Page 1

DOCUMENT FEEDER

Page 2

1 February 1994 OVERALL MACHINE INFORMATION

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Original Size and Weight: - Thin original mode -

Maximum 11" x 17"/A3

Minimum 5

Weight 11 to 34 lb/41 to 128 g/m

- Thick original mode Maximum 11" x 17"/A3

Minimum 5

Weight 14 to 34 lb/52 to 128 g/m

- Auto reverse mode Maximum 11" x 17"/A3

Minimum 8

Weight 17 to 28 lb/64 to 104 g/m

Original Feed: Automatic feed — ADF mode

Manual feed one by one — SADF mode

" x 8

1/2

" x 8

1/2

" x 11"/A5 sideways

1/2

"/A5 sideways

1/2

"/A5 sideways

1/2

2

2

2

Original Table Capacity: 35 sheets (17 lb/64 g/m2)

Maximum thickness of stacked originals:

3.4 mm

Original Set: Face up, front side. First sheet on top.

Original Transport: One flat belt

Copy Speed: - One sided mode -

20 copies/minute for 8

" x 11"/

1/2

A4 sideways (1 to 1 copy)

- Auto reverse mode -

2 copies/minute for all sizes

Power Consumption: 24 W

Dimensions (W x D x H): 27.2" x 20.4" x 4.2"/690 x 519 x 107 mm

Weight: Approximately 21.4 lb/9.7 kg

Nonrecommended Paper: The following types of paper cannot be used

with the DF.

1) Dog-eared, torn, or cre ase d paper

2) Paper with holes larger than 6 mm in

diameter

3) Damp paper

4) Coated paper (carbon paper, thermal

paper, etc.)

Feeder

Document

1

Page 3

OVERALL MACHINE INFORMATION 1 February 1994

5) Curled paper

6) Paper with clips or staples

7) Originals that are glued or taped together

8) Bound originals

9) Translucent paper (can be used in SA DF

mode)

2

Page 4

1 February 1994 OVERALL MACHINE INFORMATION

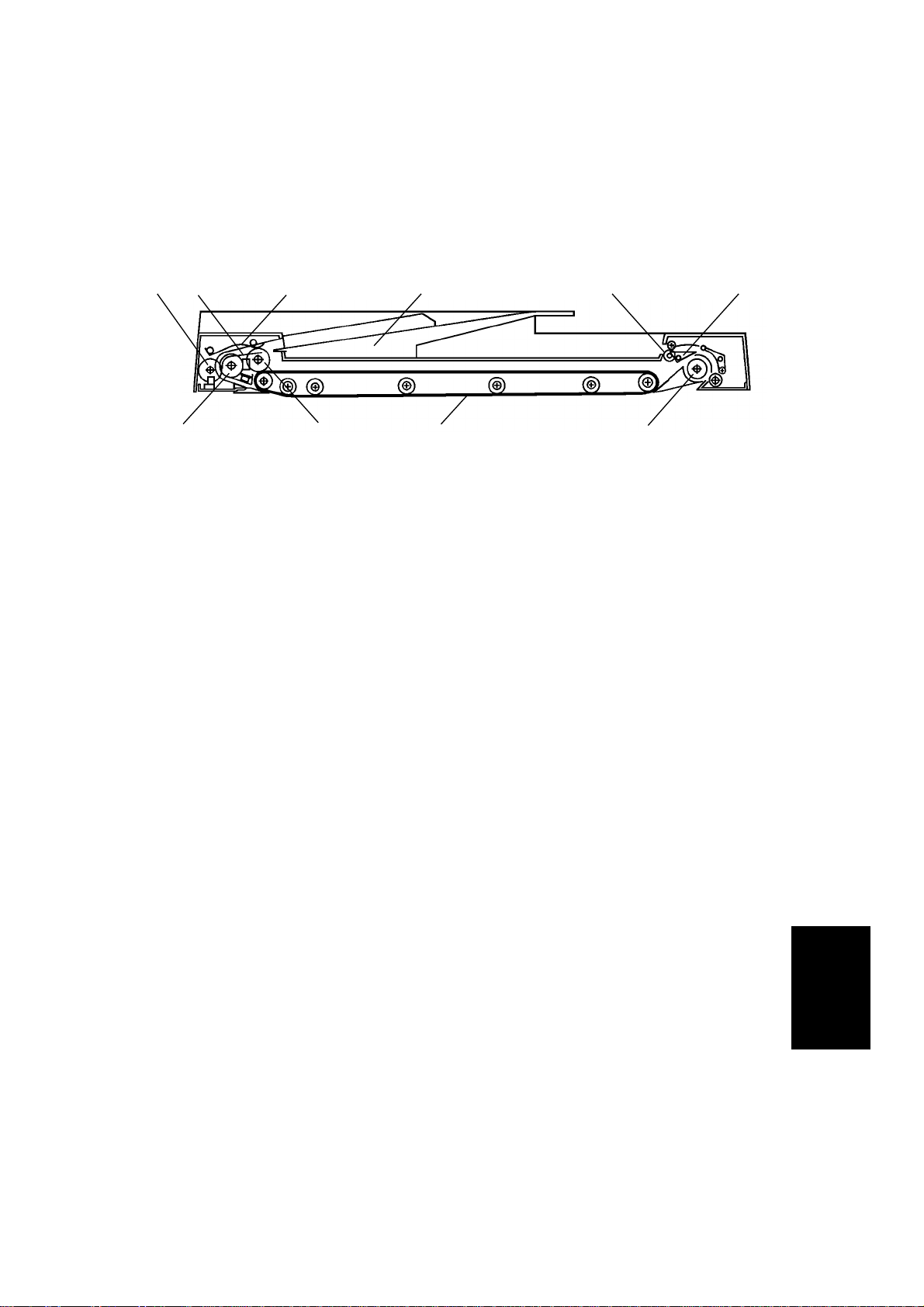

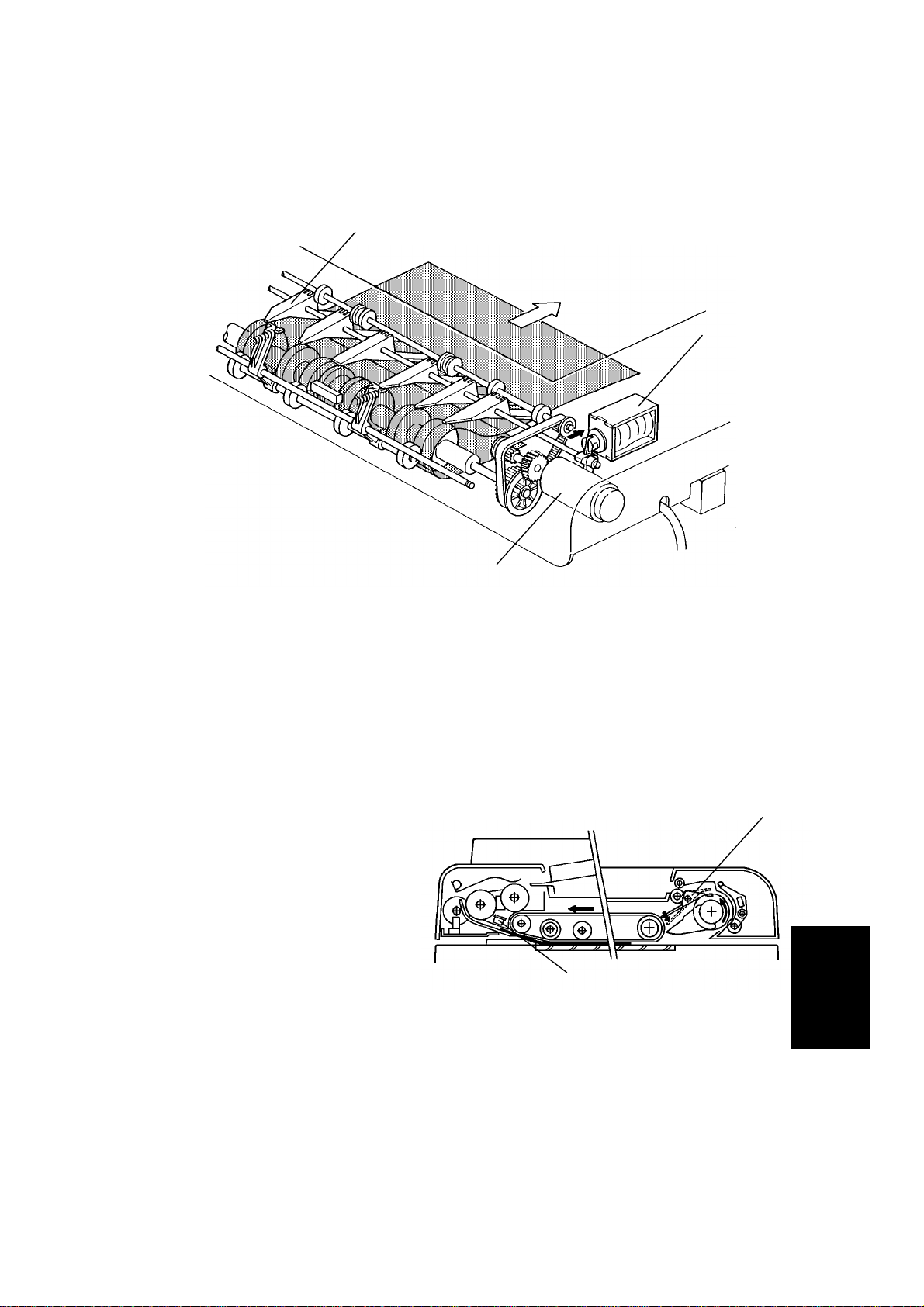

1.2 MECHANICAL COMPONENT LAYOUT

1

2

10

3

9

4

8

5

6

7

1. Pulse Generator Disk 6. Inverter Pawl

2. Friction Belt 7. Inverter Roller

3. Pick-up Lever 8. Transport Belt

4. Original Table 9. Pick-up Roller

5. Exit Roller 10. Feed Roller

Feeder

Document

3

Page 5

OVERALL MACHINE INFORMATION 1 February 1994

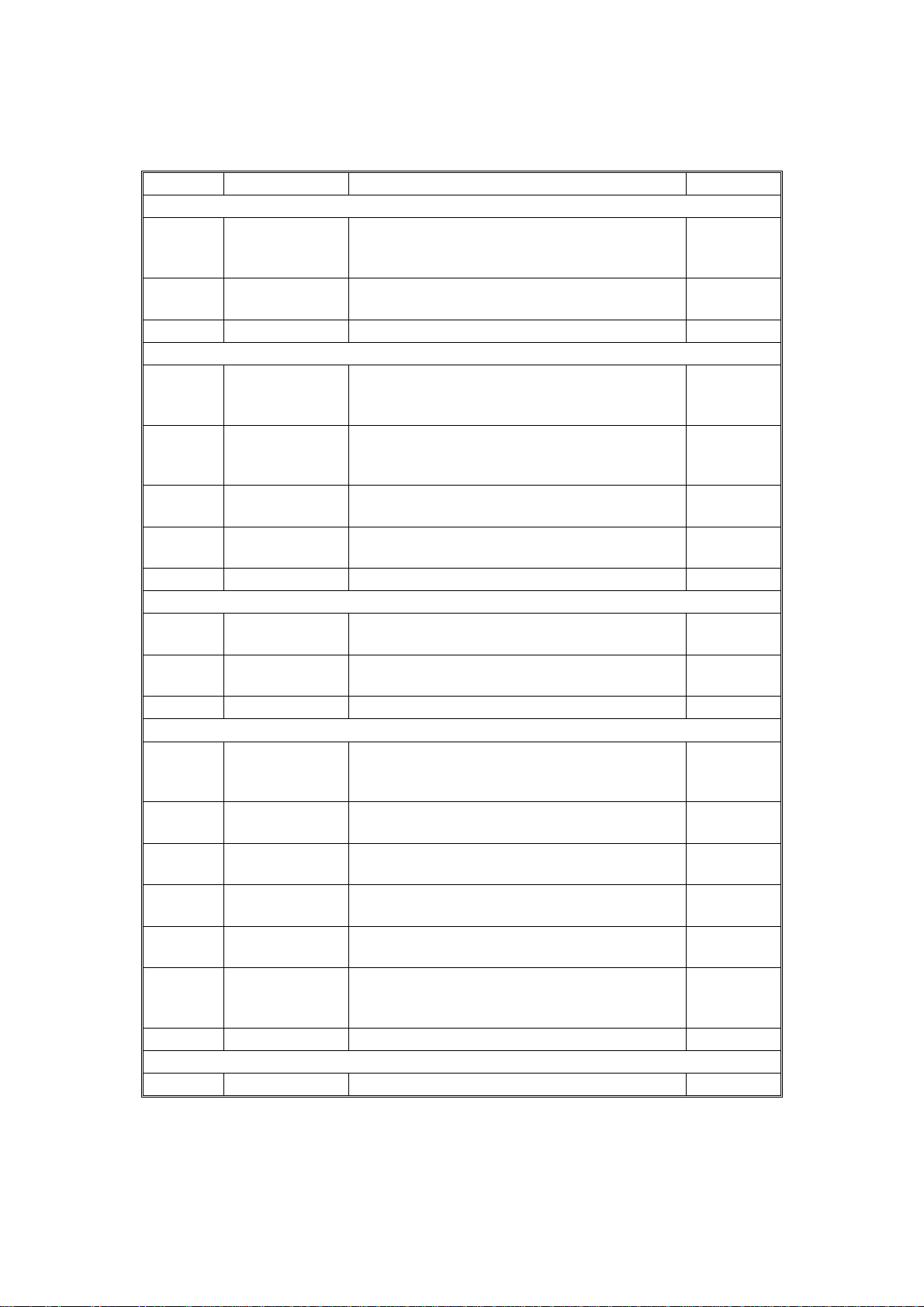

1.3 ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL NAME FUNCTION LOCATION

Motors

M1 Belt Drive Motor DC servomotor that drives to the transport belt

and feed-in system (pick-up roller, feed roller,

pull-out roller and relay roller).

M2 Feed-out Motor DC servomotor that drives the feed-out unit of

the DF.

Solenoids

SOL1 Pick-up Solenoid Energizes to press the pick-up lever against the

stack of originals in preparation for original

feed-in.

SOL2 Feed-in Solenoid Turns on to engage the feed-in clutch so

rotation is transmitted to the feed roller, pull-out

rollers, and relay rollers.

SOL3 Inverter Solenoid Energizes to invert the original when copying

two sided originals.

SOL4 Stopper

Solenoid

Energizes to down the original stopper of the

copier.

6

11

5

14

10

15

Switches

SW1 Lift Switch Informs the CPU when the DF is lifted and also

serves as the jam reset switch for the DF.

SW2 Original Select

Switch

Sensors

S1 Original Set

Sensor

S2 Registration

Sensor

S3 Original Width

Sensor

S4 Pulse Generator

Sensor

S5 Feed-out Sensor Checks for original misfeeds and sets original

S6 ADF Position

Sensor

Selects thick original mode or thin original

mode.

Informs the copier CPU that originals have

been placed and causes the Insert Original

indicator to go out.

Sets original stop timing and measures original

length.

Determines the width of the originals. 4

Generates pulses used to measure the original

length.

stop timing when in auto reverse mode.

Informs the CPU when DF is being closed so

that APS sensor can begin checking the

original size.

8

13

1

2

3

12

16

Printed Circuit Boards

PCB1 DF Main Board Controls all DF functions. 9

4

Page 6

1 February 1994 OVERALL MACHINE INFORMATION

PCB2 Indicator Panel

Contains operator indicators. 7

Board

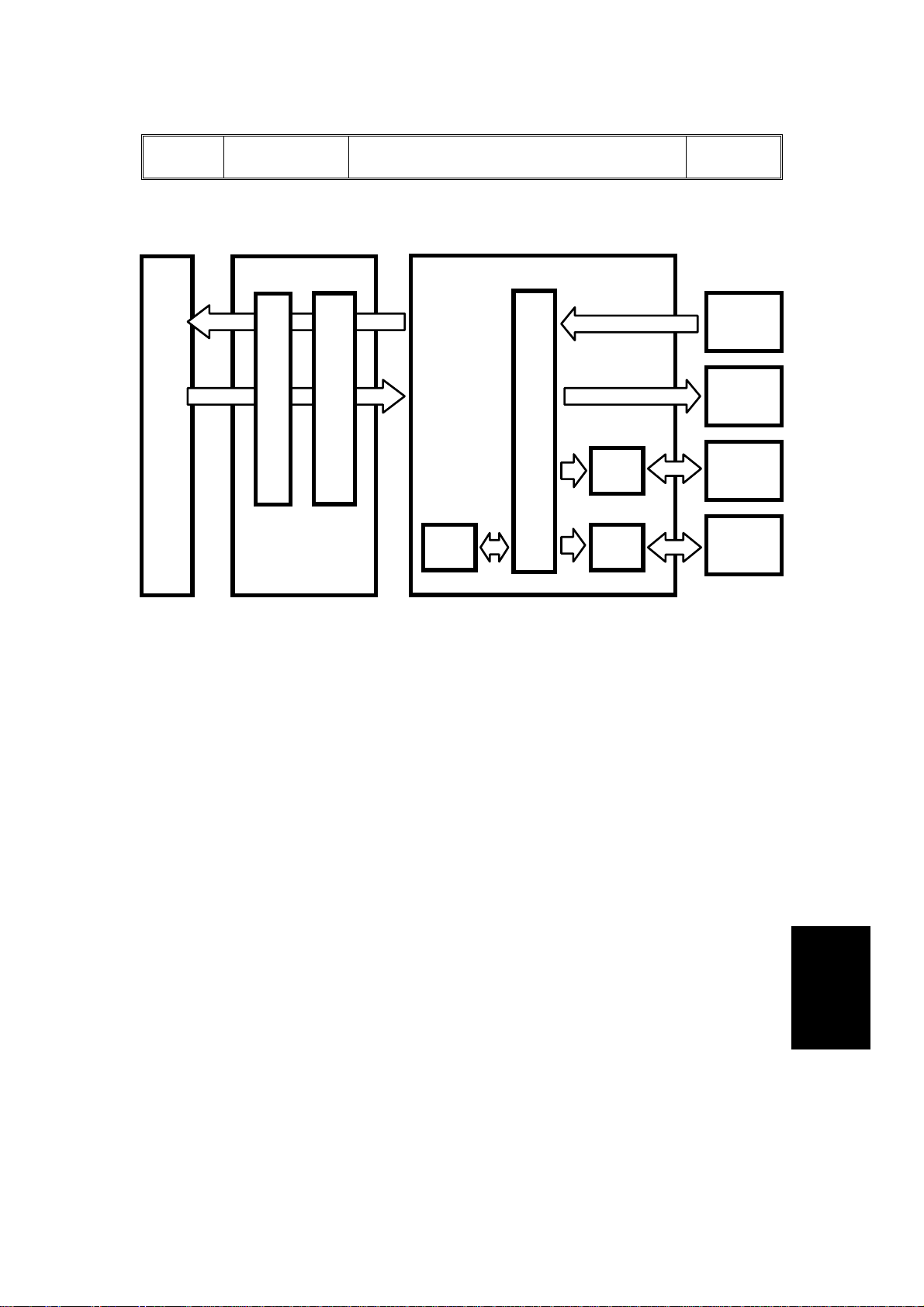

1.4 OVERALL MACHINE CONTROL

Copier

Main Board

RXD

TXD

Copier IPU Board

CPU

Serial

-Parallel

Comverter

DF Main Board

TXD

RXD

ROM

CPU

Driver

IC

Driver

IC

Sensors

Switches

Solenoids

Indicators

Belt Drive

Motor

Feed-out

Motor

The DF CPU monitors the input signals fr om th e sensors and switches, and

energizes the solenoids and the indicator LE Ds direct ly. The belt drive motor

and the feed-out motor are controlled by the DF CPU through their respective

driver ICs.

Also, the DF CPU communicates with the copier using a serial interface. The

exchanged signals are shown in the tables on the next page.

Feeder

Document

5

Page 7

OVERALL MACHINE INFORMATION 1 February 1994

1. DF ⇒ Copier

No. Signal Name Definition

1 Original Set Originals are set on the original table.

2 Copy Start Allows the copier to start copy sequence.

3 Lift Up The DF is lifted.

4 DF Misfeed Misfeed occurs in the DF.

2. Copier ⇒ DF

No. Signal Name Definition

1 Feed-in Requests the DF to feed-in the original.

2 Feed-out Requests the DF to feed-out the or ig ina l .

3 Invert Original Requests the DF to invert the original.

4 Auto Feed Shifts the DF to the auto feed mode.

Original Stay Attempt to use DF but the original from the

5

previous copy run remains on the exposure glass.

6

Page 8

1 February 1994 OVERALL MACHINE INFORMATION

1.5 BASIC OPERATION

1. One-sided Original Feed

When an original is inserted into the DF, the Insert Original indicator light

goes out and the DF informs the copier CPU that originals have been set.

When the Start key is pressed, the copier CPU sends the fe ed-in signal to the

DF. On receipt of this signal, the DF energizes the pick-up solenoid, the

feed-in solenoid, and the belt drive motor in order to feed-in the bottom sheet

of the original stack onto the exposure glass. The pick-up solenoid and the

feed-in solenoid remain energized until the original’s leading edge reaches

the DF registration sensor. The belt drive motor turns off 2,088 encoder

pulses after the original’s leading edge passes the DF registration sensor.

While feeding the original, the DF regi stra tion sensor and the paper width

sensor check the original size.

Shortly before the belt drive motor turns off, the DF CPU sends the copy start

signal to the copier. On receipt of the signal, the copier CPU starts the copy

cycle.

When the scanner reaches to th e r et urn posit i on , th e cop i er CPU sen ds th e

feed-out and the feed-in signals to the DF CPU in order to exchange the

original with the next original.

When the scanner comes to the r et urn posit i on aft er scan nin g th e last

original, the copier CPU only sends the feed-out signal in order to feed-out

the last original.

2. Two-sided Original Feed

Unlike one-sided original feed, the back side of the original must be copied

first to keep the originals and cop i es in th e cor rect order.

During original feed-in, the sequence is the same as for one-sided feed;

however, the DF CPU also energizes the feed-out motor and the inverter

solenoid a short time after the original’s leading edge has passed the DF

registration sensor. The belt drive motor continues to feed the original until

140 milliseconds after the original leading’s edge passes the feed-out sensor.

At this point the inverter mechanism inverts the original, in preparation for

copying the back side. Then the belt drive m ot or reve r ses an d th e or ig ina l is

fed towards the original stopper and is stopped at the correct position on the

exposure glass. The DF CPU sends the copy start signal a short time after

the original’s trailing edge has passed the feed-out sensor.

Feeder

Document

When the scanner reaches to th e r et urn posit i on , th e cop i er CPU sen ds th e

invert original signal to the DF CPU in order to make a copy of the front side.

The original is inverted in the same way as for back side copying.

7

Page 9

OVERALL MACHINE INFORMATION 1 February 1994

3. Semi-automatic Document Feed

If a single original is inserted into th e or ig ina l tab le an d cop i ed , th e DF shifts

to the semi-automatic fe ed mo de and light s the Aut o Fee d ind icator. The

Auto Feed indicator remains on for five seconds after the copier main motor

stops. If another origina l is inser te d with in th at five-second period, it is

automatically fed and copied.

8

Page 10

1 February 1994 DETAILED SECTION DESCRIPTION

2. DETAILED SECTION DESCRIPTION

2.1 ORIGINAL FEED

2.1.1 Original Pick-up

[B]

[C]

[A]

After setting the origina l s on the or ig ina l tab le, the originals contact the feele r

[A] of the original set sensor an d cau se th e feeler to move out of the sensor.

The DF then sends the original set signal to the copier CPU to inform it that

the DF will be used. When the Start key is pressed, the pick-up solenoid [B]

is energized. The original stack is then pressed between the pick-up lever [C]

and pick-up roller [D]. The rotation of the pick-up roller advances the bottom

original.

[D]

[A]

Feeder

Document

9

Page 11

DETAILED SECTION DESCRIPTION 1 February 1994

2.1.2 Original Separation

[B]

[A]

[B]

[C]

[A]

The feed roller [A] and the friction belt [B] are used to feed-in and separate

the originals [C]. Only the bottom original is fed because the friction belt

prevents any other originals from feeding.

Original feed starts when the feed roller starts turning and advances the

bottom original of the stack. The feed roller moves the original past the

friction belt because the drivin g fo r ce of the feed roller is greater than t he

resistance of the friction belt. The friction belt prevents multiple feeds

because the resistance of the friction belt is grea ter than the friction between

original sheets.

10

Page 12

1 February 1994 DETAILED SECTION DESCRIPTION

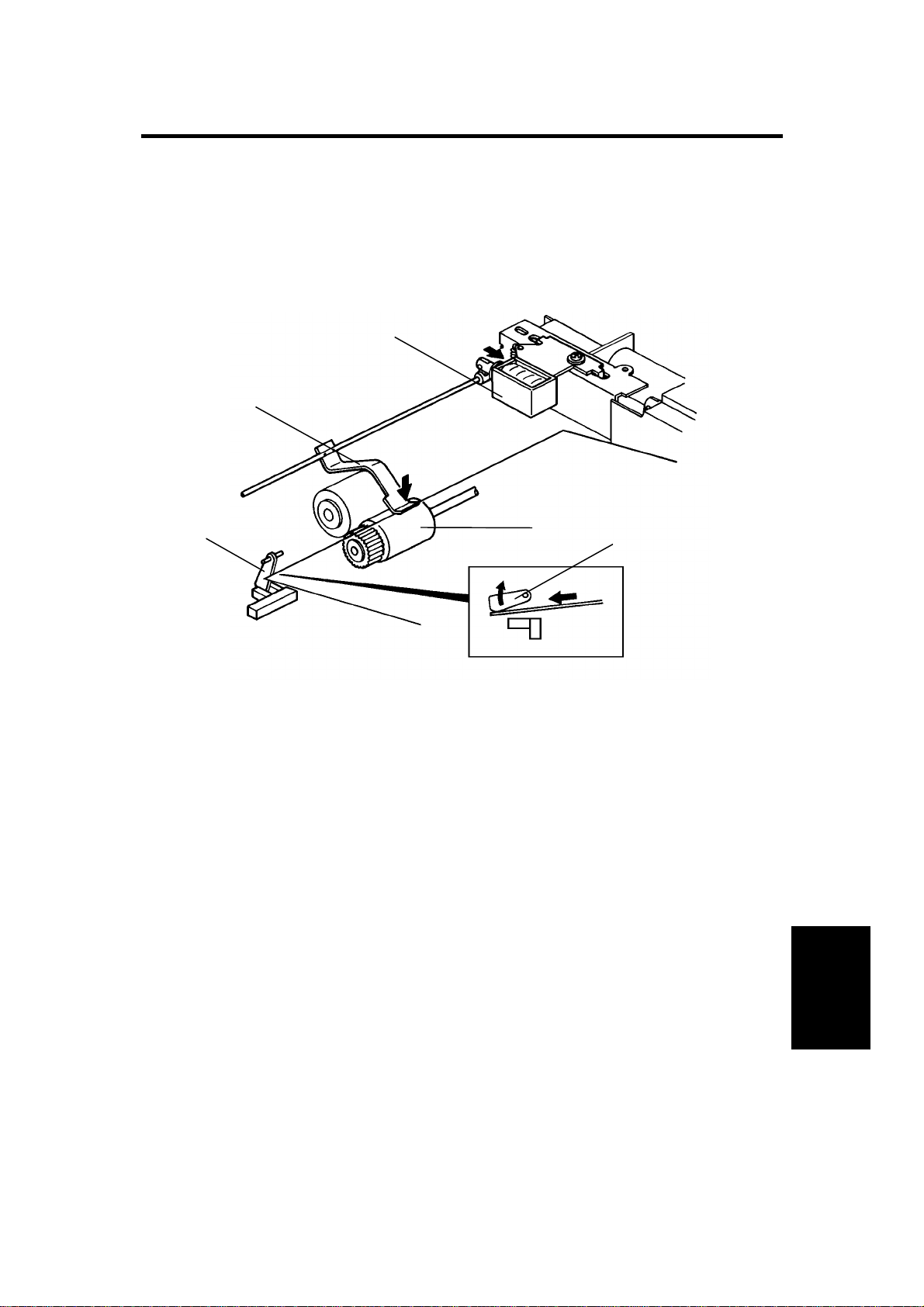

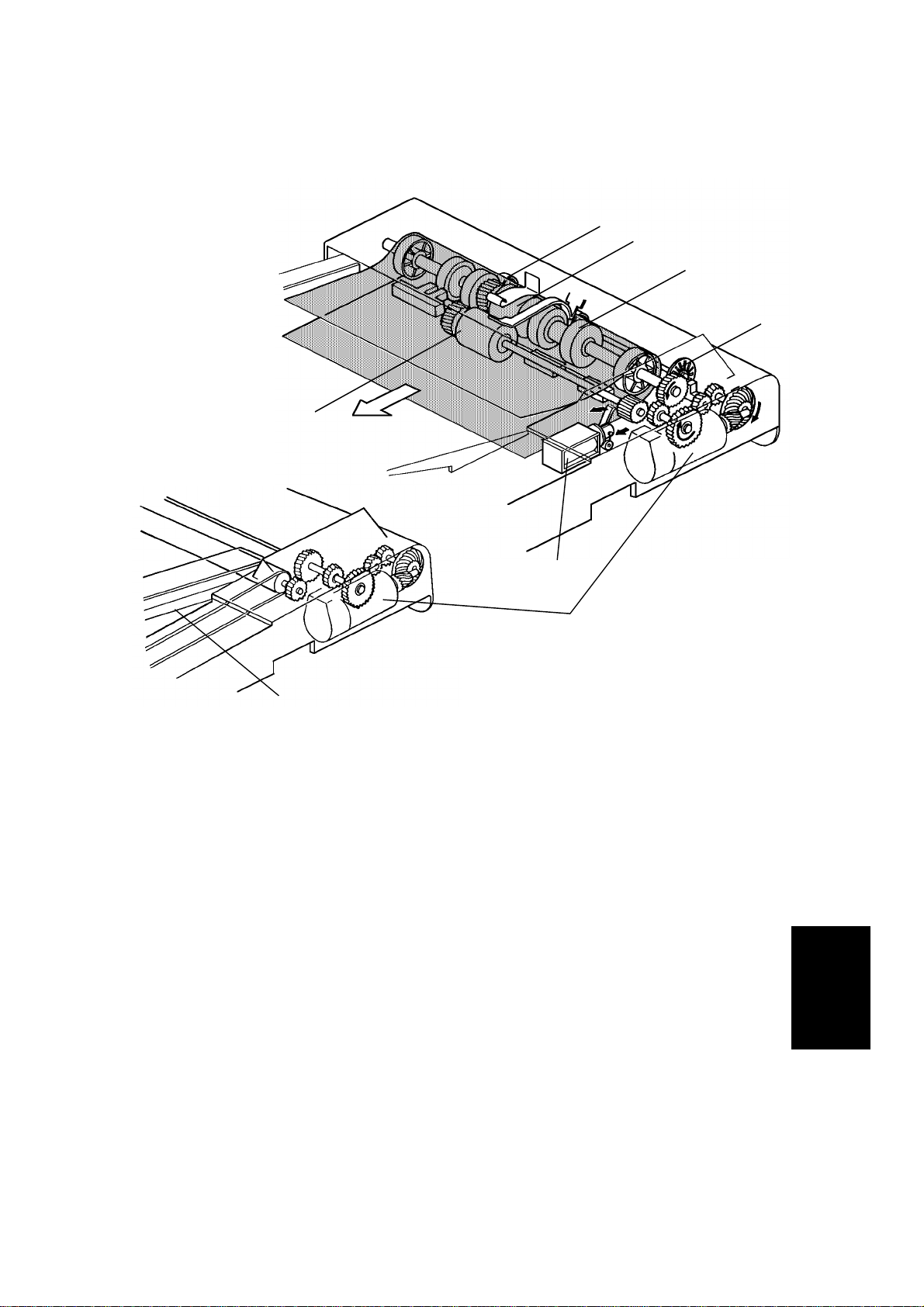

2.1.3 Original Feed-in Mechanism

[E]

[C]

[D]

[H]

[B]

[G]

[A]

[F]

The belt drive motor [A] drives th e pick- u p rolle r [B] , th e fe ed roller [C], the

pull out roller [D], the relay roller [E], and tra nsp ort belt [F] via a feed clutch

and a gear train.

The pick-up solenoid and feed-i n [G ] solenoids are energized 100

milliseconds after the Start key is pressed. Then 200 milliseconds after the

solenoids are energized, the belt drive motor starts turning. The pulse

generator disc [H] always turns when the belt drive motor is on.

2,088 encoder pulses of the belt drive motor after the original’s leading edge

passes the registration sensor, the relay rollers and the transport belt stop

turning.

Feeder

Document

11

Page 13

DETAILED SECTION DESCRIPTION 1 February 1994

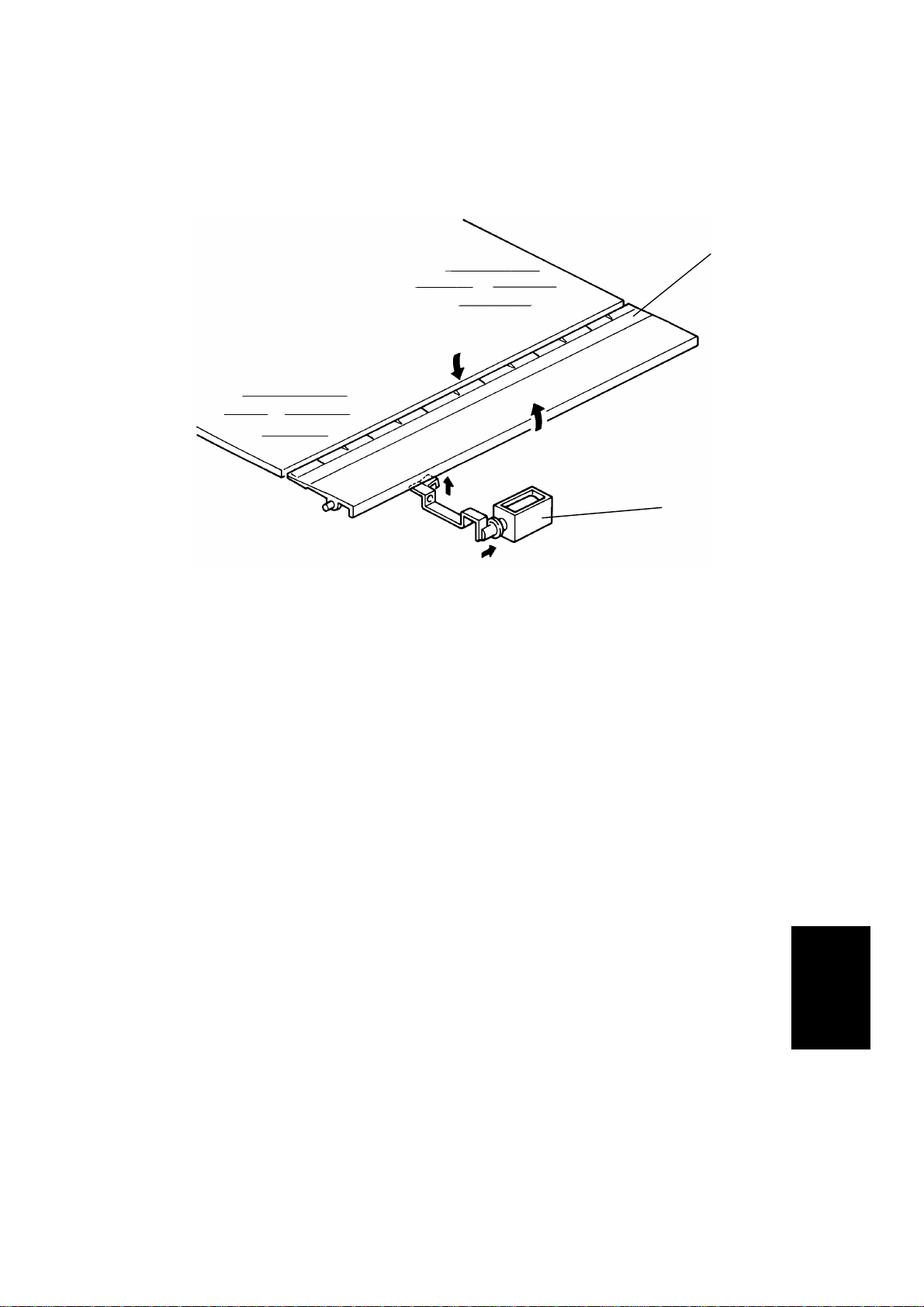

2.1.4 Original Size Detection

[C]

[B]

[A]

The DF determines original size (both width and length) through the use of

the original width sensor [A, rear of DF], registration sensor [A, center of DF],

and pulse generator sensor [B]. The original’s length is calculated by

counting the number of pulses from the pulse generator [C] while the

registration sensor is on.

Original size detection is necessary for the feed-in/feed-out timing of the DF.

12

Page 14

1 February 1994 DETAILED SECTION DESCRIPTION

2.1.5 Original Stopping Mechanism

[A]

[B]

- Original Stopper The original stopper [A] is used to align the edge of the original with the right

original scale when the thick original mode is selected.

When the thin original mode is selected, the original stopper solenoid [B] is

energized 200 milliseconds afrter the original’s leading edge passes the

registration sensor and thus the original stopper is held down until the original

is stopped on the exposure glass.

This is to prevent damaging the original’s leading edge against the original

stopper.

NOTE: a) Before the original stopper moves down to feed out the original

from the exposure glass, the be lt dr ive motor reverses, pauses

slightly, and then turns forward. This is to prevent the original’s

leading edge from being caught between the original stopper and

the exposure glass.

b) The speed of the belt drive m otor drops to 1,300 rpm f r om 2,500

rpm 1,812 pulses after the original’s leading edge passes the

registration sensor. This makes it easier for the mechanism to

stop the original at the correct position on th e exp osur e glass.

Feeder

Document

13

Page 15

DETAILED SECTION DESCRIPTION 1 February 1994

[A]

- Original Select Switch This document feeder has two dif fe r en t ways of st op pin g orig inal at the

correct position on the exposur e gla ss. The y ar e calle d th e "thin original

mode" and the "thick orig ingal mode". The mode used is determined by the

original select switch [A].

1. Thin Original Mode

The original is stopped at the correct position on the exposure glass based

on encoder pulse count. The belt dr ive m ot or sto ps 2, 088 encoder pulses

after the original’s reading edge passes the registration sensor at the

one-sided original mode. When the original is inverted in the inverter section,

the belt drive motor stops 422 encoder pulses after the original’s trailing edge

passes the feed-out sensor. (Exact timing depends on registration

adjustment.) Thin original mode is selected at the factory.

2. Thick Original Mode

When the thick original mode is selected, the original is aligned against the

original stopper. The belt drive motor stays on 21 encoder pulses longer than

when in the thin original mode. When the original is inverted, the belt drive

motor continues to reverse for 52 encoder pulses longer than when in the thin

original mode, and then turns forward for 188 encoder pulses. This forces the

original against the original stopper and th us aligns the edge of the original

with the original stopper.

NOTE: The thick original mode should be used when the customer requires

more correct leading edge registration adjustment and/or complains

of skewed copies. The thin original mode is to prevent the thin

original’s from being bent since they do not have great stiffness.

14

Page 16

1 February 1994 DETAILED SECTION DESCRIPTION

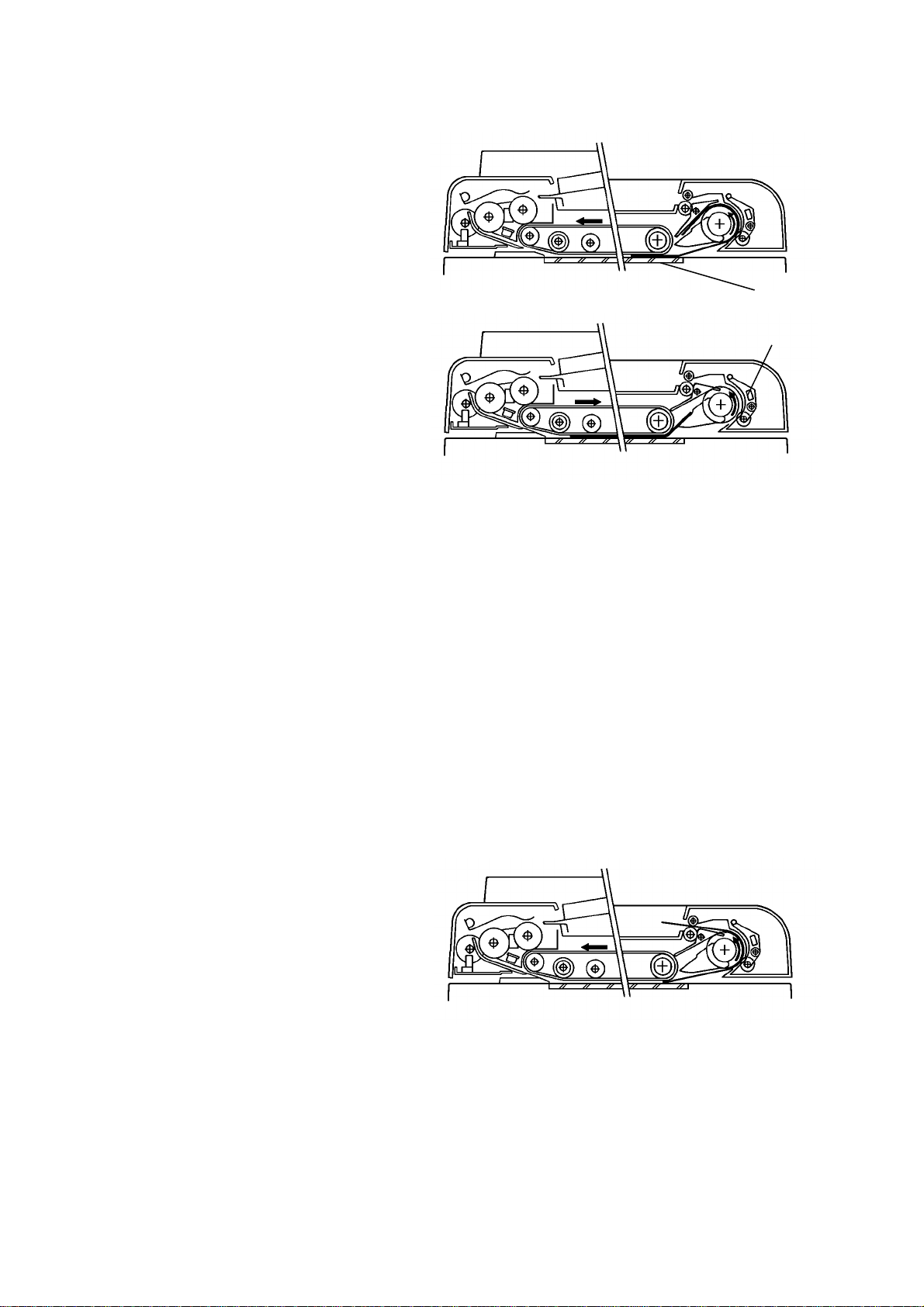

2.1.6 Original Inversion Mechanism

[D]

[C]

The two sided originals are

inverted in the feed-out unit.

1) When the Start key is

pressed, the two sided original

is fed into the feed-in un it,

passing over the DF

registration sensor [A]. The

feed-out motor [B] and the

inverter solenoid [C] turn on

200 milliseconds after the

original’s leading edge passes

the registration sensor. When

the inverter solenoid turns on,

the inverter pawls [D] rotate

counterclockwise.

[B]

[D]

[A]

Feeder

Document

15

Page 17

DETAILED SECTION DESCRIPTION 1 February 1994

2) The original is passes over the

exposure glass [A] and feeds

into the feed-out unit.

[A]

3) The original is directed onto

the exposure glass again by

the inverter pawls. The belt

drive motor now reverses 140

milliseconds after the feed out

sensor [B] turns on. The

transport belt then moves the

original toward the original

stopper.

When the original leading

edge reaches the original

stopper, the belt drive motor

stops. At the same time, the

feed-out motor and the

inverter solenoid turn off.

4) After the reverse side of the

original is exposed, the belt

drive motor, the feed-out

motor, and the inver te r

solenoid turn on, and the

original is fed into the inverter

section. (This is the same as

step 2 above.)

[B]

5) The original is fed onto the

exposure glass again as in

step 3 above. The front side of

the original is then copied.

6) After the front side of the

original has been exposed, the

original is fed out from the DF.

16

Page 18

1 February 1994 DETAILED SECTION DESCRIPTION

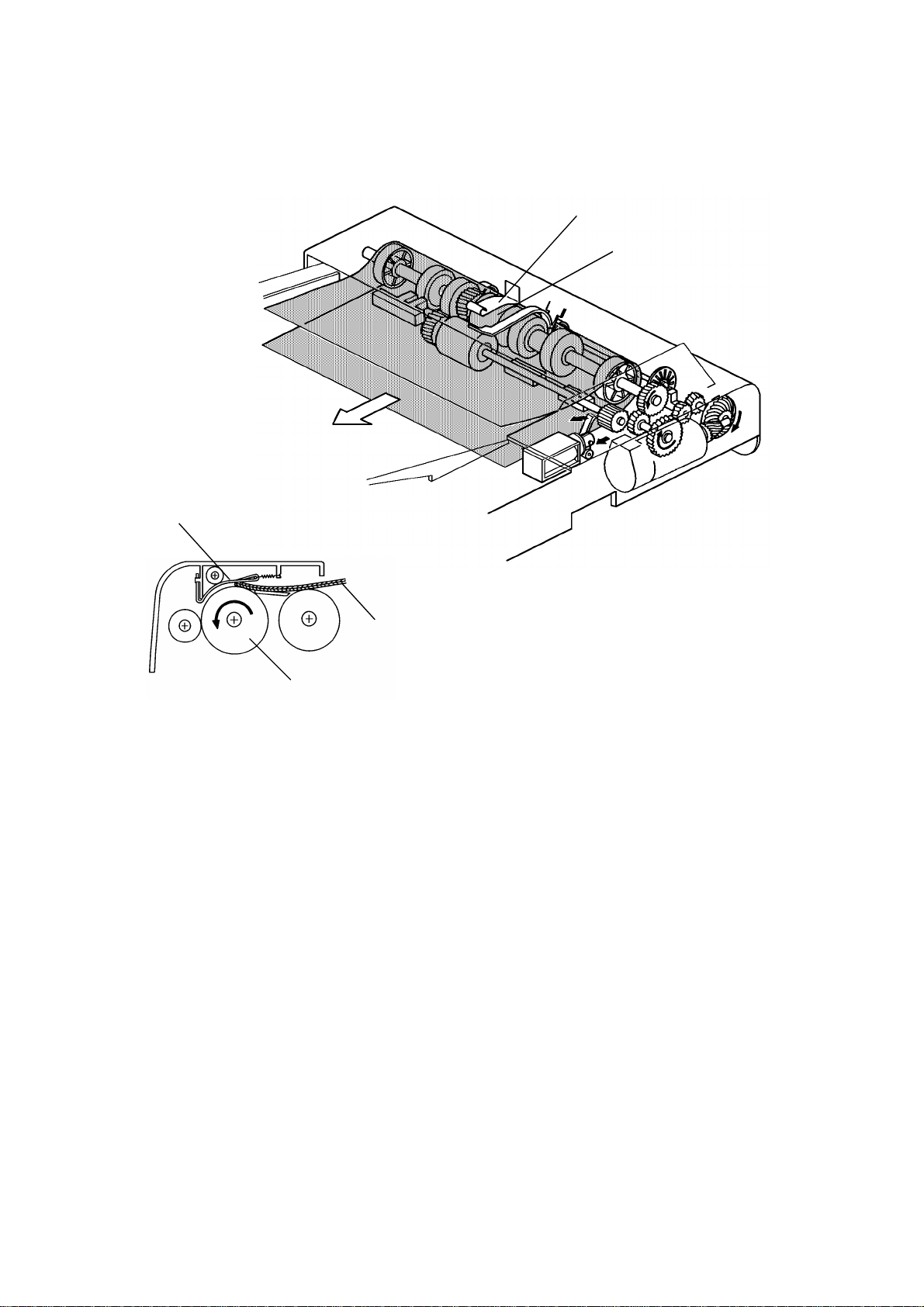

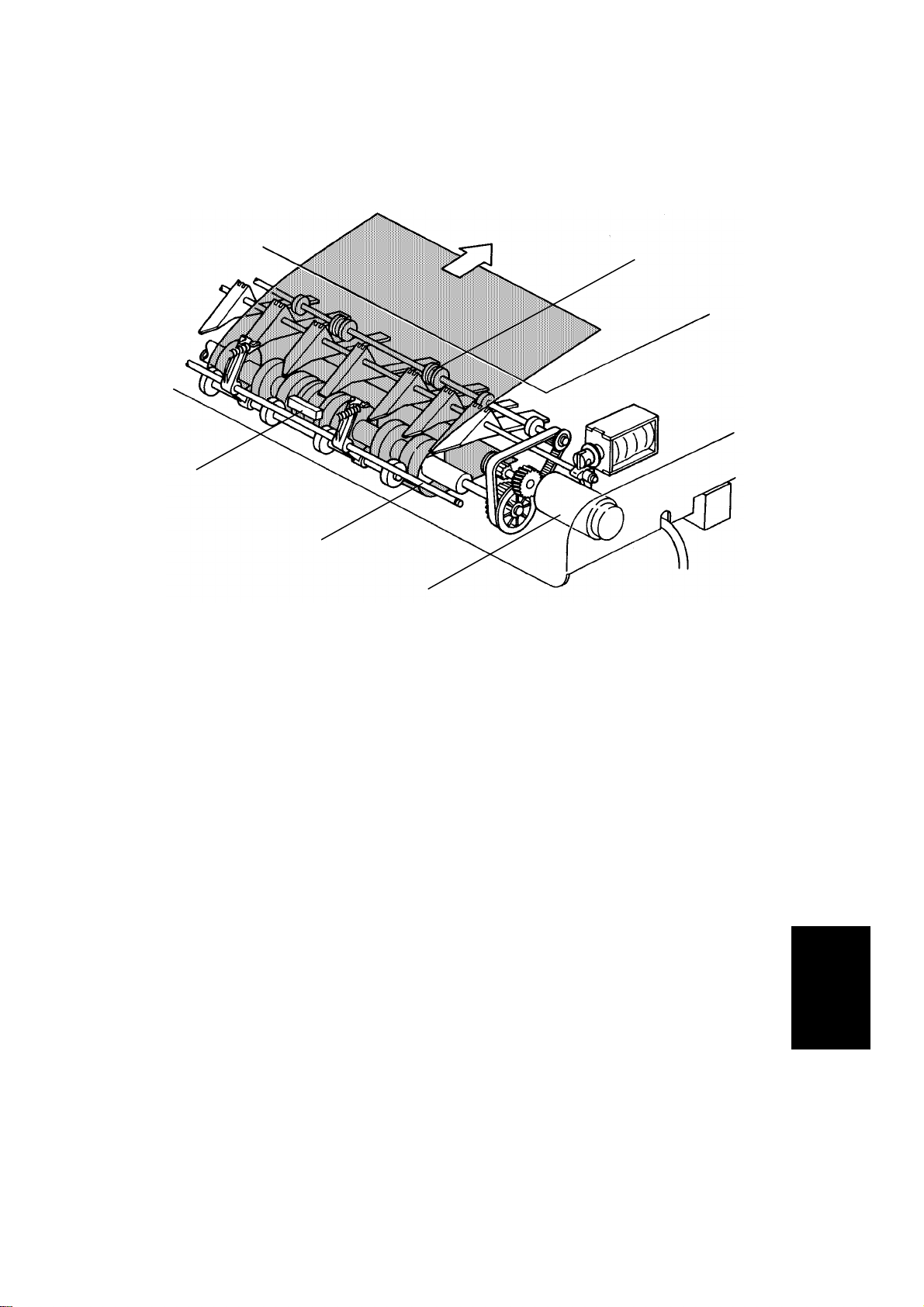

2.1.7 Original Feed-out Mechanism

[A]

[D]

[C]

[B]

The exit rollers [A] are driven by inverter motor [B]. When the document

feeder receives the feed out signal from the copier, the transport belt and the

exit rollers start turning simultaneously. The transport belt carries the original

to the inverter rollers [C] and the exit rollers take over the original feed-out.

When the original’s trailing edge passes the feed-out sensor [D], the feed-out

motor drops to half of its normal speed for 220 milliseconds and then stops.

The lower speed prevents uneve n sta cking of originals. For double letter size

originals, the feed-out motor speed does not change due to the length of the

originals.

17

Feeder

Document

Page 19

DETAILED SECTION DESCRIPTION 1 February 1994

2.1.8 Belt Drive Motor Circuit

DF Main Board (PCB 1)

CPU

Speed

Data

ON/OFF

Forward/

Reverse

Driver

IC

PWM

Driver

Circuit

+5V

Phase A

Phase B

CN102-1

CN102-2

CN103-1

CN103-2

CN103-3

CN103-4

Belt Drive

Motor

Encoder

A dc servomotor is used as the belt drive motor. The driver IC controls the

speed of the belt drive motor. The CPU sends the speed data (programmed)

to the driver IC. The driver IC sends the pulse-width -mod ulatio n (PWM)

signal to the driver circuit, which sends the motor drive pulses.

An encoder in the servomotor ha s tw o m agne tic sen s ors that generate two

pulse signals (phase A and B). The drive r IC mo nit or s th e be lt speed and

direction by these pulse signals an d use s t his data to regulate the motor’s

speed.

18

Page 20

1 February 1994 DETAILED SECTION DESCRIPTION

2.1.9 Feed-out Motor Circuit

DF Main Board (PCB 1)

CN104-A2

CPU

High/Low

ON/OFF

Driver

IC

AC Feedback

Voltage

Regulation

Motor

Drive

Circuit

CN104-A15

CN104-B8

CN104-A12

FG

Feed-out

Motor

The DF CPU sends the speed data (high or low) to the driver IC and the

motor drive circuit. The moto r dr ive cir cuit cre at es th e PW M signal and sends

the motor drive pulses to the feed-out motor.

The frequency generator of the feed-out motor makes a very low voltage ac

current which is fed back to the driver IC. The driver IC monitors the

frequency of this ac current and based on the frequency it regulates the

motor speed.

19

Feeder

Document

Page 21

DETAILED SECTION DESCRIPTION 1 February 1994

2.1.10 Input and Output Circuits

Original Set Sensor

P

S

Pulse Generator Sensor

P

S

Registration Sensor

P

S

Original Width Sensor

P

S

Feed-out Sensor

P

S

Original Select SW

CN104-B1

CN104-B9

CN104-B15

CN104-B2

CN104-A9

CN104-B17

CN104-B11

CN104-B16

CN104-A11

CN104-A1

CN104-B10

CN104-A16

DF Main Board (PCB1)

+5V

[ 12]

+5V

[0-12]

[ 5]

[ 5]

+5V

[ 5]

CPU

[ 12]

+24V

[ 24]

+24V

[ 24]

+24V

[0-24]

[0-24]

[0-24]

CN104-A10

CN104-A17

CN104-B6

CN104-A3

CN104-A6

CN104-B14

CN104-B5

CN104-A13

Insert Original

CN104-B12

Auto Feed

CN104-A4

Misfeed

Lift SW (SW1)

Pick-up

SOL

Inverter

SOL

Indicator Panel

P: Photoreceiver

S: Schmitt Trigger Circuit

Feed Out

Motor

[ 5]

[ 24]

GND

[ 24]

[ 24]

Belt Drive

Motor

Copier IPU Board

Original Position

Sensor

CN125-1

CN125-2

CN125-3

[5] Vcc

[ 5] Position Sensor

GND

The above devices are directly contro lled and monitored by the CPU. The

solenoids, motors and indicat or pa ne l are energized with +24 volts. The

sensors and switches are energized with +12 volts or +5 volts.

To energize a solenoid or indicator, the CPU drops the connected trigger line

from +24 volts to LOW. The CPU monitors the input lines of the sensors and

switch to determine when they are activated.

20

Page 22

1 February 1994 DETAILED SECTION DESCRIPTION

2.2 LIFT MECHANISM

[A]

[C]

[B]

[D]

[A]

[F]

[E]

When the document feeder is opened, the lift springs [D] provide enough

force to ensure that the document feeder does not fall onto the exposure

glass. When the document feeder is closed, points [A], [B], and [C] are

aligned and no such force is provided to the document feeder.

[C]

[B]

The lift switch is actuated when the document feeder is closed. The copier

then shifts to the document feeder mode. The lift switch also serves as the

reset switch for document feeder misfeeds.

When a book or thick (maximum thickness 60 mm) original is copied, the DF

acts as a cover for the original as shown in the figure [E]. The lift switch is

turned off during this condition, so the DF does not function. The tension of

spring [F] returns the DF to the normal condition after copying a thick original.

21

Feeder

Document

Page 23

DETAILED SECTION DESCRIPTION 1 February 1994

2.3 ORIGINAL MISFEED SENSING

The copier CPU lights the original misfeed indicator if the previous original

remains on the exposure glass after manual copying an d DF feed is

attempted. When the DF is lifted and the previous original is removed, DF

copying is permitted.

The registration sensor and the feed-out sensor are used for misfeed checks.

The functions of the two sensors are as follows:

1. One-sided original

Registration Sensor

ON check (685 ms)

Feed-out Sensor

OFF check (1,450 ms)

ON check (1,250 ms)

Belt Drive Motor

Feed-out Motor

OFF check (1,250 ms)

If the registration sensor is not actuated within 685 milliseconds after the belt

drive motor starts turning, the Original Misfeed indicator lights (ON check).

If the registration sensor does not turn off within 1,450 milliseconds, the CPU

determines that there has been an original misfeed (OFF check). The

Original Misfeed indicator also lights if the feed-out sensor is not actuated

within 1,250 milliseconds after the belt drive motor starts turning forward (ON

check), or if the feed-out sensor does not turn off within 1,250 milliseconds

after the feed-out sensor turns on (OFF check).

22

Page 24

1 February 1994 DETAILED SECTION DESCRIPTION

2. Two-sided original

Registration

Sensor

Feed-out

Sensor

ON check (685 ms)

OFF check (1,250 ms)

ON check (1,250 ms)

OFF check (1,390 ms)

Belt Drive Motor

Feed-out Motor

Forward

Reverse

The Original Misfeed indicator lights if the registration sensor is not actuated

within 685 milliseconds after the belt drive motor starts turning (ON check), or

if the registration sensor does not turn off within 1,250 milliseconds after the

feed-out motor starts turning (OFF check). If the feed-out sensor is not

actuated within 1,250 milliseconds after the resistration sensor turns off, the

Original Misfeed indicator lights (ON check). The Original Misfeed indicator

also lights if the feed-out sensor does not turn off within 1,390 milliseconds

after the feed-out sensor turns on (OFF check).

The feed-out ON/OFF check is same as for one-sided originals.

23

Feeder

Document

Page 25

Page 26

1. DUMMY

2.

Feeder

Document

Page 27

INSTALLATION 1 February 1994

3. INSTALLATION

3.1 ACCESSORY CHECK

1. Installation Procedure (115 V version only)...........1 pc

2. NECR (115 V version only) ...................................1 pc

3. Original Table ........................................................1 pc

4. Original Stopper.....................................................1 pc

5. DF Supporting Bracket ..........................................1 pc

6. Stopper Bracket.....................................................1 pc

7. Original Stopper Solenoid Assembly.....................1 pc

8. Front Scale Hinge..................................................1 pc

9. Rear Scale Hinge ..................................................1 pc

10. Scale Holder..........................................................1 pc

11. Scale Sheet...........................................................1 pc

12. Installation Screws.................................................15 pcs (total)

Pan Head Screw M5 x 10 ....................................2 pcs

Pan Head Screw M4 x 5 ......................................7 pcs

Pan Head Screw M4 x 6 (Gold: 2, Silver: 1)........3 pcs

Sunken Head Screw M3 x 5.................................1 pc

Philips Screw with Flat Washer M4 x 5................2 pcs

13. Toothed Washer....................................................5 pcs

14. Document Set Decal..............................................1 pc

15. Test Chart (A4)......................................................1 pc

16. Lift Switch Actuator................................................1 pc

17. APS Actuator.........................................................1 pc

18. Envelope for NECR (115 V version only)..............1 pc

19. DF Securing Retainer............................................1 pc

24

Page 28

1 February 1994 INSTALLATION

3.2 INSTALLATION PROCEDURE

[C]

[B]

[D]

[A]

[G]

[E]

[F]

[H]

[I]

1. Unplug the power supply cord of the main system [A], then remove the

platen cover if installed [B] (2 screws, 1 connector).

2. Remove the upper [C] and lower [D] rear covers (6 screws).

3. Remove the front [E] and right [F] scale screw covers.

4. Remove the front [G] and right [H] original scales (2 screws each).

5. Remove the exposure glass [I] as shown in the figure.

25

Feeder

Document

Page 29

INSTALLATION 1 February 1994

[A]

[B]

[C]

[D]

6. Peel off backing and stick the scale sheet [A] on the scale bracket as

shown in the figure.

7. Move the 1st scanner all the way to the left, and connect the original

stopper solenoid connector [B] to the main machine.

8. Install the original stopper solenoid [C] to the scale bracket as shown in

the figure (2 M4 x 5 screws).

9. Secure the rear scale hinge [D] as shown in the figure (1 M4 x 5 screw).

NOTE: Make sure the rear scale hinge leg is installed under the scale

bracket.

26

Page 30

1 February 1994 INSTALLATION

[B]

[C]

[A]

10. Attach the scale holder [A] under the front scale hinge [B], and set the

original stopper [C] in place as shown in the fig ure.

11. Set the original stopper to the rear scale hinge, and secure the front scale

hinge as in the figure (1 M3 x 5 sunken head screw).

NOTE: Make sure the front scale hinge leg is installed under the scale

bracket.

12. Move the 1st scanner back to its ho me po sitio n.

13. Reinstall the exposure glass.

Feeder

Document

27

Page 31

INSTALLATION 1 February 1994

[B]

[C]

[A]

[D]

14. Check and adjust the original stopper.

Adjusting standard:

a) The top of the original stopper [A] must be 1.5 to 3.0 mm higher than

the exposure glass [B]. If not, adjust the solenoid stroke by moving the

two screws [C].

b) Press down the original stop pe r [A] and conf ir m tha t th e to p of t he

original stopper is 0.5 to 2.5 mm lower than the exposure glass [D].

15. Reinstall the following parts:

a) Front original scale (2 M3 screws).

b) Front screw covers.

28

Page 32

1 February 1994 INSTALLATION

[H]

[C]

[B]

[G]

[A]

[F]

[D]

[E]

16. Remove the strip of tape an d th e pla stic ba g fr o m the DF harne ss.

17. Install the DF supporting bracket [A] (2 M5 x 10 screws, 2 toothed

washers).

NOTE: There are three holes on both sides of the DF supporting bracket.

Use the center holes for standard installation.

18. Install the DF unit [B] on the DF supporting bracket (2 M4 x 5 screws with

flat washer, 2 toothed washers).

NOTE: Insert the positioning pins [C] of the DF into the center holes [D]

of the support bracket, then slide the DF to the right.

19. Install the lift switch actuator [E] and the APS actuator [F] (1 M4 x 5 screw

each). Confirm that both actuators enter the slots when the DF is lowered.

20. Remove the shipping collar [G].

21. Lower the DF, and install the DF stopper bracket [H] (2 M4 x 5 screws).

Feeder

Document

29

Page 33

INSTALLATION 1 February 1994

[F]

[E]

[G]

[B]

[A]

[C]

[D]

[H]

22. Connect the harness of the 3P [A ] an d 4P [ B] conn ect or s as sho w n in th e

figure.

23. Mount the harness bracket [C] (2 M4 x 6 gold screws).

24. Secure the DF ground wire [D] to the harness bracket as shown (1 M4 x 6

silver grounding screw and toothed washer).

25. Remove the IPU board cover [E] (3 screws).

26. Secure the fiber cable [F] to th e 3 clamp s , an d con ne ct it to t he I PU bo ard

CN308.

27. Remove the plastic cap [G] from the rear upper cover [H] to make a hole

for the DF harness.

28. Reinstall all the covers.

NOTE: Do not pinch the fiber optics cable when reinstalling the rear upper

cover.

30

Page 34

1 February 1994 INSTALLATION

[B]

[A]

29. Insert the original table [A].

30. Stick the document set decal [B] to the DF.

31. Lift up the DF unit and select the thin mode on the original paper

thickness select switch.

32. Plug in the power supply cord and turn on the copier main switch.

33. Check machine operation and copy quality.

Feeder

Document

31

Page 35

INSTALLATION 1 February 1994

[A]

[D]

[B]

Transport Direction

[C]

Transport Direction

34. Check the original skew [A], the original leading edge registration [B]

(both one-sided and double-sided copies), and the original side edge

registration [C] according to the following step s:

35. DF height adjustment:

1) Using the DF test chart, make a copy in the pla te n mod e ( 8

" x 11"/A4

1/2

width).

2) Confirm that the original select switch is in the thin mode and again

using the test chart, make a copy in the DF mode (8

" x 11"/A4 width).

1/2

3) Compare both copies and confirm that there is no skew between them.

4) If there is skew, adjust the magnet catch positions so that the rubber

pad [D] is in contact with the front original scale (2 screws each), after

removing the DF grip (4 screws).

32

Page 36

1 February 1994 INSTALLATION

36. Original leading edge registration adjustment:

1) Using the DF test chart, make copies in both platen and DF (thin

original) modes.

2) Compare the leading edge registration of both copies, and check that

the difference between the two copies is within 2.5 mm.

3) If the difference is more than 2.5 mm, remove the DF main PCB cover

(1 screw) and adjust VR102 on the DF main PCB un til the leading

edge registration is within spe cifica tio n.

NOTE: Turning VR102 clockwise results in stopping the original later

(moving to the right).

4) Using the DF test chart, make a copy in the DF two sided-original

mode. (Insert the original face down.)

5) Compare the leading edge registration with that of the platen cover

mode copy, and check that the difference between the two copies is

within 3.50 mm.

6) If out of specification, adjust VR103 on the DF main PCB until the

leading edge registration is corre ct.

NOTE: Turning VR103 clockwise results in the original stopping later

(moving to the left).

37. Original side edge registration:

1) Using the DF test chart, make copies in both platen and DF modes.

2) Compare the side edge registration of both copies, and confirm that

the difference between the tw o cop ies is wit hin 0 ± 2 mm (in two-sided

mode 0 ± 3 mm).

3) If it is not, adjust the side edge registration using SP6-6.

NOTE: Using SP6-6, the side edge registration can be changed from

–9 to +9 mm, in 0.5 mm steps. Setting the SP6-6 to t he pl us

direction results in the copy image shift i ng to th e lef t an d vice

versa.

38. Confirm the customer’s requests, as the following functions can be

selected if necessary:

1) Each Original Size Detection: SP6-2

2) Sort Priority: SP6- 3 (wh en opt ion al sor t er installed)

3) Odd Number Duplex Copy: SP6-5

Feeder

Document

4) Thick Original Mode: Original Paper Thickness Switch

33

Page 37

SERVICE TABLES 1 February 1994

4. SERVICE TABLES

4.1 TEST POINTS

NUMBER FUNCTION

TP101

TP102

TP103

TP104

TP105

TP106

TP107

Factory use

+5 V

GND

Factory use

+12 V

+24 V

Factory use

4.2 VARIABLE RESISTORS

NUMBER FUNCTION

VR101 Belt drive motor speed adjustment.

VR102

VR103

VR106 Factory use (never adjust this VR).

Original leading edge regist r at ion adju stm e nt

(one-sided thin original mode).

Original leading edge regist r at ion adju stm e nt

(two-sided thin original mode).

4.3 LEDs

NUMBER FUNCTION

LED101

LED102

LED103

LED104

LED105

LED106 Lights when the lift sensor is turned on.

LED107

Lights when the registration sensor is

activated.

Goes out when the original width sensor is

activated.

Goes out when the feed-out sensor is

activated.

Lights when the pulse gene r at or sen s or is

activated.

Lights when the original set sensor is

activated.

Goes out when the original select switch is

turned on (when the thin original mode is

selected).

34

Page 38

1 February 1994 SERVICE TABLES

4.4 DIP SWITCHES

DPS 101

FUNCTION

-1 -2 -3 -4

1 0 0 0 Normal mode

1 0 0 1 One-sided free run: SW101 - ON

0 1 0 1 Two-sided free run: SW101 - ON

0011

Solenoid test: SW101 - solenoids ON

SW102 - solenoids OFF

1101Motor test

1 1 1 1 All indicators ON

0: OFF 1: ON

NOTE: a) To use all functions, the DPS101 must be set to the normal

mode when the main switch is turned on. At this time, the

initial sequence between the copier and the DF will take place.

b) To use all functions except for the solenoid test mode, the lift

switch must be turned on.

c) To use the one and two-sided free run modes, all sensors

must be activated in the normal manner. Therefore, place the

DF in the normal working position (dow n) and place paper on

the original table. Then, turn on SW101 at the rear side of the

DF.

35

Feeder

Document

Page 39

REPLACEMENT AND ADJUSTMENT 1 February 1994

5. REPLACEMENT AND ADJUSTMENT

5.1 FEED-IN UNIT

5.1.1 Transport Belt Replacement

[C]

[H]

[I]

[A]

[D]

[B]

1. Turn off the main switch and remove the grip [A] (4 screws).

2. Remove the DF main PCB cover [B] (1 screw, 1 connector).

3. Open the entrance guide [C] and remove the tra nsport belt assembly [D]

(5 screws).

36

Page 40

1 February 1994 REPLACEMENT AND ADJUSTMENT

[G]

[F]

[E]

4. Remove the 2 tension springs [E] and pull off the transpo r t belt [F].

NOTE: a) When installing the transport belt, make sure the belt lies

between the belt guide space r s [G] .

b) When installing the transport belt assembly [D], make sure the

positioning pin correctly fit s in the DF fram e [H], and hold open

the exit guide [I] to prevent the mylar strip from becoming

damaged.

Feeder

Document

37

Page 41

REPLACEMENT AND ADJUSTMENT 1 February 1994

5.1.2 Feed-in Unit Removal

[B]

[A]

1. Turn off the main switch.

2. Remove the transport belt assembly. (See the Transport Belt

Replacement section.)

3. Remove the belt drive motor cover [A] (4 screws).

4. Remove the feed-in unit [B] (4 screws, 7 connectors).

38

Page 42

1 February 1994 REPLACEMENT AND ADJUSTMENT

5.1.3 Pick-up Roller Replacement

[A]

[B]

[C]

[D]

1. Turn off the main switch.

2. Remove the feed-in unit. (See the Feed-in Unit Removal section.)

3. Remove the lower entrance guide [A] (2 screws).

4. Remove the original set sensor assembly [B] (1 screw), without

disconnecting the connector.

5. Remove the pick-up roller [C] (3 E-rings, 1 bushing, 1 gear).

NOTE: a) Be careful not to loosen the positioning pin [D].

b) When installing the roller, make sure the positioning pin is

correctly inserted in the cut-out of the roller.

c) When installing the gear, make sure the flat side of the gear is

facing away from the roller.

Feeder

Document

39

Page 43

REPLACEMENT AND ADJUSTMENT 1 February 1994

5.1.4 Feed-in Clutch Lubrication

[B]

[A]

1. Turn off the main switch.

[D]

[C]

2. Remove the original set sensor assembly. (See the Pick-up Roller

Replacement section.)

3. Remove the feed-in solenoid lever spring [A].

4. Remove the pick-up roller assembly [B] (2 E-rings, 2 bushings).

5. Disassemble and lubricate the feed clutch [C] (1 E-ring) with Mobil Temp.

78.

NOTE: a) Be careful not to loosen the positioning pin [D].

b) When installing the feed clutch, make sure the positioning pin

is correctly inserted in the cut-out of the clutch.

40

Page 44

1 February 1994 REPLACEMENT AND ADJUSTMENT

5.1.5 Pick-up Solenoid Adjustment

[E]

[C]

[D]

[B]

[F]

[A]

1. Turn off the main switch.

2. Place several sheets of paper [A] over the exposure glass area.

3. Lower the feed-in unit (see the Feed-in Unit Removal section) without

disconnecting the seven connectors.

4. Turn on the main switch.

NOTE: When the main switch is turned on, the DPS101 [B] setting on

the DF main PCB must be as follows:

1 = ON 3 = OFF

2 = OFF 4 = OFF

This is so that the initial check sequence can take place.

41

Feeder

Document

Page 45

REPLACEMENT AND ADJUSTMENT 1 February 1994

5. Turn off DPS101-1, then turn on DPS101-3 and 4 [B].

6. Loosen the screw fixing the pick-up solenoid [C].

7. Place the 0.15 mm thickn ess gauge [D] between the plu nger and the

solenoid.

NOTE: Two sheets of paper (20 lb/75 g/m2) can be used instead of a

thickness gauge.

8. While holding the gauge, pr ess SW101 [E] on the DF main PCB to

engage all DF solenoids.

9. Keeping a 0.15 mm gap, mo ve th e sole no id slowly un til th e pick- u p leve r

is just touching the pick-up roller.

10. Secure the screw fixing the pick-up solenoid [C].

11. Press SW 102 [F] to turn of f th e sole no ids.

12. Set the DPS101 [B] for normal mode (1 = ON, 2 = OFF, 3 = OFF, 4 =

OFF).

13. Turn off the main switch and rea ssemble the DF.

14. Check the original feed-in operation.

42

Page 46

1 February 1994 REPLACEMENT AND ADJUSTMENT

5.1.6 Feed Roller Replacement

[D]

[C]

[A]

[B]

1. Turn off the main switch.

2. Remove the lower entrance guide. (See the Pick-up Roller Replacement

section.)

3. Loosen the front bracket [A] (2 screws).

4. Release the feed roller shaft [B] from the front bracke t ( 1 E-r in g,

1 bearing).

5. Remove the feed roller [C] (3 E-rings, 1 side roller, 1 pull-out roller).

NOTE: a) Take care not to lose the positioning pins [D].

b) When installing the feed roller, make sure the gear side of the

roller faces the front (see illustration).

c) When installing the side and pull-out rollers, make sure the

positioning pins are correctly inserted in the cut-outs of the

rollers.

Feeder

Document

43

Page 47

REPLACEMENT AND ADJUSTMENT 1 February 1994

5.1.7 Feed-in Solenoid Adjustment

[B]

[C]

[A]

[D]

1. Turn off the main switch.

2. Place several sheets of paper [A] over the exposure glass area.

3. Lower the feed-in unit (see the Feed-in Unit Removal section) without

disconnecting the seven connectors.

4. Check that DPS101 [B] is set for the normal mode (1 = ON, 2 = OFF, 3 =

OFF, 4 = OFF).

5. Turn on the main switch.

6. Turn off DPS101-1, then turn on DPS101-3 and 4 [B].

7. Loosen the 2 screws securing the feed-in solenoid [C].

8. Press SW101 on the DF main PCB (to engage all DF solenoids) and

adjust the position of the solenoid until the gap [D] (see illustration) is

within 1.0 to 2.0 mm.

9. Press SW102 on the DF main PCB to turn off all DF solenoids.

10. Set the DPS101 [B] for normal mode (1 = ON, 2 = OFF, 3 = OFF, 4 =

OFF).

11. Turn off the main switch and rea ssemble the DF.

44

Page 48

1 February 1994 REPLACEMENT AND ADJUSTMENT

5.1.8 Registration Sensor and Original Width Sensor Replacement

[C]

[B]

[A]

[F]

[E]

[G]

[D]

1. Turn off the main switch.

2. Remove the pick-up roller. (See the Pick-up Roller Replacement section.)

3. Remove the sensor holder plate [A] with the 2 sensors (2 screws).

4. Remove the registration sensor [B] and the original width sensor [C] (1

screw, 1 connector each).

NOTE: The registration sensor and the original sensor can be cleaned

as follows:

Open the DF and release the lower guide plate [D] of the feed-in

unit by pushing the lever for misfe d paper removal. Then, clean

the 2 sensors [E] from the cutout portion of the plastic guide plate

[F]. Also, clean the black rubber sea ls [ G] insta lled on th e lowe r

guide plate using a blower br ush.

Feeder

Document

45

Page 49

REPLACEMENT AND ADJUSTMENT 1 February 1994

5.1.9 Friction Belt Replacement

[A]

[B]

[C]

1. Turn off the main switch.

2. Remove the seal cover [A] on top of the DF cover.

3. Remove the friction belt assembly [B] (1 screw).

4. Remove the friction belt [C] (2 springs, 1 pin) .

NOTE: If the seal cover becomes dirty or deformed , repl ace it with a new

one.

46

Page 50

1 February 1994 REPLACEMENT AND ADJUSTMENT

5.1.10 Belt Drive Motor Speed Adjustment

[B]

[A]

[D]

[C]

1. Remove the DF main PCB cover [A] (1 screw), without disconnecting the

connector.

2. Turn on DPS 101-2 and -4.

3. While turning on the lift switch manually, adjust the belt drive motor speed

to within 2,570 to 2,630 rpm using VR101 [B], so that both the Insert

Original indicator [C] and the Auto Feed indicator [D] go out.

47

Feeder

Document

Page 51

REPLACEMENT AND ADJUSTMENT 1 February 1994

NOTE: a) When the Insert Original indicator lights , turn VR101

clockwise to reduce the motor speed.

b) When the Auto Feed indicator lights, turn VR101 counter

clockwise to raise the motor speed.

c) Confirm that both indicators remain off for approximately 5

seconds, in order to steady the motor speed.

d) This procedure must be perfor m e d whe n rep l acin g th e DF

main PCB.

4. Set DPS 101 for normal mode (1 = ON, 2 = OFF, 3 = OFF, 4 = OFF).

48

Page 52

1 February 1994 REPLACEMENT AND ADJUSTMENT

5.2 FEED-OUT UNIT

5.2.1 Feed-out Unit Removal

[A]

[C]

[B]

1. Turn off the main switch.

2. Remove the DF grip [A] (4 screws).

3. Remove the feed-out motor cover [B] (4 screws).

4. Remove the feed-out unit [C] (4 screws, 1 ground wire, 3 connect ors).

Feeder

Document

49

Page 53

REPLACEMENT AND ADJUSTMENT 1 February 1994

5.2.2 Feed-out Sensor Replacement

[A]

[B]

1. Remove the feed-out unit. (See the Feed-out Unit Removal section.)

2. Remove the sensor holder plate [A] with the sensor on (1 screw, 1

connector).

3. Remove the feed-out sensor [B] from the plate (1 screw).

50

Page 54

1 February 1994 REPLACEMENT AND ADJUSTMENT

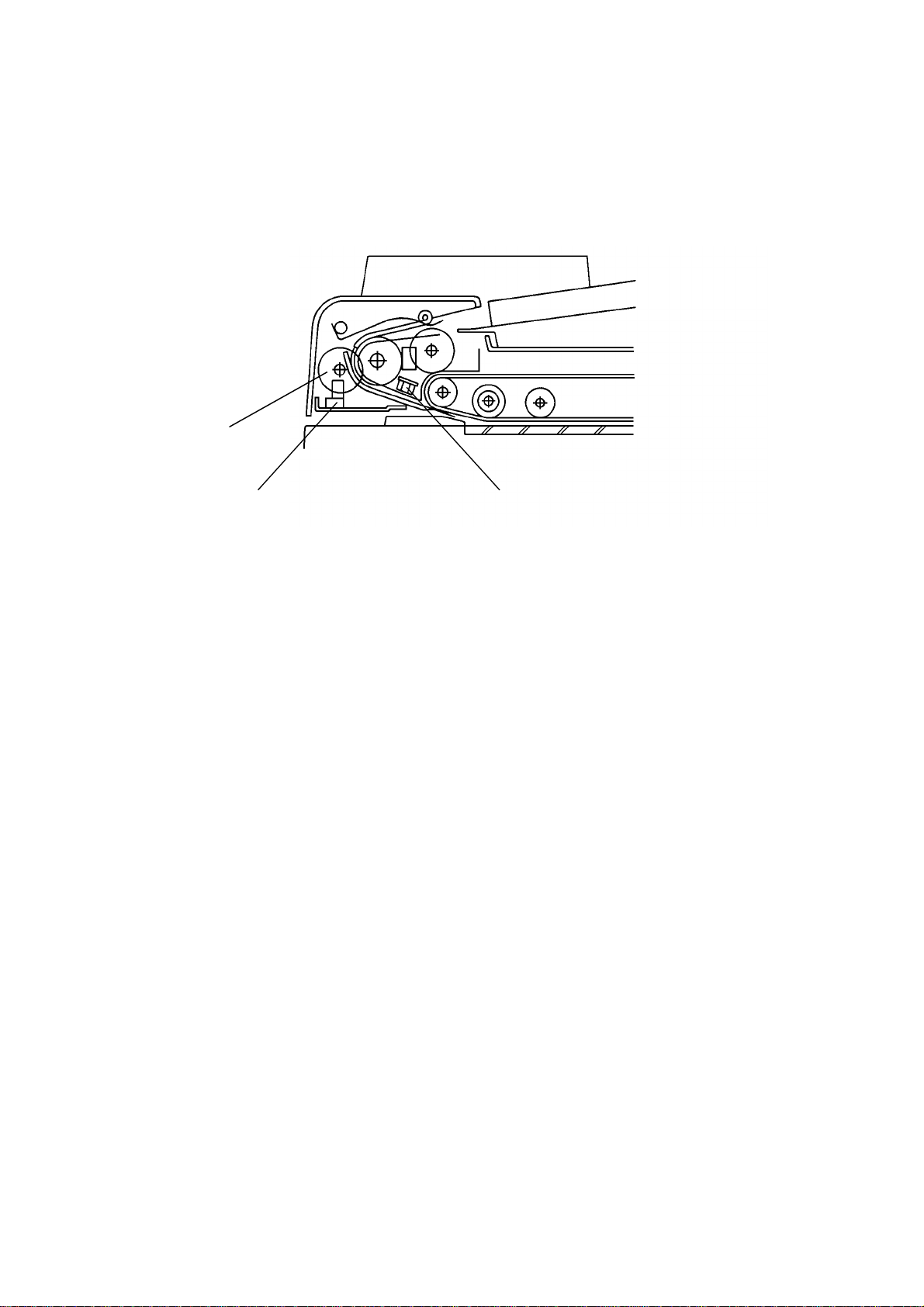

5.2.3 Timing Belt Tension Adjustment

[A]

[B]

1. Turn off the main switch.

[D]

[C]

2. Remove the feed-out unit. (See the Feed-out Unit Removal section.)

3. Unhook the rear spring [A] of the feed-out unit entrance guide.

4. Loosen the 2 screws securing the feed-out motor assembly [B].

5. With a tension gauge, pr ess th e tim in g be lt [C] in the center between the

feed-out roller drive pulley and the inverter roller drive pulley.

6. Adjust the position of the feed-out motor assembly so that the slack of the

timing belt becomes within 0.5 to 2.0 mm [D], when the tension gauge

indicates 100 g.

Feeder

Document

51

Page 55

REPLACEMENT AND ADJUSTMENT 1 February 1994

5.2.4 Inverter Solenoid Adjustment

[B]

[A]

[D]

[F]

[C]

[E]

1. Turn off the main switch.

2. Place several sheets of paper [A] over the exposure glass area.

3. Lower the feed-out unit (see the Feed-out Unit Removal section) without

disconnecting the three connectors.

4. Turn on the main switch.

NOTE: When the main switch is turned on, the DPS101 [B] setting on

the DF main PCB must be as follows: 1 = ON, 2 = OFF, 3 = O FF,

4 = OFF.

5. Turn off DPS101-1, then turn on DPS101-3 and 4 [B].

6. Loosen the screw securing the inverter solenoid [C].

7. Press SW101 [D] on the DF main PCB (to engage all DF solenoids), and

adjust the position of the solenoid until the gap [E] (see illustration) is

within 1.0 to 2.0 mm.

8. Press SW102 [F] on the DF main PCB to turn off all DF solenoids.

9. Set the DPS101 [B] for normal mode (1 = ON, 2 = OFF, 3 = OFF, 4 =

OFF).

10. Turn off the main switch and rea ssemble the DF.

52

Page 56

1 February 1994 REPLACEMENT AND ADJUSTMENT

5.2.5 Feed-out Motor Unit and Inverter Roller Replacement

[A]

[D]

[E]

[C]

[F]

[B]

[G]

CAUTION: Be careful not to mix up the springs when removing the

inverter guide plate. Be careful not to loose the positioning

pin [A].

1. Remove the feed out unit. (See the Feed-out Unit Removal section.)

2. Remove the inverter guide plate [B] (1 screw, 2 springs).

3. Remove the inverter solenoid with the bracket on [C] (1 screw).

4. Remove the feed-out motor unit [D] (2 screws), and the timing bel t [E].

5. Remove the inverter roller pulley [F] (1 E-ring).

6. Remove the inverter roller [G] (1 E-ring, 2 bushing).

NOTE: After reinstalling the feed-out motor unit, perform the following

adjustment procedur es.

a) Timing belt tension adjustment.

b) Inverter solenoid adjust m ent.

Feeder

Document

53

Page 57

REPLACEMENT AND ADJUSTMENT 1 February 1994

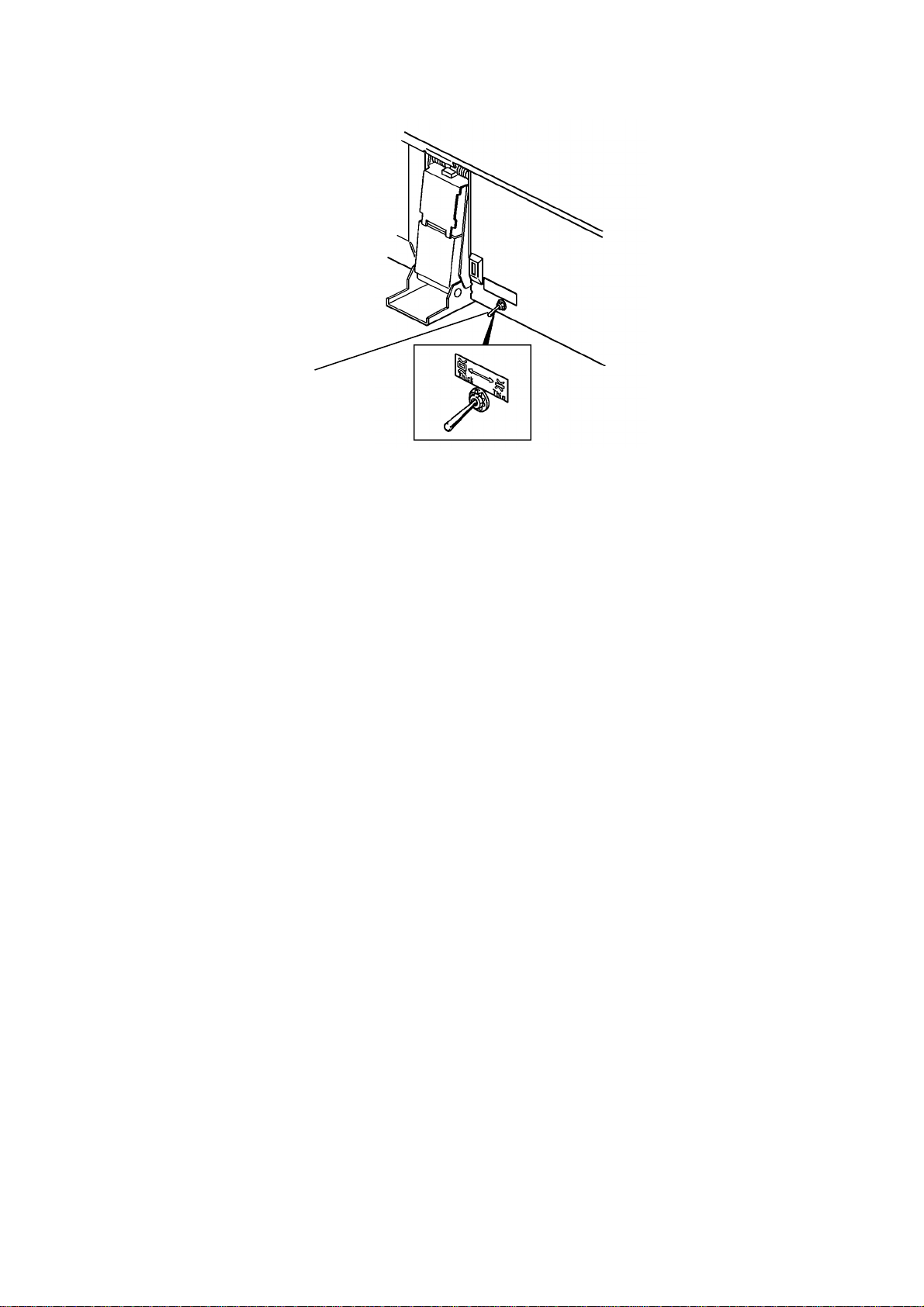

5.2.6 DF Leading Edge Registration Adjustment

[C]

[B]

[A]

1. Using the DF test chart, make a copy in the pla te n cove r mode (A 4 widt h) .

2. Confirm that the original select switch [A] is in the thin mode and again

using the test chart, make a copy in the DF mode (A4 width).

3. Compare the leading edge registration of both copies, and check that the

difference between the two copies is within 2.5 mm.

54

Page 58

1 February 1994 REPLACEMENT AND ADJUSTMENT

4. If the difference is more than 2.5 mm, remove the DF main PCB cover [B]

(1 screw, 1 connector) and adjust VR102 on the DF main PCB [C] until

the leading edge registration is within specification.

NOTE: Turning VR102 clockwise results in stopping the original later

(moving to the right).

5. Using the DF test chart, make a copy in the DF two sided-original mode.

(Insert the original face down.)

6. Compare the leading edge registration with that of the platen cover mode

copy, and check that the difference between the two copies is within 3.5

mm.

7. If out of specification, adjust VR103 on the DF main PCB until the leading

edge registration is correct.

NOTE: Turning VR103 clockwise results in the original stopping later

(moving to the left).

NOTE: This procedure must be performed when r epl acin g th e DF ma in PCB .

55

Feeder

Document

Page 59

REPLACEMENT AND ADJUSTMENT 1 February 1994

5.2.7 DF Side Edge Registration Adjustment

[C]

[B]

[E]

[D]

[A]

[D]

[E]

1. First check the position of the original path by setting the DF test chart on

the original table.

2. Press the Start key, then press the Clear/Stop key shortly after the DF

test chart is fed.

3. Open the DF carefully, and check the dist an ce be twe en the fr on t side

edge of the DF test chart and the front original scale. If it is 2.0 mm or

more, go to step 5.

4. If the distance is less than 2.0 mm, move the DF supporting bracket [A] to

the left, and then install the DF, the lift switch actuator [B], and the APS

actuator [C] using holes [D].

NOTE: a) If the distance is less, the original might hit the front original

scale, resulting in original misfeeds or skewing.

b) Moving the DF supporting bracke t on e set of ho les at a time

gives a 1.5 mm difference horizontally relative to the position

of the original path.

56

Page 60

1 February 1994 REPLACEMENT AND ADJUSTMENT

5. To adjust the side edge registration, make a copy in platen mode using

the DF test chart.

6. Again using the test chart, make a copy in DF mode.

7. Compare the side edge registration of both copies, and confirm that the

difference between the two copies is within 2.0 mm (in two-sided original

mode, within 3.0 mm).

8. If it is out of specification, adjust the side edge registration using SP

Mode No. 6-6. (For SP Mode access, see the SP Mode list.)

NOTE Using SP Mode No. 6-6, the side edge registration can be

changed from –9 to +9 mm, in 0.5 mm steps. Setting the SP

Mode No. 6-6 to the plus direction results in the copy image

shifting to the left of the copy and vice versa.

9. If the difference is more than 9 mm, move the DF supporting bracket [A]

to the right, then install th e DF, th e lift swit ch act ua to r [B] , an d the APS

actuator [C] using the holes [E]. Then, repeat steps 7 and 8.

57

Feeder

Document

Loading...

Loading...