Page 1

Penguin Series

Little/Crest/Emperor

(Machine Code: A246/A247/ A248)

Service Manual

Page 2

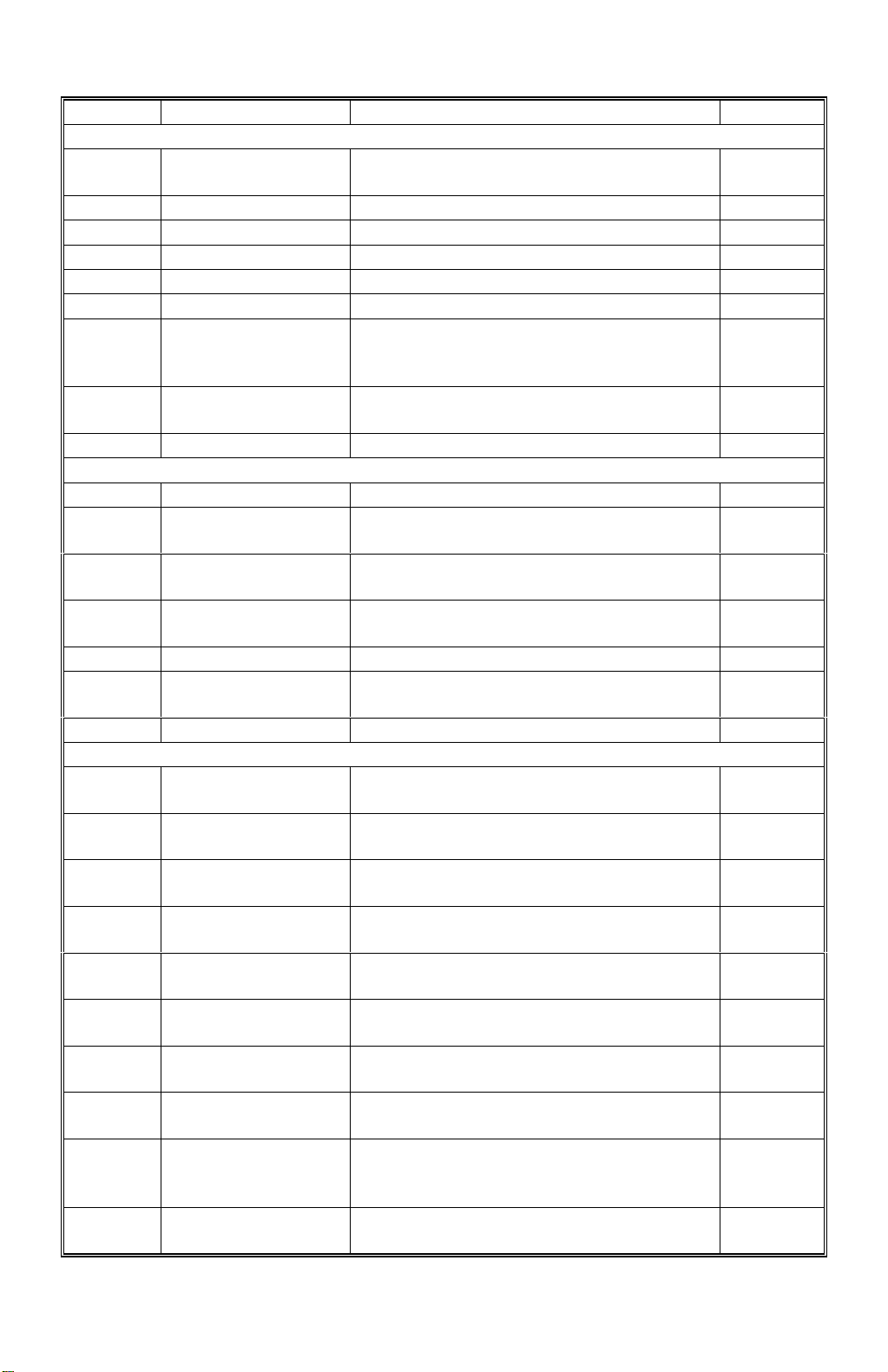

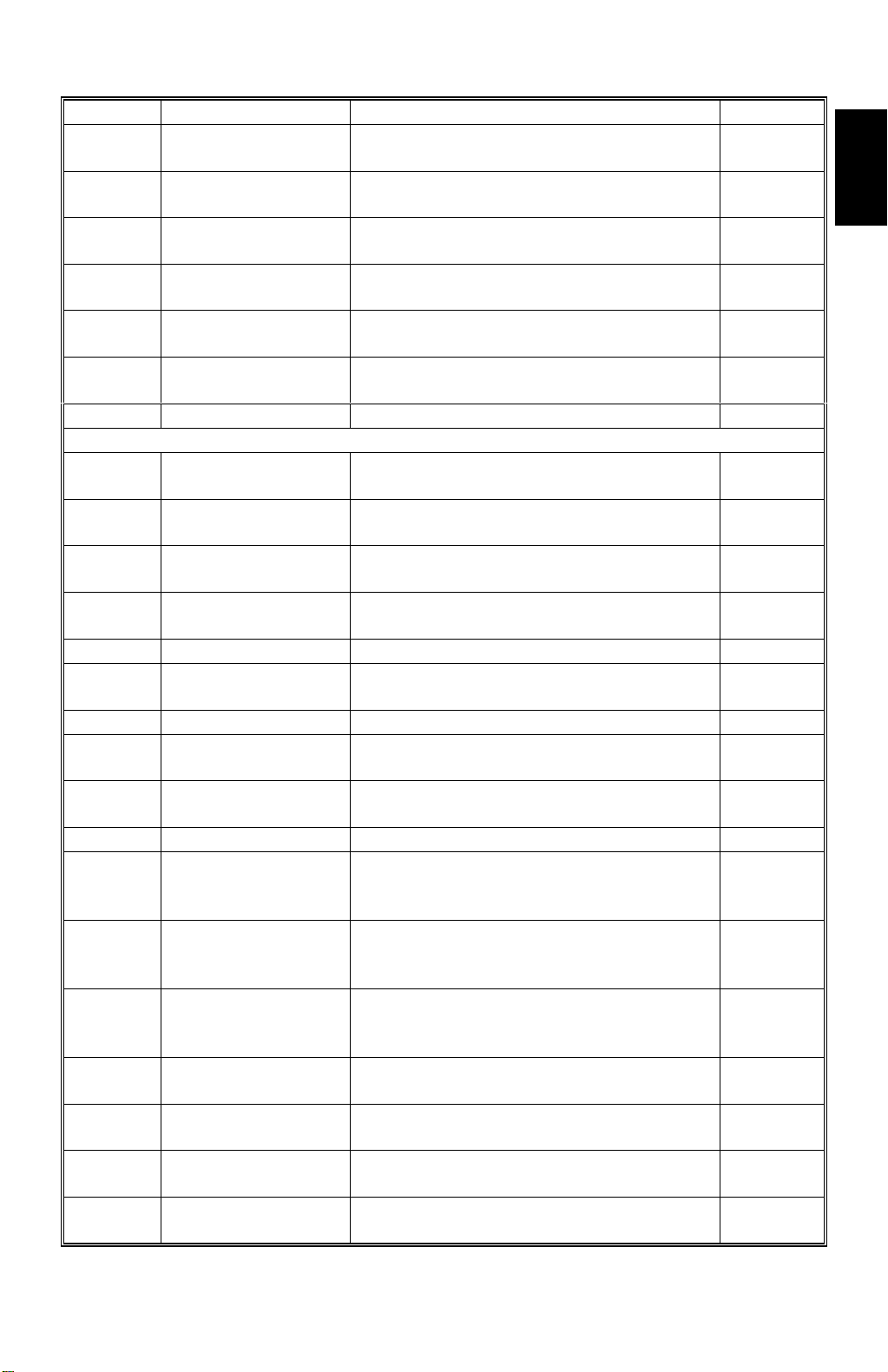

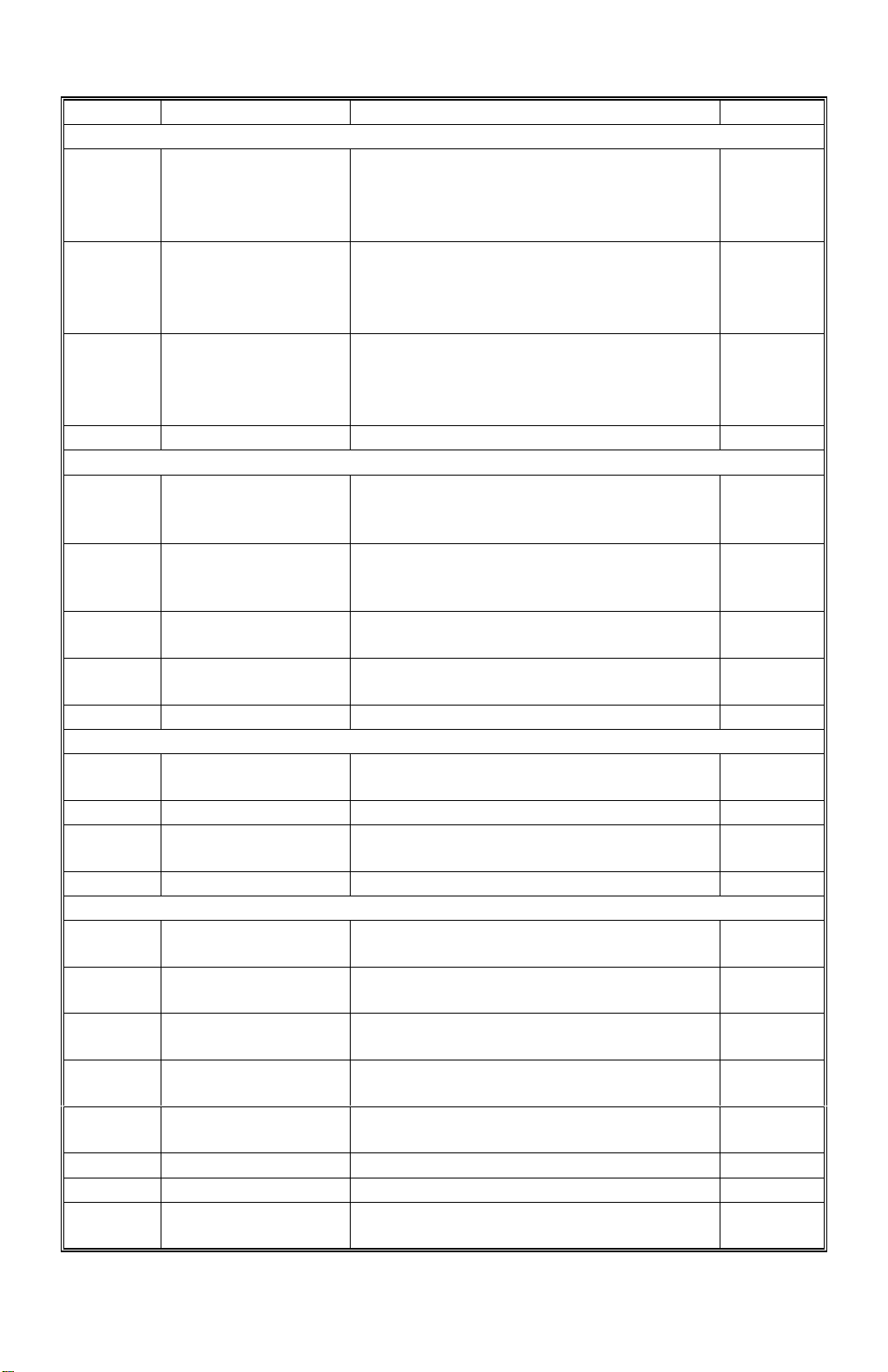

TABLE OF CONTENTS

IMPORTANT SAFETY NOTICES

1. OVERALL MACHINE INFORMATION 1-1..........................

1.1 SPECIFICATION 1-1......................................................

1.2 MACHINE CONFIGURATION 1-6..................................

1.2.1 COPIER OVERVIEW 1-6.....................................................

1.2.2 SYSTEM OVERVIEW 1-6....................................................

1.3 COPY PROCESS AROUND THE DURM 1-8................

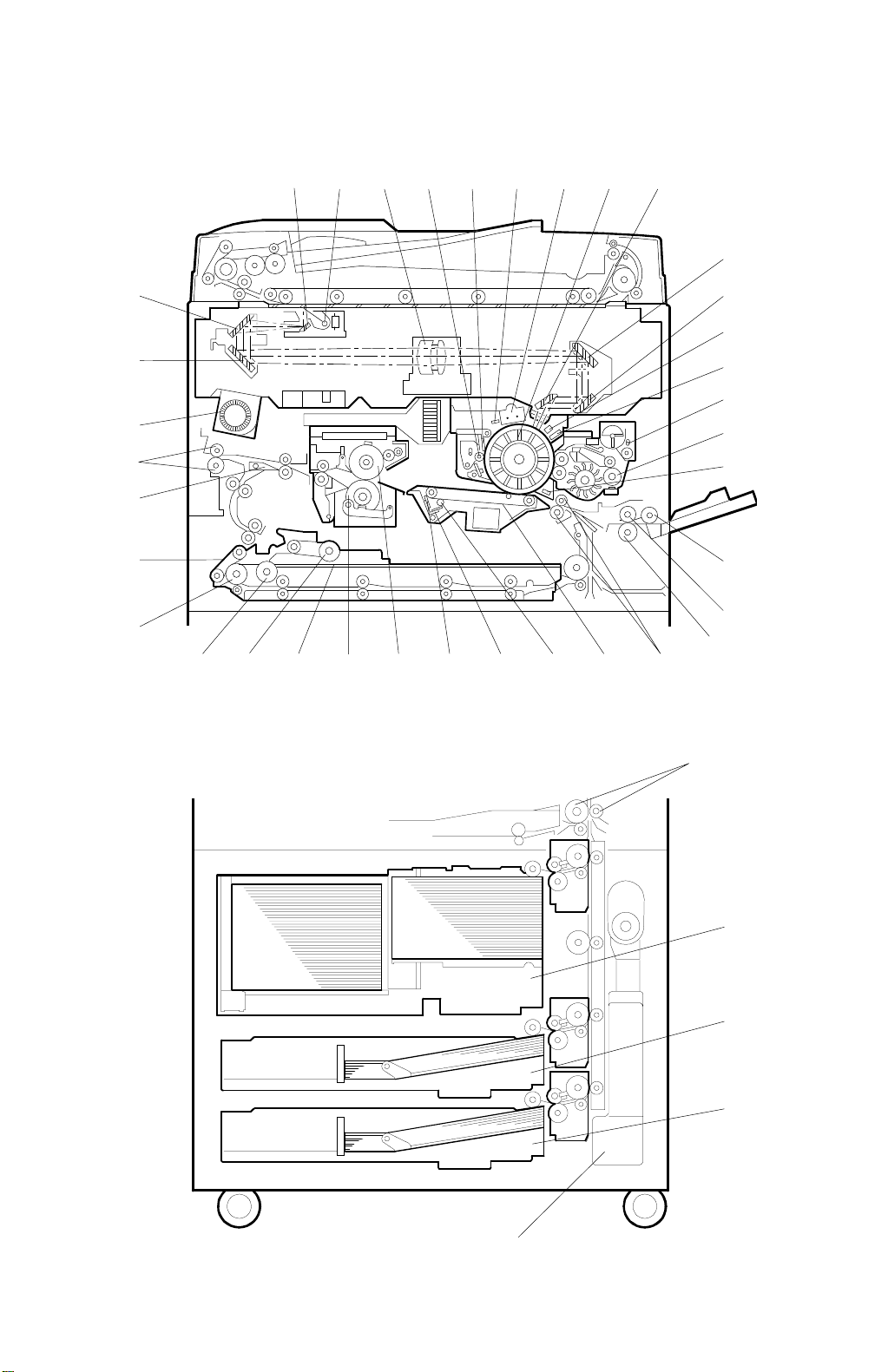

1.4 MECHANICAL COMPONENT LAYOUT 1-10..................

1.5 DRIVE LAYOUT 1-12.......................................................

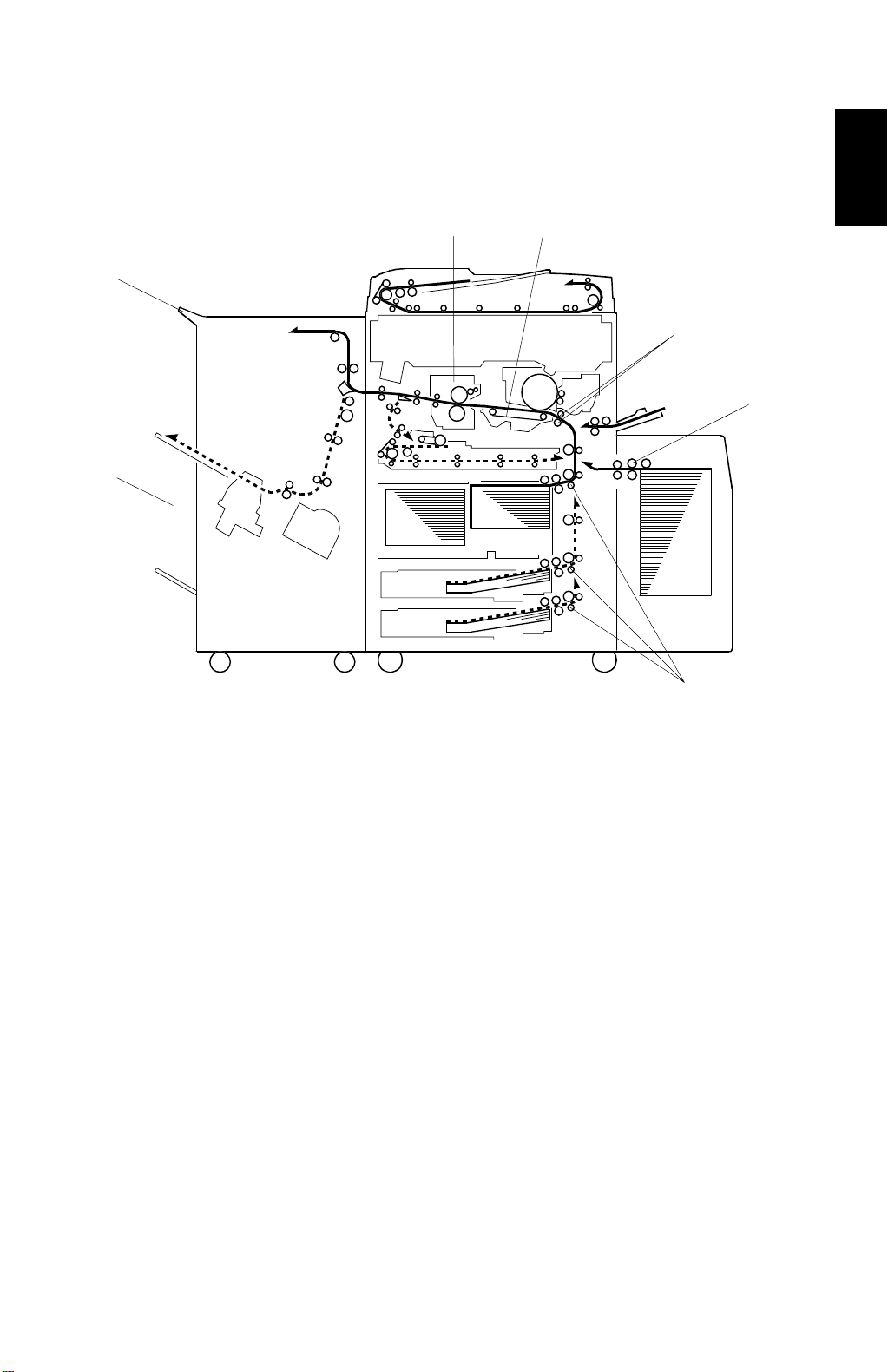

1.6 PAPER PATH 1-13...........................................................

1.6.1 STANDARD COPYING 1-13.................................................

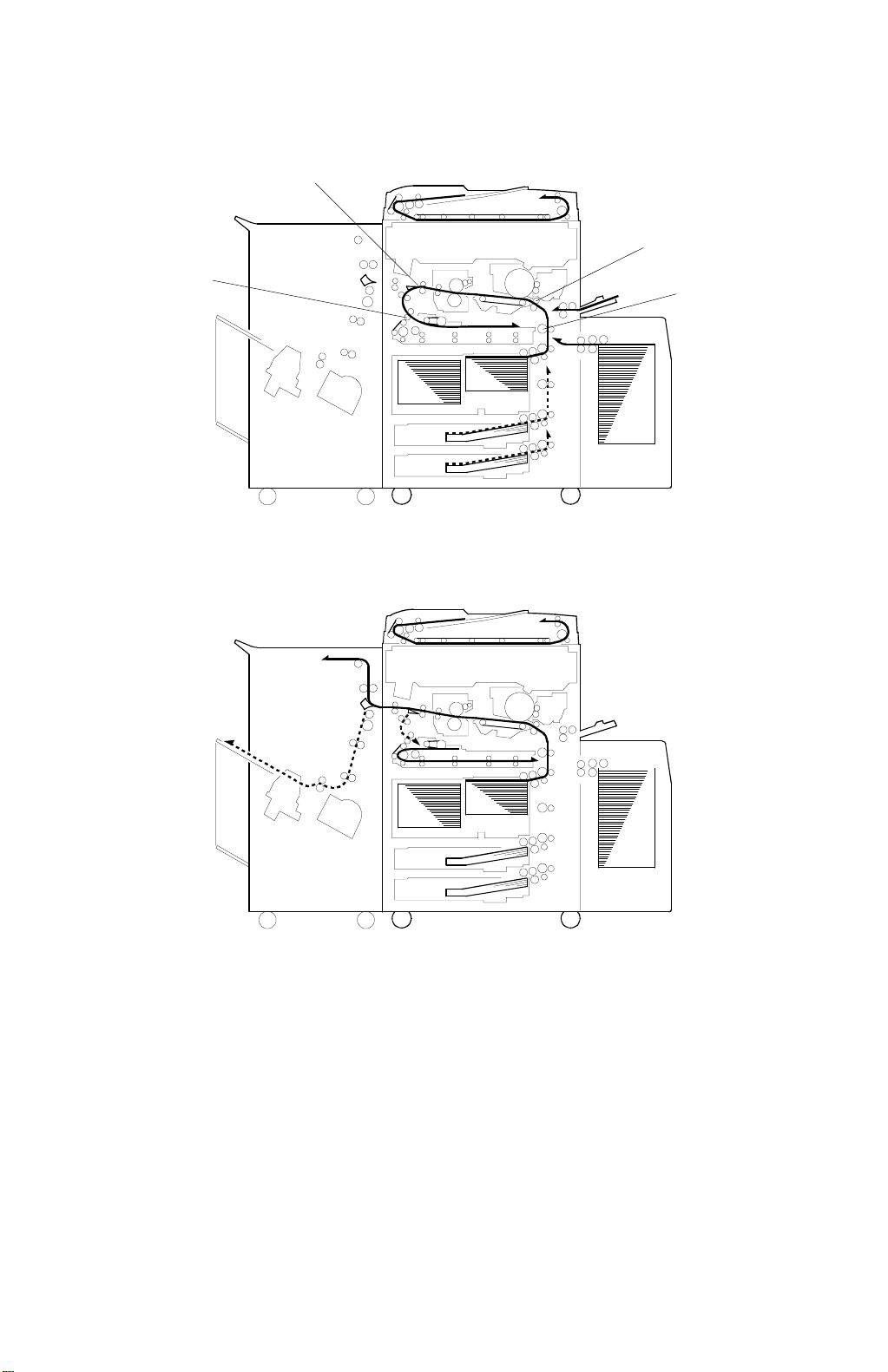

1.6.2 MULTIPLE 2-SIDE COPYING 1-14.......................................

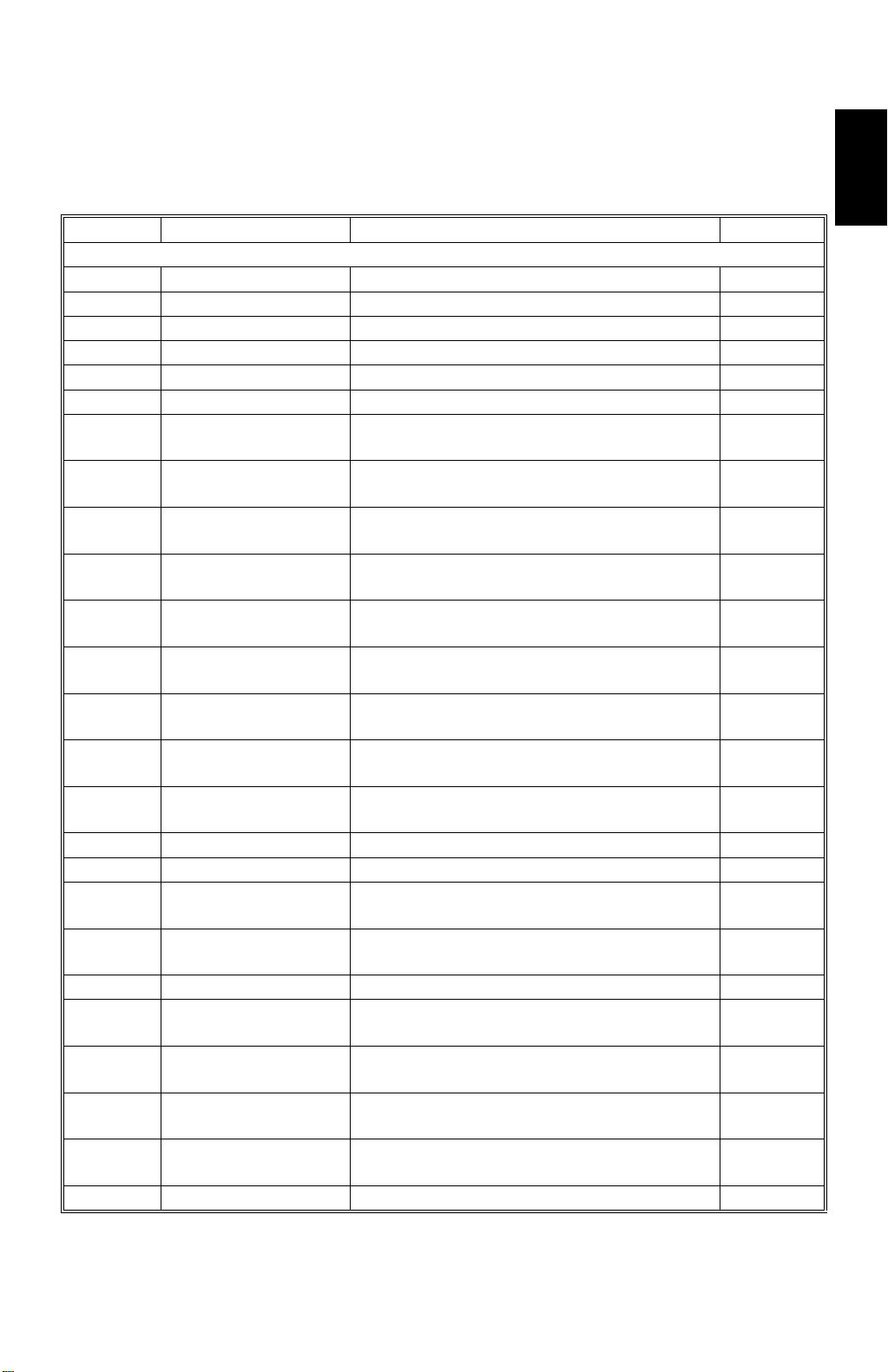

1.7 ELECTRICAL COMPONENT DESCRIPTION 1-15.........

2. DETAILED SECTION DESCRIPTIONS 2-1........................

2.1 PROCESS CONTROL 2-1..............................................

2.1.1 OVERVIEW 2-1...................................................................

2.1.2 PROCESS CONTROL DATA INITIAL SETTING 2-4..........

2.1.3 LATENT IMAGE CONTROL 2-5..........................................

2.1.4 IMAGE DENSITY CONTROL 2-12........................................

2.2 DRUM UNIT 2-18..............................................................

2.2.1 OVERVIEW 2-18...................................................................

2.2.2 OPC DRUM CHARACTERISTICS 2-19................................

2.2.3 DRUM CHARGE 2-20............................................................

2.2.4 ERASE 2-23...........................................................................

2.2.5 CLEANING 2-25....................................................................

2.2.6 QUENCHING 2-30.................................................................

2.3 DRUM CLEANING AND TONER-RECYCLING 2-31.......

2.3.1 TONER TRANSPORT 2-31...................................................

2.3.2 FILTERING 2-32....................................................................

2.3.3 PUMP MECHANISM 2-33.....................................................

2.3.4 DRIVE MECHANISM 2-34.....................................................

2.3.5 TONER COLLECTION BOTTLE 2-35...................................

2.4 OPTICS 2-36....................................................................

2.4.1 OVERVIEW 2-36...................................................................

2.4.2 SCANNER DRIVE 2-37.........................................................

2.4.3 VERTICAL LENS DRIVE 2-38...............................................

2.4.4 HORIZONTAL LENS DRIVE 2-39.........................................

2.4.5 HORIZONTAL LENS POSITIONING 2-40.............................

2.4.6 3 SCANNER DRIVE 2-42......................................................

2.4.7 OPTICS CONTROL CIRCUIT 2-43.......................................

2.4.8 AUTOMATIC IMAGE DENSITY CONTROL 2-44..................

2.4.9 MANUAL IMAGE DENSITY CONTROL 2-46........................

2.4.10 UNEVEN LIGHT INTENSITY CORRECTION 2-47.............

Page 3

2.4.11 ORIGINAL SIZE DETECTION IN PLATEN MODE 2-48......

2.4.12 HALF TONE MODE 2-50.....................................................

2.5 DEVELOPMENT 2-51.......................................................

2.5.1 OVERVIEW 2-51...................................................................

2.5.2 DEVELOPMENT MECHANISM 2-52.....................................

2.5.3 DRIVE MECHANISM 2-53.....................................................

2.5.4 CROSSMIXING 2-54.............................................................

2.5.5 DEVELOPMENT BIAS 2-55..................................................

2.5.6 TONER SUPPLY 2-60...........................................................

2.6 IMAGE TRANSFER 2-64..................................................

2.6.1 PRE-TRANSFER LAMP 2-64................................................

2.6.2 IMAGE TRANSFER AND PAPER SEPARATION 2-65.........

2.6.3 IMAGE TRANSFER AND PAPER SEPARATION 2-66.........

2.6.4 TRANSFER BELT UNIT LIFT MECHANISM 2-68.................

2.6.5 PAPER TRANSPORTATION AND BELT DRIVE 2-69..........

2.6.6 TRANSFER BELT CLEANING MECHANISM 2-70...............

2.6.7 TONER COLLECTION MECHANISM 2-71...........................

2.6.8 TRANSFER ANTI-CONDENSATION HEATER 2-72.............

2.7 PAPER FEED 2-73...........................................................

2.7.1 OVERVIEW 2-73...................................................................

2.7.2 FRR FEED SYSTEM 2-74.....................................................

2.7.3 SLIP CLUTCH MECHANISM 2-76........................................

2.7.4 FRR FEED DRIVE MECHANISM 2-77..................................

2.7.5 SEPARATION ROLLER RELEASE MECHANISM 2-79........

2.7.6 PAPER RETURN MECHANISM 2-80....................................

2.7.7 PAPER SKEW PREVENTION MECHANISM 2-81................

2.7.8 PAPER LIFT MECHANISM 2-82...........................................

2.7.9 PAPER NEAR END/PAPER END DETECTION 2-85............

2.7.10 TANDEM FEED TRAY 2-86................................................

2.7.11 PAPER SIZE DETECTION 2-90..........................................

2.7.12 VERTICAL TRANSPORT MECHANISM 2-91.....................

2.7.13 TRAY POSITIONING MECHANISM 2-92............................

2.7.14 BY-PASS FEED TABLE 2-95..............................................

2.7.15 PAPER REGISTRATION 2-98.............................................

2.7.16 REGISTRATION DRIVE MECHANISM 2-99.......................

2.7.17 GUIDE PLATE RELEASE MECHANISM 2-100....................

2.8 IMAGE FUSING 2-101........................................................

2.8.1 OVERVIEW 2-101...................................................................

2.8.2 FUSING ENTRANCE GUIDE 2-102........................................

2.8.3 FUSING DRIVE MECHANISM 2-103......................................

2.8.4 FUSING LAMP CONTROL 2-104............................................

2.8.5 INVERTER AND PAPER EXIT 2-105......................................

2.8.6 INVERTER AND EXIT DRIVE MECHANISM 2-106................

2.9 DUPLEX 2-107...................................................................

2.9.1 OVERVIEW 2-107...................................................................

2.9.2 DRIVE MECHANISM 2-108.....................................................

2.9.3 DUPLEX ENTRANCE TO DUPLEX TRAY 2-109....................

2.9.4 DUPLEX STACKING 2-110.....................................................

2.9.5 DUPLEX PICK-UP ROLLER MECHANISM 2-111..................

Page 4

2.9.6 DUPLEX PAPER FEED 2-112.................................................

2.10 ENERGY STAR COMPLIANT MACHINES (ALL 2-115....

2.11 ENERGY SAVING INFORMATION 2-117........................

2.11.1 ABOUT THE ENERGY SAVING FEATURES OF 2-117.......

3. INSTALLATION PROCEDURE 3-1......................................

3.1 INSTALLATION REQUIREMENTS 3-1..........................

3.1.1 ENVIRONMENT 3-1............................................................

3.1.2 MACHINE LEVEL 3-1..........................................................

3.1.3 MINIMUM SPACE REQUIREMENTS 3-2...........................

3.1.4 POWER REQUIREMENTS 3-2...........................................

3.2 COPIER (A246/A247/A248) 3-3.....................................

3.2.1 ACCESSORY CHECK 3-3...................................................

3.2.2 INSTALLATION PROCEDURE 3-4.....................................

3.2.3 GUIDANCE ROM INSTALLATION (OPTION: 3-14...............

3.2.4 PLATEN COVER (OPTION) INSTALLATION 3-15...............

3.2.5 KEY COUNTER HOLDER INSTALLATION 3-16..................

3.2.6 ORIGINAL TRAY INSTALLATION (OPTION) 3-18...............

3.3 UNIVERSAL TRAY (TRAY 2) 3-19..................................

3.4 550 SHEETS PAPER TRAY (TRAY 3) 3-20....................

3.5 TANDEM FEED TRAY PAPER SIZE CHANGE 3-22......

3.6 DUAL JOB FEEDER (A610) 3-25....................................

3.6.1 ACCESSORY CHECK 3-25...................................................

3.6.2 INSTALLATION PROCEDURE 3-26.....................................

3.7 SORTER STAPLER (A821) 3-29.....................................

3.7.1 ACCESSORY CHECK 3-29...................................................

3.7.2 INSTALLATION PROCEDURE 3-30.....................................

3.7.3 SORTER ADAPTER INSTALLATION (OPTION) 3-34..........

3.8 20 BIN SORTER STAPLER (A658) (A246 ONLY) 3-36..

3.8.1 ACCESSORY CHECK 3-36...................................................

3.8.2 INSTALLATION PROCEDURE 3-37.....................................

3.9 LCT (A822) 3-41...............................................................

3.9.1 ACCESSORY CHECK 3-41...................................................

3.9.2 INSTALLATION PROCEDURE 3-42.....................................

3.9.3 PAPER SIZE CHANGE 3-46.................................................

3.10 TRANSPORTATION REMARKS 3-49............................

3.10.1 TONER RECYCLING TUBE CLEANING 3-49....................

3.10.2 OTHER OPERATIONS 3-49................................................

4. SERVICE TABLES 4-1.........................................................

4.1 GENERAL CAUTIONS 4-1.............................................

4.1.1 DRUM 4-1............................................................................

4.1.2 DRUM UNIT 4-1...................................................................

4.1.3 CHARGE CORONA 4-2......................................................

4.1.4 OPTICS 4-2.........................................................................

4.1.5 ERASE LAMP 4-3................................................................

4.1.6 DEVELOPMENT UNIT 4-3..................................................

4.1.7 TRANSFER BELT UNIT 4-3................................................

Page 5

4.1.8 CLEANING SECTION 4-4...................................................

4.1.9 PRE-TRANSFER LAMP 4-4................................................

4.1.10 PAPER FEED 4-4..............................................................

4.1.11 FUSING UNIT 4-4..............................................................

4.1.12 USED TONER 4-5.............................................................

4.2 SERVICE PROGRAM MODE 4-6..................................

4.2.1 SERVICE PROGRAM MODE OPERATION 4-6.................

4.2.2 SERVICE PROGRAM MODE TABLES 4-8.........................

4.2.3 INPUT CHECK 4-45..............................................................

4.2.4 OUTPUT CHECK 4-48..........................................................

4.3 USER PROGRAM 4-51....................................................

4.3.1 HOW TO ENTER AND EXIT UP MODE 4-51.......................

4.3.2 UP MODE TABLE 4-51..........................................................

4.4 TEST POINTS/DIP SWITCHES/LEDS 4-53....................

4.4.1 DIP SWITCHES 4-53.............................................................

4.4.2 TEST POINTS 4-53...............................................................

4.4.3 FUSES 4-54...........................................................................

4.4.4 LEDS 4-54.............................................................................

4.5 SPECIAL TOOLS AND LUBRICANTS 4-54.....................

4.5.1 SPECIAL TOOLS 4-54..........................................................

4.5.2 LUBRICANTS 4-54................................................................

4.6 TOUCH PANEL DISPLAY POSITION 4-55.....................

5. PREVENTIVE MAINTENANCE SCHEDULE 5-1................

5.1 PM TABLE 5-1................................................................

5.2 PM PROCEDURE 5-5....................................................

5.2.1 CLEARING PM COUNTER 5-5...........................................

5.2.2 PM PROCEDURE 5-6.........................................................

6. REPLACEMENT AND ADJUSTMENT 6-1.........................

6.1 EXTERIOR AND INNER COVER REMOVAL 6-1.........

6.1.1 FRONT COVER 6-1.............................................................

6.1.2 REAR SIDE 6-2...................................................................

6.1.3 INNER COVER 6-3..............................................................

6.1.4 RIGHT SIDE 6-6..................................................................

6.1.5 LEFT SIDE 6-7.....................................................................

6.1.6 OPERATION PANEL 6-8.....................................................

6.1.7 UPPER COVER 6-9.............................................................

6.2 PAPER FEED 6-10...........................................................

6.2.1 PAPER TRAY UNIT REMOVAL 6-10....................................

6.2.2 PAPER TRAY REMOVAL 6-13.............................................

6.2.3 PAPER FEED ROLLERS REPLACEMENT 6-16..................

6.2.4 PAPER FEED TIMING ADJUSTMENT 6-17.........................

6.2.5 PAPER FEED CLUTCH REMOVAL (1ST TRAY 6-20...........

6.2.6 REAR FENCE RETURN SENSOR REPLACEMENT 6-24....

6.2.7 REAR FENCE HP SENSOR REPLACEMENT 6-25..............

6.2.8 BOTTOM PAPER SENSOR REPLACEMENT 6-26..............

6.2.9 BY-PASS FEED TABLE REMOVAL 6-27..............................

Page 6

6.2.10 BY-PASS FEED ROLLERS REPLACEMENT 6-28.............

6.2.11 BY-PASS PAPER SIZE SENSOR REPLACEMENT 6-29...

6.2.12 BY-PASS FEED CLUTCH AND GUIDE PLATE 6-31..........

6.2.13 REGISTRATION MOTOR REMOVAL 6-33.........................

6.2.14 PAPER DUST CLEANER CLEANING 6-34........................

6.2.15 REGISTRATION SENSOR CLEANING 6-35......................

6.2.16 UNIVERSAL TRAY SIZE SWITCH REPLACEMEN 6-36....

6.2.17 550-SHEET TRAY SET SWITCH REPLACEMENT 6-37....

6.2.18 LIFT MOTOR REMOVAL 6-38............................................

6.2.19 PAPER FEED MOTOR REMOVAL 6-39.............................

6.2.20 COPIER FEED UNIT REMOVAL 6-40................................

6.2.21 BOTTOM PLATE LIFT WIRE REPLACEMENT 6-42..........

6.2.22 550 SHEETS PAPER TRAY (TRAY 3) 6-44........................

6.2.23 TANDEM FEED TRAY PAPER SIZE CHANGE 6-46..........

6.3 OPTICS 6-49....................................................................

6.3.1 EXPOSURE GLASS REMOVAL 6-49...................................

6.3.2 EXPOSURE LAMP REPLACEMENT 6-50............................

6.3.3 OPTICS THERMOSWITCH REPLACEMENT 6-52...............

6.3.4 SCANNER HP SENSOR REPLACEMENT 6-53...................

6.3.5 ADS SENSOR REMOVAL 6-54.............................................

6.3.6 SCANNER DRIVE MOTOR 6-55...........................................

6.3.7 SCANNER DRIVE WIRES REPLACEMENT 6-56.................

6.3.8 THIRD SCANNER REMOVAL 6-72.......................................

6.3.9 THIRD SCANNER DRIVE MOTOR/HP SENSOR 6-73.........

6.3.10 LENS HORIZONTAL DRIVE HP SENSOR 6-75.................

6.3.11 LENS HORIZONTAL DRIVE MOTOR 6-77.........................

6.3.12 APS SENSOR ADJUSTMENT (SENSITIVITY 6-79...........

6.3.13 ARS SENSOR ADJUSTMENT 6-80....................................

6.4 TONER RECYCLING 6-81...............................................

6.4.1 TONER RECYCLING UNIT REMOVAL 6-81........................

6.4.2 TONER RECYCLING CLUTCH REPLACEMENT 6-82.........

6.5 DEVELOPMENT AND TONER SUPPLY 6-83................

6.5.1 DEVELOPMENT UNIT REMOVAL 6-83................................

6.5.2 DEVELOPER REPLACEMENT 6-85.....................................

6.5.3 DEVELOPMENT ROLLERS REPLACEMENT 6-87..............

6.5.4 TONER DENSITY SENSOR REPLACEMENT 6-89..............

6.5.5 TONER BOTTLE DRIVE MOTOR REPLACEMENT 6-90.....

6.5.6 DEVELOPMENT FILTER AND PRESSURE 6-91.................

6.5.7 DEVELOPMENT ROLLER SHAFT CLEANING 6-92............

6.6 DRUM UNIT 6-93..............................................................

6.6.1 DRUM UNIT REMOVAL AND OPC DRUM 6-93...................

6.6.2 QUENCHING LAMP REPLACEMENT 6-94..........................

6.6.3 GRID PLATE/CHARGE WIRE/WIRE CLEANER 6-95.........

6.6.4 ERASE LAMP AND DRUM POTENTIAL SENSOR 6-97......

6.6.5 CLEANING BLADE REPLACEMENT 6-98............................

6.6.6 CLEANING BRUSH REPLACEMENT 6-99...........................

6.6.7 PICK-OFF PAWL REPLACEMENT 6-100...............................

6.6.8 OZONE FILTER REPLACEMENT 6-101.................................

6.6.9 PRE-TRANSFER LAMP REMOVAL 6-102.............................

Page 7

6.7 TRANSFER BELT UNIT 6-103..........................................

6.7.1 TRANSFER BELT UNIT REMOVAL/INSTALLATION 6-103...

6.7.2 TRANSFER BELT REPLACEMENT 6-105.............................

6.7.3 CLEANING BLADE REPLACEMENT 6-107............................

6.8 FUSING UNIT 6-108...........................................................

6.8.1 FUSING UNIT REMOVAL 6-108.............................................

6.8.2 FUSING THERMISTOR REPLACEMENT 6-109.....................

6.8.3 FUSING THERMOFUSE REPLACEMENT 6-110...................

6.8.4 FUSING LAMP REPLACEMENT 6-111..................................

6.8.5 OIL SUPPLY/CLEANING ROLLER REPLACEMENT 6-113...

6.8.6 OIL SUPPLY CLEANING BRUSH REPLACEMENT 6-114.....

6.8.7 HOT ROLLER REPLACEMENT 6-115....................................

6.8.8 PRESSURE ROLLER AND BEARING 6-117..........................

6.8.9 FUSING STRIPPER PAWL REPLACEMENT 6-119...............

6.8.10 FUSING PRESSURE ADJUSTMENT 6-120.........................

6.8.11 PAPER EXIT UNIT REMOVAL 6-121....................................

6.8.12 EXIT SENSOR AND FUSING EXIT SENSOR 6-123............

6.8.13 DUPLEX PAPER GUIDE SENSOR AND 6-124....................

6.8.14 PRESSURE ROLLER CLEANING ROLLER 6-125...............

6.9 DUPLEX UNIT 6-126..........................................................

6.9.1 FEED ROLLER REPLACEMENT 6-126..................................

6.9.2 SEPARATION BELT REPLACEMENT 6-128..........................

6.9.3 DUPLEX UNIT REMOVAL 6-131............................................

6.9.4 SEPARATION CLUTCH/TRANSPORT CLUTCH 6-132.........

6.9.5 JOGGER MOTOR REPLACEMENT 6-133.............................

6.10 COPY QUALITY ADJUSTMENT 6-138............................

6.10.1 SP ADJUSTMENT MODE 6-138...........................................

6.10.2 SIDE-TO-SIDE REGISTRATION ADJUSTMENT 6-140........

6.10.3 UNEVEN EXPOSURE ADJUSTMENT 6-141........................

6.10.4 IMAGE DENSITY ADJUSTMENT 6-143...............................

6.10.5 SCANNER HEIGHT ADJUSTMENT 6-144...........................

6.10.6 APS SIZE CALIBRATION 6-145............................................

6.10.7 FUSING EXIT COVER MAGNET POSITIONING 6-146.......

7. TROUBLESHOOTING 7-1...................................................

7.1 SERVICE CALL CONDITIONS 7-1...............................

7.1.1 SUMMARY 7-1....................................................................

7.1.2 EXPOSURE 7-3...................................................................

7.1.3 SCANNER 7-5.....................................................................

7.1.4 LENS MAGNIFICATION 7-8................................................

7.1.5 OPTICS THERMISTOR 7-10.................................................

7.1.6 CHARGE CORONA UNIT 7-10.............................................

7.1.7 DEVELOPMENT 7-11............................................................

7.1.8 PROCESS CONTROL SENSORS 7-12................................

7.1.9 TRANSFER CURRENT 7-15.................................................

7.1.10 DRUM 7-15..........................................................................

7.1.11 PAPER FEED 7-16..............................................................

7.1.12 DUPLEX 7-19......................................................................

7.1.13 FUSING 7-20.......................................................................

Page 8

7.1.14 SYSTEM CONTROL 7-22...................................................

7.1.15 DUAL JOB FEEDER 7-23....................................................

7.1.16 SORTER STAPLER 7-24....................................................

7.1.17 OTHERS 7-28......................................................................

7.2 ELECTRICAL COMPONENT DEFECTS 7-30................

7.2.1 SENSORS 7-30.....................................................................

7.2.2 SWITCHES 7-34....................................................................

7.2.3 FUSES 7-35...........................................................................

POINT TO POINT DIAGRAM & ELCTRICAL

A246/A247/A248/A822 POINT TO POINT DIAGRAM

ELECTRICAL COMPONENT LAYOUT (A246/ A247/ A248

ELECTRICAL COMPONENT LAYOUT (A246/ A247/ A248

SORTER STAPLER (A821)

ELECTRICAL COMPONENT LAYOUT (A821)

Page 9

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

6. The copier is not attached to the table. Pushing the copier too heard may

cause it to drop onto the floor. While moving the copier, push the table.

7. When the main switch is tuned on, the machine will suddenly start turning to

perform the developer initialization. Keep hand away from any mechanical

and electrical components during this per iod.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

CAUTION:

The RAM board on the main control boar d has a li thi u m batt er y

which can explode if replaced incorrectly. Replace the RAM board

only with an identical one. Th e man u fact urer re co m men ds re pl aci ng

the entire RAM board. Do not recharge or burn this battery. Used

RAM board must be handled in accordance with local regulations.

Page 10

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductor according to

local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used RAM boards in order to dispose of them later, do not put

more than 100 RAM boards per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

Page 11

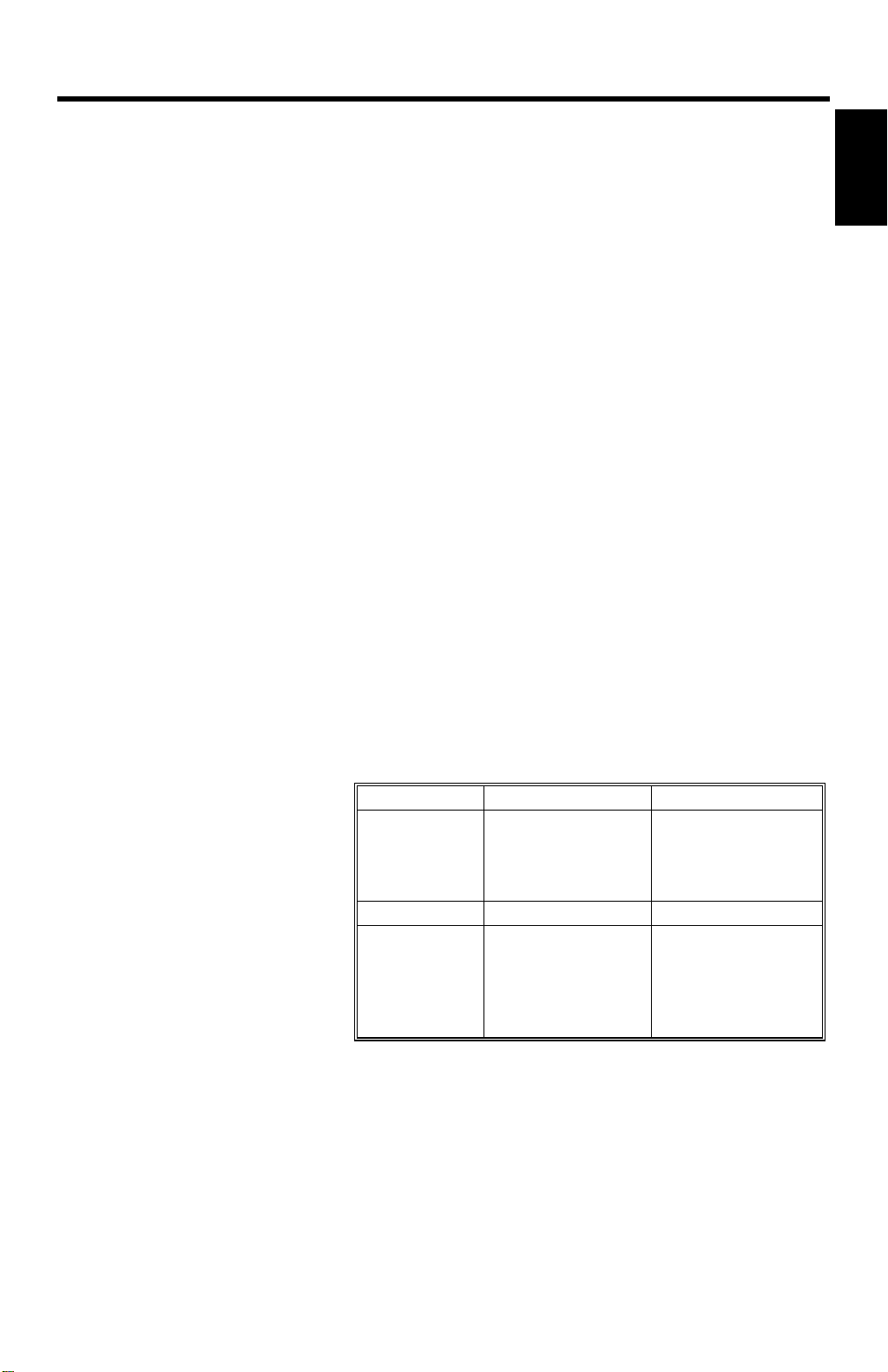

21 September 1998 SPECIFICATION

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATION

Configuration: Console

Copy Process: Dry electrostatic transfer system

Toner Supply Control: Fuzzy Control

Photoconductor: OPC drum

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Original Alignment: Left rear corner

Copy Paper Size: Maximum A3/11" x 17" (Tray & By-pass)

A4/8

Minimum A5/5

A4/8

A6/5

Duplex Copying: Maximum A3/11" x 17"

Minimum A5/5

Copy Paper Weight: Paper tray: 52 ~ 128 g/m2, 14 ~ 34 lb

By-pass feed table: 52 ~ 200 g/m2, 14 ~ 53 lb

Duplex copying: 64 ~ 104 g/m2, 17 ~ 24 lb

" x 11" (Tandem LCT)

1/2

" x 8

1/2

" x 11" (Tandem LCT)

1/2

" x 8

1/2

" x 8

1/2

" (Tray)

1/2

" (By-pass)

1/2

" (Sideways)

1/2

Overall

Information

Reproduction Ratios: 4 Enlargement and 5 Reduction + Create Margin

(93%)

A4/A3 Version LT/LDG Version

200%

Enlargement

Full Size 100% 100%

Reduction

141%

122%

115%

82%

75%

71%

65%

50%

200%

155%

129%

121%

85%

77%

74%

65%

50%

1-1

Page 12

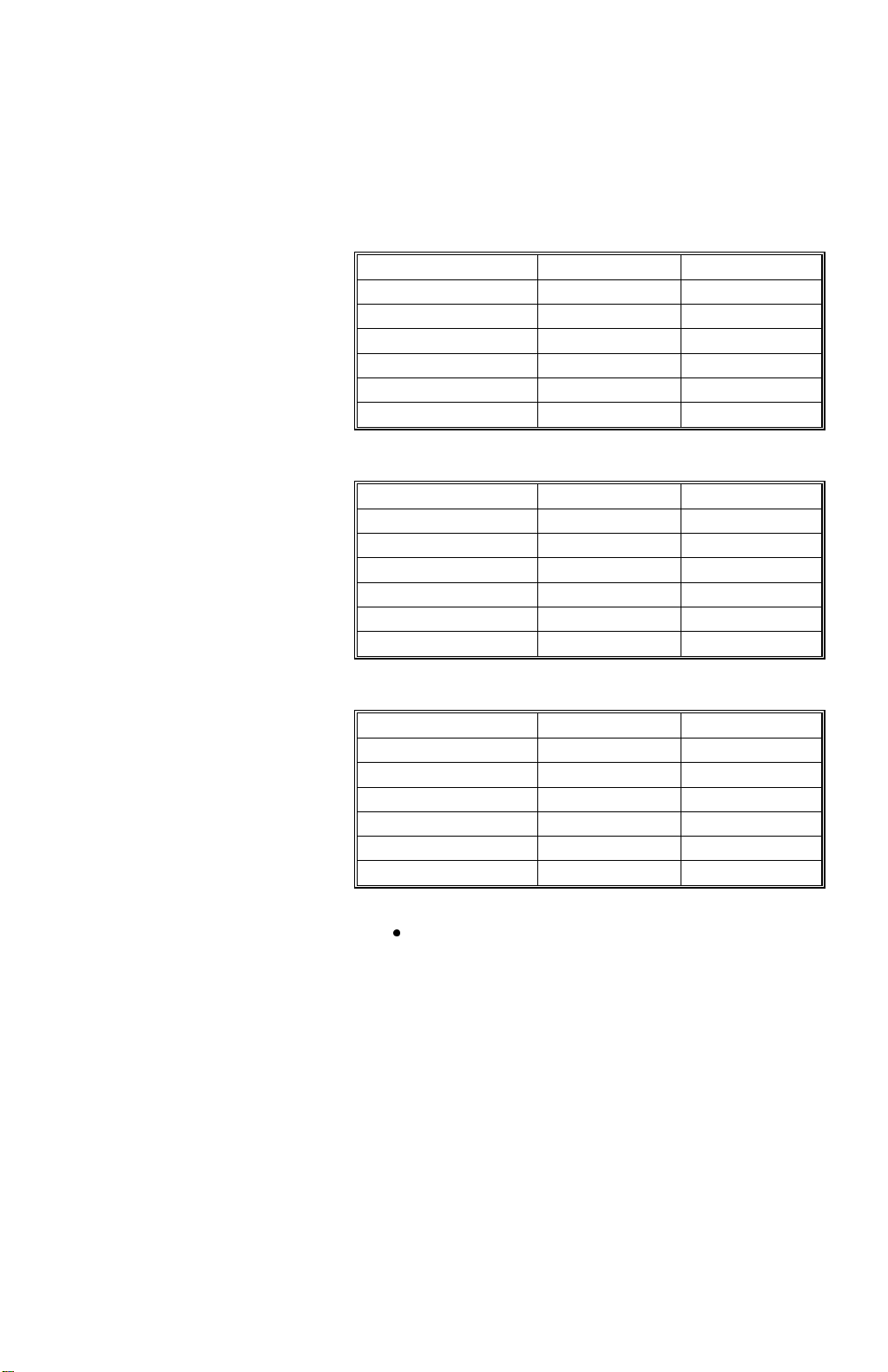

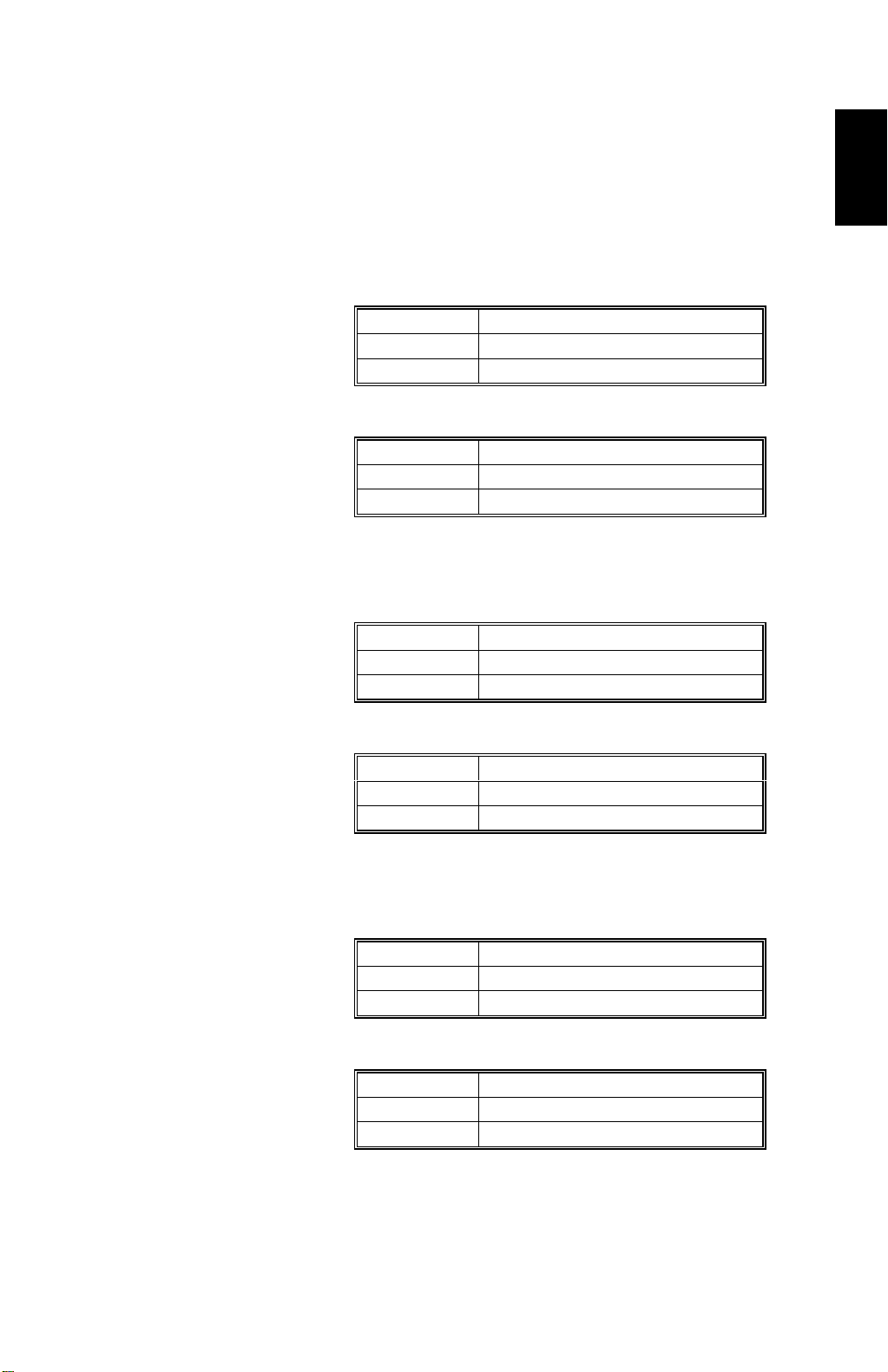

SPECIFICATION 21 September 1998

Power Source: 115 V, 60 Hz, more than 20 A (for N.A)

220 ~ 240 V, 50 Hz/60 Hz, more than 10 A (for

Europe and Asia)

Power Consumption:

- A246 copier -

Copier only Full system*

Warm up 1.20 kVA 1.22 kVA

Stand-by*

Low Power mode*

2

2

0.22 kVA 0.24 kVA

0.185 kVA 0.205 kVA

Copying 1.40 kVA 1.40 kVA

Maximum 1.70 kVA 1.75 kVA

Off-mode 0.001 kVA 0.001 kVA

- A247 copier -

Copier only Full system*

Warm up 1.20 kVA 1.22 kVA

Stand-by*

Low Power mode*

2

2

0.22 kVA 0.24 kVA

0.21 kVA 0.23 kVA

Copying 1.50 kVA 1.50 kVA

Maximum 1.70 kVA 1.75 kVA

Off-mode 0.001 kVA 0.001 kVA

- A248 copier -

Copier only Full system*

Warm up 1.20 kVA 1.22 kVA

Stand-by*

Low Power mode*

Copying 1.60 kVA 1.60 kVA

Maximum 1.70 kVA 1.75 kVA

Off-mode 0.001 kVA 0.001 kVA

2

2

0.22 kVA 0.24 kVA

0.21 kVA 0.23 kVA

1

1

1

*1Full System:

Mainframe with dual job feeder, sorter stapler

and 3,500-sheet large capacity tray

2

*

: When the anti-condensation heaters are off.

1-2

Page 13

21 September 1998 SPECIFICATION

Noise Emission: Sound Pressure Level:

The measurements are ma de accor di ng to

ISO7779

- A246 copier -

Overall

Information

Sound pressure level

Sound power level

- A247 copier -

Sound pressure level

Sound power level

(The measurements are made according to ISO 7779 at

the operator position.)

Copier only

Stand-by Less than 34 dB (A)

Copying Less than 57 dB (A) (average)

(The measurements are made according to ISO 7779.)

Copier only

Stand-by Less than 48 dB (A)

Copying Less than 71 dB (A) (average)

(The measurements are made according to ISO 7779 at

the operator position.)

Copier only

Stand-by Less than 34 dB (A)

Copying Less than 59 dB (A) (average)

(The measurements are made according to ISO 7779.)

- A248 copier -

Sound pressure level

Sound power level

Copier only

Stand-by Less than 51 dB (A)

Copying Less than 72 dB (A) (average)

(The measurements are made according to ISO 7779 at

the operator position.)

Copier only

Stand-by Less than 36 dB (A)

Copying Less than 59 dB (A) (average)

(The measurements are made according to ISO 7779.)

Copier only

Stand-by Less than 54 dB (A)

Copying Less than 73 dB (A) (average)

1-3

Page 14

SPECIFICATION 21 September 1998

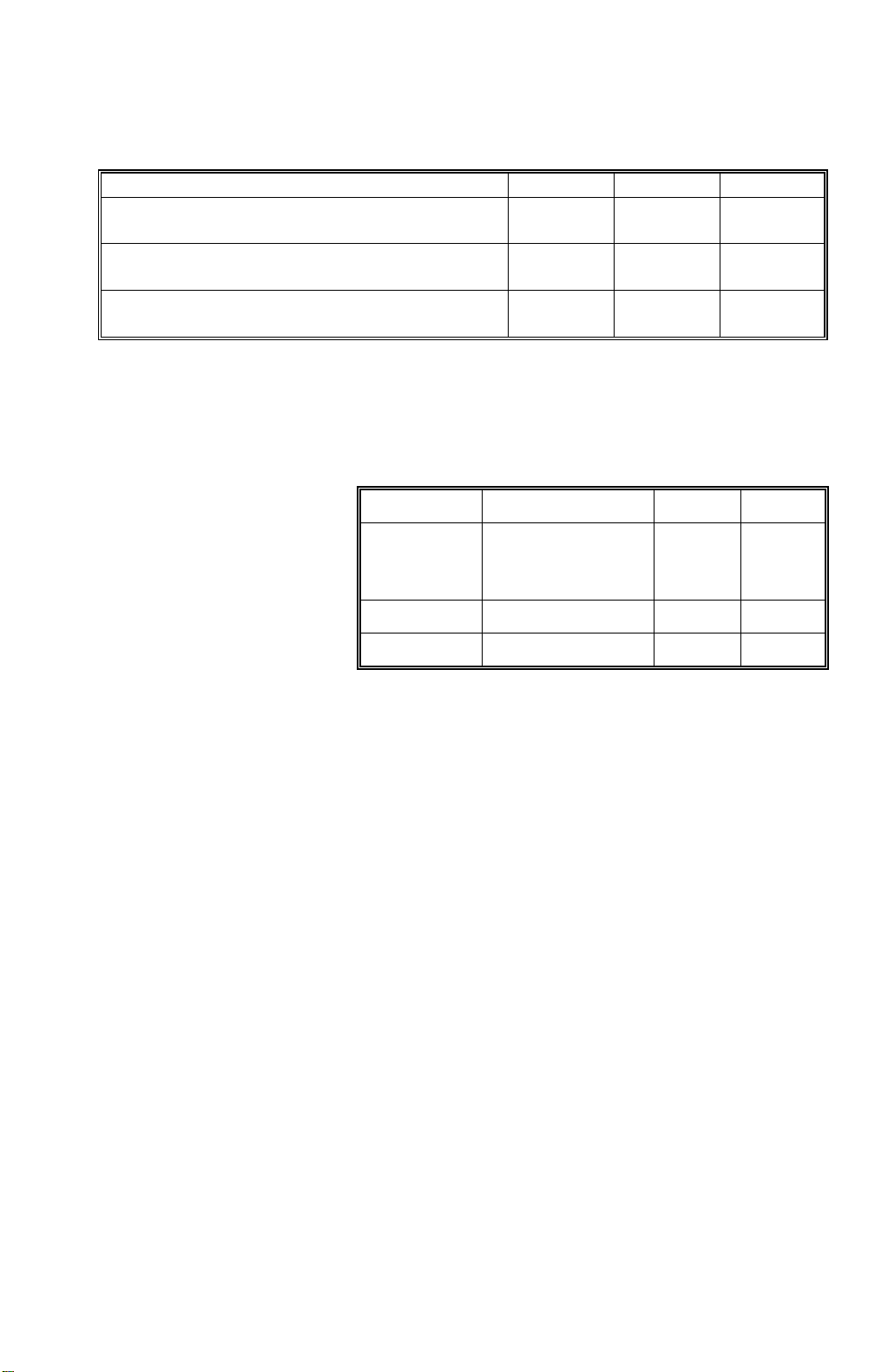

Dimensions:

Width Depth Height

Copier only

Copier with dual job feeder, sorter stapler,

and 3,500-sheet large capacity tray

Copier with dual job feeder, sorter stapler with

punch, and 3,500-sheet large capacity tray

690 mm

27.2"

1,659 mm

65.4"

1,659 mm

65.4"

698 mm

27.6"

698 mm

27.6"

698 mm

27.6"

980 mm

38.6"

1,113 mm

43.9"

1,113 mm

43.9"

Weight: Copier only: (Without the optional platen cover

= Approximately 2 kg)

Approximately 175 kg

Zoom: From 50% to 200% in 1% steps

Copying Speed:

A246 copier

A247 copier 60 31 38

A248 copier 70 36 44

A4/LT (sideways) A3/DLT B4/LG

51 (A4 others)

50 (A4/in France)

50 (LT)

26 32

Warm-up Time: Less than 5 minutes (A246 copier, 20°C)

Less than 5.5 minutes (A247/A248 copier, 20°C)

First Copy Time:

(A4/5

" x 11" sideways

1/2

3.1 seconds (A246 copier)

2.6 seconds (A247/A248 copiers)

from the 1st feed station)

Copy Number Input: Number keys, 1 to 999 (count up or count down)

Manual Image Density

9 steps

Selection:

Automatic Reset: 1 minute standard setting; can also be set from 1

second to 999 seconds or no auto reset.

Copy Paper Capacity:

By-pass feed table: approximately 50 sheets

Paper tray: approximately 550 sheets

Tandem LCT tray: approximately 1,550 sheets

Toner Replacement: 1,160 g/cartridge

1-4

Page 15

21 September 1998 SPECIFICATION

Optional Equipment:

Platen cover (A528-04)

Dual job feeder (A610)

20 bin sorter stapler (Floor type) (A821-17:

Ricoh, -22: NRG, -15: Savin/Ges U.S.A. –26:

Infotec)

3,500-sheet Large capacity tray (A822)

Receiving tray (A446-05)

Key Counter Bracket D (A509-03)

20 bin sorter Stapler (Floor type) with punch

(A821-57 (3 holes), -67 (2 holes): Ricoh, -62:

NRG, -66: Infotec, -55: Savin/Ges U.S.A.)

Guidance ROM KIT Type U (A870)

Editing sheet (spare part)

Original Tray type F (A430-07)

Sorter Adapter type L (A902-19)

20 bin sorter stapler (Hunging type) (A658)

(A246 copier only)

When the 20 bi n sorter stapler (A658) is installed onto A246 copier, sorter adapter

type L is required.

Overall

Information

1-5

Page 16

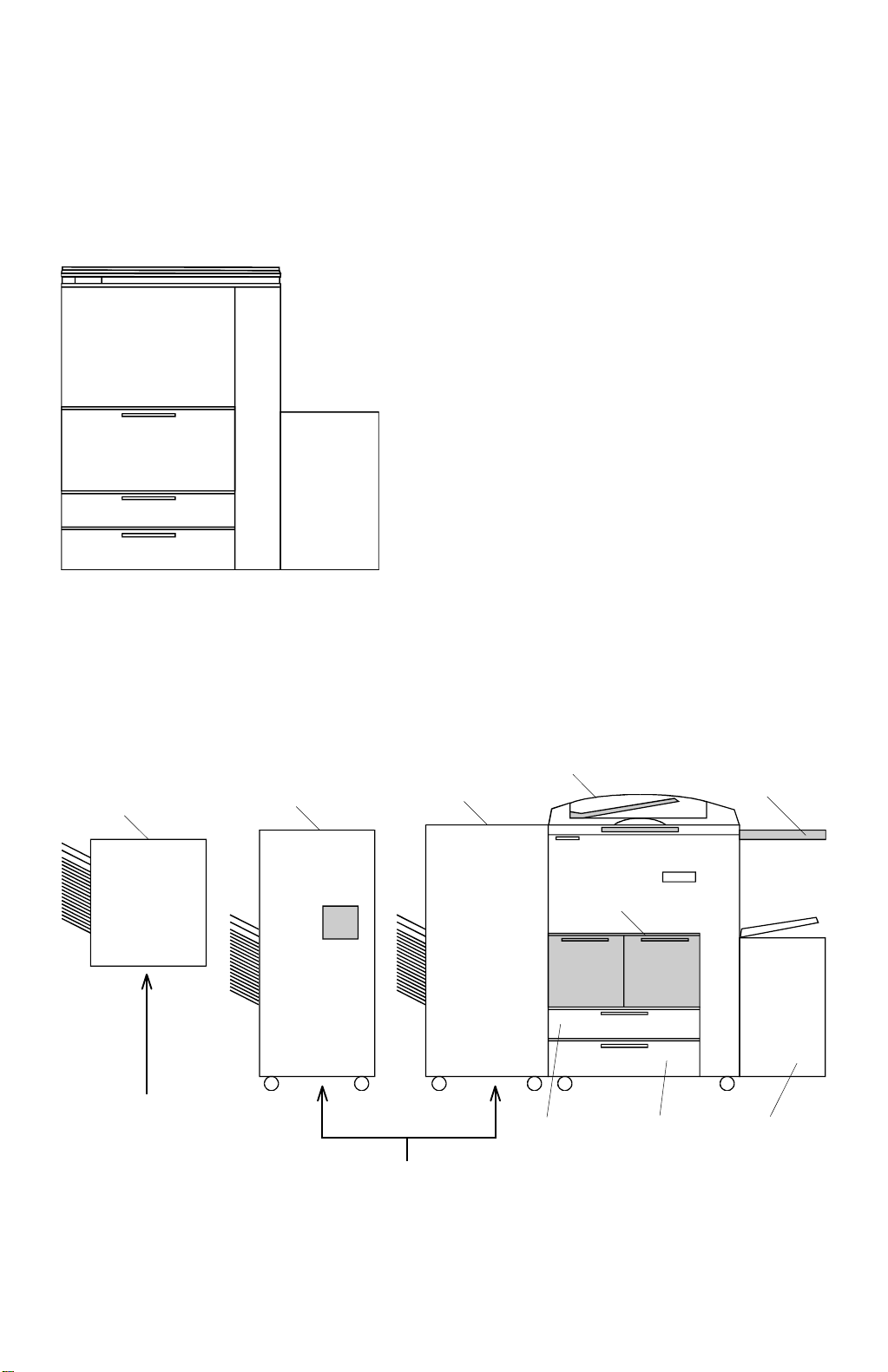

MACHINE CONFIGURATION 21 September 1998

1.2 MACHINE CONFIGURATION

1.2.1 COPIER OVERVIEW

- A246/A247/A248 copiers -

Tandem LCT

(including two 1,550-sheet LCT

Two 550-sheet paper trays

Optional 3,500-sheet large capacity tray

1,550 x 2

550

550

(3,500)

A246V500.WMF

1.2.2 SYSTEM OVERVIEW

Hunging S/S

S/S with Punch

S/S

DJF

Original Tray

Tandem LCT

Hunging Sorter Stapler

(A658)

Floor type Sorter Stapler (A821-17, -15, -22, -26)

Floor type Sorter Stapler with Punch (A821-57, -67, -55, -62, -66)

1-6

Universal

Fixed

3,500 sheets

LCT

A246V501.WMF

Page 17

21 September 1998 MACHINE CONFI GURATION

MEMO

Overall

Information

1-7

Page 18

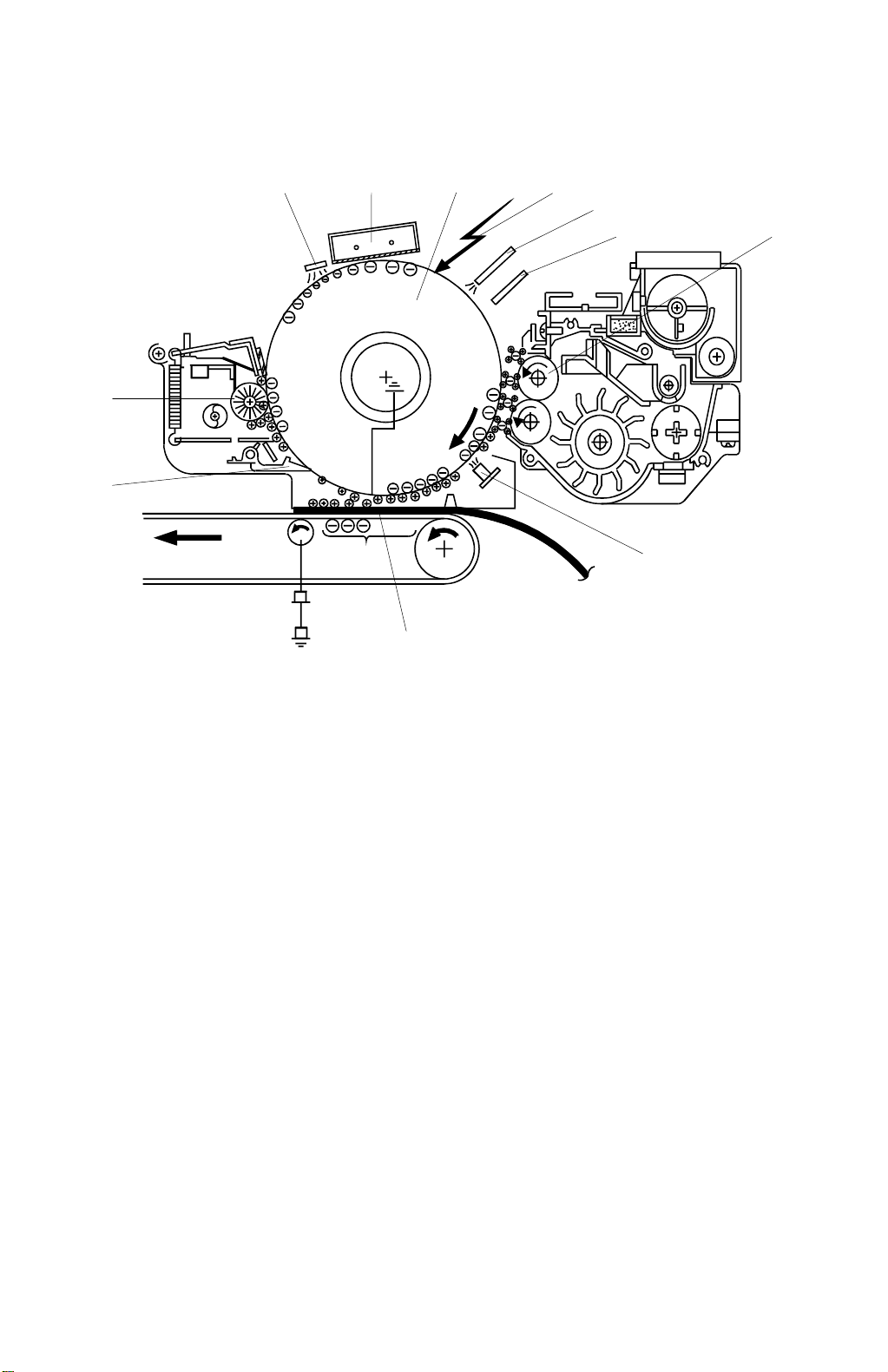

COPY PROCESS AROUND THE DURM 21 September 1998

1.3 COPY PROCESS AROUND THE DURM

10

11

12

3

4

5

6

9

7

8

A246V502.WMF

1. OPC DRUM

The organic photo conductive (OPC) drum (100 mm diameter) has high resistance

in the dark and low resistance under light.

2. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the OPC

drum. The charge remains on the surface of the drum. The amount of negative

charge on the drum is proportional to the negative grid bias voltage applied to the

grid plate on the charge corona unit.

3. EXPOSURE

An image of the original is reflected to the OPC drum surface via the optics section.

The charge on the drum surface is dissipated in direct proportion to the intensity of

the reflected light, thus producing an electrical latent image on the drum surface.

The amount of charge remaining as a latent image on the drum depends on the

exposure lamp intensity controlled by the exposure lamp voltage.

4. ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be

used for the copy image. The resistan ce of drum in the illuminated areas drops and

the charge on those areas dissipates.

1-8

Page 19

21 September 1998 COPY PROCESS AROUND THE DURM

5. DRUM POTENTIAL SENSOR

The drum potential sensor detects the electric potential on the drum to compensate

image processing elements.

6. DEVELOPMENT

Positively charged toner is attracted to the negatively charged areas of the drum,

thus developing the latent image. (The positive triboelectric charge of the toner is

caused by friction between the carrier and toner particles.)

The development bias voltage applied to the development roller shaft controls two

things:

1) The threshold level if toner is attracted to the drum or toner remains on the

development roller.

2) The amount of toner to be attracted to the drum.

The higher the negative development bias voltage is, the less toner is attracted to

the drum surface.

7. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove almost all the negative charge from the

exposed areas of the drum. This makes image transfer easier.

Overall

Information

8. IMAGE TRANSFER

Paper is fed to the drum surface at the proper timing so as to align the copy paper

and the developed image on the drum surface. Then, a negative charge is applied

to the reverse side of the copy paper by the transfer belt, producing an electrical

force which pulls the toner particles from the drum surface onto the copy paper. At

the same time, the copy paper is electrically attracted to the transfer belt.

9. PAPER SEPARATION

Paper separates from the OPC drum by the electrical attraction between the paper

and the transfer belt. The pick-off pawls help to separate the paper from the drum.

10. CLEANING

The cleaning brush removes toner remaining on the drum after image transfer and

the cleaning blade scrapes off all the remaining toner.

11. QUENCHING

Light from the quenching lamp electrically neutralizes the charge potential of the

drum surface.

1-9

Page 20

MECHANICAL COMPONENT LAYOUT 21 September 1998

1.4 MECHANICAL COMPONENT LAYOUT

34567891011

12

39

38

37

36

35

2

13

14

1

15

16

17

18

19

20

21

34 33 32 31 30 29 41 40 2323

22

A246V503.WMF

24

1-10

28

25

26

27

A246V504.WMF

Page 21

21 September 1998 MECHANICAL COMPONENT LAYOUT

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Cleaning Brush

7. Cleaning Blade

8. Quenching Lamp

9. Charge Corona Unit

10. OPC Drum

11. 6th Mirror

12. 4th Mirror

13. 5th Mirror

14. Erase Unit

15. Drum Potential Sensor

22. Registration Rollers

23. Transfer Belt

24. Vertical Transport Rollers

25. Tandem LCT Tray

26. Universal Tray (550-sheet)

27. 550-sheet Tray

28. Toner Collection Bottle

29. Transfer Belt Cleaning Blade

30. Hot Roller

31. Pressure Roller

32. Jogger Fences

33. Duplex Positioning Roller

34. Duplex Pick-up Roller

35. Duplex Feed Roller

36. Separation Belt

Overall

Information

16. Toner Hopper

17. Development Unit

18. Pre-Transfer Lamp

19. Pick-up Roller

20. Feed Roller

21. Separation Roller

37. Junction Gate

38. Exit Rollers

39. Optics Cooling Fan

40. Transfer Belt Cleaning Bias Roller

41. Transfer Belt Bias Roller Blade

1-11

Page 22

DRIVE LAYOUT 21 September 1998

1.5 DRIVE LAYOUT

917

10

2

4

5

8

3

6

A246V505.WMF

Main Motor

Scanner Drive Motor

Fusing/Duplex Drive Motor

Paper Feed Motor

Toner Collection Motor

Registration Motor

By-pass Feed Motor

By-pass Feed Clutch

Development Drive Motor

1. To OPC Drum

2. To Scanner Unit

3. To Transfer Belt Unit

4. To Paper Exit Unit

5. To Fusing Unit

6. To Duplex Unit

7. To Cleaning Unit

8. To Paper Feed Units

9. To Toner Hopper

10. To Development Unit

1-12

Page 23

21 September 1998 PAPER PATH

1.6 PAPER PATH

1.6.1 STANDARD COPYING

[D]

[F]

[E]

[C]

[B]

[A]

Overall

Information

[A]

A246V506.WMF

Paper feed begins from the exterior LCT, by-pass feed table or paper feed stations

in the paper tray unit. The copy paper then follows one of two paths inside the

copier. The path followed depends on which mode the operator has selected. For

copy processing, all sheets follow the same paths from the paper feed mechanism

[A] through the registration rollers [B], transfer belt [C], and fusing unit [D]. After

that, copies are delivered to the sorter bins [E] or proof tray [F], however, 2 sided

copies are diverted for further processing.

1-13

Page 24

PAPER PATH 21 September 1998

1.6.2 MULTIPLE 2-SIDE COPYING

a. Front Side

b. Rear Side

[B]

[A]

[D]

[C]

A246V507.WMF

A246V508.WMF

In this mode the junction gate [A] directs sheets exiting the fusing unit to the duplex

tray entrance. After that, all sheets follow the path through the duplex entrance

rollers [B].

After all front side copying is fed, the sheets on the duplex tray are fed in order

from the bottom to the top and follow the path through the duplex feed mechanism

and vertical transport rollers [C] to the registration rollers [D]. After that, these

sheets follow the same path as standard copying from the registration rollers to the

sorter.

1-14

Page 25

21 September 1998 ELECTRICAL COMPONENT DESCRIPTIO N

1.7 ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the point-to-point

diagram for the location of the components using the symbols and index numbers.

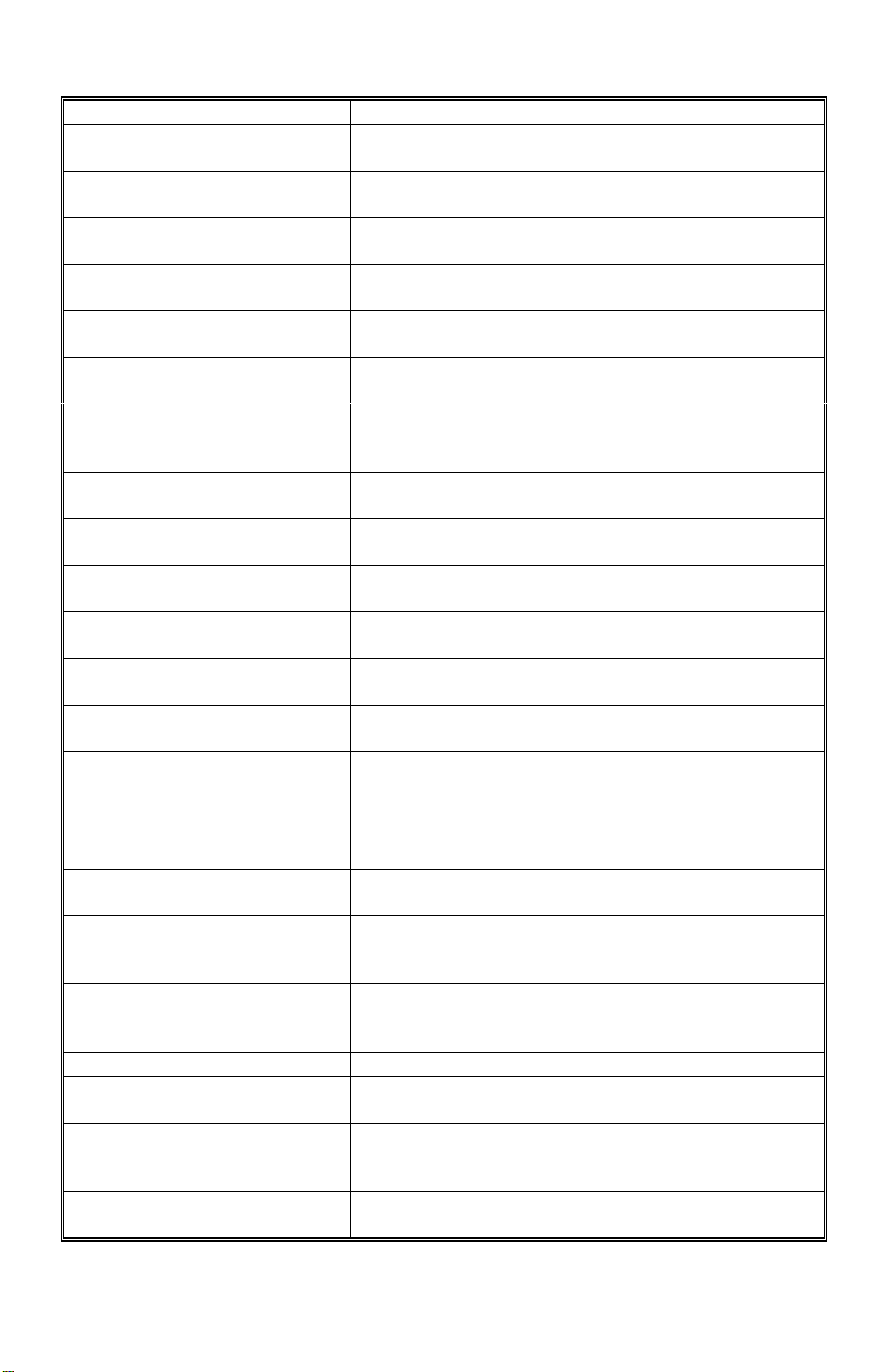

Symbol Name Function Index No.

Motors

M1 Scanner Drives the 1st and 2nd scanners. 5

M2 3rd Scanner Drives the 3rd scanner. 11

M3 Lens Horizontal Shifts the lens vertical position. 10

M4 Lens Vertical Shifts the lens horizontal position. 19

M5 Main Drives the main unit components. 120

M6 Development Dr ives the development unit. 121

M7

M8

M9

M10

M11

M12

M13

M14

M15

M16 By-pass Feed Drives the by-pass feed rollers. 124

M17 Registration Drives the r eg istr ation rollers. 123

M18

M19

M20 Optics Cooling Fan Removes heat from the optics unit. 21

M21

M22

M23

M24

Toner Bottle

Charge Wire

Cleaner

Fusing/Duplex Drives the f using unit, the duplex unit,

Toner Collection

Toner Recycle Drives the air pump to send recycled

Paper Feed Drives all feed and transport rollers in the

1st Lift

2nd Lift Raises the bottom plate in the 2nd paper

3rd Lift Raises and lowers the bottom plat e in the

Rear Fence Moves the paper stack in the left tandem

Jogger

Optics Board

Cooling Fan

Drum Cooling Fan Cools the drum unit to removes heat

Duplex Cooling Fan

Exhaust Fan Removes heat from around the fusing

Rotates the toner bottle to supply toner to

toner hopper.

Drives the charge wire cleaner to clean

the charge wire.

and the exit rollers.

Transports the collected toner in the

toner recycle unit for toner recycle.

toner to the development unit.

paper tray unit.

Raises the bottom plate in the 1st paper

tray.

tray.

3rd paper tray.

tray to the right tandem tray.

Drives the jogger fences to square the

paper stack in the duplex unit.

Removes heat from around the optics

board.

from around the duplex unit.

Cools the paper on the duplex tray to

reduce the heat around the drum.

unit.

133

30

119

126

129

94

95

97

98

55

43

118

106

114

104

Overall

Information

1-15

Page 26

ELECTRICAL COMPONENT DESCRIPTION 21 Sept ember 1998

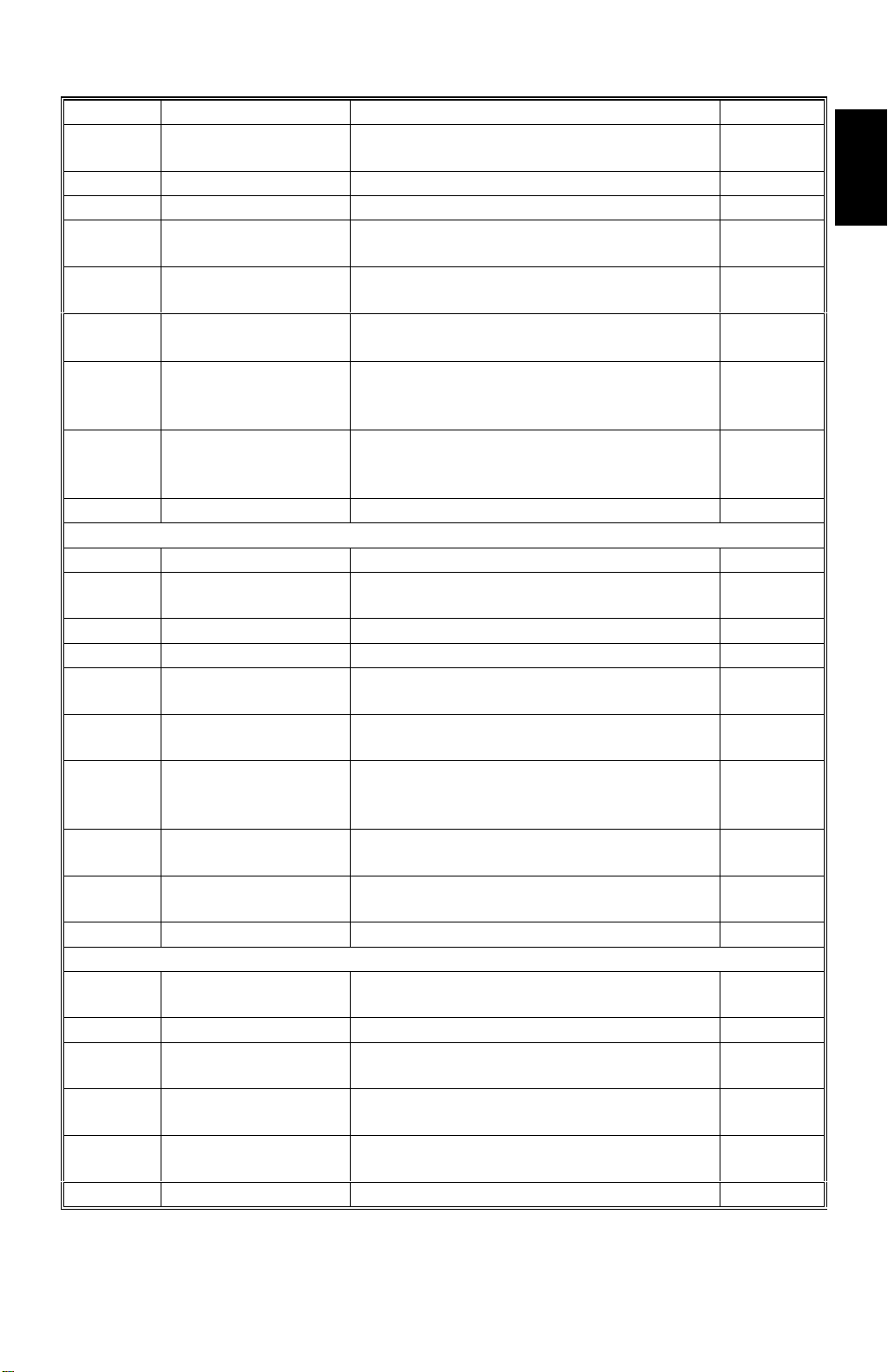

Symbol Name Function Index No.

Magnetic Clutches

MC1

Toner Supply

Turns the toner supply roller to supply

toner to the development unit.

122

MC2 Toner Recycling Dr ives the toner recycling unit. 125

MC3 1st Feed Starts paper feed from tray 1. 75

MC4 2nd Feed Starts paper feed from tray 2. 79

MC5 3rd Feed Starts paper feed from tray 3. 82

MC6 By-pass Feed Starts paper feed from the by-pass table. 64

Duplex Transport Drives the duplex transport rollers to

MC7

transport the paper to the vertical

39

transport rollers.

MC8

Duplex Feed Starts paper feed out of the duplex tray

to the duplex transport rollers.

38

Switches

SW1 Main Provides power to the copier. 117

SW2

SW3

SW4

Front Door Safety Cuts the power line and detects is the

front door is opened or not.

Toner Collection

Bottle

2nd Paper Size

Detects if the toner collection bottle is set

or not.

Determines what size paper is in the 2nd

paper tray.

115

128

100

SW5 3rd Tray Set Detects if the 3rd tray is set or not. 99

SW6

By-pass Table Detects if by-pass feed table is open or

closed.

62

Solenoids

SOL1

SOL2

SOL3

SOL4

SOL5

SOL6

SOL7

SOL8

SOL9

SOL10

Transfer Belt

Positioning

Controls the up-down movement of the

transfer belt unit.

1st Pick-up Controls the up-down movement of the

pick-up roller in tray 1.

2nd Pick-up

Controls the up-down movement of the

pick-up roller in tray 2.

3rd Pick-up Controls the up-down movement of the

pick-up roller in tray 3.

By-pass Pick-up Contr ols the up-down movement of the

pick-up roller for by-pass feed.

1st Separation

Roller

2nd Separation

Roller

3rd Separation

Roller

Right Tandem Lock

Controls the up-down movement of the

separation roller in tray 1.

Controls the up-down movement of the

separation roller in tray 2.

Controls the up-down movement of the

separation roller in tray 3.

Locks the right tandem tray during

transporting the paper from right tray to

left tray.

Left Tandem Lock Locks the left tandem tray so that it can

be separated from the right tandem tray.

34

74

78

83

63

76

81

84

96

101

1-16

Page 27

21 September 1998 ELECTRICAL COMPONENT DESCRIPTIO N

Symbol Name Function Index No.

SOL11

SOL12

SOL13

SOL14

SOL15

SOL13

Front Side Fence

Rear Side Fence Contr ols the open and close movement

Duplex Positioning Controls the up-down movement of the

Pressure Arm

Guide Plate Opens the guide plate when a paper

Junction Gate Moves the junction gate to direct copies

Controls the open and close movement

of the front side fence.

of the rear side fence.

positioning roller.

Presses the paper on the duplex tray

against the duplex feed rollers.

misfeed occurs around this area.

to the duplex tray or to the paper exit.

54

49

40

44

67

60

Sensors

S1

S2

S3

S4

Scanner HP Informs the CPU when the 1st and 2nd

scanners are at the home position.

3 rd Scanner HP

Informs the CPU when the 3rd scanner is

at the home position.

Lens Vertical HP Informs the CPU when the lens is at the

full-size position.

Lens Horizontal HP Informs the CPU when the lens is at the

horizontal home position.

2

9

7

12

S5 APS Detects original size. 20

S6

Auto Image Density

Senses the background density of the

original.

6

S7 Drum Potential Det ects the drum surface potential. 31

S8

S9

Toner Density

Image Density Detects the density of the ID sensor

Detects the amount of toner in the

developer.

pattern on the drum.

37

32

S10 Toner Near End Detects the toner end condition. 36

1st Paper Feed Controls the 1st paper feed clutch off/on

S11

timing and the 1st pick-up solenoid off

91

timing.

2nd Paper Feed Controls the 2nd paper feed clutch off/on

S12

timing and the 2nd pick-up solenoid off

89

timing.

3rd Paper Feed

S13

Controls the 3rd paper feed clutch off/on

timing and the 3rd pick-up solenoid off

87

timing.

S14

S15

S16

S17

1st Lift Detects when the paper in tray 1 is at the

correct height for paper feed.

2nd Lift

Detects when the paper in tray 2 is at the

correct height for paper feed.

3rd Lift Detect s when the paper in tray 3 is at the

correct height for paper feed.

1st Paper End Informs the CPU when tray 1 runs out of

paper.

93

80

85

92

Overall

Information

1-17

Page 28

ELECTRICAL COMPONENT DESCRIPTION 21 Sept ember 1998

Symbol Name Function Index No.

S18

S19

S20

S21

S22

S23

S24

2nd Paper End

3rd Paper End Informs the CPU when tray 3 runs out of

By-pass Paper End Informs the CPU that there is no paper in

1st Paper Near End

2nd Paper Near

End

3rd Paper Near End Informs the CPU when the paper in tray

Right Tray Down

Informs the CPU when tray 2 runs out of

paper.

paper.

the by-pass feed table.

Informs the CPU when the paper in tray

1 is almost finished.

Informs the CPU when the paper in tray

2 is almost finished.

3 is almost finished.

Informs the CPU when the bottom plate

is completely lowered, to stop the 1st tray

90

88

65

53

77

86

52

lift motor.

S25

S26

S27

S28

S29

S30

S31

S32

Right Tray Paper Detects whether there is paper in the

right tandem tray.

Front Side Fence

Open

Front Side Fence

Close

Rear Side Fence

Open

Rear Side Fence

Close

Informs the CPU when the front side

fence is open.

Informs the CPU when the front side

fence is close.

Informs the CPU when the rear side

fence is open.

Informs the CPU when the rear side

fence is close.

Rear Fence HP Informs the CPU when the tandem tray

rear fence is in the home position.

Rear Fence Return Informs the CPU when the tandem tray

rear fence is in the return position.

Left Tandem Paper Informs the CPU when the left tandem

tray runs out the paper.

50

58

57

48

47

59

51

56

S33 Paper Guide Detect s the misfeeds. 61

S34

Duplex Entrance

Detects the leading edge of the paper to

determine duplex feed clutch off timing.

45

Duplex Transport Detects the leading edge of the paper to

S35

control the jogger motor and the

42

positioning solenoid on timing.

Duplex Exit

S36

Detects the leading edge of the paper to

determine duplex transport clutch on

42

timing.

S37 Duplex Paper End Detects the paper in the duplex tray. 46

S38

S39

Jogger HP Detects if the duplex jogger fences at the

home position or not.

Vertical Transport

Detects the leading edge of the paper to

determine the paper feed timing of next

41

69

sheet.

S40

Guide Plate

Position

Detects whether the registration guide

plate is closed.

68

1-18

Page 29

21 September 1998 ELECTRICAL COMPONENT DESCRIPTIO N

Symbol Name Function Index No.

S41

Registration

Detects misfeeds and controls the

registration roller on-off timing.

70

S42 Fusing Exit Detects misfeeds. 72

S43 Exit Detects misfeeds. 73

S44

S45

S46

S47

Auto Response

Toner Overflow Detects when the toner collection bottle

Original Length

(LT version only)

Platen Cover

Position 1 (Option)

Returns the display from the screen

saver.

is full.

Detects the original length.

Inform the CPU that the platen cover is in

the up or down position (related to

17

127

8

3

APS/ARE function).

S48

Platen Cover

Position 2 (Option)

Inform the CPU that the platen cover is in

the up or down position to detect if the

4

original has been removed or not.

PCBs

PCB1 Main Controls all machine functions. 107

PCB2

AC Drive Provides ac power to the fusing lamp and

exposure lamp.

102

PCB3 DC Power Supply Provides dc power. 110

PCB4 Optic Control Controls all optics components. 105

PCB5

PCB6

PCB7

Paper Feed Control Controls all components in the paper

bank.

Operation Panel

Control

Left Operation

Panel

Controls LEDs and LCD on the operation

panel.

Interfaces the LEDs, keys, and the auto

response sensor on the left operation

109

15

18

panel.

PCB8

PCB9

Right Operation

Panel

By-pass Paper Size Inform the CPU what size of the paper is

Interfaces the LEDs and keys on the right

operation panel.

in the by-pass feed table.

13

66

Overall

Information

Lamps

L1

Exposure Lamp Applies high intensity light to the original

for exposure.

L2 Fusing Lamps Provide heat t o the hot roller. 24

L3

L4

L5

Quenching Neutralizes any charge remaining on the

drum surface after cleaning.

Erase

Discharge the drum outside of the image

area.

Pre-transfer Reduce the charge on the drum surface

before transfer.

1-19

23

28

29

33

Page 30

ELECTRICAL COMPONENT DESCRIPTION 21 Sept ember 1998

Symbol Name Function Index No.

Power Packs

Charge

PP1

Provides high voltage for the charge

corona wires and the grid plate.

Interfaces the QL, PTL, and charge wire

27

cleaner motor control signals.

Development Provides hig h volt age for the

PP2

development unit.

Interfaces the transfer p.p. and the

108

charge p.p. signals.

Transfer Provides high voltage for the transfer

PP3

belt.

Interfaces the transfer belt positioning

35

solenoid control signal.

Heaters

H1

Optic

Anti-condensation

Turns on when the main switch is off to

prevent moisture from forming on the

16

optics.

H2

Transfer

Anti-condensation

Turns on when the main switch is off to

prevent moisture from forming on the

134

optics.

H3

H4

Upper Tray Turns on when the main switch is off to

keep paper dry in the paper tray.

Lower Tray

Turns on when the main switch is off to

keep paper dry in the paper tray.

131

130

Thermistors

TH1

Optic

Monitors the temperature of the optics

cavity.

TH2 Fusing Detects the temperature of the hot roller. 25

TH3

Drum Monitors the temperature of the OPC

drum.

Others

CB1

CO1

CO2

LA1

LCD1

Circuit Breaker Provides back-up high current protection

for the electrical components.

Total Counter Keeps track of the total number of copies

made.

Key Counter

Keeps track of the total number of copies

made when the key counter is set.

Lightening Arrestor Removes current surges from the ac

input lines.

LCD Displays the operation menus and

messages.

NF1 Noise Filter Remove the electrical noise. 112

RA1 Main Power Relay Contro ls main power. 103

TF1

Fusing Thermofuse Opens the fusing lamp circuit if the fusing

unit overheats.

1

32

113

132

-

116

14

26

1-20

Page 31

21 September 1998 ELECTRICAL COMPONENT DESCRIPTIO N

Symbol Name Function Index No.

TR1

TS1

Transformer

(220 V version only)

Optics

Thermoswitch

Makes power for the exposure lamp.

Opens the exposure lamp circuit if the

optics unit overheats.

111

22

Overall

Information

1-21

Page 32

21 September 1998 PROCESS CONTROL

g

2. DETAILED SECTION DESCRIPTIONS

2.1 PROCESS CONTROL

2.1.1 OVERVIEW

Ori

inal Scale

Image Density Control (Fuzzy Control)

Latent Image Control

VD Pattern VL Pattern

Latent Image Control

Exposure Control

Charge Control

Drum Thermistor

Lamp Voltage

Grid Voltage

QL

Paper

ADS Pattern

VD Pattern

L

V

Erase Lamp

Drum Potential Sensor

Detailed

Descriptions

Pattern

Original Exposure Glass

Toner Supply On Time

Development Bias

TD Sensor

ID Sensor

Image Density Control

(Fuzzy Control)

Toner Supply Control

Main PCB

A246D529.WMF

This model uses two process control methods. One compensates for variation in

the drum potential (latent image control) and the other controls the toner

concentration and toner supply amount (image density control).

2-1

Page 33

PROCESS CONTROL 21 September 1998

Latent Image Control

QL

Charge

Exposure

Black White

Erase

A246D550.WMF

The figure shows drum potential changes during the copy process.

VO: The drum potential just after charging the drum.

VD (Dark Potential): The drum potential just after exposing the black

pattern (VD pattern)

VL (Light Potential): The drum potential just after exposing the white

pattern (VL pattern)

Potential Sensor

Drum

VR (Residual Voltage): The drum potential just after the exposure to the

erase lamp.

After long usage following installation or a PM, drum potential will gradually

increase due to the following factors:

Dirty optics or exposure lamp deterioration

A dirty charge corona casing and grid plate

A change in drum sensitivity

In this copier, the drum potential sensor detects the change in drum potential and

controls the following items to maintain good copy quality:

The grid-bias voltage

The exposure lamp voltage

The development bias voltage.

A drum thermistor detects the drum temperature and acquires data. The thermistor

uses this data to control the above voltages. It is impossible to explain this process

simply because it is controlled by methods developed in our laboratories using an

artificial neural network.

2-2

Page 34

21 September 1998 PROCESS CONTROL

Image Density Control

The following sensors control image density:

Toner Density sensor (TD sensor)

Image Density sensor (ID sensor)

Data from the TD sensor maintains the toner concentration in the developer at a

constant level. However, the image on the OPC drum varies due to the variation in

toner chargeability (influenced by the environment), even if the toner concentration

is constant. Toner concentration changes to maintain the image density on the

OPC drum because of compensation by the ID sensor.

The following items are controlled to maintain a constant copy image density:

Toner supply clutch on time

Toner supply level data (V

) of the TD sensor

REF

Detailed

Descriptions

2-3

Page 35

PROCESS CONTROL 21 September 1998

g

g

2.1.2 PROCESS CONTROL DATA INITIAL SETTING

The following flow chart shows the steps performed when turning on the machine

while the hot roller temperature is below 100°C. This initializes all the process

control settings.

Main SW ON (Fusing Temp. < 100C

Charge wire cleaning (if more than 5 k copies are made since last cleanin

Drum Potential Sensor Calibration

Drum Conditioning Start (Fusing Temp. = 180°C

VSG Adjustment

Transfer belt voltage detection

VR Measurement

VD/VL Correction

)

TD Sensor Detection

ID Sensor Detection/Correction

ADS Adjustment

See Latent Image Control section

:

e 2-5) for details.

(Pa

See Image Density Control section

:

(Page 2-12) for deteails.

See Optics section (Page 2-44) for details.

:

A246D551.WMF

2-4

Page 36

21 September 1998 PROCESS CONTROL

2.1.3 LATENT IMAGE CONTROL

Drum Potential Sensor Calibration

[A]

Case

Sensor

Output

Amp.

Detailed

Descriptions

Drum

[B]

A246D554.WMF

Main PCB

A246D552.WMF

The potential sensor [A] for the drum is just above the development unit. The

sensor has a detector that detects the strength of the electric field from the electric

potential on the drum. The output of the sensor depends on the strength of the

electric field.

Since environmental conditions affect sensor output, such as temperature and

humidity, the sensor output is calibrated during process control data initialization.

The High Voltage Control PCB [B] has two relay contacts. Usually RA602 grounds

the drum. However, during the initial setting, the main PCB turns RA601 on and

RA602 off and applies the voltage to the drum shaft.

By measuring the output of the drum potential sensor when –100 V and –800 V are

applied to the drum, the sensor output is calibrated automatically. (The machine

recognizes the relationship between actual drum potential and the potential sensor

output.)

2-5

Page 37

PROCESS CONTROL 21 September 1998

Drum Conditioning

When the fusing temperature reaches 180°C, the machine starts the drum

conditioning process. In this mode, the main motor, main charge corona, erase

lamp and development bias are activated for about 30 seconds and drum

sensitivity and residual voltage (VR) are stabilized, as in continuous copy runs.

VSG Adjustment

During drum conditioning, the ID sensor checks the reflectivity of the bare drum

and calibrates the output of the ID sensor to 4 0.2 V.

VR Measurement

O

V

[-V]

D

V

New Drum

Used Drum

Drum

Potential

L

V

Original Density

R

V

LightDark

A246D561.WMF

The above figure shows the relationship between the drum potential and the

original density. This relationship must persist to maintain copy quality.

Since this relationship tends to change to the one represented by the dotted line by

various factors, some compensation is necessary.

Increasing the exposure lamp voltage cannot compensate for the residual voltage

(VR). Therefore, other means are required to compensate for VR change.

The main control board checks the drum potential just after the erase lamp

exposure with the drum potential sensor, after drum conditioning. This measured

drum potential is in fact VR. This VR is the standard for the VD and VL corrections.

NOTE:

In the figure above, the residual voltage (VR) for the new drum is 0 V.

Actually, there is some residual voltage even on a new drum.

2-6

Page 38

21 September 1998 PROCESS CONTROL

VD Correction

Exposure

D

V

[-V]

D

V

Pattern

Glass

A246D566.WMF

R

V

Drum

Potential

-770

New Drum

Original Density

R

V

VD Compensated

After many copies

LightDark

A246D568.WMF

The drum potential just after the black pattern (VD Pattern) is exposed (VD: Dark

Potential) tends to lower during drum life due to a decrease in the capacity of the

drum to carry a charge.

Detailed

Descriptions

To check the actual VD, the first scanner moves to the home position, exposing the

VD pattern (Black) stuck on the bottom side of the exposure glass bracket on the

drum.

The main control board measures VD using the drum potential sensor and adjusts

it to a target value by adjusting the grid-bias voltage (V

GRID

).

On the other hand, the drum residual voltage (VR) changes to compensate for the

target VD voltage in the following manner:

Target VD Value: VD = VR + (–770)

The adjusted grid-bias voltage (V

) remains in memory until the next process

GRID

control data initialization.

2-7

Page 39

PROCESS CONTROL 21 September 1998

VL Correction

[-V]

Drum

Potential

-770

D

V

V

-140

Exposure

Glass

A246D566.WMF

VL Pattern

R

V

R

Original Density

Only VD Compensated

L

V

VD and VL Compensated

LightDark

A246D594.WMF

New Drum

R

V

Dirty optics and/or exposure lamp deterioration decreases the intensity of the light

that reaches the drum. In addition to this, the drum sensitivity also changes during

the life of the drum. These factors change the drum potential just after white pattern

exposure (VL: Light Potential).

To check the actual VL, the lens moves to the VL pattern check position. This

exposes the VL pattern (White) stuck underneath the original scale on the drum.

The main control board measures VL using the drum potential sensor and adjusts it

to a target value by adjusting the exposure lamp voltage (V

LAMP

).

The residual voltage (VR) change also affects VL, to compensate for the target

voltage of VL in the following manner:

Target VL Value: VL = VR + (–140)

The adjusted exposure lamp voltage (V

) is stored in memory until the next

LAMP

initial setting of the process control data.

2-8

Page 40

21 September 1998 PROCESS CONTROL

VR Correction

[-V]

D

V

R

V

Drum

Potential

-770

V

-140

L

V

R

Development Bias (VBB)

VD and VL Compensated

New Drum

R

V

Detailed

Descriptions

Dark Light

Original Density

A246D602.WMF

The potential sensor monitors potentials (VR, VD, and VL). During the check cycle,

the VD and VL patterns are exposed. The potential sensor checks the drum

potential in the area exposed by each pattern.

Compare the curve of the VD and VL compensated drum potential with the curve of

the new drum, they are parallel but the compensated potential is still higher (VR)

than the new drum potential. To prevent dirty backgrounds due to increased

residual potential, development bias (VBB) is applied as follows:

VBB = VR + (–220)

2-9

Page 41

PROCESS CONTROL 21 September 1998

Initial Setting Sequence

The following graph shows the sequence of events during the initial setting of the

process control data.

For the purpose

of ADS sensor

correction

Exposure

Lamp

Potential

Sensor

Output

800

V

100

V

1. Potential

sensor

2. VR’, VD’, VL’

Latent Image Control

V

R

V

potential

D

L

V

New V

3. V

D

D

New V

New V

New V

R

D, VL

correction

L

4. ID sensor

pattern

potential

A246D604.WMF

1. Potential sensor calibration

Measuring the output of the drum potential sensor when applying –100 V and –

800 V to the drum, automatically calibrates the sensor output (V

100

and V

See page 2-5 for details.

800

).

2. VR, VD, VL potential detection

After about 30 seconds of drum conditioning, VD and VL Patterns are

developed by using the previous grid-bias voltage (V

lamp voltage (V

The machine calculates the new V

) data to detect the VR, VD, VL data.

LAMP

and V

GRID

data using the detected VR,

LAMP

) data and exposure

GRID

VD, and VL data.

2-10

Page 42

21 September 1998 PROCESS CONTROL

3. VD and VL corrections

Using the calculated V

GRID

and V

data, the VR, VD, and VL patterns are

LAMP

redeveloped thereby determining the new VR, VD, and VL data. If both VD and

VL data are within specifications, the new VD, VL, and VR values determine the

new V

GRID

, V

and development bias (VBB).

LAMP

Specifications:

VD = –770 + VR 20 V

VL = –140 + VR 20 V

If VD is outside specifications, V

measured and VD is detected again. The same is done for VL and V

is shifted one step. Then the VD pattern is re-

GRID

LAMP

. The

above process continues until both VD and VL fall within specifications. The graph

on the previous page shows an example of when only VL was outside the

specifications at the first VL detection. It came within specifications after one V

correction by changing V

0.5 V/step, and V

LAMP

by 20 V/step.

GRID

L

Detailed

Descriptions

The machine stops VD/VL correction and uses the previous V

GRID

and V

LAMP

values during copying in the following instances:

If V

100

or V

at the calibration of the drum potential sensor is outside

800

specifications.

If VD or VL does not fall within specifications after shifting V

GRID

or V

LAMP

their maximum and/or minimum levels.

In this case, the machine indicates nothing, but the SC counter increments.

Related SC codes (see troubleshooting section for details):

Code Condition

361 Incomplete drum potential sensor calibration

364 Abnormal VD detection

365 Abnormal VL detection

366 VR abnormal

Utilizing VR in the following manner can also determine the development bias:

VBB = VR + (–220)

4. The ID sensor pattern for potential detection

This determines the ID Sensor Bias Voltage. The development control section

explains this subject in more detail (see page 2-16).

to

2-11

Page 43

PROCESS CONTROL 21 September 1998

2.1.4 IMAGE DENSITY CONTROL

Toner Density Sensor

OUT

A: V

B: V

C: V

(Gain data) is high.

OUT

is within the specification.

OUT

(Gain data) is

low

IN

V

OUT IN X

V=V

= 12 x

.

Main PCB

V

AGC

Gain

256

Gain

256

OUT

D

V

(12 V)

GND

Sensor

Output

TD

Sensor

A246D606.WMF

A246D531.WMF

Developer consists of carrier particles (iron) and toner particles (resin and carbon).

Inside the development unit, developer passes through a magnetic field created by

coils inside the toner density sensor. When the toner concentration changes, the

voltage output by the sensor changes accordingly.

<Toner Density Sensor Initial Setting>

When installing new developer with the standard toner concentration (2.0% by

weight, 20 g of toner in 1,000 g of developer), the initial setting for the developer

must be performed by using an SP mode (SP1-2-1).

During this setting, the output voltage (V

) from the auto gain control circuit

OUT

(AGC) on the main control board PCB varies to change the output voltage from the

toner density (TD) sensor. Changing the gain data does this:

V= V x

OUT IN

Gain Data

256

12 x

Gain Data

256

If the data is large, V

results in the sensor sensitivity illustrated by curve A. If the data is small, V

and the sensor output voltage also become large. This

OUT

OUT

becomes small, and the sensor output voltage becomes small. As a result, the

sensor sensitivity shifts as illustrated by curve C.

2-12

Page 44

21 September 1998 PROCESS CONTROL

By selecting the proper gain data, the sensor output is set within the targeted

control level (V

REF

, V

= 2.5 0.1 V). Now, curve B shows the sensor

REF

characteristic and the TD sensor initial setting is complete.

The selected gain data is stored in memory, and V

from the auto-gain control

OUT

circuit stays constant during the detection cycle for the toner sensor.

<Toner Supply Criteria>

Toner density detection in the developer occurs once in every copy cycle. The

sensor output voltage (VTD) during the detection cycle is compared with the toner

supply level voltage (V

REF

).

Detailed

Descriptions

2-13

A246D609.WMF

Page 45

PROCESS CONTROL 21 September 1998

<Toner Supply Clutch on Period>

To stabilize toner concentration, the toner supply (toner supply clutch ON period) is

controlled by using V

and VTD data.

REF

The toner supply is calculated after each copy. The following factors determine the

remaining toner supply:

V

V

– V

REF

REF

TD

– VTD’(VTD’ = VTD of the previous copy cycle)

A246D512.WMF

By referring to these factors, the machine recognizes the difference between the

current and target toner concentration. The machine also understands how much

the toner concentration changed and can predict how much the toner supply

amount will probably change.

Precision changes in the toner supply maintain the toner concentration (image

density). Since updating the toner supply clutch ON period is under fuzzy control,

the relation among VTD, VTD’, V

cannot be expressed by a simple algebraic

REF

formula.

<V

Correction>

REF

The image on the OPC drum changes du e to the variation in toner chargeability

(influenced by the environment) even if the toner concentration is constant. The

image density sensor (ID sensor) directly checks the image on the OPC drum and

shifts V

data (under fuzzy control) to keep the image on the OPC drum

REF

constant, as explained in the next section.

NOTE:

1) The toner end sensor detects the toner end condition (see the

development section for details).

2) The toner supply clutch turns on at intervals between each copy

process, while image development is not occurring.

2-14

Page 46

21 September 1998 PROCESS CONTROL

Image Density Sensor Detection

[B]

[C]

Drum

[A]

Bias

A246D514.WMF

A246D513.WMF

The ID sensor [A] checks VSG and VSP. The ID sensor is located underneath the

drum cleaning section.

There is no ID sensor pattern in the optics; however, the charge corona unit [B] and

the erase lamp [C] make a pattern image on the OPC drum.

Detailed

Descriptions

VSG is the ID sensor output when checking the erased drum surface.

VSP is the ID sensor output when checking the ID sensor pattern image.

To compensate for any variation in light intensity from the sensor LED, the

reflectivity of both the erased drum surface and the pattern on the drum are

checked.

VSP Detection

SG

V

Detection

1st Series of

Copies (8 copies)

2nd Series

of Copies

(5 copies)

SG

V

Detection

VSP Detection

V

Detection

SG

3rd Series

of copies

(17 copies)

SP

Detection

V

SG

V

Detection

A246D515.WMF

VSG is detected every time the machine starts copying.

During VSG detection, the development sleeve rollers do not rotate and

development bias is not applied.

If 10 or more copies are made, the copier will re-detect VSP. Since the transfer belt

must be released when checking VSP, the machine cannot check the VSP during

continuous copying.

2-15

Page 47

PROCESS CONTROL 21 September 1998

Potential

Sensor Detection

V

ID Sensor

Bias Level

4.0 V

ID Sensor

Output

P

V

–800

P

IDB

V

= VP + 300 (V)

–300

SP

V

A246D516.WMF

A246D517.WMF

While developing the ID sensor pattern, ID sensor bias is applied. ID sensor bias is

determined during process control data initialization as follows:

Apply charge while the grid voltage is –800 V to create the ID sensor pattern.

Check the drum potential (VP) of the latent image created by the charge with –800

V grid.

Adjust the ID sensor bias (V

V

= VP – (–300) (V)

IDB

) so that it satisfies the following formula:

IDB

= VP + 300 (V)

Change the bias to the calculated V

and detect VSP. The VSG value detected

IDB

during its adjustment sequence during process control data initialization and the

VSP determine the V

data. The V

REF

does not change until the next initial

IDB

setting for the process control data.

<V

After the series of copies is completed, when 10 or more copies were made, V

is updated by referring to the previous V

Correction Timing>

REF

REF

(V

’), VSG, VSP and the current TD

REF

REF

sensor output (VTD).

Since this V

V

’, VSG, VSP and VTD cannot be expressed in a simple algebraic for mula.

REF

The V

is not only updated in the above case, but also during the initial setting

REF

data updating is under fuzzy control, the relationship among V

REF

for the developer and during process control data initialization.

2-16

REF

,

Page 48

21 September 1998 PROCESS CONTROL

Sensor Abnormal Conditions

a) ID sensor (VSG, VSP) abnormal

Whenever V

data and the TD sensor output controls the toner concentration.

Normal detection of VSG and VSP occurs, as usual, during abnormal conditions. If

output returns to normal levels (VSG 2.5 V, VSP 2.5 V), the CPU returns the

toner concentration control to normal mode.

b) TD sensor (V

Whenever V

to the fixed supply mode. In this condition, the CPU never stops the toner supply.

The fixed toner supply can be changed in four steps (4%, 7%, 11%, and 14%) by