Page 1

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

1

Page 2

1. SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in or der to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

Turn off the main switch before attempting any of the procedures in the

Laser Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

2

Page 3

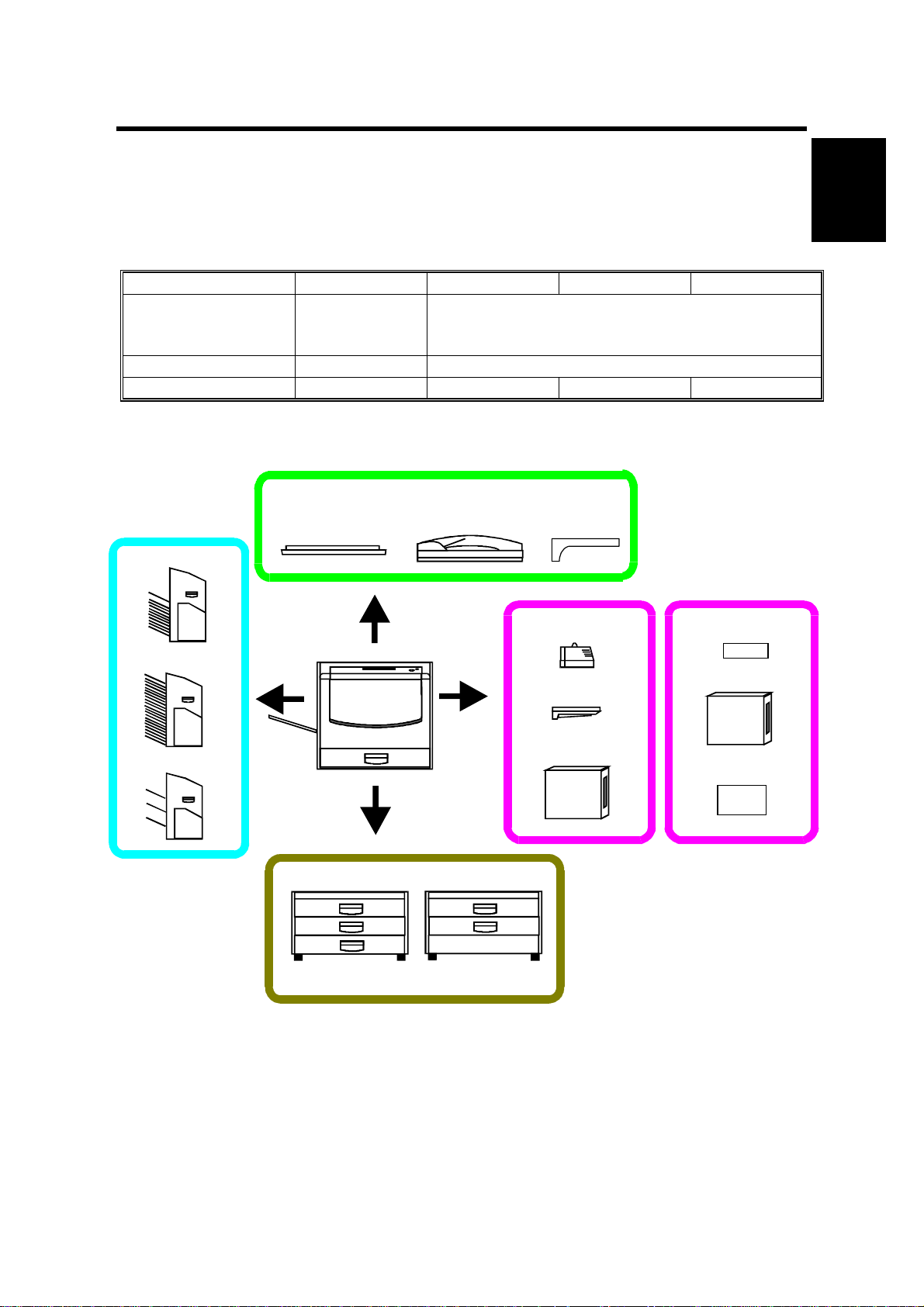

28 August, 2000 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

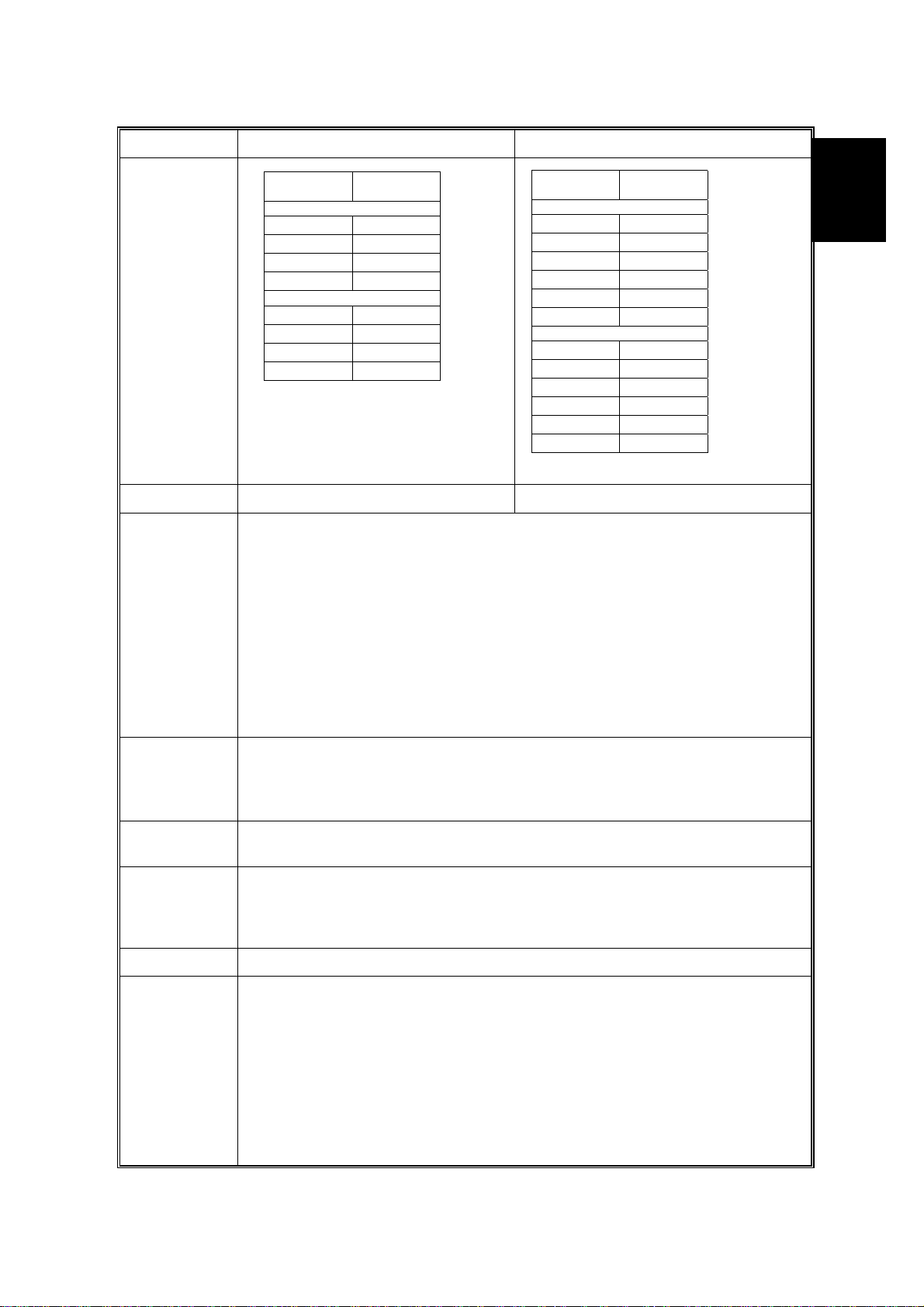

1.1.1 MACHINE CONFIGURATION

A258 / B018

Operation Panel

Paper Tray Unit

Edit Function

Sorter/Stapler

A555

A834

40-digit 4-line

LCD Hard Key

Type

500 sheets Duplex

No No Yes Option

Platen Cover

A749-01

Copier

144 mm x 192 mm (10.4 inch)

Color Touch Panel Display

A259 A260

ARDF

A663

Original Tray

A430-07

A258-259-260 copiers

FPU A846

FPU Table

A702-19

Overall

Information

B017

B017/018 copiers

Editing B380

I/F B381

A849

Paper Tray Unit (500 sheets/tray)

A833

A832

I/F A848

Fax B383

B017V501.WMF

1-1

Page 4

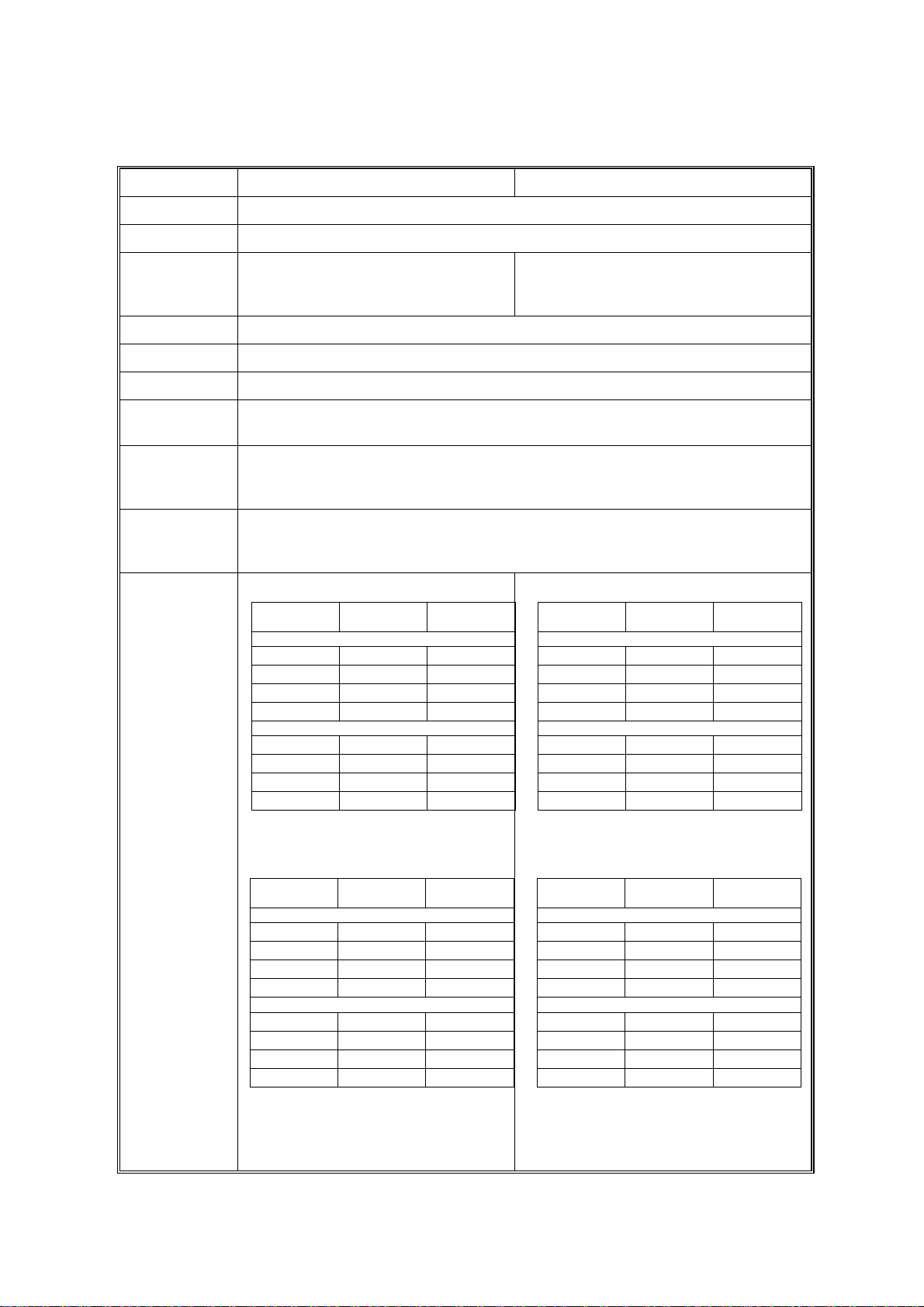

SPECIFICATIONS 28 August, 2000

1.1.2 GENERAL SPECIFICATIONS

A258/A259/A260 B017/B018

Configuration Desktop

Copy Process Dry electrostatics transfer system

Resolution Scan: 400 dpi

Copy mode: 400 dpi

Print mode: 600 dpi

Gradations 256 gradations

Originals Sheet/Book/Object

Original Size Max.: 11”x17”/A3

Copy Paper

Size

Copy Paper

Weight

Paper tray: Max. 11”x17”/A3

By-pass: Max. 12”18”/305x457mm

Paper Tray: 17 to 28 lbs. / 63 to 105 g/m

By-pass: 14 to 43 lbs. / 52 to 160 g/m

Auto duplex: 17 to 28 lbs. / 63 to 105 g/m

Reproduction

Ratios (%)

LT: 400, 200, 155, 129, 121, 100, 93, 85, 78, 73, 65, 50, 25

A4: 400, 200, 141, 122, 115, 100, 93, 82, 75, 71, 65, 50, 25

LT & A4: Programmable: 2 user ratios / Zoom : From 25 to 400 in 1% step

Copy Speed

(cpm)

A258

81/2"x11"

(S) / A4(S)

Normal Mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

OHP/Thick paper mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

63

21 11

94.5

73.5

31.5

52.5

42

3.5 1.5

11"x17" /

A3

Scan: 600 dpi

Copy mode: 600 dpi

Print mode: 600 dpi

2

2

2

B018

Normal Mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

OHP/Thick paper mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

81/2"x11"

(S) / A4(S)

11"x17" /

A3

63

25 13

94.5

73.5

31.5

52.5

42

3.5 1.5

A259/A260

81/2"x11"

(S) / A4(S)

Normal Mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

OHP/Thick paper mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

B017

11"x17" /

A3

63

28 14

94.5

73.5

31.5

52.5

42

3.5 1.5

1-2

81/2"x11"

Normal Mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

OHP/Thick paper mode

F/C

S/C (CMYK)

S/C (BG)

S/C (R)

(S) / A4(S)

31 15

3.5 1.5

11"x17" /

A3

63

94.5

73.5

31.5

52.5

42

Page 5

28 August, 2000 SPECIFICATIONS

A258/A259/A260 B017/B018

First Copy

Time

81/2"x11" (S) /

A4

Warm-up Time

Duplexing:

A258/B017:

Manual

Duplex

A259/A260/

B018:

Auto Duplex

81/2"x11"

Normal Mode

F/C

S/C (K)

S/C (CMY)

S/C (BGR)

OHP/Thick paper mode

F/C

S/C (K)

S/C (CMY)

S/C (BGR)

(S) / A4

22.4

8

10

16

35

23

25

27

Approx. 7 minutes (at 68°F / 20°C)

Manual duplexing in full color and single

color modes

Manual & auto duplexing in full color and

single color modes

Manual & auto duplexing in full color and

single color modes

Duplexing can be done on 64-105 g/m

2

81/2"x11"

Normal Mode

F/C

S/C (K)

S/C (CMY)

S/C (B)

S/C (G)

S/C (R)

OHP/Thick paper mode

F/C

S/C (K)

S/C (CMY)

S/C (B)

S/C (G)

S/C (R)

(S) / A4

22.4

8

10

19

16

16

35

23

25

30

27

27

Approx. 4.5 minutes (at 68°F / 20°C)

paper.

Overall

Information

Manual duplexing can be done through the

bypass table only, and the user should press

the Duplex Side 2 key before copying the reverse side.

NonReproduction

Area:

Leading edge: 0.2" ± 0.08" (5 mm ± 2 mm)

Side: 0.08" ± 0.08" (2 mm ± 2 mm)/

Total less than 0.16" (4 mm)

Trailing Edge: 2.0 mm + 2.0/-1.5 mm

Copy Number

Number keys, 1 to 99

Input

Copy Number

Input (Auto

Number keys

Single Color - 1 to 50: smaller than A3, 11" x 17"

Duplex)

Full Color 1 to 20: all sizes

Image Density Auto/Manual (9 steps)

Paper

Capacity

Tray:

500 sheets x 1 tray

(Manual Duplex Models: A258 / B018)

Bypass:

Normal paper (80 g/m

OHP 20 sheets

Adhesive paper 1 sheet

1 to 30: A3, 11" x17"

2

/20 lb.) 50 sheets

1-3

Page 6

SPECIFICATIONS 28 August, 2000

A258/A259/A260 B017/B018

Toner

Toner Addition (K, Y, C, M) (220 g/cartridge)

Replenishment

Copy Tray

100 sheets (11" x 17"/A3 and smaller)

Capacity

Power Source US: 120V/12A/60Hz,

Europe/Asia: 220-240V/8A/50,60 Hz

Taiwan: 110 V/12A/60Hz

Power

Consumption

Sound Power

Level

Maximum: 1.5 kVA

Average power consumption:

Stand-by 0.4 kW

Warm-up 1.3 kW

Copying 1.1 kW (B/W A4S)

Energy Saver Mode Value for standby minus 25W

Copier only Full system*

Stand-by Less than

55 dB (A)

Copying Less than

68 dB (A)

Full system:

Copier with document feeder, 500 sheets

x 3 trays unit, FPU, and a sorter stapler

0.6 kW (F/C A4S)

Less than

59 dB (A)

Less than

72 dB (A)

Copier only Full system*

Stand-by Less than

50 dB (A)

Copying Less than

68 dB (A)

Full system:

Copier with document feeder, 500 sheets x

3 trays unit, and a sorter stapler

Less than

54 dB (A)

Less than

72 dB (A)

Dimensions

(W/O Platen

Cover)

A258

A259

A260

Width Depth Height

620 mm

24.4"

620 mm

24.4"

620 mm

24.4"

680 mm

26.8"

757 mm

29.8"

757 mm

29.8"

602 mm

23.7"

602 mm

23.7"

602 mm

23.7"

Weight A258: 105 kg (231.3 lbs.)

A259/A260: 108 kg (237.9 lbs.)

Optional

Equipment

ARDF: A663

Sorter Stapler: A555 (10 bins)

A834 (20 bins)

Sorter: A849 (3 bins)

FPU: A846

FPU Holder: A702-19

Paper Tray Unit: A832 (2 trays)

A833 (3 trays)

I/F Unit: A848

RC-200: G528

Platen Cover: A749-01

Original Tray: A430-07

Key Counter

Width Depth Height

B018

B017

620 mm

24.4"

620 mm

24.4"

680 mm

26.8"

757 mm

29.8"

620 mm

24.4"

620 mm

24.4"

B018: 108 kg (237.6 lbs.)

B017: 112 kg (246.4 lbs.)

ARDF: A663

Sorter Stapler: A555 (10 bins)

A834 (20 bins)

Sorter: A849 (3 bins)

FPU: FPU Holder: Paper Tray Unit: A832 (2 trays)

A833 (3 trays)

I/F Unit: B381

RC-210: G549

Platen Cover: A749-01

Original Tray: A430-07

Key Counter

1-4

Page 7

28 August, 2000 SPECIFICATIONS

A258/A259/A260 B017/B018

- for B017 only –

Unique:

Edit Option: B380-01

Fax Option: B383

EXSAF Board: A818-10

HDD: A841-11

Fax Stamp(NA only): A563-17

Common with A230/231/232:

ISDN Unit: A816-27

PMU Board: A818-12

ISDN Unit: A816-27

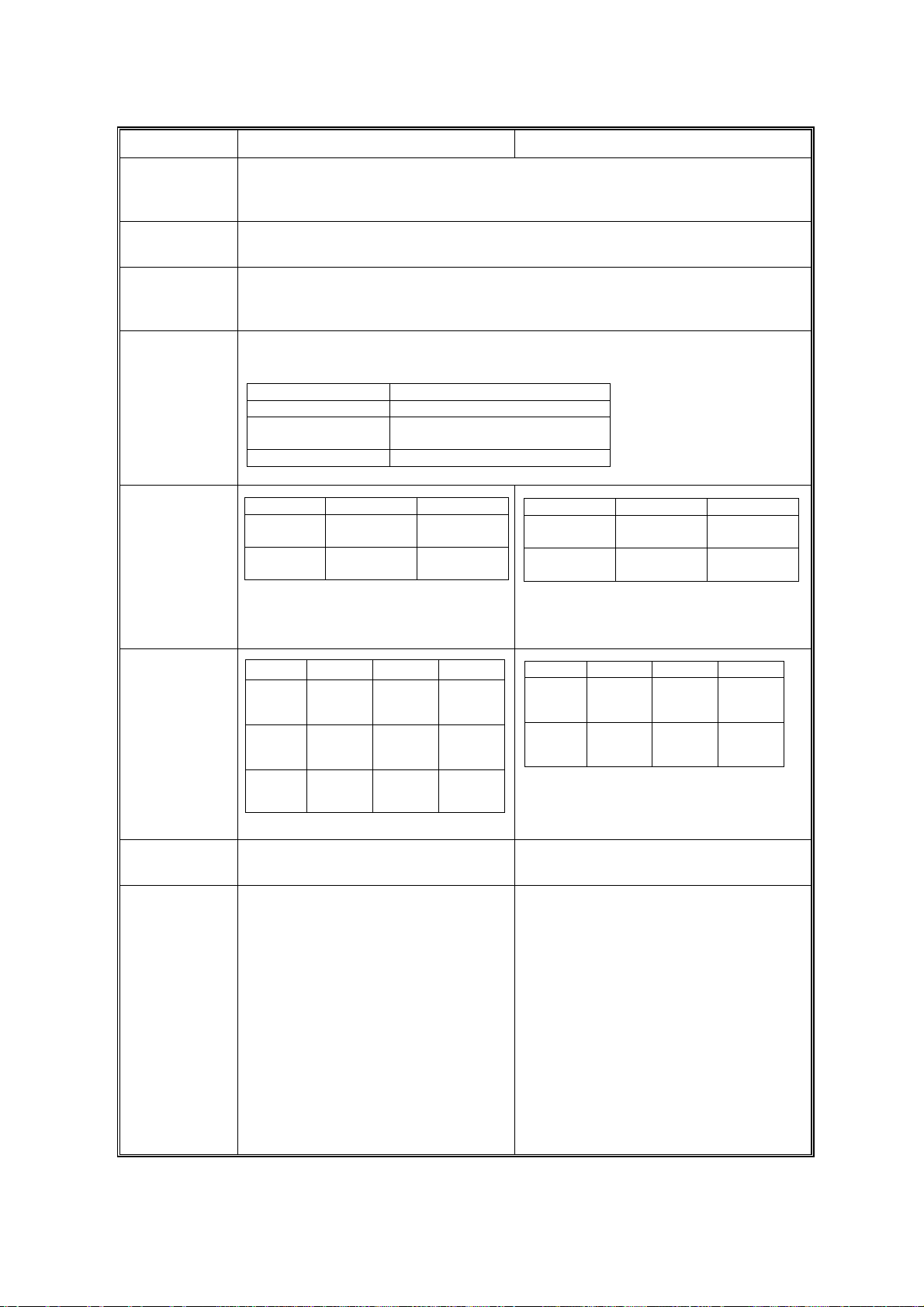

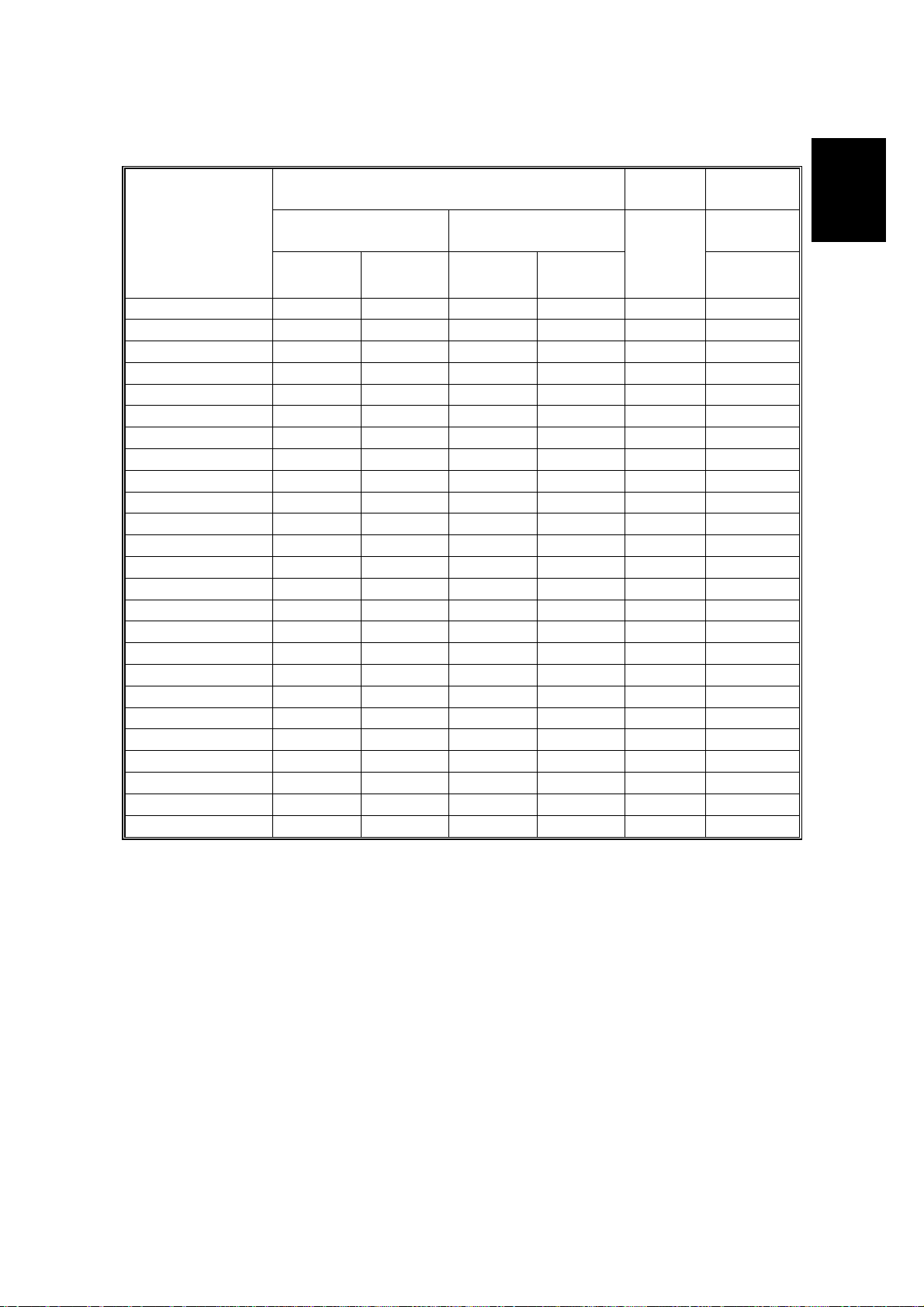

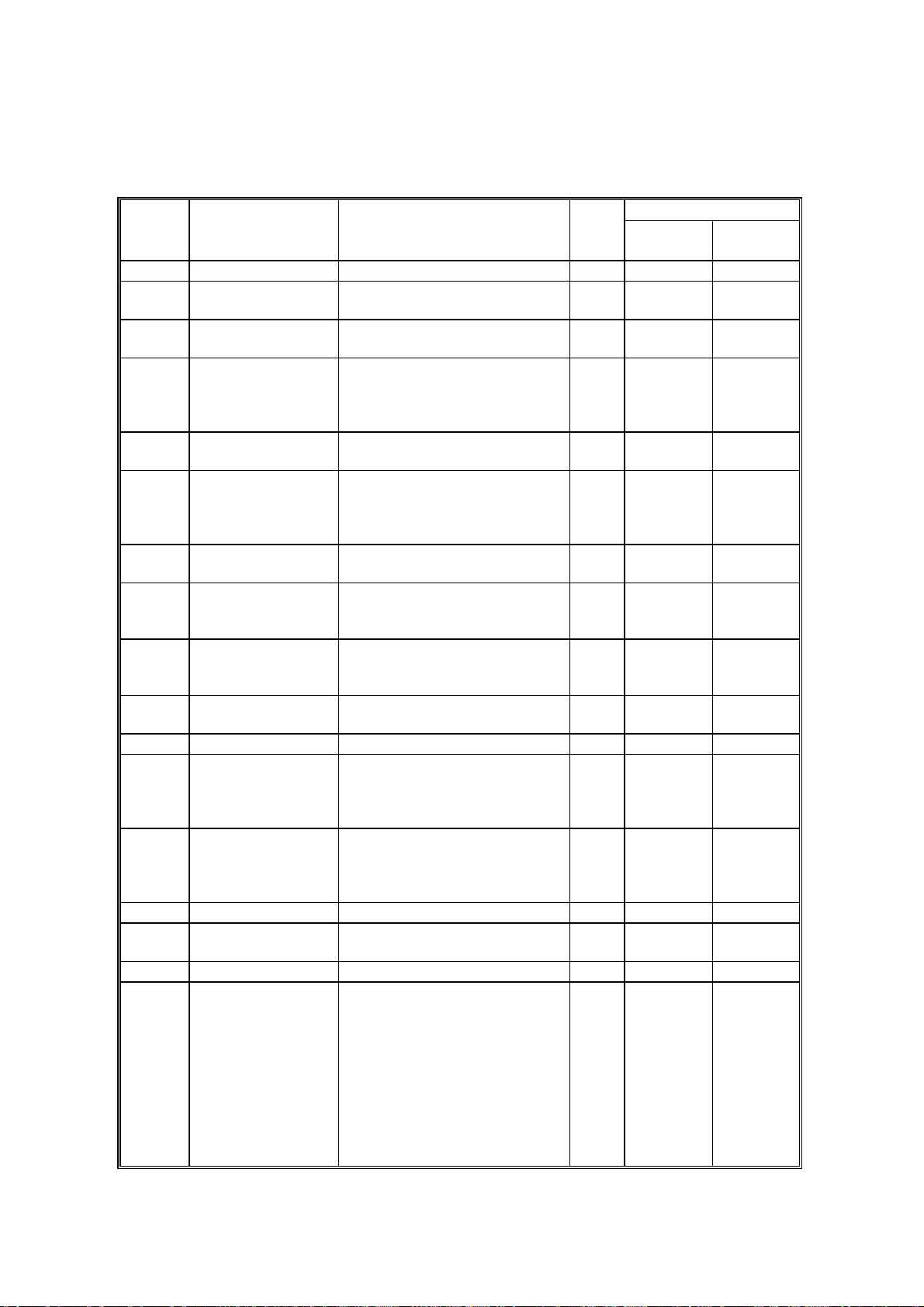

Options: Compatibility Table

OK: Can be installed

N/A: Not applicable

ARDF ARDF A663 OK

Sorter

Tray

Fax

Other

10 Bin S/S A555 OK

20 Bin S/S A834 OK

3 Bin Sorter A849 OK

2 Tray Unit A832 OKPaper

3 Tray Unit A833 OK

FPU A846 OKFPU

FPU Table A702-19 OK

I/F (Type E) A848 OK N/AI/F

I/F (Type H) B381 N/A OK

RC-200 G528 OK N/AController

RC-210 G549 N/A OK OK

Fax Option B383 N/A OK

Fax HDD A841-11 N/A OK

Handset A841-13 N/A OK

G4 Option A816-17 N/A OK

JBIG Option A818-12 N/A OK

SAF Memory A818-10 N/A OK

Fax Stamp A563-17

Platen Cover A74 9-01 OK

Original Tray A430-07 OK

Edit Option B380 N/A OK

A258 A259 A260 B018 B017

NA

Overall

Information

N/A

N/A OK

1-5

Page 8

SPECIFICATIONS 28 August, 2000

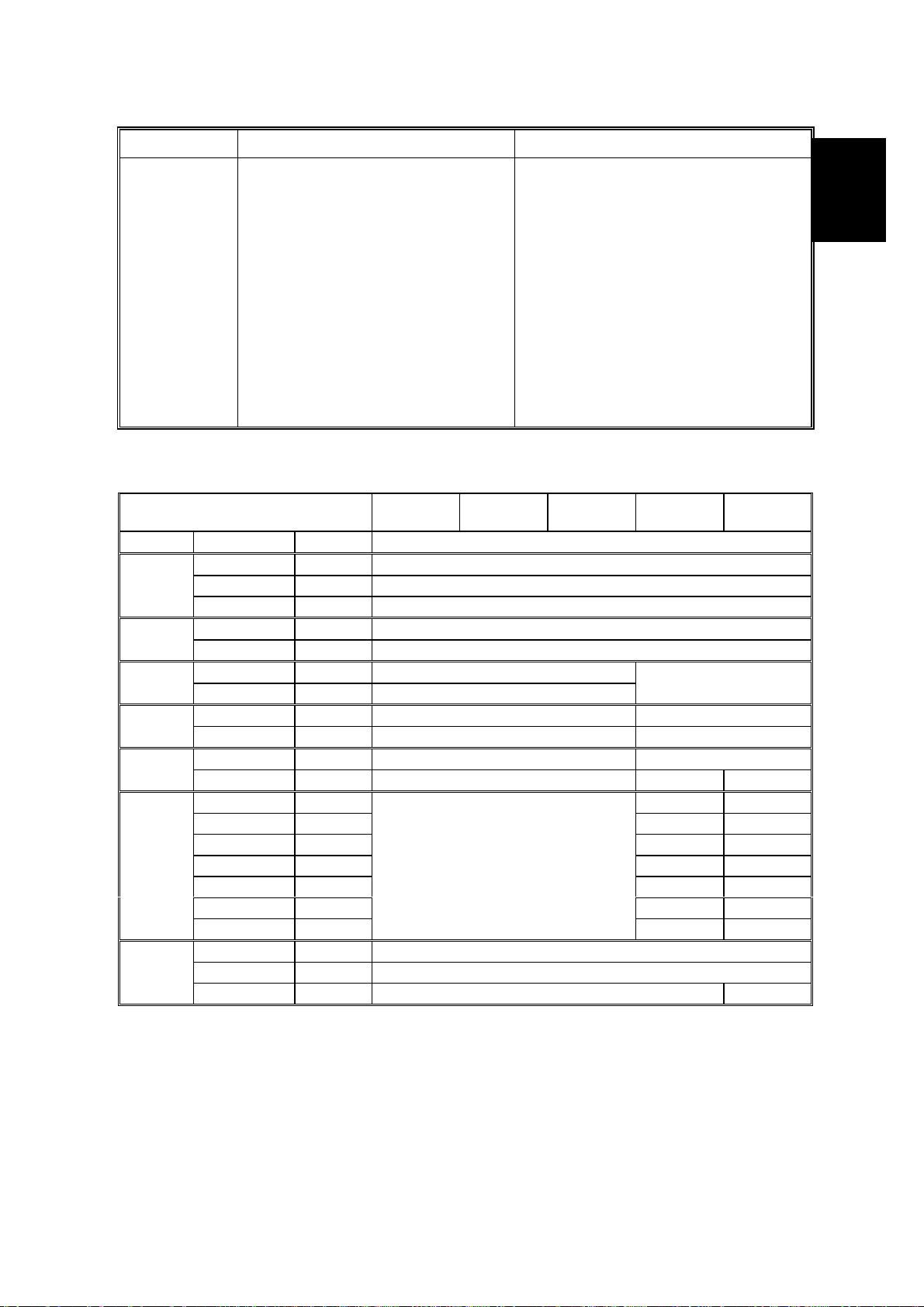

1.1.3 PLATEN/ARDF ORIGINAL SIZE DETECTION

Size (width x length)

[mm]

A3 (297 x 420) L No Yes No Yes

B4 (257 x 364) L No Yes No Yes

A4 (210 x 297) L No Yes Yes Yes

A4 (297 x 210) S No Yes Yes Yes

B5 (182 x 257) L No Yes No Yes

B5 (257 x 182) S No Yes No Yes

A5 (148 x 210) L No No* No Yes

A5 (210 x 148) S No No No Yes

B6 (128 x 182) L No No No Yes

B6 (182 x 128) S No No No Yes

11" x 17" (DLT) Yes No Yes Yes

11" x 15" No No Yes No

10" x 14" No No Yes Yes

8.5" x 14" (LG) Yes No Yes No

8.5" x 13" (F4) No No Yes Yes

8.25" x 13" No No No No

8" x 13"(F) No Yes Yes No

8.5" x 11" (LT) Yes No Yes Yes

11" x 8.5" (LT) Yes No Yes Yes

8" x 10.5" No No No No

8" x 10" No No Yes No

5.5" x 8.5" (HLT) No* No Yes No

8.5" x 5.5" (HLT) No No Yes No

A6 (105 x 148) L No No No No

Inches Metric Inches Metric

Platen ARDF

*: When the message “Cannot detect original size” appears use SP4-303 to detect

original sizes as A5 lengthwise/HLT.

*: This SP mode is only applic able for B017/018 copiers.

1-6

Page 9

28 August, 2000 SPECIFICATIONS

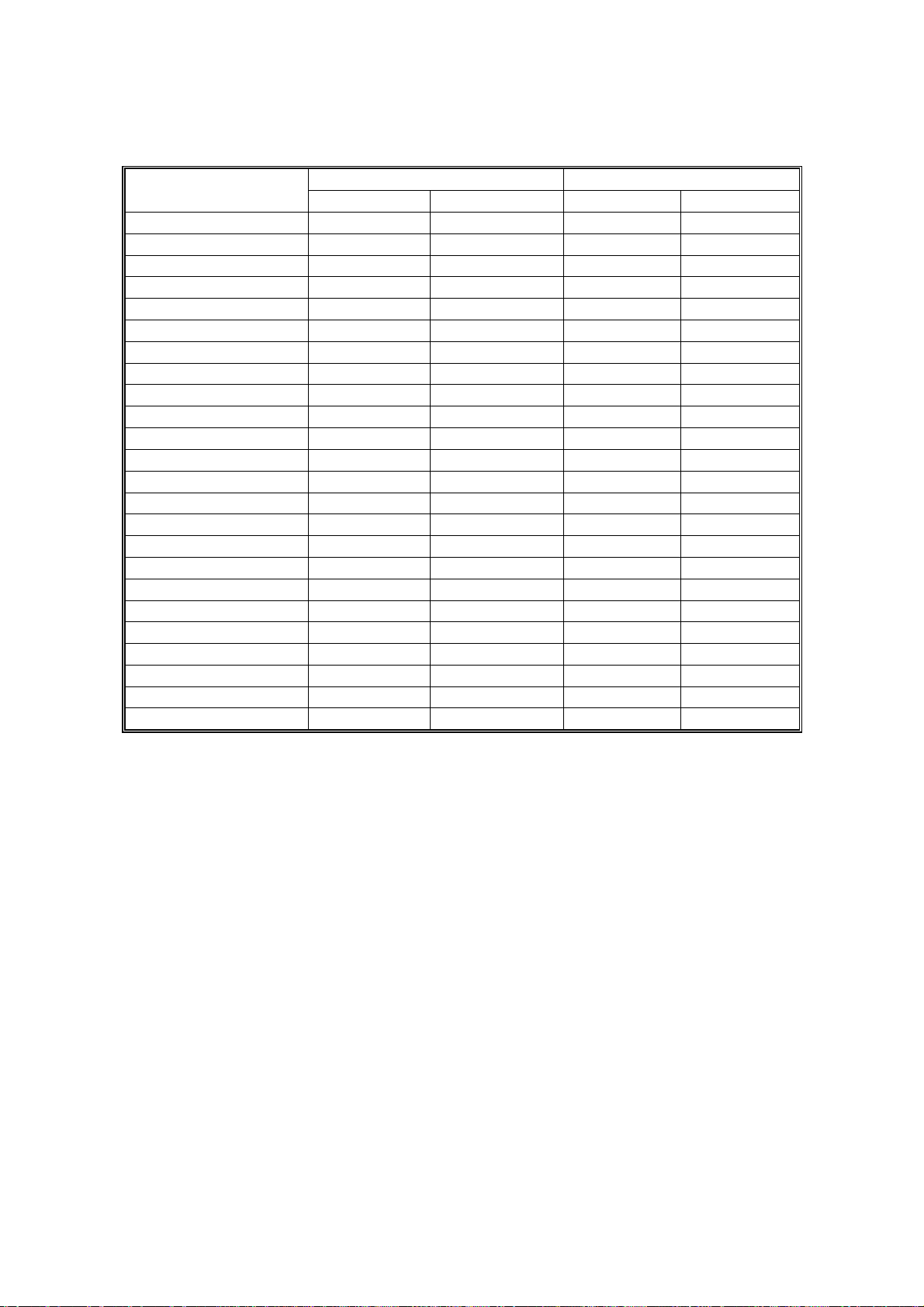

1.1.4 COPY PAPER SIZE

Size

(width x length)

[mm]

Trays in the main body

Paper Tray

(A258/B018)

Duplex Tray

(A259/A260/B017)

Inches Metric Inches Metric

By-

pass

All

versions

Optional

Sort/Stap.

A3 (297 x 420) L No Yes Yes Yes Yes Yes

B4 (257 x 364) L No Yes Yes Yes Yes Yes

A4 (210 x 297) L Yes Yes Yes Yes Yes Yes

A4 (297 x 210) S Yes Yes Yes Yes Yes Yes

B5 (182 x 257) L No Yes No Yes Yes Yes

B5 (257 x 182) S No Yes No Yes Yes Yes

A5 (148 x 210) L No Yes No No Yes Yes (1)

A5 (210 x 148) S No No Yes Yes Yes Yes (2)

B6 (128 x 182) L No No No No Yes Yes (1)

B6 (182 x 128) S No No No No No No

12” x 18” No No No No Yes Yes (3)

11" x 17" (DLT) Yes Yes Yes Yes Yes Yes

11" x 15" Yes No Yes No Yes Yes

10" x 14" Yes No Yes No Yes Yes

8.5" x 14" (LG) Yes No Yes No Yes Yes

8.5" x 13" (F4) Yes Yes Yes Yes Yes Yes

8.25" x 13" No No Yes Yes Yes Yes

8" x 13"(F) No No Yes Yes Yes Yes

8.5" x 11" (LT) Yes Yes Yes Yes Yes Yes

11" x 8.5" (LT) Yes Yes Yes Yes Yes Yes

8" x 10.5" No No Yes No Yes Yes

8" x 10" Yes No Yes Yes Yes Yes

5.5" x 8.5" (HLT) No No No No Yes Yes (1)

8.5" x 5.5" (HLT) Yes No Yes Yes Yes Yes (2)

A6 (105 x 148) L No No No No Yes Yes (2)

Overall

Information

Yes (1): Stapling is not possible.

Yes (2): Only with the proof tray. Sorter bins cannot be used.

Yes (3): 20-bin sorter (A834): Stapling is not possible.

10-bin sorter (A555): Not available

1-7

Page 10

SPECIFICATIONS 28 August, 2000

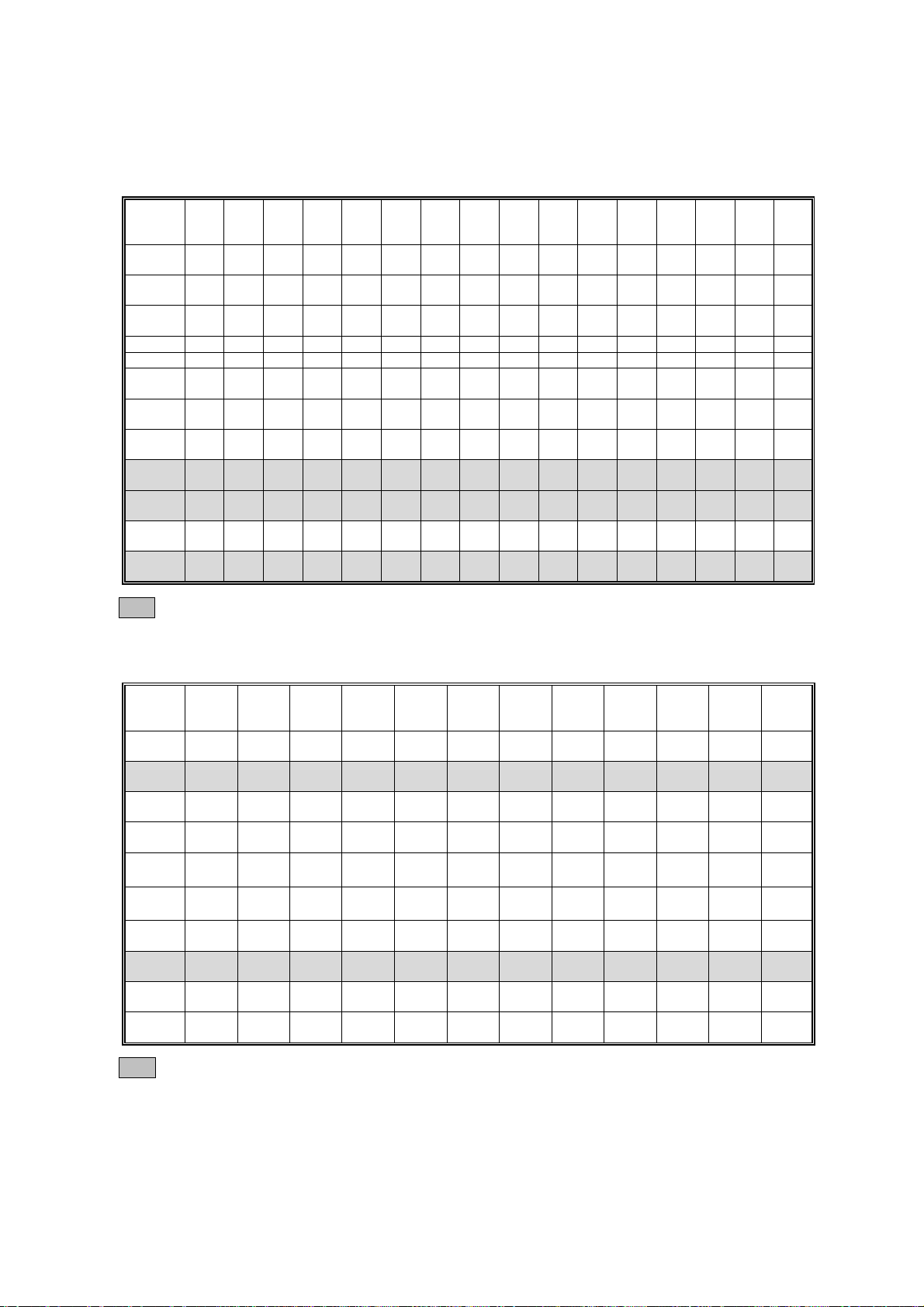

1.1.5 APS PAPER SIZES AVAILABLE

— For metric machines —

Zoom.

Ratios

A3

B4

A4L

B5L

A5L

A4S

B5S

A5S

8.5

x 11

11

x 8.5

8.5

x 13

11

x 15

200

173

163

141

122

115

100

93

87

82

75

71

65

61

57

~

~

~

~

~

~

~

~

~

~

~

~

~

174

164

142

123

116

101

94

88

83

76

72

66

——————A3—B4——A4L

8.5

—————A3B4——A4L

———A3B4—A4L

——A3B4—A4LB5L——A5L——————

A3B4—A4LB5L—A5L—————————

——————

S

A4SB5

—

—————

———

— — — — — —

— — — — — —

————A3—

— — — — — —

A4SB5

8.5

B5L——A5L————

x13

A4

S

S

A5

S

8.5

x11

11

x8.5

8.5

x13

11

x15

B5

—

——

—————————

— — — — — — — — —

— — — — — — — — —

——A4LB5L————A5L

— — — — — — — — —

S

——

A5

S

B5L — — A5L —

x13

A5

S

——————

~

62

58

8.5

B5L — A5L

x13

————

50

~

51

~

: Unavailable in platen cover mode. L: Lengthwise S: Sideways

— For standard machines (in inches)—

Zoom

Ratios

11x17

11x15

8.5x14

8.5x11

5.5

x8.5

8.5

x5.5

11x8.5

8x10

10x14

8x13

200

~

177

—————11x1711x1711x15

— — — — — 11x15 11x15 —

————

— — 11x17 —

11

x17

———

—————

— — — 11x17 10x14 8x10 — — — —

—————10x14—

———11x17—8x13————

176

~

156

11

x15

155

~

130

8.5

x14

129

~

122

8.5

x11

11

x8.5

121

~

101

11

x17

—

—

100

~

94

8.5

x14

8.5

x11

5.5

x8.5

8.5

x5.5

11

x8.5

93

~

86

——

————

——————

——————

————

85

~

78

8.5

x14

77

~

75

8.5

x14

8.5

x14

8.5

x11

8.5

x11

74

~

66

—

8.5

x11

——

——

65

~

51

8.5

x11

—

5.5

x8.5

8.5

x5.5

5.5

x8.5

5.5

x8.5

50

~

5.5

x8.5

5.5

x8.5

5.5

x8.5

—

—

—

5.5

x14

—

: Unavailable in platen cover mode.

1-8

Page 11

28 August, 2000 SPECIFICATIONS

NOTE: 1) The tables indicate the copy paper size for each original for 50 to 200 %

zoom ratios.

2) After specifying a zoom ratio, APS automatically selects a paper size if

there is an equivalent paper size available, that guarantees the quality

of the magnified copy image.

3) If there is no paper that corresponds to the detected size, the machine

displays the message "Set xx paper in tray" and stops the job (copying

is still possible).

4) For "—" in the above tables, the machine displays the message "Cannot

detect original size" and stops the job (copying is still p ossible). The

selected paper feed tray does not change.

5) When less than 49% or more than 201% is selected, APS behaves in

accordance with note 4 above.

6) APS also supports the by-pass feed table (except for non-standard

paper sizes). When the paper size selected by APS can only be fed

from the by-pass feed table, the machine displays a warning to instruct

the user to use the by-pass feed table.

7) APS does not support A6, B6, and A5.

Overall

Information

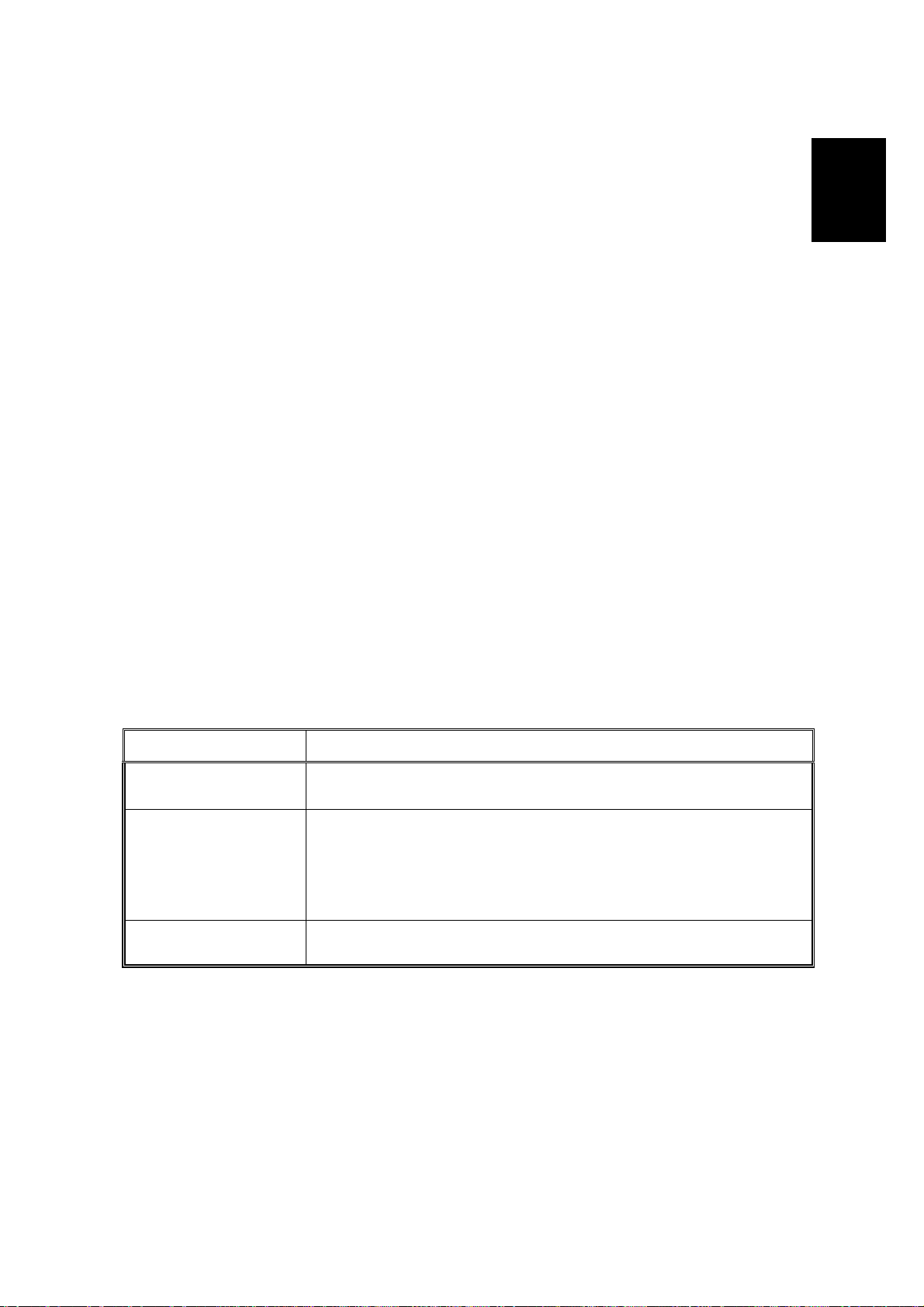

1.1.6 DISPLAY EDITOR SPECIFICATIONS

Function

Scanned image

Displayed image

Area specification

procedure

Specifications

• The scanner scans the image.

• Maximum A3/DLT (11" x 17"): Reduced image display

• 144 x 192 mm, 256 colors (8 bits/dot)

• 640 x 480 dots, 0.33 mm/dot

Reduces the dpi of scanned images to approximately 25

dpi and displays the entire image

• Zoom display: 4 levels (200%, 264%, 400%, 528%)

• Move the arrow on the screen by using the cursor key

and enter a point by pressing the coordinate entry key.

1-9

Page 12

MECHANISM OVERVIEW 28 August, 2000

1.2 MECHANISM OVERVIEW

1.2.1 IMAGE GENERATION PROCESS

10

11

9

12

1

2

3

4

5

8

1. Drum Charge

2. Quenching

3. Drum Cleaning

4. PPC (Pre-cleaning Corona)

5. Belt Transfer

6. Paper Transfer

B017V110.WMF

67

7. Paper Separation Corona

8. Belt Cleaning Unit and Lubricant

Application Brush

9. ID Sensor

10. Development

11. Potential Sensor

12. Laser Exposure

1-10

Page 13

28 August, 2000 MECHANISM OVERVIEW

(1) Drum Charge

The charge corona applies a negative charge to the OPC drum and the charge grid

ensures that this charge is even.

- B017/018 -

• A new charge corona cleaner was adopted to keep the charge wire and charge

grid clean. The cleaner starts automatically when the main switch is turned on

and if the fusing temperature is less than 100oC.

(2) Quenching

After cleaning, the OPC is fully exposed to light from an array of red LEDs, which

quench the residual charge on the OPC drum in preparation for the next copy

cycle.

(3) Drum Cleaning

The cleaning brush increases drum cleaning efficiency by applying lubricant to the

OPC drum. The cleaning blade scrapes the residual toner off the OPC drum.

Overall

Information

(4) PCC (Pre-cleaning Corona)

The PCC lowers the charge on the photoconductor drum by applying AC and

negative DC to improve the efficacy of the cleaning brush.

(5) Belt Transfer

Positive charge applied to the back of the transfer belt transfers the toner image on

the OPC drum to the transfer belt.

- B017/018 -

• The electrical resistance of the belt varies from belt to belt and directly influences

the image transfer belt bias. To optimize the image transfer belt bias a Current

Feedback System was adopted to correct the current fluctuation caused by the

variation of the electrical resistance on the belt.

• Another solenoid was added to the image transfer belt unit to keep the belt away

from the drum between copy jobs. This helps prevent drum fatigue from residual

voltage on the belt.

1-11

Page 14

MECHANISM OVERVIEW 28 August, 2000

(6) Paper Transfer

The negatively charged toner image is transferred to the paper by giving a positive

charge to the back of the paper while the paper and transfer belt are held in close

contact.

- B017/018 -

• A brush was added to the image transfer belt unit to help push the belt down.

This enables toner on the transfer belt to transfer onto the paper before the

electrical field between the transfer belt and roller affects it. This helps to

decrease the amount of scattered toner on printouts.

(7) Paper Separation Corona

After transfer, the separation corona quenches the negative charge on the paper to

reduce the attraction between the belt and paper. The curvature of the belt causes

the paper to separate from the transfer belt.

(8) Belt Cleaning Unit and Lubricant Application Brush

The brush applies lubricant, which makes it easier for the belt cleaning blade to

scrape excess toner off the transfer belt.

(9) ID Sensor

The ID sensor detects the density of the sensor patches developed on the OPC

drum. The signal from the ID sensor is used for process and toner supply control.

- B017/018 -

• A thermistor has been added to the ID sensor board. The thermistor corrects the

output from the ID sensor depending on the temperature. This supplies more

reliable data for better toner density control.

(10) Development

The latent image on the drum attracts the negatively charged toner. Toner is

preferentially attracted to those places on the drum surface where the laser

reduced the negative charge. The development units for each color are included in

the revolver unit.

- B017/018 -

• A High frequency alternating current is applied to the development bias to

optimize development. This improves the quality of grainy images.

1-12

Page 15

28 August, 2000 MECHANISM OVERVIEW

(11) Potential Sensor

The potential sensor detects the electrical potential (the strength of the electric

field) on the photoconductor dru m for process contr ol .

(12) Laser Exposure

The polygon mirror reflects the laser beam emitted from the laser diode and

projects it onto the drum through the f-theta lens, drum mirror, and toner shield

glass. The intensity of the laser output varies in correspondence with the image

data. This process creates the latent image on the drum.

- B017/018 -

• The laser power was adjusted to achieve uniform side-to-side laser power. This

causes the laser power to be applied evenly across the drum surface.

• Pulse positioning control was adopted to make the image appear smoother.

Overall

Information

1-13

Page 16

MAJOR UNIT LAYOUT AND PAPER FEED PATH 28 August, 2000

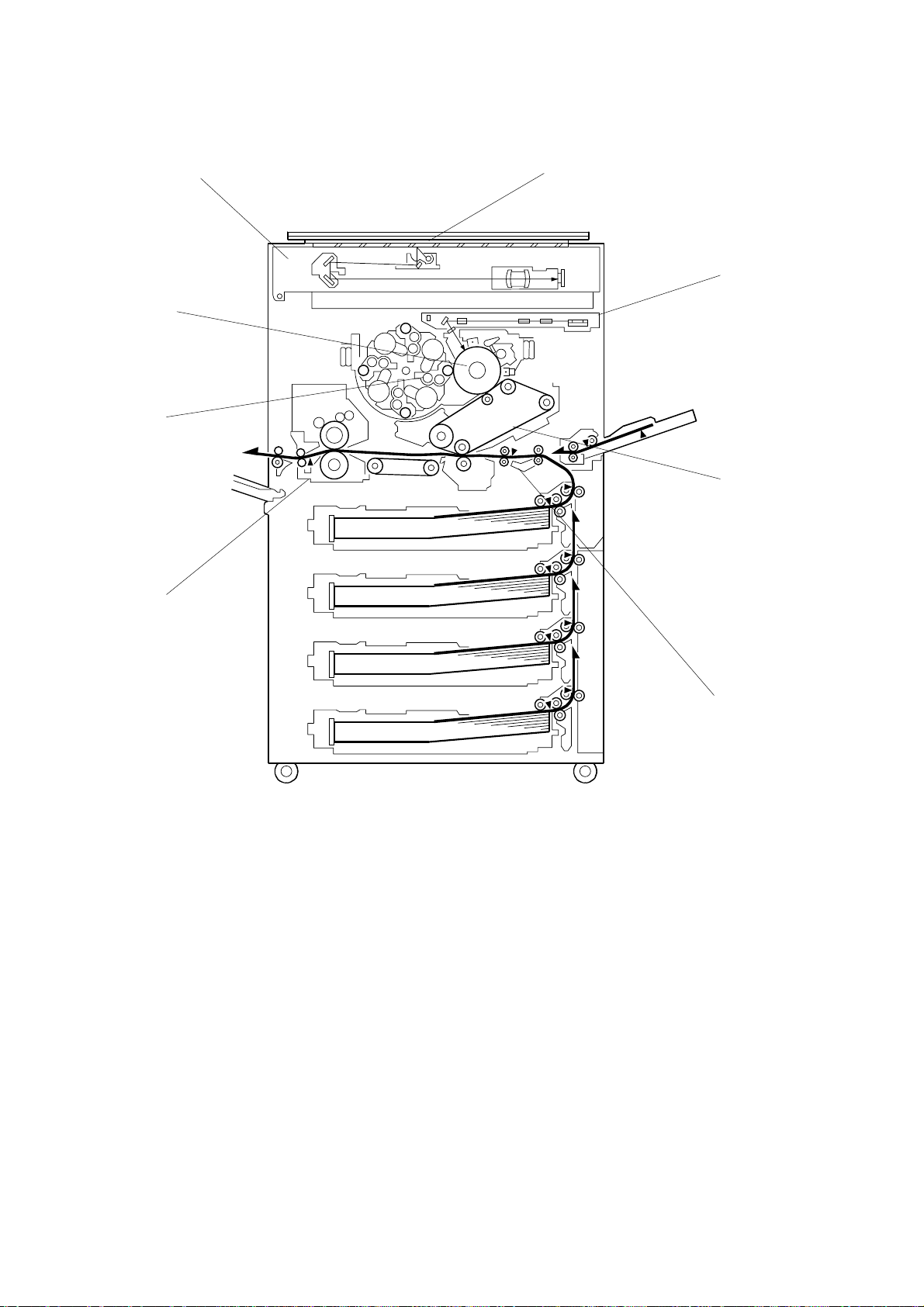

1.3 MAJOR UNIT LAYOUT AND PAPER FEED PATH

1

2

3

8

7

4

6

B017V109.WMF

(1) Scanner

• 400 dpi, 10-bit scanning in both main and sub-scan directions

(A258/259/260)

• 600 dpi, 10-bit scanning in both main and sub-scan directions (B017/018)

• 3-line CCD

• Halogen exposure lamp

• 5-phase stepper motor drive

• Dual-side continuous scan (A4) support (in continuous copy mode)

• One scan copy in mono-toner color multi-copies (B017/18)

(2) Operation panel (A259, A260, and B017)

• 10.4-inch (640 x 480) color LCD (8-bit) touch-panel

• An additional operation panel is installed when the printer controller is

installed.

5

1-14

Page 17

28 August, 2000 MAJOR UNIT LAYOUT AND PAPER FEED PATH

(3) Laser unit

• Optics: 6-sided polygon mirror + 2 f-theta lenses + BTL

• Polygon mirror motor (24,5 67 rpm) with oil bearing (A258/259/260)

• Polygon mirror motor (36,8 50 rpm) with oil bearing (B017/018)

• 400 dpi (8 bits per pixel for each color) in copy mode

600 dpi (8 bits per pixel for each color) in printer mode (A258/259/260)

• 600 dpi (8 bits per pixel for each color) in both the copy and printer modes

(B017/018)

• Modulation: PM + PWM

• Laser power correction (B017/018)

• Image rotation feature (B017/018)

(4) Transfer belt

• Transfer belt: Always in contact with the drum (A258/259/260)

• Transfer belt: In contact with drum during copy process (B017/018)

• Belt transfer: Indirect application of voltage with a roller

• Paper transfer: Roller transfer

• Registration: Synchronization by the transfer belt H.P. sensor

• Drive: Synchronized with the drum (same motor)

• Separation: Curvature separation + corona unit

• Transfer cycle: 1 belt rotation/A4, 2 rotations/A3

• Belt cleaning: Counter blade

• Lubrication: Brush roller with lubricant bar

• Bias control: Current feedback system (B107/018)

Overall

Information

(5) Paper feed/transport system

• Paper feed (A258/B018)

Front loading 500 sheets, 1-layer tray + by-pass feed

• Transport: Transport belt + fan

• Duplexing: Duplex unit installed as a standard component (A259/A260/B017)

• Paper tray (optional): Holds 500 sheets x 2 trays or 500 sheets x 3 trays.

(6) Fusing and paper exit

• Fusing: Silicone roller fusing (A258/259/260)

Fusing: Silicone belt and roller fusing (B017/018)

• Oil application method: Double roller system

• Cleaning: Cleaning rollers (for hot and pressure rollers) (A258/259/260)

Europe/Asia: Cleaning roller for hot roller, cleaning blade for pressure roller

• Cleaning: Tension roller for fusing belt, blade and pad for pressure roller.

(B017/018)

• OHP/thick paper speed change

1-15

Page 18

MAJOR UNIT LAYOUT AND PAPER FEED PATH 28 August, 2000

(7) Development and toner supply

• Development: Two-component magnetic brush d evelopment

• Development switching: Revol ver system

• Image density control: ID sensor + process control

• Toner supply: Screw-in bottle (220 g)

• Toner supply unit: Front of developer unit (rotation type)

(8) Drum unit

• The drum unit contains the photoconductor drum, charge corona unit, and

cleaning unit.

• Charge corona unit: Single-wire scorotron

• Quenching lamp: LED array

• Drive: Synchronized with the transfer belt (DC brushless motor + flywheel)

• Potential sensor included

1-16

Page 19

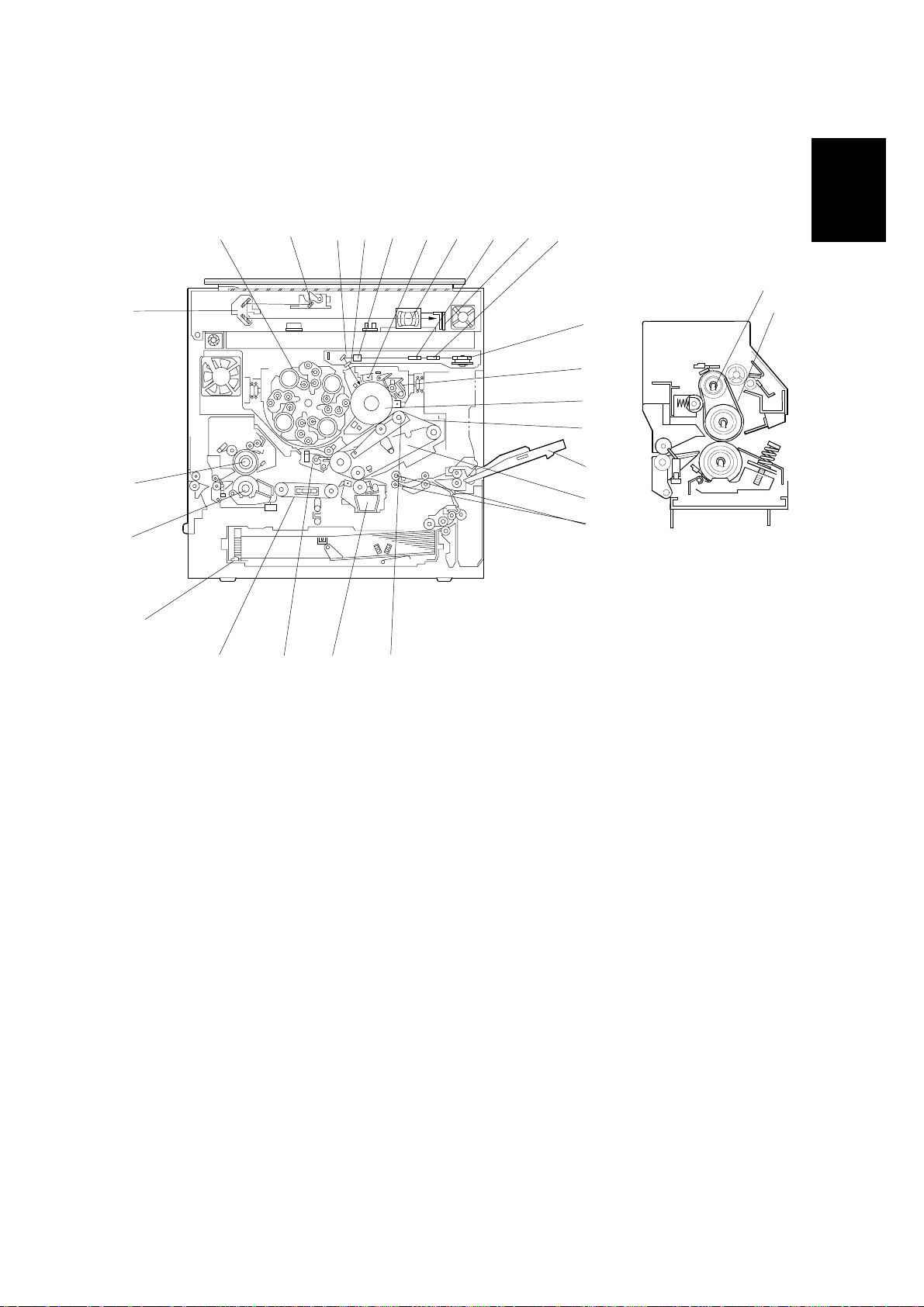

28 August, 2000 PARTS LAYOUT

1.4 PARTS LAYOUT

1.4.1 MECHANICAL COMPONENT LAYOUT

56789111314

4

3

1210

27

26

15

16

17

18

19

20

Overall

Information

2

1

22232425

1. Paper Tray (A258/B018)/Duplex Tray

(A259/A260/B017)

2. Pressure Roller

3. Hot Roller

4. 2nd Scanner

5. Revolver Develop m ent Unit

6. 1st Scanner

7. Drum Mirror

8. Toner Shield Glass

9. BTL (Barrel Torroidal Lens)

10. Charge Corona Unit

11. Scanner Lens

12. 2nd F-theta Lens

13. CCD Board

21

B017V113.WMF

B017V108.WMF

14. 1st F-theta Lens

15. Polygon Mirror

16. Drum Cleaning Unit

17. OPC Drum

18. Image Transfer Belt (ITB)

19. By-pass Feed Table

20. Image Transfer Belt Un it

21. Registration Roller

22. Transfer Belt Bias Rol ler

23. Paper Transfer Unit

24. Belt Cleaning Unit

25. Transport Belt

26. Fusing Belt (B017/018)

27. Heat Roller (B017/018)

1-17

Page 20

PARTS LAYOUT 28 August, 2000

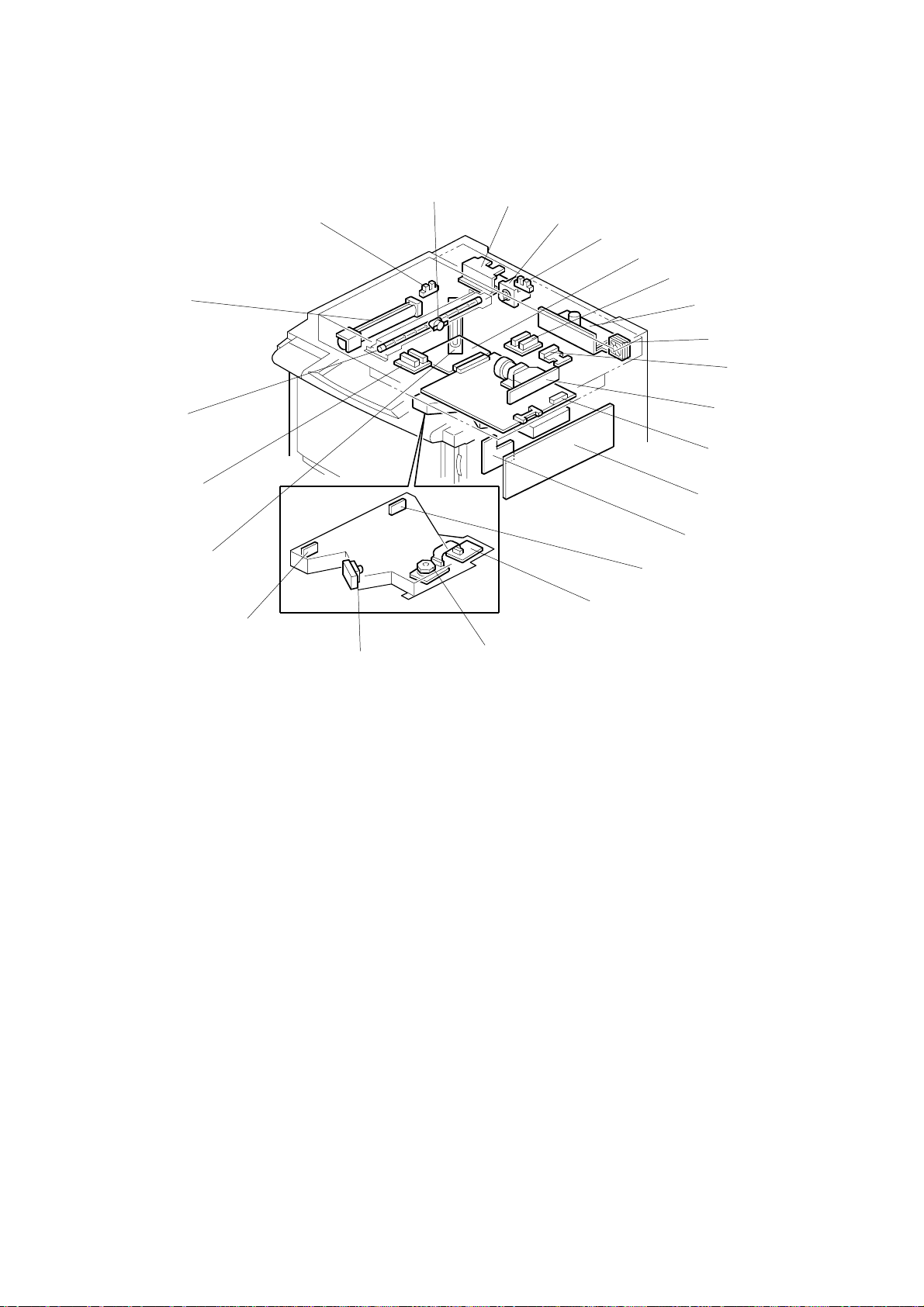

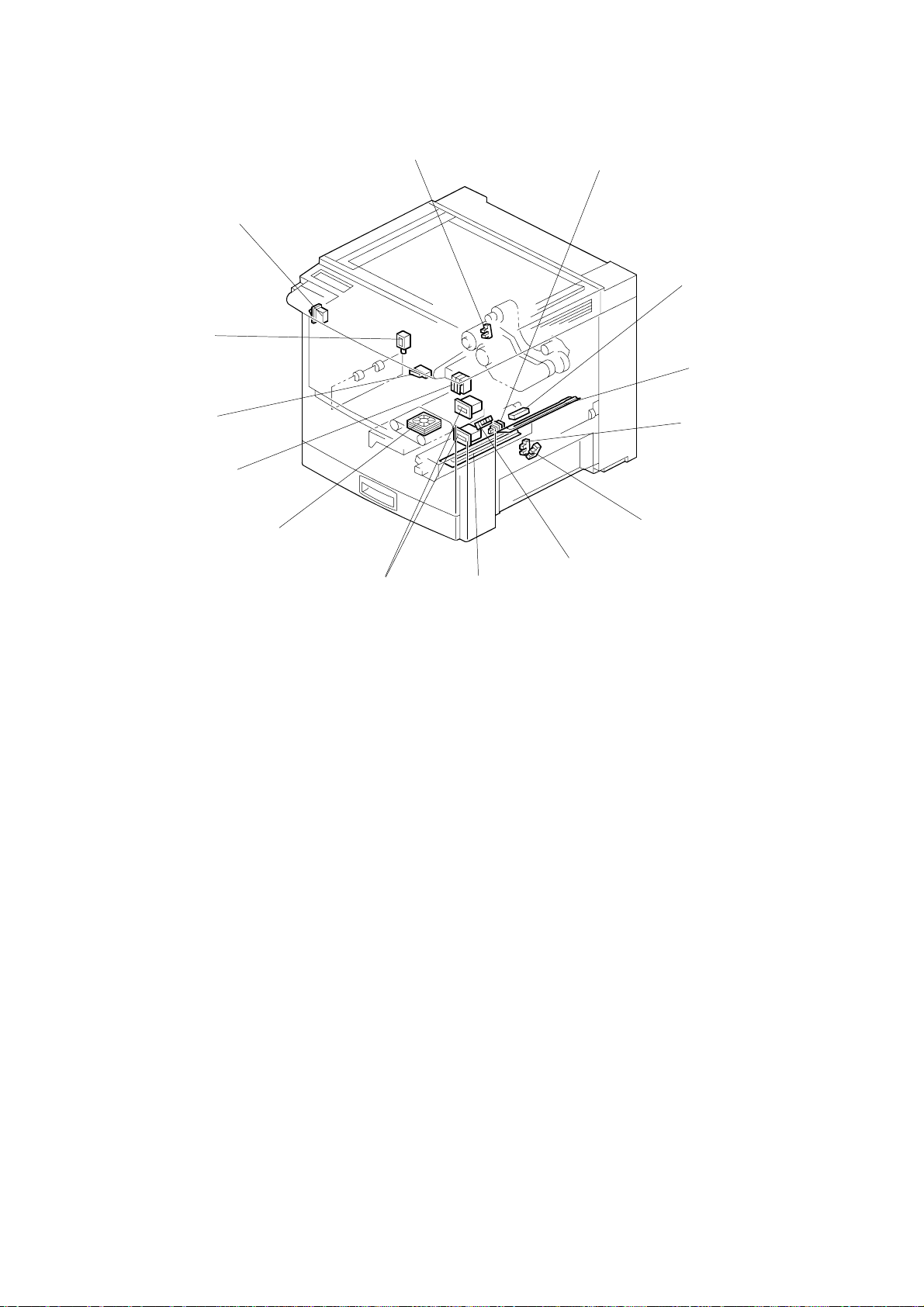

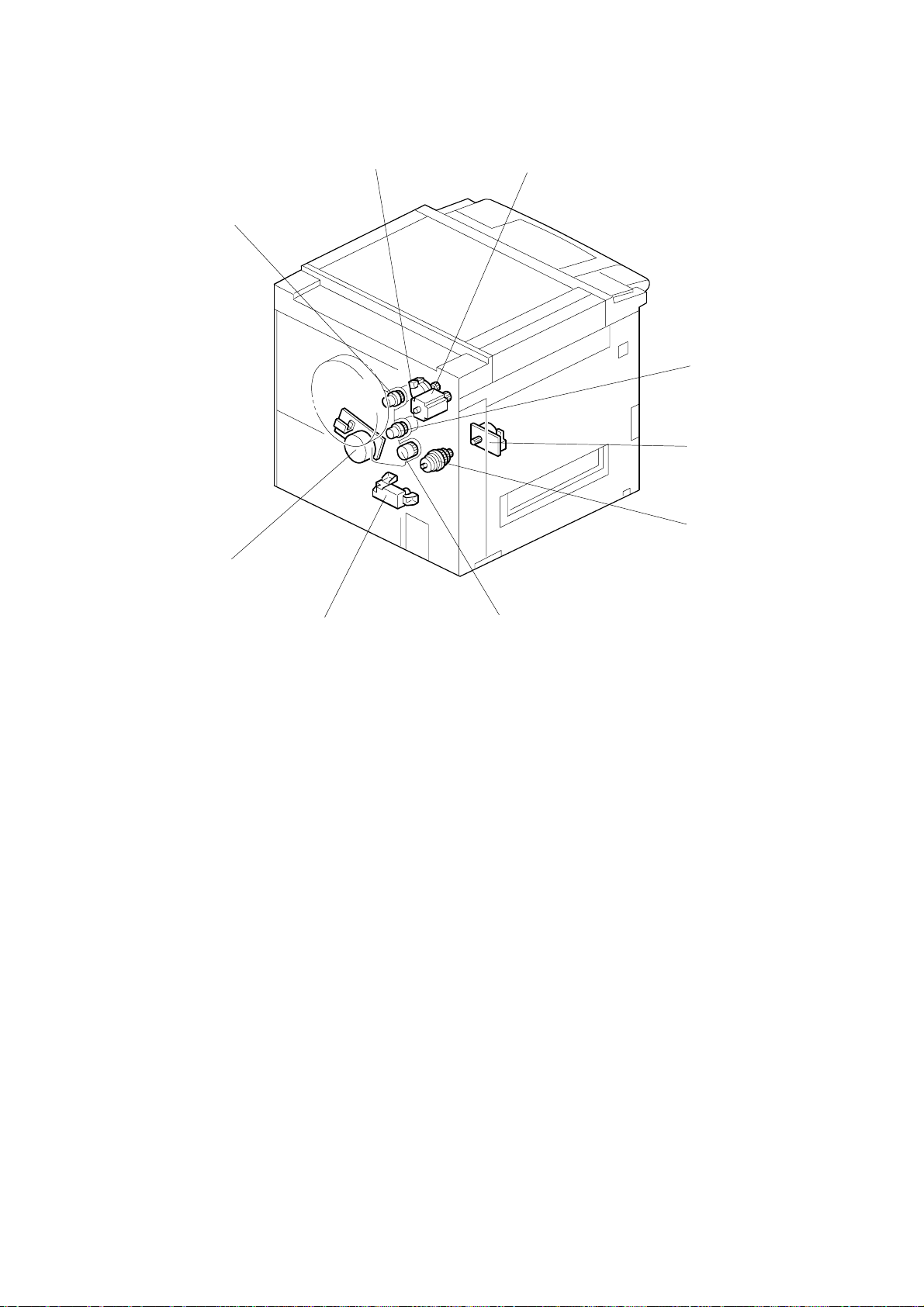

1.4.2 ELECTRICAL COMPONENT LAYOUT

- A258/259/260 -

20

19

18

17

16

21

15

22

1

2

3

4

5

6

7

23

8

9

10

11

12

13

B017V101.WMF

14

1. Scanner Motor Drive Board

2. Scanner Motor

3. Platen Cover Position Sensor

4. IDU Board

5. Original Length Sensor

6. Lamp Regulator

7. Scanner Exhaust Fan

8. CCD Board (SBU)

9. Scanner IPU Board

10. Main Control Board

11. LD (Laser Diode) Main Control Board

12. Laser Synchronizing Detector

Board 2

Diagram 1

13. Polygon Mirror Motor Drive Board

14. Polygon Mirror Motor

15. LD (Laser Diode) Drive Board

16. Laser Synchronizing Detector

Board 1

17. Optics Anti-condensation Heat er

18. Original Width Sensor

19. Exposure Lamp

20. Optics Cooling Fan

21. Scanner H.P. Sensor

22. Exposure Lamp Thermostat

23. Original Length Sensor-Sub

1-18

Page 21

28 August, 2000 PARTS LAYOUT

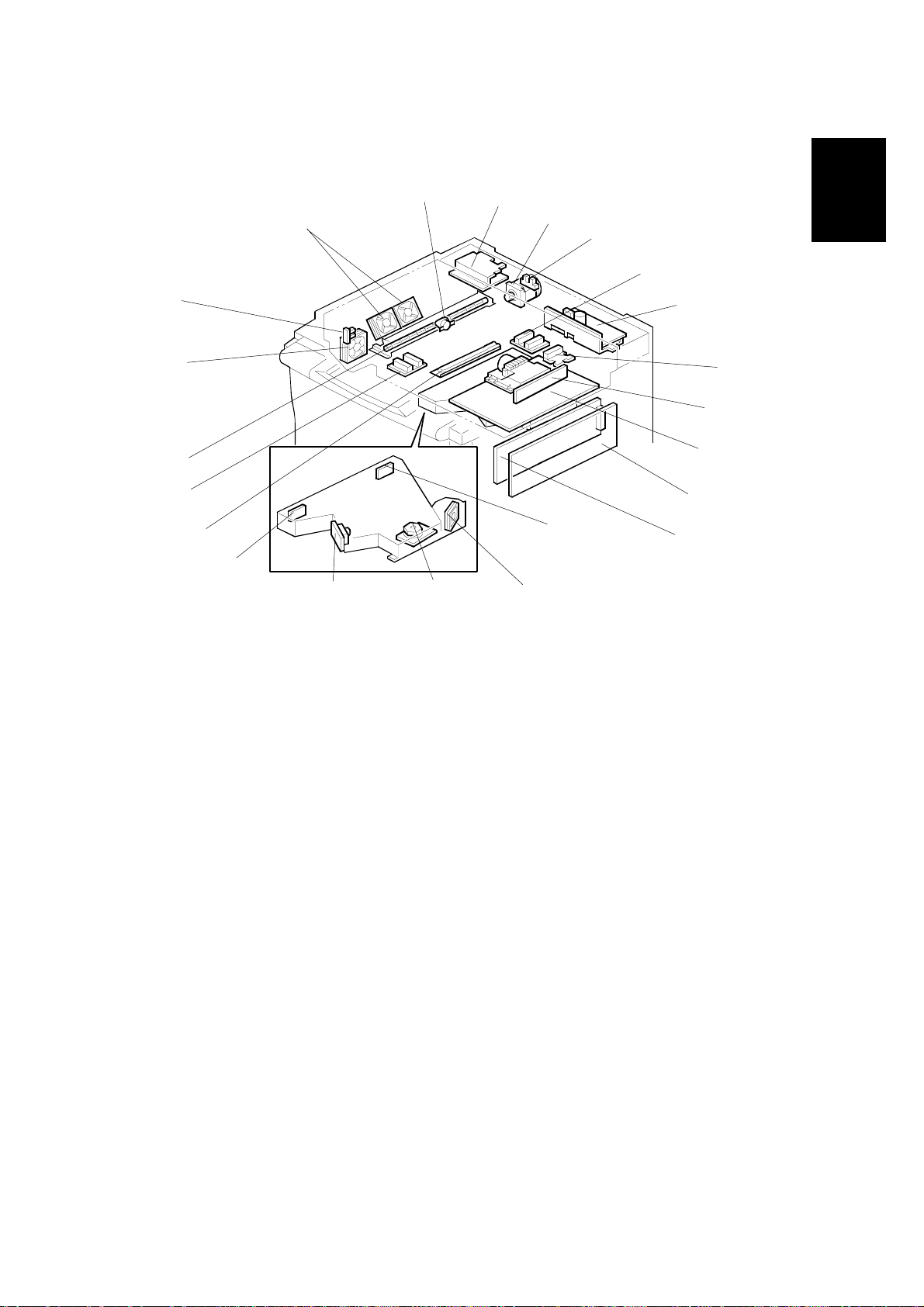

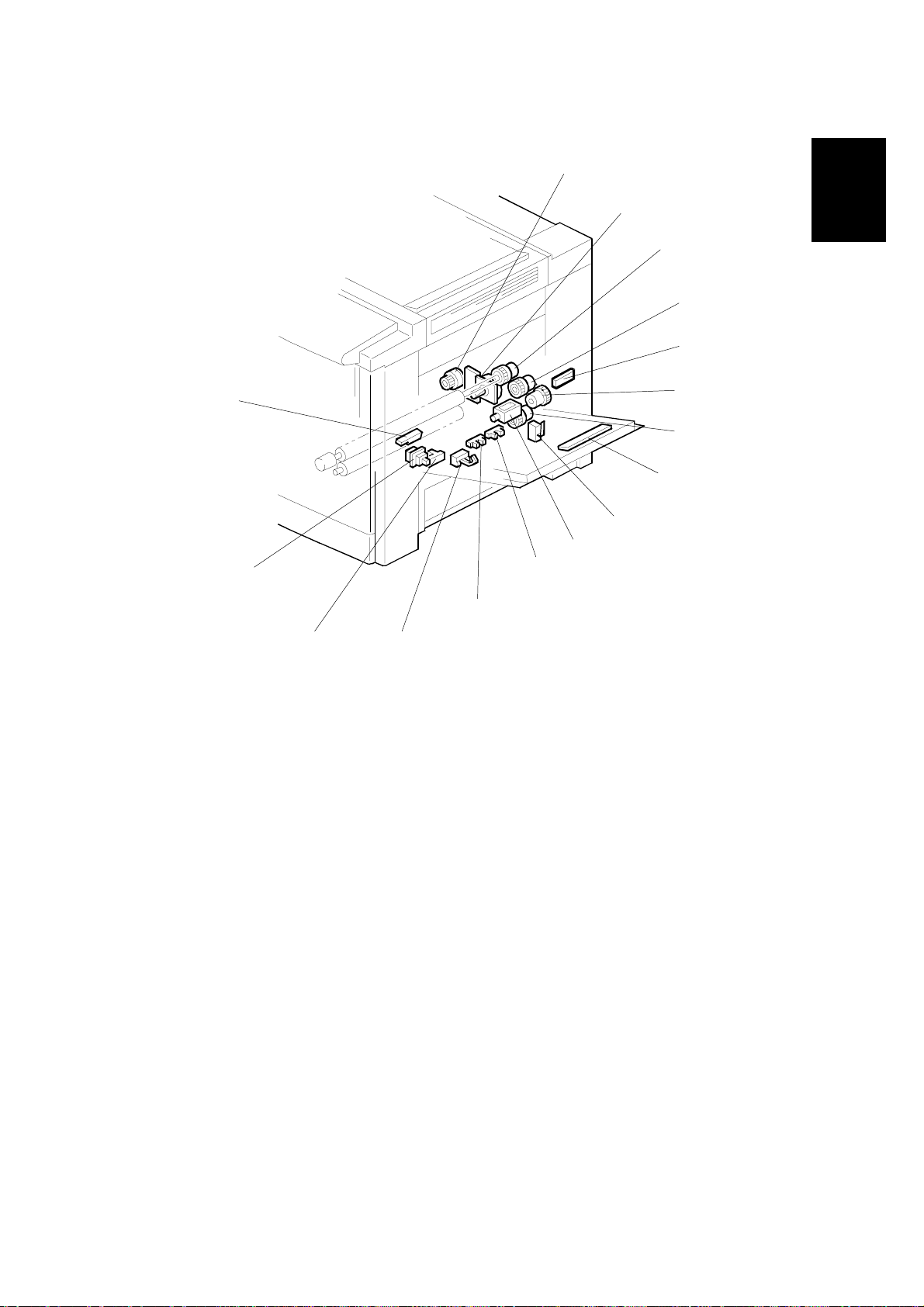

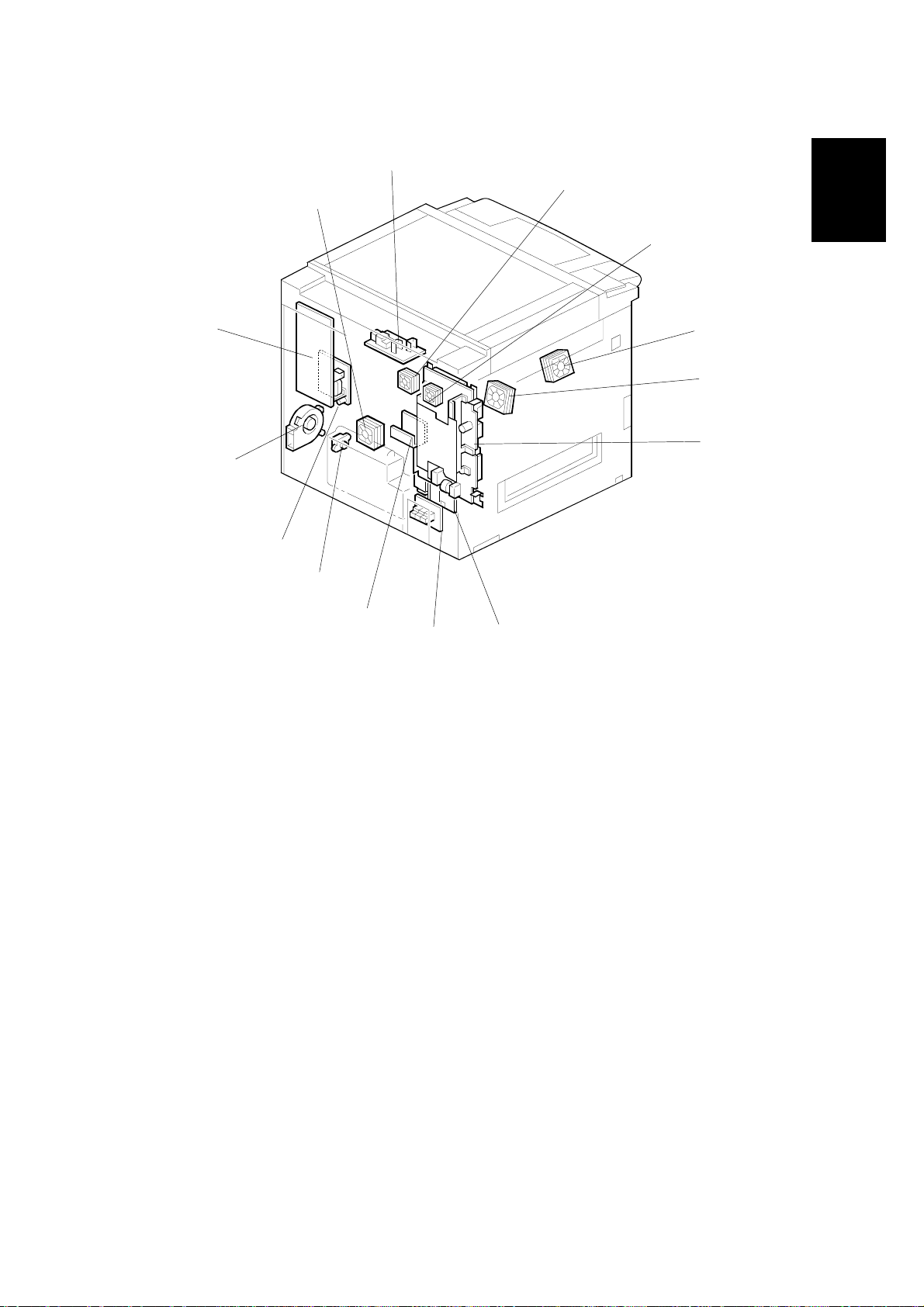

1.4.3 ELECTRICAL COMPONENT LAYOUT

- B017/018 -

21

24

19

18

17

16

20

15

22

14

1

2

3

Overall

Information

5

6

23

8

9

10

25

12

B017V117.WMF

11

1. Scanner Motor Drive Board

2. Scanner Motor

3. Platen Cover Position Sensor

4. Blank

5. Original Length Sensor

6. Lamp Regulator

7. Blank

8. CCD Board (SBU)

9. Scanner IPU Board

10. Main Control Board

11. LD (Laser Diode) Main Control Board

12. Laser Synchronizing Detector

Board 2

13. Blank

Diagram 1

14. Polygon Mirror Motor

15. LD (Laser Diode) Drive Board

16. Laser Synchronizing Detector

Board 1

17. Optics Anti-condensation Heat er

18. Original Width Sensor

19. Exposure Lamp

20. Optics Cooling Fans

21. Scanner H.P. Sensor

22. Exposure Lamp Thermostat

23. Original Length Sensor-Sub

24. IPU Cooling Fan

25. Polygon Mirror Motor Cooling Fan

1-19

Page 22

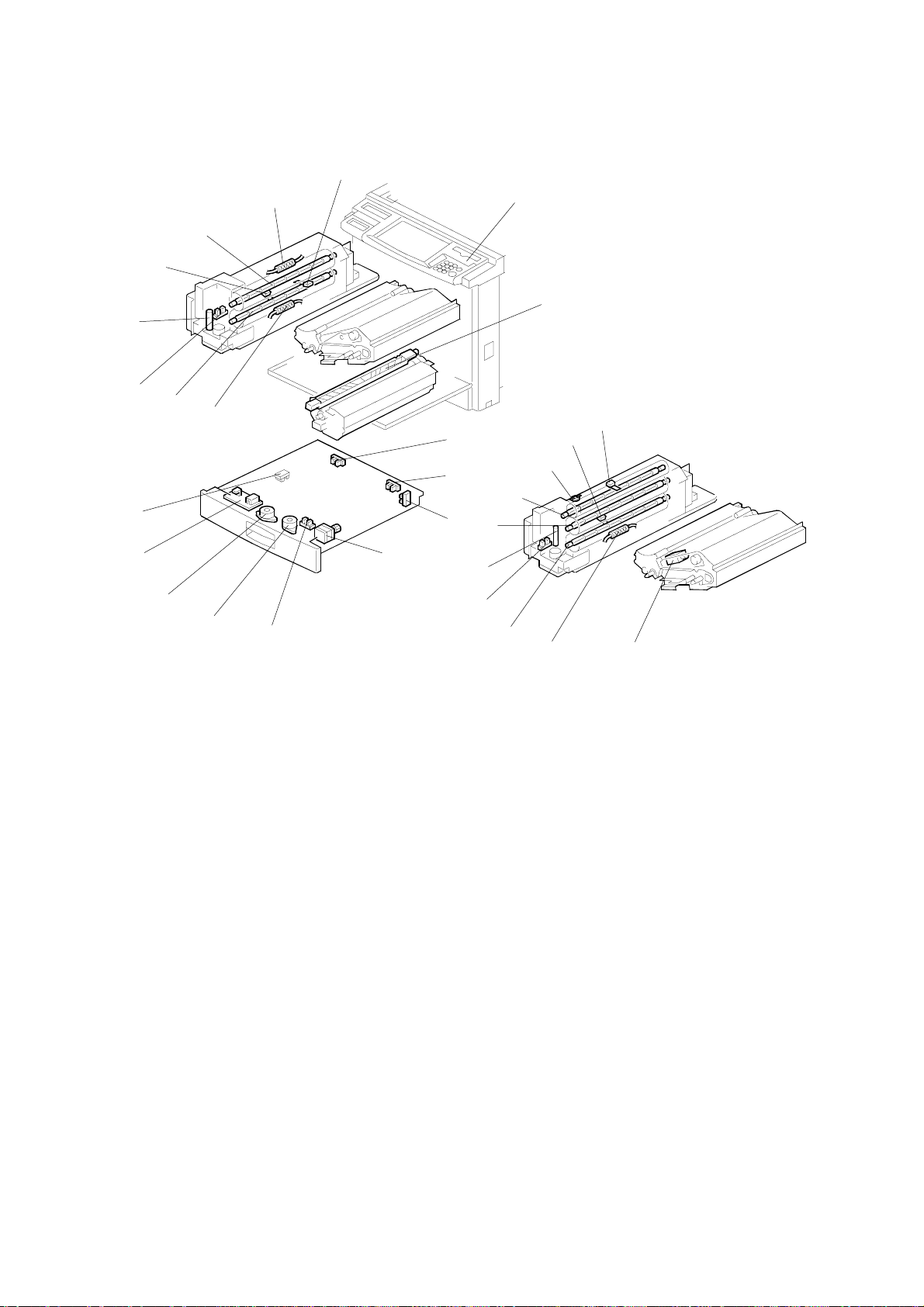

PARTS LAYOUT 28 August, 2000

14

13

12

2

3

1

4

5

6

7

11

B017V102.WMF

10

9

8

1. Main Power Switch

2. Belt Cleaning H.P. Sensor

3. Paper Tray Detector Switch

4. Transfer Belt Home Position Sensor

5. Transfer Belt Heater

6. Paper Height Sensor-1

7. Paper Height Sensor-2

8. Paper Transfer H.P. Sensor

Diagram 2

9. Paper Transfer Unit Heater

10. Counters

11. Transport Fan

12. Front Door Switch

13. Paper Exit Door Switch

(A259/A260/B017)

14. Junction Gate Solenoid

(A259/A260/B017)

1-20

Page 23

28 August, 2000 PARTS LAYOUT

1

15

14

13

12

11

9

10

B017V103.WMF

2

Overall

Information

3

4

16

5

6

7

8

1. Paper Transfer Positioning Clutch

2. Paper Feed Motor

3. Registration Clutch

4. Relay Clutch

5. By-pass Feed Clutch

6. Paper Feed Clutch

7. By-pass Paper Width Detection Board

8. Vertical Transport Switch

Diagram 3

9. By-pass Pick-up Solenoid

10. Upper Limit Sensor

11. Paper End Sensor

12. Relay Sensor

13. By-pass Paper End Sensor

14. By-pass Feed Table Switch

15. Registration Sensor

16. Temperature and Humidity Sensor

1-21

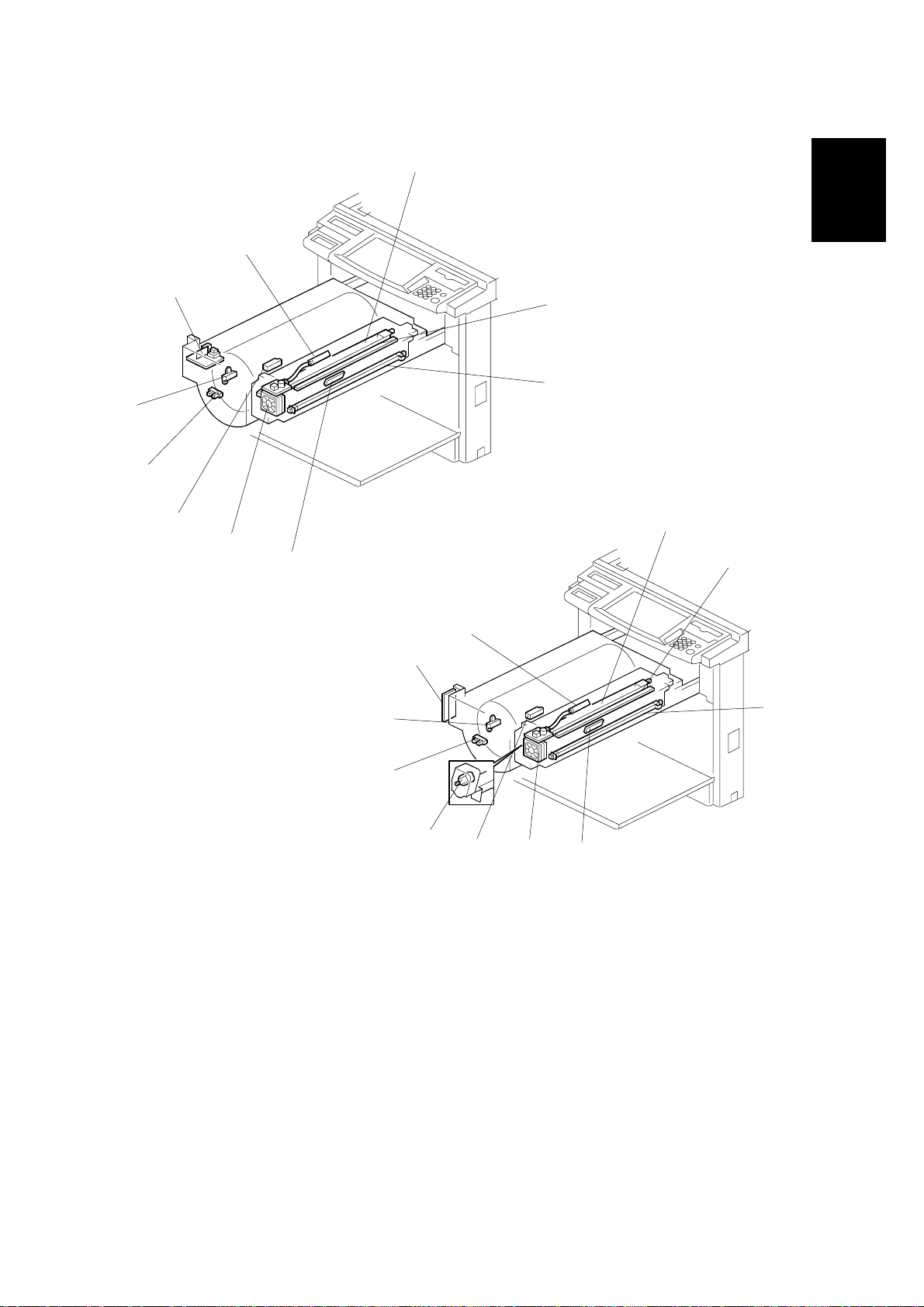

Page 24

PARTS LAYOUT 28 August, 2000

10

9

1

8

7

2

6

5

4

3

11

10

22

B017/018

21

12

20

19

13

8

18

17

16

B017V104.WMF

15

14

Diagram 4

1. Operation Panel

2. Paper Separation Corona Unit

3. Pressure Roller Thermofuse

4. Pressure Roller Fusing Lamp

5. Paper Exit Sensor

6. Oil End Sensor

7. Hot Roller Thermistor (A258/259/260)

8. Hot Roller Fusing Lamp

9. Hot Roller Thermofuse (A258/259/260)

6

5

B017V114.WMF

4

3

12. Duplex Turn Sensor

13. Duplex Paper End Sensor

14. Duplex Feed Motor

15. Side Fence Jogger HP Sensor

16. Duplex Side Fence Jogger Mot or

17. Duplex End Fence Jogger Motor

18. Duplex Control Board

19. End Fence Jogger HP Sensor

20. Heat Roller Fusing Lamp (B017/018)

23

10. Pressure Roller Thermistor

11. Duplex Entrance Sens or

21. Heat Roller Thermostat (B017/018)

22. Heat Roller Thermistor (B017/018)

23. Image Transfer Belt Re lease Solenoid

(B017/018)

1-22

Page 25

28 August, 2000 PARTS LAYOUT

1

10

Overall

Information

9

2

3

8

7

6

5

4

B017V105.WMF

1

2

10

9

8

3

1. Charge Corona Unit

2. Quenching Lamp

3. PCC (Pre-cleaning Cor ona)

4. ID Sensor

5. Charge Corona Fan

6. Toner Cartridge Sensor

7

11

6

Diagram 5

7. Revolver H.P. Sensor

8. Toner End Sensor

9. High Voltage Supply Board: B

10. Potential Sensor

11. Charge Corona Cleaner Motor

1-23

5

(B017/018)

4

B017V115.WMF

Page 26

PARTS LAYOUT 28 August, 2000

2

3

1

4

5

6

9

B017V106.WMF

1. Development Clutch

2. Toner Supply Motor

3. Revolver Motor

4. Belt Lubricant Clutch

5. Fusing Motor

8

7

Diagram 6

6. Fusing Clutch

7. Belt Cleaning Clutch

8. Tray Lift Motor

9. Drum Motor

1-24

Page 27

28 August, 2000 PARTS LAYOUT

1

2

13

12

Overall

Information

11

10

9

8

7

1. High Voltage Supply Board: C, G

2. Rear Upper Cooling Fan Motor

14

3

4

B017V107.WMF

56

Diagram 7

8. Used Toner Sensor

9. High Voltage Supply Board: T1, PCC

3. Fusing Unit Fan Motor

4. PSU (Power Supply Unit)

5. High Voltage Supply Board: T2, D

6. CSS/Bank Interface Board

7. Revolver Motor Drive Board

10. Main Exhaust Fan Motor

11. I/O (Input/Output) Control Board

12. PSU Fan Motor

13. Rear Lower Cooling Fan

14. Development Cooling Fan (B017/018)

1-25

Page 28

PARTS LAYOUT 28 August, 2000

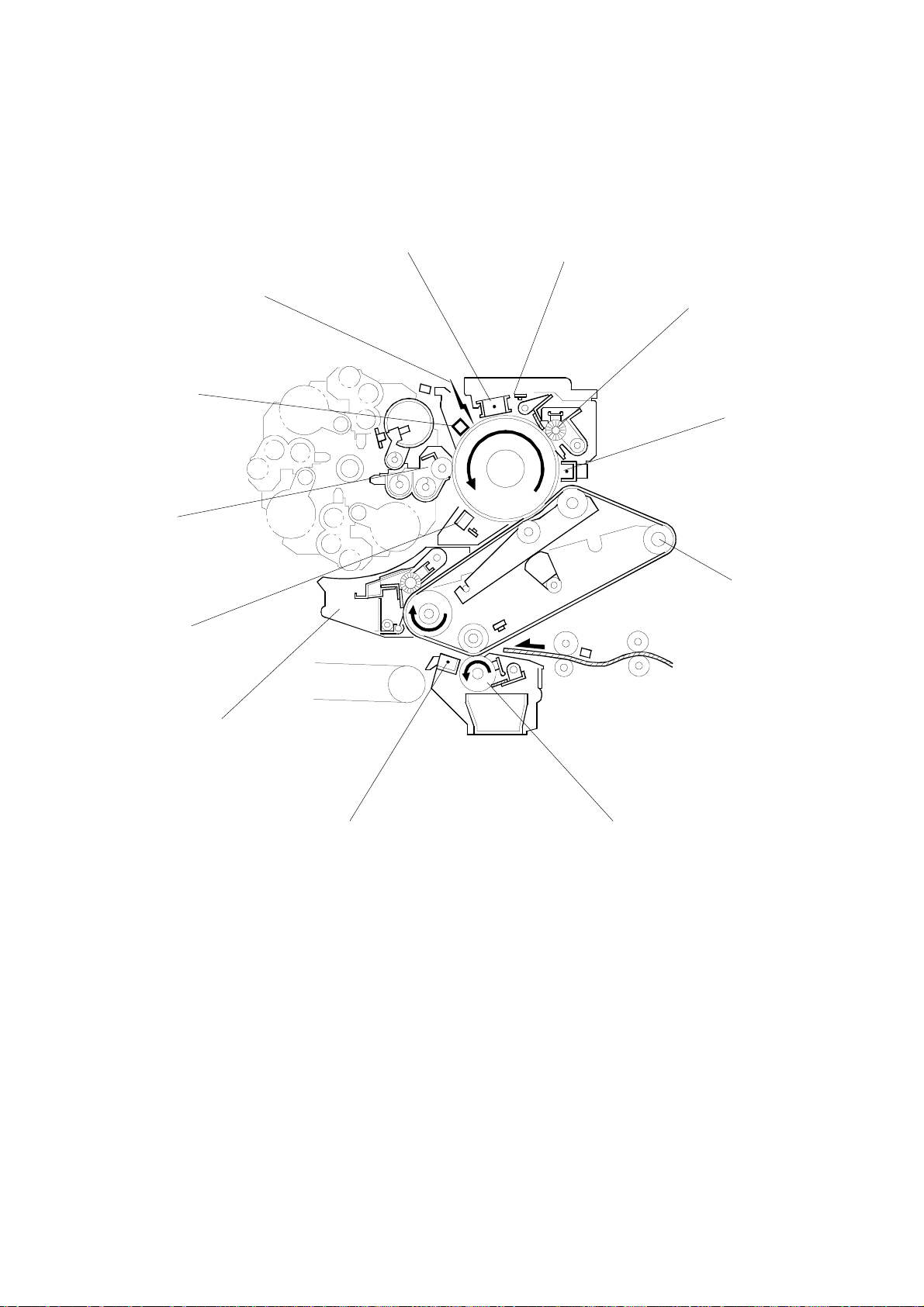

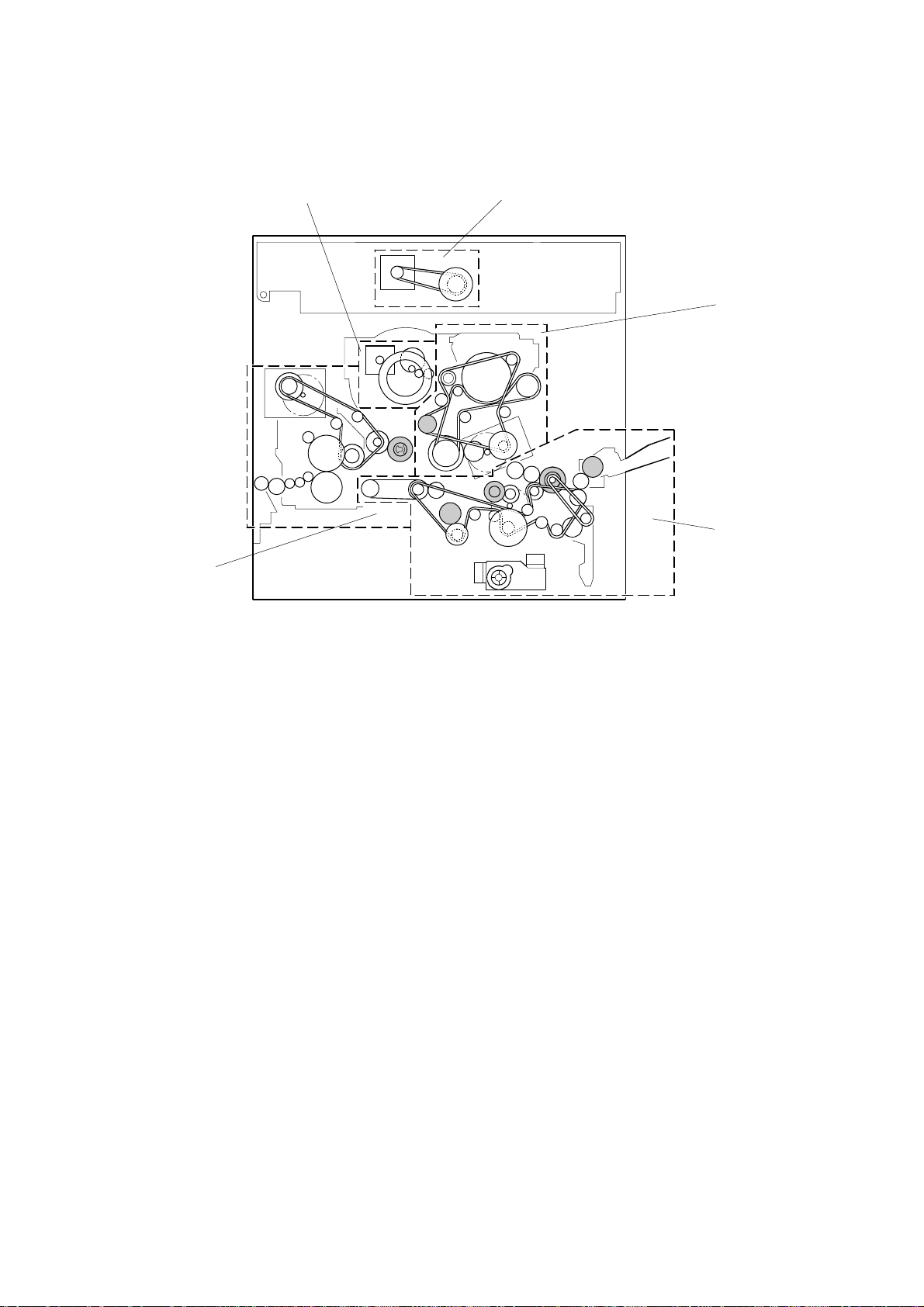

1.4.4 DRIVE LAYOUT

5

1

2

3

4

B017V111.WMF

Five motors drive the mechanical components for this machine. The drive sections

driven by these five motors are listed below.

1. Scanner Drive

2. Development/Drum/Transfer Belt

Drive

3. Paper Feed/Registration/Paper

Transfer/Transport Belt Drive

4. Fusing Unit/Paper Exit Drive

5. Revolver Drive

1-26

Page 29

28 August, 2000 PARTS LAYOUT

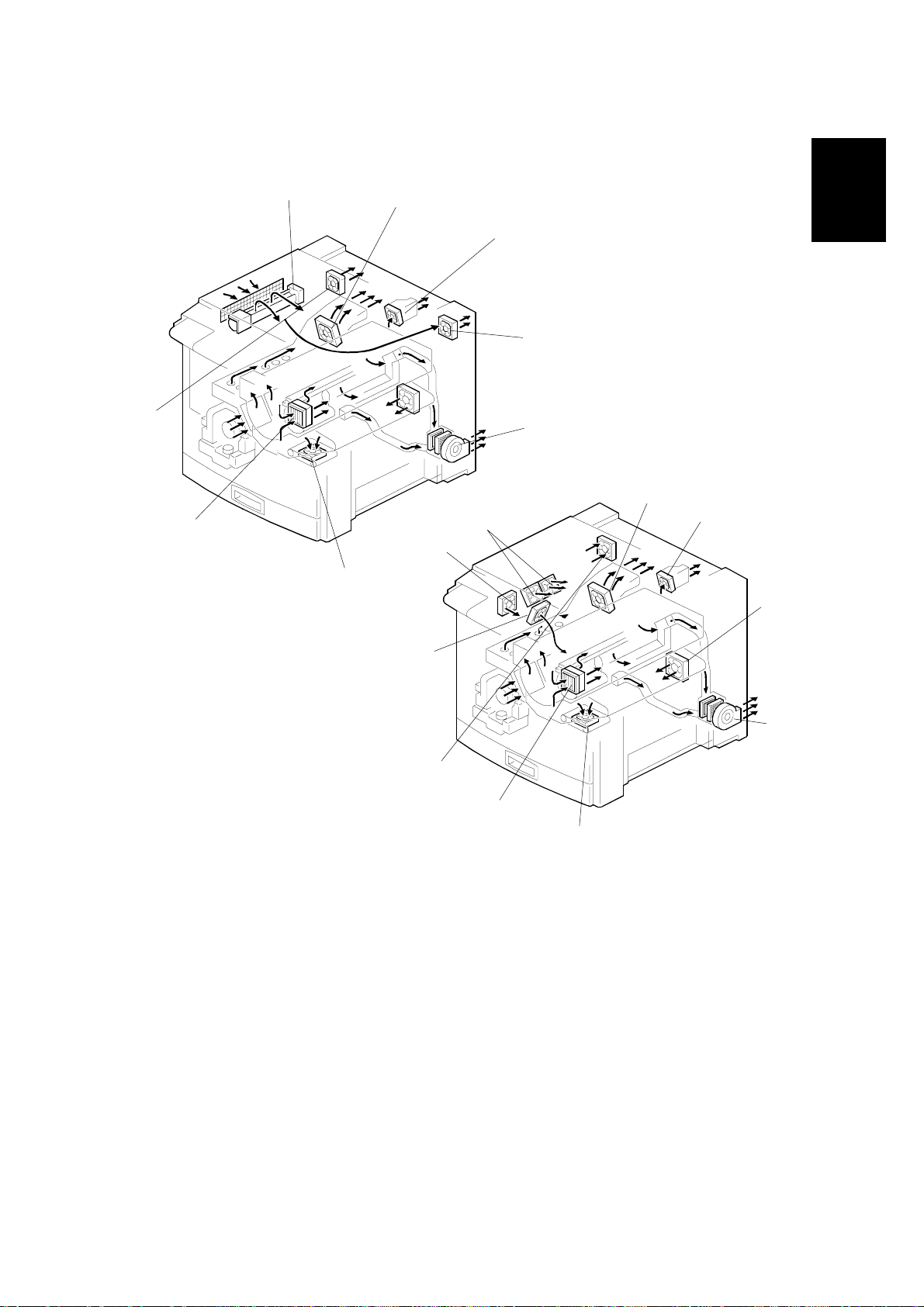

1.4.5 AIR FLOW

A258/259/260

8

7

B017V112.WMF

1

2

Overall

Information

3

4

5

2

1

3

9

6

10

1. Optics Cooling Fan

2. Fusing Unit Fan

3. Rear Upper Cooling Fan

4. Scanner Exhaust Fan

(A258/259/260)

5. Main Exhaust Fan

6. Transport Fan

11

5

8

B017/018

7

6

B017V116.WMF

7. Charge Corona Fan

8. PSU Fan

9. IPU cooling fan (B017/018)

10. Rear lower cooling fan

11. Development cooling fan (B017/018)

1-27

Page 30

PARTS LAYOUT 28 August, 2000

1.4.6 ELECTRICAL COMPONENT DESCRIPTIONS

Printed Circuit Boards

Symbol Name Function

PCB1 PSU Supplies AC and DC power. 7-4 K4 G3

PCB2

PCB3

PCB4

PCB5

PCB6

PCB7

PCB8

PCB9

PCB10

PCB11 Main control Controls the printer sequence. 1-10 J12 E10

PCB12

PCB13

PCB14 Revolver motor drive Controls the revolver motor. 7-7 F5 D4

PCB15

PCB16 LD drive Drives the laser diode. 1-15 O17 J9

PCB17

Lamp regulator Supplies AC power to the

exposure lamp.

SBU

Scanner IPU Converts the RGB image signal

Scanner motor drive

I/O control Interfaces the sensors, clutches,

High voltage supply:

C, G

High voltage supply:

T1, PCC

High voltage supply:

T2, D

High voltage supply:BSupplies power to the

Laser synchronizing

detector 1

Laser synchronizing

detector 2

Interface: CSS/Bank Connects to the CSS unit and

LD main control

Converts the light reflected from

the original into video signals.

from the CCD to a CMYK signal

and sends it to the LD main

control board.

Supplies DC power to the

scanner motor.

solenoids, and motors in the

printer module with the main

control board.

Supplies power to the charge

corona wire and grid.

Supplies power to the transfer

belt and pre-cleaning corona

unit.

Supplies power to the paper

transfer bias roller and paper

separation corona unit.

development rollers.

Detects laser main scan

synchronization while the latent

image is being written to the

drum.

Detects laser main scan

synchronization while the latent

image is being written to the

drum.

optional paper tray unit.

Controls the laser power, main

scan synchronizing sensors, and

process control gamma

correction.

Rotates scanned image

(B017/018)

Analyzes images for anticounterfeiting. (B017/018)

Index-

1-6 O7 J6

1-8 J9 G6

1-9 L8 H7

1-1 M7 H4

7-11 D14 C7

7-1 A14 A10

7-9 A2 A4

7-5 A1 A3

5-9 A3 A1

1-16 O15 J9

1-12 O15 J10

7-6 J9 F6

1-11 M16 H10

No

A258/259/

Location

260

B017/018

1-28

Page 31

28 August, 2000 PARTS LAYOUT

Location

260

Symbol Name Function

PCB18

By-pass paper width

detection

Detects the paper width on the

by-pass feed table.

Index-

No

A258/259/

3-7 A10 A5

PCB19 Operation panel Used to operate the copier. 4-1 H19

F20

(A259/A260

copiers only)

PCB20

PCB21

PCB22

PCB23

PCB24

Duplex control Controls the duplex unit.

IDU

Analyzes images for anticounterfeiting. (A258/259/260)

Polygon mirror motor

drive

Temperature and

humidity sensor

Controls the polygon mirror

motor. (A258/259/260)

Detects the ambient temperature

and humidity.

Header relay Supplies the power to the

heaters

4-18

1-4 M14 -

1-13 O15 -

3-16 E19 D11

-- H1

Motors

Symbol Name Function

Index-

No

A258/259/

M1 Scanner Drives the scanner. 1-2 M6 H4

M2

Polygon mirror Drives the polygon mirror (laser

unit).

1-14 O15 H8

M3 Revolver drive Rotates the revolver unit. 6-3 G5 E4

Drives the paper feed roller in

the duplex unit.

Drives the duplex unit side

fences.

Drives the duplex unit end

fences.

4-14

4-16

4-17

(A259/A260

copiers only)

(A259/A260

copiers only)

(A259/A260

copiers only)

M4

M5

M6

Duplex feed motor

Duplex Side fence

jogger

Duplex End fence

jogger

M7 Paper feed Drives the paper feed unit. 3-2 A12 A6

Tray lift Lifts the tray bottom plate.

M8

6-8

(A258 model

M9 Toner supply Supplies toner. 6-2 A7 A3

Drum Drives the drum, the

M10

development unit currently at the

development position, and the

6-9 A19 A9

transfer belt.

M11

M12

Fusing Drives the transport and fusing

units.

Charge corona

cleaner

Drives the charge corona

cleaner

6-5 E8 A10

5-11 - A2

Location

260

G20

G21

G21

A12

only)

B017/018

Overall

Information

D12

B017/018

E12

(B017

models only)

E12

(B017

models only)

E13

(B017

models only)

A7

(B018

models only)

1-29

Page 32

PARTS LAYOUT 28 August, 2000

Fan Motors

Symbo

l

FM1

Name Function

Transport

Attracts copy paper to the

transport belt.

Index-

No

A258/259/

2-11 A11 A6

Location

260

B017/018

FM2 Optics cooling Cools the scanner unit 1-20 O14 FM3 Charge corona Cools the charge corona unit. 5-5 A6 A3

FM4 Scanner exhaust Cools the scanner unit. 1-7 P7 FM5 Fusing unit Cools the fusing unit. 7-3 E1 D4

Main exhaust Sucks air from the charge and

FM6

transfer areas out of the

7-10 A17 A5

machine.

Rear cooling unit

(A258/59/60)

FM7

Rear upper cooling

Cools the rear section of the

copier.

7-2 E10 D3

(B017/018)

FM8 PSU Cools the PSU. 7-12 A7 A11

Rear lower cooling Cools the rear section of the

FM9

copier.

7-13 D2

FM10 Polygon mirror motor Cools the polygon mirror motor 1-25 - D6

FM11 Optics cooling 0 1-20 - J7

FM12 Optics cooling 1

Cools the scanner unit.

1-20 - J7

FM13 IPU cooling Cools the IPU section. 1-24 - J7

FM14 Development cooling Cools the development section. 7-14 - J7

Sensors

Symbol Name Function

Detects the presence or

absence of toner in a

cartridge.

Detects the presence or

absence of toner cartridges.

Detects if the revolver is at

the home position.

drum surface.

on the developed ID sensor

patch on the drum.

unit is at the home position.

Detects if there is paper on

the by-pass feed table.

position of the tray bottom

plate.

relay section.

S1

S2

S3

S4

S5

S6

S7

S8

S9

Toner end

Toner cartridge

Revolver H.P.

Potential Detects the potential of the

ID Detects the density of toner

Belt cleaning H.P. Detects if the belt cleaning

By-pass feed paper

end

Upper limit Detects the upper limit

Relay Detects paper jams at the

Index-

No

A258/259/

Location

260

B017/018

5-8 A4 A1

5-6 A4 A1

5-7 A4 A2

5-10 A5 A2

5-4 A5 A2

2-2 A8 A11

3-13 A8 A5

A13

3-10

(A258 model

only)

(B018 model

A13

3-12

(A258 model

only)

(B018 model

A7

only

A7

only)

1-30

Page 33

28 August, 2000 PARTS LAYOUT

Symbol Name Function

Tray paper end

S10

Detects if there is paper in

the paper feed tray.

Relay Detects a paper jam at the

S11

S12

S13

S14

Used toner Detects if the used toner tank

Paper transfer H.P. Detects if the paper transfer

Paper height 1

relay section

is full.

unit is at the home position.

Detects the amount of paper

in the tray.

Paper height 2 Detects the amount of paper

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

Transfer belt H.P. Detects the mark on the

Registration H.P. Detects paper jams at the

Paper exit Detects paper jams at the

Oil end

Original length

Platen cover position Detects if the platen cover is

Original length -sub Detects the length of the

Scanner H.P. Detects the scanner home

Original width Detects the width of the

Side fence jogger HP

in the tray.

transfer belt.

registration section.

paper exit.

Detects if there is silicone oil

in that tank.

Detects the length of the

original.

open or closed.

original

position.

original.

Detects the home position of

the duplex unit side fence.

End fence jogger HP Detects the home position of

S26

the duplex unit end fence.

Duplex paper end Detects if there is paper in

S27

the duplex unit.

Duplex entrance Detects when copy paper

S28

Duplex turn

S29

comes into the duplex uni t.

Detects when copy paper is

being reversed in the duplex

unit.

Index-

No

A258/259/

Location

260

B017/018

G13

3-11

(A258 model

only)

(B018 model

A14

3-12

(A259/A260

models only)

7-8 A15 A4

2-8 A15 A4

A16

2-6

(A258 model

only)

(B018 model

A16

2-7

(A258 model

only)

(B018 model

2-4 A18 A9

3-15 A19 A9

4-5 F1 D1

4-6 G1 E1

1-5 N7 J5

1-3 O7 J5

1-23 P7 I4

1-21 P14 J6

1-18 P14 J6

G22

4-15

(A259/A260

models only)

(B017 model

G22

4-19

(A259/A260

models only)

(B017 model

G22

4-13

(A259/A260

models only)

(B017 model

G23

4-11

(A259/A260

models only)

(B017 model

G23

4-12

(A259/A260

models only)

(B017 model

A7

only

A7

A8

only

A8

only

E13

only

E13

only

E13

only

E13

only

E13

only

Overall

Information

1-31

Page 34

PARTS LAYOUT 28 August, 2000

Switches

Symbol

s

SW1

SW2

SW3

SW4

SW5

SW6

Clutches

Name Function

Main power Turns the copier power on

or off.

Front door

Cuts the DC line to the high

voltage supply board when

the front door is open.

Paper exit door Det ects if the paper exit

door is open or closed.

By-pass feed table Detects if the by-pass feed

table is open or closed.

Paper tray detector Detects the presence or

absence of a paper tray.

Vertical transport

Detects if the vertical

transport door is open or

closed.

Index-

No

A258/259/

Location

260

B017/018

2-1 M1 H1

2-12 E11 A11

A7

2-13

(A259/A260

models only)

(B017 model

only)

3-14 A8 A5

A16

2-3

(A258 model

only)

(B018 model

only)

3-8 A17 A4

D2

A7

Symbol

s

CL1

CL2

CL3

CL4

CL5

CL6

CL7

CL8

CL9

Name Function

By-pass feed Transmits drive to the by-

pass feed mechanism.

Paper feed

Transmits drive to the paper

feed mechanism.

Registration T r ansmits drive to the

registration rollers.

Paper transfer

positioning

Transmits drive to the paper

transfer unit.

Development Transmits drive to the

development mechanism.

Relay Transmits drive to the relay

rollers.

Belt cleaning

Transmits drive to the belt

cleaning unit.

Fusing Transmits drive to the

fusing unit.

Belt lubricant Transmits drive to the belt

lubricant mechanism.

Index-

No

A258/259/

Location

260

B017/018

3-5 A9 A5

3-6 A17 A8

3-3 A18 A8

3-1 A11 A6

6-1 E3 D2

3-4 A18 A8

6-7 E2 D1

6-6 E1 D1

6-4 E2 D1

1-32

Page 35

28 August, 2000 PARTS LAYOUT

Solenoids

Symbol

s

SOL1

SOL2

SOL3

By-pass pick-up Lowers the by-pass pick-up

Junction gate

Image t ransfer belt

release

Name Function

roller.

Raises the junction gate for

the duplex tray.

Releases the image

transfer belt from the drum.

Lamps

Symbol Name Function

Hot roller fusing Provides heat to the hot

L1

Pressure roller

L2

fusing

Exposure Applies high intensity light

L3

Quenching Neutralizes any charge

L4

Heat roller fusing Provides heat to the heat

L5

roller.

Provides heat to the

pressure roller.

to the original for exposure.

remaining on the

photoconductor.

roller.

Index-

No

A258/259/

Location

260

B017/018

3-9 A9 A5

A7

2-14

(A259/A260

copiers only)

4-22 - A12

Index-

No

A258/259/

Location

260

B017/018

4-7 H1 E1

4-4 G1 F1

1-19 O5 J5

5-2 A6 A2

4-20 - E1

Overall

Information

D2

Heaters

Symbol Name Function

Paper transfer unit Prevents m oisture from

H1

H2

H3

Transfer belt Used to stabilize the

Optics anticondensation

forming around the paper

transfer unit.

temperature around the

transfer belt.

Prevents moisture from

forming on the optics.

1-33

Index-

No

A258/259/

Location

260

B017/018

2-9 J1 G1

2-5 K1 G1

1-17 L1 G1

Page 36

PARTS LAYOUT 28 August, 2000

Thermistors

Symbol Name Function

TH1

TH2

TH3

Pressure roller Controls the temperature of

the pressure roller.

Hot roller

Heat Roller Controls the temperature of

Controls the temperature of

the hot roller.

the heat roller.

Thermofuses

Symbol Name Function

TF1

TF2

Hot roller Protects the hot roller from

overheating.

Pressure roller

Protects the pressure roller

from overheating.

Thermostat

Index-

4-22 - E1

Index-

A258/259/

No

4-9 F1 D1

4-6 G1 -

A258/259/

No

4-8 H1 4-3 H1 F1

Location

260

Location

260

B017/018

B017/018

Symbol Name Function

Exposure lamp

TS1

Heat roller Prevents the heat roller

TS2

Prevents the exposure lamp

from overheating when it is

on for a long time.

fusing lamp from

overheating when it is on

for a long time.

Counter

Symbol Name Function

Upper mechanical Indicates the total number

CO1

CO2

Lower mechanical

of development cycles

made using the C, M, and Y

development units;

Shows the total number of

black developments.

Index-

1-22 O6 J5

4-21 - E1

Index-

2-10 A9 D6

2-10 A10 D7

No

No

A258/259/

A258/259/

Location

260

Location

260

B017/018

B017/018

1-34

Page 37

28 August, 2000 PROCESS CONTROL

2. DETAILED DESCRIPTION (B017/018)

2.1 PROCESS CONTROL

2.1.1 OVERVIEW

The process control for this machine is almost the same as for the A258/259/260

copiers. The only difference is in the potential values of VD (charge voltage), VL

(laser power), and VB (developme nt bi as) . Thes e pot enti al val ues ar e optimized for

600 dpi processing. By changing the resolution, the density of the pattern used for

process control has been changed. For process control to work properly, these

potential values were changed from the A258/259/260 copier level to their current

potential values for the B017/B018.

2.1.2 POTENTIAL CONTROL

Just like A258/259/260 copiers, there are 4 process control self-checks.

1) Forced process control self-check

2) Initial process control self-check

3) Interval process control self-check

4) Times process control self-check

Detailed

Descriptions

The different points on the process control self-check from A258/259/260 copiers

are as follows.

Initial process control self-check

• The initial process control starts automatically when the power is turned on (or

when the machine returns to stand- by mode fro m sle ep mo de) , but only if the

fusing belt in the fusing unit is less than 550C. This is because the fusing belt

temperature drops faster because the fusing belt is thinner than the hot roller.

TD auto correction (SP3-128)

• During the self-check, the machine automatically adjusts the toner concentration

if the M/A (Mass/Area) of the ID sensor pattern is out of 4.0 +/- 0.05 mg/cm2, in

order to attain proper image density. This mode is executed only when

performing the interval process control self-check. (This was executed only when

performing the initial process control self-check on A258/259/260 copiers.)

2-1

Page 38

DRUM UNIT 28 August, 2000

2.2 DRUM UNIT

2.2.1 DRIVE MECHANISM

The drive mechanism for this machine is the same as for the A258/A259/A260

copiers. However, the drum shaft extends fully from the rear to the front side in

order to prevent the photoconductor gap from fluctuating during drum rotation.

2.2.2 CHARGE CORONA UNIT CLEANER

A charge corona unit cleaner was adopted to prevent the charge corona wire and

charge grid from being contaminated with toner and paper dust.

Drive:

•

Cleaner affixed to screw rod [A].

•

Unit driven by DC motor [B] located at

copier front.

Cleaning:

[D]

•

Grid cleaner pad [C] and charge wire

cleaner pads [D].

•

Home position at copier front.

•

Machine cleans according to conditions

below:

1) When the main switch is turned on.

2) When the fusing temperature is less than 55oC.

3) When forced using an SP mode (SP2-802).

Cleaning Path:

Copier front – Rear end point – Copier front

Only the charge corona grid is cleaned during the traverse from the copier front to

the rear end point (black arrow). Both the charge wire and grid are cleaned during

this traversal from the rear end point to the copier front (white arrow).

Position Detection:

•

No sensor to detect the position of the cleaner.

•

I/O control board detects the current supplied to the motor

• It senses the sudden change in the current value, which occurs when the

cleaner reaches the end point.

• At the turnaround point, the motor reverses.

• If current does not increase within 60 seconds after motor rotation, the I/O control

board detects an open circuit or disconnected condition, stops the motor, and

then displays SC303.

[B]

[A]

B017D597.WMF

[C]

2-2

Page 39

28 August, 2000 SCANNER UNIT

Related SP modes:

1) SP2-802-000: Forced Charger Cleaning

This performs the charge and grid cleaning.

2) SP2-803-001: Auto Cleaning ON/OFF

This specifies the timing when the charger cleaning is performed.

3) SP2-803-002: Development Count

This enables charger cleaning at specified development cycle count

4) SP2-803-003: Operation Time

This specifies the operation time interval.

2.3 SCANNER UNIT

2.3.1 OVERVIEW

• Scanning resolution is 600 dpi.

• Higher resolution improves sharpness, and color and image reproduction

capability.

• A new lens, CCD, and e xposure lamp were added to attain the new 600 dpi

resolution.

• New image rotation feature

• Rotates the scanned image in 90-degree increments and then prints out.

• 80MB of memory is used for the image rotation.

• Stores up to A3/DLT mono-toner color images.

• The copier only makes one scan for the multi copy run in mono-toner

(CMYK) color copy mode.

• The image rotation circuit is in the LD main control board.

Detailed

Descriptions

2-3

Page 40

IMAGE PROCESSING 28 August, 2000

2.4 IMAGE PROCESSING

2.4.1 OVERVIEW

The following features were added to B017/018 copiers or modified from the

A258/259/260 copiers.

Image rotation feature

• Rotates up to A3/DLT full color images.

• Maintains the maximum copy speed by feeding paper sideways.

Laser power correction

• A correction value is applied to the laser power.

• This evenly applies the power across the drum surface, preventing uneven

image density images.

600 dpi resolution

• Improved sharpness and gradation of images.

• New dither patterns in copy mode

• Increased productivity in print mode (Prints images out without slowing down

the process speed for 600 dpi.)

NOTE: On the A258/259/260 copiers, the process speed changes to 2/3 of the

standard speed for 600 dpi.

Dither processing

• Two dither patterns for Text and Photo modes

• Dither pattern size is increased to improve gradation.

Pulse positioning control

• Machine can change the start timing for laser exposure.

• Makes lines appear smoother. (This improves the quality of grainy images.)

2-4

Page 41

28 August, 2000 IMAGE PROCESSING

2.4.2 IMAGE ROTATION

LD Section

Scanner

Section

R/G/B

10 bits

IPU

Section

Y/M/C/K

8 bits

Image rotation

80 MB memory

Dither

processing

Laser

exposure

B017D505.WMF

• The image rotation circuit is located on the LD control board.

• CMYK data processed in the IPU section is sent to the LD control board.

• Image rotation circuit has 80MB memory.

• 64MB to store up to A3/DLT mono toner color image data

• 16MB to store image separation data.

• After the image is rotated in this circuit, dither processing is applied to the image

data and laser exposure begins.

• Since mono-toner color (CMYK) image data can be stored in memory, the

scanner only scans the image once to make multi-copies.

2.4.3 LASER EXPOSURE

Detailed

Descriptions

[B]

[A]

B017D505.WMF

• New polygon mirror motor [ A] to achieve real 600 dpi.

• Rotates at 36,850 rpm.

• The polygon mirror motor cooling fan [B] is beside the optical housing unit

because of this high-speed rotation.

2-5

Page 42

IMAGE PROCESSING 28 August, 2000

2.4.4 LASER POWER CORRECTION

B017D507.PCX

Even if the power from the LD unit is the same from side to side, laser power is not

evenly applied across the drum surface due to the characteristics of the F-theta

and Barrel Torroidal lenses as shown by the curve in the illustration. These

characteristics cause the laser power at the center to be slightly stronger than at

either side. This causes uneven image density on your printout.

Since all scanner units have the same characteristics, a correction curve is applied

to the laser power exposed from the LD unit so that the laser power applied across

the drum surface becomes even. The curved line in the illustration becomes

straight by applying the correction to the laser power.

2.4.5 DITHER PROCESSING

B017D508.WMF

• Two dither patterns for Text and Photo modes.

• In Text mode, dither patterns are made with 2x2 dot units for fine resolution.

• In the Photo mode, dither patterns are made with 3x3 dot units.

• Using the larger unit makes the image appear smoother, improving the quality of

grainy images.

2-6

Page 43

28 August, 2000 IMAGE PROCESSING

2.4.6 PULSE POSITIONING CONTROL

• The location of the active part of the laser signal

can be on either the left or right side of each pixel.

• The positioning of the active part of the laser signal

shifts to the left or right depending on adjacent

pixel values.

• W hen scanning the gray solid image, top righ t, all

active parts locate on the left side of each pixel if

pulse-positioning control is not used.

• Engine capability problems cause these thin lines

to be reproduced improperly.

• The line is not completely straight because image

data was lost. This also causes grainy images.

Detailed

Descriptions

• Pulse positioning control thickens the lines and

reproduces them properly without any image loss.

• This causes the lines to appear smoother. (This

improves the quality of grainy images.)

B017D516.WMF

2-7

Page 44

DEVELOPMENT UNIT 28 August, 2000

2.5 DEVELOPMENT UNIT

2.5.1 OVERVIEW

To optimize image development, a high frequency AC component has been

applied to the development bias. The high frequency AC component improves the

quality of grainy images.

2.5.2 TONER SUPPLY

[B]

[A]

[C]

[E]

[D]

B017D518.WMF

B017D519.WMF

When the revolver unit rotates, small amounts of ton er tend to flow into the

development unit. This causes the toner concentration to increase. To prevent

toner from flowing into the development units, a small window [A] is added to the

development shutter [B] and a magnet [C] is attached on to the toner supply pipe

[D].

A small amount of developer flows back into the toner supply pipe through the

small window on the shutter during the revolver rotation and is caught by the

magnet. The developer caught by the magnet functions as a shield and prevents

toner from flowing into the development unit. When toner is supplied to the

development unit, the supply auger [E] rotates and supplies the proper amount of

toner.

2-8

Page 45

28 August, 2000 IMAGE TRANSFER BELT UNIT

2.6 IMAGE TRANSFER BELT UNIT

2.6.1 OVERVIEW

The image transfer function is the same as the A258/259/260 copiers. The

changes described below were applied to the B017/018 to improve reliability and

image quality.

Image transfer unit positioning

• Changed to maintain the width of the photoconductor gap.

• Changed compression spring position and the shape of the drum stay.

Current feedback system

• Optimized the image transfer bias.

• Automatically corrects the current applied to the belt to apply a constant

optimum transfer bias to the belt.

• This also prevents dark spots.

Touch and release mechanism

• Added a solenoid to the image transfer belt unit.

• Keeps the image transfer belt away from the drum between copy jobs

• Prevents drum fatigue due to residual voltage on the belt.

Paper transfer mechanism

• Added brush to the image transfer belt unit

• Changed the shape of the paper guide of the paper transfer unit.

• Ensures correct paper transfer

• Improves the quality of the toner blaster image.

Detailed

Descriptions

2-9

Page 46

IMAGE TRANSFER BELT UNIT 28 August, 2000

2.6.2 IMAGE TRANSFER BELT UNIT POSITIONING

[E]

[C]

[F]

[A]

[B]

B017D593.WMF

• The release lever [A] is at the front of the unit.

• Moving the release lever rotates the release lever cam [B].

• Rotating the release lever counterclockwise applies tension to the belt

• The positioning cam [C] located at the end of the release shaft [D] moves in the

same direction.

• The positioning cam moves along the rear frame [E]

• It is pushed outward by the rear frame because of the shape of the cam.

• A compression spring [F] is also located between the end of shaft and the

positioning cam.

• This spring applies the pressure to the image transfer belt unit and places the

unit in the proper position.

• To properly place this unit on A258/259/260 copiers:

• Compression spring put on the front side of the image transfer belt unit

• The drum stay presses the spring, which maintains the position of both the

transfer belt and drum units.

• W hen securing the transfer belt stay with screws, its position might fluctuate

slightly

• This is due to the pressure applied from the spring, causing the

photoconductor gap to change slightly.

• To maintain this gap, the compression spring position and the transfer belt

stay shape were changed for the B017/018 copiers.

2-10

Page 47

28 August, 2000 IMAGE TRANSFER BELT UNIT

[C]

[D]

[A]

Detailed

Descriptions

[B]

B017D517.WMF

The belt cleaning clutch [A] transfers drive from the fusing motor to the belt

cleaning shaft [B] through the couplings [C]. If the couplings are not properly

engaged as shown [D], this may cause SC457 (ITB cleaning unit position error).

This may happen when the machine power is on after the image transfer belt unit is

installed.

If the couplings are not properly engaged, the coupling on the belt cleaning shaft is

pressed by another coupling and the shaft moves to the front side of the copier as

shown by white arrow. Rotating the belt cleaning shaft can properly connect the

couplings by using a screwdriver to turn the shaft.

2-11

Page 48

IMAGE TRANSFER BELT UNIT 28 August, 2000

2.6.3 CURRENT FEEDBACK SYSTEM

[B1]

[C]

[B2]

[E]

[D]

[A]

B017D595.WMF

• Electrical resistance of image transfer belts varies belt to belt.

• Current applied to the image transfer belt changes due to the variation of

electrical resistance.

• The current feedback system was adopted to optimize the transfer bias.

Insulated material is used for the roller [A]

• A receptacle [B2] was added to the rear side of the belt tension roller.

• This receptacle is connected to the high voltage supply board - T1, PCC [C].

• Current flows from the high voltage supply board to receptacle [B1] to the

transfer bias roller [D] then to the belt. From the belt it is transferred to the

tension roller [E] then to the receptacle [B2] and finally back to the high voltage

supply board.

• The current fed back to the high voltage supply board changes because the

electrical resistance of the belt varies.

• The current applied to the belt is automatically corrected thereby applying a

constant optimum transfer bias to the belt.

2-12

Page 49

28 August, 2000 IMAGE TRANSFER BELT UNIT

2.6.4 TOUCH AND RELEASE MECHANISM

1 mm

[E]

[A]

[D]

[B]

[C]

B017D594.WMF

• If the image transfer belt is always in contact with the drum surface, residual

voltage remains on the belt because the bias is always applied to the image

transfer belt during operati on .

• Residual voltage may cause drum fatigue, resulting in darker bands on

copies.

• A solenoid [A] was added to the image transfer belt unit to prevent drum fatigue.

• The solenoid turns off between each copy job to keep the belt away from the

drum.

• The image transfer belt is in contact with the drum whenever it rotates

because the drum motor drives the belt.

• The soleno id turns off to keep the belt away from the drum 100 milliseconds

after the drum motor stops between each copy job

• It turns on again 100 millisec onds before the drum motor starts rotating to

bring the belt in contact with the drum.

• When the solenoid turns off, the release bracket [B] is pulled by the spring [C].

• The bracket [B] pushes the stay [D] for the insulation roller [E] down, resulting in

approximately a 1-mm clearance between the drum and belt.

Detailed

Descriptions

2-13

Page 50

IMAGE TRANSFER BELT UNIT 28 August, 2000

2.6.5 PAPER TRANSFER MECHANISM

[A]

B017D596.WMF

• Brush [A], in the image transfer belt unit, pushes the belt down.

• This ensures that paper comes in contact with the image transfer belt before

the electrical field affects the toner on the belt.

• High voltage applied to the paper transfer roller generates the electrical field.

• If this field affects the toner before the paper comes in contact with the belt,

toner will be scattered around the image on the paper or smeared.

2-14

Page 51

28 August, 2000 REGISTRATION

2.7 REGISTRATION

Detailed

Descriptions

[A]

B017D599.WMF

While making copies, paper dust is transferred to the paper transport section. The

paper transport roller is cleaned by the cleaning blade; however, paper dust may

cause cleaning efficiency to drop, resulting in the dirty backgrounds on the back

side of copies. To prevent this, a cleaning scraper [A] was added to the registration

roller section. The cleaning scraper removes paper dust off of the registration roller.

The edge of the scraper needs to be cleaned at every PM to maintain cleaning

efficiency.

2-15

Page 52

FUSING 28 August, 2000

2.8 FUSING

2.8.1 MAJOR COMPONENTS

22

21

20

19

18

17

1. Heat Roller

1

2

345

6

7

8

23

9

10

11

1213141516

B017D501.WMF

24

B017D502.WMF

13. Pressure Roller Thermofuse

2. Heat Roller Thermostat

3. Heat Roller Thermistor

4. Oil Supply Roller

5. Oil Supply Pad

6. Oil Supply Sub-Roller

7. Oil Blade

8. Fusing Belt

9. Hot Roller

10. Hot Roller Fusing Lamp

11. Pressure Roller

12. Pressure Roller Fusing Lamp

14. Pressure Roller Thermistor

15. Paper Exit Sensor

16. Fusing Exit Roller

17. Fusing Exit Sub-Roller

18. Exit Roller

19. Exit Sub-Roller

20. Pick-off Pawls

21. Tension Roller

22. Heat Roller Fusing Lamp

23. Pressure Roller Cleaning Blade

24. Pressure Roller Cleaning Pad

2-16

Page 53

28 August, 2000 FUSING

2.8.2 DRIVE MECHANISM

[A]

[C]

[F]

[B]

[D]

[G

[E]

B017D503.WMF

• The fusing motor [A] drives the fusing and paper exit units.

• The fusing clutch [B] transmits drive to the fusing drive gear [C].

• W hen the CPU detects that the fron t door is opened (by the signal from the front

door switch), it turns off the clutch,

• The clutch cuts the drive transmission from the drive gear [C].

• There are also gears [D] at the front of the hot and pressure rollers to reduce

creasing.

• The friction between the fusing belt and hot roller drives the fusing belt [E].

• The fusing belt drives the heat roller [F] using this friction.

• The tension roller [G] applies tension to the fusing belt

• The friction from the fusing belt rotates it.

• This roller cleans the fusing belt surface.

Detailed

Descriptions

2-17

Page 54

FUSING 28 August, 2000

2.8.3 FUSING UNIT

Fusing Mechanism

[A]

[C]

[K]

[I]

[B]

[G]

[H]

[J]

[D]

[E]

B017D504.WMF

[F]

• A belt fusing system was adopted to reduce the warming-up time.

• Warming-up time is 4.5 minutes.

• The heat roller [A] is made of aluminum

• The fusing belt [B] is made of resin coated with silicone rubber.

• The heat roller and fusing belt heat up faster because the heat conduction

efficiency increased compared to the hot and pressure roller system.

• The heat, hot, and pressure rollers have a fusing lamp:

• 500W [C] for the heat roller,

• 150W [D] for the hot roller [E],

• 400W [F] for the pressure roller [G].

• The heat roller thermistor [H] controls the heat and hot roller fusing lamps.

• These two lamps turn on and off simultaneously.

• The fusing lamp for the hot roller evenly heats the roller. This prevents

uneven fusing for the 1st copy after the power is switched on.

• The pressure roller thermistor [I] controls the pressure roller fusing lamp.

• W hen the main switch is turned on, the fusing rollers start rotating (idling mode)

after the fusing belt temperature reaches 150°C.

• The pressure roller then absorbs the heat of the fusing belt.

• Then, the fusing belt temperature drops from 150°C.

• Fusing rollers stop rotating after the fusing belt temperature reaches 150°C,

again.

• Temperature control is normally accomplished by turning the fusing lamps on

and off (SP mode (SP1-104).

• Thermostat [J] and thermofuse [K] prevent the temperature in the fusing section

from rising to dangerous levels.

• The heat roller thermostat [J] blows at 200°C

• The pressure roller thermofuse [K] blows at 117°C.

2-18

Page 55

28 August, 2000 FUSING

By adopting a heat roller made of aluminum, the temperature of the fusing belt

increases quickly. This may cause the fusing belt temperature to rise too high

before the thermofuse blows, therefore the thermostat was adopted. The

thermostat is in contact with the non-image area of the fusing belt and blows at

200°C.

Fusing Temperature Control

The fusing temperature depends on the selected copy modes, as shown below.

The defaults indicated in the table can be adjusted with SP modes.

State/

Mode

Rollers

Fusing:

simplex,

duplex side 1

Fusing: ,

duplex side 2

Pressure:

simplex,

duplex side 1

Pressure: ,

duplex side 2

Stand-by

Mode

175 °C 160 °C 175 °C 150 °C 170 °C

175 °C 160 °C 175 °C 150 °C 170 °C

150 °C 100 °C 150 °C 150 °C

150 °C 100 °C 150 °C 150 °C

Single Color Full Color

Normal OHP/Thick Paper

Copy Mode

Single

Color

Full Color

Detailed

Descriptions

2-19

Page 56

FUSING 28 August, 2000

Fusing/Pressurization Mechanism

[B]

[A]

[C]

[D]

[E]

B017D514.WMF

• The hot and pressure rollers are made from silicone.

• The oil supply mechanism makes it easier for paper to separate from the fusing