Page 1

Technical Bulletin No. RTB-001

SUBJECT: Dirty Background After Power up DATE:August 31, ’95

PAGE: 1 of 2

PREPARED BY: M. Mimura

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

During our on-going laboratory test, we observed a symptom which may occur in the field

as the MIF grows. The following describes the details of the problem and the action to be

taken.

< Symptom >

Dirty background on the initial one to five copies after the five minute fusing idling after

power on.

< Cause >

When the oil supply roller is not hot enough just after the fusing idle mode (cold start), the

paper dust (colored black as it is mixed with toner) on the oil supply roller moves to the hot

roller and accumulates. This paper dust sticks onto the paper, giving the copy dirty

background.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Thunderbird II

This symptom tends to occur with paper containing more calcium carbonate after more

than 50K copies usage of the oil supply roller.

< Objective Units >

The units with the following serial numbers have SP 10 4-3 set to SET at the factory.

Q’ty Serial Number

A171 - 10 0 N/A

A171 - 15 0 N/A

A171 - 17 0 N/A

A171 - 22 28

A171 - 27 59

9275070001 → 21

9275080001 → 07

A3875070057 → 85

A3875080001 → 30

Page 2

Technical Bulletin No. RTB-001

SUBJECT: Dirty Background After Power up DATE:August 31, ’95

PAGE: 2 of 2

< Action to be taken >

Change SP 10 4-3 from SET to RESET to disable the fusing idle mode. Because

changing the SP mode setting has proven not to create the problem and there are no side

effects, you should change the SP mode setting on all field machines.

< Service Manual Correction >

The default setting of SP 10 4-3 is RESET. Please correct your Service Manual.

* Default setting: The setting that the ROM selects when the RAM clear is performed.

Page 3

Technical Bulletin No. RTB-002

SUBJECT: Stack-feed from the LCT DATE: December

15, ’95

PAGE: 1 of 2

PREPARED BY: M. Mimura

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

<Symptom>

Stack-feed tends to occur from the optional LCT.

<Cause>

Paper at feeding is positioned higher than the center portion of the tray side fence, which

is to prevent multiple sheets of paper from being delivered to the feed / separation rollers.

<Action to be taken in the field>

Check and adjust the paper height as follows:

1. Detach the LCT from the copier.

2. Remove the top cover to expose the feed section.

3. Reattach the LCT to the copier.

4. Lower the paper stack by pressing the tray button. Then, pull out and push in the tray

to raise the paper stack back to the feed position.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Thunderbird II

5. Feed ten sheets from the LCT.

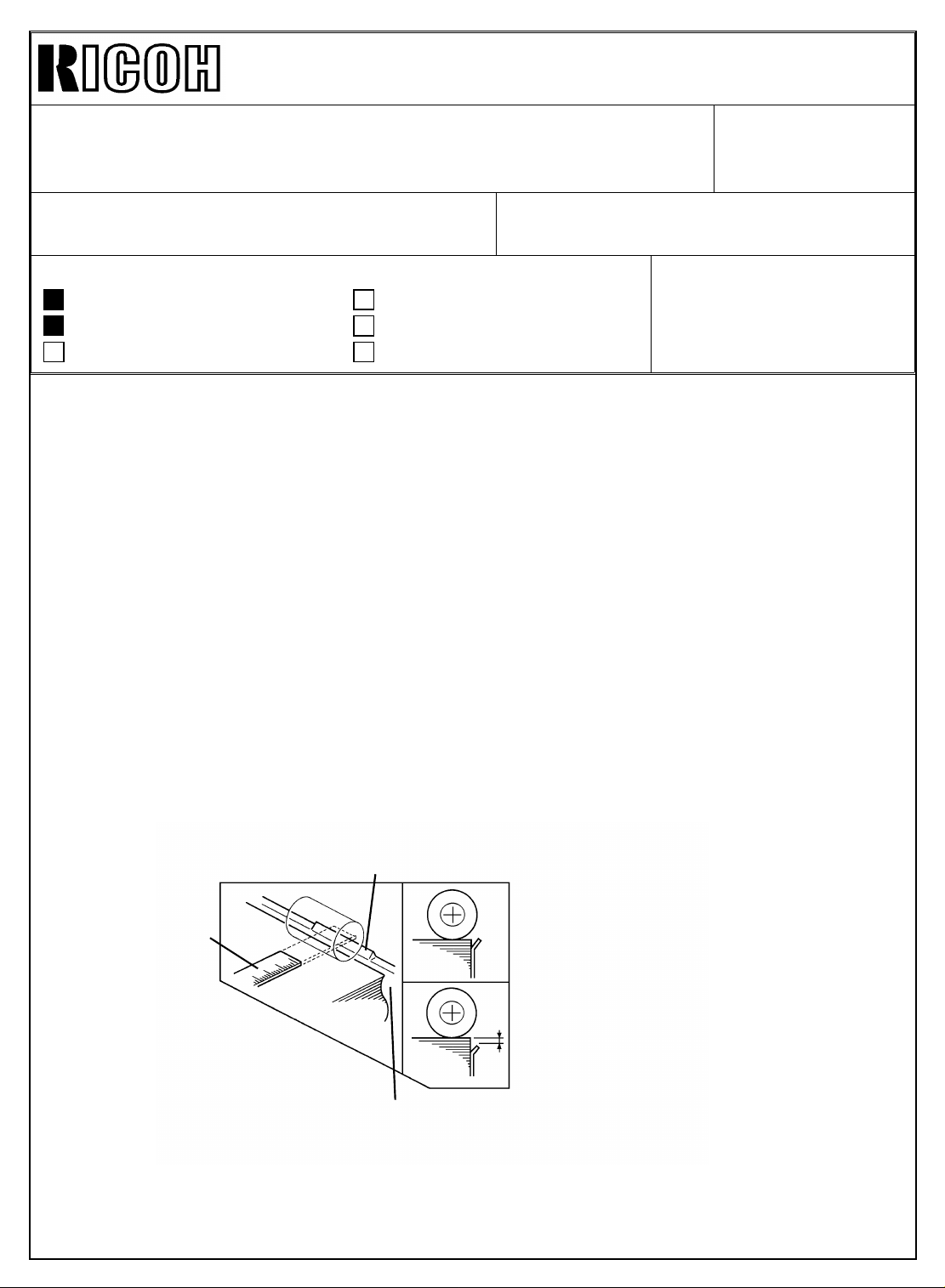

6. Insert a ruler (or a similar flat object) [A] between the paper and the feed roller and

confirm that it contacts the center portion (paper separation) of the side fence.

Center Portion

[A]

Tray Side Fence

7. If the ruler does not hit the center portion of the tray side fence, do the following steps.

8. Roughly measure how much the paper is higher than the fence.

Page 4

Technical Bulletin No. RTB-002

[C]

SUBJECT: Stack - feed from LCT DATE: December

15, ’95

PAGE: 2 of 2

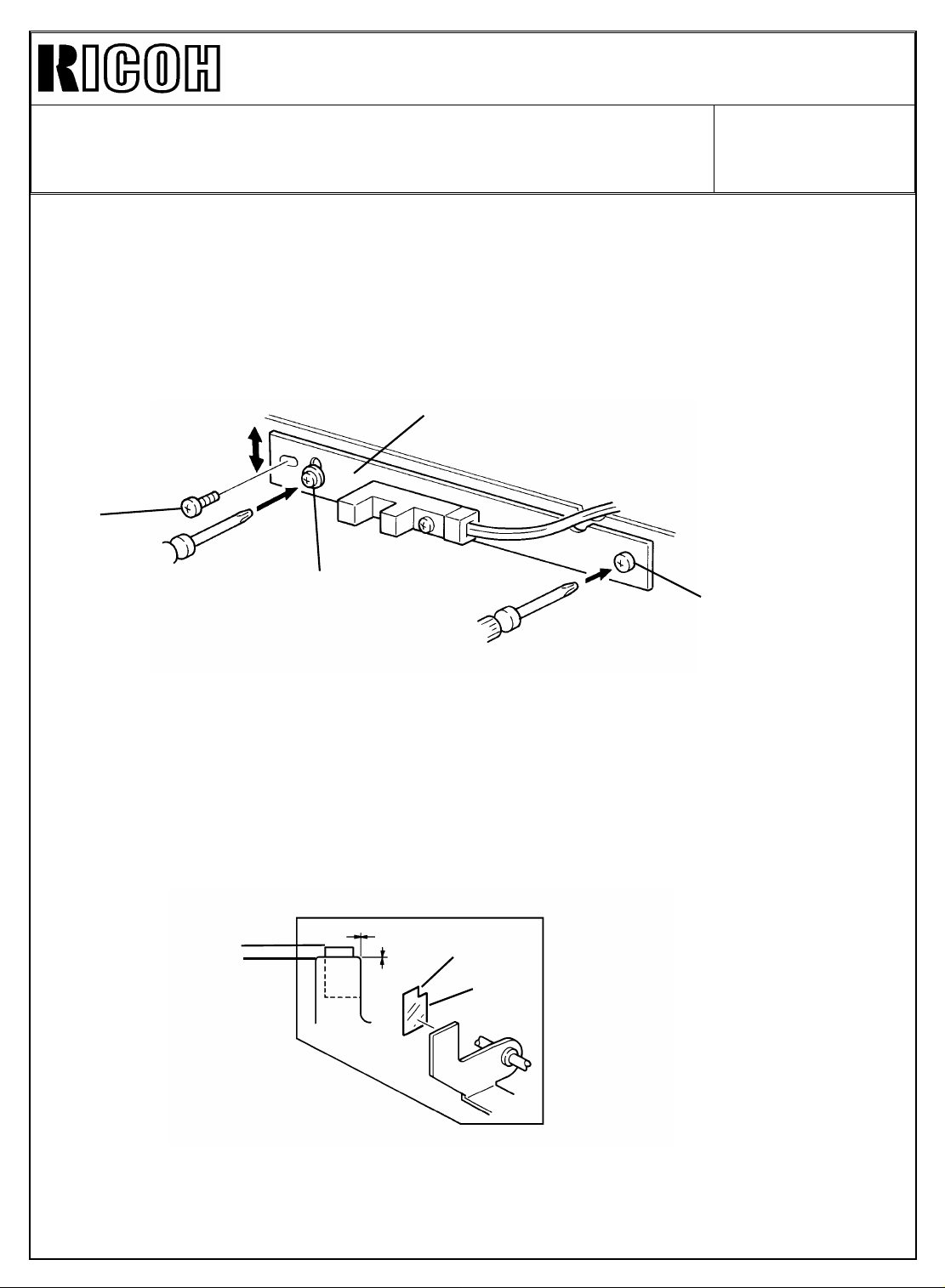

9. Remove the securing screw [B]. Note: This screw will not be used after the adjustment.

10. Loosen the securing screw [C] and adjustment screw [D] to free the sensor adjustment

plate [E].

11. Position the sensor adjustment plate to offset the excessive height.

12. Tighten the securing screw [C] and adjustment screw [D].

[E]

[B]

[D]

13. Feed paper while checking the paper height. If it is still too high or too low, repeat the

adjustment. (Adjustment target: 0 to 1.5 mm below the center part of the fence)

If the adjusting plate does not bring the paper below the fence, atach the sensor feeler

mylar [E] (#A3359500) to the upper limit sensor actuator as illustrated.

Note: Align the cut-out part [F] of the mylar with the actuator edge so that the actuator is

extended by 1 mm.

1mm

[F]

[E]

<Factory Action>

This adjustment is to be incorporated into the production line from the January ’96

production run.

Page 5

Technical Bulletin No. RTB-003

SUBJECT: 1. Required Action for Energy Star Compliant Machines

(North American versions only)

2. Mode Change in Tab Copying (All versions)

PREPARED BY: M. Mimura

FROM: 2nd Technical Support Section

DATE: February

29, ’96

PAGE: 1 of 4

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

Thunderbird II Type Y

1. Energy Star

In conjunction with the modification for Energy Star compliance. This is information for

field technicians so they can make the changes in the operation modes so as to configure

the machine for the customer specific environment / requirements. This bulletin refers to

all differences between the Energy Star compliant machines and the other machines

previously produced.

Mode Current Energy Star

Auto Off Mode When the copier is used after the weekly

timer has turned it off, the copier will turn

itself back off after the set time.

The auto off time can be set from 1 to 180

minutes, or the function can be turned off.

Default: 1 hour

Simplex / Duplex

Mode

Weekly Timer Available Because the auto off mode is a standard

SC Code N / A A new SC code # 940 has been added.

Single sided original to single sided copy is

default setting mode at the factory.

The copier turns itself off after the set time

(after the last copying job).

The time can be set from 1 to 120

minutes. This mode cannot be canceled.

Default: 90 minutes

Single sided original to two sided copy is

the default setting mode at the factory.

feature of Energy Star, the weekly timer is

no longer available.

Definition : The main switch does not turn

off after sending the reset signal

two times in a row.

Point to check : • Main Switch

• Main PCB

Because the auto off mode and default duplex mode are explained in the Operating

Instructions, make sure that the customer understands how the machine operates to save

energy.

NOTE: The Thunderbird II type X has complied with the Energy Star requirements from

the first mass-production.

Page 6

Technical Bulletin No. RTB-003

SUBJECT: 1. Required Action for Energy Star Compliant Machines

(North American versions only)

2. Mode Change in Tab Copying (All versions)

DATE: February

29, ’96

PAGE: 2 of 4

For the cut-in serial numbers, please refer to MB #13.

2. Tab Copy Mode

A function to adjust the print position for tab copying has been added.

(See the attached copy from the Operating Instructions.)

NOTE:

This function was available on the Thunderbird ΙΙ type X from the first

mass-production.

Page 7

Technical Bulletin No. RTB-003

SUBJECT: 1. Required Action for Energy Star Compliant Machines

(North American versions only)

2. Mode Change in Tab Copying (All versions)

DATE: February

29, ’96

PAGE: 3 of 4

This value adjustable

Page 8

Technical Bulletin No. RTB-003

SUBJECT: 1. Required Action for Energy Star Compliant Machines

(North American versions only)

2. Mode Change in Tab Copying (All versions)

DATE: February

29, ’96

PAGE: 4 of 4

Page 9

REVISED ON: MARCH 15, ’96

Technical Bulletin No. RTB-004

SUBJECT: Supplemental software upgrade information DATE: February

29, ’95

PAGE: 1 of 1

PREPARED BY: M. Mimura

FROM: 2nd Technical Support Section

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

Thunderbird - II

This RTB introduces minor software modifications applied to the new version ROM in MB

#13. Primary software modifications were introduced in RTB # 003.

Title Change

Dirty background Some copies with a dirty background had appeared when making

ADS copies in SP mode. This was because the lower bias limit had

been eliminated to facilitate factory adjustment. A lower bias has

now been restored to correct this problem per field request.

Combining tab and

staple modes

Designated page

copying restriction

A2 Copying (-22, -26,

- 27 versions only)

Selecting tab copying and staple copying at the same time has been

disabled.

Designated page copying onto tab sheets has been disabled in the

platen and SADF modes.

A3 double count mode (SP Special Feature P. 6-6) has been

changed as follows: Reset Set

Set Paper Size A3 A2 A3 A2

==================================================

Total Counter 1 1 → 222 → 4

A3 Counter 1 1 → 211 → 2

I

I

I

I

I

I

OHP slip sheet mode UP mode #4 [Select Special Modes]

In OHP slip sheet mode, blank slip sheets are added by default. If a

customer selects this feature, copies are made onto the slip sheets.

Default: No

Inverter pinch roller

solenoid

The energizing of the inverter pinch roller solenoid timing has been

changed from 40 to 20 ms after the paper passes through the fusing

sensor. This is a timing optimization for tab sheet copying.

Side to side

registration

After finishing the interrupt copying, the lens did not return to the

position where the lens was before the interruption.

Example:

DF mode copying -> Interrupt -> Platen mode copying (lens moves)

-> Leave Interrupt -> DF mode copying (lens stays in the platen

mode position)

This malfunction has been corrected.

For part number and cut-in serial number information, refer to MB # 13.

Page 10

Technical Bulletin No. RTB-005

[A]

[C]

[B]

SUBJECT: New Oil Supply System Information (European versions only) DATE: February

29, ’96

PAGE: 1 of 2

PREPARED BY: M. Mimura

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This RTB details the changes that the field technicians need to know when installing

and servicing the machines which have the new oil supply system (as detailed in MB #

10).

(NOTE:All the Thunderbird II type X machines have the new oil supply system.

The iformation described here is included in the type X Service Manual.)

1. At Installation

The securing brackets (shipping retainer) are being used to fix the new oil supply roller.

These brackets need to be removed at installation using the following procedure:

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Thunderbird II

[D]

[B]

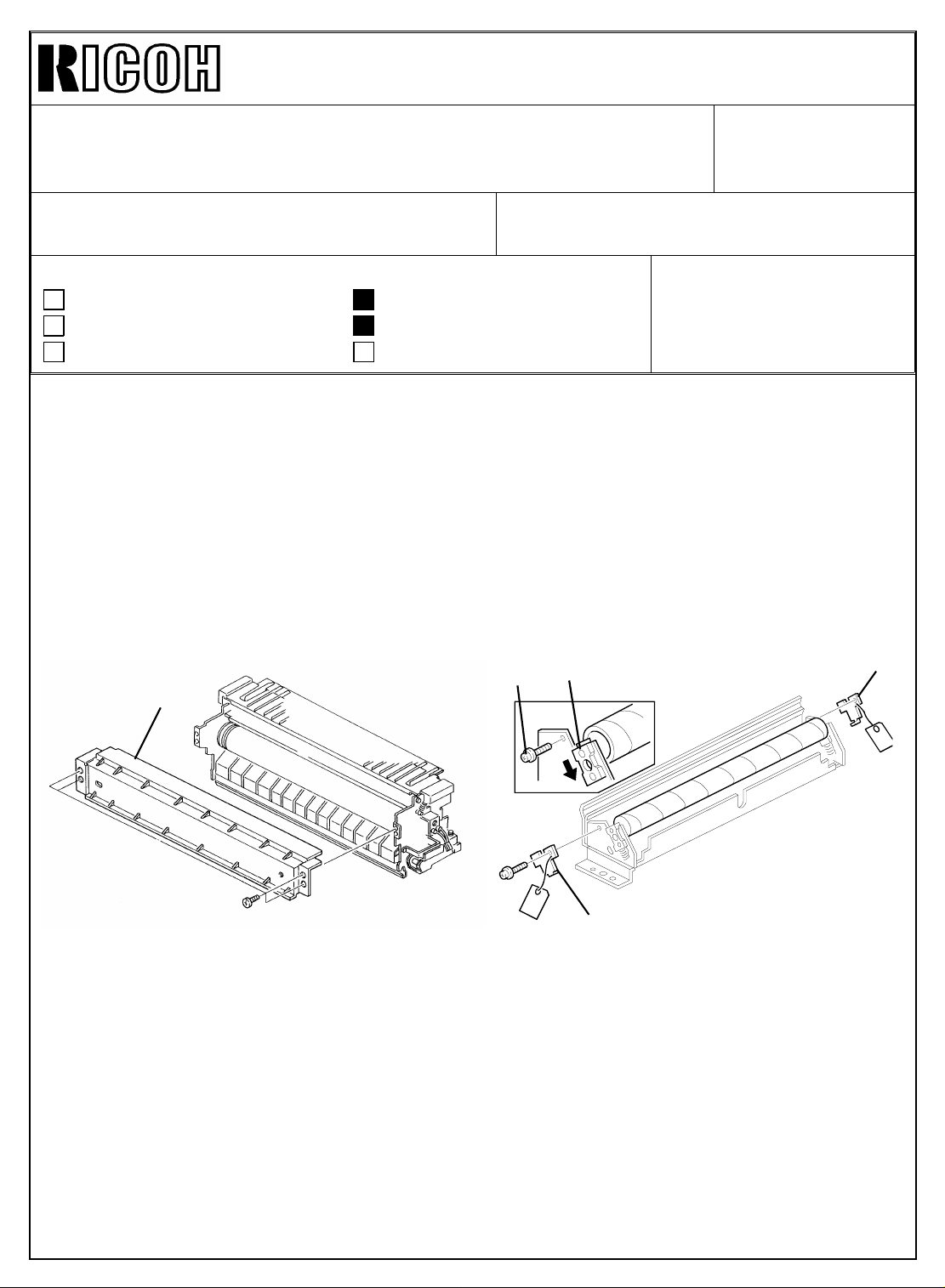

1. Pull out the fusing unit.

2. Remove the upper fusing entrance guide [A] (4 screws).

3. Remove the oil supply roller securing brackets [B] (2 screws).

4. While pushing the bushing [C] inwards, put back the screws [D].

5. Re-install the upper fusing entrance guide and push the fusing unit back in.

Page 11

Technical Bulletin No. RTB-005

[F]

SUBJECT: New Oil Supply System Information (European versions only) DATE: February

29, ’95

PAGE: 2 of 2

2. PM Items and Intervals

Parts

Oil Supply Roller

Oil Supply Cleaning Roller

Oil Supply Cleaning Blade

Oil Supply Roller Bushing

R: Replacement

3. Parts Replacement Procedure

[A]

150K 300K 450K 600K

RRRR

RRRR

RRRR

RR

[G]

[C]

[C]

[H]

[B]

[G]

[B]

[F]

[G]

1. Pull out the fusing unit.

2. Remove the upper fusing entrance guide [A] (4 screws).

3. Remove 2 springs [B] and 2 screws [C].

4. Remove the oil supply roller [D] and oil supply cleaning roller [E] (2 shoulder

screws [F] and 2 oil supply roller bushings [G]).

5. Remove the oil supply cleaning roller blade [H] (5 screws).

Important: On re-assembly, while pushing the bushing [G] inwards, put the

screws [C] back.

[E]

[D]

Page 12

REVISED ON: APRIL 30, ’96

Technical Bulletin No. RTB-006

SUBJECT: Developer leakage DATE: March 31,’96

PAGE: 1 of 3

PREPARED BY: M. Mimura

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

<Symptom>

Developer leaks from the ends of the development unit.

<Cause>

The fluidity of the developer tends to becomes lower when the toner concentration in the

developer becomes higher. Therefore, when the toner density becomes too high, the

developer does not circulate smoothly and accumulates at both ends of the development

unit.

<Countermeasure>

a) Production modification

To reduce the amount of developer leakage, the following modifications have been

applied.

1. The rear side seal has been extended by 0.5mm to the front, and a two-sided tape

has been added under the front side seal and front drum seal (refer to MB No. 2).

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Thunderbird II

2. The front side seal has been extended by 2.0 mm to the rear (refer to MB No. 15).

b) Machines in the field

1. Reduce the toner concentration by changing the SP setting. (10. SP Special

Feature - 2 PAGE 3)

In actual conditions, make test copies before and after the toner density adjustment

to compare of the copy density. To minimize the developer leakage problem, try to

reduce the toner density to the lowest limit that the customer accepts. The image

density drop caused by this procedure is none or minimal.

Current Position Lower Position

HIGH NORMAL

NORMAL LOW

(NOTE : There is possibility of having a toner adhering problem on the development

roller with extremely high toner concentration.)

2. Replace the front and rear side seals. This RTB contains information about how to

adhere the side seals to the development unit to prevent the developer leakage

which can occur if the seals are installed incorrectly.

Page 13

REVISED ON: APRIL 30, ’96

[C]

0 ~ 0.3mm

17.0mm

19.0mm

Technical Bulletin No. RTB-006

SUBJECT: Developer leakage DATE:March 31,’96

PAGE: 2 of 3

<Replacement Procedure>

[Front side]

1. Clean with alcohol the places of the development unit where the seals are to be

adhered.

2. Adhere the two sided tape [A] as shown.

NOTE: The lower casing and the front side plate are not flush where the two-sided tape is

to be pasted [B]. Carefully stick the tape to completely block the path that the

developer may leak through.

3. Adhere the front side seal [C] as shown. (The top left corner is the seal’s alignment

point.)

Width of the front side seal New part 19.0 mm

Old part 17.0 mm

4. Adhere the front drum seal [D] as shown. (The right edge is the alignment point.)

[A]

[B]

2~2.5mm

0~1mm

[D]

0 ~ 0.5mm

Page 14

REVISED ON: APRIL 30, ’96

17.0mm

17.5mm

Technical Bulletin No. RTB-006

SUBJECT: Developer leakage DATE:March 31,’96

PAGE: 3 of 3

[Rear sided]

1. Clean with alcohol the places of the development unit where the seals are to be

adhered.

2. Adhere the rear side seal [E] as shown. (The top right corner is the seal’s alignment

point.)

Width of the rear side seal New part 17.5 mm

Old part 17.0 mm

(For your reference)

In case you need to replace the rear drum seal [F], position its left edge so it

comes in contact with the development unit as shown.

NOTE: It is not necessary to replace this seal for this troubleshooting purpose.

0 ~ 0.3mm

0 ~ 0.3mm

[E]

[F]

<Confirmation Step>

Run the copier in the free run mode for the time required for 100 copies. If you observe

only a little or no developer leakage, the seals have been replaced correctly.

Page 15

Technical Bulletin No. RTB-007

SUBJECT: White Noise Condition (No Monitor Display) - Ricoh and

NRG European Type Y only

PREPARED BY: M. Mimura

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

<Symptom>

Image is not displayed on the CRT screen correctly.

<Cause>

The internal electrical terminal is out of position and has unstable contact with the CRT

body.

<Solution>

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

DATE:March 31, ’95

PAGE: 1 of 4

MODEL:

Thunderbird II

CAUTION: The CRT unit holds an electrical charge approximately three hours

after the main switch is turned off. Therefore, it is recommended to perform this

inspection on all suspected machines before the machine is powered up at

installation. If an electrical charge remains, touching the terminal with bare hands

will cause an electrical shock.

Correctly position the electrical terminal with the following procedure:

1. Ensure that you are working on a new machine which has never been powered up,

or on a field machine which has been off for more than three hours.

Suggestion: If you are not sure about the charge condition, perform "Optional

Procedure to discharge the CRT display" on page 3.

2. Remove the CRT rear cover [A] (4 screws).

[A]

Page 16

Technical Bulletin No. RTB-007

[C]

SUBJECT: White Noise Condition (No Monitor Display) - Ricoh and

NRG European Type Y only

3. Remove the operation control board [B] (4 screws).

4. Remove the inner shielding cover [C] (4 screws).

NOTE: Be careful not to hit the CRT display control unit [D] which is connected to

the CRT display [E].

[E]

DATE: March 31, ’95

PAGE: 2 of 4

[B]

5. Manually peel off a part of the rubber cap [F] and check if both terminals [G]

are in the hole, as s hown.

[G]

[Correct]

[Wrong]

[F]

[D]

Page 17

Technical Bulletin No. RTB-007

SUBJECT: White Noise Condition (No Monitor Display) - Ricoh and

NRG European Type Y only

6. If the terminal is out of position, reposition it using long nosed pliers.

7. Reassemble all parts.

NOTE: Even the terminal is out of the hole, the problem will not necessarily occur. This

is because the terminal is in contact with the outer surface of the CRT display.

However, machine vibration may break the contact.

DATE:March 31, ’95

PAGE: 3 of 4

Optional Procedure to discharge the CRT display

If the machine is already in use at a customer site, and you must go through this

procedure before the proper time allowed for electrical discharge, the CRT display can

be discharged by grounding the terminal as follows:

• Connect the CRT main frame [H] and one terminal [I] with a screwdriver rod (metal

portion) as shown in the illustration.

CAUTION : 1. Touch the main frame first for safety.

2. Never hold the screw driver rod with your bare hand while

doing this procedure.

[H]

[I]

Page 18

Technical Bulletin No. RTB-007

SUBJECT: White Noise Condition (No Monitor Display) - Ricoh and

NRG European Type Y only

<Suspected Machines>

The following table shows the machines that may have this problem.

Brand Code Total Q’ty Serial Numbers

NRG A171-22 3 9276020010 to -0012

Ricoh A171-27 58 A3876020126 to -0129

-0131 to -0134

-0136 to -0137

-0139 to -0146

-0148 to -0149

-0154 to -0167

-0170 to -0195

DATE:March 31, ’95

PAGE: 4 of 4

Page 19

Technical Bulletin No. RTB-008

SUBJECT: False jam condition cannot be reset / SC900 DATE: April 15,’96

PAGE: 1 of 2

PREPARED BY: M. Mimura

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

<Symptom>

The machine indicates a paper jam and cannot recover from the jam condition. This

occurs only when feeding from the LCT.

<Cause>

Static built up during paper feed damages IC110 on the copier main board.

<Solution>

1. Install the diode harness in the LCT. Refer to the attached Product Update Information

for the correct installation of the diode harness.

2. Make sure that the grounding wire is fixed on the copier as shown in the Installation

Procedure / Service Manual.

IMPORTANT: Connecting this ground wire on the LCT frame will not ground the LCT.

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Thunderbird II

Grounding Wire

<Factory Countermeasure>

1. The diode harness has been installed at the factory. Refer to MB # 3 of the

Thunderbird II LCT for cut-in serial numbers.

2. The grounding wire will be fixed to the copier main frame at the factory from the May

production machines.

Page 20

Technical Bulletin No. RTB-008

SUBJECT: False jam condition cannot be reset / SC900 DATE: April 15, ’95

PAGE: 2 of 2

Page 21

Technical Bulletin No. RTB-009

SUBJECT: Software upgrade Information DATE: January 15, ’97

PAGE: 1 of 2

PREPARED BY: M. Mimura

CHECKED BY: T. Inoue

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This bulletin is to inform you of the modifications included in the A and B versions of the

ROM.

ROM Part Numbers

Type Y Type X

North America

(-10, -15, -17)

A1715216 A1715316 A1705211 A1705311

A1715217 A1715317 A1705212 A1705312

A1715226 A1705221

Version Problem Modification Occurs on

" #410 " (Right Scale Solenoid)

is incorrectly displayed when the

A

B

solenoid/clutch check is enabled.

When the copier starts from the

weekly timer mode, the Mode

Clear key will not work.

The vacuum solenoid cannot be

energized due to overheating.

When the reduction is

automatically selected as the

CFF original is set, the trailing

edge erase is delayed and the

leading edge of the next original

may be copied.

Tab mode cannot be selected in

the platen or SADF mode

A registration jam occurs in Sort

Tabs mode.

The trailing edge erase is

delayed in the combination of all

edge, reduction, and left margin

modes

(-22, -26, -27)

Revision of service manual

Information only

Other

Europe

FROM: 1st Field Information Dept. QAC

MODEL:

Thunderbird II

North America

(-10, -15, -17)

The bug has been

eliminated.

The bug has been

eliminated.

The ON timing has

been optimized.

Timing of the trailing

edge erase has been

changed to prevent

copying of the

leading edge of the

next original.

Tab mode can be

selected

The bug has been

eliminated.

The bug has been

eliminated

North America

version Type Y

All non-Energy Star

compliant Type Y

Type X

Type X and Y

Type X and Y

Type X

Type X and Y

Europe

(-22, -27)

Page 22

Technical Bulletin No. RTB-009

SUBJECT: Software upgrade Information DATE: January 15, ’97

PAGE: 2 of 2

When stapling in the

duplex to simplex copy

mode, the maximum

original message is

displayed at 50.

Cut-in Serial Numbers

Version Type Y Type X

-10: 9286080001

-15: 3A26030001

A

B

-17: A3876030001

-22: 9276030001

-26: 3H40360001

-27: A3876030068

-10: 9286080001

-15: 3A26060001

-17: A3876060001

-22: 9276060001

-26: 3H40660001

-27: A3876060172

It has been corrected to

25. At the 25th sheet,

"Maximum staple

capacity is 50 sheets.

Press Start Key to

continue without

stapling. Press Cancel

Key to stop copying" is

displayed.

N/A (From first mass

production)

-10: 9306100001

-15: 3A96060001

-17: A3946060001

-22: 9296090001

-27: A3946060031

Type X

Page 23

RICOH Technical Bulletin

Model: Thunderbird II Date: 28-Feb-97

Subject: Software Update Information Prepared by: M. Mimura

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

This bulletin is to inform you of the modifications included in the C-version ROM.

ROM Part Numbers

North America

(10, -15, -17)

A1715216 A1715316 A1705211 A1705311

Troubleshooting

Mechanical

Paper path

Other ( )

Type Y Type X

Europe

(-22, -26, -27)

Part information

Electrical

Transmit/receive

North America

(-10, -15, -17)

No: 010

Action required

Service manual revision

Retrofit information

Europe

(-22,27)

1/5

A1715217 A1715317 A1705212 A1705312

A1715226 A10705221

Problem Modification Occurs in

The potential sensor output drifts,

causing improper process control. In

the worst case, an excessive amount

of developer drops due to high toner

concentration

When the 2 to 2 duplex and Tab

Sheet modes are selected, the

finisher shift tray shifts erratically in

the middle of a set.

When resuming copying after the

copier has been stopped by the bin

MAX limit in the CFF, the same page

is copied twice.

A detection process has been

added to the process control.

If the drift is defected, SC306

is displayed. See the following

pages for more details.

This bug has been fixed. Type X

When the bin MAX stops the

copier, the computer form

does not feed.

Therefore, when resuming, the

same page is copied again.

The computer form is fed at

bin MAX.

Type X and Y

Type Y

In the CFF mode, dual-sort and large

volume sort functions do not work.

(Stops after the bin MAX detection.)

This bug has been fixed. Type Y

Page 24

RICOH Technical Bulletin

Model: Thunderbird II Date: 28-Feb-97 No: 010 2/5

Cut-in Serial Numbers

Type Y Type X

-10: 928703XXXX

-15: 3A27020001

-17: A3877020001

-22: 927703XXXX

-26: 3H40370001

-27: A3877020100

-10: 930703XXXX

-15: 3A9703XXXX

-17: A3947020001

-22: 9297020001

-27: A3947020037

Page 25

RICOH Technical Bulletin

Model: Thunderbird II Date: 28-Feb-97 No: 010 3/5

Page 26

RICOH Technical Bulletin

Model: Thunderbird II Date: 28-Feb-97 No: 010 4/5

Page 27

RICOH Technical Bulletin

Model: Thunderbird II Date: 28-Feb-97 No: 010 5/5

Page 28

RICOH Technical Bulletin PAGE: 1/2

Model: Thunderbird II Date: 15-Mar-97

Subject: White spots on copies caused by developer leakage Prepared by: M. Kitajima

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 11

SYMPTOM

White spots on copies caused by developer leakage

CAUSE

The fluidity of the developer tends to become lower when the toner concentration in the

developer becomes higher. Therefore, when the toner density becomes too high, the

developer does not circulate smoothly and leaks from the development unit.

SOLUTION

When this problem occurs in machines in the field, do the following steps in the order

noted: If the problem still exists, do the next step.

1. Adjust the charge corona wire height. (When the copy image density at the machine’s

rear side is lower than that at the machine’s front side)

Reason: The ID sensor is not at the center (it is at the machine’s rear side). When the

ID at the machine’s rear side (left side of the copy) is lower than at the front

side (right side), toner is supplied because the machine detects a low toner

concentration in the developer.

2. Reduce the toner concentration by changing the SP setting (10. SP Special Feature -

2 PAGE 3).

Make test copies before and after the toner density adjustment to compare the copy

density. To minimize the developer leakage problem, try to reduce the toner density to

the lowest limit that the customer will accept. The image density drop caused by this

procedure is none or minimal.

Current Position →→ Lower Position

HIGH NORMAL

NORMAL LOW

Page 29

RICOH Technical Bulletin PAGE: 2/2

Model: Thunderbird II Date: 15-Mar-97

3. Apply the modified front and rear side tapes to the development unit to reduce the

developer leakage. Refer to RTB No. 6

4. Install the new potential sensor bracket (# A1672105). Refer to MB No. 29.

Reason: If the potential sensor bracket is not set properly, the potential sensor output

may drift, causing improper process control.

5. Install the C-version ROMs. Refer to RTB No. 10.

Reason: If the potential sensor output drifts, proper process control is not performed,

causing improper toner concentration in the developer.

No: 11

Page 30

T

Model:

Thunderbird 2

echnical

B

ulletin

Date:

15-Oct-97

No:

PAGE: 1/1

12

Subject:

(North America version only)

From:

Classification:

To meet the revision to the Energy Star restrictions, the possible time range for Auto Off

has been extended from 1 to 120 minutes to 1 to 240 minutes.

The ROM associated with this change is as follows:

A1715292A: Operation Panel ROM (IC – UVEPROM 2M x 8 150NS)

A1715293A: Operation Panel ROM (IC – UVEPROM 2M x 8 150NS)

Cut-in Serial Numbers

Destination Type X Type Y

Energy Star - Auto Off Mode

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

10 9307080001 920708xxxx

15 3A97070001 3A27080001

17 A3947070001 A3877070001

Part information

Electrical

Transmit/receive

Prepared by:

M.Mimura

Action required

Service manual revision

Retrofit information

Page 31

T

Model:

Thunderbird 2

echnical

ulletin

B

Date:

15-Nov-97

No:

PAGE: 1/1

13

Subject:

From:

Classification:

Entrance Seal - Development

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Mimura

SYMPTOM

When the drum reve rses at the end of a copy jo b, the development entrance seal

(#A1673391) is flipped upward causing toner scattering or, in the worst case, it peels off

and gets in the development rollers causing developer to fall off.

CAUSE

The pressure used to apply the entrance seal at the factory was insufficient.

SOLUTION

At the next service visit or at installation, check the entrance seal. If any indication of

deformation is observed, replace the entrance seal. We recommend that the entrance

seal be pressed down by hand to prevent future occurrences, even if there do not appear

to be any problems.

Note: When attaching the entrance seal, put it in the position furthest from the drum. If

this is not done, there may be too much contact between the seal and the drum,

which may cause flipping.

Relevant Machines

The machines in the following serial number range may have this problem:

A170-15 3A96110001 to 3A9710xxxx

A170-17 A3946110001 to A394710xxxx

A170-22 9296110001 to 929710xxxx

A170-27 A3946110021 to A394710xxxx

A171-15 3A26110001 to 3A2710xxxx

A171-17 A3876110001 to A387710xxxx

A171-22 9276110001 to 927710xxxx

A171-26 3H41160001 to 3H4107xxxx

A171-27 A3876110066 to A387710xxxx

Loading...

Loading...