Page 1

Technical Bulletin No. RTB-001

SUBJECT: Service Manual Correction DATE: March 31,

’95

PAGE: 1 of 2

PREPARED BY: S. Hizen

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Service program mode 2 - 902 is not available (2-902 will be available). Please correct

your service manual so that the mode 2 - 214 and 2 - 207 are used instead of the 2 - 902

for the development unit initial setting.

(1) The procedure #25 on the page 3-11 should be changed as follows:

25. Perform the "TD sensor initial setting" SP mode follows:

1) Enter "2" and press the "Enter" key.

2) Enter "214" and press the "Enter" key.

3) Press the "Start" key.

NOTE: The machine will automatically stop when TD sensor initial setting is

completed. (It takes about 2.5 minutes.)

Then perform the "Compulsory toner supply" SP mode as follows:

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Phoenix

1) Press the "Clear Modes" key twice.

2) Enter "2" and press the "Enter" key.

3) Enter "207" and press the "Enter" key.

4) Press the "start" key.

NOTE: The machine will automatically stop when compulsory toner supply is

completed. (It takes about 30 seconds.)

5) Compulsory toner supply must be performed twice in order to supply enough toner

to the toner hopper, so press the "Start" key again.

(2) The procedure #26 on the page 3-11 should be changed as follows:

26. A156 copier only:

Select the proper language for the guidance display as follows:

1) Press the "Clear Modes" key twice.

2) Enter "5" in the 3rd digit of the copy counter and press the "Enter" key.

3) Enter "910" and press the "Enter" key.

4) Enter the number for the desired language in the three-digit indicator and press the

"Enter" key.

1:English 2: French 3: German 4:Italian 5:Spanish 6:Swedish 7:Portuguese 8:Danish

9:Norwegian 10:Finish 11: Dutch

Page 2

Technical Bulletin No. RTB-001

SUBJECT: FIRMWARE UPDATE DATE: March 31,

’95

PAGE: 2 of 2

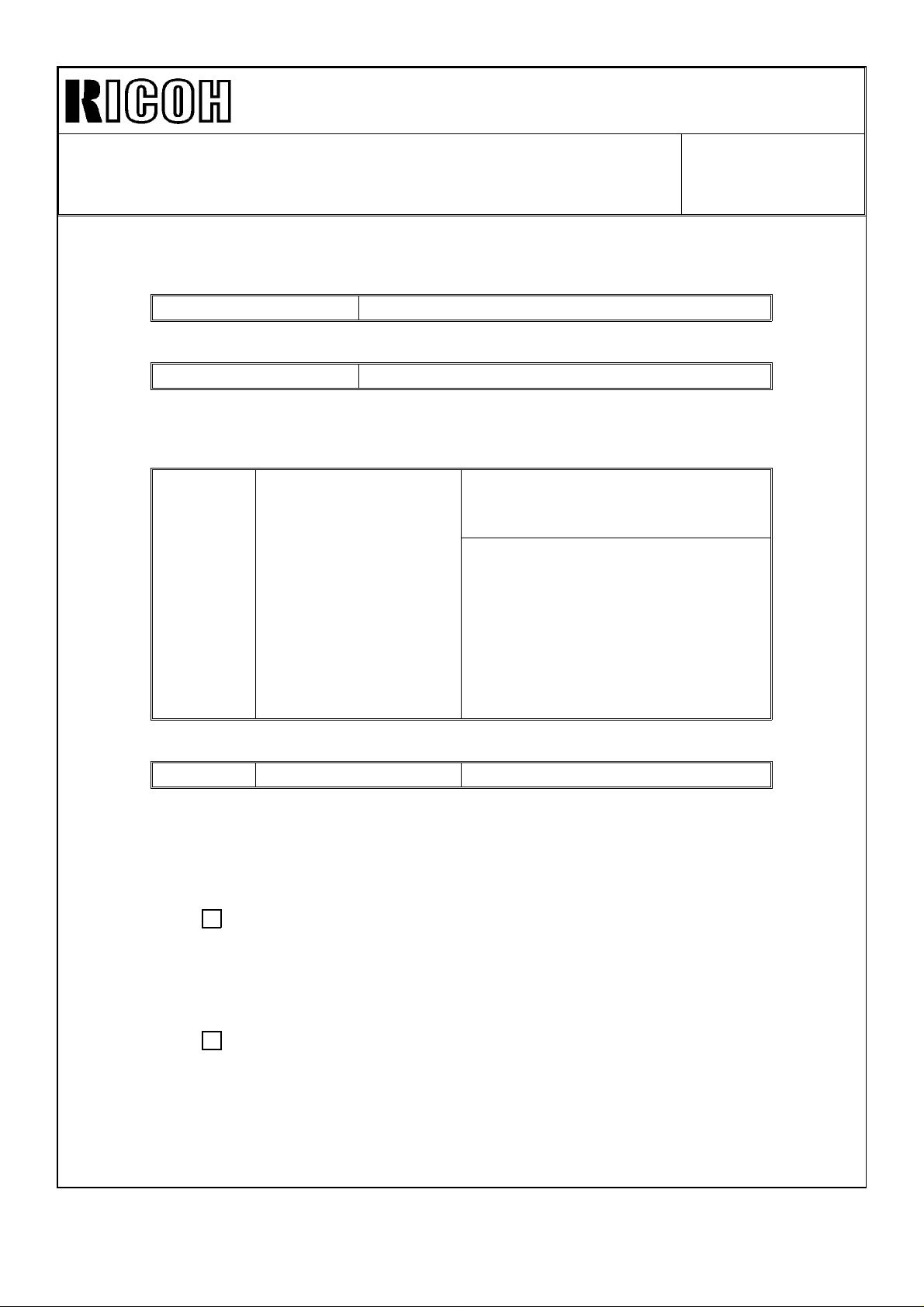

(3) Page 4 - 15

Incorrect

2 - 902 Development Unit Initial Setting

Correct

2 - 902 Not used

(4) Page 4 - 24

Incorrect

Development Unit

Initial Setting

2-902

Correct

2 - 902 Not used ----

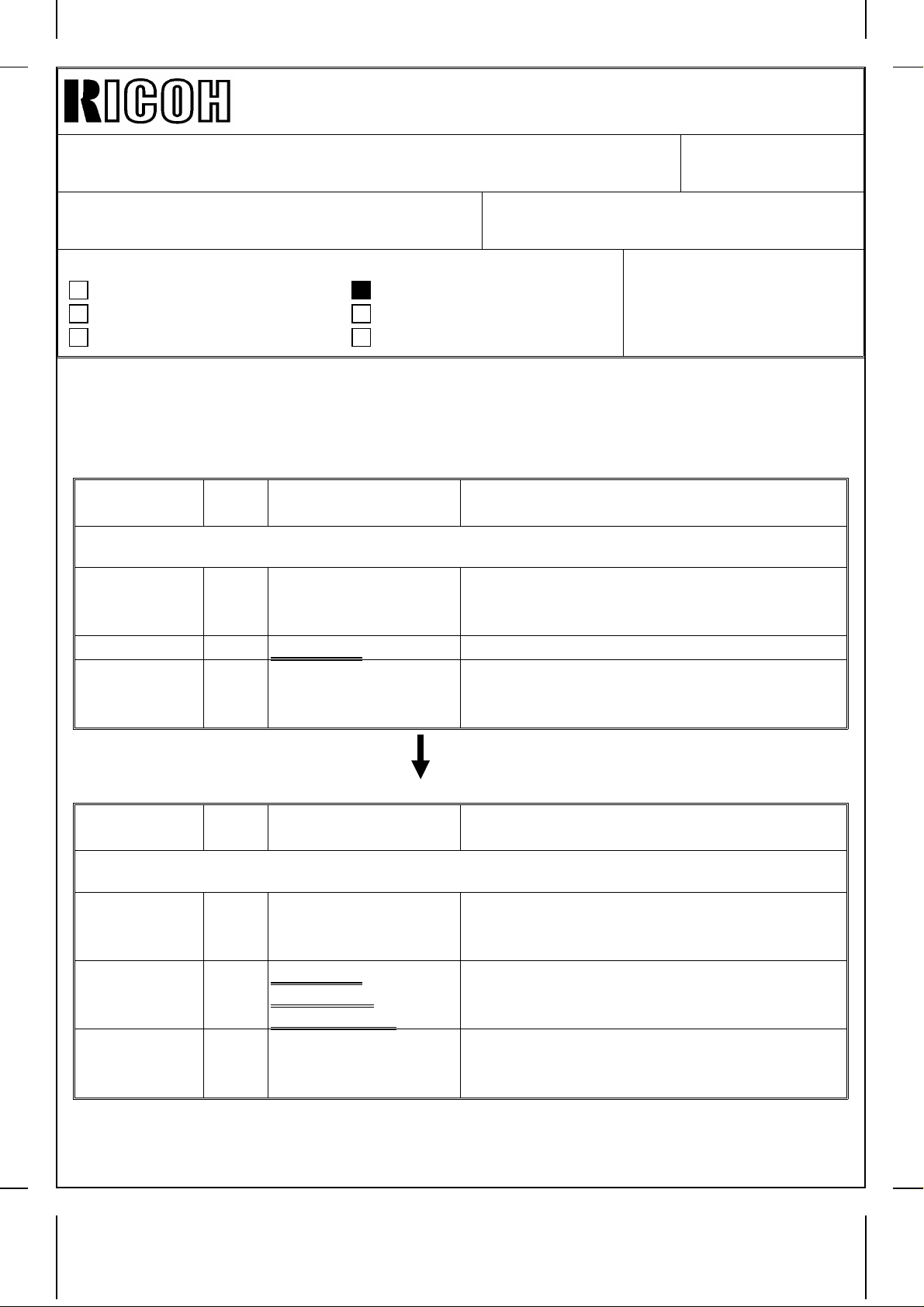

(5) Instructors Guide Step 25 on Page 11 should be changed as follows:

Incorrect:Step 25 - Development Unit Initial Setting (SP Mode 2 - 902)

This SP mode performs TD sensor initial setting and performs forced

toner supply twice.

Performs TD sensor initial setting

and then performs forced toner

supply twice.

To start this SP mode, press the

"Start" key. This SP mode has the

same effect as doing SP2-214 then

doing SP2-207 twice.

This Sp mode must be done

only at copier installation.

This SP mode takes totally about 3

minutes.

Correct: Step 25 - TD sensor initial setting (SP2 - 214) and forced toner supply (SP2

- 207) twice.

These SP modes perform TD sensor initial setting and forced toner

supply

twice.

Note: An RTB for program mode 2 - 902 will be issued as soon as the 2 - 902 is

available.

Page 3

REVISED ON AUGUST 31, ’95

Technical Bulletin No. RTB-002

SUBJECT: Service Manual Correction DATE: June 15, ’95

PAGE: 1 of 6

PREPARED BY: S. Hizen

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Please correct your service manuals as follows : The part that must be corrected is

underlined.

1. Page 1 - 17

Incorrect

Symbol

Others

CB1 9

CC1 10 Choke Coil Removes high frequency current.

TR1 7

Index

No.

Description Note

Circuit Breaker

(220 ~ 240V

machines only)

Transformer

(220 ~ 240V

machines only)

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Phoenix

(Eagle & Falcon)

Provides back-up high current protection for

electrical components.

Steps down the wall voltage to 100 Vac.

Correct

Symbol

Others

CB1 9

CC1 10

TR1 7

Index

No.

Description Note

Circuit Breaker

(220 ~ 240V

machines only)

Choke Coil

(220 ~ 240V

machines only)

Transformer

(220 ~ 240V

machines only)

Provides back-up high current protection for

electrical components.

Removes high frequency current.

Steps down the wall voltage to 100 Vac.

Page 4

REVISED ON AUGUST 31, ’95

Correct

Technical Bulletin No. RTB-002

SUBJECT: Service Manual Correction DATE: June 15, ’95

PAGE: 2 of 6

2. Page 2 - 5

Incorrect

- ADS Pattern Detection and ADS Correction -

If the user selects Auto Image Density (ADS) mode, the machine

monitors the output from the ADS sensor and adjusts the

development bias to compensate for variations in ADS sensor

response. This prevents dirty background.

Every 1,000 copies, the machine calibrates the ADS sensor output by

reading the ADS pattern under the left scale of the exposure glass.

The ADS sensor must also be recalibrated:

• If the drum is changed

• If the ID sensor is cleaned or changed

• If the exposure lamp or optics are cleaned or changed.

- ADS Pattern Detection and ADS Correction -

If the user selects Auto Image Density (ADS) mode, the machine

monitors the output from the ADS sensor and adjusts the

development bias to compensate for variations in ADS sensor

response. This prevents dirty background.

Every 1,000 copies, the machine calibrates the ADS sensor output by

reading the ADS pattern under the left scale of the exposure glass.

The ADS sensor must also be recalibrated:

• If the drum is changed

• If the ADS sensor is cleaned or changed

• If the exposure lamp or optics are cleaned or changed.

Page 5

REVISED ON AUGUST 31, ’95

Technical Bulletin No. RTB-002

SUBJECT: Service Manual Correction DATE: June 15, ’95

PAGE: 3 of 6

3. Page 3 - 1

Incorrect

Correct

1.1 ENVIRONMENT

1. Temperature Range: 10° to 30° (50°F to 86°F)

2. Humidity Range: 15% to 90% RH

3. Ambient Illumination: Less Than 1,500 lux (do not expose to

direct sunlight.)

4. Ventilation: Room air should turn over at least 3

times / hour.

1.1 ENVIRONMENT

1. Temperature Range: 10° to 30° (50°F to 86°F)

2. Humidity Range: 15% to 90% RH

3. Ambient Illumination: Less Than 1,500 lux (do not expose to

direct sunlight.)

4. Ventilation: Room air should turn over at least

3

30m / hour / person.

Page 6

REVISED ON AUGUST 31, ’95

Technical Bulletin No. RTB-002

SUBJECT: Service Manual Correction DATE: June 15, ’95

PAGE: 4 of 6

Please correct your service manuals as follows:

4. Page 5- 27

Please correct the replacement procedures for the Drum Change Roller Terminal as

follows:

4. 10 DRUM CHANGE ROLLER TERMINAL REPLACEMENT

[C]

[B]

[A]

1. Remove the drum charge roller ass’y.

2. Place the drum change roller ass’y [A] on a clean sheet of paper.

3. Remove the drum charge roller terminal [B] (1 screw).

4. Remove the roller terminal [C].

*

NOTE: 1. Never touch the surface of the drum charge roller.

[B]

2. If there is any dirt on the surface of the drum charge roller, wipe it off with a dry

cloth or a special cloth or a special cloth for the drum charge roller.

(The special cloth is available as a service part: A1539004.)

Never use alcohol or water to alean the drum charge roller.

3. When replacing the drum charge roller terminal [B], also replace the roller

*

terminal [C] at the same time.

Page 7

REVISED ON AUGUST 31, ’95

Technical Bulletin No. RTB-002

SUBJECT: Service Manual Correction DATE: June 15, ’95

PAGE: 5 of 6

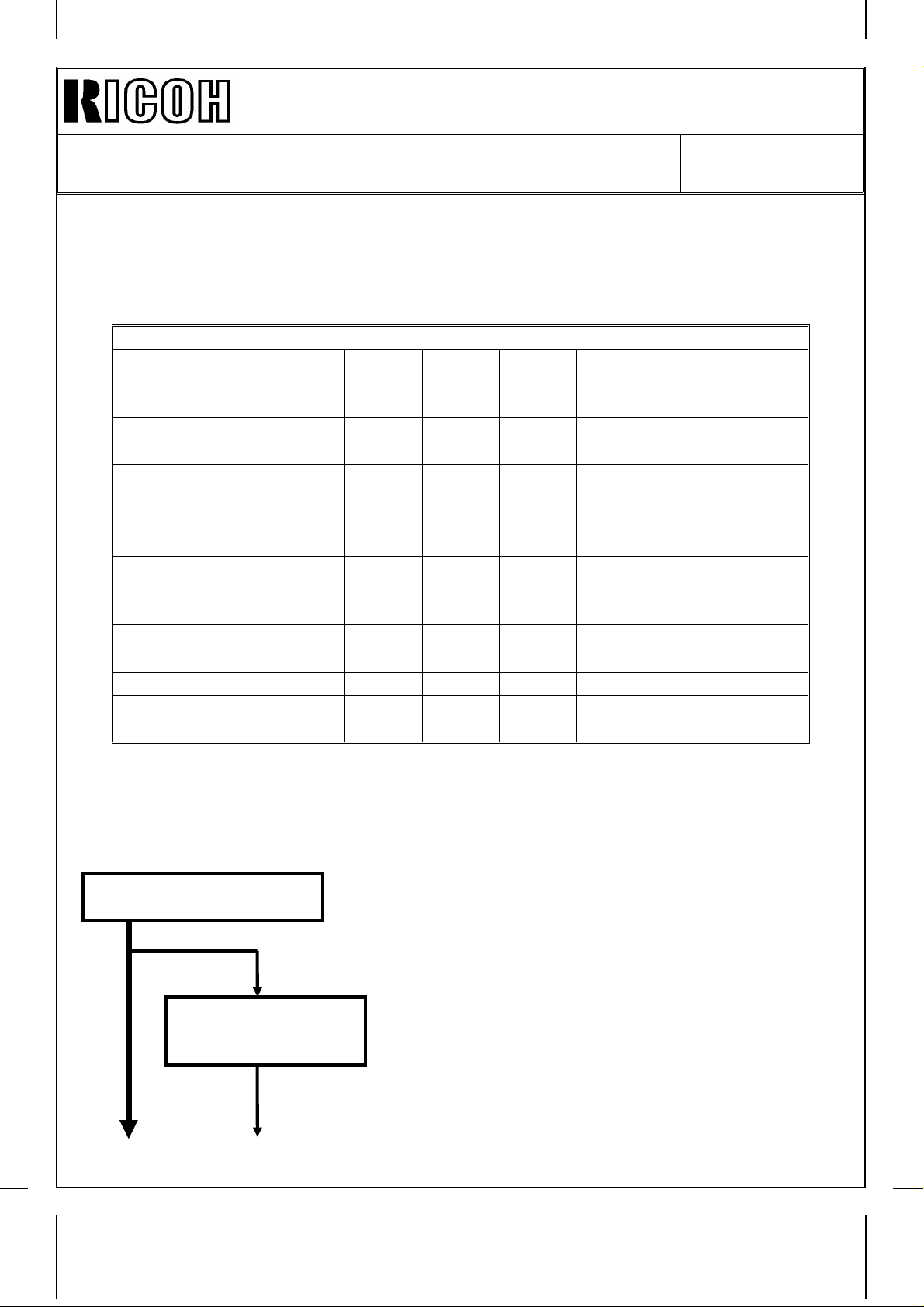

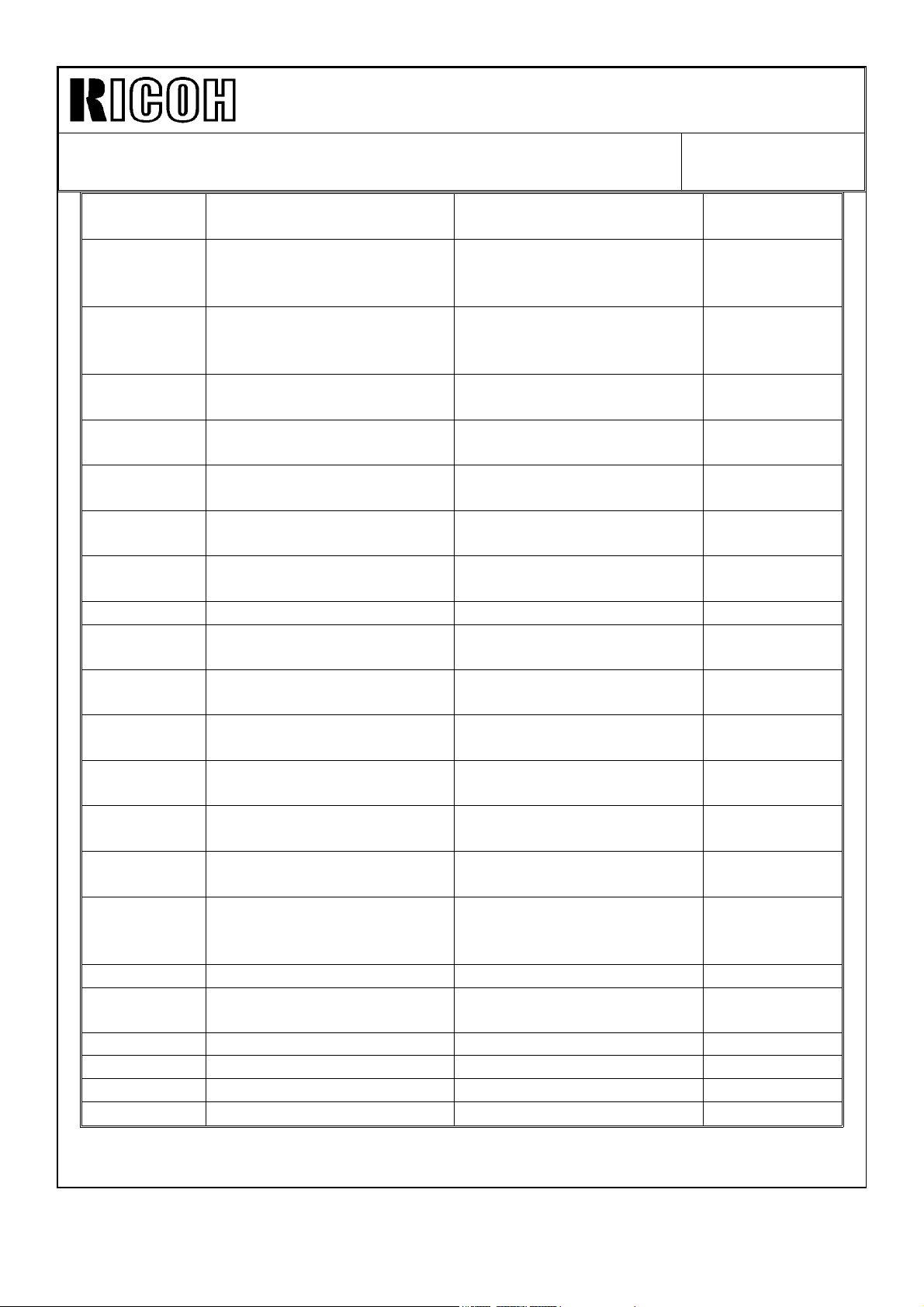

5. Page 4-54 and page 4-56

Please add the Roller Terminal to the PM table.

AROUND THE DRUM

Drum Charge

Roller R R R

Drum Charge

Roller Cleaner

Drum Charge

Roller Terminal

Roller Terminal

*

ID Sensor

Erase Lamp C C C Dry cloth

Quenching Lamp C C C Dry cloth

Pick-off Pawls C R C Dry cloth

Pre-Transfer

Lamp

RRR

RRR

RRR

CCC

CCC

Clean with the special

cloth if necessary (the

cloth must be dry)

Replace with the drum

charge roller as a set

Replace with the drum

charge roller as a set.

Replace with the drum

charge roller as a set

Blower brush. After

cleaning, do SP3-001

then SP3-1 12

Dry cloth and blower brush

6. Page 4-60

Please add the following procedure to the PM procedure.

3. Around the Drum

(every 100 or 120 k)

Replace the

pick-off pawls

(every 200/240 k).

1. Remove the drum and clean the ID sensor with

a blower brush.

2. Clean the pick-off pawls.

3. Clean the quenching, erase, and pre-transfer

lamps with a dry cloth. Discharge any static

electricity before putting them back.

4. Put back the drum.

5. Replace the drum charge roller, drum charge

roller cleaner, drum charge roller terminal,

and roller terminal.

Page 8

REVISED ON AUGUST 31, ’95

Technical Bulletin No. RTB-002

SUBJECT: Service Manual Correction DATE: June 15, ’95

PAGE: 6 of 6

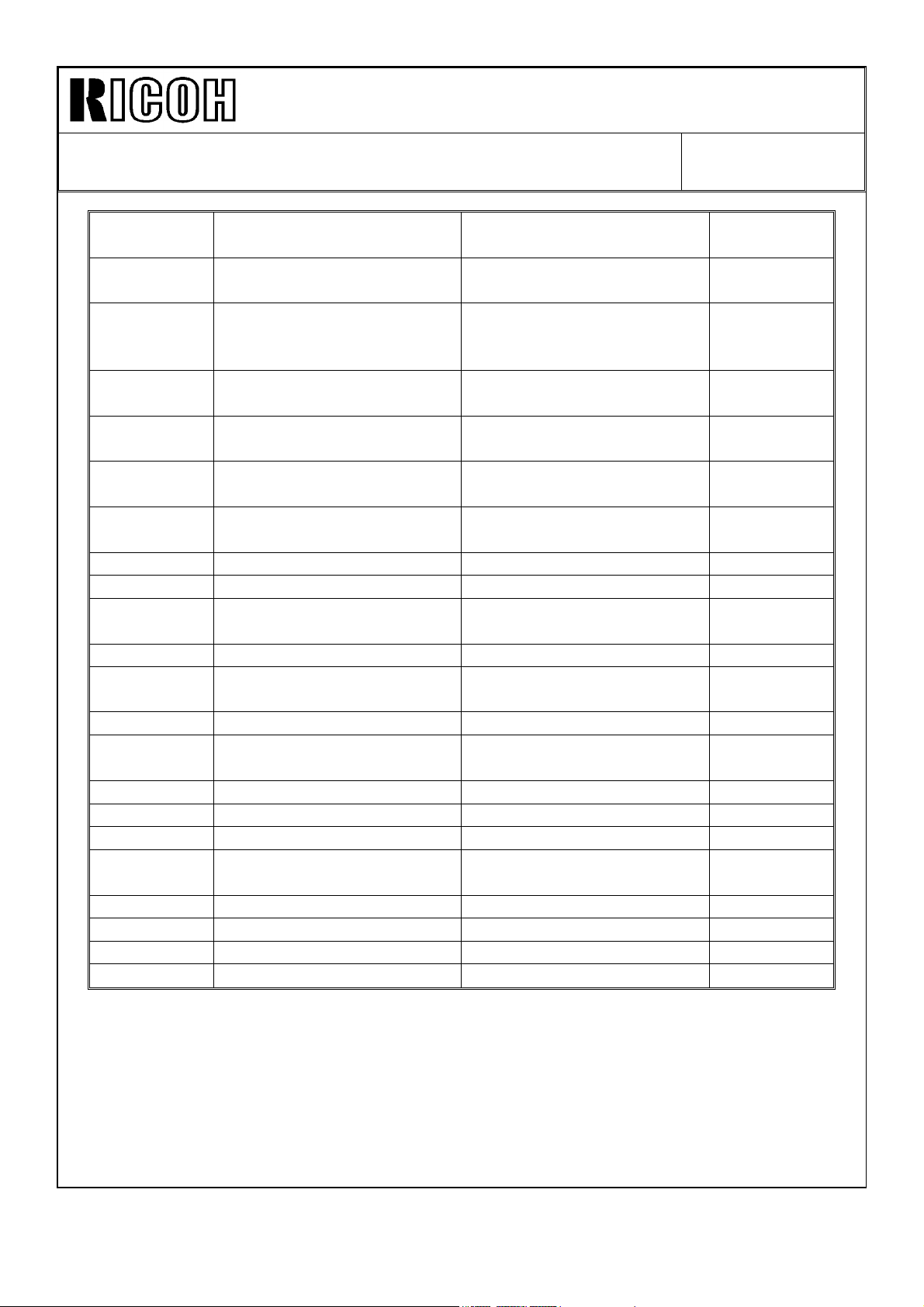

7. Page 4 - 44

Please add the following items to the SP5 - 803 SENSOR / SWITCH INPUT SIGNAL

DATA CHECK Table.

3rd

level No.

Proof Tray Exit Sensor (A554 Sorter Stapler Only)

* 56

Bin Exit Sensor (A554 Sorter Stapler)

* 57

58 Bi n Sensor (A 554 / A555 ) off on

59 Bin H . P. Sensor off on

60 Bin Lift Timing - 1 Screw (A554) / Wheel Sensor (A555) off on

61 Bin Lift Timing - 2 Sensor (A554 only) off on

63 Jogger H. P. Sensor (A554 / A555) off on

64 Grip H. P. Sensor (A554 / A555) off on

66 Staple H. P. Switch (A554 / A555) off on

67 Staple End Switch (A554 / A555) off on

68 Staple Paper Sensor (A554 / A555) off on

69

70

Sorter Entrance Sensor (A555 Sorter Stapler) Paper

Sorter Stapler Set SW. Front Door SW (A554) /

Door Safety SW. (A555)

Roller Drive Timing Sensor (A554) /

Timing Sensor (A554)

Sensor / Switch / Signal

Reading

01

Paper

detected

Paper

detected

not

detected

Door

Closed

off o n

Paper

not

detected

Paper

not

detected

Paper

detected

Door

Open

* : Revised

Page 9

Technical Bulletin No. RTB-003

SUBJECT: SP-Mode Description Cross Reference Table

(A156 copier only)

PREPARED BY: S. Hizen

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The actual messages displayed on the operation panel LCD would not be good enough for

service engineers to know what mode the machine is set in.

Therefore some description in the SP mode table of the service manual are different from

the messages displayed on the operation panel (A156 copier only) to make it clear what

mode the machine is set in.

The following is the message-description cross reference table of the SP-modes.

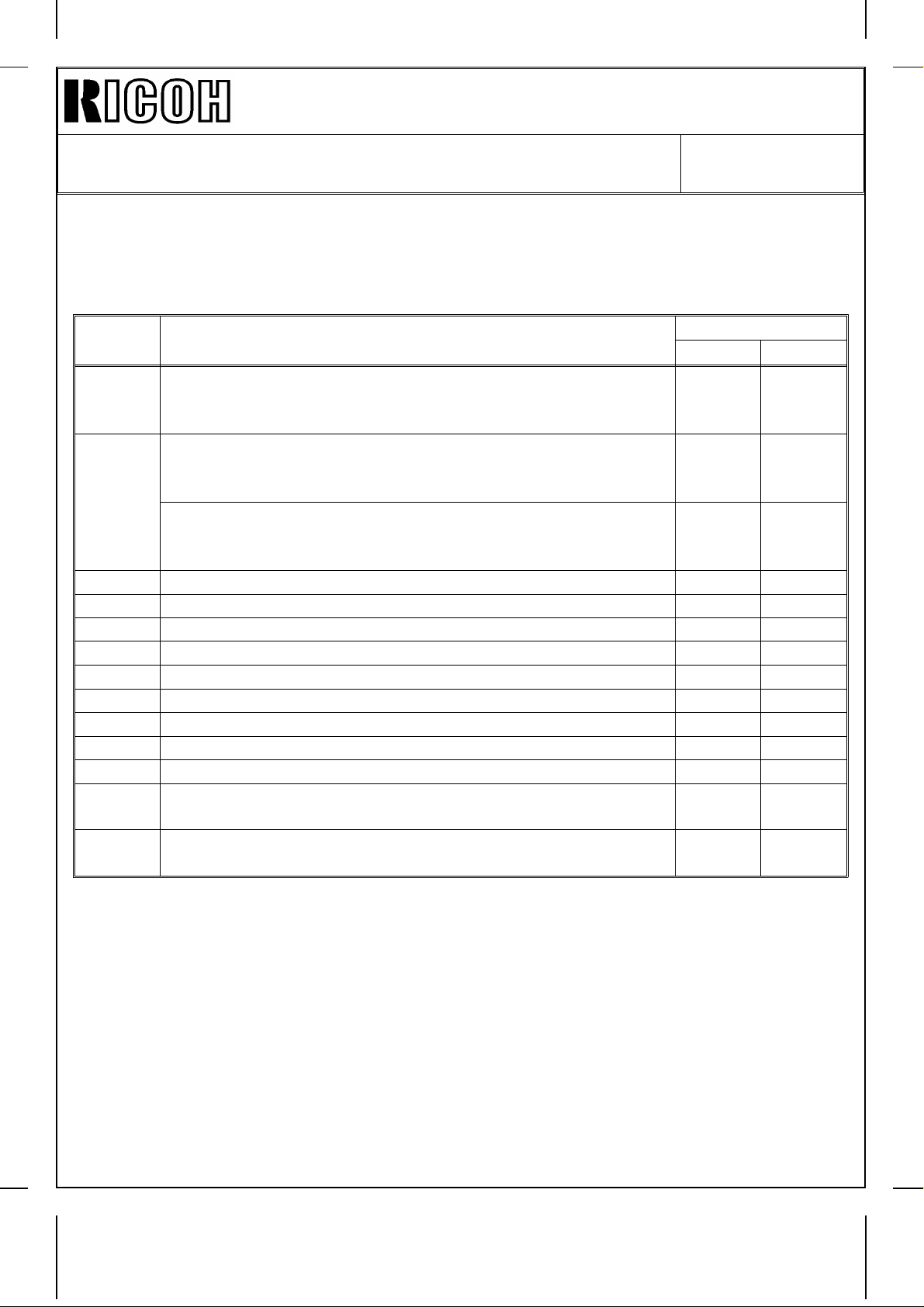

SP - No.

1 - 104 Fusing Control

1 - 105 - 001 Fusing Temperature

1 - 105 - 002 Fusing Temperature

1 - 105 - 003 Fusing Temperature

1 - 106 Fusing Temperature check Fusing Temperature Display (5)

1 - 108 Forced start mode Forced Start (5)

2 - 001 Charge voltage adjustment Drum Charge Voltage

2 - 002 Change voltage check Drum Change Voltage

2 - 003 ID sensor pattern charge

2 - 101 - 001 Lead edge erase margin

2 - 101 - 002 Lead edge erase margin

2 - 201 - 001 Development bias voltage

Message Displayed on

LCD

0: on / off 1: Phase

adjustment

adjustment

adjustment

voltage adj.

adjustment

adjustment

adjustment

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Description in Service

Manual

Fusing Temperature Control (5) see page

Fusing Temperature

Adjustment (Main Fusing

Lamp)

Fusing Temperature

Adjustment for Energy

Saver Mode.

Fusing Temperature

Adjustment (Secondary

Fusing Lamp)

Adjustment (for copying)

Display

Drum Charge Voltage

Adjustment (for making V

patterns)

Leading edge erase margin (2)

Trailing edge erase margin (2)

Development Bias

Adjustment (for copying)

DATE: May 15, ’95

PAGE: 1 of 4

Phoenix (A156 copier

only)

Reason for

difference

4/4 for reason

explanation

(2)

(2)

(2)

(4), (5)

(4), (5)

(1), (4), (5)

SP

(2), (5)

Page 10

Technical Bulletin No. RTB-003

SUBJECT: SP-Mode Description Cross Reference Table

(A156 copier only)

SP - No.

Message Displayed on

LCD

2 - 101 - 002 Development bias voltage

adjustment

Description in Service

Lightest ID Level

Development Bias

Adjustment

2 - 203 ID sensor pattern bias

voltage adj.

Development Bias

Adjustment (for making V

Manual

DATE: May 15, ’95

PAGE: 2 of 4

(2), (5) see page

4/4 for reason

explanation

(1), (5)

SP

patterns)

2 - 206 Development bias voltage

Development Bias Display (5)

check

2 - 207 Compulsory toner supply

Forced Toner Supply (3)

mode

2 - 208 - 001 Toner Supply mode

selection

2 - 208 - 002 Toner supply mode selection Toner Supply Ratio

Toner Supply Mode

Selection

(2)

(2), (5)

(TD Sensor Supply Mode)

2 - 208 - 003 Toner supply mode selection Toner Supply Ratio

(2), (5)

(Fixed Supply Mode)

2 - 215 TD sensor output check TD Sensor Output Display (5)

2 - 220 TD sensor initial output

check

2 - 222 Toner supply ratio selection Toner Supply Ratio

TD sensor Initial Output

Display

(5)

(5)

(Detect Supply Mode)

2 - 802 Main charge roller temp.

monitor

2 - 812 Drum reverse amount

adjustment

2 - 901 Main charge cleaning

0:10 1:5 2:2 3:1

3 - 002 VSG confirmation ID Sensor Initial Setting

Drum Charge Roller

Temperature

Drum Reverse Rotation

Adjustment

Drum Change Roller

Cleaning Interval

(4)

(5)

(4), (5)

(5)

Display

3 - 103 VSG / VSP monitor ID Sensor Output Display

3 - 103 - 001 : V

3 - 103 - 002 : V

SP

SG

(5)

3 - 105 VL adjustment Forced VL Detection (1), (5)

3 - 106 Vref (%)

Initial VLP / VLG Display (1), (5)

(Initial Vsl / Vsg)

3 - 107 Vsl / Vsg check Current VLP / VLG Display (1), (5)

3 - 111 Vsr / Vsg check Current V

/ VRG Display (1), (5)

RP

3 - 112 VR adjustment Forced VR Detection (1), (5)

3 - 123 Drum initial setting Drum Initialize (5)

Reason for

difference

Page 11

Technical Bulletin No. RTB-003

SUBJECT: SP-Mode Description Cross Reference Table

(A156 copier only)

SP - No.

3 - 902 Process control data initial

4 - 001 Base exposure lamp voltage Exposure lamp Voltage

4 - 002 Actual exposure lamp

4 - 008 Magnification adj. (vertical) Vertical Magnification

4 - 011 Horizontal registration adj. Lens Horizontal H. P.

4 - 101 Magnification adj.

4 - 201 Auto ADS sensor adjustment Auto ADS Gain Adjustment (1)

4 - 202 ADS sensor setting ADS Initial Gain Display (1), (5)

4 - 203 ADS sensor actual output

5 - 501 - 001 PM interval set PM Interval Setting (2)

5 - 501 - 002 PM interval set PM Interval Setting (PM

5 - 812 TEL: Telephone Number Input (5)

6 - 001 SADF auto reset SADF Auto Reset Time

6 - 009 DF free run DF Free Run with Paper (5)

7 - 401 SC total counter Total Service Call Counter (5)

7 - 402 SC counter SC Counter by Service Call (5)

7 - 502 Total jams by paper size Total Copy Paper Jam

7 - 807 - 001 SC counter clear SC Counter Clear (2)

7 - 807 - 002 SC counter clear Copy Jam Counter Reset (2)

7 - 807 - 003 SC counter clear Original Jam Counter Reset (2)

7 - 811 Original counter clear DF Counter Clear (5)

Message Displayed on

LCD

setting

voltage

(horizontal)

(V)

Description in Service

Manual

Forced Process Control (5)

Adjustment

Exposure Lamp Voltage

Display

Adjustment

Adjustment

Horizontal Magnification

Adjustment

ADS Actual Gain Display (1), (5)

Alarm Mode Setting)

Setting

Counter

DATE: May 15, ’95

PAGE: 3 of 4

Reason for

difference

(5) see page

4/4 for reason

explanation

(5)

(5)

(5)

(5)

(2)

(5)

(3)

NOTE: This cross reference table is only for the SP modes in which messages on LCD

and the descriptions in service manual are different.

Page 12

Technical Bulletin No. RTB-003

SUBJECT: SP-Mode Description Cross Reference Table

(A156 copier only)

Reason

(1) Similar descriptions to the previous model have been adopted for the service manual.

(2) The messages displayed on LCD do not change even though the different 3rd level SP

numbers are selected. Therefore, in the service manual, the correct descriptions are

written for each 3rd level SP numbers.

(3) Translation mistake of message on LCD.

(4) The part names have been changed after the translation of LCD’s message was done.

(5) The SP mode descriptions in service manual explains the actual function of the mode

as much as possible.

DATE: May 15, ’95

PAGE: 4 of 4

Page 13

Technical Bulletin No. RTB-004

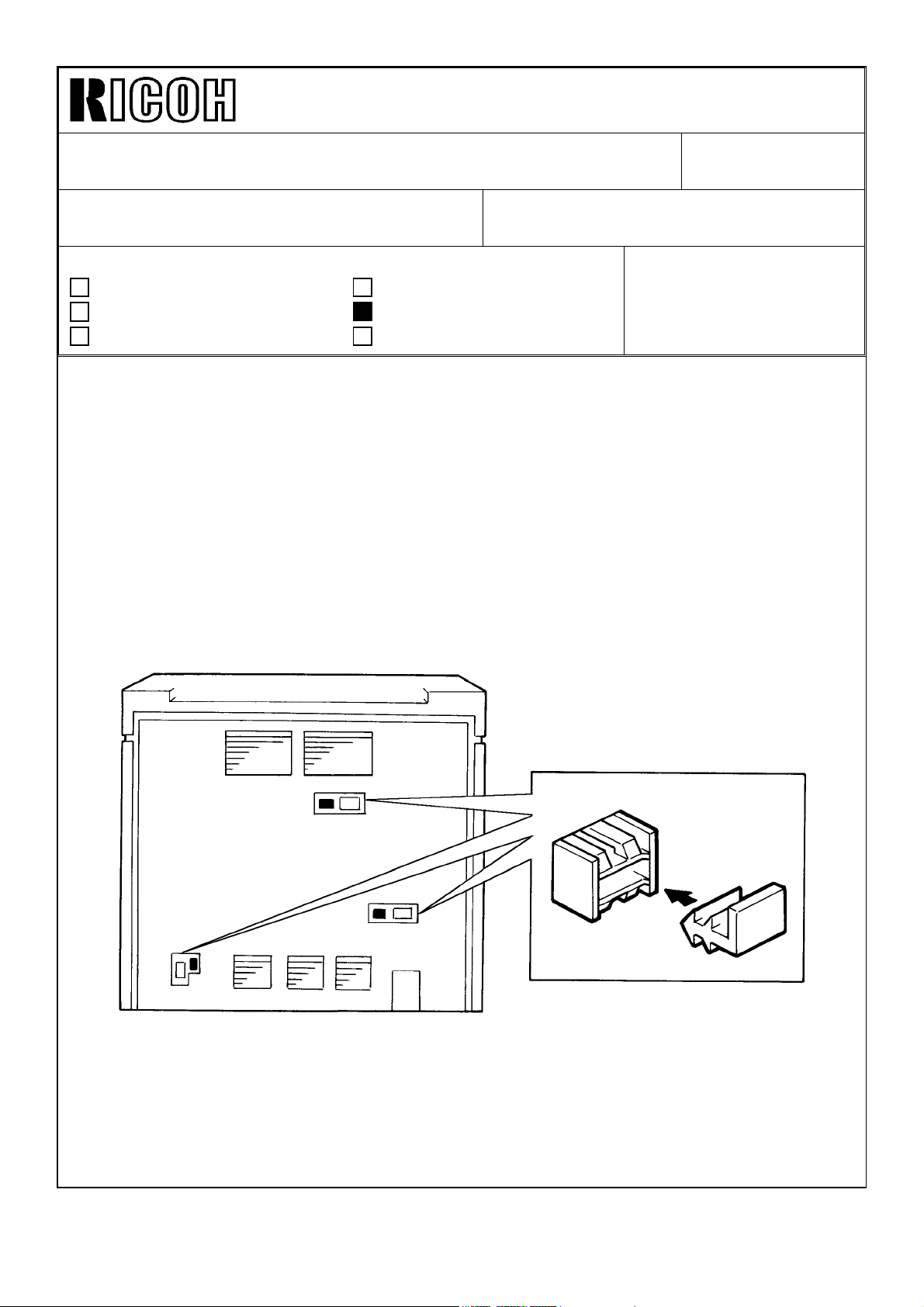

SUBJECT: Rubber Plugs for Fiber Cable Connectors DATE: May 15, ’95

PAGE: 1 of 1

PREPARED BY: S. Hizen

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

A rubber plug has been added to each fiber optics cable connector to prevent a machine

operation malfunction due to light from outside.

The plug(s) must be removed when a peripheral unit is installed. Please add a plug

removal procedure in the peripheral unit installation procedure of your service manual.

The plugs must be installed when the fiber optics cable connection is not used.

Please instruct your field techs to put the plugs in the unused connectors.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Phoenix (Eagle, Falcon)

Page 14

Technical Bulletin No. RTB-005

SUBJECT: Energy Star DATE:October 31,

’95

PAGE: 1 of 12

PREPARED BY: S. Hizen

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This RTB explains the modifications made to meet the Energy Star requirements.

With this modification, to conserve energy, the copier automatically turns off 60 minutes

after the last copying job has been completed.

The details of the machine operation can be found on pages 3 onward of this RTB.

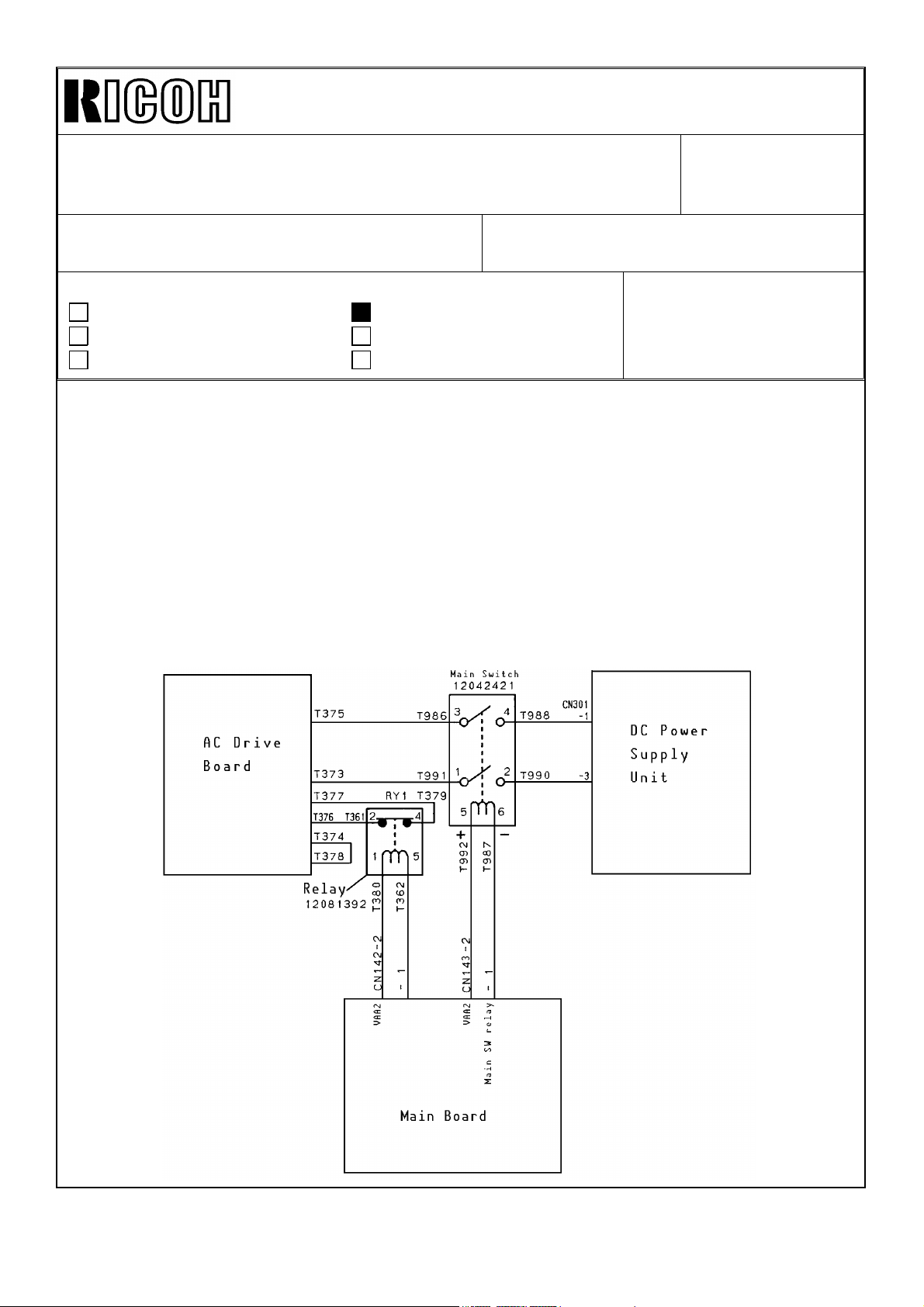

Auto Off Mode

To automatically turn off the copier, a new type of main switch with an incorporated coil is

used. When the CPU drops CN143 - 1 from +24 to 0, the main switch contact is opened.

The wiring diagram and connector layout are shown below.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

Phoenix

(Eagle, Falcon, Swallow)

-10, -15, -17 only

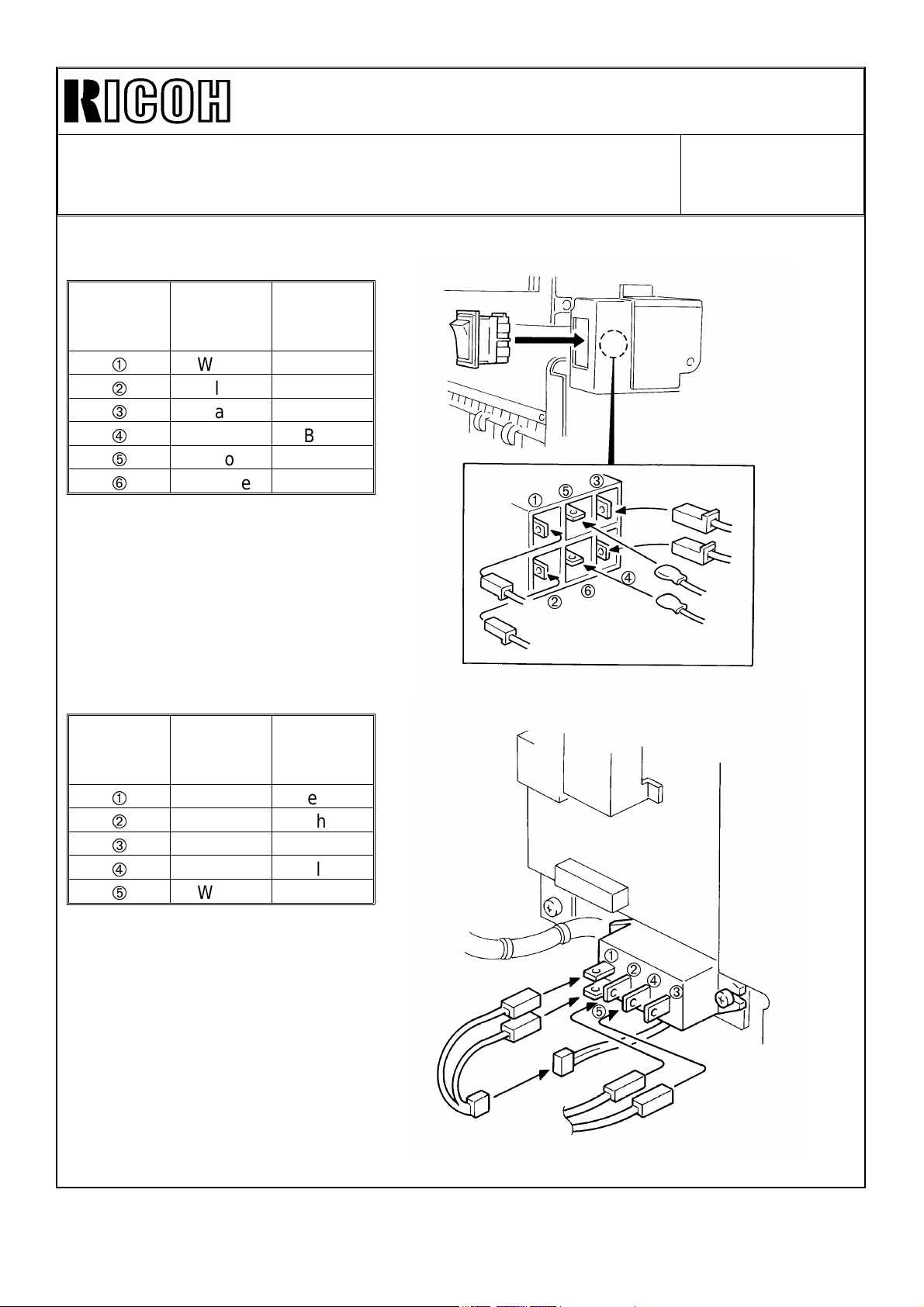

Page 15

Technical Bulletin No. RTB-005

À

Ã

SUBJECT: Energy Star DATE:October 31,

’95

PAGE: 2 of 12

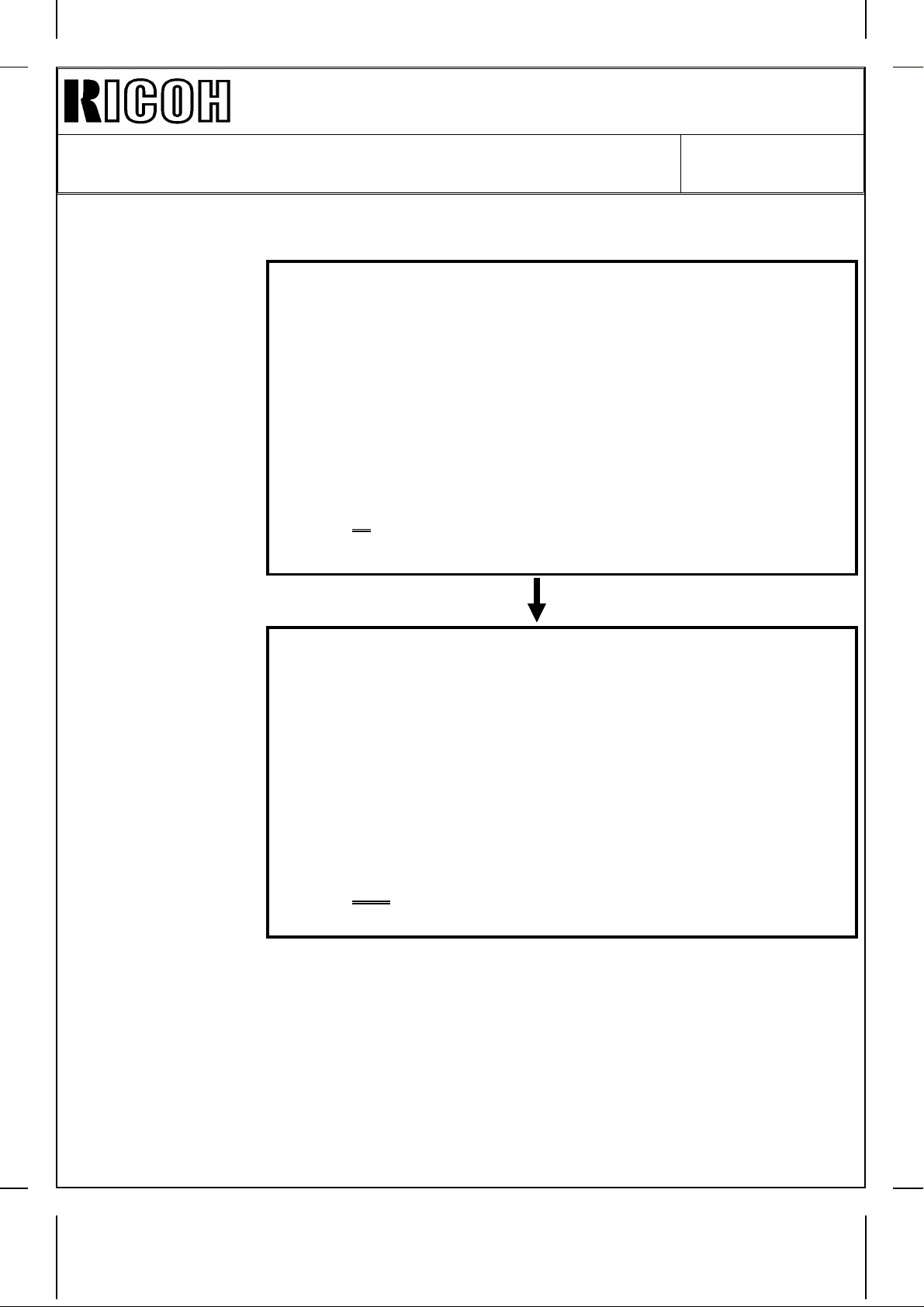

Connector Layout

Main SW

Terminal

No.

À

Á

Â

Ã

Ä

Å

Relay

Terminal

No.

À

Á

Â

Ã

Ä

Wire Color

White Yellow

Blue Blue

Black Yellow

Red Blue

Yellow White

Oranze White

Wire Color

White Yellow

Orange White

——

Black Blue

White Green

Connector

Color

Connector

Color

Á

Ä

Â

Ã

Å

À

Á

Â

Ä

Page 16

Technical Bulletin No. RTB-005

SUBJECT: Energy Star DATE:October 31,

’95

PAGE: 3 of 12

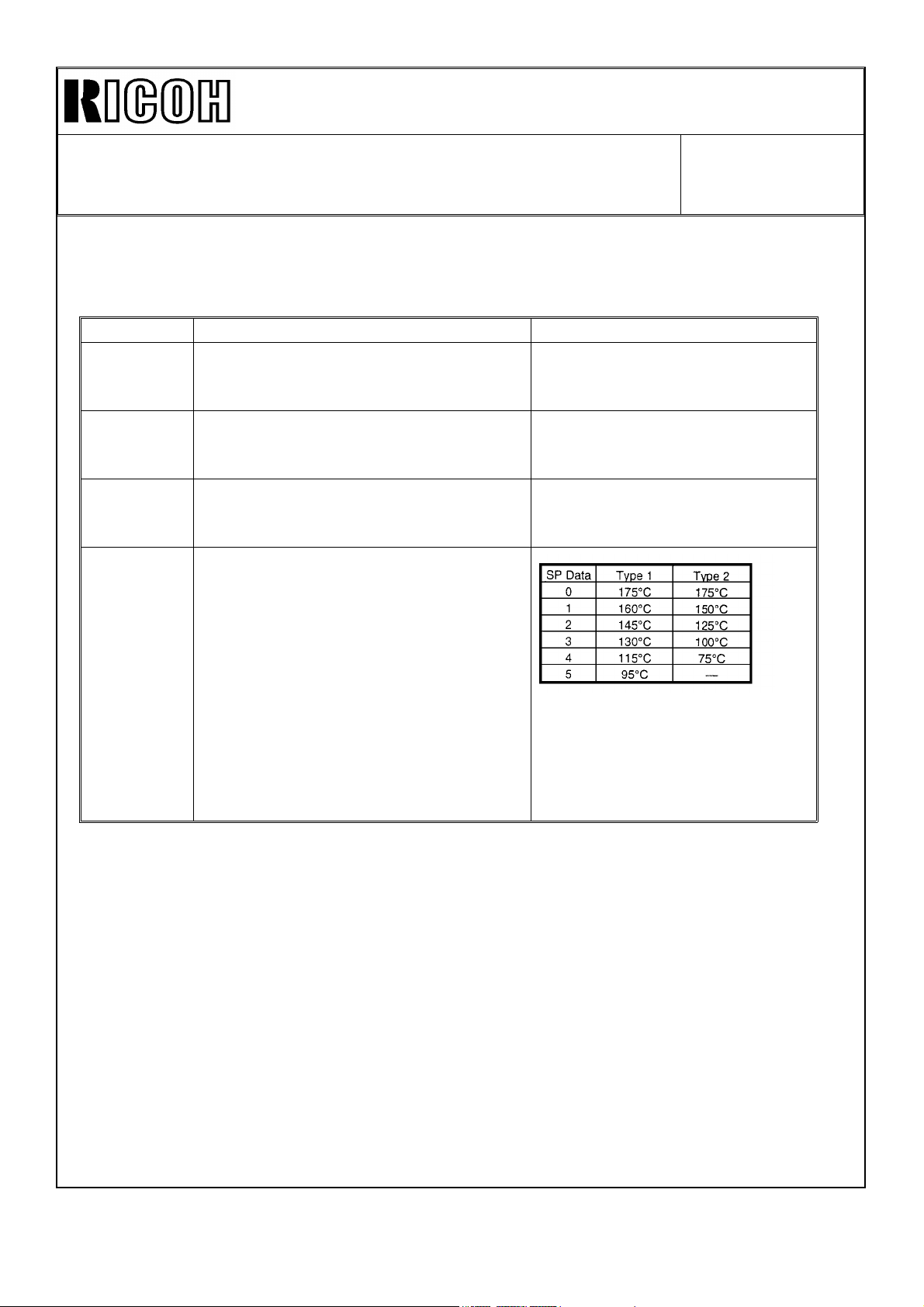

SP Mode

One SP mode has been newly provided and three SP modes have been changed in the

software ( ROM : A153 5106A).

Mode No. Function Settings

SP5-911

SP5-102

SP5-305

Copy mode when machine is turned

on can be selected.

(A156, A160, A162 copiers)

Auto energy saver time can be

selected.

Auto off time can be selected. 1 ~ 120 minutes

Fusing temperature can be selected in

energy saver mode.

1 : Duplex Copy Mode (Default)

2 : Single Side Copy Mode

1 ~ 120 minutes

(1 minute per step)

Default : 15 minutes

(1 minute per step)

Default : 60 minutes

SP5-105-002

Default

2: (145°C) : Eagle

2: (125°C) : Falcon

3: (100°C) : Swallow

SP5-102 and SP5-305 can also be selected by the customer.

Please refer to page (P3 ~ P5 : Eagle, P6 ~ P8 : Falcon, P9 ~ P11 : Swallow) of this

RTB for the procedure.

Instruction Sheet

An additional explanation sheet has been added to the operating instructions sheet.

Please refer to pages 3 through 11 of this RTB for the contents of this sheet. The Energy

Saver Mode described on the second page of this instruction sheet is the Auto Energy

Saver Mode originally available with this copier.

Page 17

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Eagle O/I)

DATE:October 31,

’95

PAGE: 4 of 12

Page 18

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Eagle O/I)

DATE:October 31,

’95

PAGE: 5 of 12

Page 19

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Eagle O/I)

DATE:October 31,

’95

PAGE: 6 of 12

Page 20

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Falcon O/I)

DATE:October 31,

’95

PAGE: 7 of 12

Page 21

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Falcon O/I)

DATE:October 31,

’95

PAGE: 8 of 12

Page 22

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Falcon O/I)

DATE:October 31,

’95

PAGE: 9 of 12

Page 23

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Swallow O/I)

DATE:October 31,

’95

PAGE: 10 of 12

Page 24

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Swallow O/I)

DATE:October 31,

’95

PAGE: 11 of 12

Page 25

Technical Bulletin No. RTB-005

SUBJECT: Energy Star

(Swallow O/I)

DATE:October 31,

’95

PAGE: 12 of 12

Page 26

Technical Bulletin No. RTB-006

SUBJECT: • Continuous Supply of power to the Jogger Motor

• Developer Leakage

PREPARED BY: S. Hizen

FROM: 1st Field Information Dept. QAC

DATE: May 15, ’96

PAGE: 1 of 4

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

Continuous Supply of power to the Jogger Motor

1. Phenomeno n:

The Jogger Motor is continuously supplied with power but does not rotate which

leads to the deformation of the mold around the duplex unit. SC525 may be

indicated for the Duplex Copy Mode because the Jogger Motor is not rotating. A

continuous supply of power will result in overheating of the Jogger Motor.

2. Possible Causes:

When the Jogger Motor is operating, if there is a drop in voltage of 5v, the ISP may

malfunction, and as a result two phases of the motor will continue to be supplied

with power.

Phoenix

Main Board

ISPCPUPSU

DRIVER

M

3. Countermeasure and Field Action :

We will change the software so that the Jogger Motor power will automatically shut

off if any of the phases of the motor runs continuously for 3 minutes or longer. The

ROM part number with this program is A153-5109. If this problem occurs, the

stepping motor part of the duplex tray may be deformed by the heat generated. We

would appreciate it if you would replace the whole duplex tray and also install the

ROM A153-5109 at that time.

Additional Information: The implementation of the modified ROM is planned for the

middle of July for the mass-production units. We would like to emphasize that the

occurrence ratio of this problem is very low.

24V

Page 27

Technical Bulletin No. RTB-006

SUBJECT: • Continuous Supply of power to the Jogger Motor

• Developer Leakage

Developer Leakage

1. Problem:

The main motor, charge roller, transfer belt and development unit are continuously

in the ON condition. This results in developer leakage from the development unit

and ultimately leads to blank copies because of a shortage of developer.

h In this case, the leaked developer accumulates in the transfer unit. Accumulation

in the rear of the development unit may indicate wear on the paddle roller shaft

caused by developer as a result of the improper placement of the V-ring, and could

necessitate replacement of the unit. There have only been a few isolated cases

reported worldwide connected with the V-ring placement and we do not anticipate

more occurrences.

2. Conditions leading to the Occurrence:

This problem may occur when the timing of the Pre-start signal and the ADS

Density signal are sent at approximately the same time when the machine is set in

the following conditions: ADS Mode, Special Paper Feed Tray (see the attached

table for details), Special CPM (see the attached table for details), 1st copy after

start-up (Including the 1st copy after the completion of the second feed in the duplex

mode), or when the copy count is 1 to N.

DATE: May 15, ’96

PAGE: 2 of 4

3. Cause:

The Pre-Start signal for the software’s engine control area is erased by the ADS

Density signal.

Normal:

ADS Density signal sent signal received ADS Density signal processed

PreStart signal sent signal received PreStart signal processed

Abnormal:

PreStart signal sent signal received ADS signal sent

signal received ADS signal processed.

h In this case, the final processing of the PreStart signal is not completed. The

control based on the image trailing edge signal of the engine control area stops

working properly and as a result the main motor, charge roller, transfer belt and

development unit remain ON.

4. Countermeasure:

We will change the software by inserting a signal processing function prior to the

signal receipt that is activated when the ADS Density signal is sent. As a result, the

abnormal signal route will be changed in the following manner.

PreStart signal sent signal received ADS Density signal sent

PreStart signal processed signal received ADS Density signal processed.

The ROM part number is also A153-5109. If this problem occurs, please replace

Page 28

Technical Bulletin No. RTB-006

SUBJECT: • Continuous Supply of power to the Jogger Motor

• Developer Leakage

DATE: May 15, ’96

PAGE: 3 of 4

Page 29

Technical Bulletin No. RTB-006

SUBJECT: • Continuous Supply of power to the Jogger Motor

• Developer Leakage

DATE: May 15, ’96

PAGE: 4 of 4

Page 30

Technical Bulletin No. RTB-007

SUBJECT: Identification of and Measures for Fusing Offset DATE: May 15, ’96

PAGE: 1 of 4

PREPARED BY: S. Hizen

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Phoenix

Identification of and Measures for Fusing Offset

By employing the proper procedures in the field, the Offset problems reported there

may be prevented. When an offset problem occurs, it is very important to correctly

isolate the cause and utilize proper measures to solve the problem. Hence, we have

compiled a list of the types of offset often encountered in the field, methods to

identify the offset and measures to be taken. This list is arranged in the following

manner: A. Offset problems related to Fusing B. Phenomena mistaken for Offset.

Each symptom presented lists causes and the measures to be taken.

A. Cases of Offset related to Fusing

1. Hot Offset (excessive fusing)

After consecutive paper feeds, periodic offsets occur (125mm pitch). Similar

problems are sometimes found when using comparatively thin paper.

Cause/Measure:

• Check the fusing temperature. Is it set too high? The maximum is 190°C.

• Is the thermistor coming in contact with the roller? Confirm that the roller comes

in firm contact with the thermistor. Check for deformation of the thermistor unit.

• Is the thickness of the paper within specifications? Standards 52~157g/m2,

14~42lbs.

h

Confirm the implementation of the anti-rise countermeasure for the thermistor.

Anti-rise countermeasure

Metal Bracket Plastic Bracket

Thermistor Thermistor

Page 31

Technical Bulletin No. RTB-007

SUBJECT: Identification of and Measures for Fusing Offset DATE: May 15, ’96

PAGE: 2 of 4

2. Cold Offset (incomplete fusing)

Offset (125mm pitch) only occurs in the morning when the machine is first turned on

or when using thick paper.

Cause/Measure:

• Low temperature environment? In conditions under 10°C and 15% humidity, prob-

lems may occur when the machine is turned on at the beginning of the day.

• Is the temperature adjusted to the proper setting? Is it set too low? The minimum is

160°C.

• Has there been a drop in voltage? Is it below 90v? In this case, the nip area should

be increased and the temperature setting should be raised.

3. Electrostatic Offset

When using OHPs or laminated paper, offsets appear scattered around the

characters.

Cause/Measure:

• Are the fusing roller and pressure roller properly grounded? Make sure that the

quenching brush on the back of the rollers is touching both the fusing and pressure

rollers.

• Is the fusing entrance guide board properly grounded? Make sure that the quenching

brush behind the unit fusing stay and the fusing entrance guide are connected when

the fusing unit is in place.

• What is the environment like? In conditions below 10°C and 15% humidity, certain

types of paper are prone to electrostatic offset.

Though certain types of paper may be subject to this condition, occurrences are quite

rare so this should not occur under normal operating conditions.

illustration from P/C P46

This brush should

contact both the

Hot and Pressure

Rollers.

Page 32

Technical Bulletin No. RTB-007

SUBJECT: Identification of and Measures for Fusing Offset DATE: May 15, ’96

PAGE: 3 of 4

4. Insufficient Cleaning Offset

Irregular occurrences, falls off when wiped by hand. Occurs over the whole surface,

large amounts involved.

• Inadequate cleaning of the pressure roller leads to residue on the pressure roller. This

reduces the lifetime of the pressure roller, and premature replacement is necessary.

• Is the cleaning roller attached?

• Is the cleaning roller rotating properly?

• Is there an uneven build up of toner?

If any of these symptoms apply, replace the cleaning roller. However, if there is

toner accumulation of about 0.5mm near the cleaning roller, the cleaning efficiency

has dropped and indicates that the roller should be replaced. If the accumulation is

less than 0.5 mm, then the chances that this roller is the cause of the problem are

very slight.

5. A narrow horizontal black line, not on the original, appears on the copy 125mm from

the front edge or it continues at a 125mm pitch.

Cause:

No blank areas on the leading and/or trailing edges.

Measure:

Blank areas should be created at both the leading and trailing edges. (This only

occurs when the blank areas are 0mm)

6. The offset picture and characters are inverted. (When using the back of the sheet, the

image aligns with the one on the other side.)

Cause:

The melting point of the toner of the image on the back of the sheet is too low.

Measure:

If the melting point of the toner is too low, stop the use of the back of the sheets.

Examples of toners with low melting points: Flash fusing , color copier,

hot transfer ribbons.

7. Irregular occurrences, falls off when wiped by hand. Related to the position of the

thermistor.

Cause/Measure:

• Toner debris accumulated on the thermistor. Caused by a dirty thermistor. Clean the

thermistor.

Page 33

Technical Bulletin No. RTB-007

SUBJECT: Identification of and Measures for Fusing Offset DATE: May 15, ’96

PAGE: 4 of 4

8. Frequent Offset; Toner accumulation on the fusing roller Cause/Measure:

Conditions 1~7 listed above did not continue?

• Abnormal Image Condition (drop in density, defective drum cleaning, defective transfer cleaning, etc.) did not continue?

• Was the total number of copies made while the machine was in use extremely high

or low?

• Is the toner a Ricoh product?

• Is the fusing roller a Ricoh product?

• Is the pressure roller a Ricoh product?

h

Some types of paper may be the cause of the problem when offset continues on

some machines. Please contact us if this is the case.

B. Phenomena mistaken for Offset

1. The offset drawings and characters are inverted (Aligned with the image on the back

of the original)

Cause: The back of the original was copied.

2. The offset pitch is 188.5mm

Cause: Scratched drum Replace the drum

3. Irregular Occurrences, Fused Image

Cause: Defective drum cleaning Confirm that the parts around the drum are

functioning properly (cleaning blade, etc.)

4. Images on the surface unrelated to the original, lines appear parallel to the paper

feed direction.

Cause: Defective drum cleaning, scratched drum, uneven lighting from the exposure

lamp Inspect the parts around the drum (cleaning blade, etc.) Check for uneven

lighting level

5. Lines appear on the back of the copy parallel to the paper feed direction.

Cause: Defective transfer belt cleaning, toner scattering in the machine

Check the transfer unit, cleaning blade. Toner scattering may occur because the

toner density is too high, so the Process Control Conditions should be checked.

Page 34

Technical Bulletin No. RTB-008

SUBJECT: ROM History from A153-5106 to A153-5109 DATE: May 15, ’96

PAGE: 1 of 1

PREPARED BY: S. Hizen

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The following is the software program history describing the changes made from

A153-5106 to the A153-5109.

1. A153-5106 to A153-5107

The transfer bias will automatically shut off when the main motor shuts off. This is

the countermeasure for the drum spot problem that occurs as a result of an

electrical leak from the transfer belt to the drum surface. .This modification will also

take care of the report from the market which stated that the transfer bias remained

on even though the machine was on stand-by.

h

Note: A153-5107 to 5107A-Software change for the ADS Control A slightly dirty

background appears a couple of millimeters from the trailing edge only if

a dark original is copied and the machine is in the ADS mode.

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Phoenix

2. A153-5107 to A153-5109

• Continuous Supply of Power to the Jogger Motor

• Developer Leakage

Please refer to RTB-006 for details.

Additional Information:

The implementation of the modified ROM # A153-5109 is planned for the middle of

July for the mass-production units. We would like to emphasize that the occurrence

ratio of this problem is very low.

Page 35

Technical Bulletin No. RTB-009

SUBJECT: Service Manual Correction DATE: May 15, ’96

PAGE: 1 of 1

PREPARED BY: S. Hizen

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Please correct your service manuals as follows:

Page 4-28

Incorrect:

5-003 APS Priority

Selection

5-004 ADS Priority

Selection

=

=

Revision of service manual

Information only

Other

Specifies whether the copier

defaults to APS or manual mode

when the main switch is turned on,

auto reset, or mode cleared.

Specifies whether the copier

defaults to ADS or manual ID mode

when the main switch is turned on,

auto reset, or mode cleared.

FROM: 1st Field Information Dept. QAC

MODEL:

Phoenix

1: APS

2. Manual

Also see

SP6-010.

1: ADS

2. Manual

Correct:

5-003 APS Priority

Selection

5-004 ADS Priority

Selection

=

=

Specifies whether the copier

defaults to APS or manual mode

when the main switch is turned on,

auto reset, or mode cleared.

Specifies whether the copier

defaults to ADS or manual ID mode

when the main switch is turned on,

auto reset, or mode cleared.

1: APS

0: Manual

Also see

SP6-010.

1: ADS

0: Manual

Page 36

Technical Bulletin No. RTB-010

SUBJECT: White Lines/Bands due to a dirty charge roller DATE: July 15, ’96

PAGE: 1 of 1

PREPARED BY: S. Hizen

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Phenomenon:

White lines/bands appear on the copy image. In almost all of these cases, the image

density is low in the lines/bands, so these areas are not as dark.

CHARGE ROLLER

CLEANING PAD

CLEANING

BLADE

DRUM

Revision of service manual

Information only

Other

Cause/Mechanism:

The amount of electrical charge on the drum is

low due to toner accumulation on the charge

roller. This decreases the charge ability. The

toner remains on the drum after it passes under

the cleaning blade and adheres to the charge

roller. The amount of toner remaining on the

drum exceeds the amount that can be cleaned

off by the charge roller cleaning pad, leading to

toner accumulation on the charge roller. The

toner accumulation level on the charge roller is

directly related to the cleaning ability of the

cleaning blade. As a result of the accumulation,

the charge ability decreases due to the toner

accumulation and leads to the white (lighter)

lines/bands on the copy.

FROM: 1st Field Information Dept. QAC

MODEL:

Phoenix

Countermeasure:

In addition to cleaning the charge roller, please check the cleaning blade. If no

defective/deteriorated areas can be found on the blade, please replace it.

Page 37

Technical Bulletin No. RTB-011

SUBJECT: DF61 Dirty Mark on Back-side of Original DATE:July 31, ’96

PAGE: 1 of 3

PREPARED BY: S. Hizen

FROM: 1st Field Information Dept. QAC

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

Phoenix-series

(DF61)

Problem: Three dirty marks on the back side of the original.

Cause: The toner on the first original is transferred to the back of the second

original due to the pressure applied by the pressure lever and the pick-up roller.

(See the illustration)

Pressure Lever

Second

Original

First Original

Pick-up Roller

Pick-up Roller

The dirty marks created are one of the limitations of the DF61. The degree to which

the marks appear varies depending on how completely the image on the first original

is fused, the type of image, and the type of paper used.

Countermeasure:

Due to this countermeasure for the DF61, the specifications listed in the service

manual have been changed as follows:

Specification Item Current DF Modified DF

Original Weight 52 to 128 g/m

2

Original Table Capacity 50 sheets at 80 g/m

2

35 sheets at 80 g/m

52 to 104 g/m

2

2

Page 38

Technical Bulletin No. RTB-011

SUBJECT: DF61 Dirty Mark on Back-side of Original DATE: July 31, ’96

PAGE: 2 of 3

The countermeasure for the dirty marks is designed to reduce the pressure applied

to the originals by replacing the entrance guide stopper spring with a new one. This

change also results in a decrease in the amount of force used to feed the original

and may create an original non-feed problem. Therefore, the separation bracket

has been modified to reduce the angle by 2 degrees.

Separation Bracket

Separation Bracket

2°

CURRENT

Modification Procedure:

1. Remove the three springs from the entrance guide stopper and install the new

spring (P/N:A548 9500) in the middle. If an original non-feed occurs, add the

outside springs (P/N:A548 9500) on both sides.

MODIFIED

Remove the spring

Remove the spring

Replace the spring with a

new one (weaker).

70g (current) → 40g (new)

Page 39

Technical Bulletin No. RTB-011

SUBJECT: DF61 Dirty Mark on Back-side of Original DATE: July 31, ’96

PAGE: 3 of 3

2. Remove the DF separation bracket. (1 snap ring)

3. Replace the separation bracket with A548 9502.

Plastic Plate

Mylar

Plastic

Plate

A548 1291

Current Type

4. Reassemble the parts.

Note: The spring (A548 9500), and the bracket (A548 9502) are available as

spare parts.

A548 9502

Modified Type

Mylar

Page 40

Technical Bulletin No. RTB-012

SUBJECT: Black lines caused by the development entrance seals DATE: Sept. 30, ’96

PAGE: 1 of 3

PREPARED BY: S. Hizen

FROM: QAC 1st Field Information Dept.

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

Problem: Black lines due to scratches on the drum.

Possible Causes: One of the possible causes of the drum scratches may be the

entrance seals on the development unit. There are two manners

in which scratches may appear on the drum.

1)

Foreign

Material

[A]

DEVELOPER

.

DRUM

DEVELOPMENT

ROLLER

The outside entrance seal [A] bends

into a Z shape. The drum may be

scratched when foreign material

gets caught between the drum and

the seal [A].

Measure: Replace the seal [A].

(Please refer to the following page

for the position in which the seal

should be applied.)

Phoenix

2)

Foreign

Material

[A]

When the inside entrance seal [B]

is longer than the outside one, if

Outside

Entrance

Seal [A]

OK

[B]

.

[B]

Inside

Entrance

Seal

Inside

Entrance

Seal

foreign material gets caught

between the drum and the outside

entrance seal [A], the drum may

be scratched due to the pressure

created by the developer. Please

check the lengths of the seals.

(Developer tends to stick on the

upper portion of the development

roller if the inside seal is longer

than the outside one.) If the inside

seal [B] is 1.5 mm or more longer

than the outside one, please

1.5 mm

NG

or

more longer

rotate the development sleeve

counterclockwise to see if any

developer falls from the upper

portion of the roller.

If some developer falls off, you

should replace the inside seal [B].

Please refer to the following page

for the position in which the seal

should be applied.

Page 41

Technical Bulletin No. RTB-012

SUBJECT: Black lines caused by the development entrance seals DATE: Sept. 30, ’96

PAGE: 2 of 3

The seal positions are as follows.

Be sure to first clean the areas where the seals will be attached.

Align the edge of the seal with the

edge of the bracket.

A

AA15 2333

AA15 2334

A

Align the edge of the seal with the edge of the bracket.

Position of the #2, #20 seals

0 ~ 1mm

#20

AA15 0231

A

#2: AA15 0382

#2

AA15 0382

Page 42

Technical Bulletin No. RTB-012

SUBJECT: Black lines caused by the development entrance seals DATE: Sept. 30, ’96

PAGE: 3 of 3

We have assigned a part number for the Entrance Seal Ass’y shown in the illustration to

make the replacement of the seals easier.

* Please refer to page 2 of 3 for the positions of the seals #2, #20

A153 3075

20

Page 43

REVISED ON OCTOBER 31, ’96

Technical Bulletin No. RTB-013

SUBJECT: Dirty Background DATE: Oct. 15, ’96

PAGE: 1 of 2

PREPARED BY: S. Hizen

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The countermeasure for the dirty background is as follows. This countermeasure is for

those machines that are installed in places with a lot of dust and have had many

service calls related to dirty background. Be sure that you check the optics cavity

because an external examination of the machine may be deceptive.

Possible Causes:

1. Low copy volume machines

The lamp voltage correction/compensation by the process control every 1K copies

cannot catch up with the lamp voltage level necessary to eliminate the dirty

background.

2. High copy volume machines

The lamp voltage increases to the maximum level, and the voltage cannot rise high

enough to create the light intensity necessary to eliminate the dirty background.

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

Phoenix (Eagle, Falcon)

Countermeasure:

1. ROM (P/N: A153-5120) The process control interval can be changed with SP Mode

3-801 to suit the environmental conditions in which the copier is installed. The

adjustment levels are as follows.

New Program (A153-5120)

SP3-801

0: OFF

1: Process Control Cycle every 1K copies (Default)

2: Process Control Cycle every 500 copies

3: Process Control Cycle every 200 copies

Page 44

REVISED ON OCTOBER 31, ’96

Technical Bulletin No. RTB-013

SUBJECT: Dirty Background DATE: Oct. 15, ’96

PAGE: 2 of 2

2. Optics Filter (P/N: A153-9515, Left/Right filter set)

Optics Filters will be assigned as service parts. (The mass-production unit does not

have these filters on the optics cavity.) This filter is designed to prevent the optics

cavity from becoming dusty. The positions in which the filters should be placed are

shown below.

Upper Cover

Filter Installation Procedure:

• Remove the upper cover

• Install both the left and right filters so that the holes in the filters are aligned with

the holes in the optics frame.

Optics Filter (Left)

Optics Filter (Right)

The optics filter will not be available as a service part until after the MB has been

issued.

Note: Do not put the filters on those Phoenix machines that usually make copies

continuously under the following conditions:

Eagle: More than 500 copies

Falcon/Swallow: More than 600 copies

If you install the optics filters on a machine which the customer may make

continuous runs which exceed the conditions set above, please set the

copy limit with SP5-017 to the maximum numbers. This is because the

temperature of the exposure glass may be much higher if the lamp voltage

has already reached the maximum level to compensate for the image

density

3. Exposure Lamp

In dusty environments, the exposure lamp should be cleaned at the same time

as the mirror and lens. If there is no improvement, please replace the

exposure lamp.

Page 45

Technical Bulletin No. RTB-014

SUBJECT: Bits of glue on the drum DATE:Oct. 31, ’96

PAGE:1 of 3

REPARED BY: S. Hizen

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Problem:

The drum becomes dirty with glue.

Possible Cause:

Glue can be transferred to the drum surface when adhesive paper is used.

Sometimes the glue stuck on the drum surface transfers to the entrance seal on the

development unit when the drum rotates in reverse. This results in the deformation of

the entrance seal on the development unit.

Countermeasure:

A mylar has been added on the upper transfer entrance guide, and the transfer guide

plate has been modified by raising the height of its ribs to alter the angle in which the

paper enters. See the illustrations below.

Revision of service manual

Information only

Other

FROM: QAC 1st Field Information Dept.

MODEL: Phoenix

A153 3899

Transfer

Guide Plate

OLD

Mylar A153 3591

A153 3901

Transfer

Guide Plate

NEW

Page 46

Technical Bulletin No. RTB-014

SUBJECT: Bits of glue on the drum DATE: Oct. 31, ’96

PAGE: 2 of 3

Technical Information

The mylar position is as follows. Turn the drum unit over and put a mylar

(A153-3591) in the position shown below.

C3

Front

A : 0 ~ 0.5 mm

B : 0 ~ 2 mm

Upper Guide

Make sure that the duplex adhesive tape does not stick out beyond the end of

the upper guide and that the mylar is flat.

Rear

Page 47

Technical Bulletin No. RTB-014

SUBJECT: Bits of glue on the drum DATE: Oct. 31, ’96

PAGE: 3 of 3

NOTE: Another possible cause of the glue on the drum surface is that

the entrance seal of the development unit is set higher than it should

be by a couple of millimeters. In this case the glue also sticks on the

edge of the development unit and the entrance seal is bent.

It is necessary to replace the entrance seals in this case.

Please refer to RTB-012.

The outside entrance

seal is easily flipped.

: NG

: OK

Normal Entrance Seal

position. No flipping.

➁

➀

The entrance seal position is

a little off (1.5 - 2.0 mm).

The first bend in the

seal appears.

➃

The edge of the seal flips

up inside easily.

The glue sticks on the

edge of the seal.

The glue sticks on

the drum surface.

➄

➂

The seal is bent at another

position and creates a Z-shape

Foreign material

sticks on the

glue. This results

in drum scratches.

Page 48

RICOH Technical Bulletin

Model: Phoenix Series Date: 28-Feb-97

Subject: Drum filming with toner Prepared by: S. Hizen

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

No: 015

Action required

Service manual revision

Retrofit information

1/1

SYMPTOM

The drum becomes covered with a black substance, most likely toner, after 8K to 20K

copies. The surface of the drum looks as if is being coated by toner across a width equal

to that of the paper or the development roller. As a result, dirty background appears all

over the copy.

CAUSE

An additive in acidic paper called talc (MgO SiO2) causes the filming problem.

The characteristics of talc make it negatively charged. The talc is electrically combined

with the positively charged toner and adheres to the drum surface in the non-image areas.

Once on the drum, the toner and talc compound is pressed down by the transfer belt and

charge roller, leading to a gradual build-up on the drum surface. The talc on the drum

surface is carried to the development unit and then accumulates there. This accumulation

of talc accelerates the filming problem in an area across the width of the development

roller.

Coated with toner

SOLUTION

Charge the type of paper used from an acidic type to a neutral type. The type of paper

can be checked in the following manner.

1. Use the testing pen. (The part number will be available soon.)

2. Burn a piece of the paper and check the color of the paper ash.

Black →acidic type

Gray/white →neutral type

NOTE: Once this problem occurs, the drum and developer in the development unit need

to be replaced and the transfer belt needs to be cleaned.

Page 49

RICOH Technical Bulletin

Paddle Roller

Bushing

MB Correction

Reissue date: 31-Mar-97

The items in bold italic have been corrected or added.

The illustrations have been changed as shown below.

Model: Phoenix Series Date: 28-Feb-97

Subject: Paddle Roller Bushing worn out Prepared by: S. Hizen

From: QAC 1st Field Information Dept. Checked by: T. Inoue

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

No: 016

Action required

Service manual revision

Retrofit information

SYMPTOM

Developer leakage from the paddle roller bushing in the development unit.

CAUSE

The V-ring on the paddle roller is out of position.

[OK] [NG]

V-ring V-ring

1/4

V-ring

touches

the plate

Metal

Plate

Developer leakage

SOLUTION

Replace the bushings and V-rings on the paddle roller.

Please refer to the following pages for the replacement procedures.

Page 50

RICOH Technical Bulletin

Model: Phoenix Series Date: 28-Feb-97 No: 016 2/4

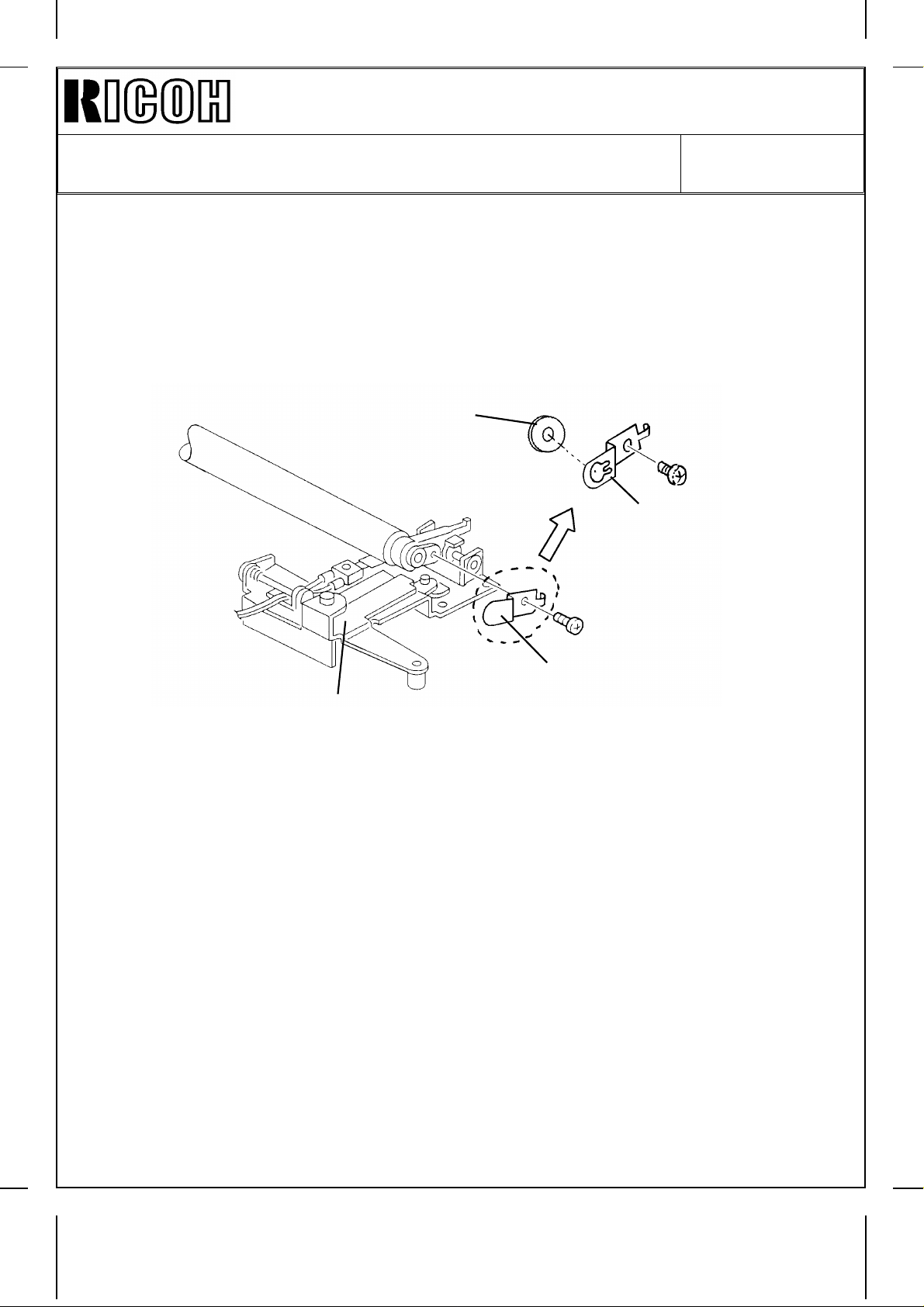

[Paddle roller replacement procedure]

1. Remove the toner hopper from the development unit.

2. Remove the three seals (AA15-0382) [A] and the one seal (AA15-0231) [B] from the

development unit.

Entrance Seal Ass’y[C]

Screw[D]

Seal [B]

Seal [A]

Side Bracket[E]

Screw [F]

3. Remove the entrance seal assembly (A153-3075) [C]

(2 screws [D])

4. Remove the side bracket [E] (2 screws: [F])

Page 51

RICOH Technical Bulletin

Paddle Roller

Bushing

Model: Phoenix Series Date: 28-Feb-97 No: 016 3/4

Screw[G]

Do not loosen this screw

[H]

[J]

[K]

[I]

[J]

[K]

5. Separate the Upper and Lower Unit (3 screws [G], 1 screw [H])

6. Remove the paddle roller ass’y [I]: A153-3063 and replace the bushings [J]: AA08-

0200 and V-rings [K] AA15-2331.

Note 1: Make sure that the V-ring is in the proper position, as shown in the illustration

below.

V-ring V-ring

V-ring

touches

the plate

Developer leakage

Metal

Plate

Good No Good

Page 52

RICOH Technical Bulletin

Model: Phoenix Series Date: 28-Feb-97 No: 016 4/4

Note 2: If the shaft of the paddle roller is worn out, replace the entire paddle roller

assembly (A153-3063) [I].

7. Reattach the Upper and Lower Units.

8. Reattach the side bracket.

9. Reattach the entrance seal ass’y and the seals.

Loading...

Loading...