Page 1

RICOH FT5540/5550/5570

RICOH COMPANY, LTD.

SERVICE MANUAL

Page 2

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

2. GUIDE TO COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.1 INTERNAL/EXTERNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.2 OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2.3 INDICATOR SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2.4 GUIDANCE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3. COPY PROCESSES AROUND THE DRUM . . . . . . . . . . . . . . . . . . 1-10

4. COPY CYCLE . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12

5. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

6. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-16

7. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-17

8. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-18

9. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . 1-23

10. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

11. AC AND DC POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . 1-29

DETAILED SECTION DESCRIPTIONS

1. DRUM

1.1 SELENIUM DRUM CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 HANDLING THE DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.3 DRUM HEATER CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2. DRUM CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 WIRE CLEANER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3 CHARGE CORONA POWER PACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 EXPOSURE LAMP CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-7

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Page 3

3.3 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.4 SCANNER MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.5 LENS/MIRROR POSlTIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

3.6 FOURTH AND FlFTH MlRROR ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

3.7 ORlGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3.8 RELATED SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

4. ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

4.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

4.2 LEAD EDGE AND TRAILING EDGE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

4.3 SlDE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

4.4 EDGE ERASE FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

4.5 ERASE LAMP CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

5. DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 OVERVlEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

5.2 DEVELOPER EXCHANGE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

5.3 DRIVE MECHANlSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

5.4 CROSSMlXlNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

5.5 IMAGE DENSlTY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

5.6 BIAS CONTROL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

5.7 RELATED SERVICE CALL CONDlTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

2-26

6. TONER DENSITY DETECTION AND TONER SUPPLY . . . . . . . . . 2-38

6.1 TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

6.2 BOTTLE DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

6.3 TONER DENSITY DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

6.4 TONER DENSITY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

6.5 TONER SUPPLY AMOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

6.6 TONER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

6.7 TONER OVERFLOW SENSOR CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

7. lMAGE TRANSFER AND PAPER SEPARATION . . . . . . . . . . . . . . 2-46

7.1 PRE-TRANSFER LAMP (PTL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

7.2 IMAGE TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

7.3 PAPER SEPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

7.4 TRANSFER/SEPARATION CORONA POWER PACK . . . . . . . . . . . . . . . . . . . . . . 2-50

7.5 PICK-OFF MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Page 4

7.6 PICK-OFF TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

7.7 PRE-TRANSFER LAMP AND QUENCHING LAMP CIRCUIT . . . . . . . . . . . . . . . . . 2-54

8. DRUM CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

8.1 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

8.2 PRE-CLEANING CORONA AND BIAS ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

8.3 DRlVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

8.4 CLEANING BLADE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

8.5 CLEANING SOLENOID CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

8.6 PRE-CLEANING CORONA ClRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

9. QUENCHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

9.1 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

9.2 PRE-QUENCHING CORONA CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

10. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

10.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

10.2 LIFT MECHANISM AND PAPER END DETECTION . . . . . . . . . . . . . . . . . . . . . . 2-64

10.3 ROLLER FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

10.4 SLIP CLUTCH MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

10.5 PAPER FEED DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

10.7 RELAY FEED AND REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

10.8 PAPER SIZE SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

10.9 LIFT MOTOR CONTROL AND PAPER END DETECTION . . . . . . . . . . . . . . . . . . 2-75

11. PAPER TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

11.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

11.2 TRANSPORT UNIT RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

12. lMAGE FUSING AND PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . 2-79

12.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

12.2 FUSING DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

12.3 ENTRANCE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

12.4 OIL SUPPLY AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-82

12.5 OIL END SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-83

12.6 FUSING EXIT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-84

12.7 FUSING CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

12.8 SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

Page 5

13. PAPER EXIT . . . . . .

13,1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-90

13.2 EXIT ROLLER DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-91

14. DUPLEX

14.1 INVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-92

14.2 DUPLEX TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

14.3 DUPLEX STACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-99

14.4 DUPLEX TRAY SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-103

14.5 DUPLEX PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-104

14.6 RELATED SERVICE CALL CONDlTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-107

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-90

2-92

15. OTHER CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-108

15.1 DC POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-108

15.2 SAFETY SWITCH CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-109

15.3 AC COMPONENT CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-110

15.4 CORONA CLEANER MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-111

15.5 PULSE GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-112

15.6 MAGNETIC CLUTCH AND SOLENOID CONTROL . . . . . . . . . . . . . . . . . . . . . . 2-113

15.7 SENSOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-114

15.8 COUNTER CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-117

INSTALLATION

1. INSTALLATION REQUIREMENTS

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 MlNlMUM SPACE REQUlREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3 MACHINE LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.4 POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

. . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

2. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1 COPIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2 CASSETTE MODIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.3 KEY COUNTER HOLDER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Page 6

SERVICE TABLES

2. SERVICE TABLES

2.1 Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2.2 Variable Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

2.3 DIP SwitchTables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2.4 User Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2.5 Service Program SP-8 Data lnput Guide Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4

3. SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . 4-7

3.1 Service Program Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

3.2 Change Adjustment Values or Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

3.3 Memory Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

3.4 Service Program Mode Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

3.5 Language Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . 4-18

5. SERVICE REMARKS

5.1 Handling The Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

5.2 Charge Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

5.3 Erase Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

5.4 Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

5.5 Development Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

5.6 Transfer and Separation Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

5.7 Cleaning Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

5.8 Pre-transfer and Quenching Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

5.9 Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

5.10 Paper Feed and Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

5.11 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

5.12 Handling PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-19

REPLACEMENT AND ADJUSTMENT

1. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Exposure Glass Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-1

Page 7

1.2 Sixth Mirror Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

1.3 Scanner Drive Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

1.4 Fourth and fifth Mirror Drive Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

1.5 Lens Drive Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

1.6 Scanner Harness Replacement (Optics Cables & Exposure Lamp) . . . . . . . . . . 5-10

2. DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

2.1 Developer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

2.2 Image Density Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

2.3 Toner Collection Bottle Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

2.4 Vsg Voltage Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

2.5 Vsg Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

2.6 Toner Supply System Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

2.7 Toner Density Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

2.8 Fixed Supply Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

2.9 Toner Amount Changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

2.10 ID Pattern Bias Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

3. CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

3.1 Pick-off Pawl Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

3.2 Cleaning Blade and Brush Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

3.3 Blade Cleaner and Bias Roller Blade Replacement . . . . . . . . . . . . . . . . . . . . . . . . 5-23

4. FUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

4.1 Fusing Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

4.2 Oil Blade Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

4.3 Thermistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

4.4 Thermofuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

4.5 Hot Roller Stripper Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

4.6 Hot Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

4.7 Pressure Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

4.8 Entrance Guide Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

4.9 Fusing Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

4.10 Hot Roller Temperature Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

4.11 Idling Period Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

5. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.1 Pick-up, Paper Feed and Separation Roller Replacement . . . . . . . . . . . . . . . . . . 5-36

Page 8

5.2 Transport Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

6. DUPLEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

6.2 Duplex Transport and Fork Gate Units Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

6.3 Jogger Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

6.4 Duplex Pick-up and Feed Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

6.5 Duplex Separation Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

6.6 Positioning and Entrance Actuator Rollers Replacement . . . . . . . . . . . . . . . . . . . 5-45

6.7 Duplex Pick-up Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

6.8 Jogger Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

7. COPY IMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

7.1 Vertical Magnification Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

7.2 Horizontal Magnification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

7.3 Focus Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

7.4 Uneven Exposure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

7.5 Light lntensity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

7.6 ADS Reference Voltage Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

7.7 ADS Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

7.8 ADS Operation Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

7.9 Erase Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

7.10 Registration Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

7.11 Side-to-Side Registration Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

8. CORONA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

8.1 Charge Corona Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

8.2 Pre-quenching Corona Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

8.3 Transfer and Separation Corona Wires Replacement . . . . . . . . . . . . . . . . . . . . . . 5-62

8.4 Charge Cleaner Drive Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

8.5 TC/SC Cleaner Drive Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

8.6 Drum Current Adjustment Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-65

8.7 Charge Corona Current Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

8.8 Transfer Corona Current Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

8.9 Separation Corona Current Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

8.10 Pre-Cleaning Corona Current Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

8.11 Pre-Quenching Corona Current Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

Page 9

9. OTHERS

9.1 Power Supply Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-73

ELECTRICAL DATA

1. Main PCB Schematic (1)

Main PCB Schematic (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

2. Optics PCB Schematic

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .

3. Paper Feed PCB Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Timer PCB Schematic

5. Timing Chart

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

. . . . . . . . . . . . . . . . . . . . 6-5

6-1

6-4

6-4

6. 20 Bin Sorter PCB Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

7. ARDF PCB Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

8. Large Capacity Tray PCB Schematic - 1,000 Sheets . . . . . . . . . . . 6-7

9. Large Capacity Tray PCB Schematic - 2,500 Sheets

. . . . . . . . . . 6-8

10. 15 Bin Sorter PCB Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

11. 15 Bin Sorter Timing Chart (A4/Letter Mode) . . . . . . . . . . . . . 6-10

12. Menu Reader PCB Schematic (upper) . . . . . . . . . . . . . . . . . . . . 6-11

13. Menu Reader PCB Schematic (lower) . . . . . . . . . . . . . . . . . . . . 6-12

PAPER BANK

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . 7-2

3. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . 7-3

4. OVERVIEW . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

5. PAPER FEED CLUTCH ON TIMING . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

6. PAPER SlZE AND VOLUME SENSORS . . . . . . . . . . . . . . . . . . . . . . 7-6

7. LIFT MOTOR CONTROL AND PAPER END DETECTION . . . . . . . 7-7

7.1 LIFT MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.2 PAPER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

. . . . .

7-4

Page 10

8. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

8.1 Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

8.2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

DOCUMENT FEEDER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. BASIC OPERATION . .

2.1 INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.2 SINGLE-SIDED ORIGINAL FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.3 TWO-SIDED ORIGINAL FEED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. FEED-IN UNIT MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

4. SEPARATION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

5. MISFEED PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

6. WEAR PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

7. FRICTION ROLLER RELEASE MECHANISM . . . . . . . . . . . . . . . . . 8-9

8. REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

9. INVERTER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

10. FEED-OUT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

11. LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. MISFEED CHECK

13. INSTALLATION . .

13.1 Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

13.2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 8-25

14.1 DF Belt Drive Motor Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

14.2 Inverter Turn Gate Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8-2

8-13

8-14

8-16

20 BIN SORTER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Page 11

2.1 CLEAR MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2.2 SORT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2.3 STACK MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2.4 EXAMPLE OF SORT MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

3. BIN DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

4. BIN HOME POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

5. BINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

6. ELECTRICAL CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

7. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

7.1 Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

7.2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

8. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 9-15

8.1 Bin Drive Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

8.2 Bin Drive Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

8.3 Bin Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

8.4 Exit Roller Drive Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

8.5 Lower Exit Roller Unit and Exit Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . 9-20

1 K LCT

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 10-2

3. DRIVE LAYOUT AND DRIVE MECHANISM . . . . . . . . . . . . . . . . . . 10-3

4. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . 10-4

5. FUNCTIONAL AND ELECTRICAL DESCRIPTlON . . . . . . . . . . . . 10-5

5.1 TRAY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

5.2 PAPER SIZE CHANGE AND DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

5.3 PAPER VOLUME DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

5.4 COVER SAFETY SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

6. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

6.1 Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

6.2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Page 12

7. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 10-15

7.1 Tray Down Sensor and Positioning Switch Replacement . . . . . . . . . . . . . . . . . . 10-15

7.2 Paper Size Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

7.3 Tray Wire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

7.4 Paper Volume Cord Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

7.5 Side Registration Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

2.5 K LCT

1. SPECIFICATIONS . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1

2. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . 11-2

3. FUNCTIONAL AND ELECTRICAL OPERATION . . . . . . . . . . . . . . 11-3

3.1 TRAY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

4. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

4.1 Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

4.2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

MENU READER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. OVERALL MACHINE CONTROL

3. DATA FORMAT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

4.1 Job Sheet Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

4.2 Menu Reader Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

4.3 Processing Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

5. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

5.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

5.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

6. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 12-11

6.1 Lower Transport Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-11

. . . . . . . . . . . . . . . . . . . . . . . . . .12-2

12-3

Page 13

TROUBLESHOOTING

1. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-1

2. DEFECTIVE SENSOR TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-8

15 BIN SORTER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 14-2

3. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

4. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . 14-4

5. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . 14-5

6. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

7. FUNCTIONAL AND ELECTRICAL DESCRIPTION . . . . . . . . . . . 14-10

7.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-10

7.2 Bin Gate Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

7.3 Relay Guide Plate Reset Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-12

7.4 Interface with the Copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-13

7.5 Jam Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

7.6 Inlet Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

7.7 Misfeed Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

8. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-19

8.1 Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-19

8.2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-20

9. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-25

10. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 14-27

10.1 Sorter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-27

10.2 Inlet sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-28

10.3 Jam Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-29

10.4 Sponge Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-30

10.5 DC Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-32

Page 14

SECTION 1

OVERALL MACHINE

INFORMATION

Page 15

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

2. GUIDE TO COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.1 INTERNAL/EXTERNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2.2 OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2.3 INDICATOR SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2.4 GUIDANCE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3. COPY PROCESSES AROUND THE DRUM . . . . . . . . . . . . . . . . . . 1-10

4. COPY CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. PAPER PATH

6. DRIVE LAYOUT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12

1-13

1-16

7. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-17

8. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-18

9. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . 1-23

10. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

11. AC AND DC POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . 1-29

Page 16

1. SPECIFICATIONS

31 August 1989

- Item -

Configuration:

Copying Process:

Original:

Original Size:

Reproduction Ratios:

Reproduction Ratio Change:

Warm-Up Time:

Copy Paper

Copying Speed:

- Specifications Desk top

Dry electrostatic transfer system

Book/Sheet

Maximum A3, 11” x 17”

5 reduction ratios, 3 enlargement ratios, zoom : – from

60% to 155% in 1% steps

- A4 Version 5R: 93%, 82%, 75%, 71%, and 65%

3E: 115%, 122%, and 141%

- Letter Version 5R: 93%, 85%, 77%, 74%, and 65%

3E: 121%, 129%, and 155%

Maximum 6.5 seconds

Within 5 minutes (Room Temp. 20°C, 68°F)

Size:

– Maximum A3, 11” x 17”

– Minimum A6, 5½” x 8½”

2

Weight: – 52 g/m

A3 A4 (S)

(11” x 17”)

F33 22

18

to 157 g/m2 (14 lb to 42 lb)

A4 (L) A5 (S)

(11” x 8½”) (8½” x 11”) 5½” x 8½”)

43 33

35

27

48

38

First Copy Time:

Copy Number Input:

F33: 3.8 seconds (A4 or 8½” x 11”) (1st cassette)

F34: 4.2 seconds (A4 or 8½” x 11”) (1st cassette)

Number keys, 1 to 999 (count up or count down)

1-1

Page 17

31 August 1989

Special Functions:

Manual Image Density

Selection:

Automatic Reset:

Paper Feed:

Paper Feed System:

Exposure System:

Lens:

Light Source:

Photoconductor:

Charge System:

Erase:

Development System:

Development:

Toner Replenishment:

Toner Consumption:

• Auto duplexing (3 modes)

• Margin adjustment (0 to 16 mm [5/8”] on both sides)

• Auto image density selection (ADS)

• Automatic paper selection (APS) (with ADF or RDH)

• Automatic reduction/enlargement (AMS) (with ADF)

• 2 single copies mode (Copies facing pages of a bound

original with one press of the Start key.)

7 steps

1 minute standard setting; can also be set to 3 minutes or

no auto reset.

All functions canceled except cassette selection. Quantity

entered returns to “1”, and reproduction ratio returns to full

size.

• Dual universal cassette feed, 500 sheets each

• Manual feed table

• Large capacity tray (LCT) (optional: 1,000 or 2,500

sheets)

• Two additional cassettes with cassette bank (optional:

500 sheets)

Feed and reverse roller

Slit exposure, moving optics

Through lens, F5, f = 215 mm

Halogen lamp (85 V, 160 W; control range 50 to 80 volts

RMS)

Selenium drum (F-type)

Dual wire dc corona

LED lamp unit (80 segments)

Magnetic brush roller

Automatic voltage change (The control board monitors the

selected image density level, drum temperature, and rest

time.)

Cartridge exchange (330 g/bottle)

10,000 copies/bottle (7%/A4)

1-2

Page 18

31 August 1989

Cleaning System:

Quenching System:

Image Transfer:

Paper Separation:

Image Fusing:

Fusing Lamp:

Oil Consumption:

Electronic Control System:

Copy Tray Capacity:

Self-diagnostics:

Service Programs:

Power Source:

Power Consumption:

Dimensions:

Blade and brush, pre-cleaning corona

Photo-quenching (cold cathode tube) and dc corona

Single wire dc corona, pre-transfer lamp

Dual wire ac corona and pick-off pawls

Heat and pressure rollers

Halogen lamp (750 W)

80,000 copies per oil tank (360 cc)

8-bit microprocessor

250 sheets (all sizes)

24 codes, displayed in Guidance Display

100 programs controlled from the operation panel

110V/60Hz –> 15A

115V/60Hz –> 15A

220V/50Hz –> 8A

240V/50Hz –> 8A

See the following table.

Warm-up

Copier

See the following table.

Numbers are in kilowatts per hour.

Copying Stand-by

1.0

1.8

The numbers are in millimeters

0.18

with inches in parenthesis:

Height

500 mm

(19.7”)

Copier only with

platen cover

Width

750 mm

Depth

763 mm

(29.5”) (30.0”)

Max.

1.5

Weight:

Full System* 1,575 mm

(62.0”) (30.0”)

763 mm

1,065 mm

(41 .9”)

*With DF, Sorter, LCT (RT21), Paper Bank, Menu Reader

(Duplex Model):

115V - 104 kg (228.5 lb)

220V - 107 kg (235.4 lb)

(Non-duplex Model): 115V - 96 kg (211.2 Ib)

220V - 99 kg (217.8 lb)

1-3

Page 19

31 August 1989

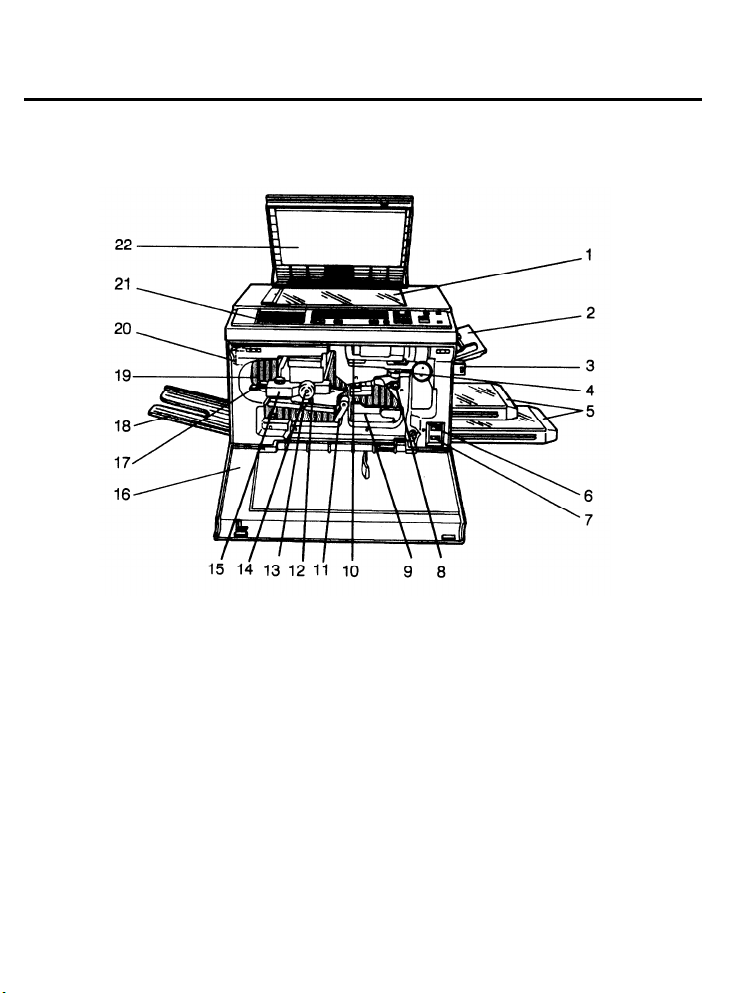

2. GUIDE TO COMPONENTS

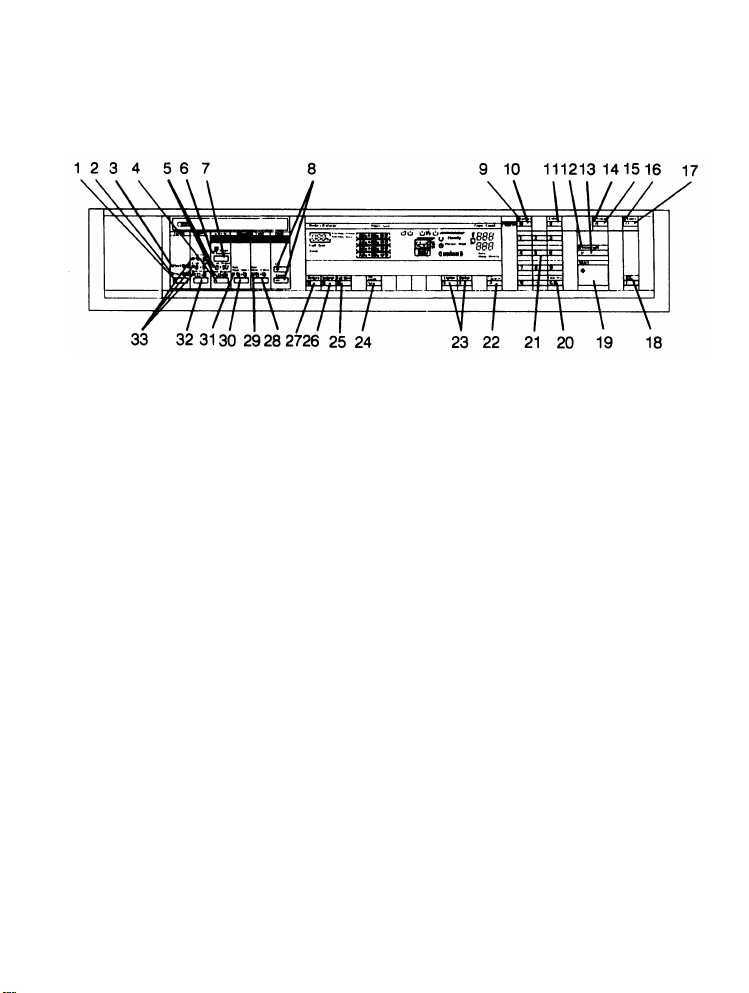

2.1 lNTERNAL/EXTERNAL

1. Exposure Glass

Position the original to be copied here.

2. Manual Feed Table

Open to manually feed the copy paper.

3. Key Counter Holder

Insert the key counter into this holder

[optional] before copying.

4. Toner Bottle Lever

Turn counterclockwise to remove the toner

bottle from its holder.

5. Cassettes

Hold the copy paper.

6. Total Counter

Shows the total number of copies made.

7. A3/11” x 17” Counter

Shows the total number of A3/11” x 17”

copies made (optional).

8. Registration Roller Knob

Turn to remove misfed paper.

1-4

Page 20

31 August 1989

9. Duplex Tray

Stores the copies before reverse side

copying.

10. Toner Bottle Holder

Swing down to replace the toner bottle.

11. Transport Unit Release Lever

Push down to lower the transport unit when

removing misfed paper.

12. Fusing Unit Release Lever

Press down to slide out the fusing unit.

13. Fork Gate Unit Lever

Press down to lower the fork gate unit.

14. Fusing Unit Knob

Turn clockwise to remove misfed paper.

15. Silicon Oil Bottle

Add silicone oil to this bottle when the Add

Oil indicator lights.

16. Front Cover

Open this cover when the Misfeed, Add

Toner, or Add Oil indicator lights.

17. Exit Guide Plate Tab

Raise this guide plate to gain access to the

exit area.

18. Copy Tray

Completed copies are delivered here.

19. Inverter Unit

Inverts and feeds copies to the duplex tray.

20. Main Switch

Turns on the machine.

21. Operation Panel

The copier’s keys and indicators are

located here.

22. Platen Cover

Lower the platen cover over originals before

copying.

1-5

Page 21

31 August 1989

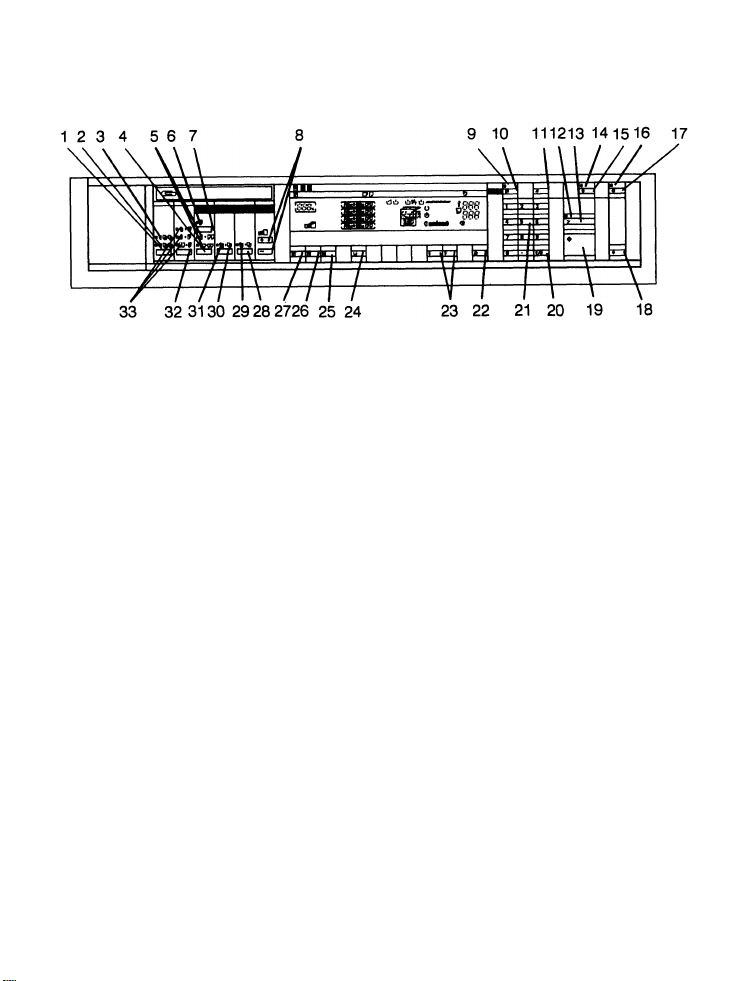

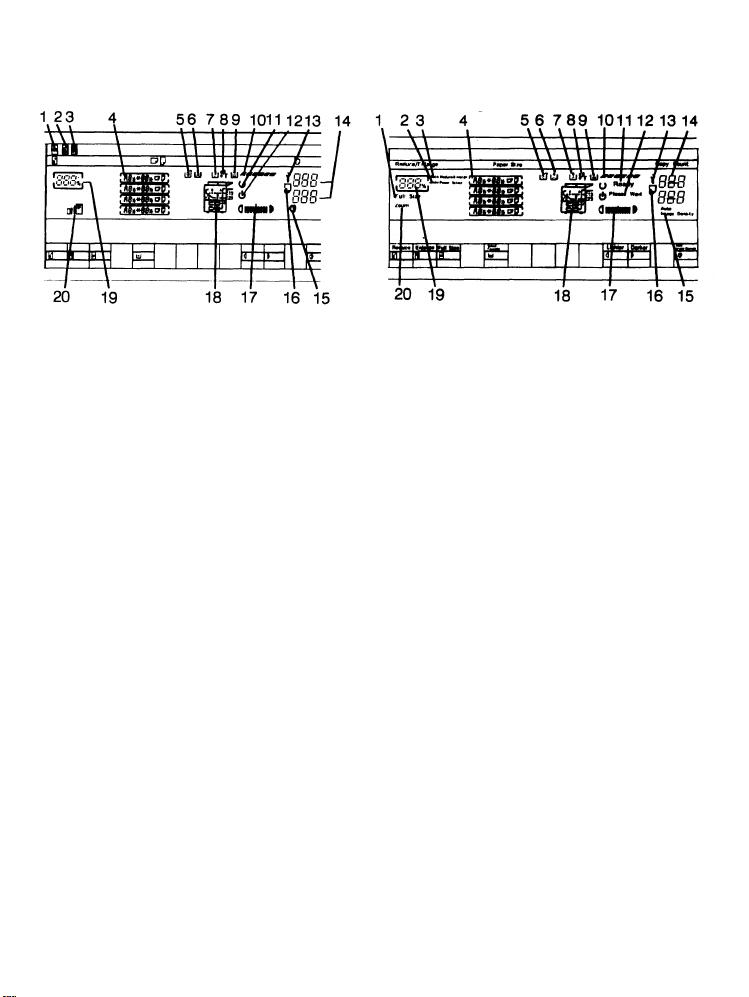

2.2 OPERATION PANEL A4/A3 Version

1. Sorter Key

Press to use the sorter. Select sort or stack

mode.

2. Stack Indicator

Lights when stack mode is selected.

3. Sort Indicator

Lights when sort mode is selected.

4.2 Single Copies Key

Press to make copies from bound originals

or two sided originals.

5.2 Single Copies Indicator

Lights when 2 single copies mode is

selected.

6. Margin Adjustment Indicator

Lights when Margin Adjustment mode is

selected.

7. Margin Adjustment Key

Press to create a margin on copies.

8. Zoom Keys

Press to alter the reproduction ratio in 1%

steps.

9. Guidance Indicator

Lights when guidance mode is selected.

10. Guidance Key

Press to select guidance mode.

11. Enter Key

Press after entering data.

12. Interrupt Indicator

Lights when interrupt mode is selected.

13. Interrupt Key

Press to make interrupt copies during a

copy run.

14. Program Indicator

Lights when the user program mode is

selected.

15. Program Key

Press to enter or recall user programs.

16. Timer Indicator

Lights when the machine has been turned

off by the weekly timer or automatic shut-off

timer.

17. Timer Key

Press to operate the copier after it has been

turned off by the weekly timer or automatic

shut-off timer.

1-6

Page 22

Letter/Legal Version

31 August 1989

18. Clear Modes Key

Press to clear the copier of previously

entered settings and modes.

19. Start Key

Press to start copying.

20. Clear/Stop Key

Press to cancel the copy number entered or

to stop copying.

21. Number Keys

Use the number keys to enter the number

of copies. Also, use to select user

programs and input original size and copy

size when in size magnification mode.

22. Auto Image Density Key

Press to select/clear automatic image

density mode.

23. Image Density Keys

Press to cancel automatic control and

manually select the image density level.

24. Select Cassette Key

Press to select a cassette.

25. Full Size Key

Press to change reproduction ratio to 100%.

26. Enlarge Key

Press to make enlarged copies.

27. Reduce Key

Press to make reduced copies.

28. Auto Reduce/Enlarge key

Press to select automatic reduce/enlarge

mode.

29. Auto Reduce/Enlarge Indicator

Lights when auto reduce/enlarge mode is

selected.

30. Auto Paper Select Key

Press to select automatic paper select

mode.

31. Auto Paper Select Indicator

Lights when automatic paper select mode is

selected.

32. Duplex Key

Press to select a duplex mode.

33. Duplex Indicators

Show selected duplex mode.

1-7

Page 23

31 August 1989

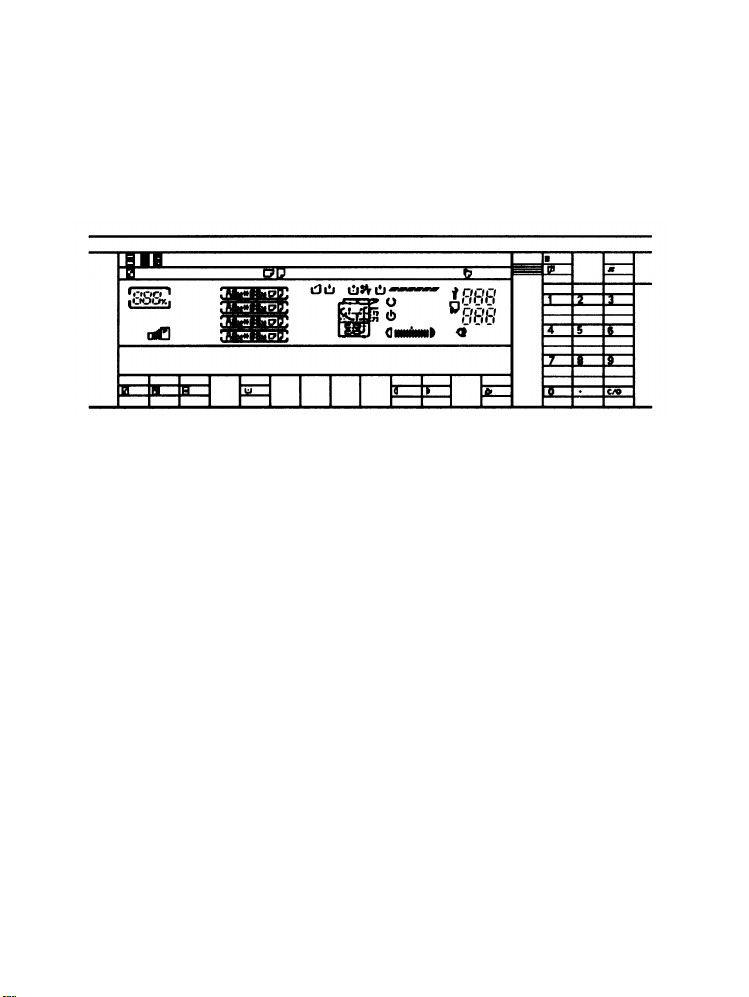

2.3 INDICATOR SCREEN A4/A3 Version

Letter/legal version

1. Full Size Mode Indicator

Lights when full size mode is selected.

2. Auto Paper Select Indicator

Lights when auto paper select mode is

selected.

3. Auto Reduce/Enlarge Indicator

Lights when auto reduce/enlarge mode is

selected.

4. Paper Size Indicator

Shows the selected cassette and paper size.

5. Empty Used Toner Indicator

Lights when the used toner bottle is full;

simultaneously, the Call Service indicator

blinks.

6. Add Toner Indicator

Blinks when the copier needs toner.

7. Add Oil Indicator

Lights when the silicone oil level is low.

8. Check Paper Path Indicator

Lights if there are misfeeds.

9. Load Paper Indicator

Lights when the selected cassette runs out

of paper.

10. Copy Cycle Indicator

Lights during a copy cycle.

11. Ready Indicator

Lights when the copier is ready to copy.

12. Wait Indicator

Lights during warm-up.

13. Call Service Indicator

Lights when the copier has a functional

problem.

14. Copy Counter Indicator

(Upper) Displays the number of copies

entered.

(Lower) While copying, it shows the number

of copies made. (If in count-down mode, it

shows the number of copies to be made.)

15. Auto Image Density Indicator

Lights when the copier is automatically

controlling image density.

16. Manual Feed Indicator

Lights when the copier is automatically

controlling image density.

17. Manual Image Density Indicator

Shows the selected image density.

18. Misfeed Location Display

Shows where to check inside the copier if

there is a misfeed.

19. Magnification Ratio Indicator

Shows the selected reproduction ratio.

20. Zoom Indicator

Lights when zoom mode is selected.

1-8

Page 24

31 August 1989

2.4 GUIDANCE DISPLAY

The Guidance Display shows information about keys and modes, and it guides you through

the procedures for operating the copier.

- Information about keys and modes -

When you need information about keys or modes, press the Guidance key and the key you

want information about.

After starting copier operation, you can get information about the current mode by pressing

the Guidance key.

Guidance is not available for the following Keys:

• Number keys

• Decimal key

• Start key

• Manual Image Density key

• Select Cassette key

1-9

Page 25

31 August 1989

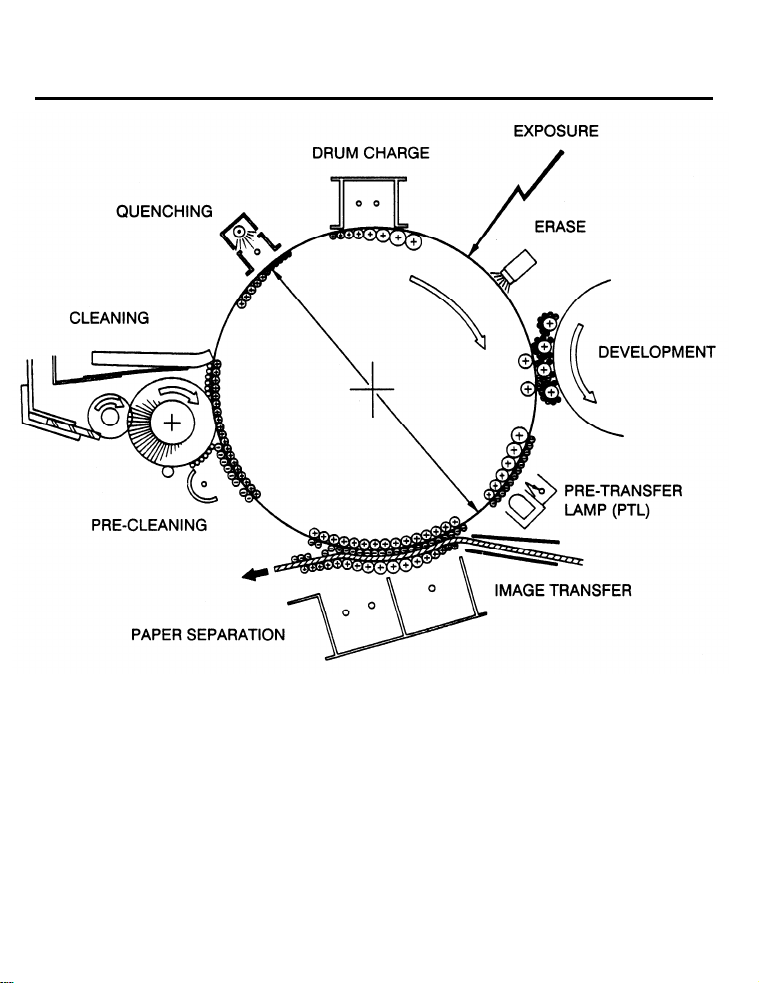

3. COPY PROCESSES AROUND THE DRUM

DRUM CHARGE

In the dark, the charge corona unit gives a uniform positive charge to the selenium drum. The

charge remains on the surface of the drum because the photoconductive selenium has

electrical resistance in the dark.

EXPOSURE

An image of the original is reflected to the selenium drum surface via the optics assembly. The

charge on the drum surface is dissipated in direct proportion to the intensity of the reflected

light, thus producing an electrical latent image on the drum surface.

1-10

Page 26

31 August 1989

ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be used for the

copy image. The resistance of the drum in the illuminated areas drops and the charge on

those areas dissipates.

DEVELOPMENT

Negatively charged toner is attracted to the positively charged areas of the drum, thus

developing the latent image. (The negative triboelectric charge is caused by friction between

the carrier and toner particles.)

PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove all positive charge from the exposed areas of the

drum. This prevents the toner particles from being reattracted to the drum surface during

paper separation and makes paper separation easier.

IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy paper and the

developed image on the drum surface. Then, a strong positive charge is applied to the back

side of the copy paper, providing an electrical force which pulls the toner particles from the

drum surface to the copy paper. At the same time, the copy paper is electrically attracted to

the drum surface.

PAPER SEPARATION

A strong ac corona discharge is applied to the back side of the copy paper, reducing the

positive charge on the copy paper and breaking the electrical attraction between the paper

and the drum. Then, the stiffness of the copy paper causes it to separate from the drum

surface. The pick-off pawls help to separate paper which has low stiffness.

PRE-CLEANING

The pre-cleaning corona (PCC) applies an ac corona with a negative bias to the drum. This

removes the positive charge from the drum and makes the negative charge on the toner

remaining on the drum even.

CLEANING

The cleaning brush removes most of the toner on the drum and loosens the remainder. Then,

the bias roller, which has a positive potential, attracts the toner particles from the cleaning

brush to keep it clean. Finally, the cleaning blade scrapes off the loosened toner.

QUENCHING

The pre-quenching corona applies a positive corona charge to the selenium drum to eliminate

any negative charge remaining from the pre-cleaning corona. Then, light from the quenching

lamp electrically neutralizes the drum.

1-11

Page 27

31 August 1989

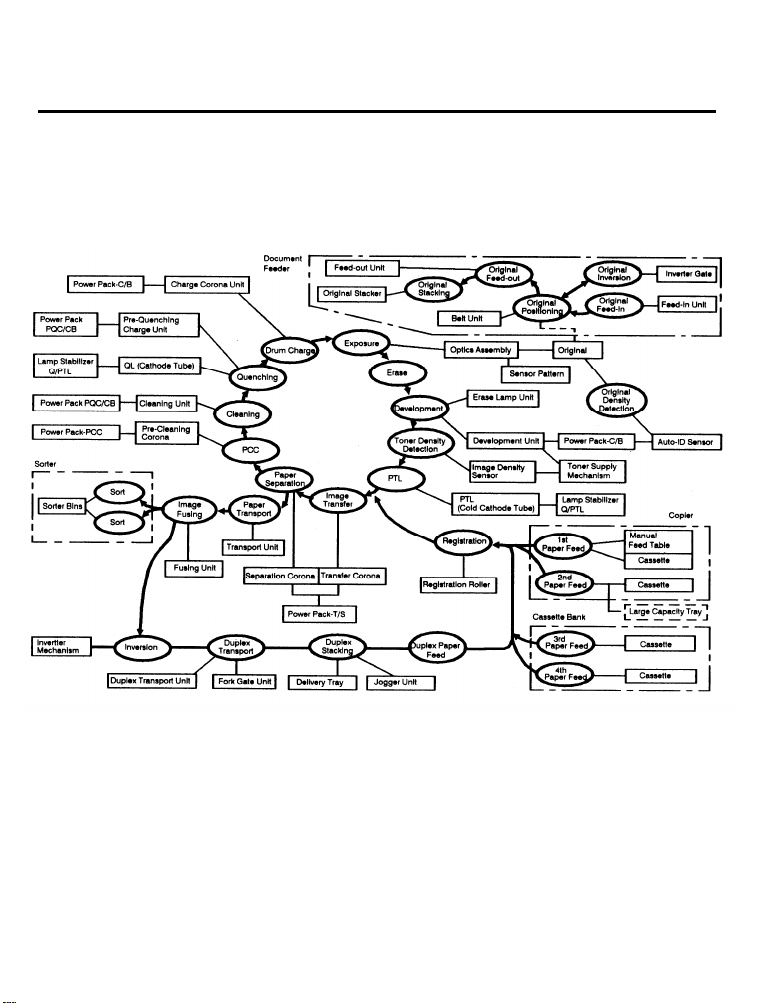

4. COPY CYCLE

1-12

Page 28

31 August 1989

5. PAPER PATH

Paper feed starts from one of the four paper feed stations. The copy paper then follows one

of two paths inside the copier. The path followed depends on which mode the operator has

selected. For copy processing, all sheets follow the same path from the paper feed

mechanism through the fusing unit. After that, normal copies are delivered to the copy tray;

however, duplex copies are diverted for further processing. The following discussion follows

the route of a single sheet of paper through a duplex cycle.

1. PRIMARY PAPER PATH

Paper Feed:

An FRR (Feed and Reverse Roller) mechanism separates one sheet of paper from the paper

stack and feeds it to the registration rollers. If the paper is fed from the second, third, or fourth

station, relay rollers move the paper to the registration roller. The registration rollers are not

turning at this time. The paper buckles slightly when the leading edge reaches the registration

rollers. Buckling seats the sheet securely between the registration rollers and corrects skew.

Registration:

At the programmed time, the registration rollers start turning to feed the paper to the drum.

Image Transfer:

The toner image on the drum surface is pulled from the drum onto the passing paper by the

transfer corona.

1-13

Page 29

31 August 1989

Paper Separation:

The electrostatic attraction between the paper and the drum is broken by the separating

corona. The suction of the vacuum fan and the weight of the paper pulls the paper onto the

transport belt. The transport belt moves the paper with the developed copy image to the

fusing unit.

Fusing:

The paper passes between two rollers which bond the toner image to the paper by applying

heat and pressure. At this point the copy is complete, and the paper path splits two ways.

Ordinary copies go directly through the exit rollers to the copy tray. Duplex copies are

diverted to the inverter unit.

1-14

Page 30

31 August 1989

2. DUPLEX COPY PATH

Inverter Unit:

The junction gate directs the paper to the inverter unit, which inverts the copy and sends it to

the duplex transport unit.

Duplex Transport:

The duplex transport rollers move the copy to the right. The appropriate fork gate is opened

according to the paper size. Then, the copy is sent to the jogger unit through the duplex

delivery tray.

Jogger Unit:

The copies are neatly stacked in the jogger unit to prepare them for duplex paper feed.

Duplex Paper Feed

The copy is kept in the duplex tray until the operator sets the next original and presses the

Start key. Then the duplex feed mechanism feeds the copy up through the first relay rollers to

the registration rollers. After reaching the registration rollers, the sheet follows the same path

as when the front side was copied. However, this time the reverse side faces up to receive the

image.

1-15

Page 31

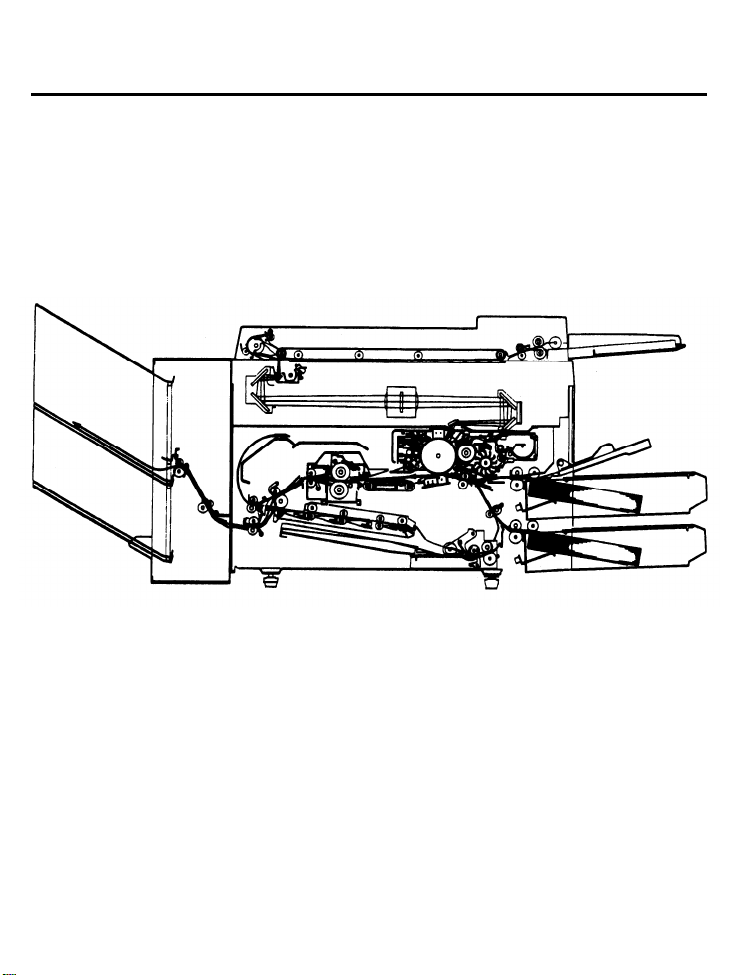

6. DRIVE LAYOUT

31 August 1989

1. Toner Supply Clutch

2. Development Drive Belt

3. Development Drive Gear

4. Development Motor

5. Drum Drive Pulley

6. Drum Drive Belt

7. Main Motor

8. Fusing/Duplex Drive Gears

9. Main Drive Belt

10. Exit Relay Roller Drive Sprocket

11. Inverter Roller Drive Gear

12. Exit Roller Drive Gear

13. Exit Drive Chain

14. Pulse Generator Drive Pulley

15. Registration Roller Drive Belt

16. Cleaning Drive Gear

17. Registration Clutch

18. Paper Feed Motor

19. Duplex Paper Feed Clutch

20. Relay Roller Clutch

21. Paper Feed Drive Chain

22. Second Paper Feed Clutch

23. First Paper Feed Clutch

1-16

Page 32

31 August 1989

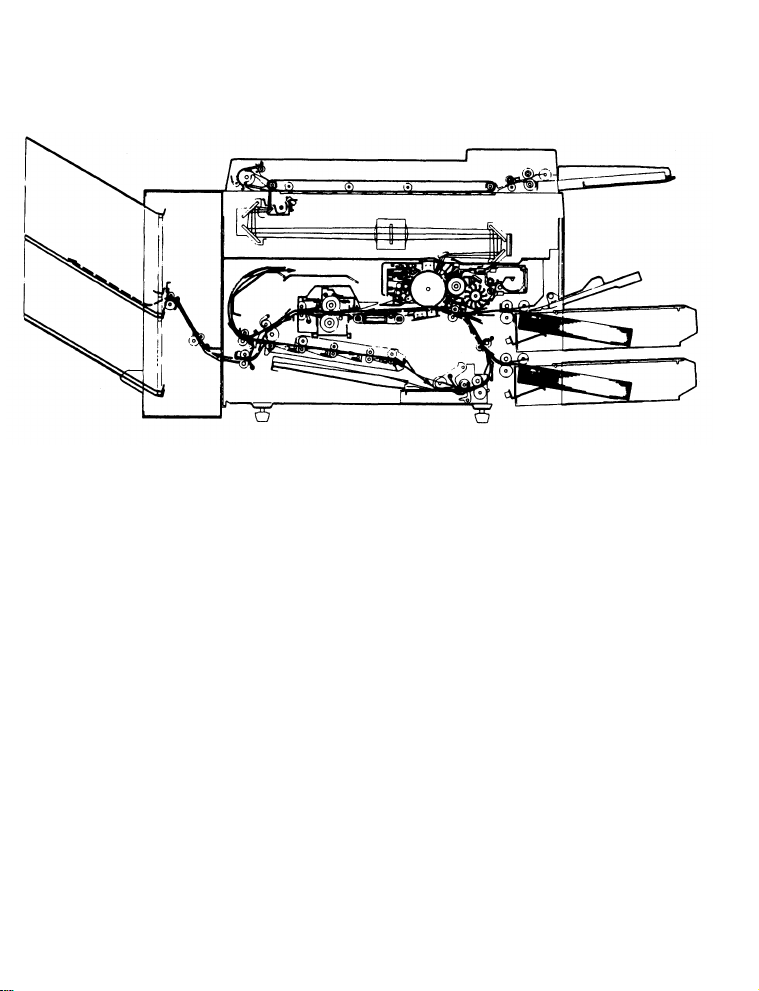

7. MECHANICAL COMPONENT LAYOUT

1. Inverter Unit

2. Third Mirror

3. Second Mirror

4. First Mirror

5. Exposure Lamp

6. Fusing Unit

7. Document Feeder

8. Transport Unit

9. Lens

10. Cleaning Unit

11. Quenching Unit

12. Charge Corona Unit

13. Drum

14. Sixth Mirror

15. Toner Shield Glass

16. Erase Lamp Unit

17. Fourth Mirror

18. Fifth Mirror

19. Toner Tank

20. Development Unit

21. Manual Feed Table

22. First Cassette

23. Large Capacity Tray

24. Transfer/Separation Corona Unit

25. Jogger Unit

26. Fourth Cassette

27. Cassette Bank

28. Third Cassette

29. Duplex Delivery Tray

30. Fork Gate Unit

31. Duplex Transport Unit

32. Sorter

Page 33

31 August 1989

8. ELECTRICAL COMPONENT LAYOUT

1. Scanner Home Position Sensor

2. 4th and 5th Mirror Drive Motor

3. Toner Overflow Sensor 10. Exposure Lamp

4. Image Density Sensor PCB

5. PQC (Pre-quenching Corona Wire)

6. QL (Quenching Lamp)

7. Erase Lamp

8. Lens Home Position Sensor

9. Toner End Sensor

11. Scanner Overrun Sensor

12. 4th and 5th Mirror Home Position Sensor

13. Auto Density (AD) Sensor

14. Development Cooling Fan Motor

1-18

Page 34

31 August 1989

15. Cooling Blower Motor

16. Platen Cover Sensor

17. CC Cleaner Home Position Sensor

18. Key Counter (Option)

19. Manual Feed Sensor

20. CC Cleaner Motor

21. 1st Cassette Paper End Sensor

22. Manual Feed Paper End Sensor

23. 1st Paper Size Sensor

24. Registration Sensor

25. Pre-Transfer Lamp (PTL)

26. 2nd Cassette Paper End Sensor

27. Total Counter

28. A3/LTG Counter (Option)

29. 2nd Paper Size Sensor

30. SC Cleaner Motor

31. Duplex Stopper SOL

32. SC Cleaner Home Position Sensor

33. Duplex Paper Sensor

34. Drum Heater

35. Duplex Entrance Sensor

36. Front Door Safety Switch

37. Fusing Lamp

38. Oil End Sensor

39. Fusing Thermistor

40. Main Switch

41. AC Drive PCB

42. Power Supply Unit

43. Exit Sensor

44. Exit Relay Sensor

45. Inverter Exit Sensor

46. Fusing Exit Sensor

47. Thermofuse

48. Fusing Exhaust Fan Motor

49. Inverter Pressure SOL

50. Junction Gate SOL

51. Anticondensation Heater (option)

52. Lens Drive Motor

1-19

Page 35

31 August 1989

53. Main Motor

54. Main Motor Capacitor

55. Charge Fan Motor

56. Pick-off SOL

57. Registration MC

58. 1st Feed Relay MC

59. Paper Feed Motor

60. Toner Supply MC

61. Knocking Solenoid

62. Development Motor

63. Development Motor Capacitor

64. Paper Feed Motor Capacitor

65. Scanner Drive Motor

66. 1st Paper Feed MC

67. 1st Lift Sensor

68. 1st Lift Motor

1-20

Page 36

31 August 1989

69. 1st Pick-up SOL

70. Manual Feed SOL

71. 2nd Paper Feed MC

72. 2nd Lift Motor

73. 1st Relay Sensor

74. 2nd Lift Sensor

75. 2nd Pick-up SOL

76. Duplex Paper Feed MC

77. Duplex Positioning SOL

78. Duplex Pick-up SOL

79. Jogger Motor

80. Main Transformer

81. Jogger Home Position Sensor

82. Cleaning SOL

83. Pulse Generator

84. Fork Gate SOL 2

85. Fork Gate SOL 1

86. Transport Unit Safety Switch

87. Terminal Block

88. Fork Gate Unit Safety Switch

89. Noise Filter

90. Circuit Breaker

91. Power Relay

1-21

Page 37

31 August 1989

92. SSR PCB

93. PQC/Cleaning Bias Power Pack

94. CC/Developer Bias Power Pack

95. PTL/QL Stabilizer

96. Paper Feed PCB

97. Operation Panel PCB

98. TC/SC Power Pack

99. Vacuum Fan Motor

100. PCC Power Pack

101. Main PCB

102. Timer PCB

103. Optics PCB

1-22

Page 38

9. ELECTRICAL COMPONENT DESCRIPTIONS

31 August 1989

NAME

MOTORS

Main

Development Cooling

Blower

Fusing Exhaust Fan

Cooling Blower

Vacuum Fan

Scanner Drive

Lens Drive

4th/5th Mirror Drive

Jogger

Cleaner Motors

Charge Fan

Development

1st/2nd Lift Motors

Paper Feed

FUNCTION

Drives all main unit components except optics unit and

fans/blower. (100 Vac)

Blows air to the development unit bottom plate.

Removes heat from around the fusing unit. (100 Vac)

Prevents build up of hot air in the optics cavity. (100 Vac)

Provides suction so paper is held firmly on the transport

belt. (100 Vac)

Drives the scanner. (dc servo)

Positions the lens. (dc stepper)

Positions the 4th/5th mirror assembly. (dc stepper)

Drives the jogger plates to keep paper evenly stacked on

the duplex tray.

Clean charge and separation wires.

Ensures even charge on the surface of the drum.

Drives development unit.

Lift paper to the appropriate feed position.

Applies paper feed drive to the 1st and 2nd feed stations.

MAGNETIC CLUTCHES

Registration

1st Paper Feed

2nd Paper Feed

1st Feed Relay

Duplex Paper Feed

Toner Supply

Drives the registration roller

Starts paper feed from the first feed station.

Starts paper feed from the second feed station.

Drives the rollers of the copier relay unit.

Feeds paper from the duplex tray.

Drives toner supply roller.

1-23

Page 39

31 August 1989

SOLENOIDS

Cleaning

Pick-off

Junction Gate

Duplex Positioning

Manual Feed

1st and 2nd Fork Gate

Duplex Pick-up

Duplex Positioning

Inverter Pressure

Duplex Stopper

1st/2nd Pick-up

SWITCHES

Main

Front Door Safety

Transport Unit Safety

Fork Gate Unit Safety

Moves the cleaning blade against the drum.

Moves the pick-off pawls against the drum.

Energizes to direct copies to the duplex tray.

Raises and lowers the sponge roller.

Raises the pick-up roller when paper is fed from the manual

feed table.

In unison, open and close the appropriate fork gates

according to paper size.

Starts feed from duplex and aids the stopper solenoid.

Lowers positioning roller.

Controls the inverter pressure roller.

Stops copy in the jogger unit.

Starts paper feed from the cassettes.

Supplies power to the copier.

Cuts ac power line.

Cuts 24-volt lines.

Cuts 24-volt lines.

SENSORS

Pulse Generator

Exit

Oil End

Toner Overflow

Toner End

Registration

Manual Feed

Scanner Home

Supplies timing pulses to the main board.

Detects misfeeds.

Detects the low oil condition.

Detects when the used toner bottle is full.

Detects when it is time to add toner.

Detects misfeeds.

Detects when the manual feed table is open.

Informs the CPU when the scanner is at the home position.

1-24

Page 40

31 August 1989

Lens Home

4th/5th Mirror Home

1st Paper Size

1st Paper End

2nd Paper Size

2nd Paper End

Scanner Overrun

1st Relay

Jogger Home

Duplex Paper

Duplex Entrance

Image Density

Auto Density (AD)

CC Cleaner Home Position

SC Cleaner Home Position

Platen Cover

Manual Feed Paper End

Fusing Exit

Inverter Exit

1st Lift

2nd Lift

Informs the CPU when the lens is at the full size position.

Informs the CPU when the 4th/5th mirror assembly is at

the full size position.

Detects the paper size in the first cassette.

Informs the CPU when the first cassette runs out of paper.

Detects the paper size in the second cassette.

Informs the CPU when the second cassette runs out of

paper.

Informs the CPU, if the scanner overshoots the home

position.

Detects misfeeds.

Informs the CPU when the jogger plates are at the home

position.

Detects whether or not paper is on the duplex tray.

Misfeed detector

Detects the density of the image on the drum.

Senses the background density of the original.

Informs the CPU when the charge wire cleaner has

reached home position.

Informs the CPU when the separation wire cleaner has

reached home position.

Informs the CPU that the platen cover is up or down.

Informs the CPU that there is no paper in the manual feed

tray.

Detects misfeeds.

Detects misfeeds.

Detects whether paper has been raised to the proper paper

feed position.

Detects whether paper has been raised to the proper paper

feed position.

1-25

Page 41

31 August 1989

THERMISTORS

Drum

Bias

Fusing

POWER PACKS/STABILIZER

Power Pack - T/S

Power Pack - CC/Bias

Power Pack - Q/BR

Power Pack - PCC

Lamp Stabilizer

HEATERS

Drum

Anticondensation (option)

Monitors the temperature around the drum. The CPU

selects the bias compensation range based on its input.

Monitors the temperature around the drum and controls

development bias compensation.

Monitors the fusing temperature and turns the fusing lamp

on/off.

Provides high voltage for the T/S coronas.

Provides high voltage for the charge corona and the

development roller bias.

Provides high voltage for the quenching corona and the

cleaning bias roller.

Provides high voltage for the pre-cleaning corona.

Provides high voltage for the quenching and pre-transfer

lamps.

Warms the drum when the main switch is off.

Prevents moisture from forming on the optics.

LAMPS

Exposure

Fusing

Erase

Quenching

Pre-transfer

PRINTED CIRCUIT BOARDS

Main

Applies high intensity light to the original for exposure.

Provides heat to the fusing unit.

Discharges the drum outside the image area. Erases

lead/trail edge.

Neutralizes any charge remaining on the drum surface after

cleaning.

Reduces charge on the drum surface before transfer.

Controls all copier functions both directly and through other

PCBs.

1-26

Page 42

31 August 1989

Optics

Operation Panel

Paper Feed

AC Drive

Timer

COUNTERS

Total

A3/11” x 17”

Key

CIRCUIT BREAKERS

Circuit Breaker

TRANSFORMERS

Main

OTHERS

Power Supply Unit

Thermofuse

AC Power Relay

Noise Filter

Main Motor Capacitor

Development Motor Capacitor

Paper Feed Capacitor

Controls the speed of the scanner, the position of the lens,

and the position of the mirrors.

Controls the LED matrix, and monitors the key matrix.

Interfaces with overall paper feed; receives input from

paper size and paper end sensors.

Drives all ac motors, the exposure lamp, and the fusing

lamp.

Controls weekly timer and timer functions.

Keeps track of the total number of copies made.

Keeps track of the total number of A3/11” x 17” copies

made. (Option)

Used for control of authorized use. Copier will not operate

until installed. (Option)

Guards against voltage surges in the input power.

Steps down the wall voltage to 100 Vac.

Rectifies 100 Vac input and outputs dc voltages.

Provides back-up overheat protection in the fusing unit.

Controls main power.

Removes electrical noise.

Start capacitor

Start capacitor

Start capacitor

1-27

Page 43

31 August 1989

10. OVERALL MACHINE CONTROL

1-28

Page 44

31 August 1989

11. AC AND DC POWER DISTRIBUTION

The illustration on this page shows the electrical power distribution in block form.

AC power (115/220 volts) is supplied from the wall outlet directly to the fusing lamp and the

step-down transformer. The transformer supplies 100 volts ac to the power supply unit, SSR

board, ac drive board, and to one side of the fans, motors, heaters, paper bank, and sorter.

The power supply unit has four dc fuses and one ac fuse.

1-29

Page 45

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 46

Contents

DETAILED SECTION DESCRIPTIONS

1. DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 SELENIUM DRUM CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 HANDLING THE DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.3 DRUM HEATER CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2. DRUM CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ., . . . . . . . . . . 2-4

2.2 WlRE CLEANER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3 CHARGE CORONA POWER PACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3.2 EXPOSURE LAMP CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.3 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.4 SCANNER MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

3.5 LENS/MIRROR POSlTlONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

3.6 FOURTH AND FlFTH MIRROR ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

3.7 ORIGlNAL SlZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3.8 RELATED SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

4. ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

4.2 LEAD EDGE AND TRAILING EDGE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

4.3 SIDE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

4.4 EDGE ERASE FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

4.5 ERASE LAMP CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

5. DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

5.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

5.2 DEVELOPER EXCHANGE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

5.3 DRIVE MECHANlSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

5.4 IMAGE DENSlTY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

5.6 BIAS CONTROL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

5.7 RELATED SERVlCE CALL CONDlTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

2-22

Page 47

6. TONER DENSITY DETECTION AND TONER SUPPLY . . . . . . . . . 2-38

6.1 TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

6.2 BOTTLE DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

6.3 TONER DENSITY DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

6.4 TONER DENSITY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

6.5 TONER SUPPLY AMOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

6.6 TONER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

6.7 TONER OVERFLOW SENSOR CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

7. lMAGE TRANSFER AND PAPER SEPARATION . . . . . . . . . . . . . . 2-46

7.1 PRE-TRANSFER LAMP (PTL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

7.2 IMAGE TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47