Page 1

DOCUMENT FEEDER

(Machine Code: B387)

Page 2

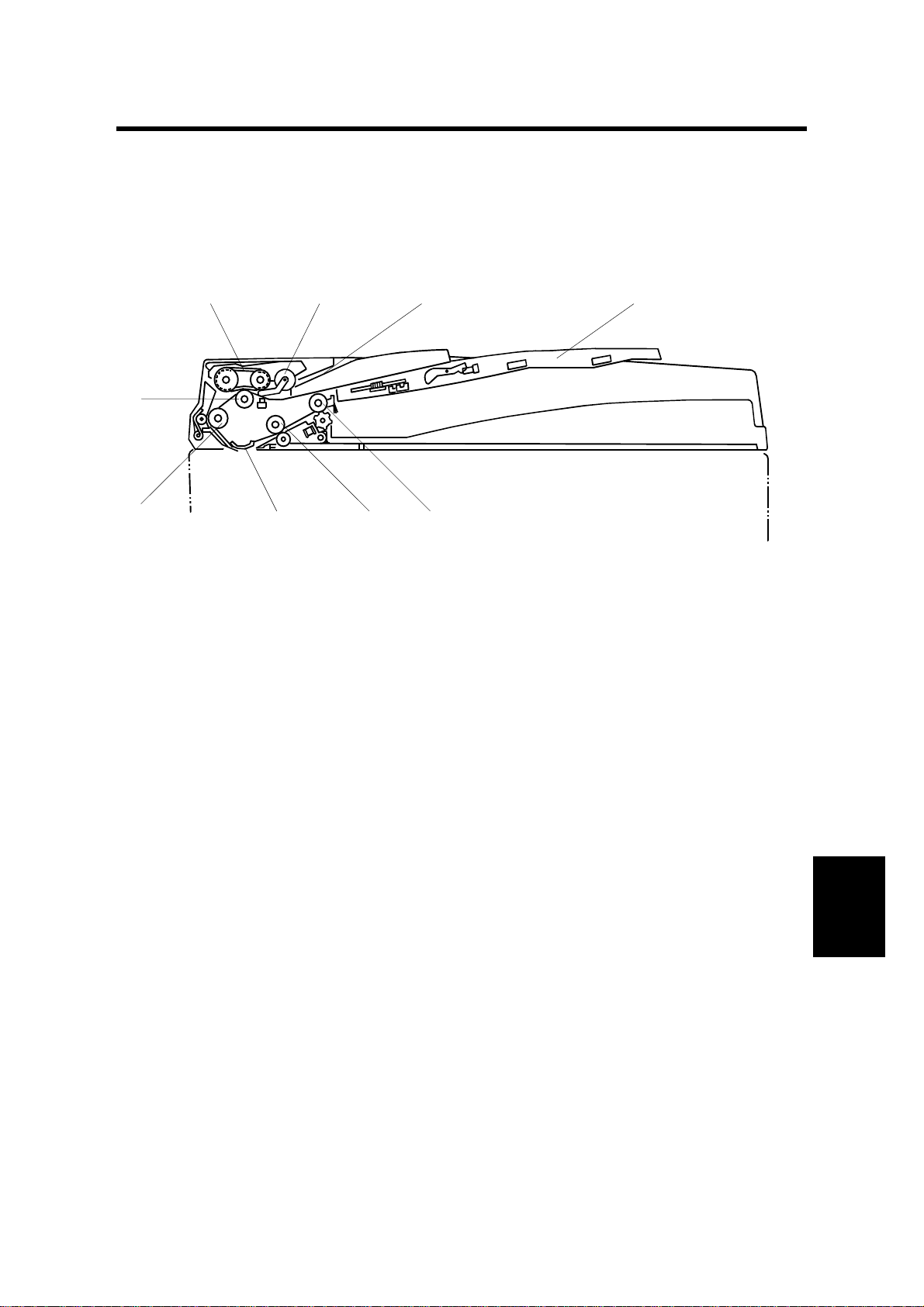

20 February, 2001 MECHANICAL COMPONENT LAYOUT

1. OVERALL INFORMATION

1.1 MECHANICAL COMPONENT LAYOUT

2

1

9

1. Separation roller

2. Original feed belt

3. Pick-up roller

4. Original entrance guide

5. Original table

3 4 5

678

B387V103.WMF

6. Original exit roller

7. 2nd transport roller

8. Original exposure guide

9. 1st transport roller

B387-1

Peripherals

Page 3

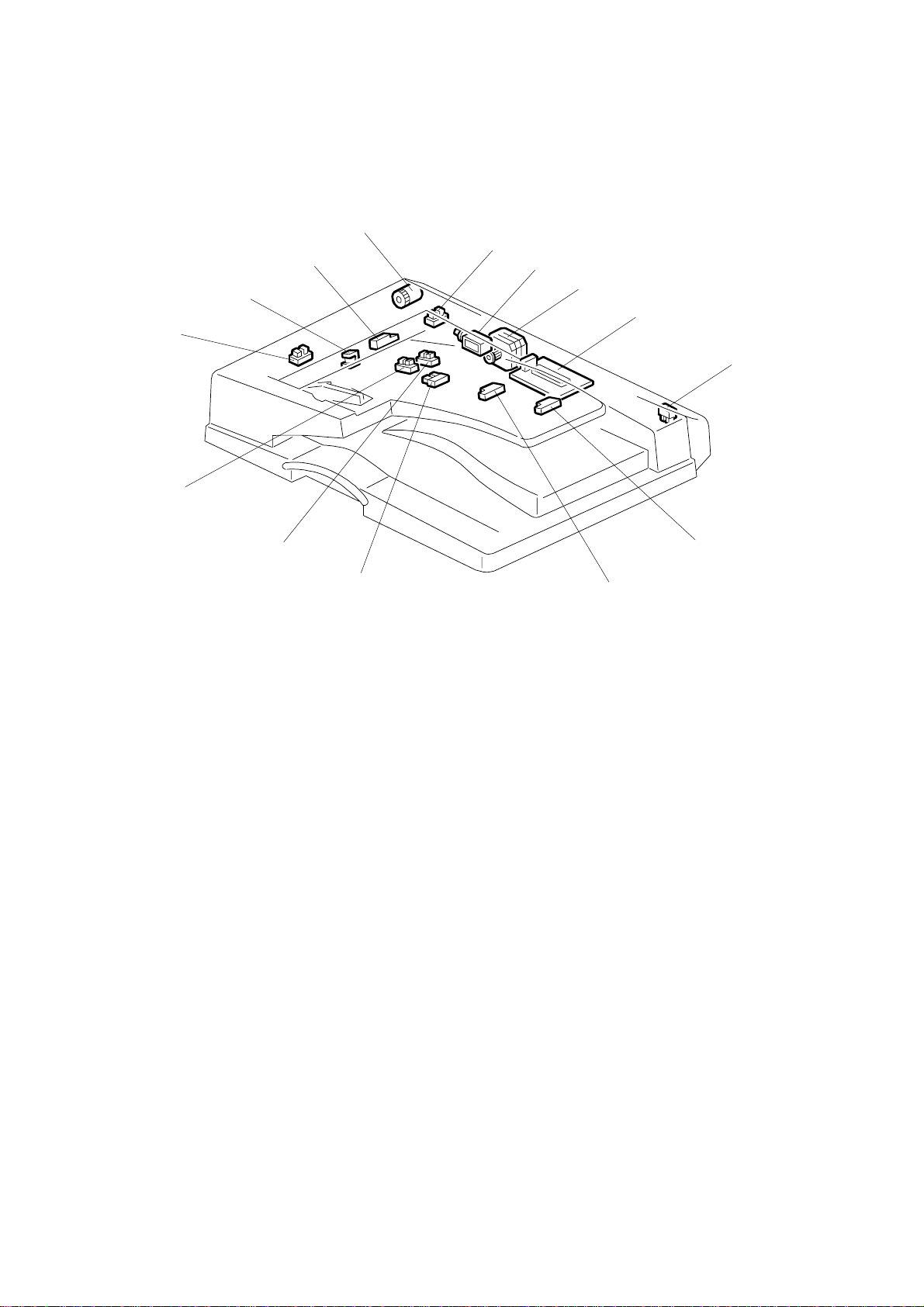

ELECTRICAL COMPONENT LAYOUT 20 February, 2001

1.2 ELECTRICAL COMPONENT LAYOUT

1

2

14

13

12

11

3

4

5

6

10

9

1. DF feed clutch

2. Feed cover open sensor

3. DF pick-up solenoid

4. DF transport motor

5. DF drive board

6. DF position sensor

7. Original length sensor 2

7

8

B387V101.WMF

8. Original length sensor 1

9. Original trailing edge sensor

10. Original width sensor 1

11. Original width sensor 2

12. Original set sensor

13. Stamp solenoid

14. Registration sensor

B387-2

Page 4

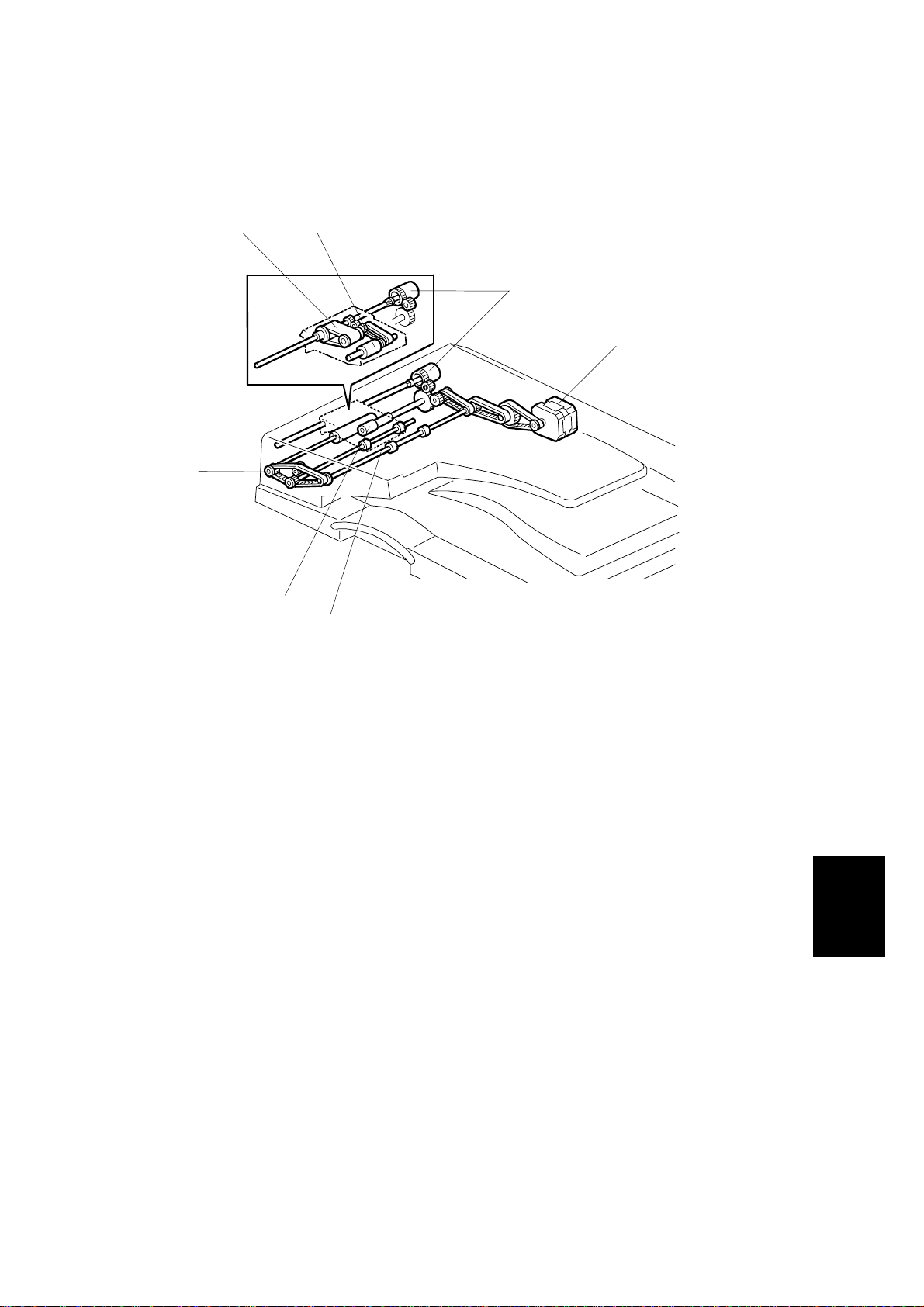

20 February, 2001 DRIVE LAYOUT

1.3 DRIVE LAYOUT

87

1

2

6

5

4

1. DF feed clutch

2. DF transport motor

3. 2nd transport roller

4. Exit roller

B387V102.WMF

5. Separation roller

6. 1st transport roller

7. Original feed belt

8. Pick-up roller

Peripherals

B387-3

Page 5

ORIGINAL SIZE DETECTION 20 February, 2001

2. DETAILED SECTION DESCRIPTIONS

2.1 ORIGINAL SIZE DETECTION

[B]

[C]

[A]

[E]

The DF uses two width sensors (width sensor 1 [A] and width sensor 2 [B]) to

detect the original width, and two length sensors (length sensor 1 [C] and length

sensor 2 [D]) to detect the original length. The DF detects the original size based

on the combination of inputs from these sensors, as indicated in the table on the

next page.

If using a non-standard original size, the user must input the original length at the

operation panel.

The original width sensors have four possible output states: P1 to P4. The output

depends on the position of the ridges on the toothed plate attached to the original

rear fence.

During one-to-one copying, copy paper is fed to the registration roller in advance to

increase the copy speed. The original exit trailing edge se nsor [E] monitors the

stack of originals in the feeder, and detects when the trailing edge of the last page

has been fed in. This stops the ADF from causing the feed of an unwanted extra

sheet of copy paper.

[D]

B387V101.WMF

B387-4

Page 6

20 February, 2001 ORIGINAL SIZE DETECTION

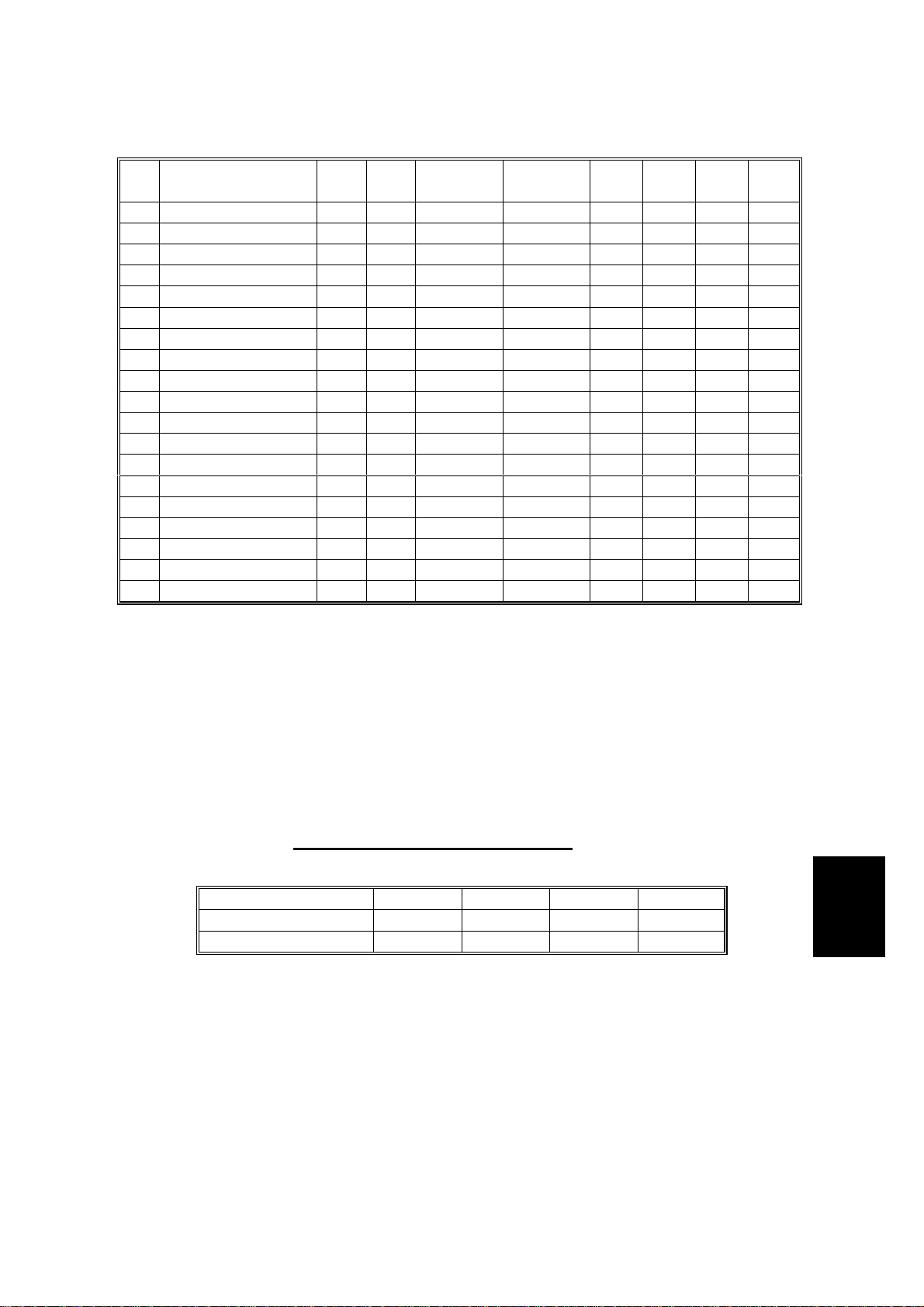

1 A3 (297 x 420)

2 B4 (257 x 364)

3 A4 SEF (210 x 297)

4 A4 LEF (297 x 210)

5 B5 SEF (182 x 257)

6 B5 LEF (257 x 182)

7 A5 SEF (148 x 210)

8 A5 LEF (210 x 148)

9 11" x 17"

10 11" x 15"

11 10" x 14"

1/2

12 8

13 8

1/2

" x 14"

" x 13"

14 8" x 13"

1/2

15 8

16 11" x 8

" x 11" SEF

1/2

" LEF

17 8" x 10" SEF

18 5

19 8

1/2

1/2

" x 8

" x 5

1/2

1/2

" SEF

" LEF

NA EU

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

1 ✗

❍

1

#

✗

❍✗

❍

2 ✗

✗❍

2

#

3 ✗

❍

#

4

4

❍✗

3

#

✗

❍✗

❍✗

Original

Length 1

Original

Length 2

P1 P2 P3 P4

ON ON - - - ON

ON ON - - ON ON - - ON - -

-----ON

ON - ON - - -

----ON-

--ON---

---ON-ON ON - - - ON

ON ON - - - ON

ON ON - - ON ON ON - ON - ON ON - ON - ON ON - ON - ON - - ON - -

-----ON

ON - - ON - -

--ON---

---ON--

NA: America (North, Middle, South) EU: Europe, Asia, China, Taiwan

✗: No ❍: Yes ON: Paper present

❍1, #1: In NA, original size 11" x 15" is detected as 11" x 17"

❍2, #2: In NA, original size 8" x 13" is detected as 8

❍3, #3: In NA, original size 8" x 10" is detected as 8

❍4, #4: In EU, original size 8" x 13" is detected as 8

1/2

1/2

1/2

" x 14"

" x 11"

" x 13"

- Original Width Sensor States -

Width Sensor 1 High Low Low High

Width Sensor 2 High High Low Low

Detection State P1 P2 P3 P4

Low = Blocked High = Open

Peripherals

B387-5

Page 7

PICK-UP AND SEPARATION 20 February, 2001

2.2 PICK-UP AND SEPARATION

[D]

[E]

[F]

[C]

[A]

B387D102.WMF

[B]

[H]

[G]

[I]

B387D106.WMF

An FRR (feed and reverse roller) system is used.

Setting original(s) onto the feed table lifts the original set sensor feeler [A], causing

the original set sensor [B] to issue a signal informing the main CPU that the DF is

ready to start feeding.

When the Start key (!) is pressed, the DF pick-up solenoid [C] turns on, causing

the transport guide [D] and pick-up roller [E] to lo wer onto the original, while at the

same time causing the original stoppers [F] to drop down to clear the feed path for

the original. After 200 ms, the DF transport motor [G] turns on, feeding the top

original page to the paper feed belt [H], where it is separated by the separation

roller [I].

B387-6

Page 8

20 February, 2001 ORIGINAL TRANSPORT AND EXIT MECHANISM

2.3 ORIGINAL TRANSPORT AND EXIT MECHANISM

[D]

[A]

[B]

[C]

B387V104.WMF

When the leading edge of the original reaches the registration sensor at [A], the DF

transport motor turns off. After a short time the DF transport motor turns on again.

The original is fed past the DF exposure glass [B], where it is scanned. It is then

fed through to the 2nd transport roller [C] and fed out by the exit roller [D].

The DF transport motor uses a constant speed to feed the original up to the

registration sensor. When the motor turns on again to feed the original to the DF

exposure glass, however, the speed depends on the selected reproduction ratio. At

100%, the speed is 89 mm/s.

Peripherals

B387-7

Page 9

STAMP 20 February, 2001

2.4 STAMP

[C]

[A]

[B]

B387D103.WMF

This function is only for fax mode. The fax unit includes the stamp.

The stamp solenoid [A] is located between the 2nd transport roller [B] and the exit

roller [C]. The copier controls this solenoid directly.

When the original reaches the stamp position, the DF transport motor stops.

Provided that the page was sent successfully (immediate transmission) or stored

successfully (memory transmission), the stamp solenoid then comes on 300 ms

after the DF motor stops. After stamping, the DF transport motor resumes feeding,

at about 1.3 times the normal speed.

The positioning of the stamp on the original can be adjusted using SP6-010.

B387-8

Page 10

20 February, 2001 TIMING CHARTS

2.5 TIMING CHARTS

2.5.1 A3

200ms

Exits

Original

Preset

No Next

Preset

No Original

Fed

Original

Preset

Next Original

Feed, Scanning, Exit Feed, Scanning, Exit

Fed

Original

50ms

50ms

168.1mm

5mm

5mm

50ms

369.1mm

369.1mm

15mm

15mm15mm

Preset

Next Original

Feed, Scanning, Exit

Feed

RXD

Fed

Original

Info

Orig. Size

TXD

50ms

OFF

MAX

READ

CW

Transport

Motor

5mm

JAM4 *1

369.1mm (Paper length - ((Separation

to Regist. Sensor) + 15mm))

JAM1 *1

200ms

OFF

ON

OFF

ON

Pick-up

Clutch

Solenoid

DF Feed

21.0mm(27.0-5-1mm)

JAM2, 3 *1

OFF

ON

Original Set

Sensor

B387-9

OFF

ON

Registration

Sensor

420mm *2

DISABLE

ENABLE

FGATE

Peripherals

This signal goes high when the laser start to wire a pate to the drum.

The distance depends on SP mode setting 6-006-2 and -3.

For information about jam conditions, see Section 1.6.

F Gate:*2

*1

B387D001.WMF

Page 11

TIMING CHARTS 20 February, 2001

2.5.2 A3, STAMP MODE

200ms

50ms

Exits

Original

168.1mm

Finish

Stamp

Stop

Stamp

Position

*2

71.2mm

Orig.

Length &

No

Orig.

No Next

Set

Original

50ms50ms

Fed

Scanning, Stamp Position Stop

Exit Stamp Exit

Stamp

Scanning, Stamp Position Stop

Feed

Original

Finish

Stamp

Stop

Stamp

Position

Present

& Next Orig.

Orig. Length

Fed

Original

Info

Orig. Size

MAX

CW

OFF

READ

50ms

50ms

200mm

JAM1 *1

200ms

ON

OFF

ON

OFF

JAM4 *1

*2

71.2mm

21.0mm(27.0-1mm)

JAM2, 3 *1

OFF

ON

420mm *2

DISABLE

ENABLE

200mm 200mm

OFF

ON

This signal goes high when the laser start to wire a pate to the drum.

The distance depends on SP mode setting 6-006-2 and -3.

For information about jam conditions, see Section 1.6.

F Gate:*2

*1

RXD

TXD

Transport

Motor

Pick-up

DF Feed

Clutch

B387-10

Solenoid

Original Set

Sensor

FGATE

Stamp

B387D002.WMF

Page 12

20 February, 2001 JAM DETECTION

2.6 JAM DETECTION

JAM 1:

If the registration sensor fails to turn on within x1 ms after the DF

transport motor comes on to feed the original from the original tray.

x1 = (114 x 1.1)/original speed + 2,000 ms

JAM 2:

If the registration sensor fails to turn off within x2 ms after the DF

transport motor comes on to feed the original from the original tray.

x2 = (original length/original speed) + 2,000 ms

JAM 3: If there is no original at the registration sensor when scanning is started,

even though the sensor had already turned on.

JAM 4: The current original is stopped after the registration sensor detects its

leading edge, but the previous original is still at the scanning position.

JAM 5: If the original stopped at the stamp position is removed.

JAM 6: If the cover is opened or the ADF is lifted up while the ADF is in

operation.

JAM 7: If the DF gate signal (indicating that the original is now in the correct

position for scanning) is not asserted whe n the original trailing edge

passes the DF exposure glass.

JAM 7 occurs when the original is pulled out while it is being scanned.

B387-11

Peripherals

Page 13

OVERALL ELECTRICAL CIRCUIT 20 February, 2001

2.7 OVERALL ELECTRICAL CIRCUIT

The DF CPU controls the DF transport motor, DF feed clutch, DF pick-up solenoid,

and stamp solenoid. The DF CPU also monitors all sensors and provides updated

status when prompted at regular intervals by the mainframe, which may then take

action based on this information. The DF/mainframe connection is checked

automatically immediately after the mainframe is powered on.

Main

Frame

Registration Sensor

Original Set Sensor

DF Position Sensor

Feed Cover Open Sensor

Original Width Sensor 1

Original Width Sensor 2

Original Length Sensor 1

Original Length Sensor 2

Original Trailing Edge Sensor

Interface

ADF Control

CPU

Driver

Driver

ADF Control Board

DF Feed Motor

DF Feed Clutch

DF Pick-up

Solenoid

Stamp Solenoid

B387-12

B387D500.WMF

Page 14

20 February, 2001 FREE RUN

2.8 FREE RUN

You can use DIP switch 100 (on the DF control board) to carry out a one-sided free

run.

Bits

1 OFF ON OFF ON

2OFFOFFONON

Mode Normal FR FR FR

FR: Free run

Procedure

1. Set bit 1 and/or bit 2 on SW100 (on the DF control board) to ON.

2. Set originals on the original table.

3. The free run starts automatically after about 2 seconds.

4. To stop the run, se t SW100 bits 1 and 2 back to OFF. To ensu re that the

system correctly resets, turn power off and then back on.

Free Run Process

1. Set originals on the DF table.

2. The first original sheet feeds into the DF.

3. The sensor detects the original.

4. The DF outputs the original to the exit tray.

5. Steps 2 through 4 repeat for each subsequent original sheet. When all

originals have been fed, the DF stops and waits for more.

Peripherals

B387-13

Page 15

EXTERIOR COVERS 20 February, 2001

3. REPLACEMENT AND AD JUSTMENT

3.1 EXTERIOR COVERS

3.1.1 REAR COVER

1. Lift the DF.

2. Unhook the three latches [A] in the

order marked on the DF body.

3. Close the DF.

4. Open the DF feed cover [B].

5. Rear cover [C] (! x 1)

3.1.2 ORIGINAL TABLE

1. Rear cover (☛ 3.1.1)

2. Original table [D] (! x 2, " x 2)

3.1.3 FRONT COVER

1. Open the DF feed cover [B].

2. Original table. (☛ 3.1.2)

3. Front cover [E] (! x 2)

[E]

[B]

[F]

[A]

B387R120.WMF

[G]

[C]

[D]

3.1.4 ORIGINAL ENTRANCE GUIDE

1. Feed unit (☛ 3.2)

2. Original table (☛ 3.1.2)

3. Roller cover [F]

4. Original entrance guide [G] (! x 4)

B387-14

B387R106.WMF

Page 16

20 February, 2001 FEED UNIT

3.1.5 DF FEED COVER

1. Rear cover (☛ 3.1.1)

2. Original table (☛ 3.1.2)

3. Front cover (☛ 3.1.3)

4. Clip [A]

5. Strap [B] (# x 1)

6. DF feed cover [C] (! x 2)

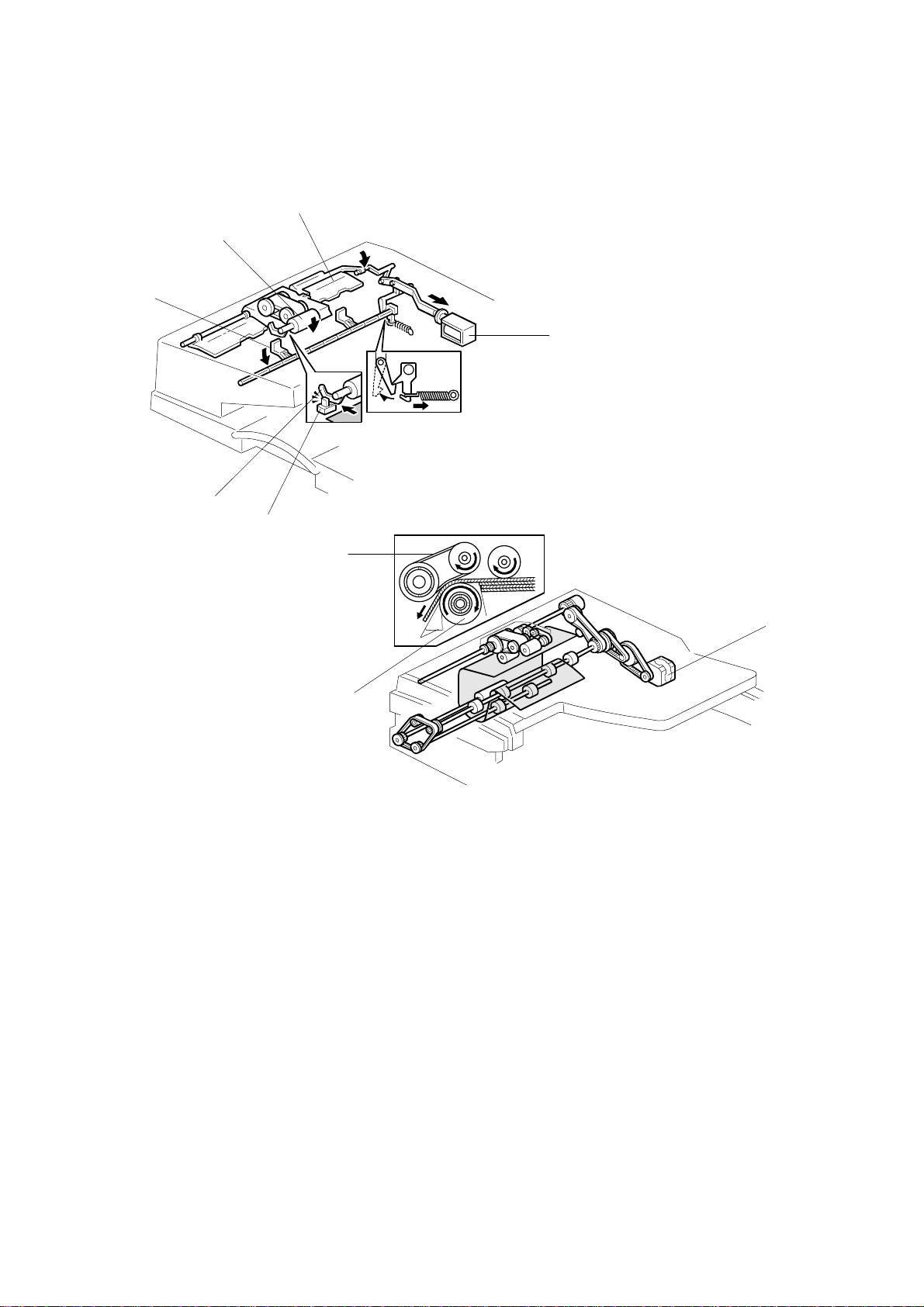

3.2 FEED UNIT

1. Open the DF feed cover [D] and

detach the strap [E] (# x 1).

2. Raise the front guide flap [F] to

about a 45-degree angle, and

push the feed unit [G] into the

spring so that it comes free.

NOTE: 1) The feed unit comes off

very easily if you first lift

flap [H] to about a 45degree angle.

2) When re installing, be

sure that the lever [I] is

above the pin [J].

[C]

[J]

[I]

[D]

[F]

[A]

[B]

B387R110.WMF

[E]

[G]

[H]

B387R101.WMF

3.3 SEPARATION ROLLER

1. Feed unit (☛ 3.2)

2. Roller cover [K]

3. Separation roller [L] (# x 1).

B387-15

[L]

[K]

Peripherals

B387R105.WMF

Page 17

PICK-UP ROLLER 20 February, 2001

3.4 PICK-UP ROLLER

[B]

[A]

[C]

B387R102.WMF

1. Feed unit (☛ 3.2)

2. Remove 2 clip rings and 1 bushing [A]

3. Pull the shaft [B] part way out at the gear end, so that the pick-up roller [C] can

be taken off.

3.5 FEED BELT

[F]

[D]

B387R103.WMF

[E]

1. Feed unit (☛ 3.2)

2. Pick-up roller housing [D]

3. Push down on the lower wings [E] of the tensioning piece [F], so that the

tensioning piece comes free of the shaft.

B387R104.WMF

[G]

4. Take the tensioning piece out, and then remove the belt [G].

B387-16

Page 18

20 February, 2001 ORIGINAL SENSORS (WIDTH, LENGTH, TRAILING EDGE)

3.6 ORIGINAL SENSORS (WIDTH, LENGTH, TRAILING

EDGE)

[A]

B387R107.WMF

[E]

[F]

[D]

B387R108.WMF

1. Original table (☛ 3.1.2)

2. Sensor platform [A] (! x 3).

3. Length sensors [B], [C] (1 connector on each sensor)

NOTE: Replace both sensors at the same time, together with the wiring and

connectors.

4. Width sensors [D], [E], and trailing edge sensor [F] (" x 1 on each sensor)

NOTE: Replace all three sensors at the same time, together with the wiring

and connectors.

[B]

[C]

Peripherals

B387-17

Page 19

ORIGINAL SET SENSOR 20 February, 2001

3.7 ORIGINAL SET SENSOR

[B]

[A]

B387R109.WMF

1. Original entrance guide (☛ 3.1.4)

2. Sensor bracket [A] (! x 1)

3. Original set sensor [B] (" x 1)

3.8 TRANSPORT MOTOR

[D]

[E]

[C]

B387R111.WMF

1. Rear cover (☛ 3.1.1)

2. Open the wire clamp [C] at the top of the motor bracket [D].

3. Motor bracket [D] (! x 2 , 1 spring)

NOTE: Unhook the spring at the board side.

4. Transport motor [E] (! x 2, " x 1)

B387-18

Page 20

20 February, 2001 FEED COVER OPEN SENSOR/

FEED CLUTCH/ROM/DF DRIVE BOARD

3.9 FEED COVER OPEN SENSOR/

FEED CLUTCH/ROM/DF DRIVE BOARD

[D]

[B]

[E]

Exterior

1. Rear cover (☛ 3.1.1)

[A]

[C]

B387R199.WMF

Feed Cover Open Sensor

2. Sensor bracket [A] (! x 1)

3. Feed cover open sensor [B] (! x 1)

Feed Clutch

2. Feed unit (☛ 3.2)

3. Feed clutch [C] (" x 1, 1 bushing, ! x 1).

NOTE: Pull the shaft inward until the clutch can be removed.

ROM

2. Replace the ROM [D] on the DF drive board.

DF Drive Board

2. DF drive board [E] (# x 3, all connectors)

B387-19

Peripherals

Page 21

REGISTRATION SENSOR 20 February, 2001

3.10 REGISTRATION SENSOR

[C]

[B]

[A]

B387R113.WMF

1. DF feed cover (☛ 3.1.5)

2. Original entrance guide (☛ 3.1.4)

3. Outer turn guide [A] (! x 2)

4. Pop out the inner turn guide [B], and remove the registration sensor [C] (" x

1)

3.11 PICK-UP SOLENOID

[D]

1. Rear cover (☛ 3.1.1)

2. Pick-up solenoid [D] (! x 2, " x 1)

B387-20

B387R112.WMF

Page 22

20 February, 2001 STAMP SOLENOID

3.12 STAMP SOLENOID

[B]

[A]

[D]

[C]

B387R114.WMF

1. Rear cover (☛ 3.1.1)

2. Disconnect the stamp solenoid connector.

NOTE: Pull out the small connector piece from the large connector. (The large

connector itself cannot fit through the hole in the frame.)

3. Lift the ADF upright and pull open the exit guide [A]. Release the front and rear

hooks [B] and open the cover [C].

4. Remove the stamp solenoid [D] (! x 1), and pull it out together with the wire.

Peripherals

B387-21

Page 23

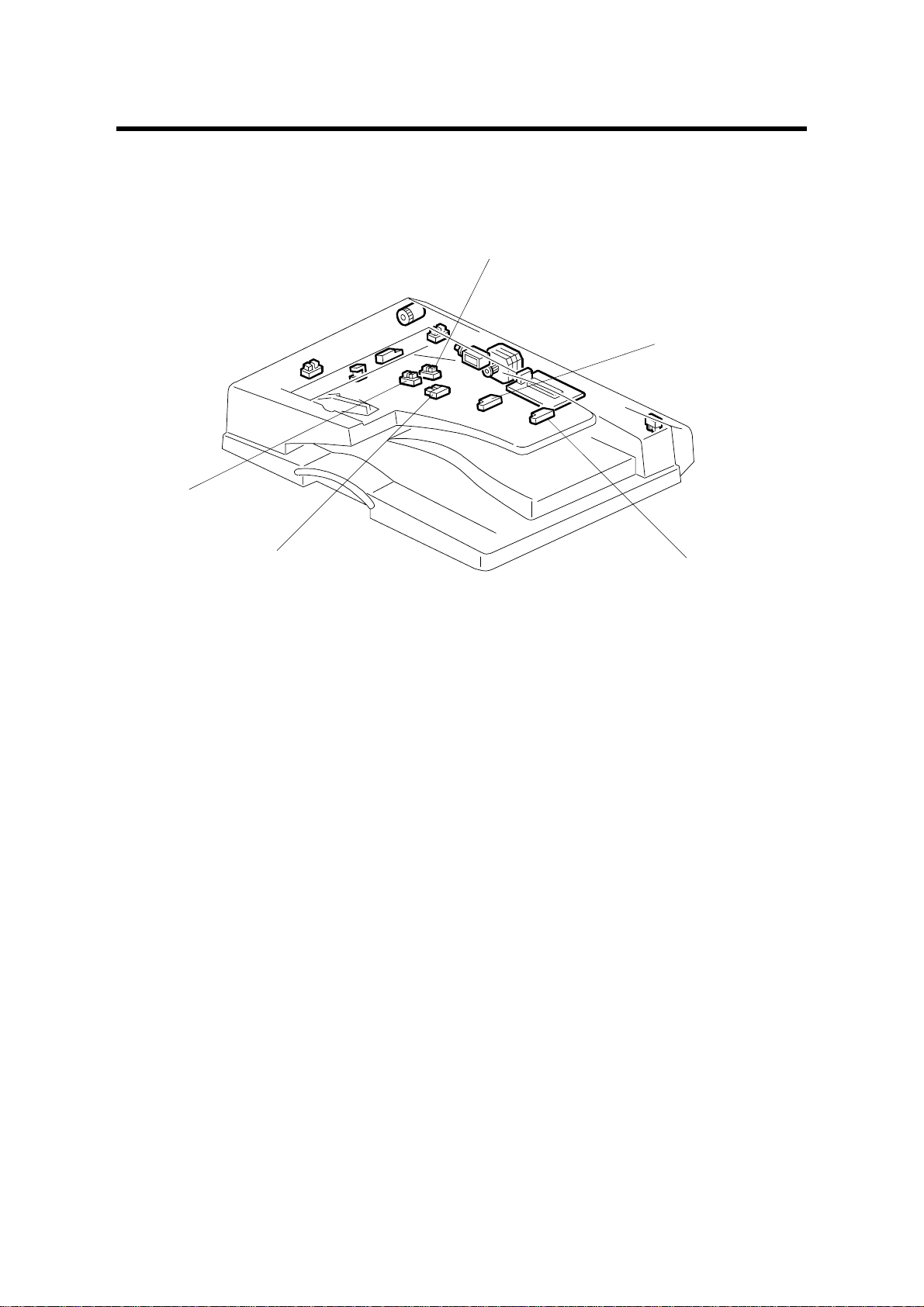

ELECTRICAL COMPONENT LAYOUT (B387)

1

14

13

2

3

4

5

12

6

11

10

9

8

7

B387V101.WMF

Symbol Name Index No. P-to-P

Motors

M1 DF Transport 4 J13

Sensors

S1 Registration 14 J14

S2 Original Set 12 J14

S3 DF Position 6 J14

S4 Feed Cover Open 2 J15

S5 Original Width 1 10 J15

S6 Original Width 2 11 J15

S7 Original Trailing Edge 9 J15

S8 Original Length 1 7 J16

S9 Original Length 2 8 J16

Solenoids

SOL1 Stamp 13 J13

SOL2 DF Pick-up 3 J14

Magnetic Clutches

MC1 DF Feed 1 J13

PCBs

PCB1 DF Drive 5 I13-16

Loading...

Loading...