Page 1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. The wall outlet should be near the copier and easily accessible.

2. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

3. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

4. If the hot roller temperature is low when the main switch is turned on, the

copier starts process control self check automatically. Keep hands away

from the mechanical and the electrical components to avoid any injury.

5. If the start key is pressed before the copier completes the warm-up period

(Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board on the main control board has a lithium battery which can

explode if replaced incorrectly. Replace the battery only with an identical

one. The manufacturer recommends replacing the entire RAM board. Do

not recharge or burn this battery. Used batteries must be handled in

accordance with local regulations.

1996 By Ricoh Com pany Ltd. All rights r eserved

Page 2

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner bottle or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductor according

to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storing larger numbers or

not sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field. The optical housing unit can only be

repaired in a factory or at a location with the requisite equipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service

depot when replacement of the optical subsystem is required.

DANGER

Use of controls, or adju stm ent, or performance of procedures other

than those specified in this manual may result in hazardous radiation

exposure.

WARNING FOR LASER UNIT

DANGER: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Page 3

INTRODUCTION

The A172/A199 copier (product name: LILY) is based on

the base copier.

(DFC-ALPHA)

This documentation gathers the A172/A199 differing points from the base

copier that service personnel will need to maintain this copier. Therefore, this

documentation should be treated as a insert version of the base copier’s

service manual, although it has a separate binder. It should always be utilized

together with the base copier’s service manual.

,

the A109 copier

Page 4

SECTION 1

OVERALL

MACHINE INFORMATION

Page 5

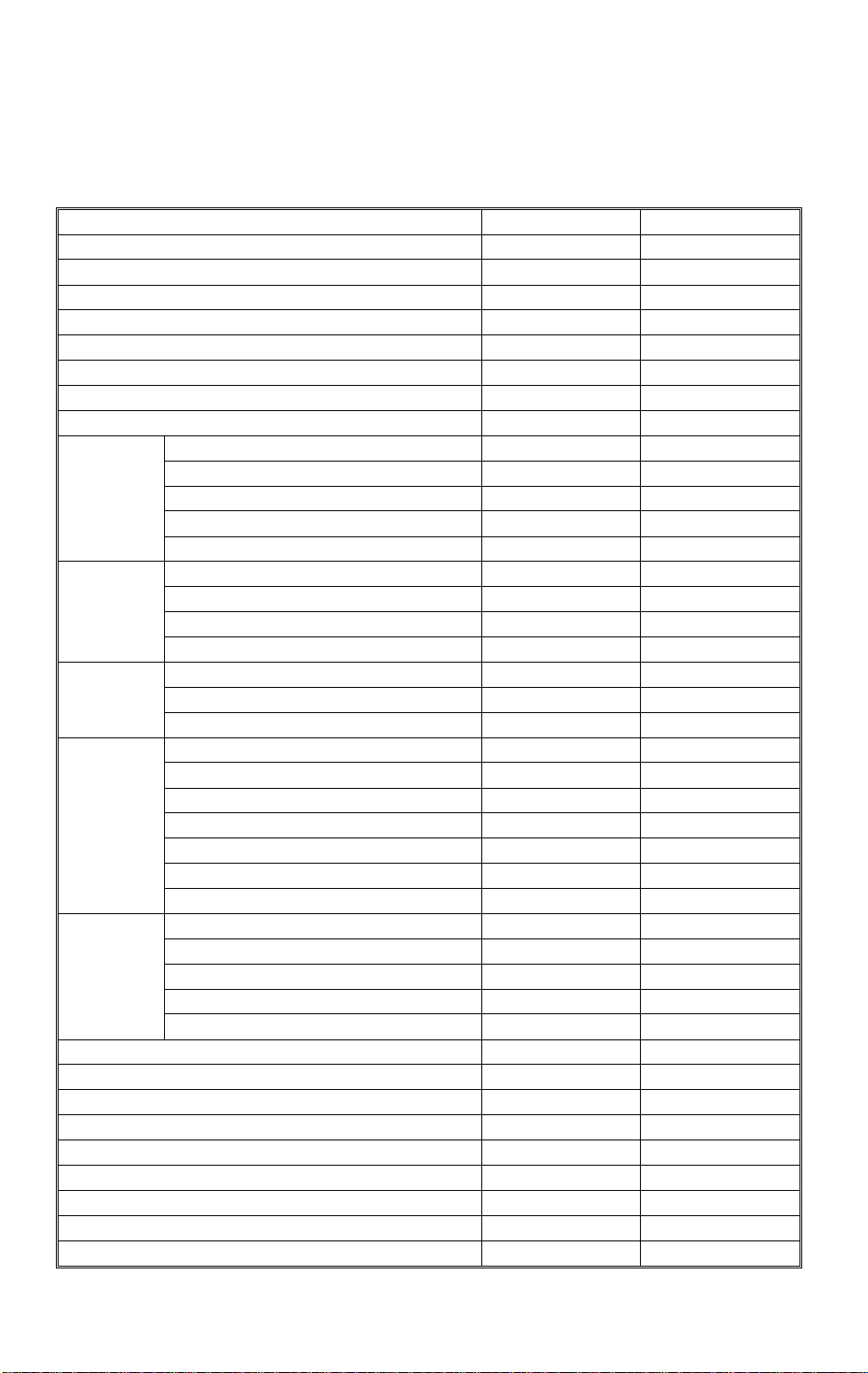

10 May 1996 MACHINE CONFIGURATION

1. MACHINE CONFIGURATION

2

1

4

Overall

Information

3

5

- Copier -

A172V500.wmf

- Full System -

A172V501.wmf

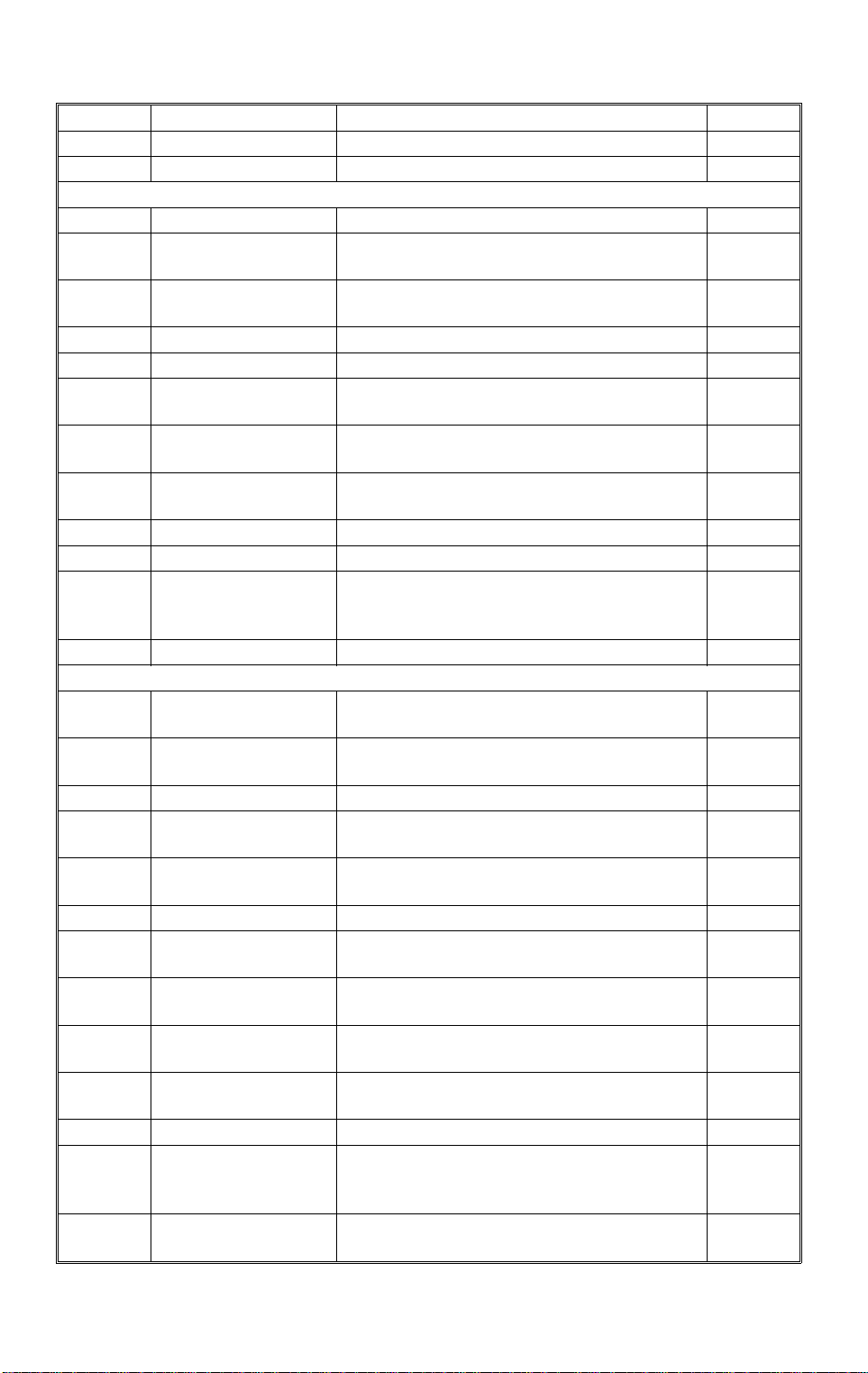

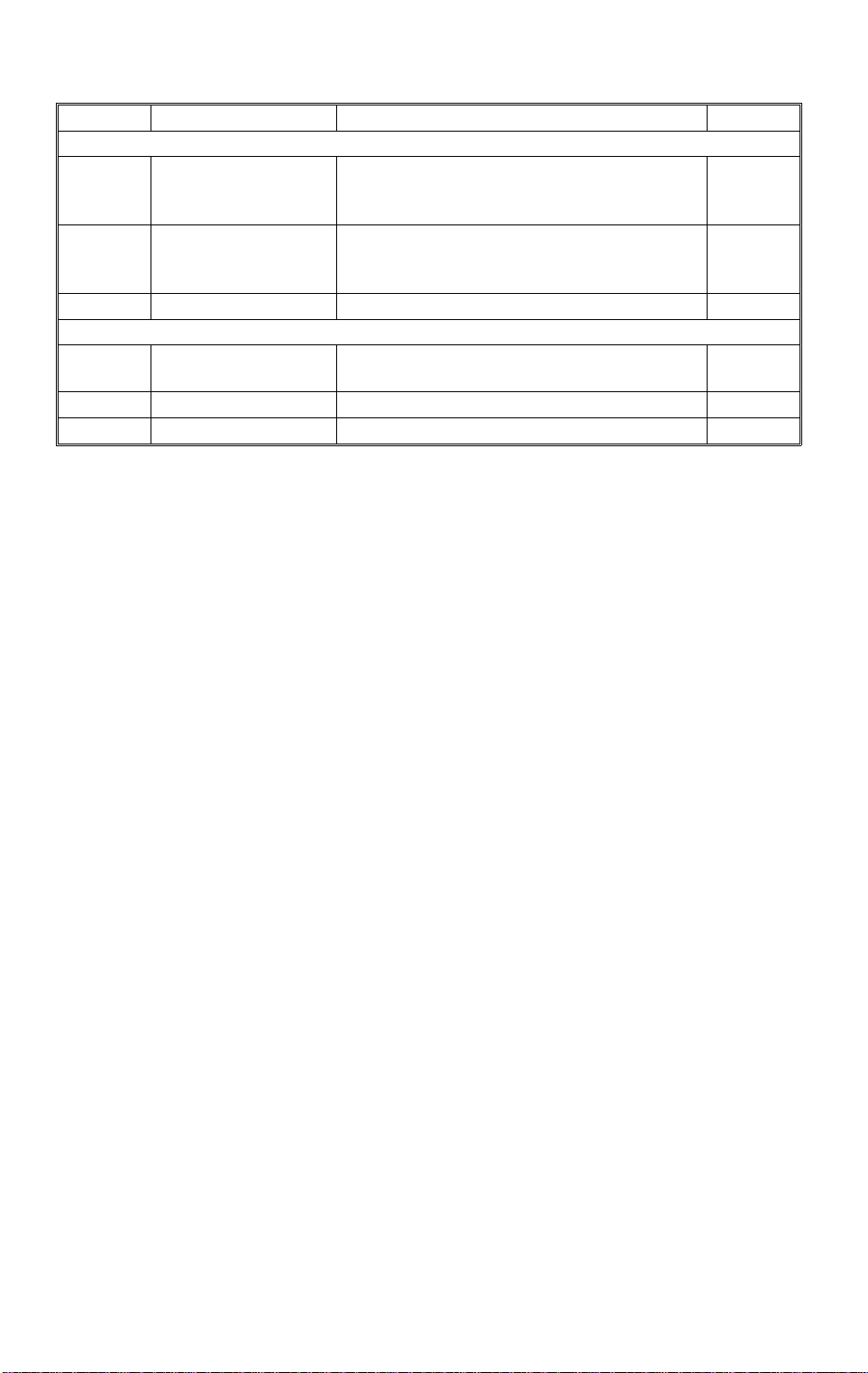

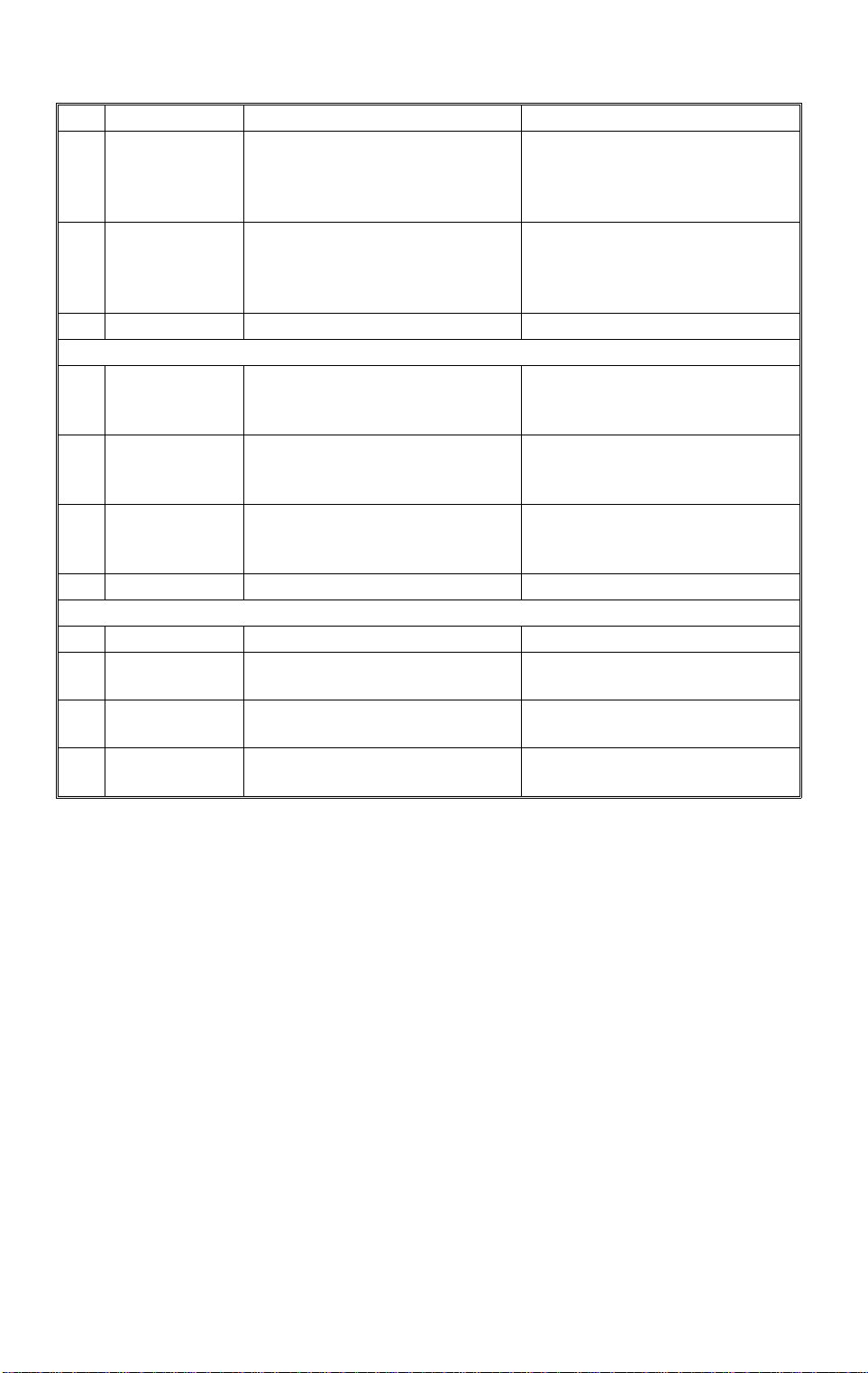

Item Machine Code Note No.

Copier

Dual Job Feeder

Sorter (15-bin)

Film Projector Unit

Holder

Language RO M

board

(for operation panel)

A172

A199

A610

A322

A718

A702-18

A654

A172 is the edit version with a full color

•

operationpanel.

A199 is the non-e di t version with a bla ck &

•

white operati on panel.

An English language ROM board is installed

•

in -17/29/10/22/15 machines.

No language ROM board is installed in

•

-27/26 machines.

Common with A1 75/ A176/A177/A191/A192

•

copiers.

A sorter adapter ( A527) is require d fo r

•

installation.

A holder (A702- 18) i s required for inst all ation.

•

The holder can be installed independently as

•

an original table.

The following languages are available:

•

English (A4), Ger man, French, Ital ian,

Spanish, (Universal).

1

2

3

4

5

—

1-1

Page 6

SPECIFICATIONS 10 May 1996

2. SPECIFICATIONS

2.1 SPECIFICATIONS

Specifications are subject to change without notice.

Configuration: Console

Copy Process: Dry electrostatic transfer system

Resolutions: 400 dpi

Gradations: 256 gradations

Original Type: Sheet/book, object

Original Size: Maximum: A3 (lengthwise), 11" x 17" (lengthwise)

Original Alignment: Rear-left corner

Paper Tray: 64 - 104.7 g/m2 or 17 - 28 lb

Copy Paper Weight:

•

Bypass Feed Tray: 64 - 157 g/m2 or 17 - 42 lb

•

Available Copy Paper Size:

Tray Paper Directi on A4/A3 version LT/DLT version

1st /2nd

Tray

3rd Tray

Bypass

Feed

Tray

Lengthwise

Sideways

Lengthwise

Sideways A4, B5, A5, 11" x 8

Lengthwise

Sideways

Non-standard

paper size

2

NOTE:

With paper heavier than 104.7 g/m

or

28 lb, use the bypass feed tray and

select Thick Paper mode.

A3, A4, 8

1/4

8

A4, A5 11" x 8

A3, B4, A4, B5, A5, 11" x 17" (DLT ), 11" x 15", 10" x 14",

1/2

8

1/2

8

A3, B4, A4, B5, A5, B6, A6 11" x 17" (DLT), 10" x 14",

A4, B5, A5, B6, 8

Horizontal di rection: 148 - 432 mm or 5.8" - 17.0"

Vertical directi on: 100 - 297 mm or 3.9" - 11.7"

1/2

" x 13" (F4),

" x 13"

" x 14" (LG), 8

1/2

" x 13" (F4), 8

" x 11" (LT), 8" x 10

1/2

1/2

" x 11" 8

1/2

", 8" x 10", 5

" (LT), 8

11" x 17" (DLT), 11" x 15",

10" x 14", 8

1/2

" x 14" (LG),

8" x 13" (F),

1/2

8

" x 11" (LT),

1/2

8" x 10

1/2

8

1/2

1/2

8

", 8" x 10"

1/2

" (LT),

1/2

" x 5

" x 5

" (HLT)

1/4

" x 13", 8" x 13" (F ),

1/2

1/2

" x 8

" (HLT)

1/2

" x 11" (LT),

" (HLT)

8" x 13" (F),

1/2

5

5

1/2

x 8

1/2

" x 11" (LT),

1/2

" x 8

1/2

" (HLT)

" (HLT)

1-2

Page 7

10 May 1996 SPECIFICATIONS

Warm-up Time:

First Copy Time:

1/2

(A4 or 8

" x 11" sideways)

Copying Speed:

(Standard modes)

About 8 minutes (at 20°C or 68°F)

Full Color (4 scans): 15.5 seconds

•

Single Color:

•

Black, Yellow, Magenta, Cyan: 8.8 seconds

Red, Green, Blue, Orange, Light Green:

11.5 seconds.

NOTE:

1) When selecting OHP/Thick Paper

modes, copying speed is reduced.

2) After changing some modes, the first

copy time will take longer than usual.

Full Color (4 scans):

•

1/2

A4 or 8

" x 11" sideways: 6 copies/minute

A3 or 11" x 17": 3 copies/minute

Single Color (Black, Yellow, Magenta, Cyan):

•

A4 or 8

1/2

" x 11" sideways: 31 copies/minute

A3 or 11" x 17": 15 copies/minute

Single Color

•

(Red, Green, Blue, Orange, Light Green):

A4 or 8

1/2

" x 11" sideways: 10 copies/minute

A3 or 11" x 17": 5 copies/minute

Overall

Information

NOTE:

When selecting OHP/Thick Paper

modes, copying speed is reduced.

Non-reproduction Area:

Leading edge: 5 ± 2 mm or 0.2" ± 0.08"

•

Side: 2 ± 2 mm or 0.08" ± 0.08", Total less than

•

4 mm or 0.16"

Trailing edge: 2 ± 2 mm or 0.08" ± 0.08"

•

Copy Number Input: Number keys, 1 to 99

Automatic Reset: 1-minute standard setting; can also be set to 10

to 900 seconds in 1-second steps, or to no auto

reset.

Paper Feed: Paper Tray x 3

(500 sheets of paper each)

Bypass Feed Tray

(50 sheets of paper with paper lighter than

2

104.7 g/m

or 28 lb)

1-3

Page 8

SPECIFICATIONS 10 May 1996

Copy Tray Capacity: 100 sheets of paper

Toner Replenishment: Bottle type (340g/bottle)

A4/A3 version: 25%, 50%, 65%, 71%, 75%,

Reproduction Ratio:

•

82%, 93%, 100%, (Full Size),

115%, 122%, 141%, 200%,

400% + User ratio x 2

LT/DLT version: 25%, 50%, 65%, 74%, 77%,

•

85%, 93%, 100%, (Full Size),

121%, 129%, 155%, 200%,

400%, + User ratio x 2

Zoom: From 25% to 400% in 1% steps

Power Source: 115 V 60 Hz, more than 12 A (for NA)

220 ~ 240 V 50/60 Hz, more than 7 A (for EU

and AA)

Power Consumption:

(Copier only)

Maximum: less than 1.5 kW

•

Warm-up: 1.40 kW

•

Stand-by: 0.93 k W

•

Copy Cycle: 1.20 kW

•

Noise Emission Sound pressure level (The measurements are

made in accordance with ISO 7779 at the

operator position.)

Copier only

Stand-by Less than 42 dB (A)

Copying Less than 56 dB (A)

Sound power level (The measurements are

made in accordance with ISO 7779.)

Copier only

Stand-by Less than 59 dB (A)

Copying Less than 69 dB (A)

Dimensions (W x D x H):

Copier Only:

•

692 x 713 x 1026 mm or 27.3" x 28.1" x 40.4"

Full System*:

•

1499 x 713 x 1099 mm or 59.1" x 28.1" x 43.2"

= Copier + Dual Job Feeder + Sorter + Ho l der

(*

)

1-4

Page 9

10 May 1996 SPECIFICATIONS

Weight:

Optional Equipment

Copier Only: 200 kg or 440.8 lb

•

Dual Job Feeder

•

Sorter

•

Sorter Adapter

•

Projector Unit

•

Holder for Projector Unit

•

Key Counter

•

Interface Kit for Controller

•

Overall

Information

1-5

Page 10

SPECIFICATIONS 10 May 1996

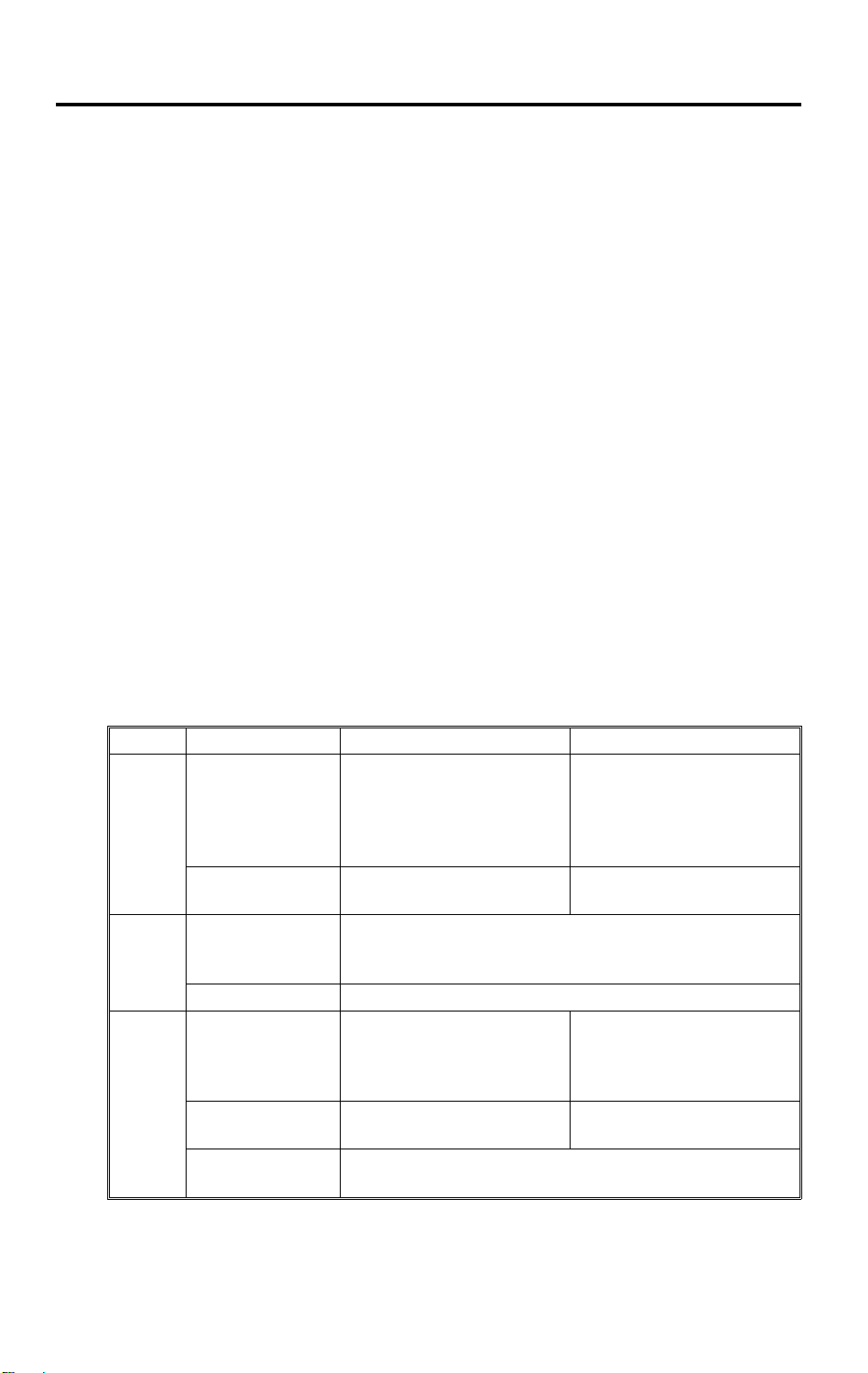

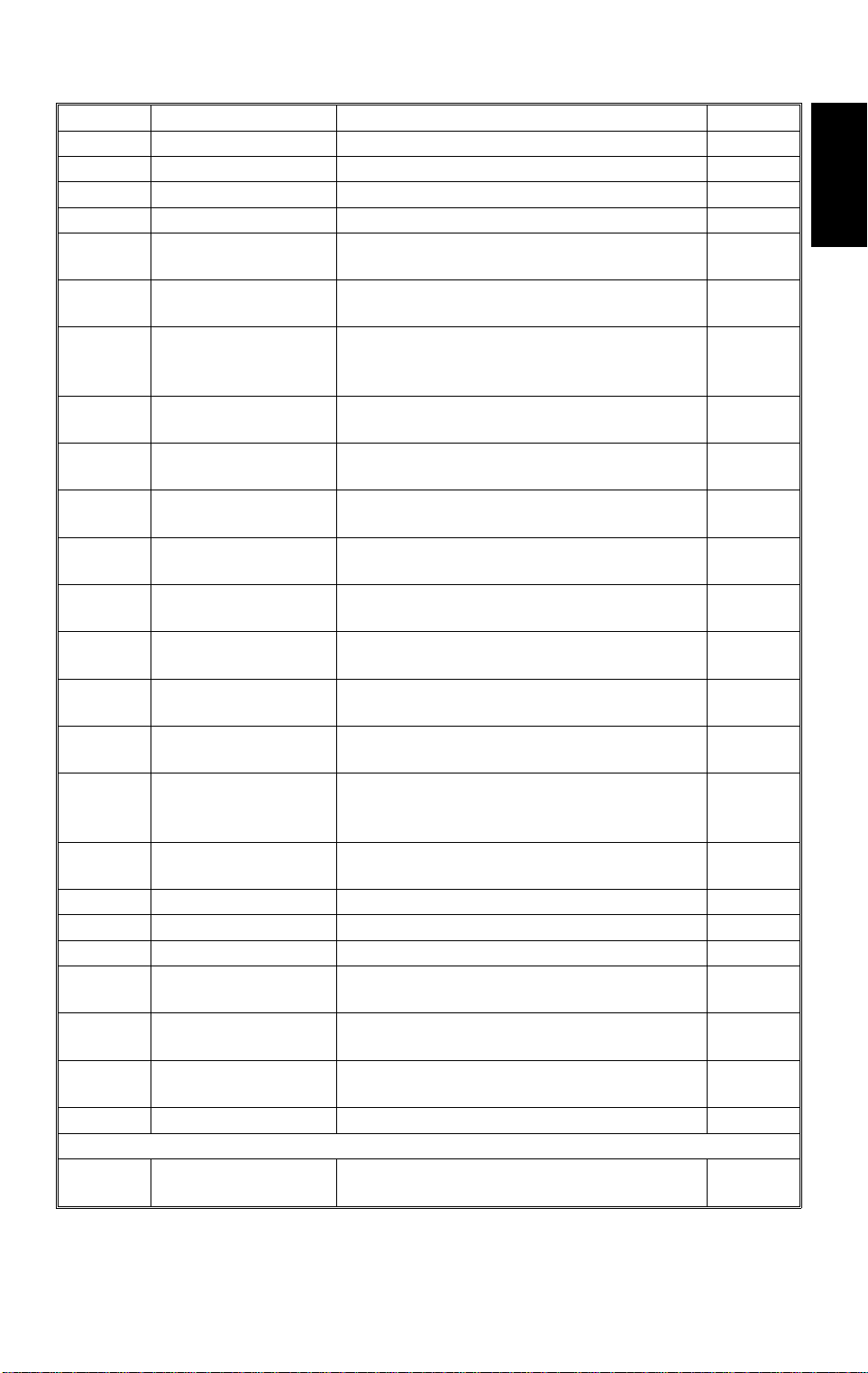

2.2 FUNCTIONS: BASIC MODEL VS EDIT MODEL

This machine comes in two versions. Refer to the following table for features

available on your machine.

Functions Edit type Basic type

Copy Image Density Adjustm ent (Auto/Manual )

Auto Color Selection

Full Color

Back

Single Color

Twin Color

Original Image Type Select io n

Paper Selection (Auto/Manual)

Preset R/E

Reducing/

Enlarging

Shift/Book

Color

Creation

Image

Creation

Color

Adjustment/

Memory

Area Editing

Interrupt Copying

Recall

Auto Reduce/Enlarge

Bypass Feed Copy i ng

Duplex Copying

Default Setting

User Tools

Display Color Full color Black & white

Zoom

Size Magnification

Directional Size Magnification

Poster Mode

Centering/Co rnering

Margin Adjustment

Erase

Single Copies

Color Conversi on

Color Erase

Color Backgroun d

Outline

Positive/Negat i ve

Shadow

Mirror

Slanted

Image Repeat

Image Overla y

User Color Memory

Single Color Adjustment

Color Balance Adjustment

Color Balance Sample

Image Adjustm ent

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

—

1-6

Page 11

10 May 1996 SPECIFICATIONS

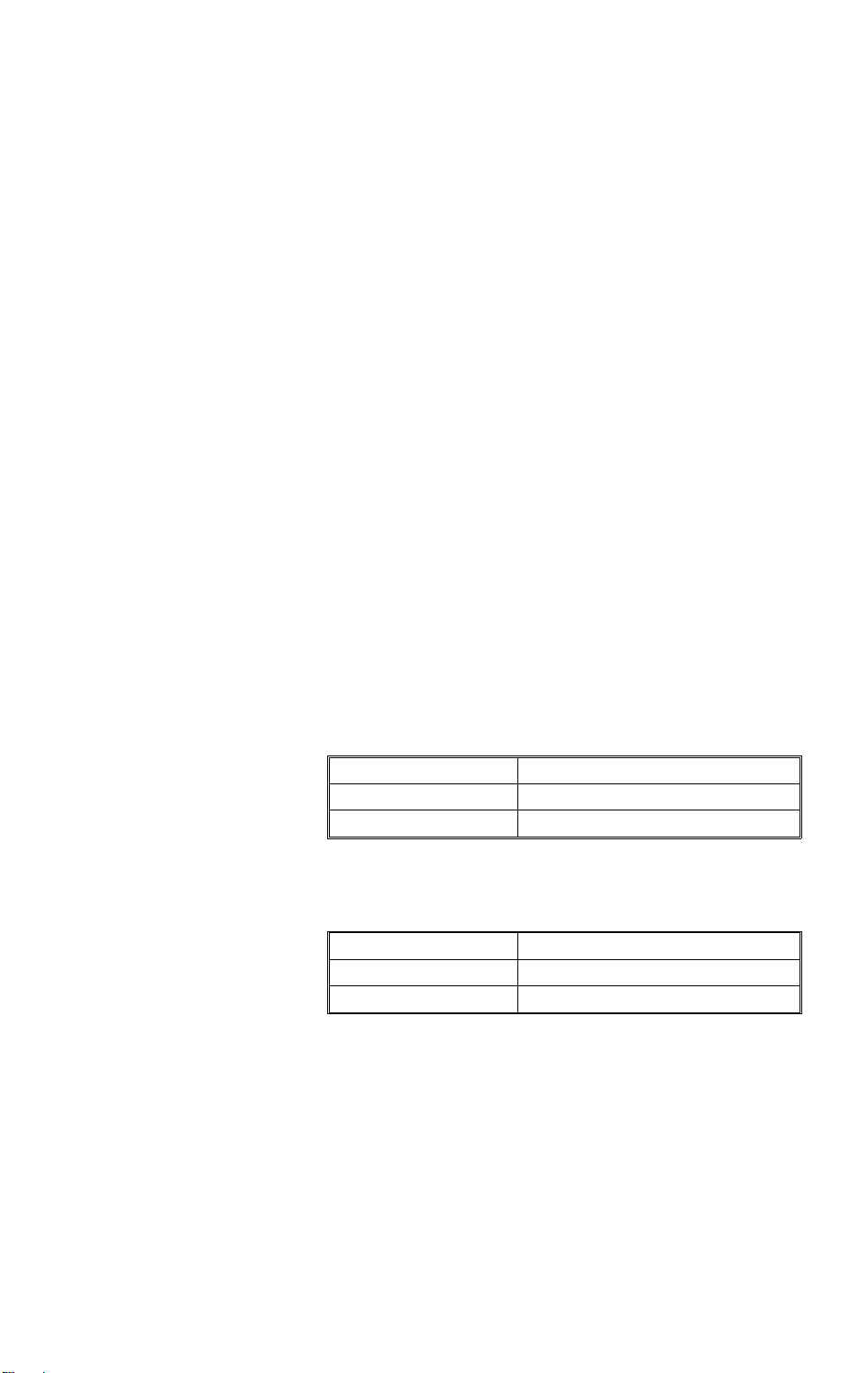

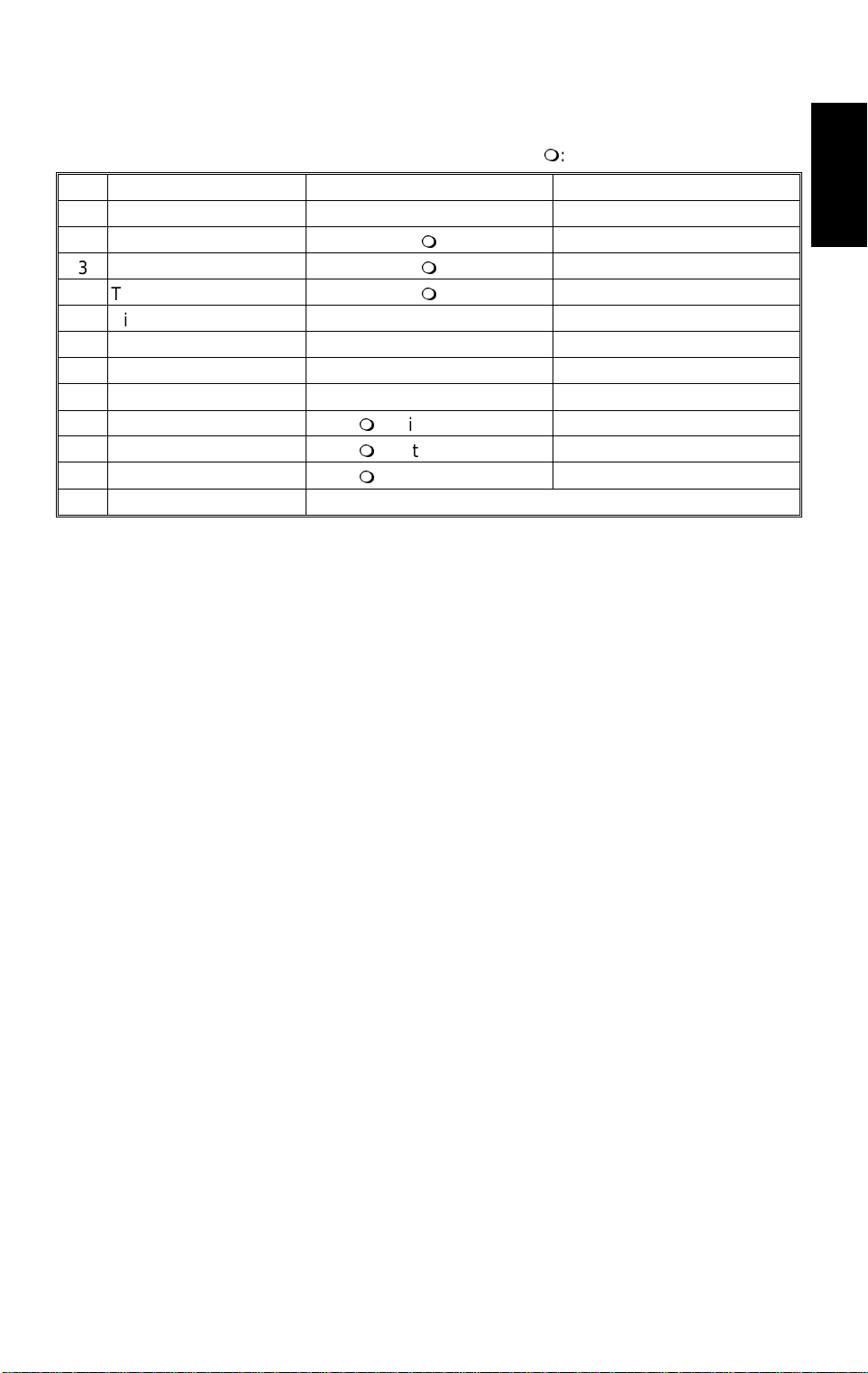

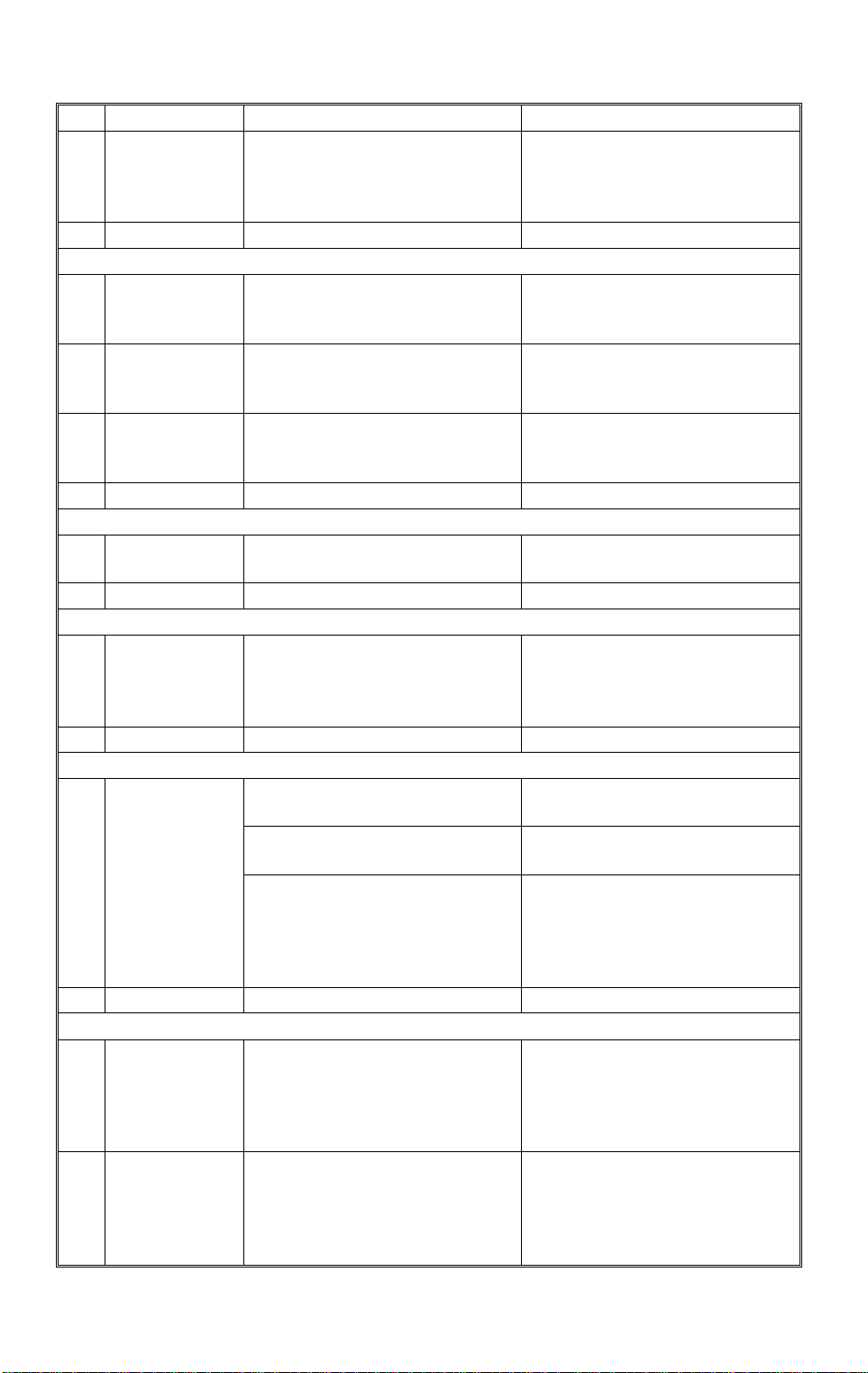

2.3 NEWLY-ADDED OPERATING FEATURES

: Available

No. Features LILY (A172/A199) DFC-ALPHA (A109 )

1 Auto Image Density Full Color & Black Copy Black Copy only

2 Auto Color Calibration

3 Duplex Copying

4 Twin Color

5 Single Color 80 (+1) colors 8 colors

6 User Color 48 colors 3 colors

7 Color Back ground 84 (+1) colors 13 colors

8 Paint 84 (+1) colors 13 colors

9 Color Line

10 Frame Line

11 Image Overlay

12 Area Editing See the next page

(Edit type only)

(Edit type only)

(Edit type only)

: Not Available

✗

✗

✗

✗

✗

✗

✗

1. Auto Image Density mode can be selected when in Full Color mode.

2. Auto Color Calibration can be performed by the user.

3. Using the by-pass feed tray, rear side copying is available.

Overall

Information

4. Twin Color mode copies black parts in black and other parts in the

selected colo r .

5. Single Color

(8 colors x 4 density levels) + (12 user colors x 4 density levels) + 1 scan

color = 81 colors

* scan color = Edit type only

6. User Color

12 colors x 4 density levels = 48 possible colors

The total percentages of the mixed colors must be 255% or less.

7. Color Background

(9 colors x 4 density levels) + (12 user colors x 4 density levels) + 1 scan

color = 85 colors

* scan color = Edit type only

8. Paint (Edit type only)

(9 colors x 4 density levels) + (12 user colors x 4 density levels) + 1 scan

color = 85 colors

* Scan color = Edit type only

9. Color Line (Edit type only)

In the Area Editing mode, designated lines can be colored.

Available colors: 85 colors = 81 Single colors + (Bk x 4 density levels)

1-7

Page 12

SPECIFICATIONS 10 May 1996

10. Frame Line

In the Area Editing mode, the outlines of the designated areas can be

colored.

11. Image Overlay

This function makes a copy merging images of two originals.

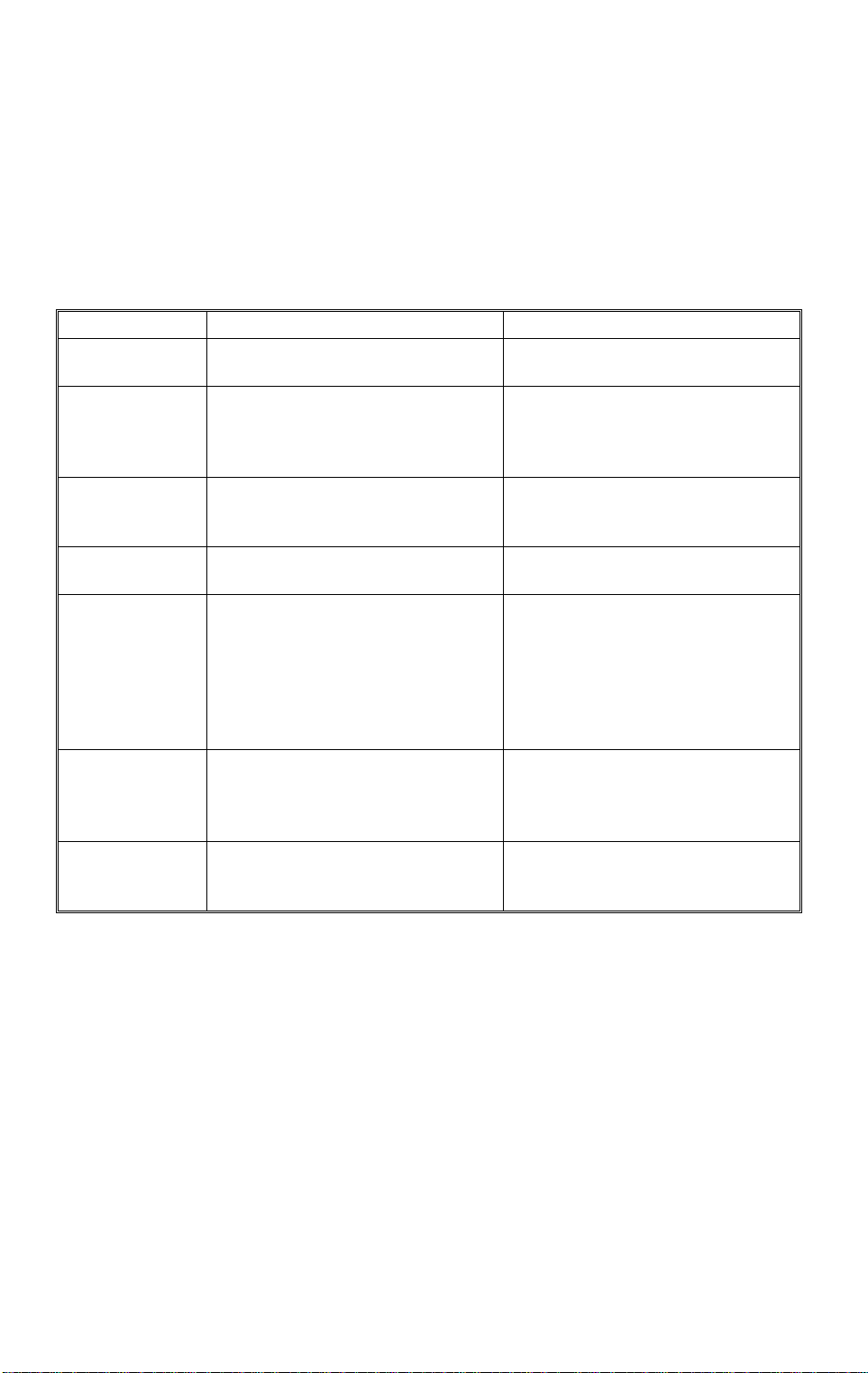

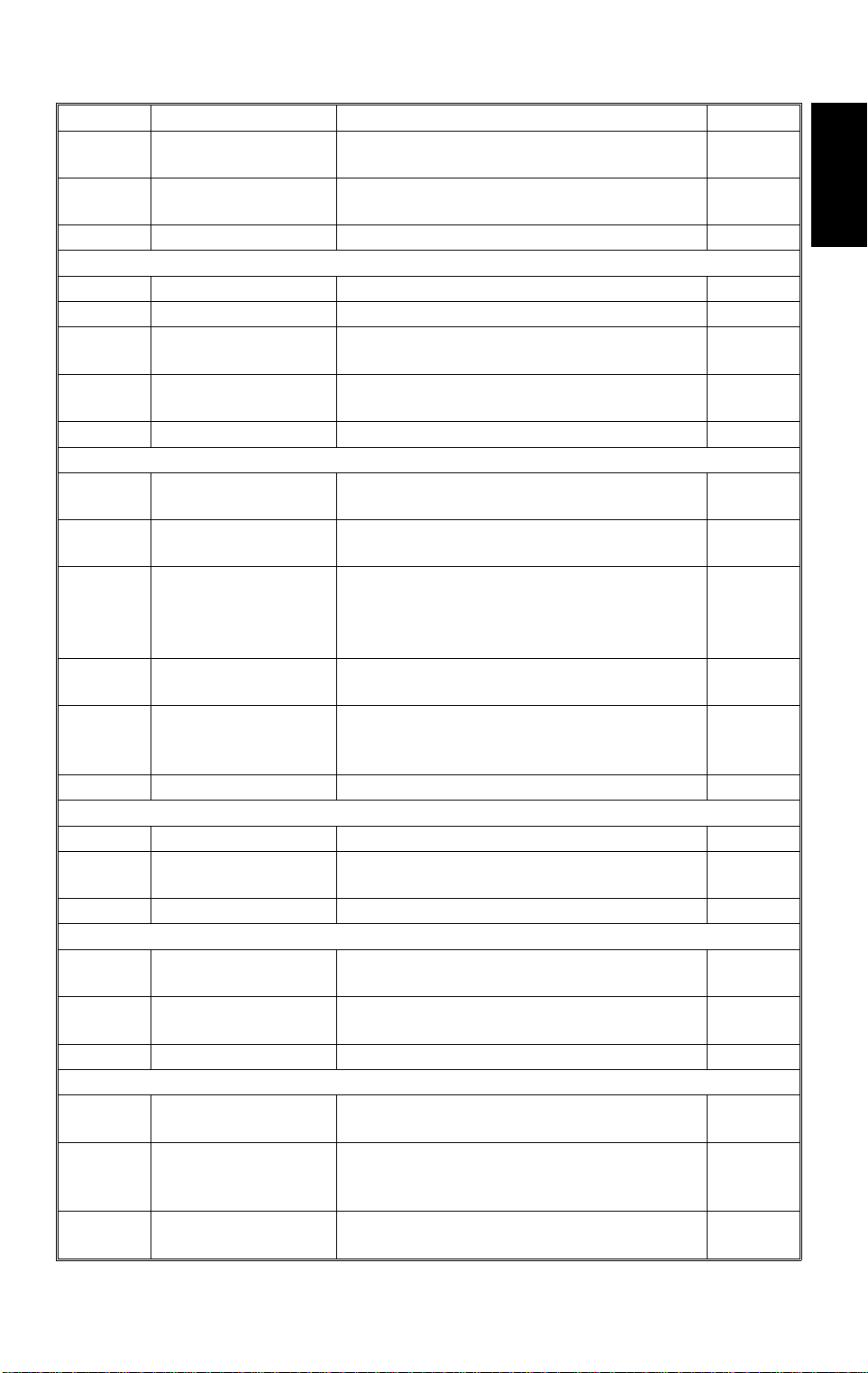

12. Area Editing mode

LILY (A172) DFC-ALPHA (A109)

Area Shape Rectangle, Polyg on, R ight Angle

Polygon, Close d Loop, Line

Number of Areas Maximum: 500 points

However, 1 area or li ne must be of

30 or fewer points.

Method of

Designati ng

Areas

Canceling Ar eas Not only single point s but al r eady

Maximum

Number of

Groups/Areas

Storin g the Area

Editing job

settings in

Program Mode

Canceling

Groups

Editor Pen and Cursor Cursor only

closed areas can b e cl eared.

15 Groups

Up to 3 job patterns can be applied .

Changing the color of one job

pattern will not affect the original

settings of the job pattern.

Always available. Not available in Creative Editing

Available. However, canceli ng a

group will remove it from the total

number of grou ps.

Rectangle, Polygon, Right Angle

Polygon, Closed Loop

Creative Editi ng: 6 Are as

1 area must be of 10 orfewer points

Color Editing: 6 Groups

Maximum 500 points

Only single points before closing

the area can be cleared.

Creative Editi ng: 3 Are as

Color Editing: 6 Groups

When in Color Editing mode, up to

3 job patterns can be applied,

Changing the color of one job

pattern will not affect the original

settings of the j ob pattern.

mode.

Available in Color Editing mode.

Not available.

1-8

Page 13

10 May 1996 SPECIFICATIONS

MEMO

Overall

Information

1-9

Page 14

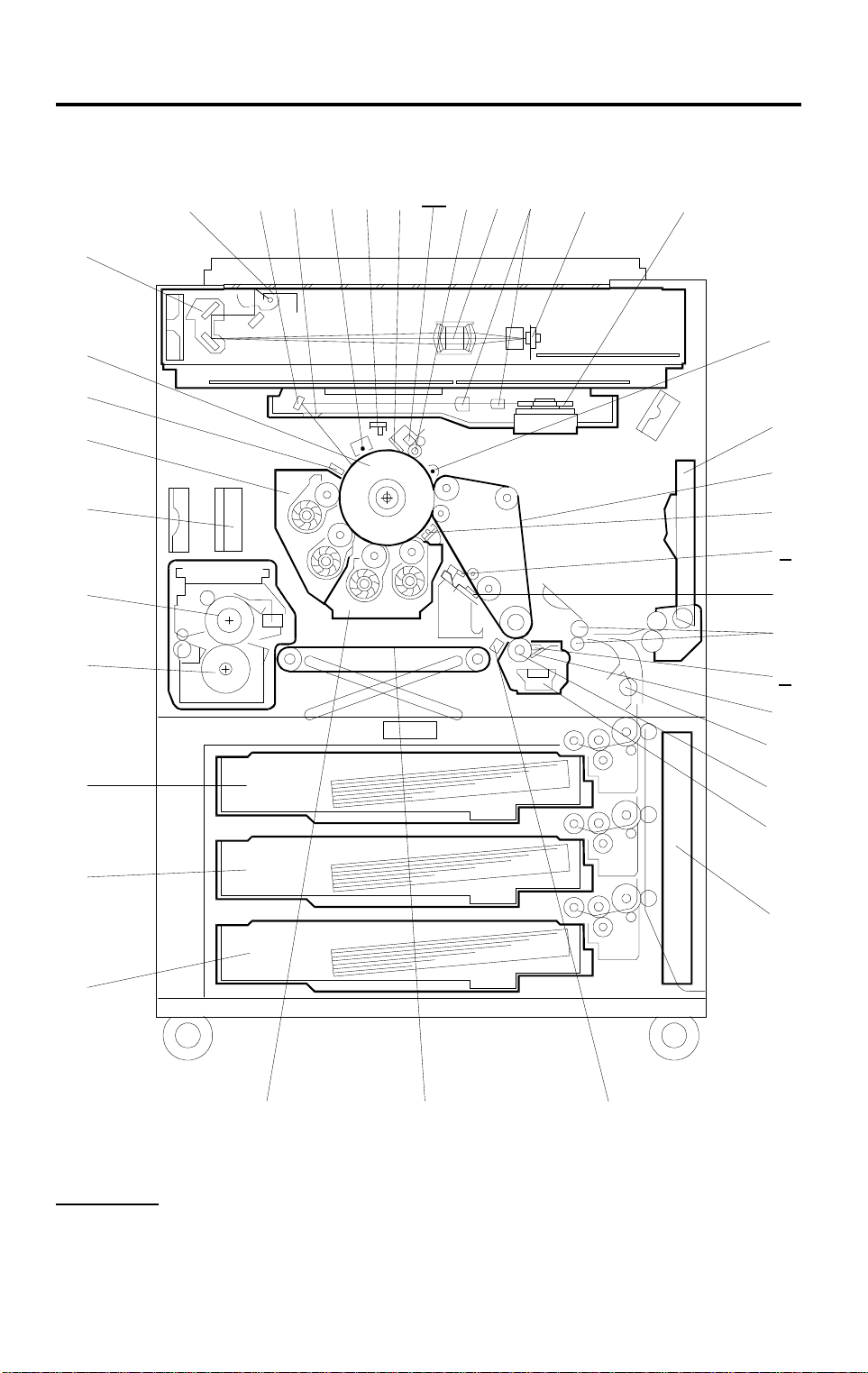

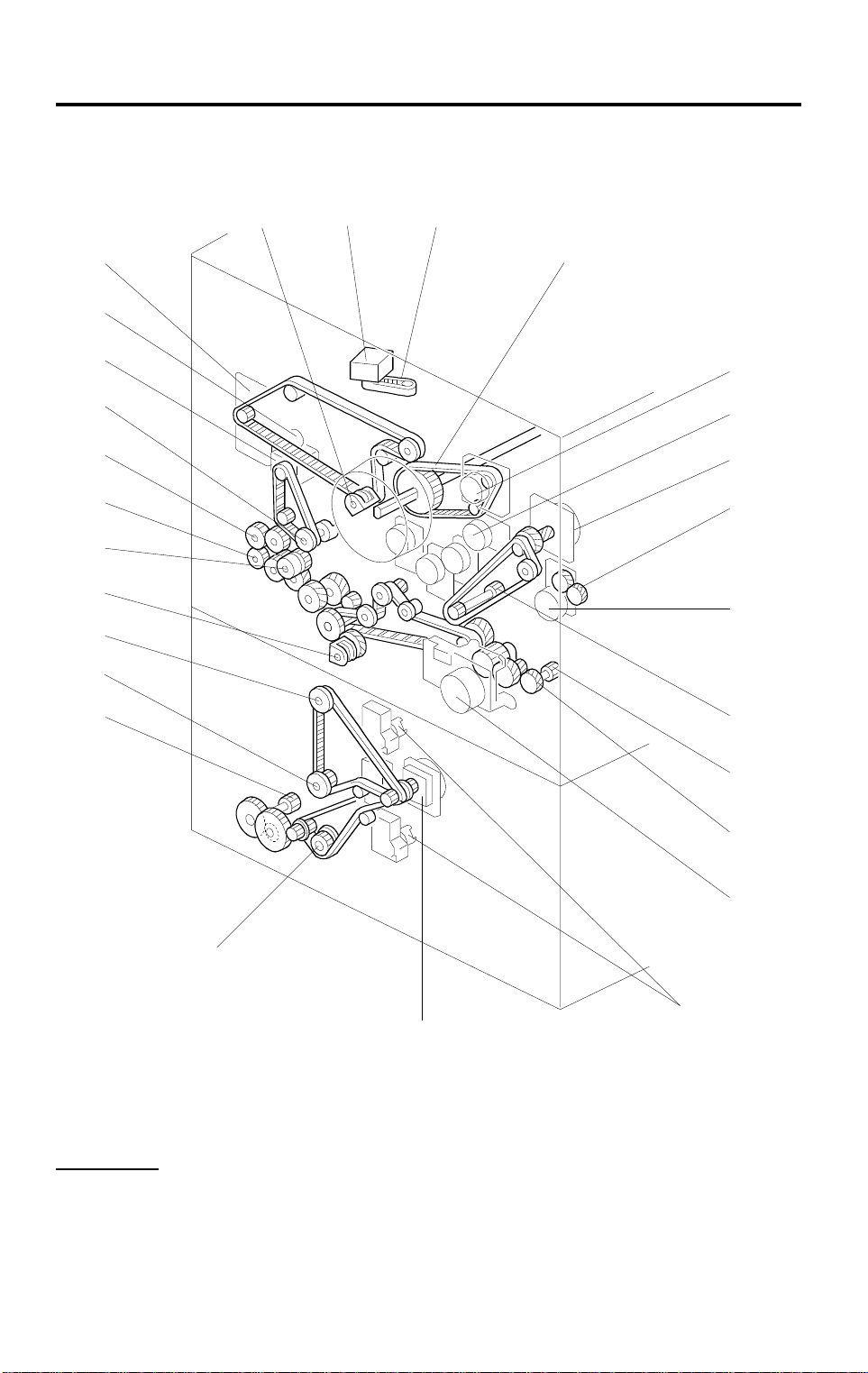

MECHANICAL COMPONENT LAYOUT 10 May 1996

3. MECHANICAL COMPONENT LAYOUT

37

38

1

2

3

26

25

24

23

27

28

29

30

31

32

33

3534

36

22

21

20

19

18

17

4

5

6

7

8

9

10

11

12

13

16

Units different from A109

Bold Italic

Bold

: Additional units

: Modified units

15

1-10

14

A172V502.wmf

Page 15

10 May 1996 MECHANICAL COMPONENT LAYOUT

1. Pre-cleaning Corona Unit

20. Pressure Roller

Overall

Information

2. By-pass Feed Table

3. Transfer Belt

4. ID Sensor

5. Belt Lubricant Bar

6. Belt Cleaning Blade

7. Registration Rollers

8. Roller Lubricant Bar

9. Transfer Roller Blade

10. Relay Roller

11. Transfer Roller

12. Toner Catch Pan

13. Toner Collection Bottle

14. Paper Discharge Plate

21. Hot Roller

22. Development Ozone Filter

23. Black/Cyan Development Unit

24. Drum Potential Sensor

25. OPC Drum

26. 2nd Scanner

27. 1st Scanner

28. Drum Mirror

29. Toner Shield Glass

30. Charge Corona Unit

31. Quenching Lamp

32. Drum Cleaning Blade

33. Drum Lubricant Bar

15. Transport Belt

16. Magenta/Yellow Development

Unit

17. 3rd Paper Tray

18. 2nd Paper Tray

19. 1st Paper Tray

Deleted units from A109

Lubricant brush

•

34. Cleaning Brush

35. Lens

36. f-theta Lenses

37. CCD Board

38. Polygon Mirror

1-11

Page 16

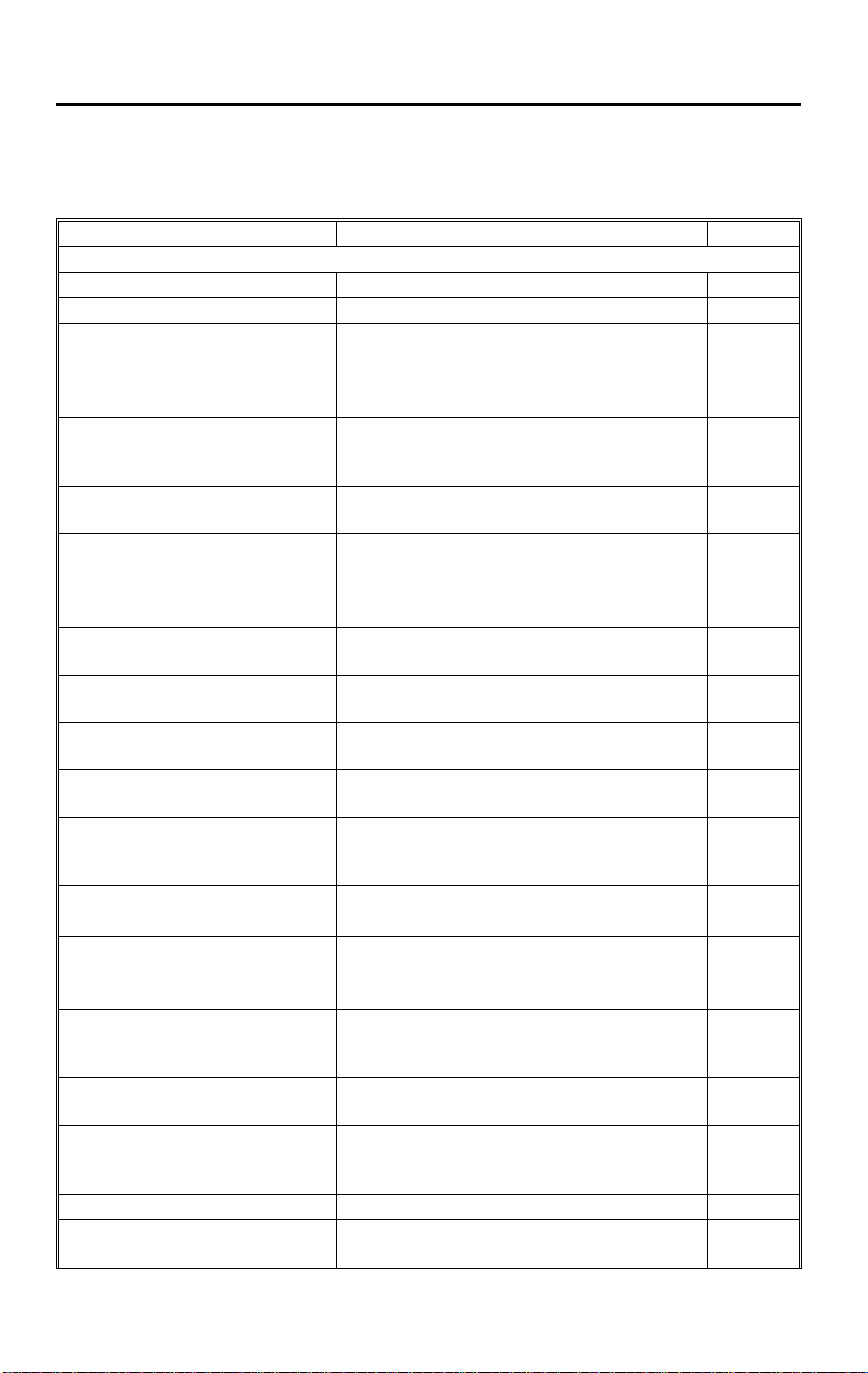

DRIVE LAYOUT 10 May 1996

4. DRIVE LAYOUT

27

26

25

24

23

22

21

20

19

18

17

1

2 3

4

5

6

7

8

9

10

16

Units different from A109

Bold Italic

Bold

: Additional units

: Modified units

11

12

13

14

15

A172V503.wmf

1-12

Page 17

10 May 1996 DRIVE LAYOUT

1. Transfer Belt Position Clutch

15. Paper Feed Motor

Overall

Information

2. Scanner Motor

3. Scanner Drive Pulley

4. Drum Timing Belt

5. Drum Motor

6. Bk-Sleeve Motor

7. Color-Development Drive Motor

8. Bk-Development Drive Gear

9. Bk-Development Drive Motor

10. Color-Development Drive Gear

11. Transport Unit Drive Gear

12. Fusing Unit Drive Gear

13. Transport Motor

14. Tray Lift Motors

16. 3rd Paper Feed Drive Pulley

17. Toner Collection Tank Drive Gear

18. 2nd Paper Feed Drive Pulley

19. 1st Paper Feed Drive Pulley

20. Transfer Roller Position Clutch

21. Registration Clutch

22. Relay Roller Drive Gear

23. By-pass Feed Drive Gear

24. Transfer Belt Drive Pully

25. Transfer Belt Motor

26. Lubricant Brush Clutch

27. Cleaning Motor

1-13

Page 18

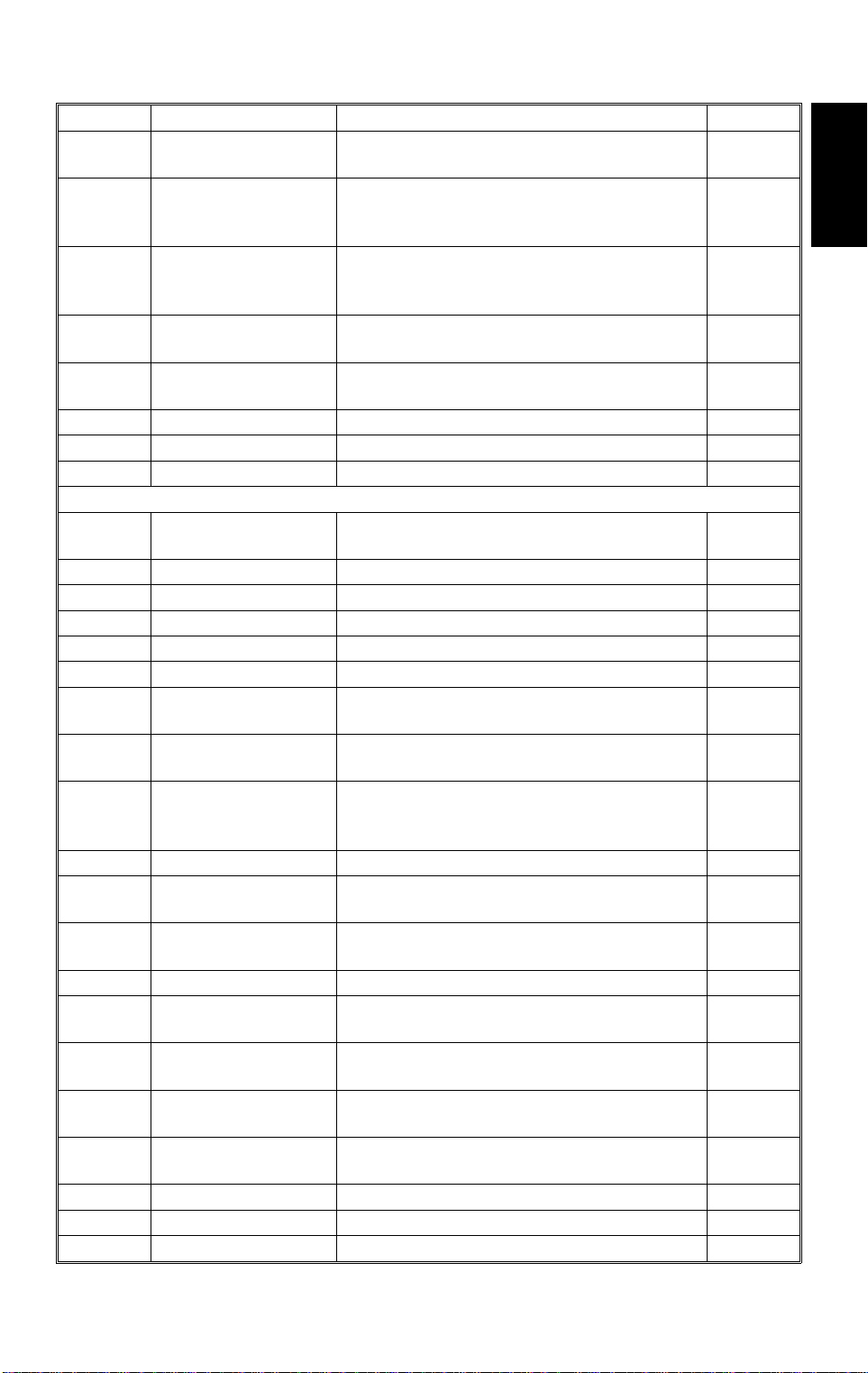

ELECTRICAL COMPONENT DESCRIPTIONS 10 May 1996

5. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the waterproof paper in the

pocket for symbols and index numbers.

Symbol Name Function Index No.

Printed Circuit Boards

PCB1 DC power supply Provides dc power. 20

PCB2 Lamp regulato r Provides d c power for the exposure l am p. 1

PCB3

PCB4

PCB5

PCB6

PCB7

AC drive Provides ac power for the hot roller and

pressure rol ler fusing lam ps.

High voltage supply C/G

High voltage supply -BSupplies high vol t age to the Y/M/C/Bk sleeve

High voltage supply T1/PCC/BR

High voltage supply -T2Supplies high voltage to the tra nsf er roller.

Supplies high voltage to the ch ar ge corona

and grid plate.

rollers as development bias or to the OPC

drum for drum potential sensor calibration.

Supplies high voltage to the be l t bias roller,

pre-clean i ng corona, and cleaning bias roll er.

11

12

26

13

17

PCB8

PCB9

PCB10

PCB11

PCB12

PCB13

PCB14 Noise filter Removes electrical noise. 23

PCB15 ID sensor Detects the density of the ID sensor pattern. 127

PCB16

PCB17 Polygon motor drive Controls the polygon motor speed. 8

PCB18

PCB19

PCB20

PCB21 Image Discriminate Used for anticou nt erfeiting. 6

PCB22

High voltage supply -DSupplies high voltage to the pa per di scharge

plate.

Main control Controls all copier functions both directly or

through othe r co ntrol boards.

Interface 1 Interfaces th e i nput/output of ele ct rical

components with the main control board.

Interface 2 Interfaces th e i nput/output of ele ct rical

components with the main control board.

Transfer belt motor

drive

Paper feed inter face Interfaces the inpu t/ output of electrical

Operation panel Cont rols the touch panel display and

CCD Converts the li ght reflected fr om th e original

Scanner contro l Processes R/G/B video signals fr om th e

Scanner drive Interfaces the input/output electrical

Display Editor

interface

Controls the speed and directi on of the

transfer bel t mot or.

components in the paper supply unit with the

main control board.

monitors the key matrix.

into analog electrical signals for the three

basic colors (R/G/B).

CCD board to be sent to the IPU board.

components in the optics cavity with the

scanner contr ol board.

Interfaces th e operation panel board with the

IPU board (A17 2 copier only).

22

15

21

18

14

19

25

9

7

3

10

1-14

Page 19

10 May 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

PCB23

PCB24

PCB25

PCB26

PCB27

PCB28 Paper width detecting Detects paper width in the by-pass feed table. 128

PCB29 Wire cleaner drive Controls ths corona wire cleaner operation. 16

Motors

M1

M2 C - Sleeve Turns the C sleeve roller in both di r ections. 31

M3 M - Sleeve Turns the M sleeve rol l er in both directions. 35

M4 Y - Sleeve Turns the Y sleeve roller in both direc tions. 34

M5 Drum Turns the drum. 28

M6 Bk - Sleeve Turns the Bk - sleeve roller in both directions. 30

M7

M8

M9

M10 Scanner Drives the 1st and 2nd scanners. 29

M11

M12

M13 Polygon Turns the polygon mirror . 47

M14

M15

M16

M17

M18 1st tray lift Lifts the 1st tray bottom plat e. 36

M19 2nd tray lift Lifts the 2nd tray bottom p l at e. 37

M20 3rd tray lift Lifts the 3rd tray bottom pl at e. 38

Operation Pane l

Control

IPU Processes R/G/B video si gnals from the

IPU interface Changes the clock frequency of R/G/B video

LD drive Generates the laser beam for printing the

Laser synchronizing

detector

Bk - Development

drive

Transport Drives the transport uni t , fusing unit, transf er

Color - Development

drive

Cleaning Drives th e dr um cleaning bru sh, the lubricant

Transfer belt Turns the transfer belt drive rol l er i n both

Paper feed Drives the pap er feed sections and the cam

Bk - Toner supply Dri ves the Bk toner tran sport and agitati on

C - Toner supply Dri ves the C toner transport and agita tion

M - Toner supply Drives the M toner transport a nd agitation

Y - Toner supply Drives the Y toner transpor t and agitation

Controls the operation pan el .

scanner control board and sends Y/M/C / Bk

video signals to the LD unit.

signals and al so sends the synchr oni zing

signal for the polygon motor.

latent image on the drum.

Detects the laser beam to control the start

timing of main scan writing.

Drives the Bk dual mixing roller.

roller, and transfer belt cleani ng unit.

Drives the Y/M/C dual mixing rollers

simultaneously.

brush, and the tr ansfer belt relea se

mechanism.

directions .

gear for the tone r collection bot tle.

mechanism.

mechanism.

mechanism.

mechanism.

24

2

4

5

66

46

45

27

32

33

39

43

42

41

40

Overall

Information

1-15

Page 20

ELECTRICAL COMPONENT DESCRIPTIONS 10 May 1996

Symbol Name Function Index No.

M21 Wire cleaner Drives the wire/grid cleaner 44

Fan Motors

FM1 Fusing exhaust Removes heat from around the fusing unit. 49

FM2

FM3

Charge inlet Provides air flow around th e drum charge

section.

Inner cooling Provides ai r f low around the toner ta nk and

development uni t s.

48

57

FM4 IPU cooling Provides air flow around the IPU board. 52

FM5 Polygon motor cooling Provides air flow around the polygon motor. 53

FM6/7

FM8/9

FM10

Transport Sucks in air to attract co py paper to the

transport belts.

Development exhaust Removes air and heat from aroun d th e drum

and development units.

Optics exhaust Exhausts air from under the le ns housing

cover.

55/54

58/59

51

FM11 LD cooling Provides air fl ow to the LD unit. 50

FM12/13 Optics cooling Blows air into the optics cavity. 60/61

FM14

DC power supply

cooling

Provides air flow to transformers and

radiation plates on the dc power supply

56

board.

Sensors

S1

S2

By-pass feed tab l e Detects whether the by-pass feed table is

open or cl osed.

Oil end Detects whether the silicone oil tank is nearly

empty or not.

S3 Exit Detects misfeeds. 100

S4

S5

Transfer belt posi t i on Detects whether the transfer belt is i n contact

with the drum or not .

Humidity Detects humidity and temperature to

calculate th e absolute humidi t y.

S6 Drum potential Detects the drum surface potential . 125

S7

S8

S9

S10

M - Toner densit y Detects the toner density in the M

development uni t .

Y - Toner density Detects the toner density in the Y

development uni t .

Bk - Toner density Detects the toner density in th e Bk

development uni t .

C - Toner density Detects the toner density in the C

development uni t .

S11 Transport Detects misfeeds. 95

Registration Detects the leading edge or trailing edge of

S12

the copy pape r to control the rotat ion of the

paper feed and r egi stration rollers.

S13

Registratio n guide set De te ct s w het her the registrati on guide plate

is set or not.

73

91

67

88

97

96

101

98

74

70

1-16

Page 21

10 May 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

S14 Bk - Toner End Detects the toner end condition of Bk toner. 94

S15 C - Toner End Detects th e to ner end conditio n of C toner. 93

S16 M - Toner End D etects the toner end condition of M t oner. 92

S17 Y - Toner End Detects the toner end condi tion of Y toner. 90

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31 Ori gi nal length - 1 D etects original length. 65

S32 Ori gi nal length - 2 D etects original length. 63

S33 Original width Detects original width. 106

S34

S35

S36

Transfer roller position Detects whether the t ra nsfer roller is in

contact with the transfer belt or not.

By-pass paper end Detects whether there is paper on the

by-pass feed table or not.

By-pass lengt h Detect s w het her paper on the by-pass feed

table is long er than A4 (Letter) side w ays or

not.

Toner overflow Dete ct s w het her the toner coll ect i on bottle is

full or not.

1st lift Detects the height of the paper st ack in the

1st paper tray to stop the 1st tray lift motor.

2nd lift Detects the height of the paper st ack in the

2nd paper tray to stop the 2nd tray li ft m ot or.

3rd lift Dete ct s the height of the pa per st ack in the

3rd paper tray to stop the 3rd tray lift motor.

1st paper end Detects whethe r there is paper in the 1st

paper tray or n ot .

2nd paper end Detects whether there is paper i n th e 2nd

paper tray or n ot .

3rd paper end Detects whether there is paper i n th e 3rd

paper tray or n ot .

1st paper feed Controls the 1st paper feed cl ut ch off/on

timing and the 1st pick-up sol enoid off timing.

2nd paper feed Cont ro l s the 2nd paper feed cl ut ch of f /on

timing and the 2nd pick-up solenoid off

timing.

3rd paper feed Controls the 3rd paper feed clutch off / on

timing and the 3rd pick-up sol enoid off timing.

Scanner unit lif t Detect s whether the scanner unit is lifted or

not.

Platen cover po si t i on Informs the CP U w het her the platen cov er is

up or down (related to APS/ARE function).

Scanner HP Informs the CPU whether the 1s t an d 2nd

scanners are at th e hom e position or not.

72

71

69

86

76

77

80

89

87

84

82

85

83

64

62

107

Overall

Information

Switches

SW1/2/3/4

Front door safet y Cuts the ac power line throu gh R A 1 and

detects whether the front door i s open or not.

1-17

102/103/

104/105

Page 22

ELECTRICAL COMPONENT DESCRIPTIONS 10 May 1996

Symbol Name Function Index No.

Vertical transport set Cuts the ac power line through RA1 and

SW5/6

detects whether the vertical transport guide

78/79

is open or not.

Main Provides power to the copier.

When it is at the st andby position, the

SW7

electrical power is suppli ed only to the

99

heaters (drum, optics anti-condensation,

tray, transfer belt/roller).

SW8

SW9

SW10

2nd paper size Detects the paper size for the 2nd paper tray

and whether the tr ay i s set or not.

3rd tray set Detects whether the 3r d paper tray is set o r

not.

1st paper size Detects the paper size for the 1st paper tray

and whether the tr ay i s set or not.

75

81

68

Magnetic Clutches

Transfer belt position Controls the touch and release operation of

MC2

the transfer be l t by u si ng drive from the

108

cleaning mot or.

MC3

By-pass feed Starts pap er feed from the by-p ass feed

table.

111

MC4 Registration Drives the registration r ol l ers. 110

Transfer roller position Controls the touch and release oper at i on of

MC5

the transfer ro ll er unit by using dri ve from the

109

transport motor.

MC6 1st feed Starts pap er feed from the 1st paper tr ay. 1 13

MC7 2nd feed Starts paper fee d from the 2nd paper tray. 114

MC8 3rd feed Starts paper feed from t he 3r d paper tray. 115

Solenoids

SOL1

SOL2

SOL3

SOL4

SOL5

SOL6

SOL7

SOL8

Cleani ng entran ce

seal

Controls the touch and relea se operation of

the cleaning entrance seal on t he t ransfer

belt cleaning unit.

Lubricant ba r Control s the touch and release operation of

the lubricant bar.

Cleaning blade Controls the touch and release operation of

the belt cleaning blade.

By-pass pick-u p Controls th e up/ down movement of the

pick-up roller in the by-pass feed station.

1st pick-up Controls the up/down movement of the

pick-up roller in the 1st feed station.

2nd pick-up Controls the up/down movement of the

pick-up roller in the 2nd feed st at i on.

3rd pick-up Controls the up/down movement of the

pick-up roller in the 3rd feed sta tion.

1st separation roller Controls th e up/ down movement of the

separation roller in the 1st feed station.

1-18

122

124

123

112

121

119

117

120

Page 23

10 May 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

SOL9

SOL10

Lamps

L1 Fusing Provides heat to the hot roller. 144

L2 Pressure Provides heat to the pressure roller. 143

L3

L4

Heaters

H1

H2

H3/H4

H5

H6

2nd separati on r ol l er Controls the up/down movement of the

separation roller in the 2nd feed station.

3rd separation roller Contro l s the up/down move ment of the

separation roller in the 3rd feed station.

Exposure Applies high intensity light to the original for

exposure.

Quenching Neutralizes any char ge remaining on the

drum surfa ce af t er cl eaning.

Lower tray (opti on) Turns on when t he m ai n switch is off to keep

paper dry in the 3r d paper tray.

Upper tray (opti on) Turns on when t he m ai n switch is off to keep

paper dry in the 1st and 2nd paper trays.

Transfer belt /rol l er Turns on when t he t ransfer roller

thermoswi t ch detects 20C° or less to keep

the resistance of the transfer ro ll er at a

constant level.

Optics

anti-condensation

Drum Turns on when t he main switch is off to

Turns on when t he main switch is off to

prevent moisture from forming on the optics.

prevent moisture from forming around the

drum.

118

116

129

126

138

134

136/137

148

131

Overall

Information

Thermistors

TH1 Fusing Monitors the temperature of th e hot roller. 133

TH2

Thermofuses

TF1

TF2

Thermoswit ches

TS1

TS2

Pressure roll er Monitors the tem per at ure of the pressur e

roller.

Fusing Opens the fus i ng l amp circuit if th e fusing

unit overheats.

Pressure roller Opens the pressure roller lamp circuit if the

fusing unit ov er heats.

Optics Opens the exposure lamp circuit if the 1st

scanner overheats.

Transfer belt /rol l er Detects the te m per ature around the transfer

roller in order to keep the resist ance of the

transfer roller at a constant level.

1-19

142

132

141

130

135

Page 24

ELECTRICAL COMPONENT DESCRIPTIONS 10 May 1996

Symbol Name Function Index No.

Counters

Black total Keeps track of the total number of scans for

CO1

Full color total Keeps track of the total numb er of scans for

CO2

Others

CB1

NF1 Noise filter Removes electrical noise. 140

CC1 Choke coil Removes high frequency cur r ent . 147

Circuit break er Provides back-up hi gh current protection for

black devel opment in both bl ack and color

copy modes.

Yellow, Magenta, and Cyan development in

both single and full color copy modes.

the electrical components.

145

146

139

1-20

Page 25

SECTION 2

DETAILED DESCRIPTIONS

Page 26

10 May 1996 MAJOR DIFFERENCES FROM THE DFC-ALPHA (A109)

1. MAJOR DIFFERENCES FROM THE

DFC-ALPHA (A109)

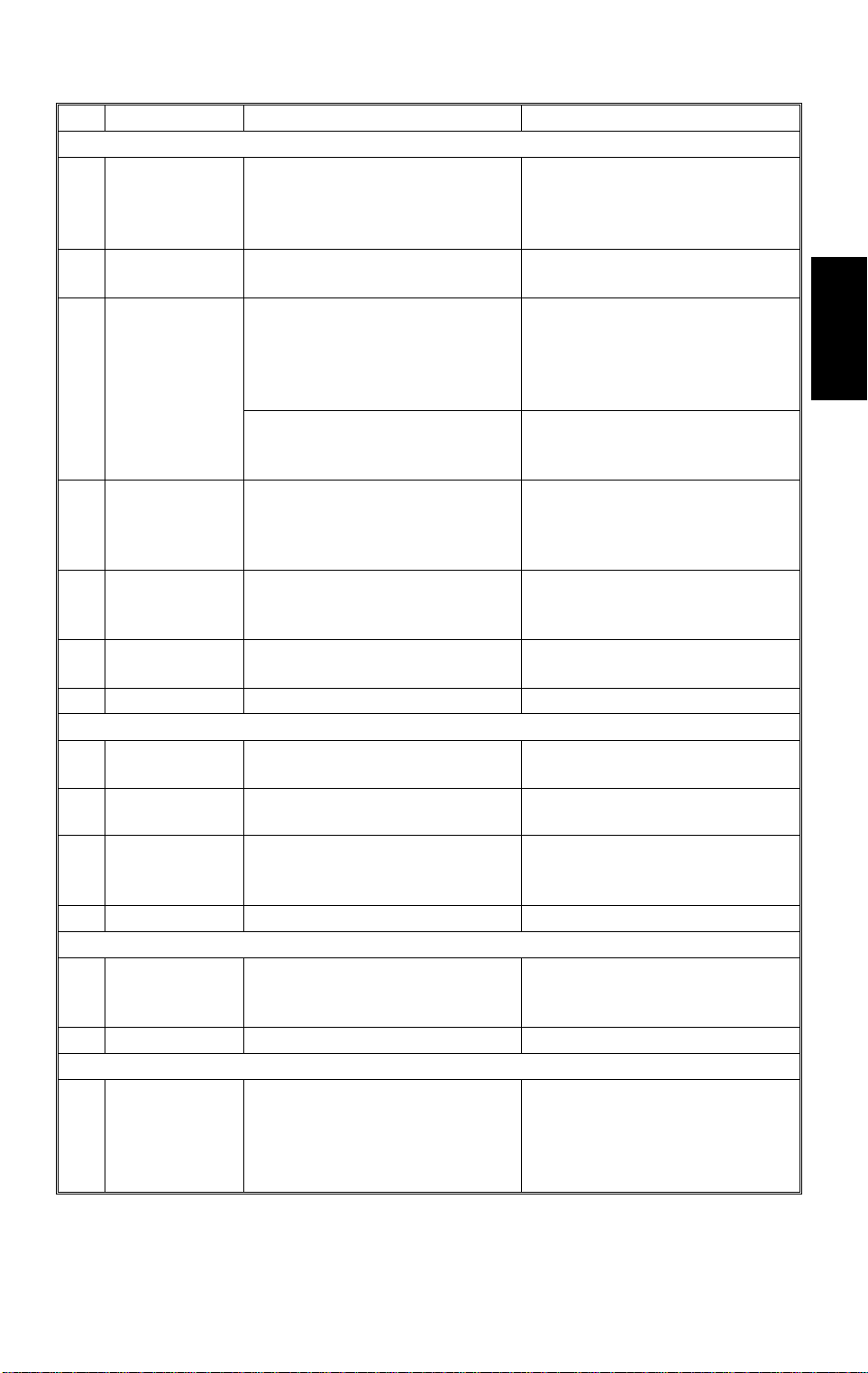

No. Item Contents Details

Process Control

Toner End

1

Detection

Latent Image

2

Control

Toner Density

3

Control

Around The Drum

OPC Drum The OPC drum layer material

1

Drum Charge

2

Wire

Drum Charge

3

Wire/Grid

Cleaning

Drum Cleaning Drum lubrication has been newly

4

The toner end detection software

has been eliminated.

The process control for latent

image control has been modified.

CNT

V

Correction has been

modified.

(Charge Transf er L ayer: CTL)

has changed.

The system has been changed

from a double-wi r e t o a

single-wire scorotron.

Drum charge wire/grid cleaning

has been newly added.

added.

The cleaning brush has been

changed from a looped-bristle

type to a straight- br i st l e ty pe.

A toner end sensor has been

added for each color. See 6.2 in

section 2 for deta i l s.

See 2.1 in section 2 for d et ai l s.

See 2.2 in section 2 for d et ai l s.

To reduce ozone a nd N O

reaction with the drum (to

prolong the life time of the drum).

See 3.1 in section 2 for d et ai l s.

See 3.2 in section 2 for d et ai l s.

See 3.4 in section 2 for d et ai l s.

To apply the lubricant evenly on

the drum. See 3.4 in section 2 for

details.

X

Detailed

Descriptions

Optics

Exposure Lamp The number of exposure la mp’s

1

Infra-red Filter The thickness of the inf ra-red

2

2nd/3rd Mirrors A heavier stabilizer has been

3

Exposure Glass A more high- conductivity gl ass is

4

Reflectors Reflectivity has increased

5

lighting points has increased

from 7 to 9.

filter has increased from 0.8 mm

to 1.0 mm.

installed on the 2nd/3rd mirrors.

used.

because of surface

improvements.

To decrease whit e bands on

copies caused by t he exposure

lamp’s lighting points.

To achieve better copy quality for

originals containing infra-red

radiance.

(prevents black areas from

becomi ng reddish)

To decrease scanner banding to

achieve better results for auto

letter/photo separation.

To decrease the possibility of the

exposure glass becoming dirty

with dust particl es.

To decrease the te m perature

around the optics c avi t y due to

less power to the exposure lamp.

2-1

Page 27

MAJOR DIFFERENCES FROM THE DFC-ALPHA (A109) 10 May 1996

No. Item Contents Details

Optics Cooling

Fan Filter

6

The filter material has changed. It

is easier to repla ce the filter.

The air flow has improved to

reduce temperature rises in the

optics cavity. For replacement,

see sec t i on 5 for det ails.

Image Processing

RGB Filter The RGB filter coefficient for

1

each copy mode (l et t er /photo)

To improve gradation and

reproduction quality.

has been changed.

Color Correction New matrixes and masking

2

coefficients have been added to

See 4.4 in section 2 for d et ai l s.

match the new copy modes.

Image

3

Separation IC

The image separ at i on IC has

been changed.

To reduce photo/ le t te r image

separation err or s i n auto detect

mode.

Laser Exposure

Drum Mirror A heavier stabilizer has been

1

installed on the Drum mirrors.

To reduce the occur r ence of

banding on copies.

Development

Development

Sleeve Roller

1

The sleeve roll ers have been

changed to a sand-blast type.

Toner Tank

Toner Tank A toner end sensor has been

added for each col or.

The gree n lever has been

eliminated.

1

A toner tank detection

mechanism has been added.

When the tank is pul l ed out, it is

disconnected e lectrically from th e

main body.

Transfer B el t

Transfer Belt

Bias

1

The number of threshold levels

that de cide transfer bel t bi as

depending on environmental

conditions has changed from 2 to

4.

Transfer Belt

Cleaning

2

The belt lubricant mechanism

has changed to ap pl y l ubricant

directly to the transfer belt.

To eliminate th e 1. 25 mm

horizontal lines in halftone image

areas caused by the grooves on

the sleeve roller.

See 6.2 in section 2 for d et ai l s.

See 6.2 in section 2 for d et ai l s.

See 6.2 in section 2 for d et ai l s.

See 7.1 in section 2 for d et ai l s.

To prevent partial bl anking of

lines (due to incomplete toner

transfer) from appearing on

copies.

See 7.2 in section 2 for d et ai l s.

2-2

Page 28

10 May 1996 MAJOR DIFFERENCES FROM THE DFC-ALPHA (A109)

No. Item Contents Details

Transfer R ol ler

Transfer

Belt/Roller

1

Heater

Transfer Rolle r The material of the transfer ro l le r

2

Transfer Roller

Bias

3

Paper

Discharge Plate

4

Paper

5

Discharge Plate

Output

Transfer Roller

6

Cleaning

The transfer roller heater has

been newly added to keep the

temperature around the transfer

roller unit at 20°C.

has been changed.

The number of threshold levels

that decide transfer roller bias

depending on environmental

conditions has been changed

from 2 to 4.

Transfer roller bi as settings for

duplex copyin g have been newly

added.

The installed a ngle of the paper

discharge plate has changed.

The output of the paper

discharge plate changes

depending on the copy paper.

The roller lubricant mechanism

has been newly added.

See 8.1 in section 2 for d et ai l s.

To improve tran sf er e ffi ciency.

See 8.2 in section 2 for d et ai l s.

See 8.2 in section 2 for d et ai l s.

To prevent toner scatter from

appearing around solid areas in

duplex mode. See 8. 4 i n section

2 for details.

See 8.4 in section 2 for d et ai l s.

See 8.3 in section 2 for d et ai l s.

Detailed

Descriptions

Fusing Unit

Hot Roller The material of the hot roller has

1

Pressure Roller The material of the pressure

2

Pressure Roller

3

Cleaning

Paper Feed

2nd Paper

1

Feed Station

Operation Panel

LCD (Liquid

Crystal Display)

1

been changed.

roller has been changed.

The pres sure rol l er cleani ng

mechanism has been newly

added.

The 2nd paper feed st at i on has

been changed to the universal

tray type.

The LCD has been changed to a

640 x 480 dot type.

A172: Full Color Display

A199: B/W Display

To make it suitable for duplex

copying.

To make it suitable for duplex

copying.

See 9.1 in section 2 for d et ai l s.

To meet customer s’ requests.

For easier operation and editing.

2-3

Page 29

MAJOR DIFFERENCES FROM THE DFC-ALPHA (A109) 10 May 1996

No. Item Contents Details

Operation

Panel Control

2

Operation

Panel Self

3

Diagnostic

Mode

Others

Drum Dri ve Th e drum drive me chanism has

1

Copier Rear

2

Frame

Fusing exhaust

3

ozone filter

The operation panel control

board has been ne w l y added.

The main control board no longer

contr ols the operation panel.

The operation panel self

diagnostics mode has been

newly added.

been changed from a series of

gears to a timing belt system.

The thickness of the rear frame

has changed from 1. 6 mm to 2.0

mm

This filter has been eliminated. Because the ozone amount has

For easier servi cing of the

machine.

Banding on copie s are reduced.

See 3.3 in section 2 for d et ai l s.

Banding on copie s are reduced.

been decrease d due to the new

charge corona unit.

—

Options

1 DJF (A610) See the DJF section for details. —

15-Bin Sorter

2

(A322)

Holder

3

(A702-18)

Film Projector

4

Unit (A718)

See the Sorter section for details.

The colo r of t he exterior covers

has been changed.

See the Film Projecto r Uni t

section for details.

—

—

—

2-4

Page 30

10 May 1996 PROCESS CONTROL

2. PROCESS CONTROL

2.1 LATENT IMAGE CONTROL

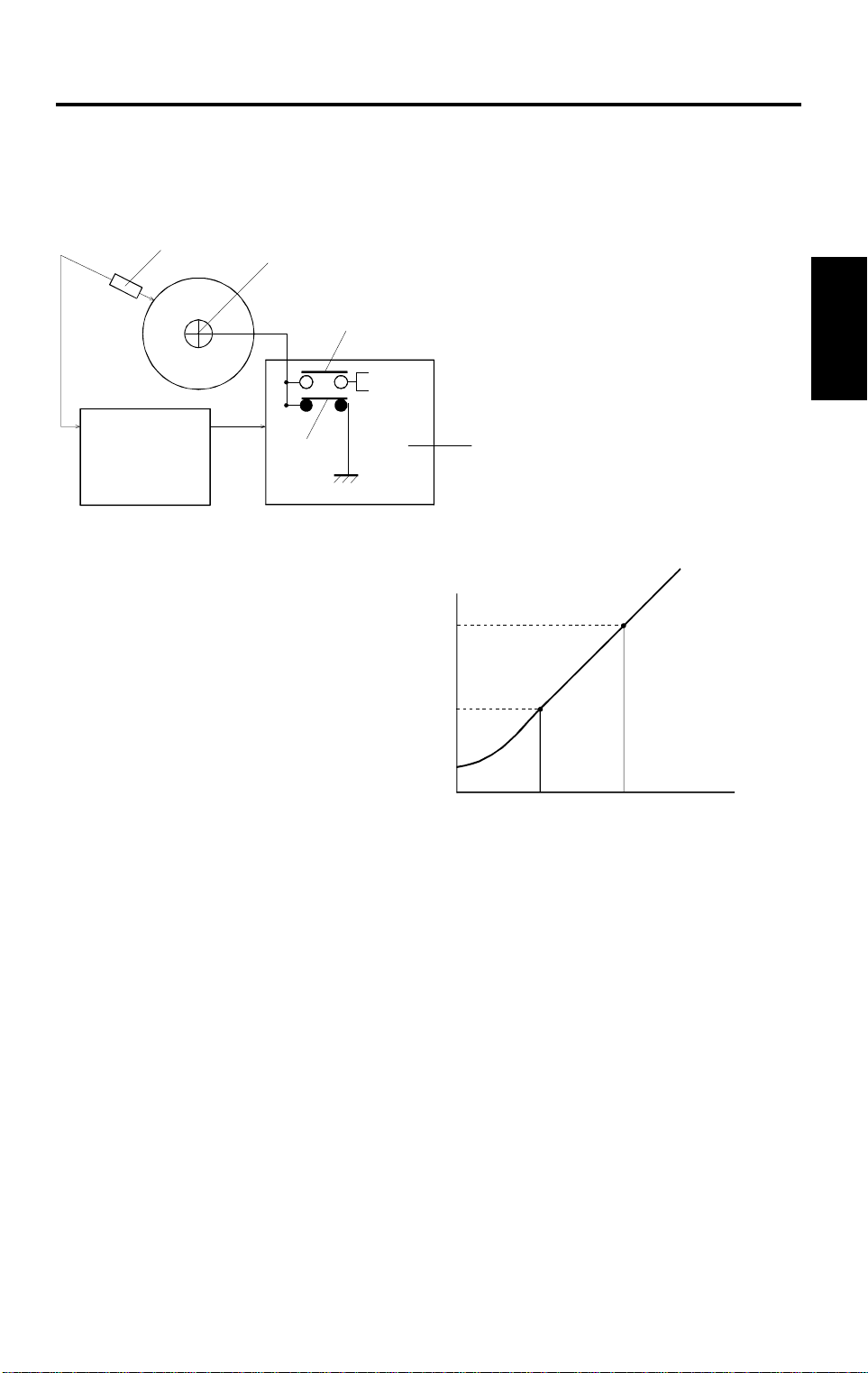

2.1.1 DRUM POTENTIAL SENSOR CALIBRATION

[A]

Main Board

[C]

RA #1

RA #2

RA#1 and RA #2 are packed in RL1 on

the High Voltage Supp l y Boar d – B.

–300 V

–600 V

A172D507.wmf

Sensor Output

V600 (V

V300 (V

)

2

1

)

Detailed

Descriptions

[B]

–300 –600

Actual Voltage

A172D508.wmf

The drum potential sensor [A] output is calibrated during the process control

self check.

The High Voltage Supply Board - B [B] has two relay contacts. Usually RA #1

grounds the drum. However, during the self check, the main CPU turns RA

#2 on and RA #1 off and applies the test voltage to the drum shaft [C]. In this

condition, the drum is isolated from the ground (floating).

By measuring the output of the drum potential sensor when –300 V (V

–600 V (V

) are applied to the drum, the sensor output is calibrated

600

300

) or

automatically. (The machine can now determine the actual drum potential

from the potential sensor output.) Using -300 and -600 V results in a more

accurate calibration of the sensor, since the voltage applied to the supply

board is much closer to the actual value, which is –450 V for V

B

(Development bias) during the process control self check.

2-5

Page 31

PROCESS CONTROL 10 May 1996

2.1.2 GRADATION PATTERN DETECTION

LD Power Level

40 mm

1st

40 mm

2nd

3rd

13th

A172D510.img

14th

A172D509.wmf

A latent image of a 14-grade gradation pattern is created for each color (Bk,

C, M, Y) by changing the LD input current.

By creating 14 grades, the machine can achieve a more precise development

gamma factor, resulting in a more reliable pointer control.

2-6

Page 32

10 May 1996 PROCESS CONTROL

2.2 TONER DENSITY CONTROL

2.2.1 V

T

V

2.5

CNT

CORRECTION

Copies

A172D511.wmf

Average ≥ 3.8

Average ≤ 2.3

2

Pattern Density (mg/cm

Gain Value = –1

Gain Value = ±0

)

Drum Potential

[A]

[C]

[B]

Detailed

Descriptions

A172D512.wmf

Gain value = +1

A172D513.wmf

Even if the toner concentration is constant, the toner density sensor output

gradually increases after new developer is installed because of developer

characteristics. Because of this, the machine believes that the amount of

toner in the developer has reduced. This causes the machine to increase the

toner concentration because the machine controls the toner concentration so

that V

To compensate for this, the V

T

stays constant.

CNT

gain is corrected by using the development

gamma curve made from the 14-grade pattern during process control self

check.

The present gamma curve [A] and the previous gamma curve [B] are

compared, and the average [C] is calculated. As shown in the diagram, the

gain is decreased by 1 when the average gradient is 3.8 or more. The

maximum compensation value is –16.

Because of this new V

CNT

correction system, the V

CNT

correction previously

performed every 200 copies is no longer necessary. Also, due to the use of

the average value, over-reduction of the gain is avoided.

2-7

Page 33

PROCESS CONTROL 10 May 1996

2.2.2 FORCED TONER CONSUMPTION MECHANISM

For customers that mainly make copies other than full color copies, the

toners other than the selected colors are not used. For these toners, the

amount of toner inside the development unit will gradually increase every 50

copies, since toner agitation is performed at this interval, and some toner is

added at this time (see section 6.1). If this condition continues, toner

scattering and toner density control failure may occur.

To compensate for this, along with the transport screw gear modification, the

machine checks the output of each TD sensor during the process control self

check. If the machine detects V

REF-VT

≥ 0.3 V, it determines that there is too

much toner inside the development unit and makes a pattern across the

whole width of the drum to forcibly consume some toner.

2.2.3 FORCED TONER SUPPLY MECHANISM

When the machine makes consecutive copies that have a large portion of

solid image areas, toner supply and agitation from the toner tank cannot keep

up with the toner consumption speed, causing lighter copies, toner scatter,

and related SC codes to appear.

To compensate for this, the output of each TD sensor is checked every copy.

When the machine detects V

T-VREF

≥ 0.5 V five times consecutively, it

determines that the amount of toner in the development unit is low. At this

moment, the copy job is interrupted, and toner is fed into the development

unit forcibly. After forced supply, the machine resumes the copy job.

2-8

Page 34

10 May 1996 DRUM UNIT

3. DRUM UNIT

3.1 DRUM CHARGE

This copier uses a single corona wire scorotron system to charge the drum.

The corona wire applies a negative charge to the drum surface. The striped

stainless steel grid plate makes the corona charge uniform and controls the

negative charge on the drum surface to -650 V (standard) by applying a

negative grid bias voltage.

The high voltage supply board –C/G gives a constant corona current (–450

A) to the corona wire, and controls the grid voltage (based on the results of

µ

process control) to maintain proper image density. Grid voltage is controlled

to match changing factors such as a dirty grid plate, dirty charge corona

casing, and OPC chargeability.

The use of the single wire scorotron system has the following advantages.

The amount of corrosive gas (O3, NOX) is reduced due to the decrease in

•

total current.

Detailed

Descriptions

The life time of the drum is increased due to the decrease in the amount

•

of corosive gas.

Uneven charge problems are alleviated due to the increase of the amount

•

of current per meter of the corona wire.

2-9

Page 35

DRUM UNIT 10 May 1996

3.2 DRUM CHARGE CORONA WIRE/GRID CLEANING

[E]

[B]

[A]

[F]

[D]

[C]

A172D524.wmf

[G]

A172D525.wmf

The flow of air around the charge corona unit may deposit toner particles and

paper dust on the corona wire or corona grid plate. These particles may

interfere with charging and cause uneven charge on the drum.

The wire cleaner [A], which consists of the wire cleaner pads [B] and the grid

plate sponge [C], automatically cleans the wire and the inside of the grid plate

to prevent such problems from appearing.

The wire cleaner is driven by a dc motor. Normally the cleaner is located at

the front end (this is home position). Whenever the main switch is turned on

while the hot roller temperature is below 80°C (before process control), the

wire cleaner motor [D] turns on to bring the wire cleaner to the rear end of the

corona unit and back to the home position. The corona wire and the inside of

the grid plate are cleaned at the same time. This procedure can be manually

performed with an SP mode as well (<2> SP Test, page 4).

When the cleaner moves from the home position to the rear position (the

white arrow in the illustration), only the grid plate is cleaned since the grid

plate sponge is always in contact. When coming back, the rib [E] on the

cleaner is forced by the opening in the corona casing, and the wire cleaner

pads contact the corona wire.

There are no home position or return position sensors. The wire cleaner drive

board at the back of the machine monitors the current applied to the motor.

When the wire cleaner reaches the end, it is stopped and the motor is locked.

At this time, the current of the motor slightly increases and the drive board

detects that it is time to rotate the motor in reverse.

Also, a grounding plate [F] is installed on the back side of the drum stay [G]

to reduce the electrical noise generated from the cleaner motor.

2-10

Page 36

10 May 1996 DRUM UNIT

3.3 DRIVE MECHANISM

[A]

[B]

A172D500.wmf

The drum is driven by the drum motor [A] through a timing belt [B].

By the use of a timing belt system, banding on copies are reduced due to the

lower mechanical load.

Detailed

Descriptions

2-11

Page 37

DRUM UNIT 10 May 1996

3.4 DRUM LUBRICATION MECHANISM

[A]

[B]

[B]

A172D501.wmf

[A]

A172D502.wmf

While the drum rotates, the cleaning brush [A] distributes lubricant from the

drum lubricant bar [B] to the surface of the drum.

This mechanism improves the copy quality, especially for letter areas in full

color mode, since it helps the toner transfer to the transfer belt. It also

improves the efficiency of drum cleaning.

To apply the lubricant to the surface of the drum evenly, a straight-bristle type

is used for the drum cleaning brush.

2-12

Page 38

10 May 1996 IMAGE PROCESSING

4. IMAGE PROCESSING

4.1 IPU SECTION BLOCK DIAGRAM

LD

Unit

Video

Controller

Bk, C, M, Y

Filter

Printer

Gradation

•

•

• Image

Creation

Detailed

Descriptions

I/F

Color ControllerDisplay Editor I/F Board

Magnification•

•

RGB

γ

Scanner

Picture

•

• Color

Correction

I/F

Filter

Element

Correction

ACS

Area

CPU

Auto L/P

Image Separation

Memory

Main Control Board

Board

IPU I/F

Board

Control

Scanner

IDU

A172D535.wmf

2-13

Page 39

IMAGE PROCESSING 10 May 1996

4.2 ACS (AUTO COLOR SELECTION)

Signal

Level

RBG

*MIN: Also known as "RGB Common D ata"

In Auto Color Selection mode, the Black Copy mode or Full Color mode is

automatically selected to match the original image. During the 1st scanning

cycle, the latent image is developed with amount of black toner according to

the corrected R/G/B video signals. If the original does not have any color

area, the 2nd scanning is aborted, and the developed image is transferred

from the transfer belt to copy paper. Then the black and white copy comes

out. If the original has a color area, copying resumes in the full color copy

mode (4 scans).

MAX

MIN

A172D526.wmf

To recognize if the original has a color area or not, the R/G/B video signals

are compared. If the maximum difference among R/G/B signal levels

(MAX-MIN in the above diagram.) is within a certain range, the original is

considered to be black and white.

This range can be changed by the user.

Black: The range is wider

Color: The range is narrower

Also, the user can select either B/W Priority or Color Priority, to reproduce the

B/W areas or Color areas well, when the ACS mode is selected.

*Factory Setting = Color Priority

2-14

Page 40

10 May 1996 IMAGE PROCESSING

When Color Priority is selected

Bk Conversion Data

255 : Letter areas

UCR

setting 1

0 255

<ACS: Color Priority>

UCR ratio: 100%

4

3

2

5

: Photo areas

8

7

6

9

RGB Common Data

Detailed

Descriptions

A172D527.wmf

a) Letter areas

The UCR ratio is set to 100% to reproduce the letter areas well. Black toner

is always used if RGB Common Data is greater than zero.

b) Photo areas

In photo areas, black toner is not used until RGB Common Data reaches a

certain value, which depends on the UCR adjustment setting (see below).

This can be one of 9 settings as shown in the above illustration.

Also, the UCR ratio changes with image density. The steeper the gradient in

the above graph, the faster the UCR ratio increases with image density (as

RGB Common Data increases).

The UCR range for the photo areas can be changed over 9 levels by the user

(Image Adjustment: UCR Adjustment) to get the best color reproduction.

2-15

Page 41

IMAGE PROCESSING 10 May 1996

When B/W Priority is selected

Bk Conversion Data

255 : Letter areas

0 255

<ACS: B/W Priority>

: Photo areas

UCR ratio: 100%

RGB Common Data

A172D528.wmf

a) Letter areas

The UCR (Under Color Removal) ratio is set to 100% to reproduce the letter

areas well.

b) Photo area

The UCR ratio is set to a higher value than for the Color Priority default

setting (level 5), so that low image density areas of B/W originals can be

reproduced well.

2-16

Page 42

10 May 1996 IMAGE PROCESSING

4.3 RGB FILTER

RGB Filter

RGB Input

Filtering

ADS (Full Color)

RGB Output

(to Color Correction)

A172D529.wmf

4.3.1 Filtering

To improve the image reproduction, the appropriate filter coefficients are

applied to the R/B/G video signals, depending on the selected image modes

(letter/photo) or the result of Auto Letter/Photo separation.

4.3.2 Auto Image Density Control (Full Color)

This mode prevents the background of an original from appearing on copies.

The Auto Image Density Level can be changed using the User Tools. (There

are 5 levels.)

Detailed

Descriptions

When Full Color mode and Auto Image Density mode are selected, video

signals corresponding to the background are detected and their output level

is set to zero. The threshold for detecting the background can be changed

over 5 levels using the User Tools.

RGB

Output Data

RGB Input Data

Threshold

A172D533.wmf

2-17

Page 43

IMAGE PROCESSING 10 May 1996

4.4 COLOR CORRECTION

(from RGB Filter)

RGB Input

Color

Correction

Positive/Negative

Background Density Control

YMCBk

CPU

Memory

Contrast

ADS

(B/W, Twin Color, Single Color)

ACC

Scan

Color

YMCBk

Color Conversion

YMCBk Output

A172D541.wmf

2-18

Page 44

10 May 1996 IMAGE PROCESSING

4.4.1 Image Modes

RGB video signals are converted to YMCBk video signals using a color

conversion table.

A172D530.wmf

a) Printed Photo/Glossy Photo mode

A suitable color conversion table for Printed Photo or Glossy Photo mode is

applied to improve the reproduction of such originals.

b) Copied Photo/Map mode

A suitable color conversion table for Copied Photo or Map mode is applied to

improve the reproduction of such originals.

c) Auto Letter/Photo mode

At the factory setting, Printed Photo mode is applied for the photo areas

detected by the Auto Letter/Photo mode.

The user can change this setting so that either of the following modes will be

applied for photo areas.

Printed Photo mode

•

Glossy Photo mode

•

Copied Photo mode

•

Detailed

Descriptions

2-19

Page 45

IMAGE PROCESSING 10 May 1996

4.4.2 Backgr ound Density Control

RGB

Output Data

Darker

Setting

Lighter

Setting

RGB Input Data

A172D531.wmf

There a 9 levels of background density controls.

a) Lighter setting

Small effect on the high image density areas, but the low image density areas

are reproduced lighter or erased.

b) Darker setting

Small effect on the high image density areas, but the low image density areas

are reproduced darker.

When combining the Full Color mode and Auto Image Density mode, the

background density may be reproduced lighter or erased. To reproduce the

color background well, it is necessary not to use Auto Image Density mode

but to adjust the background density control to a darker setting.

2-20

Page 46

10 May 1996 IMAGE PROCESSING

4.4.3 Con trast

RGB

Output Data

Weaker

Stronger

RGB Input Data

A172D532.wmf

Contrast between light and dark areas of the image can be adjusted. There

are over 9 levels.

a) Strong setting

The density of the dark image areas is increased and the density of the light

image areas is decreased.

b) Weaker setting

The density of the dark image areas is decreased and the density of the light

image areas is increased.

Detailed

Descriptions

2-21

Page 47

IMAGE PROCESSING 10 May 1996

4.4.4 Auto Image Density Control (B/W, Twin Color, Single Color)

This mode prevents the background of an original from appearing on copies.

The Auto Image Density Level can be changed using the User Tools. (There

are 5 levels.)

When B/W, Single Color, or Twin Color and Auto Image Density mode are

selected, this function combines the Background Density Control and

Contrast as shown in the following table.

ADS Level

↑

Dark +1

Standard 0

Light –1

↓

+2

–2

Backgro und

Density Control

–1 0

–1 +1

–1 +2

–2 +2

–2 +3

Contrast

2-22

Page 48

10 May 1996 IMAGE PROCESSING

4.5 ACC (AUTO COLOR CALIBRATION)

Test Pattern

Bk

Target

Actual

C

M

Bk

C

M

γ

γ

Photo mode

Y

Letter mode

Y

(4 scan)

A172D534.wmf

Detailed

Descriptions

Image Density

LM H

A172D540.wmf

Auto Color Calibration can be performed using the User Tools.

A test pattern, including the patterns for Letter mode and Photo mode, will be

printed first. The user then scans the test pattern. The resulting printer

gamma curve depends on the results of scanning the test pattern.

There are adjustment tables for L, M, H, and ID MAX values stored in the

machine. The machine applies these to approximate the actual curve to the

target curve as closely as possible.

If needed, the printer gamma curve can be adjusted further manually in the

SP mode. (See section 5, Color Balance Adjustment)

Also, a printer gamma setting can be stored in memory (temporarily or

permanently) and curve can be recalled. When the ACC is performed, the

current printer gamma setting will be automatically stored in the temporary

memory, which can be recalled after the ACC is performed. (See Section 4,

Service Tables, SP Table

.)

2-23

Page 49

IMAGE PROCESSING 10 May 1996

4.6 YMCBk FILTER

In addition to the RGB filter, the most suitable software filter is applied to

YMCBk video signals to improve the image reproduction.

High Contrast filter (emphasizing edges)

•

Smoothing filter

•

Soft

(Smoothing)

Setting 1234567

Applied

Filter Table

Letter

mode

Photo

mode

1234567

0123456

Standard

(Emphasizing Edges)

Sharp

The filter can be selected by the user by adjusting the Sharp/Soft level

(Image Adjustment).

2-24

Page 50

10 May 1996 DEVELOPMENT

5. DEVELOPMENT

5.1 DEVELOPMENT SL EEVE CLEANING

Detailed

Descriptions

A172D506.wmf

To achieve a faster CPM for black and white originals when copying 1 to 1 or

using Auto Color Select (ACS) mode, the development sleeve cleaning mode

previously performed for every original is now performed periodically.

For A4 or smaller size originals, a maximum of 40 black and white copies can

be made without the machine stopping to perform development sleeve

cleaning (20 copies for originals larger than A4 size). If a color original is

detected in between when using ACS mode, the cleaning mode is executed,

and the original counter will be reset. This setting can be changed with SP

mode.

2-25

Page 51

TONER TANK 10 May 1996

6. TONER TANK

6.1 TONER AGITATION

[B]

[A]

A172D503.wmf

Clockwise

Stop

Counter

Clockwise

Clockwise

Stop

Counter

Clockwise

One Cycle

1.0S 0.3 0.30.5S

A172D504.wmf

Cycle12345

Toner End Detection is done here

A172D505.wmf

Under the following conditions, the toner agitator [A] inside each toner tank

rotates to agitate the toner inside the toner tank.

Whenever the main switch is turned on while the hot roller temperature is

•

below 110°C.

After a multi-copy job is completed and more than 50 copies have been

•

made since the last toner agitation.

When the optional ARDF is used, the machine stops the copy cycle after

•

150 copies have been made since the last toner agitation.

When the toner tank is pushed in during a near toner end or toner end

•

condition.

As shown above, one cycle of this agitation consists of rotating in both

directions, and is performed for five consecutive cycles.

In order to prevent unnecessary toner from entering the development unit

during agitation, the transport screw gear [B] has some play before rotation is

transmitted to the transport screw.

2-26

Page 52

10 May 1996 TONER TANK

6.2 TONER END DETECTION

[A]

A172D503.wmf

Four toner end sensors [A] (which are piezoelectric) are installed on the toner

tank to monitor the near end condition for each color toner. Toner end

detection is performed during toner agitation, and the detection sequence is

as follows.

Detailed

Descriptions

1. Near Toner End Condition

The machine starts sampling the output of the toner end sensor every 0.1

second during the last three cycles of the toner agitation process (see the

previous page). If a no toner condition is detected for 90% of the

samples, the machine enters the near toner end condition.

2. Toner End Condition

When a near toner end condition is detected, a total of 30 copies can be

made using the toner for which the near end condition was detected.

After this, the machine enters the toner end condition and copying using

that toner is disabled.

3. Toner End Recovery

When the front door is opened and the toner tank rails are pulled out and

in, the machine starts to perform the toner end recovery procedure. The

sequence and the recovery condition is the same as for the near toner

end condition detection.

If the toner end condition is not cleared, copying using that particular color

toner is disabled. This prevents the customer from clearing the near end or

toner end condition by simply opening and closing the front cover or turning

the main switch off and on.

The green lever which was previously installed to prevent toner from flowing

into the development unit has been eliminated, due to the change in the toner

end detection mechanism.

2-27

Page 53

TRANSFER BELT UNIT 10 May 1996

7. TRANSFER BELT UNIT

7.1 TRANSFER BELT BIAS

Transfer B el t Bi as (Face Side: No rm al H u m idity)

Copy Mode

1C 2C 3C 4C

1st

Dev.

Cycle

2nd

3rd

4th

Transfer Belt Bias Dependi ng on Humidity Range (1C Mode: Face Side)

Bias

1410 1410 1410 1410

1490 1490 1490

1575 1575

1660

2075

1740

1410

Low1 Low2 Low3 Normal High

0 4.3 8.5 11.3 21.5

Humidity (g/m3)

A172D514.wmf

This machine changes the transfer belt bias voltage for every mode and

every copy cycle.

For 1C copy mode, which is more influenced by environmental conditions,

the transfer belt bias output is divided into five ranges by four threshold

values (as mentioned in the table above) and is determined by the output of

the humidity sensor. Only three different bias settings are present as the

factory setting for each environment.

The transfer belt bias voltage data can be monitored in the SP Adjustment

Mode P-5 and 6. These data should not be changed. For more details, see

the SP Mode Section.

2-28

Page 54

10 May 1996 TRANSFER BELT UNIT

7.2 TRANSFER BELT LUBRICATION

[C]

[C]

[E]

[A]

[B]

[E]

[A]

[D]

A172D515.wmf

ON OFF

A172D516.wmf

Detailed

Descriptions

A172/A199

A109

Amount

0 50 100 150

Copy Count

A172D517.wmf

The transfer belt lubricant bar [A] on the transfer belt cleaning unit [B] applies

lubricant directly to the transfer belt [C] after every copy.

The on/off movement of the transfer belt lubricant bar solenoid [D] which is

synchronized with the belt cleaning mechanism, pushes the lubricant bar

against the support roller [E] in the transfer belt unit.

Compared with the previous model, the amount of lubricant applied to the

transfer belt will stay at a constant level for every copy cycle. Because of this,

copy quality problems such as partial blanking of lines (due to incomplete

toner transfer) can be reduced.

2-29

Page 55

TRANSFER ROLLER UNIT 10 May 1996

8. TRANSFER ROLLER UNIT

8.1 TRANSFER BELT/ROLLER HEATER CONTROL

[A]

[B]

[C]

A172D518.wmf

HEATER THERMOSWITCH

A172D519.wmf

The resistance of the transfer roller [A] changes with the environment. It is

especially at low temperatures.

The transfer roller thermoswitch [B] detects the temperature around the

transfer roller. To keep the resistance of the transfer roller at a constant level,

when the detected temperature is 20°C or less, the transfer belt/roller heaters

[C] turn on until the temperature rises above 20°C.

The heaters are not turned on/off by the main switch. The heaters operate

whenever the copier power cord is plugged in.

2-30

Page 56

10 May 1996 TRANSFER ROLLER UNIT

8.2 TRANSFER ROLLER BIAS

<Transfer Roller Bias Coefficient by Humidity Range (1C Mode: Face Side; Normal Paper)>

Bias

1729

1573

Dev.

Cycle

1st

2nd

3rd

4th

(Photo)

4th

(Letter)

1404

1300

1001

Low1 Low2 Low3 Normal High

0 4.3 8.5 11.3 21.5

Transfer R ol ler Bias (Norma l Humidity)

Paper Mode

Normal

Paper

1300 1200 2150 2150 1300 1450

1600 1450 2200 2200 1800 1750

1900 1750 2500 2500 2100 2050

1600 1450 2200 2200 1800 1750

1600 1450 2200 2200 1800 1750

Thick

Paper

OHP:

Sideways

OHP:

Lengthwise

Humidity (g/m3)

A172D520.wmf

Normal:

Back

Thick:

Back

Detailed

Descriptions

The transfer roller bias is determined by the output of the humidity sensor. It

is divided into five humidity ranges by four thresholds, to compensate for

changes in the humidity of surrounding areas to maintain constant copy

quality.

The threshold is divided more towards the low humidity side, resulting in

more sensitivity at the low humidity end. This enables more accurate shift of

the transfer bias with small changes in the environment.

Also, the transfer roller bias is changed for each copy mode and the kind of

copy paper currently used.

NOTE:

All values shown on this page are in volts D.C..

Values shown using SP Mode <1> SP Adjustment, page 7, are in a

data format.

2-31

Page 57

TRANSFER ROLLER UNIT 10 May 1996

8.3 TRANSFER ROLLER LUBRICATION

[A]

[E]

[D]

[B]

[A]

[C]

[D]

A172D539.wmf

The transfer roller lubricant bar [A] above the cleaning blade [B] continuously

applies lubricant directly to the transfer roller [C].

Four spring plates [D] under the transfer roller guide [E] press the lubricant

bar against the transfer roller.

By applying lubricant, the cleaning efficiency of the transfer roller cleaning

blade is increased, which prevents the back side of copies from becoming

dirty with toner and paper dust.

2-32

Page 58

10 May 1996 TRANSFER ROLLER UNIT

8.4 PAPER DISCHARGE

[A]

Detailed

Descriptions

[B]

A172D521.wmf

[C]

[B]

A172D522.wmf

Discharge Plate O utput

Normal Paper Thick Paper Duplex: Fa ce Duplex: Back

4000 V 3500 V 4000 V 4000 V

The high voltage supply board -D [A] applies ac voltage to the discharge

plate [B]. The discharge plate removes any charge remaining on the paper

[C] to separate the paper from the transfer belt.

To perform an accurate discharge, the output of the discharge plate differs

with the copy mode or paper being used. For OHP mode, discharge is not

performed because the OHP sheet separates from the transfer belt as a

result of its stiffness.

2-33

Page 59

FUSING UNIT 10 May 1996

9. FUSING UNIT

9.1 ROLLER CLEANING MECHANISM

[A]

[C]

[B]

[D]

[E]

A172D523.wmf

The cleaning roller [A], which is always in contact with the hot roller [B],

collects the toner and paper dust adhering to the surface of the hot roller. The

collected matter is scraped off by a stainless steel blade [C].

The pressure roller cleaning roller [D], which is always in contact with the

pressure roller [E], collects the toner and paper dust adhering to the surface

of the pressure roller. The pressure roller cleaning roller is driven by physical

contact with the pressure roller.

The pressure roller cleaning roller prevents poor copy quality in duplex mode

(face side) and dirt on the back side of copies in normal mode. It also

prevents horizontal lines from appearing on the back side when making OHP

sheets.

2-34

Page 60

10 May 1996 FUSING UNIT

9.2 FUSING TEMPERATURE CONTROL

Each rollers are controlled at the temperature shown in the table below.

During Copying

Manual Duplex

(Back Side)

Normal:160 Normal:170

Thick

Paper: 170

Thick

Paper: 170

Hot

Roller

Temp.

Pressure

Roller

Temp.

Stand-by

180 160 170 170 170

120 Hot Roll er T em p . - 20 120 120

Normal OHP/Thick Paper

1C 2C, 3C, 4C 1C 2C, 3C, 4C 1C 2C, 3C, 4C

Detailed

Descriptions

2-35

Page 61

OPERATION PANEL 10 May 1996

10. OPERATION PANEL

This operation panel has an LCD (640 x 480 dots). Most of the keys for

functions are displayed on the LCD (Touch panel).