Page 1

RICOH Technical

Bulletin

PAGE: 1/7

Model:

Subject:

From:

Classification:

Penguin (Little, Crest, Emperor)

Duplex Jam Information

GTSS Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

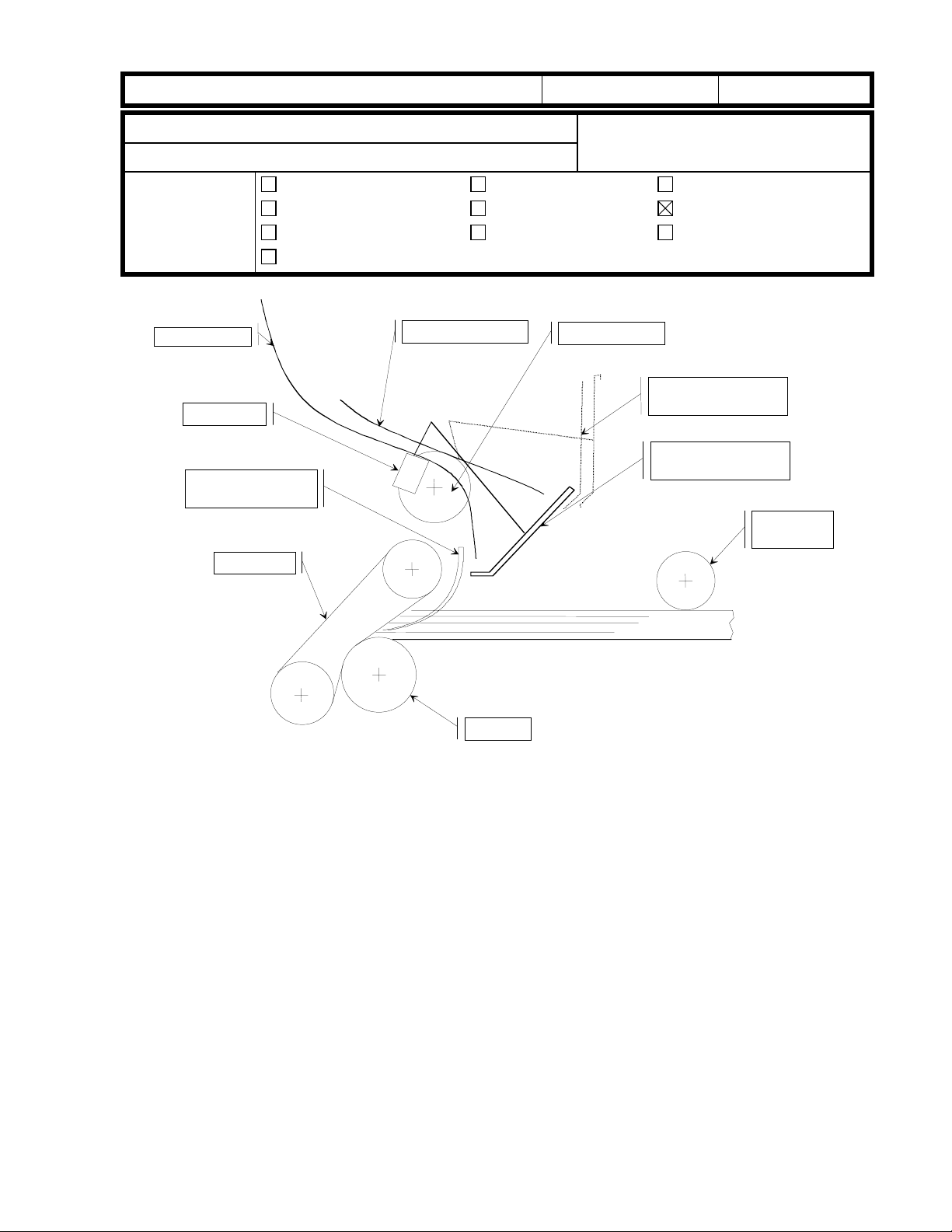

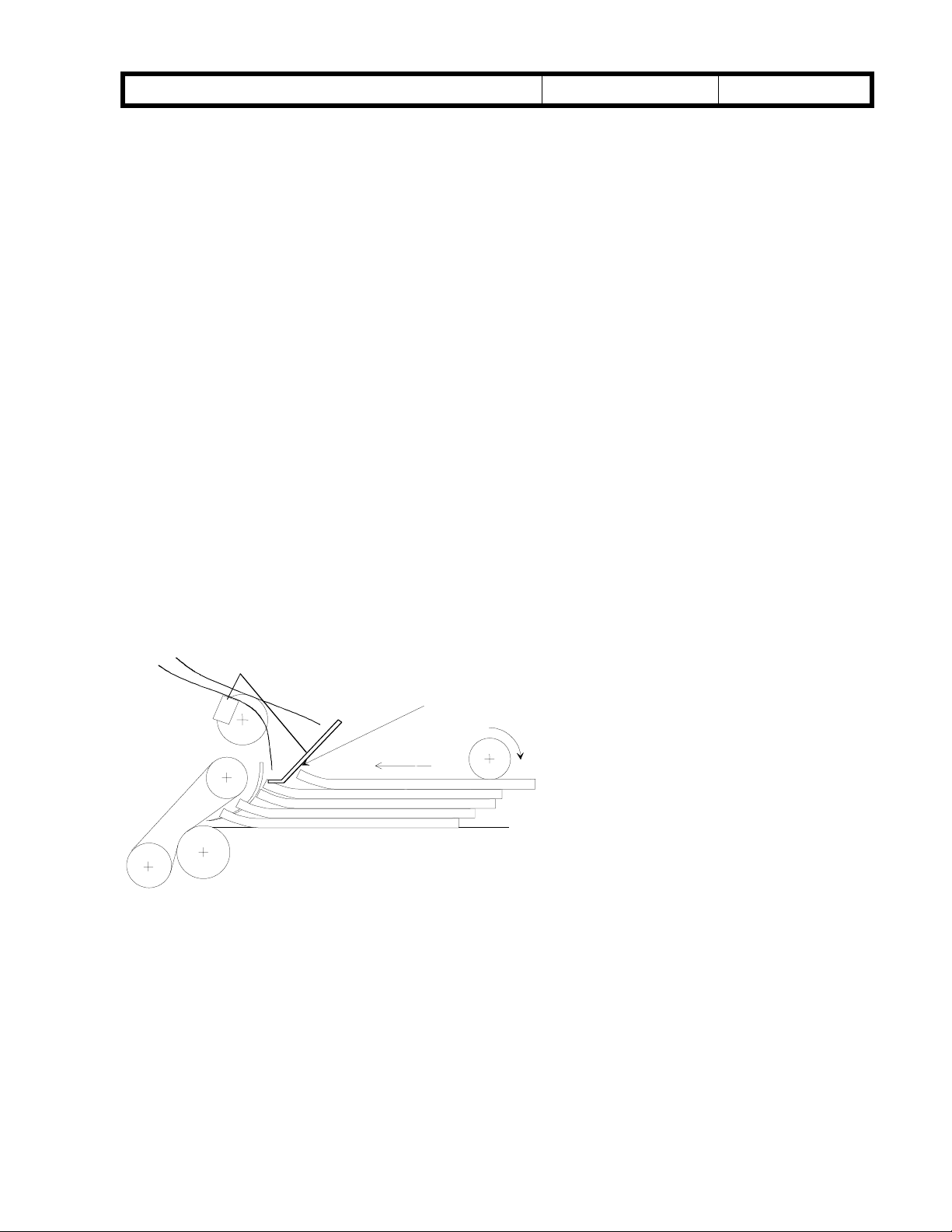

1. Stacking in the duplex feed section

A

D

F

Part information

Electrical

Transmit/receive

B

Date:

30-Nov-98

Prepared by:

C

No.: 1

H.K

Action required

Service manual revision

Retrofit information

E

G

I

H

J

Duplex entrance

Fig. 1

A: Outer inverter guide, B: Inner inverter guide, C: Duplex transport brush roller,

D: Duplex transport sensor, E: Upper position of paper guide, F: Paper holding mylar,

G: Lower position of paper guide, H: Separation belt, I: positioning roller, J: Feed roller

- Stacking mechanism -

Paper comes in down the inverter guides, and pushes the paper guide up [E].

·

Paper starts to enter the duplex tray.

·

After the trailing edge of the paper passes the duplex transport sensor [D], the paper

·

guide falls into place [G].

The brush roller [C] pushes the trailing edge of the paper so that the paper is not

·

caught in the inverter guides [A and B].

At the appropriate time after the trailing edge of the paper passes through the duplex

·

transport sensor, the positioning roller starts to rotate to deliver the paper to the duplex

feed section. The paper guide directs the paper under the mylar ([F] on the previous

page) so that the paper stacks correctly in the duplex feed section.

Page 2

RICOH Technical

Bulletin

PAGE: 2/7

Model:

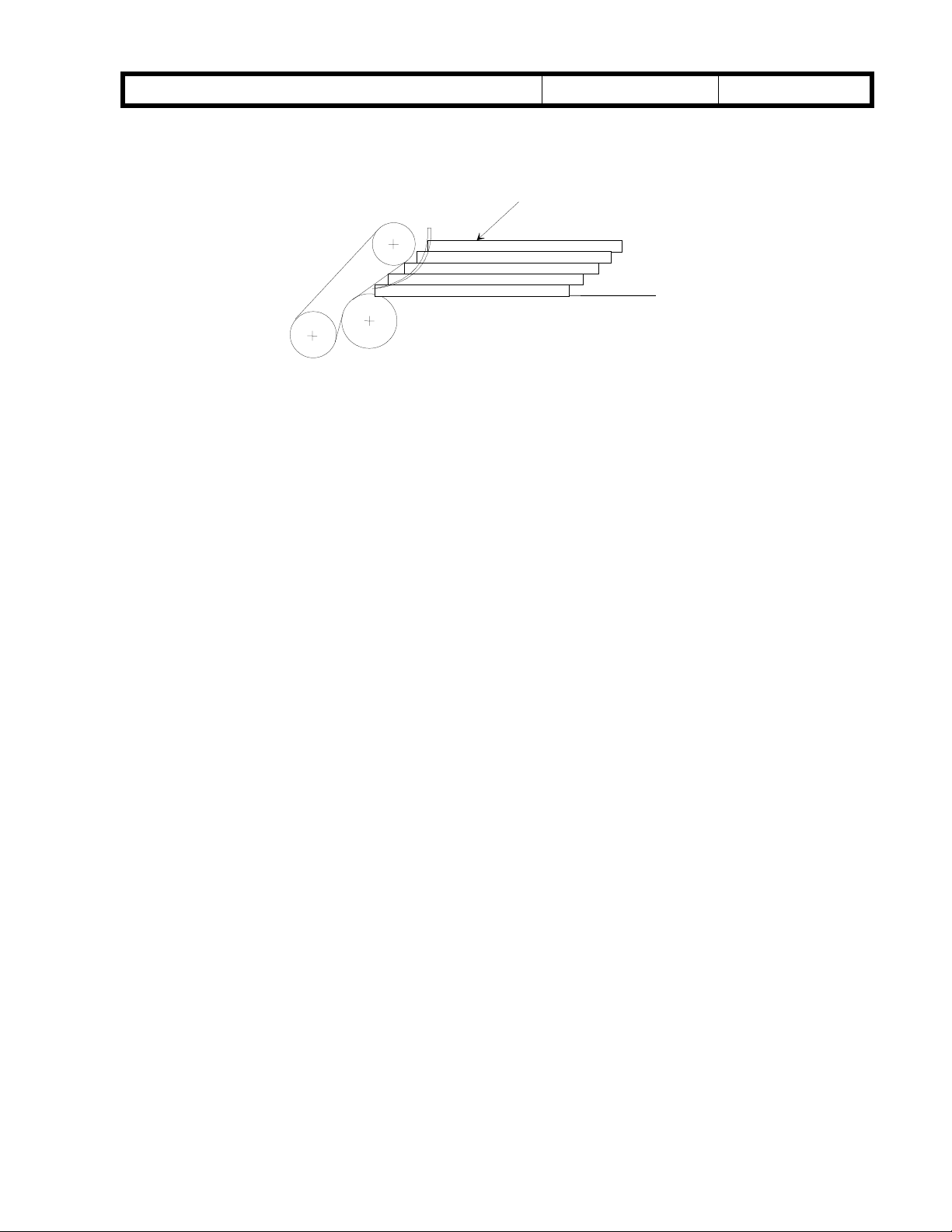

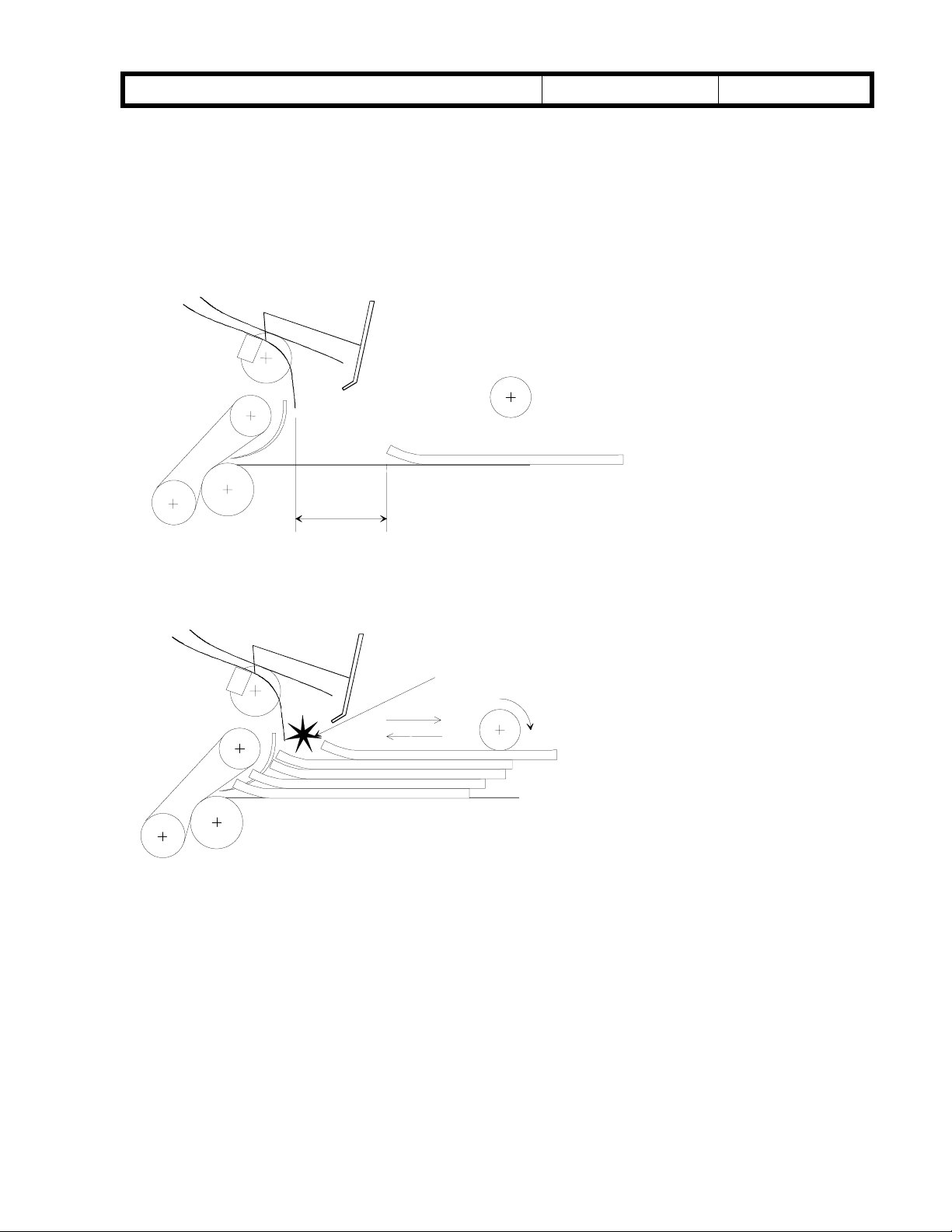

- Correct stacking condition -

Penguin (Little, Crest, Emperor)

The pages delivered by the positioning roller are stacked along the separation belt like

a staircase as shown in fig. 2. The paper holding mylar guides the paper and holds the

leading edge in the correct position for duplex feed.

Correct stacking condition

Fig. 2

Date:

Staircase stacking

30-Nov-98

No.: 1

Page 3

RICOH Technical

Bulletin

PAGE: 3/7

Model:

Penguin (Little, Crest, Emperor)

Date:

30-Nov-98

No.: 1

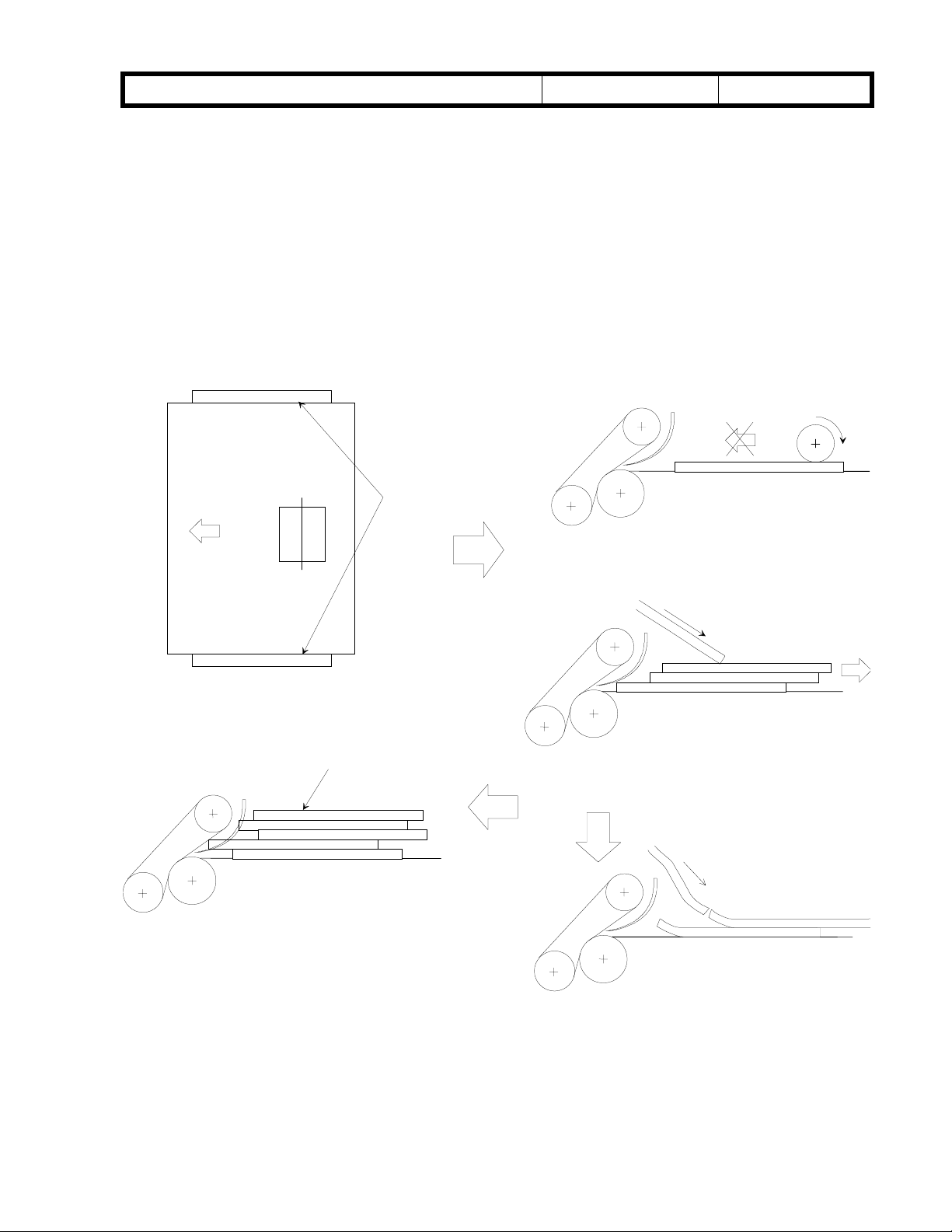

2. Duplex jam troubleshooting

Duplex jams can be caused by differences in the width of various paper brands, bad

condition of the inner inverter guide, or curled paper. The following troubleshooting

information is for these causes.

2-1. Paper wider than jogger fence span

2-1-1. Cause

If the interval between the jogger fences is less than the paper width, the positioning

roller cannot deliver the paper to the duplex feed position because of friction as the

paper rubs against the joggers. Then, duplex jams occur.

Fig. 4

Friction

Fig. 3 The jogger fence

span is less than the

paper width

Pattern 1

Not staircase stackin

This condition causes double feed and/or non feed.

Paper is not delivered to the feed

section.

Fig. 5

g

The paper holding mylar does not hold the stacked

paper properly. The next sheet pushes the stacked

paper back.

Pattern 2

Page 4

RICOH Technical

Bulletin

PAGE: 4/7

Model:

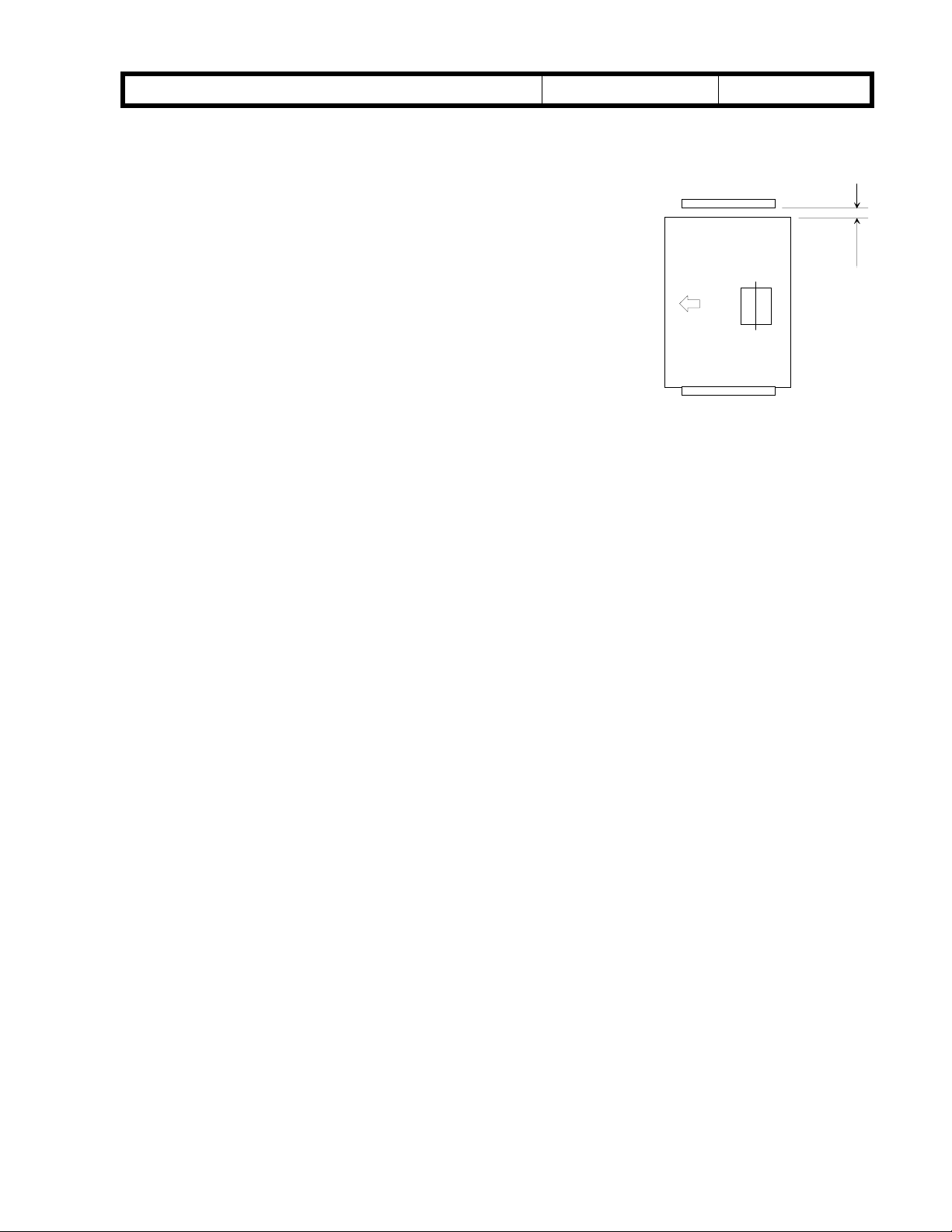

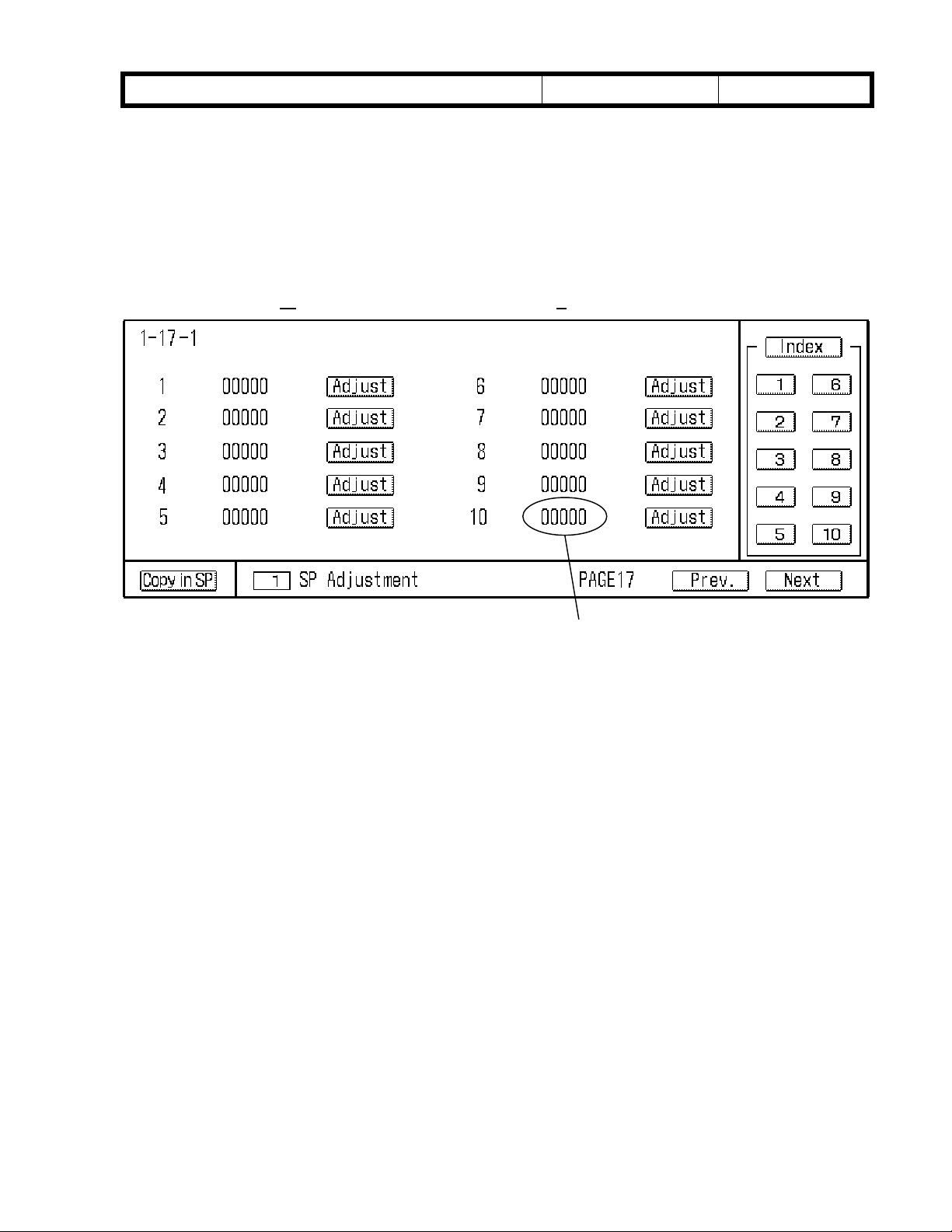

2-1-2. Duplex jogger fence span adjustment

1) By accessing SP1-7-1 (jogger span adjustment), check

2) Feed and stack one sheet of the paper of the size and

3) Open the front door, and gently pull out the duplex tray.

4) Measure the distance between rear jogger fence and

5) If the distance is not within this limit, adjust the jogger

Penguin (Little, Crest, Emperor)

the jogger sp an adjustment setting.

brand normally used in the duplex tray.

paper (3 times or more).

Adjustment standard: A = 0.5 to 1.5 mm

fence span by changing the SP mode value. Input a

wider value than you want at first, then reduce it – this

is necessary because there is a little play in the

mechanism. If the SP mode is changed from narrower

to wider, paper buckling may appear.

SP1-7-1: 0.3 mm/step

– key: Wider span, + key: Narrower spa n

Date:

30-Nov-98

Fig. 8

No.: 1

A

2-2. Deformed inner inverter guide

2-2-1. Cause

If the inner inverter guide (A2474433: Inverter Guide Plate) in the inverter unit is deformed

(for example, due to a manufacturer error), the magnets on the inner inverter guide may

not attract the outer inverter guide. Then, jams may occur when the paper enters the

duplex unit.

2-2-2. Check points for the inner inverter guide

1) When paper is stacking in the duplex unit, check if the inner inverter guide vibrates.

2) Remove the paper exit unit (refer to paper exit unit removal on page 6-121 of the

service manual). Check if the magnets on the inner inverter guide attract the outer

inverter guide.

3) If the magnets do not attract the outer inverter guide, replace the inner inverter guide.

Make sure that the magnets on the new inverter guide attract the outer inverter guide.

Page 5

RICOH Technical

Bulletin

PAGE: 5/7

Model:

2-3. Paper curl

2-3-1. Cause

Paper with a large curl (height:15 mm or more) may cause stacking failure. There are two

stacking failure patterns. Refer to patterns 1 and 2 on page 3.

2-3-2. Procedure for checking curl height

1) Raise the positioning roller by securing the positioning roller bracket with tape so that

2) Feed and stack one sheet of the paper of the size and brand normally used in the

3) Open the front door and pull out the duplex unit quickly.

4) Measure the height of the curl at the front and rear edges of the curled side of the

5) Turn the paper upside-down and repeat the above procedure three times. Find the

The paper guide can stack curled paper fairly well, as shown in Fig. 9. However, strongly

curled paper cannot be guided properly, so jams may occur. In this case, set the paper in

accordance with steps 4 and 5 in the above procedure.

Penguin (Little, Crest, Emperor)

the positioning roller does not drop.

duplex tray.

paper.

Note:

smaller curl height and set the paper so that the curl height is smaller when paper

enters the duplex tray.

During measurement the curl height may change; measure the height quickly.

Date:

30-Nov-98

No.: 1

Fig. 9

Paper is guided

Paper curled face-up is delivered to the feed

position correctly when the paper guide is at

the lower position.

Page 6

RICOH Technical

Bulletin

PAGE: 6/7

Model:

Penguin (Little, Crest, Emperor)

Date:

30-Nov-98

No.: 1

2-3-3. Strongly curled paper

If the curl is larger than 15 mm, and the returning distance (see Fig. 10) is too long or too

short, the paper guide does not work. Thus, duplex jams may occur.

In this case, SP1-9-2 (Positioning roller on) should be adjusted so that the paper is

stacked as shown in Fig. 2.

Adjustment Standard for the returning distance: 10 - 30mm

Fig. 10

Returning distance

Fig. 11

Patterns 3 and 4

Hits

incoming

paper

Pattern 3: If the returning distance is

too long, the paper guide is raised

by the next sheet at the same time

as the positioning roller delivers the

paper. So, the paper guide cannot

work as a guide, and stack failure

occurs.

Pattern 4: If the returning distance is

too short, the paper guide is still at

the upper position when the

positioning roller delivers the paper.

So, the paper guide cannot work as

a guide, and stack failure occurs.

Page 7

RICOH Technical

Bulletin

PAGE: 7/7

Model:

Measuring the returning distance

1) Raise the positioning roller by securing the positioning roller bracket with tape so that

2) Feed and stack one sheet of the paper of the normally used size and brand into the

3) Open the front door and pull out the duplex unit gently.

4) Measure the length of the returning distance as shown in Fig. 10.

Adjusting the returning distance with SP1-9-2

1) Access SP mode and change the value of SP1-9-2 (Positioning Roller On).

If the returning distance is too long, decrease the value.

If the returning distance is too short, increase the value. (5 ms/step)

- key: The positioning roller starts earlier, + key: The positioning roller starts later.

The factory setting for SP1-9-2

50/60 cpm machines: 0

70 cpm machines: 8 (Also, SP1-17-1 No.10: 1)

Penguin (Little, Crest, Emperor)

the positioning roller does not drop.

duplex tray.

Date:

30-Nov-98

SP1-17-1 No10: 0 to 1

No.: 1

Note for 70 cpm machines

We found that curled paper in the 70 cpm machines may push the paper guide more

strongly than in 50/60 cpm machines, then the paper guide may bounce back more. This

may cause stack failure. We found that the shorter distance betw een 2 sheets o f paper

may cause returning paper to hit the paper guide. To correct this, we found the best

stacking speed for 70 cpm machines. As a temporary solution, the best stacking speed is

applied to the production machines by setting the SP1-9-2 and SP1-17-1, until a

permanent solution is implemented.

Note:

If RAM clear is done accidentally, this SP value will go to "Zero".

Page 8

RICOH Technical

Bulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

We found that curled paper in the 70-cpm machines may push the paper guide more

strongly than in 50/60 cpm machines, and then the paper guide may bounce back more.

This may cause stacking failure. (Refer to RTB No. 001 for details). As the final solution,

the production machines have been modified as follows:

1. A stopper [A] has been extended to the front of the inverter plate. (There is already a

stopper on the rear side.)

2. A cutout [B] has been made in the inverter guide to prevent the stopper [A] from striking

it.

Old P/N New P/N Description Page Index Interchang

Penguin

Inverter Guide Plate & Inverter Pla te - Ass 'y

GTSS Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Jan-99

Prepared by:

No.:

2

H. Kobayashi

Action required

Service manual revision

Retrofit information

eability

A2474433 A2484433 Inverter Guide Plate 93 10 X/X

A2474442 A2484442 Inverter Plate - Ass'y 93 14 X/X

Inverter

Guide Plate B

This modification is applied to the 70-cpm version machines. To ensure good paper

stacking for 50/60-cpm version machines and to standardize the parts with 70-cpm

machines, the same modification has been applied to the 50/60-cpm version machines.

Note:

We will inform you of the cut-in serial numbers by an MB as soon as they are available.

When the old inverter guide plate or inverter plate should be replaced in the field,

replace both parts together.

A

Inverter

Plate-Ass’y

Page 9

RICOH Technical

Bulletin

PAGE: 2/2

Model:

Due to the modification on the previous page, the best stacking speed for 70-cpm

machines has been changed. Therefore, the settings of SP1-9-2 and SP1-17-1 have been

changed as follows.

The factory setting for SP1-9-2

50/60 cpm machines: 0 (no change)

70 cpm machines: -6 from 8 (Also, SP1-17-1 No.10: 0 from 1)

Penguin

Date:

31-Jan-99

No.:

2

SP1-17-1 No.10:0 from 1

Note for 70 cpm machines

The old best stacking speed for 70-cpm machines is suitable for paper stacking. Even if

the new parts are installed without changing the setting of the SP mode, a stacking failure

does not occur.

If RAM clear is done accidentally, this SP data will go to "Zero". Please note this.

Page 10

RICOH Technical

Bulletin

PAGE: 1/3

Model:

Subject:

From:

Classification:

Penguin (for North America)

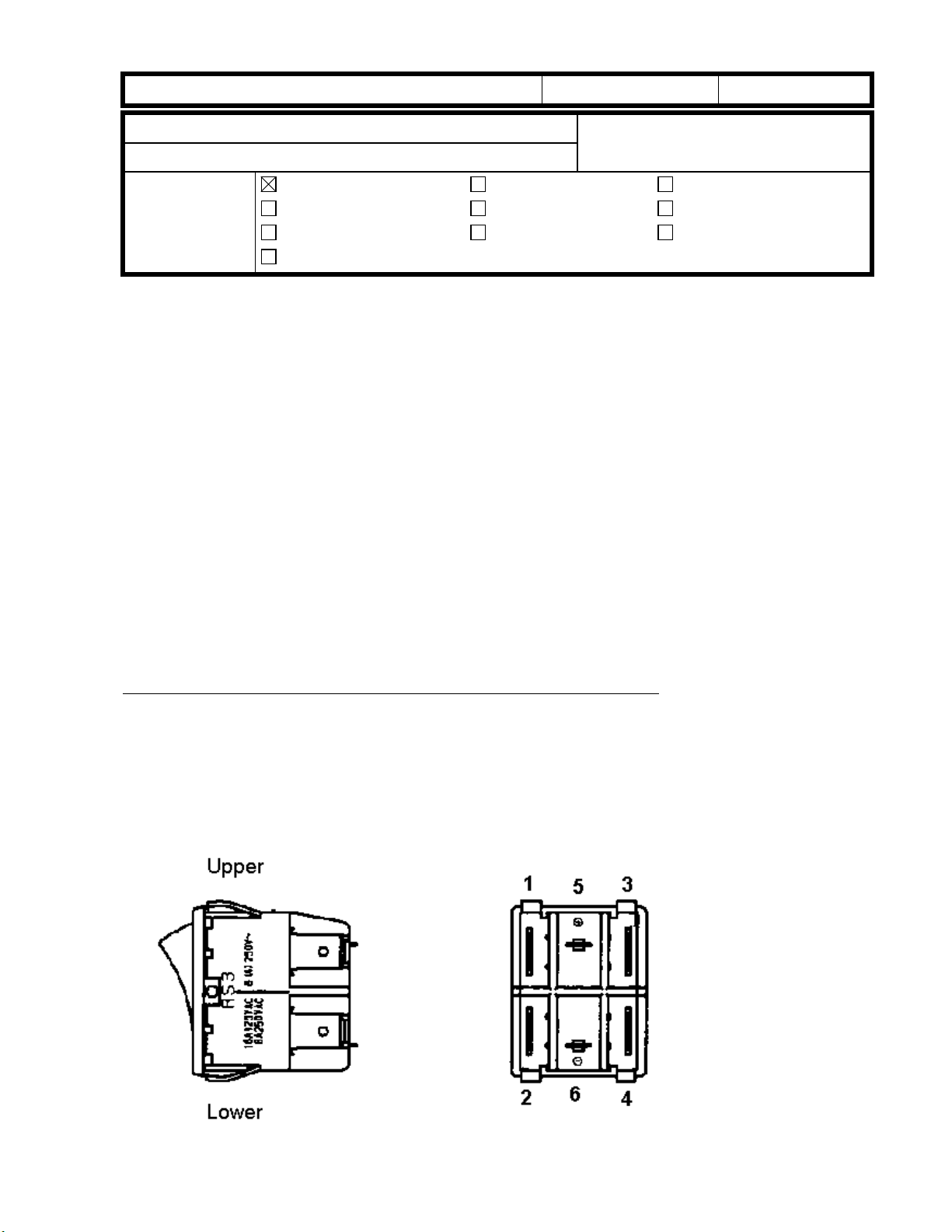

DC Harmess Short-Circuit (SC104, SC105)

GTSS Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

16-Feb-99

Prepared by:

No.:

3

F. Noguchi

Action required

Service manual revision

Retrofit information

SYMPTOM

SC104 or SC105 as a result of damage to the branch harness.

The main board may also be damaged, preventing the exposure lamp from lighting or the

registration roller motor from energizing.

CAUSE

DC main harness short-circuit caused by contact between the harness and the by-pass

feed motor rotor. This occurs because the wiring harness was routed too close to the bypass feed motor.

Rotor

Point of

Contact

Branch harness that connects

to the main board

SOLUTION

Re-tape the part of the harness that shorted-out with insulation tape.

Page 11

RICOH Technical

Bulletin

PAGE: 2/3

Model:

Penguin (for North America)

Date:

16-Feb-99

No.:

3

FIELD ACTION

At installation or customer visit, please change the routing of the branch harness.

Note: The occurrence rate for this problem is extremely low but a short-circuit may lead to

damage to the main board so please take the recommended action.

The machines targeted are the ones from the first production run until the end of January.

A246-15 2B68500001 ~ 2B69410140

2B69420001, -003, -009, -013, -016~036

A246-17 A7968500001 ~ A7969410246

A7969420083, -092~223

A247-15 2B78500001 ~ 2B79410080

A247-17 A7978500001 ~ A7979410060

A248-15 2B88510001 ~ 2B89410065

A248-17 A7988500001 ~ A798852060

A7989410002, -004, -006, -009, -011, -013, -019~023, -029, -041, -044, 049, -050

1. Disconnect CN102 & CN103 on the main board.

2. Route the branch harness that connects to CN102 & CN103 so that it passes under the

main harness before connecting it to the main board. Then reconnect CN102 &

CN103.

Branch

Harness

Rotor

Main harness

Page 12

RICOH Technical

Bulletin

PAGE: 3/3

Model:

Penguin (for North America)

Date:

16-Feb-99

No.:

3

COUNTERMEASURE

The routing of the branch harness has been changed at the factory from February 9th,

1999. The cut-in serial numbers are as follows.

A246-10: Will be implemented from the 1st production run

A246-15: 2B69420037~

A246-17: A7969420224~

A247-10: Will be implemented from the 1st production run

A247-15: 2B79420001~

A247-17: A7979420001~

A248-10: Will be implemented from the 1st production run

A248-15: 2B89420001~

A248-17: A7989420001~

Page 13

RICOH Technical

Bulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

Injury may occur due to the sharp edges on the Entrance Guide Plate (A902-5561), so at

installation please take the following measures.

File off the sharp edges on the Entrance Guide Plate.

•

When filing off the sharp edges, please be careful.

•

Countermeasure

Starting from the February 25 production run, the sharp edges on the Entrance Guide

Plate will be filed off. (Please note that the Sorter Adapter does not have a serial number

so no cut-in serial number information will be available.)

Penguin

Adapter Type L: Sharp Edges

GTSS Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other (Caution to taken at installation)

Part information

Electrical

Transmit/receive

Date:

28-Feb-99

Prepared by:

No.:

4

F. Noguchi

Action required

Service manual revision

Retrofit information

Entrance Guide Plate

Sharp Edges

Mounting Plate

Page 14

T

echnical

ulletin

B

PAGE: 1/2

Model:

Subject:

From:

Classification:

We have found a mistake in the service manual on page 3-49 (3.10 TRANSPORTATION

REMARKS). Please add a new step (carrying out SP2-2-2: Toner Collection Mode) before

the 1st step for the Toner Recycling Tube Cleaning procedure in your service manual as

follows:

Penguin

Transportation Remarks

GTSS Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Mar-99

Prepared by:

No.:

5

H. K.

Action required

Service manual revision

Retrofit information

3.10 TRANSPORTATION REMARKS

3.10.1 TONER RECYCLING TUBE CLEANING

NOTE:

1) When transporting the machine, perform the following operations.

Otherwise the path of toner may be blocked.

2) When installing a new machine or transporting the machine which has

copied less than 1,000-sheets, these actions are not necessary.

3) Be careful not to drop the toner on the floor.

•Access SP mode and carry out SP2-2-2 (Toner Collection Mode). After the toner

collection motor stops turning, exit SP mode. Then, follow the same procedure as

described in the service manual as follows:

1. Turn off the main switch.

2. Remove the lower right cover. (Refer to Lower Right Cover Removal, section

6.1.4.)

3. While unhooking the tube clip [A] disconnect the end of tube [B], as shown.

4. While putting the end of the tube into a plastic bag, unhook the tube (1 clamp)

and set it vertically.

5. Tap the tube to remove the toner, as shown.

6. Reinstall the tube.

A

→

B

Page 15

T

echnical

B

ulletin

PAGE: 2/2

Model:

Reason for adding the new step:

The toner in the transport coil [A] may drop into the ball area [B] in the filtering unit due to

vibration during machine transportation. Then this toner may block the path of toner

coming down from the transport coil.

Penguin

A

Date:

31-Mar-99

No.:

5

B

Page 16

T

echnical

ulletin

B

PAGE: 1/1

Model:

Subject:

From:

Classification:

To enable the installation of the ST29 sorter stapler on the Penguin (Little: 50 cpm), the

following items have been changed from the June 1998 production runs.

Note: For the units manufactured in May 1998 and earlier, please add the film and install

the modified ROM.

1. With some types of recycled paper, jams may occur in the bin’s end fence. To prevent

this, film (A8342145) has been attached to the anti-static brush as shown.

2. When the duplex sorter enable by-pass mode is selected with SP mode, the jogger will

be moved even when feeding small size (A5, HLT, B6 Lengthwise) paper and the jogger

may crash into the bin. To prevent this, the software has been changed so that the

jogger will not be moved for small paper sizes. (ROM A6585103B → C)

Penguin

Installation of ST29 for the Penguin (Little: 50 cpm)

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

30-Apr-99

Prepared by:

No.:

RA246006

F. Noguchi

Action required

Service manual revision

Retrofit information

Cut-in Serial Numbers

(from June ’98 production)

A658 -15:8A98060001~

-17:A7508060001~

-22:AL88060001~

-26:3N90680001~

Anti-staticBrush:A5552161

Parts Catalog Page 6

Film:A8342145

122±1 mm

0 – 1mm

Page 17

RICOH Technical

Bulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

Penguin

SC940

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

30-Nov-99

Action required

Service manual revision

Retrofit information

No.:

F.Noguchi

RA246007

SYMPTOM

SC940 will occur when the proper time is reached in Energy Star Auto Off mode

(default = 90 min).

CAUSE

Incorrect attachment of the main switch harness DC 24V lines.

When the CN No.5 and 6 lines are reversed, the main switc h is not turned off by the Auto

Off Mode.

SOLUTION

Connect the CN No.5 and 6 lines correctly.

The following are the correct settings (please note CN no. 5 and 6):

Main SW CN No. Color of CN Color of the cable

1 yellow white

2 yellow white

3 white black

4 white black

5 white white (white)

6 white black (blue)

Page 18

RICOH Technical

Bulletin

PAGE: 2/2

Model:

Penguin

Date:

30-Nov-99

No.:

RA246007

FIELD ACTION

At installation or the next customer visit, please check the main switch harness DC 24V

lines.

Range of machines:

* It is not possible to specify the exact serial number range of machines containing the

harnesses.

A246-66: From 3R52490001 to 3R53190005

-67: From A7969240001 to A7969310021

A247-66: From 3R62490001 to 3R63090001

-67: From A7979240001 to A7979310005

COUNTERMEASURE

The error in cable connection has been acknowledged by the factory and all steps have

been taken to prevent future cases.

All production runs after November 10th,1999 contain harnesses with correct connections.

Cut-in serial Numbers:

A246-62: No Production

-66: From 3R53190006

-67: From A7969310022

A247-62: No Production

-66: From 3R63190001

-67: From A7979310006

Loading...

Loading...