Ricoh MD-P2, M075 Field Service Manual

Model MD-P2

Machine Code: M075

Field Service Manual

8 October, 2010

Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the printer and peripherals, make sure that the printer

power cord is unplugged.

The wall outlet should be near the printer and easily accessible.

2.

3. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

4. The printer drives some of its components when it completes the warm-up period. Be careful to

keep hands away from the mechanical and electrical components as the printer starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while the printer is operating.

Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

Toner is non-toxic, but if you get either of them in your eyes by accident, it may cause temporary eye

discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful, get medical

attention.

Observance of Electrical Safety Standards

The printer and its peripherals must be serviced by a customer service representative who has completed

the training course on those models.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

Dispose of used toner, the maintenance unit which includes developer or the organic

2.

photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

• To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols. A fire or an explosion might occur.

1

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units

in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite

equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser

chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and

laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

• Use of controls, or adjustment, or performance of procedures other than those specified in this

manual may result in hazardous radiation exposure.

WARNING

WARNING:

Turn off the main switch before attempting any of the procedures in the Laser Optics Housing Unit

section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

2

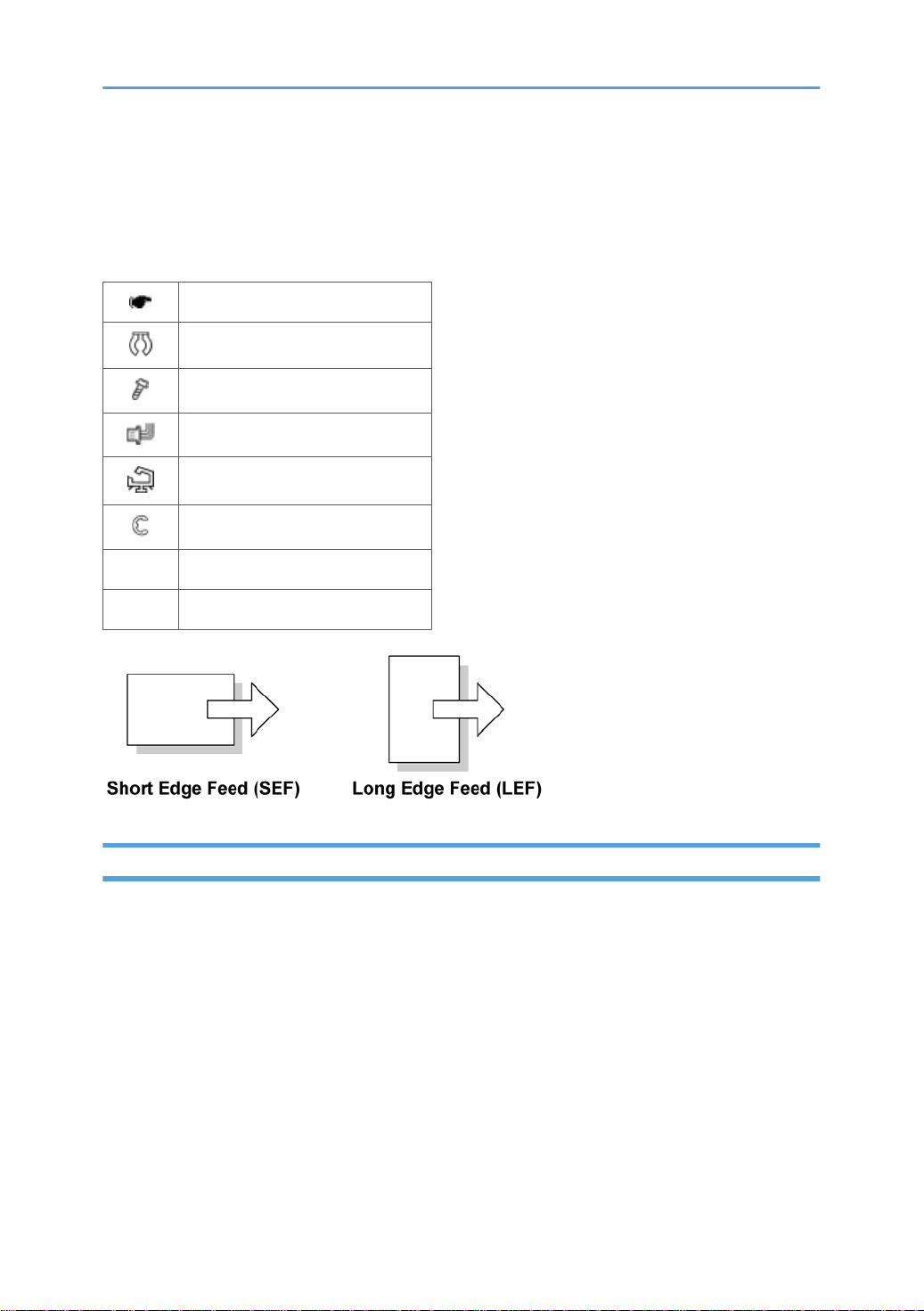

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and abbreviations

are as follows:

See or Refer to

Clip ring

Screw

Connector

Clamp

E-ring

SEF Short Edge Feed

LEF Long Edge Feed

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the

United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

Other product names used herein are for identification purposes only and may be trademarks of their

respective companies. We disclaim any and all rights involved with those marks.

3

TABLE OF CONTENTS

Safety Notices.....................................................................................................................................................1

Important Safety Notices...............................................................................................................................1

Laser Safety.....................................................................................................................................................2

Symbols, Abbreviations and Trademarks.........................................................................................................3

Trademarks.....................................................................................................................................................3

1. Product Information

Specifications......................................................................................................................................................9

Machine Overview..........................................................................................................................................10

Component Layout.......................................................................................................................................10

Paper Path....................................................................................................................................................11

Drive Layout..................................................................................................................................................12

Machine Configuration....................................................................................................................................14

Mainframe (M075) and Option................................................................................................................14

Controller Options.......................................................................................................................................14

Guidance for Those Who are Familiar with Predecessor Products..............................................................16

2. Installation

Installation Requirements.................................................................................................................................17

Environment..................................................................................................................................................17

Machine level...............................................................................................................................................18

Machine Space Requirement.....................................................................................................................18

Power Requirements....................................................................................................................................18

Installation Procedure..................................................................................................................................19

3. Preventive Maintenance

Preventive Maintenance..................................................................................................................................21

4. Replacement and Adjustment

Before You Start...............................................................................................................................................23

Special Tool......................................................................................................................................................24

Exterior Covers.................................................................................................................................................25

Rear Cover...................................................................................................................................................25

Operation Panel...........................................................................................................................................26

Right Cover...................................................................................................................................................27

Left Cover......................................................................................................................................................27

Front Cover Unit...........................................................................................................................................28

4

Laser Optics......................................................................................................................................................31

Caution Decal Location...............................................................................................................................31

LD Safety Switch...........................................................................................................................................

Laser Optics Housing Unit...........................................................................................................................32

AIO Cartridge..................................................................................................................................................36

AIO Cartridge (All In One Cartridge) .......................................................................................................36

Black AIO Motor.........................................................................................................................................36

Color AIO Motor.........................................................................................................................................39

Image Transfer..................................................................................................................................................41

Image Transfer Belt Unit..............................................................................................................................41

Agitator Motor.............................................................................................................................................42

ITB (Image Transfer Belt) Contact Motor...................................................................................................43

ITB (Image Transfer Belt) Contact Sensor..................................................................................................44

TM (Toner Mark) Sensor Base....................................................................................................................45

Waste Toner Bottle Set Sensor...................................................................................................................46

Waste Toner Overflow Sensor...................................................................................................................47

Air Intake Fan...............................................................................................................................................48

Paper Transfer..................................................................................................................................................50

Transfer Unit.................................................................................................................................................50

32

Transfer Roller..............................................................................................................................................50

Registration Roller........................................................................................................................................52

Registration Sensor......................................................................................................................................53

Registration Clutch.......................................................................................................................................54

By-pass and Duplex Clutch.........................................................................................................................55

Duplex Sensor..............................................................................................................................................56

Image Fusing....................................................................................................................................................58

Fusing Unit....................................................................................................................................................58

Fusing Lamp..................................................................................................................................................58

Thermostat....................................................................................................................................................62

Thermistors....................................................................................................................................................62

Transport/Fusing Motor..............................................................................................................................64

Paper Feed and Exit.........................................................................................................................................66

Paper Feed Clutch........................................................................................................................................66

5

Paper Feed Roller........................................................................................................................................66

Separation Pad............................................................................................................................................67

By-pass Separation Pad..............................................................................................................................68

By-pass Pick-up and Feed Rollers...............................................................................................................

Paper End Sensor.........................................................................................................................................71

By-pass Paper End Sensor..........................................................................................................................72

Paper Exit Sensor.........................................................................................................................................73

Electrical Components.....................................................................................................................................75

Eco Night Sensor.........................................................................................................................................75

Operation Panel Board Unit.......................................................................................................................75

Controller Board..........................................................................................................................................76

EGB (Engine Board)....................................................................................................................................79

Interlock Switches........................................................................................................................................81

Fusing Fan Motor.........................................................................................................................................82

LSU Fan Motor.............................................................................................................................................83

ID Chip Board..............................................................................................................................................84

PSU................................................................................................................................................................85

High Voltage Power Supply Board............................................................................................................87

Temperature/Humidity Sensor...................................................................................................................88

Tray Set Sensor............................................................................................................................................88

69

NVRAM........................................................................................................................................................89

5. System Maintenance Reference

Service Program...............................................................................................................................................93

Main SP Tables: 1............................................................................................................................................94

Service Mode...............................................................................................................................................94

Engine SP...................................................................................................................................................101

Main SP Tables: 2..........................................................................................................................................

Engine SP...................................................................................................................................................148

Configuration Page Information...................................................................................................................173

Overview....................................................................................................................................................173

Firmware Update...........................................................................................................................................174

Type of Firmware.......................................................................................................................................174

Before You Begin.......................................................................................................................................175

6

148

Updating Firmware...................................................................................................................................175

NVRAM Data Upload/Download..........................................................................................................178

Handling Firmware Update Errors...........................................................................................................180

SD Card Appli Move....................................................................................................................................182

Overview....................................................................................................................................................

Move Exec.................................................................................................................................................182

Undo Exec..................................................................................................................................................183

Card Save Function.......................................................................................................................................185

Overview....................................................................................................................................................185

Procedure...................................................................................................................................................185

Error Messages..........................................................................................................................................186

182

6. Troubleshooting

Error Messages..............................................................................................................................................189

Overview....................................................................................................................................................

Error Messages List....................................................................................................................................189

SC Conditions................................................................................................................................................192

Summary....................................................................................................................................................192

Engine SC...................................................................................................................................................193

Controller SC.............................................................................................................................................201

Image Problems.............................................................................................................................................217

Overview....................................................................................................................................................217

189

Checking a Sample Printout.....................................................................................................................217

7. Energy Saving

Energy Save...................................................................................................................................................221

Energy Saver Modes................................................................................................................................221

Paper Save.....................................................................................................................................................225

Effectiveness of Duplex/Combine Function............................................................................................225

INDEX...........................................................................................................................................................229

7

8

1. Product Information

1

Specifications

See "Appendices" for the followings;

• General Specifications

• Supported Paper Sizes

9

1. Product Information

1

Machine Overview

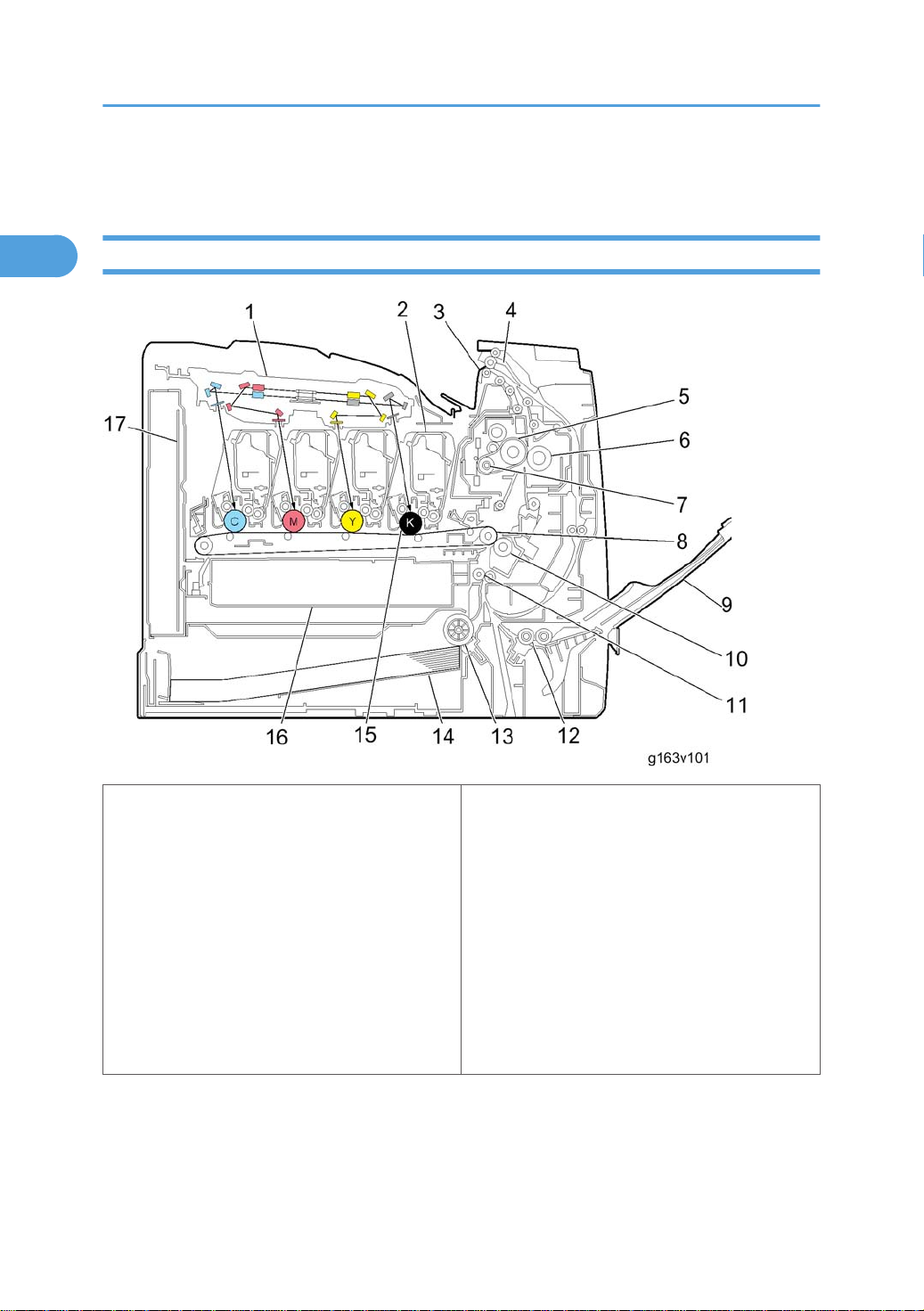

Component Layout

1. Laser Optics Housing Unit

10. Transfer Roller

2. Print Cartridge (AIO)

11. Registration Roller

3. Paper Exit

12. By-pass Feed Roller

4. Inverter Path

13. Paper Feed Roller

5. Fusing Belt

14. Tray 1

6. Pressure Roller

15. OPC (AIO)

7. Fusing Lamp

16. Waste Toner Bottle

8. ITB (Image Transfer Belt) Unit

17. EGB/ Controller Board

9. By-pass Tray

10

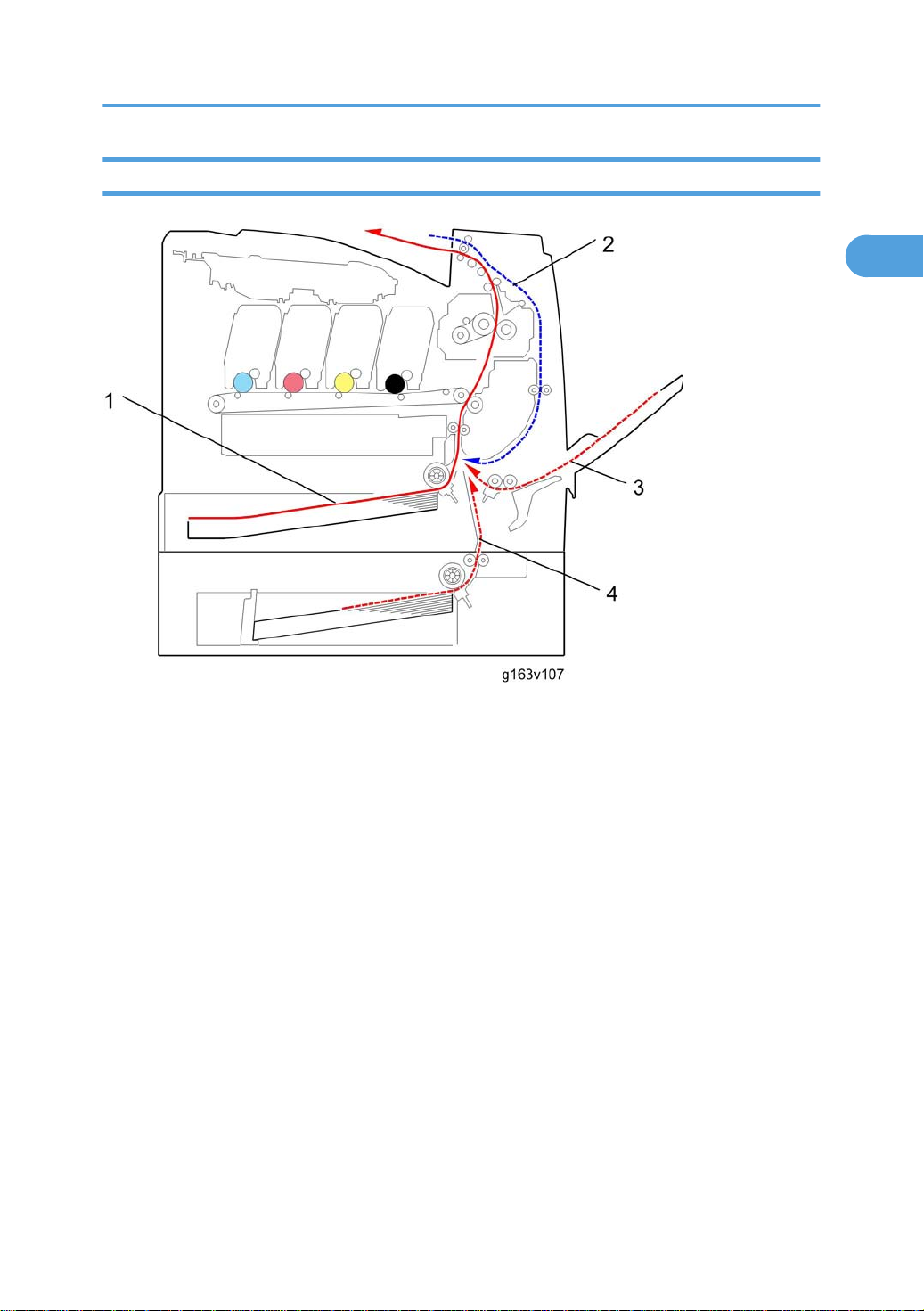

Paper Path

1

Machine Overview

1. Paper path from the tray 1 to the output tray

Paper path in the duplex path

2.

3. Paper path from the by-pass tray

4. Paper path from the optional tray 2 to the output tray

11

1. Product Information

1

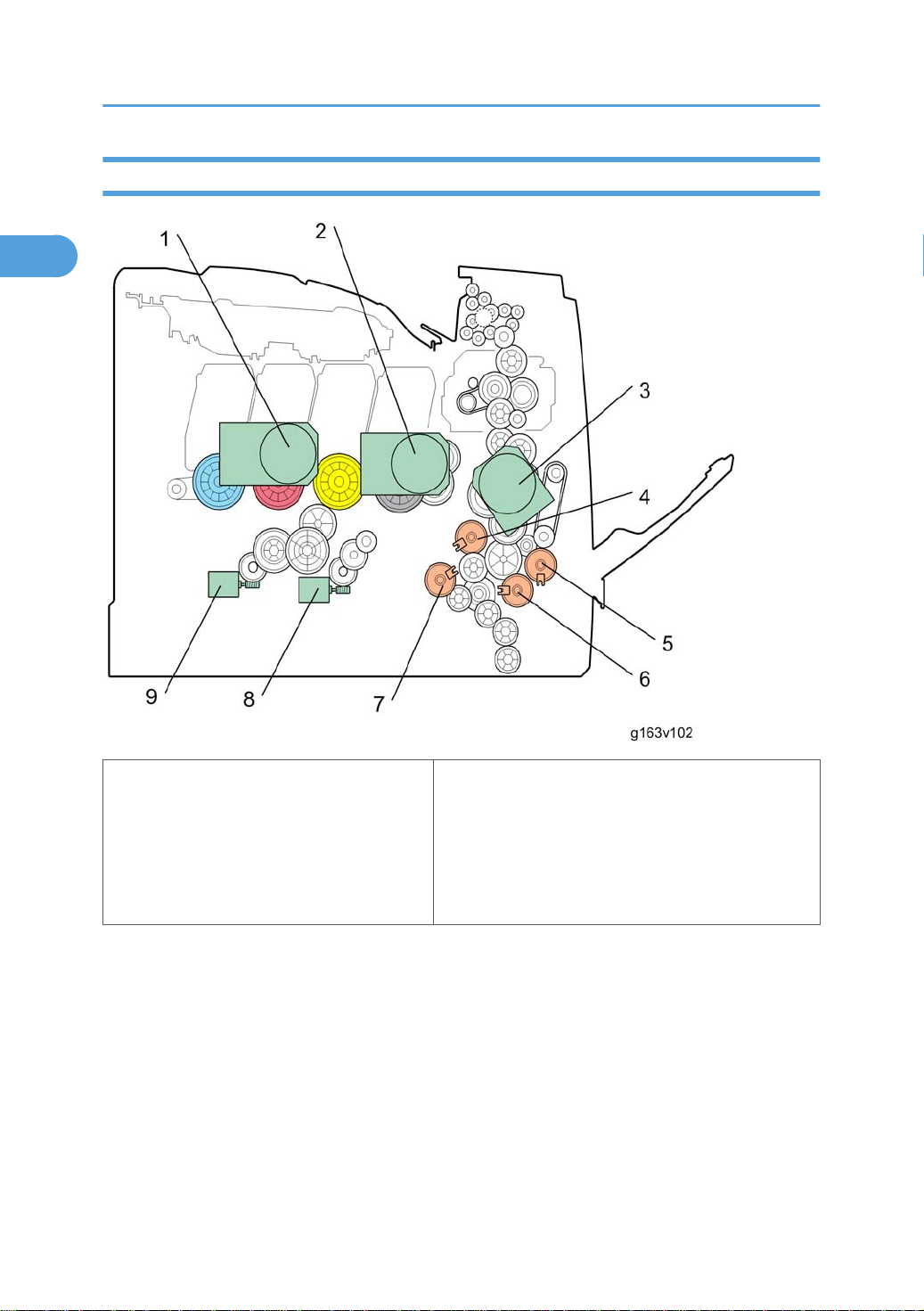

Drive Layout

1. Color AIO Motor

6. By-pass Clutch

2. Black AIO Motor

7. Paper Feed Clutch

3. Transport/Fusing Motor

8. Agitator Motor

4. Registration Clutch

9. ITB (Image Transfer Belt) Contact Motor

5. Duplex Clutch

• Color AIO Motor:

This drives the color AIO cartridges (Cyan, Magenta and Yellow)

• Black AIO Motor:

This drives the black AIO and the ITB (Image Transfer Belt).

• Transport/Fusing Motor:

This drives the fusing unit, paper feed roller, registration roller and paper exit roller* via the paper

feed clutch, registration clutch and gears. (*: This motor only drives the paper exit roller in nonduplex models.)

12

• Registration Clutch:

1

This transfers drive from the transport/ fusing motor to the registration roller.

• Duplex Clutch:

This transfers drive from the transport/ fusing motor to the duplex rollers.

• By-pass Clutch

This transfers drive from the transport/ fusing motor to the duplex rollers.

• Paper Feed Clutch:

This transfers drive from the transport/ fusing motor to the paper feed roller.

• Agitator Motor:

This moves the agitators in the waste toner bottle.

• ITB Contact Motor:

This moves the ITB into contact with and away from the color OPCs.

Machine Overview

13

1. Product Information

1

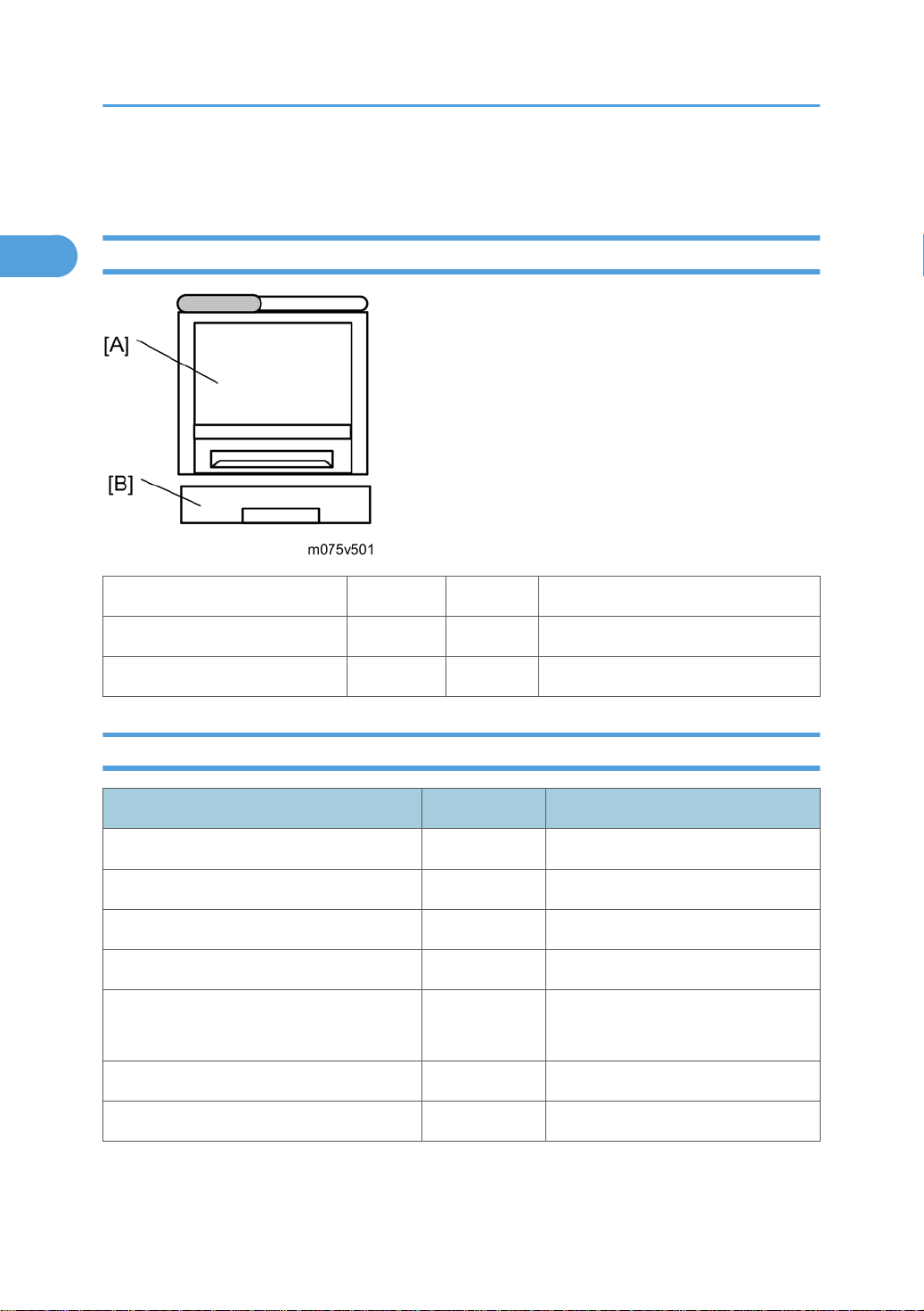

Machine Configuration

Mainframe (M075) and Option

Model Model No. Call out Description

MD –P2 M075 [A] Auto-duplex model

Paper Feed Unit TK 1010 G849 [B] Common with MD-P1

Controller Options

Item Model No. Description

Memory Unit Type G 256MB D362-21 Z-P1/ G-P3/ Al-P1/ KR-P2/ SI-P2

Memory Unit Type I 512MB D435-01 Z-P1/ DI-C1

Camera Direct Print Card Type H M385-01 Z-P1

IEEE 1284 Interface Board Type A B679-17 Z-P1/ KR-P2/ SI-P2

IEEE802.11a/g Interface

Unit Type L/M

Gigabit Ethernet Board Type A G874-01 Z-P1/ KR-P2/ SI-P2

Hard Disk Drive Option Type C320 M394-01 New

M344-01, -02 Z-P1

14

Machine Configuration

1

Item Model No. Description

VM Card (Type O)

NetWare (Type F) M394-10 New

M385-03,

-04, -05

Z-P1 (512 MB memory option is

required.)

15

1. Product Information

1

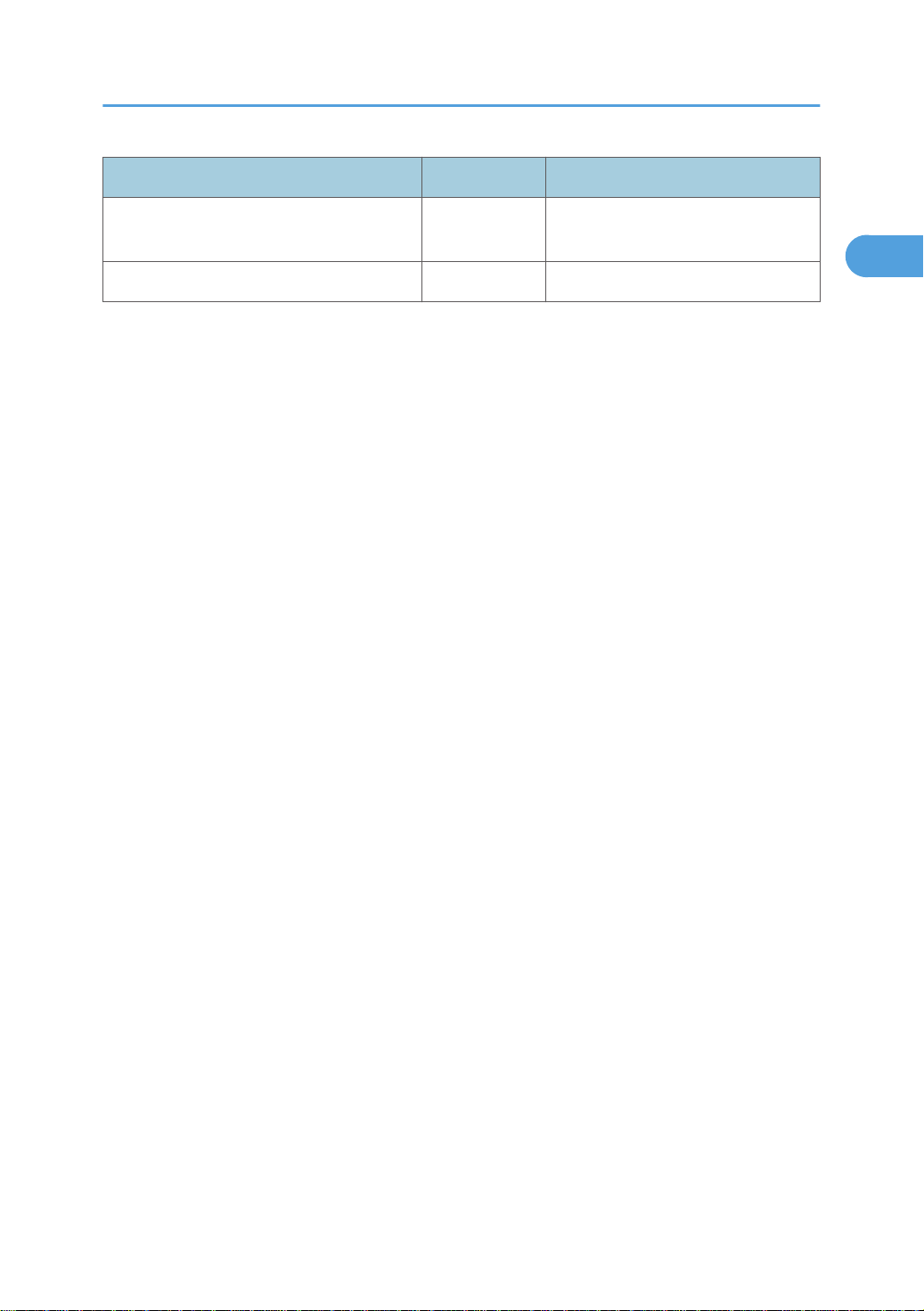

Guidance for Those Who are Familiar with Predecessor Products

Machine M075 is a similar model with Machine M040/M041. If you have experience with those

products, the following information will be of help when you read this manual.

Different Points from Previous Products

M075 M040/M041

Controller GW controller Non GW controller

SD slot 2 SD slots Not available

Operation panel 4 lines LCD 2 lines LCD

Eco night sensor (New

energy save function)

Available Not available

16

2. Installation

2

RTB 19

Installation Requirements

Environment

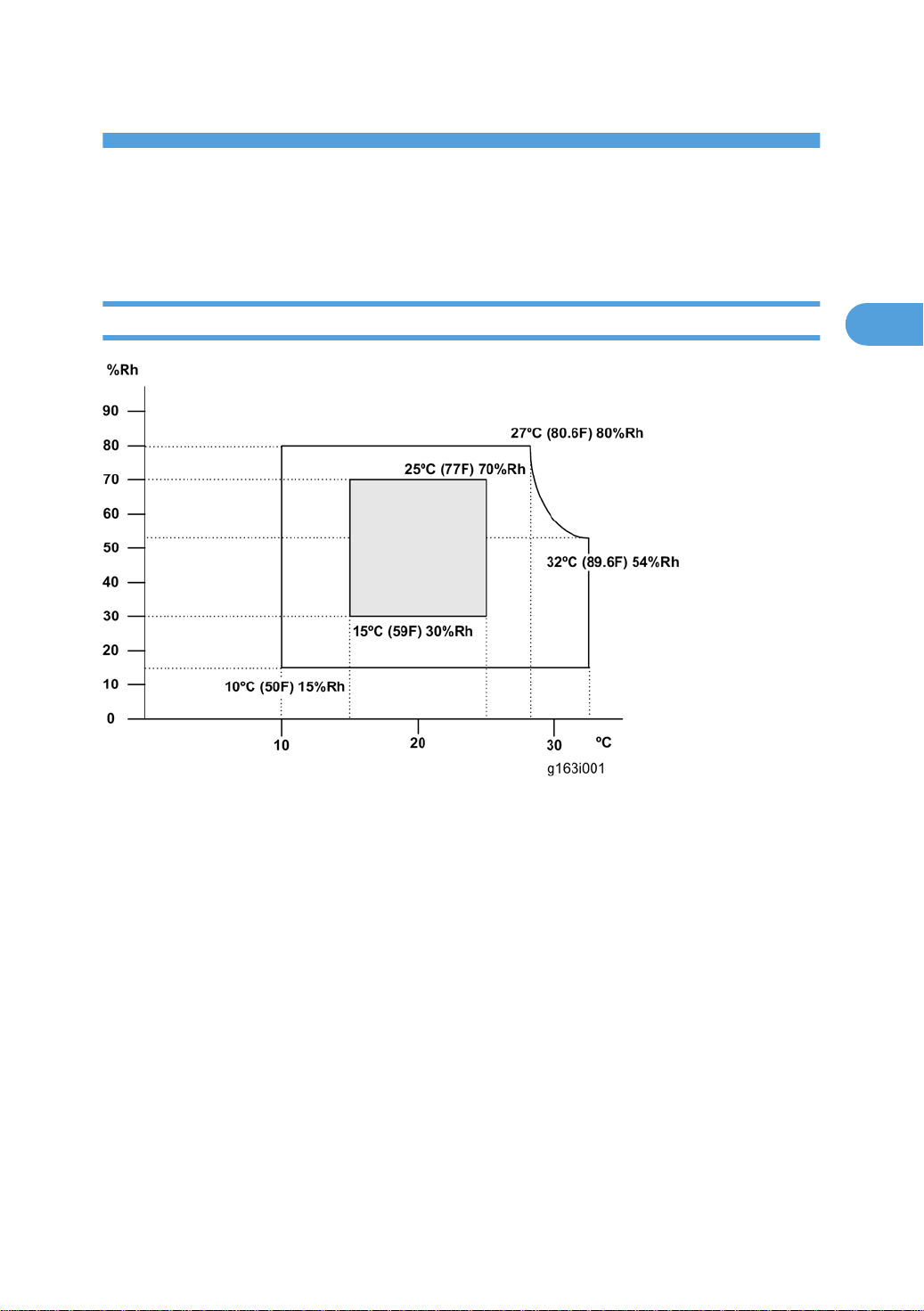

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

Humidity Range: 15% to 80% RH

2.

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person

5. Do not put the machine in areas that get sudden temperature changes. This includes:

• Areas directly exposed to cool air from an air conditioner

• Areas directly exposed to heat from a heater.

6. Do not put the machine in areas that get exposed to corrosive gas.

7. Do not install the machine at locations over 2,500 m (8,125 ft.) above sea level.

8. Put the machine on a strong, level base. (Inclination on any side must be no more than 5 mm.)

9. Do not put the machine in areas with strong vibrations.

17

2. Installation

2

Machine level

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

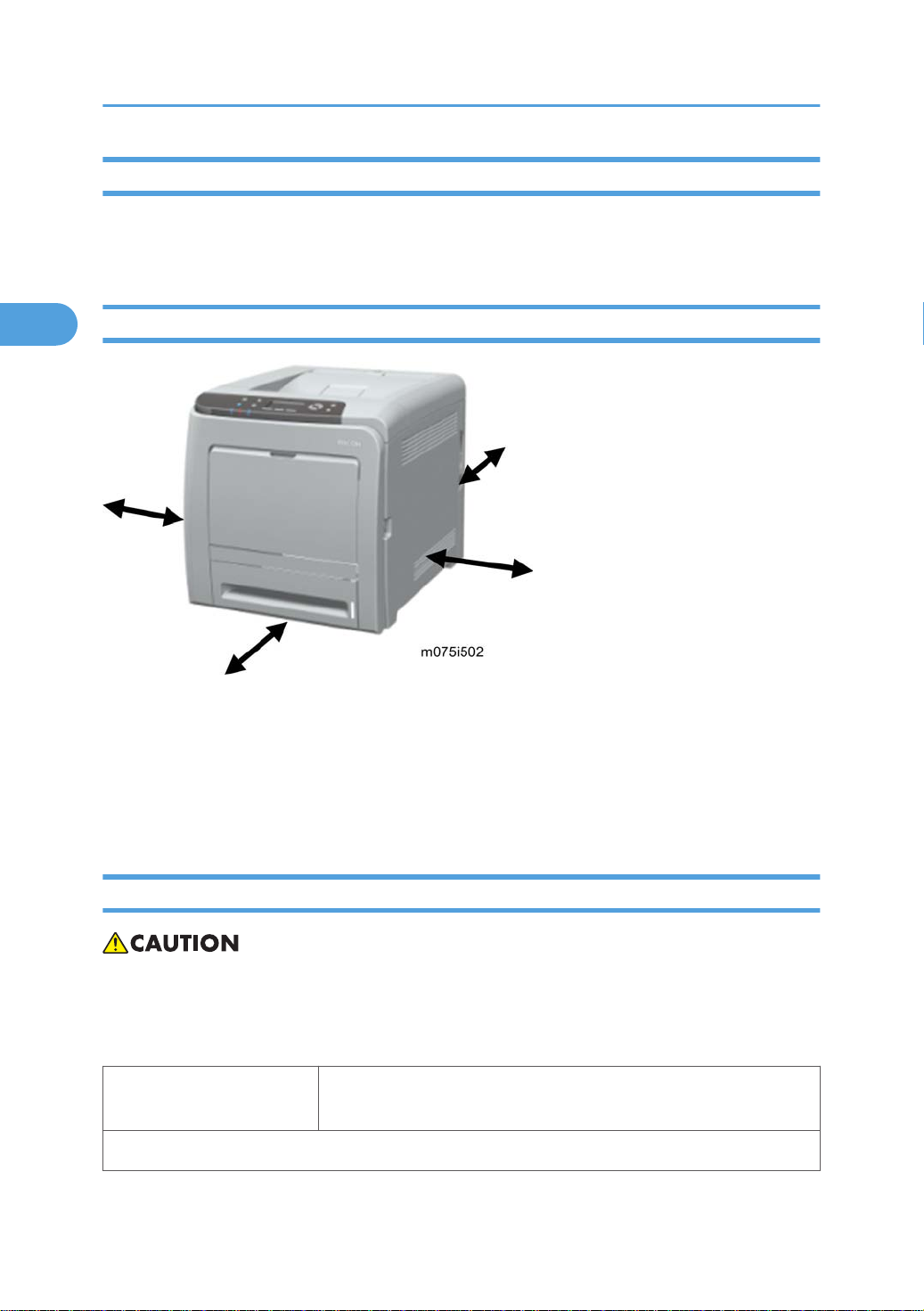

Machine Space Requirement

Put the machine near the power source with these clearances:

Left side: Over 20 cm (7.9")

Rear: Over 10 cm (4")

Right side: Over 10 cm (4")

Front: Over 70 cm (27.5")

Power Requirements

• Make sure that the plug is tightly connected to the outlet.

Avoid multi-wiring.

•

• Make sure that you ground the machine.

Input voltage level

Permitted voltage fluctuation: 10%

120 V, 60 Hz: More than 11 A (for North America)

220 V to 240 V, 50 Hz/60 Hz: More than 6 A (for Europe/ Asia)

18

Do not set anything on the power cord.

2

Installation Procedure

Refer to the Quick Installation Guide for details about installing the machine.

Installation Requirements

19

2. Installation

2

20

3. Preventive Maintenance

3

Preventive Maintenance

See "Appendices" for the "Preventive Maintenance".

21

3. Preventive Maintenance

3

22

4. Replacement and Adjustment

4

Before You Start

• If there are printer jobs in the machine, print out all jobs in the printer buffer.

• Turn off the main power switch and unplug the machine before you do the procedures in this

section.

• Always touch a grounded surface to discharge static electricity from your hands before you handle

SD cards, printed circuit boards, NVRAM or memory boards.

23

4. Replacement and Adjustment

4

Special Tool

SD card

•

24

Exterior Covers

4

Exterior Covers

• Turn off the main power switch and unplug the printer before you do the procedures in this section.

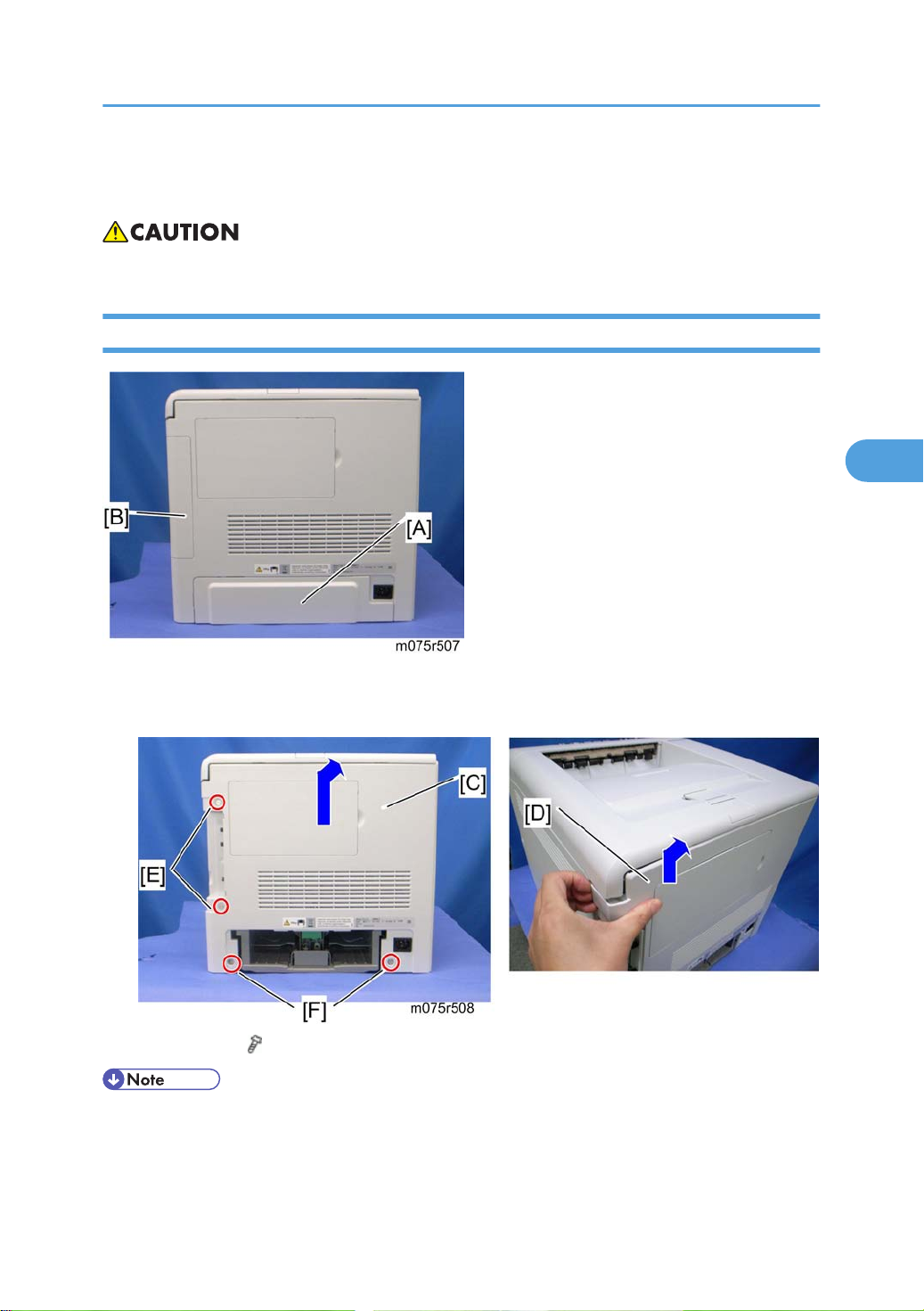

Rear Cover

1. Rear tray cover [A] (hooks)

Interface cover [B] (hooks)

2.

3. Rear cover [C] ( x 4)

• After removing four screws from the rear cover, pull the rear cover from the top right [D] to the top

left while lifting up the rear cover

Upper screw [E]: "M3x8" x 2, Lower screws [F]: "M4x10" x 2

•

25

4. Replacement and Adjustment

4

Operation Panel

1. Open the top cover [A].

26

2. Open the front cover [B].

Front harness cover [C] (

3.

x 1)

4. Operation panel [D] ( x 2, x 1)

4

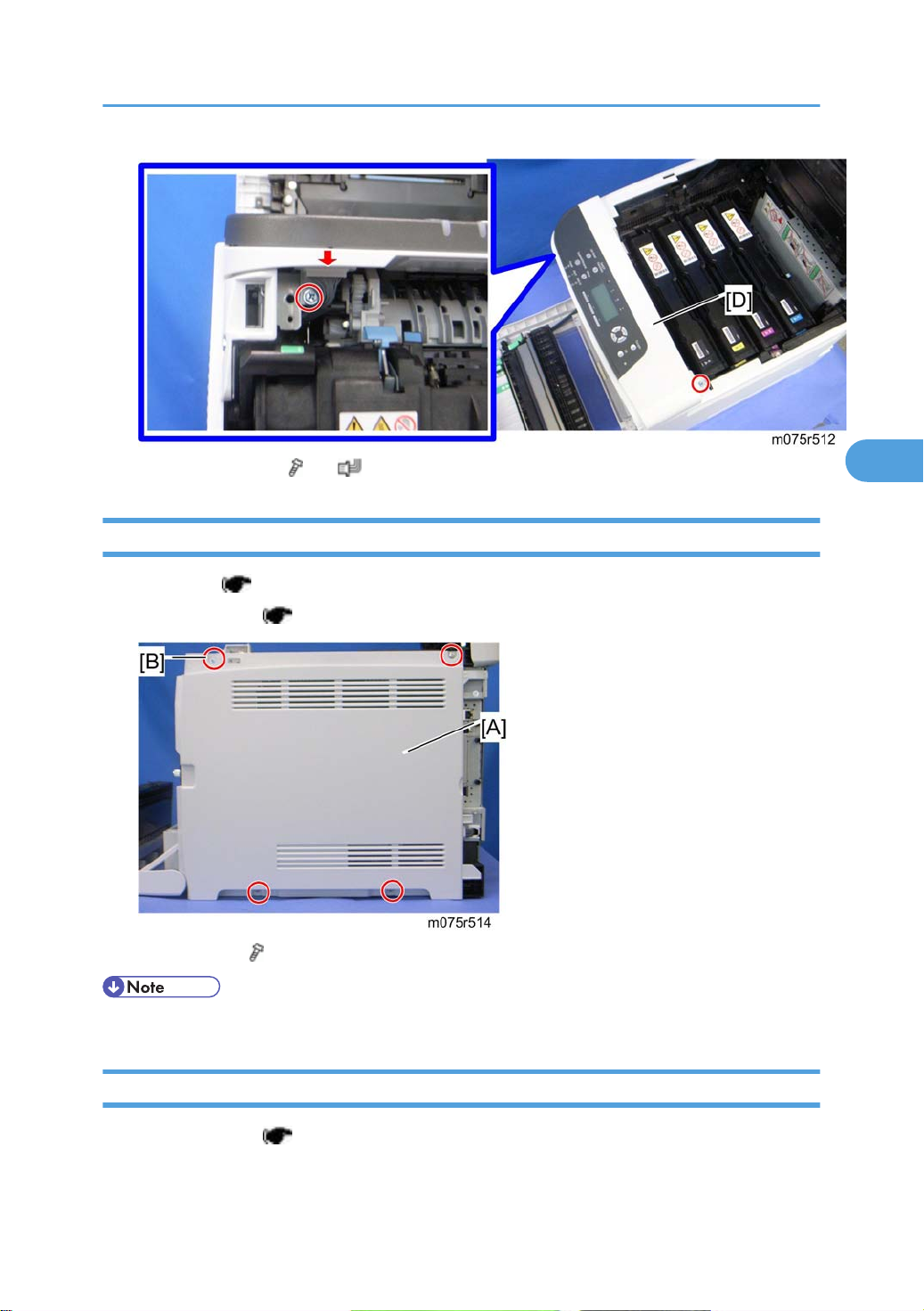

Right Cover

1. Rear cover ( p.25)

Exterior Covers

Operation panel (

2.

3. Right cover [A] ( x 4)

• Top front screw [B]: M3x8, others: M4x10

p.26)

Left Cover

1. Operation panel ( p.26)

27

4. Replacement and Adjustment

4

2. Left cover [A] ( x 3, hook at arrow mark)

• Top front screw [B]: M3x8, others [C]: M4x10

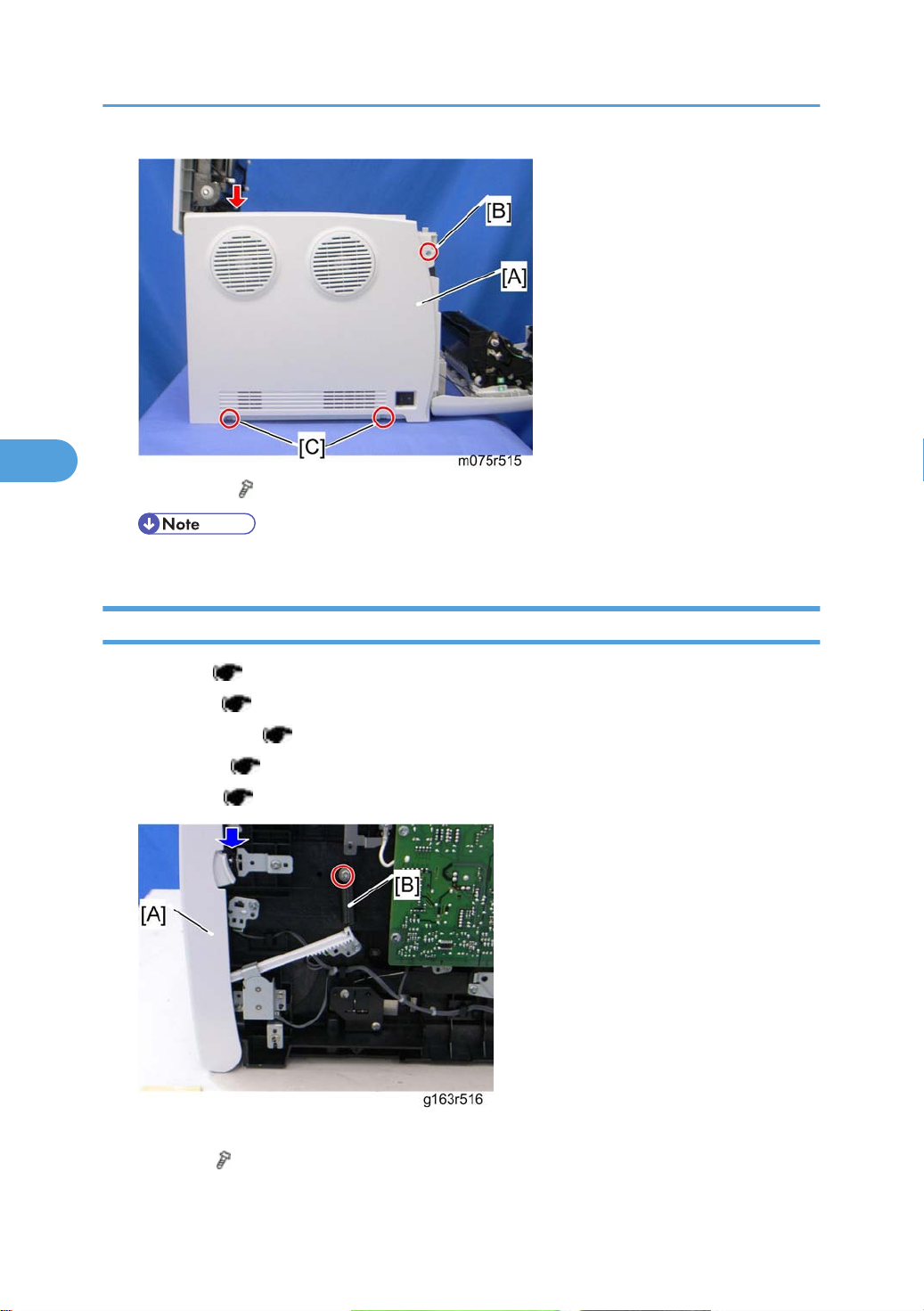

Front Cover Unit

1. Left cover ( p.27)

Rear cover (

2.

Operation panel (

3.

Transfer unit (

4.

Right cover (

5.

6. Close the front cover [A].

p.25)

p.50)

p.27)

p.26)

28

Spring [B] (

7.

x 1)

Loading...

Loading...