Page 1

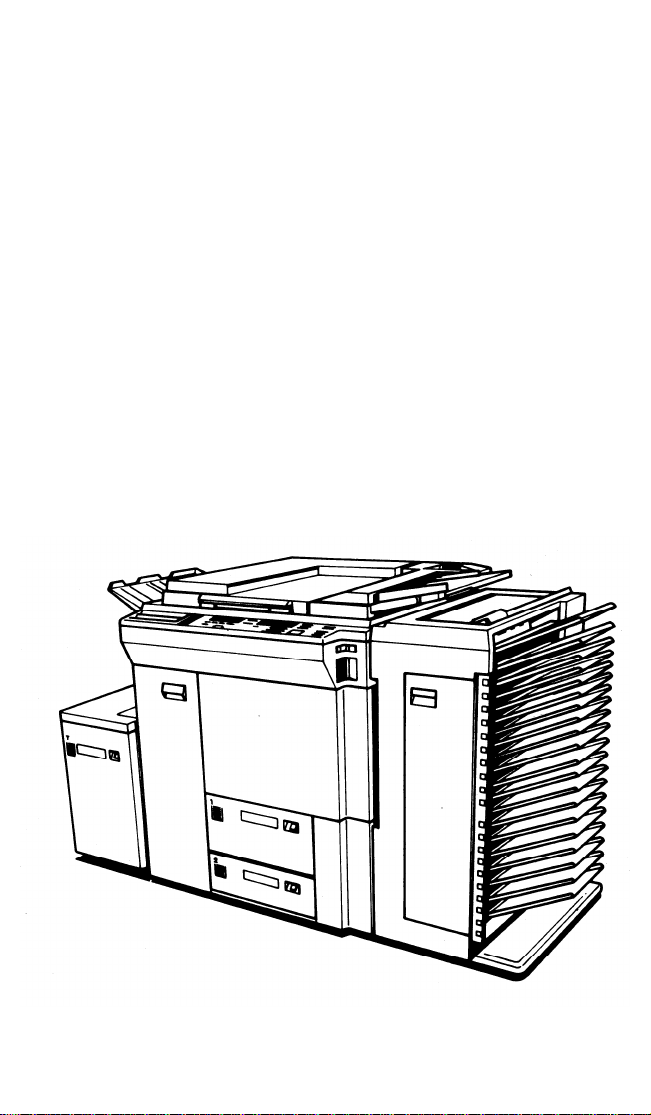

RICOH

RICOH COMPANY, LTD.

RICOH FT7060

FIELD SERVICE

MANUAL

Page 2

I. INSTALLATION

1.

Environment

2.

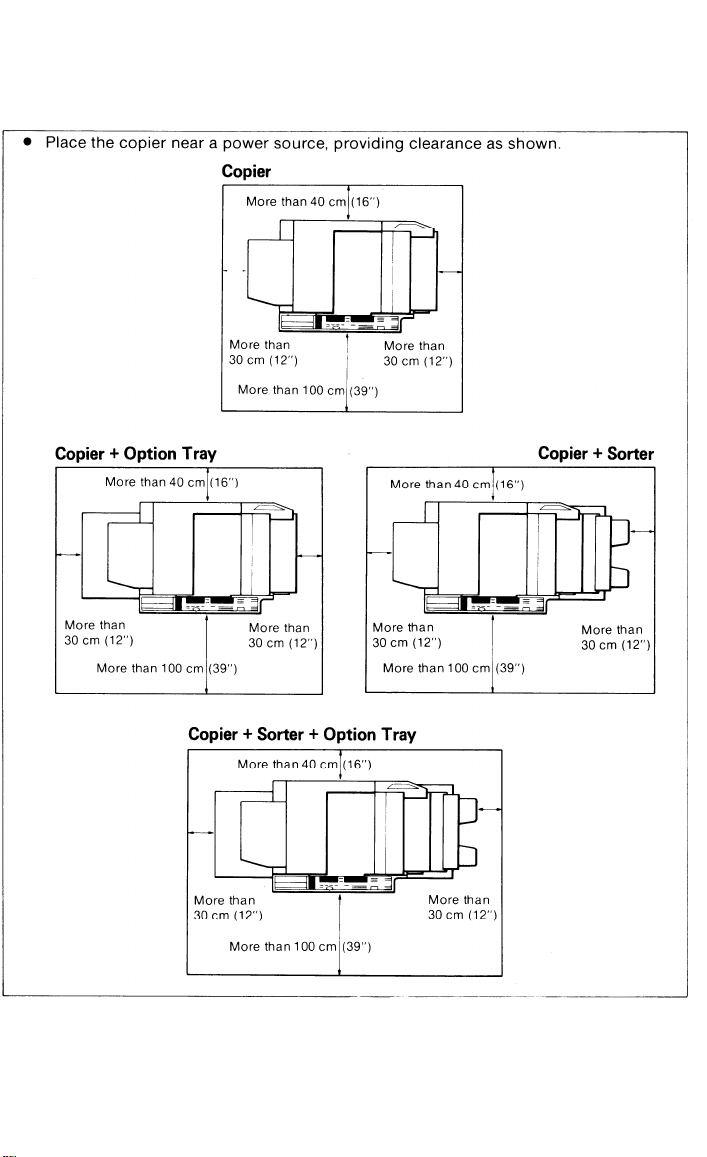

Minimum Space Requirements

Machine Level

3.

4.

Power Source

Unpacking and Installation

5.

6.

Key Counter Holder Installation

7.

A3 / 11” x 17” Counter Installation

8.

Modifying Main Transformer Voltage (220V to 240V)

9.

Preparation for Transporting the Copier . . . . . . . . . . 1-18

II. SERVICE TABLES

TABLE OF CONTENTS

1-1

1-2

1-3

1-3

1-4

1-15

1-16

1-17

PM TABLE

SERVICE TABLES

1. Test Points

2. Variable Resisters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3. Dip Switches

SERVICE REMARKS

SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . 2-12

III. REPLACEMENT AND ADJUSTMENT

EXTERIOR COMPONENT REMOVAL

1.

Exposure Glass and Operation Panel Removal

2.

Top Plate Removal

DRUM

AND CHARGE

Drum Replacement 3-3

3.

4.

Drum Thermoswitch and Heater Replacement

Charge Corona Wire Replacement

5.

Charge Cleaner Drive Wire Replacement

6.

EXPOSURE

7. Scanner Drive Wire Replacement

8. Lens Drive Wire Replacement

9. Exposure Lamp Unit Removal

DEVELOPMENT

10. Development Unit Removal

11. Developer Replacement

12. Development Roller and Paddle Roller Removal . . 3-24

13. Adjustment of Development Roller Gaps

14. Image Density Sensor Cleaning and Removal

15. Image Density Sensor Adjustment

2-1

2-5

2-6

2-7

3-1

3-2

3-4

3-5

3-6

3-7

3-17

3-21

3-22

3-23

3-26

3-28

3-29

Page 3

TRANSFER AND PICK-OFF

16. Transport Unit Removal

17. Pre-transfer Corona Wire Replacement

18. Transfer and Separation Corona Wire Replacement

19. Drive Wire Replacement (PTC and T/S Corona) . . .

20. Transport Belt Replacement

21. Registration Sensor Replacement

22. Pick-off Pawl Unit Removal . . . . . . . . . . . . . . . . . . . .

CLEANING

23. Cleaning Blade and Brush Replacement

24. Pre-cleaning Corona Wire Replacement

25. Toner Collection Coil Replacement

26. Cleaning Blade Pressure Adjustment

27. Blade Cleaner and Bias Roller Blade Replacement

28. Pre-quenching Corona Wire Replacement

FUSING

29.

Fusing Unit Removal

Hot Roller Stripper Replacement

30.

Cleaning Blade, Metering Blade,

31.

and Oil Supply Pad Replacement

32.

Hot Roller Replacement

33.

Pressure Roller Replacement

34.

Thermistor and Thermofuse Replacement

Fusing Pressure Adjustment

35.

Hot Roller Temperature Adjustment

36.

INVERTER

37. Inverter Roller Clutch Disassembly

and Adjustment

38. Inverter Gate Solenoid Adjustment

39. Inverter Gate Adjustment

3-30

3-31

3-32

3-33

3-34

3-35

3-36

3-37

3-38

3-39

3-40

3-41

3-42

3-43

3-44

3-45

3-47

3-49

3-50

3-51

3-53

3-54

3-56

3-57

PAPER FEED

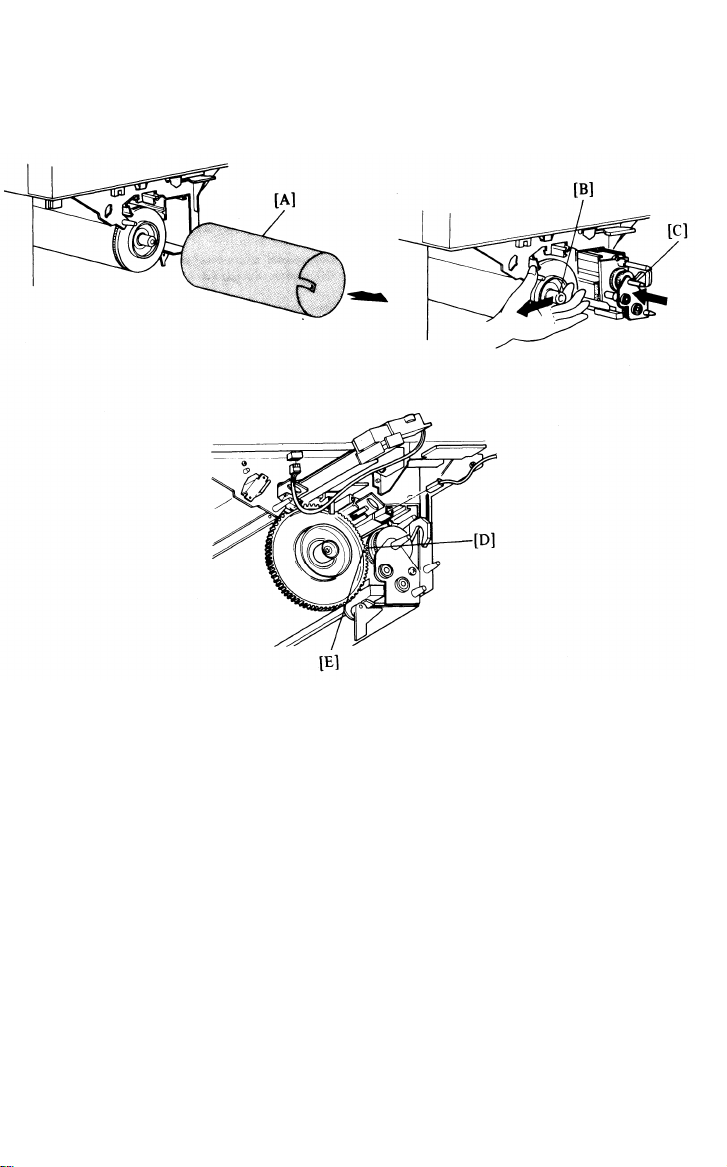

40. Paper Feed Unit Removal

41. Pick-up Roller Replacement

42. Feed Roller Replacement

43. Friction Roller Replacement

44. Paper Tray Unit and Cover Removal

45. Paper Tray Drive Wire Replacement . . . . . . . . . . . . .

46. Vertical Transport Unit Removal

DUPLEX TRAY

47.

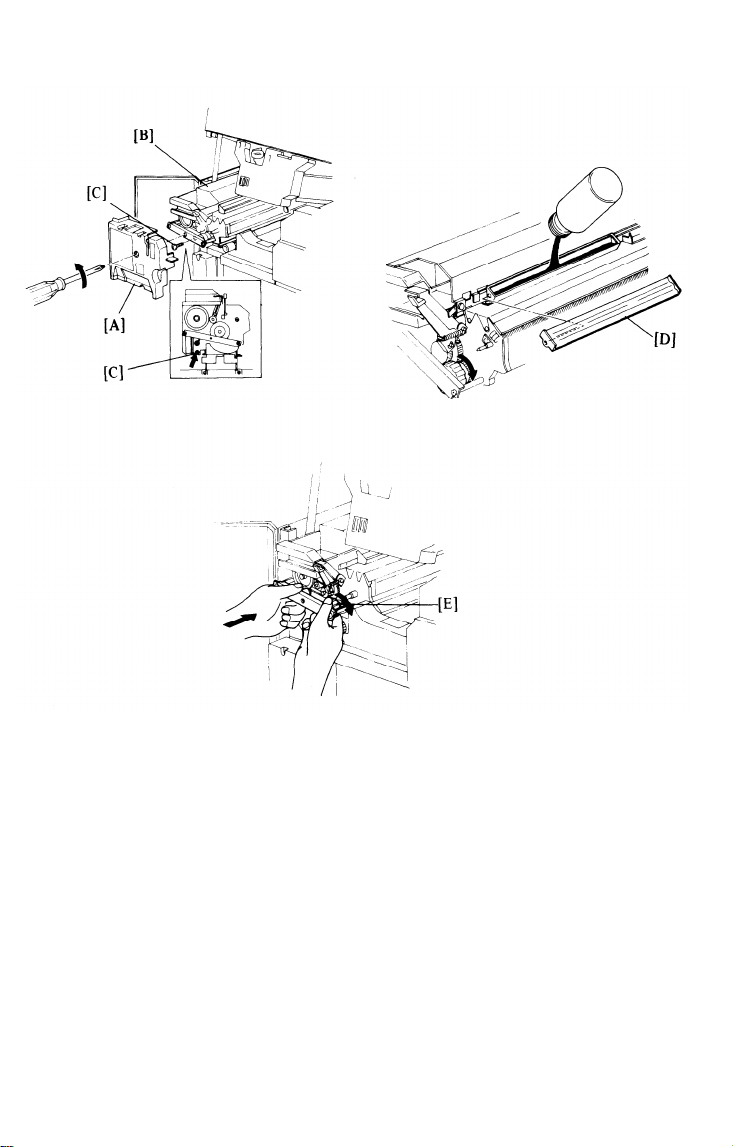

Duplex Tray Removal

Paper Feed Roller Replacement and Adjustment . . 3-68

48.

49.

Pick-up Roller Replacement

Friction Roller Replacement . . . . . . . . . . . . . . . . . . . 3-70

50.

Bottom Plate Pressure Clutch Disassembly

51.

Duplex Paper Sensor Adjustment . . . . . . . . . . . . . . . . 3-72

52.

Duplex Side Plate Drive Wire Replacement

53.

3-58

3-59

3-60

3-61

3-62

3-63

3-66

3-67

3-69

3-71

3-73

Page 4

COPY IMAGE

54. Horizontal Magnification Adjustment

55. Side-to-Side Registration Adjustment

56. Uneven Exposure Adjustment

57. Light Intensity Adjustment

58. Auto Density Sensor Adjustment

3-74

3-75

3-76

3-77

3-78

CORONA CURRENT ADJUSTMENT

59. Corona Current Adjustment Preparation

60. Charge Corona

61. Pre-transfer Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-82

62. Transfer Corona

63. Separation Corona

64. Pre-cleaning Corona

65. Pre-quenching Corona

SERVICE PROGRAM MODE

1. Factory Settings

2. Service Program Functions

IV. ELECTRICAL DATA

Main Board Schematic

1.

2.

DC Drive Board Schematic . . . . . . . . . . . . . . . . . . . . . . 4-2

Scanner Motor Control Board Schematic . . . . . . . . . . 4-2

3.

4.

Main Motor Control Board Schematic . . . . . . . . . . . . . 4-3

Lens/Mirror Motor Control Board Schematic . . . . . . 4-4

5.

6.

Timer Board Schematic

7.

Power Supply Unit Block Diagram

Operation Panel - CPU Board Schematic . . . . . . . . . . 4-7

8.

Operation Panel - CPU Board Schematic

9.

10.

AC Drive Board Schematic

11.

DF Main Board Schematic

Sorter Main Board Schematic

12.

3-79

3-81

3-83

3-84

3-85

3-86

3-87

3-88

4-1

4-5

4-6

4-8

4-8

4-10

V. DOCUMENT FEEDER

SERVICE TABLES

1. Test Point Table

2. Variable Resister Table . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. LED Table

4. DIP Switch Table

5. Blown Fuse Table

6. Switch Failure Table

7. Sensor Failure Table

5-1

5-1

5-2

5-3

5-3

5-4

Page 5

REPLACEMENT AND ADJUSTMENT

1.

Separation Roller Replacement

2.

Friction Tab Replacement

Pick-up Roller Replacement

3.

4.

Transport Unit Cover Removal

5.

Feed Belt Removal

6.

Inverter Entrance and inverter Registration

Sensor Replacement

7.

Turn Roller Replacement

8.

Exit Roller/Pull-out Roller Replacement

Inverter Roller Replacement

9.

10.

DF Removal

11.

12.

VI. SORTER

Original Skew Adjustment

Original

Leading Edge Adjustment

5-5

5-6

5-7

5-10

5-11

5-12

5-13

5-14

5-15

5-17

5-18

5-19

UNPACKING

INSTALLATION

1. Accessory Check

2. Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . 6-3

SERVICE TABLES

1. Sorter Main Board

2. Sorter Interface Board

REPLACEMENT AND ADJUSTMENT

1. Distribution Unit Removal . . . . . . . . . . . . . . . . . . . . . 6-8

2. Transport Unit Removal

3. Transport Belt Replacement . . . . . . . . . . . . . . . . . . . . 6-11

4. Jam Sensor and Bin Copy Sensor Adjustment . . . . . 6-14

5. 50Hz/60Hz Modification

VII. LARGE CAPACITY TRAY

UNPACKING

INSTALLATION

1. Accessary Check

2. Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . 7-3

REPLACEMENT AND ADJUSTMENT

1. Paper Feed Unit Removal

2. Pick-up Roller Replacement

3. Feed Roller Replacement

4. Friction Roller Replacement

5. Paper Tray Unit Removal

6. Paper Tray Drive Wire Replacement

6-1

6-2

6-6

. . . . . . . . . . . . . . . . . . . . . . . . 6-7

. . . . . . . . . . . . . . . . . . . . . . . . 6-10

. . . . . . . . . . . . . . . . . . . . . . . . 6-15

7-1

7-2

7-7

7-8

7-9

7-10

7-11

7-12

Page 6

INTRODUCTION

COPY QUALITY

White Spots

Hat Image

Blank Area

Wrinkled Copy

Unfused Copy

Horizontal White Lines (Bands)

Jitter

Hollowing Out

Fuzzy Copy

Vertical White Lines (Bands)

Uneven Density

Vertical Black Lines (Bands)

Black Spots

Dirty Background

Black Image

Blank Copy

Light Copy

PAPER JAM/MISFEED

Pick-off Jam

False Paper Jam

Duplex Tray Jam

Paper Feed Jam

Registration Jam

Exit Jam

Transport Unit Jam

Fusing Jam

8-1

8-2

8-3

8-4

8-5

8-6

8-6

8-7

8-8

8-8

8-9

8-11

8-14

8-18

8-19

8-22

8-22

8-24

8-26

8-27

8-27

8-29

8-30

8-30

8-30

8-31

FUNCTIONAL PROBLEM

Not Ready

Abnormal Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Please Wait Condition

DF

Original Jam

No Display

Abnormal Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36

SORTER

Not Ready

False Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

Jam in Sorter 8-38

Others

8-32

8-34

8-35

8-35

8-37

8-38

Page 7

SERVICE CALL

SC - l

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- l0

- 11

- 12

- 13

- 14

- 15

- 17

- 18

- 19

- 21

- 22

- 23

- 24

- 25

DEFECTIVE SENSOR TABLE

Table 8-60

CONDITIONS

Exposure

Drum Thermistor

Drum Heater

Drum Overheat

Fusing Thermistor

Fusing Lamp

Fusing Overheat

Temperature Fuse . . . . .

Optics Encode

Home Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-48

Scanner Velocity

Scanner Return

Total Counter

High Voltage Leak

Lens Drive Lock

Cleaner Motor - Charge Wire

Cleaner Motor - PTC Wire . . . . . . . . . . . . . . . 8-54

Cleaner Motor

Paper Feed Unit

Option Tray Paper Feed Unit

Upper Tray

Lower Tray

Option Tray

. . . . . . . . . . . . . . . . . . . . . . . . 8-41

. . . . . . . . . . . . . . . . . . . . . . 8-44

. . . . . . . . . . . . . . . . . . . . . . . . 8-45

. . . . . . . . . . . . . . . . . . . 8-46

. . . . . . . . . . . . . . . . . . . . . . . . 8-50

. . . . . . . . . . . . . . . . . . . . . . 8-51

. . . . . . . . . . . . . . . . . . . . . 8-52

- T/S Wire

. . . . . . . . . . . . . . . . . . . . . . . . 8-56

. . . . . . . . . . . . . . . 8-55

8-39

8-42

8-43

8-44

8-47

8-49

8-50

8-53

8-56

8-57

8-58

8-59

Page 8

SECTION 1

INSTALLATION

Page 9

CONTENTS

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.

2.

Minimum Space Requirements

Machine Level

3.

4.

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking and Installation

5.

Key Counter Holder Installation

6.

7.

A3 / 11” x 17” Counter Installation

8.

Modifying Main Transformer Voltage (220V to 240V) . .

Preparation for Transporting the Copier

9.

12 July ’86

1-1

1-2

1-3

1-3

1-4

1-15

1-16

1-17

1-18

Page 10

1. Environment

12 July ’86

1. Temperature Range

10°C to 30°C (50°F to 86°F)

2. Humidity Range 15% to 90% RH

3. Ambient Illumination Less than 1,500 lux (Do not expose to direct sunlight.)

4. Ventilation Room air should turn over at least 3 times/hour.

5. Ambient Dust Less than 0.15 mg/m

3

6. Room Size More than 10 m

(13.4 yd3)

3

(4 x 10

-3

Oz/yd3)

7. If the place of installation is air-conditioned or heated, place the

machine:

a) where it will not be subjected to sudden temperature changes from

low to high, or vice versa.

b) where it will not be directly exposed to cool air from an air con-

ditioner.

c) where it will not be directly exposed to reflected heat from a

heater.

8. Avoid placing the copier in an area filled with corrosive gas.

9. Avoid any area higher than 2,000 m (6,500 feet) above sea level.

10. Place the copier on a strong and level base,

NOTE: This copier weighs 290 kg (638 lb). Before installing, make sure

that the floor is strong enough for this machine.

This is especially required when there is other heavy equipment located

nearby.

11. Avoid any area where the copier may be subjected to strong vibration.

1-1

Page 11

12 July ’86

2. Minimum Space Requirements

1-2

Page 12

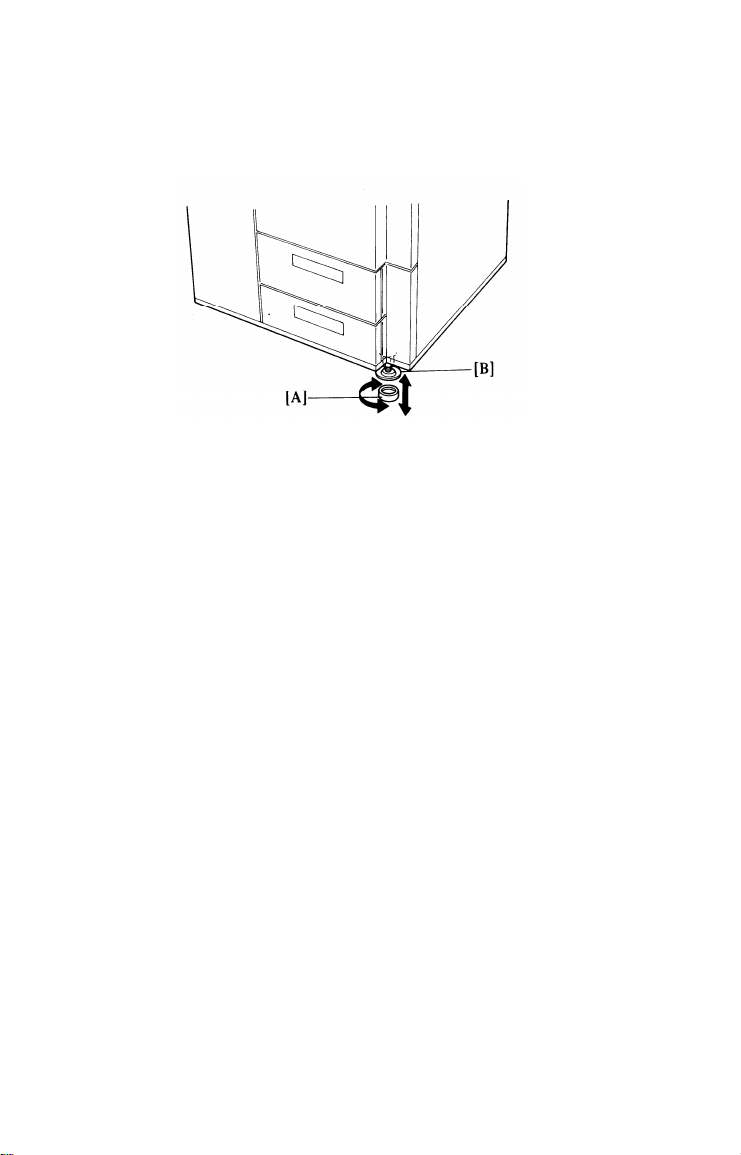

3. Machine Level

12 July ’86

1.2.Front to Back:

Right to Left:

Place the four leveling shoes [A] under the leveling feet [B] and screw

the leveling feet up or down to level the machine.

4. Power Source

Input Voltage Level

1.

115V/60 Hz - 20A

220V/50 Hz - 10A

240V/50 Hz - 10A

Permissible Voltage Fluctuation : ± 10%

2.

3.

Permissible Extension Cord: None recommended

NOTE: - Be sure to ground the machine.

wire to a gas pipe.)

- Make sure the plug is firmly inserted in the outlet.

- Should be dedicated outlet.

- Do not set anything on the power cord.

Within 5 mm (0.2”) of level

Within 5 mm (0.2”) of level

(Do not connect the grounding

1-3

Page 13

12 July ’86

5.

Unpacking and Installation

- Unpacking -

1.

Cut the bands [A] binding the carton and remove the top carton [B].

2.

Take out the accessories [C].

Remove the cushion blocks [D].

3.

4.

Open the vinyl bag.

5.

Take out the machine.

1-4

Page 14

- Accessory Check -

12 July ’86

Check the quantity

the New Equipment

DESCRIPTION

1)

Copy Tray

2)

Original Tray

3)

Screw M4 X 8 mm

4)

Leveling Shoe

5)

Cushion Block

6)

Operating Instructions

7)

Installation Procedure

8)

N.E.C.R.

9)

Envelope for N.E.C.R.

10)

Multiple Language Decals (Europe)

and condition of the accessories in the box according to

Condition Report (NECR) or the following list:

(U. S. A.)

Q’TY

1

1

2

4

2

1

1

1

1

1

1-5

Page 15

12 July ’86

- Installation Procedure -

1. Remove all external strips of tape [A] and the two sponge door cushions

[B].

2. Remove the lower right cover [C] (3 screws) and the two studs [D] securing the paper trays. Reinstall the lower right cover.

3. Open the left door, and remove the two strips of tape [E] securing the

vertical transport guide plate.

4. Open the right

sponge cushions

door.

[F].

Pull out the paper trays and remove the three

1-6

Page 16

12 July ’86

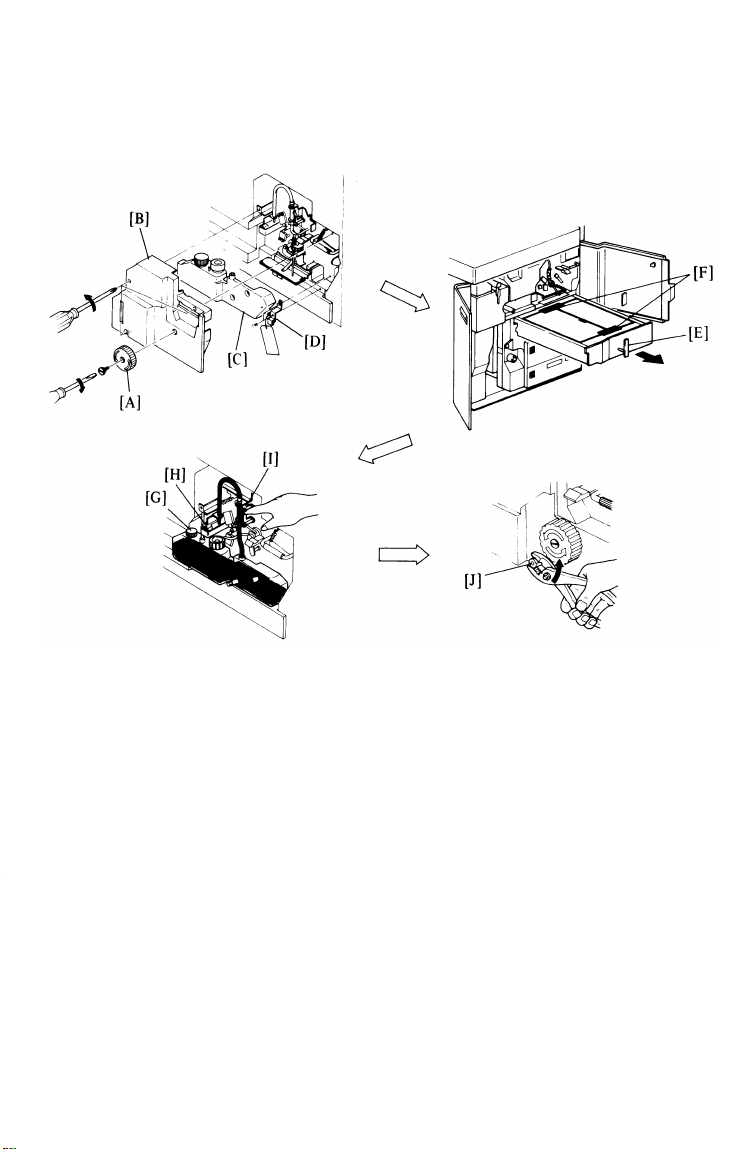

5. Open the top unit, then remove the fusing knob [A] (1 screw: reverse

thread), cover [B] (3 screws), and the oil bottle [C]. Remove the clamp

[D] (2 screws) which secures the fusing unit and the duplex tray.

6. Turn the duplex tray handle [E] to the horizontal position, pull out the

duplex tray, and remove the two strips of tape [F] securing

the duplex

unit covers. Open the duplex unit covers and carefully remove the strip

of tape securing the bottom plate. Then reset the duplex unit.

7. Unscrew the oil bottle cap [G], and fill the oil bottle with silicone oil.

Do not overfill the bottle. Reinstall the cap. Confirm that oil is supplied

to the oil sump [H] by pressing the oil supply lever [I] against the sleeve

of the oil pump several times.

8. Rotate the pressure cam shaft [J] counterclockwise until it locks (about

90°) to apply the pressure between the hot roller and the pressure

roller.

1-7

Page 17

12 July ’86

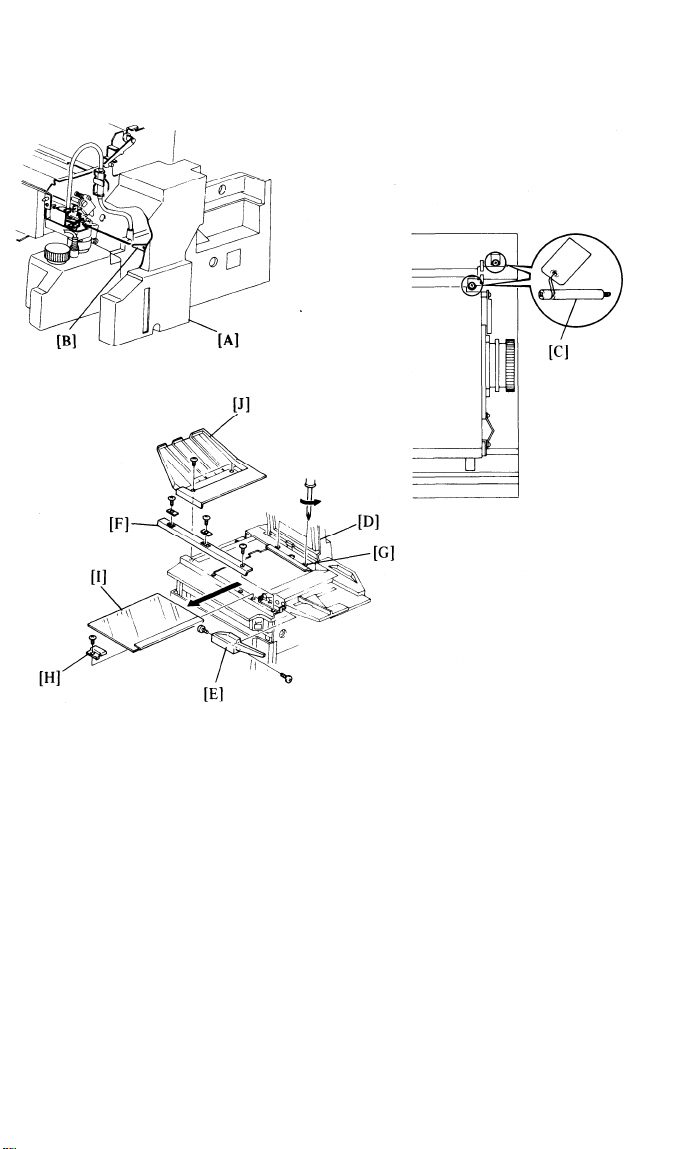

9.

Reinstall the fusing unit cover [A] and the fusing knob. Confirm that the

tab [B] on the inside of the cover lifts up the oil sump stopper. If it

does not, oil will overflow from the sump. Close the top unit.

10.

Remove the two optics studs [C] as follows:

Raise the DF transport unit [D].

a)

b)

Remove the front cover [E] of the original feed unit (2 screws).

c)

Remove the front top cover [F] (3 screws).

d)

Loosen the two screws of the rear scale [G], and remove the glass

fixing plate [H] (1 screw).

e)

Remove the exposure glass [I].

f)

Remove the two optics studs securing the lens housing and the first

scanner.

Reassemble.

g)

Install the original tray [J] (2 screws: M4 x 8 mm).

11.

1-8

Page 18

12 July ’86

1-9

12.

Open the top unit [A], and remove the drum cover [B] (2 screws).

13.

Remove the drum stay [C] by turning the knob counterclockwise.

Disconnect the charge corona wire cleaner connector [D] and remove the

14.

charge corona unit [E].

Pull out the erase unit [F] and the drum thermistor [G].

15.

Disconnect the pre-quenching corona wire cleaner connector [H], and

16.

remove the quenching lamp unit [I].

17.

Remove the cleaning unit [J].

Page 19

12 July ’86

I

CAUTION: Do not leave the top unit open, exposing an uncovered drum, for long

periods.

18.

Remove the drum protective sleeve [A] from the drum. Save the drum

protective sleeve for future use.

19.

Pressing the drum shaft [B] to the left to prevent drum damage, reinstall

the cleaning unit [C]. The cleaning unit must be inserted until the

cleaning unit drive gear [D] engages with the drum flange gear [E].

Reinstall the erase unit, the drum thermistor, the quenching lamp unit,

20.

and pre-quenching corona unit.

Reconnect the pre-quenching corona

wire cleaner connector.

21.

Reinstall the charge corona unit and reconnect the charge corona wire

cleaner connector.

22.

Reinstall the drum stay and the drum cover.

1-10

Page 20

12 July ’86

23. Prepare the development unit as follows:

Remove the development unit cover [A] (1 screw).

a)

b)

Remove the development unit [B] by removing the development unit

mounting screw [C] and place the unit on a sheet of paper.

Remove the developer inlet cover [D].

c)

d)

Pour two kilograms of developer into the development unit. While

pouring in the developer, turn the paddle roller knob [E] clockwise to

evenly distribute the developer.

Reinstall the developer inlet cover and the development unit.

e)

NOTE: Confirm that the development unit is seated on the guide rails

properly. Also, confirm that the development unit is set cor-

rectly.

If not, pull the unit out slightly, turn the paddle roller

knob, and push the unit back in.

1-11

Page 21

12 July ’86

CAUTION:

Always lower the top unit [A] before tightening the development unit

mounting screw [B]. The slot [C] on the top unit fits over the positioning pin [D] on the development unit to correctly position the development unit.

f) Close the top unit, and secure the development unit (1 screw).

g) Open the top unit again and reinstall the development unit cover.

24, Load a toner cartridge [E] as follows:

a)

Hold a new toner cartridge level and shake it well.

b)

Turn down the toner cartridge lever [F].

c)

Insert a new toner cartridge and raise the toner cartridge lever.

(Only load one toner cartridge.)

d)

Cut the green tape and push down the latch on the shutter plate.

Then, pull the shutter plate all the way out.

e)

Hold the green tab and pull the toner seal out as far as it will go.

Push the shutter plate back in completely.

f)

Close the top unit.

g)

1-12

Page 22

12 July ’86

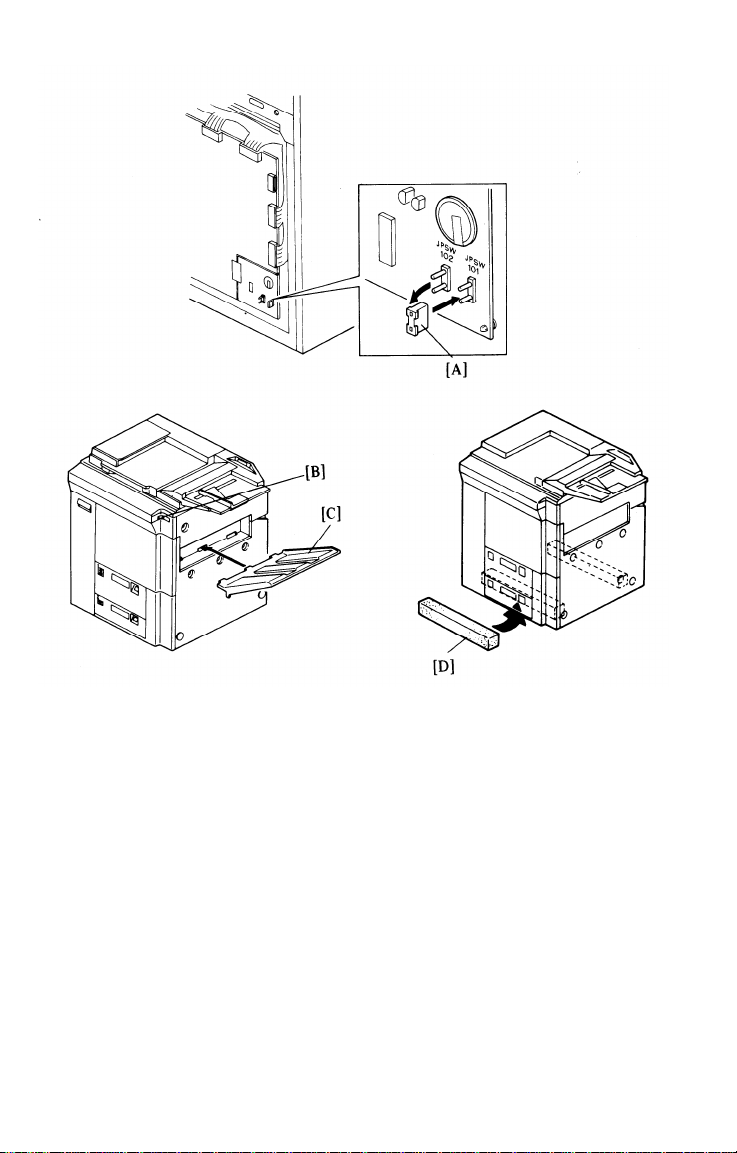

25.

Remove the lower

connector [A] on the

26.

Close the front doors and plug in the power cord. Turn on the main

left cover (2 screws), and move the jumper

timer board from JPS-102 to JPS-101.

switch [B].

While waiting for the fusing unit to warm up (about

27.

7 minutes), install

the copy tray [C].

28.

Load paper in the upper and lower paper trays.

29.

Perform drum conditioning for 15 minutes as follows:

a) Place a white sheet of A3 or 11” x 17” paper on the exposure glass

and lower the ADF transport unit.

b) Use SP 1-3 (Free Run) for

30.

Insert the sponge cushions

drum conditioning.

under the base plate of the copier at the

[D]

front and rear.

1-13

Page 23

12 July ’86

31. Set up the following items according to the customer’s requirements.

Refer to Section 3 for Service Program Mode.

SP No.

1-4

2-2

3-3

3-4

4-1

6-1

Item

Beeper Off

ID Reset Level

20 min. Fusing Timer

Copy Counter

ID Control Mode

Full Automatic DF

Feed Mode

8-2

Auto. Paper Selection. 26

10-3/4 Toner Supply Amount 28

20

32.

Set the weekly timer,

33.

Check copier and DF operation.

34.

Check copy quality. Adjust as necessary.

35.

Complete the N.E.C.R.

Automatic Reset Time

according to the customer’s request.

SP No.

21

22

23

24

25

Item

Max Copy Quantity

Magnification Ratio

Priority

Optional Magnification

Ratio

Auto. Shut-off Timer

Standard Timer Setting

EM Call Telephone No.

User Code

1-14

Page 24

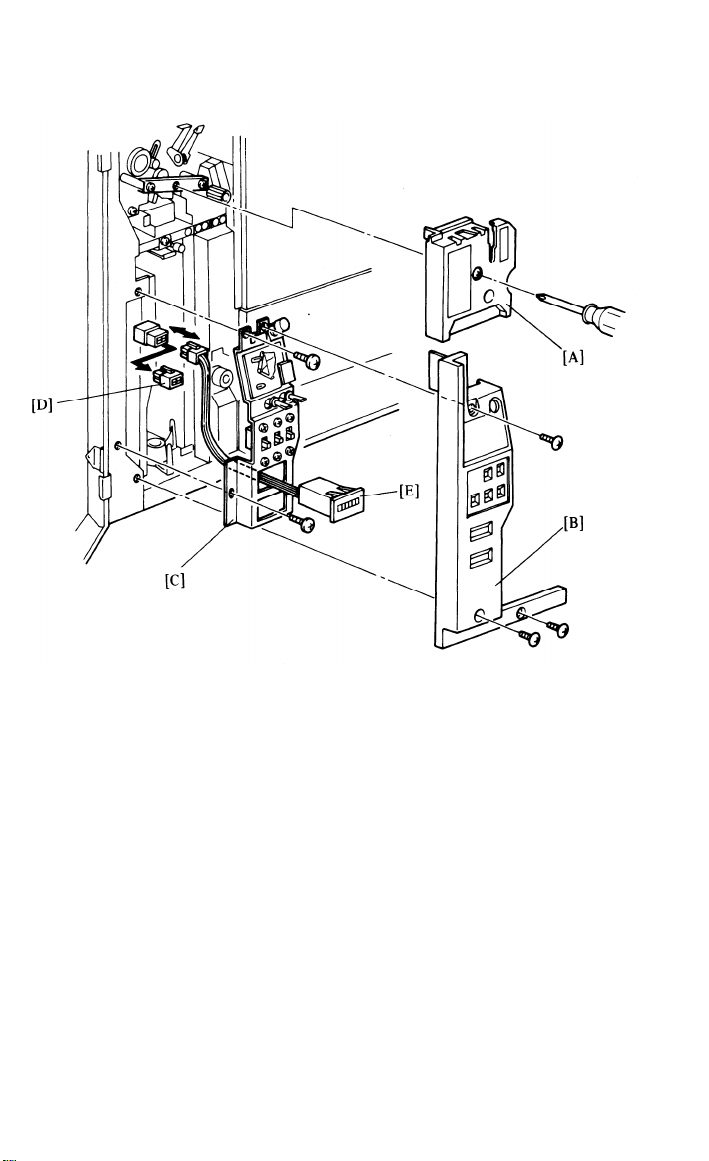

6. Key Counter Holder Installation

12 July ’86

Remove the upper front cover (2 screws).

1.

Remove the cover plate [A] and fixing plate [B] from the main switch

2.

bracket (2 screws).

Hold the fixing plate on the inside of the key counter holder and insert

3.

the key counter holder [C].

4.

Align the screw holes in the fixing plate with the mounting holes of the

key counter holder and secure the key counter holder.

NOTE: This copier can use three types of counters. Make sure to use the

correct screw holes in the fixing plate.

5.

Remove the shorting connector [D] from the key counter connector.

Connect the key counter holder.

6.

7.

Reassemble the copier and check key counter operation.

1-15

Page 25

12 July ’86

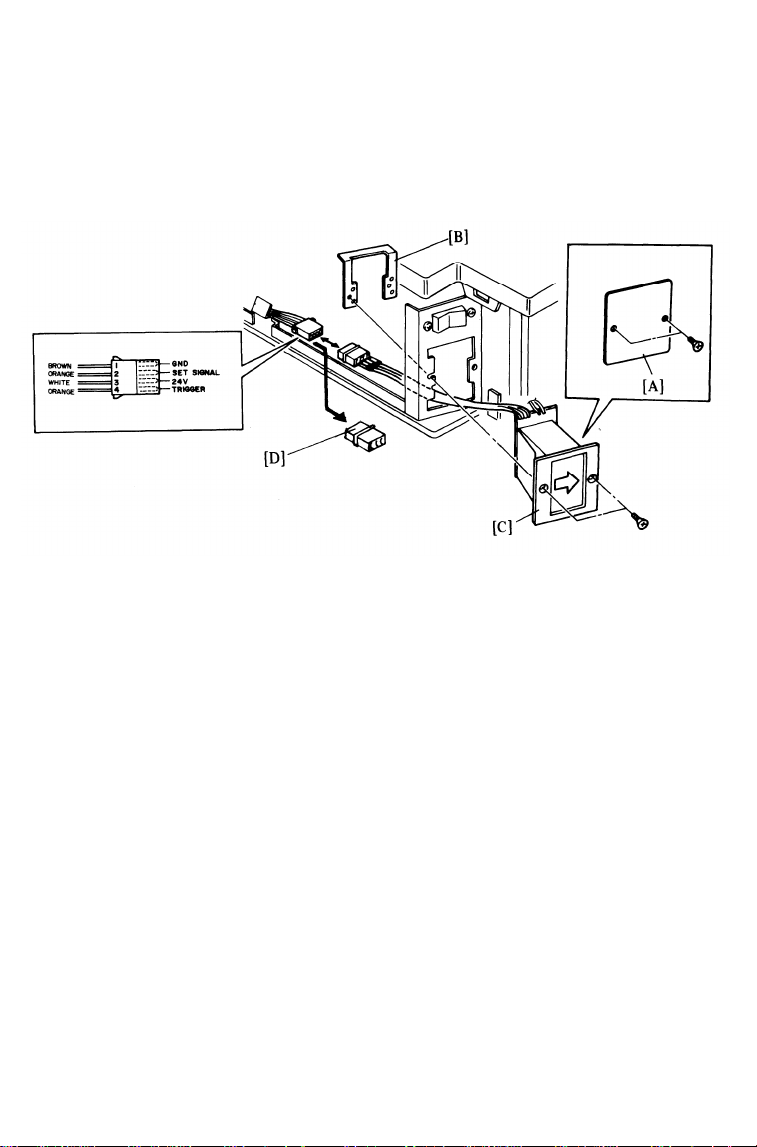

7. A3 / 11” x 17” Counter Installation

1.

Open the left door.

2.

Remove the development unit cover [A] (1 screw) and the jam indicator

cover [B] (3 screws).

3.

Remove the jam indicator bracket [C] (2 screws).

Disconnect the dummy connector from the A3 / 11” x 17” counter connec-

4.

tor [D].

Set the A3 / 11” x 17” counter [E] through the jam indicator bracket as

5.

shown.

Connect the A3 / 11” x 17” counter connector.

6.

Reassemble.

7.

Set SP 4-4 (A3 / 11” x 17” counter).

8.

9.

Check the counter operation by making an A3 / 11” x 17” copy.

1-16

Page 26

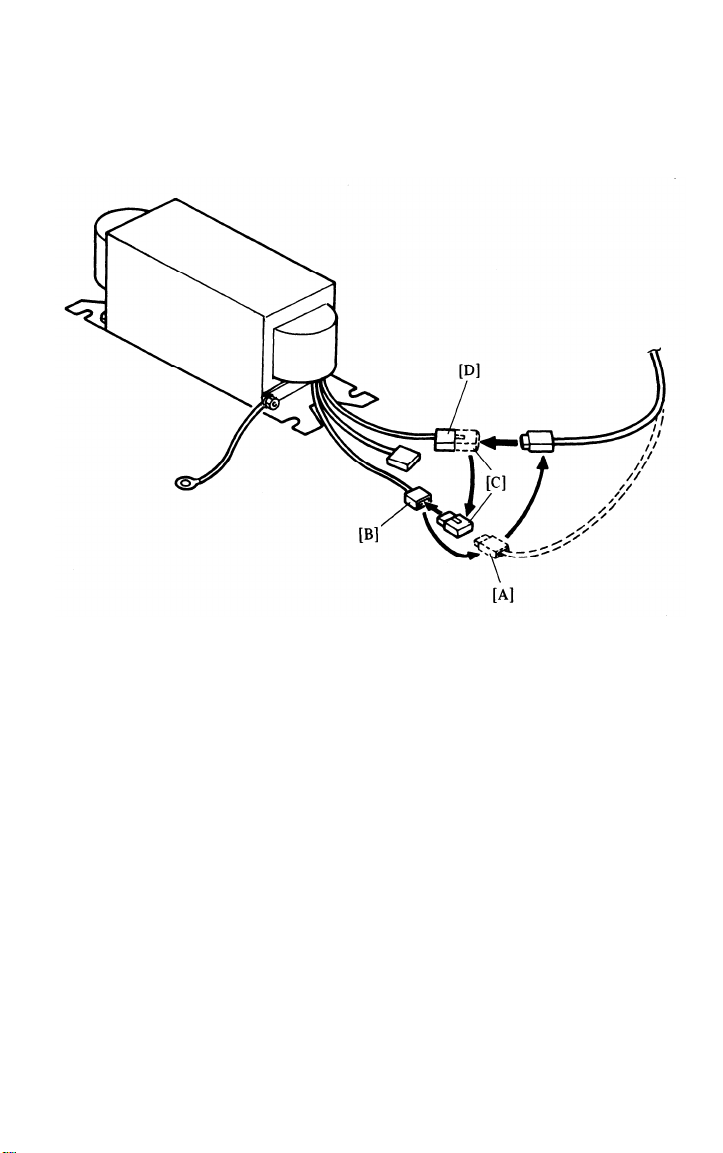

8. Modifying Main Transformer Voltage (220V to 240V)

12 July ’86

1. Remove the lower right cover (2 screws).

2. Disconnect the input line [A] from the 220 V connector [B].

3. Disconnect the dummy connector [C] from the 240 V connector [D].

4. Connect the input line to the 240 V connector.

5. Connect the dummy connector to the 220 V connector.

6. Reassemble.

1-17

Page 27

12 July ’86

1-18

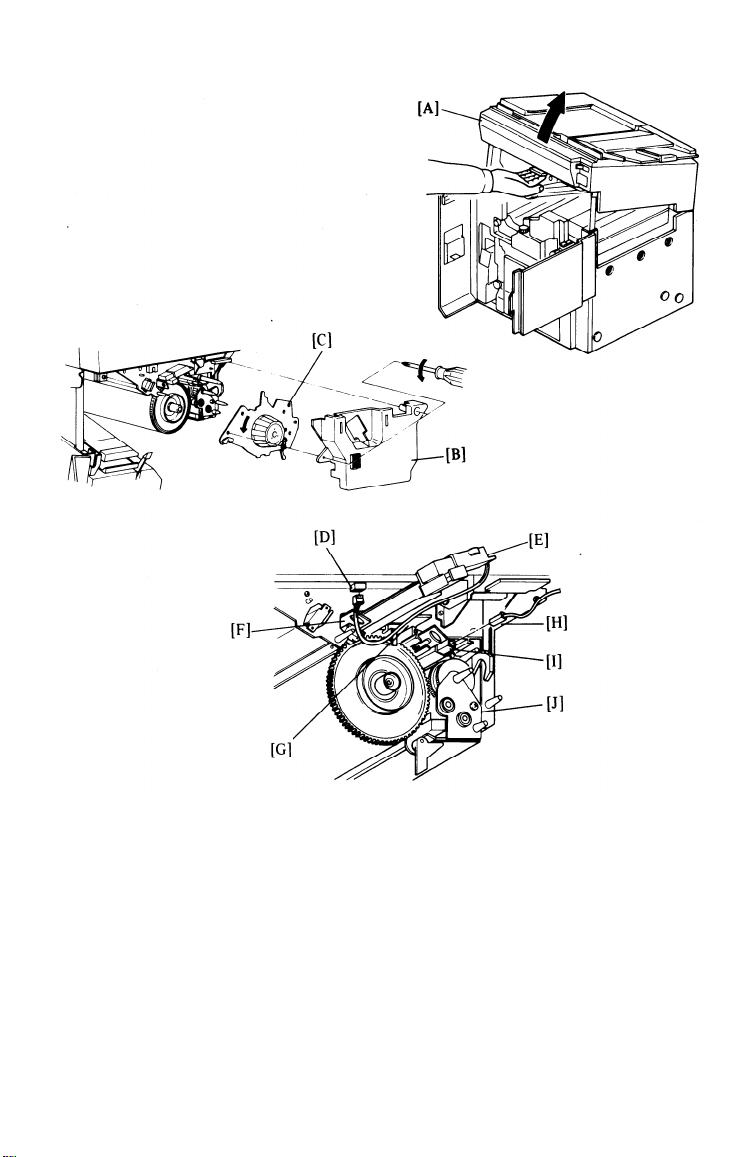

9. Preparation for Transporting the Copier

CAUTION: Before transporting the copier, be sure to prepare it as follows. The copier

may be badly damaged if it is moved without proper preparation.

1. Select the 100% magnification ratio.

2. Remove the paper from the upper and lower paper trays.

3. Turn off the main switch and unplug the copier.

4. Remove the oil bottle [A] and empty it.

5. Secure the fusing unit and duplex tray with the clamp [B] as shown (2

screws) and reassemble.

6. Remove the exposure glass.

7. Fix the lens housing and the first scanner guide bracket with studs [C]

as shown.

8. Reassemble the machine.

Page 28

12 July ’86

1-19

9.

Remove the lower right cover and fix the paper trays with studs [A].

Reinstall the lower right cover.

10.

Fix the DF,

11.

Remove the

12.

Remove the

13.

Remove the

left front door, and right front door with strips of tape.

copy tray or sorter.

original tray (2 screws).

option tray, if installed.

Page 29

SECTION 2

SERVICE TABLES

Page 30

CONTENTS

SPECIAL TOOLS AND LUBRICANTS

. . . . . . . . . . . . . . . . . . . . . . . .

12 July ’86

PM TABLE

SERVICE TABLES

1. Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2. Variable Resisters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3. Dip Switches

SERVICE REMARKS

2-1

2-5

2-6

2-7

2-12

Page 31

PM TABLE

12 July ’86

C: Clean R: Replace

Item

OPTICS

1. Mirrors, Lens

2. Exposure Glass

3. Reflector

4. Toner Shield

Glass

5. Exposure Lamp

6. Scanner Guide

Rods

7. Lens Drive Gear

8. Fan Filter

9. Exposure Damper

10. ADS

PAPER FEED UNIT

11. Feed Roller

12. Friction Roller

13. Pick-up Roller

14. Feed Sensors

15. Paper Guide

16. Tray Gear

L: Lubricate A: Add I: Inspect

EM

120K

240K

360K

c

c

c

c

c

C,L

c

c

c

c

c

c

c

c

c

c

c

c

C,L

c

c

R

R

R

c

c

c

c

c

c

c

c

C,L

c

c

c

c

c

c

c

480K

c

c

c

c

R

C,L

c

I,R

c

c

c

c

c

c

600K

c

c

c

c

c

C,L

L

c

c

c

c

c

c

c

L

c Alcohol/water

silicon cloth

c Glass cleaner

dry cloth

c Alcohol/water

silicon cloth

c

c

C,L

Launa 40 oil

or equivalent

L

Launa 40 oil

or equivalent

c

c

c Alcohol

c

Alcohol

c Alcohol

c Blower brush

c Dry cloth

Mobil Temp. 78

L

DUPLEX TRAY

17. Feed Roller

18. Friction Roller

19. Pick-up Roller

20. Drive Gears

21. Drive Chain

22. Pressure Clutch

VERTICAL TRANSPORT

AND REGISTRATION

23. Transport

Rollers

24. Guide Plates

25. Drive Gears

26. Drive Chain

27. Dust Catcher,

Roller

28. Registration

Sensor

29. Regist. Roller

30. Registration

Drive Gear

c

c

c

c

c

c

L

L

L

L

L

L

c

c

c

c

L

L

L

L

c

c

L

L

c

c

c

c

L

L

L

c

c

L

L

c

L

c

c

c

c

c

L

L

L

L

L

L

c

c

c

c

L

L

L

L

c

c

c

c

L

L

Alcohol/Water

R

R

Alcohol/Water

R

Alcohol/Water

L

Mobil Temp. 78

L

Mobil Temp. 78

L

Mobil Temp. 78

Alcohol/Water

c

c Dry cloth

L

Mobil Temp. 78

Mobil Temp. 78

L

c

Blower brush

Water

Mobil Temp. 78

L

2-1

Page 32

12 July ’86

C: Clean R: Replace

Item

TRANSPORT UNIT

31. Pick-off Sensor

32. Transport Belt,

Belt Rollers

33. Belt Drive Gear

34. Vacuum Tank

35. Vacuum Fan

Filter

36. Pick-off

Solenoid

DEVELOPMENT UNIT

37. Developer

38. Upper and Lower

Seals

39. Side Seals

40. Upper Cover

41. Gears

42. Inlet Cover

43. Belt, Pulley,

Plastic Gears

44. Bearings

45. Toner Supply

Clutch

46. Doctor Plate

L: Lubricate A: Add I: Inspect

120K

EM

240K 360K

C C C C C C

C C C C C

L L L L L

C C C C C

R R

I I I I I

R R

C C C C C C

I I I I I I

C C C C C

C C C

C C C C C

C C C C C

I

C

480K 600K 1.2M

R

R R

R

R R

C

I I,R

C

C

C C

NOTE

Blower brush

I,R Alcohol/Water

L

Mobil Temp. 78

C

Water

R

I

R

C

C

C

C

AROUND DRUM

47. Drum

48. Pick-off Pawls

49. PQC Wire

50. CC Wires

51. PTC Wire

52. TC/SC Wires

53. Wire Cleaner

Pads

54. Quenching Lamp

55. Erase Lamp Unit

56. Drum Thermistor

Unit

57. Corona Casings,

End Blocks

58. TC Casing

Cleaner Pads

59. Brush Seal

60. Image Density

Sensor

61. Charge Corona

Fan Filter

I I I I I

C C C C C

R

C

R R

*

R

R

R

C

C

R R R R

C

R R

C

R

C

C

C

C C C C C C

C C C C C C

R

R R R R R

*

R

C C C C C C

C C C C C C

R R R

C C C C C

C C C C C

C C C C C

2-2

C

R R

R R

*

R

I

Replace if

necessary

C

R

Dry Cloth

Dry Cloth

Dry Cloth

Dry Cloth

R

* Upside Down

Damp Cloth

Damp Cloth

C

C

Damp Cloth

C

Blower Brush

C

Check VSG

C

Page 33

12 July ’86

2-3

C: Clean R: Replace

Item

FUSING UNIT

62. Hot Roller,

Bearing

63. Pressure Roller

Bearing

64. Metering and

Cleaning Blades

65. Oil Pad

66. Pressure and

Hot Roller

Strippers

67. Cleaning Roller

68. Thermistor

69. Paper Guides

70. Terminal Screws

71. Inverter Roller

Clutch

72. Silicone Oil

73. Fusing Exhaust

Fan Filter

74. Cleaning Roller

Bushing

75. Inverter

Rollers

76. Gears, Chains,

Levers, Pins

L: Lubricate A: Add I: Inspect

EM

120K

240K

C

C

C

C

C

R

R

R

C

C

C

C

C

C

C

I

I

L

A

A

A

R

R

C

C

L

L

480K

R

C

C

R

C

R

C

C

C

I

A

R

C

L

C

R

R

C

C

C

C

I

L

A

R

I,R

C

L

C

C

R

C

C

C

I

A

R

C

L

1.2M

NOTE

C

C

R

R

W/Si Oil

Suitable

C

solvent

C

Alcohol only

C

C

Tighten

I

Mobil Temp 78

L

A

R

C

Mobil Temp 78

L

CLEANING UNIT

77. Cleaning Blade

78. Blade Swing Pin

79. Cleaning Brush

80. Bevel Gears

81. Blade Cleaner

82. Seals

83. Cleaning Unit

84. Toner Catcher

85. Bias Roller

Blade

86. PCC Wire

87. Toner

Receptacle

I,C

C

R

L

R

C

I,C

C

C

C

C

R

L

R

L

C

I,C

C

C

R

R

R

L

R

C

I,C

C

C

C

C

R

L

R

L

C

I,C

C

C

R

R

R

L

R

R

I,C

C

C

C

C

C

Clean Finger

R

Mobil Temp 78

L

R

Mobil Temp 78

L

R

I,C

C

C

R

Dry Cloth

R

C

Page 34

12 July ’86

2-4

C: Clean R: Replace

Item

DF UNIT

88. DF Transport

Belt

89. Separation

Tabs

90. Pick-up Rollers

91. Separation

Rollers

92. Feed-out

Rollers

93. Pull-out

Rollers

94. Sensors

95. Bushings, Worm

Gears

LCT

96. Feed Roller

97. Friction Roller

98. Pick-up Roller

99. Feed Sensors

100. Paper Guide

101. Tray Gear

102. Dust Catcher,

Rollers

L: Lubricate A: Add I: Inspect

EM

120K 240K

C

C

C

C C

C

C C C C

C

C C

C C

C C C C

C C C C C C

C C

360K 480K 600K 1.2M

C

I,R

C C C

C C

C

C

C

C

I,R

C C C

I,R

C C C

C

C

C

R

C C C

R

C C C

R

C

C C

C C

I,R I,R

I,R

L L

C C

C

L L

C C

NOTE

Belt Cleaner

Water

I,R Water

Water

I,R

C

Blower Brush

Mobil Temp 78

Alcohol/Water

Alcohol/Water

Alcohol/Water

C

Blower Brush

Dry Cloth

Mobil Temp 78

OTHERS

103. Drive Chains

104. Bushings

L L L L L L

L L L L L L

Spindle oil

Spindle oil

Page 35

SERVICE TABLES

1. Test Points

- Main Board -

Number

TP201

TP202

TP203

TP204

TP205

TP206

TP207

TP208

TP209

TP210

TP211

TP212

TP213

TP214

TP215

TP216

TP217

TP218

TP219

TP220

Function

Trigger for P.P. (PCC)

Trigger for P.P. (PTC)

Trigger for P.P. (T2)

Trigger for P.P. (S2)

Reference clock pulse to main motor board

Reference clock pulse to scanner motor

board

Reset pulse

Reset Pulse

Clock pulse

ADS voltage (Adjust using VR201)

Trigger for P.P. (C)

Trigger for P.P. (T1)

Trigger for P.P. (S1)

+24V

GND

+15V

+5V

+1.31 to 1.35V threshold voltage of IC219

(Adjust using VR202.)

Trigger for P.P. (PQC)

Input voltage of image density sensor

(Adjust using VR203.)

-Scanner Motor Control Board-

Number

Function

TP501

TP502

TP503

TP504

TP505

TP506

TP507

TP508

Scanner ON signal from Main Board

Factory Adjustment Use

+4V (Forward): -6V (Reverse)

Factory Inspection Use

Factory Adjustment Use

Factory Adjustment Use

Ground (GND)

Factory Adjustment Use

-Main Motor Control Board-

Number

TP301

TP302

Function

GND

Encoder Pulse Reference (+0.77V)

2-5

Page 36

12 July ’86

2.

Variable Resisters

- Main Board -

Number

VR201

VR202

VR203

Function

Adjusts the ADS input

Adjusts the reset voltage

Adjusts the image density sensor

voltage

- Scanner Motor Control Board -

Number

VR501

VR502

VR503

VR504

VR505

VR506

VR507

Function

Factory adjustment

Factory adjustment

Factory adjustment

Factory adjustment

Factory adjustment

Factory adjustment

Factory adjustment

- Main Motor Control Board -

Number

VR301

Function

Main motor velocity adjustment

- Lamp Regulator -

Number

VR1

VR2

Function

Lamp regulator maximum output voltage

adjustment

Light adjustment

3. Dip Switches

- Main Board -

DPS201

1234

1000

0100

Function

LT, LDG Size Machine

A4, A3 Size Machine

Note: Other settings are used for the Japanese market.

2-6

Page 37

SERVICE REMARKS

<Handling the Drum>

1.

Never touch the drum surface with bare hands.

Store the drum in a cool dry place.

2.

3.

Always wear gloves when cleaning the drum.

Prime the drum with setting powder only when the cleaning blade,

4.

cleaning brush, and drum are replaced as a set.

5.

Never expose the drum to light for a long time.

Always keep the drum in the protective sleeve when inserting or pulling

6.

the drum out of the copier.

7.

Drum conditioning is necessary when a new drum is installed. In

addition, it should be done at the following times:

a) When image density is reduced due to overexposure of the drum.

b) After cleaning the drum.

c) When the drum is lightly scratched.

8.

Before inserting or sliding out the drum, the cleaning unit should be

removed to avoid drum damage.

press the drum shaft slightly to the left.

When pulling out the cleaning unit,

12 July ’86

9.

Return used drums to the distributor according to standard procedure.

10.

Avoid leaving the top

periods of time.

<Charge Corona>

1.

Do not use emery paper

cleaning.

Do not touch the corona wire with oily hands.

2.

white bands on copies.

The corona wire height should be adjusted only when:

3.

a) The front end block is replaced.

b) The drum charge current is uneven.

4.

Make sure that the corona wires are correctly positioned between the

cleaner pads.

result.

If the wire height is incorrect, uneven image density may

unit up with the

which abrades the

2-7

drum exposed for extended

coating on the wire for wire

Oil stains may cause

Page 38

12 July ’86

<Erase Lamp>

1. A narrower lead edge erase margin increases the possibility of

jams.

2. After cleaning the

filter surface with

At least, 1.0mm of margin is necessary to prevent fusing

erase lamp filter, discharge any static charge

a finger before replacing the unit.

<Optics>

1.

Do not touch the exposure lamp positioning brackets.

2.

A small amount of launa oil or equivalent oil should be used to lubricate

the following parts:

a) Scanner Guide Rods

b) Scanner Guide Rod Pads

c) Lens Housing Guide Rods

3.

Clean the exposure glass with glass cleaner and a dry cloth to reduce

static electricity on the glass which attracts foreign substances (dust,

oil, etc.).

Do not touch the following parts with bare hands:

4.

a) Reflectors

b) Exposure lamps

c) Mirrors and lens

5.

Do not bend or crease the ribbon cable of the

exposure lamp

fiber cable of the automatic density sensor.

fusing

jams.

on the

and the

6.

To move the scanner manually, use the scanner

guide bracket,

exposure lamp unit which is easily damaged.

7.

Do not replace individual exposure lamps. Replace the exposure lamps

and reflectors as a unit.

8.

Do not touch the surface coat of the mirrors with your fingers. When

replacing the mirrors, make sure the surface coat faces the optical path.

9.

Even when the lamps are off, there is voltage present across them.

Make sure that the power is off when working in this area.

10.

Clean mirrors and lens with water or silicone cloth only.

2-8

not the

Page 39

12 July ’86

<Development Unit>

1. Do not force the development roller to turn opposite to the normal

direction of rotation because the gears may be damaged.

2. Never loosen the paint-locked screws that secure the development unit

positioning bracket. This bracket is positioned at the factory, using

special tools.

3. Always lower the top unit before tightening the development unit

mounting screw.

the front of the development unit.)

4. Be careful not to nick or scratch the development roller sleeve (which is

made of aluminum).

5. Always make sure that there are no splits in the upper brush seal.

Splits in the upper brush will cause toner scattering, resulting in a dirty

toner shield glass.

6. When the development unit is out of the copier, always place a sheet of

paper under it to prevent any small pieces of metal (staples, clips, Erings, etc.) from being attracted to the development roller and getting

inside the unit.

7. Do not take off the insulating mylar under the toner cartridge lever.

8. After servicing, make sure the bias switch is on.

(A slot on the top unit fits over the positioning pin on

<Transfer and Separation Corona>

1. Do not loosen the paint-locked screws securing the positioning plate of

the transfer and separation unit.

2. Do not loosen the paint-locked screws holding the entrance mylar guide

of the transfer and separation corona unit.

<Cleaning Unit>

1. Do not damage the cleaning blade edge. Clean the blade with a soft,

clean cloth.

2. Do not touch the cleaning brush with oily hands which impair the

cleaning function.

3. Before pulling out the cleaning unit, place a sheet of paper under it to

catch toner falling from the entrance mylar seal.

4. Before adjusting the cleaning blade pressure, check all other possible

causes.

5. Clean the toner catcher at each service call.

2-9

Page 40

12 July ’86

<Quenching Unit>

1. Clean the lamp filter with a clean damp cloth.

<Paper Feed Section>

1. Lubricate the tray motor worm gear with Mobil

2. Clean all rollers in the paper feed section with

Temp 78.

water only.

<Vertical Transport and Registration Section>

1. Never loosen the paint-locked screws securing the vertical transport unit

positioning brackets.

<Fusing Unit>

1.

After replacing the metering blade, the cleaning blade, or the hot roller,

apply silicone oil to the top of the blades to prevent the blade edge

from getting damaged due to friction.

Be careful not to damage the edges of

2.

the hot roller strippers or their

tension springs.

3.

Be careful not to bend the pressure

roller strippers to protect the

pressure roller from getting scratched.

4.

Make sure that the fusing lamps are

not in

contact with the inner

surface of the hot roller.

5.

Be careful not to damage the thermistor when

6.

Do not install the fusing lamps in the wrong

replacing the hot roller.

terminals. The 1,100W

lamp goes in the upper terminal and the 550W lamp goes in the lower

terminal.

7. Be sure to install the fusing lamps so that the end with more filaments

(colored terminals) are to front side of the machine.

<Inverter Section>

1. Clean all rollers with water and soft cloth.

2. Lubricate all clutches with Mobil Temp 78.

2-10

Page 41

<Duplex Tray>

2-11

12 July ’86

1. The rollers of the duplex tray are unique: do not mix them up with

those of the

two lowe feed trays.

<Top Unit>

1. Do not close

a) When the

b) When the

2. Do not attempt to

the top unit under the following

drum

stay is not set.

right

and left doors are closed.

adjust the drum support screw.

conditions:

<Handling PCBs>

1.2.Before removing the two ROMs on the main board, turn the main switch

off and wait about 15 minutes.

After replacing the RAM on the main board, initialize it using the SP

mode.

a. Activate CRAM by setting SP 6-4 and SP 8-4 to SET.

b. After activating CRAM, turn the power off and on.

c. Set all SP addresses to the proper position.

WARNING: The timer board has a lithium battery, which may explode if mistreated.

Do not recharge this battery, disassemble it, or dispose of it in fire. Used

timer boards should be handled according to local regulations.

Page 42

12 July ’86

SPECIAL TOOLS AND LUBRICANTS

Item

1

2

3

4

5

6

7

8

9

10

11

12

Description

Test Chart OS-UA3 -- 10 sheets

-- 100 sheets

Digital Thermometer

(HLC-60E)E

Digital Thermometer Probe

(HLC-60E)

Digital Multimeter

(BECKMAN RMS3030)

Deluxe Test Lead Accessory Kit

(BECKMAN DL241)

Corona Current Measuring Shoe

Scanner Drive Pulley Pin

Stopper Pin

Cam Positioning Pin

Scanner Drive Pulley Clamp

Wire Clamp

Lens Positioning Pin

Part No.

5446 9516

5446 9517

5420 9504

5420 9505

5420 9507

5420 9508

5446 9610

5446 9116

5446 9117

5446 9118

5446 9119

5446 9122

5219 9005

Q’ty

1

1

1

1

1

1

1

1

1

2

1

13

Thickness Gauge - 0.2mm

14

Thickness Gauge - 0.90mm

Thickness Gauge - 1.60mm

15

16

Thickness Gauge - 1.75mm

Setting Powder

17

18

Silicone Oil

19

Launa 40 Oil

Grease (MOBIL TEMP 78) 400g

20

21

Special Tool Set

(Consists of items 12 and 14)

2-12

5446 9140

5219 9001

5446 9137

5446 9138

5442 9101

5420 9550

5442 9103

5447 9078

5219 9804

1

1

1

1

Page 43

SECTION 3

REPLACEMENT AND

ADJUSTMENT

Page 44

CONTENTS

36. Hot Roller Temperature Adjustment

EXTERIOR COMPONENT REMOVAL

1. Exposure Glass and Operation Panel Removal . . . . 3-1

2. Top Plate Removal

DRUM AND CHARGE

3. Drum Replacement

4. Drum Thermoswitch and Heater Replacement . . . . . . 3-4

5. Charge Corona Wire Replacement . . . . . . . . . . . . . . . . 3-5

6. Charge Cleaner Drive Wire Replacement

EXPOSURE

7. Scanner Drive Wire Replacement

8. Lens Drive Wire Replacement . . . . . . . . . . . . . . . . . . . 3-17

9. Exposure Lamp Unit Removal . . . . . . . . . . . . . . . . . . . . 3-21

DEVELOPMENT

10. Development Unit Removal . . . . . . . . . . . . . . . . . . . . . . 3-22

11. Developer Replacement

12. Development Roller and Paddle Roller Removal . . 3-24

13. Adjustment of Development Roller Gaps

14. Image Density Sensor Cleaning and Removal

15. Image Density Sensor Adjustment . . . . . . . . . . . . . . . 3-29

TRANSFER AND PICK-OFF

16. Transport Unit Removal

17. Pre-transfer Corona Wire Replacement . . . . . . . . . . 3-31

18. Transfer and Separation Corona Wire Replacement 3-32

19. Drive Wire Replacement (PTC and T/S Corona)

20. Transport Belt Replacement . . . . . . . . . . . . . . . . . . . . 3-34

21. Registration Sensor Replacement . . . . . . . . . . . . . . . 3-35

22. Pick-off Pawl Unit Removal . . . . . . . . . . . . . . . . . . . . 3-36

. . . . . . . . . . . . . . . . . . . . . . . . . 3-23

12 July ’86

3-2

3-3

3-6

3-7

3-26

3-28

3-33

CLEANING

23. Cleaning Blade and Brush Replacement

24. Pre-cleaning Corona Wire Replacement

25. Toner Collection Coil Replacement

26. Cleaning Blade Pressure Adjustment

27. Blade Cleaner and Bias Roller Blade Replacement 3-41

28. Pre-quenching Corona Wire Replacement

FUSING

29. Fusing Unit Removal

30. Hot Roller Stripper Replacement . . . . . . .

31. Cleaning Blade, Metering Blade,

and Oil Supply Pad Replacement

32. Hot Roller Replacement

33. Pressure Roller Replacement

34. Thermistor and Thermofuse Replacement

35. Fusing Pressure Adjustment

3-37

3-38

3-39

3-40

3-42

3-43

3-44

3-45

3-47

3-49

3-50

3-51

3-53

Page 45

12 July ’86

INVERTER

37. Inverter Roller Clutch Disassembly

38. Inverter Gate Solenoid Adjustment

39. Inverter Gate Adjustment . . . . . . . . . . . . . . . . . . . . . . 3-57

PAPER FEED

40. Paper Feed Unit Removal

41. Pick-up Roller Replacement . . . . . . . . . . . . . . . . . . . . 3-59

42. Feed Roller Replacement

43. Friction Roller Replacement . . . . . . . . . . . . . . . . . . . 3-61

44. Paper Tray Unit and Cover Removal . . . . . . . . . . . . . 3-62

45. Paper Tray Drive Wire Replacement . . . . .

46. Vertical Transport Unit Removal . . . . . . . . . . . . . . . 3-66

DUPLEX TRAY

47. Duplex Tray Removal

48. Paper Feed Roller Replacement and Adjustment . . 3-68

49. Pick-up Roller Replacement . . . . . . . . . . . . . . . . . . . . 3-69

50. Friction Roller Replacement . . . . . . . . . . . . . . . . . . . 3-70

51. Bottom Plate Pressure Clutch Disassembly

52. Duplex Paper Sensor Adjustment

53. Duplex Side Plate Drive Wire Replacement

COPY IMAGE

54. Horizontal Magnification Adjustment

55. Side-to-Side Registration Adjustment

56. Uneven Exposure Adjustment . . . . . . . . . . . . . . . . . . . . 3-76

57. Light Intensity Adjustment . . . . . . . . . . . . . . . . . . . . 3-77

58. Auto Density Sensor Adjustment

and Adjustment

3-54

3-56

3-58

. . . . . . . . . . . . . . 3-60

3-63

3-67

3-71

3-72

3-73

3-74

3-75

3-78

CORONA CURRENT ADJUSTMENT

59. Corona Current Adjustment Preparation . . . . . . . . . 3-79

60. Charge Corona

61. Pre-transfer Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-82

62. Transfer Corona

63. Separation Corona

64. Pre-cleaning Corona

65. Pre-quenching Corona

SERVICE PROGRAM MODE

1. Factory Settings

2. Service Program Functions . . . . . . . . . . . . . . . . . . . . . . 3-88

3-81

3-83

3-84

3-85

3-86

3-87

Page 46

EXTERIOR COMPONENT REMOVAL

3-1

1. Exposure Glass and Operation Panel Removal

12 July ’86

1. Remove the DF front cover [A] (2 screws) and the copier front top

cover [B] (3 screws).

-

Exposure Glass -

2. Loosen the two screws securing the rear scale [C], and remove the glass

fixing plate [D] (1 screw).

3. Slide out the exposure glass [E] with the right scale. (Do not bend the

fiber-optic cables.)

-

Operation Panel -

2. Remove the upper front cover [F] (2 screws).

3. Unplug the five operation panel connectors

ground wire [H].

4. Remove the operation panel [I] (5 screws).

[G] and disconnect the

Page 47

12 July ’86

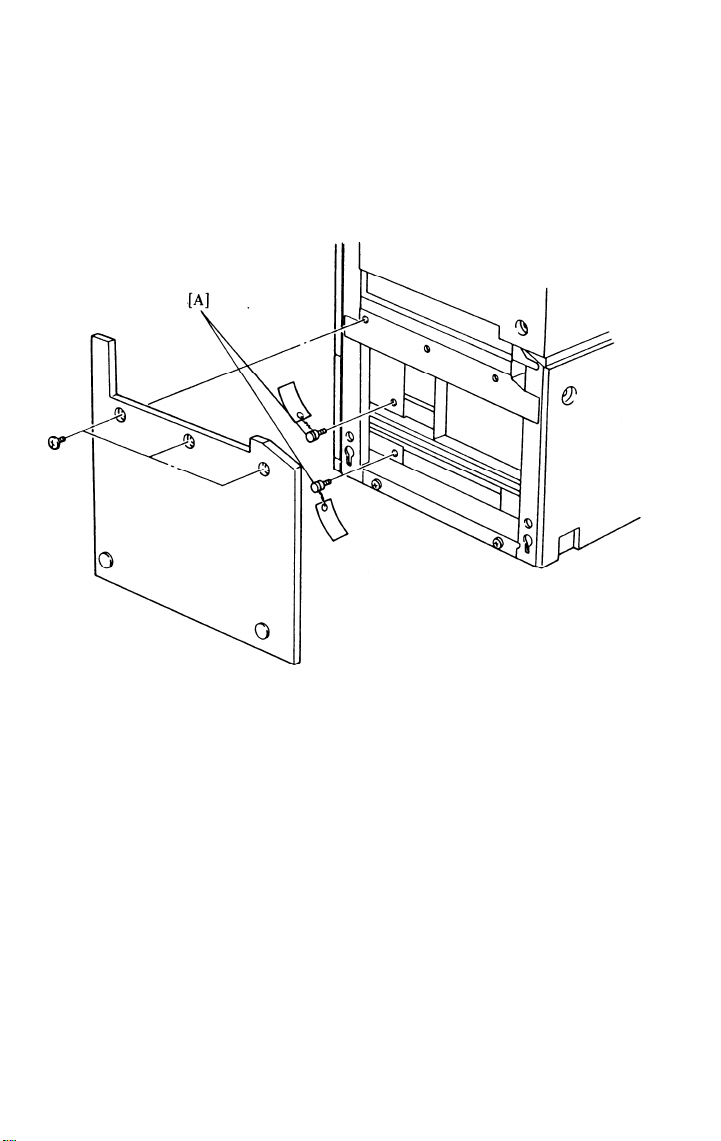

2. Top Plate Removal

1. Remove the DF transport unit and feed-in unit. (Refer to “DF Removal”

in Section 5.)

2. Remove the following parts:

a) Right top cover (2 screws)

b) Original tray (2 screws)

c) Upper front cover (2 screws)

3. Remove the platen cover support bracket [A] (2 flat-head screws and 2

pan-head screws).

4. Remove the operation panel [B] (5 connectors and 5 screws).

5. Remove the scanner home position sensor bracket [C] (1 screw).

6. Remove the top plate [D] (6 screws, 115 V machines--1 connector).

3-2

Page 48

DRUM AND CHARGE

3. Drum Replacement

1.

Open the top unit, and remove the drum cover [A] (2 screws).

2.

Remove the drum stay [B] by turning the knob counterclockwise.

12 July ’86

Remove the following parts:

3.

a) Erase unit [C]

b) Charge corona unit [D] (1 connector)

c) Drum thermistor [E]

d) Quenching unit [F] (1 connector)

e) Cleaning unit [G]

f) Drum flange gear [H]

NOTE: When removing or installing the cleaning unit, press the drum shaft to the

left to prevent drum damage.

Install the drum guide on the drum shaft, and pull out the old drum.

4.

CAUTION: If the drum is removed for maintenance purposes, the drum protective sleeve

5.

Insert a new drum with the drum protective sleeve on it, then remove

the drum protective sleeve.

must be inserted.

(Save the protective sleeve for future

maintenance.)

6.

Reassemble the machine.

7.

Place a white sheet of A3 or 11” x 17” paper on the exposure glass and

lower the ADF transport unit.

Turn on Service Program 1-3 (Free Run)

for 15 minutes.

3-3

Page 49

12 July ’86

I

4.

Drum Thermoswitch and Heater Replacement

Before starting,

rear drum heater flanges.

1.

Turn off the main switch.

2.

Remove the drum (refer to “Drum Replacement”); then, take out the

drum guide.

3.

Remove the front drum heater flange [B] (3 screws and 1 bracket).

- Drum Thermoswitch Replacement -

a) Disconnect the leads from the two thermoswitch terminals.

b) Remove the thermoswitch bracket [C] (1 screw), and remove the old

thermoswitch [D] from the bracket (2 screws).

c) Install a new thermoswitch.

- Drum Heater Replacement -

a)

Disconnect the connector [E] from the inside of the drum heater;

then, slide out the heater.

b)

Install a new drum heater.

note the locating tabs and cutouts [A] on the front and

3-4

Page 50

5. Charge Corona Wire Replacement

3-5

Remove the drum cover and take out

1.

tor).

12 July ’86

the charge corona unit (1 connec-

Remove the rear endblock cover [A].

2.

(Be careful not to break off the

side hooks).

3.

Remove the front endblock cover [B] (1 screw) and the corona wires

●

[C]

4.

Hook the small eyelets of the new wires to the tension springs [D].

5.

Hook the large eyelets of the new wires to the anchor hook [E] on the

front endblock cover.

6.

Set the wires in the grooves on the front endblock as shown [F], and

install the front endblock cover.

7.

Set the wires in the grooves on the rear endblock as shown [G], and in

stall the rear endblock cover.

8.

Ensure that the corona wires are between the cleaner pads as shown

●

[H]

9.

Reassemble; then, check the wire cleaner movement using SP 5-3.

Page 51

12 July ’86

6. Charge Cleaner Drive Wire Replacement

1. Remove the corona wires. (Refer to “Charge Corona Wire Replacement”.)

2. Remove the drive wire tension springs [A] and the old drive wire [B].

3. Wrap the new wire around the drive pulley two and one-half times [C].

4. Fit the drive ring [D] over the post of the wire cleaner.

5. Slip the wire over the idle pulley [E].

6. Route the drive wire as shown [F].

7. Make sure that the corona wires are between the cleaner pads.

8. Reassemble.

9. Check the wire cleaner movement using SP 5-3.

3-6

Page 52

EXPOSURE

7. Scanner Drive Wire Replacement

12 July ’86

1.

Remove the DF transport unit and feed-in unit. (Refer to “DF Removal”

in Section 5.)

2.

Remove the top plate. (Refer to “Top Plate Removal”.)

3.

Remove the pre-quenching corona power pack with bracket [A] (1 screw

and 2 connectors) and the main switch (2 screws).

Remove the lens housing cover [B] (3 screws).

4.

5.

Remove the optics cooling fan [C] (4 screws and 1 connector).

6.

Loosen the Allen screw on the scanner drive pulley [D] and remove the

scanner motor [E] (2 shoulder screws and 2 connectors).

7.

Loosen the two Allen screws [F] (front and rear) securing the wires to

the first scanner [G].

3-7

Page 53

12 July ’86

3-8

8. Using a flat blade screwdriver, turn the front mirror shift pulley [A]

counterclockwise and insert the stopper pin [B] into the hole.

9. Turning the front mirror shift pulley counterclockwise, remove the mir-

ror shift wire [C] and the magnification ratio adjusting ring [D].

10. Remove the wire holding plates [E] from both mirror shift pulleys (1

screw each).

11. Remove the two scanner drive wires.

Page 54

- Installation -

12 July ’86

12. Loosen the mounting screws for the front second scanner pulley bracket

[A].

13. Set the front and rear second scanner positioning clamps [B].

3-9

Page 55

12 July ’86

3-10

14.

Insert the beads of the long (gray) [A] and short (black) [B] wires into the slots of the

scanner drive pulley [C] as shown.

should be facing up.)

15.

Wrap the two wires side by side 3 times along the grooves of the scanner drive pulley.

NOTE: If the wires are properly wrapped, you will count seven wires on the scan-

ner drive pulley with the long wire to the outside of the scanner drive

pulley.

16.

Clamp the wires with the scanner drive pulley clamp [E].

17.

Reinstall the scanner drive pulley and insert the scanner drive pulley pin

[F] into the support shaft [G].

(At this time the Allen screw [D]

Page 56

12 July ’86

3-11

18. Route the short end of the scanner drive wire [A] over the pulleys in

the following order.

NOTE: Use the wire clamps [B] to prevent the wire from slipping off the pulleys.

Lower track clockwise.

(1)

Inner track clockwise.

(2)

Counterclockwise.

(3)

(Skip the tension pulley.)

(4)

Counterclockwise.

(5)

Outer track counterclockwise.

(6)

Lower track clockwise.

(7)

(2nd scanner drive pulley)

(Rear mirror shift pulley)

(2nd scanner drive pulley)

Page 57

12 July ’86

3-12

19. Route the long end of the scanner drive wire [A] over the pulleys in

the following order.

Upper track clockwise.

(1)

Lower track clockwise.

(2)

Inner track counterclockwise.

(3)

Clockwise.

(4)

Skip the tension pulley.

(5)

Clockwise.

(6)

Outer track clockwise.

(7)

Lower track clockwise.

(8)

Upper track clockwise.

(9)

(Front mirror shift pulley.)

(2nd scanner drive pulley.)

(2nd scanner drive pulley.)

Page 58

12 July ’86

20.

Wrap both ends of the wire around the scanner wire drive pulley. Insert the

beads [A] into the slots of the pulley.

21.

String the wire over the front and rear tension pulleys [B].

22.

Reinstall the scanner motor (2 shoulder screws and 2 connectors) and

tighten the Allen screw of the scanner drive pulley. Adjust the gap between the pulley and the motor (2.00 ± 0.3 mm).

23.

Reinstall the optics cooling fan and cover (4 screws and 1 connector).

3-13

Page 59

12 July ’86

Remove

and the

25.

Remove

Hook up the wire tension springs [A].

26.

Tighten the front and rear scanner pulley brackets [B] (2 screws each).

27.

Slide the second scanner manually several times to ensure proper move-

28.

ment.

the scanner drive

pulley clamps.

the front and rear

pulley pin, the

second scanner

3-14

scanner drive pulley

positioning clamps.

clamp,

Page 60

12 July ’86

29.

Using a flat blade screwdriver

counterclockwise until the slot [B] is facing up.

30.

Insert the bead of the mirror shift wire [C] into the slot of the mirror

shift pulley.

31.

Route the mirror shift wire as shown, and insert the magnification ratio

adjusting ring [D] into the holder [E].

32.

Secure the wire holding plates [F] to the mirror shift pulleys (1 screw

each, front and rear).

33.

Insert the lens positioning pin [G] through the lens bracket as shown

[H].

Adjust the clearance between the housing bracket and the stopper pin [I]

34.

to within 0.1 mm ring [J].

ment.

This is part of the coarse horizontal magnification adjust-

Remove the stopper pin from the mirror shift pulley.

0.5 mm by turning the magnification ratio adjusting

turn the mirror shift pulley [A]

3-15

Page 61

12 July ’86

35. Set the front and rear second scanner positioning clamps.

36. Adjust the distance between the rear second scanner bracket [A] and

the rear first scanner bracket [B] as shown. (Distance: 120 mm) This is

also part of the coarse horizontal magnification adjustment.

37. Tighten the front and rear drive wire clamps [C] on the first scanner (1

Allen screw each).

38. Remove the front and rear second scanner positioning clamps.

39. Slide the first and second scanners manually several times to ensure

proper movement.

40. Reassemble the machine except the upper front cover.

41. Adjust the horizontal magnification ratio.

cation Adjustment”.)

42. Reassemble.

3-16

(Refer to “Horizontal Magnifi-

Page 62

8. Lens Drive Wire Replacement

3-17

12 July ’86

1.

Remove the

2.

Remove the

panel.

3.

Remove the lens housing cover (3 screws) and the drum cover (2

screws).

4.

Remove the main switch [A] (2 screws).

5.

Using a flat blade screwdriver,

counterclockwise. Insert the stopper pin [C] into the hole.

6.

Remove the mirror shift wire [D] and magnification ratio adjusting ring

[D].

7.

Remove the left support bracket [E] (2 screws) and the top unit release

lever assembly [F] (3 screws).

wires.)

Remove the harnesses [G] from the three twist clamps [H]

8.

nect the three connectors from their respective terminals

lens drive unit.

upper front cover.

top front cover, exposure glass, original tray, and operation

turn the front mirror shift pulley [B]

(It is all right to let them hang from the

and discon-

around the

Page 63

12 July ’86

9. Remove the lens drive wire [A] from

screw).

10. Remove the lens drive unit [C] from the

tors).

11. Release the lens drive wire tensioning mechanism [D] (2 screws).

12. Loosen the wire securing screw [E] and remove the old wire [F].

3-18

the wire clamp [B] (1 Allen

copier (3 screws and 3 connec-

Page 64

12 July ’86

13. Insert the cam positioning pin [A] into the hole and tighten it. This positions the lens in the 100% reproduction setting.

14. Insert the painted portion of the wire [B] into the slot [C] in the lens

drive pulley [D] and secure it with a screw.

NOTE: The lens drive wire joiner [E] should be on the bottom as shown.

15. Wrap the top section of the wire [F] 1¼ times clockwise and the bottom

section of the wire [G] l¼ times counterclockwise around the lens drive

pulley as shown.

16. Hook up the wire to the tension pulley [H].

17. Adjust the lens drive wire tension. (See the adjustment table.)

3-19

Page 65

12 July ’86

18.

Reinstall the lens drive unit (3 screws and 3 connectors).

CAUTION: The lens housing cover support bracket [A] must be under the scanner

drive wire [B]. This wire sometimes gets caught when installing the

lens drive unit.

19.

Clamp the harnesses with the three twist clamps, and connect the three

connectors and the two terminals.

20.

Manually position the lens to 100% by inserting the lens positioning

pin.

21.

Route the mirror shift wire [C] as shown.

22.

Secure the lens drive wire to the wire clamp.

23.

Remove the lens positioning pin, stopper pin,

pin.

Reassemble the copier.

24.

Check lens change operation in all magnification ratios.

and the cam positioning

3-20

Page 66

9. Exposure Lamp Unit Removal

3-21

12 July ’86

1.

Turn off the main switch.

2.

Remove the exposure glass.

3.

Remove the rear scale [A] (2 screws).

4.

Disconnect the ribbon cable connector [B].

5.

Remove the automatic density sensor (ADS) with bracket [C] (1 screw).

6.

Manually position the first scanner so that the access holes in the top

(Refer to “Exposure Glass Removal”.)

plate align with the exposure lamp unit mounting screws [D] as shown.

CAUTION: - To move the first scanner manually, use the first scanner guide bracket.

7.

Loosen the two exposure lamp unit mounting screws and remove the ex-

Do not use the exposure lamp unit.

- Do not remove the reflector mounting screws.

- Do not bend the fiber-optic cable.

posure lamp unit [E] from the copier as shown.

8.

Check the light intensity and adjust if necessary. (See “Light Intensity

Adjustment.)

Page 67

12 July ’86

3-22

DEVELOPMENT

10. Development Unit Removal

1. Open the top unit, and remove the development unit cover [A] (1

screw).

2. Remove the development unit [B] (1 screw, M4 x 10 [C]).

CAUTION: Always lower the top unit before tightening the development unit mounting

screw. A slot [D] on the top unit fits over the positioning pin [E] on the

front of the development unit to correctly position the front of the development unit.

Note: When the development unit is installed:

- Check that the development unit is seated in the guide rails.

- Turn the paddle roller knob [F] clockwise to confirm that the development

unit gear is properly engaged.

- After closing the top unit, secure the development unit with the M4 x 10

screw.

Page 68

11. Developer Replacement

12 July ’86

1.

Remove the development unit cover (1 screw).

2.

Remove the developer exchange plate [A] (1 screw).

3.

Close the doors and use SP 1-1 (Tribo charge) for about 1 minute to

dump the old developer.

4.

Turn off the main switch.

5.

Clean and reinstall the developer exchange plate.

6.

Remove the development unit.

7.

Remove the developer catch pan [B], and dispose of the old developer.

Then, reinstall the developer catch pan.

8.

Remove the developer inlet cover [C] and pour two kilograms of

developer into the development unit.

turn the paddle roller

developer.

9.

Reassemble the machine

knob [D] clockwise to evenly distribute the

and use SP 1-1 (Tribo charge) for 3 minutes.

3-23

While pouring in the developer,

Page 69

12 July ’86

12. Development Roller and Paddle Roller Removal

1.

Remove the developer.

2.

Place the development unit on a clean sheet of paper with the develop-

(Refer to “Developer Removal”.)

ment roller facing up.

Remove the gear cover [A] (1 screw) and the upper cover [B] (4 screws,

3.

1 connector).

CAUTION: Do not loosen the magnet angle plate [C]. It is factory preset using a

4.

Remove the following parts:

a) The

b) The

c) The

d) The

NOTE:

5.

Remove the lower cover [J] (5 screws).

special tool at the factory.

unit handle [D] (2 screws)

rear belt tensioner [E] (1 screw) and the drive belt [F]

two screws securing the bias plate [G]

developer Exchange Plate (1 screw)

The first time the lower cover is removed, Pull out the developer exchange plate (1 screw) and cut the lower side seals [H,I] along the gap

between the lower cover and the main body of the development unit as

shown. This allows the lower cover to be separated.

3-24

Page 70

12 July ’86

6.

Remove the development roller [A] and the paddle roller

7.

Reassemble when the development roller and the paddle

stalled, do the following:

- Position the development roller so that the magnet angle pin [C] fits

into the flat surface [D] of the development roller shaft.

- Position the development roller and the paddle roller so that the

notch [E] on the bearing casing fits into the projection [F] of the

frame.

3-25

[B].

roller are in-

Page 71

12 July ’86

13. Adjustment of Development Roller Gaps

- The Flow Gap -

- The Pre-doctor Gap -

- The Doctor Gap -

ADJUSTMENT STANDARD: 1.75 mm ± 0.15 mm

ADJUSTMENT STANDARD: 1.6 mm ± 0.1 mm

ADJUSTMENT STANDARD: 0.9 mm ± 0.1 mm

1. Remove the developer. (Refer to “Developer Removal.”)

2. Remove the upper and the lower covers. (Refer to “Development Roller

and Paddle Roller Removal”.)

3. Clean the surface of the development roller, doctor blade, flow plate,

and the pre-doctor plate with a soft cloth.

- The Flow Gap -

1.

Remove the doctor blade [A] (2 screws).

2.

Loosen the flow plate (3 screws [B]).

3.

Insert a 1.75 mm thickness gauge [C] between the flow plate [D] and the

development roller [E] at the positions shown.

Tighten the flow plate while pressing down the development roller and

4.

pressing the flow plate against the thickness gauge.

5.

Check that the flow gap is correct and even at all positions.

3-26

Page 72

12 July ’86

3-27

- The Pre-doctor Gap -

1. Remove

[B]).

2. Insert a

and the

3. Tighten the pre-doctor plate while pressing down the development roller

and pressing the pre-doctor plate against the thickness gauge.

4. Check that the pre-doctor gap is correct and even at all positions.

- The Doctor Gap -

1.

Install the doctor blade [F]. (Tighten screws [G] temporarily.)

2.

Insert a 0.9 mm thickness gauge [H] between the doctor blade and the

development roller [I].

3.

Tighten the doctor blade (2 screws) while pressing down the development

roller and pressing the doctor blade against the thickness gauge.

4.

Check that the doctor gap is correct and even at all positions.

the paddle roller [A] and loosen the pre-doctor plate (5 screws

1.60 mm thickness gauge [C] between the pre-doctor plate [D]

development roller [E] at the positions shown.

Page 73

12 July ’86

3-28

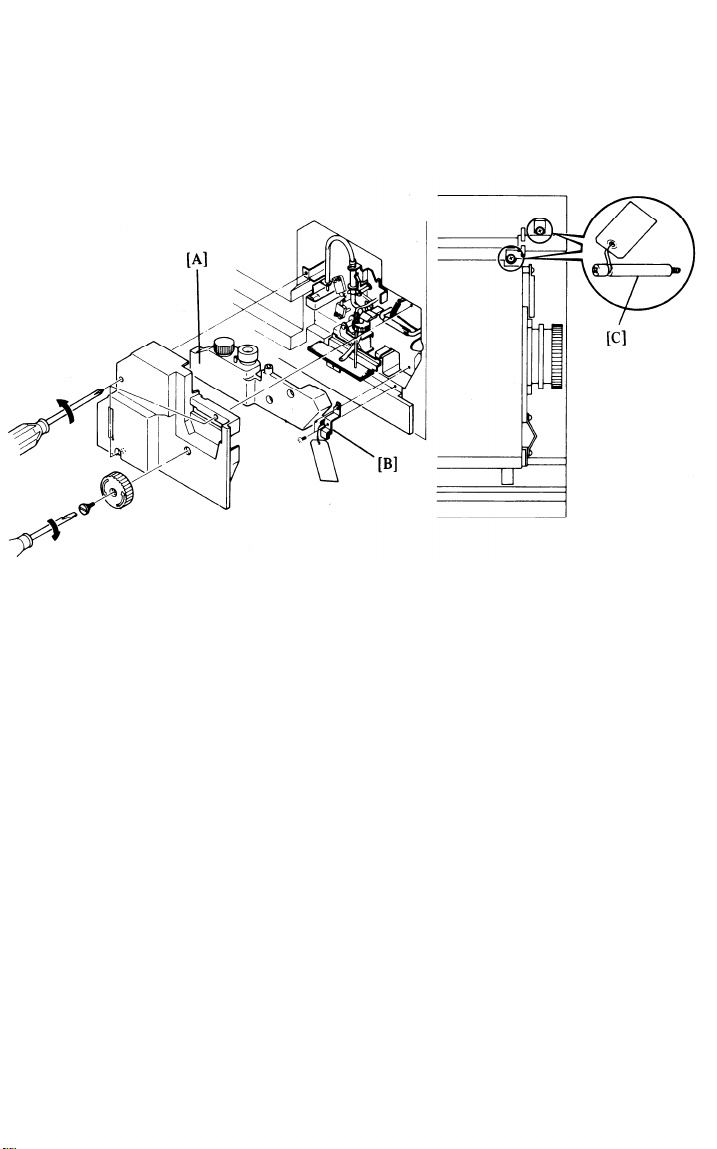

14. Image density Sensor Cleaning and Removal

2. Loosen the screw [A] securing the

3. Pull the image density sensor unit

-

Cleaning -

a) Clean the image density sensor

b) Discharge any static electricity built up on the sensor during

cleaning. A clean finger will serve as a discharge medium.

- Unit Removal -

a) Disconnect the 6P connector [D].

b) Remove the bushing [E].

c) Remove the image density sensor unit.

image density sensor unit [B].

to release it.

[C] using a dry cloth.

Page 74

15. Image Density Sensor Adjustment

3-29

12 July ’86

ADJUSTMENT STANDARD: 2.0 ± 0.1

V (VSG)

1. Clean the following parts:

a)

Lens and Mirrors

b)

Exposure Glass

c)

Toner Shield Glass

d)

Corona Wires

e)

Erase Lamp

f)

Quenching Lamp

Image Density Sensor

g)

NOTE: Discharge any static electricity on the sensor after cleaning it. A clean

finger will serve as a discharge medium.

2.

Place 3 sheets of paper on the exposure glass.

3.

Set SP 1-3, 2-3, and 29. Reset SP 2-4.

4.

Press the Start key.

5.

Adjust the output of the image density sensor (VSG) using VR203 on the

main board.

Page 75

12 July ’86

TRANSFER AND PICK-OFF

16. Transport Unit Removal

1. Slide out the fusing unit.

2.

Remove the following parts:

a) Development unit (Refer to “Development Unit Removal”.)

b) Transport unit cover [A] (2 screws)

c) Drum (Refer to “Drum Replacement”.)

Remove the transport unit [B] (1 screw).

3.

4.

Reassemble. When reinstalling the unit,

the back of the unit to align the locating pins.

3-30

it may be necessary to lift

Page 76

17. Pre-transfer Corona Wire Replacement

12 July ’86

1.

Remove the transport unit cover [A] (2 screws).

2.

Remove the pre-transfer corona unit [B] (1 screw and 2 connectors

[C]).

3.

Remove the front endblock cover [D] (1 screw) and rear endblock cover

[E]. (Be careful not to break off the side hooks.)

4.

Unhook the spring [F] and remove the old corona wire.

5.

Clean the front and rear endblocks and the corona casing.

6.

Hook the large eyelet [G] of the new corona wire to the rear anchor

post

●

7.

Hook the tension spring to the small eyelet [H]‚ and then hook it to

the front terminal.

8.

Make sure that the corona wire is between the cleaner pads.

9.

Reassemble, then check the wire cleaner movement using SP 5-3.

3-31

Page 77

12 July ’86

18. Transfer and Separation Corona Wire Replacement

1.

Slide out the fusing unit and remove the transport unit cover (2

screws).

2.

Slide out the transfer and separation corona unit (1 connector).

3.

Remove the front and rear paper guides [A].

4.

Remove the front endblock cover [B] and rear endblock cover [C] (1

screw).

5.

Remove the old corona wires.

6.

Clean the front and rear endblocks and corona casing.

7.

Hook the large eyelets [D] of the new corona wires to the front anchor

posts.

8.

Hook the tension springs [E] to the small eyelets and then hook the

tension springs to the rear terminal springs [F]. (Be sure to use the correct springs as shown in the illustration.)

9.

Check that the wires are in the positioning grooves.

10.

Make sure that the corona wire is between the cleaner pads.

11.

Reassemble.

12.

Check the wire cleaner movement using SP 5-3.

(Be careful not to break off the side hooks.)

3-32

Page 78

19. Drive Wire Replacement (PTC and T/S Corona)

3-33

12 July ’86

1.

Remove the corona wire(s).

2.

Wrap the guide wire [A] twice

Hook the guide wire to the idle pulley(s) [C].

3.

4.

Hook the drive ring(s) over the post(s) of the wire cleaner(s) [D].

5.

Hook the tensioning spring(s) [E] to both sides of the wire tensioner.

6.

Make sure that the corona wires are between cleaner pads.

7.

Reassemble.

8.