Page 1

AUTO REVERSE DOCUMENT FEEDER

(

Machine Code:

B386)

Page 2

10 August, 2001 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Original Size: Standard sizes

Single-sided mode: A3 to A5, DLT to HLT

Double-sided mode: A3 to A4, DLT to LT

Non-standard sizes (Single-sided mode only)

Max. width 297 mm

Min. width 105 mm

Max. length 1260 mm

Min. length 128 mm

Original Weight: Single-sided mode: 52~128 g/m2,14~34 lb

Double-sided mode: 52~10 5 g/m2,14~28 lb

Table Capacity: 30 sheets (70 kg)

Original Standard Position: Center

Separation: FRR

Original Transport: Roller transport

Original Feed Order: From the top original

Reproduction Range: 25 to 200 % (Sub scan direction only)

Power Source: 24 & 5 Vdc from the copier

Power Consumption: 50 W

Dimensions (W x D x H): 550 x 470 x 110 mm

Weight: 10 kg

B386-1

Options

Page 3

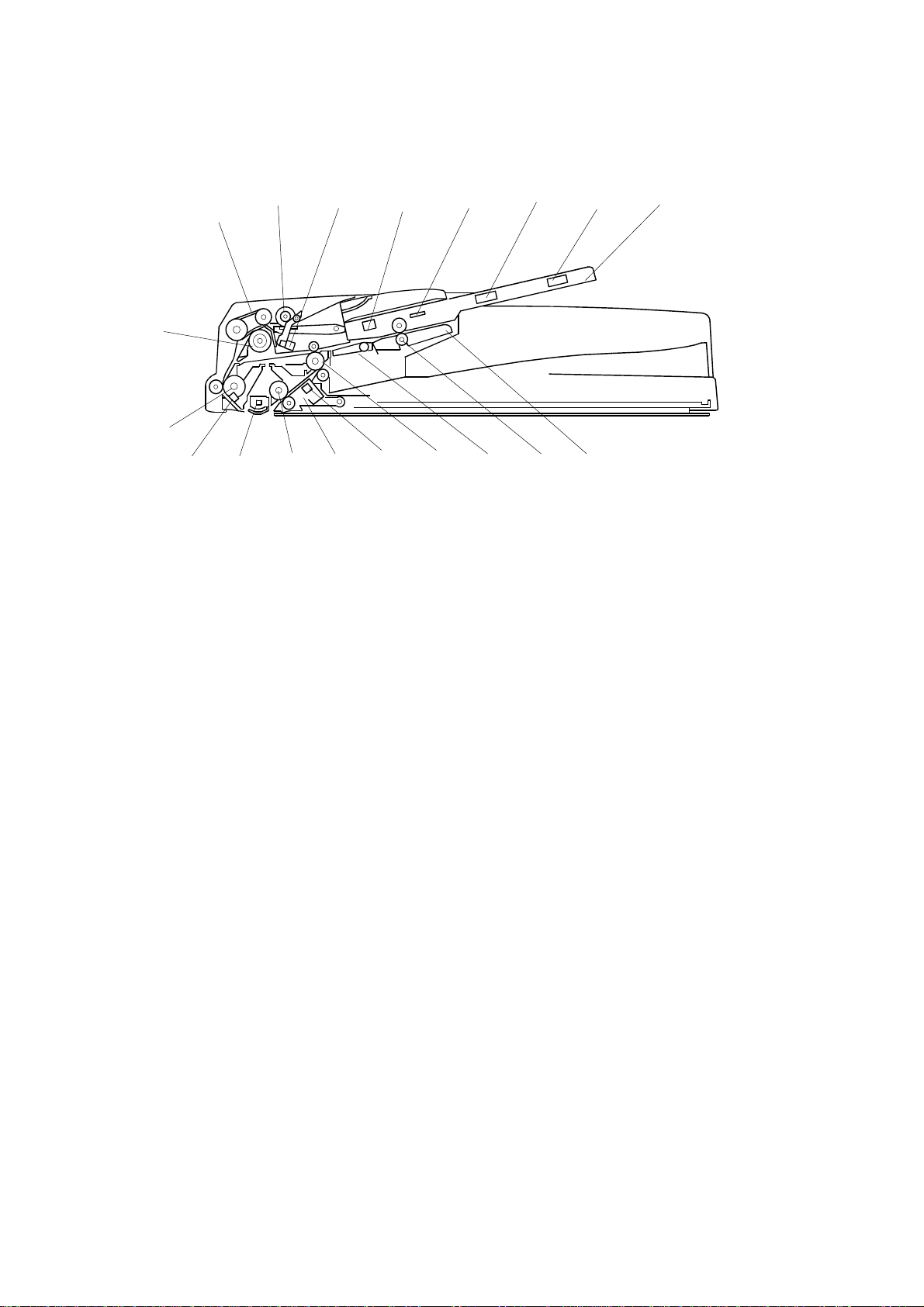

MECHANICAL COMPONENT LAYOUT 10 August, 2001

1.2 MECHANICAL COMPONENT LAYOUT

2

3456789

1

1. Separation Roller

2. Paper Feed Belt

3. Pick-up Roller

4. Original Set Sensor

B386D201.WMF

11 1012131415181917 16

11. Reverse Roller

12. Junction Gate

13. Exit Roller

14. Original Exit Sensor

5. Original Trailing Edge Sensor

6. Original Width Sensor Board

7. Original Length Sensor 1

8. Original Length Sensor 2

9. Original Table

10. Reverse Table

15. Stamp

16. 2nd Transport Roller

17. Original Exposure Guide

18. Registration Sensor

19. 1st Transport Roller

B386-2

Page 4

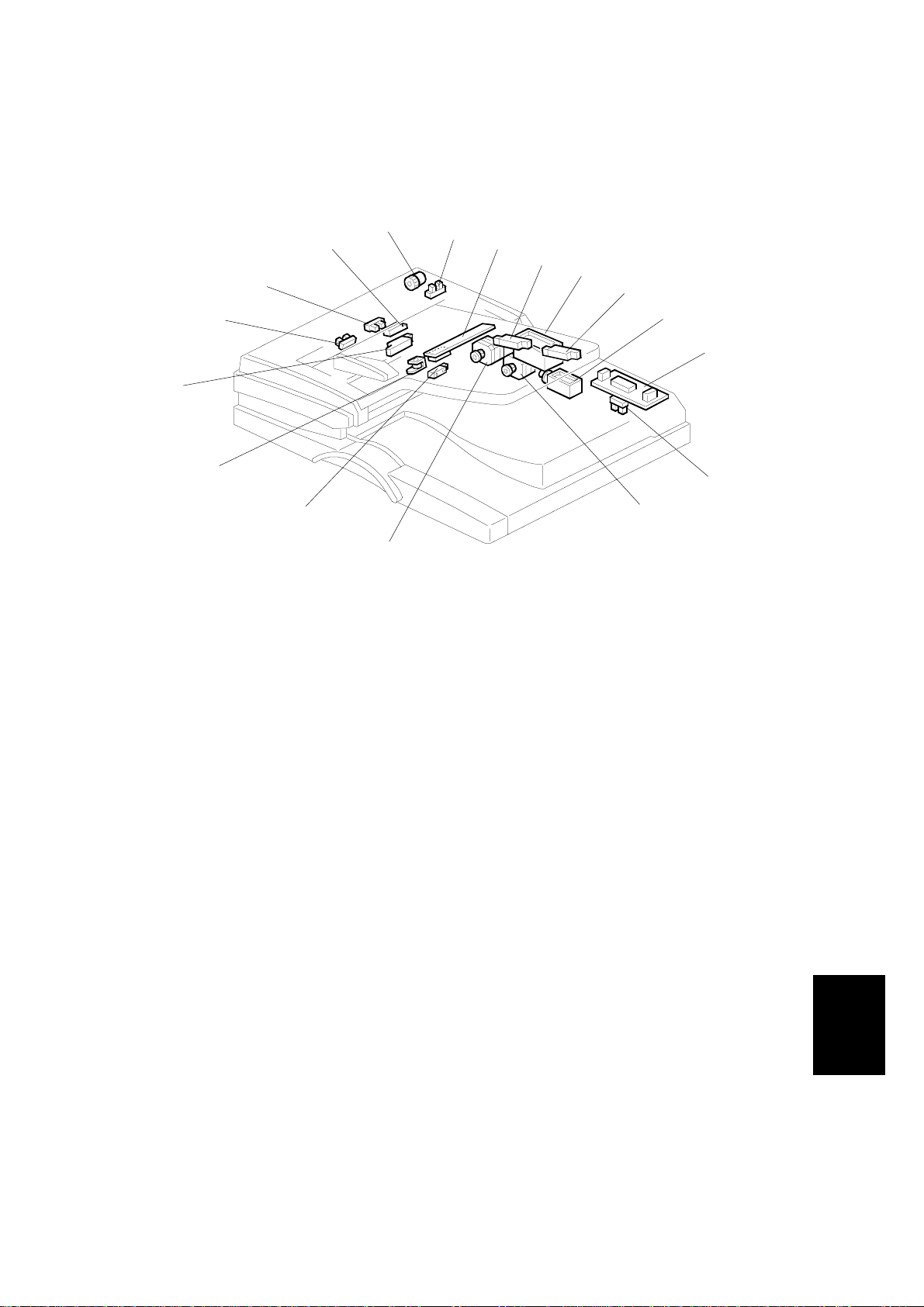

10 August, 2001 ELECTRICAL COMPONENT LAYOUT

1.3 ELECTRICAL COMPONENT LAYOUT

16

15

14

13

1. DF Feed Clutch

12

17

11

1

2

3

4

5

6

7

8

9

10

B386D202.WMF

10. DF Feed Motor

2. Feed Cover Sensor

3. Original Width Sensor Board

4. Original Length Sensor 1

5. DF Pick-up Solenoid

6. Original Length Sensor 2

7. Junction Gate Solenoid

8. DF Drive PCB

9. DF Position Sensor

11. DF Transport Motor

12. Original Exit Sensor

13. Stamp Solenoid

14. Original Trailing Edge Sens or

15. Original Set Sensor

16. Original Reverse Sensor

17. Registration Sensor

Options

B386-3

Page 5

ELECTRICAL COMPONENT DESCRIPTION 10 August, 2001

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function

Motors

M1 DF Feed Drives the feed belt, separation, pick-up, and

reverse table rollers.

M2 DF Transport Drives the transport and exit rollers 11

Sensors

S1 DF Position Detects whether the DF is lifted or not. 9

S2 Registration

S3 Feed Cover Open

Sensor

S4 Original Width

Sensor Board

S5 Original Length - 1 Detects the original length. 4

S6 Original Length - 2 Detects the original length. 6

S7 Original Set Detects if an original is on the feed table. 15

S8 Original Exit

S9 Original Trailing

Edge

S10 Original Reverse

Sensor

Solenoids

SOL1 DF Pick-up

SOL2 Stamp Energizes the stamper to mark the original. 13

SOL3 Junction Gate Opens and closes the junction gate. 7

Detects the leading edge of the original to turn

off the DF feed and transport motors, detects

the original exposure timing, and checks for

original misfeeds.

Detects whether the feed-in cover is opened or

not.

Detects the original width. 3

Detects the leading edge of the original to turn

on the junction gate solenoid and checks for

original misfeeds.

Detects the trailing edge of the original to turn

off the transport and feed motor and junction

gate solenoid.

In single-sided mode, used to detect original

misfeeds.

Detects the trailing edge of the last original to

stop copy paper feed and to turn off the

transport motor, and checks for original

misfeeds.

Detects when the original is fed from the

reverse area during duplex scanning.

Controls the up-down movement of the original

table.

Index

No.

10

17

2

12

14

16

5

Clutches

MC1 DF Feed Transfers transport motor drive to the pick-up

roller and feed belt.

PCBs

PCB1 DF Drive

Interfaces the sensor signals with the copier,

and transfers the magnetic clutch, solenoid and

motor drive signals from the copier.

B386-4

1

8

Page 6

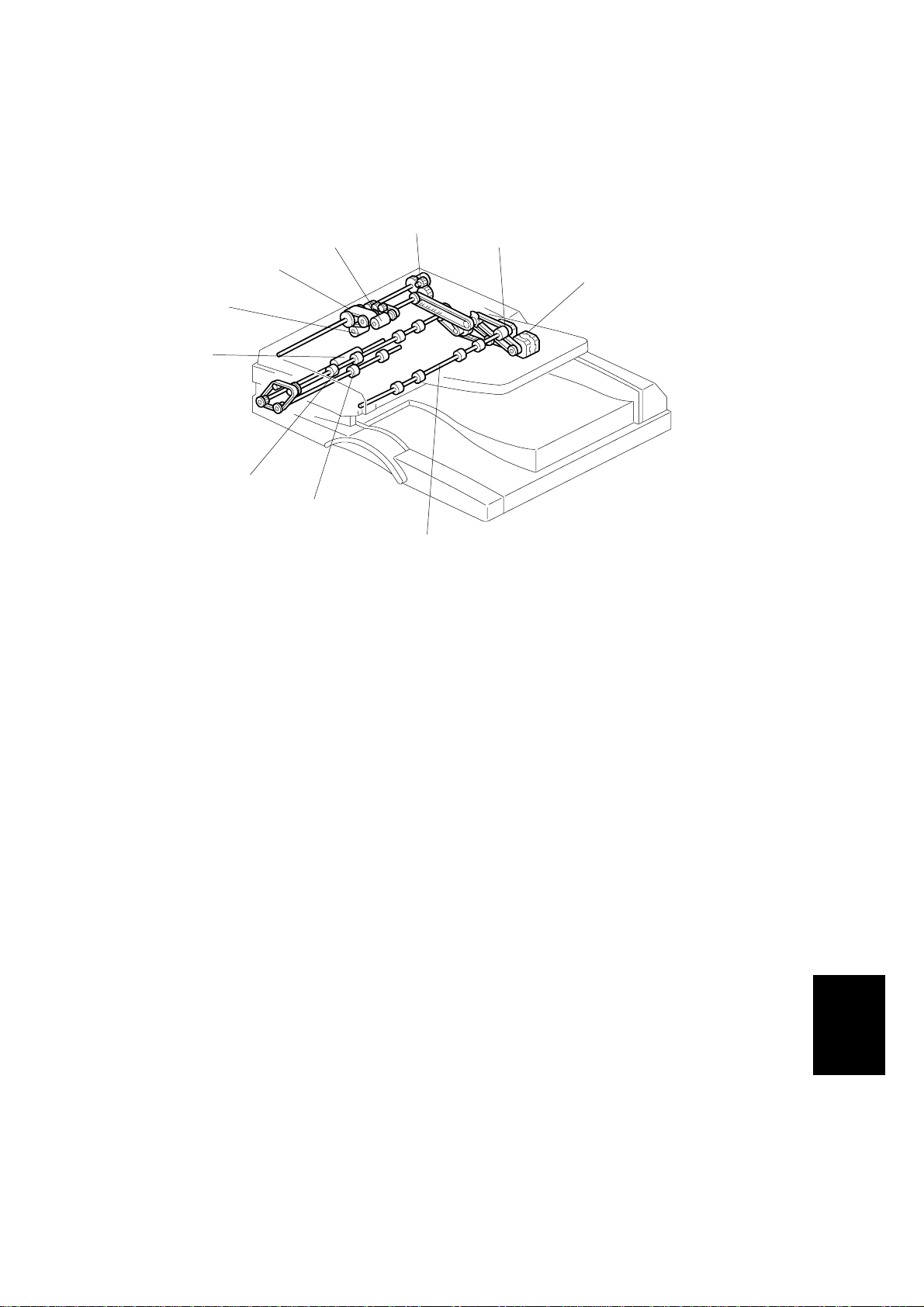

10 August, 2001 DRIVE LAYOUT

1.5 DRIVE LAYOUT

2

1

10

9

1. Separation Roller

2. Original Feed Belt

4

3

5

6

8

7

B386D203.WMF

6. DF Feed Motor

7. Reverse Table Roller

3. Pick-up Roller

4. DF Feed Clutch

5. DF Transport Motor

8. 2nd Transport Roller

9. Exit Roller

10. 1st Transport Roller

Options

B386-5

Page 7

ORIGINAL SIZE DETECTION 10 August, 2001

2. DETAILED SECTION DESCRIPTIONS

2.1 ORIGINAL SIZE DETECTION

[A]

[B]

[C]

B386D503.WMF

The original size detection mechanism consists of the original width sensor board

[A] and two original length sensors-1 [B] and -2 [C]. Based on the combined output

of the length sensors and the width sensor board, the machine can detect the size

of the original. This integrated detection mechanism is detailed in the table on the

next page.

Note that the width sensor’s terminal plate is attached to the original guide, so the

widths of the originals must all be the same.

B386-6

Page 8

10 August, 2001 ORIGINAL SIZE DETECTION

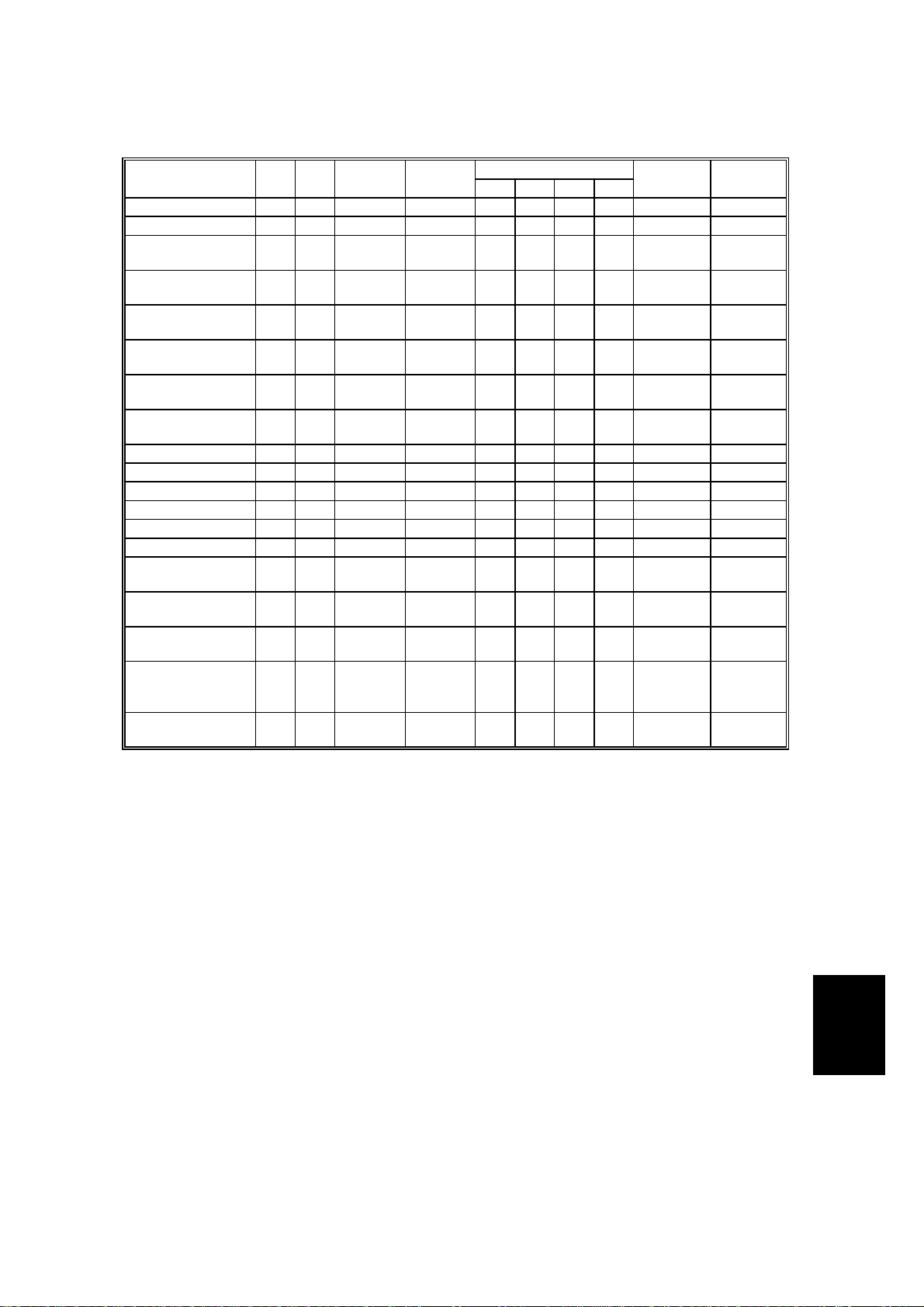

A3 (297 x 420)

B4 (257 x 364)

A4 (Lengthwise)

(210 x 297)

A4 (297 x 210)

(Sideways)

B5 (182 x 257)

(Lengthwise)

B5 (257 x 182)

(Sideways)

A5 (148 x 210)

(Lengthwise)

A5 (210 x 148)

(Sideways)

11" x 17" (DLT)

11" x 15"

10" x 14"

8.5" x 14" (LG)

8.5" x 13" (F4)

8" x 13" (F)

8.5" x 11"

(Lengthwise)

8.5" x 11"

(Sideways)

10" x 8"

(Lengthwise)

5.5" x 8.5"

(Lengthwise)

(HLT)

5.5" x 8.5"

(Sideways) (HLT)

NA EU

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

✗✗

✗❍

❍✗

❍✗

❍✗

❍✗

✗❍

❍❍

❍✗

❍✗

❍✗

❍✗

❍✗

Original

Width-1

LLON———ONON

LH—ON——ONON

HL——ON—ON—

LLON—————

HH———ONON—

LH—ON————

HH———ON——

HL——ON———

LLON———ONON

LLON———ONON

LH—ON——ON—

HL——ON—ON—

HL——ON—ON—

HL——ON—ON—

HL——ON—ON—

LLON—————

LH—ON——ON—

HH———ON——

HL——ON———

Original

Width-2

Original Width-3

P4 P3 P2 P1

Original

Length-1

Original

Length-2

Key

✗

: No, ❍: Yes

ON: Paper present

NA: North America, EU: Europe

NOTE: 1) P1-P4 represent the four positions on the width sensor board. ON

indicates the presence of the terminal plate in a given position. “Original

Width-1” and “Original Width-2” are the outputs from the sensor board to

the DF main board. The state of these outputs (L or H) depends on the

position of the terminal plate on the sensor board (P1, P2, P3, or P4).

For example, if the terminal plate is at P4, both outputs are L.

2) A reading of “L” on either of the width sensor outputs indicates that the

terminal plate is connecting the GND pattern with the width sensor

output signal line.

3) The machine cannot detect more than one size of originals in the same

job.

B386-7

Options

Page 9

ORIGINAL SIZE DETECTION 10 August, 2001

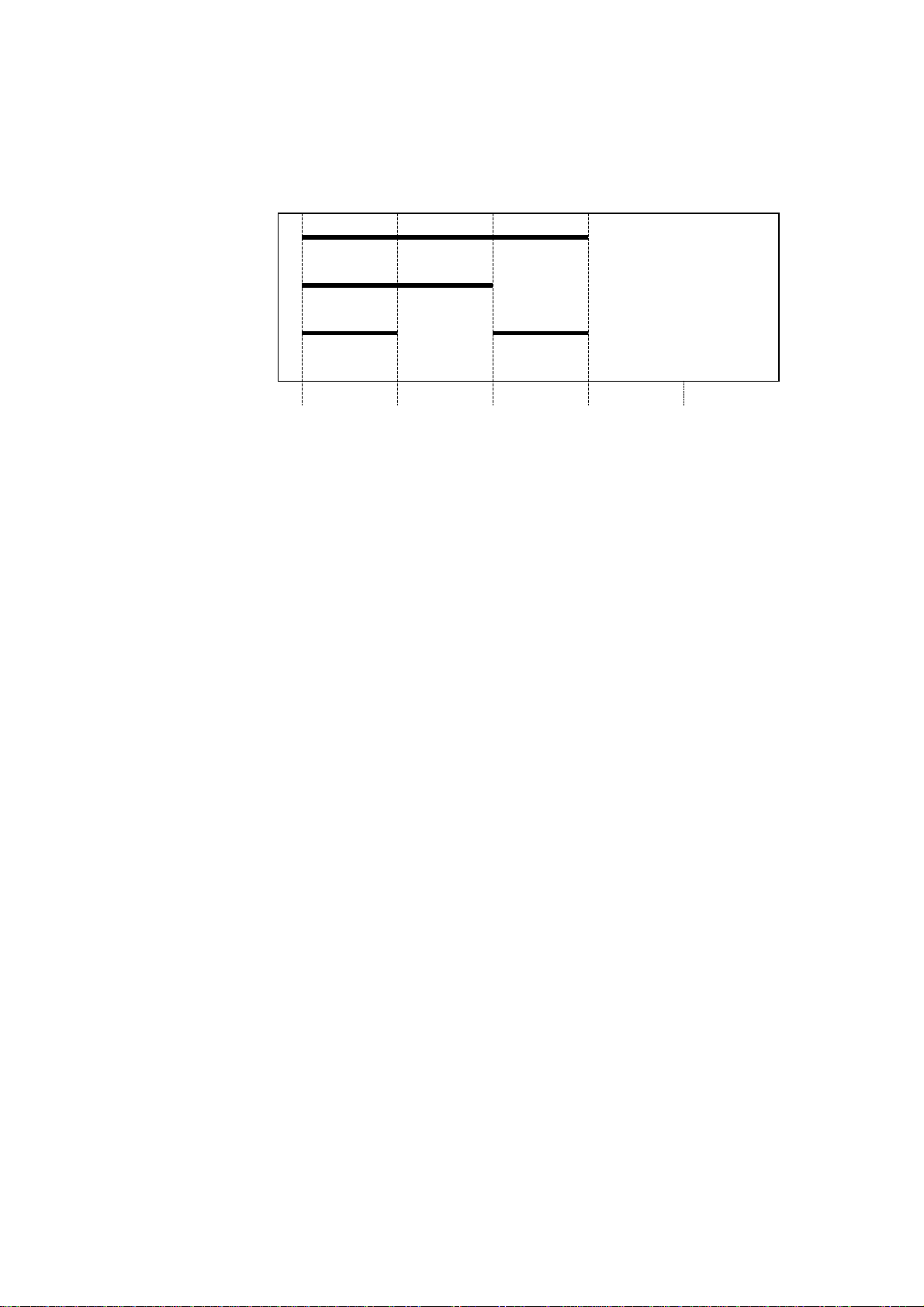

Original Width Sensor Board

GND Pattern

Original Width 1

Original Width 2

Original Side

Guide Position

The signal is "L" when the terminal plate is connected to the GND pattern.

A3/A4S B4/B5S A4L/A5S B5L/A5L

P1P2P3P4

B386D501.WMF

B386-8

Page 10

10 August, 2001 MIXED ORIGINAL SIZE MODE

2.2 MIXED ORIGINAL SIZE MODE

This section explains what happens when the user selects mixed original size

mode.

Because this ADF is a sheet-through document feeder, the method for original

document width detection is the same as when the originals are the same size, but

the document length detection method is different. Therefore, the scanning speed

is slightly slower.

Document length detection

From when the registration sensor switches on until it switches off, the CPU counts

the transport motor pulses. The number of pulses determines the length of the

original.

Feed-in cycle

When the original size for the copy modes listed below cannot be determined, the

image cannot be correctly scaled (reduced or enlarged) or processed until the

original’s length has been accurately detected. The length must be determined

before the image is scanned.

Auto Reduce/Enlarge

Centering

Erase Center/Border

Booklet

Image Repeat

The originals follow this path:

1. Length detection ! Scanning glass ! Inverter table

2. Inverter table ! Scanning glass ! Inverter table (restores the original order)

3. Inverter table ! Scanning glass (image scanned) ! Exit tray

Normal feed-in

In a copy mode other than those listed above, when the reduction/enlargement

ratio has been determined, the originals are scanned normally. In order to store the

scanned images, a large area of memory (the detected original width x 432 mm

length) is prepared. Next, only the portion of the image up to the detected original

length is read from memory and printed.

B386-9

Options

Page 11

PICK-UP AND SEPARATION 10 August, 2001

2.3 PICK-UP AND SEPARATION

[E]

[A]

[B]

[C]

[D]

[B]

B386D504.WMF

[F]

[G]

B386D505.WMF

The original is set with the image facing up. The original pushes actuator [A] and

the original set sensor [E] is activated.

After pressing the start button, the pick-up solenoid [D] is activated and the lift plate

[C] lifts the original up until it comes in contact with the pick-up roller [B]. The pickup roller then feeds the top sheet of paper.

After being fed from the pick-up roller, the topmost sheet is separated from the

stack by the separation roller and sent to the first transport roller.

The mechanism is an FRR system, consisting of the original feed belt [F] and

separation roller [G].

B386-10

Page 12

10 August, 2001 ORIGINAL TRANSPORT AND EXIT

2.4 ORIGINAL TRANSPORT AND EXIT

2.4.1 SINGLE-SIDED ORIGINALS

[E]

[A]

[F]

[B]

[C]

[D]

B386D506.WMF

The DF feed motor feeds the separated original to the first transport roller [A] at

maximum speed. When the registration sensor [B] detects the leading edge, the

motor stops for a short while. Then the feed and transport motors turn on again,

and feed the original through scanning area at a lower speed (the scanning area

contains the original exposure guide [D] and DF exposure glass [C]). After

scanning, the original is fed out by the second transport roller [E] and exit roller [F].

B386-11

Options

Page 13

ORIGINAL TRANSPORT AND EXIT 10 August, 2001

2.4.2 DOUBLE-SIDED ORIGINALS

[A]

[B]

[G]

[C]

B386D204.WMF

[A]

[F]

[E]

[D]

[E]

[D]

[F]

B386D205.WMF

When the re gistration senso r [B] detects the leading edge of t he original, the DF

feed motor (which drives the feed roller) and transport motor (which drives the

transport roller) both switch off. After a brief interval, the transport motor alone

reactivates to drive the first [A] and second transport roller [G] and the exit roller

[F]. The front side of the original is then scanned.

When the original exit sensor [C] detects the leading edge of the original, the

junction gate solenoid is activated and the junction gate [D] opens. The original is

then transported towards the reverse table [H].

Soon after the trailing edge of the original passes the exit sensor [C], the junction

gate solenoid switches off and the junction gate [D] is closed. When the original

has been fed onto the reverse table, the DF feed motor switches on in reverse. The

original is then fed by the reverse roller [E] and then by the exit roller [F] and first

transport roller [A] to the scanning area (where the reverse side will be scanned).

B386-12

Page 14

10 August, 2001 ORIGINAL TRANSPORT AND EXIT

[H]

[I]

B386D206.WMF

[J]

B386D207.WMF

The original is then sent to the reverse table [H] a second time to be turned over.

This is done so that the duplex copies will be properly stacked front side down in

the exit tray [J] in the correct order.

2.4.3 ORIGINAL TRAILING EDGE SENSOR

During one-to-one copying, copy paper is fed to the registration roller in advance

(while the original is still being scanned), to increase the copy speed. The trailing

edge sensor monitors the stack of originals in the feeder, and detects when the

trailing edge of the last page h as been fed in. The main CPU then stops the copier

from feeding an unwanted extra sheet of copy paper.

B386-13

Options

Page 15

STAMP 10 August, 2001

2.5 STAMP

[C]

[A]

[B]

B386D507.WMF

This function is only for fax mode.

There is a stamp [A] between the 2nd transport roller [B] and the exit roller [C], and

its solenoid is controlled by the copier directly.

When the original reaches the stamp position, the DF feed m otor stops. A t 300

milliseconds after stopping the DF feed motor, the stamp solenoid turns on if the

page was sent successfully (immediate transmission) or stored successfully

(memory transmission). After stamping, the DF feed motor starts again to feed out

the document, and its speed is about 1.3 times the normal speed.

The stamping position on the original can be changed by adjusting SP6-010.

B386-14

Page 16

10 August, 2001 TIMING CHART

2.6 TIMING CHART

LT SIDEWAYS STAMP MODE (DOUBLE-SIDED ORIGINAL MODE)

FGATE

Registration

Sensor

Trailing Edge

Sensor

Reverse

Sensor

Exit Sensor

Sensor

Original Set

Solenoid

Stamp

Rreverse

Solenoid

DF Pick-up

Solenoid

Clutch

DF Feed

Transport

Motor

Feed Motor

TXD

RXD

DISABLE

ENABLE

JAM 8

OFF

ON

JAM 1A, 1B

JAM 2

OFF

Original Set Size Code

Original Feed

Feed Completion

Original Scan Start

Next Original Check

OFF

ON

ON

ON

ON

ON

ON

ON

ON

READ

MAX

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

READ

MAX

1000ms

JAM 3 JAM 4

JAM 5

is 238mm or more.

Original Size

Stamp Stop Position

Original Stop Stamp Stop Position

Feed motor turns if sub-scan

Exit Completion

Feed Completion

Stamp & Reverse Original Scan Start Stamp & Reverse Original Scan Start Stamp & Reverse Original Scan Start Stamp & Reverse

Original Not Set

Next Original

Check

Original Size

Stamp Stop Position

Original Stop Stamp Stop Position

Feed motor turns if sub-scan

is 238mm or more.

Exit Completion

B386D101.WMF

Options

B386-15

Page 17

CONDITION OF JAM DETECTION 10 August, 2001

2.7 CONDITION OF JAM DETECTION

JAM 1A:If the registration sensor does not turn on within 114 mm x 2 since the feed

motor started (twice the distance between the original set position and the

(registration senso r).

JAM 1B:Duplex mode only: If the registration sensor does not turn on within 161 mm

x 1.5 since the feed motor started (1.5 times the distance between the

original reverse position and the registration sensor).

JAM 2: If the registration sensor does not turn off within 1260 mm x 1.1 since the

feed motor started (1.1 times the distance between the paper stop position at

registration and the maximum original length).

JAM 3: If the original exit sensor does not turn on within 92 mm x 1.5 since the feed

motor started (1.5 times the distance between registration sensor and exit

sensor)

JAM 4: If the original exit sensor does not turn off within original length + 120 mm

since the transport motor started after the exit sensor turns on

JAM 5: Duplex mode only: If the original reverse sensor does not turn on within 161

mm x 1.4 since the feed motor started (1.4 times the distance between the

original reverse position and the registration sensor).

JAM 6: If the feeding original is removed.

JAM 7: If the cover is opened or the ADF is lifted while the ADF is in operation.

JAM 8: If an area outside the maximum scannable area is selected.

JAM 9: If scanning of the previous original is not completed when the registration

sensor detects the leading edge of the current original.

B386-16

Page 18

10 August, 2001 OVERALL ELECTRICAL CIRCUIT

2.8 OVERALL ELECTRICAL CIRCUIT

The DF CPU controls the transport motor, DF feed motor, DF feed clutch, junction

Gate solenoid, stamp solenoid, and pick-up solenoid. The DF CPU also monitors

all DF sensors and provides updated status information when prompted at regular

intervals by the mainframe, which may then take action based on this information.

The DF–mainframe connection is checked automatically just after power is

supplied to the mainframe.

Main

Frame

Registration Sensor

Original Set Sensor

DF Position Sensor

Feed Cover Open Sensor

Original Width Sensor Board

Original Length Sensor 1

Original Length Sensor 2

Original Trailing Edge Sensor

Original Exit Sensor

Original Reverse Sensor

Interface

ADF Control

CPU

Driver

Driver

ADF Control Board

DF Feed Motor

DF Transport

Motor

DF Feed Clutch

Junction Gate

Solenoid

DF Pick-up

Solenoid

Stamp Solenoid

B386D500.WMF

B386-17

Options

Page 19

DIP SWITCHES 10 August, 2001

3. SERVICE TABLES

3.1 DIP SWITCHES

SW100

1234

0 0 0 0 Normal operating mode (Default)

0 0 0 1 No function

0 0 1 0 Free run with two-sided original 100%

0 0 1 1 DF feed clutch operates

0 1 0 0 Free run with one-sided original 32.6%

0 1 0 1 DF pick-up solenoid operates

0 1 1 0 Motors rotate

0 1 1 1 No function

1 0 0 0 Free run with one-sided original 100%

1 0 0 1 Junction gate solenoid operates

1 0 1 0 Free run without two-sided original 100%

1 0 1 1 No function

1 1 0 0 Free run without one-sided original 100%

1 1 0 1 Stamp solenoid operates

1 1 1 0 Free run with two-sided original 32.6%

1 1 1 1 Free run without two-sided original 100%

Description

B386-18

Page 20

10 August, 2001 DF EXIT TABLE AND COVER

4. REPLACEMENT AND ADJUSTMENT

4.1 DF EXIT TABLE AND COVER

[B]

[C]

[D]

[A]

1. Open the DF feed cover.

2. Remove the front cover [A] (3 screws).

Remove the rear cover [B] (3 screws).

3. Open the reverse table [C].

Remove the original exit table [D] (3 screws).

B386R506.WMF

B386-19

Options

Page 21

ORIGINAL FEED UNIT 10 August, 2001

4.2 ORIGINAL FEED UNIT

[A]

B386R500.WMF

1. Open the left cover.

2. Detach the paper feed unit by sliding it toward the front of the machine (springloaded side) and then lifting the far side.

B386-20

Page 22

10 August, 2001 LEFT COVER

4.3 LEFT COVER

[B]

[A]

B386R507.WMF

1. Remove the front and rear covers.

2. Remove the left cover [A].

3. Remove the lower left stay unit [B] (2 screws).

B386-21

Options

Page 23

PICK-UP ROLLER 10 August, 2001

4.4 PICK-UP ROLLER

[A]

1. Remove the original feed unit.

2. Replace the pick-up roller [A] (1 snap ring).

B386R501.WMF

B386-22

Page 24

10 August, 2001 FEED BELT

4.5 FEED BELT

[A]

B386R204.WMF

[C]

1. Remove the original feed unit.

2. Open the paper feed guide [A].

3. Remove the belt holders [B].

4. Replace the feed belt [C].

[B]

B386R205.WMF

Options

B386-23

Page 25

SEPARATION ROLLER 10 August, 2001

4.6 SEPARATION ROLLER

[A]

[C]

[B]

B386R502.WMF

1. Lift the original feed guide [A].

2. Remove the separation roller cover [B].

3. Replace the separation roller [C].

B386-24

Page 26

10 August, 2001 ORIGINAL SET/ORIGINAL REVERSE SENSOR

4.7 ORIGINAL SET/ORIGINAL REVERSE SENSOR

[A]

[B]

[C]

[D]

B386R201.WMF

1. Open the left cover.

2. While pushing the left and right pawls [A], open the original feed guide plate [B].

3. Remove the original set sensor [C]

4. Remove the original reverse sensor [D].

Options

B386-25

Page 27

ORIGINAL SIZE SENSOR 10 August, 2001

4.8 ORIGINAL SIZE SENSOR

[A]

[B]

[C]

B386R503.WMF

[E]

[D]

B386R504.WMF

1. Open the original table [A].

2. Remove the upper part of the table (3 screws).

3. Replace the width sensor board [B], length sensor (–1 [C] and –2 [D]) and

trailing edge sensor [E].

[F]

NOTE: To ensure proper detection of paper size,

after wiping off the sensor board and

terminal plate with a dry cloth (or cloth with

alcohol), apply silicone grease (KS-660) to

the terminal plate [F].

B386R505.WMF

B386-26

Page 28

10 August, 2001 ORIGINAL FEED DRIVE

4.9 ORIGINAL FEED DRIVE

[B]

[A]

[C]

[D]

[E]

B386R202.WMF

First remove the rear cover. Then follow the instructions below for each part

replacement:

DF Feed Clutch

1. Replace the DF feed clutch [A] (1 E-ring, 1 connector).

Pick-up Solenoid

1. Replace the pick-up solenoid [B] (3 screws, 1 snap ring, 1 connector).

Transport Motor

1. Remove the bracket [C] (2 screws).

2. Replace the transport motor [E] (2 screws, 1 connector).

DF Feed Motor

1. Remove the bracket [C] (2 screws).

2. Replace the DF feed motor [D] (2 screws, 1 connector).

B386-27

Options

Page 29

REGISTRATION SENSOR 10 August, 2001

4.10 REGISTRATION SENSOR

[B]

[A]

1. Remove the front and rear covers.

2. Remove the transport guide plate [A].

3. Replace the registration sensor [B].

B386R508.WMF

B386-28

Page 30

10 August, 2001 STAMP SOLENOID AND ORIGINAL EXIT SENSOR

4.11 STAMP SOLENOID AND ORIGINAL EXIT SENSOR

[A]

[B]

[C]

B386R509.WMF

[D]

B386R203.WMF

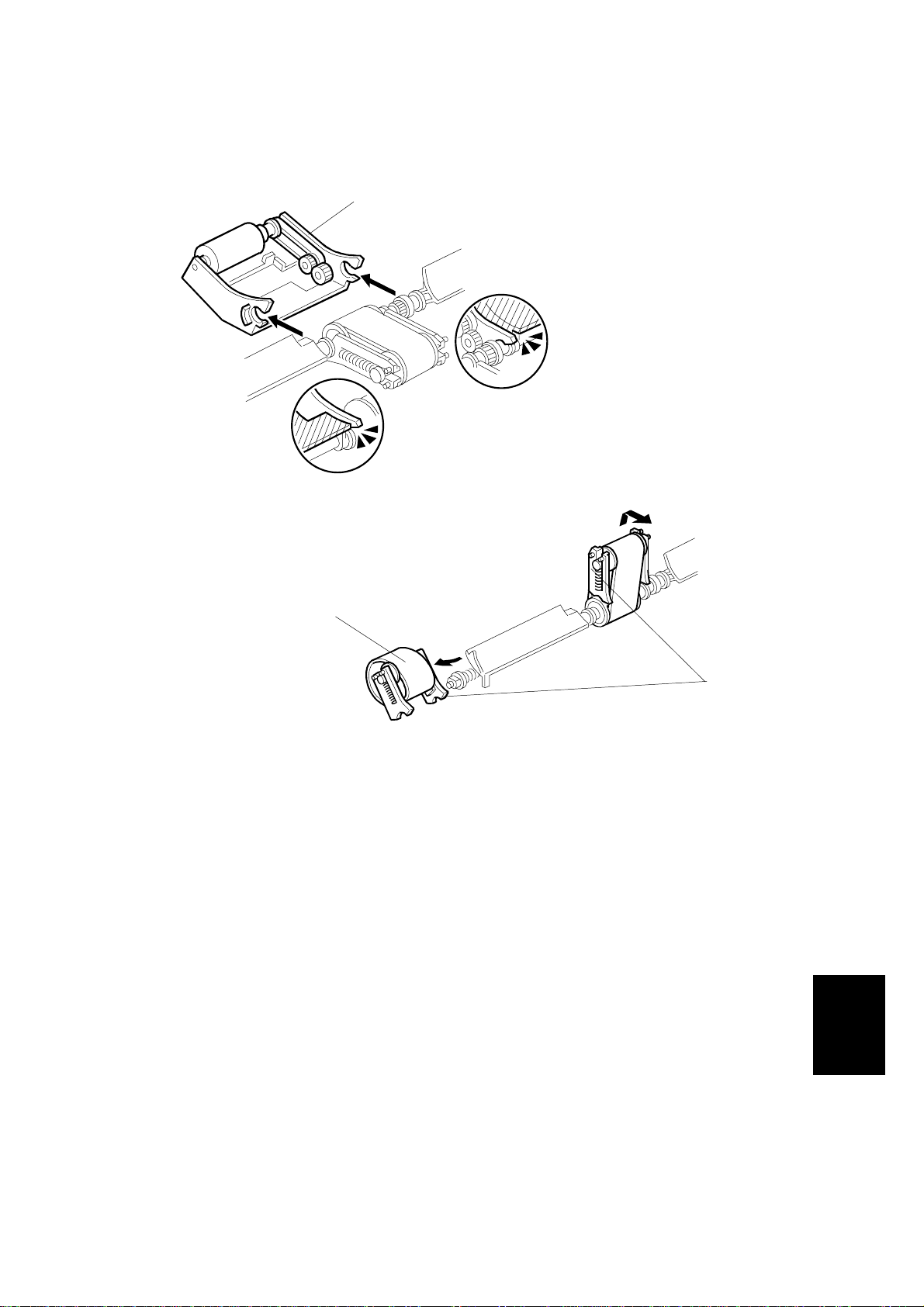

1. Remove the rear cover (1 connector). Also remove the upper cover (the exit

tray).

2. Open the exit guide plate [A]. Next, detach the unit by inserting a screwdriver or

other tool into one of the small openings [B] on either side of the guide plate

holder and pushing firmly .

3. Remove the stamp solenoid [C] (1 screw).

4. Remove the original exit sensor [D] (1 connector).

B386-29

Options

Page 31

1

2345678910

ARDF (B386) Point to Point Diagram

A

B

C

Feed Cover Open

D

Registration

Sensor

Original Set

Sensor

DF Position

Sensor

Sensor

Original Exit

Sensor

S2

S7

S1

S3

S8

CN301-3

-2

-1

CN302-3

-2

-1

CN303-3

-2

-1

CN304-3

CN305-3

-2

-1

-2

-1

CN200-1

-2

-3

CN201-1

-2

-3

CN202-1

-2

-3

CN200CN201CN202CN203

CN200-3

-2

-1

CN201-3

-2

-1

CN202-3

-2

-1

CN102-1

-2

-3

CN102-4

-5

-6

CN102-7

-8

-9

CN102-10

-11

-12

-13

CN103-1

-2

-3

GND

["5] Registration

+5V

GND

[!5] Original Set

+5V

GND

[!5] DF Position

+5V

N.C.

GND

[!5] Feed Cover Open

+5V

GND

["5] Original Exit

+5V

+24V

+24V

GND

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

+24V

Junction Gate [!5]

+24V

DF Pick-up [!24]

+24V

+24V

GND

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

+24V

Stamp [!24]

CN106-1

CN107-1

CN108-1

-2

CN109-1

CN109-8

-2

-3

-4

-5

-6

-7

-2

-2

-3

-4

-5

-6

-7

-9

CN204-7

-6

-5

-4

-3

-2

-1

CN205-7

-6

-5

-4

-3

-2

-1

CN206-2

-1

CN204

CN205CN206

CN204-1

-2

-3

-4

-5

-6

-7

CN205-1

CN206-1

-2

-2

-3

-4

-5

-6

-7

M1

SOL3

SOL1

M2

SOL2

DF Feed

Junction

Gate

DF

Pick-up

DF

Transport

Stamp

Solenoid

A

B

C

D

-2

-1

-2

-1

-3

-2

-1

CN203-1

-2

-3

CN306-3

Original Reverse

Sensor

Original Width

Sensor

S10

CN307-3

S4

E

CN308-4

Original Length 1

Sensor

S5

F

CN309-4

Original Length 2

Sensor

S6

-3

-2

-1

CN203-3

-2

-1

CN103-4

CN104-1

CN104-4

CN104-8

-10

-11

-5

-6

-2

-3

-5

-6

-7

-9

GND

[!5] Original Reverse

+5V

GND

[!5] Original Width 1

[!5] Original Width 2

+5V

[!5] Original Length 1

GND

[!5] LED 3

+5V

[!5] Original Length 2

GND

[!5] LED 1

+24V

DF Feed [!24]

N.C.(-12V)

GND

+5V

DF GATE ["5]

RXD [5 → 5/0]

ZESM

TXD [5 → 5/0]

+5V

N.C.

+24V

+24V

+24V

+24V

GND

GND

GND

GND

CN109-10

-11

CN100-1

-2

-3

-4

-5

-6

-7

-8

CN101-1

-2

-3

-4

-5

-6

-7

-8

-9

CN207-2

-1

CN207

CN207-1

-2

CN332-B8

-B7

-B6

-B5

-B4

-B3

-B2

-B1

CN332-A9

-A8

-A7

-A6

-A5

-A4

-A3

-A2

-A1

MC1

Copier

DF Feed

Clutch

E

F

G

T1

SYMBOL TABLE

DC Line

Pulse Signal

Signal Direction

! Active Low

" Active High

[ ] Voltage

G

Original Trailing

Edge Sensor

S9

CN310-4

-3

-2

-1

CN104-12

-13

-14

-15

+5V

[!5] Trailing Edge

GND

[!5] LED 2

DF Drive Board

(PCB1)

1 2345678910

Page 32

ARDF (B386) ELECTRICAL COMPONENT LAYOUT

1

2

17

16

15

14

3

4

5

Symbol Name Index No. P to P

Motors

M1 DF Feed 10 A9

M2 DF Transport 11 C9

Sensors

6

7

8

S1 DF Position 9 B2

S2 Registration 17 A2

S3 Feed Cover Open 2 C2

S4 Original Width Sensor Board 3 E2

S5 Original Length - 1 4 F2

S6 Original Length - 2 6 F2

S7 Original Set 15 B2

S8 Original Exit 12 D2

S9 Original Trailing Edge 14 G2

S10 Origi nal Reverse 16 D2

13

12

11

10

B386D202.WMF

Solenoids

9

SOL1 DF Pic k- up 5 B9

SOL2 Stamp 13 D9

SOL3 Junction Gate 7 B9

Clutches

MC1 DF Feed 1 D9

PCBs

PCB1 DF Drive 8 G6

Loading...

Loading...