Ricoh FT9105 Safeti Notices

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier are supplied with electrical

voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior

covers off or open while the main switch is turned on, keep hands away

from electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filter installed.

2. Always replace the ozone filter with the specified one at the specified

interval.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The main control board has a lithium battery which can explode if

handled incorrectly. Do not replace the battery. Do not recharge, or burn

this battery. Used batteries must be handled in accordance with local

regulations.

3. The power supply unit should never be disassembled or repaired in the

field.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner cartridges or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries (main control boards) in order to

dispose of them later, do not put more than 100 batteries (main control

boards) per sealed box. Storing larger numbers or not sealing them

apart may lead to chemical reactions and heat build-up.

SECTION 1

OVERALL MACHINE INFORMATION

6 November 1997 Specificatio ns

1. OVERALL MACHINE INFORMATION

1.1 Specifications

1.1.1 Copier

Main body

Configuration: Console

Copy Process: Dry Electrostatic Transfer System

Originals: Sheet/Book

Original Size: Maximum: 11" x 17", A3

Copy Paper Size: Maximum: 11" x 17", A3

Minimum: B5, 8

Copy Paper Weight: Standard Copying:60 ∼ 163 g/m2, 16 ∼ 43 lb or 90 lb index

Duplex copying: 64 ∼ 120 g/m2, 17 ∼ 32 lb

Warm Up Time: Within 7.0 minutes ( room temp. 20°C, 73°F)

First Copy Time: 6.5 seconds (8

Copying Speed: 105 copies/minute ±2% (A4, B5, 8

84 copies/minute ±2% (B4)

63 copies/minute ±2% (A3, 11" x 17")

Optional Equipment: Finisher

Large Capacity Tray

Key Counter

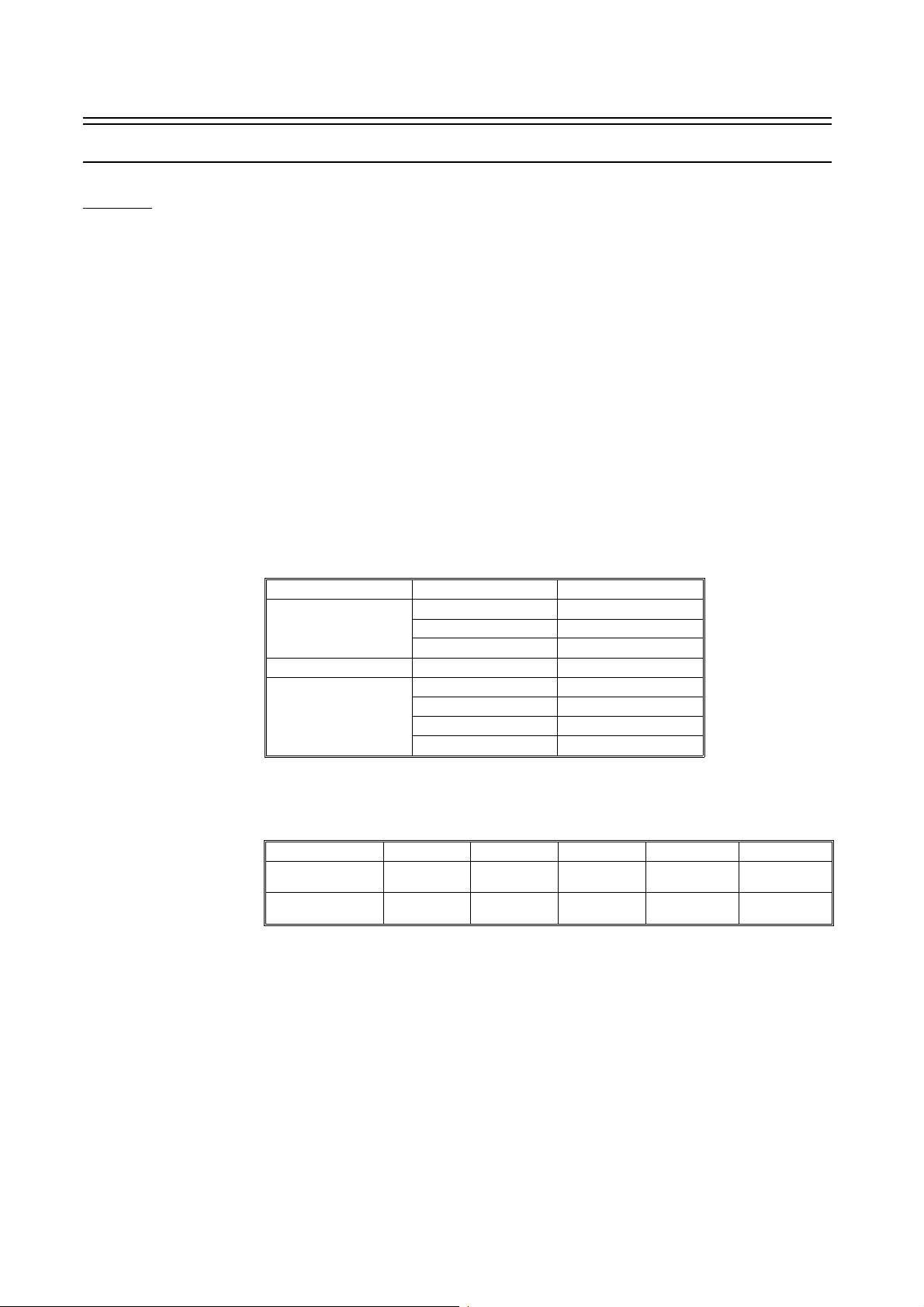

Reproduction Ratios: See the following table:

" x 11"

1/2

" x 11", A4, feed from 3rd tray)

1/2

" x 11", 8

1/2

" x 14", 8

1/2

" x 13")

1/2

LT/DLT version A4/A3 version

Enlargement

Full Size

Reduction

141% 141%

129% 122%

121% 115%

100% 100%

93% 93%

77% 82%

74% 71%

65% 65%

* Desired reproduction ratio(s) can be selected from 3 enlargements and 4 reductions.

Zoom: 64 ∼ 142% (1%/step)

Copy Tray Capacity: 200 sheets (80 g/m2 paper, in continuous copying mode)

Duplex Tray Capacity:

A3, B4, 11" x 17",

1/2

x 14"

8

1/2

" x 11"

1/2

" x 13",

A4, B5, 8

8

64 g/m2, 17 lb 80 g/m2, 20 lb 90 g/m2, 24 lb 105 g/m2, 28 lb 120 g/m2, 32 lb

50 40 35 30 26

80 80 70 61 53

Toner Replenishment: Cartridge exchange

Paper Feed: 1st tray: 500 sheets (80 g/m2, 20 lb paper, not exceeding load limit decal)

2nd tray:1,000 sheets (80 g/m2, 20 lb paper, not exceeding load limit decal)

3rd tray: 1,000 sheets (80 g/m2, 20 lb paper, not exceeding load limit decal)

Oil Tank Capacity: 3,000 cc

Power Source: 240 V, 60 Hz, 30 A

380/400/415 V, 50 Hz, 3 phase, 16 A/phase

Maximum Power 4.4 kW (Full system)

Consumption: 3.9 kW (Copier with RDH)

Weight: 499 kg, 1,100 lb (including RDH)

Environmental Conditions: Temperature: 10 ~ 30°C

Humidity: 15 ~ 90%

Standard Condition: 23°C, 65%

1-1

Specifications 6 November 1997

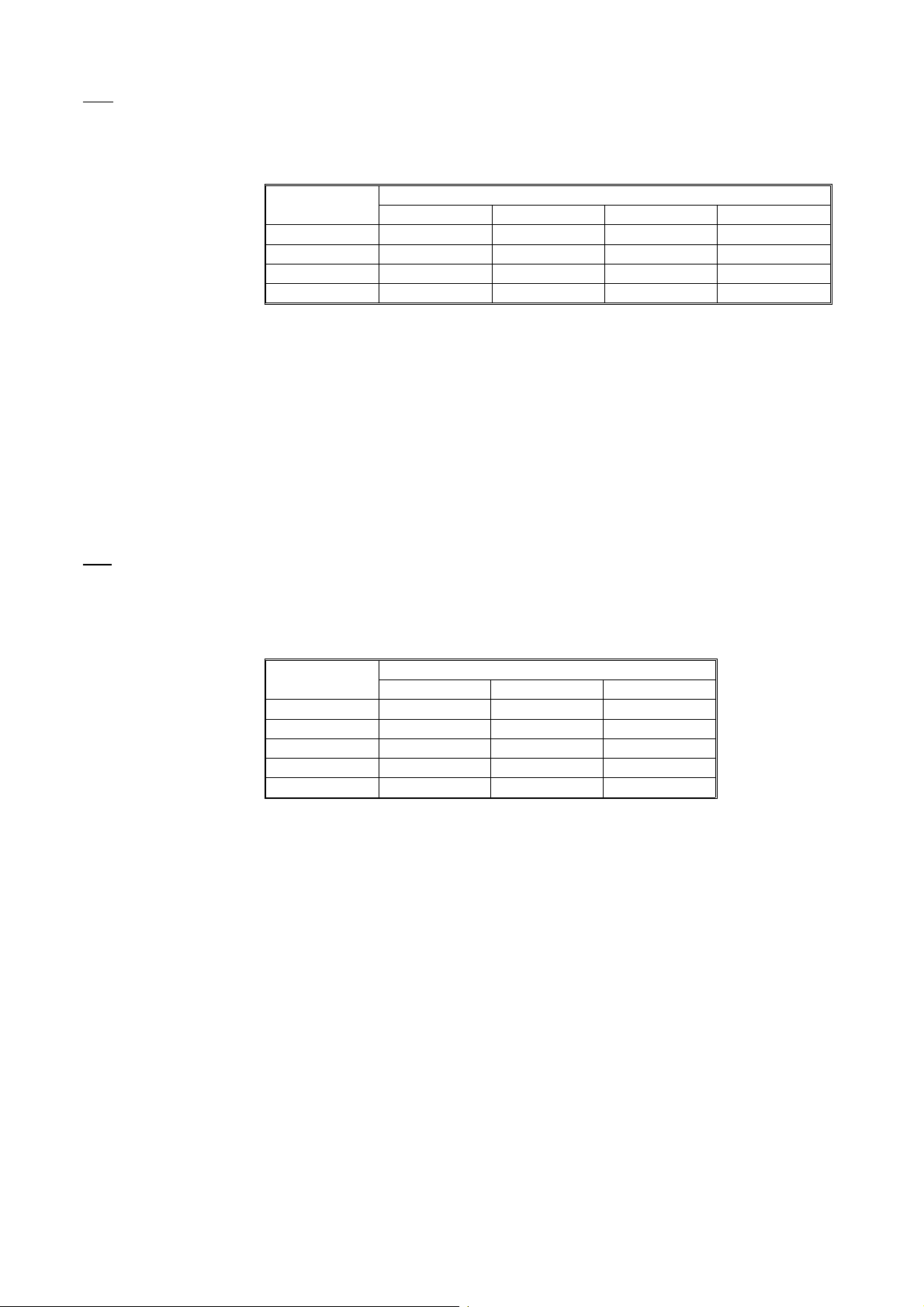

RDH

Original Size: Maximum: 11" x 17", A3

Minimum: B5

Original Weight: 64 ~ 120 g/m2, 17 ~ 32 lb

Original Set Capacity:

Original Weight

2

120 g/m

105 g/m

80 g/m

64 g/m

, 32 lb

2

, 28 lb

2

, 20 lb

2

, 17 lb

A3 or 11" x 17" B4 or 8

20 originals 20 originals 50 originals 50 originals

30 originals 40 originals 60 originals 60 originals

40 originals 60 originals 80 originals 80 originals

50 originals 100 originals 100 originals 100 original s

Original Size

1/2

" x 14" A4 or 8

1/2

" x 11" B5

Original Set: Face down

Original Feed Speed: 105 originals/minute (A4, 81/2" x 14" or smaller)

84 originals/minute (B4)

63 originals/minute (A3)

Power Source: 24 V, 3.6 A (from copier)

40 V, 1.5 A (from copier)

Maximum Power 130 W, 40 V, 1.5 A

Consumption:

Weight: 25 kg, 55.1 lb

ADF

Original Size: Maximum: 11" x 17", A3

Minimum: B5

Original Weight: 52 ~ 128 g/m2, 14 ~ 34 lb

41 ~ 157 g/m2, 11 ~ 43 lb or 90 lb index (when one original is set)

Original Set Capacity:

Original Weight

2

128 g/m

105 g/m

80 g/m

64 g/m

52 g/m

, 34 lb

2

, 28 lb

2

, 20 lb

2

, 17 lb

2

, 14 lb

A3 or 11" x 17" A4 or 8

18 originals 29 originals 29 originals

21 originals 36 originals 36 originals

27 originals 45 originals 45 originals

30 originals 50 originals 30 originals

30 originals 30 originals 30 originals

Original Set: Face down

Original Feed Speed: 84 originals/minute (A4, 8

63 originals/minute (A3)

21 originals/minute (2-up mod e)

Power Source: 24 V, 2.0 A (from copier)

Maximum Power 40 W

Consumption:

Weight: 12 kg, 26.5 lb

" x 14" or smaller)

1/2

Original Size

1/2

" x 11" B5

1-2

6 November 1997 Specificatio ns

1.1.2 LCT

Copy Paper Size: Legal (8

B4 (257 mm x 364 mm), A4 (210 mm x 297 mm),

B5 (182 mm x 210 mm)

Copy Paper Weight: Same as copier

Tray Capacity: Approximately 4,500 sheets (80 g/m2 paper, not exceeding upper limit decal)

Power Source: 100 V, 50/60 Hz (from copier)

Weight: 78 kg, 172 lb

" x 14"), Letter (8

1/2

" x 11"),

1/2

1.1.3 Finisher

Paper Size: Maximum: 11" x 17"/A3

Minimum: B5 sideways

Paper Weight: Standard copying: 52 ∼ 163 g/m2, 14 ∼ 43 lb or 90 lb index

Staple mode: 64 ∼ 80 g/m2, 17 ∼ 20 lb

Paper Capacity: Standard copying: 2,000 sheets: 8

1,000 sheets: Other sizes (20 lb/80 g/m2)

Staple mode: See the following table:

" x 11"/A4 or smaller size (20 lb/80 g/m2)

1/2

Number

of Originals

2 ∼ 10 sheets

11 ∼ 20 sheets

21 ∼ 30 sheets

31 ∼ 40 sheets

41 ∼ 50 sheets

Size

1/2

" x 11"/A4

8

or smaller size

100 sets* 100 sets 100 sets

100 sets 50 sets 50 sets

67 sets 34 sets 34 sets

50 sets 25 sets 25 sets

40 sets 20 sets —

*: Up to 100 stapled copy sets can be stacked because the stapled copy set makes an

uneven stack on the tray.

Stapling Capacity: 11" x 17"/A3 (20 lb/80 g/m2): from 2 to 30 sheets

Other sizes (20 lb/80 g/m2): from 2 to 50 sheets

Staple Replenishment: Cartridge exchange (5,000 pieces/cartridge)

Power Source: AC 100 V (from the copier)

Maximum Power 150 W

Consumption:

Weight 78 kg, 172 lb

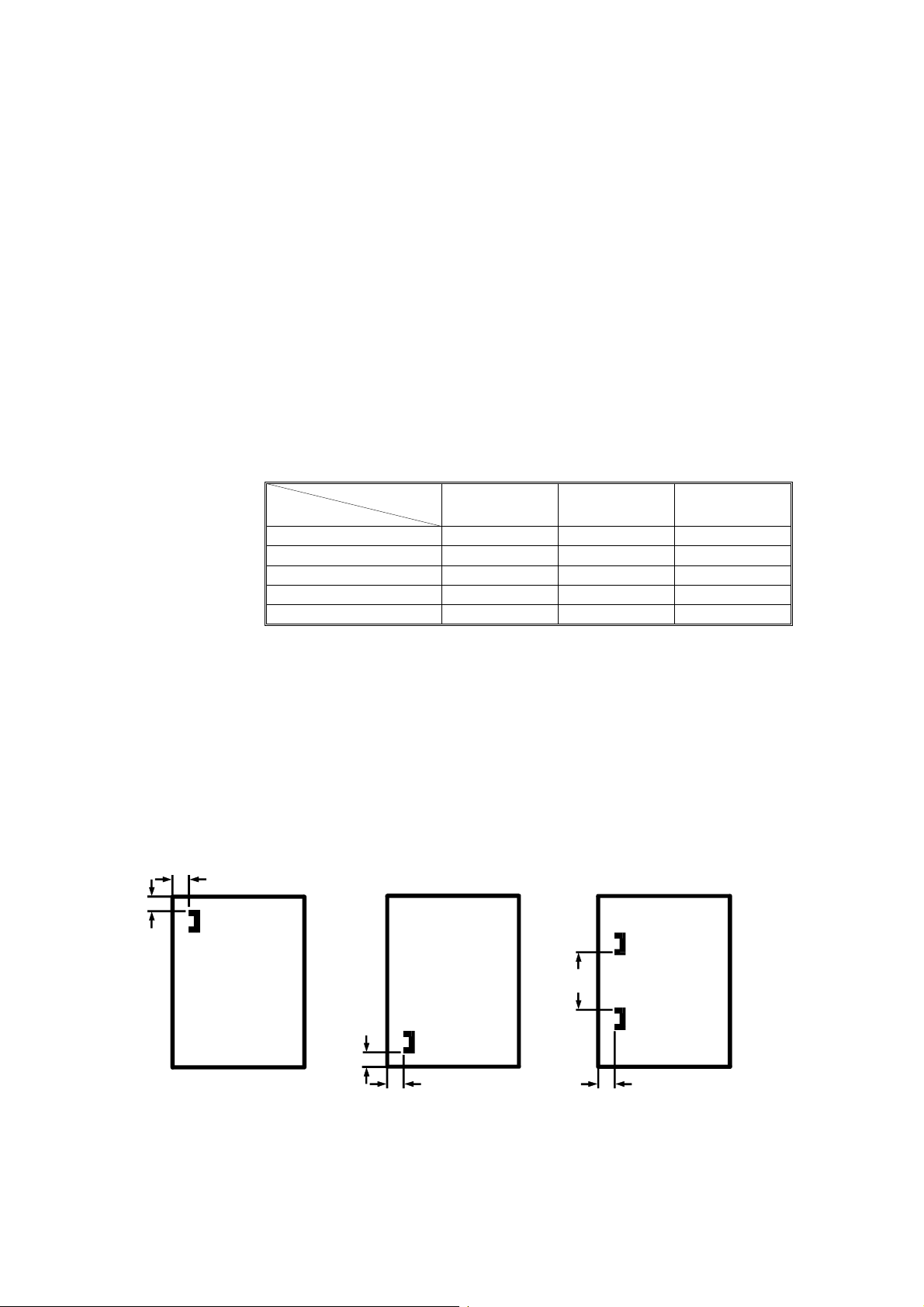

Stapling Position:

a

b

(1 staple) (2 staples)

1/2

x14"/B4 11" x 17"/A3

8

a = 0.2" ± 0.08" (5 ± 2 mm)

b = 0.2" ± 0.1" (5 ± 2.5 mm)

b

b

aa

a = 0.2" ± 0.08" (5 ± 2 mm)

b = 0.2" ± 0.1" (5 ± 2.5 mm)

a = 0.2" ± 0.08" (5 ± 2 mm)

b = 5.20" ± 0.08" (132 ± 2 mm)

(8

" x 11"/A4 or smaller size)

1/2

b = 10.5" ± 0.08" (265 ± 2 mm)

(8

" x 14"/B4 or larger size)

1/2

1-3

Noise 6 November 1997

1.2 Noise

During warm-up: 64 dB

During standby: 54 dB

Sound pressure level (The measurements are made according to ISO 7779.)

Full system

Operation position

bystander position

74 dB (A)

74 dB (A)

Sound power level (The measurements are made according to ISO 7779.)

Full system

Stand-by

Copying

67 dB (A)

85 dB (A)

1.3 Power Consumpti on

Copier only Full system*

Warm-up

Stand-by

Copying

Maximum

2.3 kW 2.4 kW

0.33 kW 0.41 kW

3.4 kW 3.6 kW

3.9 kW 4.4 kW

*Full system: Copier with large capacity tray and finisher.

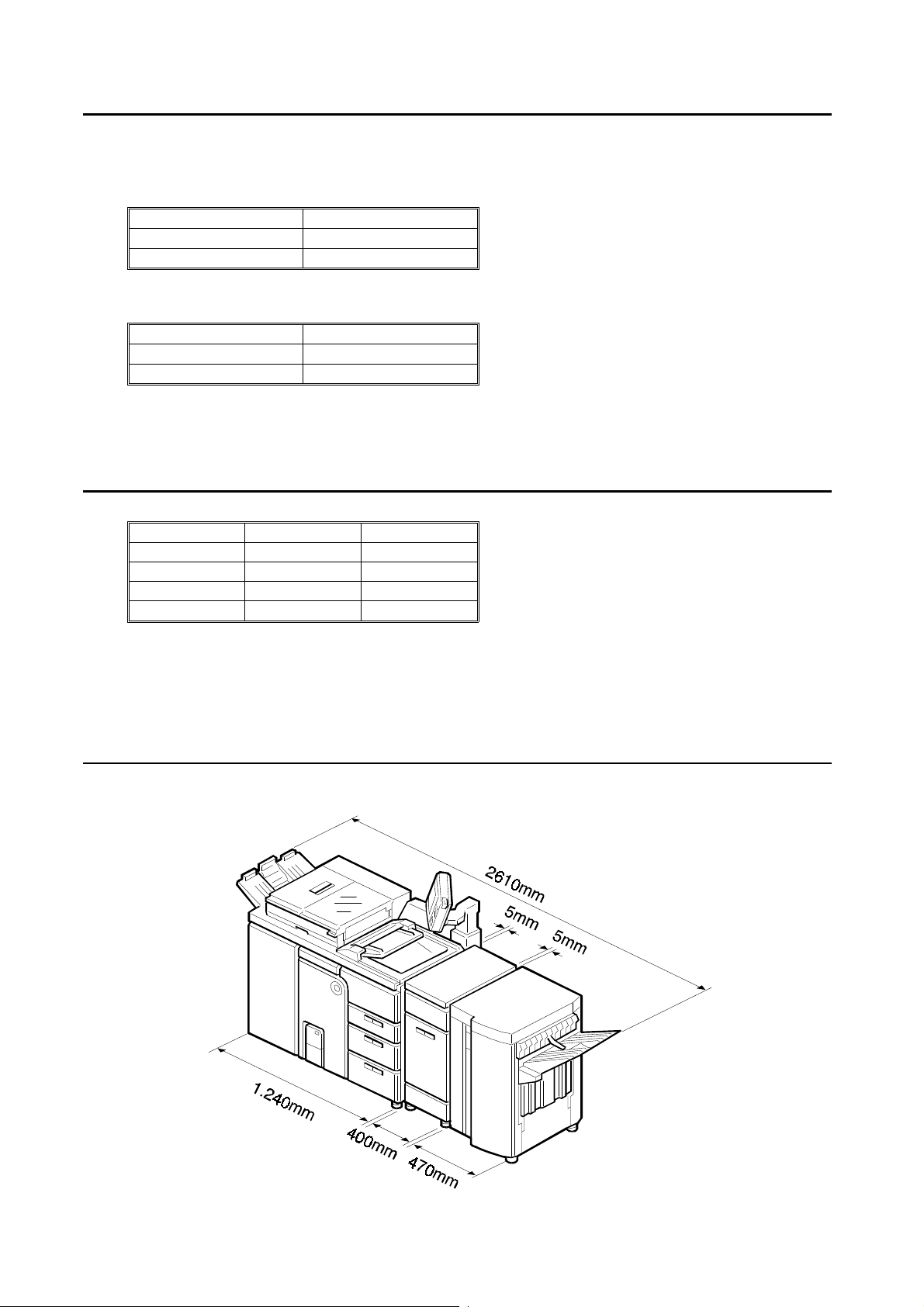

1.4 Machine Dimensions

1.4.1 Full System

1-4

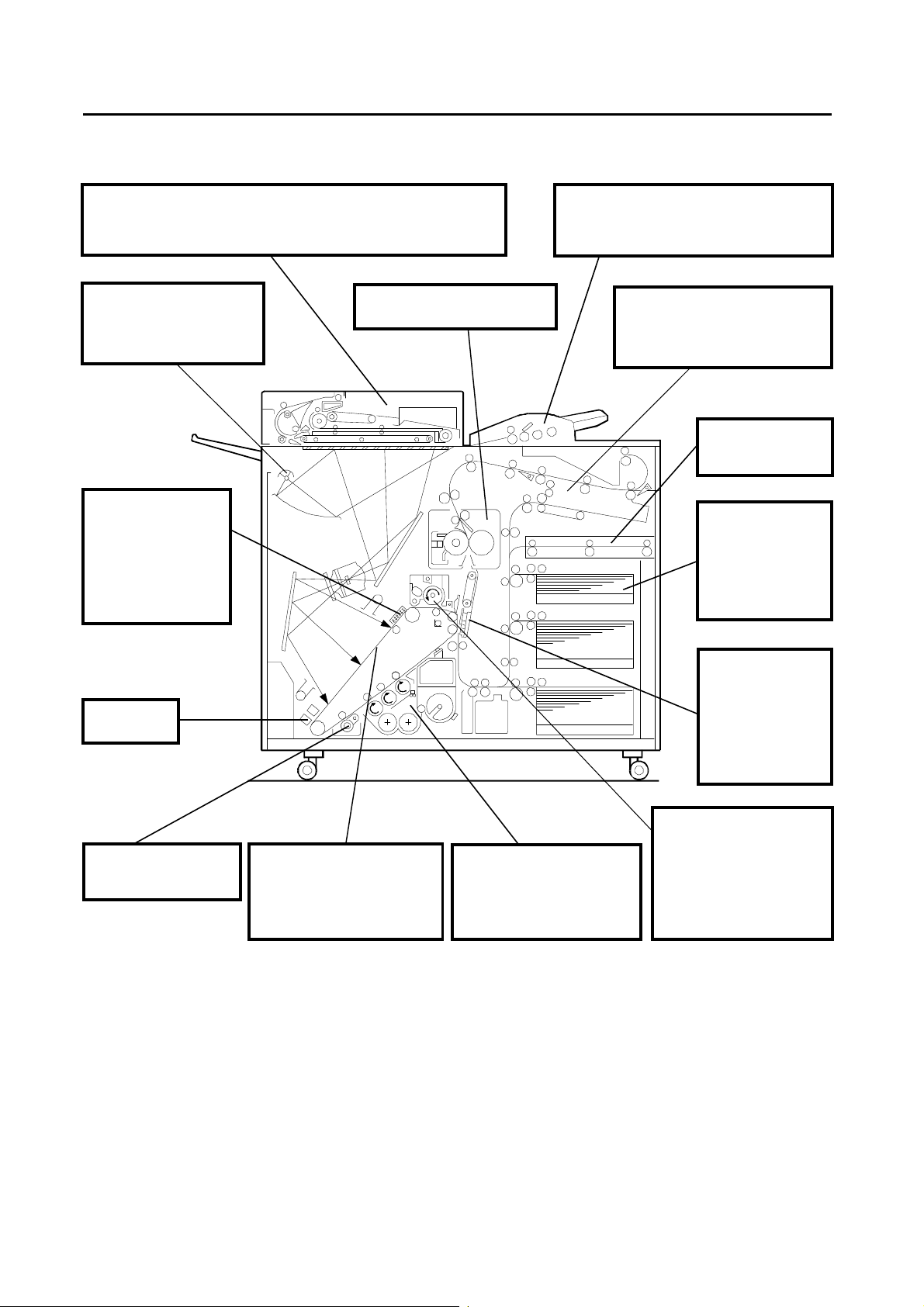

6 November 1997 Main Unit Layout Diagram

1.5 Main Unit Layout Diagram

RDH

The air knife separates the leading edges of the originals. The lowest

original is held against the trans port belts by the suction of the vacuum fa n

and fed by the belts. Even in one-to-one copying, this high-speed RDH can

meet 105 CPM. Automatic duplex copying is a lso available.

Exposure unit

A xenon lamp is used for flash

exposure. A stepper motor

moves mirrors and lens for the

desired magnification:

0.64 to 1.42

Charge corona unit

Scorotron system is

employed to gi ve a

uniform and constant

electric charge on the

OPC. (–) dc high voltage

is applied to a tungsten

wire, and the OPC is

charged negatively by

corona discharge.

Fusing unit

Heat and pressure roller system is

used with silicon oil.

ADF

The ADF accepts wider range of paper

thickness than the RDH. Friction separation

system is used and maximum 45 sheets (80

2

g/m

, 20 lb) of original can be set at a time.

Duplex unit

The air kni fe separates the leading

edge of the copies. The lowest copy

is held against the transport belts by

the suction of the vacuum fan and

fed by the bel ts .

Horizontal transport

unit

Transpor t s pa per from

the LCT.

Paper feed tray

The upper tray stacks

up to 500 sheets. The

middle and lower

trays stack up to

1,000 sheets. FRR

system is used as the

paper feed

mechanism.

Eraser unit

Erase system

employs LEDs.

OPC cleaning brush

Removes filming material

from the OPC surface and

refreshes OPC surface.

Photoconductor

An OPC belt is used as the

photoconductor. Its image

producing area is equally divided

into 5 A4/B5 segments, 4 B4

segments, or 3 A3 segments,

accordin g to the copy pap er size.

Development unit

Employs a magnetic brush

system using 3 magnetic rollers.

For toner density control, toner

density and ID sensors are

used. Toner is replenished from

a cartridge.

Transfer an d

separation unit

A high voltage

negative corona

transfers positively

charged toner to

paper. A high voltage

ac corona br ea k s t he

attraction between the

paper and OPC.

Cleaning unit

Magnetic brush system for

cleaning. Scavengin g roller

collects toner from the

magnetic brush. (–) dc bias

voltage is applied to the

cleaning roller and scavenging

roller. (+) dc is applied to the

PCC to increase cleaning

efficiency.

1-5

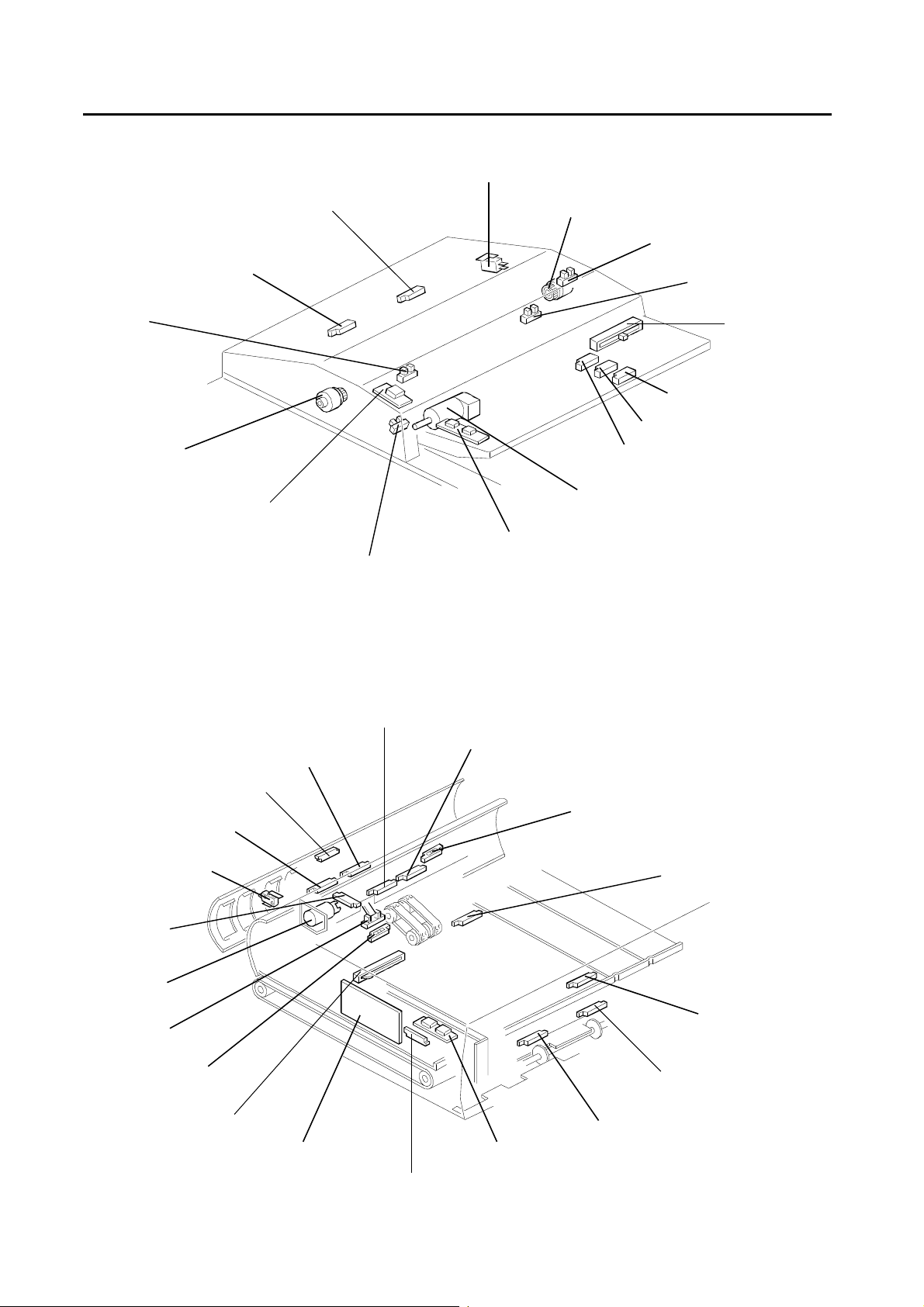

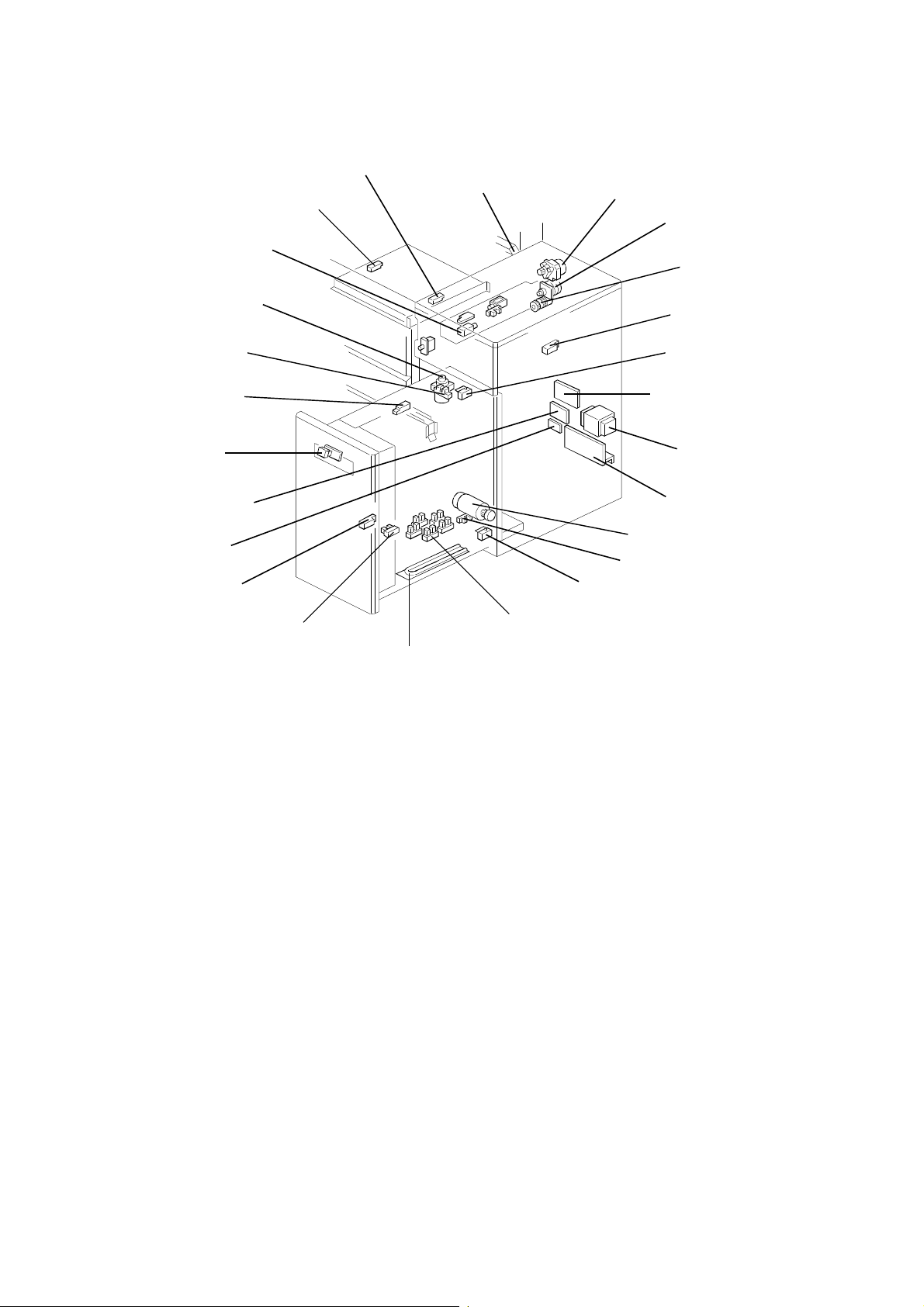

Electrical Component Layout 6 November 1997

1.6 Electrical Component Layout

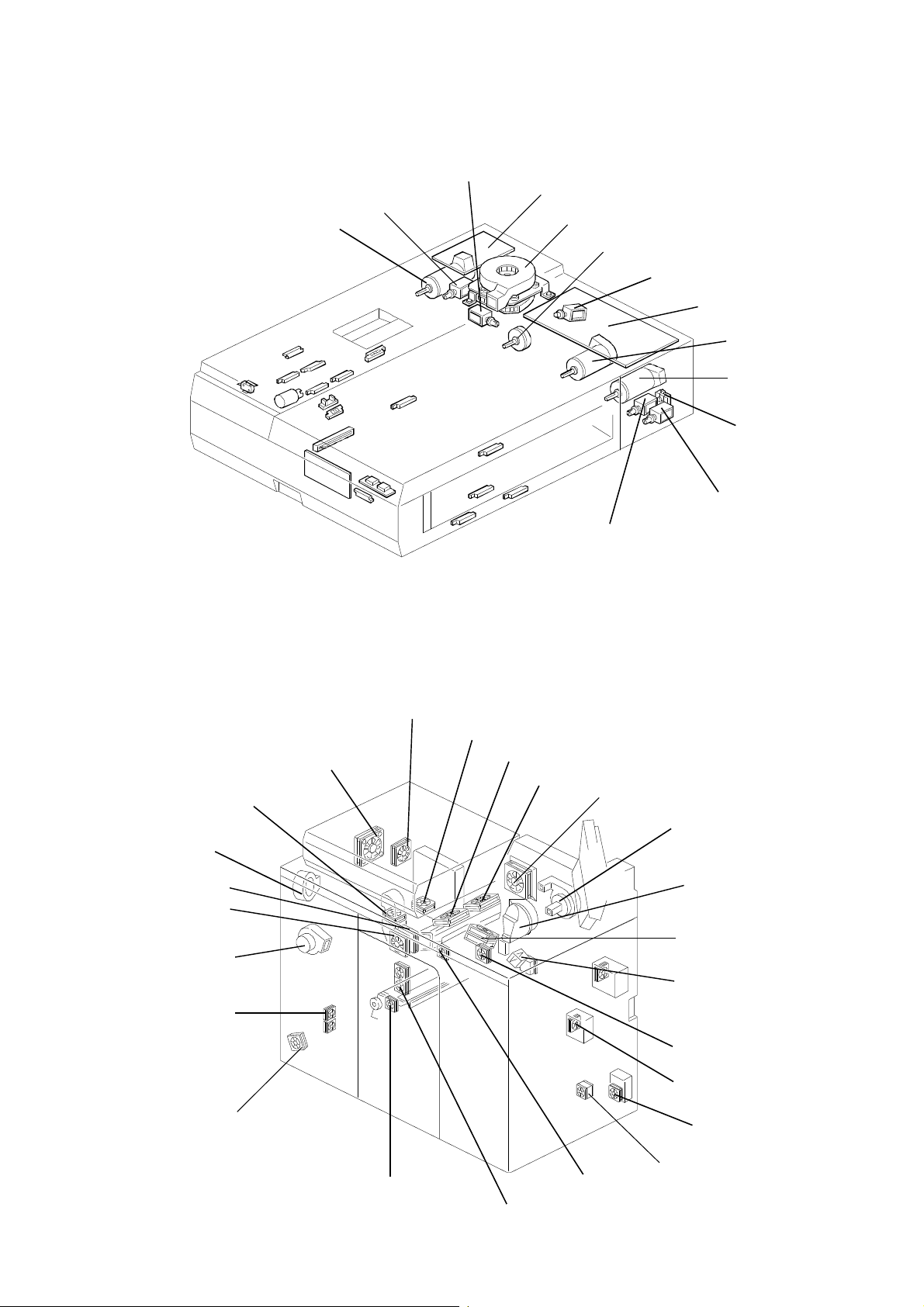

1.6.1 ADF

Feed Cover Safety Switch

Original Feed Sensor: Front

Original Sensor: Front

Separation Roller Clutch: Front

1 to 1 Start key

Original Feed Sensor: Rear

Pick-up Roller H.P. Sensor

Separation Roller Clutch: Rear

Entrance Cover Sensor

Original Sensor: Rear

ADF Size

Detection Sensor

Trailing Edge Sensor: B4

Trailing Edge Sensor: A4

Trailing Edge Sensor: B5

ADF Motor

Display Board

1.6.2 RDH Front View

2nd Reverse Sensor

1st Reverse Sen sor

Inverter C over Switch

Recycle Arm

Height Sensor

Recycle Arm

Solenoid

Recycle Arm

Sensor

Original Set Sensor

Original Size Sensor

ADF Exit Sensor: Front

ADF Exit Sensor: Rear

Entrance Sensor

Exit Sensor

1st Transport Sensor

2nd Transport Sensor

Registration Sensor: Rear

Registration Sensor: Front

Harness Relay Board

Display Board

Length Sensor

1-6

6 November 1997 Electrical Comp on en t La yo ut

1.6.3 RDH Rear View

Reverse Junction Solenoid

ADF Exit Gate Solenoid

Revers e M o tor

Blower Control Board

Blower Motor

Original Feed Clutch

Shutter Solenoid

RDH Control Board

Original Feed

Motor

Transport Motor

Lift Switch

1.6.4 Fan Motor s

Rear Cooling fan

Flash Blower

2nd Fusing Cooling Fan

1st Fusing Cooling Fan

Front Cooling Fan

Flash Power Cooling Fan

Exposure Cooling Fan

Entrance Gate Solenoid

Registration Gate Solenoid

Flash Cooling Exhaust Fan

Front Curl Remover Fan

Rear Curl Remover Fan

Fusing Cooling Exhaust Fan

Duplex Blower

Vacuum Fan

Ozone Exhaust Fans

Cleaning Coil Cooling Fan

Inner Cover Cooling Fan

Eraser Blower

Cleaning Inside Cooling Fan

DC Power Cooling Fan

1-7

ID Sensor Blower

Paper Tray

DC Cooling Fan

Development

DC Cooling Fan

PCB Cooling Fan

Cleaning Cooling Fan

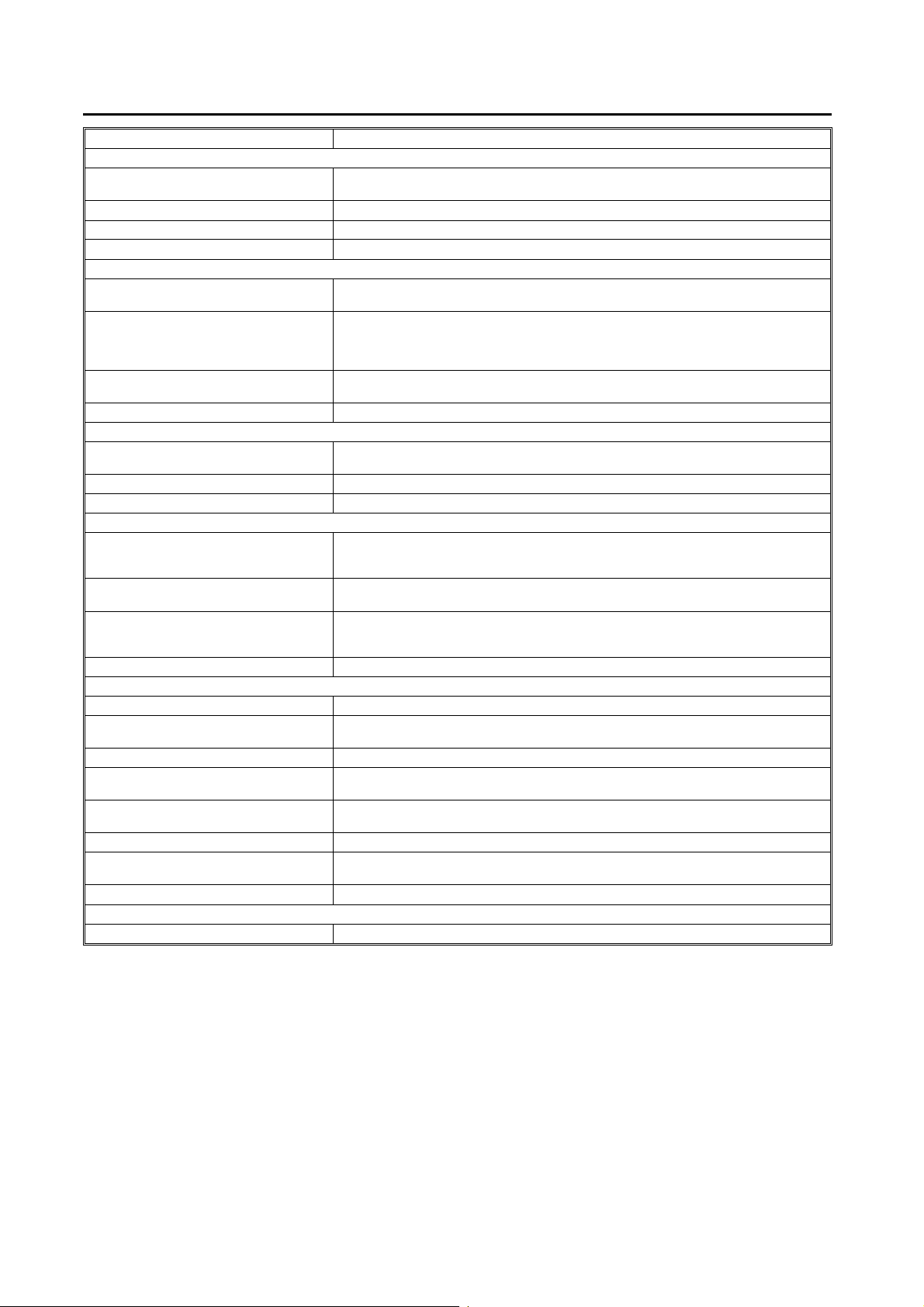

Electrical Component Layout Diagram 6 November 1997

1.7 Electrical Component Layout Diagram

1.7.1 Copier

Switches and Se ns or s

Duplex Exit Sensor

Cleaning Coil Sensor

Eject Tray Sensor

Copy Tray Sensor

Duplex Entrance Junction Sensor

Upper Duplex Feed

Sensor Board

Lower Duplex Feed

sensor Board

Lower Duplex End Sensor

Eject Junction Sensor

Upper Duplex End Sensor

Separation Pawl Sensor

Jogger H.P. Sensor

Separation Motor Rotation Sensor

Back Fence H.P. Sensor

Right Upper Door Sensor

Paper Volume Sensor

DC Drive Board For Paper Tray

Paper Width Sensor Board

Paper Length Sensor

Paper Set Sensor

Lower Limit Sensor

Toner Near End Sensor

Fusing Exit Sensor

Tray Lowering Switch

ID Sensor

ADF Size Sensor

Upper Limit Sensor

Copy Tray Switch

Main Switch

Front Door Switch

Separation Sensor

Right Upper Door Switch

Cartridge Set Switch

Front Door Sensor

Flash Safety Switch

OPC Sensor

Magnification Sensor

Right Shield H.P. Sensor

Left Shield H.P. Sensor

Sector Sensor

Toner Density Sensor

Cartridge Shutter Switch

1-8

6 November 1997 Electrical Component Layout Diagram

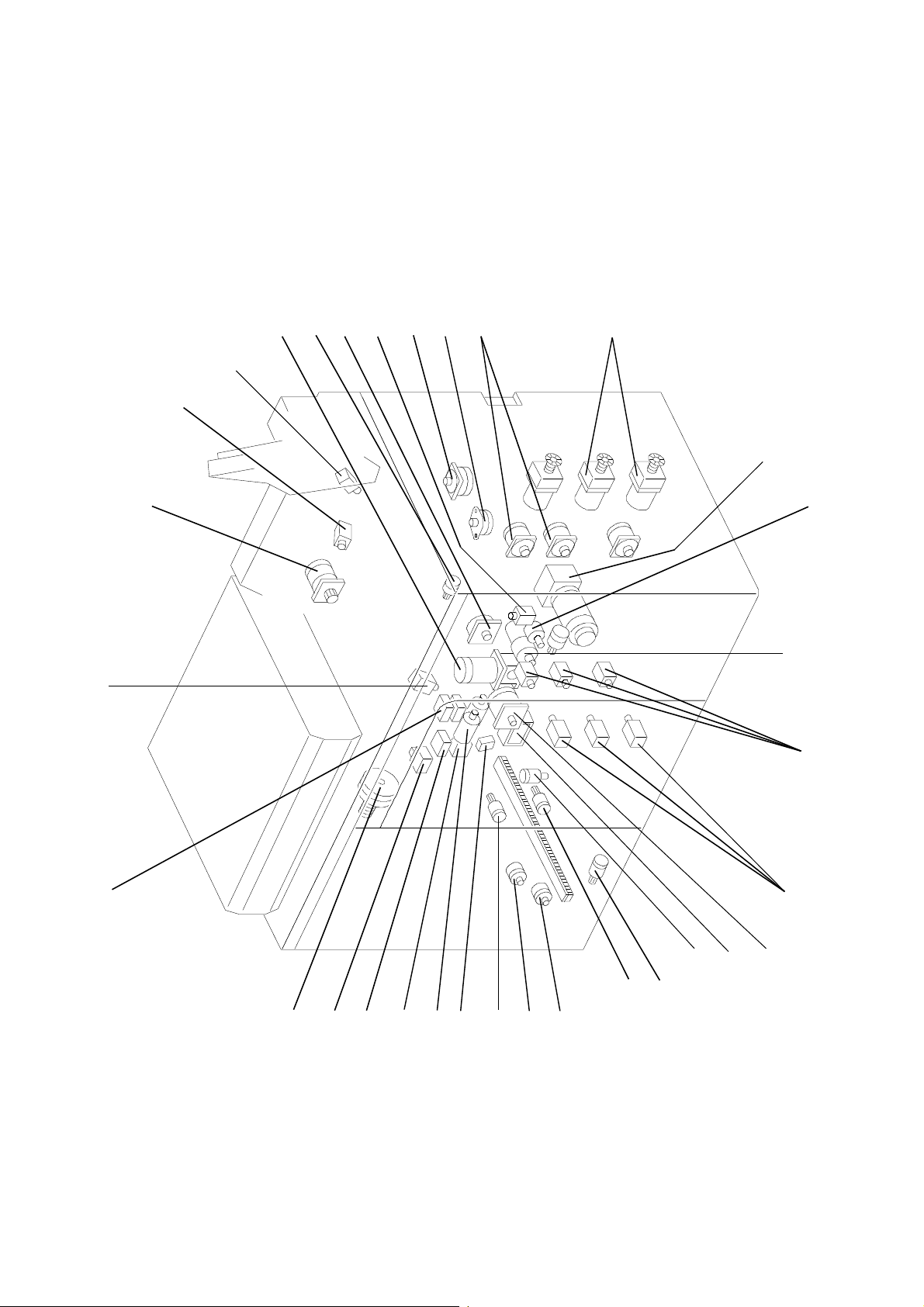

Motor and Soleno ids

Back Fence Motor

Development Motor

Duplex Jab Separation Motor

Air Knife Solenoid

Duplex Vacuum Solenoid

Eject Junction Solenoid

Registration Motor

Jogger Motor

Paper Feed Motor

Tray Motor

Main Motor

Duplex Feed Motor

Relay 1

Duplex Entrance Junction Solenoid

Agitator Motor

Toner Supply Motor

Pick-up Solenoid

Reverse Roller Replace Solenoid

Oscillating motor

Tracking Motor

OPC Cleaning Motor

OPC Cleaning Brush drive Solenoid

Relay 3

Relay 2

Noise Filter

Mirror/lens motor

Circuit Breaker

Charge Wire Cleaner Motor

OPC Cleaning Brush Pressure

Left Shield Motor

Right Shield Motor

OPC Motor

1-9

Electrical Component Layout Diagram 6 November 1997

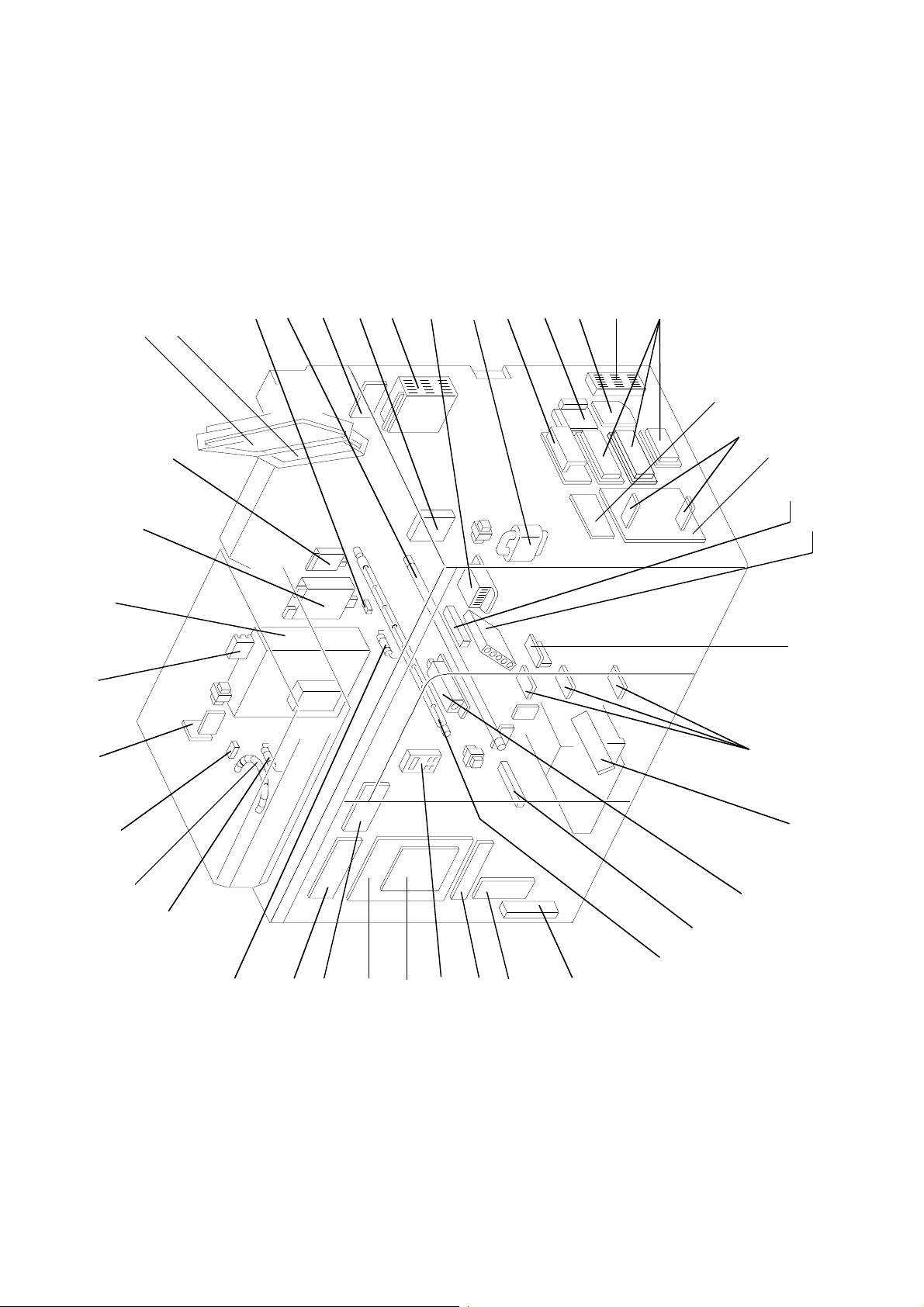

Others

Timer Board

Quenching Lamp

Thermistor

LCD Display

Operation Unit PCB

Cleaning Power Pack

Charge Power Pack

Flash Power Supply

SSR

ADF DC Power Supply

Paper Feed DC Power Supply

Power Transformer

Development Power Pack

Main/OPC Motor Drive Board

Duplex Blower Drive Board

Development DC Power Supply

Jogger Motor Drive Board

Paper Feed Motor Drive Board

Solenoid Drive Board

Dehumidification Heater

Paper Feed Control Board

QL Stabilizer

T & S Power Pack

Registration Sensor

Relay Board

Trigger Transformer

Xenon Lamp

Thermofuse

Potential Sensor

Thermofuse

Interface Board

Main Control Board

DC Motor Drive Board

Total Counter

Anticondensation Heater

Potential Control Board

Mirror/lens Motor Drive Board

Outside Ozone Exhaust Fan Battery

Fusing Lamp

Paper Feed Sensor

Toner Density Control Board

PCC Power Pack

1-10

6 November 1997 Electrical Component Layout Diagram

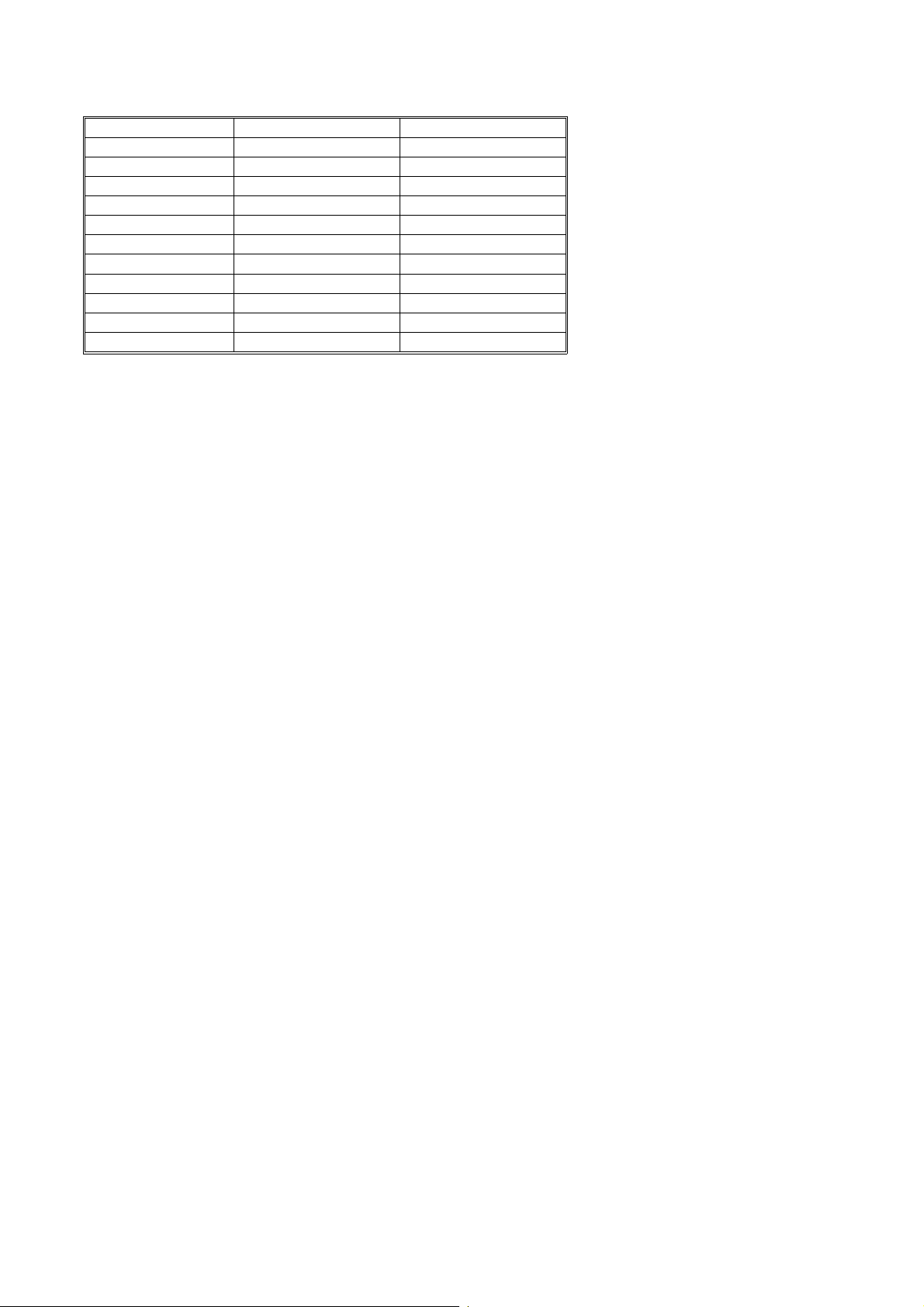

LCT

Entrance Sensor

Pick-up Solenoid

Horizontal Transport Exit Sensor

Paper Feed Sensor Board

Paper Feed Motor

Transport Motor

Paper Feed Clutch

Back Fence Motor

Back Fence Set Sensor

Upper Limit Sensor

Tray Lowering Switch

Transport Motor Drive Board

Relay Board

Paper End Sensor

Lower Limit Sensor

Back Fence H.P. Sensor

Upper Limit Overrun Switch

Paper Feed M oto r D r iv e B o ard

Transform er (A6595500)

LCT Board (A6595110)

Tray Motor

Paper Volume Sensor

Lower Limit Overrun Switch

LCT Size Sensors

Defumidification Heater

1-11

NEW FEATURES OF THE BIG BIRD (comparing with the F5) 6 November 1997

1.8 NEW FEATURES OF THE BIG BIRD (comparing with the F5)

Item Description

OVERALL

ADF The SADF mechanism has been modified into ADF whi ch enables maximum 45 (80

Copy Speed The copy speed has been increased from 101 CPM to 105 CPM.

Operatio n Unit To improve operation, a large LCD operatio n unit has been applied.

Paper Feed

Reverse roller pressure adjustment

mechanism

Reverse roller releas e mechanism This mechanism prevents paper, which is caught between the feed roller and the rev erse

The humidity sensor The humidity sensor has been removed. A swi tch to turn on/of f the paper tray heater has

Fusing

Oil collecting tube To prevent the oil collecting tube from cloging, the shape of the oil collection part has

Serviceability of f using unit The metering blade removal procedure has become easier.

2

g/m

, 20 lb) continuous original feed.

The reverse roller pressure adjustment mechanism has been added to counter paper

multi-feeds or misfeeds due to various friction of the paper surface.

roller, from tearing when the paper tray is pulled out. W hen a paper feed operation is

finishe d, the reverse roller release solenoid (2-way solenoid) is energized to release the

reverse roller from the feed roller.

been added instead.

been modified.

Duplex

Duplex multi-feed detection mechanism Duplex multi-feed detection mechanism has been added. Number of a copy set i s

Reverse roller pressure adjustment

mechanism

Modification of the duplex vacuum unit To increa se the margin for the duplex multi-feeds, the shape of the duplex vacuum unit

LCT

Paper Tray Capacity The paper tray capacity has been increased from 3,000 sheets to 4,500 sh eets.

Unifying the rear side fence for LT version

and A4 version

Doors for Jam Removal The upper cover has been fixed. The upper front door can be opened instead.

Electr ical Component Layout The positions of the LCT control board and the transformer have been changed to the

Manual Tray Unlock Mechanism To enable pulling out the paper tray when the power is off, even if the paper table is up,

Reverse Roller release Mec hanism Same as the copier paper feed.

Reverse roller pressure adjustment

mechanism

Finisher

Stapler The type of the stapler has been changed. (Refer to Sectional Description)

detected by this mechanism, and duplex multi-feed is d etected if the number is less than

the number of the original.

Same as the paper feed unit

has been modified. Additi onally, to counter the misfeeds of A3 copies in the duplex unit,

the speed of t he duplex vacuum fan motor has been changed.

The two types of the rear side fence have been unified into 1 type which can be used for

both LT version and A4 version.

rear side of the LCT to inc rease tray paper capacity.

the manual tray unlock mechanism has been added. (Refer to Sectional Descriptions)

Same as the co pier paper feed.

1-12

6 November 1997 NEW FEATURES OF THE BIG BIRD (comparing with the F5)

1.8.1 SPEC UP POINTS (Comparing with F5)

Item Big Bird F5

Copy Speed 105 cpm (A4/LT) 101 cpm (A4/LT)

First Copy T ime 6.5 seconds 6.7 seconds

ADF Yes (Max. 50 sheets) No (SADF only)

2-up Mode Yes No

LCT Paper Capacity 4,500 sheets 3,000 sheets

Preset Mode Yes No

Sample Copy Yes No

Margin Erase Yes No

Program Mode 25 job settings 10 job settings

Manual Image S etting 13 steps 7 steps

Tab Copy Yes No

1-13

SECTION 2

DETAILED SECTIONAL DESCRIPTIONS

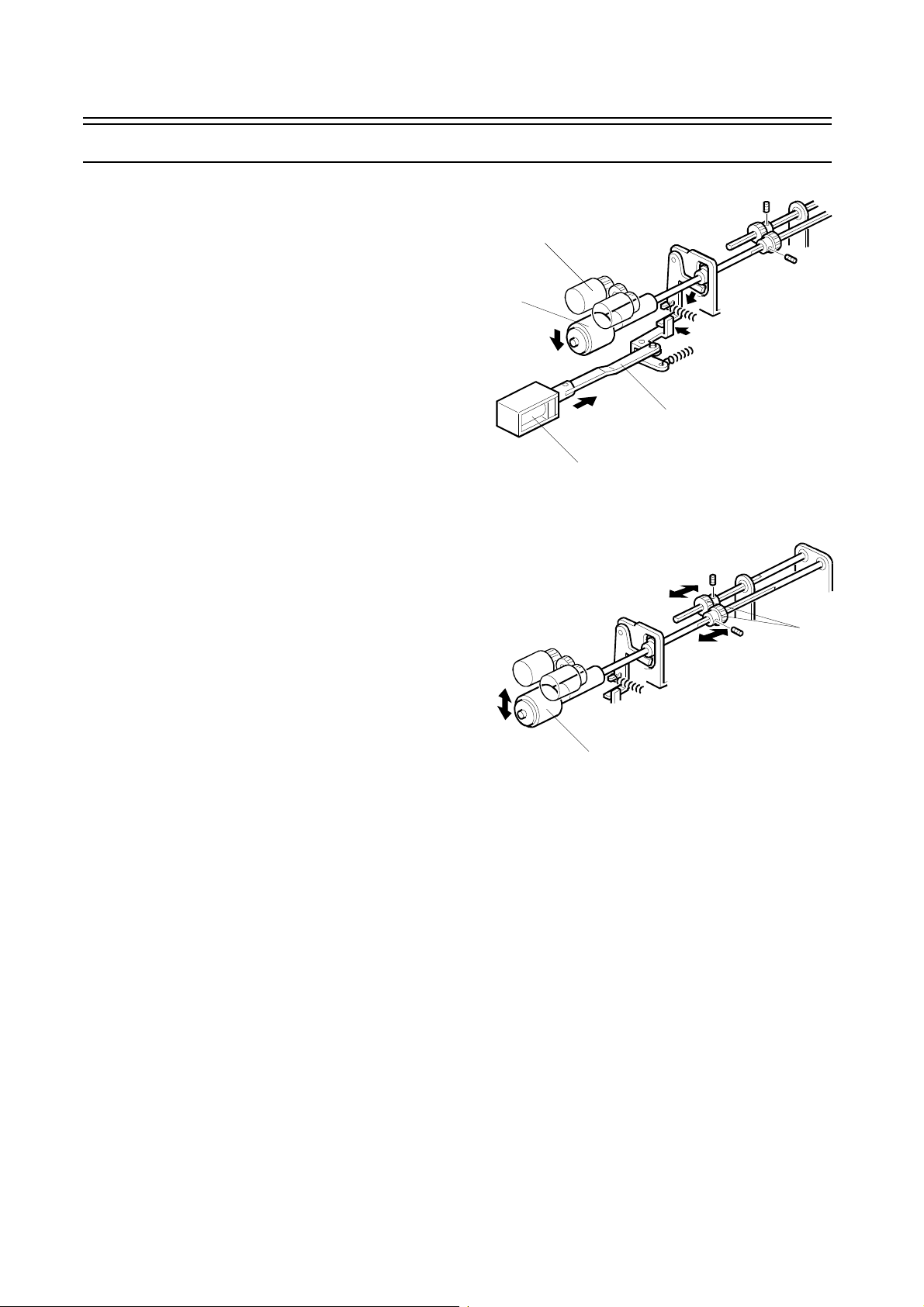

6 November 1997 Paper Feed

2. DETAILED SECTIONAL DESCRIPTIONS

2.1 Paper Feed

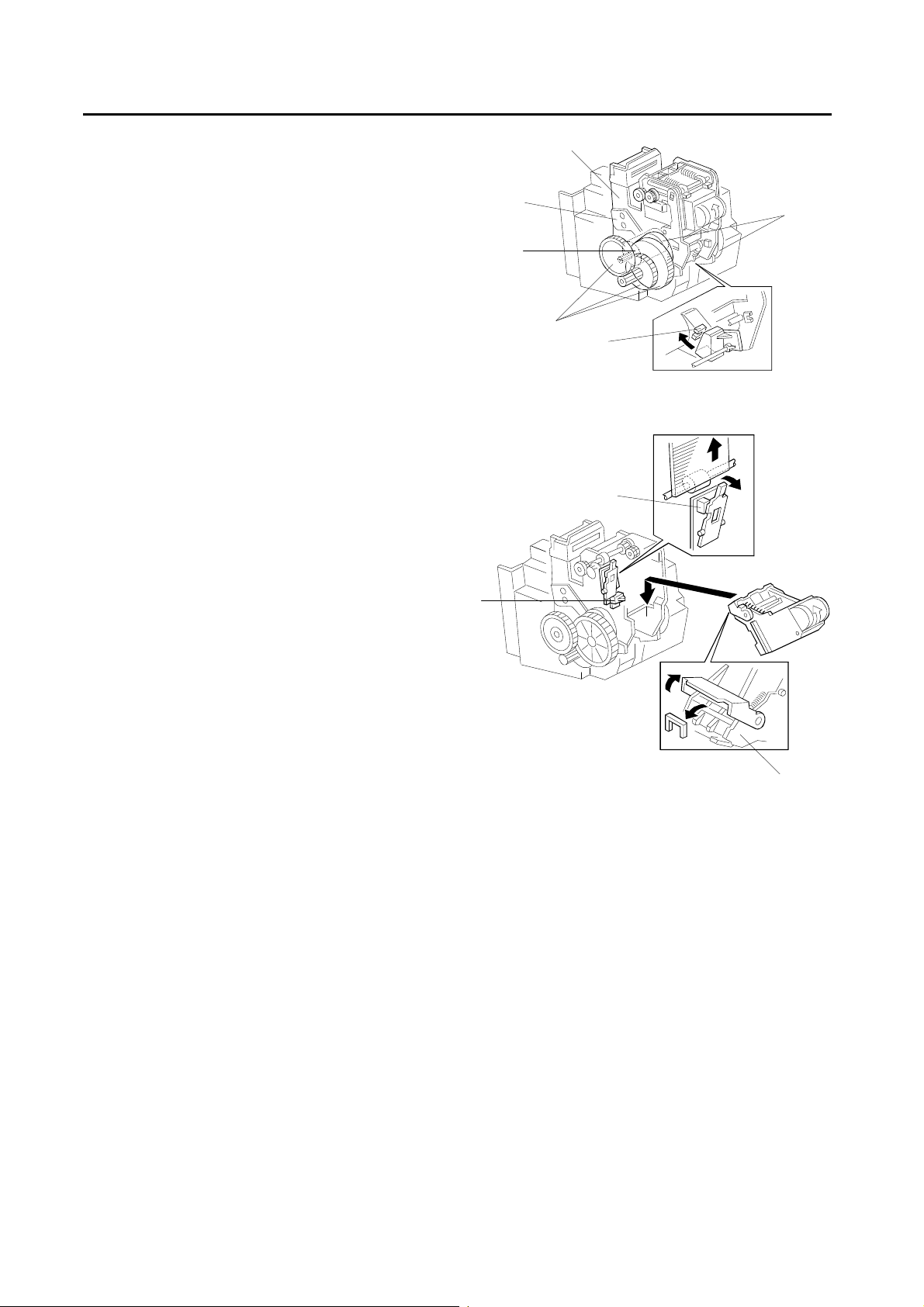

2.1.1 Reverse Roll er Release Mechanism

To prevent the paper getting caught between the feed

roller [A] and the reverse roller [B] and tearing when the

paper tray is pulled out, a reverse roller release

mechanism is used.

At 20 ms after the Print key is pressed, the reverse roller

release solenoid [C] is energized for 540 ms to pull the

link [D]. The reverse roller is pushed up to the feed roller

due to the spring tension. Th e soleno id keeps its

position after it is de-energized.

At 8 seconds after the last paper of the copy job is fed

(or 8 seconds after a paper jam is detected), the

solenoid is energized to move the link in the direction of

the arrow, and the reverse roller is released from the

feed roller.

[A]

[B]

[D]

[C]

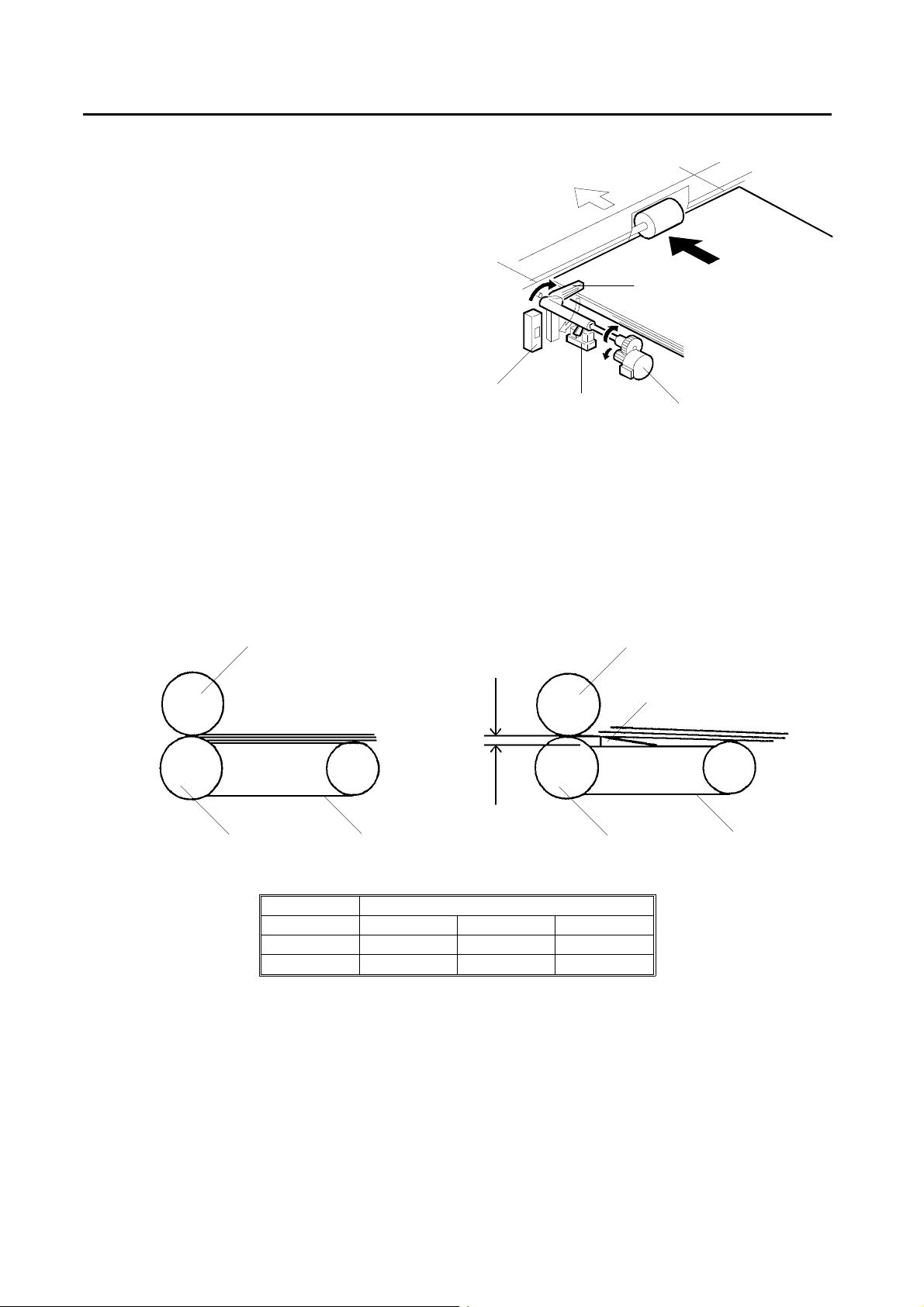

2.1.2 Separation Pressure Adjustment Mechanism

To counter paper misfeed or mult i-fe ed caused by

variations in the friction of paper surfaces, a separation

pressure adjustment mechanism has been added.

By changing the positions of the gears [E] which transfer

the motor drive to the reverse roller [F], the pressure

between the feed roller and the pressure roller will be

changed.

To counter paper multi-feed, the gear position should be

shifted to the rear side to decrease the pressure.

2.1.3 Anti-humidity Heater Switch

To prevent the paper from absorbing moisture,

anti-humidity heaters are installed in the 2nd tray and

the 3rd tray.

The heaters can be turned on and off with the switch on

the left side of the machine independent from the main

switch.

[E]

[F]

2-1

Duplex Unit 6 November 1997

2.2 Duplex Unit

2.2.1 Duplex Multi-feed Detection Me chanism

To detect paper multi-feeds in single-sided to

double-sided copies, a detection mechanism has been

installed in the duplex unit.

When the last page of a set of copies has been

delivered to the duplex unit, the duplex separation motor

[A] is energized, and the separation pawl [B] is set on

the top of the paper stack. The motor stops when the

separation motor rotation sensor [C] is actuated.

When the last paper of the set is fed out, the sepa rat i on

pawl rotates in the direction of the arrow, and the

separation pawl sensor [D] is activated.

The CPU counts the number of the copies, and if the

number is less than the number of the originals, a duplex

multi-feed is detected and copying stops.

To recover a duplex multi-feed, the operator should

remove the set of copies in the shift tray, and the original

should be reset on the RDH in the original order.

[D]

[B]

[A][C]

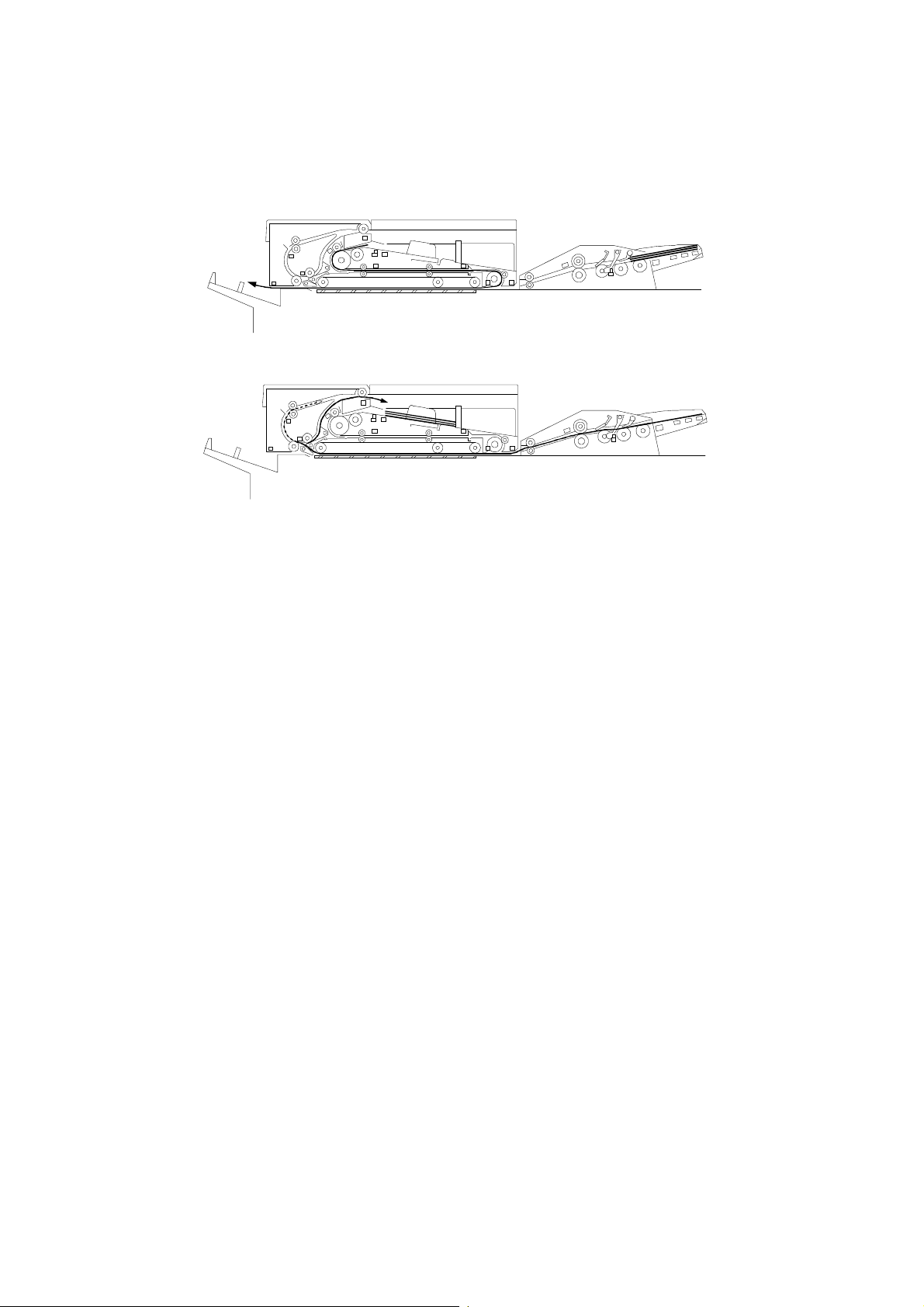

2.2.2 Duplex Vacuum Un it (The Difference Betw een the F5 model and the Big Bird)

To reduce the possibility of duplex multi-feeds, the shape of the duplex vacuum unit guide [E] has been changed.

Also, the angle of the paper which goes in the separation section has been changed.

Additionally, to reduce misfeeds when A3/DLT size paper is used, the vacuum fan speed has been changed as shown

below.

Reverse Roller

Feed Roller

Paper Stack

F5

Big Bird

3.5 mm

Transport Belt

Vacuum Fan Speed (rpm)

1 to 20 21 to 35 36 or more

4,500 6,000 7,000

6,000

←

Feed Roller

7,000

Reverse Roller

[E]

Transpor t Be lt

2-2

6 November 1997 Operation Unit

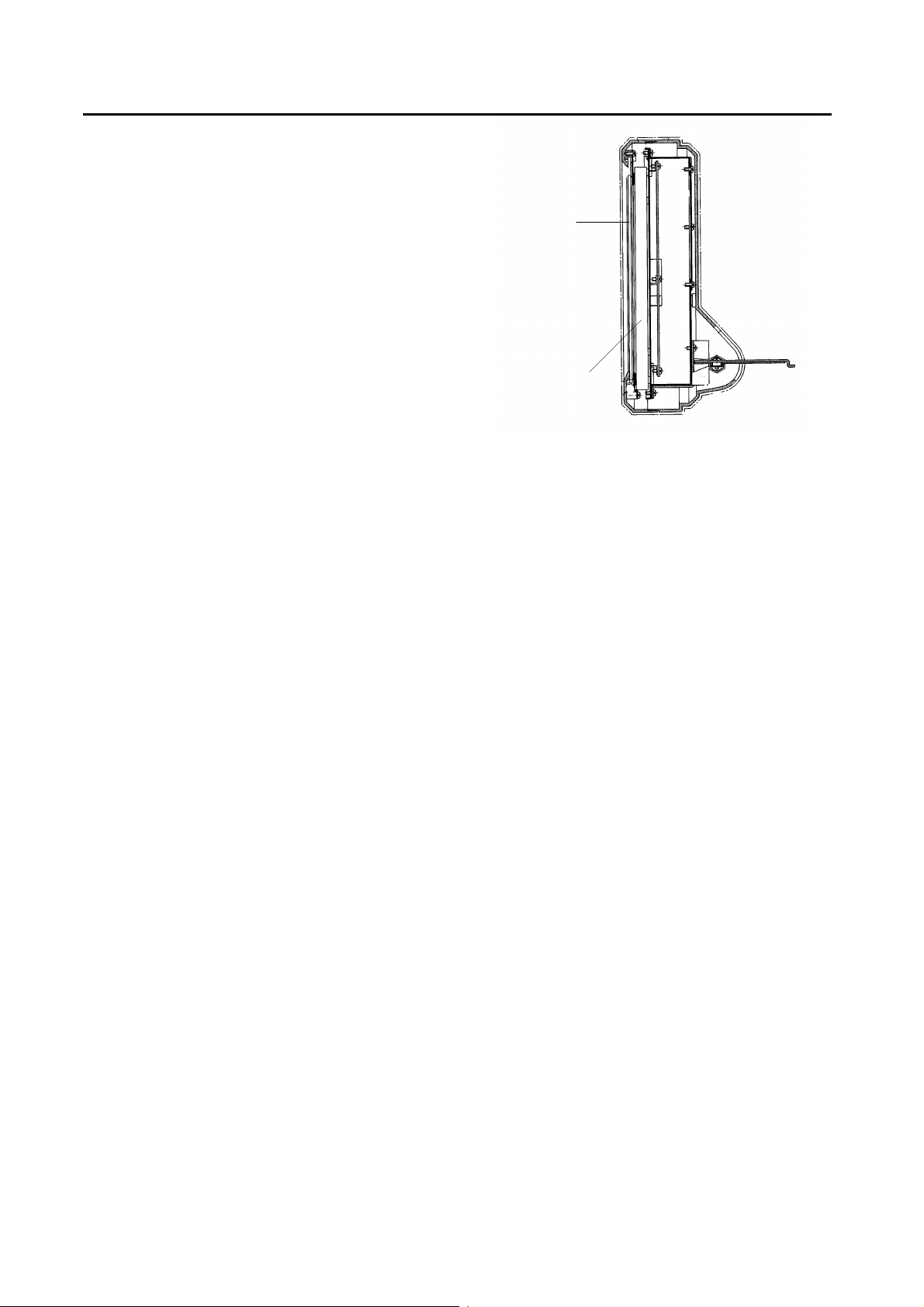

2.3 Operation Unit

The 680 x 480 dot LCD [A] is used for the operation unit.

The display is covered by the touch panel [B] which is an

analog resistor type.

The operation unit control board detects the position that

an operator touches by scanning the matrix of the touch

panel.

A LED indicator is installed on the top of the operation

unit. The indicator shows the conditions of the machine

as follows:

Green: The machine is in the ready condition.

Red (lights): The machine is operating.

Red (blinks): The machine is has a problem.

[B]

[A]

2-3

RDH/ADF 6 November 1997

2.4 RDH/ADF

A newly added ADF, which transports originals straight

through, accepts thinner originals which cannot be used

in the RDH. As only 1 set of copies can be made using

the ADF at a time, this should be used to make a copy of

a fragile original. Multiple copies of this can then be

make with the RDH.

2.4.1 Overall

When the Start key (or the 1-to-1 Copy Start key) is

pressed after the original is set in the ADF, the bottom

page is separated from the original stack and

transported to the exposure glass.

In the 1-to-1 mode, after the original is exposed, it is

transported to the original exit tray.

In the duplex mode, the original is inverted in the RDH

after the front side is exposed and transported to the

exposure glass again. Then the reverse side is exposed

and inverted. Then original is transported to the original

tray.

The original feed interval of the ADF is longer than the

RDH, so the A4 1-to-1 copy speed of the ADF is 84 cpm.

2.4.2 ADF Original Detection

When an original stack is set on the original table, the

original sensor feeler [A] is pushed up by the original

and the original sensor [B] is activated.

To detect two sets of originals separately in the ADF

2-up mode, two original feelers are used for original

detection. If 2-up mode is not selected, the original is

detected when one of the sensors is activated.

There are two indicators on the ADF original feed

section: Original Set and Auto Feed. The Original Set

indicator turns off when an original is inserted. The Auto

Feed indicator lights for 5 seconds after the last copy

using the ADF is finished. If an original is set while this

indicator is lit, the machine automatically starts feeding

the original.

If the "1-to-1 Copy Start key" is pressed while an original

is set, one if copies is made from the original, ignoring

the operation panel setting.

If original stacks are set both in the ADF and the RDH,

the machine starts copying the originals in the RDH

when the Start key is pressed.

2.4.3 ADF Size Detection

When one of the side guides is slid, the other guide also

moves due to the rack and pinion. The lever of the ADF

size detector (a variable resistor) [C] moves with the rear

guide. The original width is detected by checking the

potential of the sensor terminal. As the difference of the

width between LG and B4 is too small to detect,

reflective photo-sensor (trailing edge sensor - B4) is

used to distinguish between B4 and LG.

The three reflective photo-sensors are used to detect the

trailing edge of the last original. The paper feeding must

be stopped just after the last original is started (paper is

fed before the original is fed, because the paper path is

long).

Relay Roller

RDH

[A]

Friction Blade

Trailing Edge

Sensors

ADF

[B]

[C]

Trailing Edge Sensor: B4

Trailing Edge Sensor: A4/LT

2-4

Trailing Edge Sensor: B5

6 November 1997 RDH/ADF

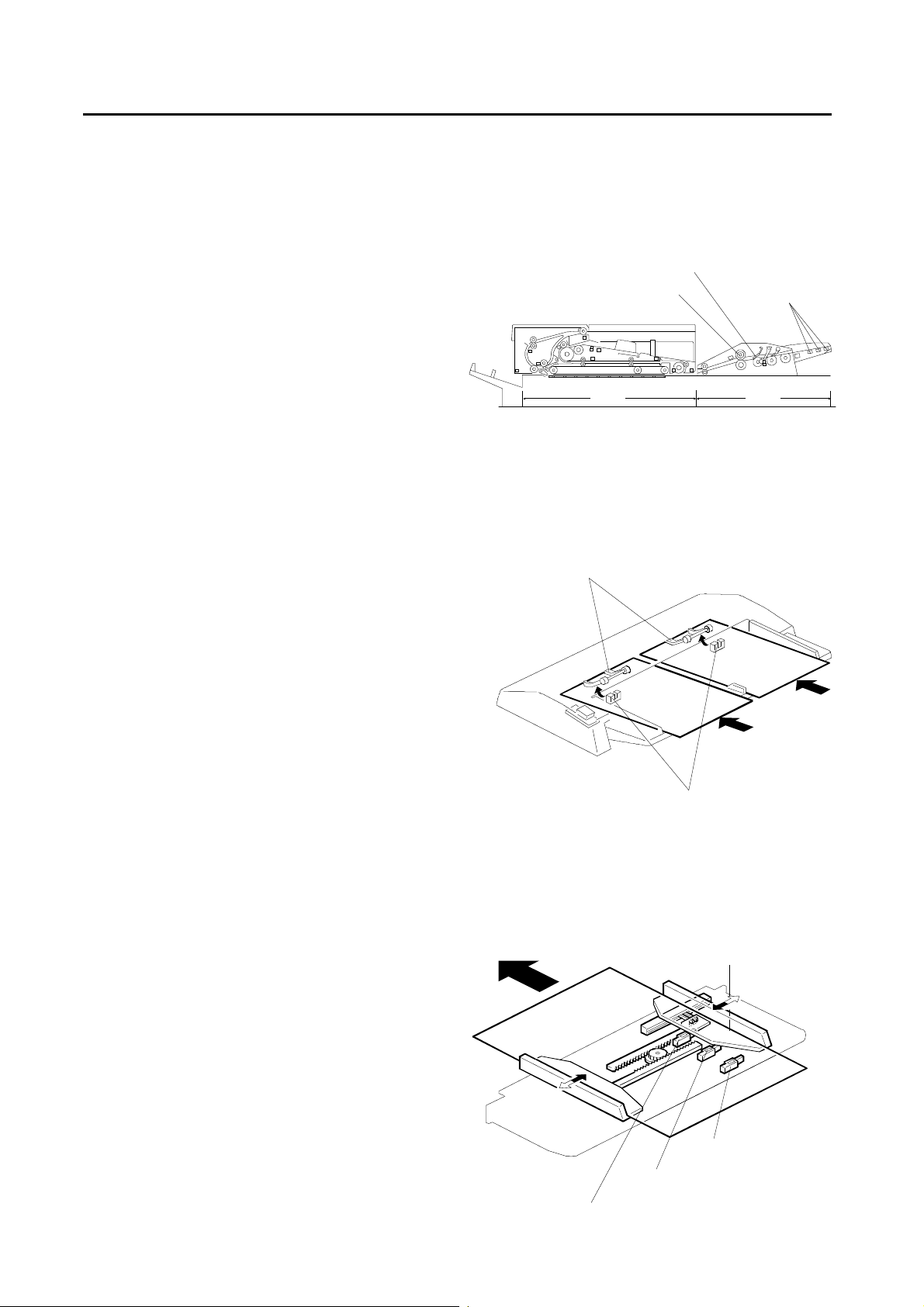

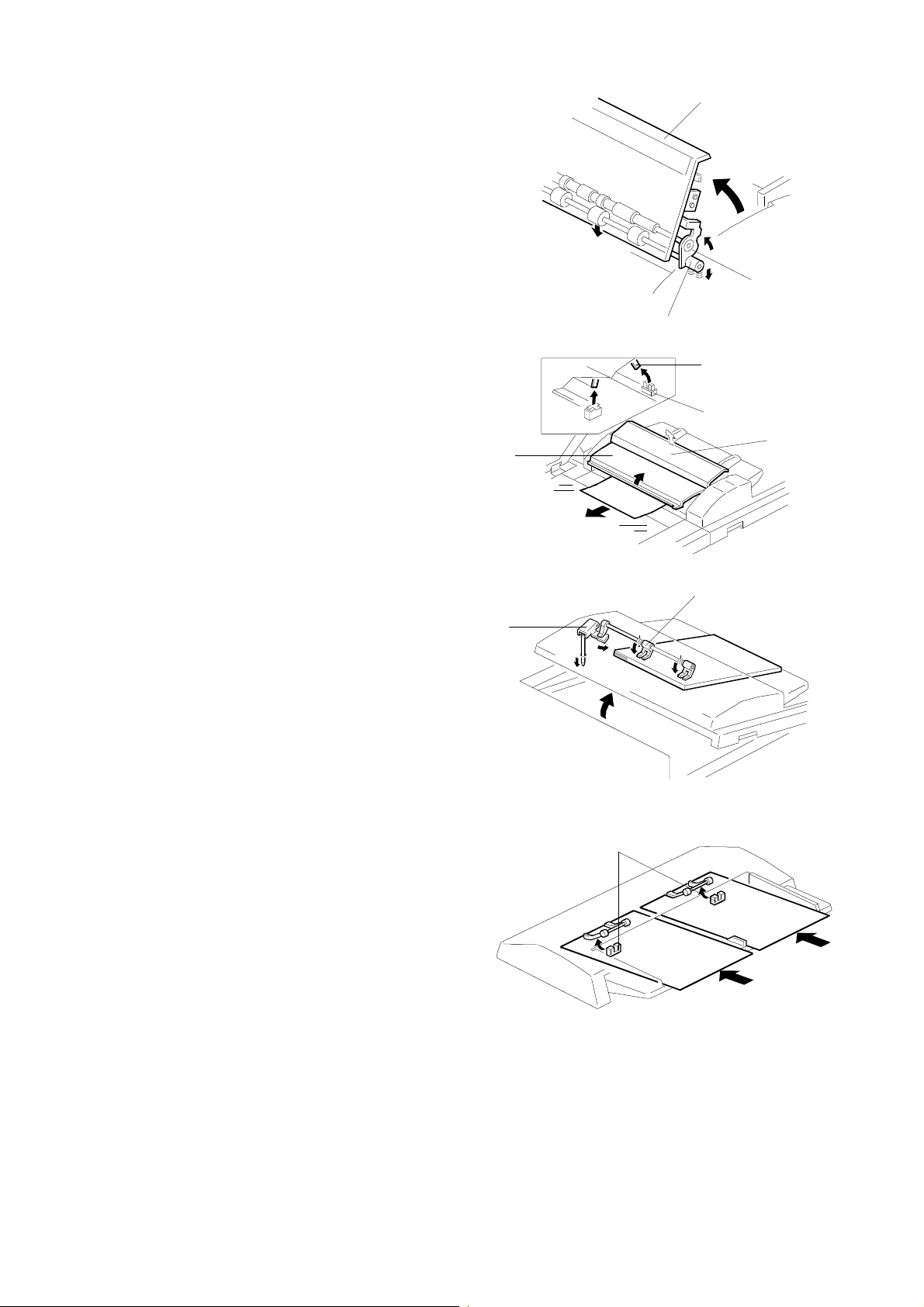

2.4.4 ADF Separatio n M echanism

After the Start key is pressed, the bottom original is

separated by the separation rollers [A] and the friction

blade [B] and it is transported to the relay rollers [C].

The separation rollers have a one- way clutch inside .

After the drive motor stops, the rollers continue to turn in

the feed direction.

The friction blade is pressed against the separation

rollers by two adjustment screws at the front and rear of

the blade holder.

2.4.5 Pick-up Roller

The entrance guide mylar [D] holds the originals against

the pick-up rollers to facilitate paper feed.

The pressure release cam lobe [E] pushes the lever [F]

upward to release the pressure mylar [G]. This makes it

easier to set the originals.

During paper feed, the cam rotates and the pressure

mylar pushes down the entrance guide mylar because of

the force of the return spring. The pressure mylar lever

stops at the stopper [H] to prevent too much pressure

being applied.

A heart shape cam [I] is installed on the pick-up roller

shaft. When the cam follower [J] drops into the

depressed portion of the heart-shaped cam, the pick-up

roller stops. At this time, the flat surface of the pick-up

rollers is level with the original table.

[C]

[D]

[G]

[F]

[E]

[B]

[A]

[H]

[J]

[I]

2.4.6 ADF Drive Mechanism

The two-directional original feed motor [K] drives the

pick-up rollers [L], the separation rollers [M], and the

lower relay roller [N]. Two one-way gears [O] and a

one-way pulley [P] control the roller rotation.

Upon receiving the paper-feed signal from the copier,

the original feed roller rotates clockwise, and the pick-up

rollers and the upper relay roller rotates in the paper

feed direction. The pick-up roller has a home position

sensor [Q]. When the sensor detects that the roller has

completed a full turn, the original feed motor starts

reversing.

When the motor reverses, the one-way pulley and the

gear driving the pick-up and separation rollers become

idle and the rollers stop. The relay rollers continue to

turn in the paper feed direct ion beca use of the one-wa y

clutched.

Two separation shafts and two electromagnetic clutches

[R] are used to control the front and rear separation

rollers separately. In normal mode, the two clutches are

energized at the same time to transmit the rotation of the

original feed motor. In ADF 2-up mode, when one of the

original stacks is finished, the clutch for the finished

original is de-energized to prevent the separation rollers

from wearing.

[P]

[R]

[Q]

[O]

[N]

[M]

[R]

[L]

[K]

2-5

RDH/ADF 6 November 1997

2.4.7 Relay Roller Pressure Release Mechanism

When the ADF right cover [A] is opened, the bushing [B]

of the pull-out roller is pressed down by the raised

portion of the friction blade frame [C]. This releases the

pull-out roller pressure to make misfed originals removal

easier. The feeler [D] moves away from the entrance

cover sensor [E], and the machine detects that the cover

is open.

The ADF left cover [F] also can be opened for easy jam

removal.

[A]

[C]

[B]

[D]

[E]

[A]

[F]

2.4.8 ADF Original Hold Mechanism

To prevent the originals in the ADF from dropping when

the duplex door is opened, an original hold mechanism

is installed.

While the duplex door is closed, the lever [G] is pushed

up by the shaft, and the original holding arms [H] are

released from the originals.

When the duplex door is opened, the shaft moves down

and the originals are held by the arms.

2.4.9 ADF 2-up Mode

In ADF 2-up mode, two originals (lengthwise) are fed

together to the exposure glass, and the originals are

copied together on one sheet.

To detect the front and rear originals separately, two

photosensors [I] and two actuators are used, and the

front and rear separation rollers are controlled

separately using two electromagnetic clutches.

When both front and rear original set sensors are

actuated, the front and rear separation roller clutches

are energized at the same time. When one of the

originals is finished, copying stops. If the Print key is

pressed in this condition, copying starts again by driving

only the separation rollers for the remaining originals.

In normal copying, the original runs 7 mm after the

trailing edge of the original passes the right scale, then it

is reversed 12 mm make sure it steps against the right

scale.

In ADF 2-up mode, the original runs 15 mm and

reversed 30 mm This extra reverse feed ensures that

the original steps against the right scale. It is needed

because the original is fed lengthwise an has less

contact with the rollers, so slippage is more.

"Center Erase" is automatically selected in 2-up mode.

[H]

[G]

[I]

2-6

6 November 1997 RDH/ADF

2.4.10 Preset Mode

Using Preset mode, the second copy job, which automatically starts after the 1st job is finished, can be set while the 1st

copy job is in progress.

To enter the Preset mode, the operator should press the "Preset" key on the display while the machine is operating in the

RDH mode.

In Preset mode, the RDH and the ADF operate in the following steps:

After the RDH job is finished, the originals in the RDH are delivered to the original exit tray one by one.

The originals in the ADF are transported into the RDH one by one.

The 2nd job is operated in RDH mode.

After the job is finished, the originals stay in the RDH.

There are several limitations and notes concerning the Preset mode.

•

The original size for the 2nd job must be the same as the 1st job.

•

Cover Sheet mode, Slip Sheet mode, and size magnification cannot be used in the 2nd job.

•

The Interrupt key is disabled while the Preset mode is used.

•

The Energy Saver key is disabled while the Preset mode is used.

•

Preset mode cannot be used with Stack mode.

•

Preset mode cannot be used with 2-up mode.

•

Preset mode cannot be used with Thin Paper mode.

The machine checks if the 2nd job is possible, after the 1st job is finished.

The 2nd job is automatically canceled in the following conditions.

•

If a User Program is operated or the RDH original is removed while the machine is standing by.

•

If the front door is opened while setting up the 2nd job at the operation panel.

•

If a paper jam occurs during the 1st job.

•

If an original jam occurs while the original in the ADF is transported to the RDH.

2-7

RDH/ADF 6 November 1997

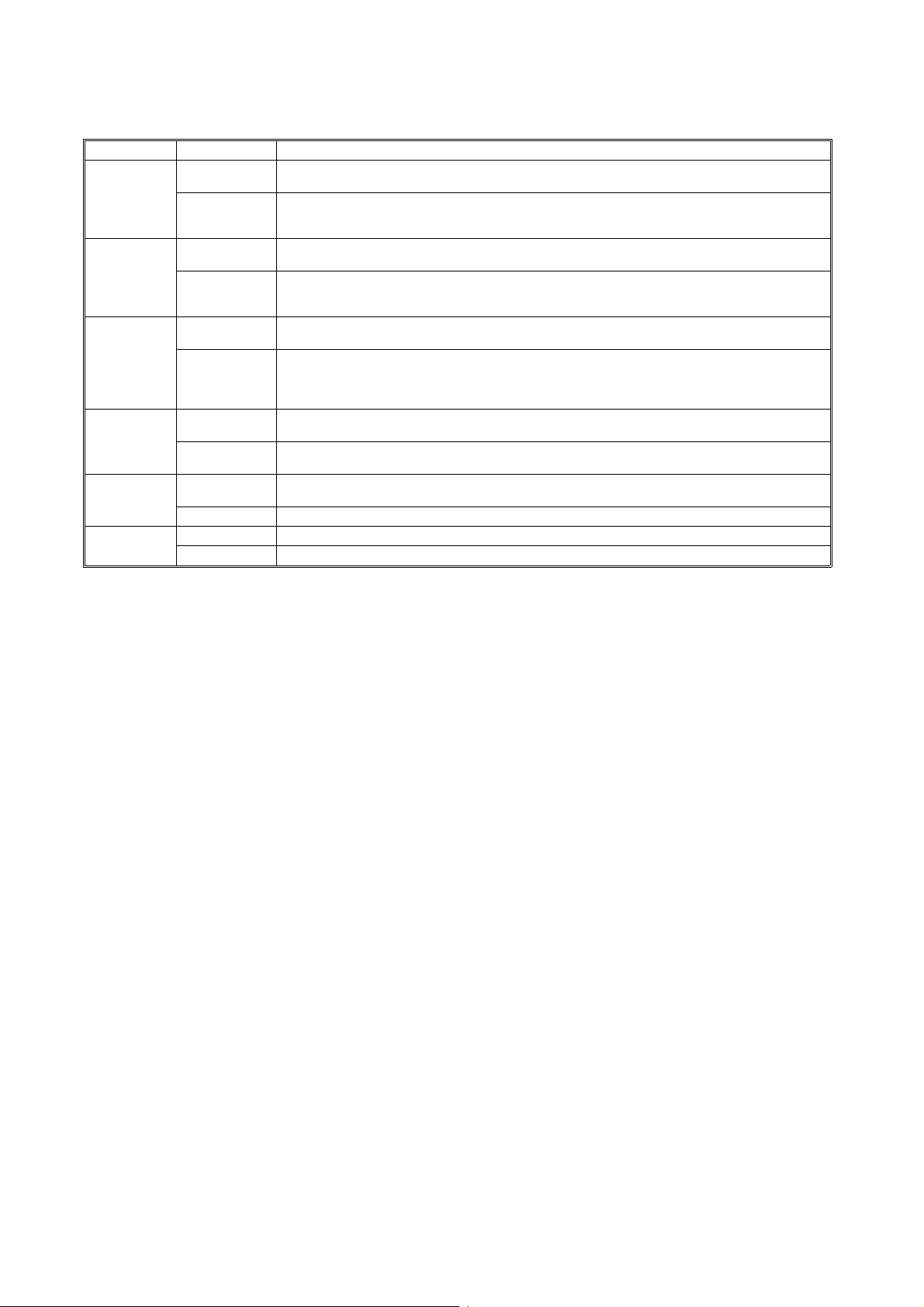

2.4.11 ADF Electrical C omponent Defects

The table below shows the expected symptoms when a photosensor is defective.

Sensor Sensor Status Expected Symptom

Trailing Edge

Sensor (B4)

Trailing Edge

Sensor (A4/LT)

Trailing Edge

Sensor (B5)

Pick-up Roller

H.P. Sensor

Original Set

Sensors

Original Feed

Sensors

ON

OFF

ON

OFF

ON

OFF

ON

(Interrupted)

OFF

(Not interrupted)

ON

OFF The machine works normally in normal mode. If 2- up mode is used, the original is not fed.

ON An original ja m is detecte d after the Start key is pressed.

OFF An original jam is dete cted after the Start key is pressed.

When an A4/LT or smaller original is used, the machine works normally. I f a l arger original is used,

an original jam is detected.

When an A4/LT or smaller original is used, the machine works normally. I f a l arger original is used

and the number of sheets is more than 2,copying stops after 2 sheets are copied. Even if the

original is larger than A4, the machine works normally if the number of the originals is 2 or less.

When an A4/LT s ize original is used, the machine work s normally. If the original size is not A4, an

original ja m is detected.

When an A4/LT or smaller original is used, the machine works normally. I f a l arger original is used

and the number of sheets is more than 2, copying stops afte r 2 sheets are copied. Even if the

original is larger than A 4/LT, the machine works normally if the number of sheets is 2 or less.

When an A4/LT or la rger original is used, the machine works normally. If B5 size paper is used,

paper jam is detected.

When A4/LT or larger size original is used, the machine works normally. If B5 size paper is used, a

paper jam is detected. If B5 size paper is used and the number of sheets is more tha n 2, copying

stops afte r 2 sheets are copied. Even if the original is B5, the machine works normally if the

number of sheets is 2 or less.

The pick-up roller turns for 1 second, then the "READY" lamp turns off.

The pick-up roller turns for 1 second, then an original jam is detected.

The machine works normally in normal mode. If 2-up mode is used, an original jam is detec ted

after the last original is fed.

2-8

6 November 1997 LCT

2.5 LCT

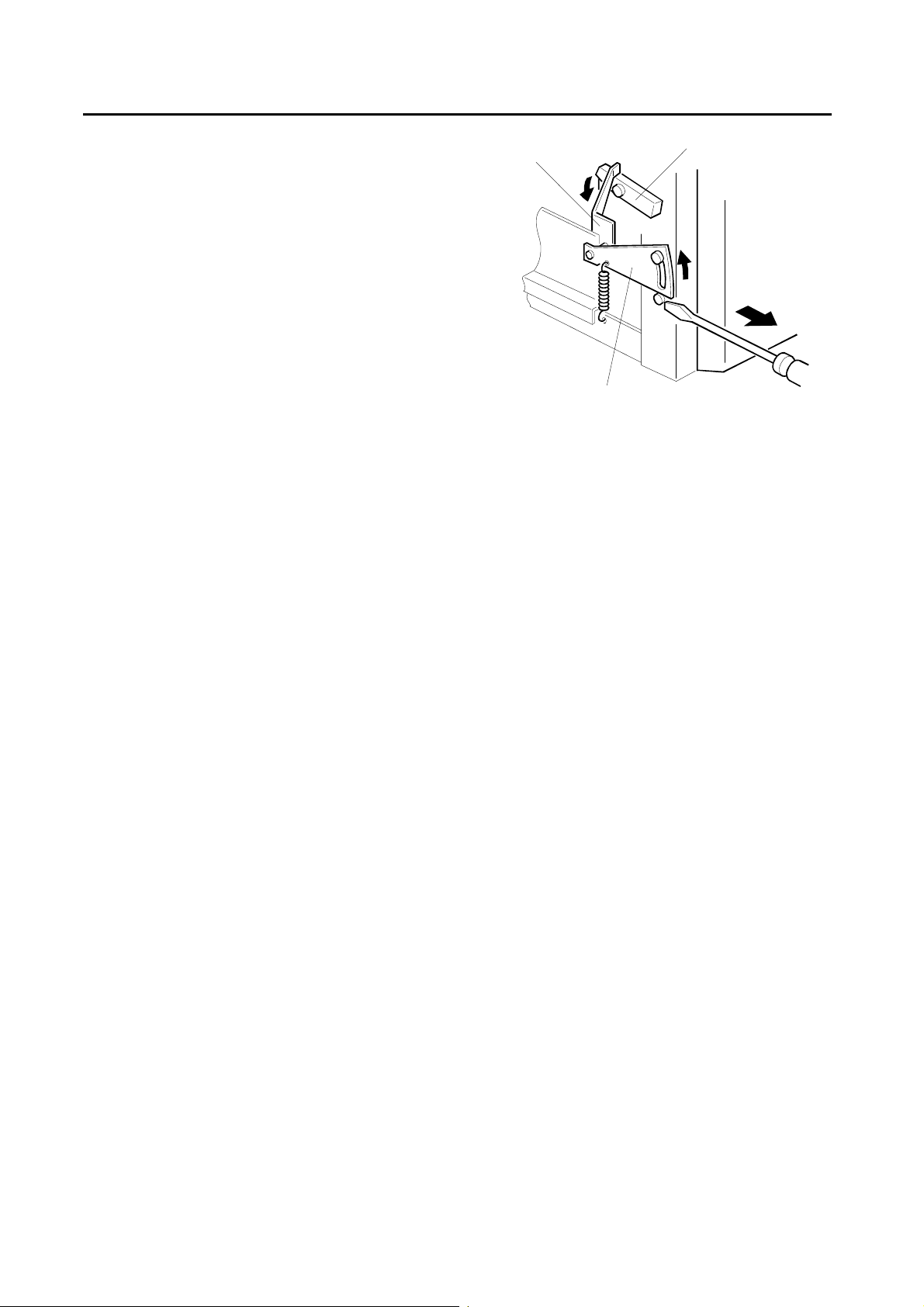

2.5.1 Manual Tray Un l ock Mechanism

To enable the paper tray to be pulled out when the

power is off, even if the paper table is up, a manual tray

unlock mechanism has been added.

Normally, when the paper table is up, the lever [A] locks

the paper tray and it cannot be pulled out.

If the release lever [B] is pushed up, the arm [C] pushes

down the lock lever, and the paper tray is unlocked.

[C]

[A]

[B]

2-9

Finisher 6 November 1997

2.6 Finisher

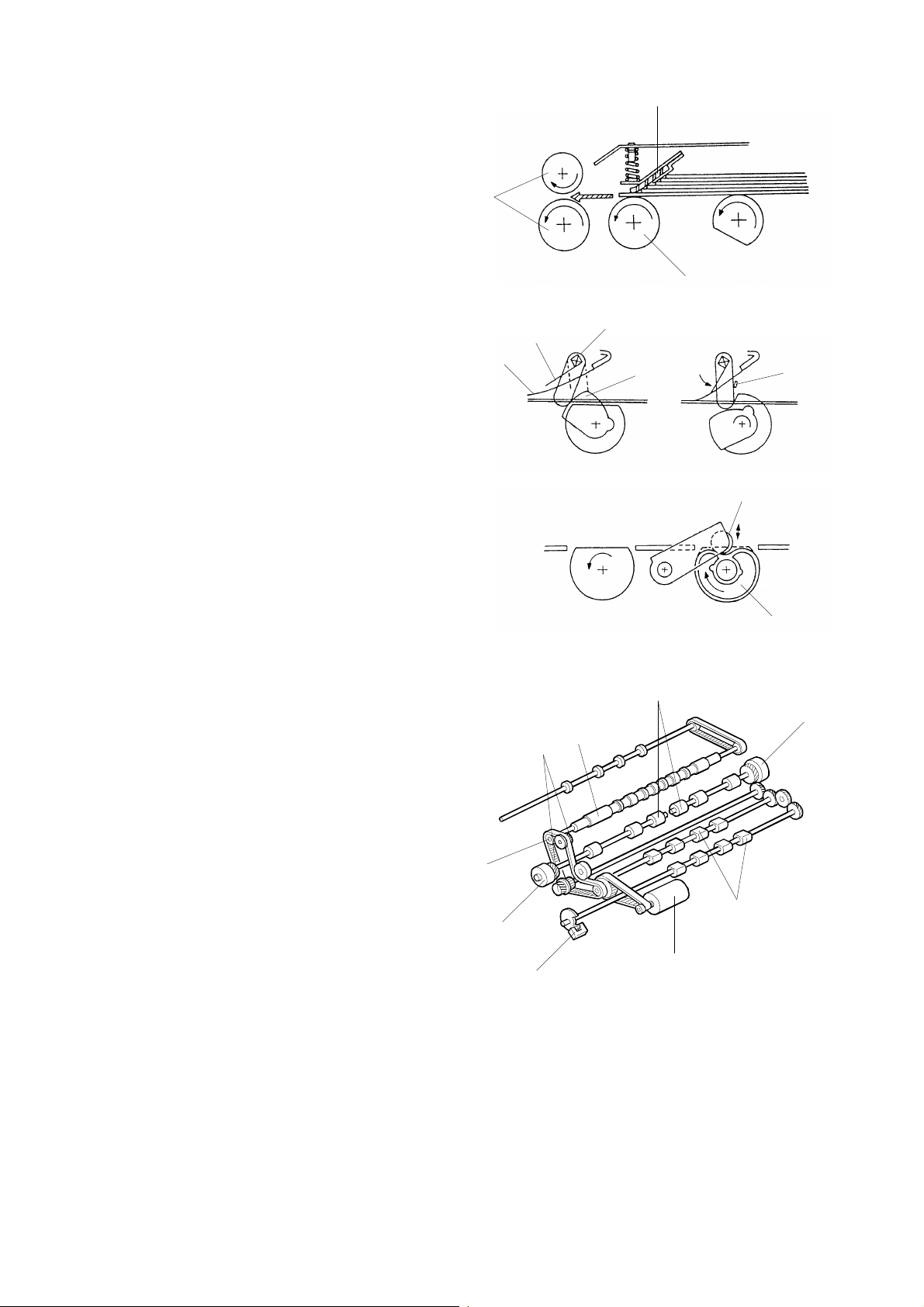

2.6.1 Stapler

The staple hammer [A] is driven by the stapler motor [B]

via gears [C], two eccentric cams [D], and two links [E].

When the aligned copies are brought to the stapling

position by the positioning roller, alignment brush roller

and jogger fences, the stapler motor starts. When the

cams complete one rotation, the staple hammer home

position sensor [F] turns on, detecting the end of the

stapling operation. The stapler motor then stops.

There are two sensors in the stapler unit. One is the

staple end switch [G] for detecting staple end conditions

(it detects when there is only one sheet of staples left in

the cartridge). The other is the cartridge set switch [H]

for detecting whether a staple cartridge is installed.

When a staple end or no staple cartridge condition is

detected, a message is displayed advising the operator

to install a staple cartridge. If this condition is detected

during a copy job, the indication will appear, but will not

stop the copy job.

The staple cartridge has a clinch area [I], in which the

jammed staples are left. Operators can remove the

jammed staples from the cartridge.

[E]

[B]

[A]

[D]

[C]

[F]

[G]

[H]

[I]

2-10

SECTION 3

INSTALLATION

6 November 1997 Installation Requirements

3. INSTALLATION

3.1 Installation Requirements

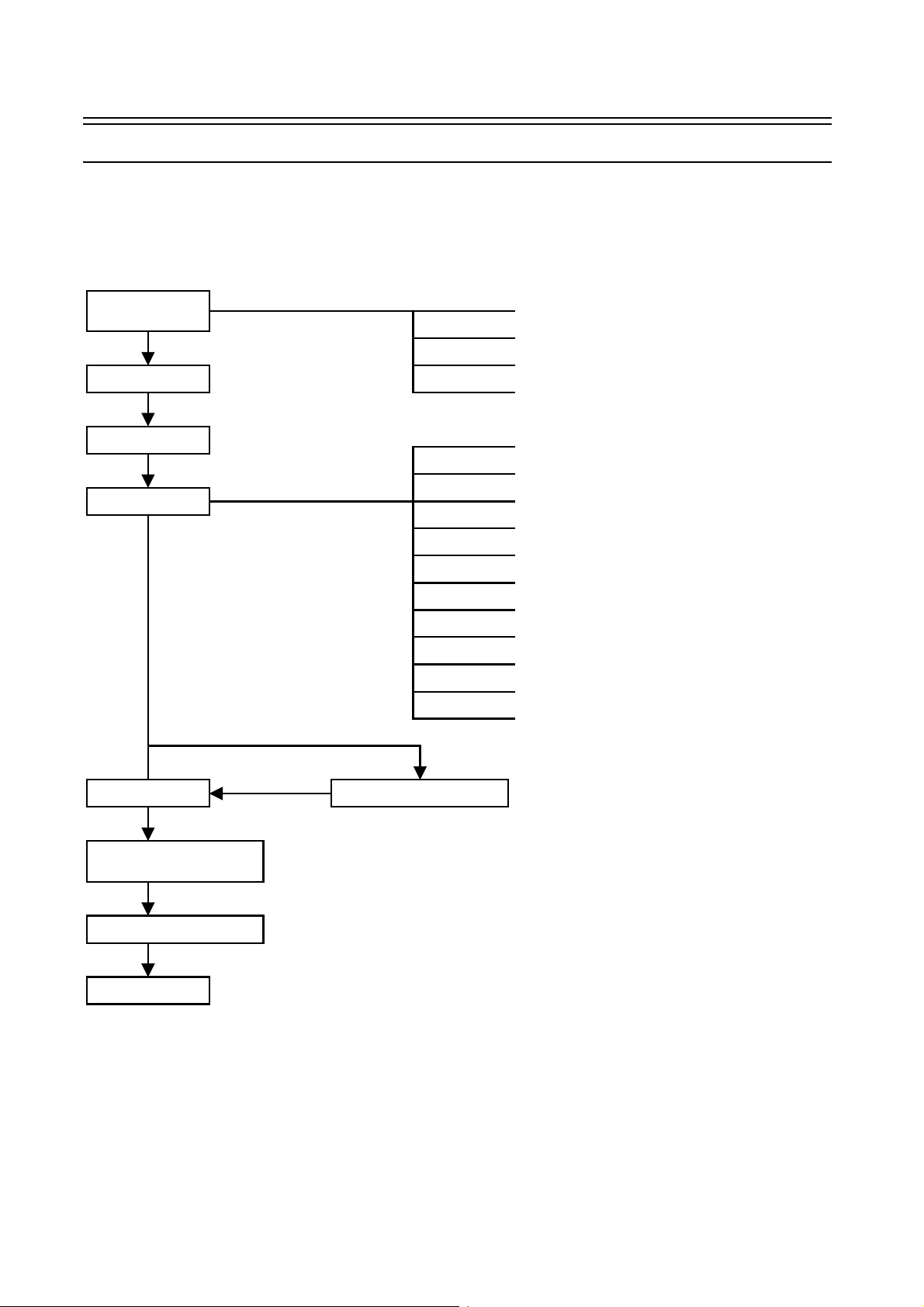

3.1.1 Delivery And Ins tallation Work Flow

Installation

condition check

Delivery

Clamp removal

Main body setup

•

Installation environment, floor strength

•

Space around the machine, delivery route

•

Power supply

•

The user's acceptance of the limited items for

using the machine (See User Guidance

Items section for the limited items.)

•

Supply developer

•

Supply cleaning carrier

•

Set the OPC belt

•

Supply silicone oil

•

Install the cleaner carrier and development vessels

•

Install the operation unit

•

Install the power plug and cord

•

Leveling

•

Install the original stacker

•

Install the toner cartridge

•

Add copy paper

Machine power on

Operation check as far as the

machine stand-by condition

Machine operation check

User guidance

Installation of peripherals

3-1

Installation Requirements 6 November 1997

3.1.2 Environment

Select the conditions which fully satisfy the following items at installation.

1.

Avoid a place exposed to direct sunlight or other strong light (should be below 1500 lux).

2.

Avoid locations with high temperatures or high humidity, or low temperatures and low humidity. (Standard range of

temperature and humidity: 10°C to 30°C, 15% to 90%)

3.

Avoid places with hot air or strong heat sources.

4.

Avoid locations subject to abrupt temperature changes.

5.

Avoid small or dusty rooms.

6.

Avoid poorly ventilated locations. (Air turnover should be 3 times or more per hour per person.)

7.

Install the machine flat on the floor. It must be level within 5 mm front to rear and 5 mm left to right. This is mainly

to prevent tilt from affecting the tracking operation of the OPC belt.

8.

Align the position of the LCT and finisher with the copier. First, adjust the height of the peripherals on the basis of

the exterior cover position. Finally, align the paper transport guide plate height between each unit. This is to

prevent paper misfeeds where each unit connects.

9.

The unit must be installed on a floor which can support its total weight: copier including ADF 499 kg, finisher 77

kg, and LCT 78 kg.

10.

Provide enough space, 100 cm in front, 60 cm in rear, and 30 cm on both sides for operation and service. No

fluorescent lights should be installed above the operation unit. (This is to make it easier to see the operation

display.)

3.1.3 Power connection (For the European version machine only)

1.

Plug

The plug must be approved under the TÜV safety standard and for a three-phase power supply.

2.

Power supply cord

1) The cord must be approved under the TÜV safety standard and have five wires inside. The cross-sectional

area of each wire must be 2.5 mm2, and the outside diameter of the cord must be 14 to 18 mm. (The capacity

must be over 600 volts and 16 A for each phase.) The length must be 5 m or less even if an extension cord is

used.

2) The socket outlet of the power source must be installed near the copier and must be easily accessible. (If the

power supply cord is permanently connected, a readily accessible disconnect device must be incorporated in

the fixed wiring.)

3-2

Loading...

Loading...