Ricoh FT7770 Service manual

RICOH FT7770

RICOH COMPANY, LTD.

SERVICE MANUAL

TABLE OF CONTENTS

SECTION 1:

MAIN SPECIFICATIONS

GUIDE TO COMPONENTS

HOW TO USE THE GUIDANCE DISPLAY

DISPLAY CONTROL KEYS

THE COPY CYCLE

COPY PROCESSES AROUND THE DRUM

PAPER PATH

MECHANICAL COMPONENT LAYOUT

ELECTRICAL COMPONENT LAYOUT

DRIVE LAYOUT

ELECTRICAL COMPONENT DESCRIPTIONS

OVERALL MACHINE CONTROL

AC AND DC POWER DISTRIBUTION

OVERALL MACHINE INFORMATION

1.

Copier Exterior

2.

Copier Interior

3.

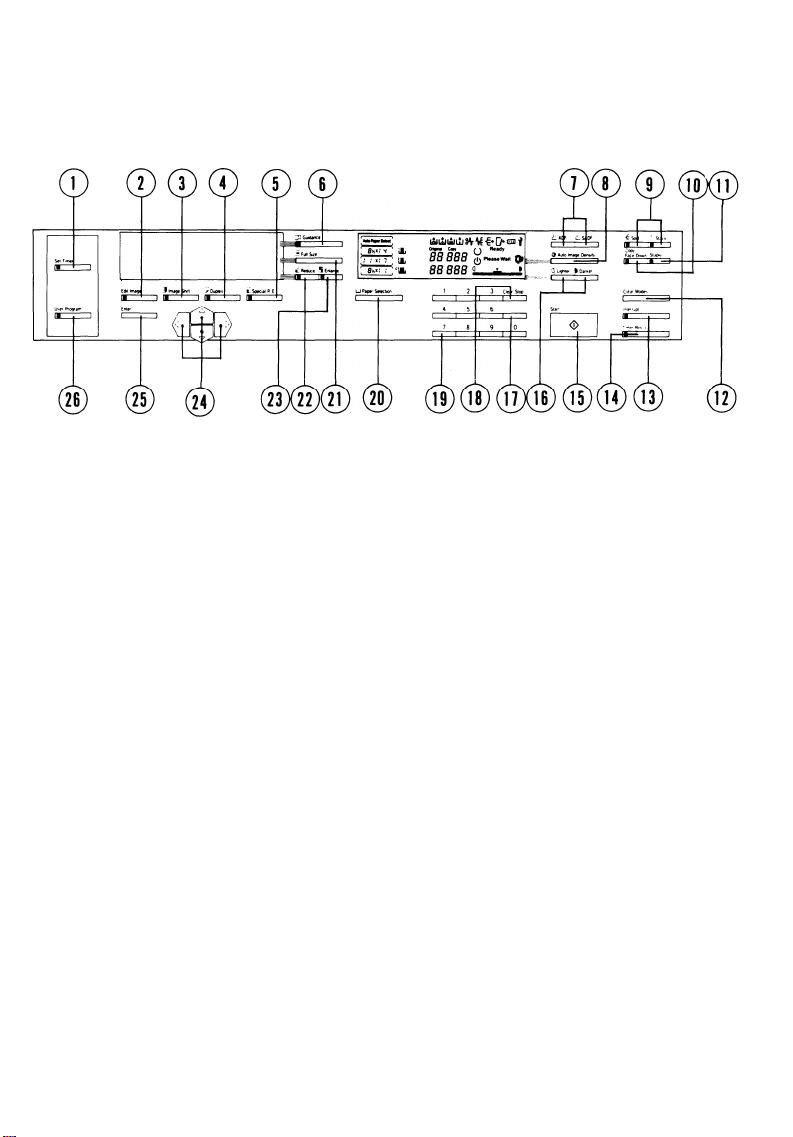

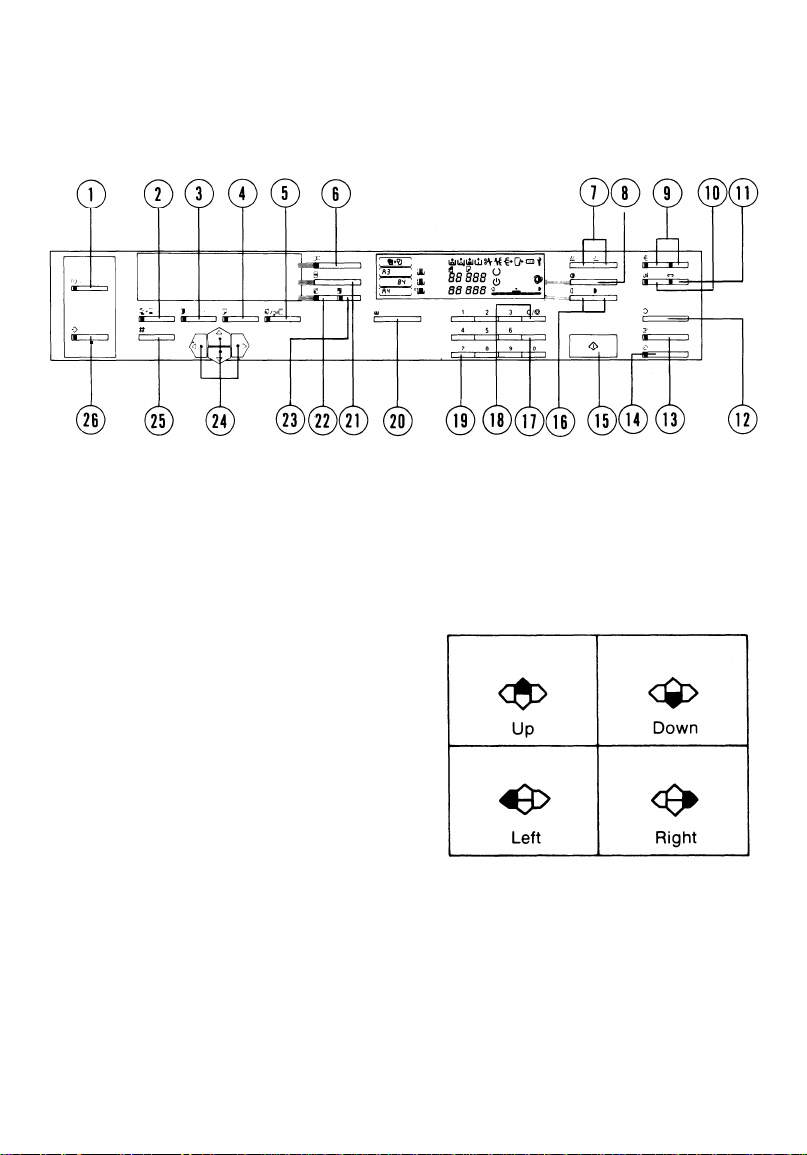

Operation Panel

1-1

1-4

1-8

1-10

1-14

1-15

1-16

1-17

1-18

1-20

1-22

1-26

1-27

1-34

1-35

SECTION 2:

DRUM

CHARGE

ERASE

DETAILED SECTION DESCRIPTION

1.

Selenium Drum

2.

Drum Thermistor Unit

3.

Drum Heater Circuit

1.

Corona Unit

2.

Corona Unit Ventilation

3.

Wire Cleaner

4.

Charge Power Pack

1.

Introduction

2.

Side Erase and leading/Trailing Edge Erase

3.

Erase Lamp Circuit

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

EXPOSURE

1.

2.

3.

4.

5.

6.

Introduction

Exposure Lamp Unit

Automatic Image Density Sensing

Lamp Regulator

Optics Cooling Fan

Anticondensation Heater

2-11

2-12

2-13

2-14

2-16

2-16

SCANNER DRIVE

LENS AND MIRROR POSITIONG

DEVELOPMENT UNIT

TRANSFER AND SEPARATION

1.

Introduction

2.

Scanner Motor Control

1.

Lens Positioning

2.

Second Scanner Shift

3.

Lens/Mirror Position Initialization

1.

Introduction

2.

Drive Mechanism

3.

Cross Mixing

4.

Knocking Solenoid

5.

Toner Density Control

6.

Image Density Control

7.

Bias for ID Sensing

8.

Bias Circuit

9.

Development Drive Motor

1.

PTC (Pre-TransferŽCorona) and PTL

(Pre-Transfer Lamp)

2.

Image Transfer

3.

Paper Separation

4.

TC/SC Wire Cleaner

5.

Pick-off Pawls

6.

PTC Power Pack and PTL Stabilizer

7.

Transfer/Separation Power Pack

2-17

2-18

2-20

2-22

2-23

2-24

2-26

2-27

2-28

2-29

2-33

2-37

2-38

2-40

2-42

2-42

2-43

2-44

2-45

2-46

2-47

CLEANIG

1.

2.

3.

4.

5.

6.

7.

QUENCHING

1.

2.

3.

Introduction

Drive Mechanism

Cleaning Blade Pressure Mechanism

Used Toner Removal

Cleaning Solenoid Circuit

PCC Power Pack

Cleaning Bias Power Pack

Introduction

Pre-Quenching corona Circuit

Quenching Lamp Circuit

2-49

2-50

2-51

2-53

2-55

2-56

2-57

2-58

2-59

2-60

PAPER FEED

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Introduction

Feed Unit Mechanism

FER Operation

Paper Tray Drive Mechanism

Friction Roller Reverse Mechanism

Paper Volume Detection

Guide Posts and Paper Size Detection

Tray Lock and Positioning

Paper Size Board

220/240-Volt Paper Size Sensor

Tray Motor Circuit

Paper Tray Heaters

Tray Set Detection

2-61

2-62

2-63

2-64

2-65

2-66

2-67

2-68

2-69

2-70

2-71

2-72

2-73

VERTICAL TRANSPORT AND REGISTRATION

PAPER TRANSPORT

FUSING

INVERTER

DUPLEX TRAY

Introduction

1.

Drive Mechanism

2.

Jam Check Timing

3.

Introduction

1.

Vacuum Fan

2.

Introduction

1.

Pressure Mechanism

2.

Oil Supply

3.

4.

Oil End Sensor

5.

Drive Mechanism

6.

Fusing Lamp Circuit

Introduction

1.

Operation

2.

3.

Inverter Rollers

Inversion

4.

Junction Gate

5.

Introduction

1.

Drive Mechanism

2.

3.

Fork Gate

Paper Positioning

4.

Bottom Plate Mechanism

5.

6.

Duplex Paper Feed

7.

Duplex Motor Circuit

Circuit

2-74

2-76

2-78

2-79

2-80

2-81

2-82

2-83

2-84

2-85

2-86

2-88

2-89

2-91

2-92

2-93

2-94

2-96

2-96

2-97

2-98

2-99

2-100

TOP UNIT

1.

2.

Release Mechanism

Drum Support

2-101

2-102

OTHER CIRCUITS

1.

Counters

2.

Photosensor

3.

Photointerrupters

Solenoids

4.

5.

Magnetic Clutches

6.

Monitor Board

7.

Operation Panel

AC Drive Board

8.

9.

Ozone Fan

Corona Cleaner

10.

2-103

2-105

2-106

2-107

2-108

2-109

2-110

2-111

2-112

2-113

SECTION 3:

INSTALLATION REQUIREMENT

INSTALLATION

KEY COUNTER HOLDER INSTALLATION

A3/11” x 17” COUNTER INSTALLATION

MODIFYING MAIN TRANSFORMER VOLTAGE (220V to 240V)

PREPARATION FOR TRANSPORTING THE COPIER

SECTION 4:

PM TABLE

LUBRICATION PARTS

SERVICE TABLES

INSTALLATION

1.

Environment

2.

Minimum Space Requirement

3.

Machine Level

4.

Power Source

1.

Unpacking

2.

Accessory Check

3.

Installation Procedure

SERVICE TABLES

1.

Test Points

Variable Resistors

2.

3.

Dip Switches

3-1

3-2

3-3

3-3

3-4

3-5

3-6

3-15

3-16

3-17

3-18

4-1

4-8

4-11

4-11

4-12

4-12

SERVICE REMARKS

SPECIAL TOOLS AND LUBRICANTS

SECTION 5:

EXTERIOR COMPOMENT REMOVAL

REPLACEMENT AND ADJUSTMENT

1.

Exposure Glass and Operation Panel Removal

Top Plate Removal

2.

4-13

4-18

5-1

5-2

DRUM AND CHARGE

1.

Drum Replacement

2.

Drum Thermoswitch and Heater Replacement

3.

Charge Corona Wire and

Cleaner Pad Replacement

5-3

5-4

5-5

EXPOSURE

DEVELOPMENT

TRANSFER AND PICK-OFF

CLEANING

1.

Scanner Drive Wire Replacement

2.

Lens Drive Wire Replacement

3.

Exposure Lamp Unit Removal

1.

Development Unit Removal

Developer Replacement

2.

3.

Development Roller and

Paddle Roller Removal

4.

Adjustment of Development Roller Gaps

Image Density Sensor Cleaning and Removal

5.

6.

Image Density Sensor Adjustment

1.

Transport Unit Removal

2.

Transfer Ozone Filter Replacement

3.

Pre-transfer Corona Wire Replacement

4.

Transfer/Separation Corona Wire

and Cleaner Pad Replacement

5.

Transport Belt Replacement

6.

Registration Sensor Replacement

7.

Pick-off Pawl Unit Removal

Cleaning Blade and Brush Replacement

1.

2.

Pre-cleaning Corona Wire Replacement

Toner Collection Coil Replacement

3.

4.

Cleaning Blade pressure Adjustment

5.

Blade Cleaner and Bias Roller Blade Replacement

6.

Pre-quenching Corona Wire Replacement

5-6

5-16

5-20

5-21

5-22

5-23

5-25

5-27

5-28

5-29

5-30

5-31

5-32

5-33

5-34

5-35

5-36

5-37

5-38

5-39

5-40

5-41

FUSING

1.

Fusing Unit Removal

2.

Hot Roller Stripper Replacement

3.

Cleaning Blade, Metering Blade,

and Oil Supply Pad Replacement

4.

Hot Roller Replacement

5.

Pressure Roller Replacement

6.

Thermistor and Thermofuse Replacement

7.

Fusing Pressure Adjustment

Hot Roller Temperature Adjustment

8.

5-42

5-43

5-44

5-46

5-48

5-49

5-50

5-52

INVERTER

1.

2.

3.

Inverter Roller Clutch Disassembly

and Adjustment

Return Pinch Roller Solenoid Adjustment

Inverter Gate Solenoid Adjustment

5-53

5-55

5-56

PAPER FEED

DUPLEX TRAY

COPY IMAGE

CORONA CURRENT ADJUSTMENT

1.

Paper Feed Unit Removal

2.

Pick-up Roller Replacement

3.

Feed Roller Replacement

4.

Friction Roller Replacement

5.

Paper Tray Unit and Cover Removal

6.

Paper Tray Drive Wire Replacement

Vertical Transport Unit Removal

7.

1.

Duplex Tray Removal

2.

Paper Feed Roller Replacement and Adjustment

Pick-up Roller Replacement

3.

4.

Friction Roller Replacement

5.

Bottom Plate Pressure Clutch Disassembly

6.

Duplex Paper Sensor Adjustment

7.

Duplex Side Plate Drive Wire Replacement

1.

Horizontal Magnification Adjustment

2.

Side-to-Side Registration Adjustment

3.

Uneven Exposure Adjustment

4.

Light Intensity Adjustment

5.

Auto Density Sensor Adjustment

1.

Corona Current Adjustment Preparation

2.

Charge Corona

3.

Pre-transfer Corona

4.

Transfer Corona

5.

Separation Corona

6.

Pre-cleaning Corona

7.

Pre-quenching Corona

5-57

5-58

5-59

5-60

5-61

5-62

5-65

5-66

5-67

5-68

5-69

5-70

5-71

5-72

5-73

5-74

5-75

5-76

5-77

5-78

5-80

5-81

5-82

5-83

5-84

5-85

SERVICE PROGRAM MODE

1.

Factory Settings

2.

How to access SP41 to SP53

3.

Service Program Functions

5-86

5-87

5-88

SECTION 6:

ELECTRICAL DATA

MAIN BAORD SCHEMATIC 1

MAIN BAORD SCHEMATIC 2

MAIN BAORD SCHEMATIC 3

DC DRIVE BOARD SCHEMATIC

SCANNER MOTOR CONTROL BOARD SCHEMATIC

MAIN MOTOR CONTROL BOARD SCHEMATIC

LENS/MIRROR MOTOR CONTROL BOARD SCHEMATIC

POWER SUPPLY UNIT BLOCK DIAGRAM

AC DRIVE BOARD SCHEMATIC

OPERATION PANEL-CPU BOARD SCHEMATIC

SECTION 7:

SPECIFICATIONS

MECHANICAL COMPONENT LAYOUT

ELECTRICAL COMPONENT LAYOUT

ELECTRICAL COMPONENT DESCRIPTIONS

DOCUMENT FEEDER

6-1

6-2

6-3

6-4

6-5

6-6

6-6

6-7

6-9

6-10

7-1

7-2

7-3

7-4

BASIC OPERATION

1.

Single-Sided Original Feed

2.

Two-Sided Original Feed

3.

Computer From Feed

FEED-IN UNIT

1.

Original Feed-in

2.

Drive Mechanism

3.

Pressure Mylar Release

4.

Separation of Originals

5.

Relay Roller Pressure Release

TRANSPORT AND INVERSION UNIT

1.

Original Transport

2.

Transport Belt Drive Mechanism

3.

Original Inversion and Feed-out

4.

Inversion and Feed-out Drive Mechanism

5.

Lift Mechanism

COMPUTER FORM FEED

7-5

7-7

7-9

7-10

7-12

7-14

7-15

7-16

7-17

7-18

7-19

7-20

7-22

7-23

ELECTRICAL OPERATION

Interface With Copier

1.

2.

Feed-in Sensor

3.

Motor Control

4.

Original Size Sensing

5.

DF Misfeed Check

6.

Application Switch

7.

Form Size Switch

8.

CFF Feed Hole and Set Sensors

7-24

7-25

7-26

7-27

7-29

7-30

7-31

7-32

SERVICE

REPLACEMENT AND ADJUSTMENT

TIMING CHART 1

TABLES

1.

Test Point Table

2.

Variable Resistor Table

3.

LED Table

4.

DIP Switch Table

5.

Blown Fuse Table

6.

Switch Failure Table

7.

Sensor Failure Table

1.

Separation Roller Replacement

2.

Friction Tab Replacement

3.

Pick-up Roller Replacement

4.

Transport Unit Cover Removal

5.

Feed Belt Removal

6.

Inverter Entrance and Inverter

Sensor Replacement

7.

Turn Roller Replacement

8.

Exit Roller/Pull-out Roller Replacement

9.

Inverter Roller Replacement

10.

DF Removal

11.

Original Skew Adjustment

12.

Original Leading Edge Adjustment

13.

Registration Sensor

Threshold Level Adjustment

14.

Feed-in, Belt, and Inverter Motor

Speed Adjustment

7-33

7-33

7-34

7-35

7-36

7-36

7-37

7-38

7-39

7-40

7-43

7-44

Registration

7-45

7-46

7-47

7-48

7-50

7-51

7-52

7-53

7-54

7-55

TIMING CHART 2

DF MAIN BAORD SCHEMATIC

SECTION 8:

SPECIFICATIONS

MECHANICAL COMPONENT LAYOUT

ELECTRICAL COMPONENT LAYOUT

ELECTRICAL COMPONENT DESCRIPTIONS

LARGE CAPACITY TRAY

7-56

7-57

8-1

8-2

8-3

8-4

MECHANICAL OPERATION

1.

Basic Operation

2.

Feed Unit Mechanism

3.

Tray Drive Mechanism

4.

Friction Roller Reverse Mechanism

5.

Paper Volume Detection

6.

Guide Plate and Paper Size Detection

7.

Tray Lock and Positioning

ELECTRICAL OPERATION

1.

Tray Motor Circuit

2.

Paper Tray Heater

3.

Tray Set Detection

8-5

8-6

8-7

8-8

8-8

8-9

8-10

8-11

8-12

8-12

INSTALLATION

1.

Accessory Check

2.

Installation Procedure

REPLACEMENT AND ADJUSTMENT

1.

Paper Feed Unit Removal

2.

Pick-up Roller Replacement

3.

Feed Roller Replacement

4.

Friction Roller Replacement

5.

Paper Tray Unit Removal

6.

Paper Tray Drive Wire Replacement

SECTION 9: SORTER

SPECIFICATIONS

MECHANICAL COMPONENT LAYOUT

ELECTRICAL COMPONENT LAYOUT

SORTER DRIVE

ELECTRICAL COMPONENT DESCRIPTIONS

MECHANICAL OPERATION

1.

Basic Operation

2.

Transport Belt Mechanism

3.

Turn Gate

4.

Misfeed Clearance Release Mechanism

5.

Manual Feed

6.

Bin Gate Operation

8-13

8-14

8-18

8-19

8-20

8-21

8-22

8-23

9-1

9-2

9-3

9-4

9-6

9-8

9-10

9-11

9-12

9-13

9-14

ELECTRICAL OPERATION

1.

Interface with The Copier and AC Power

2.

Timing Exit, and Manual Feed Sensors

3.

Bin and Jam Sensors

4.

Bin and Turn Gate Solenoids

5.

Safety Switches

6.

Distribution Drive Clutch

9-15

9-16

9-17

9-18

9-19

9-20

INSTALLATION

Accessory Check

1.

2.

Installation Procedure

9-21

9-22

SERVICE TABLES

1.

Sorter Main Board

2.

Sorter Interface Board

REPLACEMENT AND ADJUSTMENT

1.

Distribution Unit Removal

2.

Transport Unit Removal

3.

Transport Belt Replacement

Jam Sensor and Bin Copy Sensor Adjustment

4.

5.

50Hz/60Hz Modification

SORTER MAIN BOARD SCHEMATIC

SECTION 10:

SPECIFICATIONS

COMPONENT LAYOUT

MECHANICAL OPERATION

ELECTRICAL OPERATION

INSTALLATION

SORTER CONNECTOR UNIT

1.

Circuit

Main Board

2.

DC Power Supply

3.

Sensor Input Circuit

4.

5.

Bin Drive Circuit

Accessory Check

1.

Installation Procedure

2.

9-25

9-26

9-27

9-29

9-30

9-33

9-34

9-35

10-1

10-2

10-2

10-3

10-3

10-4

10-5

10-6

10-7

10-8

REPLACEMENT AND ADJUSTMENT

1.

Tension Adjustment

2.

50Hz/60Hz Modification (Sorter Connector Unit)

SECTION 11:

SPECIFICATIONS

COMPONENT LAYOUT

ELECTRICAL COMPONENT DESCRIPTIONS

OVERALL MACHINE CONTROL

SORTER STAPLER

Mechanical Component Layout

1.

2.

Electrical Component Layout

3.

Drive Layout

10-15

10-16

11-1

11-2

11-3

11-5

11-7

11-11

BASIC OPERATION

11-12

MECHANICAL OPERATION

1.

Transport Section

Turn Gate Section

2.

3.

Distribution Section

4.

Side Plate

5.

Staple Unit

6.

Misfeed Clearance

ELECTRICAL OPERATION

1.

Bin/Jam sensor

Safety Switch

2.

3.

Service Call Conditions

INSTALLATION

SERVICE TABLES

REPLACEMENT AND ADJUSTMENT

Accessory Check

1.

Installation Procedure

2.

1.

Test Point Table

Variable Resister

2.

LED Table

3.

4.

DIP Switch Table

Stapler Removal

1.

2.

Staple Positioning Adjustment

3.

Gripper Assembly Removal

Gripper Rubber Replacement

4.

5.

Gripper Solenoid Adjustment

Jammed Staple Removal

6.

7.

Staple Unit Drive Belt and

Side Plate Drive Belt Tension Adjustment

The Other Drive Belts Tension Adjustment

8.

Jam Sensor and Bin Copy Sensor Adjustment

9.

Release Mechanism

Table

11-13

11-14

11-15

11-16

11-18

11-23

11-24

11-25

11-27

11-29

11-30

11-34

11-34

11-34

11-34

11-35

11-37

11-38

11-39

11-40

11-41

11-42

11-43

11-44

TIMING CHART

SORTER STAPLER MAIN BOARD BLOCK DIAGRAM

SORTER STAPLER MAIN BAORD SCHEMATIC

SECTION 12:

SPECIFICATIONS

OVERALL MACHINE CONTROL

DATA FORMAT

MENU READER

11-45

11-46

11-47

12-1

12-2

12-3

BASIC OPERATION

INSTALLATION

Job Sheet Reading

1.

2.

Menu Reader Indicator Lights

3.

Processing Errors

1.

Accessory Check

2.

Installation Procedure

12-4

12-6

12-7

12-8

12-9

REPLACEMENT AND ADJUSTMENT

Lower Transport Roller Replacement

MENU READER CONTROL BOARD SCHEMATIC

SECTION 13:

INTRODUCTION

COPY QUALITY

White Spots

Hat Image

Blank Area

Wrinkled Copy

Unfused Copy

Horizontal White Lines (Bands)

Jitter

Hollowing Out

Fuzzy Copy

Vertical Black Lines (Bands)

Uneven Density

Vertical Black Lines (Bands)

Black Spots

Dirty Background

Black Image

Black Copy

Light Copy

PAPER JAM/MISFEED

Pick-off Jam

False Paper Jam

Duplex Tray Jam

Paper Feed Jam

Registration Jam

Exit Jam

Transport Unit Jam

Fusing Jam

TROUBLESHOOTING

12-11

12-12

13-1

13-2

13-3

13-4

13-5

13-6

13-6

13-7

13-8

13-8

13-9

13-11

13-14

13-18

13-19

13-22

13-22

13-24

13-26

13-27

13-27

13-29

13-30

13-30

13-30

13-31

FUNCTIONAL PROBLEM

Not Ready

Abnormal Indications

Please Wait Condition

13-32

13-32

13-34

DF

Original Jam

No Display

Abnormal Indication

SORTER

Not Ready

False Jam

Jam in Sorter

Others

SERVICE CALL CONDITIONS

SC - 1

SC - 2 Drum Thermistor

SC - 3 Drum Heater

SC - 4

SC - 5

SC - 6 Fusing Lamp

SC - 7 Fusing Overheat

SC - 8

SC - 9 Optics Encode

SC - 10

SC - 11 Scanner Velocity

SC - 12 Scanner Return

SC - 13

SC - 14

SC - 15

SC - 21 Paper Feed Unit

SC - 22

SC - 23 Upper Tray

SC - 24

SC - 25 Option Tray

Service Call -

Exposure

Drum Overheat

Fusing Thermistor

Temperature Fuse

Home Sensor

Total Counter

High Voltage Leak

Lens Drive Lock

Option Tray Paper Feed Unit

Lower Tray

Sorter with Stapler

13-35

13-35

13-36

13-37

13-37

13-38

13-38

13-39

13-41

13-42

13-43

13-44

13-44

13-45

13-46

13-47

13-48

13-49

13-50

13-50

13-51

13-52

13-53

13-53

13-54

13-55

13-56

13-57

DEFECTIVE SENSOR TABLE

Table

13-60

SECTION 14: SORTER/STAPLER CONNECTOR UNIT

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

3. MECHANICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

4. ELECTRICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

5. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

5.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

5.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

5.2.1 First Sorter/Stapler Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

5.2.2 Second Sorter/Stapler Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-12

5.3 50Hz-60Hz MODIFlCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

6. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 14-17

6.1 TENSION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

SECTION 15: FT7870 SERVICE MANUAL

l. SPECIFICATIONS (Compared with F21) . . . . . . . . . . . . . . . . . . . . . . 15-1

2. GUIDE TO COMPONENTS (Compared with F21) . . . . . . . . . . . . . . . 15-2

2.1 OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-2

2.2 ELECTRlCAL/MECHANlCAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

2.3 DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-4

3. SECTIONAL DESCRIPTIONS (Compared with F21) . . . . . . . . . . . . . 15-5

3.1 PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

3.1.1 Drum Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

3.1.2 Rest Time Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

3.1.3 Toner End Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

3.2 FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

3.2.1 Fusing Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

3.2.2 Counter Measure for Toner Build Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

4. INSTALLATION AND OPTION INTERCHANGEABILITY . . . . . . . . . . 15-8

4.1 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-8

4.2 OPTION INTERCHANGEABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-8

5. SERVICE TABLE (Compared with F21) . . . . . . . . . . . . . . . . . . . . . . . 15-9

5.1 PM TABLE (Differences Between F21 and F22) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-9

5.2 VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-9

5.3 SERVICE REMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-10

6. ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-11

6.1 IMAGE DENSITY SENSOR/AUTO DENSITY SENSOR ADJUSTMENT . . . . . . . . . . . 15-11

6.2 FUSING UNIT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-11

6.3 HOW TO ACCESS THE SP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-12

6.4 ADDITIONAL SP MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-12

6.5 SP MODE FACTORY SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-13

6.6 DRUM CURRENT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-13

7. ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-15

7.1 TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-15

8. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

8.1 SERVICE CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

8.2 HOW TO RESET THE OPTICS AND FUSING SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

SECTION 1

OVERALL MACHINE

INFORMATION

CONTENTS

MAIN SPECIFICATIONS

GUIDE TO COMPONENTS

1.

Copier Exterior

Copier Interior

2.

3.

Operation Panel

HOW TO USE THE GUIDANCE

DISPLAY CONTROL KEYS

THE COPY CYCLE

COPY PROCESSES AROUND THE DRUM

PAPER PATH

MECHANECAL COMPONENT LAYOUT

ELECTRICAL COMPONENT LAYOUT

DRIVE LAYOUT

ELECTRICAL COMPONENT DESCRIPTIONS

OVERALL MACHINE CONTROL

AC AND DC POWER DISTRIBUTION

DISPLAY

1-1

1-4

1-8

1-10

1-14

1-15

1-16

1-17

1-18

1-20

1-22

1-26

1-27

1-34

1-35

MAIN SPECIFICATIONS

- Item - - Specifications -

30 April, ’89

Configuration:

Copying Process:

Original Feed: Automatic reversing

Original Size:

Reproduction Ratios:

Reproduction Ratio

Change:

Warm Up Time: Approximately 6 minutes

Copy Paper:

Console

Dry electrostatic transfer system

Computer/Continuous form feeder (CFF)

Maximum A3, 11” x 17”

4 reductions, 3 enlargements, 1 option, zoom -

64% to 141% (1%/step)

- A4 Version 4R: 93%, 82%, 71%, and 65%

3E: 115%, 122%, and 141%

- Letter Version 4R: 93%, 77%, 74%, and 64%

3E: 121%, 129%, and 141%

One optional ratio can be programmed in addition

to the above.

Maximum 6 seconds

Size:

- Maximum A3,

- Minimum A5,

document feeder (ARDF)

(Room Temp. 20°C, 68°F)

11” x 17”

5½” x 8½”

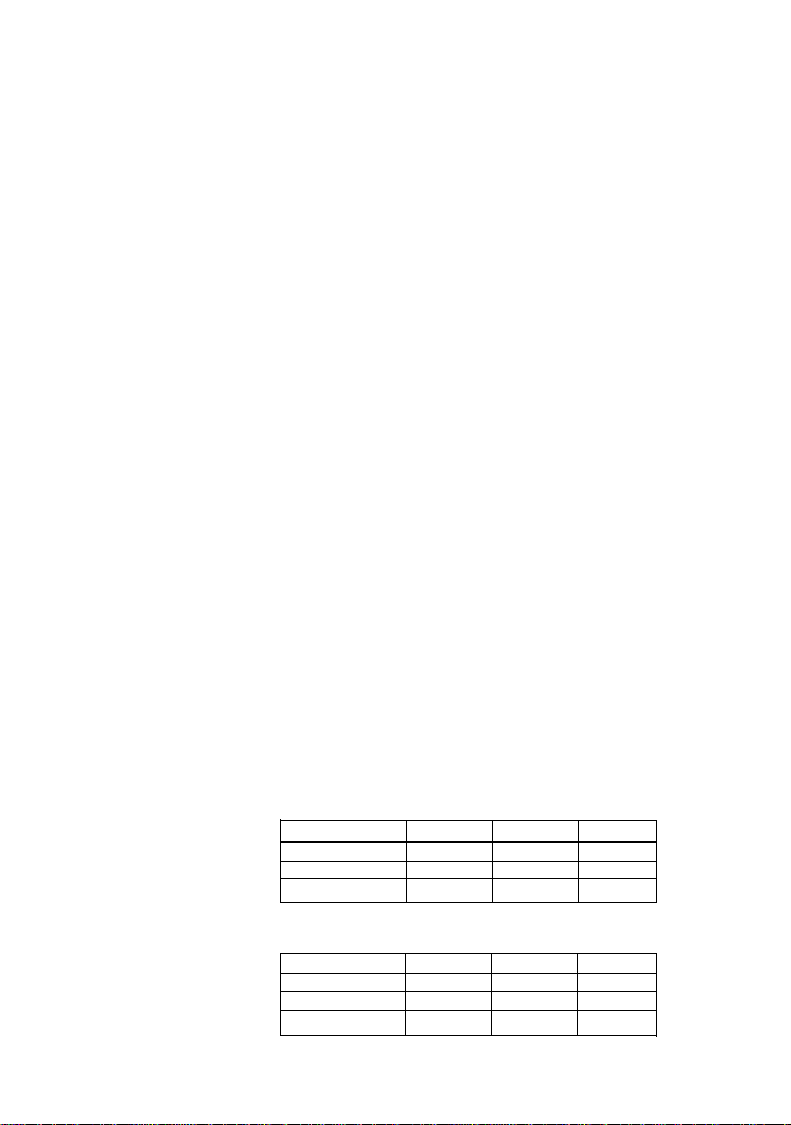

Copy Speed:

Weight:

- A4 version -

- LT version -

DLT: 11” x 17”

LG: 8.5” x 14”

LT: 8.5” x 11”

- Maximum 90 grams (24 lb)

- Minimum 60 grams (16 lb)

Ratio

1:1.41

1:1

1:0.65

Ratio

1:1.41

1:1

1:0.65

A3

41

41 65

41

DLT LG LT

41 56 56

41

41

1-1

A4

56

61

64 64

61

A5

56

72

67

61

30 April, ’89

First Copy Time:

Copy Number Input:

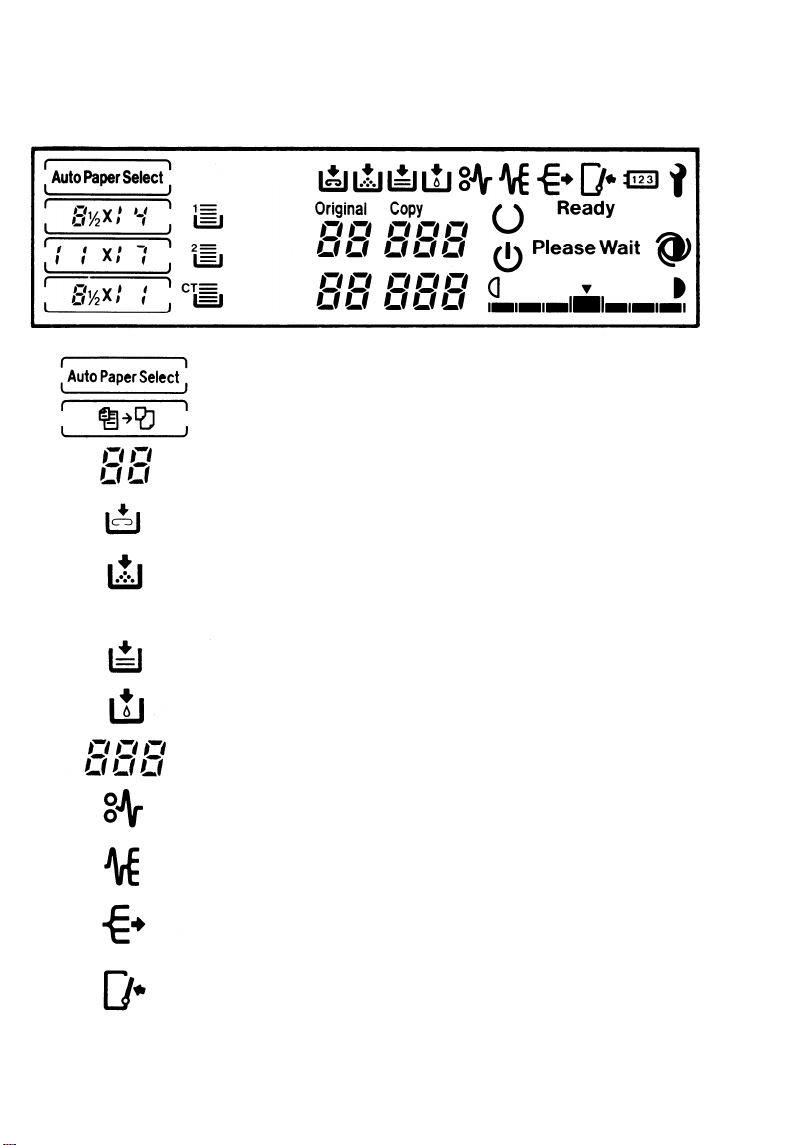

Operation Display: Guidance display LCD and indicator LCD

Image Density Automatic Density Selection (ADS) + Manual

Selection: Selection (7 Steps)

Special Features: 1. Size Magnification

Paper Stock:

3.9 seconds (A4 or 8.5” x 11” fed from upper tray)

1 to 999 using number keys

2. Image Shift (Right and left)

A4 version (Letter version): Adjustable from 0

to 21 mm (3/4”) at 1 mm (1/8”) increments

3. Automatic Duplex (3 modes)

4. Edit Image

a. Erase Borders

b. Erase Image

c. Overlay Image

5. Automatic Paper Selection (APS)

6. Automatic Reduction/Enlargement (AMS)

7. Weekly Timer

Upper tray: 1000 sheets

Lower tray: 500 sheets

Copy Tray Capacity:

Copy Face Down:

Toner Replenishment: Cartridge exchange

Toner Consumption:

Automatic Reset: 1 minute (Can be set to 5 seconds, 3 minutes, or

Automatic Shut-off: 30 minutes, 1 hour, 3 hours, or “Infinite” can be

250 sheets (All sizes)

Automatic

20,000 copies/cartridge (ID 1.3)

17,000 copies/cartridge (ID 1.4)

(650 g/cartridge, A4 or 8.5” x 11”, 7% original)

no automatic reset.)

All functions are cancelled except image density

selection. Copies Entered is set to “1”, the copy

ratio is returned to full size, the upper tray is

selected, and all special features are reset.

programmed.

1-2

30 April, ’89

Self-diagnostic

Codes:

Service Programs:

Power Requirements:

Power Consumption:

(kw/h)

Dimensions:

Weight:

Optional Equipment:

24 codes (See the field manual for details)

More than 50 programs can be controlled from the

operation panel for efficient maintenance service.

115 V, 60 Hz, 20 A

220 V, 50 Hz, 10 A

240 V, 50 Hz, 10 A

Warm-up Copying Standby Off

Copier

Sorter -LCT

Sorter -Connector

Sorter Stapler

*Fusing lamp off

Height: 1,020 mm, 40.2”

Depth: 790 mm, 31.1”

Width:

290 kg, 639 lb

20 bin sorter

Large capacity tray (2,200 sheets)

Sorter stapler

Sorter connector unit

Menu Reader

Key Counter

11” x 17”/A3 counter

1.7

--

1,216 mm, 47.9”

1.75

0.12 -- --

0.13 -- --

0.20 -- --

0.20

0.2*

0.04

1-3

30 April, ’89

1. GUIDE TO COMPONENTS

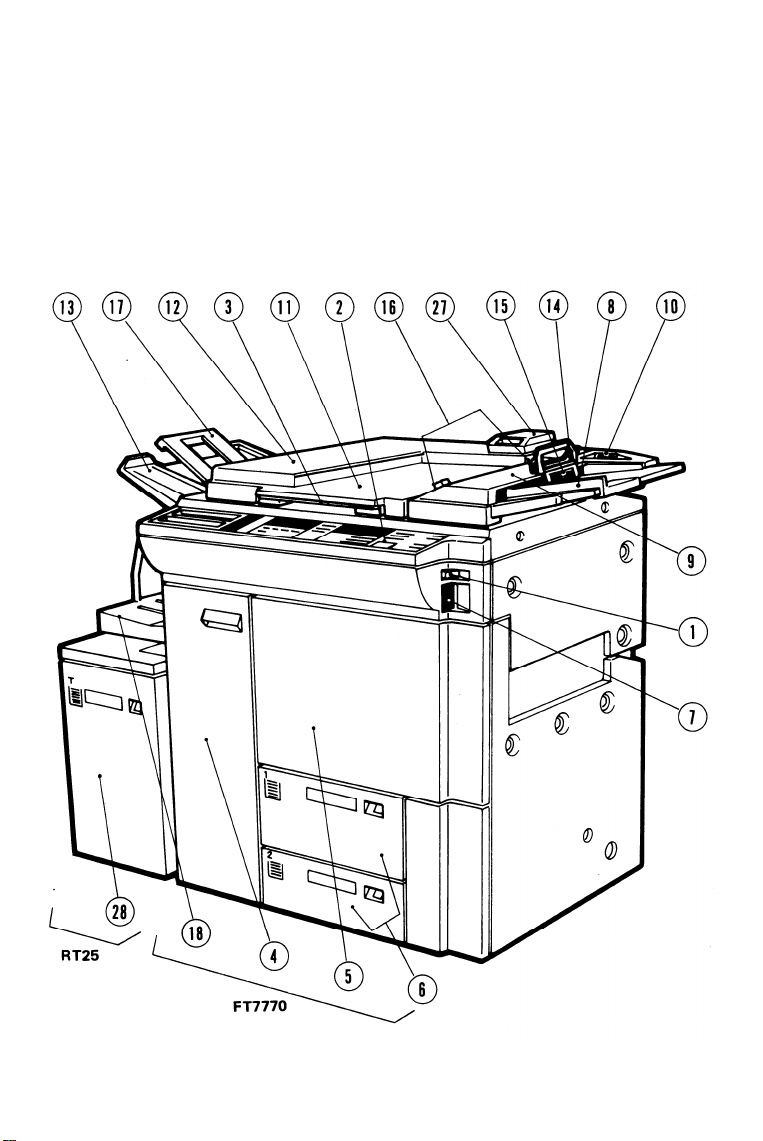

1-1. EXTERIOR

1-4

Copier

No. Name

1.

Main Switch

2.

Control Panel

3.

Exposure Glass

Left Door

4.

Right Door

5.

Paper Trays

6.

Key Counter Port

7.

8.

Original Guide

Plate

9.

Original

Feed-in Unit

DF Indicator Panel

10.

Belt Unit

11.

Reverse Section

12.

13.

Original Tray

14.

Computer Form Fence

30 April, ’89

Function

Turns the machine on or off.

Operator controls and indicators for the main copier and

sorter are located here.

Place originals here for copying.

Provides access for supplying toner and removing

misfeeds.

Provides access for removing misfeeds.

The two trays hold up to 1,500 sheets of paper — 1,000 in

the upper tray and 500 in the lower tray.

Insert the key counter (option) here.

Place originals here for automatic or semi-automatic

feeding.

Separates originals and feeds them to the belt unit.

Document feeder indicators are located here.

Automatically transports and positions original docu-

ments. (Place book originals directly on the exposure

glass.)

Turns over the originals for automatic copying of the

reverse side.

Originals are stacked here after copying.

Keeps a stack of computer forms straight so that they

will feed smoothly.

Feed Stopper

15.

Edge Guides

16.

17.

Computer Form Guide

18.

Stacker

Menu Reader

27.

28.

Access Cover

Prevents originals from being inserted while copying

computer forms.

Keep computer forms straight as they are fed into the

document feeder.

Sends computer forms to the stacker.

Receives computer forms after copying.

Reads job sheets and sets operation modes automati-

cally.

Provides access for removing misfeeds.

1-5

30 April, ’89

1-6

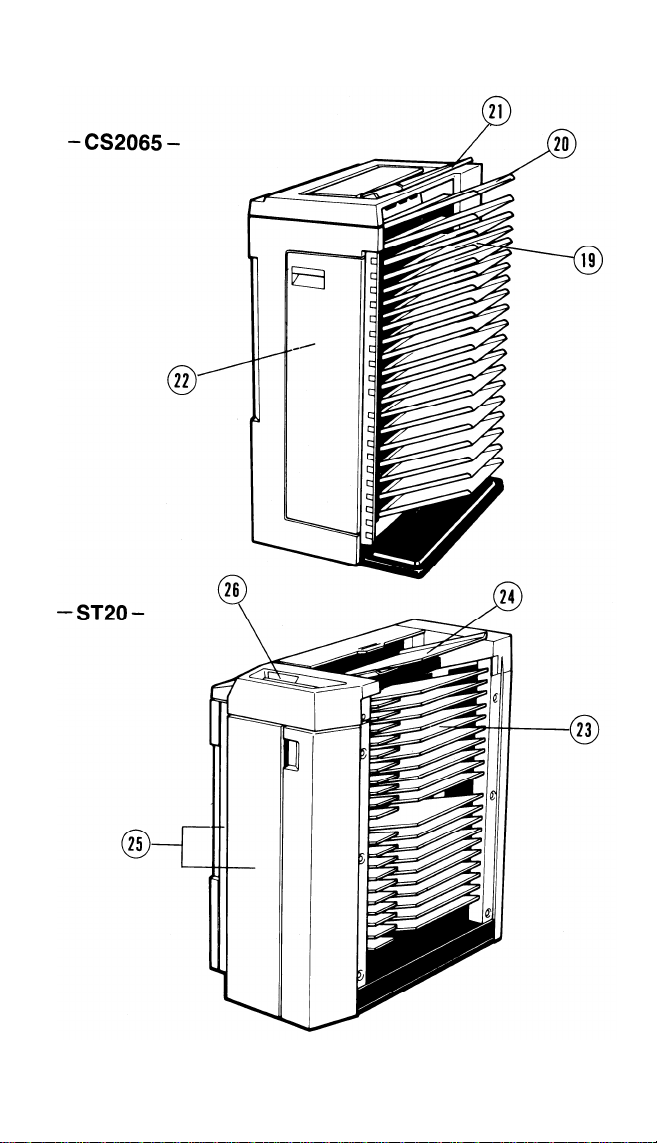

Sorter – CS2065 (Option)

30 April, ’89

19. Sorter Bins

20. Proof Tray When not in sort or stack mode copies are delivered

21. Manual Feed Entrance Used to manually feed sheets to the sorter bins. (For

22. Front Door

Copies will be sorted or stacked here.

here.

job recovery, blank separators, etc.)

Provides access for removing misfed paper from the

sorter.

Sorter/Stapler – ST20 (Option)

23.

Sorter Bins

Proof Tray

24.

25.

Right and Left Doors

26.

Staple Indicators

Copies will be sorted, stacked, or stapled here.

When not in sort, stack, or staple mode, copies are de-

livered here.

Provide access for removing misfed paper from the

sorter/stapler.

Lights while stapling.

1-7

30 April, ’89

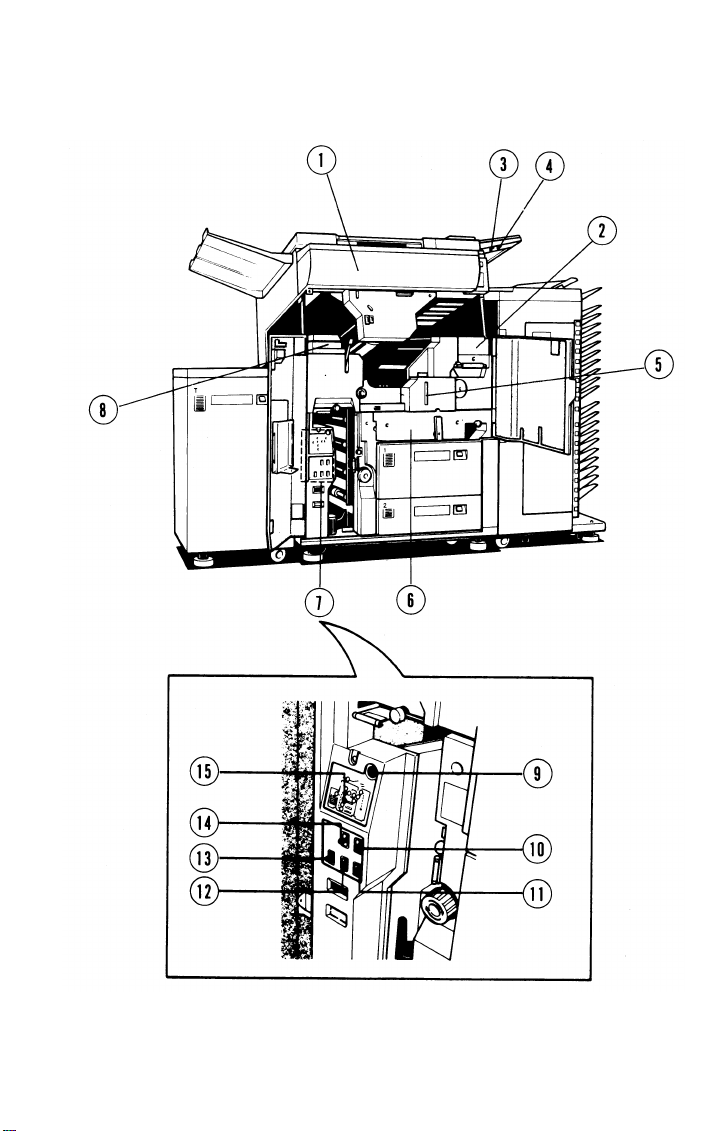

1-2. COPIER INTERIOR

1-8

30 April, ’89

No.

11. Tray Auto-Shift Switch

13. Humidity Switch

14. Image Density Switch

Name

1. Top Unit

2. Fusing Unit

3. Original Application

Switch

4. Form Size Switch

5. Oil Bottle

6. Duplex Tray

7. Internal Panel

8. Toner Cartridge

9. SC Reset Switch

10. Exposure Switch

12. Paper Application

Switch

15. Misfeed Monitor

Function

The top swings up for misfeed removal.

Pull out to remove misfed paper from the fusing area.

When copying thin originals with the document feeder,

set this switch to the right position.

When using the computer form feeder, select the computer form size with this switch.

Add silicone oil to this bottle when the Add Oil indicator

lights.

Holds copies while they are recycled for duplex copying.

The misfeed monitor and several control switches are

located here.

Change the toner cartridge when the Add Toner indica-

tor lights.

Resets the copier from a service call condition.

To prevent blue lines from being copied, increase exposure intensity with this switch.

Used to select or deselect limitless paper feed.

When copying on tracing paper or when image density is

low, set this switch to “Translucent paper”.

Controls a heater which keeps paper dry.

Ask your service engineer how to use this switch.

Shows the location(s) of misfed paper.

1-9

30 April, ’89

1-3. OPERATION PANEL Keys

* Letter/Legal Version

1.

Set Timer Key

Press to preset the power on/off time

for each day of the week.

Edit Image Key

2.

Press to select one of the three edit

modes.

3.

Image Shift Key

Press to change the size of the margin

on copies.

4.

Duplex Key

Press to select one of the three duplex

modes.

5.

Special R/E Key

Press to select one of the three special

reduce or enlarge modes.

6.

Guidance Key

Press to start guidance in the display.

ADF/SADF Select Keys

7.

Press to select automatic or semi-

automatic document feed.

Auto Image Density Key

8.

Press to resume automatic control of

image density.

9.

Sorter Keys

Press to select sort and stack modes

or to deselect the sorter.

Copy Face Down Key

10.

When this key is pressed, copies will

be delivered to the copy tray face down.

11.

Staple Key

Press to staple sorted copies.

12.

Clear Modes Key

Press to cancel all previously entered

settings and modes.

13.

Interrupt Key

Press to make interrupt copies during

a multicopy run; then, press again and

press the Start key to resume the multicopy run.

Timer Release Key

14.

Press to use the copier after the auto

on/off timer has turned the machine

off.

15.

Start Key

Press to start operation.

16.

Manual Image Density Keys

Press to make copies lighter or darker.

Use this key to cancel automatic control and to manually select the image

density level.

1-10

* A4/A3 Version

17.

Decimal Point Key

Press to enter the decimal point when

entering the sizes of originals or copies

while in size magnification mode.

18.

Clear/Stop Key

Press to cancel the copy number

entered. While copying, press to stop

copy operation.

19.

Numeric Keys

Normally, the numeric keys are used

to enter the desired number of copies.

They are also used to preset the power

on/off timer and to input the sizes of

the original and copy when in size

magnification mode.

Paper Selection Key

20.

Press to change the selected paper tray.

21. Full Size Key

Press to make copies the same size as

the original.

22. Reduce Key

Press to make reduced copies. Suc-

cessive key strokes change the ratio.

(cyclical indication)

30 April, ’89

Enlarge Key

23.

Press to make enlarged copies. Successive key strokes change the ratio.

Display Control Keys

24.

Press to make choices in the guidance

display. The following symbols will

guide your choices.

25.

Enter Key

Press to input information into the

copier’s memory.

26.

User Program Key

Press to input or call user programs.

1-11

30 April, ’89

Indicators

* Letter/Legal Version

Auto Paper Selection

Indicates that the copy paper matching the original size will be

automatically selected.

Original Recovery Counter (upper display)

If a misfeed occurs while in ADF mode, this indicator shows

how many originals must be reset before resuming copying.

Load Staples

Lights when the staple cartridge is empty.

Add Toner

Blinks when it is time to change the toner cartridge. When

continuously lit, the copier cannot be used until a new toner

cartridge has been inserted.

Load Paper

Lights when the tray in use runs out of paper.

Add Oil

Lights when the silicone oil level gets too low.

Copies Entered Counter (upper display)

Shows the number of copies entered.

Check Paper Path

Indicates that a misfeed has occurred within the copier.

Sorter Misfeed

Indicates that a misfeed has occurred within the sorter.

Take Out Copies

Turns on when the sorter bins are full.

Close Door

Lights if one of the doors is open. The machine will not oper-

ate until all doors are closed.

1-12

Loading...

Loading...