Page 1

RICOH FT5560

RICOH COMPANY, LTD.

FIELD SERVICE

MANUAL

Page 2

TABLE OF CONTENTS

I. INSTALLATION

INSTALLATION REQUIREMENTS

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Machine Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Minimum Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

COMPONENT INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . 1-6

SYSTEM CONFIGURATION TABLE . . . . . . . . . . . . . . . . . . . . .

How to Use

PAPER BANK INSTALLATION

Accessory Check . . .

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . .

1-7

1-8

1-9

Page 3

LARGE CAPACITY TRAY INSTALLATION

Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Installation Procedure With Paper Bank

(5th feed station) .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-17

Installation Procedure Without Paper Bank

(3rd feed station)

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . 1-17

Common Procedure for LCT Installation . . . . . . . . . . . . . 1-19

COPIER INSTALLATION

Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Installation Procedure . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

1-26

Cassette Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

Key Counter Holder Installation . . . . . . . .

. . . . . . . . . . .

1-35

Accessory Counter Installation . . . . . . . . . . . . . . . . . . . . 1-37

DUPLEX UNIT INSTALLATION

Accessory Check . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

1-38

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Page 4

MINI SORTER INSTALLATION

Accessory Check . .

Removal of Shipping Retainers . . . . .

Adapter Accessory Check

Installation Procedure . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

1-46

1-46

1-47

1-48

MIDI SORTER INSTALLATION

Accessory Check . .

Removal of Shipping Retainers . . .

Adapter Accessory Check . . . .

Installation Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-51

1-51

1-52

1-53

DOCUMENT FEEDER INSTALLATION

Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

1-57

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

AUTO REVERSE DOCUMENT FEEDER

Accessory Check . . . . .

Installation Procedure . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

1-66

1-68

COLOR UNIT INSTALLATION

Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . .

1-75

1-76

Page 5

PREPARATION FOR TRANSPORTING THE COPIER

Short Haul Transportation . . . . . . . . .

Long Haul Transportation By Vehicle .

. . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . .

1-79

1-81

II. SERVICE TABLES

SERVICE PROGRAM MODE OPERATION

Data Check Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Change Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Service Program Mode Table . .

Input Check Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

User Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

SERVICE REMARKS . . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . .

2-6

2-8

2-32

Page 6

Ill. REPLACEMENT AND ADJUSTMENT

OPTICS

1. Fiber Optics Cable Replacement . . . . . . . . . . . . . . . . . 3-1

2. Auto Paper Size Sensor . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3. Length Sensing Adjustment . . . . . . . . . . . . . . . . . . . . . . 3-5

DEVELOPMENT AND TONER SUPPLY

1. Image Density Sensor Removal

2. Image Density Check and Adjustment

3. Toner Supply Clutch Disassembly

CLEANING

1. Cleaning Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

2. Pick-off Pawl Replacement . . . . . . . . . . . . . . . . . . . . . . 3-12

3. Bias Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . 3-14

4. Bias Roller Blade Replacement . . . . . . . . . . . . . . . . . . 3-15

PRE-QUENCHING

1. Pre-Quenching Corona Unit Replacement . . . . . . . . . . 3-16

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . .

. . . . . . .

3-6

3-7

3-9

Page 7

PAPER FEED

1. Feed Roller/Friction Pad Gap Adjustment . . . . . . . . 3-17

2. Registration Clutch Adjustment . . . . . . . . . .

. . . . . . . .

3-18

FUSING

1. Checking Hot Roller Temperature . .

2. Changing Hot Roller Temperature

3. Fusing Pressure Adjustment . . . . .

4. Entrance Guide Height Adjustment

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . .

3-19

3-20

3-21

3-22

COPY IMAGE

1. Light Intensity Adjustment . . . . . . . . . . . . . . . . . . . . . 3-23

2. Auto ID Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . 3-26

3. Horizontal Magnification Adjustment . . . . . . . . . . . . 3-28

4. Vertical Magnification Adjustment

5. Lead Edge Registration Adjustment . .

6. Lead Edge Erase Margin Adjustment . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . .

3-29

3-30

3-32

CORONA

1. Charge Corona Wire Replacement . . . . . . . . . . . . . . . . . 3-34

2. Charge Cleaner Drive Wire Replacement . . . . . .

. . . .

3-36

3. Pre-Quenching Corona Wire Replacement . . . . . . . . . . 3-37

Page 8

DRUM CURRENT ADJUSTMENTS

1. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3-41

2. Charge Corona

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . .

3. Transfer Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

4. Separation Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

5. Pre-cleaning Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

6. Pre-quenching Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

LARGE CAPACITY TRAY

l. Tray Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

2. Tray Down Sensor and Positioning

Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3. Paper Size Sensor Replacement . . . . . . . . . . . . . . . . . . 3-55

4. Side Registration Adjustment . . . . . . . . . . . . . . . . . . . 3-56

DUPLEX UNIT

1. Positioning Roller and Drive Belt Replacement . . 3-58

2. Positioning Roller Pressure Adjustment . . . . . . . . . 3-59

3. Jogger Home Position Adjustment . . . . . . . . . . . . . . . . 3-60

Page 9

MIDI

DOCUMENT FEEDER ARDF

SORTER

Bin Drive Belt Replacement .

1.

2.

Bin Drive Motor Replacement

Bin Replacement .

3.

4.

Exit Roller Drive Motor Replacement .

Lower Exit Roller Unit and

5.

Exit Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . 3-66

1. DF Belt Drive Motor Speed Adjustment

2. DF Registration Adjustment . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

3-61

3-63

3-64

3-65

3-68

3-70

IV. ELECTRICAL DATA

SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Page 10

SECTION I

INSTALLATION

Page 11

I. INSTALLATION

lnstallation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Component Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

System Configuration Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Paper Bank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Large Capacity Tray lnstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Copier Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Duplex Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Mini Sorter lnstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 1-46

Midi Sorter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-51

Document Feeder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-57

Auto Reverse Document Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-66

Color Unit lnstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

Preparation for Transporting the Copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-70

Page 12

INSTALLATION REQUIREMENTS

1-1

ENVIRONMENT

1. Temperature Range: 10°C to 30°C (50°F to 86°F)

2. Humidity Range: 15% to 90% RH

3. Ambient Illumination: Less than 1,500 Iux (Do not expose to direct sunlight)

4. Ventilation: Room air should turn over at least 3 times/hour.

3

5. Ambient Dust: Less than 0.15 mg/m

6. Room Size: More than 10 m

3

7. If the installation place is air-conditioned or heated, place the machine:

a. Where it will not be subjected to sudden temperature changes.

b. Where it will not be directly exposed to cool air from an air conditioner in sum-

mer.

(4 x 10¯³ oz/yd3)

(13.4 yd3)

31 March 1987

c. Where it will not be directly exposed to reflected heat from a space heater in

winter.

Page 13

31 March 1987

8. Avoid placing the copier in an area filled with corrosive gas.

9. Avoid any area higher than 2,000 meters (6,500 feet) above sea level.

10. Place the copier on a strong and level base.

11. Avoid any area where the copier may be subjected to frequent strong vibration.

1-2

Page 14

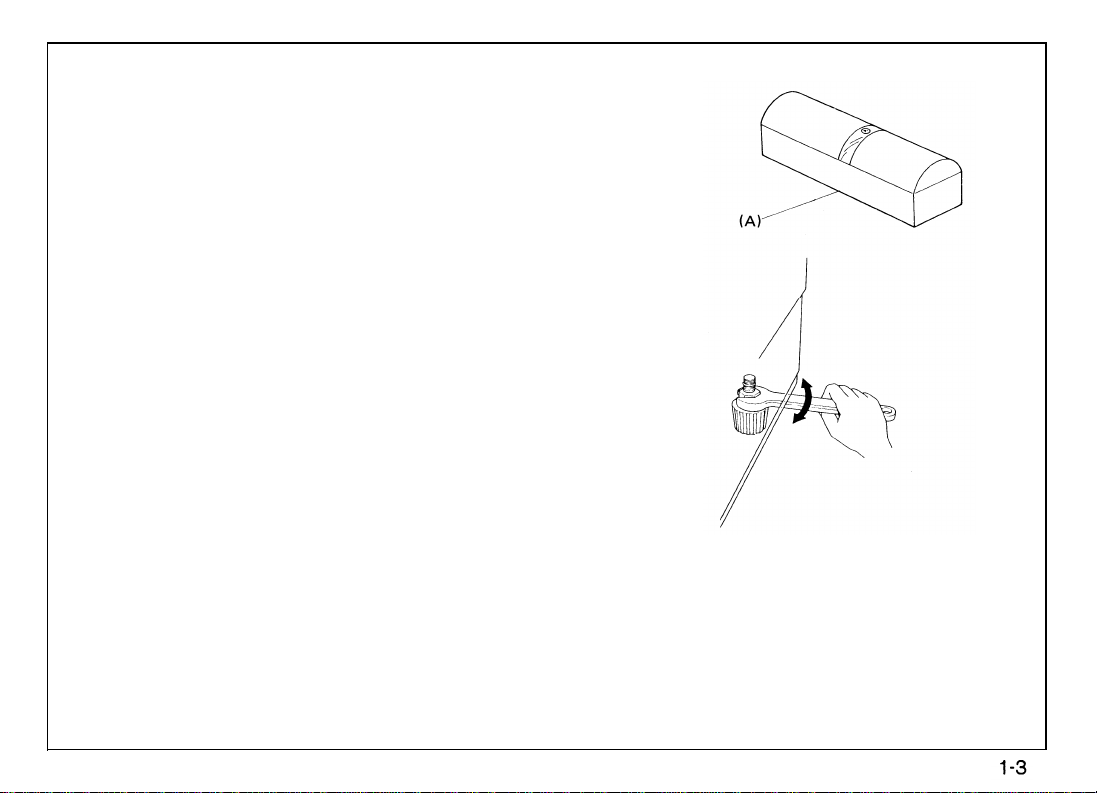

MACHINE LEVEL

1. Front to back: Within 5 mm (0.2”) of level

2. Right to left: Within 5 mm (0.2”) of level

31 March 1987

(Legs may be screwed up or down to level the machine. Set a carpenter’s level

the exposure glass.)

[A] on

Page 15

31 March 1987

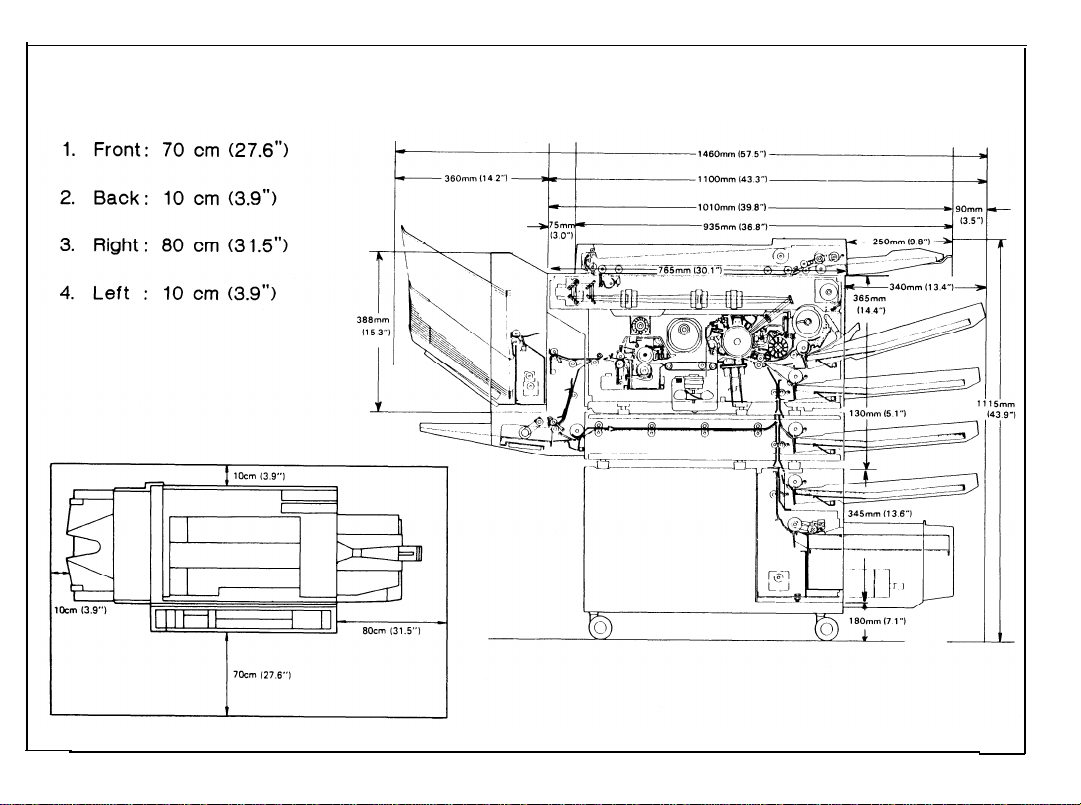

MINIMUM SPACE REQUIREMENTS

1-4

Page 16

POWER REQUIREMENTS

1.

Input voltage level

110V/60Hz : More than 15A

115V/60Hz : More than 15A

220V/50Hz : More than 7A

240V/50Hz : More than 7A

2.

Permissible voltage fluctuation: 10%

31 March 1987

3.

Permissible extension cord:

At least 300V, 30A capacity and less than 5 meters

(16.4 ft) long.

NOTES: a)

Be sure to ground the machine. (Do not connect the grounding wire to a gas

pipe.)

b)

Make sure the plug is firmly inserted in the outlet.

Avoid multi-wiring.

c)

Do not set anything on the power cord.

4.

1-5

Page 17

31 March 1987

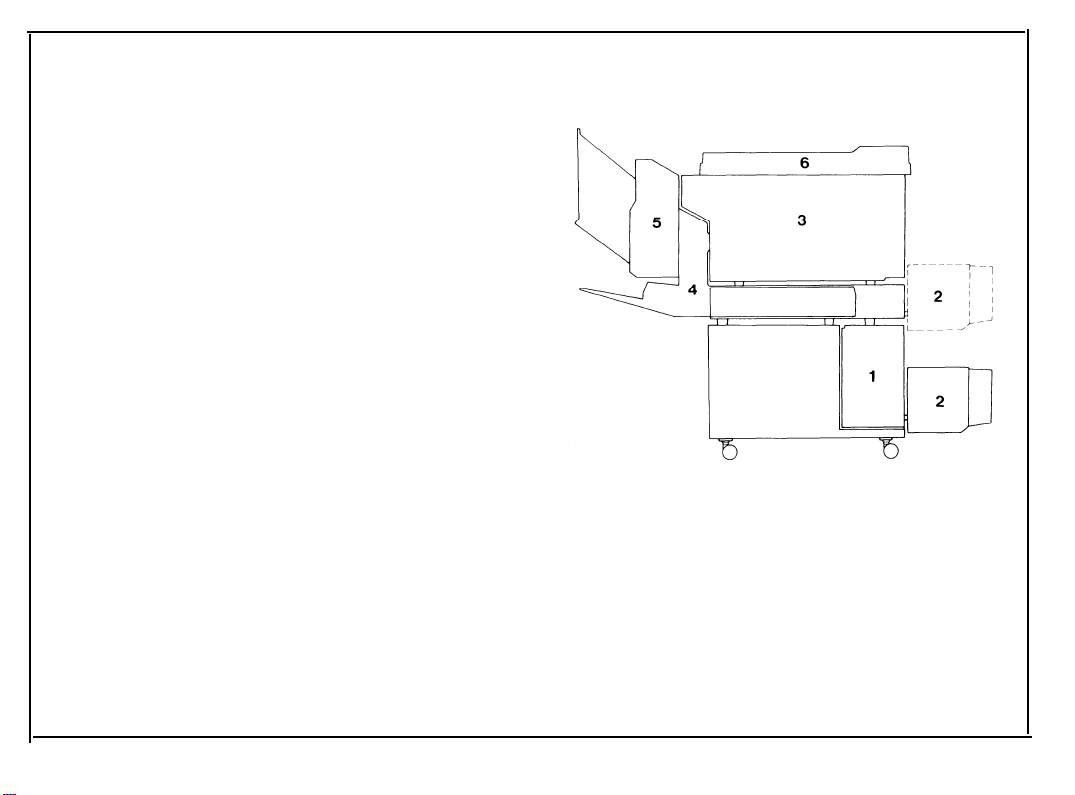

COMPONENT INSTALLATION PROCEDURE

1.

Paper Bank

2.

Large Capacity Tray

Copier

3.

Auto Duplex Unit

4.

Sorter

5.

Document Feeder

6.

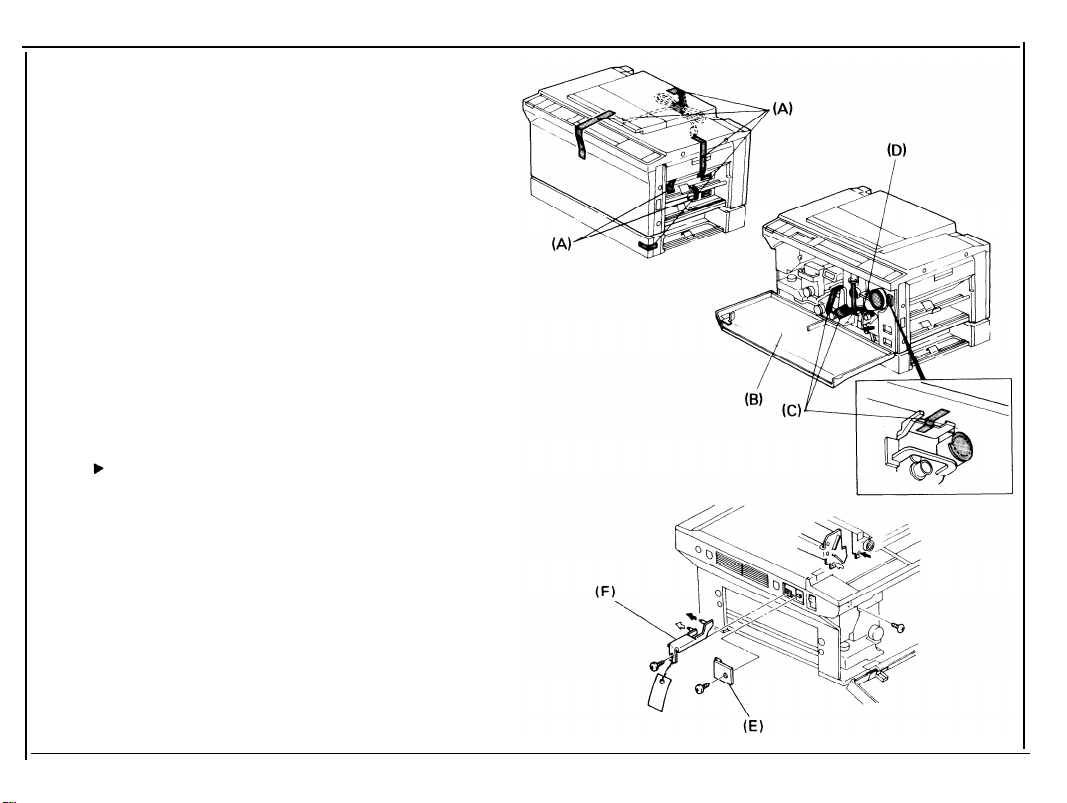

The illustration to the right shows the relative order of installing the different components to the

base copier to obtain the system configuration

desired by the customer. This installation proce-

dure has been tailored to this illustration. The installation of components should start from the

lower numbered components and progress to

higher numbered components.

NOTE: When not instaIling the duplex unit or the

sorter save the duplex unit or sorter key

tops and key covers for future use.

1-6

Page 18

31 March 1987

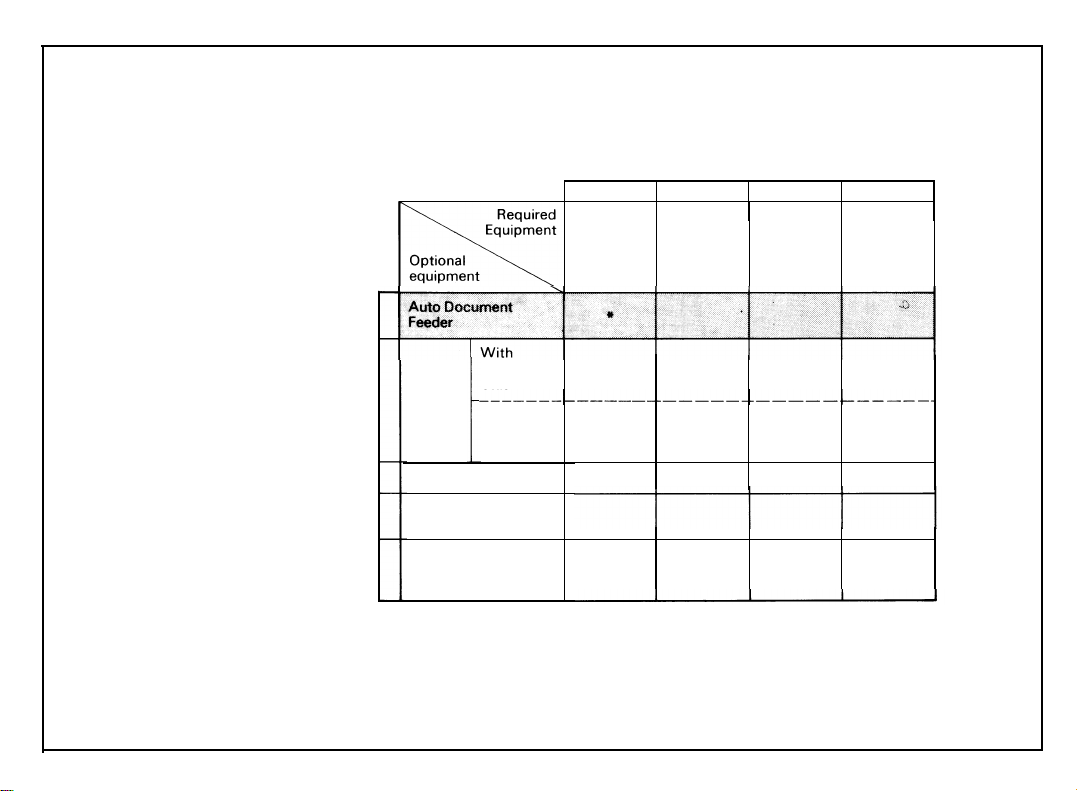

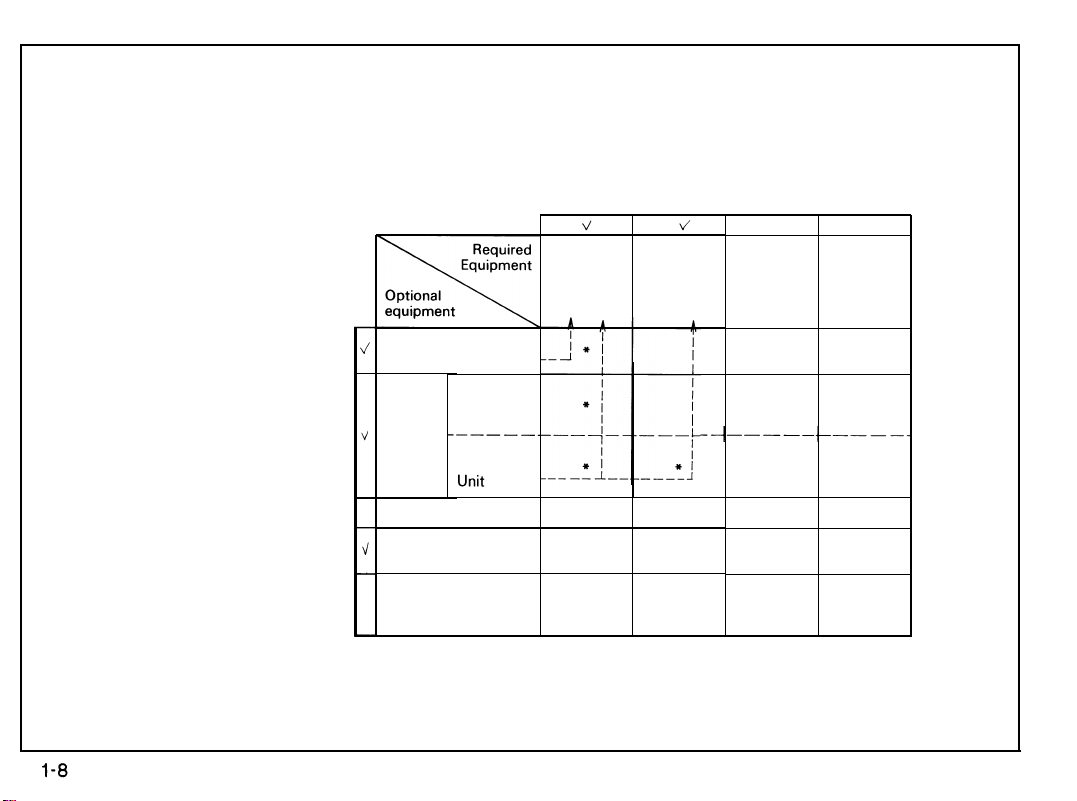

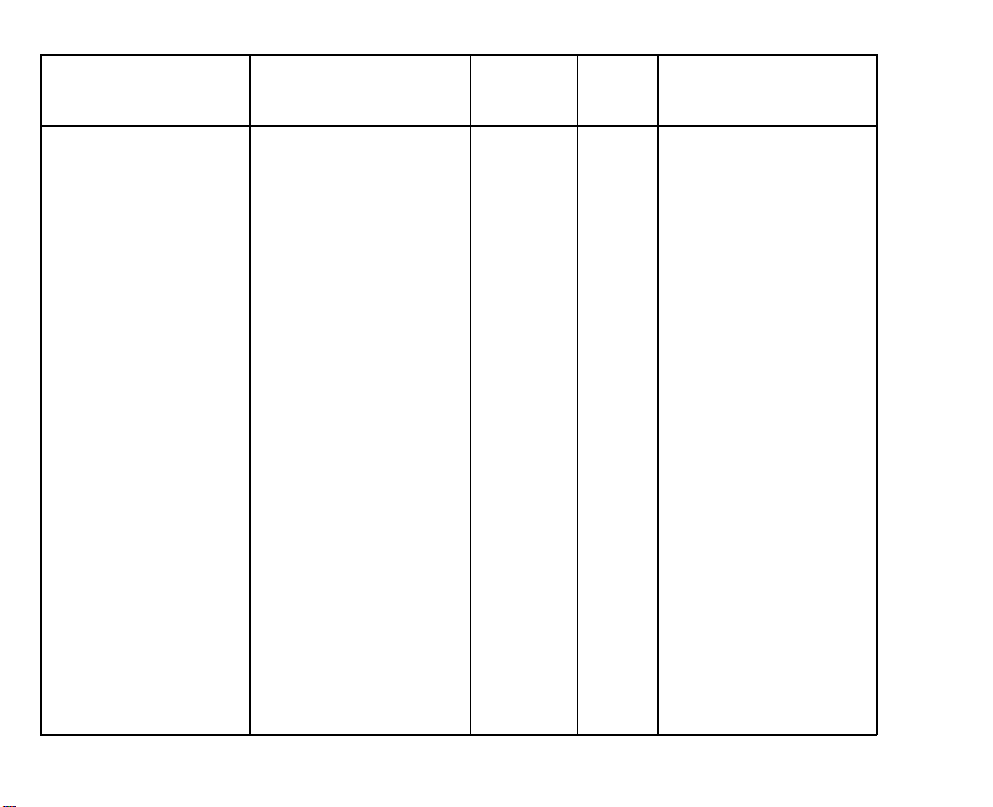

SYSTEM CONFIGURATION TABLE

Use this table to determine what extra equipment is required to install the optional equipment.

Duplex

Sorter

Duplex Unit

Large Capacity

Tray

Paper Bank

(4th and 5th

Cassette)

Unit

Without

Duplex

Unit

Interface

Board Adapter

(Note 2)

*

* *

*

Sorter

System Optional

Table Cassette

* *

(Note 1)

NOTE 1: All copiers have three cassettes as accessories.

NOTE 2: If the copier already has an ADF, sorter, or duplex unit installed, you do not need an in-

terface board.

1-7

Page 19

31 March 1987

HOW TO USE:

As shown in the following example, check off each piece of optional equipment to be installed. For each checked item,

Check off each piece of required

the asterisks to the right show the required equipment.

equipment.

Auto Document

Feeder

With

Duplex

Sorter

Duplex Unit

Large Capacity

Tray

Paper Bank

(4th and 5th

Cassette)

Unit

Without

Duplex

Interface Sorter

Board Adapter

(Note 2)

*

System

Table Cassette

* *

Optional

(Note 1)

Page 20

31 March 1987

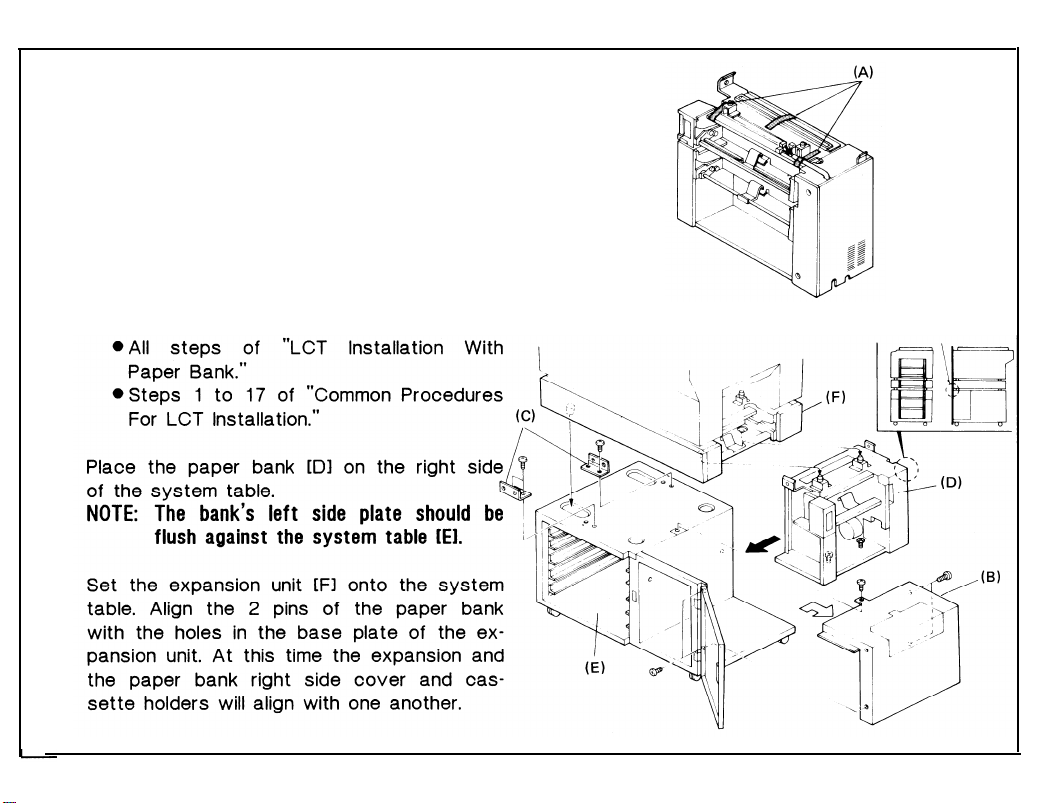

PAPER BANK INSTALLATION

ACCESSORY CHECK

Check the quantity and condition of the accessories in the box according to the following

list:

1. Installation procedure

(115V - English only, 220V - five languages)

2. New Equipment Condition Report

3. Envelope - NECR (115V only)

4. Expansion docking bracket

5. Expansion docking plate

6. Mylar paper guide

7. Expansion relay roller unit

8. Spring

9. Nylon wire clamp - large (10N)

10. Nylon wire clamp - small (4N)

11. Bank docking bracket

12. Pan head screw - M4 X 8

13. Pan head screw with washer - M4 X 8

14. Shoulder screw

15. Decal - Misfeed

16. Multilingual decals (220/240V only) 1 set

(115V - English only, 220V - five languages)

1

1

1

2

2

1

1

1

1

1

1

16

2

1

1

1-9

Page 21

31 March 1987

INSTALLATION PROCEDURE

1. Remove the strips of shipping tape [A].

2. Remove the right side of the system table

[B] (5 screws).

3. Install the front and rear expansion docking

brackets [C] on the system table as shown

(2 screws each).

Note: If an LCT is to be installed in the system,

first perform the following:

4.

5.

1-10

Page 22

6. Remove the front [A] and rear [B] covers

from the expansion unit (2 screws each).

7. Adjust the height of the paper bank:

a. Remove the internal cover [C] from the

paper bank (2 screws).

b. Using the height adjusting bolts [D], raise

or lower the paper bank so that both the

front [E] and rear [F] screw holes of the

paper bank and expansion unit align.

c. Secure the paper bank to the expansion

unit (2 screws).

d. Open the system table front door [G],

swing out the 4th paper feed station [H],

and secure the paper bank to the front

side of the system table (1 screw).

e. Remove the bank rear cover [I] and the

bank rear right cover [J] (2

screws

each), then secure the bank to the rear

side of the system table (1 screw).

f. Install the bank docking bracket [K] (2

screws).

g. Install the internal cover to the paper

bank (2 screws).

8. Install the front [L] and rear [M] expansion

docking plates as shown (2 screws each).

31 March 1987

1-11

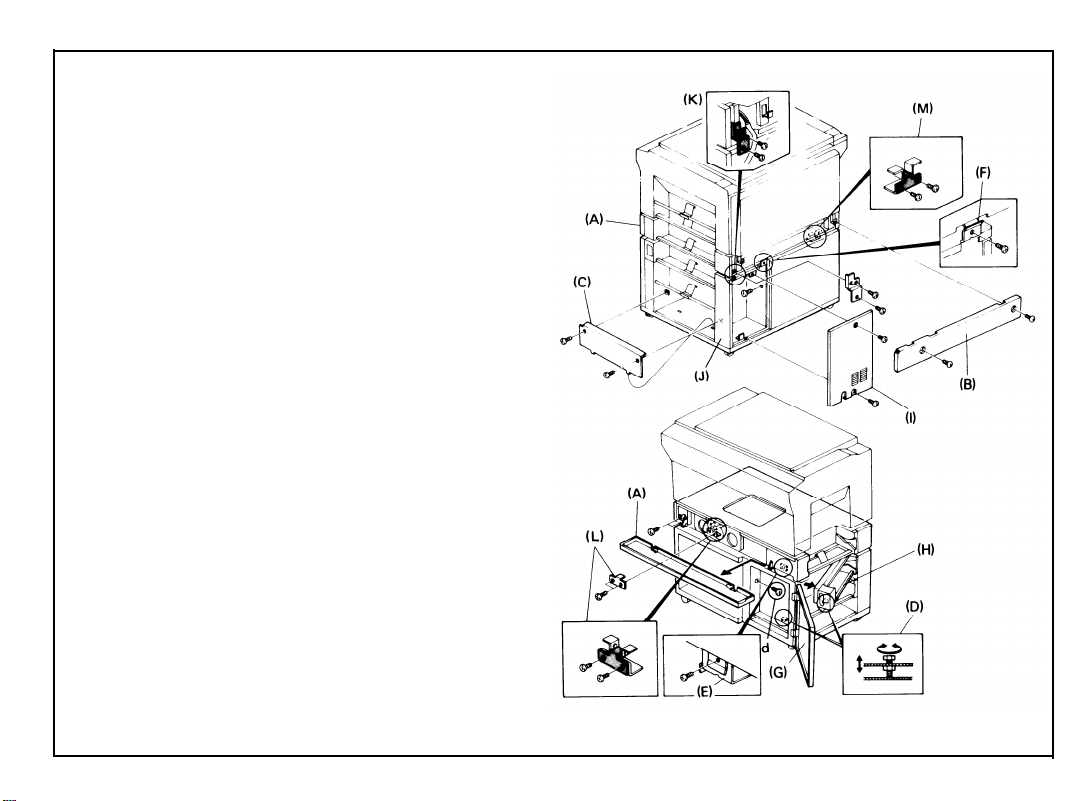

Page 23

31 March 1987

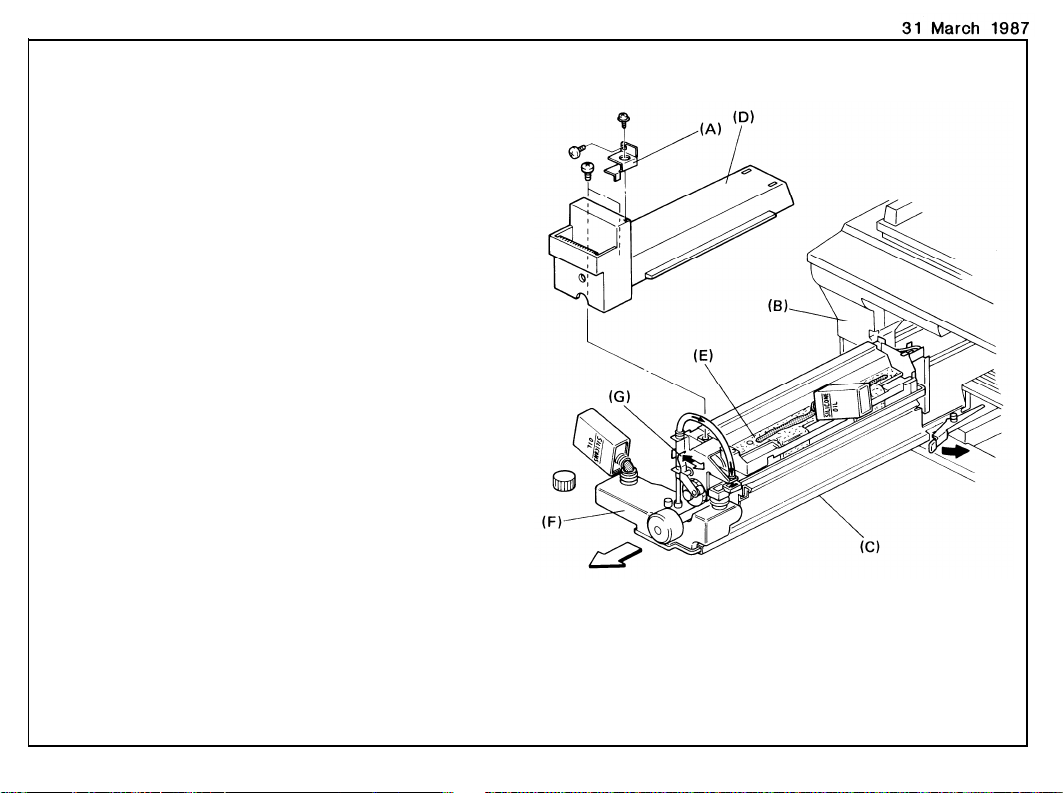

9.

Remove the front right [A] and rear right [B]

covers of the expansion unit (front - 2

screws, rear - 1 screw).

10.

Remove the right side safety switch assembly [C] (1 screw).

11.

Remove the copier rear cover (4 screws)

lower the PCB plate (2 screws), and disconnect the expansion interface harness from

the copier.

12.

Pull the 3rd feed unit out [D] (4 screws).

13.

System without duplex unit only:

Install the mylar paper guide [E] on the expansion relay roller unit.

1-12

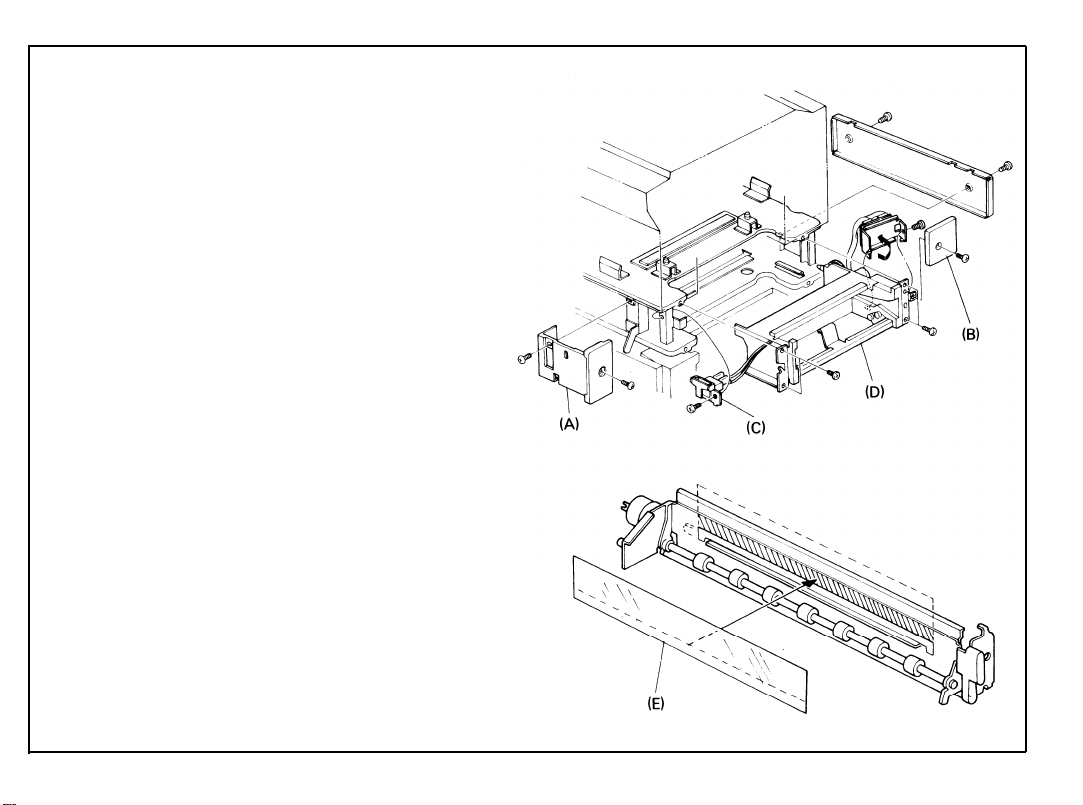

Page 24

14.

While doing this step:

a. Run the expansion relay unit harness [A]

(except the clutch harness) through the

harness access hole [B] on the rear side of

the 3rd paper feed unit [C].

b. Set the front of the relay unit before set-

ting the hook on the rear.

Mount the expansion relay roller unit [D] on

the 3rd feed unit. (front: 1 screw and 2

hooks, rear: 1 shoulder screw and 1 hook).

Hook the spring [E] between the guide plate

15.

lever [F] and the 3rd feed unit mounting

bracket.

While doing this step, you must pass the ex-

16.

pansion interface harness and the safety

switch assembly around their respective expansion unit uprights.

Plug the 5P connector (red) [G], into CN912

of the 3rd paper feed PCB [H], connect the

other end to the expansion relay clutch [I],

and clamp the harnesses with the twist

clamp [J].

Reinstall the 3rd paper feed unit and the

17.

safety switch assembly (1 screw) in the expansion unit (4 screws).

31 March 1987

1-13

Page 25

31 March 1987

1-14

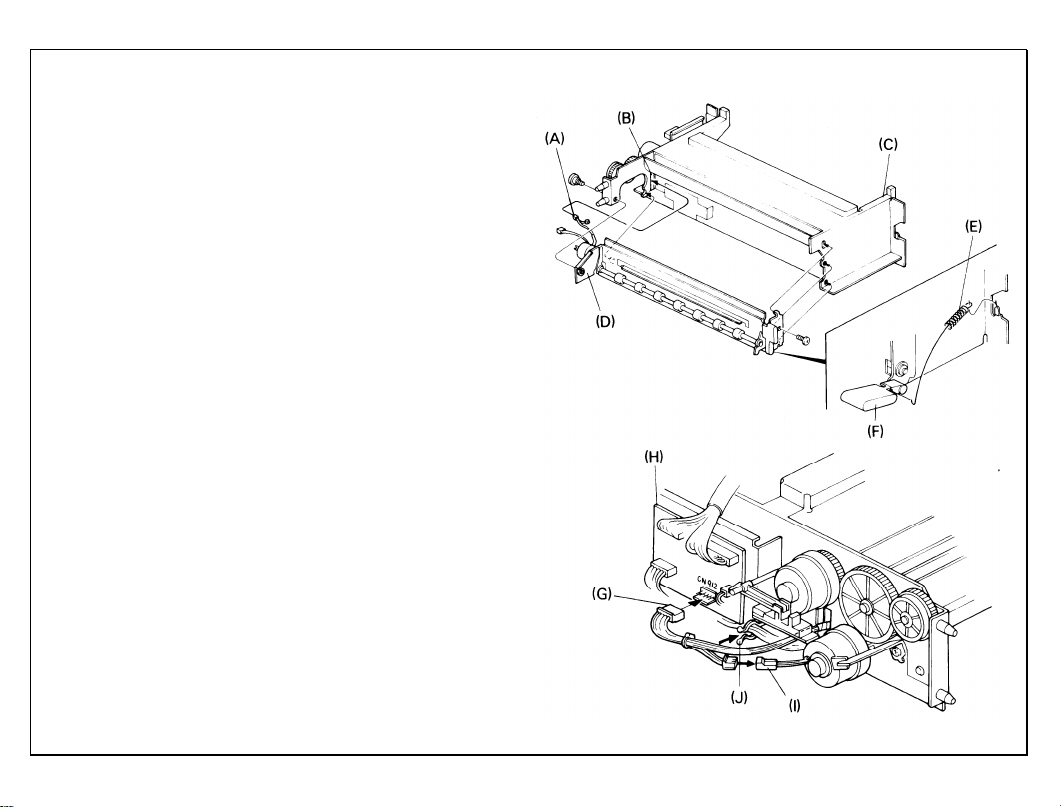

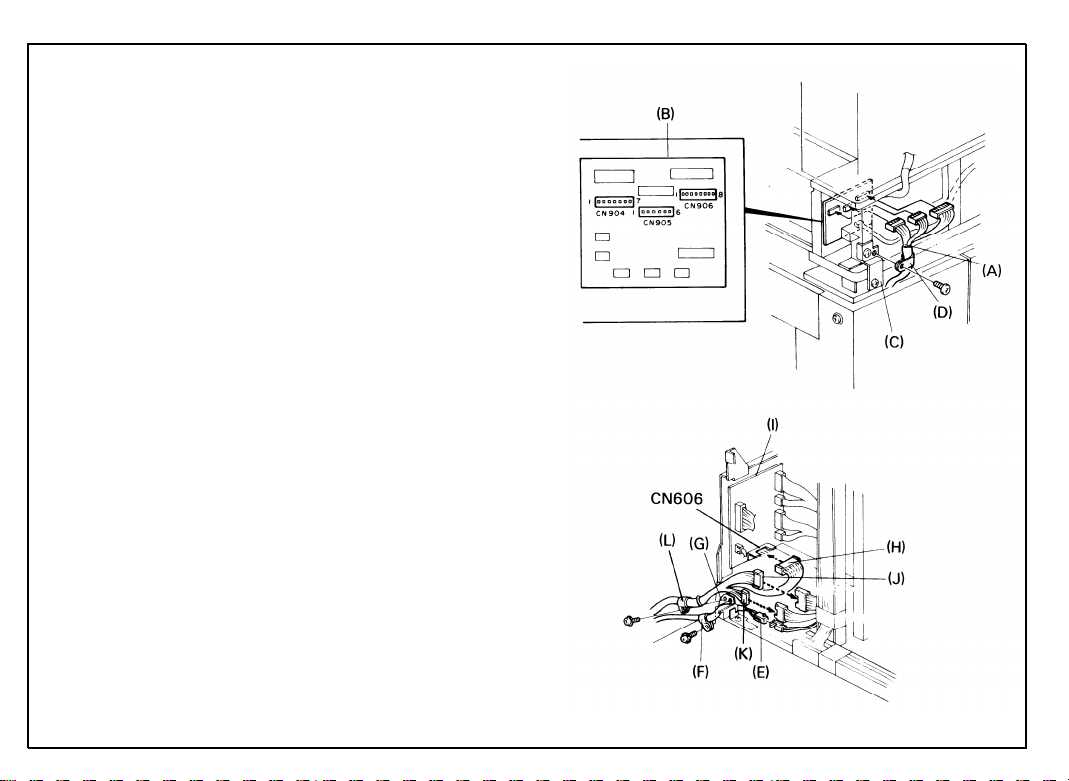

18.

Connect the bank interface harness [A] to

the 3rd paper feed PCB [B] as shown.

Clamp the bank interface harness to the

19.

bank docking bracket [C] with the large

nylon wire clamp [D] (1 screw with washer).

20.

a. Connect the ac paper bank harness [E]

to the copier and clamp the harness with

the small nylon wire clamp [F] on the left

image plate of the PCB plate [G] as

shown (1 screw with washer).

b. When doing this step, run the harness

from the left side of the PCB plate so

that the rear cover may close properly.

Connect the 9P expansion interface harness connector [H] to CN606 of the

paper feed PCB [I] and 2 free connectors (8P [J] and 6P [K]) to free connectors from the dc harness.

c. Fix the expansion interface harness to

the left hinge plate of the PCB plate with

the nylon wire clamp [L] (1 screw with

washer).

Page 26

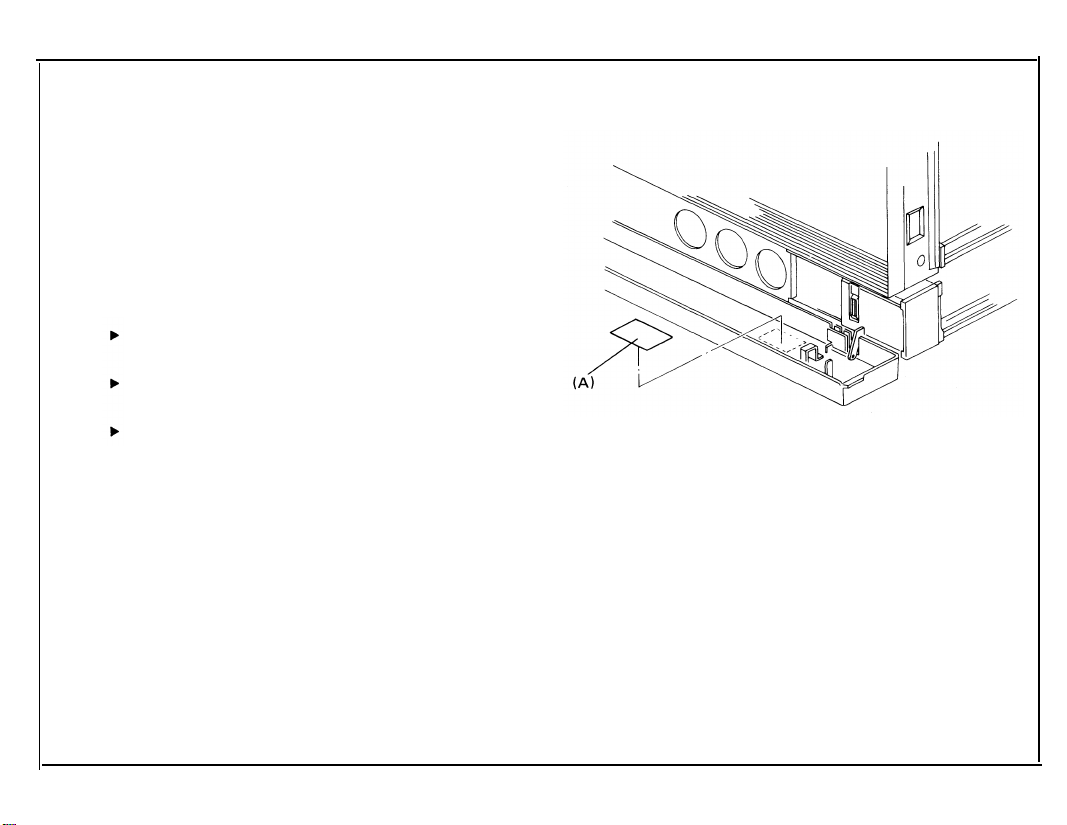

Stick the “Misfeed E” decal [A] on the front

21.

cover of the expansion unit as shown.

When reinstalling the expansion rear cover,

22.

place the bank ac harness inside the expansion unit.

Reinstall all covers except under the follow-

23.

ing conditions.:

If the LCT is to be installed, leave off

the bank rear cover.

If the duplex unit is to be installed, leave

off the expansion rear cover.

Leave off the copier rear cover if the du-

plex unit, DF, and/or sorter are to be installed.

24. Fill out the New Equipment Condition Report.

31 March 1987

1-15

Page 27

31 March 1987

COPIER INSTALLATION

ACCESSORY CHECK

Check the quantity and condition of the accessories in the box according to the following

list:

1. Installation procedure

(115V - English only, 220V - five languages)

2. New Equipment Condition Report

3. Envelope - NECR (115V only)

4. Cassette - large

5. Cassette - small

6. Receiving tray

7. Original holder

8. Editing sheet

9. Operating instructions

(115V - English only 220V - five languages)

10. Operating instruction cards

(115V - English only 220V - five languages)

11. Sort/Stack Key Cover

12. Sort/Stack Key Top

13. Duplex Key Cover

14. Duplex Key Top

15. Multilingual decals (220/240V only)

If not installing the duplex unit or sorter, save the duplex unit and sorter key tops and key

covers for future use.

1

1

1

1

2

1

1

1

1

1 set

1

1

1

1

1 set

1-25

Page 28

31 March 1987

INSTALLATION PROCEDURE

1.

Remove the shipping tape [A] from the copier as shown.

Open the copier front cover [B], remove the

2.

shipping tape [C] and the wedge [D] between the registration rollers as shown.

Remove the copier scanner lock plate

3.

cover [E] (1 screw).

Remove the copier scanner lock plate [F] (1

4.

screw).

Save the scanner lock plate for future

use.

Reinstall the copier scanner lock plate

5.

cover.

1-26

Page 29

6. Remove the fusing lock plate [A] (2

screws).

7. Use one of the screws removed in the previous step to secure the inner cover [B].

8. Pull out the fusing unit [C] to the lock position and remove the fusing unit cover [D] (2

screws).

9. Prime the oil supply pad [E] with silicon oil.

10. Fill the oil tank [F] with silicon oil.

11. Manually operate the oil pump lever [G] and

confirm proper operation and condition of

the silicon oil supply system.

12. Reassemble the fusing unit and return it to

its original position.

1-27

Page 30

31 March 1987

13. Raise the development lock lever [A] and

pull out the development unit [B]. Place the

unit on a clean sheet of paper.

14. Separate the toner tank [C] from the development unit [D] (2 screws).

15. Pour one bottle [E] of developer into the development unit while turning the knob [F]

counterclockwise to distribute the developer.

16. Remount the toner tank on the development

unit.

1-28

Page 31

17.

Swing the toner collection bottle cover [A]

to the left (1 screw) and unplug the toner

overflow sensor connector [B].

Remove the toner collection bottle [C].

18.

Lower the T/S corona unit [D].

19.

20.

Place a sheet of paper [E] over the T/S

corona unit.

21.

Remove the charge corona cover [F] (1

screw).

22.

Unplug the charge corona connectors

and remove the charge corona unit [H]

23.

Remove the quenching charge unit [I].

Remove the drum stay [J] (reverse thread-

24.

ed knob and 1 screw).

[G]

1-29

Page 32

31 March 1987

25. Remove the cleaning unit [A]. Dust the

cleaning blade [B] and brush [C] with setting powder (P/N 54429101).

26. Reinstall the cleaning unit.

27. Pull out the drum protective sleeve [D].

Save the drum protective sleeve for fu-

ture use when servicing the copier.

28. Reinstall the drum stay (1 knob and 1

screw), the quenching charge unit, and the

charge corona unit.

29. Reconnect the charge corona connectors

and reinstall the charge corona unit cover

(1 screw).

30. Remove the paper over the T/S corona unit

and return the T/S corona unit to its original

position.

1-30

Page 33

31. Reinstall the toner collection bottle [A] and

plug in the toner overflow sensor connector

[B].

32. Make sure that the hooks of the transport

plate [C] are positioned underneath the

bottle cover [D], then reinstall the toner collection bottle cover [E] (1 screw).

31 March 1987

CAUTION:

When installing the development unit

[F], be sure the development unit rail is

properly engaged with the guide rail in

the copier.

33. Reinstall the development unit.

1-31

Page 34

31 March 1987

1-32

34.

Install one toner cartridge [A].

Confirm that the toner cartridge gear is

properly engaged by attempting to

rotate the cartridge counterclockwise.

When the toner cartridge gear is properly engaged, the toner cartridge will not

rotate freely.

35.

240 volt areas only:

Remove the copier rear cover (3 screws),

disconnect the wire from the 220-volt terminal [B], and connect it to the 240-volt terminal [C] as shown. Reinstall the copier rear

cover.

Page 35

36.

Put five sheets of white paper (A3 or 11” x

17”) on the exposure glass.

37.

Lower the platen cover.

38.

Plug in the machine and turn on the main

switch.

39.

After pressing the Clear Modes Key, the

Clear/Stop Key, and the Recall/Enter Key in

that order, enter 10 using the Number Keys.

Press the Recall/Enter Key again.

After the warm up period is completed,

40.

press the Start key for drum conditioning.

After the machine stops, turn off the main

41.

switch.

Install the operating instruction cards [A]

42.

over the Dip switch cover as shown (twosided tape).

Install the original holder [B] on the platen

43.

cover as shown and install the receiving

tray [C].

Load paper into the cassette and check

44.

machine operation and copy quality.

Fill out the New Equipment Condition Report.

43.

31 March 1987

1-33

Page 36

CASSETTE MODIFICATION

1. Take off the cassette cover [A].

2. Remove the side fences [B] (1 screw each)

and the bottom plate [C].

3. Reposition the rear fence [D] in the desired

paper size position (1 screw).

Paper size positions are shown on the

inside of the cassette.

4. Reinstall the bottom plate.

5. Reinstall the side fences in the desired

paper size position.

6. Attach the proper paper size decals [E] on

the cassette at the positions shown.

7. Insert the actuator plate [F] in the slot on

the front of the cassette as shown.

1-34

Page 37

KEY COUNTER HOLDER INSTALLATION

Note: Ricoh, Hecon, and Hengstler key counters

are recommended for this copier.

1.

Remove the right front cover [A] (2

screws).

2.

Remove the cover plate [B] (2 screws).

3.

Pull out the 4P key counter connector [C]

through the key counter access hole and

remove the shorting plug [D].

4.

Connect the 4P connector on the key counter holder [E] to the key counter harness.

5.

Hold the fixing plate on the inside of the

key counter bracket [F] and insert the key

counter holder.

31 March 1987

1-35

Page 38

31 March 1987

1-36

6. Align the holes in the fixing plate with the

mounting holes of the key counter holder

and secure the key counter holder.

Note:

The fixing plate has three sets of

holes. Make sure to use the holes that

match the type of counter when installing.

7. Reinstall all covers.

Page 39

ACCESSORY COUNTER INSTALLATION

1.

Remove the front cover [A] (1 knob screw).

2.

Pull out the fusing unit [B] about half way.

3.

Remove the front inner cover [C] (5

screws); this cover should be removed from

the top first.

4.

Remove the accessory counter cover plate

[D] (2 screws).

5.

Push the accessory counter [E] into the

space provided until it locks.

6.

Connect the 2P connector [F] on the accessory counter to the counter harness [G].

7.

Reinstall all covers.

31 March 1987

1-37

Page 40

COLOR UNIT INSTALLATION

ACCESSORY CHECK

Check the quantity and the condition of the accessories in the box according to the following list:

31 March 1987

1.

Actuator -- Red

Actuator -- Blue

2.

Actuator -- Green

3.

Screw

4.

5.

Color Decal Sheet

Note: The color development unit should be installed after

This procedure should be done when the color developer

-- M3 x 4

1

1

1

1

1

drum conditioning is finished.

is replaced.

1-75

Page 41

31 March 1987

INSTALLATION PROCEDURE

1.

Install the appropriate color actuator [A]

on the color development unit.

Stick the appropriate decal [B] on the de-

2.

velopment unit handle.

3.

Separate the toner tank [C] from the de-

velopment unit [D] (2 screws).

Pour one bottle of color developer [E]

4.

into the development unit while turning

the knob [F] counterclockwise to distribute the developer.

1-76

Page 42

Steps 5 through 16 should also be done when

color developer is replaced.

5.

Remount the toner tank onto the develop-

ment unit.

Making sure that the color development

6.

unit is properly engaged with the unit

guide rail of the copier, install the color

development unit [A].

7.

Install a color toner cartridge [B].

8.

Remove the DIP switch cover [C] on the

left side of the operation panel (1 screw)

and turn on DIP SW5 [D].

9.

Plug in the machine and turn on the main

switch. Confirm that the color toner indicator is displayed on the operation panel.

Press the Program key. “20” should be

10.

displayed in the Copy Counter.

31 March 1987

11.

Put five sheets of white paper (A3 or

11” x 17”) on the exposure glass.

1-77

Page 43

31 March 1987

12.

Lower the platen cover.

13.

After the warm up period is completed,

press the Start key.

14.

After the machine stops, press the appropriate Number key according to the following list:

Red toner: 7

Green toner: 8

Blue toner: 9

15.

Turn off the main switch and the DIP

switch.

16.

Reinstall the DIP switch cover (1 screw).

1-78

Page 44

PREPARATION FOR TRANSPORTING THE COPIER

SHORT HAUL TRANSPORTATION

Before moving the copier from its place of installation, be sure to prepare it for transporta-

tion as follows:

31 March 1987

CAUTION:

1.

2.

3.

4.

The copier may be seriously damaged if it is moved without proper

preparation.

the drum protective sleeve [A].

Insert

Re-install the development unit.

Re-install the drum stay and charge

corona unit.

Secure the following items with tape:

Manual feed table

Platen cover or document feeder

The power supply cord (roll up first)

Expansion front cover

System table front door

1-79

Page 45

31 March 1987

5.

Remove the sorter to prevent damage to

the bins.

6.

Remove the

7.

Remove the

8.

Remove the

ment feeder.

Remove

9.

3rd feed

duplex receiving tray.

cassettes.

original table from the docu-

the

LCT if it is installed in the

station.

1-80

Page 46

LONG HAUL TRANSPORTATION BY VEHICLE

If the machine is to be transported by vehicle,

do the following

pleted the above

steps after you have comshort haul procedure.

31 March 1987

1. Remove the

developer from the develop-

ment unit.

2. Place a wedge between the registration

rollers.

3. Remove the sorter and secure the follow-

ing items with tape.

top cover

jam clearing tray

bins--tape the right and left edges of

the spacers together.

4. Remove the scanner lock plate cover [A]

and install the scanner lock plate [B].

NOTE: Confirm that the scanner is at the

home position.

1-81

Page 47

5.

Secure the following items with tape:

T/S corona release lever to the drum

stay knob

Transport plate to the toner collec-

tion bottle cover

Toner shield glass

1st and 2nd feed guide plates

6.

Remove the LCT if it is installed in the

5th feed station.

7.

Secure the LCT covers and power supply

cord with tape.

8.

Separate the system into the two units

as follows:

Paper Bank and System Table

Copier, duplex unit and/or document

feeder

9.

Tape the bank interface harness and ac

harnesses to the top of the bank.

1-82

Page 48

SECTION II

Page 49

II.

SERVICE TABLES

PM Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Service Program Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Service Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Page 50

PM TABLE

C: Clean R: Replace L: Lubricate A: Add I: Inspect

31 March ’87

ITEM

OPTICS

1. Mirrors, lens, reflectors, toner

shield glass

2. Exposure glass

3. Platen cover sheet

4. Scanner guide rod

and plate

5. Guide rod felt

6. APS sensor

7. ADS sensor

PAPER FEED

8. Paper feed roller

9. Friction pad

10. Paper feed guide

plate

11. Registration sensor

EM

80K 160K

C

C C

C C C C

C C C C

L L L L

L

C

C C

C C

C

R R R R

C

R R R R

C C

C C C C

240K 320K

L

C C C

C

L

C

C C

NOTES

C

C

C

L

C

Alcohol or water (silicone

cloth)

Alcohol or water

Alcohol or water (replace if

necessary)

Launa oil or equivalent

Launa oil or equivalent

(if necessary)

Dry cloth

Dry cloth

Water

Water

Blower brush

2-1

Page 51

31 march ’87

C: Clean R: Replace L: Lubricate A: Add I: Inspect

ITEM

12. Cassette bottom

plate pad

13. Paper feed sensor

AROUND DRUM

14. Corona wires

15. Wire cleaner

16. End blocks and casing

17. Transfer guide plate

18. PTL filter

19. QL filter

20. ID sensor

21. Erase lamp unit

EM

80K 160K

C

240K 320K

C

C

C C C

C R R R R

R R R R

C C C

C

C

C

C

C

C C C

C

C C

C C C

C

C

C

C

C C

C

C

NOTES

C

C

Alcohol or water

Blower brush

Dry cloth

Dry cloth

Dry cloth

C

Dry cloth, discharge before

installation.

C

Dry cloth, discharge before

installation.

Blower brush

C

Dry cloth

2-2

Page 52

C: Clean R: Replace L: Lubricate A: Add I: Inspect

31 March ’87

ITEM

CLEANING UNIT

22. Cleaning blade

23. Cleaning seal

24. Cleaning brush

25. Bias roller blade

26. Bias roller

27. Cleaning unit

28. Pick-off pawls

29. Used toner bottle

DEVELOPMENT UNIT

30. Developer

31. Upper brush seal

32. Side seals

33. Development unit guide

34. Toner supply clutch

35. Filter casing

EM

C

C

80K

R

C

R

R

C

C

C

C

R

C

C

C

C

160K

R

C

R

R

C

C

C

C

R

C

C

C

L

C

240K

R

C

R

R

C

C

C

C

R

C

C

C

C

320K

R

C

R

R

C

C

C

C

R

C

C

C

L

C

NOTES

Dust with setting powder

Replace if necessary

Dust with setting powder

Replace if necessary

Empty of used toner

If necessary

Mobil Temp 78

2-3

Page 53

31 march ’87

C: Clean R: Replace L: Lubricate A: Add I: Inspect

ITEM

FUSING UNIT

36. Hot roller

37. Pressure roller

38. Stripper pawls

39. Oil supply pad

40. Oil blade

41. Fusing entrance and

exit guides

42. Oil sump

43. Oil tank

OTHERS

44. Development drive

chain

45. Main drive chain

46. Transport belt

47. Bushings

48. Fusing drive gear

49. Development sleeve

gear

50. Resin gear

EM

80K 160K

C R C R

C

R

C

R

R R R R

C

R

C C C

C

C C C

C C C C

L L

L L

C

L

L L

L

L

240K 320K

C

R

C

R

C

R

C

C

C

L

L

L

NOTES

If necessary

Replace if necessary

Prime with silicone oil

Prime with silicone oil

Suitable solvent

Remove paper clay

with pipette

Spindle oil

Mobil Temp 78

Alcohol or water

Spindle oil

Mobil Temp 78

Silicone G-40M

Silicone G-40M

2-4

Page 54

C: Clean R: Replace L: Lubricate A: Add I: Inspect

31 March ’87

ITEM

DUPLEX UNIT

51. Duplex spring clutch

52. Paper feed roller

53. Friction pad

54. O-ring

55. Positioning roller

DOCUMENT FEEDER

56. Belt

57. Pick-up roller

58. Feed roller

59. Friction roller

LARGE CAPACITY TRAY

60. Pick-up roller

EM

C

C

C

C

C

80K

C

C

C

C

160KL240K

R

R

R

C

C

C

C

C

320K

L

C

C

C

C

R

NOTES

Mobil Temp 78

Dry cloth

Belt cleaner, replace if

necessary

Water, replace if necessary

Water, replace if necessary

Water, replace if necessary

Water

2-5

Page 55

31 march ’87

SERVICE PROGRAM MODE OPERATION

The service program mode is used to (1) check electrical data and (2) change modes or

adjustment values. The factory settings are stored in ROM; other settings are stored in

permanent (battery maintained) RAM.

1.

Data Check Mode

1.

Remove the DIP switch cover on

Copy Counter will start blinking.

2.

Enter the number of the desired

Service Program Mode table.

3.

Press the Enter (#) key.

4.

The appropriate data will be displayed in the Magnification indicator.

5.

After you have finished with the service program mode, turn off DIP SW No. 8.

the operation panel and turn on DIP SW 201-8. The

SP Mode using the numeral keys according to the

2-6

Page 56

2. Data Change Mode

1. Follow steps 1-3 of the preceding procedure.

2. Factory setting values or mode will be displayed in the Magnification indicator (threedigit indicator). (If the data values are not to be changed, turn off DIP SW 201-8.)

3. Enter the desired value or mode using the numeral keys according to the Service

Program Mode table.

4. Turn off DIP SW 201-8.

• The following procedure can also be used to access program numbers 10, 11, 90,

91, and 92 instead of using DIP SW 201-8.

1. Press the Mode Clear key.

2. Press the Clear/Stop key.

3. Press the Enter key; at this time the Copy Counter should blink.

4. Enter the desired number using the numeral keys.

5. Press the Enter key.

• Service program mode is cleared by pressing the Clear Modes key.

2-7

Page 57

31 march ’87

3. Service Program Mode Table

Mode No.

5 Exposure Lamp Free run with expo-

OFF Free Run sure lamp OFF

6 Jam Detection

OFF

7 Charge Wire

Cleaner

8 Input Check

9 Exposure Lamp

output regulator output.

Function

Copies are made

without jam detection.

Charge wire cleaner

motor operation.

Displays the input

from sensors.

Displays lamp

Data Factory Comments

Setting

The total counter

advances while

copying.

The motor starts

when Enter key is

pressed. Stops after

1 cycle (about 60 s).

For data, see the

input check table.

Input #1 then press

the Enter key. The

lamp stays on 10 s.

2-8

Page 58

31 March ’87

Mode No.

Function

Data

Factory Comments

Setting

10 Drum Condi- Used to condition a Enter 10 via the

tioning new drum.

number keys. 100 will

appear in the copy

counter. Press Start

to activate.

For 50 copies, lamp is

on. Then lamp OFF

until Vsp > 0.4 V.

Then, lamp on for

rest of cycle. Press

C/S to stop.

11 All Indicators Turns on all the in-

ON

dicators on the operation panel.

13 Destination Shows the market

Code

the machine is

intended for.

D = Japan

A = USA

C = Canada

E = Europe

F = Taiwan

2-9

Page 59

31 march ’87

Mode No.

Function

15 Auto Reset Selects auto reset

Time

16 Count Up/Down

of 1 or 3 minutes.

Selects count up

or count down.

17 Auto Cassette Selects auto-

Shift cassette shift

mode

18 Beeper

Turns beeper ON

or OFF

19 Image Density Selects the pri-

Mode

ority of image

density control

when the main

switch is turned on.

20 Feed Station Selects feed station

Priority priority at power on. 1: 1st

Data Factory Comments

Setting

0: 1 min.

0

1: 3 min.

2: None

0: UP

0

1: DOWN

0: ON

1: OFF

0

Copier automatically

shifts to another

cassette holding same

size paper when paper

runs out.

0: ON

0

1: OFF

0: ADS

0

1: Manual

0: LCT

0

2-10

Page 60

31 March ’87

Mode No.

21 APS Priority

22 Auto Mode

Reset

23 Free Size

28 Auto Sort Mode

29 Fusing Unit

Idle

Function

Selects APS or manual

Sets the auto-reset

time.

Enables originals of

various sizes to be

fed from the same

stack.

Sort mode is automatically selected

when more than 2 originals are set on the

DF original table and

the entered quantity

is greater than 2.

Selects fusing unit

idling mode.

Data Factory Comments

Setting

0: APS

0

1: Manual

0: 4 s

1: 60 s

0: Normal

0

Timer starts from

original feed out.

0

1: Free

0: Normal

1: Sort

Sorter and DF must

0

be installed on the

machine.

0: OFF

0

Idles for 15 s.

1: ON

30 Toner Supply

Mode

Selects toner supply

system.

0: Detect

1: Fixed

0

2-11

Page 61

31 march ’87

Mode No.

31 Toner Supply

Amount (Detect

Mode)

32 Toner Supply

Amount (Fixed

Mode)

33 ID Sensor

Bias (Black

Toner)

35 Toner Supply

Function

Determines how much

toner is supplied in

detect mode.

Determines how much

toner is supplied in

fixed mode.

Sets the bias voltage applied to the

bias roller when

sensing image

density.

ID sensor check is

performed every 5

copies. Changes

toner end level

from 0.75 V to

0.7 V.

Data Factory

Setting

0: 30%

0

1: 15%

2: 45%

3: 60%

0: 7%

0

1: 3.5%

2: 10.5%

3: 14%

0: 500

0

1: 440

2: 470

3: 530

0: Normal

0

1: ON

Comments

500 V = normal

440 V = lightest

470 V = light

530 V = dark

2-12

Page 62

31 March ’87

Mode No.

36 Margin

Adjustment

37 Lead Edge Sep- Sets the Iength of

aration Corona

Timing

Function

Data

Selects the preset 0: 5 mm

margin adjustment 1: 10 mm

value.

2: 15 mm

0: 10 mm

time that the lead 1: 15 mm

edge separation corona

is applied.

38 Erase margin Sets the width of 0: 10 mm

the erase margin.

1: 5 mm

2: 15 mm

3: 20 mm

39 Charge Wire Sets charge wire

Cleaner

cleaner operation to

0: ON

1: OFF

ON or OFF.

41 Lead Edge Adjusts the lead 0 - 15

Erase Margin edge margin.

Adjustment

Factory Comments

Setting

0

0

Use when separation

problems occur.

0

0

8

1 mm per step

+7 mm to -8 mm

42 Registration Adjusts registration.

Adjustment

0 - 15

8

1 mm per step

+7 mm to -8 mm

2-13

Page 63

31 march ’87

Mode No.

Function

Data Factory Comments

43 Vertical Adjusts magnification 0 - 15

Magnification

Adjustment

in the paper travel

direction.

44 Horizontal Adjusts magnification 0 - 15

Magnification

perpendicular to the

Adjustment direction of paper

travel.

46 Size Detec-

tion Error

Corrects size

detection.

0 - 15

Correction

49 Fusing Tempera- Adjusts fusing temp.

ture Adjustment

50 Length Detec-

tion Check

Displays the length

detected by the size

0: Normal

1: Low

detection circuit.

Setting

8

8

8

0

0.2% per step

+1.4% to -1.6%

0.2% per step

+1.4% to -1.6%

1 mm per step

+7 mm to -8 mm

185°

175°

Press Start key

to display. Do not

repeat more than 10

times to avoid overheating the fiber

optic cables.

2-14

Page 64

31 March ’87

Mode No.

51 Exposure Lamp

Voltage Check

52 Fusing Temper-

ature

53 Drum Tempera-

ture

54 Vsg Adjustment

55 Vsg/Vsp

Check

56 ADS Reference

Voltage

Function

Displays exposure

lamp voltage.

Displays the fusing

temperature.

Displays the drum

temperature.

Turns on ID sensor

LED.

Displays Vsg and Vsp.

Sets ADS reference

voltage for standard

originals. Press Print

to start and C/S

to stop.

Data

Factory

Setting

Comments

Adjust Vsg with VR

on the ID sensor board

LED turns on 10 s

(no drum rotation).

Average value of

10 copies.

Machine starts free

run.

2-15

Page 65

31 march ’87

Mode No.

57 ADS Voltage

(Non-standard

Original)

58 APS Sensor

Adjustment

59 Bias Voltage

Function

Checks ADS Voltage

for non-standard

Originals. Press

Start key to turn

on. Press C/S to

stop.

Adjusts the APS

sensor voltage with

standard original.

Press Start key to

turn on. After pressing # key, press 0

to set length voltage or press 1 to

set width voltage.

Press C/S to stop.

Displays bias voltage.

Press Start to turn on.

Press C/S to stop.

Data

Factory

Setting

Comments

Machine starts free

run.

Machine starts free

run. APS voltage is

adjusted.

Without temperature

compensation.

2-16

Page 66

31 March ’87

Mode No.

60 Toner Density

Recovery

70 Color Toner

Supply Amount

(Fixed Mode)

73 Color Toner

Copy Count

Function

After the Start key

is pressed, the

toner supply clutch

turns on and free run

starts. Free run stops

and constant supply

is reset when Vsp

becomes < 0.5 V.

Selects the color

toner supply ratio.

Shows the number

of color copies

made.

Data

0: 14%

1: 7%

2: 21%

3: 28%

4: 35%

5: 42%

6: 49%

7: 56%

0: Red

1: Green

2: Blue

Factory

Setting

0

Comments

Use this mode to

bring a Iow toner

condition back to

normal. Use only

with black toner.

During this period,

Vsp is displayed. Press

0 to display Vsg.

Multiply number

by 100. Example:

24 = 2400 sheets.

Cannot be reset

unless memory is

cleared.

2-17

Page 67

31 march ’87

Mode No.

Function

74 Door Open Sets the copier to

Location

Indicator

show the locations

of open doors using

the Jam indicator.

75 ID Sensor Sets the bias volt-

Bias (Color

Toner)

age applied to the

bias roller when

sensing image

density.

76 Sorter Bin

Capacity

77 Odd Number

Duplex Copy

Sets the stack mode

quantity limit.

Sets the copier to

eject the final copy

if an odd number of

originals is copied.

(When copying single

sided originals

only.)

Data Factory Comments

Setting

0: OFF

1: ON

0: 620

1: 590

0

Not effective for

the front door.

0

620 V = normal

590 V = lighter

2: 650 650 V = darker

Limit is determined

0: No limit

1: Limit

0: ON

1: OFF

0

by paper size.

When on, the final

0

sheet is fed out; when

off, it stays in the

duplex tray.

2-18

Page 68

31 March ’87

Mode No.

79 Maximum Repro-

duction Ratio

86 PM Counter

87 PM Copy

Count

88 PM Counter

Check

89 PM Counter

Reset

90 User Code

Mode

Function

Sets the maximum

reproduction ratio.

Turns on the PM

counter.

Sets the interval

of the PM counter.

Displays contents

of the PM counter.

Resets the PM

counter.

Selects user code

mode. (Key counter

shorting connector

must be removed.)

Data

0: 155%

1: 200%

0: OFF

1: ON

0: 80 k

1: 60 k

2: 100 k

0: OFF

1: ON

Factory

Setting

0

0

0

0

Comments

For PB machines, 0 is

ON and 1 is OFF.

When the PM count is

exceeded the Service

Call and Key Counter

indicators blink.

Use after performing

PM.

If on, must enter a

code to copy. See

user code table.

Reset after 60s or if

C/S and CIear Modes

pressed together.

2-19

Page 69

31 march ’87

Mode No.

Function

91 User Code Displays the contents

Counter Check

of each user counter.

Use + and - keys to

select user code (lower

two digits of user

code displayed in copy

counter). First 3 digits

of copy count are

displayed in Magnification indicator.

Press “.”

to display

second 3 digits.

92 User Code

Counter Reset

Resets user counters.

Select the user code

counter using + and -

keys. To reset press

1 then #.

Data

Factory

Setting

Comments

User counters count

from 0 to 999999

(endless count).

2-20

Page 70

31 March ’87

Mode No.

93 Maximum Copy

Function

Limits the maximum

Quantity copy quantity that

can be entered.

97 Clear Service

& Jam Count

98 Clear

Counters

Clears the service

call and jam counters. must be on.

Clears the following Cleared at factory.

counters:

- counters 100 to 139 must be on.

- user program

- PM counter

- User code counter

99 Clear All

Memory

Clears all counters

and returns all modes

to factory settings.

Data Factory Comments

Setting

0

The indicator blinks

and the limit quantity is displayed.

If you enter 0, the

max is 999.

Otherwise, max is

number entered.

DIP SW 201-7

DIP SW 201-7

Test pin 101 and

102 shorted.

DIP SW 201-7

must be on.

2-21

Page 71

31 march ’87

Mode No.

100 Main Motor

ON Time

101 Total Copies

102 Duplex Copies

Function

Displays the total

(accumulated) time

that the main motor

has operated.

Displays the total

number of copies.

Displays the total

number of duplex

copies made.

Data

Factory

Setting

Comments

Time in hours.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

2-22

Page 72

31 March ’87

Mode No.

103 DF Copies

104 Sort Copies

105 Paper Bank

Copies

106 LCT Copies

Function

Displays the total

number of copies

made using the DF.

Displays the total

number of copies

made using the

sorter.

Displays the total

number of sheets

fed from the paper

bank unit.

Displays the total

number of sheets

fed from the LCT.

Data Factory Comments

Setting

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

2-23

Page 73

31 march ’87

Mode No.

108 A3/11 x 17

Copies

109 A4/8-1/2 x 11

Copies

111 Reduction

Copies

112 Enlarged

Copies

Function

Displays the total

number of A3 or

11 x 17 copies.

Displays the total

number of A4 or

8-1/2 x 11 copies.

Displays the total

number of reduction

copies.

Displays the total

number of enlarged

copies.

Data

Comments

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

The first three digits

are shown in the Msgnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

2-24

Page 74

31 March ’87

Mode No.

Function

Data Factory Comments

Setting

114 Originals Displays the total The first three digits

Copied

number of originals

copied.

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

115 Originals Displays the total

Copied Using

DF

number of originals

copied using the DF.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

120 Total Service Displays the total

Calls

number times that the

Service Call indicator

has turned on.

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

121 Service Calls Displays the total

for Optics

number “Optics”

service calls.

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

2-25

Page 75

31 march ’87

Mode No.

122 Service Calls

for Exposure

123 Service Calls

for Drive

124 Service Calls

for Fusing

Function

Displays the total

number of “Exposure”

service calls.

Displays the total

number of “Drive”

service calls.

Displays the total

number of “Fusing”

service calls.

Data Factory

Setting

Comments

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

This service call can

result from the pulse

generator or corona

wire cleaner sensor.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

2-26

Page 76

31 March ’87

Mode No.

125 Service Calls

for Interface

Communication

130 Paper Jams

131 Feed Jams

132 Fusing Jams

Function

Displays the total

number of “Interface

Communication” service

calls.

Displays the total

number of paper jams.

Displays the total

number of entrance

area paper jams.

Displays the total

number of jams at the

fusing unit.

Data Factory Comments

Setting

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.” to display

the second 3 digits.

2-27

Page 77

31 march ’87

Mode No.

134 Duplex Jams

136 Exit Jams

137 Paper Bank

Jams

138 Sorter Jams

Function

Displays the total

number of jams in the

duplex area.

Displays the total

number of jams in the

exit area.

Displays the total

number of paper bank

jams.

Displays the total

number of sorter

jams.

Data

Factory

Setting

Comments

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Magnification indicator.

Press “.”

to display

the second 3 digits.

The first three digits

are shown in the Mag-

nification indicator.

Press “.”

to display

the second 3 digits.

2-28

Page 78

31 March ’87

Mode No.

Function

139 DF Jams Displays the total

number of DF jams.

Data

Factory Comments

Setting

The first three digits

are shown in the Magnification indicator.

Press

“.” to display

the second 3 digits.

2-29

Page 79

31 march ’87

Input Check Table

No.

1

3

4

5

6

7

11

15

16

17

18

20

21

22

25

26

27

28

29

Item

Registration Sensor

Exit Sensor

Relay Roller Sensor

Relay Roller Sensor

Relay Roller Sensor

Duplex Exit Sensor

Duplex Tray Sensor

Sorter Inlet Sensor

Sorter Bin Sensor

Sorter Home Position Sensor

Sorter Cover Switch

Toner End Sensor (Color)

Key Counter Noise Prevention Switch 0

Charge Corona Wire Cleaner Sensor 0

Paper Bank Installed

Large Capacity Tray

Duplex Unit Installed

Midi Sorter Installed

Mini Sorter Installed

#3

#4

#5

Installed

Normal Mode

0

0

0

0

0

0

0

0

1

0

1

1

1

1

1

1

1

2-30

Page 80

USER CODES

There are 20 user codes as follows:

31 March ’87

2

3

4

5

6

7

8

9

10

1

1101

1202

1303

1404

1505

1606

1707

1808

1909

2010

11

12

13

14

15

16

17

18

19

20

2111

2212

2313

2414

2515

2616

2717

2818

2919

3020

2-31

Page 81

31 march ’87

SERVICE REMARKS

General Caution:

Keep hands away from mechanical drive components when the copier is warming up. This is

to avoid possible injury when the copier starts idling at the end of warm up.

NOTE:

The following two items are the only service remarks that are unique to this copier. For

other service remarks, refer to the base machine’s manual (F9 manual).

1. When the main board is removed from the PCB plate, do not put it on a conductive

surface. (This is to avoid discharging the battery of the user program memory.)

2. When installing a new RAM board on the main board, clear its RAM as follows:

a. Make sure that the main switch is off.

b. Fix the new main board to the PCB plate and plug in all the connectors.

c. Connect test pins TP101 and TP102 with a jumper wire.

d. Turn on the main switch.

e. Turn on DIP switch 201-7 and 201-8.

f. Press 9, 9, #, and 1 in that order.

g. Turn off the main switch and remove the jumper wire.

3. Make sure the main switch is off when you install a previously used RAM board on a

new main board.

2-32

Page 82

SECTION Ill

REPLACEMENT AND

ADJUSTMENT

Page 83

III. REPLACEMENT AND ADJUSTMENT

Page 84

OPTICS

1.

FIBER OPTICS CABLE REPLACEMENT

1.

Remove the front cover [A] (1 knob screw)

and pull the fusing unit [B] about halfway

out.

2.

Remove the front inner cover [C] (5

screws).

Remove the power relay bracket [D] (1

3.

screw).

Disconnect the exposure lamp harness [E]

4.

(2p white connector).

Take off the left scale (2 short screws).

5.

Remove the exposure glass.

6.

31 March ’87

3-1

Page 85

31 March ’87

7.

Remove the front terminal cover [A] (1

screw).

8.

Unhook the fiber optics cable [B] from the

reflector cover [C] and remove the reflector

cover (2 screws).

9.

Remove the leads to the exposure lamp

terminals [D].

10.

Remove the auto ID sensor [E] and length

sensor [F] (1 screw).

Remove the width sensor [G] (1 screw).

11.

12.

Remove the scanner harness [H] from the

1st scanner [I] (1 screw).

13.

Slide the scanner to the right and remove

the female end of the exposure lamp power

supply harness [J] from the copier.

Remove the scanner harness from the har-

14.

ness hold-down block [K] (1 screw).

15.

Release the fiber optics cable from the

clamps [L], then remove it.

16.

Slide the scanner to the left and remove

the lens housing cover [M] (3 screws).

Release the fiber optics cable from the

17.

clamps [N] in the optics cavity.

3-2

Page 86

18.

Remove the copier rear cover (3 screws).

Using a small screwdriver [A], disconnect

19.

the fiber optic cables from CN109 [B] on

the main board and CN407/408 [C,D] on the

optics board.

NOTE: Be careful not to damage the ends of

the cables.

20.

Lower the PCB plate [E].

21.

Pull the fiber

optics cables

[F] into the

tics cavity.

Replace the fiber optics cables.

22.

31 March ’87

3-3

Page 87

31 March ’87

2. AUTO PAPER SIZE SENSOR ADJUSTMENT ADJUSTMENT STANDARD: +3 ± 0.1 V

1.

Turn off the main switch.

2.

Remove the rear cover (3 screws).

3.

Remove the DIP switch cover [A] on the

left side of the operation panel (1 screw)

and turn on DIP SW 201-8.

4.

Place 5 sheets of A3 (11” x 17”) paper on

the exposure glass.

5.

Turn on the main switch and press “5”,

then “8”, then the “#” key.

6.

Wait for the copier to warm up; then, press

the Start key.

7.

Press the “0” key and adjust the paper

length sensor using VR401 on the optics

board [B].

8.

Press the “1” key and adjust the paper

width sensor using VR402 on the optics

board [B]. (Turn clockwise to increase [H].

Turn counterclockwise to decrease [L].)

9.

Press the C/S key to stop the copier.

10.

Turn off the main switch then turn off DIP

SW 201-8.

3-4

Page 88

3. LENGTH SENSING ADJUSTMENT

Turn off the main switch.

1.

2.

Remove the DIP switch cover [A] on the

left side of the operation panel (1 screw)

and turn on DIP SW 201-8.

3.

Place the A3 test chart on the exposure

glass.

Turn on the main switch, then press “5”,

4.

“0”, and “#”. The length of the test chart is

displayed in the Magnification Ratio indicator. (The correct length for A3 is 420.)

If the length displayed is not 420, the

5.

adjusting procedure is as follows:

1) Remember the number displayed by SP

mode #50 and subtract it from 420.

2) Add this difference to the number

displayed (flashing) by SP mode #46.

(Press “#”, “4”,

“6”, and “#” in that or-

der.)

3) Enter this number and press the Enter

key.

Confirm that the length is correct by

6.

repeating the above procedure.

31 March ’87

3-5

Page 89

31 March ’87

DEVELOPMENT AND TONER SUPPLY

1. IMAGE DENSITY SENSOR REMOVAL

1. Open the front cover.

2. Remove the development unit [A].

3. Slide out the image density senso

4. Clean or replace the sensor.

3-6

Page 90

2. IMAGE DENSITY SENSOR CHECK AND ADJUSTMENT

ID sensor adjustment is required in the following

cases:

•

When the

•

When the

•

When the

ID sensor board is replaced.

main board is replaced.

drum has been replaced and Vsg

—

is not within specifications.

•

When a problem with toner supply occurs

and checking the ID sensor shows that the

Vsg is not within specifications.

ADJUSTMENT STANDARD: +4 V ± 0.2 V

1. Clean the Image density sensor.

2. Copy a white sheet of paper to ensure that

the ID development area on the drum is

clean.

31 March ’87

3. Turn off the main switch.

3-7

Page 91

31 March ’87

4. Remove the DIP switch cover [A], and turn

on DIP SW 201-8.

5. Turn on the main switch; then, press “5”,

“4”, and “#” in that order.

Vsg is displayed in the Magnification indica-

tor for ten seconds.

6. Adjust Vsg using the variable resistor [B]

on the front of the ID sensor board [C].

(Turn clockwise to increase [Hl]. Turn

counterclockwise to decrease [L].)

7. Turn off the main switch and DIP SW 201-8.

3-8

Page 92

3. TONER SUPPLY CLUTCH DISASSEMBLY

1.

Remove the rear cover (3 screws).

2.

Lower the PCB plate (2 screws).

3.

Disconnect the harness [A] of the bias

power pack (10p connector) and remove

the bias power pack bracket [B] (2 screws

and 1 connector).

4.

Disconnect the cooling blower connector [C]

(2p) and the lens drive motor connector [D]

(6p)

Remove the screw [E] securing the dc har-

5.

ness guide.

Remove the development drive support

6.

bracket [F] (2 screws, 1 E-ring, and 1 bushing).

Remove the toner supply clutch assembly

7.

[G] from the drive shaft while pushing the

main drive chain to the right (1 Allen

screw).

31 March ’87

3-9

Page 93

8. Disassemble the toner supply clutch.

9. Clean the clutch hub [A], spring [B], and

gear [C]. Then, lightly grease the spring

with Mobil Temp 78.

NOTE: • When reassembling, make sure that

the chamfered end [D] of the clutch

sleeve is to the outside.

• When securing the Allen screw of the

clutch hub, insert a 0.1 mm gap

gauge [E] between the E-ring [F] and

the toner supply roller drive gear [G]

as shown in the figure.

3-10

Page 94

CLEANING

1. CLEANING UNIT REMOVAL

1. Raise the development lock lever and pull

out the development unit. Place the unit on

a clean sheet of paper.

2. Swing the toner collection bottle cover [A]

to the left (1 screw) and unplug the toner

overflow sensor connector [B].

3. Remove the toner collection bottle [C].

4. Lower the T/S corona unit [D].

5. Place a sheet of paper [E] over the T/S

corona unit.

6. Remove the charge corona cover [F] (1

screw).

7. Unplug the charge corona connectors [G]

and remove the charge corona unit [H].

8. Remove the pre-quenching corona unit [I].

9. Remove the drum stay [J] (knob and 1

screw).

10. Slide out the cleaning unit [K].

CAUTION: Be sure the pick-off pawls are kept

away from the drum when removing

the cleaning unit or serious drum

damage will result.

3-11

Page 95

31 March ’87

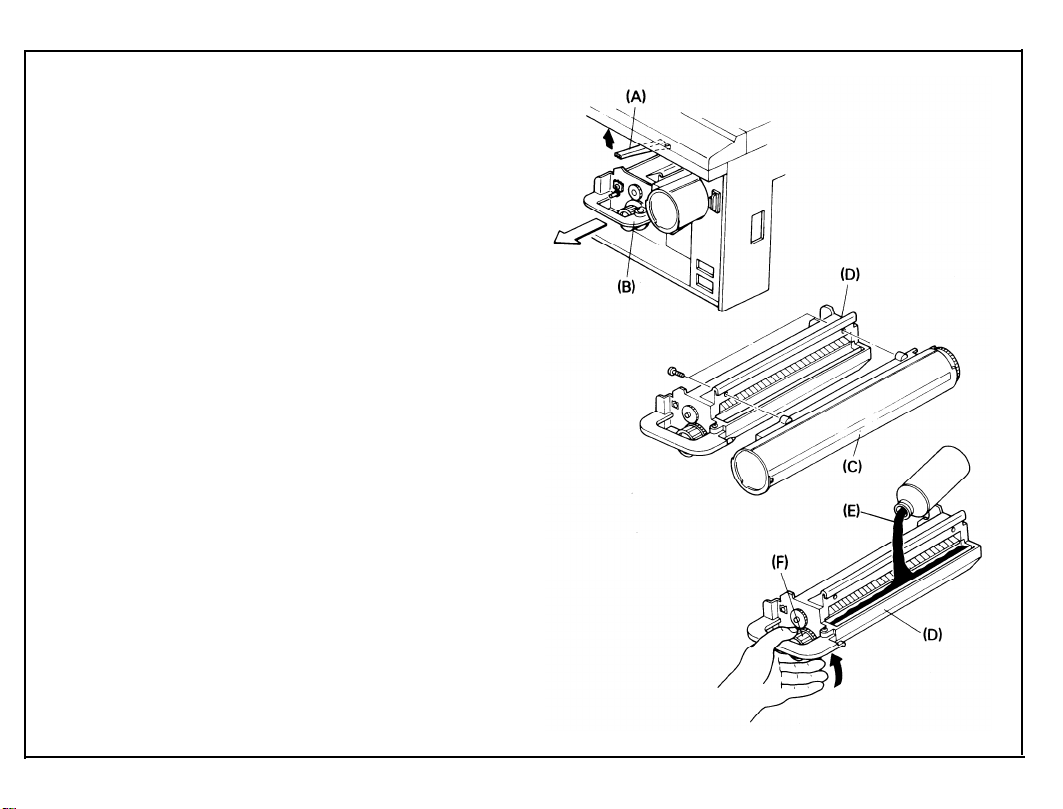

2. PICK-OFF PAWL REPLACEMENT

1. Remove the pick-off guide plates [A] (1

screw each).

2. Remove the pawl shaft pin [B] from the

pawl shaft [C].

3. Push the pawl shaft to the rear and slide

off the cam holder [D] from the front side

plate.

4. Take out the whole pawl shaft assembly.

5. Slide off the cam holder and cam rider [E].

6. Slide off the front pick-off pawl [F] (1 posi-

tioning pin) and the front pawl spring [G] (1

screw).

7. Slide off the rear pick-off pawl [H] (1 positioning pin [I]).

8. Set new pick-off pawls on the shaft and

position them with the positioning pins and

pawl springs.

3-12

Page 96

9. Assemble the pawl shaft assembly and

slide it into the cleaning unit until the shaft

touches the rear side plate.

NOTE: • When installing the cam holder and

the cam rider, align X and Y as

shown in the figure.

• Make sure that the spring end is in

the small hole on the rear side plate.

10. Install the pawl shaft pin.

11. Push the spring collar [A] to the rear and

rotate it one turn as shown in the figure.

Then set the collar on the pin [B].

NOTE: Make sure that the end of the spring is

correctly positioned in the groove of the

collar.

12. Reassemble.

31 March ’87

3-13

Page 97

31 March ’87

3. BIAS ROLLER REPLACEMENT

Remove the bottle joint seal [A] and the to-

1.

ner collection coil cover [B] (1 screw).

2.

Remove the bushing [C] of the cleaning

bias roller (1 E-ring).

3.

Remove the cleaning unit drive gear [D] (1

Allen screw).

4.

Remove the idle gear [E] (1 E-ring)

5.

Remove the pressure arm [F] (1 screw and

1 spring).

Remove the cam gear [G] (1 E-ring).

6.

Remove the spring plate [H] (1 screw).

7.

8.

Remove the cleaning bias roller gear [I]

(1 E-ring).

9.

Remove the bias roller bracket [J] and pull

out the bias roller [K] from the rear.

3-14

Page 98

4. BIAS ROLLER BLADE REPLACEMENT

31 March ’87

1. Remove

2. Remove

the spring plate [A] (1 screw).

the cleaning bias blade [B] (1

screw).

Take care not to damage the pick-off pawls.

3-15

Page 99

31 March ’87

PRE-QUENCHING

1. PRE-QUENCHING CORONA UNIT REPLACEMENT

1. Open the copier’s front cover

2. Remove the charge corona

screw).

3. Unplug the charge corona connectors [C]

and pull out the charge corona unit [D].

4. Pull out the pre-quenching corona unit [E].

[A].

cover [B] (1

Page 100

PAPER FEED

1. FEED ROLLER/FRICTION PAD GAP ADJUSTMENT

This adjustment is required when multifeeding

occurs or paper fails to feed and after replacing

the friction pad.

ADJUSTMENT STANDARD: 215 ± 15 grams

1. Remove the screw [A] from the pad

bracket.

2. Loosen the screw [B] and the screw [C] of

the pad bracket.

3. Adjust the gap as closely as possible by

moving the screw [B] of the pad bracket

up and down. After that, use the cam collar

screw [D] for fine adjustment.

31 March ’87

3-17

Loading...

Loading...