Ricoh FT5233-S AUTO REVERSE DOCUMENT FEEDER

AUTO REVERSE

DOCUMENT FEEDER

(Machine Code: A497)

12 February 1992 SPECIFICATIONS

1. SPECIFICATIONS

Original Size: Max A3, 11" x 17"

Min B6, 5

Original Weight: 42~128 g/m2 (11~34lb)

-SADF. ADF

52~104 g/m2 (14~28lb)

-SADF. ADF. ARDF

Original Feed Mode: Automatic feed ADF

Manual feed one by one SA DF

Auto Reverse Feed ARDF

1/2

" x 8

1/2

"

Original Table Capacity: Max 50 sheets (A4/8

" x 11)

1/2

52 g/m2 (14lb)

Original Separation: Feed and Friction Belts

Original Transport: One flat belt

Original Stop System: Dc servo motor control system

Copying Speed: Continuous copy

33 copies/minute (A4/8

Single copy

31 copies/minute (A4/8

Power Source: 24V from copier, 1.8A

Power Consumption: 45W

Dimensions

(W x D x H):

670 x 468 x 120 mm

(26.4" x 18.5" x 4.8")

Weight: Approximately 9.5 kg (21lb)

" x 11" sideways)

1/2

" x 11" sideways)

1/2

ARDF

1

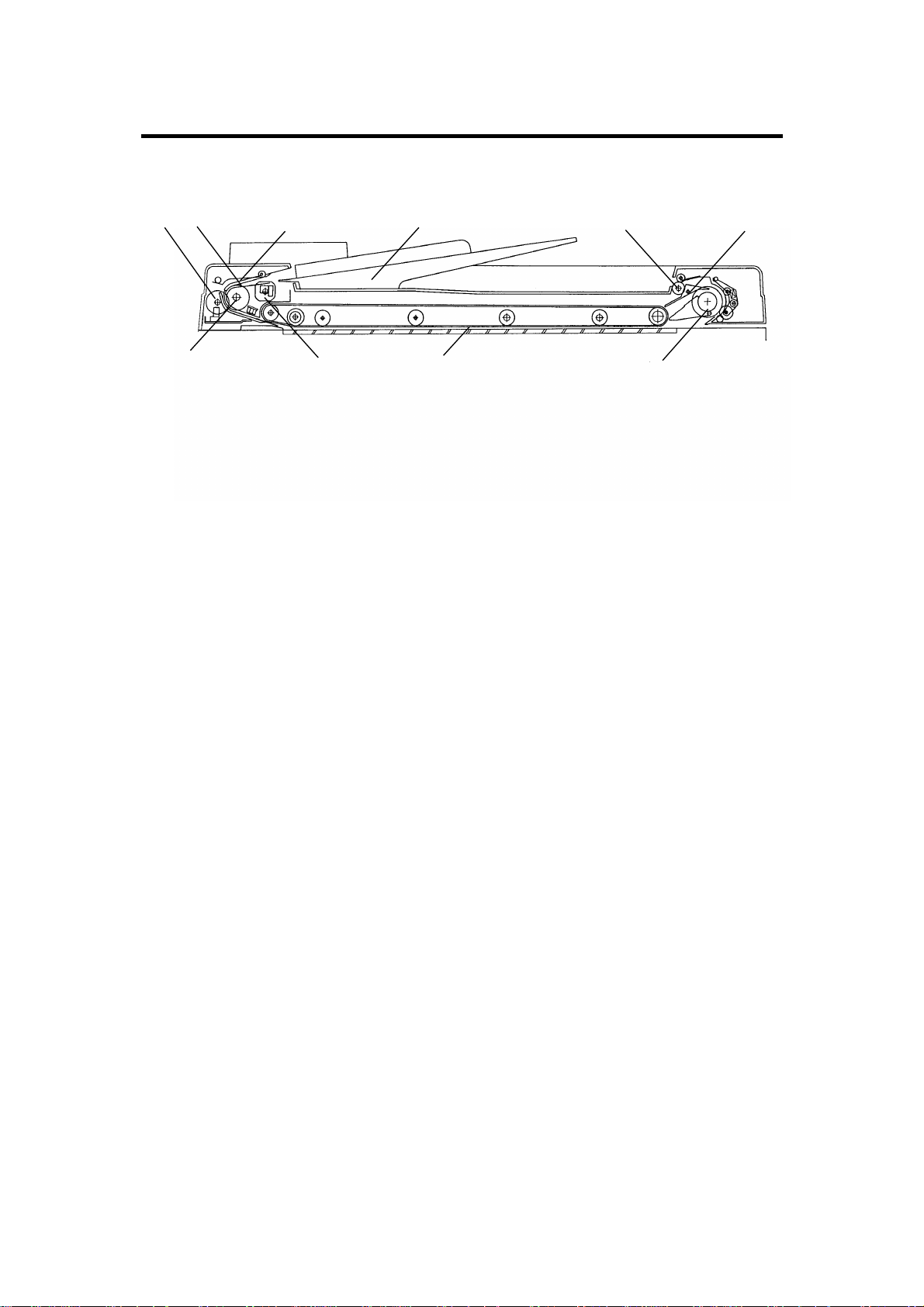

MECHANICAL COMPONENT LAYOUT 12 February 1992

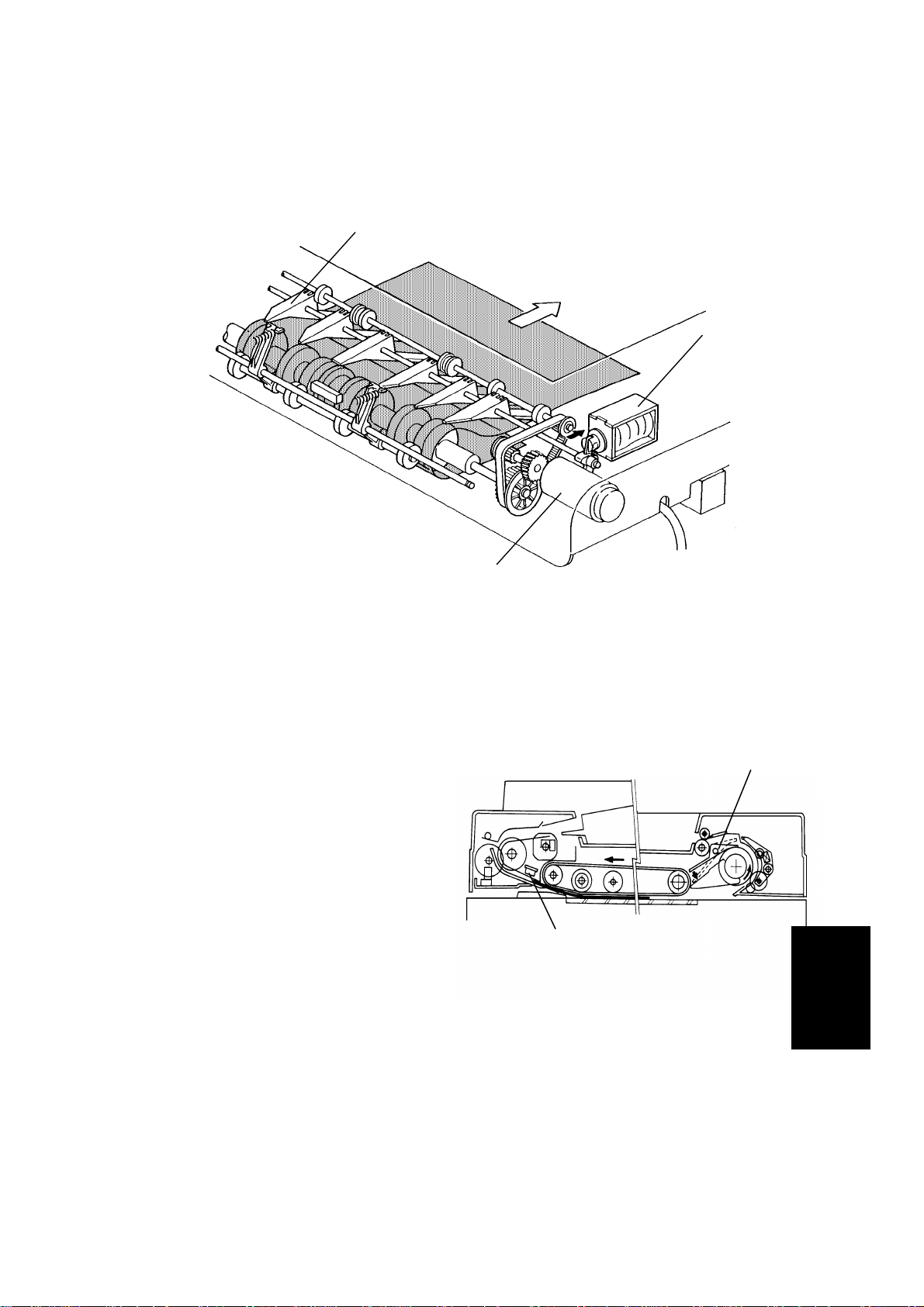

2. MECHANICAL COMPONENT LAYOUT

1

2

3

4

5

6

10

1. Pulse Generator Disk

2. Friction Belt

3. Pick-up Lever

4. Original Table

5. Exit Roller

9

8

6. Inverter Pawl

7. Inverter Roller

8. Transport Belt

9. Pick-up Roller

10. Feed Roller

7

2

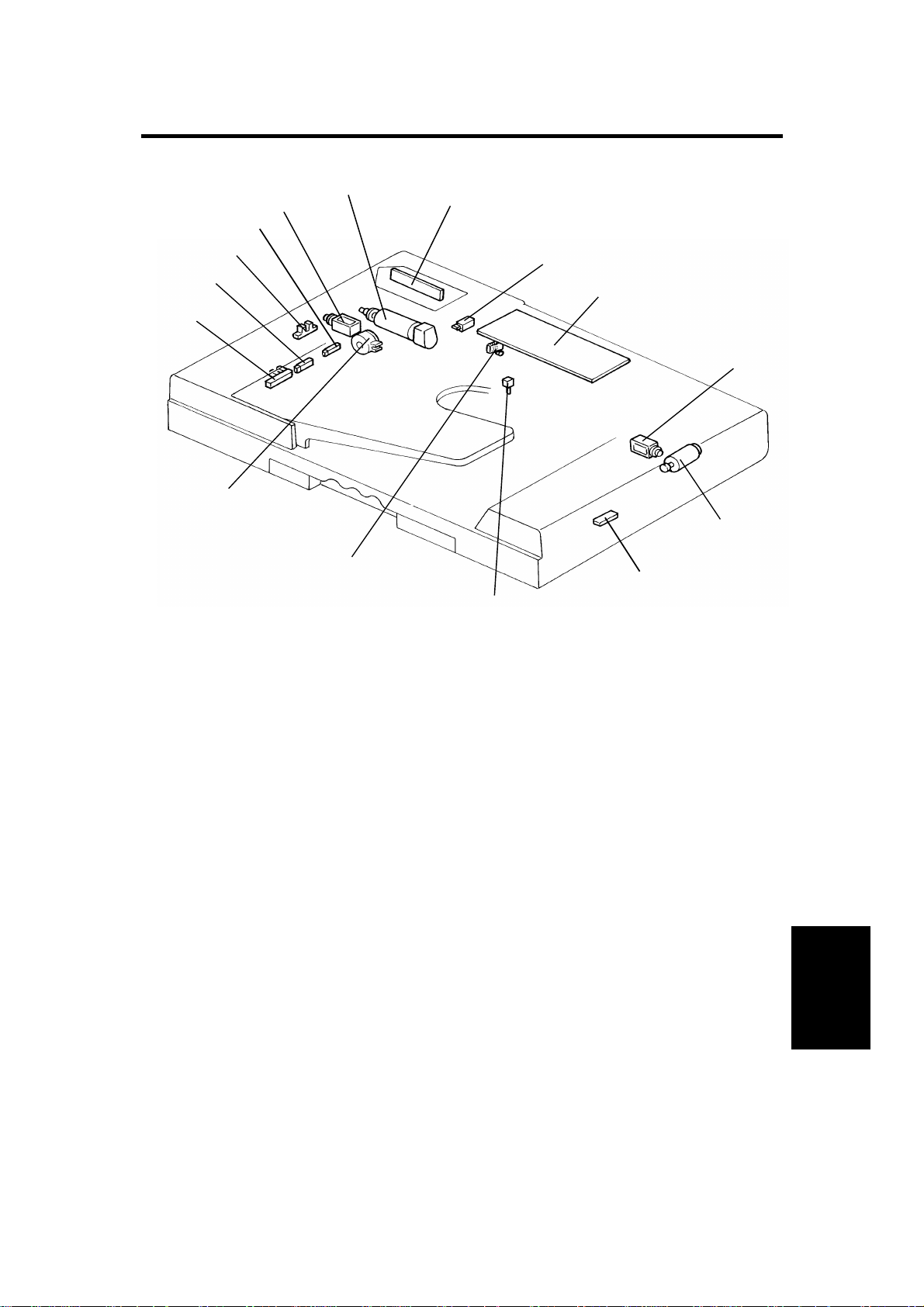

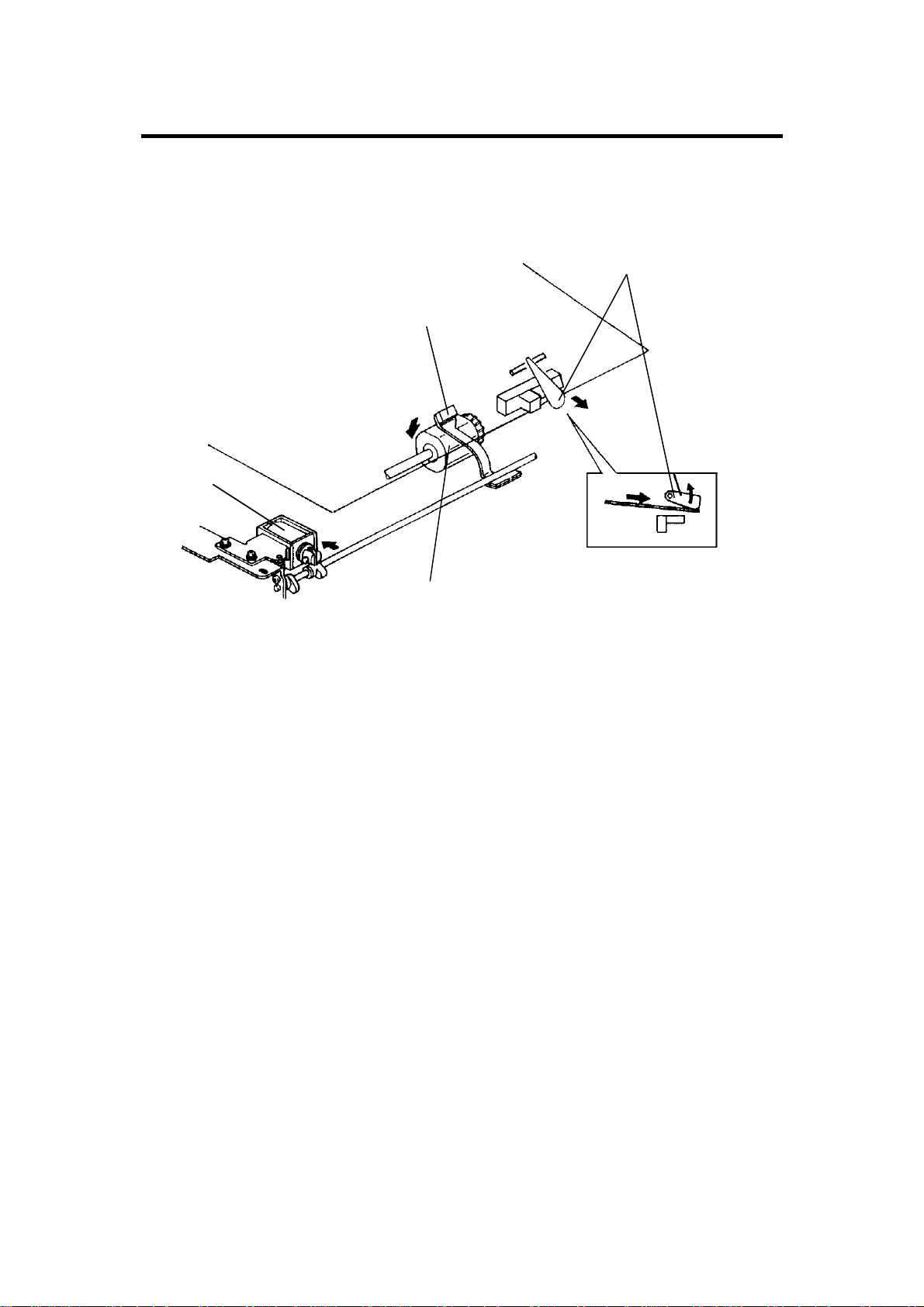

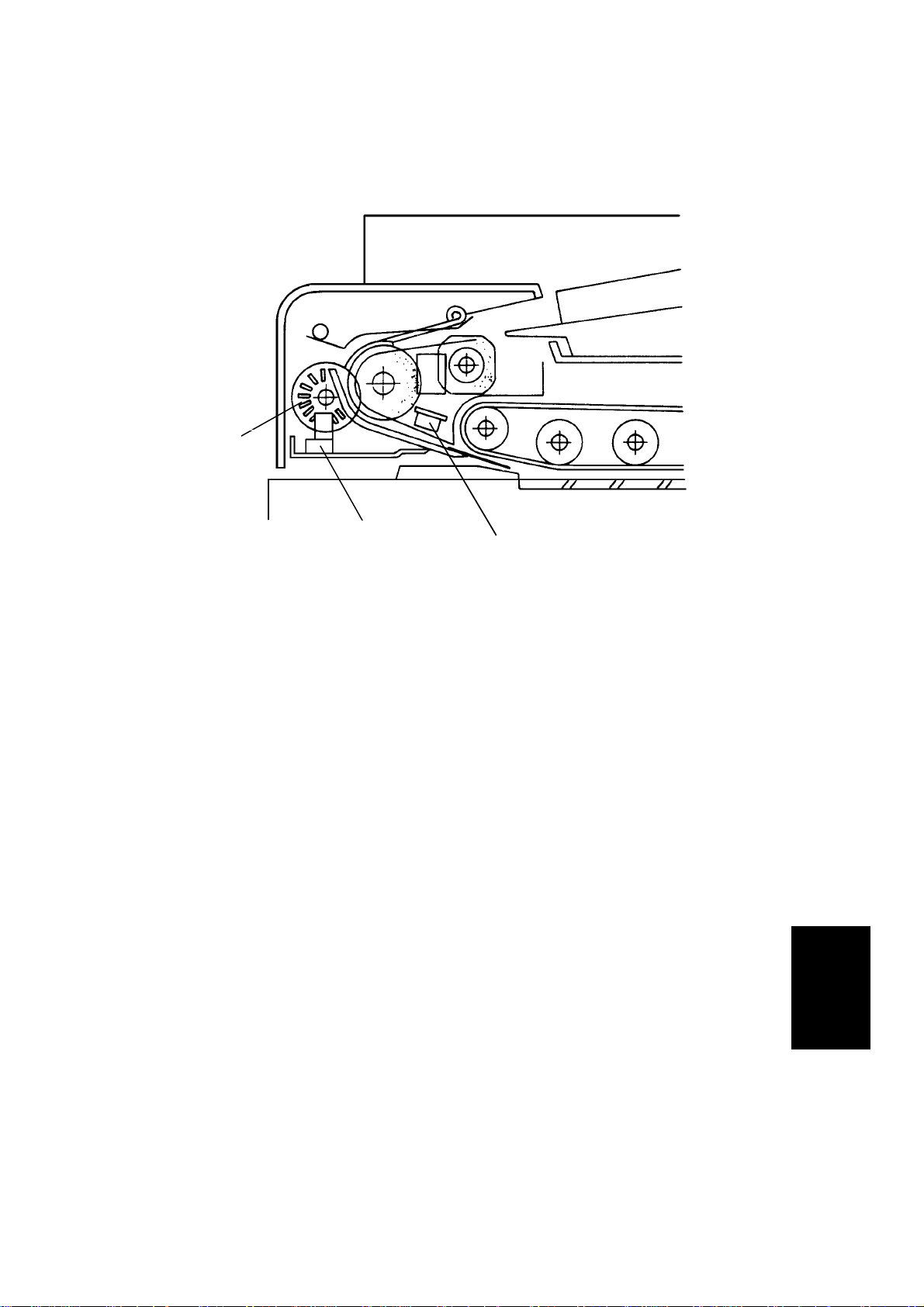

12 February 1992 ELECTRICAL COMPONENT LAY OUT

3. ELECTRICAL COMPONENT LAY OUT

6

5

4

7

3

2

1

15

14

1. Original Set Sensor

2. Registration Sensor

3. Pulse Generator Sensor

4. Original Width Sensor

8

9

10

11

12

13

9. DF Main Board

10. Inverter Solenoid

11. Feed-out Motor

12. Feed-out Sensor

5. Pick-up Solenoid

6. Belt Drive Motor

7. Indicator Panel

8. DF Position Sensor

13. Original Select Switch

14. Lift Switch

15. Feed-in Clutch

ARDF

3

ELECTRICAL COMPONENT DESCRIPTIONS 12 February 1992

4. ELECTRICAL COMPONENT DESCRIPTIONS

MOTORS

NAME FUNCTION LOCATION

DC servomotor that drives to the transport

Belt Drive Motor

Feed-out Motor

SOLENOIDS

NAME FUNCTION LOCATION

Pick-up Solenoid

Inverter Solenoid

belt and feed-in system (pick-up roller, feed

roller, pull-out roller and relay roller).

DC servomotor that drives the feed-out unit

of the DF.

Energizes to press the pick-up lever against

the stack of originals in preparation for

original feed-in.

Energizes to invert the original when

copying two sided originals.

6

11

5

10

SWITCHES

NAME FUNCTION LOCATION

Lift Switch

Original Select

Switch

Informs the CPU when the DF is lifted and

also serves as the jam reset switch for the

DF.

Selects thick original mode or thin original

mode.

14

13

4

12 February 1992 ELECTRICAL COMPONENT DESCRIPTIONS

SENSORS

NAME FUNCTION LOCATION

Original Set

Sensor

Registration

Sensor

Original Width

Sensor

DF Position

Sensor

Pulse Generator

Sensor

Informs the main system’s CPU that

originals have been placed and causes the

Insert Original indicator to go out.

Sets original stop timing and measures

original length.

Determines the width of the originals. 4

Informs the CPU when DF is being closed

so that APS sensor can begin checking the

original size.

Generates pulses used to measure the

original length.

1

2

8

3

Checks for original misfeeds and sets

Feed-out Sensor

original stop timing when in auto reverse

12

mode.

MAGNETIC CLUTCH

NAME FUNCTION LOCATION

Feed-in Clutch

Energizes to rotate the feed roller, pull-out

rollers, and relay roller

PRINTED CIRCUIT BOARDS

NAME FUNCTION LOCATION

DF Main Board Controls all DF functions. 9

Indicator Panel

Board

Contains operator indicators. 7

15

ARDF

5

BASIC OPERATION 12 February 1992

5. BASIC OPERATION

1. One-sided Original Feed

When an original is inserted into the DF, the Insert Original indicator light

goes out and the DF informs the main system’s CPU that originals have been

set.

When the Start key is pressed, the main system’s CPU sends the feed-in

signal to the DF. On receipt of this signal, the DF energizes the pick-up

solenoid, the feed-in clutch, and the belt drive motor in order to feed-in the

bottom sheet of the original stack onto the exposure glass. The pick-up

solenoid and the feed-in clutch remain energized until the original’s leading

edge reaches the DF registration sensor. The belt drive motor turns off 2,088

encoder pulses after the original’s leading edge passes the DF registration

sensor.

While feeding the original, the DF registration sensor and the original width

sensor check the original size.

Shortly before the belt drive motor turns off, the DF CPU sends the copy start

signal to the main system. On receipt of the signal, the main system’s CPU

starts the copy cycle.

When the scanner reaches to the return position, the main system’s CPU

sends the feed-out and the feed -in signals to the DF CPU in order to

exchange the original with the ne xt or ig ina l .

When the scanner comes to the r et urn posit i on aft er scan nin g th e last

original, the main system’s CPU only sends the feed-out signal in order to

feed-out the last original.

2. Two-sided Original Feed

Unlike one-sided original feed, the back side of the original must be copied

first to keep the originals and cop i es in th e cor rect order.

During original feed-in, the sequence is the same as for one-sided feed;

however, the DF CPU also energizes the feed-out motor and the inverter

solenoid a short time after the original’s leading edge has passed the DF

registration sensor. The belt drive motor continues to feed the original until

85 milliseconds after the original leading’s edge passes the feed-out sensor.

At this point the inverter mechanism inverts the original, in preparation for

copying the back side. Then the belt drive motor reverses and the original is

fed towards the original stopper and is stopped at the correct position on the

exposure glass. The DF CPU sends the copy start signal a short time after

the original’s trailing edge has passed the feed-out sensor.

6

12 February 1992 BASIC OPERATION

When the scanner reaches to the return position, the main system’s CPU

sends the invert original signal to the DF CPU in order to make a copy of the

front side. The original is inverted in the same way as for back side copying.

3. Semi-automatic Document Feed

If a single original is inserted into th e or ig ina l tab le an d cop i ed , th e DF shifts

to the semi-automatic feed mode and lights the Auto Feed indicator. The

Auto Feed indicator remains on for four seconds after the main system’s

main motor stops. If another original is inserted within that fo ur - se cond

period, it is automatically fed an d copied.

ARDF

7

ORIGINAL FEED 12 February 1992

6. ORIGINAL FEED

6.1 ORIGINAL PICK-UP

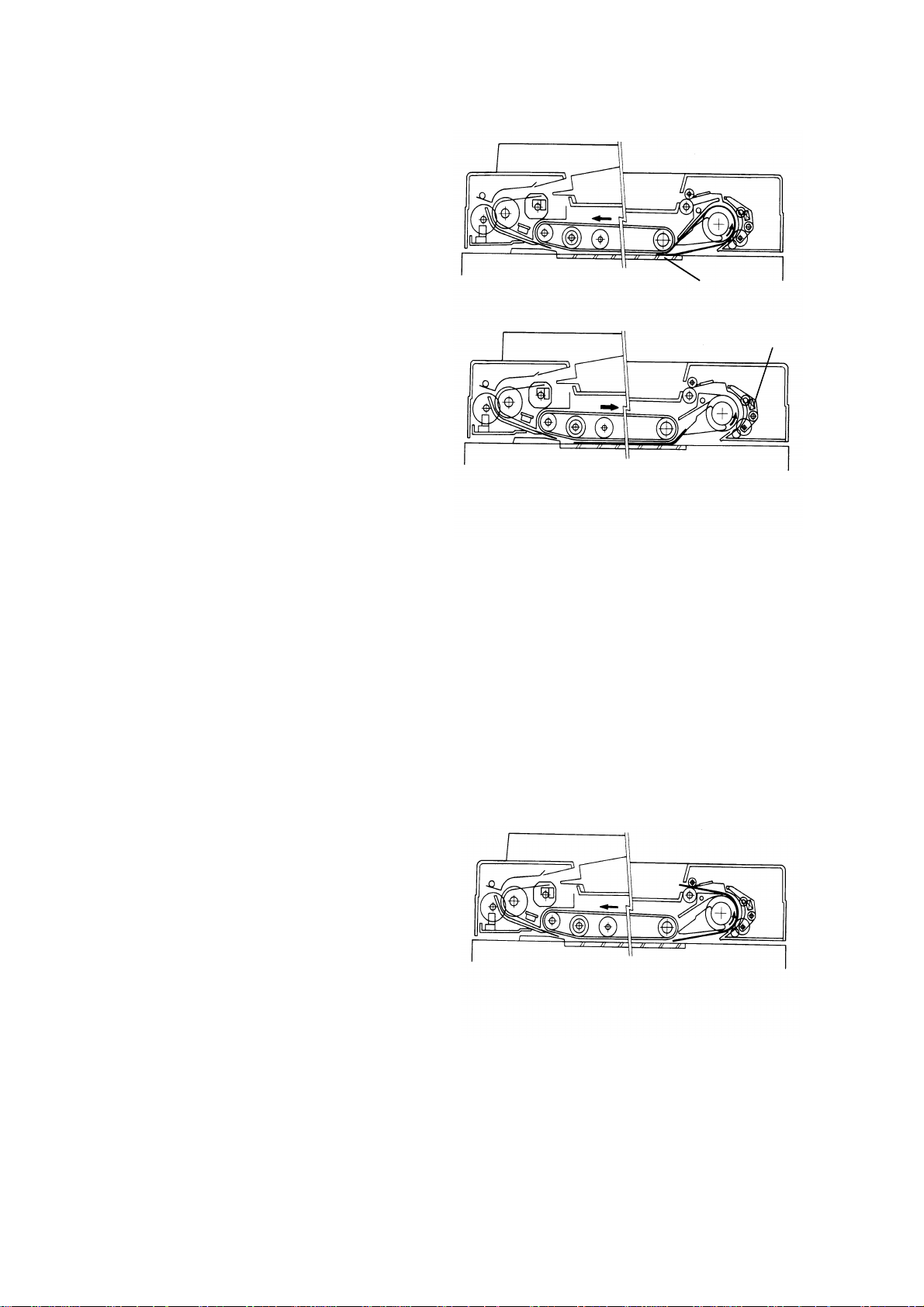

[A]

[C]

[B]

[D]

After setting the origina l s on the or ig ina l tab le, the originals contact the feele r

[A] of the original set sensor an d cau se th e feeler to move out of the sensor.

The DF then sends the original set signal to the main system’s CPU to inform

it that the DF will be used. When the Start key is pressed, the pick-up

solenoid [B] is energized. The original stack is then pressed between the

pick-up lever [C] and pick-up roller [D]. The rotation of the pick-up roller

advances the bottom original.

8

12 February 1992 ORIGINAL FEED

6.2 ORIGINAL SEPARATION

[B]

[A]

[B]

[C]

[A]

The feed roller [A] and the friction belt [B] are used to feed-in and separate

the originals [C]. Only the bottom original is fed because the friction belt

prevents any other originals from feeding.

Original feed starts when the feed roller starts turning and advances the

bottom original of the stack. The feed roller moves the original past the

friction belt because the drivin g fo r ce of the feed roller is greater than the

resistance of the friction belt. The friction belt prevents multiple feeds

because the resistance of the friction belt is grea ter than the friction between

original sheets.

ARDF

9

ORIGINAL FEED 12 February 1992

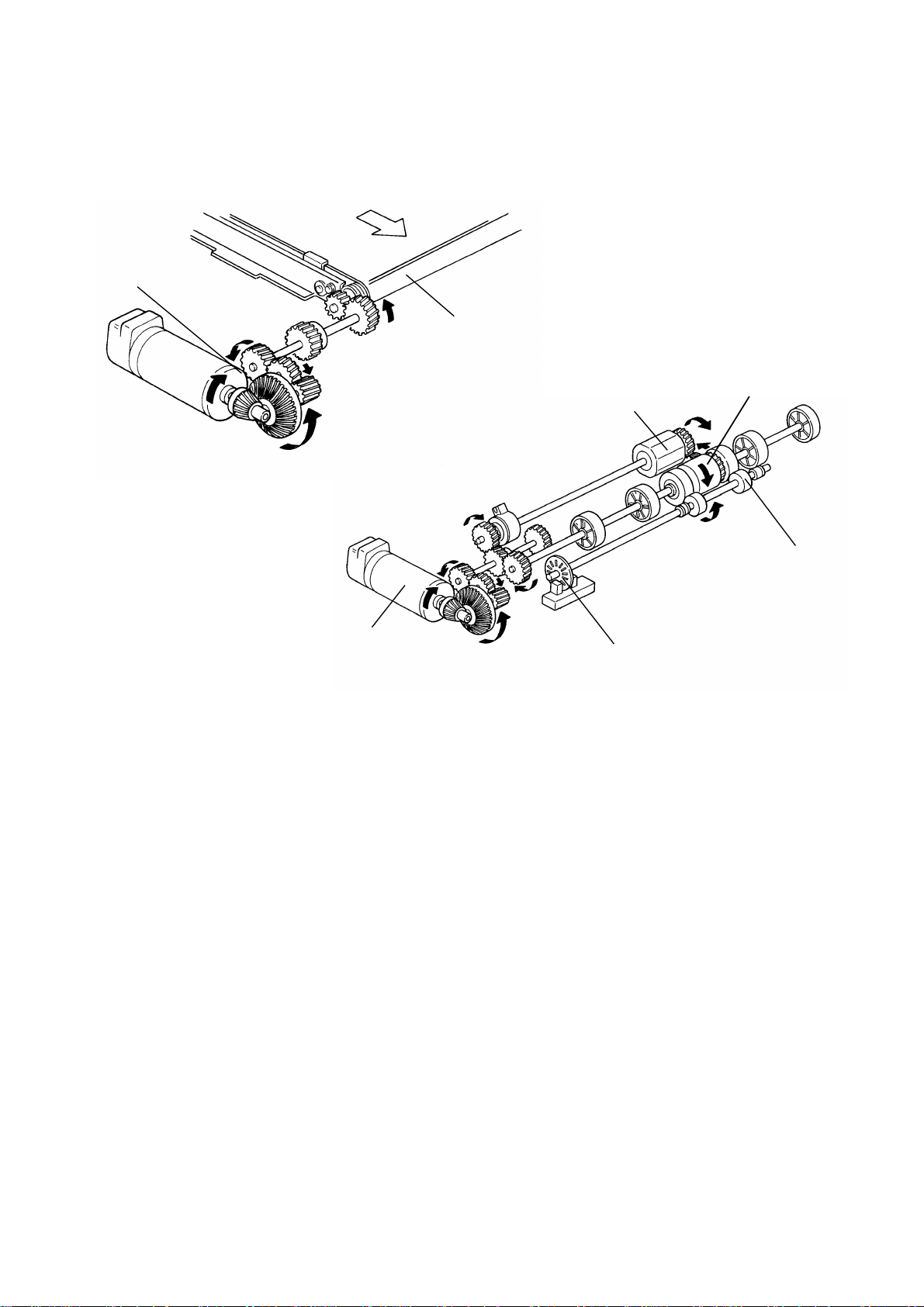

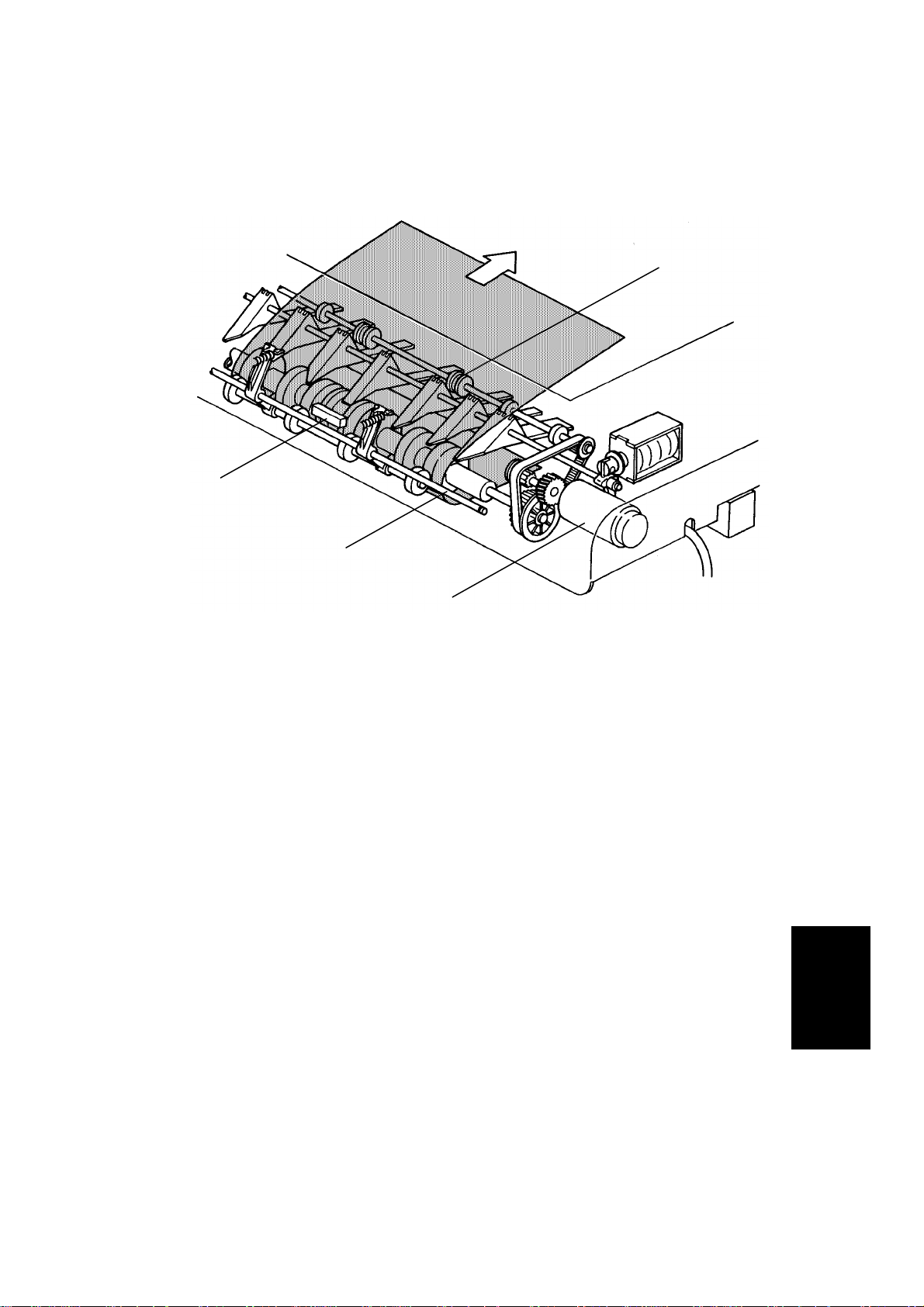

6.3 ORIGINAL FEED-IN MECHANISM

[D]

[F]

[C]

[B]

[A]

[F]

The belt drive motor [A] drives th e pick- u p rolle r [B] , th e fe ed roller [C], and

transport belt [D] via a feed clut ch an d a ge ar tr a in. And, the pull out roller [E]

is driven by friction with the feed ro ller.

[E]

The pick-up solenoid is energized 100 milliseconds after the Start key is

pressed. Then 100 milliseconds after the solenoid is energized, the belt drive

motor starts turning. The pulse generator disc [F] on the pull-out roller shaft

always turns when the belt drive motor is on in the forward direction.

238 encoder pulses of the belt drive motor after the original’s trailing edge

passes the registration sensor, the relay rollers and the transport belt stop

turning.

10

12 February 1992 ORIGINAL FEED

6.4 ORIGINAL SIZE DETECTION

[C]

[B]

[A]

The DF determines original size (both width and length) through the use of

the original width sensor [A, rear of DF], registration sensor [A, center of DF],

and pulse generator sensor [B]. The original’s length is calculated by

counting the number of pulses from the pulse generator [C] while the

registration sensor is on.

The original width sensor is turned on when the original width is 204 mm (8")

or more. It is in the same position (front to back) as the original width sensor

in the copier.

Original size detection is necessary for APS, AMS and the feed-in/feed-out

timing of the DF.

11

ARDF

ORIGINAL FEED 12 February 1992

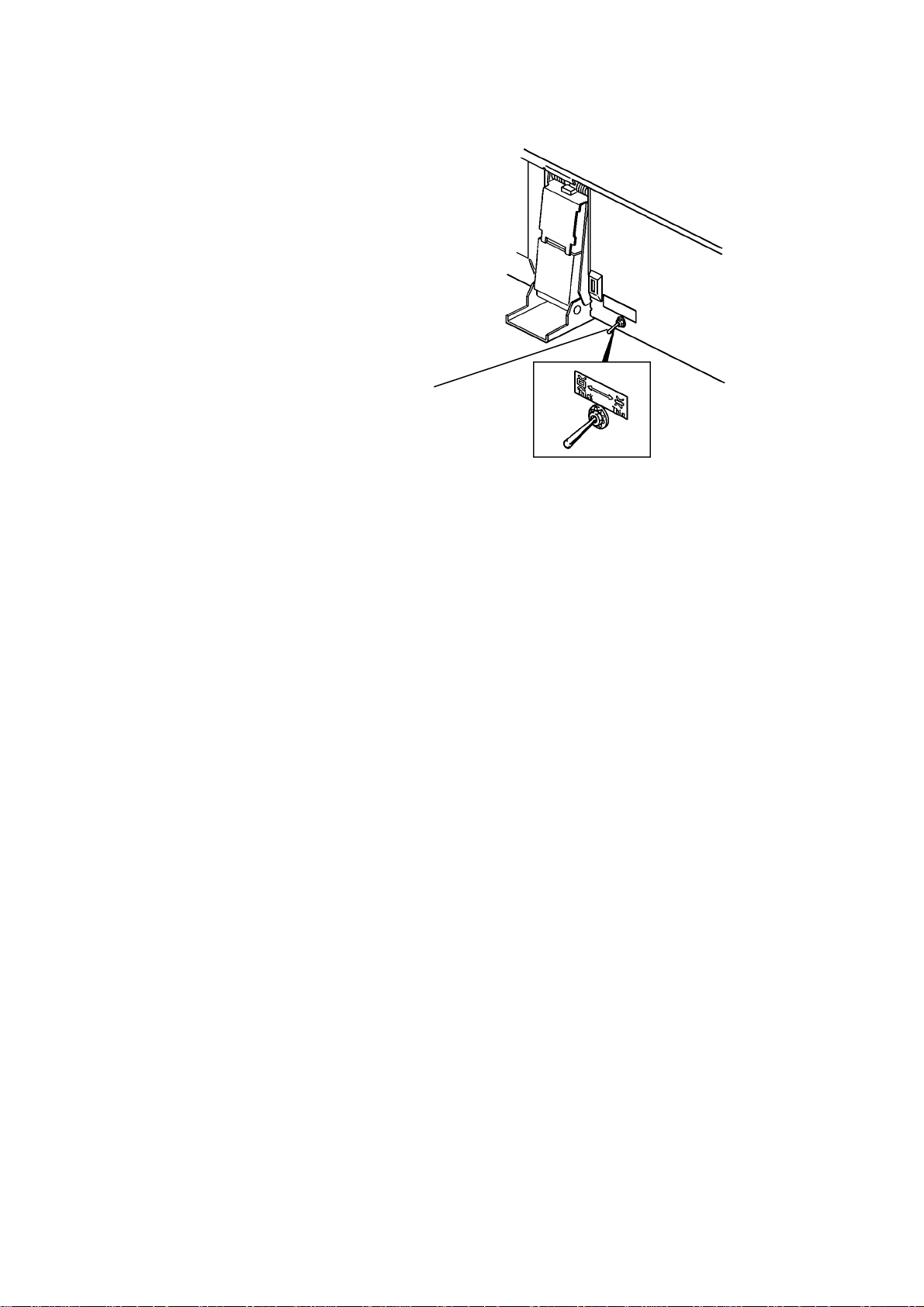

6.5 ORIGINAL SELECT SWITCH

[A]

This document feeder has two dif fe r en t ways of st op pin g orig inal at the

correct position on the exposur e gla ss. The y ar e calle d th e "thin original

mode" and the "thick orig inal mode". The mode used is det er m ined by the

original select switch [A].

1. Thin Original Mode

The original is stopped at the correct position on the exposure glass based

on encoder pulse count. For the first side of the original, the belt drive motor

stops 238 encoder pulses after the original’s trailing edge passes the

registration sensor in the one-sided original mode. For the reverse side of the

original, the belt drive motor reverses its rotation 85 m sec after the leading

edge passes the feed-out sens or. It stops after 2805 pulses. (Exact timing

depends on registration adjustment.) Thin original mode is selecte d at the

factory.

2. Thick Original Mode

When the thick original mode is selected, the original is aligned against the

original scale. For the first side, the belt drive motor stays on 36 encoder

pulses longer than when in the thin original mode, and then reverses for 62

encoder pulses. This forces the original against the original scale and thus

aligns the edge of the original with the original scale.

For the reverse side, the belt drive motor continues to reverse for 62 encoder

pulses longer than when in the thin original mode.

NOTE: The thick original mode should be used when the customer

requires more correct leading edge registration adjustment or

when these are complaints of skewed copies. The thin original

mode is to prevent the thin original’s from being bent since they

do not have great stiffness.

12

12 February 1992 ORIGINAL FEED

6.6 ORIGINAL INVERSION MECHANISM

[D]

[C]

The two sided originals are

inverted in the feed-out unit.

1) When the Start key is

pressed, the two sided original

is fed into the feed-in un it,

passing over the DF

registration sensor [A]. At the

same time, the feed-out motor

[B] starts turning

The inverter solenoid [C] turns

on 100 milliseconds after the

original’s trailing edge passes

the registration sensor

When the inverter solenoid

turns on, the inverter pawls [D]

rotate counterclockwise.

[B]

[D]

[A]

ARDF

13

ORIGINAL FEED 12 February 1992

2) The original passes over the

exposure glass [A] and feeds

into the feed-out unit.

[A]

3) The original is directed onto

the exposure glass again by

the inverter pawls. The belt

drive motor now reverses 85

milliseconds after the feed out

sensor [B] turns on. The

transport belt then moves the

original toward the original

scale.

When the original leading

edge reaches the original

scale, the belt drive motor

stops. At the same time, the

feed-out motor and the

inverter solenoid turn off.

4) After the reverse side of the

original is exposed, the belt

drive motor, the feed-out

motor, and the inver te r

solenoid turn on, and the

original is fed into the inverter

section. (This is the same as

step 2 above.)

[B]

5) The original is fed onto the

exposure glass again as in

step 3 above. The front side

of the original is then copied.

6) After the front side of the

original has been exposed, the

original is fed out from the DF.

14

12 February 1992 ORIGINAL FEED

6.7 ORIGINAL FEED-OUT MECHANISM

[A]

[D]

[C]

[B]

The exit rollers [A] are driven by inverter motor [B]. When the document

feeder receives the feed out signal from the main system, the transport belt

and the exit rollers start turning simultaneously. The transport belt carries the

original to the inverter rollers [C] and the exit rollers take over the original

feed-out. When the original’s trailing edge passes the feed-out sensor [D], the

feed-out motor drops to half of its normal speed for 350 milliseconds and then

stops. The lower speed prevents uneven stacking of originals. For A3 or

double letter size originals, the feed-out motor speed does not change due to

the length of the originals.

ARDF

15

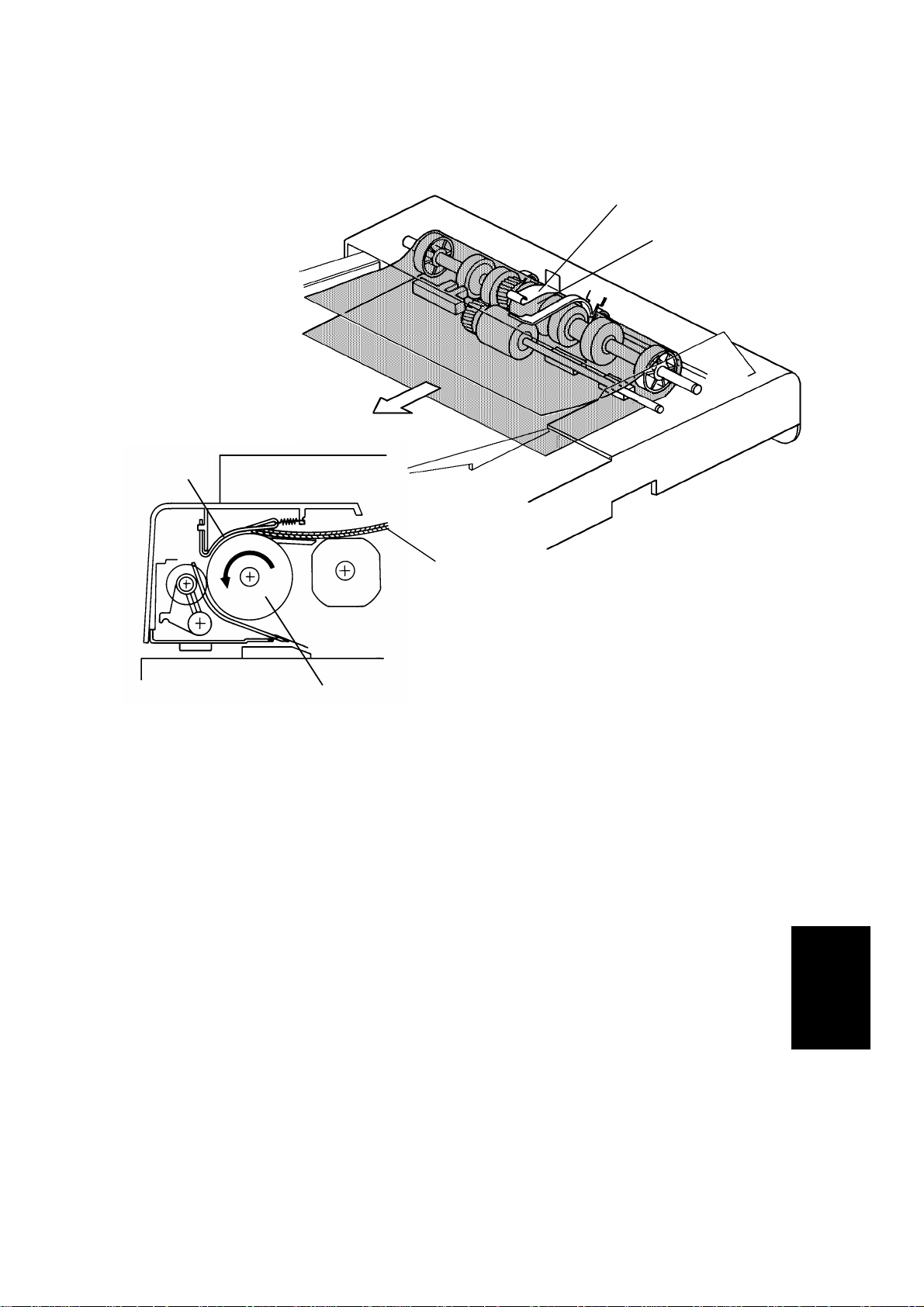

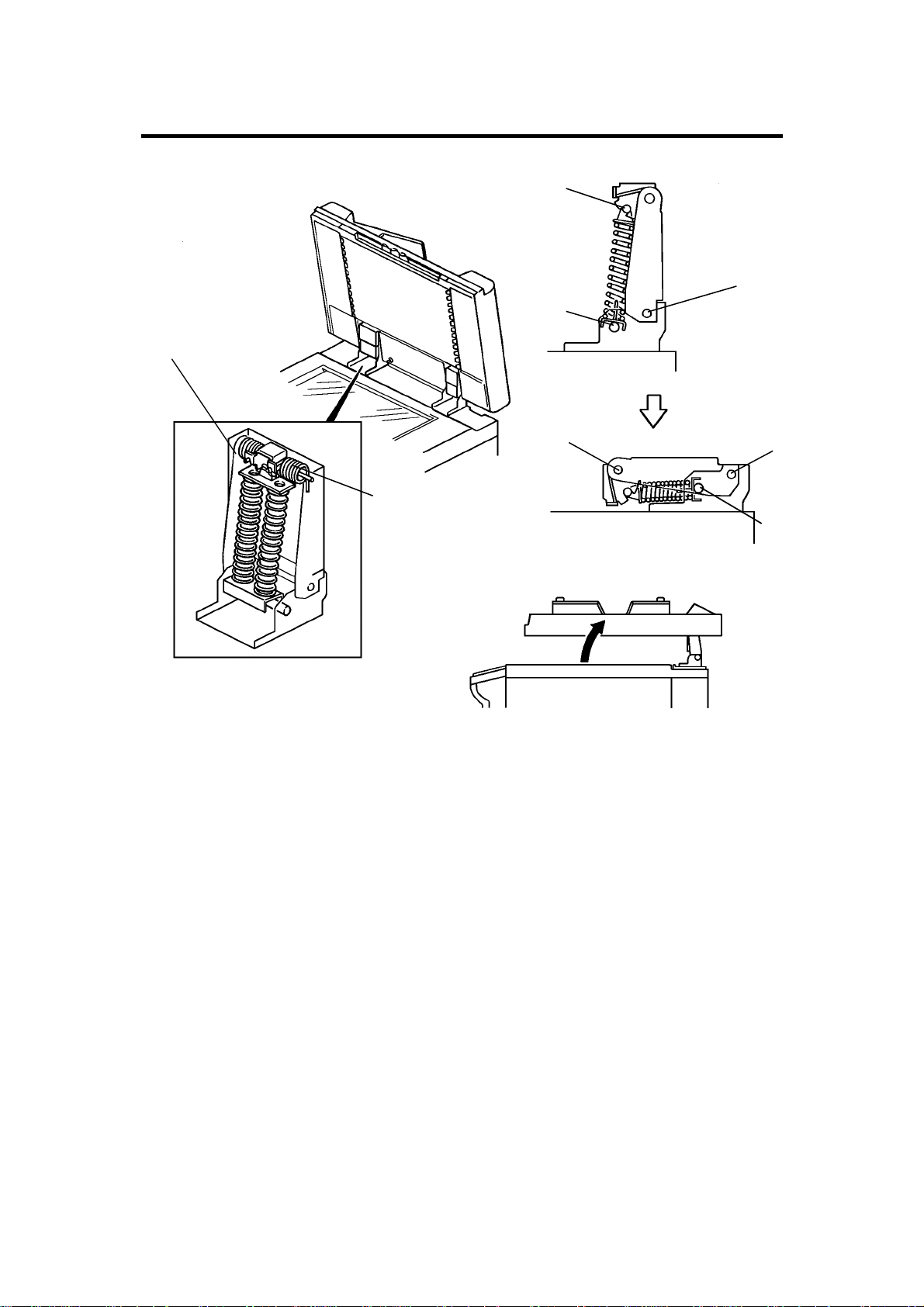

LIFT MECHANISM 12 February 1992

7. LIFT MECHANISM

[D]

[F]

[A]

[B]

[A]

[C]

[C]

[B]

[E]

When the document feeder is opened, the lift springs [D] provide enough

force to ensure that the document feeder does not fall onto the exposure

glass. When the document feeder is closed, points [A], [B], and [C] are

aligned and no such force is provided to the document feeder.

The lift switch is actuated when the document feeder is closed. The main

system then shifts to the document feeder mode. The lift switch also serves

as the reset switch for document feeder misfeeds.

When a book or thick original (maximum thickness 60 mm) is copied, the DF

acts as a cover for the original as shown in the figure [E]. The lift switch is

turned off during this condition, so the DF does not function. The tension of

spring [F] returns the DF to the normal condition after copying a thick original.

16

12 February 1992 ORIGINAL MISFEED SENSING

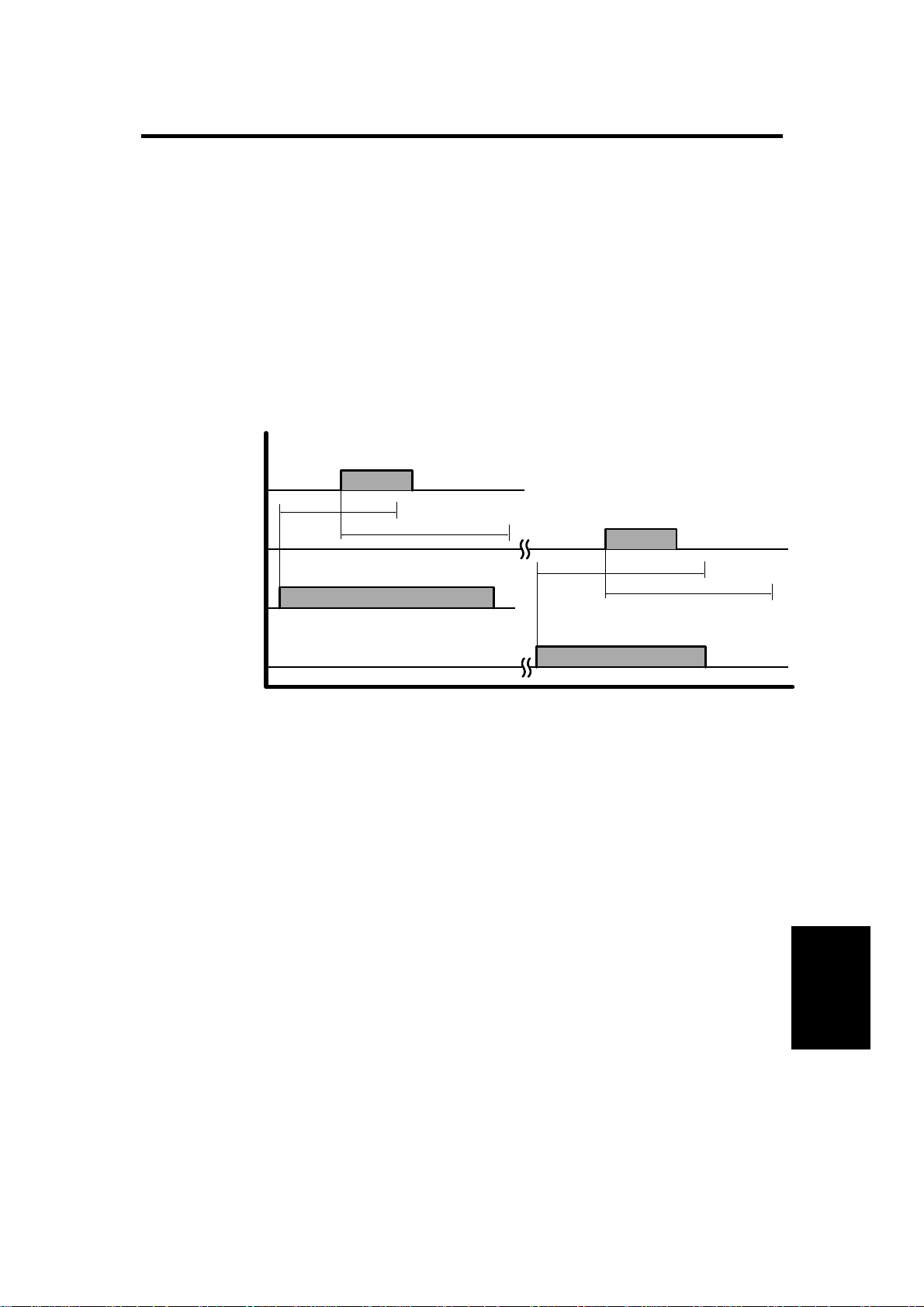

8. ORIGINAL MISFEED SENSING

The main system’s CPU lights the original misfeed indicator if the previous

original remains on the exposure glass after manual copying and DF feed is

attempted. When the DF is lifted and the previous original is removed, DF

copying is permitted.

The registration sensor and the feed-out sensor are used for misfeed checks.

The functions of the two sensors are as follows:

8.1 ONE-SIDED ORIGINAL

Registration Sensor

ON check (540 ms)

Feed-out Sensor

OFF check (780 ms)

ON check (780 ms)

Belt Drive Motor

Feed-out Motor

OFF check (780 ms)

If the registration sensor is not actuated within 540 milliseconds after the belt

drive motor starts turning, the Original Misfeed indicator lights (ON check).

If the registration sensor does not turn off within 780 milliseconds, the CPU

determines that there has been an original misfeed (OFF check). The

Original Misfeed indicator also lights if the feed-out sensor is not actuated

within 780 milliseconds after the belt drive motor starts turning forward (ON

check), or if the feed-out sensor does not turn off within 780 milliseconds

after the feed-out sensor turns on (OFF check).

ARDF

17

Loading...

Loading...