Page 1

DOCUMENT FEEDER

(Machine Code: B444)

Page 2

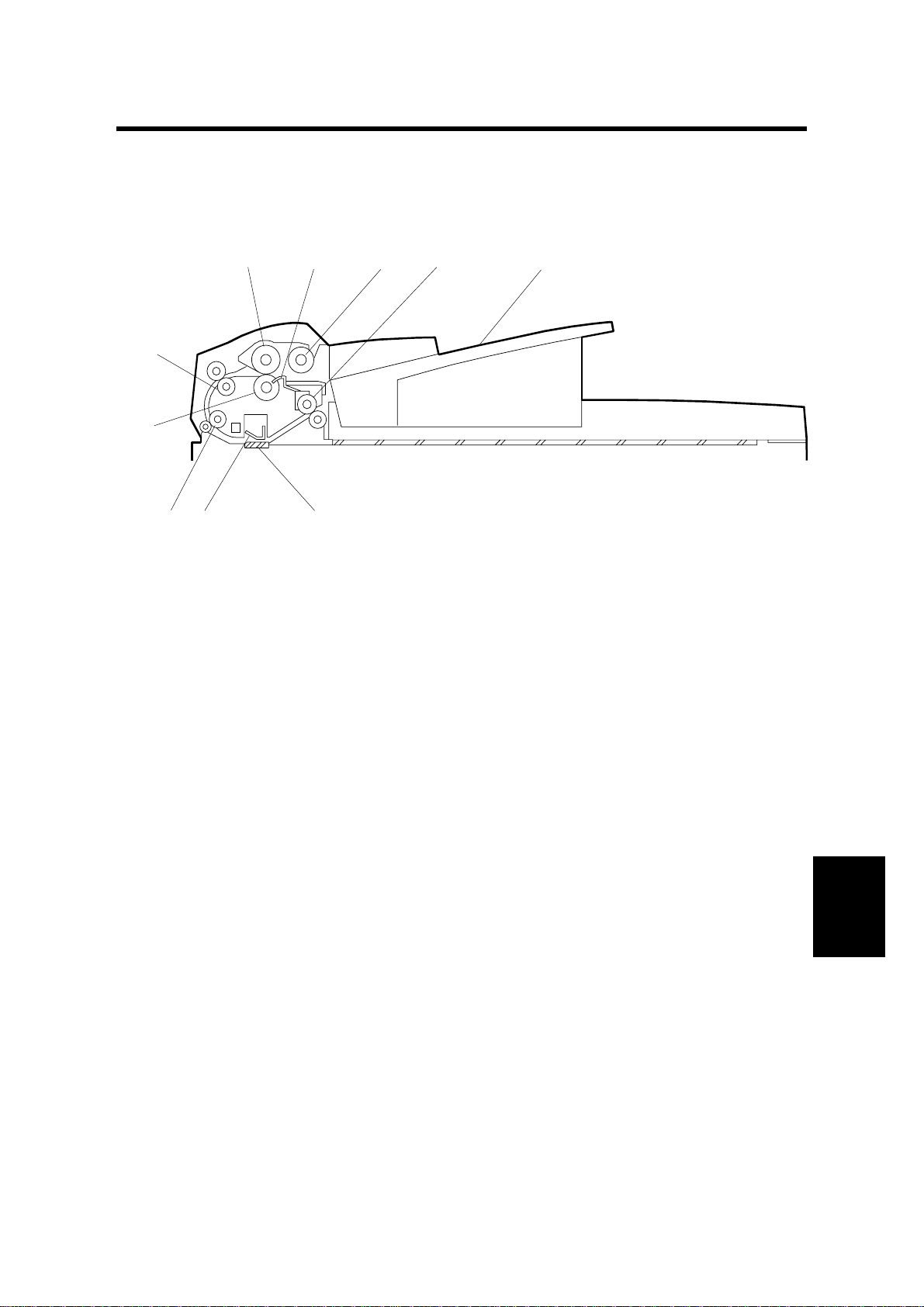

24 July, 2001 MECHANICAL COMPONENT LAYOUT

1. OVERALL INFORMATION

1.1 MECHANICAL COMPONENT LAYOUT

1

10

9

8

1. Feed roller

2. Original set sensor

3. Pickup roller

4. Original exit roller

5. Original table

2

3

4

5

B444V102.WMF

67

6. DF exposure glass

7. White plate

8. 2nd transport roller

9. Separation roller

10. 1st transport roller

B444-1

Peripherals

Page 3

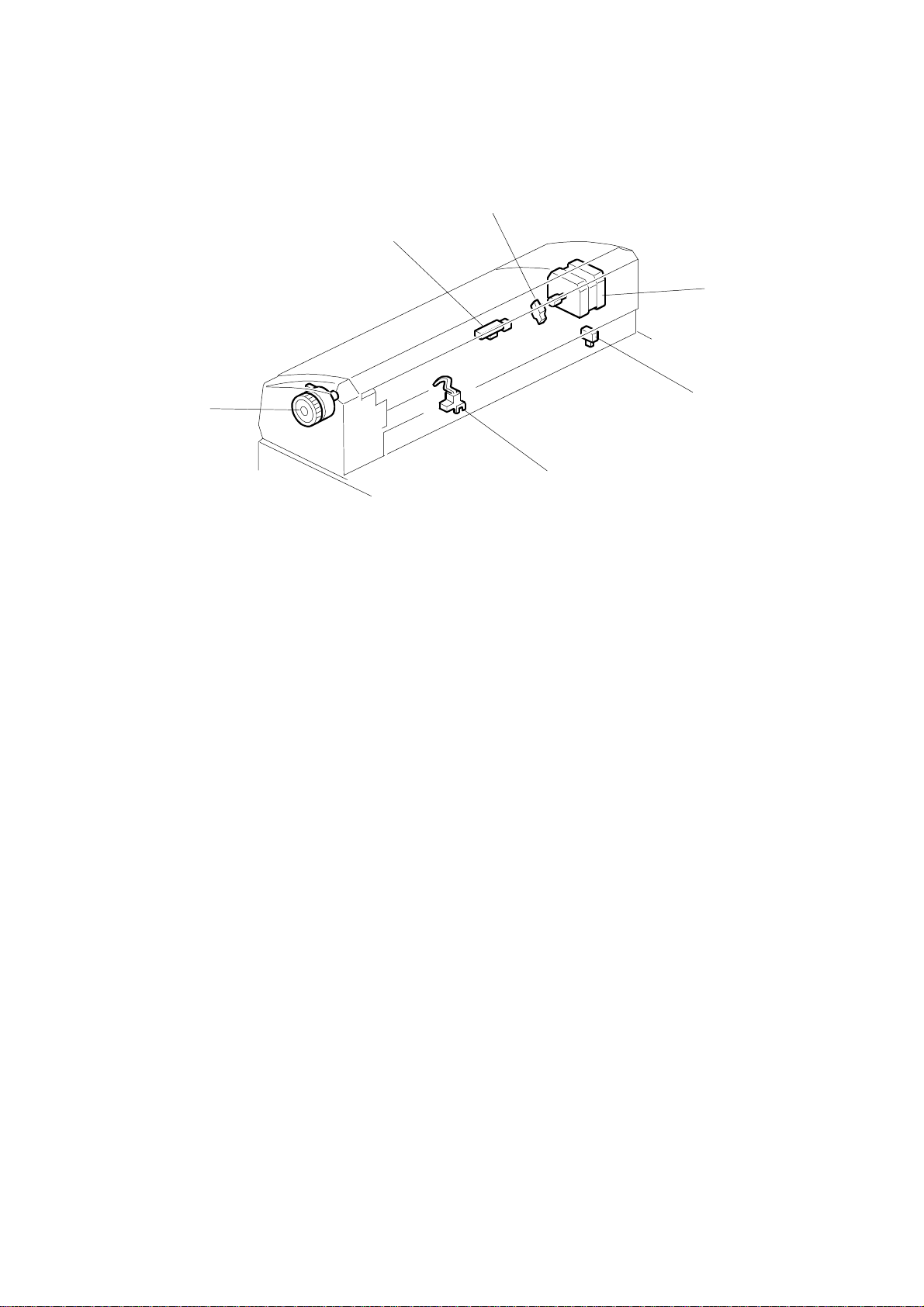

ELECTRICAL COMPONENT LAYOUT 24 July, 2001

1.2 ELECTRICAL COMPONENT LAYOUT

3

2

4

5

1

6

B444V101.WMF

1. DF feed clutch

2. Original registration sensor

3. Guide open sensor

4. DF motor

5. Unit open switch

6. Original set sensor

B444-2

Page 4

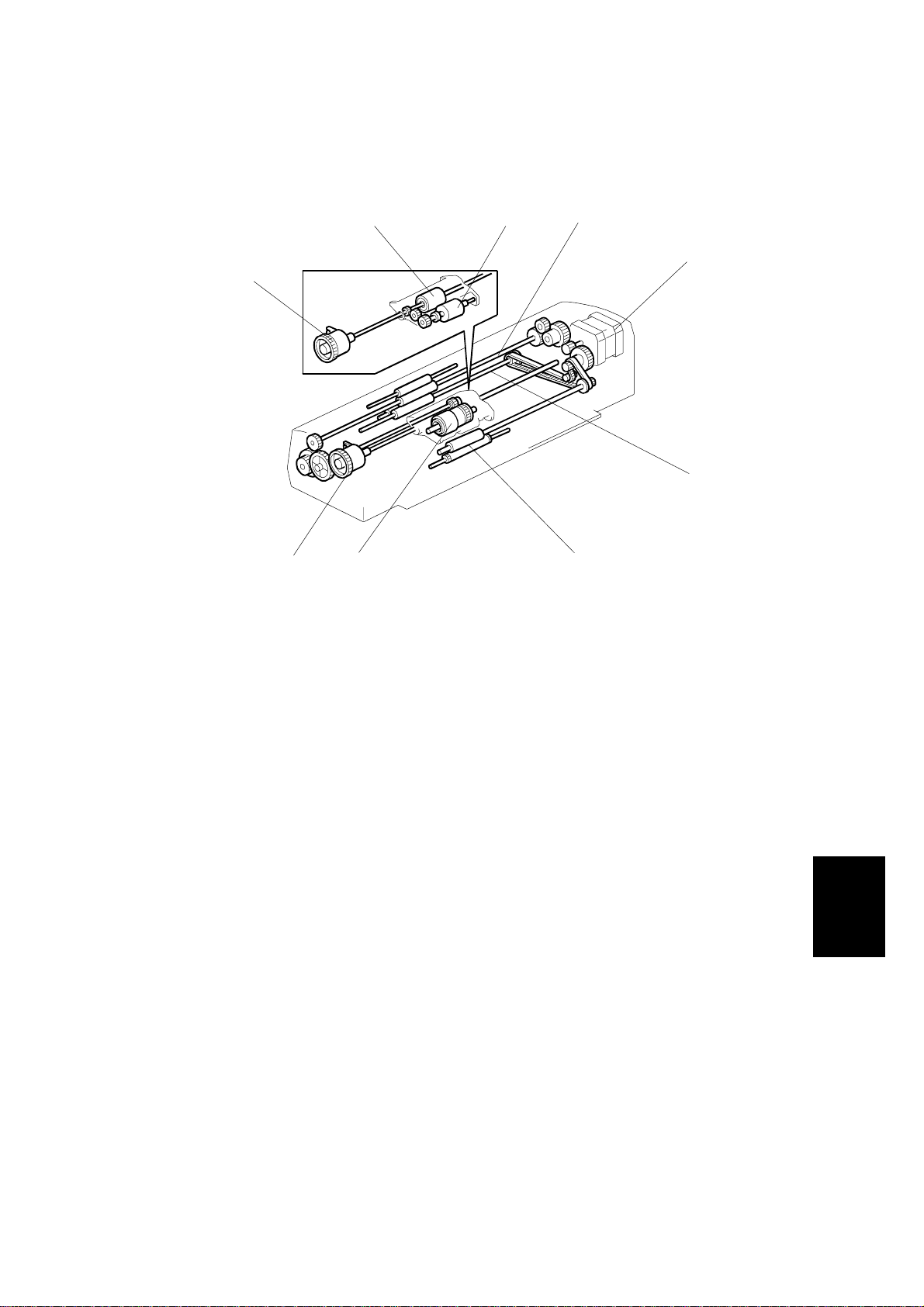

24 July, 2001 DRIVE LAYOUT

1.3 DRIVE LAYOUT

6

6

1. 1st transport roller

2. DF motor

3. 2nd transport roller

4. Exit roller

7 8

B444V104.WMF

5

1

2

3

4

5. DF separation roller

6. DF feed clutch

7. DF feed roller

8. DF pickup roller

B444-3

Peripherals

Page 5

PICK-UP AND SEPARATION 24 July, 2001

2. DETAILED SECTION DESCRIPTIONS

2.1 PICK-UP AND SEPARATION

[A]

[C]

The ADF uses an FRR (feed & reverse roller) system.

Setting paper lowers the feeler [A], causing the original set sensor [B] to inform the

CPU that the ADF is ready to feed.

Press ! → short time lag → DF feed clutch engages → DF motor starts.

The motor drives the DF pickup roller, DF feed roller, DF separation roller, and

transport rollers. The pickup roller drives the top sheet(s) between the feed and

separation roller, where the top sheet is separated and fed to the transport rollers.

[B]

B444V102.WMF

2.2 CLUTCH OPERATION

The DF feed clutch is provided to stop feeding in the event of a jam. During jamfree operation the clutch remains activated for the entire feed cycle. In the event of

a jam the clutch disengages (by torque limiter).

2.3 TRANSPORT AND EXIT

During pickup and feeding of the first sheet, the scanner moves to carry out white

adjustment and then scanning correction.

A short time after the sheet reaches the original registration sensor [C], the DF

motor stops briefly, the scanner moves to DF scan position, and the white peak is

read. The DF motor then restarts and the sheet is scanned. The exit roller ejects

the sheet.

Features of the transport mechanism:

• White peak is read for each sheet. If timing allows, the DF motor continues

running while the peak is read between consecutive trailing and leading edges.

If timing does not allow, the DF motor stops and then restarts.

• Shading correction is repeated every 10 sheets. The DF motor must stop and

restart to carry out this correction.

• Following feeding of the last sheet, the DF motor reverses briefly, raising the

pickup roller.

B444-4

Page 6

24 July, 2001 UNIT OPEN SWITCH AND GUIDE OPEN SENSOR

2.4 UNIT OPEN SWITCH AND GUIDE OPEN SENSOR

The guide open sensor is ON while the DF guide is open, and the unit open switch

is ON when the DF unit itself is raised. The machine will not carry out scanning

when either of these is ON, but will instead display a message instructing the user

to close the DF.

2.5 OVERALL ELECTRICAL CIRCUIT

FCU

Excitation

Sync/Async

Microstep Switch

CN9

Driver Current

Switch

CN10

DF Connection Board

4052

UMG8N

Low Pass Filter

SLA7033M

Motor

Driver

2SD1781

Transistor

CN104

CN105

CN106

DF Motor

Original Set

Sensor

Original

Registration

Sensor

Guide Open

Sensor

DF Feed

Clutch

Peripherals

B444-5

CN107

DF Unit

Open Switch

B444D103.WMF

Page 7

DF UPPER COVERS 24 July, 2001

3. REPLACEMENT AND AD JUSTMENT

3.1 DF UPPER COVERS

1. Open the upper guide [A].

2. DF front upper cover [B] and/or DF rear

upper cover [C] (1 screw each)

[B]

3.2 ORIGINAL TABLE

1. Push the original table [A] to the left

so that the three latches come free

of the platen cover [B], and lift off.

NOTE: When reinstalling, first set

the table flat onto the platen

cover so that the latches go

all the way in to the

openings, and be sure that

the contact area around

each latch is flush against

the cover. Then push so

that latch [1] locks into

place, then latch [2], and

then latch [3].

[1]

[3]

[C]

[A]

B444R101.WMF

[A]

[2]

[B]

B444R103.WMF

3.3 FEED UNIT

1. Raise the upper guide [A].

2. Feed unit [B] (! x 1).

[A]

[B]

B444R105.WMF

B444-6

Page 8

24 July, 2001 DF PICKUP ROLLER

3.4 DF PICKUP ROLLER

1. Feed unit (☛ 3.3)

2. Remove E-ring [A].

3. DF pickup roller [B].

[A]

3.5 DF FEED ROLLER

1. Feed unit (☛ 3.3)

2. Remove E-ring [A].

3. Lift catch [B] and pull shaft in indicated

direction.

4. DF feed roller [C]

[B]

B444R107.WMF

[C]

[B]

[A]

B444-7

B444R108.WMF

Peripherals

Page 9

DF SEPARATION ROLLER 24 July, 2001

3.6 DF SEPARATION ROLLER

1. Feed unit (☛ 3.3)

2. Open the center lid [A]

3. Lift out the separation roller ass'y [B].

4. DF separation roller [C]

[A]

[C]

B444R113.WMF

[B]

B444R110.WMF

B444-8

Page 10

24 July, 2001 DF MOTOR

3.7 DF MOTOR

1. Copier rear cover (☛ Copier Service

Manual, Section 3.3.2)

2. DF rear upper cover (☛ 3.1)

[B]

3. Unscrew and lift away the rear lower

cover [A] (" × 2).

NOTE: It is not necessary to

disconnect all connectors and

remove the cover completely.

When replacing, remember tha t

the left screw [B] must also go

through the ground line [C].

4. Motor bracket [D] (2 screws at [E]).

NOTE: Before removing the bracket,

open the three clamps (not

shown) on the bracket and

take the wiring out of the

them.

5. Motor [F] (2 screws at [G], # × 1).

[C]

B444R114.WMF

[D]

[A]

[E]

NOTE: When reinstalling, be sure that the

belt [H] is arranged as shown in the

illustration.

[H]

[G]

B444R106.WMF

[F]

Peripherals

B444R115.WMF

B444-9

Page 11

DF FEED CLUTCH 24 July, 2001

3.8 DF FEED CLUTCH

1. DF front upper cover (☛ 3.1)

2. Metal retainer [A](" × 2)

3. DF feed clutch [B] (# × 1)

3.9 SENSORS

[A]

[C]

[B]

[A]

B444R104.WMF

B444R109.WMF

1. Feed unit (☛ 3.3)

2. Three lids [A] (" × 2)

[B]: Original set sensor (# × 1)

[C]: Original registration sensor (# × 1)

[D]: Guide open sensor (# × 1)

B444R111.WMF

[B]

[D]

B444R112.WMF

B444-10

Page 12

24 July, 2001 DF EXPOSURE GLASS

3.10 DF EXPOSURE GLASS

1. Press the DF latch and raise the DF

body.

2. Original exit guide [A] (" × 3)

3. DF exposure glass [B]

NOTE: When reinstalling, set the

glass so that its padded side is

facing up.

3.11 DF CONNECTION BOARD

1. Copier rear cover (☛ Copier Service

Manual, Section 3.3.2)

2. DF connection board [A] (" × 5, all

connectors)

[B]

[A]

B444R116.WMF

[A]

B444R117.WMF

Peripherals

B444-11

Loading...

Loading...