SECTION 1

OVERALL MACHINE

INFORMATION

1. SPECIFICATIONS

Configuration: Console

Number of Bins: 20 + Proof Tray

Paper for Proof Tray: Size: Maximum: A3, 11" x 17"

Minimum: A6 lengthwise,

51/2" x 81/2"

Weight: 52 ∼ 157 g/m2, 14 ∼ 41lb

Paper for Bins: Sort/Stack mode

Size: Maximum: A3, 11" x 17"

Minimum: A5 lengthwise,

51/2" x 81/2" lengthwise

Weight: 52 ∼ 93 g / m2, 14 ∼ 24 lb

Staple mode

Size: Maximum: A3, 11" x 17"

Minimum: B5, 81/2" x 11"

Weight: 64 ∼ 80g/m2, 17 ∼ 20 lb

10 July 1991

Paper Capacity: Proof tray: 150 sheets (80 g/ m2, 20 lb)

Bins:

1 sided copies 2 sided copies

Sort mode 50 Sheets 50 Sheets

Stack mode 40 Sheets 35 Sheets

(80 g/m2, 20 lb)

Staple Capacity: From 2 to 30 sheets (80 g/m2, 20 lb)

Staple Position:

a = 5 ± 2 mm (0.2" ± 0.08")

b = 5 ± 2 mm (0.2" ± 0.08")

a

b

1-1

10 July 1991

Staple Time: Within 2 seconds/staple

Staple Replenishment: Cartridge exchange (5,000 pieces/cartridge)

Power Source: AC 100 V (from copier)

Power Consumption: Average: less than 80 W

Maximum:

in sort/stack mode: less than 90 W

in staple mode: less than 170 W

Dimensions:

(W x D x H)

610 x 675 x 1035 mm

24.1" x 26.6" x 40.8"

Weight: Approximately 80 kg (177 lb)

1-2

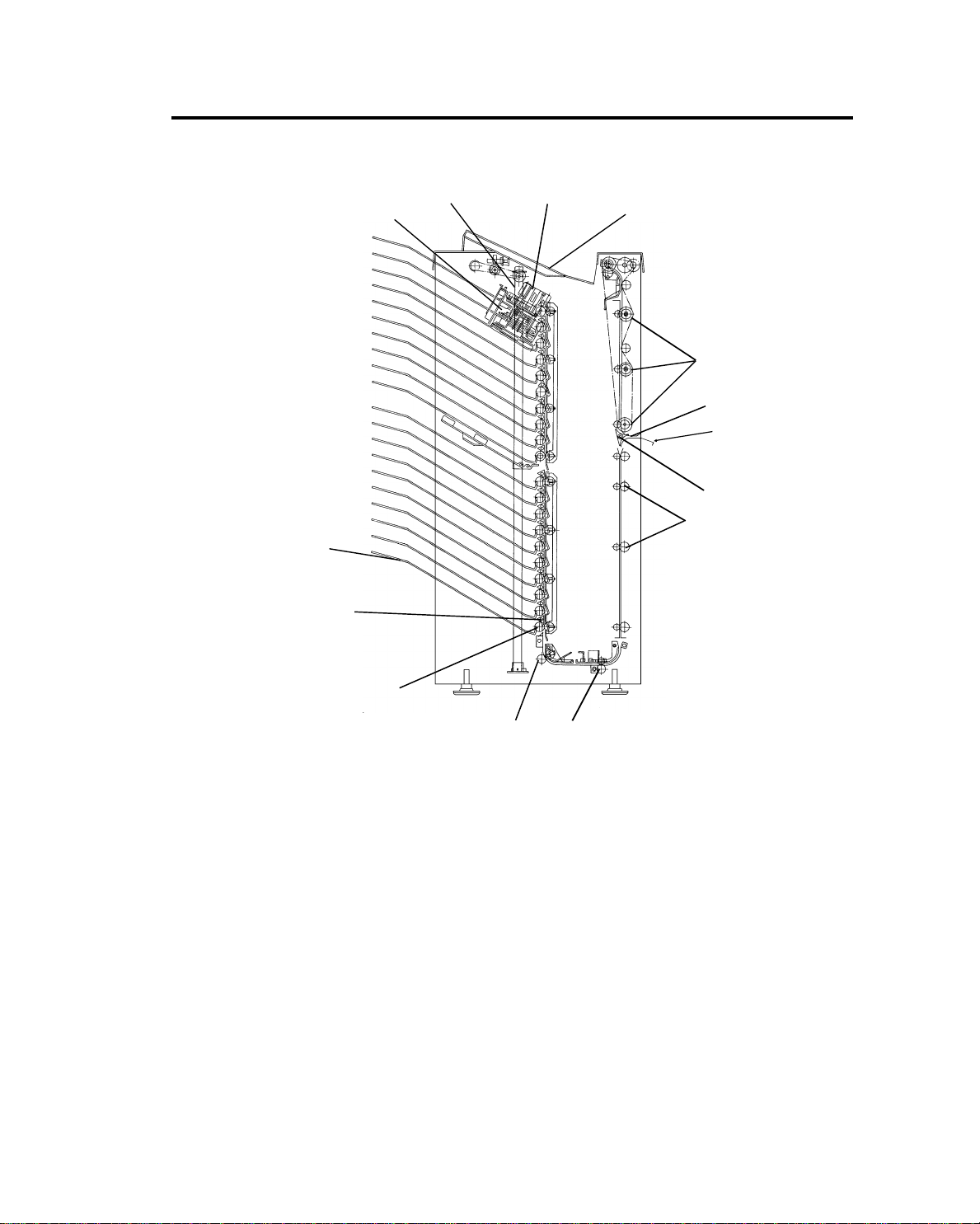

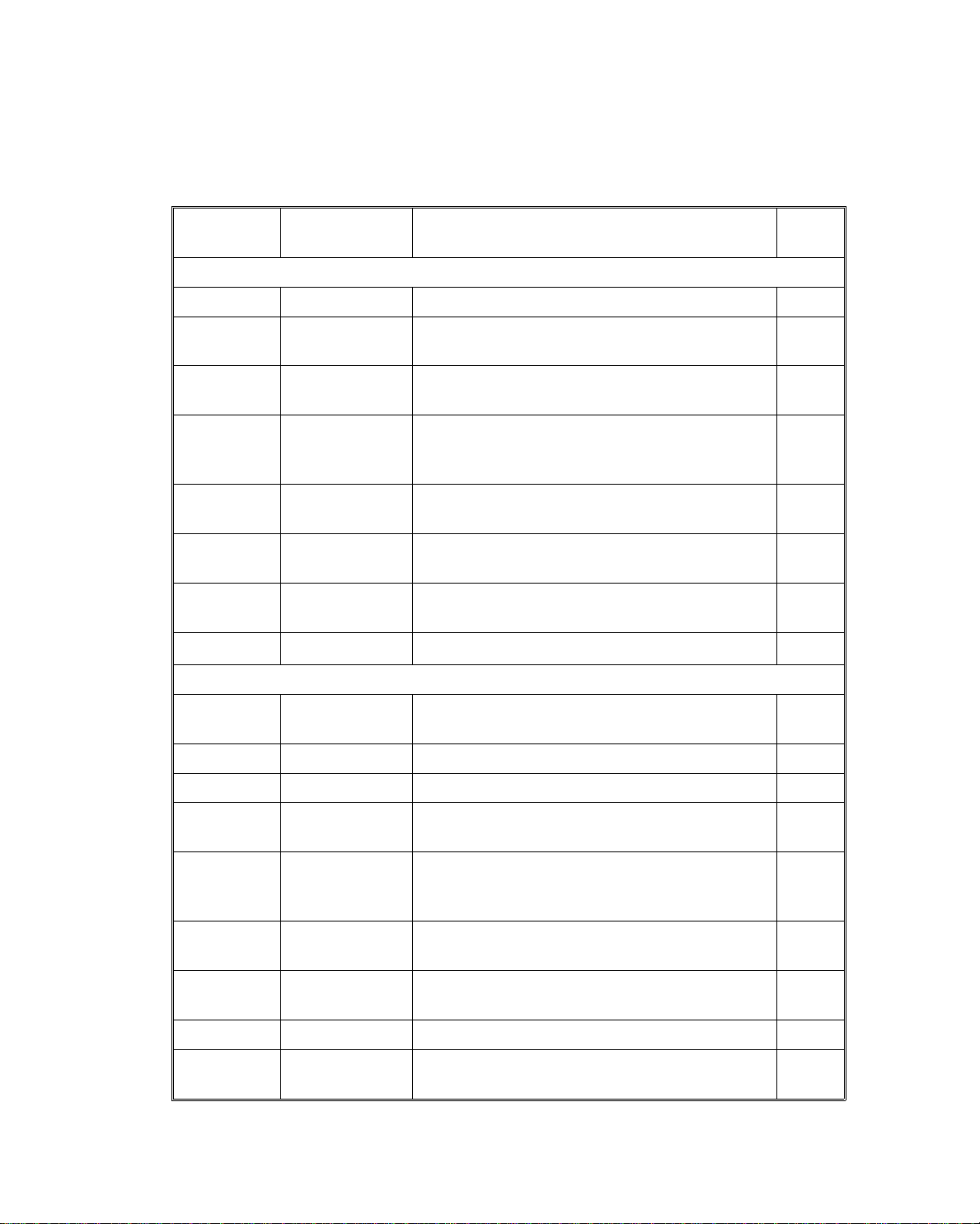

2. COMPONENT LAYOUT

5

6

2.1 MECHANICAL COMPONENT LAYOUT

10 July 1991

11

10

12

13

14

1

2

3

4

9

8

1. Proof Tray

2. Vert ical Transport Rollers

3. Upper Entrance Guide

4. Lower Entrance Guide

5. Turn Gate

6. Diagonal Transport Rollers

7. 1st Horizontal Transport Roller

8. 2nd Horizontal Transport Roller

9. Distribution Rollers

10. Bin Gates

11. Bins

12. Grip Assembly

13. Jogger Plate

14. Stapler

1-3

7

3

5

10 July 1991

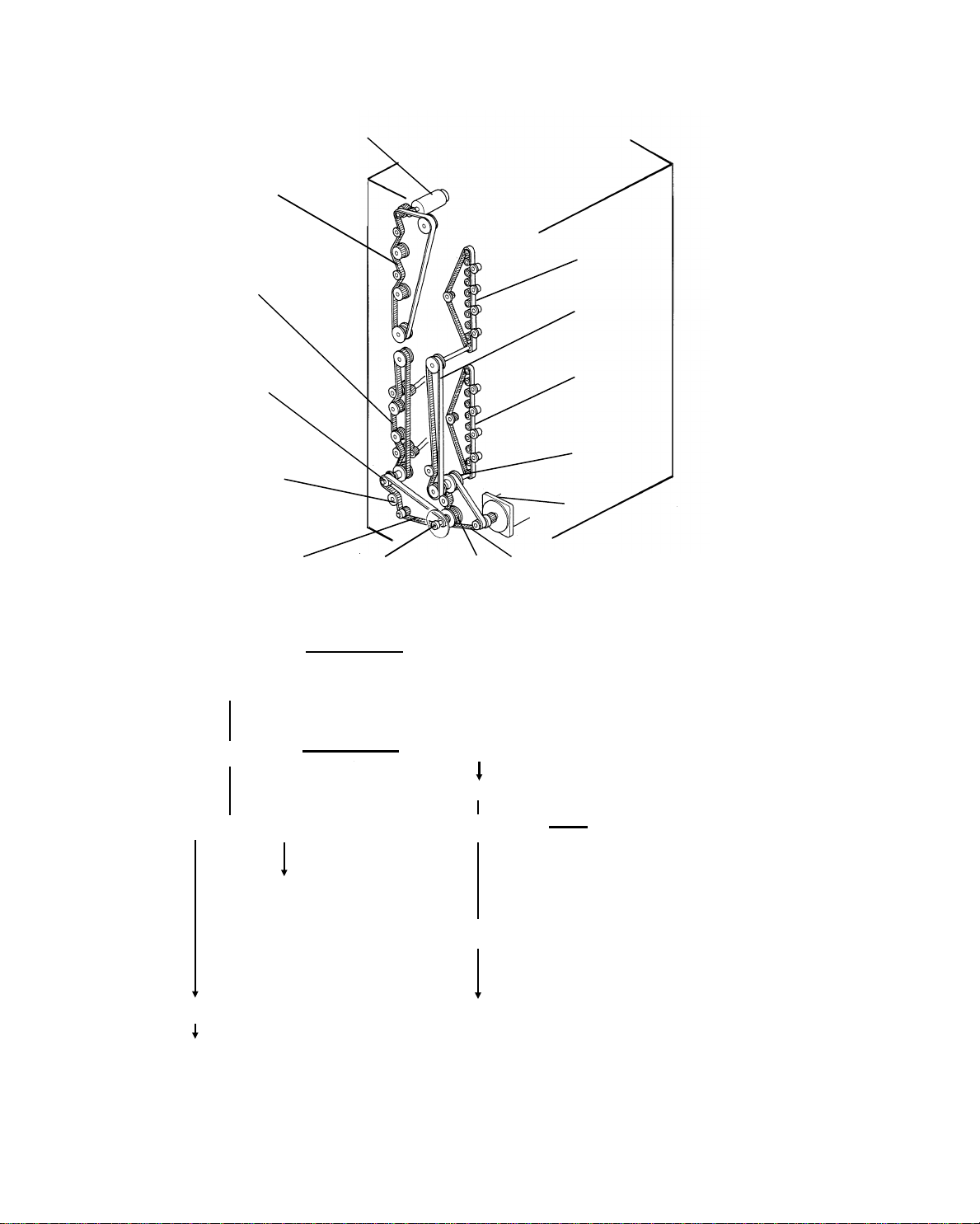

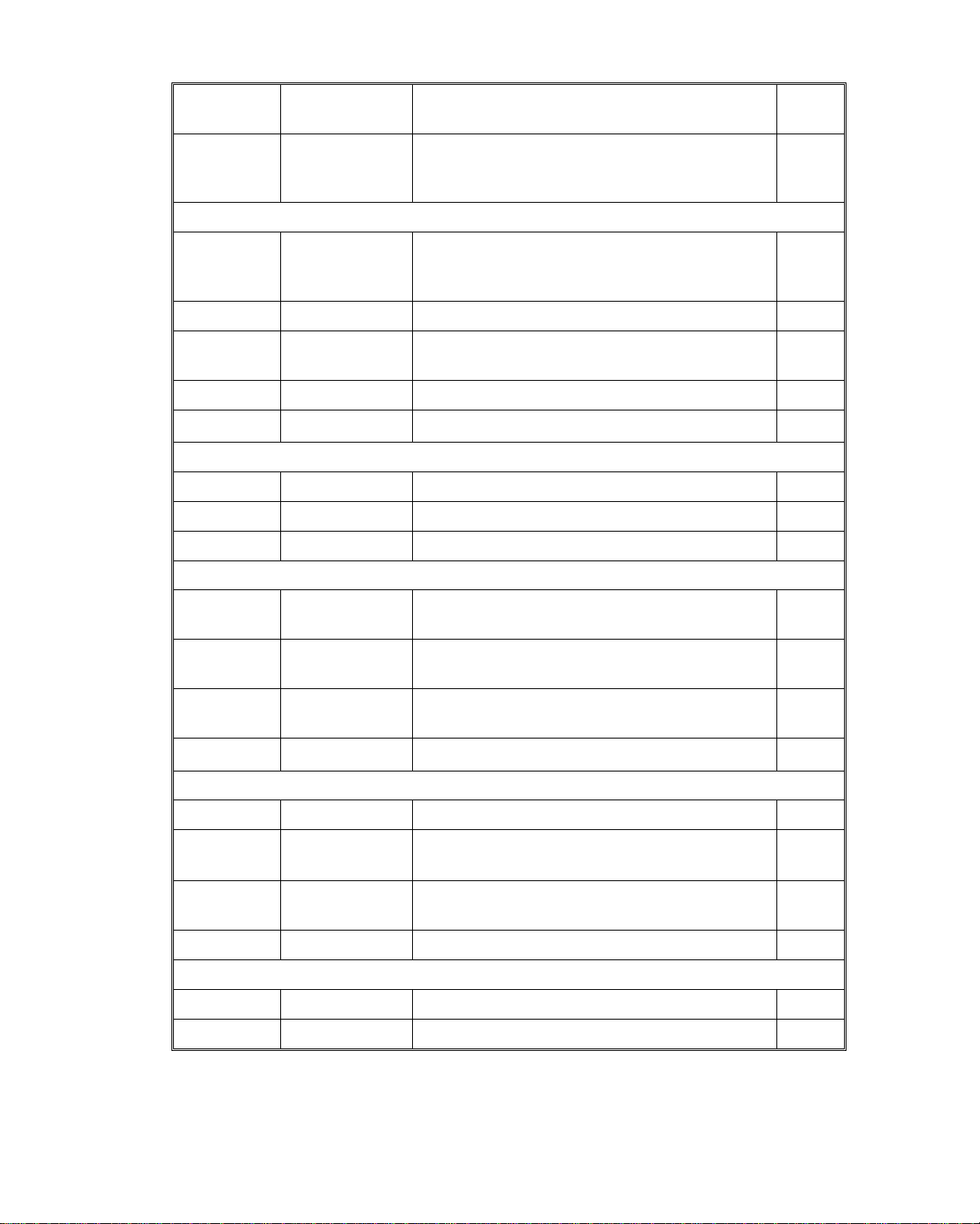

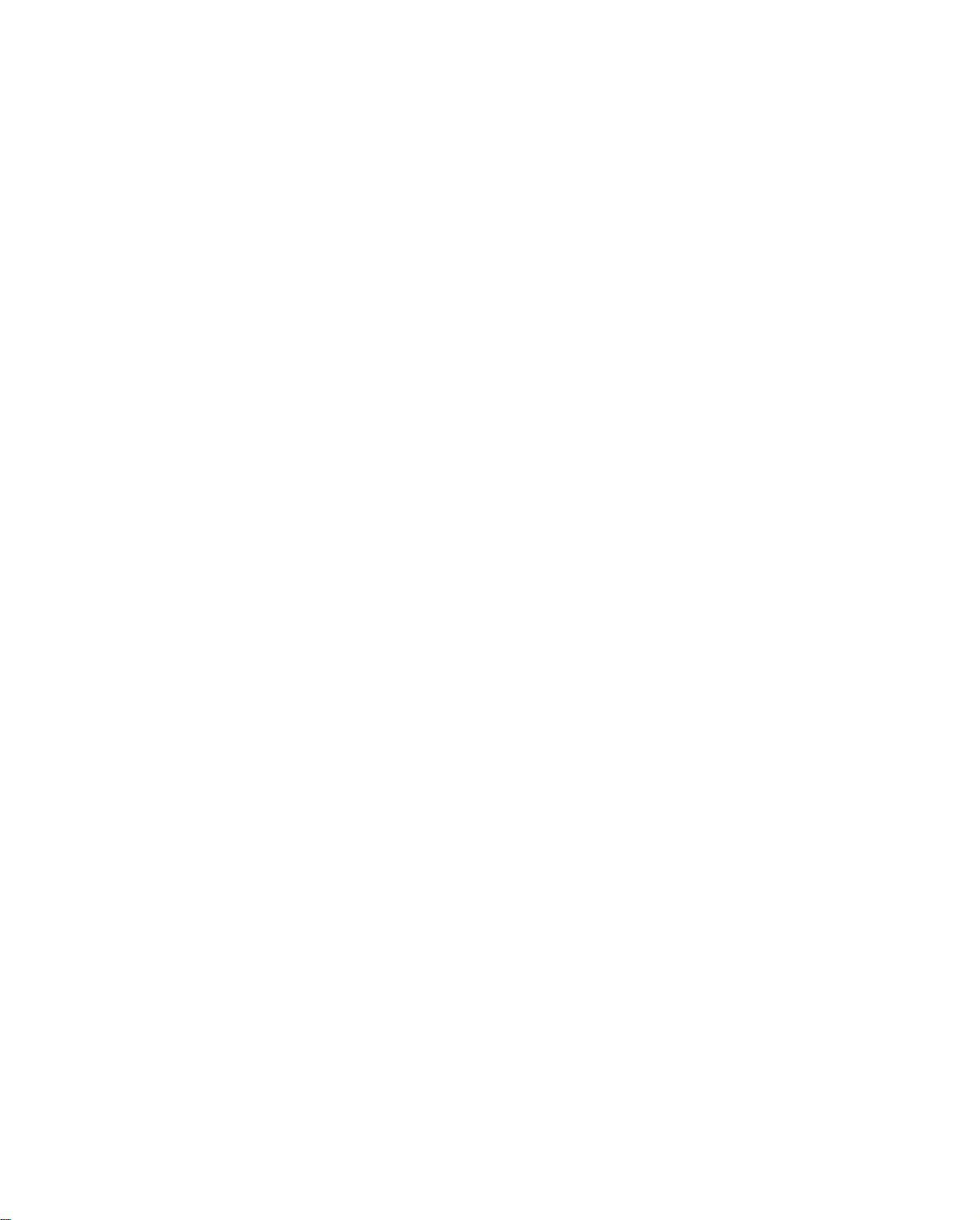

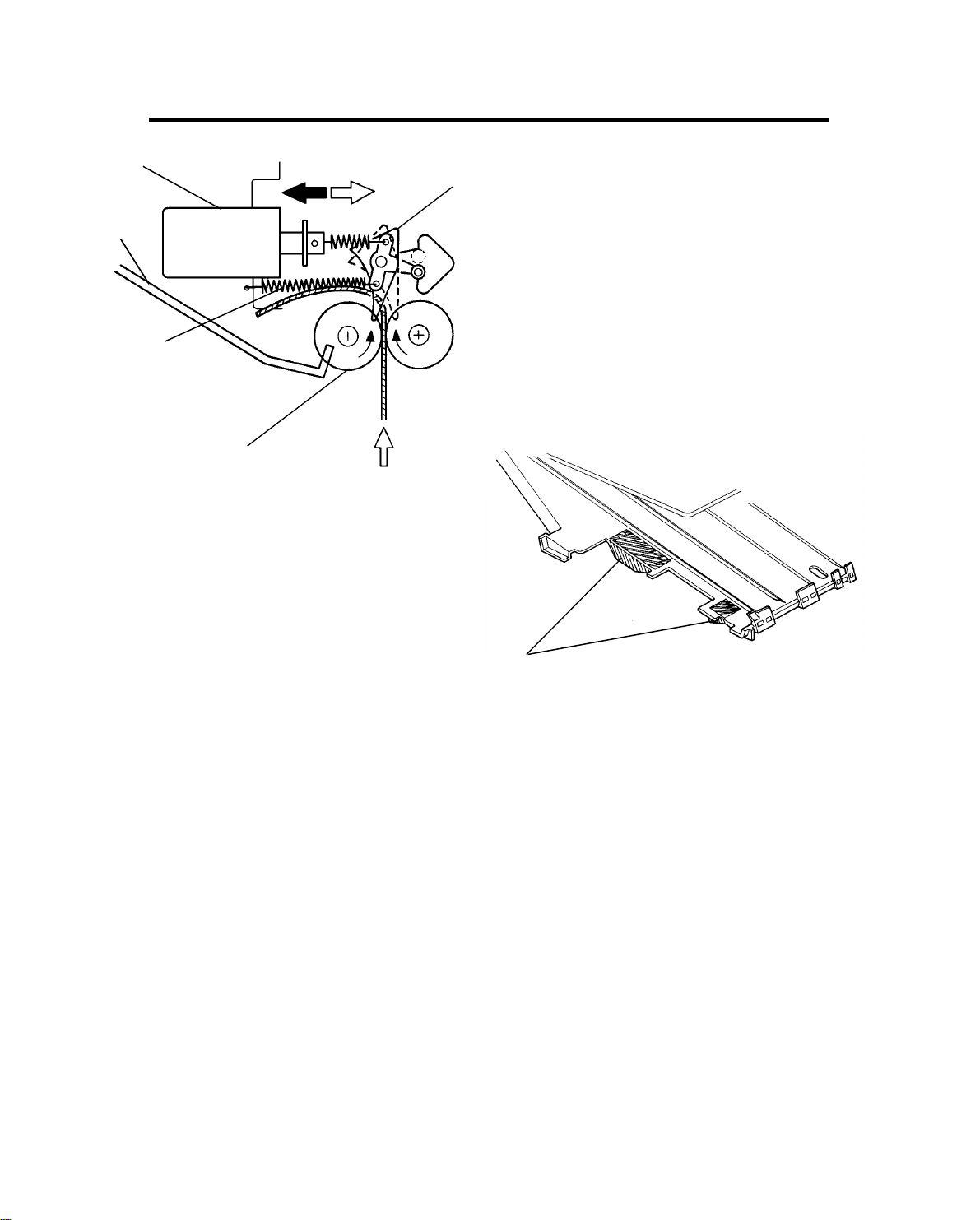

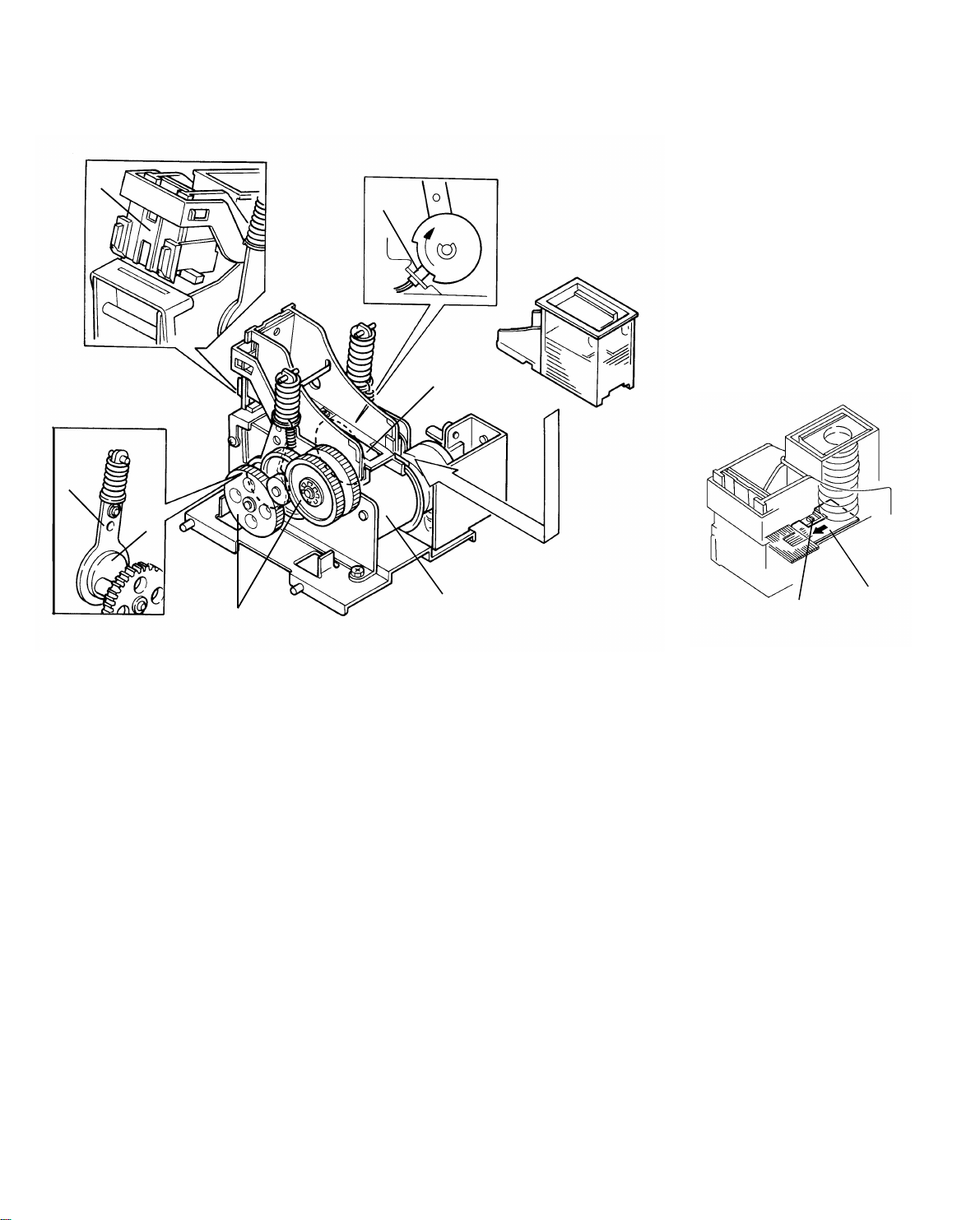

2.2 DRIVE LAYOUT

1

14

13

2

12

4

11

6

10

9

7

8

The drive train is as follows:

Proof Motor [1] Vertical Transport Rollers Drive Belt [14]

Main Motor [6]

Timing Belt [7] Timing Pulley [8]

2nd Horizontal Transport Roller [9]

Timing Pulley [5] Timing Belt [10] 1st Horizontal Transport

Roller [11]

11th∼20th Distribution

Rollers [4]

Timing Pulley [12]

Timing Belt [3] Diagonal Transport Rollers Drive Belt [13]

1st∼10th Distribution Rollers [2]

1-4

10 July 1991

2.3 ELECTRICAL COMPONENT DESCRI P TI ON

Please refer to the Electrical Comp on ent La you t on the Reverse side of the

Point to Point (Water Pro of Paper) fo r symbol an d ind ex number.

SYMBOL NAME FUNCTION

Motors

M1 Proof Drives the vertical transport rollers. 1

M2 Staple Unit Drive

M3 Stapler

M4 Grip

M5

M6 Jogger

M7 Main

Sensors

Bin Side Plate

Drive

Drives the staple unit up and down to the

appropriate bin.

Feeds the staples and drives the stapler

hammer.

Drives the grippers forward and backward into

the bin to grip the copies and bring them to the

stapling position.

Drives the bin side plate. 16

Drives the jogger plate to jog the copies against

the bin side plate.

Drives the distribution, horizontal transport, and

diagonal transport rollers.

INDEX

NO.

5

9

11

20

21

S1 Exit

S2 Staple Unit H.P. Detects if the staple unit is in the home position. 6

S3 Grip H.P. Detects if the grippers are in the home position. 10

S4

S5 Bin Transport

S6

S7

S8 Jogger H.P. Detects if the jogger plate is in the home position. 22

S9 Timing

Staple Unit

Position

Bin Side Plate

Release

Bin Side Plate

H.P.

Detects paper jams at the sorter exit (Proof

Tray).

Detects the position of the staple unit. 12

Detects paper jams between the entrance guide

and the horizontal transport rollers in the

sort/stack or staple mode.

Detects if the bin side plate is in the released

position.

Detects if the bin side plate is in the home

position.

Provides pulses to the sorter stapler main

control board.

2

15

18

19

24

1-5

10 July 1991

SYMBOL NAME FUNCTION

Detects if there is paper jams at the distribution

S10 Bin/Jam (LED)

Sensors

S11

S12 Paper Detects whether copies are under the hammer. 14

S13 Staple H.P.

S14 Staple End Detects the staple end 7

Switches

SW1 Door Safety Controls the 100 V ac line. 4

SW2 Door Safety Controls the 24 V dc line. 3

Solenoids

Bin/Jam (Photo

Tr.)

section and detects if there is paper in the bins

(light emitting element).

Detects paper jams at the distribution section

and detects if there is paper in the bins (light

receiving element)

Detects if the staple hammer is in the home

position.

INDEX

NO.

30

17

8

SOL 1 Grip

SOL 2 ∼20

SOL 21 Turn Gate

Circuit Board

PCB 1 Main Control Controls all sorter stapler functions. 26

PCB 2 Bin Solenoid

PCB 3 Bin Solenoid

Capacitor

C Main Motor Motor start capacitor. 23

Bin

Opens and closes the grippers to grip copies on

the bins.

Opens and closes the bin gate to direct the

copies into the appropriate bin.

Opens and closes the turn gate to direct the

copies into either the proof tray or the bins.

Interfaces between the bin gate solenoids (sol 2

∼ 10) and the main control board.

Interfaces between the bin gate solenoids (sol

11 ∼ 20) and the main control board.

13

28

29

27

25

1-6

3. BASIC OPERATION

[B]

3.1 NORMAL MODE AND SORT/STACK MODE

[F]

[D]

[A]

[C]

10 July 1991

[E]

Copies exiting the copier pass thro ug h the entrance guide plates [A] to the

turn gate section. The turn gate [B] will send copies eith er to the proof tray or

to the bins, depending on the mod e.

- Normal mode - (from the turn gate section to the proo f tra y)

The turn gate solenoid [C] is energized and the turn gate turns clockwise

when the start key is pressed. The proo f mot or [D] ro ta te s the vertica l

transport rollers [E] and exit roller [F]. The turn ga te direct s copie s thro ug h

the vertical transport sect ion to th e proof tray.

In this mode, if a misfeed is detected in the sorter stapler, th e pro of moto r

stops and the turn gate sole no id turns off. The main moto r starts rotating.

Copies going through the copier are sent to the 1st bin through the diagonal

transport, horizo nt al transport, and distribu tio n section.

1-7

10 July 1991

- Sort/Stack mode - (fro m t he turn gat e sect ion to th e bin s)

[H]

[G]

[B]

[F]

[A]

[D]

[C]

[E]

The turn gate solen oid [A] stays off and th e turn gate [B] also stays up when

the start key is pressed. The main motor [C] rotates the diagonal transport

rollers [D], horizontal transpo rt rolle rs [E] , and dist ribu tio n rolle rs [F].

The turn gate directs copies to the diagonal tran spo rt section. The diagonal

transport section fee ds cop ies dia go na lly. This is beca use copies are brought

to the front side in advan ce for easier jogging.

Copies are directed to the distrib ut ion section through the diagonal and

horizontal transp ort section. The appropriate bin ga te [G] opens and copies

are delivered to each bin.

The jogger plate [H] the n jog s to squ are the copies each time.

In this mode, if a misfeed is detected in the sorter stapler, the main mot or

stops. The proof motor sta rts rot at ing and the turn gate solenoid energizes.

Copies going throu gh the copier are directed to the proo f tray.

1-8

3.2 STAPLE MODE

10 July 1991

[A]

1

2

3

4

When the final set of copies is jog ged in the sort mode (figure 1), the stap le

unit staples the stacked copies as follows:

The grippers (A) move forward, and grip the copies (f igu re 2). The grip pers

bring the copies up underneath the stapler (f igu re 3). The stapler staples the

copies (figure 4). The copies are pushed back into th e bin . The grippers open

and return to the home posit ion. The staple unit moves to th e next bin (figure

5).

When the final set of copies is sta ple d, the stap le unit is ra ised to th e home

position.

5

There are two staple modes.

1) Automatic stapling:

In ADF mode, when the staple mode is select ed before pressin g the start

key, copies will be delivered to each bin and sta ple d auto mat ically.

2) Manual stapling:

In sort mode, after copies are sort ed in bins, the copies will be stapled

when the staple key is pressed. In sta ck mode, manual stapling is

impossible.

1-9

SECTION 2

SECTIONAL DESCRIPTION

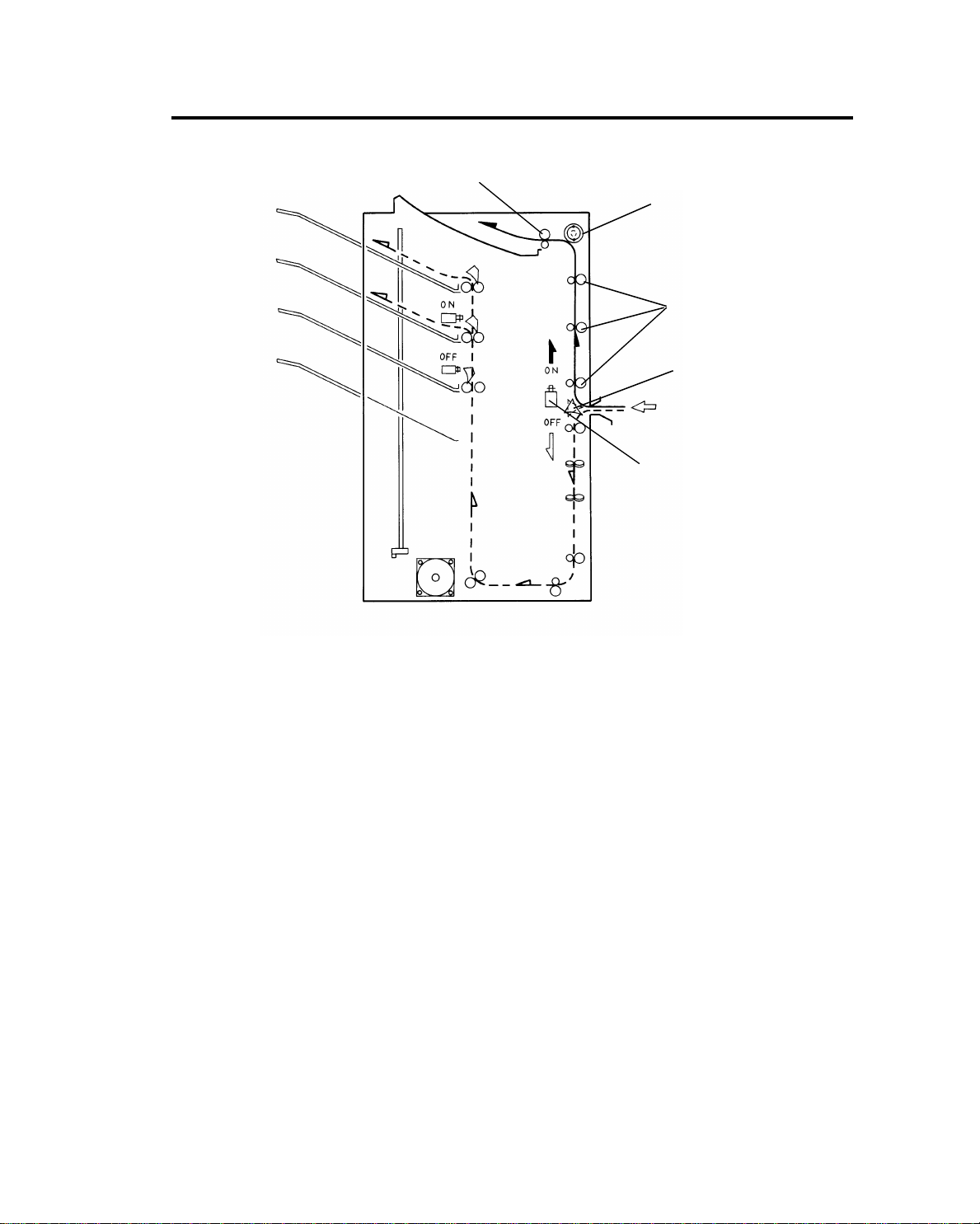

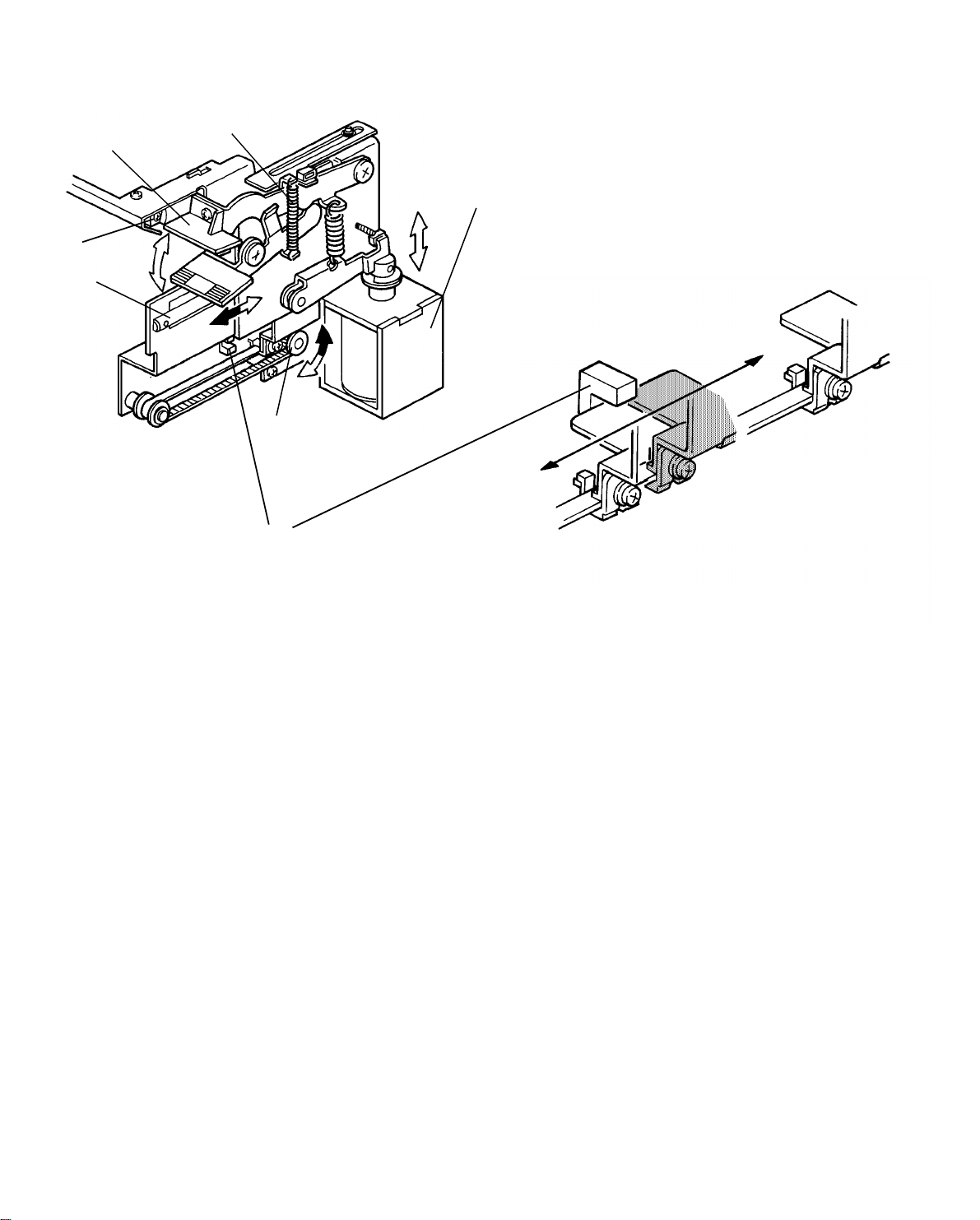

1. TURN GATE SECTION

[C]

[B]

10 July 1991

OFF

ON

[A]

[D]

The turn gate send s copies to the proof tray or th e bins depending on the

mode. In the normal mode , th e turn gate solenoid [A] turns on. The turn gate

[B], directs copies upward [C] th rough the vertical transport sect ion to the

proof tray.

In the sort, stack, or staple mode, the turn gate solenoid stays off. The tu rn

gate directs copies downward [D] to th e dia go nal t ran spo rt section.

2-1

10 July 1991

2. DIAGONAL TRANSPORT SECTION

[B]

[A]

In the sort, stack, or staple mode , th e dia gona l tran sport rollers [A] bring the

copies to the front side du ring transportation. Copies go to the horizont al

transport section alon g the diagonal transpo rt sto pp er [B].

2-2

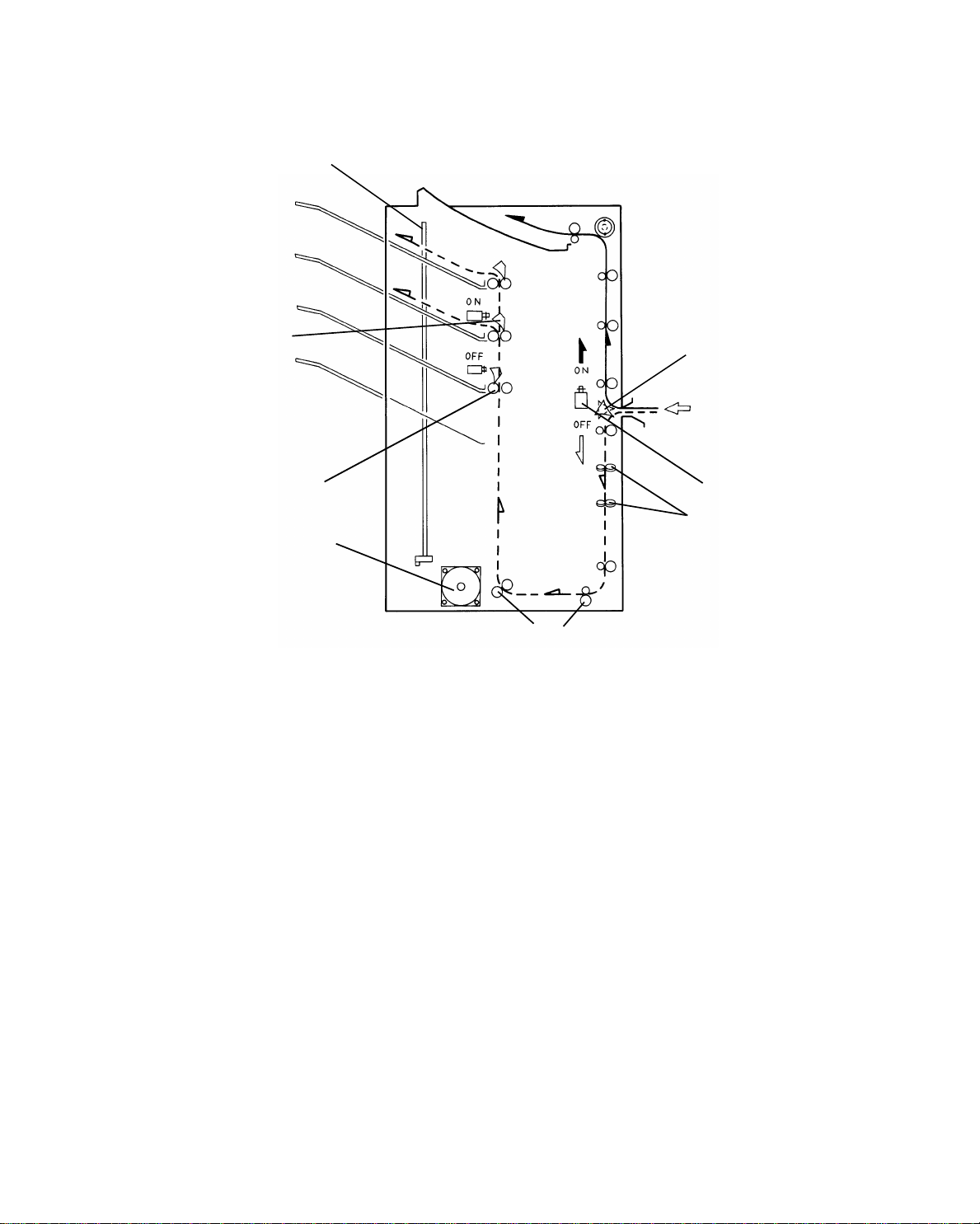

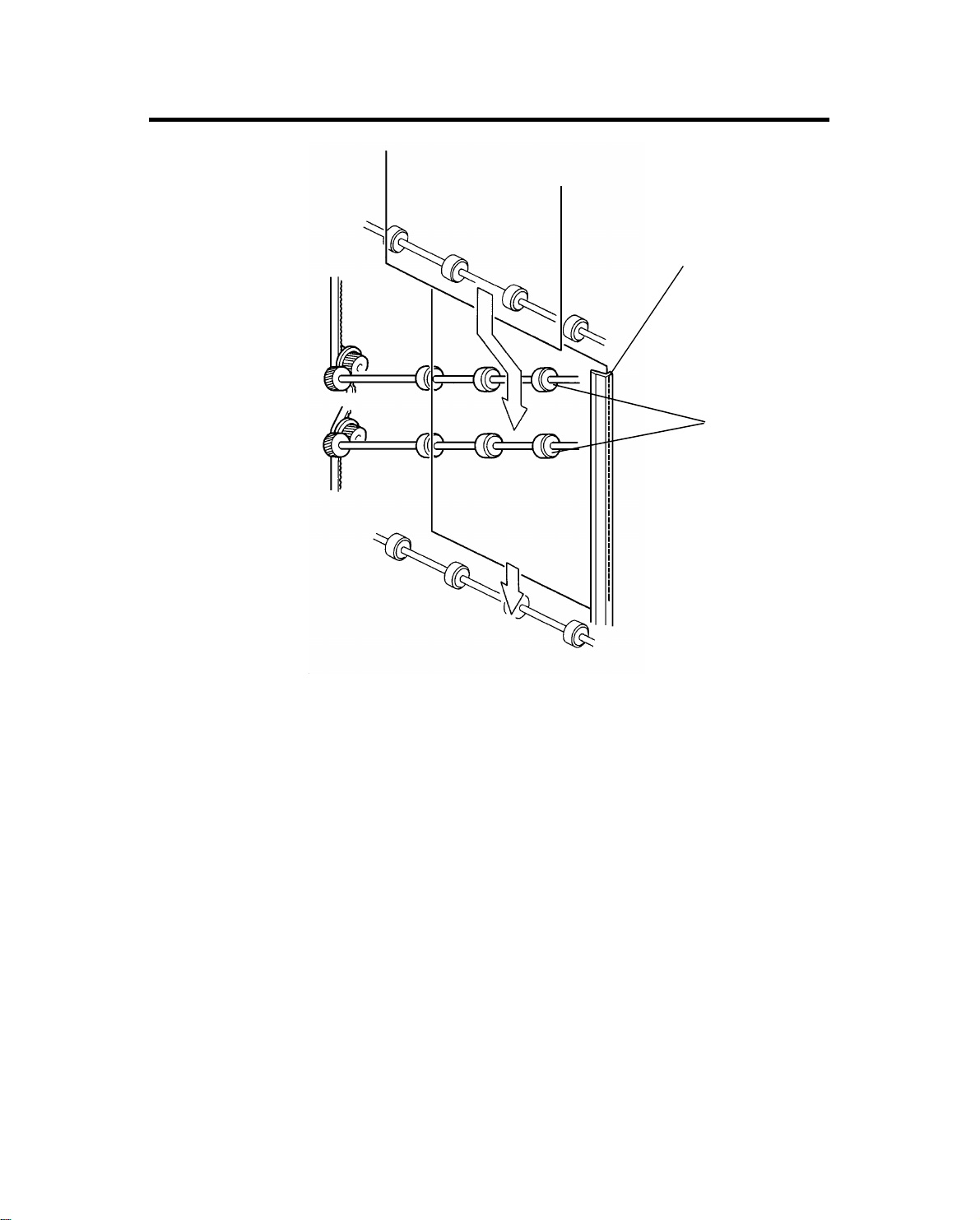

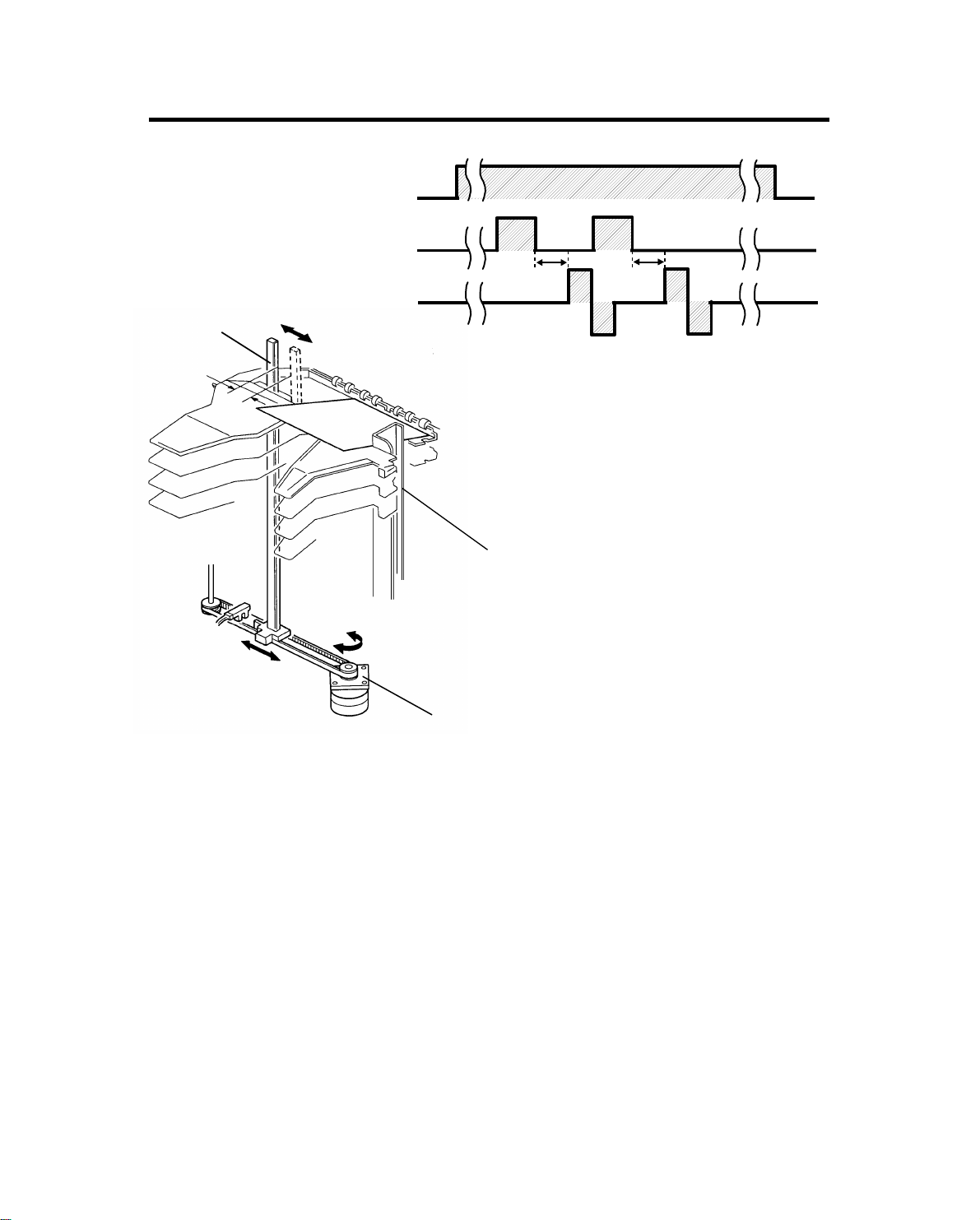

3. DISTRIBUTION SECTION

[B]

[E]

[C]

[A]

OFFON

10 July 1991

[D]

[F]

The distribution sect ion has the distribution rolle rs [ A] , 20 bin gates, and 19

bin gate solenoids (the 1st bin gate is always open).

When a bin gate solenoid [B] is of f, the return spring [C] holds the bin gate [D]

out of the paper path, allowin g the copies to pass to the upper bin.

The appropriate bin ga te solenoid turns on and open s the bin ga te . The other

solenoids are of f. Th e cop ies go to the bin [E] throug h th e ga te.

To prevent copies from curling an d so cau sing misstapling or wrong staple

positioning, th e bin has pa pe r flat teners [F] on the front side of th e bin .

2-3

C

10 July 1991

4. JOGGER SECTION

Copier

Main Motor

Jam Sensor

Jogger Motor

[B]

C

C: Depening on selected paper size.

[D]

[A]

When the start key is pressed in the sort, stack, or staple mode, the copier

sends the paper size informatio n to the sorte r stap ler un it. In acco rda nce with

this data, the jogger motor [A] drives th e jog ger plate [B] from the jogger

home position to where the width is 10 mm wider than the selected paper.

After the trailing edge of a copy passes th e jam sen sor (th e bin /ja m sensor),

and after the appropriate timing [C] for the select ed paper, the jogg er mot or

rotates and reverses. This makes the jogger plate push all the copies against

the bin side plate [D] to square the stack. Also, this makes the jogger plate

return to where the width is 10 mm wider than the selected pa pe r for the next

copy.

When the bin sensor in the bin/ja m sensor detects that all copies are

removed from the bins afte r jogg ing is fin ishe d, the jogg er pla te re tu rns to it s

home position.

2-4

10 July 1991

- Jogger off conditions -

1. Under the following conditions, the jogger plate does not jog after copies

are delivered to the bins.

• If paper is loaded in a bin by hand while the sort/sta ck, or

staple mode is selected.

• If the selected pape r size doe s not ma tch stap ling

specifications.

• If copies of different width are delivere d to the bins.

2. If paper is in a bin before the main switch is turned on, the sort /st ack

mode is disabled when th e sort er key is p resse d.

2-5

10 July 1991

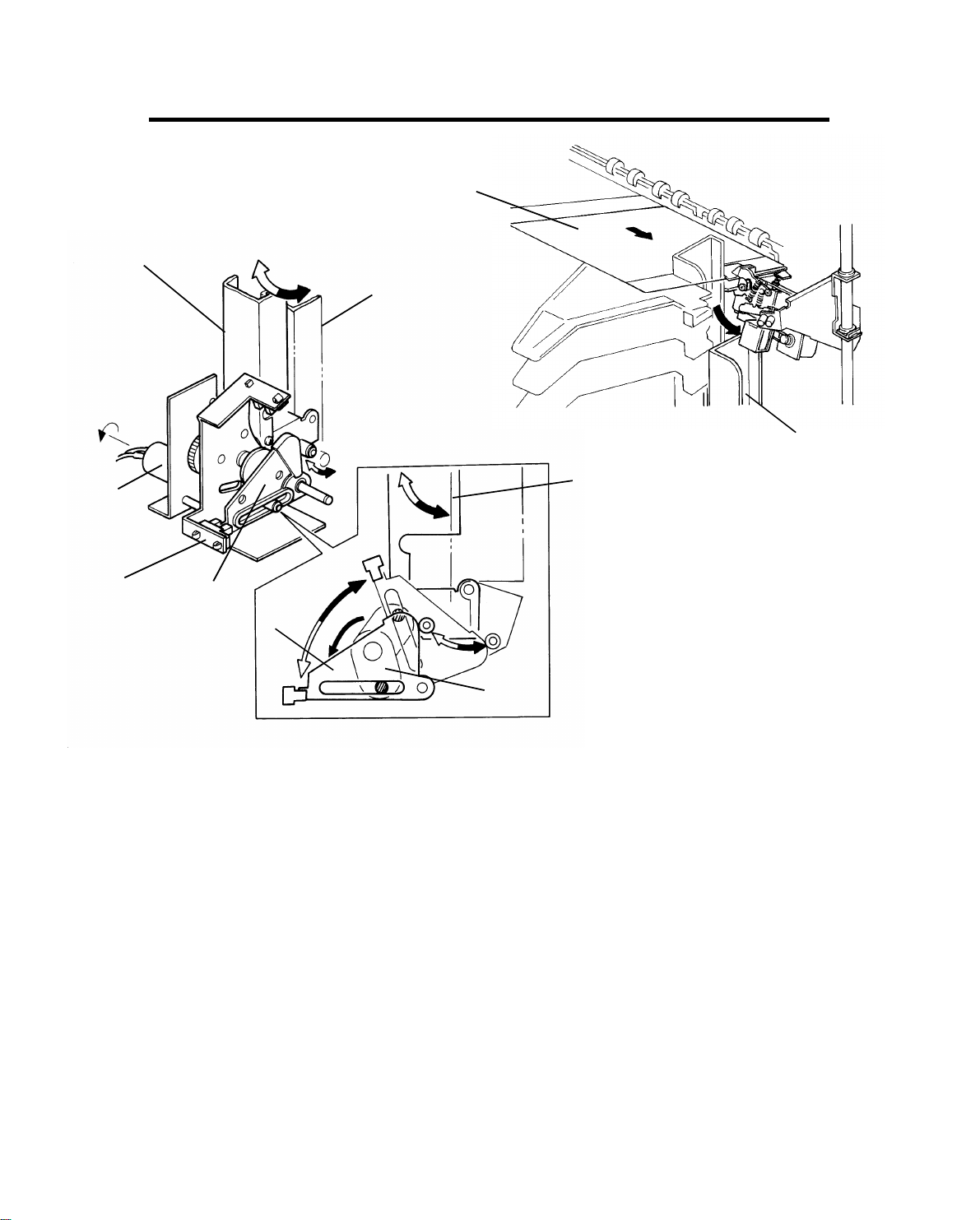

5. BIN SIDE PLATE DRIVE SECTION

[F]

[A]

[E]

[E]

[B]

[G]

[E]

[D]

[D]

[C]

The bin side plate [A] is alwa ys in the home posit ion except during the staple

operation. The bin side plate takes part in the jogger f un ctio n (see jogger

section).

In the staple mode when all the copies have been jogged by the jogger plate,

the bin side plate drive motor [B] rotates the cam drive plate [C]. The pin on

the cam drive plate raises and lowers the actu at or cam [D], and the actuator

cam makes the bin side plate [E] move to the front side . Thus, the bin side

plate does not interf ere wit h th e copies [F] being brought to th e sta ple

position by the grip assembly.

When the staple operation for the final set of co pie s is completed, the bin

side plate drive motor rotates th e cam drive plat e until th e bin side pla te

home position sensor [ G] is act ua te d. This makes the bin side plate re tu rn to

the home position.

2-6

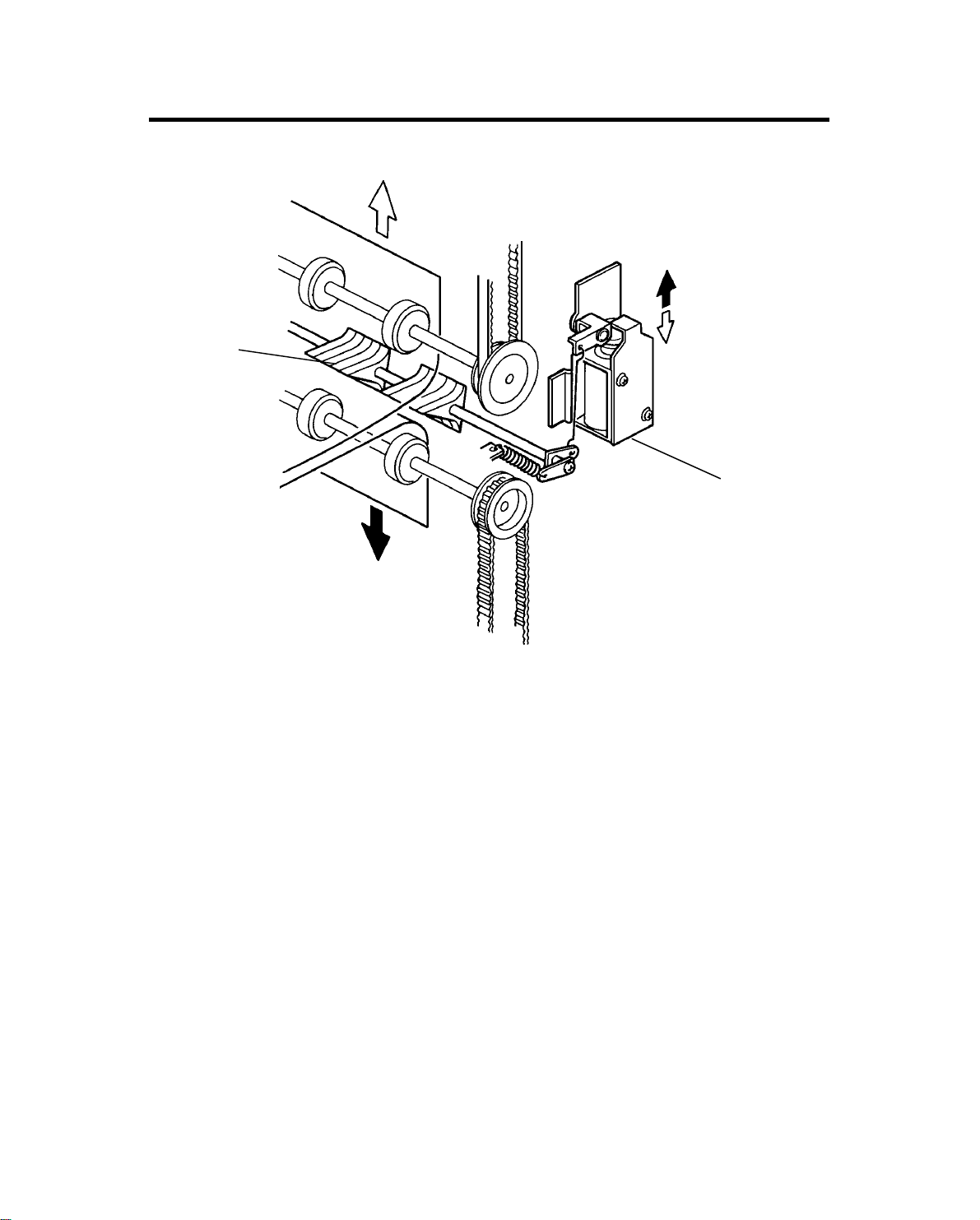

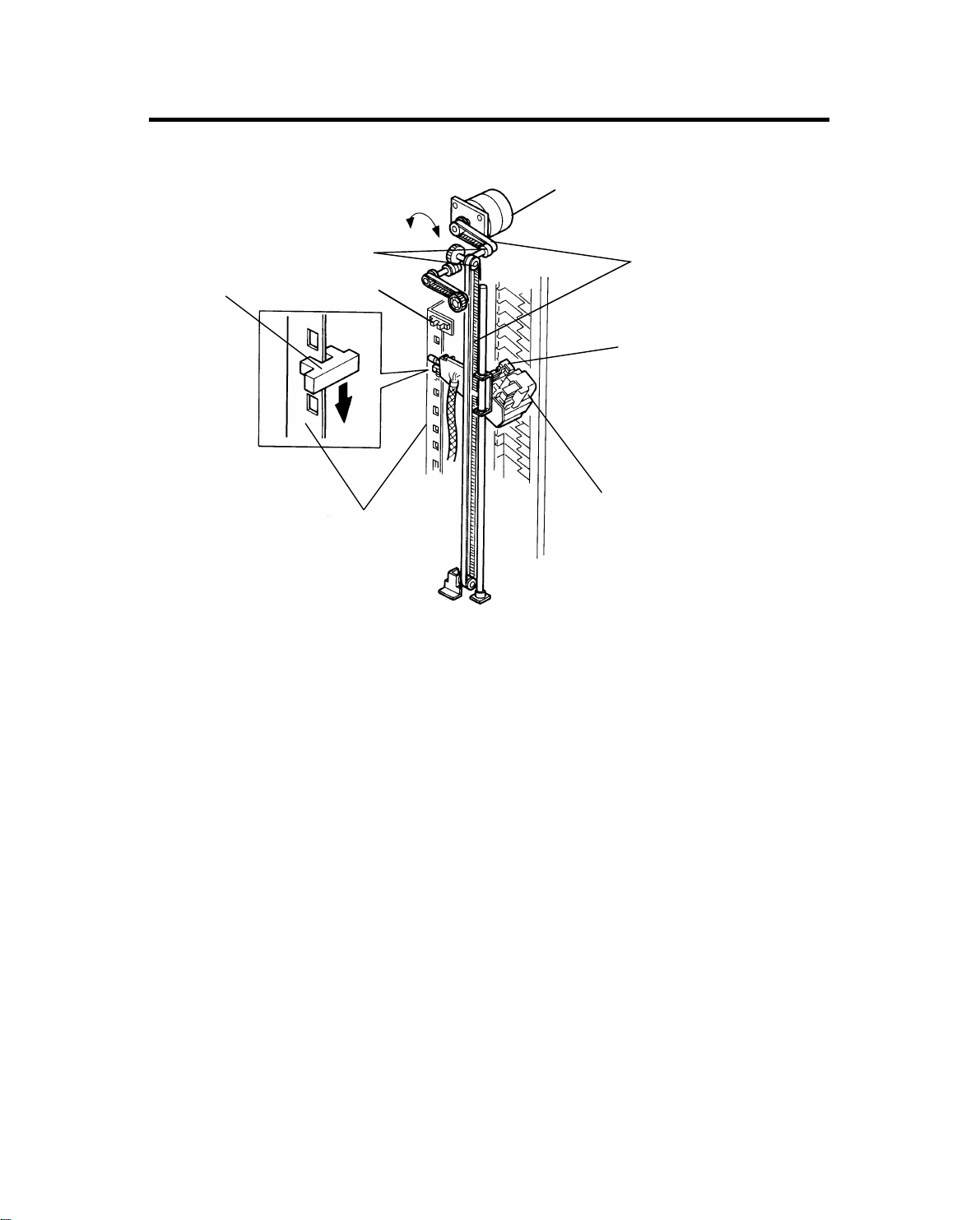

6. STAPLE UNIT

6.1 STAPLE UNIT DRIVE MECHANISM

10 July 1991

[C]

[D]

[F]

The staple unit consists of the grip assemb ly [A] and the stap ler [B ]. The

staple unit is lowered from the home position (the first bin ) to the 20th bin in

order to staple the copies in each bin. The grip assemb ly grips th e cop ies

stacked in the bin and positions them underneath the stapler. The stapler

staples the copies.

[H]

[G]

[E]

[A]

[B]

When the first set of copies is stapled, the staple unit drive mot or [C] drives

the staple unit downward via timing pulleys [D], and timin g belts[ E] . While the

staple unit is being lowered , th e sta ple unit posit ion sensor [F] tracks the

position actuator plate [G], generating an on/off signal that is sent to the

sorter stapler main control board. This way, the posit ion of the staple unit is

detected and the staple unit drive moto r st ops t he stap le un it whe n it rea ches

the next bin. When the la st set of cop ies in the bin is stapled, the stap le un it

drive motor reverses until the sta ple unit home posit ion sensor [H] is

actuated. At this time, th e sta ple unit is in the home po sitio n.

Because lifting the unit req uire s mo re torque than lowering it, the lifting spe ed

is about one third of the lowering speed.

2-7

[J]

[H]

10 July 1991

6.2 GRIP ASSEMBLY

[E]

[C]

[B]

[F]

[D]

[A]

[I]

[G]

When the bin side plate sta rts movin g to the front side, the grip mo to r [ A]

drives the grippers [B] into the bin. The grippers track the grip per guide [C].

The grip motor stops the grippers at the grip position. The grip solen oid [D] is

energized and it closes the grippers to grip cop ies in th e bin . Whe n th e bin

side plate reaches th e front side, the grip motor reve rses an d brings the

grippers with the copies to the staple position. The paper sensor [E ] checks if

copies are brought to the staple position correctly. Then, the copie s are

stapled, and the grip motor drives the grippers with the sta ple d copies ba ck

into the bin .

When the grip solenoid turns off, the return spring [F] opens the grippers. The

copies remain in the bin. Then , th e grippers return to the home posit ion for

the next cycle.

The grip home position senso r [G] is actuated while the grippers move from

the home position [H] to the grip position [I]. This sensor is deactuate d while

the grippers move from the home position to the staple position [J]. The

sorter stapler main control board sends the approp riat e pulses to the grip

motor (stepper motor) to determine the grip position and sta ple posit ion .

When the main switch is turned on, the grip motor turns forwa rd an d

backward to check wheth er th e grippers are in the home positio n. If no t, the

grip motor returns the grippers to their home posit ion .

2-8

[H]

[F]

10 July 1991

6.3 STAPLER

[C]

[G]

[B]

[E]

[A]

[D]

The stapler motor [A] drives the sta ple sheet drive belt [B].

The staple sheets are fed under th e hammer [C] .

The stapler motor drives th e sta ple hammer via gears [D], two eccentric ca ms

[E], and two links [F].

When the aligned copies are brought to the staple position by the grippers,

the stapler motor starts rot ating. When the cams complete one rotation, th e

staple home position sensor [G] is d eactuated. The stapler motor then stops.

When the paper sensor in the grip assembly does not detect that the copies

are under the hammer, th e sta pler motor does not rotate.

A paper sheet [H] with a notch cut-in is positioned at the bottom of the staple

cartridge. This paper sheet is fed out aft er th e last stap le she et . Whe n th e

leading edge of the not ch in the sheet is detecte d by the staple end senso r

[I], the sorter sta ple r unit recognizes the staple ne ar en d con dition. After the

job is completed, the Add Sta ple indicator lights on the cop ier operation panel

and the Start key turns to re d whe ne ver the staple mode is selected.

[I]

2-9

10 July 1991

- Staple prohibit conditions -

1. Under the following conditions, the staple mode is prohibited when the

staple key on the operation panel is pressed.

• If paper is in a bin before the main switch is turned on.

• If the selected pape r size doe s not ma tch stap ling

specifications.

2. Under the following conditions, the staple mode is canceled.

• If paper is loaded in a bin by hand while the staple mode is

selected.

• If only one sheet is delivered to th e bin.

• If the number of sheets stapled excee ds the staple capacity.

3. Under the following conditions, the manu al sta plin g mode in sort mode is

prohibited.

• If paper is loaded in a bin by hand while the sort mode is

selected.

• If the paper size in the bin does not match sta plin g

specifications.

• If only one sheet is delivered to th e bin.

• If copies of different width are de livere d to the bin.

• If copies already stapled are left in the bin.

2-10

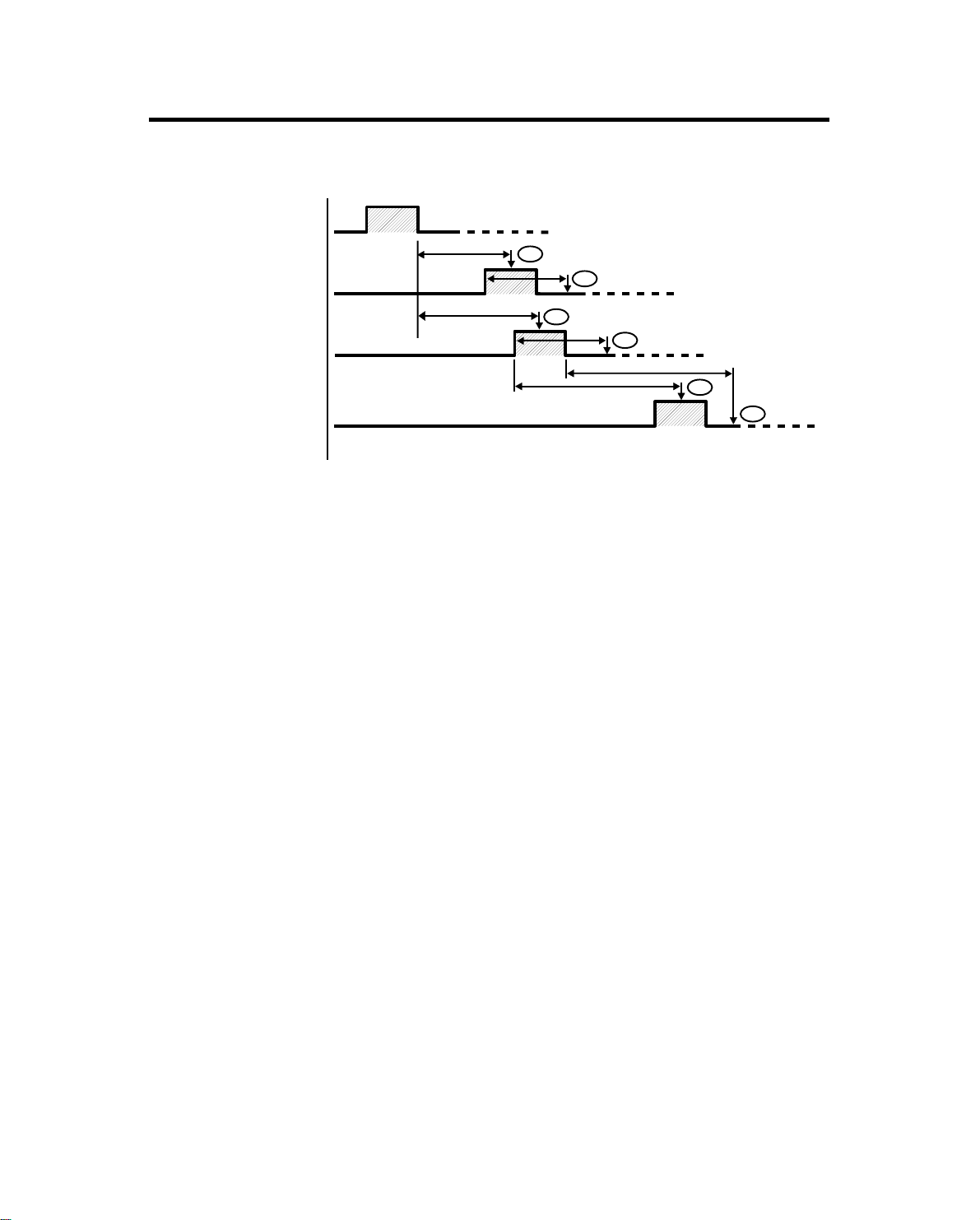

7. JAM DETECTION AND STAPLE ERROR

Copier Exit Sensor

J1

(1,300m sec)

J2

Sorter Exit Sensor

Bin transport

Sensor

Jam Sensor

360pls

J3

*This is jam checking timing for the 1st bin. Timing

depends on the bins.

(1,900m sec)

ON Check

220pls

J4

436pls*

436pls*

1 pulse ≈ 5.13 ms

J5

10 July 1991

J6

7.1 SORTER JAMS

The sorter stapler main control board detects jams when the following

conditions are detect ed . In these cases, a jam signal is sent to th e copier, the

copier stops the paper feed and indicates a sorter misfeed.

- Normal mode -

J1: The sorter exit sensor ha s not turned on for 1,300 ms after t he copie r exit

sensor turns off (paper check).

J2: The sorter exit sensor sta ys on fo r 1,9 00 ms or more (no pape r check).

- In sort/stack or staple mode -

J3: The bin transport senso r h as no t tu rned on for 360 pulses after the copier

exit sensor turns on (paper check).

J4: The bin transport senso r st ays on for 22 0 pu lses (no pap er check).

J5: The jam sensor has not tu rned on for the appropria te numb er of pulses

after the bin transport sen sor tu rns on (pap er che ck). This nu mbe r

depends on the bin. (See the diagram in the next page.)

J6: The jam sensor has not turne d of f afte r t he app rop riat e number of pulses

after the bin transport sen sor tu rns of f (no pap er che ck). This nu mbe r

depends on the bin. (See the diagram in the next page.)

2-11

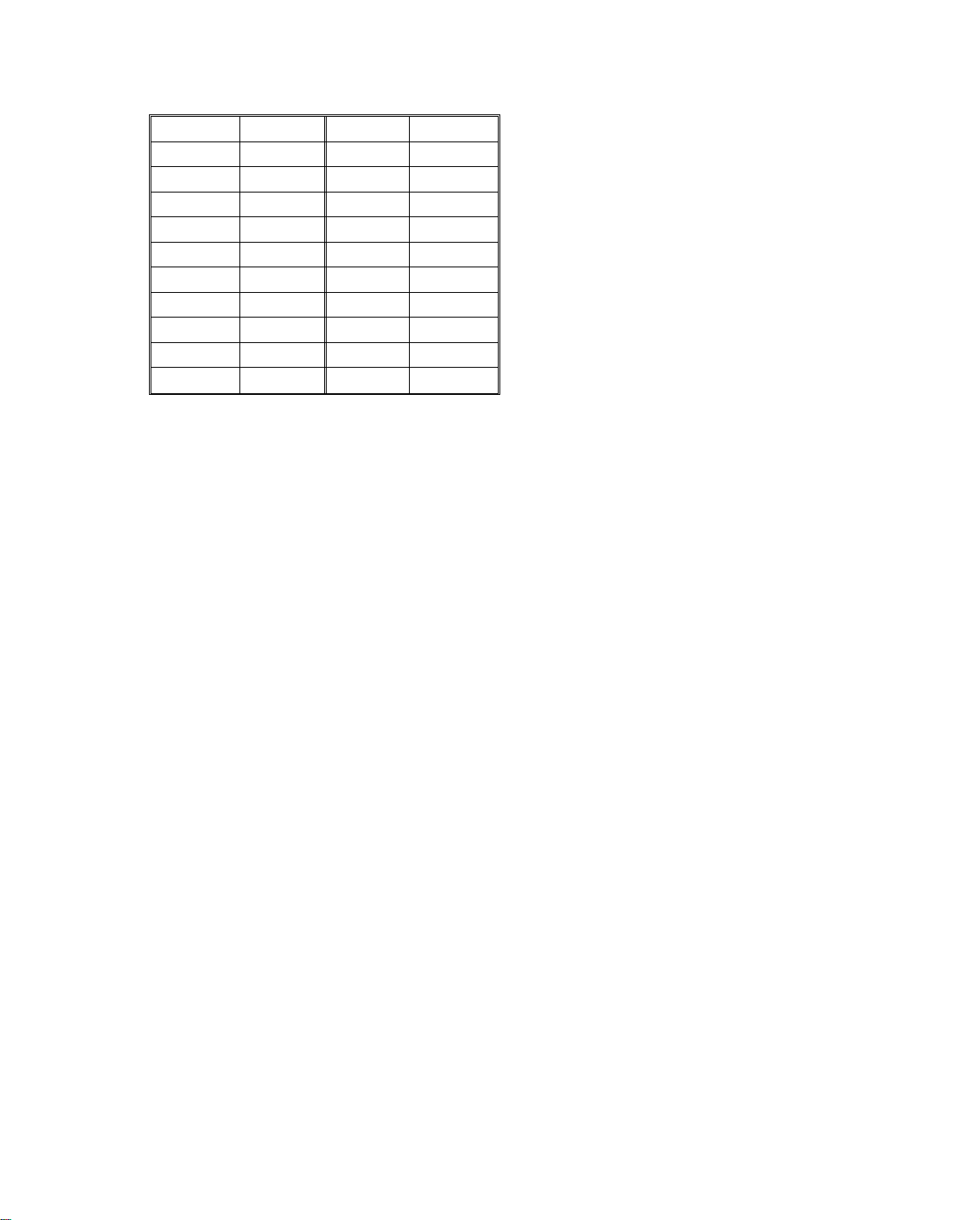

10 July 1991

- Jam checking timing diagram -

Bin no. Pulses Bin no. Pulses

1 436 11 294

2 422 12 280

3 408 13 266

4 394 14 252

5 382 15 240

6 368 16 226

7 354 17 214

8 342 18 200

9 328 19 186

10 314 20 174

7.2 STAPLE ERROR

The sorter stapler main control board detects a staple error when the

following conditions are detected.

Error 1 The paper sensor in the grip assembly turns on (paper is still in

the grip assembly) while the staple unit is being lowere d.

In this case, a staple error sign al is sent to the copier. The copier

cancels the staple mode and indicates a staple error.

After paper left in th e grip pe rs is remo ved , the staple unit returns

to the home position. Whe n the staple key is pressed, th e stapler

begins to staple the rest of the copie s st art ing from th e bin

following the bin where the jam happened.

Error 2 The paper sensor in the grip assembly does not turn on (paper is

not in the grip assembly) when the grippers are in the staple

position.

In this case, the staple unit skip s stap ling this bin and moves to

the next bin for staplin g.

2-12

Home

c

ON

10 July 199

1

8. TIMING CHART

0145678910111213141516172627

Timing Chart 1 (Normal mode: B5 sideways 5 copies)

Copier main

I/F Receive from copier

I/F Send to copier

Proof Motor

Turn Gate Solenoid

Exit Sensor

motor on signal

OFF

OFF

ON

ON

500msec

Timing Chart 2 (Sort & Staple mode: B5 si deway s 2 originals x 5 copies)

Copier mainl

I/F Receive from copier

I/F Send to copier

Main Motor

Bin Transport Sensor

2nd Bin Solenoid

3rd Bin Solenoid

4th Bin Solenoid

5th Bin Solenoid

Jam Sensor

Jogger Motor

Staple Unit Operation

Forward

Reverse

*A (Staple Unit Operation)

Bin Side Plate Drive Moto r

Bin Side Plate H.P. Sensor

Bin Side Plate Release Sens o r

Grip Motor

Grip Solenoid

Stapler Motor

Staple H.P. Sensor

Staple Unit Drive Motor

Staple Unit H.P. Sensor

Staple Unit Position Sensor

Forward

Reverse

Home

Down

Up

motor on signal

ON

OFF

OFF

16 17 18 19 20 21 22 23 24 25 26

ON

Released

OFF

ON

OFF

OFF

ON

150msec

250msec

262pls

250msec

OFF

Home

(OFF)

(ON)

1 staple cycle

Sorter exit signal

ON

248pls

OFF

OFF

300msec

Sorter exit signal

ON

234pls

ON

OFF

222pls

OFF

Copier main

motor off signal

ON

Solenoid on timing

Bin No.12345678910

Pulses — 262 248 234 222 208 194 182 168 154

Bin No. 11 12 13 14 15 16 17 18 19 20

Pulses 134 120 106 92 80 66 54 40 26 14

Jogger start timing

Paper Size A3 B4 A 4S A4L B5S B5L DLT LG LTS LTL

Timing [msec] 640 530 300 395 300 315 665 510 300 360

S: Sideways L: Lengthways

Copier main motor off signal

Stapling on signal

*A

[sec]

[se

2-13

SECTION 3

INSTALLATION

10 July 1991

1. ACCESSORY CHECK

Check the quantity and cond itio n of the accessories in the box according to

the following list:

1. Front Connecting Bracket ......................................................1

2. Rear Connecting Bracket ......... ............ .. ............ ............ .. .....1

3. Locking Bracket .....................................................................2

4. Fixing Bracket ........................................................................1

5. Upper Entrance Guide Mylar .................................................1

6. Lower Entrance Guide Mylar .................................................2

7. Sorter Stapler Key She et .............. .......... .......... .. .......... .........1

8. Staple Position Decal ...........................................................1

9. Staple Cartridge .....................................................................1

10. Stepped Screw ......................................................................2

11. Grounding Screw with Toot he d Wash er.... .............................1

12. Philips Pan Head Screw-M4 x 8 ............................................6

13. Caster Stopper .......................... ............................................ 2

14. Operating Instructions

Number of Languages: (-15, -17 machines).. .. ...................1

(-16 machine)...............................2

(-25, -26 machines)......................5

15. New Equipment Condition Report

(-17, -27 machines only).........................................................1

16. Envelope for N.E.C.R.

(-17 machine only) .................................................................1

17. Installation Procedure ...........................................................1

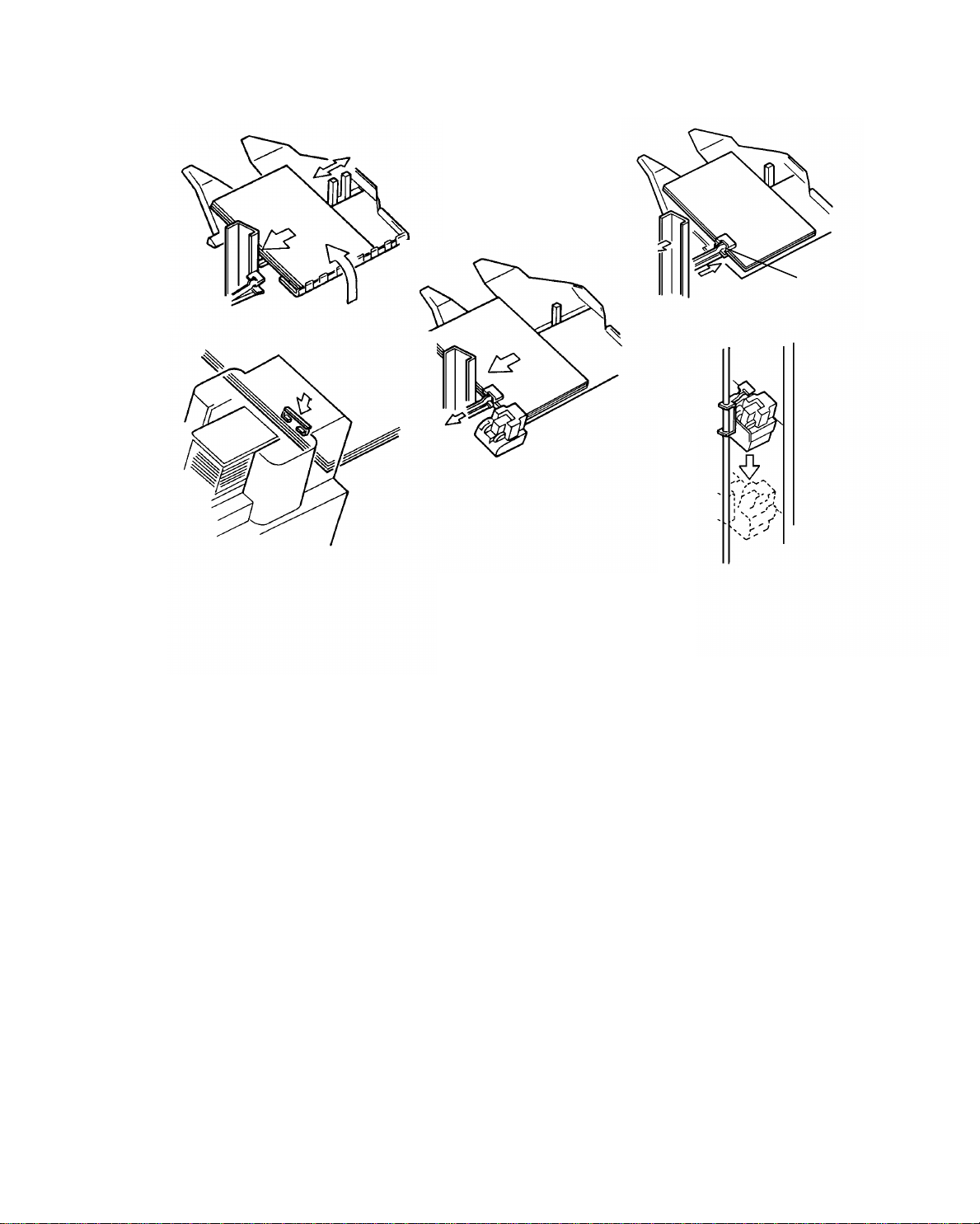

[F]

10 July 1991

2. INSTALLATION PROCEDURE

[D]

[B]

[A]

[C]

[E]

[B]

CAUTION: Unplug the copier power cord before star ting the foll owi ng

procedure.

1. Remove the strip of tape [A] on the front door.

2. Open the front door, th en remove 5 strips of tape [B] and a styrofo am

block [C]. Raise the staple unit by rotating the staple unit positionin g kno b

[D] counterclockwise, the n remo ve th e sponge cushion [E] underneath.

3. Remove the copier upper rear cover (2 screws) and the sorter stapler

rear cover (remove 3 screws, loosen 1 screw).

4. Remove 3 plastic caps [F] from the copier up per le ft cover.

[A]

10 July 1991

[C]

[D]

[B]

[C]

[E]

5. Install the front and re ar con ne cting brackets [A], [B] on the copie r a s

shown (2 screws each).

6. Stick the upper entrance guide myla r [C] on the copier upper left cover

and stick the two lower entrance gu ide mylars [ D] on the exit cove r as

shown.

7. For now, install the fixing bracket [E ] on the sorter stapler at the lowest

position (2 screws). (See step 11)

10 July 1991

[B]

[A]

[C]

8. Pass the harnesses [A] th rou gh the access hole an d connect the sorter

stapler with the copier. Make su re th at the stud on the front conn ect ing

bracket [B] is positioned in the sorter stapler positioning hole.

NOTE: Be careful not to damage the harnesses and the entrance guide

mylars when connecting the sorter stapler with the copier.

9. Secure the grounding wire [C] under the optics control board (1 grounding

screw with toothed wash er), and coup le the 3 connectors as follows:

Sorter Stapler Connecto r Copier Connector

2p (Red) 2p (Red)

4p (White) 4p (White)

2p (Fiber Optic Cable) CN114 on the main board

[A]

[A]

10 July 1991

[C]

[B]

10. Install the locking brackets [A] at the front and the re ar to secure the

sorter stapler to the copier (1 stepped screw each).

11. Loosen the 2 screws, lift the fixing bracket [B] up against the copier base

plate and retighten the screws.

[D]

12. Remove the finisher key sheet [C] an d stick th e sorter stapler key sheet

[D] on the operation panel.

[C]

10 July 1991

[A]

[B]

[C]

13. Stick the staple position deca l [A] on the ARDF as sho wn. (If there is n o

ARDF, stick it on the corresponding position of the platen cover. )

14. Remove the green plastic clip [B ] fro m the staple cartridge, and install the

cartridge in the stapler.

15. Reinstall the covers.

16. Turn on the main switch of the copier and test the operation of the sorte r

stapler.

NOTE: * The copier recognizes automatically that th e sorter stapler is

installed, so it is unnecessary to set the SP #71.

* The stapler will not be stapling for the first 10 or so copies until

the first staple comes to th e pro pe r position from the cartridge.

17. If at the top the gap bet ween the sorter stapler a nd the copier is too great,

adjust the gap by placing ca ste r st oppe rs [ C].

SECTION 4

SERVICE TABLES

10 July 1991

1. SERVICE TABLES (MAIN CONTROL BOARD)

1.1 DIP SWITCHES

DIP SW 100 0 : OFF 1 : ON

1234 5 6 Function Remarks

0 0 0 0 0 Proof Motor Speed Adjustment #1

1 0 0 0 0 Sorter Free Run #2

0 1 0 0 0 Staple Unit Free Run #3

*

1 1 0 0 0 Sorter & Staple Unit Free Run #4

1

0 0 1 0 0 Lowers Staple Unit (To 6th Bin)

1 0 1 0 0 Lowers Staple Unit (To 20th Bin)

0 1 1 0 0 Releases Bin Side Plate

0 0 0 0 0 1 Bin/Jam Sensor Adjustment

0 0 0 0 0 0 Initial Normal Setting

NOTE: *1 Confirm the setting from DIP SW100-2 to -6 before turn ing on

DIP SW100-1 (Start SW function).

Turn off DIP SW100-1 to st op the fun ction.

Remarks

#1: The proof motor a nd turn gate solenoid turn on.

#2: The main motor turn s on. Th e bin solenoids turn on in order and th e

jogger motor drives the jogger pla te (B5 lengthwise size) as each bin

solenoid turns on.

#3: The staple unit (grip asse mbly and stapler) movement is repeate d fro m

the 1st to 20th bins. When there is no paper in a bin, staplin g op era tion is

skipped for that bin.

#4: #2 and #3 are repeated together.

Combinations oth er than those above are used only a t th e factory.

4-1

10 July 1991

1.2 LED AND VARIABLE RESISTORS

LED NO. VR NO. FUNCTION

100 100 Adjusts jam sensor sensitivity.

101 101 Adjusts bin sensor sensitivity.

102 102 Adjusts proof motor speed.

1.3 TEST POINTS

NUMBER FUNCTION

TP 100 GND

TP 101 + 5 V

TP 102 + 24 V

4-2

10 July 1991

2. PREVENTIVE MAINTENANCE SCHEDULE

2.1 PM TABLE

C: Clean L: Lubricate

EM 320K NOTE

Transport, Distribution, and Exit Rollers C Da mp clot h

Bins C Damp cloth

Bin/Jam, Paper Sensors C Blower brush

Launa oil or equivalent;

Bushings L

Gears L

Worm gears L

Diagonal Transport Rollers C Damp cloth

Diagonal Transport Stoppe r C Alcohol

Staple Unit Guide Rod, Pa d L Launa oil

if bushings generate

noise.

Grease-501;

if gears generate noise.

Heat Resisting Grease

MT-78;

if worm gears generate

noise.

2.2 REGULAR PM EXPLANATIO N

The diagonal transport rolle rs a nd/o r t he diag on al tra nsport stopper become

dirty because of paper dust an d to ne r adh ering to them. This causes copies

to transport incorrectly, skew, an d jam. Clean ing them is required at regular

intervals.

If the diagonal transport stopper mylar is deformed or damaged, cop ies

transport incorrectly, skew, and jam. In this case , replace the mylar.

4-3

SECTION 5

REPLACEMENT

AND

ADJUSTMENT

10 July 1991

1. STAPLER REMOVAL AND REINSTALLATION

[B]

[A]

1. Open the front cover.

[C]

2. Push up the stapler relea se lever [A] and remove the stapler [B].

3. Reinstall the stapler.

NOTE: 1. The connector shut ter release plate [C] sho uld be inse rted as

shown.

2. Make sure that the sta ple r re lea se lever is lowered to the

original position after th e sta ple r is correc tly set .

5-1

[D]

10 July 1991

2. GRIP ASSEMBLY REMOVAL AND GRIP

SOLENOID ADJUSTMENT

2.1 GRIP ASSEMBLY RE MOV A L

[E]

[C]

[B]

[A]

[F]

[G]

[H]

[I]

1. Open the front cover [A].

2. Remove the proof tray [B] (5 screws) and fron t cove r [ C] (4 screws).

3. Move the grip assembly [D] betwe en the 1st bin and 7th bin by tu rnin g the

knob [E].

4. Remove the stapler [F] by pressing up the stapler release lever [G].

5. Remove the frame connector cover [ H] (2 screws).

6. Disconnect the 3 connectors [I ] an d remove the staple harness [J] (2

screws) from the frame connector cover.

5-2

[J]

[B]

10 July 1991

[D]

[C]

[A]

[E]

7. Remove the harness cover [A] (2 screws).

8. While holding the grip assembly [B], remove the timing belt clamp [C] (2

screws). Gently lower the grip assembly to the bottom.

9. Remove the fixing plate [D] (1 screw).

10. While holding the grip assemb ly, pu ll out the staple un it gu ide rod [E] from

the grip assembly.

5-3

10 July 1991

2.2 GRIP SOLENOID ADJUSTME NT

[B]

[A]

(C)

Adjustment standard: 2.5 ± 0.5 mm

1. Remove the grip assembly (see the grip assembly removal).

2. Adjust the gripper solenoid stroke (2 screws).

When the solenoid plunger [ A] is pressed so tha t th e grip pe r arms [ B]

touch each other, the gap (C) should be 2.5 ± 0.5 mm.

5-4

10 July 1991

3. DIAGONAL TRANSPORT STOPPER MYLAR

REPLACEMENT

[B]

[A]

1. Open the front doo r .

2. Release the transport plate.

3. Remove the diagonal transport stopper [A] (3 screws).

4. Slide out the mylar [B] from the diagonal tran sport stopper as shown.

5-5

[G]

[C]

10 July 1991

4. JOGGER PLATE REMOVAL AND

REINSTALLATION

4.1 JOGGER PLATE REMOVAL

[A]

[F]

[D]

[B]

1. Remove the proof tray [A] (5 screws) and the bot tom cover [B ] (2 screws).

2. Push the upper part of the jogger plate [C] to the left and hold it.

3. After that, pull the jogger plate up and hold it.

4. Swing the jogger plate out of th e bo ttom holder [D], and gently let the

jogger plate fall out of the upp er ho lde r [ F].

5. Pull the jogger plate out through the stay ho le [G].

5-6

4.2 JOGGER PLATE REINS TALLATI ON

[C]

[C] [B]

[E]

10 July 1991

[E]

[A]

[D]

1. Insert the jogger plate [A] through the stay ho le [B].

2. Insert the jogger plate into the ho le of the upper holder [ C] as shown and

hold it.

3. Position the jogger plate at the lower holder [D].

NOTE: The pressure springs [E] sho uld be placed as shown.

5-7

10 July 1991

5. BIN REMOVAL

[C]

[A]

Good

No good

[B]

1. Remove the front and rear covers (4 screws each).

2. Remove the jogger plate (see jog ger p lat e remo val).

3. Turn on the main switch.

4. Turn on DIP SW100-3, -4 and -1 [A]. Make sure you turn on the switch es

in that order.

5. When the bin side plate [B]is rele ased, turn off the main switch .

6. Pull out the sorting bins [C].

NOTE: 1. The 10th and 20th bins do not have an antista tic bru sh.

2. When reinstalling th e bin s be sure tha t the bins are positioned

correctly as shown.

3. After reinstalling the bins, turn off DIP SW100-1, -3 and -4.

5-8

6. TRANSPORT PLATE REMOVAL

[A]

[E]

[C]

[D]

10 July 1991

[B]

[F]

6.1 VERTICAL TRANSPORT PLATE REMO VAL

1. Remove the rear cover (4 screws).

2. Remove the turn gate lever [A] (1 screw).

3. Open the front door [B].

4. Remove the snap ring [C], th en lift an d remove the vertical the transport

plate [D].

6.2 DIAGONAL TRANSPORT PLATE REMO VAL

1. Open the front cover [B].

2. Remove the snap ring [E], then lift and remove the diagonal transport

plate [F].

5-9

10 July 1991

6.3 DISTRIBUTION TRANSPO RT PLATE REMO VAL

[B]

[C]

1. Open the front cover [A].

2. Remove the snap ring [B].

3. Lift and remove the dist ribution transport plate [C].

[A]

5-10

10 July 1991

7. VERTICAL TRANSPORT UNIT REMOVAL

[A]

[C]

[B]

1. Remove the proof tray (5 screws) and the rear cover (4 screws).

2. Disconnect the proof motor/exit sensor connector [A] and the turn gate

solenoid connector [B].

3. Remove the vertical transport un it [C] (6 screws, an d 1 screw fo r t he

harness clamp).

5-11

10 July 1991

8. DIAGONAL TRANSPORT UNIT REMOVAL

[A]

[C]

[B]

1. Remove the rear cover (4 screws).

2. Loosen the timing belt [A].

3. Remove the support bracket [B] (2 screws) an d th e timin g be lt .

4. Remove the diagonal transport unit [C] (7 screws).

5-12

9. BELT TENSION ADJUSTMENT

[A]

[B]

[D]

[C]

[E]

[F]

10 July 1991

[G]

aa

a: Bending (mm)

[H]

[B]

1. Remove the respective covers for the following belt tension adjustment:

Timing Belt [A] .......... .. ........ Proof Tray

Timing Belt [B] .......... .. ........ Proof Tray

Bottom Cover

Timing Belt [D] .................... Rear Cover

Timing Belt [G] .......... .......... Rear Cove r

Timing Belt [C] .................... Rear Cover

Timing Belt [C] .................... Rear Cover

Timing Belt [E] .......... .......... Rear Cover

Timing Belt [H] .................... Rear Cover

Timing Belt [G] .......... .......... Rear Cove r

2. Adjust the timing belt te nsio n as follows:

Timing Belt Bending Pressure

A 4 mm

B 5 mm

C 5 mm

D 8 mm

E 8 mm

F 6 mm

G 5 mm

H 6 mm

5-13

200±50 g

50±20 g

140±40 g

100±50 g

100±50 g

100±50 g

200±50 g

100±50 g

[B]

10 July 1991

10.MAIN CONTROL BOARD REPLACEMENT

AND ADJUSTMENT

10.1 MAIN CONTROL BOARD REPLACEMENT

[B]

[D]

[B]

[A]

1. Remove the rear cover [A] (4 screws).

2. Disconnect the main control board connectors [B] and fiber cable [C].

NOTE: When disconnecting the fibe r ca ble , do not pull it by th e cable,

but by the connector.

3. Replace the main control board [D] and con nect th e con ne cto rs.

4. Turn on the main switch.

5. Adjust the proof moto r sp eed an d bin/jam sensors (see next two pages).

6. Turn off the main switch.

[C]

5-14

10.2 PROOF MOTOR SPE ED ADJ USTME N T

10 July 1991

1. Turn on DIP SW100-1 [A].

[C]

[B]

[A]

2. If LED102 [B] is on, turn VR102 [C] coun te rclockwise unt il LED1 02 turn s

off.

3. Turn VR102 clockwise until LED102 starts blinking and go on turning until

it is continuously on.

4. Turn off DIP SW100-1.

5-15

10 July 1991

10.3 BIN/JAM SENS OR ADJ USTME N T

[A]

[B]

[C]

[D]

[E]

1. Turn on DIP SW 100-6 [A].

2. If LED100 [B] and LED101 [C] are on, turn VR100 [D] and VR101 [E]

clockwise until LED100 and LED101 turn off.

3. Turn VR100 and VR101 counterclockwise until LE D100 and LED101

start blinking and go on turning until they are continuou sly on.

4. Turn off DIP SW 100-6.

5-16

11.MAIN MOTOR REPLACEMENT

[B]

10 July 1991

[A]

[L]

[K]

[G]

[J]

[I]

1. Remove the rear cover [A] (4 screws).

2. Remove the timing pulleys [B, C] (1 Allen screw each) and timing belt [D].

[O]

[F]

[M]

[N]

[H]

[E]

[D

[C]

3. Remove the support bracket [E] (4 screws, and 2 screws for th e ha rne ss

clamps).

4. Remove the timing sensor bracket [F] (1screw).

5. Loosen the timing belt and remove the timing belts [G, H].

6. Remove the disk [I] and the timing pulley [J] (1 Alle n screw ea ch).

7. Remove the capacitor [K] (1 screw) and disconnect the motor harness [L].

8. Remove the grounding wire [M] (1 screw) the main motor assembly (4

stepped screws).

9. Remove the timing pulley [N] (1 Allen screw) and rep lace the main motor

[O] (3 screws).

NOTE: The timing pulley is used for both the 50 Hz and 60 Hz machines.

50 Hz = 18T 60 Hz = 14T

5-17

SECTION 6

TROUBLESHOOTING

10 July 1991

1. SERVICE CALL CONDITIONS

1.1 CODE # A1 – PROOF MOTOR ERROR

- Definition -

When the proof motor is turning, the encoder pulse takes over 250 msec to

change.

- Possible Causes -

• The proof motor is defective

• The main control board is defective

- Action -

Turn the main switch off and on.

Does the proof motor turn wh en the main switch is turne d on?

Yes No

Check the continuity between CN140 and CN400 through CN405.

Good No good

Repair the harness.

Replace the proof moto r.

Replace the main control board or the proo f mot or.

6-1

10 July 1991

1.2 CODE # A2 – TIMI NG SENSOR OUTPUT ERROR

- Definition -

When the main motor is turning , the timin g sen sor ou tp ut take s over 100

msec to change.

- Possible Causes -

• The timing sensor is defective

• The main motor is defective

• The main control board is defective

- Action -

Turn the main switch off and on.

Does the main motor turn when the main switch is turne d on?

Yes No

Check the voltage between CN300-1 and CN300-2.

100 V 0 V

Check the copier

Check the continuity betwe en CN310 -1 an d CN31 0-2 .

Good No good

Replace the door safety switch (AC).

Check the continuity betwe en CN330 -1 an d CN33 0-2 .

Good No good

Replace the main motor.

Check the continuity between CN300 and CN120 through CN310

and CN330.

Good No good

Repair the harness.

Replace the main control board .

6-2

Check the timing sensor. (between CN180-7 and the ground)

Good No good

≤ 1.0 V > 1.0 V

≥ 4.0 V < 4.0 V

Check the continuity between CN180 and CN450.

Good No Good

Repair the harness.

Replace the timing sensor.

Replace the main control board .

10 July 1991

6-3

10 July 1991

1.3 CODE # A3 – JOGGER H.P. SENSOR OUTPUT ERROR

- Definition -

• When the jogger plate moves forward, the home position sensor takes

over 150 msec to turn off.

• When the jogger plate moves backward , th e ho me position sensor

takes over 1 sec to turn on.

- Possible Causes -

• The jogger H.P. sensor is defective

• The jogger motor is defective

• The main control board is defective

• The timing belt is not fixed

- Action -

Turn the main switch off and on.

Does the jogger plat e move when the main switch turned on?

Yes No

Does the jogger motor turn?

Yes No

Check the continuity between CN170 and CN470.

Good No go od

Repair the harness.

Check the continuity of the jo gger motor.

Good No good

Replace the jogger motor.

Replace the main control board .

Attach the holder to the belt.

6-4

Check the jogger H.P. sensor. (between CN190-1 and the ground)

Good No good

≥ 4.0 V < 4.0 V

≤ 1.0 V > 1.0 V

Check the continuity between CN190 and CN475.

Good No good

Repair the harness.

Replace the jogger H.P. sensor.

Replace the main control board .

10 July 1991

6-5

10 July 1991

1.4 CODE # A4 – STAPLE UNI T POSITION ERROR

- Definition -

When the staple unit lowers t o th e ne xt bin , the staple unit position sensor

stays on for more than 1 sec or stays off for more than 50 0 msec.

- Possible Causes -

• The staple unit H.P. sensor is defective

• The staple unit position sensor is defective

• The staple unit drive motor is defective

• The main control board is defective

- Action -

Turn the main switch off and on.

Does the staple unit drive motor tu rn whe n th e main switch is turned on?

Yes No

Check the continuity between CN150 and CN485.

Good No good

Repair the harness.

Check the continuity of the st aple un it drive motor.

Good No good

Replace the staple unit drive moto r.

Replace the main control board .

Check the staple unit H.P. Sensor. (between CN18 5-9 and the ground)

Good No good

≥ 4.0 V < 4. 0 V

≤ 1.0 V > 1. 0 V

Check the continuity between CN185 and CN480.

Good No good

6-6

10 July 1991

Good No good

Repair the harness.

Replace the staple unit H.P. sensor.

Check the staple unit position sensor. (between CN185-10 and the ground)

Good No good

≥ 4.0 V < 4. 0 V

≤ 1.0 V > 1.0 V

Check the continuity between CN185 and CN570 through CN560.

Good No good

Repair the harness.

Replace the staple unit position sensor.

Replace the main control board .

6-7

10 July 1991

1.5 CODE # A5 – GRIP MOTOR ERROR

- Definition -

When the grip motor moves forward or ba ckward , th e grip H.P. sensor output

takes over 250 msec to change .

- Possible Causes -

• The grip H.P. sensor is defective

• The grip motor is defective

• The timing belt is not fixed

• The main control board is defective

- Action -

Turn the main switch off and on.

Does the grip motor turn when the main switch is turne d on?

Yes No

Check the continuity between CN160 and CN510 through CN550.

Good No good

Repair the harness.

Check the continuity of the grip motor.

Good No good

Replace the grip motor.

Replace the main control board .

Is the grip H.P. sensor actuato r att ach ed to the timin g belt?

Yes No

Attach the actuator to the timing belt.

Check the grip H.P. sensor. (between CN185-8 and the ground)

Good No good

≤ 1.0 V > 1. 0 V

≥ 4.0 V < 4. 0 V

6-8

Check the continuity between CN185 and CN580 through

CN560.

Good No go od

Repair the harness.

Replace the grip H.P. sensor.

Replace the main control board .

10 July 1991

6-9

10 July 1991

1.6 CODE # A6 – STAPLE ERROR

- Definition -

The stapler motor takes more th an 800 msec f or one sta ple cycle (from H.P.

to H.P.).

- Possible Causes -

• Stapler is defective

- Action -

Turn the main switch off and on.

Does the stapler motor turn when the main switch is turned on?

Yes No

Check the continuity between CN195 and CN500 through CN540.

Good No good

Repair the harness.

Check the continuity of the stapler motor.

Good No good

Replace the stapler.

Replace the main control board .

Check the staple H.P. Sen sor. (between CN185-6 and the grou nd )

Good No good

≤ 1.0 V > 1. 0 V

≥ 3.5 V < 3. 5 V

Check the continuity between CN195 and CN500 through CN540.

Good No good

Repair the harness.

Replace the staple r.

Replace the main control board .

6-10

10 July 1991

1.7 BIN SIDE PLATE DRIV E MO TOR E RROR

- Definition -

• When the bin side plate open s, th e bin side plate drive motor ta kes

more than 1 sec to activate the bin side plat e release sensor.

• When the bin side plate close s, th e bin side plate drive motor ta kes

more than 1.27 sec to activat e th e bin side plate H.P. senso r.

• The bin side plate H.P. sensor and release sensor turn on at the same

time.

- Possible Causes -

• The bin side plate H.P. sensor is defective

• The bin side plate release sensor is defective

• The bin side plate drive motor is defective

• The main control board is defective

- Action -

Turn the main switch off and on.

Does the bin side plate drive motor tu rn whe n the main swit ch is turn ed on?

Yes No

Check the continuity between CN170 and CN455.

Good No good

Repair the harness.

Check the continuity of the bin side plat e drive motor.

Good No good

Replace the bin side plate drive motor.

Replace the main control board .

Check the bin side plate H. P. sensor. (between CN190-3 and the ground)

Good No good

≥ 4.0 V < 4.0 V

≤ 1.0 V > 1.0 V

6-11

10 July 1991

Check the continuity between CN190 and CN460.

Good No good

Repair the harness.

Replace the bin side plate H.P. sensor.

Check the bin side plate re lea se sensor. (between CN19 0-2 and the grou nd )

Good No good

≥ 4.0 V < 4.0 V

≤ 1.0 V > 1.0 V

Check the continuity between CN190 and CN465.

Good No good

Repair the harness.

Replace the bin side pla te release sensor.

Replace the main control board .

6-12

2. ELECTRICAL COMPONENT DETECTS

2.1 SENSORS

10 July 1991

Component

(Symbol)

Exit Sensor

(S1)

Staple Unit

H.P. Sensor

(S2)

Grip H.P.

Sensor (S3)

≥ 4.0 V

≤1.0 V

≥ 4.0 V

≤1.0 V

≤1.0 V

≥ 4.0 V

CN Condition

open

(stays

High)

140-2

185-9

185-8

shorted

(stays

Low)

open

(stays

High)

shorted

(stays

Low)

open

(stays

High)

shorted

(stays

Low)

Symptom

Main SW turns on Ready condition

"Sorter misfeed.

–

"Sorter misfeed.

Remove any misfed

paper" is displayed.

Staple unit goes down

and does not return to

home position.

"Staple error. Inspect

the stapler" is

displayed. After the

front door is

opened/closed, the

message will

disappear. However,

"SC code (A4)" will be

displayed when staple

mode is selected.

"Staple error. Inspect

the stapler" is

displayed. After the

front door is

opened/closed, the

message will

disappear. However,

"SC code (A5)" will be

displayed when staple

mode is selected.

"Staple error. Inspect

the stapler" is

displayed. After the

front door is

opened/closed, the

message will disappear.

Remove any misfed

paper" is displayed

when copies are made

in normal mode.

After stapling is done,

the staple unit does not

return to home position.

"Staple error. Inspect

the stapler" or "SC code

(A4)" is displayed when

copies are made in

staple mode.

"Staple error. Inspect

the stapler" or "SC code

(A5)" is displayed when

copies are made in

staple mode.

6-13

10 July 1991

Component

(Symbol)

Staple Unit

Position

Sensor (S4)

Bin

Transport

Sensor (S5)

Bin Side

Plate

Release

Sensor (S6)

≥ 4.0 V

≤ 1.0 V

≥ 4.0 V

≤ 1.0 V

≥ 4.0 V

≤ 1.0 V

CN Condition

open

(stays

High) –

shorted

185-10

180-5

190-2

(stays

Low)

open

(stays

High)

shorted

(stays

Low)

open

(stays

High) –

shorted

(stays

Low)

Symptom

Main SW turns on Ready condition

Staple error. Inspect the

stapler" or "SC code

(A4)" is displayed when

copies are made in

staple mode.

"Staple error. Inspect

the stapler" is

displayed. After the

front door is

opened/closed, the

message will

disappear. However,

"SC code (A4)" will be

displayed when staple

mode is selected.

–

"Sorter misfeed.

Remove any misfed

paper." is displayed.

–

"Staple error. Inspect

the stapler" is displayed

when copies are made

in staple mode.

"Sorter misfeed.

Remove any misfed

paper." is displayed

when copies are made

in sort/stack or staple

mode.

"Sorter misfeed.

Remove any misfed

paper." is displayed

when copies are made

in sort/stack or staple

mode.

The bin side plate does

not release. The stapler

operation is performed

without any indication

on the display.

"Staple error. Inspect

the stapler." is

displayed. The bin side

plate drive motor turns

continuously when

copies are made in

staple mode.

6-14

10 July 1991

Component

(Symbol)

Bin Side

Plate H.P.

Sensor (S7)

Jogger H.P.

Sensor (S8)

Timing

Sensor (S9)

≥ 4.0 V

≤ 1.0 V

≥ 4.0 V

≤ 1.0 V

≥ 4.0 V

≤ 1.0 V

CN Condition

open

(stays

High)

190-3

shorted

(stays

Low)

open

(stays

High)

shorted

190-1

180-7

(stays

Low)

open

(stays

High)

shorted

(stays

Low)

Symptom

Main SW turns on Ready condition

"Staple error. Inspect

the stapler." is

displayed.

"Please wait" is

displayed and the bin

side plate drive motor

turns continuously.

"Sorter misfeed.

Remove any misfed

paper." is displayed.

"Sorter misfeed.

Remove any misfed

paper." is displayed.

After the front door is

opened/closed, the

message will disappear.

However, "SC code

(A3)" is displayed when

sort/stack or staple

mode is selected.

"Sorter misfeed.

Remove any misfed

paper." is displayed.

"Staple error. Inspect

the stapler." is displayed

when copies are made

in staple mode. After the

front door is

opened/closed, the

message will disappear.

However, "SC code

(A7)" will be displayed

when staple mode is

selected.

The bin side plate drive

motor turns continuously

turning when the start

key is pressed.

"Sorter misfeed.

Remove any misfed

paper." is displayed

when copies are made

in sort/stack or staple

mode.

"Sorter Misfeed.

Remove any misfed

paper." is displayed.

"Sorter misfeed.

Remove any misfed

paper." or "SC code

(A2)" is displayed when

copies are made in

sort/stack or staple

mode.

6-15

10 July 1991

Component

(Symbol)

Bin/Jam

Sensor

- LED (S10)

Bin/Jam

Sensor

- Photo Tr.

(S11)

Paper

Sensor

(S12)

–

≥ 4.0 V

≤ 1.0 V

≤ 1.0 V

≥ 4.0 V

CN Condition

open

(stays

Low)

Bin

140-3

shorted

(stays

HIgh)

open

(stays

Low)

Jam

140-4

shorted

(stays

High)

open

(stays

High)

Bin

180-4

180-6

180-5

shorted

(stays

Low) –

open

(stays

High)

Jam

shorted

(stays

Low)

open

(stays

High)

shorted

(stays

Low)

Symptom

Main SW turns on Ready condition

"Remove copies from

the copy tray" is

displayed when

sort/stack or staple

mode is selected.

––

"Sorter misfeed.

Remove any misfed

paper," is displayed.

––

–

–

"Sorter misfeed.

Remove any misfed

paper," is displayed.

–

"Remove copies from

the copy tray" is

displayed when

sort/stack or staple

mode is selected.

"Sorter misfeed.

Remove any misfed

paper," is displayed

when copies are made

in sort/stack or staple

mode.

No staple operation

even though copying is

completed in staple

mode.

"Remove copies from

the copy tray" is

displayed when

sort/stack or staple

mode is selected.

"Sorter misfeed.

Remove any misfed

paper," is displayed

when copies are made

in sort/stack or staple

mode.

"Sorter misfeed.

Remove any misfed

paper" is displayed

when copies are made

in sort/stack or staple

mode.

"Staple error. Inspect

the stapler" is displayed

and no staple operation

when copies are made

in staple mode.

No staple operation

even though a set of

copies is at the staple

position.

6-16

10 July 1991

Component

(Symbol)

Staple H.P.

Sensor

(S13)

Staple End

Sensor

(S14)

≤ 1.0 V

≥ 3.5 V

≥3.0 V

<1.0 V

CN Condition

open

(stays

High)

185-6

shorted

(stays

Low)

open

(stays

High)

185-7

shorted

(stays

Low)

Symptom

Main SW turns on Ready condition

"Staple error. Inspect

the stapler." After the

front door is

opened/closed, the

message will

disappear. However,

"SC code (A6)" will be

displayed when staple

mode is selected.

–

–

"Staple error. Inspect

the stapler" or "SC code

(A6)" is displayed when

copies are made in

staple mode.

"Add staple" indicator

lights even though the

staple cartridge is not

empty when staple

mode is selected.

"Add staple" indicator

does not light even

though the staple

cartridge is empty when

staple mode is selected.

6-17

10 July 1991

2.2 SWITCHES

Componen t and

Door

Safety

SW (AC)

(SW1)

open open

Main SW

OFF→ON

Ready

Condition

open shorted

shorted open

shorted shorted

open open

open shorted

shorted open

shorted shorted

Condition

Door

Safety

SW (DC)

(SW2)

Symptom

"Close the sorter cover" is displa yed even

though sorter front door is closed.

"Sorter misfeed. Remove any misfed

paper" is displayed although the re is no

paper in sorter stapler.

"Close the sorter cover" is displa yed even

though sorter front door is closed.

"Close the sorter cover" is not displa yed

even though sorter front door is opened.

"Close the sorter cover" is displa yed even

though sorter front door is closed.

"Sorter misfeed. Remove any misfed

paper" or "SC code (A2)" is displayed

when copies are made in sort/stack or

staple mode.

"Close the sorter cover" is displa yed even

though sorter front door is closed.

"Close the sorter cover" is not displa yed

even though sorter front door is opened.

6-18

[B]

1 mm gap

10 July 1991

3. OTHERS

3.1 IMPROPER STAPLING

- Phenomenon -

• Incomplete stapling: The staples are not flush with the paper surface.

2 to 30 sheets of paper

Flat Stapling

(Normal)

• No stapling: No staple s are dispensed from the staple r.

Incomplete stapling

(Loose)

- Possible Causes -

1. If a staple [A] jams inside the

staple bending gate [B], the gate

cannot close completely. Staples

are not crimped completely, and

there is about a 1 mm gap

between the staple and the paper

surface.

2. A bent staple prevents the staple

push plate [C] from moving

downward.

Another possibility is that the staple

[C]

sheet has not yet reached the

stapling position.

[A]

- Action -

1. Remove the jammed staple [D] from

the staple bending gate [E].

6-19

[E]

[D]

Incorrect

10 July 1991

2. (1) Remove the staple cartridge , th en

check for any staples jammed in the

stapling mechanism [A]. To remove

jammed staples, spread apart the

side plates [B] and slide up the front

pressure guide plate [C].

[A]

[B]

[C]

NOTE: When installing the staple

cartridge, make sure that all

the staple sheets [D] are in

the initial position.

[D]

(2) Install the staple cartrid ge , th en

make copies in staple mode unti l

the staple sheet reaches the

stapling position.

Correct

6-20

Loading...

Loading...