Page 1

Technical Bulletin No. RTB-003

SUBJECT: F410 RDH Finisher system duplex method change

(manual corrections)

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

For the F410, the alternate paper feed system is disabled.

The following is the new method the F410 uses for copying 1 sided originals to 2 sided

copies.

Please delete pages 14, 15, and 16 of the RDH section and insert the following

explanation.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F410

DATE: SEP. 15. ’93

PAGE: 1 of 2

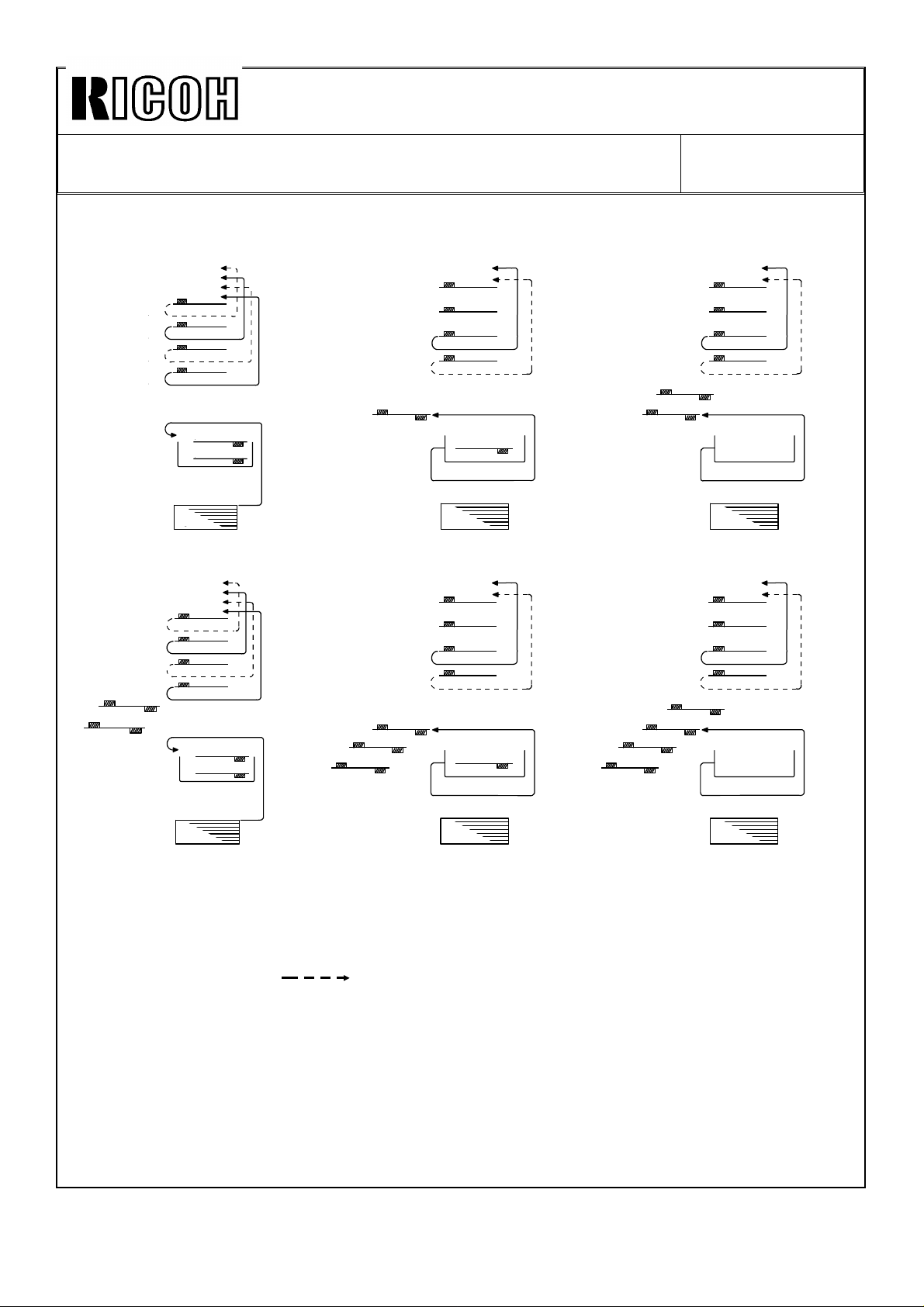

1 SIDED ORIGINAL TO 2 SIDED COPY MODE

When making two-sided copies, first of all, the even pages of the originals placed on the

RDH are copied to the paper from the paper tray. They are stored in the duplex tray. Then

the originals are recirculated, and the odd pages of the originals are copied to the sheets

stored in the duplex tray.

When making two or more sets of copies, the following copy sets are made in the same

way as the first set copy.

Therefore, the original recirculates twice for each copy set.

-Operation- (For example)

Two sets of two-sided copies are made from four one-sided originals.

1) When the start key is pressed, the 4th and 2nd originals are scanned then these

copies are stacked in the duplex tray. The 3rd and 1st originals have only

passed over the exposure glass [Fig. 1].

2) Soon after the 1st recirculation is completed, the second recirculation starts. The

4th originals just passes the exposure glass then the 3rd original is scanned.

This image is copied onto the copy which has been fed from the duplex tray and

is then fed out onto the finisher [Fig. 2].

3) The 2nd original just passes the exposure glass and then the 1st original is

scanned. The copy from the duplex tray is fed for copying the 1st original and

then fed out onto the finisher. At this moment, the duplex tray becomes empty

[Fig. 3].

4) The following steps repeat steps 1) to 3). [Fig. 4] to [Fig. 6].

Page 2

Technical Bulletin No. RTB-003

2 43’

4’3’1’

2’

②

③

SUBJECT: F410 RDH Finisher system duplex method change

(manual corrections)

<RDH>

1

2

3

4

<Duplex>

2

4

<Paper tray>

Fig 1

3’

4’

1’

2’

2’

3’

4

2

Fig 2

❶

①

❷

DATE: SEP. 15. ’93

PAGE: 2 of 2

1’

Fig 3

❸

❹

❸

④

1’

3’

2

4

②

1’

3’

④

❹

❸

④

2

4

②

1’

3’

❸

❶

❷

❶

②

④

2

4

Fig 4 Fig 5 Fig 6

1 2 3 4: 1st recirculated

1’ 2’ 3’ 4’: 2nd recirculated

① ② ③ ④: 3rd recirculated

❶ ❷ ❸ ❹: 4th recirculated

: Without exposing

(for RDH)

Page 3

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 9 of 13

Page 6-19 1.15

• Incorrect

1.15 DUAL JOB FEEDER

Definition: [Level:B]

Encoder pulse is not detected by the DJF main board......

Possible causes

DJF feed motor defective

DJF transport motor defective

DJF feed out motor defective

DJF inverter motor defective

• Correct

1.15 DUAL JOB FEEDER/RECIRCULATING DOCUMENT HANDLER

Definition: [Level:B]

Encoder pulse is not detected by the DJF/RDH main board......

Possible causes

DJF/RDH feed motor defective

DJF/RDH transport motor defective

DJF/RDH feed out motor defective

RDH inverter motor defective

Page 4

Page 35 of RDH step #2

Since there is no LED cover, delete the cover [A] from the illustration and correct the

following sentence.

•Incorrect

Close the RDH and remove the LED cover [A] (1 screw).

•Correct

Close the RDH.

[A]

Page 5

Technical Bulletin No. RTB-019

SUBJECT: RDH Original Size Misdetection DATE:

February. 15,1994

PAGE: 1 of 10

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

When the RDH detects different original sizes on successive jobs, the RDH stops the

operation and indicates an original jam.

REASON OF THE MISDETECTION

Revision of service manual

Information only

Other

[B]

FROM: Copier Technical Support Section

MODEL:

RDH for F410

[C]

[A]

Original length is detected by the pulse generator sensor [A]. the RDH counts pulses from

the point where the leading edge of the original activates the registration sensor [B] until

the trailing edge of the original de-activates the registration sensor. The pulse count is

compared with the reference data which is stored in the ROM to judge the original size.

The pulse generator wheel is driven by the driven pull-out roller [C].

From October to November 1993 production, grease was applied to the four driven roller

shaft holders. When this grease on the shaft holders is contaminated with paper dust, it

increases the mechanical load to the driven pull- out roller shaft resulting in the slippage

between this roller and the original.

Due to the slippage, the pulse count varies. Because of this pulse variation, it is possible

that the RDH detect the original length incorrectly.

Page 6

Technical Bulletin No. RTB-019

SUBJECT: RDH Original Size Misdetection DATE:

February. 15,1994

PAGE: 2 of 10

COUNTERMEASURES

• Software modification-1

To improve the original length size detection accuracy, the pulse number reference data

has been corrected. (ROM part number from A3785810C to A3785810D).

• Software modification-2

UK (8" x 10") size lengthwise and GT (8" x 10 1/2") size lengthwise paper are very similar

and it is very difficult to distinguish them by the pulse number.

Therefore, the software has been changed to detect as only UK size lengthwise when

either of sizes is fed. (By changing the DIP switch combination, RDH can be set to detect

GT lengthwise).

Since the mixed size original detection is not necessary for the RDH, this function was

eliminated. RDH detects only the first original size for auto paper size selection, (ROM part

number from A3785810D to A3785810F).

NOTE: The part number A3785810E does not exist.

• Mechanical modification (Driven pull-out roller holders)

To reduce the pulse count variation, four holders of driven pull out roller have been

modified. To reduce the friction between the roller shaft and the holders, the inner

diameter of the holders has been widened.

• Production procedure change

The grease is not applied.

Page 7

Technical Bulletin No. RTB-019

SUBJECT: RDH Original Size Misdetection DATE:

February. 15,1994

PAGE: 3 of 10

FIELD MACHINE COUNTERMEASURE

Change the ROM on the RDH main board from A3785810C or A3785810D to A3785810F.

Clean the driven pull-out roller shaft with alcohol.

Replace the four driven pull-out roller holders.

Refer to the countermeasure procedure on the following pages.

The modification has been implemented on mass-production machines from the following

serial number:

A378-10 5393120001∼

A378-15 4143120001∼

A378-17 From the first production machine

A378-22 5343120001∼

A378-26 3E01230001∼

A378-27 A3403120109∼

Page 8

Technical Bulletin No. RTB-019

SUBJECT: RDH Original Size Misdetection DATE:

February 15, 1994

PAGE: 4 of 10

REPLACEMENT PROCEDURE

[A]

[a]

[B]

[b]

[a]

[C]

[b]

[D]

[b]

[F]

1. Remove the cover [A] (2 screws).

2. Remove the rear cover [B]. (Remove 2 screws, loosen 2 screws [a].)

3. Open the f eed guide [C ].

4. Remove the front cover [D]. (Remove 2 screws, loosen 3 screws [b].)

5. Slide the exit unit [E] fully to the left.

6. Remove the bracket [F] (2 screws).

[E]

[G]

7. Replace the ROM [G].

NOTE: Be sure the ROM is set in correct direction. Confirm whether all ROM legs are

set in the socket correctly.

8. Turn on the DIP SW 1-1. (Other DIP SWs should be still off)

NOTE: If in this condition either UK (8" x 10") lengthwise or GT (8" x 101/2")

lengthwise size originals are set, RDH recognizes them as UK lengthwise size.

If DIP SW 1-1 is still off, the RDH recognizes them as GT lengthwise size.

9. Install the bracket [F].

Page 9

Technical Bulletin No. RTB-019

[G]

SUBJECT: RDH Original Size Misdetection DATE:

February 15, 1994

PAGE: 5 of 10

[C]

[B]

[D]

[A]

[E]

[F]

[G]

10. Remove the encoder assembly [A] (1 stepped screw).

11. Remove the bushing [B].

12. Remove the gear [C].

13. Remove the two screws [D] fixing the wire clamps.

NOTE: Do not pull the harness too strongly, otherwise the sensor [E] will be pulled out.

14. Move the main motor bracket [F] up and hold it (5 screws).

NOTE: This step is necessary to access the screw [G] behind this motor.

15. Remove 2 screws [G].

Page 10

Technical Bulletin No. RTB-019

[A]

SUBJECT: RDH Original Size Misdetection DATE:

February 15, 1994

PAGE: 6 of 10

[D]

16. Remove 2 screws [A].

[F]

[C]

[B]

[F]

[D]

[E]

[G]

17. Remove the pull out roller stay [B].

18. Remove the registration sensor bracket [C] (2 screws [D]).

19. Remove the original feed out stay [E] (2 screws [F]).

20. Remove the pull out roller [G].

Page 11

Technical Bulletin No. RTB-019

[C]

SUBJECT: RDH Original Size Misdetection DATE:

February 15, 1994

PAGE: 7 of 10

[A]

[C]

[D]

21. Completely wipe off the grease on the pull out roller shaft [A] with alcohol.

22. Remove inner springs (Silver) [B] and outer springs (Black) [C].

23. Replace 4 arms [D] (1 screw each).

24. Install inner springs (Silver) [B] and outer springs (Black) [C].

NOTE: Inner springs and outer springs are different, do not mix them.

[B]

[B]

Page 12

Technical Bulletin No. RTB-019

[D]

[C]

[H]

SUBJECT: RDH Original Size Misdetection DATE:

February 15, 1994

PAGE: 8 of 10

[B]

[E]

[E]

[E]

[A]

[G]

[I]

[F]

25. Assemble the original guide plate [A], the pull out roller [B], the original feed-out stay [C],

and the registration sensor bracket [D] as shown (4 screws [E])

26. Install the pull out roller stay [F] (4 screws).

NOTE: Before fixing the 4 screws, close the feed guide [G] so that the pull out roller

arms [H] locate above the projections [I] on the feed guide.

Page 13

Technical Bulletin No. RTB-019

SUBJECT: RDH Original Size Misdetection DATE:

February 15, 1994

PAGE: 9 of 10

[A]

This should be a

short gold

colored screw

[B]

[D]

[C]

OK

[E]

27. Install the main motor bracket [A] (5 screws).

28. Fix the wire cramps [B] (2 screws).

29. Install the gear [C].

30. Install the bushing [D].

31. Install the encoder assembly [E] (1 stepped screw).

NOTE: 1. Make sure that the stepped screw [F] is correctly tightened as shown.

2. Make sure that the sensor [G] is set on the bracket properly.

[G]

[F]

NO

Good

Page 14

Technical Bulletin No. RTB-019

SUBJECT: RDH Original Size Misdetection DATE:

February 15, 1994

PAGE: 10 of 10

[C]

[B]

[A]

32. Install the front cover [A] (5 screws).

33. Install the rear cover [B] (4 screws).

34. Install the cover [C] (2 screws).

Page 15

Technical Bulletin No. RTB-042

SUBJECT: USER REMARKS WHILE SETTING THE ORIGINAL ON

THE RDH

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

During field survey, we found cases that an incorrect feed out unit position created original

jams.

Please instruct the customer to set the feed out unit in the correct position.

Especially for machines which are used by many casual customers, it will be helpful for

reducing the original jams by putting a copy of the page 2 of this RTB on the wall behind

the RDH.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: RDH for

DATE: JULY 31 ’94

PAGE: 1 of 2

F410/F420

Page 16

Technical Bulletin No. RTB-042

SUBJECT: USER REMARKS WHILE SETTING THE ORIGINAL ON

THE RDH

DATE: JULY 31 ’94

PAGE: 2 of 2

To prevent original jams,

slide the feed-out unit [A] to match the size marks on

the front of the recirculating document handler (RDH).

[A]

Page 17

Technical Bulletin No. RTB- 046

SUBJECT: SOFTWARE MODIFICATION DATE: Dec. 31, ’94

PAGE: 3 of 7

2. "B" version ROMs

From the following serial numbers, the EPROMs (A0965151A and A0965153A) on the

main board have been updated to version "B".

NOTE: We will re-issue this RTB as soon as the cut-in serial number becomes

available.

Code Serial Number

A095-10 5204

A095-15 264

A095-17 A3354

A095-22 5234

A095-26 3D5

A095-27 A3354

A095-29 A3354

A096-10 5244

A096-15 284

A096-17 A3364

A096-22 5274

A096-26 3D6

A096-27 A3364

A096-29 A3364

A097-10

A097-15

A097-17

A097-22

A097-26

A097-27

A097-29

Caution: Whenever replacing from the old main ROMs to the new version ROMs in

the field, this modification is necessary.

The following are corrected by this software change:

2-1. Machine enters the screen saver mode during auto counting

If the time to enter the screen saver mode (this time can be changed by using User tools)

comes during the auto count mode, the machine enters the screen saver mode. After

counting all originals, the machine indicates the original jam condition.

Page 18

Technical Bulletin No. RTB- 046

SUBJECT:SOFTWARE MODIFICATION DATE: Dec. 31, ’94

PAGE: 4 of 7

2-2. Operating time indication is incorrect

During operation, the time remaining before the end of the copy job is indicated by

animation on the touch panel screen.

During the duplex mode by using RDH and Finisher, the indicated time was incorrect.

<Countermeasure>

For the single side original to duplex copy mode, it is impossible to calculate the time due

to a highly complex operation using the alternate feed system. Therefore, in this mode,

the operating time is not indicated.

For the duplex original to duplex copy mode, the accuracy of the indicated operation time

has been improved.

2-3. RDH and Finisher, copy set limitation (maximum: 50 sets)

When using the RDH and Finisher, the selectable copy set for sort mode should be "999"

(In the sort mode, due to the alternate feed operation, the paper stocked in the duplex tray

is always less than 50 sheets). However, it was limited to 50. If a larger number was

entered, it was canceled and "50" was displayed.

2-4. RDH and Finisher, Copier misfeed caused by the original misfeed

When an original exit jam occurs in the RDH, it should not cause a copier misfeed (the

copier should exit all sheets in the copier then stop) but actually a misfeed also occurs in

the copier. This symptom occurs depending on the copy tray selected and the size of the

copy paper. (The combination of the longer paper path and shorter paper length tends to

create this symptom.)

Page 19

REVISED ON: APRIL 15, ’96

Technical Bulletin No. RTB-051

SUBJECT: RDH Original Auto Count Disabled

(North America versions only)

PREPARED BY: M. Mimura

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

<Symptom>

When making one sided to two sided duplex copies with Energy Star compliant

machines, the RDH will not count the number of originals (faulty Even original mode).

<Cause>

Software error

<Field Solution>

1. Turn on the copier main switch with the RDH installed.

Revision of service manual

Information only

Other

FROM: 1st Field Information Dept. QAC

MODEL:

DATE: February

29, ’95

PAGE: 1 of 2

F410 / 420

2. Press the One Side → Two Sided duplexing key. (This key is the default selection

key on Energy Star machines. However, it must be pressed again for this

operation.)

3. Press the User Program key.

4. Store the current mode in the program #5.

5. Turn the machine off and on.

6. Confirm that the RDH counts the number of originals. (Confirmation also can be

done by pressing the Check Modes key. If "Even" is not displayed on the

Duplex/Series Copies tag, the correction has been successful.)

NOTE: 1. If the default mode is changed to single-side copying or two-sided to

two- sided duplexing, selecting the one-sided to two-sided mode will not

cause the problem.

2. The above procedure is to be done one time only per machine.

The corrected data will be kept on the RAM board.

Page 20

REVISED ON: APRIL 15, ’96

Technical Bulletin No. RTB-051

SUBJECT: RDH Original Auto Count Disabled

(North America versions only)

<Affected Machines>

Energy Star compliant machines configured with the RDH. See MB # 114 for cut-in

serial number information of the Energy Star modification.

<Factory Action>

The program has been corrected to reflect the solution. The part numbers of the

new ROM are as follows:

A0965155 B

A0965157 B

The new ROMs have been implemented to the production machines from the

following serial numbers:

Model Code Cut-in Serial No.

F400 A095-10

A095-15

A095-17

F410 A096-10

A096-15

A096-17

F420 A097-10

A097-15

A097-17

52064300 02

26643002 28

A3356430 280

524604XX XX

28644000 01

A3366430 322

528604XX XX

29644000 01

A3376440 001

DATE: February

29, ’95

PAGE: 2 of 2

Loading...

Loading...