Page 1

Iumml

FT6645/6655

Operating

Instructions

‘\

/

‘k

Page 2

Notes:

The model names of the machines do not a pear in the following pages.

CfCheck the type of your machine before rea ing this manual.

(For details, see page 2.)

Type 1 = FT6645

Type 2 = FT6655

Certain types may not be available in some countries. For details, please contact

vour local dealer.

Note: Certain options ma not be available in some countries. For details, please

Jcontact your local eater.

Ricoh shall not be responsible for any damage or expense that may result from the use

of parts other than genuine Ricoh parts in your Ricoh office product.

I For good copy quality, Ricoh recommends that you use genuine Ricoh toner.

~ower source:

‘lease make sure to connect the power cord to a power source as above. For details

about Dower cord. see Daae iv.

120V, 60 Hz, more than 20A

I

@ Copyright 1993 Ricoh Co., Ltd.

Page 3

SAFETY INFORMATION

SAFETY INFORMATION

When using your copier, the following safety precautions should always be followed.

Safety During Operation

In this manual, all safety messages are identified by the words “WARNING” and “Caution”.

These words mean the following:

WARNING:

Important information to alert you to a situation that might cause serious injury and

damage to your property if instructions are not followed.

Caution:

Impotiant information that tells how to prevent damage to equipment, or how to avoid a

situation that might cause minor injury.

WARN/NG:

Cl Since some parts of the copier are supplied with high electrical voltage, touch only the parts

specified in this manual and the machine’s display.

Do not modify or replace any parts other than the ones specified in this manual and the

Cl

machine’s display.

IJ Do not incinerate toner or toner containers. Toner dust may ignite when exposed to open

flame.

Cl Do not store toner where it will be exposed to heat.

Cl Do not eat or swallow toner, and keep it out of reach of children.

Cl The fusing unit maybe very hot. Be careful when handling it.

Caution:

~ While copying, do not turn off the main switch.

Cl While copying, do not open the front doors.

U While copying, do not unplug the power cord.

Cl Do not lay anything weighing more than 10 kg (22 lb) on the exposure glass.

C’JKeep corrosive /iquids, such as acid, off the machine.

Cl Do not allow paper clips, staples, or other small metallic objects to fall inside the machine.

Page 4

SAFETY INFORMATION

General Safety Information

~ &lways turn the copier off when you have finished copying for the day, but leave it plugged

.

D When the copier will not be used for a long period, disconnect the power cord.

Cl If the copier must be transported by vehicle, please contact your service representative.

5 When the main switch is in the Stand-by position, the anticondensation heaters are on. In

case of emergency, unplug the machine’s power cord.

~ The main plug on this equipment must be used to disconnect main power.

Page 5

Copier Environment

INSTALLATION REQUIREMENTS

INSTALLATION REQUIREMENTS

Copier Environment

The installation location should be carefully chosen because environmental conditions greatly

affect the performance of a copier.

- Optimum environment conditions -

tJ Temperature: 10- 30”C (50 - 86°F)

Cl Humidity:

D A strong and level base.

0 The copier must be level within 5 mm (0.2”) both front to rear and left to right.

D To avoid possible build-up of ozone, make sure to locate this copier in a large well ventilated

room which has air turnover of more than 30ms/hr/person.

15- 90?40

Environments To Avoid

D Locations exposed to direct sunlight or strong light (more than 1,500 Iux).

D Locations directly exposed to cool air from an air conditioner or heated air from a

heater. (Sudden temperature changes may cause condensation within the copier.)

D Places where the copier may be subjected to frequent strong vibration.

C!Dusty areas.

ClAreas with corrosive gases.

~ Places higher than 2,000 m

(6,500 ft) above sea level.

.,.

Ill

Page 6

INSTALIJ4TION REQUIREMENTS

Power Connection

Avoid multiwiring.

D

Cl Make sure that the wall outlet is near the copier and easily accessible.

D Make sure the plug is firmly inserted in the outlet.

~ Voltage must not fluctuate more than 10YO.

Cl Do not set anything on the power cord.

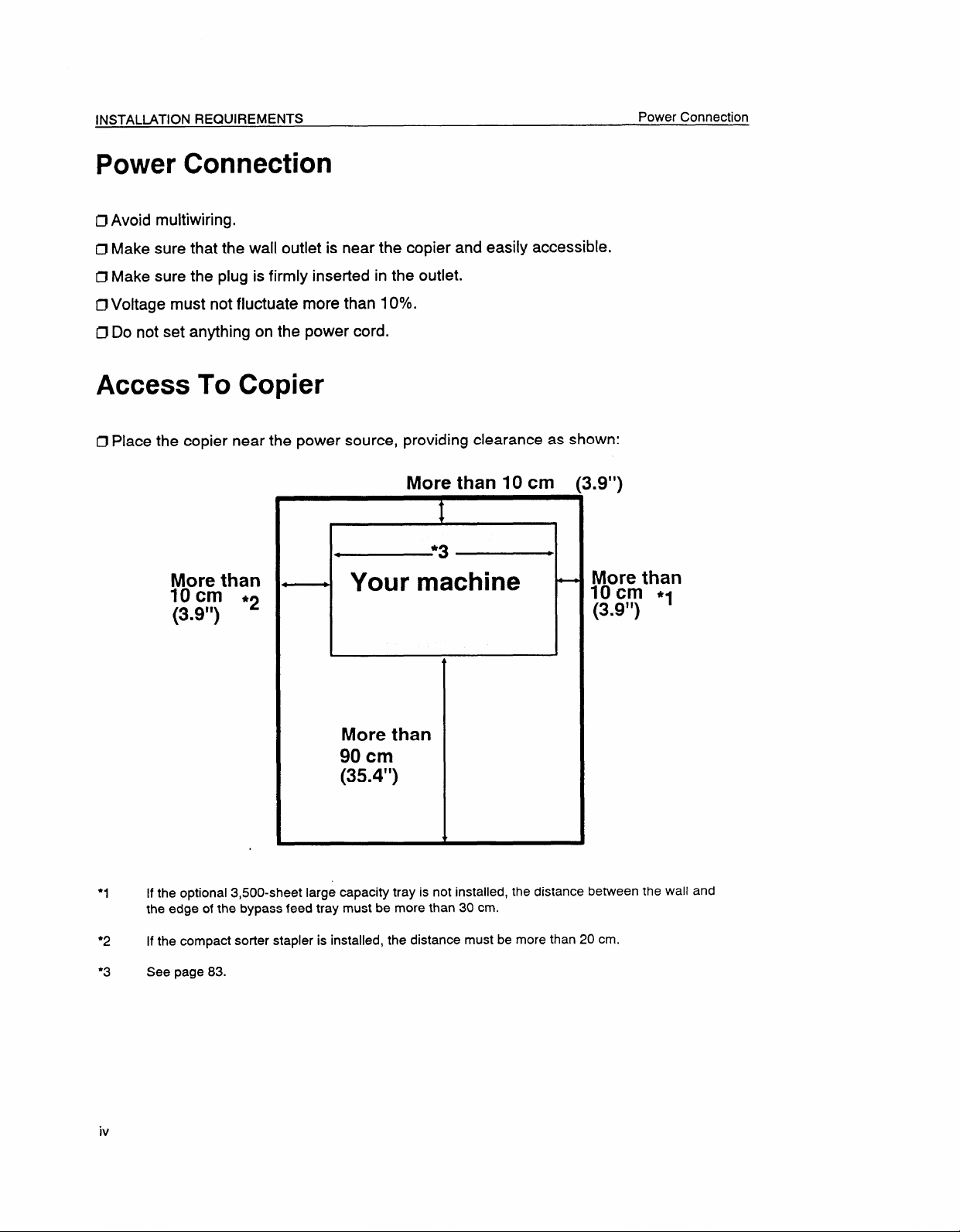

Access To Copier

IJ Place the copier near the power source, providing clearance as shown:

Power Connection

More than 10 cm

L9”)

F===

More than

10cm *2

(3.9”)

●1 Ifthe optional 3,500-sheet large capacity tray is not installed, the distance between the wall and

the edge of the bypass feed tray must be more than 30 cm.

--i

Your machine

P

More than

90 cm

(35.4”)

I

More than

10cm *1

(3.9”)

●2 Ifthe compact sorter stapler is installed, the distance must be more than 20 cm.

●3 See page 83.

iv

Page 7

STORAGE OF SUPPLIES

STORAGE OF SUPPLIES

Storage Of Supplies

Paper Storage

Paper should always be stored properly, Improperly stored paper may result in poor image

reproduction, creased copies, and paper misfeeds.

~ Avoid storing paper in humid areas. (Under high temperature and high humidity conditions,

store copy paper in a vinyl bag,)

Z1Do not store paper where it will be exposed to heat.

U Store on a flat surface.

7 Use older stock first.

~ Do not lay heavy objects on paper.

~ Keep open reams of paper in the package, and store as you would unopened paper.

Toner Storage

~ Store in a cool, dark place.

Cl Do not store toner where it will be exposed to heat.

~ DO not lay anything heavy on toner.

Page 8

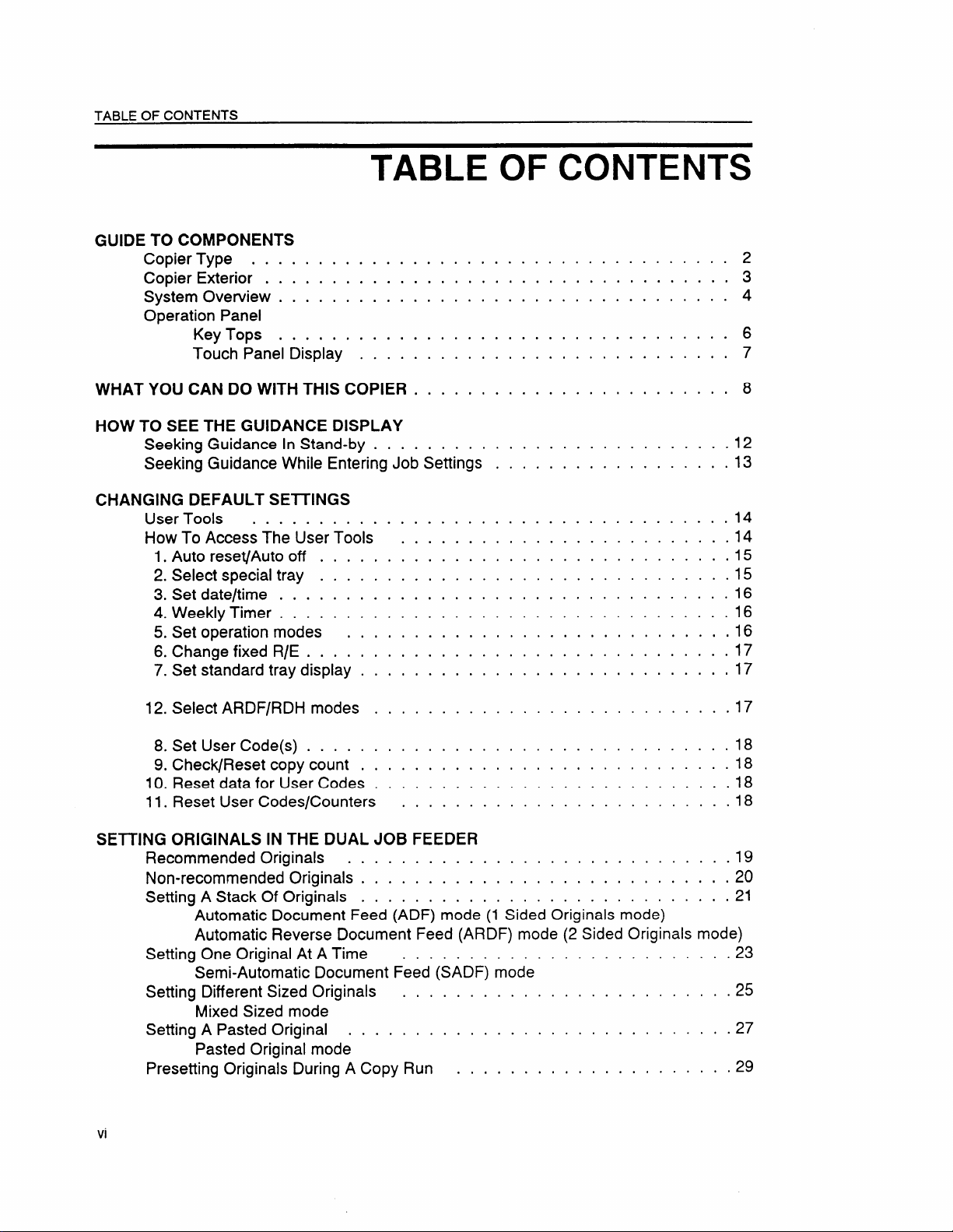

TABLE OF CONTENTS

TABLE OF CONTENTS

GUIDE TO COMPONENTS

Copier Type . . . . . . . . . . . . .

Copier Exterior . . . . . . . . . . . .

System Overview . . . . . . . . . . .

Operation Panel

Key Tops . . . . . . . . . . .

Touch Panel Display . . . . .

WHAT YOU CAN DO WITH THIS COPIER .

HOW TO SEE THE GUIDANCE DISPLAY

Seeking Guidance In Stand-by . . . .

Seeking Guidance While Entering Job Settings

CHANGING DEFAULT SETTINGS

User Tools . . . . . . . . . . . . . . . . . .

How To Access The User Tools . . . . . . .

l. Autoreset/Auto off . . . . . . . . . . . . .

2. Select special tray . . . . . . . . . . . . .

3. Setdate/time . . . . . . . . . . . . . . . .

4. Weekly Timer . . . . . . . . . . . . . . . .

5. Set operation modes . . . . . . . . . . .

6. Change fixed R/E . . . . . . . . . . . . . .

7. Set standard tray display . . . . . . . . . .

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 3

.

.

.

. 4

.

.

.6

.

.

. 7

.

.

.

. 8

.

.

. 12

.

.

. 13

.

.

.14

.

.

.

.14

.

,15

.15

.

. 16

.

.

.16

,16

.

.

.

. 17

.

, 17

.

.

12. Select ARDF/RDH modes . . . . . . . . .

8. Set User Code(s) . . . . . . . . . . . . . .

9. Check/Reset copy count . . . . . . . . . .

10. Reset data for User Codes . . . . . . . . .

11. Reset User Codes/Counters . . . . . . .

SETTING ORIGINALS IN THE DUAL JOB FEEDER

Recommended Originals . . . . . . . . . . .

Non-recommended Originals . . . . . . . . . .

Setting A Stack Of Originals . . . . . . . . . .

‘Automatic Document Feed (ADF) mode (1 Sided Originals mode)

Automatic Reverse Document Feed (ARDF) mode (2 Sided Originals mode)

Setting One Original At ATime . . . . . . . . . . . . . . . . . . . . . . ...23

Semi-Automatic Document Feed (SADF) mode

Setting Different Sized Originals . . . . . . . . . . . . . . . . . . . . . . ...25

Mixed Sized mode

Setting A Pasted Original .,... . . . . . . . . . . . . . . . . . . . . . ...27

Pasted Original mode

Presetting Originals During A Copy Run . . . . . . . . . . . . . . . . . . . . .29

.17

.18

.18

.18

.18

.

.

.

.

.

.

.

.

.

.

.

.19

.20

.

.21

Page 9

TABLE OF CONTENTS

SEITING ORIGINALS IN THE RECIRCULATING DOCUMENT HANDLER

.

.

.

Recommended Originals . . . . . .

Non-recommended Originals . . . . .

Setting Originals . . . . . . . . . . .

SETTING ORIGINALS ON THE EXPOSURE

. . . . .

. . . . .

. . . . .

GLASS

.

.

.

●

,

✎

.

.

.

✎

.

.

.

. . . . . .

.

.

.

.

,

.

.

. . . . . .

. . . . . .

.

. . . . . .

.

.

.

.

BASIC FUNCTIONS AND KEY TOPS

.

.

,

.

sort , .,.....0.0.000.

Stack . . . . . . . . . . . . . . . .

Stapling Gopies. o . . . . . . . . . .

Manual Staple . . . . . . . . . . . .

Special Brig . . . . . . . . . . . . . .

Preset . . . . . . . . . . . . . . . .

Program Key . . . . . . . . . . . . .

Interrupt Key . . . . . . . . . . . . .

Auto Start Mode . . . . . . . . . . .

●

.

.

.

✎

.

.

✎

.

.

✎

.

.

✎

.

.

✌

●

.

✎

✎

.

✌

✃

.

✎

✎

.

✌

.

.

✎

.

.

✎

.

.

.

✎

.

.

.

✎

.

.

.

,

●

.

.

.

✎

.

●

.

●

.

✎

.

✎

.

.

●

● ✎✎✌✎✎

.

.

.

.

✎

✎ ✎ ✎ ✎ ✎ ✎

.

.

.

.

●

✎

✌

✎

✎

.

.

✎ ✎ ✎ ✎ ✎ ✎

.

✎

.

.

.

✎ ✎ ✎ ✎ ✎ ✎

✎

✎ ✎ ✎ ✎ ✎ ✎

.

.

.

●

0

...0.

.

✎

.

●

●

✎

✎

●

.

. . . . . .

● . . . . .

,

. . . . . .

.

.

.

.

.

FUNCTIONS ON OPERATION SCREENS

Reduce/Enlarge . . . . . . . . . . .

Duplex/Series Copies (Duplex) . . . .

Duplex/Series Copies (Series Duplex)

Duplex/Series Copies (Series Copies)

Duplex/Series Copies (Combine) . .

Edit Image(Editing/Centering) . . . .

Edit Image (Margin Adj.) . . . . . .

Cover/Slip Sheet (Front Cover) , . . .

Cover/Slip Sheet (Front/Back) . . . .

Cover/Slip Sheet (Paper Designate) .

Cover/Slip Sheet (OHP Slip Sheet) .

✎

✎

✎

.

.

✎

✎

.

.

✎

✎

.

.

✎

✎

.

.

✎

✎

.

.

✎

●

●

.

✎

✎

✎

.

●

●

s

✎

.

✎

✎

✎

.

●

✎

✌

.

✎

✎

✎

✎

✎

.

✎

✎

.

✎

✎

✎

✎

.

✎

✎

.

✎

✎

✎

✎

.

✎

✎

●

.

✎

✎

✎

.

●

●

✌

.

✎

✎

.

✎

✎

✎

.

✌

✎

✎

✎

.

.

. . . . . .

✎

✎

.

. . . . . .

✎

.

✎

.

. . . . . .

✎

✎

.

.

✎

.

. . . . . .

✎

.

✎

. . . . . .

✎

.

.

✎

,, .,,,

✌

.

.

✎

.

. . . . . .

✎

.

✎

●

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

,.,

,

. . . . . .

.

. . . . . .

.

. . . . . .

.

.

.

.

.

.

.

.

.

.

,

.

,

.

.

.

.

.

.

.

.

,,0

●

✎

✎

✎

.31

.

.

.

.32

.

.

.

.32

.

.

.

.

.34

.

.

.37

.

.

.

.38

●

.

.

✎

.39

.

.

,41

✎

.

.

✎

.41

.

.

,41

✎

.

.

.42

✎

.

.

✎

.

.42

.

.42

✎

.

.

✎

.

.

.43

.44

✎

.

.

.48

✎

.

.

,50

✎

.

.

✎

.52

.

.

✎

.56

●

,

.59

✎

✎

.

.60

✎

✎

.

.61

✎

✎

.

✎

.62

●

.

.63

✎

✎

.

LOADING PAPER . . . . . . . . . . . . .

550-sheet Paper Tray . . . . . . . .

Tandem Paper Tray . . . . . . . . .

1,500-sheet Large Capacity Tray . .

✎

✎

✎

✎

Optional 3,500-sheet Large Capacity Tray

Bypass Feed Tray . . . . . . . . . . .

CHANGING PAPER SIZE . . . . . . . . . . .

WHAT TO DO WHEN THINGS GO WRONG . .

USER REMARKS . . . . . . . . . . . . . . .

DO’SAND DONUTS . . . . . . . . . . . . . . .

DAILY MAINTENANCE

Copier . . . . . . . . . . . . . . . . . .

Dual Job Feeder . . . . . . . . . . . . .

Recirculating Document Handler . . . .

“

✎

✎

✎

.

✎

✎

.

✎

✎

✎

✎

✎

.

✎

✎

.

✎

✎

.

✎

✎

.

✎

✎

.

●

✎

✎

.

✎

.

✎

✎

.

✎

✎

✎

,

●

✎

.

✎

.

✎

✎

✎

✎

✎

.

✎

✎

✎

.

✎

✎

.

✎

✎

✎

✎

.

✎

✎

✎

,

✎

✎

✎

.

✎

✎

✎

.

✎

✎

✎

.

✎

✎

✎

.

✎

✎

✎

.

✎

✎

✎

.

✎

✎

✎

.

✎

✎

✎

.

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

●

✎

●

✎

✎

✎

✎

✎

✎

✎

. . . . . .

.

. . . . . .

.

. . . . . .

.

., .,..

.

●

. . . . . .

.

. . . . . .

.

. . . . . .

.

. . . . . .

.

. . . . . .

.

. . . . . .

.

. . . . . .

.

. . . . . .

.

. . . . . .

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

✎

.64

.

.66

✎

✎

.

.67

✎

✎

.

.69

✎

✎

.

● 70

✎

✎

,

.71

✎

✎

.

, 73

✎

✎

.

.75

✎

✎

.

.76

✎

✎

.

.77

✎

✎

.

.78

✎

✎

.

. 79

✎

✎

.

.80

✎

✎

.

Page 10

TABLE OF CONTENTS

SPECIFICATIONS

Copier . . . . . . . . .

Dual Job Feeder . . . .

Compact Sorter Stapler .

Floor Type Sorter Stapler

.

.

.

.

...

.

.

.

.

.

Recirculating Document Handler

Finisher . . . . . . . . . . . . .

3,500-sheet Large Capacity Tray

COMBINATION CHART . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 81

.

.

.

. 85

.

.

. 86

.87

. 88

.

.

.

. 89

.

.

.

. 90

.

.

.

. 92

.

.

INDEX . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 94

.

.

.

Page 11

Before reading this Operating Instructions,

please refer to pages 2-5 to know which type

of copier and system you have.

1

Page 12

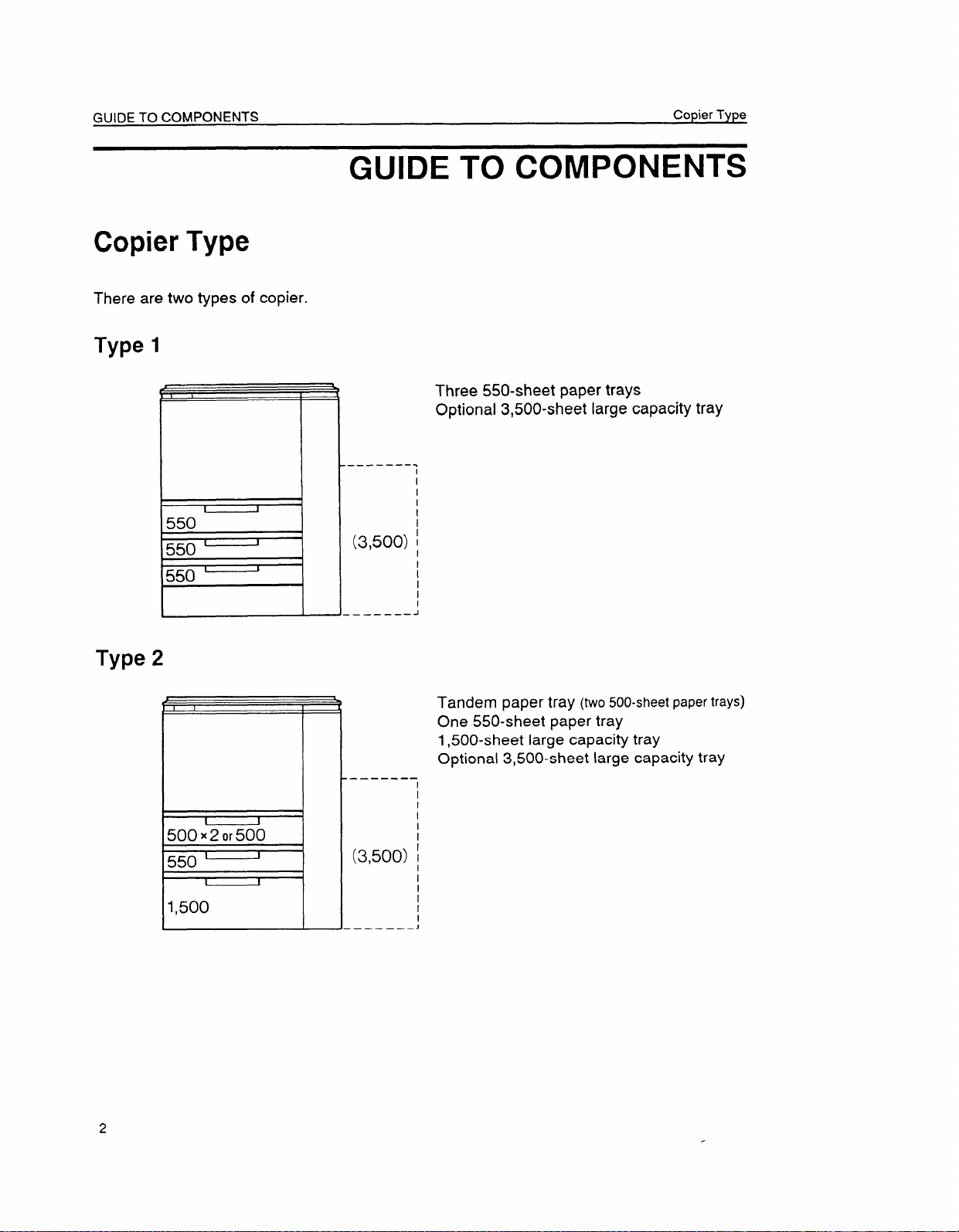

GUIDE TO COMPONENTS

Copier Type

There are two types of copier.

Copier Type

GUIDE TO COMPONENTS

Type

Type

1

a?,

1

550

550

550

P

2

—-——----

(3,500)

.—— — ———

————---

t

Three 550-sheet paper trays

Optional 3,500-sheet large capacity tray

/

I

I

I

I

-1

Tandem paper tray (two 500-sheet paper trays)

One 550-sheet paper tray

1,500-sheet large capacity tray

Optional 3,500-sheet large capacity tray

I

*

1

I

I

(3,500) I

I

!

I

~-.--.--!

2

Page 13

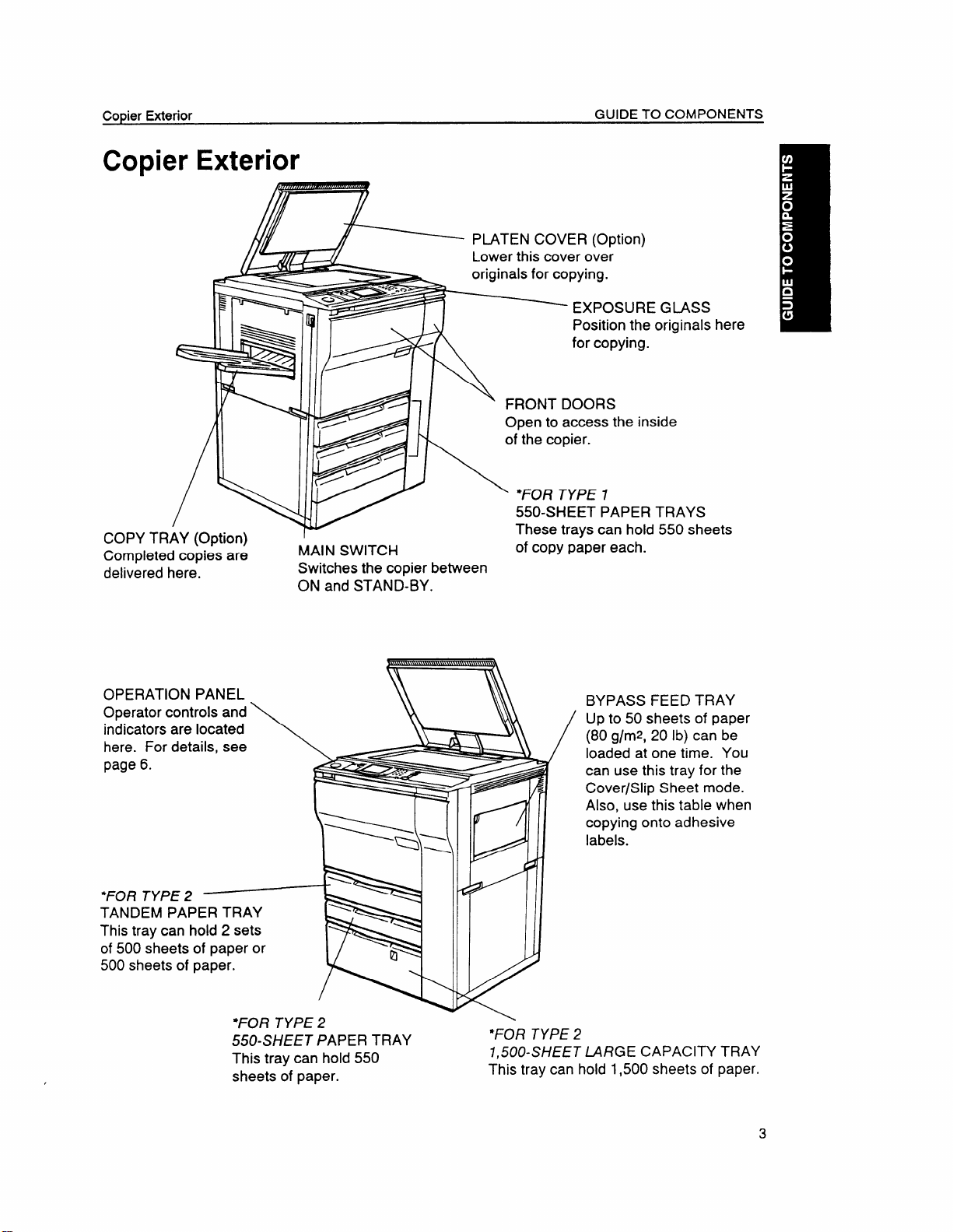

Copier Exterior

Copier Exterior

GUIDE TO COMPONENTS

Ss

als here

:

8

●

●

L

/\ ~ /

COPY TRAY (Option)

Completed copies are

delivered here.

Ep J\

MAIN SWITCH

Switches the copier between

ON and

STAND-BY.

“FOR TYPE 1

550-SHEET PAPER TRAYS

These trays can hold 550 sheets

of copy paper each.

BYPASS FEED TRAY

Up to 50 sheets of paper

(80 g/rep, 20 lb) can be

loaded at one time. You

can use this tray for the

Cover/Slip Sheet mode.

Also, use this table when

copying onto adhesive

labels.

*FOR TYPE 2

55CKWEET PAPER TRAY

This tray can

sheets of paper.

hold 550

\

*FOR TYPE 2

7,500-SHEET

This tray can hold 1,500 sheets of paper.

LARGE CAPACITY TRAY

3

Page 14

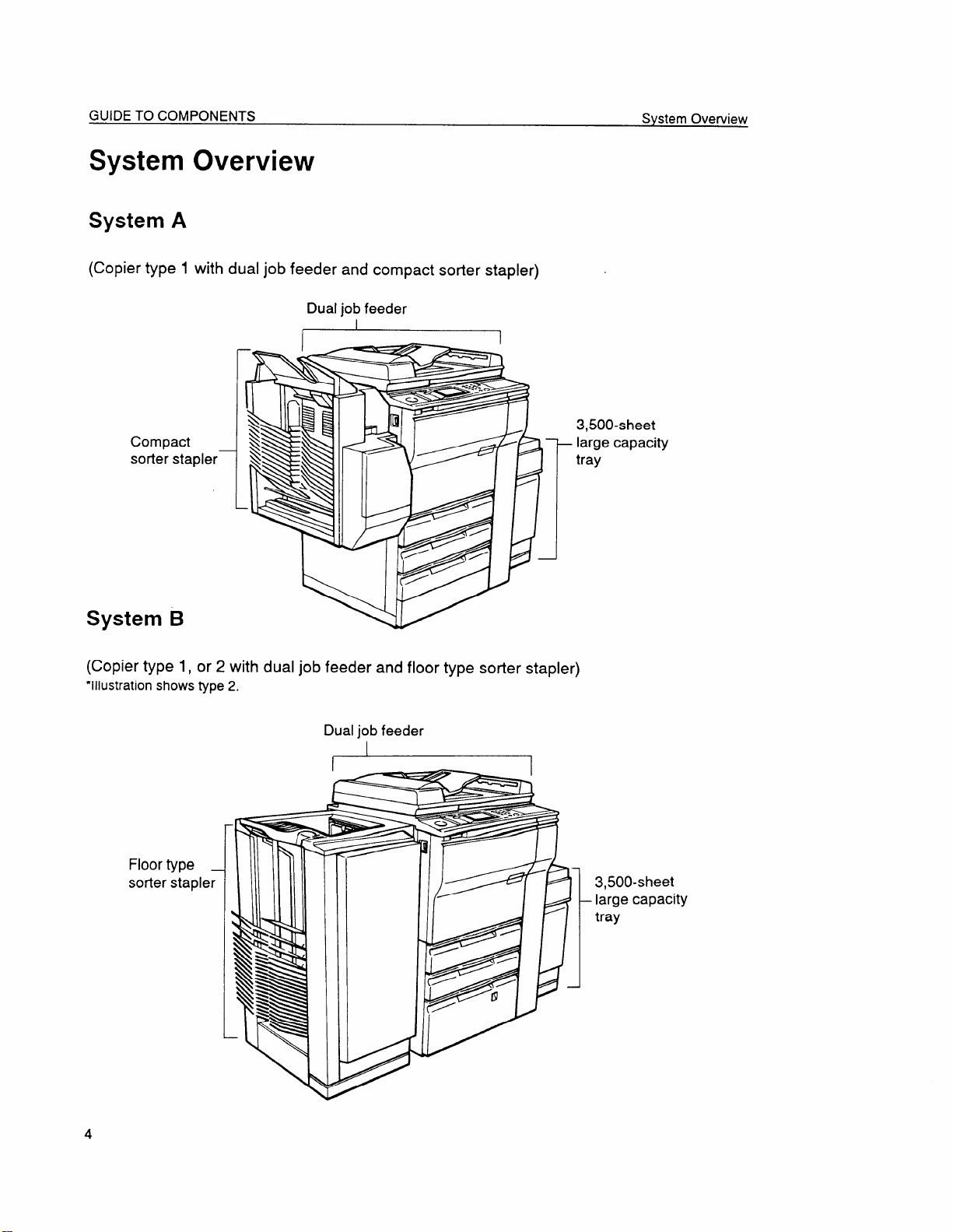

System Overview

System A

(Copier type 1 with dual job feeder and compact sorter stapler)

Dual job feeder

1

Compact

sorter stapler—

3,500-sheet

large capacity

–

tray

System B

(Copier type 1, or 2 with dual job feeder and floor type sorter stapler)

“Illustration shows type 2.

Dual job feeder

.

Floor type _

stapler

sorter

.

3,500-sheet

large capacity

tray

Page 15

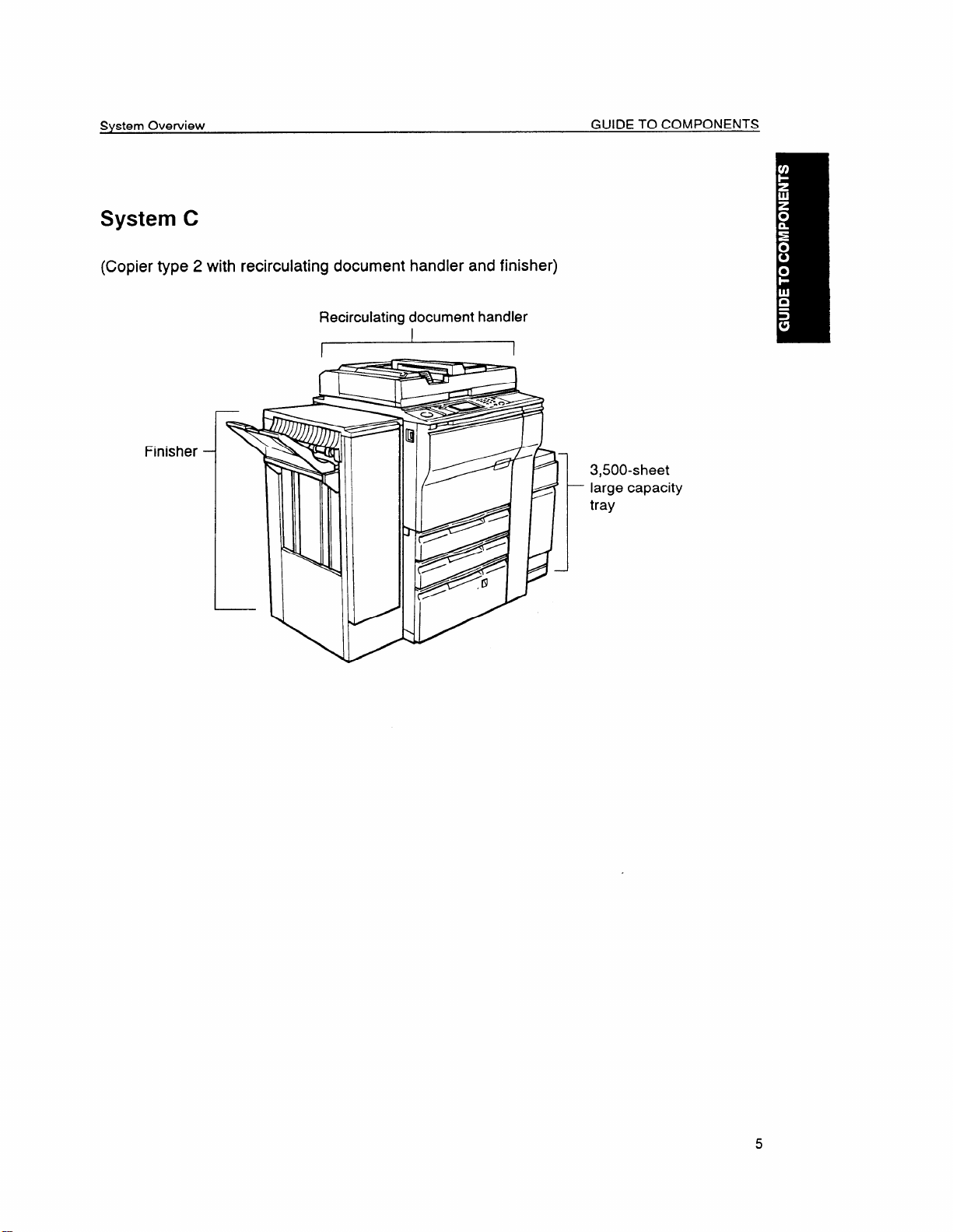

System C

(Copier type 2 with recirculating document handler and finisher)

Recirculating document handler

I 1

i-f==

Finisher

L

/

3,500-sheet

large capacity

–

tray

Page 16

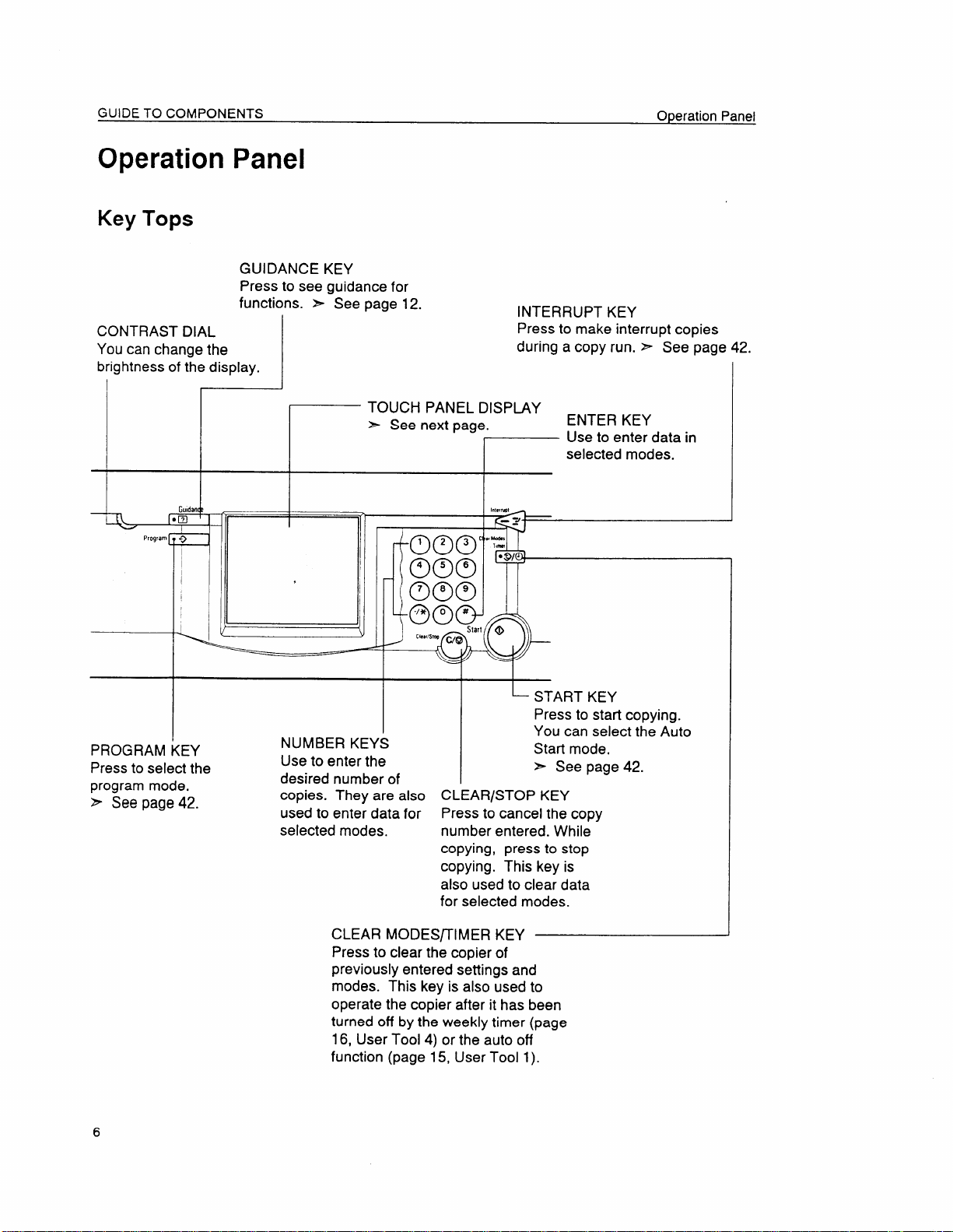

GUIDE TO COMPONENTS

Operation Panel

Key Tops

GUIDANCE KEY

Press to see guidance for

functions. > See page 12.

CONTRAST DIAL

You can change the

brightness of the display.

I

Program ~ ->

I

I

I

I

INTERRUPT KEY

Press to make interrupt copies

during a copy run. Z- See page 42.

TOUCH PANEL DISPLAY

~ See next page.

Operation Panel

ENTER KEY

Use to enter data in

selected modes.

I

I

I

I

PROGRAM ~EY

Press to select the

program mode,

> See page

42.

,

)

NUMBER KEYS

Use to enter the

desired number of

copies. They are also

used to enter data for

selected modes.

L

~ START KEY

Press to start copying.

You can select the Auto

Start

~ See page 42.

CLEAR/STOP KEY

Press to cancel the copy

number entered. While

copying, press to stop

copying. This key is

also used to clear data

for selected modes.

CLEAR MODES/TIMER KEY

Press to clear the copier of

previously entered settings and

modes.

operate the copier after it has been

turned off by the weekly timer (page

16, User Tool 4) or the auto off

function (page 15, User Tool 1).

This key is also used to

mode.

Page 17

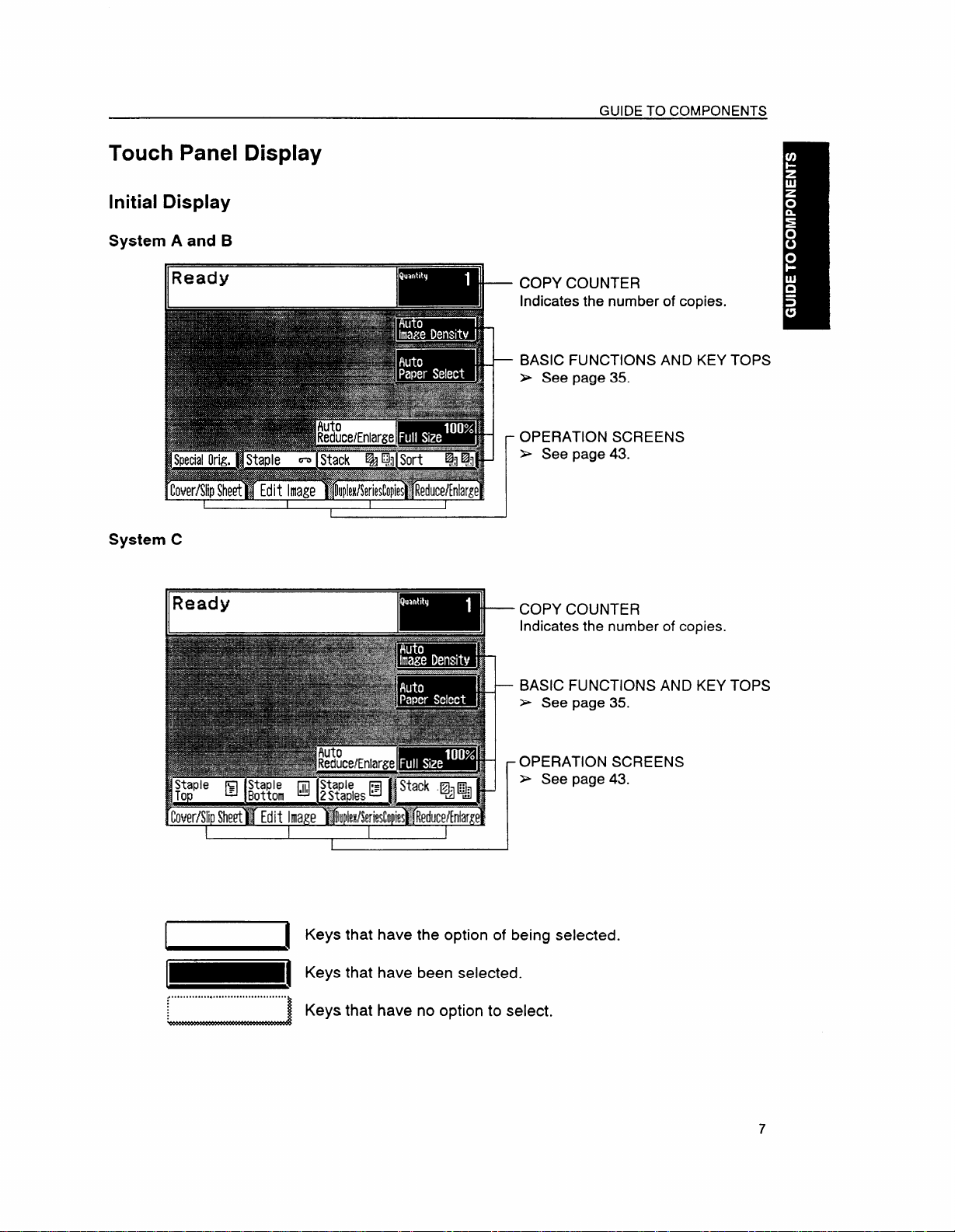

Touch Panel Display

Initial Display

System A and B

GUIDE TO COMPONENTS

System C

COPY

OPERATION SCREENS

COPY COUNTER

COUNTER

Indicates the number of copies.

BASIC FUNCTIONS AND KEY TOPS

x See page 35.

S See page 43.

Indicates the number of copies.

BASIC FUNCTIONS AND KEY TOPS

~ See

page 35.

~

........................................

OPERATION SCREENS

S Seepage 43.

Keys that have the option of being selected.

Keys that have been selected.

Keys that have no option to select.

1

Page 18

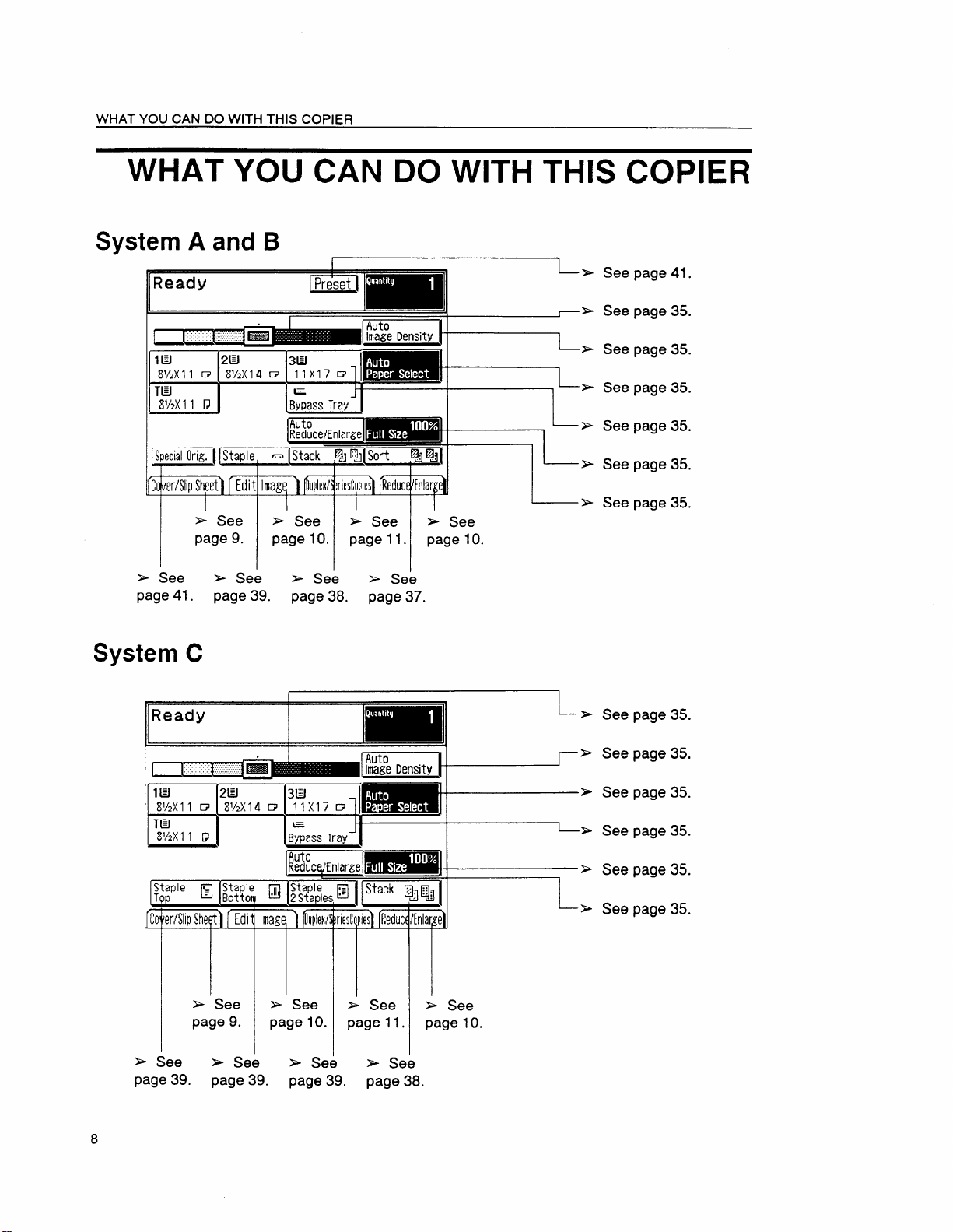

WHAT YOU CAN DO WITH THIS COPIER

WHAT YOU CAN DO WITH THIS COPIER

System A and B

Ready

1“

[

lEJ 2H

81/2x 11 w

TEJ

8V2X11 U

I

8’/2X 14 w

3EI

11X17G

&

.Bwass Tray

Auto

I I

CC~erfSlipShyt] ( Edit Imagq ) f

~ See

page 9.

+ See

page 10.

i

* See ~ See

page 11. page 10.

~> See page 41.

- S See page 35.

X See page 35.

~ See page 35.

1

E

See page 35.

L

S See page

35.

s See

page 41.

System C

t.

Ready

,.,,,.:.,.,......... ..:

I “~

[

lEI

sl/p)(11

T@

8’/2X11

~ See

page 39. page 38. page 37.

.........

2EI

W

W2X14 D

Q

E See s See

page 9.

&

* See

3EJ

llx17c7

=

ByPassTray

page 10.

S See ~ See

page 11.

~ See

page 10.

L-_

~ See page 35.

~ See page 35.

~ See page 35.

S See page 35.

~ See page 35.

S See page 35.

See

~

s See * See

page 39. page 39. page 39. page 38.

8

* See

Page 19

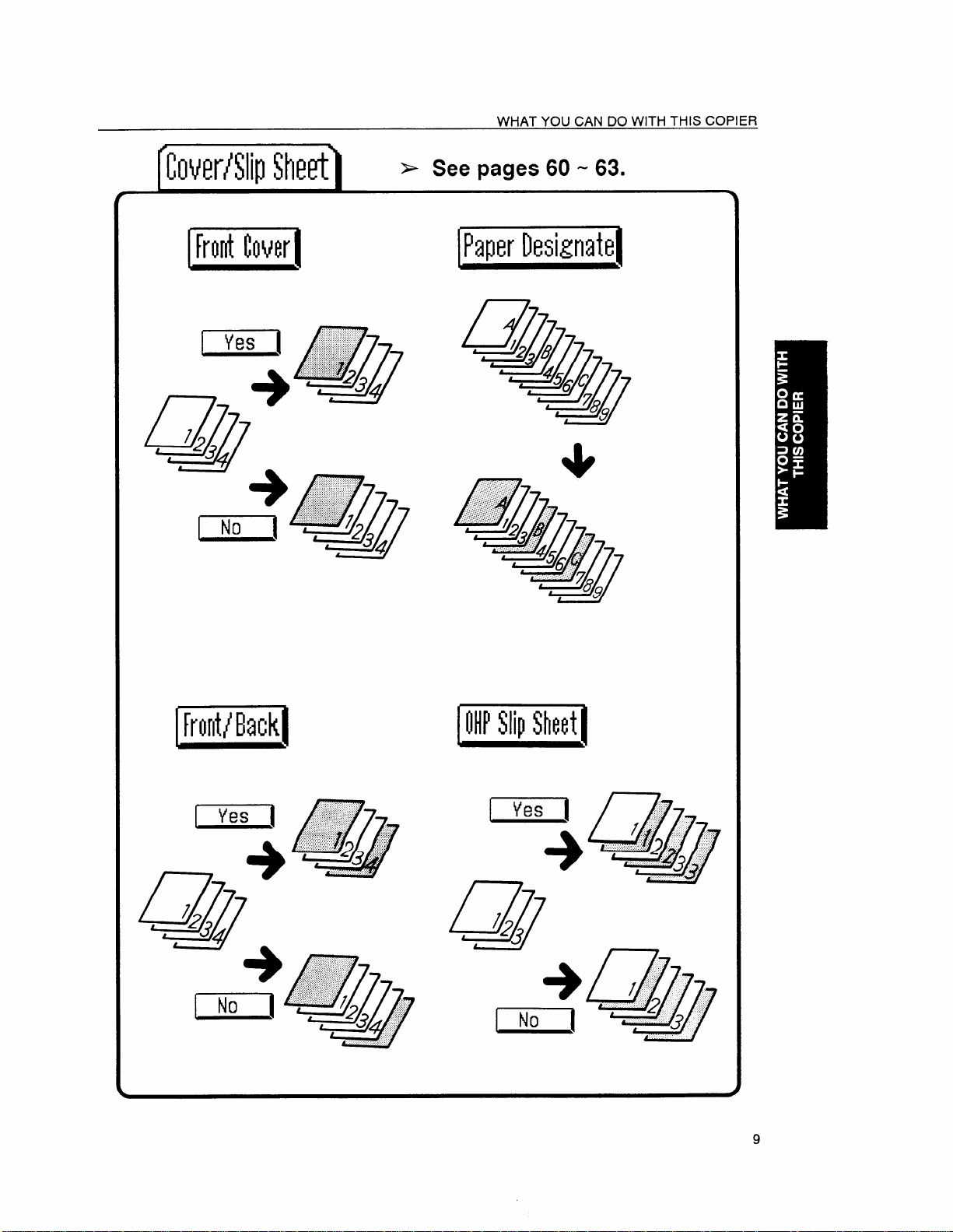

WHAT YOU CAN DO WITH THIS COPIER

.,2

(“)

~hmthwrl

+ See pages 60-63.

lPaperIlesignatel

.,

...

.“,...,,:..,....

..,.,.,.,:.,...,.:,,,,,,,...,.

@i@@fl

+

3.,

“456

789

IN’Yip$hod

m

+

+

@q/

1...”

...........,,,,

#

“2

‘““

33 ‘

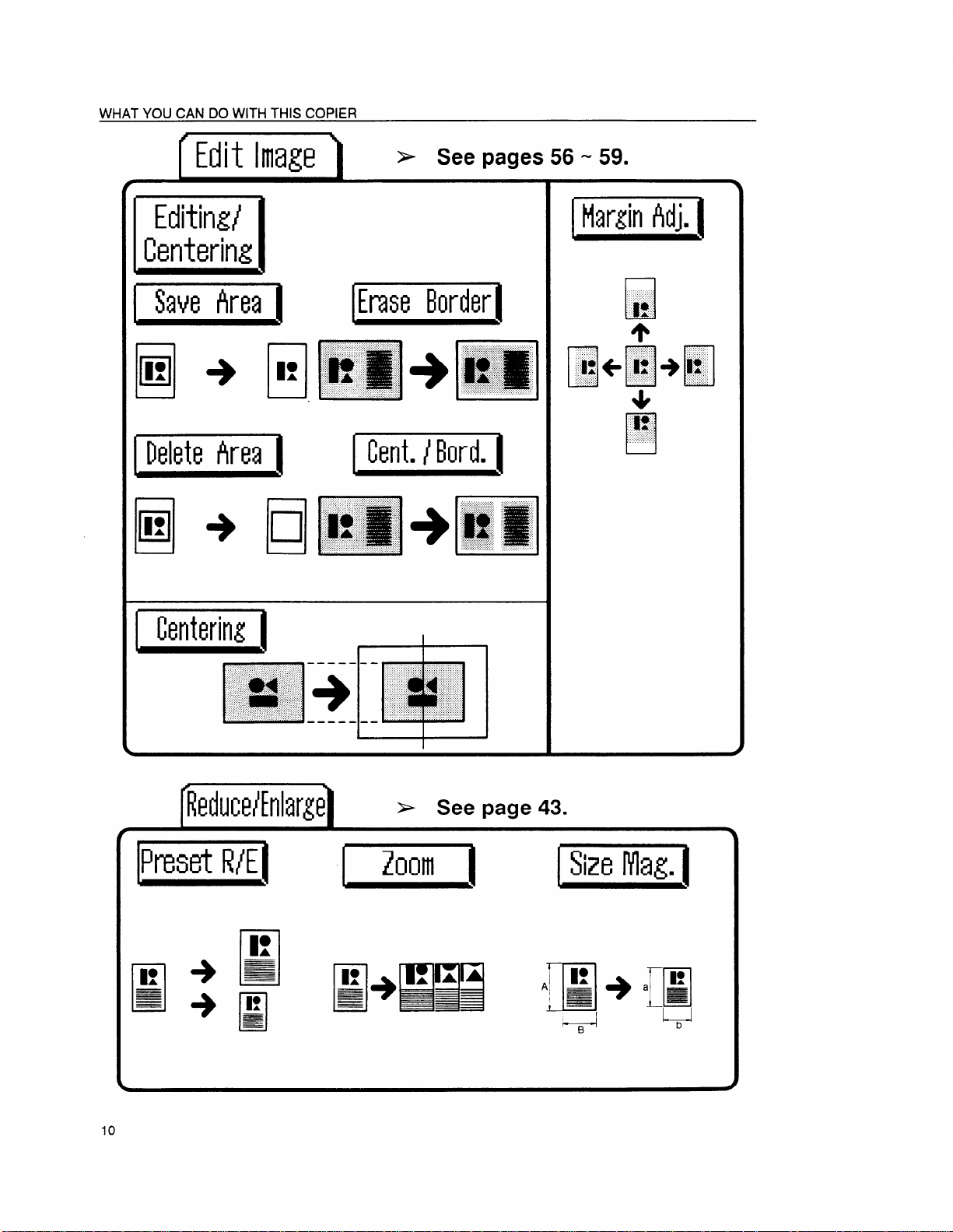

Page 20

WHAT YOU CAN DO WITH THIS COPIER

(“”

Editing/

Centwing

I !hveha I

I 1 f

IMeteAreaI

p

A

El

El

* See pages 56-59.

Erm Borderl

Cent./Bord.I

I

IEm!!LJ

+

l%se’t wl

10

(i-e’

* See page 43.

I hull I

Page 21

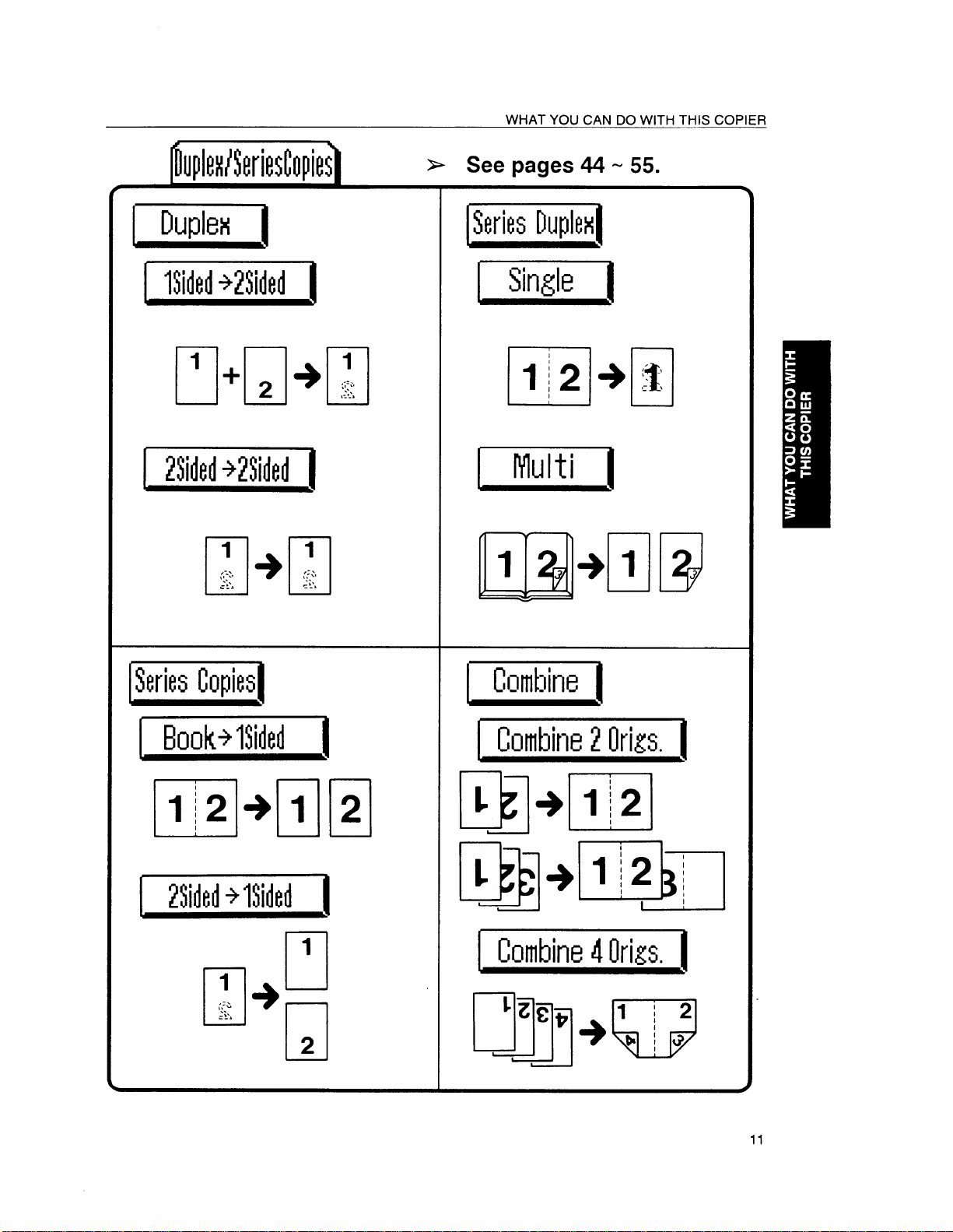

Dupbl I

WHAT YOU CAN DO WITH THIS COPIER

~ See pages 44-55.

1

+

m

2

Kl%l

1

●rl

:~:

,--.-’,

J

Combine

I hnbine2Nkn. I

Emml

1

1

,’,:&

=’;-.,

u

J

+

2

1

I

ICombine4Min. I

+

1

1

11

Page 22

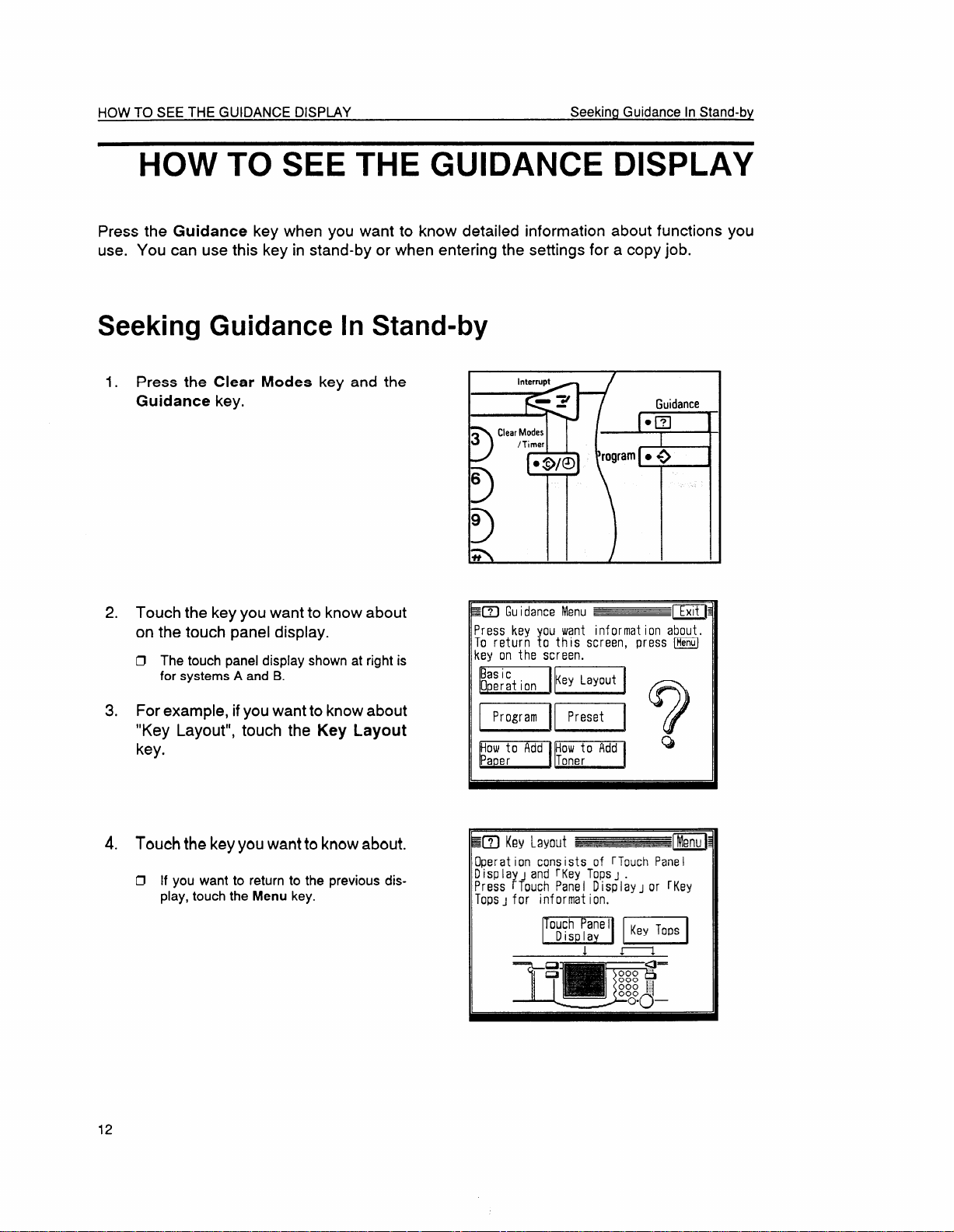

HOW TO SEE THE GUIDANCE DISPLAY

Seeking Guidance In Stand-by

HOW TO SEE THE GUIDANCE DISPLAY

Press the Guidance key when you want to know detailed information about functions you

use. You can use this key in stand-by or when entering the settings for a copy job.

Seeking Guidance In Stand-by

1. Press the Clear Modes key and the

Guidance key,

2. Touch the key you want to know about

on the touch panel display.

O The touch panel display shown at right is

for systems A and B.

3. For example, if you want to know about

“Key Layout”, touch the Key Layout

key.

&

be’

/ Guidance

~~ Guidance Menu

Press key you want information about.

To return to this screen, press m

key on the screen.

Pn=q ~

mm Q

m

4. Touch the key you want to know about.

IJ If you want to return to the previous dis-

play, touch the

12

Menu key.

~m Key Layout

Operation consists of rTouch Pane I

DisplayJ and rKey TOpSJ .

Press rTouch Panel DispiayJ or rKey

TOpSJfor information.

ID

enu

Page 23

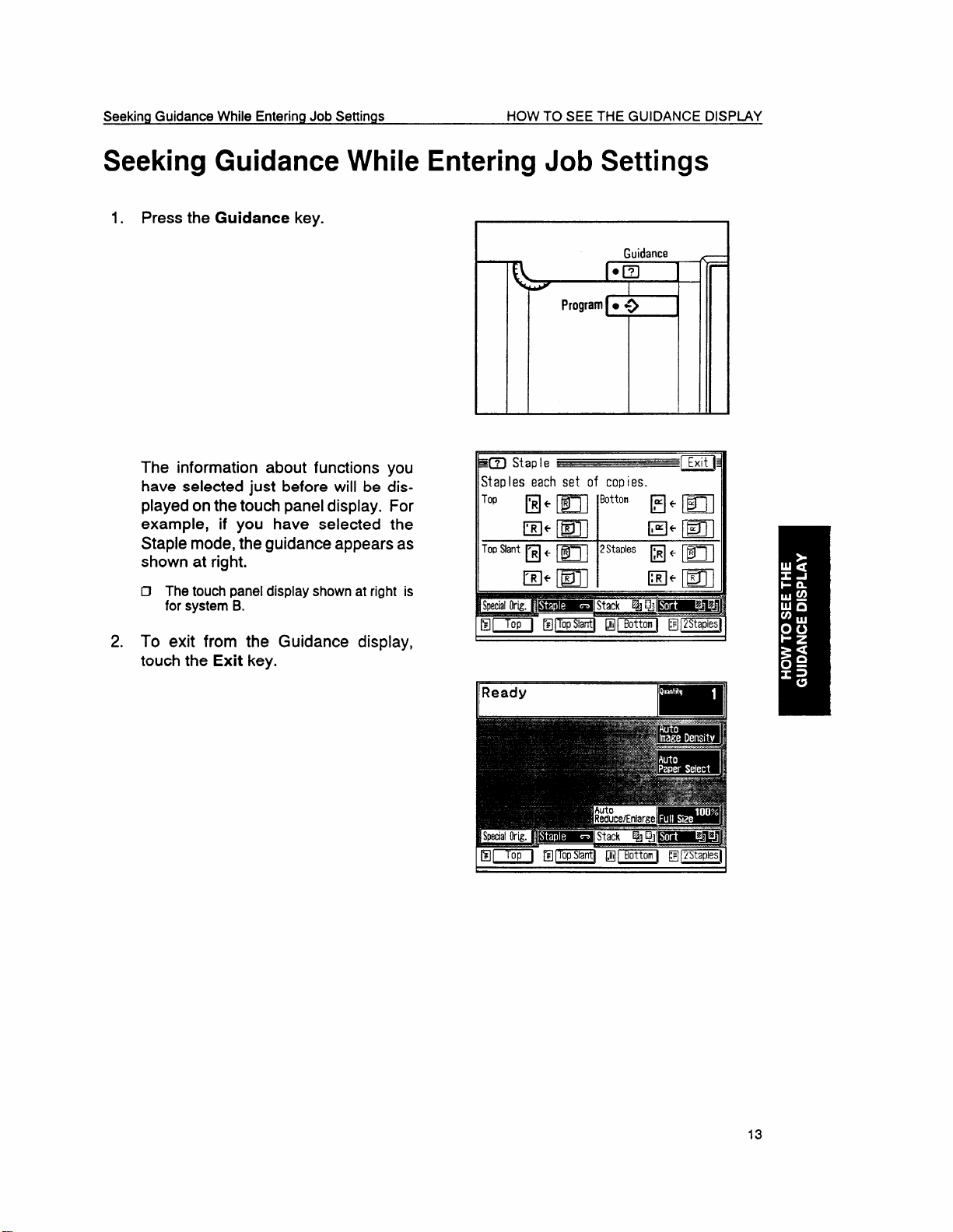

Seeking Guidance While Entering Job Settings

HOW

TO SEE THE GUIDANCE DISPLAY

Seeking Guidance While Entering

1. Press the Guidance key.

I

The information about functions you

have selected just before will be displayed on the touch panel display. For

example, if you have selected the

Staple mode, the guidance appears as

shown at right.

Cl The touch panel display shown at right is

for system B.

Job Settings

Guidance

•~

#

Program● +>

I

n

1

2.

To exit from the Guidance display,

touch the Exit key.

13

Page 24

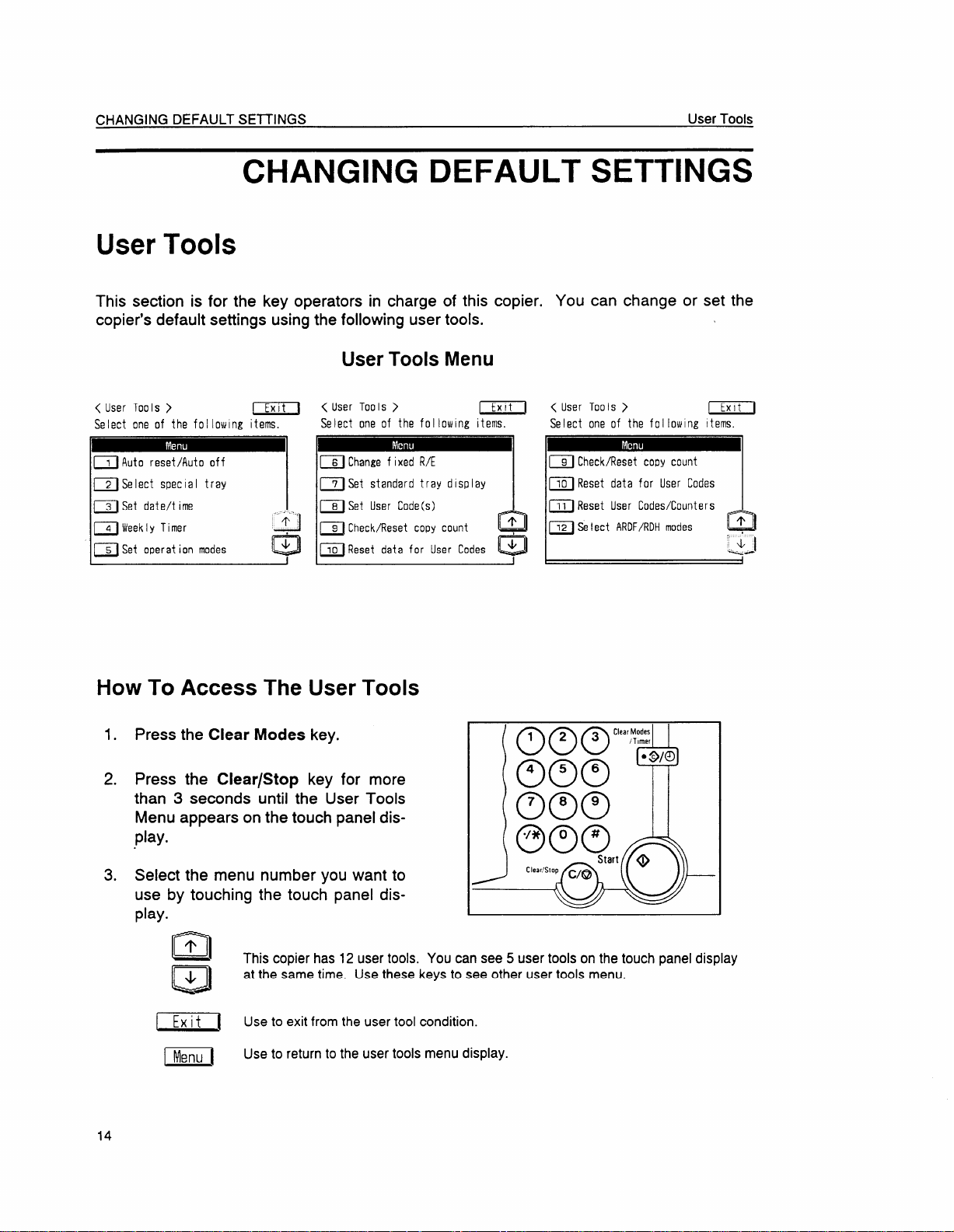

CHANGING DEFAULT SE7TINGS User Tools

CHANGING DEFAULT SETTINGS

User Tools

This section is for the key operators in charge of this copier.

copier’s default settings using the following user tools.

User Tools Menu

<UserTools>

Selectone of the folloiulngitems.

~ Auto rwet/Auto off

~Select specialtray ~Set standardtraydisplay

~ Set date/tIme

~Weekly Timer ~

~ Set operation modes

m

a

< User Tools>

Selectone of the followingItems.

~ ChangefixedR/E

~ Set UserCode(s)

~ Check/Resetcopy count @

~Reset data for User Codes @

m

How To Access The User Tools

10

Press the Clear Modes key.

You can change or set the

< User Tools>

Selectone of the folIowlng[terns.

~ Check/ResetCODY count

~ Resetdatafor User Codes

n ResetUserCodes/Counters

~ SelectARDF/RDH modes m

m

Q1

:Q

2.

Press the Clear/Stop key for more

than 3 seconds until the User Tools

Menu appears on the touch panel dis-

play.

3.

Select the menu number you want to

use by touching the touch panel display.

~

(Ml

+

a

(~[ U.e to exit from

Imd

This copier has 12 user tools. You can see 5 user tools on the touch panel display

at the same time. Use these keys to see other

Use to return to the user tools menu display.

14

user tools menu.

the usertocd Condition

Page 25

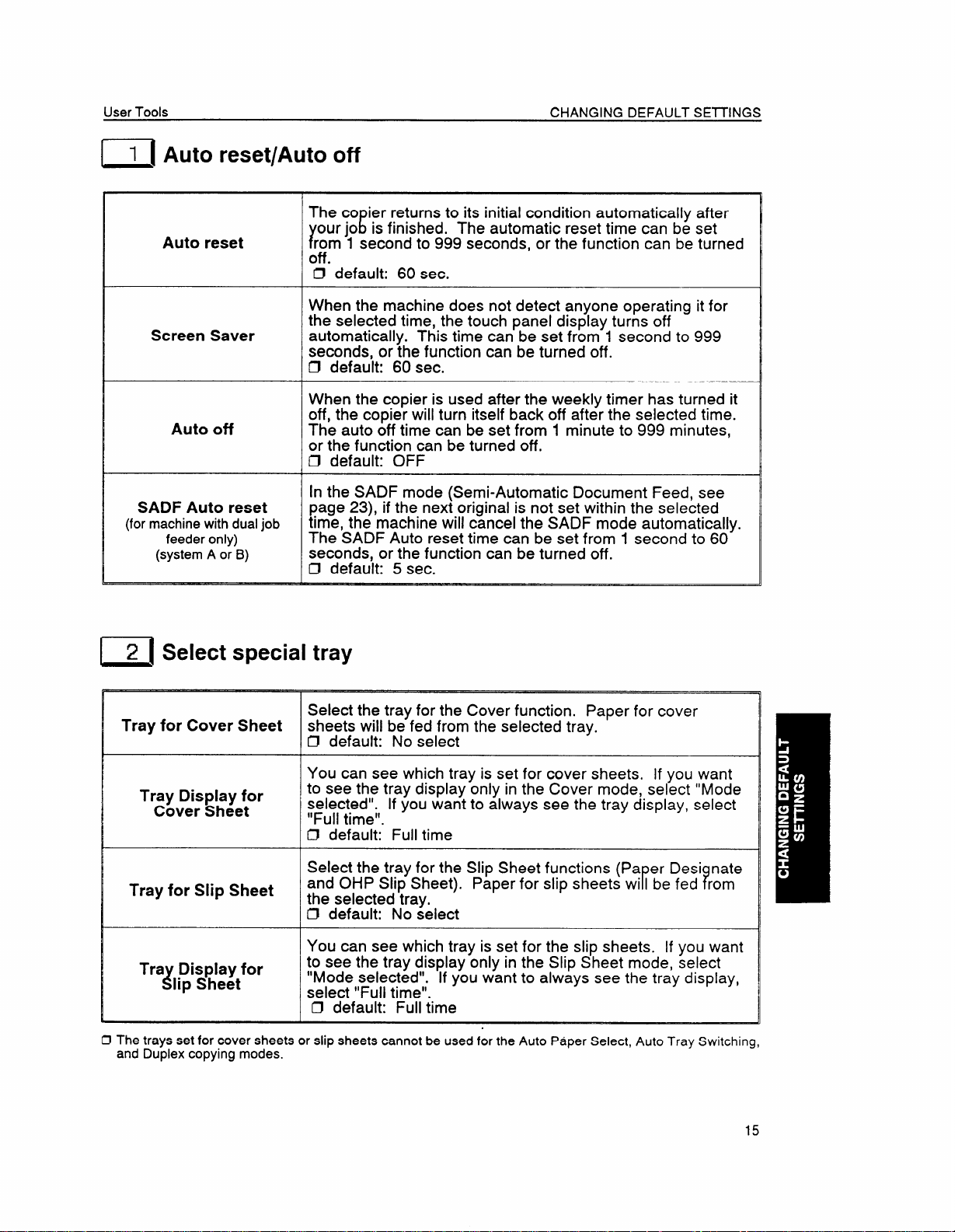

User Tools

[~[ Auto reset/Auto off

The co ier returns to its initial condition automatically after

r

Auto reset

Screen Saver

Off The auto off time can be set from 1 minute to 999 minutes,

Auto

SADF Auto reset

(for machine with dual job

feeder only)

(system

A or B)

rom 1 second to 999 seconds, or the function can be turned

off .

~ default: 60 sec.

When the machine does not detect anyone operating it for

the selected time, the touch panel display turns off

automatically. This time can be set from 1 second to 999

seconds, or the function can be turned off.

~ default: 60 sec.

When the copier is used after the weekly timer has turned it

off, the copier will turn itself back off after the selected time.

or the function can be turned off.

~ default: OFF

In the SADF mode (Semi-Automatic Document Feed, see

page 23), if the next original is not set within the selected

time, the machine will cancel the SADF mode automatically.

The SADF Auto reset time can be set from 1 second to 60

seconds, or the function can be turned off.

Cl default: 5 sec.

CHANGING DEFAULT SEl17NGS

Eour jo is finished. The automatic reset time can be set

I 2 ~Select special tray

Select the tray for the Cover function. Paper for cover

Tray for Cover Sheet

Tray Display for

Cover Sheet

\

Tray for Slip Sheet

1

Tra Display for

i

lip Sheet

1

D The trays set for cover sheets or slip sheets cannot be used for the Auto Paper Select, Auto Tray Switching,

and Duplex copying modes.

sheets will be fed from the selected tray.

Cl default: No select

You can see which tray is set for cover sheets, If you want

to see the tray display only in the Cover mode, select “Mode

selected”. If you want to always see the tray display, select

“Full time”.

0 default: Full time

Select the tray for the Slip Sheet functions (Pa er Desi nate

and OHP Slip Sheet). Paper for slip sheets

the selected tray.

O default: No select

You can see which trav is set for the slit) sheets. If vou want

to see the tray display-only in the Slip S’beet mode, ~elect

“Mode selected”. If you want to always see the tray display,

select “Full time”.

I Cl default: Full time

WI I be fed rom

‘t’ ?

15

Page 26

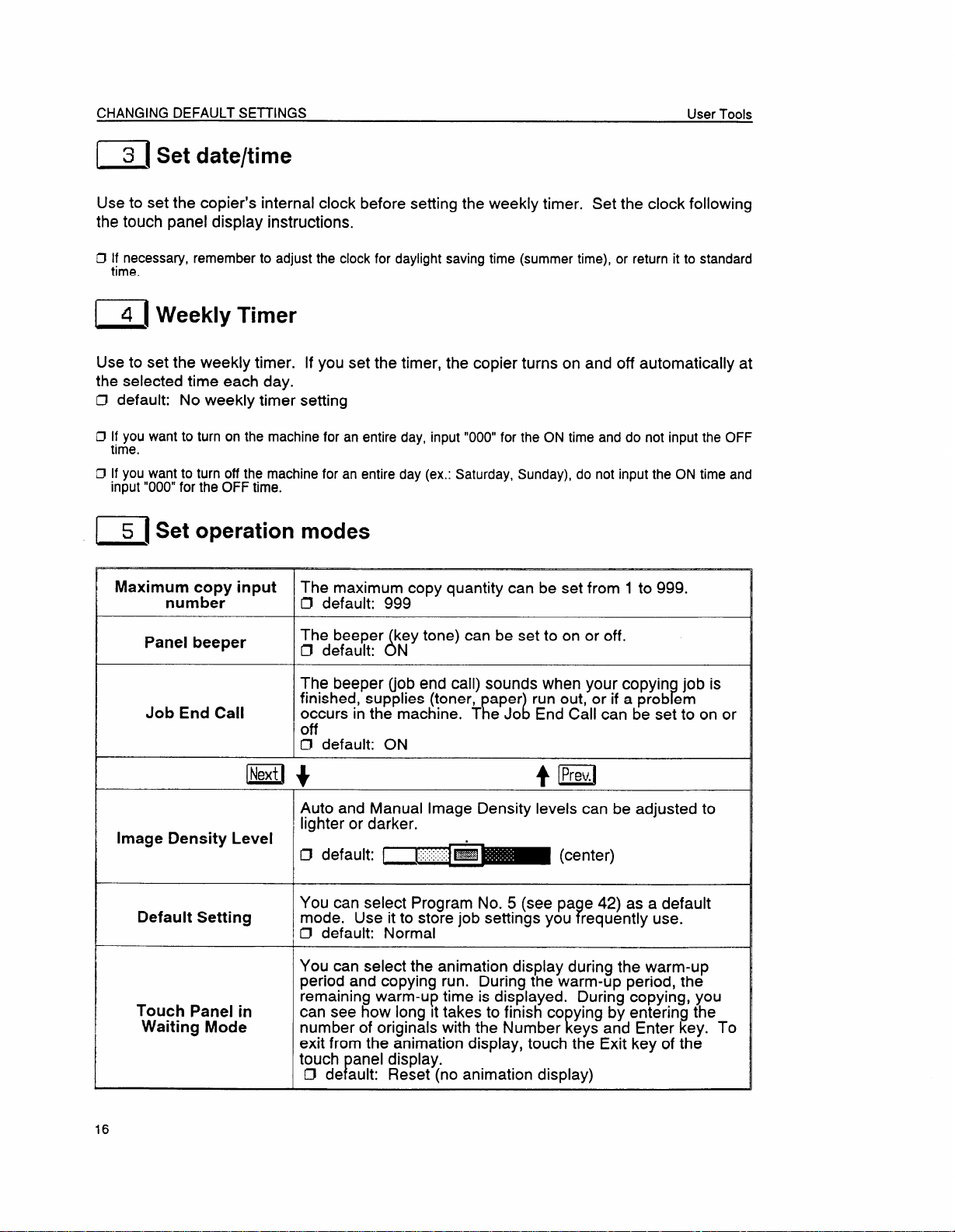

CHANGING DEFAULT SEITINGS

User Tools

Use to set the copier’s internal clock before setting the weekly timer. Set the clock following

the touch panel display instructions.

If necessary, remember to adjust the clock for daylight saving time (summer time), or return it to standard

0

time.

[~1 Weekly Timer

Use to set the weekly timer. If you set the timer, the copier turns on and off automatically at

the selected time each day.

D default: No weekly timer setting

O If you want to turn on the machine for an entire day, input “000” for the ON time and do not input the OFF

time.

If you want to turn off the machine for an entire day (ex.: Saturday, Sunday), do not input the ON time and

El

input “000” for the OFF time.

~[ Set operation modes

Maxim; ~mc:~ry input The maximum copy quantity can be set from 1 to 999.

Cl default: 999

Panel beeper

The beeper key tone) can be set to on or off.

ACl default: N

The beeper (job end call) sounds when your copyin job is

Job End Call occurs in the machine. T e Jo End Call can be set to on or

RL

finished, supplies (toner,

Faper run out, or if a prob em

off

~ default: ON

m+

+ ~~

Auto and Manual Image Density levels can be adjusted to

lighter or darker.

Image Density Level

Cl default: ~ IW;:; &

~~~ (center)

You can select Program No. 5 (see pa e 42) as a default

Default Setting ?mode. Use it to store job settings you requently use.

Cl default: Normal

You can select the animation display during the warm-up

period and copying run. During the warm-up period, the

remaining warm-up time is displayed. During copying, you

Touch Panel in

Waiting Mode

can see how long It takes to finish co ying by entering the

Enumber of originals with the Number eys and Enter key. To

exit from the animation display, touch the Exit key of the

touch anel display.

PCl de ault: Reset (no animation display)

16

Page 27

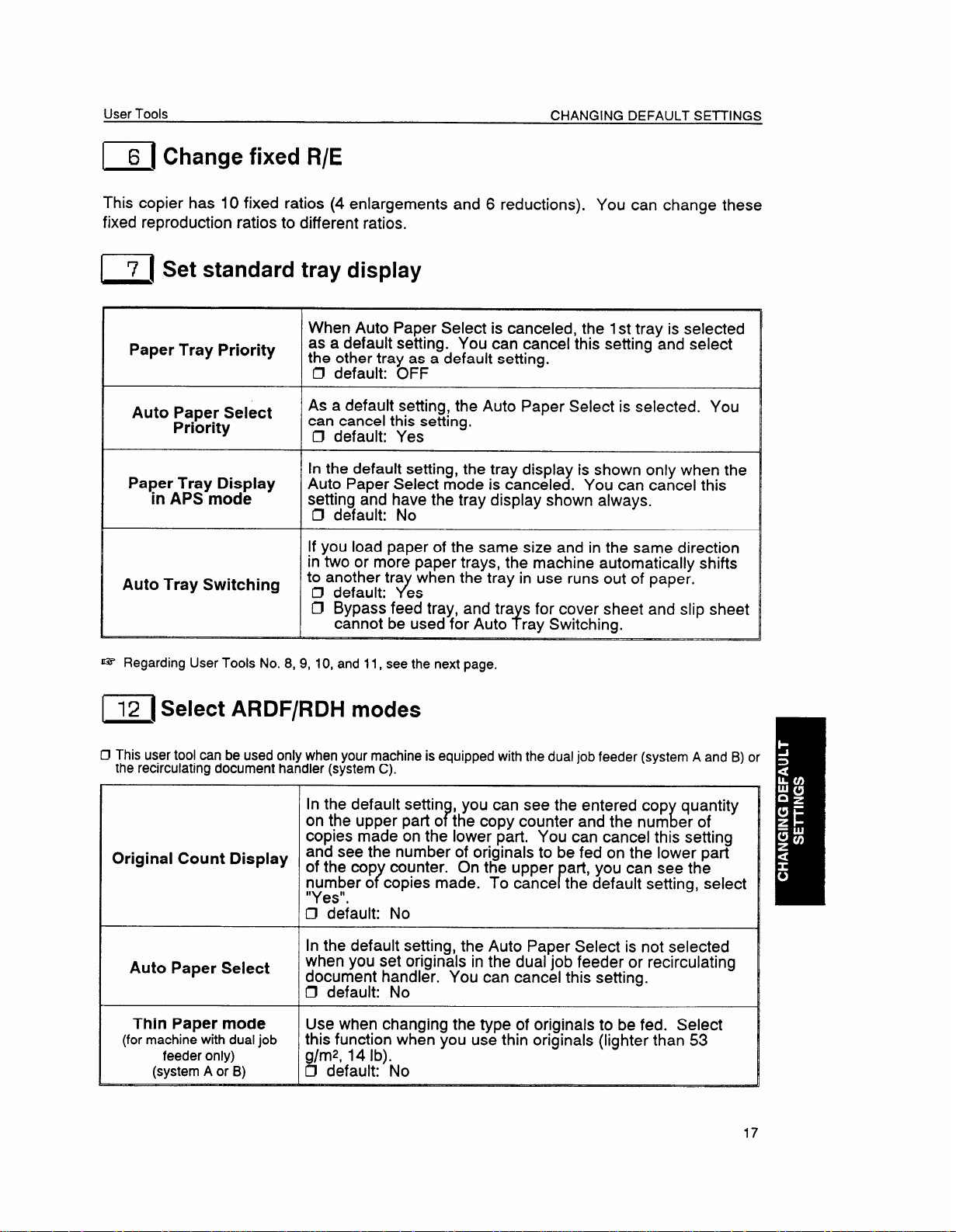

User Tools

CHANGING DEFAULT SETTINGS

~[

This copier has 10 fixed ratios (4 enlargements and 6 reductions). You can change these

Change fixed R/E

fixed reproduction ratios to different ratios.

7 Set standard tray display

n

When Auto Paper Select is canceled, the 1st tray is selected

Paper Tray Priority

as a default setting. You can cancel this setting and select

the other tray as a default setting.

~ default: OFF

Auto Paper Select

Priority

Paper Tray Display

in APS mode

As a default setting, the Auto Paper Select is selected. You

can cancel this setting,

Cl default: Yes

In the default setting, the tray display is shown only when the

Auto Paper Select mode is canceled. You can cancel this

setting and have the tray display shown always.

~ default: No

If you load paper of the same size and in the same direction

in two or more paper trays, the machine automatically shifts

Auto Tray Switching

to another tra when the tray in use runs out of paper.

Cl default: es

J

Cl Bypass feed tray, and tra s for cover sheet and slip sheet

{cannot be used for Auto ray Switching.

~ Regarding User Tools No. 8, 9, 10, and 11, see the next page.

[ 12 ISelect ARDF/RDH modes

O This user tool can be used only when your machine is equipped with the dual job feeder (system A and B) or

the recirculating document handler (system C).

In the default settin , you can see the entered cop quantity

?

t

r

Original Count Display

Auto Paper Select

Thin Paper mode

(for machine with dual job

only)

feeder

(system A or B)

on the upper part o the copy counter and the num er of

copies made on the lower part. You can cancel this setting

and see the number of originals to be fed on the lower part

of the cop counter. On the upper art, you can see the

number o copies made. To cance the default setting, select

?

“Yes”.

I ~ default: No

I

In the default setting, the Auto Paper Select is not selected

when you set originals in the dual job feeder or recirculating

document handler. You can cancel this setting.

~ default: No

Use when changing the type of originals to be fed. Select

this function when you use thin originals (lighter than 53

g/mz, 14 lb).

Cl default: No

17

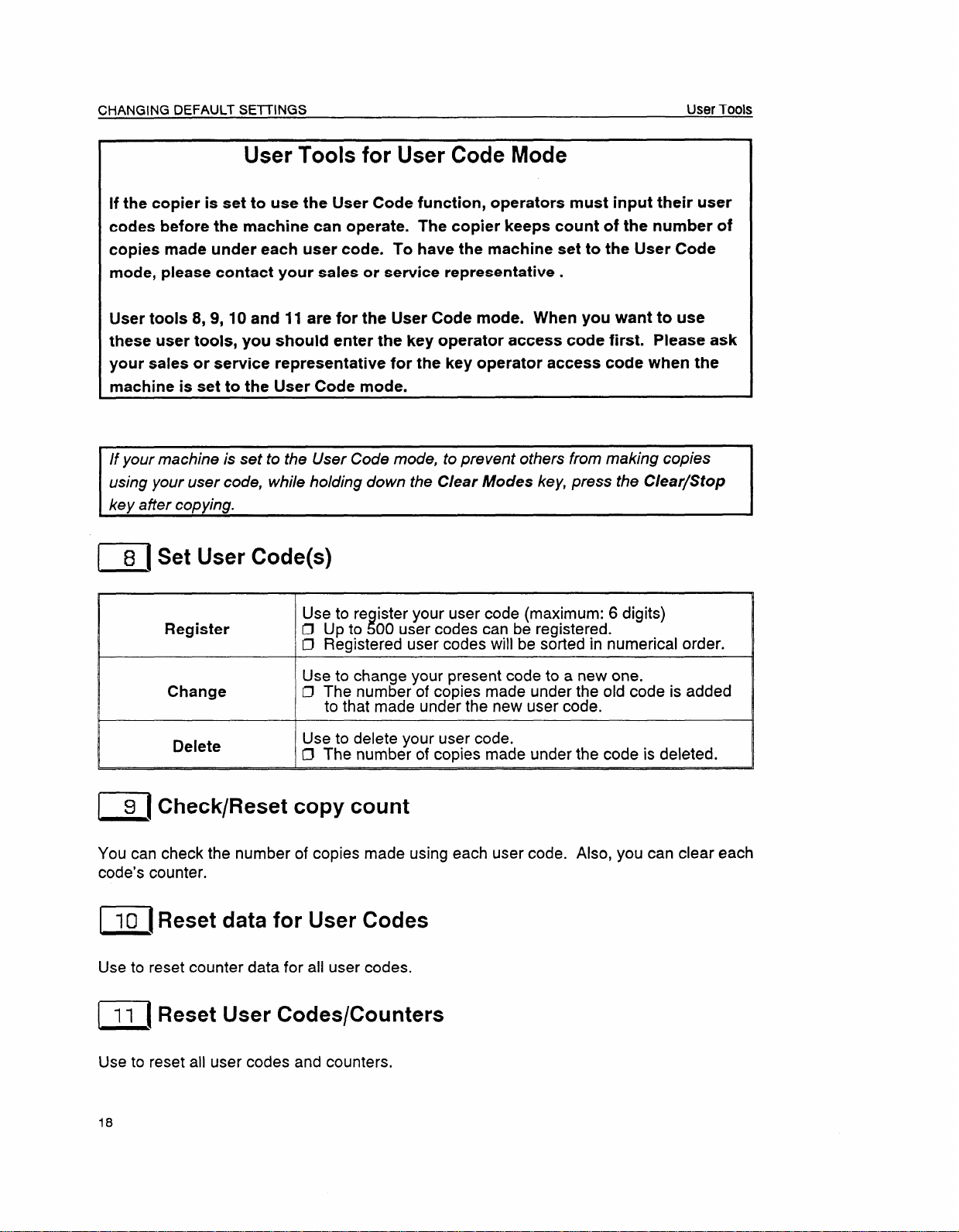

Page 28

CHANGING DEFAULT SETTINGS

User Tools

User Tools for User Code Mode

If the copier is set to use the User Code function, operators must input their user

codes before the machine can operate. The copier keeps count of the number of

copies made under each user code. To have the machine set to the User Code

mode, please contact your sales or service representative .

User tools 8,9, 10 and 11 are for the User Code mode. When you want to use

these user tools, you should enter the key operator access code first. Please ask

your sales or service representative for the key operator access code when the

machine is set to the User Code mode.

If your machine is set to the User Code mode, to prevent others from making copies

using your user code, while holding down the Clear Modes key, press the Clear/Stop

kev afier coDvina.

~[ Set User Code(s)

Use to re ister your user code (maximum: 6 digits)

Register ~Cl Up to 00 user codes can be registered.

~ Registered user codes will be sorted in numerical order.

to change your present code to a new one.

Change

Delete

g Check/Reset copy count

c1

You can check the number of copies made using each user code. Also, you can clear each

code’s counter.

Use

D The number of copies made under the old code is added

to that made under the new user code.

Use to delete your user code.

~ The number of copies made under the code is deleted.

~[Reset data for User Codes

Use to reset counter data for all user codes.

11 Reset User Codes/Counters

n

Use to reset all user codes and counters,

18

Page 29

Remmmended Originals

SEITING ORIGINALS IN THE DUAL

SETTING ORIGINALS IN THE DUAL JOB

FEEDER

Recommended Originals

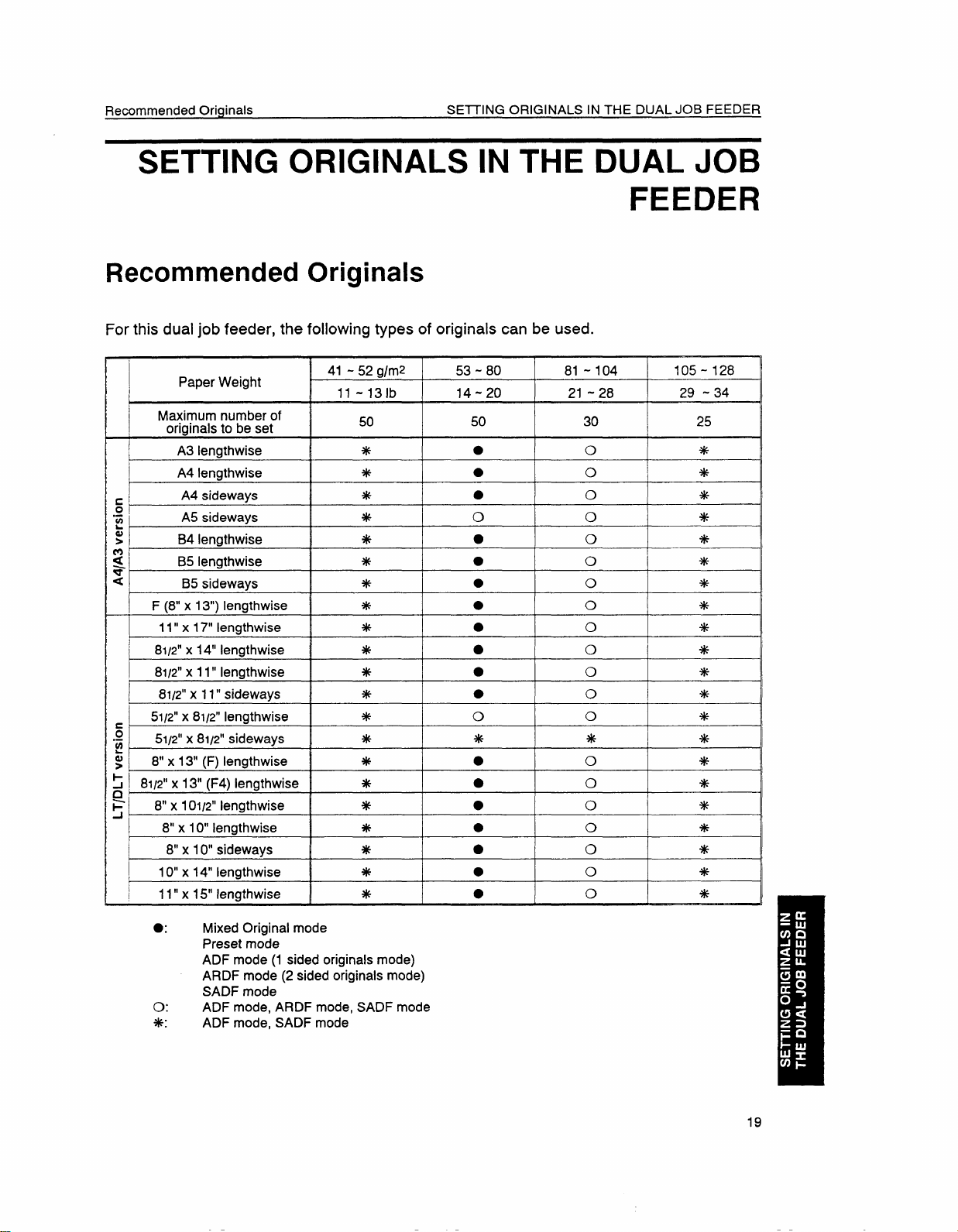

For this dual job feeder, the following types of originals can be used.

JOB FEEDER

Paper Weight

Maximum number of

originals to be set

A3 lengthwise *

A4 lengthwise *

c.

01

z

b

a)

>

2

*

<

~

.-

(0

&

; I

cl)

F

J

I 8“ x 10“ lengthwise

I

~ 10“

I

A4 sideways *

A5 sideways

B4 lengthwise

B5 lengthwise * ●

B5 sideways *

F (8” x 13“) lengthwise *

11” x 17“ lengthwise * ●

81/2” x 14“ lengthwise

81/2”x 11” lengthwise

81I2”x 11” sideways *

51/2” x 81/2” lengthwise * o 0 *

51@’ x 81/2” sideways

8“ x 13” (F) lengthwise

81I2”x 13“ (F4) lengthwise

x 10IK!”lengthwise

8“

8“ x 10“ sideways

x 14” lengthwise

x 15“ lengthwise *

11”

41-52 glmz 53-80

11 -131b 14-20

50

* o

*

*

*

j

i

* * * +$

* ●

*

*

*

*

* ●

50

●

●

●

●

●

●

●

●

●

●

●

o

●

●

81-104

21-28

30 25

o

o

o

0

o

o

o

o *

o *

o *

o

o

o *

o +$

o

0 *

o

o

o

105-128

29 -34

*

*

4$

*

*

*

*

*

*

*

*

*

*

●✚

Mixed Original mode

Preset mode

ADF mode (1 sided originals mode)

ARDF mode (2 sided originals mode)

mode

SADF

o: ADF mode, ARDF mode, SADF mode

*:

ADF mode, SADF mode

Page 30

SEITING ORIGINALS IN THE DUAL JOB FEEDER

Non-recommended Oriqinals

Non-recommended Originals

Caution: The following types of originals are not recommended for use with the dual job

feeder. Please place them directly on the exposure glass.

Originals thicker than 128 g/rep,34 lb

o

Originals thinner than 41 g/rep,11 lb

n

c1

Paper with any kind of coating

Originals smaller than A5 sideways,

o

0

Originals larger than A3, 11” x 17“

0

Folded, curled, creased, or damaged originals

Mailing labels, or perforated originals

c1

o

Bound, stapled, or clipped originals

0

OHP transparencies

Thermal fax paper

0

(such as carbon) on the back, or originals that are taped together

5112”x 8112”

20

Page 31

Setting A Stack Of Originals

SEITING ORIGINALS IN THE DUAL JOB FEEDER

Setting A Stack Of Originals

Automatic Document Feed (ADF) mode (I Sided originals mode)

Automatic Reverse Document Feed (ARDF) mode

(2 Sided Originals mode)

In this mode, the operator inserts a stack of originals of the same size into the original table.

These originals are individually fed onto and removed from the exposure glass.

1. Correct any curl, fold, or crease in the

originals before setting. Square the

stack of originals.

9V

.Q

2. Confirm that the Insert Original

dicator is lit before setting.

3. Confirm that no previous originals

remain on the exposure glass.

4. Adjust the original guide to the original

size.

in-

21

Page 32

5, Set originals face up into the dual job

feeder until the

dicator goes off.

IJ The original guide must touch the front

side of the originals.

Cl Do not stack originals above the limit

mark.

Insert Original in-

Press the Start key,

6.

The bottom sheet of the original stack

(last page) is fed into the dual job

feeder first.

‘f=%+

I

I

22

Page 33

Setting One Original At A Time SETTING ORIGINALS IN THE DUAL JOB FEEDER

Setting One Original At A Time

Semi-Automatic Document Feed (SADF) mode

In thk mode, the operator inserts one original at a time into the dual job feeder. The original

automatically fed onto and removed from the exposure glass.

is

Correct

1.

originals before setting.

Confirm that the Insert Original in-

2.

dicator is lit before setting.

Confirm that no previous originals

3.

any curl, fold, or crease in the

remain on the exposure glass.

+@

Qv

4

b

a

tlb

Adjust the original guide to the original

4.

size.

23

Page 34

SEITING ORIGINALS IN THE DUAL JOB FEEDER

5. Set the original face up into the dual

job feeder until the Insert Original

indicator goes off.

O Start with the last page of the originals.

O The original guide must touch the front

side of the original.

6. Press the Start key.

Setting One Original At A Time

-

J

7.8.While the Auto Feed indicator is lit

after an original is fed, set the next

original. The original is automatically

fed and copied.

O While the

dual job feeder is ready for another

original. (You can change this time by

User Tool 1. See page 15.)

Repeat steps

Auto Feed indicator is lit, the

5 and 7 until copying is

completed.

24

Page 35

Setting Different Sized Originals SE7TING ORIGINALS IN THE DUAL JOB FEEDER

Setting Diffe Sized Originals

Mixed Sized mode

In this mode, you can set originals with different widths and lengths together into the dual job

feeder. You can use the following sizes:

A4/A3 version:

LT/DLT version:

1.

Touch the Special Orig. key of the

touch panel display. (See page 41.)

2.

Touch the Mixed Sizes key of the

touch panel display. (See page 41.)

3.

Correct any curl, fold or

originals before setting.

A3, B4, A4 and B5

11” x 17”, 81/2” x 14”, and 81iz” x 11“

4.

Confirm that the Insert Original indicator is lit before setting.

5.

Confirm that no previous originals

remain on the exposure glass.

25

Page 36

SEITING ORIGINALS INTHE DUAL JOB FEEDER

6. Adjust the original guide to match the

widest original.

7. Set the originals face up into the dual

job feeder until the insert Original

indicator goes off.

Setting Different Sized Originals

Cl Originals must be aligned to the rear-left

corner of the dual job feeder,

8. Press the Start key.

as shown.

1, I

—

.

—

7

—

—

—

—

T-Q

J

L IF7

Page 37

Setting A Pasted Original

SEITING ORIGINALS IN THE DUAL JOB FEEDER

Setting A Pasted Original

Pasted Original mode

In this mode, you can set a pasted original into the dual job feeder.

o In this mode, you can set one original at a time.

1. Touch the Special Orig. key of the

touch panel display. (See page 41.)

2. Touch the Pasted Original key of the

touch panel display. (See page 41.)

3. Correct any curl, fold or crease in the

originals before setting.

1

4. Confirm that the Insert Original in-

dicator is lit before

5. Confirm that

remain on the

6. Adjust the original guide to the original

size.

setting.

no previous originals

exposure glass.

27

Page 38

SETTING ORIGINALS IN THE DUAL JOB FEEDER

one pasted original face Up into the

Set

7.

dual job feeder until the

Insert Original

indicator goes off.

O Start with the last page of originals.

Cl The original guide must touch the front

side of the original.

Setting A Pasted Original

8. Press the

Start key.

9. While the Auto Feed indicator is lit

after an original is fed, set the next

original. The original is automatically

fed and copied.

~ While the Auto Feed indicator is lit, the

dual job feeder is ready for another

original. (You can change this time by

User Tool 1. See page 15.)

Clear/Stop~

I

I J “’WL N ))!

—..

10. Repeat steps 7 and 9 until copying is

completed.

28

Page 39

Presetting Originals During A Copy Run

SETTING ORIGINALS IN THE DUAL JOB FEEDER

Presetting Originals During A Copy Run

1. Touch the Preset key of the touch

panel display. (See page 41.)

Following the instructions on the dis-

2.

play, set the copy job settings for your

next job.

3.

Touch the Exit key of the touch panel

display.

Copying

You can preseta jobwith~

llEiD

AutoImageDensity 213 Iyzxlq~

m

Sort

The touch panel display changes as

shown.

Set the originals for your next job on

top of the originals being copied.

Without forcing them, push them in

completely.

O Do not insert the originals too strongly.

Place the preset originals on top

of the originals being copied,

Press ~.

then

Firstoriginals Presetoriginals

J “

I

J[

29

Page 40

SETTING ORIGINALS IN THE DUAL JOB FEEDER

Touch the Exit key of the touch panel

5.

display.

After your first job is finished, the next

will start automatically.

job

Presetting Originals During A Copy Run

,,PJ,esej,,

~–’”7

Place the preset originals on top

of the originals being copied,

then press ~.

First originals

~

;[

/A[=i[ Exit

Presetoriginals

—J—l==\ q

1

;

~

~[

!(

1 @

J“

ClWhen presetting ajob using the compact sorter stapler, you have to remove the currentjob’s copies from the

sorter stapler before the preset job can start.

O When presetting a job using the

before the preset job can start. You have to do this

when you make 11 or more copies in the current job.

when you make 10 copies in the current and 10 or more for the next.

when you make 9 or less copies for the current and 11 or more for the next.

floor type sorter stapler, you might have to remove the current job’s copies

I u

1$

I

q

30

Page 41

Recommended Originals

SEITING ORIGINALS IN THE RECIRCUI,ATING DOCUMENT HANDLER

SETTING ORIGINALS IN THE

RECIRCULATING DOCUMENT HANDLER

Recommended Originals

For this recirculating document handler, the following types of originals can be used.

52-103

SIZE

c

o

,-

~

@

>

2

a

u

c

o

.-

~

@

;

n

i=

J

0 Translucent paper cannot be recirculated.

A3 lengthwise

F (8” x 13“) lengthwise

A4 sideways

A4 lengthwise

A5 lengthwise

11” x 17“ lengthwise

81/2”x 14 lengthwise

11” x 15“ lengthwise

10“ x 14“ lengthwise

8112°x 13“ (F4) lengthwise

8“ x 13“ (F) lengthwise

81I2”x 11“”sideways

8112”x 11” lengthwise

51/2”x 81/2”lengthwise

x 10“ lengthwise

8“

14-27 (lb)

25 sheets 20 sheets

(g/m2)

50 sheets

50 sheets

104

28

40 sheets

20 sheets

40 sheets *3O sheets

●l-L--- -.:-:--1- -----~ k- ---: -..,,1-+-4

I [lt5Sf5 UIIYIIIWS LXIIIIIU1 LW l~LJIGUldl~U.

105-128

29-34

*2O sheets

’30 sheets

31

Page 42

SETTING ORIGINALS IN THE RECIRCULATING DOCUMENT HANDLER

Non-recommended Originals

Non-recommended Originals

Caution: The following types of origins/s are not recommended for use with the recirculat-

ing document handler. Please place them directly on the exposure glass.

O Originals thicker than 128 g/m2, 34 lb

D Originals thinner than 52 g/rep, 14 lb

D Paper with any kind of coating (such as carbon) on the back, or originals that are taped together

D Originals smaller than A5 lengthwise, 51/2” x 81/2” lengthwise

O Originals larger than A3, 11” x 17“

C! Folded, curled, creased, or damaged originals

IJ Mailing labels, perforated originals, or pasted originals

Cl Bound, stapled, or clipped originals

IY OHP transparencies

C! Thermal fax paper

Setting Originals

1. Correct any curl, fold, or crease in the

originals before setting.

O If you want to use originals of which you

cannot correct the curl, fold, or crease, do

the following:

O First make one set of copies of originals,

and use these copies as the recirculating

originals.

Limit the number of copies for one set of

originals to 30.

2. Confirm that the Set Original indicator

is lit. If it is not lit, confirm that the

feed-out unit and feed-in unit covers

are closed properly.

O Make sure that no previous originals

remain on the exposure glass or in the

recirculating document handler.

1

I

-1

I

32

Page 43

Setting Originals

3. Adjust the original guides to the

original width.

SETTING ORIGINALS IN THE RECIRCUIJ+TING DOCUMENT HANDLER

4. If you have more than two originals,

square the stack of originals. Set the

originals face up in the original stacker.

The Set Original indicator should turn

off.

O Originals should be the same size.

Slide the feed-out unit to match the

5.

size marks on the front side of the

recirculating document handler.

I

33

Page 44

SEl17NG ORIGINALS ON THE EXPOSURE GIASS

SETTING ORIGINALS ON THE

EXPOSURE GLASS

If your machine is equipped with the platen cover

1. Lift the platen cover.

2. Set the original face down on the exposure glass.

aligned to the rear left corner.

The original must be

O Before pressing the Start key, lower

platen cover.

If your machine is equipped with the dual job feeder

1. Lift the dual job feeder.

2. Set the original face down on the exposure glass.

aligned to the rear left corner,

Before pressing the Start key, lower the

O

dual job feeder.

If your machine is equipped with the recirculating document handler

1. Lift the recirculating document hand-

ler.

The original must be

the

2. Set the original face down on the exposure glass. The original must be

aligned to the rear left corner.

~ Before pressing

recirculating document handler.

34

the Start key, lower the

Page 45

BASIC FUNCTIONS AND KEY TOPS

BASIC FUNCTIONS AND KEY TOPS

The copier automatically controls the image density accord-

ing to the original background density.

,:,::.=::,.:x,:x

~

I

1

m

-Want’ouseo

After canceling the Auto Image Density, use these keys to

adjust the image density manually. To get a darker image,

touch the right keys. To get a lighter image, touch the left

keys.

The copier selects a suitable size of copy paper based on

the original size and the reproduction ratio.

If you use translucent or transparent paper as an original, the original size

IJ

might not be detected correctly.

O When you use Auto Paper Select when placing the original directly on the

exposure glass, make sure that the platen cover, dual job feeder, or

recirculating document handler is lowered before pressing the Start key.

If not, the original size might not be detected correctly.

After canceling Auto Paper Select, select the paper tray you

Use to make the copy image the same size as the original

image.

IEEiil

The copier automatically selects the proper reproduction

ratio suitable for the selected paper. All originals are copied

onto the same selected paper size.

O If you use translucent or transparent paper as an original, the original size

might not be detected correctly,

IJ When you use the Auto Reduce/Enlarge when placing the original directly

on the exposure glass, make sure that the platen cover, dual job feeder,

or recirculating document handler is lowered before pressing the Start

key. If not, the original size might not be detected correctly.

35

Page 46

BASIC FUNCTIONS AND KEY TOPS

P!zJ

m

When you have selected functions on operation screens, this

key appears on the touch panel display. Touch this key to

see at a glance all the modes you selected.

After the Check Modes key is touched, this key appears on

the touch panel display. Touch this key to return to the display when the Check Modes key was touched.

When you select functions on the operation screens, this key

appears on the touch panel display. Touch this key to

change settings of the following modes.

Copy paper size

Image density control

Finishing (Sort, Stack, and Staple)

Special original setting (system A and B only)

36

..’-

Page 47

sort BASIC FUNCTIONS AND KEY TOPS

Before using the Sort function, please refer to page 4 and 5 to know which system you have because this

function is different depending on the system you have.

System A and B

copy of each original is delivered to each bin and copies are collated into sets.

One

.

System C

System C does not have

the Sort key. As a default setting, copies are assembled as sets in

sequential order by sliding the shift tray from side to side.

System

O For the Sort function, the following limitations apply:

Maximum paper size

Minimum paper size

Maximum paper

weight

Minimum paper

weight

Maximum capacity

Paper that cannot

be used

A

1

A4, 81I2” x 11” or smaller:

System A

A3,11’’x17° A3,11’’x17° A3,11’’x17°

A5 Ierqthwise A4, 81/2” x 11”

51/2”x 81/2’ lengthwise

93 g/m2, 25 lb 157 g/mz, 42 lb

52 g/m2, 14 lb

30 sheets/bin

B4, 81/2” x 14“ or larger:

15 sheets/bin 40 sheets/bin 1,000 sheets

System B

Post cards, tracing paper, OHP sheets, and adhesive labels

System C

System B

Sideways:

Lengthwise:

A5, 5112°x 81I2”

52 g/m2, 14 lb

all sizes:

50 sheets/bin 1,500 sheets

2 sided copies:

A4, 8112”x 11” or smaller:

B4, 8112”x 14“ or larger:

System C

A5, 511Y’x 8112°

157 g/mz, 42 lb

52 g/mz, 14 lb

37

Page 48

BASIC FUNCTIONS AND KEY TOPS

Stack

EEDm!

Before using the Stack function, please refer to page 4 and 5 to know which system you have because

this function is different depending on the system you have.

System A and B

All copies of each original are delivered to the same bin.

System C

Copies from different copy runs are grouped into individual stacks by sliding the shift tray from

side to side.

System A

O For the Stack function, the following limitations apply:

I

Maximum paper size

Minimum paper size

{

Maximum paper

weight

Minimum paper

weight

all sizes:

Maximum capacity

Pape;Jh~~emnot

System A

A3,11’’x17°

A5 Ien?thwise

5112”x 81/2’ lengthwise Lengthwise:

93 g/mz, 25 lb

52 g/mz, 14 lb

15 sheets/bin

System B

Sideways:

all sizes:

2 sided copies:

Post cards, tracing paper, OHP sheets, and adhesive labels

System B

A3,11’’x17°

A4, 8112”x 11“

A5, 511z!”x 81I2”

157 g/mz, 42 lb

52 g/mz, 14 lb

40 sheets/bin

35 sheets/bin

System C

System C

A3,11’’x17°

A5, 5112’x 81I2”

157 g/mz, 42 lb

52 g/mz, 14 lb

A4, 81/2” x 11” or smaller:

1,500 sheets

B4, 81/2” x 14“ or larger:

1,000 sheets

O When using A3, 11” x 17“ paper with system A, it might happen that the compact sorter stapler does not stack

15 sheets depending on the paper brand and condition.

38

Page 49

Stapling Copies

BASIC FUNCTIONS AND KEY TOPS

Stapling Copies

‘ Before using the Staple function, please refer to page 4 and 5 to know which system you have because

this function is different depending on the system you have.

In the Staple function, groups of copies are automatically stapled.

D If you select this function, the Sort function is automatically selected.

Stapling Position and Original Setting

System B [-1

System C

available

Not

Not available

qmq%q

Page 50

BASIC FUNCTIONS AND KEY TOPS

rl Forthe Staple function, the following limitations apply:

Stapling Copies

System B System C

Maximum paper

size

Minimum paper

size

Maximum paper

weight

Minimum paper

weight

A3,11’’x17”

B5, 8112°x 11”

80 g/mz, 20 lb

1

52 g/m2, 14 lb

A3,11”x17° A3,11’’x 17”

B5, 8112°x 11“

80 g/mz, 20 lb 80 g/mz, 20 lb

64 g/m2, 17 lb

A4, 81/2” x 11” or smaller:

from 2 to 20 sheets all sizes:

Stapler capacity

from 2 to 50 sheets

B4, 8112°x 14“ or larger:

from 2 to 10 sheets

Pape~~hua;;$nnot

Post cards, tracing paper, OHP sheets, and adhesive labels

O In the Staple mode, do not use paper that is curled or has low stiffness.

B5, 8112”x 11”

64 g/m2, 17 lb

A4, 81/2” x 11” or smaller:

from 2 to 50 sheets

B4, 81/2” x 14“ or larger:

from 2 to 30 sheets

Page 51

BASIC FUNCTIONS AND KEY TOPS

This key can be used only when you have system A or B.

[

You can staple copies sorted in bins after copying is finished.

(This key has two functions. See below.)

This key can be used only when your machine is equipped with the dual job feeder (system A or B).

1

Use this key when you want to set the different sized

DiEEiEl

~ thedual job feeder. > Seepage 27.

originals together in the dual job feeder. The machine auto-

matically detects the size of each original to be fed. You can

set the following original sizes together. > See page 25.

A4/A3 version: A3, B4, A4 and B5

LT/DLT version: 11” x 17”, 81/2” x 14”, and 81/2” x 11“

Use this key when you want to copy pasted originals using

I

I

IEa

This key can be used only when your machine is equipp

[

You can set the copy settings for your next job. The next job will starl automatically after the

current job is completed. E See page 29.

Cl When presetting a job using the compact sorter stapler, you have to remove the current job’s copies from the

sorter stapler before the preset job can start.

O When presetting a job using the floor type sorter stapler, you might have to remove the current job’s copies

before the preset job can start. You have to do this

when you make 11 or more oopies in the current job.

when you make 10 copies in the current and 10 or more for the next.

when you make 9 or less copies for the current and 11 or more for the next.

ed with the dual job feeder (system A or B).

41

J

Page 52

BASIC FUNCTIONS AND KEY TOPS

●

Program

You can store up to 5 frequently used copy job settings in machine memory, and recall them

for future use.

You can select the Program N0,5 as a default setting using the User Tool 5. See page 16.

O

Entering a program

Recalling a program

Interrupt

● t>

1. Set the copy settings you want to put into memory.

2. Press the Program key.

3. Follow the instructions on the touch panel display.

1.

2. Follow the instructions on the touch panel display.

Press the Program

w

v

key.

~ -J

a

Press to interrupt a multicopy run to make urgently needed copies. The interrupted copy job

settings are stored in the machine’s memory. After interrupt copying is completed, press this

key again to recall the previous copy job settings.

Auto Start Mode

When you press the Start key during warm-up, copying will start automatically after warm-up

is completed. The Start key blinks in red and green alternately in this mode.

42

Page 53

Reduce/Enlarge

FUNCTIONS ON OPERATION SCREENS

FUNCTIONS ON OPERATION SCREENS

You can select one of 10

6 reduction ratios and 4

ratios are preset.

O You can change the fixed ratios using User

Tool 6. See page 17.

The reproduction ratio can be changed

from 50% to 200?10in 10/0steps. There

are two ways to change ratios.

preset ratios.

enlargement

El El ‘efau’t

Il?!k?w

Input the desired ratio using the Num-

ber keys.

The suitable reproduction ratio will be

automatically selected when you enter

the lengths of the original (A) and the

copy image you want (B).

43

Page 54

FUNCTIONS ON OPERATION SCREENS

Duplex/Series Copies (Duplex)

I

1

mm

Before using this function, please refer to page 4 and 5 to know which system you have because this

function is different depending on the system you have.

O A right margin (5 mm, 0.2”) is set on the back side automatically.

System A and B

If your machine is equipped with the dual job feeder (system A or B), you should select one of three keys

(Autocount, Even, or Odd)

If you select the Autocount function, the machine automatically counts the number of

originals. After selecting the Autocount function, follow the instructions on the touch panel

display.

44

Page 55

Duplex/Series Copies (Duplex)

FUNCTIONS ON OPERATION SCREENS

Select

Select this key if the number of originals is odd.

this key if the number of originals is even.

+

Wnen you set originals in the dual job

feeder, the last page of originals

should be on the bottom as shown,

ma

432’

II

I

II

45

Page 56

FUNCTIONS ON OPERATION SCREENS

Duplex/Series Copies (Duplex~

System C .

If your machine is equipped with the recirculating document handler (system C), the Autocount function is

default. Do the following.

1. Set the stack of originals face up in the recirculating document handler.

2.

Press the

The machine starts counting originals. After counting is finished, copying will

start automatically.

Start key.

lJN!wLl

t

11. 1 I

‘“-4’ “ L

When you set originals in the recirculating document handler, the last

page of the originals should be on the

bottom as shown.

46

Page 57

Duplex/Series Copies (Duplex)

mmml

This function makes 2 sided copies from 2 sided originals.

When you set originals in the dual job

feeder, the last page of the originals

should be on the bottom as shown.

FUNCTIONS ON OPERATION SCREENS

When you set originals in the recir-

culating document handler, the last

page of the originals should be on the

bottom as shown .

47

Page 58

FUNCTIONS ON OPERATION SCREENS

w

Qm

Duplex/Series Copies (Series Duplex~

IJoThe following functions cannot be used if copy paper larger than A4 sideways or 8112”x 11”

selected.

The center of an original is determined according to the selected copy paper and

sure to select copy paper and reproduction ratio suitable for the original.

This function makes 2 sided copies from 2 facing pages of a bound (book) original.

When you use the dual job feeder, the

last page of the originals should be on

the bottom as shown.

reproduction

sideways is

ratio. Make

48

When you use the recirculating docu-

ment handler, the last page of the

originals should be on the bottom as

shown.

I

L

s

-1

I

k

f

1

I

1

When you place the original on the

exposure glass, start with the last page

of originals as shown.

O Make sure that the original binding is

centered with the book mark on the rear

scale.

Page 59

Duplex/Series Copies (Series Duplex)

Use this function to have the copies face each other exactly as the bound (book) originals

do. When you use this function, place the original on the exposure glass face down.

For bound originals read from left to right, place the original on the exposure glass with the

cover right side up. You should start with the last page of the originals and the last page

should be aligned to the left scale as shown.

FUNCTIONS ON OPERATION SCREENS

p

+

II

D The center of an oriqinal is determined according to the selected COPYpaper and reproduction ratio. Make

sure to select copy japer and reproduction ratio ~uitable for the original. ~ Make sure that the original binding is centered with the book mark on the rear scale.

O For bound originals read from right to left, place the book with the cover upside down.

Cl You can use this function with the dual job feeder (system

(system C), too,

p

+

II

A or B) or the recirculating document handler

49

Page 60

FUNCTIONS ON OPERATION SCREENS

I

Book+l$iM

2$idod+I$idod

Duplex/Series Copies (Series Copies~

This function makes 1 sided copies from two facing pages of bound (book) originals.

Cl This function cannot be used if copy paper larger than A4 sideways or 81/2” x 11” sideways is selected.

O The center of an original is determined according to the selected copy paper and reproduction ratio. Make

sure to select copy paper and reproduction ratio suitable for the original.

When you set originals in the dual job

feeder, the last page of the originals

should be on the bottom as shown.

When you set originals in the recirculating document handler, the last

page of the originals should be on the

bottom as shown.

1

When you place the original on the

exposure glass, start with the last page

ofooriginals as shown.

50

Make sure that the original binding is

centered with the book mark on the rear

scale.

Page 61

LJlll

’234

When you set originals in the dual job

feeder, the last page of the originals

should be on the bottom as shown.

When you set originals in the recirculating document handler, the last

page of the originals should be on the

bottom as shown.

51

Page 62

FUNCTIONS ON OPERATION SCREENS

I

Duplex/Series Copies (Combine)

7--R

htocount

r

Lven I

Odd

51/2”sideways

originals on one copy.

I-MEL!mm

- Combine2Origs.

Combine4Orixs.

~

The Combine function can be used only when your machine is equipped with the dual job feeder (system

- A or B).

Cl When using the Combine functions, please select the copy paper size below.

This function automatically combines two 1 sided

A4/A3 version:

LT/DLT version: 81/2” x 11” sideways, 81/2” x

A4 sideways, B5 sideways, A5 sideways

(for system A or B)

I

If you select the Autocount function, the machine automatically counts the number of originals.

1

I

When you use the dual job feeder, the

last page of the originals should be on

the bottom as shown.

52

r

-I

Page 63

Duplex/Series Copies (Combine)

FUNCTIONS ON OPERATION SCREENS

1

I

I

L

z

@

Select this key if the number of originals is even.

I

I

I

I

1

I

When you set originals in the dual job

feeder, the last page of

should be on the bottom

the originals

as shown.

53

Page 64

FUNCTIONS ON OPERATION SCREENS

Select this key if the number of originals is odd.

Duplex/Series Copies (Combine)

5

I

I

I

I

I

When you set originals in the dual job

feeder, the last page of the originals

should be on the bottom as shown,

54

Page 65

Duplex/Series Copies (Combine)

FUNCTIONS ON OPERATION SCREENS

This function makes one 2 sided copy from four 1 sided originals.

O After selecting the Combine 4 Origs. function, you have to select the Autocount key or Number keys key to

input the number of originals.

Example: Number of originals: 7

A-

When using the dual job feeder, the

last page of the originals should be on

the bottom as shown.

+

55

Page 66

When making copies in the Editing/Centering mode, set the originals in the dual iob feeder

or the recirculating document handler as shown.

,.. .___—

P

. . .

1

When making co~ies in the Edit-

ing/Centering mode, place the original

on the exposure glass as shown.

\\”

T!N

O In the Save Area and the Delete Area modes, the designated line will vary by f5 mm ( + 0.2”). Therefore,

leave at least 5 mm (0.2”) between the designated line and the image. If this clearance is narrower than this,

undesired image portions might be deleted or saved.

This function erases everything except

the designated area.

c1

If you want to use an editing sheet to

designate the area, please contact your

sales or service representative.

56

Page 67

FUNCTIONS ON OPERATION SCREENS

Edit Image(Editing/Centering]

This function centers the original

image on the copy.

58

Page 68

Edit Image (Margin Adj.)

FUNCTIONS ON OPERATION SCREENS

You can make margins by shifting the image to the left or right, and towards the top or bottom.

This function is convenient when binding copies.

o A41A3 version

Maximum margin width: Left and right:

Cl LT/DLT version

Maximum margin width: Left and right:

o When you make 2 sided copies from 1 sided originals, a right margin (5 mm, 0.2”) is selected for the back

side automatically.

Top and bottom: 15 mm in 2.5 mm steps

Top and bottom:

16 mm in 1 mm steps

0.6” in 0.1” steps

0.6” in 0.1” steps

Margin on 2 sided copies

D

For binding, set the left margin for the front side, and the right margin for the back side.

3Y

Page 69

FUNCTIONS ON OPERATION SCREENS

“,

>.

Cover/Slip Sheet (Front Cover)

Cover mode

The Front Cover function can be used only when your machine is equipped with the dual job feeder (sys-

tem A or

Cl ~5hen using the Front Cover function, you should set the tray for cover sheets using User Tool 2. See page

B) or the recirculating document handler (system C).

Cl You can also select the bypass feed tray for cover sheets.

In this case, make sure to set paper for cover

sheets that are identical in size and direction with the paper to which you are copying, because the machine

cannot detect the length of paper set in the bypass feed tray.

D Two paper trays of identical size and direction are required for this function.

The original on the top of the stack will be copied on the front cover sheet. Front cover sheets

will be fed from the tray set by User Tool 2.

.(hmq+,[r~ ~.. ~ .. ~.‘ ., ~ . ...,

,

● I

I

A blank front cover sheet is added as the first page of the copy set. Front cover sheets will

be fed from the tray set by User Tool 2.

60

Page 70

The Fron~Back Covers function can be used only when your machi~e is equipped with the dual job

feeder (system

~ When using the Front/Back Covers function, you should set the tray for cover sheets using User Tool 2. See

page 15.

You can also select the bypass feed tray for cover sheets. In this case, make sure to set paper for cover

0

sheets that are identical in size and direction with the paper to which you are copying, because the machine

oannot deteot the length of paper set in the bypass feed tray.

Cl Two paper trays of identical size and direction are required for this function.

The originals on the top and bottom of the stack will be copied on cover sheets. Cover sheets

will be fed from the tray set by User Tool 2.

A or B), or the recirculating document hand/er (system C).

.

““”;;”~-

Blank front and back covers are added to the copy set. Cover sheets will be fed from the tray

set by User Tool 2.

61

Page 71

FUNCTIONS ON OPERATION SCREENS

The Paper Designate function can be used only when your machine is equipped with the dual job feeder

(system A or B), or the recirculating document handler (system C).

Before using this function, please refer to pages 4 and 5 to know which system you have because this

function is different depending on the system you have.

Cover/Slip Sheet (Paper Designate)

System A and B (with dual job feeder)

After selecting this function, you have to select the Autocount key or the Number keys key

to input the number of originals.

System C (with recirculating document handler)

After selecting this function, the machine starts counting the number of originals automatically.