Page 1

Aficio Color 3006/4006/4106

(Iris/Lilac, A258/A259/A260)

Service Manual

Issued February 24, 1999, Ricoh CO., LTD.

Page 2

ø

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

1

Page 3

1.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispos e of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

ø

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

ø

WARNING

Turn off the main switch before attempting any of the procedures in the

Laser Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

2

Page 4

TABLE OF CONTENTS

1. OVERALL MACH INE INFORMATION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.1.1 MACHINE CONFIGURATION ......................................................... 1-1

1.1.2 GENERAL SPECIFICATIONS......................................................... 1-2

1.1.3 PLATEN/ARDF ORIGINAL SIZE DETECTION................................ 1-6

1.1.4 COPY PAPER SIZE......................................................................... 1-7

1.1.5 APS PAPER SIZES AVAILABLE..................................................... 1-8

1.1.6 NOISE EMISSION........................................................................... 1-9

1.1.7 POWER CONSUMPTION.............................................................. 1-10

1.1.8 DISPLAY EDITOR SPECIFICATIONS.......................................... 1-10

1.2 MECHANISM OVERVIEW ..................................................................... 1-11

1.2.1 IMAGE GENERATION PROCESS................................................ 1-11

1.3 MAJOR UNIT LAYOUT AND PAPER FEED PATH................................ 1-14

1.4 PARTS LAYOUT .................................................................................... 1-17

1.4.1 MECHANICAL COMPONENT LAYOUT........................................ 1-17

1.4.2 ELECTRICAL COMPONENT LAYOUT......................................... 1-18

1.4.3 DRIVE LAYOUT............................................................................. 1-25

1.4.5 AIR FLOW ..................................................................................... 1-26

1.4.5 ELECTRICAL COMPONENT DESCRIPTIONS............................. 1-27

Printed Circuit Boards........................................................................ 1-27

Motors................................................................................................ 1-28

Fan Motors......................................................................................... 1-28

Sensors.............................................................................................. 1-29

Switches............................................................................................. 1-30

Clutches............................................................................................. 1-30

Solenoids........................................................................................... 1-31

Lamps................................................................................................ 1-31

Heaters .............................................................................................. 1-31

Thermistors........................................................................................ 1-31

Thermofuses...................................................................................... 1-31

Thermostat......................................................................................... 1-31

Counter.............................................................................................. 1-32

2. DETAILED DESCRIPTIONS .......................................................2-1

2.1 PROCESS CONTROL.............................................................................. 2-1

2.1.1 OVERVIEW ..................................................................................... 2-1

2.1.2 POTENTIAL CONTROL .................................................................. 2-2

Overview.............................................................................................. 2-2

Potential Control Timing....................................................................... 2-2

2.1.3 PROCESS CONTROL SELF CHECK ............................................. 2-4

Flow Chart............................................................................................ 2-4

Step 1: VSG Adjustment...................................................................... 2-5

Step 2: ID Sensor Pattern Generation.................................................. 2-5

I

Page 5

Step 3: Sensor Pattern Potential Detection.......................................... 2-6

Step 4: Sensor Pattern Density Detection............................................ 2-7

Step 5: Toner Amount Calculation ....................................................... 2-8

Step 6: Development Potential Calculation.......................................... 2-9

Step 7: Selecting the Optimum VD, VB, VL .......................................2-10

2.1.4 PROCESS CONTROL γ CORRECTION....................................... 2-11

What is process control γ?................................................................. 2-11

How is it done?................................................................................... 2-11

Process control gamma correction timing.......................................... 2-12

2.2 TONER SUPPLY CONTROL.................................................................. 2-13

2.2.1 TONER SUPPLY CONTROL METHOD........................................ 2-13

2.2.2 FUZZY CONTROL MODE............................................................. 2-13

2.2.3 VSP DETECTION FOR TONER SUPPLY CONTROL .................. 2-14

2.2.4 CALCULATING THE AMOUNT OF TONER ON THE DRUM....... 2-14

Fuzzy Logic Algorithm........................................................................ 2-14

Image Area Ratio............................................................................... 2-15

2.2.5 FIXED SUPPLY MODE ................................................................. 2-15

2.2.6 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS..........2-15

2.2.7 DETECTING TONER NEAR END/END......................................... 2-16

Toner Near-end.................................................................................. 2-16

Toner End.......................................................................................... 2-16

Toner near end detection................................................................... 2-17

Toner end detection........................................................................... 2-17

Toner end recovery............................................................................ 2-18

Toner replenishment confirmation mode............................................ 2-18

2.3 DRUM UNIT............................................................................................ 2-19

2.3.1 OVERVIEW ................................................................................... 2-19

2.3.2 DRIVE MECHANISM..................................................................... 2-20

2.3.3 DRUM CHARGE............................................................................ 2-21

2.3.4 DRUM CLEANING......................................................................... 2-22

2.3.5 PCC............................................................................................... 2-22

2.3.6 QUENCHING................................................................................. 2-23

2.3.7 CARRIER CATCHER .................................................................... 2-23

2.4 SCANNER UNIT..................................................................................... 2-24

2.4.1 OVERVIEW ................................................................................... 2-24

2.4.2 SCANNER..................................................................................... 2-25

2.4.3 SCANNER DRIVE ......................................................................... 2-26

2.4.4 COLOR CCD ................................................................................. 2-27

2.4.5 WHITE PLATE SCANNING........................................................... 2-28

2.4.6 SCANNER IPU BOARD................................................................. 2-28

2.4.7 ORIGINAL SIZE DETECTION....................................................... 2-29

2.4.8 OTHERS........................................................................................ 2-31

Anti-condensation Heater................................................................... 2-31

Fans................................................................................................... 2-31

2.5 IMAGE PROCESSING ........................................................................... 2-32

2.5.1 OVERVIEW ................................................................................... 2-32

2.5.2 SCANNER SECTION BLOCK DIAGRAM...................................... 2-33

2.5.3 SCANNER SECTION .................................................................... 2-34

Photoelectric Conversion (by the CCD) ............................................. 2-34

II

Page 6

Signal Processing (in the Analog ASIC)............................................. 2-34

A/D Conversion.................................................................................. 2-34

Shading Circuit................................................................................... 2-35

D/A Conversion.................................................................................. 2-37

Scan Line Correction.......................................................................... 2-37

2.5.4 IPU SECTION BLOCK DIAGRAM................................................. 2-38

2.5.5 IPU SECTION................................................................................ 2-39

Picture Element Correction and Scanner Gamma Correction............ 2-39

ACS (Auto Color Selection)................................................................ 2-41

Auto Letter/Photo Separation............................................................. 2-42

Filtering and Color Conversion........................................................... 2-44

Changes in UCR Ratio with Image Density and Copy Mode ............. 2-50

UCA (Under Color Addition)............................................................... 2-50

Main Scan Magnification.................................................................... 2-51

Mirror Image....................................................................................... 2-51

Gamma (γ) Correction (Printer Gamma)............................................ 2-52

Area Editing........................................................................................ 2-55

CPU ................................................................................................... 2-55

IPU Board Test................................................................................... 2-55

2.6 LASER EXPOSURE............................................................................... 2-56

2.6.1 OVERVIEW ................................................................................... 2-56

2.6.2 OPTICAL PATH............................................................................. 2-57

Overview............................................................................................ 2-57

F-theta Lenses and the BTL............................................................... 2-59

Laser Synchronizing Detector Boards................................................ 2-60

Gradation Control (Laser Pulse Width and Laser Power Modulation) 2-61

600 DPI Writing.................................................................................. 2-62

Auto Power Control (APC)................................................................. 2-63

LD Safety Switches............................................................................ 2-64

2.6 DEVELOPMENT UNIT........................................................................... 2-65

2.6.1 OVERVIEW ................................................................................... 2-65

2.6.2 REVOLVER MECHANISM............................................................. 2-66

Overview............................................................................................ 2-66

Revolver Drive.................................................................................... 2-67

Revolver Home Position Detection..................................................... 2-68

2.6.3 DEVELOPMENT MECHANISMS................................................... 2-69

Overview............................................................................................ 2-69

Development Drive............................................................................. 2-70

Developer Agitation............................................................................ 2-70

Toner Agitation................................................................................... 2-71

Development Bias.............................................................................. 2-72

Toner Supply Mechanism ..................................................................2-73

Toner Cartridge Detection.................................................................. 2-74

Incorrect Toner Installation Prevention............................................... 2-74

Toner End Detection.......................................................................... 2-75

2.7 TRANSFER BELT UNIT......................................................................... 2-76

2.7.1 OVERVIEW ................................................................................... 2-76

2.7.2 BELT TRANSFER MECHANISMS ................................................ 2-77

Transfer Belt Drive............................................................................. 2-77

III

Page 7

Transfer Belt Release Lever............................................................... 2-78

Belt Transfer Bias............................................................................... 2-79

Belt Mark Detection............................................................................ 2-80

Transfer Belt Cleaning Mechanism.................................................... 2-81

2.7.3 PAPER TRANSFER MECHANISM................................................ 2-85

Paper Transfer Unit Contact/Release Mechanism............................. 2-85

Paper Transfer Bias Roller Drive........................................................ 2-86

Paper Transfer Bias Roller Cleaning.................................................. 2-87

Paper Transfer Bias........................................................................... 2-88

2.7.4 PAPER SEPARATION MECHANISM............................................ 2-90

2.8 PAPER FEED AND REGISTRATION..................................................... 2-91

2.8.1 OVERVIEW ................................................................................... 2-91

2.8.2 PAPER TRAY................................................................................ 2-92

Paper Feed/Separation...................................................................... 2-92

Separation and Pick-Up Roller Release............................................. 2-92

Paper Lift............................................................................................ 2-93

Paper End Detection..........................................................................2-94

Paper Size Setting ............................................................................. 2-94

Tray Paper Height Sensor.................................................................. 2-95

2.8.3 BY-PASS TRAY............................................................................. 2-96

By-pass Table Mechanism................................................................. 2-96

Paper Feed/Separation...................................................................... 2-96

Paper End Detection..........................................................................2-97

Paper Size Detection ......................................................................... 2-98

Pick-up Roller..................................................................................... 2-99

2.8.4 REGISTRATION MECHANISM AND PAPER FEED DRIVE......... 2-99

2.9 PAPER TRANSPORT, FUSING, AND PAPER EXIT ........................... 2-100

2.9.1 MAJOR COMPONENTS.............................................................. 2-100

2.9.2 DRIVE MECHANISM................................................................... 2-101

2.9.3 FUSING UNIT.............................................................................. 2-102

Fusing Mechanism........................................................................... 2-102

Fusing Temperature Control............................................................ 2-102

Fusing/Pressurization Mechanism................................................... 2-103

Oil Supply Mechanism ..................................................................... 2-104

Cleaning Mechanism........................................................................ 2-105

2.9.4 INVERTER AND PAPER EXIT MECHANISMS........................... 2-106

Paper Exit......................................................................................... 2-106

Junction Gate Mechanism (A259/A260 Only).................................. 2-106

Paper Exit Door Mechanism (A259/A260 Only)............................... 2-107

2.10 DUPLEX TRAY (A259/A260 COPIERS ONLY)..................................2-108

2.10.1 OVERVIEW ............................................................................... 2-108

2.10.2 DRIVE MECHANISM................................................................. 2-109

2.10.3 PAPER FEED INTO THE DUPLEX TRAY................................. 2-110

1. Duplex Stacking........................................................................... 2-110

2. Paper Feed from the Duplex Tray................................................2-110

3. Duplex Entrance To Duplex Tray................................................. 2-111

2.10.4 JOGGER MECHANISM............................................................. 2-112

2.10.5 PAPER FEED FROM THE DUPLEX TRAY............................... 2-113

Bottom Plate Lift Mechanism ........................................................... 2-113

IV

Page 8

Paper Feed-out mechanism............................................................. 2-114

2.11 OTHERS............................................................................................. 2-115

2.11.1 SYSTEM CONFIGURATION..................................................... 2-115

2.11.2 POWER STATES ...................................................................... 2-116

Energy Saver Mode ......................................................................... 2-116

Power-off (Sleep) State.................................................................... 2-116

Main Power Switch Off State ........................................................... 2-117

Power State Transition Diagram...................................................... 2-117

2.11.3 TOUCH PANEL (A259/A260 MACHINES ONLY)...................... 2-118

2.11.4 BUS SWITCH BOARD (OPTIONAL)......................................... 2-119

3. INSTALLATION PROCEDURE...................................................3-1

3.1 INSTALLATION REQUIREMENTS .......................................................... 3-1

3.1.1 DIMENSIONS.................................................................................. 3-2

3.1.2 ENVIRONMENTAL REQUIREMENTS............................................ 3-3

3.1.3 MINIMUM SPACE REQUIREMENTS.............................................. 3-5

3.1.4 POWER REQUIREMENTS.............................................................. 3-6

3.2 COPIER INSTALLATION.......................................................................... 3-7

3.2.1 ACCESSORY CHECK..................................................................... 3-7

3.2.2 COPIER INSTALLATION PROCEDURE......................................... 3-8

Tape Removal...................................................................................... 3-8

Removing the Inner Transfer Cover and Paper Transfer

Locking Screw.................................................................................. 3-10

Developer Installation......................................................................... 3-12

Pressure Release Lever Set-up......................................................... 3-17

Installing Fusing Silicone Oil.............................................................. 3-18

Initialization and Function Checks...................................................... 3-19

Setting the Tray Paper Size............................................................... 3-20

Setting the Language and Unit of Measurement................................ 3-21

Resetting the Counter........................................................................ 3-21

3.2.2 RELOCATION PROCEDURE........................................................ 3-22

3.3 PAPER TRAY UNIT (A832/A833)........................................................... 3-23

3.3.1 ACCESORY CHECK..................................................................... 3-23

3.3.2 INSTALLATION............................................................................. 3-24

TRAY HEATER (OPTION)................................................................. 3-27

3.4 PLATEN COVER (A749-01)................................................................... 3-28

3.5 ARDF (A663).......................................................................................... 3-29

3.5.1 ACCESSORY CHECK................................................................... 3-29

3.5.2 INSTALLATION............................................................................. 3-30

3.6 20-BIN SORTER STAPLER (A834)........................................................ 3-31

3.6.1 ACCESSORY CHECK................................................................... 3-31

3.6.2 INSTALLATION............................................................................. 3-32

3.7 10-BIN SORTER STAPLER (A555)........................................................ 3-36

3.7.1 ACCESSORY CHECK................................................................... 3-36

3.7.2 INSTALLATION............................................................................. 3-37

3.8 3-BIN SORTER (A849)........................................................................... 3-42

V

Page 9

3.8.1 ACCESSORY CHECK................................................................... 3-42

3.8.2 INSTALLATION............................................................................. 3-43

3.9 FILM PROJECTOR TABLE (A702-19)................................................... 3-45

3.10 FILM PROJECTOR UNIT (A846) ......................................................... 3-47

3.10.1 ACCESSORY CHECK................................................................. 3-47

3.10.2 INSTALLATION............................................................................ 3-48

3.11 CONTROLLER INTERFACE TYPE E (A848)....................................... 3-55

3.12 OTHERS............................................................................................... 3-59

3.12.1 ORIGINAL TABLE INSTALLATION PROCEDURE..................... 3-59

3.12.2 KEY COUNTER HOLDER INSTALLATION PROCEDURE......... 3-60

4. SERVICE TABLES......................................................................4-1

4.1 SERVICE PROGRAM (SP) MODES........................................................ 4-1

4.1.1 HOW TO ENTER SP MODE............................................................ 4-1

4.2 SP MODE TYPES .................................................................................... 4-1

4.3 SP MODE TABLE..................................................................................... 4-2

4.4 SP MODE ADDITIONAL NOTES .............................................................4-3

4.4.1 SP5-804 OUTPUT CHECK............................................................ 4-3

4.4.2 SP5-803 INPUT CHECK.................................................................. 4-5

Printer .................................................................................................. 4-5

Sorter................................................................................................... 4-7

ARDF................................................................................................... 4-8

4.4.3 SP5-955-018 TEST PATTERN SELECTION................................... 4-8

4.4.4 5-955-001 LD_PWM (DOT, LINE)................................................... 4-8

4.4.5 5-955-002 TO 5-955-016 LD_PWM (16-GRADATION)................... 4-9

4.4.6 5-995-017 LD_PWM (COLOR PATCHES)...................................... 4-9

4.5 USER TOOL...........................................................................................4-10

4.5.1 USER TOOL MENU....................................................................... 4-10

System settings.................................................................................. 4-10

COPY FEATURES............................................................................. 4-11

4.5.2 SYSTEM SETTINGS..................................................................... 4-12

4.5.3 COPY FEATURES......................................................................... 4-16

General Features............................................................................... 4-16

Image Adjustment.............................................................................. 4-19

Set Favorite Keys............................................................................... 4-21

Special Modes.................................................................................... 4-21

4.6 TP/SW/LED/FUSE.................................................................................. 4-22

4.6.1 MAIN CONTROL BOARD TEST POINTS..................................... 4-22

4.6.2 SCANNER IPU BOARD TEST POINTS........................................ 4-23

4.6.3 LD MAIN CONTROL BOARD TEST POINTS................................ 4-24

4.6.4 I/O CONTROL BOARD TEST POINTS ......................................... 4-25

4.6.5 SWITCH SPECIFICATIONS.......................................................... 4-28

Scanner IPU Board............................................................................ 4-28

4.6.6 LED SPECIFICATIONS.................................................................4-28

4.6.7 FUSE SPECIFICATIONS .............................................................. 4-29

PSU (US model)................................................................................. 4-29

PSU (European/Asian Model)............................................................ 4-30

VI

Page 10

5. PREVENTIVE MAINTENANCE...................................................5-1

5.1 PM PROCEDURES.................................................................................. 5-1

5.1.1 PM-RELATED COUNTERS............................................................. 5-1

5.1.2 REGULAR PREVENTIVE MAINTENANCE FLOW DIAGRAM........ 5-3

5.2 REGULAR PM ITEMS.............................................................................. 5-7

Regular PM Table................................................................................ 5-7

6. REPLACEMENT AND ADJUSTMENT ........................................ 6-1

6.1 COVERS, FANS, AND FILTERS.............................................................. 6-1

6.1.1 FRONT, INNER, AND INNER TRANSFER COVERS ..................... 6-1

6.1.2 REAR COVERS............................................................................... 6-2

6.1.3 RIGHT COVERS.............................................................................. 6-3

6.1.4 LEFT COVERS................................................................................ 6-3

6.1.5 EXPOSURE GLASS........................................................................ 6-4

6.1.6 OPERATION PANEL....................................................................... 6-4

6.1.7 UPPER COVERS ............................................................................ 6-4

6.1.8 USED TONER TANK....................................................................... 6-5

6.1.9 CHARGE CORONA FAN FILTER ................................................... 6-5

6.1.10 MAIN EXHAUST FAN FILTER....................................................... 6-6

6.1.11 SCANNER EXHAUST FAN FILTER.............................................. 6-6

6.1.12 MAIN EXHAUST FAN.................................................................... 6-7

6.2 DRUM UNIT.............................................................................................. 6-8

6.2.1 PULLING OUT THE REVOLVER/DRUM DRAWER...................... 6-10

6.2.2 DRUM REPLACEMENT................................................................ 6-12

6.2.3 CLEANING BLADE AND PCC WIRE REPLACEMENT................. 6-14

6.2.4 CLEANING BRUSH REPLACEMENT........................................... 6-15

6.2.5 LUBRICANT BAR REPLACEMENT.............................................. 6-16

6.2.6 CHARGE CORONA GRID AND WIRE REPLACEMENT.............. 6-17

6.2.7 POTENTIAL SENSOR REPLACEMENT....................................... 6-18

6.3 SCANNER UNIT..................................................................................... 6-19

6.3.1 EXPOSURE LAMP REPLACEMENT............................................ 6-19

6.3.2 SBU REPLACEMENT.................................................................... 6-20

6.3.3 SCANNER IPU BOARD REPLACEMENT..................................... 6-21

6.3.4 SCANNER WIRE/SCANNER MOTOR REPLACEMENT .............. 6-22

6.3.5 APS SENSORS............................................................................. 6-26

6.3.6 SCANNER HP SENSOR............................................................... 6-27

6.4 COPY IMAGE ADJUSTMENT................................................................ 6-28

6.4.1 PRINTER GAMMA ADJUSTMENT................................................ 6-28

Setting the KCMY standard values.................................................... 6-28

Gamma Data Print Out....................................................................... 6-28

KCMY color balance adjustment........................................................ 6-28

Adjustment procedure........................................................................ 6-29

Standard Copy Quality....................................................................... 6-30

6.4.2 ACC TARGET ADJUSTMENT....................................................... 6-31

6.4.3 MAIN SCAN DOT POSITION CORRECTION............................... 6-32

VII

Page 11

6.5 LASER OPTICS SECTION..................................................................... 6-34

6.5.1 POLYGON MIRROR MOTOR REPLACEMENT............................ 6-35

6.5.2 LASER SYNCHRONIZING DETECTOR BOARD AND LD UNIT

REPLACEMENT...................................................................................... 6-37

6.5.3 SQUARENESS ADJUSTMENT..................................................... 6-38

6.6 DEVELOPMENT UNIT........................................................................... 6-40

6.6.1 REPLACING THE DEVELOPER................................................... 6-40

Developer Collection Procedure......................................................... 6-40

Installing New Developer ................................................................... 6-43

6.6.2 POST DEVELOPER COLLECTION PROCEDURE....................... 6-46

6.6.3 DEVELOPMENT UNIT REPLACEMENT....................................... 6-47

6.6.4 TONER COLLECTION TRAY CLEANING..................................... 6-48

6.7 TRANSFER BELT UNIT......................................................................... 6-49

6.7.1 TRANSFER BELT SECTION......................................................... 6-49

Transfer Belt and Cleaning Unit......................................................... 6-49

Cleaning Blade Replacement............................................................. 6-52

Lubricant Bar and Lubricant Brush Replacement............................... 6-53

6.7.2 PAPER TRANSFER UNIT............................................................. 6-54

Lubricant Bar And Blade Replacement.............................................. 6-54

Paper Separation Corona Wire Replacement.................................... 6-54

Transfer Roller Replacement............................................................. 6-55

6.8 PAPER FEED AND REGISTRATION SECTION.................................... 6-56

6.8.1 BY-PASS FEED TABLE REMOVAL.............................................. 6-56

6.8.2 BY-PASS PAPER WIDTH DETECTION BOARD REPLACEMENT6-56

6.8.3 BY-PASS FEED, PICK-UP AND SEPARATION ROLLERS,

AND TORQUE LIMITER REPLACEMENT.................................... 6-57

6.8.4 BY-PASS FEED UNIT REPLACEMENT........................................ 6-58

6.8.5 REGISTRATION SENSOR REPLACEMENT................................ 6-58

6.8.6 VERTICAL TRANSPORT DOOR REPLACEMENT....................... 6-59

6.8.7 PAPER TRAY PICK-UP, PAPER FEED, AND SEPARATION

ROLLER REPLACEMENT............................................................. 6-59

6.8.8 PAPER FEED UNIT AND CLUTCH REPLACEMENT................... 6-60

6.8.9 COPY IMAGE AREA ADJUSTMENT ............................................ 6-61

Preparation ........................................................................................ 6-61

Leading Edge Registration................................................................. 6-62

Side-to-side Registration.................................................................... 6-63

6.9 PAPER TRANSPORT, FUSING, AND PAPER EXIT SECTIONS.......... 6-64

6.9.1 FUSING UNIT REMOVAL ............................................................. 6-64

6.9.2 TRANSPORT UNIT REMOVAL..................................................... 6-65

6.9.3 FUSING UNIT TOP COVER REMOVAL .......................................6-66

6.9.4 OIL SUPPLY PAD AND OIL BLADE REPLACEMENT.................. 6-67

6.9.5 HOT ROLLER THERMOFUSE REPLACEMENT.......................... 6-68

6.9.6 FUSING UNIT DISASSEMBLY...................................................... 6-68

6.9.7 CLEANING ROLLER SCRAPER CLEANING................................ 6-69

6.9.8 HOT ROLLER THERMISTOR REPLACEMENT............................ 6-70

6.9.9 HOT ROLLER FUSING LAMP REPLACEMENT........................... 6-71

6.9.10 HOT ROLLER AND CLEANING ROLLER REPLACEMENT

AND CLEANING........................................................................... 6-72

VIII

Page 12

6.9.11 PRESSURE ROLLER AND PRESSURE ROLLER FUSING

LAMP........................................................................................... 6-73

6.9.12 PRESSURE ROLLER THERMOFUSE AND THERMISTOR

REPLACEMENT.......................................................................... 6-74

6.9.13 NIP BAND WIDTH ADJUSTMENT.............................................. 6-75

6.9.14 CAUTIONS TO BE TAKEN WHEN USING A FUSING UNIT

THAT HAS BEEN IN STOCK FOR A LONG PERIOD.................. 6-76

6.10 DUPLEX UNIT...................................................................................... 6-77

6.10.1 DUPLEX UNIT REMOVAL........................................................... 6-77

6.10.2 SEPARATION ROLLER REPLACEMENT................................... 6-77

6.10.3 FEED ROLLER REPLACEMENT................................................ 6-78

6.10.4 DUPLEX FEED MOTOR REPLACEMENT.................................. 6-79

6.11 SYSTEM AND ELECTRONICS............................................................ 6-81

6.11.1 IPU PROGRAM DOWNLOADING............................................... 6-81

6.11.2 MAIN PROGRAM DOWNLOADING............................................ 6-82

6.11.3 NV-RAM UPLOADING AND DOWNLOADING............................ 6-83

Upload/Download Procedure............................................................. 6-83

6.11.4 RAM CLEAR................................................................................ 6-84

RAM Clear Procedure........................................................................ 6-84

Precautions when replacing the NV-RAM.......................................... 6-85

6.11.5 TOUCH PANEL CALIBRATION (A259/A260 ONLY)................... 6-86

7. TROUBLESHOOTING.................................................................7-1

7.1 SERVICE CALL (SC) ERRORS ............................................................... 7-1

7.1.1 SC TYPES AND RESETTING PROCEDURES............................... 7-1

7.2 SC CODE TABLE..................................................................................... 7-2

7.3 PROCESS CONTROL ERROR CONDITIONS ........................................ 7-3

7.3.1 PROCESS CONTROL SELF-CHECK RESULTS (SP3-975-00)..... 7-3

7.3.2 DEVELOPER SETUP RESULTS (SP3-964-00).............................. 7-4

7.3.3 SELF-CHECK PROCESS CONTROL RELATED SCS ................... 7-5

7.4 DRUM LIGHT FATIGUE........................................................................... 7-6

IX

Page 13

OPTIONS

ARDF (A663)

1. SPECIFICATIONS.................................................................A663-1

2. COMPONENT LAYOUT........................................................A663-2

2.1 MECHANICAL COMPONENTS..........................................................A663-2

2.2 ELECTRICAL COMPONENTS...........................................................A663-3

3. ELECTRICAL COMPONENT DESCRIPTION.......................A663-4

4. DETAILED DESCRIPTIONS.................................................A663-5

4.1 ORIGINAL PICK-UP MECHANISM....................................................A663-5

4.2 SEPARATION AND PAPER FEED MECHANISM..............................A663-6

4.3 FRICTION BELT DRIVE MECHANISM..............................................A663-7

4.4 ORIGINAL SIZE DETECTION............................................................A663-8

4.5 PAPER TRANSPORT MECHANISM..................................................A663-9

4.6 THICK/THIN ORIGINAL MODES ..................................................... A663-10

4.7 ORIGINAL FEED-OUT MECHANISM...............................................A663-11

4.8 TWO-SIDED ORIGINAL FEED MECHANISM..................................A663-12

5. TIMING CHARTS ................................................................A663-13

5.1 A4 SIDEWAYS: 1 SIDED ORIGINAL ...............................................A663-13

5.2 COMBINE 2 ORIGINAL MODE........................................................A663-14

5.3 A4 SIDEWAYS: DUPLEX.................................................................A663-15

6. SERVICE TABLES..............................................................A663-16

6.1 DIP SWITCHES................................................................................A663-16

6.2 VARIABLE RESISTORS...................................................................A663-17

6.3 LED...................................................................................................A663-17

6.4 FUSE................................................................................................A663-17

7. REPLACEMENT A N D ADJUSTMENT................................A663-18

7.1 TRANSPORT BELT REPLACEMENT..............................................A663-18

7.2 FEED ROLLER REPLACEMENT..................................................... A663-19

7.3 FRICTION BELT REPLACEMENT...................................................A663-20

7.4 ORIGINAL SET AND WIDTH SENSOR REPLACEMENT................A663-21

7.5 VERTICAL REGISTRATION ADJUSTMENT...................................A663-22

7.5.1 ONE SIDED THIN ORIGINAL MODE......................................A663-22

7.5.2 TWO SIDED ORIGINAL MODE...............................................A663-23

7.6 SIDE-TO-SIDE REGISTRATION (DF POSITIONING)

ADJUSTMENT..................................................................................A663-24

X

Page 14

PAPER TRAY UNIT (A832/A833)

1. PRODUCT OVERVIEW..........................................................

1.1 SPECIFICATIONS..............................................................................A833-1

1.2 COMPONENT DESCRIPTION...........................................................A833-1

1.2.1 PAPER FEED MECHANISM.....................................................A833-1

1.3 COMPONENT LAYOUTS...................................................................A833-2

1.3.1 ELECTRICAL COMPONENT LAYOUT.....................................A833-2

1.3.2 DRIVE LAYOUT.........................................................................A833-3

1.3.3 DISASSEMBLY AND ADJUSTMENT PROCEDURES..............A833-4

(1) Pick-up, paper feed, and separation rollers..............................A833-4

(2) Bank paper feed and tray lift motors......................................... A833-4

(3) Paper feed clutch......................................................................A833-5

(3) Relay clutch..............................................................................A833-5

(4) Paper feed unit.........................................................................A833-6

20-BIN SORTER (A834)

1. OVERALL MAC HINE INFORMATION...................................

1.1 SPECIFICATIONS..............................................................................A834-1

1.2 COMPONENT LAYOUT.....................................................................A834-3

1.2.1 MECHANICAL COMPONENT LAYOUT .................................... A834-3

1.2.2 DRIVE LAYOUT.........................................................................A834-4

1.2.3 ELECTRICAL COMPONENT DESCRIPTION...........................A834-5

A833-

A834-

1

1

2. DETAILED DESCRIPTIONS ..................................................

2.1 BASIC OPERATION...........................................................................A834-6

2.1.1 NORMAL MODE AND SORT/STACK MODE............................A834-6

Normal (Proof) Mode......................................................................A834-6

Sort Mode ......................................................................................A834-6

Stack Mode....................................................................................A834-7

2.1.2 STAPLE MODE.........................................................................A834-8

Mechanism.....................................................................................A834-8

Automatic Stapling.........................................................................A834-8

Manual Stapling .............................................................................A834-8

2.1.3 BIN DRIVE MECHANISM..........................................................A834-9

2.1.4 BIN HOME POSITION............................................................. A834-10

2.1.5 JOGGER MECHANISM...........................................................A834-11

2.1.6 GRIP ASSEMBLY....................................................................A834-12

2.1.7 STAPLER UNIT.......................................................................A834-13

2.1.8 STAPLER SWITCH .................................................................A834-14

Staple Mode Disabling Conditions...............................................A834-14

2.1.9 PAPER FEED AND MISFEED DETECTION TIMING..............A834-15

Proof ModeA4 sideways, five copies, 150 mm/s..........................A834-15

Sorter ModeA4 sideways, two copies a of two-page original,

150 mm/s.....................................................................................A834-15

A834-

6

XI

Page 15

Staple ModeA4 sideways, two copies of a two-page original, after

sorting, 150 mm/s.........................................................................A834-16

2.1.10 JAM DETECTION..................................................................A834-17

Paper JamA4 sideways................................................................A834-17

Staple Jam...................................................................................A834-17

3. REPLACEMENT AND ADJUSTEMENT ..............................

3.1 EXTERIOR COVER REMOVAL.......................................................A834-18

3.1.1 FRONT COVER.......................................................................A834-18

3.1.2 REAR COVER.........................................................................A834-18

3.1.3 TOP COVER............................................................................A834-18

3.1.4 LOWER COVER......................................................................A834-18

3.2 STAPLER UNIT REMOVAL..............................................................A834-19

3.3 GRIP ARM REPLACEMENT............................................................A834-20

3.4 BIN REMOVAL.................................................................................A834-21

3.5 TRANSPORT MOTOR REMOVAL...................................................A834-22

10-BIN SORTER (A555)

A834-

18

1. SPECIFICATIONS.................................................................A555-1

2. COMPONENT LAYOUT........................................................A555-3

2.1 MECHANICAL COMPONENT LAYOUT.............................................A555-3

2.2 DRIVE LAYOUT .................................................................................A555-4

2.3 ELECTRICAL COMPONENT DESCRIPTION....................................A555-5

3. BASIC OPERATION...............................................................

3.1 NORMAL MODE AND SORT/STACK MODE.....................................A555-6

3.2 STAPLE MODE..................................................................................A555-8

3.3 BIN DRIVE MECHANISM.................................................................A555-10

3.4 BIN HOME POSITION......................................................................A555-11

3.5 JOGGER MECHANISM....................................................................A555-12

3.6 GRIP ASSEMBLY.............................................................................A555-13

3.7 STAPLER UNIT................................................................................A555-14

3.8 STAPLER SWITCH..........................................................................A555-15

3.9 PAPER FEED AND MISFEED DETECTION TIMING ......................A555-16

3.10 JAM DETECTION...........................................................................A555-18

A555-

6

4. SERVICE TABLES...............................................................

4.1 DIP SWITCHES................................................................................A555-19

4.2 TEST POINTS..................................................................................A555-20

4.3 LED...................................................................................................A555-20

4.4 VARIABLE RESISTOR.....................................................................A555-20

5. REPLACEMENT AND ADJUSTMENT .................................

5.1 EXTERIOR COVER REMOVAL.......................................................A555-21

5.2 STAPLE UNIT REMOVAL................................................................A555-21

5.3 GRIP ARM REPLACEMENT............................................................A555-22

XII

A555-

A555-

19

21

Page 16

5.4 BIN REPLACEMENT........................................................................A555-23

5.5 TRANSPORT MOTOR REPLACEMENT..........................................A555-24

5.6 BIN JAM SENSOR ADJUSTMENT ..................................................A555-25

3-BIN SORTER (A849)

1. SPECIFICAT IONS..................................................................

2. COMPONENT LAYOUT.........................................................

2.1 MECHANICAL COMPONENT LAYOUT.............................................A849-2

2.2 DRIVE LAYOUT .................................................................................A849-3

2.3 ELECTRICAL COMPONENT DESCRIPTION....................................A849-4

3. DETAILED SECTION DESCRIPTIONS..................................

3.1 BASIC OPERATION...........................................................................A849-5

3.1.1 FACE-UP MODE .......................................................................A849-5

3.1.2 FACE-DOWN MODE.................................................................A849-6

3.2 1ST BIN UP/DOWN MECHANISM.....................................................A849-7

3.3 1ST BIN SIDE-TO-SIDE SHIFT MECHANISM...................................A849-8

3.4 PAPER FEED AND MISFEED DETECTION TIMING ........................A849-9

3.5 JAM DETECTION.............................................................................A849-11

4. REPLACEMENT AND ADJUSTMENT .................................

4.1 EXTERIOR COVER AND BIN REMOVAL........................................A849-12

4.2 TRAY LIFT/SHIFT MOTOR ASSEMBLY REMOVAL .......................A849-13

4.3 ENTRANCE MOTOR REPLACEMENT............................................A849-14

4.4 EXIT MOTOR REPLACEMENT........................................................A849-15

4.5 STACK HEIGHT SENSOR AND 1ST EXIT

SENSOR REPLACEMENT...............................................................A849-16

4.6 2ND / 3RD EXIT SENSOR AND INVERTER

SENSOR REPLACEMENT...............................................................A849-18

A849A849-

A849-

A849-

1

2

5

12

FPU (A846)

1. SPECIFICAT IONS..................................................................

A846-

2. ELECTRICAL COMPONENT LAYOUT

AND DESCRIPTIONS...........................................................

3. SECTIONAL DESCRIPTIONS................................................

3.1 OVERVIEW ........................................................................................ A846-3

3.2 SHADING ...........................................................................................A846-4

3.3 MIRROR UNIT....................................................................................A846-5

XIII

A846A846-

1

2

3

Page 17

APPENDIX

1. TIMMING CHART

A4 SIZE B/W MODE......................................................................................1

A4 SIZE FULL COLOR MODE......................................................................2

A3 SIZE B/W MODE......................................................................................3

A3 SIZE FULL COLOR MODE......................................................................4

2. SP MODE TABLE

3. SC CODE TABLE

XIV

Page 18

24 February, 1999 SPECIFICATIONS

0

9

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

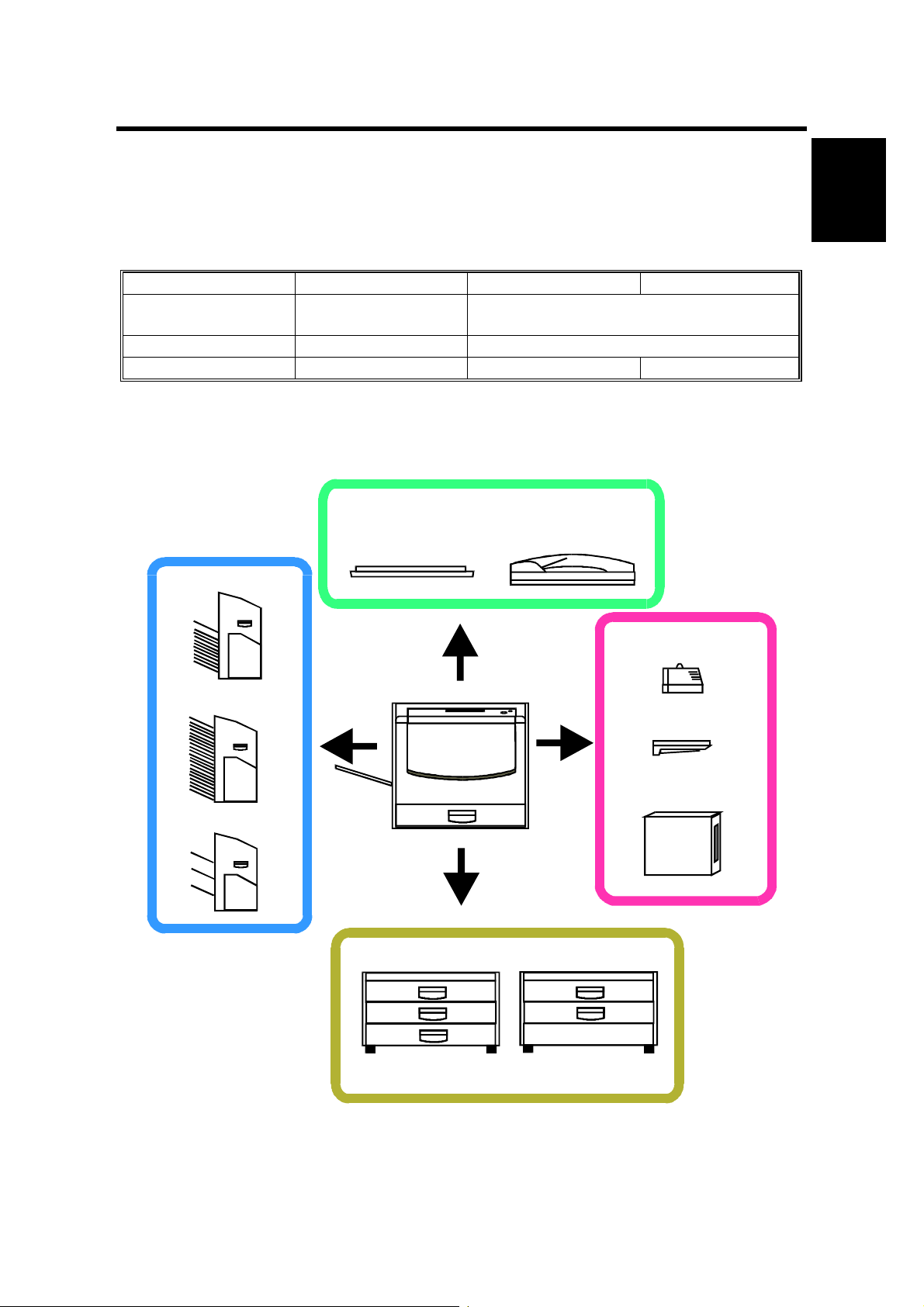

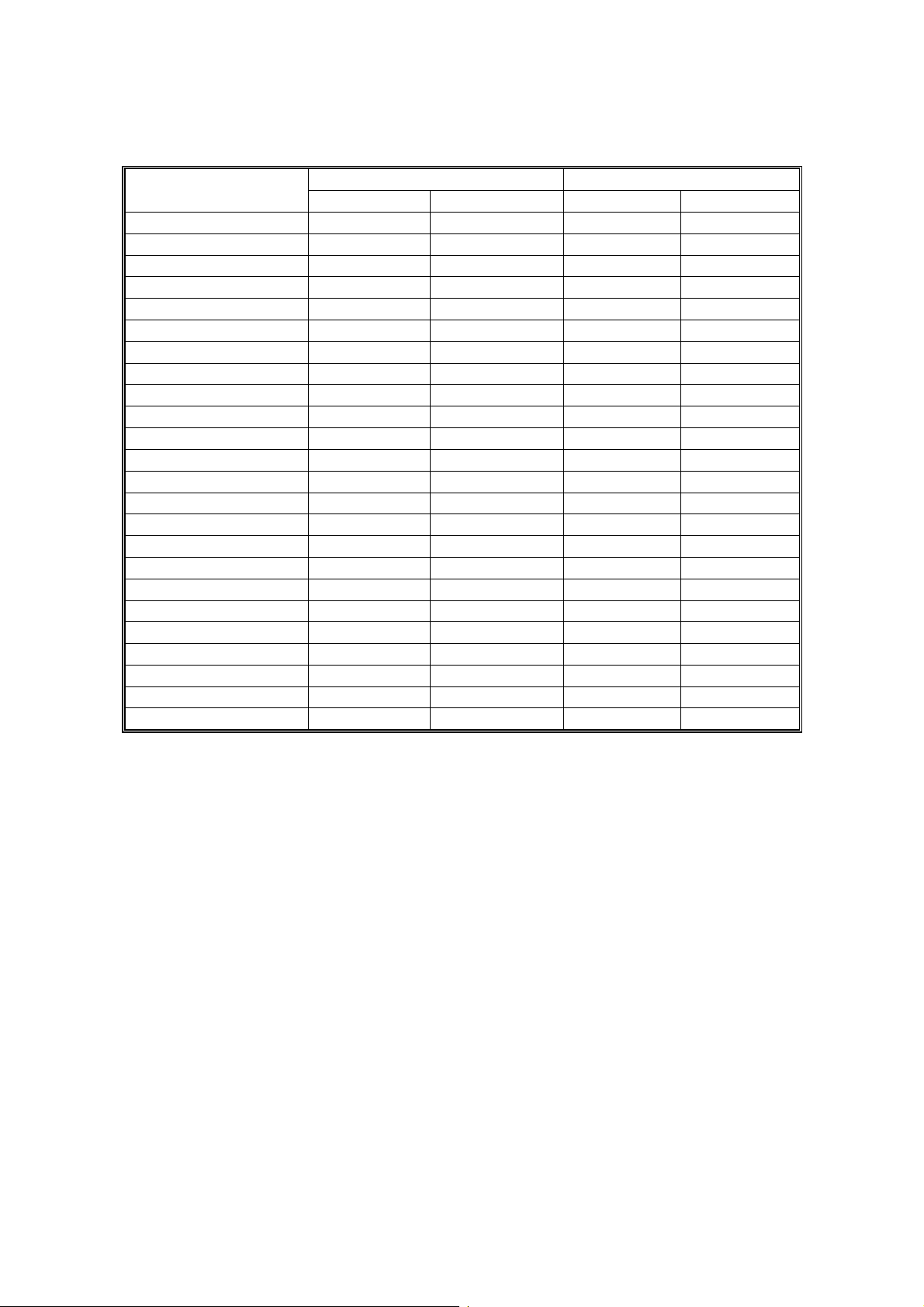

1.1.1 MACHINE CONFIGURATION

A258 A259 A260

Operation Panel

Paper Tray Unit

Edit Function

Sorter/Stapler

A555

40-digit 4-line LCD

Hard Key Type

500 sheets Duplex

No No Yes

Platen Cover

A749-00

Overall

Information

144 mm x 192 mm (10.4 inch)

Color Touch Panel Display

ARDF

A663

A834

A849

Copier

Paper Tray Unit (500 sheets per tray)

A833

A832

FPU A846

FPU Table

A7

2-1

I/F A848

A259V501.WMF

1-1

Page 19

SPECIFICATIONS 24 February, 1999

1.1.2 GENERAL SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Resolution:400 dpi; Printer mode 600 dpi

Gradations: 256 gradations

Originals: Sheet/Book/Object

Original Size: Maximum 11" x 17" /A3

Copy Paper Size:

Maximum Minimum

Paper Tray Feed

(A258 only)

Bypass Feed

Copy Paper Weight:

Paper Tray Feed

Bypass Feed

Auto Duplex Tray

11" x 17" /A3 5

12" x 18"/305 mm x 457 mm A6(L)

17 to 28 lbs. 64 to 105 g/m

14 to 43 lbs. 52 to 160 g/m

17 to 28 lbs. 64 to 105 g/m

2

2

2

1/2

x 8

/A5(L)

1/2

Reproduction Ratios:

8

" x 11"LT/11" x 17"DLT

1/2

A4/A3 version

version

Enlargement

Full size

Reduction

Programmable

121, 129, 155, 200, 400% 115, 122, 141, 200, 400%

100% 100%

25, 50, 65, 73, 78, 85, 93% 25, 50, 65, 71, 75, 82, 93%

2 user ratios 2 user ratios

Zoom: From 25% to 400 % in 1% steps.

1-2

Page 20

24 February, 1999 SPECIFICATIONS

Copying Speed:

8

" x 11" (S) /A4 11" x 17"/A3

1/2

Normal Mode

Full Color (4 scans) 6 cpm 3 cpm

Single Color (C, M Y, K) A258: 21 cpm

A259/260: 28 cpm

A258: 11 cpm

A259/260: 14 cpm

Single Color (B, G) 9 cpm 4.5 cpm

Single Color (R) 7 cpm 3.5 cpm

OHP/Thick Paper Mode

Full Color (4 scans) 3 cpm 1.5 cpm

Single Color (C, M Y, K) 5 cpm 2.5 cpm

Single Color (G, B) 4 cpm 2 cpm

Single Color (R) 3.5 cpm 1.5 cpm

Duplexing: Same as Normal Mode speed in the above table

Printer Speed: 2/3 the speeds shown in the above table

First Copy Time (A258/259/260):

Overall

Information

8

" x 11" (S) /A4

1/2

Normal Mode

Full Color (4 scans) 22.4 seconds

Single Color (K) 8 seconds

Single Color (C, M, Y) 10 seconds

Single Color (B, G, R) 16 seconds

OHP/Thick Paper Mode

Full Color (4 scans) 35 seconds

Single Color (K) 23 seconds

Single Color (C, M, Y) 25 seconds

Single Color (B, G, R) 27 seconds

Warm-up Time: Approx. 7 minutes (at 68°F / 20°C)

1-3

Page 21

SPECIFICATIONS 24 February, 1999

Duplexing:

Basic Manual Duplex

Model (A258):

Basic Auto Duplex

Model (A259):

Edit Auto Duplex Model

(A260):

Manual duplexing in full color and single

color modes

Manual & auto duplexing in full color and

single color modes

Manual & auto duplexing in full color and

single color modes

Duplexing can be done on 64-105 g/m2 paper.

Manual duplexing can be done through the

bypass table only, and the user should press

the Duplex Side 2 key before copying the reverse

side.

Non-Reproduction Area:

Leading Edge:

Side:

0.2" ± 0.08" (5 mm ± 2 mm)

0.08" ± 0.08" (2 mm ± 2 mm)/

Total less than 0.16" (4 mm)

Trailing Edge:

2.0 mm + 2.0/-1.5 mm

Copy Number Input: Number keys, 1 to 99

Copy Number Input

(Auto Duplex):

Number keys

Single Color - 1 to 50: smaller than A3, 11" x 17"

1 to 30: A3, 11" x17"

Full Color 1 to 20: all sizes

Image Density: Auto/Manual (9 steps)

Automatic Reset: Yes (10 to 990 seconds or Off)

Paper Capacity: Tray:

500 sheets x 1 tray

(Basic Manual Duplex Model: A258)

Bypass:

Normal paper (80 g/m2/20 lb) 50 sheets

OHP 20 sheets

Adhesive paper 1 sheet

Toner Replenishment: Toner Addition (K, Y, C, M) (220 g/cartridge)

Copy Tray Capacity: 100 sheets (11" x 17"/A3 and smaller)

Power Source: US: 120V/12A/60Hz,

Europe/Asia: 220-240V/8A/50,60 Hz

Taiwan: 110 V/12A/60Hz

Maximum Power

1.5 kVA

Consumption:

1-4

Page 22

24 February, 1999 SPECIFICATIONS

Dimensions (without Platen Cover):

Width Depth Height

A258

A259

A260

Height: 1,018 mm with optional paper tray unit

620 mm

24.4"

620 mm

24.4"

620 mm

24.4"

680 mm

26.8"

757 mm

29.8"

757 mm

29.8"

602 mm

23.7"

602 mm

23.7"

602 mm

23.7"

Weight: Manual Duplex: 105 kg (231.3 lbs.)

Auto Duplex: 108 kg (237.9 lbs.)

Optional Equipment: Automatic Document Feeder (ARDF): A663

Sorter Stapler: A555 (10 bins), A834 (20 bins),

Sorter: A849 (3 bins)

Film Projector: A846

Holder for Film Projector Unit: A702-19

Paper Tray Unit: A832 (2 trays), A833 (3 trays)

Key Counter

Platen Cover: A749-00

Original Tray: A430-07 (Type F)

Overall

Information

1-5

Page 23

SPECIFICATIONS 24 February, 1999

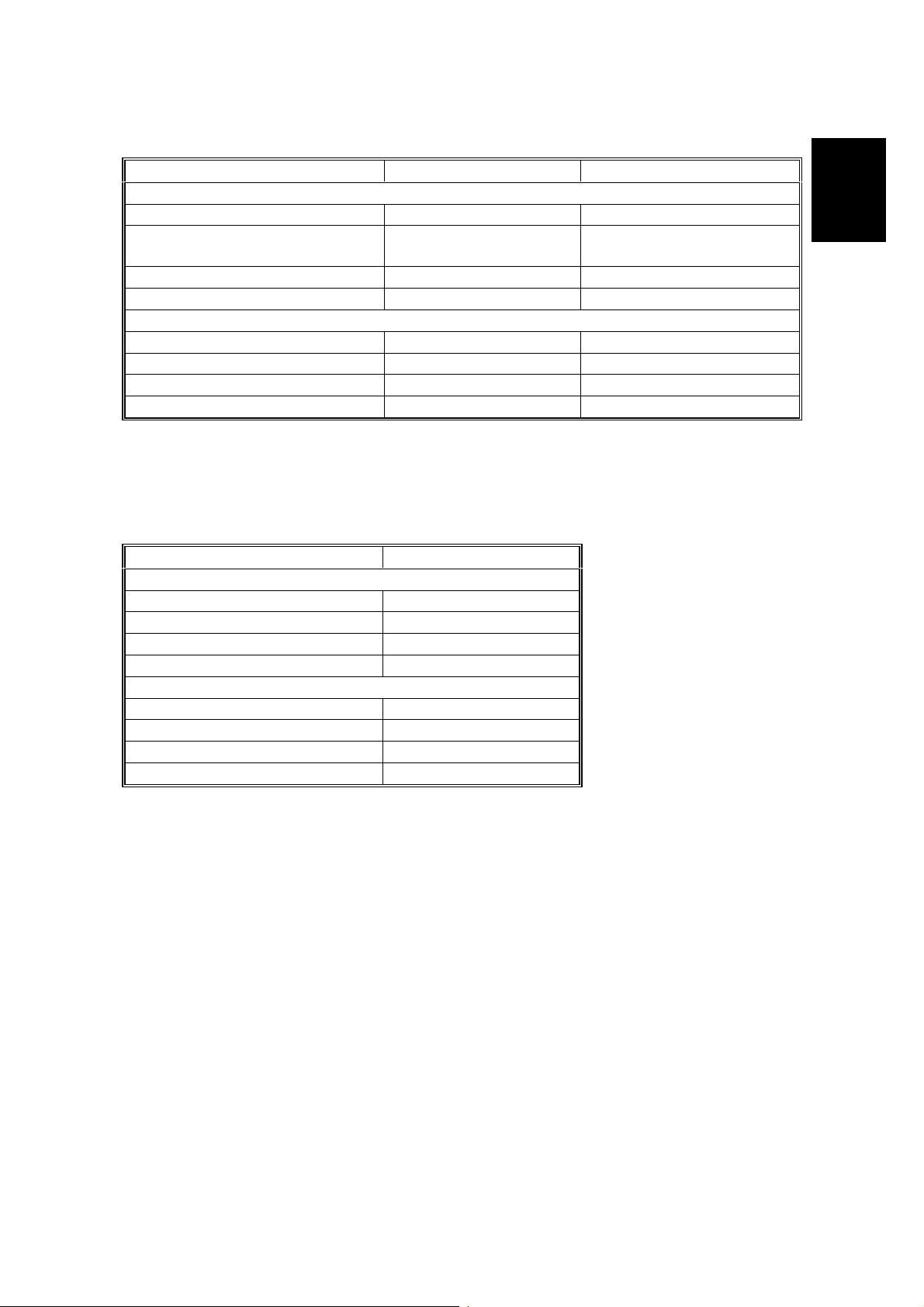

1.1.3 PLATEN/ARDF ORIGINAL SIZE DETECTION

Size (width x length)

[mm]

A3 (297 x 420) L No Yes No Yes

B4 (257 x 364) L No Yes No Yes

A4 (210 x 297) L No Yes Yes Yes

A4 (297 x 210) S No Yes Yes Yes

B5 (182 x 257) L No Yes No Yes

B5 (257 x 182) S No Yes No Yes

A5 (148 x 210) L No No* No Yes

A5 (210 x 148) S No No No Yes

B6 (128 x 182) L No No No Yes

B6 (182 x 128) S No No No Yes

11" x 17" (DLT) Yes No Yes Yes

11" x 15" No No Yes No

10" x 14" No No Yes Yes

8.5" x 14" (LG) Yes No Yes No

8.5" x 13" (F4) No No Yes Yes

8.25" x 13" No No No No

8" x 13"(F) No Yes Yes No

8.5" x 11" (LT) Yes No Yes Yes

11" x 8.5" (LT) Yes No Yes Yes

8" x 10.5" No No No No

8" x 10" No No Yes No

5.5" x 8.5" (HLT) No* No Yes No

8.5" x 5.5" (HLT) No No Yes No

A6 (105 x 148) L No No No No

Inches Metric Inches Metric

Platen ARDF

*: For A5 lengthwise/HLT, SP4-303 can be used to select “Cannot detect

original size” or “A5 lengthwise/5.5" x 8.5"(HLT)”.

1-6

Page 24

24 February, 1999 SPECIFICATIONS

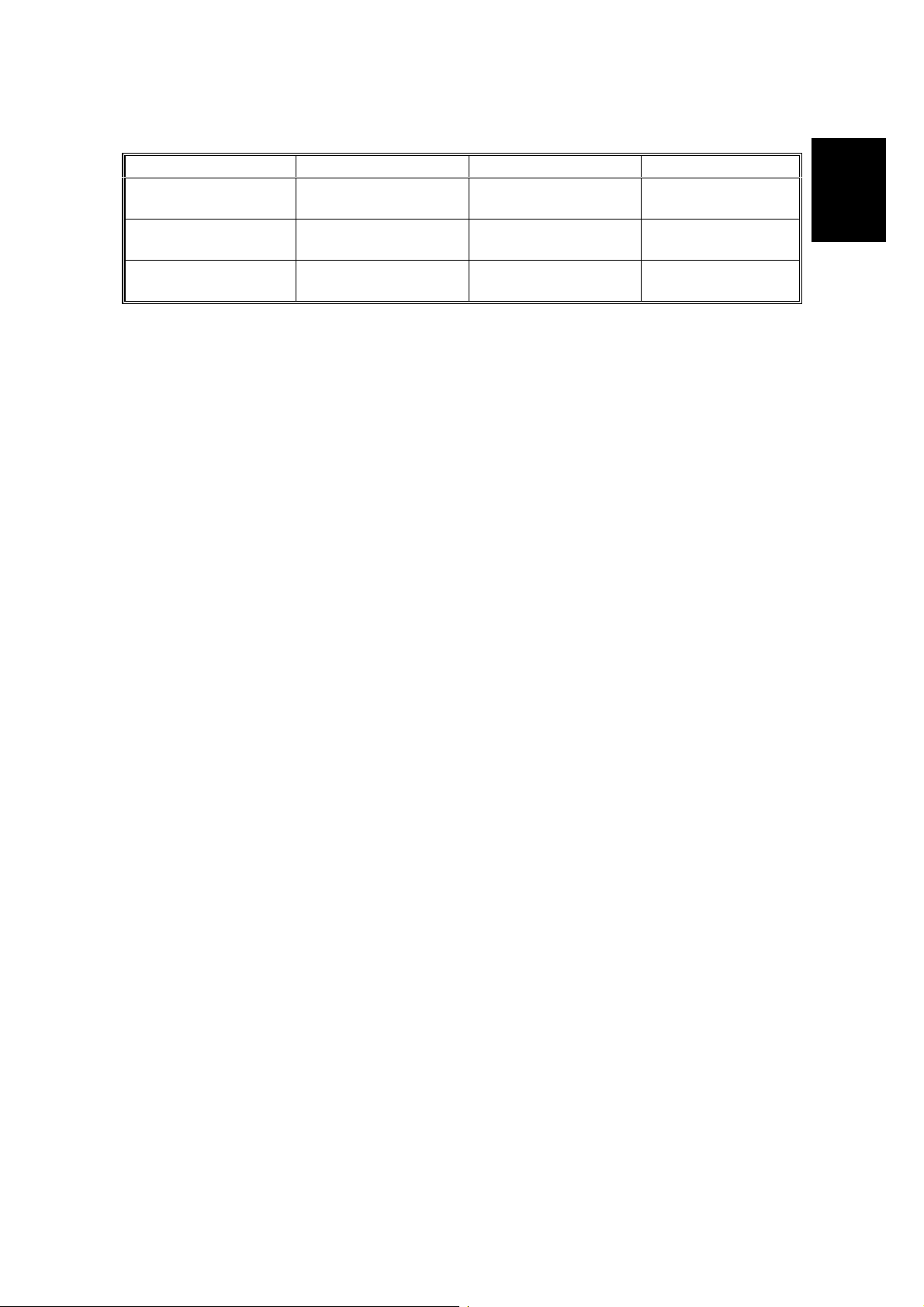

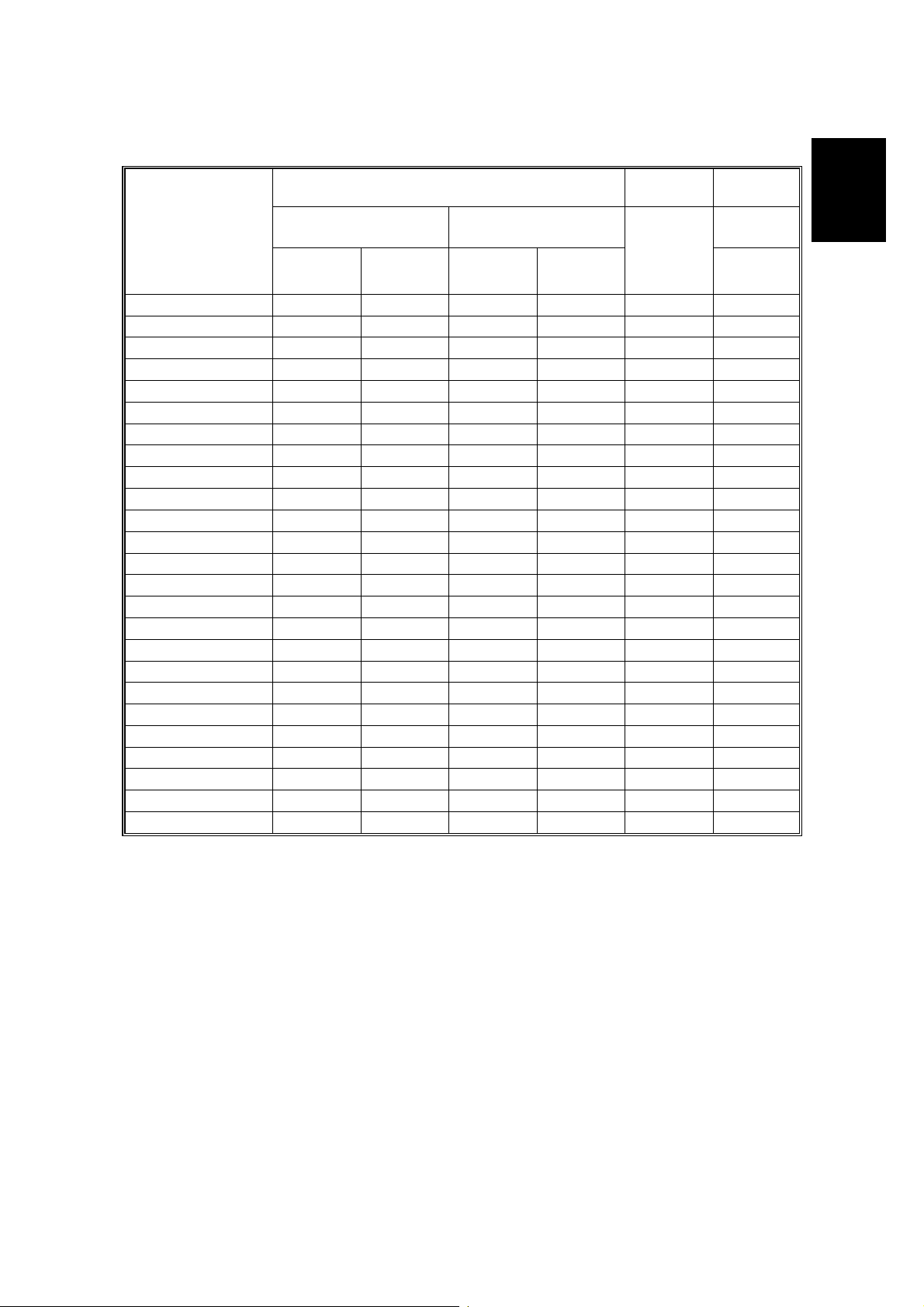

1.1.4 COPY PAPER SIZE

Optional

S.Stapler

Size

(width x length)

[mm]

Trays in the main body Bypass

Paper Tray (A258)

Duplex Tray

(A259/A260)

Inches Metric Inches Metric

All

versions

(A258/

259/260)

A3 (297 x 420) L No Yes Yes Yes Yes Yes

B4 (257 x 364) L No Yes Yes Yes Yes Yes

A4 (210 x 297) L Yes Yes Yes Yes Yes Yes

A4 (297 x 210) S Yes Yes Yes Yes Yes Yes

B5 (182 x 257) L No Yes No Yes Yes Yes

B5 (257 x 182) S No Yes No Yes Yes Yes

A5 (148 x 210) L No Yes No No Yes Yes (1)

A5 (210 x 148) S No No Yes Yes Yes Yes (2)

B6 (128 x 182) L No No No No Yes Yes (1)

B6 (182 x 128) S No No No No No No

12” x 18” No No No No Yes Yes (3)

11" x 17" (DLT) Yes Yes Yes Yes Yes Yes

11" x 15" Yes No Yes No Yes Yes

10" x 14" Yes No Yes No Yes Yes

8.5" x 14" (LG) Yes No Yes No Yes Yes

8.5" x 13" (F4) Yes Yes Yes Yes Yes Yes

8.25" x 13" No No Yes Yes Yes Yes

8" x 13"(F) No No Yes Yes Yes Yes

8.5" x 11" (LT) Yes Yes Yes Yes Yes Yes

11" x 8.5" (LT) Yes Yes Yes Yes Yes Yes

8" x 10.5" No No Yes No Yes Yes

8" x 10" Yes No Yes Yes Yes Yes

5.5" x 8.5" (HLT) No No No No Yes Yes (1)

8.5" x 5.5" (HLT) Yes No Yes Yes Yes Yes ( 2)

A6 (105 x 148) L No No No No Yes Yes (2)

Overall

Information

Yes (1): Stapling is not allowed.

Yes (2): Using the proof tray only. Sorter bins cannot be used.

Yes (3): 20-bin sorter (A834): Stapling is not allowed.

10-bin sorter (A555): Not available

1-7

Page 25

SPECIFICATIONS 24 February, 1999

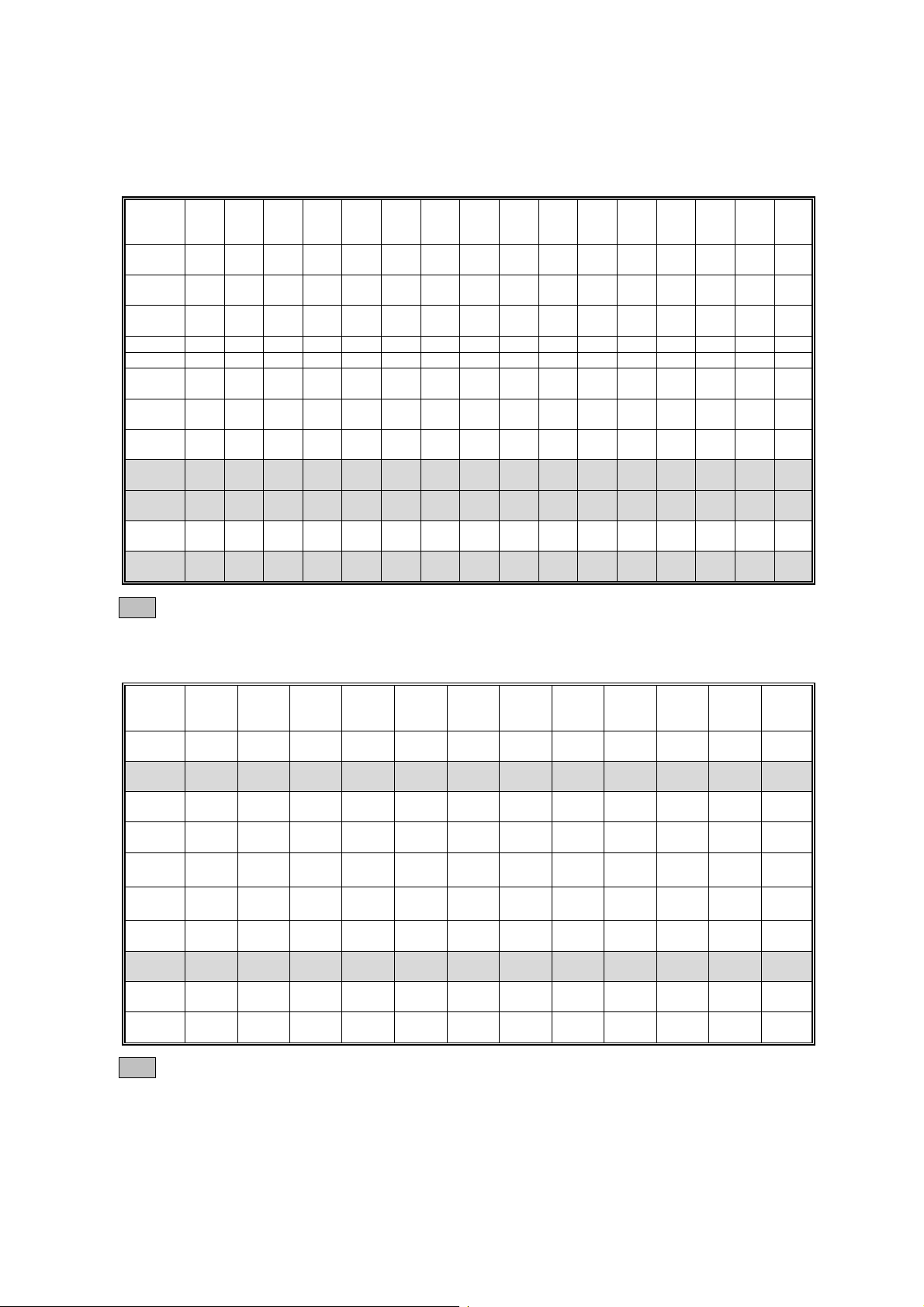

1.1.5 APS PAPER SIZES AVAILABLE

— For metric machines —

200

173

163

141

122

115

100

93

87

82

75

71

65

61

57

50

~

51

A3

B4

A4L

B5L

A5L

A4S

B5S

A5S

8.5

x 11

11

x 8.5

8.5

x 13

11

x 15

~

~

~

~

~

~

~

~

~

~

~

~

~

174

164

142

123

116

101

94

88

83

76

72

66

——————A3—B4——A4L

—————A3B4——A4L

———A3B4—A4L

——A3B4—A4LB5L——A5L——————

A3B4—A4LB5L—A5L—————————

——————

S

A4SB5

—

—————

———

— — — — — —

— — — — — —

————A3—

— — — — — —

A4SB5

8.5

B5L——A5L————

x13

A4

S

S

A5

S

8.5

x11

11

x8.5

8.5

x13

11

x15

B5

—

S

——

—————————

— — — — — — — — —

— — — — — — — — —

——A4LB5L————A5L

— — — — — — — — —

8.5

B5L — — A5L —

x13

——

A5

S

A5

S

——————

~

62

58

8.5

B5L — A5L

x13

————

~

: Not allowed in platen cover mode. L: Lengthwise S: Sideways

— For standard machines (in inches)—

11x17

11x15

8.5x14

8.5x11

5.5

x8.5

8.5

x5.5

11x8.5

8x10

10x14

8x13

200

~

177

—————11x1711x1711x15

— — — — — 11x15 11x15 —

————

— — 11x17 —

11

x17

———

—————

— — — 11x17 10x14 8x10 — — — —

—————10x14—

———11x17—8x13————

176

~

156

11

x15

155

~

130

8.5

x14

129

~

122

8.5

x11

11

x8.5

121

~

101

11

x17

—

—

100

~

94

8.5

x14

8.5

x11

5.5

x8.5

8.5

x5.5

11

x8.5

93

~

86

——

————

——————

——————

————

85

~

78

8.5

x14

77

~

75

8.5

x14

8.5

x14

8.5

x11

8.5

x11

74

~

66

—

8.5

x11

——

——

65

~

51

8.5

x11

—

5.5

x8.5

8.5

x5.5

5.5

x8.5

5.5

x8.5

50

~

5.5

x8.5

5.5

x8.5

5.5

x8.5

—

—

—

5.5

x14

—

: Not allowed in platen cover mode.

1-8

Page 26

24 February, 1999 SPECIFICATIONS

NOTE:

1) The tables indicate the copy paper size for each original for 50 to 200 %

zoom ratios.

2) After specifying a zoom ratio, APS automatically selects a paper size

that guarantees the quality of the magnified copy image, if there is a

paper size available for the equivalent standard reproduction ratio.

3) If there is no paper that corresponds to the detected size, the machine

displays the message "Set xx paper in tray" and stops the job (copying

is still possible).

4) For "—" in the above tables, the machine displays the message "Cannot

detect original size" and stops the job (copying is still po ssible). The

selected paper feed tray does not change.

5) When less than 49% or more than 201% is selected, APS behaves in

accordance with note 4 above.

6) APS also supports the by-pass feed table (except for non-standard

paper sizes). When the paper size selected by APS can only be fed

from the by-pass feed table, the machine displays a warning to instruct

the user to use the by-pass feed table.

7) APS does not support A6, B6, and A5.

Overall

Information

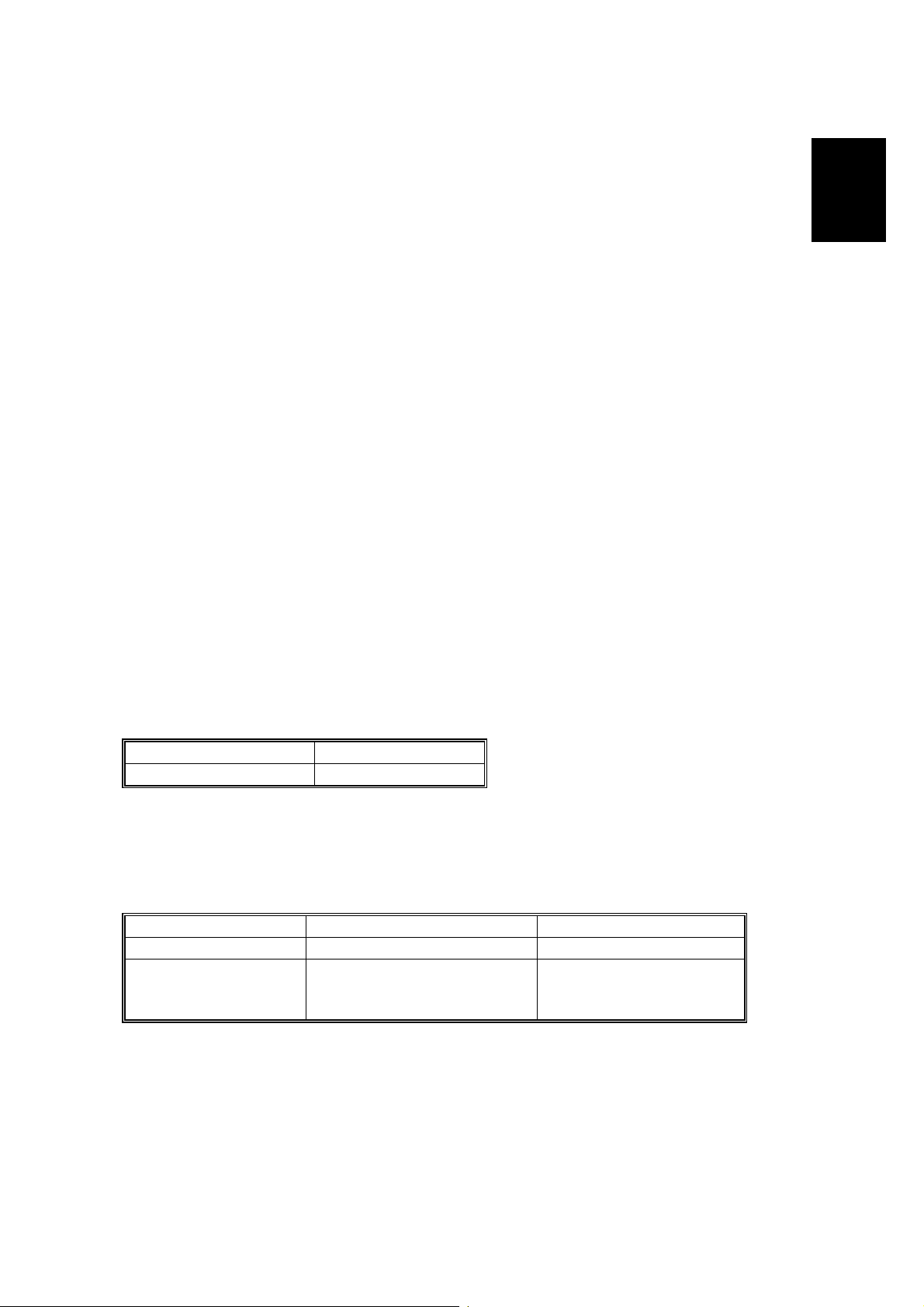

1.1.6 NOISE EMISSION

Sound pressure level

The measurements were made in accordance with ISO 7779 at the operator

positions.

Copier only Full system*

Less than 38.5 dB (A) Less than 55 dB (A)

*: Full system: Copier with document feeder, 500 sheets x 3 trays unit, FPU,

and a sorter stapler.

Sound power level

The measurements were made in accordance with ISO 7779.

Copier only Full system*

Stand-by Less than 55 dB (A) Less than 59 dB (A)

Copying

(This value is for the

black copy mode.)

*: Full system: Copier with document feeder, 500 sheets x 3 trays unit, FPU,

and a sorter stapler.

Less than 68 dB (A) Less than 72 dB (A)

1-9

Page 27

SPECIFICATIONS 24 February, 1999

1.1.7 POWER CONSUMPTION

(1) Maximum power cons umption

1.5 kVA

(2) Average power consumption

A258/A259/A260 Copiers

Standby

Warm-up

Copying

Energy Saver Mode

0.4 kW

1.3 kW

1.1 kW (B/W A4 å)

0.6 kW (full color A4 å)

Value for standby minus 25 W

1.1.8 DISPLAY EDITOR SPECIFICATIONS

Scanned image

Displayed image

Area specification

procedure

•

The copier's scanner scans the image.

•

Maximum A3/DLT (11" x 17"): Redu ced image display

•

144 x 192 mm, 256 colors (8 bits/dot)

•

640 x 480 dots, 0.33 mm/dot

Reduces the dpi of scanned images to approximately 25

dpi and displays the entire image

•

Zoom display: 4 levels (200%, 264%, 400%, 528%)

•

Move the arrow on the screen by using the cursor key

and enter a point by pressing the coordinate entry key.

1-10

Page 28

24 February, 1999 MECHANISM OVERVIEW

1.2 MECHANISM OVERVIEW

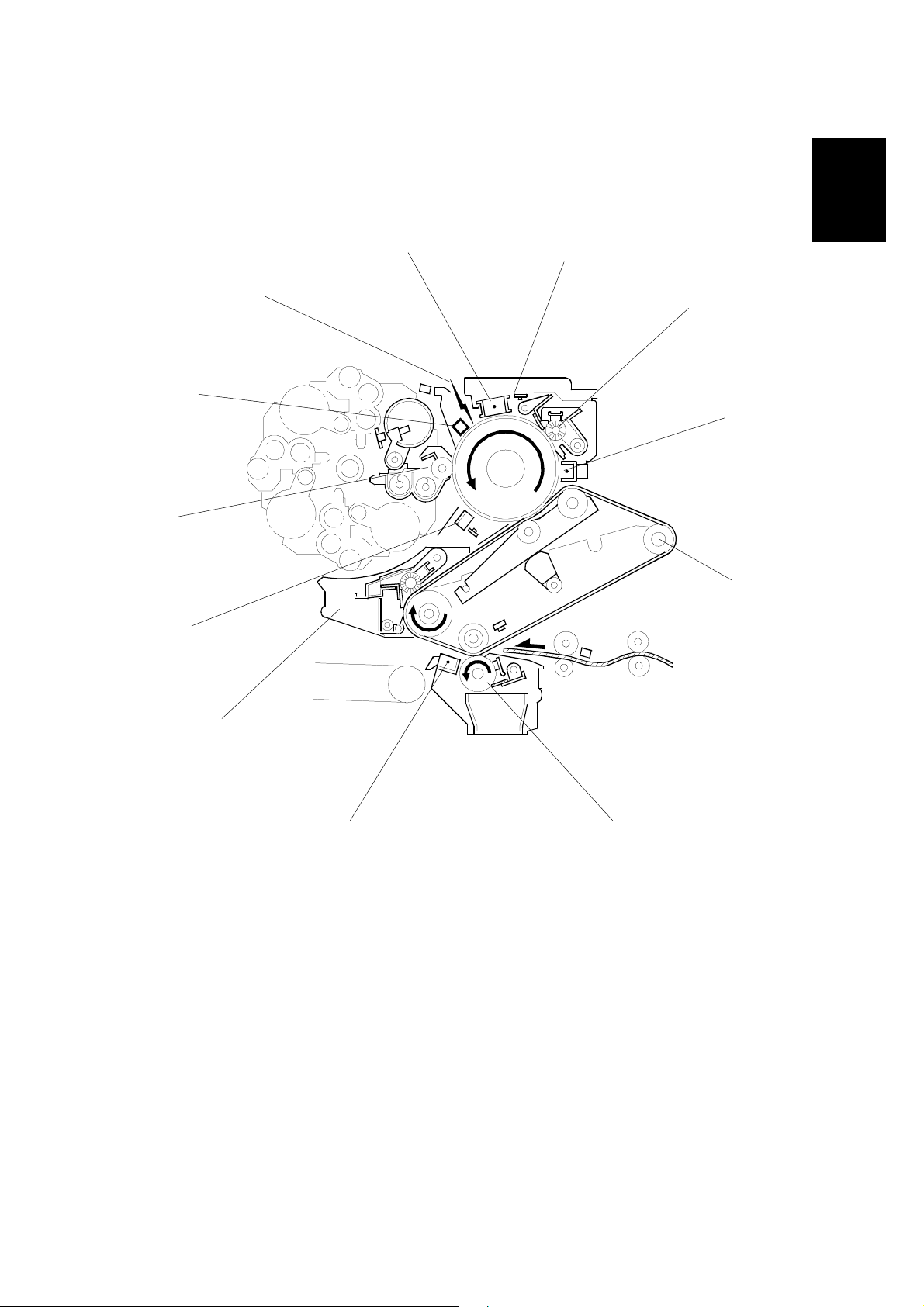

1.2.1 IMAGE GENERATION PROCESS

Overall

Information

10

11

9

12

1

2

3

4

5

8

A259V110.WMF

67

1-11

Page 29

MECHANISM OVERVIEW 24 February, 1999

(1) Drum charge

The charge corona applies a negative charge to the OPC drum and the grid

ensures that this charge is even.

(2) Quenching

After cleaning, the OPC is fully exposed to light from an array of red LEDs,

quenching the residual charge on the OPC drum in preparation for the next copy

cycle.

(3) Drum Cleaning

The cleaning brush increases drum cleaning efficiency by applying lubricant to the

OPC drum. The cleaning blade scrapes the residual toner off the OPC drum.

(4) PCC (Pre-cleaning corona)

The PCC discharges the photoconductor drum and applies AC and negative DC to

reduce the charge holding the residual toner to the drum, thereby improving the

efficacy of the cleaning brush.

(5) Belt transfer

Positive charge applied to the back of the transfer belt transfers the toner image on

the OPC drum to the transfer belt.

(6) Paper transfer

The negatively charged toner image is transferred to the paper by giving a positive

charge to the back of the paper while the paper and transfer belt are held in close

contact.

(7) Paper separation corona

After transfer, the separation corona quenches the negative charge on the paper to

reduce the attraction between the belt and paper. The curvature of the belt causes

the paper to separate from the transfer belt.

(8) Belt cleaning unit and lubricant application brush

The brush applies lubricant, which makes it easier for the counter blade to scrape

excess toner off the transfer belt.

1-12

Page 30

24 February, 1999 MECHANISM OVERVIEW

(9) ID sensor

The ID sensor detects the density of the sensor patches developed on the OPC

drum. The signal from the ID sensor is used for process control and toner supply

control.

(10) Development

The latent image on the drum attracts the negatively charged toner. Toner is

preferentially attracted to those places on the drum surface where the laser

reduced the negative charge. The development units for each color are included in

the revolver unit.

(11) Potential sensor

The potential sensor detects the electrical potential (the strength of the electric

field) on the photoconductor dru m for process contr ol.

(12) Laser exposure

The polygon mirror reflects the laser beam emitted from the laser diode and

projects it onto the drum through the f-theta lens, drum mirror, and toner shield

glass. The laser output varies in intensity to correspond to the image data, and this

forms a latent image on the drum.

Overall

Information

1-13

Page 31

MAJOR UNIT LAYOUT AND PAPER FEED PATH 24 February, 1999

1.3 MAJOR UNIT LAYOUT AND PAPER FEED PATH

1

2

3

8

7

4

6

1-14

5

A259V109.WMF

Page 32

24 February, 1999 MAJOR UNIT LAYOUT AND PAPER FEED PATH

(1) Scanner

1. 400 dpi, 10-bit scanning in both main and sub-scan directions

2. 3-line CCD

3. Halogen exposure lamp

4. 5-phase stepper motor drive

5. Dual-side continuous scan (A4) support (in continuous copy mode)

(2) Operation panel (A259, A260)

1. 10.4-inch (640 x 480) color LCD (8-bit) touch-panel

2. An additional operation panel is installed when the printer controller is installed.

(3) Laser unit

1. Optics: 6-sided polygon mirror + 2 f-theta lenses + BTL

2. Polygon mirror motor (16535 rpm) with ball bearing

3. 400 dpi (8 bits per pixel for each color) in copy mode

600 dpi (8 bits per pixel for each color) in printer mode

4. Modulation: PM + PWM

Overall

Information

(4) Transfer belt

1. Transfer belt: Always in contact with the drum

2. Belt transfer: Indirect application of voltage with a roller

3. Paper transfer: Roller transfer

4. Registration: Synchronization by the transfer belt H.P. sensor

5. Drive: Synchronized with the drum (same motor)

6. Separation: Curvature separation + corona unit

7. Transfer cycle: 1 belt rotation/A4, 2 rotations/A3

8. Belt cleaning: Counter blade

9. Lubrication: Brush roller with lubricant bar

1-15

Page 33

MAJOR UNIT LAYOUT AND PAPER FEED PATH 24 February, 1999

(5) Paper feed/transport system

1. Paper feed (A258)

•

Front loading 500 sheets, 1-layer tray + by-pass feed

2. Transport: Transport belt + fan

3. Duplexing: Duplex unit installed as a standard component (A259/A260 only)

4. Paper tray (optional): Holds 500 sheets x 2 trays or 500 sheets x 3 trays.

(6) Fusing and paper exit

1. Fusing: Silicone roller fusing

2. Oil application method: Do uble roller system

3. Cleaning: Cleaning rollers (for hot and pressure rollers)

Europe/Asia:

Cleaning roller for hot roller, cleaning blade for pressure roller

4. OHP/thick paper speed change

(7) Development and toner supply

1. Development: Two-component magnetic brush development

2. Development switching: Revolver system

3. Image density control: ID sensor + process control

4. Toner supply: Screw-in bottle (220 g)

5. Toner supply unit: Front of developer unit (rotation type)

(8) Drum unit

1. The drum unit contains the photoconductor drum, charge corona unit, and

cleaning unit.

2. Charge corona unit: Single-wire scorotron

3. Quenching lamp: LED array

4. Drive: Synchronized with the transfer belt (DC brushless motor + flywheel)

5. Potential sensor included

1-16

Page 34

24 February, 1999 PARTS LAYOUT

1.4 PARTS LAYOUT

1.4.1 MECHANICAL COMPONENT LAYOUT

5 6 7 8 9 11 13 14

1210

Overall

Information

4

3

2

1

1. Paper Tray (A258)/Duplex Tray

(A259/A260)

2. Pressure Roller

3. Hot Roller

4. 2nd Scanner

5. Revolver Development Unit

6. 1st Scanner

7. Drum Mirror

8. Toner Shield Glass

9. BTL (Barrel Torroidal Lens)

10. Charge Corona Unit

11. Scanner Lens

12. 2nd F-theta Lens

15

16

17

18

19

20

21

A259V108.WMF

22232425

14. 1st F-theta Lens

15. Polygon Mirror

16. Drum Cleaning Unit

17. OPC Drum

18. Transfer Belt

19. By-pass Feed Table

20. Transfer Belt Unit

21. Registration Roller

22. Transfer Belt Bias Roller

23. Paper Transfer Unit

24. Belt Cleaning Unit