Ricoh NC100 Service Manual

1 January 1990

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Electrostatic transfer system

Originals: Book/sheet, fixed plate n

Original Alignment: Left side and centered

Maximum Original Size: A3, 11" x 17"

Copy Paper Size: Maximum: A3, 11" x 17"

Minimum: A6, 81/2" x 51/2"

Copy Paper Weight: Black or single color copies: 52 to 104 g

14 to 28 lb

Full color copies: 64 to 104 g

17 to 28 lb

Copying Speed: Black: 24 cpm (A4, 81/2 " x 11")

12 cpm (A3, 11" x 17", 81/2" x 13")

Single Color: 6 cpm (all sizes)

Full Color: 4 cpm (all sizes)

Photo Mode: 2 cpm (all sizes)

First Copy

(A4, 81/2" x 11" sideways):

Warm-up Time: Within 5 minutes (Room temperature 20°C)

Automatic Reset: After 60 seconds (Adju stable from 0 to 180

Photoconductor: Organic photoconductor drum, 120 mm in

Black: 6.5 seconds (9.0 s for ID

sensor check cycle)

Single Color (Y, M, C): 13 seconds

Single Color (B, G, R): 18 secon ds

Full Color: 23 seconds

Photo Mode: 38 seconds

minutes by SP mode)

– Black/Color Copy:Black mode

– Copy Counter : 1

– Reproduction Ratio: Full size

– Interrupt Mode: OFF

– Sort/Stack OFF

– Image Density Auto ID

– Program Mode OFF

– All application modes: OFF

diameter

Drum Charge: Double-wire with grid wires (Neg at ive Cha rge )

1-1

1 January 1990

Erase Lamp: 128 LEDs (2.5 mm)

Fixed Reproduction Ratio s:3 enlargeme nt ratios and 4 reduction ratios, plus

two programmable ratios bet wee n 50 % and 200%

Zoom Range: Zoom from 50% to 200% in 1% increments

(Partial enlargemen t for ra tio s abo ve 142%.)

Scanning System: One directional scanning with mirrors an d len s

Scanner Light Source: Halogen bulbs in two series (320 W/single series,

640 W/both series)

Exposure System: Slit expo sure , moving optics

Lens: Through lens, f = 215 mm, F = 4.5

Development: Dual-component dry toner system (Black: 1.2 kg,

color: 0.7 kg)

Toner Replenishment: Black: 390 gram cartridge

Color: 100 gram cartridge

Toner Consumption:

(A4 or 81/2" x 11",

Black: 6,800 copies/cartridge

Color: 1,800 copies/cartridg e

7% Originals)

Development Bias: Negative variable bias

Toner Density Control: Primary: Toner density sensor in dev. unit

Secondary: Pattern den sity dete ction by

photosenso r

Image Transfer: Single wire DC corona (variable nega tive charg e

through transfer drum sheet)

Paper Separation: Clamp mechanism, single wire AC corona, and

pick-off pawls

OPC Drum Cleaning: Magnetic brush (250 grams of clea nin g carrier)

with bias roller and pre-cleaning corona (single

wire AC corona)

Quenching: Photo quenching by LEDs

Paper Feeding: Double universal cassettes (250 she et capacity)

Paper Feed System: Feed and reverse roller (FRR) system

Image Fusing: Heat and pressure type, silicone rub be r ro llers

and silicone oil

Fusing Lamp: Halogen lamp, 750 W/1 15 V or 220 V

1-2

1 January 1990

Copy Tray Capacity: 100 sheets for A3 (11" x 17")

250 sheets for all other p ape r sizes

Self-diagnostic Codes: 40 codes, indicated in the copy counter

Power Source: 115 V, 60 Hz, 15 A

220/240 V, 50 Hz, 8 A

Power Consumption: Maximum: 1.4 kW

Warm-up: 0.9 kW (average)

Ready: 0.15 kW (fusing lamp off)

Copy cycle: 1.0 kW (average)

Dimensions (W x D x H): Machine body: 835 x 760 x 507 millimeters

32.87 x 29.92 x 19.9 6 inch es

Weight: Approximately 145 kg (319 lb)

Optional Equipment: — ARDF (automatic reverse document

feeder)

— 20 bin sorter

— 3rd paper feed table

— Editor

— OHP Fuser

— Key counter (locally procured )

1-3

1 January 1990

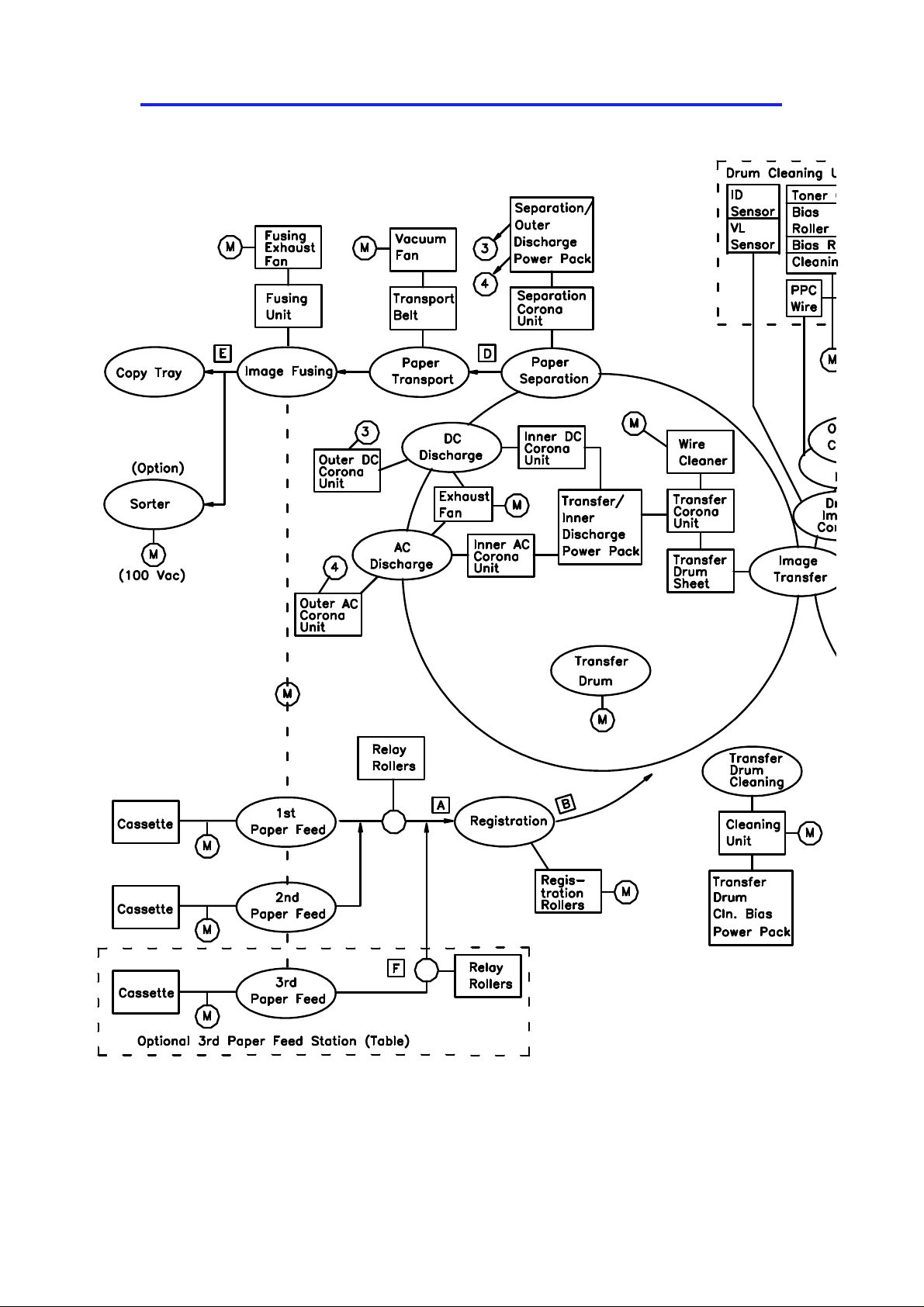

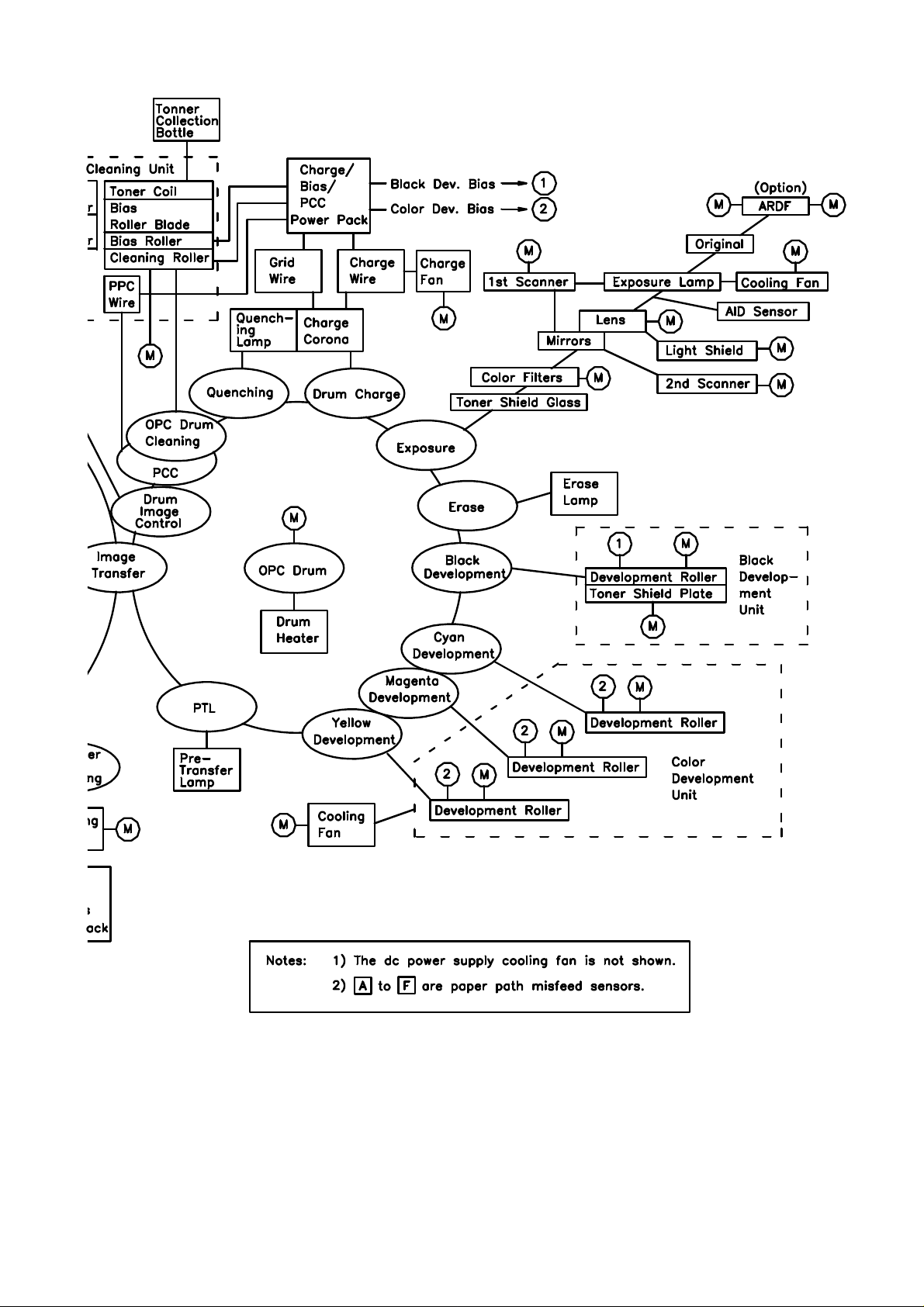

2. COPY CYCLE

1-4

1 January 1990

1-5

1 January 1990

3. BASIC CONCEPTS OF COLOR COPYING

3.1 COLOR REPRODUCTION PROCE SS

3.1.1 Light

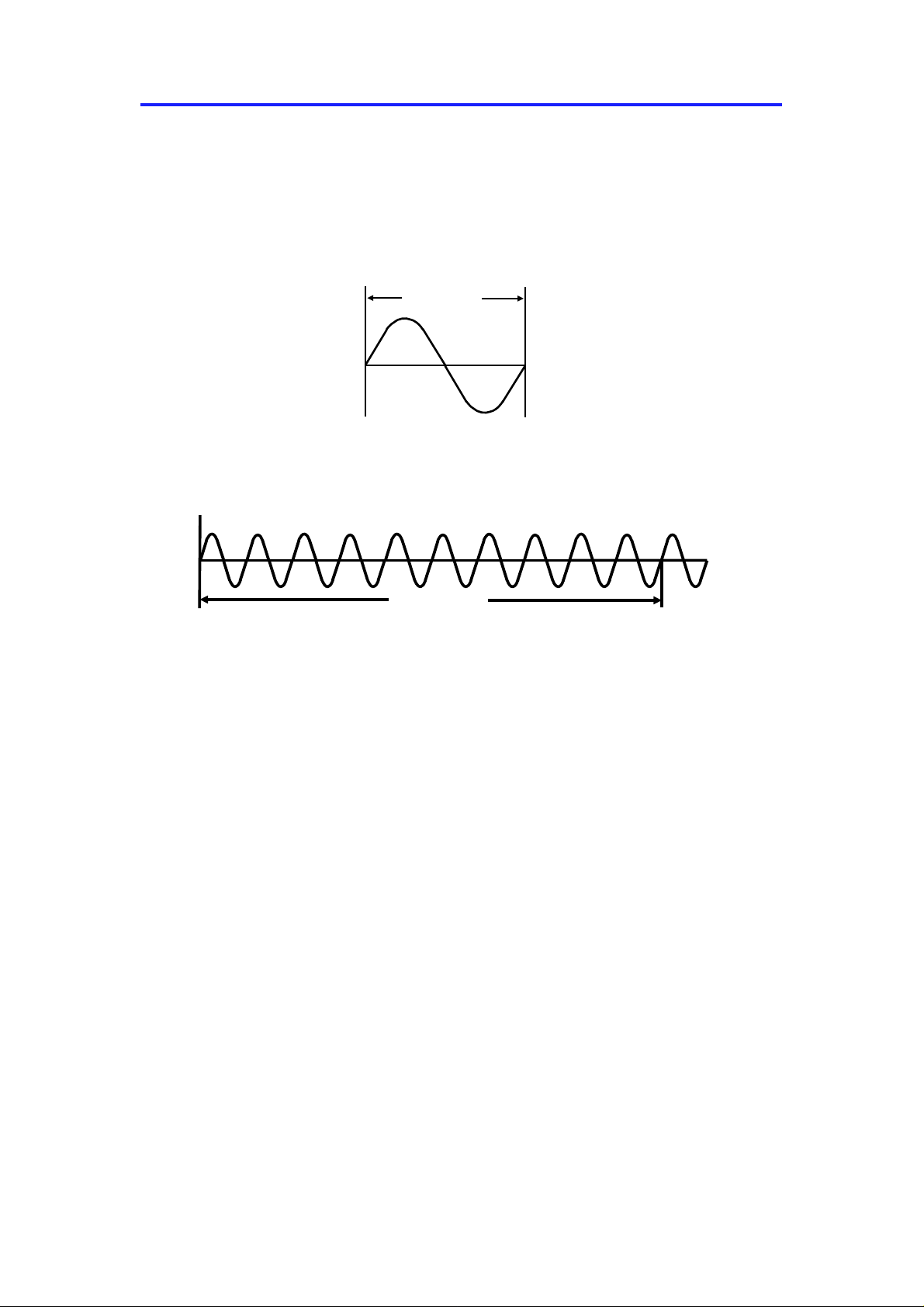

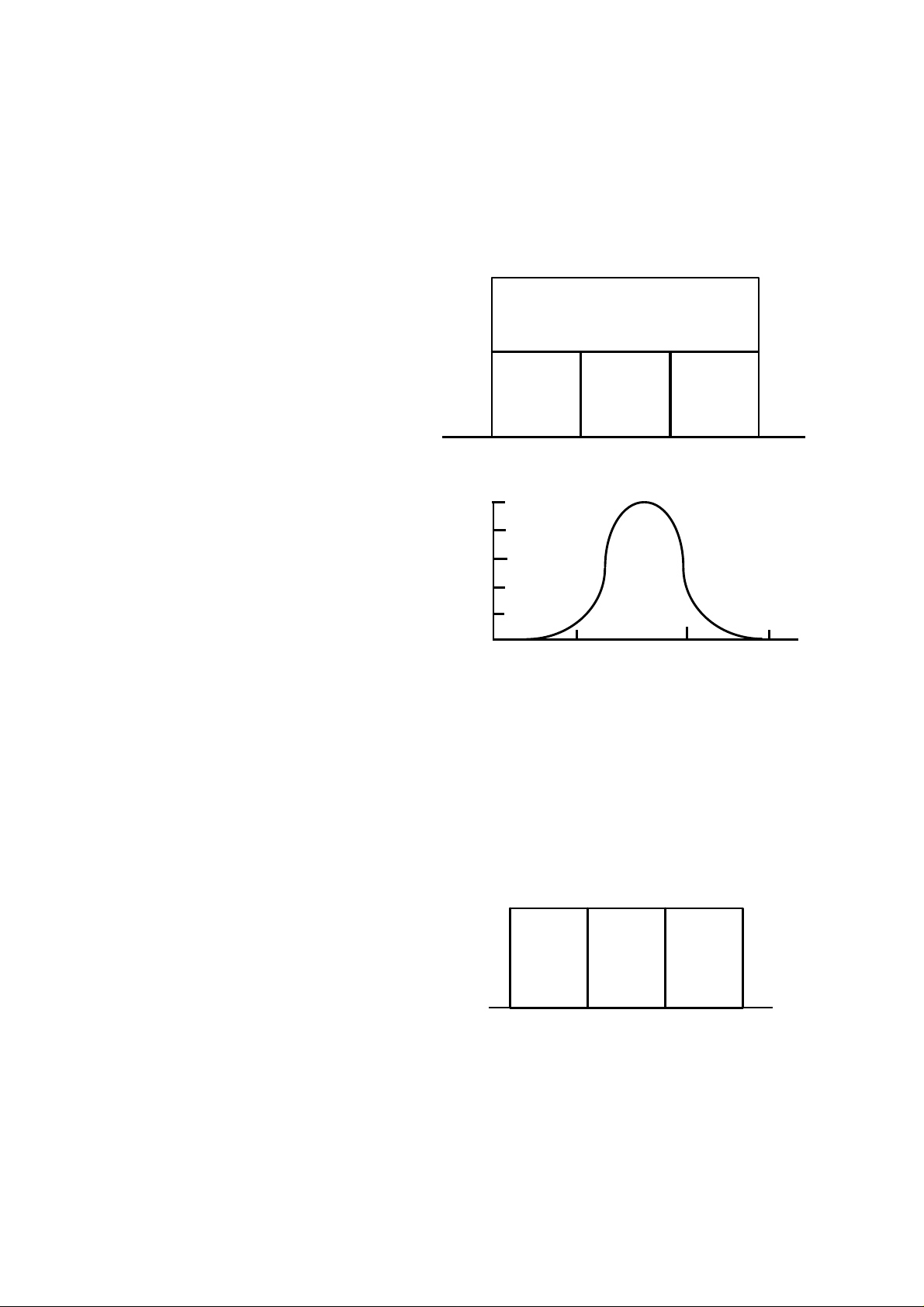

(1) Basic Wave Theory

a. Wavelength --- Length for on e wave cycle

Wavelength

b. Frequency --- The number of waves gene rat ed per seco nd. The unit

of frequency is Hz.

1 second

NOTE: The frequency of the above wave is 10 Hz.

c. Velocity --- The distance a wave travels in one second.

Velocity = Wavelength x Frequency

1-6

1 January 1990

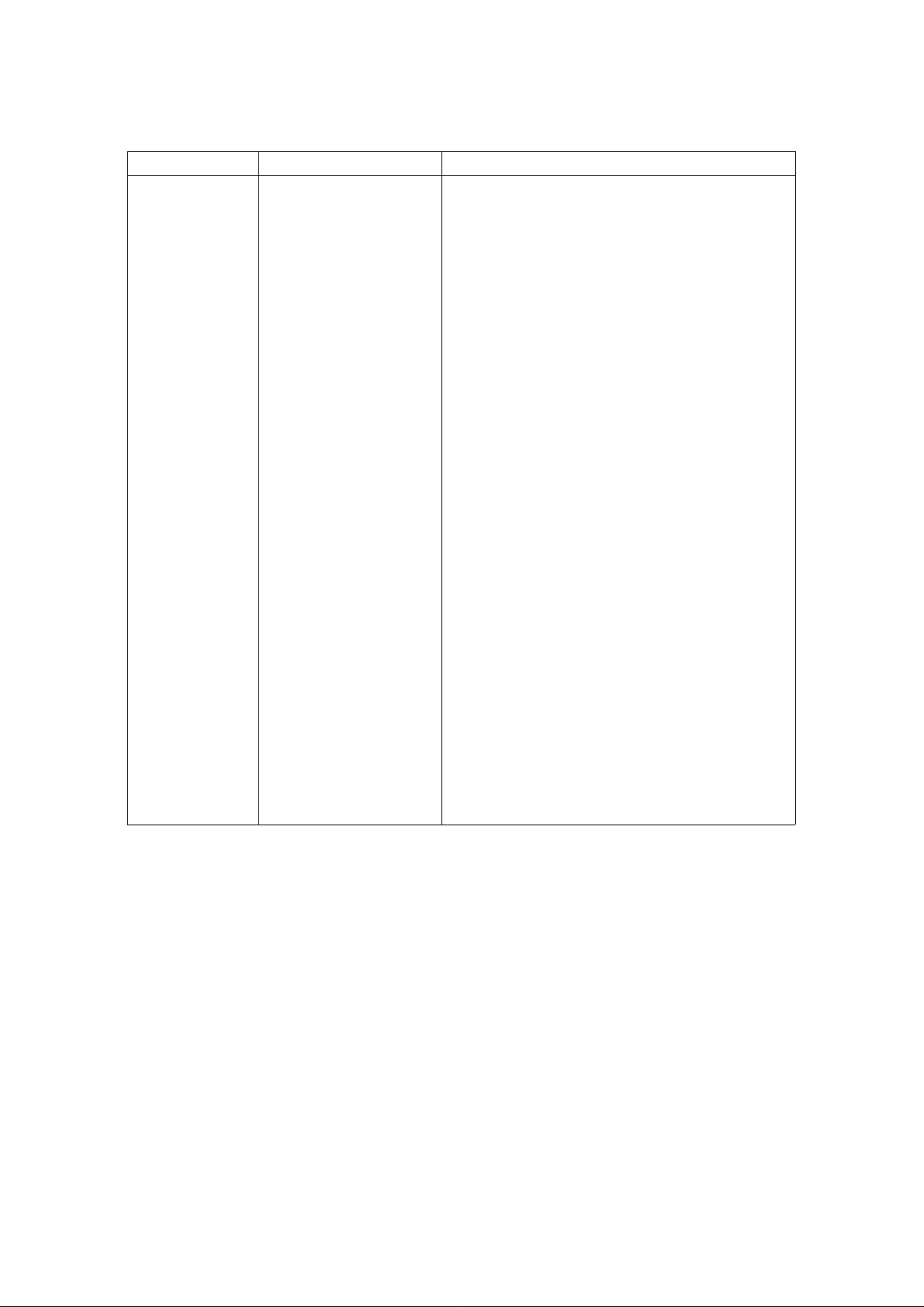

(2) Kinds of electromagnetic radiatio n --- Ligh t is one kind of electromagnetic radiation.

Wavelength Frequency Description/Application

∞ – 10

km

0 – 30KHz

Radio waves:

10km – 1

1km – 100

100m – 10

km

m

m

30KHz – 300KHz

300KHz – 3MHz

3MHz – 30MHz

LF(low frequency): Long wave

MF (medium frequency): Medium wave

HF (high frequency): Short wave

Radio/microwave s:

10m – 1

m

30MHz – 300MHz

VHF (very high frequency ): Very short

wave

1m – 10

cm

300MHz – 3 GHz

UHF (ultra high frequency): Ultra short

wave

10cm – 1cm

3GHz – 30GHz

SHF (super high frequency): Centimeter

wave

1

cm

– 1

mm

1

mm

0.1

– 0.1

mm

mm

–700nm

700 – 630 nm

630 – 590 nm

590 – 560 nm

560 – 510 nm

510 – 450 nm

450 – 400 nm

16

3x10

3x10

– 3x1011Hz

11

– 3x10

12

Hz

3x1012 –

3.8x1014Hz

(3.8 – 4.8) x 10

14

Hz

(4.8 – 5.1) x 1014Hz

(5.1 – 5.4) x 1014Hz

(5.4 – 5.9) x 1014Hz

(5.9 – 6.7) x 1014Hz

EHF (extremely high " ): Millimeter wave

Submillimeter wave

Infrared rays (heat generation)

Visible light:

Red

Orange

Yellow

Green

Blue

Purple

(6.7 – 7.5) x 1014Hz

400 – 10 nm

10 – 0.001n m

Less than

0.1nm

7.5x1014 –

3x1016Hz

3x1016 – 3x20

20

Hz

Ultraviolet light

X rays

Gamma rays

More than 3x1016Hz

1-7

1 January 1990

3.1.2 Light and Color

(1) White Light

When sunlight passes thro ugh a prism, it separates into various colors.

This is because sunlight is compo sed of light of different wavelengths.

It is called "white light" sin ce sun light is sensed as "white" by the eye s.

(2) Wavelength and Color

The eye senses a differe nt color when light with a different wavelength

reaches the eye.

• Light with a 580 nm

wavelength is recognized as "Yellow".

• Light with a 610 nm

wavelength is recog-

Ultraviolet

light

Violet Blue Green Yellow Orange Red

Blue (B)

Green (G)

Red (R)

nized as "Orange".

When light rays with

wavelengths between 400

and 500 nm reach the eye,

violet-blue (in this manual, it is

called "Blue") is recognized.

Also, "Green" is recognized fo r

light with wavelengths between

500 and 600 nm, and "Red" is

recognized for light with

400

100

80

60

40

20

500 600 700

wavelengths from 600 to 700

nm.

400

500

600

The sensitivity range for the eye is 400 to 700 nm, and the peak

sensitivity is at 556 nm.

Infrared rays have a wavelen gth of more than 700 nm and ultra viole t

rays have a wavelength of less than 400 nm. Neith er are visible to the

eye.

Infrared

light

700 nm

(3) Color of objects

When an object is exposed by th e white light, it absorbs some rays and

reflects other rays.

a. When light rays around 610

nm are reflected, and other

Blue

Green

Red

rays are absorbed, this

object is said to be "Orange".

(B)

(G)

(R)

b. When all light rays are

reflected, the object is

400 500 600

recognized as "White".

c. When all rays are absorbed, the ob ject is recogn ized as "Bla ck".

1-8

700nm

When a white object is seen through a red filter, it is seen to be "red".

Although it reflects all light rays, only red can pass through a red filter.

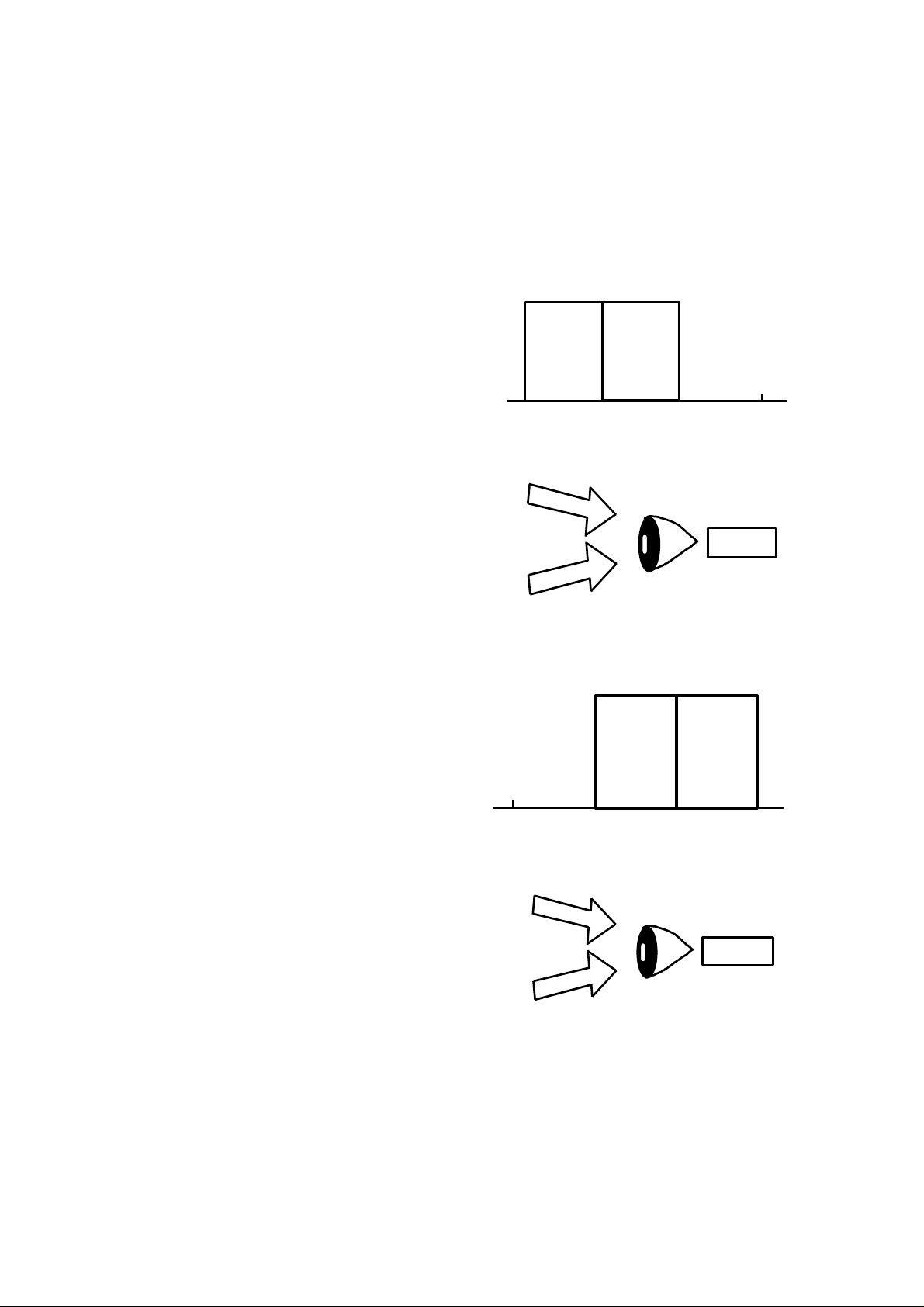

(4) The three basic colors

The eye contains three kinds of color sensitive cells. These cells are

called B cones, G cones, and R cones an d they are sensitive to "blue",

"green", and "red" light. The pe rception of color depends on the relative

level of excitation of these cells. Blue, gree n and red are calle d th e

"Three Basic Colors".

3.1.3 Light Mixture

Blue

Green

(1) Blue + Green

When both "Blue" and "Green"

light reach the eyes, the eyes

sense a clear light blue, which

(B)

400 500 600 700nm

(G)

is called "Cyan". Since white

light is composed of "Blu e" ,

"Green", and "Red" light,

"Cyan" means that the re d

component has been

eliminated from white light.

Blue (B)

Green (G)

"Cyan" and "Red" are called

"Complimentary Colors".

1 January 1990

Cyan (C)

(2) Green + Red

When both "Green" and "Red"

light reach the eyes, they sense

"Yellow". Since "Yellow" means

that "Blue" is eliminated from

white light, "Yello w" an d "B lue "

are called "Complimentary

Colors".

1-9

Green

(G)

400 500 600 700nm

Green (G)

Red (R)

Red

(R)

Yellow (Y)

1 January 1990

(3) Blue + Red

When both "Blue" and "Red"

light reach the eyes, they sense

purple-red color, which is called

"Magenta". "Magenta" and

"Green" are "Complimentary

Colors".

(4) Summary

Light

White

B

C

M

Y

R

G

Black

3.1.4 Color Toner

Toner

Y

G

B

Magenta (M)

G

M

Red

(R)

R

C

Blue

(B)

400 500 600 700nm

Blue (B)

Red (R)

Light

R

MC

Toner

B

Y

Complimentary Colors

(1) Light Reflective Characteristics

a. Cyan Toner

"Cyan" toner absorbs "Re d"

rays and reflects "Blue" and

"Green" rays. Reflected "B"

B

M

Y

R

White

C

G

and "G" rays are seen as

"Cyan".

RB

G

Blue

(B)

400 500 600 700nm

Green

(G)

B

White paper

b. Magenta Toner

"Magenta" toner abso rbs "G reen" rays and reflects "Blue" and "Red"

rays. Reflected "B" and "R" rays are seen as "Mag enta".

Blue

Red

RB

G

B

G

Toner

C

R

(B)

400 500 600 700nm

(R)

1-10

White paper

Toner

M

R

1 January 1990

c. Yellow Toner

"Yellow" toner absorbs "Blue" rays and reflects "Green" and "Red" rays.

Reflected "green" and "red " ligh t rays are seen as "Yellow".

Red

(R)

400 500 600 700nm

2) Color Toner Mixtures

a. Cyan + Magenta

When cyan and magenta

toner are combined on wh ite

paper, the magenta layer

absorbs green and th e cyan

layer absorbs red. As a

result, blue is reflected.

b. Magenta + Yellow

When magenta and yellow

toner are combined on wh ite

paper, the magenta layer

absorbs green, and the

yellow layer absorbs blue.

As a result, red is reflected.

c. Cyan + Yellow

Green

(G)

R

G

B

Y

G

Toner

White paper

Y

G

R

B

C

RB

G

B

White paper

R

G

B

White paper

Black

M

M Toner

Toner

C

R

Y Toner

Toner

M

When "Cyan" and "Yellow"

toner are combined on wh ite

paper the "C" layer absorbs

"Red", and the "Y " layer

absorbs "Blue". As a result,

"Green" is reflected.

d. Cyan + Magenta + Yellow

When all three color toners are

combined, the cyan la yer ab sorb s red,

the magenta layer absorbs green, and

the yellow layer absorbs blue. As a

result, no visible light is reflecte d, and

we see black.

1-11

R

G

B

White paper

R

G

B

White paper

G

Y

Toner

C

Toner

Black

Y Toner

M

C

Toner

Toner

1 January 1990

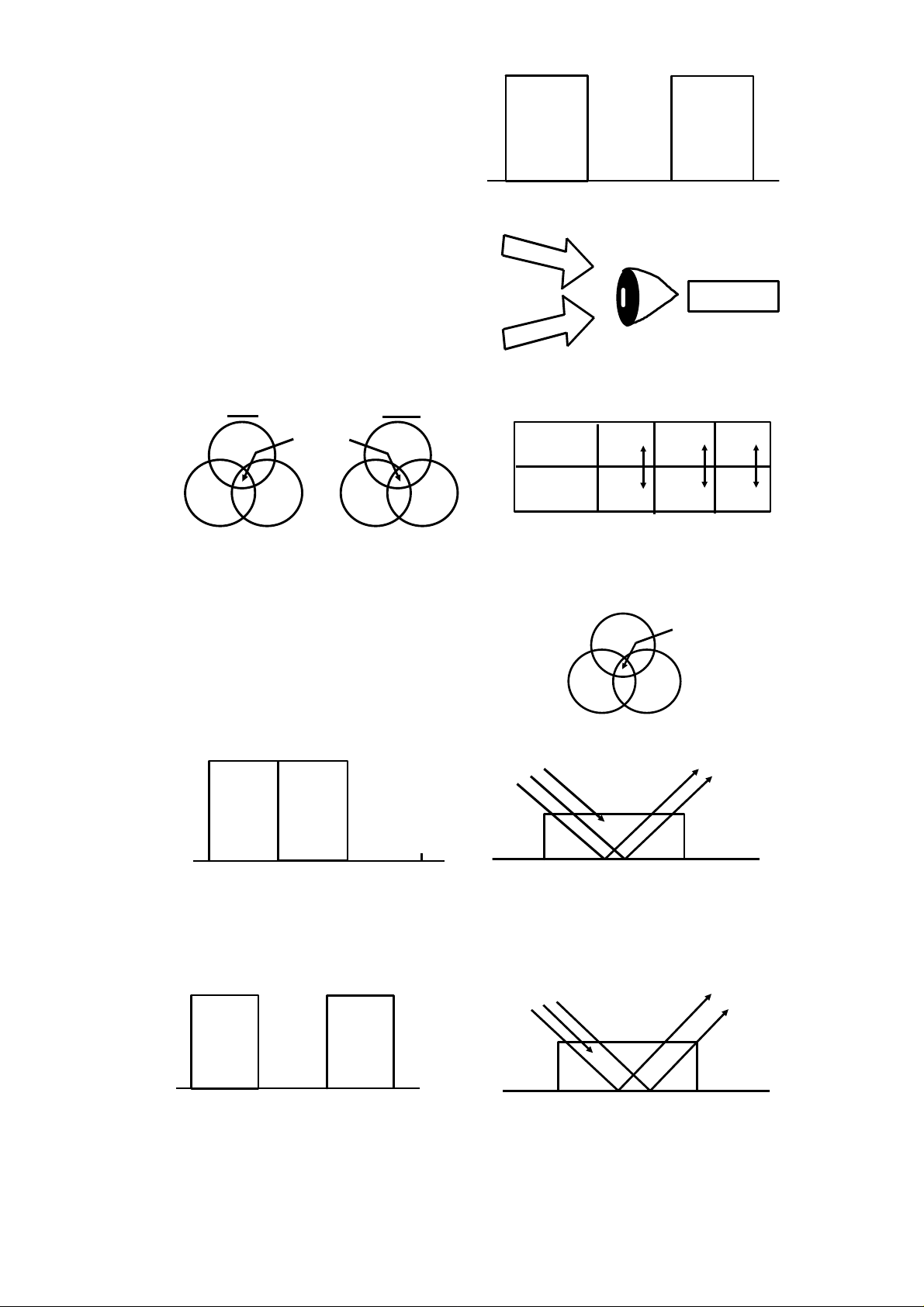

3.1.5 The Characteristics of Filters

(1) Red Filter

The "Red" filter allows "Re d" lig ht to pa ss through and absorbs "Blue"

and "Green".

B

Red

G

R

(R)

400 500 600 700nm

(2) Green Filter

The "Green" filter allows "Gree n" light to pass through and absorbs

"Blue" and "Red".

B

Green

(G)

400 500 600 700nm

G

R

(3) Blue Filter

The "Blue" filter allows "Blue" light to pass through and ab sorbs "Green"

and "Red" rays.

B

Blue

G

R

R Filter

G Filter

(B)

400 500 600 700nm

B Filter

1-12

1 January 1990

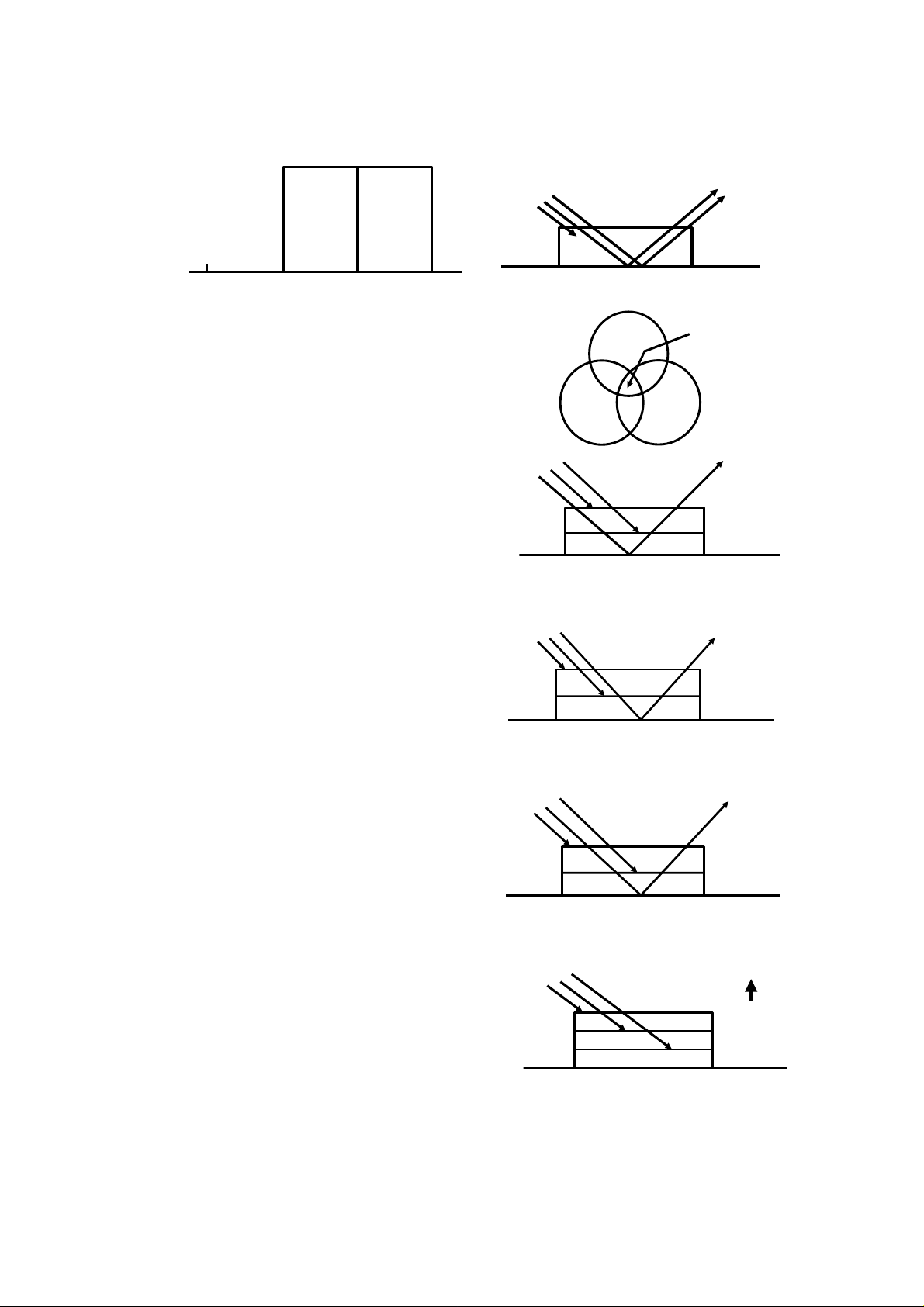

3.1.6 Full Color Copy Process

Three filters (red, green, blue) and three color tone rs (cyan, magent a, yellow) are used to make full color copies as follo ws.

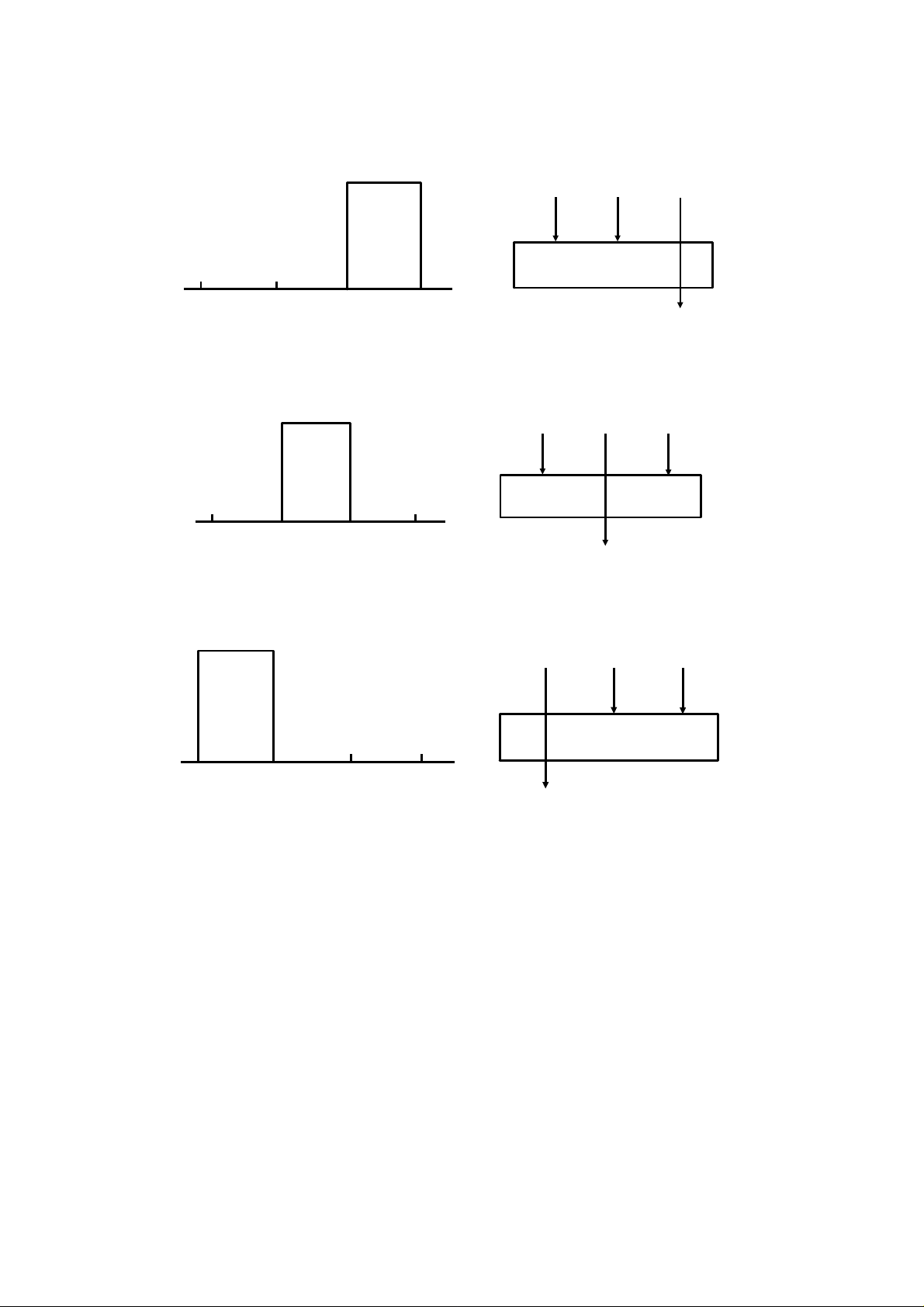

(1) 1st Cycle: Cyan Development with "Red" filter exposure

Original

Red

Filter

OPC

Drum

Cyan

Development

White

BGR BGRBRG

BGRYCM

B

GR

Toner

C

C

OPC Drum

C

Black

C

C C

Paper

Image

Transfer

(2) 2nd Cycle: Magenta Development with "Green" filter exposure

Original

Green

Filter

OPC

Drum

Magenta

Development

White Black

BGRYCM

BGR BGRBRG

BGR

M MM

Toner

M

OPC Drum

Image

Transfer

M

C

C C

M M

Paper

C C

M

C

(3) 3rd Cycle: Yellow Development with "Blue" filter exposure

Original

Blue

Filter

OPC

Drum

Yellow

Development

White Black

BGRYCM

BGR

BGR

Y

Y

OPC Drum

Toner

Y

BGRBRG

Y

1-13

Image

Transfer

YM

White

BGRYCM

Y

Y C M CCC

M

Paper

Image Fusing

Paper

Y

M

Black

12

2

1 January 1990

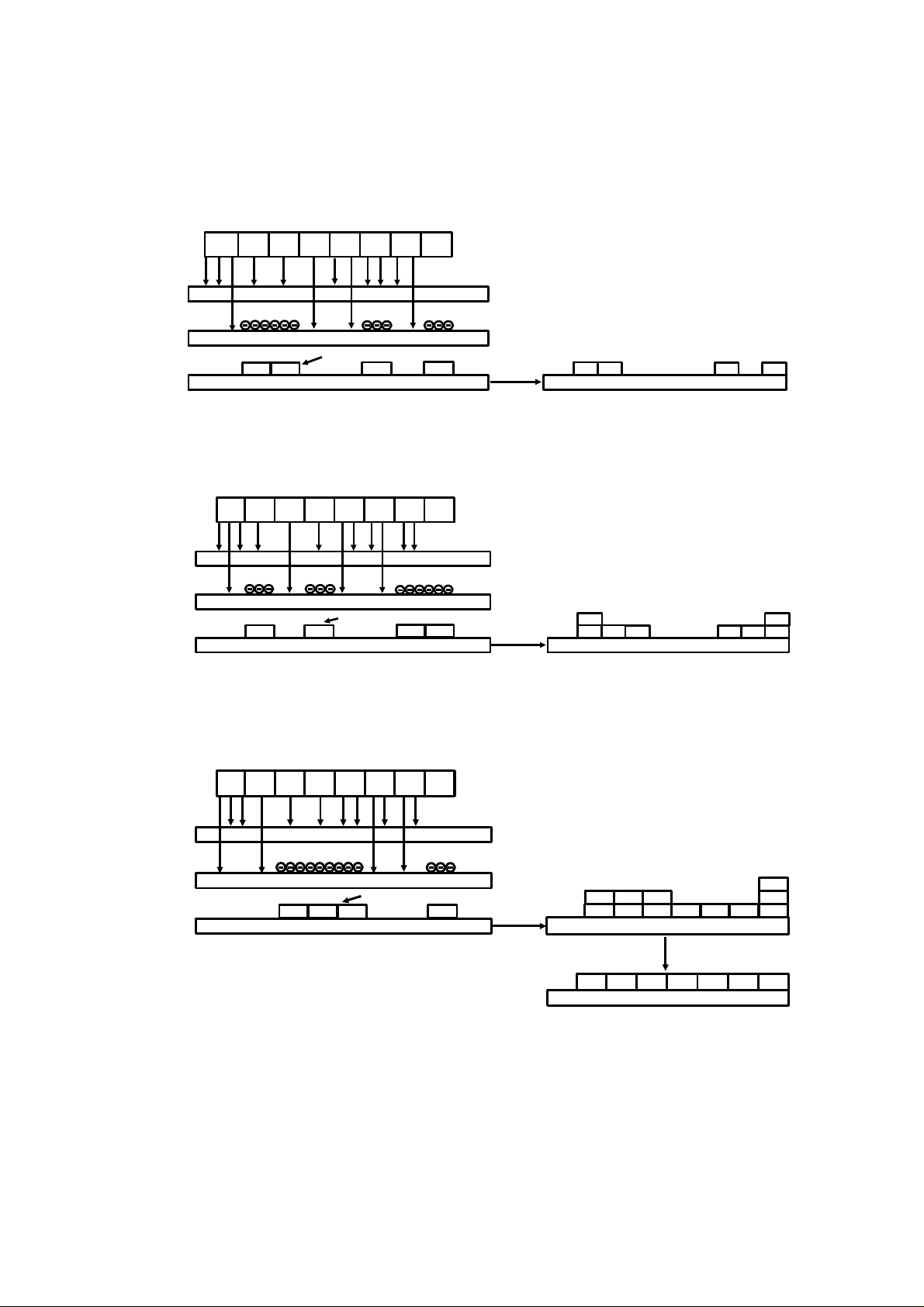

4. DRUM PROCESSES

3

14

15

10

9

13

8

16

7

11

4

5

6

1

5

6

(1) OPC Drum

A unique OPC drum (120 mm diameter) ha s high re sista nce in the dark

and low resistance under light.

The drum speed is 226 mm/sec. in black development mode and 113

mm/sec. in color development mode.

(2) Drum Charge

In the dark, the charge corona unit applies a negative charge to the

drum. The grid plate ensures tha t th e charge is applied uniformly. The

charge remains on the drum surface because the photoconductive drum

has high electrical resistance in the dark.

1-14

1 January 1990

(3) Exposure

An image of the original is reflected to the OPC drum via mirrors, a len s,

and a light separation filter. The charge on the drum surface is

dissipated in direct pro portion to the intensity of th e ligh t exposing the

OPC drum, thus producing an electrical latent image.

The neutral density filter is used in bla ck and sin gle color cop y mo des.

The color filters are used in fu ll co lor cop y mode and single color erase

mode.

In full color mode, the original is scanned three times with a diffe ren t

filter being used each time (red filter for cyan development, gre en filte r

for magenta development, blue filter for yellow development).

(4) Erase

The erase lamp (red LED with 2.5 mm steps) illuminates the areas of

the charged drum surface that will not be use d for the copy imag e. The

resistance of the drum in the illuminated areas drops and the charge

dissipates.

(5) Development

Each time a scan is made, the development roller moves negatively

charged black, cyan, magenta, or yellow developer to the OPC drum.

The toner is attracted to the negat ively cha rge d are as on the drum

surface, thus developing the latent image. The other color developers

remain inside the development unit.

(6) Toner Density Detection

The toner density sensor on the bot to m of each de velo pment unit

detects the magnetic perme ability of deve loper each time a scan is

made. If the voltage outpu t by the to ner den sity sen sor is lo wer th an the

standard output volta ge , ad ditional toner is supplied. (The standard

output voltage is stored in memory wh en deve loper is replaced, and it is

updated by ID sensor data.) The toner density sensor also detects when

toner is about to run out.

(7) Pre-transfer Lamp (PTL)

The pre-transfer lamp LEDs illuminat e the OPC drum to lower the dru m

potential for image transfer and OPC drum cleanin g.

(8) Image Transfer

Copy paper is fed to the transfer drum and th e lea din g edge is clamped .

A negative charge is applie d to the backsid e of paper through the

transfer drum sheet. This cha rge pulls th e tone r part icles on the OPC

drum surface onto the copy paper.

1-15

1 January 1990

When the transfer corona current is applied, the copy paper is

electrically attracte d to the tran sfer drum sheet. In full color mode , the

copy paper makes three passes through the image transfer area. Since

the transfer drum sheet has alre ad y been cha rged during the first

transfer cycle, the second tran sfer charge must be higher than the first

charge for image tran sfe r to take place. The same is true for the third

transfer cycle.

(9) Drum Image Control

a. ID Sensor

The sensor pattern is made by charging a strip of the drum and then

erasing all but a small section of the charged area. This section is

developed with a higher development bias than normal. (There is no

sensor pattern in the optics.) The ID senso r (p hoto sensor) detects the

reflectivity of the pattern and the era sed drum surf ace and outputs

two voltages. The ratio of the one output voltage to the other changes

whenever the toner den sity of the sensor pattern chang es. The toner

supply level voltage of the toner density sensor is then shifte d to

increase or decrease the tone r con centration in the develope r and

maintain the correct amou nt of ea ch colo r o f to ne r on th e OPC drum.

This keeps the colors in balance .

b. VL Sensor

To prevent dirty background on cop ies due to drum residual charge

and exposure decay of the drum surf ace , the exposure lamp voltage

is shifted up based on the comparison of VL sensor data with initial set

data. The VL pat te rn is located in the optics, and it is developed

during the copier warm-up cycle if the main switch is turned on and

the fusing tempera ture is lower than 50°C.

(10) Pre-cleaning Corona

The pre-cleaning corona (PCC) a pplies an AC corona with a positive

DC bias to the drum. This reduces the electrical attra ctio n of toner to the

drum so that it will be easier to clea n th e drum.

(11) Drum Cleaning

Negatively charged cleaning carrier attracts positively charged toner

from the drum surface.

The cleaning bias roller has a negat ive bia s t hat ele ctrically separates

toner from the cleaning carrier. The bias blade then peels toner off the

roller, and the cleaning coil carries toner to the collectio n bott le.

1-16

1 January 1990

(12) Quenching

After toner is removed from th e OPC drum surface, the quenchin g lamp

(LEDs) turns on to electrically neutralize the dru m.

(13) Paper Separation

The clamper opens and push es th e pa pe r up. The pick-off pawls then

peel the paper off the transfer drum. An AC separation corona breaks

the electrical attraction between the copy pa per and the drum so th at

the paper separates easily fro m the drum.

(14) DC Discharge

The inner DC discharge corona applies a positive potent ial to the

negatively charged inner surf ace of th e transfer drum sheet. The outer

DC discharge corona applies a nega tive potential to the oute r surface of

the transfer drum sheet. This discharges the transfer drum sheet.

(15) AC Discharge

An AC discharge with different frequency is applied to bo th the inne r

and outer sides of the transf er dru m sh eet. This neutralizes the transfer

drum sheet.

(16) Transfer Drum Cleaning

After the copy cycle, th e cleaning brush contacts th e tra nsfer drum

sheet and removes tone r on th e transfer drum. The transfe r drum may

become dirty if there is a paper jam or if a large original is copied onto a

small sheet of copy paper. This is to avoid to ne r stain s on th e reverse

side of the next copy.

1-17

1 January 1990

5. PAPER PATH

(5) (6)

(4)

(3)

(2)(1)

(1) Paper Feed

This copier uses the feed and reverse roller (FRR) system. The FRR

mechanism takes a sheet off the pap er sta ck a nd fee ds it to the

registration rollers.

The cassette can hold 250 sheets of paper.

The standard version of th is copier has two paper feed station s. An

additional paper feed station is available when the copier is installed

with the optional table.

(2) Registration

When the copy paper reaches the reg istra tion rollers (not turning at this

time), it buckles slightly to correct skew an d sea t be twe en the ro llers.

1-18

1 January 1990

The registration rollers start turn ing to feed paper to the paper clamp .

The rollers turn quicker than normal at this time so that the paper

buckles slightly when the leading edge con tacts the clamp. This

ensures that there will be no skewing when the paper is clamped.

(3) Image Transfer and Paper Separa tio n

See the Drum Processes section.

(4) Paper Transport/Image Fusing

After paper separat ion , the paper is transported to th e fu sing rollers by

the transport belt. The transport vacuum fan pulls the paper onto the

belt to ensure smooth tra nsport.

The paper passes betwee n the fusing rollers, which bond the ton er to

the paper with heat and pressure.

(5) Copy Tray/Sorter

The copy is fed out to the copy tray by the exit rollers o r to th e top bin of

the 20 bin sorter.

The sort and stack functions of the sorter can only be used wit h

black/white copies.

(6) Auto Reverse Document Feeder

The optional document fe eder ha s thre e mod es: ADF, SA DF, ARDF.

The bottom sheet is separate d fro m the origin al sta ck b y the sepa rat ion

belt and is fed to the exposure glass.

1-19

123

11

10

1 January 1990

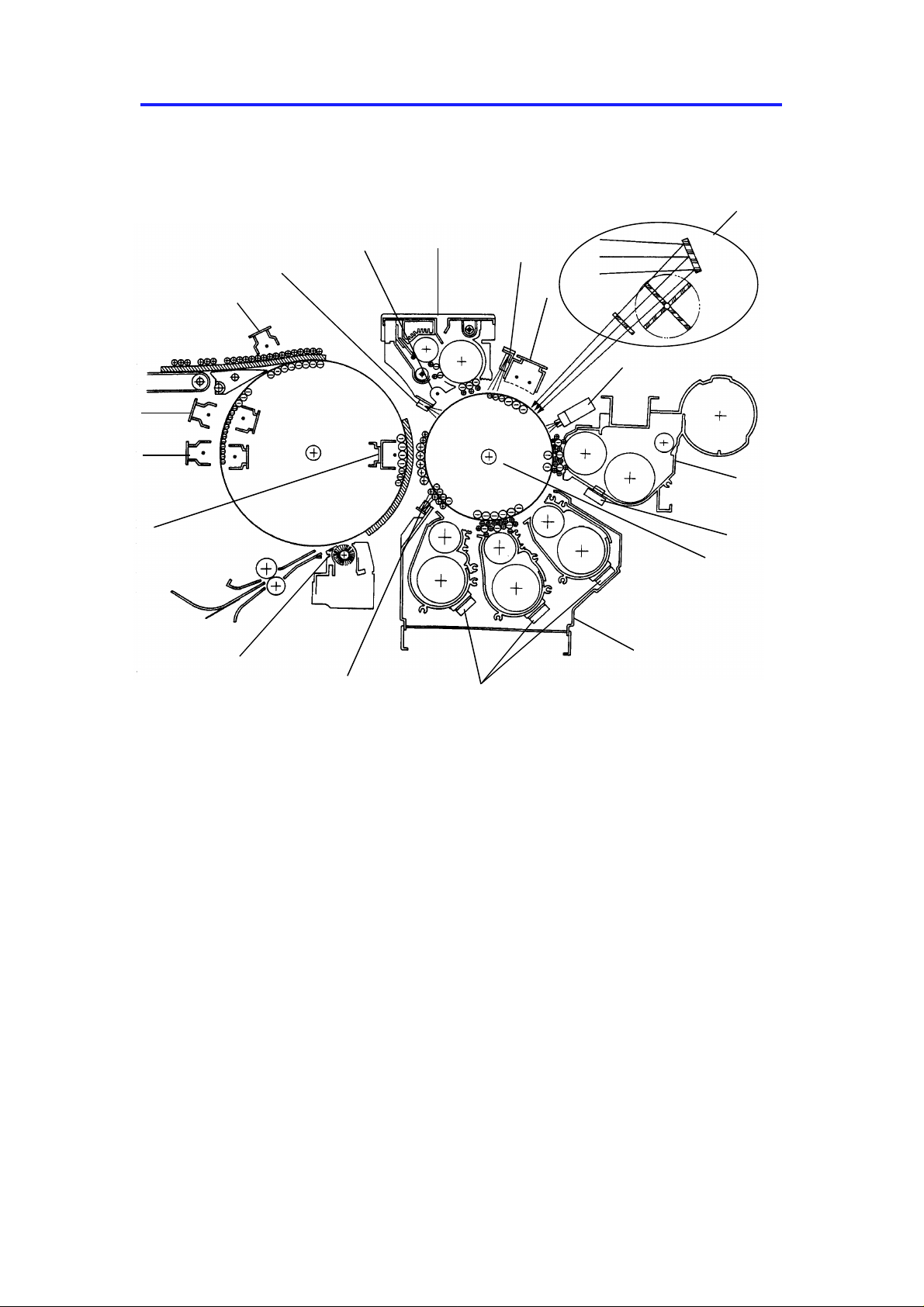

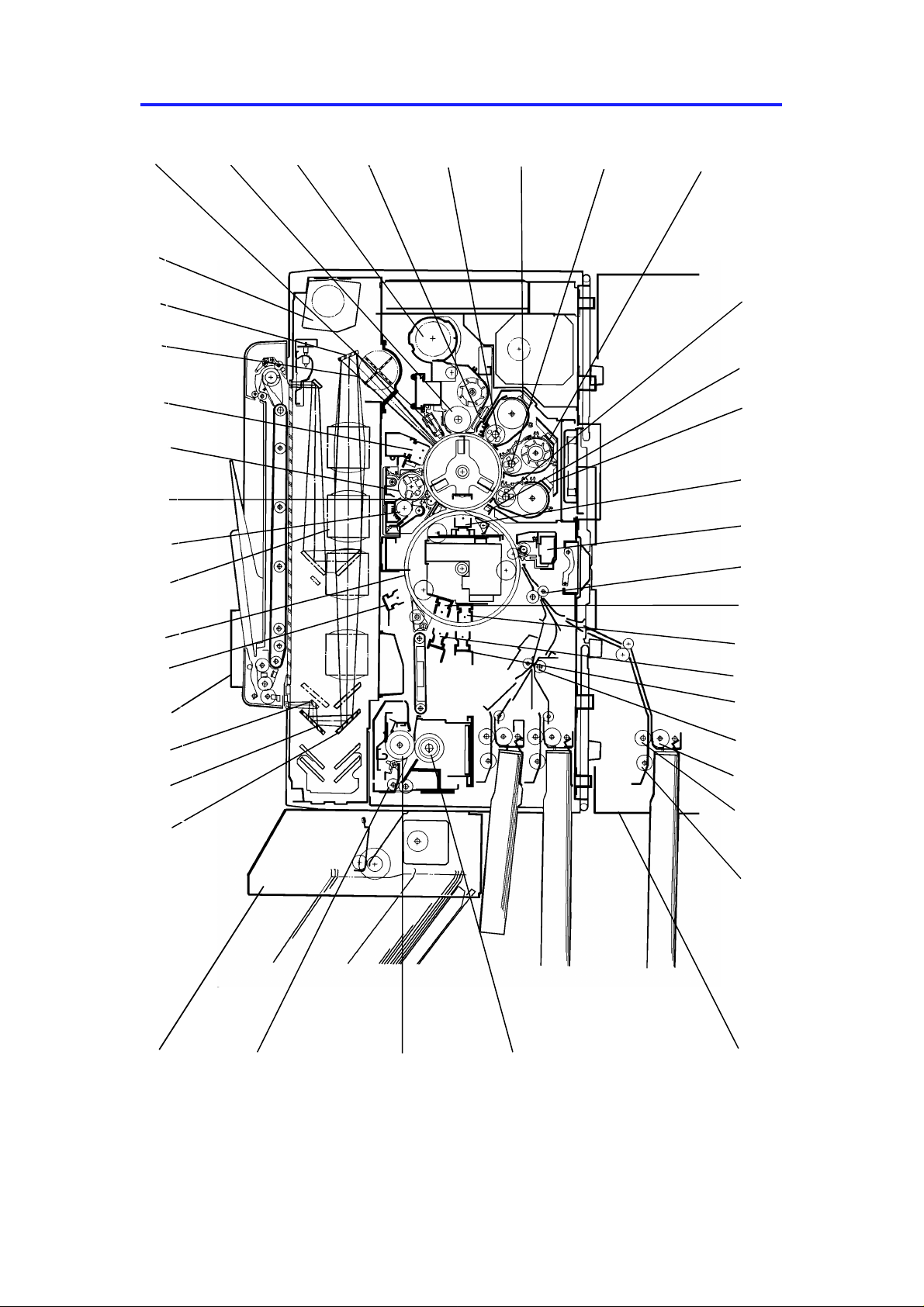

6. MECHANICAL COMPONENT LAYOUT

14

13

12

15

9

16 17

8

7

18

19

20

21

22

23

24

25

26

27

28

29

41

6

5

4

40

39

38

30

31

32

33

34

35

36

37

1-20

1 January 1990

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. ARDF

5. Separation Corona Unit

6. Transfer Drum

7 . Lens

8. Cleaning Bias Roller

9. PCC

10. Cleaning Roller

11. Charge Corona Unit

12. Color Filters

13. 4th Mirror

22. Magenta Toner Density Senso r

23. Cyan Development Rolle r

24. Pre-transfer Lamp (PTL)

25. Cyan Toner Density Sensor

26. Transfer Corona Unit

27. Transfer Drum Cleaning Unit

28. Registration Roller

29. Inner Discharge DC Corona

30. Inner Discharge AC Corona

31. Outer Discharge DC Corona

32. Outer Discharge AC Corona

33. Relay Roller

34. Reverse Roller

14. Optics Cooling Fan

15. Erase Lamp

16. Black Development Roller

17. Black Toner Supply Unit

18. Black Toner Density Sensor

19. Yellow Development Roller

20. Yellow Toner Density Sensor

21. Magenta Develop ment Roller

35. Paper Feed Roller

36. Pick-up Roller

37. Table with 3rd Paper Feed Unit

38. Pressure Roller

39. Hot Roller

40. Exit Roller

41. Sorter

1-21

3

23

1 January 1990

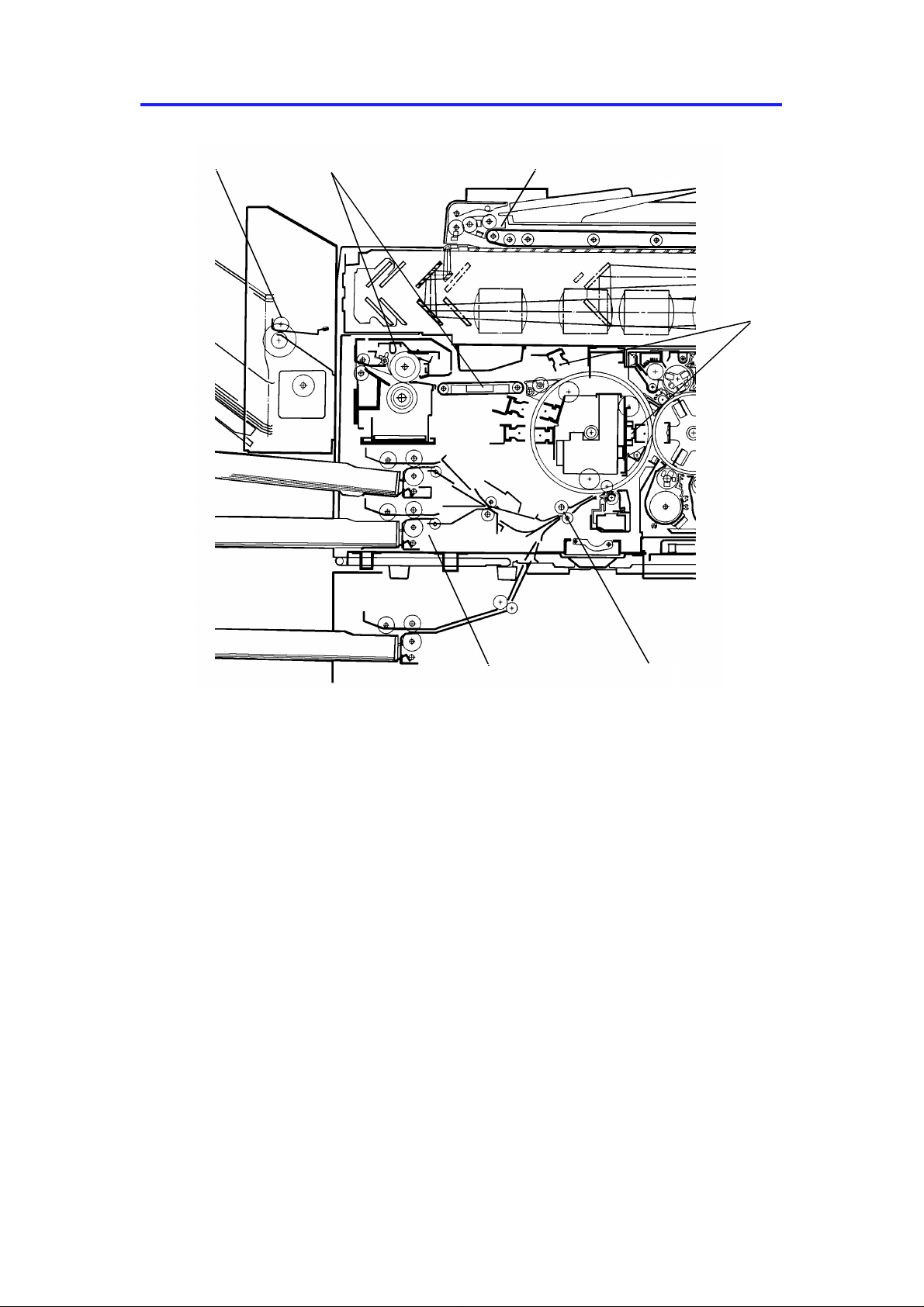

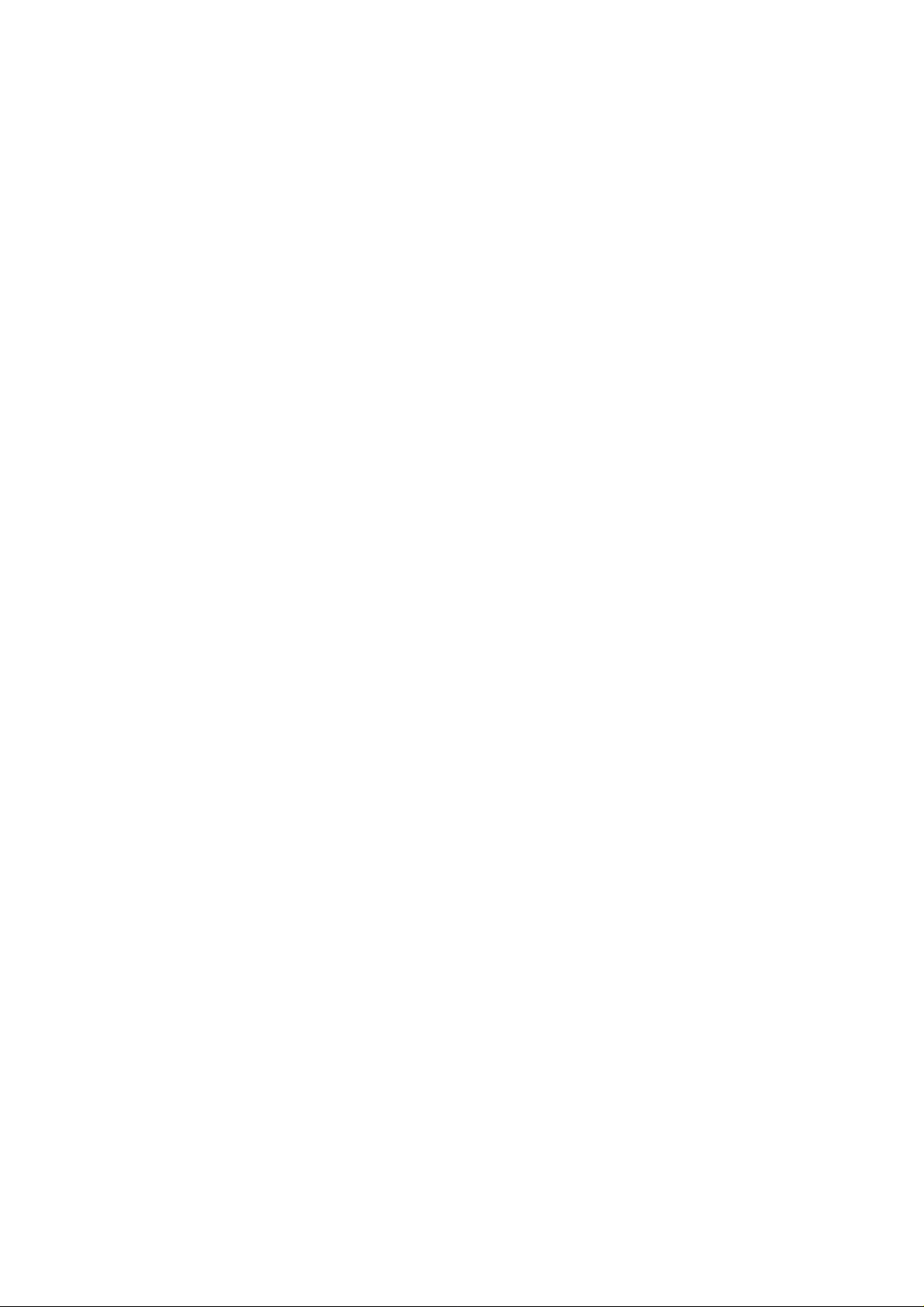

7. ELECTRICAL COMPONENT LAYOUT

7.1 MAIN FRAME (1)

38

37

36

35

34

33

32

39

40

41

42

43

4544

1

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

31

30

29

28

27

26

25

18

19

20

21

22

24

1-22

1 January 1990

1. 1st Scanner HP Sensor

2. 2nd Scanner HP Sensor

3. Sorter Inte rfa ce PCB

4. Exposure Lamp Unit

5. Separation Power Pack

6. Cleaning Motor Pulse Sensor

7. Lens HP Senso r

8. Toner Overflow Sensor

9. Light Shield HP Sensor

10. Charge Power Pack

11. Process PCB

12. Motor PCB

13. Cyan Dev. Motor Sensor

24. Operation Panel PCB

25. 2nd Registration Sensor

26. Pick-off Sensor

27. 1st Registration Sensor

28. Auto ID Sensor

29. Relay Sensor

30. Color Scan Counter

31. Black Scan Counter

32. 2nd Lift Se ns o r

33. 1st Lift Senso r

34. 2nd Paper Size Sensor

35. 1st Paper Size Sensor

36. Front Cover AC Safety Switch

14. Magenta Dev. Motor Sensor

15. Yellow Dev. Motor Sensor

16. Cleaning Sensor

17. ID Sensor

18. VL Sensor

19. Main PCB

20. Servomotor PCB

21. DC Power Supply PCB

22. Filter HP Sensor

23. Total Copy Counter (Ricoh

version only)

37. Front Cover DC Safety

Switch

38. Main Switch

39. 2nd Paper End Sensor

40. 1st Paper End Sensor

41. Circuit Breaker

42. Noise Filter

43. Anti-condensation Heater

44. Main Relay

45. AC Drive PCB

1-23

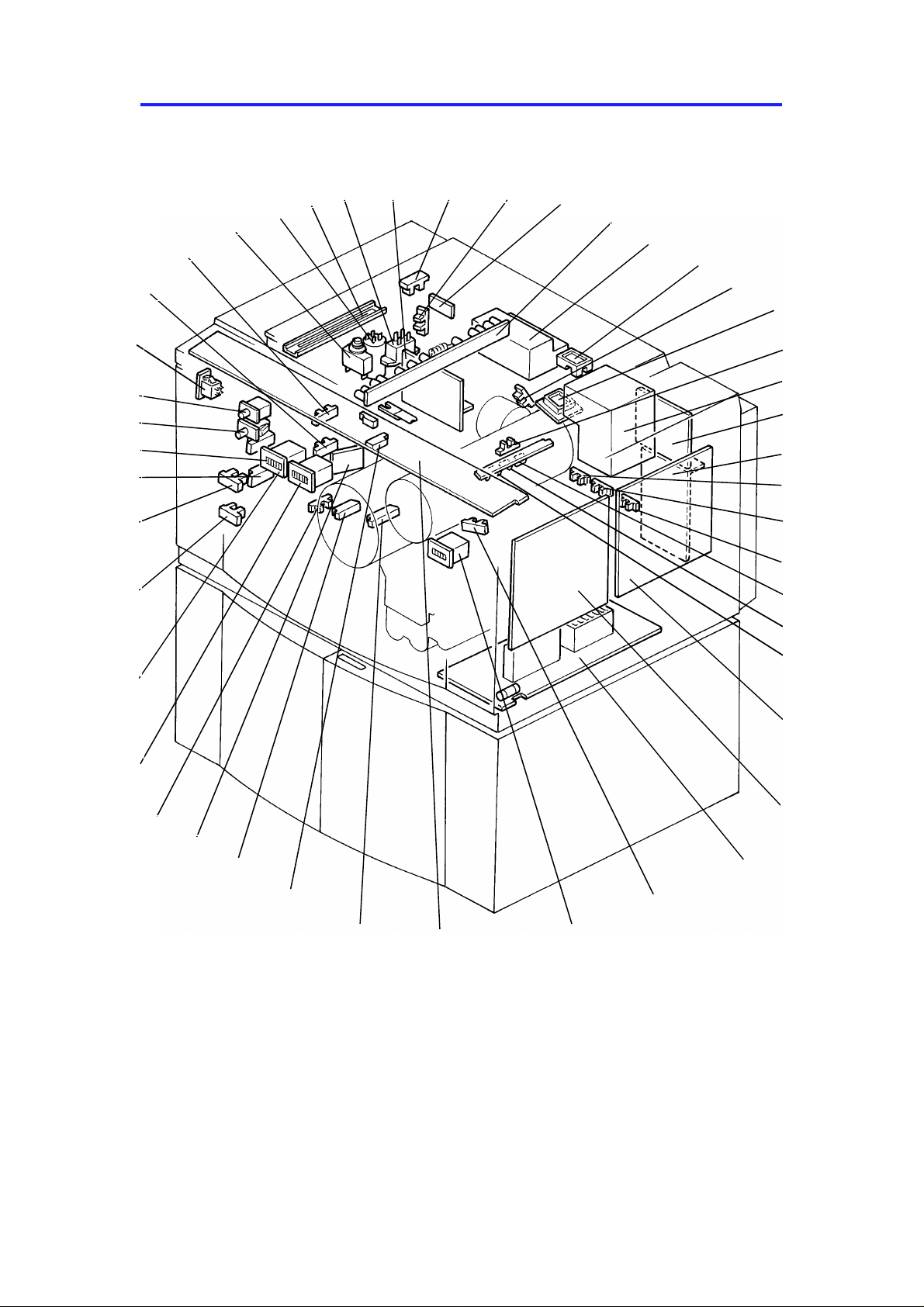

52

62

51

1 January 1990

7.2 MAIN FRAME (2)

72

71

70

69

68

73

74

46 47 48 49 50

53

54

55

56

57

58

67

66

65

64

59

60

61

63

1-24

1 January 1990

46. Lens Motor

47. Transport Vacuum Fan

48. Fusing Exhaust Fan

49. Paper Feed Motor

50. Transformer

51. 1st Lift Motor

52. Transfer Exhaust Fan

53. Charge Fan

54. OPC Drum Cleaning Motor

55. Light Shield Mot or

56. Scanner Motor

57. Optics Cooling Fan

58. Development Drive Motor

61. Cyan Development Motor

62. Power Supply Cooling Fan

63. Development Cooling Fan

64. Filter Motor

65. Pre-transfer Lamp (PTL)

66. Erase Lamp

67. Quenching Lamp

68. 2nd Feed Clutch

69. 1st Feed Clutch

70. Pick-up Solenoid

71. Relay Roller Clutch

72. Registration Motor

73. 2nd Lift M otor

59. Yellow Development Moto r

60. Magenta Development Motor

74. 2nd Scanner Position Motor

1-25

1 January 1990

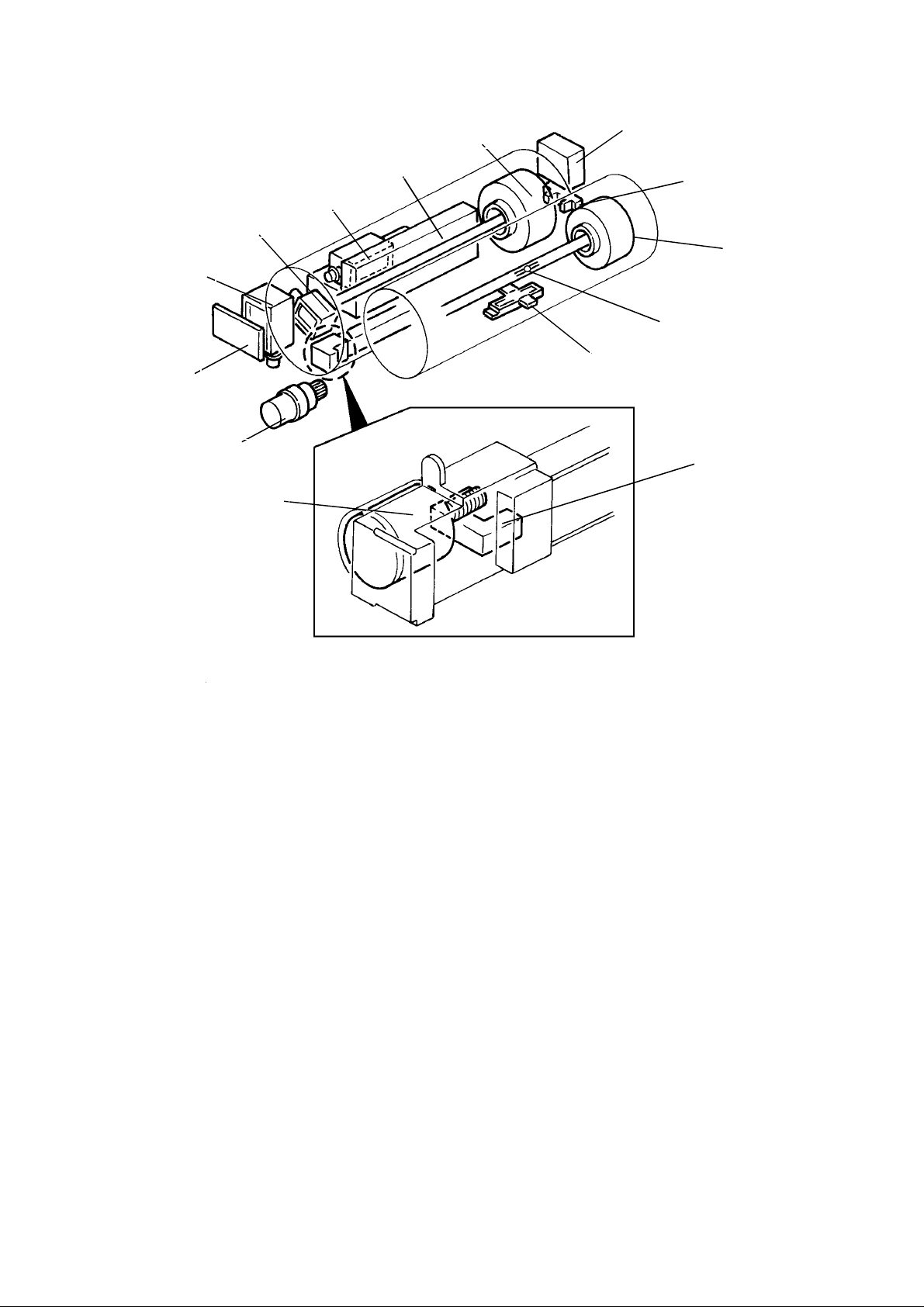

7.3 OPC DRUM AND TRANSFER DRUM

88

75

75

83

84

82

85

81

86

87

76

77

78

79

80

75. Transfer Drum Cleaning PP

76. Transfer Drum HP Sensor

77. OPC Drum Motor

78. Drum Thermoswitch

79. OPC Drum Heater

80. Wire Cleaner HP Sensor

81. Transfer Corona Wire Cleaner

Motor

82. Transfer Drum Cleaning Motor

83. Transfer Drum Interface PCB

84. Transfer Drum Cleaning

Solenoid

85. Paper Clamp Solenoid

86. Cleaning Suppo rt So lenoid

87. Transfer PP

88. Transfer Drum Motor

1-26

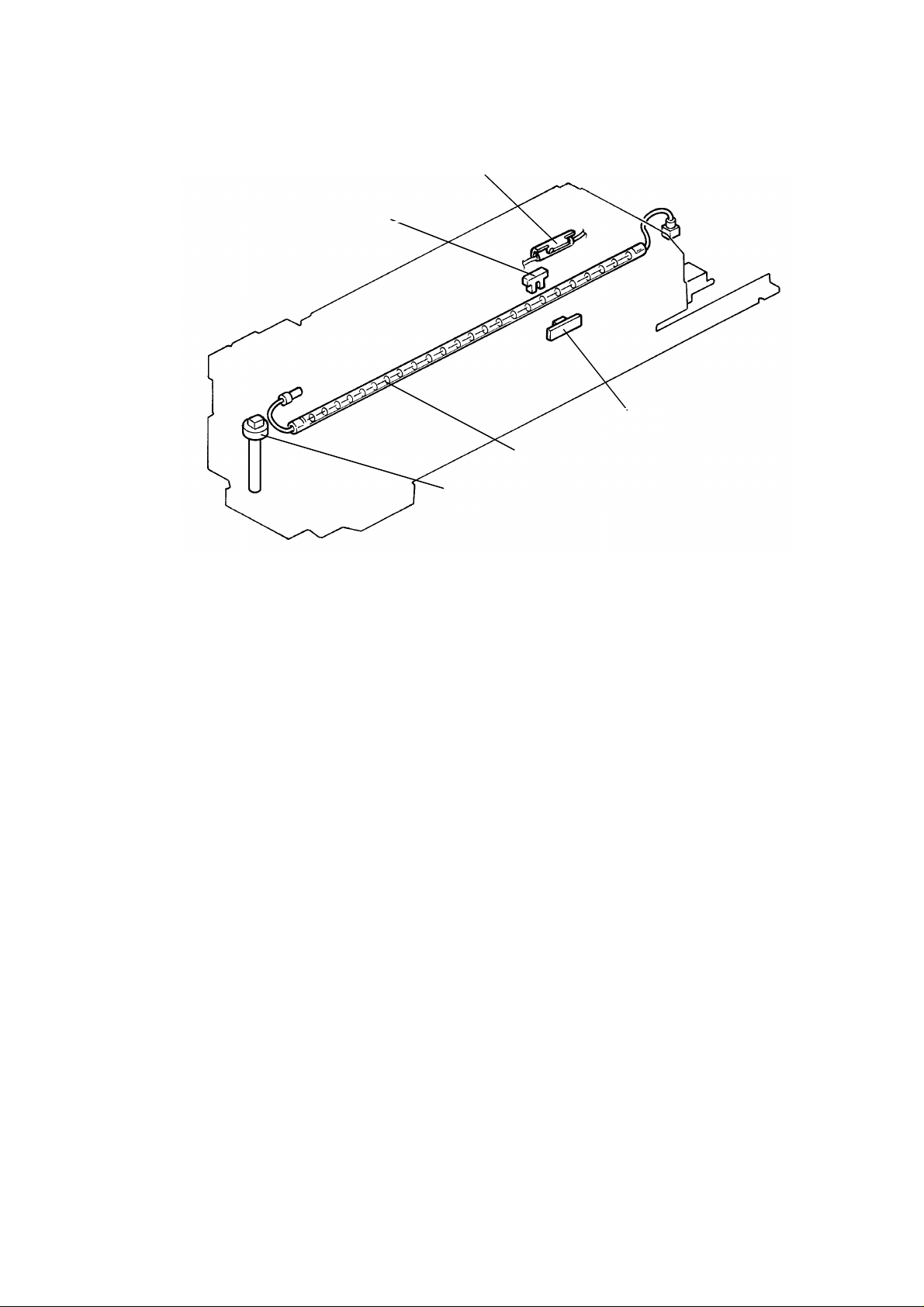

7.4 COLOR DEVELOPMENT UNIT

89

1 January 1990

90

91

94

93

92

89. Cyan Toner Density Sensor

90. Magenta Toner Density Sensor

91. Yellow Toner Density Sensor

92. Yellow Toner Supply Clutch

93. Magenta Toner Supply Clutch

94. Cyan Toner Supply Clutch

1-27

1 January 1990

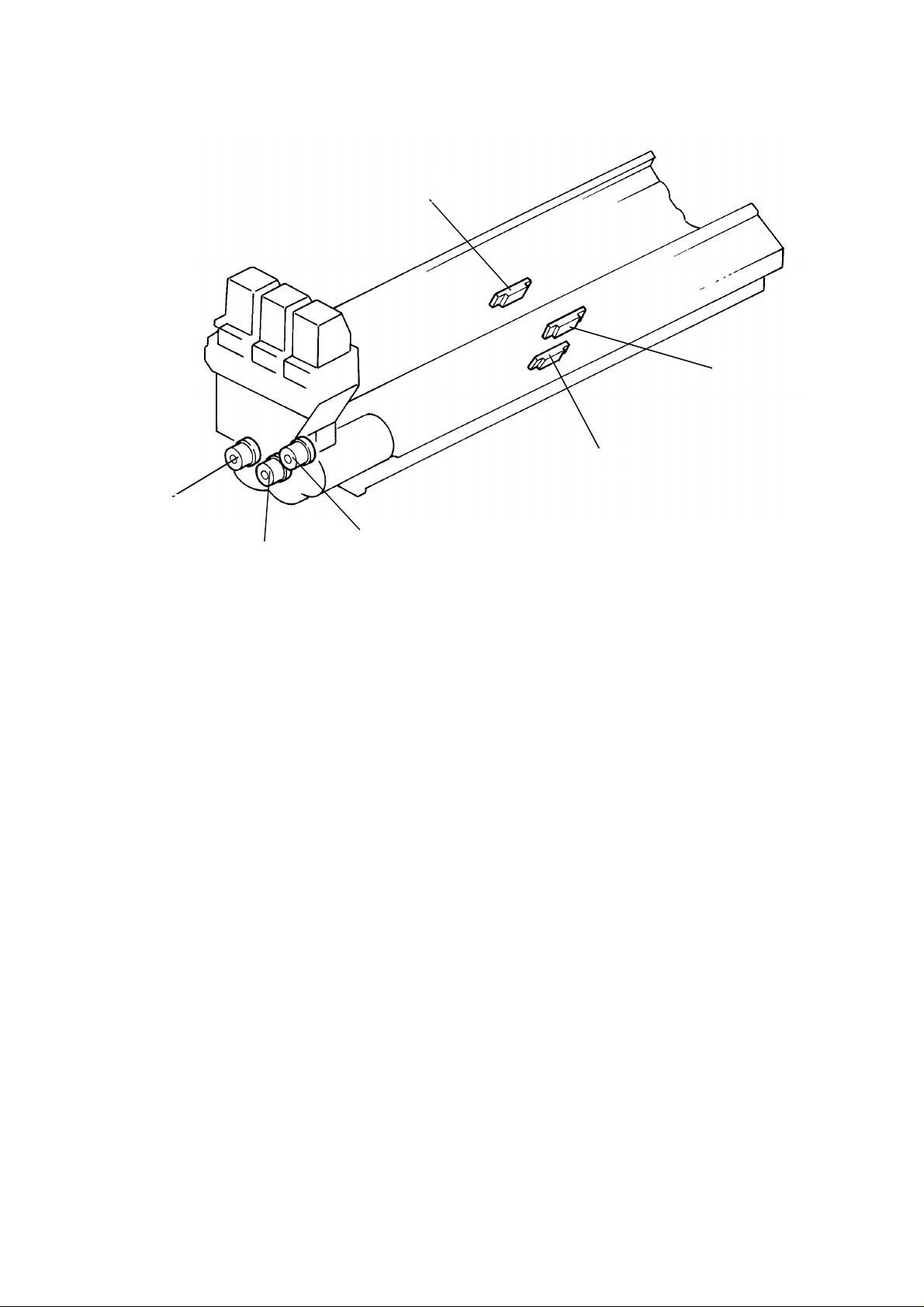

7.5 BLACK DEVELOPMENT UNIT

99

95

96

98

97

95. Black Toner Supply Clutch

96. Black Toner Density Sensor

97. Magnetic Shield Sensor

98. Magnetic Shield HP Sensor

99. Magnetic Shield Motor

1-28

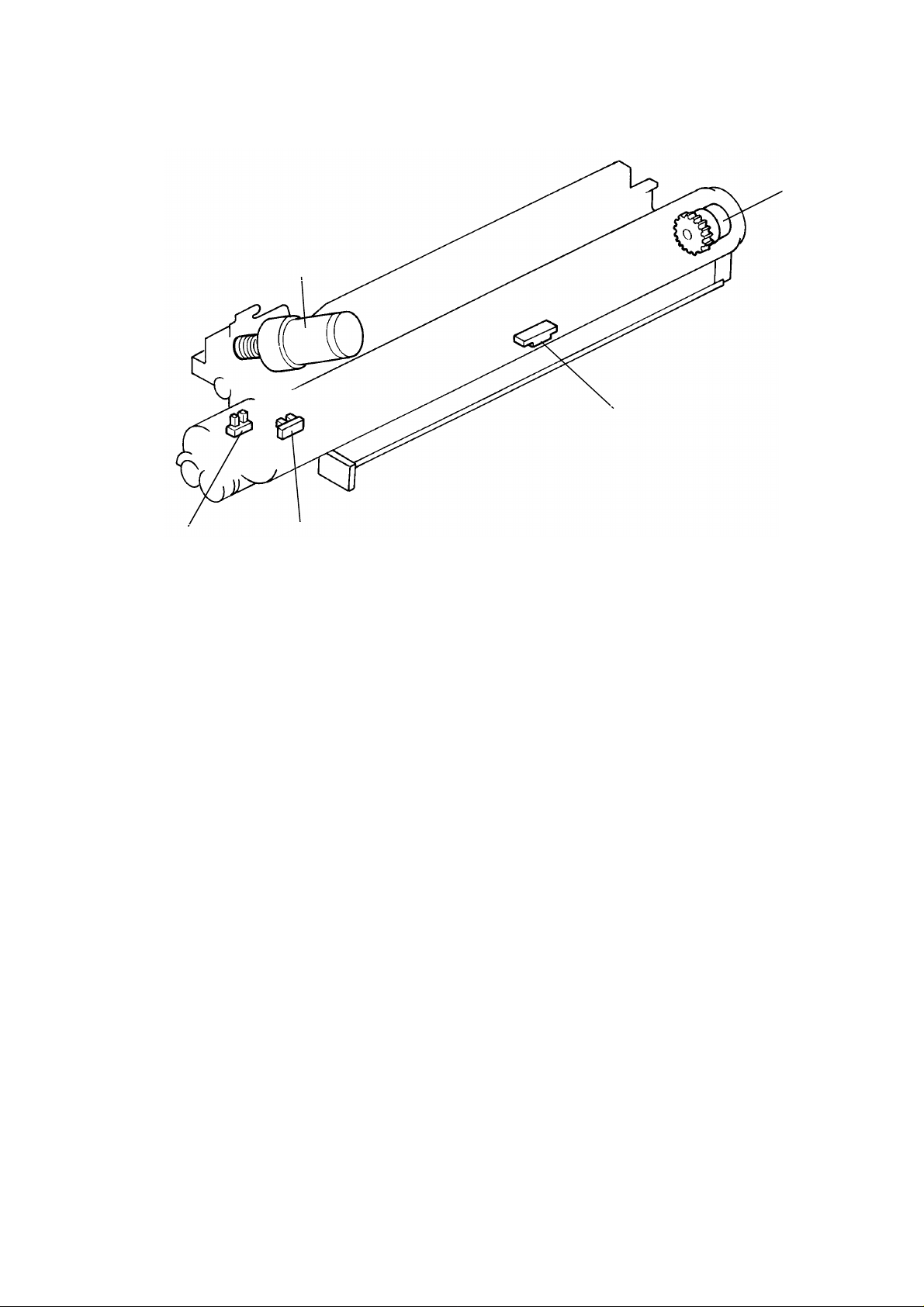

7.6 FUSING UNIT

1 January 1990

100

104

101

102

103

100. Fusing Thermofuse

101. Fusing Thermistor

102. Fusing Lamp

103. Oil End Sensor

104. Exit Sensor

1-29

1 January 1990

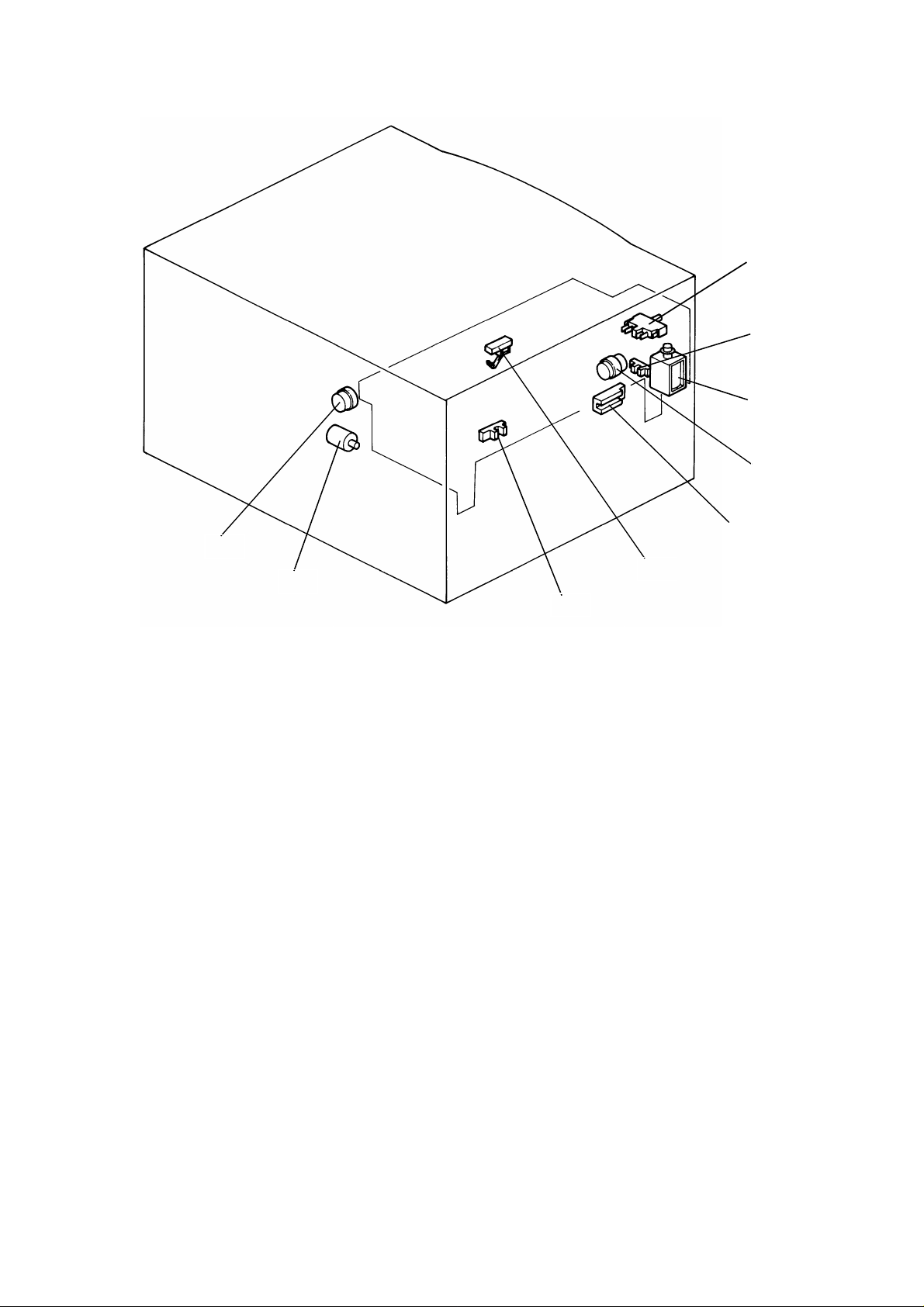

7.7 3RD PAPER FEED UNIT

105

106

107

108

113

112

105. 3rd Paper Feed SW

106. 3rd Lift Sensor

107. Pick-up Solenoid (3rd Paper

Feed)

108. 3rd Feed Clutch

109. 3rd Paper Size Sensor

109

110

111

110. Relay Sensor (3rd Paper

Feed)

111. 3rd Paper End Sensor

112. 3rd Lift Motor

113. Relay Roller Clutch (3rd Paper

Feed)

1-30

Loading...

Loading...