Ricoh MV310 Service Manual

LSO

RICOH MV310

SERVICE MANUAL

May 22nd, 1995

Subject to change

I

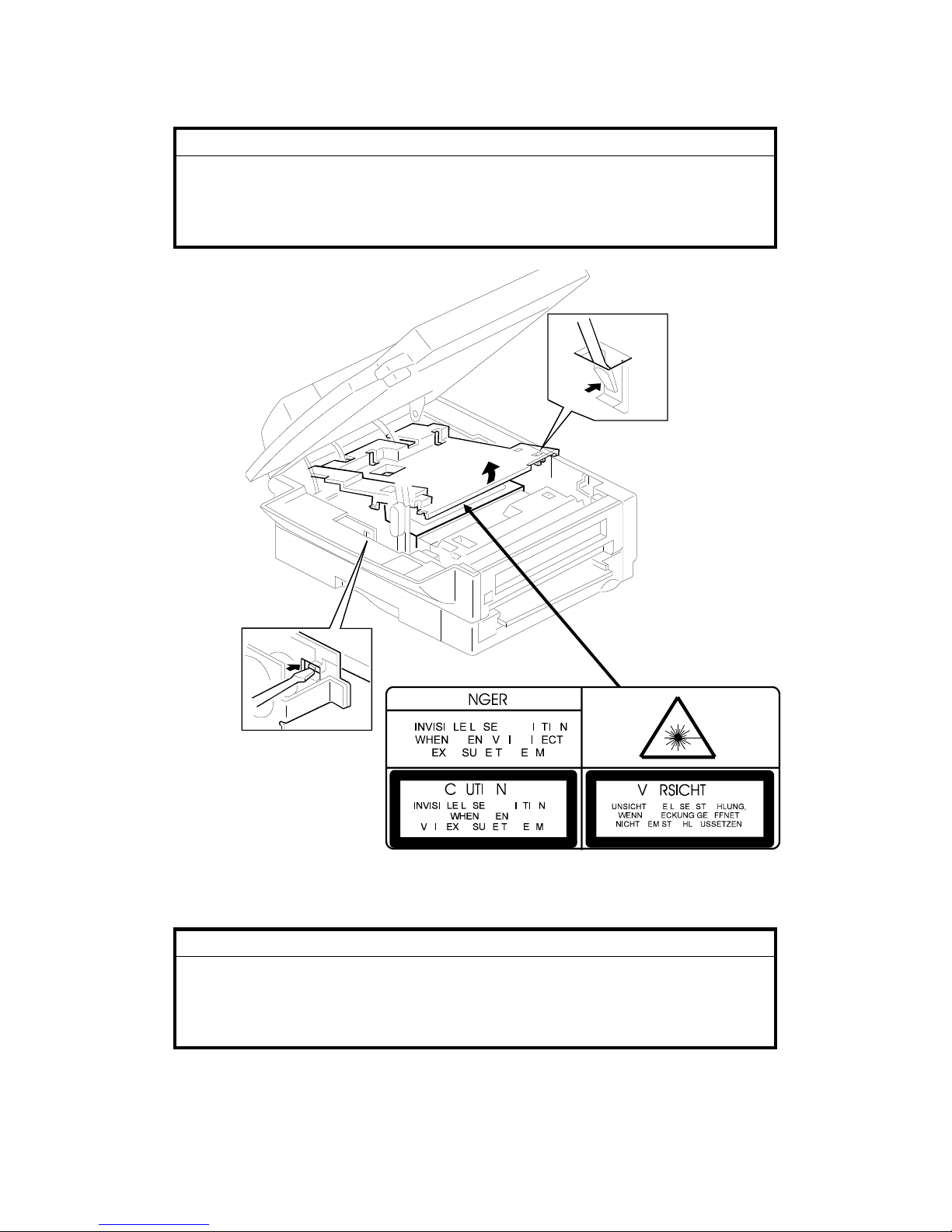

WARNING

THIS MACHINE CONTAINS A LASER BEAM GENERATOR. LASER

BEAMS CAN CAUSE PERMANENT EYE DAMAGE. DO NOT OPEN THE

LASER UNIT OR LOOK ALONG THE LASER BEAM PATH WHILE THE

MAIN POWER IS ON.

Lithium Batteries (Memory Back-up)

I

CAUTION

The danger of explosion exists if a battery of this type is incorrectly

replaced. Replace only with the same or an equiv al ent type

recommended by the manufacture r. Discard used batteries in

accordance with the manufactur er’ s instr uctions.

Table of Contents

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . 1-1

1.2. FEATURES . . . . . . . . . . . . . . . . . . . . . 1-3

1.3. COMPONENT LAYOUT . . . . . . . . . . . . . . . . 1-6

1.3.1. Mechanical Compon en ts . . . . . . . . . . . . . . 1-6

1.3.2. Electrical Compone nt s . . . . . . . . . . . . . . . 1-8

1. PCBs . . . . . . . . . . . . . . . . . . . . . . 1-9

2. Motors and Clutches . . . . . . . . . . . . . . . . 1-9

3. Sensors . . . . . . . . . . . . . . . . . . . . . 1-10

4. Interlock Switches . . . . . . . . . . . . . . . . . 1-10

5. Others . . . . . . . . . . . . . . . . . . . . . . 1-11

6. Options . . . . . . . . . . . . . . . . . . . . . 1-12

1.4. OVERALL MACHINE CONTROL . . . . . . . . . . . . 1-13

1.5. VIDEO DATA PATH . . . . . . . . . . . . . . . . . . 1-14

1.5.1. Transmission . . . . . . . . . . . . . . . . . . . 1-14

1.5.2. Reception . . . . . . . . . . . . . . . . . . . . 1-15

1.5.3. Copying . . . . . . . . . . . . . . . . . . . . . 1-16

1.5.4. Printing usin g th e Optional Printer Inte rface . . . . . . . 1-18

1.6. POWER DISTRIBUTION . . . . . . . . . . . . . . . . 1-19

1.6.1. Distribution Diagra m . . . . . . . . . . . . . . . . 1-19

1.6.2. Memory Back-up Circuit . . . . . . . . . . . . . . 1-20

2. DETAILED SECTION DESCRIPTIONS

2.1. SCANNER . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1. Overview . . . . . . . . . . . . . . . . . . . . 2-1

1. Book Scanner . . . . . . . . . . . . . . . . . . . 2-1

2. ADF . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2. Original Dete ctio n . . . . . . . . . . . . . . . . . 2-3

1. Book Scanner . . . . . . . . . . . . . . . . . . . 2-3

2. ADF . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.3. Scanning . . . . . . . . . . . . . . . . . . . . 2-6

1. Contact Image Sensor . . . . . . . . . . . . . . . 2-6

2. Main Scan Resolution an d Widt h (Book Scanner) . . . . . 2-7

3. Main Scan Resolution an d Widt h (ADF) . . . . . . . . . 2-8

4. Sub Scan Resolution s and Len gt h (Bo ok Sca nn er) . . . . 2-8

5. Sub Scan Resolution s and Len gt h (ADF) . . . . . . . . 2-8

6. Sub Scan Resolution Conve rsion . . . . . . . . . . . 2-9

2.1.4. Drive Mechanism . . . . . . . . . . . . . . . . . 2-10

1. Book Scanner . . . . . . . . . . . . . . . . . . . 2-10

2. ADF . . . . . . . . . . . . . . . . . . . . . . . 2-11

3. Scanner Po sition Fine Adjustment . . . . . . . . . . . 2-12

2.1.5. Pick-up and Feed (ADF) . . . . . . . . . . . . . . 2-13

2.1.6. Separation Mechanism (ADF) . . . . . . . . . . . . 2-13

2.1.7. Stamping (ADF) . . . . . . . . . . . . . . . . . . 2-14

2.1.8. Error Conditio ns . . . . . . . . . . . . . . . . . 2-15

1. Book Scanner . . . . . . . . . . . . . . . . . . . 2-15

2. ADF . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.1.9. Vid eo Processing . . . . . . . . . . . . . . . . . 2-17

1. Analog Signal Processing . . . . . . . . . . . . . . 2-17

2. Digital Video Processing Steps . . . . . . . . . . . . 2-18

3. Video Processing Parameters . . . . . . . . . . . . 2-22

2.2. PRINTING . . . . . . . . . . . . . . . . . . . . . . 2-23

2.2.1. Printing Pro cess - Overview . . . . . . . . . . . . . 2-23

2.2.2. OPC Drum . . . . . . . . . . . . . . . . . . . . 2-24

2.2.3. Charge . . . . . . . . . . . . . . . . . . . . . 2-24

2.2.4. Laser Exposu re . . . . . . . . . . . . . . . . . . 2-26

1. Overview . . . . . . . . . . . . . . . . . . . . . 2-26

2. Block Diagram . . . . . . . . . . . . . . . . . . . 2-27

3. Error Conditions . . . . . . . . . . . . . . . . . . 2-27

4. Print Den sity Adjustment . . . . . . . . . . . . . . . 2-28

5. Enlargement . . . . . . . . . . . . . . . . . . . 2-28

6. Toner Saving Mode . . . . . . . . . . . . . . . . . 2-29

2.2.5. Toner Supply . . . . . . . . . . . . . . . . . . . 2-30

2.2.6. Development . . . . . . . . . . . . . . . . . . . 2-33

2.2.7. Paper Feed . . . . . . . . . . . . . . . . . . . 2-38

1. Overview . . . . . . . . . . . . . . . . . . . . . 2-38

2. Paper Lift Mechanism . . . . . . . . . . . . . . . . 2-39

3. Paper Size and Paper End Detection . . . . . . . . . . 2-40

4. Pick-up and Separation . . . . . . . . . . . . . . . 2-42

5. Drive Mechanism . . . . . . . . . . . . . . . . . 2-42

2.2.8. Registration . . . . . . . . . . . . . . . . . . . 2-45

2.2.9. Transfer and Separation . . . . . . . . . . . . . . 2-47

2.2.10. Cleaning . . . . . . . . . . . . . . . . . . . . 2-50

2.2.11. Fusing . . . . . . . . . . . . . . . . . . . . . 2-51

2.2.12. Page Separat ion and Data Reduction . . . . . . . . 2-55

2.2.13. Paper Size Sele ction . . . . . . . . . . . . . . . 2-57

2.3. SYSTEM FEATURES . . . . . . . . . . . . . . . . . 2-58

2.3.1. Power Saver Modes . . . . . . . . . . . . . . . . 2-58

1. Going into a Power Saver Mode . . . . . . . . . . . . 2-59

2. Going into Level 2 Mode from Le vel 1 Mod e . . . . . . . 2-61

3. Receiving a Fax Message in Power Sa ver Mod e . . . . . 2-63

4. Sending a Fax Message or Cop ying in Power Saver Mode . 2-65

2.3.2. Auto matic Service Ca lls . . . . . . . . . . . . . . 2-67

1. Service Call Conditions . . . . . . . . . . . . . . . 2-67

2. Excessive Jam Alarms . . . . . . . . . . . . . . . 2-68

3. Periodic Service Call . . . . . . . . . . . . . . . . 2-69

4. PM Call . . . . . . . . . . . . . . . . . . . . . 2-70

5. Effective Term of Se rvice Ca lls . . . . . . . . . . . . 2-70

2.4. PCBs . . . . . . . . . . . . . . . . . . . . . . . 2-71

2.4.1. FCE . . . . . . . . . . . . . . . . . . . . . . 2-71

2.4.2. FDU . . . . . . . . . . . . . . . . . . . . . . 2-73

2.4.3. PSU . . . . . . . . . . . . . . . . . . . . . . 2-74

2.4.4. NCU (USA) . . . . . . . . . . . . . . . . . . . 2-75

1. Jumpers . . . . . . . . . . . . . . . . . . . . . 2-75

2.4.5. NCU (Europe/Asia) . . . . . . . . . . . . . . . . 2-76

1. Control Signals and Jump ers . . . . . . . . . . . . . 2-76

3. INSTALLATION

3.1. INSTALLING THE MACHINE . . . . . . . . . . . . . . 3-1

3.2. INITIAL PROGRAMMI NG . . . . . . . . . . . . . . . 3-1

3.3. OPTIONAL UNITS . . . . . . . . . . . . . . . . . . 3-2

3.3.1. Counter . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.2. Printer I nt erface . . . . . . . . . . . . . . . . . . 3-3

4. SERVICE TABLES AND PROCEDURES

4.1. SERVICE LEV EL FUNCTIONS . . . . . . . . . . . . . 4-1

4.1.1. Bit Switch Prog rammin g (Fun ction 01) . . . . . . . . . 4-1

4.1.2. System Parameter List (Function 02) . . . . . . . . . 4-2

4.1.3. Error Code Display (Fun ctio n 03 ) . . . . . . . . . . . 4-2

4.1.4. Service Monitor Report (Fun ction 04) . . . . . . . . . 4-2

4.1.5. Protocol Dump (Function 05) . . . . . . . . . . . . 4-3

4.1.6. RAM Display/Rewrite (Funct ion 06) . . . . . . . . . . 4-3

4.1.7. RAM Dump (Function 06) . . . . . . . . . . . . . . 4-4

4.1.8. Counter Display/Rewrite (Function 07) . . . . . . . . . 4-4

4.1.9. NCU Parameters (Fun ction 08) . . . . . . . . . . . . 4-5

4.1.10. Modem Test (Function 08) . . . . . . . . . . . . . 4-6

4.1.11. DTMF Tone Test (Function 08) . . . . . . . . . . . 4-6

4.1.12. Modem Detection Test (Function 08) . . . . . . . . . 4-7

4.1.13. Ringer Test (Fun ction 08) . . . . . . . . . . . . . 4-7

4.1.14. Operat ion Panel Test (Function 09) . . . . . . . . . 4-8

4.1.15. LED Arra y Test (Function 10) . . . . . . . . . . . . 4-8

4.1.16. ADF Test (Function 10) . . . . . . . . . . . . . . 4-9

4.1.17. Book Mode Scanner Mech an ism Test (Funct ion 10) . . . 4-9

4.1.18. Auto Pa per Select Mode Test (Function 10) . . . . . . 4-10

4.1.19. Image Sensor Check/Clock Reset (Function 10) . . . . 4-10

4.1.20. Printer Test Pa tt erns (Function 11) . . . . . . . . . . 4-11

4.1.21. Printer Mechanism Test - Free Ru n (Fu nction 11) . . . . 4-12

4.1.22. RAM Tests (Functio n 1 2) . . . . . . . . . . . . . . 4-12

4.1.23. Software Down load (Function 12) . . . . . . . . . . 4-13

4.1.24. Software Uplo ad (Fu nct ion 12) . . . . . . . . . . . 4-14

4.1.25. SRAM Data Downloa d (Function 12) . . . . . . . . . 4-15

4.1.26. Serial Numbe r (Function 14) . . . . . . . . . . . . 4-16

4.1.27. Service Statio n Tele ph on e Number (Function 13) . . . . 4-17

4.2. BIT SWITCHES . . . . . . . . . . . . . . . . . . . 4-18

4.2.1. System Switche s . . . . . . . . . . . . . . . . . 4-18

4.2.2. Scanner Switche s . . . . . . . . . . . . . . . . 4-28

4.2.3. Printer Switch es . . . . . . . . . . . . . . . . . 4-29

4.2.4. Communicatio n Swit ches . . . . . . . . . . . . . . 4-32

4.2.5. G3 Switches . . . . . . . . . . . . . . . . . . . 4-38

4.3. NCU PARAMETERS . . . . . . . . . . . . . . . . . 4-44

4.4. DEDICATED TRANSMISSION PARAMETERS . . . . . . . 4-72

4.4.1. Programming Proce du re . . . . . . . . . . . . . . 4-72

4.4.2. Paramete rs . . . . . . . . . . . . . . . . . . . 4-73

4.5. SERVI CE RAM ADDRESSES . . . . . . . . . . . . . . 4-75

4.6. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . 4-87

4.7. PM TABLE . . . . . . . . . . . . . . . . . . . . . 4-87

5. REPLACEMENT AND ADJUSTMENT

5.1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1. ADF . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2. Operatio n P an el a nd Cop y Tray . . . . . . . . . . . 5-3

5.1.3. Platen Cover and Original Scales . . . . . . . . . . . 5-3

5.1.4. Top Cover and Exposure Glass . . . . . . . . . . . 5-4

5.1.5. Left, Front, and Rear Cover . . . . . . . . . . . . . 5-4

5.2. SCANNER . . . . . . . . . . . . . . . . . . . . . 5-5

5.2.1. Contact Image Sensor . . . . . . . . . . . . . . . 5-5

5.2.2. Fluorescent Lamp Sta bilize r . . . . . . . . . . . . . 5-6

5.2.3. Original Size, Plat en Co ver, and Scanner H. P. Sensors . . 5-6

5.2.4. Scanner Motor . . . . . . . . . . . . . . . . . . 5-7

5.3. LASER PRINTING COMPONE NTS . . . . . . . . . . . 5-7

5.3.1. Inner Cover . . . . . . . . . . . . . . . . . . . 5-7

5.3.2. Laser Unit . . . . . . . . . . . . . . . . . . . . 5-8

5.3.3. Laser Diode Unit and Hexagon al Mirror Mot or . . . . . . 5-9

5.4. DEVELOPMENT . . . . . . . . . . . . . . . . . . . 5-10

5.4.1. Master Drum . . . . . . . . . . . . . . . . . . . 5-10

5.4.2. Development Unit . . . . . . . . . . . . . . . . . 5-10

5.4.3. Transfer Roller . . . . . . . . . . . . . . . . . . 5-11

5.4.4. Main Moto r and Gea r s . . . . . . . . . . . . . . . 5-11

5.4.5. Replacing th e Deve lopment Unit . . . . . . . . . . . 5-12

5.5. FUSING . . . . . . . . . . . . . . . . . . . . . . 5-15

5.5.1. Thermisto r . . . . . . . . . . . . . . . . . . . . 5-15

5.5.2. Fusing Unit . . . . . . . . . . . . . . . . . . . 5-15

5.5.3. Hot Roller Strippers . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.5.4. Fusing Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.5.5. Hot Roller . . . . . . . . . . . . . . . . . . . . 5-18

5.5.6. Pressure Roller . . . . . . . . . . . . . . . . . . 5-20

5.5.7. Thermost at an d Th ermofuse . . . . . . . . . . . . . 5-20

5.6. PAPER FEED . . . . . . . . . . . . . . . . . . . . 5-21

5.6.1. Paper Feed Roller and Clutch . . . . . . . . . . . . 5-21

5.6.2. Paper End Sensor . . . . . . . . . . . . . . . . . 5-21

5.6.3. Registratio n Sensor and Pressure Rollers . . . . . . . 5-22

5.6.4. Paper Feed Motor, Gears and Registration Roller . . . . 5-22

5.6.5. Bypass Feed Sensor . . . . . . . . . . . . . . . . 5-23

5.6.6. Paper Size Se nsor . . . . . . . . . . . . . . . . 5-23

5.7. PCBs . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.7.1. PSU . . . . . . . . . . . . . . . . . . . . . . 5-24

5.7.2. NCU . . . . . . . . . . . . . . . . . . . . . . 5-24

5.7.3. FDU and FCE . . . . . . . . . . . . . . . . . . 5-25

5.7.4. Power Pack . . . . . . . . . . . . . . . . . . . 5-26

5.8. OTHERS . . . . . . . . . . . . . . . . . . . . . . 5-26

5.8.1. Ozone Filter and Fan Moto r . . . . . . . . . . . . . 5-26

5.8.2. Toner End Sensor . . . . . . . . . . . . . . . . . 5-27

5.9. ADF . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.9.1. ADF Ro ller Asssembly an d Covers . . . . . . . . . . 5-27

5.9.2. Pick-up Roller . . . . . . . . . . . . . . . . . . 5-28

5.9.3. Feed Roller . . . . . . . . . . . . . . . . . . . 5-28

5.9.4. Separation Roller . . . . . . . . . . . . . . . . . 5-29

5.9.5. ADF Motor and Covers . . . . . . . . . . . . . . . 5-29

5.9.6. R0 and R1 Rollers . . . . . . . . . . . . . . . . . 5-30

5.9.7. R2 Roller . . . . . . . . . . . . . . . . . . . . 5-30

5.9.8. Document Se nso r and Wid th Sen sor . . . . . . . . . 5-31

5.9.9. Scan Line Sensor . . . . . . . . . . . . . . . . . 5-32

5.9.10. Cover Sensors . . . . . . . . . . . . . . . . . . 5-32

5.10. 100 SHEET PAPER CASSETTE (OPTIONAL) . . . . . . . 5-34

5.10.1. Relay Connector and Gear Cover . . . . . . . . . . 5-34

5.10.2. Paper End Sensor a nd Drive Components . . . . . . . 5-35

5.10.3. Paper Size Sensor . . . . . . . . . . . . . . . . 5-36

5.11. IMAGE ADJUSTMENT . . . . . . . . . . . . . . . . 5-37

5.11.1. Overview . . . . . . . . . . . . . . . . . . . . 5-37

5.11.2. Scanner Parameters . . . . . . . . . . . . . . . 5-38

1. Contrast . . . . . . . . . . . . . . . . . . . . . 5-38

2. Margins . . . . . . . . . . . . . . . . . . . . . 5-38

5.11.3. Printer Parameters . . . . . . . . . . . . . . . . 5-40

1. Margin (Main Scan Direction) . . . . . . . . . . . . . 5-40

2. Margin (Sub Scan Direction ) . . . . . . . . . . . . . 5-41

5.11.4. Scanner Video Processing Para meters . . . . . . . . 5-42

1. Contrast . . . . . . . . . . . . . . . . . . . . . 5-42

2. Image P roce ssing Parameters Ad justment . . . . . . . . 5-43

6. TROUBLESHOOTING

6.1. COPY QUALITY TROUBLESHOOTING . . . . . . . . . . 6-1

6.1.1. Blank Copies . . . . . . . . . . . . . . . . . . . 6-2

6.1.2. Black Copies . . . . . . . . . . . . . . . . . . . 6-4

6.1.3. Dirty Background . . . . . . . . . . . . . . . . . 6-5

6.1.4. Uneven Image Den sity . . . . . . . . . . . . . . . 6-6

6.1.5. Vertical Black Lines . . . . . . . . . . . . . . . . 6-7

6.1.6. Horizontal Black Line s . . . . . . . . . . . . . . . 6-8

6.1.7. Vertical White Line s . . . . . . . . . . . . . . . . 6-9

6.1.8. Horizontal White Lines . . . . . . . . . . . . . . . 6-10

6.1.9. Black Dots/Spots . . . . . . . . . . . . . . . . . 6-11

6.1.10. White Spots in Black Image Areas . . . . . . . . . . 6-12

6.1.11. Faint Copies . . . . . . . . . . . . . . . . . . 6-13

6.1.12. Vertical Black Band . . . . . . . . . . . . . . . . 6-15

6.1.13. Unfused Copies . . . . . . . . . . . . . . . . . 6-16

6.1.14. Ghost Image . . . . . . . . . . . . . . . . . . 6-16

6.1.15. Toner on the Back of the Printer Paper . . . . . . . . 6-17

6.1.16. Misaligned Output (Dat a shif te d to the right or le ft ) . . . 6-18

6.1.17. Misaligned Output (Image shifted vertically)/Reduced Image 6-18

6.2. MECHANICAL PROBLEMS . . . . . . . . . . . . . . 6-19

6.2.1. ADF . . . . . . . . . . . . . . . . . . . . . . 6-19

1. Non Feed . . . . . . . . . . . . . . . . . . . . 6-19

2. Jam . . . . . . . . . . . . . . . . . . . . . . . 6-20

3. Skew . . . . . . . . . . . . . . . . . . . . . . 6-21

4. Multi-feed . . . . . . . . . . . . . . . . . . . . 6-21

6.2.2. Book Scanner . . . . . . . . . . . . . . . . . . 6-22

1. Abnormal Noise . . . . . . . . . . . . . . . . . . 6-22

2. Scanner Home Position Error (Erro r Code 9-11) . . . . . 6-22

3. Automatic P ap er S election Error . . . . . . . . . . . . 6-23

4. Scanning Start Position Error (Error Code 1-09) . . . . . 6-23

6.2.3. Printer . . . . . . . . . . . . . . . . . . . . . 6-24

1. Non-feed . . . . . . . . . . . . . . . . . . . . . 6-24

2. Paper Jam - Inside the Printer . . . . . . . . . . . . 6-25

3. Jam - Fusing Exit . . . . . . . . . . . . . . . . . 6-26

4. Skew . . . . . . . . . . . . . . . . . . . . . . 6-27

5. Multi-feed . . . . . . . . . . . . . . . . . . . . 6-27

6.3. SERVICE CALL CONDITIONS . . . . . . . . . . . . . 6-28

6.4. ERROR CODES . . . . . . . . . . . . . . . . . . . 6-32

6.5. ELECTRICAL COMPONENT DE FECTS . . . . . . . . . 6-39

6.5.1. Defective Sensor Table . . . . . . . . . . . . . . . 6-39

6.5.2. Blown Fuse Tab le . . . . . . . . . . . . . . . . . 6-40

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS

Type

Desktop transceiver

Circuit

PSTN, PABX

Connection

Direct couple

Book Scanner

Document Size:

Smaller than 257 x 364 mm

[10.1 x 14.3 ins]

Thickness: Less than 30 mm

Weight: Less than 5 kg

ADF

Document Size

Length: 105 - 364 mm

[4.1 - 16.5 ins]

Up to 1200 mm [47.2 ins],

manually assisted

Width: 148 - 257 mm

[5.8 - 10.1 ins]

Thickness: 0.05 to 0.2 mm [2 to 8 mils]

(equivalent to 50 - 90 g/m

2

)

0.04 to 0.4 mm [1.6 to 16 mils],

manually assisted

(equivalent to 40 - 120 g/m

2

)

Document Feed

Automatic feed, face up

ADF Capacity

30 sheets (using 20 lb paper)

Scanning Method

Contact image sensor, with xenon lamp

Maximum Scan Width

256 mm [10.1 ins] ± 0.25%

Scan Resolution

Fax mode

Standard: 8 x 3.85 lines/mm [203 x 98 dpi]

Detail: 8 x 7.7 lines/mm [203 x 196 dpi]

Fine: 8 x 15.4 lines/mm [203 x 392 dpi]

Copy mode:

16 x 15.4 lines/mm [406 x 392 dpi]

Memory Capacity

ECM: 64 or 128 kB; single or double buffer

SAF: 576 kB (45 pages/A4)

Protocol

Group 3 with ECM

Compression

MH, MR, EFC, MMR, SSC (MMR only with

ECM)

Storage to SAF memory for tx: MMR and/or

raw data

Modulation

V.29 (QAM), V.27ter (PHM), V.21 (FM)

Data Rate (bps)

9600/7200/4800/2400, Automatic fallback

I/O Rate

With ECM: 0 ms/line

Without ECM: 2.5, 5, 10, 20, or 40 ms/line

Transmission Time

9 s at 9600 bps; Measured with G3 ECM using memory for a CCITT #1 test document

(Slerexe letter) using standard resolution

Printing System

Laser printing, plain paper, dry toner

Printing Time

10 ppm for A4 size paper

Paper Size

Standard Cassette:

USA: Half-Letter, Letter, Legal

Europe/Asia: A4, A5, B5, F, F4

Optional 100 Sheet Cassette:

USA: Half-letter, Letter, Legal

Europe/Asia: A4, A5, B5 lengthwise, F/F4

Paper Capacity

Standard Cassette: - 250 sheets

Optional 100 Sheet Cassette:

- 100 sheets

Bypass Feeder: - 1 page

Maximum Printing Width

248 mm [9.8 ins]

Printer Resolution

Fax/Copy Mode: 16 x 15.4 lines/mm

[406 x 392 dpi]

Printer Mode: 300 x 300 dpi

Power Supply

USA: 115 ± 20 Vac, 60 ± 1 Hz

Europe/Asia: 220 Vac +20/-10%, 50 ± 1 Hz

May 22nd, 1995 OVERALL MACHINE INFORMATION

SPECIFICATIONS

1-1

Power Consumption

Standby: Minimum 2 W, Normal 70 W

Transmitting: 35 W

Receiving: 200 W

Copying: Normal 300 W, Maximum 800 W

Operating Environment

Temperature: 17 - 28 °C [63 - 82 °F]

Humidity: 40 - 70 %Rh

Dimensions (W x D x H)

555 x 555 x 342 mm [21.9 x 21.9 x 13.5 ins]

Excluding handset, trays, and optional units

Weight

30 kg [66 lbs]

Excluding handset, trays, and optional units

OVERALL MACHINE INFORMATION May 22nd, 1995

SPECIFICATIONS

1-2

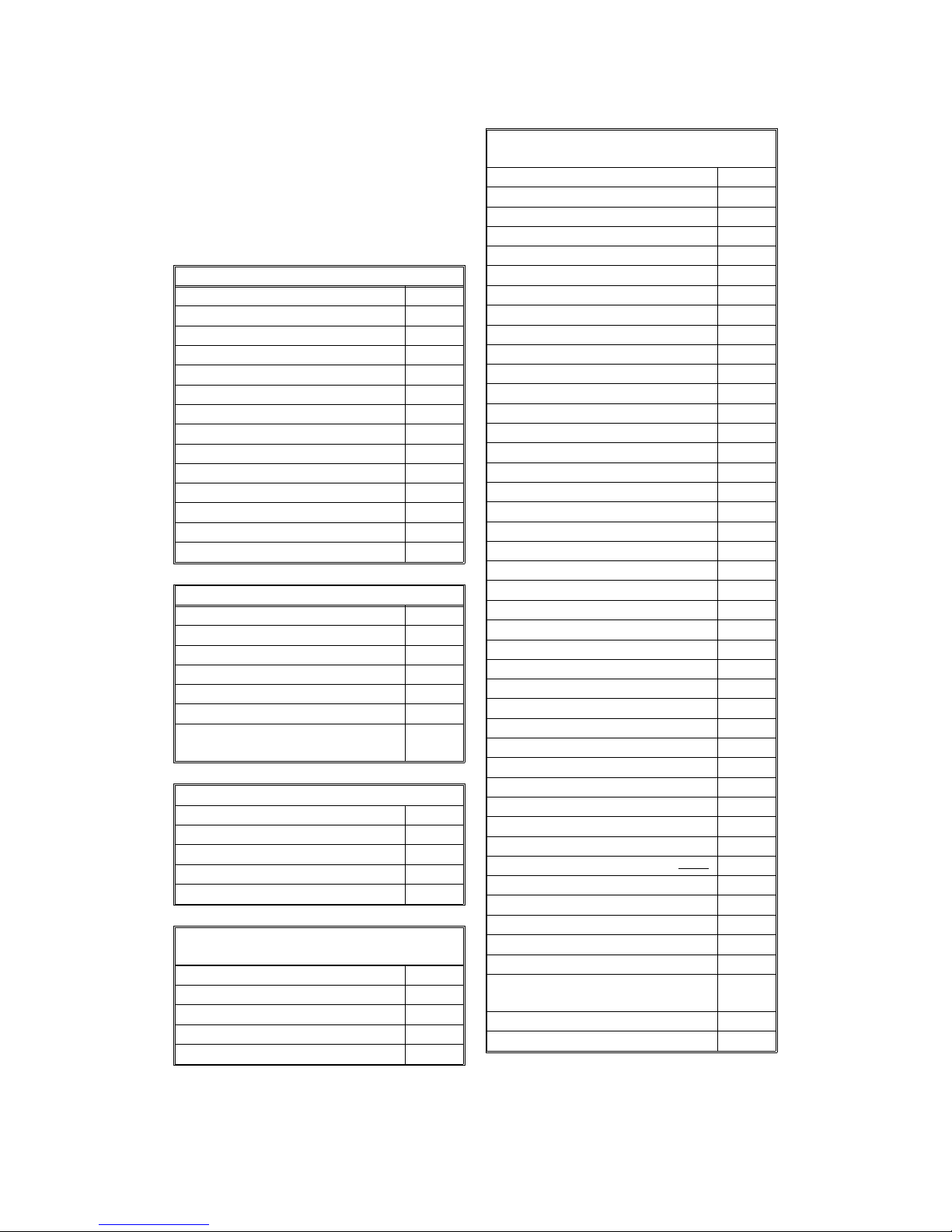

1.2. FEATURES

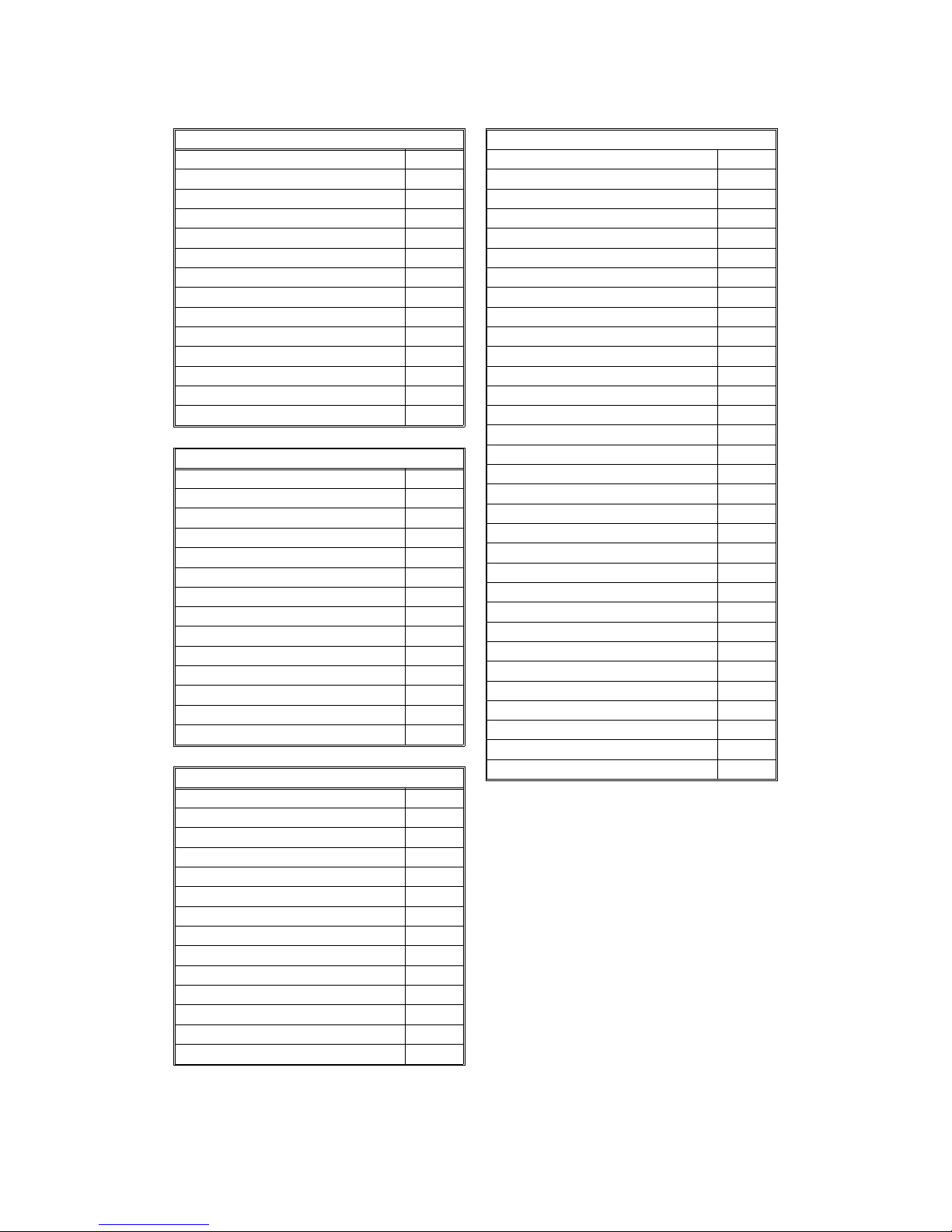

KEY: O = Used, X = Not Used

A = With optional 100 sheet cassette only

B = With optional counter only

C = With optional handset only

D = With printer interface only

Equipment

ADF O

Book scanner O

Built-in handset X

Bypass feed: 1 sheet O

Optional cassette: 100 sheets A

Cabinet X

Counter B

Cutter X

Handset C

Hard disk X

Manual feed mechanism X

Marker (Stamp) O

Monitor speaker O

Printer interface option D

Video Processing Features

Contrast O

Auto image density control O

Halftone (Basic & Error Diffusion) O

MTF O

Reduction (Fax) O

Resolution O

Smoothing to 16 x 15.4 l/mm

(Fax)

O

Communication Features - Aut o

Automatic fallback O

Automatic redialing O

Confidential reception X

Dual Access O

Substitute reception O

Communication Features -

User Selectable

Action as a transfer broadcaster X

AI Redial (last ten numbers) X

Answering machine interface X

Authorized Reception O

Auto-answer delay time X

Communication Features -

User Selectable

Auto dialing (pulse or DTMF) O

Auto Document X

Auto image density selection O

Automatic Voice Mess age X

Batch Transmission X

Broadcasting O

Chain Dialing X

Communication Result Display X

Confidential ID Override X

Confidential Transmission X

Direct Fax Number Entry O

Economy Transmission X

Fax on demand X

Forwarding X

Free Polling X

Groups (3 groups) O

Group Transfer Station X

Hold X

ID Transmission Option X

Immediate Redialing O

Immediate transmission O

Keystroke Programs X

Memory transmission O

Multi-step Transfer X

Next Transfer Station X

OMR X

On Hook Dial O

Ordering Toner X

Page Count O

Personal Codes X

Personal Codes with Conf. ID X

Polling Reception O

Polling Transmission X

Polling tx file lifetime in the SAF X

Quick Dial (20 stations) O

Reception modes (Fax, Tel,

Auto) O

Reduction O

Remote control features X

Remote Transfer X

Restricted Access X

Secured Polling X

Secured Polling with Stored ID

Override

X

Secure Transmission X

Send Later O

May 22nd, 1995 OVERALL MACHINE INFORMATION

FEATURES

1-3

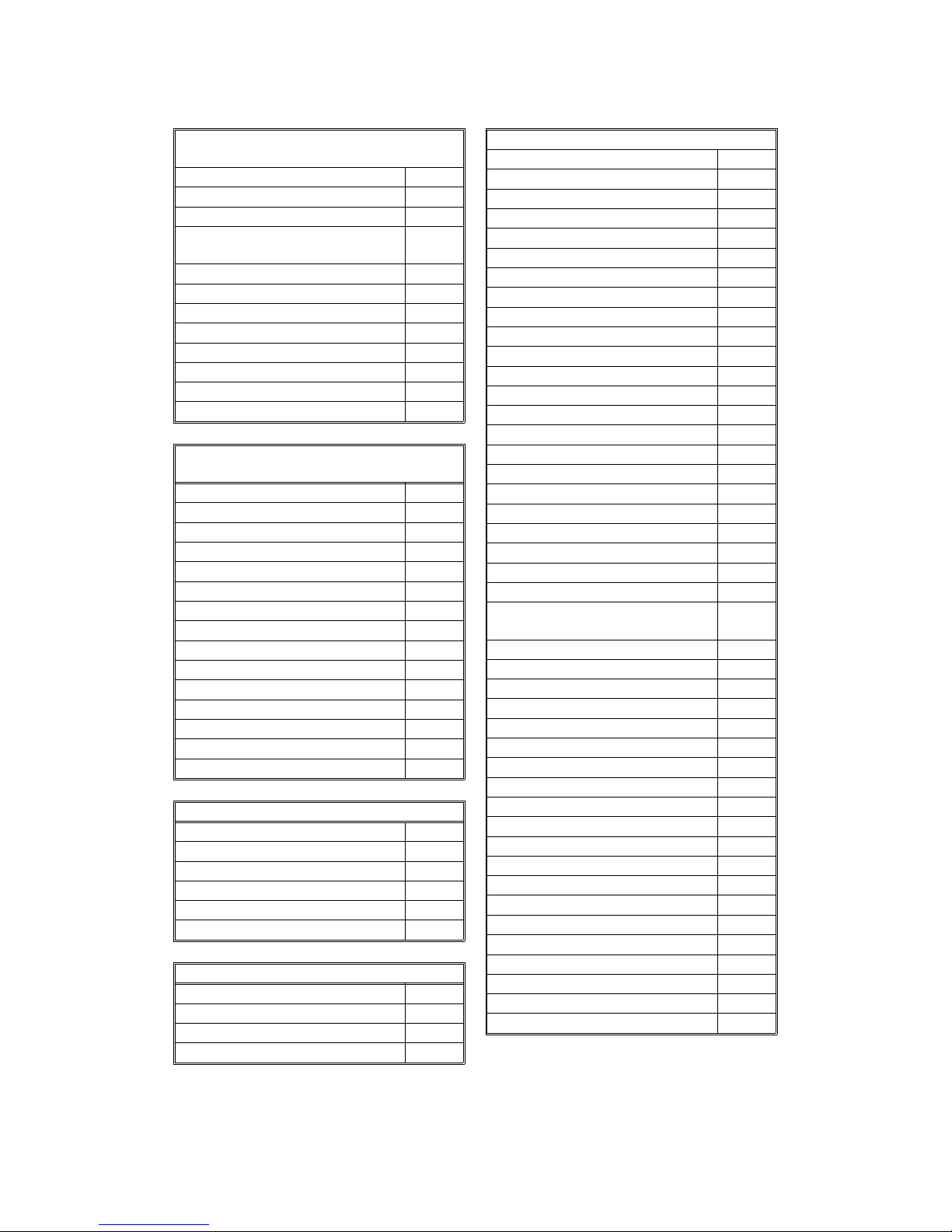

Communication Features -

User Selectable

Silent ringing detection X

Specified Image Area X

Speed Dial (50 stations) O

Super Fine Resolution

(16 x15.4 l/mm : 400 x 400 dpi)

X

Telephone Directory X

Tonal Signal Transmission O

Transfer Request X

Transmission Deadline (TRD) X

Turnaround Polling X

Two-step Transfer X

Two in one X

Voice Request (immed. tx only) X

Communication Features -

Service Selectable

AI Short Protocol O

Auto-reduction override option O

Busy tone detection O

Closed Network (tx and rx) X

Continuous Polling Reception X

Dedicated tx parameters O

ECM O

EFC O

Inch-mm conversion X

Page retransmission O

Page separation mark O

Protection against wrong conn. O

Resol’n stepdown override option X

Short Preamble X

Well log O

Copier Features

Auto Image Density O

Auto Paper Select (Book mode) O

Reduction/Enlargement O

Erase center/border O

Distribution number printing O

Center marks O

Other User Features

Area Code Prefix X

Auto Service Call O

Center mark O

Checkered mark X

Other User Features

Clearing a memory file O

Clearing a polling file O

Clock O

Confidential ID X

Copy mode O

Copy Mode Restriction X

Counters O

Daylight Saving Time (USA only) O

Destination Check X

Direct entry of names O

File Retention Time X

File Retransmission O

Function Programs X

ID Code X

Label Insertion ("From xxx") X

Language Selection O

LCD contrast control Service

Memory Lock X

Memory Lock ID X

Modifying a memory file X

Multi Sort Document Reception X

Multicopy mode (up to 99) O

Own telephone number X

Power Saver (Night Timer and

standby mode)

O

Print density control O

Printing a memory file O

RDS on/off O

Reception Mode Switching Timer X

Reception time printing X

Remaining memory indicator O

Remote ID X

Reverse Order Printing X

RTI, TTI, CSI O

Secure ID X

Service Report Transmission O

Speaker volume control O

Specified Cassette Selection X

Substitute reception on/off O

Telephone line type O

Toner saving mode O

TTI on/off O

User Function Keys X

User Parameters O

Wild Cards O

OVERALL MACHINE INFORMATION May 22nd, 1995

FEATURES

1-4

Reports - Automatic

Charge Control Report X

Communication Failure Report O

Confidential File Report X

Error Report O

Memory Storage Report O

Mode Change Report X

Polling Clear Report X

Polling Reserve Report O

Polling Result Report O

Power Failure Report O

TCR O

Toner Cassette Order Form X

Transfer Result Report X

Transmission Result Report O

Reports - User-initiated

Authorized Reception List O

Charge Control Report X

File List O

Forwarding List X

Group List O

Personal Code List X

Program List X

Quick Dial List O

Specified Cassette Selection List X

Speed Dial List O

TCR O

Transmission Status Report X

User Function List X

User Parameter List O

Service Mode Features

Auto Paper Select Test O

Back-to-back test O

Bit switch programming O

Book Test O

Buzzer test O

Cable equalizer O

Comm. parameter display O

Counter check O

Country code O

DTMF tone test O

Echo countermeasure O

Effective term of service calls O

Error code display O

Excessive jam alarm O

Service Mode Features

File Transfer O

Hex Dump List E

LCD contrast adjustment O

Line error mark O

Memory file printout (all files) O

Modem test O

NCU parameters O

Operation panel test O

Periodic service call O

PM Call O

Printer mechanism test X

Printer test patterns O

Programmable attenuation X

Protocol dump list O

RAM display/rewrite O

RAM dump O

RAM test O

Ringer test X

Scanner lamp test O

Scanner mechanism test O

Sensor initialization X

Serial number O

Service monitor report O

Service station number O

Software upload/download O

SRAM data download O

Status Sheet D

System parameter list O

Technical data on the TCR O

Thermal head parameters X

Transmission Status Report X

User data transfer O

Memory Files

Max. number of files: 100

Max. number of stations/file: 100

Max. number of stations overall: 200

Max. number of pages overall: 150

May 22nd, 1995 OVERALL MACHINE INFORMATION

FEATURES

1-5

1.3. COMPONENT LAYOUT

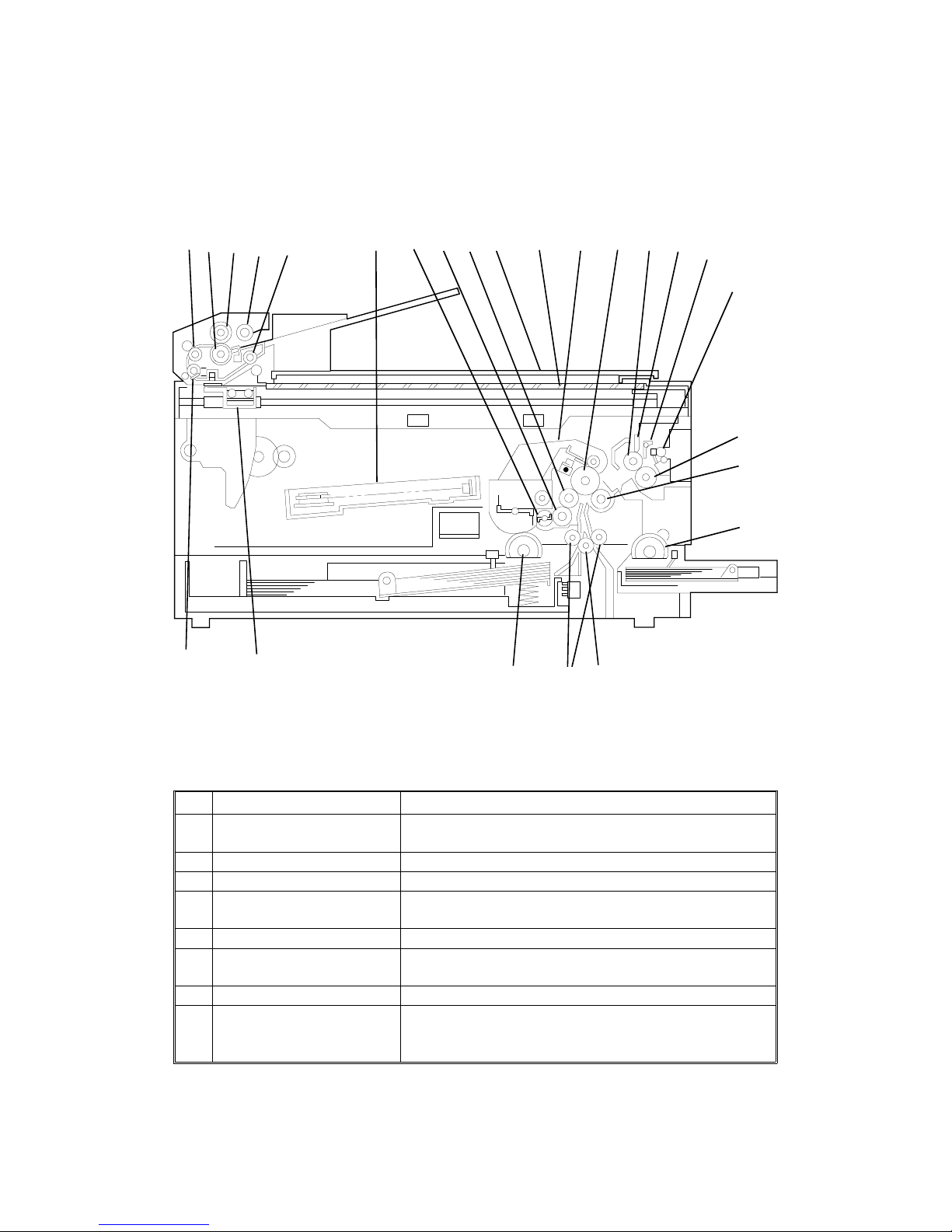

1.3.1. Mechanical Components

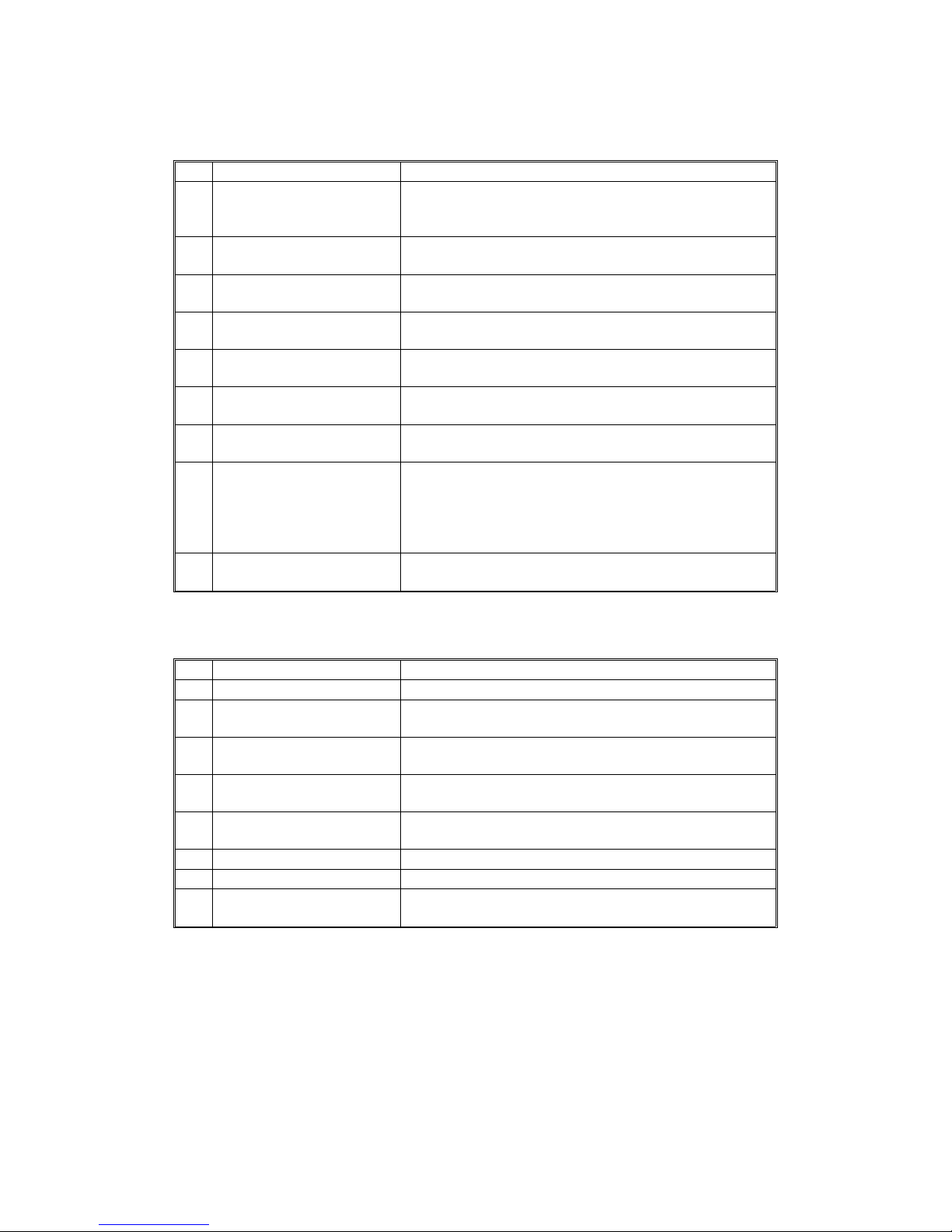

No. Name Description

1

Scanner Contains a contact image sensor and a xenon lamp

driver.

2 R1 Roller Feeds the document through the scanner.

3 R0 Roller Feeds the document into the scanner.

4

Separation roller Prevents more than one sheet from feeding into the

scanner.

5 Document Feed Roller Feeds the document into the scanner.

6

Pick-up Roller Picks up pages of the document from the document

table one at a time.

7 R2 Roller Feeds the document through the scanner.

8

Laser Unit This consists of the LDDR (Laser Diode Driver),

Focusing lens, Fθ Lenses, Hexagonal mirror motor, and

other laser optic components.

1

2

3

5

7

6

4

8

9

10

11

12

13 14

15

16

17

18

19

20

21

22

25 24

23

H521V501.wmf

OVERALL MACHINE INFORMATION May 22nd, 1995

COMPONENT LAYOUT

1-6

No. Name Description

9

Toner Supply Bar This stirs up and transfers toner to the toner application

roller.

10 Toner Application Roller This roller transfers toner to the development roller.

11 Development Roller This roller applies toner to the latent image on the drum.

12

Platen Cover This covers the original which was placed on the

exposure glass.

13 Exposure Glass Book scanner reads the original on it.

14

CTM (Cleaning Toner

Magazine)

This consists of the toner cartridge, cleaning unit, used

toner tank, charge corona unit, and quenching lamp.

15

OPC Drum The latent image is written to this Organic

Photoconductor Drum.

16 Hot Roller Heat from this roller fuses the toner to the copy paper.

17

Cleaning Pad This cleans up and spreads silicone oil on the surface

of the hot roller.

18 Hot Roller Strippers These take the paper off the hot roller after fusing.

19 Paper Feed-out Rollers These feed the paper out of the printer.

20 Fusing Pressure Roller This applies pressure to the paper during fusing.

21

Transfer Roller This applies a charge to the paper to pull the toner off

the drum and onto the copy paper.

22

Paper Feed Rollers (100

Sheet Cassette)

These pick up the top sheet of paper from the stack in

the optional 100 sheet cassette and feed it into the

printer.

23 Registration Roller This carries out the registration process.

24

Paper Feed Pressure

Rollers

These feed paper from the cassette or bypass feed slot

into the printer.

25

Paper Feed Rollers These pick up the top sheet of paper from the stack in

the cassette and feed it into the printer.

May 22nd, 1995 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

1-7

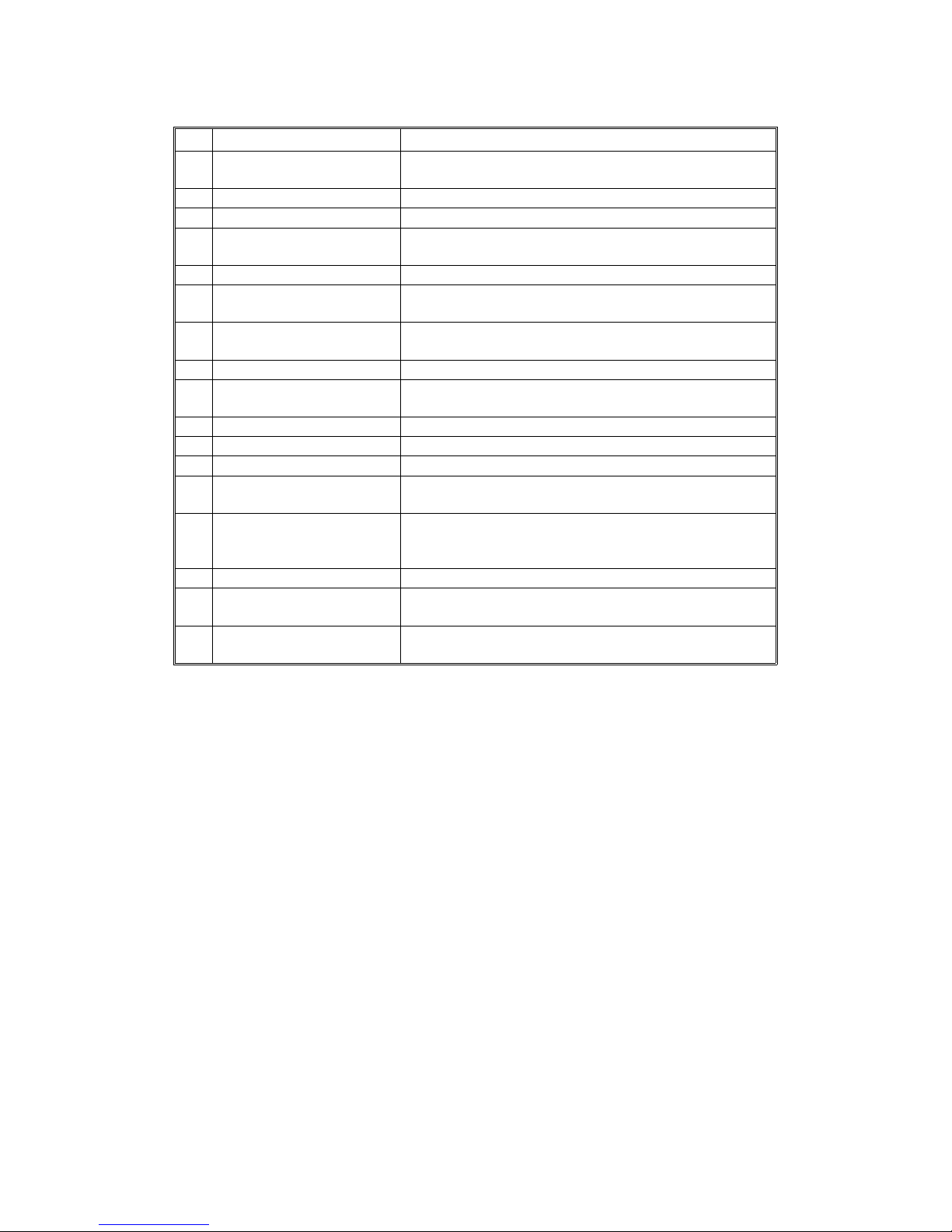

1.3.2. Electrical Components

3

4

1

5

16

15

6

7

8

14

9

10

11

12

13

2

H521V503.wmf

17

24

20

21

23

19

22

25

26

27

28

29

18

30

31

32

33

34

35

36

37

38

39

40

41

42

H521V504.WMF

OVERALL MACHINE INFORMATION May 22nd, 1995

COMPONENT LAYOUT

1-8

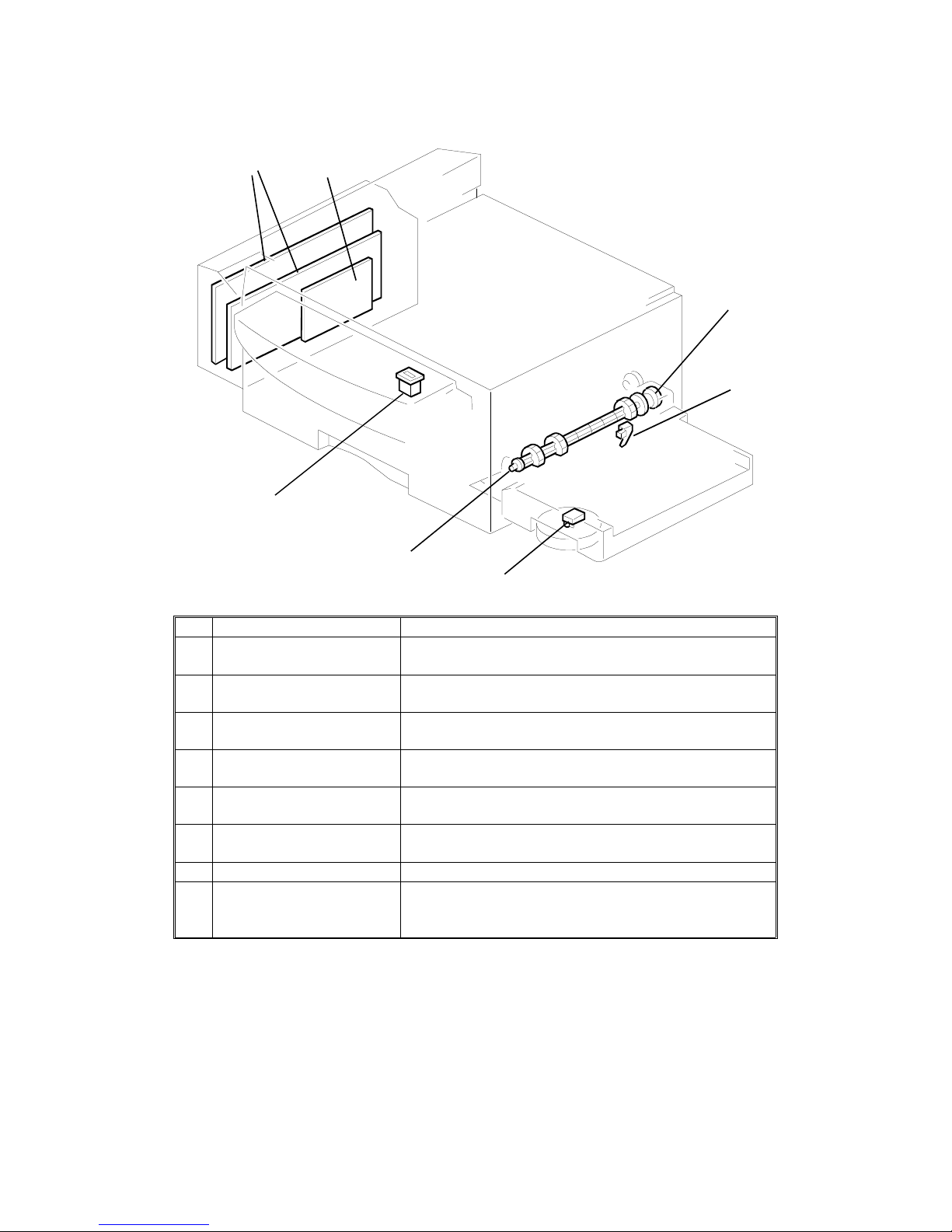

1. PCBs

No. Name Description

3

FDU (Facsimile Driver

Unit)

This board contains drivers for the motors, a dc-dc

converter, the energy saving mode cpu, and other drive

electronics.

2

FCE (Facsimile Control

Engine)

This board controls the machine. It contains the main

cpu, flash ROM, system RAM, and so on.

5

NCU (Network Control

Unit)

This board contains a relay and switches for interfacing

the machine to the network and the handset.

1

OPU (Operation Panel

Unit)

This board controls the operation panel.

7

PSU (Power Supply Unit) This board supplies power to the machine, and

switches the fusing lamp on/off.

15

LDDR (Laser Diode

Driver)

This board drives the laser diode.

14

Power Pack This supplies high voltages to the corona wire, transfer

roller, and development bias terminal.

9

Contact Image Sensor

and Xenon Lamp

This sensor reads and converts the light reflected from

the document into an analog video signal. It uses an

RMLA (Roof Mirror Lens Array ) sensor unit.

The xenon lamp which illuminates the document is

contained in this unit.

16

IC Card This contains a DRAM which is used as page memory

for 400 x 400 dpi printing of incoming B4 faxes.

2. Motors and Clutches

No. Name Description

6 ADF Motor This stepper motor drives the scanner.

10

Main Motor This brushless dc motor drives the drum, fusing unit,

development unit, and CTM.

12

Paper Feed Motor This stepper motor drives the registration roller and the

paper feed mechanisms in the cassettes.

8

Hexagonal Mirror Motor This high-speed dc motor drives the hexagonal mirror

in the laser printer optics.

41

Ozone Fan Motor This removes ozone-laden air from the vicinity of the

drum, and filters out the ozone.

29 Cooling Fan Motor This cools the interior of the machine.

4 Scanner Motor This stepper motor drives the book scanner.

11

Paper Feed Clutch This transfers main motor drive to the cassette and

bypass tray paper feed mechanisms.

May 22nd, 1995 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

1-9

3. Sensors

No. Name Description

17 Document Sensor This detects the presence of a document in the feeder.

19

Scan Line Sensor This detects when a page is approaching the auto

shading position.

20

Document Width Sensor This detects when a B4 width [10.1"] document has

been placed in the feeder.

39 Toner End Sensor This detects when the toner has run out.

40

Paper Size Detector This detects the paper size installed in the cassette.

The user must install the correct actuator.

33 Paper End Sensor This detects when the paper in the cassette has run out.

37

Registration Sensor This detects when paper has reached the registration

roller.

31

Paper Feed-out Sensor This detects when the paper has been fed out of the

printer.

32

Paper Exit Cover Switch This detects whether the paper feed-out cover is open

or closed.

36

Bypass Feed Sensor This detects when a sheet of paper has been inserted

into the bypass feed slot. Then the registration roller

feeds the paper a short distance into the machine to

prepare for printing, and stops.

21 ADF Cover Switch This detects whether the ADF cover is open or closed.

28

Scanner Home Position

Sensor

This detects when the image sensor is at home position.

2324Paper Size Sensors These detect the size of the paper which was placed

on the exposure glass.

25 Platen Cover Sensor This detects whether the platen cover is open or closed.

22 ADF Switch This detects whether the ADF unit is open or closed.

4. Interlock Switches

No. Name Description

27

30

Fusing Unit Cover

Interlock Switches

If the fusing unit cover and/or top cover are open, these

interlock switches interrupt the +5VLD power supply for

the laser diode and the +24VD power supply for the

power pack, motors, and other components.

OVERALL MACHINE INFORMATION May 22nd, 1995

COMPONENT LAYOUT

1-10

5. Others

No. Name Description

18

Stamper Ass’y This stamps a red circle on each page that is

successfully fed through the scanner.

38

Thermostat This interrupts the ac power supply to the fusing lamp if

the temperature of the thermostat surface exceeds

400°C.

35 Thermistor This monitors the temperature inside the fusing unit.

34 Fusing Lamp This fuses the toner to the paper.

42

Monitor Speaker This allows the user to listen to the condition of the

telephone line.

26

Zener Diode This ensures that the charge given to the drum by the

charge corona wire does not exceed -750 volts.

13 Lamp Stabilizer This supplies power to the xenon lamp.

May 22nd, 1995 OVERALL MACHINE INFORMATION

COMPONENT LAYOUT

1-11

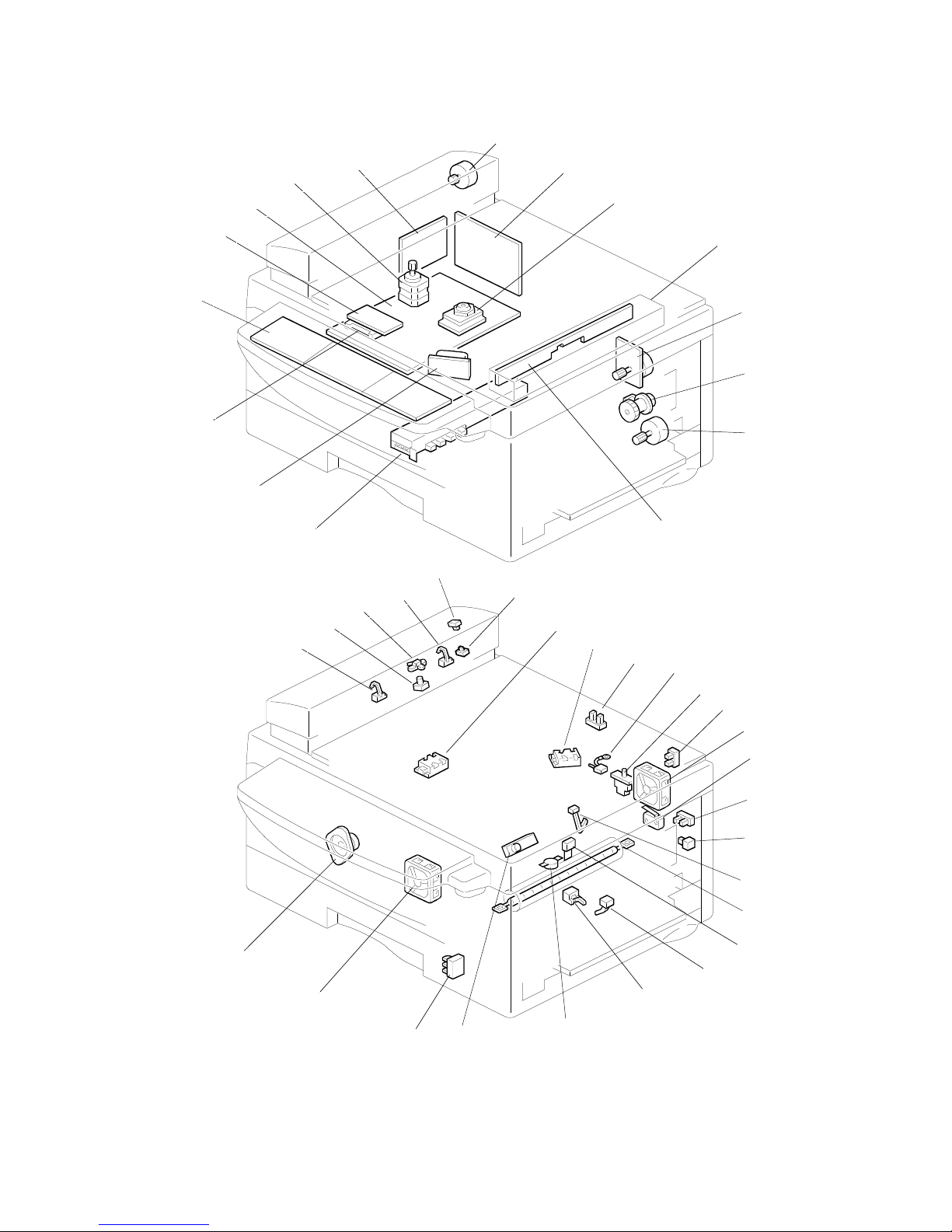

6. Options

No. Name Description

1

Printer Interface This allows the machine to be connected to a computer

as a laser printer.

2

RS232C Interface Board* This allows the machine to be connected to a computer

as an external fax device for example.

3

Paper Feed Clutch (100

Sheet Cassette)

This transfers motor drive to the mechanisms in the

100 sheet cassette.

4

Paper End Sensor (100

Sheet Cassette)

This detects when the paper in the optional 100 sheet

cassette has run out.

5

Paper Size Detector (100

Sheet Cassette)

This detects the paper size installed in the optional 100

sheet cassette.

6

Paper Feed Roller (100

Sheet Cassette)

This feeds paper from the 100 sheet cassette into the

machine.

7 Counter This counts the number of prints.

8

100 Sheet Cassette This increases the paper capacity of the machine, and

allows the machine to have more than one paper size

available at the same time.

* This option may not be available in some countries.

12

3

4

5

6

7

H521V505.wmf

OVERALL MACHINE INFORMATION May 22nd, 1995

COMPONENT LAYOUT

1-12

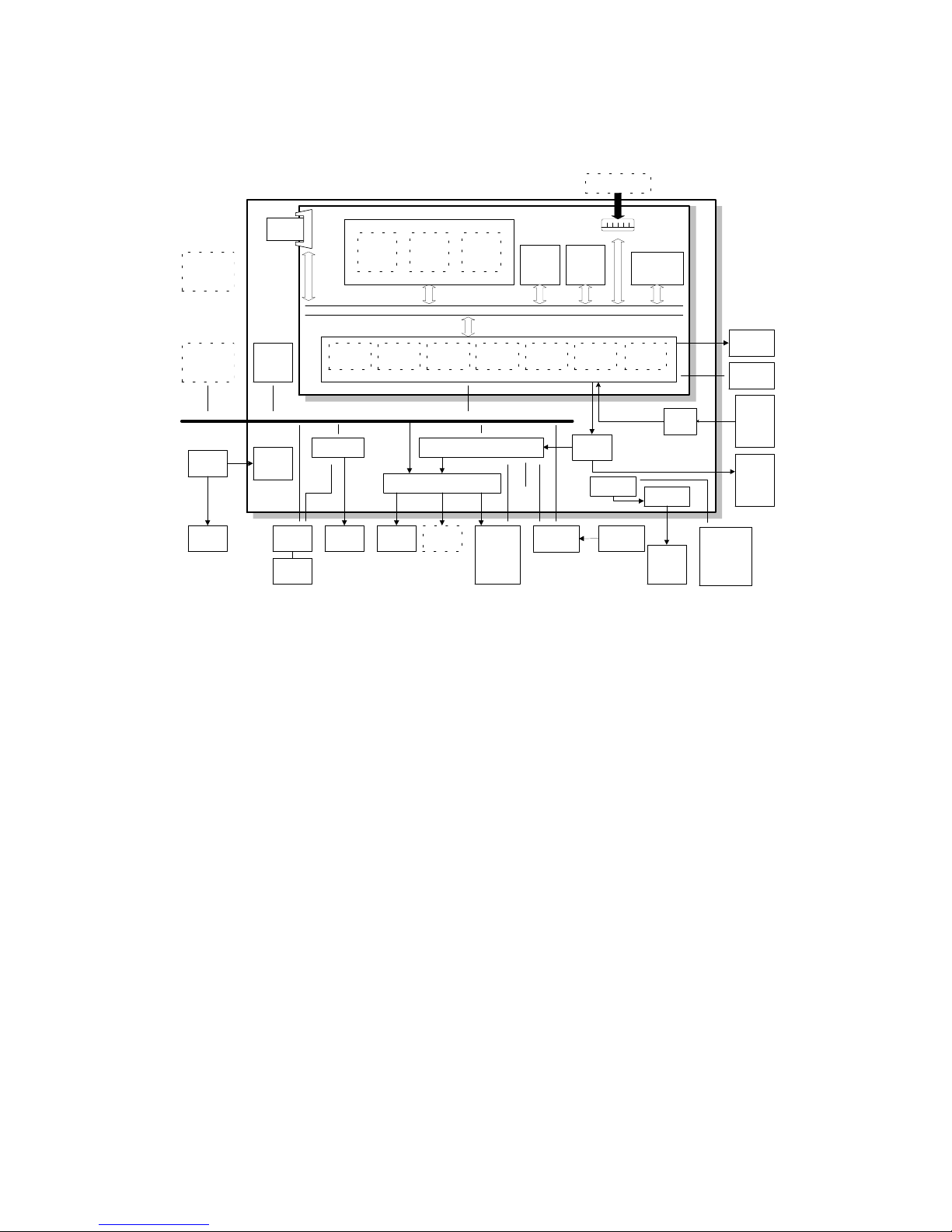

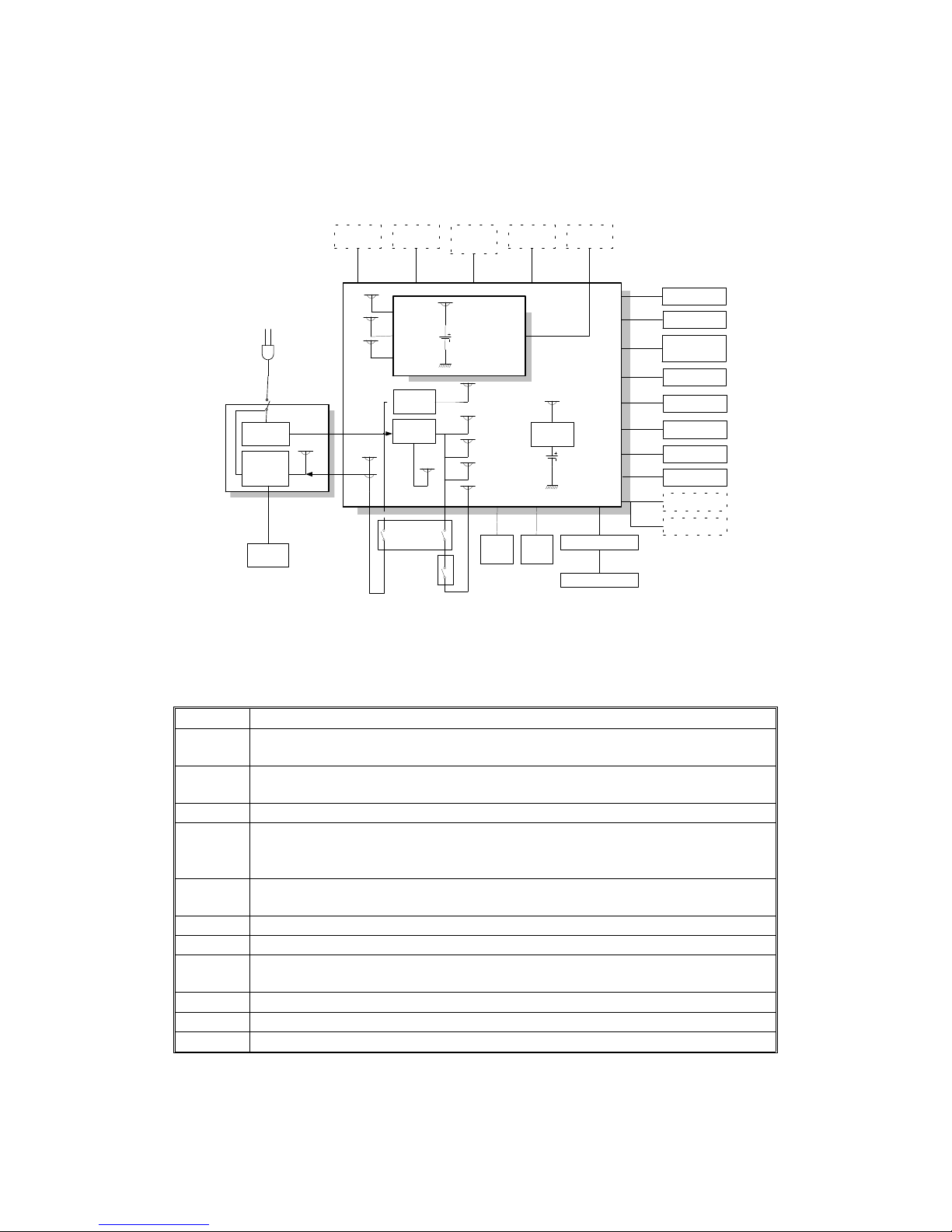

1.4. OVERALL MACHINE CONTROL

The FCE (Facsimile Control Engine) board contain s the FCIP (Facsimile Control and Image Processor), DRAM, SRAM, Syst em ROM, and video

processing memory, and it controls the entire system through th e FDU (Facsimile Driver Unit) board.

There are two cpus in the mach ine : the main cpu (FCIP) on the FCE board

and the energy saver cpu on the FDU board. In energy saver mode, the main

CPU switches off and the energy saver CPU takes over.

The FCIP consists of the following component blocks:

• MDM - Modem• RU8 CPU - Main CPU

• DMAC - DMA Controller• LIF- Laser Interface

• DIP - Digital Image Processor• PRIF - Printer Interface

• DCR - Data Compression and Reconstruction

The 4 MB DRAM contains the SAF memory, ECM buffer memory, work area,

and page memory. For B4 size copies at 16 x 15.4 dot/mm resolution, a page

memory IC card is installed. A rechargeable battery backs up th e DRA M for

one hour.

The system ROM uses a 512 KB (4 Mbits) flash ROM. Software in this ROM

can be rewritten from the IC card slot or by RDS.

FCE

FCE

Contact

Image

Sensor

Amp

Optional

100 Sheet

Cassette

Optional

Printer I/F

Energy

Saver

CPU

System

ROM

(Flash)

System

RAM

(SRAM)

DATA/ADDRESS BUS

Optional

RS232C I/F

Video

SRAM

Drivers

(FPD)

Driver

LDDR

Thermistor

Scanner

and

printer

components

and

sensors

Operation

Panel

Driver

Optional

Counter

Power

Pack

SpeakerNCU

Handset

Control

Signals

DRAM

System

RAM

ECM/SAF

Memory

Page

Memory

FCIP

MDM

CPU

RU8

DMAC DCR DIP LIF

External I/O (EXIO)

DC-DC

Converter

Hybrid IC

(HIC)

PSU

Fusing

Lamp

Page

Memory

PRIF

PSIF

Sensors

Paper

feed

motor

Book scanner

components

and

ADF sensor

ADF

and

book

scanner

motors

FDU

H521V506.wmf

May 22nd, 1995 OVERALL MACHINE INFORMATION

OVERALL MACHINE CONTROL

1-13

1.5. VIDEO DATA PATH

1.5.1. Transmission

Immediate Transmission:

Scanned data form the contact imag e sen sor passes to the DIP block in the

FCIP. After analog/digital video processing, the DCR block comp resse s t he

data for transmission. The co mpre ssed data then passes either to the FIFO

memory or to the ECM memory, before it is sent to the telephone line through

the modem.

Memory Transmission:

First, the scanned data is stored in the SAF memory after compressio n in the

DCR block.

At the time for transmission, the DCR block decompre sses the data from the

SAF memory, then compresses it again after handshaking with the oth er te rminal is done. The compressed data the n passes eit he r to th e FIFO memory

or to the ECM memory, before it is sent to the telephone line through the modem.

FDU

FCE

DRAM

Video

Processing

Memory

Amplifier

Attenuator

Line

Buffer

/FIFO

Memory

ECM/

SAF

Memory

NCU

Amplifier

MDM

FCIP

DATA/ADDRESS BUS

HIC

To the network

Original

Image Sensor

Xenon Lamp

Contact Image Sensor Assembly

DCR

DIP

DIP: Digital Image Processor

DCR: Data Compression and Reduction

MDM: Modem

H521V507.wmf

OVERALL MACHINE INFORMATION May 22nd, 1995

VIDEO DATA PATH

1-14

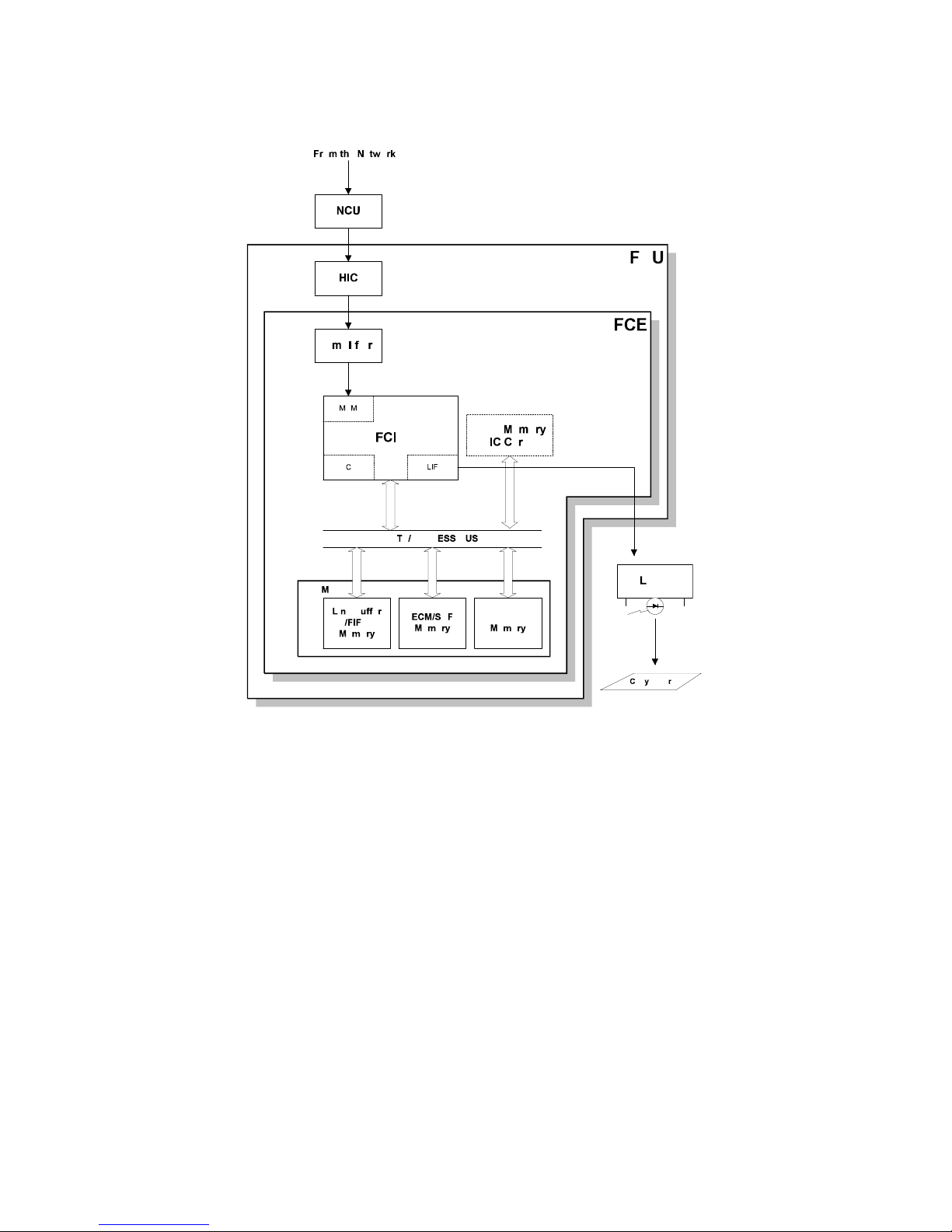

1.5.2. Reception

Data from the line passes to the modem th rou gh the NCU and hybrid IC. After the modem demodulates the dat a, the data pa sses to the DCR block,

through either the FIFO or the ECM memory, where the data is decompressed to raster imag e d at a. At the same time, the compressed data pa sses

to the SAF memory as a backup in case of mechanical problems during printing (substitute rece pt ion).

The raster image data is then p asse d t o t he pa ge memo ry fo r printing. After a

page of data has been stored in the pag e memo ry, the data is sent to the

LDDR through the LIF block.

MDM: Modem

DCR: Data Compression and Reduction

LIF: Laser Interface

H521V508.wmf

May 22nd, 1995 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

1-15

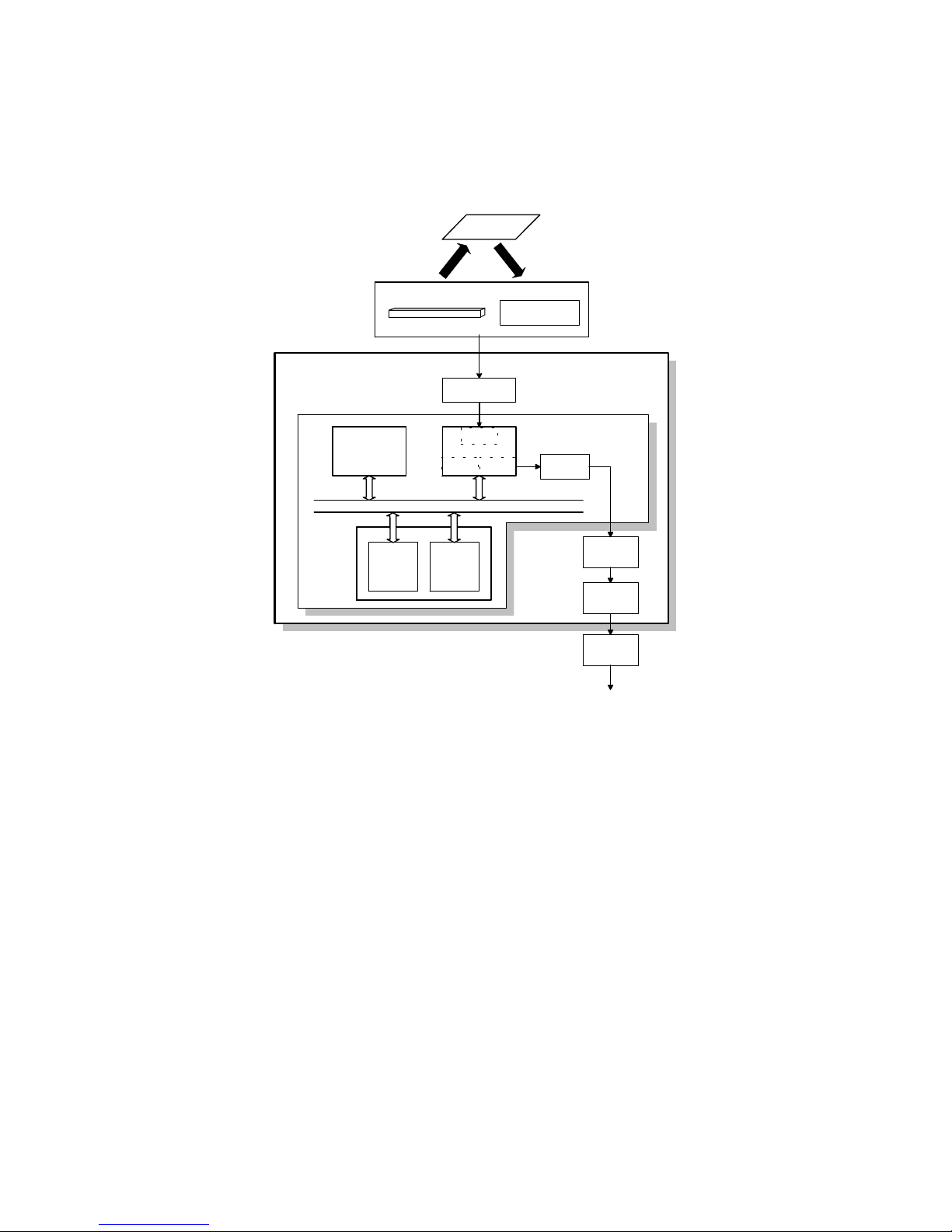

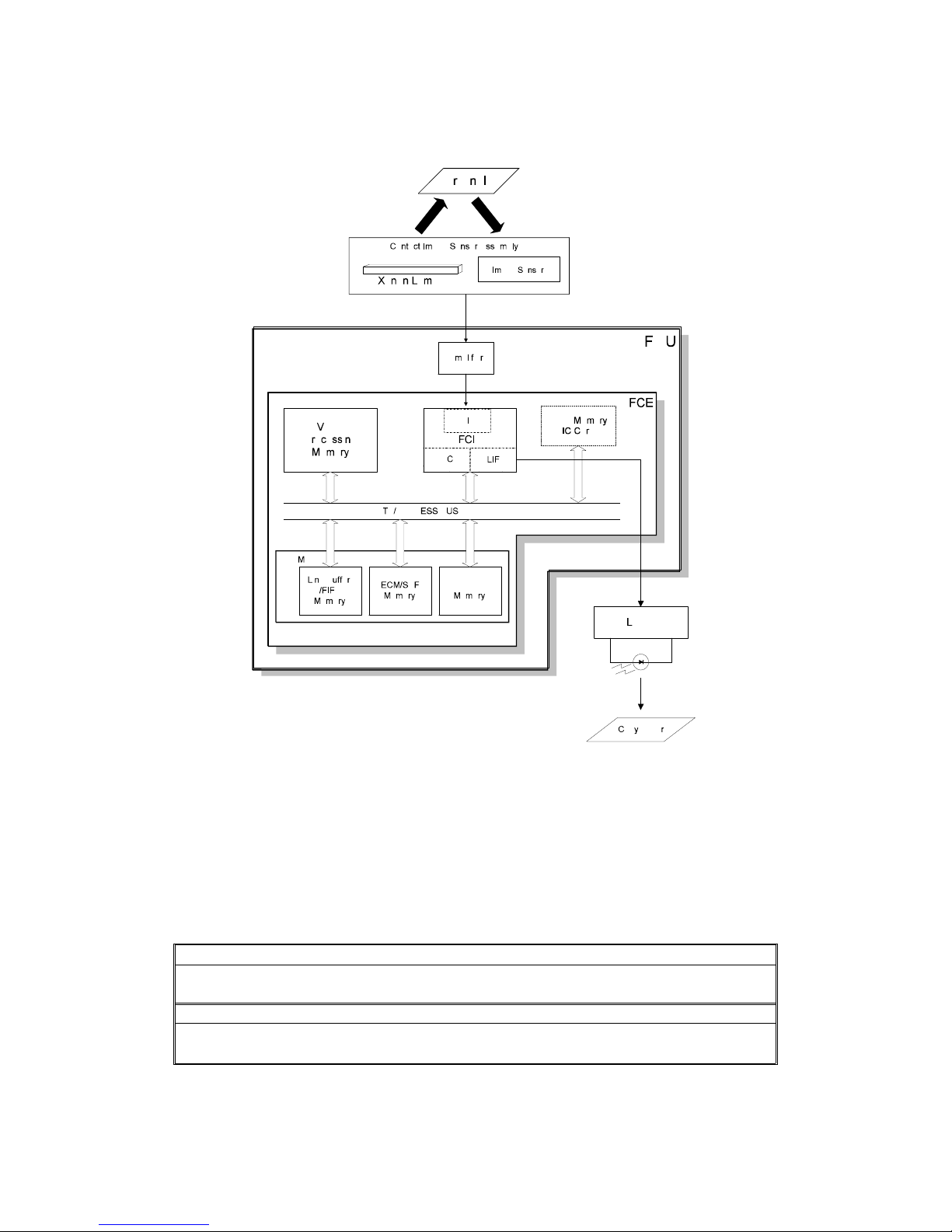

1.5.3. Copying

The scanned data passe s to th e pa ge memory af ter video processing in the

DIP block. After a page of data ha s be en sto red in the page memory, the data

is sent to the LDDR through the LIF block.

Reproduction/Enlargem ent Rati os

The following reproduction ratios are available:

Reduction 50% 65% 71% 74% 77% 82% 87% 93%

US Yes Yes No Yes Yes No No Yes

Europe/Asia Yes No Y es No No Yes Yes Yes

Enlargement 115% 121% 122% 129% 141% 155% 200%

US NoYesNoYesNoYesYes

Europe/Asia Yes No Y es No Yes No Y es

DIP: Digital Image Processor

DCR: Data Compression and Reduction

LIF: Laser Interface

H521V509.wmf]

OVERALL MACHINE INFORMATION May 22nd, 1995

VIDEO DATA PATH

1-16

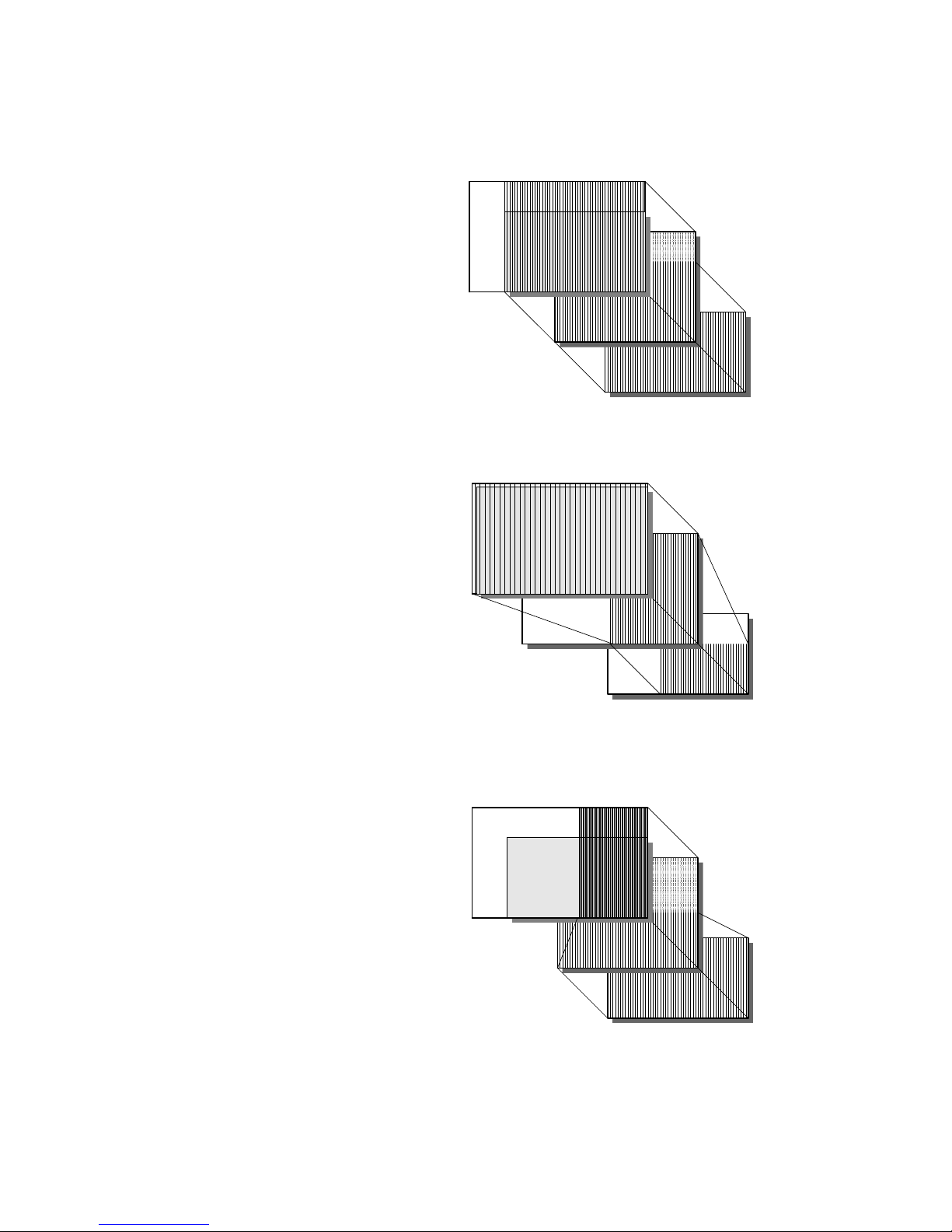

Reduction and Enlargement

The reduction/e nla rgement process

is done in two steps, one at the scanner, and the other at the printer.

At the scanner, the machine changes

the motor speed to get a reduced/enlarged image in the sub-scan

direction. For example, the machine

doubles the motor speed to get 50%

reduction (halving the numb er of

scan lines), and slows the motor

speed down by half to get 200% enlargement (doubling the number of

scan lines). The scanne r alwa ys

scans the full B4 (216 mm) width in

the main scan direction. The sca nned

data is then stored in the page memory for printing.

At the printer, the machine deletes

certain specified bits from each line

to reduce the printing image in the

main-scan direction. For examp le,

every other bit is deleted to get a

50% reduced image.

Also, the machine chang es th e laser

pulse width for each pixel to enlarg e

the printing image in the main-scan

direction. For example, the machine

doubles the pulse width to get a

200% enlarged image.

Scanner

Page Memory

Printer

Original

H521V513.wmf

Full Size

Scanner

Page Memory

Printer

Original

H521V514.wmf

50% Reduction

Scanner

Page Memory

Printer

Original

H521V515.wmf

200% Enlargement

May 22nd, 1995 OVERALL MACHINE INFORMATION

VIDEO DATA PATH

1-17

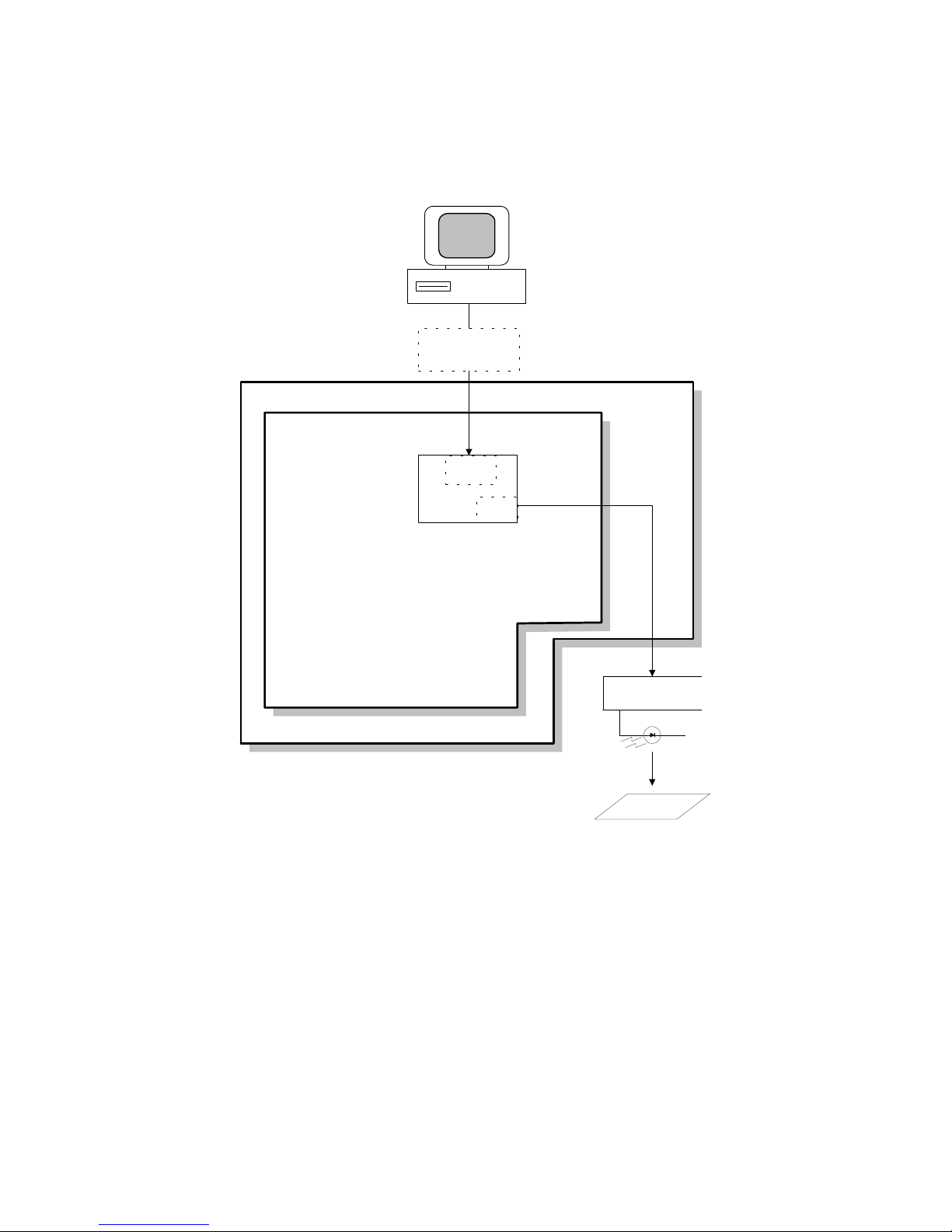

1.5.4. Printing using the Optional Printer Interface

After a page of data has been stored in the prin ter in te rfa ce’s page memory,

the data is sent directly to the LIF through the PRIF (Printer Interface) block.

FDU

FCE

LIF

FCIP

LDDR

Copy

Paper

PRIF

Optional Printer

Interface

PRIF: Printer Interface

LIF: Laser Interface

H521v512.wmf

OVERALL MACHINE INFORMATION May 22nd, 1995

VIDEO DATA PATH

1-18

1.6. POWER DISTRIBUTION

1.6.1. Distribution Diagram

The PSU supplies +24V dc power to the FDU. The FDU converts the +24V

dc power supply to the following supplie s.

+5V This is normally on when the main switch is on.

+5VE

This is used for watching the activation signal when the machine is in energy

saving mode.

+5VLD

This supplies the laser diode. It is interrupted if the fusing unit cover interlock

switch opens.

+5VV This is a more stable power supply than +5V. It is used for the image sensor.

+5VD

This supplies the DRAM and the page memory card on the FCE to back up the

stored data for one hour, if the power is switched off and some data is stored in

them. A rechargeable lithium battery is used to generate +5VD.

+5VBAT

This supplies the system RAM on the FCE to back up the programmed data, if

the power is switched off. A lithium battery is used to generate +5VBAT.

+24V This is normally on when the main switch is on.

+24VD This is interrupted if the fusing unit cover interlock switch opens.

+24VIN

This supplies +24V to the fusing unit on/off switching circuit. It is interrupted if

the fusing unit cover interlock switch opens.

+24VM This is interrupted if the machine enters energy saving mode.

-5V This is used for the image sensor.

+12VP This is used for the page memory card.

+24VM

+5V

+5VV

-5V

+24V

+5VE

+5VLD

+5V

+5VE

Motors

Feed Clutch

Stamp

Cooling Fan

Ozone Fan

Power Pack

Thermistor

Printer Sensors

+24VM

+24VD

Optional

Counter

Optional 100

Sheet

Cassette

Optional

Printer I/F

Main Switch

+24VD

+24VD

+5V

+5V

+24VM

+5V

FDU

PSU

Fusing

Lamp

AC

Main

Power

AC Switching

Circuit

Interlock

Switch

LDDR

Image Sensor

Book Scanner

Operation Panel

NCU

+24VD

+24VM

+5V

+24V

+5V

+5VLD

+12VD

+5V

-5V

+5vv

+5VE

+5V

DC-DC

Converter

12VP

DC-DC

Converter

24VM

24VD

24VIN

Fusing Lamp

ON/OFF

Switching

Circuit

AC115V or 230V

+5VBAT

Optional

RS232C I/F

+5V

IC

Card

+12VP

+5V

+5VD

Xenon Lamp

+24VM

Optional ADF

+24VM

+5V

+5VD

+5V

DC-DC

Converter

+24VD

FCE

+24V

H521V510.wmf

May 22nd, 1995 OVERALL MACHINE INFORMATION

POWER DISTRIBUTION

1-19

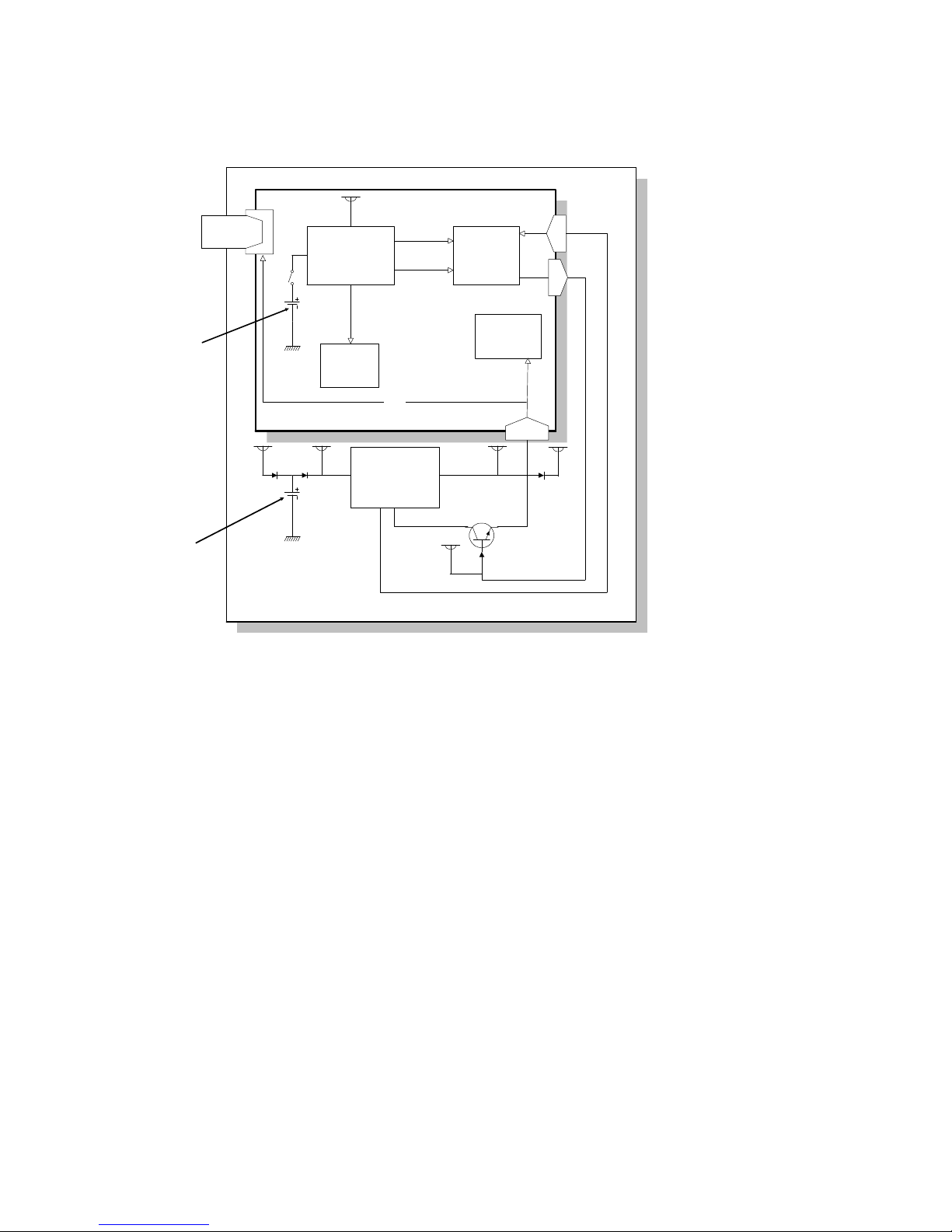

1.6.2. Memory Back-up Circuit

The +5VBAT supply from the lithium battery [A] backs up the system RAM

which contains system paramet ers an d pro grammed telephone numbers,

and the real time clock in the main cpu. The 5RTCCS sig na l tells th e ma in

cpu whether the back-up powe r (+5VB AT) is coming from the battery or from

the +5V power supply.

A rechargeable lithium batt ery [B ] an d the dc/ dc con verter on the FDU back

up the DRAM (SAF memory) for one hour, if there is data in the SAF memory

and the power is switched off. While the main power is on, the +5VE supply

recharges the batte ry. The battery recharges in o ne or two days.

The battery [B] generates ab out 3 volt s (max. 3. 2 vo lts). The dc/dc converte r

(IC12) lifts this voltage to 5 volt s so it can be used as the +5VD supply for

SAF backup. The CPU monitors the voltage of the +5VD sup ply with the

1VDET signal. When the battery has run down, and the volta ge is lower tha n

4.4 volts, the CPU stops the dc/dc converter by dropping 1SAFFG to low and

the machine stops backing up th e memo ry.

There is no battery switch for the battery [B].

FDU

FCE

FCIP

Switching

Circuit

System

RAM

DRAM

POWERS

5RTCCS

+5VBAT

+5V

+5VE

+5V

D

+5VD

1VDET

1SAFFG

CN1-92

CN1-94

CN1-96

Q5

+5VD

Page

Memory

DC/DC

Converter

[IC12]

+5V

+5V

+5VBAT

[A]

[B]

H521V511.wmf

OVERALL MACHINE INFORMATION May 22nd, 1995

POWER DISTRIBUTION

1-20

2. DET AILED SECTION DESCRIPTIONS

2.1. SCANNER

2.1.1. Overview

1. Book Scanner

The scanner motor [A] drives th e scan ne r [ B] through the timing belt [C] and

drive wire [D]. The shaft [E] guide s sca nner movement in the sub-sca n direction. Inside the scann er [B ] are a contact image sensor (containing a sensor

element and xenon lamp) and a xenon lamp driver.

The scanner [B] consists of a contact image sensor and a xen on lamp driver.

The original width senso r [ F] an d len gth sensor [G] togeth er de te ct the size of

the original placed on the exposu re gla ss.

The scanner home position sensor [H] allows the scanner return to th e same

position after scanning.

The platen cover switch [I ] de te cts if the cover is opened or not.

[H]

[F]

[E]

[B]

[D]

[C]

[A]

[I]

[G]

H521D011.wm f

May 22nd, 1995 DETAILED SECTION DESCRIPTIONS

SCANNER

2-1

2. ADF

The sheet through type ADF feeds th e docu men t from t he top page of t he

document stack on th e ta ble.

The pick-up [A] and feed roller [B] feed the original into th e scanner, and the

separation roller [C] help s to feed one sh eet at a time. Then, the R0 [D], R1

[E], and R2 [F] rollers feed the documen t th rou gh the scann er.

At the time of scannin g th e do cument, the scanner ([ B] on the previous page)

moves down to the scanning position under the exposu re g lass [ G] . The shading plate [H] pushes the docu ment to the exposure glass at the sca n line , so

that the document is with in th e image sensor’s range of focus.

After scanning, t he ADF f ee ds out the document o nto the platen cover, and

the scanner moves back to its home position at the right end of the scanner.

Unlike a copier’s ADF, this ADF does not have a document length sensor. So,

some of the copier features a re n ot ava ilable when the ADF is used. Ref er t o

“Original Detection - ADF” later in this chapter.

[A]

[B]

[C]

[D]

[E]

[G]

[F]

[H]

H521D008.wmf

DETAILED SECTION DESCRIPTIONS May 22nd, 1995

SCANNER

2-2

Loading...

Loading...