Page 1

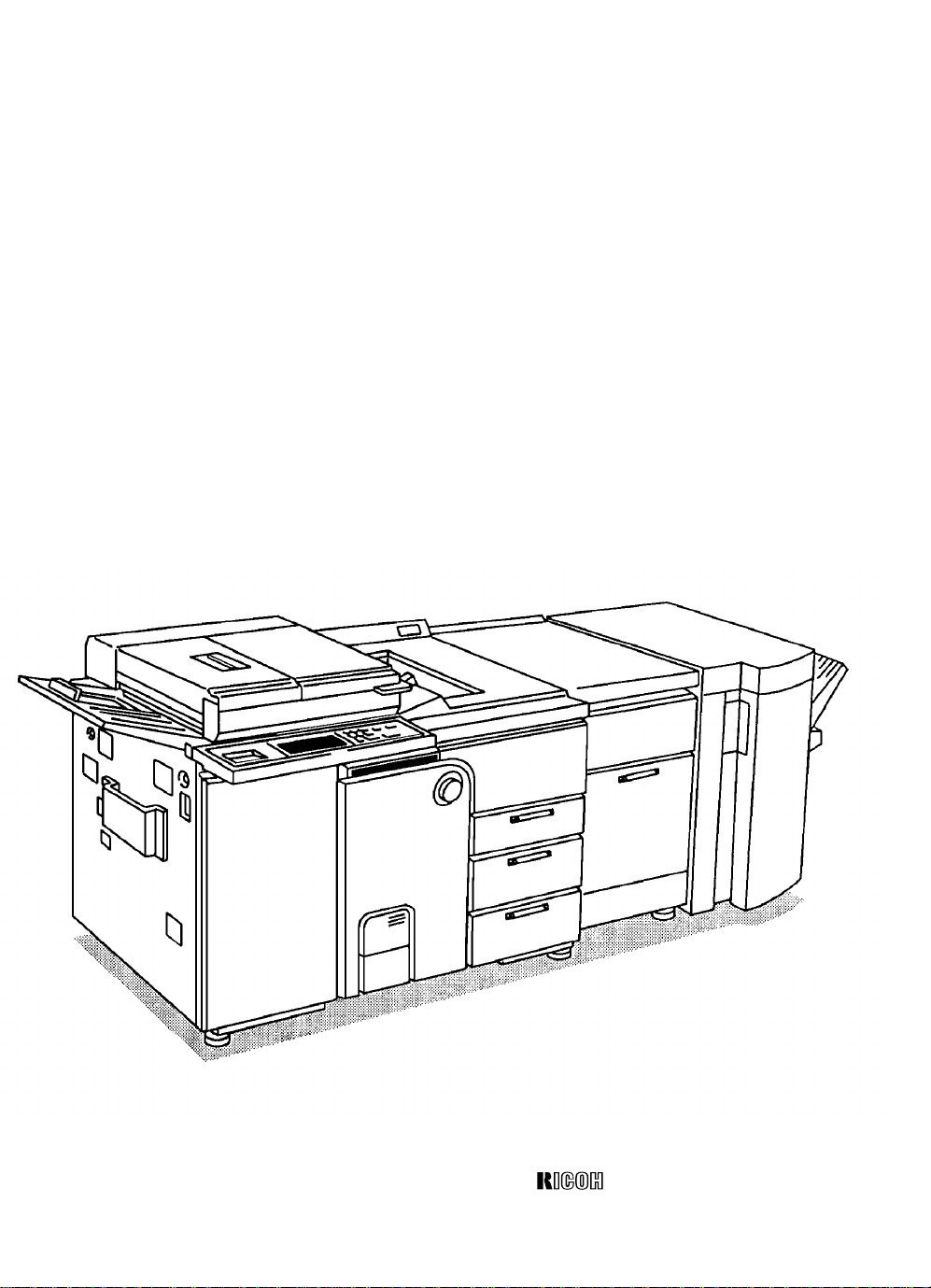

RICOH FT9101

FIELD SERVICE MANUAL

LARGE CAPACITY TRAY RT32

FINISHER SR500

PRINTER CONNECTOR UNIT PCU10

KEY COUNTER/PRINTER

CONNECTOR BRACKET KP10

COMPANY, LTD.

Page 2

Read This First

A few simple symbols and notations are used to help you read faster and find the information you

need. Before you use this guide, glance over this list of special notations and be sure you

understand what they mean.

NOTE

Information under this heading describes helpful hints, restrictions, and how to avoid difficulties.

CAUTION

Failure to pay attention to CAUTION notices can

result in damage to the equipment.

WARNING

Warnings are for your safety. Failure to pay

attention to WARNING information can be

dangerous to you and others.

Page 3

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier are supplied with electrical

voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filter installed.

2. Always replace the ozone filter with the specified one at the specified

interval.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get medical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The main control board has a lithium battery which can explode if handled

incorrectly. Do not replace the battery. Do not recharge, or burn this

battery. Used batteries must be handled in accordance with local

regulations.

Page 4

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductors

according to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries (main control boards) in order to

dispose of them later, do not put more than 100 batteries (main control

boards) per sealed box. Storing larger numbers or not sealing them apart

may lead to chemical reactions and heat build-up.

Page 5

SECTION 1

OVERALL MACHINE INFORMATION

Page 6

1 July 1994 Installation Requirements

1. INSTALLATION

1.1 Installation Requirements

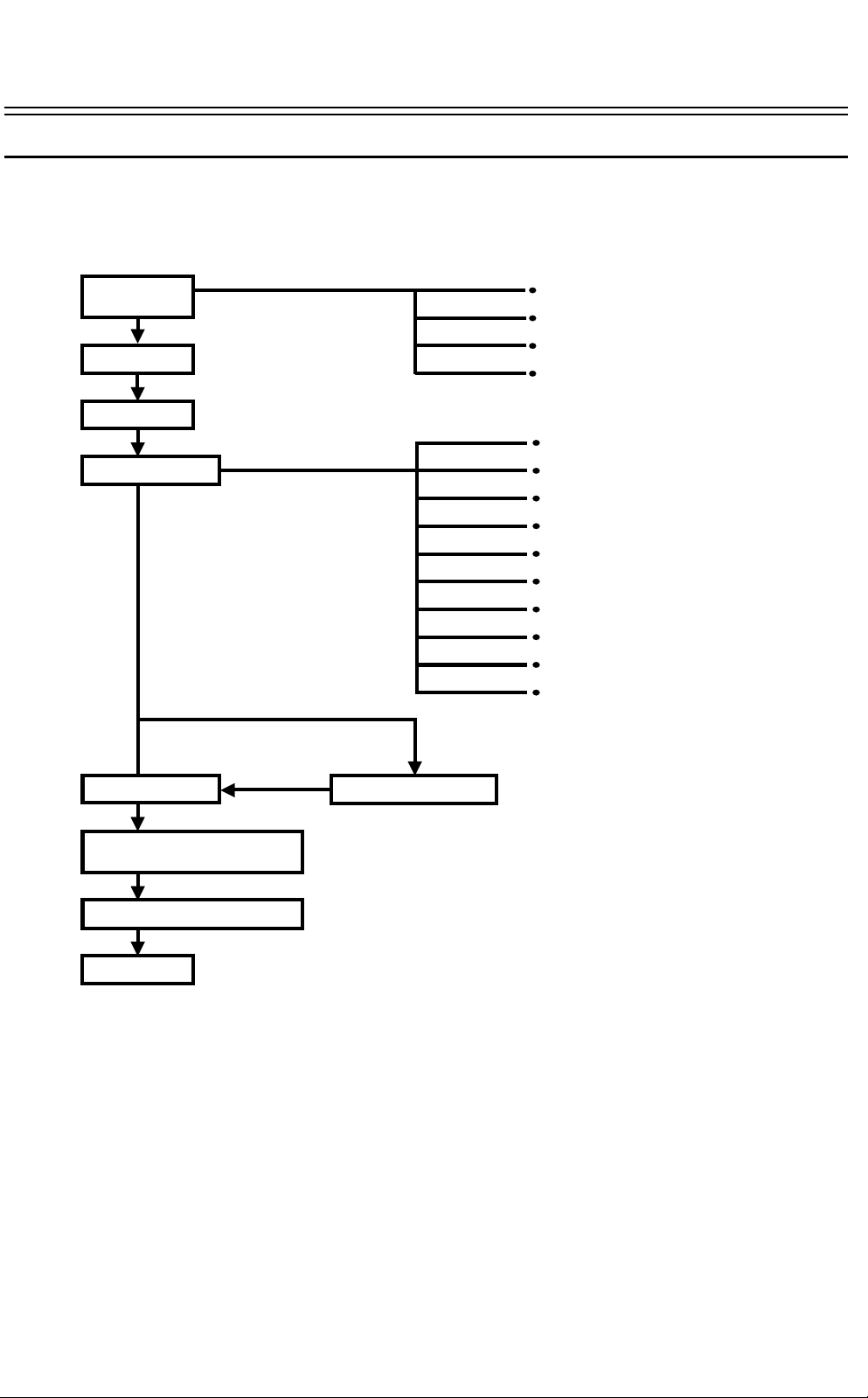

1.1.1 Delivery and installation work flow

Installation

condition check

Delivery

Clamp removal

Main body setup

Machine power on

Installation environment, floor strength

Space around machine, delivery route

Power supply

The user’s acceptance of the limited items

for using the machine (See User Guidance

Items section for the limited items.)

Supply developer

Supply cleaning carrier

Set OPC belt

Supply silicon oil

Install power plug and cord

Leveling

Installing original stacker

Installing sub-tray

Installing toner cartridge

Setting copy paper

Installation of peripherals

Operation check as far as the

machine stand-by condition

Machine operation check

User guidance

1-1

Page 7

Installation Requirements 1 July 1994

1.1.2 Environment

Select the conditions which fully satisfy the following items at installation.

Avoid a place exposed to direct sunlight or other strong light (should be below 1500 lux).

1.

Avoid locations wit h hi gh tem pe r at ure s or hi gh hum id it y, or low te mp era tu r es and low

2.

humidity. (Standard ran ge of te mp era ture and humidity: 10

Avoid places with hot air or strong heat sources.

3.

Avoid locations subject to abrupt temperature changes.

4.

Avoid small or dusty roo ms .

5.

Avoid poorly ventilated locations. (Air turno ve r sho ul d be 3 tim es or more per ho ur pe r

6.

person.)

Install the machin e flat on the floor. It must be level within 5 mm front to rear and 5 mm left

7.

to right. This is mainly to prevent affecting the tracking operation of the OPC belt.

Align the position of the LCT and finisher with the copier. First, adjust the height of

8.

peripherals on the basis of the exterior covers position. Finally, align the paper transport

guide plate height between each unit. This is to prevent paper misfeeds where each unit

connects.

The unit must be insta lled on a floor which can support its total weight : copier including ADF

9.

482 kg, finisher 77 kg, and LCT 75 kg.

Provide enough space, 100 cm in front, 60 cm in rear and 30 cm on both side s for operation

10.

and service. No fluorescent lights should be installed above the operation unit. (This is to

make it easier to see the operation display.)

o

C to 30oC, 15% to 90%)

1.1.3 Power connection (For the European version machine only)

Plug

1.

The plug must be approved under the TÜV safety standard and for a three-phase power supply.

Power supply cord

2.

The cord must b e approved unde r the TÜV safety standard and have five wire s inside. The

cross-sectional area of ea ch wire must be 2. 5 mm

be 14 to 18 mm. (The capa city must be over 6 00 volt s and 16 A for each ph ase. ) The lengt h

must be 5 m or less even if an extension cord is use d.

2

, and the outside diameter of the cord must

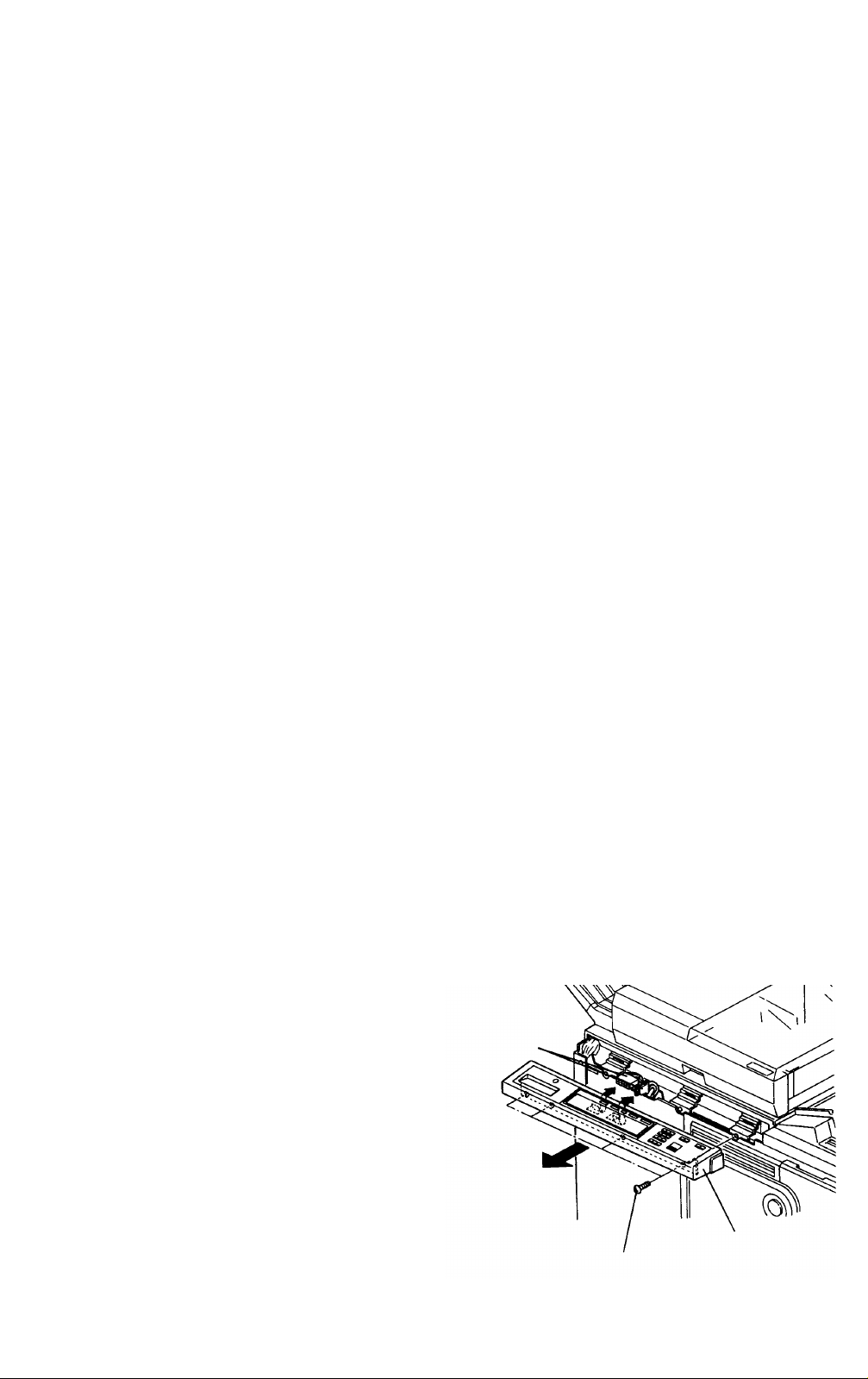

1.1.4 Transportation

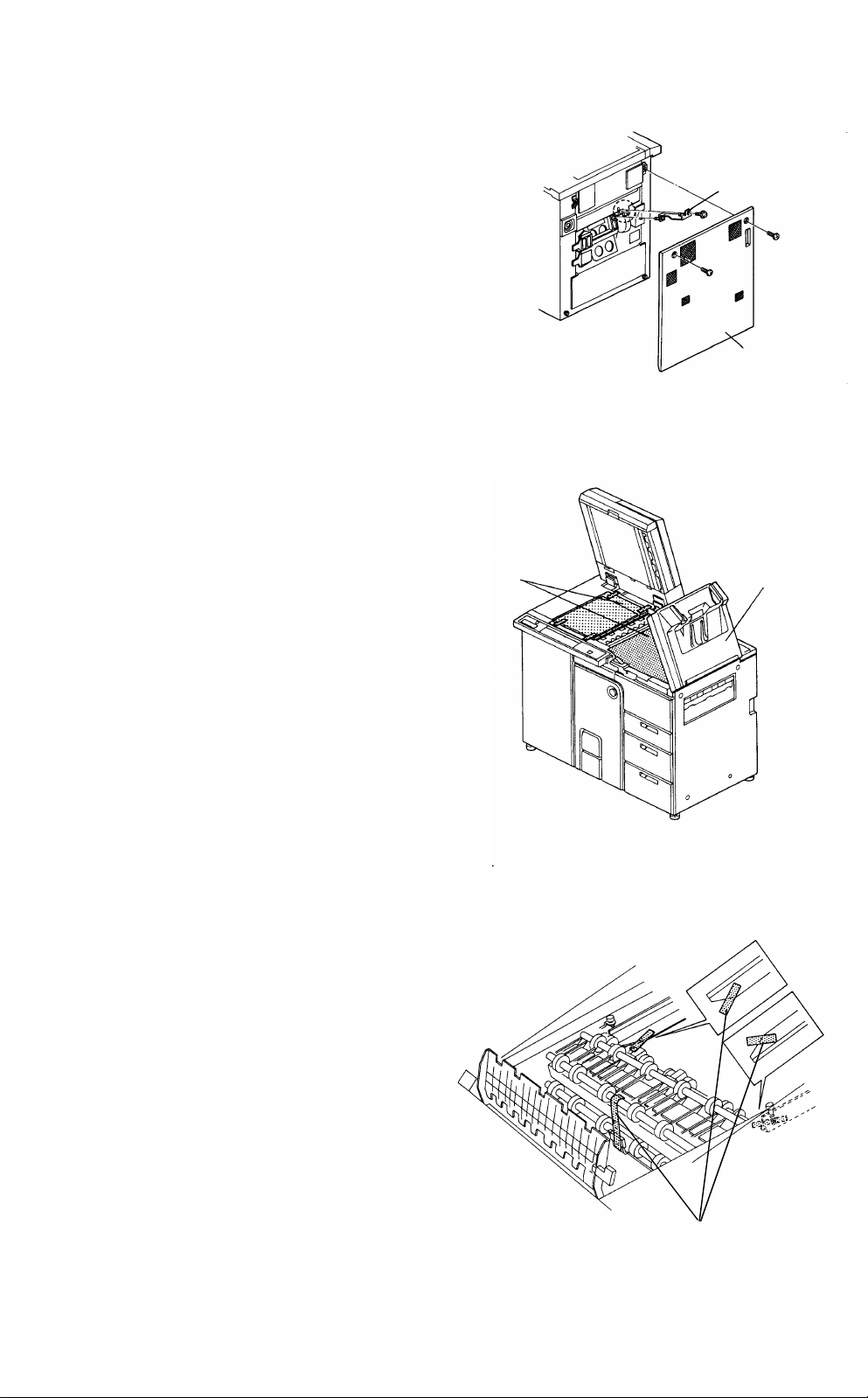

Remove the operation unit before

transporting the copier if the copier cannot

get into the elevat or or co py room . Thi s

reduces depth to 775 mm from 830 mm.

Remove the cardboard packing in advance.

Remove four screw s (M4 x 6) from the operation

1.

unit.

Remove the connector for the operation unit and

2.

remove the operation unit.

CAUTION

Never carry the copier side down.

Connector

1-2

Operation unit

4 screws (M4 x 6)

Page 8

1 July 1994 Copier Installation

1.2 Copier Installation

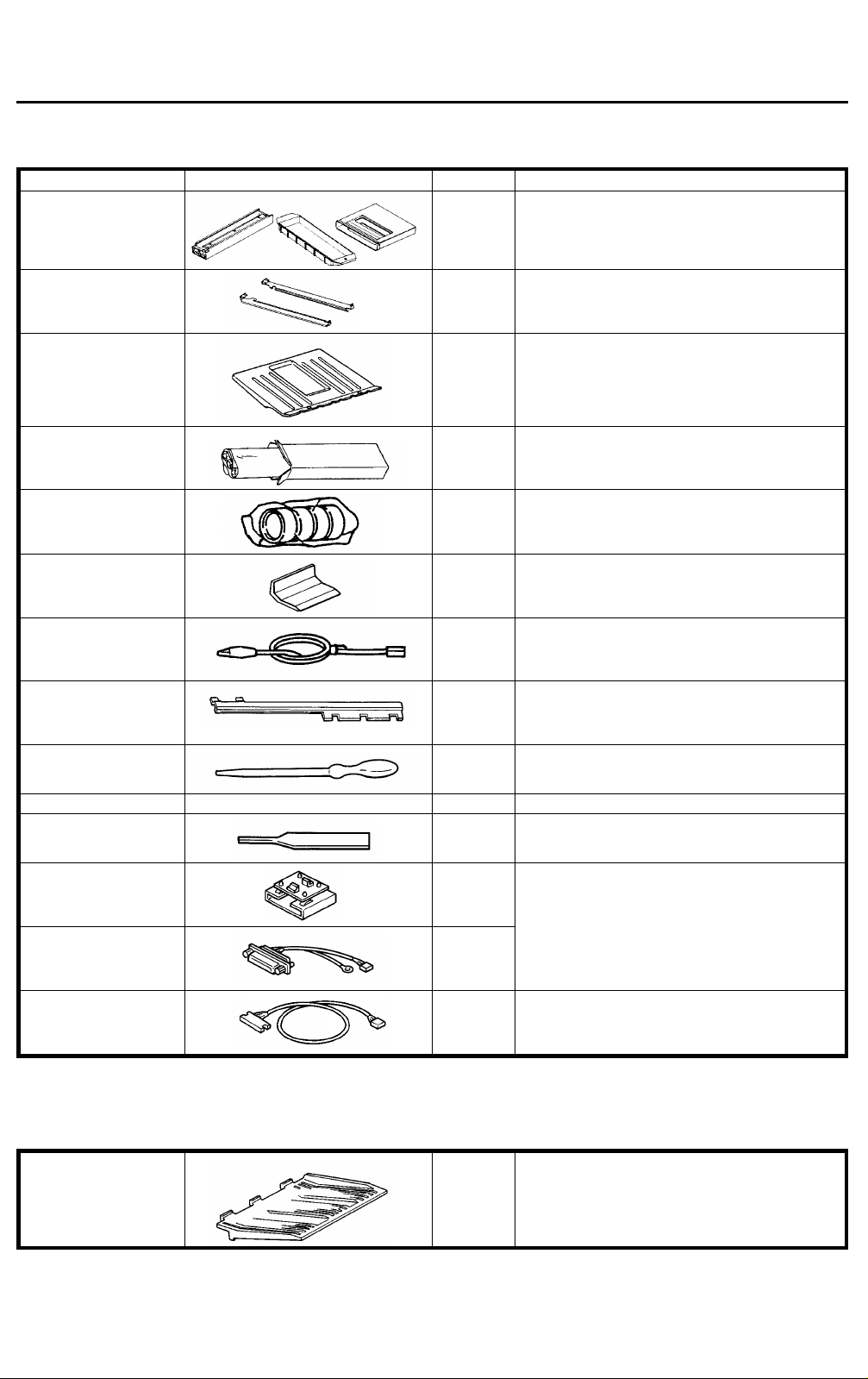

1.2.1 Accessory list

Name Diagram Quantity Use

Developer vessel

Cleaning carrier vessel

Cleaning carrier magnet

1 of each To collect the developer and cleaning carrier.

Vessel rail

Original stacker

OPC belt

Leveling shoe

Original back fence

Development unit

grounding harness

Tray fences fixing plate 3 To fix the paper tray side fences.

Syringe

2 To set the developer vessel.

1 To receive originals from the ADF.

1

4 For the docking position adjustment.

1 To install on the original stacker.

1 To avoid damage of the image density sensor board

when a vacuum cleaner is used.

1 To apply silicon oil in the fusing unit.

Plated screw M 4 x 8 4 To secure the vessel rails.

Counter reset key

Printer interface board 1 To connect a printer using service tool [6]. These

Short printer harness

Long printer harness

1 To reset the total counter to 0.

parts are needed when the optional printer

connector unit is installed. Keep these parts for

future use.

1

1 To connect a printer using service tool [6].

NOTE

When the optional fin is he r is no t us ed , the sub-tray (P/N-A029146 0) mu st be ord ere d and used.

Sub-tray 1 To receive copies fed out. (Not required when the

sorter is used.)

1-3

Page 9

Copier Installation 1 July 1994

1.2.2 Removing the clamps

ADF

Remove the cushions from the paper feed tray, the

1.

cushion from the co py tray, and the strips of

filament tape from the exterior.

Cushions (2)

Cushion Cushions (3)

Open the center door and remove the 7 strips of

2.

filament tape and a cushion from the transport unit.

Remove the right cover (2 screws). Then, remove

3.

the clamps from tray 1, tray 2 and tray 3 using a

slot head screwdriver.

Center door

Cushion

Clamp

Right cover

1-4

Page 10

1 July 1994 Copier Installation

Take off the left cover and remove the red bracket

4.

holding the second mirror.

Remove the protective sheets of the expo sure

5.

glass and copy tray.

Protective sheet

Holder bracket

Copy tray

Remove the strips of filament tape from the duplex

6.

unit.

Filament tape

1-5

Page 11

Copier Installation 1 July 1994

To remove the inner cover, remove the left door

7.

fixing screw (2 screws), and di sc on ne ct the cooling

Left door

fan connector.

Cooling fan

connector

Inner cover

Remove the first mirror bracket (red bracket).

8.

To enable accessing the service tool password,

9.

turn on DIPSW101-2.

Remove the OPC cleaning unit fixing screw to pull

10.

Mirror

bracket

out the unit, and cut the unit fastener.

To pull out the fusing unit, remove the front fusing

11.

cover (2 screws) and one unit fixing screw.

Remove the cover from the right side of the unit (4

12.

screws).

Loosen the pressure fixing screws to remove the

13.

wedges on the front and far side. Re-tighten the

pressure fixing screws.

Install the fusing right side cover.

14.

NOTE

Install the front fusing cover after pouring silicon oil.

Peel off the plain sheet behind the fusing oil pan.

15.

Unit fixing screw

Unit fixing screw

(before removal)

Front fusing cover

Wedge

Unit fixing screw

Unit fastener

Wedges

Pressure

fixing screw

Pressure fixing screw

1-6

Sheet

Page 12

1 July 1994 Copier Installation

1.2.3 Setting up the copier

Release the development backup rollers by the

1.

lever, and remove the development unit fixing

bracket. Then, slide out the unit.

Development

backup lever

Fixing bracket

Remove the filter cover from the developer supply

2.

port (2 screws). While turning the development

knob in the direction opposite to the arrow, put in 4

bags (1 kg/bag) of developer from the supply port.

CAUTION

• Clean off the developer on the unit casing.

It may touch the OPC surfa ce.

• Do not put in another compound (cleaning

carrier, etc.) by mistake.

Filter cover

Developer

Developer

supply port

Casing

Reinstall the fi lter cover.

3.

Turn the development knob in the direction of the

4.

arrow and return the developer from the

development roller to the unit inside.

Development knobDevelopment knob

Filter cover

Development knob

1-7

Page 13

Copier Installation 1 July 1994

Slide in the development unit, and fix it with the

5.

fixing bracket.

Fixing bracket

Release the cleaning backup roller by the lever,

6.

Cleaning fixing screw

and remove the cleaning fixing screw to pull out

the cleaning unit.

Remove the upper cover from the cleaning unit (4

7.

screws). Put in one bag of cleaning carrier (700 g)

on the cleaning roll er (rig ht sid e of t he uni t).

CAUTION

• Be sure that the carrier is not in the

scavenging roller side.

• Do not put in another compound by

mistake, such as developer, etc.

• Distribute the carrier evenly by turning the

knob. This unit has no agitation mechanism

as the development unit does.

Upper cover

Cleaning carrier

Cleaning roller

Cleaning

backup lever

Close the upper cover, set the unit in the main

8.

body, and secure it with the fixing screw.

Fixing screw

1-8

Page 14

1 July 1994 Copier Installation

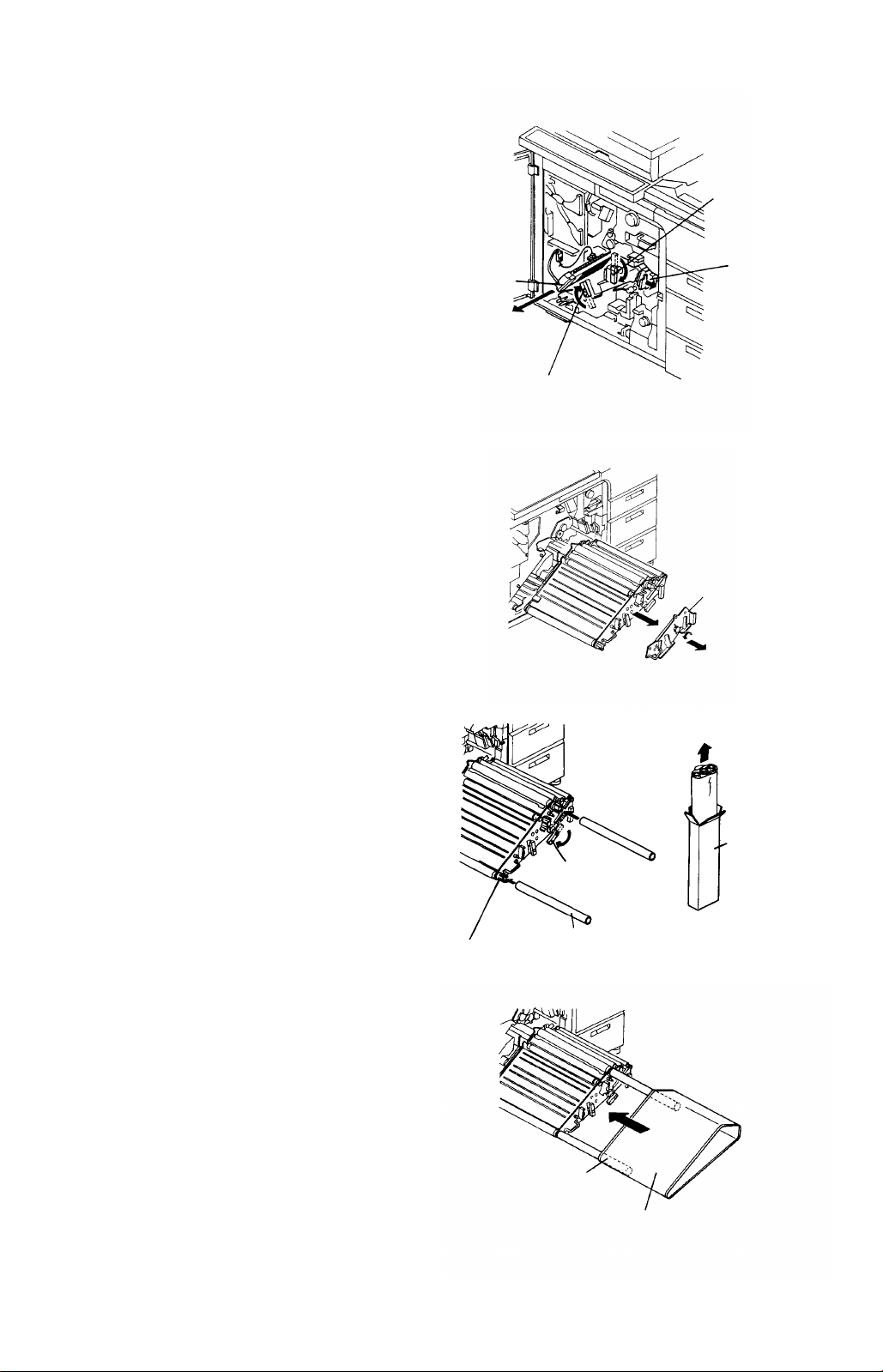

Pull out the charge corona unit, and release the

9.

transport unit.

Release the development and cleaning back-up

10.

levers, and turn the development knob in the

direction of the arrow. Then, remove the OPC unit

stay to pull out the OPC unit.

CAUTION

Charge corona unit

Development back-up lever

Cleaning

back-up lever

Transport unit

Be sure to return the developer from the

development roller to the inside of the unit

before pulling out the OPC unit. Do this by

turning the development knob.

Insert two paper tubes (OPC belt accessories) in

11.

the two guide holders of the OPC unit. Then,

release the pressure rele as e le ve r t o lo os en the

tension, and pull the OPC belt out of the case.

Use the paper tubes as guides to fit the OPC belt

12.

to the unit.

CAUTION

• As you fit the OPC belt, be sure to prevent

folds and contact between the side plate of

the OPC unit and the belt end. Do not

touch the OPC surface directly.

•

Set the OPC belt so that the OPC home

mark is on the rear side of the machine.

• The rear side of the OPC belt must be und er

the OPC sensor.

Guide holder

Pressure

release lever

Paper tube

OPC home

mark side

OPC unit stay

OPC belt case

OPC belt

1-9

Page 15

Copier Installation 1 July 1994

Set the OPC belt in the center of the unit and

13.

restore tension to the belt with the pressure

release lever.

Pressure release lever

OPC sensor

Set the OPC unit in the main body and install the

14.

OPC unit stay.

Set two backup levers, and position the charge

15.

corona unit, its connector, and transpo rt unit.

Install the inner cover (2 screws and a connector)

16.

and left door (2 screws).

Charge corona unit

OPC unit stay

Transport unit

Backup levers

Left door

1-10

Inner cover

Page 16

1 July 1994 Copier Installation

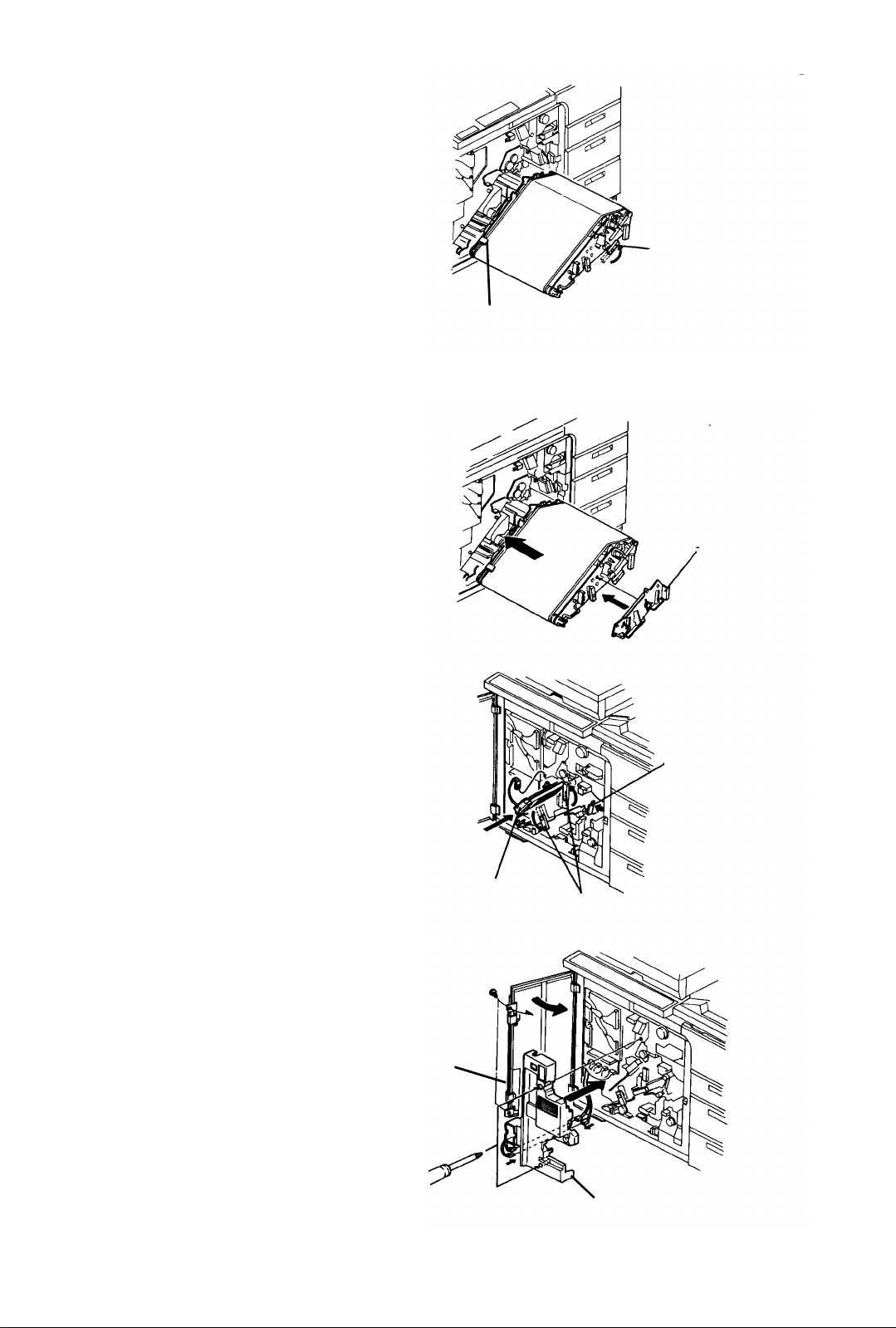

Pull out the fusing unit and remove the front fusing

17.

cover.

Put silicon oil in the oil sump. About 80 g of oil is

18.

sufficient.

Install the front cover and set the unit in the main

19.

body.

Put two cans of silicon oil in the oil tank. (2/3 of

20.

capacity make s ab out 200,000 copies .)

CAUTION

Never remove the oil supply unit from the fusing

unit to prevent oi l marks on copies. It can be

removed only when the oil blade, metering

blade, and oil supply felt are replaced with new

ones.

Oil tank

Tighten the screw (M4 x 8 plated screw:

21.

accessory) on the rear of the vessel rails

(accessories). Put the screws in the hole at the

bottom rear of the machine frame.

Fit the vessel rails on the bottom of the machine,

22.

and secure each of them with the screw (M4 x 8

plated screw) from the front of the machine. Set

the developer vessel (accessory) on the rail. Put

the cleaning carrier vessel and magnet (both

accessories) in the developer vessel.

Cleaning

carrier vessel

Cleaning

carrier magnet

Vessel rail

Developer vessel

1-11

Page 17

Copier Installation 1 July 1994

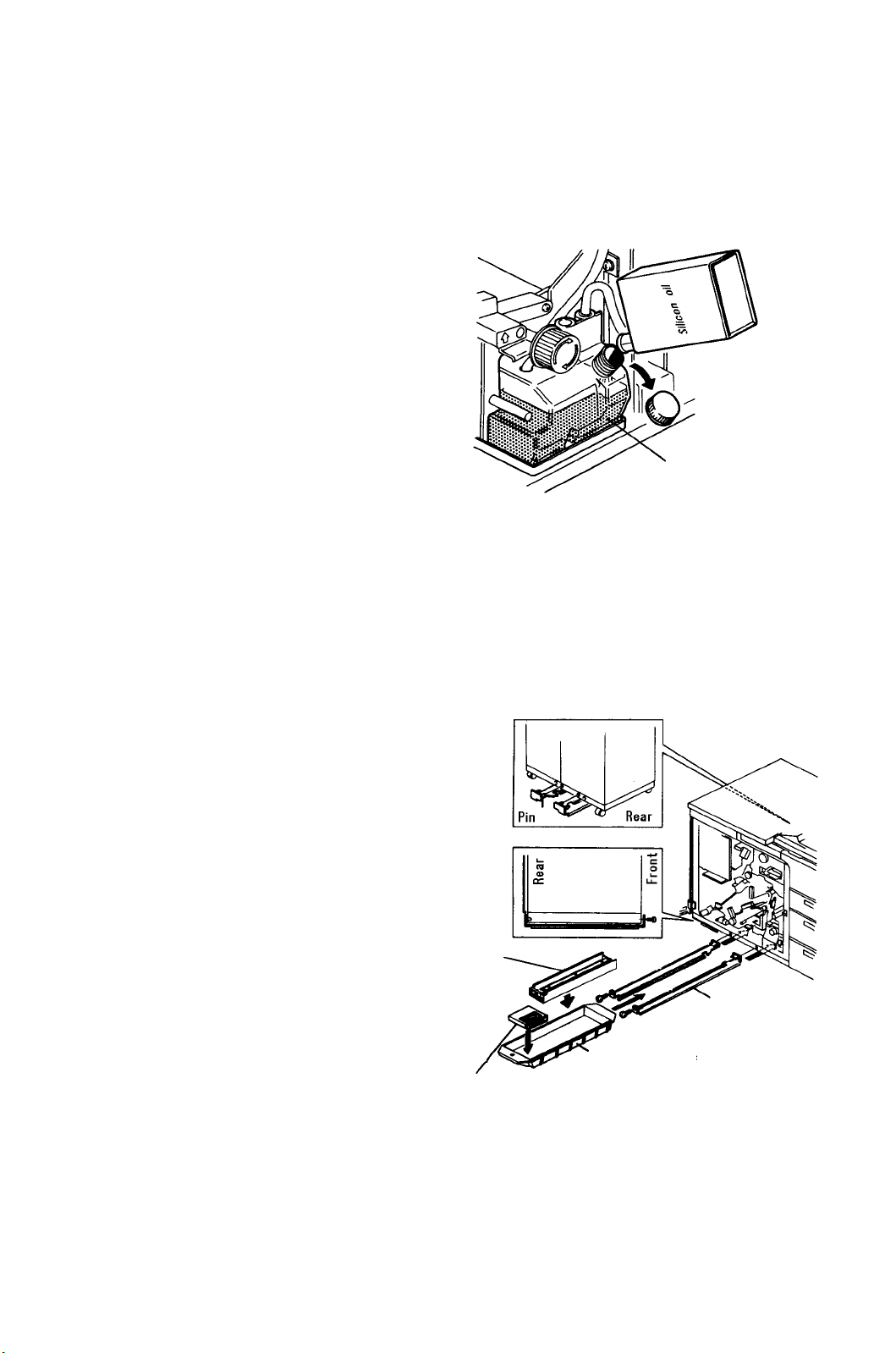

European version machine only (Steps 23 to 27)

CAUTION

The power supply cord and plug for the

European version machine must meet the

following requirements:

•

The plug must be approved under the TÜV

safety standard and for a three-phase

power supply.

• The cord must be approved under the TÜV

safety standard and have five wires inside.

The cross-sectional area of each wire must

be 2.5 mm

cord must be 14 to 18 mm. (The capacity

must be over 600 volts and 16 A for each

phase.) The length must be 5 m or less

even if an extension cord is used.

2

, and the outside diameter of the

Remove the rear left cover (2 screw).

23.

Remove the power supply cord bracket (2 screws).

24.

Then, pass the power supp ly cord t hro ug h th e co rd

bushing.

Connect the five wires of the power supply cord to

25.

the appropriate terminals as shown.

CAUTION

• Secure each wire to the terminals firmly

with screws.

• The grounding wire is green and yellow.

Reinstall the power supply cord bracket. Then,

26.

tighten the nut to secure the bushing with the cord.

CAUTION

Be sure that the cord bu shin g se cures the cord

firmly.

Install a plug on the other end of the power supply

27.

cord.

CAUTION

• Connect five wires to each of the terminals

’L1’, ’L2’, ’L3’, ’N’, and "Grounding" in the

same order as on the machine.

•

Secure each wire to the plug firmly with

screws.

The machine is set up for a 400 volts 3-phase

power supply (Eu ropean version) or 240 vo lts

single phase powe r supply (U.S.A. ver sion) at

the production li ne. To install the machine in

areas where the power supply is 380 or 415 volts

(220 or 230 volts single phase), follow the steps

below:

Loose the screw and disconnect the wire from the

28.

400 volts (or 240 volts) terminal.

Connect the wire to an appropriate terminal and

29.

tighten the screw. The terminal to be connected

depends on the power supply from the wall outlet.

CAUTION

The 200 volts terminal ne ver be used. The copier

requires 380 volts (or 220 v olts sin gle pha se) at

least.

Cord fixing nut

220 or

380V

230 or

400V

240 or

415V

Cord bushing

Power supply cord bracket

1-12

Page 18

1 July 1994 Copier Installation

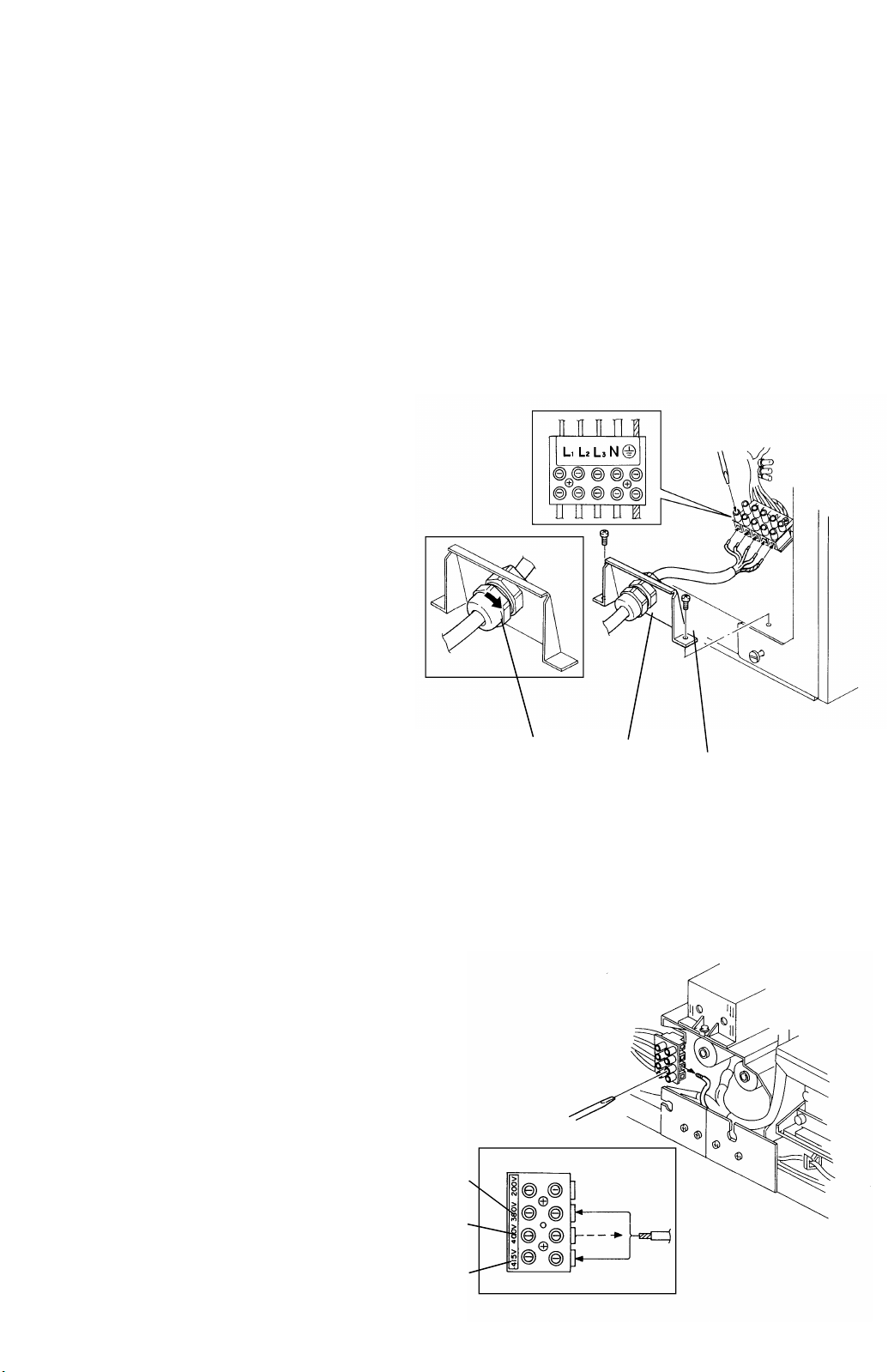

Remove the rear right cover (2 screws).

30.

Be sure that the proper connector of the harness

31.

from the timer board is set. The color of each

connector means the following:

Black: for 380 or 220V power su pp ly

Red: for 400 or 230V power supp ly

Red

connector

Black

connector

Timer board

transformer

Yellow: for 415 or 240V power su pp ly

If the connector setting does not meet the power

32.

supply, connect an appropriate connector.

Yellow

connector

Set the leveling shoes (accessories) to level the

33.

machine.

STANDARD

Difference, front to rear Within 5 mm

Difference, left to right Within 5 mm

Screws securing

upper left cover

CAUTION

Using a level gauge, level the machine flat on

Original stacker

the floor. This is mainly to pre vent affectin g the

tracking operation of the OPC belt.

Install the exterior covers.

34.

NOTE

Do not install the exterior covers at this stage if the

finisher or LCT is to be installed.

Fit the original stacker (accessory) and sub-tray

35.

(must be ordered separately if necessary). To fit

the original stacker, use screws which secu red the

upper left cove (M4 x 12 plated screw).

Put the original back fence (accessory) on the

36.

original stacker.

NOTE

The sub-tray i s no t req uired if the fi nish er is u sed.

It is installed i n the LCT if the LC T is us ed and the

finisher is not.

Sub-tray

Leveling shoe

1-13

Page 19

Copier Installation 1 July 1994

When inch size originals are used, make a slot as

37.

shown to stop the original stopper at the 8

1/2

inch

position.

CAUTION

When the slot is made, opera ting cautions must

be instructed to operators, so that operators

can adjust the original stopper position

correctly according to the original size set in the

ADF. The A4 position and 8

1/2

inch position are

very close. If the o riginal stopp er position is not

proper, original misfeeds will occur.

Set the toner cartridge.

38.

CAUTION

Shake the toner cartridge well be fore you s et it.

Set paper in each paper tray.

39.

CAUTION

Original stopper

Do not block the fan filter windows of the left

and rear exterior covers.

1-14

Page 20

1 July 1994 Machine Operation Check

1.3 Machine Operation Check

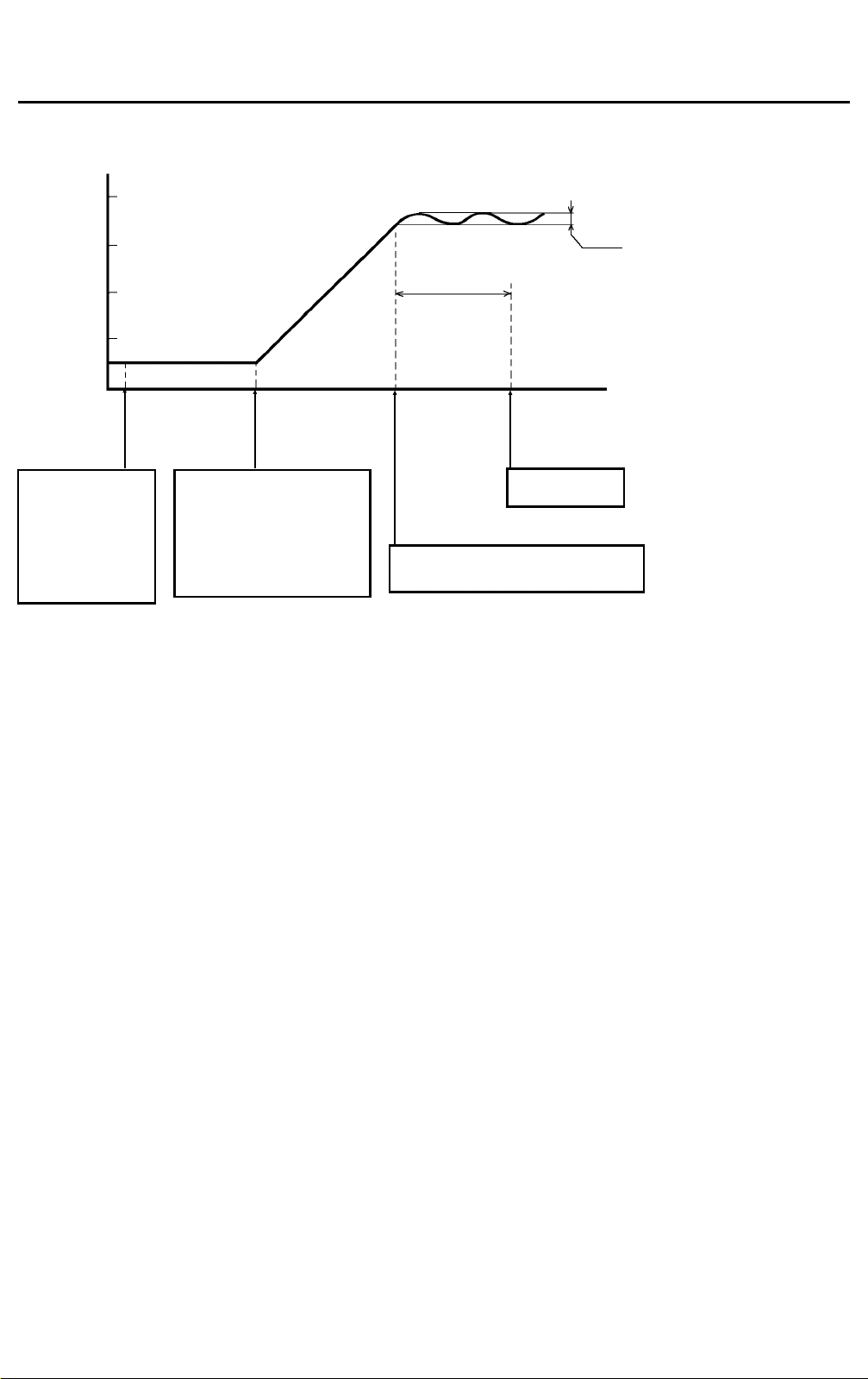

1.3.1 Stand-by operation check

200

Fusing Temp.

[° C]

100

Power

connection

The cleaning coil

cooling fan, two

ozone exhaust fans

(behind the rear left

cover), and

cleaning unit

cooling fan (behind

the left cover) start

turning.

Main switch

ON

1. Configuring the first and

second mirrors.

2. The fusing heater ON.

3. The OPC belt ON (2 turns).

4. The Tracking motor ON .

5. All the fans ON except for

the duplex and ADF blowers.

1.3.2 Copier operation check

CAUTION

175 ° C

175 to 180 ° C

Approx.

30 sec.

The Start key

turns green.

The idling mode starts (30 seconds).

The main motor repeats turning on and

off four times during this period.

Before making copies, carry out forming for the developer, OPC belt, and cleaning

carrier (in this order) using service tool [3-04].

1.

Check the stand-by operation referring the above. Connect the power plug, then turn on the

main switch.

2. Access the service tool, and do all formings.

3. Check that all the keys on the operation panel and paper tray down keys work properly.

4. Check that safety switches of the center door, upper right door, and copy tray work properly.

5. Place a sheet on the original table of the ADF and check that the ADF mode is selected.

Also, insert a sheet in the SADF table and check that the SADF mode is selected.

1-15

Page 21

Machine Operation Check 1 July 1994

1.3.3 Copy quality check

CAUTION

Before checking copy image quality, check the toner density control data in the

service tool [4-02] screen. Perform setting C if the data is not correct. Also, check the

AID reference voltage in the [4-03] screen using the PC-1 chart. Perform setting A if

the value is not correct. (If the AID reference voltage is within the standard, you do

not have to perform setting A.)

1.

To check the copy image quality and paper transportation in the copier, make some copies

in the platen cover (no ADF and SADF) and AID (Auto Image Density) modes using a test

chart.

2. Follow the steps below to complete the image quality adjustment. (Refer to the following

page for the standards.)

1) Position a test chart on the exposure glass. Make copies to check the side-to-side registration.

Adjust it by changing the paper tray position, if necessary. Repeat this step for all paper trays.

2) Select the paper tray which has the largest paper size.

3) Access the service tool and select the [5-02] screen. Check and adjust all items in that screen.

4) Leave the service tool, and select the paper tray which has another paper size.

5) Again, check and adjust the erase margin and duplex side fences width on the [5-02] screen.

Repeat this step for each paper size which will be used by the customer.

6) To check and adjust the side-to-side registration of the back side of the copy, make copies

in the duplex mode.

7) Remove the test chart from the exposure glass and insert an original in the SADF. Make

copies to check and adjust the leading edge and side-to-side registration in the SADF mode.

8) Place some originals in the ADF. Make copies to check and adjust the side-to-side registration

in the ADF mode.

CAUTION

a) The side-to-side registration must be checked for all paper trays.

b) The erase margin and duplex side fence width must be checked for all paper sizes.

c) If the erase margin is not sufficient, thin black lines may sometimes appear on

copies (especially on the side edges of copies in the ADF mode). This is because the

side-to-side registration varies slightly on each copy if an operator does not set the

original side guides securely. You have to make more than 10 copies and check that

all of them are within specifications after the adjustment.

d) Check the side-to-side registration of the back side of the copy in the duplex mode

before installing the peripherals. If the value is outside specifications, you have to

remove the copier right cover.

3.

Put about 20 originals on the ADF and make one set of copies in the single original duplex

mode. Repeat this procedure for all paper trays.

4. Put about 100 originals on the ADF and make one set of copies in the 2-sided original du-

plex mode.

5. Insert an original in SADF and check that copying is normal.

6. If peripherals are installed, check that they works properly.

1-16

Page 22

1 July 1994 Table of Image Quality Standards

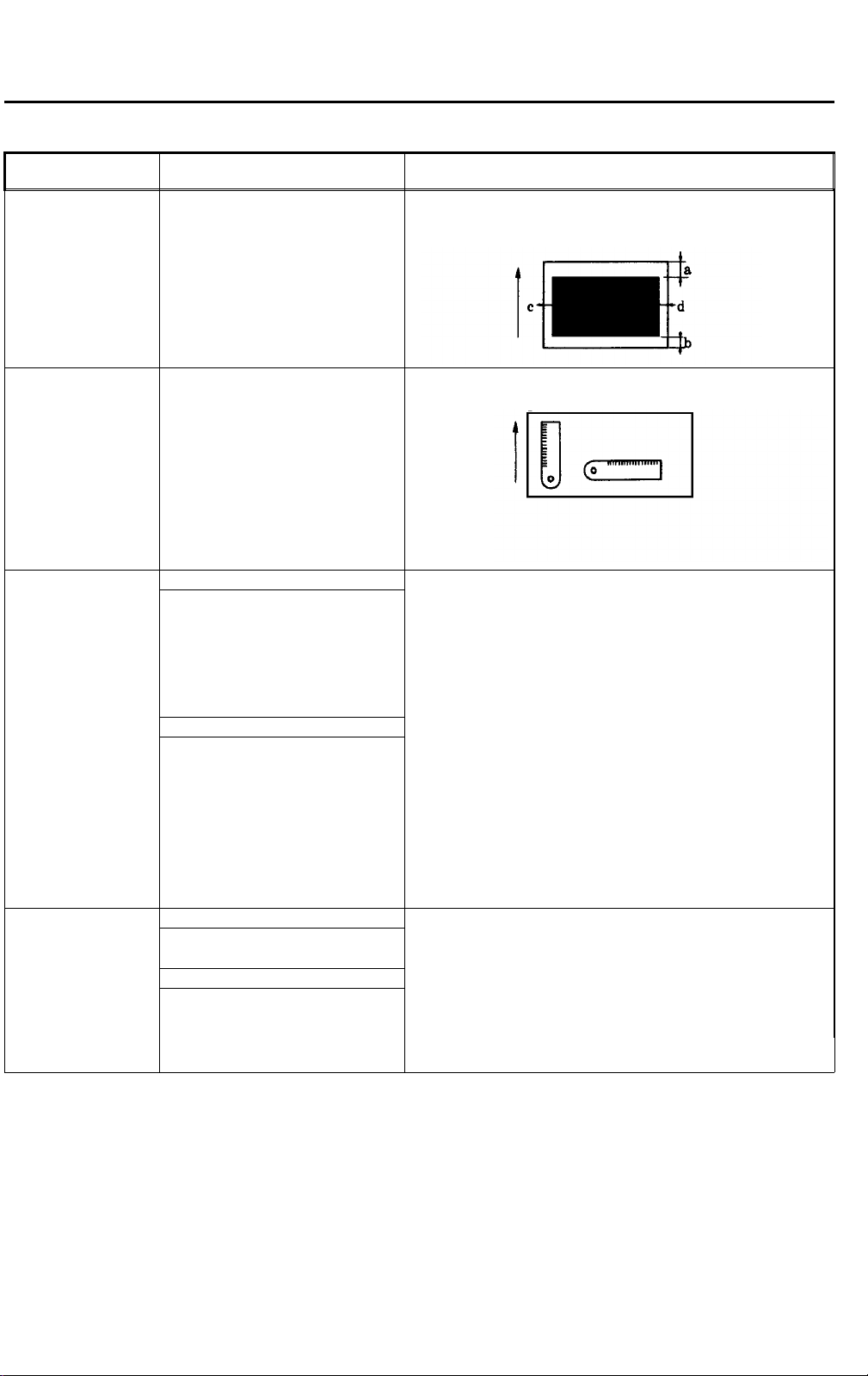

1.4 Table of Image Quality Standards

Item Standard Measuring Method

Erase margin a) Leading edge 1

b) Trailing edge 1

c) Left side edge 1

d) Right side edge 1

< c+d ≤ 7 mm

2

≤a≤7 mm

≤b≤5 mm

≤c≤5 mm

≤d≤5 mm

Make one solid black copy and measure blank dimensions at four

edges. After the adjustment, make more than 10 copies and check

the variation.

Error in magnification In full size mode: Within

In magnification mode: Within

Registration Platen cover mode

a) Leading edge: 0

b) Left and right edges: 0

These values also valid on the 2-sided

copy.

ADF/SADF mode

a) Leading edge:

--3 to +5 mm (ADF mode)

--4 to +6 mm (SADF mode)

b) Left and right edges: 0

The difference of the side-to-side

registration between the front and

back side must be within 5 mm.

± 2 mm

± 0.5%

± 2 mm

± 5 mm

Copy a scale and measure copy dimensions.

±1.0%

Copy a test chart and compare the image position difference

between the original and the copy. After the adjustment, make more

than 10 copies and check the variation.

Skew Platen cover mode Copy a test chart and compare the image position difference

± 1 mm/200 mm or less. between the original and the copy.

a)

ADF/SADF mode

± 1.5 mm/100 mm or less (on

a)

smaller than A4/Letter paper).

± 1 mm/100 mm or less (on

b)

A4/Letter or larger paper).

1-17

Page 23

User Guidance Items 1 July 1994

1.5 User Guidance Items

This section contains important information regarding efficient operation of the machine.

1.5.1 Guidance items prior to the installation

Items requiring user approval after explanation. This has to be done before machine installation.

Paper to use

1. We recommend using neutral paper as copy paper to prevent abnormal images. Some acid

papers contain talc, and this white powder will appear on the OPC surface as spots. This

causes abnormal copies, which have dirty spots on the background.

2. We recommend using lengthwise grain in all cases to prevent creased copies.

How the original influences copy images

1. In patched originals, shadows around the patched part appear on copies as black lines.

2. In OHP originals, drawn pictures and characters are copied double.

Smoothing original curls

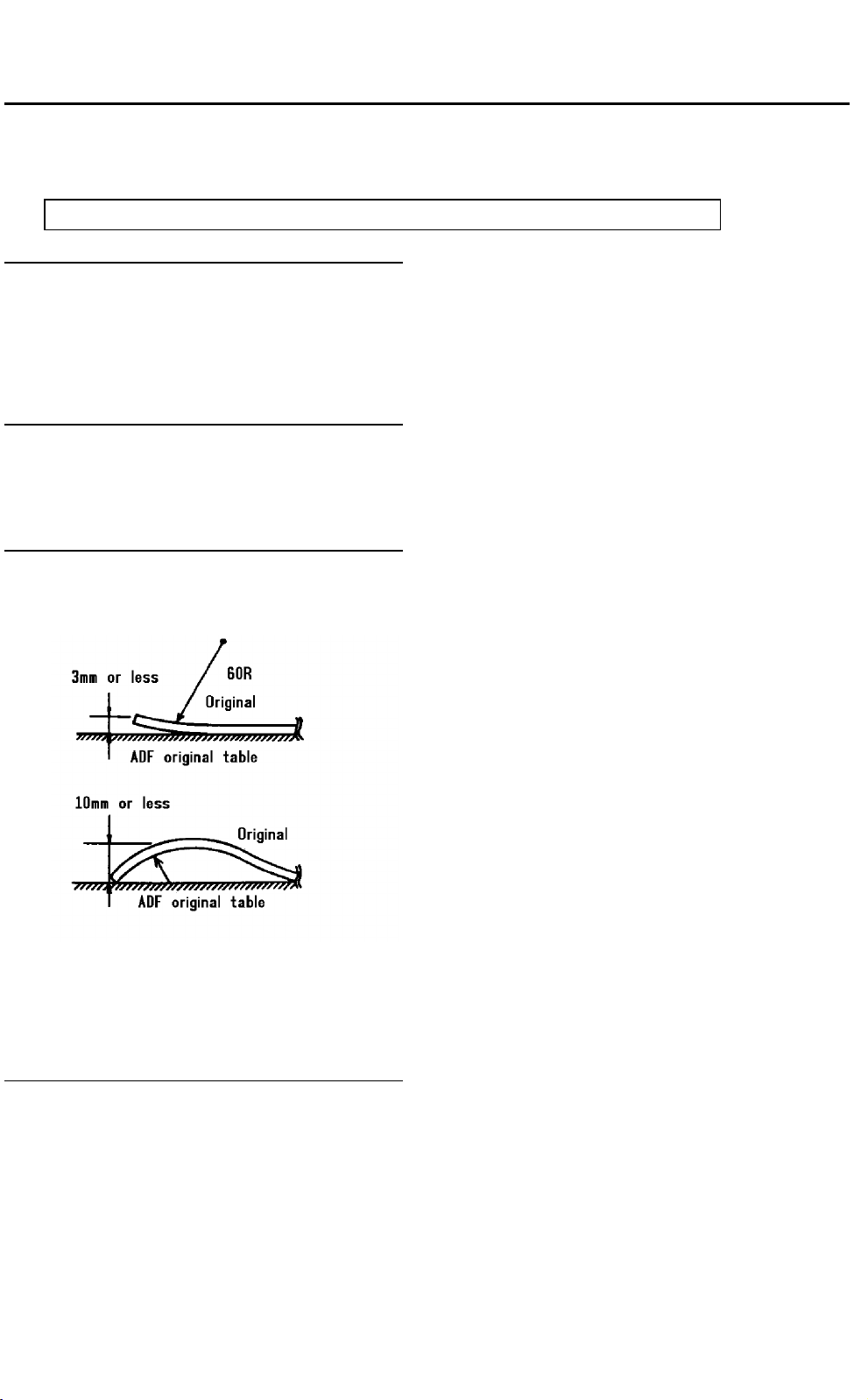

To avoid transport trouble, advise users to correct large curls before setting the original. Refer to

the illustrations and information given below.

Face curl (3 mm or less)

No curl is acceptable for thick

originals of 65 g/m

Back curl (10 mm or less)

1.

The original cannot be transported if it curls (face curl).

2

or heavier.

2. The original cannot be transported if it curls down (back curl) 10 mm or more.

Original to use

There are some types of paper that should not to be used as originals with the ADF. The following

are some examples:

1. Dog-eared, torn, or creased paper

2. Coated paper (carbon paper, thermal paper, etc.)

3. Curled paper

4. Originals that are glued or taped

1-18

Page 24

1 July 1994 User Guidance Items

5. Translucent paper (including OHP)

NOTE

The above types of paper may be used as an

original in the SADF mode.

6. Damp paper

7. Bound originals

8. Paper that is thicker or thinner than specified for this machine

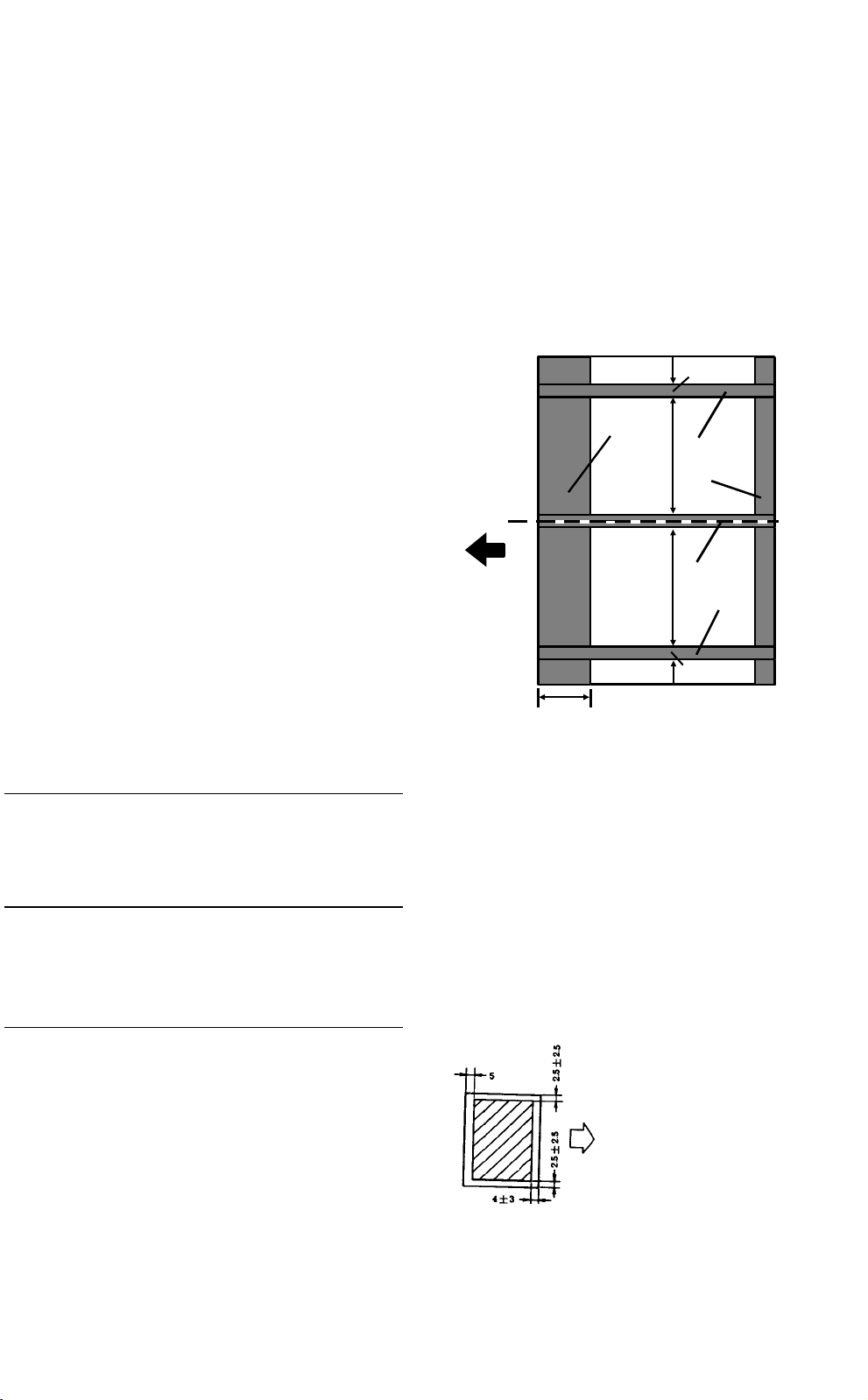

Originals that have holes as shown cannot be used in

the ADF mode.

A: No holes are allowed on the leading

edge. (To prevent multifeeding.)

B: No holes are allowed in these areas.

(The recycle arm may be caught in the

holes.)

C: Holes larger than 6 mm in diameter are

not allowed on the trailing edge.

D: Holes larger than 10 mm in diameter are

not allowed in the center. (To prevent sensor’s misdetection.) This type of paper cannot be used in the SADF mode either.

[Leading edge]

[Leading edge]

A

100 mm

100 mm

10 mm

B

C

D

B

10 mm

50 mm

Paper replenishment

When the 2nd or 3rd paper tray runs out of paper and the indication Add paper lights in red, this

means there are still about 50 sheets of paper left in the tray.

Fusing oil

The pick-off pawls of the fusing unit sometimes make slight oil marks on the leading edge of copies .

Copy image area

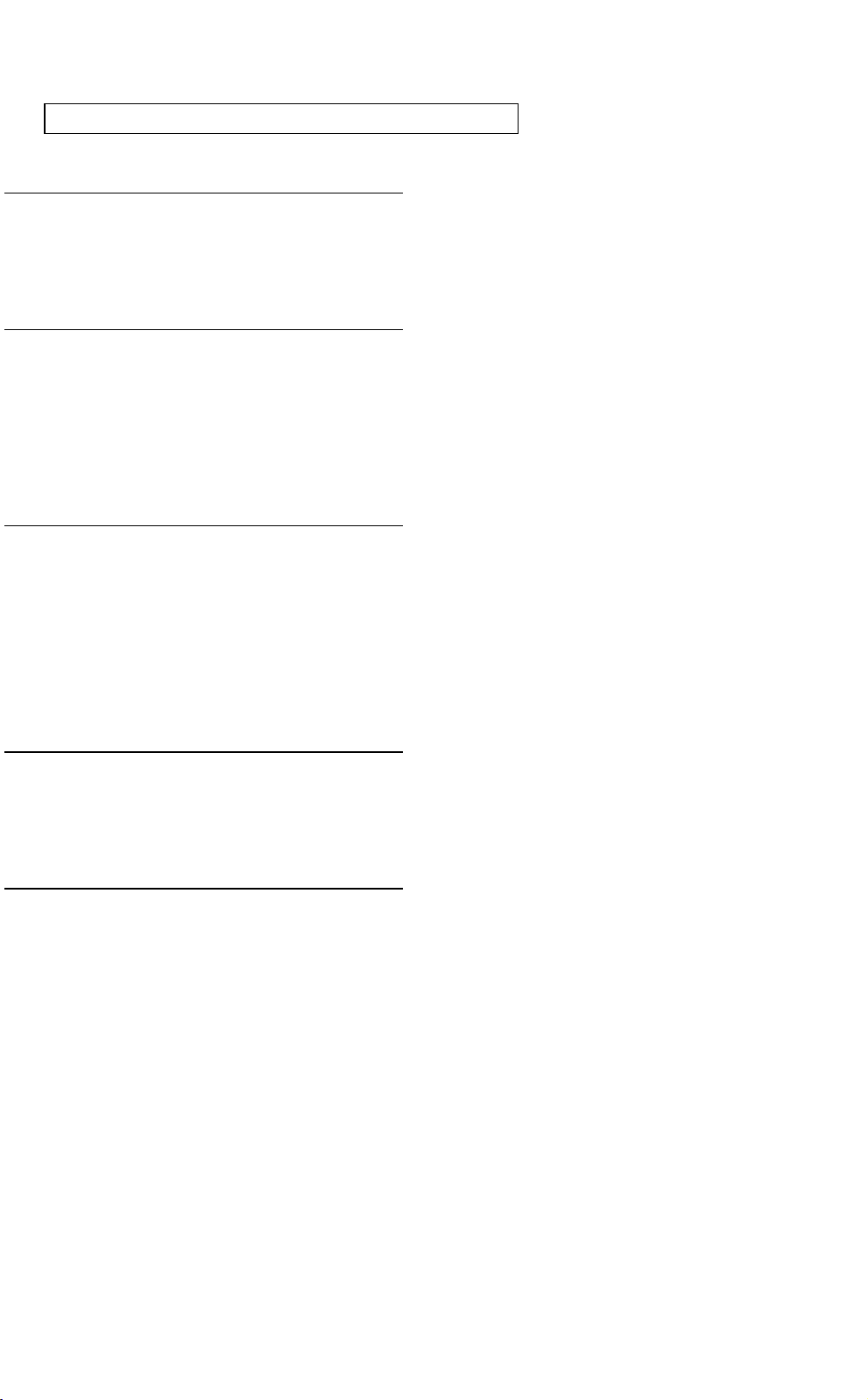

1. The blank range is provided as shown to prevent

original shadows on copies.

2. Damp copy paper will have an 8 mm blank margin

(or less) at the trailing edge of the front side, and if

duplex copying, the back side will have a blank

margin of 10 mm (or less) at the trailing edge.

Total of left and right

should be 7 mm or

less.

1-19

Page 25

User Guidance Items 1 July 1994

1.5.2 Additional guidance items

Explain the following if the user is unfamiliar with the subject items.

Stacking duplex copies

When a large number of duplex copies (100 copies or more) are produced, we recommend using

the finisher so they are stacked in the shift tray because toner from the stacked copies on the copier’s copy tray may be deposited by heat.

How the main switch is used

The ozone exhaust fans and transport vacuum fan continue to operate when the main switch is

OFF to discharge air from the machine. This prevents image deterioration on the OPC caused by

fumes, which is produced by the corona discharge. Also, heaters turn on when the main switch is

OFF and prevent condensation on the mirror and lens and damp paper in trays. Advise users never

to pull out the power plug or shut off power from the source. Tell them to use the main switch to

power off.

Toner cartridge replacement

Used toner is collected in the toner cartridge and is never used again because it cannot be used for

copying. Direct users about the following points.

1. Never pull the shutter again after the cartridge is set. If the shutter is pulled, the collected

toner is used again.

2. Firmly pull the vinyl sheet on the shutter when installing a new cartridge. If not, only about

half the amount of toner in the cartridge will fall to the development unit. This may cause a

used toner blockage on the way from the cleaning unit.

Loading paper

When loading paper in the paper trays, do not exceed the load limit. It is indicated by a decal. If paper is excessively loaded, the top of the paper stack may hit the pick-up roller and damage it when

the paper tray is set.

Loading original

When loading paper on the original table of the ADF, keep the maximum capacity (40 sheets for A3

or 11" x 17" original and 80 sheets for the other sizes original). The load limit is indicated by a decal. If originals are excessively set in the ADF, original misfeeding or multifeeding may occur because of the original separation system. The air knife cannot separate the originals when weight of

the original stack is too heavy.

1-20

Page 26

1 July 1994 Setting User and Service Tools

1.6 Setting User and Service Tools

Explain all user tool items and some of the service tools to the customer. Then, listen to the customer’s requests and set the copier accordingly.

Keep the set items using the following format. (If the main control board is replaced, you can set all

items again using the format.)

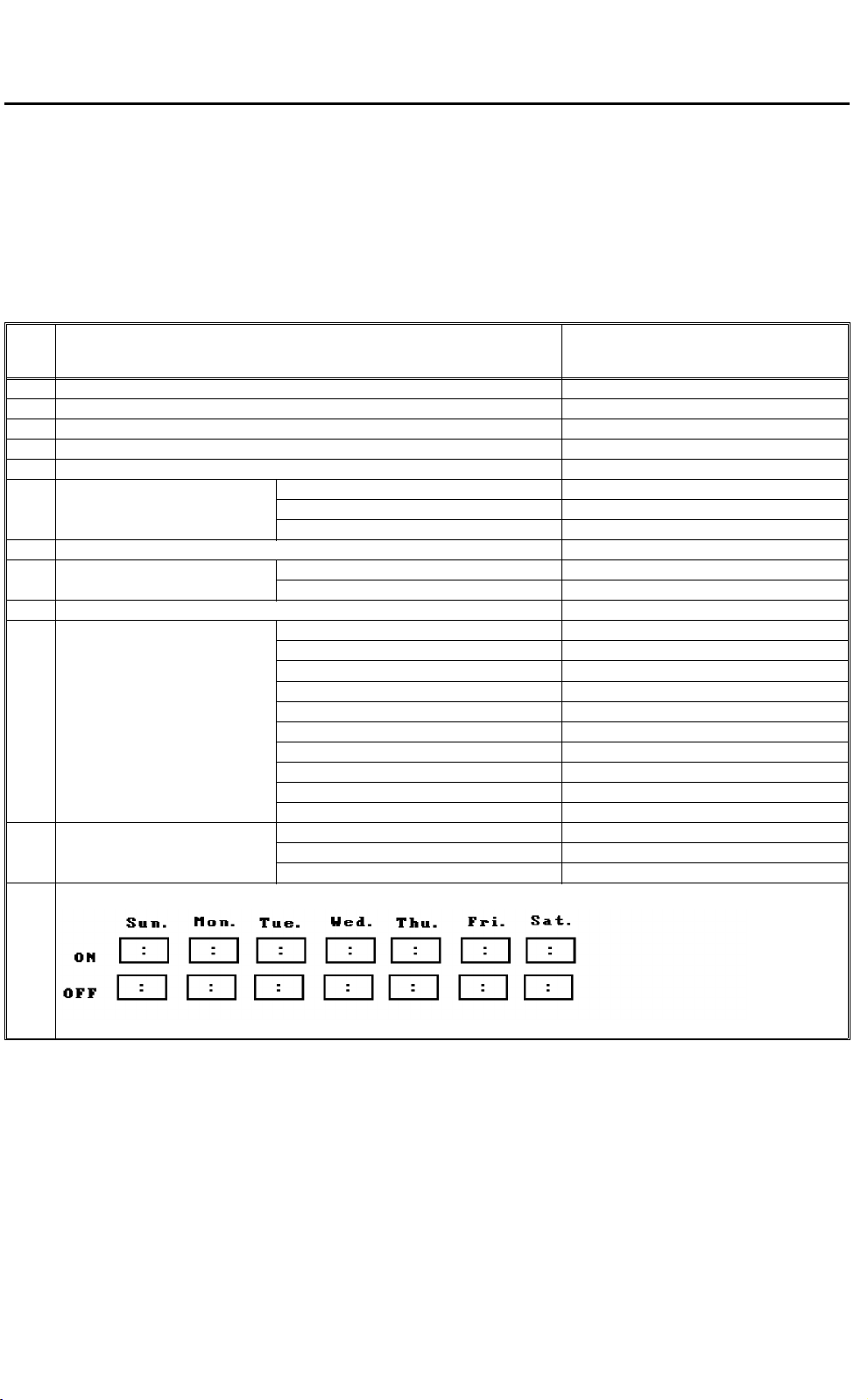

1.6.1 User tools

* Bold letters in "Set Data" shows the initial setting.

Menu

no.

1 Total sheets copied ---2 Auto image density level selection [Lighter] [Normal] [Darker]

3 Copy/Original size selection [A3] [11 x 17] [A4] [8

4 Segment skip ---5 Date/Time setting ---6 Disable display Margin adjustment [ON] [OFF]

7 Disable units ---8 Select special tray Cover [Tray 1]

9 User access code ----

10 User Utility Select the finisher mode [Sort] [Stack]

11 Set staple position 1 staple upper 0 to 20 [ ] 10

12 Weekly timer

Description Set Data

Duplex [ON] [OFF]

Magnification [ON] [OFF]

Slip sheet [Tray 1] [Tray 2] [Tray 3]

Staple in stack mode [Yes] [No]

Auto tray switching [Yes] [No]

3-side full image copy [Yes] [No]

Select count up or down mode [Up] [Down]

Display the number of originals [Yes] [No]

Exit originals to tray [Yes] [No]

Select face up/down in stack mode [Face up] [Face down]

Reverse back cover sheet [Yes] [No]

Copy onto slip sheets [Yes] [No]

1 staple lower 0 to 20 [ ] 10

2 staples 0 to 20 [ ] 10

ON: 00:00, OFF: 23:59

1/2 x 13]

1-21

Page 27

Setting User and Service Tools 1 July 1994

1.6.2 Service tools

* Bold letters in "Set Data" shows the initial setting.

Menu no. Description Set Data

1-01 Key operator access code 000 to 099 [ ] 000

1-02 Service access code 99900 to 99999 [ ] 99900

1-03 Service telephone number [ ]

1-04 Disable display Full size indicator: [OFF] [ON]

Tray keys in APS mode: [OFF] [ON]

Density keys in AID mode: [OFF] [ON]

1-05 Weekly timer This function can be set with user tool no. 12.

1-06 Toner supply amount [15%] [30%] [45%] [60%]

1-07 Charge wire cleaning [YES] [NO]

1-08 Option installation [Tray 4] [Finisher] [Key Counter]

2-01 Count up/down [UP] [DOWN]

2-02 Set user program number 0 to 10 [ ] 10

2-03 Set fixed reproduction ratios See the table below.

2-04 Delete fixed reproduction ratios No delete

[Initial Data]

[Set Data]

2-05 Set back side margin 0 to 21 mm in left or right.

2-06 Maximum copy number 1 to 9999 [ ] 9999

2-07 Staple copy limit 1 to 50 [ ] 50

2-08 Free/user access code operation [Free use][Access code] [Access code/super user mode]

2-09 3-side full image [YES] [NO]

2-10 Auto tray switching [YES] [NO]

2-11 Original count display [YES] [NO]

2-12 Set special paper tray [NO] [Tray 1] [Tray 2] [Tray 3] [Tray 4]

2-13 Auto reset , auto off Auto reset: [5 sec.] [1 min.] [3 min.] [

2-14 Key tone Loudness: [OFF] [Low] [Normal] [High]

2-15 Set exit tray copy limit [300] [350] [400] [NO]

2-16 Set initial display Display type selection: [Key operator] [Operator]

[ ] mm [Left] [Right] 5 mm Right

∞ ]

Auto off: [30 min.] [1 hr.] [3 hr.] [

Tone pitch: [1] [2] [3] [4] [5]

Auto tray selection: [YES] [NO]

Tray selection priority: [APS] [Tray 1] [Tray 2] [Tray 3] [Tray 4]

Image density level selection:

[AID]

Density levels [1] [2] [3] [4] [5] [6] [7]

Finishing: [No Staple] [1 upper] [1 lower] [2]

∞ ]

1-22

Page 28

1 July 1994 Setting User and Service Tools

Menu no. Description Set Data

2-16 Set initial display Margin adjustment mode selection:

4-01 Process control Grid: [ ] step

4-02 Toner density control Target toner density: [ ] volts

4-04 OPC cleaning operation [OFF] [5K] [10K] [20K] 10K

4-05 Utility Mode no. 1 (0 to 15): [ ] 0

[No]

Front side:

0 to 21 mm in left or right

[ ] mm [Left] [Right] 0 mm

Back side:

0 to 21 mm in left or right

[ ] mm [Left] [Right] 5 mm Right

Duplex mode selection:

[No]

⇒ Duplex mode]

[Single

⇒ Duplex mode]

[Duplex

⇒ Single mode]

[Duplex

Reproduction mode selection:

[Full-size]

Fixed reproduction [ ] %

Zoom reproduction [ ] %

Auto paper selection [A3] [B4] [A4] [B5]

Copies number setting: 1 t0 9999 [ ] 1

Flash: [ ] step

Bias: [ ] step

Pcc: [ ] step

VD: [ ] volts

VL: [ ] volts

VPCC: [ ] volts

ID pattern level: [1] [2] [3] [4]

Mode no. 2 (0 to 15): [ ] 10

Mode no. 3 (0 to 15): [ ] 0

Mode no. 4 (0 to 15): [ ] 0

Mode no. 5 (0 to 15): [ ] 0

Mode no. 6 (ON or OFF): [ ] OFF

Mode no. 7 (ON or OFF): [ ] ON-8, 10

Mode no. 8 (ON or OFF): [ ] ON-10

Mode no. 9 (ON or OFF): [ ] OFF

Mode no. 10 (ON or OFF): [ ] ON-9

Mode no. 11 (ON or OFF): [ ] OFF

Mode no. 12 (ON or OFF): [ ] OFF

Mode no. 13 (ON or OFF): [ ] OFF

Mode no. 14 (ON or OFF): [ ] OFF

NOTE: When mode no. 5 is set at 8 to 15, modes no. 6 to 14 have

different functions. So, describe the set number of mode no. 5 with

"ON" when filling in the set data of modes no. 6 to 14. For example, if

mode no. 6 is turned ON while mode no. 5 is set at 8, describe the set

data of mode no. 6 as "ON-8".

5-02 Copy image Lead/trail edge erase: Lead [ ] mm, Trail [ ] mm

Side edge erase: Front [ ] mm, Rear [ ]mm

Lead edge registration: [ ] mm

Reproduction: [ ] %

Duplex side fences width: [ ] mm

5-03 Fusing temperature 0 to 15 [ ] 8 or 9

5-07 Set staple position This function can be set with user tool no 11.

1-23

Page 29

Fusing

High

Voltage

Drive

Optics

Imaging

Process

Paper Feed

Du-

plex

Control

Develop-

ment

Logging Data Sheet 1 July 1994

1.7 Logging Data Sheet

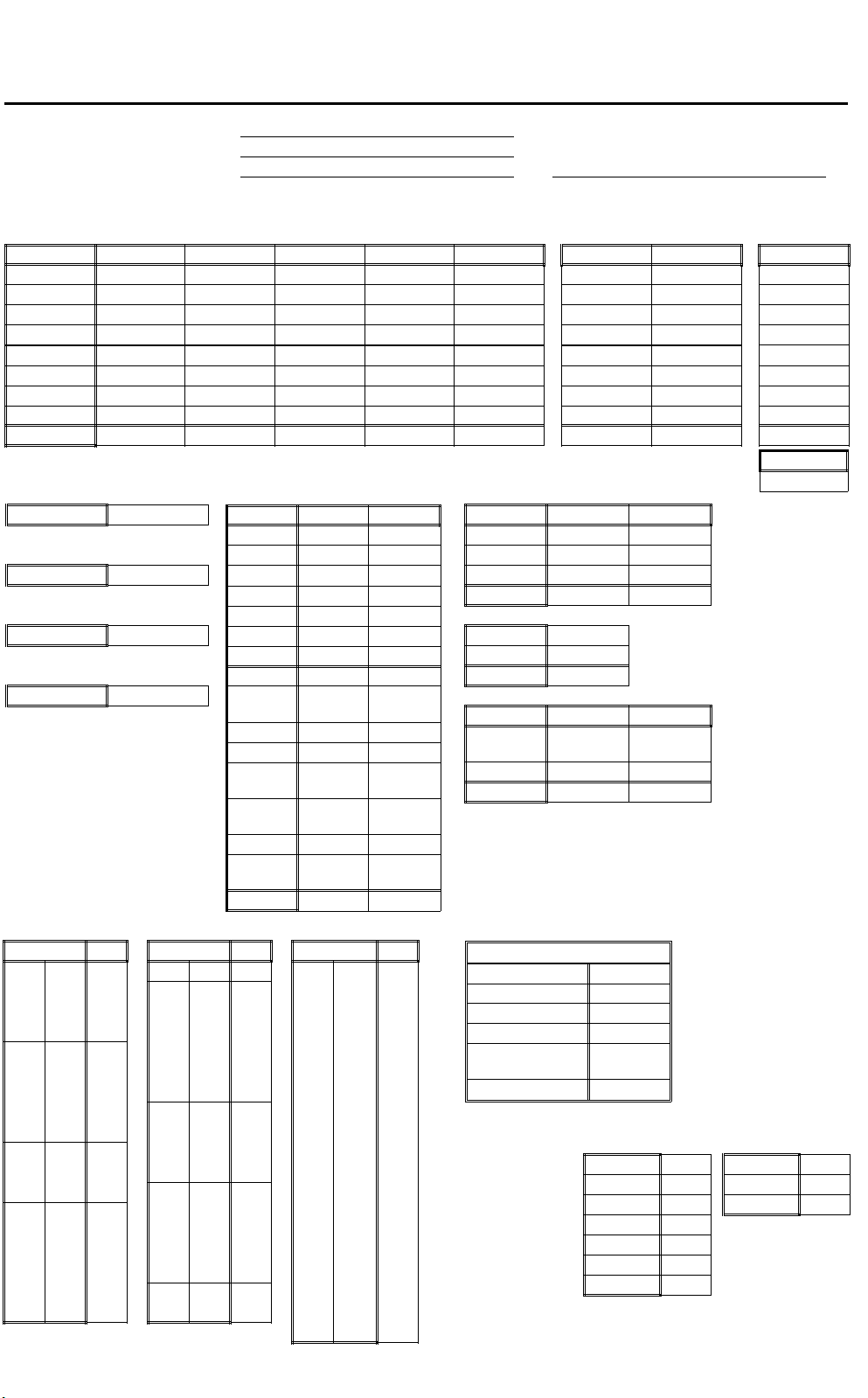

[3-01] Tray Copies

Size Tray 1 Tray 2 Tray 3 Tray 4 Total Duplex Finisher RDH

A3 -------B4

A4

B5

Sub Total --------

11 x 17 --------

1/2 x 14

8

1/2 x 11

8

Total

[3-04] Supply yield

OPC

Developer

CL Carrier

Staple 1

[3-07] Service Calls

Code Code Code

1 36 80

2 40 81

3 41 82

4 42 83

10 43 84

11 44 85

12 45 86

13 50 87

17 51 88

20 52 89

22 55 90

23 60 91

30 61 93

31 62 94

32 63 95

33 64 96

34 70 97

35 71 98

Date:

Customer:

Serial No. Copy Counter:

[3-02]

Duplex/Finishing Copies

[3-05] Copier Misfeeds

Location ON OFF

Tray 1

Tray 2

Tray 3

Tray 4

Regist

Pick-off

Fusing

Sub Total

Duplex

gate

Exit gate

Exit tray

Horz.

Trans 1

Horz.

Trans 2

LCT Top

Duplex

Feed

Total

99

[3-06] RDH/Finisher Misfeeds

Location ON OFF

RDH Feed

RDH Trans

RDH Exit

Total

SADF Feed

SADF Exit

Total

Location ON OFF

Inverter

Unit

Finisher

Total

[3-08] Operation Time

Hours

Power ON

Fusing Lamp

Main Motor

OPC Belt Motor

Development

Motor

Wire Motor

Mark cleared item(s)

Developer

CL Carrier

[3-03]

Original Feeds

3-01 3-05

3-02 3-06

3-03 3-07

OPC

Staple 1

1-24

SADF

Page 30

1 July 1994 Logging Data Sheet

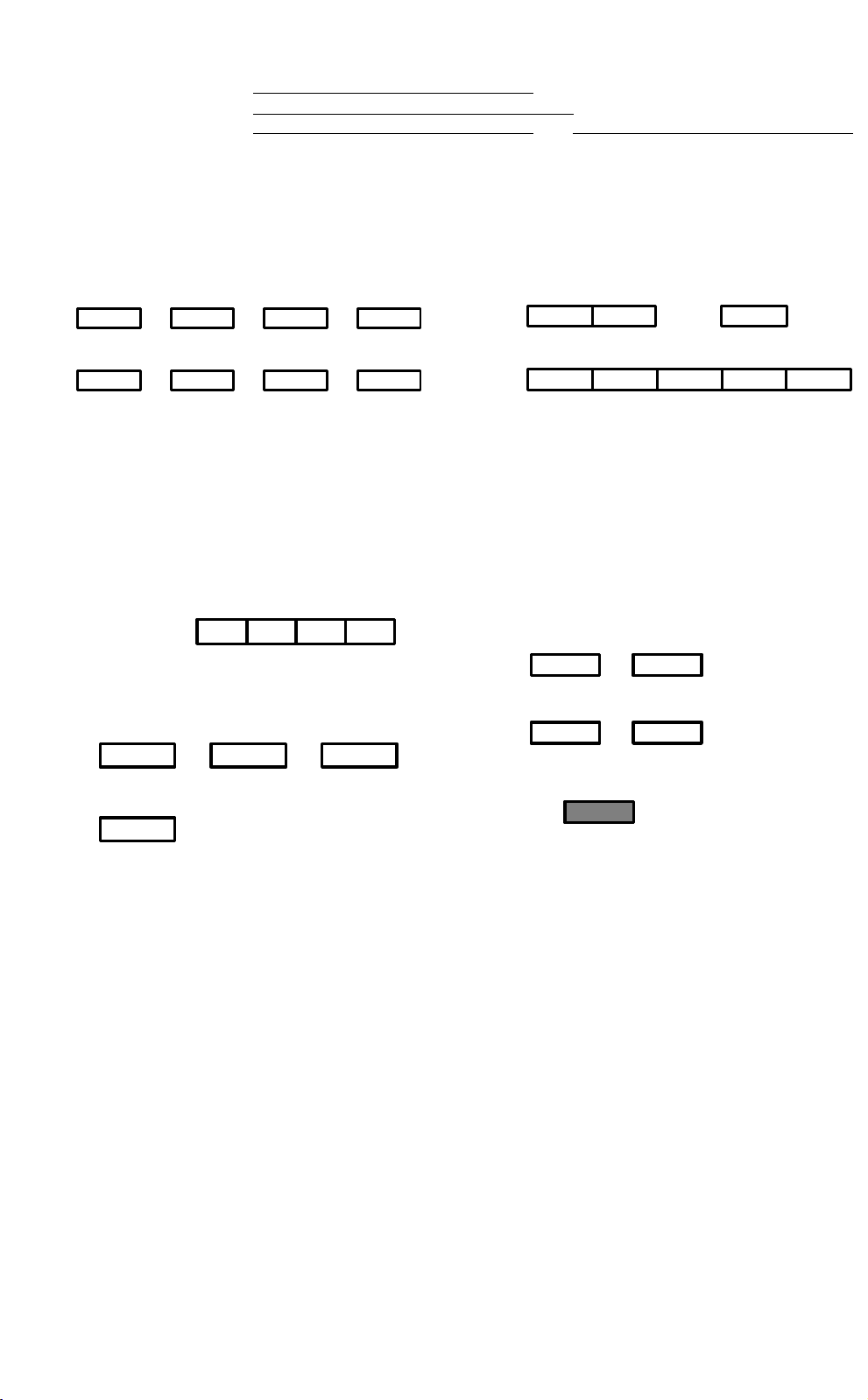

[4-01] Process Control

Setting

Grid

(step)

Shift

(step)

Flash

[4-02] Toner Density Control

Date:

Customer:

Serial No. Copy Counter:

Bias

PCC

Target

(volts)

Actual

(volts)

VD VL VR

VPCC

ID

Sensor

Actual

SG/VSP

V

ID Pattern Level

SP

V

(volts)

Lighter

1 2 3 4

V

SG

(volts)

Darker

T. D.

Sensor

Setting

Actual

Developer

Forming

Target T. D.

(volts)

ON

Pattern

Potential

(volts)

1-25

Page 31

Logging Data Sheet 1 July 1994

Logging Data Sheet (Misfeeds)

Item

Mark for data clear

Tray 1 ON

Tray 2 ON

Tray 3 ON

Tray 4 ON

Regist ON

Pick-off ON

Fusing ON

Sub total ON

Duplex

Gate

Exit

Gate

Exit Tray ON

Horz.

Trans. 1

Horz.

Trans. 2

LCT Top ON

Duplex

Feed

Total ON

RDH Feed ON

RDH Trans ON

RDH Exit ON

Total ON

SADF Feed

SADF Exit

Total

Inverter

Unit

Finisher ON

Total ON

Date

Counter

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

Customer

Serial No.

1-26

Page 32

1 July 1994 Logging Data Sheet

Logging Data Sheet (Service Calls)

Item

Mark for data clear

1

2

3

4

10

11

12

13

17

20

22

23

30

31

32

33

34

35

36

40

41

42

43

44

45

50

51

52

55

60

61

62

63

64

70

71

80

81

82

83

84

85

86

87

88

89

90

91

93

94

95

96

97

98

99

Date

Counter

Customer

Serial No.

1-27

Page 33

Tray 1

Tray 2

Tray 3

Tray 4

Duplex

Finisher

RDH

Logging Data Sheet 1 July 1994

Logging Data Sheet (Copies/Originals)

Item Date

Counter

Mark for data clear

A3

A4

B5

11" x 17"

1/2 x 14"

8"

1/2 x 11"

8"

Sub total

A3

A4

B5

11" x 17"

1/2 x 14"

8"

1/2 x 11"

8"

Sub total

A3

A4

B5

11" x 17"

1/2 x 14"

8"

1/2 x 11"

8"

Sub total

A4

B5

1/2 x 14"

8"

1/2 x 11"

8"

Sub total

Total

A3

B4

A4

B5

11" x 17"

1/2 x 14"

8"

1/2 x 11"

8"

Total

A3

B4

A5

B5

11" x 17"

1/2 x 14"

8"

1/2 x 11"

8"

Total

A3

B4

A4

B5

11" x 17"

1/2 x 14"

8"

1/2 x 11"

8"

Total

SADF

Customer

Serial No.

1-28

Page 34

Operation Time

Supply Yield

1 July 1994 Logging Data Sheet

Logging Data Sheet (Others)

Item Date

Counter

Power ON

Fusing Lamp

Main motor

OPC Belt motor

Development motor

Wire Cleaner Motor

OPC

Developer

Cleaning Carrier

Staple 1

[4-01] Process Control

Grid Setting (step)

Shift (step)

Flash Setting (step)

Shift (step)

Bias Setting (step)

Shift (step)

PCC Setting (step)

Shift (step)

VD Target (volts)

Actual (volts)

VL Target (volts)

Actual (volts)

VR Actual (volts))

VPCC Target (volts)

Actual (volts)

ID sensor Actual (volts)

[4-02] Toner Density Control

SP Actual (volts)

V

SG Actual (volts)

V

T.D. Sensor (volts)

SG/VSP

V

Target

T. D.

Pattern

Potential

Target (volts)

Actual (volts)

Target (volts)

Actual (volts)

Remarks

Customer

Serial No.

1-29

Page 35

1.8 LCT Installation

LCT Installation

1 July 1994

1.8.1 Accessories list

Name Diagram Quantity Use

Horizontal transport unit 1 This is the relay transport part between LCT

and the copier and is attached to the copier.

Rear side fence 1 Rear side fence for the tray when 11" x 8 1/2"

Lock lever assembly 1 Guide plate open/close lever to be attached

Knob assembly 1 Manual drive knob to be attached to the

Sub-tray auxiliary plate 1 Auxiliary stay when the sub-tray is fitted to

Docking pin 2 This is used for docking between LCT and

Zinc plated

Fixing stepped screw 2 Stud to install the sub-tray auxiliary plate.

Leveling shoe 4 For the docking position adjustment.

Wire saddle 2 For clamping the power harnesses of the

or 14" x 81/2" size paper (A4 size for the

U.S.A. version machine) is used. (Not

required if such paper is not used.)

to the horizontal transport unit.

horizontal transport unit.

LCT. (Not required when the finisher is used.)

the copier and is attached to the copier.

(Not required if the finisher is used.)

LCT and finisher to the exterior cover.

Pan head machine screw M4 x 6 6 For fixing the horizontal transport unit, lock

Grounding screw M4 x 8 1 For fixing the protective earth wire of the

Plated screw M4 x 6 2 For fixing the sub-tray auxiliary plate.

Upper cover stopper 1 To prevent fall of something placed on the

lever and knob.

power supply harness (The copier side).

LCT upper cover when the cover is opened.

NOTE:

When the optional finisher is not used, the

sub-tray (P/N-A0291460) must be ordered and

used with the LCT.

1-30

Page 36

1.8.2 Removing the clamps

1 July 1994

LCT Installation

1. Remove the strips of filament tape holding the

upper cover.

2. Open the upper cover, and remove the filament

tape and cushion.

Cushion

Filament tape

Filament tape

3. Remove the two screws so that the upper front

cover can slide up.

NOTE

The LCT upper front cover can be slid up to remove

the misfed paper at the paper feed section.

4. Remove the right cover and rear cover.

5. Remove the rear side fixing bracket (4 screws).

6. Remove the front fixing bracket (2 screws) from

the right side.

7. Pull out the tray, and remove the two screws so

you can remove the front fixing bracket.

8. Reinstall the exterior covers.

Back side of front cover

Front

Upper cover

Upper

front cover

Front fixing bracket

1-31

Front fixing bracket

set screw

Fixing bracket

Page 37

9. Pull out the paper feed tray, and remove the back

LCT Installation

1 July 1994

fence fixing cushion.

10. Remove the strips of filament tape from the table

bottom plate.

Cushion material

Filament tape

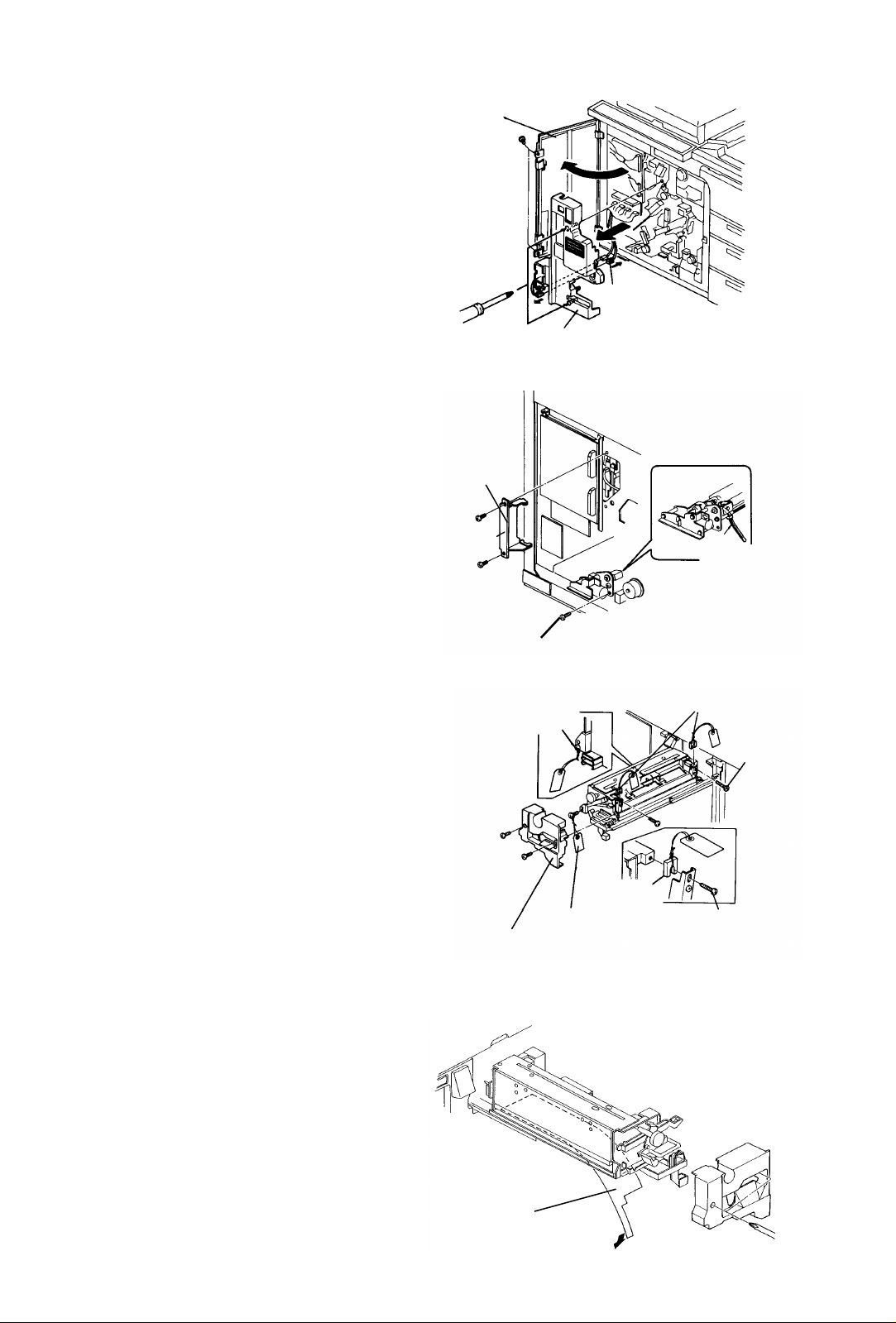

11. Take the horizontal transport unit out of the

accessory box, and remove the mylar protecting

cardboard and strips of filament tape.

Filament tape

Mylar protecting cardboard

Filament tape

Filament tape

1-32

Page 38

1.8.3 Setting up the LCT

1 July 1994

LCT Installation

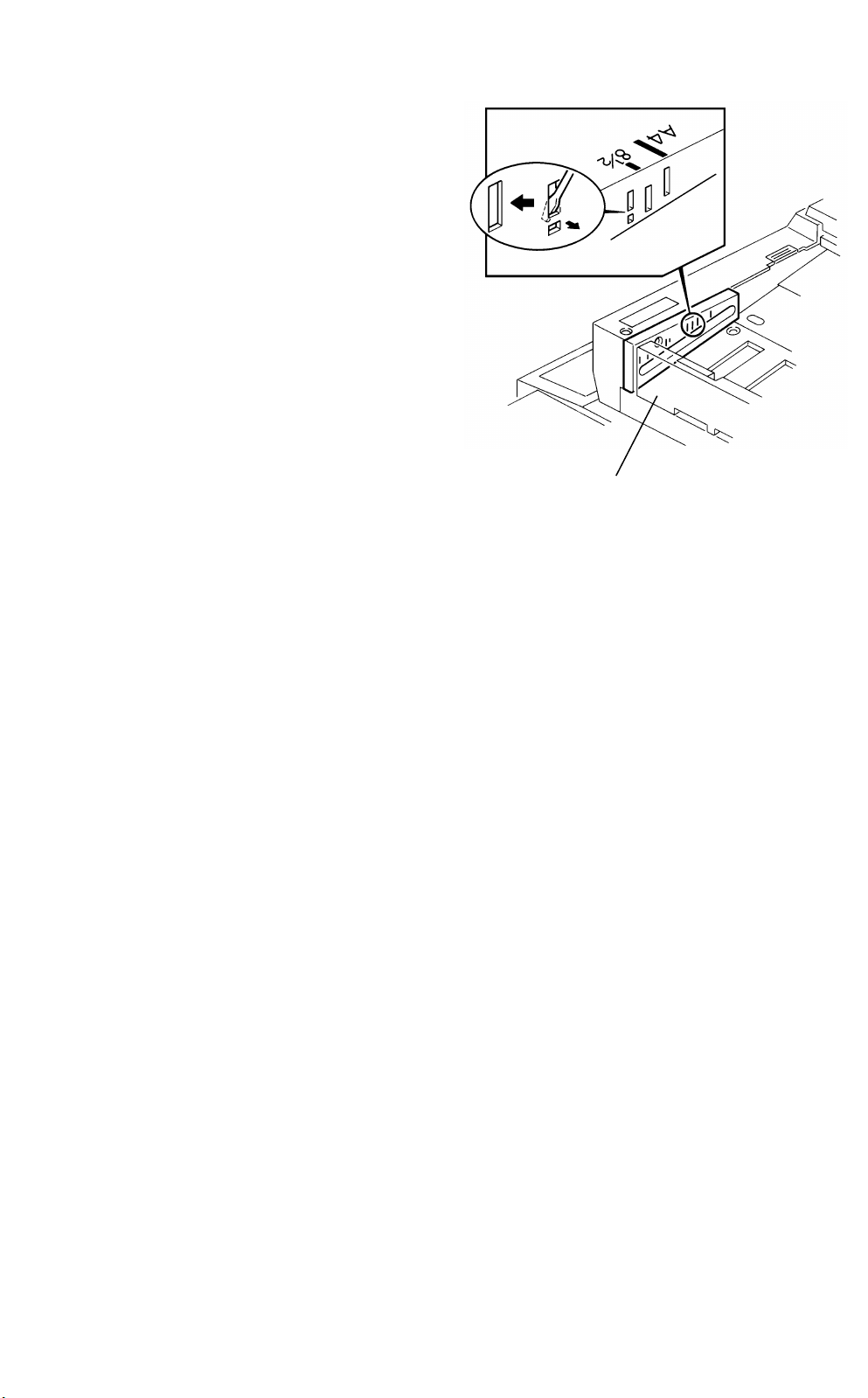

1. Remove the copier right cover, rear right cover and

sub-tray auxiliary plate.

NOTE

The sub-tray auxiliary plate is no longer needed.

2. Insert the horizontal transport unit (accessory) in

the lower side of the duplex unit, and fasten the

unit with the two M4 x 6 screws (accessory). At

the same time, connect 4P connector of the unit to

the copier.

Sub-tray auxiliary plate

Right cover

Horizontal transport unit

3. Open the right cover and fasten the lock lever

assembly and knob assembly with each of two M4

x 6 screws (all are the accessories).

CAUTION

While holding down the small white roller of the

upper left guide plate, tighten the lock lever

assembly. Be sure that the lock lever bracket

pushes down the upper left guide plate when it

is locked.

M4 x 6 (2)

4P connector

Right cover

Knob assembly

Lock lever assembly

1-33

Page 39

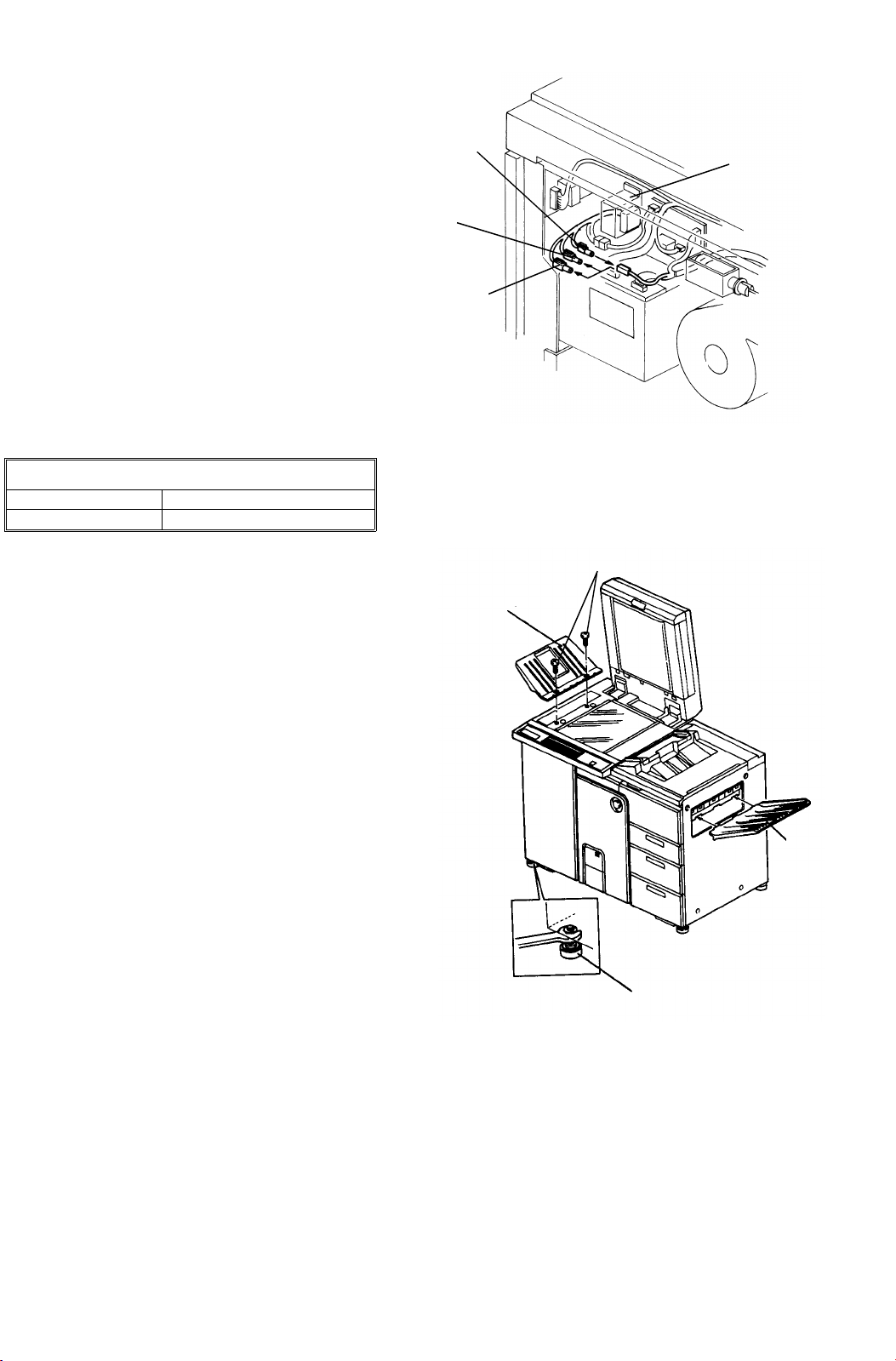

4. Remove the shielding cover for the LCT harness

LCT Installation

1 July 1994

and the rear right cover from the copier.

Remove one screw to remove the connector cover.

Connector cover

5. Pass the LCT power and signal harnesses through

the copier frame hole, and fix the harness fixing

bracket with the two truss screws removed above.

6. Connect the 15P and 34P connectors respectively.

NOTE

The maximum load current of the LCT is 0.95 A.

7. Take the protective earth wire, feed it through

holes provided as shown, and fix it with the

grounding screw (accessory).

8. Fit the connector cover and copier rear right cover

if the finisher will not be installed.

9. Set the two wire saddles (accessories) in the hole

of the LCT rear cover, and put the power cord from

the LCT in it.

NOTE

One of the wire saddles is for the harness from the

finisher.

M4 x 6 truss screws (2)

Protective earth wire

Grounding screw

Truss screw

LCT power and

signal harnesses

15P connector

Harness

fixing

bracket

Shielding cover for

LCT (lower side)

Frame hole

34P connector

Connector cover

10. Remove two blind caps from the copier right cover,

and reinstall the right cover. Then, install the

docking pins to the copier base.

Right cover

Main body

Docking pin

1-34

Page 40

11. Be sure the linking stay of the LCT is locked. Align

1 July 1994

LCT Installation

the copier docking pins with the LCT linking holes,

and press the LCT until the pins click.

NOTE

If the finisher will be fitted, dock it with the copier

after the finisher’s harnesses are connected to the

copier.

12. Place the leveling shoes (accessories) under the

stands. Then, turn the stand nuts to align the

docking position.

CAUTION

Align the position of the LCT with the copier.

First, roughly adjust the LCT height on the basis

of the exterior covers position. Then, open the

LCT upper cover and check the lower paper

guide plate position using a flat plate like a

scale. Finally, align the paper transport guide

plate height between the LCT and copier. This

is to prevent paper misfeeds where the units

connect.

NOTE

LCT

Linking stay

If the finisher is to be installed, do the position

adjustment procedure after installing the finisher.

13. If the finisher is not used, remove the two screws

from the sub-tray auxiliary plate fitting holes. Then,

fit the sub-tray auxiliary plate with the fixing

stepped screws (both accessory), and set the

sub-tray.

NOTE

The sub-tray must be ordered separately. The part

number is A0291460.

14. Access service tool [1-08], and set the LCT

function.

Fixing stepped

screw

LCT right cover

Sub-tray

Sub-tray auxiliary plate

1-35

Page 41

1.9 Finisher Installation

Finisher Installation

1 July 1994

1.9.1 Accessories list

Check the quantity and condition of the accessories in

the box according to the following list.

1. Cushion (575 x 15 x 5 mm) 1

2. Docking Pin 2

3. Docking Support Plate 1

4. Wire Clamp 1

5. Panhead Screw with Washer 1

6. Optical Fiber Cable 1

7. Power Harness 1

8. Panhead Screw M4 x 6 4

9. Ground Screw M4 x 8 (with Lock Washer) 2

10. Shift Tray 1

11. Plated Panhead Screw M4 x 8 4

12. Staple Cartridge 1

13. Original Set Position Decal 1

1-36

Page 42

1.9.2 Removing the clamps

1 July 1994

Finisher Installation

CAUTION

Unplug the copier power cord before starting

the following procedure.

1. Remove the strips of filament tape on the finisher

and remove the styrofoam blocks.

Filament

tape

Filament

tape

Styrofoam

blocks

Filament

tape

2. Remove the fixing screw and cut the bind for the

stapler using pliers.

Fixing screw

Filament

tape

Filament

tape

Bind

1-37

Page 43

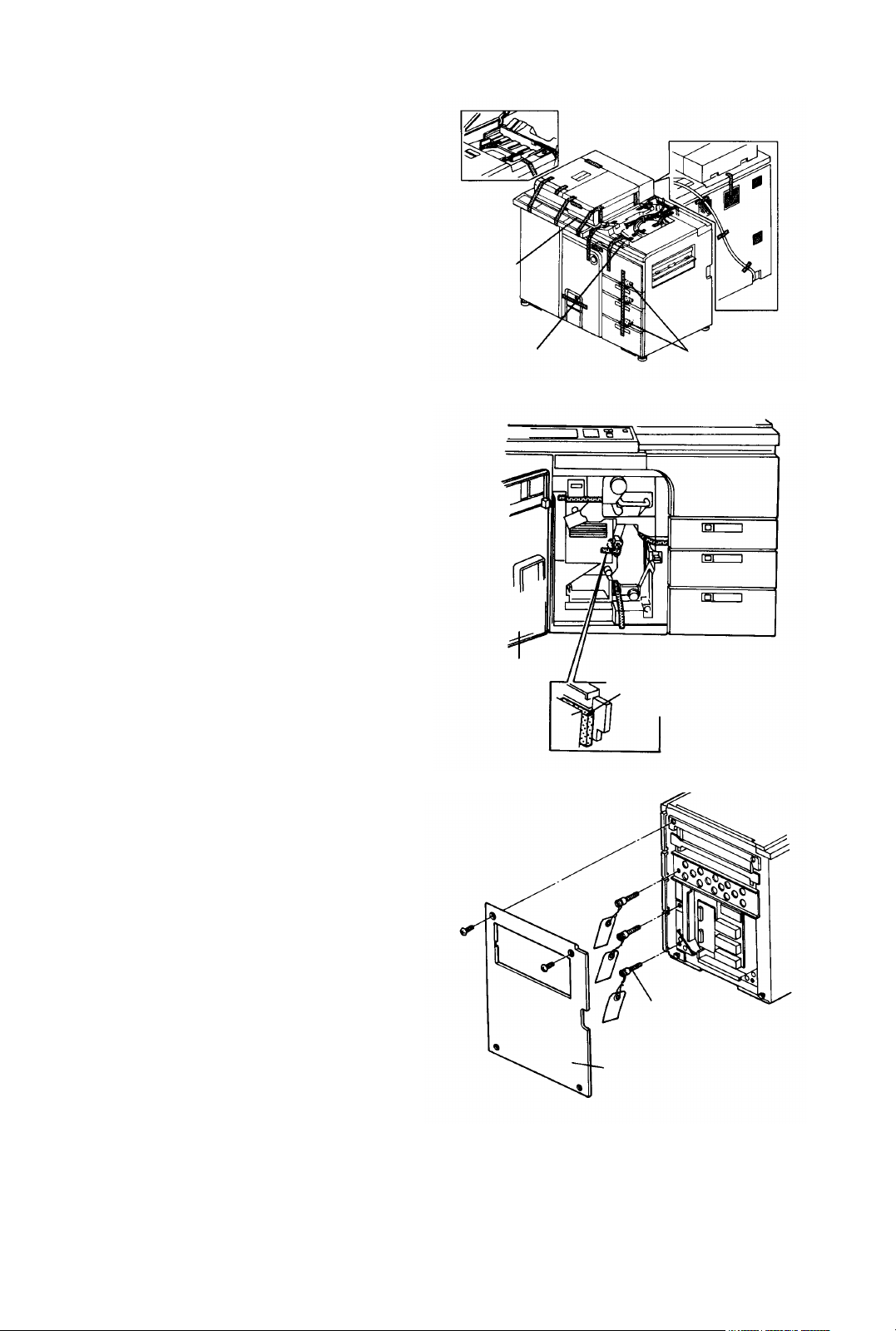

1.9.3 Harness connection to the copier

Finisher Installation

1 July 1994

1. Remove the copier right cover (2 screws). If the

LCT is not used, remove the two blind caps in the

right cover and sub-tray auxiliary plate.

NOTE

The sub-tray auxiliary plate can no longer be used.

Auxiliary plate

Right cover

Blind caps

2. Remove the blind cover (upper side).

3. Remove the rear right cover (2 screws), then

remove the connector cover.

Rear right cover

Connector cover

Blind cover

1-38

Page 44

4. Install the harness bracket of the power cord

1 July 1994

Finisher Installation

(accessory) with the two M4 x 6 pan head screws

(accessories).

5. Take the grounding wire, feed it through hole

provided as shown. Secure it with the M4 x 8

grounding screw (accessory). The grounding

screw must be firmly secured in place with a force

10 to 15 kgfcm torque.

6. Set the optical fiber cable connectors from the

copier and finisher in the sockets of the harness

bracket. Also, connect 3P connector to the power

cord.

CAUTION

The connectors (male) and sockets (female)

must be set as shown.

Grounding

wire

Harness

bracket

Connector

cover

3P connector

7. Reinstall the connector cover and rear right cover.

8. Install the copier right cover. If the LCT is not used,

install the two docking pins (accessories).

Optical

fiber cable

connectors

Right

cover

Docking

pins

1-39

Page 45

1.9.4 Docking preparation

Finisher Installation

1 July 1994

NOTE

This procedure is required only when the LCT is

used with the finisher.

1. Remove the right cover (5 screws) then remove

the two blind caps.

2. Install the two docking pins (accessory).

3. Remove the 4 screws.

4. Install the docking support plate (accessory).

Tighten the 4 screws removed in the above step

while holding the plate up.

NOTE

The docking support plate is required to strengthen

the docking parts in the LCT. The left side of the

finisher is supported only by the two docking pins.

5. Reinstall the LCT right cover.

1.9.5 Harness connection and docking

1. Remove the inverter rear cover (4 screws).

Docking pins

Screws

Docking support

plate

2. Pass the power cord and optical fiber cable

(connected to the copier side) through the harness

docking hole. Then, secure the harness bracket

with the two M4 x 6 screws (accessories). At the

same time, bring the optical fiber cable into the

clamp in the harness bracket and secure it with the

wire clamp and panhead screw with washer

(accessories).

CAUTION

Clamp the optical fiber cable in the harness

bracket so that the portion between the finisher

and LCT (or copier) is longer than that of the

power cord.

3. Connect the power cord connector to the dc power

supply PCB and the optical fiber cable connector

to the inverter control PCB. Then, secure the

grounding wire with the M4 x 8 grounding screw

(accessory) as shown. The grounding screw must

be firmly secured in place with a force of 10 to 15

kgfcm torque.

CAUTION

The optical fiber cable connector must be set to

the socket on the PCB properly as it has the

setting direction.

4. Bind the power cord with the wire clamp.

5. Reinstall the inverter rear cover.

Inverter

rear cover

Optical

fiber cable

connector

Harness

bracket

Clamp

Wire clamp

Grounding

screw

Harness

docking hole

Wire

clamp

Power cord

connector

1-40

Page 46

6. Stick the cushion (accessory) on the left side of the

1 July 1994

Finisher Installation

finisher as shown.

7. Open the finisher and inverter front doors. Then

remove the linking stay access hole cover (2

screws).

8. Be sure that the linking stay of the finisher is in the

lock position. Align the docking pins with the

linking holes of the finisher, and press the finisher

until the docking pins click. Reinstall the linking

stay access hole cover.

9. Install the finisher shift tray with four M4 x 8 plated

panhead screws (accessories).

Cushion

0 to 2 mm

5 to 10 mm

Shift tray

Linking stay

10. Open the finisher front door and install the staple

cartridge (refer to the instruction decal on the rear

side of the front door):

a) Pull out the staple unit.

b) Release the lock lever and turn the

stapler counterclockwise until it locks.

c) Remove the green plastic clip from the

staple cartridge, and install the cartridge

in the stapler.

d) Set the stapler to its original position.

e) Push the staple unit in its original posi

tion.

Staple unit

Cover

Green

plastic

clip

Lock lever

1-41

Page 47

11. Put the two leveling shoes (accessories) under the

Finisher Installation

1 July 1994

stands.

12. From the front and rear, check the clearance

between the exterior covers of the finisher and

copier (or LCT). It must be 3 to 7 mm. To adjust

the position of the finisher with the copier (or LCT),

turn the stand’s nuts as shown.

5 ± 2 mm

5 ± 2 mm

Leveling shoe

13. From the top of the finisher, check the position of

the finisher with the copier (or LCT). The finisher

must be aligned with the copier (or LCT) as shown

in the upper illustration. Adjust the finisher height

by turning the stand’s nuts again, if necessary.

14. Stick the original set position decal (accessory) on

the RDH as shown.

15. Plug the power cord and turn on the main switch of

the copier. Wait for the copy stand-by condition.

16. Access service tool [1-08] and set the finisher

function.

17. Test the operation of the finisher.

NOTE:

• Select the staple mode (2 staple mode) and

make more than 10 sets of copies before starting the stapling operation test. This is because

the staple unit performs stapling motion without

staples until the first staple from the cartridge

reaches the proper position for stapling. This

procedure is required only after installing the

first staple cartridge.

• If customer prefer the shift tray rise mode,

which is to rise the shift tray when the paper on

the tray is removed during a copy run, turn on

dip switch 101-1 on the finisher control PCB.

100 mm

0 ± 1 mm

Decal

0 ± 1 mm

10 mm

1-42

Page 48

1.10 Printer Installation

1 July 1994

Printer Installation

1.10.1 Accessories list

Check the quantity and condition of the accessories in

the box according to the following list.

Key counter bracket accessory check

1. Snap Bushing 1

2. Wire Clamp 2

3. Philips Sunken Head Screw - M3 x 8 2

4. Philips Pan Head Screw - M4 x 8 4

5. Philips Plated Screw - M4 x 8 4

6. Grounding Screw with Star Washer 2

7. Philips Plated Screw - M3 x 6 2

8. Key Counter Hole Blind Cover 1

9. Key Counter Fixing Plate 1

10. Printer Connector Hole Blind Cover 1

Printer connector unit accessory check

1. Grounding Screw with Star Washer 2

2. Philips Plated Screw - M4 x 8 1

3. Wire Clamp 1

NOTE:

The printer interface board (P/N A112 5060), printer

harness (P/N A531 5420), 2 connector joint studs

(2 x P/N 1102 4039), and 4 nylon studs (4 x P/N

1105 0193), which are the copier’s accessories, are

required for the printer connector unit installation.

1.10.2 Installation procedure

1. Remove the exterior cover in the rear of the copy

tray (3 screws). Then, remove the two cover

brackets (2 screws each).

2. Install the key counter/printer connector bracket

with four M4x8 philips pan head screws and one

grounding screw (accessories).

3. Install the snap bushing (accessory) as shown.

4. Remove the copier rear right cover (2 screws).

5. Take the two connectors which are clamped

behind the key counter/printer connector bracket,

then feed them through the hole in the bottom of

the bracket as shown.

Exterior

cover

Cover

bracket

Snap bushing

Grounding

screw

Connector

bracket

Cover

bracket

1-43

Page 49

6. If an optional key counter is installed, install the

Printer Installation

1 July 1994

key counter receptacle with the two M3x8 philips

sunken head screws and key counter fixing plate

(accessories).

NOTE

The key counter must be one of the following:

- Hengstler (For the European version machine only)

- Hecon

- Veeder Root

Shorting

connector

Key

counter

receptacle

Key counter

fixing plate

7. Remove the shorting connector, then connect the

connectors from the key counter and copier.

8. Install the two wire clamps (accessories) and

clamp the harness as shown.

9. If the optional printer connector unit is not

installed, install the printer connector hole blind

cover with the two M3x6 philips plated screws (all

are accessories).

10. If the optional printer connector unit is

installed, install it with the grounding screw and

M4x8 philips plated screw (accessories).

11. Connect the connector of the harness form the

copier to the PCB on the printer connector unit.

12. Install the 4 nylon studs, then the printer interface

board. Connect the connector of the harness from

the printer connector unit to the interface board.

13. Install the printer harness with the two connector

joint studs.

NOTE

The printer interface board (P/N A112 5060), printer

harness (P/N A531 5420), 2 connector joint studs

(2 x P/N 1102 4039), and 4 nylon studs (4 x P/N

1105 0193), which are copier accessories, are

required for the printer connector unit installation.

Connector

joint studs

Grounding

screw

Wire clamp

Connector

[E]

Optional printer

connector unit

Blind cover

Printer interface

board

Grounding

screw

Nylon

studs

Wire

clamp

Printer

harness

Blind cover

Fixing

plate

14. Connect the other end of the printer harness to the

connector on the printer interface board.

15. Fix the grounding wire with the grounding screw

(accessory). Then, install the wire clamp

(accessory) then clamp the printer harness with

the clamp as shown.

16. 1If an optional key counter is not installed, install

the key counter hole blind cover with the two M3x8

philips sunken head screws and key counter fixing

plate (accessories).

1-44

Page 50

17. Install the key counter/printer connector bracket

1 July 1994

Printer Installation

cover [A] with the grounding screw [B] and the 4

M4x8 philips plated screws (accessories).

NOTE

If the optional printer connector is installed, a printer

with a standard RS232C interface is required. Use

a printer with the following functions:

Mode: Asynchronous

Data format: Start/Stop/Data: 1 bit each

Data bit length: 8 bits

Parity permission: With

Parity setting: Even parity

Baud rate setting: 1,200 bps

Connector: 25 pins, D-connector

Bracket

cover

Grounding

screw

1-45

Page 51

SECTION 2

REPLACEMENT AND ADJUSTMENT

Page 52

2. REPLACEMENT AND ADJUSTMENT

1 July 1994

Paper Feed

2.1 Paper Feed

2.1.1 Replacing the feed, reverse and pick-up rollers

PM cycle: Replace every 400K

NOTE

One set of the feed, reverse and pick-up rollers can

feed up to approximately 150,000 sheets of paper.

If the paper trays are not used evenly, replace the

rollers that are worn more with the rollers that are

worn less. Do this before any rollers wear out.

1. Press the tray down keys for all paper trays.

2. Turn off the main switch.

3. Pull out and remove the 1st tray (2 screws).

CAUTION

Note that the unit fixing screws are the stepped

screw on the right side and the plated screw on

the left side.

4. Pull out the 2nd and 3rd trays.

Stepped screw

Plated screw

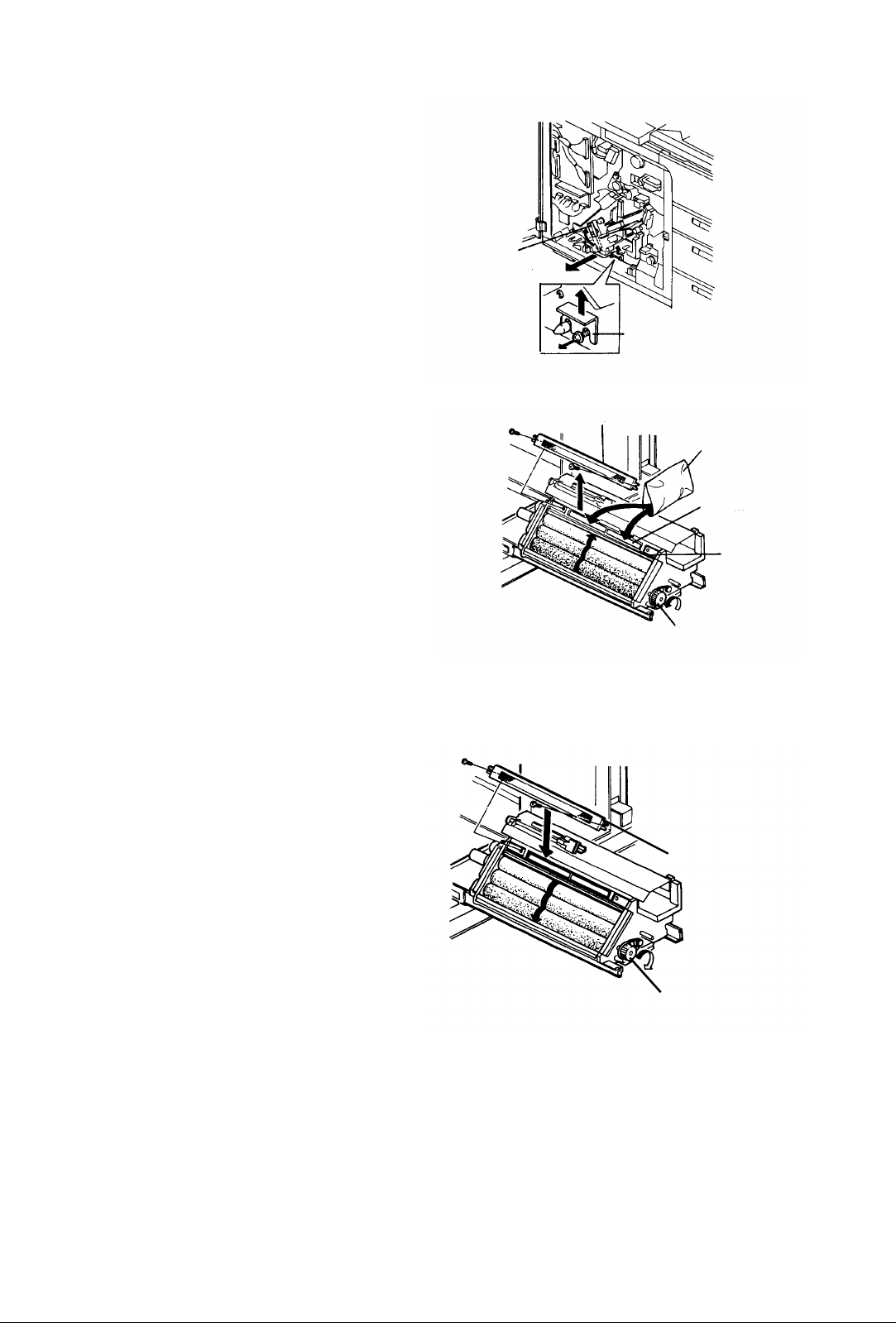

5. Remove stop rings from rollers in the 1st, 2nd, and

3rd feed station.

6. Slide and remove rollers and replace rollers.

CAUTION

• Do not touch the new roller surfaces with

bare hands.

• Install the feed roller in the correct direction.

Paper feed roller

Pick-up roller

Reverse roller

2-1

Page 53

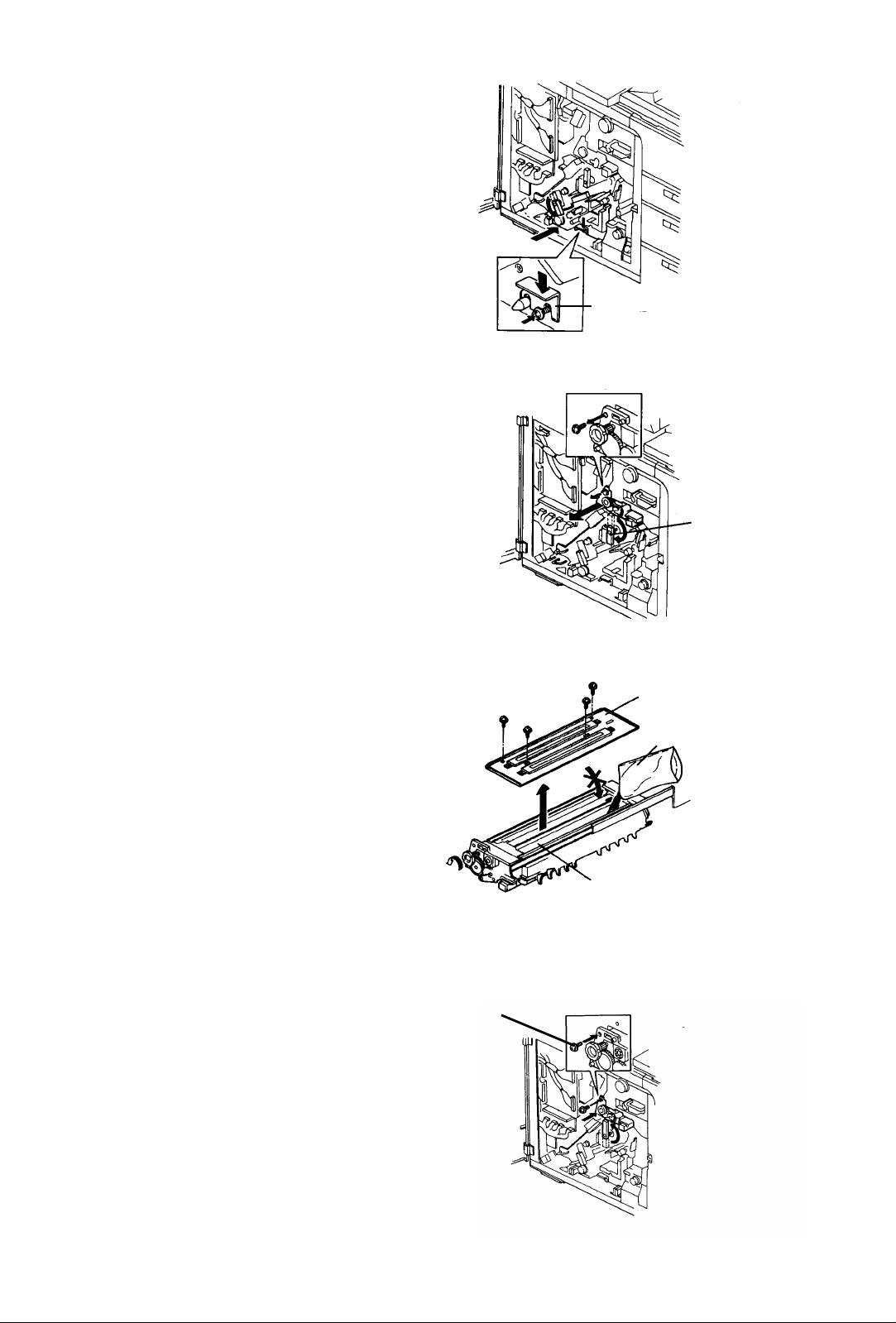

2.1.2 Replacing parts in the paper feed unit

Paper Feed

1 July 1994

Replace parts in the paper feed unit when:

• Electric parts are changed (paper feed motor,

various sensors and pick-up solenoid).

• The grip roller is replaced.

Removing paper feed unit

1. Remove the inner cover(s) from the vertical

transport unit.

2. Remove the paper tray from the paper feed station

as it is required to remove the feed unit.

3. Disconnect and put the paper feed connector to

the far side.

4. Loosen the slot head fixing shaft and pull it about

10 mm in the direction of the arrow.

Remove for the

1st tray

Remove for the

2nd or 3rd tray

1st tray

2nd tray

3rd tray

Paper feed connector

5. When you need to remove the feed unit at the third

feed station, remove the oil pump unit bracket (2

screws).

(-) fixing shaft

Fitting screw

Oil pump unit bracket

Oil tube

2-2

Page 54

6. Remove the screws from the paper feed unit fixing

1 July 1994

Paper Feed

bracket.

7. Hold the far side of the unit to move it to the right

and push the front to the far side to remove the

unit.

Checking the unit

Bracket

fixing

screw

Bracket fixing screw

1. Remove the paper tray.

2. Loosen and pull the (slot head) fixing shaft without

removing the two screws from the paper feed unit

fixing bracket.

3. The far side of the unit can be opened and closed

using the front as a fulcrum.

Replacing the torque limiter

1. Remove the paper feed unit.

2. To pull out the reverse roller, remove the stop ring.

3. Remove the reverse roller pressure arm stopper

(one screw).

4. To replace the torque limiter, lower the reverse

roller pressure arm.

CAUTION

• Because the torque limit pressure is

properly adjusted, do not loosen the torque

limiter stopper screws.

• Never touch the reverse roller surface with

bare hands.

Breaker

fixing

screw

Reverse roller

pressure arm

Stopper

Stop ring

Reverse

roller

(Minus head) fixing shaft

[NG]

Stopper

Torque limiter

2-3

Page 55

Replacing the pick-up solenoid

Paper Feed

1 July 1994

1. Remove the paper feed unit.

2. Mark the position of the solenoid bracket.

3. Remove the two solenoid bracket fixing screws

(gold color).

4. Remove the pick-up solenoid from the bracket and

replace it.

CAUTION

• Pull out one side of the plunger spring pin

about 4 mm and put it in the pick-up roller

arm hole.

• The solenoid bracket should be in the

marked-off position. The pick-up roller rise

amount various with the position.

5. Remove the E-ring from both sides and replace

the grip roller.

6. Assemble in the reverse order.

NOTE

The golden screw (zinc plated) shows the location

adjusted at assembly during manufacture.

Therefore, pay attention to how the screw is set

originally before you start working. When the screw

is loosened, adjustment is required.

4 mm

Pick-up solenoid

Gold screw

Pick-up roller arm

Solenoid bracket

2-4

Page 56

2.1.3 Replacing parts in the paper trays

1 July 1994

Paper Feed

PM cycle: Lubricate the tray motor worm

gear every 800K

1. Pull out the tray.

2. Remove the front and rear knobs (2 screws each),

and the tray bottom plate (6 screws). You can

replace the anti-condensation heater and paper

size sensors.

3. Remove the front tray cover (4 screws). You can

replace the front tray drive wire.

4. Remove the paper tray from the rails (2 screws)

when:

• Replacing the rear tray drive wire

• Replacing the tray motor and DC drive board

• Lubricating the worm gear

Tray drive wire layout diagram

The numbers shows the assembly steps.

FRONT REAR

Knob

Tray bottom

plate

Front tray cover

2 turns

clockwise

(blue wire)

Secure the

tension pulley

2 turns counterclockwise (blue wire)

2.5 turns counterclockwise

2.5 turns

clockwise

Secure the tension

pulley

2-5

Page 57

2.1.4 Replacing the registration sensor

Paper Feed

1 July 1994

1. Turn off the main switch. Open the front door, and

remove two screws to allow it to open further.

2. Remove the inner cover (2 screws and one

connector).

CAUTION

Do not pull the harness to the cooling fan in the

inner cover.

3. Turn the lever to release the development backup

roller of the OPC unit.

4. Remove the development unit fixing plate (one

screw), and slightly pull out the unit to disengage

the joint gear at the rear of the unit.

5. Turn the development knob to collect the

developer on the development sleeve.

CAUTION

Be sure to collect the developer, because the

developer may attach to the side plate of the

OPC unit, fraying or damaging the OPC belt.

Lever

Development knob

Fixing bracket

6. Slide out the development unit.

7. Remove the registration sensor (2 screws and one

clamp).

8. Remove the main body rear left cover (2 screws).

9. Remove the connector going to the registration

sensor from the back.

10. Reassemble in the reverse order.

CAUTION

Never touch the OPC belt.

2.1.5 Replacing the registration motor

1. Turn off the main switch.

2. Remove the rear left cover, then remove the

cleaning coil cooling fan.

3. Disconnect the connector from the registration

motor.

4. Loosen two screws of the universal joint attached

to the registration motor shaft.

5. Remove two screws fixing the registration motor.

6. Replace the registration motor and reassemble it

in the reverse order.

Clamp

Fixing screw

Registration motor

Fixing screw

Registration sensor

Connector for

registration motor

2-6

Page 58

2.1.6 Cleaning the paper dust collecting vessel

1 July 1994

Paper Feed

PM cycle: Clean every 1,200K

1. Pull out the 3rd tray.

2. Turn off the main switch. Open the front door, and

remove two screws to allow it to open further.

3. Remove the inner cover from the lower of the

vertical transport unit (3 screws).

4. Remove the OPC unit inner cover (2 screws and a

connector).

CAUTION

Do not pull the connector of the cooling fan in

the machine.

5. Turn the lever to release the development backup

roller of the OPC unit.

6. Remove the development unit fixing plate (one

screw), and slightly pull out the unit to disengage

the joint gear at the rear of the unit.

7. Turn the development knob to collect the

developer on the development sleeve.

CAUTION

Be sure to collect the developer because it may

stick to the side plate of the OPC unit, fraying or

damaging the OPC belt.

Paper dust

collecting vessel

Fixing screw

8. Slide out the development unit and remove the unit

from the rails.

9. Remove the vessel fixing screw from the front, and

remove the paper dust collecting vessel.

10. Clean inside of the vessel using a dry cloth, and

reassemble in the reverse order.

2-7

Page 59

2.1.7 Removing the vertical transport unit

Paper Feed

1 July 1994

You will have to remove the vertical transport unit when:

• Replacing the drive system

• Replacing each roller

WARNING

• Due to the weight, two operators are required.

• Be sure to pull out the power cord during work.

1. Pull out all paper trays.

2. Turn off the main switch.

3. Open the upper right door.

4. Open the front door.

5. Remove all inner covers: fusing, vertical transport

upper and vertical transport lower.

6. Remove two screws each to remove all paper

trays.

CAUTION

Vertical transport

upper inner cover

Plated screw

Fusing

inner

cover

Vertical transport

lower inner cover

Stepped screw

Tray fixing screws are stepped screws on the

right side and plated screws on the left side.

Take care during reinstallation.

7. Remove the upper and lower door catch magnets

with their brackets.

Door catch

magnet, upper

bracket

Door catch

magnet, lower

bracket

2-8

Page 60

8. Remove the horizontal transport unit inner cover.

1 July 1994

Paper Feed

9. Disconnect the front door switch harness

connectors.

CAUTION

Terminals on both sides are blue and the two

center terminals are yellows. Re-install them

correctly.

10. Disconnect the connector from the front door

sensor.

11. Mark off the position of the front door switch

bracket.

12. Remove the front door switch bracket (2 screws).

Front door

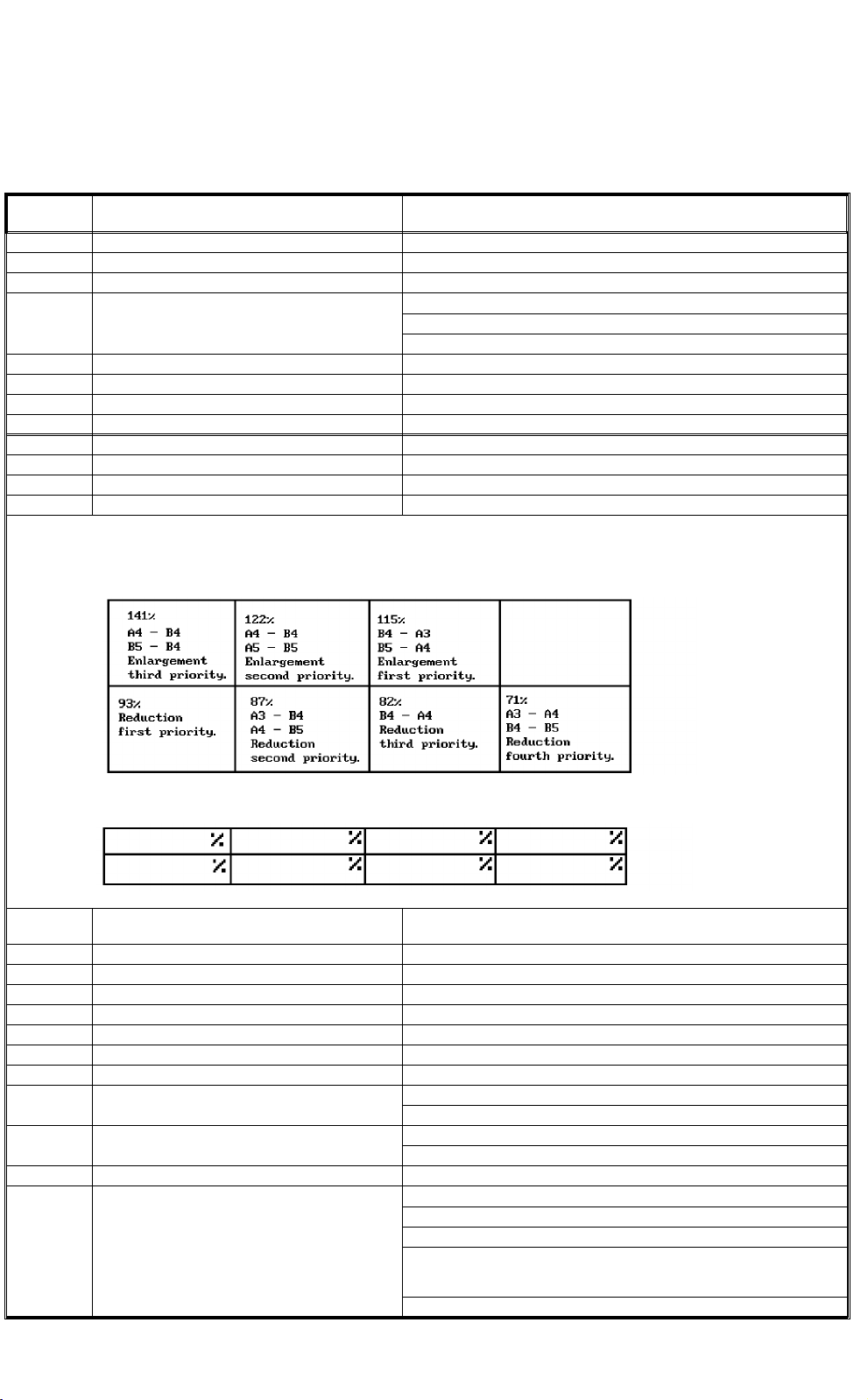

sensor