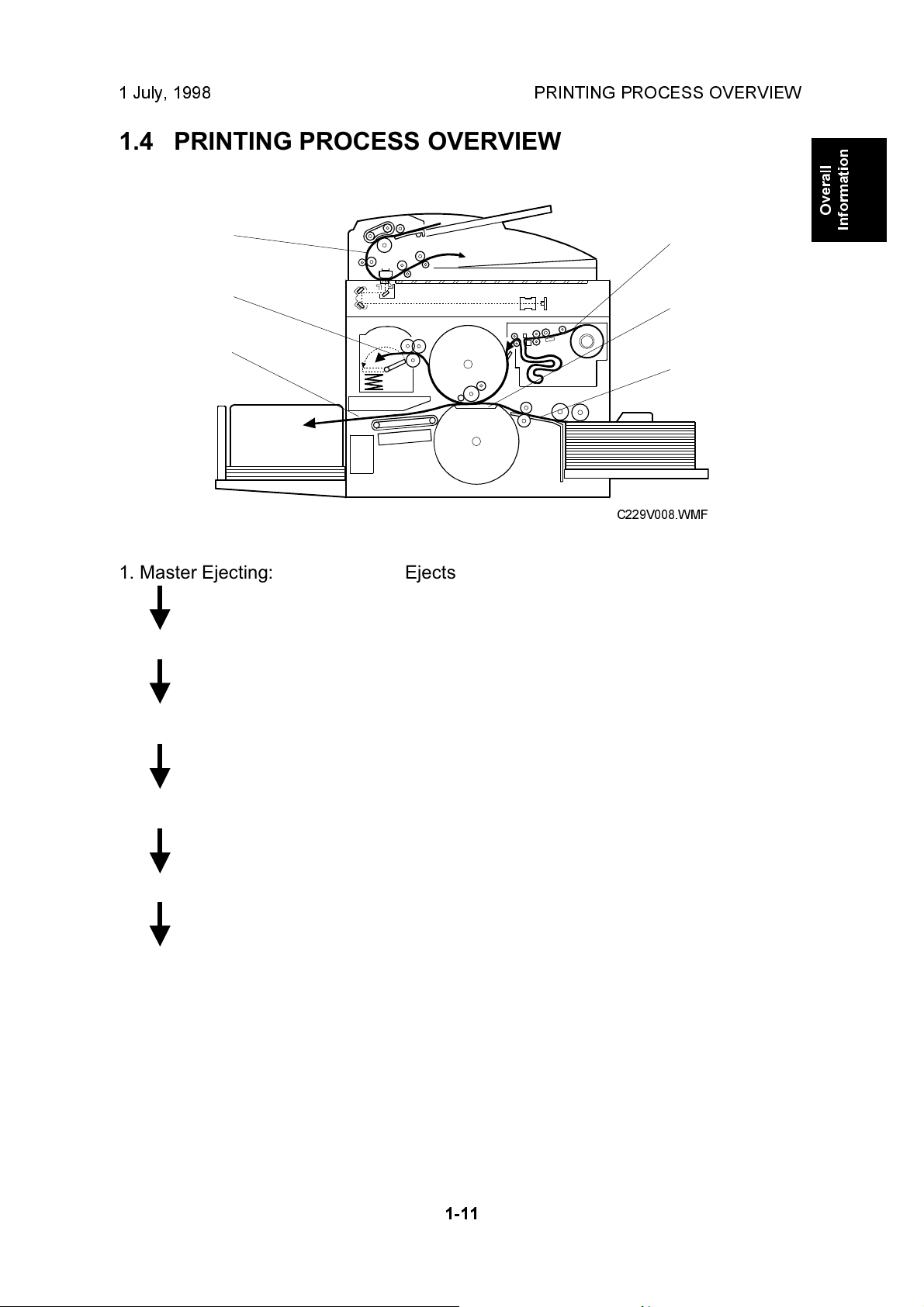

1.4 PRINTING PROCESS OVERVIEW

2

3

Overall

Information

1

5

6

4

C229V008.WMF

1. Master Ejecting: Ejects the used master wrapped around the drum

into the master eject box.

2. Scanning: Scans the original image with the CCD through the

mirrors and the lens.

3. Master Feeding: Converts the image signal read by the CCD into

digital signals and sends them to the thermal head to

develop the image on the master. The master then

wraps around the drum.

4. Paper Feeding: Sends paper to the drum section.

5. Printing: Presses the paper fed from the paper feed section

against the drum. This transfers ink to the paper

through the drum screen and the master.

6. Paper Delivering: Peels off the printed paper with the exit pawls and air

knife, and ejects the paper onto the paper delivery

table.

NOTE:

Some parts of the master eject, scanning, and master feeding processes

are carried out at the same time. Paper feeding also starts before the

master feeding process has finished.

1-11

Page 17

MECHANICAL COMPONENT LAYOUT 1 July, 1998

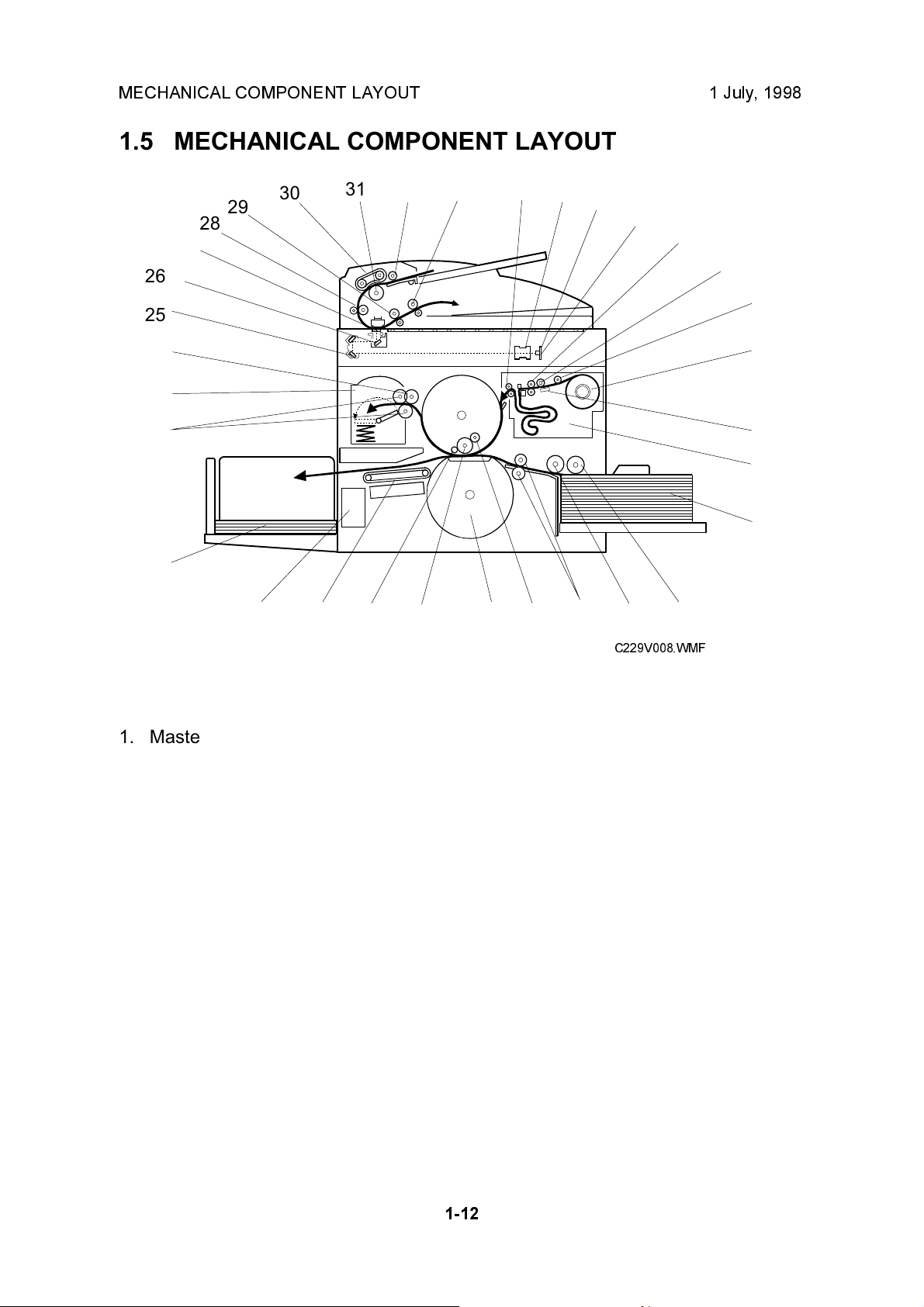

1.5 MECHANICAL COMPONENT LAYOUT

26

25

24

23

22

21

27

28

29

30

31 32 33

12

3

4

5

6

7

8

9

10

11

121314151617181920

1. Master Feed Control Roller

2. Lens

3. CCD

4. SBU

5. Tension Roller

6. Platen Roller

7. Master Set Roller

8. Master Roll

9. Thermal Head

10. Master Buffer Duct

11. Paper Table

12. Paper Feed Roller

13. Paper Separation Roller

14. Registration Rollers

15. Doctor Roller

16. Pressure Cylinder

17. Ink Roller

C229V008.WMF

18. Idling Roller

19. Transport Belts

20. Job Separator Unit

21. Paper Delivery Table

22. Master Eject Rollers

23. Master Eject Box

24. Master Pick-up Roller

25. 2nd Scanner

26. 1st Scanner

27. DF Exposure Glass

28. 1st Transport Roller

29. 2nd Transport Roller

30. Original Feed Belt

31. Separation Roller

32. Pick-up Roller

33. Original Exit Roller

1-12

Page 18

1 July, 1998 ELECTRICAL COMPONENT LAYOUT

1.6 ELECTRICAL COMPONENT LAYOUT

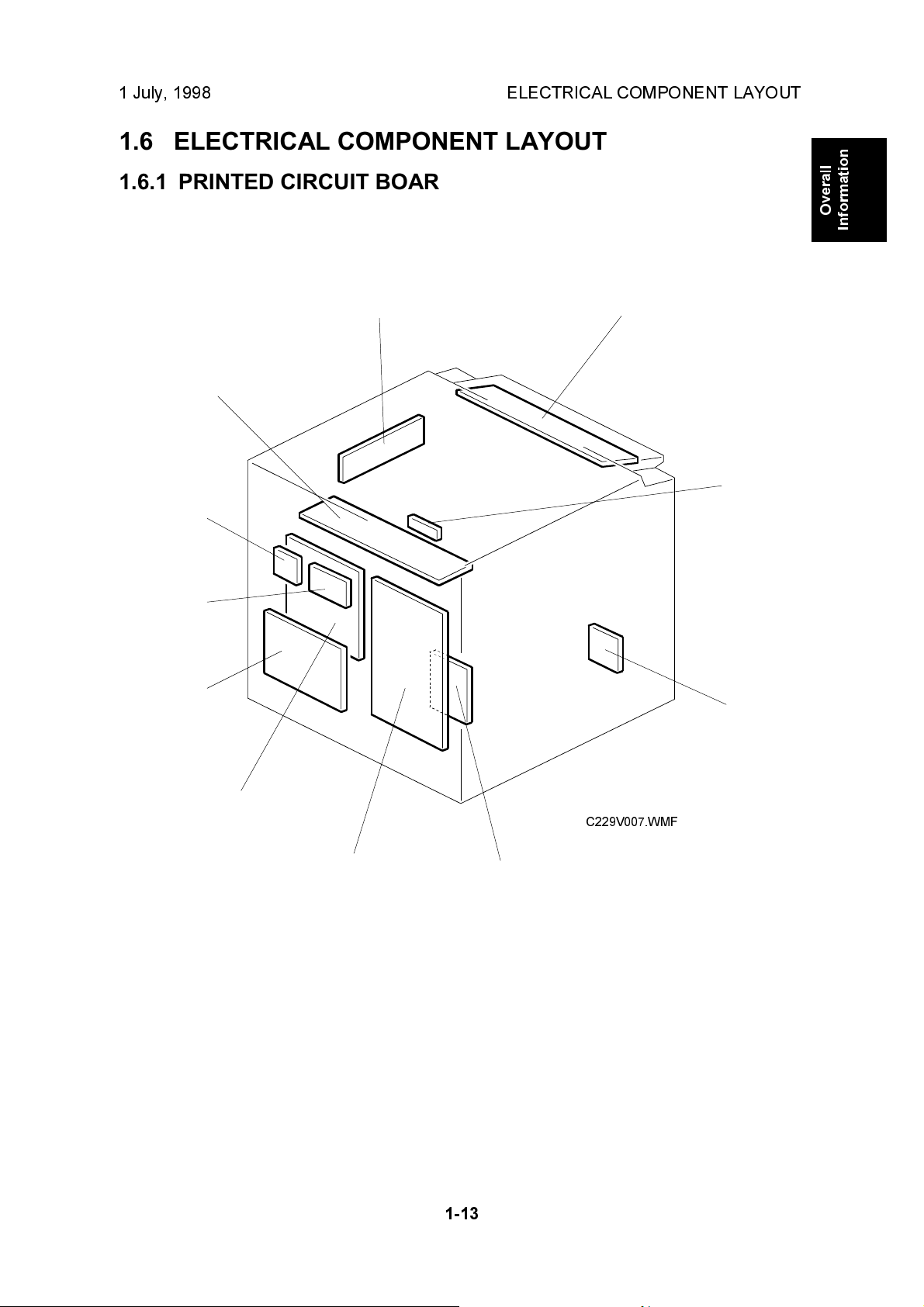

1.6.1 PRINTED CIRCUIT BOARD LAYOUT

Overall

Information

10

9

8

7

11

1

2

3

6

C229V007.WMF

5

1-13

4

Page 19

ELECTRICAL COMPONENT LAYOUT 1 July, 1998

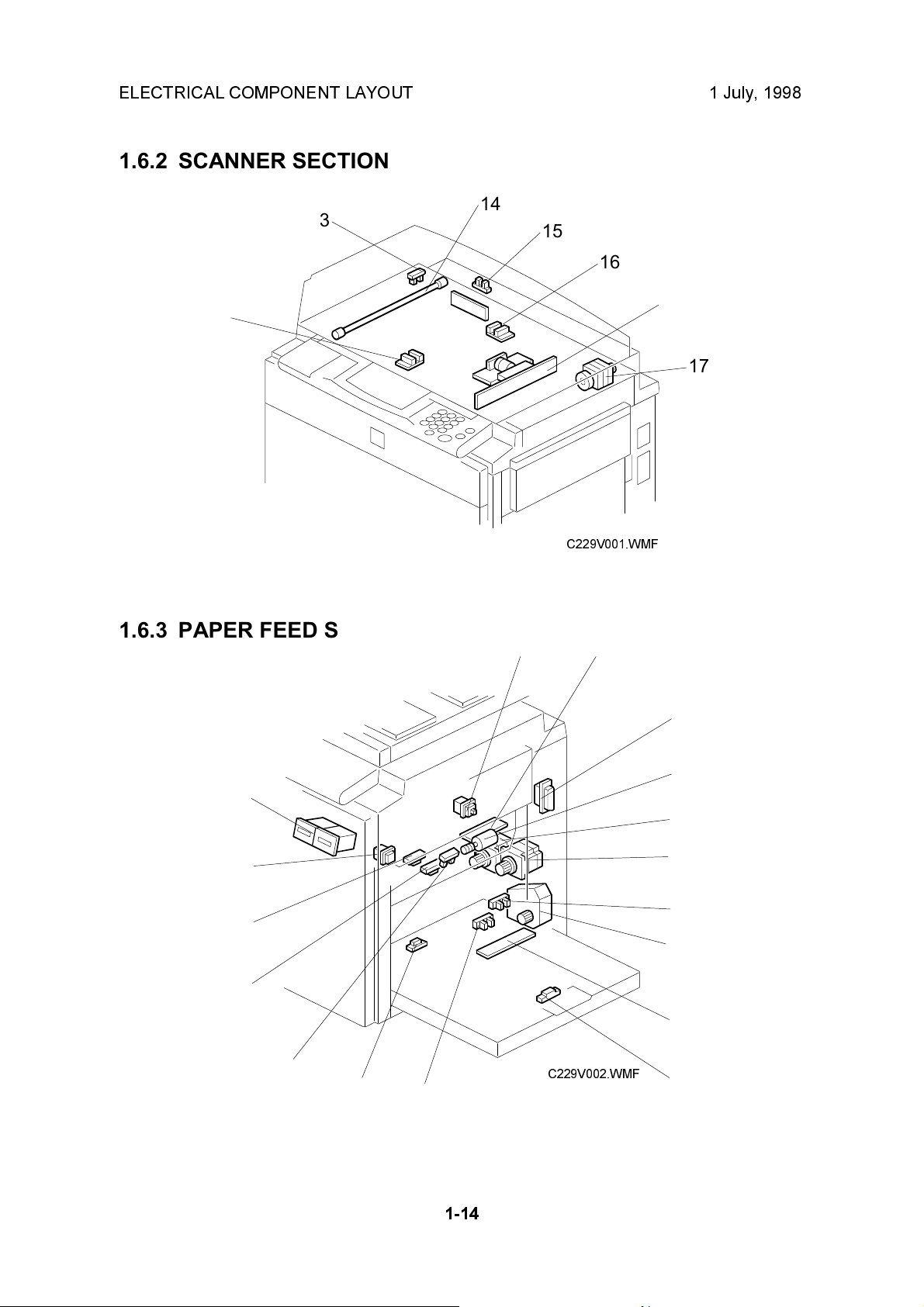

1.6.2 SCANNER SECTION

14

13

15

16

12

1.6.3 PAPER FEED SECTION

18

11

17

C229V001.WMF

19

20

34

33

32

31

30

29

28

1-14

C229V002.WMF

21

22

23

24

25

26

27

Page 20

1 July, 1998 ELECTRICAL COMPONENT LAYOUT

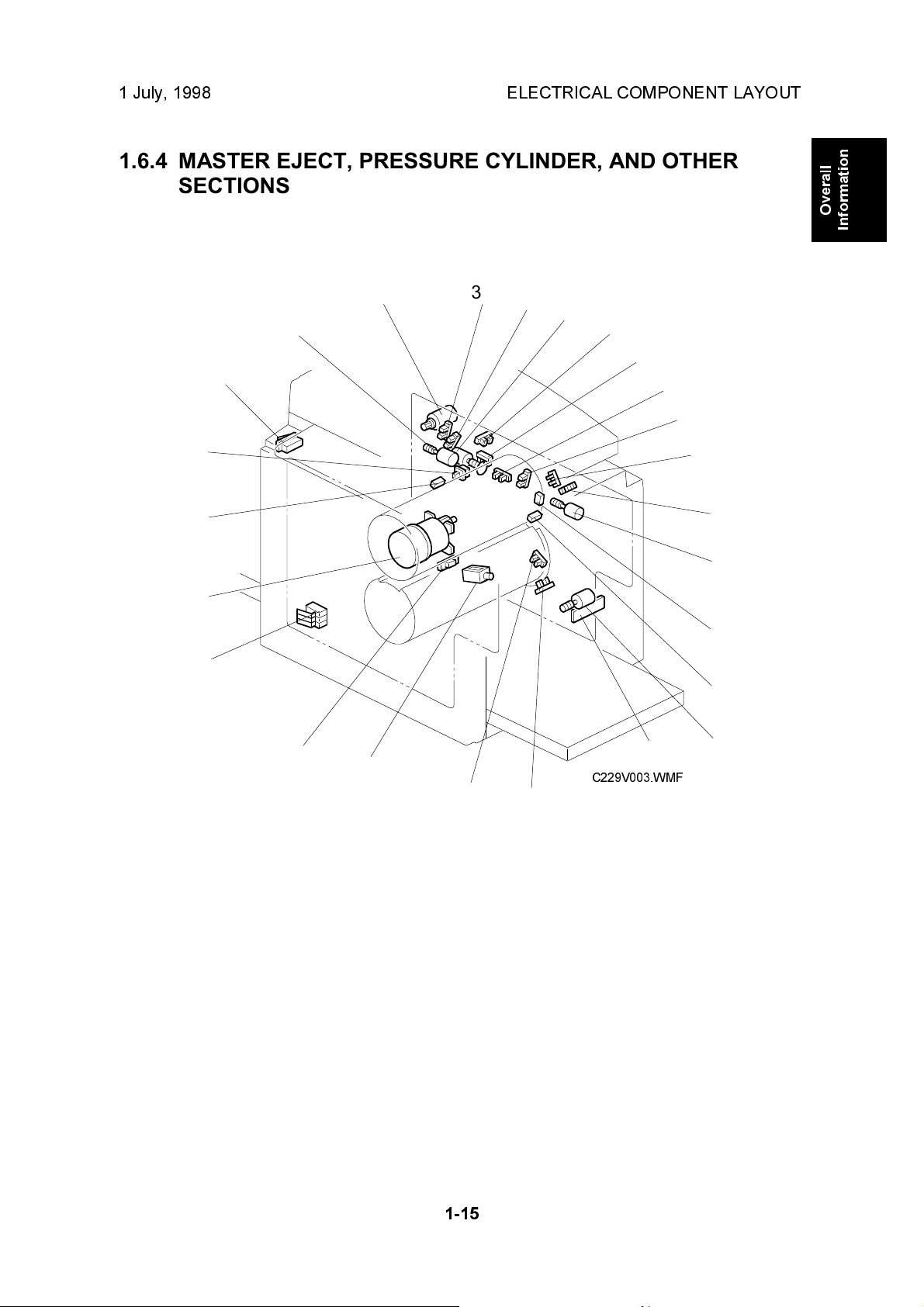

1.6.4 MASTER EJECT, PRESSURE CYLINDER, AND OTHER

SECTIONS

Overall

Information

59

58

57

56

35

36

55

54

37

53

38

39

52

40

41

42

43

44

45

46

47

48

49

50

51

C229V003.WMF

1-15

Page 21

ELECTRICAL COMPONENT LAYOUT 1 July, 1998

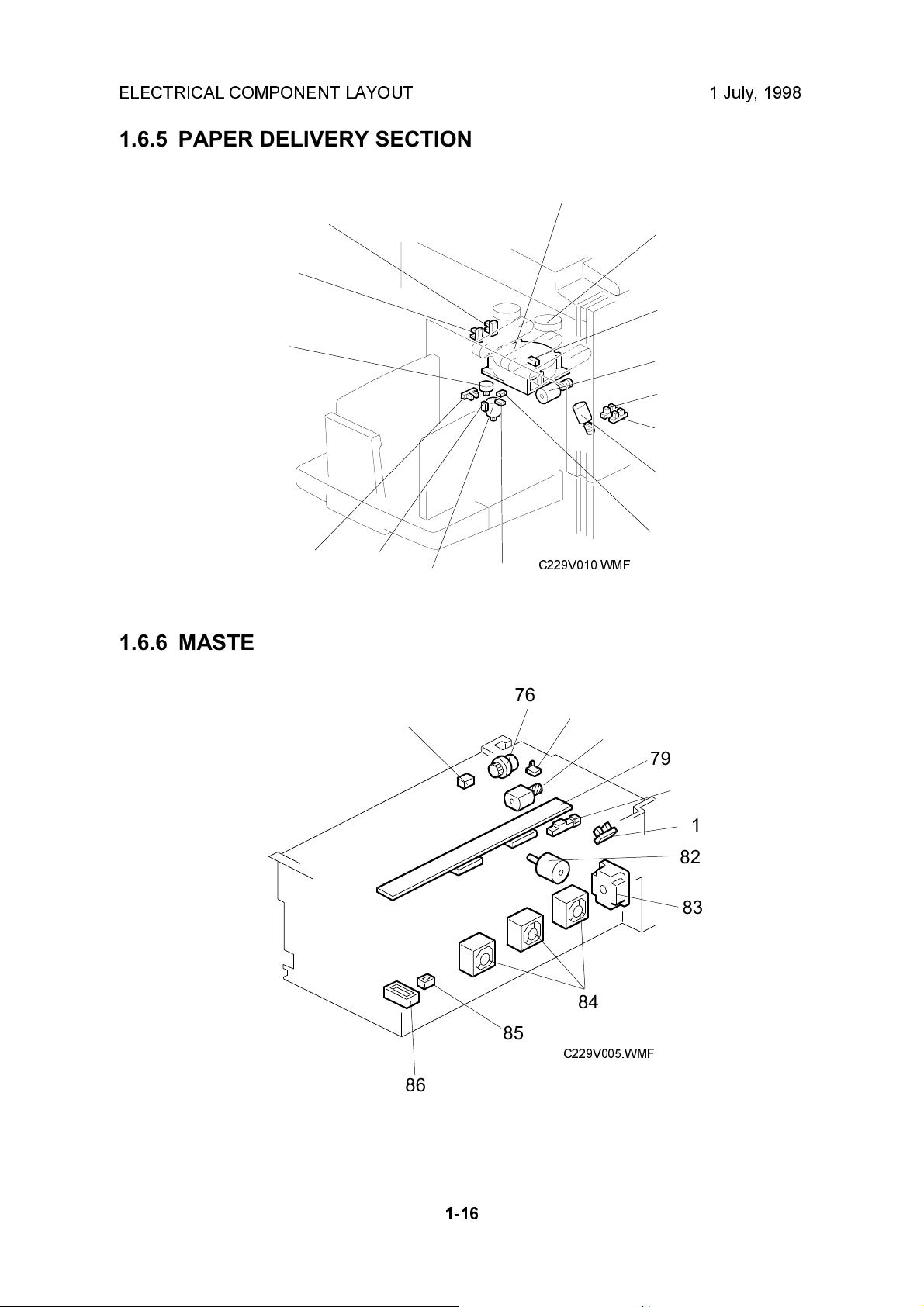

1.6.5 PAPER DELIVERY SECTION

60

74

73

72

71

70

1.6.6 MASTER MAKING UNIT

61

62

63

64

65

66

67

C229V010.WMF

6869

75

76

77

78

79

80

81

82

83

84

85

C229V005.WMF

86

1-16

Page 22

1 July, 1998 ELECTRICAL COMPONENT LAYOUT

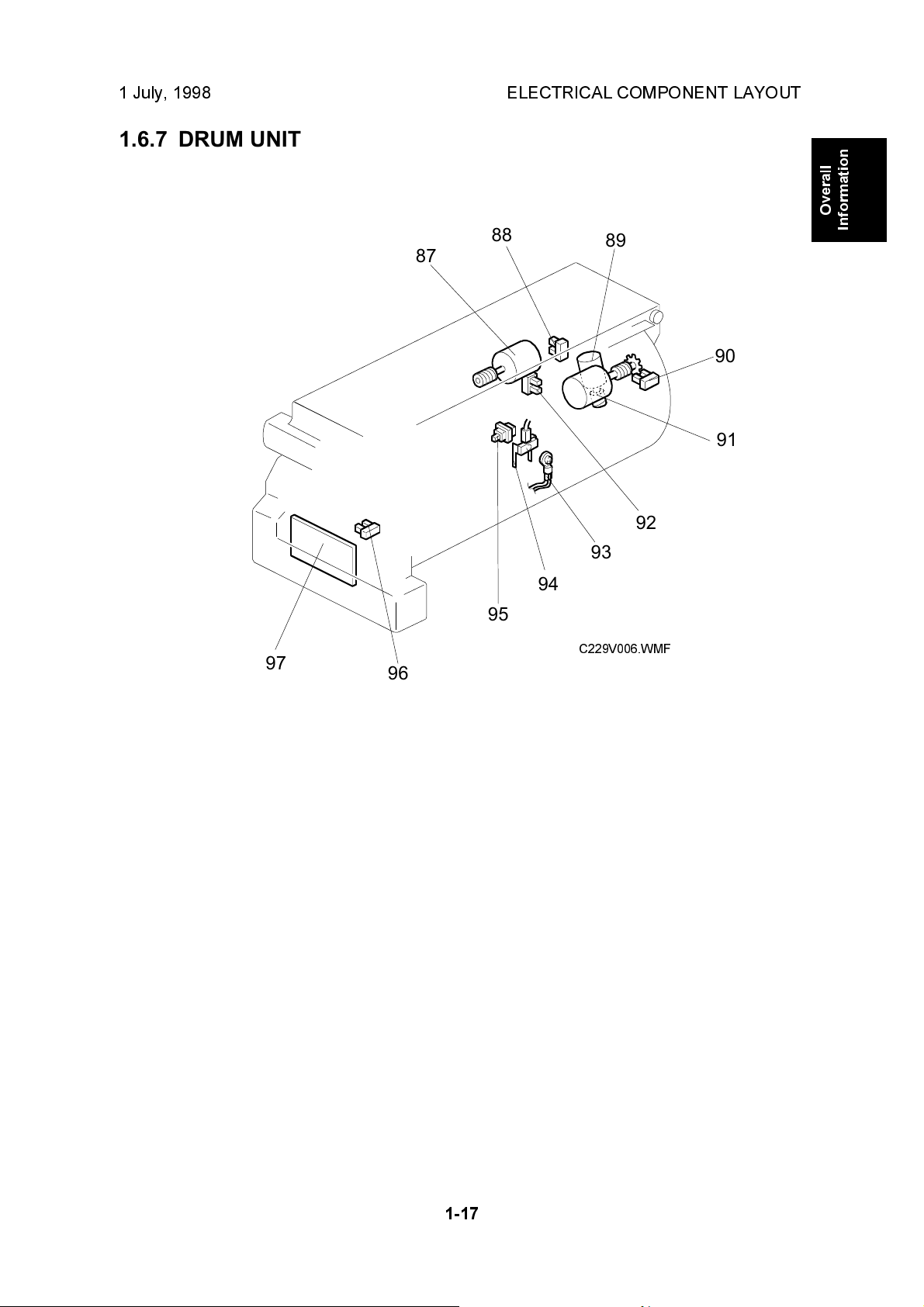

1.6.7 DRUM UNIT

88

87

89

90

91

92

Overall

Information

97

93

94

95

C229V006.WMF

96

1-17

Page 23

ELECTRICAL COMPONENT LAYOUT 1 July, 1998

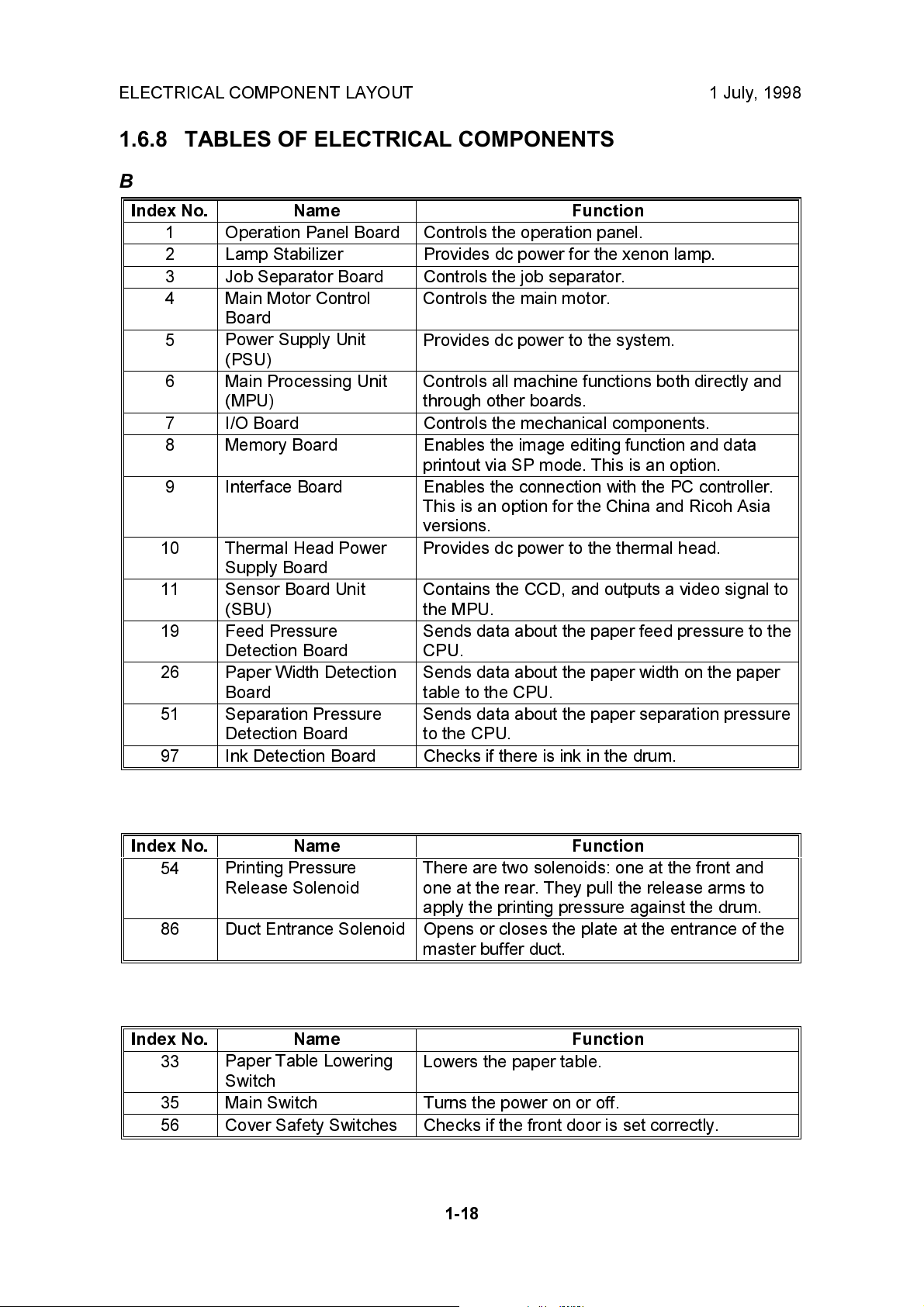

1.6.8 TABLES OF ELECTRICAL COMPONENTS

Boards

Index No. Name Function

1 Operation Panel Board Controls the operation panel.

2 Lamp Stabilizer Provides dc power for the xenon lamp.

3 Job Separator Board Controls the job separator.

4 Main Motor Control

Board

5

6 Main Processing Unit

7 I/O Board Controls the mechanical components.

8 Memory Board Enables the image editing function and data

9 Interface Board Enables the connection with the PC controller.

10 Thermal Head Power

11

19

26 Paper Width Detection

51 Separation Pressure

97 Ink Detection Board Checks if there is ink in the drum.

Power Supply Unit

(PSU)

(MPU)

Supply Board

Sensor Board Unit

(SBU)

Feed Pressure

Detection Board

Board

Detection Board

Controls the main motor.

Provides dc power to the system.

Controls all machine functions both directly and

through other boards.

printout via SP mode. This is an option.

This is an option for the China and Ricoh Asia

versions.

Provides dc power to the thermal head.

Contains the CCD, and outputs a video signal to

the MPU.

Sends data about the paper feed pressure to the

CPU.

Sends data about the paper width on the paper

table to the CPU.

Sends data about the paper separation pressure

to the CPU.

Solenoids

Index No. Name Function

54

86 Duct Entrance Solenoid Opens or closes the plate at the entrance of the

Printing Pressure

Release Solenoid

There are two solenoids: one at the front and

one at the rear. They pull the release arms to

apply the printing pressure against the drum.

master buffer duct.

Switches

Index No. Name Function

33

35 Main Switch Turns the power on or off.

56 Cover Safety Switches Checks if the front door is set correctly.

Paper Table Lowering

Switch

Lowers the paper table.

1-18

Page 24

1 July, 1998 ELECTRICAL COMPONENT LAYOUT

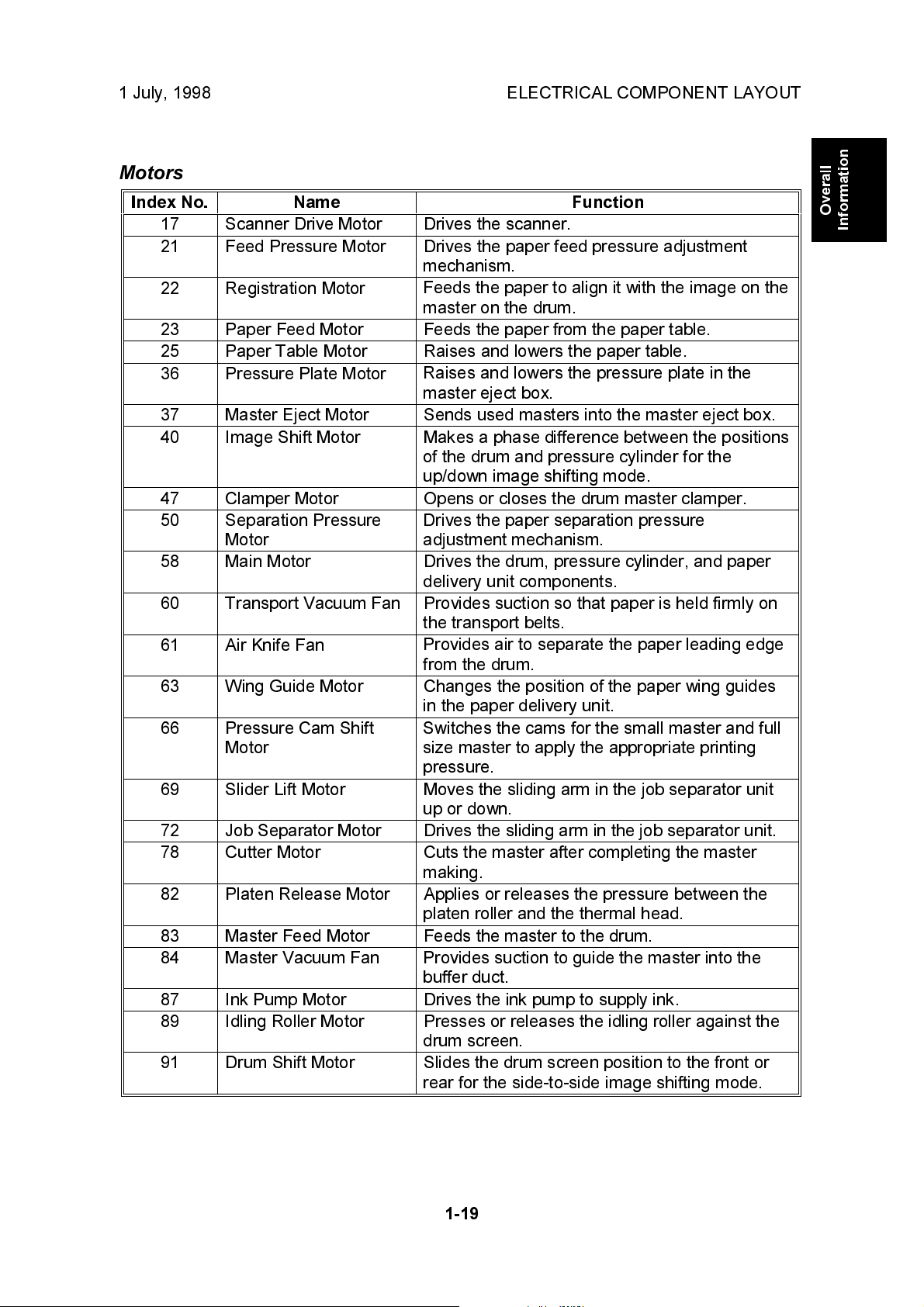

Motors

Index No. Name Function

17 Scanner Drive Motor Drives the scanner.

21 Feed Pressure Motor Drives the paper feed pressure adjustment

mechanism.

22 Registration Motor

Feeds the paper to align it with the image on the

master on the drum.

23 Paper Feed Motor Feeds the paper from the paper table.

25 Paper Table Motor Raises and lowers the paper table.

36 Pressure Plate Motor

Raises and lowers the pressure plate in the

master eject box.

37 Master Eject Motor Sends used masters into the master eject box.

40 Image Shift Motor Makes a phase difference between the positions

of the drum and pressure cylinder for the

up/down image shifting mode.

47 Clamper Motor Opens or closes the drum master clamper.

50

Separation Pressure

Motor

Drives the paper separation pressure

adjustment mechanism.

58 Main Motor Drives the drum, pressure cylinder, and paper

delivery unit components.

60 Transport Vacuum Fan Provides suction so that paper is held firmly on

the transport belts.

61 Air Knife Fan

Provides air to separate the paper leading edge

from the drum.

63 Wing Guide Motor Changes the position of the paper wing guides

in the paper delivery unit.

66 Pressure Cam Shift

Motor

Switches the cams for the small master and full

size master to apply the appropriate printing

pressure.

69 Slider Lift Motor Moves the sliding arm in the job separator unit

up or down.

72 Job Separator Motor Drives the sliding arm in the job separator unit.

78 Cutter Motor Cuts the master after completing the master

making.

82 Platen Release Motor Applies or releases the pressure between the

platen roller and the thermal head.

83 Master Feed Motor Feeds the master to the drum.

84 Master Vacuum Fan

Provides suction to guide the master into the

buffer duct.

87 Ink Pump Motor Drives the ink pump to supply ink.

89 Idling Roller Motor Presses or releases the idling roller against the

drum screen.

91 Drum Shift Motor Slides the drum screen position to the front or

rear for the side-to-side image shifting mode.

Overall

Information

1-19

Page 25

ELECTRICAL COMPONENT LAYOUT 1 July, 1998

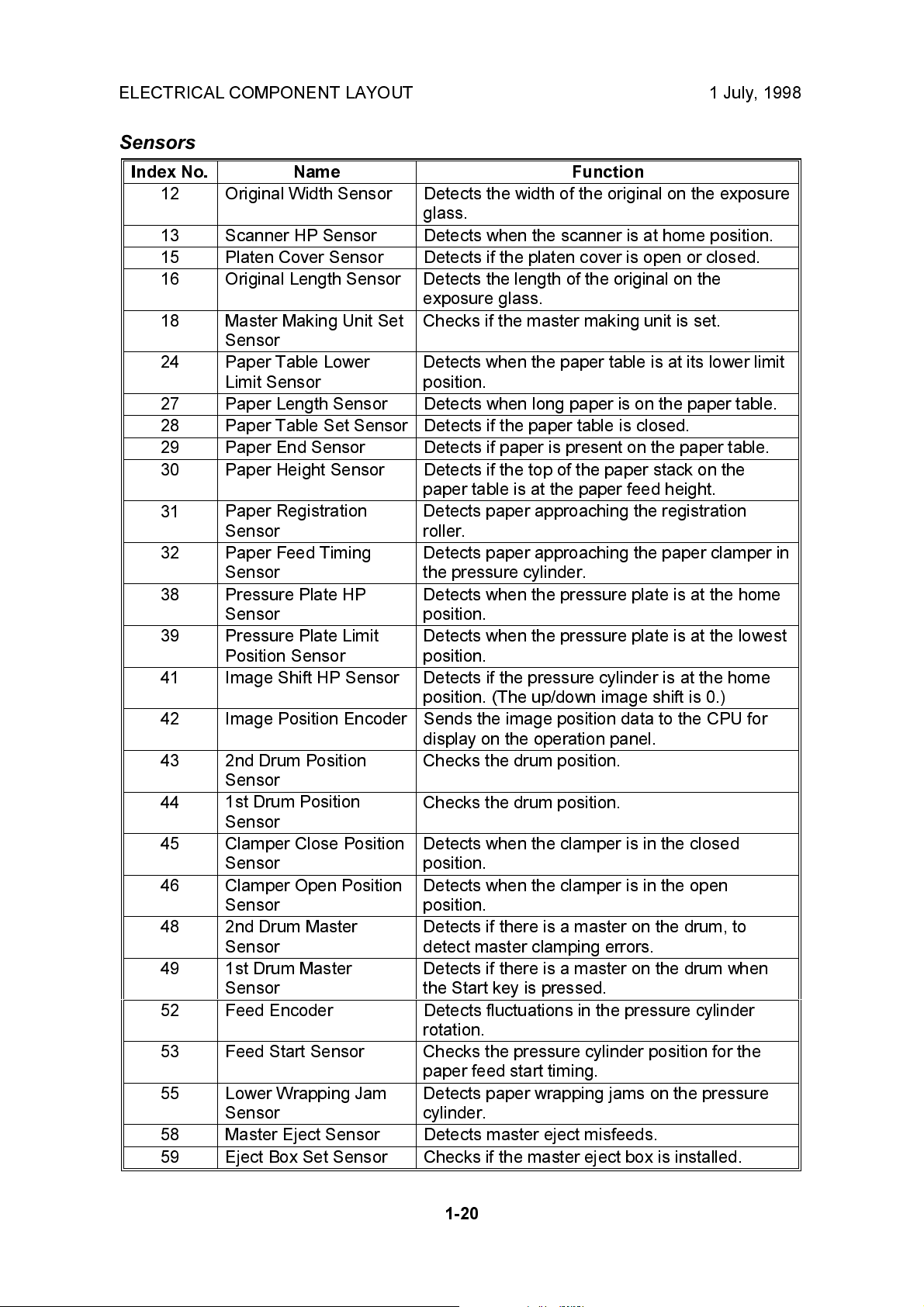

Sensors

Index No. Name Function

12 Original Width Sensor Detects the width of the original on the exposure

glass.

13 Scanner HP Sensor Detects when the scanner is at home position.

15 Platen Cover Sensor Detects if the platen cover is open or closed.

16 Original Length Sensor

18 Master Making Unit Set

Sensor

24 Paper Table Lower

Limit Sensor

27 Paper Length Sensor Detects when long paper is on the paper table.

28 Paper Table Set Sensor Detects if the paper table is closed.

29 Paper End Sensor Detects if paper is present on the paper table.

30 Paper Height Sensor Detects if the top of the paper stack on the

31

32 Paper Feed Timing

38 Pressure Plate HP

39 Pressure Plate Limit

41 Image Shift HP Sensor

42 Image Position Encoder Sends the image position data to the CPU for

43 2nd Drum Position

44

45 Clamper Close Position

46 Clamper Open Position

48

49 1st Drum Master

52 Feed Encoder Detects fluctuations in the pressure cylinder

53 Feed Start Sensor

55 Lower Wrapping Jam

58 Master Eject Sensor Detects master eject misfeeds.

59 Eject Box Set Sensor Checks if the master eject box is installed.

Paper Registration

Sensor

Sensor

Sensor

Position Sensor

Sensor

1st Drum Position

Sensor

Sensor

Sensor

2nd Drum Master

Sensor

Sensor

Sensor

Detects the length of the original on the

exposure glass.

Checks if the master making unit is set.

Detects when the paper table is at its lower limit

position.

paper table is at the paper feed height.

Detects paper approaching the registration

roller.

Detects paper approaching the paper clamper in

the pressure cylinder.

Detects when the pressure plate is at the home

position.

Detects when the pressure plate is at the lowest

position.

Detects if the pressure cylinder is at the home

position. (The up/down image shift is 0.)

display on the operation panel.

Checks the drum position.

Checks the drum position.

Detects when the clamper is in the closed

position.

Detects when the clamper is in the open

position.

Detects if there is a master on the drum, to

detect master clamping errors.

Detects if there is a master on the drum when

the Start key is pressed.

rotation.

Checks the pressure cylinder position for the

paper feed start timing.

Detects paper wrapping jams on the pressure

cylinder.

1-20

Page 26

1 July, 1998 ELECTRICAL COMPONENT LAYOUT

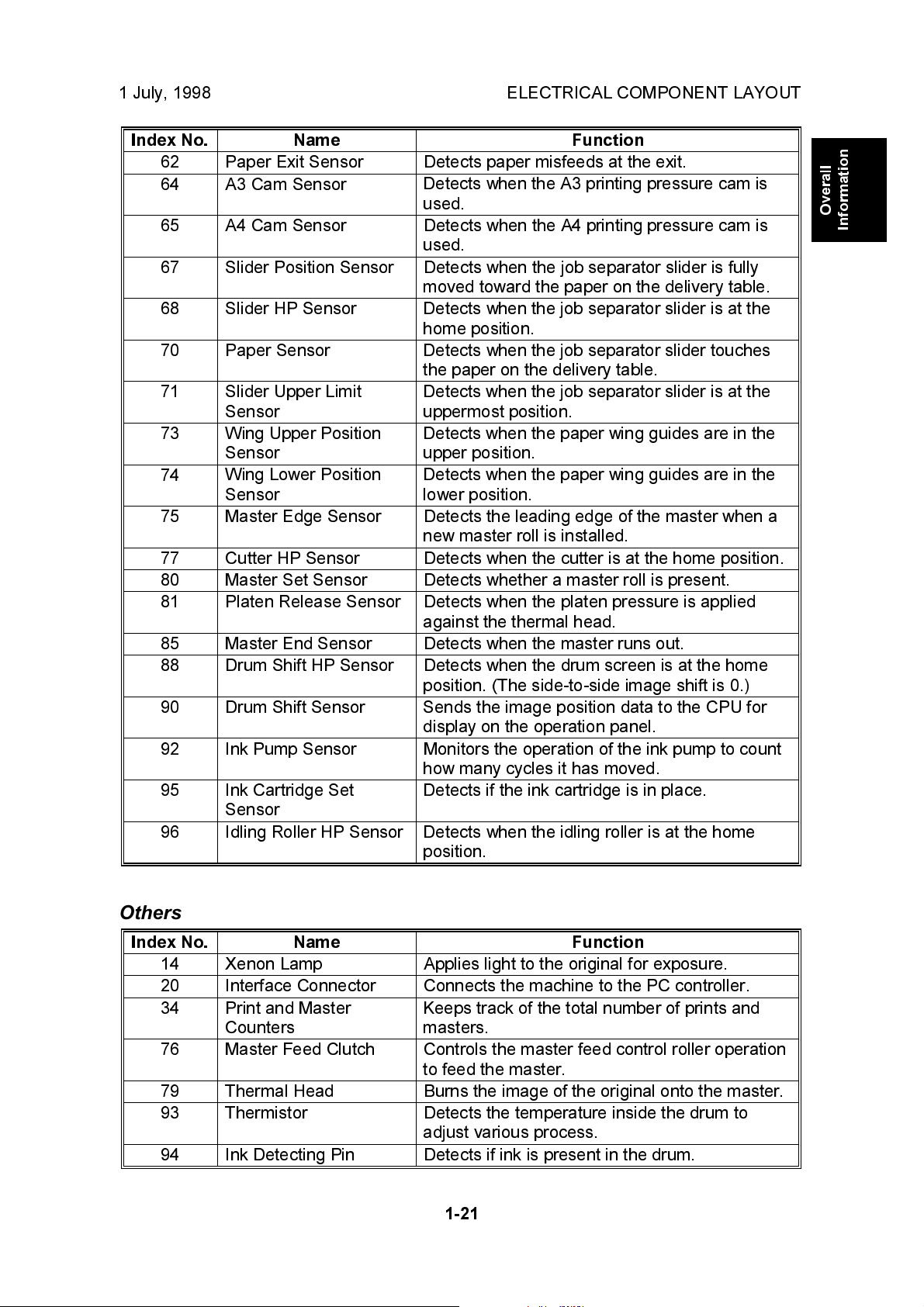

Index No. Name Function

62 Paper Exit Sensor Detects paper misfeeds at the exit.

64 A3 Cam Sensor

Detects when the A3 printing pressure cam is

used.

65 A4 Cam Sensor Detects when the A4 printing pressure cam is

used.

67 Slider Position Sensor Detects when the job separator slider is fully

moved toward the paper on the delivery table.

68 Slider HP Sensor

Detects when the job separator slider is at the

home position.

70 Paper Sensor

Detects when the job separator slider touches

the paper on the delivery table.

71 Slider Upper Limit

Sensor

73 Wing Upper Position

Sensor

74

Wing Lower Position

Sensor

Detects when the job separator slider is at the

uppermost position.

Detects when the paper wing guides are in the

upper position.

Detects when the paper wing guides are in the

lower position.

75 Master Edge Sensor Detects the leading edge of the master when a

new master roll is installed.

77 Cutter HP Sensor Detects when the cutter is at the home position.

80 Master Set Sensor Detects whether a master roll is present.

81 Platen Release Sensor Detects when the platen pressure is applied

against the thermal head.

85 Master End Sensor Detects when the master runs out.

88 Drum Shift HP Sensor Detects when the drum screen is at the home

position. (The side-to-side image shift is 0.)

90 Drum Shift Sensor

Sends the image position data to the CPU for

display on the operation panel.

92 Ink Pump Sensor Monitors the operation of the ink pump to count

how many cycles it has moved.

95 Ink Cartridge Set

Detects if the ink cartridge is in place.

Sensor

96 Idling Roller HP Sensor

Detects when the idling roller is at the home

position.

Overall

Information

Others

Index No. Name Function

14 Xenon Lamp Applies light to the original for exposure.

20 Interface Connector Connects the machine to the PC controller.

34 Print and Master

Counters

76 Master Feed Clutch Controls the master feed control roller operation

79 Thermal Head Burns the image of the original onto the master.

93 Thermistor Detects the temperature inside the drum to

94 Ink Detecting Pin Detects if ink is present in the drum.

Keeps track of the total number of prints and

masters.

to feed the master.

adjust various process.

1-21

Page 27

DRIVE LAYOUT 1 July, 1998

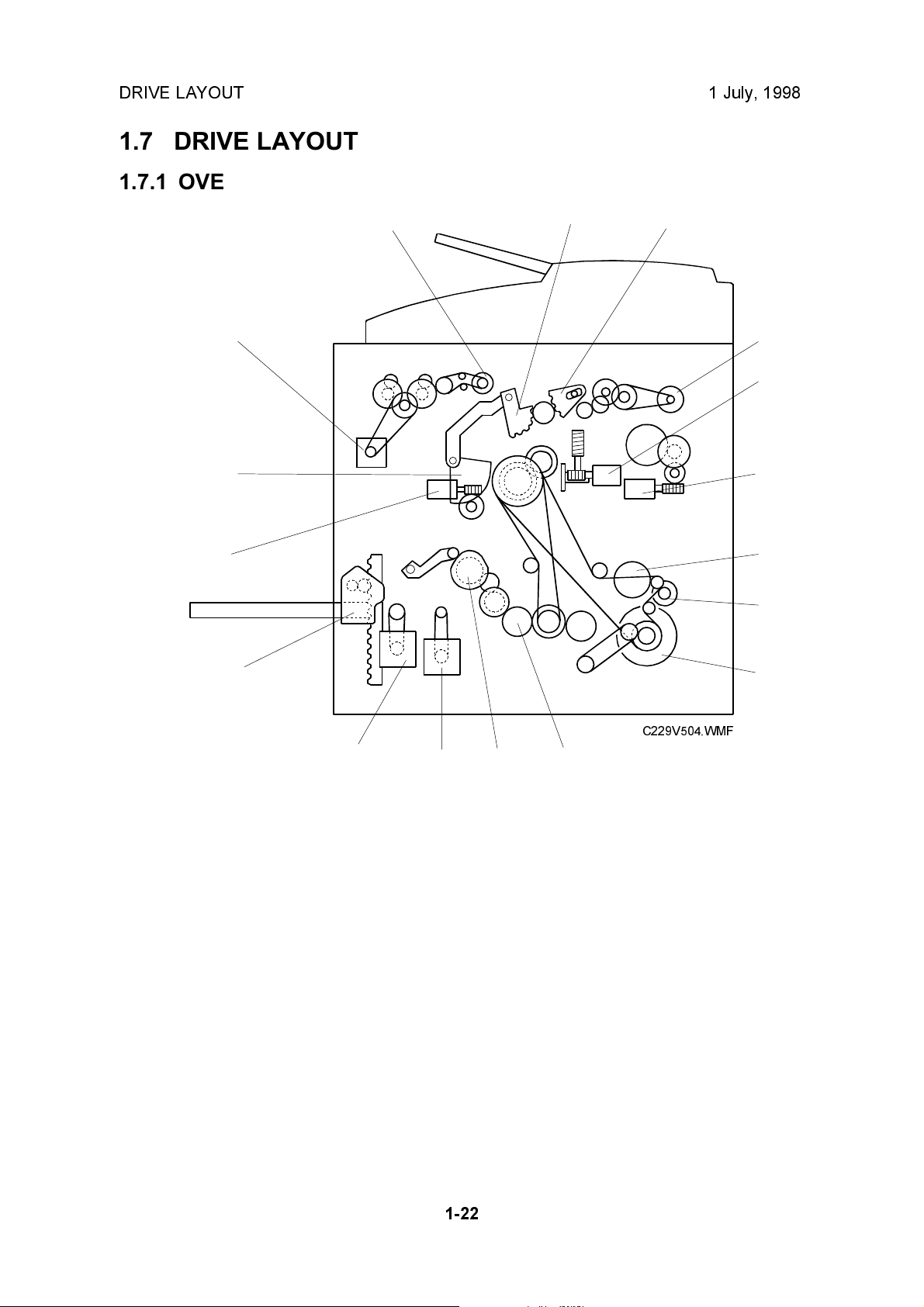

1.7 DRIVE LAYOUT

1.7.1 OVERVIEW

16

15

14

17

1

2

3

4

5

6

7

13

12

1. Clamper Opening Arm Sector

Gear (for the master eject position)

2. Master Pick-up Roller Sector Gear

3. Master Eject Motor

4. Image Shift Motor

5. Pressure Plate Motor

6. Exit Pawl Drive Cam Gear

7. Paper Delivery Unit Drive

Gear/Pulley

8. Main Motor

C229V504.WMF

11

10

9. Pressure Cylinder Drive Gear

(Including the Scissors Gear)

10. Registration Roller Lifting Cam Drive

Gear

11. Registration Motor

12. Paper Feed Motor

13. Paper Table Motor

14. Clamper Motor

15. Drum Guide

16. Master Feed Motor

17. Master Feed Clutch

9

8

1-22

Page 28

1 July, 1998 DRIVE LAYOUT

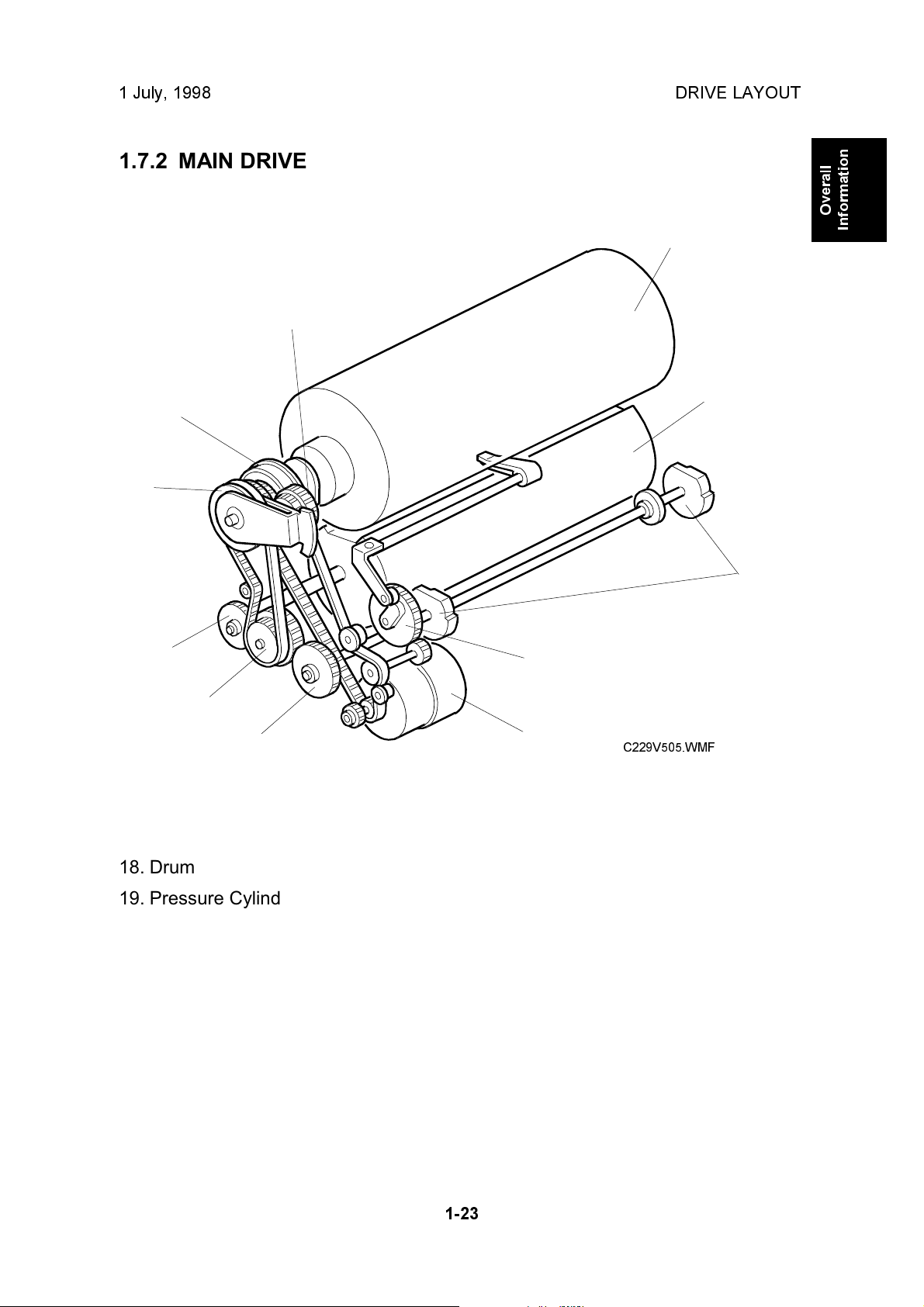

1.7.2 MAIN DRIVE

18

28

Overall

Information

26

25

27

24

23

19

20

21

22

C229V505.WMF

18. Drum

19. Pressure Cylinder

20. Printing Pressure Cam

21. Exit Pawl Drive Cam Gear

22. Main Motor

23. Printing Pressure Cam Drive Gear

24. Idler Gear/Pulley

25. Pressure Cylinder Drive Gear

(including the Scissors Gear)

26. Primary Gear/Pulley

27. Drum Drive Gear/Pulley

28. Image Shift Gear

1-23

Page 29

1 July, 1998 SCANNER AND OPTICS

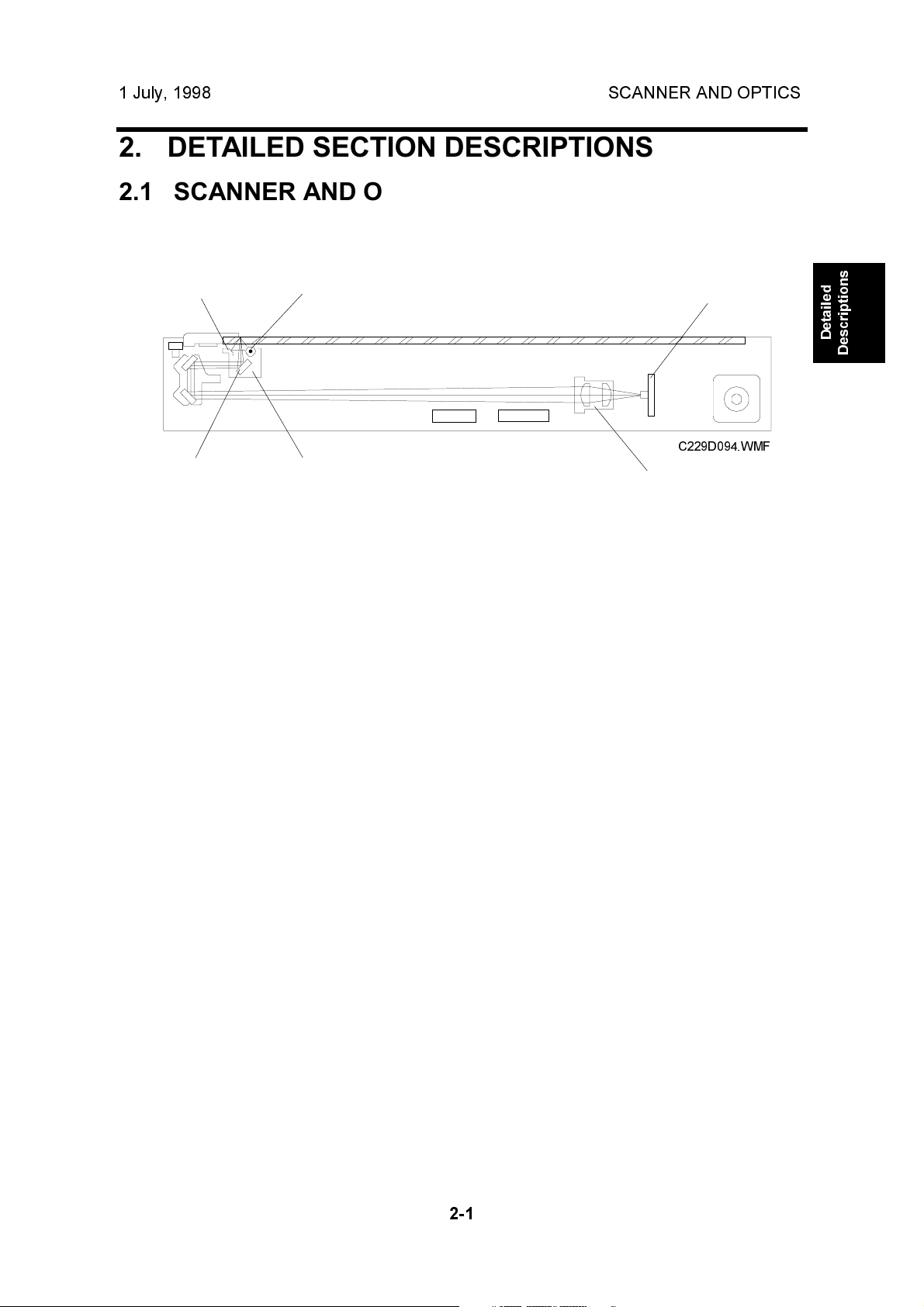

2. DETAILED SECTION DESCRIPTIONS

2.1 SCANNER AND OPTICS

2.1.1 OVERVIEW

[E]

[F]

The exposure lamp, a xenon lamp [A], illuminates the original. The 1st, 2nd, and

3rd mirrors, and a lens [B] reflect the image onto a CCD (Charge Coupled Device)

[C].

The 1st scanner [D] consists of the exposure lamp, a reflector [E], and the 1st

mirror [F].

A DC power supply energizes the exposure lamp to avoid uneven light intensity

when the 1st scanner moves in the sub-scan direction. The entire exposure lamp

surface is frosted to ensure even exposure in the main scan direction.

The reflector reflects light with almost equal intensity, to reduce shadows on pasted

originals.

[A]

[D]

[C]

C229D094.WMF

[B]

Detailed

Descriptions

2-1

Page 30

SCANNER AND OPTICS 1 July, 1998

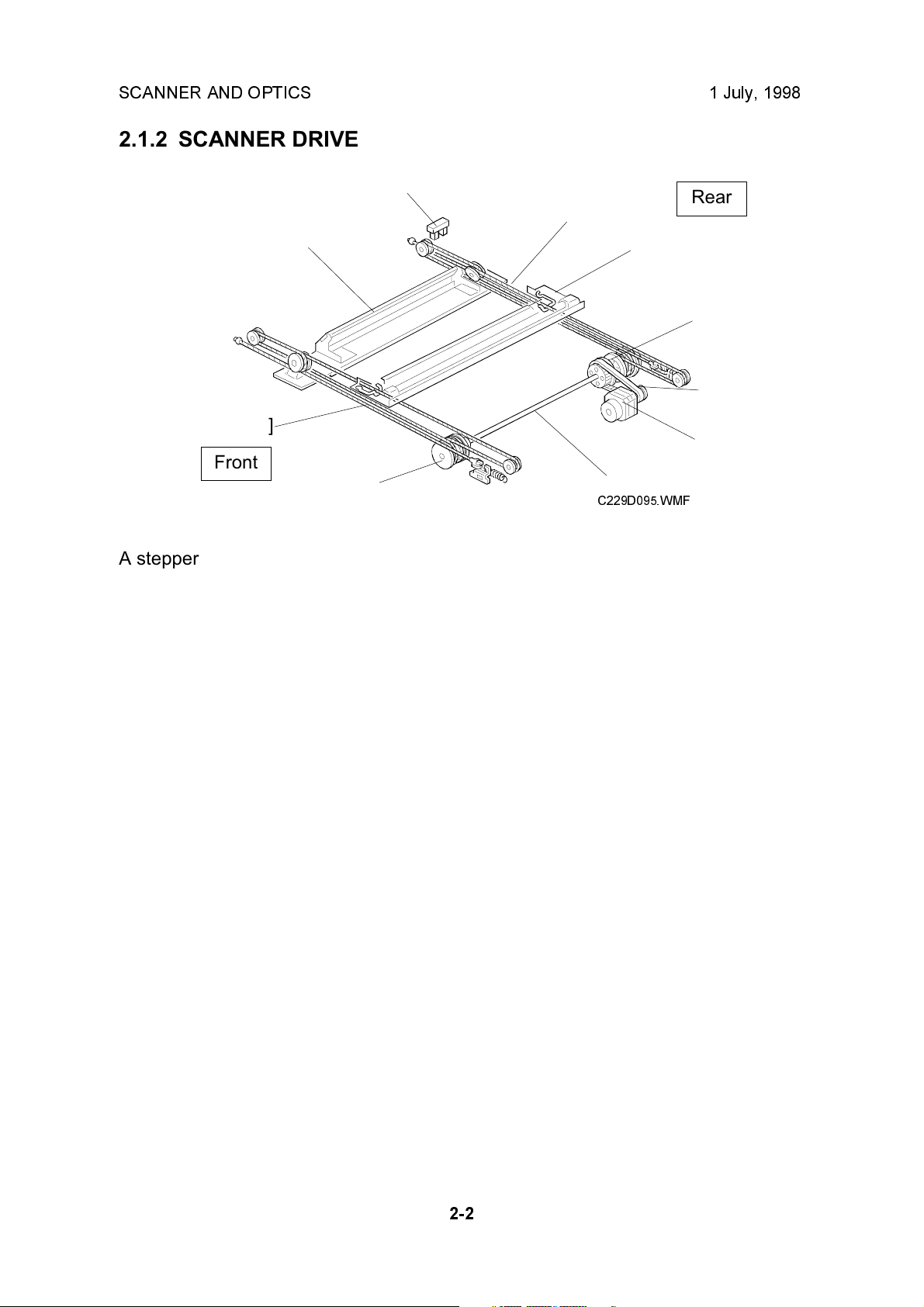

2.1.2 SCANNER DRIVE

[H]

Rear

[G]

[C]

[B]

[E]

[D]

[G]

[A]

Front

[E]

[F]

C229D095.WMF

A stepper motor drives the scanner. The scanner drive motor [A] drives the 1st and

2nd scanners [B, C] through the timing belt [D], scanner drive pulley [E], scanner

drive shaft [F], and two scanner wires [G].

- Book mode -

The scanner drive board controls and operates the scanner drive motor. In full size

mode, the 1st scanner speed is 42.33 mm/s during scanning. The 2nd scanner

speed is half that of the 1st scanner.

In reduction or enlargement mode, the scanning speed depends on the

magnification ratio (M: 0.50 to 2.00). The returning speed is always the same, in

both full size and magnification modes. Changing the scanner drive motor speed

changes the image length in the sub-scan direction. Image processing on the MPU

board accomplishes reduction and enlargement in the main scan direction.

SP6-011-1 changes the motor speed and therefore adjusts the magnification ratio

in the sub-scan direction.

- ADF mode -

During scanning, the scanners are always in their home positions (when the

scanner H.P sensor [H] detects the 1st scanner). The ADF motor feeds the original

through the ADF. In reduction/enlargement mode, changing the ADF motor speed

changes the image length in the sub-scan direction. Magnification in the main scan

direction is done on the MPU board, in the same manner as book mode.

SP6-011-2 changes the ADF motor speed and therefore adjusts the magnification

ratio in the sub-scan direction.

2-2

Page 31

1 July, 1998 SCANNER AND OPTICS

2.1.3 ORIGINAL SIZE DETECTION IN PLATEN MODE

[B]

Detailed

Descriptions

[A]

[C]

C229D096.WMF

C229D120.WMF

[C]

C229D116.WMF

In Platen mode, the size of paper on the paper table usually determines the image

reading area for the original. If Reduction or Enlargement mode is used, the

magnification ratio affects the image reading area.

However, for Auto Magnification, Image Rotation, or Image Repeat modes

combined with Platen mode, the original width [A] and length [B] sensors detect the

original size.

The sensors for original size detection are in the optics cavity. There are four

reflective sensors in the 115V machines, and six reflective sensors in the 220/240V

machines.

2-3

Page 32

SCANNER AND OPTICS 1 July, 1998

The platen cover sensor [C] or the DF position sensor [D] informs the main CPU of

the original size when the platen is about 15 cm above the exposure glass. At this

time, only the sensors located underneath the original receive the reflected light

and switch on. The other sensors remain off. The main CPU can recognize the

original size from the number of activated sensors.

Original Size Length Sensors Width Sensors

A4/A3 version LT/DLT version L1 L2 L3 L4 S1 S2

A3 11" x 17" O O O O O O

B4 10" x 14" O O O O O X

F4 8

A4L 8

B5L - O X X X X X

A4S 11" x 8

B5S - X X X X O X

1/2

" x 14" (8" x 13") O O O X X X

1/2

" x 11" O O X X X X

1/2

"XXXXOO

NOTE:

1) O: On (Paper Present), X: Off

2) The length sensors L3 and L4 are only used in the 220/240V machines.

The above table shows the sensor output for each original size. A message will

appear in the operation panel display for other combinations.

2-4

Page 33

1 July, 1998 IMAGE-PROCESSING

2.2 IMAGE-PROCESSING

2.2.1 OVERVIEW

SBU

CCD

Detailed

Descriptions

Thermal

Head

IPU

Memory

Board

(Option)

MPU

C229D501.WMF

The CCD converts the light reflected from the original into an analog signal. The

CCD line has 5,000 pixels and the resolution is 400 dpi (15.7 lines/mm).

After the above process, the A/D converter built into the SBU transforms the analog

signals into 8-bit signals. This assigns a value to each pixel from a scale of 256

grades. Then, the digitized image data goes to the MPU board.

The image data then goes to the IPU (Image-processing Unit) IC on the MPU

board, which carries out the following processes on the image data:

1. Auto shading

2. Filtering (MTF and smoothing)

3. Magnification

4. Binary processing

2-5

Page 34

IMAGE-PROCESSING 1 July, 1998

2.2.2 AUTO BACKGROUND CORRECTION

[A]

C229D097.WMF

Auto background correction mode can be used in Photo/Letter, Photo, and Tint

modes. The default setting does not allow the user to select auto background

correction mode. (Use SP 2-31 to enable this mode.)

Auto background correction prevents the background of an original from appearing

on copies.

While scanning the original, the background density detection area [A] is also

scanned. This area [A] is a narrow strip at the start of the main scan line, as shown.

As the scanner scans down the page, the IPU on the MPU detects the peak white

level for each scan line, within this narrow strip only. From this peak white level, the

IPU determines the reference value for the A/D conversion for the scan line. The

IPU then sends the reference value to the reference controller on the SBU.

When an original with a gray background is scanned, the density of the gray area

is the peak white level density. Therefore, the original background will not appear

on copies. This feature corrects any changes in background density down the

page, because peak level data is taken for each line scanned.

2-6

Page 35

1 July, 1998 IMAGE-PROCESSING

2.2.3 AUTO SHADING

C229D504.WMF

There are two auto shading methods: black level and white level correction. Auto

shading corrects errors in the signal level for each pixel.

Detailed

Descriptions

- Black Level Correction -

The CPU reads the black dummy data from one end of the CCD signal (64 pixels

are blackened at the end) and takes an average of the black dummy data. Then,

the CPU deletes the black level value of each image pixel.

- White Level Correction -

The machine reads a reference waveform from the white plate, before scanning the

original. The average of the white video level for each pixel is stored as the white

shading data in the IPU.

The IPU chip corrects the video signal information for each pixel obtained during

image scanning.

2-7

Page 36

IMAGE-PROCESSING 1 July, 1998

2.2.4 FILTERING AND MAIN SCAN MAGNIFICATION/REDUCTION

Overview

Filtering and main scan magnification process the image data after auto shading.

However, to reduce moire in the image, the processing order depends on the

reproduction ratio, as follows:

1) Reduction and Full size

Main Scan Reduction ® Filtering

2) Enlargement

Filtering ® Main Scan Magnification

Filtering

The MTF and smoothing filters are software filters that enhance the desired image

qualities of the selected original mode.

The MTF filter, used in all modes except Tint mode (which uses the smoothing

filter), sharpens the image.

SP6-082 adjusts the filter strengths for MTF mode.

The diagram below shows how the number stored in the SP mode afects the

strength of the filter.

NOTE:

1) Do not set the filter strength number to 1. Abnormal images may result.

2) The smoothing filter strength is not adjustable.

11 8 2

2-8

C229D505.WMF

Page 37

1 July, 1998 IMAGE-PROCESSING

Main Scan Magnification/Reduction

Detailed

Descriptions

C229D506.WMF

The IPU chip handles reduction and enlargement in the main scan direction.

NOTE:

Changing the scanner speed accomplishes reduction and enlargement in

the sub-scan direction.

When making a copy using the ADF, the magnification circuit creates a mirror

image. This is because the scanning starting position in the main scan direction is

at the other end of the scan line in ADF mode (as compared with platen mode). In

platen mode, the original is placed face down on the exposure glass, and the

corner at [A] is at the start of the main scan. The scanner moves down the page. In

ADF mode, the ADF feeds the leading edge of the original to the DF exposure

glass, and the opposite top corner of the original is at the main scan start position.

To create the mirror image, the CPU stores the main scan line data in the LIFO

(Last In First Out) memory on the MPU, from the last pixel. When loading the main

scan line data from the LIFO memory, the CPU loads the first pixel of the main

scan line.

2-9

Page 38

IMAGE-PROCESSING 1 July, 1998

2.2.5 BINARY PROCESSING

In the IPU chip, the 8-bit data is converted into 1-bit data for black or white pixels.

The binary processing for the letter mode is different from that for the photo mode

and the letter/photo mode as follows:

1) Letter mode: Binary processing

2) Letter/Photo mode: Binary processing

3) Photo mode: Binary processing + error diffusion + dithering

These processes are used as follows.

- Binary Processing with Gamma Curve Compensation -

This process converts each video signal level from 8-bit to 1-bit (black and white

image data) in accordance with a threshold value.

The threshold value changes based on a compensation curve (Gamma curve)

which corresponds to selected image settings. For example, if a darker image is

selected, a compensation curve, which converts each pixel value to a higher

number, is selected. This ensures accurate generation of the gray scale from black

to white.

- Error Diffusion - (Photo mode only)

The error diffusion process reduces the difference in contrast between light and

dark areas of a halftone image. This process corrects each pixel using the

difference between it and surrounding pixels. It then compares the corrected pixels

with the error diffusion matrix.

- Dithering - (Photo mode only)

Dithering compares each pixel with a pixel in the dither matrix. Several matrixes

are available, to increase or decrease the detail on the copy.

2-10

Page 39

1 July, 1998 IMAGE-PROCESSING

2.2.6 OPTIONAL MEMORY BOARD

The optional memory board, or editing function board, has 4-Mbyte RAM, which

corresponds to the amount of memory required for an A3 original. This enables the

following image editing functions.

- Memory Combine Mode -

Combined images of 4, 8, or 16 originals are printed on the same sheet of paper.

- Overlay -

Overlay merges two different originals onto the same sheet of paper.

- Stamp Printing Mode -

This mode enables stamping modes such as, the date, page number, preset

message, and user custom stamps.

Detailed

Descriptions

- Make-up Printing Mode -

The user makes command sheets to specify how various areas of the original will

be processed. The user must be sure to scan the command sheets before the

original. The image-processing chip in the MPU modulates the image data for the

command sheet and then stores the modulated command data on the memory

board.

The image data for the original is also converted and modulated. The MPU edits

the modulated image data, the stored command area data, and the background

pattern.

Positive/Negative can be used with this mode.

- Report Print Mode -

This mode prints the following data:

· User reports

· Jam and error counter data

· The number of people in each class set by the user

· Number of prints and masters for each user code account

· SP mode data for service

- Image Rotation Mode -

When the orientation for the original differs from the paper selected, the machine

automatically rotates the original image 90 degrees to match the paper orientation.

SP 2-150 can disable this mode.

2-11

Page 40

IMAGE-PROCESSING 1 July, 1998

2.2.7 THERMAL HEAD

Specifications

· Length 292.6 mm

· Number of thermal head elements 4608

· Density of thermal head elements 400 dpi

Thermal Head Control

The thermal head contains heating elements at a density of 400 dpi. The thermal

heating elements melt the over-coating and polyester film layers of the master, in

accordance with the image signal for each pixel.

This model has an independent power supply unit for the thermal head. It applies

power (VHD) to the thermal heating elements. The power source varies from one

head to another since the average resistance of each element varies. Therefore,

when replacing the thermal head or power supply unit, it is necessary to readjust

the applied voltage to the specific value for the thermal head.

Thermal Head Protection

The thermistor on the thermal head provides thermal head protection, preventing

the thermal head from overheating when processing a solid image. The CPU

checks for any abnormal condition when the Start key is pressed; it displays an SC

code on the operation panel as follows:

SC Code Conditions

SC03-03

SC03-02

SC03-01

SC03-00

Over 54°C

Under - 20°C (Normally in this case, the thermistor

is open, or a related connector is disconnected.)

When the pulse width that controls the thermal

head energy becomes abnormal, master making

stops and generates this SC code.

The CPU monitors the ID signal from the thermal

head, which identifies the thermal head type. If an

abnormal ID signal is detected just after installing

the master making unit in the machine, it generates

this SC code.

Detecting

Component

Thermistor

Thermistor

MPU

MPU

2-12

Page 41

1 July, 1998 IMAGE-PROCESSING

Remarks for Handling the Thermal Head

Pay careful attention to the following remarks when servicing:

·

·

Do not touch the surface

with bare hands. If this

occurs, clean the surface

with alcohol.

·

Do not damage the

heating elements.

Platen

Master

Remove any foreign materials from

the platen roller.

·

Remove foreign materials.

·

Do not touch the master film

surface with bare hands.

·

There are some ICs inside

the metal cover. Do not push

the cover down.

·

Do not touch the connector

terminals with bare hands, to

prevent damage from static

electricity.

Detailed

Descriptions

MPU

Thermal Head

·

Connect and disconnect the connectors

carefully. Keep them horizontal and

firmly reconnect them.

·

Adjust the voltage supplied to match the

specified value for the thermal head.

Connector

PSU

- Other Remarks -

Avoid using the machine under humid conditions. Moisture tends to condense on

the thermal head, damaging the elements.

2-13

Page 42

MASTER EJECT 1 July, 1998

2.3 MASTER EJECT

2.3.1 OVERVIEW

[A]

[B]

[C]

[E]

[D]

C229D106.WMF

The master remains wrapped around the drum to prevent the ink from drying.

Therefore, making a new master begins from the master ejecting process.

When the Start key is pressed to scan the original, the drum rotates from the home

position to the master eject position. As soon as the drum reaches the master eject

position, the drum master clamper [C] opens. The drum position lock mechanism

locks the drum at this position to prevent the drum from moving during master

ejection.

At the same time, the master pick-up roller [A] touches the drum, picking up the

leading edge of the master on the drum. Then, the master is caught by the upper

and lower master eject rollers [B] and is transported into the master eject box [E].

When the trailing edge of the master passes the roller, the pressure plate [D]

begins to compress the master into the box.

Before this process is complete, the original scanning and master making has

already started, and the drum will then rotate to the master making position.

2-14

Page 43

1 July, 1998 MASTER EJECT

2.3.2 MASTER EJECT MECHANISM

Overview

[A]

[B]

[C]

Rear

Detailed

Descriptions

[F]

Front

[E]

[D]

C229D112.WMF

Two photosensors (the 1st and 2nd drum position sensors) and the feeler on the

rear drum flange determine the drum position. The drum is at the home position

when the feeler actuates the 1st drum position sensor. At this position, the drum

master clamper, which clamps the leading edge of the master onto the drum, is

located at the bottom of the drum. (For details, refer to Drum Drive Mechanism in

the Drum section.)

The drum turns 114.5 degrees from the home position to reach the master eject

position (there is no sensor for master eject position detection main motor

encoder pulses only). As soon as the drum stops, the clamper motor [B] starts to

open the drum master clamper [F]. The master pick-up roller [D] moves against the

drum at the same time, because it is connected through an idle gear.

A link plate connects the drum guide [E] to the clamper opening arm [A]. So, when

the arm moves, the drum guide also moves, and this locks the drum position.

NOTE:

1) To lock the drum, the drum guide catches one of two studs at different

positions on the drum. The drum guide catches one stud at the master

eject position [C], and the other stud at the master making position.

2) The drum master clamper also opens when the drum is at the master

making position. However, it uses a different clamper-opening arm. For

details, refer to the Master Making section.

3) Do not clean the inside of the master clamper with alcohol or other

strong solvents. Use a cloth dampened with water. This prevents the

magnetic force from weakening. This part requires periodic cleaning.

2-15

Page 44

MASTER EJECT 1 July, 1998

Drum Lock Mechanism

The clamper motor drives

the drum guide [C]. The

clamper closed position

Rear

[A]

sensor [A] and clamper

open position sensor [B]

monitor the position of the

[B]

drum guide.

When the drum reaches

the master eject position,

the drum guide moves until

the clamper open position

sensor [B] is actuated then

deactuated (the actuator

must go through the

sensor). This engages the

stud on the rear drum

flange.

Before the drum starts

rotating to the master

Front

[C]

making position, the drum

guide returns to the home

position. The clamper

closed position sensor [A] determines this position.

NOTE:

The same drum guide also moves when the drum is at the master making

position. (There is another stud on the rear drum flange, which is used to

secure the drum at the master making position.)

A link plate at the master eject position synchronizes the master clamper

with the drum guide movement.

To open the clamper, the drum guide (with the clamper opening arm) must

move a greater distance than at the master making position. Therefore, at

the master eject position, the drum guide moves (to open the master

clamper) until the clamper open position sensor [B] turns on (interrupted by

the feeler) and then turns off again, as shown in the diagram. Refer to the

Master Feed section to compare the two mechanisms.

C229D107.WMF

2-16

Page 45

1 July, 1998 MASTER EJECT

Master Pick-up Roller Drive and Master Clamper Open

Rear

[D]

[C]

Front

[B]

[A]

C229D081.WMF

When the clamper motor opens the drum master clamper [B], the master pick-up

roller [A] contacts the leading edge of the master on the drum. The clamper motor

moves the master pick-up roller against the drum through the idle gear [D], while

driving the clamper opening arm [C].

Detailed

Descriptions

At the same time as the drum master clamper [B] closes after the master is picked

up, the master pick-up roller [A] also moves back to the original position.

The drum guide is also released at the same time. The drum continues turning

towards the master making position while the used master is removed from the

drum.

2-17

Page 46

MASTER EJECT 1 July, 1998

Master Eject and Transportation

[A]

Rear

[B]

Front

C229D082.WMF

The master pick-up roller [A] and the upper and lower master eject rollers [B] all

turn together. They start turning as soon as the drum reaches the master eject

position.

The rollers stop once the leading area of the master is picked up from the drum.

(The master eject sensor detects this.) Then, when the drum starts turning, they

turn on again to feed the ejected master to the eject box while the drum turns

towards the master making position.

The master eject sensor (not shown) is located just under the lower master eject

roller, and it monitors the master feeding. If the master is not properly picked up,

i.e. it does not activate the sensor; the operation panel displays a master eject jam

message.

2-18

Page 47

1 July, 1998 MASTER EJECT

Master Eject Roller Unit Drive

The master eject motor [A] turns

[A]

the master pick-up roller [B] with

the upper and lower master eject

rollers [C].

[B]

When the unit is slid out

(explained below), the joint [D]

disengages.

[D]

[C]

C229d513.WMF

Detailed

Descriptions

Master Eject Roller Unit Slide-out Mechanism

The master eject roller unit

[E] can be slid out of the

machine as shown for easy

master jam removal.

The unit contains the master

pick-up roller, upper and

lower master eject rollers,

and the master eject sensor.

C229D083.WMF

[E]

2-19

Page 48

MASTER EJECT 1 July, 1998

[B]

[C]

Master Eject Box Mechanism

[A]

C229D092.WMF

C229D085.WMF

[D]

The user can slide the master eject box out from the operation side of the machine.

The front handle of the box [A] has a lock mechanism as shown above.

The master eject box contains a pressure plate [B], which compresses the ejected

masters in the box. The pressure plate also works as a guide plate feeding the

ejected master into the box.

An independent dc motor, the pressure plate motor, drives the pressure plate. The

motor is in the pressure plate drive unit, on the rear frame of the machine separate

from the master eject box.

When the master eject box is slid out, the joint [D] for the pressure plate drive

disengages. At the same time, the lock lever [C] turns, due to tension from a

spring, to hold the pressure plate [B] in the home position.

When the master eject box is re-installed, the drive joint [D] is connected and the

pressure plate lock lever [C] is released as shown above.

2-20

Page 49

1 July, 1998 MASTER EJECT

The ejected masters in the

box can be taken out by

sliding the eject lever [A]. The

[A]

inner bottom case [C] moves

towards the rear of the box.

Masters are ejected from an

open door at the rear of the

box. The side opposite the

eject lever side [A] of the

inner bottom case is

connected to a belt [B]. This

helps the inner bottom case

move smoothly.

Detailed

Descriptions

When the master eject box is

removed, a push switch (the

eject box set sensor) turns

off, and the operation panel

displays a message.

[C]

[B]

C229D084.WMF

2-21

Page 50

MASTER EJECT 1 July, 1998

2.3.3 PRESSURE PLATE DRIVE MECHANISM

Overview

There are three phases.

· Homing

At power on or when recovering from an error or jam, the machine makes sure

that the pressure plate is at home position. This is because, if certain errors

occur, the pressure plate may not be in the home position at the start of a job

· Master ejection

The pressure plate rotated into a position where it can act as a feed guide for the

used master on its way to the eject box.

· Compression

The pressure plate compresses the master into the box.

Drive

[D]

[E]

[C]

[A]

[B]

C229D514.WMF

The pressure plate motor [A] drives the pressure plate [B] through the pressure

plate gear [C]. This gear contains actuators for the home position sensor [D] and

the limit position sensor [E]. These two sensors monitor the pressure plate position.

The diagram shows a front view of the mechanism. The actuators are on the rear

of the pressure plate gear, which is shown as see-through for ease of viewing.

2-22

Page 51

1 July, 1998 MASTER EJECT

Homing Operation

At power on or when recovering

from an error or jam condition, the

machine carries out the pressure

plate homing operation.

If certain errors occur, the

pressure plate may not be in the

home position. The homing

operation starts by turning the

pressure plate toward the drum

and then it returns to the home

position.

The homing operation is as

follows:

1. The pressure plate turns

clockwise (as seen from the

operation side) until both the

pressure plate HP sensor [A]

and the limit position sensor

[B] are actuated.

C229D089.WMF

Master Eject

Ready Position

[A]

[B]

Detailed

Descriptions

Passed the home

position slightly

2. As shown in the upper right

diagram, the pressure plate turns

counterclockwise until the home

position sensor [A] is actuated

twice then de-activated. The

status of the sensor [A] changes:

on Þ off Þ on Þ off.

3. The pressure plate has just

slightly passed the home position.

Then, as shown in the lower right

diagram, the pressure plate again

turns clockwise to return to the

exact home position. The home

position sensor status changes

now from: off Þ on Þ off.

C229D114.WMF

Passed the home

position slightly

[A]

[B]

Home

Position

2-23

Page 52

MASTER EJECT 1 July, 1998

[A]

Shift to the Master Eject

Position

[B]

When the Start key is pressed to

make a new master, the drum

turns to the master eject position.

During this period, the pressure

plate travels to the master eject

ready position.

The pressure plate turns

clockwise (as seen from the

operation side) until both the

pressure plate HP sensor [A] and

the limit position sensor [B] are

actuated.

Home

Position

Master Eject

Ready Position

C229D086.WMF

Ejected Master Compression

When the ejected master has been fed to the master eject box, the pressure plate

compresses the master. During this operation, the machine can recognize how full

the eject box is by monitoring the lower limit and home position sensors.

When there are no or very few masters in the box

If there are no or only a few masters

[A]

in the box, the pressure plate can

move to its lowest position. The

pressure plate limit position sensor

detects this position.

The pressure plate turns

counterclockwise from the master

eject ready position until the limit

position sensor [B] has been actuated

twice. The sensor status changes:

on Þ off Þ on.

The pressure plate stays at the lower

limit position for 2 seconds, then

returns to the home position.

Lower Limit

Position

C229D087.WMF

2-24

Page 53

1 July, 1998 MASTER EJECT

When there are a lot of masters

If there are a lot of used masters in

the box, the pressure plate cannot

move to the lower limit position.

If the lower limit position sensor [B]

is not actuated within 7 seconds

after the pressure plate starts

traveling from the master eject ready

position, the pressure plate motor

stops.

The pressure plate stays in the

same position for 2 seconds to

compress the masters. Then, it

returns to the home position.

There is a torque limiter [C] built into

the gear. When the built-up masters

in the box block pressure plate

movement, the torque limiter allows

this gear to slip.

C229D108.WMF

[C]

[A]

[B]

Detailed

Descriptions

Master

Compression

Position

Master Box Full Detection Mechanism

As explained above, the pressure

plate motion range narrows as the

ejected masters build up in the box.

The stopping position of the pressure

plate therefore gets closer to the

home position.

When the pressure plate cannot travel

past the master box full position from

the master eject ready position, this

means that the master box is full.

In this case, the home position sensor

[A] remains actuated as shown on the

right.

The home position sensor status

changes (from the master eject ready

position): on Þ off Þ on Þ off Þ on,

and stays on. This means the master

box is full and the operation panel

displays a message.

C229D088.WMF

[A]

Master Box

Full Position

2-25

Page 54

MASTER EJECT 1 July, 1998

(

)

r

Pressure Plate Operation Timing Chart

Does not reach here after 6 seconds

Þ

Motor locked

HP Sensor

Limit Position

Sensor

Pressure Plate

Motor

Drum

HP

Master Box Direction

Eject

Position

Drum Direction

Compressing Position

Stays for 2 seconds

HP Returned

Check when rotating in the

master box direction

Number of HP Sensor On or Off Edges

(The first on edge is just after the motor

starts.)

- Check Timing -

When one of the following

occurs:

1. When the Limit Position

Sensor turns on.

·

5 timesÞNormal

·

4 timesÞMaster box full

·

Less than 4ÞPressure plate locked

(SC06-00 lights)

2. 6 seconds after the moto

turns on.

This timing chart shows how the machine counts the number of home position

sensor on and off edges to check if the eject box is full or if the mechanism is

jammed.

The signal is checked when:

· The limit position sensor turns on this is when the pressure plate has turned all

the way to the lower limit position inside the box, which is only possible if the box

is fairly empty.

· At 6 s after the motor turns on

2-26

Page 55

1 July, 1998 MASTER FEED

[E]

[A]

2.4 MASTER FEED

2.4.1 OVERVIEW

[B]

[C]

[D]

[L]

[F]

[K]

[G]

[J]

[H]

[I]

C229D115.WMF

A: Master Edge Sensor G: Master Roll

B: Tension Roller H: Master End Sensor

C: Platen Roller I: Master Vacuum Fans

D: Thermal Head J: Master Buffer Duct

E: Master Set Roller K: Cutter

F: Master Set Sensor L: Master Feed Control Roller

Original scanning starts when an original is set and the Start key is pressed.

Master making begins at the same time. Although master ejecting is done first,

scanning starts very soon after.

Detailed

Descriptions

The master is a low fiber content paper coated with a thin heat-sensitive film. The

heating elements of the thermal head [D] burn the film to copy the scanned image.

The master is fed while the thermal head develops the image on it. The master

vacuum fans [I] temporarily suck the fed master into the master buffer duct [J]. This

is done because the used master is still being ejected from the drum. When the

drum comes to the master making position, the master is fed to the drum and the

drum master clamper on the drum clamps the master.

The drum then turns to wrap the master around the drum. When the master has

been pulled out of the duct and is pulled tight at the cutter, the cutter [K] cuts the

master.

At the same time as the master is wrapping, a sheet of paper, called the trial print,

is fed. This ensures that ink transfers to the master on the drum, and that there is a

sufficient density of ink for the print run to start. The drum then returns to the home

position and is ready for printing.

2-27

Page 56

MASTER FEED 1 July, 1998

2.4.2 MASTER SET MECHANISM

Master Roll Set

The master set sensor [A]

checks to see if the master roll

was installed properly. After

inserting the master making unit,

the sensor detects the leading

edge of the master. The master

is fed in until the leading edge

reaches the master feed control

roller.

[A]

C229D102.WMF

Master Feed and Stop Control (Edge Detection)

While the master is being fed

after a roll is put in the machine,

the master edge sensor [B]

[B]

[C]

checks the leading edge of the

master.

The master is fed 18 mm more

after the master edge sensor [B]

is activated. It has now been

caught by the master feed

control roller [C] and it stops.

This is the stand-by position for

master making.

While the master is fed, the

C229D103.WMF

platen roller pressure, which is

used to press the master against the thermal head, is repeatedly applied and

released using the platen pressure release mechanism. This prevents master skew

or creasing after a roll has been put in the machine. A later section will describe

this process in more detail.

2-28

Page 57

1 July, 1998 MASTER FEED

Master Buffer Duct Entrance Control

While the master is being

transported to the master

feed control roller [A], the

duct entrance solenoid [C]

[B]

[A]

Rear

closes the master buffer

duct entrance plate [B]. This

prevents the duct entrance

from catching the leading

edge of the master.

After the master feed

control roller [A] catches the

master leading edge, the

entrance plate is opened.

(The normal position of the

entrance plate is open.)

Front

Detailed

Descriptions

Master End Detection

There is a solid-fill black area at

the end of the master roll. When

the master end sensor [D]

detects this area, the operation

panel displays the master end

message.

As the master is semitransparent, the sensor can

detect the black area at the end

of the roll when there are still a

few layers of clear master on the

roll. When this happens, master

roll near-end is detected.

C229D004.WMF

[C]

2-29

[D]

C229D104.WMF

Page 58

MASTER FEED 1 July, 1998

2.4.3 MASTER MAKING AND FEED MECHANISM

Master Feed Mechanism

[A]

[B]

[C]

[D]

Rear

View

[F]

C229D003.WMF

[E]

The master feed motor [F], a stepper motor, drives the master feed control [A],

tension [B], platen [C] and master set [D] rollers.

The tension roller feeds the master slightly faster than the platen roller, to prevent

the master from creasing. Therefore, the master between the platen roller and

thermal head is always under tension.

There is a torque limiter [E] built into the tension roller drive gear. This allows the

tension roller to become free from the master feed motor drive when the master is

under excessive tension, to prevent damage to the master.

NOTE:

Strips of mylar under each master feed roller prevent the master from

being wrapped around the rollers. Be careful not to damage or set the

mylars in the incorrect position because they damage easily. For details,

refer to the Replacement and Adjustment section.

2-30

Page 59

1 July, 1998 MASTER FEED

Platen Roller Pressure Release

[C]

Rear

View

Detailed

Descriptions

[B]

[D]

[A]

C229D002.WMF

The platen release motor [A] gives half a turn to the platen release cam [B] to apply

or release the platen roller [C] pressure. As the motor turns, the actuator on the

gear interrupts the platen release sensor [D]. When the pressure is released, the

actuator interrupts the sensor.

NOTE:

When installing the gear with the actuator, remember that the setting

position depends on the platen release cam position. For details, refer to

the Replacement and Adjustment section.

Just before master making, the platen release motor starts turning until the sensor

is inactive; this indicates that the platen pressure is now applied to prepare for

master making.

When master making is complete, the motor turns again until the sensor is

activated, releasing the platen pressure. This allows the user to remove a jammed

master. Also, in standby mode, there is no pressure between platen roller and

thermal head, so that the user can take out the master.

As explained in Master Feed and Stop Control, the platen roller pressure is

repeatedly applied and released to prevent master skew or creasing after a roll has

been put in the machine. To do this, the motor continues turning for 3 seconds.

2-31

Page 60

MASTER FEED 1 July, 1998

Master Buffer Mechanism

Rear

[A]

Front

C229D000.WMF

[B]

To minimize master processing time, the master is stored in the master buffer duct

[A] after the thermal head transfers the image to it. The stored master is fed out

from the duct when the drum reaches the master making position after master

ejecting.

The master buffer duct is located under the master feed path. A two-level chamber

inside the duct can hold a sufficient length of the master for A3 printing.

As soon as master making starts, the three master vacuum fans [B] start turning,

creating suction to guide the master into the duct [A]. At this time, the master feed

control roller has already caught the leading edge of the master. This roller does

not start turning until the drum reaches the master making position and the master

clamper opens (because the master feed clutch disconnects the master feed motor

drive).

The master is fed while the thermal head writes the image on it. As the leading

edge of the master stops, the suction guides the fed master into the master buffer

duct and stores it as shown in the above diagram.

When the drum comes to the master making position, the master feed control roller

starts turning and feeds out the master that is stored in the duct.

2-32

Page 61

1 July, 1998 MASTER FEED

2.4.4 WRAPPING THE MASTER AROUND DRUM

[F]

Front

[A]

C229D091.WMF

Rear

[G]

[D]

Detailed

Descriptions

[C]

[E]

[B]

Drum Lock and Master Clamper Open

As explained in the Master Eject section, the drum guide [A] holds the drum at the

master eject and master making positions.

When the drum reaches the master making position, the drum guide moves to

engage the stud [B] on the rear drum flange until the clamper open position sensor

[C] is actuated. (The other stud was used for the master eject position.)

The master clamper opening arm [D] is just above the drum guide. The arm is

different from the one used for opening the master clamper at the master eject

position. The clamper motor [E] drives the arm and opens the master clamper [F],

in synchronization with the drum guide movement.

The drum guide moves (to open the master clamper) until the clamper open

position sensor is interrupted by the feeler. Then it stops immediately (unlike at the

master eject position of the drum) as shown in the diagram.

Before the drum starts turning to start wrapping the master on the drum, the drum

guide returns to the home position until the clamper close position sensor [G] is

activated. The master clamper opening arm also returns, closing the master

clamper.

2-33

Page 62

MASTER FEED 1 July, 1998

Master Feed Control Roller Mechanism

Front

[B]

[A]

Rear

C229D090.WMF

The master feed clutch [A] connects and disconnects the drive from the master

feed motor to the master feed control roller [B]. The master feed control roller only

turns in the following cases:

· When a master roll is put in the machine, the master is fed until the master feed

control roller catches the leading edge of the master.

· During master clamping, the master feed control roller turns and sends the

leading edge to the clamper position.

· While the master is being wrapped around the drum, the master feed control

roller turns to feed the master, in synchronization with the drum rotation.

2-34

Page 63

1 July, 1998 MASTER FEED

Master Clamping and Wrapping around the Drum

Rear

Detailed

Descriptions

Front

[A]

C229D006.WMF

The master feed clutch turns on to feed out the master from the master buffer duct.

The master is fed out 31 mm and reaches the drum master clamper [A]. The

master feed clutch turns off temporarily.

The master clamper is closed and the drum starts turning to wrap the master

around the drum. At the same time, the master feed clutch turns on again to feed

the master, synchronizing it with the drum rotation.

When master making is complete and the master is stored in the master buffer

duct, the drum turns continuously to wrap the master. The cutter cuts the master

when there is no master left in the duct, and the master at the cutter is stretched

tightly; this ensures a clean cut.

A sheet of paper, called the trial print, is fed at the same time as the master

wrapping. To ensure that ink transfers to the master on the drum, the drum rotates

at its lowest speed (16 rpm). This ensures that the print run starts up with a

sufficient ink density.

The drum then returns to the home position, ready for printing.

2-35

Page 64

MASTER FEED 1 July, 1998

Master Cut and Buffer Duct Entrance Control

When the thermal head has

finished making the master

and the master has been fed

[A]

out of the duct, the cutter [A]

will cut the master.

In preparation for making the

next master, the leading edge

of the next master is

continuously fed to the

master feed control roller [B].

The new master is fed 32 mm

past the cut position and

stopped.

[B]

NOTE:

As explained in

Master Feed and

Stop Control in 2.5.2

Master Set

Mechanism, the

master edge sensor

only controls the

master stop position

at the master feed

control roller after a

roll is put into the

machine.

The duct entrance plate

stays open, except in the

following two cases. To

close off the duct, the duct

entrance solenoid closes

the master buffer duct

entrance plate [C].

· While the leading edge of

the next master is being

fed to the master feed

control roller [B]

· After a roll is put in the

machine (as explained in

"2.5.2 Master Set

Mechanism").

Front

[B]

C229D105.WMF

Rear

C229D005.WMF

[C]

2-36

Page 65

1 July, 1998 MASTER FEED

Cutter Mechanism

Detailed

Descriptions

[E]

[A]

[B]

[C]

C231D573.WMF

Rear

View

[D]

The cutter motor [D] drives the screw shaft [A], moving the cutter holder [C] forward

and backward.

There are two cutter blades [B] in the holder. While the cutter holder [C] travels to

the front (the operation side of the machine), the blades cut the master. The cutter

motor keeps turning in one direction. However, the cutter holder returns to the

home position when it reaches the front end of the cutter unit because of the two

different spirals threaded on the screw shaft [A].

When the cutter holder reaches the home position, the cutter home position sensor

[E] is activated by the holder and the motor stops.

2-37

Page 66

MASTER FEED 1 July, 1998

2.4.5 MASTER MAKING UNIT SLIDE-OUT MECHANISM

The master making unit can be

slid out along the guide rails.

There are three connectors,

which enable electrical contact

for the installed unit.

The master making unit set

sensor [A] (a push switch)

detects when the unit is out. The

operation panel displays a

message in this case.

[A]

C229D100.WMF

2.4.6 OPENING DOOR FOR MISFED MASTER REMOVAL

There is a jam removal dial to

manually rotate the master feed

rollers. If pieces of the master

remain in the master buffer duct,

open the door [B] to remove them.

Normally, pieces of master do not

remain in the duct. Therefore, the

door is only for emergency cases.

[B]

C229D101.WMF

2-38

Page 67

1 July, 1998 DRUM

2.5 DRUM

2.5.1 OVERVIEW

[C]

[A]

[G]

[D]

[E]

C229D109.WMF

[B]

[F]

Detailed

Descriptions

The drum surface is composed of a stainless-steel screen (metal screen [A]) and

two layers of polyester screens (cloth screen [B]). In addition, a drum master

clamper [C] clamps the leading edge of the master wrapped around the drum.

Inside the drum are the ink roller [D] and doctor roller [E], which create a precisely

maintained gap, known as the doctor gap, to supply a thin layer of ink on the

screens and master [F].

This machine uses the drum idling roller [G] to supply ink onto the screens and

master before printing. The length of time the machine was not in use determines