Page 1

RICOH FT8780

SERVICE MANUAL

Page 2

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. While the machine warms up, it will suddenly start turning to perform the

process control data initialization. Keep hands away from any mechanical

and electrical components during this period.

2. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier and the second sorter power cord is unplugged.

3. The wall outlet should be near the copier and easily accessible.

4. Note that some components of the copier, the paper tray unit, and the

2nd sorter are supplied with electrical voltage even if the main switch is

turned off.

5. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

6. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get medical

attention.

Page 3

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board on the main control board has a lithium battery which can

explode if replaced incorrectly. Replace the battery only with an identical

one. The manufacturer recommends replacing the entire RAM board. Do

not recharge or burn this battery. Used batteries must be handled in

accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, developer, and photoconductors according to

local regulations.

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storing larger numbers or

not sealing them apart may lead to chemical reactions and heat build-up.

Page 4

SECTION 1

OVERALL MACHINE

INFORMATION

Page 5

Overall

Information

6 March 1992 SPECIFICATIONS

1. SPECIFICATIONS

Main Copier

Copier

Configuration: Console

Copy Process: Dry Electrostatic Transfer System

Originals: Sheet/Book

Original Size: Maximum: 11" x 17", A3

Copy Paper Size: Maximum: 1st and 2nd tray 8

1/2" x 14", A4

3rd tray 11" x 17", A3

Minimum: 1st and 3rd tray 5

2nd tray 8

1/2" x 81/2", A5

1/2" x 11", A4

Copy Paper Weight: Standard Copying: 14 ~ 42 lb, 52 ~ 157 g/m

Duplex Copying: 17 ~ 28 lb, 64 ~ 105 g/m

Warm Up Time: Within 8.0 minutes (room temp. 68°F, 20°C)

First Copy Time: 3.9 seconds (8

Copying Speed: 80 copies/minute (8

1/2" x 11", A4, feed from 3rd tray)

1/2" x 11", A4)

Optional Equipment: 20 Bin Sorter 1

20 Bin Sorter 2

Menu Reader

Key Counter

Receiving Tray

Guidance ROM Kit

2

2

1-1

Page 6

SPECIFICATIONS 6 March 1992

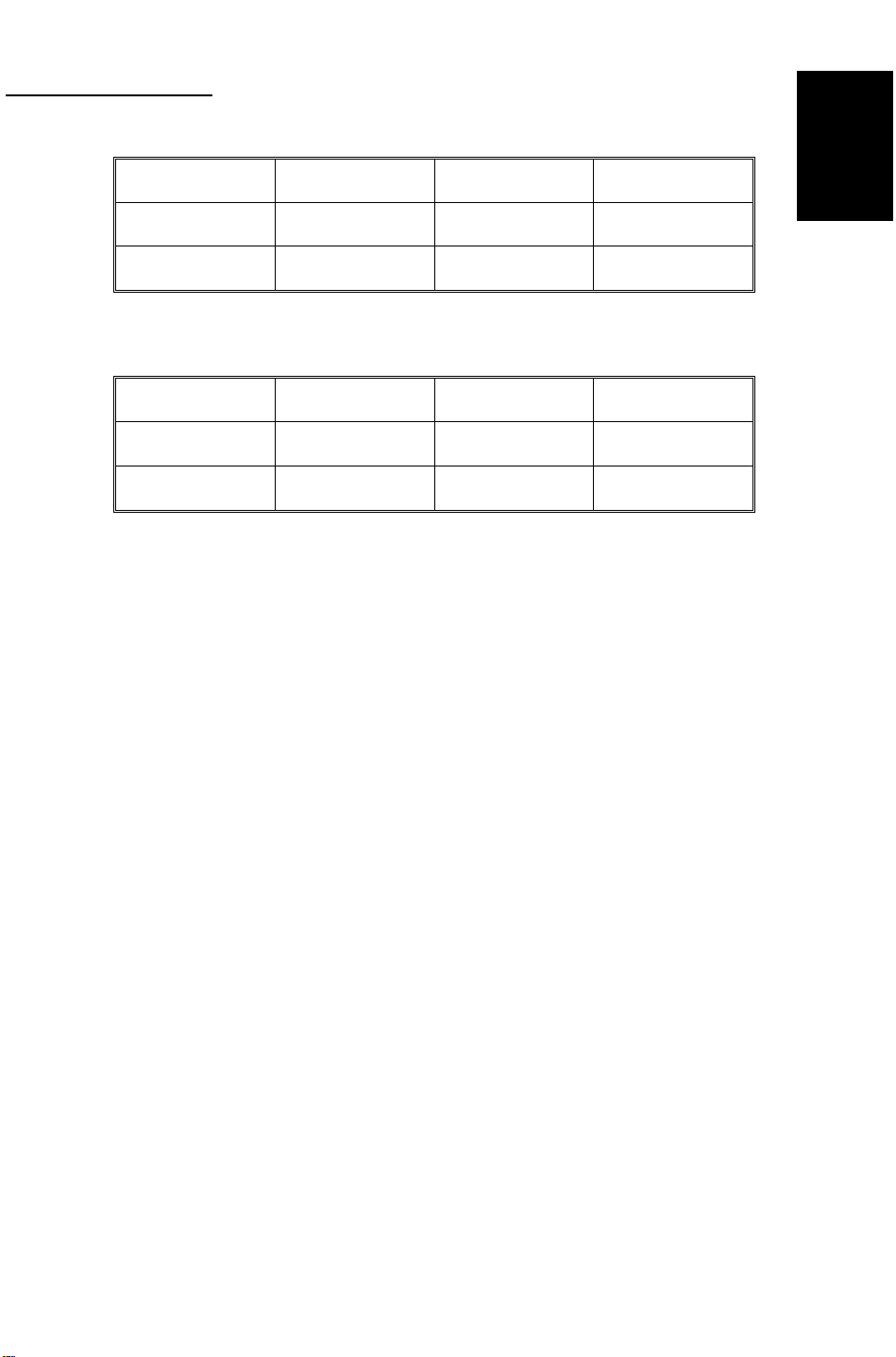

Reproduction Ratios: See the following table:

LT/DLT version A4/A3 version

200% 200%

Enlargement

155% 141%

129% 122%

121% 115%

Full Size 100% 100%

93% 93%

77% 82%

Reduction

74% 71%

65% 65%

50% 50%

Zoom: 50 ~ 200%

Copy Exit Tray Capacity: 250 Sheets

Toner Replenishment: Cartridge exchange (1500 g)

Paper Feed: 1st tray (550 sheets)

2nd tray (3,000 sheets)

3rd tray (1,500 Sheets)

Power Source: 120 V, more than 20 A (LT/DLT version)

220, 230, 240 V, more than 10 A (A4/A3 version)

Power Consumption:

Maximum during LT/DLT version A4/A3 version

Stand-by 1.90 kw 2.00 kw

Copying Cycle 1.71 kw 1.75 kw

Dimensions: Copier Only: 49.3" x 29.9" x 56.9"

(1253 x 760 x 1444.5 mm)

With Sorter: 81.5" x 34.4" x 56.9"

(2070 x 873 x 1444.5 mm)

Weight: Copier Only: 892 lb (405 kg)

With 2 Sorters: 1308 lb (593 kg)

Noise Emission: Copier Only: 63 dB

With Sorter: 64 dB

1-2

Page 7

Overall

Information

6 March 1992 SPECIFICATIONS

Document Feeder

Original Size:

Stack feed mode Single feed mode Duplex mode

Maximum 11" x 17", A3 11" x 17", A3 11" x 17", A3

Minimum 8

1/2" x 11", A4 51/2" x 81/2", A5 81/2" x 11", A4

Original Weight:

Stack feed mode Single feed mode Duplex mode

Maximum 34 lb, 128 g/m

Minimum 14 lb, 52 g/m

2

43 lb, 157 g/m

2

11 lb, 35 g/m

2

2

Feed-in Unit Capacity: 50 Sheets (80 g/m2, 20 lb)

CFF Original Stack Height:Maximum: 50 mm

Original Set: First sheet on top, stack face down

25 lb, 93g/m

14 lb, 52 g/m

2

2

1-3

Page 8

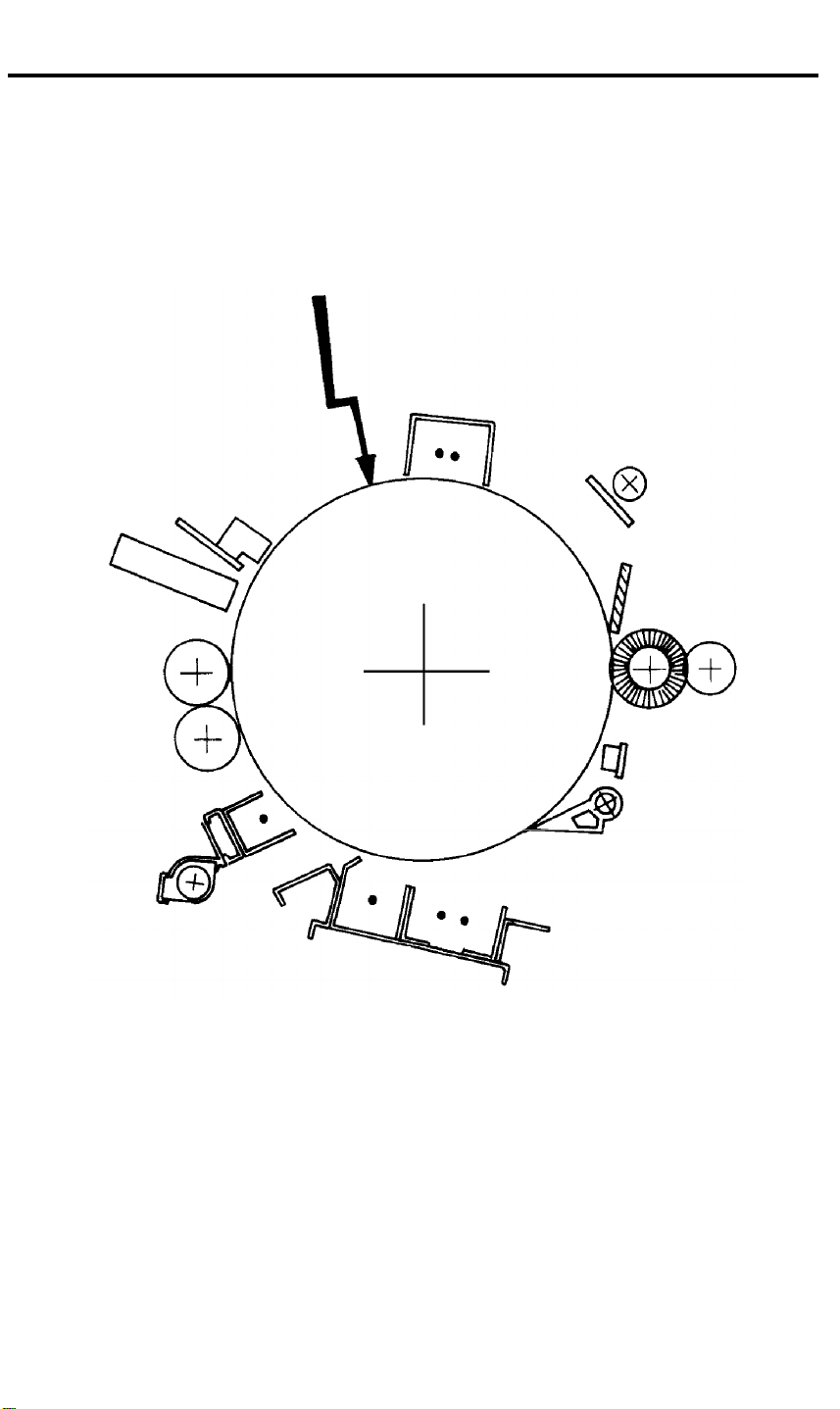

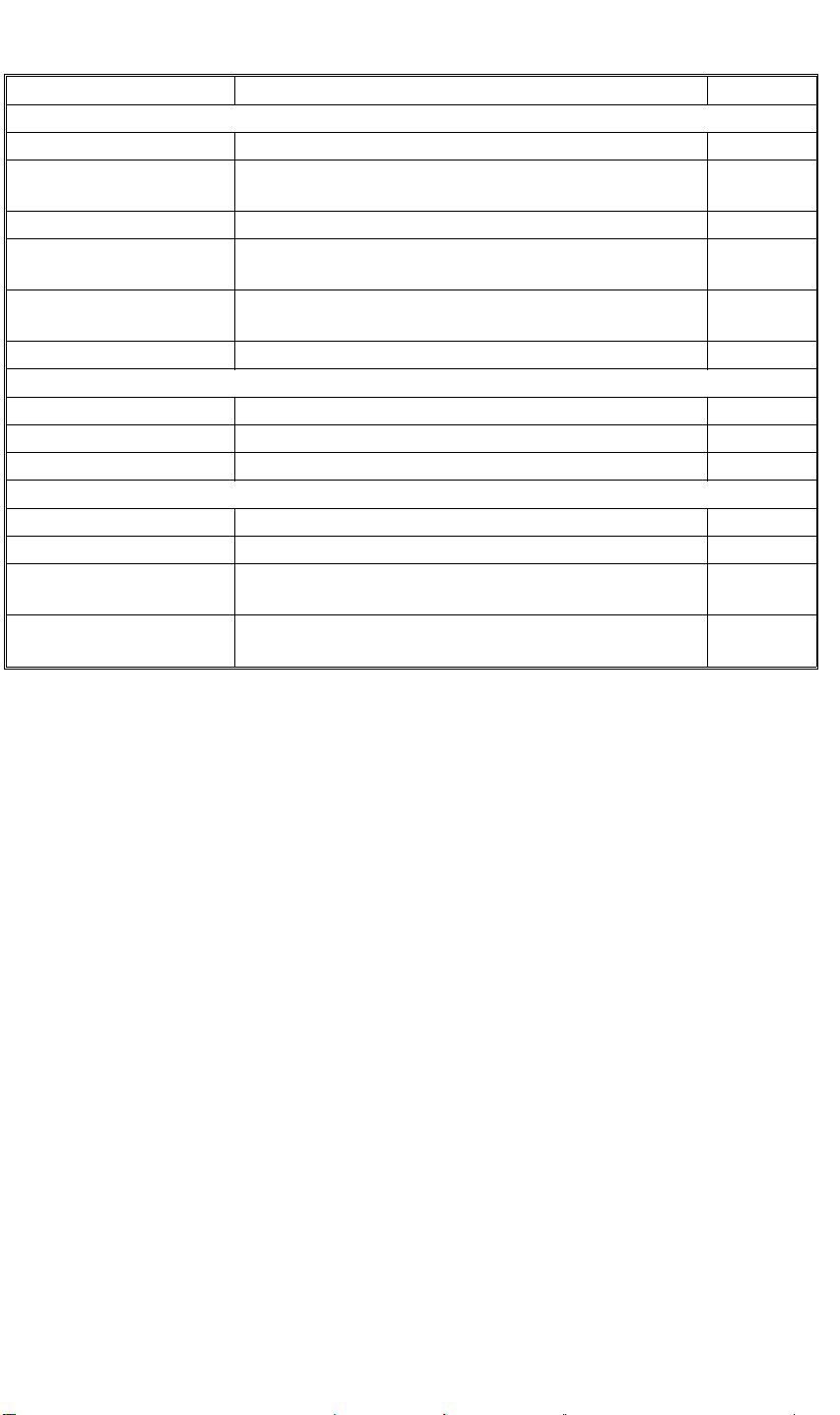

COPY PROCESSES AROUND THE DRUM 6 March 1992

2. COPY PROCESSES AROUND THE DRUM

2

1

10

3

4

9

5

6

7

8

1-4

Page 9

Overall

Information

6 March 1992 COPY PROCESSES AROUND THE DRUM

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform positive charge to the selenium drum.

The charge remains on the surface of the drum because the photoconductive selenium

has electrical resistance in the dark.

2. EXPOSURE

An image of the original is reflected to the selenium drum surface via the optics

assembly. The charge on the drum surface is dissipated in direct proportion to the

intensity of the reflected light, thus producing an electrical latent image on the drum

surface.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be used

for the copy image. The resistance of the drum in the illuminated areas drops and the

charge on those areas dissipates.

4. DRUM POTENTIAL SENSOR

The drum potential sensor detects the electric lines of force from the electric potential on

the drum to compensate image processing elements.

5. DEVELOPMENT

Negatively charged toner is attracted to the positively charged areas of the drum, thus

developing the latent image. (The negative triboelectric charge is caused by friction

between the carrier and toner particles.)

6. PRE-TRANSFER

The pre-transfer corona (PTC) applies a negative dc charge and an ac charge to the

drum. The dc charge increases the negative potential of the toner to improve toner

transfer to paper. The ac charge decreases positive charge on the drum and makes

paper separation easier. The pre-transfer lamp (PTL) also makes paper separation

easier by illuminating the drum and decreasing the positive charge on the drum.

7. IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy paper and the

developed image on the drum surface. Then, a strong positive charge is applied to the

back side of the copy paper, providing an electrical force which causes the copy paper to

be attracted to the drum’s surface. At the same time, the toner particles are pulled to the

copy paper from the drum’s surface.

8. PAPER SEPARATION

A strong ac corona discharge is applied to the back side of the copy paper, reducing the

positive charge on the copy paper and breaking the electrical attraction between the

paper and the drum. Then, the stiffness of the copy paper causes it to separate from the

drum surface. The pick-off pawls help to separate paper which has low stiffness.

9. CLEANING

The cleaning brush first removes remaining toner on the drum surface. Then, the

cleaning blade which is angled against drum rotation (counter blade system) removes

the rest of the toner. The flick roller mechanically removes the toner on the cleaning

brush.

10. QUENCHING

Light from the quenching lamp electrically neutralizes the drum surface.

1-5

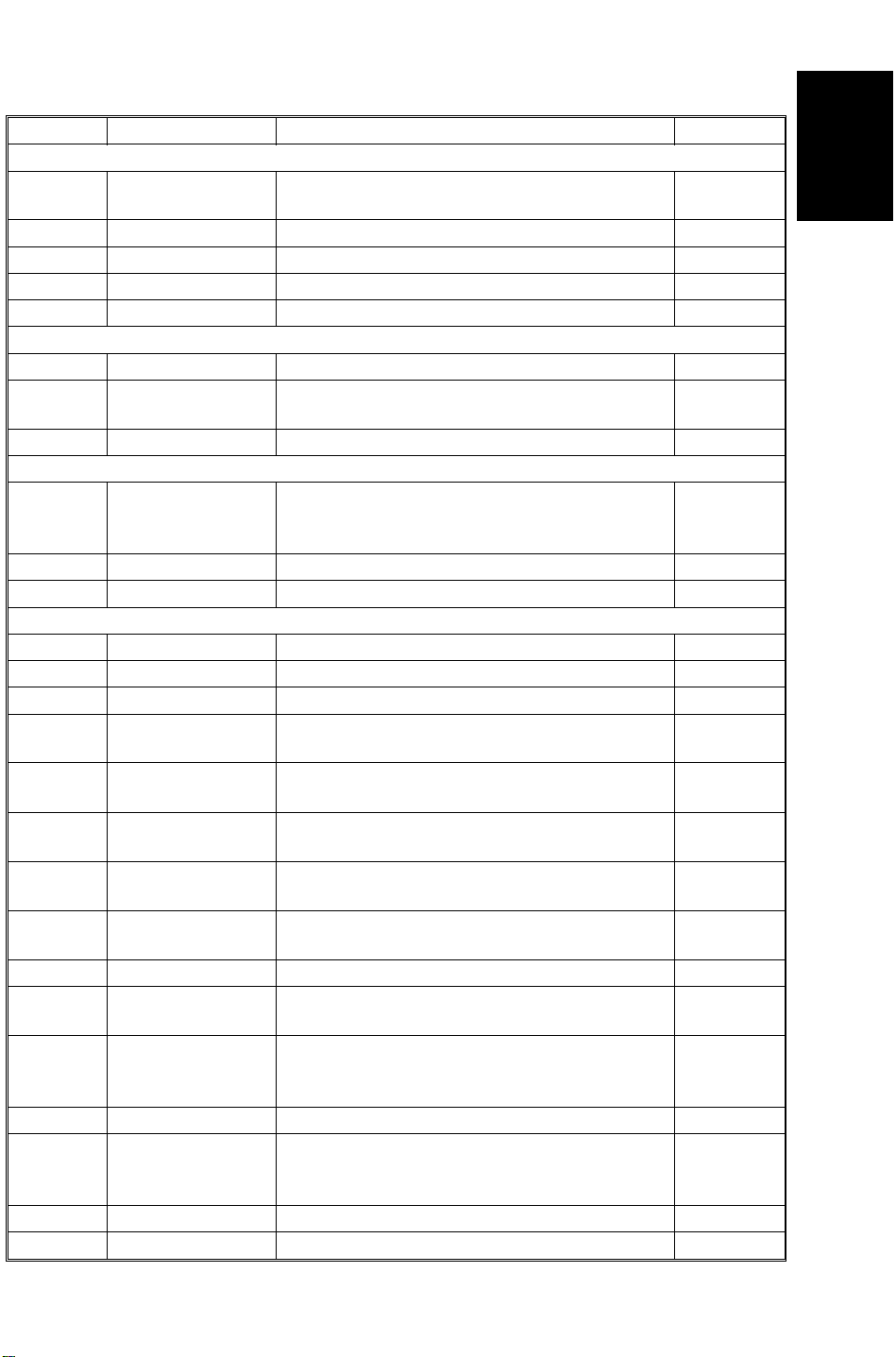

Page 10

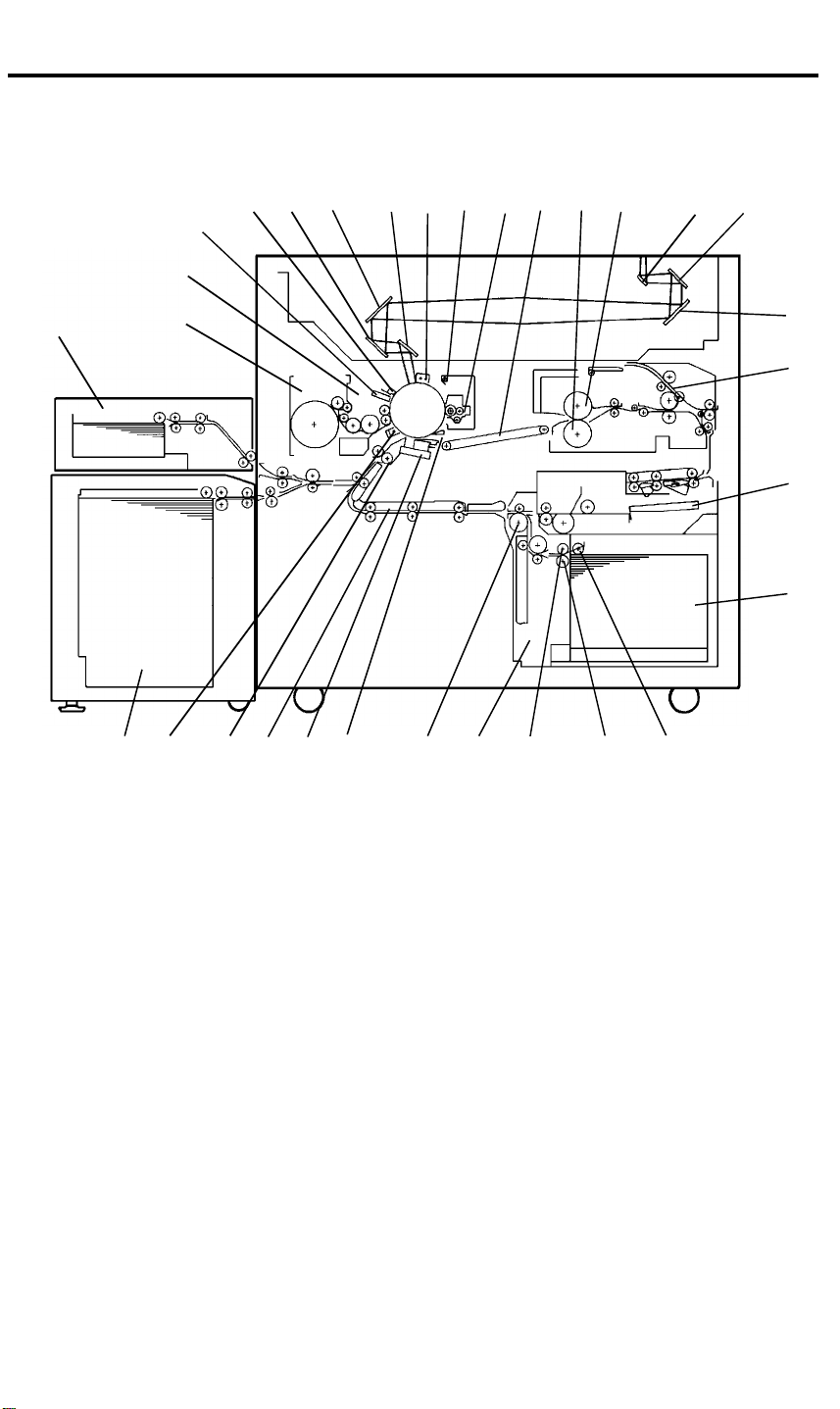

MECHANICAL COMPONENT LAYOUT 6 March 1992

3. MECHANICAL COMPONENT LAYOUT

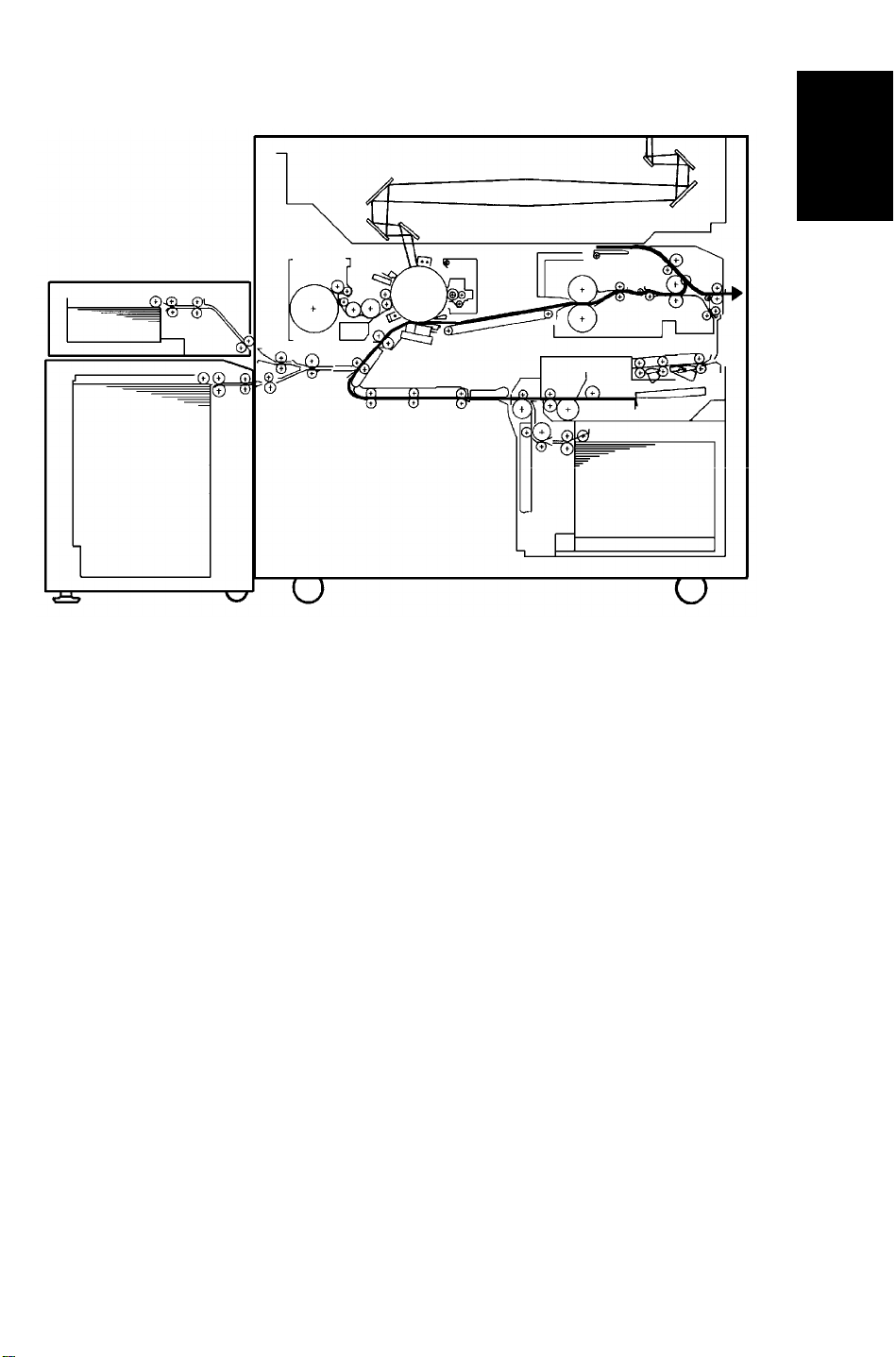

3.1 COPIER

18 19

22 23 24 25 26 27 28 29 30 31 1 2

21

20

3

4

5

6

7891011121314151617

1. First Mirror

2. Second Mirror

3. Third Mirror

4. Inverter Guide Plates

5. Duplex Tray

6. Third Tray

7. Pick-up Roller

8. Separation Roller

9. Paper Feed Roller

10. Vertical Transport Unit

11. Relay Rollers

12. Pick-off Pawls

13. Transfer and Separation

Corona Unit

14. Horizontal Transport Unit

15. Registration Rollers

16. Pre-transfer Corona Unit

17. Second Tray

18. First Tray

19. Toner Hopper

20. Development Unit

21. Drum Thermistor and Drum

Potential Sensor

22. Erase Lamp

23. Fifth Mirror

24. Fourth Mirror

25. Sixth Mirror

26. Charge Corona Unit

27. Quenching Lamp

28. Cleaning Unit

29. Transport Unit

30. Pressure Roller

31. Hot Roller

1-6

Page 11

Overall

Information

6 March 1992 MECHANICAL COMPONENT LAYOUT

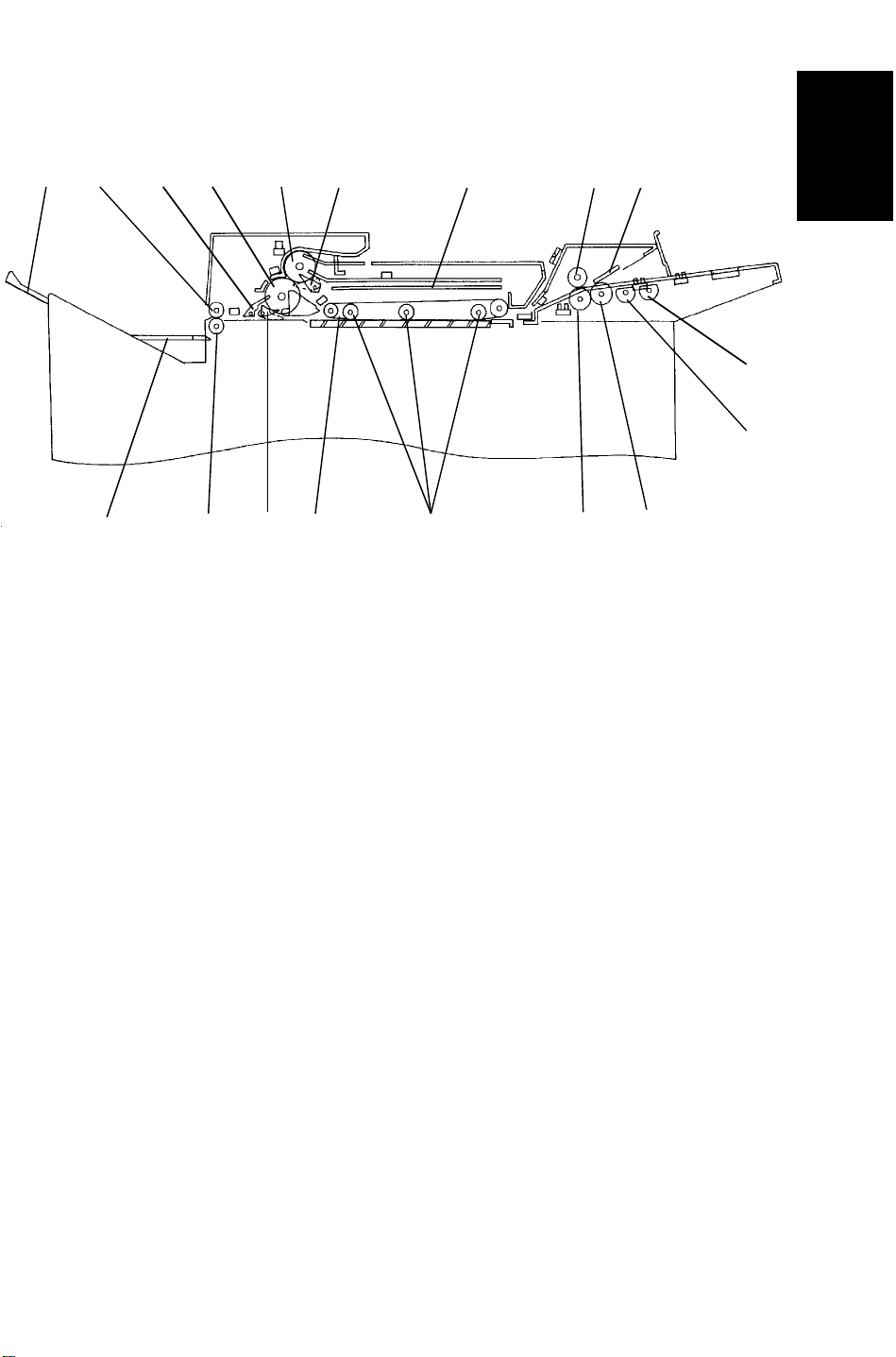

3.2 ARDF

1 2 3 4 5 6 7 8 9

10

11

12131415161718

1. Original Tray Extension

2. Upper Exit Rollers

3. Upper Inverter Gate

4. Lower Inverter Rollers

5. Upper Inverter Rollers

6. Switch Back Gate

7. Switch Back Tray

8. Upper Relay Roller

9. Friction Tab

10. 1st Pick-up Rollers

11. 2nd Pick-up Rollers

12. Separation Rollers

13. Lower Relay Roller

14. Pressure Rollers

15. Transport Belt

16. Lower Inverter Gate

17. Lower Exit Rollers

18. CFF Guide

1-7

Page 12

ELECTRICAL COMPONENT DESCRIPTIONS 6 March 1992

4. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the Point to

Point (Water proof paper) index numbers.

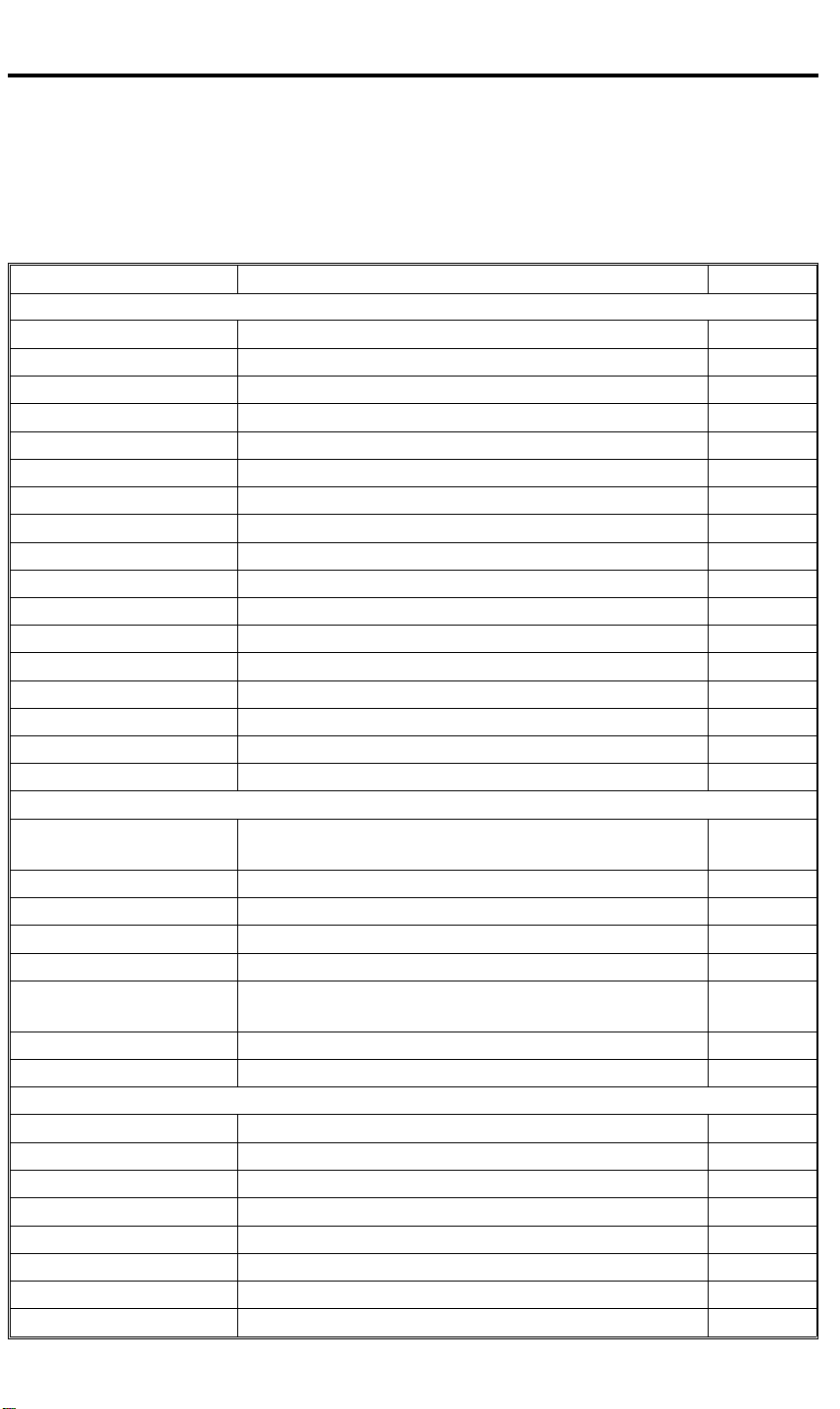

4.1 COPIER

Name Function Index. No.

Motors

1st Tray Drive Drives the bottom plate in the 1st tray. 132

2nd Tray Drive Drives the bottom plate in the 2nd tray. 139

3rd Tray Drive Drives the bottom plate in the 3rd tray. 65

Charge Wire Cleaner Drives the charge corona wire cleaner. 74

Development Drives the development unit. 51

Fusing Cooling Fan Cools fins of the de-curling roller. 58

Fusing Exhaust Fan Removes the heat in the de-curling unit. 56

Lens Horizontal Drive Shifts the lens horizontal position. 54

Lens Vertical Drive Shifts the lens vertical position. 57

Main Drives the main unit components. 73

Mirror Unit Drive Positions the mirror unit. 78

Optics Cooling Removes the heat from the optics unit. 77

Scanner Drive Drive the 1st and 2nd scanners. 55

T & S Wire Cleaner Drives the transfer and separation wire cleaner. 72

Toner Supply Rotates the toner supply roller. 75

Vaccum Fan Removes the heat and dust in the machine. 52

Clutches

LCT Drive Transmits the main copier drive to the 1st and 2nd

feed sections.

Paper Feed - 1st Tray Drives the paper feed roller of the 1st tray. 134

Paper Feed - 2nd Tray Drives the paper feed roller of the 2nd tray. 159

Paper Feed - 3rd Tray Drives the paper feed roller of the 3rd tray. 66

Paper Feed - Duplex Drives the paper feed roller of the duplex unit. 67

Vertical Transport Unit

Drive

Registration Drives the registration roller. 79

PCBs

DC Drive Drives dc components. 116

Drum Current Detection Measures the corona current. 106

Main Controls overall machine operation. 122

Motor Control Controls the dc motors. 123

DC Motor Drive Drives the dc motors. 101

Operation Unit Controls the monitor display. 124

PTL Controls the pre-transfer lamp operation. 121

Quenching Lamp Controls the quenching lamp operation. 120

Transmits the main copier drive to the vertical

transport unit and the 3rd tray.

76

68

1-8

Page 13

Overall

Information

6 March 1992 ELECTRICAL COMPONENT DESCRIPTIONS

Name Function Index. No.

Interface Interface between the main PCB and other PCBs. 115

Vaccum Motor Controls the vacuum fan motor operation. 108

Power Packs

Charge Provides power for the charge corona wire. 103

Development Bias Provides power for the development bias. 104

PTC Provides power for the pre-transfer corona wire. 107

Separation Provides power for the separation corona wire. 105

Transfer Provides power for the transfer corona wire. 102

Power Supply Unit Provides dc power to dc components. 119

Relays

Anticondensation Heater Provides power to the anticondensation heater. 113

Drum Heater 1 Provides power to the drum heater. 114

Drum Heater 2 Provides power to the drum heater. 110

Fusing SSR (16 A) Provides power to the 720 W fusing lamp. 111

Fusing SSR (20 A) Provides power to the 900/950 W fusing lamp. 112

Relay Unit Provides ac power to ac components. 118

Sensor

Auto Responce Turns on the display from the screen saver condition. 93

Drum Potential Detects the drum surface voltage. 95

Duplex Entrance Detects misfeeds. 12

Exit Detects misfeeds. 10

Fusing Unit Detects misfeeds. 9

Image Density Measures the density of the image on the drum. 87

Jogger Home Position Detects when the duplex side plate is at the home

position.

Lens Horizontal Encoder Detects the lens horizontal drive motor operation. 5

Lens Horizontal Home

Position

Lens Vertical Encoder Detects the lens vertical drive motor operation. 7

Lens Vertical Home

Position

Lower Limit - 1st Tray Turns off the 1st tray motor when the tray reaches

Lower Limit - 2nd Tray Turns off the 2nd tray motor when the tray reaches

Lower Limit - 3rd Tray Turns off the 3rd tray motor when the tray reaches

Mirror Unit Encoder Detects the mirror drive motor operation. 29

Mirror Unit Home

Position

Paper End - 1st Tray Detects the presence of paper in the 1st tray. 159

Paper End - 2nd Tray Detects the presence of paper in the 2nd tray. 146

Detects when the lens is at the horizontal home

position.

Detects when the lens is at the vertical home

position.

the down position.

the down position.

the down position.

Detects when the mirror unit is at the home position.

15

4

6

138

140

41

3

1-9

Page 14

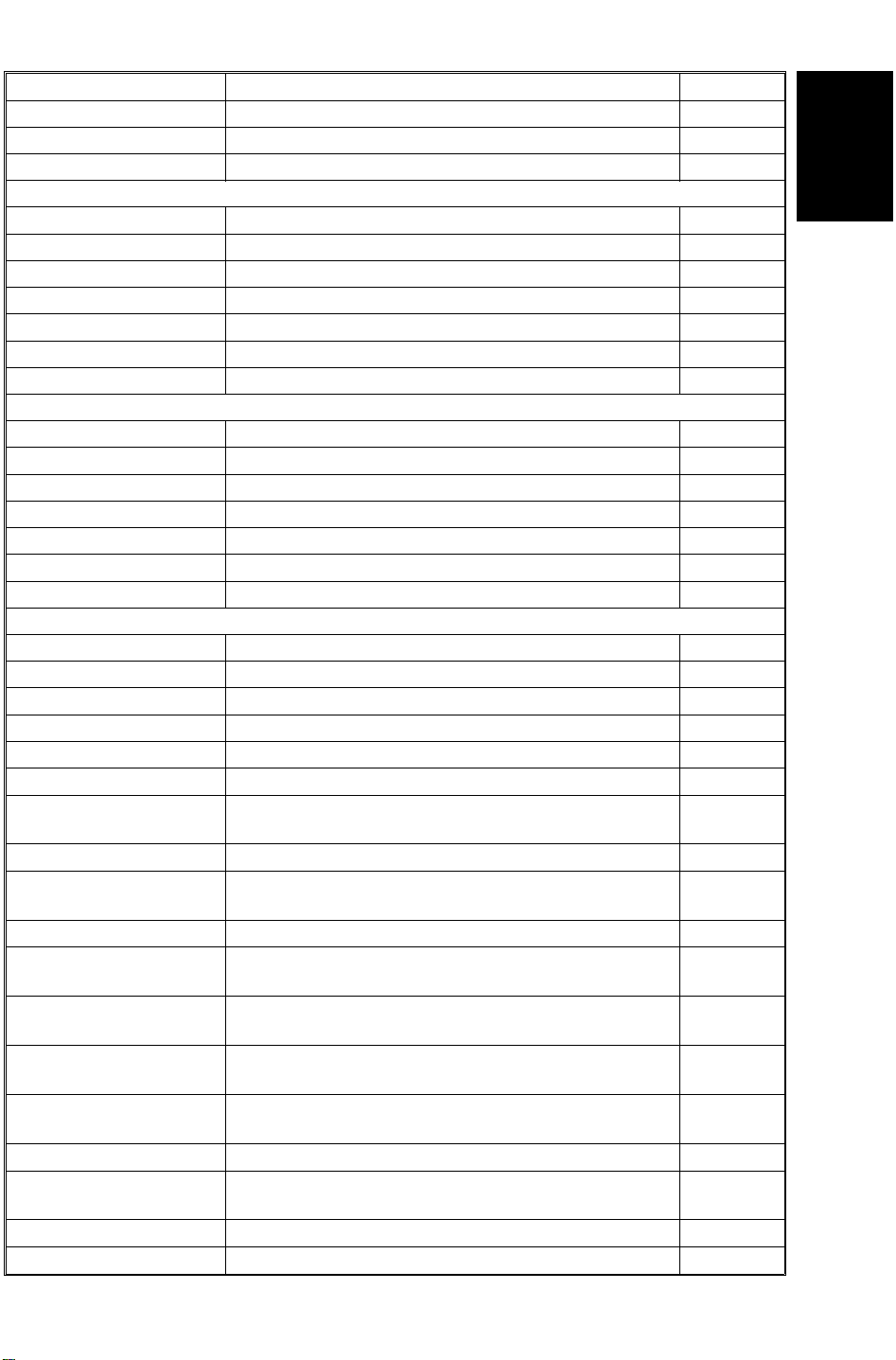

ELECTRICAL COMPONENT DESCRIPTIONS 6 March 1992

Name Function Index. No.

Paper End - 3rd Tray Detects the presence of paper in the 3rd tray. 42

Paper End - Duplex Detects the presence of paper in the duplex tray. 13

Paper Feed - 1st Tray Turn off the 1st tray paper feed clutch. 154

Paper Feed - 2nd Tray Turn off the 2nd tray paper feed clutch. 147

Paper Feed - 3rd Tray Turns off the 3rd tray paper feed clutch. 16

Paper Feed - Duplex Turns off the duplex paper feed clutch. 18

Paper Size 1 - 1st Tray Determines what paper size is in the 1st tray. 133

Paper Size 1 - 2nd Tray Determines what paper size is in the 2nd tray. 142

Paper Size 1 - 3rd Tray Determines what paper size is in the 3rd tray. 35

Paper Size 2 - 1st Tray Determines what paper size is in the 1st tray. 157

Paper Size 2 - 2nd Tray Determines what paper size is in the 2nd tray. 143

Paper Size 2 - 3rd Tray Determines what paper size is in the 3rd tray. 34

Paper Size 3 - 1st Tray Determines what paper size is in the 1st tray. 137

Paper Size 3 - 2nd Tray Determines what paper size is in the 2nd tray. 144

Paper Size 3 - 3rd Tray Determines what paper size is in the 3rd tray. 33

Paper Size 4 - 1st Tray Determines what paper size is in the 1st tray. 135

Paper Size 4 - 3rd Tray Determines what paper size is in the 3rd tray. 32

Paper Size 5 - 3rd Tray Determines what paper size is in the 3rd tray. 39

Paper Size 6 - 3rd Tray Determines what paper size is in the 3rd tray. 38

Paper Size 7 - 3rd Tray Determines what paper size is in the 3rd tray. 37

Paper Size 8 - 3rd Tray Determines what paper size is in the 3rd tray. 36

Paper Volume - 1st Tray Detects the amount of paper in the 1st tray. 131

Paper Volume - 2nd

Tray

Detects the amount of paper in the 2nd tray.

149

Paper Volume - 3rd Tray Detects the amount of paper in the 3rd tray. 31

Pick-up Position -

Duplex

Registration Sensor Detects the lead edge of paper to determine the stop

Return Home Position Detects when the 1st scanner is at the return

Scanner Home Position Detects when the 1st scanner is at the home

Detects the duplex pick-up roller position.

timing of a feed clutch and detects misfeeds.

position.

position.

17

22

27

8

Toner Cartridge Detects when a toner cartridge is in the machine. 2

Toner Coil Overload Detects the toner collection coil drive gear operation. 1

Toner Near End Detects toner near end condition. 28

Transport Detects misfeeds. 20

Tray Paper Position Detects the top sheet position in the 2nd tray. 141

Upper Limit - 1st Tray Sends signal to stop lifting up the 1st tray bottom

plate.

Upper Limit - 2nd Tray Sends signal to stop lifting up the 2nd tray bottom

plate.

Upper Limit - 3rd Tray Sends signal to stop lifting up the 3rd tray bottom

plate.

161

158

14

1-10

Page 15

Overall

Information

6 March 1992 ELECTRICAL COMPONENT DESCRIPTIONS

Name Function Index. No.

Solenoids

2nd Tray Lock Locks the 2nd tray. 136

Cleaning Brings the cleaning blade into contact with the drum. 53

Fork Gate 1 Varies the paper path in the duplex unit depending

on paper size.

Fork Gate 2 Varies the paper path in the duplex unit depending

on paper size.

Inverter Gate Drives the inverter gate up and down. 61

Junction Gate Drives the junction gate up and down. 60

Pick-up - 1st Tray Lifts the pick-up roller of the 1st tray. 155

Pick-up - 2nd Tray Lifts the pick-up roller of the 2nd tray. 148

Pick-up - 3rd Tray Lifts the pick-up roller of the 3rd tray. 70

Pinch Roller Brings the return pinch rollers into contact with a

paper.

Pressure Plate Brings the pressure plate on papers in the duplex

unit.

Positioning Lowers the positioning roller in the duplex unit. 64

Duplex Paper Stopper Lowers the paper stopper in the duplex unit. 71

62

63

59

69

Switches

1st Tray Down Lowers the 1st tray bottom plate. 151

1st Tray Set De-energizes power when the 1st tray is slided to

the left.

2nd Tray Down Lowers the 2nd tray bottom plate. 150

3rd Tray Down Lowers the 3rd tray bottom plate. 40

Anticondensation Turns on the tray heaters. 23

Error Reset Resets error condition. 11

Left Door 1 Turns off the main motor when the left door is open. 25

Left Door 2 Turns off dc 24 volts lines when the left door is open. 24

Main Supplies power to the copier. 26

Right Door 1 Turns off dc 24 volts lines when the right door is

open.

Right Door 2 Turns off the main motor when the right door is open. 19

Tray Cover Turns off components when the tray left top cover is

open.

Heaters

1st Tray Removes humidity from the paper in the 1st tray. 156

2nd Tray Removes humidity from the paper in the 2nd tray. 145

3rd Tray Removes humidity from the paper in the 3rd tray. 92

Anticondensation Prevents moisture from forming on the lens and

mirrors.

Drum Warms the drum when it gets too cool. 96

Exposure Lamp Warms the exposure lamp when it gets too cool. 86

160

21

153

83

1-11

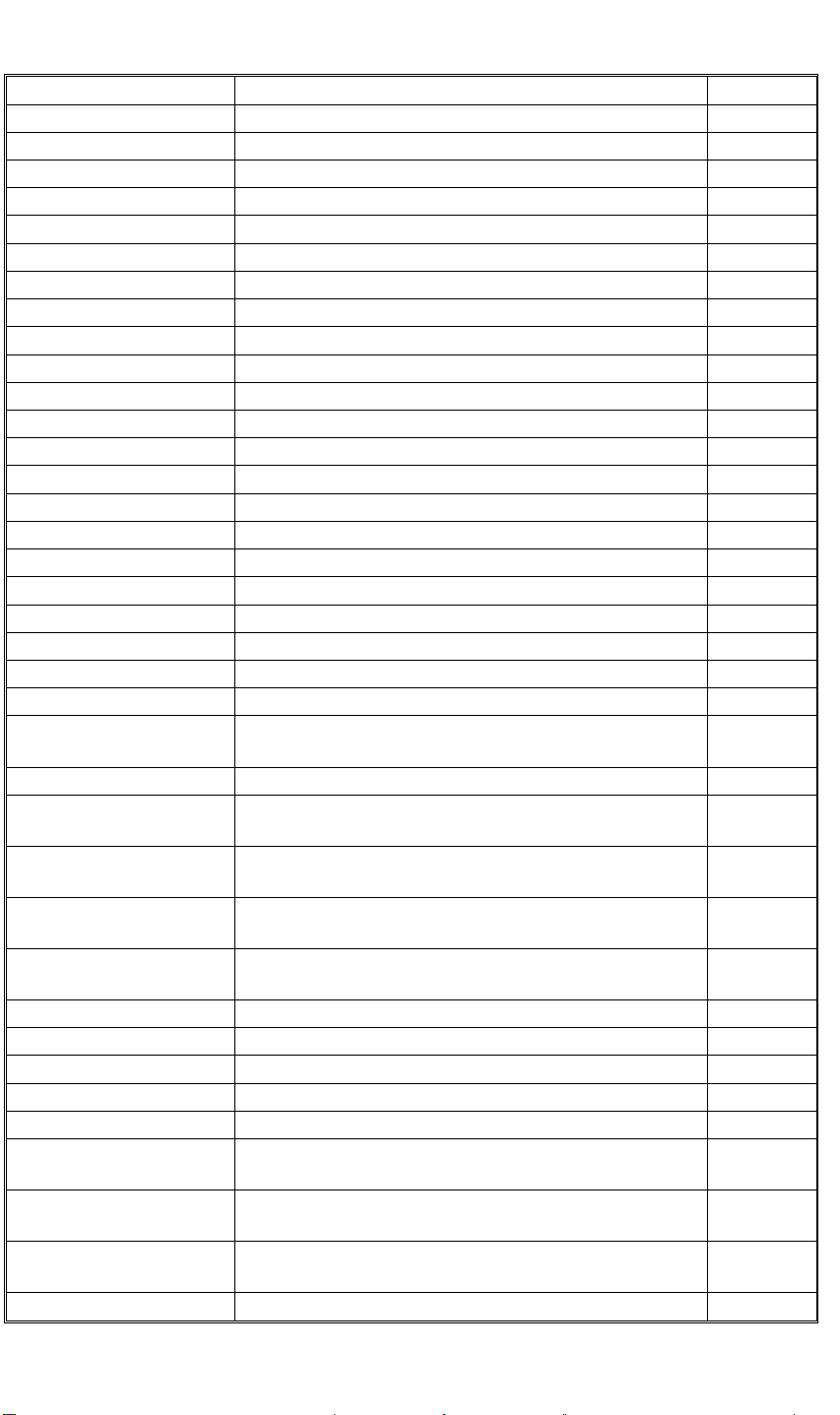

Page 16

ELECTRICAL COMPONENT DESCRIPTIONS 6 March 1992

Name Function Index. No.

Lamps

Exposure Exposes the original with high intensity light. 85

Fusing 1 Provides heat to the hot roller and keeps the roller at

the operating temperature.

89

Fusing 2 Provides heat to the hot roller during warm-up. 90

Pre-Transfer Removes excessive positive charge from the drum

surface to the transfer and separation process.

Quenching Electrically neutralizes the drum surface prior to

charging.

81

82

Thermistors

Drum Monitors the drum temperature. 94

Fusing Monitors the hot roller temperature. 88

Other Components

Total Counter Keeps a count of the number of copies made. 117

FL Stabilizer Stabilizes power to the exposure lamp. 109

Thermofuse Provides back-up overheat protection in the fusing

unit.

Anticondensation

Turns off the anticondensation and drum heaters.

Thermoswitch

91

84

1-12

Page 17

Overall

Information

6 March 1992 ELECTRICAL COMPONENT DESCRIPTIONS

4.2 ARDF

Symbol Name Function Index. No.

Motors

M1

M2 Belt Drives the transport belt. 16

M3 Inverter Drives the inverter rollers and the exit rollers. 17

M4 Job Separation Drives the job separator. 5

Circuit Boards

PCB1 DF Main Controls overall ARDF functions. 3

PCB2

Solenoids

SOL1

SOL2 Inverter Gate Opens the inverter gate. 23

Feed-in Drives the pick-up rollers, separation rollers

and relay rollers.

Indicator Indicates the Insert Original indicator and the

Auto Feed indicator.

Switch Back Switches the switch back gate position to

directs the original to the switch back tray or

onto the exposure glass.

2

6

15

Sensors

S1 Entrance Cover Detects if the entrance cover is open. 4

S2 Lift Detects if the transport unit is open. 14

S3 Inverter Cover Detects if the inverter cover is open. 22

S4

S5

S6

S7

S8

S9 Inverter Jam Detects paper jams in switch back operation. 18

S10

S11

S12 Exit Detects paper jams. 21

S13

S14 Original Width Detects the original width. 13

S15 Timing Supplies timing pulses to the DF main board. 10

Pick-up Roller H.P. Detects if the pick-up roller is in the home

position.

Job Separation

H.P.

Job Completion Detects that last original of the first job is fed

Original Detects if the original is set on the original

Registration Sets the feed-in motor, belt motor and inverter

Inverter

Registration

Inverter Entrance Sets the inverter motor and the belt motor off,

CFF Detects if the computer form is set in the CFF

Detects if the job separator is in the home

position.

from the original table.

table.

motor off timing. Detects original misfeed.

Sets the inverter motor and the belt motor off,

reversing timing. Detects original jams.

reversing timing, inverter solenoid and switch

back solenoid off timing.

guide. Counts the holes lined up on the

computer form.

1

7

8

9

12

19

20

11

1-13

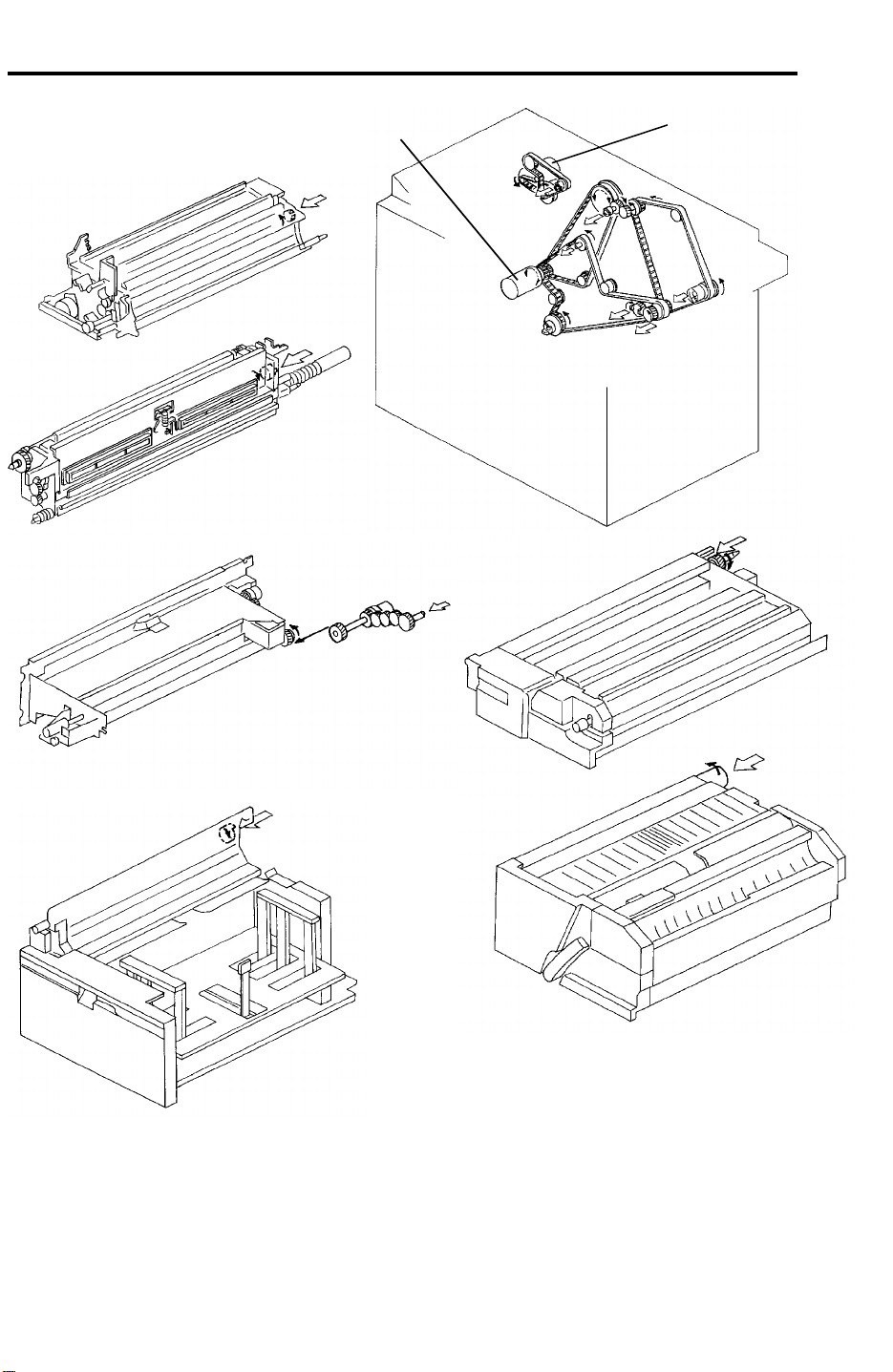

Page 18

DRIVE LAYOUT 6 March 1992

5. DRIVE LAYOUT

1

A

A

2

B

C

E

B

C

E

D

F

F

D

1. Main Motor

2. Development Drive Motor

A : Development Unit

B : Cleaning Unit

C : Relay Transport Unit (to 1st & 2nd Tray)

D : Fusing Unit

E : Vertical Transport Unit

F : Duplex Unit

1-14

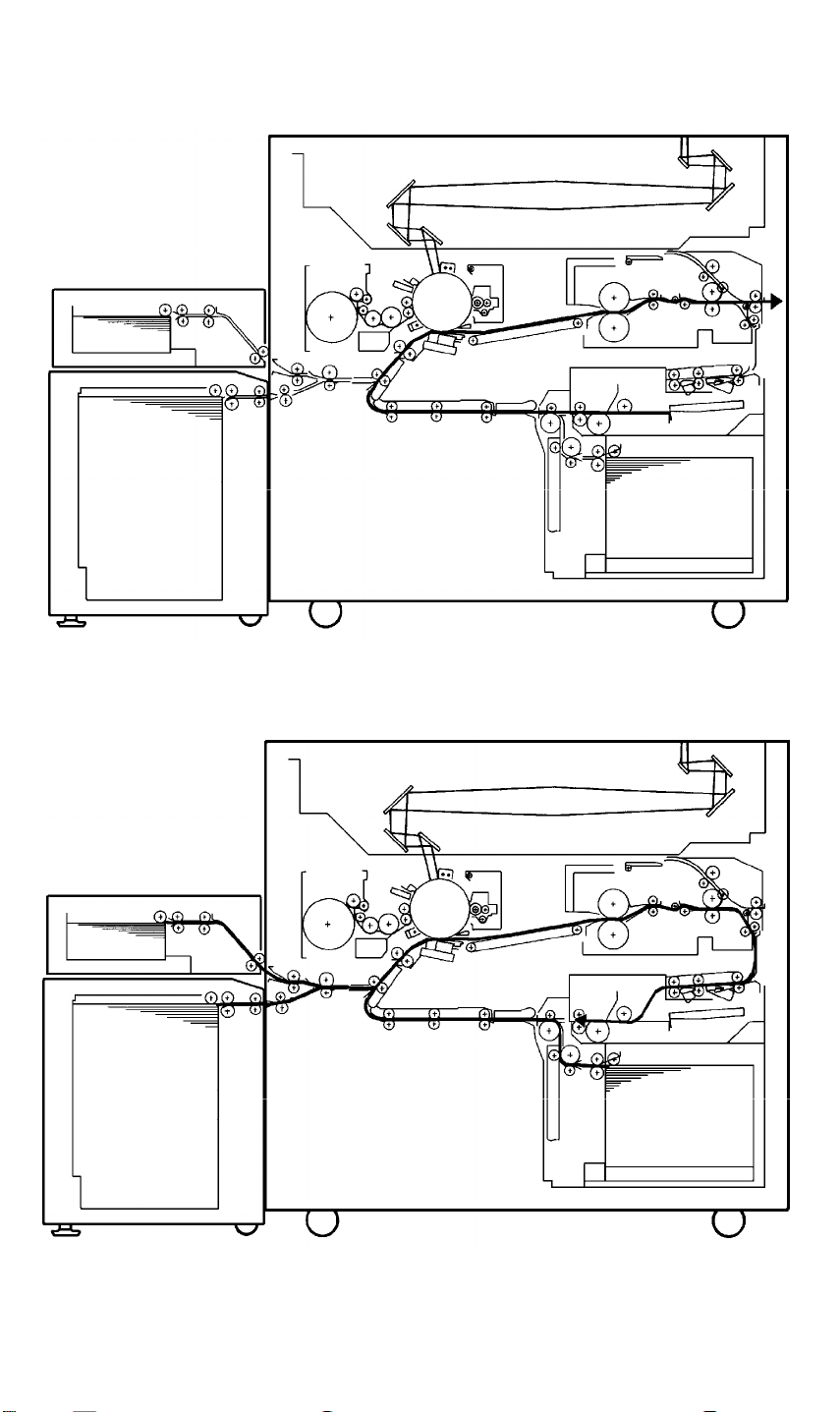

Page 19

Overall

Information

6 March 1992 PAPER PATH

6. PAPER PATH

6.1 SINGLE SIDED COPY -- COPY FACE DOWN

6.2 DUPLEX MODE (1ST SIDE)

1-15

Page 20

PAPER PATH 6 March 1992

6.3 DUPLEX MODE (2ND SIDE)

6.4 IMAGE OVERLAY MODE (1ST SIDE)

1-16

Page 21

Overall

Information

6 March 1992 PAPER PATH

6.5 IMAGE OVERLAY MODE (2ND SIDE)

1-17

Page 22

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 23

6 March 1992 PROCESS CONTROL

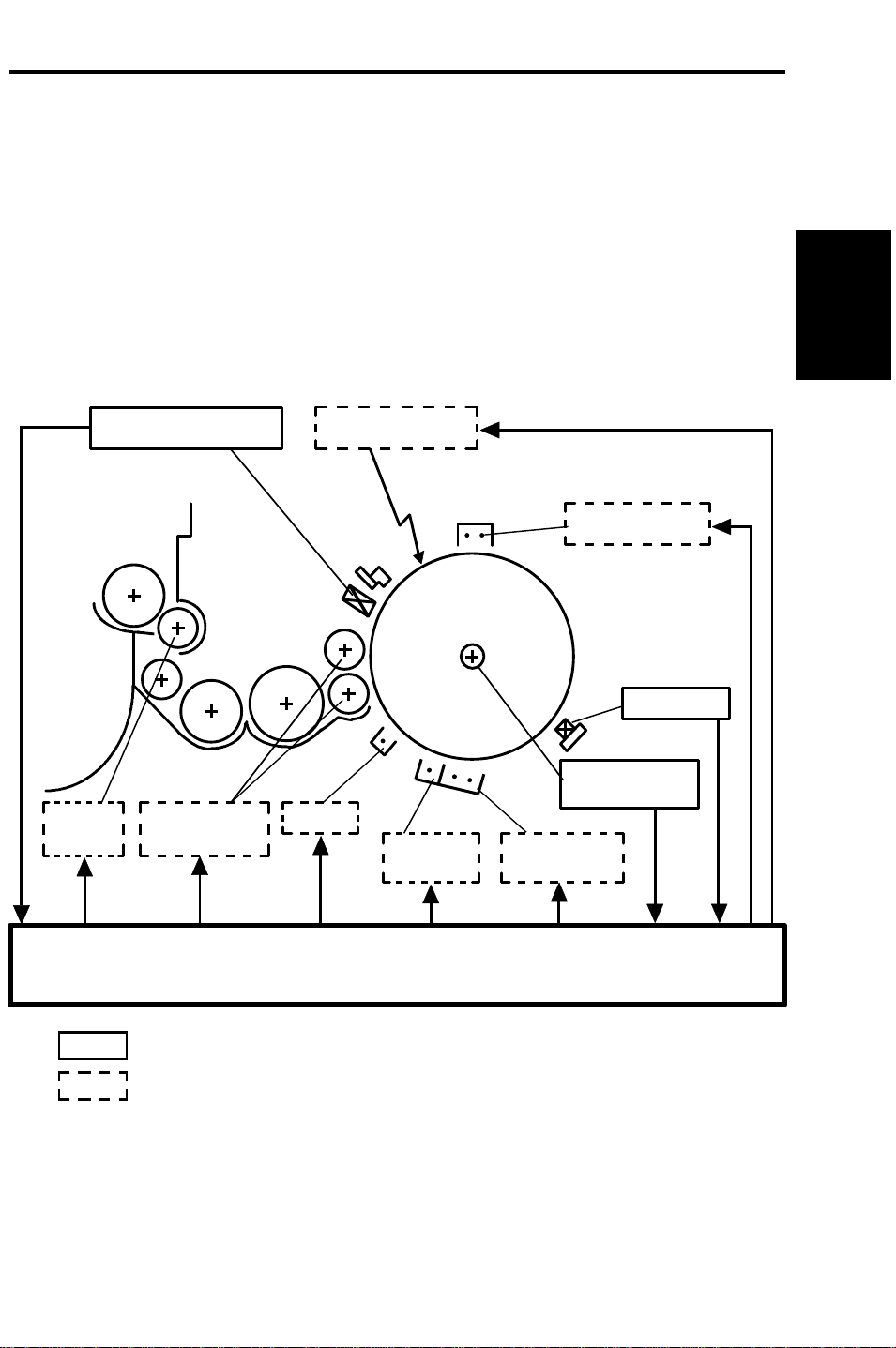

1. PROCESS CONTROL

1.1 OVERVIEW

The characteristics of each unit which is related to the copy image

reproduction are changed by various factors. To get stable images over long

periods and in continuous copy runs, these characteristic changes have to be

compensated.

The following figure and table show how these factors are compensated on

this copier.

Detailed

Descriptions

Potential Sensor

Toner

Supply

Development

Bias

Exposure Lamp

PTC

Main PCB

Transfer

Corona

Charge Corona

ID Sensor

Drum Current

Detection PCB

Separation

Corona

: Sensing Item

: Controlled Item

2-1

Page 24

PROCESS CONTROL 6 March 1992

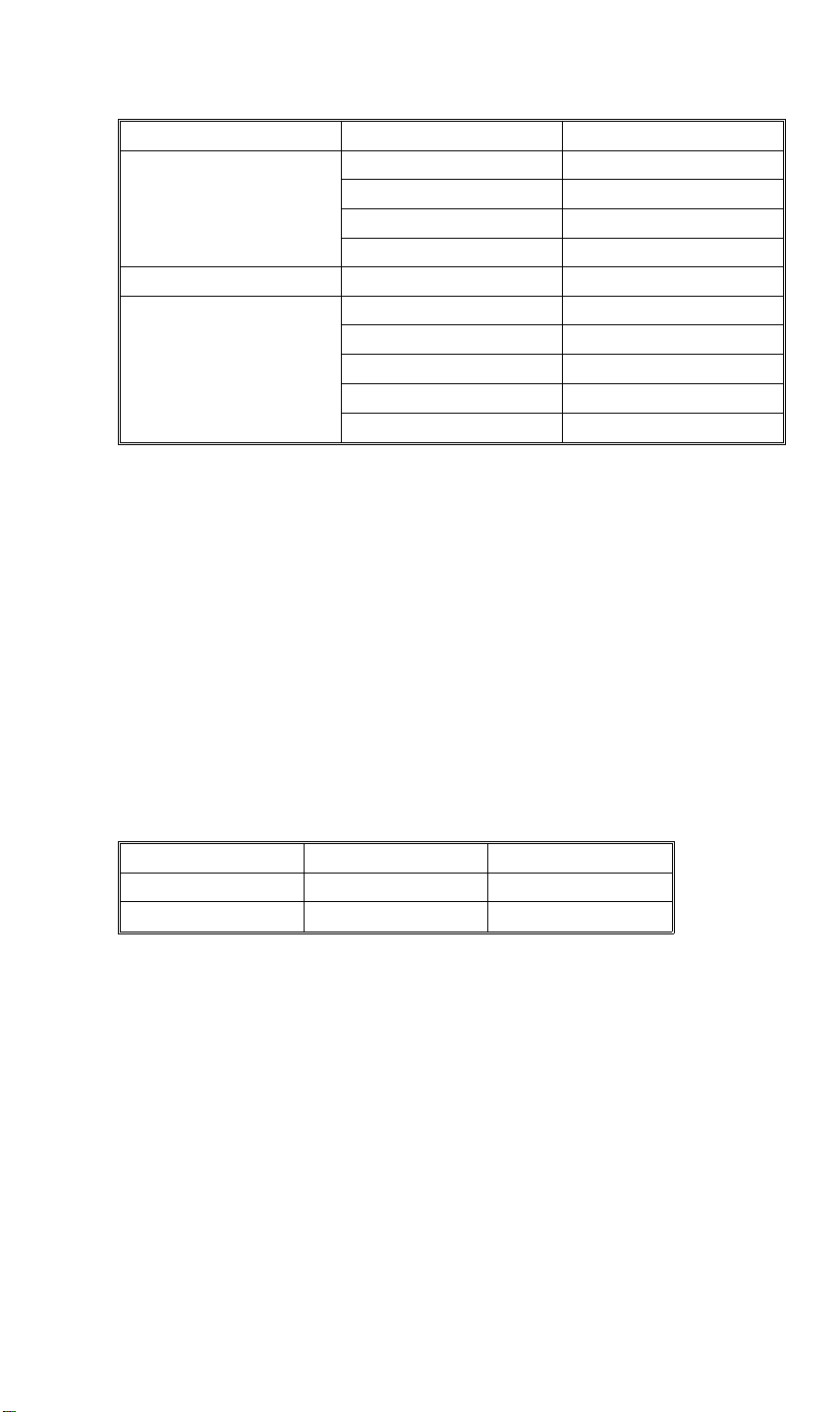

Section Characteristics Causes of Change Compensation Method

Drum Charge

Potential

Sensitivity Repeat Stress

Residual

Voltage

Charge

Corona

Exposure Lamp Intensity Repeat Stress Measure the drum potential of a part

Development Amount of

Charge

Potential

Mirror

Reflectivity

Lens Clearness

Toner Charge

Repeat Stress

Temperature

Humidity

Temperature

Humidity

Repeat Stress

Temperature

Humidity

Dirtiness

Temperature

Humidity

Dirtiness

Repeat Stress

Temperature

Humidity

Measure the drum potential of a part

that was not exposed (Dark Potential)

with the potential sensor and adjust

the charge corona output.

Measure the drum potential of a part

that was exposed (Light Potential) and

adjust the exposure lamp voltage.

Measure the drum potential of a part

that was erased by the erase lamp

(residual voltage) and adjust the

development bias, light potential, and

dark potential

Measure the drum potential of a part

that was not exposed (dark potential)

and adjust the charge corona output.

that was exposed (light potential) and

adjust the exposure lamp voltage.

Measure the reflected light intensity of

the ID sensor pattern and adjust the

toner density in the development unit.

2-2

Page 25

6 March 1992 PROCESS CONTROL

1.2 IMAGE CONTROL

1.2.1 Latent Image Control

QL

Charge

V0

Exposure

Black White

Vd

VL

Erase

Potential

Sensor

Vr

Drum

The figure shows the changes of the drum potential during the copy process.

V0: The drum potential just after charging the drum.

Vd (Dark Potential): The drum potential just after exposing the black

pattern (Vd pattern)

Detailed

Descriptions

VL (Light Potential): The drum potential just after exposing the white

pattern (VL pattern)

Vr (Residual Voltage): The drum potential just after the exposure of the

erase lamp.

2-3

Page 26

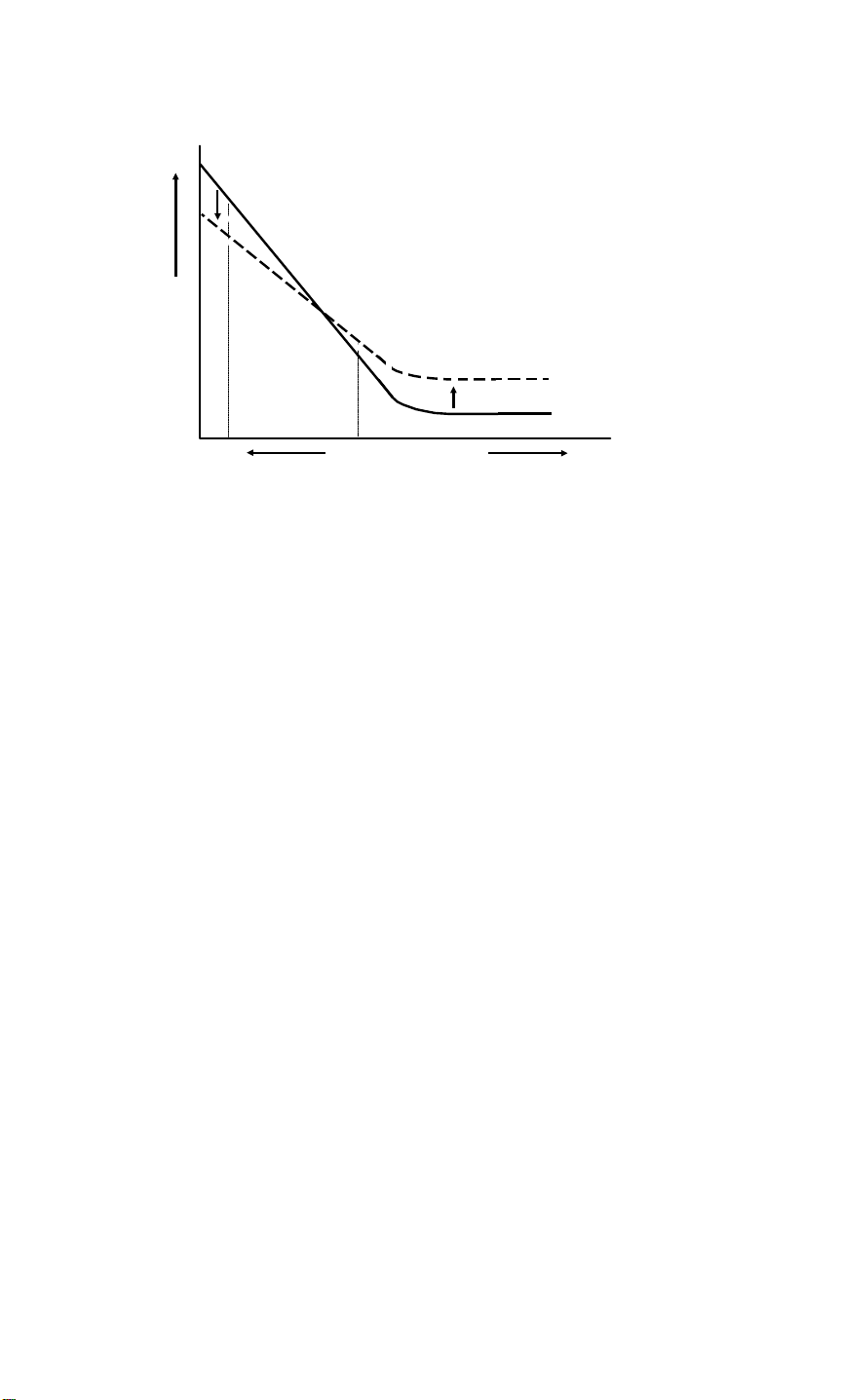

PROCESS CONTROL 6 March 1992

V0

[V]

Vd

Drum

Potential

VL

Vr

LightOriginal DensityDark

The above figure shows the relationship between the drum potential and the

original density (exposing light intensity). To get constant copy quality, this

relationship must be maintained.

Since this relationship tends to change to the one represented by the dotted

line by various factors, compensations are required as follows:

A decrease in dark voltage (Vd) is compensated for by increasing the charge

corona output. A increase in light voltage (VL) is compensated for by

increasing the exposure lamp voltage. Since the residual voltage (Vr)

increase cannot be compensated for by increasing the lamp voltage, it is

compensated by increasing the development bias voltage and changing the

Vd and VL standard value.

1.2.2 Image Density Control

To maintain constant copy image density, the ID sensor detects the toner

amount of the ID sensor pattern. From this, it is understood that drum

potential is stabilized with the above compensations. According to the

detection results, the toner density in the development unit is controlled so

that the toner amount on the sensor pattern is constant.

The following sections explain the details of these compensations.

2-4

Page 27

6 March 1992 PROCESS CONTROL

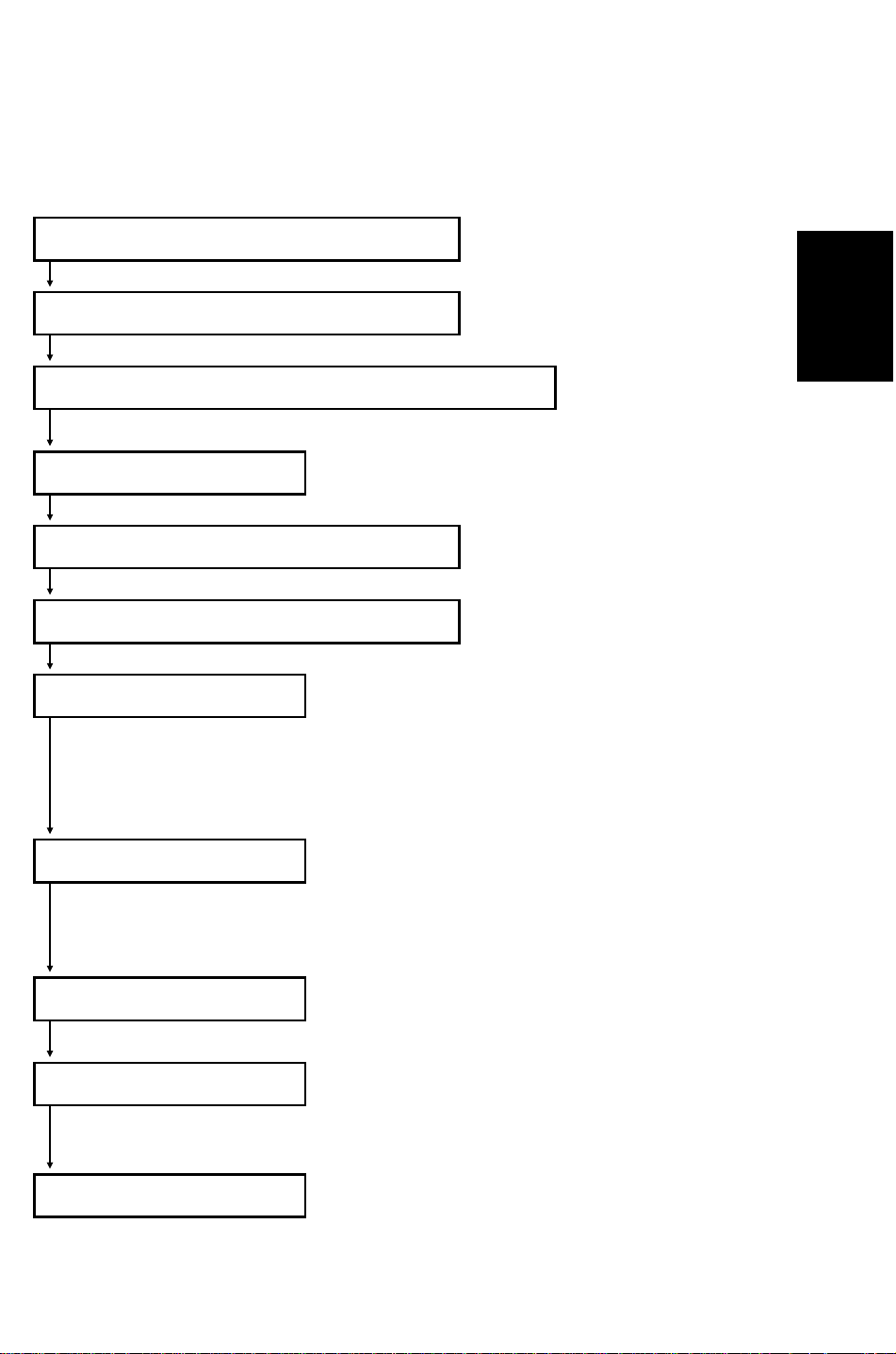

1.3 PROCESS CONTROL DATA INITIALIZATION

The following flow chart shows all the steps that will be performed whenever

the main switch is turned on while the hot roller temperature is below 100°C.

This initializes all the process control settings.

Main SW On (Fusing Temp. < 100°C)

Drum Potential Sensor Calibration

Drum Conditioning Start (Fusing Temp. = 160°C)

• Exposure lamp ON

Vsg Adjustment

Lamp Intensity Sensor Calibration

Detailed

Descriptions

Charge Corona Current Adjustment

Vr Measurement

• Lens position shift

• Exposure lamp OFF

• Scanner moves to return position (Vd Pattern)

• Exposure lamp ON

Vd Correction

• Exposure lamp OFF

• Scanner returns to home position (VL Pattern)

• Exposure lamp ON

VL Correction

• Exposure lamp OFF

V01 Detection

• Scanner moves to return position (ADS Pattern)

• Exposure lamp ON

ADS Adjustment

2-5

Page 28

PROCESS CONTROL 6 March 1992

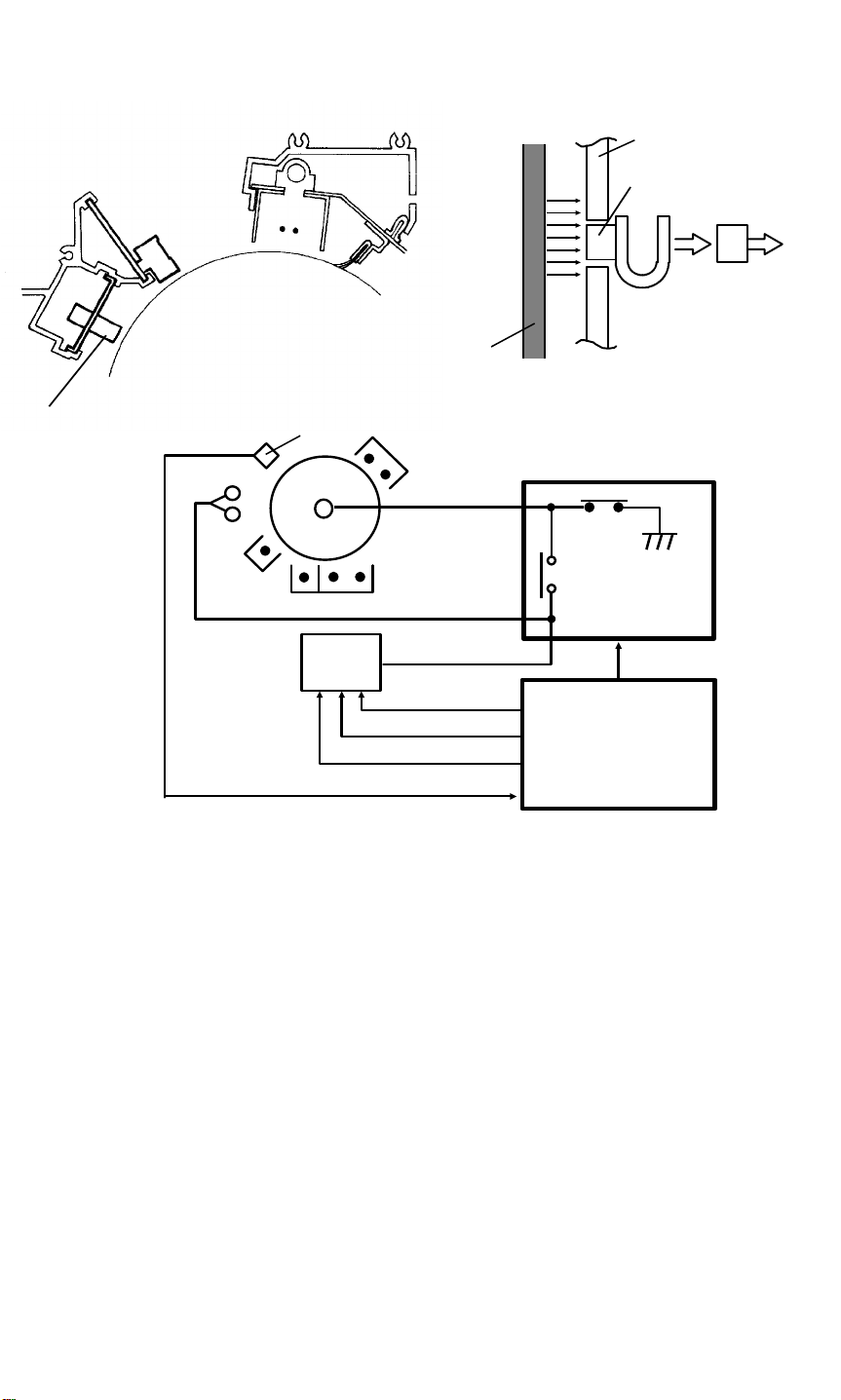

1.3.1 Drum Potential Sensor Calibration

[A]

Potential Sensor

Bias

P.P.

Case

Sensor

Output

Amp.

Drum

RA2

RA1

Drum Current

Detection PCB

Relay

TRIG 1 (800V)

TRIG 2 (100V)

PWM

Sensor

Main PCB

The drum potential sensor [A] is located just above the development unit. The

sensor has a detector which detects the electric lines of force from the

electric potential on the drum. The output of the sensor depends of the

number of electric lines of force.

Since the output of the sensor is affected by environmental conditions, such

as temperature and humidity, the sensor output is calibrated during process

control data initialization.

The drum current detection board has two relay contacts. Usually RA2

grounds the drum. However, during the initialization, the main PCB turns RA1

on and RA2 off and applies the development bias to the drum shaft.

By measuring the outputs of the drum potential sensor when +100 V and

+800V are applied to the drum, the sensor output is calibrated automatically.

2-6

Page 29

6 March 1992 PROCESS CONTROL

1.3.2 Drum Conditioning

When the drum temperature reaches 160°C, the machine starts the drum

conditioning process. In this mode, all the coronas and lamps around the

drum are activated and drum sensitivity is stabilized, as in continuous copy

runs.

1.3.3 Vsg Adjustment

During drum conditioning, the ID sensor checks the bare drum’s reflectivity

and calibrates the output of the ID sensor to +4 V.

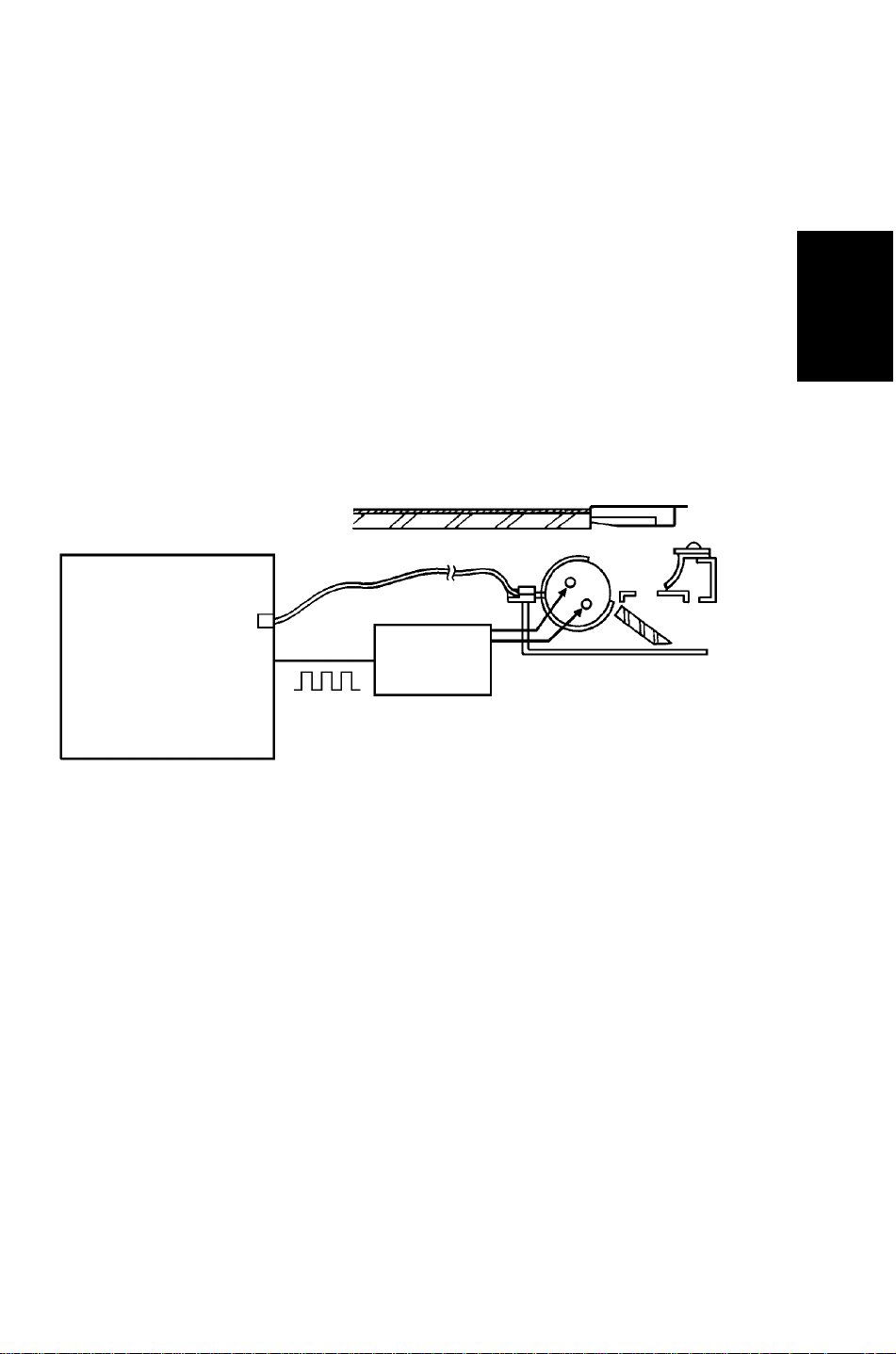

1.3.4 Lamp Intensity Sensor Calibration

Detailed

Descriptions

Main PCB

PWM

FL

Stabilizer

The exposure lamp intensity is monitored by the main PCB through the fiber

optics cable. A photodiode on the main PCB converts the light intensity to a

dc voltage. The main PCB sends a PWM signal with a 100% duty cycle to the

FL stabilizer and checks the monitored voltage, adjusting it to +3 V. This +3 V

is used as the light intensity standard.

2-7

Page 30

PROCESS CONTROL 6 March 1992

1.3.5 Charge Corona Current Adjustment

+12V

GND

-12V

CN342-3

CN342-2

CN342-1

CN341-4

RA1

CN341

-1

CN341-2

Potential S.

CN103-B24

Id Set

CN103-A14

CN104-A28

CN104-B1

CN104-A1

RA2

RA2

RA1

HIC1

CN342

-4

T343

CN342

CN342

-5

-6

-7

-8

Drum Current Detect PCB MainPCB

PCL

DC

AC

The charge corona current is measured and adjusted automatically by the

drum current detect PCB.

The charge corona current flows to the drum current detect PCB through the

drum and the drum shaft. The drum shaft is grounded by the drum current

detect PCB usually. However, during the process control data initialization,

the main PCB activates the corona current circuit in the drum current

detection PCB which converts the drum current to a voltage and separates it

into ac and dc component outputs. Then, the main PCB reads them through

A/D converters as digital data. The main PCB adjusts the corona current by

controlling the PWM signal to the charge corona power pack.

When the auto drum current adjustment mode is selected by the SP mode,

the drum current detect PCB is used to measure and adjust other corona

outputs in the same way.

2-8

Page 31

6 March 1992 PROCESS CONTROL

1.3.6 Vr Measurement

[V]

Drum

Potential

V0

Vd

VL

Vr

Dark Light

Original Density

The drum residual voltage (Vr) tends to increase during the drums life due to

electrical fatigue. The residual voltage cannot be reduced even if the

exposure lamp voltage is increased. Therefore, the Vr change has to be

compensated by other means.

Detailed

Descriptions

The main PCB checks the drum potential just after the erase lamp exposure,

by the drum potential sensor during drum conditioning. The drum potential is

in fact Vr. This measured Vr is used as the standard for the following other

compensations.

1. Vd Correction

2. VL Correction

2-9

Page 32

PROCESS CONTROL 6 March 1992

1.3.7 Vd Correction

[V]

Vd

Drum

Potential

Exposure

Glass

Vd Pattern

Dark

Original Density

Vr

Light

The drum potential just after the black pattern (Vd Pattern) is exposed (Vd:

Dark Potential) tends to lower during drum life due to a decrease in the

drum’s capacity to carry a charge.

To check the actual Vd, the first scanner moves to the return position and the

Vd pattern (Black) stuck on the bottom side of the exposure glass bracket is

exposed on the drum.

The main PCB measures Vd through the drum potential sensor and adjust it

to a target value by adjusting the charge power pack output.

On the other hand, there is a change of the drum residual voltage (Vr), so

that the target Vd voltage is compensated as follows:

Target Vd Value: Vd = Vr + 770 V

The adjusted charge power pack output control value (PWM value) is kept in

memory until the next initialization.

If the target value cannot be achieved within the charge power pack output

control range, the copier indicates the system error on the CRT screen. The

copier tries the Vd check again after the error reset. Even if the second Vd

adjustment fails, no SC condition is displayed. The previous power pack

output control data will be used in this case.

2-10

Page 33

6 March 1992 PROCESS CONTROL

1.3.8 VL Correction

[V]

VL Pattern

Drum

Potential

Dark

VL

Original Density

Vr

Light

Detailed

Descriptions

Dirty optics and/or exposure lamp deterioration decreases the intensity of the

light that reaches the drum. In addition to this, the drum sensitivity also

changes during the drum’s life. These factors change the drum potential just

after white pattern exposure (VL: Light Potential).

To check the actual VL, the first scanner moves to the home position and the

VL pattern (White) stuck on the bottom side of the exposure glass bracket is

exposed on the drum.

The main PCB measures the VL through the drum potential sensor and

adjusts it to a target value by adjusting the exposure lamp output.

The residual voltage change also affects VL, so that VL’s target voltage is

compensated as follows:

Target Value of VL: VL1 = Vr + 50 -- 5N (volt)

NOTE: N is the setting for the exposure lamp adjustment in the SP mode.

Maximum of 5N = 50

The adjusted exposure lamp output control value (PWM value) is kept in

memory until the next initialization.

If the target value cannot be achieved within the exposure lamp output

control range, the copier indicates the system error on the CRT screen. The

copier tries the VL check again after the SC reset. Even if the second VL

adjustment fails, no SC condition is displayed. The previous exposure lamp

output control data will be used in this case.

2-11

Page 34

PROCESS CONTROL 6 March 1992

1.3.9 V01 Measuring

[V]

Drum

Potential

Dark

V0

Vd

Original Density

Light

Since the ID sensor pattern on the drum is made by the erase lamp and

charge corona (except for B4/81/2" x 14" copy mode due to the lens horizontal

movement. See toner density detection and supply section for details), the

sensor pattern density varies with drum potential just after the charge corona

(V0) is applied.

To measure the toner density properly, the development bias for the ID

sensor pattern is corrected by measuring the actual drum potential after the

charge corona.

During the process control data initialization, the drum potential after the

charge corona is applied when the drum sensitivity is stabilized (V01) will be

measured and used to determine the bias voltage for the ID sensor pattern

development in continuous copy run. The details will be explained in the

toner density detection section.

2-12

Page 35

6 March 1992 PROCESS CONTROL

1.3.10 ADS Adjustment

Exposure Glass

ADS Pattern

ADS Pattern

Detailed

Descriptions

The ADS pattern is located underneath the exposure glass bracket. During

the process control data initialization, the ADS reference voltage is adjusted.

When the first scanner is moved to the return position for the Vd adjustment,

the main PCB checks the ADS voltage through the ADS fiber optics cable.

The measured voltage is calibrated to the standard voltage (3 V) as the

reference for the auto image density control.

2-13

Page 36

PROCESS CONTROL 6 March 1992

1.4 COMPENSATIONS DURING COPY CYCLE

During continuous copying, the drum sensitivity changes due to the electrical

fatigue. The drum sensitivity also changes during rest time.

The following compensations are used for the drum sensitivity changes in the

copy cycle:

VL Pattern

[V]

Drum

Potential

V0

Vd

VBB

VL

Vr

Dark Light

Original Density

1.4.1 VL Compensation

The drum light potential (VL) is changed during the copy cycle.

To get constant image quality in continuous copy runs, the development base

bias is compensated during the copy cycle.

At the beginning of each original scanning, the VL sensor pattern is

developed on the drum. The main PCB monitors the drum potential (VL2) of

the latent image of the VL sensor pattern through the drum potential sensor,

and adjusts the development base bias.

See development bias section for details.

Development Base Bias: VBB = VL2 + 170 + 5N

NOTE: N is the setting for the exposure lamp adjustment in the SP mode.

2-14

Page 37

6 March 1992 PROCESS CONTROL

1.4.2 V02 Measuring

Start key

Charge

Corona

Exposure

Lamp

Scanner

Drum

Potential

Sensor

F

R

V02 VL2 VL2 VL2 VL2 VL2 VL2 VL2 VL2

9 10 112 3 4 51

Detailed

Descriptions

During the process control data initialization, V01 is measured to determine

the development bias for the ID sensor pattern in continuous copy runs. This

bias cannot be used for the initial part of the copy run (less that 10 copies)

due to the different drum potential after the charge corona is applied.

Whenever the Start key is pressed, the drum potential after the charge

corona is measured at the beginning of the copy run (V02).

V02 is used to determine the development bias voltage for the ID sensor

pattern which is made at the first copy.

The details will be explained in the Image Density Control section.

2-15

Page 38

DRUM 6 March 1992

2. DRUM

2.1 OVERVIEW

[E]

[A]

This model uses an FO-type drum made by applying an urethane resin

coating [A] on an F-type drum [B]. This coating provides a long life and

minimize the white line problems on the half-tone areas.

[C]

Al

[B]

[F]

[D]

For the F-type drum, the charge carrying layer [C] is made by the drum

conditioning. Since the FO-type drums are coated after the charge carrying

layer has been made, it is not necessary to perform the drum conditioning at

the new drum installation.

When drum temperature drops below the permissible level, extreme

sensitivity changes occur. Additionally, the temperature changes can cause

condensation. To maintain a constant drum temperature, a drum heater [D]

(100 V 140 W) which is controlled by a thermistor [E] and two thermoswitches

[F] is used.

2-16

Page 39

6 March 1992 DRUM

2.2 DRUM HEATER CONTROL

160°C 65°C

CN-3

CN-2

CN-1

RA354

RA353

AC100V

Drum Heater

RA

Drum Thermistor

RA353RA354

RA

Drum Heater 1

Drum Heater 2

24V

CN251-B25

24V

CN251-B30

5V

CN251-B26

CN251-A30

Relay PCB

Drum Thermistor

CN255-B9

CN255-A28

CN104-A4

Drum

Heater 1

Drum

Heater 2

A/D

Converter

CN102-A2

CN103-B26

Main PCB

24V

ON

The drum thermistor monitors the drum surface temperature. When the

measured temperature reaches 41°C, the main PCB determines that the

copier is ready to make copies.

When the main switch is off, the drum heater relays (RA353 and RA354) are

off, so that the drum heater is controlled by the 65°C thermoswitch. The

thermoswitch is on at 50°C and off at 65°C.

Detailed

Descriptions

When the main switch is on, RA354 is on and bypasses the 65°C

thermoswitch from the drum heater control circuit. RA353 turns on or off

according to the temperature detected by the drum thermistor.

The drum surface temperature is controlled between 41°C and 50°C.

To minimize the power consumption, RA353 is turned on to bypass the drum

heater during the copy cycle.

2-17

Page 40

DRUM CHARGE 6 March 1992

3. DRUM CHARGE

3.1 CHARGE CORONA UNIT

[A]

This copier uses a dual carbon coated tungsten wire corotron for the drum

charge. The corona wire generates a corona of positive ions when the charge

power pack [A] applies a high voltage.

The output of the charge power pack is determined by the CPU based on the

process control data.

The charge power pack has a leakage sensor. If a leak (short circuit) is

sensed, the output is interrupted.

2-18

Page 41

6 March 1992 DRUM CHARGE

3.2 CORONA UNIT VENTILATION

Detailed

Descriptions

If ozone produced by the corona charge stays in the charge corona area, it

may cause uneven corona charging to the drum. To prevent this, ozone is

vacuumed out by the vacuum fan through the duct and toner filter in the

transport unit, then changed to oxygen by the ozone filter before blown out of

the copier.

2-19

Page 42

DRUM CHARGE 6 March 1992

3.3 CORONA WIRE CLEANER

Paper dust, or toner particles on the charge corona wires may interfere with

charging and cause an uneven charge on the drum. The wire cleaner

prevents this problem by automatically wiping the charge corona wires clean.

Once every 5000 copies, the wire cleaner is activated when the main switch

is turned on. The hot roller temperature must be less than 100°C for the wire

cleaner to be activated.

When the dc motor in the front end block turns on, it drives the cleaner

bracket from the home position to the rear end of the corona unit and then

back again.

2-20

Page 43

6 March 1992 DRUM CHARGE

3.4 CHARGE CORONA POWER PACK

CN311-8

CN311-1

CN311-10

24VP

24V

GND24VP

DC Power Supply

CN302-3 CN302-4

CN304-1

A

RA

CN303-2

303

CN341-6

CN341-8

Door

SW

A

24 V

GND

Drum Current

CN103-A22

DC Drive PCB

Detect PCB

PWM

TRIG

Main PCB

Charge

Corona P.P.

The main PCB sends a PWM (Pulse Width Modulation) signal to the charge

corona power pack. According to the PWM ratio, the dc power pack outputs a

high dc voltage to the charge corona wires. The main PCB determines the

PWM ratio based on the process control data.

Detailed

Descriptions

There is a safety relay (RA303) on the dc drive board which is activated by a

signal from the main PCB. In case of the SC conditions related to the high

voltage devices and the abnormal exposure lamp on, the main PCB turns the

RA303 to cut the power of dc 24 V to the power pack through its contact.

2-21

Page 44

ERASE 6 March 1992

4. ERASE

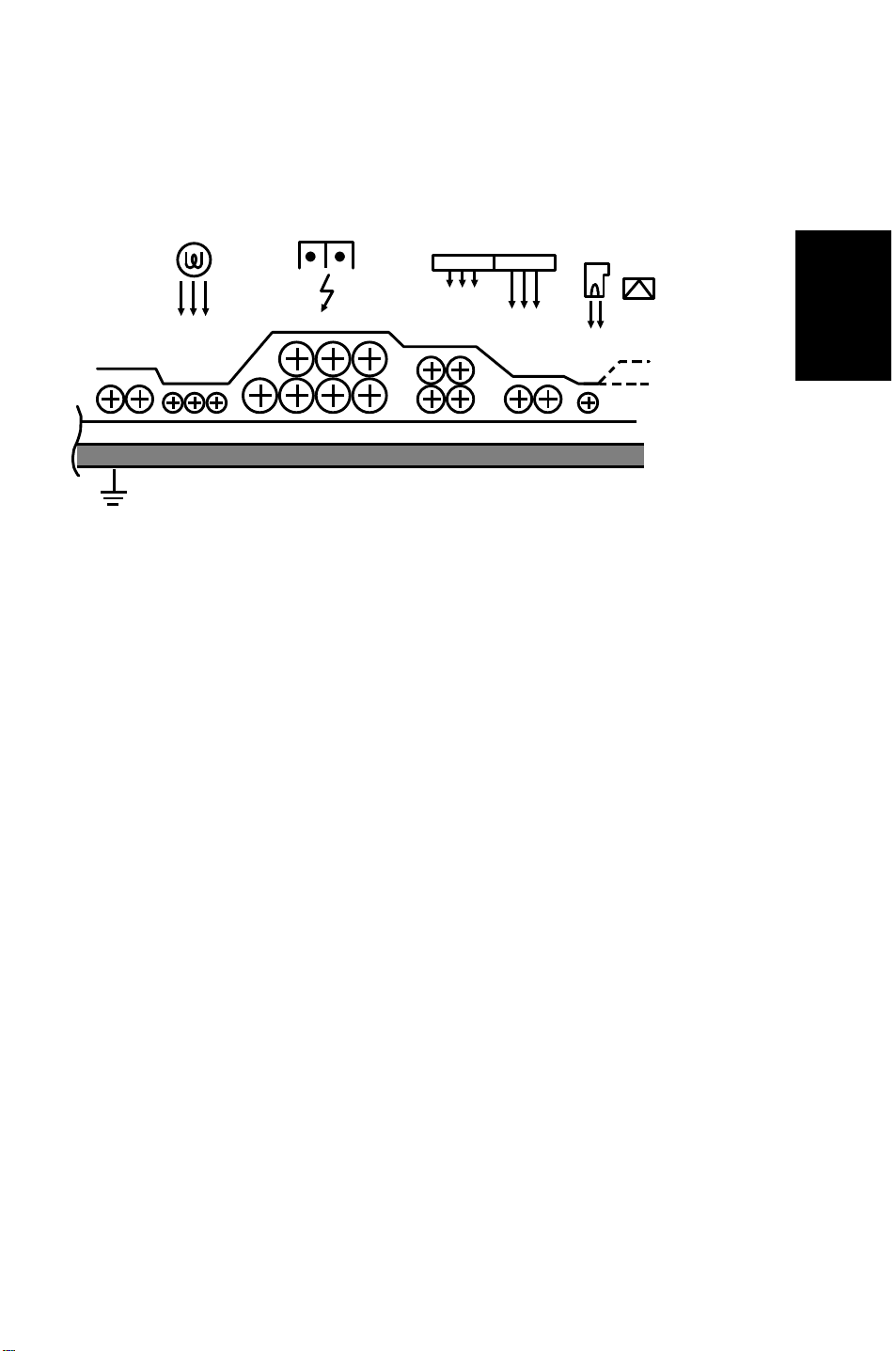

4.1 OVERVIEW

[A]

The electrical charge of the area that does not require any image will be

removed by the erase lamp unit [A].

This reduces toner consumption, and the load of the cleaning unit.

The erase lamp unit consists of 90 yellow-green LEDs. This reduces drum

light fatigue and allows precise control of the light width.

The erase lamp unit is controlled by the main PCB based on factors such as

the reproduction ratio, paper size, SP mode settings, and the image editing

settings.

The maximum erase margin error in the image editing mode is 6 mm.

2-22

Page 45

6 March 1992 ERASE

4.2 ERASE LAMP CIRCUIT

5V

OFF ON

CLOCK

LATCH

CN113-6

CN113-2

CN113-7

CN113-3

CN113-1

CN113-4

CN113-5

S-IN

GND IS

GND CK

LATCH

5V

5V

CK

CN651-5

CN651-E

CN651-6

CN651-F

CN651-4

CN651-2

CN651-8

S-IN

CLK

DCKQ

FF

LATCH

D

FF

CK

Q

CN651-C

CN561-1

CN561-A

CN561-3

GND

5V LED

GND-LED

CN311-8

CN311-15

CN311-16

Main PCB Erase Lamp Unit DC Power

Supply

The main PCB sends the serial bit data to the erase lamp unit with the clock

signal. The latch signal holds the ON/OFF condition of the LEDs.

The following charts show the erase lamp control timing.

1. When the ID sensor pattern is not made.

(A4/LT, Full Size, and 3rd Feed Mode)

Start Main Motor ON Regist Trail Edge Main Motor OFF

Detailed

Descriptions

1102*1 420* 1633

300 204

VL Pattern

All ON

816 *1

82

All ON

47*3

53*3

50

2. When the ID sensor pattern is made.

(A4/LT, Full Size, and 3rd Feed Mode)

Start Main Motor ON Regist Trail Edge Main Motor OFF

300 204

All ON

816*1

1466 *1

1602 *1

108

5954

82

420*2 1633

All ON

47*3

53*3

VL Pattern

50

ID PatternV02

NOTE: 1. Depends on the paper feed station.

2. Depends on the paper size.

3. Will be changed in Margin Adjustment and Image Editing Mode.

2-23

Page 46

OPTICS 6 March 1992

5. OPTICS

5.1 OVERVIEW

[A]

[C]

[B]

The optics unit reflects an image of the original on the exposure glass onto

the selenium drum. This forms a latent electrical image of the original.

On this model, to minimize power consumption, a fluorescent lamp is used

for the exposure lamp [A].

Six high reflection mirrors are used to make the optics unit smaller and obtain

a the wide reproduction ratio range (50 -- 200%).

The lens [B] is driven by two stepper motors for (1) vertical direction (parallel

to the paper feed direction) and (2) horizontal direction movements.

To correct focal length change in reduction and enlargement modes, the

mirror unit [C] (4th and 5th mirrors) position is adjusted by a stepper motor.

The exposure glass has a special coating on one side to minimize the static

electricity which may be produced by the original using the document feeder.

The coated side is marked and should face up.

2-24

Page 47

6 March 1992 OPTICS

5.2 SCANNER DRIVE

[C]

[D]

[A]

Detailed

Descriptions

[B]

A dc servo motor is used as the scanner drive motor [A].

The scanner drive motor drives first [B] and second scanner [C] using four

scanner drive wires. The second scanner speed is half of the first scanner

speed.

The first and second scanners are supported by the front and rear guide rails

[D]. To minimize the friction between the scanners and guide rails, the play of

the scanner movement is minimized by high wire tension.

2-25

Page 48

OPTICS 6 March 1992

5.3 SCANNER POSITION SENSORS

[A]

[B]

There are two scanner position sensors located at the front side of the optics

unit.

The scanner home position sensor [A] is used to detect the home position at

the machine initialization and during the scan cycle.

The scanner return position sensor [B] is used to detect the scanner position

for the process control data initialization (Vd and ADS data). The return

position sensor is not used during normal copying.

2-26

Page 49

6 March 1992 OPTICS

5.4 VERTICAL LENS DRIVE

[B]

[A]

The lens vertical drive motor [A] changes the lens vertical position in

accordance with the selected reproduction ratio.

A stepper motor (Approx. 1.8° (0.05 mm)/step) is used to drive the lens

through the lens drive belt.

The lens vertical home position sensor [B] detects the lens vertical position

for full size mode. The motor control PCB keeps track of the lens position

based on the number of pulses sent to the lens vertical drive motor.

[C]

Detailed

Descriptions

The lens vertical drive encoder [C] installed on the drive pulley is used to

detect if the vertical lens base locks.

2-27

Page 50

OPTICS 6 March 1992

5.5 HORIZONTAL LENS DRIVE

[B]

[A]

The original horizontal position on the exposure glass varies in modes (such

as platen, ADF, and CFF modes) for easy original handling. On the other

hand, the center is the standard position of the paper feed.

Therefore, the lens horizontal position has to be changed according to paper

size, reproduction ratio, and the original modes.

A stepper motor (approx. 7.5° (0.35 mm)/step) is used to drive the lens

through the lens drive wire.

The lens horizontal home position sensor [A] is used to detect the lens

horizontal position for A4/LT sideways, full size, and ADF mode.

The other positions are determined by counting the number of motor drive

pulses.

The lens horizontal drive encoder [B] installed on the drive pulley is used to

detect if the horizontal lens base locks.

2-28

Page 51

6 March 1992 OPTICS

5.6 HORIZONTAL LENS POSITIONING

5.6.1 For Original Position

Copy Paper

6.35

2.5

100%

Lens Position

Horizontal

CFF

12.7

ADF

5

Platen

Original Front

Edge

There are three standard original positions for the platen, ADF, and CFF

modes.

ADF mode original position is 5 mm to rear of the platen mode original

position to maintain the original transport path (5 mm from the front scale).

CFF mode original position is 17.7 mm (5 + 12.7 mm) to rear of the platen

mode original position. This is to maintain the traction hole part transport path

(12.7 mm) in ADF.

The above figure shows the lens horizontal positions for each original mode

when the identical size paper is used.

Detailed

Descriptions

5.6.2 For Paper Size

Copy Paper

100%

Lens

Position

Horizontal

Original Front

Edge

To keep the high paper feed performance, the center is assigned as the

paper feed standard position. Therefore, the lens horizontal position is

changed according to the paper size.

The figure shows the lens horizontal position for each paper size in full size

mode.

2-29

Page 52

OPTICS 6 March 1992

5.6.3 For Reproduction Ratio

50%

Copy Paper

Vertical

100% 200%

Horizontal

Lens Position

Original

Front Edge

When the reproduction ratio is changed, the vertical position of the lens is

changed. At the same time, the total focal length has to be changed to adjust

the image focusing. For this focal length change, the horizontal position of the

lens is also adjusted.

The figure shows the lens horizontal position for 50, 100 and 200%.

2-30

Page 53

6 March 1992 OPTICS

5.7 MIRROR UNIT DRIVE

[A]

Detailed

Descriptions

To compensate the focus change at the reproduction change, the mirror unit

(4th and 5th mirrors) position is changed.

A stepper motor (Approx. 7.5° (0.1 mm)/step) is used for the mirror unit drive.

A mirror unit home position sensor [A] is used to detect the unit position for

full size mode. The motor control PCB keeps track of the unit position based

on the number of motor drive pulses.

2-31

Page 54

OPTICS 6 March 1992

5.8 MOTOR DRIVE CIRCUIT

Sensors Encoders

Main

PCB

Serial

Interface

Motor

Control PCB

E

Encoder

DC Motor

Drive PCB

Scanner

M

Drive

Horizontal

M

Drive

Vertical Drive

M

Mirror Unit

M

Drive

The motor control PCB communicates with the main PCB through the serial

interface lines. The motor control PCB monitors all the sensor signals and

controls the motors through the dc motor drive PCB.

The development motor and the main motor are also be controlled by the dc

motor control PCB.

2-32

Page 55

6 March 1992 OPTICS

5.9 EXPOSURE LAMP UNIT

[C]

[A]

Detailed

Descriptions

[B]

[D]

This copier uses a fluorescent lamp [A] (100 V 84 W). This has the following

advantages:

• Low power consumption

• There is no bright point and it is easy to get even luminescence

• A narrow light wave band allows more accurate focusing for various

kinds of originals

• High-speed scanner operation vibration resistance

• Omni-directional luminescence reduces original shadow

Since low fluorescent tube temperature will result in delayed lighting and

intensity variation, a tube-type heater (38 V 60 W) [B] is used to maintain the

fluorescent tube temperature at approximately 40°C.

The lamp unit has a thermofuse [C] to monitor the lamp temperature and a

thermofuse [D] (139°C) for safety.

2-33

Page 56

OPTICS 6 March 1992

5.10 EXPOSURE LAMP CONTROL

[C]

PWM

[B]

[A]

Exposure lamp intensity must be stabilized during the copy cycle to get a

constant latent image on the drum. The main PCB [A] monitors and maintains

the light intensity through a fiber optics cable [B]. According to the measured

value, a lamp power signal (PWM signal) is sent to the fluorescent lamp

stabilizer [C].

The PWM signal output is determined based on the standard value (+3 V at

PWM 100% duty cycle) which is set at the process control data initialization

(see the Process Control Section for details).

2-34

Page 57

6 March 1992 OPTICS

5.11 AUTO IMAGE DENSITY CONTROL

50 mm 26 mm

26 mm

50 mm

166 mm

Detailed

Descriptions

The original background density is read through a fiber optics cable on the

exposure lamp unit. The sampled strip is at the leading edge of the original

and the size depends on the scanner speed (reproduction ratio).

The fiber optics cable conducts the light to a photodiode on the main PCB.

The photodiode then converts the density to the ADS voltage. The CPU

compares it with the standard ADS value (+3 V), which is set at the process

control data initialization by checking density of the white pattern underneath

the left exposure glass holder and adjust the development bias accordingly.

Detailed bias control is described in the development bias section.

2-35

Page 58

OPTICS 6 March 1992

5.12 UNEVEN LIGHT INTENSITY CORRECTION

[B]

[A]

[C]

The slit plate [A] corrects the uneven light intensity at the ends and center of

the fluorescent lamp [B] and evenly distributes light reflected from the original.

To compensate for reduced light at the lens edges, the shading plate [C] is

located in front of the lens. Additionally, the shading plate compensates the

light intensity when the lens horizontal position is shifted.

2-36

Page 59

6 March 1992 OPTICS

5.13 ANTI-CONDENSATION HEATER

[B]

[A]

To prevent condensation in the optics unit, a 40 W anti-condensation heater

[A] is installed at the bottom of the lens unit.

The anti-condensation heater is controlled by a thermoswitch [B] (On at

17°C, Off at 25°C) under the following conditions:

Detailed

Descriptions

1. The main switch is off.

2. The main switch is on, fusing lamp off in stand-by mode.

3. Machine off condition in weekly timer mode.

The anti-condensation heater has a thermofuse (169°C).

5.14 OPTICS COOLING FAN

[B]

[A]

[C]

The light intensity will be decreased if the fluorescent lamp temperature

becomes too high. The optics cooling fan [A] blows in cool air from outside

through an air filter [B]. Air from the fan also passes through the 6th mirror slit

[C] to the drum area. This prevents the optics area from being contaminated

by scattered toner in the drum unit.

2-37

Page 60

DEVELOPMENT 6 March 1992

6. DEVELOPMENT

6.1 OVERVIEW

[E]

[G]

[D]

[C]

[F]

[A]

[B]

This copier uses a double roller (diameter 20 mm each) development system.

This system differs from single roller development system in that (1) it

develops the image in a narrow area and (2) it develops the image twice.

Also, fine toner and developer (smaller particle size) are used. As a result,

the image quality, especially of thin lines, the trailing edge of half-tone areas,

and black solid areas are improved.

A dc motor is used to drive the development unit.

The developer is supplied to the developer guide [A] upper side by the

paddle roller [B]. The magnet of the upper development roller [C] attracts the

developer to the roller surface.

The doctor blade [D] trims the developer to the desired thickness and creates

back spill to the cross mixing mechanism [E]. The developer is transferred to

the lower development roller [F] and then returned to the agitator roller [G]

area via a paddle roller.

The development motor has two speeds. When the motor turns at high

speed, the developer is supplied to the development rollers. After image

development, the motor turns at slower speed to return the developer to the

development unit from the development roller sleeves. This prevents

developer spillage during the unit replacement.

The development rollers are given a positive bias to prevent the toner from

being attracted to the non-image areas, on the drum surface, that may have a

slight residual positive charge. The bias voltage is determined based on the

factors checked by the process control system.

2-38

Page 61

6 March 1992 DEVELOPMENT

6.2 DRIVE MECHANISM

[G]

[E]

[F]

[A]

[D]

[C]

[B]

All the development unit parts, except the toner supply brush, are driven by

the development drive motor (dc motor).

Detailed

Descriptions

The toner supply brush is driven by the toner supply motor.

The development motor drives the development drive gear through two

timing belts. The rotation is transferred as follows:

Upper/Lower

Development

Drive Gear [A]

Auger

Drive

Gear [B]

Idle Gear [C]

Timing Belt [E]

Dev. Roller [D]

Toner Mixing Vane

Drive Gear [F]

Idle Gear

Paddle Roller [G]

Since reversed toner mixing vane rotation could damage something, a

one-way clutch is installed to the mixing vane drive gear.

2-39

Page 62

DEVELOPMENT 6 March 1992

6.3 CROSS MIXING

[E]

[A]

[D]

[C]

[B]

This copier uses a standard cross-mixing mechanism to keep the toner and

developer evenly mixed. It also helps agitate the developer to prevent

developer clumps from forming, and helps create the triboelectric charge.

The developer on the turning upper development roller is split into two parts

by the doctor blade. The part trimmed by the doctor blade goes to the

backspill plate [A].

As the developer slides down the backspill plate to the agitator [B], the mixing

vanes [C] move it slightly toward the rear of the unit.

Part of the developer falls into the auger inlet [D] and is transported to the

front of the unit by the auger [E].

The agitator moves the developer slightly to the front as it turns, so the

developer stays level in the development unit.

2-40

Page 63

6 March 1992 DEVELOPMENT

6.4 DEVELOPMENT BIAS

6.4.1 Bias Power Pack

Potential Sensor

Bias

P.P.

PWM Duty Cycle = t2/t1 x 100 (%)

Output = 10 x PWM Duty Cycle (V)

TRIG 1 (800V)

TRIG 2 (100V)

PWM

Sensor

t2

t1

RA2

RA1

Drum Current

Detection PCB

Relay

Main PCB

Detailed

Descriptions

TRIG1 TRIG2 OUTPUT (V)

L H +800

H L +100

L L depends on the PWM signal

H H 0

The bias power pack has three input terminals. Two of them are used as the

output selector as shown in the table. When both terminals are low, the

output can be controlled by the other input terminal which receives the PWM

signal from the main PCB.

+800 and +100 V are used to calibrate the drum potential sensor in the

process control data initialization.

2-41

Page 64

DEVELOPMENT 6 March 1992

6.4.2 Bias Control In Copy Cycle

The bias output is determined by four factors.

The total bias is described as;

VB = VBB + VBA + VBS (ADS Mode)

VB = VBB + VBM (Manual ID Mode)

1) Base Bias (VBB)

[V]

Drum

Potential

Dark

V0

Vd

Original Density

VL

VBB

Vr

Light

As explained in the process control section, the base bias for development is

determined by the drum light potential (VL) measured in each original scan.

The base bias is also affected by the exposure lamp adjustment setting in the

SP mode.

VBB = VL2 + 170 + 5N

NOTE: N = Number of the lamp adjustment setting in SP mode.

2) ADS Compensation (VBA)

(V)

260

200

100

0

Dark ADS voltage (V) Light

1 2 3

0.97 V

2.75 V

According to the original background density, the bias is compensated. The

compensation value is determined with the voltage measured by the ADS

sensor (ADS Voltage) as follows:

VBA = --146 x (VADS -- 2.75)

NOTE: VBA has a limited range from 0 V to +260 V.

2-42

Page 65

6 March 1992 DEVELOPMENT

3) Manual ID Selection Position Compensation (VBM)

(V)

120

60

0

7 4

--60

--120

--180

1

ID Selection

According to the manual ID selection position, the bias is compensated as

follows:

VBM = 60 x M -- 240 (When M = 1 to 6)

60 x M -- 360 (When M = 7)

NOTE: M = Manual ID selection position. M ranges from 1 (darkest) to 7

(lightest).

When manual ID is set to 7 (lightest), the charge corona output is

lowered by 10% PWM duty cycle.

Detailed

Descriptions

4) SP Mode ID Selection Compensation (VBS)

In the SP mode, the image density level in the ADS mode can be selected

from four steps. The VBS is determined by the SP setting as follows:

Selected level VBS (V)

L +60

N 0 (Default)

H --60

VH --120

2-43

Page 66

DEVELOPMENT 6 March 1992

6.4.3 Bias for the ID Sensor Pattern

A3/11" x 17"

Lens Position

VL Pattern

B4/81/2" x 14"

A4/81/2" x 11"

Exposure Glass

ID Sensor

Pattern

Outside

The lens horizontal position is different in the used paper size on this mode.

On the other hand, the ID sensor position is fixed at one position. Therefore,

the ID sensor pattern on the back side of the exposure glass bracket will be

positioned on the drum only when B4/81/2" x 14" size paper is used.

The sensor pattern on the drum is made for each paper size as follows

(100%):

Paper Size Pattern (Black)

A4/A5/81/2" x 11"/51/2" x 81/2" Outside image of exposure glass (no light)

B4/81/2" x 14" ID sensor pattern on the exposure glass

bracket

A3/11" x 17" Exposure lamp off (no light)

The potential of the drum in these cases, the no light and the ID sensor

pattern exposure, is not the same. So the ID sensor bias (VBP) is determined

using two base voltages, V0 for the no-light condition and VD for the pattern.

VBP (no light) = --360 + V0

VBP (ID Pattern) = --360 + Vd

The Vd value which is determined during the process control data

initialization will be used.

V01 and V02, which are explained in the process control section, are used for

the VBP calculation as the V0 (drum potential after the charge corona) value.

The VBP can be changed by the SP mode (Toner Density Correction).

The following compensation will be applied to the above VBP.

Setting L N H VH

(V) --60 0 +60 +120

Default: H (+60 V)

2-44

Page 67

6 March 1992 TONER DENSITY DETECTION AND SUPPLY

7. TONER DENSITY DETECTION AND SUPPLY

7.1 TONER SUPPLY MECHANISM

[B]

[A]

[B]

[D]

[C]

The main PCB monitors the ID sensor pattern density on the drum through

the ID sensor once every ten copies and turns on the toner supply motor

when the pattern density is low (if Vsp/Vsg ≥ 1/13).

The toner supply motor [A] turns the toner supply roller [B] for a certain period

based on the paper size and the supply amount set by SP mode.

Detailed

Descriptions

A brush roller with low rotation torque and that can supply large amounts of

toner even with low operation speed, is used for the toner supply roller.

Toner mixing vanes [C] turn slowly while contacting the inner wall surface of

the toner tank whenever the development motor is turning. This prevents

toner blockages, and supplies toner to the toner agitator [D].

2-45

Page 68

TONER DENSITY DETECTION AND SUPPLY 6 March 1992

7.2 TONER DENSITY DETECTION

7.2.1 ID Sensor Pattern Production

Main SW

ON

Counter A

Counter B

ID Sensor Pattern

Start Key

Start Key Start Key

1 2 3 1 2 10

1 2 3 1 2 10 11 1 2

1 2 3 4 5 13 1 2 3

11

1 2

Drum sensitivity varies from copy to copy. Especially, drum rest time affects

drum sensitivity.

To compensate the sensitivity changes in the copy run, the ID sensor

development timing and development bias is controlled using two copy

counters.

Counter A:

Counts the copy number. Resets when the Start key is pressed.

Counter B:

Counts the copy number. Resets if the accumulated number is 10 or

above when the Start key is pressed, or when the ID sensor pattern is

made.

NOTE: Both counters are reset when the main switch is turned on or the

doors are opened.

The ID sensor pattern is made in the following conditions:

1) At the leading edge of the first copy cycle after the main switch is

turned on or when the doors are opened.

2) If A ≥ 10

At the trailing edge of the copy cycle when;

A = 10n (n: any numeric number)

3) If A < 10

When the last copy is finished and B ≥ 10, then the pattern is

developed at the leading edge of the next copy cycle.

2-46

Page 69

6 March 1992 TONER DENSITY DETECTION AND SUPPLY

7.2.2 Toner Density Detection

(V)

Vsg = 4.0

1/13 Vsg = 0.31

LED

ON

LED

ON

Detailed

Descriptions

Vsg

0

Bare

drum

Sensor

pattern

(T)

Vsp

Vsg

Vsp

Low image

density

1/13 Vsg

0

High image density

The ID sensor measures the density of the ID sensor pattern developed on

the drum. The main PCB receives two values of the sensor output, the value

for the sensor pattern (Vsp) and the value for the bare drum (Vsg).

Toner will be supplied under the following condition:

Vsp/Vsg ≥ 1/13

2-47

Page 70

TONER DENSITY DETECTION AND SUPPLY 6 March 1992

7.2.3 ID Sensor Abnormal Conditions

a. Vsp Abnormal

If the measured Vsp is 1.4 V (when Vsg = 4 V) or more and this condition is

detected five times in a row, a system error condition will be indicated on the

CRT and the 7% fixed toner supply control will be used for the rest of the

copy run.

b. Vsg Abnormal

If the measured Vsg during ID sensor pattern detection is 2.5 V or less and

this condition is detected five times in a row, a system error condition will be

indicated on the CRT and the 7% fixed toner supply control will be used for

the rest of the copy run.

If both abnormal values return to normal during the copy run, the toner supply

control will also be returned to normal.

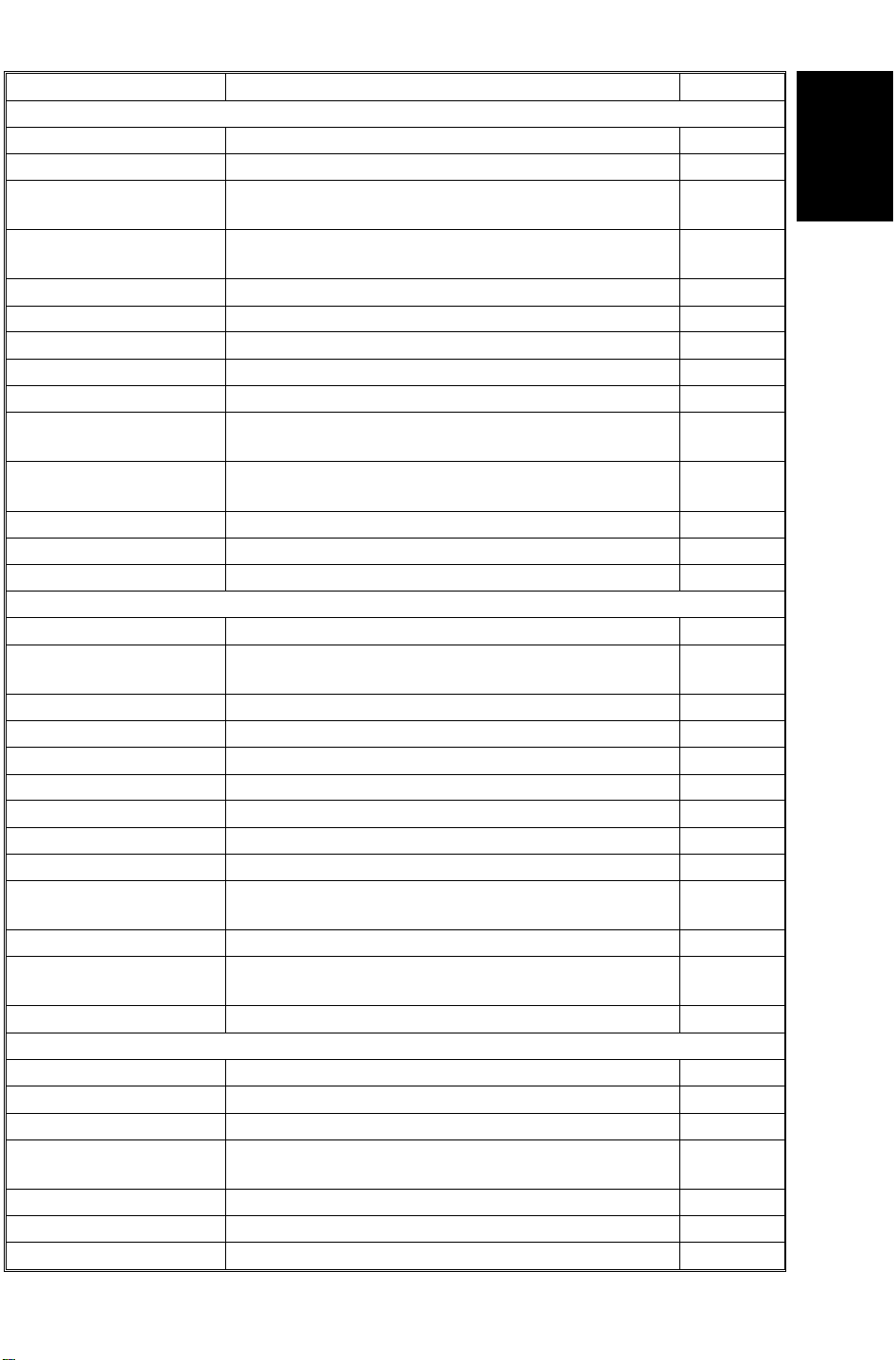

7.3 TONER SUPPLY AMOUNT

Vsp (V)

(at Vsg = 4.0 V)

0.3 ≤ Vsp < 0.4

0.4 ≤ Vsp < 0.5

0.5 ≤ Vsp

The toner supply ratio is determined based on the supply amount data in SP

mode and Vsp values as shown in the above table.

The table shows the amount for the A3/DLT mode. When smaller paper is

used, the supply amount becomes half.

The toner supply roller turns for a period based on the selected supply ratio.

Toner Supply Amount Data in SP Mode

15% 30% 45% 60%

7 15 15 30

15 30 45 45

30 45 60 60

2-48

Page 71

6 March 1992 TONER DENSITY DETECTION AND SUPPLY

7.4 TONER CARTRIDGE

[A]

Detailed

Descriptions

[B]

When the toner cartridge is set, the toner cartridge sensor [A] is de-actuated.

The main PCB monitors the toner cartridge sensor signal and detects if the

cartridge is replaced at the toner end condition. The main PCB inhibits

copying if there is no toner cartridge.

The toner cartridge is also used as the used toner collection tank. The copy

image becomes poor if the collected toner is re- used. To prevent accidental

re-used of the collected toner, a spring plate lock mechanism [B] is installed.

The lock allows the toner cartridge shutter to be pulled and returned only

once.

2-49

Page 72

TONER DENSITY DETECTION AND SUPPLY 6 March 1992

7.5 TONER END DETECTION

7.5.1 Toner Near End Detection

[C]

[B]

[A]

[D]

[E]

Toner near end is detected by measuring physical amount of toner remaining

in the toner tank by the following mechanism.

The toner near end feeler [A] has a magnet [B] and is installed on the toner

mixing vane drive shaft [C]. The toner near end sensor [D] is located

underneath the toner tank (outside) and has the sensor actuator [E] with a

magnet. When the toner tank has enough toner, the toner near end feeler

does not lower due to the resistance of toner.

When the remaining toner amount in the toner tank becomes below

approximately 250 grams, the near end feeler lowers and repulses the

sensor actuator by the magnet’s repulsion force. This actuates the toner near

end sensor. When the main PCB senses the toner near end sensor actuation

three times in a row, the toner near end condition is displayed on the CRT

screen to let the operator know to replace the toner cartridge. In the toner

near end condition, copies can be made until the toner end is detected by the

ID sensor.

2-50

Page 73

6 March 1992 TONER DENSITY DETECTION AND SUPPLY

7.5.2 Toner End Detection

When little toner remains in the toner tank, the amount of toner supplied to

the development unit decreases, and the image of the ID sensor pattern gets

lighter.

When the Main PCB detects the low ID sensor pattern density condition

(Vsp/Vsg > 1/8) more than three times in a row during the toner near end

condition (physical check), the toner end condition is displayed on the CRT

screen and copying is inhibited until the toner cartridge is replaced.

Detailed

Descriptions

2-51

Page 74

IMAGE TRANSFER AND PAPER SEPARATION 6 March 1992

8. IMAGE TRANSFER AND PAPER

SEPARATION

8.1 PRE-TRANSFER DISCHARGE

[A]

[B]

The pre-transfer corona (PTC) [A] and pre-transfer lamp (PTL) [B] are used

to prevent incomplete toner transfer and pick-off pawl marks on the copy.

To prevent incomplete toner transfer, the PTC reduces drum potential by

applying an ac corona. The PTC also applies a dc negative charge at the

same time to keep the toner potential negative.

The PTL further reduces the drum potential. Since the PTC gave a negative

charge not only to the toner but also to the non image (no toner) area on the

drum, PTL reduces the negative charge on the drum which may attract copy

paper and cause pick-off pawl marks.

2-52

Page 75

6 March 1992 IMAGE TRANSFER AND PAPER SEPARATION

8.2 IMAGE TRANSFER

[A]

Detailed

Descriptions

[B]

The copy paper is fed from the registration section to the transfer and

separation section through the guide mylar [A] which holds the copy paper so

that the paper sticks to the drum surface.

The transfer corona [B] applies a positive charge from the back side of the

copy paper to attract the negatively charged toner image from the drum to the

copy paper.

2-53

Page 76

IMAGE TRANSFER AND PAPER SEPARATION 6 March 1992

8.3 PAPER SEPARATION

[A]

To break the attraction between the paper and the drum, the separation

corona applies an ac corona to the back side of the paper. The stiffness of