Ricoh NC8115.015 IMPORTANT SAFETY NOTICES

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYS ICAL INJURY

1. Before disassembling or asse mblin g pa rts of the copie r and perip herals,

make sure that the copier power cord is unplu gg ed.

2. The wall outlet should be near the copier an d easily accessible.

3. Note that some compo ne nt s of th e copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operat ion check ha s to be made with exterior covers

off or open while the main switch is turned on, kee p ha nds away from

electrified or mechanically drive n comp on ents.

5. If the hot roller temperature is lo w when the main switch is turned on, the

copier starts process cont rol self check au to matically. Keep hands away

from the mechanical and the ele ctrical components to avoid any injury.

6. The inside and the met al pa rts of the fusin g un it be come extremely hot

while the copier is operat ing . Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters an d th e ozone neutralizers with the ones

specified at the spe cifie d intervals.

3. Toner and developer are non-to xic, bu t if you get eith er of them in your

eyes by accident, it may cause temp ora ry e ye disco mfo rt. Try to remove

with eye drops or flush with wat er as first aid. If un succe ssfu l, ge t med ical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be insta lled and maintained by a

customer service represen tative who has completed the training course

on those models.

2. The RAM board on the main control board has a lithium battery which can

explode if replaced incorre ctly. Re pla ce th e ba tt ery on ly with an iden tica l

one. The manufacturer reco mmen ds replacing the entire RAM board. Do

not recharge or burn this ba tt ery. Used batteries must be handle d in

accordance with local regula tio ns.

1995 By Ricoh Company Ltd. All rights reserved

SAFETY AND ECOLOGICAL NOTES FOR DISP OS AL

1. Do not incinerate the toner bottle or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used tone r, developer, and organic photoconductor according

to local regulations. (These are non-to xic supplies.)

3. Dispose of replaced parts in acco rda nce with local regulations.

4. When keeping used lithiu m bat teries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storin g larger nu mbe rs or

not sealing them apart may lead to che mical rea ctions and heat build-up.

LASER SAFETY

The Center for Devices and Radio log ical Hea lth (CDRH) prohibits the repair

of laser-based optical units in th e fie ld. The optical housing unit can only be

repaired in a factory or at a location with the requisite eq uipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field . Cust omer engineers are therefore

directed to return all chassis and lase r subsyst ems to the factory or service

depot when replacement of th e optical subsystem is required.

WARNING:

Use of controls, or adjustment, or performance of procedure s oth er th an

those specified in this manual may result in hazardous radiation exp osu re.

WARNING FOR LASER UNIT

WARNING:

CAUTION MARKING:

Turn off the main switch before atte mpting any of the

procedures in the Laser Unit sectio n. Laser beams can

seriously damage your eyes.

SECTION 1

OVERALL MACHINE

INFORMATION

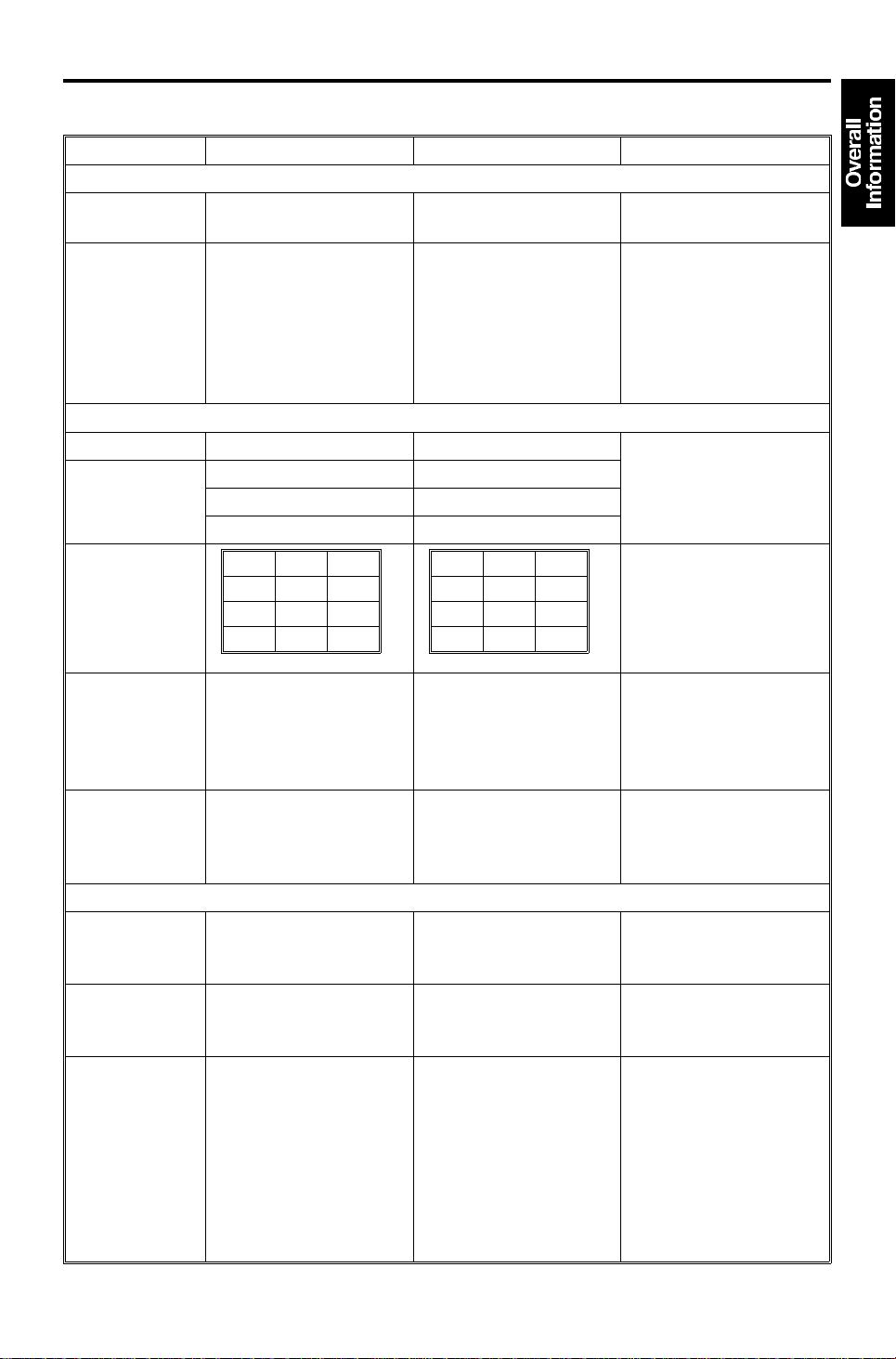

5 January 1995 DIFFERENCES

1. DIFFERENCES

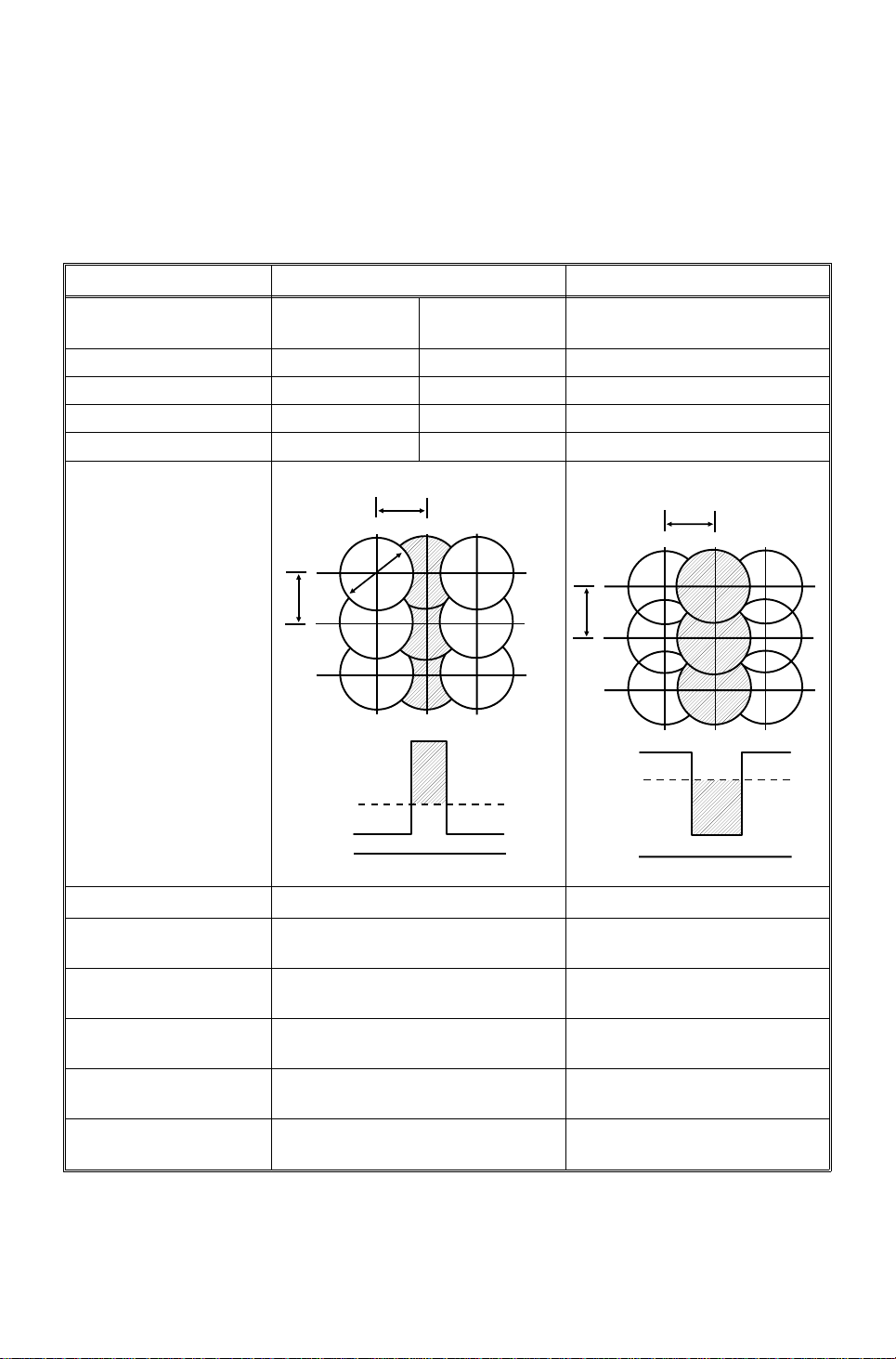

DESCRIPTION MODEL A092 MODEL A105 Reason for modification

SCANNER

Resolution 16 lines/mm (406.4 dpi) 400 dpi To meet printer

standard.

CCD Drive

Board Set

IMAGE PROCESSING

Gradation 64 gradation 6 bit 256 gradation 8 bit To improve copy

Dithering

Pattern Matrix

RGBγ

Parameter

Memory 18 MBytes (1M x 144) 64 MBytes (4M x 128) An image defined at 8

4 Color

Developing

(Y, M, C, Bk)

LASER

Gradation 64 steps by using

Polygon Motor

Rotation Speed

Horizontal

Magnification

&

Printing Start

Adjustment

Method

CCD Drive Board CCD

Pre-amp Board and

Video Processing

Board

These boards have to

be replaced as a set.

Letter: 2 x 2 Letter: 1 x 1

Photo/Letter: 3 x 3 Photo/Letter: 2 x 1

Photo: 4 x 4 Photo: 2 x 2

LH

R65

G55

B75

Image repeat

Edit image

These cannot use

black developing.

dither matrix

(8 steps/pixel)

9000 rpm 8858.3 rpm As the resolution has

Adjusted by DGSs on

the drum exposure

control board.

CCD Pre-amp Board

has been eliminated.

CCD Drive Board and

Video Processing

Board these two

boards can be

replaced separately.

LH

R87

G86

B96

The functions at left

can now use black

developing.

256 gradation

(256 steps/pixel)

Adjusted keys on the

operation panel. (SP

mode)

To ease servicing.

quality.

To meet the new type

toner.

bits per pixel requires

much more memory

than one defined at 3

bits per pixel.

To improve the copy

quality.

To improve the copy

quality.

been changed from

406.4 dpi to 400 dpi.

To ease servicing.

1-1

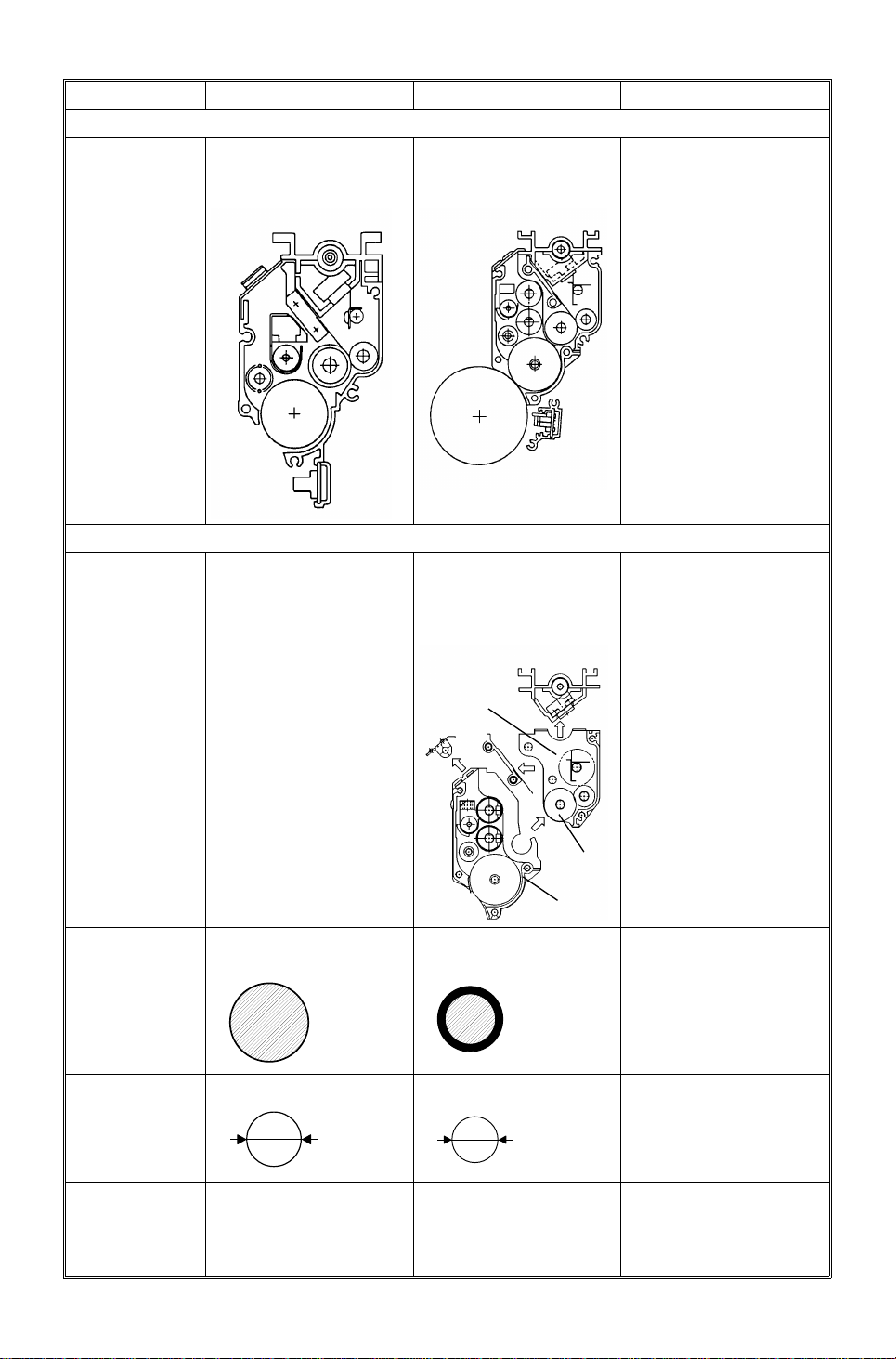

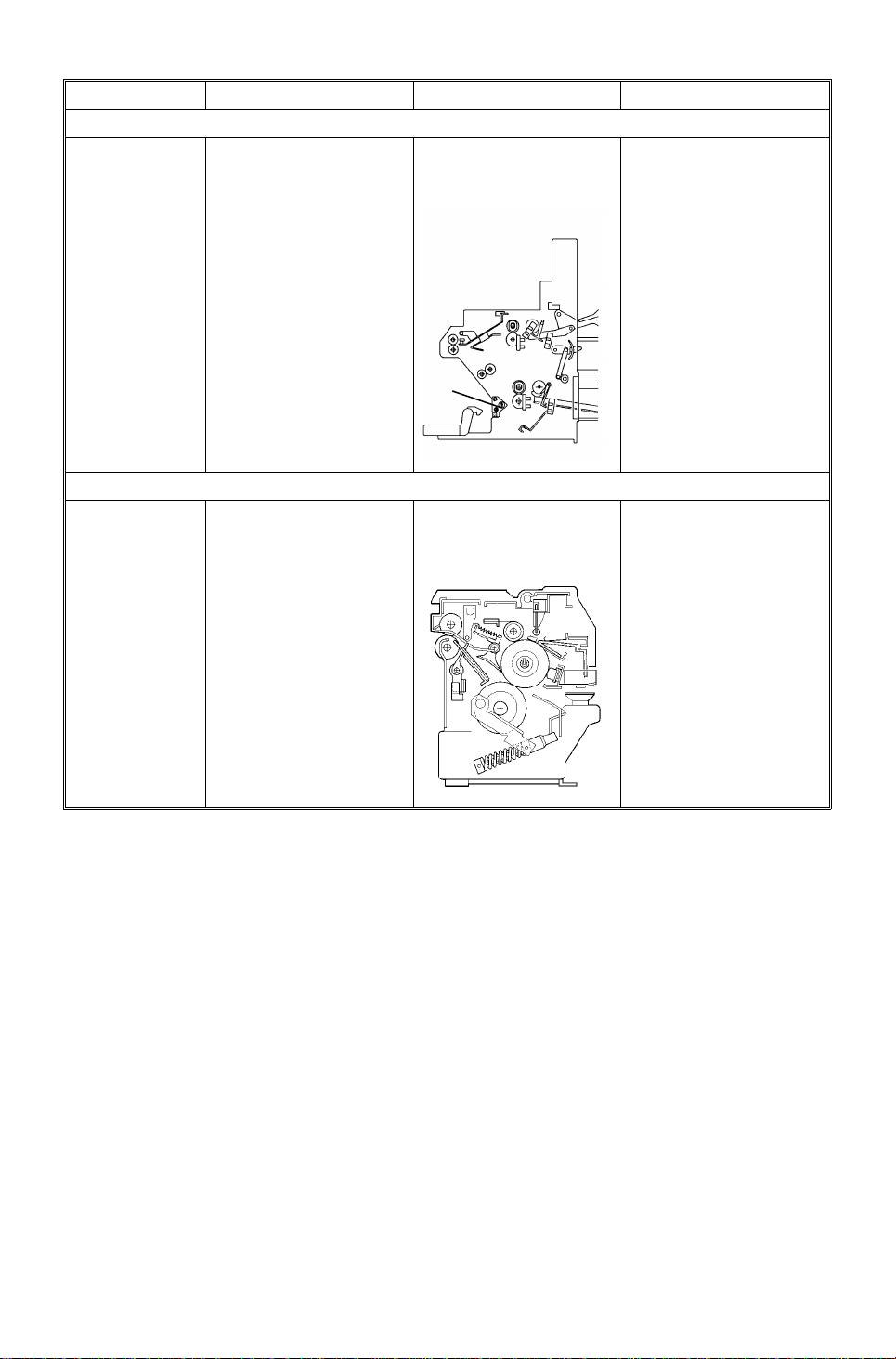

[B]

DIFFERENCES 5 January 1995

DESCRIPTION MODEL A092 MODEL A105 Reason for modification

ID SENSOR

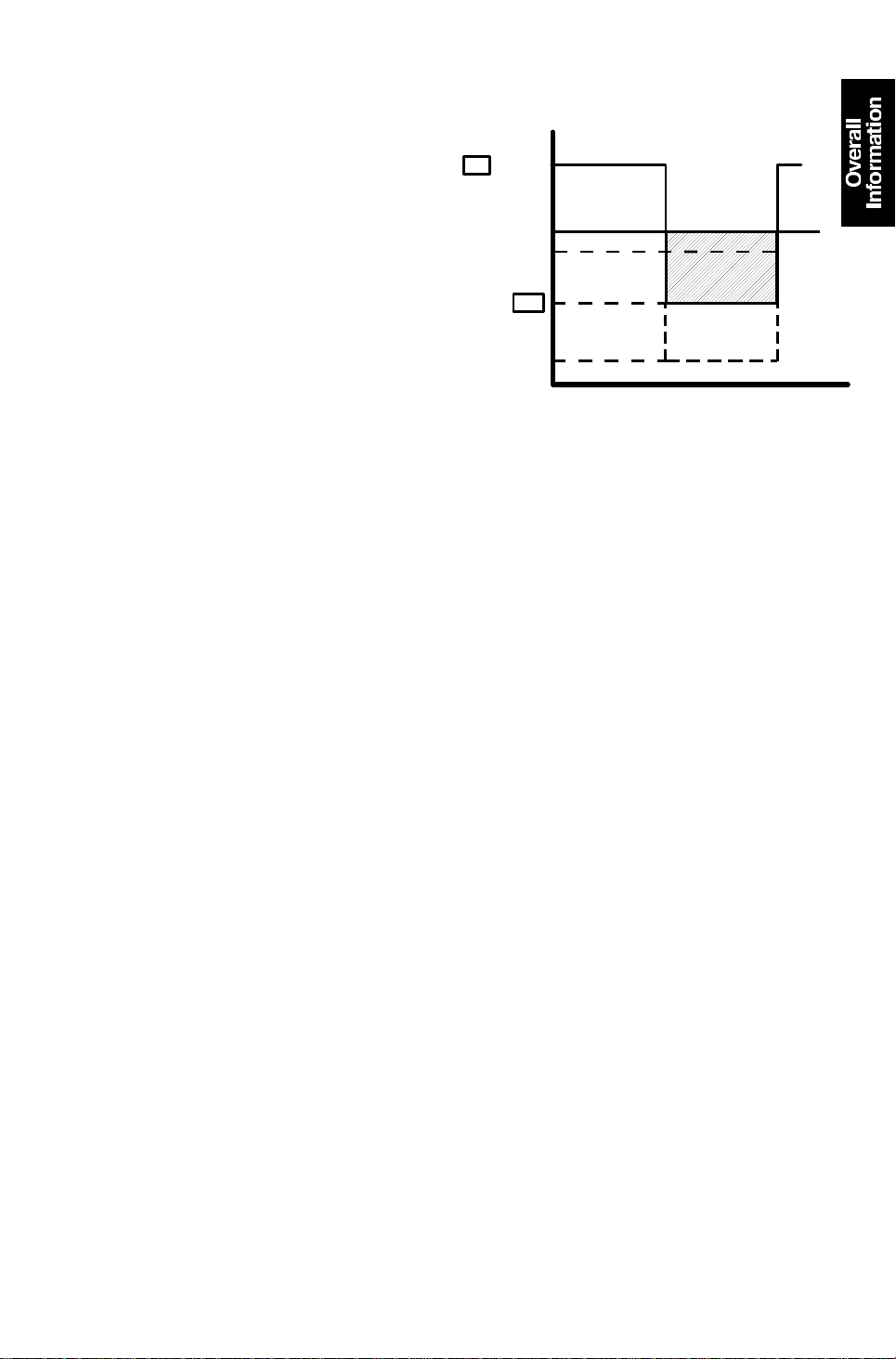

ID Sensor ID sensor is set on the

casing of the

development unit.

DEVELOPMENT UNIT

Unit Separation Cannot be separated

sub-tank from

main-tank.

ID sensor is set on the

casing of the copier.

Can be separated the

sub-tank [A] from the

main-tank [B]

When replacing the

development unit, it is

not necessary for

model A105 to perform

Vmin check.

Because, the ID sensor

is set separately from

the casing of the

development unit.

To replace the toner

supply roller [C].

Developer for

all colors

Toner

Diameter for

all colors

Toner Supply

Roller

[A]

[C]

Uncoated ferrite carrier. Silicon coated ferrite

carrier.

250 g/bag 200 g/bag

12 µm

Rubber roller Silicon rubber roller To improve toner

6.4 µm

To prolong the life of

the developer.

15K → 20K

To increase the charge

ability of the developer.

To improve the

resolution of copy

image.

supply capacity.

1-2

5 January 1995 DIFFERENCES

DESCRIPTION MODEL A092 MODEL A105 Reason for modification

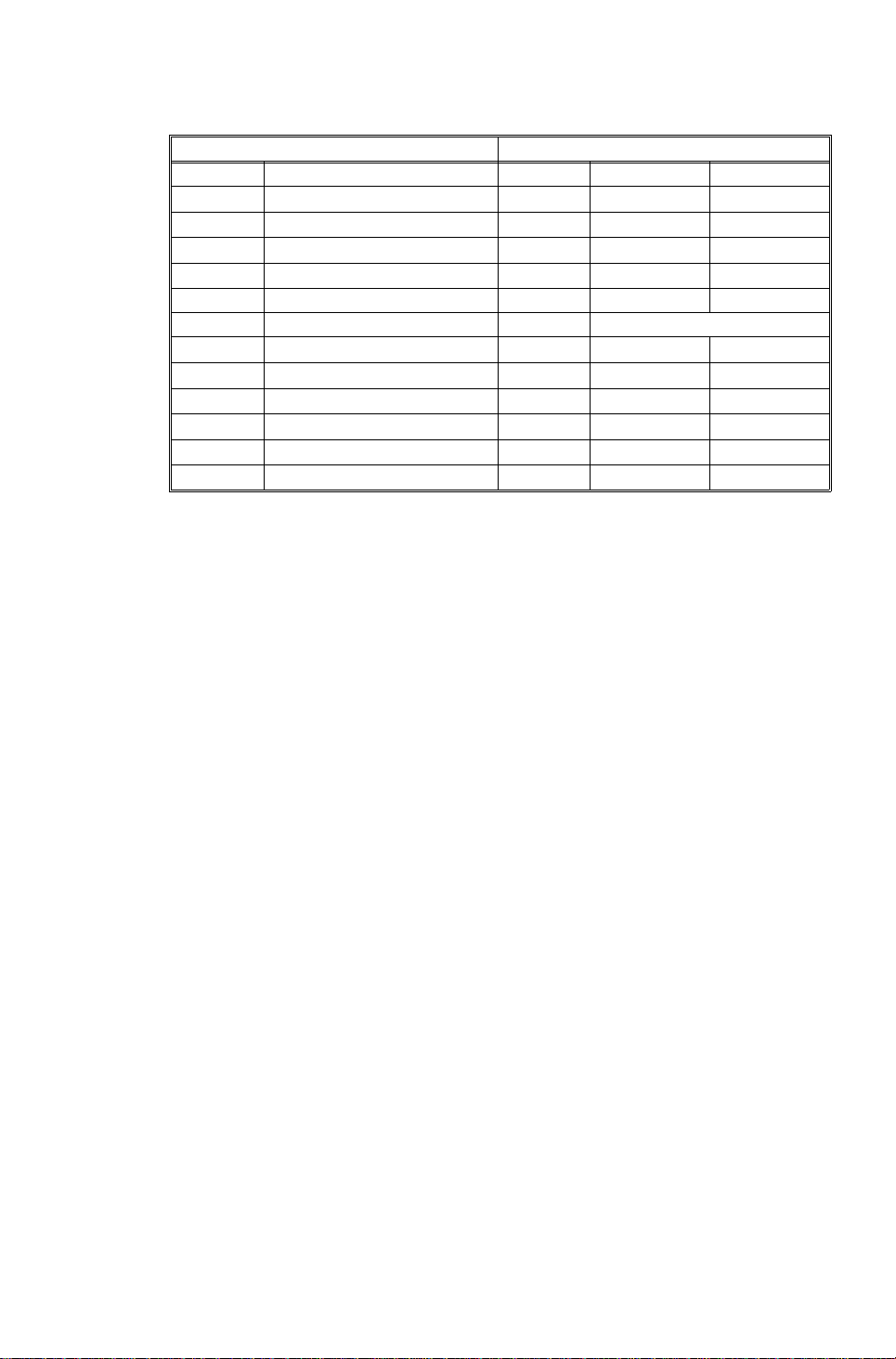

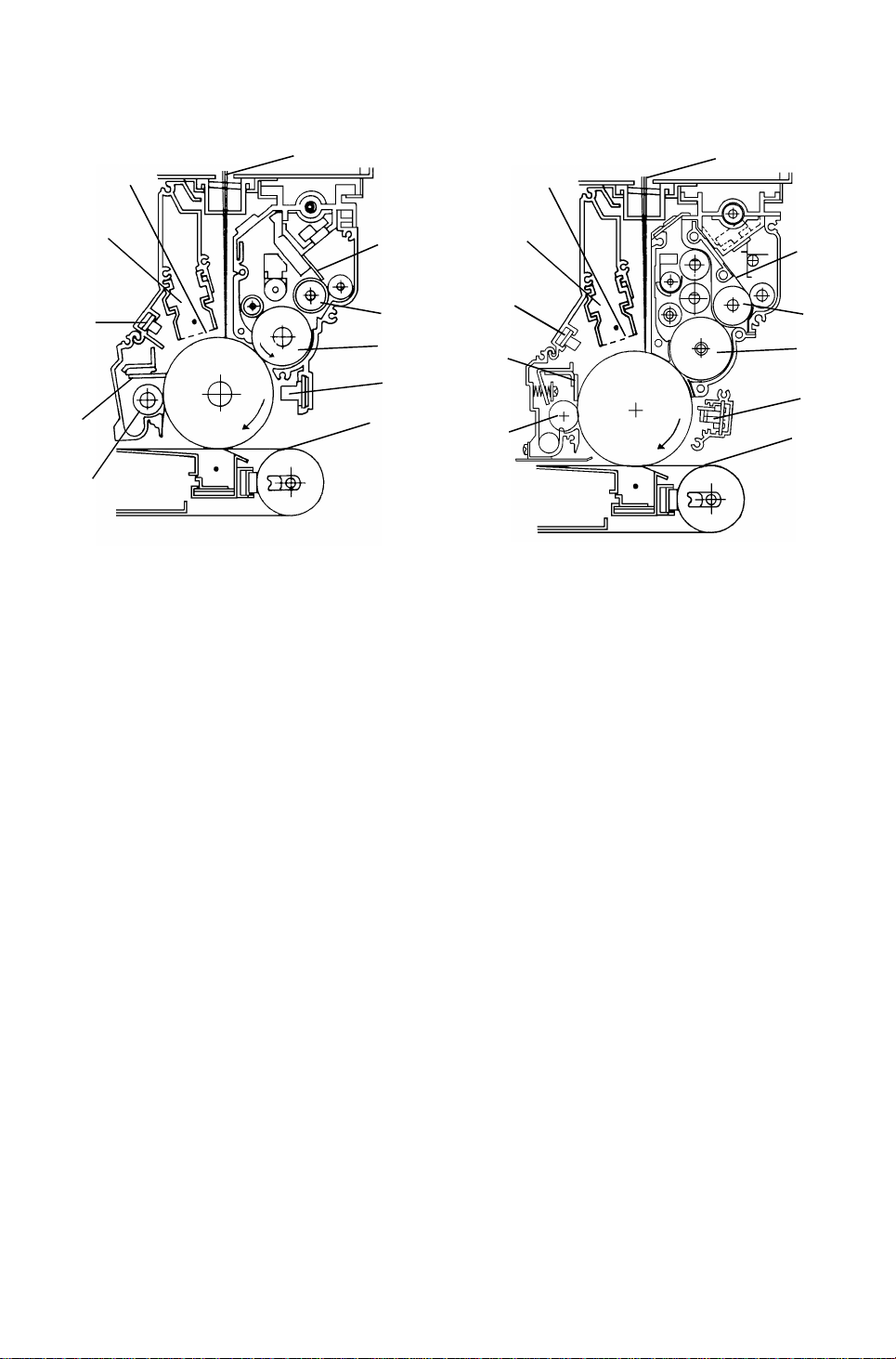

Cross-mixing

Mechanism

Add upper auger [A]

and upper transfer

roller [B].

[A]

[B]

To stabilize the image

density.

To eliminate the

un-even density band

(12 mm/0.47 inch

pitch).

To power up the mixing

function.

Bias

Development

Sleeve Speed

TRANSFER UNIT

Transfer Drive

Roller

Transfer Belt

Discharge

CLEANING UNIT

Cleaning

Method

–DC (–278V ∼ –678V)

Drum speed : Sleeve

speed = 1 : 2.3

Low impedance High impedance To insure cyan toner is

Trailing blade Counter blade The new toner consists

–DC+AC

DC (–278V ∼ –678V)

AC (1 kV peak to peak)

Drum speed : Sleeve

speed = 1 : 1.6

To get uniform density

on copies.

transferred to the copy

paper.

of smaller particles.

To remove the smaller

particles of the new

toner and to improve

the durability of the

cleaning blade.

1-3

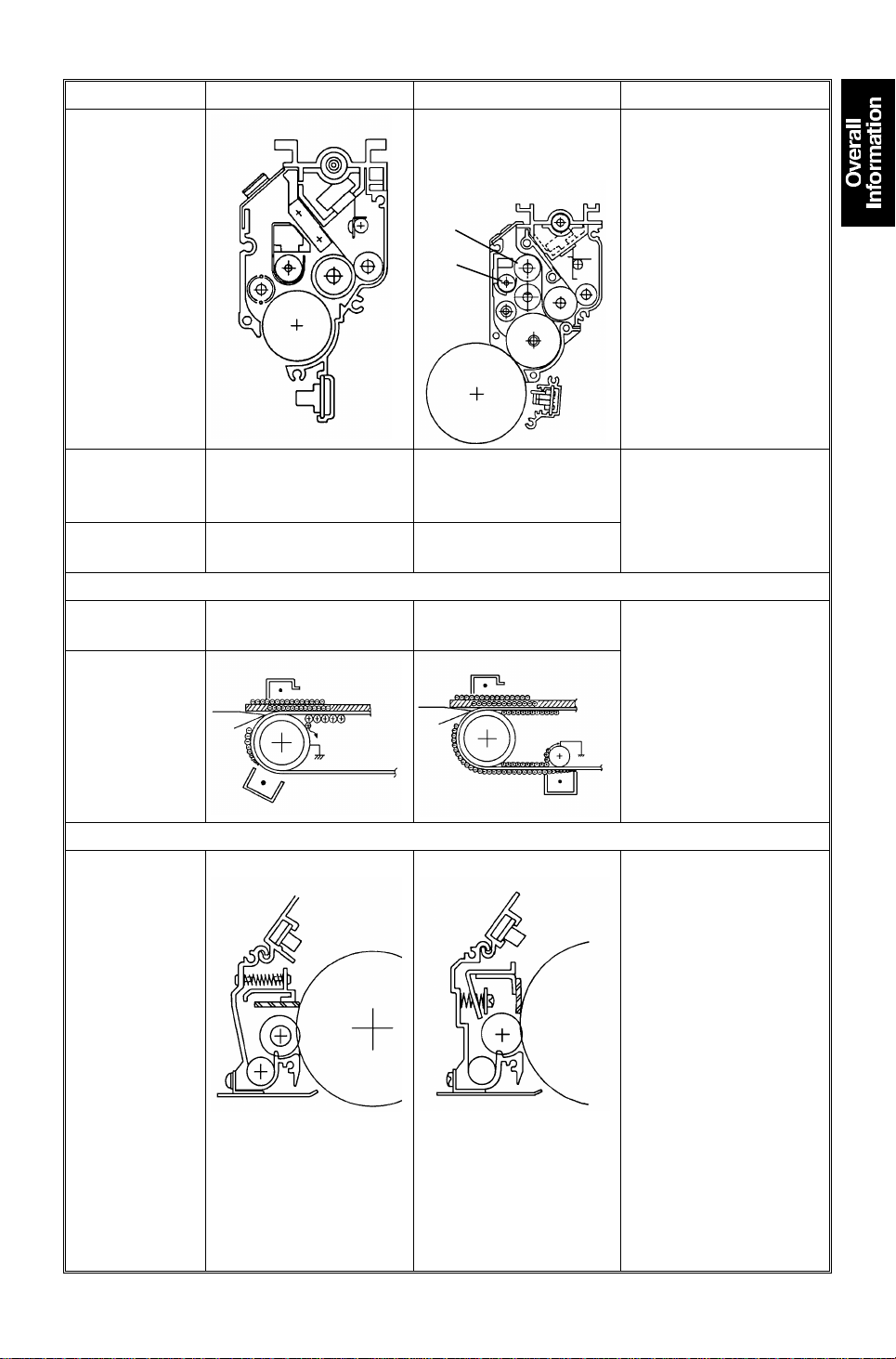

DIFFERENCES 5 January 1995

DESCRIPTION MODEL A092 MODEL A105 Reason for modification

PAPER FEED UNIT

Paper Feed

Unit Parallel

Adjustment

Mechanism [A]

This mechanism has

been applied by the

engineering change.

This mechanism has

been applied from the

1st production run.

To adjust the skew and

the color layer

alignment at the trailing

edge.

[A]

FUSING

Hot Roller

Cleaning

Mechanism

Not Used A cleaning roller and

cleaning scraper have

been added.

To increase durability

of fusing unit.

NOTE: This is not a complete list of the differen ces be twe en the mo del A09 2

and A105, but does illustrate the major differences.

1-4

5 January 1995 SPECIFICATIONS

2. SPECIFICATIONS

Configuration: Console type

Copy Process: Laser electrostatic transf er/ tetradrive system

Originals: Book/sheet, fixed plate n

Original Alignment: Front-right corner

Maximum Original Size: A3, 11" x 17"

Copy Paper Size: Maximum: A3, 11" x 17

Minimum: A6 (lengthwise only), 51/2" x 81/2"

Copy Paper Weight: 64 to 157 g, 17 to 42 lb

(Paper with more than 128 g/34 lb and OHP film

should be used with Thick Paper/OHP mode.)

Copy Speed: <Model A092>

14.5 cpm/81/2" x 11" sideways, or smaller

15 cpm/A4, sideways, or smaller

7.5 cpm/A3, 11" x 17"

<Model A105>

15 cpm/81/2" x 11" sideways, or smaller

15 cpm/A4, sideways, or smaller

7.5 cpm/A3, 11" x 17"

(In thick paper/OHP mode, copy speed is reduced

to one half. )

First Copy: 18 seconds/A4, 81/2" x 11" sideways

(In thick paper/OHP mode, it is 35 seconds.)

Warm-up Time: Within 8 minutes (at room temperature 20°C/68°F)

Copy Counter: 1 to 99

(Maximum set number is adjustable with SP38.)

Automatic Reset: After 60 seconds (Adjustable from 1 to 180

minutes, or no reset with SP37 .)

Photo Conductor: Organic photoconductor (OPC) drum, 60 mm in

diameter, 4 drum system driven by a dc servo

motor through a single drive shaft (tetradrive).

Drum Charge: Single wire with grid plate (negative charge),

variable grid voltage type.

1-5

SPECIFICATIONS 5 January 1995

Fixed Reproduction

5 enlargement ratios and 7 redu ctio n ratios

Ratios:

Letter Version A4 version

1 : 4.00 400% copy 1 : 4.00 400% copy

1 : 2.00

1 : 1.55

1 : 1.29

1 : 1.21

1 : 1 100% copy 1 : 1 100% copy

1 : 0.93 To create margin 1 : 0.93 To create margin

1 : 0.85

1 : 0.77

1 : 0.74

1 : 0.65

1 : 0.50

1 : 0.25 25% copy 1 : 0.25 25% copy

5

1/2" x 81/2" ⇒ 11" x 17"

5

1/2" x 81/2" ⇒ 81/2" x 17"

8

1/2" x 11" ⇒ 11" x 17"

8

1/2" x 14" ⇒ 11" x 17"

8

1/2" x 13" ⇒ 81/2" x 11"

8

1/2" x 14" ⇒ 81/2" x 11"

11" x 15" ⇒ 8

11" x 17" ⇒ 8

11" x 17" ⇒ 5

1/2" x 11"

1/2" x 11"

1/2" x 81/2"

1 : 2.00

1 : 1.41

1 : 1.22

1 : 1.15

1 : 0.82

1 : 0.75

1 : 0.71

1 : 0.65

1 : 0.50

A5 ⇒ A3 A6 ⇒ A4

A4 ⇒ A3 A5 ⇒ A4

F ⇒ A3 A4 ⇒ B4

B4 ⇒ A3

F ⇒ A4 B4 ⇒ A4

B4 ⇒ F4 B4 ⇒ F

A3 ⇒ A4 A4 ⇒ A5

A3 ⇒ F

A3 ⇒ A5 A4 ⇒ A6

Reproduction error:

±0.5% for full size mode, ± 1.0% for other ratios.

Zoom: From 25% to 400%, 1% steps

(In thick paper/OHP mode, from 25% to 200% )

Scanning System: One way scanning with optical fiber arra y and full

size color CCD’s, single scan with simultaneous

B, G, R, color separation.

<Model A092> 16 dots/mm, 256 gradation

<Model A105> 400 dpi, 256 gradation

Scanner Light Source: Two fluorescen t lamp s

Drum Exposure System: 4 semiconductor lase r bea ms (1 la ser beam pe r

OPC drum), one dimensional simultaneous

scanning onto 4 drums with one polygon

motor/two polygon mirrors.

<Model A092> 16 dots/mm, 64 gradations

<Model A105> 400 dots/inch, 256 gradations

Development: Dual component dry toner/single development

roller system. (Negative toner charge/Negative

drum charge process.)

Developer: <Model A092>

- Bk, Y, C: 250 g/bag

- M: 200 g/bag (same as that of model A105)

<Model A105>

- Bk, M, Y, C: 200 g/bag

1-6

5 January 1995 SPECIFICATIONS

Toner: <Mod el A0 92>

- Bottle Type: 400 g/bo ttle

- Consumption: 9000 copies/A4, 81/2" x 11"

(5% image area for each color)

<Model A105>

- Bottle Type: 340 g/bottle

- Consumption: 7000 copies/A4, 81/2" x 11"

(5% image area for each color)

Development Bias: <Model A092> Negative dc variable bias

<Model A105>Negative dc and ac variable bias

Image Transfer: Single wire dc positive charge from the reve rse

side of the transfer belt.

Paper Transport: One flat transf er be lt syste m

Paper Separation: Primary: Paper curvature separation

Secondary: Pick-off pawls, and single wire

separation ac corona fo r pa per

discharge.

Transfer Belt Discharge: <Model A092> Single wire ac corona

<Model A105> Single wire ac corona and

discharge roller

Transfer Belt Cleaning: Blade and brush cleaning

OPC Drum Cleaning: <Model A092> Trailing blade and brush

cleaning

<Model A105> Counter blade and brush

cleaning

Quenching: Photo quenching by LEDs

Paper Feeding: Dual cassettes (500 sheet capacity each ), an d a

bypass feed table (20 shee ts)

Paper Feed System: Feed and reverse roller (FRR) system

Image Fusing: Hea t an d pressure type with silicone oil. Silicone

hot-roller, and silicone pressure roller.

Fusing Lamp: Halogen lamp (220 – 240 V/550 W, 115 V/550 W)

Silicone Oil Consumptio n: 350 cc per 35,000 copies (A4/81/2" x 11")

Copy Tray Capacity: 100 sheets

1-7

SPECIFICATIONS 5 January 1995

Self-diagnostic Codes: 72 codes

Process Control: Drum potential control

Development bias control

Toner supply roller bias contro l

Copy Counters: Two counters (Double count mode for A3/DLT

can be set with SP45.)

• Single color copy counter (inclu din g bla ck)

• Full color copy counter

User Code Mode: 2 0 4 digits numbers from 0001 to 9999

Power Source: 220 – 240 V/50 Hz: 8 A

115 V/60 Hz: 12 A

Power Consumption: Maximum: 1.4 kW

Warm-up: 0.9 kW (average)

Ready: 0.5 kW (average)

Copy cycle: 1.0 kW (average)

Dimensions (W x D x H): Main frame only: 930 mm x 725 mm x 930 mm

(36.6" x 28.5" x 36.6")

With platen cover, copy tray, and A3/DLT

cassette in the lower fee d sect ion:

1695 mm x 725 mm x 954 mm

(66.7" x 28.5" x 37.6")

Weight: Main frame only without consumables:

<Model A092> 285 kg (628.3 lbs) or less

<Model A105> 285 kg (628.3 lbs) or less

Main frame with consumables:

<Model A092> 296 kg (652.6 lbs) or less

<Model A105> 300 kg (661.4 lbs) or less

Optional Equipment: - Editor (This is standard for Model A105.)

- SPU SPU(Model A984-27) can only be connected

to Model A092-25 and A092-27.

SPU (Model A711-27) can be connected

to Model A105-25 and A105-27.

SPU(Model A984-17) can be connected

to Model A092-17 and A105-17.

- Key counter (locally procured)

1-8

5 January 1995 SPECIFICATIONS

<Additional Features>

User Program Mode: 5 modes (The image repeat mode and the poster

mode can not be stored as a program mode.)

Original Recognition

Mode:

The default is the Off mode. Using SP-31, the On

mode can be selected. In AP S/ARE, Centering,

Mirroring, Slanted Image modes, the On mode is

automatically selected.

Color Selection: The default is Full Color. Using SP-44, the Black

mode can be selected as th e de fault mode.

Single color: 9 kinds

black, yellow, orange, red, magenta, blue,

cyan, green, light green .

Optional single color:

3 user programmable colors can be registered.

Original Modes: 4 modes

- Automatic Letter/Photo separation (Auto)

mode: Default

- Letter mode

- Letter/Photo mode

- Photo mode

The default mode can be changed by SP40, and

41.

In the Auto mode, photo areas are processed

using the Phot o mode as a default.

(It can be changed from Photo mode to

Letter/Photo mod e with SP43.)

APS: Pre-scanning type

Paper Weight: Thick Paper/OHP mode:

Process speed is changed from 75 mm/sec. to

37.5 mm/sec. This mode is for paper that is

128 g/34 lb or heavier and for OHP film.

Thin Paper:

The fusing temperat ure during the copy run is

controlled at 143°C (131°C for mo del A 105) rather

than 148°C (135°C for model A105). (By SP 42 ,

the default mode can be set at the Thin Paper

mode.)

1-9

SPECIFICATIONS 5 January 1995

Special Reduce/Enla rge : - ARE (Auto Reduce/Enlarge)

- Directional size magnification

- Directional magnification

- Size magnification

- Zoom

Edit Image: - Centering

- Save area

- Delete area

Image Creation: - Outline mode

- Positive/Negative mode

- Shadow mode

- Image Repeat mode

- Mirror Image mode

- Slanted Image mode

- Poster mode (Model A105 only)

Color Creation: - Color Background mode

- Color Conversion mode

- Pastel Image mode

- Posterization mode

- Solarization mode

- Mosaic mode

<Image Adjustments>

Image Density Selection: 9 ste ps

Color Balance: For black, cyan, magenta, and yello w, ad just ab le

in 9 steps. Adjusted balance can be stored as a

default setting by pressin g th e Ba lance Memory

key.

Color Adjustment: Colo r t one of gree n, cyan, blue , mag en ta, red, or

yellow can be independently adjusted to one of

the neighboring colors. This can be done with up

to three colors.

Sharp/Soft: Adjusts the sharpness of the copy image.

Contrast: Adjusts the contrast bet ween light and dark parts

of the copy image.

Background Density

Adjusts background image density of the copy.

Control:

1-10

5 January 1995 SPECIFICATIONS

User Tool/Service Tool:

<Model A092>

For users

For service

<Model A105>

For users

For service

10 user tools (UT-1 to UT-10) for 115 V version

11 user tools (UT-1 to UT-11) for 230 V version

SP mode (SP-1 to SP-92)

SPT/SPD mode

SP Test mode (SPT-0 to SPT-119)

SP Data mode (SPD-1 to SPD-898)

11 user tools (UT-1 ∼ 10 and 12) for 115 V version

12 user tools (UT-1 ∼ 12) for 230 V version

SP mode (SP-1 to SP-95)

5 SP modes have been added from model A092.

SPT/SPD mode

SP Test mode (SPT-0 to SPT-119)

SP Data mode (SPD-1 to SPD-898)

1-11

COPY PROCESS 5 January 1995

3. COPY PROCESS

3.1 OVERVIEW

[E]

[D]

[C]

[B]

[A]

The main marketing strengt hs of this cop ier are:

1) High productivity with the world’s fa ste st dig ital full color copy speed

(15 cpm/A4, 14.5 cpm/LT: Model A092, 15 cpm/A4, LT: Model A105).

2) A wide variety of copy paper can be use d, such as he avy pa pe r (up to

157 g/42 lb), and small paper (up to A6 lengthwise or 5 1/ 2 " x 81/2").

To achieve this productivity, this machine adapts four OPC drums, fo ur laser

beams, and one time scanning with a simultaneous B, G, R, (Blue Gre en

Red) color separation system (tetradrive system). Paper is transported on a

flat transfer belt [A] where the toner image on each drum is transferred to the

paper in order. These four layers of color to ne r image are fused on the paper.

For compactness, each drum is 60 mm in diame te r, an d th ey are located at

110 mm intervals. From the right side , th e drums are: black [B], magenta [C] ,

yellow [D], and cyan [E]. Ea ch drum has the following compon en ts aro un d it:

• Charge corona unit

• Development unit

• ID sensor

• Transfer corona unit (below the transfer belt)

• Drum cleaning unit

• Quenching lamp (LEDs)

1-12

5 January 1995 COPY PROCESS

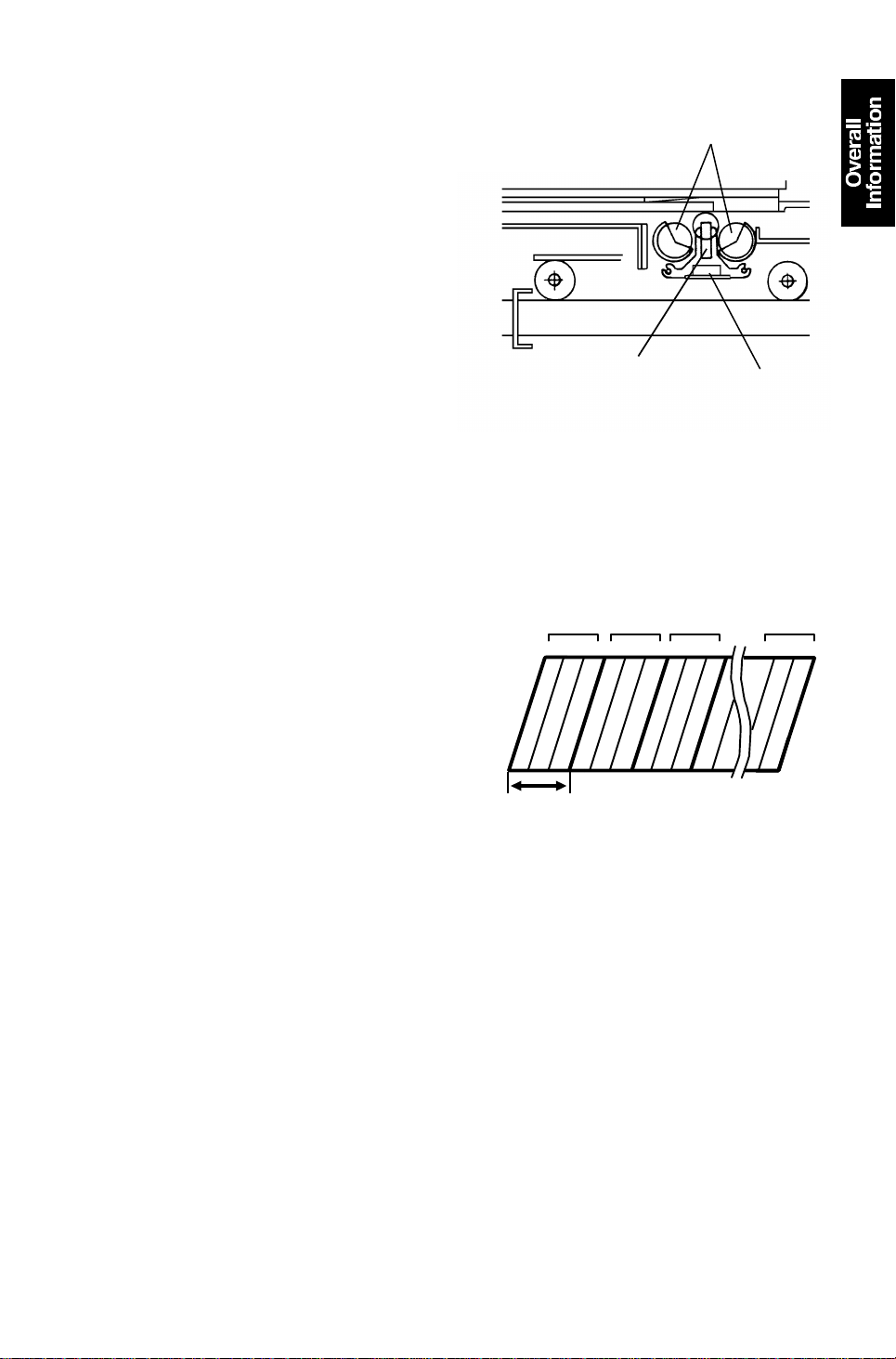

3.2 SCANNING

3.2.1 O riginal Scanning

The color original is illuminate d by two

exposure lamps [A]. Reflected light

from the original passe s through the

optical fiber array [B] to the full size

color CCD [C].

(CCD = Charge coupled device)

The CCD converts the light intensity to

an electrical value.

The scanner which is composed of th e

exposure lamps, optical fib er arra y, an d

CCD, is always in contact with the

exposure glass while scanning.

3.2.2 P hoto-electric Conversion

[B]

[A]

[C]

The full size color CCD has blue, green,

or red filters on each picture element

(pixel) in a line. Three elements, with

1 2880/chip23

B G R B G R B G R

the filters for each color, are used as

one unit for color separation of the

original image.

<Model A092>

16 pixels per 1 mm = 406.4 pixels per

inch (DPI)

62.5 µ (Model A092)

63.5 µ (Model A105)

<Model A105>

400 pixels per inch (DPI)

The CCD converts the light intensity

into an electrical analog signal.

3.2.3 Analog-digital Conversion

The analog signal outp ut from the CCD is digitized. Eight bit s are used for

each picture element (pixe l), which gives 256 gra da tio n ste ps.

3.2.4 RGB Separation

Signals from the 14,60 0 pict ure elements are separate d int o th ree groups of

red, green, and blue picture elements.

1-13

COPY PROCESS 5 January 1995

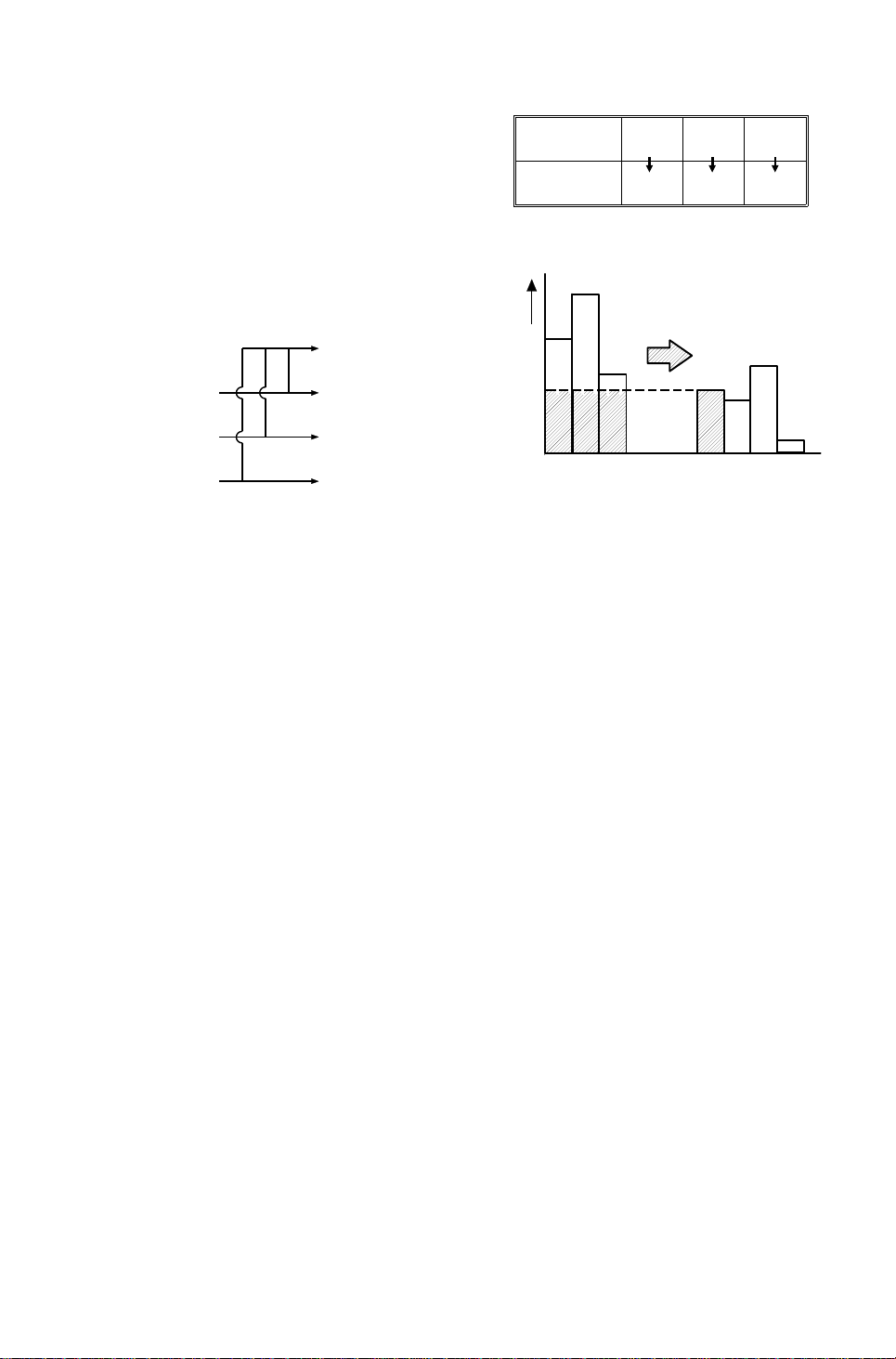

3.2.5 Image Processing

Image processing fo r various copy

Filter B G R

modes is done in the image processing

PCB’s.

Toner Y M C

The 8-bit gradation digital data for one

set of red, green and blue elements is

changed to the data for four toner

200

colors:

150

Black data (Bk)

Green data (G) Magenta data (M)

Blue data (B) Yellow data (Y)

Red data (R) Cyan data (C)

100

80

CMY BkC MY

(UCR Ratio: 80%)

80

120

70

20

The black output is determined by the CMY data (which is a result of the

RGB data). A common value is su bt racted from the C, M, and Y values and

this value becomes the black value. This is called UCR (Unde r Color

Removal).

<Model A092>

There are 8 laser exposure grad ation steps (7 levels + laser off), so only 3

data bits are needed. The four color da ta are con vert ed from 8-b its to 3-bit s.

64 kinds of 4 x 4 bit dither matrices (Photo mode) a re use d to make 64

gradations of the copy image.

<Model A105>

There are 256 laser exposure gradation steps (255 levels + laser off), so

8 data bits are needed. One pixel ca n mak e 256 gra dations of the copy

image.

1-14

5 January 1995 COPY PROCESS

3.3 LASER EXPOSURE

1. There are four laser beams (one beam per drum) and two polygon

mirrors in the laser unit. The two polygon mirrors are turne d using one

motor.

The laser beam is reflected by the turn ing polygon mirror, and passes

through a complex lens (called the f θ lens) to the drum.

Using one surface of the po lygo n mirror, one main scan line is made. The

main scan direction is:

1st (black) and 2nd (magenta) drums: front to rear.

3rd (yellow) and 4th (cyan) drums: rear to front.

2. The laser beam switches on an d of f at very high frequency to make an

image with 16 dots/lines per 1 mm (400 dpi for Model A105).

<Model A0 92>

Furthermore, the on-time (PWM) per dot for th e laser bea m is contro lled

in 8 steps based upon the 3-bit data sent from the image processing unit.

<Model A105>

Furthermore, the on-time per dot for the laser beam is controlled 256

steps based upon the 8-bit data sent from the image proce ssing unit.

As a result, the negatively charge d dru m pot ential drops to the

appropriate level, fo rming an electrical latent image on the drum.

Unlike other PPCs, the exposed areas correspond to the dark image

areas on the original (ima ge area expo sure).

3. The data for black is sent just aft er image processing to the laser unit for

laser exposure on the black drum.

However the data for the other three colors is stored in the memory

board, and is sent to the laser unit at the app rop riat e time . This is t o align

the horizontal direction of the image deve lop ed on each of the four drums.

1-15

COPY PROCESS 5 January 1995

3.4 DRUM PROCESSES

[A]

[K]

<Model A092> <Model A1 05>

[D]

[B]

[F]

[E]

[C]

[B]

[A]

[K]

[I]

[D]

[G]

[I]

[H]

[J]

[J]

3.4.1 Charge

<Model A092 & A105>

In the dark the charge corona unit [A] applies a ne gative charge to the drum.

The grid plate [B] ensures that the charge is applied un iformly and that the

amount of the charge applied is correct. The charge remain s o n th e surf ace

of the drum because the photoconductive drum has a high electrical

resistance in the dark.

[F]

[E]

[C]

[G]

[H]

3.4.2 Development

<Model A092 & A105>

The magnetic developer brush on th e development roller [C] comes in

contact with the latent imag e on the drum surf ace. Negatively charged toner

particles are electrostatically at tracted to the areas of the drum surface whe re

the laser [D] has reduced the negative charge on the drum.

Unlike most PPCs, this machine uses a Neg at ive/Negative development

system. (Negative/Nega tive : Neg ative toner developed on a negative ly

charged drum.)

Another unique point is how the toner is supp lied to th e de velo pe r. Ton er is

supplied in an even and th in laye r o n th e sup ply roller [E] using a metering

blade [F].

While toner is passing the metering blade, the toner becomes negatively

charged, and is caught by the positively cha rged carrier in the development

unit.

1-16

V0

(= V )

L0

V

L1

V

L3

V

L7

VB

5 January 1995 COPY PROCESS

3.4.3 ID Sensor

The ID sensor [G] is used to detect the

different kinds of patterns developed on

the drum. It has two basic functions.

It’s used to control the density of tone r

in the devel oper.

It’s used to select the best process

conditions such as, charge grid volt age

[V0], development bias [VB] and laser

power (remaining or residual drum

voltage after level 3 exposure [VL3]:

Development Potential : VB – VL3

A092/ level 4 exposure [VL4]: A105).

3.4.4 Image Transfer

Copy paper is fed to the transfer belt [H] by the registra tio n rolle rs. A positive

charge is applied to the ba ckside of the paper through the tra nsfer belt. This

charge pulls the toner particles on the OP C drum surface onto the copy

paper.

After the first toner transfer (black), th e entire copy pape r is electrica lly held

on the belt’s surface.

Transfer charge for mag en ta , yellow, and cyan is stepped up to pull a new

color toner layer onto the paper.

3.4.5 Paper Separation

The paper’s stiffness causes it to sep ara te from th e transfer belt when the

belt turns sharply at the sep aration point. This is called "curvatu re

separation". To ensu re separation of paper that has low stiffness, this

machine also uses a separa tio n corona, for paper potent ial discharge, and

pick-off pawls. Three pick-off pawls to uch the belt just befo re th e lea din g

edge of the paper reaches the pick-off position.

3.4.6 Drum Cleaning and Quenching

The cleaning blade [I] and cleaning brush [J] remove an y ton er rema ining on

the drum surface and the toner is carried to the toner collection bottle.

The quenching lamp (LEDs) [K] electrically neutralize the surface of th e drum.

1-17

COPY PROCESS 5 January 1995

3.4.7 Transfer Belt Discharge and Cleaning

After paper separation , the resid ua l elect rical po te nt ial is discharged by the

belt discharge corona. Then , an y toner remaining on the belt surface is

removed by the belt cleaning brush and blade.

1-18

[A]

5 January 1995 COPY PROCESS

3.5 NEGATIVE/NEGATIVE DEVELOPMENT PROCE SS

VL1 : ∼ VL7

Drum voltage on the

image areas

(exposed by laser).

V0 :

Drum voltage on the

nonimage areas

(background).

VB

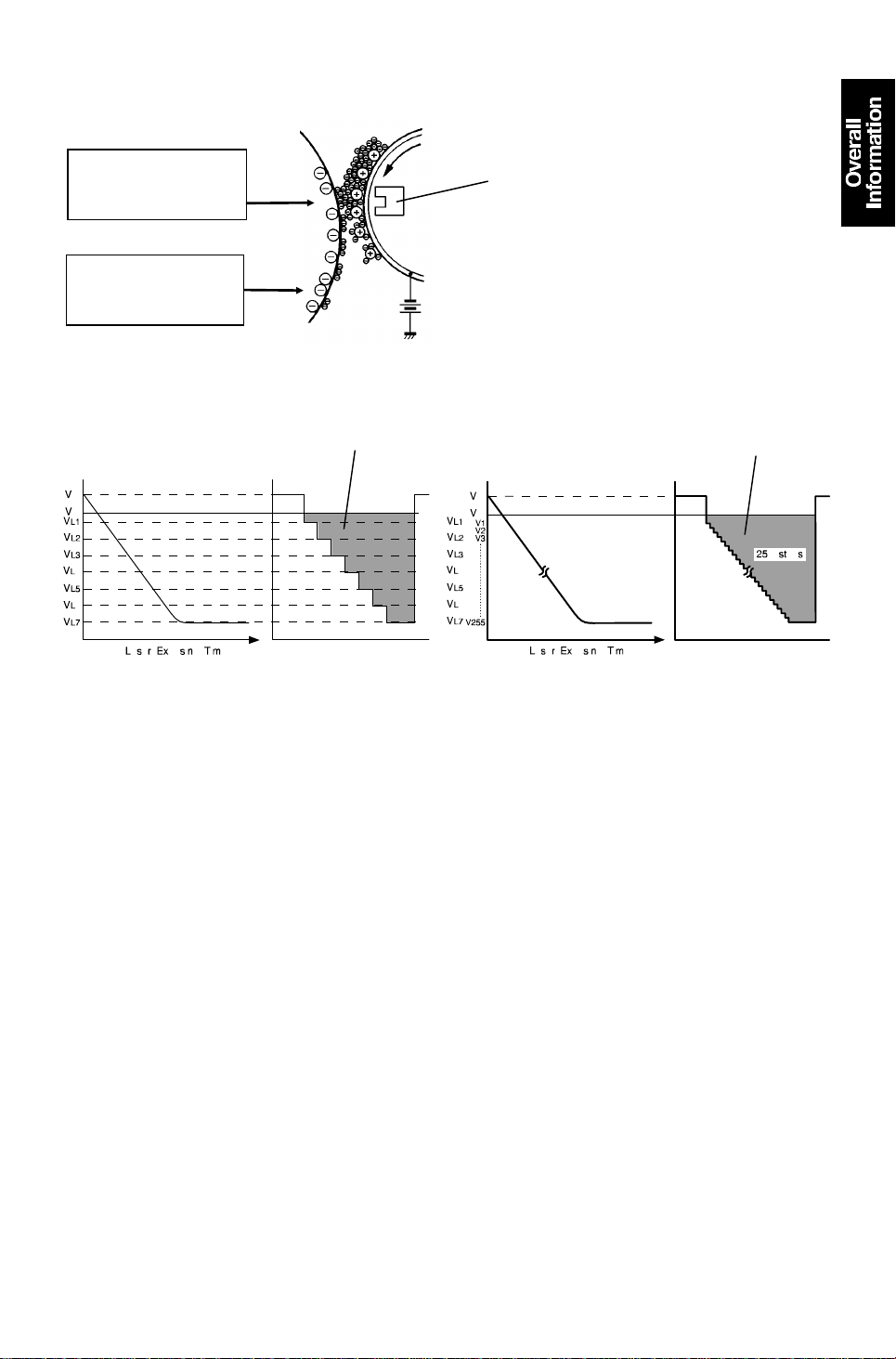

<Model A092>

Example = Pointer 10

0: –510V

V

B: –408V

V

L3: –282V

V

Example = Pointer 22

Development

Potential

<Model A105>

0: –698V

V

B: –561V

V

L3: –396V

V

Development

Potential

Most copiers use either a positively charged photoconductor and negat ively

charged toner or a negatively charg ed photo con du cto r a nd posit ively charged

toner. This is known as positive/n egative development. However, this

machine uses a negative/negative process where both the drum surface

charge and the tone r charge are negative.

Several forces interact in th e de velo pment process to produce a visible

image on the OPC drum. These forces are the charge pat te rn of the latent

image, the developme nt bias, the magnetic field of the de velo pment roller,

the positive triboelectric charge of the carrier, and the negative triboelectric

charge of the toner.

One of the most importan t of these forces is the charge patt ern of th e latent

image on the drum. To make the late nt image, the laser exposes an area of

the drum surface. The laser on-time for on e pulse is co nt rolle d using a pulse

width modulation circuit (PWM).

<Model A092>

The on-time is determined according the 3-bit data sent from the IPU (10 ∼

120 nsec).

<Model A105>

The on-time is determined accordi ng to the 8-bit data se nt from the IP U

(2 ∼ 86 nsec).

1-19

COPY PROCESS 5 January 1995

VD: Drum charge potential

V0: Non exposed area (Non imag e are a on origin al) = VD

<Model A092>

V0: Remaining drum voltage at laser dat a 0 (No lase r expo sure)

VL1: Remaining drum voltage at lase r dat a 1 (Sh ort est pha se)

|

VL7: Remainin g drum voltage at laser data 7 (Full phase)

<Model A1 05>

V0: Remaining drum voltage at laser dat a 0 (No lase r expo sure)

VL1: Remaining drum voltage at lase r dat a 34

VL2: Remaining drum voltage at lase r dat a 46

VL3: Remaining drum voltage at lase r dat a 63

VL4: Remaining drum voltage at lase r dat a 80

VL5: Remaining drum voltage at lase r dat a 127

VL6: Remaining drum voltage at lase r dat a 191

VL7: Remaining drum voltage at lase r dat a 255 (Lo ng est phase)

256 step laser exposure is used for copying. 7 step (VL1 ∼ VL7) laser

exposure is for process control.

<Model A092 & A105>

The power pack for each drum applies a dc negative bias [VB] (75 ∼ 160 V

lower than V0) to the developme nt roller sleeve. The main magnet [A] is

located inside the sleeve, facing the drum.

The toner is negatively charged and the carrier is positively charged due to

the agitation of th e toner and developer inside th e de velo pment unit (tribo

electric charge).

In a negative/negative process, toner particle s are at tra cte d to the drum

areas exposed by the laser hence, to the lower drum potential areas.

Development poten tial is the gap from VB (bia s) to VLX (Laser exposed area,

X=1 to 7).

1-20

5 January 1995 COPY PROCESS

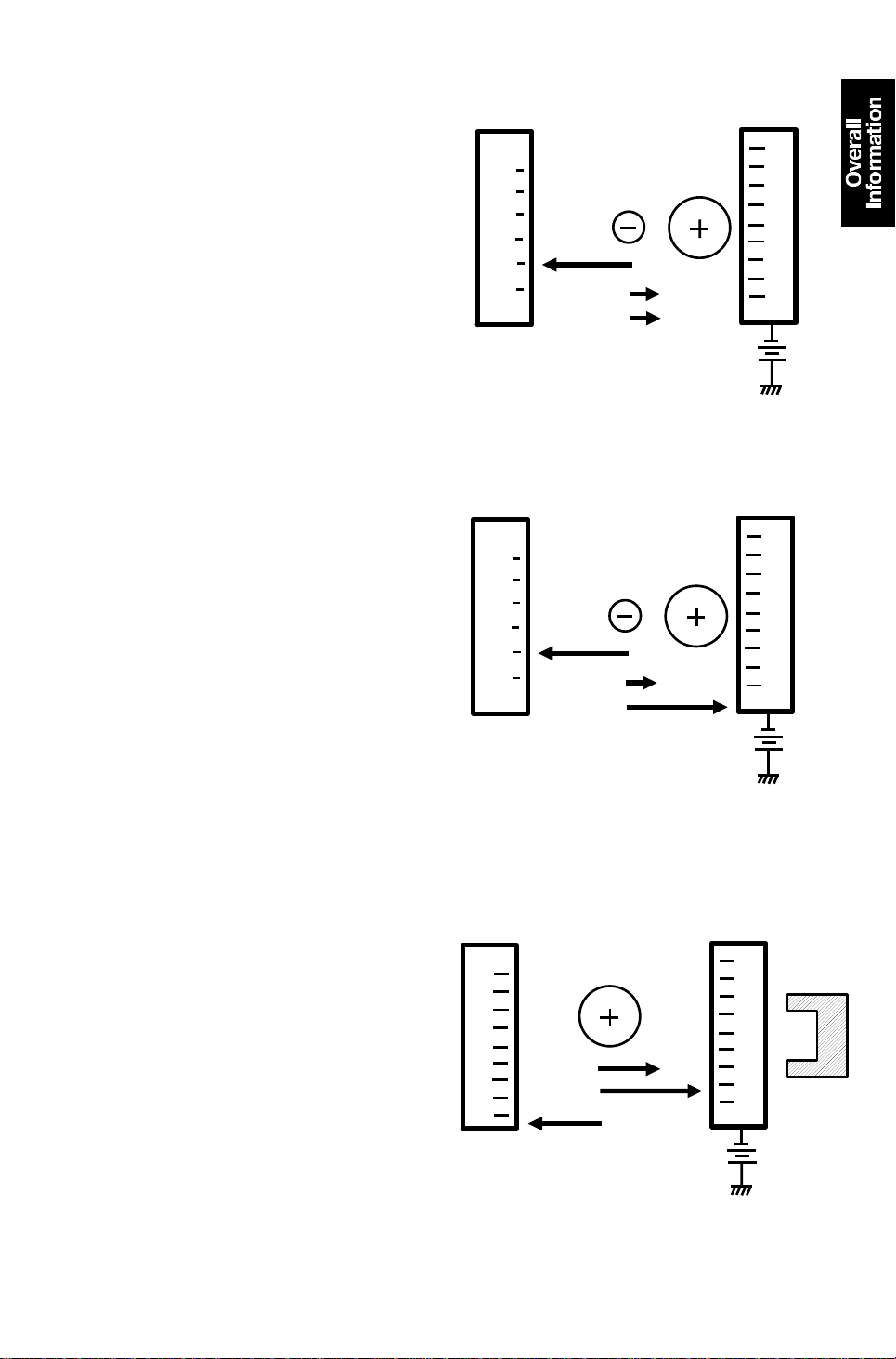

In the development area , the following

forces act on the toner particles:

Fc: The attractive force between toner

(–) and carrier (+)

FD: The repelling force between toner

(–) and the drum charge (–)

FB: The repelling force between the

toner (–) and the devel opment

roller bias (–)

The forces on the expo sed areas of the

drum are such that:

FB > FC + FD (Fig. 1)

This means toner is repelled from the

carrier to the drum. (FD is very small in

the image areas.)

The non-exposed areas of the drum are

such that.

FB < FC + FD (Fig. 2)

Here FD is very large and repels toner

from the non image areas.

You might expect that the positively

charged carrier would be attract ed to

the negatively charged nonima ge area s

of the drum. However, this does no t

happen. In the de velopment area, the

following forces act on the carrier

particles:

FMC:The attractive force of the magnet

on the carrier

DRUM

VL

Fig. 1

DRUM

VD

Fig. 2

DRUM

VD

F

F

B

B

Carrier

Toner

Toner

Fc

F

Fc

F

DEV.

ROLLER

Carrier

D

BIAS

DEV.

ROLLER

Carrier

D

BIAS

DEV.

ROLLER

MAGNET

FBC: The attractive force between the

carrier and development bias

FDC: The attractive force be twe en the

carrier (+) and the non-exposed

areas of the drum (–)

Since FDC < FMC + FBC (Fig. 3), the

carrier remains on the developmen t

roller’s sleeve.

1-21

Fig. 3

F

BC

F

MC

F

DC

BIAS

COPY PROCESS 5 January 1995

Positive/Negative Development VS. Negative/Negative Development

(2-component dry development process)

In a negative/negative process, some copy problems are exactly opposite to

what many copier service people have in tuitively come to expect. The table

below gives some of the diffe ren ces be twe en the posit ive/negative process

and the negative/negative process.

Positive/Negative Negative/Negative

Type of Laser He-neon

(gas, 630 nm)

Photoconductor Se Drum OPC OPC

Charge Corona Positive Negative Negative

Carrier Charge Positive Negative Positive

Toner Charge Negative Positive Negative

Photoconductor

Background exposure Image exposure

Exposure

He-neon or

semiconductor

P

Semiconductor

(765 ∼ 795 nm)

P

P: Pitch (1/16mm +

62.5µ for model

A092, 63.5µ for

model A105)

D: Laser beam

diameter

V

D: Drum voltage

B: Bias voltage

V

R: Residual voltage

V

Copy Problems

1. No photoconductor

charge

2. Low photoconductor

charge

3. High development

bias

4. Low development

bias

5. Stained toner shield

glass

D

P

VD

V

V

0V

P

B

R

White copy Black solid copy

Low image density Dirty background

Low image density Dirty background

Dirty background Low image density

Black stripes White stripes

D

V

V

B

0V

1-22

5 January 1995 MECHANICAL COMPONENT LAYOUT

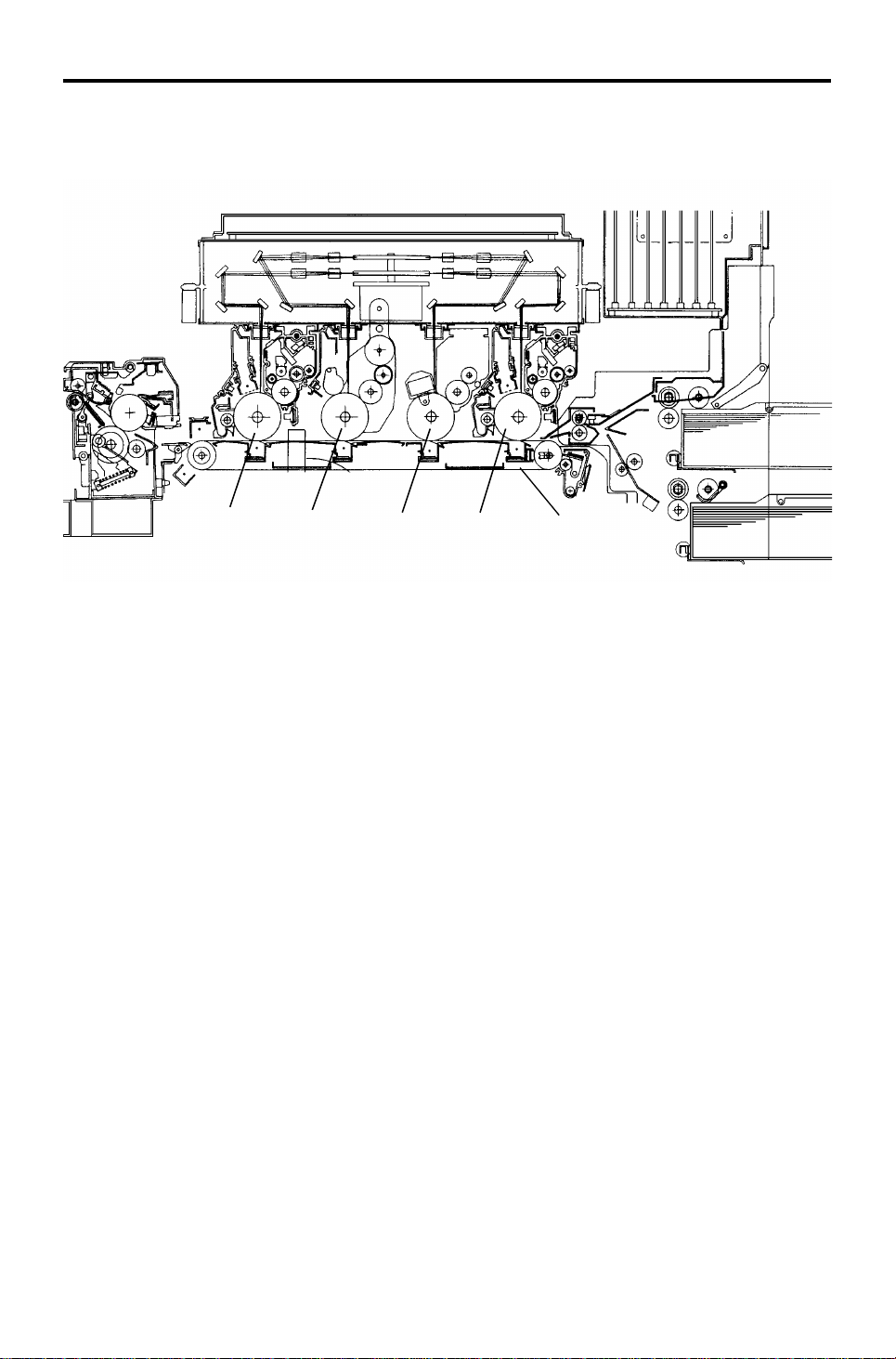

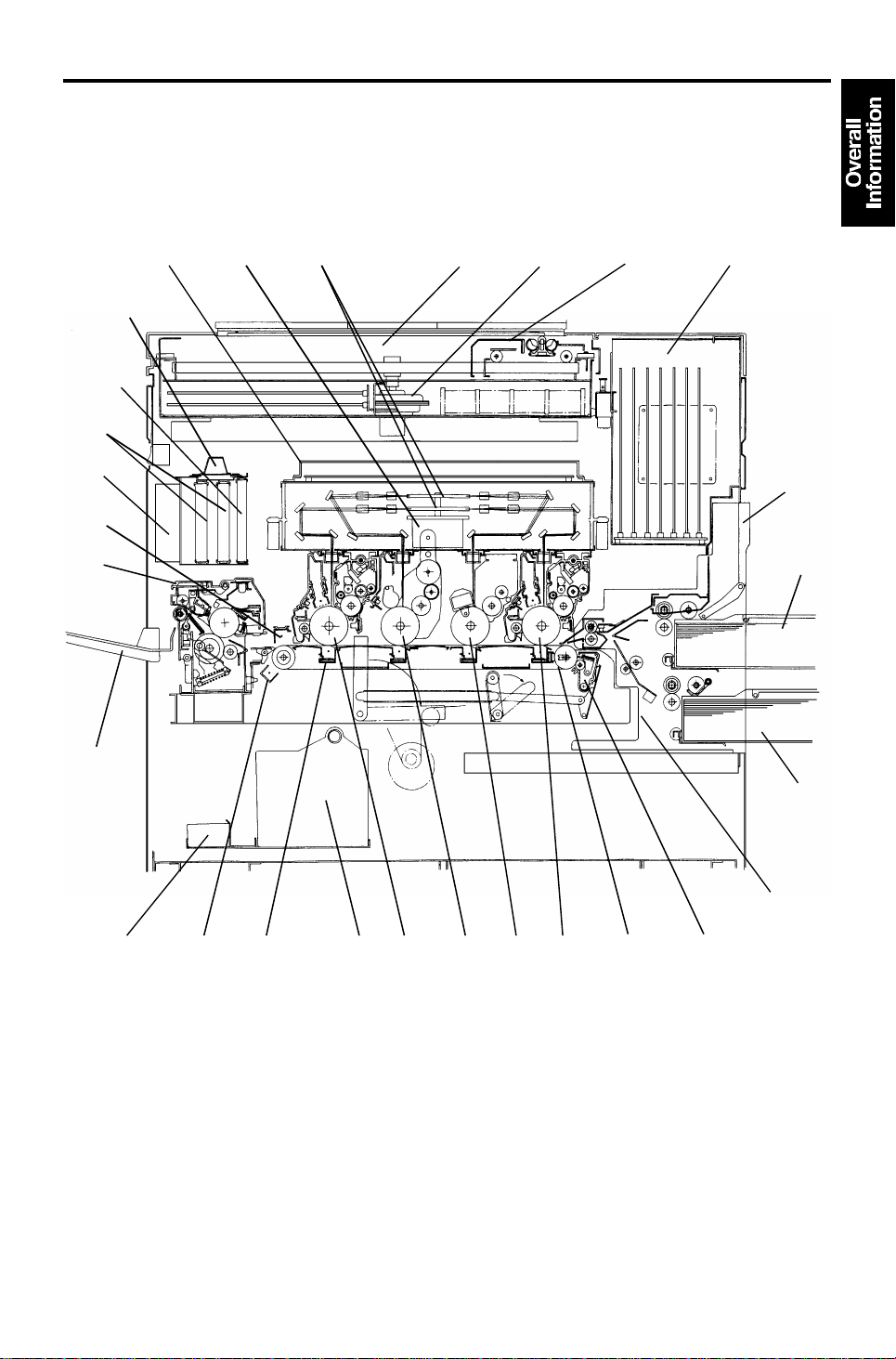

4. MECHANICAL COMPONENT LAYOUT

26

25

24

23

22

28

27

12

3

45

67

8

9

1-23

10

11

1415161718192021

13

12

MECHANICAL COMPONENT LAYOUT 5 January 1995

1. Laser Unit

2. Polygon Motor

3. Polygon Mirrors (2 pcs)

4. Scanner Unit

5. Scanner Motor

6. Scanner

7. IPU Section (7 PCB’s)

8. By-pass Table

9. Upper Cassette

10. Lower Cassette

11. Paper Feed Unit

12. Transfer Belt Cleaning Unit

13. Transfer Belt Unit

15. Magenta OPC Drum

16. Yellow OPC Drum

17. Cyan OPC Drum

18. Toner Collection Bott le

19. Transfer Corona (4 pcs)

20. Belt Discharge Corona

21. Developer Catch Pan

22. Copy Tray

23. Fusing Unit

24. Separation Corona

25. Fusing Exhaust Fan (2 pcs)

26. Exit Ozone Filters (2 pcs)

27. Dust Filter

14. Black OPC Drum

28. Ozone Neutralizer

1-24

11

12

4

13

14

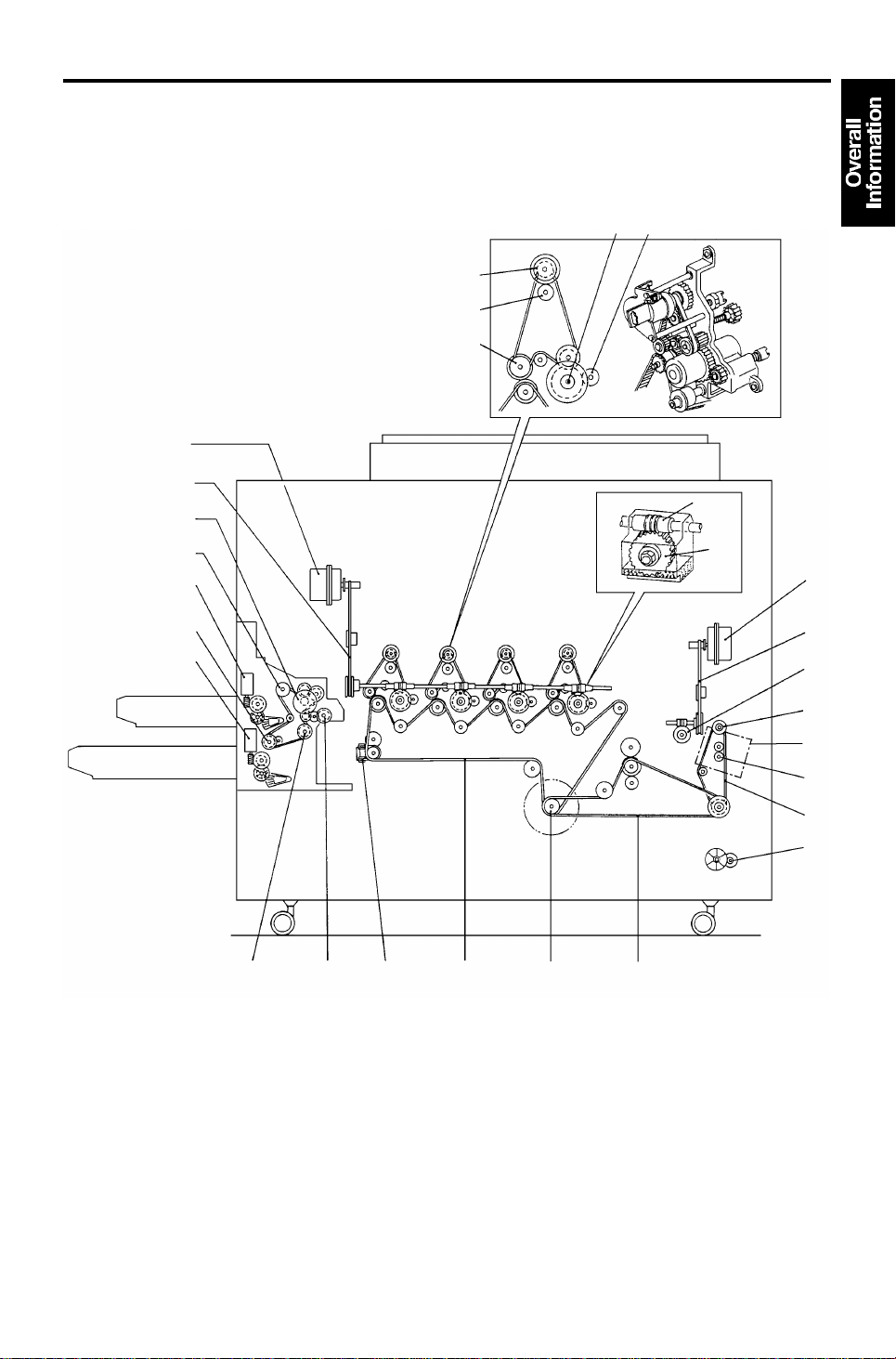

5 January 1995 DRIVE LAYOUT

5. DRIVE LAYOUT

15

16

17

18

19

20

21

22

10

23

24

25 26

9

8

7

27

28

6

5

1

23

1-25

DRIVE LAYOUT 5 January 1995

1. Toner Collection Coil Drive Belt

2. 1st Timing Belt

3. Main Motor

4. 2nd Timing Belt

5. Developer Removal Motor

6. 3rd Timing Belt

7. Fusing Unit Drive Gear

8. Transfer Belt Drive Worm Wheel

9. Transfer Belt Drive Timing Belt

10. Transfer Belt Drive Motor

11. Drum Drive Worm Wheel (4 pcs)

12. Drum Drive Worm Gear (4 pcs)

13. Cleaning Unit Drive Gear (4 pcs)

16. Toner Supply Drive Gear (4 pcs)

17. Development Unit Drive Gear

(4 pcs)

18. Drum Drive Motor

19. Drum Drive Timing Belt

20. Paper Feed Motor

21. Upper Paper Feed Clut ch

22. Upper Lift Motor

23. Lower Paper Feed Clut ch

24. Lower Lift Motor

25. Relay Clutch

26. Registration Clutch

27. Fusing Unit Idling Motor

(Model A105 only)

14. OPC Drum Shaft (4 pcs)

15. Toner Supply Clutch (4 pcs)

28. Fusing Idling Gear

(Model A105 only)

1-26

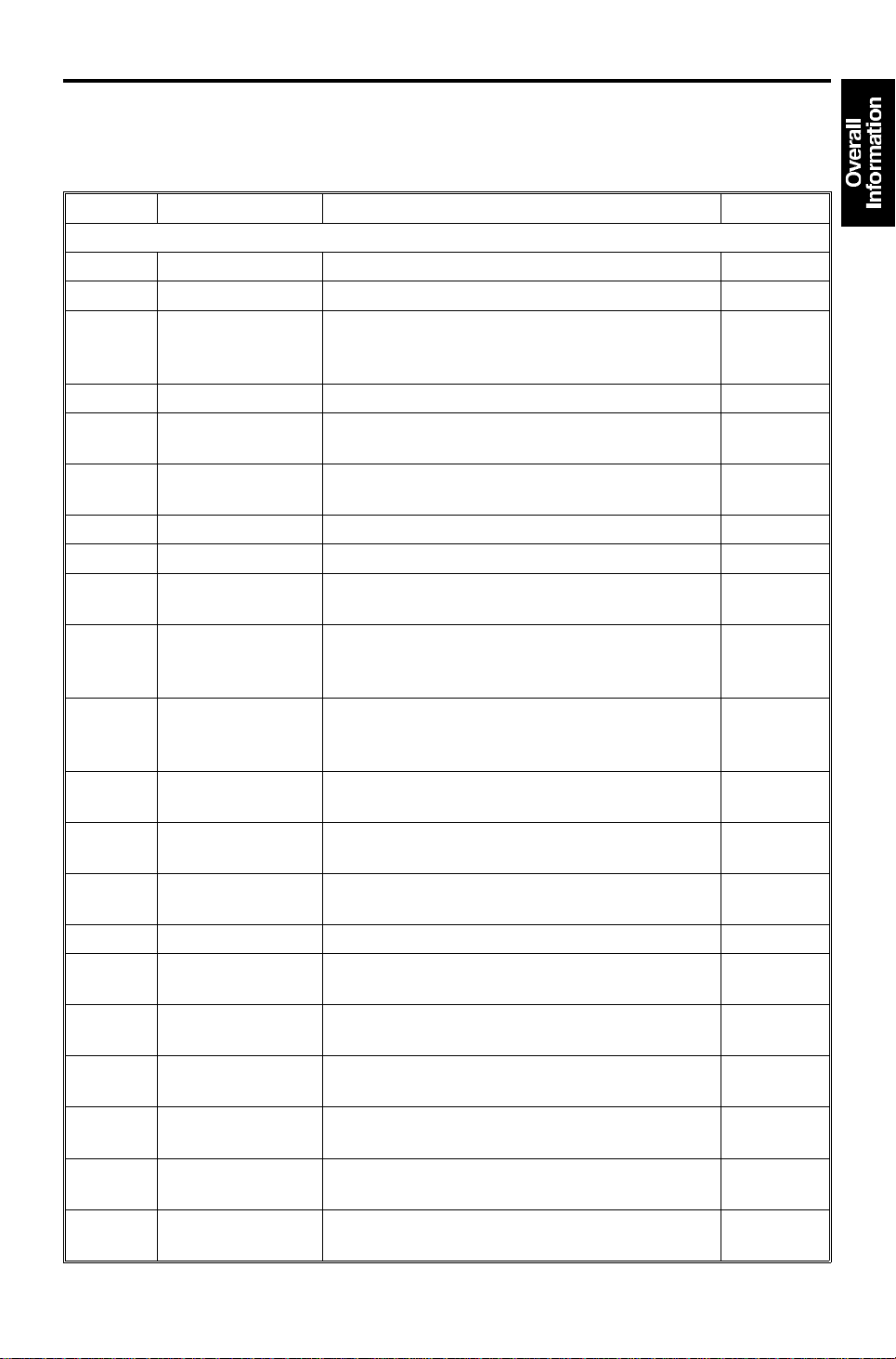

5 January 1995 ELECTRICAL COMPONENT DESCRIPTIONS

6. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical compone nt layou t on the reverse side of the poin t to

point (water proof sheet).

SYMBOL NAME FUNCTION LOCATION

MOTORS

M1 Scanner Motor Drives the scanner ( dc servomotor). 53

M2 Polygon Motor Turns two polygon mirrors (dc servomotor). 71

M3 Main Motor Drives the development units, cleaning units,

toner collection coil, belt cleaning unit, and

fusing unit.

M4 Drum Motor Turns the four OPC drums (dc servo motor). 10

M5 Transfer Belt

Motor

M6 Paper Feed Motor Drives the paper feed rollers, relay rollers,

M7 Upper Lift Motor Lifts the upper cassette’s bottom plate. 93

M8 Lower Lift Motor Lifts the lower cassette’s bottom plate. 99

M9 Toner Supply

Motor – Black

M10 Toner Supply

Motor – Magenta

M11 Toner Supply

Motor – Yellow

M12 Toner Supply

Motor – Cyan

M13 Developer

Removal Motor

M14 Front Scanner

Fan

M15 Rear Scanner Fan Cools the scanner cavity. 58

M16 Front IPU Inlet

Fan

M17 Rear IPU

Exhaust Fan

M18 Rear Exhaust Fan Always turns during power on to cool the air

M19/20 Fusing Exhaust

Fans (2 pcs)

M21 Charge Fan

– Black

M22 Charge Fan

– Magenta

Turns the transfer belt (dc servomotor). 6

registration rollers.

Supplies black toner from the toner supply unit

to the toner container in the development unit.

Supplies magenta toner from the toner supply

unit to the toner container in the development

unit.

Supplies yellow toner from the toner supply

unit to the toner container in the development

unit.

Supplies cyan toner from the toner supply unit

to the toner container in the development unit.

Is used when developer is removed from the

development units.

Cools the scanner cavity. 65

Cools the IPU cavity by taking air from outside

the copier.

Cools the IPU cavity by blowing hot air out of

the copier through an ozone filter.

around the fusing unit.

Cool the air around the fusing unit and OPC

drums through ozone filters during copy run.

Provides a flow of air to the charge corona

unit, ID sensor, and the toner shield glass.

Same function as M21. 8

12

113

123

125

127

129

2

23

11

4

44

8

1-27

Loading...

Loading...