Ricoh MPC 1500sp Troubleshooting Manual

MPC 1500sp

Technicians

Troubleshooting Guide

This guide is designed to help you with known issues.

Produced by M. Drage v1.2

White or Coloured Lines

Before completing any of the following, REMOVE AND

CLEAN THE MAINTENANCE UNIT. Pay particular

attention to the wiper area, the roller and first cap.

CLEAN ONLY WITH A CLOTH DAMPENED WITH

WATER - NO CHEMICALS!

Once the above has been completed, move onto head cleaning or flushing.

Select User tools, Maintenance, Head Cleaning or Flushing.

To check which print head is blocked use the Nozzle Check Pattern.

To clean, select CLEAN from the menu - you will have a check box by each

colour. Use the right arrow to select and the down arrow to move onto the

next item.

This is a good one

This shows that the black and cyan print heads are blocked

Sometimes you will have to perform head cleaning more than once to

resolve the issue. If after 4 head cleans, you still have a problem, then try

head flushing. If after this, there is still an issue, then try physically cleaning

the heads.

ONLY USE SPECIALISED HEAD CLEANING CLOTHS

PART NUMBER B2299311

If this is happening regularly there are a few options you can try depending

on when the lines appear.

1. If the symptom occurs when a printout is made after leaving the

machine unused for a long time, make sure the Engine Firmware is

v1.10 or later. This will ensure the head home position is correct, thus

ensuring the heads are capped correctly on the maintenance unit.

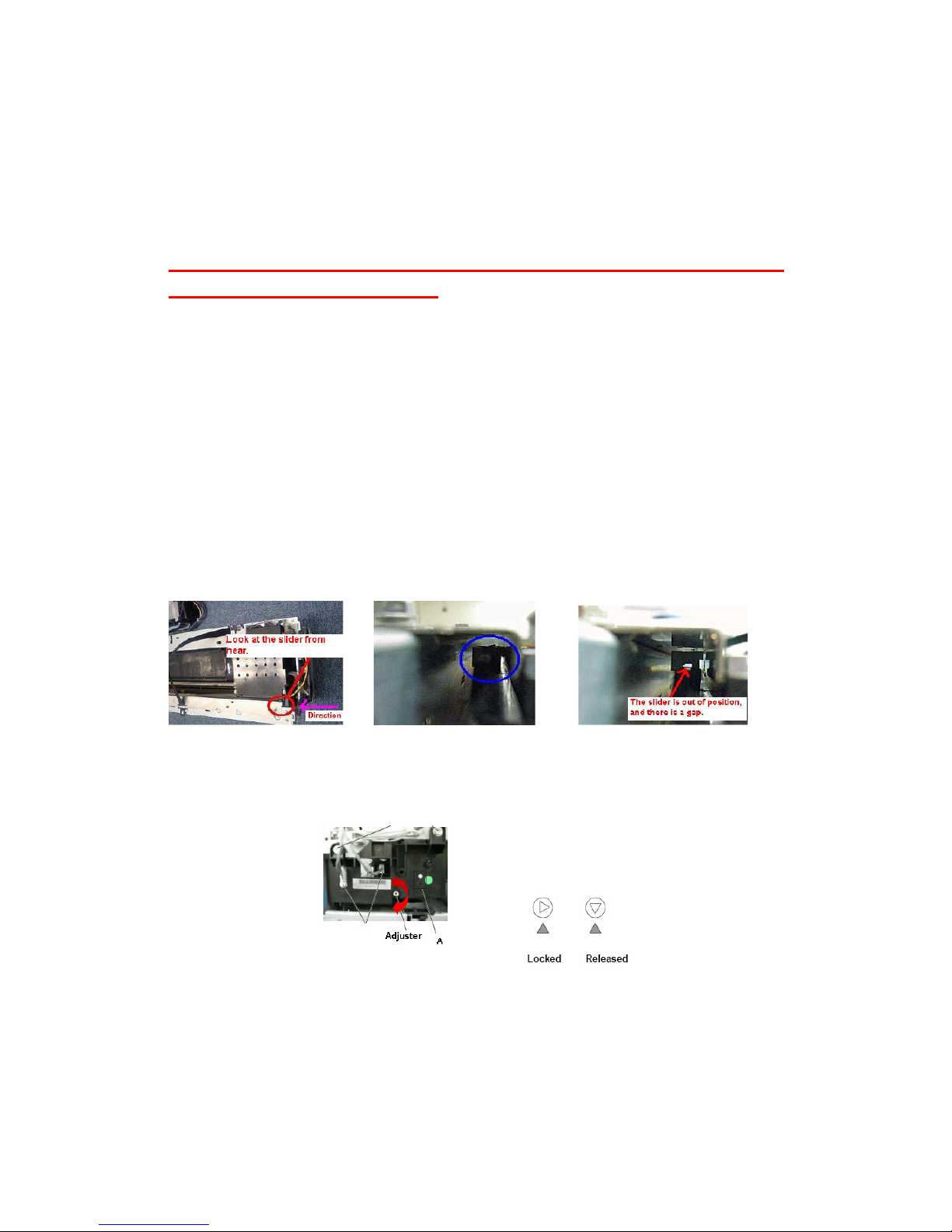

2. Make sure the carriage slide is in the correct position. If it is not then,

as previously the heads will not cap correctly, thus drying out. Use

the following guide to check and adjust.

Correct position Incorrect position

Release the lock for the maintenance unit. To do this turn the adjuster clockwise until the

heads of the triangles line up.

Slide the carriage until the small white part in the photo lines up with the hole.

Lift up the carriage unit and insert a small slot screwdriver into the hole and push until

you hear a click.

If the carriage slide is out of position you may get SC202 and/or jams in

areas A/C.

3. If the machine is installed in an environment with a relative humidity

of 15% or less, the ink will dry out quicker, as this is outside of the

machines operational specification and the machine will have to be

moved to a more suitable environment.

4. If the symptom occurs during regular use, then set SP2 508 001

(Exhalation Interval Change) to a value of 1 (every 15 seconds), also

do ONE of the following:

Set bit 6 of SP3 112 004 (print mode setting1) to a value of 1.

Ink mist can easily be generated when using paper with a high surface

impedance such as recycled paper. This mist can clog the nozzles.

Or

Change the setting of SP3 112 004 (print mode setting 4), so that auto

shading is performed more often.

xxxxx000: Default (1 time per approx 300 pages)

xxxxx001:1.3 times

xxxxx002:2 times

xxxxx003:4 times

xxxxx004:10 times. Remember, the more times it cleans, the

slower the print.

5. Each visit, clean the maintenance unit, if you have tried all of the

above you may have to replace the maintenance unit.

Smudged images

This is usually caused when the customer copies or prints onto unsuitable

paper. If the paper is not absorbent enough, the ink cannot dry before the

print head returns. Unfortunately there is no hard and fast rule as to the type

of paper that should be used - it is just a matter of trial and error.

Smudged copies can also occur if the paper is too thick. This product is able

to feed up to 105gms from the trays, 162gms from the bypass and 220gms

from the one sheet bypass. If the customer is using 220gms paper, then the

envelope lever may have to be used (in the down position), this will raise the

print head by about 2mm giving more clearance. Make sure the lever is put

back to normal (up position) as this may cause quality issues when using

normal paper.

Envelope lever

Loading...

Loading...