T

Model:

Phoenix II Series

echnical

B

ulletin

Date:

15-Sep-97

No:

PAGE: 1/4

1

Subject:

From:

Service Manual Revision

QAC 1st Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

J.Kasamoto

The lists for SP5-803 (Sensor/Switch Input Signal Data Check) and SP5-804 (Electrical

Component Check) have been changed from the Phoenix Mark Ι series, and this

information was not listed in the insert version service manual. Please add the following

lists to your Phoenix Mark ΙΙ series manual.

The reason for the change is related to the new sorters that can be installed on the Mark ΙΙ

series.

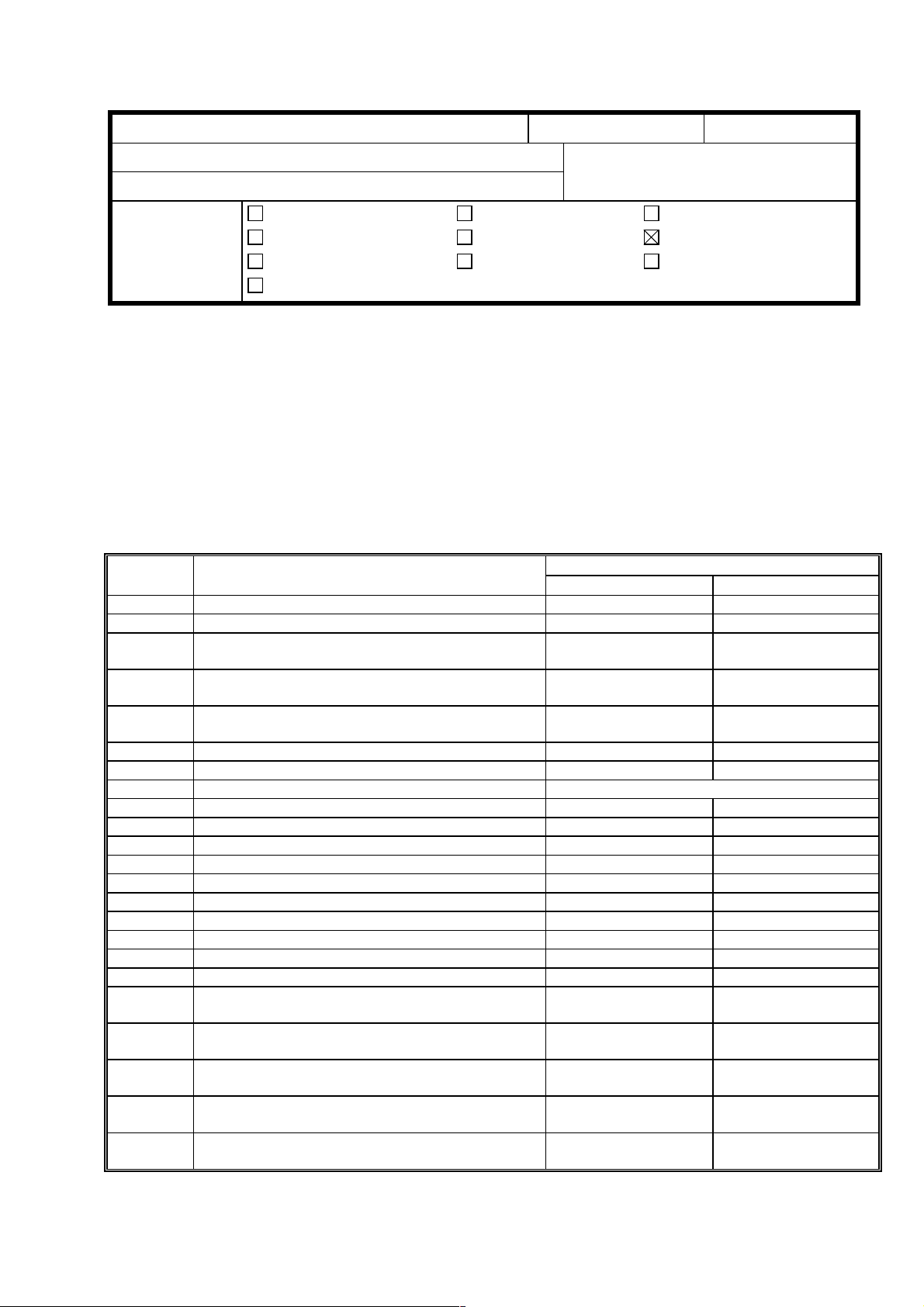

SP5-803 SENSOR/SWITCH INPUT SIGNAL DATA CHECK

3rd level Reading

No Sensor/Switch/Signal 0 1

1 Upper Relay Sensor Paper not detected Paper detected

2 Lower Relay Feed Sensor Paper not detected Paper detected

3 3rd Tray Paper Feed Sensor

(Paper Tray Unit)

4 4th Tray Paper Feed Sensor

(Paper Tray Unit)

5 5th Tray Paper Feed Sensor

(Paper Tray Unit)

6 Registration Sensor Paper not detected Paper detected

7 Fusing Exit Sensor Paper not detected Paper detected

8 By-pass Feed Paper Width Sensor See the Note after the end of this table.

9 By-pass Feed Paper End Sensor Paper detected Paper not detected

10 By-pass Feed Table Switch Table is closed Table is open

11 Upper Tray Paper End Sensor Paper detected Paper not detected

12 Upper Tray Upper Limit Sensor Down Up

13 Not Used - 14 Upper Tray Switch Not set Set

15 Lower Tray Paper End Sensor Paper detected Paper not detected

16 Lower Tray Upper Limit Sensor Down Up

17 Not Used - 18 Lower Tray Switch Not set Set

19 1st Tray Paper End Sensor

(Paper Tray Unit)

20 1st Tray Upper Limit Sensor

(Paper Tray Unit)

21 1st Tray Set Sensor

(Paper Tray Unit)

22 2nd Tray Paper End Sensor

(Paper Tray Unit)

23 2nd Tray Upper Limit Sensor

(Paper Tray Unit)

Paper not detected Paper detected

Paper not detected Paper detected

Paper not detected Paper detected

Paper detected Paper not detected

Down Up

Not set Set

Paper detected Paper not detected

Down Up

T

3rd level Reading

No Sensor/Switch/Signal 0 1

24 2nd Tray Set Sensor

(Paper Tray Unit)

25 3rd Tray Paper End Sensor

(Paper Tray Unit)

26 3rd Tray Upper Limit Sensor

(Paper Tray Unit)

27 3rd Tray Set Sensor

(Paper Tray Unit)

28 LCT Paper End Sensor Paper detected Paper not detected

29 LCT Upper Limit Sensor Off On

30 LCT Lower Limit Sensor Off On

31 LCT Connector Not connected Connected

32 LCT Tray Down Switch Off On

33 LCT Cover Switch Cover closed Cover open

34 Original Length Sensor 2 Off On

35 Original Length Sensor 3 Off On

36 Original Length Sensor 4 Off On

37 Original Width Sensor 5 Off On

38 Original Width Sensor 6 Off On

39 Original Width Sensor 7 Off On

40 Scanner H.P. Sensor Off On

41 Lens Horizontal H.P. Sensor Off On

42 Lens Vertical H.P. Sensor Off On

43 3rd Scanner H.P. Sensor Off On

44 Optics Thermistor Off On

45 Platen Cover Close Sensor Platen cover open Platen cover closed

46 Platen Cover Open Sensor Platen cover closed Platen cover open

47 Vertical Guide Set Switch Vertical guide closed Vertical guide open

48 Paper Exit Cover Switch Paper exit cover

49 Front Cover Switch Front cover closed Front cover open

50 Sorter Entrance Sensor (A556/A557) Off On

51 Sorter Bin H.P. Sensor (A556/A557) Off On

52 Sorter Bin Lift Sensor (A556/A557) Off On

53 Sorter Cover Switch (A556/A557) Cover closed Cover open

54 Sorter Entrance Sensor (A664) Off On

55 Sorter Proof Exit Sensor (A664) Off On

56 Sornter Bin (Jam) Sensor (A664/A658/A555) Off On

57 Sorter Bin (Jam) Sensor (A664/A658/A555) Off On

58 Sorter Bin Home Position Sensor

(A664/A658/A555)

59 Sorter Wheel Sensor (A664/A658/A555) Off On

60 Sorter Bin Rear Plate Open Sensor (A664) Off On

61 Sorter Bin Rear Plate H.P. Sensor (A664) Off On

62 Sorter Jogger H.P. Sensor (A664/A658/A555) Off On

63 Sorter Grip H.P. Sensor (A664/A658/A555) Off On

64 Sorter Staple Hammer H.P. Sensor (A664) Off On

65 Sorter Staple Unit H.P. Sensor (A664/A658/A555) Off On

66 Sorter Staple End Sensor (A664/A658/A555) Off On

67 Sorter Stapler Paper Sensor (A664/A658/A555) Off On

68 Sorter Door Safety Switch (A664/A658/A555) Off On

69 Sorter Transposrt Motor Encoder (A664) Off On

70 Sorter Cartridge Set Switch (A664) Off On

71 Sorter Staple Unit Set Switch (A664) Off On

echnical

B

ulletin

Not set Set

Paper detected Paper not detected

Down Up

Not set Set

Paper exit cover

closed

Off On

open

PAGE: 2/4

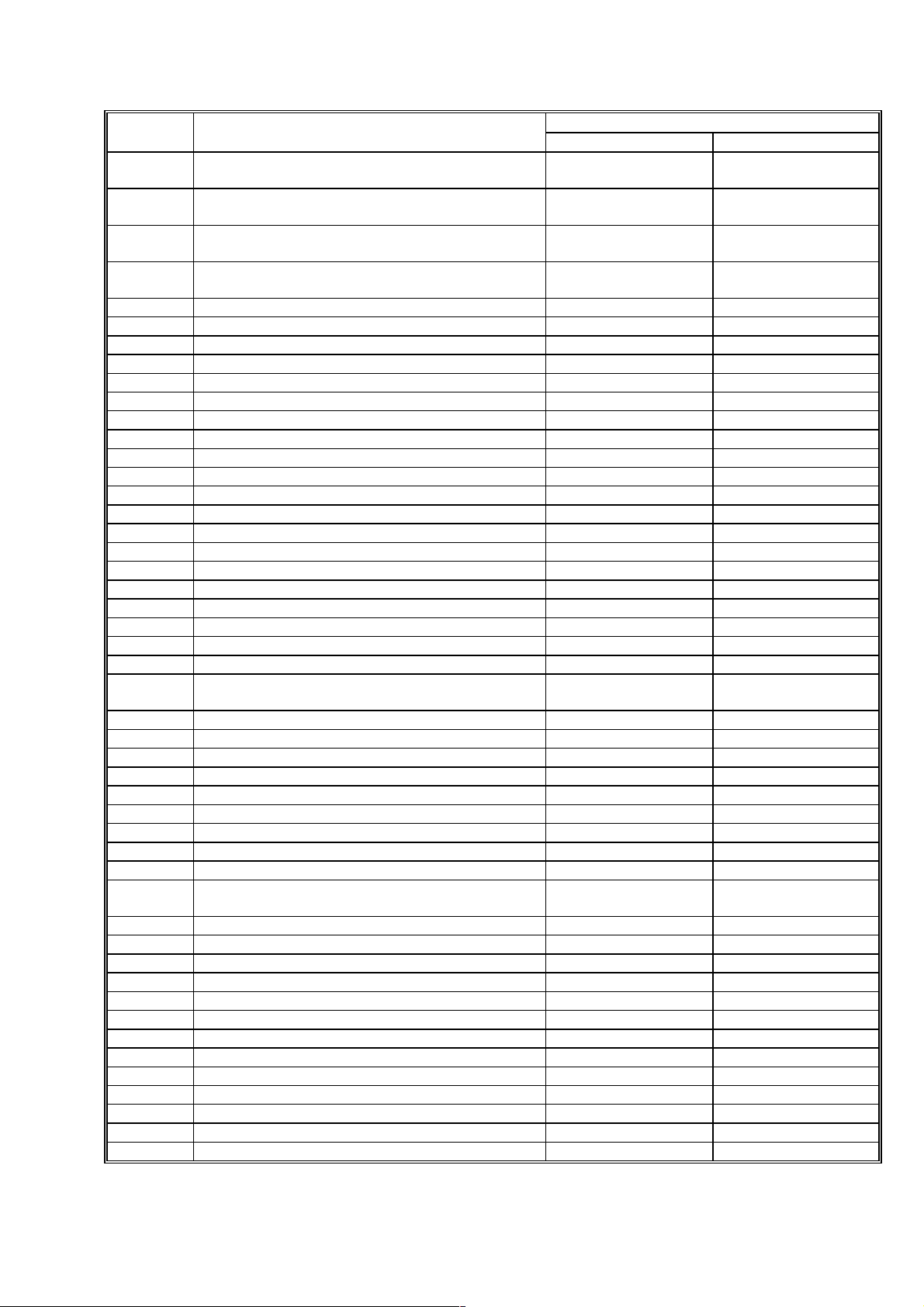

T

3rd level Reading

No Sensor/Switch/Signal 0 1

72 Sorter Staple Unit Pulled-out Position Sensor

(A664)

73 Duplex Entrance Sensor Off On

74 Duplex Turn Sensor Off On

75 Duplex Paper End Sensor Paper detected Paper not detected

76 Upper Tray Switch Not set Set

77 Duplex Side Fence Jogger H.P. Sensor Off On

78 Duplex End Fence Jogger H.P. Sensor Off On

80 Main Motor Lock Off On

81 Fusing Unit Set Sensor Not set Set

82 Transfer Belt Contact H.P. Sensor Off On

83 Toner End Sensor Toner remains Toner end

84 Key Counter Set Not set Set

85 Not Used - 86 Total Counter On Off On

87 Auto Response Sensor Off On

90 ADF Original Width Sensor-3 Off On

91 ADF Original Width Sensor-2 Off On

92 ADF Original Width Sensor-1 Off On

93 ADF Registration Sensor Paper not detected Paper detected

94 ADF Feed Out Sensor Paper not detected Paper detected

95 ADF Position Sensor ADF closed ADF open

96 ADF APS Start Sensor On Off

97 ADF Feed In Cover Open Sensor Cover closed Cover open

98 ADF Feed Out Cover Open Sensor Cover closed Cover open

echnical

B

ulletin

Off On

PAGE: 3/4

SP5-804 ELECTRICAL COMPONENT CHECK

3rd level No. Electrical Component

1 Main Motor

2 Relay Clutch

3 Registration Clutch

4 Transfer Belt Contact Clutch

5 Junction Gate SOL

6 Not Used

7 Sorter Drive Motor (A556 and A557 Sorters only)

8 By-pass Feed CL

9 By-pass Feed Pick-up SOL (A153 and A157 Copiers only)

10 Upper Paper Feed CL

11 Upper Tray Separation SOL

12 Upper Tray Pick-up SOL

13 Upper Tray Lift Motor (Up)

14 Upper Tray Lift Motor (Down)

15 Lower Paper Feed CL

16 Lower Tray Separation SOL

17 Lower Tray Pick-up SOL

18 Lower Tray Lift Motor (Up)

19 Lower Tray Lift Motor (Down)

20 LCT Pick-up SOL

21 Not Used

22 Not Used

T

3rd level No. Electrical Component

23 LCT Display

24 Bin Drive Motor Up (A556/A557)

25 Bin Drive Motor Down (A556/A557)

26 Sorter Main Motor (A664/A658/A555)

27 Sorter Main Motor (Counterclockwise) (A664)

28 Sorter Exit Motor (A664)

29 Sorter Turn Gate Solenoid (A664)

30 Sorter Bin Drive Motor (A664/A658/A555)

31 Sorter Jogger Motor (A664/A658/A555)

32 Sorter Bin Rear Plate Drive Motor (A664)

33 Sorter Grip Motor (A664/A658/A555)

34 Sorter Grip Arm Positioning Solenoid (A664)

35 Sorter Grip Solenoid (A664)

36 Sorter Stapler Drive Motor (A664)

37 Sorter Staple Motor (A658/A555)

40 Exposure Lamp

41 Quenching Lamp, PTL

42 Toner Supply CL

43 Development CL

44 Toner Supply Bottle Motor

45 Machine Shut Off

46 Not Used

47 Exhaust Fan

48 Optics Cooling Fan

49 Not Used

50 ADF Feed-in Motor

51 ADF Feed-in Motor (Reverse)

52 ADF Belt Drive Motor

53 ADF Belt Drive Motor (Reverse)

54 ADF Feed-out Motor

55 ADF Inverter SOL

56 ADF Display On

echnical

ulletin

B

PAGE: 4/4

T

Model:

Phoenix II Series (Swallow II)

echnical

B

ulletin

Date:

15-Dec-97

No:

PAGE: 1/4

2

Subject:

From:

Classification:

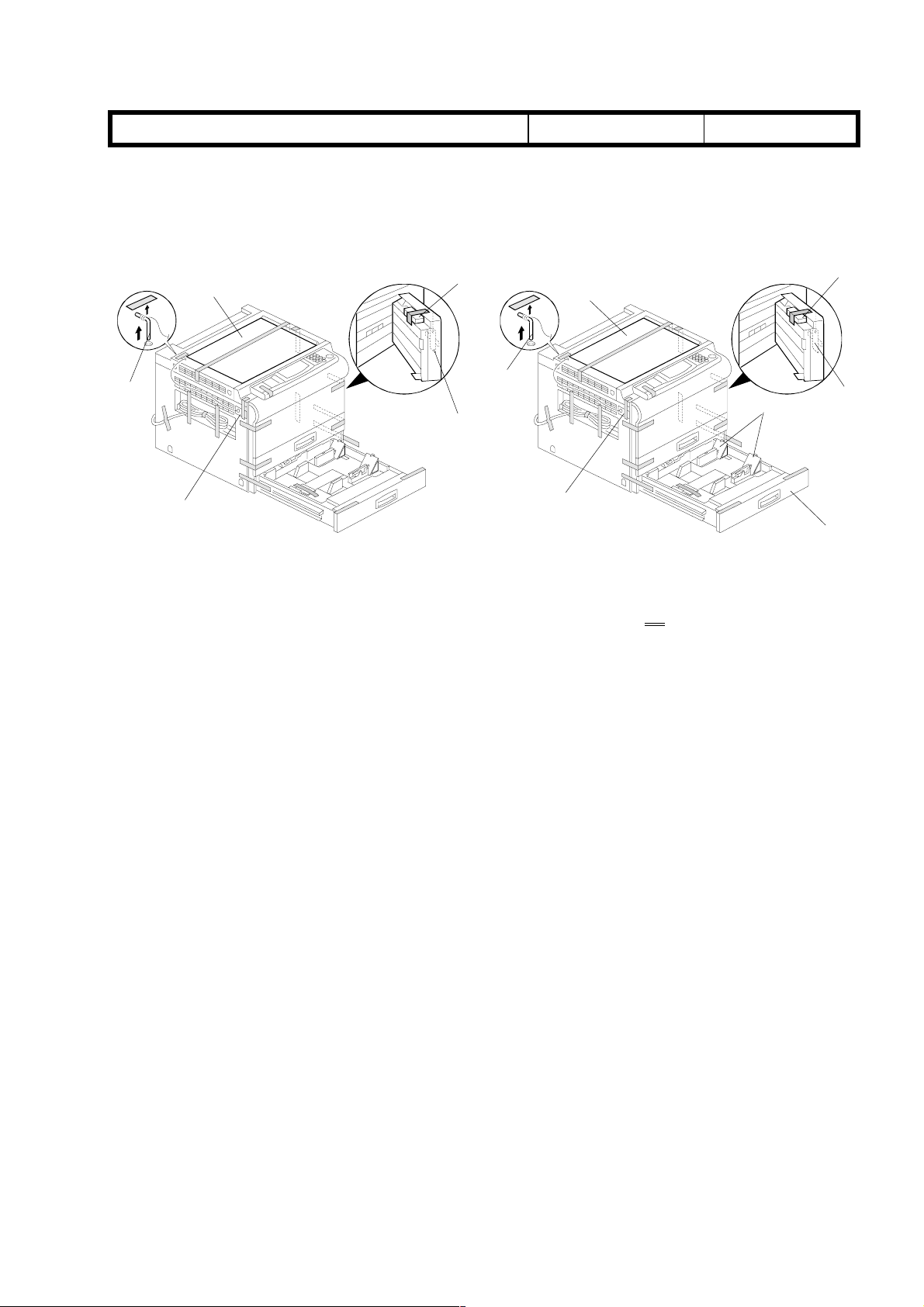

1. Please correct your Service Manual as follows:

Page 13/14

Page 20

<OLD>

Service Manual Revision

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

L1, L2 and L3, delete the sentences marked with *.

Callout [A] was positioned incorrectly in the illustration.

Part information

Electrical

Transmit/receive

<NEW>

Prepared by:

Action required

Service manual revision

Retrofit information

K. Miura

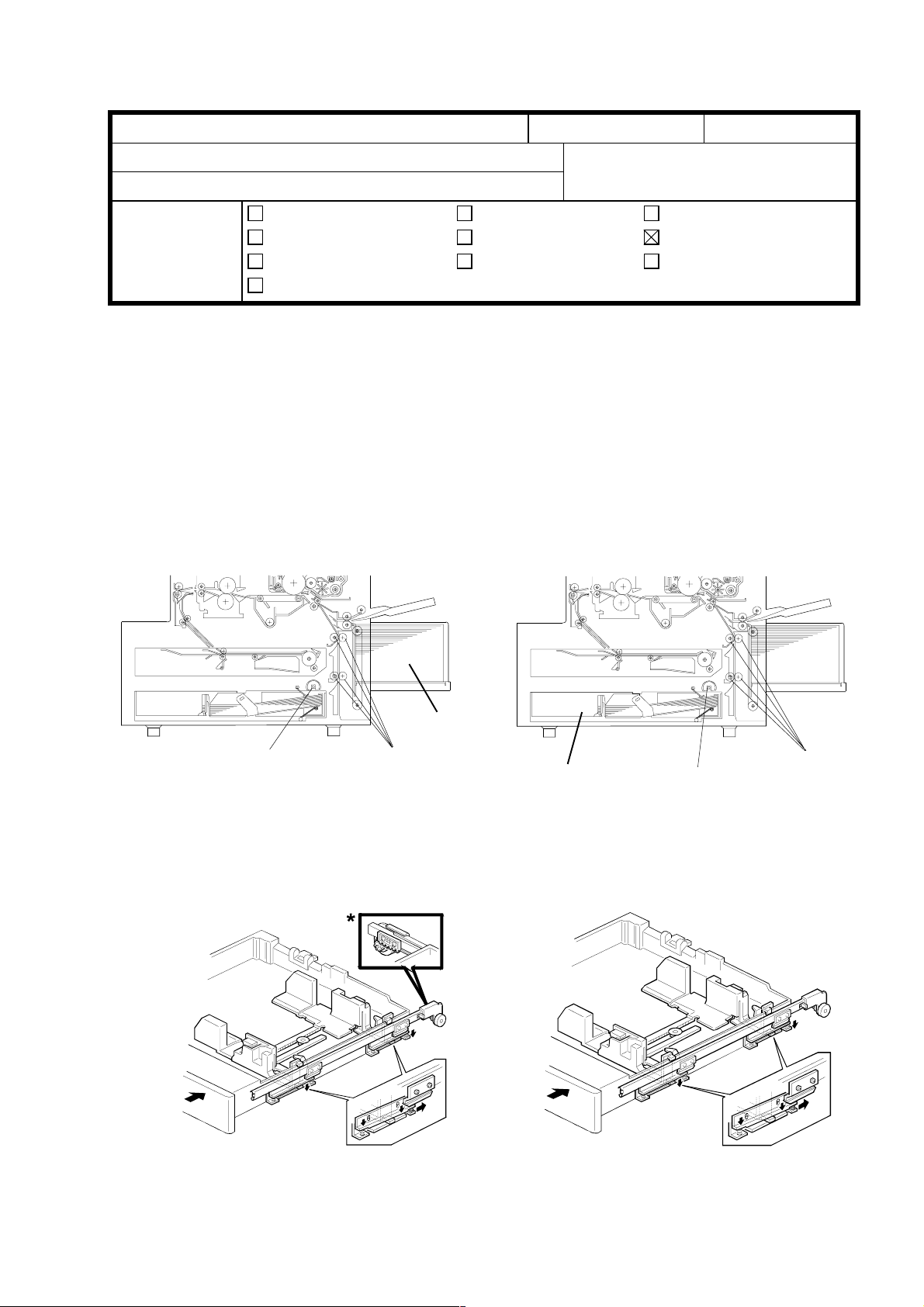

Page 24

This copier does not have a damper at the end of the paper tray guide rail. Delete

the last sentence and also the illustration as shown below.

<OLD>

[B]

[C]

* [A]

*[A]

<NEW>

[B]

[C]

T

Model:

Page 27

Phoenix II Series (Swallow II)

Callouts [G] and [H] were not included in the illustration.

echnical

B

ulletin

Date:

15-Dec-97

No:

PAGE: 2/4

2

<OLD>

[A]

Page 32

[E]

[B]

Change the paragraph

IMPORTANT

<NEW>

[C]

[E]

[A]

[D]

[B]

from step 20 to step 21.

[C]

[D]

[H]*

[G]*

T

(

)

y

p

y

p

(

p

y-p

(

)

Model:

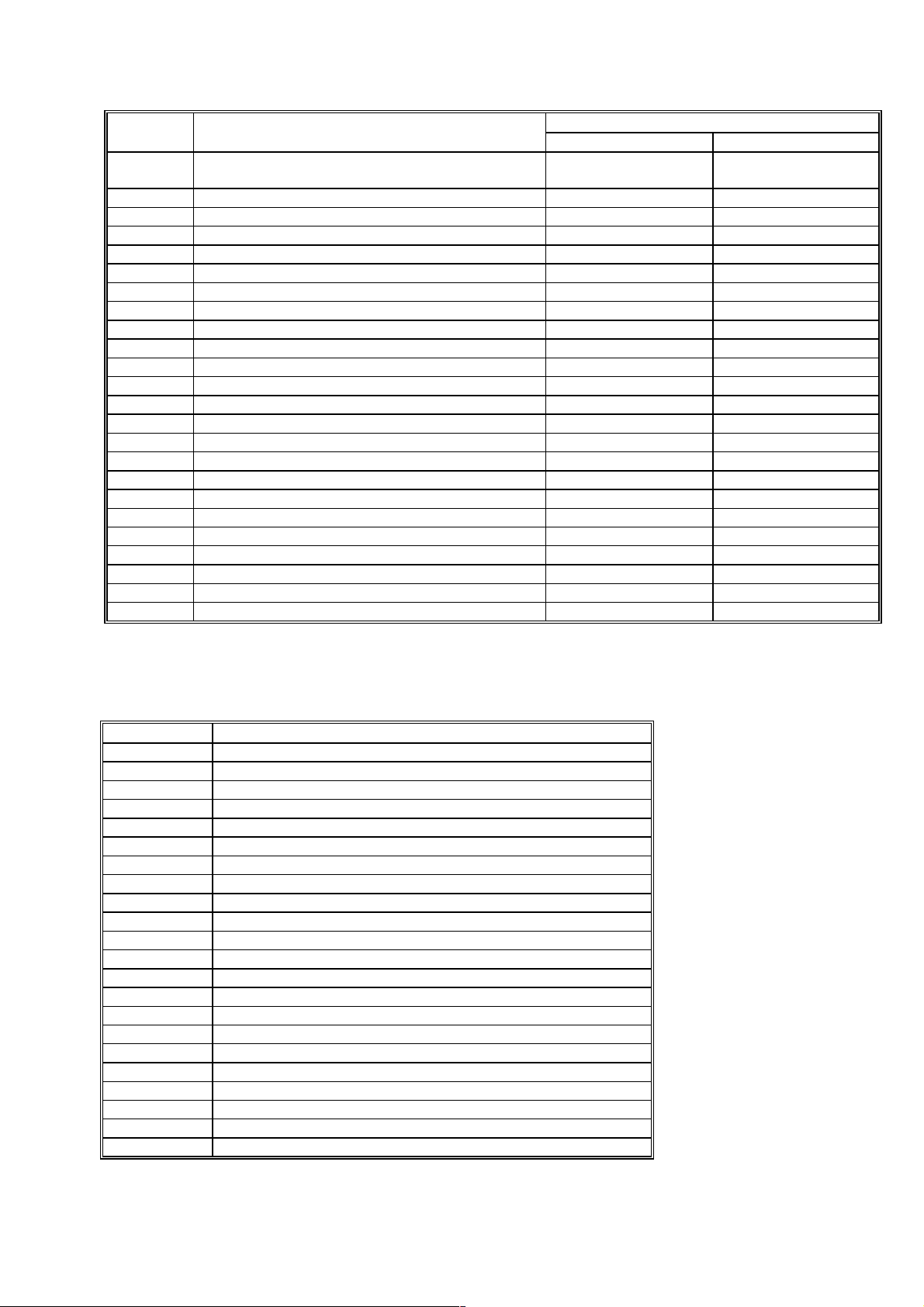

Page 73

Phoenix II Series (Swallow II)

echnical

B

ulletin

Date:

15-Dec-97

No:

PAGE: 3/4

2

Replace

Page 73

following page.)

4. Cleaning Unit

(every 120 k)

5. Development Unit

every 120 k

with the following information. (Refer to the explanations on the

Clean the inside of the cleaning unit and the

1.

seals.

Replace the cleaning blade.

2.

Remove the old developer.

1.

*1

Clean the development unit and seals.

2.

Clean around the openings of the toner supply

3.

unit with a blower brush.

Pour in a pack of new developer.

4.

Replace the development filter.

5.

6. Paper Feed

(every 120 k for each

paper feed station)

*3

Replace pick-up,

feed and se

rollers for b

feed, and the LCT

every 240 k

*4

Replace the

se

aration torque

limiter for the b

ass feedstation

every 240 k).

aration

ass

.

-

1.

Clean the paper guide plate.

*2

Clean the paper feed, pick-up, separation, and

2.

rela

rollers for by-pass feed, and the LCT.

Replace the paper feed rollers for each paper

3.

feed station.

Replace the bottom plate pad for each paper

4.

feed station, by-pass feed, and the LCT.

Clean the registration rollers.

5.

T

Model:

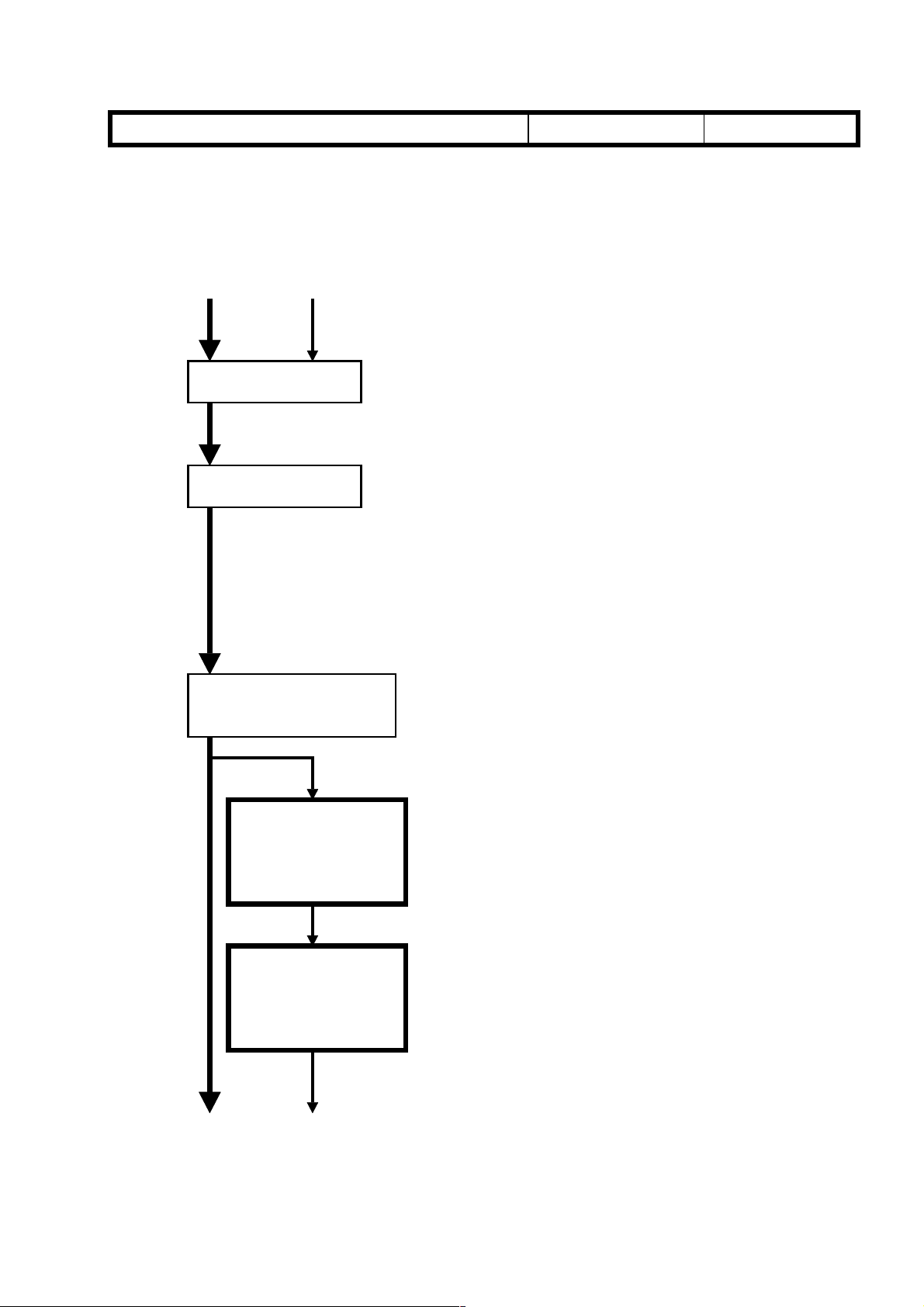

2. The paper registration mechanism has been changed from the Swallow Mark I, and this

information was not listed in the insert version service manual. Please add the following

to your Swallow II manual.

Phoenix II Series (Swallow II)

*1

The manual has been corrected. The PM interval for the development unit is 120k.

*2

The explanations have been revised to match the PM table.

*3

The paper feed station only has semi-circular feed rollers, which are replaced every

120k.

*4

“A214 only” has been deleted, since all models have a by-pass feed separation

torque limiter.

echnical

B

ulletin

Date:

15-Dec-97

No:

PAGE: 4/4

2

9.5 PAPER REGISTRATION

This copier does

registration rollers. (The rollers marked * on the illustration below.) The upper roller

is driven by the lower roller due to pressure from springs.

not

have gears on the front side that engage the upper and lower

*

T

Model: Swallow 2 Date:

echnical

B

ulletin

98 Mar 13

No:

PAGE: 1/2

3

Subject:

From:

Classification:

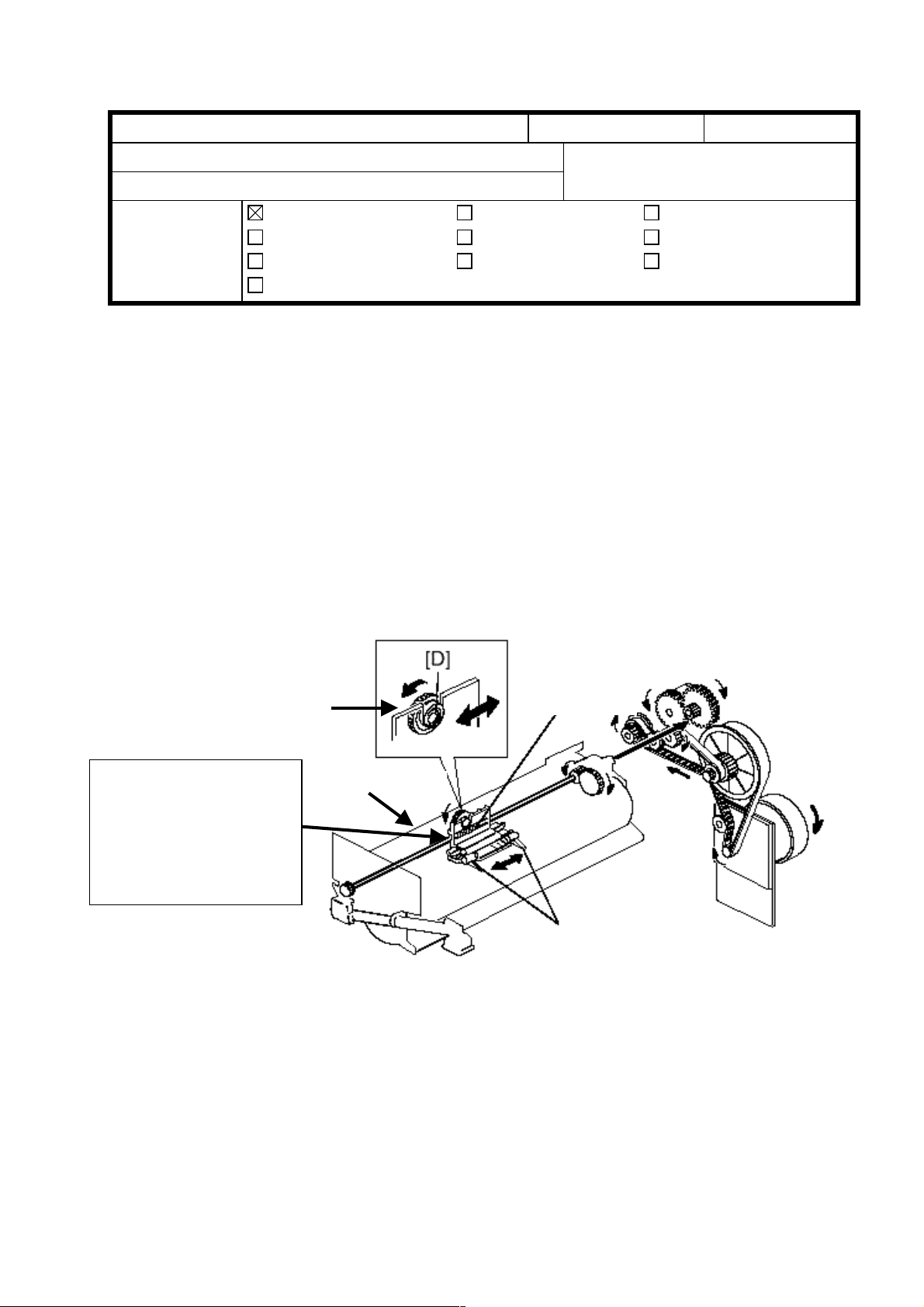

Knocking Noise from Pick-off Pawl Cam Gear

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by: S. Hizen

Action required

Service manual revision

Retrofit information

SYMPTOM

♦ A knocking sound from the drum unit.

♦ No side-to-side movement of the pick-off pawls

CAUSE

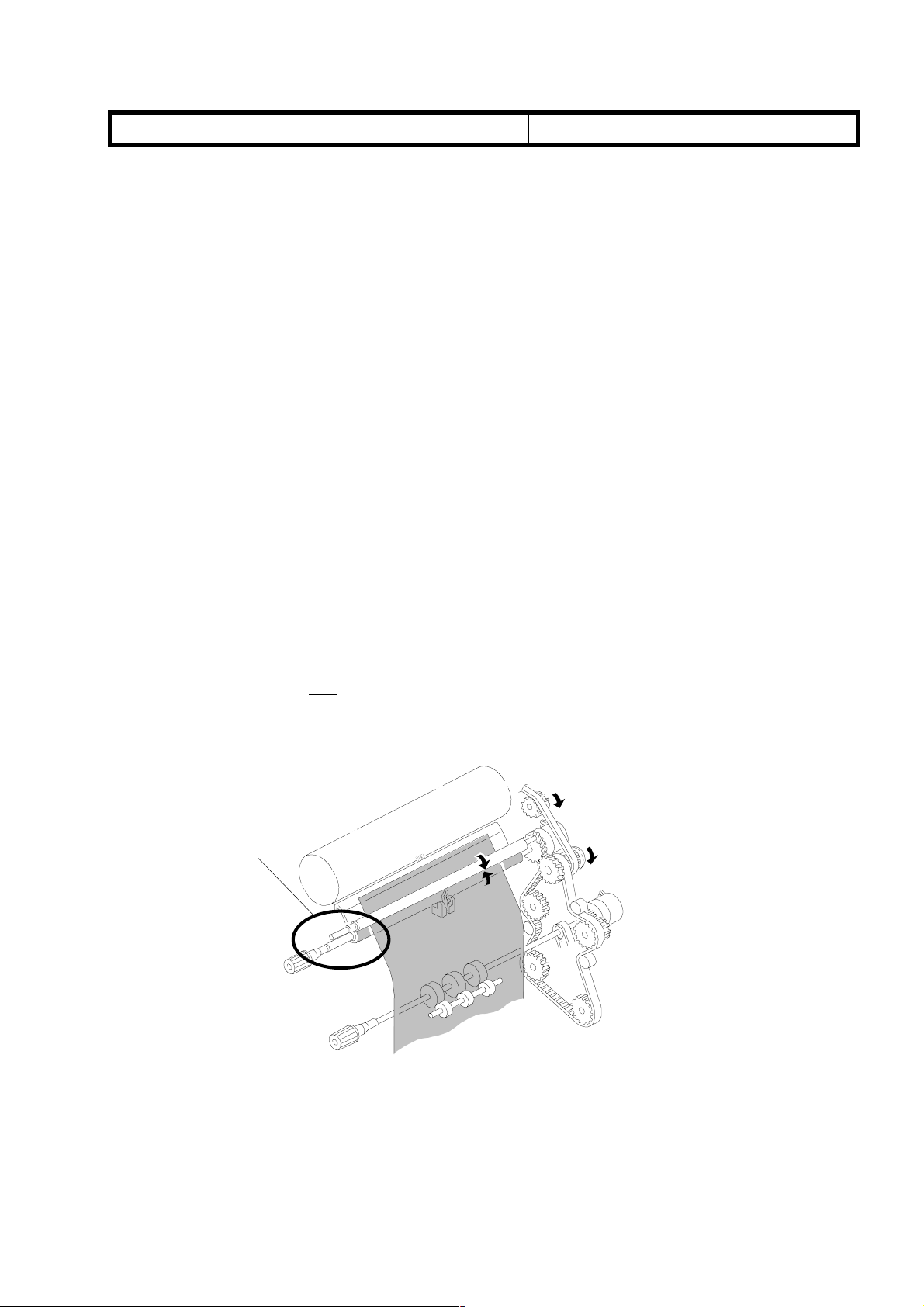

The cam gear (P/N: AB01-7376) on the drum unit is not meshing properly with the worm

gear shaft (P/N: AA14-0560) of the pick-off pawl. The distance between the cam gear and

the worm gear shaft is wider than the specifications.

SOLUTION

Change the 40Z cam gear to a 42Z cam gear (P/N: A212-3567: Black Cam Gear).

Cam Gear

Make sure that the

cam gear is meshing

properly with the worm

gear. If not, please

change the cam gear

from 40Z to 42Z.

Drum Frame

Worm Gear

Pick-off Pawls

COUNTERMEASURE

The cam gear has been changed from 40Z (P/N: AB01-7376) to 42Z (P/N: A212-3567) in

the mass-production units. The color of the cam gear has also been changed from white

to black.

T

echnical

B

ulletin

PAGE: 2/2

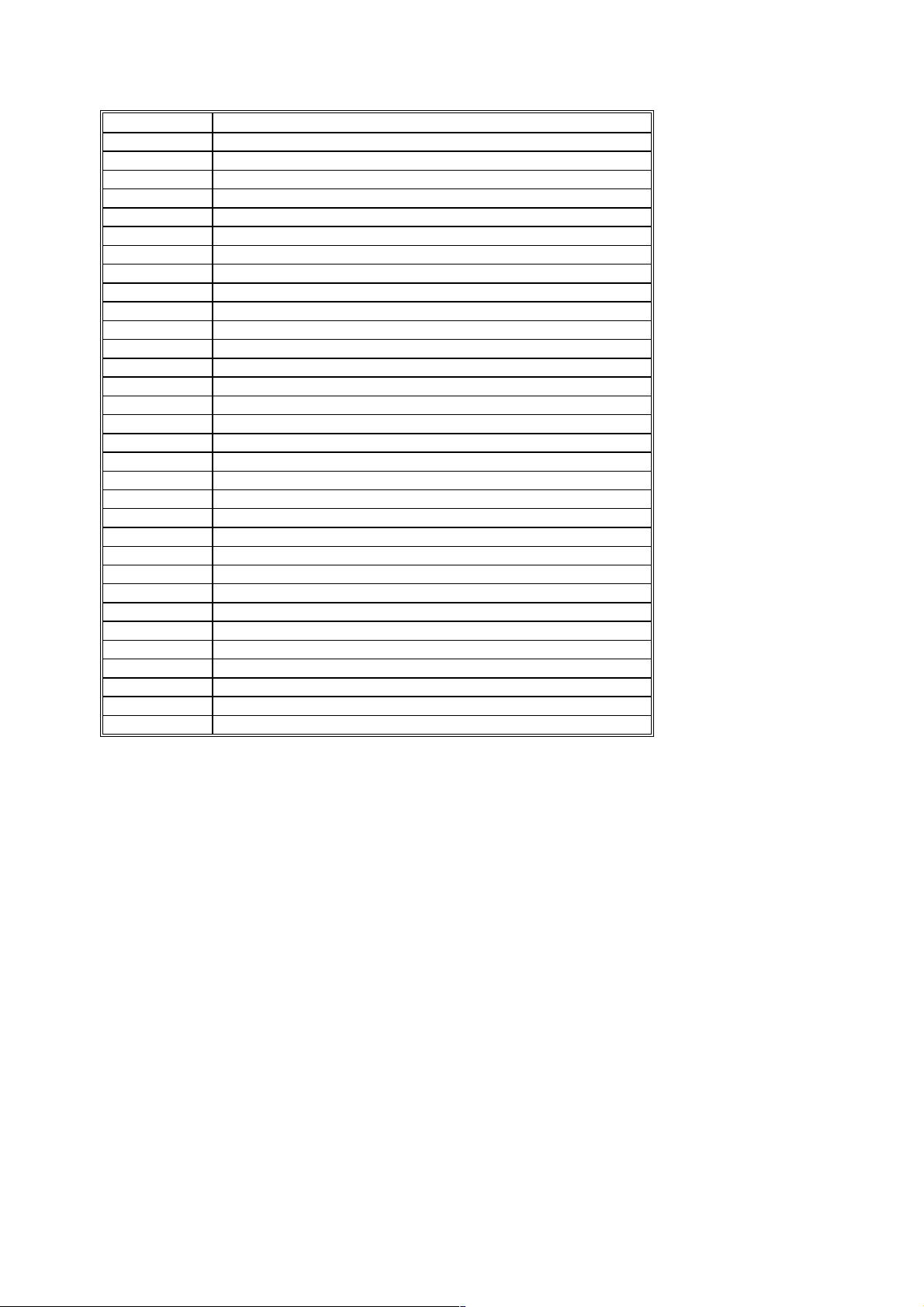

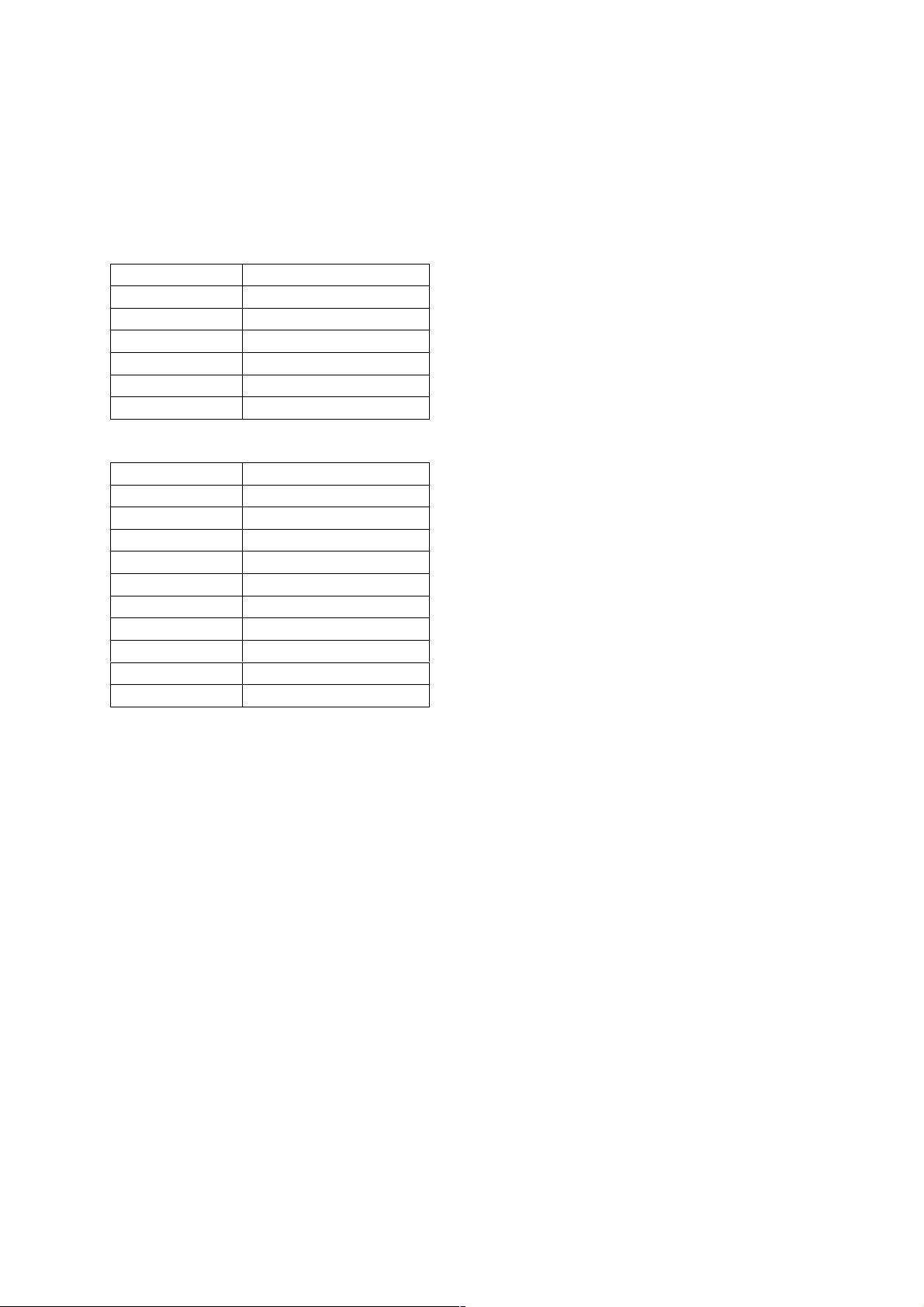

Targeted Machines

The cam gear modification has been implemented from the following units onward.

Start serial numbers for 42Z cam gear

RIF Units

Model Serial Numbers

A212-52 AP08630135~

A212-56 3M96380001~

A212-57 A7668630001~

A214-52 AP28630001~

A214-56 3N06380001~

A214-57 A7678630001~

Sindo Ricoh Units

Model Serial Numbers

A212 -10 AP18020001~

-15 1B18020001~

-17 A7668020293~

-22 AP08020021~

A214 -10 AP38020001~

-15 1B28020001~

-17 A7678020285~

-22 AP28030001~

-27 A7678030031~

-29 A7678030001~

Loading...

Loading...