Ricoh FT6765 Service manual

SECTION 1

OVERALL MACHINE

INFORMATION

30 November 1990

1. SPECIFICATIONS

- Item - - Specifications Configuration : Console

Copying Process: Dry electrostatic transfer system

Original: Book/Sheet

Original Size: Maximum A3, 11" x 17"

Reproduction Ratios: 5 reduction ratios, 3 enlarg ement ratios

(One more reduction ratio and

enlargement ratio can be set by SP mode)

zoom :— from 60% to 155% in 1% steps

- A4 Version 5R: 93%, 82%, 75%, 71%, and 65%

3E: 115%, 12 2%, and 141%

- Letter Version 5R: 93%, 85%, 77%, 74%, and 65%

3E: 121%, 12 9%, and 155%

Reproduction Ratio Cha nge: Maximum 6.5 seconds

Warm-Up Time: Within 5 minutes (Room Temp. 200C,

680F)

Copy Paper Size: — Maximum A3, 11" x 17"

— Minimum A6, 51/2" x 81/2"

Weight: — 52 g/m2 to 157 g/m2 (14 lb

to 42 lb)

Copying Speed: 52 cpm/11" x 81/2"

53 cpm/A4 sideways

25 cpm/A3, 11" x 17"

First Copy Time: 3.6 seconds (A4 or 81/ 2 " x 11") (LCT feed)

Copy Number Input: Number keys, 1 to 999 (count up or down)

Special Functions:

•

Auto duplexing (3 modes)

•

Margin adjustment (0 to 16 mm [5/8"]

on both sides)

•

Auto image density selection (ADS)

1-1

30 November 1990

•

Automatic paper selection (APS)

•

Automatic reduction/e nla rge ment (AMS)

•

2 single copies mode (Copies facing

pages of a bound original)

•

Cover sheet mode (with ADF or RDH)

Manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute standard setting; can also be set

to 3 minutes or no auto reset.

All functions canceled except cassette

selection. Quantity en te red returns to "1",

and reproduction ratio re tu rns to full size.

Paper Feed:

•

3000 sheet large capacity tray (LCT)

•

Dual 500 sheet universal cassettes

•

Manual feed table

Paper Feed System: Feed and reverse roller

Exposure System: Slit exposure, moving optics

Lens: Through lens, F5, f=215 m m

Light Source:

•

Halogen lamp (85 V, 160 W; control

range 50 to 80 volts RMS)

•

Automatic voltage change (VL Sensor)

Photoconductor: Selenium drum (F-type)

Charge System: Dual wire dc coron a

Erase: LED lamp unit (80 segments)

Development System:

•

Magnetic brush roller

•

Double roller development

Development: Automatic voltage change (The control

board monitors the sele cte d image density

level, drum temperature, and rest time.)

Toner Replenishment: Cartridge exchange (480 g/bottle)

Toner Consumption: 12,000 copies/bottle (7%/A4)

Cleaning System: Blade and brush, pre-cleaning corona

Quenching System: Photo-quenching (cold cathode tube) and

dc corona

1-2

30 November 1990

Image Transfer: Single wire dc corona, pre-transfer lamp

Paper Separation: Dual wire ac corona and pick-off pawls

Image Fusing: Heat and pressure rollers

Fusing Lamp: Halogen lamp (820 W)

Oil Consumption: More tha n 80,0 00 copie s per oil tank

(519 cc)

Electronic Control System: 8-bit microprocessor

Copy Tray Capacity: 250 sheets (all sizes)

Self-diagnostics: 34 codes for the main copie r

8 codes for the finisher

Service Programs: 100 programs controlled from the

operatio n panel

Power Source: 110V/60Hz ⇒ 15A (for Taiwan)

115V/60Hz ⇒ 15A (for N.A.)

220V/50Hz ⇒ 8A (for EU.)

220V/60Hz ⇒ 8A (for EU.)

240V/50Hz ⇒ 8A (for EU.)

Power Consumption

(copier only)

Dimensions:

Weight:

See the following table. Numbers are in

kilowatts per hour.

Warm-up Copying Stand-by Max

0.82 1.26 0.7 1.5

Width Depth Height

Copier only with

platen cover

Full System

(DH, Finisher)

Copier Only 210kg (463lb) 220 kg (485lb)

DF, Sorter 240.5kg (530lb) 250.5 kg (552.3lb)

DH, Finisher 273 kg (601.9lb) 283 kg (623lb)

909mm (35.8") 743mm

(29.3")

1,494 mm

(58.9")

115V version: 220V version:

743mm

(29.3")

1,072 mm

940mm

(37.0")

(42.3")

1-3

14

10

9

7

30 November 1990

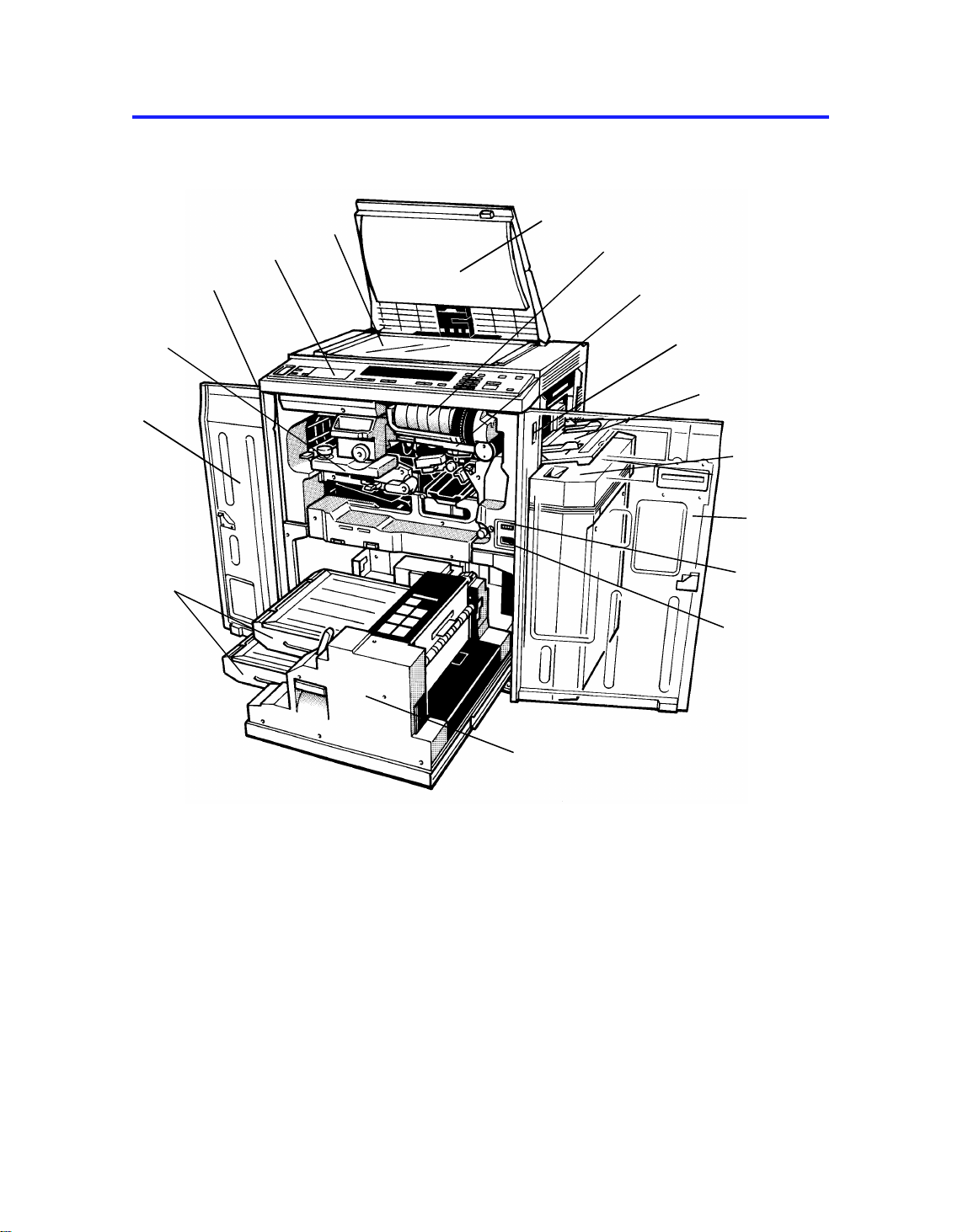

2. GUIDE TO COMPONENTS

2.1 INTERNAL & EXTERNAL

5

4

3

2

1

16

6

8

11

12

13

1. Left Door

Open to access the inside of th e

copier.

2. Oil Bottle

Add silicone oil to this bottle.

3. Main Switch

Switches the copier between on

and stand-by condition s.

4. Operation Panel

Operator controls and indicators

are located here.

15

5. Exposure Glass

Position originals here for cop ying .

6. Platen Cover

Lower this cover over originals for

copying.

7. Toner Bottle

Toner is supplied from this bottle.

8. Toner Bottle Holder

Install the toner bottle here.

9. Key Counter Holder

Insert the optional key cou nter here.

1-4

30 November 1990

10. By-pass Feed table

Open to copy on to paper of

non-standard size or weight.

11. Large Capacity Tray

This tray can hold 3,000 sheets of

copy paper. (A4/81/2" x 11"

sideways)

12. Right Door

Open to access the inside of th e

copier.

13. Total Counter

Shows the total number of copies

made.

14. A3/DLT Counter

Shows the total numb er of A3/ DLT

copies made.

15. Cassette Bank

This bank can hold two 500-sheet

cassettes.

16. Paper Cassette

These two cassettes can ho ld

500-sheets of copy paper e ach .

1-5

2

1

13

30 November 1990

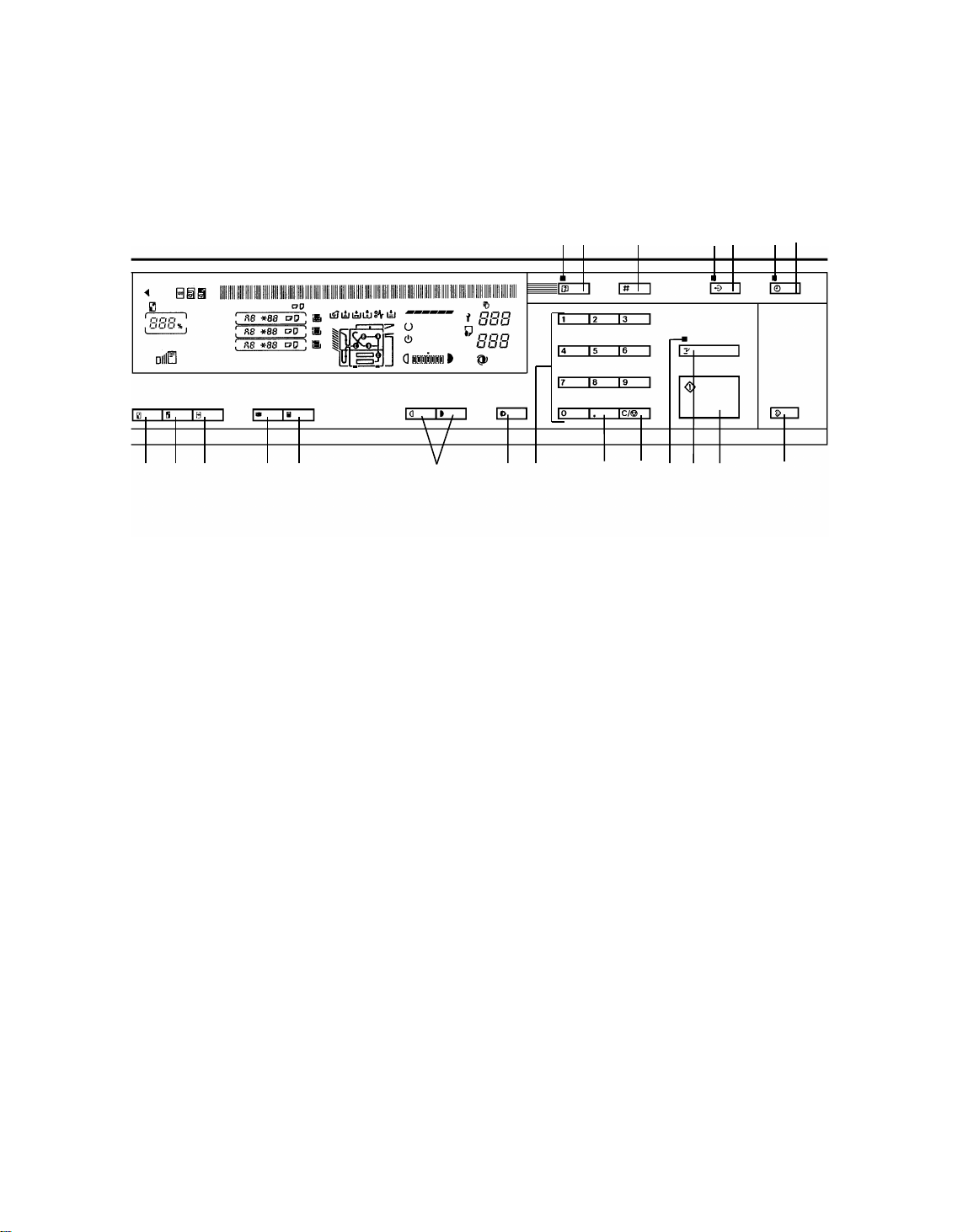

2.2 OPERATION PANEL

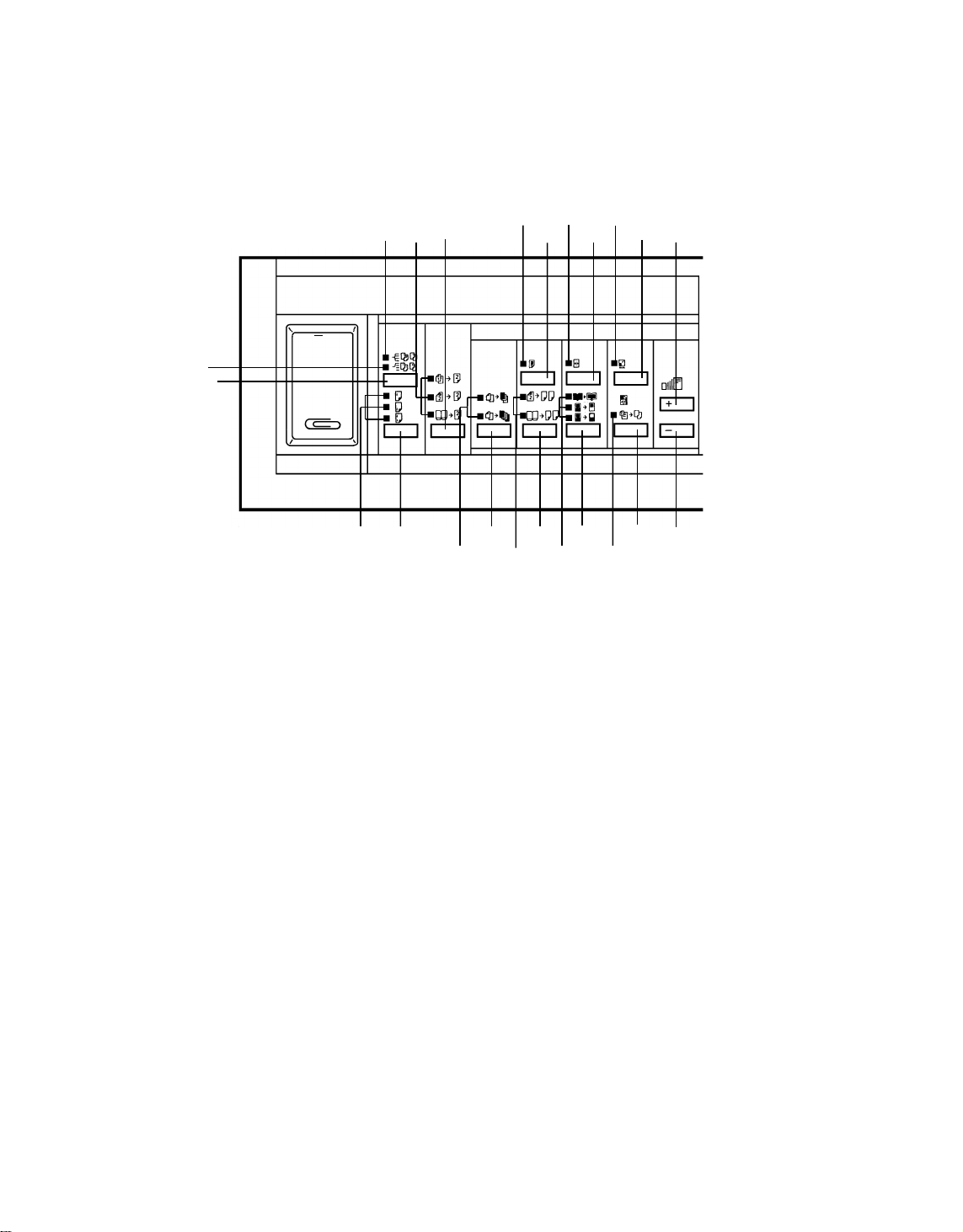

2.2.1 Keys and Indicators for Basic Functions

A4/A3 Version

34567

21 171820 19

16

1. Guidance Indicator

Lights when in guidance mode.

2. Guidance Key

Press to select guidance mod e.

3. Enter Key

Use to enter or change data in

selected modes.

4. Program Indicator

Lights when the copier is in user

program mode.

5. Program key

Press to input or recall user

program.

6. Timer Indicator

Lights when the mach ine has been

turned off by the weekly timer or

automatic shut-off timer.

15

14

12

891011

7. Timer Key

Press to operate the copier after it

has been turned off by the weekly

timer or automatic shut-off timer.

8. Clear Modes Key

Press to clear the copier of

previously entered settings and

modes.

9. Start Key

Press to start copying.

10. Interrupt key

Press to make interrupt copies

during a copy run.

11. Interrupt Indicator

Lights when interrupt mo de is

selected.

12. Clear/Stop Key

Press to cancel the copy number.

While copying press to stop

copying.

1-6

LT/DLT Version

2

1

13

30 November 1990

34567

21 171820 19

16

13. Decimal Point Key

Use to input data for selected

modes.

14. Number Keys

Use to enter the desired number of

copies. They are also used to en te r

data for selected modes.

15.Auto Image Density Key

Press to select/cancel aut oma tic

image density mode.

16. Manual Image Density Keys

Use to cancel automatic control and

manually select the image density

level.

15

14

12

11

910

8

17. Auto Paper Select Key

Press to select/cance l aut o pa pe r

select mode.

18. Select Cassette Key

Press to select a cassette for paper

feed.

19. Full Size Key

Press to make the copy image s the

same size as these of the orig ina ls.

20. Enlarge Key

Press to make enlarged copies.

21. Reduce Key

Press to make reduced cop ies.

1-7

17

30 November 1990

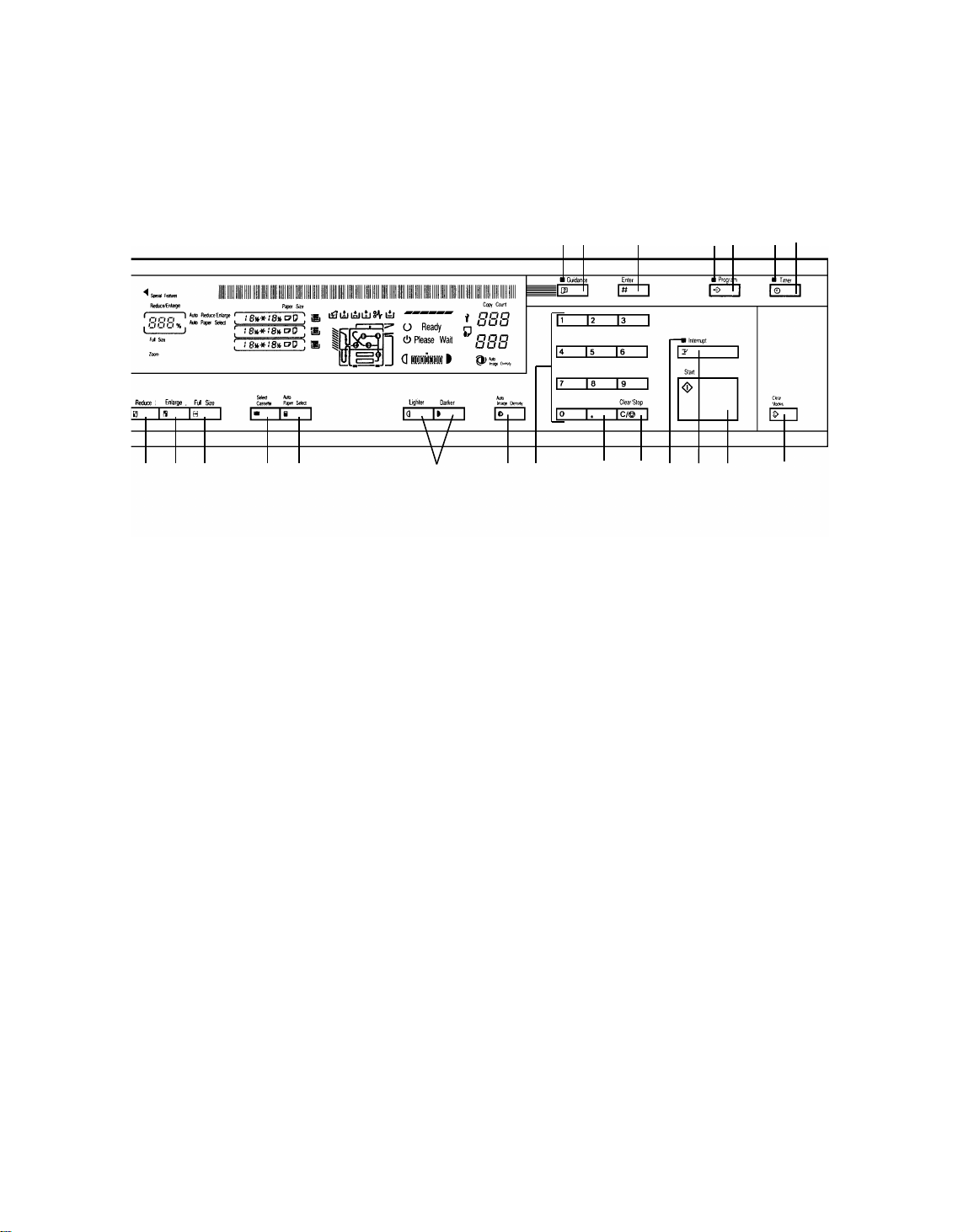

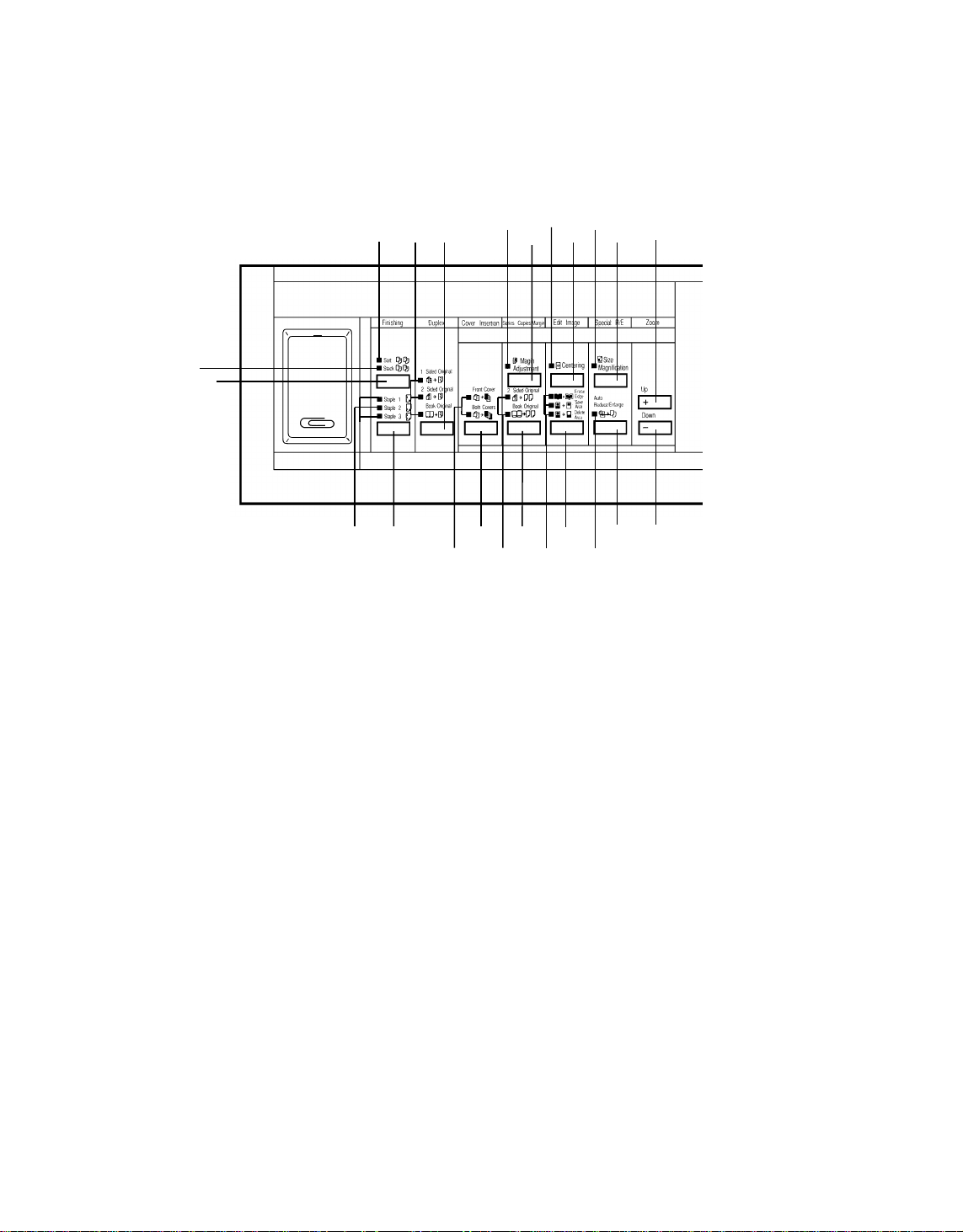

2.2.2 Keys and Indicator for Special/Optional Functions

A4/A3 Version

56

7

8

910111213

4

3

14

1

2

1. Staple Key

Press to select one of three staple

modes. (Optional recycling

document handler and finisher are

required.)

2. Staple Indicators

Show which staple mode is

selected.

3. Sorter Key

Press to select sort or stack mode.

(Optional sorter, or finishe r and

recycling document handler are

required.)

4. Stack Indicator

Lights when in stack mode.

5. Sort Indicator

Lights when in sort mode.

6. Duplex Indicators

Show which duplex mode is

selected.

22

23 21

7. Duplex Key

Press to select one of three duplex

modes.

8. Margin Adjustment Indicator

Lights when margin adjust men t

mode is selected.

9. Margin Adjustment Key

Press to set the margin on copy.

10. Centering lndicator

Lights when cente ring mode is

selected.

11. Centering Key

Press to vertically center an original

image on a copy.

12. Size Magnification Indicator

Lights when size magnificat ion

mode is selected.

20

19

18

16

15

1-8

LT/DLT version

3

4

567

30 November 1990

8

910111213 14

12

13. Size Magnification Key

Press to select size magnification

mode.

14. Zoom Up Key

Press to increase the rep rod uction

ratio in 1% steps.

15. Zoom Down Key

Press to reduce the reproduction

ratio in 1% steps.

16. Auto Reduce/Enlarge Key

Press to select auto reduce /enlarge

mode.

17. Auto Reduce/Enlarge

Indicator

Lights when auto redu ce/enlarge

mode is selected.

18. Edit Image Key

Press to select one of three edit

image modes.

22

23 21

20

19

17

151618

19. Edit Image Indicators

Show which edit image mode is

selected.

20. Series Copies Key

Press to make copies from book

originals or 2-sided originals.

21. Series Copies Indicators

Show which series copies mode is

selected.

22. Cover Insertion Key

Press to select cover insertion

mode. (Optional document feeder

and sorter, or recycling document

handler and finisher are require d. )

23. Cover Insertion Indicators

Show which cover insertion mode is

selected.

1-9

15

17

30 November 1990

2.2.3 Indicator Screen

A4/A3 version

1234 5678910111213 14

1. Full Size Indicator

Lights when full size mode is selected.

2. Auto Paper Select Indicator

Lights when auto pap er sele ct

mode is selected.

3. Auto Reduce/Enlarge Indicator

Lights when auto redu ce/enlarge

mode is selected.

4. Paper Size Indicators

Show the size and direction of the

paper.

5. Paper Volume Indicators

When the amount of paper remaining in cassettes.

6, Used Toner Bottle Indicator

Lights when the use d toner bottle is

full. Call your service representative.

16

181920212223

7. Add Toner Indicator

Blinks when it is time to change the

toner bottle. When it is continuously

lit, the copier cannot be used until a

new bottle is installed.

8. Add Staple Indicator

Lights when the staple cartridge

runs out of staples.

9. Add Oil Indicator

Lights when the silicone oil level

gets too low. Add silicone oil to the

bottle.

10. Check Paper Path Indicator

Lights if there is a misfeed within

the machine.

11. Load Paper Indicator

Lights when the cassette or tray in

use runs out of paper.

1-10

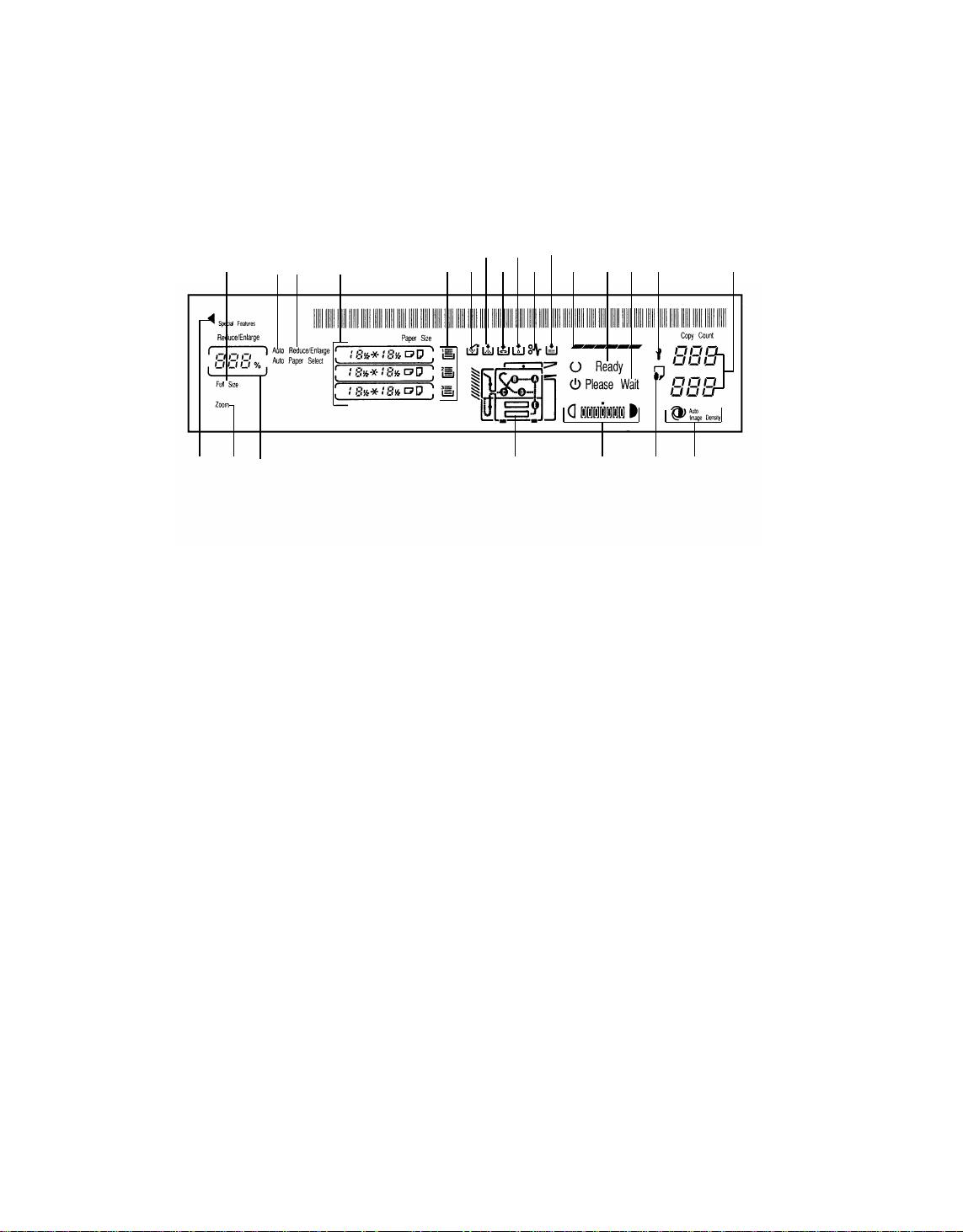

LT/DLT version

15

17

18

1234 56

7

91011

8

12 1314

1920212223

30 November 1990

16

12. Copy Cycle Indicator

Displays the stage of the copy cycle

in progress.

13. Ready Indicator

Lights when the mach ine is ready to

make copies.

14. Wait Indicator

Lights when the mach ine is not

ready to copy.

15. Call Service Indicator

Lights when there is a funct ional

problem within the machine . Call

your service representative .

16. Copy Counter

(Upper) Displays the number of

copies entered.

(Lower) While copying, it sho ws the

number of copies made.

17. Auto Image Density Indica tor

Lights when the copier is

automatically controlling the image

density.

18. By-pass Feed Indicator

Lights when the by-pass feed table

is open.

19. Manual Image Density

Indicator

Shows the manually selected image

density.

20. Misfeed Location Display

Shows the location(s) of misfed

paper.

21. Magnification Ratio Indicator

Shows the selected rep rod uction

ratio.

22. Zoom Indicator

Lights when in zoom mode.

23. Special Features Indic ator

Lights when special/optional

function is selected.

1-11

DEVELOPMENT

30 November 1990

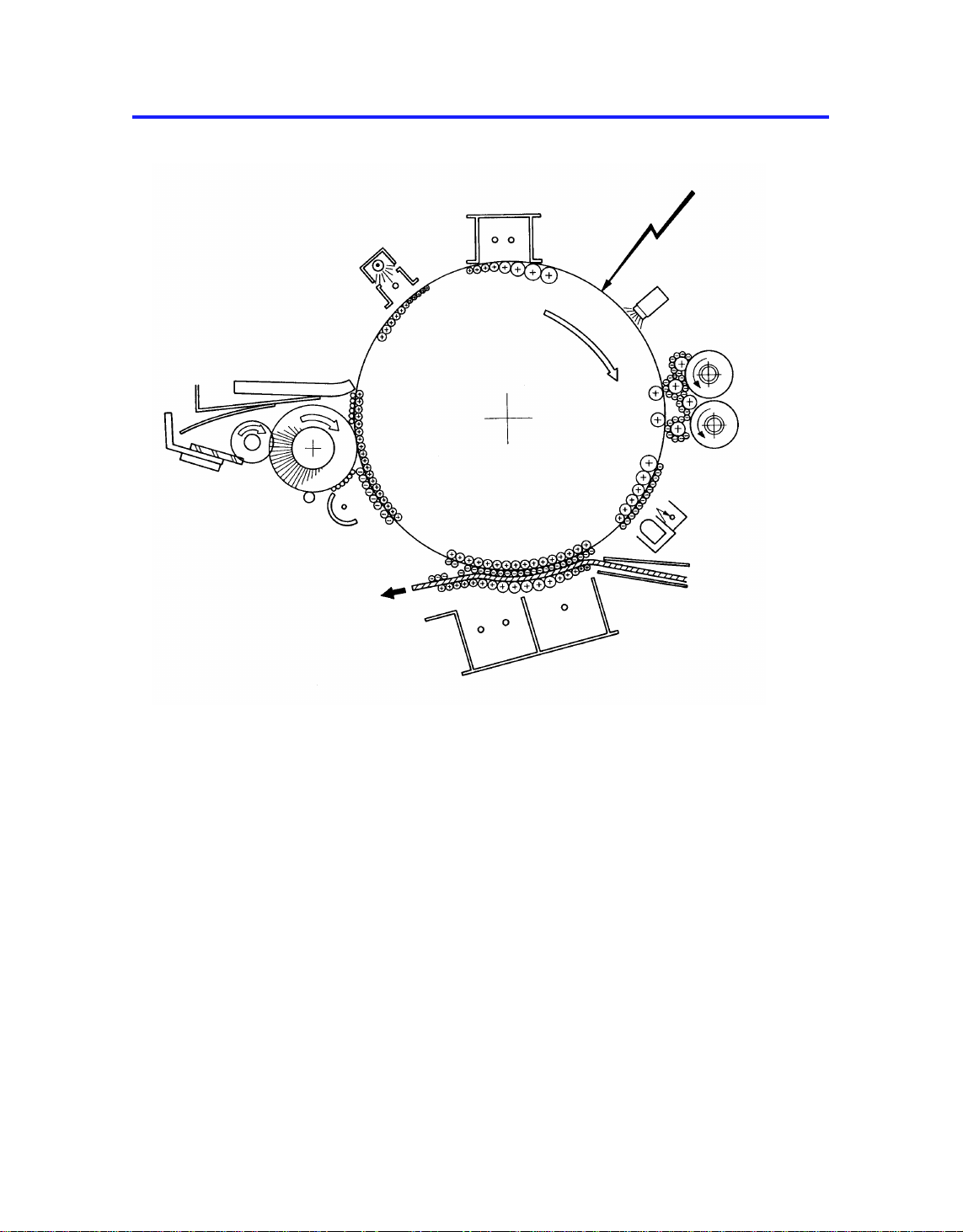

3. COPY PROCESSES AROUND THE DRUM

EXPOSURE

DRUM CHARGE

QUENCHING

CLEANING

PRE-CLEANING

PAPER SEPARATION

ERASE

PRE-TRANSFER

LAMP (PTL)

IMAGE TRANSFER

DRUM CHARGE

In the dark, the charge corona unit gives a uniform positive charge to the

selenium drum. The charge rema ins on the surface of the drum because the

photo conductive seleniu m has ele ctrical resistance in the dark.

EXPOSURE

An image of the original is reflected to the selenium drum surface via the

optics assembly. The charge on the drum surface is dissipated in direct

proportion to the intensity of the reflected light, thus producing an elect rical

latent image on the drum surface.

ERASE

The erase lamp illuminates the areas of th e cha rge d dru m su rfa ce th at will

not be used for the copy image. The resistance of the drum in the illuminated

areas drops and the charge on those areas dissipates.

1-12

30 November 1990

DEVELOPMENT

Negatively charged toner is attract ed to the positive ly charg ed area s of the

drum, thus developing the late nt image . (The negat ive tu rbo electric charge is

caused by friction between the carrier and toner pa rticle s.)

PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove all positive charge from the exposed

areas of the drum. This prevents th e tone r particles from being reattracted to

the drum surface during paper separation and makes paper separation

easier.

IMAGE TRANSFER

Paper is fed to the drum surface at the prop er time so as to align the copy

paper and the develope d image on the drum surface. Then, a stron g po sitive

charge is applied to the back side of the copy pape r, pro viding an electrical

force which pulls the toner particles from the drum surface to the copy paper.

At the same time, the copy paper is electrically attracted to the drum surfa ce.

PAPER SEPARATI ON

A strong ac corona discharge is applied to the back side of the cop y pap er,

reducing the positive cha rge on the copy paper and breakin g th e electrical

attraction betwee n the paper and the drum. Then, th e stiffness of the copy

paper causes it to separate fro m the drum surf ace . The pick-off pawls help to

separate paper which has low stiffness.

PRE-CLEANING

The pre-cleaning corona (PCC) a pplies an ac coron a with a negat ive bia s to

the drum. This removes the positive cha rge from the drum and makes the

negative charge on the toner remaining on the dru m even .

CLEANING

The cleaning brush remo ves most of the toner on the drum and loosens the

remainder. Then, the bias roller, which has a positive potential, attracts the

toner particles from the cleaning brush to keep it clean. Finally, th e clea nin g

blade scrapes off th e loosened toner.

QUENCHING

The pre-quenching corona applies a positive corona cha rge to th e selenium

drum to eliminate any negative charge remainin g from t he pre-cle aning

corona. Then, light fro m the quench ing lamp electrically neutralizes the drum .

1-13

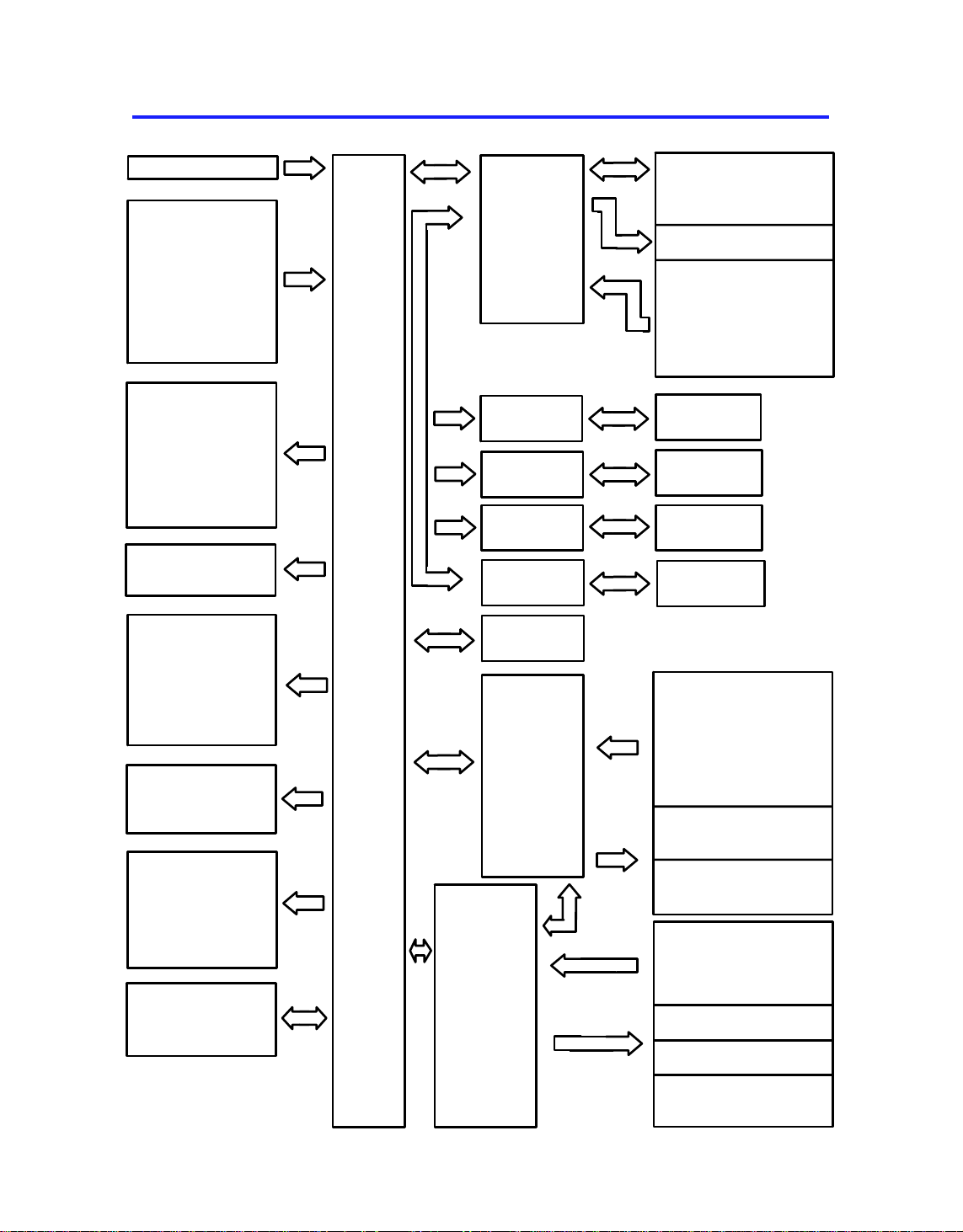

30 November 1990

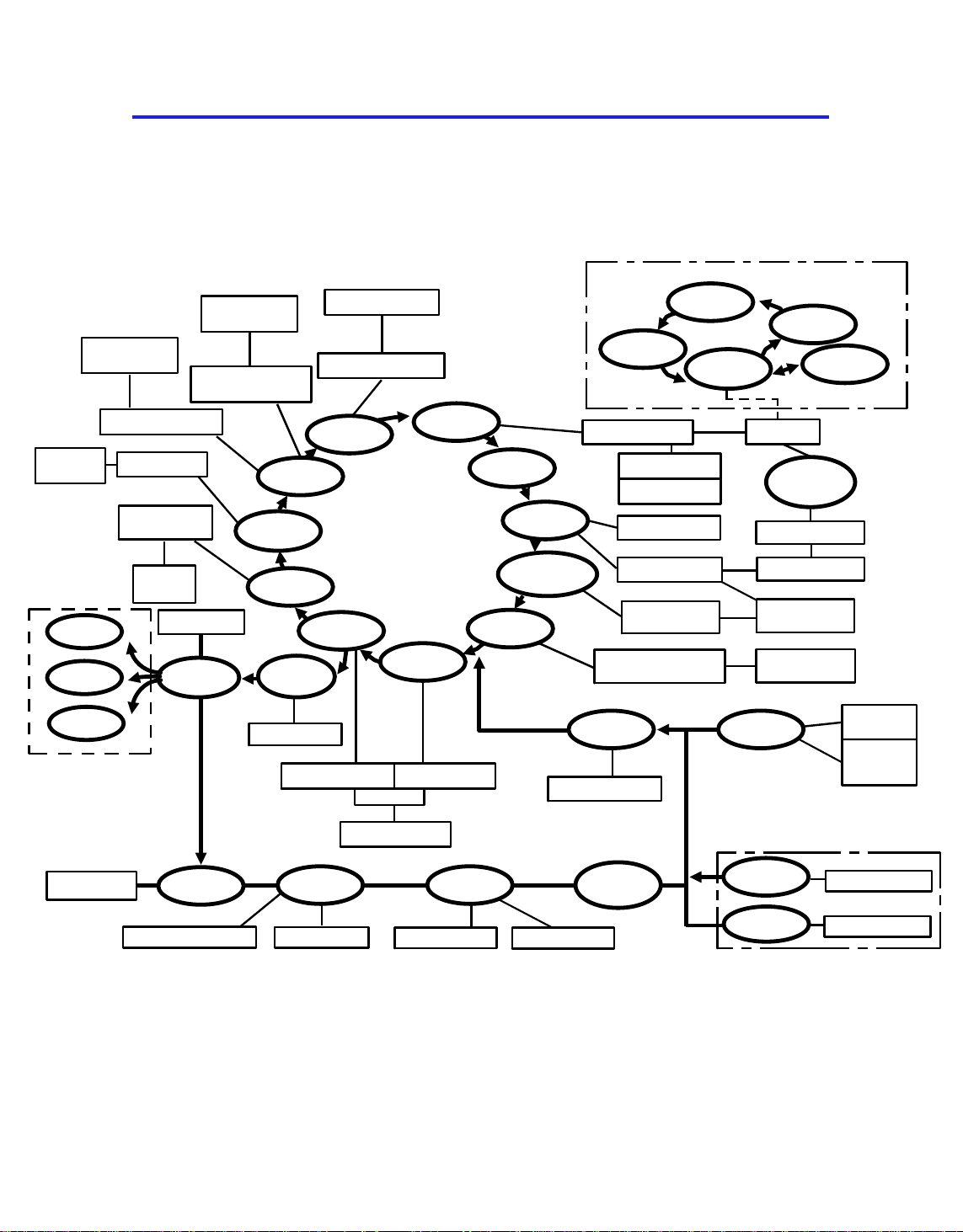

4. COPY CYCLE

RDH/ARDF

Lamp Stabilizer

Power Pack

PQC/CB

Finisher/Sorter

Sort

Stack

Staple

Q/PTL

QL (Cathode Tube)

Cleaning Unit

Pre-Cleaning

Corona

Power

Pack-PCC

Fusing Unit

Image

Fusing

Power Pack

PQC/CB

Pre-Quenching

Charge Unit

Cleaning

Transport Unit

Power Pack-C/B

Charge Corona Unit

Drum Charge

Quenching

PCC

Paper

Separation

Paper

Transport

Separation Corona

Exposure

Image

Transfer

Transfer Corona

Erase

Development

Toner Density

Detection

PTL

Original

Feed-in

Optics Assembly

ID Sensor Pattern

VL sensor Pattern

Erase Lamp Unit

Development Unit

Image Density

Sensor

PTL

(Cold Cathode Tube)

Registration

Registration Roller

Original

Stacking

Original

Positioning

Original

Auto-ID Sensor

Power Pack-C/B

Toner Supply

Mechanism

Lamp Stabilizer

Q/PTL

1st

Paper Feed

Original

Feed-out

Original

Density

Detection

Original

Inversion

Manual

Feed Table

Large

Capacity

Tray

Inverter

Mechanism

Inversion

Duplex Transport Unit

Duplex

Transport

Fork Gate Unit

Power Pack-T/S

Delivery Tray

Duplex

Stacking

1-14

Jogger Unit

Duplex Paper

Feed

Cassette Bank

2nd

Paper Feed

3rd

Paper Feed

Cassette

Cassette

30 November 1990

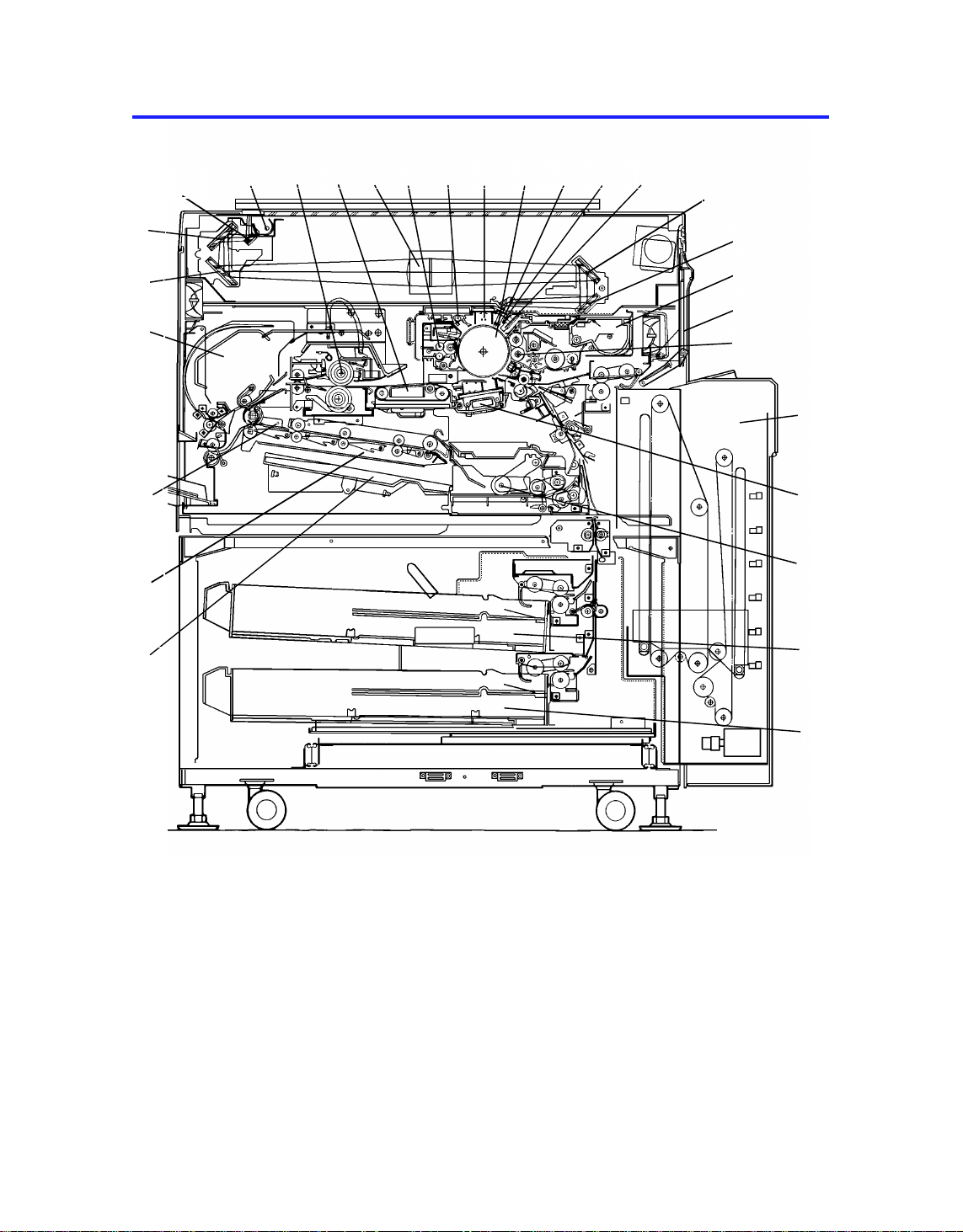

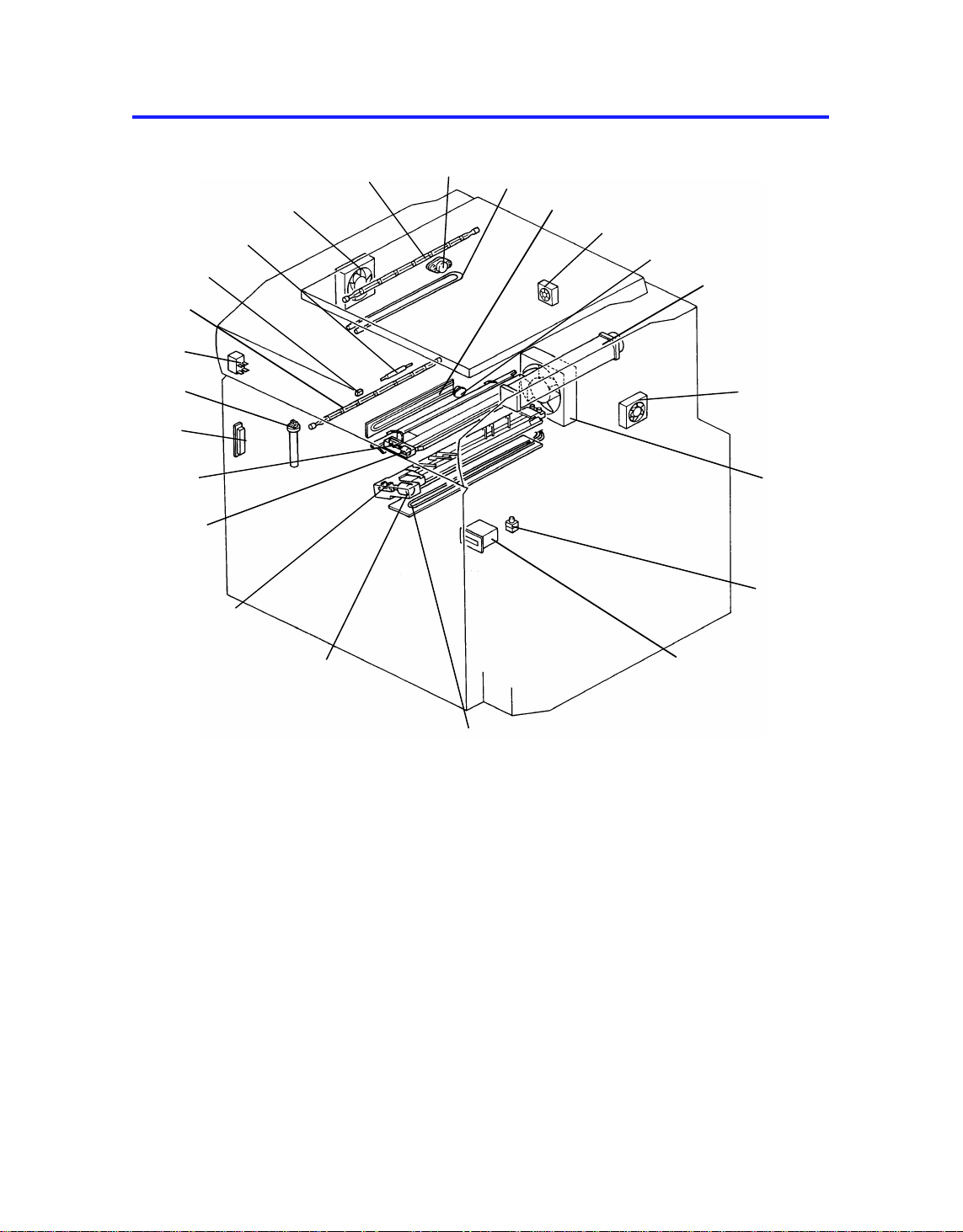

5. MECHANICAL COMPONENT LAYOUT

3

2

1

28

27

26

4

5 6 7 8109

11 12 13 14 15

16

17

18

19

20

21

22

23

24

1. Inverter Unit

2. Third Mirror

3. Second Mirror

4. First Mirror

5. Exposure Lamp

6. Fusing Unit

7. Transport Unit

8. Lens

9. Cleaning Unit

10. Quenching Unit

11. Charge Corona Unit

12. Drum

13. Toner Shield Glass

14. Sixth Mirror

25

15. Erase Lamp Unit

16. Fourth Mirror

17. Fifth Mirror

18. Toner Tank

19. Manual Feed Table

20. Development Unit

21. Large Capacity Tray

22. T/ S Corona Unit

23. Jogger Unit

24. Third Cassette

25. Second Cassette

26. Duplex Delivery Tray

27. Fork Gate Unit

28. Duplex Transport Unit

1-15

30 November 1990

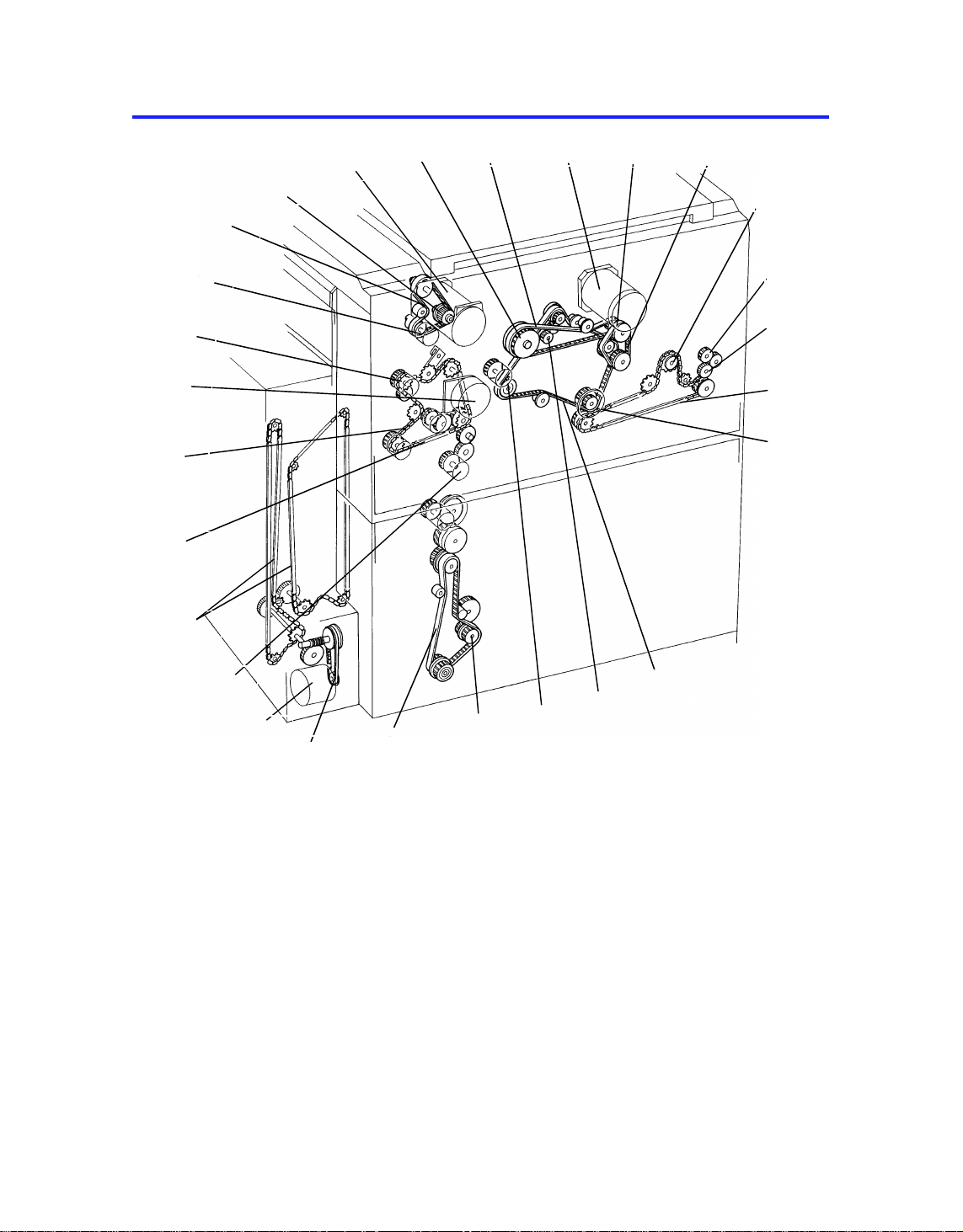

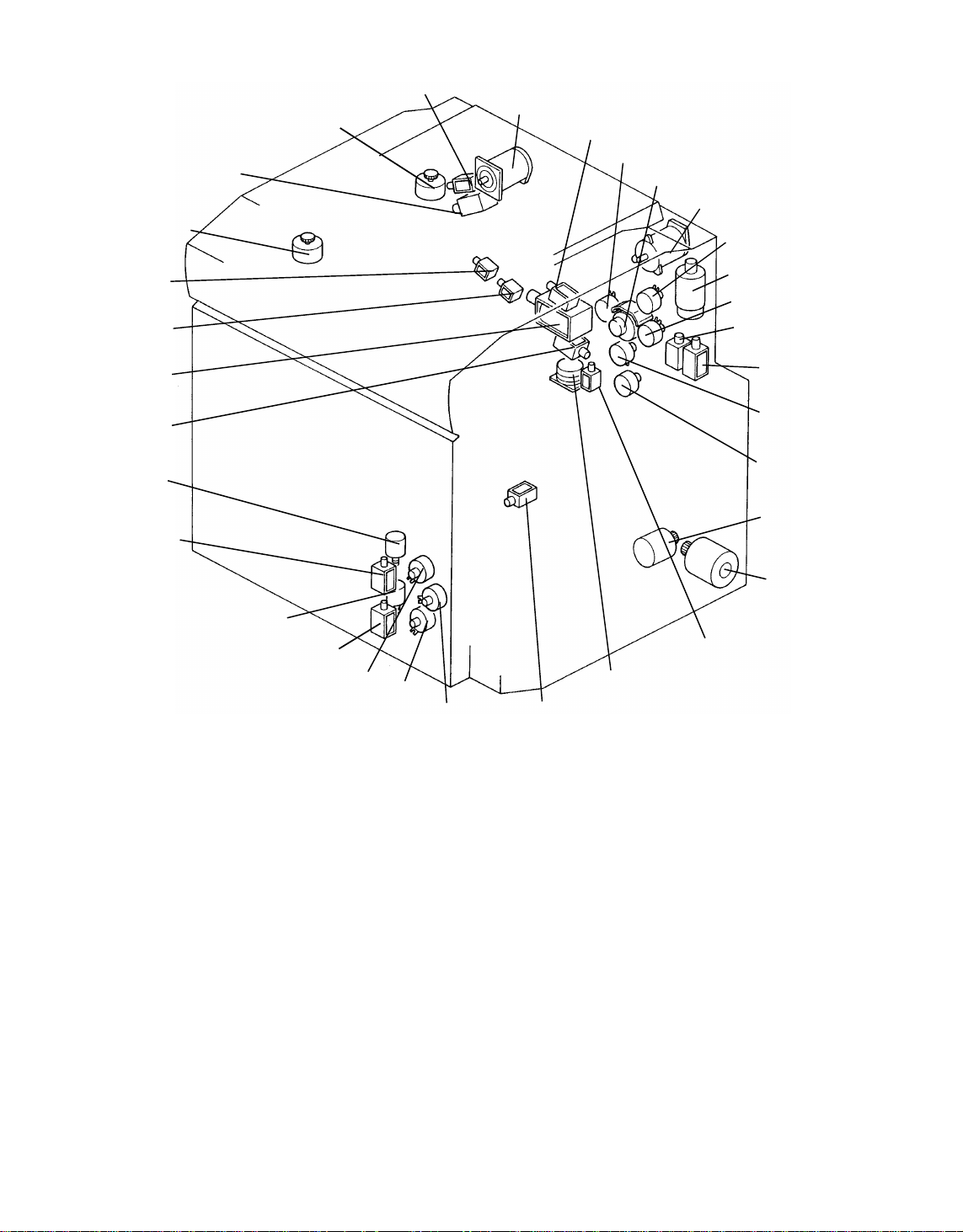

6. DRIVE LAYOUT

26

25

24

23

22

27

3

4

2

1

5 6

7

8

9

10

11

12

13

21

20

19

1. Development Drive Belt

2. Development Drive Gear

3. Development Motor

4. Drum Drive Pulley

5. Drum Drive Belt

6. Main Motor

7. Fusing/Duplex Drive Gear

8. Main drive Belt

9. Exit relay Roller Drive Sprocket

10. Inverter Roller Drive Gear

11. Exit Roller Drive Gear

12. Exit Drive Chain

13. Pulse Generator Drive Pulley

18

14

17

16

14. Registration Roller Drive Belt

15. Cleaning Drive Gear

16. Registration Clutch

17. 3rd Paper Feed Drive Gear

18. Cassette Bank Drive Belt

19. LCT Bottom Plate Drive Belt

20. LCT Motor

21. Duplex Paper Feed Clutch

22. LCT Bottom Plate Drive Chains

23. Relay Roller Clutch

24. Paper Feed Drive Chain

25. Paper Feed Motor

26. 1st Paper Feed Clutch

27. Toner Supply Clutch

15

1-16

21

30 November 1990

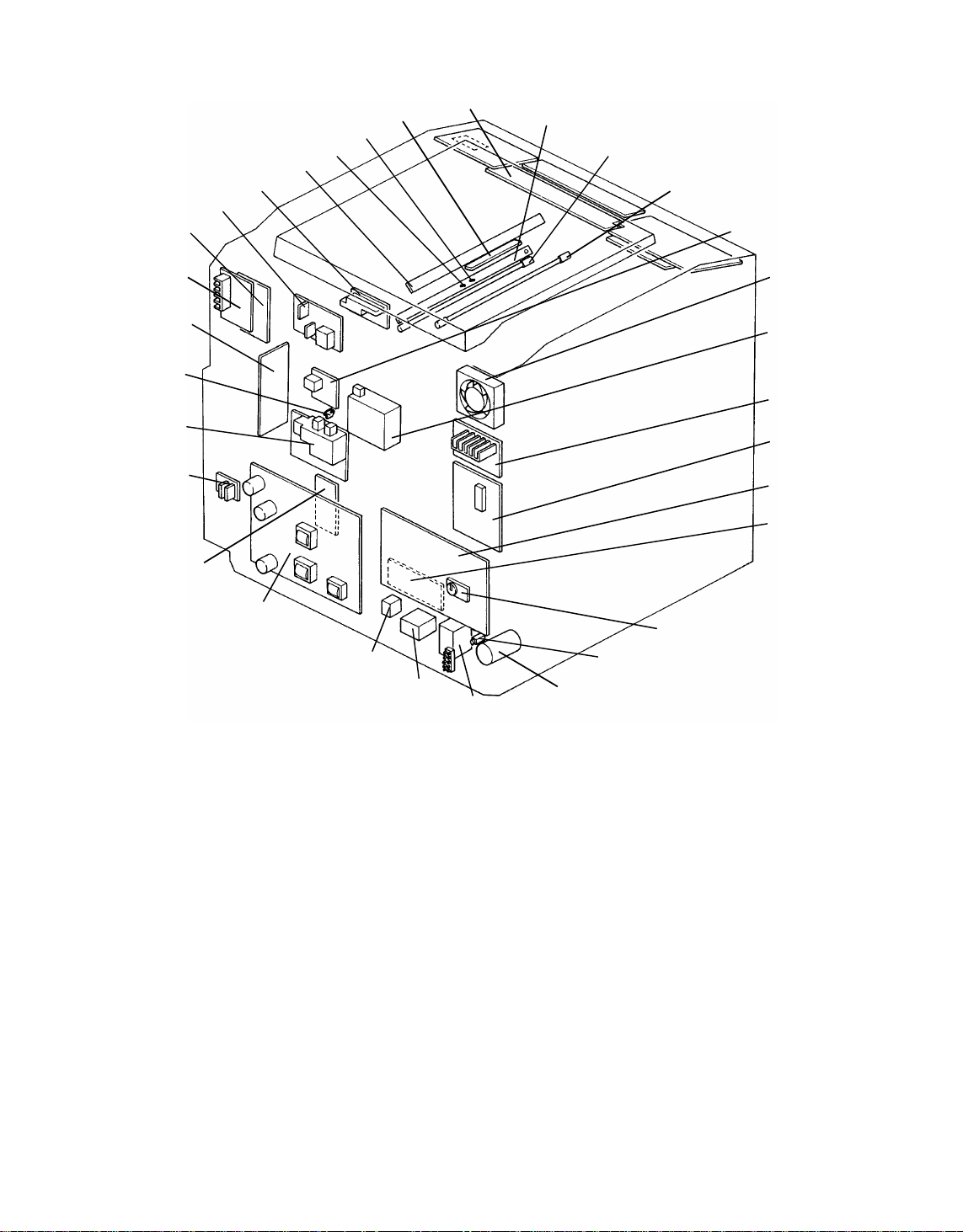

7. ELECTRICAL COMPONENT LAYOUT

23

22

1

20

19

5

4

3

2

18

6

7

8

9

10

11

12

13

14

17

1. Fusing Lamp

2. Fusing Thermistor

3. Thermofuse

4. Fusing Exhaust Fan Motor

5. Exposure Lamp

6. Optics Thermoswitch

7. Anticondensation Heater

8. Cleaning Heater

9. Charge Fan Motor

10. Cleaning Thermoswitch

11. Cooling Blower Motor

12. Development Cooling Fan Motor

13. Vacuum Fan Motor

15

16

14. LCT Down Switch

15. Total Counter

16. Drum Heater

17. SC Cleaner Motor

18. SC Cleaner Home Position

Sensor

19. CC Cleaner Motor

20. CC Cleaner Home Position

Sensor

21. Printer Connector (RS232C)

22. Oil End Se nsor

23. Main switch

1-17

30 November 1990

25

26

27

28

29

30

31

32

55

54

53

52

51

50

24

49

48

47

46

45

33

34

35

36

37

38

39

40

41

42

43

44

24. 4th and 5th Mirror Drive Motor

25. Junction Gate Sol.

26. Lens Drive Motor

27. Inverter Pressure Sol.

28. Main Motor

29. Pick-off Sol.

30. Registration MC

31. Paper Feed Motor

32. Development Motor

33. Toner Supply MC

34. Scanner Drive Motor

35. 1st Paper Feed MC

36. 1st Pick-up Sol.

37. Manual Feed Pick-up Sol.

38. 1st Feed Relay MC

39. Duplex Paper Feed MC

40. Cassette Bank Drive Motor

41. LCT Motor

42. Duplex Positioning Roller Sol.

43. Jogger Motor

44. Duplex Stopper Sol.

45. 2nd Feed Relay MC

46. 3rd Paper Feed MC

47. 2nd Paper Feed MC

48. 3rd Pick-up Sol.

49. 3rd Lift Motor

50. 2nd Pick-up Sol.

51. 2nd Lift Motor

52. Duplex Pick-up Sol.

53. Cleaning Sol.

54. Fork Gate Sol. 2

55. Fork Gate Sol. 1

1-18

30 November 1990

85

84

83

82

81

86

80

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

79

78

56. Power Pack-CC/Bias

57. Power Pack-PQC/Cleaning

Bias

58. Erase Lamp

59. Bias Thermister

60. Drum Thermister

61. Registration Sensor

62. Operation Panel PCB

63. Image Density Sensor PCB

64. Pre-transter Lamp

65. Quenching Lamp

66. PTL/QL Stabilizer

67. Fusing Cooling Fan

68. Power Pack-PCC

69. Main Motor PCB

70. Optics PCB

77

73

74

75

76

71. Main PCB

72. AC Drive PCB

73. Memory Board

74. Circuit Breaker

75. Noise Filter

76. Main Transformer

77. Power Relay

78. Condition Relay

79. DC Power Supply PCB

80. Cassette Bank PCB

81. SSR PCB

82. Power Pack-T/S

83. Toner Overflow Sensor

84. Paper Feed PCB

85. Development Motor PCB

86. Paper Feed Motor PCB

1-19

105

30 November 1990

90

89

88

87

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

87. Original Width Sensor

88. Original Length Sensor

89. Auto Density Sensor

90. Fork Gate Unit Safety Switch

91. Lens Home Position Sensor

92. Scanner Home Position Sensor

93. Scanner VL Position Sensor

94. 4th/5th Mirror Home

Position Sensor

95. Duplex Entrance Sensor

96. Toner End Sensor

97. 1st Lift Sensor

98. Jogger Home Position Sensor

99. 1st Relay Sensor

100. LCT Cover Sensor

101. LCT Cover Switch

102. 1st Paper Volume

103. LCT Lower Limit Sensor

104. Paper Position Sensor

105. LCT Lower Limit Safety Switch

91

92

93

94

95

96

97

98

99

104

106

107

108

109

110

111

106. 3rd Relay Sensor

107. 2nd Paper Volume Sensor

108. 3rd Paper Volume Sensor

109. 3rd Paper End Sensor

110. 2nd Paper End Sensor

111. 3rd Paper Size Sensor

112. 2nd Paper Size Sensor

113. 2nd Relay Sensor

114. Manu al Fee d Sensor

115. 3rd Lift Sensor

116. 2nd Lift Sensor

117. 1st Paper End Sensor

118. Manual Paper End Sensor

119. Duplex Paper Sensor

120. Pulse Generator

121. Transport Unit Safety Swit ch

122. Front Door Safety Switch

123. Exit Sensor

124. Fusing Exit Sensor

125. Exit Relay Sensor

126. Inverter Exit Sensor

100

101

102

103

1-20

30 November 1990

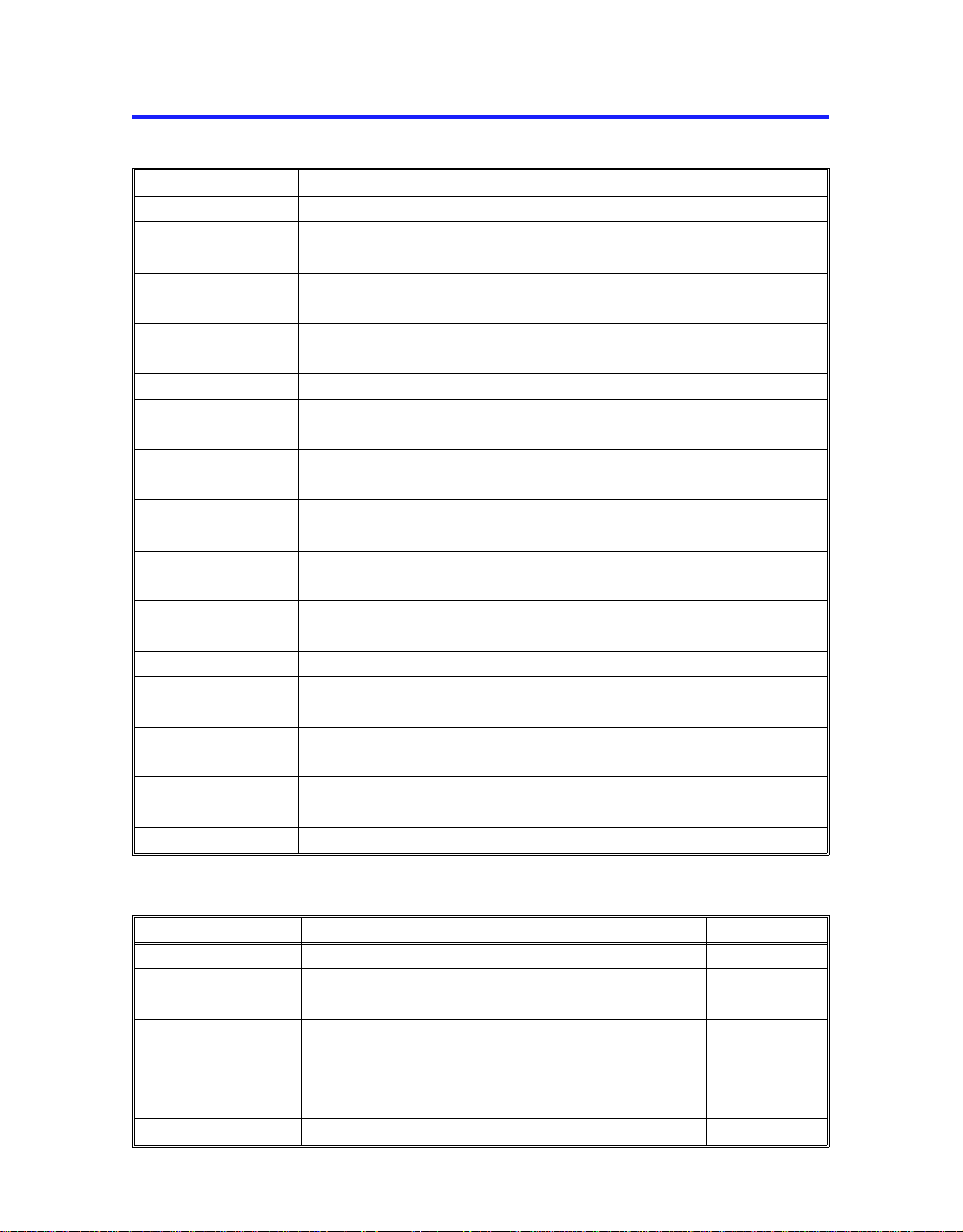

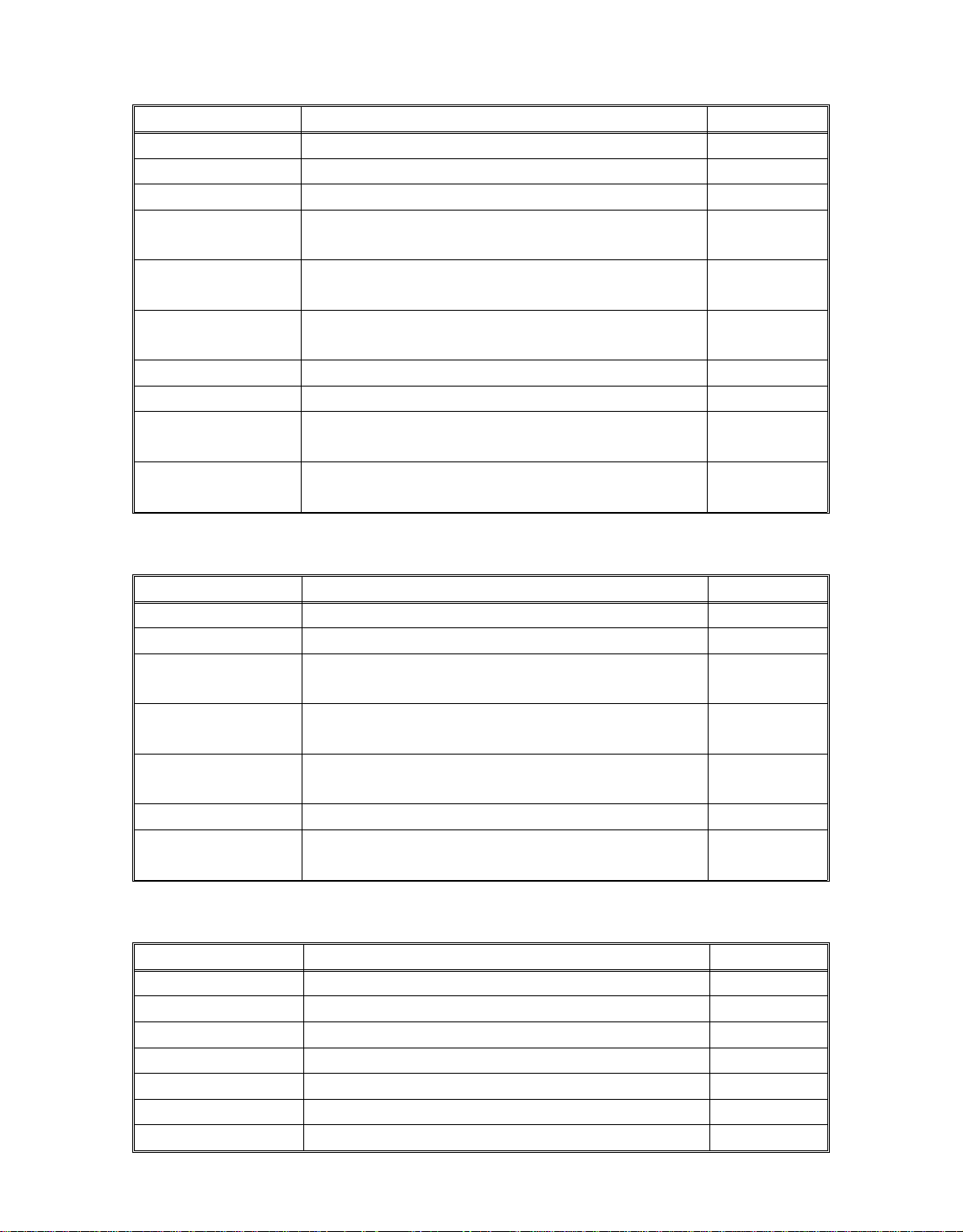

8. ELECTRICAL COMPONENT DESCRIPTIONS

MOTORS

NAME FUNCTION LOCATION

Main Drives the main unit components. 28

Development Drives the development unit. 32

Paper Feed Drives the feed sectio n. 31

Development

Cooling Fan

Fusing Exhaust

Fan

Fusing Cooling Removes heat from around the fusing unit. 67

Cooling Blower Prevents build up of hot air in the optics

Vacuum Fan Provides suction so paper is held firmly on

Scanner Drive Drives the scanner. (dc servo) 34

Lens Drive Positions the lens. (dc stepper) 26

4th / 5th Mirror

Drive

Jogger Drives the jogger plates to keep paper

Cleaner Motors Clean charge and separation wires. 17, 19

Charge Fan Ensures even charge on the surface of the

LCT Rises and lowers the LCT bottom plate.

Cassette Bank

Drive

Lift Motors Lift paper to the appropriate feed position. 49, 51

Blows air to the developme nt unit bottom

plate.

Removes heat from around th e fu sing unit. 4

cavity.

the transport belt.

Positions the 4th/5t h mirror assembly. (dc

stepper)

evenly stacked on the duple x t ray.

drum.

(ac motor)

Drives the 2nd/3rd paper feed sections. 40

12

11

13

24

43

9

41

MAGNETIC CLUTCHES

NAME FUNCTION LOCATION

Registration Drives the reg istra tio n rolle r 30

Paper Feed

Clutches

Feed Relay

Clutches

Duplex Paper

Feed

Toner Supply Drives toner supply roller. 33

Starts paper feed from each feed stat ion. 35, 96, 47

Drives the relay rollers. 38, 45

Feeds paper from the duplex tray. 39

1-21

30 November 1990

SOLENOIDS

NAME FUNCTION LOCATION

Cleaning Moves the clean ing blade against the drum. 53

Pick-off Moves the pick-off pawls against the drum. 29

Junction Gate Energizes to direct copies to the duple x tray. 25

Fork Gate

Solenoids

In unison, open and close the appropriate

fork gates according to pap er size.

54, 55

Duplex Pick-up Start s fee d from duplex an d aids the

stopper solenoid.

Duplex

Lowers positioning roller. 42

Positioning

Inverter Pressure Controls the inverter pressure roller. 27

Duplex Stopper Stops copy in the jogger unit. 44

Pick-up

Picks paper up from each feed sta tio n. 36, 48, 50

Solenoids

Manual Feed

Pick-up

Raises the pick-up roller when paper is fed

from the manual feed table.

52

37

SWITCHES

NAME FUNCTION LOCATION

Main Supplies power to the copier. 23

Front Door Safety Cuts ac power line. 122

Transport Unit

Cuts 24-volt lines. 121

Safety

Fork Gate Unit

Cuts 24-volt lines. 90

Safety

LCT Lower Limit

Cuts the signal line of the tray down. 105

Safety

LCT Down Lowers the LCT bottom plate. 14

LCT Cover Cuts power to the LCT when LCT cover is

101

opened.

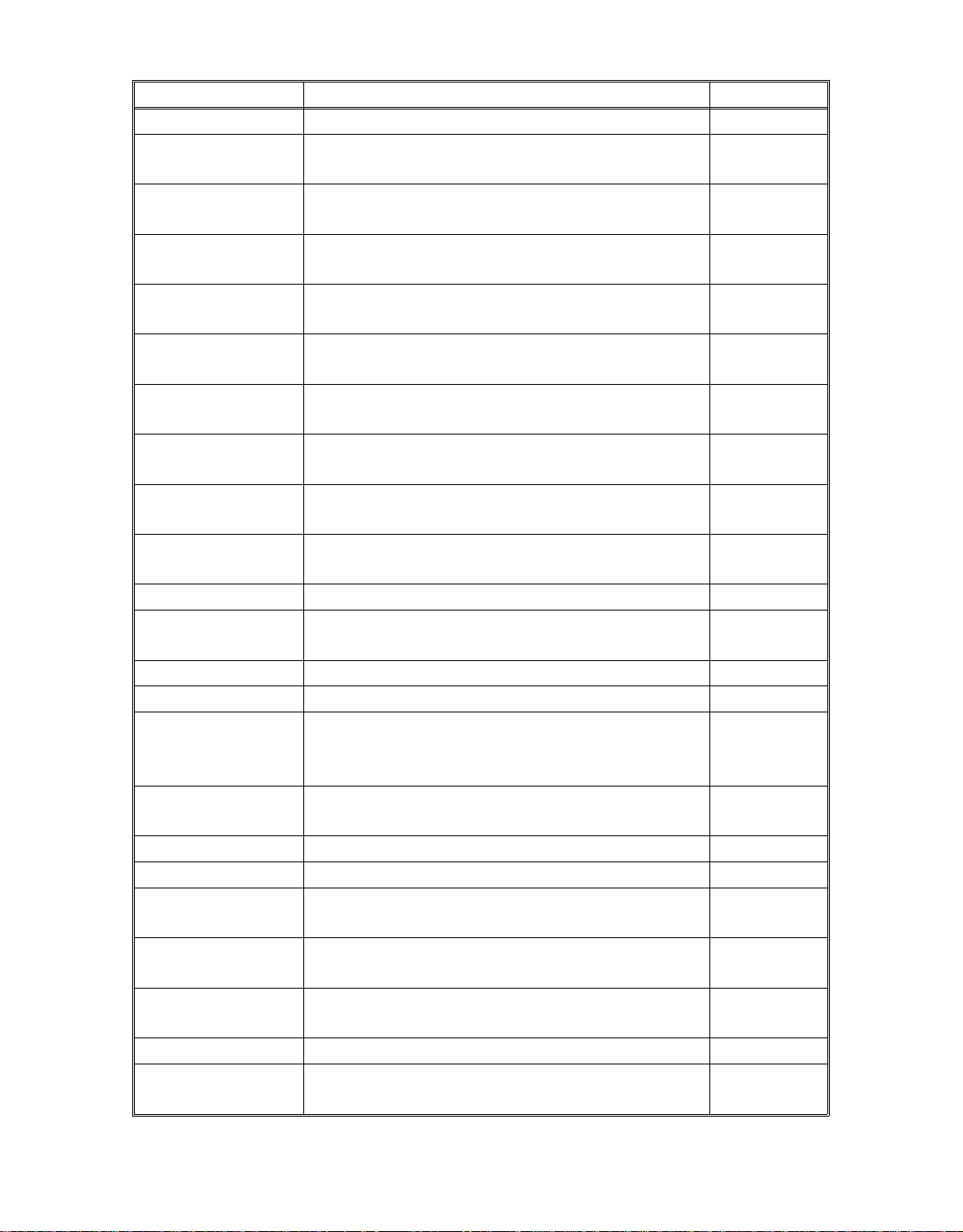

SENSORS

NAME FUNCTION LOCATION

Pulse Generator Supplies timing pulses to the main board. 120

Exit Detects misfeeds. 123

Exit Relay Detects misfeeds. 125

Oil End Detects the low oil condition. 22

Toner Overflow Det ect s when the used ton er bo tt le is full. 83

Toner End Detects when it is time to add toner. 96

Registration Detects misfeeds. 61

1-22

30 November 1990

NAME FUNCTION LOCATION

Manual Feed Detects when the manual feed table is open. 114

Scanner Home

Position

Lens Home

Position

4th/5th Mirror

Home Position

Paper Size

Informs the CPU when the scanner is at the

92

home position.

Informs the CPU when the lens is at the full

91

size position.

Informs the CPU when the 4th / 5th mirror

94

assembly is at the full size position.

Detects the paper size in the cassette. 111, 112

Sensors

Paper End

Sensors

Scanner VL

Position

Informs the CPU when the copy paper runs

out.

Informs the CPU when the scanner reaches

the VL pattern sensing position.

109, 110,

117

93

Relay Sensors Detects misfeeds. 99, 106,

113

Jogger Home

Position

Duplex Paper Detects whether or not paper is in the

Informs the CPU when the jogger plates are

at the home position.

98

119

duplex tray.

Duplex Entrance Misfeed detector 95

Auto Density Senses the background density of the

89

original.

Original Width Detects the original width. 87

Original Length Detects the original length. 88

Charge Cleaner

Home Position

Informs the CPU when the charge wire

cleaner has reached home po sitio n.

18, 20

Sensors

Manual Feed

Paper End

Informs the CPU that there is no paper in

the manual feed tray.

118

Fusing Exit Detects misfeeds. 124

Inverter Exit Detects misfeeds. 126

Lift Sensors Detects whether paper has been raised to

the proper paper feed position.

LCT Cover Informs the CPU when the LCT cover is

97, 115,

116

100

closed.

LCT Lower Limit Informs the CPU when the LCt bottom plate

103

reaches the lower limit position.

Paper Position Detects the paper position. 104

Paper Volume Detects the amount of paper in

LCT/cassettes.

102, 107,

108

1-23

30 November 1990

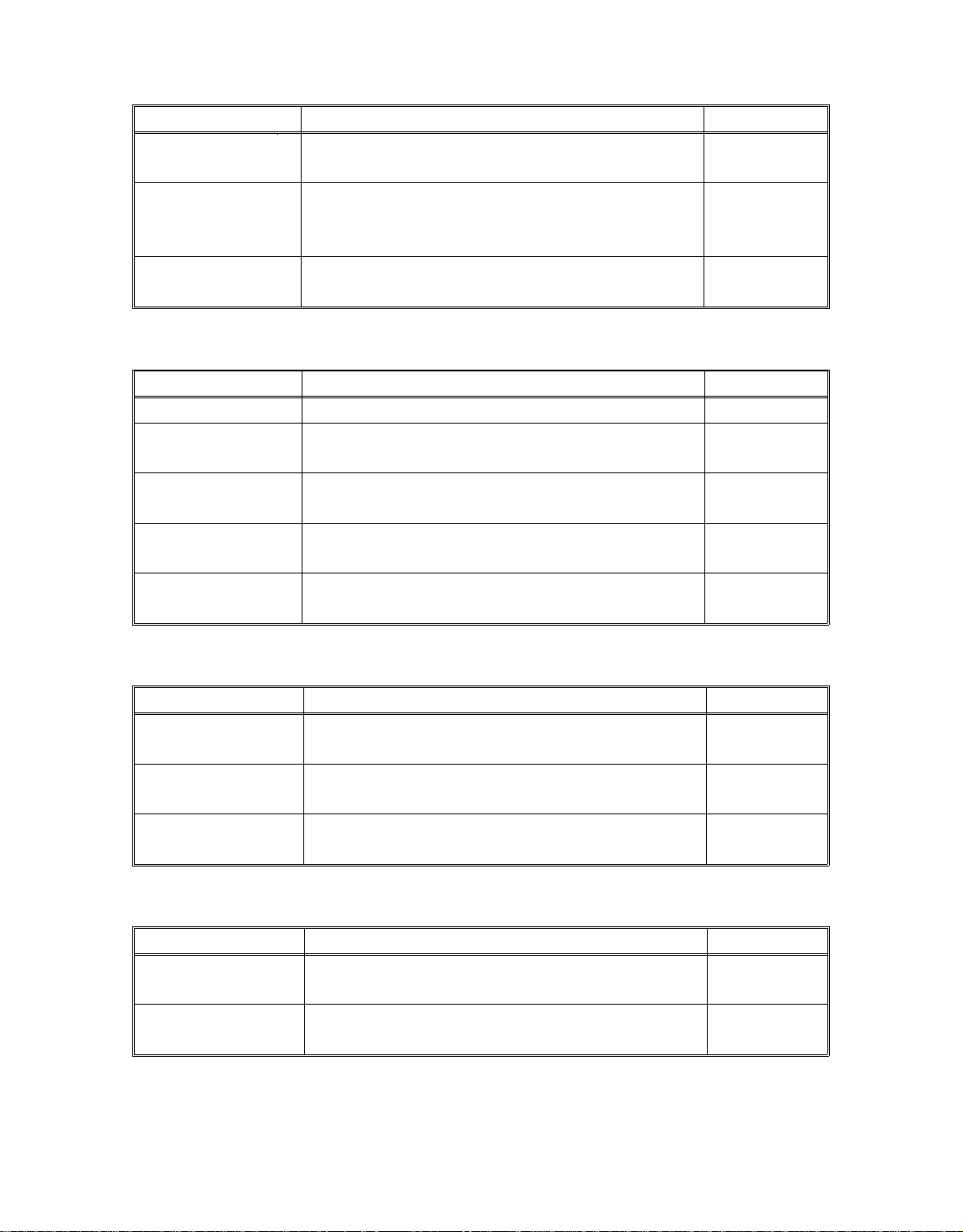

THERMISTORS

NAME FUNCTION LOCATION

Drum Monitors the temp era tu re around the drum

and controls the rest-time comp ensation.

Bias Monitors the temperature aroun d the drum

and controls developmen t rest time bia s

compensation.

Fusing Monitors the fusing temperature and turns

the fusing lamp on/off.

POWER PACKS/STABILIZER

NAME FUNCTION LOCATION

Power Pack - T/S Provides high voltage for th e T/S coronas. 82

Power Pack CC/Bias

Power Pack PQC/Cleaning

Power Pack PCC

Provides high voltage for the charge corona

and the development roller bias.

Provides high voltage for the quenching

corona and the cleaning bias roller.

Provides high voltage for the pre-cleaning

corona.

PTL/QL Stabilizer Provides high voltage for the quenching

and pre-transfer lamps.

60

59

2

56

57

68

66

HEATERS

NAME FUNCTION LOCATION

Drum Warms the drum when the main switch is

off.

Cleaning Warms the cleaning section when the main

switch is off.

Anticondensation Prevents moisture from forming on the

optics.

THERMOSWITCHES

NAME FUNCTION LOCATIO N

Optics Provides overheat protection in the optics

unit.

Cleaning Provides overheat pro te ctio n in the

cleaning unit.

16

8

7

6

10

1-24

30 November 1990

LAMPS

NAME FUNCTION LOCATION

Exposure Applies high intensity light to the original for

exposure.

Fusing Provides heat to the fusing unit. 1

Erase Discharges the drum outside the image

58

area. Erases lead/trail edge.

Quenching Neutralizes any charge remaining on the

65

drum surface after cleaning.

Pre-transfer Reduces charge on the drum surface

64

before transfer.

PRINTED CIRCUIT BOARDS

NAME FUNCTION LOCATION

Main Controls all copier functions both directly

71

and through other PCB s.

Optics Controls the speed of the scanner, the

70

position of the lens, and the position of the

mirrors.

Operation Panel Contro ls the LED mat rix, and mon ito rs the

62

key matrix.

Main Motor Controls the speed of the main motor. 69

Development

Motor

Paper Feed Motor Controls the speed of the paper feed drive

Controls the speed of the development

motor.

85

86

motor.

Paper Feed Interfaces with overall pap er fe ed ; rece ives

84

input from paper size and paper end

sensors.

DC Power Supply Rectifies 100 Vac input and outputs dc

79

voltages.

Image Density Detects the density of the image on the

63

drum.

Cassette Bank Interfaces with overa ll cassette bank drive. 80

AC Drive Drives the exposure lamp and the fusing

72

lamp.

Memory Controls weekly timer and memory

73

functions.

SSR Switches the LCT bottom plate up/down 81

5

1-25

30 November 1990

OTHERS

NAME FUNCTION LOCATION

Circuit Breaker G uards against voltage surges in the input

power.

Main Transformer Steps down the wall voltage to 100 Vac. 76

Thermofuse Provides back-up overheat protection in the

fusing unit.

Total Counter Keeps track of the total number of cop ies

made.

Power Relay Controls main power. 77

Condition Relay Controls the heaters on/off. 78

Noise Filter Removes electrical noise. 75

Printer Connector Used for connection to the printer

(RS 232C serial interface).

74

3

15

21

1-26

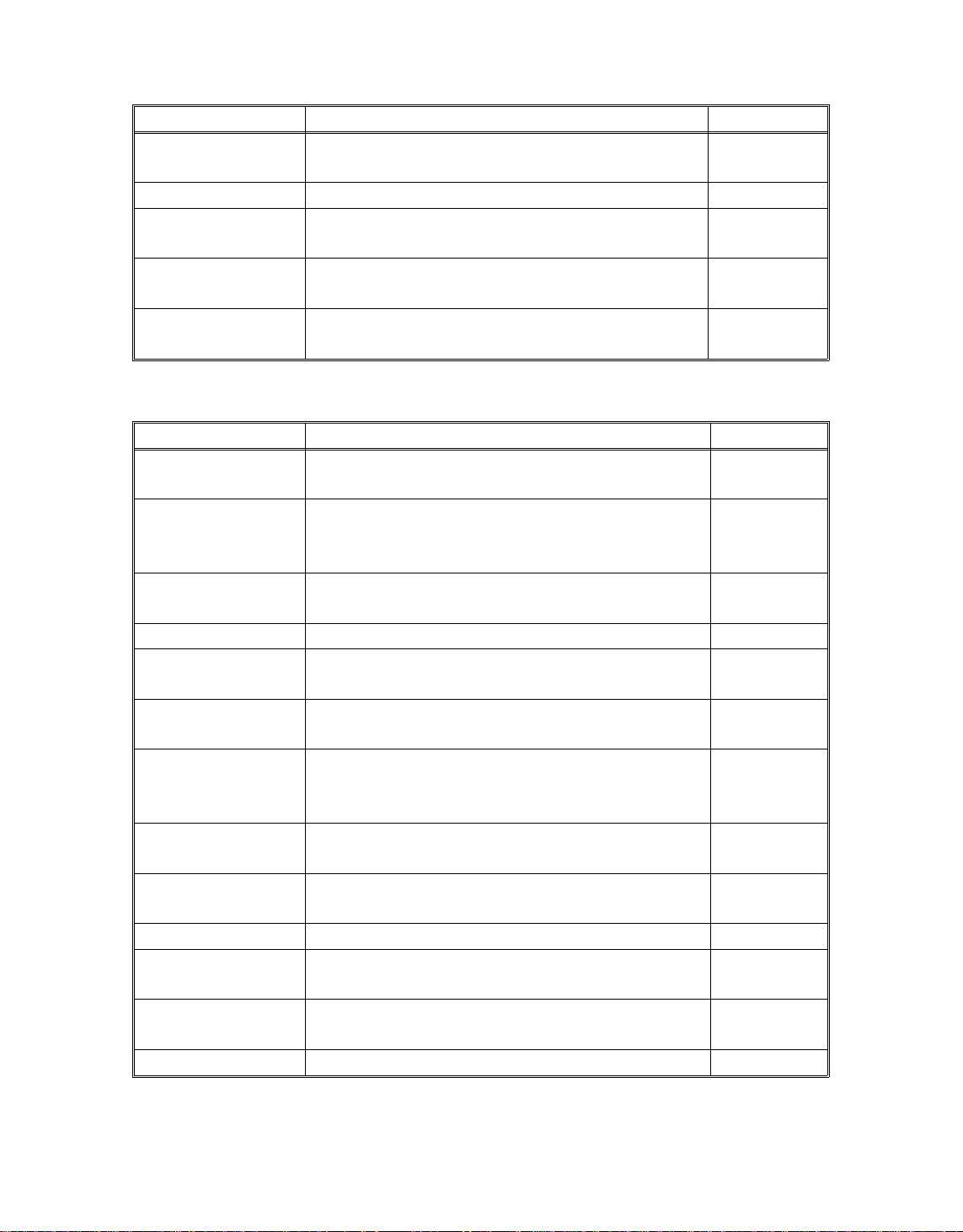

9. OVERALL MACHINE CONTROL

30 November 1990

Pulse Generator

Sensors

-Toner Overflow

-Exit

-Inverter Exit

-Duplex entrance

-Duplex Paper

-Jogger H.P.

-Toner End

-Oil End

-Image Density

Solenoids

-Fork Gate

-Inverter Return

-Junction Gate

-Duplex Positioning

-Duplex Stopper

-Duplex Pick-up

-Pick-off

-Cleaning

Magnetic Clutches

-Duplex Paper Feed

-Toner Supply

Motors

-Jogger

-Vacuum Fan

-Fusing Exhaust

-Charge Fan

-Development

Cooling Fan

-Ozon Fan

Counters

-Total

-Key

-A3/LDG

Erase Lamp

Power Packs

-PQC/Cleaning Bias

-CC/Development

Blas

Quenching Lamp

Stabilizer

ARDF/Sorter

RDH/Finisher

Menu Sheet Reader

RS232C Interface

Main PCB

Optics PCB

Main Motor

Development

Motor PCB

Paper Feed

Motor PCB

AC Drive

Operation

Panel PCB

Paper Feed

Casstte Bank

(2nd/3rd Feed)

PCB

PCB

PCB

PCB

Motors

-Scanner Drive

-Lens Drive

-4th/5th Mirror Drive

-CC Cleaner Motor

-SC Cleaner Motor

Sensors

-Scanner Home Position

-Scanner Overrun

-Lens H.P.

-4th/5th Mirror H.P.

-CC Cleaner H.P.

-SC Cleaner H.P.

Main Motor

Development

Motor

Paper Feed

Motor

Exposure Lamp

Fusing Lamp

Sensors

-Registration

-1st Relay

-Manual Feed

-Manual Feed Paper End

-Paper End

-Lift

-Paper Volume

Solenoids

-Manual Feed

-Pick-up

Magnetic Clutch

-Paper Feed

-Relay

Sensors

-Paper End (2)

-Paper Volume (2)

-Paper Size (2)

-Lift Relay (2)

Moters

-Lift (2)

Solenoids

-Pick-up (2)

Magnetic Clutch

-Paper Feed (2)

-Relay

1-27

30 November 1990

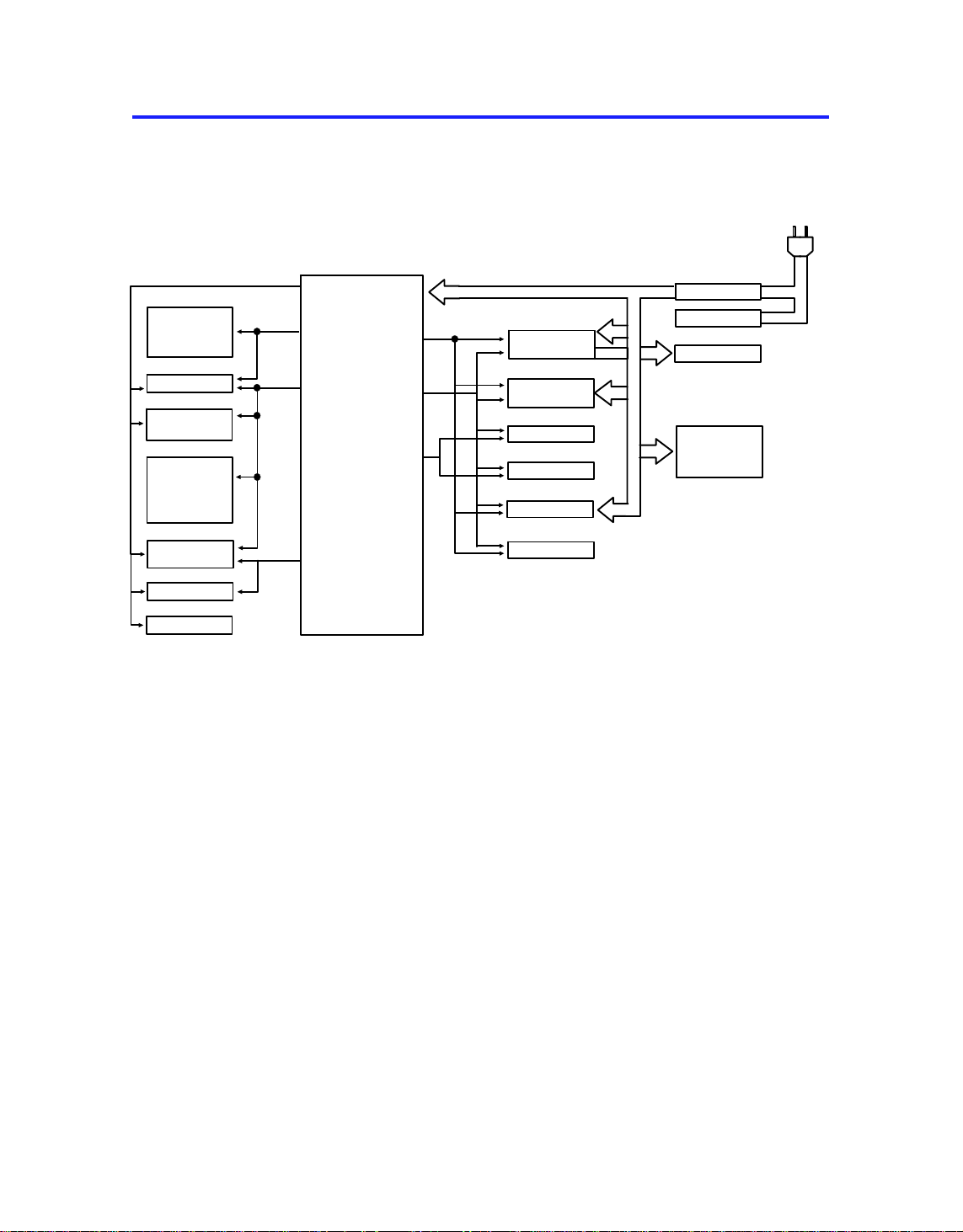

10. AC AND DC POWER DISTRI BUTI ON

AC Power

Main Motor PCB

Dev. Motor PCB

Paper Feed Motor

Optics PCB

Main PCB

Paper Feed PCB

Clutches

Motors

Solenoids

Counters

Relays

Operation Panel

Power Packs

Erase Unit

PCB

PCB

5V (VC)

24V (VM)

24V (VA)

24V (VP)

DC

Power

Supply

5V (VC)

24V (VF)

24V (VA)

AC Drive

PCB

Cassette Bank

(2nd /3rd Feed)

ARDF/RDF

Finisher

Sorter

Menu Reader

Transformer

Fusing Lamp

Exp Lamp

Drum Heater

Anticondensation

Heater

Cleaning Heater

The illustration on this page shows the electrical power dist ribution in block

form.

AC power (115/220 volts) is supplied from the wall outlet directly to the fusing

lamp and the step-down tran sfo rmer. The transformer supplies 100 volts ac

to the power supply unit, the ac drive board , the pa per ban k (2nd /3 rd pa per

feed station)and sorter.

The power supply unit produ ces fo ur 24 volts an d on e 5 volt s t o operate the

PCB’s, the clutches, the moto rs, the solenoids, the counters, th e rela ys, the

power packs and the era se unit.

1-28

SECTION 2

SECTIONAL DESCRIPTION

Loading...

Loading...