Page 1

10-BIN

SORTER STAPLER

(Machine Code: A555)

Page 2

13th January 1995 SPECIFICATIONS

1. SPECIFICATIONS

Paper Size for Bins: Sort/Stack Modes:

Maximum: A3, 11 x 17"

Minimum: B5, 81/2 x 11"

Paper Weight for Bins: Sorting:

52 ~ 157 g/m2 (14 ~ 42 lb)

Stacking:

52 ~ 157 g/m2 (14 ~ 42 lb)

Stapling:

52 ~ 80 g/m2 (14 ~ 21 lb)

Bin Capacity: Sorting:

A4, 81/2 x 11" or smaller: 30 copies

B4, 81/2 x 14" or larger: 25 copies

Stacking:

A4, 81/2 x 11" or smaller: 25 copies

B4, 81/2 x 14" or larger: 20 copies

Stapler Capacity: 2 ~ 20 copies

Proof Tray Capacity: 100 copies (52 ~ 80 g/m2 / 14 ~ 21 lb)

50 copies (81 ~ 128 g/m2 / 22 ~ 34 lb)

30 copies (129 ~ 157 g/m2 / 35 ~ 42 lb)

Number of Bins: 10 bins + proof tray

Stapling Position:

a = 6 ± 3 mm

b = 6 ± 3 mm

a

b

Stapler

10-bin Sorter

1

Page 3

SPECIFICATIONS 13th January 1995

Staple Replenishmen t: Cartridge exchange (2,00 0 sta ple s/cartridge)

Power Source: DC 24V, 5V (from the copier)

Power Consumption: Average: less than 33 W

Average for Sorting: less tha n 25 W

Average for Stapling : less th an 33 W

Weight: 12.4 kg (27.4 lb)

Dimensions (W x D x H): 381 x 548 x 443 mm (15.0" x 21.6" x 17.5")

2

Page 4

13th January 1995 COMPONENT LAYOUT

2. COMPONENT LAYOUT

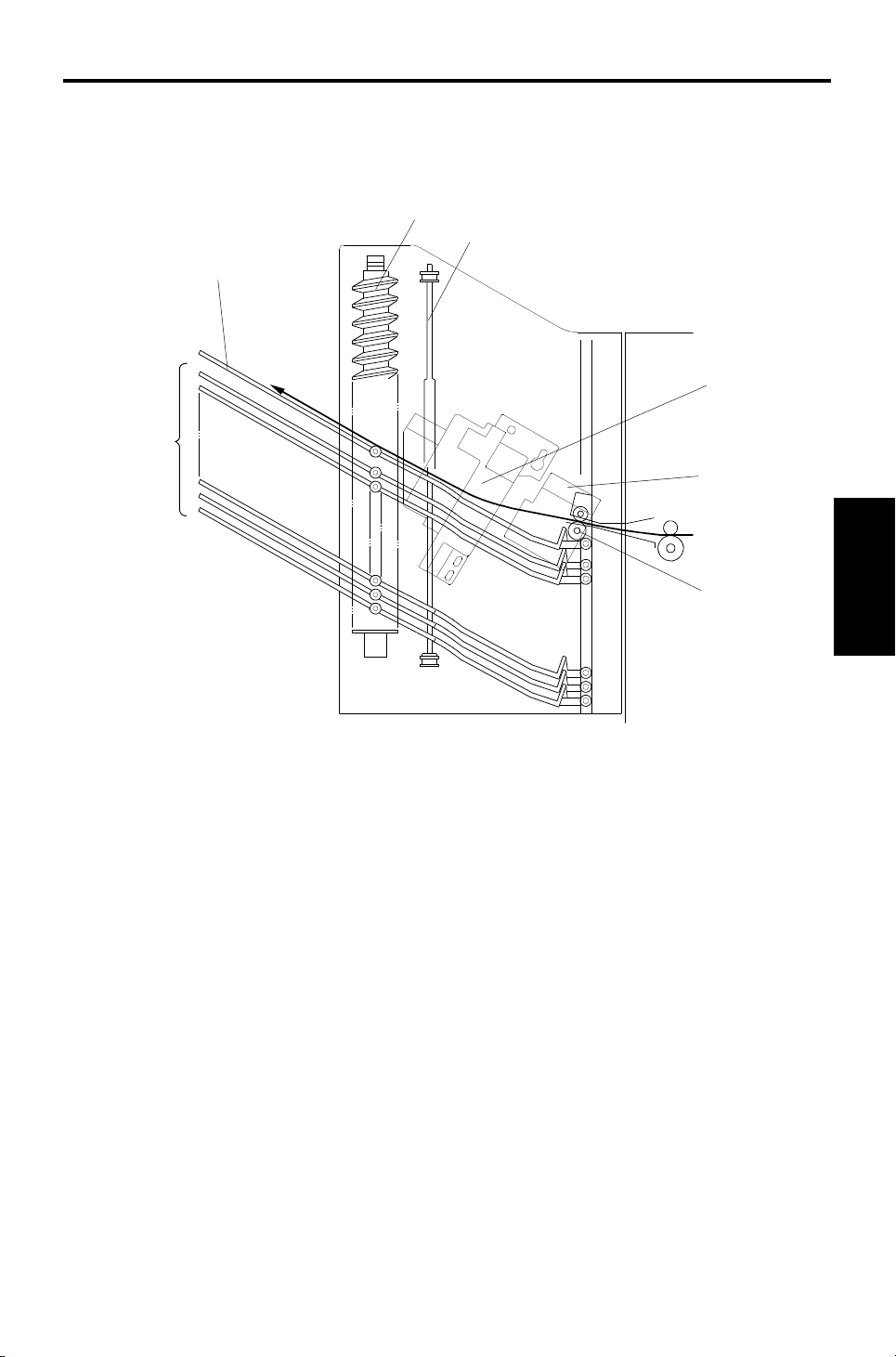

2.1 MECHANICAL COMPONENT LAYOUT

1

2

7

3

6

5

1. Helical Wheels

2. Jogger Plate

3. Grip Assembly

4. Transport Rollers

5. Staple U nit

6. Bins

7. Proof Tray

4

Stapler

10-bin Sorter

3

Page 5

COMPONENT LAYOUT 13th January 1995

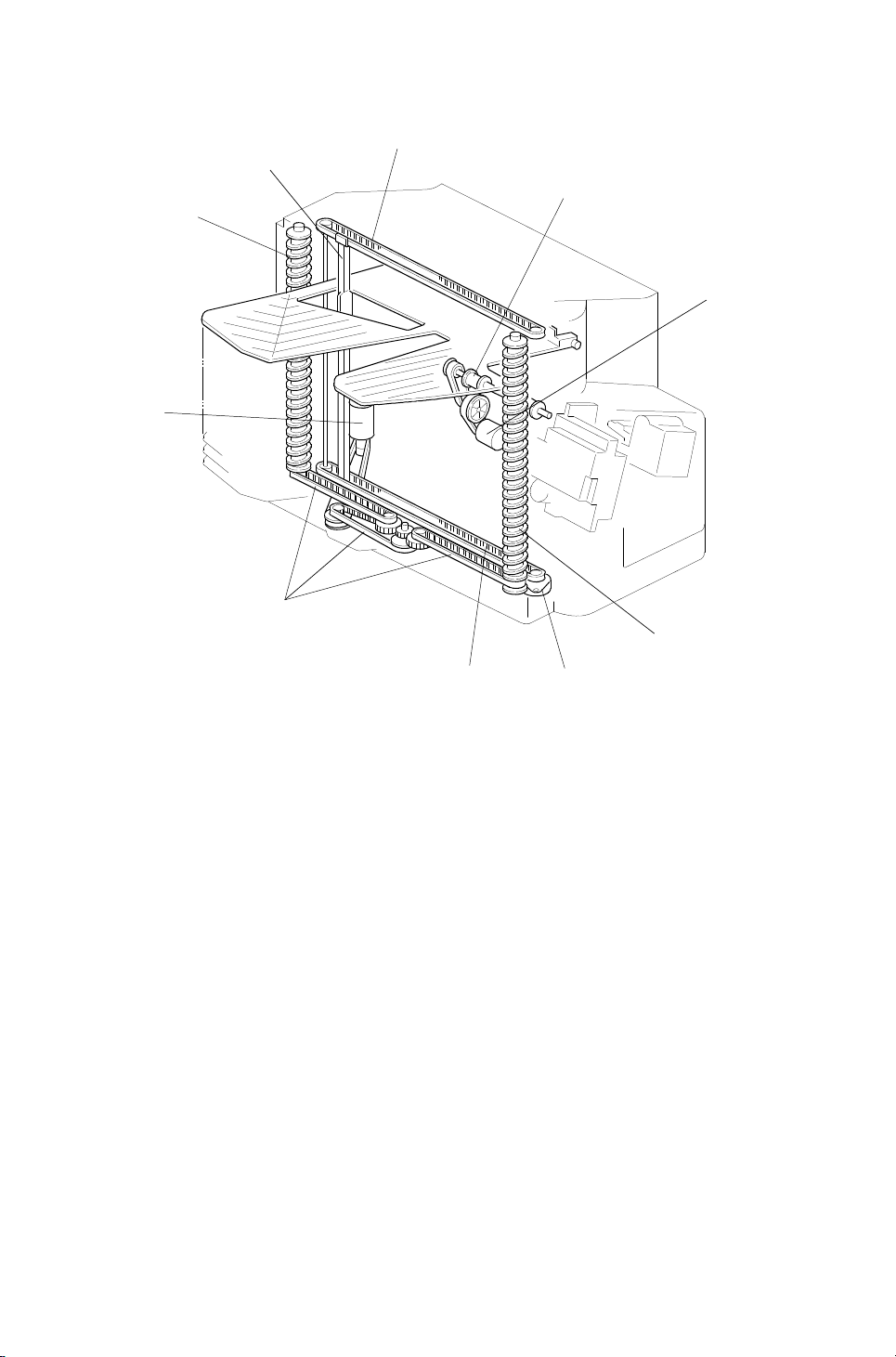

2.2 DRIVE LAYOUT

1

8

2

3

4

7

1. Jogger Drive Belt

2. Transport Roller

3. Helical Wheels

4. Transport Motor

6

3

1

5

5. Jogger Motor

6. Wheel Drive Belts

7. Bin Drive Motor

8. Jogger Plate

4

Page 6

13th January 1995 COMPONENT LAYOUT

2.3 ELECTRICAL COMPONENT DESCRI P TI ON

Refer to the electrical compone nt layou t on the reverse side of the Poin t to

Point Diagram (on waterproof paper).

Symbol Index No. Description Note

Motors

M1 14 Transport Drives the transport roller

M2 9

M3 16 Bin Drive Drives the bins

M4 6 Stapler Drives the stapler hammer

M5 3

Sensors

S1 1

S2 2 Sorter Entrance Detects paper jams

S3 15

S4 13

S5 4

S6 5

S7 11

S8 10 Wheel Detects the bin position.

S9 12

S10 18

S11 19 Staple End Detects when the staples run out

Switches

SW1 8

SW2 7 Stapler Cuts the signals to the stapler.

Circuit Board

PCB1 17 Main Controls all sorter/stapler functions

Jogger Drives the jogger plate to square the

copies

Grip Drives the grippers forwards and back

into the bin to grip the copies and

bring them to the stapling position

Bin

(Phototransistor)

Jogger H.P. Detects whether the jogger plate is in

Timing Provides pulses to the sorter stapler

Stapler Paper Detects whether any copies are under

Grip H.P. Detects when the grip assembly cam

Bin

(LED)

Bin H.P. Detects whether the bins are at home

Staple H.P. Detects whether the stapler hammer

Door Safety Cuts the dc +24V supply when either

Detects whether there is any paper in

the bins (light receiving element)

its home position

main board.

the hammer.

gear has rotated once

Detects whether there is paper in the

bins (light emitting element)

position

is at home position

the unit or the stapler cover is opened.

Stapler

10-bin Sorter

5

Page 7

BASIC OPERATION 13th January 1995

3. BASIC OPERATION

3.1 NORMAL MODE AND SORT/STACK MODE

[E]

[A]

[B]

[D]

Copies exiting the copier pass thro ug h the entrance guide plate [A]. The

transport roller will send copies eit he r to th e pro of tray or to each bin,

depending on the select ed mode .

During copying, all rollers in the sorter stapler transport the paper at a speed

which depends on the copier. When the trailing edge of th e copy passes the

fusing exit sensor, the speed of the rollers changes to 600 mm/s. This ma kes

enough time for the jogger plate to squa re the sta ck of pa per a nd to sta ck the

paper smoothly into the bins.

- Normal (proof) mode -

When the Start key is pressed, the tran sport motor [B] energizes to rota te the

transport roller. The transport roller sends copies to the proof tray directly.

- Sort mode -

When sort mode is selected, the bin drive motor [C] energize s to rotat e the

helical wheels. The helical wheels [D] rotate twice to move the top bin to the

transport roller position , then the first cop y is delivered to the top bin.

[C]

After the first copy of the first origina l h as been fed to th e top bin , th e bin

drive motor moves the bins up one step (the helical wheels rotate once) so

that the second copy of the first orig inal will be delivered to the next bin .

The jogger plate [E] squares the copies after each copy has been fed to a

bin. After the copies of the first orig ina l h ave been delivered to each bin, the

sorter stapler maintains its status (t he bin drive moto r does not rota te ).

6

Page 8

13th January 1995 BASIC OPERATION

The first copy of the second origina l is delivere d to the fina l bin th at was used

for the first original, the n th e fin al bin descends one step. The bins de scend

each time a copy of the seco nd original is delivered.

The direction of motion of the bins alt ern at es fo r each page of the original

until the copy run is finished.

- Stack mode -

[A]

When stack mode is selected, the top bin advances to the transport roller

position in the same way as in sort mode.

After the first copy is delive red to the top bin, the jogger plate [A] moves

across to square the copy. The jogger plate squares th e copies after each

copy has been fed to a bin.

After one set of copies for the first orig ina l h as been delive red to the to p bin ,

the bin drive motor moves th e bin s up on e ste p. Then, one set of copies of

the second original will be delivered to the next bin.

Stapler

10-bin Sorter

7

Page 9

BASIC OPERATION 13th January 1995

3.2 STAPLE MODE

[B]

[A]

[C]

[D]

The stapler is only available in sort mode.

When the jogger plate has square d th e fin al set of cop ies, the grip arms [A ]

move inside the front side frame and catch the pape r. The grip asse mbly

brings the copies into the stapler [B], and the stapler staples the copies.

After stapling, the grip asse mbly [C] brings the stapled copies back to the bin

and releases the copies. Then the grip asse mbly goes ba ck to th e no rmal

position. The bin eithe r a dva nces or descends one step depen ding on

whether the number of originals is odd or even [D].

When the final set of copies has been stapled, the bins go back to the

standby position.

8

Page 10

13th January 1995 BASIC OPERATION

There are two staple modes.

Automatic Stapling

In ADF mode, when staple mod e is selected before pressing th e St art key,

copies will be delivered to each bin and stap led aut oma tica lly.

Manual Stapling

In platen cover mode, after the copies have been sorted into the bins, the

staple mode LED starts to blink. If the sort key is presse d while this LED is

blinking, the copies will be stapled.

Stapler

10-bin Sorter

9

Page 11

BASIC OPERATION 13th January 1995

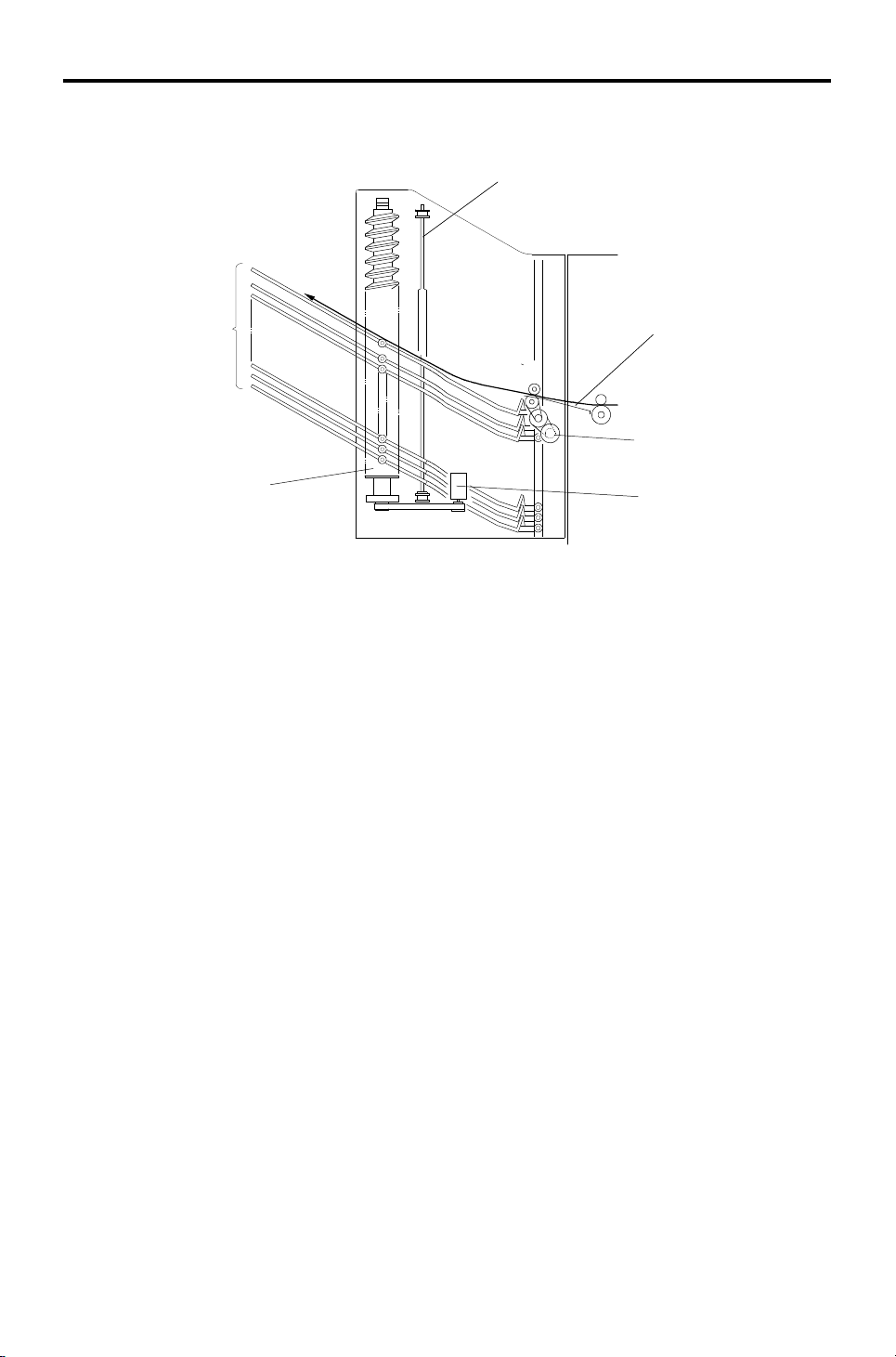

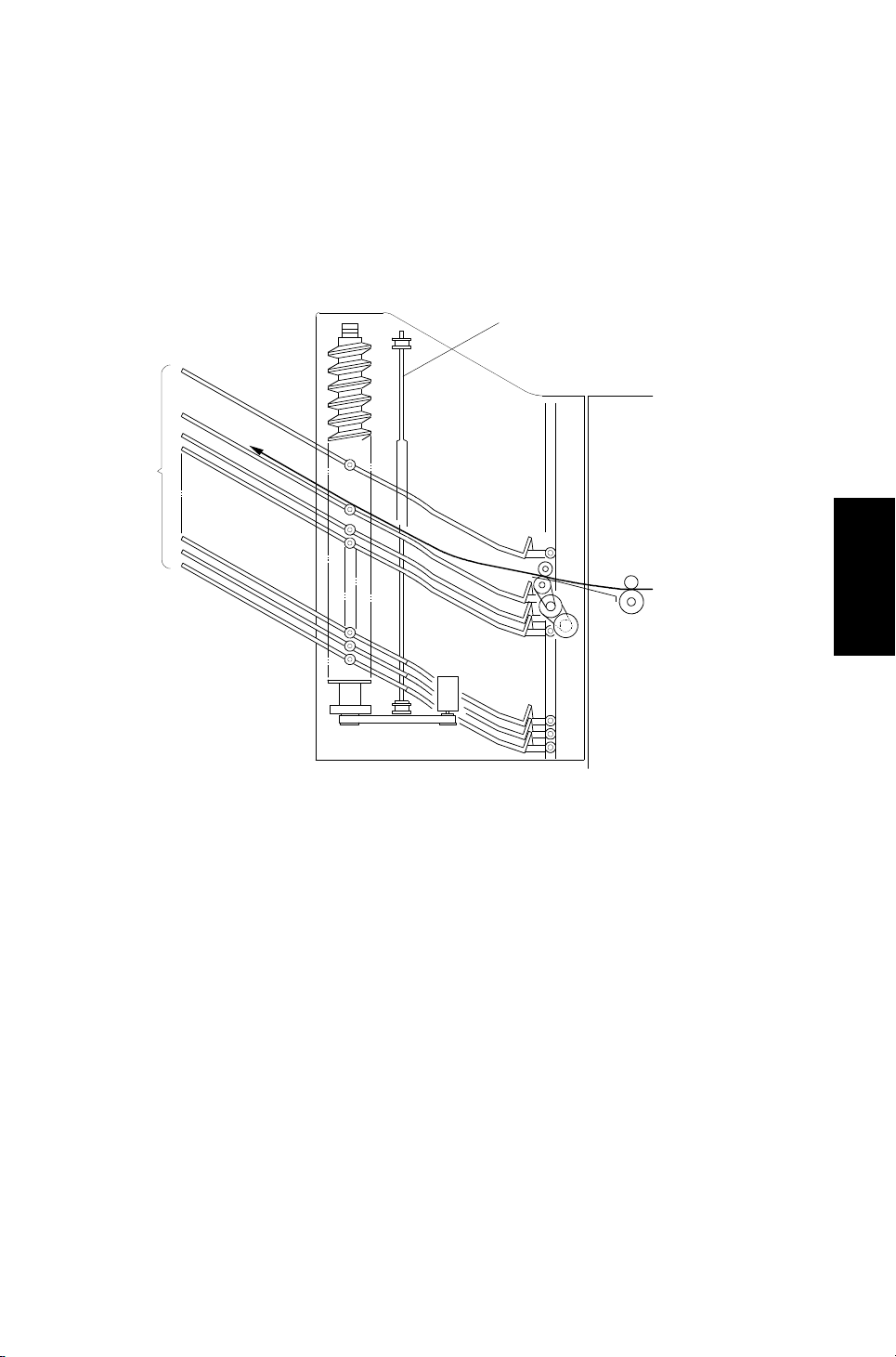

3.3 BIN DRIVE MECHANISM

[A]

[A]

[B]

[C]

[D]

The bin drive mechanism moves th e bin s up an d do wn to receive copies.

There are four pins on each bin . Two pins fit into the slots [A] in bot h th e front

and rear side frames; the pin s slide up and down in these slots. The other

two pins fit into the slot in the helical wh eels; as th e helical wheels turn, these

pins move up and down, and the oth er pins move up and down in the slots at

the other end of the bin.

The bin drive motor [B] drives the helical wheels thro ug h four timin g belts [C] .

When the motor rotates clockwise, the bins lift; whe n it rot ates

counterclockwise, the bins lower. There is a wheel sensor actuator [D] on the

front helical wheel; the actu at or has a slo t which det ect s when the helica l

wheel has rotated once.

When the bins are advanced, the helical wheels rotate once for each step. As

the pitch of the spiral on the helical wheel is greater when the bins are at the

staple and paper exit area th an wh en the bins are elsewhere, the amoun t of

bin shift is greater when the bins are at the sta ple and pap er exit area . This

leaves enough space to stap le an d stack the copies. Also, this re du ces th e

total machine height.

10

Page 12

13th January 1995 BASIC OPERATION

3.4 BIN HOME POSITION

[A]

The bin home position senso r [ A] ensu res that the proof tray is lower t ha n th e

transport roller when the bins are in the home position.

When the main switch is turned on, the sorter staple r initia lizes itself to check

whether the component parts work or not. At this time , th e bin drive mot or

raises the bins for a few moments, then it lowers the bins until th e bott om bin

actuates the bin home posit ion sensor.

Stapler

10-bin Sorter

11

Page 13

BASIC OPERATION 13th January 1995

3.5 JOGGER MECHANIS M

[B]

[E]

[D]

[C]

[A]

The jogger motor [A] drives the jogge r plate [B] through the timing belt s [C].

The jogger is at home position when the actuator on the jo gger plate goes

into the jogger home position sen sor [D] .

At standby, the jogger plate is at the home position. When the Start ke y is

pressed, the copier sends the paper size informa tio n to the sorte r stap ler.

In sort, staple, and sta ck mo de s, th e jogger moves three times to squa re the

stack of paper. First, whe n th e pa pe r has be en fed comple tely into the bin (at

the proper time after th e copy has passed through th e en tra nce sensor [E],

depending on the paper length), the jogger mot or moves the jogger plate out

of the jogger home posit ion. Then, the jogger mot or drives the jogger plate to

the width of the copy. Finally, the jogger plate moves inward to push all the

copies against the fron t side frame, which squares the sheets of paper. Then

the jogger plate returns to the home position.

12

Page 14

13th January 1995 BASIC OPERATION

3.6 GRIP ASSEMBLY

[G]

[H]

[I]

[J]

[D]

[B]

[E]

[C]

[F]

[A]

The grip assembly consists of the grip motor [A], the timin g belt [B ], the drive

gear [C], the grip home position sen sor [D] , an d the cam gear [E].

The grip motor drives the cam gear through the timing belt and drive gear.

Cam gear rotation drives the mechanism that ca tch es the copies and moves

the grip arm unit [F]. When the cam gear rotates clockwise one full turn, the

grip arm moves to catch the copies an d returns to the home positio n to

prepare for stapling. After stapling, the cam gear rotate s counte rclockwise

once so that the staple d copies go back to the bin, and the cam gea r re tu rns

to its home position.

Stapler

10-bin Sorter

When the cam pushes the roller [G] on the lever [H] and the lever pushes the

grip arm, the grip arm can catch the copies.

A pin [I] on the cam gear fits into the slot in the grip arm un it. So, when the

cam gear rotates, the slot moves the grip arm unit inward and outward.

The actuator [J] on the cam gear activates the grip home positio n sen sor

once every rotation of the cam gear. This allows th e sort er sta pler to

determine that the cam gear has rotated once.

13

Page 15

BASIC OPERATION 13th January 1995

3.7 STAPLER UNIT

[C]

[D]

[A]

[F]

[G]

[H]

[E]

[B]

The stapler motor [A] drives the staple hammer [B] using the gears [C] and

the eccentric cam [D].

The roller [E] feeds the staple sheets un de r the hamme r.

When the aligned copies are brought to the staple position by the grip unit,

the stapler motor starts rotat ing and the copies are stapled. Wh en the cam

completes one rotation, the staple ho me po sitio n sen sor [F] is deact ua te d

and the stapler motor stops.

When the stapler paper sensor [G] in the grip asse mbly does no t de te ct an y

copies under the hammer, the stap ler mot or do es not rotate.

When the trailing edge of th e last staple sheet pass throu gh the stap le en d

sensor [H], the sorter stap ler en ters t he st aple ne ar end con dition. After the

current job is completed, th e Ad d St ap les ind icator lights on the operation

panel. Then the copie r cann ot be use d whenever the staple mode is

selected.

14

Page 16

13th January 1995 BASIC OPERATION

3.8 STAPLER SWITCH

[A]

[B]

The stapler switch [A] be low th e grip assembly cuts the signal to the stap ler.

In proof mode, all bins lower and pu sh th e leve r [ B] . This open s the st apler

switch so that the signal to the staple r is cut. In sort an d sta ple mode s, all

bins are advanced and the switch is closed so that the signal ca n be supplied

to the stapler.

- Staple Disabling Conditions -

1. Under the following conditions, staple mode is disabled.

If there is paper in a bin before the main switch is turned on.

If the selected paper size does not match the stapling specification s.

If the paper is fed from the by-pass feed table.

If the stack or interrupt modes are selected.

2. Under the following conditions, staple mode is canceled if it had been

selected.

Stapler

10-bin Sorter

If paper is inserted into a bin by hand while the stap le mod e is select ed .

If only one sheet is delivered to th e bin.

If the number of sheets to be stapled exceeds th e sta pler capacity.

15

Page 17

BASIC OPERATION 13th January 1995

3.9 PAPER FEED AND MISFE ED DE TECTION TIMING

– Proof Mode –

A4 sideways, 5 copies, 150 mm/s

*1: The value of the low sp ee d depe nd s on th e copier.

– Sorter Mode –

A4 sideways, two copies a of two-page original, 150 mm/s

*1: The start timing of the bin drive and the jogger motors depend on the

paper size as shown in the following table.

*2: Bin No.

Paper Size

A3/11"x17" 138 ms 292 ms

B4 218 ms 212 ms B5 sideways 218 ms 212 ms

A4 sideways/

11"x8

1/2"

Bin drive

motor timing

138 ms 292 ms B5 lengthwise 368 ms 62 ms

Jogger motor

timing

Paper Size

lengthwise/

1/2"x11"

8

16

A4

Bin drive

motor timing

312 ms 118 ms

Jogger motor

timing

Page 18

13th January 1995 BASIC OPERATION

– Staple Mode –

A4 sideways, two copies of a two-page origin al, aft er sorting, 150 mm/s

Stapler

10-bin Sorter

17

Page 19

BASIC OPERATION 13th January 1995

3.10 JAM DETECTION

– Paper Jam –

J1: The sorter entran ce sensor does not turn on within 2 s afte r t he fusing

exit sensor has turned on.

J2: The fusing exit senso r doe s not turn off within 11.4 s aft er the sorter

entrance sensor has turned on.

J3: The sorter entran ce sensor does not turn off with in 1 s aft er the fusing

exit sensor has turned off.

– Staple Jam –

In the following condit ion s, a staple jam will occur and the sorter jam indicator

on the operation panel will light.

1. If the stapler paper sensor is on when the main swit ch tu rns on or ju st as

the stapler cover is closed.

2. If the stapler paper sen sor sta ys o n af te r t he stap ling job ha s bee n

finished.

18

Page 20

13th January 1995 INSTALLATION

4. INSTALLATION

4.1 ACCESSORY CHECK

Check the quantity and cond itio n of the accessories in the box against the

following list:

1. Misfeed Removal Decal............. .. .. .... .. .. .. .. .. .. .... .. .. ..1

2. Staple Position Decal.............. .............. .. .. ..............1

3. Chain .......................................................................1

4. Cap Remover ...................... .. .. .. .. .............. .. .. ..........1

5. Philips Pan Head Screw 4 x 8......... .. .......... .. ..........1

6. Philips Pan Head Screw 4 x 14..................... .. .. .. .. ..4

7. New Equipment Condition Report............. .. .. .. .. .. ....1

8. Installation Procedure.................. .......... .......... ........1

Stapler

10-bin Sorter

19

Page 21

INSTALLATION 13th January 1995

4.2 INSTALLATION PROCEDURE

– Incorrect Lifting Method –

[A]

[B]

[B]

[C]

[B]

[C]

NOTE: When this unit is installed in the A157, A159, A160, A1 61 , an d A1 62

copiers, the sorter adapter (A5 68 ) shou ld be installed before the

sorter stapler.

CAUTION

!

Unplug the copier power cord before starting the fol low ing proc edur e.

Do not lift the sorter stapler by holding the entrance

guide [A]. Otherwise, the resul ting damage may cause paper jams to

occur at the entrance.

1. Remove the strips of tape.

[C]

2. Remove the cardboard pieces [B] and the foam blocks [ C].

20

Page 22

[D]

13th January 1995 INSTALLATION

– A153/A155/A156 copiers –

[A]

[D]

[B]

[D]

[B]

[C]

– A157/A159/A160/A161/A16 2 copiers –

[D]

[E]

[B]

[C]

3. Remove the caps [A] with nipp ers.

4. For A153, A155, and A156 copiers:

Fit the hooks [B] on the sorter stapler mounting frame [C] into the

openings [D]. Then tig ht en four M4 x 14 screws.

For A157, A159, A160, A161, and A162 copiers:

First, remove the screw [E], and fit th e ho oks [B ] on the sorte r stap ler

mounting frame [C] into the openings [D]. Then tighten four M4 x 14

screws.

Stapler

10-bin Sorter

21

Page 23

[F]

INSTALLATION 13th January 1995

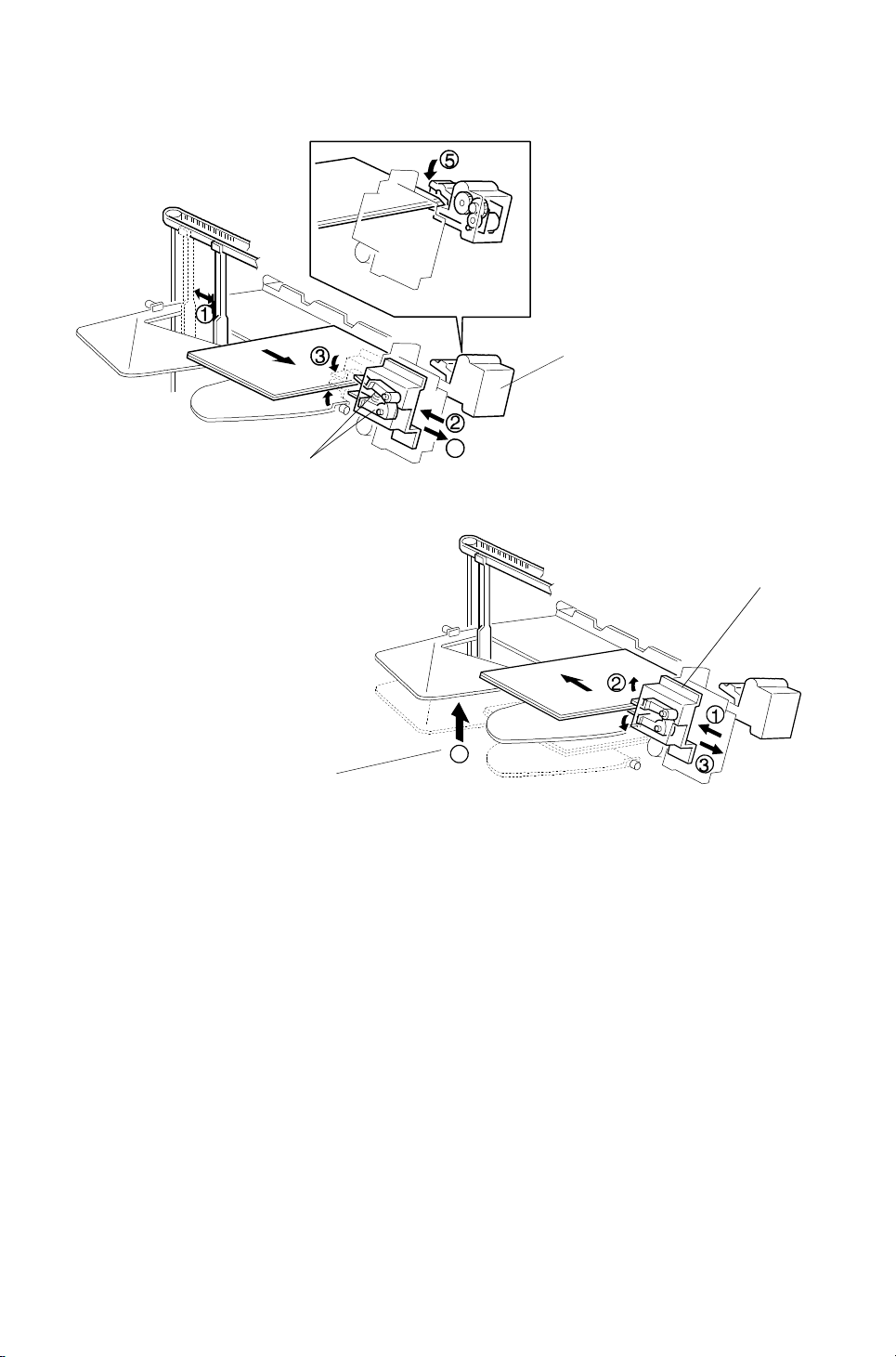

– Incorrect Lifting Method –

[B]

[C]

[H]

[G]

[A]

[E]

[D]

5. Install the sorter stapler [A] on the frame [1 M4 x 8 screw].

NOTE: Do not lift the sorter stapler by holdin g the entrance guide [B]

when installing it.

6. Tighten 1 M4 x 8 screw [C].

NOTE: This screw prevents the sorter stapler from fa lling down .

7. Connect the cable [D] and th e op tic cable [E].

8. Install the chain [F] as shown .

9. Attach the misfeed removal decal [G] and th e sta ple posit ion deca l [ H] as

shown above.

22

Page 24

13th January 1995 INSTALLATION

[B]

[A]

[C]

[E]

[D]

10. Open the front door [A] of the sort er sta pler and swing the staple unit [B]

up.

11. Remove the green plastic clip [C] from th e staple cartridge and correct

the position of the sta ple sheet [D] to make it flush with the other sheets

in the cartridge.

12. Install the cartridge [E] in the staple r while ho ldin g the staple unit.

13. Put the staple unit back to the orig ina l position, close the sorter stap ler

front door, and plug in the copier.

14. Turn on the main switch, and test the operation of the sorte r stapler.

NOTE: The stapler will not be stapling for the first 5 or so copies after

installation until the first stap le come s to th e proper position from

the cartridge.

Stapler

10-bin Sorter

23

Page 25

SERVICE TABLES 13th January 1995

5. SERVICE TABLES

5.1 DIP SWITCHES

DIP SW100

Switch No.

1 2345

Off Off Off Off Off Normal Setting

On On Off Off Off Sorter Free Run

On Off On Off Off Staple Free Run

On On On Off Off System Free Run

Off Off Off Off On

Bin Jam Sensor Adjustment (see

section 6.6)

Using a Free Run Mode

1. Select the type of f ree ru n th at you need using switche s 2 and 3.

2. Set switch 1 to 1. The free run starts.

Function

3. To stop the free run, set switch 1 to 0.

4. Return switches 2 and 3 to their factory settin gs.

Free Run Mode Types

- Sorter Free Run Mode -

This mode advances and lowers the bins, moves the jogger plate, and

changes the roller rotation speed fro m lo w to hig h for e ach bin.

- Staple Free Run Mode -

This mode performs the jogger plate, grip assembly, and staple move men ts

for each bin.

- System Free Run Mode -

This mode performs both sorter free run and staple free run modes.

24

Page 26

13th January 1995 SERVICE TABLES

5.2 TEST POINTS

Number Function

TP100 +24 V

TP101 +5 V

TP102 GND

5.3 LED

Number Function

LED100 Bin jam sensor status

5.4 VARIABLE RESIS TOR

Number Function

VR100

Bin jam sensor (LED) adjustment

(see Bin Jam Sensor Adjustment)

Stapler

10-bin Sorter

25

Page 27

REPLACEMENT AND ADJUSTMENT 13th January 1995

6. REPLACEMENT AND ADJUSTMENT

6.1 EXTERIOR COVE R REMO VAL

[D]

[A]

[C]

[B]

1. Rear Cover [A] (2 screws)

2. Front Cover [B] (3 screws)

3. Lower Cover [C] (1 screw)

4. Top Cover [D] (2 screws)

6.2 STAPLE UNIT REMOVAL

[A]

1. Remove the front cover (see Exterio r Co ver Remo val).

2. Swing up the staple unit [A].

3. Remove the staple unit (1 connector, 1 ground wire, 1 clip).

26

Page 28

13th January 1995 REPLACEMENT AND ADJUSTMENT

6.3 GRIP ARM REPLACEMENT

[A]

[D]

[C]

[E]

[B]

[G]

[F]

1. Remove the front cover (see Exterio r Co ver Remo val).

2. Remove the grip assembly [A] (4 screws, 2 connect ors, 1 grou nd ing wire).

3. Remove the holder bracket [B] (1 screw).

4. Remove the spring [C] and remove the slider [D].

5. Remove the grip arm unit [E] (1 screw, 1 clip).

Stapler

10-bin Sorter

6. Remove the grip arm plate [F] (2 screws).

7. Replace the grip arms [G].

27

Page 29

[F]

[J]

REPLACEMENT AND ADJUSTMENT 13th January 1995

6.4 BIN REPLACEMENT

[D]

[E]

[C]

[B]

[A]

[K]

[L]

[I]

[H]

[G]

[K]

[J]

[I]

[H]

1. Remove the front, rear, and top covers (see Exterior Cover Removal).

2. Remove the spring [A] and the grip cover [B] (2 screws).

3. Remove the upper stay bracket [C] (6 scre ws, 1 gro un din g wire, 1

connector).

4. Remove the timing belt [D].

5. Remove the jogger guide plate [E ] (4 screws).

6. Remove the wheel sensor bracket [F] (1 screw).

7. Remove the bushings [G] (1 clip each).

8. Remove the actuators [H], belts [I ], and the gears [J] (1 clip on each side).

9. Remove the helical wheels [K].

10. Remove the bins [L].

NOTE: When putting back the he lical wheels at both the front and re ar of the

machine, the parts labeled A should be pointing direct ly away from

the machine.

28

Page 30

[B]

[G]

13th January 1995 REPLACEMENT AND ADJUSTMENT

6.5 TRANSPORT MOTOR REPLACEMENT

[A]

[C]

[E]

[F]

[D]

[H]

1. Remove the sorter stapler [A] (1 screw, 1 chain ).

2. Remove the lower plate [B] (3 screws).

3. Remove the entrance guide [C] (4 screws).

4. Remove the transport motor unit [D].

5. Remove the collar [E].

6. Remove the transport roller [F] (2 bushings, 1 gear).

Stapler

10-bin Sorter

7. Remove the transport motor cover [G].

8. Remove the transport motor [H] (3 screws).

29

Page 31

REPLACEMENT AND ADJUSTMENT 13th January 1995

6.6 BIN JAM SENSOR ADJUS TMENT

After replacing the sorter main board, perform the bin jam sensor adju stme nt

as follows.

1. Turn on the main switch.

2. Remove any copies from the bins.

3. Set switch 5 of DIP SW 100 on the sorter main board to the ON position.

4. Turn VR 100 until LED 100 goes off.

30

Page 32

Page 33

10 BIN SORTER STAPLER (A5 55 ) E LECTRI CAL CO MPNENT

3

LAYOUT

16

15

17

14

13

1

2

4

5

6

7

12

11

19

10

8

9

18

Page 34

Description Index No. P to P Location

Bin Sensor (Photo tr.) (S1) 1 I15

Sorter Entrance Sensor (S2) 2 F15

Grip Motor (M5) 3 I2

Stapler Paper Sensor (S5) 4 A15

Grip H.P. Sensor (S6) 5 B15

Stapler Motor (M4) 6 E1

Stapler Switch (SW2) 7 F5

Door Safety Switch (SW1) 8 C5

Jogger Motor (M2) 9 H2

Wheel Sensor (S8) 10 C15

Bin Sensor (LED) (S7) 11 K15

Bin H.P. Sensor (S9) 12 H15

Timing Sensor (S4) 13 G15

Transport Motor (M1) 14 E16

Jogger H.P. Sensor (S3) 15 J15

Bin Drive Motor (M3) 16 K2

Main Board (PCB1) 17 F8

Staple H.P. Sensor (S10) 18 E1

Staple End Sensor (S11) 19 E1

Loading...

Loading...