Page 1

®

®

RICOH GROUP COMPANIES

A175/A176/A177

SERVICE MANUAL

PN: RCSM7650

Page 2

®

®

SERVICE MANUAL

A175/A176/A177

RICOH GROUP COMPANIES

Page 3

Page 4

A175/A176/A177

SERVICE MANUAL

PN: RCSM7650

Page 5

Page 6

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or certified

by successfully completing a Ricoh Technical

Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

Page 7

Page 8

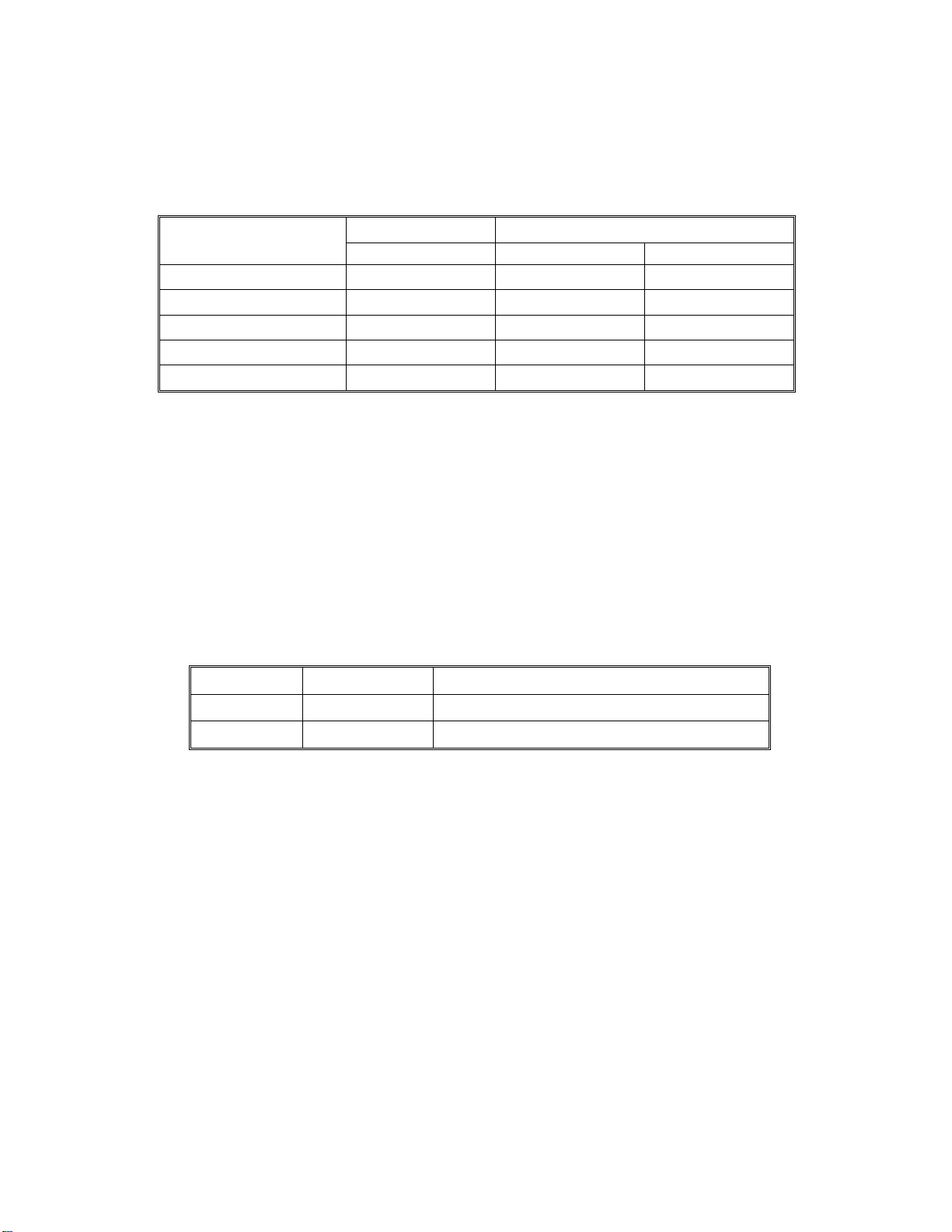

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

A175 2651 FT7650 9500

A176 2760 FT7660 9600

A177 2770 FT7670 9700

DOCUMENTATION HISTORY

REV. NO.

*

DATE COMMENTS

9/96 Original Printing

Page 9

Page 10

Table of Contents

1. OVERALL MACHINE INFORMATION

1. SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. MACHINE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2.1 COPIER OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2.2 SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3. COPY PROCESS AROUND THE DRUM . . . . . . . . . . . . . . . . . . . . 1-8

4. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . 1-10

5. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

6. PAPER PATH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

6.1 STANDARD COPYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

6.2 MULTIPLE 2-SIDED COPYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

7. ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . 1-15

2. DETAILED SECTION DESCRIPTIONS

1. PROCESS CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1.1 Latent Image Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.1.2 Image Density Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1.2 PROCESS CONTROL DATA INITIAL SETTING. . . . . . . . . . . . . . . . . . . . . . . . 2-4

1.3 LATENT IMAGE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1.3.1 Drum Potential Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1.3.2 Drum Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

1.3.3 V

1.3.4 V

1.3.5 V

1.3.6 V

1.3.7 V

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SG

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

R

Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

D

Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

L

Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

R

1.3.8 Initial Setting Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

1.4 IMAGE DENSITY CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

1.4.1 Toner Density Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

SM i A175/A176/A177

Page 11

1.4.2 Image Density Sensor Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1.4.3 Sensor Abnormal Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.2 OPC DRUM CHARACTERISTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.3 DRUM CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.3.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.3.2 Air Flow Around the Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.3.3 Charge Wire Cleaning Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.4 ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.4.2 Lead Edge and Trail Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.4.3 Side Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.5 CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.5.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.5.2 Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.5.3 Cleaning Blade Pressure Mechanism and Side-to-Side Movement. . . . . 2-27

2.5.4 Toner Collection Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.5.5 Pick-off mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.5.6 Pre-Transfer Lamp (PTL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.5.7 Toner Collection Bottle Set Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.6 QUENCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

3. OPTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

3.2 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

3.3 VERTICAL LENS DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

3.4 HORIZONTAL LENS DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

3.5 HORIZONTAL LENS POSITIONING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

3.5.1 For Original Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

3.5.2 For Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

3.5.3 For Reproduction Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

3.6 3RD SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

3.7 OPTICS CONTROL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

3.8 AUTOMATIC IMAGE DENSITY CONTROL SYSTEM (ADS) . . . . . . . . . . . . . 2-39

A175/A176/A177 ii SM

Page 12

3.9 MANUAL IMAGE DENSITY CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

3.10 UNEVEN LIGHT INTENSITY CORRECTION . . . . . . . . . . . . . . . . . . . . . . . . 2-42

3.11 ORIGINAL SIZE DETECTION IN PLATEN MODE . . . . . . . . . . . . . . . . . . . . 2-43

3.12 HALF TONE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

4. DEVELOPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

4.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

4.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

4.3 CROSSMIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

4.4 DEVELOPMENT BIAS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

4.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

4.4.2 Bias Control In Copy Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

4.4.3 Bias Control Out of Copy Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

4.4.4 ID Sensor Pattern Bias. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

4.5 TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

4.5.1 Toner Supply Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

4.5.1a Toner Density Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

4.5.2 Toner End Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

4.5.3 Toner Supply Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

4.5.4 Bottle Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

5. IMAGE TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

5.1 PRE-TRANSFER LAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

5.2 IMAGE TRANSFER AND PAPER SEPARATION OVERVIEW. . . . . . . . . . . . 2-61

5.3 IMAGE TRANSFER AND PAPER SEPARATION MECHANISM . . . . . . . . . . 2-62

5.4 TRANSFER BELT UNIT LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

5.5 PAPER TRANSPORTATION AND BELT DRIVE MECHANISM . . . . . . . . . . . 2-65

5.6 TRANSFER BELT CLEANING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

5.7 TONER COLLECTION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

6. PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

6.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

6.2 FRR FEED SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

6.2.1 Pick-up Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

6.2.2 Feed and Separation Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

6.3 SLIP CLUTCH MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

6.4 FRR FEED DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

SM iii A175/A176/A177

Page 13

6.5 SEPARATION ROLLER RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . 2-74

6.6 PAPER RETURN MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

6.7 PAPER SKEW PREVENTION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

6.8 PAPER LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

6.9 PAPER NEAR END/PAPER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . 2-79

6.10 TANDEM FEED TRAY (A176/A177/A191/A192 Copiers Only) . . . . . . . . . . . 2-80

6.10.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

6.10.2 Fences Drive Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

6.10.3 Rear Fence Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-82

6.10.4 Tray Lock Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-83

6.11 PAPER SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-84

6.12 VERTICAL TRANSPORT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

6.13 TRAY POSITIONING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

6.14 BUILT IN LCT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

6.14.1 Paper Tray Lift Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

6.14.2 Tray Lock Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

6.15 BY-PASS FEED TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-90

6.15.1 Feed Mechanism/Paper End Detection . . . . . . . . . . . . . . . . . . . . . . . . . 2-90

6.15.2 Table Open/Close Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-91

6.15.3 Paper Size Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-92

6.16 PAPER REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-93

6.17 REGISTRATION DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-94

6.18 GUIDE PLATE RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

7. IMAGE FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

7.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

7.2 FUSING ENTRANCE GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-97

7.3 FUSING DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-98

7.4 FUSING LAMP CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-99

7.5 INVERTER AND PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-100

7.6 INVERTER AND EXIT DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . 2-101

8. DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-102

8.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-102

8.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-103

8.3 DUPLEX ENTRANCE TO DUPLEX TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . 2-104

A175/A176/A177 iv SM

Page 14

8.4 DUPLEX STACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-105

8.5 DUPLEX PICK-UP ROLLER MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . 2-106

8.6 DUPLEX PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-107

9. ENERGY STAR COMPLIANT MACHINES

(North American version only) . . . . . . . . . . . . . . . . . . . . . . . . . 2-109

10. ENERGY SAVING INFORMATION . . . . . . . . . . . . . . . . . . . . . . 2-111

10.1 About The Energy Saving Features of this Copier . . . . . . . . . . . . . . . . . . . . 2-111

10.1.1 Auto Off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-111

10.1.2 Low Power Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-112

10.1.3 Duplex Default Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-113

3. INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 ENVIRONMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 MACHINE LEVEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2. COPIER INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2.2 COPIER INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

2.3 GUIDANCE ROM, INSTALLATION

(OPTION: EUROPE VERSION ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.4 PLATEN COVER (OPTION) INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

2.5 PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.5.1 550 Sheets Paper Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.5.2 1,500 Sheets Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

2.6 KEY COUNTER HOLDER INSTALLATION (OPTION) . . . . . . . . . . . . . . . . . . 3-19

2.7 IMAGE DENSITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3. DUAL JOB FEEDER (A610) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

4. SORTER STAPLER (A606). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

4.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

4.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

SM v A175/A176/A177

Page 15

5. RECIRCULATING DOCUMENT HANDLER (A607) . . . . . . . . . . . 3-32

5.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

5.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

6. FINISHER (A608) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

6.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

6.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

7. LCT (A609). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

7.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

7.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

7.2.1 PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

4. SERVICE TABLES

1. SERVICE REMARKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 HANDLING THE DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 CHARGE CORONA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.4 OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.5 ERASE LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.6 DEVELOPMENT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.7 TRANSFER BELT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.8 CLEANING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.9 PRE-TRANSFER LAMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.10 PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1.11 FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2. SERVICE PROGRAM MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1.1 Service Program Access Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1.2 To Exit SP Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2.1.3 To Return to the Index Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

2.1.4 Change the Menu Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

2.1.5 Access to "Copy in SP" Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

2.2 SERVICE PROGRAM MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

2.3 SENSOR/SWITCH/SIGNAL DATA CHECK (INPUT MODE) . . . . . . . . . . . . . 4-40

A175/A176/A177 vi SM

Page 16

2.4 ELECTRICAL COMPONENT CHECK (OUTPUT MODE). . . . . . . . . . . . . . . . 4-46

2.5 USER TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

2.5.1 How To Access The User Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

2.6 TOUCH PANEL DISPLAY POSITION ADJUSTMENT . . . . . . . . . . . . . . . . . . 4-52

3. PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . . . 4-54

3.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

3.2 EXPLANATION OF REGULAR PM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

3.3 REGULAR PM PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

5. REPLACEMENT AND ADJUSTMENT

1. EXTERIOR AND INNER COVER REMOVAL . . . . . . . . . . . . . . . . . 5-1

1.1 FRONT SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.1 Left Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1.2 Right Front Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.2 REAR SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.2.1 Upper Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.2.2 Lower Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.2.3 Left Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

1.2.4 Right Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

1.2.5 Shutter Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.3 RIGHT SIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

1.3.1 Feed Unit Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

1.3.2 Upper Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

1.3.3 Lower Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

1.4 LEFT SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

1.4.1 Upper Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

1.4.2 Lower Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

1.5 OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

1.6 UPPER SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

1.6.1 Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

1.6.2 Rear Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

2. OPTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

2.1 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

SM vii A175/A176/A177

Page 17

2.2 EXPOSURE LAMP REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

2.3 OPTICS THERMOSWITCH REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . 5-13

2.4 SCANNER HP SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

2.5 ADS SENSOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

2.6 SCANNER DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

2.7 SCANNER DRIVE WIRES REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

2.8 SCANNER CONTROL ADJUSTMENT (except for 70 CPM version) . . . . . . . 5-32

2.9 THIRD SCANNER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

2.10 THIRD SCANNER DRIVE MOTOR/HP SENSOR REPLACEMENT. . . . . . . 5-34

2.11 LENS HORIZONTAL DRIVE BELT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . 5-35

2.12 LENS VERTICAL DRIVE BELT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

2.13 ORIGINAL SIZE SENSORS

(2 LENGTH SENSORS, 1 WIDTH SENSOR) . . . . . . . . . . . . . . . . . . . . . . . . 5-38

3. DEVELOPMENT AND TONER SUPPLY. . . . . . . . . . . . . . . . . . . . 5-39

3.1 DEVELOPMENT UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

3.2 DEVELOPER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

3.3 DEVELOPMENT ROLLERS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-43

3.4 TONER DENSITY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-46

3.5 TONER BOTTLE DRIVE MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . 5-47

4. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

4.1 DRUM UNIT REMOVAL AND OPC DRUM REPLACEMENT . . . . . . . . . . . . . 5-48

4.2 QUENCHING LAMP REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

4.3 GRID PLATE/CHARGE WIRE/WIRE CLEANER REPLACEMENT. . . . . . . . . 5-50

4.4 ERASE LAMP AND DRUM POTENTIAL SENSOR REPLACEMENT. . . . . . . 5-52

4.5 CLEANING BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

4.6 CLEANING BRUSH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

4.7 PICK-OFF PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

4.8 TONER COLLECTION MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 5-56

4.9 OZONE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

5. TRANSFER BELT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

5.1 TRANSFER BELT UNIT REMOVAL/INSTALLATION . . . . . . . . . . . . . . . . . . . 5-58

5.2 TRANSFER BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

5.3 CLEANING BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

6. PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

6.1 PAPER TRAY UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

A175/A176/A177 viii SM

Page 18

6.2 PAPER TRAY REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

6.3 PAPER FEED ROLLERS REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

6.4 TANDEM REAR FENCE DRIVE BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . 5-67

6.5 TANDEM SIDE FENCE MOTOR REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

6.6 PAPER FEED TIMING ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-70

6.7 PAPER FEED CLUTCH REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

6.8 BY-PASS FEED TABLE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

6.9 BY-PASS FEED ROLLERS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

6.10 BY-PASS PAPER SIZE SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . 5-79

6.11 BY-PASS FEED CLUTCH REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

6.12 REGISTRATION CLUTCH REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-83

6.13 PAPER DUST CLEANER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-84

6.14 REGISTRATION SENSOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-85

6.15 COPIER FEED UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-86

6.16 TANDEM FEED TRAY PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . 5-88

6.17 UNIVERSAL TRAY PAPER SIZE CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . 5-92

7. FUSING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

7.1 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

7.2 FUSING THERMISTOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-94

7.3 FUSING THERMOFUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-95

7.4 FUSING LAMP REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

7.5 HOT ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-97

7.6 PRESSURE AND BEARING ROLLER REPLACEMENT . . . . . . . . . . . . . . . . 5-99

7.7 FUSING STRIPPER PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-100

7.8 FUSING PRESSURE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-101

7.9 PAPER EXIT UNIT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-102

7.10 OIL SUPPLY/CLEANING ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . 5-104

7.11 PRESSURE ROLLER CLEANING ROLLER REPLACEMENT . . . . . . . . . . 5-105

8. DUPLEX UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-106

8.1 FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-106

8.2 SEPARATION BELTS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-108

8.3 DUPLEX UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-110

8.4 SEPARATION CLUTCH/TRANSPORT CLUTCH REMOVAL. . . . . . . . . . . . 5-111

8.5 JOGGER MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-112

8.6 COPY QUALITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-117

SM ix A175/A176/A177

Page 19

8.6.1 SP Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-117

8.6.2 Side-to-side Registration Adjustment

(except for copier with RDH and Finisher) . . . . . . . . . . . . . . . . . . . . . . . 5-119

8.6.3 Side-to-side Registration Adjustment

(copier with RDH and Finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-120

8.6.4 Uneven Exposure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-121

8.6.5 Image Density Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-123

8.6.6 Scanner Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-124

6. TROUBLESHOOTING

1. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 SUMMARY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.2 EXPOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

1.3 SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

1.4 LENS MAGNIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

1.5 OPTICS THERMISTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

1.6 MAIN CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

1.7 DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

1.8 PROCESS SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

1.9 TRANSFER CURRENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

1.10 DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

1.11 PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

1.12 DUPLEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

1.13 FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

1.14 SYSTEM CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

1.15 DUAL JOB FEEDER/RECIRCULATING DOCUMENT HANDLER . . . . . . . . 6-19

1.16 FINISHER/SORTER STAPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

1.17 OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

2. ELECTRICAL COMPONENT DEFECTS. . . . . . . . . . . . . . . . . . . . 6-25

2.1 SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

2.2 SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

2.3 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

2.3.1 DC Power Supply Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

A175/A176/A177 x SM

Page 20

Rev. 10/99

8.6.1 SP Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-117

8.6.2 Side-to-side Registration Adjustment

(except for copier with RDH and Finisher) . . . . . . . . . . . . . . . . . . . . . . . 5-119

8.6.3 Side-to-side Registration Adjustment

(copier with RDH and Finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-120

8.6.4 Uneven Exposure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-121

8.6.5 Image Density Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-123

8.6.6 Scanner Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-124

6. TROUBLESHOOTING

1. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.1 SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1.2 EXPOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

1.3 SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

1.4 LENS MAGNIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

1.5 OPTICS THERMISTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

1.6 MAIN CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

1.7 DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

1.8 PROCESS SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

1.9 TRANSFER CURRENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

1.10 DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

1.11 PAPER FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

1.12 DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

1.13 FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

1.14 SYSTEM CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

1.15 DUAL JOB FEEDER/RECIRCULATING DOCUMENT HANDLER . . . . . . . . 6-19

1.16 FINISHER/SORTER STAPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

1.17 OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

2. ELECTRICAL COMPONENT DEFECTS. . . . . . . . . . . . . . . . . . . . 6-25

2.1 SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

2.2 SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

2.3 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

2.3.1 DC Power Supply Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

3. ROM HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

A175/A176/A177 x SM

Page 21

7. DUAL JOB FEEDER DF62 (A610)

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. COMPONENT LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

2.2 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

3. ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . 7-5

4. ORIGINAL PICK-UP MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

5. SEPARATION AND FEED MECHANISM . . . . . . . . . . . . . . . . . . . . 7-8

6. FRICTION BELT DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . 7-9

7. ORIGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

8. TRANSPORT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

8.1 BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

8.2 THIN/THICK ORIGINAL MODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

9. ORIGINAL FEED-OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . . 7-15

10. TRANSPORT BELT LEVELING MECHANISM . . . . . . . . . . . . . . 7-16

11. LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

12. SPECIAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

12.1 PRESET MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

12.2 TWO-SIDED ORIGINAL FEED (AUTO REVERSE) MODE . . . . . . . . . . . . . 7-19

12.3 COMBINE TWO ORIGINALS MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

13. TIMING CHARTS WITH ORIGINAL MISFEED DETECTION . . . 7-23

13.1 A4 SIDEWAYS: ONE-SIDED, TWO ORIGINALS . . . . . . . . . . . . . . . . . . . . . 7-23

13.2 COMBINE TWO ORIGINALS MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

13.3 A4 SIDEWAYS: TWO-SIDED, TWO ORIGINALS . . . . . . . . . . . . . . . . . . . . . 7-25

14. SERVICE TA BLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

14.1 DIP SWITCHES AND SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

14.2 VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

14.3 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

14.4 FUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

15. REPLACEMENTS AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . 7-28

15.1 UPPER COVER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

15.2 TRANSPORT BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

SM xi A175/A176/A177

Page 22

15.3 FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

15.4 FRICTION BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

15.5 ORIGINAL SET/FEED, REGISTRATION-1/-2,

AND ORIGINAL WIDTH-1/-2/-3 SENSOR REPLACEMENT. . . . . . . . . . . . . 7-33

15.6 FEED-OUT UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

15.7 FEED-OUT MOTOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

15.8 INVERTER SOLENOID REMOVAL AND ADJUSTMENT . . . . . . . . . . . . . . . 7-36

15.9 FEED-OUT SENSOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

15.10 INVERTER ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

15.11 DF POSITION/APS START SENSOR REPLACEMENT . . . . . . . . . . . . . . . 7-39

15.12 BELT DRIVE MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

15.13 FEED-IN UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

15.14 FEED-IN MOTOR REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

15.15 FRICTION BELT MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 7-43

15.16 FEED-IN CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

15.17 STOPPER SOLENOID REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

15.18 VERTICAL REGISTRATION ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . 7-46

15.18.1 One-sided Original Mode (Thin Paper). . . . . . . . . . . . . . . . . . . . . . . . . 7-46

15.18.2 Two-sided Original Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

15.19 SIDE-TO-SIDE REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 7-50

15.20 PREVENTING THE REAR SIDE OF ORIGINALS

FROM BECOMING DIRTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

8. SORTER STAPLER ST28/ST28P (A606)

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. COMPONENT LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.1 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.2 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

3. ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . 8-5

4. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

4.1 NORMAL (PROOF MODE) AND SORT/STACK MODE . . . . . . . . . . . . . . . . . . 8-7

4.2 STAPLE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

5. TURN GATE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

6. BIN DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

A175/A176/A177 xii SM

Page 23

7. BIN HOME POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8. JOGGER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

9. BIN REAR PLATE DRIVE SECTION. . . . . . . . . . . . . . . . . . . . . . . 8-17

10. GRIP ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

11. STAPLE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

11.1 STAPLE UNIT DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

11.2 STAPLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

11.3 PUNCH MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

11.4 STAPLE UNIT PULLED-OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

12. JAM DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

13. TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

13.1 SORTER/STAPLER TIMING CHART (PROOF MODE) . . . . . . . . . . . . . . . . 8-26

13.2 SORTER/STAPLER TIMING CHART (STAPLE MODE). . . . . . . . . . . . . . . . 8-27

14. SERVICE TABLES (MAIN CONTROL BOARD). . . . . . . . . . . . . 8-28

14.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

14.2 PUNCH POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

14.3 TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

14.4 FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

15. REPLACEMENTS AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . 8-30

15.1 EXTERIOR COVER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

15.2 STAPLER REMOVAL AND REINSTALLATION . . . . . . . . . . . . . . . . . . . . . . 8-32

15.3 JOGGER PLATE REMOVAL AND INSTALLATION . . . . . . . . . . . . . . . . . . . 8-33

15.4 BINS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

15.5 MAIN MOTOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

15.6 GRIP ASSEMBLY REMOVAL, AND GRIP SOLENOID

AND GRIP POSITIONING SOLENOID ADJUSTMENT. . . . . . . . . . . . . . . . . 8-39

15.7 MAIN CONTROL BOARD REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

15.8 GRIP MOTOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-41

15.9 STAPLE POSITION ADJUSTMENT & PUNCH POSITION. . . . . . . . . . . . . . 8-42

15.10 HELICAL WHEELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

15.11 PUNCH UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49

SM xiii A175/A176/A177

Page 24

9. RECIRCULATING DOCUMENT HANDLER DH500 (A607)

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 9-2

3. ELECTRICAL COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . 9-3

4. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

4.1 ONE-SIDED ORIGINAL FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

4.2 TWO-SIDED ORIGINAL FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

5. FEED-IN DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

6. ONE-TURN SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

7. ORIGINAL SETTING FOR RECYCLE. . . . . . . . . . . . . . . . . . . . . . . 9-9

8. ORIGINAL FEED-IN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9. ORIGINAL INVERSION MECHANISM . . . . . . . . . . . . . . . . . . . . . 9-11

10. ORIGINAL FEED-OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . 9-13

11. ALTERNATE PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

12. ORIGINAL MISFEED SENSING . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

12.1 One-sided original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

12.2 Two-sided original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

13. SERVICE TA BLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

13.1 TEST POINT TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

13.2 FUSE TABLE (Main Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

13.3 LED TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

13.4 DIP SWITCH TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

14. REPLACEMENTS AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . 9-22

14.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

14.2 PAPER FEED ROLLER REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

14.3 FRICTION BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

14.4 PAPER EXIT TRANSPORT BELT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 9-25

14.5 RDH MAIN CONTROL BOARD REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

14.6 RDH LEADING EDGE REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . 9-27

14.7 MOTOR SPEED CHECK & ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

A175/A176/A177 xiv SM

Page 25

10. FINISHER SR900 (A608)

1. OVERALL MACHINE INFORMATION . . . . . . . . . . . . . . . . . . . . . 10-1

1.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

1.2 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

1.3 ELECTRICAL COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

1.4 DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

1.5 BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

2. SECTIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

2.1 PAPER DELIVERY SWITCHING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

2.2 SHIFT TRAY UP/DOWN MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

2.3 SHIFT TRAY SIDE-TO-SIDE SHIFT MECHANISM. . . . . . . . . . . . . . . . . . . . . 10-9

2.4 STAPLE UNIT PAPER POSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

2.5 JOGGER MOVEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

2.6 STAPLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10- 12

2.7 STAPLER UNIT SIDE-TO-SIDE MOVEMENT. . . . . . . . . . . . . . . . . . . . . . . . 10-13

2.8 FEED-OUT TO SHIFT TRAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

3. SERVICE TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

3.1 TEST POINT TABLE (Main Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

3.2 FUSE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

3.3 LED TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

3.4 DIP SW TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

3.4.1 Factory Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

3.4.2 Motor Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

3.4.3 Free Run Test Mode Without Paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

3.4.4 Off Line Test Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

3.4.5 Shift Tray Rise Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

4. REPLACEMENTS AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . 10-18

4.1 EXTERIOR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

4.2 ALIGNMENT BRUSH ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 10-19

4.3 SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

4.4 POSITING ROLLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

4.5 BELT TENSION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

SM xv A175/A176/A177

Page 26

11. LARGE CAPACITY TRAY RT34 (A609)

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . 11-2

3. ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . 11-3

4. MECHANICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

5. PAPER LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

6. PAPER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

7. REPLACEMENTS AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . . 11-8

7.1 PAPER FEED ROLLERS REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

7.2 LCT FEED CLUTCH REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

7.3 UPPER COVER SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

7.4 SIDE-TO-SIDE REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 11-11

BULLETINS

A175/A176/A177 xvi SM

Page 27

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disass em bling or ass em blin g par ts of the c opier and peripherals,

make sur e that th e c opier power c or d is unplugge d.

2. Th e wall out let sho uld be near the copier and easily acc es s ible.

3. Not e that s om e c om ponents of the c opier and the paper tray unit are

supplied wit h electrical v olta ge ev en if the main switch is turned off.

4. If any adjustment or oper ation ch ec k has to be made wit h ex terior cov er s

off or ope n while t he m ain switch is turned on, ke ep hands away from

electrifie d or m ec hanically dr iven c om ponents .

5. Th e ins ide and the metal pa r ts of the fusing unit bec om e extrem ely hot

while the cop ier is operating . Be c ar efu l to avoid t ouc hing thos e

components with your bare hands.

6.T he copier is not at tached to the table. Pushing th e c opier too hea rd ma y

cause it t o dr op onto the floor . While m ov ing th e c opier, push th e table .

7. Wh en the main swit c h is tuned on, the machine will suddenl y star t

turning to perform the developer initialization. Keep hans away from any

mecha nic al and elect r ic al com ponents du r ing this period.

HEALTH SAFE TY CONDI TIONS

1. Never operate the copier without the ozone filters installed.

2. Always re place th e oz one fi lters with the s pec ifi ed ones at the spe c ified

interv als.

3. To ner and dev elop er ar e non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as firs t aid . If uns ucc es s ful, get

medi c al attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

cust om er s er v ice r epr esentativ e who has com plet ed the training cours e

on those models.

CAUTION

2. The RAM board on the main control board has a lithium battery

which can explod e if replaced in correc t ly. Repl ace the RAM board

only with an identical one. The manufac turer recommends

replacing the ent ire RAM board. Do not recharge or burn this

batt ery. Used RAM board must be hand led in ac cordance with

loca l r eg ula tions.

SM i A175/A176/A177

Page 28

SAFETY AND ECOLOGICA L NOTES FOR DISPOSAL

1. Do not inc inerat e the toner c ar tridge or the us ed tone r . T oner dus t may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, dev eloper, an d or ganic phot oc onductor acc ording

to local regulations . (Th es e ar e non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. Wh en k eeping use d RA M boar ds in or der to dispose of them later, do not

put mor e th an 100 RAM boards per s ealed box. Stor ing larger num bers

or not s ealing them apart may lead to chemical r eactions and hea t

build- up.

A175/A176/A177 ii SM

Page 29

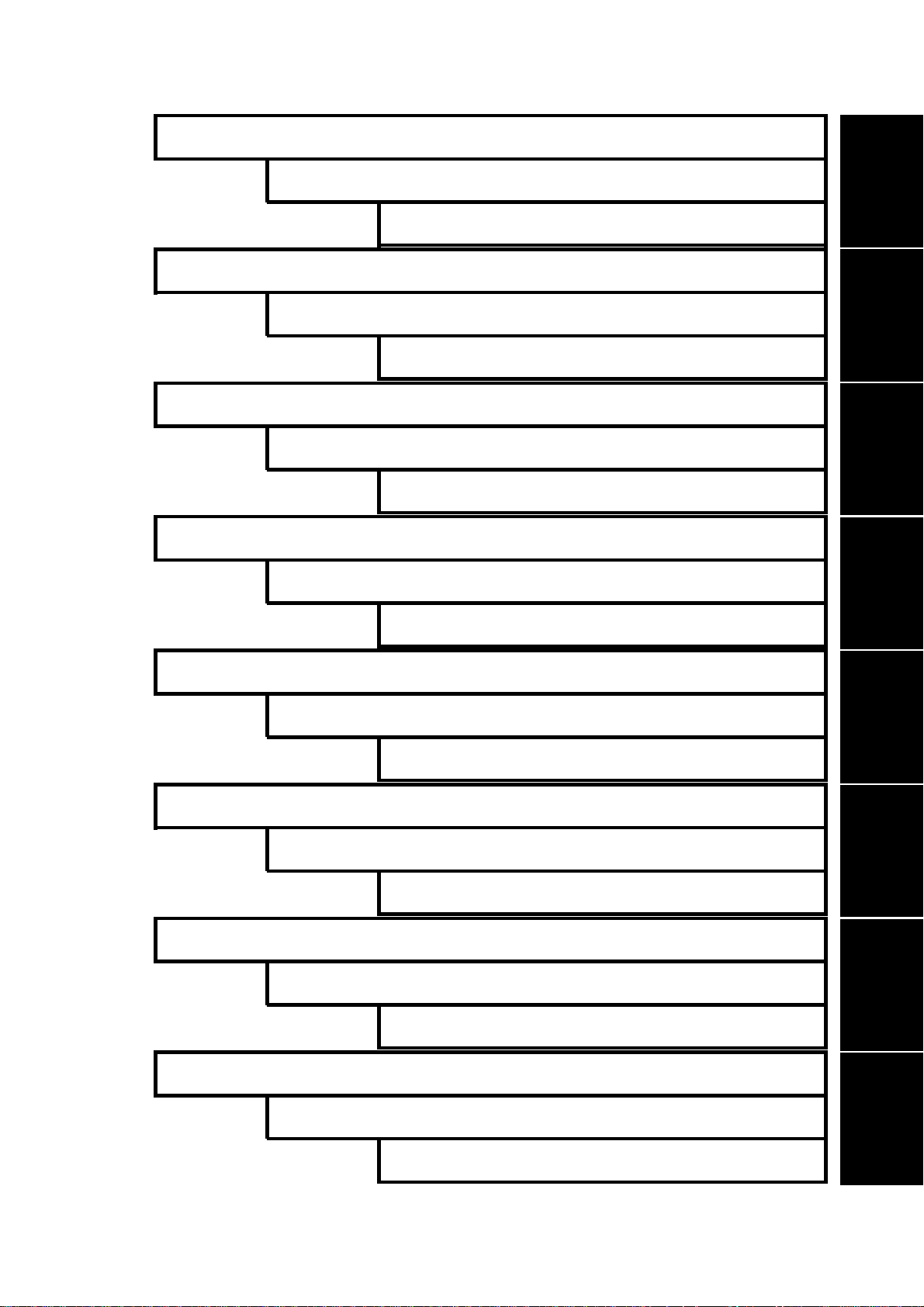

TAB INDEX

OVERALL MACHINE INFORMATION

RECIRCULATING DOCUMENT HANDLER DH500 (A607)

DETAILED SECTION DESCRIPTIONS

FINISHER SR900 (A608)

INSTALLATION

LARGE CAPACITY TRAY RT34 (A609)

TAB POSITION 1

TAB POSITION 2TAB POSITION 3TAB POSITION 4

SERVICE TABLES

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

DUAL JOB FEEDER DF62 (A610)

TAB POSITION 5TAB POSITION 6

SORTER STAPLER ST28/ST28P (A606)

TAB POSITION 7TAB POSITION 8

Page 30

Page 31

SECTION 1

OVERALL MACHINE

INFORMATION

Page 32

Page 33

1. SPECIFICATION

Configuration: Console

Copy Process: Dry electrostatic transfer system

Toner Supply Control: Fuzzy Control

Photoconductor: OPC drum

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Original Alignment: Left rear corner

Copy Paper Size: Maximum A3/11" x 17"

Minimum A5/5

B5/8

A6/5

1/2

1/2

1/2

1/2

" x 8

" (Tray)

" x 11" (1.5 k LCT)

1/2

" x 8

" (By-pas s)

Duplex Copying: Maximum A3/11" x 17"

Minimum A5/5

1/2

" x 8

1/2

" (sidewa ys)

Copy Paper Weight: Paper tray: 52 ~ 128 g/m

Bypass feed table: 52 ~ 157 g/m

Duplex copying: 64 ~ 104 g/m

Reproduction Ratios: 4 Enlargement and 6 Reduction

A4/A3 Version LT/LDG Version

200%

Enlargement

Full Size 100% 100%

Reduction

141%

122%

115%

93%

82%

75%

71%

65%

50%

2

, 14 ~ 34 lb

2

, 14 ~ 42 lb

2

, 17 ~ 24 lb

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

Inform a tion

Overal l Ma chine

SM 1-1 A175/A176/A177

Page 34

Power Source: 115 V, 60 Hz, more than 20 A (for N.A)

220 ~ 240 V, 50 Hz/60 Hz, more than 10 A (for

Europe and Asia)

Power Consumption: A175 copier

Copier only Full system*

Warm-up 1.20 kVA 1.22 kVA

Stand-by 0.22 kVA 0.24 kVA

Copying 1.40 kVA 1.40 kVA

Maximum 1.70 kVA 1.75 kVA

A176 copiers

Copier only Full system*

Warm-up 1.20 kVA 1.22 kVA

Stand-by 0.22 KVA 0.24 kVA

Copying 1.50 kVA 1.50 kVA

Maximum 1.70 kVA 1.75 kVA

A177 copiers

Copier only Full system*

Warm-up 1.20 kVA 1.22 kVA

Stand-by 0.22 kVA 0.24 kVA

Copying 1.60 kVA 1.60 kVA

Maximum 1.70 kVA 1.75 kVA

*Full System:

Mainframe with dual job feeder, floor type

•

sorter stapler and 3,500-sheet large capacity

tray

Mainframe with recirculating document

•

handler, finisher and 3,500-sheet large

capacity tray

A175/A176/A177 1-2 SM

Page 35

Noise Emiss ion : Sound Pressure Le ve l:

The measurements are made according to

ISO7779

A175 copier

Sound pressure level

(The measurements are made according to ISO 7779 at

the operator position.)

Stand-by less than 34 dB (A)

Copying less than 57 dB (A) (average)

Inform a tion

Overal l Ma chine

Copier only

Sound power level

A176 copiers

Sound pressure level

Sound power level

A177 copiers

Sound pressure level

(The measurements are made according to ISO 7779.)

Copier only

Stand-by less than 48 dB (A)

Copying less than 70 dB (A) (average)

(The measurements are made according to ISO 7779 at

the operator position.)

Stand-by less than 34 dB (A)

Copying less than 59 dB (A) (average)

(The measurements are made according to ISO 7779.)

Stand-by less than 48 dB (A)

Copying less than 73 dB (A) (average)

(The measurements are made according to ISO 7779 at

the operator position.)

Copier only

Copier only

Copier only

Stand-by less than 36 dB (A)

Copying less than 59 dB (A) (average)

Sound power level

SM 1-3 A175/A176/A177

(The measurements are made according to ISO 7779.)

Copier only

Stand-by less than 50 dB (A)

Copying less than 73 dB (A) (average)

Page 36

Dimensions:

Width Depth Height

Copier only 690 mm

27.2"

Copier with dual job feeder, sorter stapler, and

3,500-sheet large capacity tray

Copier with dual job feeder, sorter stapler with

punch, and 3,500-sheet large capacity tray

Copier with recirculating document handler,

finisher, and 3,500-sheet large capacity tray

1,659 mm

65.4"

1,659 mm

65.4"

1,764 mm

65.9"

690 mm

27.2"

690 mm

27.2 mm"

690 mm

27.2"

690 mm

27.2"

980 mm

38.6"

1,116 mm

43.9"

1,113 mm

43.9

1,112 mm

43.8"

Weight: Copier only: (Without the optional platen cover

= Approximately 2 kg)

A175 copier: Approximately 161 kg

A176/A177 copiers: Approximately 164 kg

A191/A192 copiers: Approximately 167 kg

Zoom: From 50% to 200% in 1% steps

Copying Speed:

A175 copier

A176 copiers 60 31 38

A177 copiers 70 36 44

A4/LT (sideways) A3/DLT B4/LG

51 (A4 others)

50 (A4/in France)

50 (LT)

26 32

Warm-up Time: Less than 5 minutes (20°C) (A175 copier)

Less than 5.5 minutes (20°C) (A176/A177

copiers)

First Copy Time:

(A4/81/2: x 11" sideways

3.1 seconds (A175 copier)

2.6 seconds (A176/A177 copiers)

from the 1st feed station)

Copy Number Input: Number keys, 1 to 999 (count up or count down)

Manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute standard setting; can also be set from

1 second to 999 seconds or no auto reset.

A175/A176/A177 1-4 SM

Page 37

Copy Paper Capacity:

By-pass feed table: approximately 50 sheets

•

Paper tray: approximately 550 s heets

•

Tandem tray: approximately 500 sheets

•

Large capacity tray: approximately 1500

•

sheets

Toner Replenishment: 1,100 g/cartridge, Yield 38K/cartridge 6% original

Developer Replenishment: Black only, 1Kg/Bag. Yield 120K/Bag

Optional Equipment:

Platen cover (A528-04)

•

Dual job feeder (A610)

•

Recirculating document handler (A607)

•

20 bin sorter stapler (Floor type) (A606-17)

•

Finisher (A608)

•

3500-sheet Large capacity tray (A609)

•

Receiving Tray (A446-05)

•

Key Counter Bracket D (A509-03)

•

20 bin sorter stapler (Floor type) with punch

•

(A606-57),

Editing sh ee t (spare pa r t)

•

Inform a tion

Overal l Ma chine

SM 1-5 A175/A176/A177

Page 38

2. MACHINE CONFIGURATION

2.1 COPIER OVERVIEW

There are three types of mainframe.

FT7650 (A175) copier

Four 550-sheet paper trays

Optional 3,500-sheet large capacity

tray

50

550

550

(3,500)

550

550

FT7660/7670 (A176/A177) copiers

Tandem paper tray

(including two 500-sheet paper tray)

One 550-sheet paper tray

1,500-sheet built-in large capacity

tray

Optional 3,500-sheet large capacity

tray

50

500 x 2 or 500

550

(3,500)

1,500

A175/A176/A177 1-6 SM

Page 39

2.2 SYSTEM OVERVIEW

DJF vers ion

Mainframe type FT7650/7660/7670 (A175/A176/A177) with dual job feede r

and floor type sorter stapler. The mainframe in the illustration below is the

FT7660.

Dual job feeder (DF62)

Inform a tion

Overal l Ma chine

Floor type

sorter stapler

(ST28) or

3,500-sheets

large capacity

tray (RT34)

Floor type

sorter stapler

with punch

(ST28P)

RDH version

The mainframe FT7650/7660/7670 (A175/A176/A177) with recirculating

document handler and finisher. The mainframe in the illustration below is the

FT7660.

Recirculating document handler (DH500)

Finisher

(SR900)

3,500-sheets

large capacity

tray (RT34)

SM 1-7 A175/A176/A177

Page 40

3. COPY PROCESS AROUND THE DRUM

10

9

1. OPC DRUM

The organic photo conductive (OPC) drum (100 mm diameter) has high

resistance in the dark and low resistance under light.

11

8

5

4312

7

6

2. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the

OPC drum. The charge remains on the surface of the drum. The amount of

negative charge on the drum is proportional to the negative grid bias voltage

applied to the grid plate on the charge corona unit.

3. EXPOSURE

An image of the original is reflected to the OPC drum surface via the optics

section. The charge on the drum surface is dissipated in direct proportion to

the intensity of the reflected light, thus producin g an electrical latent image

on the drum surface.

The amount of charge remaining as a latent image on the drum depends on

the exposure lamp intensit y controlled by the exposure lamp voltage.

4. ERASE

The erase lamp illuminates the areas of the charged drum surface that will

not be used for the co py image. The resistance of drum in the illuminated

areas drops and the charge on those areas dissipates.

5. DRUM POTENTIAL SENSOR

The drum potential sensor detects the electric potential on the drum to

compensate ima ge processing elements.

A175/A176/A177 1-8 SM

Page 41

6. DEVELOPMEN T

Positively charged toner is attracted to the negatively charged areas of the

drum, thus developing the latent image. (The positive triboelectric charge of

the toner is caused by friction between the carrier and toner partic les.)

The development bias voltage applied to the development roller shaft

controls two things:

1) The threshold level if toner is attracted to the drum or toner remains on

the dev elopmen t roller.

2) The amount of toner to be attracted to the drum.

The higher the negative development bias voltage is, the less toner is

attracted to the drum surface.

7. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove almost all the negative charge from

the exposed areas of the drum. This makes image transfer easier.

8. IMAGE TRANSFER

Paper is fed to the drum surface at the proper timing so as to align the copy

paper and the developed image on the drum surface. Then, a negative

charge is applied to the reverse side of the copy paper by the transfer belt,

producing an electrical force which pulls the toner particles from the drum

surface onto the copy paper. At the same time, the copy paper is electrically

attracted to the transfer belt.

Inform a tion

Overal l Ma chine

9. PAPER SEPARATIO N

Paper separates from the OPC drum by the electrical attraction between the

paper and the transfer belt. The pick-off pawls help to separate the paper

from the drum.

10. CLEANING

The cleaning brush removes toner remaining on the drum after image

transfer and the cleaning blade scrapes off all the remaining toner.

11. QUENCHING

Light from the quenching lamp electrically neutralizes the charge potential of

the drum surface.

SM 1-9 A175/A176/A177

Page 42

4. MECHANICAL COMPONENT LAYOUT

39

38

37

36

34

2

1

511

6

8

9

7

10

12

13

14

15

16

17

18

19

20

21

22

35

34

33

32

31 30

23

24

25

26

27

40

28

29

A175/A176/A177 1-10 SM

Page 43

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Cleaning Brush

7. Cleaning Blade

8. Quenching Lamp

9. Charge Corona Unit

10. OPC Drum

11. 6th Mirror

12. 4th Mirror

13. 5th Mirror

22. Registration Rollers

23. Transfer Belt

24. Vertical Transport Rollers

25. Tandem Tray

550-sheet Tray

26. Universal Tray

27. 1500-sheet L CT

550-sheet Tray

28. Toner Collection Bottle

29. Transfer Belt Cleaning Blade

30. Hot Roller

31. Pres su re Ro ller

32. Jogger Fences

33. Duplex Positioning Roller

Inform a tion

Overal l Ma chine

14. Erase Unit

15. Drum Potential Sensor

16. Toner Hopper

17. Development Unit

18. Pre-Transfer Lamp

19. Pick-up Roller

20. Feed Ro lle r

21. Separation Roller

34. Duplex Pick-up Roller

35. Dupl ex Fe e d Roller

36. Separation Belt

37. Juncti on Gate

38. Exit Rollers

39. Optics Cooling Fan

40. 550-sheet Tray

SM 1-11 A175/A176/A177

Page 44

5. DRIVE LAYOUT

❾

❽

❼

❻

❺

9

10

11

1

❶

❷

2

3

4

5

❸

6

8

❹

Main Motor

❶

Scanner Drive Motor

❷

Fusing/Duplex Drive Motor

❸

Paper Feed Motor

❹

Toner Collection Motor

❺

Registration Clutch

❻

By-Pass Fe ed M oto r

❼

BY-Pass Feed Clutch

❽

Development Drive Motor

❾

7

1. OPC Drum

2. Scanner Unit

3. Transfer Belt Unit

4. Paper Exit Unit

5. Fusing Unit

6. Duplex Unit

7. Paper Trays

8. Paper Feed Units

9. Toner Hopper

10. Development Unit

11. Cleaning Unit

A175/A176/A177 1-12 SM

Page 45

6. PAPER PATH

6.1 STANDARD COPYING

[E]

[F]

[D]

[C]

Inform a tion

Overal l Ma chine

[B]

[A]

[A]

Paper feed begins from the exterior LCT, by-pass feed table or paper feed

stations in the paper tray unit. The copy paper then follows one of two paths

inside the copier. The path followed depends on which mode the operator

has selected. For copy processing, all sheets follow the same paths from the

paper feed mechanism [A] through the registration rollers [B], transfer belt

[C], and fusing unit [D]. After that, copies are delivered to the sorter bins [E]

or proof tray [F], however, 2 sided copies are diverted for further processing.

SM 1-13 A175/A176/A177

Page 46

6.2 MULTIPLE 2-SIDED COPYING

[A]

[B]

a. Front Side

[D]

[C]

b. Rear Side

In this mode the junction gate [A] directs sheets exiting the fusing unit to the

duplex tray entrance. After that, all sheets follow the path through the duplex

entrance rollers [B].

After all front side copying is completed, the sheets on the duplex tray are

fed in order from the bottom to the top and follow the path through the duplex

feed mechanism and vertical transport rollers [C] to the registration rollers

[D]. After that, these sheets follow the same path as standard copying from

the registration rollers to the sorter.

A175/A176/A177 1-14 SM

Page 47

7. ELECTRICAL COM PONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the attached

Point to Point for symbols and index numbers.

Symbol Name Function Index No.

Motors

M1

M2

M3

M4

M5

M6

M7

M8

M9

M10

M11

M12

M13

M14

M15

M16

M17

M18

M19

M20

Scanner Drive Drives the 1st and 2nd scanners (dc

servo).

Exhaust Fan Removes the heat from around the

fusing unit.

Main Drives the main unit components.

Development Drive Drives the development unit.

By-pass Feed Drives the by-pass feed rollers.

3rd Scanner Drive Drives the 3rd scanner (dc stepper)

Toner Bottle Drive Rotates the toner bottle to supply

toner to the toner hopper.

Charge Wire Cleaner

Drive

Jogger Drives the jogger fences to square the

Lens Horizontal Drive Shifts the lens horizontal position.

Lens Vertical Drive Shifts the lens vertical position.

Optic Cooling Fan Removes heat from the optics unit.

Fusing/Duplex Drive Drives the fusing unit, the duplex unit,

Paper Feed Drives all feed and transport rollers in

1st Lift Raises the bottom plate in the 1st

2nd Lift Raises the bottom plate in the 2nd

Toner Collection Transports the collected toner to the

3rd Lift

(4 Tray version only)

Side Fence Drive

(Tandem version only)

Rear Fence Drive

(Tandem version only)

Drives the main charge wire cleaner

to clean the charge wire.

paper stack in the duplex tray (dc

stepper).

and the paper exit rollers.

the paper tray unit.

paper tray.

paper tray.

toner collection bottle.

Raises the bottom plate in the 3rd

paper tray.

Opens and closes the front and the

rear side fences of the tandem tray.

Moves the papers stacked in the left

tandem tray to the right tandem tray.

42

43

44

45

46

47

48

49

50

51

52

53

54

90

91

92

93

94

95

96

Inform a tion

Overal l Ma chine

LCT Motor

M21

SM 1-15 A175/A176/A177

(1,500 Tray version only)

Lifts and lowers the LCT bottom plate

to bring paper to the feed position and

allow loading of the paper.

127

Page 48

Symbol Name Function Index No.

M22

AC Drive Cooling Fan

(60/70 CPM version only)

Remove heat from around the AC

drive unit.

141

Optic Cooling Fan-2

M23

M24

M25

M26

* (A: 60/70 CPM, B: 50/51 CPM)

Magnetic Clutches

MC1

MC2

MC3

MC4

MC5

MC6

MC7

MC8

MC9