Page 1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJ URY

1. While the machine warms up, it will suddenly start turning to perform the

process control data initializa tio n. Keep hands away from any mechanical

and electrical components during this perio d.

2. Before disassembling or assembling parts of the copier and periph erals,

make sure that the copie r and the secon d sorter power cord is unplugged.

3. The wall outlet should be near the copie r and easily acce ssible .

4. Note that some comp onen ts of the copier, the paper tray un it, and the

2nd sorter are supplied with electrical volta ge even if the main switch is

turned off.

5. If any adjustment or operation check has to be made with exte rior cove rs

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

6. The inside and the meta l pa rt s of the fusing unit become ext reme ly hot

while the copier is operating. Be careful to avoid touch ing tho se

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filte rs in sta lled.

2. Always replace the ozo ne filte rs wit h th e specified ones at the specified

intervals.

3. Toner and developer a re non-toxic, but if you get either of them in your

eyes by accident, it may cause tempo rary eye discomf ort. Try to remove

with eye drops or flush with water as f irst aid . If unsu ccessful, get medical

attention .

Page 2

OBSERVANCE OF ELECTRICAL SAFETY S TANDARDS

1. The copier and its peripherals must be inst alle d and main ta ine d by a

customer service represent at ive who has completed the training course

on those models.

2. The RAM board on the main contro l board ha s a lithium battery which can

explode if replaced incorrectly. Replace the battery only with an ide nt ical

one. The manufacture r recomme nd s replacing the entire RAM board. Do

not recharge or burn this battery. Used batteries must be handled in

accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DI S POSAL

1. Do not incinerate the ton er cartridge or the used tone r. Ton er du st may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, developer, and photoconductors according to local

regulations.

3. Dispose of replaced part s in accord an ce with local regulations.

4. When keeping used lithium batteries in order to disp ose of them later, do

not put more than 100 batteries per sealed box. Storing larger numb ers or

not sealing them apart may lead to chemica l re act ions and heat build-up.

Page 3

Table of Contents

This manual describes new items for th e Thund erb ird II type X (A170).

Please refer to the Thunderbird II type Y (A171) manual for the descriptions

marked with "*" in the page column.

1. OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. COPY PROCESSES AROUND THE DRUM . . . . . . . . . . . . . . . . . . . . *

3. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . *

3.1 COPIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3.2 RDH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4. ELECTRICAL COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . . . *

4.1 COPIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4.1.1 Copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4.2 RDH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

5. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6. PAPER PATH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2. DETAILED SECTION DE SCRIPTIONS

1. PROCESS CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2. DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3. DRUM CHARGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4. ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5. OPTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6. DEVELOPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6.4.3 Bias for the ID Sensor Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

7. TONER DENSITY DETECTION AND SUPPLY. . . . . . . . . . . . . . . . . . *

8. IMAGE TRANSFER AND PAPER SEPARATION. . . . . . . . . . . . . . . . *

9. CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

Page 4

10. QUENCHING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

11. PAPER FEE D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

12. TRANSPORT UNIT AND REGISTRATION . . . . . . . . . . . . . . . . . . . . *

13. FUSING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

14. INVERTER AND PAPER EXIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

15. DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

15.8 DUPLEX END FENCE AND 2ND PAPER END SENSOR. . . . . . . . . . . . . . . 2-2

16. RDH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

16.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

16.1.1 No Inversion Original Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

16.1.2 Inversion Original Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

16.1.3 Sided Original 2 Sided Copy Mode (one set of copies) . . . . . . . . . . . . . 2-7

16.1.4 Two or More copies (alternate paper feed). . . . . . . . . . . . . . . . . . . . . . . 2-7

16.1.5 2 Sided Original 2 Sided Copy Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

16.1.6 2 Sided Original 1 Sided Copy Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

16.2 ORIGINAL SET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

16.2.1 Stack Feed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

16.2.2 Single Feed Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

16.3 ORIGINAL FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

16.3.1 Original Separation/Feed (Original Stack Mode). . . . . . . . . . . . . . . . . . 2-15

16.4 SINGLE FEED MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

16.4.1 Registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

16.4.2 Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

16.5 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

16.5.1 Feed Motor Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

16.5.2 Belt Drive Motor Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

16.5.3 Inverter Motor Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

16.6 ORIGINAL POSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

16.7 CFF MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

17. OPERATION UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

Page 5

18. MOVING ORIGINAL SCAN AND BY-PASS FEED TABLE . . . . . . . *

19. ENERGY START COMPLIANT MACHINES

(NORTH AMERICAN VERSION ONLY) . . . . . . . . . . . . . . . . . . . 2-24

3. INSTALLATION

1. INSTALLATION REQUIREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 MACHINE LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3. INSTALLATION PROCEDURE (COPIER). . . . . . . . . . . . . . . . . . . . 3-5

3.1 A3/11" x 17" COUNTER INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.2 KEY COUNTER HOLDER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4. INSTALLATION PROCEDURE (LCT) . . . . . . . . . . . . . . . . . . . . . . 3-14

4. SERVICE TABLES

1. SERVICE REMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.12 RDH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.13 FINISHER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. SERVICE PROGRAM MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.1.1 To Access SP Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.1.2 To Exit SP Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.1.3 Change the Menu Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2.2 SP MODE FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

2.3 SP MODE INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

3. DIP SWITCH TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

3.3 RDH MAIN CONTROL PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

3.4 RDH LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Page 6

4. PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . . . 4-39

4.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

4.2 REGULAR PM SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

5. REPLACEMENT AND ADJUSTMENT

1. EXTERIOR AND INNER COVERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . *

2. OPTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

3. DEVELOPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

4. CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

5. AROUND THE DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6. LCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

7. 1ST, 2ND, AND 3RD TRAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

8. REGISTRATION AND TRANSPORT. . . . . . . . . . . . . . . . . . . . . . . . . . *

9. IMAGE FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

9.3 OIL SUPPLY ROLLER REPLACEMENT (European Version Only). . . . . . . . . 5-1

10. INVERTER & PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

11. DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

12. ARDF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

13. RDH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

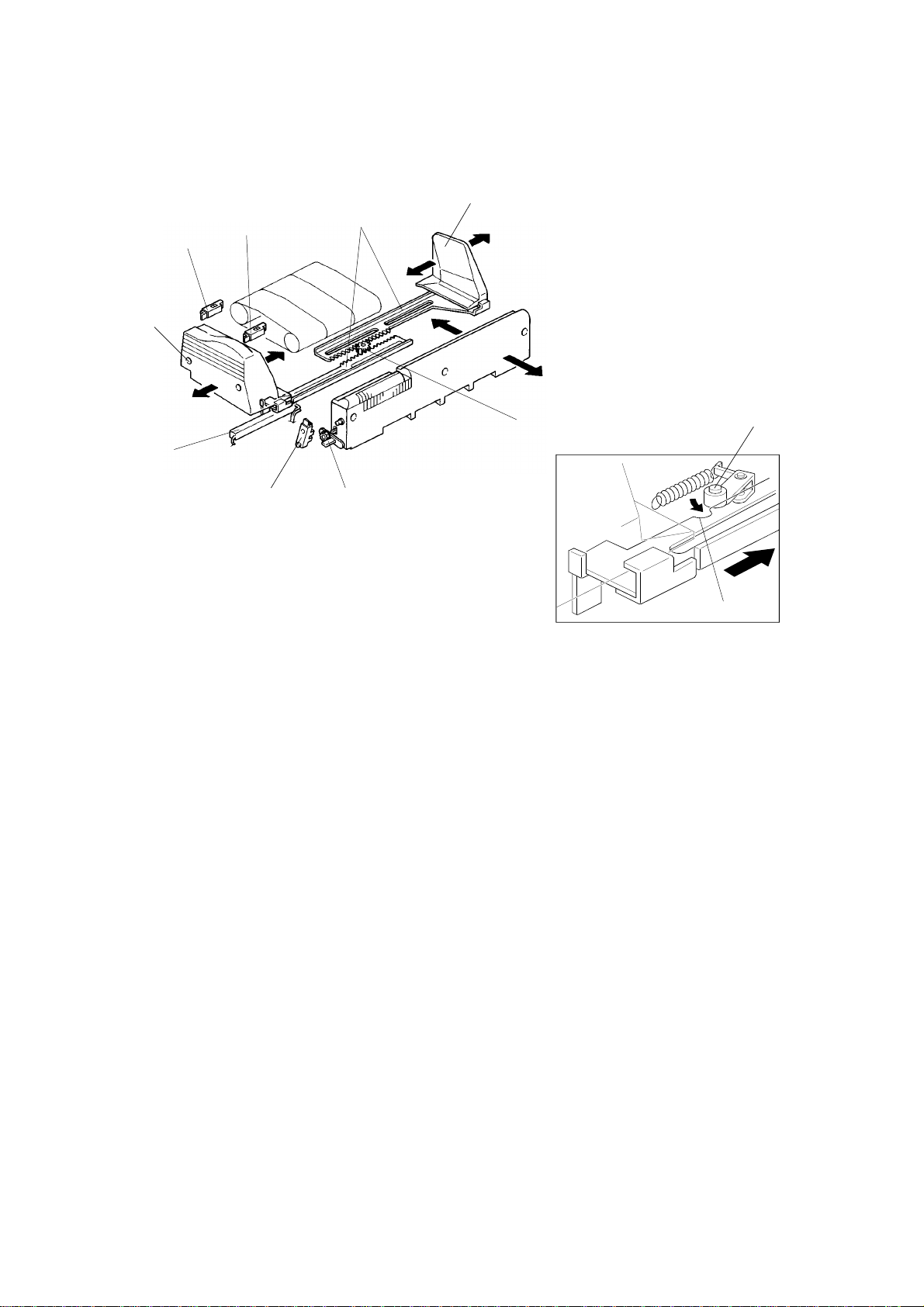

13.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

13.2 FEED-IN BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

13.3 SIDE-TO-SIDE REGISRATION ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . 5-4

13.4 ORIGINAL HEIGHT SENSOR POSITION ADJUSTMENT . . . . . . . . . . . . . . 5-5

13.5 RDH UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

13.6 RDH LEVELING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

13.7 SINGLE FEED TABLE REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

13.8 SINGLE FEED SET SENSOR AND REGISTRATION SENSOR

REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

13.9 VACUUM SHUTTER SOLENOID ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 5-11

Page 7

13.10 EXIT ROLLER SOLENOID ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-12

13.11 INVERTER BLOWER MOTOR BELT TENSION ADJUSTMENT . . . . . . . 5-13

13.12 BELT DRIVE, FEED, AND INVERTER BLOWER MOTOR TENSION

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

13.13 BELT TENSION ADJUSTMENT FOR BELT DRIVE MOTOR . . . . . . . . . . 5-15

14. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

6. TROUBLESHOOTING

1. SYSTEM ERROR AND SERVICE CALL CONDITIONS . . . . . . . . . 6-1

2. BLOWN FUSE TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

FINISHER

1. OVERALL MACHINE INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 ELECTRICAL COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 BASIC OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. SECTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 PAPER DELIVERY SWITCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 SHIFT TRAY UP/DOWN MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 SHIFT TRAY SIDE TO SIDE SHIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . 10

2.4 STAPLE UNIT PAPER POSITIONING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 JOGGER MOVEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 STAPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 STAPLER UNIT SIDE TO SIDE MOVEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.8 FEED-OUT TO SHIFT TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 8

4. SERVICE TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 TEST POINT TABLE (Main Board). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 FUSE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 DIP SW TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.1 Motor Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Free Run Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 LUBRICATION POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6.1 Shift Tray Positioning Roller Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6.2 Jogger/Staple Unit Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6.3 Shift Tray Drive Gears. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 25

5.1 EXTERIOR REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 STAPLE UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3 SHIFT TRAY UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4 JOGGER UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 ALIGNMENT BRUSH ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 29

5.6 JOGGER DRIVE BELT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.7 EXIT ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.8 SHIFT TRAY POSITIONING ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . 32

5.9 SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.10 BELT TENSION ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page 9

SECTION 1

OVERALL MACHINE

INFORMATION

Page 10

31 January 1996 SPECIFICATIONS

1. SPECIFICATIONS

Main Copier

Copier

Configuration: Console

Copy Process: Dry Electrostatic Transfer S yste m

Originals: Sheet/Book

Original Size: Maximum: 11" x 17", A3

Copy Paper Size: Maximum: 1st and 2nd tray 11" x 17", A3

3rd tray 81/2" x 14", B4

Minimum: 51/2" x 81/2", A5

Copy Paper Weight: Standard Copying: 14 ~ 42 lb, 52 ~ 157 g/m

Duplex Copying: 17 ~ 28 lb, 64 ~ 105 g/m

2

2

Warm Up Time: Within 8.0 minutes (room temp. 68°F, 20°C)

First Copy Time: 4.7 seconds (81/2" x 11", A4, feed from 3rd tray)

Copying Speed: 80 copies/minute (81/2" x 11", A4)

60 copies/minute (11" x 17", A3)

Optional Equipment: Finisher (A593)

Large Capacity Tray (A592)

Key Counter Bracket Set (A59 8 - 02)

Key Counter (Procured locally)

Key Counter Holder (Procured loca lly)

Receiving Tray (spare part)

Guidance ROM Kit (A603)

Reproduction Ratios: See the following table:

LT/DLT version A4/A3 version

200% 200%

Enlargement

Full Size 100% 100%

Reduction

155% 141%

129% 122%

121% 115%

93% 93%

77% 82%

74% 71%

65% 65%

50% 50%

1-1

Page 11

SPECIFICATIONS 31 January 1996

Zoom: 50 ~ 200%

Toner Replenishment : Cartridge exchange (1, 50 0 g)

Paper Feed: 1st tray (500 sheets)

2nd tray (500 sheets)

3rd tray (1,700 Sheets)

Power Source: 240 V, 20 A or more (LT/DLT version)

220, 230, 240 V, 13 A or more (A4 /A 3 version)

Power Consumption:

LT/DLT version

Copier only Full system*

Warm up less than 2.10 kW less than 2.15 kW

Stand-by less than 0.50 kW less than 0.55 kW

Copying less than 2.50 kW less than 2.60 kW

Maximum less than 2.60 kW less than 2.70 kW

* Full system: Copier with RDH, large capacity tray, and a finisher.

A4/A3 version (at 230 V)

Copier only Full system*

Warm up less than 2.10 kW less than 2.15 kW

Stand-by less than 0.50 kW less than 0.55 kW

Copying less than 2.50 kW less than 2.60 kW

Maximum less than 2.60 kW less than 2.70 kW

* Full system: Copier with RDH, large capacity tray, and a finisher.

Dimensions:

Width Depth Height

Copier with RDH and copy tray 1,215 mm

47.8"

Copier with RDH, large capacity tray, and a

finisher

2,110 mm

83.1"

760 mm

29.9"

760 mm

29.9"

Weight:

1,445 mm

56.9"

1,445 mm

56.9"

A4\A3 version

Copier with RDH 378 kg

835.4 lb

Copier with RDH, large capacity tray, and a

finisher

1-2

469 kg

1036.5 lb

Page 12

31 January 1996 SPECIFICATIONS

Noise Emission:

Sound pressure level

(The measurements are made according to ISO 7779 at the operator position.)

Copier only Full system*

Stand-by less than 43 dB (A) less than 43 dB (A)

Copying

* Full system: Copier with RDH, large capacity tray, and a finisher.

less than 69 dB (A)

(average)

less than 75 dB (A)

(average)

Sound power level (The measurements are made according to ISO 7779.)

Copier only Full system*

Stand-by less than 57 dB (A) less than 57 dB (A)

Copying less than 75 dB (A) less than 83 dB (A)

* Full system: Copier with RDH, large capacity tray, and a finisher.

1-3

Page 13

SPECIFICATIONS 31 January 1996

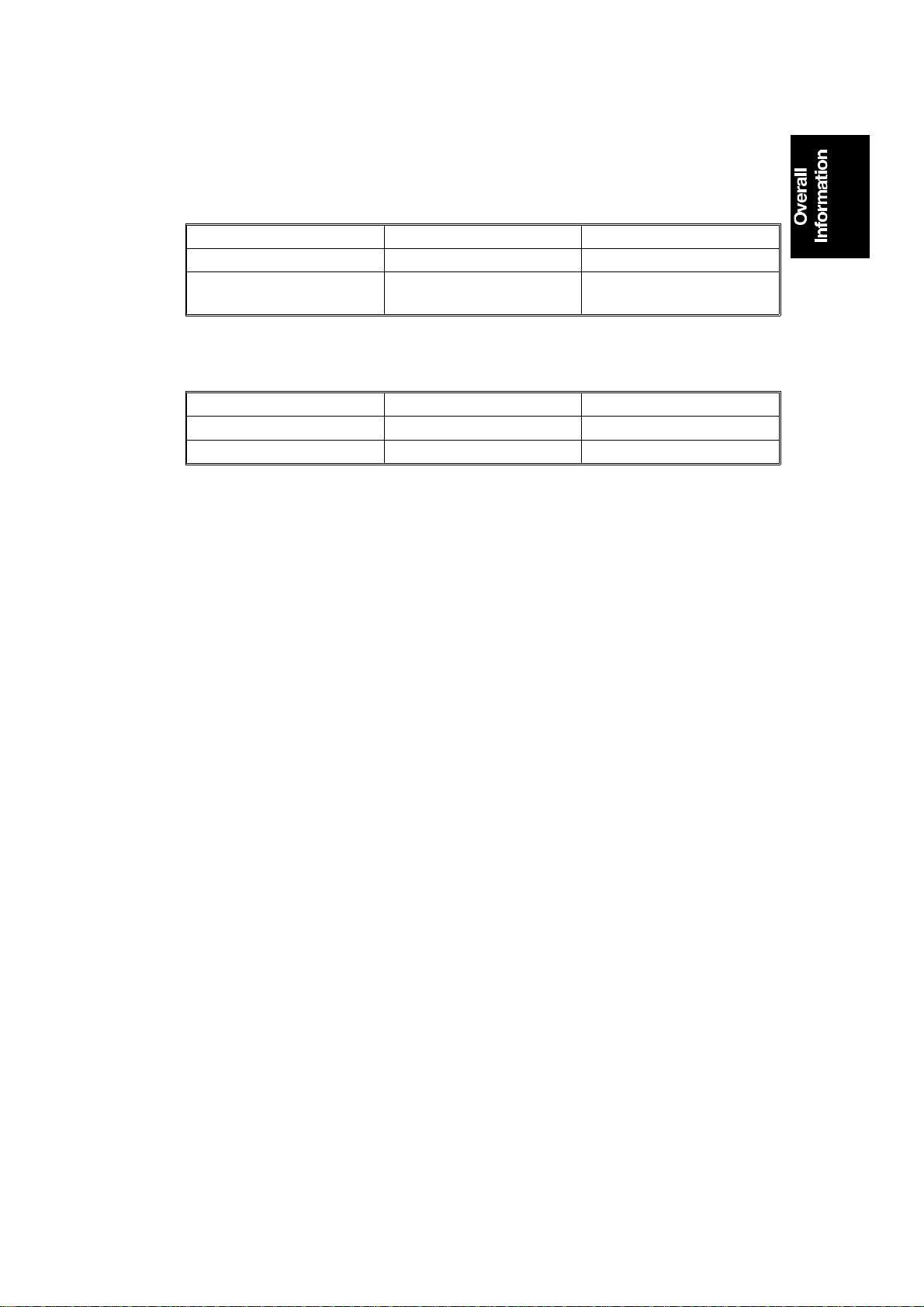

Recycling Document Handler

Original Size:

Stack feed mode Single feed mode CFF mode

Maximum 11" x 17", A3 11" x 17", A3 11" x 9

8

Minimum 8" x 10

1/2", A4 51/2" x 81/2", A5

11" x 14

1/2"

1/2" x 12"

7/8"

Original Weight:

Stack feed mode Single feed mode CFF mode

Maximum 28 lb, 105 g/m

Minimum 17 lb, 64 g/m

2

2

43 lb, 165 g/m

14 lb, 52 g/m

2

2

20 lb, 75 g/m

17 lb, 64 g/m

2

2

Number of originals to be set:

RDH mode

Size

Weight

64 g/m

17 lb

2

75.2 g/m

20 lb

2

80 g/m

2

21 lb

A4

8" x 10

1/2" x 11"

8

8

1/2" x 13"

1/2" x 14"

8

B4

10" x 14"

A3

11" x 17"

1/2"

100 sheets 100 sheets 100 sheets 80 sheets

100 sheets 90 sheets 80 sheets 60 sheets

80 sheets 70 sheets 70 sheets 50 sheets

60 sheets 50 sheets 50 sheets 40 sheets

SADF mode: 1 sheet

Number of Recycles: Maximum: 60 times

CFF Original Stack Height:Maximum: 76 mm

Original Set: First sheet on top, stack face down

104.7 g/m

28 lb

2

1-4

Page 14

31 January 1996 MECHANICAL COMPONENT LAYOUT

3. MECHANICAL COMPONENT LAYOUT

3.2 RDH

1

15

2

14 13

3456

12

11

10

7

9

A170V500.img

8

1. Inverter Roller

2. Inverter Exit Roller

3. Air Knife Nozzle

4. Exit Roller

5. Original Guide

6. Feed-in Belt

7. Original Stopper

8. Right Turn Roller

9. Belt Drive Roller

10. Transpo rt Belt

11. Transport Rollers

12. Original Feed Roller

13. Inverter Entrance Roller

14. Single Feed Exit Gat e

15. Inverter Middle Roller

1-5

Page 15

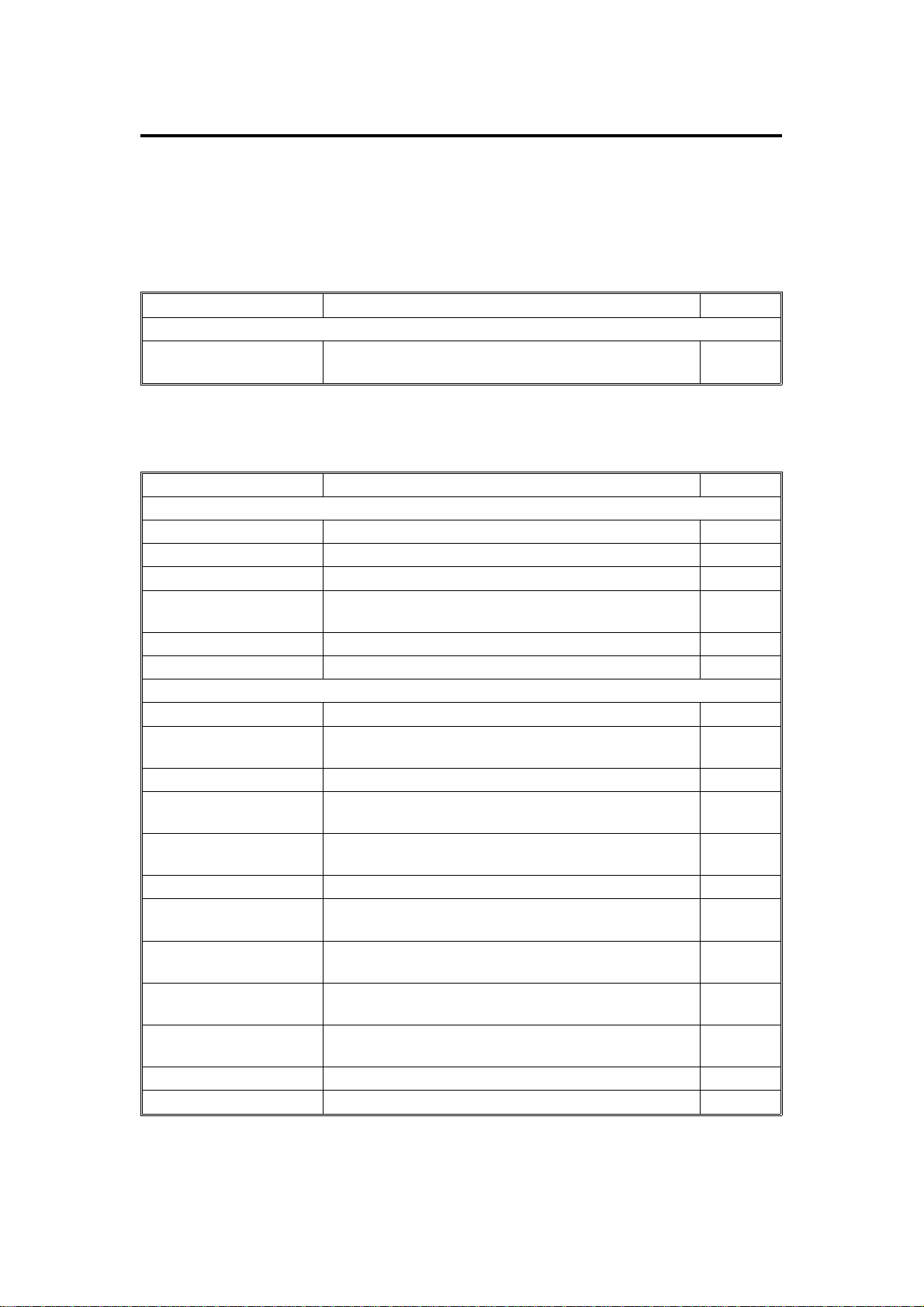

ELECTRICAL COMPONENT DESCRIPTIONS 31 January 1996

4. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical compon en t layo ut on the reverse side of the Point to

Point (Water proof paper) index numbers.

4.1.1 Copier

Name Function Index No.

Sensors

2nd Paper End - Duplex Detects whether any paper is left in the duplex unit or

not.

4.2 RDH

Name Function Index No.

Motors

Feed Drives the feed and transport rollers. 3

Belt Drive Drives the transport belt. 7

Inverter Drives the inverter and exit rollers. 34

Blower Supplies air to the air knife and draws air from the

vacuum section.

Separator Drives the original separator. 21

153

5

Sensors

Original Set Detects if the original is set on the document handler. 31

Entrance Detects the original leading edge and de-energizes

the feed belt drive clutch.

1st Transport Detects jams in the transport section. 16

2nd Transport Detects the original leading edge and lowers the

original feed motor speed.

Registration Detects the original trailing edge for the original stop

position calculation.

Inverter Entrance Detects jams in the transport belt section. 24

1st Inverter Detects the original trailing edge and reverses the

inverter drive motor rotation.

2nd Inverter Detects the original leading edge and energizes exit

roller release solenoid.

Exit Detects the original leading edge and lowers the

inverter drive motor speed.

Single Feed Set Detects the leading edge of the original in the single

feed table and turns the original feed motor.

Single Feed Exit Detects jams in single feed mode. 25

Lift Detects if the RDH is open. 2

33

15

12

29

30

32

13

1-6

Page 16

31 January 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Name Function Index No.

CFF Detects if the computer form is set in the CFF guide.

Counts the holes lined up to the computer form.

Original Length Detects if the original stopper is set for 8

1/2" position. 19

9

Original Height Detects the original height on the RDH. 20

Separator H.P. Detects if the original separator is in the home

position.

22

Separator Detects if the last original of the original stack is fed. 23

Inverter Unit Cover

(Switch)

Original Width

(Potentiometer)

Single Feed Original

Width (Potentiometer)

Original Incorrect

Positioning

Detect if the inverter unit cover is opened.

Detects the original width in the stack feed mode.

Detects the original width in the single feed mode.

Detects when an original has been placed incorrectly

on the RDH original table.

27

17

14

35

Solenoids

Vacuum Shutter Closes the vacuum shutter. 4

Single Feed Gate Lowers the single feed gate. 8

Single Feed Exit Lifts the single feed exit gate. 26

Exit Roller Releases the exit driven rollers from the exit drive

rollers.

28

Clutches

Feed Belt Drive Transmits the original feed motor drive to the feed

belt rollers.

10

Feed Belt Brake Stops the feed belt rotation. 11

PCBs

Main Control Controls overall RDH operation. 6

Blower Motor Control Controls the vacuum motor operation. 1

Indicator Indicates the single feed mode indicators. 18

1-7

Page 17

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 18

31 January 1996 DEVELOPMENT

6. DEVELOPMENT

6.4.3 Bias for the ID Sensor Pattern

ID Sensor

Full Size

Enlargement

Reduction

VL Pattern

ID Sensor Pattern

Exposure Glass

A170D500.wmf

Outside

The ID sensor pattern canno t alwa ys be use d for t he ima ge den sity dete ctio n

due to the position of th e ID sen sor an d bo th the positioning and size of the

ID sensor pattern on the dru m.

The outside of the exposure glass (no light) is exposed on th e drum and used

as the ID sensor pattern in redu ctio n mode.

No light: Reproduction ratio < 77%

ID pattern: Reproduction ratio ≥ 77%

The ID sensor bias (VBP) is determined using the following base voltage in

every case.

VBP = –360 + V0

V01 and V02, which are explained in the process control section, are used for

the VBP calculation as the V0 (drum potential af te r t he ch arg e coro na ) value.

The VBP can be changed by the SP mode (Toner Densit y Correct ion).

The following compensation will be applied to the above VBP.

Setting L N H VH

(V) –60 0 +60 +120

Default: H (+60 V)

2-1

Page 19

[A]

[D]

DUPLEX 31 January 1996

15. DUPLEX

15.8 DUPLEX END FENCE AND 2ND PAPER END SENSOR

[B]

[C]

[A]

[E]

After the duplex paper e nd senso r [ A] det ect s t hat there is no paper in the

paper feed section, th e du ple x end fen ce [B] moves the stack copy to the

paper feed section [C] in th e du ple x unit in the alternate paper fe ed mode .

The 2nd paper end sensor [D] detect s whet he r or not any sta ck co py is left in

the stack position [E] or not after duplex paper end sensor de te cts that there

is no paper in the paper feed section.

[C]

A170D529.wmf

2-2

Page 20

31 January 1996 DUPLEX

A170D527.wmf

A170D530.wmf

2-3

Page 21

[J]

RDH 31 January 1996

16. RDH

16.1 OVERVIEW

16.1.1 No Inversion Original Cycle

[B]

[E]

When the start key is pressed, the blowe r mo to r start to rotate. It supplies air

to the air knife and draws air from the vacuum section. Sheets are separated

at the leading edge [A] of the paper sta ck. The air comes from the nozzle [B]

and the bottom sheet of th e stack paper is held against the fee d-in belts [C]

by air suction [D]. The feed moto r d rives th e feed drive [E], transport [F], and

right turn [G] rollers. The botto m sh eet of the paper is delivered through the

feed drive, transport, right turn rollers to the registration section [H] and is

stopped. To stop the original shee t at the prop er po sitio n in th e reg istra tio n

section, the feed mo to r ro ta tion speed is reduced by half when the 2nd

transport sensor [I] detects the leading edge of the original. The belt drive

motor then starts to rotate the tra nsp ort belt [J] to direct the sheet of paper

onto exposure glass. At the same time, the next original is fed.

[A]

[D]

[F]

[C]

[H]

[I]

[G]

A170D501.img

2-4

Page 22

31 January 1996 RDH

[H]

[G]

[F]

[D]

[A]

[E]

[B]

[C]

A170D502.img

At the appropriate time, the transport belt delivers the original on the

exposure glass to the inverter section [A], and the following origin al is mo ved

onto the exposure glass, and the 3rd sheet of original is fed. The 1st original

is passed into the inverte r section through the inverter en tra nce [B], inverter

middle [C], and inverter [D] rolle rs u nt il the trailin g edge of th e orig inal is

detected by the 1st in vert er sensor [E]. The inverter mid dle [C] an d inverter

[D] rollers then rotate in the opposite direction. The inverter exit rollers [F]

rotates only in the paper exit direction . However, the contact between the

inverter exit roller [F] and inverter exit driven roller [G] is released whe n the

2nd inverter sensor [H] is activa te d by th e original. This way, the inverter exit

roller does not interfere with the original switch back cycle while the inverter

middle and inverter rollers begin reverse rotation. The original is delivered

through the inverter entrance [B] and inverter exit [F] rollers to the orig ina l

table. This continues until all o rigin als ha ve been retu rne d to the origin al

table. The originals are stacked on the original table where they wait fo r t he

next copy cycle.

2-5

Page 23

RDH 31 January 1996

16.1.2 Inversion Original Cycle

[A]

[B]

[B]

[C]

A170D503.img

Until the original reaches to th e inve rte r sectio n [A], the sequence is the same

as for no inversion original cycle. The inve rte r rollers [B ] rotate in the original

exit direction. The original is now inve rted and exited to the original table [C].

This continues until all originals have be en invert ed . The inverted originals

are then fed from the origin al table for copying of the reve rse side. The

sequence is the same as for th e front side copying. The origin als ret urn and

are stacked on the original table where they wait for the next copy cycle.

2-6

Page 24

[C]

31 January 1996 RDH

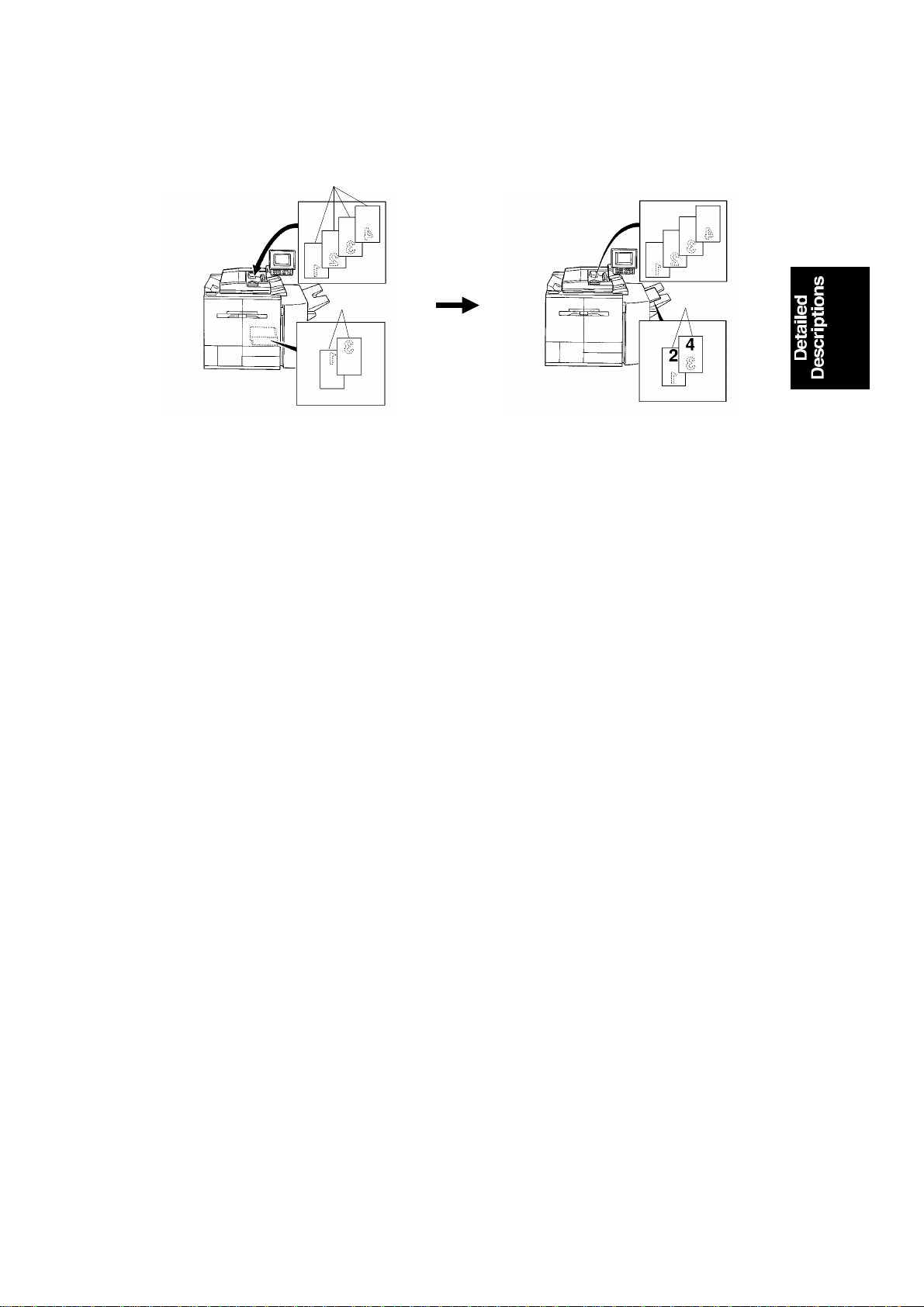

16.1.3 1 Sided Original 2 Sided Copy Mode (one set of copies)

[A]

[B]

A170D504.img

A170D505.img

No inversion original cycle is used for this mo de.

All the originals [A] are fed starting from the botto m origin al she et . First, odd

numbered originals (in case of the illust ration: 1st and 3rd originals) are

copied and even numbered orig ina ls copy is skip ped. The cop ied pap er [B ] is

stacked in the duplex tray. The origin als are re tu rn to the origin al ta ble, and

the original feed is then repeated. This time the odd numbered origin als cop y

is skipped and even numbered originals are copie d on the reverse sid e of the

copy paper [C], which is fed from the duplex tray.

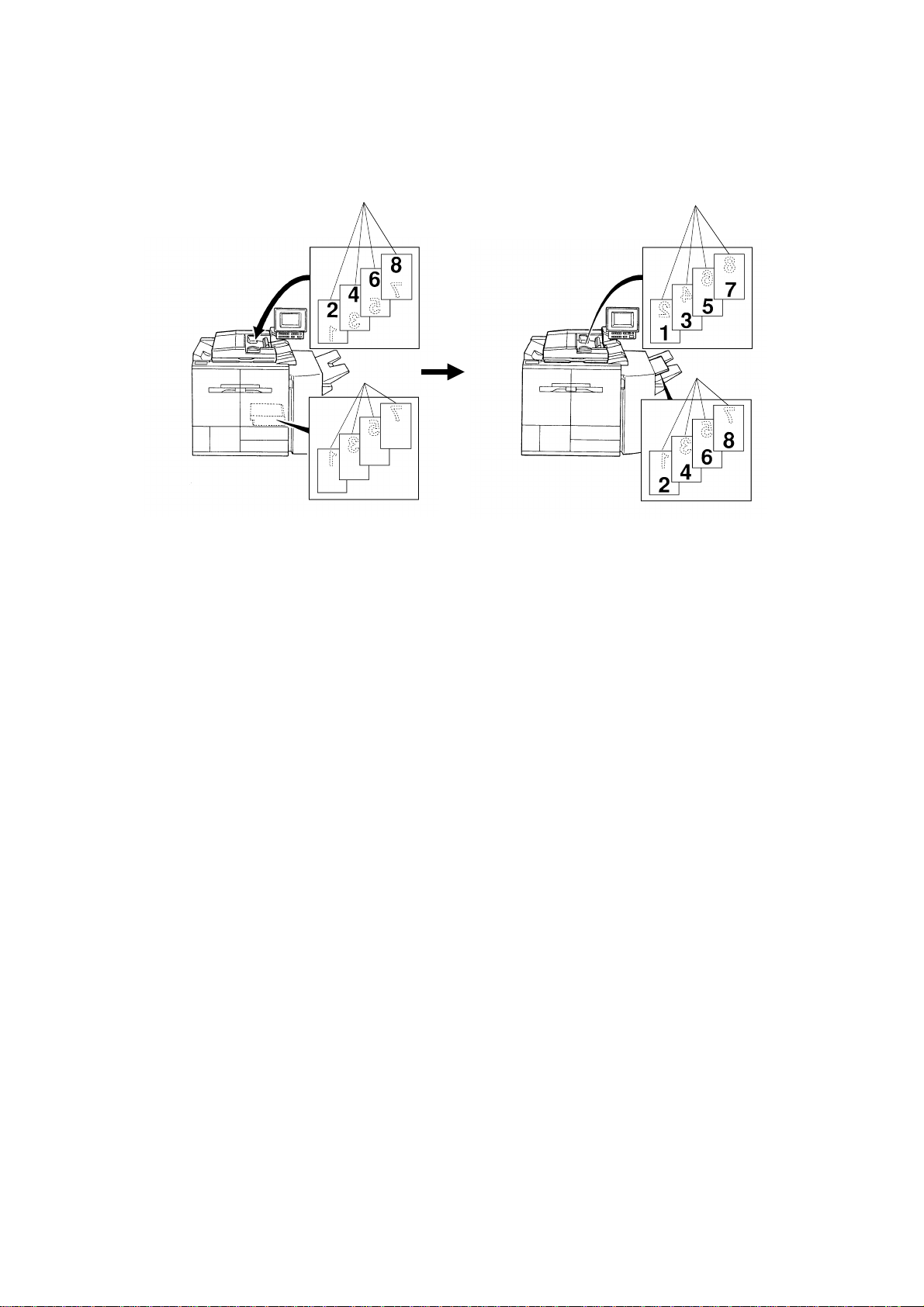

16.1.4 Two or More Copies (alternate paper feed)

An alternate paper fe ed system can be used when the RDH and Finishe r are

installed.

This alternate paper feed system is a relatively efficient way to make two or

more two-sided copies from two or more one-sided origin als whe n the cop ier

is equipped with an RDH.

No inversion original cycle is used for this mo de.

When making two-sided copies, first of all, the odd pages of the originals

placed on the RDH are copied on paper from th e paper t ray. They are then

stored in the duplex tray. Then the orig inals are recirculated, and the even

pages of the originals are copied on the sheets store d in th e du plex tray.

When making two or more sets of copies, the odd pages of the origin als are

copied and the copies are sto red in the duplex tray. Then all the pa ges o f th e

recirculated original are copie d. Odd pages are copied onto new copy paper.

Even pages are copied onto paper from th e duple x t ray. Finally th e eve n

pages of the recirculated originals are copie d on the sheets stored in the

duplex tray. See the next page for example.

This system has many benefits.

2-7

Page 25

RDH 31 January 1996

– Operation –

Example:

Two sets of two-sided copies are made from four one-sid ed originals.

1) When the start key is pressed, th e 1st and 3rd orig inals are scanned,

then the copies are stacked in the duplex tray. The 2nd and 4th originals

have only passed over the expo sure glass [Fig 1].

2) The 1st original is scanned. The copy is stacked in the duplex tray.

Soon after this, the bo tt om copy in the duplex tray is fed [Fig 2].

3) The 2nd original is scanned. The copy which has been fed rea che s the

drum for copying the 2nd original, and is then fed out onto the copy tray

[Fig 3].

4) The 3rd original is scanned, and th e cop y is stacked in the duplex tray.

Soon after this, the bo tt om copy in the duplex tray is fed [Fig 4].

5) The 4th original is scanne d. The copy which has been fed reaches the

drum for copying the 4th original, and is then fed out onto the copy tray

[Fig 5]. The stack in the duplex un it is moved to the duplex paper feed

section by the duplex end fence.

6) The 1st original is fed into the scanner and is fed out from the RDH

without exposing. After this, the bottom cop y in the dup lex tra y is fed in

preparation for th e reve rse side copying [Fig 6].

7) The 2nd original is scanned. The copy which has been fed rea che s the

drum for copying the 2nd original, and is then fed out onto the copy tray

[Fig 6].

8) The 3rd original passes over the expo sure glass. Aft er this, the bottom

copy in the duplex tray is fed in preparat ion for the reverse side copying

[Fig 7].

9) The 4th original is scanne d, the copy which has been fed reaches the

drum for copying the 4th original, and is then fed out onto the copy tray

[Fig 7].

2-8

Page 26

31 January 1996 RDH

4

3

2

1

3

1

C

B

3

1

1

1

3

1

A

Fig 3Fig 2Fig 1

3

3

1

3

1

3

3

1

2

1

Fig 7

Fig 6Fig 5Fig 4

A: Paper Tray

B: Duplex Unit

C: RDH

3

1

m

: Recirculated

l

: 3rd recirculated

: Without exposing

(for RDH)

A170D506.wmf

2-9

Page 27

RDH 31 January 1996

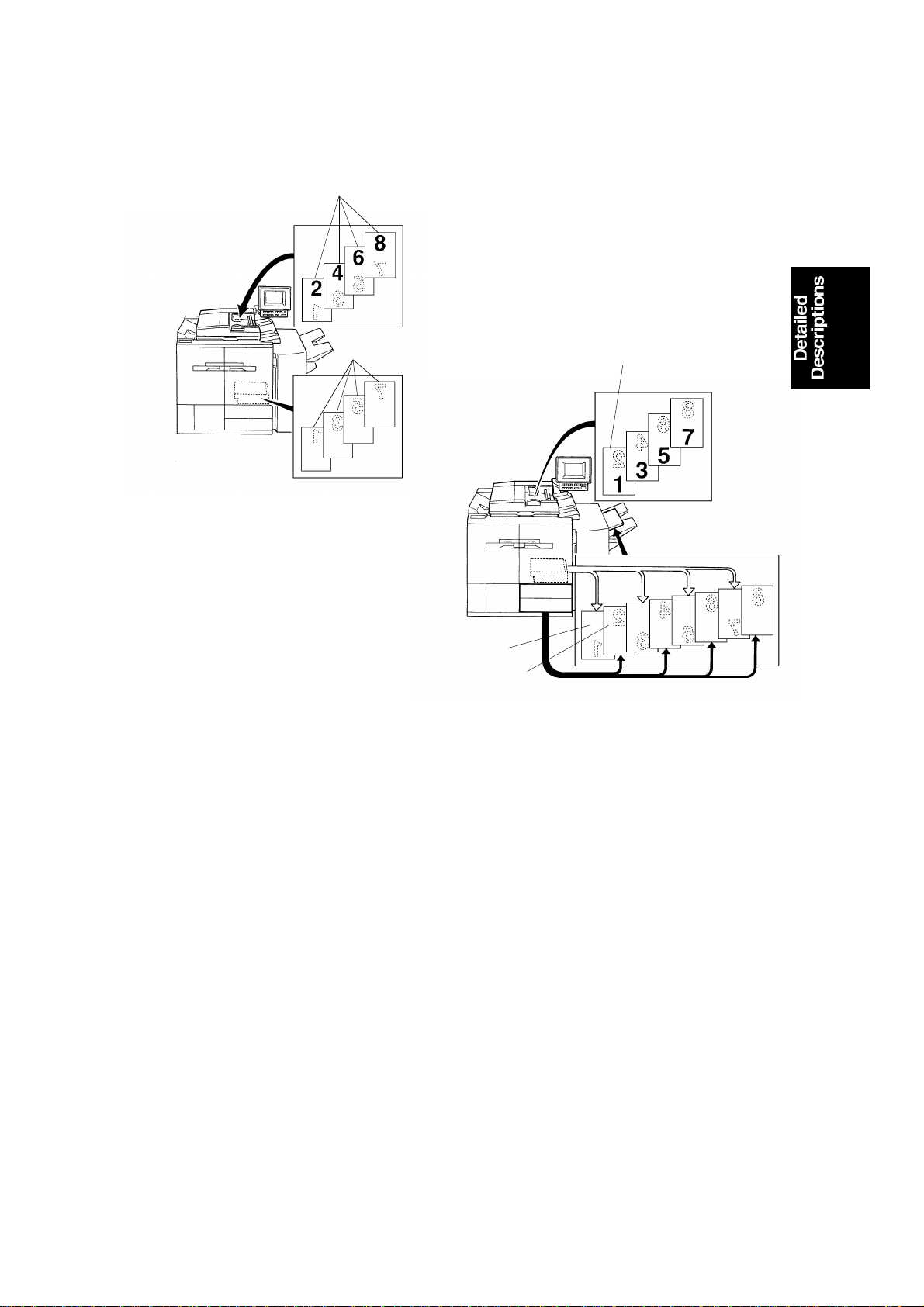

16.1.5 2 Sided Original 2 Sided Copy Mode

[A]

[B]

A170D507.img

[C]

[D]

A170D508.img

Inversion original cycle is used for this mode. All the origin als [A ] are fed

starting from the bottom o rigin al she et. First, the front side of the originals are

copied. The copied paper [ B] is stacked in the duplex tray. The originals [C]

are inverted and return to the origin al ta ble . The origin al fe ed is then

repeated. This time the reverse side of the originals are copied on the

reverse side of the copy paper [D], which is fed from the duplex tray.

2-10

Page 28

[E]

31 January 1996 RDH

16.1.6 2 Sided Original 1 Sided Copy Mode

[A]

[B]

A170D507.img

[D]

[C]

A170D509.img

Inversion original cycle is used for this mode. All the origin als [A ] are fed

starting rom the bottom original sheet. First ly, the fro nt sid e of all the originals

are copied and the cop ied pap er [B ] is st acke d in the duplex tray. The

originals [C] are inverted and re turn to the origin al ta ble . The origin al fe ed is

then repeated. This time, the bott om cop y sh eet is fed from th e duple x tr ay

and exited from the copier with ou t copying [C]. The reverse side of th e

bottom original sheet [D] is then copie d to paper [E ], which is fed from the

paper tray, and the copy is exited from the copie r [E] . This cop y se quen ce

exiting from the duplex tray followed by the paper tray is alte rna te ly repe ated .

2-11

Page 29

RDH 31 January 1996

16.2 ORIGINAL SET

16.2.1 Stack Feed Mode

[D]

[B]

[A]

[D]

[E]

[G]

[J]

[C]

[I]

[H]

A170D510.img

[K]

1. Original set detection

A170D528.wmf

The originals are detected by the original set sensor [A] when they are

stacked on the original t ab le. If the original incorrect positio nin g sensor [B]

detects originals placed inco rrectly on the RDH original table, a messa ge is

displayed advising the user to set th e originals at the correct position.

2. Size detection

The original width is detected by the origin al width sensor [B] under the front

original guide [D]. Movin g the guide changes the value of th e sen sor. (The

sensor is a potentiometer.) Th e fro nt origin al gu ide and rear orig inal guide [E]

are moved by the racks [F] and pin ion [G] at the same time. The act ua to r [ H]

of the original stopper activat es th e original length sensor [I]

(photo-interrupte r) t o dete ct if the original stopper is set for the 81/2 inch

position. LG (81/2" x 14" = 216 x 356 mm) or B4 (257 x 364 mm) size is

distinguished by the combination of the origina l leng th se nso r (a ctiva ted or

not) and the value of the origin al widt h sensor. This is because the LG and

B4 widths are very close.

The original guides are stopped at the pape r size posit ion (A 4 for EU/LT, LG

for USA). They click into position when the roller [J] on the lock arm dro ps

into the semicircular stopper [K].

2-12

Page 30

[C]

31 January 1996 RDH

[B]

[E]

[E]

[A]

[D]

[F]

[E]

A170D511.img

A170D512.img

3. Original separator

The original stack which has been fed and return ed to the orig inal table, and

the original stack which has no t been fed yet, are separated by the original

separator [A] mechanism.

When the start key is pressed, the sepa rator motor [B] rotates un til th e

original separator act ua to r [ C] act ivates the separator home position sensor

[D]. The original separato r is set on the original top sheet. The originals which

are fed and returned to the origin al table are stacked on the original

separator. When the last original (to p sheet under the orig ina l sepa rat or) is

fed from the original table, the orig inal separator drops and activates th e

separator sensor [E].

If the next copy cycle continues, th e sep ara to r moto r rota te s and the origin al

separator is set on the original top sheet ag ain aft er th e tra iling edge of the

last original sheet passe s thro ug h the exit sensor [F].

2-13

Page 31

[E]

RDH 31 January 1996

16.2.2 Single Feed Mode

[A]

[C]

A170D513.img

[D]

[B]

[F]

A170D514.img

1. Original set detection

The original is detected by the single feed set sensor [A] when the original is

set on the single feed tab le.

2. Size detection

The original width is detected by the sin gle feed orig inal width sensor [B]

under the rear original guide [C]. Moving the guide chan ges t he value of th e

sensor. (The sensor is a potentiometer.) The front original guide [D] and rea r

original guide are moved by the racks [E] and pinion [F] at the same time. As

the original length sensor is not use d for t he single feed mode, the original

length is not detected . When the B4 or LG original is set on th e sing le feed

table, the origina l size is dete rmine d by the machine version.

(U.S.A. version machine ... LG, Euro pe version ma chin e .. . B4 ).

2-14

Page 32

31 January 1996 RDH

16.3 ORIGINAL FEED

16.3.1 Original Separation/Feed (Original Stac k Mode)

[A]

[B]

[E]

[F]

[D]

[B]

[C]

A170D515.img

[F]

[G]

[H]

A170D516.img

1. Air knife and shutter

The air from the blower motor [A] is blown thro ug h the air knif e nozzles [B] to

the leading edge [C] of the original stack. The blowe r moto r keeps blowin g air

from the beginning to the end of the origin al stack mode to prevent

multi-feeding.

After the originals are separated by the air knife, the vacuum shutter solenoid

[D] is energized by a paper feed signal from the main PCB. The vacuum

shutter [E] closes the air hole on th e vacu um du ct [F] . The blowe r draws air

from the vacuum section [F] . The botto m shee t orig inal [G] is held against the

feed-in belts by the suction . Until, the feed-in belt rotat es. The bottom sheet

original [H] is then fed.

2-15

Page 33

RDH 31 January 1996

[A]

Table 1

Table 2

Small

Size

Large

Size

Small

Size

Large

Size

A4

1/2

8 x 10

81/2 x 11

1/2 x 13

8

B4

A3

1/2 x 14

8

10 x 14

11 x 17

A4

1/2

8 x 10

81/2 x 11

1/2 x 13

8

B4

A3

1/2 x 14

8

10 x 14

11 x 17

A170D517.img

Original Height Sensor

OFF ON

3000 rpm

7000 rpm

3500 rpm

Number of Originals

5 or less from 6 to 12 13 or more

3000 rpm

7000 rpm

3500 rpm

2. Blower motor speed

To ensure good original separation and origin al re-st ackin g on the origin al

table, the blower motor speed is chang ed accord ing to the original stack

height, or the number of originals stacked. The blower motor speed is

determined for the 1st copy cycle by the original stack height as detected by

the original height sensor [ A] (Table 1). From th e 2nd cop y cycle, th e blo wer

motor speed is determined by the numbe r of orig ina ls coun te d by the main

PCB (Table 2).

When the number of the originals is 3 or less, the origin al set sensor is

de-activated when the last original is fed and before the 1st origin al ret urn s to

the original table. During this pe riod the blowe r motor stops rotating to ensure

correct stacking the originals.

2-16

Page 34

[D]

[E]

31 January 1996 RDH

16.4 SINGLE FEED MODE

16.4.1 Registration

[B]

[A]

[C]

[D]

A170D518.img

When the single feed set sensor [A] detects the leading edge of the orig ina l

the feed motor rotates and the right turn roller [B] transports the original. At

the same time the single fe ed gat e sole no id [C] is energized and the single

feed gate [D] is lowered. The feed mot or an d sing le fe ed gat e soleno id are

energized until the registration sensor [E] detects the leading edge of the

original. The original is transported until hits the single feed gate, which

corrects the original feed skew. At th e same time th e right turn roller stops

rotating.

2-17

Page 35

[B]

RDH 31 January 1996

16.4.2 Feed

[C]

[D]

[G]

[A]

[F]

[E]

A170D519.img

When the start key is pressed, the rig ht turn roller [A] and transport belt [B]

rotate. The origina l is delivered onto the exposure glass. Aft er the scanner

scans the original, the transpo rt be lt sta rt to ro ta te to deliver it. At the same

time the inverter entrance [C] an d inve rter middle [D] rollers rotate and the

single feed exit solenoid [E ] is ene rgized. The single feed exit gate [F ] lift s up,

exiting the original to the left top cover [G].

16.4.3 16.4.3 Exit Gate

In single feed mode and CFF mode , the single feed exit solenoid is ene rgize d

while the belt drive motor is driving the transport belt, and is de-energized

when the transport belt stops rotating. This solenoid on off operation is

performed to keep the solenoid reliable.

2-18

Page 36

[A]

31 January 1996 RDH

16.5 DRIVE MECHANISM

16.5.1 Feed Motor Drive

[B]

[G]

[C]

A170D520.img

[H]

[H]

[D]

[A]

[E]

[F]

[C]

A170D521.img

All the feed rollers and transport rollers (with the exception of the fee d belt

drive rollers [A]) begin to rotate to geth er with the feed mot or [B]. The feed belt

drive clutch [C] is energized accordin g to the appropriate original fee d timin g.

When the clutch is energized, the feed motor drive will be transmitt ed thro ugh

the gears [D] and timing belt [E] , an d th e feed belt brake clutch shaf t [F] to

the feed belt drive rollers. The feed belt bra ke clut ch [G] stops the feed belt

rotation when the feed belt drive clutch is de-energized to prevent

multi-feeding of originals. When the feed belt brake clutch is energ ized ,t he

rotating clutch disk [H] is stopped by the clutch which is fixed on the frame .

2-19

Page 37

RDH 31 January 1996

16.5.2 Belt Drive Motor Drive

[B]

[A]

A170D522.img

The transport belt [A] is driven by the belt drive mot or [B ] via timin g belts an d

pulleys.

2-20

Page 38

[H]

31 January 1996 RDH

16.5.3 Inverter Motor Drive

[A]

[C]

[B]

[D]

[E]

[F]

A170D522.img

[G]

[D]

[A]

A170D523.img

The inverter motor [A] rot at es fo rward s or b ackwa rds acco rding to the

appropriate timing. The invert er middle [B] and inverter [C] rollers ro ta te

forwards and backwards the inve rte r mo to r drive. However, inverter entran ce

[D], inverter exit [E], and exit [F] rollers rot at e in only o ne direct ion.

The relay pulley [G] and inverter roller pu lley [H] have a built - in one way

clutch inside. When the inverter motor rot at es forward s (b lack arro w

direction), the inverter rolle r pulley [H] rotates the inverte r ent ran ce roller [D].

In this case the relay pulley [G] freely rotates due to the one way clutch

inside. All rollers rotate in the original feed directio n.

While the inverter motor rotates backward s (white arrow dire ctio n), the relay

pulley [G] rotates the inverter entrance roller [ D]. In th is ca se th e inverter

roller pulley [H] freely rotat es due to the one way clutch inside. The invert er

entrance, inverter exit, and exit rollers rotate in the original exit direction.

However, the inverter middle and inverter rollers rotate in the original

switching back direction.

2-21

Page 39

RDH 31 January 1996

16.6 ORIGINAL POSITIONING

Thin Paper Mode

[A]

A170D524.img

Thick Paper Mode

A170D525.img

Customers can choose the paper tra nsp ort mode by "User Tool" depending

on the thickness of the original used.

– In thin paper mode –

The belt motor stops exactly when the trailin g ed ge of the original passes the

right scale [A] edge. (The timing is measu red by the timing sensor after

registration sensor is activated. )

– In thick paper mode –

To correct skewing on the exposure glass, the origin al runs 10 mm after the

trailing edge passes the right scale . The belt motor then reverses and the

original travels until it meets the right scale.

If extremely thin paper is used in the thick paper mod e, the paper may float

near the scale. This will result in poor image quality or original copy wrinklin g.

The factory setting is "Thin Pap er Mode:.

2-22

Page 40

31 January 1996 RDH

16.7 CFF Mode

[C]

[A]

[E]

[D]

[B]

A170D526.img

When the CFF guide lever [ A] is slid to the left, the CFF sensor [B] comes out

of the single feed rear guide [C]. This sensor consists of one CFF set sensor

[D] and two CFF feed hole sensors [E]. The CFF set sensor detects if the

computer form is set in the CFF guide.

The CFF feed hole sensor coun ts th e ho les line d up to th e computer form.

2-23

Page 41

A170D531.img

Energy Star Compliant Machines (North American versions only) 31 January 1996

19. Energy Star Compliant Machines (North

American versions only)

In conjunction with the modification for the Ene rgy St ar compliance, field

technicians are reque ste d to understand the changes in op eration modes so

as to set up the machine for the custo mer specific environment/require men ts.

The following table shows all diff erences between the Energy Star co mplia nt

machines and the Non-Energy St ar comp liant machines.

Mode Non-Energy Star Energy Star

Auto Off Mode When the copier is used after the

weekly timer has turned it off, the

copier will turn itself back off after

the selected time.

The auto off time can be set from 1

to 180 minutes, or the function can

be turned off.

Default: 1 hour

Simplex/Duplex

Mode

Weekly Timer Available Because the auto off mode is a

SC Code N/A A new SC code # 940 has been

Single sided original to single sided

copy is default setting mode at the

factory.

The copier turns off after the

selected time after the last copying

job.

The time can be adjusted from 1 to

120 minutes. This mode cannot be

canceled.

Default: 90 minutes

Single sided original to two sided

copy is default setting mode at the

factory.

mandatory standard feature of the

Energy Star standards, the weekly

timer is no longer available.

added.

Definition: The main switch does

not turn off after sending

the reset signal two times

in a row.

Point to check: • Main Switch

• Main PCB

Because the auto off mode and default duplex mode are explained in the

Operating Instru ctions, make sure that the cust ome r u nd erst an ds ho w the

machine operates to save en ergy.

2-24

Page 42

SECTION 3

INSTALLATION

Page 43

31 January 1996 INSTALLATION REQUIREMENT

1. INSTALLATION REQUIREMENT

1.1 ENVIRONMENT

1. Temperature Range: 10°C to 30°C (50°F to 86°F)

2. Humidity Range: 15% to 90% RH

3. Ambient Illumination: Less than 1,500 lux (do not exp osure to direct

sunlight)

4. Ventilation: Min imum spa ce 20 m3.

Room air should turn over at least

30 m3/hr/person.

5. Ambient Dust: L ess th an 0.1 5 mg/ m3 (4 x 10

6. If the machine location is a ir-con dit ioned or heated, place the machine:

a) where it will not be subjected to sudden temperature changes.

b) where it will not be directly exposed to cool air from an air-conditioner

in the summer.

c) where it will not be directly exposed to ref lect ed heat fro m a space

heater in winter.

7. Avoid placing the machine in an area filled wit h corro sive ga s.

8. Avoid any places higher than 2,000 meters (6,500 fee t) ab ove seal level.

9. Place the machine on a stro ng and level ba se.

10. Avoid any area where the machine may be frequently subje cte d to strong

vibration.

-6

oz/yd3)

1.2 MACHINE LEVEL

1. Front to back level: within 5 mm (0.2")

2. Right to left level: within 5 mm (0.2")

3-1

Page 44

More than 11.8"

(300 mm)

INSTALLATION REQUIREMENT 31 January 1996

1.3 MINIMUM SPACE REQUIRE MENTS

More than 15.8"

(400 mm)

More than 11.8"

(300 mm)

More than 39.4"

(1000 mm)

A170I500.img

3-2

Page 45

31 January 1996 INSTALLATION REQUIREMENT

1.4 POWER REQUIREMENTS

1. Input voltage leve l:

240 V/60 Hz: 20A or more (for U.S.A. version)

220 V/230 V/240 V/50 Hz: 13A or more (for Eu rop ea n versio n)

2. Permissible voltage fluctuation: ±10%

3. Do not set anythin g on the power cord.

CAUTION:

N

a) Make sure the plug is firmly inserted in the outlet.

b) Avoid multi-wiring.

240V

(U.S.A. version)

220 / 230 / 240V

(European version)

3-3

A170I501.img

Page 46

ACCESSORY CHECK 31 January 1996

2. ACCESSORY CHECK

Check the quantity and condition of the accessories in the box acco rding to

the following list:

1. Operation Unit ................. .. ...................... 1

2. Operation Unit Stand..................... .. ........ 1

3. Fusing Unit Release Lever.............. .. .. .. .. 1

4. Drum Guide ......................... .. .. .. .. .. .. .... .. .. 1

5. Leveling Shoe.......................... .. .............. 4

6. Operating Instru ctio ns Holder ................. 1

7. Editing Sheet (U.S.A version only).......... 1

8. M4 x 6 Screw .................... ............ .......... 4

9. M5 x 8 Screw .................... ............ .......... 4

10. M3 x 10 Screw............................... .. ........ 2

11. M4 x 8 Screw ........ .. ............ ............ ........10

12. Harness Clamp...................... ............ ...... 2

13. Bushing ........... .............................. .. ........ 1

14. Operation Unit Sto pp e r................ .. .......... 1

15. Drum Guide Bracket........................ .. .. .. .. 1

16. Left Lower Inner Cover.................... ........ 1

3-4

Page 47

31 January 1996 INSTALLATION PROCEDURE (COPIER)

3. INSTALLATION PROCEDURE (COPIER)

[A]

[A]

[F]

[C]

[D]

[B]

A170I503.wmf

[G]

[H]

CAUTION:

N

A70I502.img

A170I504.wmf

While the leveling shoes are not i nsta ll ed, do not completely pull out

many units simultaneousl y. Otherwise, the machine could topple.

NOTE: Keep the shipping retain ers af ter installing the machine. They will be

reused if in the futu re the machine is transported to another location.

Proper reinstallation of th e ship ping retainers is required in order to

avoid any transport damage.

1. Remove the strips of the filament ta pe [A] .

[E]

[J]

[I]

2. Open the left and right front do ors [B , C] an d remo ve th e strip s of fila men t

tape [D]. Remove the styrofoam blocks [E] and the cushion [F].

3. Remove the left vertical transp ort fixing bracket [G] (1 screw), pull out the

left vertical transport unit , an d inst all th e lef t lowe r inne r cover [H] (2

screws).

4. Remove the tray fixing bracke t [I ] (1 screw) an d rein stall the removed

screw [J] on the 3rd tray cover.

3-5

Page 48

INSTALLATION PROCEDURE (COPIER) 31 January 1996

[B]

[G]

[F]

[A]

A170I505.img

[D]

[E]

[C]

A170I506.img

A170I523.img

[H]

[E]

A170I524.wmf

[I]

A170I507.wmf

5. Remove the fusing cover [A ] (3 screws), fixing bracket [B] (1 screw), and

reinstall the fusing cover. In stall the fusing unit release lever [C] , tu rn the

lever clockwise, and fix it (1 M5 x 8 screw).

(European version only)

a) Pull out the fusing unit.

b) Remove the upper fusing entra nce guide [D] (4 screws).

c) Remove the oil supply roller securing brackets [E] (2 screws).

d) While pushing the bushings [F] inwards, put back the screws [G].

e) Re-install the upper fusing entrance guide and push in the fusing unit.

6. Remove the right cover [H] (2 screws) an d 2 stu ds [I ] securing the paper

tray. Reinstall the right cover.

3-6

Page 49

31 January 1996 INSTALLATION PROCEDURE (COPIER)

[J]

[D]

[C]

[I]

[F]

[A]

[B]

[E]

A170I508.img

[L]

[N]

[G]

[H]

A170I509.img

[K]

[M]

A170I510.img

7. Remove the front scale holder [ A] (2 screws), fro nt scale [B] (2 screws),

exposure glass [C], left top cover [D] (8 screws), and right rear cover [E]

(front view, 2 screws).

8. Remove the 3rd scanner securing bracket [F] (1 screw), scanner securing

screw [G], and lens securing bracket [H] (1 screw).

NOTE: The scanner fixing screw is required when replacing the scanner

wire. Please keep it for future use.

9. Reinstall the exposure glass, fron t scale, front scale holder, and the left

top cover.

NOTE: • The mark [I] on the edge of the glass should face up. This side

is smoother and it generates less sta tic ele ctricity when the

DF is used.

• Use the flat head screw for 5 screws [J].

10. Remove the left inner cove r [K] (4 screws), strip of fila men t tape [L]. Then,

remove the PTC unit [M], and th e de velopment unit [N] (1 screw and 1

connector).

3-7

Page 50

[J]

INSTALLATION PROCEDURE (COPIER) 31 January 1996

[B]

[A]

A170I511.img

[I]

[D]

[C]

A170I512.img

[F]

[H]

[G]

[E]

A170I513.img

11. Remove the charge corona unit [A] (1 connector and 1 clamp) and erase

unit [B].

12. Lower the transport unit by the lever [C] as shown and remove the drum

stay [D] and cleaning unit [E].

13. Remove the drum potential se nso r [F] (2 connectors), ID sensor [G], and

drum protection sleeve [H].

14. Reinstall all the units arou nd the drum exce pt for th e de velo pment unit

and PTC unit.

NOTE: Press the drum shaft [I] to the left and align the clean ing unit to

the guides [J] to prevent th e dru m dama ge when reinstalling the

cleaning unit.

3-8

Page 51

31 January 1996 INSTALLATION PROCEDURE (COPIER)

[A]

A170I514.img

A170I515.img

15. Remove the developme nt filter [A] from the developme nt unit .

16. Pour the developer (1 bag: 1.7 kg) evenly between the left and right side

of the development unit and rein sta ll the deve lop ment filter. Then,

reinstall the developmen t unit (1 connector and 1 screw), and PTC unit on

the copier.

17. Load toner as follows (refer to the instruction decal):

a) Shake a new toner cartridge well while holding it horizonta lly.

b) Turn the green lever clockwise.

c) Insert the cartridge an d ret urn the green lever to the down po sitio n.

d) Cut the green tape.

e) Press down tab 1 and pull shutter 2 until you see the gre en tab 3.

f) Grasp tab 3 and pull the seal until yo u see the re d line .

g) Push the shutter back in.

18. Install the left inner cover an d set the tran spo rt un it.

3-9

Page 52

INSTALLATION PROCEDURE (COPIER) 31 January 1996

[B]

[E]

[F]

[C]

[A]

A170I516.img

[D]

[G]

A170I517.img

19. Connect the operation unit [A ] to the operation unit stand [B] (4 screws

and 2 connectors).

20. Install the operation unit (1 M5 x 8 screw [C] and 1 connect or [D]) and the

operation unit stopper [E] (2 M5 x 8 scre ws). The oval hole [F] of the

operation unit stopper should be at the lower position.

NOTE: • 2 height positions of the oper at ion unit can be selected by the

positions of securing screw [C].

• The operation unit can be moved le ft to righ t by removing one

M5 x 8 screw [C] when the operation unit is mounted at the

lower position.

21. Secure the grounding wire [G] of th e op era tio n un it (1 screw) an d rein sta ll

the right rear cover.

3-10

Page 53

31 January 1996 INSTALLATION PROCEDURE (COPIER)

[B]

[A]

A170I518.img

c

[C]

1

0

A170I519.img

[D]

[E]

A170I525.wmf

23. Insert the leveling shoes [A] under the feet, and level the machine by

securing down the feet.

24. Guidance ROM Kit installation (-27 versions only). Remove the operation

unit rear cover [B] (4 screws) and install the appropriate ROMs [C] to the

operation unit board . Distin gu ish the chips (0, 1, and c) by the last 2 digit s

of their part number. The lowest one is installed at 0, the mid dle one at 1,

the highest one at c.

25. Reinstall all the covers.

26. Install the copy tray or follo w t he finish er un it inst allation.

27. Plug in the power cord and turn on the main switch.

28. Install the drum guide bracket [D] (1 long screw) (Replace the screw with

long one.) and set the drum guide [E].

29. Check the copy quality and the copier operation.

3-11

Page 54

INSTALLATION PROCEDURE (COPIER) 31 January 1996

3.1 A3/11" x 17" COUNTER INSTALLATIO N

[A]

[B]

[C]

A170I520.img

CAUTION:

N

Unplug the copier power cord before starting the following procedure.

1. Open the right fron t do or an d remo ve the right inner cover [A] (3 screws).

2. Install the A3/11" x 17" counter [B] (1 connector).

3. Cut the cap [C] of the righ t inner cover by the pliers.

4. Reassemble.

5. Plug in the copier power cord and turn on th e main switch.

6. Set the A3/1 1" x 17" counter mode on by using SP mod e.

7. Check the counter ope rat ion by making an A3/11" x 17" copy.

3-12

Page 55

[I]

31 January 1996 INSTALLATION PROCEDURE (COPIER)

3.2 KEY COUNTER HOLDER INSTALLATION

[C]

[H]

[F]

[B]

[A]

A170I522.img

CAUTION:

N

A170I521.img

[J]

[E]

Unplug the copier power cord before starting the following procedure.

NOTE: The Key Counter Bracket Set includes the following part s. The key

counter holder and key counter should be procured locally.

1. Key Counter Bracket............. .. ............ .. .. ..........1

2. Key Counter Plate Nut.......................................1

3. Key Counter Cover.................. ............ .. .. ..........1

4. Bushing..............................................................1

5. Screws...............................................................8

6. Clamp................................................................1

1. Open the right front door an d remo ve the right inner cover (3 screws).

[G]

[D]

2. Remove the dummy connector [A].

3. Remove the right cover [B] (2 screws) a nd sma ll cap [C] .

4. Connect the key count er ho lder [D] to key counter bracket [E] with key

counter plate nut [F] (2 screws).

5. Run the key counter harn ess [G] through the bushing [H] an d right cover

hole [I] and fix the key counter ha rne ss (1 screw and 1 harness clamp).

6. Install the key counter bracket to the right cover (3 screws).

7. Set the key counter ha rne s s conn ect or to the 4P connector from the

copier.

8. Reinstall the right cover.

9. Install the key counter cover [J] (2 screws).

10. Reassemble the machine.

3-13

Page 56

INSTALLATION PROCEDURE (LCT) 31 January 1996

4. INSTALLATION PROCEDURE (LCT)

[C]

[A]

Check the quantity and condition of the accessories in the box acco rding to

the following list.

[A]

[E]

[B]

A592I506.wmf

[D]

A592I500.img

1. By-pass Feed Lower Cover

(European version only) ..........................................1

2. By-pass Rear Lower Cover

(European version only) ..........................................1

3. Screw-M4 x 8 (Eropean version only)................... ...3

4. Grounding Screw-M4 x 8............... ............ ............ ...2

5. Screw-M4 x 12........................... .. .. .... .. .. .. .. .. .. .... .. .. .. .1

CAUTION:

N

Unplug the copier and 2nd sorter power cord starting the following

procedure.

1. Remove the strips of filament tape [A] of LCT.

2. Open the top cover [B] and remove the up per cover [C] (6 screws).

3. Remove the rear cover [D] (2 screws).

4. Remove the fixing plate [E] (3 screws).

3-14

Page 57

[H]

31 January 1996 INSTALLATION PROCEDURE (LCT)

[F]

[C]

[D]

[G]

[B]

[A]

A592I501.img

A592I507.wmf

[E]

[D]

A592I505.img

5. Remove the left lower cover [A ] (3 screws) of the copier and remove the 3

caps [B]. Remove the upper by-pa ss f eed cove r [C] (2 screws: Non

by-pass feed version only) and lower by-pass feed cover [D] (2 screws).

6. Remove the left rear cover [E] of the copier and cut 2 binds [F] for the

LCT interface harness by th e plie rs.

7. Remove the dummy connector [G].

NOTE: The dummy connector is required when operating the copier

without the LCT. Keep it for future use.

8. Secure the ground wire [H] to the copier (1 grounding screw).

3-15

Page 58

[A]

[J]

A592I504.img

INSTALLATION PROCEDURE (LCT) 31 January 1996

[C]

[F]

[E]

A592I503.img

[B]

[G]

A592I508.wmf

[D]

[I]

A592I502.img

[H]

9. Reinstall all the LCT covers.

10. Install the LCT grounding wire [A] (1 grounding screw).

11. Pass 4 connectors of the inte rface harness [B] through the rear upper

hole [C] of the left lower cover, pass the grounding wire [A ] unde r t he left

lower cover, and install the left lower cove r. (Do no t fix th e screw [D].)

[G]

12. (By-pass feed version only) Insta ll t he by-pa ss f eed lowe r cover [E]

(2 screws) and by-pass rear lower cover [F] (1 screw).

13. Loosen th e nu ts [G] of the feet [H] .

14. Set 4 connectors to th e con ne ctors [G] of the LCT harness.

15. Mount the LCT unit on the copier (Insert the 2 mounting studs [I] into the

docking holes [J]).

16. Fix the LCT unit to the copier (1 screw [D]).

17. Screw down the feet [H] to level the LCT so that th e LCT is p ara llel to the

copier.

18. (Non by-pass feed version only) Reinst all th e up per b y-pa ss fee d cove r.

19. Carry out the LCT Paper Feed Timing Adjust men t by usin g SP mode

(9 SP Adjustment, 9-1 Paper Fee d Timing Adju stme nt : LCT).

20. Check the LCT operation.

3-16

Page 59

SECTION 4

SERVICE TABLES

Page 60

31 January 1996 SERVICE REMARKS

1. SERVICE REMARKS

1.12 RDH

1. Take care not to damage the harnesses of the original tab le by pu lling

roughly when you remove the orig ina l tab le.

2. Take care not to injure yourself by dropping the RDH unit when removing

it.

3. After replacing the RDH main PCB or RDH RAM boa rd, perf orm the RDH

motor adjustment, RDH registration adjustment, and CFF registration

adjustment. (This allows the RDH t o communicate with the copier main

PCB.)

1.13 FINISHER

1. Do not turn on the main switch while the shift tray is not installed. Both the

stack height sensor and the shift tray upper limit switch do not work

without the shift tray, an d causes the tray lift mechanism b roke n.

2. Before removing the timing belt s, mark th e po sitio n of the tension

brackets.

4-1

Page 61

SERVICE PROGRAM MODE 31 January 1996

2. SERVICE PROGRAM MODE

2.1 SERVICE PROGRAM MODE OPE RATION

The service program (SP) mode is used to che ck electrical data and change

modes or adjustment values.

2.1.1 To Access SP Mode

1. Turn on DIP SW #3 on the Reset Switch PCB.

2. Input "99900 " usin g the number key tops on the operation unit, the n th e

index menu of SP modes is displa yed.

3. Touch a number on the disp lay to access the required funct ion.

NOTE: While any of the following conditions exist, you can no t access the SP

mode.

1. Toner end

2. Paper jam

3. Machine error or service call (SC)

4. Door open

2.1.2 To Exit SP Mode

1. Return to the index menu by touching on the display.

2. Touch .

Quit

Index

3. Turn off DIP SW #3 on the Rese t Swit ch PCB.

2.1.3 Change the Menu Screen

1. To move to the next page , touch .

2. To move to the previous pag e, tou ch .

3. To return the index menu , to uch .

Next Pg.

Prev. Pg.

Index

A170M500.img

4-2

Page 62

31 January 1996 SERVICE PROGRAM MODE

2.2 SP MODE FUNCTION

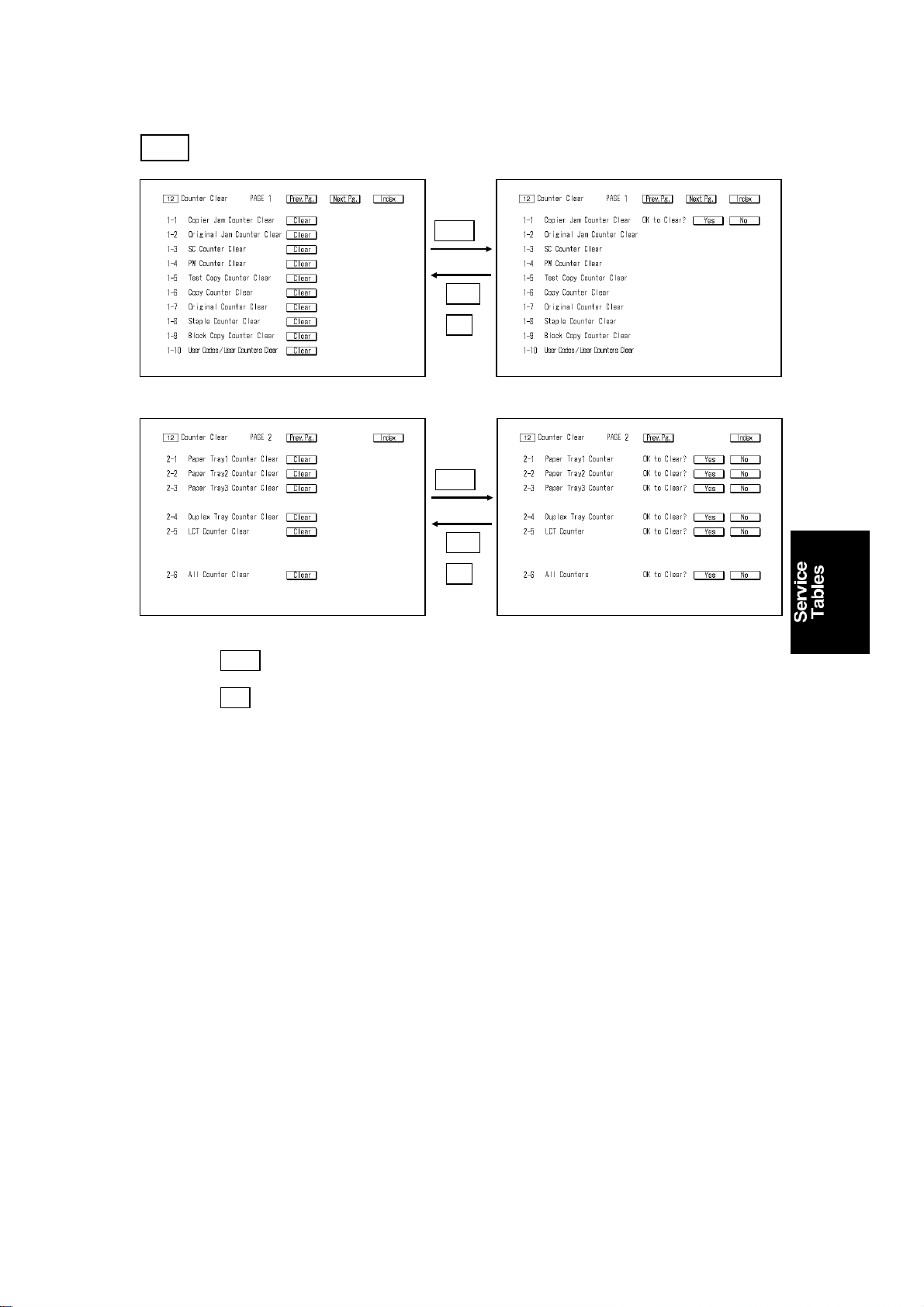

1 Jam Counters

A170M501.img

A170M502.img

Location Code

A 1st Tray

B 2nd Tray

C 3rd Tray

D Not used

E Horizontal Transport Unit

F Registration

G Paper Separation

H Fusing Unit

I Paper Exit

1 Duplex Entrance

J

2 Duplex Paper Feed

J

K Duplex Exit

S By-pass Feed Table

U LCT

R1 Finisher Entrance

R2 Finisher Exit

R3 Jogger Unit Entrance

R4 Jogger Unit

A170M542.img

P1 RDH Feed-in

P2 RDH Transport Unit

P3 RDH Feed-out

A170M503.img

NOTE: To clear the counters, use SP mode (Counter Clea r).

4-3

12

Page 63

SERVICE PROGRAM MODE 31 January 1996

2 Daily / Weekly Jam Counters

Week 1 means the first week of a

month

Counters are not cleared at the end

of the week or month.

For example, if this menu is

A170M504.img

displayed on Monday, th e cou nters

of Tuesday through Friday show the

data for the previous week.

A170M505.img

A170M506.img

NOTE: To clear the counters, use SP mode (Counter Clea r).

12

4-4

Page 64

SET

31 January 1996 SERVICE PROGRAM MODE

3 Copy Counters

A170M507.img

A170M508.img

A170M543.img

The test mode copy counter displays

the number of copies in SP Test

Mode .

8

This counter only counts up when

Test Copy Counter ON is

(SP mode PAGE 5).

10

The block copy counter disp lays the

number of copies made since a

block copy counter clear was done

(SP mode PAGE 3). Use the

11

block copy counter display when the

machine is connected to a Remo te

Diagnostic System.

NOTE: 1. To clear the counters, use SP mode Counter Clear).

12

2. The total number of copies can only be cle are d by perfo rming the

RAM clear.

4-5

Page 65

SERVICE PROGRAM MODE 31 January 1996

4 Daily/Weekly Copy Counters

A170M509.img

NOTE: To clear the counters, use SP mode (Counter Clea r).

12

5 Operating Time

This displays the total rotation time of

the main motor. Minutes are not

displayed.

A170M510.img

NOTE: This counter can only be cleared by RAM clear.

(Main board DIP SW #1: ON, #2: OFF)

4-6

Page 66

31 January 1996 SERVICE PROGRAM MODE

6 SC Counters

A170M511.img

A170M512.img

A170M514.img

A170M516.img

A170M513.img

A170M518.img A170M515.img

NOTE: To clear the counters, use SP mode (Counter Clea r).

12

4-7

A170M517.img

Page 67

SERVICE PROGRAM MODE 31 January 1996

7 Sensor Outputs

ID Sensor

A170M519.img

Vsg

Vsp ID sensor output for pattern

ID sensor output for bare drum

surface

Drum Potential Sensor

Vd set up value during the

Vd

process control sequence

VL1

VL2 VL value during the copy cycle

V

V

VL set up value during the

process control sequence

Residual voltage during the

Vr

process control sequence

Potential sensor output when

100

100V is applied to the drum shaft

Potential sensor output when

800

800V is applied to the drum shaft

Drum potential just after charging

01

V

during the process control

sequence

Drum potential just after charging

02

V

during the copy cycle

Exposure Sensor

Initial

Current Current value

Initial value during the process

control sequence

ADS Sensor

ADS sensor output value during

Vs

the process control sequence

ADS sensor output value during

Vo

the copy cycle

Development Bias

Latest output of the development

Vb

bias during a copy cycle.

4-8

Page 68

31 January 1996 SERVICE PROGRAM MODE

Sensor Output-Sta ndar d Data

The ranges of items in the sensor output of the SP mode are as fo llows:

During process control During copying Remarks

Vsg 3.7 ~ 4.3 3.8 ~ 4.2 Lower than 2.5

(SC353)

Vsp

V100 0.10 ~ 1.00 —

V800 2.00 ~ 3.92 —

Vd

VL1

VL2

Vr

V01

V02

Exposure Sensor 1.6 ~ 3.5 (Initial) 1.6 ~ 3.5 (Current)

ADS Sensor 2.7 ~ 3.6 (Vs) 1.0 ~ 3.6 (Vo) Vo depends on the

Exposure Lamp

Heater Temperature

Vd = (Vr + 770) ± 5%

VL1 = (Vr + 50 – 10n) ± 5%

VL2 ≤ VL1 + 100

Vr ≤ 250

Vd ≤ V01 ≤ Vd + 100

V01 – 30 ≤ V02 ≤ V01 + 100

45 ~ 60°C

—

0.2 ~ 0.5 Higher than 1.4

(SC352)

Out of range (SC307)

Out of range (SC108)

originals.

Paper Feed Time

Displays the interval bet wee n the

time a paper feed clutch turns on and

the time the registration sensor turns

on.

Reference Times (theoret ical valu es

assuming no paper slippage):

If the displayed time varies by more

than 32 ms, check the appro pria te

feed clutch if the clutch disk surface

A170M520.img

is dirty.

(ms)

1st Tray 1,336

2nd Tray 1,617

3rd Tray 620

By-pass 444

Duplex Tray 1,741

LCT 730

4-9

Page 69

SERVICE PROGRAM MODE 31 January 1996

8 SP Test Mode – 1 (PAGE 1 - 1)

A170M521.img

Sensors