Page 1

SECTION 1

OVERALL MACHINE INFORMATION

Page 2

13th January 1995 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x17" (Paper trays)

Minimum

A5/81/2" x 51/2" sideways (Paper trays)

A4/11" x 81/2" sideways (LCT)

A6/51/2" x 81/2" lengthwise (By-pass)

Duplex Copying: Maximum

A3/11" x 17"

Minimum

A5/81/2" x 51/2" (sideways)

Copy Paper Weight: Paper tray:

52 ~ 128 g/m2, 14 ~34 lb

(A153, A155, and A156 copiers)

64 ~ 90 g/m2, 17 ~ 24 lb

(A157, A159, and A160 copiers)

By-pass:

52 ~ 157 g/m2, 14 ~42 lb

LCT:

52 ~ 128 g/m2, 14 ~ 34 lb

Duplex copying:

64 ~ 105 g/m2, 17 ~ 24 lb

Overall

Information

Reproduction Ratios: 4 Enlargement and 6 Red uction

A4/A3 Version LT/DLT Version

200%

Enlargement

Full size 100% 100%

Reduction

1-1

141%

122%

115%

93%

82%

75%

71%

65%

50%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

Page 3

SPECIFICATIONS 13th January 1995

Power Source: 120V/60Hz:

More than 12 A (for North America)

220V ~ 240V/50Hz:

More than 7 A (for Europe)

220V/50Hz:

More than 7 A (for Asia)

110V/60Hz:

More than 14 A (for Taiwan)

220V/60Hz:

More than 7 A (for Saudi Arabia, Philippines)

Power Consumption:

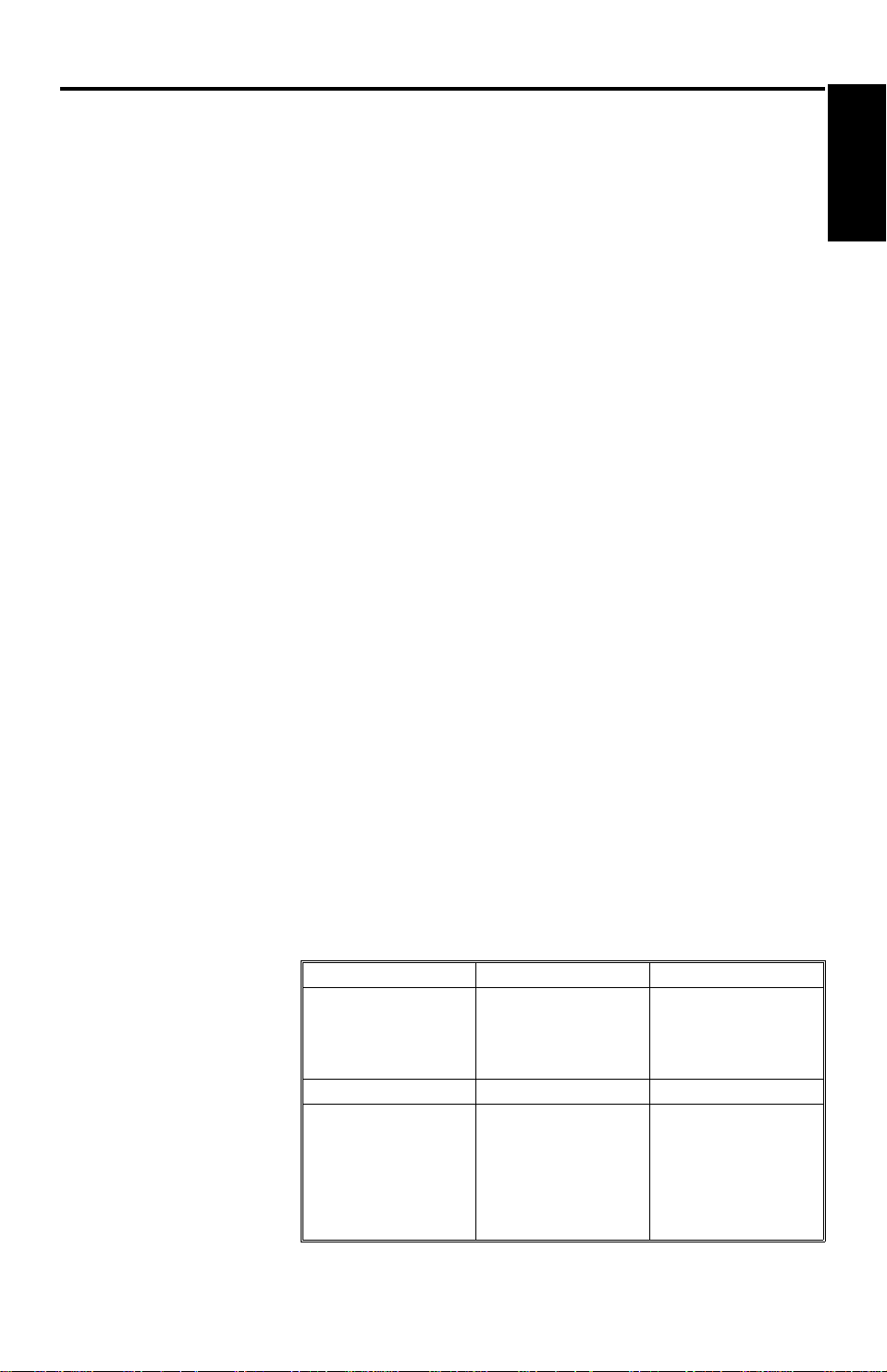

A153, A155, and A156 copiers A157, A159, and A160 copiers

Copier Only Full System Copier Only Full System

Maximum 1.45 KW 1.50 KW 1.45 KW 1.50 KW

Copying 1.00 KW 1.00 KW 0.80 KW 0.80 KW

Warm-up 0.90 KW 0.92 KW 0.90 KW 0.92 KW

Stand-by 0.16 KW 0.19 KW 0.15 KW 0.17 KW

1 0.15 KW 0.17 KW 0.14 KW 0.16 KW

Energy

Saver

Auto Off 0.02 KW 0.04 KW 0.02 KW 0.04 KW

2 0.13 KW 0.15 KW 0.12 KW 0.13 KW

3 0.12 KW 0.14 KW 0.09 KW 0.10 KW

4 0.11 KW 0.12 KW 0.07 KW 0.08 KW

5 0.09 KW 0.11 KW 0.05 KW 0.06 KW

6 0.07 KW 0.09 KW – –

NOTE: 1) Full System: Copier + ADF + Paper Tray Unit + 20 Bin S/S

2) Energy Saver: Se e SP 1-105-002

3) Auto Off: See SP5-305

Noise Emission:

A153, A155, and A156 copiers A157, A159, and A160 copiers

Copier Only Full System* Copier Only Full System*

1. Sound Power Level

Copying 66 dB(A) 68 dB(A) 61 dB(A) 67 dB(A) (L

Warm-up 41 dB(A) 41 dB(A) 39 dB(A) 40 dB(A) (L

Stand-by 41 dB(A) 41 dB(A) 39 dB(A) 40 dB(A) (L

2. Sound Pressure Level at the operator position

Copying 58 dB(A) 57 dB(A) 54 dB(A) 56 dB(A) (L

Warm-up 33 dB(A) 27 dB(A) 32 dB(A) 27 dB(A) (L

Stand-by 33 dB(A) 27 dB(A) 32 dB(A) 27 dB(A) (L

NOTE: The above measurements are to be made according to ISO 77 79 .

* : Full System: Copier + ADF + Paper Tray Unit +10 Bin S/S .

WA)

WA)

WA)

PA)

PA)

PA)

1-2

Page 4

13th January 1995 SPECIFICATIONS

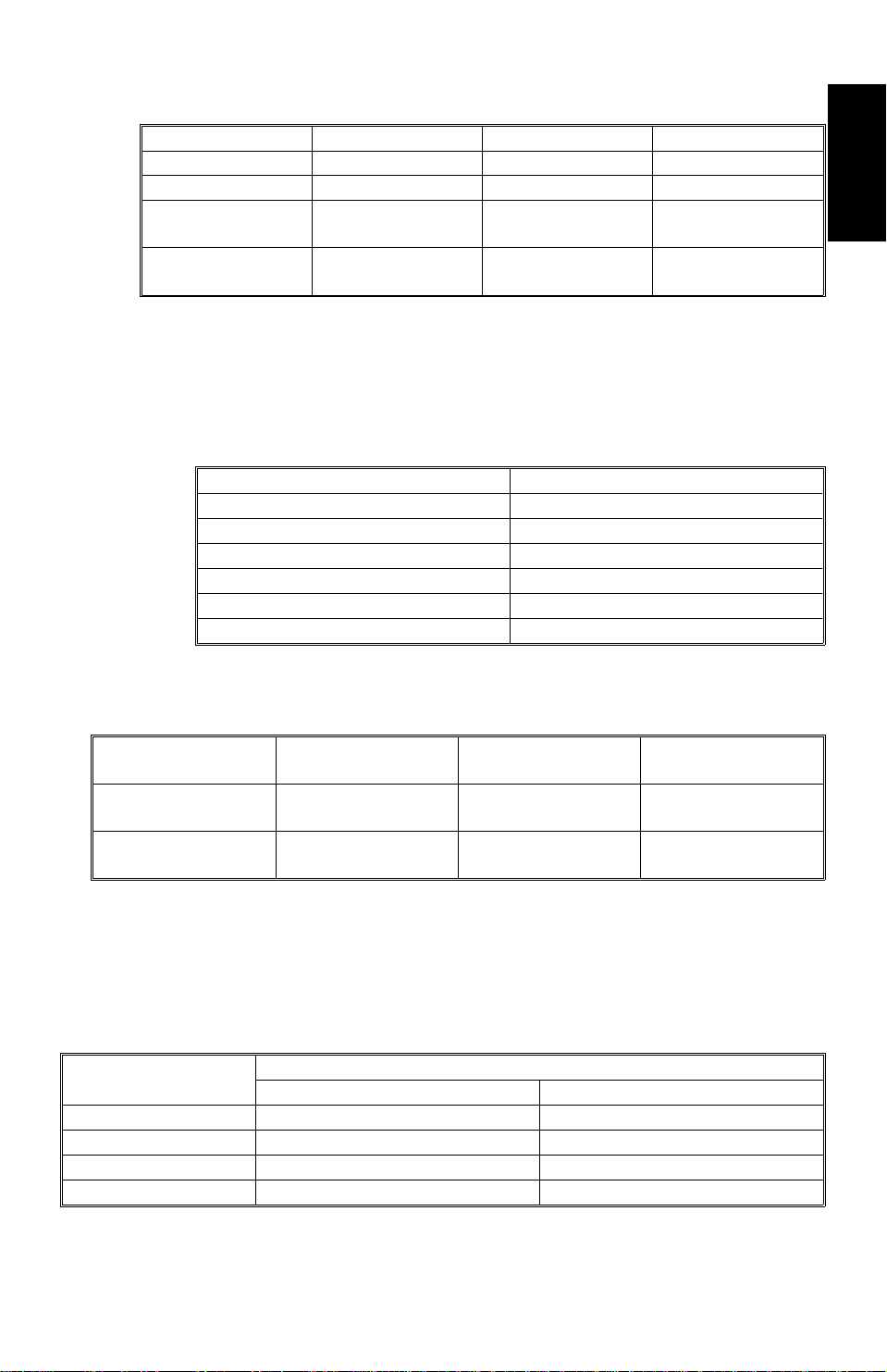

Dimensions:

Width Depth Height

A153 copier 1030 mm (40.6") 655 mm (25.8") 606 mm (23.9")

A157 copier 900 mm (35.5") 655 mm (25.8") 606 mm (23.9")

A155 and A156

copiers

A159 and A160

copiers

1258 mm (49.6") 655 mm (25.8") 606 mm (23.9")

1128 mm (44.5") 655 mm (25.8") 606 mm (23.9")

Measurement Conditions

1) With by-pass feed table closed

2) With platen cover and copy tray attached

3) With LCT cover closed

Weight:

Weight

A153 copier About 70 kg (154.2 lb)

A155 copier About 78 kg (171.9 lb)

A156 copier About 82 kg (180.7 lb)

A157 copier About 67 kg (147.7 lb)

A159 copier About 75 kg (165.4 lb)

A160 copier About 80 kg (176.4 lb)

Overall

Information

Zoom: From 50% to 200% in 1% steps

Copying Speed (copies/minute):

A153, A155, and

A156 copiers

A157, A159, and

A160 copiers

A4 sideways/

11" x 8

1/2"

35 20/19 22

27 15/14 17

A3/11" x 17" B4/8

Warm-Up Time A153, A155, and A156 copiers:

Less than 110 second s (2 0 ° C)

A157, A159, and A160 copiers:

Less than 80 seconds (20°C)

First Copy Time:

Paper Feed Station

1st Tray 5.2 s (except for A156) 5.9 s (except for A160)

2nd Tray 5.7 s 6.6 s

By-pass 4.8 s 5.6 s

LCT 5.0 s 5.9 s

A153, A155, and A156 copiers A157, A159, and A160 copiers

A4/11" x 8

1/2" (sideways)

1/2" x 14"

Note: In A156 and A160 copiers, the 2nd tray in th e above tab le is called the

1st tray (see Installation - Paper Feed St at ion Definition).

1-3

Page 5

SPECIFICATIONS 13th January 1995

Copy Number Input: Ten-key pad, 1 to 999 (count up or count down)

Manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute is the standard set ting; it can be

changed to a maximum of 999 seconds or no

auto reset by SP mode.

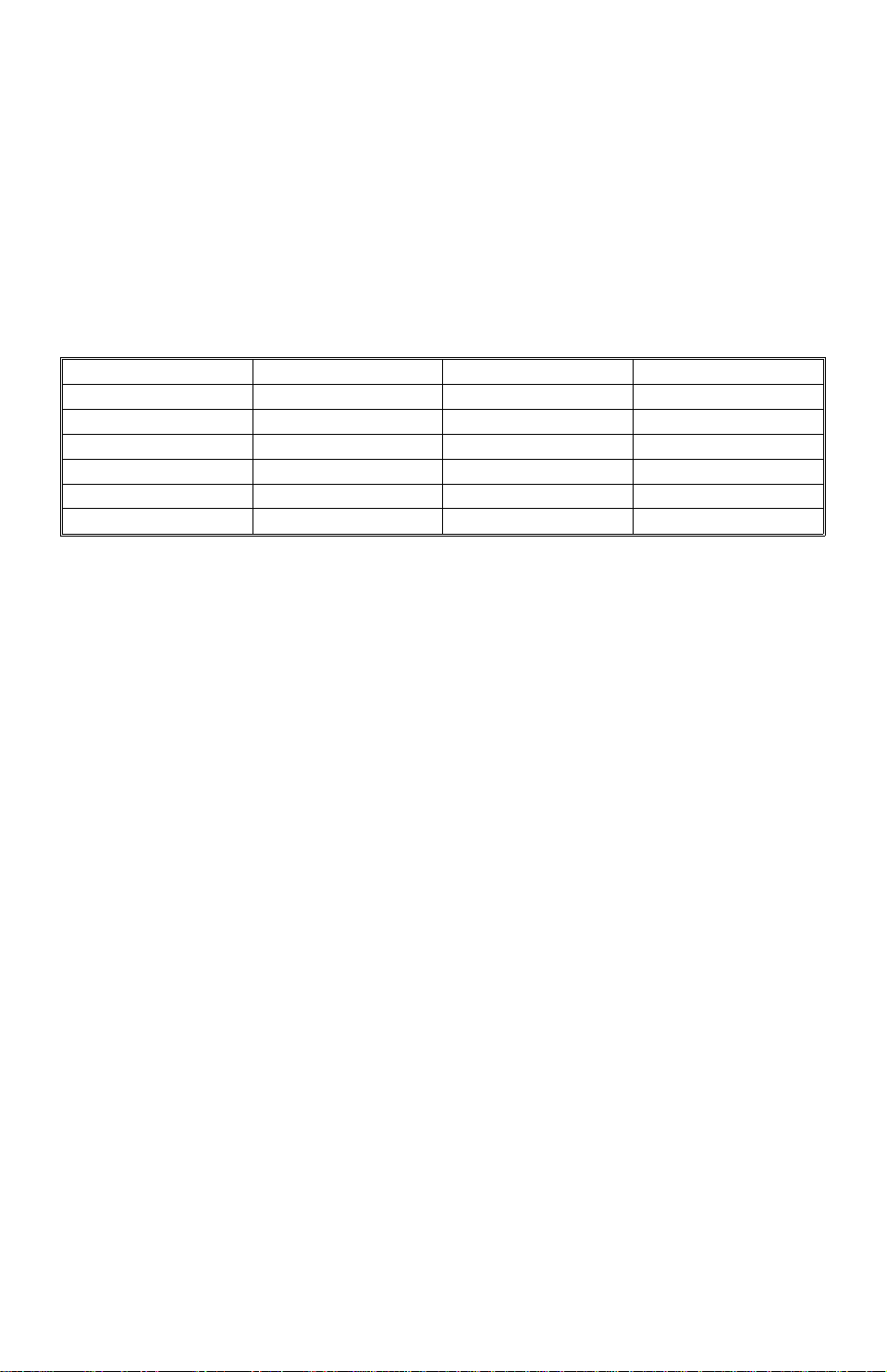

Copy Paper Capacity:

Paper Tray By-pass Feed LCT

A153 copier About 500 sheets x2 About 40 sheets –

A155 copier About 500 sheets x2 About 40 sheets About 1000 sheets

A156 copier About 500 sheets x1 About 40 sheets About 1000 sheets

A157 copier About 250 sheets x2 About 40 sheets –

A159 copier About 250 sheets x2 About 40 sheets About 1000 sheets

A160 copier About 250 sheets x1 About 40 sheets About 1000 sheets

Duplex Tray Capacity

[A156/A160]:

50 sheets (30 sheets for A3/11"x17"

81 ~ 105g/m2, 21.5 ~ 27.9 lb paper)

Toner Replenishment: Cartridge exchange (415 g/cartridge)

Optional Equipment: • Platen cover

• Document feeder

• Paper tray unit with two paper trays

• Paper tray unit with three paper trays

• 10 bin micro sorter

• 20 bin mini sorter

• 10 bin sorter stapler

• 20 bin sorter stapler

• Sorter adapter (required when installing 20

bin mini sorter, 10 bin sorter stapler, or 20

bin sorter stapler for A1 57, A1 59 , an d A1 60

copiers)

• Key counter

• Tray heater

• Optical anti-condensation heater

• Original length sensor for 11 " x 15" size

paper (only for LT/DLT version)

• ADS sensor for particular types of red orig ina l

1-4

Page 6

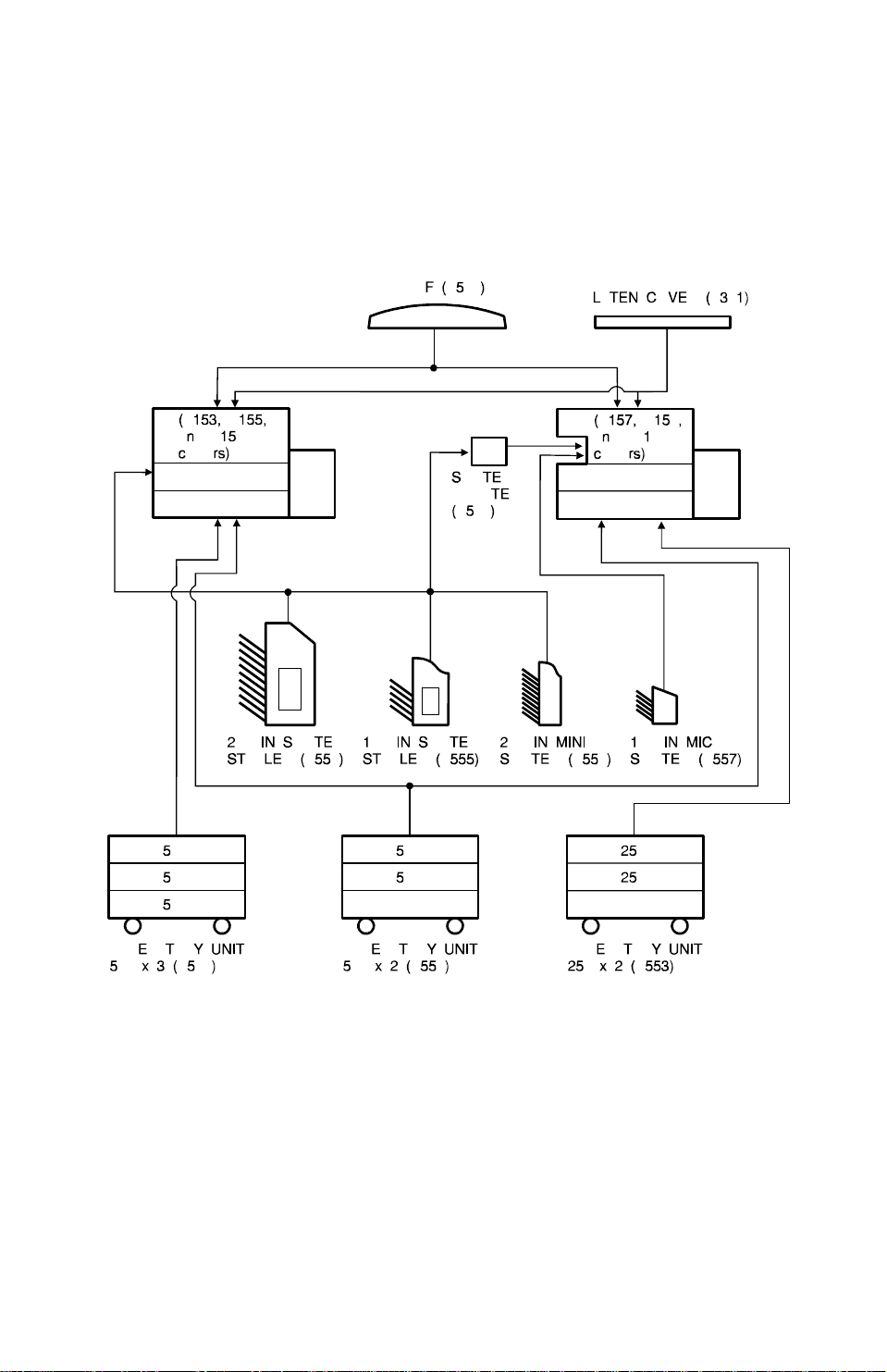

13th January 1995 MACHINE CONFIGURATION

2. MACHINE CONFIGURATION

2.1 COPIER

Overall

Information

1-5

Page 7

MACHINE CONFIGURATION 13th January 1995

2.2 OPTIONAL EQUIPMENT

1-6

Page 8

29

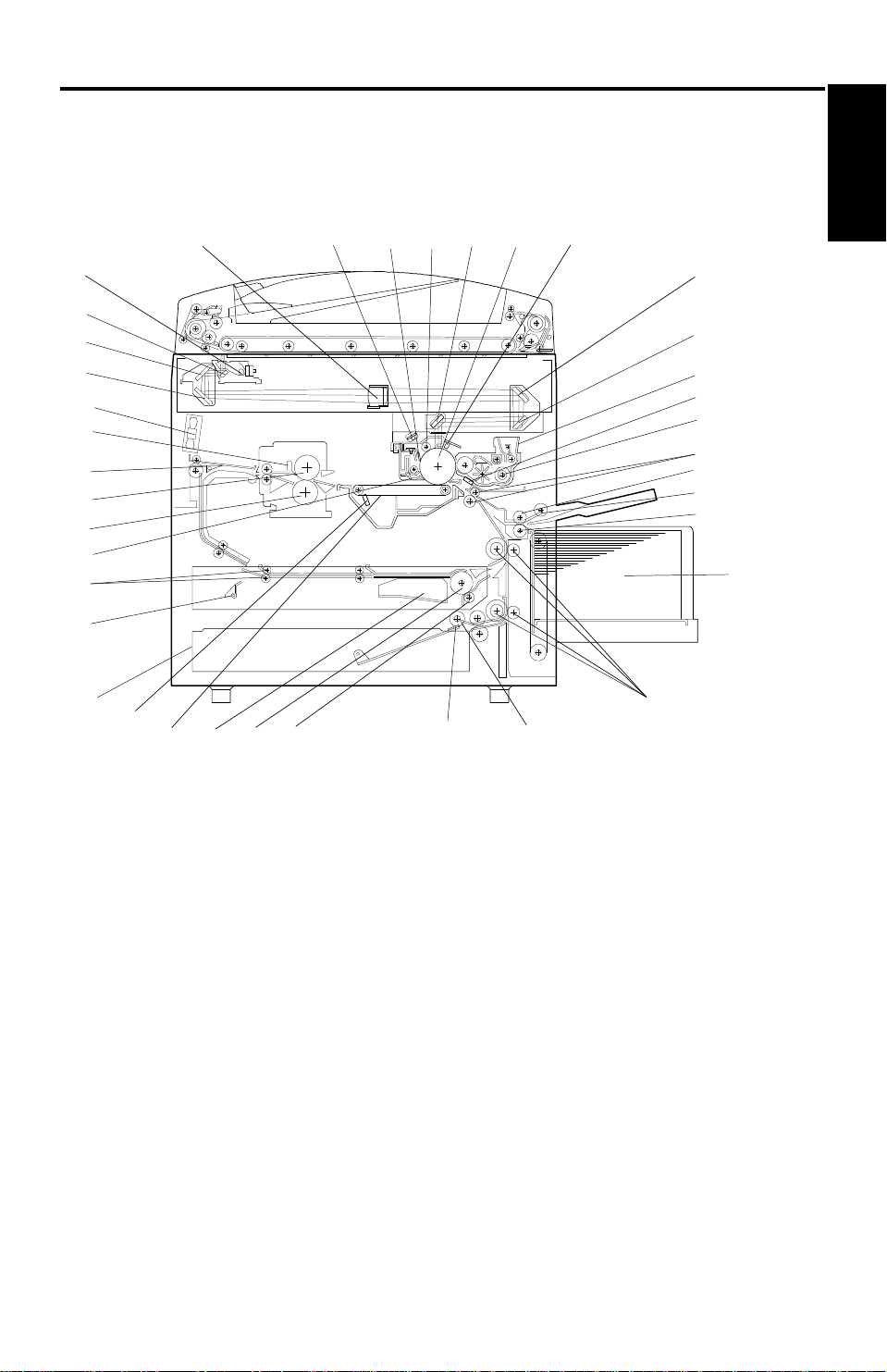

13th January 1995 MECHANICAL COMPONENT LAYOUT

3. MECHANICAL COMPONENT LAYOUT

– A156 copier –

5

6

7

1098

11

Overall

Information

4

3

2

1

38

37

36

35

34

33

32

31

30

28

27

26

25

12

13

14

15

16

17

18

19

20

21

22

24 23

NOTE: 1. The A153 copier is the same as the A15 6 cop ier exce pt that the

A153 does not have a duplex tray or an LCT.

2. The A155 copier is the same as the A15 6 cop ier exce pt that the

A155 does not have a duplex tray.

1-7

Page 9

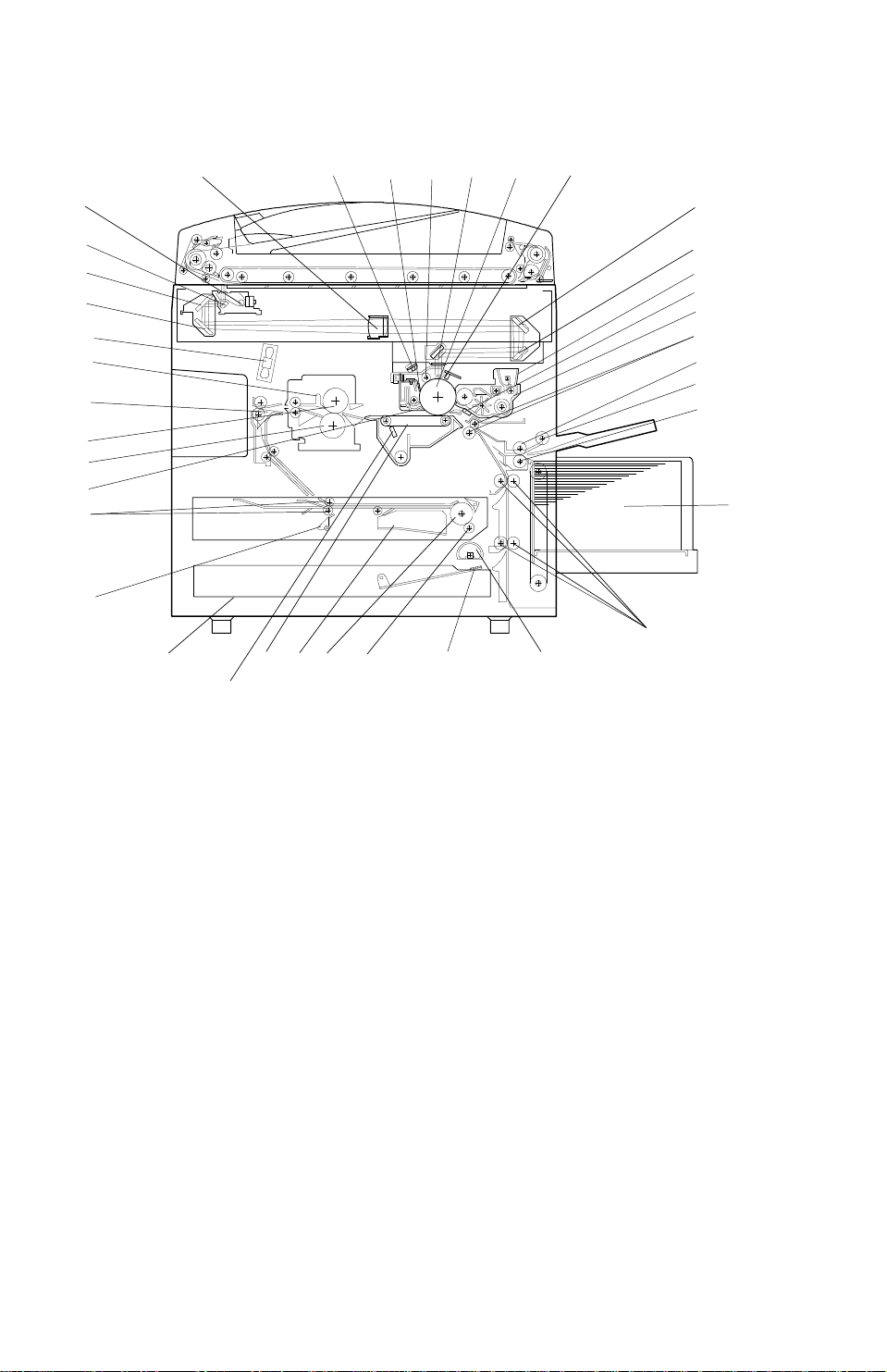

MECHANICAL COMPONENT LAYOUT 13th January 1995

– A160 copier –

4

3

2

1

38

37

36

35

34

33

32

31

30

5

6

7

1098

11

12

13

14

15

16

17

18

19

20

21

22

28

27

26

25

24

23

29

NOTE: 1. The A157 copier is the same as the A16 0 cop ier exce pt that the

A157 does not have a duplex tray or an LCT.

2. The A159 copier is the same as the A16 0 cop ier exce pt that the

A159 does not have a duplex tray.

1-8

Page 10

13th January 1995 MECHANICAL COMPONENT LAYOUT

1. 3rd Mirror

22. Vertical Transport Rollers

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Quenching Lamp

7. Drum Cleaning Blade

8. Drum Charge Roller

9. 6th Mirror

10. OPC Drum

11. Erase Lamp

12. 4th Mirror

13. 5th Mirror

14. Toner Supply Unit

23. Paper Feed Roller

The roller for A153/A155/A156

copiers is different from that

for A157/159/160 copiers.

24. Friction Pad

25. Duplex Friction Roller

26. Duplex Feed Roller

27. Jogger Fence

28. Transfer Belt

29. Transfer Belt Cleaning Blade

30. Lower Paper Tray

31. End Fence

32. Entrance Rollers

33. Pick-off Pawls

Overall

Information

15. Pre-transfer Lamp

16. Development Unit

17. Registration Rollers

18. Feed Roller

19. Pick-up Roller

20. Separation Roller

21. Large Capacity Tray

34. Pressure Roller

35. Hot Roller

36. Junction Gate

37. Hot Roller Strippers

38. Transport Fan

1-9

Page 11

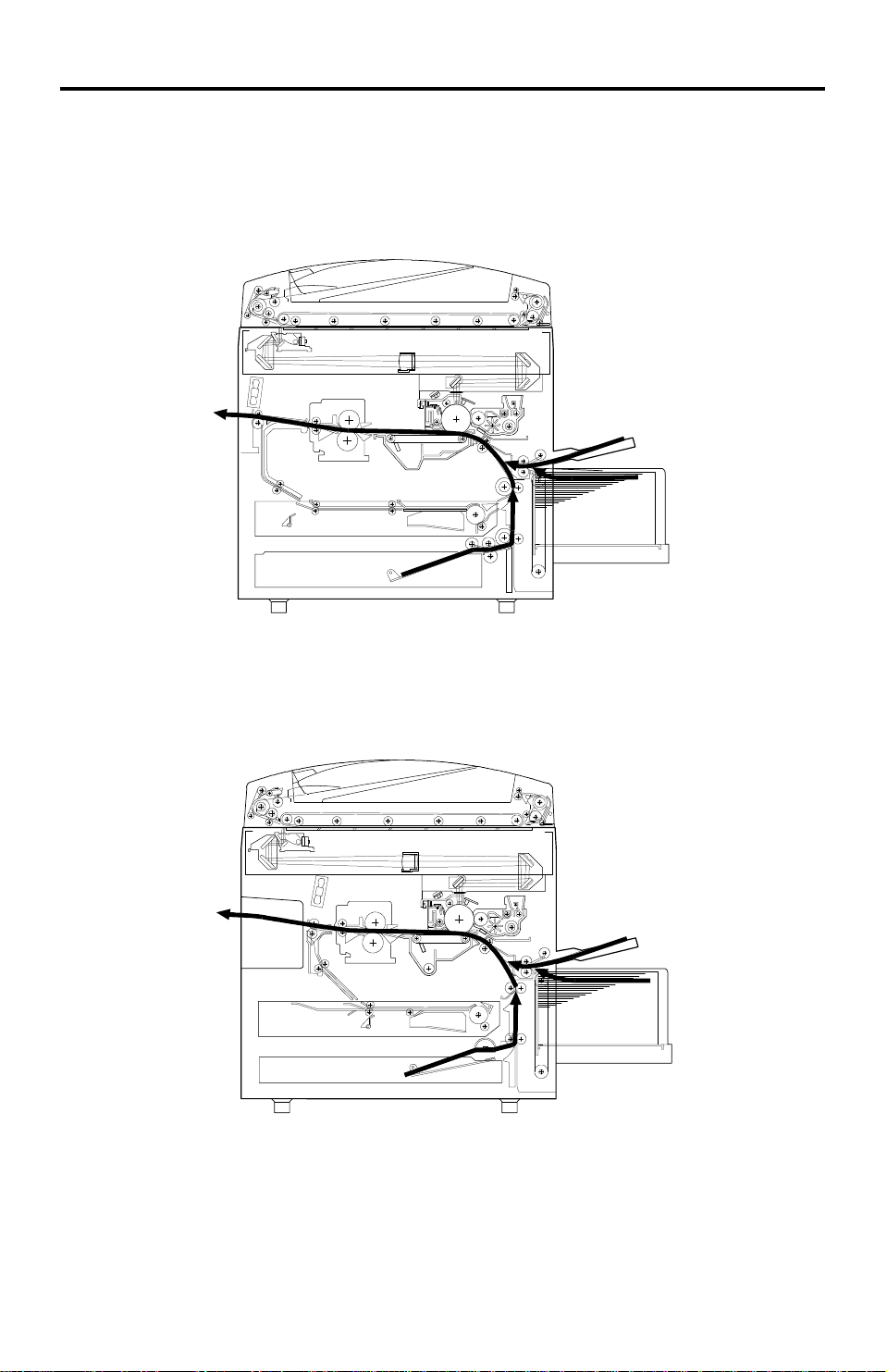

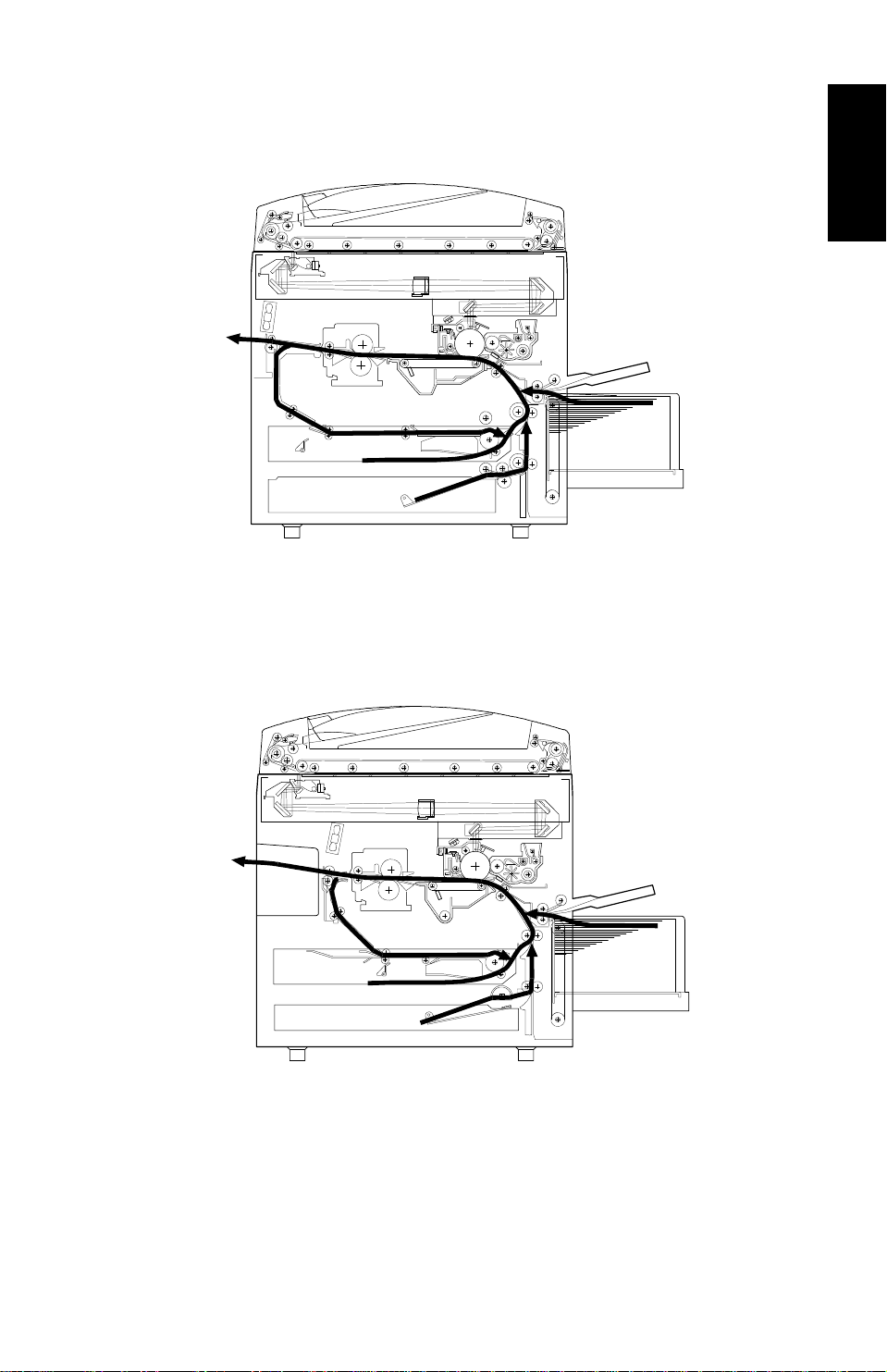

PAPER PATH 13th January 1995

4. PAPER PATH

4.1 NORMAL COPYING

– A156 copier –

–A160 copier –

1-10

Page 12

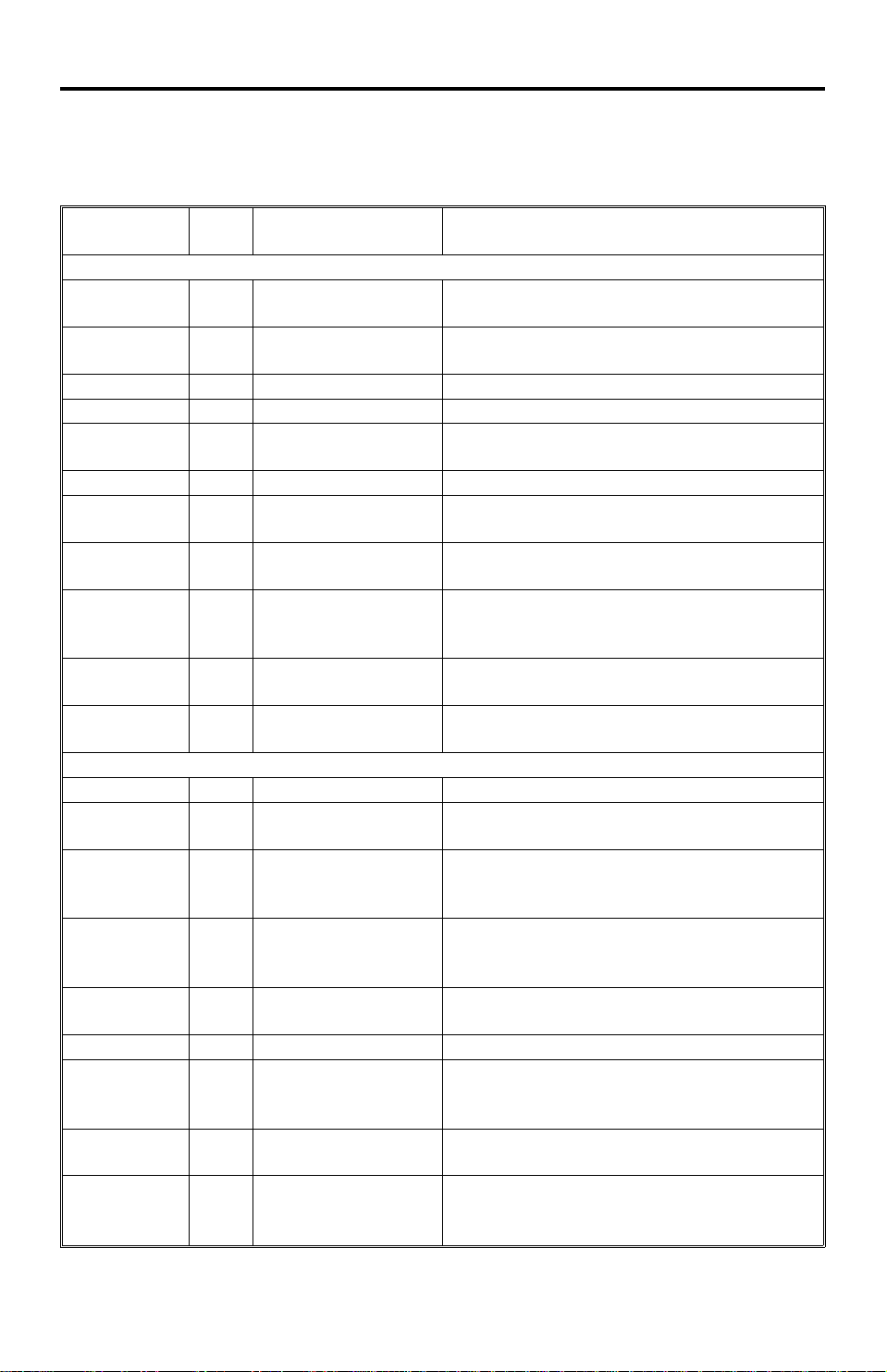

13th January 1995 PAPER PATH

4.2 DUPLEX COPYING

– A156 copier –

Overall

Information

– A160 copier –

1-11

Page 13

ELECTRICAL COMPONENT DESCRIPTIONS 13th January 1995

5. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical compone nt layou t an d the po int to point diag ram on the

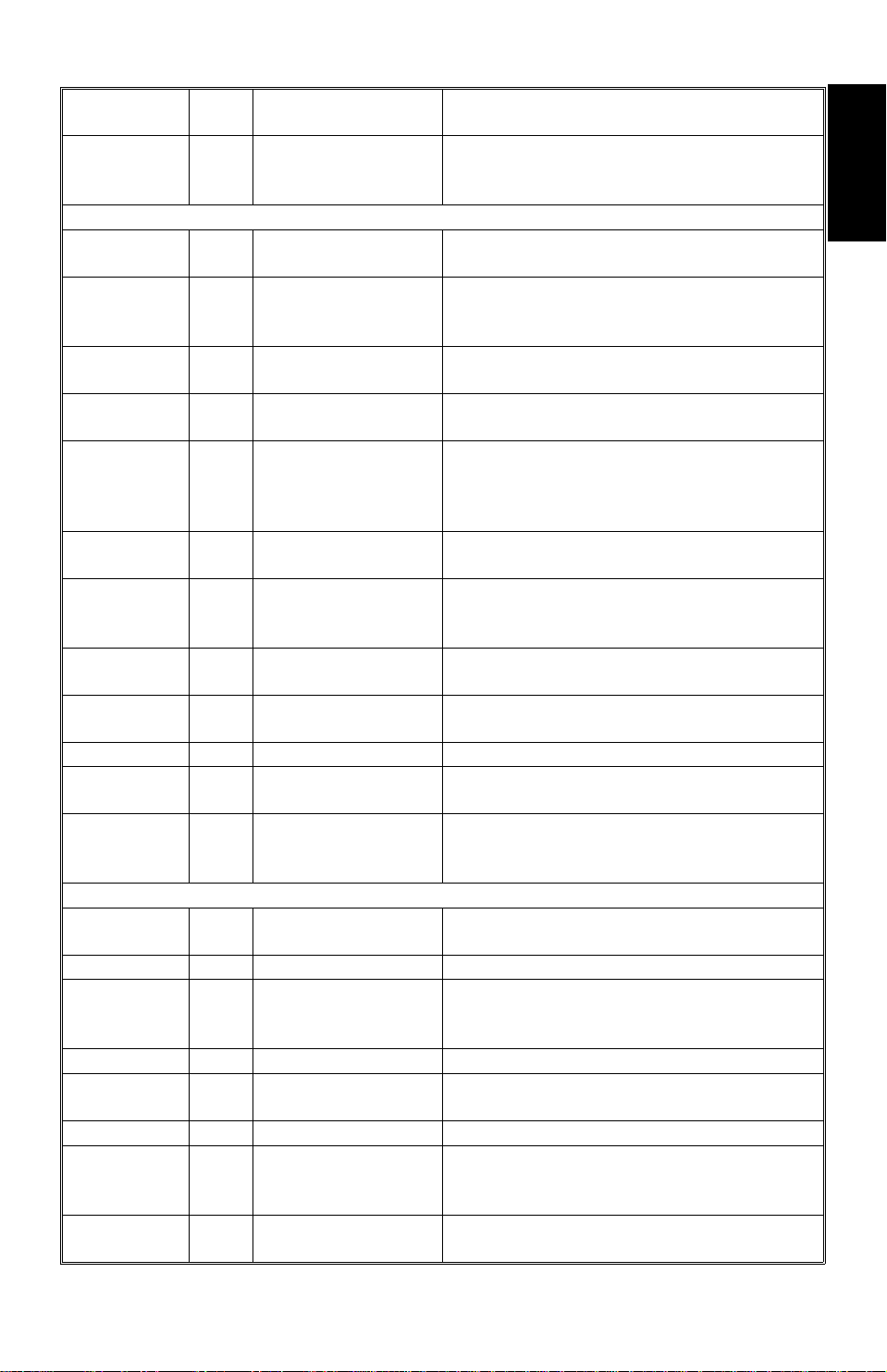

waterproof paper in th e pocket for symbols and index numbers.

Symbol

Printed Circuit Boards

PCB1 14

PCB2 12

PCB3 11 DC Power Supply Provides dc power.

PCB4 96 Main Motor Control Controls the rotation of the main motor.

PCB5 1

PCB6 55 T High Voltage Supply Supplies high voltage to the transfer belt.

PCB7 3

PCB8 8

PCB9 63

PCB10 6

PCB11 102

Motors

M1 88 Main Drives the main unit components.

M2 79

M3 97

M4 86

M5 99

M6 94 Optics Cooling Fan 1 Removes heat from the optics unit.

M7 95

M8 89

M9 90

Index

No.

Description Note

Main Control Controls all copier functions both directly or

through other control boards.

AC Drive Provides ac power to the exposure lamp and

fusing lamps.

CB High Voltage

Supply

Operation Panel Controls the LED matrix, and monitors the

Noise Filter (220 ~

240 V machines only)

Duplex Control

(Duplex machines

only)

Liquid Crystal Display

(A156 machines only)

LCT Interface

(LCT machines only)

Toner Bottle Drive Rotates the toner bottle to supply toner to

Upper Tray Lift

(A153/A155

machines only)

Lower Tray Lift

(A153/A155/A156

machines only)

LCT Lift

(LCT machines only)

Optics Cooling Fan 2

(A153/A155/A156

machines only)

Exhaust Fan 1 Removes the heat from around the fusing

Exhaust Fan 2

(A153/A155/A156

machines only)

Supplies high voltage to the drum charge

roller and development roller.

key matrix.

Removes electrical noise.

Controls the operation of the duplex tray.

Controls the guidance display and displays

guidance for machine operation.

Interfaces the LCT control signal between

the main board and the LCT.

the toner supply unit.

Raises the bottom plate in the upper paper

tray.

Raises the bottom plate in the lower paper

tray.

Lifts up and lowers the LCT bottom plate.

Removes heat from the optics unit.

unit.

Removes the heat from around the fusing

unit.

1-12

Page 14

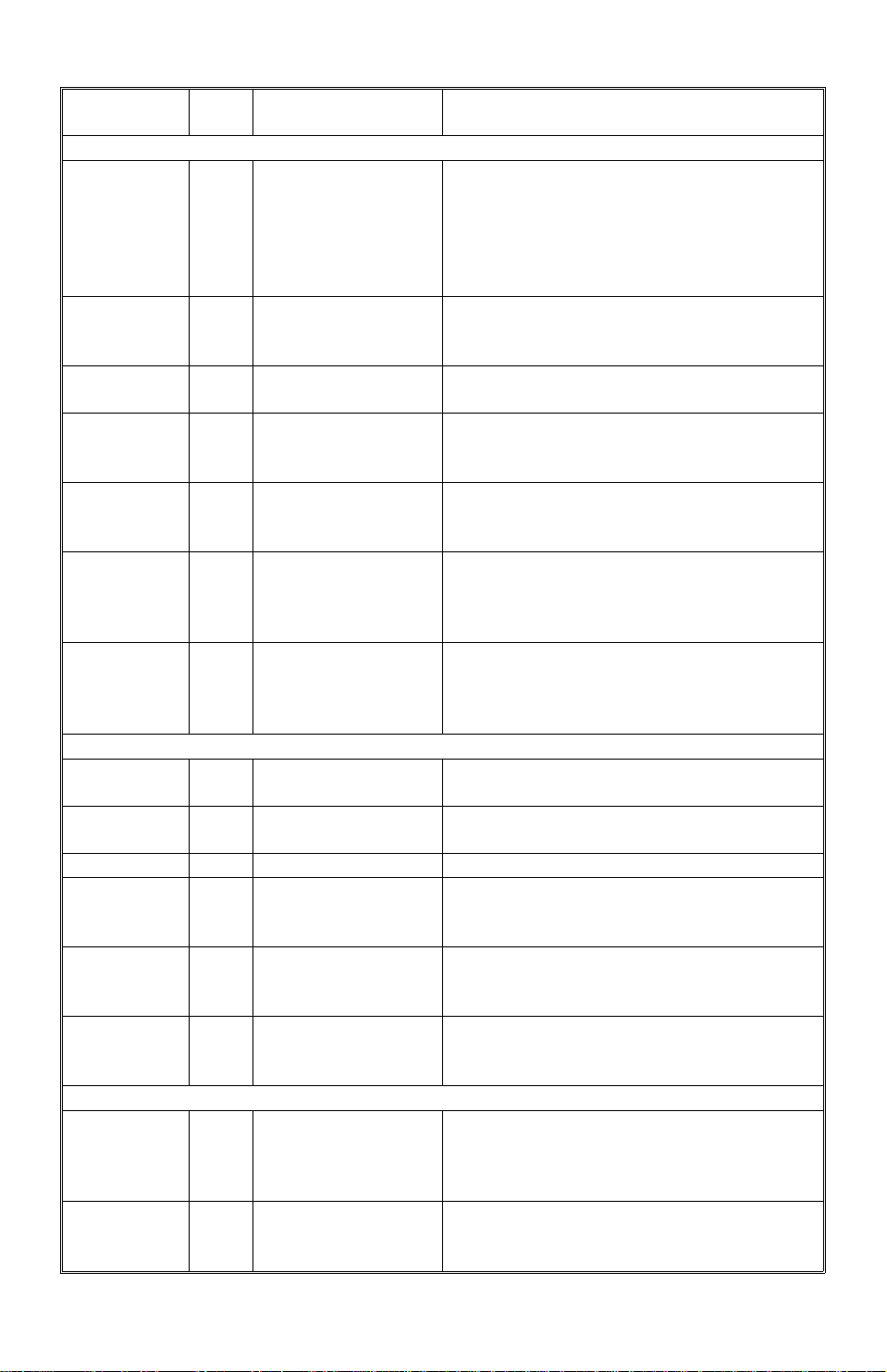

13th January 1995 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol

M10 92

M11 78 3rd Scanner Drive Drives the 3rd scanner (dc stepper motor).

M12 87 Lens Vertical Drive Shifts the lens vertical position.

M13 77 Lens Horizontal Drive Shifts the lens horizontal position.

M14 58

M15 61

M16 60

Sensors

S1 27

S2 31

S3 51

S4 107

S5 29

S6 52

S7 106

S8 30

S9 100

S10 26

S11 28

Index

No.

Description Note

Scanner Drive Drives the 1st and 2nd scanners (dc stepper

motor).

Duplex Feed

(Duplex machines

only)

End Fence Jogger

(Duplex machines

only)

Side Fence Jogger

(Duplex machines

only)

By-pass Feed Paper

Width

By-pass Feed Paper

End

Upper Tray Paper

End

(Non-duplex

machines only)

Upper Relay Detects the leading edge of paper from the

Upper Tray Upper

Limit

(A153/A155

machines only)

Lower Tray Paper

End

Lower Relay Detects the leading edge of paper from the

Lower Tray Upper

Limit

(A153/A155/A156

machines only)

LCT Lower Limit

(LCT machines only)

LCT Paper End

(LCT machines only)

LCT Upper Limit

(LCT machines only)

Drives the feed roller and moves the bottom

plate up and down.

Drives the end fence jogger to square the

paper stack.

Drives the side fence jogger to square the

paper stack.

Informs the CPU what width paper is in the

by-pass feed table.

Informs the CPU that there is no paper in the

by-pass tray.

Informs the CPU when the upper paper tray

runs out of paper.

upper tray to determine the stop timing of the

upper paper feed clutch, and detects

misfeeds.

Detects the height of the paper stack in the

upper paper tray to stop the upper tray lift

motor.

Informs the CPU when the lower paper tray

runs out of paper.

lower paper tray to determine the stop timing

of the lower paper feed clutch, and detects

misfeeds.

Detects the height of the paper stack in the

lower paper tray to stop the lower tray lift

motor.

Sends a signal to the CPU to stop lowering

the LCT bottom plate.

Informs the CPU when the LCT runs out of

paper.

Sends a signal to the CPU to stop lifting the

LCT bottom plate.

Overall

Information

1-13

Page 15

ELECTRICAL COMPONENT DESCRIPTIONS 13th January 1995

Symbol

S12 28

S13 50

S14 53

S15 39

S16 20

S17 15

S18 24

S19 21

S20 45 Fusing Exit Detects misfeeds.

S21 16

S22 54

S23 43

S24 23

S25 13

S26 44

S27 19

S28 56

S29 57

S30 62

S31 59

S32 64

Index

No.

Description Note

Registration Detects the leading edge of the copy paper

to determine the stop timing of the paper

feed clutch, and detects misfeeds.

Image Density

(ID)

Toner Density

(TD)

Lens Horizontal HP Informs the CPU that the lens is at the

Lens Vertical HP Informs the CPU that the lens is at the

Scanner HP Informs the CPU when the 1st and 2nd

3rd Scanner HP Informs the CPU when the 3rd scanner is at

Original Length-2 Detects the length of the original. This is one

Platen Cover Informs the CPU whether the platen cover is

Toner End Instructs the CPU to add toner to the toner

Auto Response Returns the operation panel display and exits

Transfer Belt ContactHPInforms the CPU of the current position of

Auto Image Density

(ADS Sensor)

Original Width Detects the width of the original. This is one

Original Length-1 Detects the length of the original. This is one

Duplex Paper End

(Duplex machines

only)

Duplex Turn

(Duplex machines

only)

Duplex Entrance

(Duplex machines

only)

Side Fence Jogger

HP (Duplex machines

only)

End Fence Jogger

HP (Duplex machines

only)

Detects the density of various patterns on

the drum during process control.

Detects the amount of toner inside the

development unit.

horizontal home position.

full-size position.

scanners are at the home position.

the home position.

of the APS (Auto Paper Select) sensors.

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

supply unit, and detects toner end conditions.

from the energy saver mode.

both the transfer belt unit and the drum

charge roller unit.

Detects the background density of each

original in ADS mode.

of the APS (Auto Paper Select) sensors.

of the APS (Auto Paper Select) sensors.

Detects paper in the duplex tray.

Detects the trailing edge of the copy paper to

determine the jogging timing, and detects

misfeeds.

Detects misfeeds.

Detects the home position of the duplex side

fence jogger.

Detects the home position of the duplex end

fence jogger.

1-14

Page 16

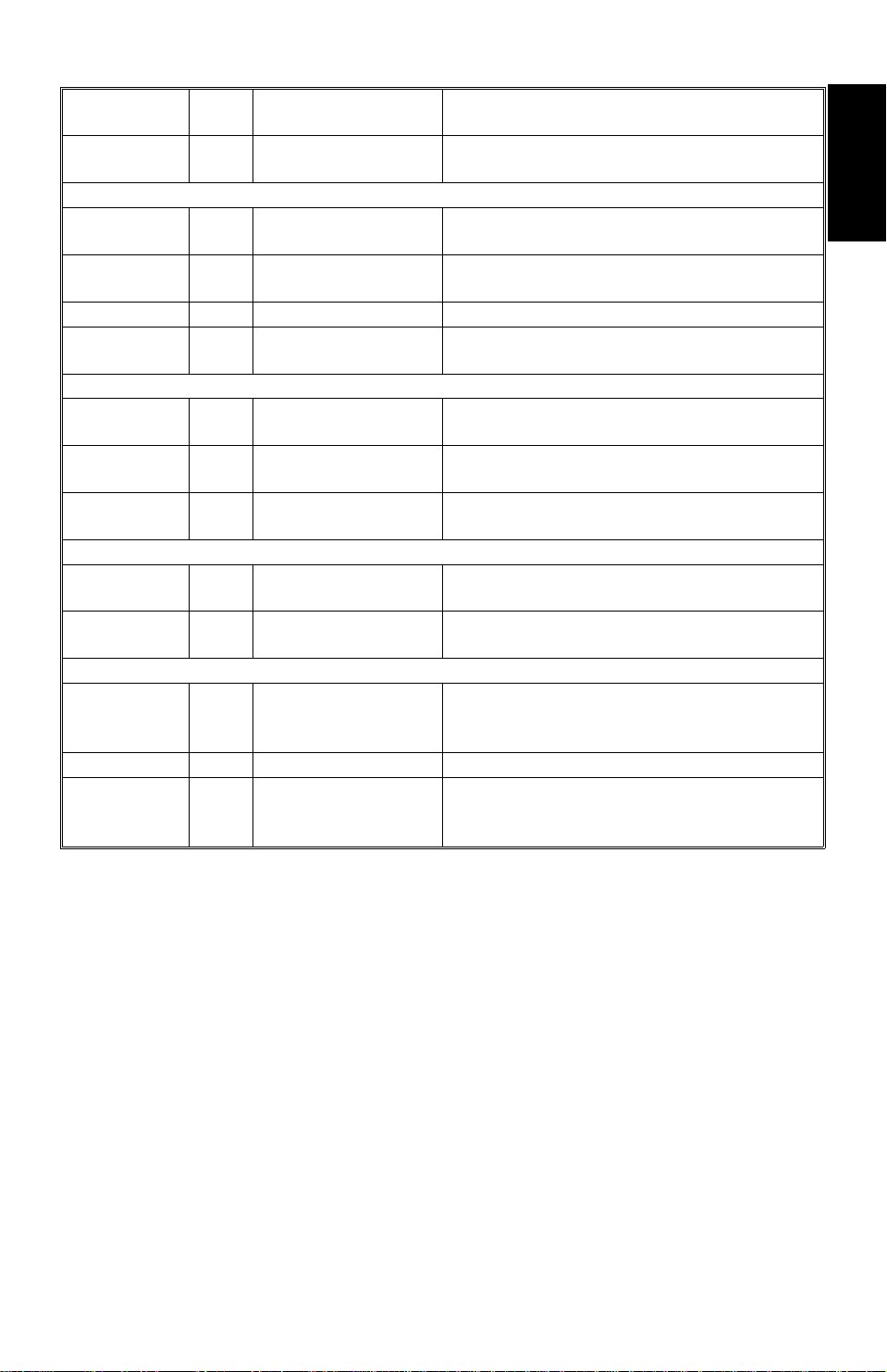

13th January 1995 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol

S33 22

Switches

SW1 33

SW2 36

SW3 35

SW4 104

SW5 25

SW6 34

SW7 32

SW8 105

SW9 103

SW10 42 Main Supplies power to the copier.

SW11 41

SW12 48

Magnetic Clutches

CL1 72

CL2 71 Development Drives the development roller.

CL3 93

CL4 73 Registration Drives the registration rollers.

CL5 74

CL6 76 Relay Drives the relay rollers.

CL7 84

CL8 85

Index

No.

Description Note

Original Length

(Option for N.

American models)

By-pass Feed Table Detects whether the by-pass feed table is

Upper Tray

(Non-duplex

machines only)

Lower Tray Detects whether the lower paper tray is in

Tray Down

(LCT machines only)

Upper Tray Paper

Size

(Non-duplex

machines only)

Lower Tray Paper

Size

Vertical Guide Set

(Non-LCT machines

only)

LCT Cover-1

(LCT machines only)

LCT Cover-2

(LCT machines only)

Front Cover Safety Cuts the ac power line and detects whether

Exit Cover Safety

(A157/A159/A160

machines only)

Toner Supply Turns the toner supply roller to supply toner

Transfer Belt Contact Controls the touch and release movement of

By-pass Feed Starts paper feed from the by-pass feed

Upper Paper Feed

(Non-duplex

machines only)

Lower Paper Feed Starts paper feed from the lower paper tray.

Detects original length for 11" x 15" paper.

open or closed.

Detects whether the upper paper tray is in

place or not.

place or not.

Sends a signal to the CPU to lower the LCT

bottom plate.

Determines what size of paper is in the

upper paper tray.

Determines what size of paper is in the lower

paper tray.

Detects whether the vertical guide is open or

not.

Detects whether the LCT cover is open or

not.

Cuts the dc power line of the LCT lift motor.

the front door is open or not.

Cuts the ac power line and detects whether

the exit cover is open or not.

to the development unit.

both the transfer belt unit and the drum

charge roller unit.

table or LCT.

Starts paper feed from the upper paper tray.

Overall

Information

1-15

Page 17

ELECTRICAL COMPONENT DESCRIPTIONS 13th January 1995

Symbol

Solenoids

SOL1 75

SOL2 91

SOL3 98

SOL4 80

SOL5 82

SOL6 81

SOL7 83

Lamps

L1 17

L2 65

L3 66 Secondary Fusing Provides heat to both ends of the hot roller.

L4 4

Index

No.

Description Note

LCT machines:

LCT/By-Pass Pick-up

Solenoid

Non-LCT machines:

By-pass Pick-up

Solenoid

Junction Gate

(Duplex machines

only)

LCT Pick-up

(LCT machines only)

Upper Tray Pick-up

(A153/A155

machines only)

Lower Tray Pick-up

(A153/A155/A156

machines only)

Upper Tray

Separation

(A153/A155

machines only)

Lower Tray

Separation

(A153/A155/A156

machines only)

Exposure Applies high intensity light to the original for

Main Fusing Provides heat to the central area of the hot

Pre-transfer Reduces the charge remaining on the drum

Picks paper up from the by-pass feed table.

When paper is fed from the LCT, this

solenoid assists SOL3.

Moves the junction gate to direct copies to

the duplex tray or to the paper exit.

Picks up paper from the LCT.

Controls the up/down movement of the

pick-up roller in the upper paper tray.

Controls the up/down movement of the

pick-up roller in the lower paper tray.

Controls the up-down movement of the

separation roller in the upper paper tray feed

station.

Controls the up-down movement of the

separation roller in the lower paper tray feed

station.

exposure.

roller.

surface before transfer.

L5 5

L6 2

Heaters

H1 38

H2 46

Quenching Neutralizes any charge remaining on the

drum surface after cleaning.

Erase After exposure, this eliminates the charge on

areas of the drum that will not be used for

the image.

Drum Turns on when the main switch is off to keep

the temperature around the drum charge

roller at a certain level. Also prevents

moisture from forming around the drum.

Optics

Anti-condensation

(option)

Turns on when the main switch is off to

prevent moisture from forming on the optics.

1-16

Page 18

13th January 1995 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol

H3 37

Thermistors

TH1 69

TH2 70

TH3 47 Optics Monitors the temperature of the optics cavity.

TH4 49

Thermofuses

TF1 68

TF2 67

TF3 18

Counters

CO1 40

CO2 N/A

Others

CB1 9

CC1 10 Choke Coil Removes high frequency current.

TR1 7

Index

No.

Description Note

Lower Tray

(option)

Main Fusing Monitors the temperature at the central area

Secondary Fusing Monitors the temperature at the ends of the

Drum Charge Monitors the temperature of the drum charge

Main Fusing Provides back-up overheat protection in the

Secondary Fusing Provides back-up overheat protection in the

Exposure Lamp Opens the exposure lamp circuit if the 1st

Total Keeps track of the total number of copies

Key

(option)

Circuit Breaker

(220 ~ 240V

machines only)

Transformer

(220 ~ 240V

machines only)

Turns on when the main switch is off to keep

paper dry in the lower paper tray.

of the hot roller.

hot roller.

roller.

fusing unit.

fusing unit.

scanner overheats.

made.

Used for control of authorized use. The

copier will not operate until it is installed.

Provides back-up high current protection for

electrical components.

Steps down the wall voltage to 100 Vac.

Overall

Information

1-17

Page 19

3

4

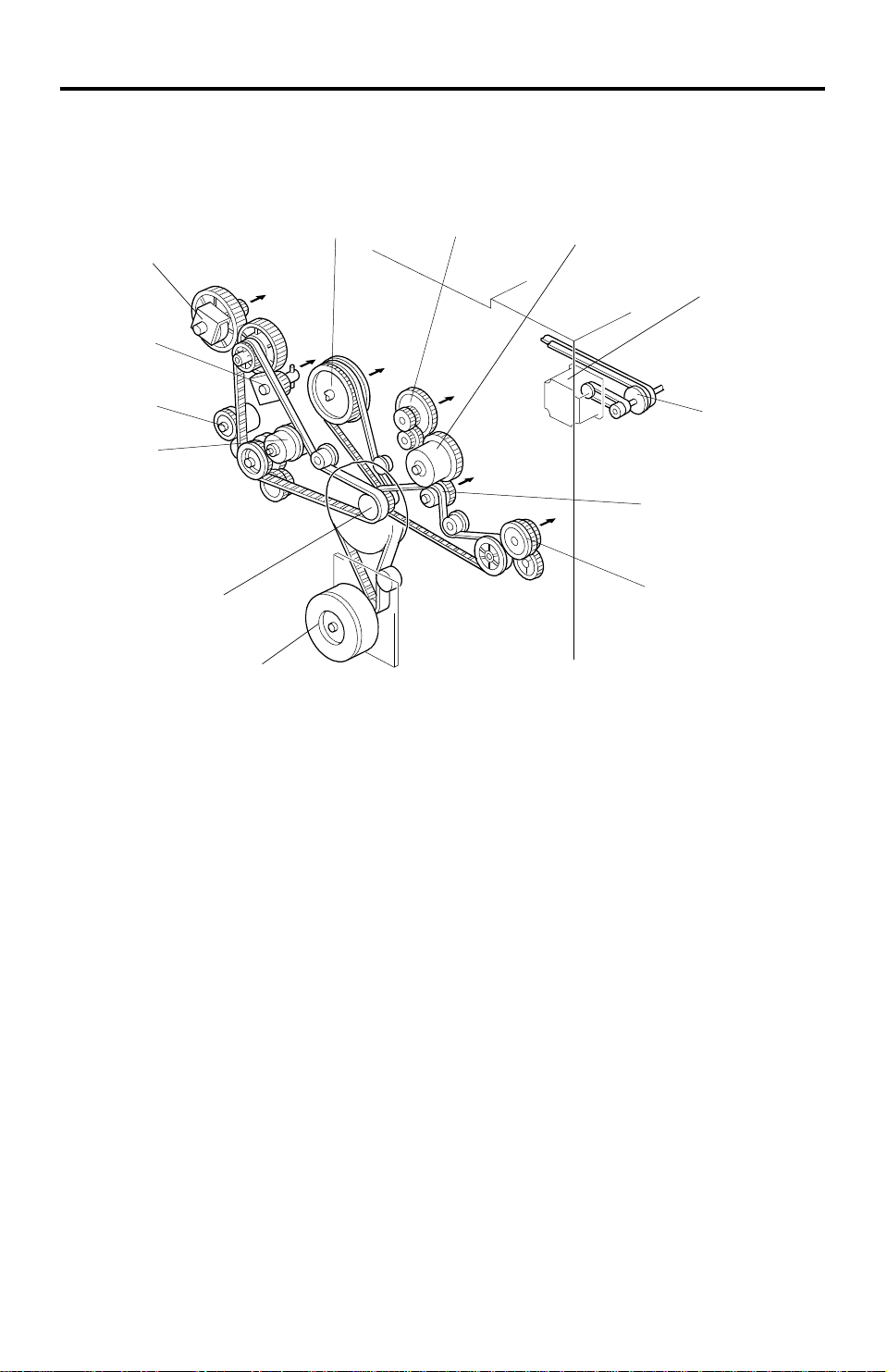

DRIVE LAYOUT 13th January 1995

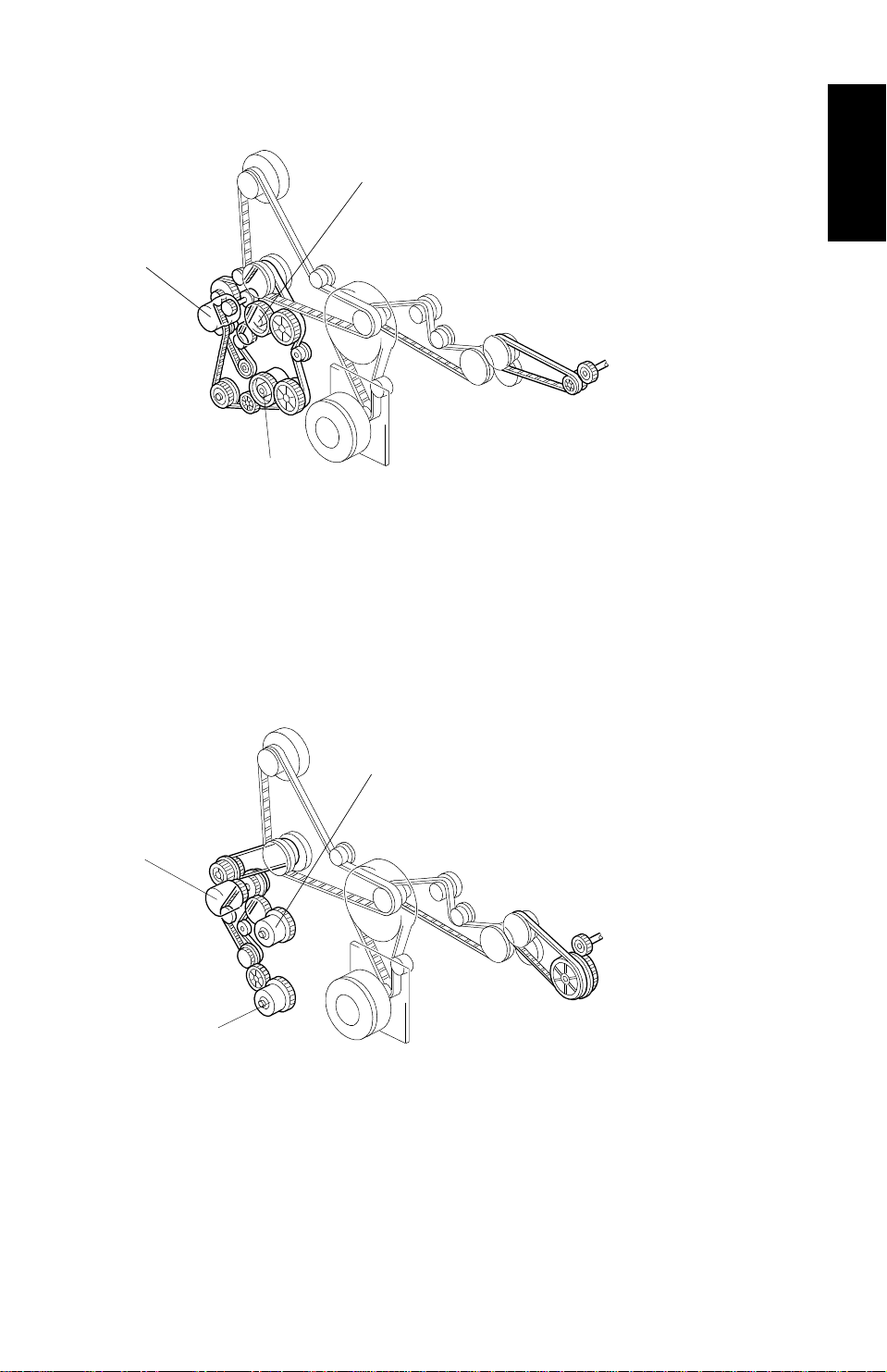

6. DRIVE LAYOUT

6.1 ALL MODELS

13

12

11

10

1

9

8

2

5

6

7

1 . Drum Drive Pulley

2. Drum Charge Roller Drive Gear

3. Transfer Belt Conta ct Clut ch

Gear

4. Scanner Drive Motor

5. Scanner Drive Pulley

6. Transfer Belt Drive Gear

7. Fusing Unit Drive Gear

8. Main Motor

9. Main Pulley

10. Registration Clutch Gear

11. By-pass Feed Clutch Gear

12. Development Drive Clutch Gear

13. Toner Supply Clutch Gear

1-18

Page 20

13th January 1995 DRIVE LAYOUT

6.2 A153/A155/A156

1

3

2

1. Upper Paper Feed Clutch Gear (A153/A155 only)

2. Lower Paper Feed Clutch Gear

3. Relay Clutch Gear

6.3 A157/A159/A160

Overall

Information

1

3

2

1. Upper Paper Feed Clutch Gear (A157/A159 only)

2. Lower Paper Feed Clutch Gear

3. Relay Clutch Gear

1-19

Page 21

SECTION 2

DETAILED DESCRIPTIONS

Page 22

13th January 1995 PROCESS CONTROL

1. PROCESS CONTROL

1.1 OVERVIEW

1.1.1 Copy Process around the Drum

2. EXPOSUR E

1. DRUM CHARGE

9. QUENCHING

8. CLEANING

3. ERASE

4. DEVELOPMENT

Detailed

Descriptions

ID

SENSOR

PICK-OFF

PAWLS

TRANSFER BELT

Fig. 1 Copy Process Around the Drum

1. DRUM CHARGE

In the dark, the drum charge roller gives a uniform negative cha rge to the

organic photo-conduct ive (OPC) drum. The charge remains on th e surface of

the drum because the OPC layer has a high electrical resistan ce in the dark.

The amount of negative charge on the dru m is propo rtio na l to th e negative

voltage applied to the drum charg e rolle r.

7. PAPER

SEPARATION

5. PRE-TRANSFER

LAMP

6. IMAGE

TRANSFER

2-1

Page 23

PROCESS CONTROL 13th January 1995

2. EXPOSURE

An image of the original is reflected onto the OPC drum surface via the optics

assembly. The charge on the drum surface is dissipated in direct proportion

to the intensity of the refle cte d light, thus producing an electrical latent image

on the drum surface.

The amount of remaining charg e as a lat ent image on the drum depends on

the exposure lamp intensity, which is co nt rolle d by the exposure lamp voltage.

3. ERASE

The erase lamp illuminates the areas of th e cha rge d dru m su rfa ce th at will

not be used for the copy image. The resistance of the drum in the illuminated

areas drops and the charge on those areas dissipates.

4. DEVELOPMENT

As a result of the development potential (the difference of charged voltage

between the drum and the toner), ton er is att ract ed to the are as of the drum

where the negative charge is greater than that of the toner, and the latent

image is developed.

The development bias volt ag e ap plied to the developmen t rolle r shaft

controls two things:

1) The threshold level fo r wh et he r t on er is attracted to the drum or

whether it remains on the development roller.

2) The amount of toner to be attracted to the drum.

The higher the negative develo pme nt bias volt ag e is, th e less toner is

attracted to the dru m surface.

5. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove almost all the negative charge from

the exposed areas of the drum. This prevents the toner particles fro m bein g

reattracted to the drum surf ace during paper separation and makes pa pe r

separation easier.

2-2

Page 24

13th January 1995 PROCESS CONTROL

6. IMAGE TRANSFER

Paper is fed to the area between the drum surf ace and the tran sfer belt at the

proper time so as to align the copy paper and the develope d image on the

drum surface. Then, the tran sfer bias roller applies a strong negative cha rge

to the reverse side of the copy paper through the tran sfer belt. This negative

charge produces an electrical fo rce which pulls the toner particles from t he

drum surface on to the copy paper. At the same time , th e cop y pap er is

electrically attracted to the transfer belt.

7. PAPER SEPARATION

Paper separates from the OPC drum as a result of the electrical attra ction

between the paper and the transfe r belt . The pick-off pawls help separate the

paper from the drum.

8. CLEANING

The cleaning blade remove s ton er rema ining on the drum after the image is

transferred to the pa pe r.

9. QUENCHING

Light from the quenching lamp electrically neutralizes the charge on the dru m

surface.

Detailed

Descriptions

2-3

Page 25

PROCESS CONTROL 13th January 1995

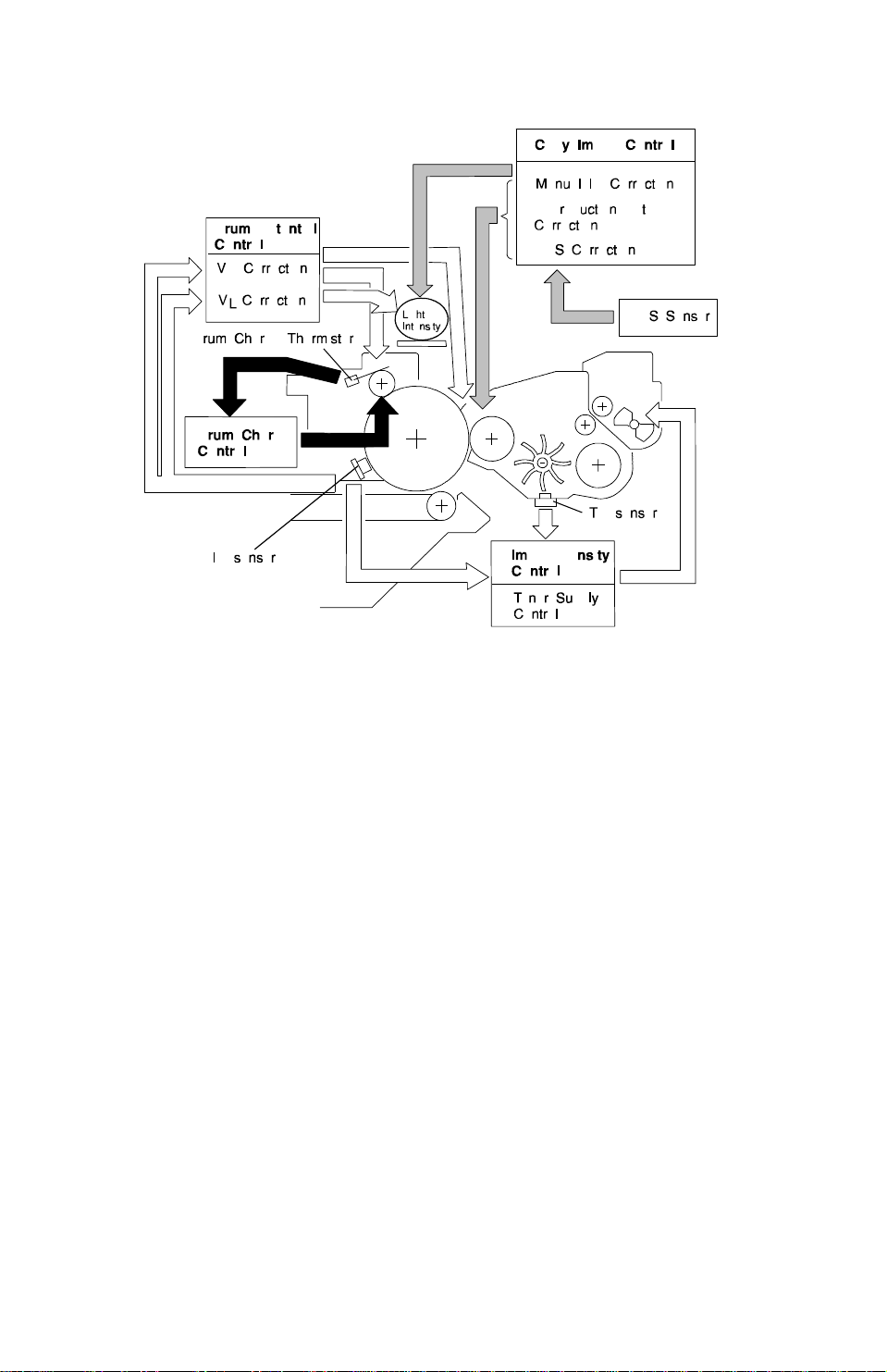

1.1.2 Factors Affecting Process Control

Fig. 2 Process Control

In this copier, the fo llowin g items are controlled durin g th e copy process to

maintain good copy quality:

• Exposure lamp voltage

• Drum charge roller voltage

• Development bias voltage

• Toner supply

The machine controls th e ab ove by monitoring the following electrical

components:

• Operation panel (manual ID selection and reproduction ratio)

• ADS sensor

• TD sensor

• ID sensor

• Drum charge thermistor

• Paper size detecto rs

• RAM board (drum rotatio n time , SP mode data, and paper size da ta)

2-4

Page 26

13th January 1995 PROCESS CONTROL

1.1.3 Process Control Procedures

This section outlines how the machine controls the copy process based on

the inputs from various sensors.

Copy Image Control

This is how the machine adjusts copy processes based on settings input at

the operati on panel.

- Manual ID Correction -

If the user inputs the imag e de nsit y manu ally, the machin e ad just s the

exposure lamp voltage an d the development bias to achie ve th e selected

image density.

- Reproduction Ratio Correction -

If the user selects a 116% or great er en larg ement ratio or a 50% reduction

ratio, the machine corrects the development bia s to comp en sate for the loss

in light intensity reaching the drum.

Detailed

Descriptions

- ADS Pattern Detection and ADS Correction -

If the user selects Auto Ima ge Density (ADS) mode, the machine monitors

the output from the ADS sensor and ad just s the deve lop ment bias to

compensate for variatio ns in ADS sensor response. This preven ts dirty

background.

Every 1,000 copies, the machine calibrates the ADS sensor output by

reading the ADS patt ern und er th e left scale of the exposure glass.

The ADS sensor must also be reca librated:

• If the drum is changed

• If the ID sensor is clean ed or chan ged

• If the exposure lamp or optics are cleaned or cha ng ed .

Image Density Control

This is how the machine corrects th e con centration of toner in the developer

based on readings from the ID (Image Density) and TD (Ton er Den sity)

sensors.

- VSP and VSG Detection/ID Correction -

The machine uses VSP and VSG rea din gs by the ID sensor, along with

readings from the toner density sensor, to determine if the toner

concentration in the deve lop er is at th e optimu m le vel.

2-5

Page 27

PROCESS CONTROL 13th January 1995

The amount of ton er supplied to the VSP pattern must remain constant. To

ensure this, the mach ine app lies a correction to the develop men t bias for V SP

patterns when combine d readings from the TD and ID sensors indicate that

the carrier is ageing. This correction is called "ID Correction".

- Toner Supply -

There are three toner supply modes.

Detect toner supply: Toner supply varies with paper size, the latest TD

sensor reading, and the latest VSP and VSG readings by the ID sensor. For

example, toner supply will be increased if the toner weight rat io in th e

developer is decreasin g, or if the most recent VSP pattern was detected as

being relatively light.

Fixed supply mode: The toner supply remains constant, but can be adjuste d

with an SP mode.

TD supply mode: Toner supply varies with TD sen sor outp ut . For example, if

the toner weight ratio has decreased since TD sensor supply mode was

selected, toner supply is increased.

Drum Potential Control

This is how the machine compensates for aging of the drum an d th e

exposure lamp, and for the temperature around the drum charge roller.

- VR Pattern Detection and VR Correction -

As the drum gets older, the drum’s residual voltage grad ually increases due

to electrical fatigue. Ligh t fro m t he expo sure lamp will not erase the increased

residual voltage effe ctive ly a nd dirty ba ckgro un d will result .

Every 1,000 copies, part of the drum is developed with the VR pattern

development bias. If the re is residu al voltage on the drum, this area of the

drum will attract some toner, making a V R pattern. The ID sensor response to

this pattern is compare d with the response of the ID sensor to a bare area of

the drum. The higher the residu al volt ag e on the drum is, th e da rker th e VR

pattern is. If the pattern is too dark, the drum will not be discharg ed

sufficiently. As a result, the machine will increase the negative de velo pment

bias to prevent dirty background. If it does, image density will drop. To

prevent this, the machine will a lso incre ase the negative drum charge roller

voltage.

(The VRP/VRG range to which the above mentioned bias and charg e

corrections are applied may be shift ed to can cel the ef fe ct of ID correct ion.)

VR correction data must be reset by SP mode if the drum is chan ge d or if th e

ID sensor is cleaned or replaced.

2-6

Page 28

13th January 1995 PROCESS CONTROL

- VL Pattern Detection and VL Correction -

This is how the machine adjusts the expo sure lamp voltage to compensate

for the effects of drum wea r, dirty optics, and response of the drum to lig ht .

Every 1,000 copies, an imag e of the VL pattern under the left scale bracket is

made on the drum. The machine compares the response of the ID sensor to

this image with the response to a bare are a of the drum.

The exposure lamp voltage is adjust ed if there ha ve be en significant changes

from the measurements made from when a new drum or lamp was installe d.

(The VLP/VLG range to which the abo ve men tioned lamp voltage adjustment

is applied may be shifted to cancel the effect of ID correction .)

Initial VLP/VLG detection must be done by SP mode if a new drum is installed

or if the exposure lamp is cleaned or replaced.

- T/H Correction -

The efficiency of tran sfer of charge from the drum charg e roller to the drum

varies with the temperature near the dru m charg e rolle r. Also, the drum

potential after cha rging varies with the accumula te d rotation time of the drum.

Detailed

Descriptions

A thermistor measures the temperature near the drum charge roller, and the

CPU keeps track of how long th e dru m h as rot at ed for.

The machine adjusts th e dru m ch arg e roller voltage depending on the

temperature and accumulated rotation time.

This section has provided an overview of all the proce ss cont rol procedures

done by the machine. The next few pa ge s will exp lain each of th ese in more

detail. At the end, there will be a summary.

2-7

Page 29

PROCESS CONTROL 13th January 1995

1.2 COPY IMAGE CONTROL

Copy image control adju sts the development bias and exp osure lamp voltage

to take account of the repro du ction ratio and image densit y. The ima ge

density is either selected by th e use r or det ect ed automa tically.

1.2.1 Manual ID Correction

If the user selects the image density man ua lly, th e selected manual ID level

affects the exposure la mp volt ag e an d th e de velopment bias as follows.

- Exposure Lamp Voltage -

As the ID level increases from 1 to 7, the exposu re lamp voltage is increased

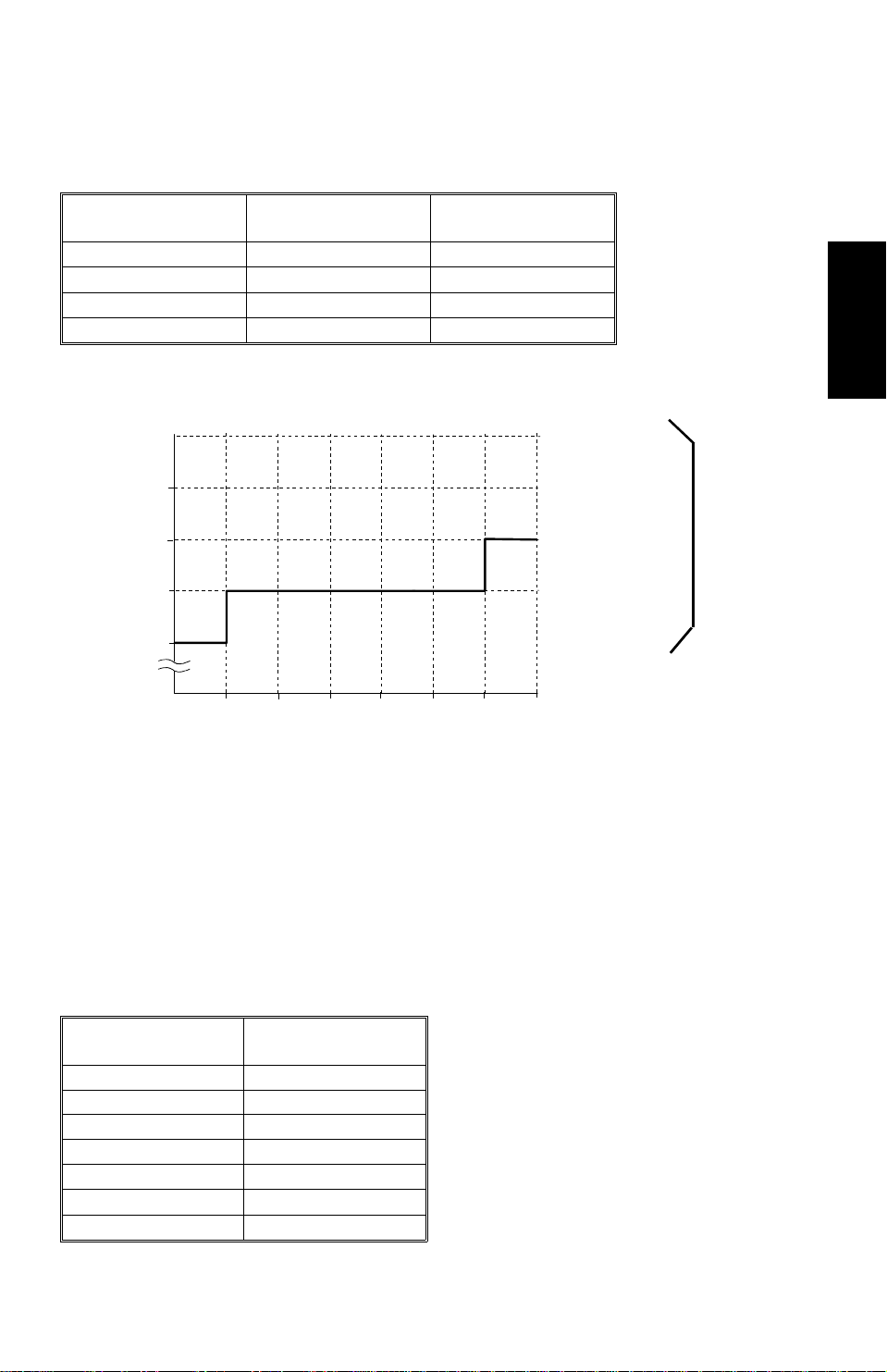

as shown in the following table.

Table 1. Exposure lamp vol tage control by manua l ID level

ID Level Lamp Voltage

1 Vexp –4.0 V

2 Vexp –3.0 V

3 Vexp –1.5 V

4

5 Vexp +1.5 V

6 Vexp +4.0 V

7 Vexp +6.0 V

Vexp ±0.0 V

Vexp = Lamp voltage selecte d with SP4-001. It can be between 50 and 75 V.

It is factory set, and varies from copier to copier.

- Development Bias -

The greater the nega tive voltage, the paler th e imag e on the drum. However,

the development bias is adjust ed only at the extre me light and dark ends of

the manual ID range.

Table 2. Development bias control by manua l ID level

ID Level Development Bias

1 +80 V

2

3

4

5

6

7 SP2-201-002 (see below)

±0 V

±0 V

±0 V

±0 V

±0 V

Note: The base developme nt bias volt age is -2 40 Volt s.

2-8

Page 30

ID Level

–320

(Lighter)

–240

(Darker)

–360

(Lightest)

13th January 1995 PROCESS CONTROL

For ID Level 7 (lightest copie s), th ere are fo ur possible development bias

correction setting s tha t can be selected with SP2-20 1-0 02 , as sho wn be low.

Table 3. Lightest ID level developme nt bias (ID Leve l 7)

SP2-201-002 Setting Density

1 (Factory Setting) Normal –40 V

2 Dark

3 Lighter –80 V

4 Lightest –120 V

Dev. Bias

Correction Voltage

±0 V

In summary, the development bias at various ID level settings is shown below.

Development Bias Voltage

–320

SP2-201-002

–280

–240

–160

–280

(Normal)

1765432

for ID Level 7

Detailed

Descriptions

1.2.2 Reproduction Ratio Correction

At reproduction ratio s of 50 % an d 11 6% or g rea ter, the intensity of light

reaching the drum from the origin al drops significantly, which could cause

copies to become underexposed (too dark).

To compensate for th is, a de velopment bias correction voltage is applied as

shown in Table 4. This correction incre ases the development bias volta ge ,

restoring the copy image densit y to normal.

Table 4. Reproduction ratio correction

Reproduction

Ratio (%)

181 ~ 200 –100 V

161 ~ 180 –80 V

142 ~ 160 –60 V

123 ~ 141 –40 V

116 ~ 122 –20 V

51 ~ 115

50 –30 V

Development Bias

Correction Voltage

±0 V

2-9

Page 31

[A]

PROCESS CONTROL 13th January 1995

1.2.3 ADS Correction

ADS pattern

Fig. 3 ADS pattern

If the user selects Auto Image Density (ADS) mod e, the output of the ADS

sensor is used to correct the develop ment bias; the exposure lamp volta ge is

kept at the setting for ID level 4 and is not adjusted.

In ADS mode, the ADS sensor [A] detects the original background density.

To prevent dirty background from appearing on copies, the CPU corrects the

development bias vo lta ge for the original. To do this, it compa res the ADS

sensor output from the origin al [VADS (original)] with a stored reference value

[VADS (pattern)] that was taken earlier from the ADS sen sor pa tt ern . The

correction is shown in table 5, and is app lied every cop y.

Table 5. ADS data correction

ADS Density SP5-106

Setting Copy Density

0 Darker 816 x (AR – 0.79)

1 Normal 816 x (AR – 0.85)

2 Lighter 816 x (AR – 0.95)

Development Bias Correction Voltage

Where AR (ADS Ratio) = VADS (original)/VADS (pattern)

Note that there are three possib le corrections. The default sett ing is 1

(normal). However, for example , if the use r requ ires cop ies to be darker

when using ADS mode, a tech nicia n can set SP5-106 to 0.

VADS (pattern) is checked every 1,00 0 cop ies. (See process control checks

at every 1,000 copies on p2-29.) It is kept at 2.7±0.1 volts by a gain

adjustment.

See the "Optics - Automatic Image Density Cont rol Syst em (ADS)" section for

more details on how the ADS sensor mea sure s the backg rou nd and on how

[VADS (pattern)] is corrected every 1,000 copies.

2-10

Page 32

35 mm

13th January 1995 PROCESS CONTROL

1.3 IMAGE DENSITY CONTROL

1.3.1 Overview

The machine controls th e toner supply mechanism using th e toner density

sensor (TD sensor) and the image density sensor (ID sensor).

Readings from the TD sensor are use d to keep the ton er con cen tration in the

developer at a constant level. However, the image on the OPC drum varies

due to the variation in toner chargea bilit y, which is influenced by the

environment, eve n if th e toner concentration is con sta nt. Because of this,

readings from the ID sensor are used to cha ng e the tone r concentration to

keep the image density on the OPC drum constant.

1.3.2 VSP and VSG Detection

[D]

[C]

[A]

Drum

LED

ON

LED

ON

Detailed

Descriptions

V

SG

Dev.

V

SP

bias

[B]

65 mm

The ID sensor [A] (below the drum cleaning section) checks the follo wing

voltages.

• VSG: the ID sen sor outp ut when checkin g the era sed drum surface.

• VSP: the ID sen sor ou tput when checking the Vsp pat te rn image.

In this way, the reflectivity of both the erased drum surf ace and the patte rn on

the drum are checked. This compensates for any variations in light intensity

from the LED component of the sensor or the reflectivity of the drum.

The VSP pattern [B] is made on the OPC drum b y the drum cha rge roller [C]

and the erase lamp [D].

2-11

Page 33

VSP Detection

3rd Series of

Copies (17

copies)

PROCESS CONTROL 13th January 1995

VSP Detection

12345678 9101112

1st Series of Copies

VSG

(8 copies)

Detection

• VSG is measured at the start of every copy run.

• VSP is detecte d at the end of a copy run if 10 or more copies ha ve be en

V

SG

Detection

V

SP Detection

2nd Series

of Copies

(5 copies)

13

14 15

SG

V

Detection

29

30

31

V

SG

Detection

made since VSP was last measure d. The transfer belt must be rele ase d to

measure VSP, so it cannot be checked during a copy run .

1.3.3 ID Correction for the VSP Pattern

Background

Developer consists of carrier particles (fe rrite and resin) an d to ner p art icles

(resin and carbon). The positive trib oe lect ric ch arg e on the ton er is cause d by

friction between the carrier and to ne r part icles. However, the chargeability of

carrier decreases with time. Therefore, if the toner weight ratio in the

developer is the same, the amou nt of positive tribo electric charge for one

particle of toner decreases. This is becau se the number of toner particles

which surround one carrier particle is the same, but the charg ea bilit y of one

particle of carrier is less than before.

If the development pot en tia l, that is, the difference of voltage between the

development roller and the drum for the V SP pattern is the same, more toner

particles are attracted to the VSP pattern , because one particle of toner has

less positive charge than before. (Mo re tone r part icles are requ ired to

balance the charge of the VSP pattern.)

If the ID sensor were to check t he VSP pattern’s reflectivity unde r this

condition, the VSP pattern would be darker than before. The CPU would then

incorrectly conclude that the toner weight ratio in the deve loper is too high

even though the ratio actually re main s the same. The CPU wou ld th en

decrease the toner clutch on time, leading to a low percentage of tone r in the

developer by weight as the copy cou nt rises.

If uncontrolled, th is would cause some side effects, such as low image

density or developer adherin g to the copy. To prevent the se side eff ects, ID

correction is done when the VSP pattern is made.

2-12

Page 34

13th January 1995 PROCESS CONTROL

The idea behind ID correction is to cancel th e effe ct on the VSP pattern of the

decrease in the chargability of carrier with time. ID correction is done by

changing the develo pment bias for the VSP pattern so that it has the same

darkness even though the charg ea bility of the carrier has changed .

ID Correction Method

The machine determines whether the developme nt bias ne ed s adjusting by

monitoring the density of the toner/carrier mixtu re in the development unit .

When the toner weight ratio in the developer changes, the voltage output by

the TD sensor changes accordingly. The smaller the toner wight ratio in th e

developer is, the gre at er th e TD se nso r o ut pu t is, as sho wn in th e diagram

below.

Detailed

Descriptions

When new developer with th e sta nd ard concentration (2 .0 % by weight, 20 g

of toner in 1,000 g of developer) is installe d, the TD sensor initial setting must

be done with SP mode 2-214. This sets the sensor output to 2.5 ± 0. 1 V.

As shown earlier, the charge ab ility of carrier in the developer decreases with

the copy count. If no corre ction is done, the CPU tries to decre ase the ton er

weight ratio in the develo pe r. So this eventually causes the reading from th e

TD sensor to exceed its maximum acceptable value (initial value + 1. 0 V).

If the corrected TD sensor output VTREF exceeds the upper limit over 100

times continuously, development bias for the VSP pattern is corrected. VTREF

is the current TD sensor output wit h a corre ction factor included that is base d

on the VSP/VSG ratio from the ID sensor (see VSP and VSG Detection)

calculated every 10 copies or so (see Toner Supply Control - Detect Sup ply

Mode for more about VTREF).

The first time this happens, the correction is -40 V. If the upper limit is

exceeded 100 consecutive times ag ain later, an extra -40 V correction is

applied (see the following table). There sho uld be no need for furt her st eps,

because the toner proportion by weight will stabilize before this.

2-13

Page 35

PROCESS CONTROL 13th January 1995

Table 6. ID correction

Step Development Bias Correction for the VSP Pattern

Initial 0 V

1st –40 V

2nd –80 V

If no correction is applied, the charge on the drum for the VSP pattern is –600

V, and the developme nt bias fo r t he VSP pattern is –300 V. So there is a

difference of 300 V between the deve lopment roller and the drum for the VSP

pattern.

When the ID correction is applied, the voltage difference is reduced. For

example, if a –40 V ID correction is applied, the difference in voltage is:

Before ID Correction: –300 – (–600) = 300 V

After ID Correction: –300 – 40 – (–600) = 260 V

As a result, the effect of the change in chargeabilit y of the carrie r part icles is

canceled. The darkn ess of the VSP pattern returns to normal.

1.3.4 Toner Supply Control During Copying

There are three modes for con tro lling the toner supply.

• Detect supply mode

• Fixed supply mode

• TD sensor supply mode

The mode can be selected with SP2-208-001. The factory setting is detect

supply mode.

Toner clutch on time is calculated by the following formu la.

S x AT x TSC ⁄⁄ 100

Toner CL on time [ms] =

TS

(Formula 1)

where: S = Copy paper size [cm2]

AT = Amount of ton er de veloped on the latent ima ge per un it area

= 0.7 [mg/cm2] (constant)

TSC = Toner supply coefficient [% ]

TS = Amount of toner supplied per unit of time

= 0.183 [mg/ms] (for A153, A155, and A156 copiers)

= 0.133 [mg/ms] (for A157, A159, and A160 copiers)

AT and TS are constant, an d S de pe nd s only on pap er size, but TSC is

determined in different ways depending on which toner supply mode is in use.

2-14

Page 36

13th January 1995 PROCESS CONTROL

Determination of TSC

TSC is an estimate of the proportion of black area in the image that is made

by the machine.

(1) Detect Supply Mode

In detect supply mode, TSC is determined from out puts fro m bot h the TD and

ID sensors, in conjunctio n with the toner supply ratio that has been selected

for this mode.

- Toner Supply Ratio -

This is selected with SP2-22 2. Th e set tings are 1 (7%), 2 (15%), 3 (30%), or

4 (60%). The default is 15%.

- TD and ID Sensor Outputs -

The machine calculates a value for VT-VTREF.

VT: Current TD sensor output

•

• VTREF: TD sensor output at the latest V SP detection corrected for ID

sensor output (VSP/VSG); this is calculat ed every 10 or so copies (see

VSP/VSG Detection for more on VSP and VSG).

VTREF is determined as follows.

VTREF = VTP + ∆∆ VREF (Formula 2)

VTP = TD sensor output at VSP detection

•

• ∆VREF = Correction factor based on VSP/V SG (from the ID sensor

output), determined by the following table.

Table 7.

VSP pattern

darker

VSP pattern

lighter

VSP/VSG

~ 0.075 +4 x 0.0196

0.076 ~ 0.090 +2 x 0.0196

0.091 ~ 0.105

0.106 ~ 0.125 –2 x 0.0196

0.126 ~ 0.160 –4 x 0.0196

0.161 ~ 0.205 –6 x 0.0196

0.206 ~ 0.500 –8 x 0.0196

0.501 ~ The previous V

∆∆ VREF [V]

±0

TREF

Detailed

Descriptions

TSC [%] is then determined from VT-VTREF and the toner supply ratio, as

shown by table 8.

2-15

Page 37

PROCESS CONTROL 13th January 1995

Table 8. Toner Supply Coefficient (%)

(VT-VTREF)

/0.0196

~ 0 0 0 0 0

1 ~ 3 7 15 30 60

4 ~ 5 15 30 45 60

6 ~ 7 30 45 60 60

8 ~ 60 60 60 60

Supply Ratio (SP Mode Setting)

7% 15% 30% 60%

For example, if the toner sup ply rat io is 15% and (VT-VTREF)/0.0196 is 4.5,

TSC is 30. This value is then used in the formula to determine the toner

supply clutch on time given at the sta rt of this discussion. (See formula 1.)

This all means that, if the ID sensor reading indicated that the most recent

VSP pattern was relatively light, th e toner supp ly clutch will stay on for long er.

(If VSP/VSG is higher, ∆∆ VREF is smaller [Table 7]. This means th at VTREF is

smaller [Formula 2], leading to a larger V T -VTREF. So, for a part icula r ton er

supply ratio, the TSC valu e will be higher [Table 8], so the clut ch stays on for

longer [Formula 1].)

(2) Fixed Supply Mode

TSC [%] is fixed. It is selected with SP mode 2-208-003 as shown below.

Table 9. Toner Supply Coefficient (%)

SP2-208-003 Value

1234

TSC [%] 2 4 6 11

NOTE: Default = 6%

The machine automatica lly switches to fixed supply mode if the ID or TD

sensor fail (see section 1.3.5.).

(3) TD Sensor Supply Mode

TSC [%] is determined as shown in Table 8 fo r det ect supp ly mode .

However, the toner supp ly ratio and V T – V TREF are both determined in

different ways. In particular, the ID sensor outp ut is ignored.

- Toner Supply Ratio -

The supply ratio is selected with SP2-208-002. The set tings are 1 (7%), 2

(15%), 3 (30%), or 4 (60%). The default is 15%.

- VT – VTREF -

• VTREF = VTREF at the moment that TD sensor supply mode was selected.

• VT = Current TD sensor output

1.3.5 Toner Supply in Abnormal Sensor Conditions

2-16

Page 38

13th January 1995 PROCESS CONTROL

If any sensor errors occur under dete ct sup ply mode, toner supply mode is

changed automatically as shown be low.

Table 10.

Error Abnormal Condition

ID Sensor

Adjustment Error

Abnormal ID

Sensor (V

Abnormal ID

Sensor (V

TD Sensor

Adjustment Error

TD Sensor (V

Measurement Error

Drum Charge

Thermistor Error

Abnormal Drum

Charge Thermistor

Output

SP)

SG)

T)

When ID sensor output

cannot be adjusted to 4.0 ±

0.2 V

If V

SP > 2.5 V during VSP

detection.

If V

SG < 2.5 V during VSG

detection

When TD sensor output

cannot be adjusted to 2.5 ±

0.1 V

If VT > 4.0 V or VT < 0.3 V

during V

Temperature detected by the

drum charge thermistor is

below 0°C or above 60°C

Temperature detected by the

drum charge thermistor (T) is

between 0 °C and 20°C

T detection.

Fallback Toner

Supply Mode

Fixed Supply Mode None

Fixed Supply Mode

Fixed Supply Mode

Fixed Supply Mode

Fixed Supply Mode

Fixed Supply Mode None

TD Sensor Supply

Mode

Display on

Operation Panel

None

Manual ID level or

ADS indicator

blinks

Manual ID level or

ADS indicator

blinks

None

NOTE: No indicat ion is displayed under the "abnormal drum ch arg e

thermistor output" con dition, because the mach ine soon recovers due

to the heat inside th e mach ine.

Detailed

Descriptions

2-17

Page 39

Drum

residual

voltage

Light intensity

PROCESS CONTROL 13th January 1995

1.4 DRUM POTENTIAL CONTROL

The characteristics of the drum vary with the tempe rat ure arou nd the drum,

and they change as the drum gets older. To take account of these and other

related factors, this machine has the following three drum potential con tro l

routines.

• VR pattern correction

• VL pattern correction

• T/H correction

1.4.1 VR Pattern Correction

(V)

Copy volume

(V)

Drum

potential

Old Drum

New Drum

As the drum ages, the drum residual volta ge grad ua lly increases due to

electrical fatigue (see the upper left chart ). In other words, as the drum gets

older, light does not discharg e it as much (see the upper right chart). This

may cause dirty background on copies. VR pattern detection every 1,000

copies using the ID sensor avoids this problem.

0V Bias

VRP

VR Pattern

ID Sensor

Every time VR pattern detectio n is don e, a strip acro ss the drum is charg ed

using zero development bias an d th e standard charge on the drum cha rge

roller that is used for copyin g (with all corrections included). At the same time ,

all the blocks of the erase lamp turn on to illumin at e this charged area of the

drum.

2-18

Page 40

ID correction

0 V

–40 V

–80 V

13th January 1995 PROCESS CONTROL

If there is residual volta ge on th e dru m, this area of the drum will attra ct some

toner, making a VR pattern. The ID sensor che cks the refle ctivity of the VR

pattern. This sensor output voltage is VRP.

In VR detection, VRP is compared with VRG.

• VRG is the reflectivity of the bare area of the drum, measured by the ID

sensor. It has the same value as VSG (see Image Density Con tro l - VSG

and VSP Detection).

• VRP is the output from the ID sensor reflected from the VR pattern.

When the drum residual voltage increases, the VR pattern becomes darker.

Then, VRP decreases and the VRP/VRG ratio decreases.

Then the CPU increases the ne ga tive development bias voltage to prevent

dirty background, and simultane ou sly increa ses the negative drum charge

roller bias voltage to preven t low imag e densit y. This is t he VR correction.

Table 11. VR correction

RP/VRG

V

x 100(%)

ID Correction Drum Charge Roller

±±0 V

64 ~ 100 60 ~ 100 54 ~ 100

47 ~ 63 42 ~ 59 36 ~ 53 –40 V –40 V

35 ~ 46 30 ~ 41 24 ~ 35 –80 V –80 V

26 ~ 34 21 ~ 29 16 ~ 23 –120 V –120 V

0 ~ 25 0 ~ 20 0 ~ 15 –160 V –160 V

–40 V –80 V

Correction Voltage

±0 V ±0 V

Development Bias

Correction Voltage

For example, taking th e ID correction to be zero for now, if VRP/V RG is 45%,

the drum charge and development bias corrections will both be -80V.

VR correction also depends on the current VSP pattern ID correction that is

being used. If develo pment bias has been increased by ID corre ction, the VR

correction may be smaller in some cases t o take this into account. This is

shown by both the table above and the following figure.

Detailed

Descriptions

2-19

Page 41

PROCESS CONTROL 13th January 1995

Using the same example to illustrate this, but with an ID correction of -40 V,

the corrections will both be -40 V this time.

Note that forced VR detection by SP mode must be done when a new drum is

installed or the ID sensor cle aned or repla ced. (See Service Tables Practical SP Mode Use Tables for the corre ct sequence of SP modes to

perform at this time). The correction is done in the same way as describe d

above.

2-20

Page 42

13th January 1995 PROCESS CONTROL

1.4.2 VL Pattern Correction

VL Pattern

ID Sensor

(V)

Drum

Potential

Initial

Conditions

Exposure lamp voltage

Deteriorated

Conditions

(V)

Dirty optics or deterioration of th e exposure lamp decreases the intensit y of

the light that reaches the drum via th e optics cavit y. As more copies are

made during the drum’s life, the photoconductive layer gets worn and the

response of the dru m to th e exposure lamp weakens.

VL pattern correction counteracts dirty backg rou nd caused by the factors

mentioned above.

The VL pattern is a light gray sensor pattern on the ope rator side of the

bottom of the left scale bracket. The ID sensor outp ut at VSG dete ctio n in

memory is used again as VLG (the refle ctivit y of the bare are a of the drum).

Detailed

Descriptions

When VL pattern de te ction starts, the exposure lamp turns on and the main

motor stays on to rotate the dru m. The drum charge roller, all the blocks of

the erase lamp, the pre-transfer lamp, and the quenching lamp turn on. Then,

the appropriate blocks of the era se lamp turn off and on to ma ke a VL pattern

on the drum surface.

In VL detection, VLP is compared with VLG.

• VLG is the reflectivity of the bare area of the drum, measured by the ID

sensor. It has the same value as VSG (see Image Density Con tro l - VSG

and VSP Detection).

• VLP is the output from the ID sensor reflected from the VL pattern.

2-21

Page 43

PROCESS CONTROL 13th January 1995

VL detection is done at the following times:

• Every 1000 Copies

• Forced Detection: whenever a new drum or exposure lamp is installed, or

exposure lamp voltage is adjust ed , or whe n the optics are cleaned, forced

VL detection (SP3-105 ) must be execu te d. (S ee Service Ta ble s - Practical

SP Mode Use Tables for the correct seque nce of SP modes t o perfo rm at

this time).

Forced VL detection is differe nt from th e routine 1,000 copy VL detection,

so it is explained below in detail.

During forced VL detection, BL and VREF are determined as shown below.

NOTE: BL = Development bias used for VL correction.

SP3-105

START: BL = -50V

BL= BL -20V

Fig. 19

VLP, VLG detection

NO

VLP/VLG > 0.45?

BL = current BL

V

REF

_

YES

= VLP/V

LG

BL starts at -50 V and -20 V is added until the value of VLP is appropriate.

VL Correction Method

During VL pattern de te ctio n, lamp volt ag e, drum cha rge voltage and

development bias are as follows.

• Lamp voltage: same as during normal copying (ADS mode)

• Drum charge voltage for the VL pattern: same as du ring norma l co pyin g

• Development bias for forced VL detection: BL + VR correction + VBL(ID)

Development bias for VL detection every 1000 copies:

•

= BL + (–25 V) + VR correction + VBL(ID)

VBL (ID) is an ID compensation fact or ba sed on th e curre nt ID correction

used for the VSP pattern (see Image Density Control fo r det ails on this ID

Correction). It is applied as sho wn in Tab le 12 .

Table 12

ID correction 0 V –40 V –80 V

V

BL(ID)

±0 V

–10 V –20 V

2-22

Page 44

ID correction

0 V

–40 V

–80 V

13th January 1995 PROCESS CONTROL

- Forced VL Detection -

When forced VL detection (SP3-105) is exe cut ed , th e CPU sto res the VL

reference value (V REF) in memory (see Fig. 19).

VREF = initial VLP/VLG

- Every 1,000 copies -

After the forced VL detection , V L de te ction is performed at the end of eve ry

1000 copies. The VLP/V LG value at that time is called VDAT.

VDAT = current VLP/VLG

- During Copying -

The CPU compares the late st VDAT with the latest VREF and applies a VL

correction to the exposure lamp voltage as shown below.

Table 13. VL Correction

ID Correction Lamp

±±0 V

–40 V –80 V

Correction

Voltage

Detailed

Descriptions

DAT/VREF

V

x 100 (%)

146 ~ 156 ~ 168 ~ –1 V

101 ~ 145 101 ~ 155 101 ~ 167

~ 100 ~ 100 ~ 100 +1 V

±0 V

In general, the lamp will be dimmed slightly if the VLP pattern reflectivity has

increased significan tly (th e V LP patte rn is pale r), and mad e bright er if th e

reflectivity has decreased (the VLP pattern is darker).

VL correction also depends on the current VSP pattern ID correction that is

being used (see Image Den sity Con trol - ID Correction for the V SP pattern).

For example, taking th e ID correction to be zero for now, if VDAT/VREF is

150%, the lamp correction will be -1V (made slightly dimmer). Usin g the

same example, but with an ID correction of -40V, the correction will be 0 V

this time.

2-23

Page 45

PROCESS CONTROL 13th January 1995

1.4.3 T/H Correction

Potential of new drum

Change in drum potential

with use

The drum charge efficiency is t he ratio of the charge actually on the drum to

the charge that was applied to the dru m. It varies with the temperature

around the drum charge roller. It dro ps of f at lower te mpe rat ures, so the

lower the temperature is, the high er th e cha rge tha t is required.

Also, as the drum ages, the photocon du ctive layer ge ts worn . This cau ses a

decrease in the drum pote nt ial after charging.

The drum charge thermistor detects the tempe rat ure (T) aro und the dru m

charge roller. The drum charge ro ller volt ag e is chan ged to account for the

effects of temperat ure on dru m charg e ef ficiency.

The CPU also keeps track of the drum rotat ion time (H) that corresponds to

the wear on the drum surface. The drum cha rge roller voltage is increased at

set intervals.

These corrections for the drum charg e rolle r volta ge are calle d T/H corre ctio n.

The T/H correction that is applie d du ring copying differs from that applied

when making ID sensor patterns. See below for how the correction is

determined.

The T/H correction difference be twe en the A15 3, A155, and A15 6 copiers

and the A157, A159, and A160 copiers is a result of th e dif ference in copy

processing speed (200 mm/s fo r the A15 3, A155, and A15 6 copiers,

compared with 150 mm/s for the A157, A159, and A160 copiers).

2-24

Page 46

13th January 1995 PROCESS CONTROL

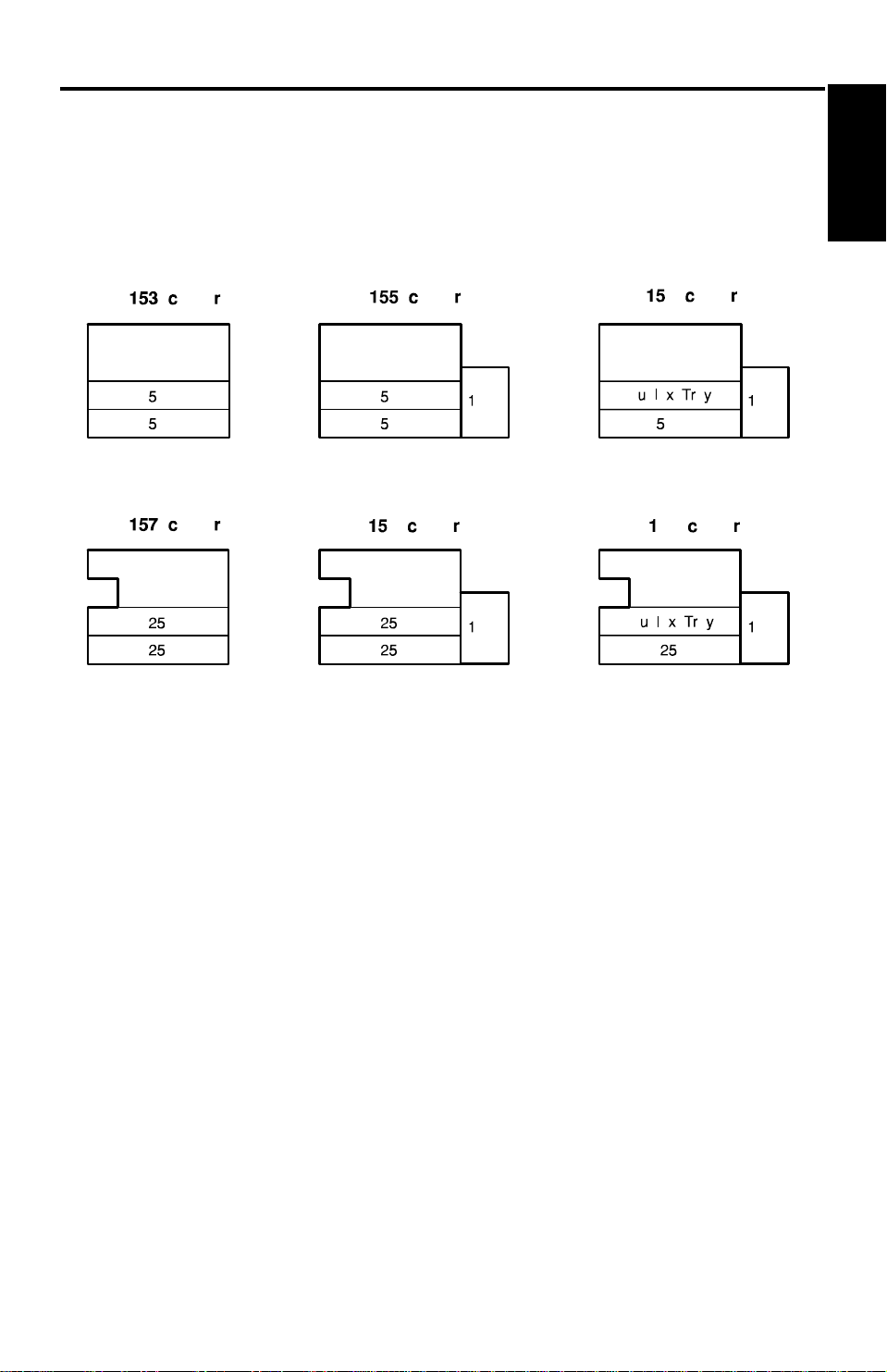

Table 14. T/H Correction (Copying) - Base drum charge voltage = -1500 V

A153, A155, and A156 copiers

Drum Charge Roller

Temperature (T )

37.1 ≤ T

29.6 ≤≤ T < 37.1

17.9 ≤≤ T < 29.6

12.6 ≤≤ T < 17.9

T < 12.6 -639.0 -800.0 -961.0

0 ≤≤ H < 40 40 ≤≤ H < 110 110 ≤≤ H

-60.0 -60.0 -60.0

-203.4 + 3.9xT -203.4 + 3.9xT -203.4 + 3.9xT

-729.1 + 21.6xT -923.9 + 28.2xT -1116.1 + 34.7xT

-1345.1 + 56.0xT -1705.8 + 71.9xT -2068.9 + 87.9xT

Drum Rotation Time (H)

A157, A159, and A160 copiers

Drum Charge Roller

Temperature (T)

32.4 ≤≤ T

28.2 ≤≤ T < 32.4

18.0 ≤≤ T < 28.2

12.4 ≤≤ T < 18.0

T < 12.4 -530.0 -669.0 -808.0

0 ≤≤ H < 40 40 ≤≤ H < 110 110 ≤≤ H

-80.0 -80.0 -80.0

-426.7 + 10.7xT -426.7 + 10.7xT -426.7 + 10.7xT

-621.8 + 17.6xT -768.4 + 22.8xT -912.2 + 27.9xT

-1028.6 + 40.2xT -1357.2 + 55.5xT -1689.7 + 71.1xT

Drum Rotation Time (H)

Table 15. T/H Correction (VSP Pattern) - Base drum char ge = -1300 V

A153, A155, and A156 copiers

Drum Charge Roller

Temperature (T)

37.1 ≤≤ T

29.6 ≤≤ T < 37.1

17.9 ≤≤ T < 29.6

12.6 ≤≤ T < 17.9

T < 12.6 -387.0 -508.0 -629.0

0 ≤≤ H < 40 40 ≤≤ H < 110 110 ≤≤ H

+40.0 +40.0 +40.0

-103.4 + 3.9xT -103.4 + 3.9xT -103.4 + 3.9xT

-489.9 + 16.9xT -603.8 + 20.8xT -717.6 + 24.6xT

-862.5 + 37.7xT -1164.2 + 52.1xT -1465.9 + 66.4xT

Drum Rotation Time (H)

Detailed

Descriptions

A157, A159, and A160 copiers

Drum Charge Roller

Temperature (T)

32.4 ≤≤ T

28.2 ≤≤ T < 32.4

18.0 ≤≤ T < 28.2

12.4 ≤≤ T < 18.0

T < 12.4 -331.0 -426.0 -520.0

0 ≤≤ H < 40 40 ≤≤ H < 110 110 ≤≤ H

+24.0 +24.0 +24.0

-283.9 + 9.5xT -283.9 + 9.5xT -283.9 + 9.5xT

-402.6 + 13.7xT -532.4 + 18.3xT -662.2 + 22.9xT

-719.3 + 31.3xT -919.5 + 39.8xT -1117.6 + 48.2xT

Drum Rotation Time (H)

For example, when copying with an A157 copie r at 25 °C with a dru m t hat ha s

a rotation time of 100 hours:

• The T/H correction is -768.4 + (22.8 x 25) V = -198.4 V.

• The drum charge roller voltage is the base voltage plus the T/H correction

= (-1500) - 198.4

= -1698.4 V.

2-25

Page 47

PROCESS CONTROL 13th January 1995

1.5 PROCESS CONTROL DURING ABNO RMAL CONDI TI O N S

When an abnormal sensor condition occurs, some process controls are

disabled.

Abnormal

Condition

Thermistor Error

TD Sensor

Adjustment Error

TD Sensor

Detection Error

SP Error

V

V

L Error

ID Sensor

Adjustment Error

SG Error

V

ID Sensor

Adjustment

Executed

Process Control

R Correction VL Correction

V

Disabled

ID sensor adjustment error → Disabled

If the ID sensor can be adjusted → Executed

ADS Sensor

Adjustment

2-26

Page 48

13th January 1995 PROCESS CONTROL

1.6 SUMMARY

1.6.1 Process Control and Sensor Detection Timi ng

A summary of process control and correction timing is shown below.

Correction

Manual ID

correction

Reproduction

ratio

correction

ADS

correction

ID

correction

and

Toner

density

control

R

V

correction

V

L correction

T/H

correction

Electrical

Component

Sensor

Output Used

Correction Timing

Forced

Correction

Operation

panel

——

Operation

panel — —

ADS sensor

VADS (pattern)

V

ADS (original)

—

New drum,

ADS sensor,

or exposure

lamp

ID sensor V

SG New drum or

ID sensor

replacement

TD sensor V

SP About every

V

T When the

developer is

changed

ID sensor V

RP, VRG New drum or

ID sensor

replacement

ID sensor V

LP, VLG New drum or

exp. lamp

• Drum

charge

roller

thermistor

• RAM Board

T:

(temperature)

H:

(drum

rotation time)

H is reset at

the drum

initial setting

Automatic

Correction

Every copy in

manual ID

mode

Every copy in

reduce/enlarge

mode

• ADS Mode:

Once per

original

(ARDF

mode), or

once when

the Start

key is

pressed

(Platen

mode)

Every 1000

copies

At the start of

each copy job

10 copies

Every copy

After every

1000 copies

Every copy

Corrected

Value

• Lamp

voltage

• Dev. bias

Development

bias

Development

bias

• VADS

(pattern)

is

stored

• Dev. bias

• Toner

supply

clutch ON

time

• Drum

charge

roller

voltage

• Dev. bias

Lamp voltage

Drum charge

roller voltage

Detailed

Descriptions

2-27

Page 49

PROCESS CONTROL 13th January 1995

1.6.2 Process Control Checks During Machine Operation

This section shows what the machine checks and recalibrates to cont rol the

copy process at different times.

Every Copy

The machine automatica lly adjusts the following process con tro l p ara met ers

every copy.

Uses:

IMAGE DENSITY

CONTROL

VSG Correction

Done at the start of every

copy run

ID Sensor

Affects:

Development bias

Toner supply clutch on time

IMAGE DENSITY

CONTROL

T

V

Correction

DRUM POTENTIAL

CONTROL

T/H Correction

Reduce

or Enlarge

Mode?

Which ID Mode?

MANUAL

Done every copy

Done every copy

YES

ADS

COPY IMAGE CONTROL

Reproduction Ratio

Correction

COPY IMAGE CONTROL

ADS Correction

Uses:

TD sensor

Affects:

Development bias

Toner supply clutch on time

Uses:

Drum charge thermistor

Drum rotation time to date

Affects:

Drum charge roller voltage

Uses:

Selected reproduction ratio

Affects: Development bias

Done: Every copy

Uses: ADS sensor

Affects: Development bias

Done:

Single copy of an original Every copy

More than one copy of the

same original Every copy (but only for the

first copy run)

COPY IMAGE CONTROL

Manual ID Correction

IMAGE DENSITY

CONTROL

VSP Detection

Uses:

Selected image density setting

Affects: Development bias

Exposure lamp voltage

Done: Every copy

Done at the end of the copy

run if more than 10 copies

have been made since the

previous V

SP

detection.

2-28

Uses: ID Sensor

Affects: Development bias

Toner supply clutch on time

Page 50

13th January 1995 PROCESS CONTROL

Every 1000 Copies

After every 1,000 copies, the machine calibrates the following reference

values for the various pro cesses that are used in process cont rol.

NOTE: If the aut o pro cess con trol mode has been disabled wit h SP 3-801,

this process control cycle will not be perfo rmed .

Uses:

IMAGE DENSITY CONTROL

SG

Reset

V

Resets VSG to 4 ± 0.2 V.

ID sensor

Affects:

Development bias

Toner supply clutch on time

Detailed

Descriptions

DRUM POTENTIAL

CONTROL

R

Correction

V

DRUM POTENTIAL

CONTROL

L

Correction

V

COPY IMAGE CONTROL

Auto ADS Gain Adjustment

Measures V

Sets VRG = V

Measures V

Sets VLG = V

Adjusts ADS sensor ouput

voltage for the ADS

sensor pattern to 2.7 ± 0.1

V.

After Adding New Developer

RP

LP

SG

SG

Uses:

ID sensor

Affects:

Development bias

Drum charge roller voltage

Uses:

ID sensor

Affects:

Exposure lamp voltage

Uses:

ADS sensor output

Affects: Development bias

The technician must do the follo wing SP mode after adding new de velo pe r.

SP 2-214

IMAGE DENSITY CONTROL

TD Sensor Initial Setting

Resets the TD sensor output to 2.5 ± 0.1 V

Resets ID correction for the V

SP

pattern to

zero (this affects development bias and

exposure lamp voltage)

2-29

Page 51

PROCESS CONTROL 13th January 1995

After Installing a New Drum

The technician must do a series of SP mod es to reset the process control

parameters related to the drum.

SP 3-123

Resets the following

V

correction level

DRUM INITIALIZATION

R

V

correction level

L

T/H correction level

Drum rotation time

IMAGE DENSITY CONTROL

CONTROL V

SG

Reset

V

DRUM POTENTIAL

Exposure Lamp Voltage

R

Detection

ADJUSTMENT

SP 3-001

Adjusts V

to 4 ± 0.2 V

SG

SP3-112

Detects the initital V

R

value for the new drum

SP4-001

See "Removal and Adjustment Copy Quality Adjustments"

COPY IMAGE CONTROL

Auto ADS Gain Adjustment

DRUM POTENTIAL

CONTROL

L

Detection

V

SP 4-201

Adjusts the ADS sensor

output to 2.7 ± 0.1 V

SP 3-105

Detects the initial V

value for the new drum

2-30

LP/VLG

Page 52

Development bias, dr um charge voltage, and e xposure lamp voltage

6th January 1995

The following table shows how process control affects development bias, drum charge, and exposure lamp voltages for various machine

operations.

Mode Development Bias [V] Drum Charge Voltage [V] Exposure Lamp Voltage [V]

2-31

Reproduction

correction

Reproduction

+

ratio

correction

Reproduction

+

correction

ratio

ratio

Copying

ADS mode

Manual

ID

mode

ID

Level

1 ~ 6

ID

Level

7

(–240) + ADS correction +

(–240) +

(–240) +

Manual ID

correction

Lightest ID level

dev.

bias

VSP Pattern Detection (–300) + BP + ID correction

VR Pattern Detection 0

VL

Pattern

Detection

Non Image Area

Forced VL

Detection

VL Detection

Auto ADS Gain

Adjustment

BL +

correction

BL + (–25) +

(–200) +

VR

+ VBL (ID)

VR

correction

VR

correction

+ VBL (ID) Vexp +

+ VBL (ID)

00

+

VR

+

correction

VR

correction

VR

+

correction

+ B

+ B

+ B

(–1500) +

(–1300) +

(–1500) +

VR

correction

correction

VR

correction

+

T ⁄ H

+

T ⁄ H

correction

+ CP

T ⁄ H

correction

+ C

+ C

0 0

Vexp +

Vexp +

Manual ID

Vexp +

correction

correction

0

0

Vexp

correction

correction

VL

+

VL

VL

VL

correction

NOTE:

B = Development bias adjustment factor, selected with SP2-201-001.

BP = Correction to the development bias used for making for V

SP patterns, selected with SP2-203.

BL = The value of the development bias that was reached during the most recently performed forced V

V

BL (ID) = ID compensation factor based on the current ID correction used for making VSP patterns.

C = Correction to the drum charge voltage, selected with SP2-001.

CP = Correction to the drum charge voltage for maknig V

SP patterns, selected with SP2-003.

Vexp = Exposure lamp voltage, selected with SP4-001.

PROCESS CONTROL

L detection routine.

Page 53

1

DRUM 13th January 1995

2. DRUM

2.1 DRUM UNIT

4

5

6

The drum unit consists of the components shown in the ab ove illustration. An

organic photoconductor (OP C) drum (dia met er: 60 mm) is used for this model.

3

7

2

8

1. OPC Drum

2. Drum Charge Roller

3. Drum Charge Roller Cleaner

4. Drum Charge Thermistor

5. Cleaning Blade

6. Pick-off Pawl

7. ID Sensor

8. Recycled Toner Transport

Coil

2-32

Page 54

13th January 1995 DRUM

2.2 DRIVE MECHANISM

[A]

Detailed

Descriptions

[D]

[C]

[B]

The drive from the main motor is transmitted to the drum drive pulle y via the

timing belt [A]. The pick-off pawls [B] are alwa ys in contact with the drum