Ricoh NC8115.015 Service Manual SF

SLIDE PROJECTOR UNIT

Model A092-17 A092-25 A092-27 A105-17 A105-27

A984-17 O X X O X

A984-27 X O O X X

A711-27XXXXO

O: The SPU can be connected to the copier.

X: The SPU cannot be con ne cted to the copier due to th e safety

standard.

5 January 1995 SPECIFICATIONS

1. SPECIFICATIONS

Acceptable Film Type: 35 mm positive and negative film, mounted film or

strip film (up to six frames per strip)

Warm-up Time: 0 sec.

Copy Speed: 4 cpm/81/2"x11", A4

1st Copy Time: 42 sec. (After pressing the start key)

Magnification Range: 50 to 400% ratios smaller than 50% are not

available when using the SPU

Focusing: Fixed focus

Projection Method: Slit (Horizontal)

Scanning Method: Moving Film

Projection Ratio: x 8.73

NOTE: For 115V/60HZ version, 93% is

automatically selected on the main fra me.

Effective Film Area: 21.5 x 33.0 mm (Full film size 24 x 36 mm)

Copy Image Size: 194 x 288 mm (Centering mode )

NOTE: Paper must be set lengthwise.

Power Source: 115 V/50, 60 Hz/ 10 A

220 ~ 240 V/50, 60 Hz/7 A

Power Consumption: 0.25 kw

Dimensions (W x D x H): Projector Unit:

12.5" x 18.5" x 11.4" (317 x 470 x 289 mm)

Mirror Unit:

1.8" x 10.1" x 1.8" (44 x 248 x 44 mm)

Weight: Projector Unit: Approx. 28.7 lbs (13.0 kg)

Mirror Unit: Approx. 1.1 lbs (0.5 kg)

1

COMPONENT LAYOUT 5 January 1995

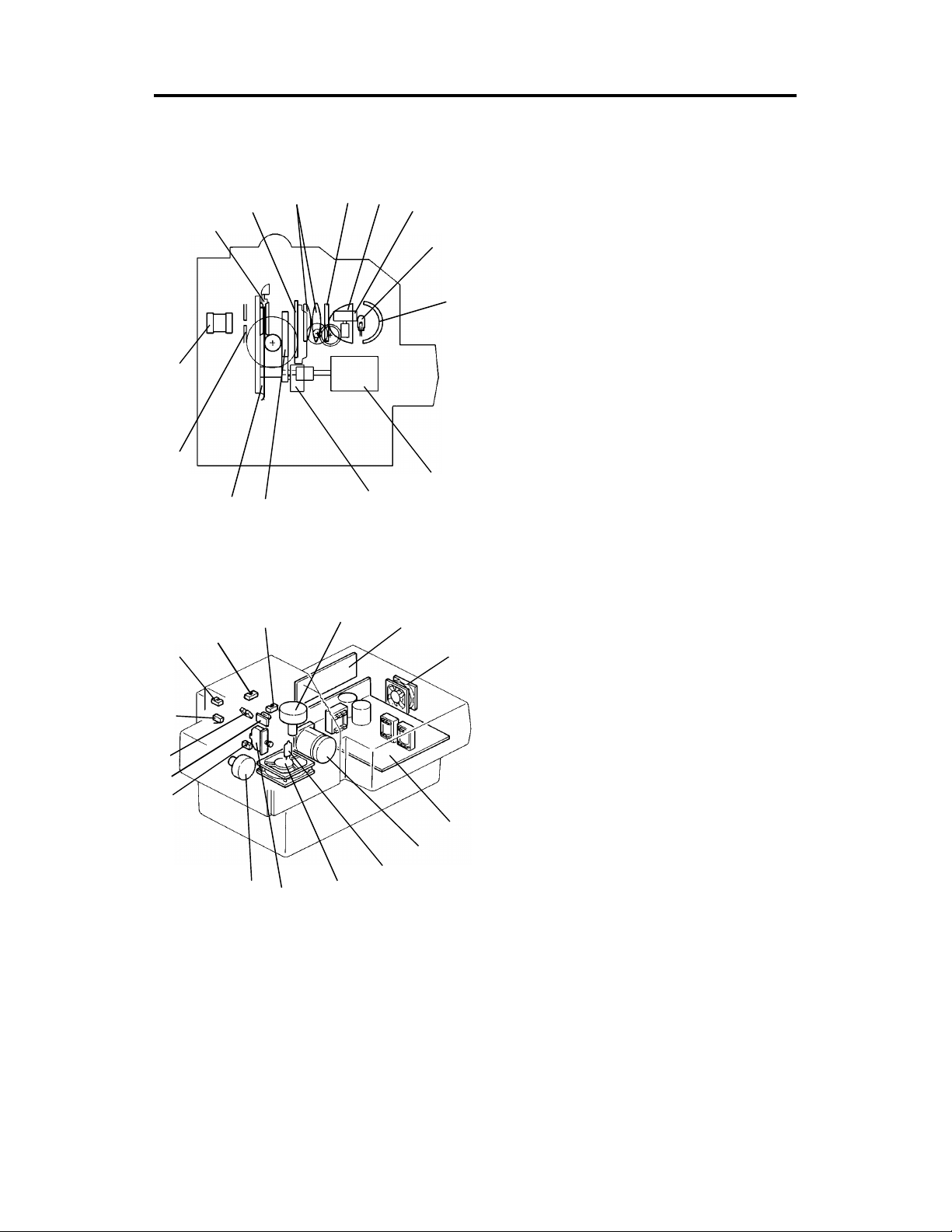

2. COMPONENT LAYOUT

Mechanical Components

Electrical Components

16

15

14

13

1

14

13

12

2

1

12

34

2

11

3

11

10

4

5

10

9

6

9

5

8

7

8

6

7

1. Film Holder

2. Light Compensation Filter

3. Condenser Lens

4. Heat Filter

5. Nonspherical Lens

6. Light Compensation Filter Motor

7. Halogen Lamp

8. Reflector

9. Film Scanning Motor

10. Color Compensation Filter Mot or

11. Color Compensation Filter

12. Film Scanning Belt

13. Diaphragm

14. Projection Lens

1. Film Scan H.P. Sensor

2. Mount Holder Set Se nsor

3. Light Compensation Filter H.P.

4. Light Compensation Filter Motor

5. Main PCB

6. PSU Outlet Fan

7. PSU (Power Supply Unit)

8. Film Scanning Motor

9. Halogen Lamp

10. Lamp Inlet Fan

11. Safety Switch

12. Color Compensation Filter Mot or

13. Color Compensation Filter H.P .

Sensor

14. Thermo Fuse

15. Lens Cover Sensor

16. Film Strip Holder Set Sensor

2

5 January 1995 ELECTRICAL COMPONENT DESCRIPTIONS

3. ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Location

Motors

M1

M2 PSU Outlet Fan Cools the PSU. 6

M3

M4

M5

Switches

SW1

Sensors

S1

S2

S3

S4

S5

S6

Light Compensation

Filter Motor

Film Scanning Motor Stepping Motor to move the film for

Lamp Inlet Fan Provides a flow of air to the halogen lamp to

Color Compensation

Filter Motor

Safety Switch Cuts DC 15 V current of the halogen lamp

Film Scan H.P. Sensor Notifies the CPU when the film is at the

Mount Holder Set

Sensor

Light Compensation

Filter H.P. Sensor

Color Compensation

Filter H.P. Sensor

Lens Cover Sensor Notifies the CPU whether the lens cover is

Film Strip Holder Set

Sensor

Stepping motor to move the light

compensation filter up and down.

scanning.

cool it.

Stepping Motor to turn the color

compensation filter.

when the lamp cover is opened.

home position.

Notifies the CPU when the mount holder is

set.

Notifies the CPU when the light

compensation filter is at the home position.

Notifies the CPU when the color

compensation filter H.P. sensor is at the

home position.

open or closed.

Notifies the CPU when the film strip holder

is set.

4

8

10

12

11

1

2

3

13

15

16

PCBs

PCB1

PCB2

Lamp

L1

Others

TF

Main PCB Controls the slide projector unit’s function

and communicates with the copier.

PSU Provides DC 15 V, 5 V, 12 V, and 24 V

current.

Halogen Lamp Supplies high intensity light to the film for

exposure.

Thermofuse Opens the 15 V line if the halogen lamp

overheats.

3

5

7

9

14

[D]

BASIC OPERATION 5 January 1995

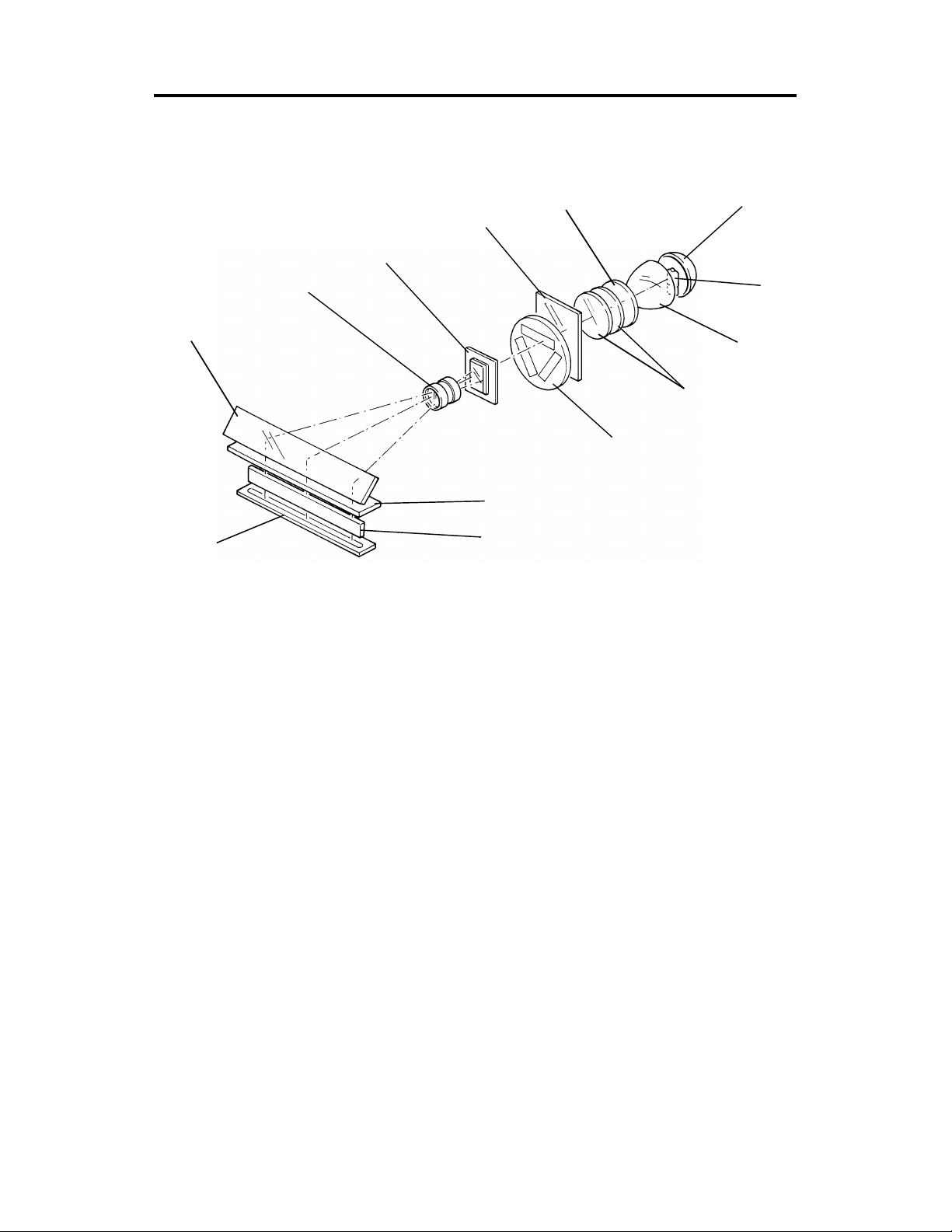

4. BASIC OPERATION

4.1 SUMMARY

[F]

[H]

[I]

[J]

[E]

[G]

[K]

[M]

[L]

[B]

[A]

[C]

The light of the haloge n lamp (150 W, 15 V) [A] is reflected by the reflector

[B] and it goes through the nonsphe rical len s [ C], the hea t filt er [D] , th e

condenser lens [E], the ligh t compensation filter [F], the color comp en sat ion

filter [G], and the film [H].

The heat filter cuts off heat from th e halog en lamp and pre vents the film from

deforming.

The light goes through the proje ctio n len s [I] , it is reflected 90° by the mirror

[J] and goes through the frost ed glass (up per layer: fresnel lens, lower layer:

diffused surface) [K] and the optical fib er arra y [L] to the full color CCD [M]

located on the copier’s scan ne r u nit .

NOTE: Film mounts with protective glass or filters can not be used. The se

are too thick to let the slide mount ho lde r clo se pro pe rly, resu ltin g in

a poorly focused image. In this case, take the film out of th e mount

with film protection glasses and set it to a normal mount for copying.

4

5 January 1995 BASIC OPERATION

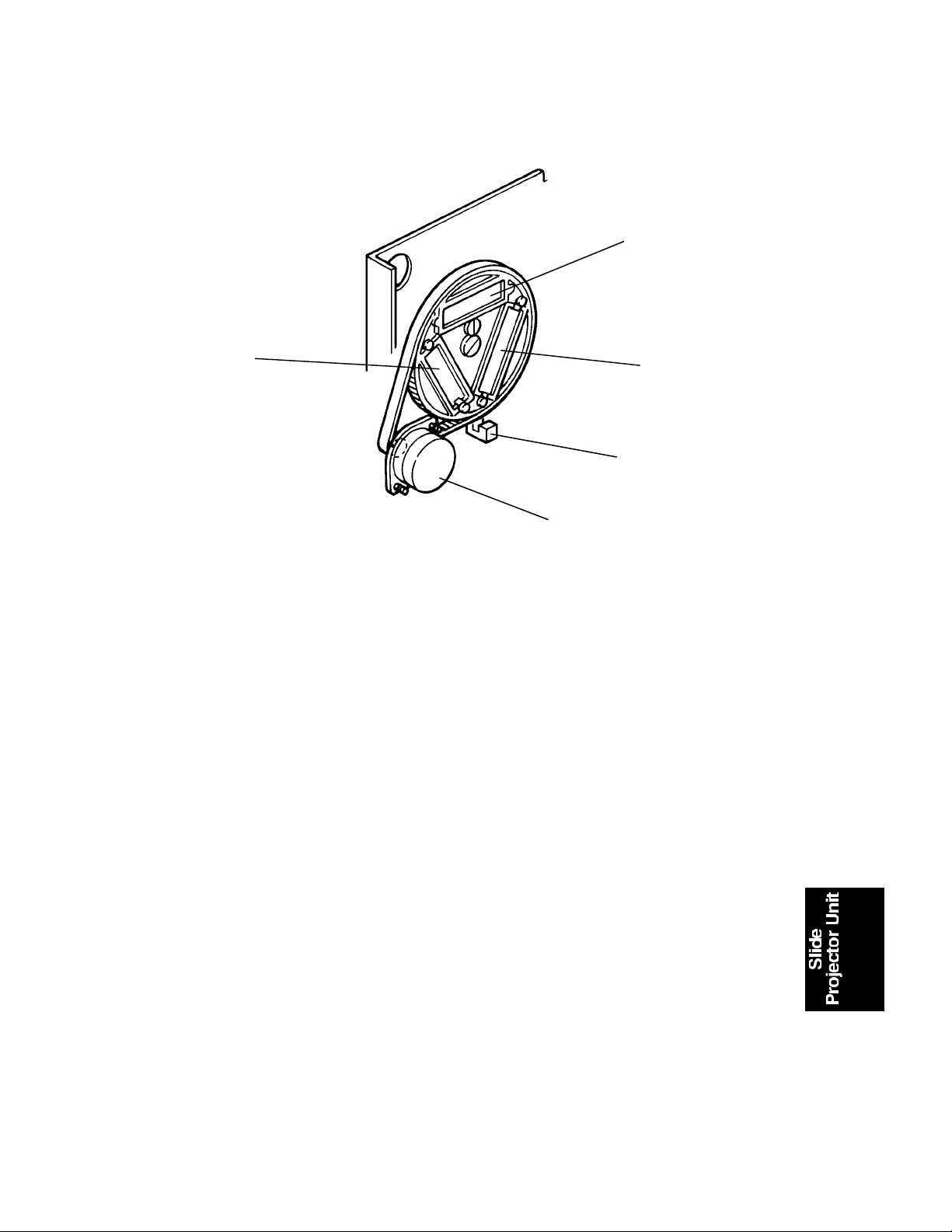

4.2 FILM COLOR CORRECTION

[C]

[A]

[B]

[D]

[E]

The RGB Gamma characteristics are diff ere nt betwee n positive film and

negative film. The color compensation filters are used to compen sat e the

RGB Gamma characteristics of each film.

There are 3 windows on the disk. One is the filter [A] for positive film, one is

the filter [B] for negative film, the other is no filter [C] fo r detecting initial

condition, or for SPU focus adjustment (SP92).

Home position is detected by the color compensation filter H.P. senso r [D].

The color compensatio n filter is rotated by the colo r compensation filter moto r

[E].

5

BASIC OPERATION 5 January 1995

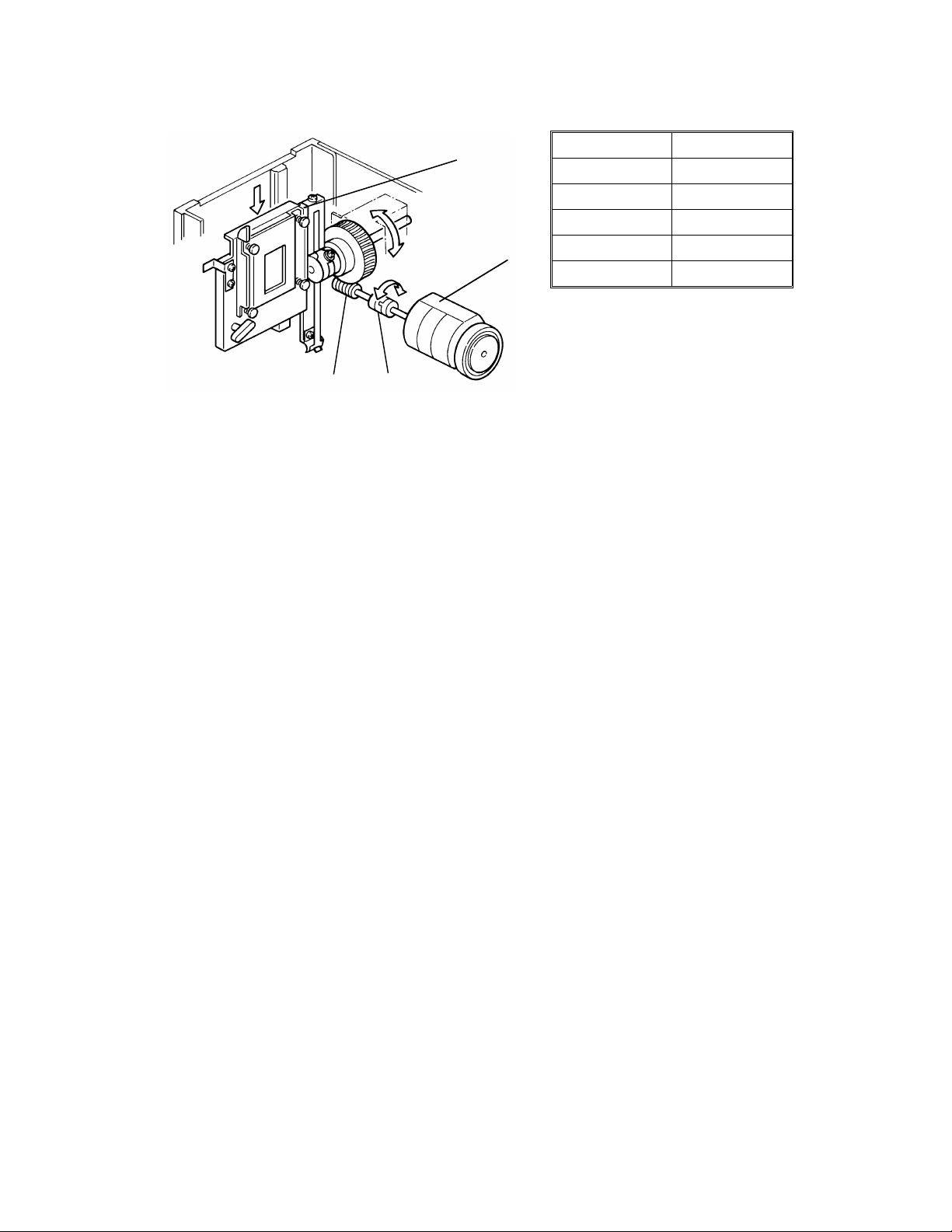

4.3 FILM SCANNING

[D]

[A]

Magnification Speed

50% 17.17 mm/sec

100% 8.59 mm/sec

200% 4.29 mm/sec

300% 2.86 mm/sec

400% 2.15 mm/sec

[B][C]

The film is scanned by being moved.

The scanner of the cop ier sta ys at 45 mm lef t of its h ome posit ion. The film is

moved down 50 mm (the length of film is 35 mm) at a specifie d speed . Se e

the table above.

The film scan motor [A] moves th e film up and down . The drive is tran sfe rred

through the coupling [B], worm gear [C], and film scan belt [D].

When 100% magnification is selected from the operation panel, the 35 mm

film image is actually enlarged 873% on the cop y.

For other magnification ratios, film scanning speed controls magnification in

the paper feeding direction, while image processing controls magnification in

the main scan direction.

Concerning leading edge regist ration and side to side registration, the y will

be easily changed between each copy or each orig inal due to its reproduction

ration (1 : 8.73). If the scann ing is delaye d 0.5mm, the image is shifted about

4 mm to the trailing edge.

For 115V/60Hz models, 93% reproduction ratio is automatically selected to

accommodate 81/2" x 11" paper. 11" (279 mm) is too short to sele ct 100%.

The Effective film area is 21.5 x 33 mm.

• Copy image on A4 lengthwise paper (210 x 297 mm):

21.5 x 8.73 = 187.7 mm

33 x 8.73 = 288.1 mm

• Copy image on 81/2" x 11" lengthwise paper (216 x 279):

187.7 x 0.93 = 174.6 mm

288.1 x 0.93 = 268.0 mm

6

5 January 1995 BASIC OPERATION

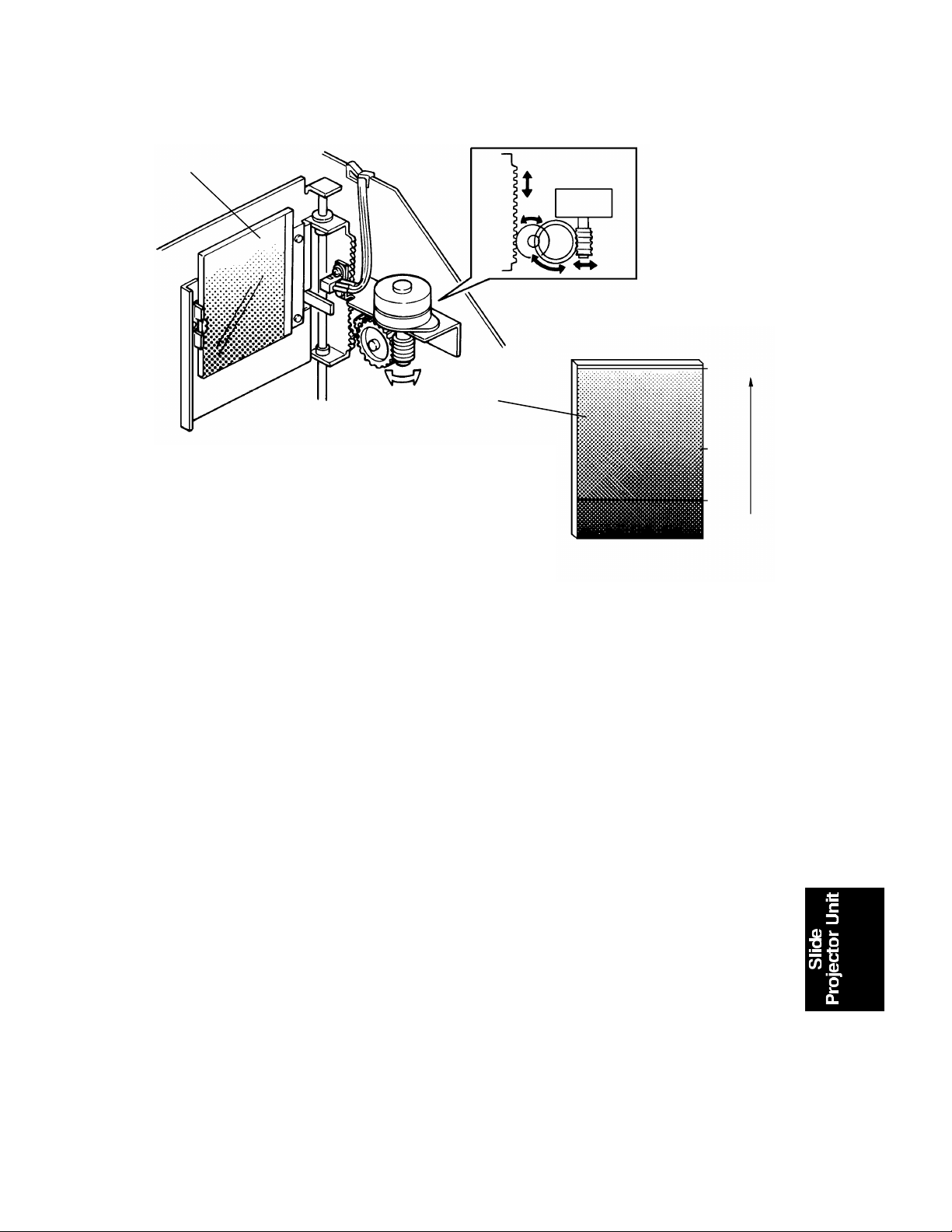

4.4 SHADING

[A]

100%

[A]

50%

Light

30%

0%

Dark

Shading corrects the following variations of the video data.

• V aria tions in sensitivity between bits of the CCD (arising from

production processes).

• V ariations in characteristics of th e colo r co mpe nsa tion filter,

light compensation filte r, mirror un it, lense s, an d op tica l fiber

array unit in the copier.

• L oss of brightness at both front and rear ends of the exposure

on the CCD.

• V aria tions in characteristics of the negative film

Negative film:

Color negative film comes in many kinds. A negative is a photo image laid on

a transparent strip of pla stic (calle d a ba se). All emulsio ns are to some extent

similar, but most bases are diffe ren t. Th e bases will a ff ect color ba lan ce, but

the effect is corrected by the shading function.

Positive films:

Positive films have more or less identical bases. So , the film base does no t

affect shading.

7

BASIC OPERATION 5 January 1995

Before scanning the original film, the shading function must be performed.

Set the base film (negative film mode) or no film (positive film mod e) in th e

film holder and press the shading key. The film holder goes down and stops

in position for scannin g of its the center area. The machine reads it as it

would a white reference board.

In this case, the light compensa tio n filt er [A] goes down to expose the 30%

density area of its filter. (100% : Clear, 0%: Pure black) See the previous

page. The maximum data is compared with the data in of the Video

Processing Board. If th e da ta is lower (darker) than the data in this bo ard , the

light compensatio n filter will be moved to expose the lighter area. If the dat a

is higher (brighter) than the data in the board, the filte r will be moved to

expose the darker area. Th e ap pro priate color compensation filter is selected.

For the next step, the machine scans 16 lines while the film is going up. The

Video Processing Board avera ges t he 16 line s pixel by pixe l fo r one main

scan, and the calculate d da ta is stored in that board. This is the wh ite wave

form data, which is used to correct the distortion of the video signal. Se e

page 2-29 of the PDC-1E service manual.

NOTE: If the mirror unit on the exp osu re gla ss suffers any vibration after

shading, vertical lines will appear on the copy image due to impro per

shading data of each picture eleme nt of the CCD.

To prevent or minimize these lines, do the follo wing ;

1) Fix the machine on the floor using four leveling shoes.

2) Advise the operator to take care against vibration s to th e copier

after shading.

3) Reset the mirror unit and perform shad ing again.

However, in negative mode, vertical lines in low tone areas are

normal, and it is not possible to eliminate th em comp letely. In

positive mode, these lines will be reproduced in high tone areas on

the copy.

8

Film movement

5 January 1995 BASIC OPERATION

4.5 AUTO IMAGE DENSITY

Trailing edge

35 mm

Leading edge

: Scanning area

: Pre-scanning area

After shading, the origin al film [A ] is pre-scanned to detect the brightest poin t.

The pre-scanning area is smaller than the scann ing area .

Exposure area: 35 mm x 24.0 mm

Pre-scanning area: 31 mm x 20.2 mm

Scanning area: 33 mm x 22.2 mm

Based on the data from t he brigh te st po int, the light compensat ion filter

position is re-adjusted. This prescanning is performed just be fo re cop ying.

9

[A]

BASIC OPERATION 5 January 1995

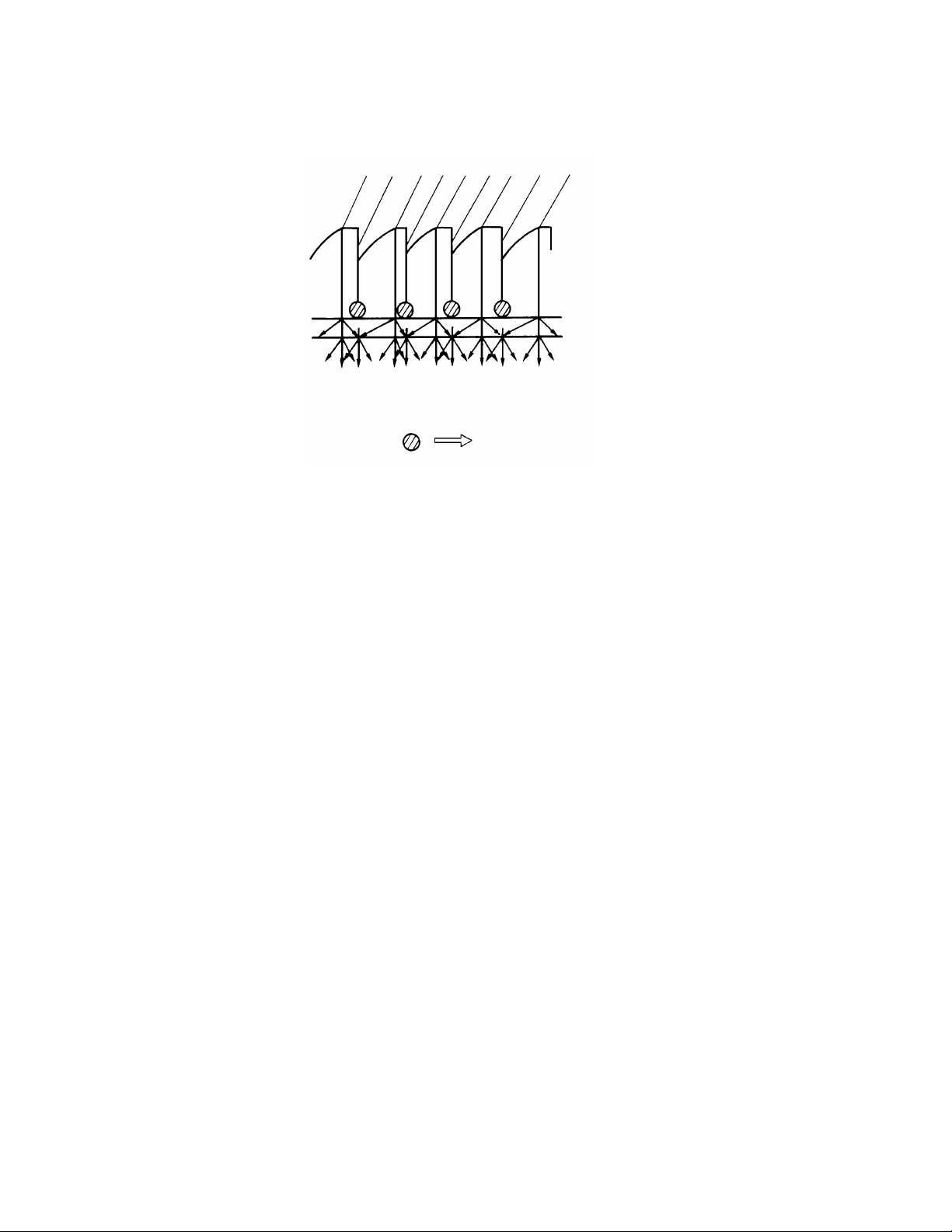

4.6 MIRROR UNIT

Light

[B]

Shadow

The mirror unit consists of the mirror, and th e frosted glass (upper layer:

fresnel lens, lower layer: diff use d surf ace). See the summary.

The fresnel lens [A] chang es th e ref lect ed image light path to para llel, and the

frosted glass [B] clears the shad ow fro m t he fresn el lens.

The image is formed on the frosted glass, which is in contact with the cop ier’s

exposure glass. The image is t he n see n by th e op tical fiber array.

10

Loading...

Loading...