Page 1

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

Installation Procedure

Please add the following steps after step 24 on page 3-58 of the service manual.

Iris/Lilac

Color Controller Installation Procedure

Technical service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

25. Turn on the machine.

If the machine is A259 or A260, skip the remainder of this step.

For A258 machines, use SP7-801-000 to confirm that the firmware version of

the main control board is v.6.43 or later. If it is not, the copier's firmware must

be upgraded (to allow the controller connection).

26. Change SP3-125-000 from 0 (Default) to 2.

27. Enter SP3-126-000 then:

A258: Press 1 and #

A259/260: Press ON.

Part information

Electrical

Transmit/receive

Date:

30-Apr-99

Prepared by:

No.:

RA258001

Y. Sasa ki

Action required

Service manual revision

Retrofit information

28. After doing the forced process control self check, check that the result is “1”

(successful) using SP3-975. (A259/260 machines automatically display the

result on the screen). If the result code is a number other than 1, consult the

error code chart (see the troubleshooting section of the service manual).

29. Do the ACC for printer. If necessary, do the AutoCal procedure of the controller

calibration.

30. Check SP6-910-000. The setting should be “1” for the controller.

-Explanationz SP3-125-000 [Potential Control] (0: Auto, 1: FIX, 2: Auto+2/3 Spd)

0: The machine does the process control self check only at normal speed for

1: The machine does not do the process control self check. It applies fixed

2: The machine does the process control self check at normal speed for copier

copier mode.

voltages for Vb, Vd, and Vl.

mode. The machine then confirms the process control self check information

at 2/3 speed for the printer mode. Therefore it takes a little longer to finish the

process control self check.

z SP6-910-000 [Printer/Scanner key setting]

When installing the E-300 controller, this should be set to 1. If the setting is 0,

the Printer/Scanner key on the controller LCD panel does not work.

Page 2

RICOH Technical

Bulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

This RTB explains the user tools (system settings) which affect the copier/printer

operations.

1. AOF Setting

When installation of system software is nece ssary, make sure that the AOF setting is OFF

using the user tools.

Iris/Lilac

User tools for the printer system

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-May-99

Prepared by:

No.:

RA258002

Y. SASAKI

Action required

Service manual revision

Retrofit information

If the AOF setting is ON, the machine might go into the sleep mode and the system

software download might fail.

2. System Reset: (Default: On [60 seconds])

When the copier is in the following modes, print jobs are not accepted. The “System

Reset” resets these modes when the copier is left unoperated for the selected period of

time.

Interrupt mode (The condition in which the interrupt key is pressed.)

l

Sorter mode

l

Duplex mode

l

ADF mode (after cancelling ADF mode, the originals which are in the ADF are

l

automatically fed out.)

Note: The above modes are not reset by the “Copy Reset”.

3. Interleave Print (Default: On)

When “Interleave Print” is on, the machine accepts a print job while copying, or vice versa.

The copy job and the print job are printed alternately 1 sheet at a time in normal mode, or

2 sheets at a time in double-page transfer mode (two pages at once on the transfer belt).

When the setting is off, the machine prints the first job completely, then it waits for the

Function Reset interval, and the second job is started.

Page 3

RICOH Technical

Bulletin

PAGE: 2/2

Model:

4. Interleave Priority: (Default: On) (A259/A260 only)

Do not use this user tool.

5. Function Reset (Default: On [60 seconds])

The “Function Reset” only works when “Interleave Print” is set to OFF.

Iris/Lilac

Date:

31-May-99

No.:

RA258002

Page 4

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Iris/Lilac

SC Codes

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Jul-99

Prepared by:

No.:

RA258003

T. Itoh

Action required

Service manual revision

Retrofit information

SC codes 410, 901, and 902 are missing from the service manual. Please correct your

service manual.

SC

Code

SC410 Paper

Item Detection Condition Possible Cause Troubleshooting Procedure

separation

current leak

When the current

leak is detected for

2 seconds while the

paper separation

corona is on.

•

Paper

separation

corona unit not

set properly

•

Corona wire

broken

•

Defective high

voltage supply

board (T2, D)

•

Defective I/O

control board

•

Defective

main control

board

1. Check to see if the separation

corona unit is set properly.

2. Replace the corona wire if it is

broken.

3. Check to see if the connectors are

properly connected.

4. Clean the receptacle.

5. Replace the high voltage supply

board (T2,D).

6. Replace the I/O control board.

7. Replace the main control board.

- Signal Check -

CN227-A1 on the I/O control board

SC901 Upper total

counter error

SC902 Lower total

counter error

•

Feedback

signal stays low

when the main

switch is turned

on.

•

Feedback

signal stays low

just before the

trigger signal

goes on.

•

Feedback

signal stays high

just before the

trigger signal

goes off.

Poor connection

of the connectors

Defective counter

1. Check if the connectors are properly

set.

2. Replace the total counter.

With the current software, SC410 is detected only in the print mode. This SC code was

falsely detected during the development stage, so it was temporarily deleted from the

software. However, the software change was only reflected in the copy mode. The cause

of the false detection was found recently and the modification will be applied. The software

will be modified to reflect this SC code in the copy mode as well.

Page 5

T

echnical

ulletin

B

PAGE: 1/1

Model:

Subject:

From:

Classification:

Please make note of the following remarks in order to prevent damage to the drum

potential sensor and/or detection errors.

Iris/Lilac

Handling of drum potential sensor

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Jul-99

Prepared by:

No.:

RA258004

T. Itoh

Action required

Service manual revision

Retrofit information

REMARKS

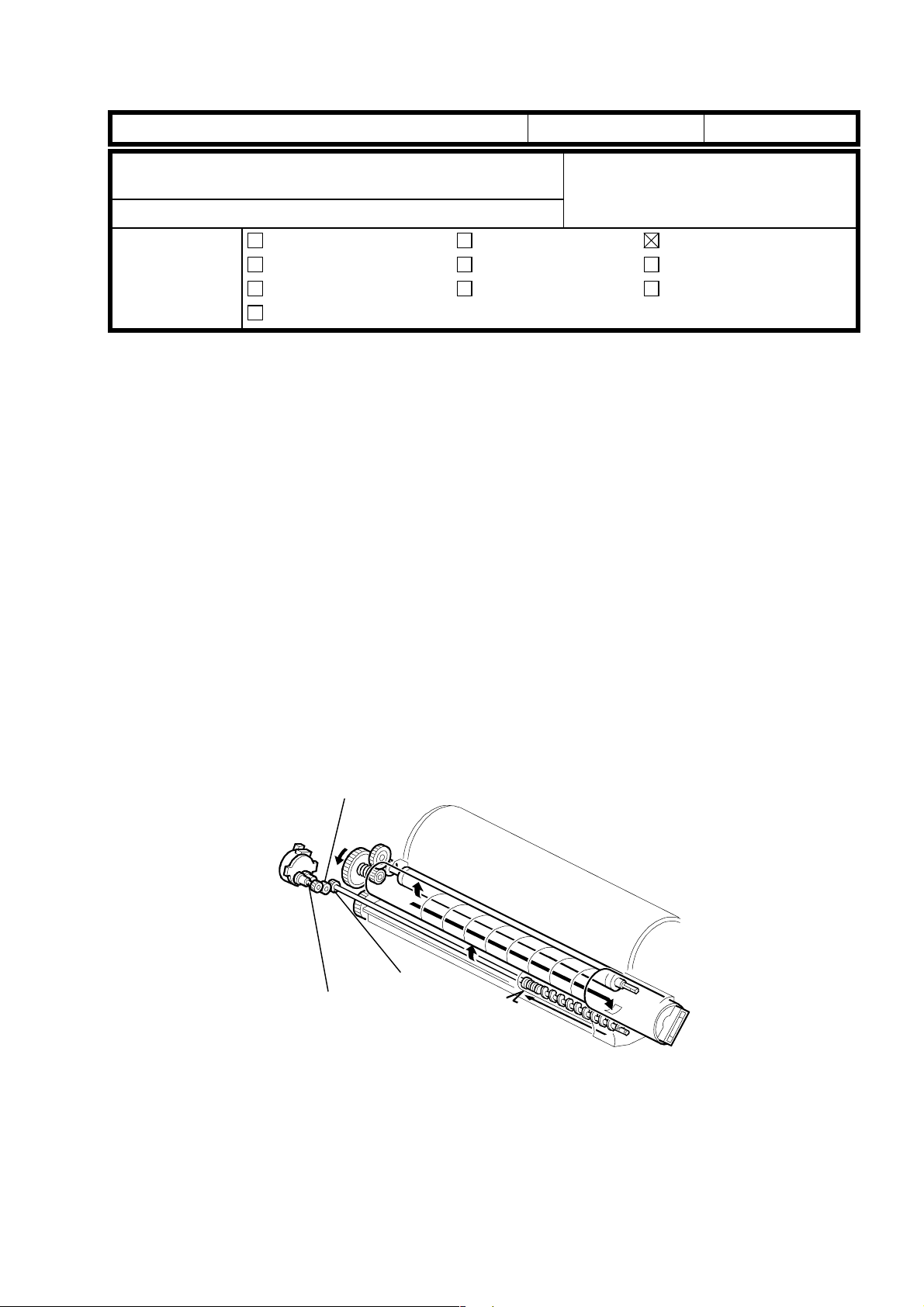

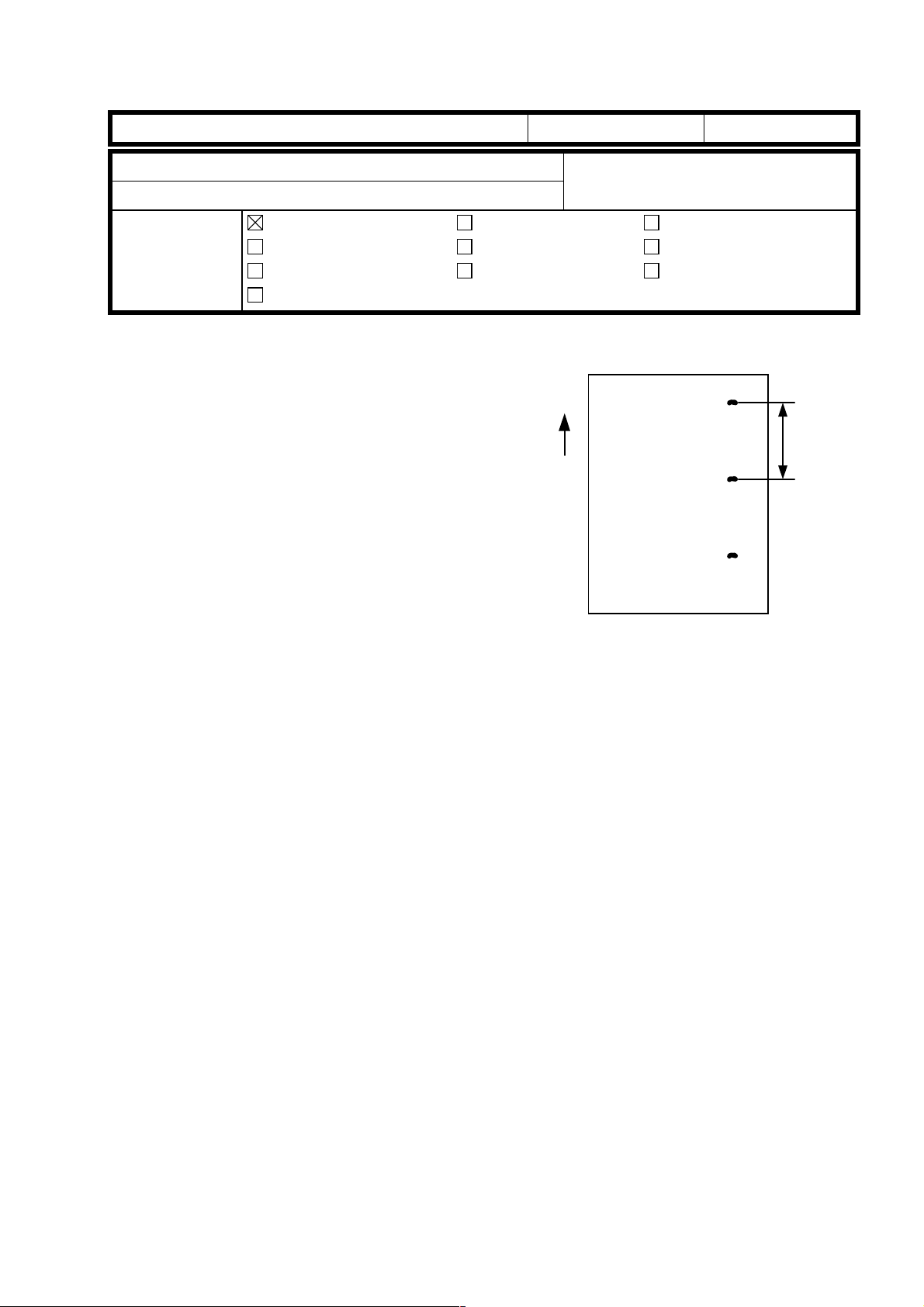

• The sensor is very sensitive. Do not drop the sensor or subject the probe [A] to shock

in any way. Please handle it carefully.

• The service manual shows that the setting powder is applied to the drum in the drum

unit. If the powder goes into the sensor through the window [B] or accumulates around

the window, it may cause the sensor to detect the potential incorrectly. Therefore,

please apply the setting powder to the drum before the drum is placed in the drum unit.

• If the potential sensor is not installed correctly in the drum unit, an error such as 20*,

41* or SC387 will result during the process contro l self-check.

[A]

[B]

Page 6

T

echnical

ulletin

B

PAGE: 1/2

Model:

Subject:

initialization

From:

Classification:

The following problem was reported from the field.

Iris/Lilac

False Bk Toner end detection / Error 511 at developer

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Jul-99

Prepared by: T. Itoh

No.:

RA258005

Action required

Service manual revision

Retrofit information

SYMPTOM

1. False Bk toner end detection during developer initialization

2. Developer setup error code 511 during developer initialization

CAUSE

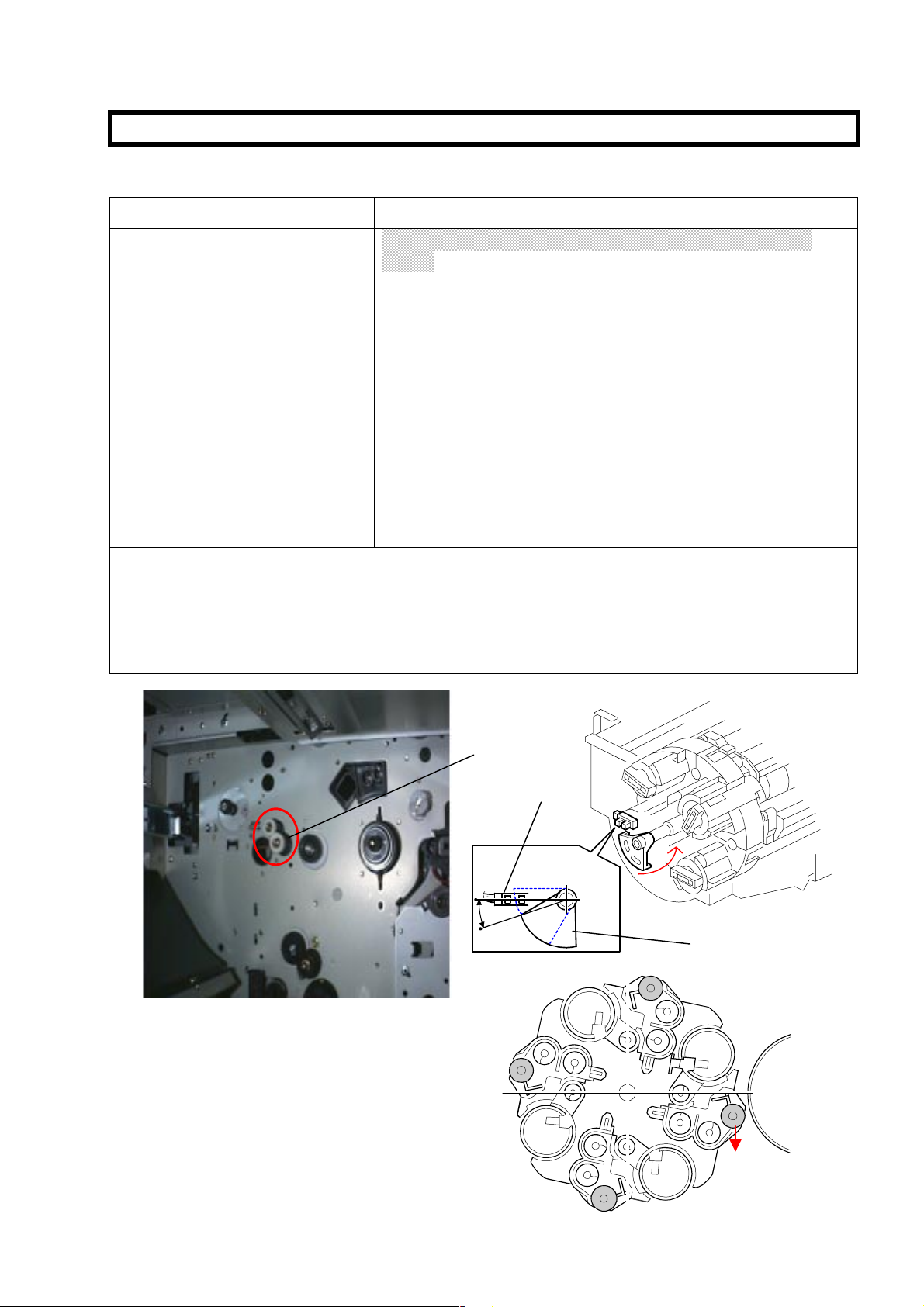

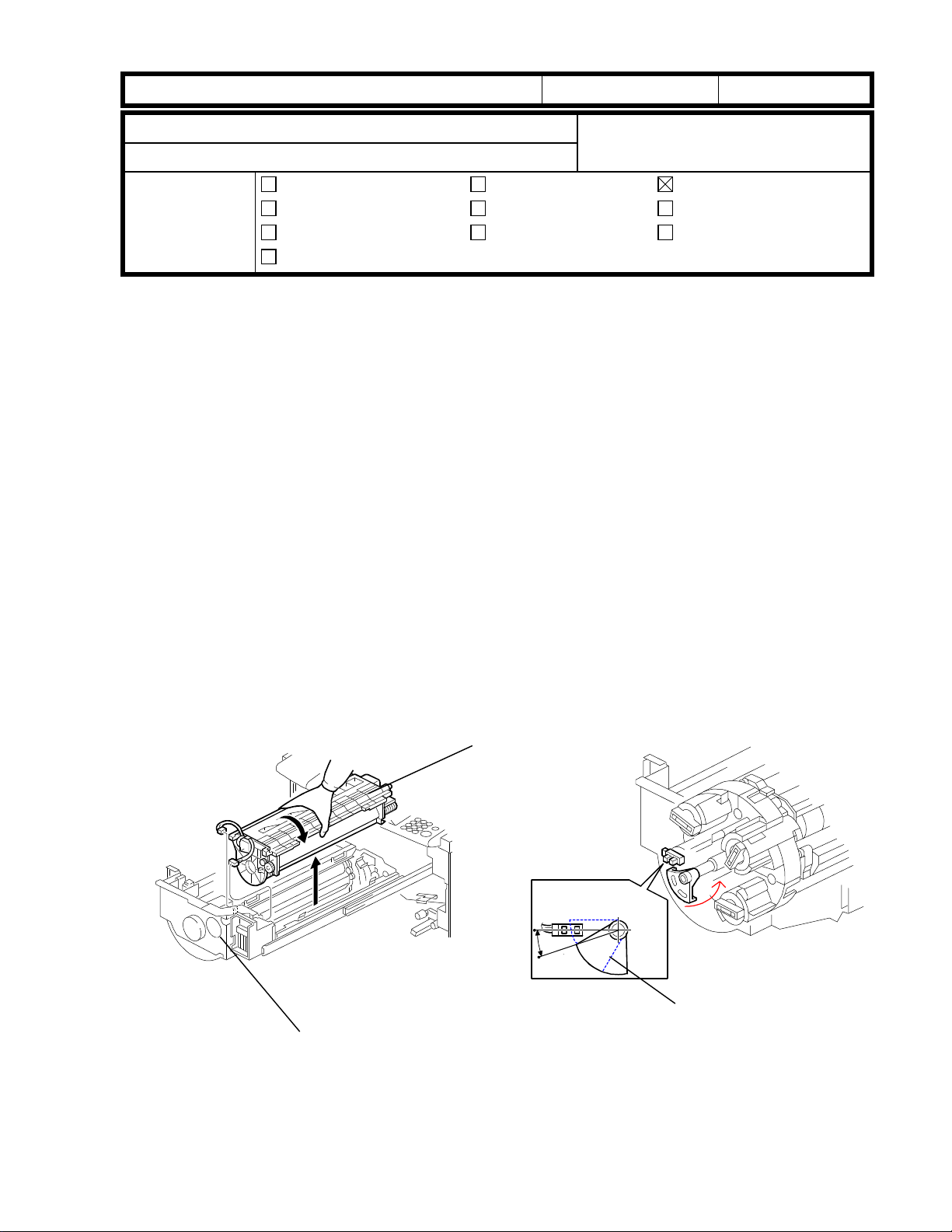

1. The toner supply motor gear [A] and toner supply gear [B] were not properly engaged.

This caused the toner to be not supplied. The toner supply motor may have been

incorrectly positioned and then secured in this position during the production stage. In

such a case, either the motor gear [A] did not touch the toner supply gear [B] and/or the

gears were engaged too tightly, causing the gear shafts [C] to bend.

2. The toner supply gear [B] was broken. When the drawer unit is inserted in the machine

with the development unit located at the development position, the toner supply gear [B]

contacts the motor gear [A]. This may cause the gear [B] to be broken.

[A]

[B]

[C]

Page 7

T

echnical

ulletin

B

PAGE: 2/2

Model:

Iris/Lilac

Date:

15-Jul-99

No.:

RA258005

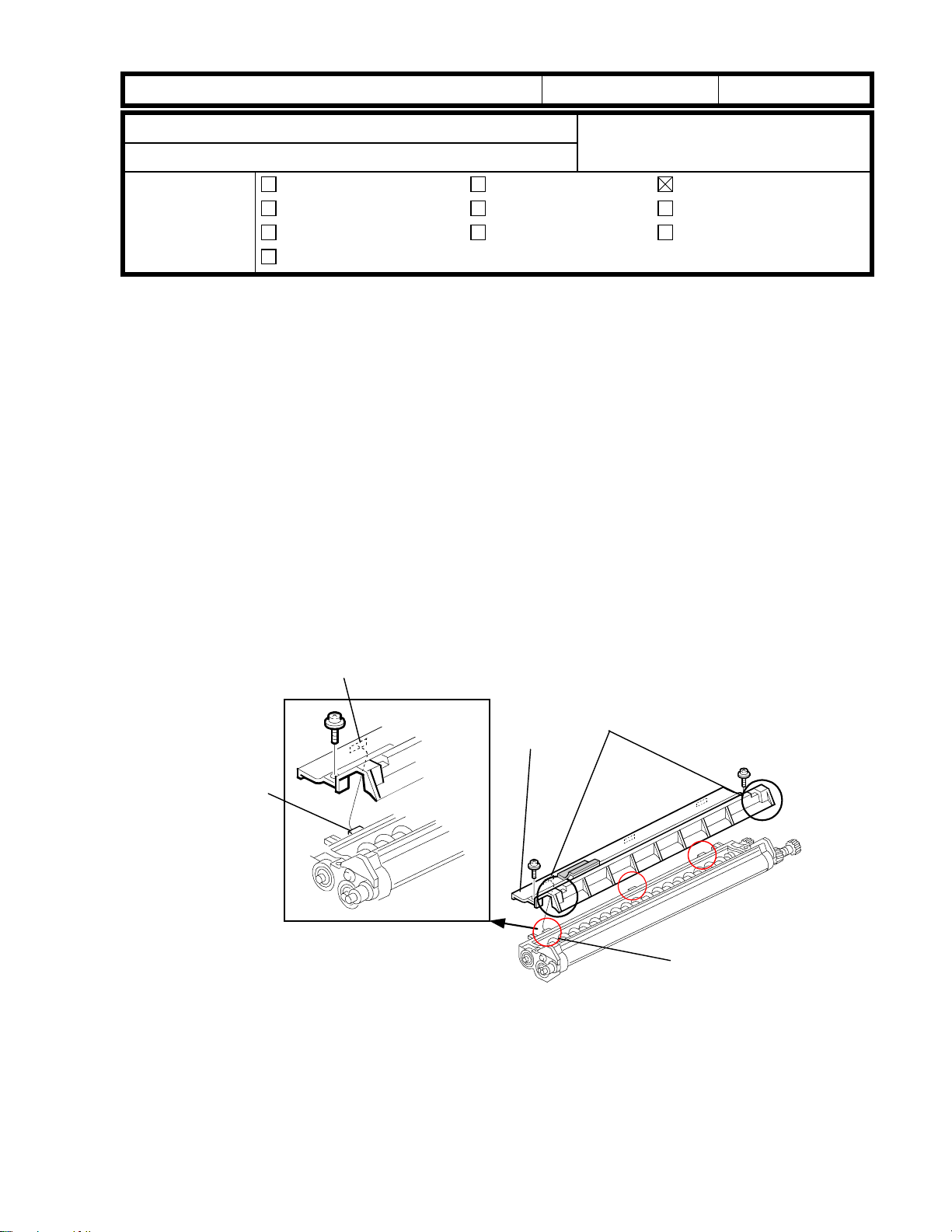

SOLUTION

Production Field

1 It has been ensured that

the motor was properly

placed and secured in

the correct position. This

procedure has been

reflected in production

runs from April’99

onward.

2 When inserting the drawer unit into the machine, place the development un i t in a

position so that there is sufficient distance between the development sleeve and

the drum. Insert the drawer unit.

When installing machines produced in February and

March, check whether the toner supply motor is properly

positioned after the drawer unit is pulled out and make

sure that the plastic part (black) [A] is correctly placed in

the cutout in the rear frame. (Please refer to the picture

below this table.)

If the motor is not correctly positioned, remove the

motor.

If the gears on the motor shaft are properly engaged,

•

reposition the motor in the cutout properly.

If the gears on the motor shaft are not properly

•

engaged or the shafts have already been bent,

replace the motor.

Rotate the revolver counterclockwise so that the actuator [B] is positioned inside

the dotted lines as shown in the illustration.

[A]

[C]

[B]

Page 8

T

echnical

B

ulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

Iris/Lilac

Toner Hopper Seal

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

SYMPTOM

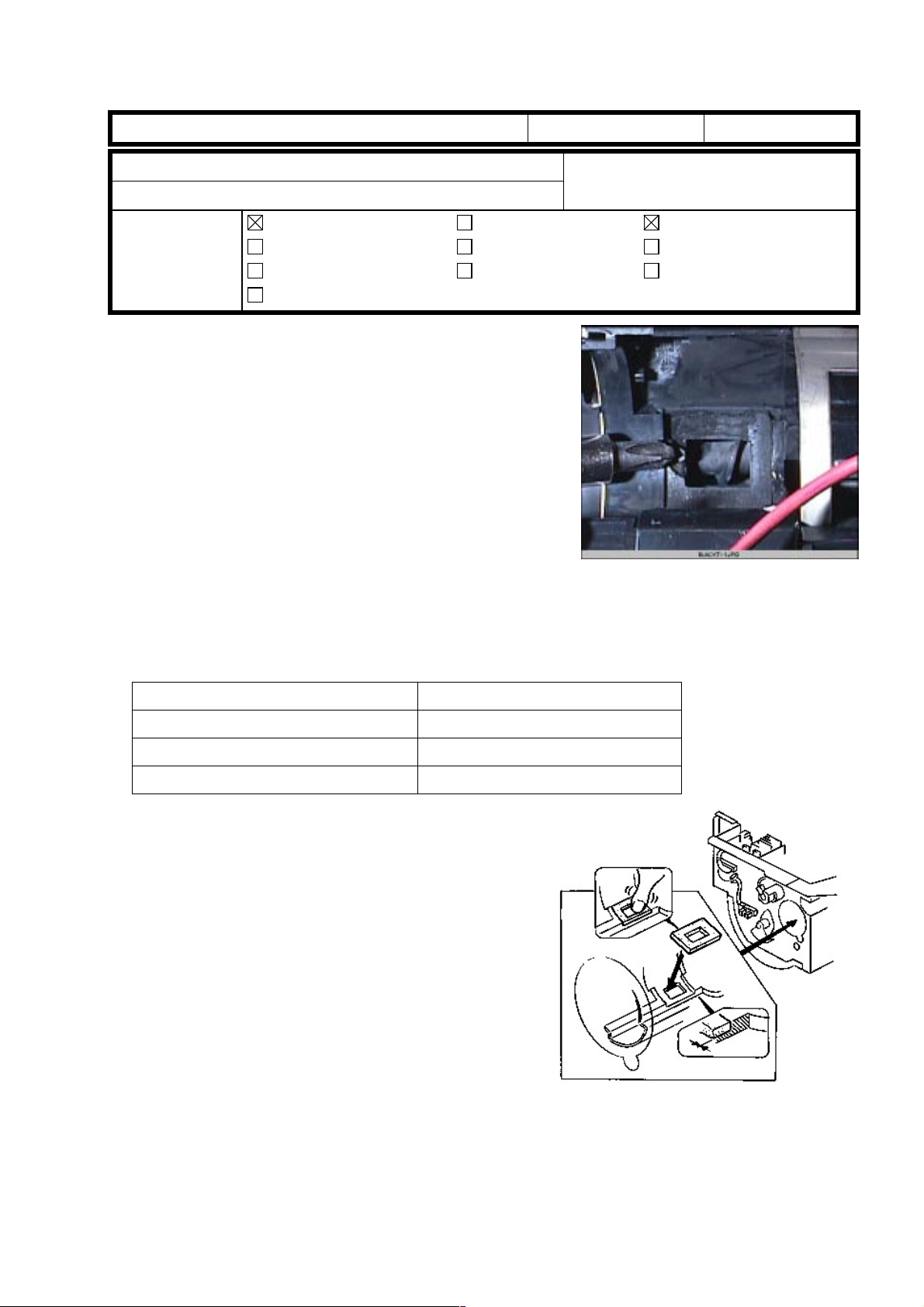

The toner hopper seal was damaged and peeled off as

shown in the picture. This caused the fit of the toner

bottle to become tight and/or the toner to leak and

scatter.

CAUSE

The toner hopper seal was not firmly attached to the

toner hopper. Therefore, when the toner bottle was

installed, the seal became torn off.

15-Jul-99

Prepared by:

Action required

Service manual revision

Retrofit information

T. Itoh

No.:

RA258006

SOLUTION

• The production procedure has been improved and the toner hopper seal was firmly

attached by pressing. This modification was reflected in the production as shown below.

Model Code

A258-17, 15, 19, 22, 26, 29, 55, 65 From the April ’99 production

A258-27 From the March ‘99 production

A259-All, A260-All From the first mass production

• If this problem is found in the field, replace

the seal by following the procedure described

below.

1. Remove the toner bottle.

2. Pull out the drawer unit.

3. Remove the damaged seal and clean the

surface of the toner hopper where the seal is

attached using alcohol.

NOTE: Make sure that no parts of the torn seal

fall into the toner hopper. If this

happens, white lines may result.

4. Attach the new seal. Make sure that it is

properly fixed in place by pressing firmly.

NOTE: P/N of toner hopper seal : #A2593346.

Page 9

T

echnical

B

ulletin

PAGE: 2/2

Model:

5. Remove the toner collection tray (saucer) and reattach the parts removed.

NOTE:

Iris/Lilac

During the above procedure, take extra caution so that your finger does not

become caught between the drawer unit and revolver.

Date:

15-Jul-99

No.:

RA258006

Page 10

T

Model: Iris/Lilac Date: 15-July-99 No.: RA258007

echnical

ulletin

B

PAGE: 1/1

Subject:

From:

Classification:

Dirty background

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

T. Itoh

SYMPTOM

Dirty background faintly appears in copy mode.

CAUSE

The reproduction of highlight areas has been improved from the previous products.

Therefore, the background of an original tends to come through on the copies.

SOLUTION

When receiving a complaint about the dirty background, please explain the above

mentioned cause, then, provide the customer with proper instructions, depending on the

mode selected as shown in the following table.

Symptom/Mode Troubleshooting

Dirty background in FC copy

mode

Back side of the original

appears

Dirty background in B&W

copy mode

(See NOTE.)

NOTE: To reduce the complaints from users, the following SP mode has been added. When

this SP mode is set to 1, Text mode becomes the default setting for the B&W copy mode.

SP mode : 5-005-008

Value range :0 or 1

Default : 0

Setting = 0 :The mode set in the User Tool (Copier Feature) is selected in the B&W copy

mode.

Setting =1 :When the B&W copy mode is selected, Text mode is automatically selected

regardless of the setting in the User Tool.

Instruct the user to select the Auto Image Density mode.

Instruct the user to select the Letter mode.

The Auto Image Density mode detects the background density

of an original, so it does not appear on the copy during the

image processing. This mode is effective for originals that have

high-density backgrounds like newspapers, but not for originals

that have low-density backgrounds.

Page 11

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

Iris/Lilac

Dirty marks at 142mm intervals

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

SYMPTOM

Dirty marks appear at 142 mm intervals on outputs.

Date:

15-Jul-99

Prepared by:

No.:

RA258008

T. Itoh

Action required

Service manual revision

Retrofit information

142 mm

CAUSE

Foreign material may be attached to the transfer belt drive roller.

SOLUTION

Clean the transfer belt drive roller.

NOTE: When this pr oblem happens and the drive roller is not cleaned, the transfer belt

itself may develop a ridged deformation along its length as a result of the foreign

material. This line/ridge is reflected in the copies.

Page 12

T

echnical

B

ulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

Iris/Lilac

Dark spots in solid areas

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Jul-99

Prepared by: T. Itoh

No.:

RA258009

Action required

Service manual revision

Retrofit information

SYMPTOM

In solid areas, dark spots appear as

shown in the illustration.

CAUSE

• The electrical resistance of the image transfer belt has a specified tolerance. If the

electrical resistance is in the lower area of the specification, the pre-fixed transfer bias

becomes higher than the optimum value. In this case, toner transferred onto the belt

tends to be re-attracted to the drum.

• Small carrier particles in the development unit tend to be physically attracted to the

drum. The carriers transferred onto the belt create a gap between drum and belt. Toner

on some parts of the transfer belt where the carriers are transferred are not re-attracted

to the drum due to the gap. The result is dark spots in solid areas as shown above.

• It is known that the dark spots problem tends to appear as the development potential

becomes higher. If the residual voltage detected by the drum potential sensor is 30V or

less, the potential sensor is damaged and this may cause the dark spots.

SOLUTION

1. Check the residual voltage with SP3-111-00. If the voltage is 30V or less, replace the

drum potential sensor and check whether or not the problem disappears. If not, see

step 2.

2. Decrease the transfer belt bias with SP mode as shown below.

In Copy mode: SP2-301-01 to 04

SP Mode Default Step 1 Step 2 Step 3 Step 4

SP2-301-01 1st color 1700 1200 1000 800 600

SP2-301-02 2nd color 1800 1300 1000 800 600

SP2-301-03 3rd color 1900 1400 1000 800 600

SP2-301-04 4th color 2000 1500 1000 800 600

Page 13

T

echnical

B

ulletin

PAGE: 2/2

Model:

NOTE 1:

Decrease the transfer belt bias from the 1st to 4th color by 500 volts each (Step 1) as

•

When the tr ansfer bias is decreased, it may cause the image in t he solid area to

•

In Print mode (2/3 speed):

SP2-301-13 1st color 800 1000 800 600

SP2-301-14 2nd color 900 1100 800 600

SP2-301-15 3rd color 1000 1200 800 600

Iris/Lilac

shown in the above table. Then, check whether the dark spots have disappeared

completely or partially. If the dark spots are still present on the cop y, decrease the bias

again as shown and check the results.

become rough or light since there will be less toner transferred onto the belt and/o r it

may cause firefly spots due to a small amount of clogged toner that causes a gap

between drum and belt. When the belt bias is decreased, check the level of both the

dark spots and rough image/firefly spots. Select the proper bias that gives the best

overall results.

SP2-301-13 to 16

DefaultSP Mode

S/M Ver. 6.43

Date:

15-Jul-99

Step 1 Step 2

No.:

RA258009

SP2-301-16 4th color 1100 1300 800 600

NOTE 2:

The default settings listed in the service manual has been changed in the main

•

software (Ver. 6.43) as shown in the above table.

Refer to the points explained in

•

3. Do the ACC (Auto Color Calibra tion ) after adjusting the transfer bias.

REMARKS:

When adjusting the transfer belt bias for da r k spots, the image quality concern ing the dark

spots, rough image, and firefly spots should be checked whenever the image transfer belt

is replaced. Also, if necessary, readjust the transfer belt bias.

NOTE 1

.

Page 14

T

echnical

B

ulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

The following problem was reported in the Japanese market. When servicing, please make

note of the following points in order to prevent these problems.

Iris/Lilac

How to route the oil supply tube

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Jul-99

Prepared by:

No.:

RA258010

T. Itoh

Action required

Service manual revision

Retrofit information

SYMPTOM

• Noise from the fusing section

• The oil supply roller does not rotate.

CAUSE

Silicone oil was not supplied to the oil supply pad and the pad became dry. When the

upper cover was installed, the cover pushed the oil supply tube [A] and the tube bent as

shown in Picture 3.

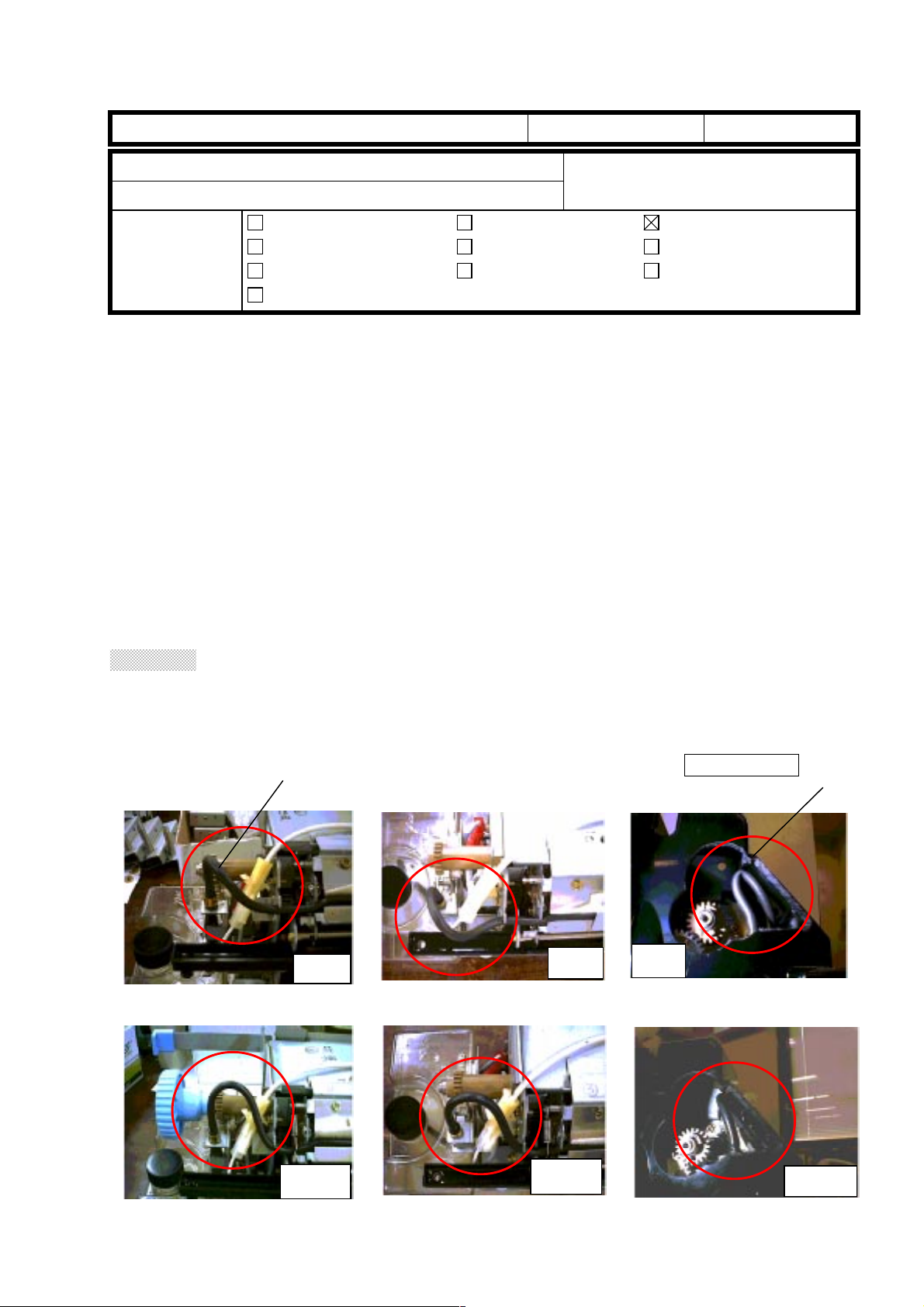

SOLUTION

In the field

If the oil supply tube [A] is routed as shown in Pictures 1 & 2, the tube may bend when the

upper cover [B] is installed as shown in Picture 3. To prevent this, the oil supply tube has

to be routed as shown in Pictures 4 & 5.

[A]

Picture 1 Picture 2 Picture 3

NG

Picture 4 Picture 5 Picture 6

NG: No Good

[B]

NG

Good

Good

Good

Page 15

T

echnical

B

ulletin

PAGE: 2/2

Model:

Mass production

In order to prevent this problem, the length of the oil supply tube will be changed from

290 mm to 265 mm.

Iris/Lilac

Date:

15-Jul-99

No.:

RA258010

Page 16

T

[A]

echnical

B

ulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

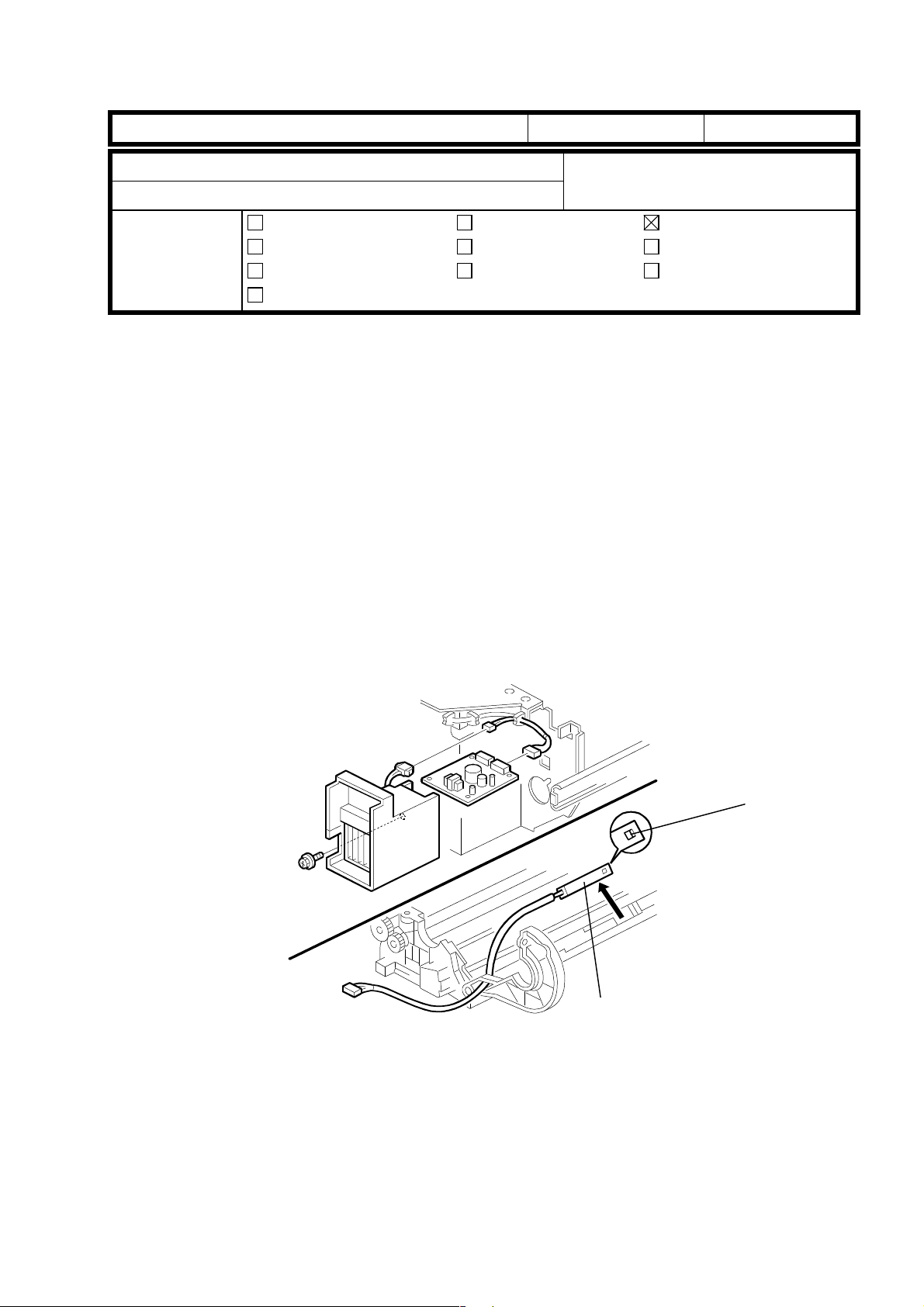

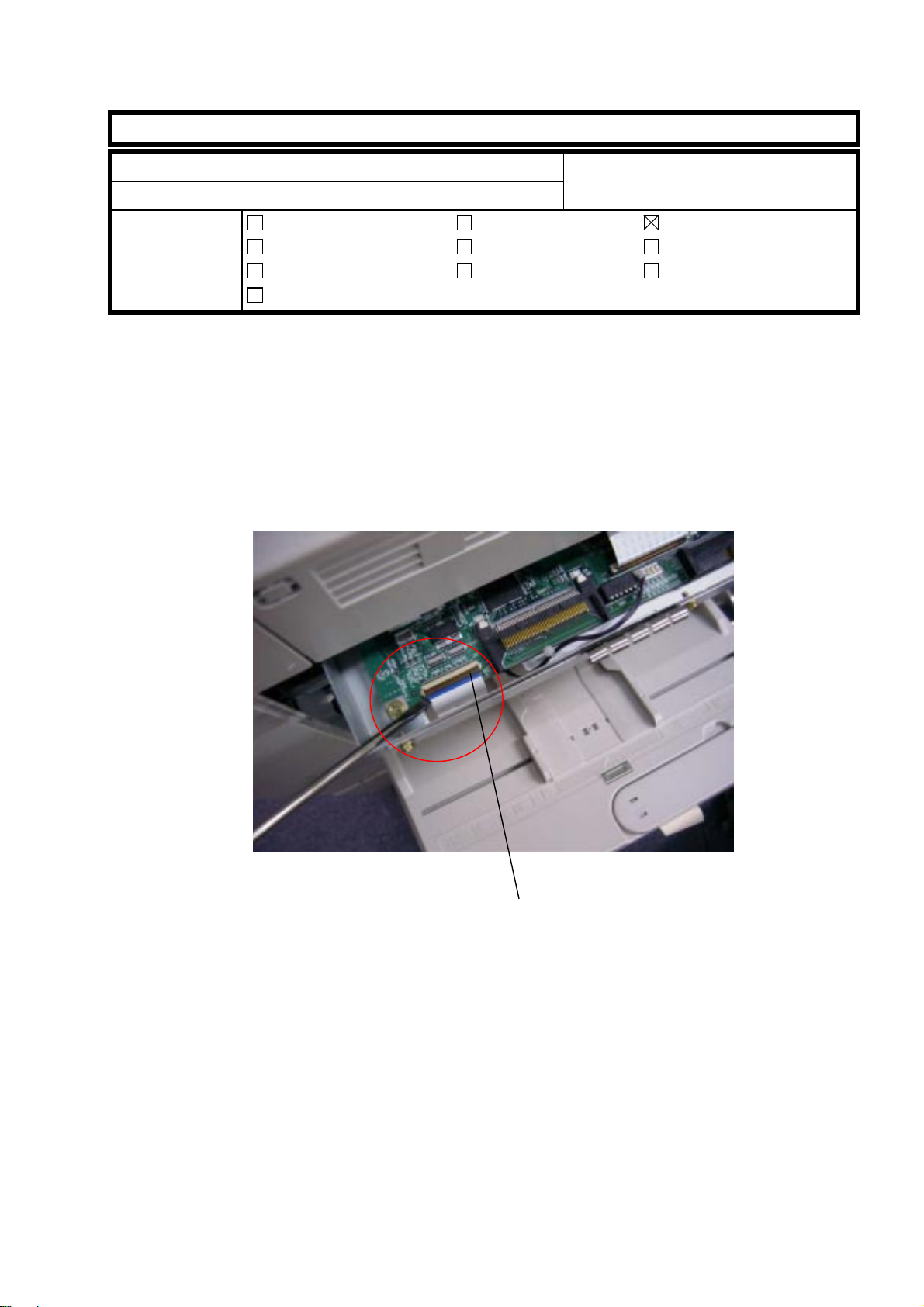

Some problems related to SC 326 or the ARDF were reported from the Japanese market.

These problems were caused by mistakes during installation. Please note the remarks

explained below and keep these items in mind when installing the I/F kit.

Iris/Lilac (Controller Interface Type E)

Remarks at Controller I/F kit installation

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Jul-99

Prepared by:

No.:

RA258011

T. Itoh

Action required

Service manual revision

Retrofit information

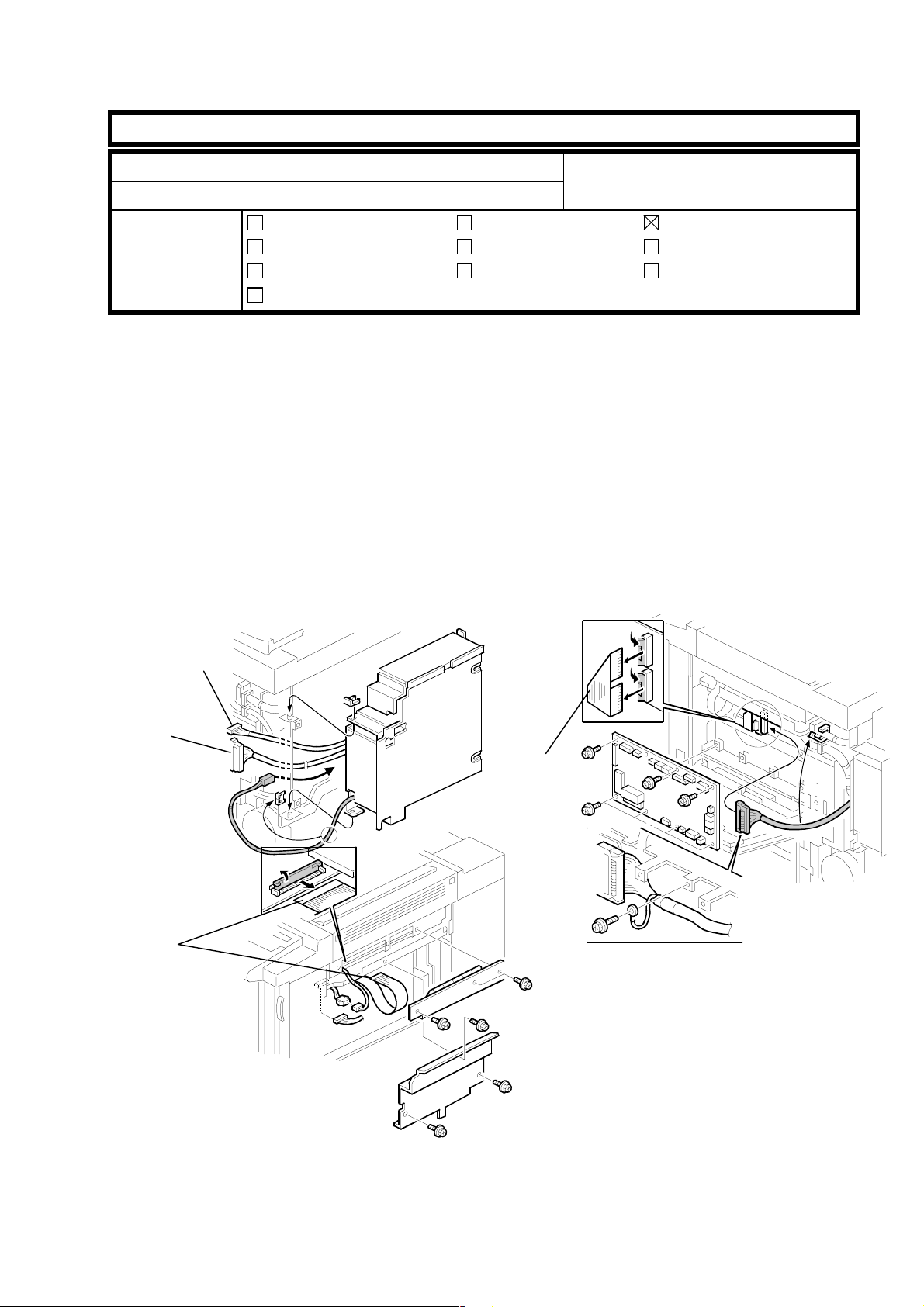

Remarks

1. Please remember that if the connectors are not properly connected or the shorting

cable is not removed, SC326 will occur. At each step of installation, make sure that:

(1) The 100-pin shielded cable connector [A] is properly connected.

(2) The I/F cable connector [B] is properly connected.

(3) The shorting cable [C] is removed.

(4) The LD flat cable [D] is properly connected.

[B]

[D]

[C]

Page 17

T

echnical

ulletin

B

PAGE: 2/2

Model:

2. Make sure that fiber optic cable connectors are correctly connected to the main control

Iris/Lilac (Controller Interface Type E)

board. White marks are painted on the connectors. If the fiber optic cables are

connected to the wrong connectors on the main board, the ADF will not function.

Date:

15-Jul-99

No.:

RA258011

Page 18

RICOH Technical

Bulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

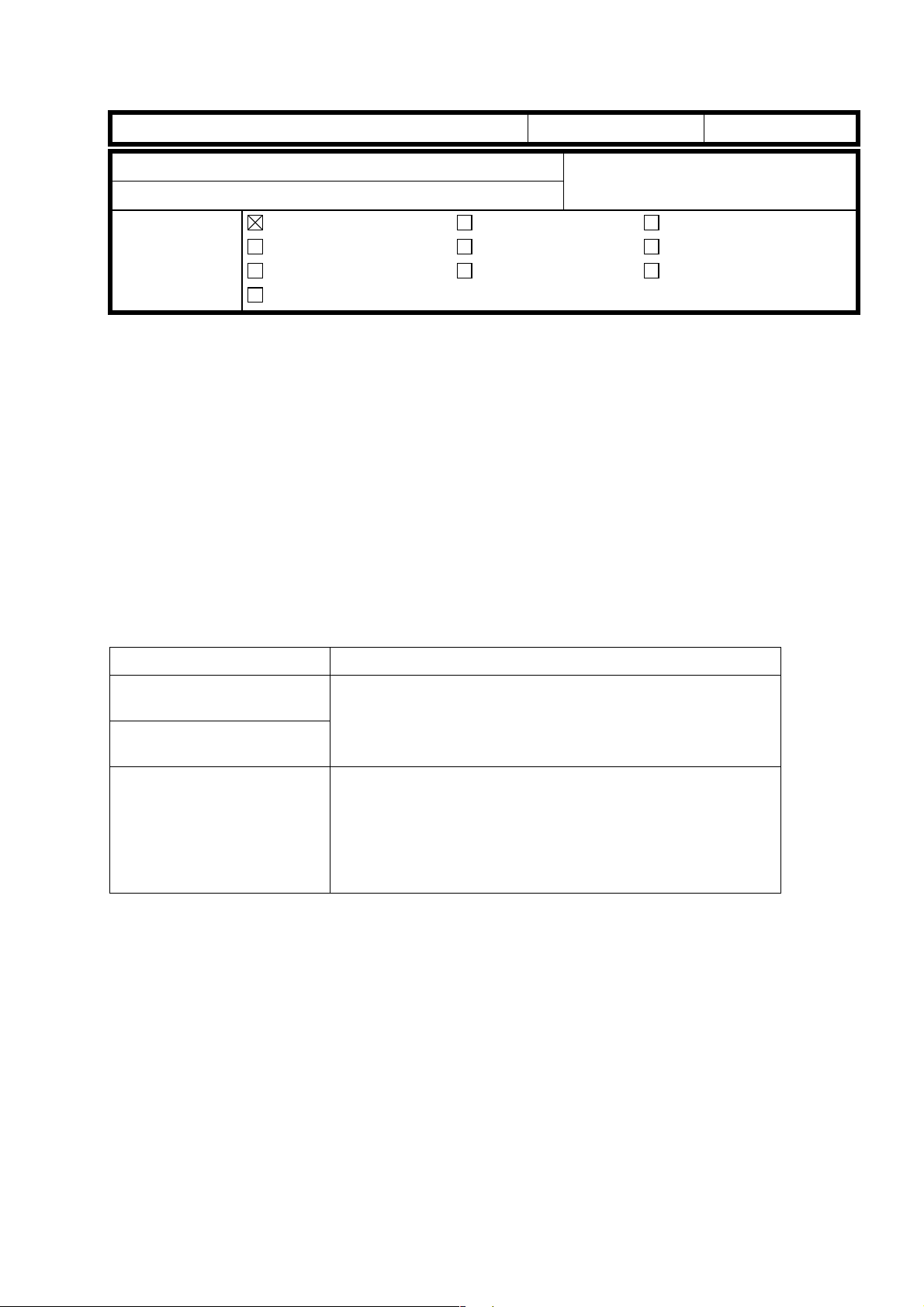

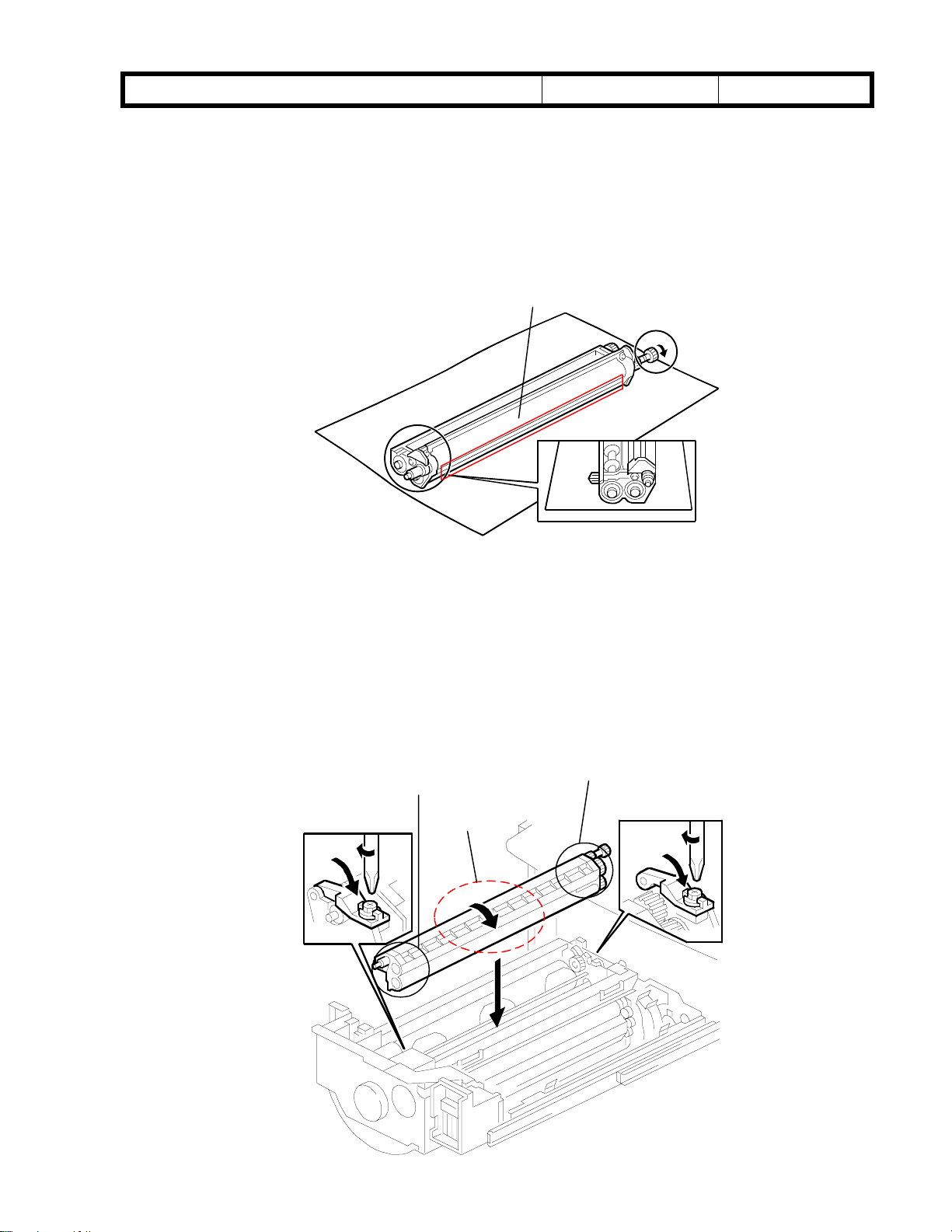

It is explained in the service manual that the drum unit [A] should be removed and covered

with a black sheet of paper or 5 or more white sheets when the drawer unit [B] is pulled

out. This will prevent light fatigue, which causes darker bands.

In addition, please make note of the following items when servicing the revolver section.

NOTE:

Iris/Lilac

Remarks at servicing (to prevent drum damage)

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

When the revolver unit is rotated without removing the drum unit, the development

sleeve may come in contact with the drum surface. This may damage the drum

and result in dots on the copies. This is due to the fact that normally, the PG (gap

between the drum and sleeve) is properly maintained when the drawer unit is in

the machine. Therefor e, pl eas e make sure that the drum unit is remov ed

whenever servicing the revolver section.

Part information

Electrical

Transmit/receive

Date:

15-Oct.-99

Prepared by:

Action required

Service manual revision

Retrofit information

T. Itoh

No.:

RA258012

NOTE:

NOTE:

Before installing the drum unit in the drawer unit, the revolver unit should be

rotated so that the actuator [C] is positioned in the sensor as explained in RTB

005.

Release the transfer belt pressure whenever pulling out the drawer unit from the

machine. If pulling out the drawer unit without releasing the pressure, the drum

and/or belt may be damaged.

[A]

[B]

[C]

Page 19

RICOH Technical

Bulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

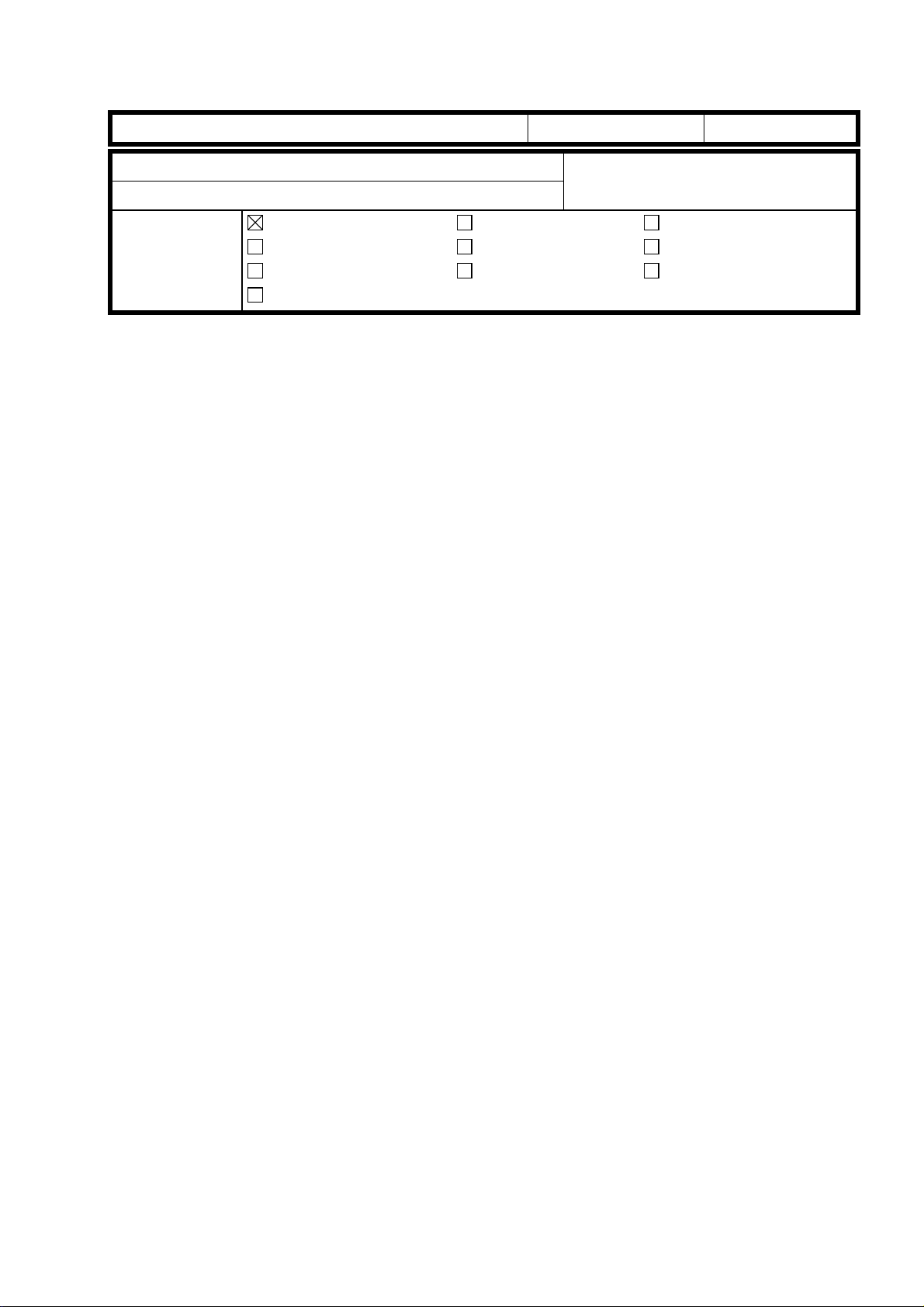

It was reported that developer spilled out from the development unit during developer

initialization at the time of machine installation. To prevent any future occurrence, please

make note of the following remarks regarding developer replacement and servicing of the

development unit. (Some of these are explained in the service manual, page 3-15.)

Remarks:

1. When replacing the developer, place the development unit on a flat level surface.

2. When attaching th e developer cover [A], set the cover by pressing both sides [B] as

There are 3 cutouts [C] in the developer cover. When positioning the cover on the

development unit, each projection [D] on the development unit should be set into each

cutout properly. If the developer cover is not properly set, developer may leak from the gap

between cover and development unit.

Iris/Lilac

Remarks during developer replacement

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

shown below and make sure that the cover is properly positioned.

Part information

Electrical

Transmit/receive

Date:

15-Oct.-99

Prepared by:

Action required

Service manual revision

Retrofit information

T. Itoh

No.:

RA258013

[D]

[C]

[B]

[A]

[D]

Page 20

RICOH Technical

Bulletin

PAGE: 2/2

[B]

Date:

15-Oct.-99

[A]

Model:

3. After pouring developer in the development unit, place the development unit in the

Iris/Lilac

developer scoop-up position [A] as shown. Then, make sure that the developer brush

on the sleeve [B] is properly inserted into the development unit by rotating the gear in

the direction of the arrow as shown below. If the developer is not poured while the unit

is on a flat level surface, the casing might be bent. This causes the developer to spill

out from the development unit. If it happens, the developer should be removed and

placed on a clean sheet of paper, then poured back into the unit.

No.:

RA258013

4. When installing each development unit, do not hold the cente r part [C] of the unit. Both

sides [D] of the unit should be held by hand. If the center part of the development unit

is held by hand, the casing of the unit may bend. The developer may then spill onto

the casing and out of the development unit. If this happens, the developer should be

removed, placed onto a clean sheet of paper and poured back into the development

unit.

[D]

[C]

[D]

Page 21

T

echnical

B

ulletin

PAGE: 1/5

Model:

Subject:

From:

Classification:

It was reported in the Japanese market that image quality problems or SC326 occur due to

a defective BUSSW board in the Interface Kit. This RTB outlines the troubleshooting

procedure.

Iris/Lilac (Controller Interface Type E)

SC326 / Abnormal Image

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Nov-99

Prepared by:

No.:

RA258014

T. Itoh

Action required

Service manual revision

Retrofit information

SYMPTOM

1. Blank I mage or Vertic al Li nes

2. SC326

NOTE:

This problem occurs in copy or scanning mode only. It does not occur during print

jobs.

CAUSE

Normally, the input pins (#12 to 17) of IC18 on the BUSSW board are not used for the

function of the IC18. However, due to an error in the software programmed in IC18, these

pins were allocated as output pins. The resulting increase in power consumption causes

the IC to heat up and malfunction.

NOTE:

1. Blank I mage or Vertic al Li nes

When the IC does not renew the scanned image data due to the cause explained above,

blank image or vertical lines appear on the outputs depending on the image of the first line

scanned in.

2. SC326

After analysis and testing of the PCBs returned from the field, it was found that the

cause explained above was a majority of the causes. The other causes are

isolated cases.

• If the first line scanned in is blank, the output is blank.

• If the first line scanned in contains an image, the output will contain vertical lines.

When the IC does not send the LSYNC signal to the ASIC, the FGATE signal cannot be

generated (causing SC326).

Page 22

T

echnical

B

ulletin

PAGE: 2/5

Model:

Iris/Lilac (Controller Interface Type E)

Date:

15-Nov-99

No.:

RA258014

SOLUTION

On the production line

The BUSSW board has been modified twice as shown below. The boards thought to be

causing the problem are #A8485108. The problem does not occur with the Interface Kits

containing #A8485105 or #A8485112, as these boards do not use IC18.

Model Code Modification (1)

Old P/N New P/N

A848-17, 27, 55, 65 A8485105 A8485108

Modification (2)

Old P/N New P/N

A8485108 A8485112

Cut-in Serial Number

Modification (1)

Product Code Cut-in Serial Number

A848-17 H0990300475

A848-27 H0990300944

A848-55 From first mass production

A848-65 From first mass production

NOTE:

Modification (2)

NOTE:

IC18 was added to the PCB for both Japanese and overseas versions since the

board was used for all machines.

Product Code Cut-in Serial Number

A848-17 H0990600001

A848-27 H0990600176

A848-55 L0409060095

A848-65 L0409060180

The same PCB was used for Japanese and overseas versions (with IC18

installed). However, since only the Japanese versions actually use IC18, it was

removed from the overseas versions. The board for all overseas versions has then

been given a new part number.

The action described on the following pages is required on the field machines equipped

with the Interface Kits containing #A8485108. The serial numbers of these Interface Kits

are listed on the next page.

Page 23

T

echnical

B

ulletin

PAGE: 3/5

Model:

Iris/Lilac (Controller Interface Type E)

Date:

15-Nov-99

In the field

Serial number of I/F kits thought to be causing this problem:

Product Code From To

A848-17 H0990300475 H0990500282

A848-27 H0990300944 H0990500512

A848-55 From first mass production L0409050064

A848-65 From first mass production L0409050094

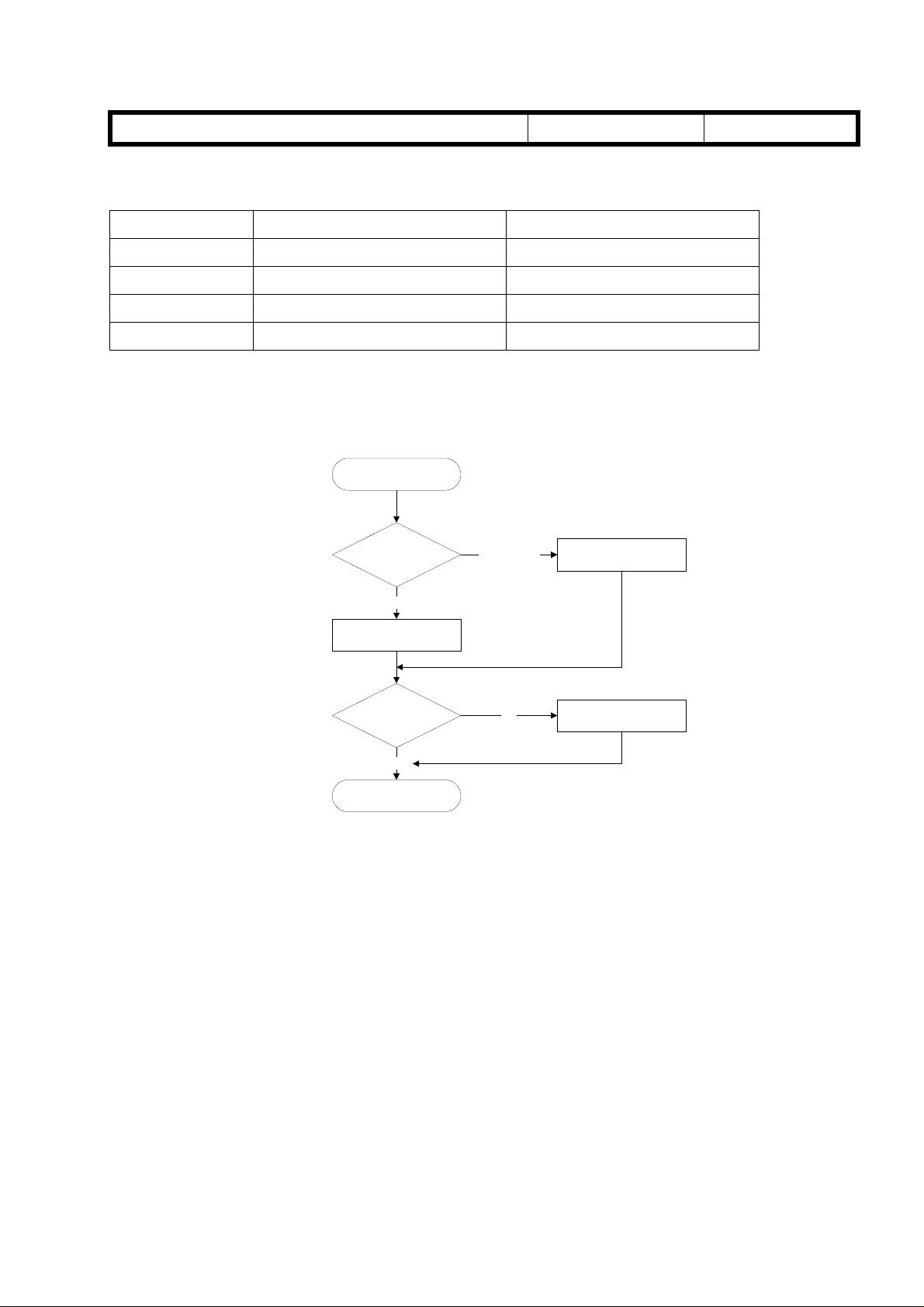

[1] Troubleshoot as shown below when the problem is reported.

Start

In which mode problem

occurs?

Copy or Scan

Regardless of

mode selected

Check the connectors from I/F

kit is properly set to copier.

Printing an internal pattern in

SP 5-955 may specify a cause

of the problem. If the problem

does not occur, this may be

caused by poor connection of

connectors.

(SC326 or abnormal images)

No.:

Refer to RTB #011.

RA258014

NOTE:

NOTE:

Replace BUSSW board

Follow the troubleshooting

Problem solved?

Yes

END

NO

described in SC CODE

section of S/M (page 9).

If the problem is related to IC18, the replaced (old) PCB can be re-used after

cutting pins #12 - 17. If occurrences still continue after cutting the pins, the

problem is being caused by another PCB component.

If the BUSSW board (IC18) causes the problem and the part is not available,

cutting the pins (#12 - 17) of IC18 as explained in section [2] on page 5 of this RTB

solves the problem.

Page 24

T

echnical

B

ulletin

PAGE: 4/5

Model:

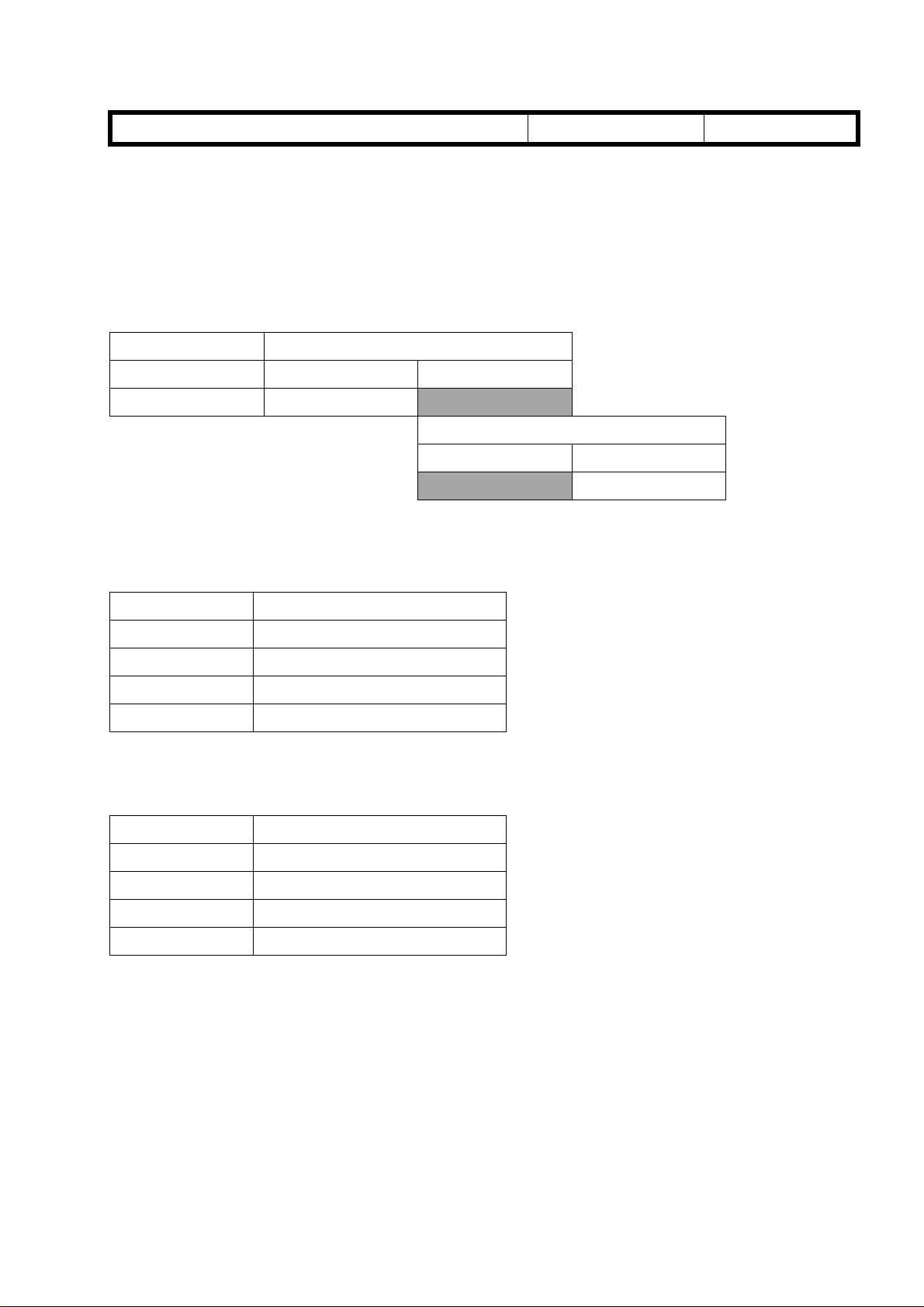

- BUSSW Board Replacement Procedure -

Iris/Lilac (Controller Interface Type E)

[B]

[C]

[A]

Date:

15-Nov-99

[D]

No.:

RA258014

1. Turn off the main switch and unplug the power cord.

2. Disconnect the cable(s) from the controller.

3. Remove the exterior covers (used toner cover and I/F unit cover).

4. Remove the controller from the I/F unit (6 screws).

5. Remove the cover plate [A] (2 screws).

6. Remove the AC drive board [B] (4 screws and 2 connectors).

7. Remove the shielding plate [C].

8. Replace the BUSSW board [D] (4 screws, 1 grounding screw, and 2 connectors).

Page 25

T

echnical

B

ulletin

PAGE: 5/5

Model:

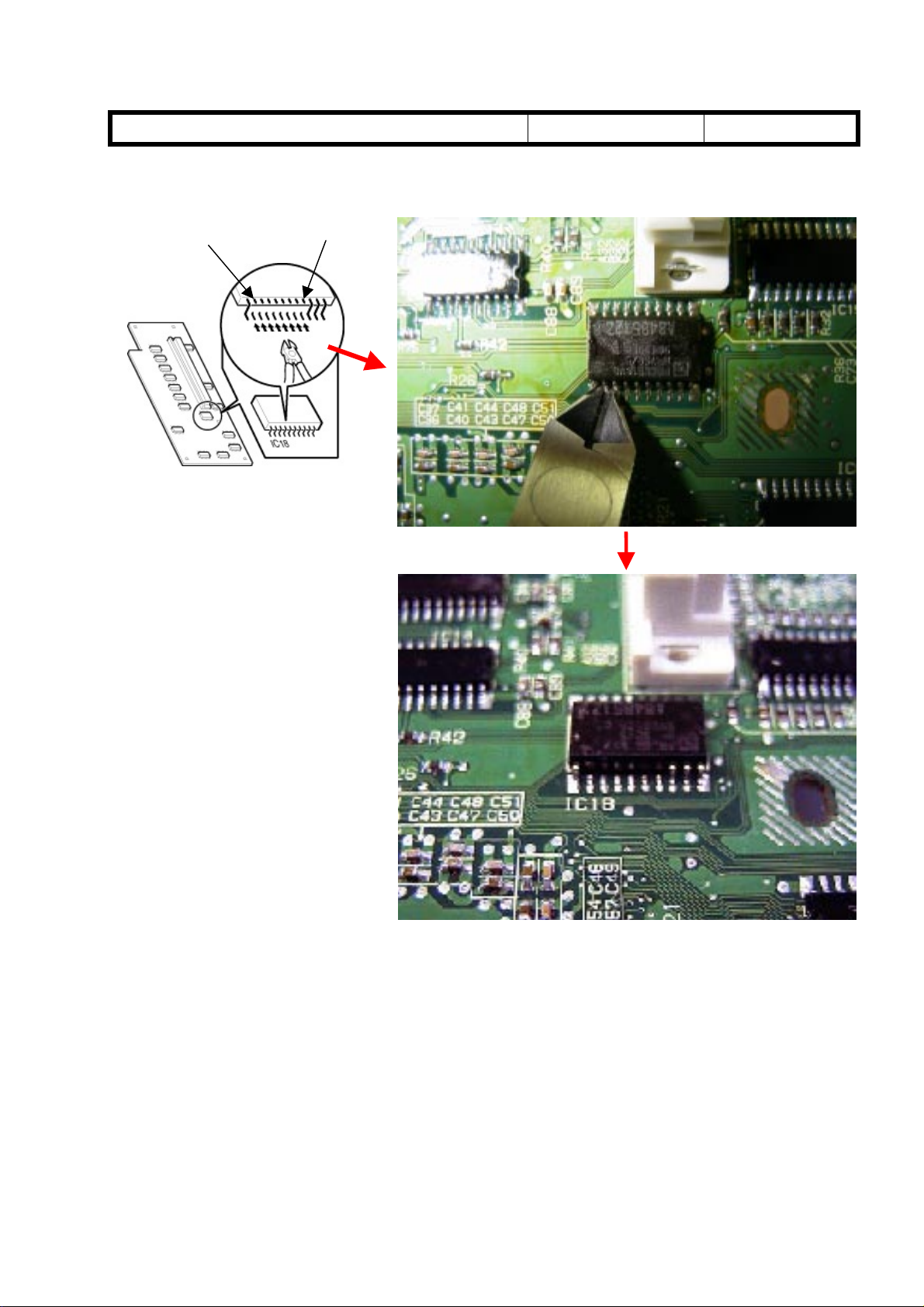

[2] Do the following at installation or next visit to prevent any future occurrence.

Iris/Lilac (Controller Interface Type E)

Pin 12

Pin 17

Date:

15-Nov-99

No.:

RA258014

1. Remove the BUSSW board by following the procedure described on the previous page.

2. Using small cutting pliers, cut pins #12 to 17 so that they do not touch other pins or

patterns. This will prevent a short circuit.

3. Remove the cut pins from the board surface.

NOTE:

Be careful not to damage the PCB pattern or cut other pins. If pins #11 or 18 are

cut, this will cause SC326.

Page 26

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

It was reported that connector 408 [A] on the IPU board breaks easily during servicing. It

seems to happen when the connector is opened by hand (e.g. using the forefinger or index

finger). Please make note of the remarks below and keep this point in mind when

accessing the IPU board.

Remarks

Open the connector carefully by using a small-blade screwdriver. (See the photo below.)

Iris/Lilac

Remarks during servicing on IPU board

Technical services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Nov-99

Prepared by:

No.:

RA258015

T. Itoh

Action required

Service manual revision

Retrofit information

[A]

Page 27

RICOH Technical

Revised: 15-Dec-99

Bulletin

PAGE: 1/6

Model:

RTB Correction

The information underlined below has been added.

Subject:

From:

Classification:

It was reported in the Japanese market that image quality problems or SC326 occur due to

a defective BUSSW board in the Interface Kit. This RTB outlines the troubleshooting

procedure.

Iris/Lilac (Controller Interface Type E)

SC326 / Abnormal Image

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Nov-99

Prepared by:

Action required

Service manual revision

Retrofit information

T. Itoh

No.:

RA258014a

SYMPTOM

1. Blank I mage or Vertic al Li nes

2. SC326

NOTE:

This problem occurs in copy or scanning mode only. It does not occur during print

jobs.

CAUSE

Normally, the input pins (#12 to 17) of IC18 on the BUSSW board are not used for the

function of the IC18. However, due to an error in the software programmed in IC18, these

pins were allocated as output pins. The resulting increase in power consumption causes

the IC to heat up and malfunction.

NOTE:

1. Blank I mage or Vertic al Li nes

When the IC does not renew the scanned image data due to the cause explained above,

blank image or vertical lines appear on the outputs depending on the image of the first line

scanned in.

2. SC326

After analysis and testing of the PCBs returned from the field, it was found that the

cause explained above was a majority of the causes. The other causes are

isolated cases.

If the first line scanned in is blank, the output is blank.

·

If the first line scanned in contains an image, the output will contain vertical lines.

·

When the IC does not send the LSYNC signal to the ASIC, the FGATE signal cannot be

generated (causing SC326).

Page 28

RICOH Technical

Revised: 15-Dec-99

Bulletin

PAGE: 2/6

Model:

Iris/Lilac (Controller Interface Type E)

Date:

15-Nov-99

No.:

RA258014a

SOLUTION

On the production line

The BUSSW board has been modified twice as shown below. The boards thought to be

causing the problem are #A8485108. The problem does not occur with the Interface Kits

containing #A8485105 or #A8485112, as these boards do not use IC18.

Model Code Modification (1)

Old P/N New P/N

A848-17, 27, 55, 65 A8485105 A8485108

Modification (2)

Old P/N New P/N

A8485108 A8485112

- Additional Information – Modification As shown in the picture, there are two

types of BUSSW board (P/N #A8485108).

Type 1 is the board on which an IC [A] has

been manually soldered. Type 2 contains

an IC18 soldered onto the circuit pattern

by machine.

[A]

Type 1

[A]

Type 2

Type 1 is the board that was modified in

the production (from #A8485 105). This

board contains one of the two ICs as

shown in the picture to the right [A]. The

only difference is in the size.

The function of the additional IC and IC18

is exactly the same. IC18 is soldered onto

the reverse side of the Type 2 board.

Cut-in Serial Number

Modification (1)

Product Code Cut-in Serial Number

A848-17 H0990300475

A848-27 H0990300944

A848-55 From first mass production

A848-65 From first mass production

NOTE:

IC18 was added to the PCB for both

Japanese and overseas versions

since the board was used for all

machines.

Page 29

RICOH Technical

Revised: 15-Dec-99

Bulletin

PAGE: 3/6

Model:

Iris/Lilac (Controller Interface Type E)

Date:

15-Nov-99

No.:

RA258014a

Modification (2)

Product Code Cut-in Serial Number

A848-17 H0990600001

A848-27 H0990600176

A848-55 L0409060095

A848-65 L0409060180

NOTE:

The same PCB was used for Japanese

and overseas versions (with IC18

installed). However, since only the

Japanese versions actually use IC18, it

was removed from the overseas

versions. The board for all overseas

versions has then been given a new

part number.

- Additional Information – Cut-in Serial Number #A8485105 has been modified to #A8485108 by soldering an IC onto the board as

explained. This special modification was not controlled at the factory. Therefore, it is not

possible to specify the exact serial numbers of the I/F units that contain the modified

board. The table below contains our estimation of the serial number. The modification was

applied to a total of 112 boards, which means that 112 of the following 159 I/F units may

contain modified boards.

Serial number No. of units

H0990300648 - 0660 13 unitsA848-17

H0990300692 - 0709 18 units

A848-27

A848-65 L0409030014 - 0043 30 units

H0990301002 - 1015 14 units

H0990301188 - 1202 15 units

H0990301248 - 1316 69 units

Total 159 units

The action described on the following pages is required for the field machines equipped

with the Interface Kits containing #A8485108. The serial numbers of these interface kits

are described below.

In the field

Serial numbers of I/F kits thought to be causing this problem:

Product Code From To

A848-17 H0990300475 H0990500282

A848-27 H0990300944 H0990500512

A848-55 From first mass production L0409050064

A848-65 From first mass production L0409050094

Page 30

RICOH Technical

Revised: 15-Dec-99

Bulletin

PAGE: 4/6

Model:

Iris/Lilac (Controller Interface Type E)

Date:

15-Nov-99

[1] Troubleshoot as shown below when the problem is reported.

Start

In which mode problem

occurs?

Copy or Scan

Replace BUSSW board

Problem solved?

Yes

Regardless of

mode selected

NO

Check the connectors from I/F

kit is properly set to copier.

Follow the troubleshooting

described in SC CODE

section of S/M (page 9).

Printing an internal pattern in

SP 5-955 may specify a cause

of the problem. If the problem

does not occur, this may be

caused by poor connection of

connectors.

(SC326 or abnormal images)

No.:

Refer to RTB #011.

RA258014a

NOTE:

NOTE:

END

If the problem is related to IC18, the replaced (old) PCB can be re-used after

cutting pins #12 - 17. (If the PCB is Type 1, it is not repairable and therefore not

re-usable.) If occurrences still continue after cutting the pins, the problem is being

caused by another PCB component.

If the BUSSW board (IC18) causes the problem and the part is not available,

cutting the pins (#12 - 17) of IC18 as explained section [2] on page 6 of this RTB

solves the problem. (If the PCB is Type 1, the procedure on page 6 is not

applicable.)

Page 31

RICOH Technical

Revised: 15-Dec-99

Bulletin

PAGE: 5/6

Model:

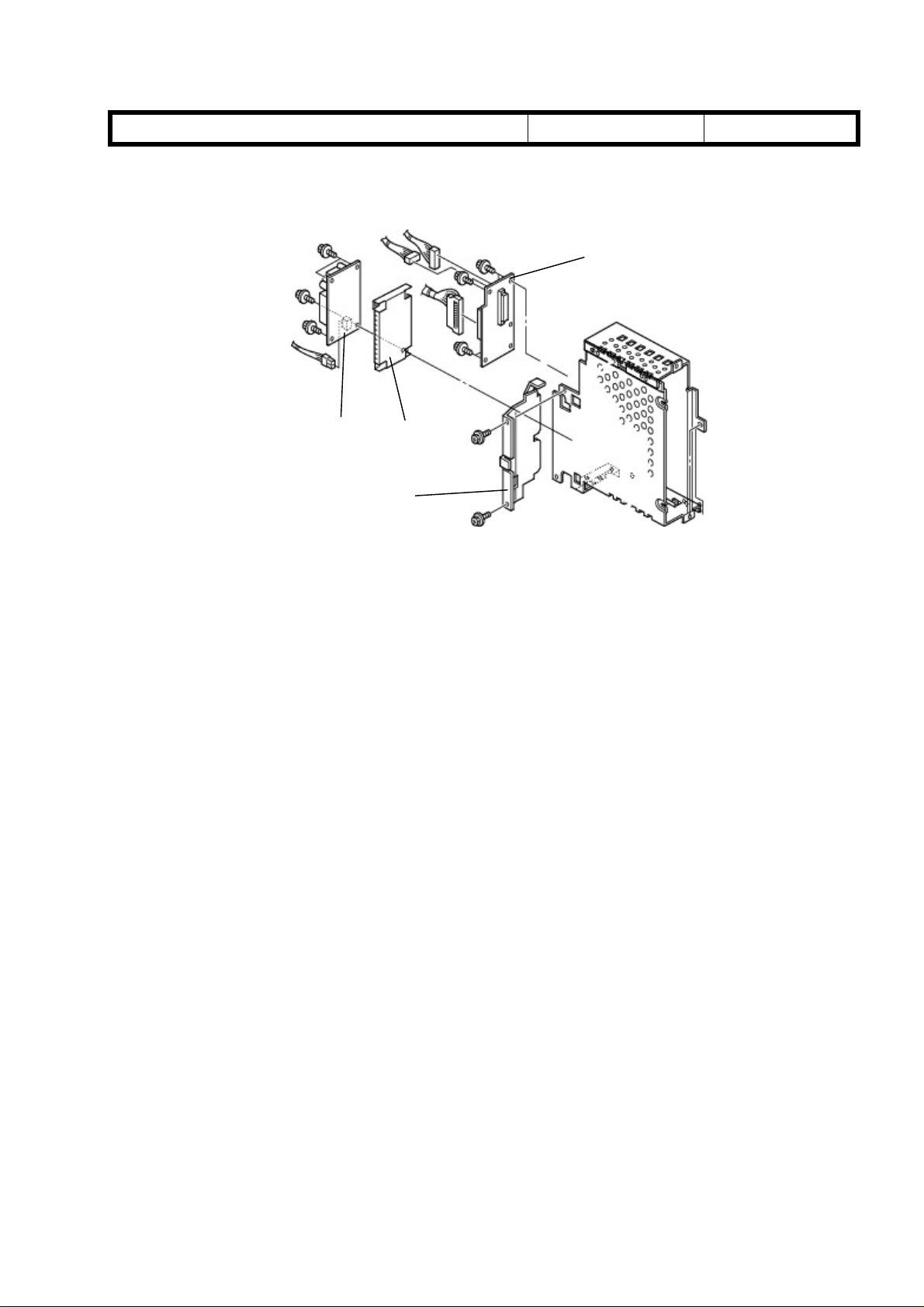

- BUSSW Board Replacement Procedure -

Iris/Lilac (Controller Interface Type E)

[B]

[C]

[A]

Date:

15-Nov-99

[D]

No.:

RA258014a

1. Turn off the main switch and unplug the power cord.

2. Disconnect the cable(s) from the controller.

3. Remove the exterior covers (used toner cover and I/F unit cover).

4. Remove the controller from the I/F unit (6 screws).

5. Remove the cover plate [A] (2 screws).

6. Remove the AC drive board [B] (4 screws and 2 connectors).

7. Remove the shielding plate [C].

8. Replace the BUSSW board [D] (4 screws, 1 grounding screw, and 2 connectors).

Page 32

RICOH Technical

Revised: 15-Dec-99

Bulletin

PAGE: 6/6

Model:

[2] Follow the procedure below at installation or next visit to prevent any future

NOTE:

If the BUSSW board contains

an IC [A], that has been

manually soldered on, the

procedure described below is

not applicable. The BUSSW

board would need to be

replaced with #A8485112

when the problem occurs.

Iris/Lilac (Controller Interface Type E)

occurrence.

PIN 12

PIN 17

Date:

15-Nov-99

No.:

RA258014a

[A]

1. Remove the BUSSW board by following the procedure described on the previous page.

2. Using small cutting pliers, cut pins #12 to 17 so that they do not touch other pins or

patterns. This will prevent a short circuit.

3. Remove the cut pins from the board surface.

NOTE:

Be careful not to damage the PCB pattern or cut other pins. If pins #11 or 18 are

cut, this will cause SC326.

Page 33

RICOH Technical

Reissued: 15-Jan-00

Bulletin

PAGE: 1/8

Model:

Iris/Lilac

Date:

31-Dec-99

No.:

RA258016

RTB Correction

The items in bold Italics have been corrected (on pages 3/8 and 8/8).

Subject:

From:

Classification:

Banding

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Part information

Electrical

Transmit/receive

Other ( )

Occurrences of banding have been reported from the field (1.5-mm, 6-mm, 8-mm, and 12-mm). The causes

for each type of banding are different. This RTB explains how to verify each type and apply the

corresponding solution.

SYMPTOM/CAUSE/SOLUTION

Mode SolutionType

Copy Print

1.5-

mm

6-mm No Yes The rotation speed stability of

8-mm No Yes The AC current of the paper

12-mm Yes No The frequency generated by

No Yes The coupling of the drum

vibrates and generates a

specific frequency. This

frequency causes 1.5-mm

banding only in 2/3 speed

mode.

the drum motor varies part by

part. If the rotation speed is

not constant, the image

development process is

affected (especially in 2/3

speed mode, causing 6-mm

banding).

separation corona generates

noise, which affects the

paper transfer corona. The

frequency of the AC current

causes 8-mm pitch banding

only in 2/3 speed mode.

the gears in the drum drive

unit causes 12-mm banding

only in standard speed

mode.

Cause

No : This type of banding does not occur in this mode.

Yes: This type of banding can occur in this mode.

The material of the coupling

located in the drum shaft

holder (#A2592251) has

been changed from plastic to

metal.

P/N: #A2592251

NOTE:

not been changed; but the

old part was never stocked at

the SPC in Japan.

The rotation speed stability of

the drum motor has been

improved.

P/N changed:

#AX060162 -> #AX060197

The frequency of the AC

current has been changed on

the high voltage supply board

(T2, D).

P/N changed:

#A2595055 -> #A2595058

The gears have been

modified to reduce the

specific frequency generated

when the gears rotate.

P/N changed:

#AB017512 -> #AB017521

#AB017477 -> #AB017520

Prepared by:

T. Itoh

Action required

Service manual revision

Retrofit information

Production In the field

·

Replace the drum

shaft holder.

Refer to page 5/8.

The part number has

·

Replace the motor.

Refer to page 6/8.

·

Replace the high

voltage supply board

(T2, D).

·

If the new board is not

available, rerouting the

high voltage cable of

the paper transfer

corona may solve the

problem. If not, the

board should be

replaced with a new

one.

Refer to page 6/8.

·

Replace the gears with

modified ones.

Refer to page 7/8 to 8/8.

Please refer to “WORKFLOW” on page 3/8 for troubleshooting procedures.

Page 34

RICOH Technical

Reissued: 15-Jan-00

Bulletin

PAGE: 2/8

Model:

NOTE:

Iris/Lilac

If the dark spots described in RTB 009 appear on the outputs due to an

Date:

31-Dec-99

No.:

inappropriate transfer bias setting, this may cause an uneven image that

resembles a banding image. Please follow the procedures in RTB 009 first when

dark spots appear on the outputs.

Cut-in Serial Number of Modifications

Iris (A258)

SERIAL NUMBERCODE

1.5-mm 6-mm 8-mm 12-mm

A258-15 3B39100001 3B39100001 3B39080001 3B39020066

A258-17 H0191100001 H0191100001 H0190500091 H0190200131

A258-19 H0191100051 H0191100051 H0190800221 H01903XXXXX

A258-22 AY79090251 AY79100001 AY79050111 AY7903XXXX

A258-26 3S51090001 3S51090001 3S50590041 3S5039XXXX

A258-27 H0191000001 H0191000001 H0190500380 H01903XXXXX

A258-29 H0191000376 H0191000376 H0190500486

A258-55 L0369100001 L0369100001 L0369060147

A258-65 L0369100025 L0369100025 L0369080237

From the fist mass

production

RA258016

Lilac (A259/A260)

SERIAL NUMBERCODE

1.5-mm 6-mm 8-mm 12-mm

A259-15 3B4910XXXX 3B4911XXXX 3B4909XXXX

A259-17 H02910XXXXX H02911XXXXX H02909XXXXX

A259-22 AY99090011 AY99100001 AY99060001

A259-26 3S60990001 3S91090001 3S60690001

A259-27 H0290900001 H0291000001 H0290600001

A259-29 H0290900048 H0291000033 H0290600087

A259-55 L037910XXXX L037911XXXX L037909XXXX

A259-65 L0379100001 L0379100001 L0379070001

A260-15 3B5910000 1 3B59100001 3B5 905 0001

A260-17 H0390900001 H0391000001 H039050 010 1

A260-22 AZ19090001 AZ19100001 AZ19060001

A260-26 3S7099000 1 2S71090001 3S7 079 0001

A260-27 H03910XXXXX H03911XXXXX H0390600104

A260-29 H0390900051 H0391000026 H039060 018 6

A260-55 L0389090001 L0389100001 L0389060001

A260-65 L0389100061 L0389100061 L0389060041

From the fist mass

production lot

From the fist mass

production lot

Page 35

RICOH Technical

g

g

g

g

g

g

Reissued: 15-Jan-00

Bulletin

PAGE: 3/8

Model:

Iris/Lilac

- WORKFLOW -

START

Make print samples in SP mode.

Refer to Step [1].

Make prints samples usin

customer's image file.

Are dark spots appearing?

NO

Date:

SP5-955-018 : Set to "11".

SP

-955-001 : Set to "90".

5

SP2-920-000 : Set to "1".

YES

Adjust the transfer belt bias by

followin

31-Dec-99

RTB #009.

No.:

RA258016

Check the type of banding.

Is banding type identifiable

(esp. 6 or 8mm)?

YES

Replace the appropriate part.

Refer to the first pa

Make print samples using customer's

ima

Check if the problem is solved.

e of this RTB.

e file.

END

NO

The dither patterns used in the SP and

printer modes (controller) are different. The

dither pattern used in the controller is

desi

Therefore, the final result should be

evaluated based on the outputs printed

usin

Follow the procedure

described in Step [1].

ned to reduce the banding level.

the customer's image file.

Page 36

RICOH Technical

Reissued: 15-Jan-00

Bulletin

PAGE: 5/8

Model:

[1] How to measure the width of the banding

1. Print the test pattern in SP mode.

2. Switch to copy mode and select B&W and A3 (DLT) size mode. Then, print out the test

3. Select 5 or 10 bands [A] which are visible on the test pattern printed out and measure

NOTE:

Iris/Lilac

SP5-955-018 : Set to “11” (1-dot main scan line)

·

SP5-955-001 : Set to “90” or “128” (LD PWM value) depending on the image

·

density on the output.

SP2-920-000 : Set to “1” to print the test pattern in 600 dpi mode if the

·

problem is related to the print mode.

pattern.

the value [A]. Calculate the width [B] of the banding by dividing [A] by the number of

bands (5 or 10).

The way to distinguish between 6-mm and 8-mm banding is as follows.

Date:

31-Dec-99

No.:

RA258016

If the pitches are not clearly visible and it is difficult to judge whether the width is 6 or 8

mm, check if the banding disappears or is improved by disconnecting the connector [C] of

the paper separation corona.

If the banding disappears or is improved, it is 8-mm banding.

·

If nothing is changed, it is 6-mm banding.

·

Disconnecting the connector of the paper separation corona itself is not expected to cause

paper jams. However, please use a recommended type of paper if available. After the test

is finished, make sure that the connector is re-connected properly.

[C]

B

.

A

.

Page 37

RICOH Technical

Reissued: 15-Jan-00

Bulletin

PAGE: 6/8

Model:

[2] 1.5-mm Banding : Drum Shaft Holder Replacement Procedure

1. Pull out the drawer unit.

2. Follow steps 1-8 of the replacement

3. Remove the receptacle [A] (1 screw).

4. Replace the drum shaft holder [B] (6

NOTE:

A total of 4 different plates have been

prepared for both sides of the drum shaft

holder. The difference between [C] and [D]

or between [E] and [F] is the thickness.

The difference between [C] and [E] or

between [D] and [F] is the shape. These

differences exist so that the 4 plates can

be easily distinguished.

Iris/Lilac

NOTE:

some sheets of paper on the unit to

protect it from light fatigue.

procedure for 12-mm bandi ng (see

page 7/8 of this RTB.)

screws).

Remove the drum unit and put

[A]

Date:

[C]

31-Dec-99

[D]

[B]

No.:

RA258016

The rear frame, where the drum shaft

holder is installed, is slightly tilted. These

springs are used to correct the angle of

the frame.

The number of spring plates installed is

different from machine to machine,

depending on the angle at which the

frame is tilted.

When replac ing the drum shaft holder, it is

also necessary to replace the plates (if

present).

[E]

[F]

Page 38

RICOH Technical

Reissued: 15-Jan-00

Bulletin

PAGE: 7/8

Model:

[3] 6-mm Banding : Drum Motor Replacement Procedure

1. Remove the rear cover.

2. Remove the stay [A].

3. Disconnect the connector from the

[4] 8-mm Banding : High Voltage Supply Board - T2/D Replacement Procedure

Iris/Lilac

drum motor [B] and replace the motor.

[B]

Date:

31-Dec-99

[A]

No.:

RA258016

1. Remove the rear cover.

2. Replace the high voltage supply board

- T2/D [A].

NOTE:

If the part is not available, rerouting the

high voltage cable [B] of the paper transfer

corona sometimes improves the situation

or solves the problem. If nothing changes,

the high voltage supply board should be

replaced.

As explained, the frequency of the AC current has been

changed. The suffix of the service part number for the

high-voltage power supply assembly was therefore

changed from “A2595055D” to “A2595088E”.

For purposes of parts control in the field, the service part

number has been changed from #A2595055 to

#A2595058. This means that #A2595055E and

A2595058 are the exact same part.

The part number printed on the high voltage supply

board (#A2595055E and A2595058) is #AZ320095B (the

modified board).

[B]

[A]

Page 39

RICOH Technical

Reissued: 15-Jan-00

Bulletin

PAGE: 8/8

Model:

[5] 12-mm Banding : Gear Replacement Procedure

1. Remove the following parts:

2. Remove the 3 screws securing the

NOTE:

PSU and I/O board.

3. Disconnect the connector of the drum

4. Rotate the drum motor

5. Loosen the screw [G] and remove the

6. Remove the drum motor (4 screws)

7. Remove the 3 connectors from the

8. Remove the tension spring [I]. Then,

Iris/Lilac

Rear covers / Fly-wheel [A] / Stay [B]

PSU and the 4 screws securing the

I/O control board. Then, move these

two parts aside to make space to

remove the drum drive unit [C].

It is not necessary to remove the

motor [D].

counterclockwise manually so that the

screw [E] of the drum pulley [F] faces

downward.

tension spring [H].

and drum pulley (1 screw)

drive unit and remove the unit (4

screws and 2 stud screws).

remove the unit cover plate [J] (3

screws).

[A]

Date:

[D]

[B]

[I]

31-Dec-99

[C]

No.:

[G]

RA258016

[F]

[E]

[H]

NOTE:

(1) Before opening the drive unit, note the

routing of the timing belts as well as

the positioning of the pulleys.

This will make it much easier to put the

belts and pulleys back after the

procedure.

(2) Do not open the drive unit completely.

If this is done, the timing belt and

pulleys will come off the unit. Open the

cover just enough for gear replacement

(see the photo).

[J]

[K]

Page 40

RICOH Technical

Reissued: 15-Jan-00

Bulletin

PAGE: 9/8

Model:

9. Replace the white and black gears [K].

10. Reinstall the upper cover plate. Make

11. Reinstall the drive unit and drum

12. Reinstall the drum motor [D] (4

13. Connect the tension spring [E] and

Iris/Lilac

(The black gear is secured with 2

screws.)

sure that the heads [A] of the studs

are in position in the holes in the cover

plate.

NOTE:

[B] are properly set as shown.

pulley by pressing the timing belt [C]

down as shown.

screws).

rotate the motor

6 times. Secure the screw [F].

Make sure that the timing belts

counterclockwise

5-

Date:

31-Dec-99

[A]

No.:

[B]

RA258016

NOTE:

Before securing the screw, the motor

should be rotated after hooking the spring.

If this is not done, the proper tension will

not be applied to the belt, causing the

timing belt to jump during operation. This

may cause a partial color shift image.

14. Reinstall all other parts removed.

[C]

[D]

[F]

[E]

Page 41

RICOH Technical

Bulletin

PAGE: 1/3

Model:

Subject:

From:

Iris/Lilac

Curved dark bands / Uneven image density

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

31-Dec-99

Action required

Service manual revision

Retrofit information

T. Itoh

No.:

RA258017

SYMPTOM

Curved dark bands [A] or uneven image

density appears due to a dirty charge

corona unit.

[A]

CAUSE

The charge corona fan stays on while the main switch is on. Since the charge corona fan

draws the air into the machine, the charge corona unit becomes dirty due to dust in the air.

The problem occurrence depends on the environmental conditions where the machine is

installed.

NOTE:

This problem has been reported only from the Ja panese market, so far. The

problem occurred especially in environments where a humidifier (supersonic wave

type) was used. A substance left after moisture evaporates adheres to the charge

corona unit, causing this problem.

SOLUTION

As a solution to this problem, two modifications have been applied. One involves SP mode

and the other is a grid cleaning pad. There are notes on how to apply the solution to the

field machines depending on the environment and/or the condition of the machine. Please

investigate which solution (either or both) should be applied.

Solution [1]: SP Mode

The software has been modified and the following SP mode was added.

SP No. Item

[Displayed]

03-980-00: Charge Corona Fan ON/OFF Timing Setting

03-980-00 MCFanCtrl 0 0: Stays on

Default Value Range Step SP7-

902/3

1: Turn off at

specific timing

Description

Specifies the off timing of the

charge corona fan.

When SP3-980-00 is set to “1”, the fan turns off 30 seconds after the drum motor stops or

when Energy Saver mode turns on. (The fan turns on again when the drum motor turns on

or when Energy Saver mode turns off.) This SP mode can extend the time until the charge

corona unit is considered dirty.

Page 42

RICOH Technical

Bulletin

PAGE: 2/3

Model:

This software change has been implemented in the main firmware (Ver. 6.621) on the

·

This software change has been implemented from the first mass production units on

·

NOTE:

When activating this SP mode, the transfer belt heater should be disconnected. This is

·

When activating this S P mode, please check the C/O (copies per origina l ) in full color

·

Solution [2]: Grid Cleaning Pad

Iris/Lilac

Iris. (This modification has been applied from the July production run.)

the Lilac.

Please read the following notes when changing the setting of this SP mode.

because the temperature inside the machine tends to increase since the charge

corona fan turns off at the timing explained above. (Please refer to the following page

for the procedure.)

copy mode. The output signal from the ID sensor tends to fluctuate due to temperature

changes inside machine. This may cause image the density to fluctuate if the C/O is

20 (20 repeat copies) or more.

Date:

31-Dec-99

No.:

RA258017

In addition to the SP mode, a grid cleaning pad (#A2592311) has been added to the upper

frame of the drum unit (as shown in the picture) from the June production run onward.

(Please refer to MB #18 for the Iris and #15 for the Lilac for the cut-in serial number.)

This modification enables service technicians or users to clean the grid plate. Please use

this pad if the problem is reported.

NOTE:

The grid cleaning pad tends to be worn away while cleaning the grid plate, and needs to

be replaced after being used for cleaning around 100 times. Although this is a consumable

part in this case, this part is not assigned as a PM part since the problem occurrence is

very rare.

Installation Procedure:

1. Using alcohol, clean the

The charge corona unit is normally secured with a screw. When asking users to

clean the charge corona unit, please remove the screw and instruct them to set

the charge corona unit properly after cleaning it. If the charge corona unit is not set

properly, this causes an SC301 or a blank image problem.

upper frame of the drum

unit where the grid cleaning

pad is attached.

2. Attach the cleaning pad [A]

as shown in the picture.

Page 43

RICOH Technical

Bulletin

PAGE: 3/3

Model:

Iris/Lilac

[B]

Date:

31-Dec-99

No.:

[A]

RA258017

1. Remove the lower rear cover.

2. Remove the used toner bottle (1 connector).

3. Remove the high voltage supply board -T2/ D [A] (1 screw and 2 connectors).

4. Disconnect the connector [B] of the heater located behind the high voltage supply

board.

Page 44

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

Classification:

Please correct your service manuals as follows:

1. Page 2-3 (5) ACC-Run-Time Process Control Self Check

Iris/Lilac models do not have this function, so please delete the explanation from your

service manual. This function is only used in the Cattleya.

2. Page 6-83 6.11.3 NV-RAM UPLOADING AND DOWNLOADING

Iris/Lilac

Service Manual

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

29-Feb-00

Prepared by:

Action required

Service manual revision

Retrofit information

T. Itoh

No.:

RA258018

“With SP mode, copier settings can be uploaded to a Flash ROM card from the NVRAM inside the machine or downloaded from a flash ROM card to the NV-RAM.”

This explanation is wrong. When executing the upload or download with SP5-824 or 825,

uploading

downloading

No settings are uploaded or downloaded from the flash ROM card (IC card). The IC card

that contains the main program needs to be set in the main control board slot whenever

uploading or downloading.

transfers the data from the NVRAM to the flash ROM on the main board and

transfers the data from the flash ROM to the NVRAM.

Page 45

RICOH Technical

Bulletin

PAGE: 2/4

Model:

Iris/Lilac

Date:

29-Feb-00

No.:

RA258018

3. Appendix – 2 SP MODE TABLE

SP-5-114-000 Account color mode setup [Color Mode Selection : Key Card]

·

When the key counter has been installed or the user code mode has been enabled, it is

possible to select color mode(s) which are only accessible by using the key counter or

user code. The default setting for this SP mode is 15. This means that the key counter or

user code is always required whenever making copies.

Setting Black/White Single Color Twin Color Full Color

1 Counter

2 Counter

3 Counter Counter

4 Counter

5 Counter Counter

6 Counter Counter

7 Counter Counter Counter

8 Counter

9 Counter Counter

10 Counter Counter

11 Counter Counter Counter

12 Counter Counter

13 Counter Counter Counter

14 Counter Counter Counter

15 Counter Counter Counter Counter

Counter: A key counter or user code is required to make copies. The number is then

counted up by the key counter or the user code counter.

No mark: Copies can be made without a key counter or user code.

NOTE:

When SP-5-104-000 (A3/DLT double count) is set to 1 (double count), the mechanical total

counters and electrical counters on the operation panel count each copy/development

twice for A3/DLT. However, a key counter counts up only once. This is a specification

carried over from the Azalea.

Page 46

RICOH Technical

Bulletin

PAGE: 3/4

Model:

SP2-301 to 316 (except for SP2-311) - Belt transfer & Paper Transfer Bias

·

SP No. Default value in

02-301-01 1700 1700

02-301-02 1800 1800

02-301-03 1900 1900

02-301-04 2000 2000

02-301-05 1700 1700

02-301-06 1800 1800

02-301-07 1700 1700

02-301-08 1800 1800

02-301-09 1900 1900

02-301-10 1700 1700

02-301-11 1000 1700

02-301-12 1000 300

02-301-13 800 1000

02-301-14 900 1100

02-301-15 1000 1200

02-301-16 1100 1300

02-301-17 1200 1200

02-301-18 1300 1300

02-301-19 800 1100

02-301-20 900 1200

02-301-21 1000 1300

02-301-22 1200 1200

02-301-23 1700 1700

02-301-24 0 0

02-301-25 1700 1700

SP No. Default value in

02-313-01 100 100

02-313-02 100 100

02-313-03 200 200

02-313-04 250 250

02-313-05 100 100

02-313-06 100 100

02-313-07 100 250

02-313-08 100 300

02-313-09 100 100

02-313-10 100 100

02-313-11 200 270

02-313-12 100 270

Iris/Lilac

The default data described in the manual is incorrect. Please correct your manual.

The default value has been changed to the appropriate value in Ver. 6.43.

The default value has been changed for white lines on OHPs in Ver. 6.621.

The default value has been changed for white lines on OHPs in Ver. 6.621 (only for EU version).

Correct default

service manual

service manual

value

Correct default

value

Date:

SP No. Default value in

02-310-01 1 1

02-310-02 7 10

02-310-03 15 18

02-310-04 15 18

02-310-05 15 18

02-310-06 8 8

02-310-07 10 10

02-310-08 10 10

02-310-09 10 10

02-310-10 7 8

02-310-11 10 10

02-310-12 10 10

02-310-13 10 10

02-310-14 7 10

02-310-15 15 18

02-310-16 15 18

02-310-17 15 18

02-310-18 13 12

02-310-19 7 15

02-310-20 7 15

02-310-21 7 15

02-310-22 6 7

02-310-23 7 9

02-310-24 7 9

02-310-25 7 9

02-310-26 13 10

02-310-27 7 15

02-310-28 7 15

02-310-29 7 15

29-Feb-00

service manual

No.:

RA258018

Correct default

value

Page 47

RICOH Technical

Bulletin

PAGE: 4/4

Model:

SP No. Default value in

02-314-01 0 0

02-314-02 0 0

02-314-03 0 0

02-314-04 0 0

02-314-05 03

02-314-06 0 0

02-314-07 0 0

02-314-08 0 0

02-314-09 0 0

02-314-10 0 0

02-314-11 0 0

02-314-12 0 0

02-314-13 30

02-314-14 0 0

02-314-15 0 0

02-314-16 0 0

02-314-17 0 0

02-314-18 2 2

02-314-19 2 2

02-314-20 2 2

02-314-21 2 2

02-314-22 4 4

02-314-23 4 4

02-314-24 4 4

02-314-25 0 0

02-314-26 0 0

02-314-27 0 0

02-314-28 0 0

Iris/Lilac

service manual

Correct default

value

SP No. Default value in

02-315-01 3 -1

02-315-02 0 -1

02-315-03 0 -1

02-315-04 0 -1

02-315-05 0-1

02-315-06 0-1

02-315-07 0-1

02-315-08 0-1

02-315-09 0-1

02-315-10 0-1

02-315-11 0-1

02-315-12 0-1

02-315-13 3-1

02-315-14 0-1

02-315-15 0-1

02-315-16 0-1

02-315-17 0-1

02-315-18 0-1

02-315-19 0-1

02-315-20 0-1

02-315-21 0-1

02-315-22 0-1

02-315-23 0-1

02-315-24 0-1

02-315-25 0-1

02-315-26 0-1

02-315-27 0-1

02-315-28 0-1

Date:

29-Feb-00

service manual

No.:

RA258018

Correct default

value

SP No. Default value in

service manual

02-316-01 100 100

02-316-02 89 89

02-316-03 100 100

02-316-04 100 100

02-316-05 70 75

02-316-06 80 70

02-316-07 100 100

02-316-08 89 89

02-316-09 100 79

02-316-10 87 70

02-316-11 100 100

02-316-12 100 100

02-316-13 120 95

02-316-14 87 70

02-316-21 100 100

02-316-22 100 100

02-316-23 100 100

02-316-24 100 100

Correct default

value

02-316-25 100 125

02-316-26 100 100

02-316-27 100 100

02-316-28 100 100

02-316-29 100 100

02-316-30 100 100

02-316-31 100 100

02-316-32 100 100

02-316-33 100 100

02-316-34 100 100

Page 48

RICOH Technical

Bulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

Iris/Lilac

Squeaking noise

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

29-Feb-00

Action required

Service manual revision

Retrofit information

T. Itoh

No.:

RA258019

SYMPTOM

A squeaking noise is generated in the development unit.

CAUSE

The vibration generated from the doctor blade during the development process is

transferred to the upper cover. This results in a squeaking noise.

SOLUTION

To absorb the vibration, four foam rubber pads have been attached to the development

cover. If the squeaking noise occurs in the field machines, please follow the procedure

described below. Please refer to MB #22 (Iris) and #19 (Lilac) for the cut-in serial number

information.

1. Make a full color copy and check when

the noise occurs (i.e. at which color in

the development process).

2. Turn off the main switch.

3. Pull out the drawer unit.

4. Remove the drum unit and place a few

sheets of paper on the unit to prevent the

drum from developing light fatigue.

5. Remove the relevant development

unit(s).

6. Remove the development cover [A] (3

screws).

7. With damp and dry cloths, clean the

areas on the front and reverse sides of

the development cover where the pads

will be attached.

[A]

[B]

[C]

8. Attach 3 foam rubber pads [B] to the reverse side of the development cover as shown.

Page 49

RICOH Technical

Bulletin

PAGE: 2/2

Model:

9. Reinstall the development cover and attach one foam rubber pad [C] to the front side

10. Reassemble the machine.

Iris/Lilac

of the cover, as shown.

Date:

29-Feb-00

No.:

RA258019

Page 50

!"#$% T

echnical Bulletin

PAGE: 1/2

Model:

Subject:

From:

Iris/Lilac

Bypass Tray Modificaition

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

06-Apr-00

Prepared by:

No.:

RA258020

T. Itoh

Action required

Service manual revision

Retrofit information

SYMPTOM

Paper jam at the by-pass tray.

CAUSE

Even if the user selects ‘sideways’ with the operation panel, the paper orientation is

automatically reset to ‘lengthwise’ if the by-pass tray side fences are moved to the 12” size

position. This may result in a paper jam.

SOLUTION

A stopper has been added to the front side fence so that the maximum width that can be

set is A3 (11”). This stopper can be pulled out to make copies with paper larger than this

size.

• Please refer to MBs, which will be issued soon, for the cut-in serial number.

• An errata sheet (see the next page) has been enclosed with the modified production

units. An English version is enclosed with North American models and 5 languages are

enclosed with Europe/Asia models.

To add the stopper [A], the shape of the front side fence [B] was modified. Please refer to

the next page.

New parts:

#A2592972: Front Side Fence

#A2592973: Side Fence Stopper

NOTE: The part number of the by-pass feed table assembly has not changed, but the

suffix has. Therefore, please order the above two parts separately to apply the

modification in the field.

Page 51

!"#$% T

echnical Bulletin

PAGE: 2/2

Model:

Iris/Lilac

Date:

06-Apr-00

No.:

RA258020

Errata Sheet:

NOTE: This sheet is for Europe/Asia versions. For the North America version, the paper

size indicated is 11”x17”, not A3.

[B]

[A]

Page 52

!"#$% T

echnical Bulletin

PAGE: 1/2

Model:

Subject:

From:

Iris/Lilac

Dust Filter

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

22-Jun-00

Prepared by:

No.:

RA258021

T. Itoh

Action required

Service manual revision

Retrofit information

The dust filter has been modified twice. This RTB explains the modification history and

some notes for servicing in the field.