Page 1

Technical Bulletin No. RTB-001

SUBJECT: Light Copies DATE: Nov. 30, ’96

PAGE: 1 of 2

PREPARED BY: F. Noguchi

FROM: 1st Field Information Dept. QAC

CHECKED BY: T. Inoue

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

F401/411/421

<Symptom>

When making multiple copies (100~300) of an original with a high image area ratio

(example: Test Chart=35%), there is a drop in the copy image density.

<Cause>

The toner supply level is less than the toner consumption level.

<Field Action>

1. If the customer frequently makes copies of originals with an image area ratio of more

than 30%, please change the toner supply ratio from "N" to "H". (SP Adjustment, page

7, Factory Use-T)

Note: If the toner supply level of "H" is selected, dirty background may appear in

non-image areas during toner supply.

Explanation

To prevent dirty background during toner supply with the F401S, the toner supply rate

default level has been lowered. (A 6% letter original has been found to be the type of

original most often used in the field.)

F401S F400S

L N H L N H

Toner Supply Co-efficient x 0.3 x 0.5 x 1.0 x 0.5 x 1.0 x 1.5

Max. Toner Supply Ratio 30% 30% 60% 30% 60% 90%

2. During installation or demonstrations, please do not use an original with a high image

area ratio, like the test chart, in the multi-copy mode (100~300).

Reason: Vsp is detected after the copy run has been completed if 10 or more copies

are made after the last Vsp detection. Since the transfer belt must be released when

checking Vsp, a Vsp check cannot be done during a multi-copy run. Therefore, the

toner density control during a multi-copy run will try to get close to the VT based on the

Vref determined at the time of the last ID Sensor detection. In other words, it tries to

maintain the toner density at the level set during the last ID sensor check. At the start

of the copy run, if Vsp<1/10Vsg then the toner supplied will be insufficient. After the

multi-copy run, the ID Sensor detection was performed and Vref was changed but

since the toner density did not reach the targeted toner density level, the image density

dropped during the next multi-copy run.

<Service Manual Correction> (See attached page)

Section 4: Service Tables

2. Service Program Mode

2.2: Service Program Mode Table

Page 4-12

Page 2

Technical Bulletin No. RTB-001

SUBJECT: Light Copies DATE: Nov. 30, ’96

PAGE: 2 of 2

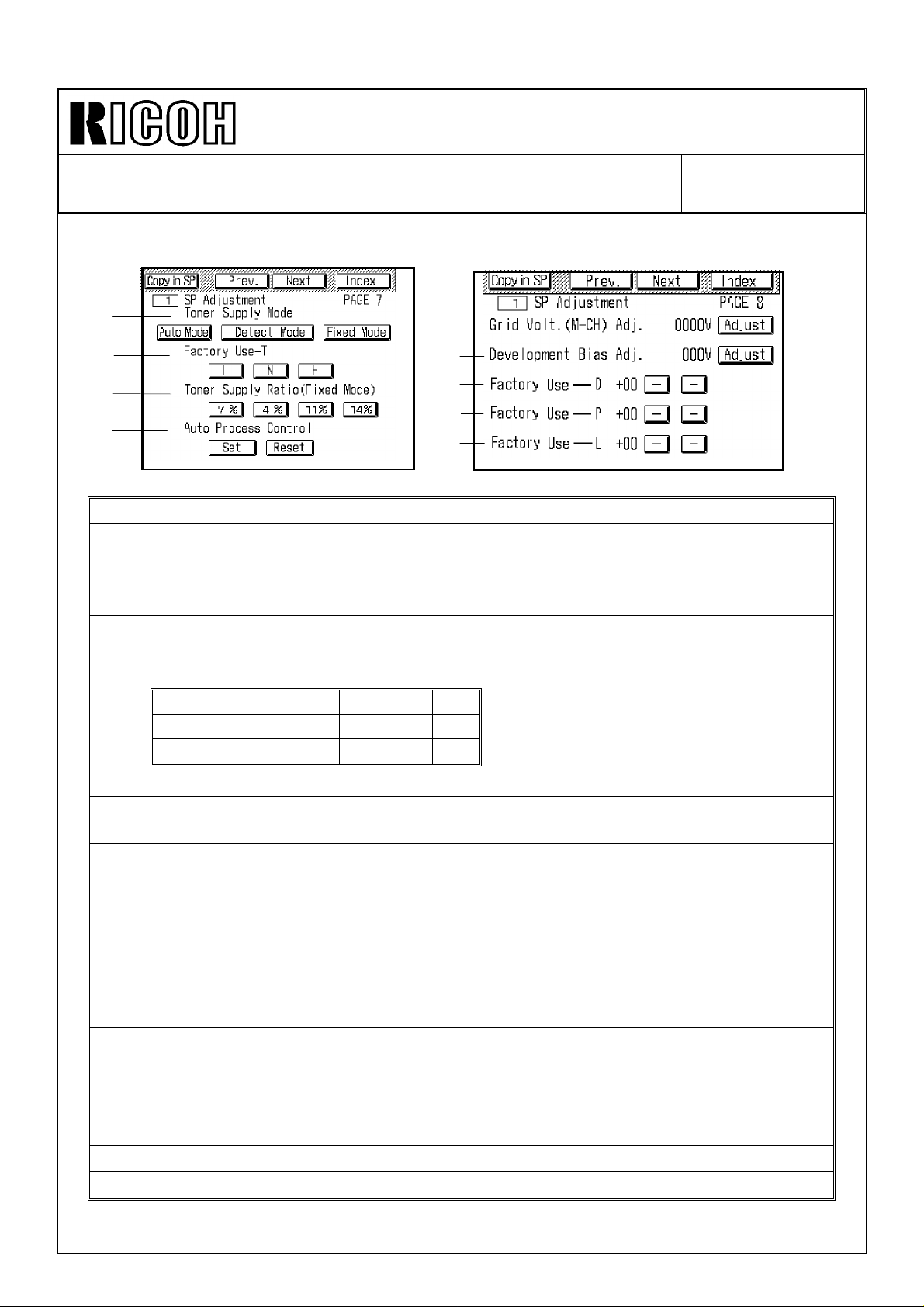

SP ADJUSTMENT

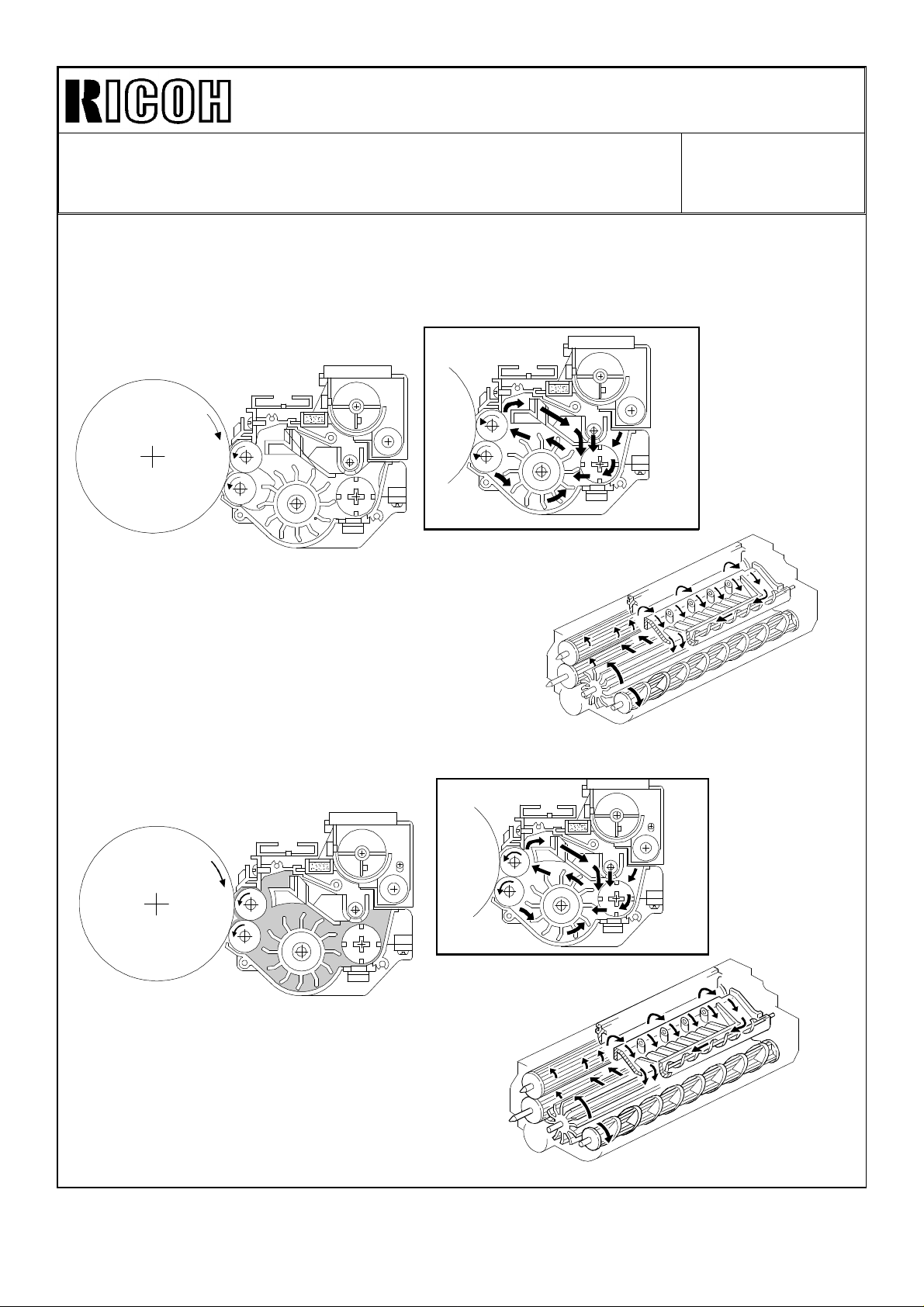

❶

❷

❸

PAGE 7

❼

PAGE 8

❺

❻

❽

❹

A176M508.img

Item Function Note

Selects toner supply mode.

(See the process control section for

❶

details about each supply mode.)

Default: Auto Mode

Changes the toner supply level in auto

and detect toner supply mode.

Default: N

Toner Supply level L N H

❷

Toner Supply Co-effcient x 0.3 x 0.5 x 1.0

Max. Toner Supply Ratio 30% 30% 60%

❾

Select "Auto Mode" in the field.

Select "N" in the field.

A176M509.img

Changes the toner supply ratio in fixed

❸

toner supply mode. Default: 4%

Enables and disables the auto process

control (VR, VL, VD corrections).

❹

(See the process control section for

details.) Default: Set

Inputs the grid bias voltage when auto

process control is disabled or after

❺

RAM is cleared (1 V/step).

Default: 870 V

Inputs the development bias voltage

when auto process control is disabled

❻

or after RAM is cleared (1 V/step).

Default: 220 V

Factory use only Do not change the setting in the field.

❼

Factory use only Do not change the setting in the field.

❽

Factory use only. Do not change the setting in the field.

❾

Be careful, there is no overtoning

protection system.

Normally select "Set". Select "Reset"

only to check if the cause of the

problem is related to process control or

not.

Enter the setting using the number

keys, then touch "Enter".

Enter the setting using the number

keys, then touch "Enter".

Page 3

Technical Bulletin No. RTB-002

SUBJECT: Service Remarks and Service Manual Correction DATE: 15,January

’97

PAGE: 1 of 3

PREPARED BY: H. K.

FROM: 1st Field Information Dept. QAC

CHECKED BY: T. Inoue

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:F401/F411/F421

1. Service Remarks (service manual page 4-5)

As one of the service remarks for the fusing unit, please add the following to your service

manual.

Symptom: A smeared image appears on the leading edge at about 10 mm on the 1st copy

at the machine installation.

Details: Silicone oil may slightly soak into the surface of the hot roller during machine

storage. The silicone oil may stick to the surface of the pressure roller when the hot roller

contacted the pressure roller at installation. The pressure roller may slip due to the oil

because the hot and pressure rollers are new. Therefore, a smeared image may appear

on the leading edge at about 10 mm on the 1st copy. This is because the hot roller is

rubbing the leading edge of the copy on the pressure roller.

Action: This symptom occurs only at the 1st copy after installation. Make sample copies

and make sure that the symptom does not recur after several copies.

2. Exposure Lamp for 230 V machines

Due to the use of the transformer, the same exposure lamps (AX520016 for the 50 CPM

machine, AX520020 for the 60/70 CPM machine) as for the 110 ~ 120 V version machines

are used for the 230 V machines. The exposure lamps for the 230 V machines in the

F400/F410/F420 are different from those for the 110 ~ 120 V machines in the

F400/F410/F420. Please note that the exposure lamps for the 230 V machines of

F401/F411/F421 cannot be installed in the F400/F410/F420 machines. Please see the

following table.

F401

(50/51 CPM)

AX520016 Yes No No Yes Yes No No No No

AX520020 No Yes Yes No No Yes No No No

AX520018 No No No No No No Yes Yes No

AX520022 No No No No No No No No Yes

F411

(60 CPM)

F421

(70 CPM)

F400

(45 CPM)

110~120V

F410

(55CPM)

110~120V

F420

(65 CPM)

110~120V

F400

(45 CPM)

230V

F410

(55 CPM)

230V

F420

(65 CPM)

230V

Yes : Can be used.

No : Cannot be used.

Page 4

Technical Bulletin No. RTB-002

SUBJECT: Service Remarks and Service Manual Correction DATE: 15,January

’97

PAGE: 2 of 3

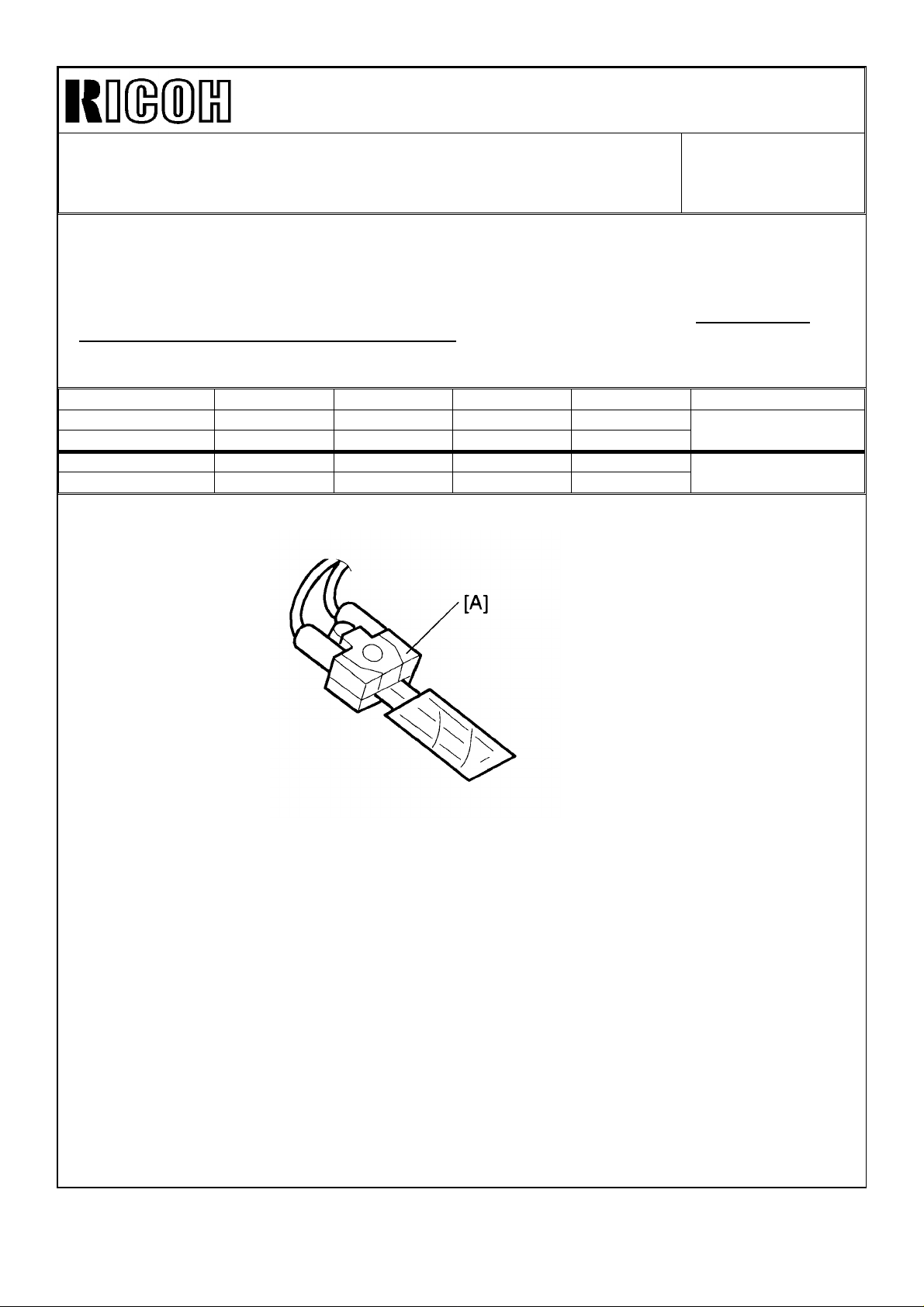

3. Fusing Thermistor Replacement (service manual page 5-94) and PM item (service

manual 4-55 and 4-60)

We found that if silicone oil is applied at the point where the thermistor comes in contact

with the hot roller, this may result in peeling of the film on the thermistor. Do not apply

silicone oil to the hot roller thermistor [A]. The hot roller thermistor PM action has been

revised. Please see the following table.

EM 120K 240K 360K NOTE

Incorrect Suitable solvent.

Fusing Thermistor

Correct Replace if necessary.

Fusing Thermistor I I I

C C C

Refer to NOTE 6

Page 5

Technical Bulletin No. RTB-002

SUBJECT: Service Remarks and Service Manual Correction DATE: 15,January

’97

PAGE: 3 of 3

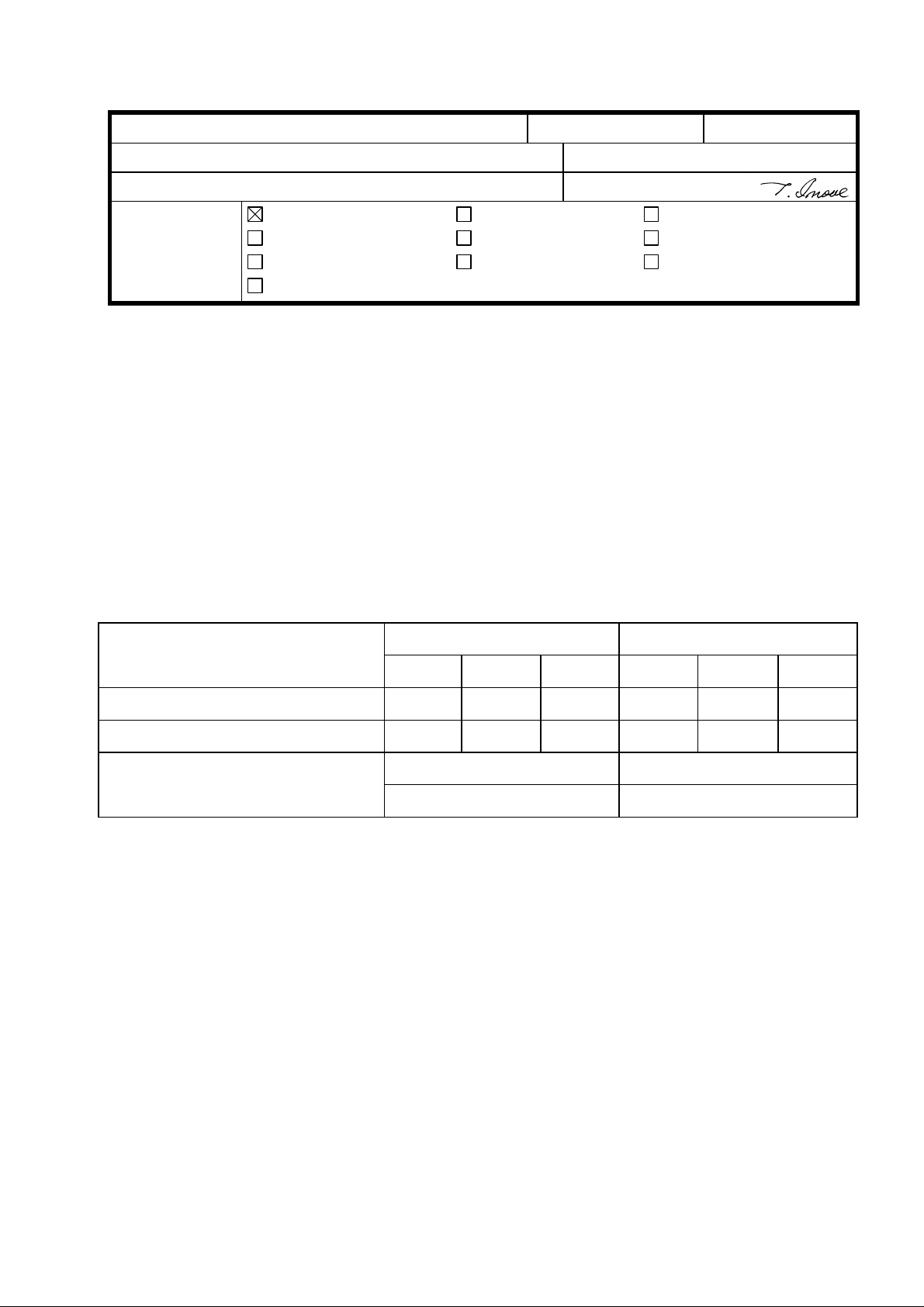

4. Illustration Correction for the Paddle Roller (service manual page 2-46 and 2-48)

The illustrations for the paddle roller on page 2-46 and 2-48 are incorrect. Please correct

your service manuals as shown below.

Incorrect

Correct

2 - 46

2 - 48

2 - 46

2 - 48

Page 6

RICOH Technical Bulletin PAGE: 1/1

Model: F401/411/421 Date: 15-Mar-97

Subject: Light Copies (2) Prepared by: F.Noguchi

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 003

SYMPTOM

When making multiple copies (100-300) of an original with a high image area ratio

(example:Test Chart=35%), there is a drop in image density.

CAUSE

The toner supply level is less than the toner consumption level.

SOLUTION

The toner supply ratio has been changed with the ROM modification listed below.

Please replace the ROMs as necessary.

Old New

L N H L N H

Toner Supply Coefficient x0.3 x0.5 x1.0 x0.5 x1.0 x1.5

Max Toner Supply Ratio 30% 30% 60% 30% x60% x60%

ROM ~A1755151J ~A1755151K

~A1755153J ~A1755151K

Note:

1. If the toner supply ratio has been changed from “N” to “H” (SP Adjustment, page 7,

Factory Use-T) as described in RTB-001, please return the setting to “N” when the new

ROMs are installed.

2. If dirty background appears in non-image areas during toner supply, please change the

toner supply ratio from “N” to “L”.

3. If the slitter in the Toner Supply Unit is removed, the seal may get caught in the slitter

when the slitter is reattached. Please exercise caution to prevent this from happening.

<Cut-in Serial Numbers>

Will be provided as soon as it becomes available.

Page 7

RICOH Technical Bulletin PAGE: 1/9

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

Subject: Cardinal Bird Information Prepared by: H. Kobayashi

From: QAC 1st Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 4

1. Introduction

In addition to F401 (50 cpm machine), another 50 cpm machine (Cardinal Bird) is required

to increase our MIF in the high speed segment. Cardinal Bird is designed and produced

with re-manufactured parts. Ricoh collects the used F400 series machines from the

Japanese domestic market. A Ricoh factory will disassemble the collected machines,

select the re-usable parts from the disassembled parts, and assemble the machines as

new products using the selected re-usable parts and the new parts. (All the PM parts are

new parts.) As a result, the Cardinal Bird is service-friendly because the machine

configuration and PM parts are very similar to the F401 series.

Page 8

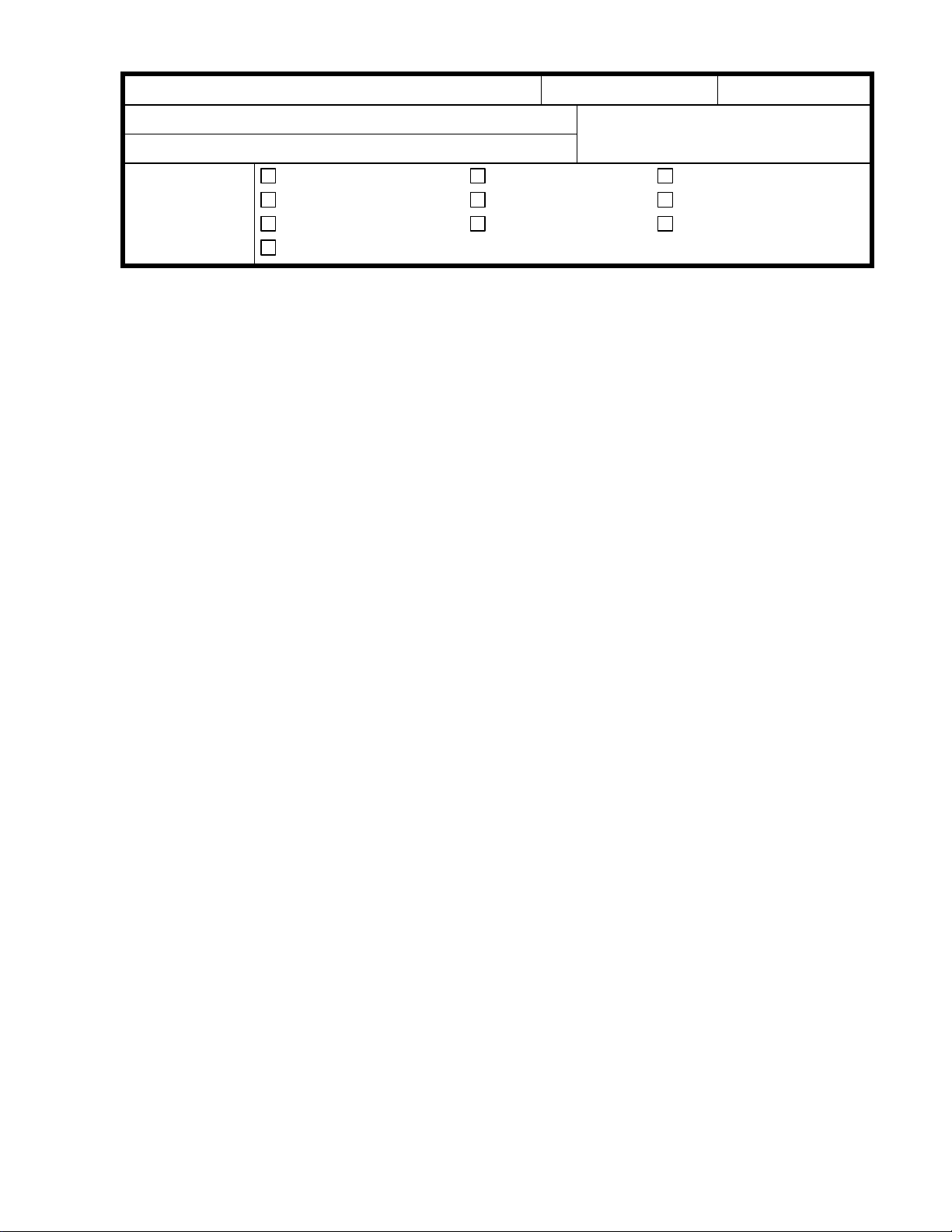

RICOH Technical Bulletin PAGE: 2/9

Leveling feet

No. 17

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

No: 4

2. Sales/Service remarks

In addition to the F401/F411/F421 sales/service remarks, the following remarks are added

as the Cardinal Bird sales/service remarks because the Cardinal Bird has remanufactured parts.

No. Item Category Details Action to be

taken/Remarks

17 Leveling

feet

18 Old parts

before

modification

A, B This machine has a re-manufactured bottom plate.

There are two types of bottom plate. One has two

leveling feet installed. The other has four leveling

feet.

B a) This machine has re-manufactured parts. Among

these parts, there will be some sets of old parts

before modification. These old parts are not often

replaced in the field. However, the old part should

be replaced, together with new ones, as a set if

the old part is replaced in the field because the

old parts were modified as a set.

Please refer to the following F400 MBs.

A0964718

A0964715

A0964715 (MB34)

Please accept

this.

Please accept

replacement of

the old parts

together with the

new parts as a

set.

A0964883

A0965743 A0975473 (MB111)

A0961816 A0971816

A0966303 A1766303 (MB139)

A0966338 A1766338

A0966337 A1766337

b) The jogger sensor bracket has been added for

factory purposes only. There are two types of

duplex unit.

Non-jogger sensor bracket type and jogger sensor

bracket type

A0964762 (Newly added) (MB95)

A0964887 (MB95)

A0964886

Please note that

there are two

types of duplex

unit.

Page 9

RICOH Technical Bulletin PAGE: 3/9

#11

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

No: 4

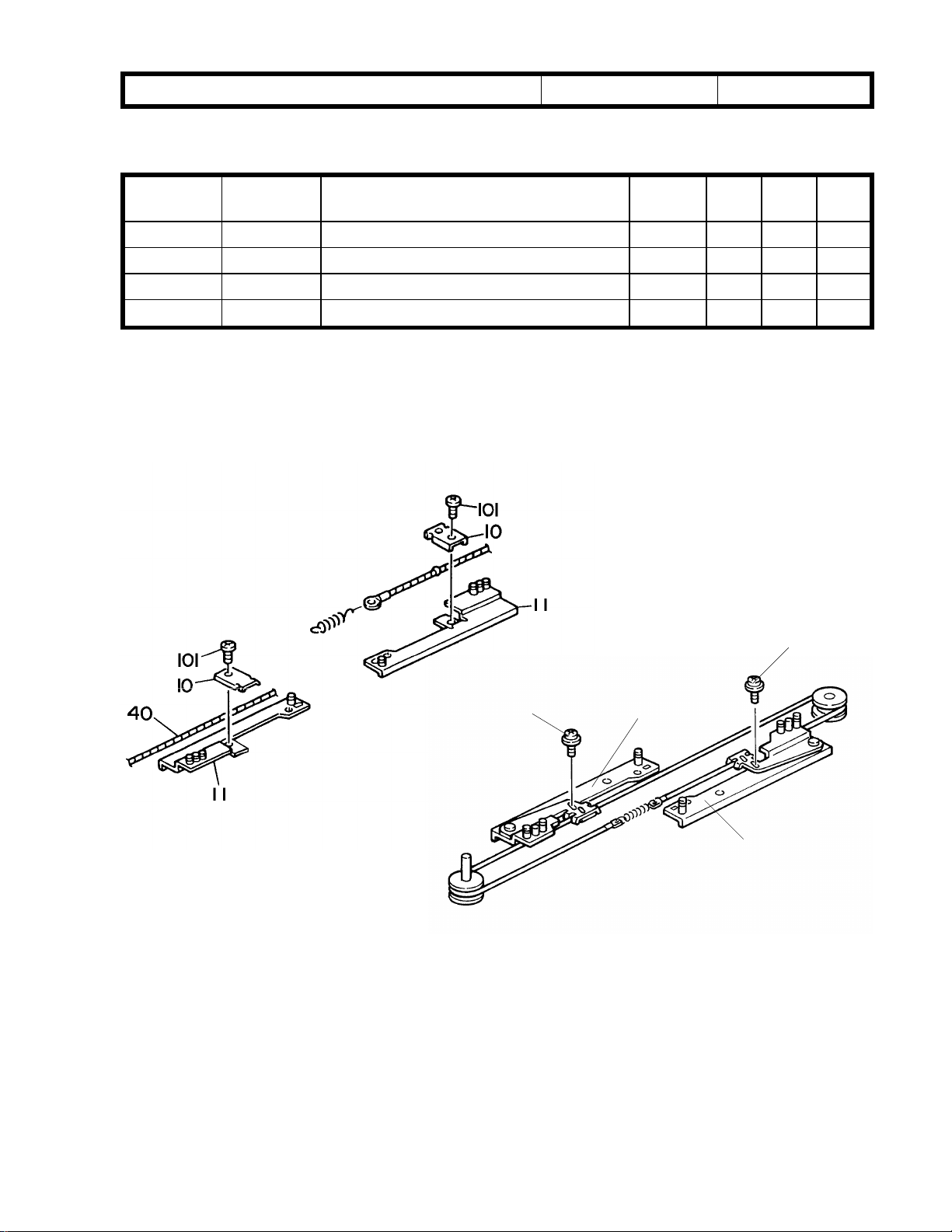

- MB34 -

Old part

number

A0964718 Wire Fixing Plate

A0964715 A0964715 Jogger Support Plate

04340080B Philips Tapping Screw - M4 x 8

New part

number

09514008B Philips Screw with Washer - M4 x 8

Description Qty Int Page Index

2 → 0

2 → 2

n → n-2

n → n+2

X/ 77 10

/O 77 11

X/ 77 101

/O 77 103

To facilitate manufacturing, the wire fixing plate has been mounted on the jogger support

plate. The part number of the jogger support plate is still the same because the old part

was never shipped out as a service part.

#103

#103

#11

Page 10

RICOH Technical Bulletin PAGE: 4/9

# 44

# 108

**

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

No: 4

- MB95 -

Old part

number

A0964883 A0964887 Duplex Lock Lever

A0964894 A0964895 Duplex Harness Bracket

New part

number

A0964762 Jogger Sensor Bracket

A0964886 Duplex Lock Arm

04340080B Philips Tapping Screw - M x 8

Description Qty Int Page Index

0 1

0 1

1 1

1 → 1

n → n+2

*New index number

73 *45

73 *44

X/X 73 3

X/X 75 26

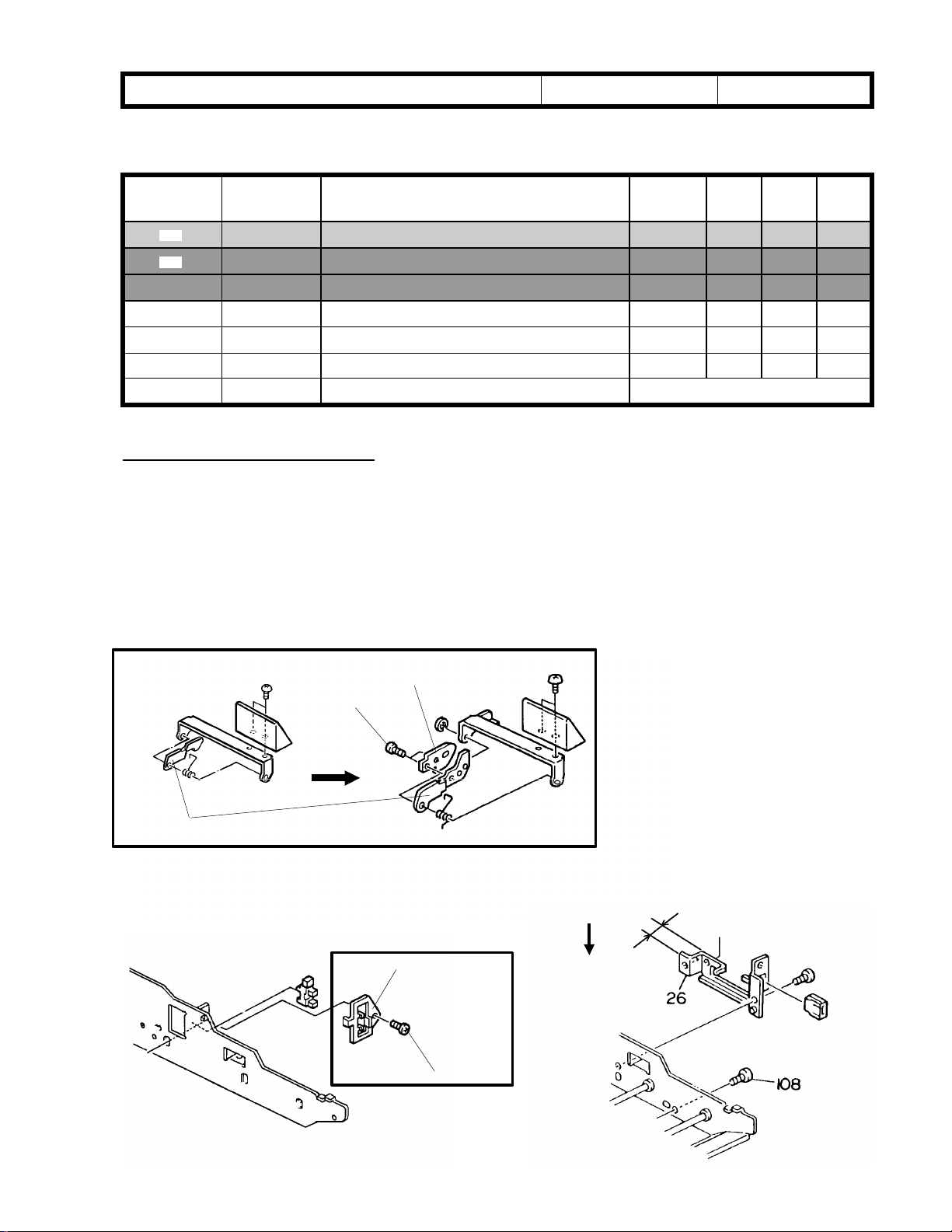

DETAILS OF MODIFICATION

1. The mechanism for the duplex side registration adjustment, which was originally

designed for other models, has been incorporated into the F400/F410/F420. By

changing the position of # 44 against # 3 (one screw, # 108), side registration can be

adjusted ±1.5 mm. At the same time, the height of the duplex harness bracket (# 26)

has been increased by 2 mm to ensure the engagement of the duplex connector.

2. The jogger sensor bracket (# 45) has been added for factory use only.

# 3 Duplex Lock

11.5 mm

# 45

13.5 mm

*

# 101

Page 11

RICOH Technical Bulletin PAGE: 5/9

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

- MB111 -

Old part

number

A0961921 A0971921 Scanner Drive Shaft C

A0961925 A0971925 Front Wire Pulley C

A0071920 A0971746 Exposure Glass Cushion C

A0965473 A0975473 Outer Optics Harness C

11026245 11026283 Connector - 2P

11026246 11026284 Connector - 3P

11026247 11026285 Connector - 4P

11026260 11026285 Connector - 3P

Old part

number

A0961766 A0971766 Lens Slider C

A0961816 A0971816 Sensors Bracket - Lens Position C

A0961994 A0971994 Filter Holder C

AA150336 AA150378 Front Shelding Mylar C

A0961766 A09771766 Lens Slider C

AC051013 AC051016 Lens Guide Red - X C

AC051015 AC051017 Guide Red - 3rd Scanner C

New part

number

A0971698 Scanner Cushion C

New part

number

Description Rank Qty Int Page Index

Description Rank Qty Int Page Index

1 → 1

1 → 1

0 → 2

4 → 4

1 1

1 → 1

1 → 1

1 → 1

1 → 1

1 → 1

1 1

1 → 1

1 → 1

1 → 1

1 → 1

1 → 1

No: 4

O/O 23 1

O/O 23 2

27 28

O/O 19 15

X/X 23 31

O/X 23 117

O/X 23 118

O/X 23 120

O/X 23 119

O/O 31 11

X/X 23 21

O/O 21 11

O/O 31 7

O/O 31 11

O/X 25 2

O/X 29 25

Page 12

RICOH Technical Bulletin PAGE: 6/9

28

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

DETAILS OF MODIFICATION

The parts listed on the front pages have been modified for part standardization with other

models.

- Supplemental explanation for outer optics harness The sensor bracket has been modified as shown below right. At the same time, four

relay connectors (index # 118 through # 120), which have been changed from the

type attachable in the bracket holes to the flat type, have been incorporated into the

outer optics harness.

Sensor Bracket

No: 4

# A0975473

Scanner Cushion

Page 13

RICOH Technical Bulletin PAGE: 7/9

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

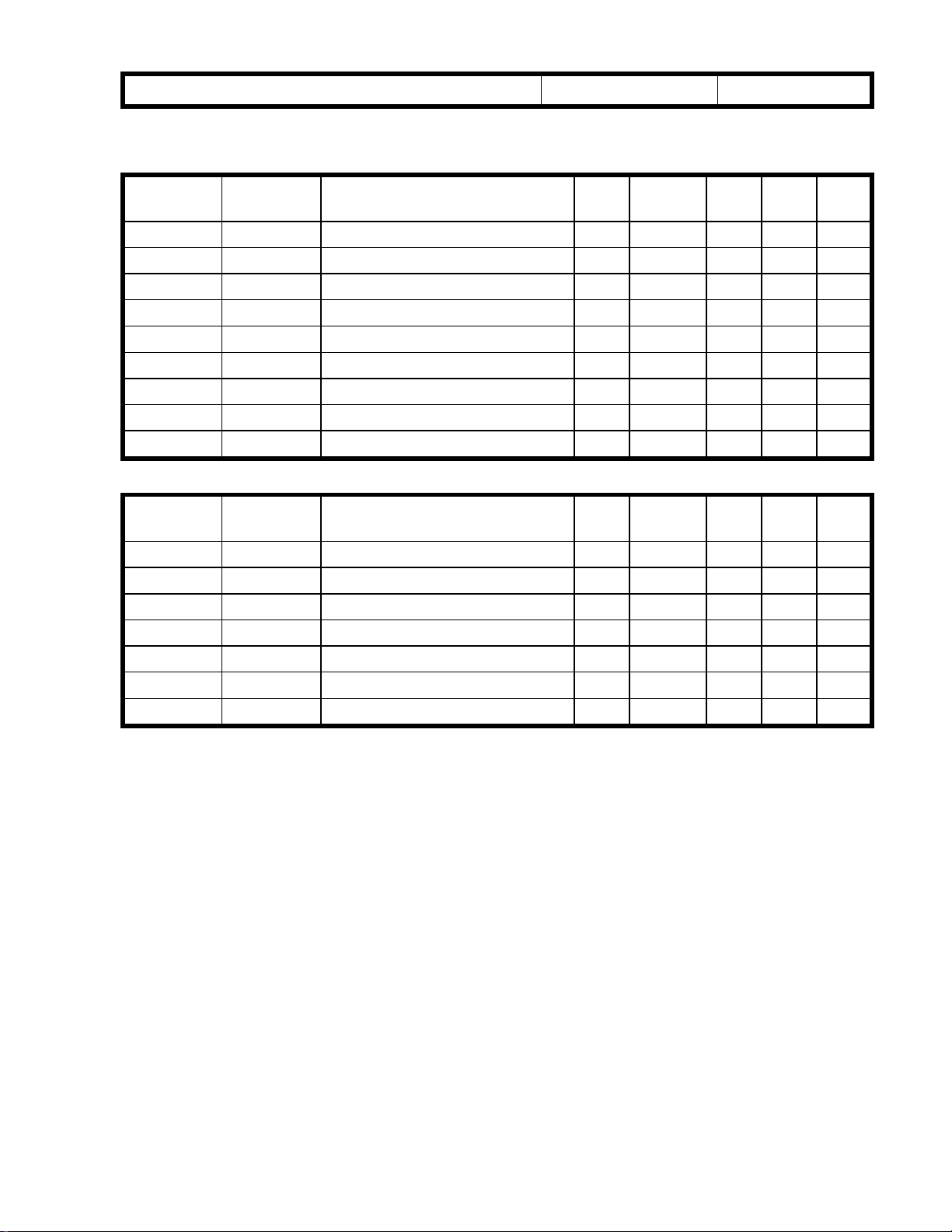

- MB139 -

Due to parts standardization, the following parts have been changed.

Since the location of the position sensor bracket on which the separation roller stay is

installed has been moved 5 mm towards the rear, please replace the 3 parts listed above

at the same time. Also because the old parts were molded, they will no longer be

available.

Old part

number

A096 6303 A176 6306 Separation Roller Stay 3 - 3 X/X 39 44 *

A096 6338 A176 6338 Separation Guide 3 - 3 X/X 39 42 *

A096 6337 A176 6337 Paper Feed guide 3 - 3 X/X 39 14 *

The interchangeability is O/O as a set.

New part

number

Description Qty Int Page Index Note

No: 4

-Old-

12.5 mm

-New-

7.5 mm

-Old-

Blue circle

(for Cardinal Bird only)

Page 14

RICOH Technical Bulletin PAGE: 8/9

550

550

3,500

550

storage

550

3,500

550

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

No: 4

3. Service manual

The Cardinal Bird service manual, which is to be inserted into the F401/F411/F421

service manual, will be prepared.

4. Parts catalog

The Cardinal Bird parts catalog, which is the F401/F411/F421 copier parts catalog and

which can be used as the F401/F411/F421/Cardinal Bird copier parts catalog, will be

prepared.

5. Machine configuration

There are two types of mainframe.

A220 - (10, 17, 20, 29,:) copiers

Three 550-sheet paper trays

Optional 3,500-sheet large capacity tray

A220 - (22: china) copiers

Two 550-sheet paper trays

storage tray

Optional 3,500-sheet large capacity tray

Page 15

RICOH Technical Bulletin PAGE: 9/9

Model: F401/F411/F421/Cardinal Bird Date: 15-Jun-97

No: 4

6. Transport Guide of the lower drum unit

To ensure paper transport, the 60/70 cpm type of transport guides are added to the pickoff pawl section.

7. PSU

As a re-manufactured PSU (AZ240019:100/115 V) is used for this machine, a transformer

has been added to the 220/230/240 V versions. Please note that the PSU (AZ240021) for

the 220/230/240 V versions of the F400/F410 cannot be used for the 220/230/240 V

versions of the Cardinal Bird

A220 -10,-17

(Cardinal)

AZ240019 Yes Yes Yes No

AZ240021 No No No Yes

Yes: Can be used.

No: Cannot be used.

A220 -20, -22, -29

(Cardinal)

F400/F410

(U.S.A.)

F400/F410

(220/230/240 V)

Page 16

RICOH Technical Bulletin PAGE: 1/1

Model: F401/411/421/Cardinal Date: 31-Aug-97

Subject: ON/OFF Control vs Phase Control Prepared by: H.K.

From: QAC 1st Field Information Dept.

Classification:

We have found a mistake in the service manual on page 2-98 (Fusing Lamp Control).

Please correct your service manual as follows:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 5

Incorrect

By cutting JP501 on the optics control board, the control mode changes to another mode.

Correct

The fusing temperature control mode cannot be changed on the European version

machines. The electrical noise margin is not enough to meet the European Standards for

the European version for F401/F411/F421. The mode can be changed on the other

version machines as follows.

F401/F411/Cardinal

JP501 U.S.A. and Asia versions European version

Cut On-off control On-off control

Not cut Phase control On-off control

F421

DPS501 U.S.A. and Asia versions European version

ON On-off control On-off control

OFF Phase control On-off control

For reference, the mode change for the F400 series (all versions) is as follows:

F400/F410/F420

JP501 U.S.A. and Asia versions European version

Cut On-off control Phase control

Not cut Phase control On-off control

Page 17

T

Model:

LCT for F401/411/421

echnical

ulletin

B

Date:

15-Oct-97

No:

PAGE: 1/2

6

Subject:

From:

Classification:

LCT Jam

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Kitajima

SYMPTOM

Paper jams occur when feeding from the LCT. The characteristics of this problem

are as follows.

1. Constant jams from LCT installation onwards.

2. Non-paper feed jams.

3. Sometimes there is a crease in the central part of the leading edge of the paper,

which results in skewing.

CAUSE

There is a burr in the welded area of the entrance guide plate in the LCT paper feed

section.

SOLUTION

When this problem occurs in machines in the field or when installing an LCT on which the

countermeasure has not been implemented, please check for burrs in the following

manner.

1. Remove the paper feed unit of the LCT.

2. Carefully insert a piece of OHP sheet along the entrance guide plate as shown.

OHP Sheet

Burr

Page 18

T

Model:

3. If the OHP gets scratched, the burr on the entrance guide plate should be filed away in

4. If the OHP does not get scratched, there is no burr. Another cause needs to be found.

LCT for F401/411/421

the manner shown.

echnical

ulletin

B

Date:

15-Oct-97

No:

PAGE: 2/2

6

Cut-in Serial Number

The proper part has been included in machines with the following serial numbers.

MODEL

NAME

NRG RT34 120/ 60 U. S. A. , Canada

Savin RT34 120/ 60 U. S. A. A609 - 15 5A47470001

Ricoh RT34 120/ 60 U. S. A. A609 - 17 A7077480009

NRG RT34 230/ 50 Europe etc. A609- 22 AF17450001 AF17450002,006,009,

Infotec RT34 230/ 50 Europe A609 - 26 3K84770029

Ricoh RT34 230/ 50 Europe, Asia etc. A609 - 27 A7077470683

V/ Hz DESTINATION CODE SERIAL

NUMBER

A609 - 10 AF07480001

etc.

Exception

A7077480010,012∼189,

275∼276

011∼012,014∼017,023,025

3K84770030∼034,036∼037,

039,044,046∼048

A7077470684,695∼697,

700∼714,717,719∼720,731,

735,744∼802

Page 19

T

Model:

F401/F411/F421

echnical

B

ulletin

Date:

31-Jan-98

No:

PAGE: 1/3

7

Subject:

From:

Classification:

This bulletin is to inform you of the modifications applied to the L-version ROMs.

ROM Part Number

Old New

A1755151K A1755151L

A1755153K A1755153L

1. Energy Star (North America version)

A. Auto-Off Mode Settings

The range of settings for Auto-off Mode has been changed from “1 to 120 minutes”

to “1 to 240 minutes”. The default will not change (90 minutes).

B. Auto-off Release

The weekly timer has been made available. Note that the Off key is displayed on the

screen when setting the time for Auto-off mode, but this key can not be used.

Software update information

QAC Field Informat ion Dept.

Troubleshooti ng

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Kitajima

2. The following symptoms have been corrected.

1. When the following procedure is done, the data for Erase Center/Border is cleared.

① Erase Center/Border Reduce/Enlarge

② Interrupt

③ Interrupt Release

④ Edit Image

⑤ Press Erase Center/Border key

This symptom is duplicated when using the store Program Recall/Program

Interrupt /Interrupt Release key.

2. The duplex jam caused by poor paper stacking in the duplex tray may occur in the

following condition .

• DF version

• Centering mode

• A4 sideways copy paper

• 50 set(s) of copy(ies)

• Double-sided Mode

The jam occurs in the 70 cpm machine more often than in the 60 cpm machine.

Page 20

T

Model:

MODEL

NAME

Ges 2651

NSA 4651

SVN 9500

Savin 9500 120/ 60 U. S. A. A175 - 15 A175 - 15 4A77480002

Ricoh FT7650 120/ 60 U. S. A. A175 - 17 A175 - 17 A7037470373

Ricoh FT7650 110/ 60 Taiwan A175 - 19 A7037070226

Spirio 5000 230/ 50 Korea A175 - 21 A7037070176

Ges 2651

NSA 4651

Rex 8651

Infotec

5501DZ

Ricoh FT7650 230/ 50 Europe, etc. A175 - 27 A7037080130

Ricoh FT7650 230/ 50 Asia, etc. A175 - 29 A7037070001

Ges 2760

NSA 4760

SVN 9600

Savin 9600 120/ 60 U. S. A. A176 - 15 A176 - 15 4A87470001

Ricoh FT7660 120/ 60 U. S. A. A176 - 17 A176 - 17 A7047470001

Ricoh FT7660 110/ 60 Taiwan A176 - 19 A704802xxxx

NSA 4760

Ges 2760

Ricoh FT7660 230/ 50 Asia, etc. A176 - 29 A7047070001

F401/F411/F421

V/ Hz DESTINATION CODE SERIAL

120/ 60 U. S. A. , Canada,

etc.

230/ 50 Europe, etc. A175 - 22 AC47070001

230/ 50 Europe A175 - 26 3K10770001

120/ 60 U. S. A. , Canada,

etc.

230/ 50 Asi a, etc. A176 - 22 AD27070001

echnical

JAPAN PRODUCTION REI PRODUCTION

A175 - 10 A175 - 10 A C67470139

A176 - 10 A176 - 10 A D47470002

B

NUMBER

ulletin

Date:

31-Jan-98

No:

CODE SERIAL

PAGE: 2/3

7

NUMBER

RPL PRODUCTION

MODEL

NAME

Ges 2651

NSA 4651

Rex 8651

Infotec

5501DZ

Ricoh FT7650 230/ 50 Europe, etc. A175 - 67 A7038210001

V/ Hz DESTINATION CODE SERIAL

NUMBER

230/ 50 Europe, etc. A175 - 62 AC48210001

230/ 50 Europe A175 - 66 3K12180001

Page 21

T

Model:

MODEL

NAME

NSA 4770

SVN 9700

Ges 2770

Savin 9700 120/ 60 U. S. A. A177 - 15 A177 - 15 5A67470001

Ricoh FT7670 120/ 60 U. S. A. A177 - 17 A177 - 17 A7107470047

spirio 7000 230/ 50 KOREA A177 - 21 A7107080131

NSA 4770

Ges 2770

Ricoh FT7670 230/ 50 Asia, etc. A177 - 29 A7107070001

Ges 2660

NSA 4660

REX 8660

Infotec

5601DZ

Ricoh FT7660 230/ 50 Europe, etc. A191 - 27 A7057070001

Ges2670

NSA 4670

Rex 8670

Infotec

5701DZ

Ricoh FT7670 230/ 50 Europe, etc. A192 - 27 A7117070001

F401/F411/F421

V/ Hz DESTINATION CODE SERIAL

120/ 60 U. S. A. , Canada,

etc.

230/ 50 Asi a, etc. A177 - 22 AE07070001

230/ 50 Europe, etc. A191 - 22 AC87110001

230/ 50 Europe A191 - 26 3K20770001

230/ 50 Europe, etc. A192 - 22 AD67070001

230/ 50 Europe A192 - 26 3K30770001

echnical

JAPAN PRODUCTION REI PRODUCTION

A177 - 10 A177 - 10 A E27470001

B

NUMBER

ulletin

Date:

31-Jan-98

No:

CODE SERIAL

PAGE: 3/3

7

NUMBER

RPL PRODUCTION

MODEL

NAME

Ges 2660

NSA 4660

REX 8660

Infotec

5601DZ

Ricoh FT7660 230/ 50 Europe, etc. A191 - 67 A7058210001

V/ Hz DESTINATION CODE SERIAL UMBER

230/ 50 Europe, etc. A191 - 62 AC88210001

230/ 50 Europe A191 - 66 3K22180001

Page 22

T

echnical

B

ulletin

RTB Correction

Reissue date:

The serial numbers for REI production have been added in bold italics.

Model:

F401/411/421

28-Feb-99

Date:

15-Jul-98

No:

PAGE: 1/4

8

Subject:

From:

Classification:

An SP mode has been added for the F421 (70 CPM) to reduce the chances of stacking

problems in the duplex tray when non-recommended paper or paper with a large curl is

used.

Software Update Information

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

ROM Part Number

Old New

A1755151L A1755151M

A1755153L A1755153M

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F.Noguchi

SYMPTOM

1. Duplex tray stack jams

2. No-feed paper jams during duplex unit paper feed

CAUSE

Stacking problems in the duplex tray when paper with a large curl (more than 10 mm: not

within specifications) is used.

SOLUTION

Since this is a paper-related problem, please select #3 or #4 in the SP Mode as

necessary.

Please refer to the SP Mode table on the attached sheet.

Note:

The cut-in serial number list has been attached for your reference.

(REI: under investigation)

This ROM is used for the F401 series but this SP Mode can function on the F421

only.

Page 23

T

Model:

F401/411/421

echnical

B

ulletin

Date:

15-Jul-98

③,④

No:

PAGE: 2/4

8

Item Function Note

①

②

③

④

Note:

on the paper and will improve the stacking of curled paper in the duplex unit.

Selects whether the Taiwanese paper

sizes (8k, 16k) are detected in the 2

tray or not.

Selects the machine version. 50 CPM version in France…..1

Selects the positioning roller ON

timing.

Selects the paper feed interval from

the paper tray for the front side of the

copy in the duplex mode.

Either ③ or ④ can be used to increase the time the inverter weight presses down

1: Please do not use this with thin paper that is less than 80g/m2.

∗

2: Use of setting 2 (397ms) is recommended.

∗

Please note that ③ and ④ cannot be used at the same time.

nd

European and Asian versions only

Not detected: 0 (Default)

8k, 16k, paper sizes are detected: 1

Others (Default)…………….. 0

80 ms………………………….1

150 ms (Default)…………… 0

397 ms…………………..…….2

368 ms (Default)……………...0

1

∗

2

∗

Page 24

T

Model:

MODEL

NAME

Ges 2651

NSA 4651

SVN 9500

Savin 9500 120/ 60 U. S. A. A175 - 15 A175 - 15

Ricoh FT7650 120/ 60 U. S. A. A175 - 17 A175 - 17

Ricoh FT7650 110/ 60 Taiwan A175 - 19 A7038010113

Spirio 5000 230/ 50 Korea A175 - 21 A703802xxxx

Ges 2651

NSA 4651

Rex 8651

Infotec

5501DZ

Ricoh FT7650 230/ 50 Europe, etc. A175 - 27 A7038020312

Ricoh FT7650 230/ 50 Asia, etc. A175 - 29 A7038010001

Ricoh FT7650 230/50 China A175 - 69 A7038050001

Ges 2760

NSA 4760

SVN 9600

Savin 9600 120/ 60 U. S. A. A176 - 15 A176 - 15

Ricoh FT7660 120/ 60 U. S. A. A176 - 17 A176 - 17

Ricoh FT7660 110/ 60 Taiwan A176 - 19 A7048050002

NSA 4760

Ges 2760

Ricoh FT7660 230/ 50 Asia, etc. A176 - 29 A7048010001

Ricoh FT7660 230/50 China A176 - 69 A7048050001

F401/411/421

V/ Hz DESTINATION CODE SERIAL

120/ 60 U. S. A. , Canada,

etc.

230/ 50 Europe, etc. A175 - 22 AC48010001

230/ 50 Europe A175 - 26 3K1028xxxx

120/ 60 U. S. A. , Canada,

etc.

230/ 50 Asia, etc. A176 - 22 AD28010001

echnical

JAPAN PRODUCTION REI PRODUCTION

A175 - 10 A175 - 10

A176 - 10 A176 - 10

B

NUMBER

ulletin

Date:

15-Jul-98

CODE SERIAL

No:

8

NUMBER

AC68420001

4A78410204

A703841397

AD48420001

4A88420001

A7048420001

PAGE: 3/4

RPL PRODUCTION

MODEL

NAME

Ges 2651

NSA 4651

Rex 8651

Infotec

5501DZ

Ricoh FT7650 230/ 50 Europe, etc. A175 - 27 No implementation

V/ Hz DESTINATION CODE SERIAL NUMBER

230/ 50 Europe, etc. A175 - 62 No implementation

230/ 50 Europe A175 - 66 No implementation

Page 25

T

Model:

MODEL

NAME

NSA 4770

SVN 9700

Ges 2770

Savin 9700 120/ 60 U. S. A. A177 - 15 A177 - 15

Ricoh FT7670 120/ 60 U. S. A. A177 - 17 A177 - 17

spirio 7000 230/ 50 KOREA A177 - 21 A710802xxxx

NSA 4770

Ges 2770

Ricoh FT7670 230/ 50 Asia, etc. A177 - 29 A7108010001

Ricoh FT7670 230/50 China A177 - 69 A7108030001

Ges 2660

NSA 4660

REX 8660

Infotec

5601DZ

Ricoh FT7660 230/ 50 Europe, etc. A191 - 27 A705802xxxx

Ges2670

NSA 4670

Rex 8670

Infotec

5701DZ

Ricoh FT7670 230/ 50 Europe, etc. A192 - 27 A7118010001

F401/411/421

V/ Hz DESTINATION CODE SERIAL

120/ 60 U. S. A. , Canada,

etc.

230/ 50 Asia, etc. A177 - 22 AE08010001

230/ 50 Europe, etc. A191 - 22 AC88010001

230/ 50 Europe A191 - 26 3K2028xxxx

230/ 50 Europe, etc. A192 - 22 AD68010001

230/ 50 Europe A192 - 26 3K30180001

echnical

JAPAN PRODUCTION REI PRODUCTION

A177 - 10 A177 - 10

B

NUMBER

ulletin

Date:

15-Jul-98

CODE SERIAL

No:

8

NUMBER

AE28430001

5A68420001

A7048420001

PAGE: 4/4

RPL PRODUCTION

MODEL

NAME

Ges 2660

NSA 4660

REX 8660

Infotec

5601DZ

Ricoh FT7660 230/ 50 Europe, etc. A191 - 67 No implementation

V/ Hz DESTINATION CODE SERIAL UMBER

230/ 50 Europe, etc. No implementation

230/ 50 Europe A191 - 66 No implementation

Page 26

T

Model:

F401/411/421

echnical

B

ulletin

Date:

31-Jul-98

No:

PAGE: 1/2

9

Subject:

From:

Classification:

As per field request, the built-in LCT lift wire replacement procedure is now described as

follows (built-in LCT version only):

Built-in LCT Lift Wire

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

H.Kobayashi

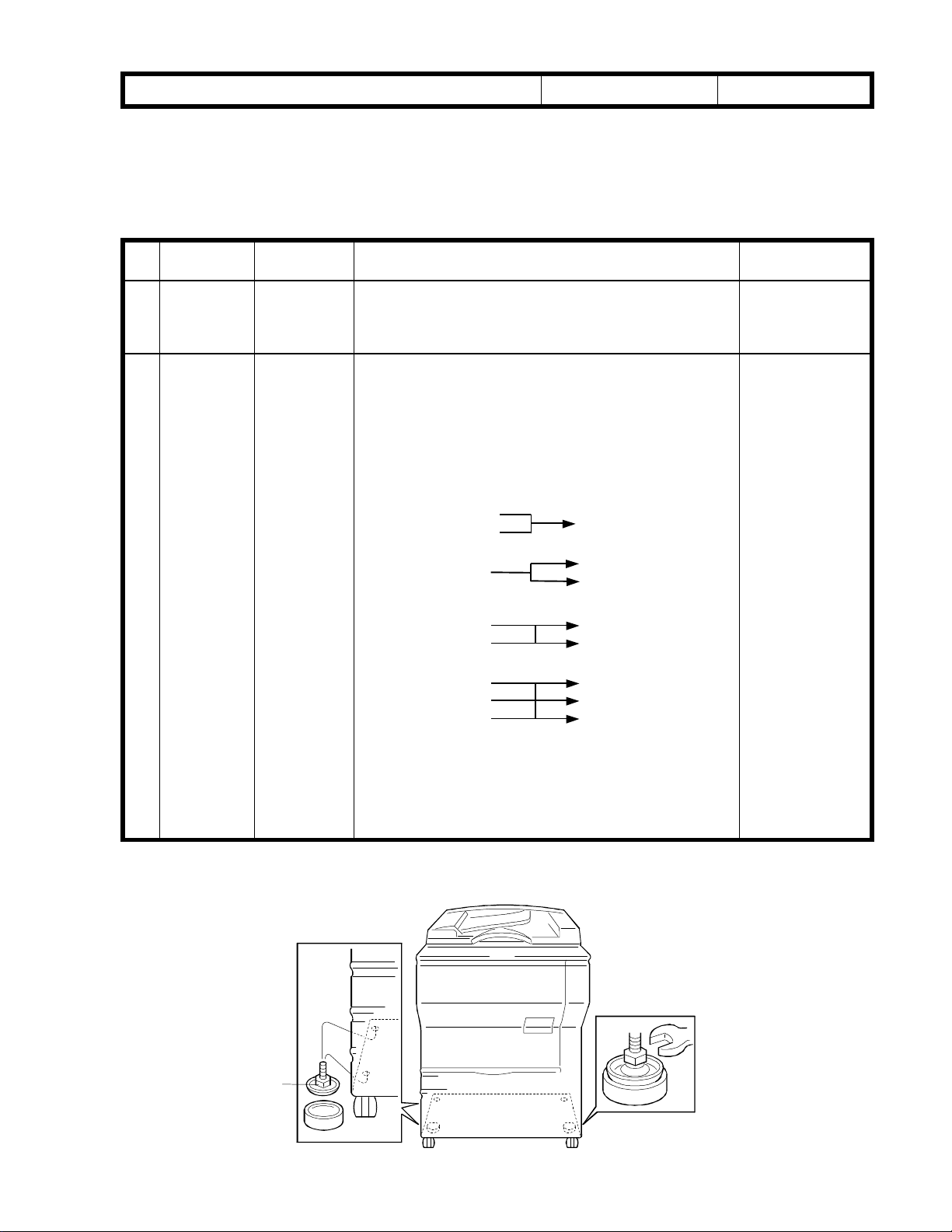

Built-in LCT Tray Lift Wire Replacement

A229R677.WMF

[A]

[B]

A229R676.WMF

1. Remove the built-in LCT. (Refer to Paper Tray Removal.)

2. Remove the front cover [A] (4 screws, 1 connector, 3 hooks).

3. Remove the 3rd tray lift motor unit [B] (4 screws, 1 connector).

Page 27

T

Model:

F401/411/421

echnical

[B]

[A]

B

ulletin

Date:

31-Jul-98

No:

PAGE: 2/2

9

[C]

[C]

A229R679.WMF

1. Remove the spring [A].

2. Remove the wire [B].

3. Wind the end of the new wire with no marking around the tray lift drive pulley [C] in the

correct direction, as shown. (①).

4. Route the wire with the ball as shown (②, ③, ④, ⑤, ⑥, ⑦, and ⑧).

5. Wind the end of wire with marking around the tray lift drive pulley in the correct

direction, as shown (⑨).

6. Put the spring back on the wire tension bracket.

7. Wind the new tray lift wire for the other side as well.

Page 28

T

Model:

F401/411/421

echnical

B

ulletin

Date:

31-Aug-98

No:

PAGE: 1/2

10

Subject:

From:

Classification:

Medaka (Short black lines)

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Kitajima

SYMPTOM

Medaka (short black lines) on copies.

CAUSE

If a large number of duplex copies is made, the temperature in the machine will rise

because the paper that has passed through the fusing section increases the amount of

heat. Paper dust may also cause this problem but the degree will vary depending on the

type of paper used. The mixture of toner and paper dust is attracted to the drum surface.

Since the temperature in the machine is higher, this mixture becomes softer and makes it

more difficult for the cleaning blade and brush to completely remove it from the drum.

SOLUTION

Install the lubricant bar on an individual basis if Medaka appear.

Before installing it, the developer should be replaced. Also, the drum should be cleaned

completely or replaced.

Installation Procedure

1. Prepare the lower drum unit

∗This part is only installed in the F411 and F421 in the Japan version of the machine.

2. Replace the lower drum unit with

3. Change the VP value from 0V (default ) to –

1 (PAGE 8, Item 8).

Since the ID sensor pattern becomes lighter as a result of the lubrication, the toner

∗

concentration in the developer becomes much higher, causing the toner scattering or dirty

background.

(P/N: A1763510)

P/N A1763510

❺

❻

❼

❽

❾

.

.

40V

using the SP Mode adjustment

Page 29

T

[B]

Model:

PM parts are newly added, and they should be replaced every 120K copies. Both parts

are included in the lower drum unit.

F401/411/421

echnical

B

ulletin

Date:

31-Aug-98

No:

PAGE: 2/2

10

A1763515

A1763522

The replacement procedure for the lubricant bar is as follows.

1. Remove the cleaning release lever

2. Remove the spring

3. Remove the cam gear-35Z

4. Remove the cleaning brush bushing

5. Remove the cleaning blade bracket ass’y

6. Remove the lubricant bar ass’y

7. Remove the lubricant bar seal

8. Remove the stopper

Lubricant Bar

Lubricant Bar Seal

[B].

[E]

[C]

[A]

(1 screw).

[C]

(1 E-ring, spacer M-6).

[D]

(1 screw).

[E].

[F]

(3 screws).

[G]

(3 screws) and replace it.

[H]

and replace the lubricant bar

[A]

[I].

[D]

[F]

[G]

[I]

[H]

Page 30

RICOH Technical

Bulletin

Model: F401/411/421, Cardinal Bird Date: 31-Oct-98 No.: 11

PAGE: 1/3

Subject:

From:

Development Entrance Seal Replacement

GTS and S Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

This is to inform about a problem that could occur in theory.

This problem, however, will not occur at an early stage but may develop as the machine is

used over a long period of time. This problem may only occur when the photoconductor

gap (PG) is at the narrowest setting (0.65 mm) and the doctor gap is at the widest setting

(0.70 mm). This PG/DG setting does not exist in production machines as far as checked in

the factory but is still within the adjusting range.

- Problem -

The lower seal (straight; the upper seal is a loop) of the development unit entrance seal

ass'y (P/N A2293092) may get pinched between the developer and the drum if a large

amount of developer accumulates near the photoconductor gap (PG). The seal may be

pulled out of position by the friction caused by the rotation of the drum. In the worst case,

the seal would peel off.

Upper seal

Lower seal

Drum

PG

Developer accumulation

DG

Upper development roller

- Cause -

The width of the lower seal is 18 mm, which may be too much. This problem does not

occur with the previous entrance seal ass'y (P/N A0963103) that has a width of 17mm.

- Countermeasure -

The width of the lower seal will be returned to the original 17 mm from 18 mm. Though the

17 mm lower seal may wrap up, the function of this part is not adversely affected. The part

number of the new development unit entra nce s eal ass'y will be A2293091.

Page 31

RICOH Technical

Bulletin

Model: F401/411/421, Cardinal Bird Date: 31-Oct-98 No.: 11

- Targeted Machines -

PAGE: 2/3

Model Code Brand Destination Total Sub-

Total

F401

F411

F421

F421

Cardinal

Bird

A175-19 Ricoh Taiwan 242 75

A175-22 NRG Europe, etc. 10 10 AC48070001 thru AC48070010

A175-29 Ricoh Asia, Oceania 90 90 A7038070021 thru A7038070110

A175-69 R ic oh Hong Kong,

China

A176-19 Ricoh Taiwan 155 50

A176-29 Ricoh Asia, Oceania 81 41

A176-69 R ic oh Hong Kong,

China

A177-29 Ricoh Asia, Oceania 57 24

A177-69 R ic oh Hong Kong,

China

A192-22 NRG Europe, etc. 70 30

A192-26 Infotec Europe, etc. 65 40

A192-27 Ricoh Europe, etc. 42 32

A220-17 Ricoh USA, Canada 23 23 A7598070001 thru A7598070023

34 20

8 2

4 1

Serial Numbers

A7038070111 thru A7038070185

167

A7038080015 thru A7038080181

A7038070001 thru A7038070020

14

A7038080001 thru A7038080014

A7048070044 thru A7048070093

105

A7048080047 thru A7048080151

A7048070003 thru A7048070043

40

A7048080007 thru A7048080046

A7048070001 thru A7048070002

6

A7048080001 thru A7048080006

A7108070002 thru A7108070025

33

A7108080004 thru A7108080036

A7108070001

3

A7108080001 thru A7108080003

AD68070001 thru AD68070030

40

AD68080001 thru AD68080040

3K30780001 thru 3K30780040

25

3K30880001 thru 3K30880025

A7118070001 thru A7118070032

10

A7118080001 thru A7118080010

Page 32

RICOH Technical

Model: F401/411/421, Cardinal Bird Date: 31-Oct-98 No.: 11

- Replacement Procedure -

Bulletin

PAGE: 3/3

1. Remove the 2 screws

2. While pulling on the lock clip

3. Install a new entrance seal ass’y.

[A]

that secure the entrance seal.

[B]

, slip off the entrance seal ass’y

[A]

[C]

[C]

.

[B]

Page 33

T

Reissued: 30-Apr- 99

echnical

B

ulletin

PAGE: 1/1

Model:

F401/411/421/C-Bird

Date:

15-Apr-99

No.:

RA175012a

RTB Correction

The items (cut-in serial number) in bold italics have been corrected.

Subject:

From:

Classification:

DJF Software Modification History

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

DJF modifications and history are as follows.

Main ROM(A6105820) modification history

Suffix Description Cut-in Serial Number

C This ROM was used from the first production run. A610-15: A16060001

D To prevent original jams:

In the limitless mode, if a new original is fed whil e t h e

paper trays are being switched, a j am will occur.

E This version is the same as that of “C”.

Notes

A software change will not prevent original jams in the

limitless mode if a new original is fed while the paper

trays are being switched.

Since the occurrence rate of this problem is extremely

low, this is being treated as a product limitation.

F Standardization with the Peng uin series A610-15: 6A18030001

G To prevent the following proble ms when the 2 in 1 mode

is used:

z

The machine stops (but t he print key remains red) after

the job if the number of origi nals and the number

input on the main unit differ.

z

After an odd nu mber o f originals is used, the image in

the next copy job is elongated or a paper jam

occurs.

H To prevent original non-feed out in European v ersion

main frame ma ch ine s :

Due to the difference in the feed-in and feed-out timing

for the B6Y size paper, three or igi nals will be set on the

exposure glass at the same time as opposed to two.

Prepared by:

A610-17: A7146060001

A610-22: AB86060001

A610-26: J90660001

Not implemented

A610-15: 6A16120001

A610-17: A7146110001

A610-22: AB87010001

A610-26: 3J90170001

A610-17: A714803000

A610-22: AB88030001

A610-26: 3J90680001

A610-15: 6A18060001

A610-17: A7148060001

A610-22: AB88060001

A610-26: 3J90680001

A610-15: 6A18100001

A610-17: A7148100001

A610-22: AB88100001

A610-26: 3J91080001

F. Noguchi

Action required

Service manual revision

Retrofit information

Page 34

Technical

Bulletin

PAGE: 1/2

Model:

Subject:

From:

F401/411/421

F401S Software Modification History

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

30-Jun-99

Prepared by:

No.:

RA175013

F.Noguchi

Action required

Service manual revision

Retrofit information

F401S software modifications and their history are as follows:

Main ROM (A1755151, A1755153) modification history

Suffix Description Cut-in Serial Numbers:

H This ROM was used from the first production run. From 1st production

J For Japanese versions only. NA

K When making multi-copies (100-300) of an original with a high

image area ratio (such as Test Chart=30 %), t here is a drop in

the image density. To prev ent this, the toner supply ratio has

been changed as follows:

Old New

LNHLNH

Toner Supply

Co-efficient

Max Toner

Supply Ratio

Refer to RTB No. 003 (issu ed on 15-Mar-97).

x0.3 x0.5 x1.0 x0.5 x1.0 x1.5

30% 30% 60% 30% 60% 60%

NA

L 1. Energy St ar (Nort h America version)

1) The available range for the Auto-off Mode ha s been changed

from “1 to 120 minutes” to “1 to 240 minutes”. The default

will not change (90 minut es) .

2) The weekly timer has been made available. Note that the

OFF key is displayed on the screen in the Setting Time for the

Auto-Off mode but cannot be u sed.

2. The following symptom has been correct ed:

1) When doing the following procedure, the input data for th e

Erase Center/Border mode is erased (reset t o 0).

Erase Center/Border Reduce/Enlarge

Interrupt

Interrupt Release

Edit Image

Press Erase Center/Border key

This symptom is duplicated when using the store Progra m

Recall/Program Interrupt /Interrupt Release key.

Refer to RTB No.007.

Page 35

Technical

Bulletin

PAGE: 2/2

Model:

M An SP Mode has been added as an individual measure for the

F401/411/421

2) A duplex jam caused by poor paper stacking in the duplex tray

may occur under the following conditions:

DF version

Centering mode

A4 sideways copy paper

50 sets of copies

Double-sided

Refer to RTB No. 007 (issued on 15-Mar-97).

F421 (70 CPM) to reduce the possibility of stacking problems in

the duplex tray (when a non-recommended paper type or paper

with a large curl is used).

Since this is a paper-related problem, please set #3 or #4 in the

SP Mode as necessary. Please refer to the SP Mode table

shown on page 2 of RTB 8a.

Note:

However, this SP Mode can function on the F421 only.

Refer to RTB No.008a.

This version of the ROM is used in the F401 series.

Date:

30-Jun-99

No.:

RA175013

Refer to RTB No.008a.

N To prevent the following errors, the software has been modi f ied.

1. When repeatedly performing the following copy job, an ADF

jam occurs and the machine stalls while still in the “copies

in progress” mode:

- Using the ADF

- 50 originals (2 sets of copies)

- Sort

2. If the user activates the interrupt mode during a copy job

3. The erase lamp turns on when a paper jam occurs.

selected

using the ADF (e.g. to perform another job), the original

counter data resets back to 0 when exiting the mode.

Consequently, the OPC drum experiences light fatigue

from this exposure and horizontal white lines appear on the

copies.

As a service part only

Loading...

Loading...