Page 1

SECTION 1

OVERALL MACHINE

INFORMATION

Page 2

Overall

Information

1 February 1994 SPECIFICATIONS

1. SPECIFICATIONS

Copy Process: Laser electrostatic transfer system

Originals: Book/sheet, fixed platen

Original Alignment: Front-right corner

Maximum Original Size: 11" x 17"/A3

Copy Paper Size: Maximum: 11" x 17"/A3

Minimum: 5

1/2" x 81/2"/A5

Copy Paper Weight: Bypass feed: 17 to 42 lb/64 to 157 g/m

Side cassette: 17 to 42 lb/64 to 157 g/m

Front trays: 17 to 28 lb/64 to 104 g/m

Copying Speed: 30 copies per minute (81/2" x 11" sideways)

31 copies per minute (A4 sideways)

18 copies per minute (11" x 17")

18 copies per minute (A3)

First Copy: 5.8 seconds (8

1/2" x 11"/A4 sideways) from

side cassette

Warm-up Time: Within 5 minutes

(Room temperature 23°C/73°F)

Copy Counters:

Set counter: 1 to 999 (max. is adjustable by SP mode)

Copy counter: 1 to 999 ( count-up or count-down, can be

selected by SP mode)

Paper Capacity: Cassette: 250 sheets

Manual feed table: 30 sheets

2

2

2

Copy Tray Capacity: 250 sheets (8

1/2" x 14"/B4 and smaller)

100 sheets (11" x 17"/A3)

Automatic Reset: After 60 seconds (3 min. can be selected by

SP mode)

-- Reproduction Ratio: Full size

-- Interrupt Mode: OFF

-- 2 Single Copies: OFF

-- Sort/Stack: OFF

* : It is possible to be changed by

SP mode

-- Duplex: OFF

-- Set Counter: 1

-- Copy Counter: 0

1-1

Page 3

SPECIFICATIONS 1 February 1994

-- Image Density: Auto ID *

-- User Program Mode: OFF

-- Total Area Editing: OFF

-- Letter/Photo mode: Letter mode

-- Designated Area Editing: OFF

-- Cassette: 1st or LCT *

-- Auto Reduce/Enlarge: OFF

-- Auto Paper Selection: ON *

Photoconductor: Organic photoconductor drum

Drum Charge: Dual-wire with grid plate (Negative Charge)

Fixed Reproduction Ratios: 6 enlargement ratios and 7 reduction ratios

A4/A3 version LT/LDG version

800%

400%

Enlargement

Full Size 100% 100%

Reduction

200%

141%

122%

115%

93%

82%

75%

71%

65%

50%

25%

800%

400%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

25%

Zoom: From 25% to 800% in 1% increments.

Allows independent horizontal and vertical

percentage.

Scanning System: CCD, one directional scanning with mirrors

and lens

Picture Element Density: 400 dots per inch (15.7 lines/mm)

Scanner Light Source: Two fluorescent lamps (green light)

Exposure System: Semiconductor laser, one dimensional

scanning

Development:

• Dual-component dry toner system

• Double roller development

Toner Replenishment: 300 gram cartridge

1-2

Page 4

Overall

Information

1 February 1994 SPECIFICATIONS

Toner Consumption: 5,500 copies/cartridge

1/2" x 11"/A4, 6% Originals)

(8

Development Bias: Negative fixed bias

Toner Density Control: Pattern density detection by photosensor

Image Transfer: Single wire dc (positive charge)

Paper Separation: Dual wire ac corona and pick-off pawls

Cleaning: Cleaning blade, cleaning brush, and

pre-cleaning corona

Quenching: Photo quenching by LEDs

Paper Feed System: Feed and reverse roller

Image Fusing: Heat and pressure type, teflon (upper) and

silicone rubber (lower) rollers

Fusing Lamp: Halogen lamp (115 V, 750 W/230 V, 800 W)

Silicone Oil Consumption: More than 80,000 copies/500 cc

1/2" x 11"/A4 copies)

(8

Printer Feature

Memory: Instruction ROM: 4 Mbytes

Font ROM: 2 Mbytes

Base RAM: 8 Mbytes

PDL/Emulation: Adobe PostScript Level 2

HP LaserJet

compatible with HP LaserJet

ΙΙΙ (PCL-5) Emulation and

ΙΙΙsi, ΙΙD

Graphics:

Compressed files: Decompress raster graphic files (as per

Adobe PS 2 and HP PCL 5 specifications)

Conversion: Automatically convert 300 dpi bit-mapped

graphics for HP PCL 5 mode.

1-3

Page 5

SPECIFICATIONS 1 February 1994

Fonts:

Adobe type 1: Outline fonts: Zapf Chancery, Zapf Dingbats,

Symbol plus four styles (normal, italic, bold,

bold-italic) each of Avant Garde Bookman,

Courier, Helvetica, Helvetica Narrow, New

Century Schoolbook, Times Palatino

HP/Intellifonts: Outline fonts: Zapf Dingbats plus four styles

(normal, italic, bold, bold-italic) each of

Univers, Univers Condensed, CG Times

Soft font capability: Outline fonts downloadable to memory or

optional hard disk

Printer Port: RS232C serial

Bi-directional Centronics parallel

RS422 Appletalk

Scanner Feature

Scan Area: Max. 11" x 17"/A3

Scan Time: Max. 2 seconds (8

1/2" x 11"/A4 at full size

mode (400 dpi)

Document Type: Book/Sheet

Image Reduction: 25% (100 dpi) 50% (200 dpi) 75% (300 dpi)

Output Data: Binary Digital Data

-- Black and White (fixed threshold)

-- Photo Mode (dither pattern)

Brightness: From 1 to 7

Host Interface: SCSI-II

Self-diagnostic Codes: 35 codes, indicated in the guidance display

Power Source:

115 V/60 Hz/15 A, 220

∼ 240 V/50 Hz/8 A

Power Consumption: Maximum: 1.50 kW

Warm-up: 0.9 kW (average)

Copy cycle: 1.1 kW (average)

Stand-by: 0.15 kW

1-4

Page 6

Overall

Information

1 February 1994 SPECIFICATIONS

Dimensions (W x D x H): Machine frame only: 27.6" x 28.8" x 23.8"

700 x 732 x 605 mm

Full system: 63.0" x 28.8" x 44.5"

1600 x 732 x 1130 mm

Weight: Approximately 216.1 lb/112 kg (Main frame

only)

Approximately 413.6 lb/188 kg (Full system)

Optional Equipment: -- ARDF (automatic reverse document feeder)

-- 10 bin sorter

-- Auto duplex and LCT (1000 sheet) unit

-- LCT (1000 sheet) unit

-- Hard disk drive (40 MB)

-- Memory module unit (4 MB)

-- Scanner interface board

-- Key counter (locally procured)

1-5

Page 7

DRUM PROCESSES 1 February 1994

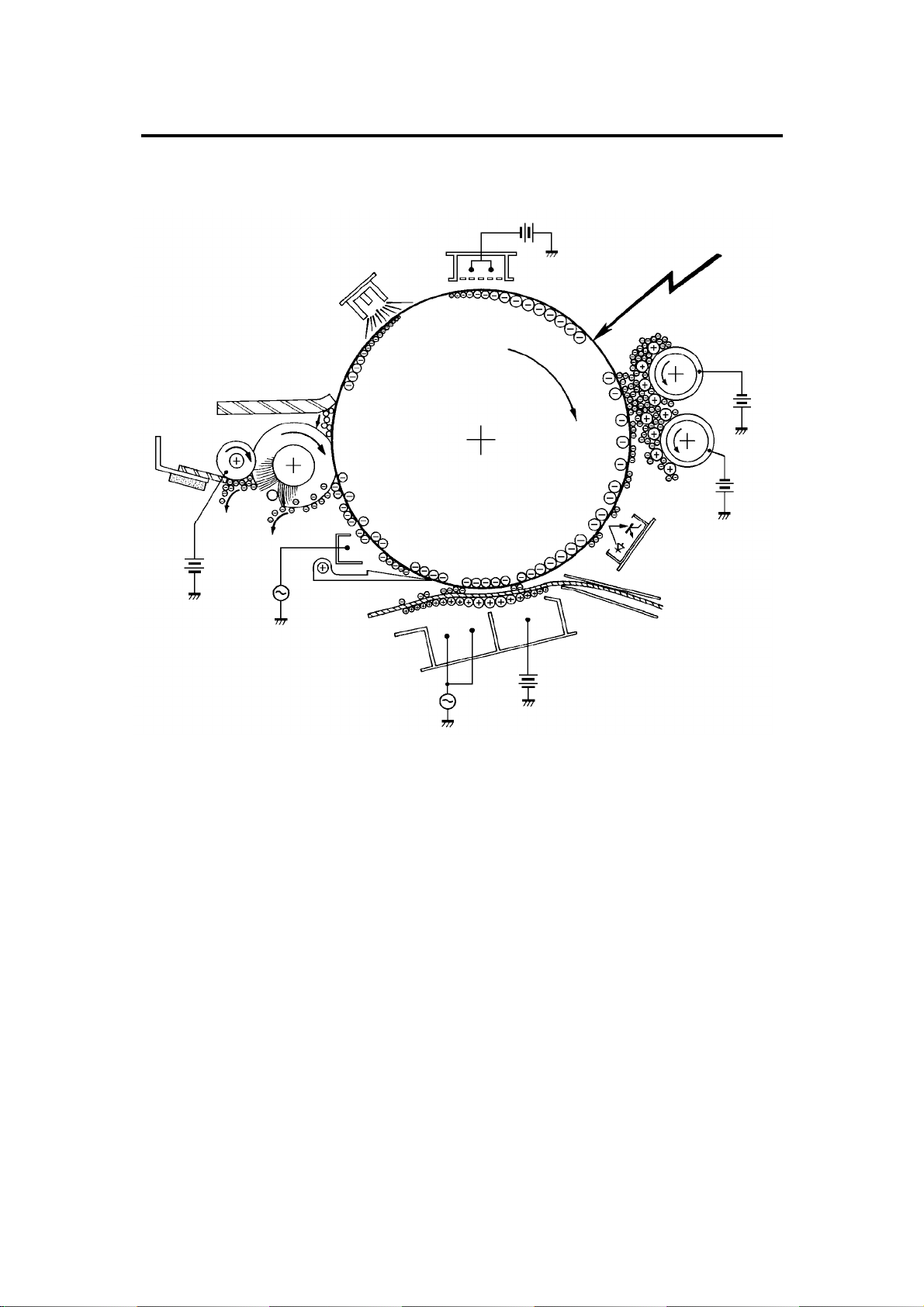

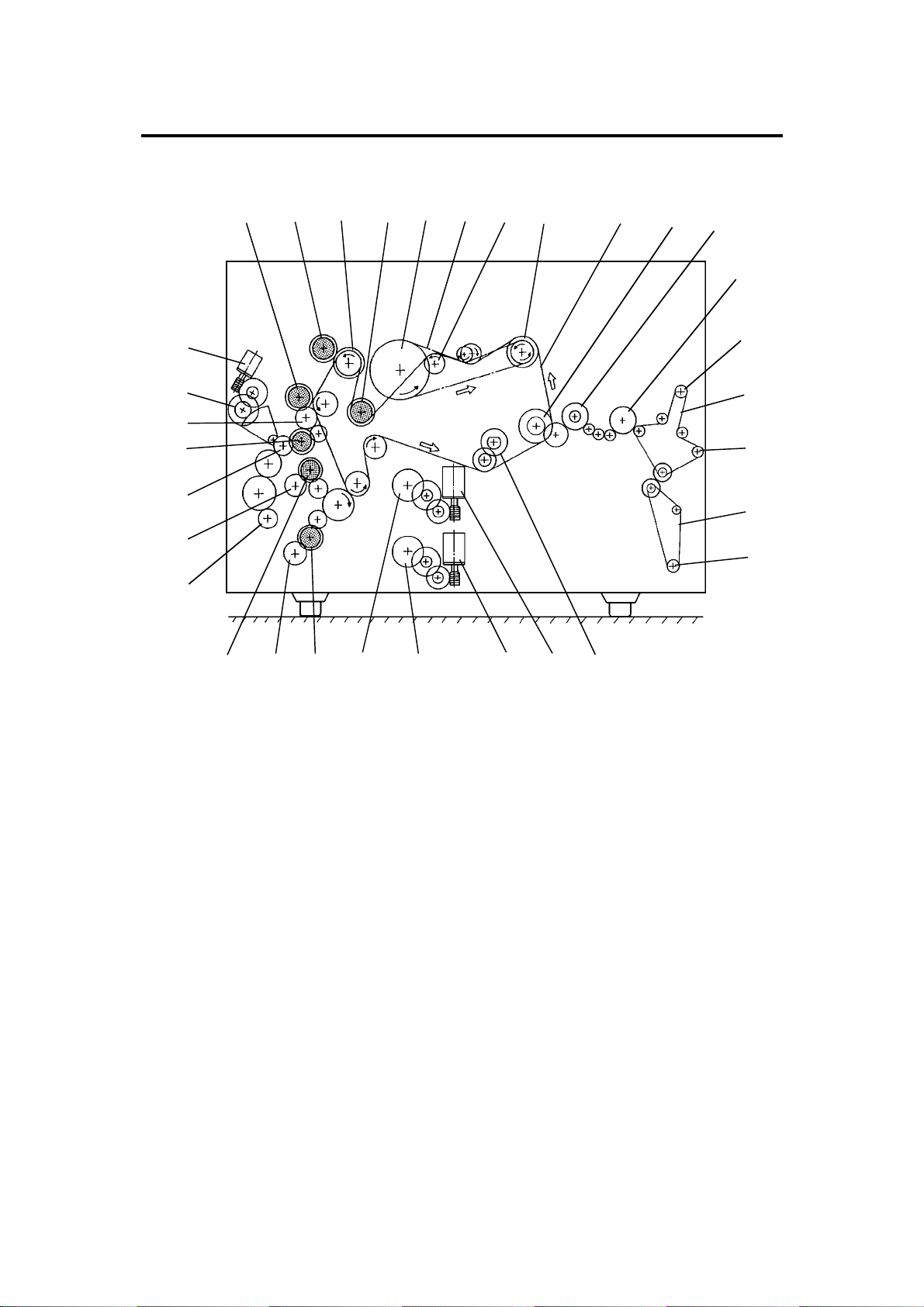

2. DRUM PROCESSES

8

1

2

9

3

4

7

5

6

1. Charge

In the dark the charge corona unit applies a negative charge to the drum.

The grid plate ensures that the charge is applied uniformly. The charge

remains on the surface of the drum because the photoconductive drum has a

high electrical resistance in the dark.

2. Laser Exposure

A laser beam exposes the drum, forming an electrical latent image on the

drum surface.

3. Development

The magnetic developer brush on the development rollers comes in contact

with the latent image on the drum surface. Toner particles are

electrostatically attracted to the areas of the drum surface where the laser

reduced the negative charge on the drum.

1-6

Page 8

Overall

Information

1 February 1994 DRUM PROCESSES

4. Image Density Detection

On every 10th copy cycle, the laser forms a sensor pattern on the drum

surface. The ID sensor measures the reflectivity of the pattern. When the

image density of the pattern becomes too low, toner is supplied to the

development unit.

5. Image Transfer

Copy paper is fed to the drum surface while a positive charge is applied to

the back side of the paper. The positive charge pulls the toner particles from

the drum surface onto the paper.

6. Paper Separation

A strong ac corona discharge is applied to the back side of the copy paper,

reducing the charge on the paper and breaking the electrostatic attraction

between the paper and the drum. Then, the stiffness of the copy paper

causes it to separate from the drum. The pick-off pawls help to separate

paper which has low stiffness.

7. Pre-cleaning Corona (PCC)

The PCC applies a strong ac corona discharge to the drum. This completely

discharges the positive potential applied to the non-paper areas of the drum

at the transfer section. The PCC has a negative bias which increases the

negative charge on the toner remaining on the drum. This makes it easier for

the cleaning brush to remove the toner from the drum surface.

8. Cleaning

The cleaning brush and cleaning blade remove any toner remaining on the

drum surface. The cleaning brush is conductive and receives a positive

charge from the bias roller (to which +150 Vdc is applied). This helps it to

clean the negatively charged toner from the drum. The bias roller and a

beater bar remove the toner from the cleaning brush.

9. Quenching

The light from the quenching lamp electrically neutralizes the surface of the

drum.

1-7

Page 9

COPY PROCESS 1 February 1994

3. COPY PROCESS

This section gives an overview of the copy process used in this machine. For

more details, see the appropriate section description in the second chapter.

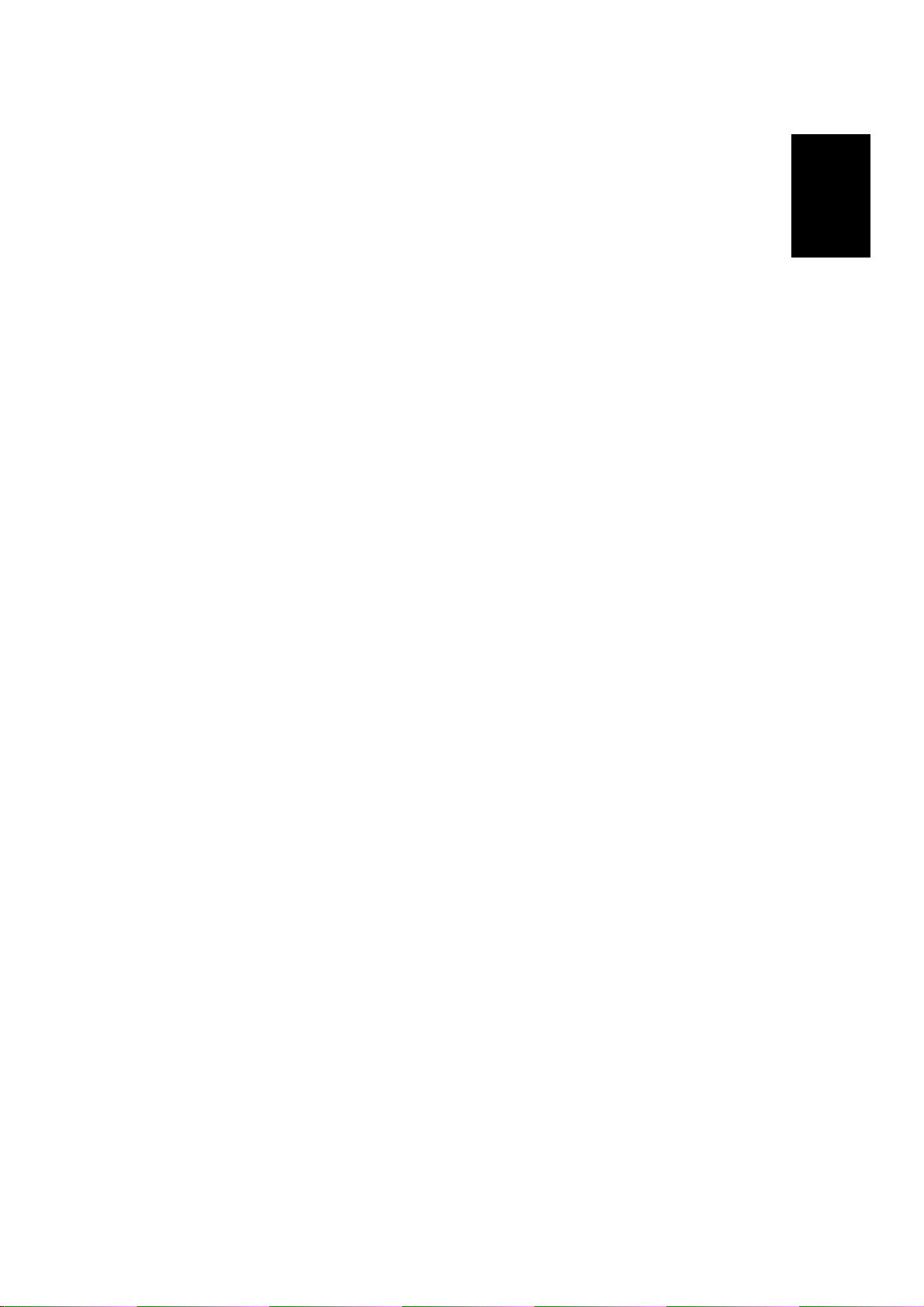

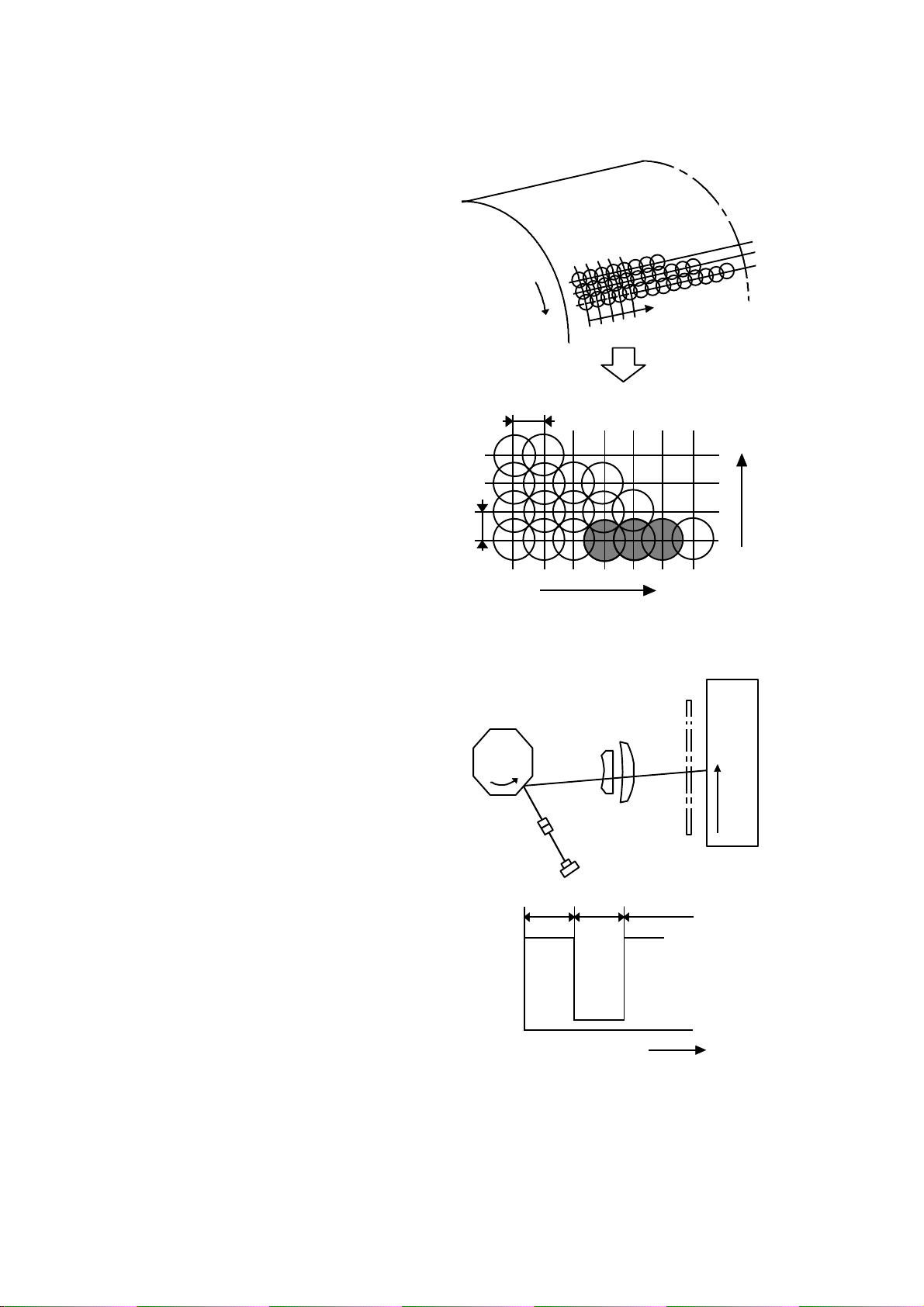

3.1 SCANNING AND IMAGE PROCESSING

3.1.1 Original Scanning

[A]

[A]

[B]

Main Scan

Sub Scan

The scanner lamps [A] expose the original as in a normal copier. However,

the optical system directs the light to the CCD [B] (charge coupled device)

rather than a drum or OPC belt. The CCD converts the light intensity to

electrical charges.

In this machine, the "main scan" direction refers to the direction perpendicular

to scanner and paper travel. The "sub scan" direction is the direction of

scanner movement, paper movement, and drum rotation.

1-8

Page 10

Overall

Information

1 February 1994 COPY PROCESS

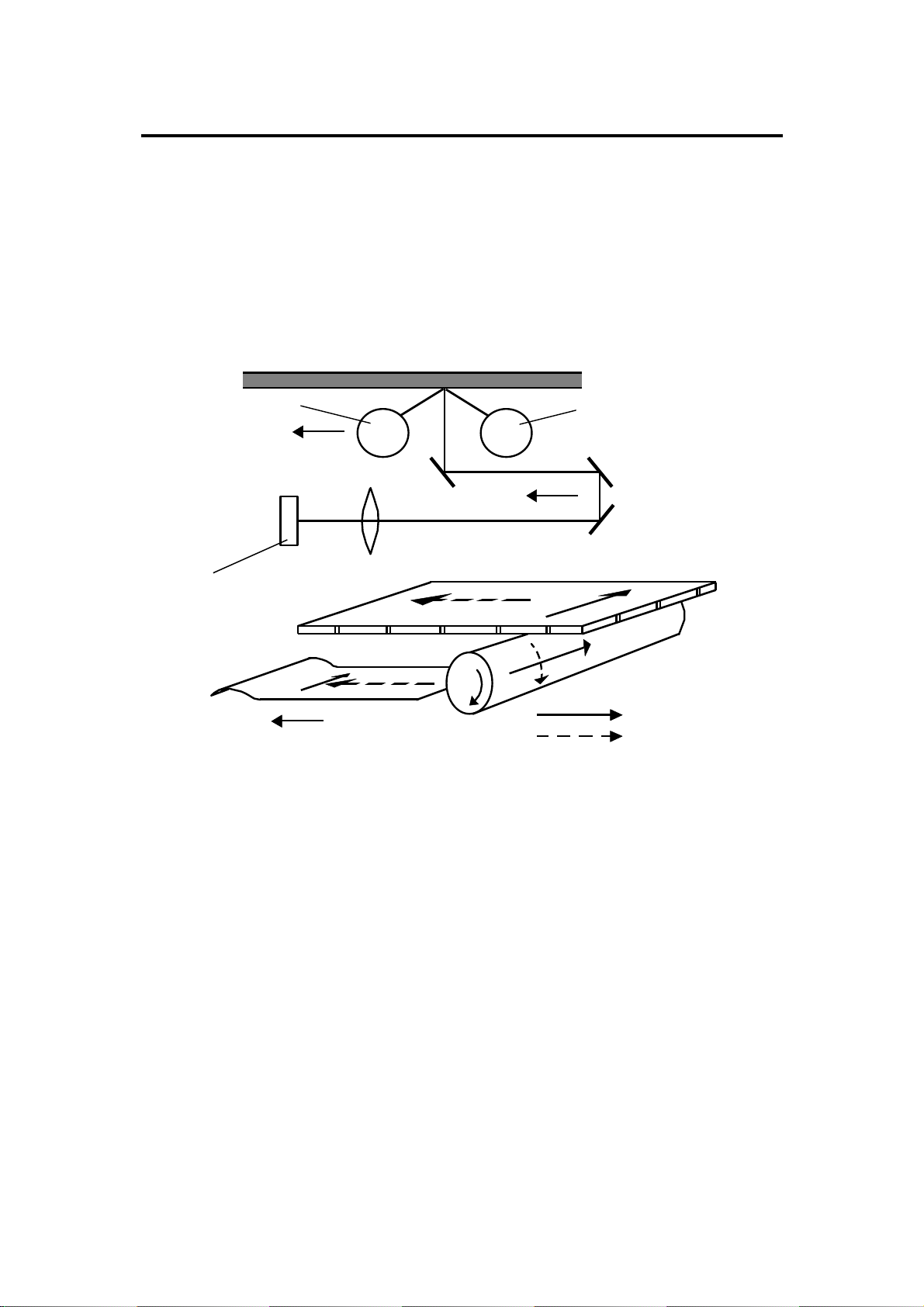

3.1.2 Photoelectric Conversion

The CCD contains 5,000 picture elements (pixels) in a line (400

dots/inch, 15.7 dots/mm). It converts

the original light intensity into an

electrical signal (analog).

Voltage

2

CCD

Output

Main

Scan

White

3.1.3 Analog to Digital Conversion

The analog signal output from the

CCD is digitized. Eight bits are used

for each pixel (picture element)

which gives 256 gradation steps

(256 level grayscale).

3.1.4 Image Processing

The digitized signal is then processed to convert the 8-bit grayscale

image to 4-bit data which the laser

unit can print (16 level grayscale).

The image is processed in one or

more of the following ways:

• Main scan magnification (sub

scan magnification is changed

by varying the scanner speed)

8-Bit

Data

4-Bit

Data

Black

Analog

0 5000

27

26

25

24

23

22

21

2

1

0 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95

CCD Element

A/D Conversion

8 bits/256 graduation

(Digital)

(F)

Black

Voltage

0.84

0.81

0.78

0.75

0.72

0.69

0.63

5000

: CCD Output

: 8-Bit Digital

• Letter mode (line image) or

photo mode processing

(8)

• Identification of designated areas

• Double copy image processing

White

(0)

GrayWhite Black

1-9

Page 11

COPY PROCESS 1 February 1994

3.2 DRUM EXPOSURE

A semiconductor laser exposes the

drum. The laser is switched on and

off at a very high frequency according to the image signal. Where the

laser beam strikes the drum, the

negative charge (about --850 volts)

on the drum drops (to about --100

volts), forming an electrical latent

image on the drum surface.

5

4

3

2

1

3’

2’

1’

Pitch

1/400"

(63.5

The laser beam is reflected by a

turning polygon mirror. The light

passes through a complex lens

(called the f

Θ lens) to the drum.

Main scanning (or in this case writing) is from front to rear, and one

surface of the polygon mirror is used

for each line.

µ)

Polygon

Mirror

Pitch 1/400" (63.5µ)

1 2 3 4 5 6 7

Mainscan

fΘ Lens

Laser

Drive

4’

3’

2’

1’

Subscan

R

Drum

F

1-10

OFFONOFF

--850 V

Mainscan

Page 12

Overall

Information

1 February 1994 COPY PROCESS

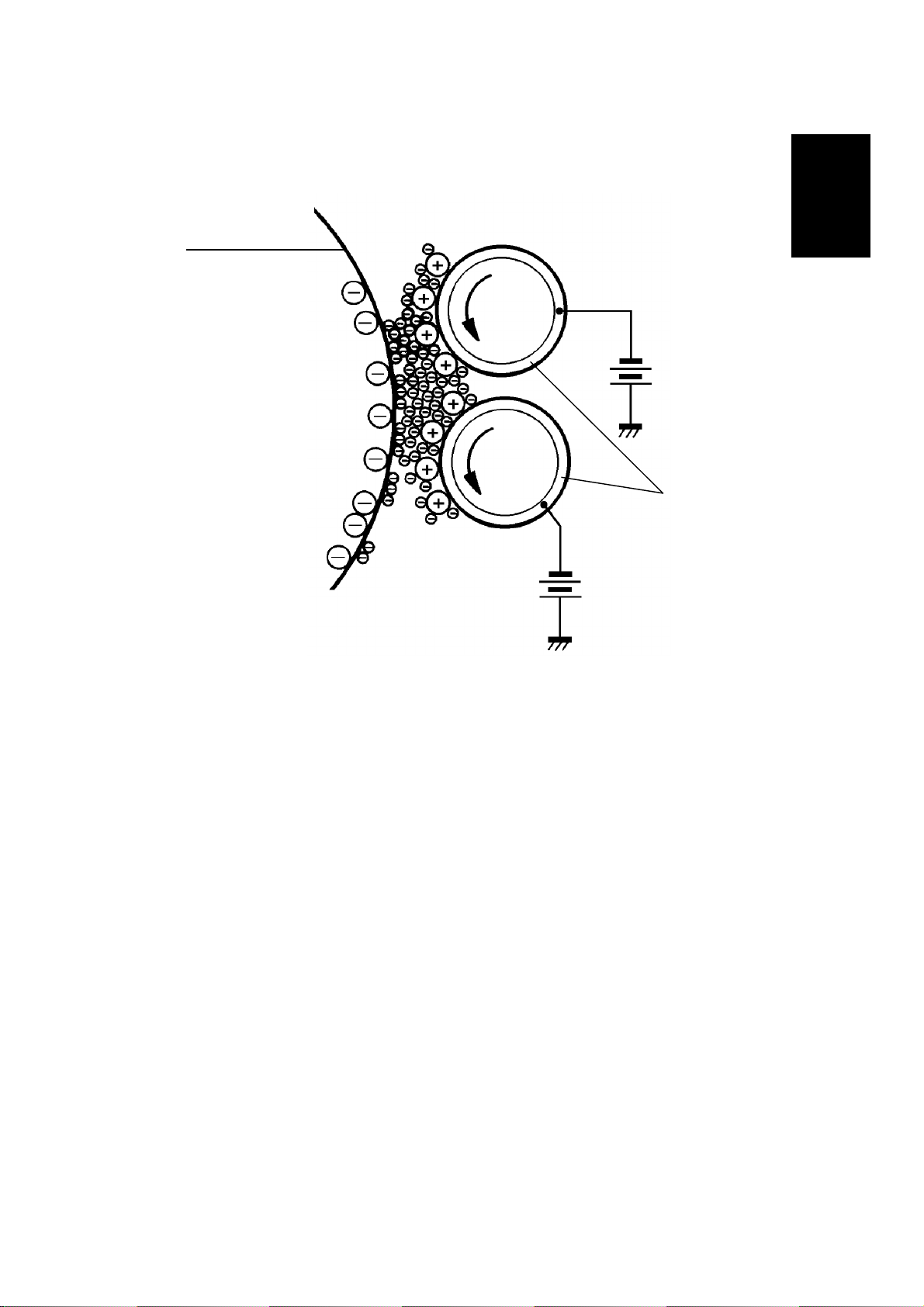

3.3 DEVELOPMENT PROCESS

[A]

[B]

A: OPC Drum

B: Development Roller

Most copiers use either a positively charged photoconductor and negatively

charged toner or a negatively charged photoconductor and positively charged

toner. This is known of as positive/negative development. However, this

machine uses a negative/negative process where both the drum surface

charge and the toner charge are negative. The negative/negative process

has certain advantages for laser printing, but some copy problems are

exactly opposite from what many copier service people have intuitively come

to expect. The table on the following page gives some of the differences

between the positive/negative process and the negative/negative process.

1-11

Page 13

COPY PROCESS 1 February 1994

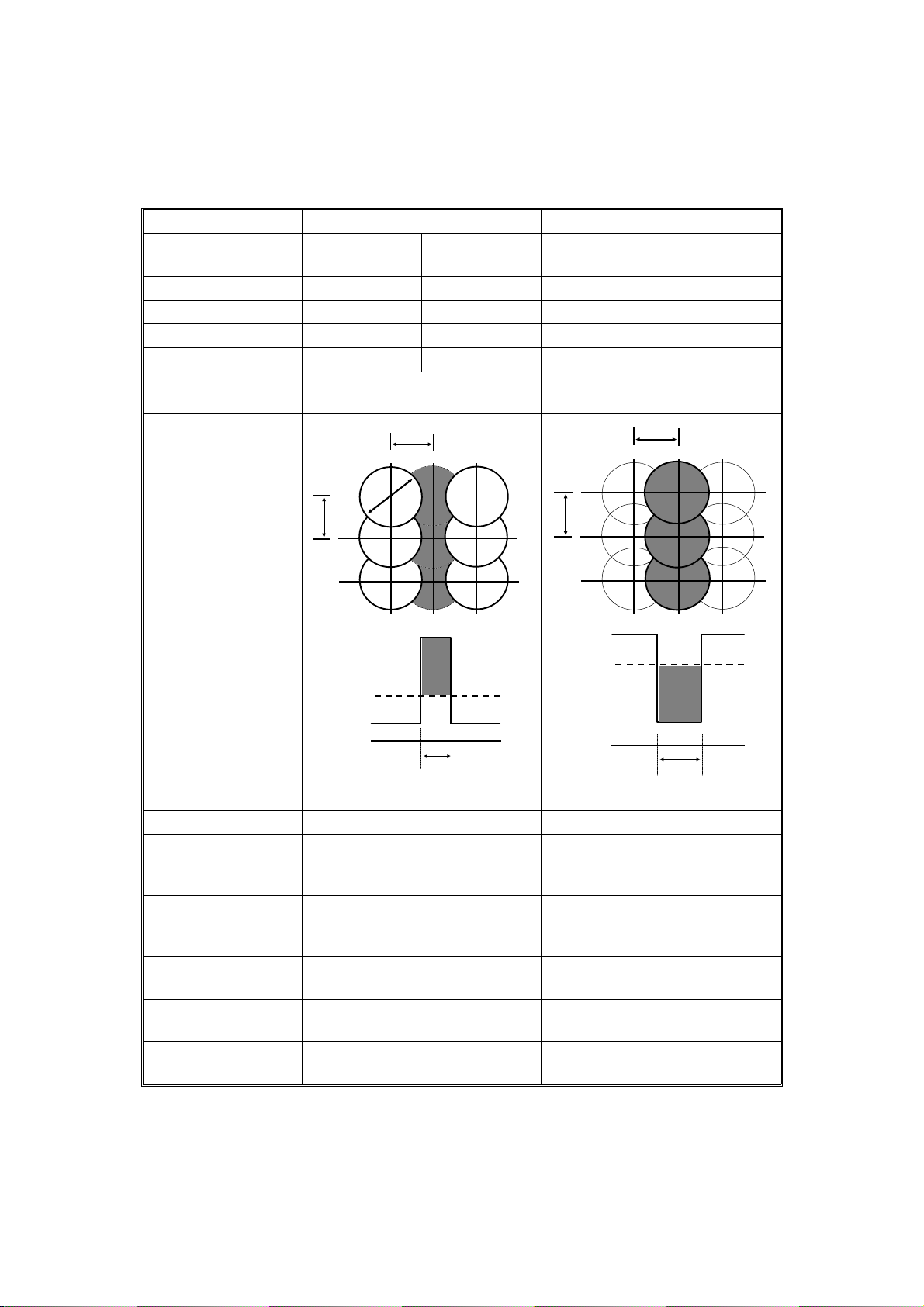

Positive/Negative Development VS. Negative/Negative Development

(2- component dry development process)

Positive/Negative Negative/Negative

Type of Laser He-neon (gas,

630 nm)

Photoconductor Se Drum OPC OPC

Charge Corona Positive Negative Negative

Carrier Charge Positive Negative Positive

Toner Charge Negative Positive Negative

Photoconductor

Exposure

Background exposure (write to

white)

He-neon or

semiconductor

Semiconductor (780 nm)

Image exposure (write to black)

P: Pitch (1/400"

in this model)

D: Laser beam

diameter

V

D: Drum voltage

V

B: Bias voltage

V

R: Residual

voltage L1, L2: Line

width (L1 < L2 for

the same laser

beam diameter)

Copy Problems

1. No

photoconductor

charge

2. Low

photoconductor

charge

3. High

development bias

4. Low development

bias

5. Stained toner

shield glass

P

D

V

V

0V

P

B

R

P

D

V

L1

P

White copy Black solid copy

Low image density Dirty background

Low image density Dirty background

Dirty background Low image density

Black stripes White stripes

V

D

B

V

R

V

0V

L2

1-12

Page 14

Overall

Information

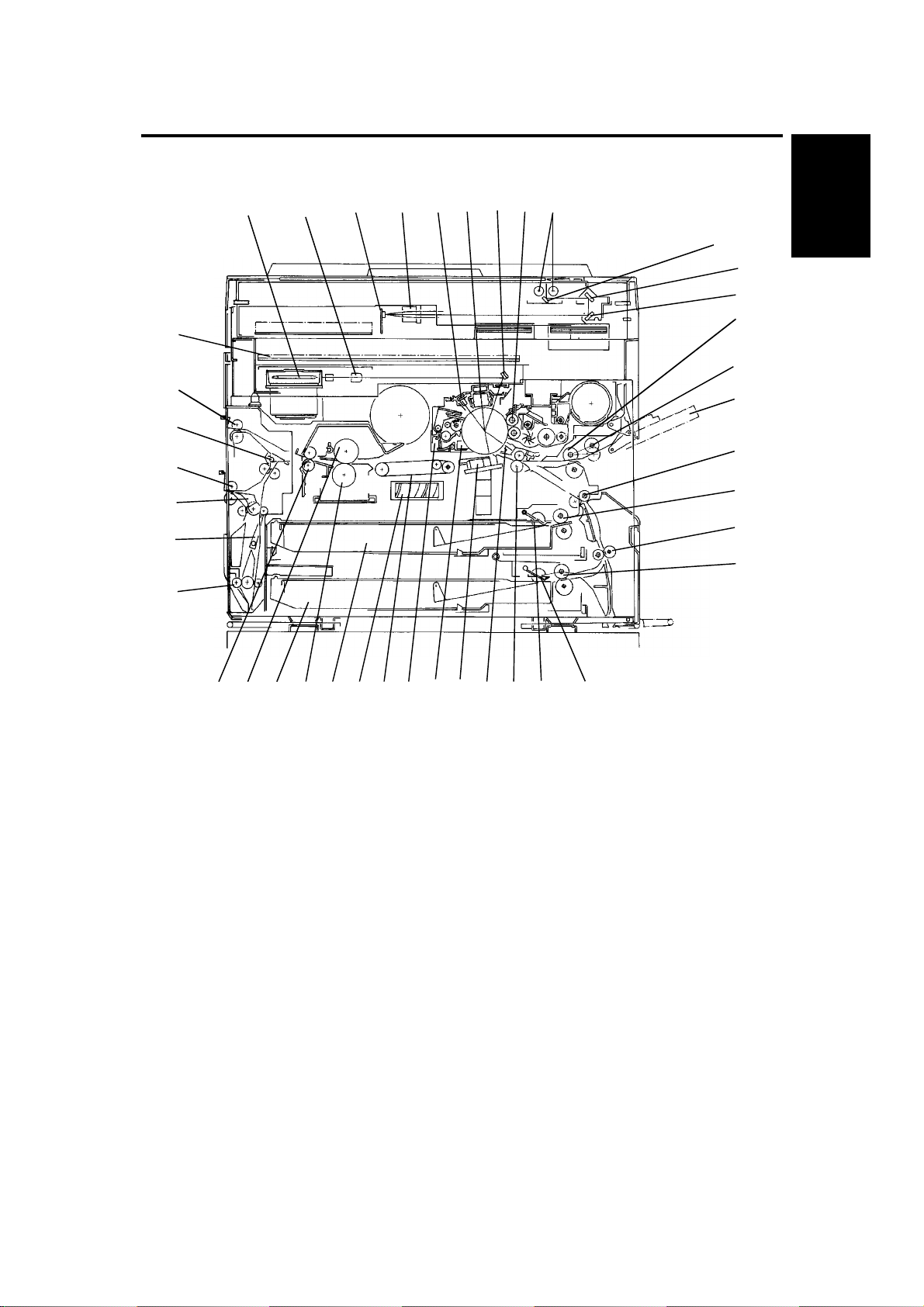

1 February 1994 MECHANICAL COMPONENT LAYOUT

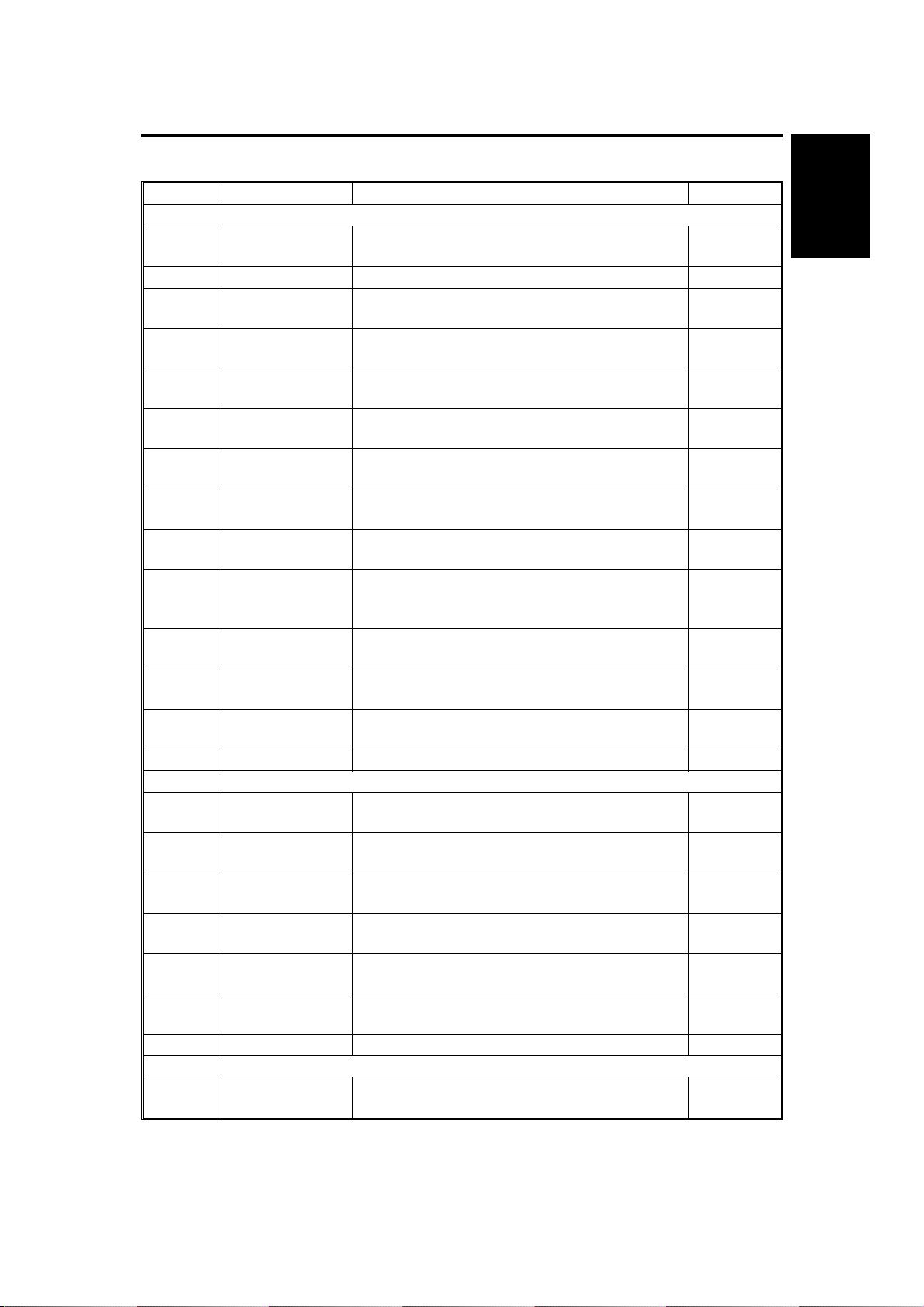

4. MECHANICAL COMPONENT LAYOUT

40

39

38

37

36

35

34

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

17

18

19

33 32 31 30 29 28 27 26 25 24 23 22 21 20

1. Polygon Mirror Motor

2. F

θ Lens

3. Sensor Board Unit (SBU)

4. Lens

5. Quenching Lamp

6. Charge Corona Unit

7. Drum Mirror

8. Development Rollers

9. Exposure Lamps

10. First Mirror

11. Second Mirror

12. Third Mirror

13. Side Paper Feed Roller

14. Side Pick-up Roller

15. Multi By-pass Tray

16. First Relay Roller

17. First Paper Feed Roller

18. Second Relay Roller

19. Second Paper Feed Roller

20. Second Pick-up Roller

21. First Pick-up Roller

22. Registration Rollers

23. Image Density Sensor

24. Transfer/Separation Corona Unit

25. Pre-Cleaning Corona Unit

26. Cleaning Unit

27. Transport Belt

28. Vacuum Fan

29. First Cassette

30. Pressure Roller

31. Second Cassette

32. Hot Roller

33. Fusing Exit Roller

34. Return Pinch Roller

35. Return Gate

36. Inverter Entrance Gate

37. Lower Exit Rollers

38. Junction Gate

39. Upper Exit Rollers

40. Printer Control Board

1-13

Page 15

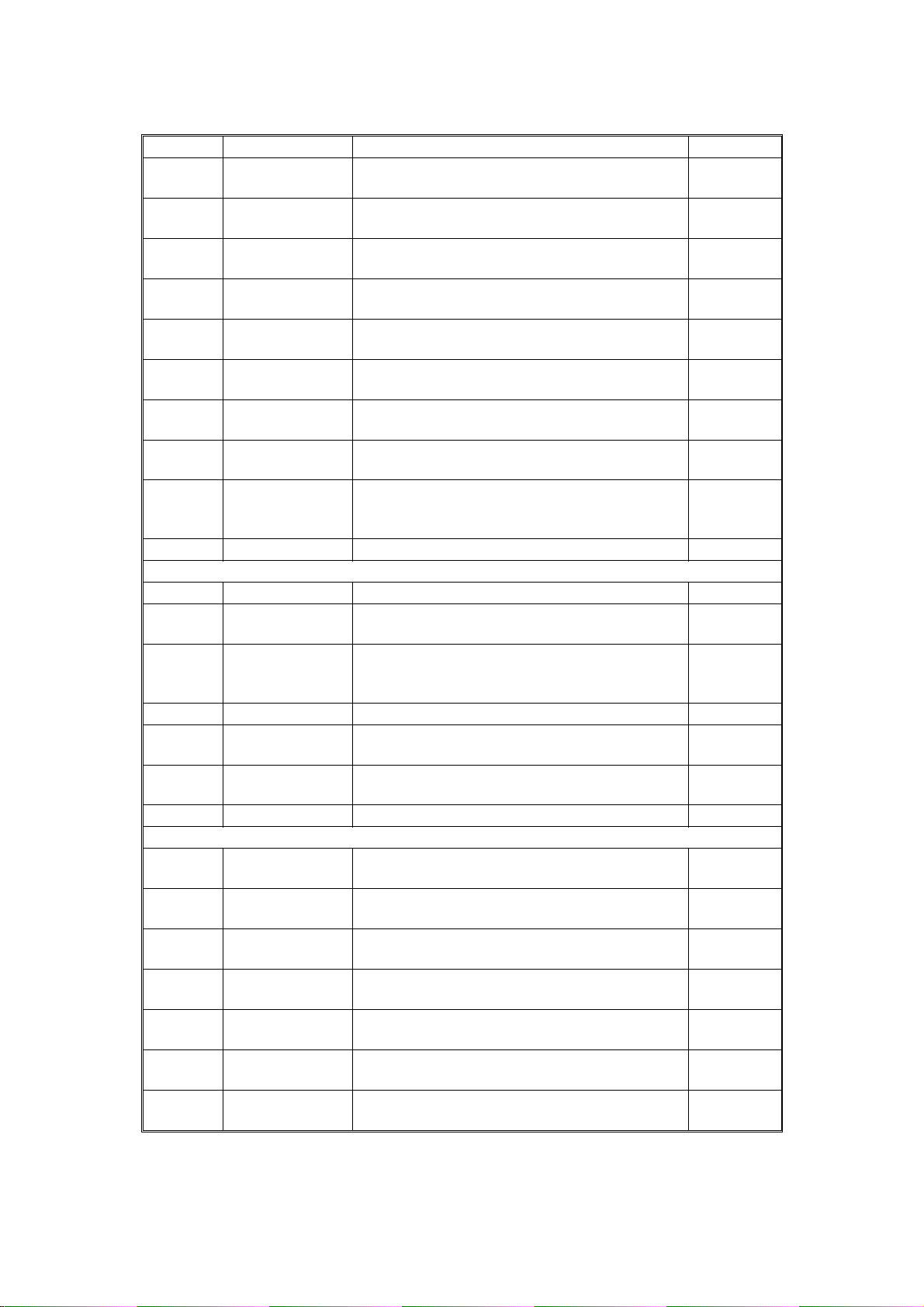

DRIVE LAYOUT 1 February 1994

5. DRIVE LAYOUT

32

31

30

29

28

27

26

1 2 3

4 5

6 7 8

9

10

11

12

13

14

15

16

17

25

1. Side Paper Feed Clutch

2. Toner Supply Clutch

3. Development Clutch

4. Registration Clutch

5. Drum Drive Gear

6. Drum Drive Belt

7. Cleaning Drive Gear

8. Main Motor Gear

9. Main Drive Chain

10. Fusing Drive Gear

11. Hot Roller Drive Gear

12. Inverter Unit Drive Gear

13. Upper Exit Roller Gear

14. Exit Roller Drive Belt

15. Lower Exit Roller Gear

16. Reverse Pinch Roller Drive Belt

24 23

22

21

20

17. Reverse Pinch Roller Gear

18. Used Toner Tank Drive Gear

19. First Paper Lift Motor

20. Second Paper Lift Motor

21. Second Paper Lift Gear

22. First Paper Lift Gear

23. Second Paper Lift Gear

24. Second Separation Roller Gear

25. First Paper Feed Clutch

26. Second Relay Roller gear

27. First Separation Roller Gear

28. First Relay Roller Gear

29. Relay Clutch

30. Side Separation Roller Gear

31. Side Paper Lift Gear

32. Side Paper Lift Motor

19 18

1-14

Page 16

Overall

Information

1 February 1994 ELECTRICAL COMPONENT DESCRIPTIONS

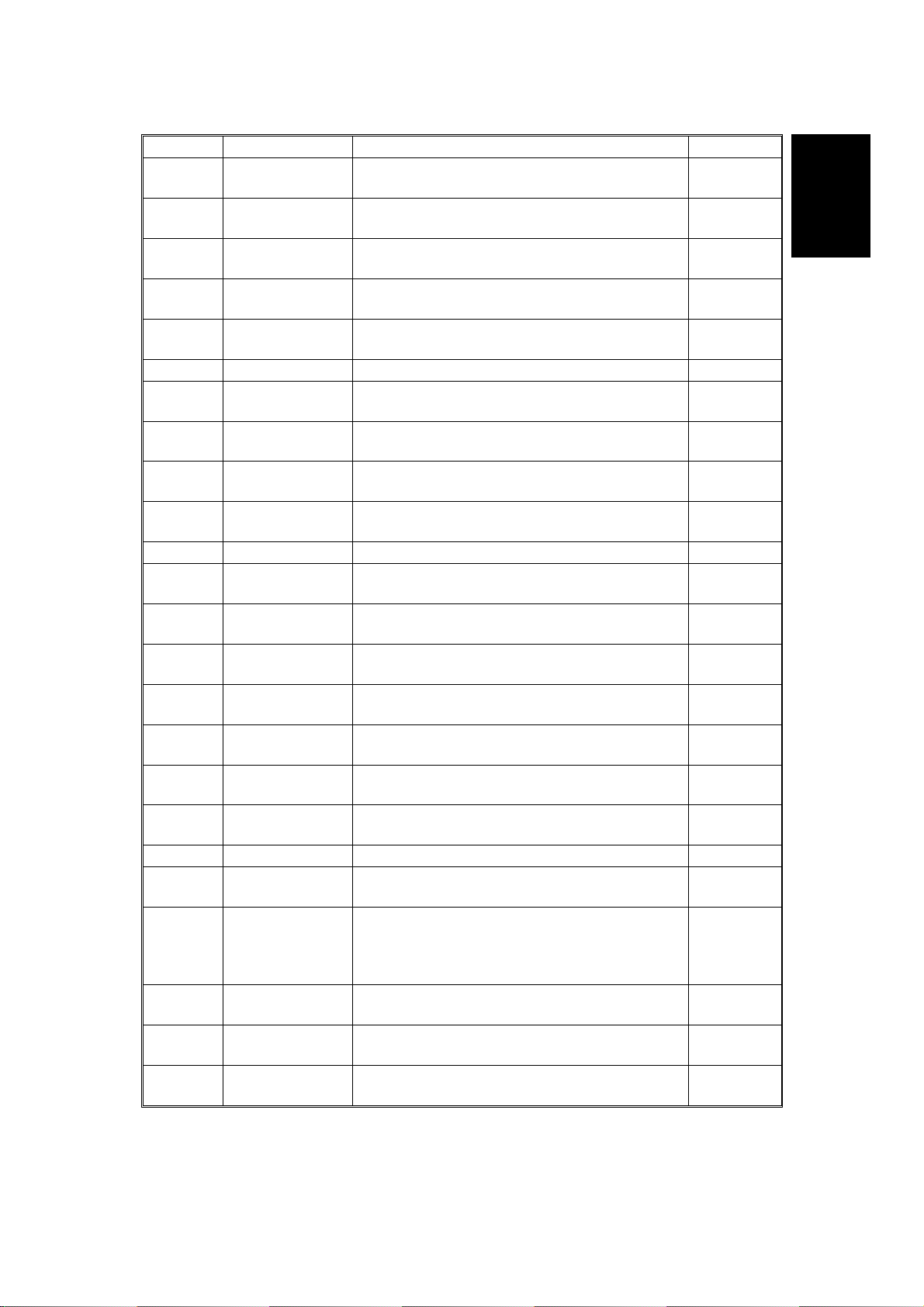

6. ELECTRICAL COMPONENT DESCRIPTIONS

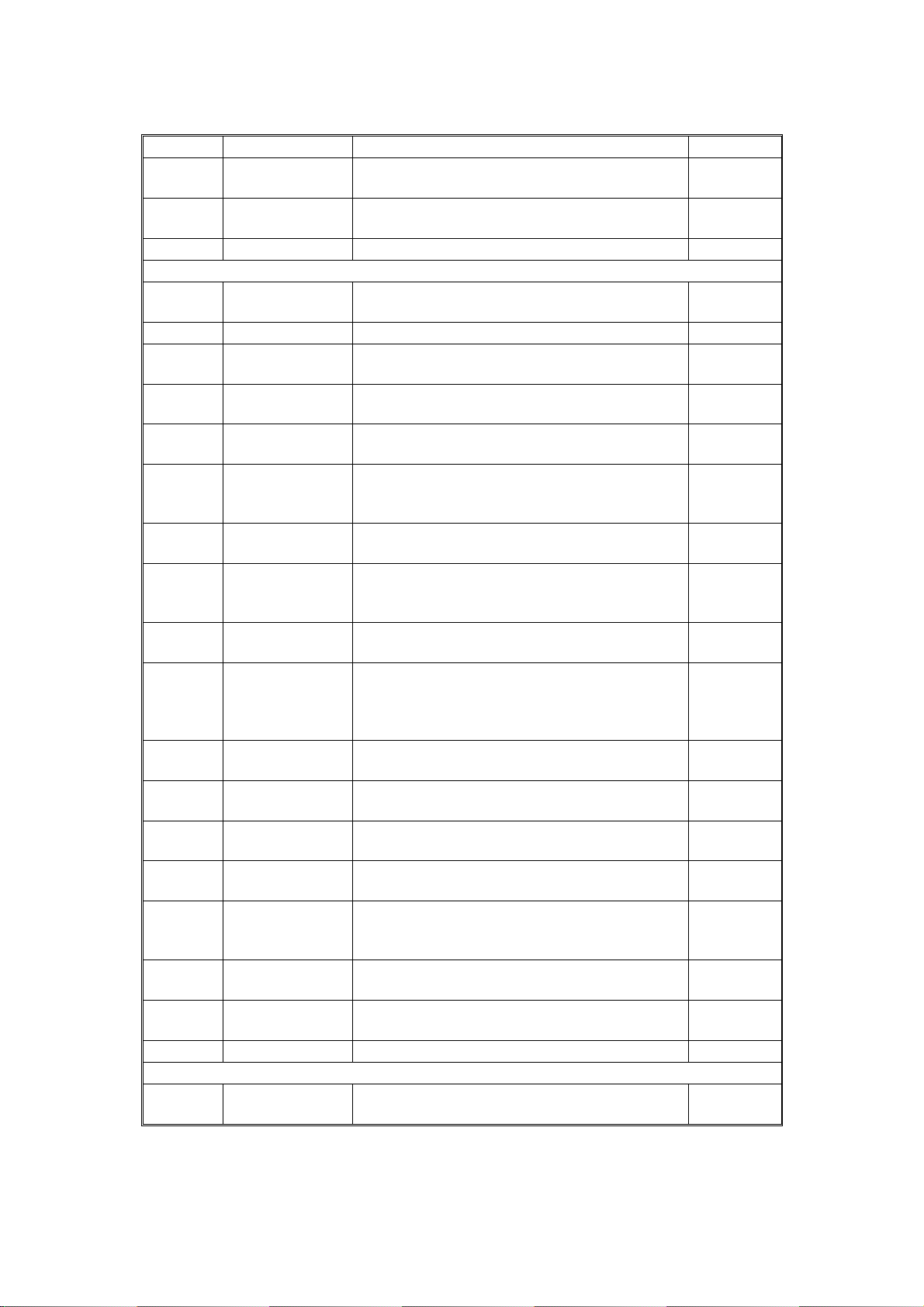

SYMBOL NAME FUNCTION INDEX NO.

Motors

M1 Main Motor Drives all the main unit components except for

the optics unit and fans.

M2 Scanner Motor Drives the scanner. 21

M3 Side Paper Lift

Motor

M4 1st Paper Lift

Motor

M5 2nd Paper Lift

Motor

M6 Polygon Mirror

Motor

M7 Optics Cooling

Fan Motor

M8 Exhaust Fan

Motor

M9 Printer Controller

Fan Motor

M10 Printer Controller

Cooling Fan

Motor

M11 Charge Fan

Motor

M12 Vacuum Fan

Motor

M13 LD Cooling Fan

Motor

Lifts the side cassette’s bottom plate. 15

Lifts the 1st cassette’s bottom plate. 9

Lifts the 2nd cassette’s bottom plate. 8

Turns the polygon mirror. 4

Cools the optics cavity. 3

Removes the air around the transport and the

fusing unit.

Removes the air around the printer I/F board. 2

Cools the printer I/F board area. 19

Provides a flow of air to the charge corona unit

to prevent uneven charge.

Provides suction so that paper is held firmly on

the transport belt.

Cools the LD driver board area. 6

18

1

16

7

Magnetic Clutches

MC1 Registration

Clutch

MC2 Side Paper Feed

Clutch

MC3 Relay Roller

Clutch

MC4 1st Paper Feed

Clutch

MC5 2nd Paper Feed

Clutch

MC6 Development

Clutch

Solenoids

SOL1 Toner Supply

Solenoid

Turns the registration rollers. 10

Starts paper feed from the side feed station. 14

Turns the relay rollers. 13

Starts paper feed from the first feed station. 12

Starts paper feed from the second feed station. 11

Transmits the main motor drive to the

development drive gears.

Turns on to supply toner to the development

unit.

1-15

17

99

Page 17

ELECTRICAL COMPONENT DESCRIPTIONS 1 February 1994

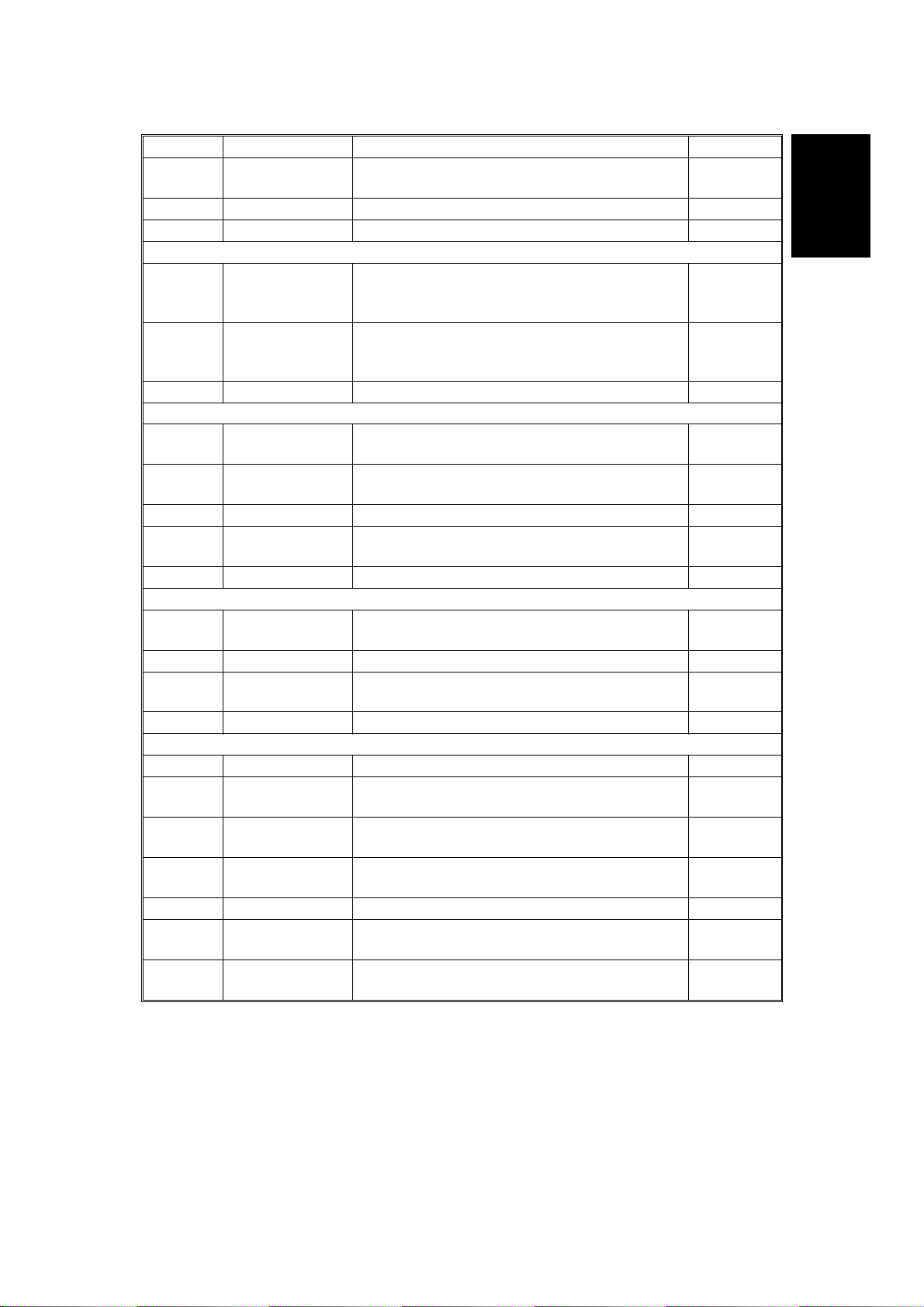

SYMBOL NAME FUNCTION INDEX NO.

SOL2 Cleaning

Solenoid

SOL3 Side Pick-up

Solenoid

SOL4 1st Tray Lock

Solenoid

SOL5 2nd Tray Lock

Solenoid

SOL6 2nd Pick-up

Solenoid

SOL7 1st Pick-up

Solenoid

SOL8 Return Pinch

Roller Solenoid

SOL9 Junction Gate

Solenoid

SOL10 Inverter

Entrance

Solenoid

Presses the cleaning blade against the drum. 98

Controls the up-down movement of the side

pick-up roller.

Locks the first tray during coping cycle. 96

Locks the second tray during coping cycle. 95

Controls the up-down movement of the second

pick-up roller.

Controls the up-down movement of the first

pick-up roller.

Opens the return gate and presses the return

pinch roller against the return roller.

Opens the junction gate. 23

Opens the inverter entrance gate. 24

97

94

93

64

Switches

SW1 Main Switch Provides the power to the copier. 35

SW2 Front Door

Safety Switches

SW3 Anti-

condensation

Switch

SW4 Function Switch Provides the power to the printer I/F board. 36

SW5 Right Upper

Door Switch

SW6 Left Upper Door

Switch

Sensors

S1 Scanner H.P.

Sensor

S2 Scanner Unit Lift

Sensor

S3 Original Length

Sensor

S4 Original Width

Sensor 1

S5 Original Width

Sensor 2

S6 Platen Cover

Position Sensor

S7 Manual Feed

Width Sensor

Cuts dc power and the +5 volts for the laser

operation when the front cover is opened.

Cuts the power to the tray and lamp heaters,

drum heater, and the anti-condensation heater

when the switch turns off.

Detects when the right upper door is opened. 54

Detects when the left upper door is opened. 25

Notifies the CPU when the scanner is at the

home position.

Notifies the CPU when the scanner unit is

closed.

Detects the original length. 29

Detects the original width. 66

Detects the original width. 67

Gives the signal to perform original size

detection with open platen cover condition.

Informs the CPU of the width of paper which is

in the multi by-pass tray.

38

32

62

63

65

57

1-16

Page 18

Overall

Information

1 February 1994 ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL NAME FUNCTION INDEX NO.

S8 Side Paper Lift

Sensor

S9 Side Paper Size

Sensor

S10 1st Upper Limit

Sensor

S11 2nd Upper Limit

Sensor

S12 Manual Feed

Sensor

S13 Oil End Sensor Detects when it is time to add silicone oil. 37

S14 1st Paper Set

Sensor

S15 2nd Paper Set

Sensor

S16 1st Lower Limit

Sensor

S17 2nd Lower Limit

Sensor

S18 1st Relay Sensor Detects misfeeds. 49

S19 2nd Relay

Sensor

S20 Side Relay

Sensor

S21 2nd Paper End

Sensor

S22 1st Paper End

Sensor

S23 2nd Paper Size

Sensor

S24 1st Paper Size

Sensor

S25 Registration

Sensor

S26 ID Sensor Detects the density of the image on the drum. 40

S27 Fusing Exit

Sensor

S28 Platen Cover

Sensor

S29 Side Paper End

Sensor

S30 Toner Overflow

Sensor

S31 Upper Exit

Sensor

Detects the correct feed height of the side

cassette.

Informs the CPU what size paper is in the side

cassette.

Detects the correct feed height of the first

cassette.

Detects the correct feed height of the second

cassette.

Detects whether or not the manual feed table is

in the down position.

Detects whether or not the first paper tray is in

the main frame.

Detects whether or not the second paper tray

is in the main frame.

Detects the bottom plate of the first cassette is

in the down position.

Detects the bottom plate of the second

cassette is in the down position.

Detects misfeeds. 48

Detects misfeeds. 47

Informs the CPU when the second cassette

runs out of paper.

Informs the CPU when the first cassette runs

out of paper.

Informs the CPU what size paper is in the

second cassette.

Informs the CPU what size paper is in the first

cassette.

Detects misfeeds. 41

Detects misfeeds. 34

Detects when the platen cover or the DF is

closed, and gives the signal to perform original

size detection with closed platen cover

condition.

Informs the CPU when the side cassette runs

out of paper.

Detects when the used toner tank is full. 39

Detects misfeeds. 28

59

58

56

55

60

53

50

52

51

46

45

43

42

31

44

1-17

Page 19

ELECTRICAL COMPONENT DESCRIPTIONS 1 February 1994

SYMBOL NAME FUNCTION INDEX NO.

S32 Lower Exit

Sensor

S33 Inverter

Entrance Sensor

PCBs

PCB1 Main PCB Controls all copier functions both directly and

PCB2 AC Drive PCB Provides ac power to the fusing lamp. 76

PCB3 DC Drive PCB Drives the dc components such as the

PCB4 Operation Panel

PCB Unit

PCB5 Sensor Board

Unit (SBU) PCB

PCB6 Video

Processing Unit

(VPU) PCB

PCB7 Main Motor

Control PCB

PCB8 Image

Processing Unit

(IPU) PCB

PCB9 Laser Diode

(LD) Drive PCB

PCB10 Pulse Width

Modulation

(PWM) Control

PCB

PCB11 Printer Power

Supply PCB

PCB12 Printer Control

PCB

PCB13 Printer I/F Board

PCB

PCB14 Polygon Mirror

Motor Drive PCB

PCB15 Scanner I/F

Board PCB

(Option)

PCB16 DC Power

Supply PCB

PCB17 Inverter Drive

Board PCB

Detects misfeeds. 30

Detects misfeeds. 26

78

through other PCBs.

77

solenoids and sensors.

The user controls the machine through this

PCB.

Digitizes the original image as it is scanned. 75

Processes video read in through the SBU. 70

Controls the main motor. 20

Processes image read in through the VPU. 69

Controls the laser diode. 71

Provides the pulse to the other PCBs and

components.

Provides the power for the printer I/F board. 68

Controls the printer functions. 81

Connects the interface harnesses for the

printer.

Controls the polygon mirror motor. 5

Connects the interface harnesses for the

scanner.

Provides dc power to the copier. 102

Controls the inverter unit. 27

73

72

79

80

Lamps

L1 Exposure Lamp Provides light to reflect the original’s image

onto the SBU.

1-18

104

Page 20

Overall

Information

1 February 1994 ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL NAME FUNCTION INDEX NO.

L2 Quenching Lamp Neutralizes any charge remaining on the drum

surface after cleaning.

L3 Fusing Lamp Provides heat to the hot roller. 86

Power Packs

PP1 Transfer/

Separation

Power Pack

PP2 C/G/B/BR Power

Pack

Heaters

H1 Anticondensation

Heater

H2 Tray Heater Prevents moisture from forming inside the

H3 Lamp Heater Warms the exposure lamp. 103

H4 Drum Heater Keeps the drum warm to prevent condensation

Provides high voltage power for the transfer

corona, pre-cleaning corona and the

separation corona.

Provides high voltage power for the charge

corona wire, development bias, grid bias and

cleaning bias.

Prevents moisture from condensing on the

optics.

copier.

on the drum.

74

92

100

101

89

90

Counters

CO1 Total Counter Counts the number of pages in copy and print

mode.

CO2 Print Counter Counts the number of pages in print mode. 84

CO3 Key Counter

(Option)

Others

TH Thermistor Senses the temperature of the hot roller. 87

TF Thermofuse Opens the fusing lamp circuit if the fusing unit

NF Noise Filter Removes electrical noise from the AC input

CB Circuit Breaker Guards against voltage surges in the AC input

LS Lamp Stabilizer Powers the exposure lamps. 82

SMD Scanner Motor

Driver

HDD Hard Disk Unit

(Option)

Used for control of authorized use. Copier will

not operate until activated.

overheats.

line.

line.

Controls the scanner motor. 22

Stores the fonts for printer. 61

83

91

85

88

33

1-19

Page 21

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 22

1 February 1994 DRUM

1. DRUM

1.1 DRUM CHARACTERISTICS

The organic photoconductor (OPC) drum has the following characteristics:

• It is able to accept a high negative electrical charge in the dark. (The

electrical resistance of the OPC drum is high in the absence of light.)

• The electric charge on the drum surface dissipates when the drum is

exposed to light. (The conductivity of the OPC drum is greatly enhanced

by exposure to light.)

• The OPC drum used in this machine is specially made for use with diode

lasers. It responds well to the 780 nm wavelength light of the laser used in

this machine.

Detailed

Descriptions

2-1

Page 23

DRUM 1 February 1994

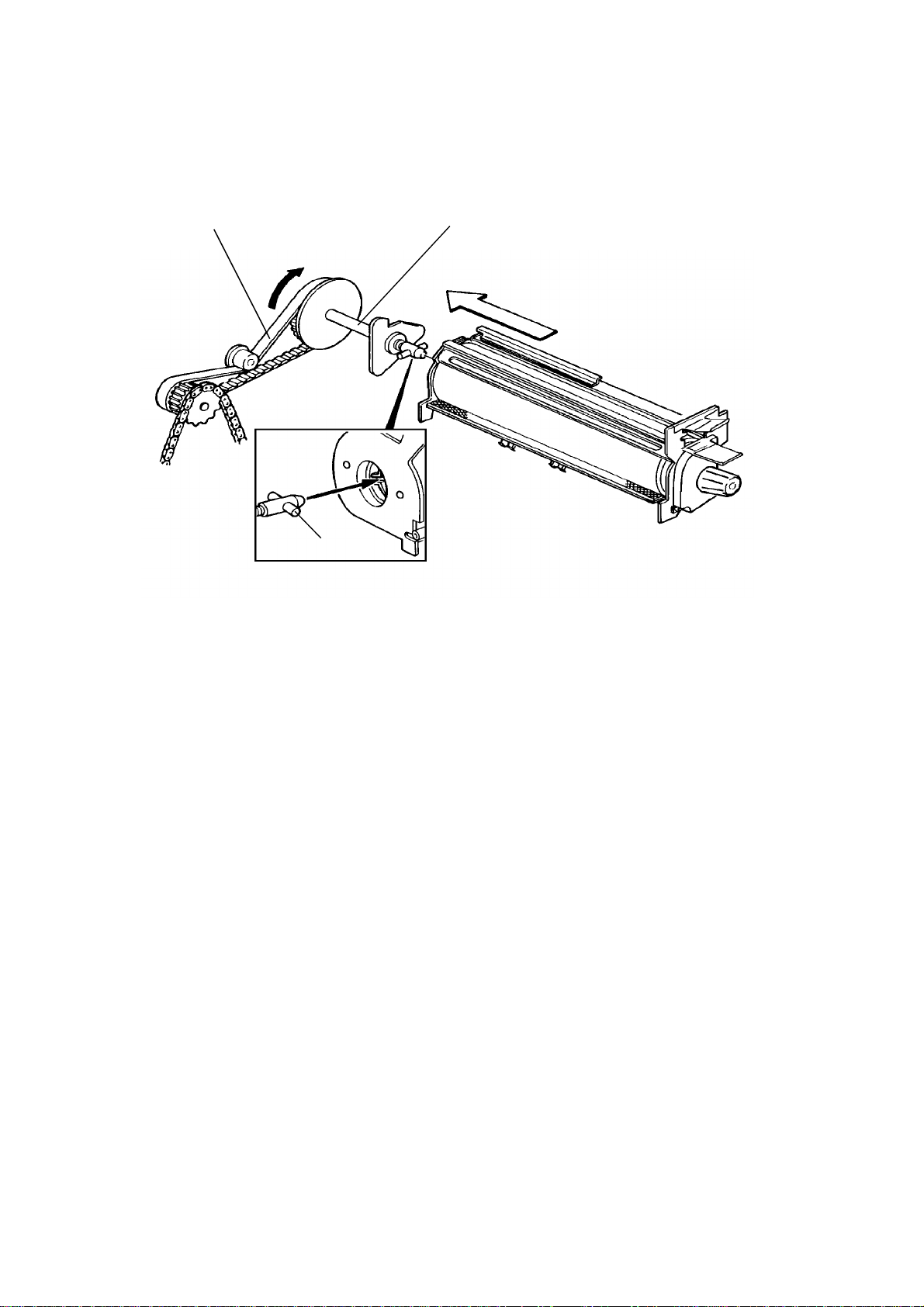

1.2 DRUM DRIVE

[B]

[A]

[C]

The main motor turns the drum drive shaft [A] through the timing belt [B]. A

drive pin [C] on the end of the drum drive shaft fits into slots in the end of the

drum. This pin turns the drum whenever the main motor is on.

2-2

Page 24

1 February 1994 CHARGE

2. CHARGE

2.1 OVERVIEW

[A]

[P1]

Detailed

Descriptions

[C]

[D]

[B]

C/G/B/BR

P.P.

[C]

[D]

[B]

This model uses a dual wire corona unit [A] to charge the OPC (organic

photoconductor) drum [B]. The corona wire [C] generates a corona of

negative ions when a high negative voltage is applied to it by the charge/grid/

bias/bias roller power pack. To make the negative corona uniform, a thin

stainless steel grid [D] is installed on the charge corona unit. The drum

receives a charge of approximately --850 volts.

2-3

Page 25

CHARGE 1 February 1994

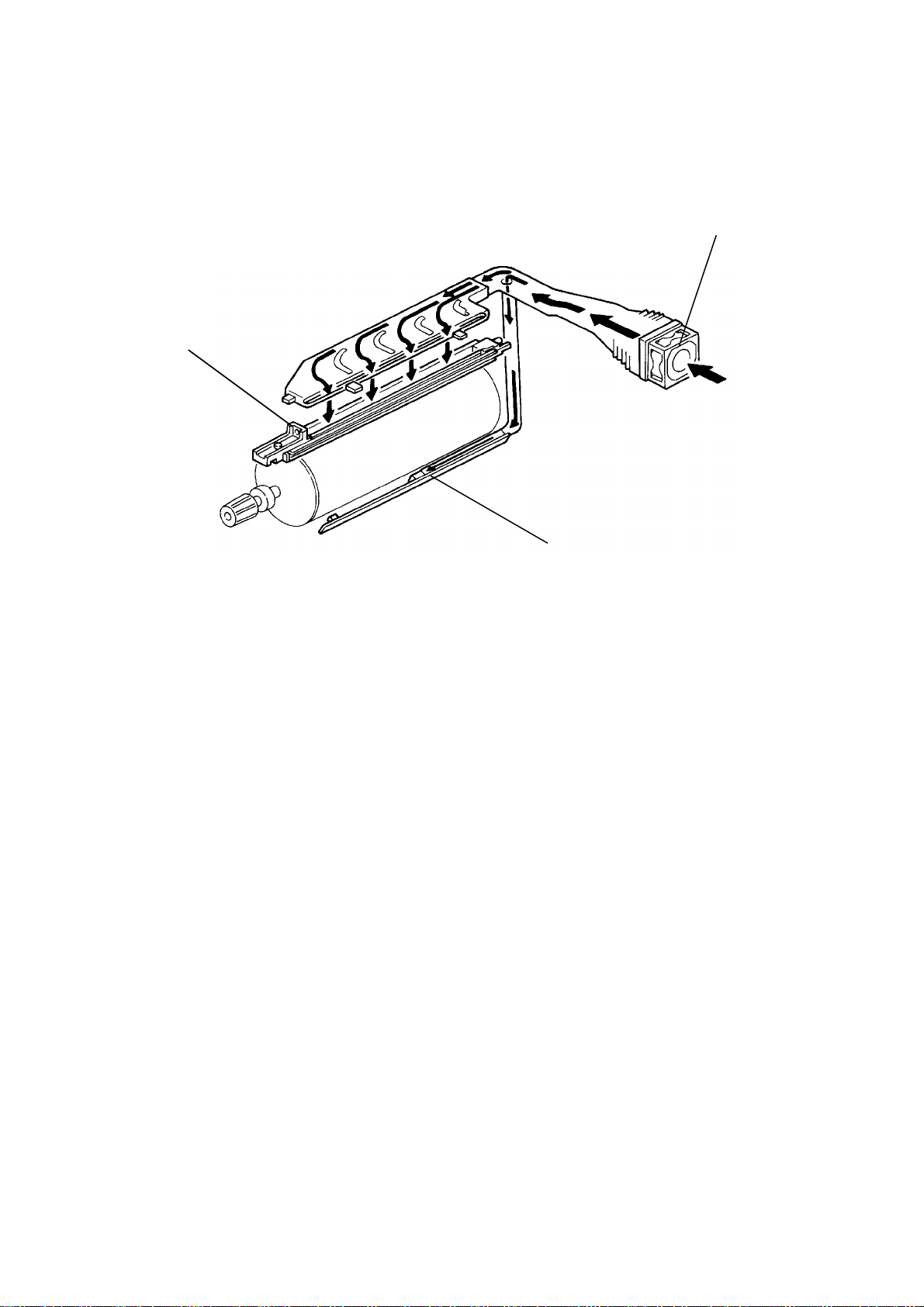

2.2 CHARGE VENTILATION

[A]

[B]

[C]

Ozone from the charge corona unit can oxidize the surface of the drum. This

oxidization can cause dirty background. To prevent this, the charge fan [A]

circulates air through the charge corona unit [B]. The airflow from this fan is

also directed to the auto image density sensor [C]. This helps to prevent

toner from settling on the auto ID sensor.

The charge fan turns on and off at the same time as the main motor.

2-4

Page 26

1 February 1994 CHARGE

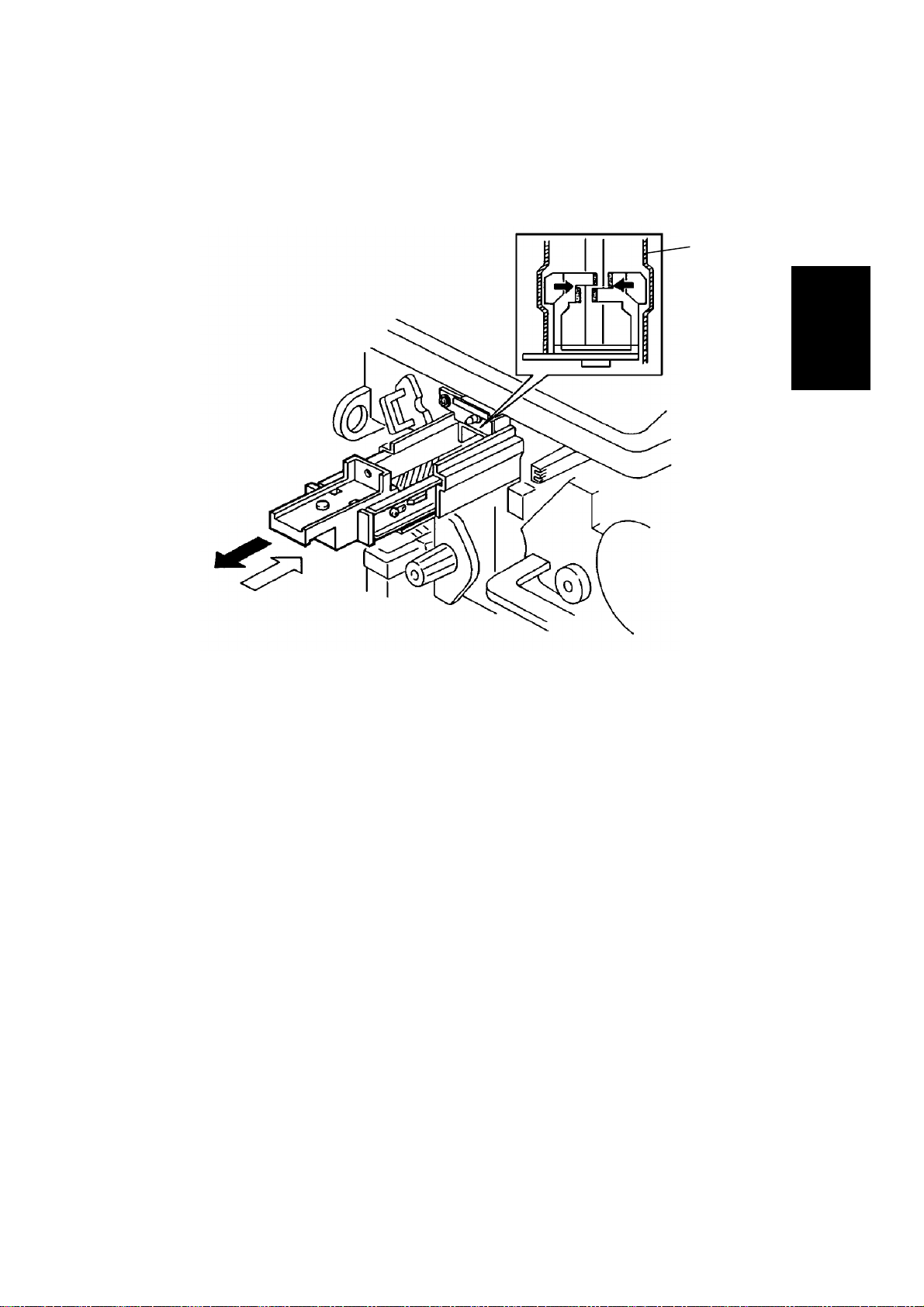

2.3 CORONA WIRE CLEANER

[A]

[B]

Detailed

Descriptions

Toner particles or paper dust may be deposited on the corona wire by the air

flow around the charge corona unit. Such particles may interfere with

charging and cause dark lines on copies. The wire cleaner [A] allows the

operator to correct this problem by pulling out and pushing in the charge

corona unit.

When the corona unit is seated, the cleaning pads are held away from the

corona wire as shown in the illustration. However, when the charge corona

unit is pulled out, the wire casing [B] pushes the cleaning pads against the

wire as shown in illustration.

2-5

Page 27

CHARGE 1 February 1994

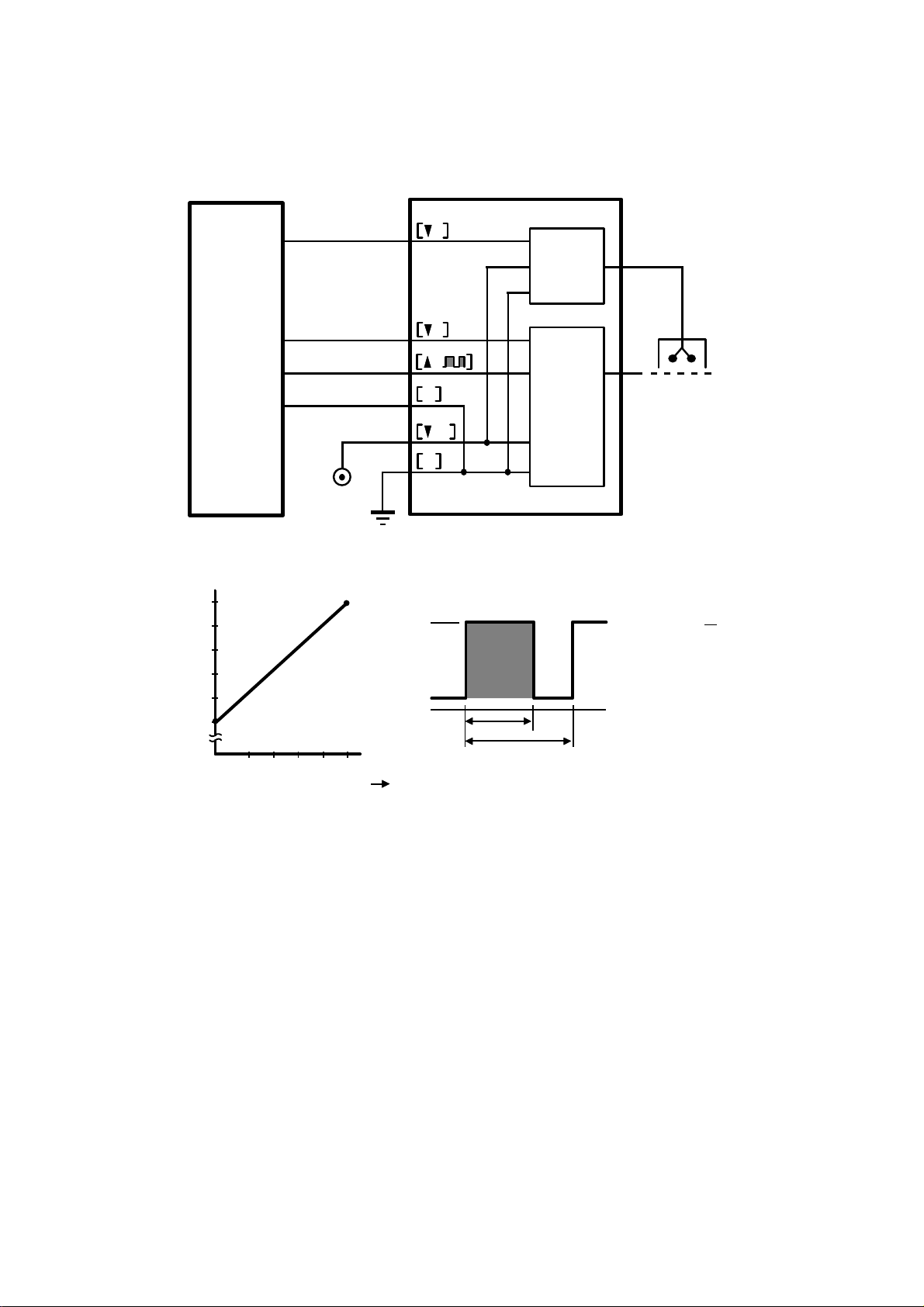

2.4 CHARGE CORONA CIRCUIT

Main Board

C-Trigger

G-Trigger

G-PWM

GND-Vcc

Grid voltage

(kV)

-0.5

-0.6

-0.7

-0.8

-0.9

-1.0

0

CN156

CN511

-A6

-A7

-A2

-A1

CN510

+24V (V )

AA

GND

20 40 60 80 100 (%)

PWM Duty

-4

-3

-8

-9

-1

-3

G-PWM

C/G/B/BR Power Pack

5

Charge

5

5

0

Grid

24

0

H

L

0

t2

t1

Charge

PWM Duty =

t1 = 1 ms

t2 = 0 ∼ 1 ms

Grid

t2

x 100 (%)

t1

The dc power supply board provides +24 volts (VAA) to the C/G/B/BR power

pack. The CPU drops CN156-A6 and -A7 from +5 volts to 0 volt. These are

the trigger signals for the high voltage power to the charge corona wire

(approx. --6.5 kV) and the grid wire (approx. --0.87 kV). The actual charge

applied to the OPC drum is approximately --850 volts.

<PWM (Pulse Width Modulation) Control>

Instead of a variable resister, the PWM control is used for the grid voltage.

The output level of the grid voltage increases as the duty of the G-PWM

signal increases as shown above.

The grid bias can be set by the SP2-1-1 (Grid Bias Adjustment).

2-6

Page 28

1 February 1994 SCANNING

3. SCANNING

3.1 OVERVIEW

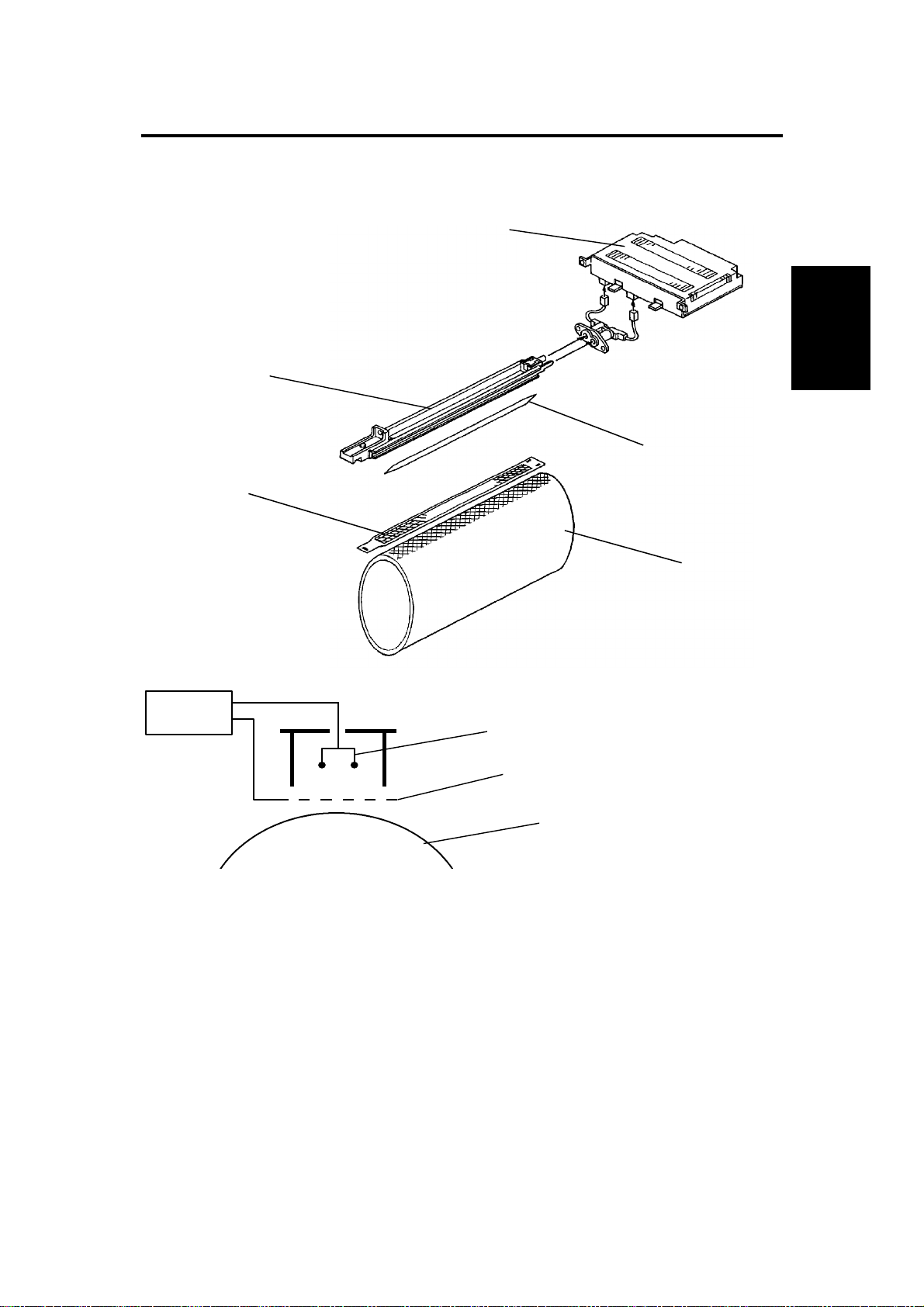

[E]

[A]

[G]

[C]

Detailed

Descriptions

[F]

During scanning an image of the original is reflected on the CCD (charge

coupled device) of the SBU (sensor board unit) via the optics assembly as

follows:

Scanner Lamp [A] ⇒ Original ⇒ First Mirror [B] ⇒ Second Mirror [C]

⇒ Third Mirror [D] ⇒ Lens [E] ⇒ CCD (on SBU) [F]

Light from a band across the entire width (main scanning direction) of the

document is focused on the CCD by the lens (1 : 0.1102 ratio). The CCD has

5,000 picture elements which convert the light intensity into electric charges.

The image reading plate on the VPU converts the CCD charges into a 8-bit

(256 gradations) digital signal. 2835 lines are digitized per second.

The scanning resolution is 400 dpi (15.7 dots/mm) in the main scanning

direction. In full size mode it is also 400 dpi in the sub scanning direction.

(The scanner speed is 180 mm/s when in full size mode.)

[B]

[H]

[D]

The white plate [G] is scanned prior to scanning the original. This gives a

consistent white value which is used as a reference value to correct for

variations in the fluorescent lamp or irregularities in the light striking the CCD.

The anti-condensation heater [H] keeps moisture from forming inside the

scanner unit.

2-7

Page 29

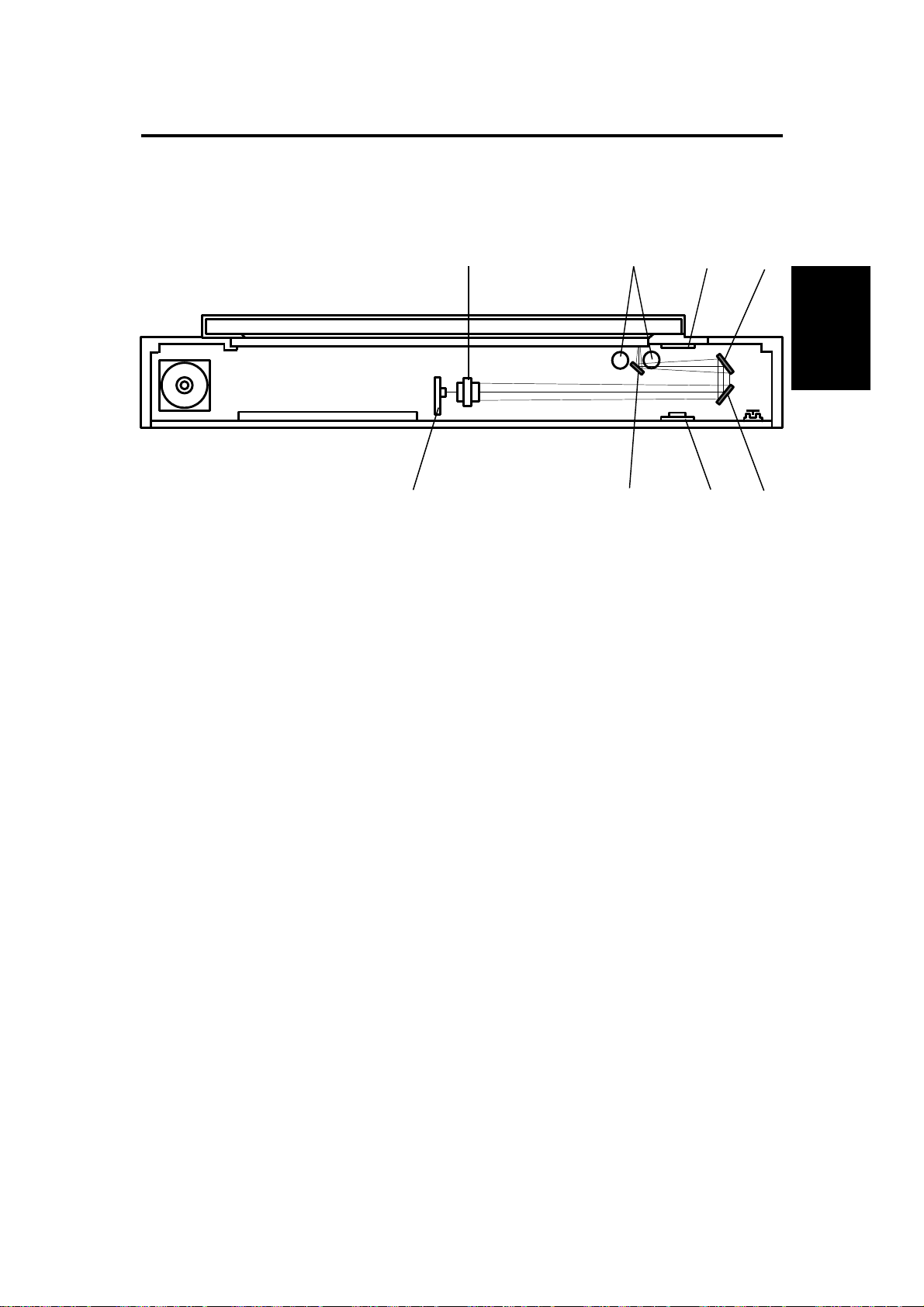

SCANNING 1 February 1994

3.2 SCANNER LAMP

[B]

[A]

[C]

[D]

[E]

(without lamp grid) (with lamp grid)

The scanner lamps [A] are green fluorescent lamps with apertures so that

most of the light is output in a single direction. They are controlled by the IPU

board [B]. The scanner lamp stabilizer [C] drives the lamps with 15 W, 50 kHz

power. The high frequency is necessary to achieve an even supply of light to

the CCD, because the time for charging the CCD is 0.5 msec.

The scanner lamp heaters [D] keep the scanner lamp’s temperature at 40°C.

This is necessary because the light intensity will be insufficient if the scanner

lamp’s temperature is too low.

To prevent the light from being diffused, the lamp grid [E] is installed above

the lamps. This grid can minimize the flare as shown the above illustration.

2-8

Page 30

1 February 1994 SCANNING

3.3 SCANNER LAMP CIRCUIT

Lamp Heater

Thermistor

Lamp Heater

Scanner Lamp

2

1

2

1

1

CN657-4

2

1

2

-3

-2

-1

-10

-9

-8

-7

CN656-3

-2

-1

Lamp

Stabilizer

CN305-14

-13

-12

-11

CN305-7

-6

-5

[5] Vcc

[0--5] Thermistor

[▼24] Lamp Heater

[24] VAA

[0] G.VAA(INV)

[24] VAA

[▼24] FLON

IPU Board

Detailed

Descriptions

The scanner lamp stabilizer is powered by +24 volts from CN305-6. To turn

on the scanner lamp, the IPU board drops CN305-5 to Low. The scanner

lamp stabilizer then provides high frequency power to the filaments of the

scanner lamp.

The IPU board monitors the temperature of the scanner lamps through the

lamp thermistor, and turns the scanner lamp heaters on and off to keep the

scanner lamps at 40°C. It generally takes about 1 minute for the scanner

lamps to reach 40°C after the main switch is turned on.

2-9

Page 31

SCANNING 1 February 1994

3.4 SCANNER DRIVE

[D]

[E]

[A]

[B]

[C]

This model uses a dc servomotor [A] to drive the scanners.

The first scanner [B] consists of the scanner lamps and the first mirror, and

the second scanner [C] consists of the second and third mirrors. Unlike most

conventional copiers, four drive wires move these scanners. Four wires are

used to keep scanner movement very smooth.

The rear wire clamp [D] of the first scanner also works as the actuator of the

scanner home position sensor [E].

2-10

Page 32

1 February 1994 SCANNING

3.5 SCANNER DRIVE CIRCUIT

IPU Board

Vcc [5]

ECA

ECB

GND [0]

REVTTL

DGND

FWDTTL

DGND

REVOC

DGND

FWDOC

DGND

SHORT

DGND

GND [0]

H.P. Sensor [▲5]

Vcc [5]

Scanner

Unit Lift Sensor [▲5]

Vcc [5]

GND [0]

Feed-back

CN303-1

-2

-3

-4

CN302-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

CN305-10

-9

-8

CN318-1

-8

-3

Encoder

Speed/Direction control

H.P. Sensor

Scanner Unit

Lift Sensor

Scanner

Drive Motor

Power

CN331-1

CN332-1

-10

Motor Drive

Board

[▲24V] FWD

-2

[▲24V] REV

-3

[0] GND

REVTTL

-2

DGND

-3

FWDTTL

-4

DGND

-5

REVOC

-6

DGND

-7

FWDOC

-8

DGND

-9

SHORT

DGND

Detailed

Descriptions

Unlike most conventional copiers, two PCBs are used to operate the scanner

drive motor. The IPU board receives the feed-back data for the motor speed

and the direction from the motor encoder and then, sends the control signal

to the motor drive board. In accordance with these control signals, the motor

drive board supplies the power, so that the scanner drive motor rotates at the

proper speed and direction.

By keeping the control signal lines away from the power supply lines, the

influence of any electrical noise is minimized.

2-11

Page 33

SCANNING 1 February 1994

[B]

[A]

For field servicing, the scanner unit can be opened. When the scanner unit is

lifted, the actuator [A] of the scanner unit lift sensor [B] moves out of the

sensor (CN318-8 0 ⇒ 5 V).

Then, the CPU prohibits the scanner motor from rotating, for safety.

2-12

Page 34

1 February 1994 SCANNING

3.6 ORIGINAL SIZE DETECTION IN PLATEN MODE

[B]

[C]

[F]

Detailed

Descriptions

[A]

[G]

[D]

[E]

An original width sensors [A] and an original length sensor [B] are under the

exposure glass [C]. The original width sensor consists of four reflective

photosensors. The original length sensor consists of three reflective

photosensors.

While the main switch is on, these sensors are active and the IPU board

receives their output signals. The IPU board checks the output signals twice

as the platen cover (document feeder) is being closed.

The first check is done when the platen cover position sensor [D] turns on.

(When the document feeder is installed, the first check is done when the DF

position sensor [G] on the document feeder turns on.) The platen cover

position sensor is actuated when the platen cover (document feeder) is

lowered to about 10 cm (4") above the exposure glass. At this time only the

sensors located underneath the original receive the reflected light. These

sensors output LOW signals.

2-13

Page 35

SCANNING 1 February 1994

The second check is done when the platen cover closed switch [E] turns on.

This is when the platen cover (document feeder) is completely closed. The

platen cover closed switch is a reed switch. A magnet [F] mounted on the

platen cover (document feeder) actuates the reed switch.

The second check is necessary to confirm that the original size detected at

the first check is correct. This double check prevents original size detection

errors that may occur if a black solid area on the original is positioned directly

over a sensor.

When a copy is made with the platen cover (document feeder) open, the

CPU checks the original size when the Start key is pressed.

The following illustration shows the location of the original width and length

sensors. The table shows the sensor output (HIGH, LOW) for each original

size.

S1

S3

L1

L2

L3

S2

S4

Sensors

Original Size

11" x 17" A3 0 0 0 0 0 0 0

10" x 14" B4 1 0 0 0 0 0 0

1

8

⁄

" x 14" ---- 1 0 0 1 0 0 0

2

1

8

⁄

" x 11" A4 (L) 1 1 1 1 0 0 0

2

8" x 10" B5 (L) 1 1 1 1 1 0 0

11" x 8

5

8

1

⁄

" A4 (S) 1 1 1 0 0 0 0

2

1

1

⁄

" x 8

⁄

2

1

⁄

2

" A5 (L) 1 1 1 1 1 1 0

2

1

" x 5

⁄

" A5 (S) 1 1 1 1 1 0 1

2

---- F 1 1 0 1 1 0 0

Original Length Sensor Original Width Sensor

L1 L2 L3 S1 S2 S3 S4

0: LOW

1: HIGH

NOTE: In case of other combinations, the "Original Size not sensed" will be

indicated.

2-14

Page 36

1 February 1994 IMAGE PROCESSING

4. IMAGE PROCESSING

This section deals with the processing of scanner data from its generation by

the CCD until its output to the laser unit as serial data.

4.1 OVERVIEW

Detailed

Descriptions

SBU

VPU

C

C

D

Analog

8 bit

IPU

GATE ARRAY

1~6

MAIN PCB

4 bit 4 bit

Laser

Section

The CCD generates an analog video signal. The SBU then sends the analog

video signal to the VPU board.

The processing of the VPU (Video Processing Unit) includes signal

composition, variable amplification, and digitization.

The IPU (image processing unit) processes the 8-bit signal. This processing

includes several functions, for example, halftone imaging, MTF (modulation

transfer function) correction, and main scan magnification. The IPU

generates a 4-bit signal which is sent to the laser section through the main

PCB.

The main PCB sends the 4-bit signal to the laser section.

2-15

Page 37

IMAGE PROCESSING 1 February 1994

4.2 SENSOR BOARD UNIT

4.2.1 Basic Functions

Even

CCD

Reflected

light

Amplifier

ODD

Switching clock

Photoelectric

conversion

Signal

amplification

The illustration above shows the main elements of the SBU (sensor board

unit) in block form. The SBU performs the following functions:

Photoelectric conversion: The light reflected from the original is converted to

an analog signal. This is done by the CCD, which has 5,000 picture

elements. The resolution is 400 dots per inch (15.7 lines/mm).

Signal amplification: To speed up processing, odd and even pixels are read

from the CCD separately and then amplified.

2-16

Page 38

1 February 1994 IMAGE PROCESSING

4.2.2 SBU Circuit Operation

SBU: Sensor Board Unit

Lens

CCD

5000

12 V

1

2

3

OS1

OS2

AMP

AMP

VIDEO1

VIDEO2

GND

VPU

VPU

VPU

CCD: Charge Coupled Device

The SBU converts the light reflected from the document to two analog

signals. The following covers how the video data is changed at each step of

the process.

-- Photoelectric Conversion --

Detailed

Descriptions

The CCD elements convert the light from the image to an analog signal. To

increase the scanning speed, the CCD handles the odd pixel (picture

element) data and even pixel data separately. Odd data is output from OS1

and even data is output from OS2. After amplification, the wave form of these

signals is similar to the illustration on the next page. The timing of these

signals is as follows:

2-17

Page 39

IMAGE PROCESSING 1 February 1994

Main Scan 1 line

TG

O

/

O

/

O

/

OS

1

2

1OS

B1 B3

2

B2 B26 B28

B25 B27

B29

B30

D

U

M

M

Y

D

U

M

M

Y

3

1

2

5 4995

Odd video data

4

Even video data

4997

4996

4998

4999

5000

D

U

M

M

Y

D

U

M

M

Y

Clock

Video

Signal

O/ TG: Clock for main scan

O/ 1 and O/ 2: Clock pulses

OS1: Odd video data

OS2: Even video data

2-18

Page 40

1 February 1994 IMAGE PROCESSING

4.3 VIDEO PROCESSING UNIT

4.3.1 Basic Function

From

SBU

VPU (Video Processing Unit)

Amplifier

Amplifier

AGC data *

(4 bits)

From

IPU

Variable

amplification

Switching clock

Signal

composition

* AGC: Auto Gain Control

From

IPU

DA 01- DA 08

A/D

converter

AD clock

From

IPU

Signal

digitalization

8-bit data

To IPU

Detailed

Descriptions

The illustration above shows the main elements of the VPU (video

processing unit) in block form. The VPU performs the following functions:

Variable amplification: The pixels of the signal are amplified using the AGC

(auto gain control) signal. This is to compensate for variations in the light

source.

Signal composition: The odd and even signals are merged into a single video

signal.

Signal digitization: The analog signal is converted to an 8-bit digital signal

and then sent to the IPU.

2-19

Page 41

IMAGE PROCESSING 1 February 1994

4.3.2 VPU Circuit Operation

IPU

SBU

IPU

IPU

VPU: Video Processing Unit

12 V

VIDEO1

VIDEO2

-12 V

PWIND

AEMODE

SHADE

TP203

VR201

TP204

VR202

12 V

TP209

VR205

12 V

PEAK

HOLD

VR203

VR204

REF(+)

HC4066

A/D

MP7688

REF(-)

AUTO

GAIN

PXSW1

PXSW2

AGC1

AGC2

AGC3

AGC4

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

CLOCK

IPU

IPU

IPU

The VPU converts the analog video data from the SBU to an 8-bit digital

video data signal. The following covers how the video data is changed in

each step of the process.

-- Variable Amplification --

The video signals are adjusted by VR203 for odd pixel data and VR204 for

even pixel data and the auto gain control.

NOTE: VR203 and VR204 are used to adjust the overall video signal level.

100%

100%

80%

Too low

100%

Good level

TP209

Too big

2-20

Page 42

1 February 1994 IMAGE PROCESSING

-- Signal Composition --

The odd and even video signals are merged by IC HC4066.

HC4066

1 3 5 4995

2 4 4996

4997

4998

4999

5000

-- Auto Gain Control --

The video signal is modified by

AGC1 -- 4, supplied from the IPU.

This compensates for fluctuations

of the scanner lamp light level (due

to temperature and time). The gain

value is decided by scanning the

white plate prior to scanning the

original.

-- Signal Digitization --

3V

2

1

The wave form at TP209

3 4 4998

0.55 ms

4999

5000

Detailed

Descriptions

The adjusted video data goes to the A/D converter (MP7684), which converts

the serial video data to 8-bit digital data.

2-21

Page 43

IMAGE PROCESSING 1 February 1994

4.3.3 Auto Image Density Control

VIDEO PROCESSING UNIT (VPU)

Video

Auto ID Measuring Area

Peak

Hold

Vin

+Ref

-Ref

AEMODE

PWIND

Sub Scan

A/D

CN321

-53

-54

-55

-56

-57

-58

-59

-60

-39

-37

IMAGE PROCESSING

UNIT (IPU)

AGC

CN301

-53

-54

-55

-56

-57

-58

-59

-60

-39

-37

GA2

Main

Scan

64mm

8.3mm

1 to 3 mm

Unlike standard analog copiers, this machine does not prescan using an

image sensor to determine original image density. Instead, this machine

measures the background density of a 64 millimeter wide area of the

document continuously while the original is scanned. Data from the CCD is

used to check the background density, and the scanned data is made lighter

or darker by the A/D (analog/digital) converter in the VPU.

The scanned video data goes from the CCD to both the A/D converter and

the peak hold circuit. The peak hold circuit selects the peak voltage for each

line scanned and sends it as "+Ref" to the A/D converter. The "--Ref" input is

always 0 volts.

2-22

Page 44

1 February 1994 IMAGE PROCESSING

SFGATE

1 Line

LSYNC

AEMODE

PWIND

Auto image density measuring area

1 Page

To enable "+Ref", GA1 on the IPU sends 2 signals. One is AEMODE, which

goes to Low when the machine starts scanning and then goes High again

after scanning is complete. The other signal is PWIND, which is a pulse

signal which determines how wide the auto image density measuring area is.

This means the peak hold circuit functions only while PWIND is Low.

The A/D converter decides the appropriate video data based on both signals,

then digitizes the data signal.

Detailed

Descriptions

Analog Digital

White

Black

+Ref

Range

2.9 V

1.7 V

0 V

256

256

255

4

3

2

1

...........................

............................

............................

............................

............................

............................

............................

00000000

00000000

00000001

11111100

11111101

11111110

11111111

256 levels calculated

as follows:

D= Vin x

(D is the Digital data)

256

+Ref

+Ref can take values from +1.7 volts to +2.9 volts. The A/D converter divides

+Ref into 256 levels and digitizes the data signal (Vin) based on these levels.

The above chart shows how this is done.

2-23

Page 45

IMAGE PROCESSING 1 February 1994

Subscanning

Detection

Area

4

3

2

Sub-scanning

1

Reference

(+Ref)

2.9V

1.7V

0V

The reference value (+Ref) changes according to the image density in the

area measured. However, to prevent dirty backgrounds due to sudden

changes in the area sampled, the response to a light to dark change is

slower than the response to a dark to light change.

This is illustrated above. At point (1) where the sampled image changes from

black to white, +Ref changes to 2.9 volts immediately. At points (2), (3), and

(4), +Ref starts decreasing slowly, but it returns to 2.9 volts immediately as

soon as white is encountered in the detection area.

2-24

Page 46

1 February 1994 IMAGE PROCESSING

4.4 IMAGE PROCESSING UNIT

4.4.1 Basic Functions

Video Processing

Unit (VPU)

8-bit Video

AGC Reference

Timing

Image Processing Unit (IPU)

GA1

GA2

GA3

GA4

CPU

GA5

GA6

Drive

Timing

10-bit Data

Command

Main PCB

Thermister

Sensors

Motor

Lamp

Heater

Solenoid

Detailed

Descriptions

PROM

RAM

The IPU uses six gate arrays (custom made LSIs) to process the video data.

These gate arrays, which are labeled GA1 - GA6 in the above illustration,

have the following functions.

-- Gate Array 1 (GA1) --

Timing control and CCD drive clock

-- Gate Array 2 (GA2) --

Auto shading and Auto gain control (AGC)

-- Gate Array 3 (GA3) --

MTF (modulation transfer function) processing, Flare prevention and

Smoothing

2-25

Page 47

IMAGE PROCESSING 1 February 1994

-- Gate Array 4 (GA4) --

Main scanning magnification

-- Gate Array 5 (GA5) --

Gamma (γ) correction, Binary processing and 16 level grayscale processing

-- Gate Array 6 (GA6) --

Marker area detection, Background Numbering, Binary and 16 level

grayscale processing control

2-26

Page 48

1 February 1994 IMAGE PROCESSING

4.4.2 IPU Data Flow

VPU

8-bit Video Signal

Auto-shading

(GA2)

Letter Mode

Processing

MTF Correction

(GA3)

16 Level Grayscale

Processing

(GA5)

Magnification

Gamma Correction

Photo Mode

Processing

Smoothing

(GA3)

(GA4)

(GA5)

MTF Correction

(GA3)

Binary Processing

(GA5)

Letter/Photo

Mode Processing

Marker Area

(GA6)

Detailed

Descriptions

Image Editing

(GA6)

4-bit Video Signal (16 Level Grayscale Processing)

1-bit Video Signal (Binary Processing)

Main Board

The 8-bit video data from the VPU goes first to GA2 for auto-shading. The

corrected data then goes to GA3.

At GA3 data processing splits into letter mode processing, photo mode, and

letter/photo mode processing. For letter mode and letter/photo mode

processing, GA3 applies the MTF correction. For photo mode processing, it

applies a smoothing function.

Next the video data goes to GA4 where the magnification correction is

applied (if necessary).

After magnification, the data goes to GA5, where it is subjected to a gamma

correction. If the marker function is selected, the magnification processing

data goes to GA6, where the image data for marker area recognition is

produced. Then it goes to image editing.

2-27

Page 49

IMAGE PROCESSING 1 February 1994

If binary processing is selected, the magnification processing data goes to

the binary processing mode in GA5, where it is converted to a black and

white signal bit image.

If 16 level grayscale processing is selected, the gamma correction data goes

to the 16 level grayscale processing mode in GA5, where it is distributed over

16 levels.

16 level grayscale processing and binary processing can be chosen for each

original mode (letter, photo and letter/photo) through the SP4-403.

Finally, the output data from GA5 goes to the image editing section in GA6,

where background numbering and marker image data are processed. Then

the appropriate video data is ready for output to the main board.

2-28

Page 50

1 February 1994 IMAGE PROCESSING

4.4.3 Auto Gain Control (GA2)

VPU IPU

5

AGC1

5

5

5

AGC2

AGC3

AGC4

Video Data

2K

3.9K

8.2k

16k

22K

HA2540

A/D

8 bit

Video Data

GA2 applies a 4-bit auto gain control (AGC) signal to the VPU (Video

Processing Unit) during document scanning. The AGC is based on the peak

white level detected when the white plate is read prior to document scanning.

It corrects for variations in the output of the scanning lamp. (The scanner

lamps are fluorescent lamps, so output will vary depending on temperature

and age.)

Detailed

Descriptions

As shown in the above schematic, the 4-bit AGC information changes the

amplification factor of the amplifier (HA2540) on the VPU.

2-29

Page 51

IMAGE PROCESSING 1 February 1994

4.4.4 Auto Shading (GA2)

There are two auto shading methods. One is black level correction and the

other is white shading. These functions are as follows.

-- Black Level Correction --

Video Signal

After Correction

White Level

Black Level

1 line

Output

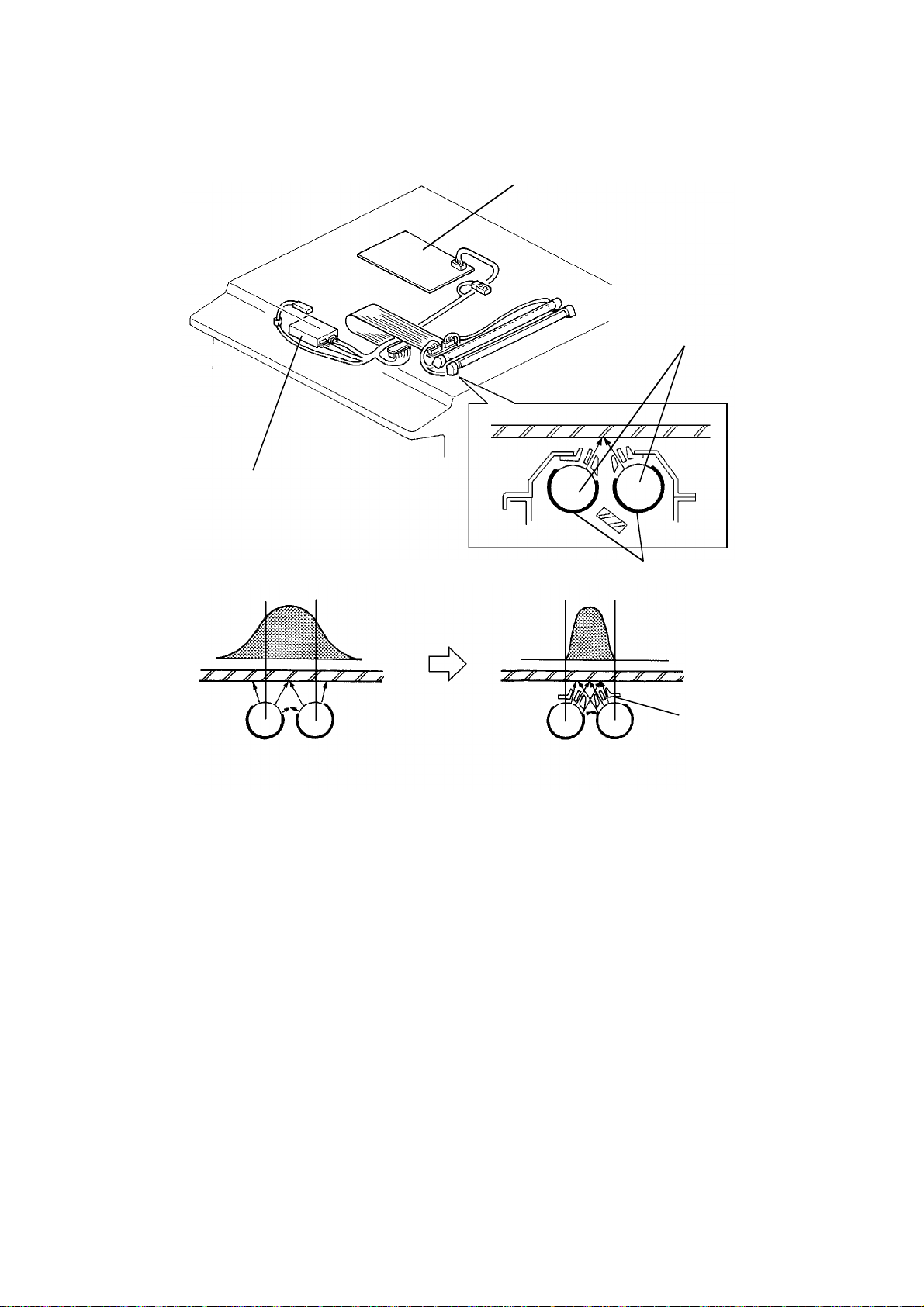

(V)

0

Video Signal

Before Correction

1 line

White Level

Black Level

Output

(V)

0

Black level correction works similarly to white shading, but sets the black

base rather than the white one.

The video data is scanned by the CCD with the scanner lamps turned OFF.

Each CCD element should therefore send identical almost near 0 V output,

but this is not the case. This is because of variations in sensitivity between

elements of the CCD. So, this function is necessary to improve copy quality

in black areas.

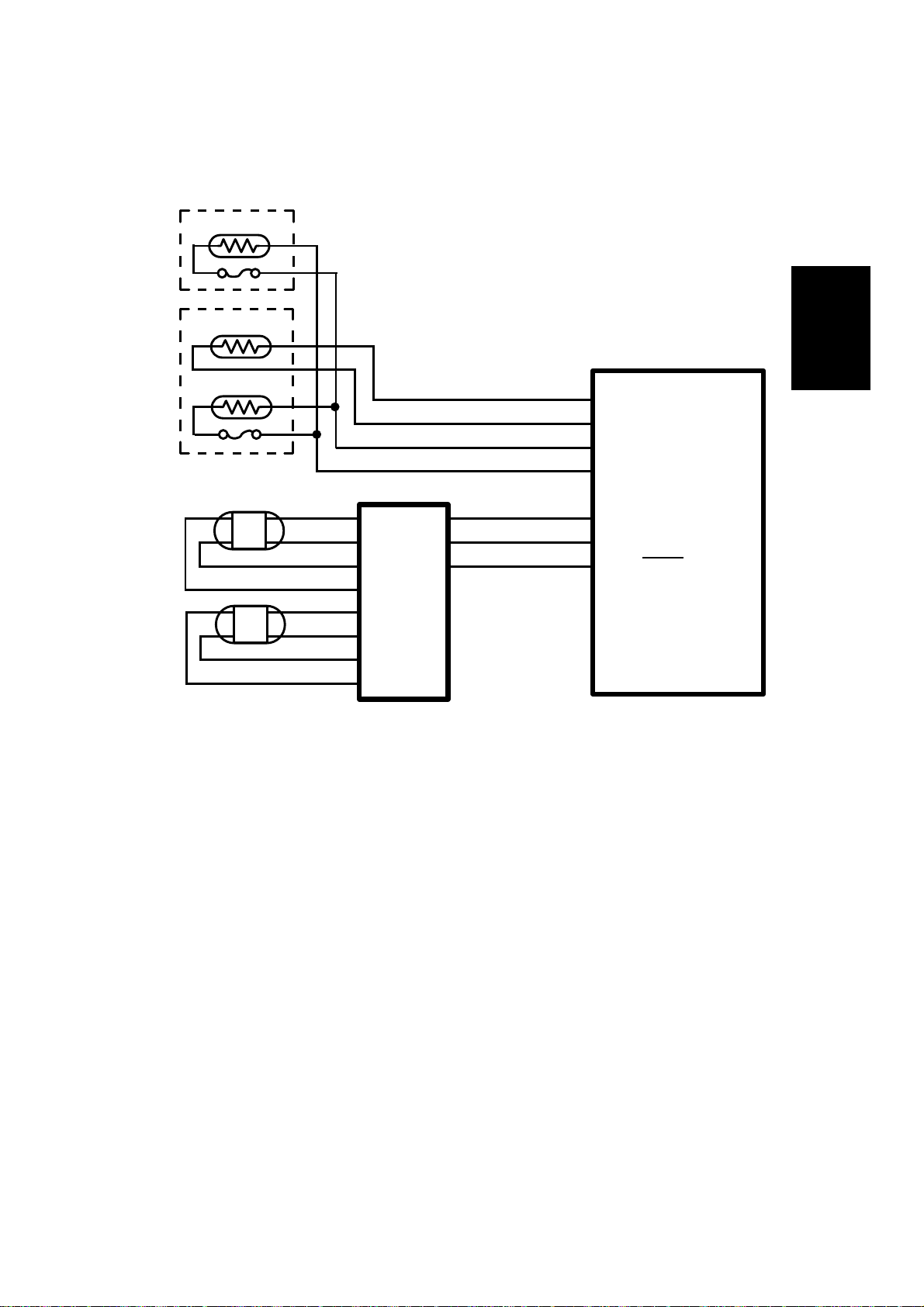

Before scanning the document, the CCD scans the black level for each

pixels. Then this data is stored in RAM. The video signal information obtained

during white platen scanning is then modified by the black level data just

described: for each element, the black level result is subtracted from the

white level result. After this correction, the black level of each element will be

even.

2-30

Page 52

1 February 1994 IMAGE PROCESSING

-- White Shading --

Video Signal Video Signal

Output

(V)

Before Correction

(V)

Distortion

1 line 1 line

When scanning the white plate.

After Correction

Detailed

Descriptions

Like auto gain control, auto shading is based on image data read from the

white plate. However, auto shading differs from auto gain control in that it is a

bit by bit correction rather than an overall correction. Auto shading is

necessary for the following reasons:

• Variations in sensitivity between bits of the CCD. (This arises from

production processes.)

• Variations in characteristics of the lens and mirror reflectivity.

• Loss of brightness toward the ends of the fluorescent lamps.

Before scanning the document, the machine reads a reference waveform

from the white plate (which has a uniform color and reflectivity). The white

plate video level for the each pixel is written to RAM. After black level

correction, the video signal information obtained during image scanning is

then input and corrected in accordance with the white waveform data which is

read out from RAM. In this way distortion is eliminated and a signal

containing only image data is achieved.

2-31

Page 53

IMAGE PROCESSING 1 February 1994

4.4.5 Smoothing Function (GA3)

After auto-shading the next step in photo mode processing is the smoothing

step. Basically, this step improves the image by smoothing the gradient of

photo originals.

(Example)

14 14 1814 14

14

5

14

14

18

1 2 2 2 1

2 4 4 4 2

2 4 4 4 2

2 4 4 4 2

1 2 2 2 1

17

5

141414 18 19

18 19

18

18 19 20 21

18 19 20 21

Filter

(1/64)

Result

Image

: Object Pixel

The smoothing algorithm is: the values of the 24 pixels surrounding the object

pixel and the object pixel are multiplied by the data in accordance with the

filter. Then they are added together. The result is then divided by 64 and

rounded off to yield the new value of the pixel. If this procedure is applied to

the example, the value of the pixel shown in the figure changes from 18 to 17.

This algorithm is applied to all pixels. If the pixel is on the edge of the image

area, the missing data is assumed to be "0".

2-32

Page 54

1 February 1994 IMAGE PROCESSING

There are other filters for this process. Normally, the filter used is the filter

above but these filters can be selected by SP4-407-2 depending on the

original. The type of filter for each SP4-407-2 setting are as follows.

0:

1 2 2 2 1

1 4 4 4 1

2 4 8 4 2

1 4 4 4 1

1 2 2 2 1

1:

1 2 2 2 1

2 4 4 4 2

2 4 4 4 2

2 4 4 4 2

1 2 2 2 1

2:

1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

1 1 1 1 1

(High contrast)

(1/64)

Detailed

Descriptions

(Standard)

(1/64)

(Low contrast)

(1/25)

SP4-407-2 is normally set at 1. Set it at 2 to improve the reproduction of low

contrast originals.

2-33

Page 55

IMAGE PROCESSING 1 February 1994

4.4.6 Flare Prevention (GA3)

When the CCD scans across the edge of a black solid image, the reflected

light from both the white and black areas go to CCD elements. This will cause

the edge of the image on the copy to be blurred when 16 level grayscale

processing is used. To prevent this, there are two methods. One is optical,

the other is electrical.

The optical one is simply to place a lamp grid above the lamps to minimize

the width of exposure light. The electrical one is to use smoothing filters.

2-34

Page 56

1 February 1994 IMAGE PROCESSING

4.4.7 Modulation Transfer Function Correction (GA3)

Black

Real

Image

A

White

Black

CCD

Output

B

White

B

x 100 = MTF (%)

A

When a letter mode or letter/photo mode image is converted to an electrical

signal (for example by a CCD), the signal deteriorates (contrast becomes

less) as the width and spacing of the black and white areas becomes

narrower. The ratio of the difference between the black and white levels of

the signal and the difference between the black and white levels of the

original is called the modulation transfer function or MTF. The MTF is usually

expressed as a percentage.

If the MTF is too low, some parts of the image may be lost. To prevent this,

the image data is enhanced by applying an MTF correction.

Detailed

Descriptions

(a) Section of document (b) Enlarged view of dot

0 0 0 0

0 42 11 0

105

0 42 0

0 11 11 0

0 0 0 0

(c) Image data after

A/D conversion

(d) Copy without MTF

correction

(Threshold level; 127)

2-35

Page 57

IMAGE PROCESSING 1 February 1994

Consider a small black point on a document as shown in the previous

illustration. The 8-bit image data (range 0 to 255) for this section of the

original is shown in (c). If the threshold level is 127, then all the pixels in this

area will become white and the dot will not be reproduced (d).

Such image loss is prevented by providing MTF correction as follows:

-1

-3 -2-2

-1 -3 -3 -1

-2

35

-3

-1

-2

1/11

The value of the pixel is multiplied by 35. Then the new value of the pixel is

reduced by 3 times the value of the pixels to the left, right, above and below,

the values of the pixels two steps to the left, right, above and below, the

values of the pixels to the opposite angles. Then the new value of the pixel is

divided by 11. If the new number is greater than 256, it is reduced to 256.

The MFT algorithm is as follows.

C = {A x (24 x N + 11) + B x N} / 11

A = Value of the object pixel

B = Value of the calculated surrounding the object pixel

N = The strength of the filter

C = Calculated value

0 0 0

0 93 0

0

0

255

0 89

0 0 0.5

0 0 0

(e) Image data after

MTF correction

0

0

0

(f) Copy after MTF correction

After MTF correction is applied the image data of our example becomes as

shown in (e) above. The copy after correction (f) has the dot that was on the

original.

2-36

Page 58

1 February 1994 IMAGE PROCESSING

The MTF algorithm and filter differ by magnification and original type (letter

and letter/photo mode) and they are selected by the CPU. The algorithms

and filters are as follows.

• Letter Mode

Magnification Type of filter Strength of filter

25 ∼ 54%

55 ∼ 79%

80 ∼ 179%

180 ∼ 379%

380 ∼ 800%

• Letter/Photo Mode

A 1/2

A 1

B 1

C 1/2

C 1/4

Magnification Type of filter Strength of filter

25 ∼ 800%

A 1/8

Type of filter

A B C

-1

-4

-3 -3

24

-1-1

-2 -3 -2

-3 -335 -1-1

Detailed

Descriptions

-4

-2 0 -2

-3 -335 -1-1

-4

1/8

-2 -3 -2

-1

-2 0 -2

1/11 1/11

C = {Ax(24xN+11)+BxN}/11C = {Ax(24xN+11)+BxN}/11C = {Ax(16xN+8)+BxN}/8

-4

The strength of the filter can be changed using SP4-407-1 and SP4-407-3.

Normally the value of the SP modes is set at "1", the value of the filter

strength is set according to the above table. If set at "0", each filter strength

value of the above table changes to 1/2 of what it was. If set at "2", the

strength filter value is doubled.

2-37

Page 59

IMAGE PROCESSING 1 February 1994

4.4.8 Main Scan Magnification (GA4)

80% Reduction

Scanned Data

Points

Calculated Data

Points

Reduced Image

Data Points

1 2 3 4 5 6 7 8 9 10

1" 2" 3" 4" 5" 6" 7" 8"

140% Enlargement

Scanned Data

Points

Calculated Data

Points

Enlarged Image

Data Points

1 2 3 4 5 6 7 8 9 10

1"

2" 3" 4" 5" 6" 7" 8" 9" 10" 11" 12" 13" 14"

Reduction and enlargement in the sub scan direction is done by changing the

scanner speed. However, reduction and enlargement in the main scan

direction is handled by the IPU.

Scanning and laser writing are done at a fixed pitch (the CCD elements

cannot be squeezed or expanded). So, to reduce or enlarge an image, GA4

calculates imaginary points that would correspond to a physical enlargement

or reduction of the image. It then calculates the correct image density for

each of the imaginary points based on the image data of the nearest four true

points. The calculated image data then becomes the new (reduced or

enlarged) image data.

NOTE: The actual calculations for main scan magnification uses a process

known as the polynomial convolution method. This mathematical

process is beyond the scope of a service manual and will not be

covered here.

2-38

Page 60

1 February 1994 IMAGE PROCESSING

4.4.9 Gamma Correction (GA5)

HH

CCD

ID

L

L H

Original ID Original ID

CCD

ID

L

L H

This corrects the response of the CCD to the various shades in the gray

scale from black to white. For digital processing techniques to be most

effective, the relationship between original ID and CCD output voltage should

be constant, as shown in the diagram on the left. However, in reality, the

response is more like that shown in the diagram on the right. Gamma

correction corrects this deviation in CCD response.

Detailed

Descriptions

2-39

Page 61

IMAGE PROCESSING 1 February 1994

4.4.10 Grayscale to Black and White Conversion (GA5)

After gamma correction, the image data goes to the functions for 16 level

grayscale. Prior to this each pixel is represented by 8 bits, yielding a 256

level grayscale. The laser uses 4 bits, yielding a 16 level grayscale per pixel.

The 16 level grayscale processing steps convert 8-bit image data to 4-bit

image data suitable for printing. The binary processing steps convert the 8-bit

image data to single-bit image data.

-- 16 Level Grayscale Processing --

Gamma (γ) Correction

Photo mode Letter/Photo mode

8 8

Letter mode

Dithering

8

Error Diffusion

6

Pulse Width

Modulation

4 4

To: Main Board

There are three 16 level grayscale processing methods, depending on the

document mode, as shown in the above illustration.

• Letter Mode

After γ correction, the video data is transformed from an 8 bit data signal

to a 4 bit data signal by the pulse width modulation function.

• Photo Mode

After γ correction, the video data is transformed from an 8 bit data signal

to a 4 bit data signal in accordance with the dither matrix in the ROM (IC

123) on the IPU board.

• Letter/Photo Mode

After γ correction, the video data goes to the error diffusion function where

it reduces the difference in contrast between light and dark areas of the

photo image. The corrected data then goes to the pulse width modulation

function where it is converted to a 4 bit video signal.

2-40

Page 62

1 February 1994 IMAGE PROCESSING

- Binary Processing -

Letter, Photo, Letter/Photo mode

Magnification

6

Binary Processing

1

Main Board

Binary processing, which is used for character or line originals, is simpler

than dithering. Binary processing is performed using the first 6 bits of the 8 bit

data from the magnification function. In binary processing all image data

pixels are compared to a single threshold level. A pixel is set to black if its

value is above the threshold level or it is set to white if it is equal to or below

the threshold level.

The binary processing threshold level for each manually selectable ID level is

shown in the following table.

ID Level 1 2 3 4 5 6 7

Threshold Level 16 24 28 32 40 44 48

Darker Lighter

Detailed

Descriptions

2-41

Page 63

IMAGE PROCESSING 1 February 1994

4.4.11 Marker Area Detection (GA6)

Density

Black

63

Threshold

Level

40

14

White

0

Main Scanning

More than 1 mm

(Marker)

More than 1 mm

(Marker)

The marker area detection function determines what parts of the image have

been designated for special processing. The area is designated on the

original using a marker.

Marker area detection is based on the fact that the image density of the

marker ink is between the "black" of the original image and the "white" of the

background areas. As shown in the above illustration, the IPU assumes that

the image element is made by a marker if it has a value above 14 but less

than the threshold level and is wider than 1 millimeter.

When the marker area designation function is used, letter mode is

automatically selected. The default threshold level is 40 (manual ID level 5),

but it can be changed to any other manual ID level using SP4-406.

SP4-406: Marker Density

Adjustable range = 0 to 3 Standard = 0

2-42

Page 64

1 February 1994 IMAGE PROCESSING

4.4.12 Background Numbering (GA6)

Copies have a number appear in the background of the copy. This function

can help the customer keep track of confidential documents.

The patterns for background numbering are stored in a ROM (IC126) on the

IPU. When the background numbering function is selected, the patterns are

sent from the ROM. Then the data will be sent to the laser section.

Image density for the background numbering can be changed using SP4-405.

SP4-405: Background Numbering Density

Adjustable range = 0 or 1 Standard = 1

Detailed

Descriptions

2-43

Page 65

LASER EXPOSURE 1 February 1994

5. LASER EXPOSURE

5.1 OVERVIEW

[B]

[A]

This machine uses a laser diode to produce electrostatic images on an OPC

(organic photoconductor) drum [A]. This gives high picture quality and

enables high-speed writing. The laser diode unit [B] converts image data from

the main PCB into laser pulses through the PWM board, and the optical

components direct these pulses to the OPC drum.

Exposure of the drum by the laser beam creates the latent image. The laser

beam makes the main scan while drum rotation controls the sub scan.

The drum is charged to about --850 volts. The charge on the areas hit by the

laser beam drops to about --100 volts.

2-44

Page 66

1 February 1994 LASER EXPOSURE

5.2 OPTICAL PATH

[B]

[D]

[E]

[C]

Detailed

Descriptions

[A]

[J]

[F]

[I]

[G]

[H]

The output path from the laser diode to the OPC drum is shown above.

The LD unit [A] outputs the laser beam to the polygon mirror [B] through the

cylindrical lens [C].

The polygon mirror reflects a full main scan line with a single surface of the

mirror. The laser beam goes through the 1st fΘ lens [D] and, 2nd fΘ lens [E].

The drum mirror [F] reflects the laser beam to the drum [G] through the toner

shield glass [H].

To determine the main scan starting position, the laser beam is reflected from

the the synchronizing mirror [I] to the laser synchronizing detector [J].

The other end of this cable connects to the synchronization detection circuit

on the main board.

2-45

Page 67

LASER EXPOSURE 1 February 1994

5.2.1 Laser Diode Unit

[B]

Laser beam

(to cylindrical

lens)

[A]

[C]

[D]

Laser beam cross

section after

collimating lens

Laser beam cross

section after

aperture

The laser diode unit consists of the laser diode [A], the collimating lens [B],

aperture [C], and the LD driver PCB [D].

The LD driver PCB excites the laser diode, causing it to radiate coherent light

at 780 nm with about 15 mW power.

The collimating lens forms the radiating beams into a parallel beam.

After the collimating lens, the aperture alters the beam, giving it a smaller

cross-section, as shown above.

2-46

Page 68

1 February 1994 LASER EXPOSURE

[C]

[A]

[B]

5.2.2 Cylindrical Lens

The laser beam is focused by the cylindrical lens [A], and sent to the polygon

mirror.

5.2.3 Polygon Mirror

The polygon mirror assembly consists of the polygon mirror motor [B] and the

polygon mirror itself [C].

As the mirror rotates, it reflects the laser beam across the OPC drum, via the

fΘ lens and the drum mirror. One main scan line is made by the beam

reflected from one face of the polygon mirror.

Detailed

Descriptions

The mirror is precisely ground to enable high reflectivity and to prevent pixel

(picture element) misalignment on the drum in both the main scan and sub

scan directions.

2-47

Page 69

LASER EXPOSURE 1 February 1994

5.2.4 F-Theta Lenses

Wide Spaced

Narrow Spaced

[A]

Evenly

spaced

pixels

The angles between pixels are equal. However, if the beam were to go

directly to the drum as shown in the upper illustration, the spacing between

pixels would differ according to the angle of the beam. The pixels near the

end of the drum would be further appart than those near the middle of the

drum. The pixels would also be slightly thicker toward the ends of the drum

than in the middle.

The fΘ lenses [A] correct for this by deflecting the beam slightly inward to

insure uniform picture element spacing and diameter. The fΘ lenses also