Page 1

RICOH FT5580/FT5590

RICOH COMPANY, LTD.

FIELD SERVICE MANUAL

Page 2

CONTENTS

INSTALLATION

Environment

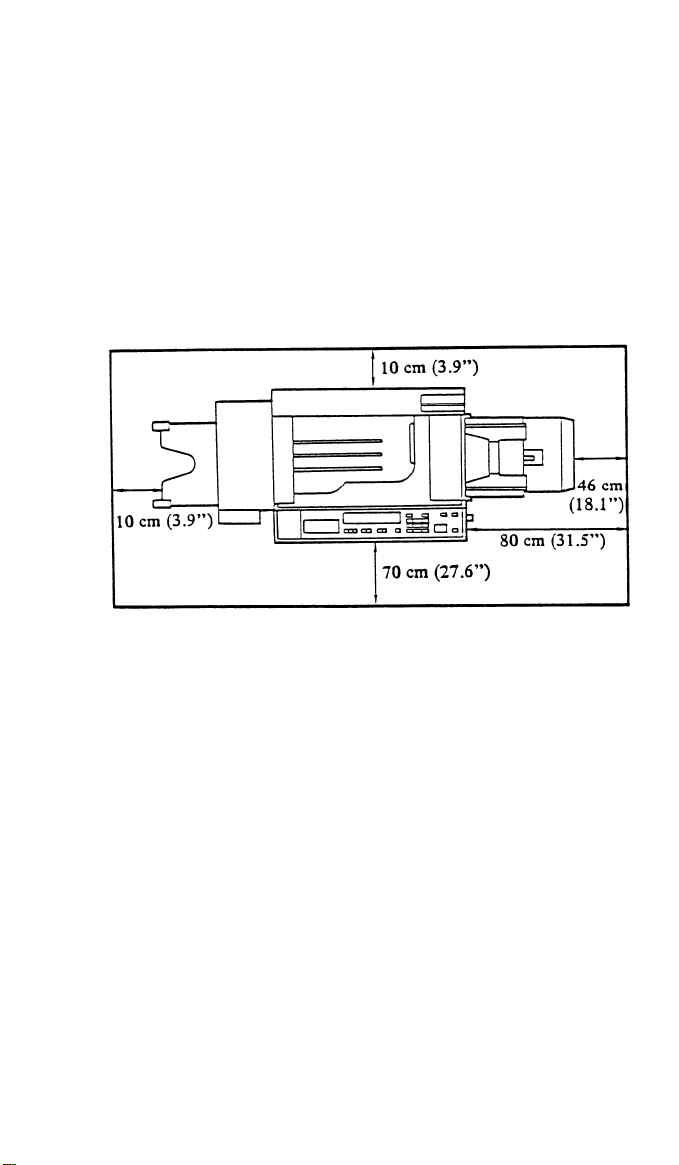

Minimum Space Requirements

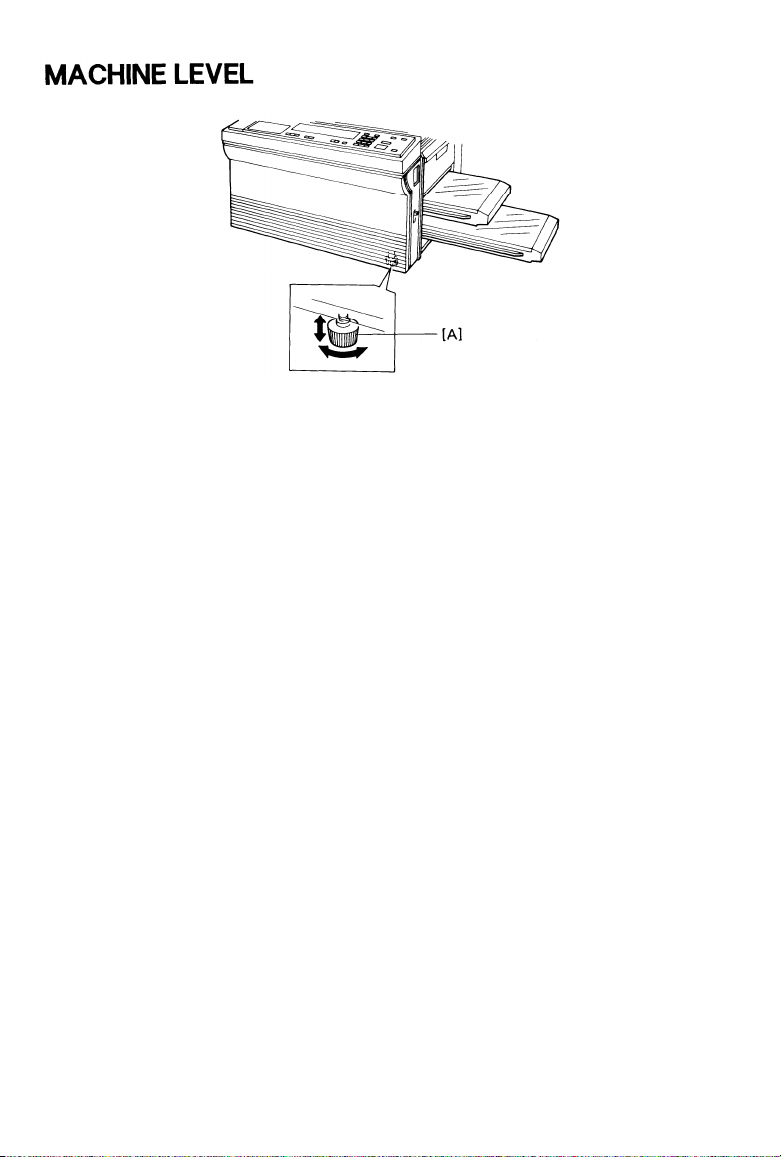

Machine Level

Power Source

Accessary Check

Installation Procedure

Cassette Modification

Key Counter Holder Installation

SERVICE TABLES

PM Tables

Service Tables

1. Test Points

2. Variable Resistors

3. DIP Switches Tables

4. User Codes Table

5. Service Program SP-8 Data Input Guide Table

Service Program Mode Operation

1. Service Program Access Procedure

2. Change Adjustment Values or Modes

3. Memory Clear Procedure

4. Service Program Mode Table

5. Language Code Table

Special Tools and Lubricants

Service Remarks

1. Handling the Drum

2. Charge Corona

3. Erase Lamp

4. Optics

5. Development Unit

6. Transfer and Separation Corona

7. Cleaning Unit

8. Pre-transfer & Quenching Unit

9. Fusing

10. Paper Feed and Duplex

11. Optional Equipment

12. Handling PCBs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 June 1987

1- 1

1- 2

1- 3

1- 3

1- 4

1- 5

1-13

1-14

2- 1

2- 4

2- 4

2- 5

2- 5

. . . . . . . . . . . . . . . . . . . . . . . .

2- 6

2- 7

2- 7

2- 8

2-10

2-19

2-20

2-21

2-21

2-22

2-22

2-22

2-23

2-23

2-23

2-23

2-24

2-24

2-24

REPLACEMENT AND ADJUSTMENT

Optics

1. Exposure Glass Removal

2. Sixth Mirror Replacement

3. Scanner Drive Wire Replacement

4. Fourth and Fifth Mirror Drive Wire Replacement

5. Lens Drive Wire Replacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 2

3- 3

. . . . . . . . . . . . . . . . . . . . .

3- 7

3- 8

Page 3

12 June 1987

6. Scanner Harness Replacement

(Optics Cables & Exposure Lamp)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 9

Development

1. Developer Replacement

2. Image Density Sensor Removal

3. Toner Collection Bottle Cleaning

4. Vsg Voltage Checking

5. Vsg Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

6. Toner Supply System Checking

7. Toner Density Recovery

8. Detect/Fixed Mode Selection

9. Toner Amount Changing

10. ID Pattern Bias Voltage Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11

3-12

3-13

3-14

3-16

3-17

3-17

3-17

3-17

Cleaning

1. Pick-off Pawl Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

2. Cleaning Blade and Brush Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3. Blade Cleaner and Bias Roller Blade Replacement . . . . . . . . . . . . . . . . . 3-21

Fusing

1. Fusing Unit Removal

2. Oil Blade Replacement

3. Thermistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

4. Thermofuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

5. Hot Roller Stripper Replacement

6. Hot Roller Replacement

7. Pressure Roller Replacement

8. Entrance Guide Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

9. Fusing Pressure Adjustment

10. Hot Roller Temperature Adjustment

11. Idling Period Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-22

3-23

3-26

3-27

3-29

3-31

3-32

Paper Feed

1. Pick-up, Paper Feed and Separation Rollers Replacement . . 3-33

2. Transport Unit Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-34

Duplex

1. Invertor Unit Removal

2. Duplex Transport and Fork Gate Units Removal . . . . . . . . . . . . . . . . . . . . . . 3-36

3. Jogger Unit Removal

4. Duplex Pick-up and Feed Rollers Replacement . . . . . . . . . . . . . . . . . . . . . . . . 3-38

5. Duplex Separation Roller Replacement

6. Positioning and Entrance Actuator Rollers Replacement . . . . . . 3-40

7. Duplex Pick-up Solenoid Adjustment

8. Jogger Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-35

3-37

3-39

3-41

Copy Image

1. Vertical Magnification Adjustment

2. Horizontal Magnification

3. Focus Adjustment

4. Uneven Exposure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

5. Light Intensity Adjustment

6. Setting ADS Reference Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

7. ADS Voltage Adjustment

8. ADS Operation Checking

9. OW/OL Sensor Voltage Adjustment

10. OL Sensor Length Sensing Adjustment

11. Erase Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

12. Registration Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-43

3-44

3-45

3-47

3-48

3-49

3-50

3-51

Page 4

Corona

and Exit Sensor Replacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Charge Corona Wire Replacement

2. Pre-quenching Corona Wire Replacement

3. Transfer and Separation Corona Wires Replacement

4. Charge Cleaner Drive Wire Replacement

5. TC/SC Cleaner Drive Wire Replacement

6. Drum Current Adjustment Preparation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Others

1. Power Supply Unit Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL DATA

3-53

3-55

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

3-56

3-57

3-58

3-59

3-66

1.

Main PCB Schematic

2.

Optics PCB Schematic

3.

Paper Feed PCB Schematic

4.

Timer PCB Schematic

5.

Timing Chart

6.

Sorter PCB Schematic

7.

ARDF PCB Schematic

8.

Large Capacity Tray Schematic - 1,000 sheets . . . . . . . . . . . . . . . . . . . . . . .

9.

Large Capacity Tray Schematic - 2,500 sheets

10.

15 Bin Sorter PCB Schematic

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. 15 Bin Sorter Timing Chart

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DOCUMENT FEEDER

Installation

1. Accessory Check

2. Installation Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement and Adjustment

1. DF Belt Drive Motor Speed Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SORTER

Installation

1. Accessory Check

2. Installation Procedure

Replacement and Adjustment

1. Bin Drive Belt Replacement

2. Bin Drive Motor Replacement

3. Bin Replacement

4. Exit Roller Drive Motor Replacement

5. Lower Exit Roller Unit Replacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4- 1

4- 2

4- 3

4- 4

4- 5

4- 6

4- 7

4- 8

4- 9

4-10

4-11

5- 1

5- 2

5- 8

6- 1

6- 2

6- 5

6- 7

6- 8

6- 9

6-10

Page 5

LARGE CAPACITY TRAY (1,000 SHEETS)

Installation

1. Accessory Check

2. Installation Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement and Adjustment

Tray Down Sensor and Positioning Switch Replacement

1.

Paper Size Sensor Replacement

2.

Tray Wire Replacement

3.

4.

Paper Volume Cord Replacement

5.

Side Registration Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LARGE CAPACITY TRAY (2,500 SHEETS)

Installation

1. Accessory Check

2. Installation Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CASSETTE BANK

Installation

1. Accessory Check

2. Installation Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING

Service Call Conditions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

10- 1

7- 1

7- 2

7- 6

7- 8

7- 9

7-12

7-14

8- 1

8- 2

9- 1

9- 2

FT6620

Manual Level

Accessory Check

Installation Procedure

Optics

1. Exposure Glass Removal

Development

1. Developer Replacement

2. Toner Collection Bottle

Paper Feed

1. Pick-up, Paper Feed and Separation Roller Replacement . . . .

2. Transport Unit Removal

Duplex

1. Invertor Unit Removal

2. Duplex Transport and Fork Gate Unit Removal

3. Jogger Unit Removal

Others

1. Power Supply Unit Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11- 1

11- 2

11- 3

11-14

11-15

11-16

11-17

11-18

11-19

11-20

11-21

11-22

Page 6

15 BIN SORTER

Installation

1. Accessory Check

2. Installation Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement and Adjustment

1. Sorter Removal

2. Inlet Sensor Replacement

3. Jam Sensor Replacement

4. Sponge Roller Replacement

5. DC Motor Replacement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Table

1. LEDs

2. Dip Switch

3. Service Program Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12- 1

12- 2

12- 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12- 8

12- 9

12-10

12-12

12-13

12-13

12-14

Page 7

SECTION 1

INSTALLATION

Page 8

CONTENTS

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Space Requirements

Machine Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessary Check

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cassette Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Counter Holder Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1- 1

1- 2

1- 3

1- 3

1- 4

1- 5

1-13

1-14

Page 9

ENVIRONMENT

1.

Temperature Range: 10°C to 30°C (50°F to 80°F)

12 June 1987

Humidity Range:

2.

3.

Ambient Illumination: Less than 1,500 Iux (Do not expose to

15% to 90% RH

direct sun light.)

4.

Ventilation: Room air should turn over at least 3

times/hour.

3

5.

Ambient Dust: Less than 0.15 mg/m

Room size More than 10 m

6.

If the place of installation is air-conditioned or heated, place the

7.

3

(4 x 10

(13.4 yd3)

machine:

a) where it will not be subjected to sudden

temperature changes

from low to high, or vice versa.

b) where it will not be directly exposed to

cool air from an air

conditioner.

where it will not be directly exposed to reflected heat from a

c)

heater.

Avoid placing the copier in an area filled with corrosive gas.

8.

Avoid any area higher that 2,000 m (6,500 feet) above sea level.

9.

10.

Place the copier on a strong and level base.

11.

Avoid any area where

the copier may be subjected to strong

vibration.

-3

Oz/yd3)

1-1

Page 10

12 June 1987

MINIMUM SPACE REQUIREMENTS

1-2

Page 11

Front to Back: Within 5 mm (0.2”) of level

1.

12 June 1987

Right to Left:

2.

3. Screw the leveling feet [A] up or down to level the machine.

Within 5 mm (0.2”) of level

POWER SOURCE

Input voltage Level

1.

110 V/60 Hz - 15A

115 V/60 Hz - 15A

220 V/50 Hz - 8A

240 V/50 Hz - 8A

Permissible Voltage Fluctuation : 10%

2.

Permissible Extension Cord : None recommended

3.

NOTE: -

Be sure to ground the machine.

grounding wire to a gas pipe.)

- Make sure the plug is firmly inserted in the outlet.

- Should be a dedicated power outlet.

- Do not set anything on the power cord.

(Do not connect the

1-3

Page 12

12 June 1987

ACCESSARY CHECK

Check the quantity and condition of the accessories in the box according

to the following list:

1. Editing Sheet

2. Sort/Stack Key Top

3. Sort/Stack Key Cover

4. NECR

5. Cassette -

6. Cassette - Small

7. Paper Size

Actuator Plate

8. Paper Size Decal

9. Toner Catch Pan

10. Copy Tray

11. Original Holder

12. Operating Instructions

- English

- Five languages

Large

USA

1

1

1

1

1

2

4

8

1

0

0

1

0

Europe

1

1

1

1

1

2

3

6

1

1

0

0

1

Middle East

& Asia

1

1

1

1

2

1

5

10

1

1

1

1

0

Taiwan

1

1

1

1

2

2

6

12

1

1

1

1

0

13. Envelope - NECR

14. Multiple Language

Decal

1-4

1

1

0

1

0

1

0

1

Page 13

INSTALLATION PROCEDURE

12 June 1987

NOTE:

-USA version-

The platen cover and the original stacker are needed as options

if DF is not to be installed.

sorter is not to be installed.

-European version-

The platen cover and the original stacker are needed as options

if DF is not to be installed.

is needed if one of the following optional languages is wanted on

the guidance display.

Option ROM

0: Swedish

1: English

2: Danish

3: Norwegian

4: Finnish

5: Dutch

(The English in both the optional and the standard ROMs are the

same.)

Standard ROM

0: Japanese

1: English

2: French

3: German

4: Italian

5: Spanish

Also, the copy tray is needed if the

Also, the guidance ROM kit (option)

1-5

Page 14

12 June 1987

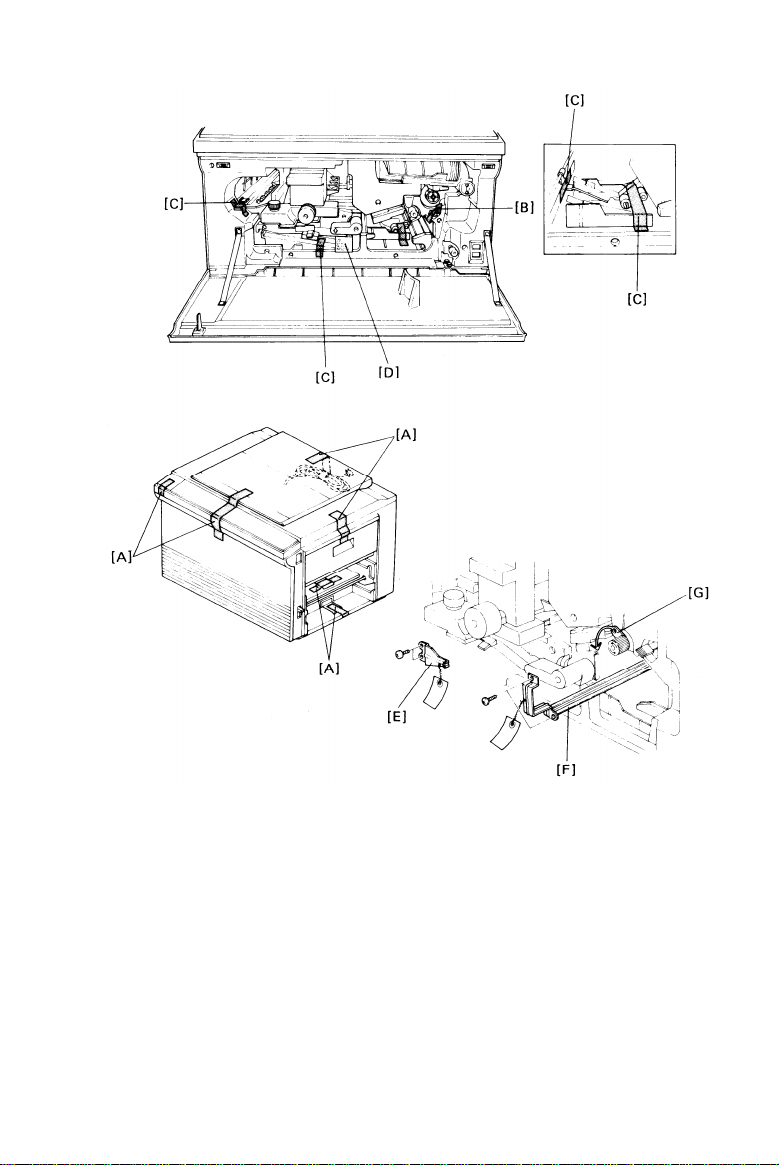

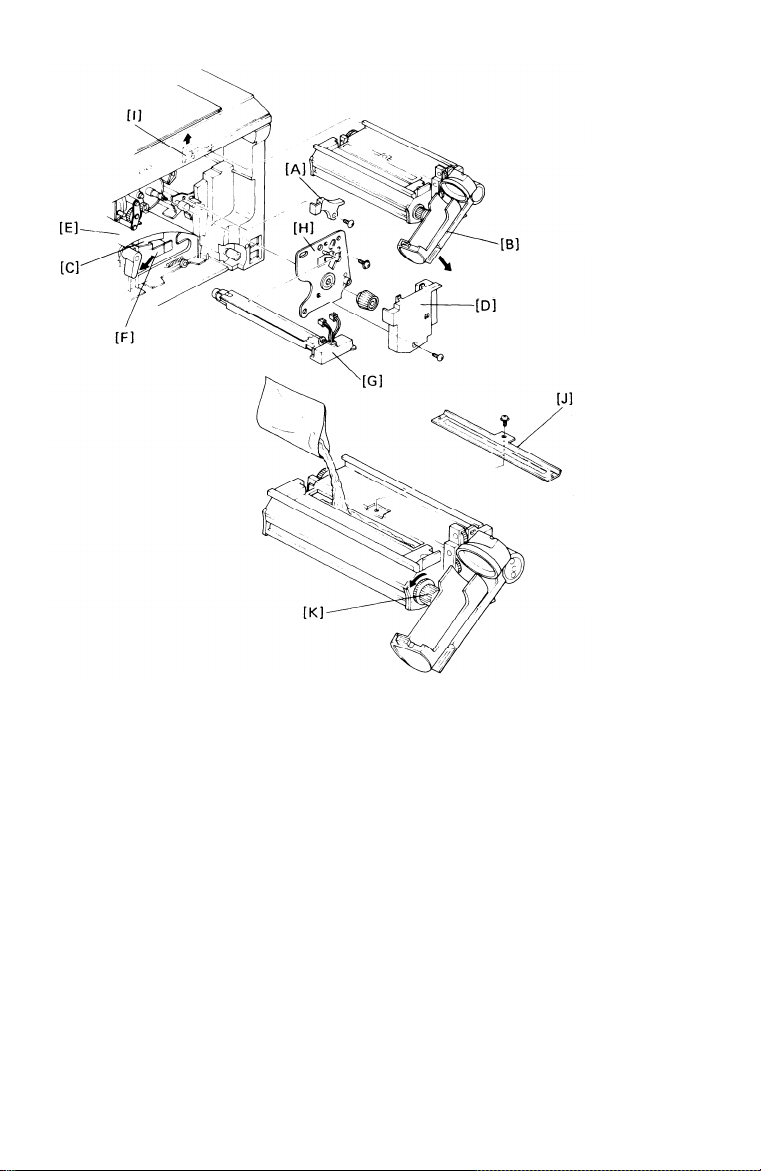

Remove the strips

1.

2.

Remove the strips

Non-duplex model

Duplex model

Remove the

3.

4.

Remove the

of tape [A], and open the front cover.

of tape as follows:

---

[B]

--- [B+C]

fork gate unit support cushion [D] (Duplex model only).

fork gate unit lock plate [E] (2 screws) (Duplex model

only).

5.

Remove the transport unit lock plate [F] (2 screws) and the wedge

[G] from between the registration rollers.

1-6

Page 15

12 June 1987

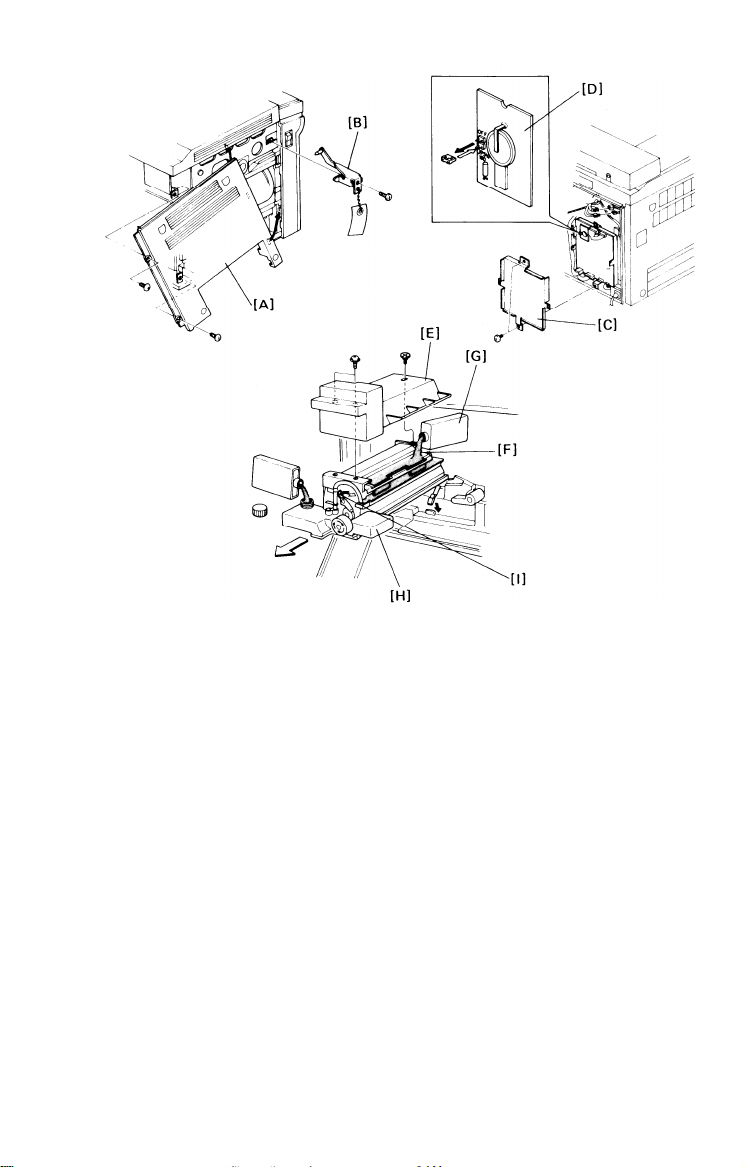

6. Remove the rear cover (2 screws), the left cover [A] (2 screws), and

the scanner lock plate [B] (1 screw).

NOTE:

Reinstall the screw for future use.

scanner lock plate.

It is necessary to reinstall it if the copier

Do not throw away the

is to be transported long distances (by vehicle).

7. Remove the main PCB shielding plate [C] (2 screws), and move the

jumper connector (JPSW 191) on the timer PCB [D] from the upper

(printed “OFF”) to the lower position. Then, reinstall the removed

covers if no peripherals are to be installed.

8. Remove the fusing unit,

then remove the fusing unit cover [E] (2

screws, 1 shoulder screw).

9. Prime the oil supply pad [F] with silicon oil [G]. Then, fill the oil tank

[H] with silicon oil.

10. Manually operate the oil pump lever [I] and confirm correct operation

and the overall condition of the silicon oil supply assembly.

Then,

reassemble the fusing unit.

1-7

Page 16

12 June 1987

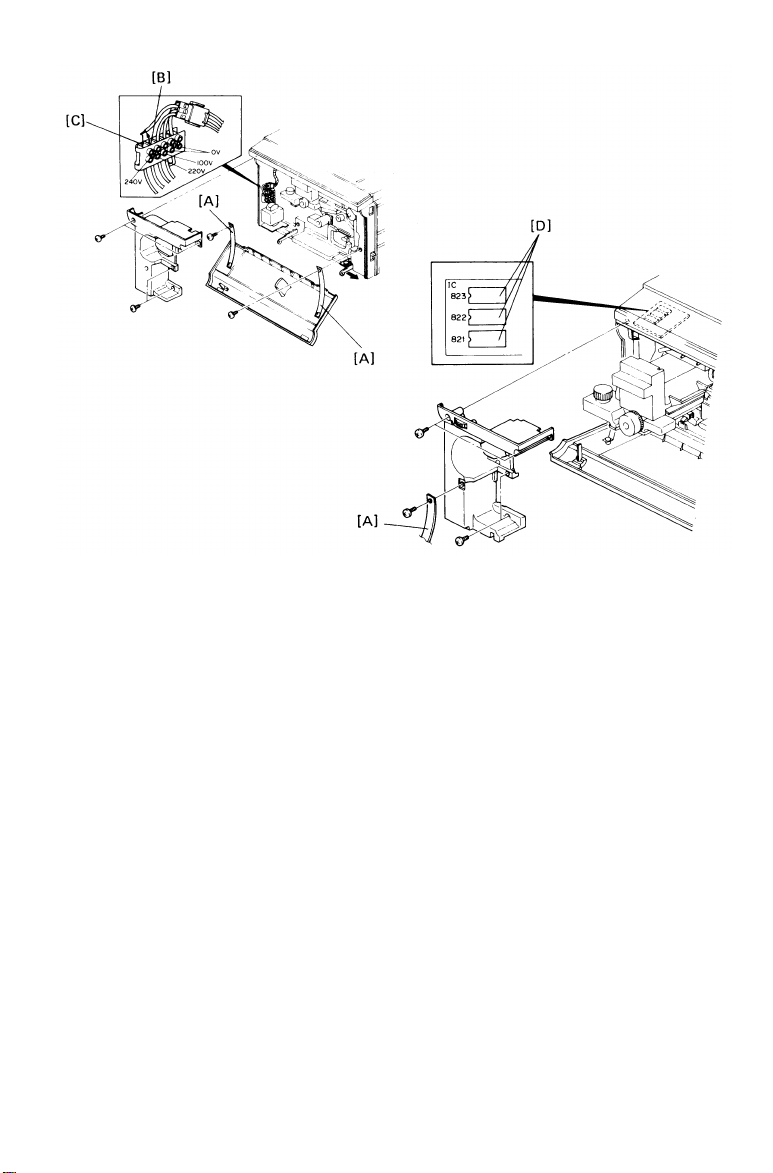

11. European version only:

-220 to 240 volts conversion-

a) Remove the support straps [A] (1 screw each), the front cover

(2 knob screws) and the left inner cover (4 screws).

b) Disconnect the wire from the 220 volt terminal [B], and connect

this wire to the 240 volt terminal [C] as shown.

-Guidance ROM kit installation-

a) Replace the three ROMs [D] (IC 821, 822 & 823) on the

operation panel with the ROMs of the guidance ROM kit.

b) Reinstall the right inner and the front covers.

1-8

Page 17

12 June 1987

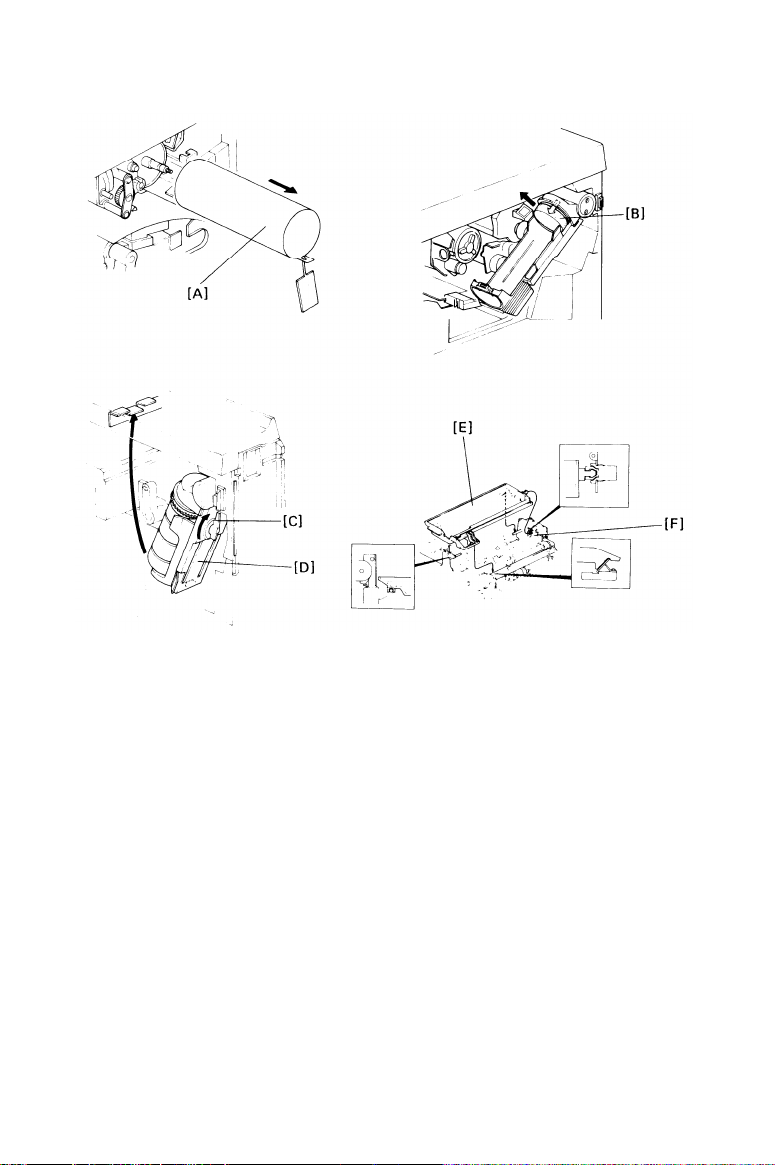

Reinstall the fusing

12.

Remove the image

13.

Pull down the toner bottle holder [B], lower the transport unit [C], and

14.

unit.

density sensor cover [A].

remove the drum inner cover [D] (1 screw).

Put a sheet of paper [E] on the T/S corona unit [F].

15.

Remove the charge corona unit [G] (2 connectors), and remove the

16.

drum stay [H] (1 screw, knob - reverse thread).

17.

Place a sheet of paper on the floor.

Raise the development unit lock

lever [I], remove the development unit, and place it on the paper.

18.

Remove the developer inlet cover [J] (1 screw).

19.

Pour one kilogram of developer into the development unit while

turning the knob [K] counterclockwise to distribute the developer.

20.

Reinstall the developer inlet cover.

1-9

Page 18

12 June 1987

21.

Pull out the drum protective sleeve [A] from the drum.

NOTE:

Save the drum protective

sleeve for future use when

servicing the copier.

Reinstall all removed parts, and return them to their original position.

22.

Remove the toner tank plug [B] and load the toner bottle onto the

23.

bottle holder.

Then, fix the bottle with the lever [C], and raise the

holder [D] up to the bracket.

Install the toner catch pan [E] on the jogger unit [F].

24.

1-10

Page 19

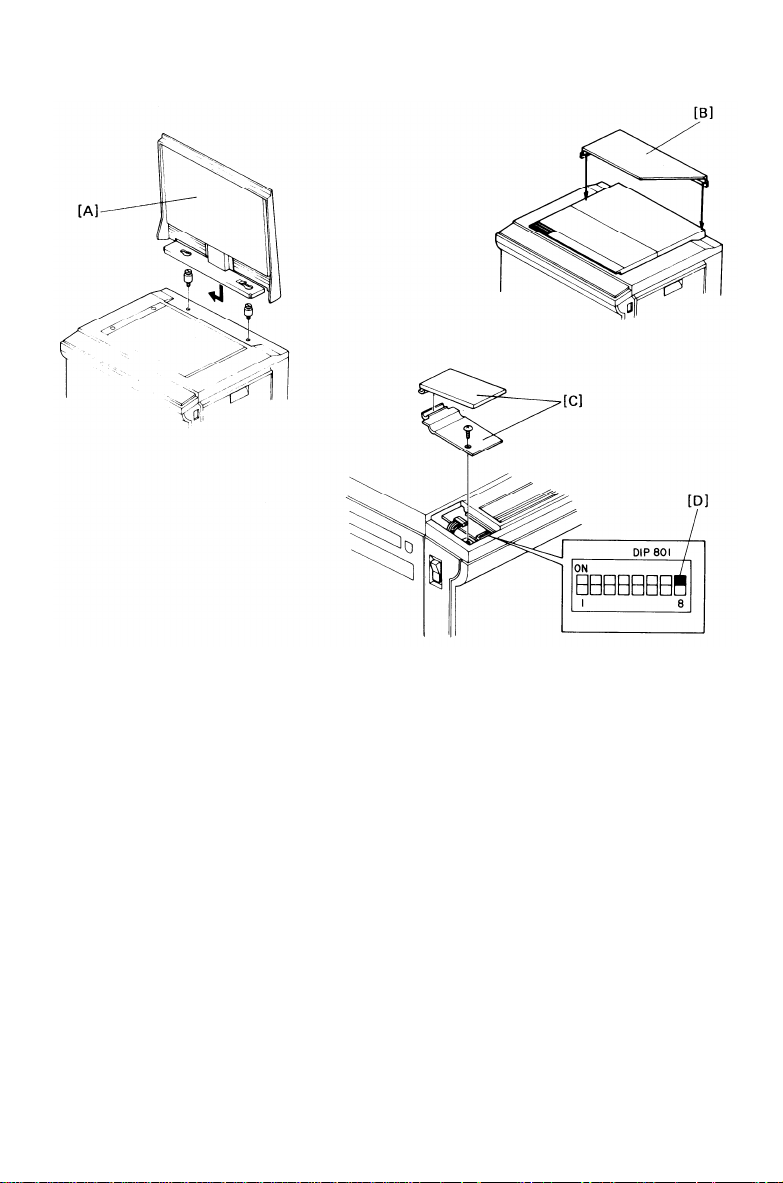

12 June 1987

25.

Install the platen cover [A] (2 stud screws) and the original holder [B]

(Two sided tape) as necessary.

26.

Remove the DIP switch cover [C] (1 screw), and turn on DIP switch

801-8 [D]. Then, plug in the machine and turn on the main switch.

27.

Set the proper language in the guidance display using SP 12 (LT

Version) or SP 13 (A4 Version).

To access SP (Service program mode), enter 12 or 13 using the

number keys.

Press the Recall/Enter key.

1-11

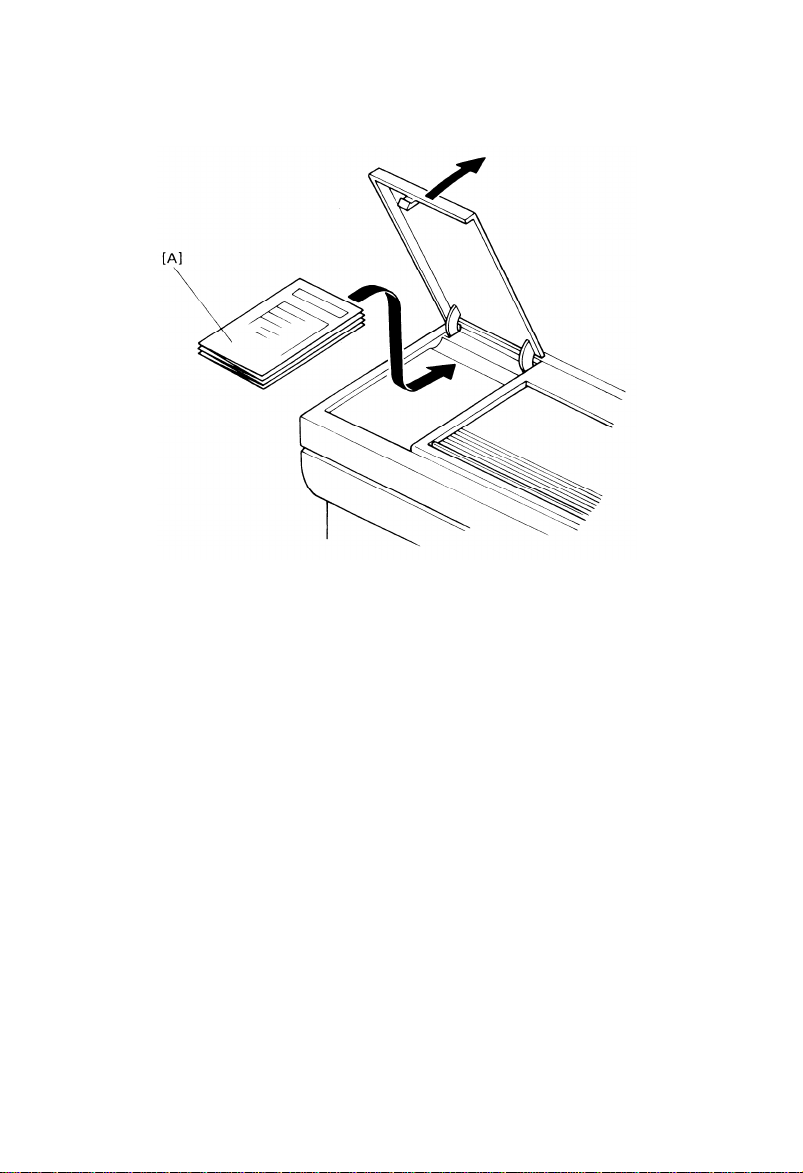

Page 20

12 June 1987

28.

Put five sheets of white paper (A3 of 11” x 17”) on the exposure

glass.

Set SP 10 for drum conditioning.

29.

30.

After the warm up period is completed, press the Start Key to start

drum conditioning.

(100 is automatically displayed on the copy

counter by SP 10.)

31.

Set all appropriate SP modes as required.

Turn off the main switch the DIP switch 801-8, and reinstall the DIP

32.

switch cover. Then, turn on the main switch.

33.

Install the operating instruction cards [A] over the DIP switch cover

(two-sided tape). Then, install the receiving tray.

34.

Load paper into the cassette, then check the machine operation and

the copy quality.

35.

Fill out the New Equipment Condition Report.

1-12

Page 21

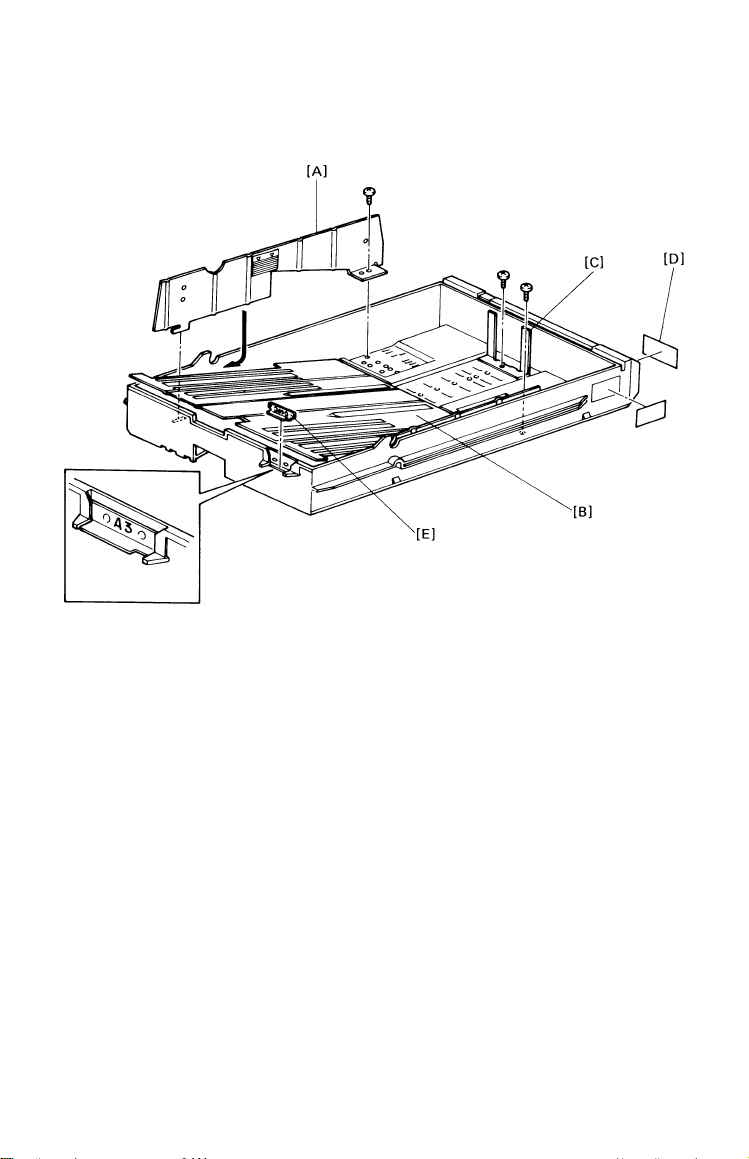

CASSETTE MODIFICATION

12 June 1987

1. Remove the cassette cover.

2. Remove the side fences [A] (1 screw each) and the bottom plate [B].

3. Reposition the rear fence [C] (1 screw) in the desired paper size

position.

NOTE:

4. Reinstall the bottom plate.

5. Reinstall the side fences in the desired paper size position.

6. Attach the appropriate paper size decals [D] on the cassette at the

positions shown.

7. Insert the desired actuator plate [E] in the slot on the front of the

cassette as shown.

Paper size positions are shown on the inside of the cassette.

1-13

Page 22

12 June 1987

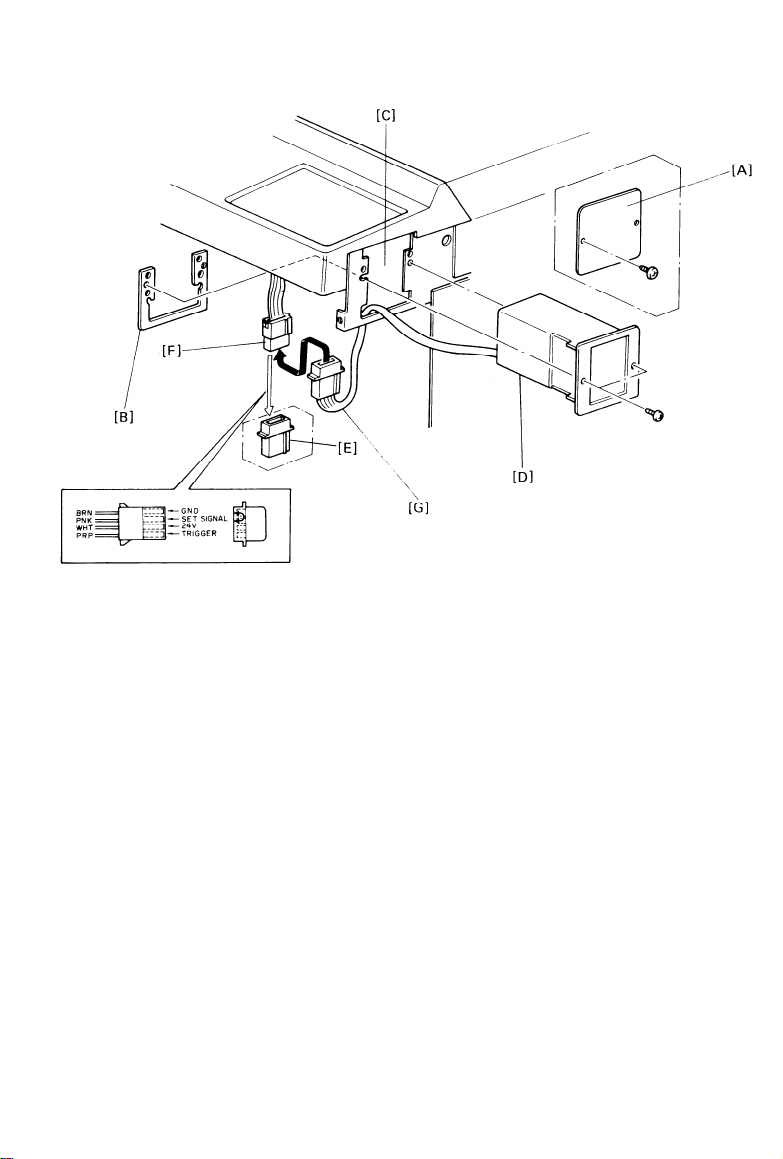

KEY COUNTER HOLDER INSTALLATION

Remove the front cover (2 screws).

1.

Remove the right inner cover (4 screws) and right front cover (1

2.

screws).

3.

Remove the cover plate [A] and fixing plate [B] from the key counter

bracket [C].

4.

Hold the fixing plate on the inside of the key counter bracket and

insert the key counter bracket. Insert the key counter holder [D].

5.

Align the holes in the fixing pIate with the mounting holes of the key

counter holder and secure the key counter holder.

NOTE:

Remove the shorting plug [E] from the key counter connector [F].

6.

Plug in the key counter harness [G].

7.

Reassemble the copier.

8.

operation.

NOTE:

The fixing plate has three sets of holes. Make sure to use

the holes that match the type of counter.

Insert the key counter and check

Confirm that SP 90 (Secret mode) is set in “No” position.

1-14

its

Page 23

SECTION 2

SERVICE TABLES

Page 24

CONTENTS

PM Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2- 1

Service Tables

1. Test Points

2. Variable Resistors

3. DIP Switches Tables

4. User Codes Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Service Program SP-8 Data Input Guide Table . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2- 4

2- 4

2- 5

2- 5

2- 6

Service Program Mode Operation

1. Service Program Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Change Adjustment Values or Modes

3. Memory Clear Procedure

4. Service Program Mode Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Language Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools and Lubricants

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2- 7

2- 7

2- 8

2-10

2-19

2-20

Service Remarks

1. Handling the Drum

2. Charge Corona

3. Erase Lamp

4. Optics

5. Development Unit

6. Transfer and Separation Corona

7. Cleaning Unit

8. Pre-transfer & Quenching Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Fusing

10. Paper Feed and Duplex

11. Optional Equipment

12. Handling PCBs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-21

2-21

2-22

2-22

2-22

2-23

2-23

2-23

2-23

2-24

2-24

2-24

Page 25

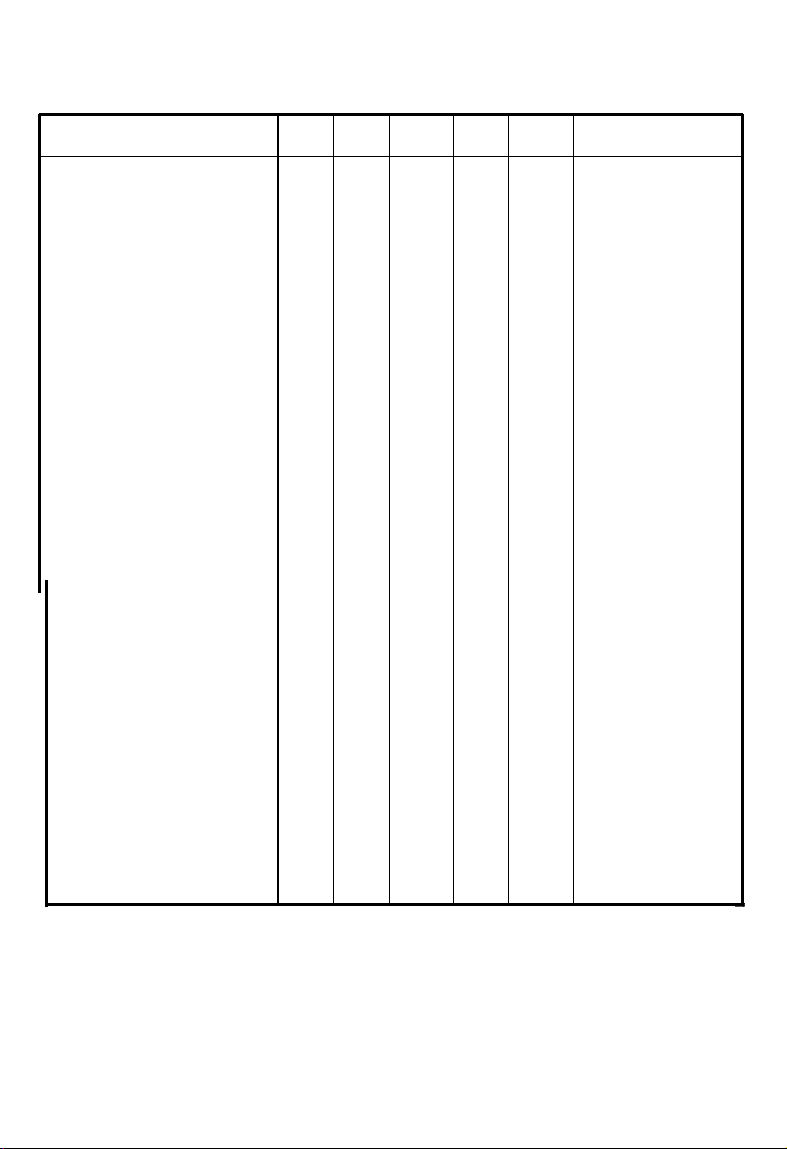

C: Clean R: Replace L: Lubricate A: Add I: Inspect

ITEM

OPTICS

Mirrors, Lens Reflectors,

Toner Shield Glass

Exposure Glass

Platen Cover

Exposure Lamp

Scanner Guide Rods

and Plate

Guide Rod Felt

ADS/APS Sensors

EM

C

C

C

80k

C

C

C

I

C,L

I

C

160k

C,L

12 June 1987

240k

320k

C

C

C

C

I

C,L

I

C

C

C

C

C

C

I

I

C,L

I

I

C

C

NOTE

Alcohol/Water

Glass Cleaner

Alcohol/Water

Replace if necessary

Launa Oil

Replace if necessary

Blower Brush Only

PAPER FEED

Paper Feed Rollers

Pick-up Rollers

Separation Rollers

Slip Clutch

Registration Roller

Lift Motor Worm Gear

and Worm Wheel

Paper Feed Guide Plate

Registration Sensor

Cassette Bottom Plate

Pad

Paper Dust Cleaner

Relay Rollers

AROUND DRUM

Corona Wires

Wire Cleaner Pad

End Blocks and Casing

Cleaner Drive Wire

PTL Filter

QL Filter

ID Sensor

Erase Lamp Unit

R

R

C

R

C

R

C

L

C

L

C

C

C

C

C

I

R

C

C

I

C

C

R

R

R

R

R

L

L

C

C

L

L

C

C

C

C

C

C

C

C

C

C

I

I

R

R

C

C

I

I

C

C

Damp Cloth

R

R

Damp Cloth

Damp Cloth

R

L

Mobil Temp.78

C

Damp Cloth

L

Mobil Temp.78

C

Damp Cloth

C

Blower Brush

C

Damp Cloth

C

Damp Cloth

C

I

Replace if necessary

R

Dry Cloth

C

Replace if necessary

I

C

Dry Cloth, Discharge

before installation

C

C

C

C

Dry cloth, Discharge

C

before installation

C

C

C

C

C

C

C

C

C

Blower Brush

Dry Cloth

2-1

Page 26

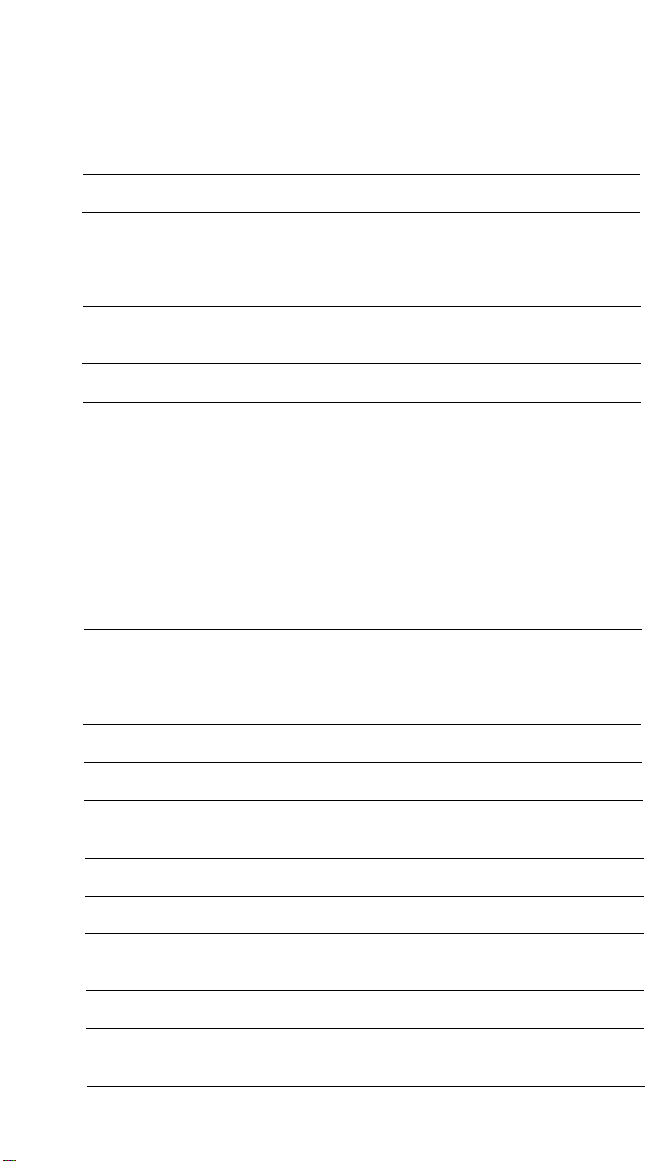

12 June 1987

ITEM

EM

80k

160k

CLEANING UNIT

Cleaning Blade

Cleaning Seals

Cleaning Brush

Bias Roller

Bias Roller Blade

Pick-off Pawls

R R R

I I

R R R

I I I

C

C

I I I I

DEVELOPMENT UNIT

Developer

Upper Brush Seal

R R R R

C

C

Development Unit Drive

Gears

Development Filter

L L

R R R R

FUSING UNIT

Hot Roller

Pressure Roller

Stripper Pawls

Oil Supply Pad

Oil Blade

I

I

I

R

R

C C C C

R R R R

R R

Fusing Entrance &

Exit Guide

Oil Sump

Oil Tank

C C

C

C

A A A A A

Gears L L L

OTHERS

Transport Ozone Filter

R R R

Registration Roller

Gears L

First Relay Roller Gears

First Relay Rollers

Drive Chains and Belts

Transport Belt

Vacuum Fan Filter

Exit Relay Rollers

Bushings

L

L L

C C C C

I I I

C C C

R

R

C C C C

L

240k 320k

R

I I

R

I

R C

C C

L

L

R

R

C

C

C C

L

R

L

L

L

L

I

C

R R

L

NOTE

Clean or replace if

necessary

Clean if necessary

Dry Cloth

Clean if necessary

Mobil Temp.78

Prime with oil when

replacing

Prime with oil when

replacing

Suitable Solvent

Mobil Temp.78

Mobil Temp.78

Mobil Temp.78

Damp Cloth

Replace if necessary

Damp Cloth

Damp Cloth

2-2

Page 27

12 June 1987

ITEM

DUPLEX

Inverter Support Roller

lnverter Pressure Roller

Positioning Roller Drive

Belt

Positioning Roller

Duplex Slip Clutch

Duplex Pick-up Roller

Duplex Separation Roller

Duplex Feed Roller

DOCUMENT FEEDER

Belt

Pick-up Roller

Feed Roller

Friction Roller

CASSETTE BANK

Pick-up Roller

Feed Roller

Friction Roller

EM

80k

C

C

C

C

240k 320k

160k

C C

C C C

C C C

R C R

L L L

C C

C

C

C

C

C

C

R

R C R

R C

C C

C C R C

C

C

R

C C R C

C C

C

C

C

C

R

R C R

R C R

NOTE

Damp Cloth

C

Damp Cloth

Damp Cloth

Damp Cloth

Mobil Temp.78

C

L

R

Damp Cloth

Damp Cloth

Damp Cloth

R

Belt cleaner,

C

replace if necessary

Water, replace if

R

necessary

C

R

Water, replace if

necessary

Water, replace if

R

necessary

C

R

Water, replace if

necessary

Water, replace if

necessary

Water, replace if

necessary

2-3

Page 28

12 June 1987

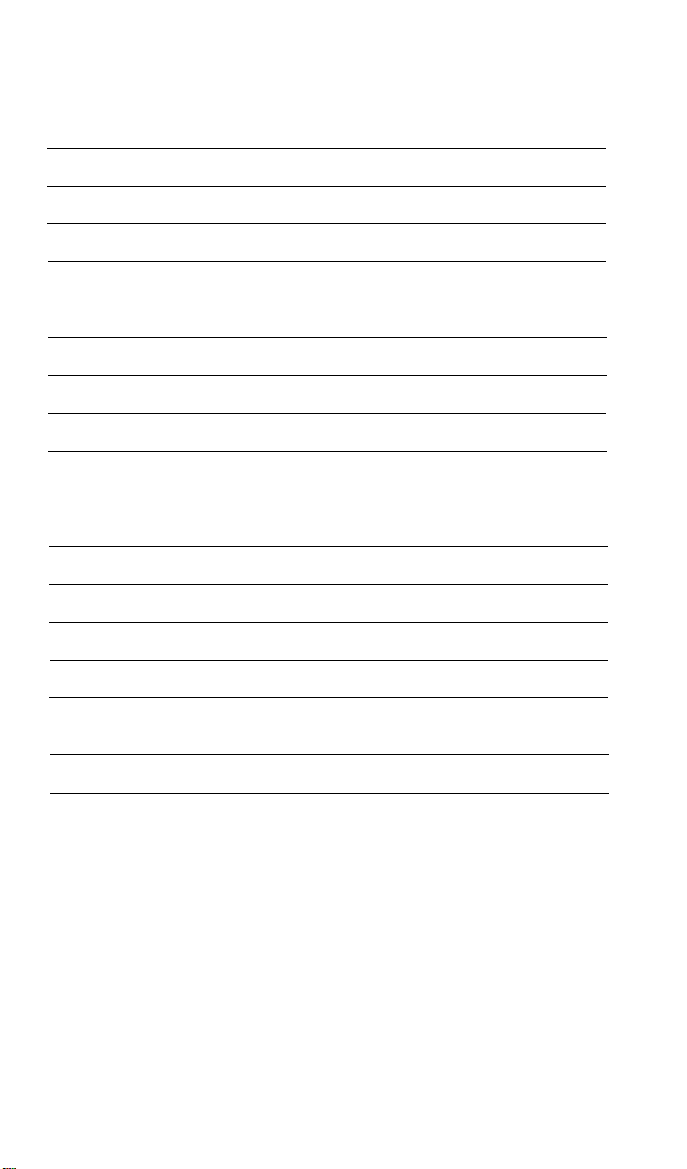

SERVICE TABLES

1. Test Points

- Main Board Number

TP100 Input voltage of image density sensor.

TP101

TP102

TP103

- Scanner Control Number

TP301

TP303

TP304

TP305

TP306

TP307

TP308

TP309

TP310

TP311

TP312

Function

+24 V

+5 V

GND

Function

+24 V (Vm)

Factory Use

Factory Use

Factory Use

Factory Use

Factory Use

Original Density Voltage

Scanner Forward Signal (Low Active)

Scanner Return Signal (Low Active)

GND

+5 V (Vc)

2. Variable Resistors

- ID Sensor Board VR

Function

VR-1

- Main Board VR

VR-100

- Optics Control Board VR

VR-301 APS Width Sensor (OWS) Voltage Adjustment

VR-302

LED Light Intensity Adjustment

Function

ADS Voltage Adjustment

Function

APS Length Sensor (OLS) Voltage Adjustment

2-4

Page 29

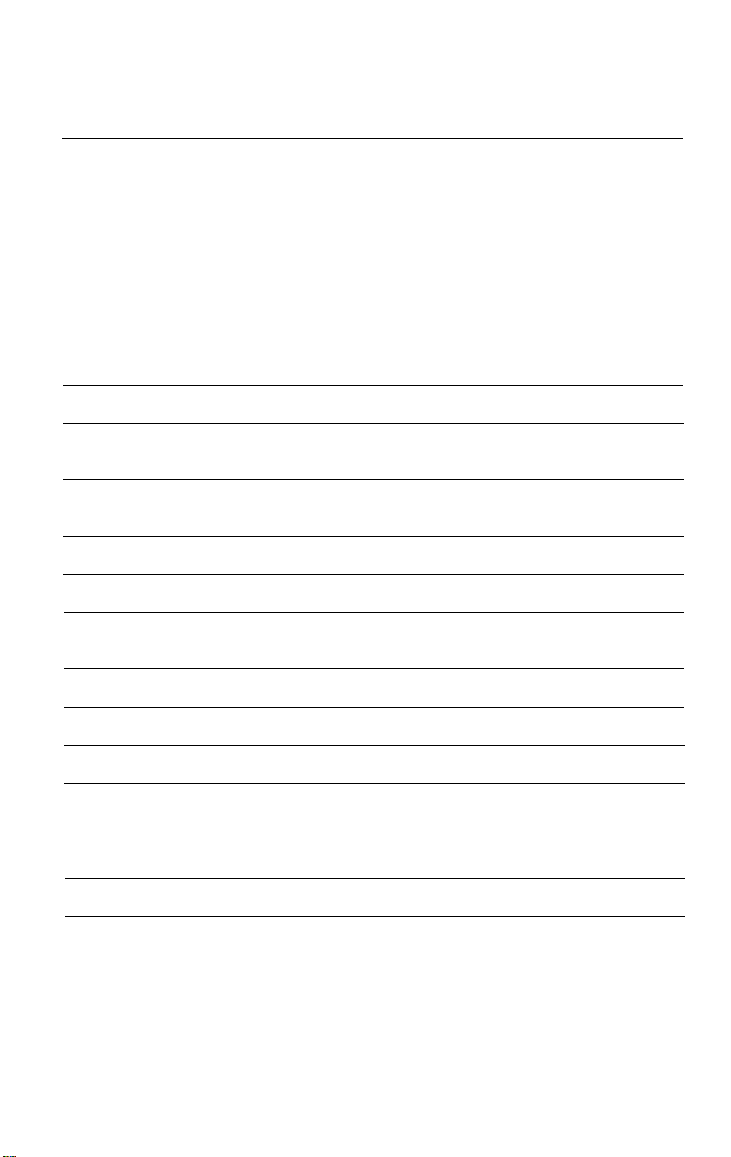

3. DIP Switches Tables

DIP SW 801 (Operation panel)

12 June 1987

SW #

1*

2

Description

Free run

Not used

3

4

Language code (see language code table)

5

6

7

Not used

Clear counter (see CLEAR MEMORY PROCEDURE)

8 Service Program mode access

* When ON, the SP mode is disabled.

DIP SW 100 (Main Board)

SW #

1

2

3

Description

Factory use only (must be off)

Factory use only (must be off)

Disables the oil end sensor operation

4,5

6,7

Not used

8

RAM clear (See CLEAR MEMORY PROCEDURE)

4. User Codes Table

There are 20 user codes as follows:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1101

1202

1303

1404

1505

1606

1707

1808

1909

2010

11. 2111

12. 2212

13. 2313

14. 2414

15. 2515

16. 2616

17. 2717

18. 2818

19. 2919

20. 3020

2-5

Page 30

12 June 1987

5. Service Program SP-8 Data Input Guide Table INPUT #

1

2

3

4

5

6

8

9

10

11

12

15

16

17

18

20

21

24

SENSOR

DATA

Registration sensor

Fuser sensor

Exit sensor

Relay roller sensor #1

Relay roller sensor #2

Relay roller sensor #3 DATA 1 . .

When paper is present

Inverter entrance sensor

Inverter exit sensor

DATA 0 . . When paper is not

Duplex entrance sensor present

Duplex paper sensor

Jogger home position DATA 0 . . Jogger at H.P.

Sorter inlet sensor

Sorter bin sensor DATA 0 . . Paper not present

Sorter home position

DATA 1 . .

Bins at H.P.

sensor

Sorter door safety switch

Toner end sensor

DATA 0 . . Sorter door closed

DATA 1 . . Toner present

Total counter confirmation DATA 0 . . Confirmation signal

signal

LOW (T.C. off)

Pressure pIate reed switch DATA 1 . . Pressure plate down

25

27

30

31

32

33

35

Paper bank set signal

Duplex unit set signal

Paper lift sensor #1

Paper lift sensor #2

Paper lift sensor #3

Paper lift sensor #4

Cassette release sensor

DATA 1 . . Paper bank installed

DATA 1 . . Duplex unit installed

DATA 1 . . Cassette lifted

DATA 0 . . Cassette down

DATA 1 . . Cassette #1 released

For all sensors, DATA is displayed in the guidance display.

2-6

Page 31

12 June 1987

SERVICE PROGRAM MODE OPERATION

The service program mode is used to check electrical data and change

modes or adjustment values.

1. Service Program Access Procedure

1.

Turn the main switch off.

Remove the DIP switch cover on the Operation Panel and turn on DIP

2.

SW 801-8, then turn the main switch on.

NOTE:

3.

Using the numeric key board, enter the desired SP mode number

according to the Service Program Mode Table. The SP program can

also be selected with the magnification keys (+, -), in this case SP

numbers are scanned through. After selecting an SP number, press

the ENTER key (#).

NOTE:

To abandoned SP mode, turn the main switch OFF, set DIP SW 801-8

4.

to the off position, and turn the main switch on.

At this point the guidance display will prompt...

“PROGRAM No.” . . . . . . . . . . . . . . No. 5

To cancel an already entered program, press the clear key.

Also, if an invalid SP number is entered, “Press Clear key” is

displayed.

—

2. Change Adjustment Values or Modes

1.

Follow steps 1-3 of the preceding procedure.

Factory setting values or mode will be displayed in the Guidance

2.

Display.

Enter the desired value or mode using the numeral keys according to

3.

the Service Program Mode table.

Turn off the main switch, set DIP SW 801-8 to the off position, and

4.

turn the main switch on.

The

following procedure can also be used to access program numbers 80, 81, 90, 91,

92 instead of using DIP SW 801-8.

and

1.

Press the Mode Clear key.

Press the Clear/Stop key.

2.

Press the Enter key, simultaneously the Guidance Display prompts

3.

“PROGRAM No.” . . . . . . . NO. 80

2-7

Page 32

4. Enter the desired number using the number keys or zoom keys.

5. Press the Enter key.

• Service program mode is cleared by pressing the Clear Modes key.

3. Memory Clear Procedure

<SP-97 “Clears service counters and jam counters”>

Service Program SP-97 is used to clear all self-diagnostic counters and

paper jam counters.

To perform this clear function,

performed.

1.

Turn main switch OFF

Turn ON DIP SW 801-7, 8 on the operation panel and turn the main

2.

switch ON.

Select Service program SP-97 and and press the “1” key on the key

3.

pad, then press the Enter key.

At this point Service Programs SP-120 through 139 will be cleared,

and default to “0”

Turn off the main switch.

4.

5.

Turn DIP SW 801-7 and 8 off.

Turn the main switch ON to resume normal copier operation.

6.

<SP-98 “Clears all counters”>

Service Program SP-98 is used to clear all copy counter, self-diagnostic

counters and jam counters at once.

To perform this clear function, follow the same procedure as previously

describe but using SP-98 instead.

The following programs will be cleared:

the following procedure must be

1) SP-100 through SP-139

2) SP-85 (E.M. call telephone number)

3) SP-86 through SP-89 (PM counter)

4) All User Programs are cleared

2-8

Page 33

5) Secret Mode counters 1-20 are cleared.

<SP-99 “Clear all memory”>

12 June 1987

This Service Program

clears all those service programs previously

described as well as all adjustments and modes. All mode default to

factory settings.

1. Turn the main switch OFF

2. Turn on DIP SW 801-7 and 8 on the operation board.

3. Turn on DIP SW 100-8 on the main board.

4. Turn the main switch on.

5. Select SP-99 and press the

“1” key on the key pad, then press the

Enter key to perform memory clear function.

6. Turn the main switch OFF and reset DIP switches to the OFF

position, then turn the main ON to resume copier operation.

2-9

Page 34

12 June 1987

4. Service Program Mode Table

Mode No.

5 Exposure Lamp

OFF Free Run

6 Jam Detection

OFF

7 Corona wire

cleaner function

8 Input Check

10 Drum Condi-

tioning

11 All Indicators

ON

12 Language (LT

version only)

13 Language (A4

version only)

Function

Free run with exposure lamp OFF.

Copies are made

without jam detection.

CC/TC cleaner motors

operation.

Displays the input

from sensors.

Used to condition a

new drum.

Turns on all the indicators on the operation panel.

Selects desired language. (French or

English

Selects language.

(Japanese, English

French, German,

Italian and Spanish)

Data

0: E

1: F

0: J

1: E

2: F

3: G

4: I

5: S

Factory

Setting

0: E

“No” is displayed

when 0 is selected.

The motor starts

when Enter key is

pressed. Stops after

1 cycle.

For data, see the

input check table.

100 will appear in the

copy counter. Press

Start to activate.

DIP SW 801-3, 4, 5

must be set. See

DIP SW tables.

DIP SW 801-3, 4, 5

must be set. See

DIP SW tables.

15 Auto Reset

Time

16 Count Up/Down

17 Auto cassette

shift

Selects auto reset

of 1 or 3 minutes.

Selects count up

or count down.

Selects autocassette shift

mode.

2-10

0: 1 min.

1: 3 min.

2: none

0: UP

1: DOWN

0: YES

1: NO

0

0

Copier automatically

0

shifts to another

cassette holding same

size paper when paper

runs out.

Page 35

12 June 1987

Mode No.

18 Beeper

19 Auto ID

Priority

20 Feed Station

Priority

21 APS Priority

22 SADF Shut-Off

Time

23 Free Size

24 RDH/ARDF

priority

25 Staple limit

Function

Turns beeper ON

or OFF.

Selects the priority

of image density

control when the main

switch is turned on.

Selects feed station

priority at power on.

Selects APS or

manual.

Selects shut-off time

for SADF mode.

Enables originals of

various sizes to be

fed from the same

stack.

Selects RDH or ARDF.

Sets staple limit at

35 copies.

Data

0: YES

1: NO

0: ADS

1: Manual

0: 1st

1: 2nd

(LCT)

0: Yes

1: No

0: 4 sec.

1: 60 sec.

0: No

1: Yes

0: RDH

1: ARDF

0: Yes

1: No

Factory

Setting

0

0

0

0

0

0

0

0

Comments

Possible in SADF

Mode.

Only if RDH/ARDF

is installed.

Finisher only.

26 Shift stack

27 Side erase

28 Sort Priority

Shift stack mode is

automatically selected

when no staple.

Decreases side

erase margins

about 5mm each.

Sort Mode is automatically selected

when more than 1

original is set on

the DF table and the

entered copy quantity

is greater than 2 and

less than 20.

2-11

0: No

1: Yes

0: No

1: Yes

0: Normal

1: Sort

Finisher only.

0

0

First LEDs inside

the paper boundaries

turn on.

Sorter and DF must

0

be installed on the

machine.

Page 36

12 June 1987

Mode No.

30 Toner Supply

Mode

31 Toner Supply

Amount (Detect

Mode)

32 Toner Supply

Function

Selects toner supply

system.

Determines how much

toner is supplied in 1: 15%

detect mode.

Determines how much

Amount (Fixed toner is supplied in 1: 4%

and Detect) fixed and detect mode.

33 ID Sensor

Bias

Sets the bias voltage

applied to the bias

roller when sensing 2: 470

image density. 3: 530

34 Bias shift

Permanently shifts bias

output. 1: 60 V

37 Lead Edge Sep-

Sets off timing of

aration Corona the separation

timing

38 Edge erase

corona. 2: 13 mm

Sets the width of

margin erase.

Data Factory Comments

Setting

0: Detect

1: Fixed

0: 30%

0

See SP31/SP32 for

ratios.

0

2: 45%

3: 60%

0: 7%

0

2: 11%

3: 14%

0: 500

1: 380

500 V = normal

0

470 V = Iight

380 V = lightest

530 V = dark

0

0: N

Shifts all bias levels

including ID pattern

2: 120 V

0: 10 mm

1: 7 mm

bias.

Use when separation

0

problems occur.

7 mm: -10 msec.

13 mm: +10 msec.

0: 10 mm

0

1: 5 mm

2: 15 mm

3: 20 mm

39 Charge wire

Cleaner

41 Lead Edge

Erase Margin edge margin.

Adjustment

42 Registration

Sets charge wire

cleaner operation to

ON or OFF.

Adjusts the lead

Adjusts registration.

0: ON

1: OFF

0 - 15

0 - 15

0

Cleaner motor turns

on every 5K copies at

power up.

0.6 mm per step.

8

(max. -4.8 mm to

+4.2 mm)

8

0.6 mm per step.

Adjustment (max. -4.8 mm to

+4.2 mm)

43 Vertical

Magnification

Adjusts magnification

in the paper travel

0 - 15

8

-0.8% to +0.7%

Adjustment direction.

2-12

Page 37

12 June 1987

Mode No.

44 Horizontal

Magnification

Adjustment

45 Lens tolerance

adjustment

46 Size detection

error correction

47 Focus

Adjustment

48 Light Intensity

adjustment

49 Fusing Tempera-

ture Adjustment

50 Original Length

Detection Check

51 Exposure Lamp

Voltage Check

52 Fusing Temper-

ature

Function

Adjusts magnification

perpendicular to the

direction of paper

travel.

Adjusts lens position

to correct focus.

Corrects size

detection.

Adjusts 4th/5th mirror

position to correct

focus.

Adjusts exposure lamp

voltage.

Adjusts fusing temp.

Displays the length

detected by the size

detection circuit.

Displays exposure

lamp voltage.

Displays the fusing

temperature.

Data

0 - 15

0 - 15

0 - 15

0 - 15

50 - 80

Vac

175 - 190

degrees

Factory Comments

Setting

-0.8% to +0.7%

8

-0.8% to +0.7%

8

1 mm per step.

8

-8 mm to +7 mm

8

0.215 mm per step.

-1.72 mm to +1.505

mm

To adjust voltage,

65

enter lamp voltage

with key pad in

0.5-volt steps.

175 to 190 degrees in

185

1 degree steps.

Press # key to

display.

Exposure lamp stays

on for 10 seconds. Do

not repeat more than

5 times to avoid over

heating the optics

cavity.

53 Drum Tempera-

ture

54 Vsg Adjustment

Displays the drum

temperature.

Turns on lD sensor

LED.

Adjust Vsg with VR

on the ID sensor board.

LED turns on 10 s

(no drum rotation).

2-13

Page 38

12 June 1987

Mode No.

Function

Data

Factory Comments

Setting

55 Vsg/Vsp

Check

56 Auto ID voltage

Displays Vsg and Vsp. Vsp/Vsg value updated

every 10 copies.

Automatically adjusts Free run starts. Auto

adjustment the auto ID reference ID adjusted

57 Auto lD voltage

value display K values.

original)

voltage.

Displays Voltage and

Press Start key to

automatically.

Machine starts free

run.

K = SP57/SP56

turn on. Press C/S

to stop.

58 APS Sensors

operation check

Checks operation of Vl: Length

fiber optics sensors

voltage run. APS voltage is

Machine starts free

standard original. Vw: Width automatically adjusted.

Press Start key to

turn on.

voltage while maintaining the

exposure lamp voltage

at 70.0 vac.

59 Bias Voltage

Displays bias voltage

Press Start to turn on.

Press C/S to stop.

V0:

ID pattern

V1:

Without temperature

compensation.

Developer

bias

60 Toner Density After the Start key

Recovery

is pressed, the V1: Vsp

toner supply clutch

turns on and free run

starts. Free run stops

V0: Vsg

Use this mode to

bring a low toner

condition back to

normal. 100% is

selected.

and constant supply

is reset when Vsp

becomes < 1/8 Vsg.

61 Idling Period

Selection

71 Sorter/finisher

operation

72 ARDF/RDH

Selects idling period

at power-up. 1: 10 min.

Enables sorter or

finisher operation.

Enables ARDF or

operation RDH operation.

76 Sorter Bin

Capacity

Sets the stack mode

quantity limit.

0: 5 min.

0

2: 15 min.

0: NO

0

1: Sorter

2: Finisher

0: No

0

1: ARDF

2: RDH

0: No Iimit

Limit =

0

1: Limit Use with finnisher.

2-14

35 sheet/bin

Page 39

12 June 1987

Mode No.

77 Odd Number

Duplex Copy

80 Clock set

81 Weekly timer

set

82 Automatic

shut off.

85 EM call

phone number.

86 PM Counter

87 PM Copy

Count

Function

Sets the copier to

eject the final copy

if an odd number of

originals are set.

Sets the machine

clock.

Programs the machine

to turn ON/OFF each

day of the week.

Selects automatic

shut off time.

Sets phone # of serv-

ice representative.

Turns on the PM

counter.

Sets the interval

of the PM counter.

Data

0: Yes

1: No

0: No

1: 30 min.

2: 1 hour

3: 3 hours

0: No

1: Yes

0: 80 k

1: 60 k

2: 100 k

Factory

Setting

0

0

0

0

Comments

When off, the final

sheet is fed out; when

on, it stays in the

duplex tray.

Also accessible by

the customer using

the key board.

Also accessible by the

customer using the

key board.

Use decimal key

for a space.

88 PM Counter

Check

89 PM Counter

Reset

90 User Code

Mode

91 User Code

Counter Check

Displays contents

of the PM counter.

Resets the PM

counter.

Selects user code

mode. (Key counter

shorting connector

must be removed.)

Displays the contents

of each user counter.

Use + and - keys to

select user code.

2-15

0: No

1: Yes

0: No

1: Yes

When the PM count is

exceeded the Service

call and Key Counter

indicators blink.

Use after performing

PM.

0

If on, must enter a

code to copy. See

user code table.

Reset after 60 s or if

C/S and Clear Modes

pressed together.

Accessible through key

board.

User counters count

from 0 to 99999.

Accessible through

keyboard.

Page 40

12 June 1987

Mode No.

92 User Code

Function

Resets user’s counters

Counter Reset Select the user code

counter using + and keys. To reset press

“1” then #.

93 Maximum Copy Limits the maximum

Quantity

copy quantity that

can be entered.

97 Clear S/C

Clears the service

& Jam Count call and jam counters.

98 Clear

Clears the following

Counters counters: 1: Yes

- total copies

- S/C & Jam counter

- Job Program

- PM counter

- Service Tel. #

- User Code Counter

99 Clear All

Memory

Clears all counters

and returns all modes

to factory setting.

Data

Factory Comments

Setting

0: No

Accessible through

1: Yes keyboard.

999

The indicator blinks

and the limit quantity is displayed.

If you enter 0, the

max is 999.

Otherwise, max is

number entered.

0: No

1: Yes

0

DIP SW 801-7

on operation

must be on.

0: No

DIP SW 801-7

on operation

must be on.

0

0: No

1: Yes

DIP SW 100-8 (Main

board) and DIP SW

801-7 on the operation

panel must be ON.

100 Main Motor Displays the total

ON time check

(accumulated) time

that the main motor

has operated.

101 Total Copies

Displays the total

number of copies.

102 Duplex Copies

103 DF Copies Displays the total

Displays the total

number of duplex

copies made.

number of copies

made using the DF.

2-16

0

Time in hours.

0

0

0

Page 41

12 June 1987

Mode No.

104 Sort Copies

105 Cassette

Bank Copies

106 LCT Copies

108 A3/11 x 17

Copies

109 A4/8-1/2 x 11

Copies

111 Reduction

Copies

112 Enlarged

Copies

Function

Displays the total

number of copies

made using the

sorter.

Displays the total

number of sheets

fed from the cassette

bank unit.

Displays the total

number of sheets

fed from the LCT.

Displays the total

number of A3 or

11 x 17 copies.

Displays the total

number of A4 or

8-1/2 x 11 copies.

Displays the total

number of reduction

copies.

Displays the total

number of enlarged

copies.

Data

Factory

Setting

0

0

0

0

0

0

0

Comments

114 Originals

Copied

115 Originals

Copied Using

DF

120 Total Service

Calls

121 Service Call

Breakdown

Displays the total

number of originals

copied.

Displays the total

number of originals

copied using the DF.

Displays the total

number times that the

service call indicator

has turned on.

Displays the total

number of each

service call using

+ and - keys.

0

0

0

0

2-17

Page 42

12 June 1987

Mode No.

130 Paper Jams

131 Feed Jams

132 Fuser jams

133 Inverter jam

134 Duplex Jams

135 Duplex misfeed

136 Exit Jams

137 Cassette bank

Jams

Function

Displays the total

number of paper jams.

Displays the total

number of entrance

area paper jams.

Displays the total

number of jams at the

fusing unit.

Displays total number

of jams at the inverter

unit.

Displays the total

number of jams in the

duplex area.

Displays total number

of misfeed from duplex

selection.

Displays the total

number of jams in the

exit area.

Displays the total

number of paper bank

jams.

Data Factory Comments

Setting

0

0

0

0

0

0

0

0

138 Sorter Jams

139 DF Jams

Displays the total

number of sorter

jams.

Displays the total

number of DF jams.

2-18

0

0

Page 43

5. Language Code Table

12 June 1987

DIP-801

3

4

0 0

0

1

0

1

1

0 0

1

0

1 1

1 1

Destinations Paper

5

1

PITNEY BOWES

0

KALLE INFOTEC

RICOH EUROPE

RICOH ASIA/

MIDDLE EAST

NASHUA SOUTH

1

AMERICA

RICOH USA

SAVIN

1

0

RICOH TAIWAN

NASHUA EUROPE A4

1

Size

LT 0: English

A4

LT 0: English

LT

LT

A4

SP-12

1: French

No Function

1: French

0: English

1: French

0: English No Function

1: French

No Function Same as Ricoh Europe

No Function

SP-13

No Function

Original

0: Japanese 0: Swedish

1: English

2: French

3: German

4: Italian

5: Spanish

No Function

No Function

NOTE: When language se-

lection is required,

turn off DIP-801-3.

Original

0: Japanese

1: English

2: French

3: German

4: Italian

Option

1: English

2: Danish

3: Norwegian

4: Finnish

5: Dutch

Option

0: Swedish

1: English

2: Danish

3: Norwegian

4: Finnish

2-19

Page 44

12 June 1987

SPECIAL TOOLS AND LUBRICANTS

Item

1 Test Chart OS-A3 -- 10 sheets

2 Digital Thermometer

3 Digital Thermometer Probe

4 Digital Multimeter

5 Test Lead Kit

6 Drum shoe

7 Shoe Adaptor

8 Omega Clamp

9 Thickness Gauge - 0.2mm

10 Thickness Gauge - 0.75mm

11 Setting Powder

12 Silicone Oil

Description

-- 100 sheets

(HLC-60E)

(HLC-60E)

(BECKMAN RMS3030)

(BECKMAN DL241)

(2 pcs / set)

Part No. Q’ty

5420 9516

5420 9502

5420 9504

5420 9505

5420 9507

5420 9508

5442 9106

5447 9104

5205 9111

5446 9140

5215 9500

5442 9101

5420 9550

1

1

1

1

1

1

1

2

1

1

1

1

13 Launa 40 Oil

14 Grease (MOBIL TEMP 78) 400g

2-20

5442 9103

5447 9078

1

1

Page 45

12 June 1987

SERVICE REMARKS

1. Handling The Drum

1. Never touch the drum surface with bare hands.

2. Store the drum in a cool dry place.

3. Always wear gloves when cleaning the drum.

4. Prime the drum with setting powder only when the cleaning blade,

cleaning brush, and drum are replaced as a set.

5. Never expose the drum to light for a long time.

6. Always keep the drum in the protective sleeve when inserting or

pulling the drum out of the copier.

7. Drum conditioning is necessary when a new drum is installed. In

addition, it should be done at the following times:

a) When image density is reduced due to overexposure of the drum.

b) After cleaning the drum.

c) When the drum is lightly scratched.

8. Before inserting or sliding out the drum, the cleaning unit should be

removed to avoid drum damage.

press the drum shaft slightly to the left.

9. Return used drums to the distributor according to standard procedure.

When pulling out the cleaning unit,

2. Charge Corona

1. Do not use emery paper which abrades the coating on the wire for

wire cleaning.

2. Do not touch the corona wire with oily hands. Oil stains may cause

white bands on copies.

3. The corona wire height should be adjusted only when:

a) The front end block is replaced.

b) The drum charge current is uneven.

4. Make sure that the corona wires are correctly positioned between the

cleaner pads.

2-21

Page 46

12 June 1987

3. Erase Lamp

1. A narrower lead edge erase margin increases the possibility of fusing