Page 1

MENU READER

(Machine Code: A952)

Page 2

6 March 1992 SPECIFICATIONS

1. SPECIFICATIONS

- Item - - Specification Job Sheet

1. Material:

2. Size:

3. Weight:

4. Markers:

Job Sheet Feed Method: Fed in and out automatically

Reading Time: Approximately 2.5 seconds

Power Source: +24 volts and +5 volts (from copier)

Dimensions:

(W x D x H)

Weight: 1.42 lb (640 g)

Paper

2.6" x 5.9" (67 mm x 150 mm)

22 lbs to 43 lbs (83 g to 161 g)

Black pencil, HB or higher (HB, B, 2B, etc.)

Marker (Black)

Ball-point pen (Black)

4.4" x 6.5" x 1.8"

(112 mm x 165 mm x 45 mm)

Menu Reader

1

Page 3

OVERALL MACHINE CONTROL 6 March 1992

2. OVERALL MACHINE CONTROL

+24V

ROM

Mark

Detection

Sensor

LED

Indlcator

Sheet

Detection

Sensor

+15V

+5V

Address

Latch

Signal

Amplification

LED

Drive

CPU

+5V

+15V

+24V

Motor

Drive

Level

Conversion

Voltage

Monitor

External

Reset

Power

Supply

Motor

Copier

The menu reader is controlled by the copier.

2

Page 4

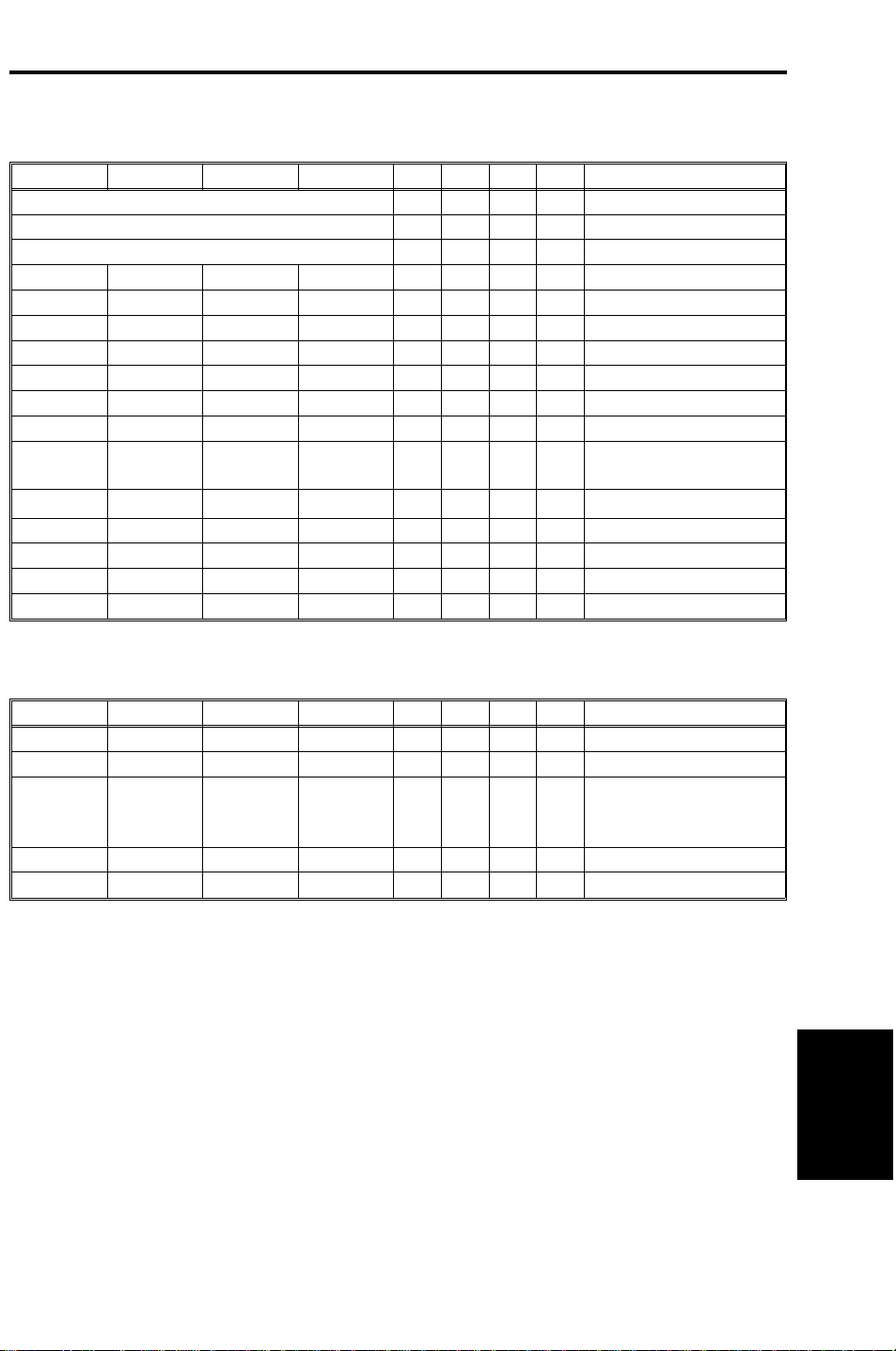

6 March 1992 DATA FORMAT

3. DATA FORMAT

Menu Reader → Copier

b7 b6 b5 b4 b3 b2 b1 b0 DATA CONTENTS

B C D 0 0 0 0 Copy Quantity x 1

B C D 0 0 0 1 Copy Quantity x 10

B C D 0 0 1 0 Copy Quantity x 100

Size 4 Size 3 Size 2 Size 1 0 0 1 1 Paper Size

Enlarge 3 Enlarge 2 Enlarge 1 100% 0 1 0 0 Reproduction Ratio-1

Reduce 4 Reduce 3 Reduce 2 Reduce 1 0 1 0 1 Reproduction Ratio-2

0 2 : 1 2 : 2 1 : 2 0 1 1 0 Duplex

0 0 Stack Sort 0 1 1 1 Sorter

0 0 0 Staple 1 0 0 0 Staple

0 0 0 Reserve-1 1 0 0 1 Reserve-1

0

0 0

0 0 0 Reserve-4 1 1 0 0 Reserve-4

----- ------ ------ ------ 1 1 0 1

------ ------ ------ ------ 1 1 1 0

Reserve

2-2

Reserve

2-2

0

Reserve

2-1

Reserve-3 1 0 1 1 Reserve-3

1 0 1 0 Reserve-2

1 1 1 1 Control Data

Copier → Menu Reader

b7 b6 b5 b4 b3 b2 b1 b0 DATA CONTENTS

------ ------ ------ ------ 0 0 0 0 Insert Sheet OK/NG

------ ------ ------ ------ 0 0 0 1

.

.

.

------ ------ ------ ------ 1 1 1 0

1 1 1 1 1 1 1 1 Send OK

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

The contents of the reserve bytes are different in each market.

Menu Reader

3

Page 5

BASIC OPERATION 6 March 1992

4. BASIC OPERATION

4.1 JOB SHEET READING

[A]

[C][B]

When a job sheet is inserted, the sheet detection sensor [A] detects the

leading edge of the job sheet. The job sheet is then fed in by the upper and

lower transport rollers [B, C].

4

Page 6

6 March 1992 BASIC OPERATION

[A]

[C]

[B]

[D]

[F]

[E]

[G]

The mark detection sensor [A] detects the reference line [D] and reads the

job sheet. The mark detection sensor is composed of 4 photosensors. The

sensor on the right [B] detects the reference line and reference marks [E],

and the other sensors [C] read the job sheet data.

The menu reader CPU monitors signals from the mark detection sensor and

measures the time between each reference mark. There are 25 reference

marks along the sheet edge. After the 25th reference mark is read, the job

sheet is fed out by the upper and lower transport rollers [F, G].

The operation panel status changes after the job sheet is read, and the job

sheet information is sent to the copier CPU.

Menu Reader

5

Page 7

BASIC OPERATION 6 March 1992

4.2 MENU READER INDICATOR LIGHTS

Red Light Green Meaning

1 OFF ON A job sheet can be inserted.

2 ON OFF

3 Blinks OFF

4 OFF Blinks

5 Blinks Blinks

A job sheet is being read or the copier

Start key stays red.

A job sheet read error has occurred; the

menu reader stops reading. Check the job

sheet to make sure it is marked correctly

and insert it again.

Note: The red light blinks for 6 seconds;

then, it stays on.

A conversion error has occurred; insert the

job sheet again.

Note: The green light blinks for 6 seconds;

then, it stays on.

The RAM contents have been changed or

the menu reader has failed to read the

ROM contents.

Note: Turn the main switch off and on.

6

Page 8

6 March 1992 BASIC OPERATION

4.3 PROCESSING ERRORS

Reference Line

If the reference line does not reach the mark detection sensor within 2.6

seconds after the job sheet is fed in, the job sheet is fed out. (Feeding out

takes 1.6 seconds.) The red light blinks for 6 seconds; then, the job sheet

can be reinserted.

Reference Mark

If the mark detection sensor detects the reference line and then fails to detect

a reference mark within 0.2 seconds, or if it fails to detect a reference mark

within 0.1 seconds, the job sheet is fed out and the red light blinks for 6

seconds; then, the job sheet can be reinserted.

NOTE: Occasionally, the job sheet feeds out to the rear side of the menu

reader after a failure to detect the reference mark number.

Marking

When two or more selections are made for the same item, the menu reader

cannot process the job sheet and the red light blinks (indicating an error).

NOTE: 1. When an item is not marked on the job sheet, the menu reader

automatically reads as follows:

-- Item -- -- Indicator - Copy Quantity 1

Reproduction Ration 100%

2. The job sheet may jam inside the menu reader if it is smaller

than the specified size.

CAUTION: Sensors were set at the factory and cannot be adjusted in

the field.

Menu Reader

7

Page 9

INSTALLATION PROCEDURE 6 March 1992

5. INSTALLATION PROCEDURE

[B]

[A]

[E]

[D]

[C]

[F]

CAUTION: Before installing the Menu Reader, make sure that the

copier is unplugged.

1. Remove the left upper cover [A] (2 screws), left top cover [B] (7 screws),

left rear cover [C] (2 screws), and right rear cover [D] (2 screws).

2. Peel the backing off the strips of double-sided adhesive tape [E] and stick

the menu reader on the DF [F] as shown.

8

Page 10

6 March 1992 INSTALLATION PROCEDURE

[F]

[B]

[C]

[H]

[G]

[A]

3. Run the menu reader harness [A] through the bracket hole [B].

4. 220/230/240 V versions only

Install the ferrite core [C] on the menu reader harness as shown.

5. Canadian market machines only

To comply with C.S.A. standards, connect the sub harness [D] for C.S.A.

(P/N: A9529506) to the 10p connector of the menu reader harness.

[E]

[D]

6. Connect the 10p connector of the menu reader harness to CN110 of the

main control board and secure the grounding wire [E] with a M4 x 6 screw.

NOTE: Do not use the screw longer than 6 mm for securing the

grounding wire, otherwise the screw contacts the development

unit.

7. Clamp the menu reader harness (1 clamp [F] and 1 screw).

8. Reinstall the left top cover. (Pass the menu reader harness through the

cutout [G] of the left top cover.)

NOTE: Do not use the screw longer than 6 mm for 4 screws [H], other

wise the screw contacts the first scanner.

9

Menu Reader

Page 11

INSTALLATION PROCEDURE 6 March 1992

[B]

[A]

9. Wrap the grounding wire [A] twice around the coil [B] and secure the wire

to the bracket (1 screw).

10. Reinstall all the covers.

11. Plug in the copier and turn on the main switch.

12. Check the operation of the menu reader.

10

Page 12

6 March 1992 REPLACEMENT AND ADJUSTMENT

6. REPLACEMENT AND ADJUSTMENT

6.1 LOWER TRANSPORT ROLLER UNIT REPLACEMENT

[A]

[B]

1. Turn off the main switch.

2. Remove the menu reader from the copier (3 strips of velcro tape).

3. Remove the upper cover [A] (4 screws) and the reader unit [B] (2 screws,

10P connector).

11

Menu Reader

Loading...

Loading...