Ricoh df71 Service Manual

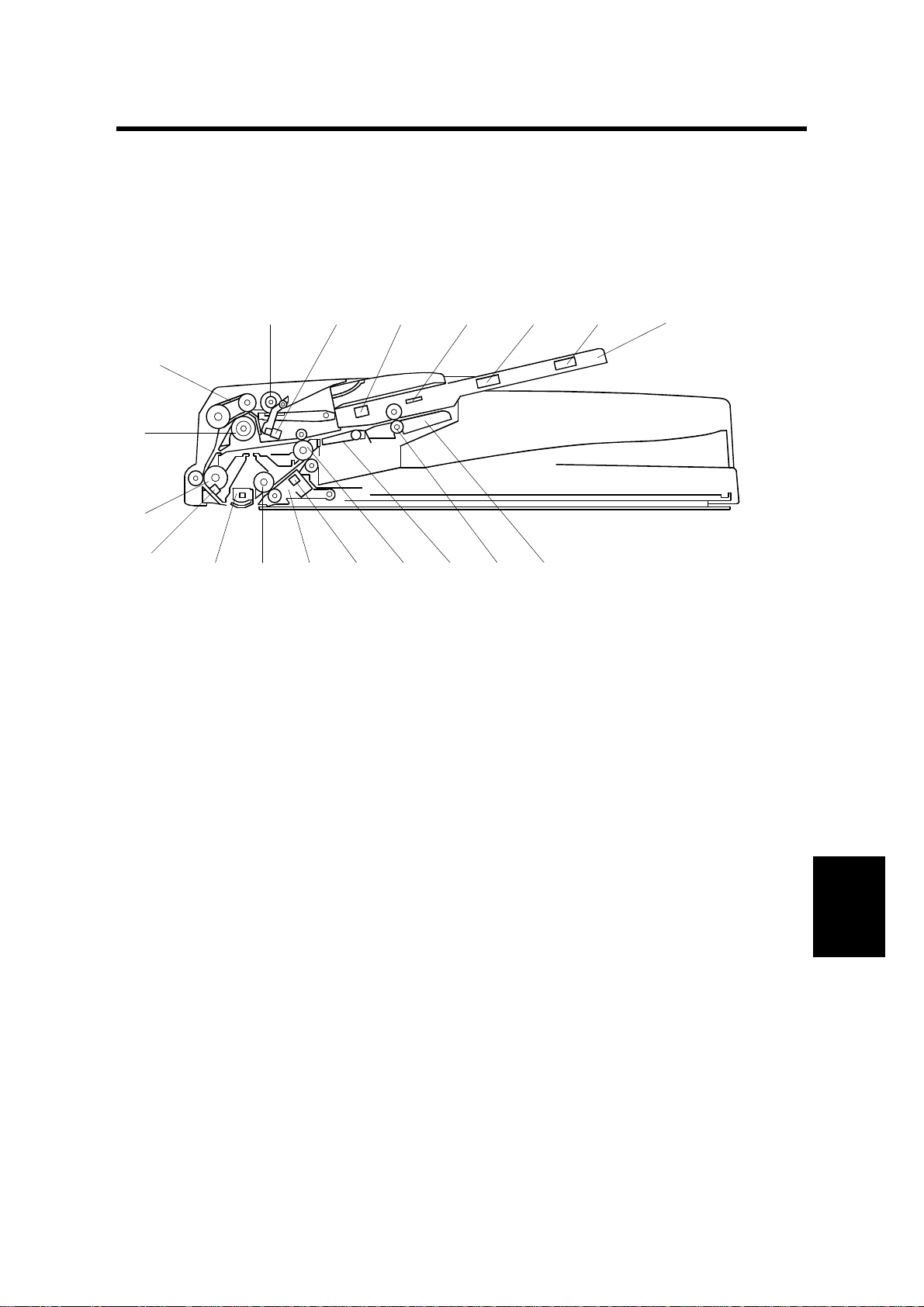

AUTO REVERSE DOCUMENT FEEDER

(Machine Code: B379)

20 February, 2001 MECHANICAL COMPONENT LAYOUT

1. OVERALL MACHINE INFORMATION

1.1 MECHANICAL COMPONENT LAYOUT

3 4 5 6 7 8

2

1

19

18

1617

15 14 13 12 11 10

1. Separation Roller

2. Paper Feed Belt

3. Pick-up Roller

4. Original Set Sensor

5. Original Trailing Edge Sensor

6. Original Width Sensor Board

7. Original Length Sensor 1

8. Original Length Sensor 2

9. Original Table

10. Reverse Table

9

B379D201.WMF

11. Reverse Roller

12. Junction Gate

13. Exit Roller

14. Original Exit Sensor

15. Stamp

16. 2nd Transport Roller

17. Original Exposure Guide

18. Registration Sensor

19. 1st Transport Roller

Peripherals

B379-1

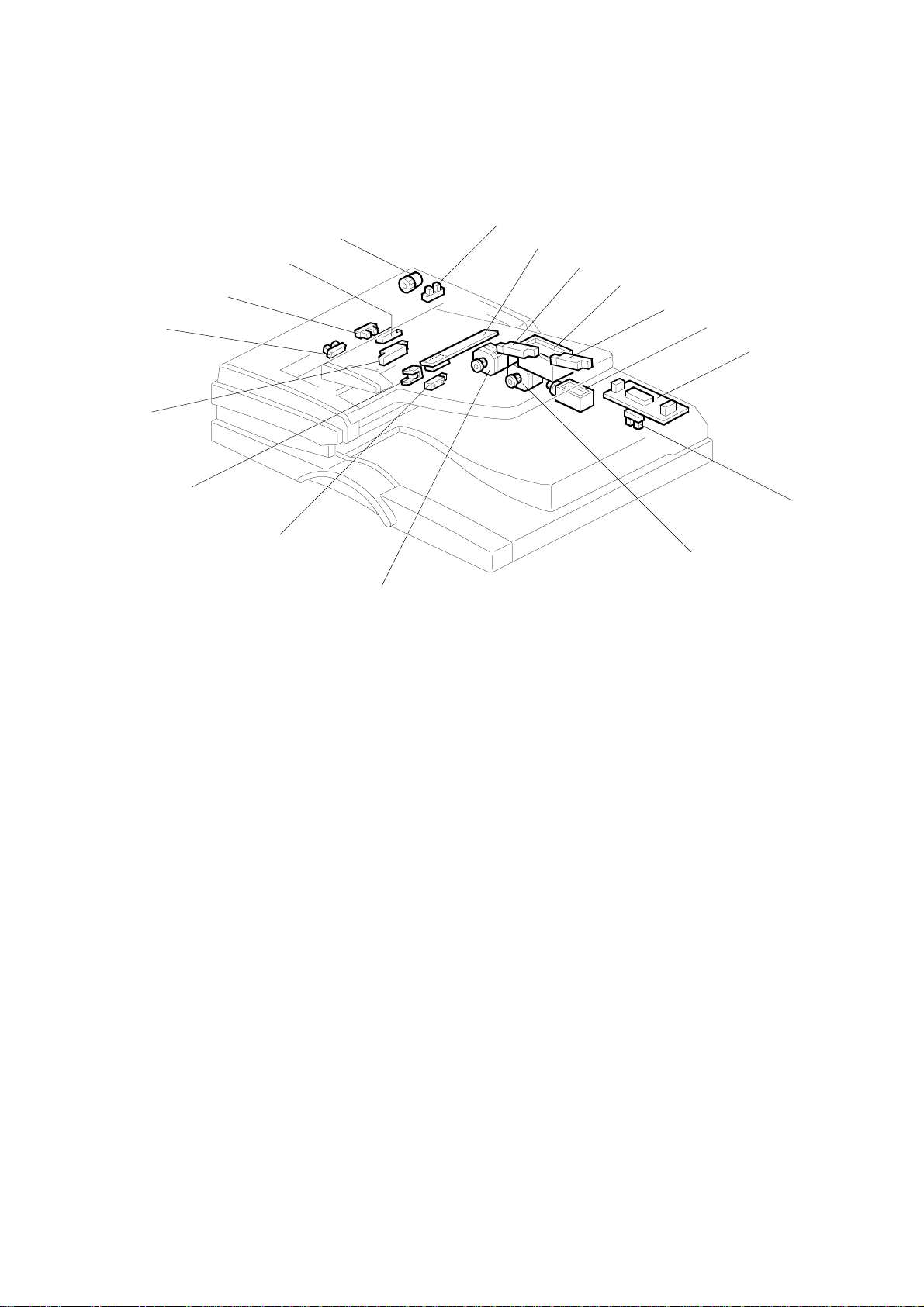

ELECTRICAL COMPONENT LAYOUT 20 February, 2001

1.2 ELECTRICAL COMPONENT LAYOUT

14

15

13

16

12

17

1

3

4

5

6

7

8

9

10

2

11

B379D202.WMF

1. DF Feed Clutch

2. Feed Cover Sensor

3. Original Width Sensor Board

4. Original Length Sensor 1

5. DF Pick-up Solenoid

6. Original Length Sensor 2

7. Junction Gate Solenoid

8. DF Drive PCB

9. DF Position Sensor

10. DF Feed Motor

11. DF Transport Motor

12. Original Exit Sensor

13. Stamp Solenoid

14. Original Trailing Edge Sens or

15. Original Set Sensor

16. Original Reverse Sensor

17. Registration Sensor

B379-2

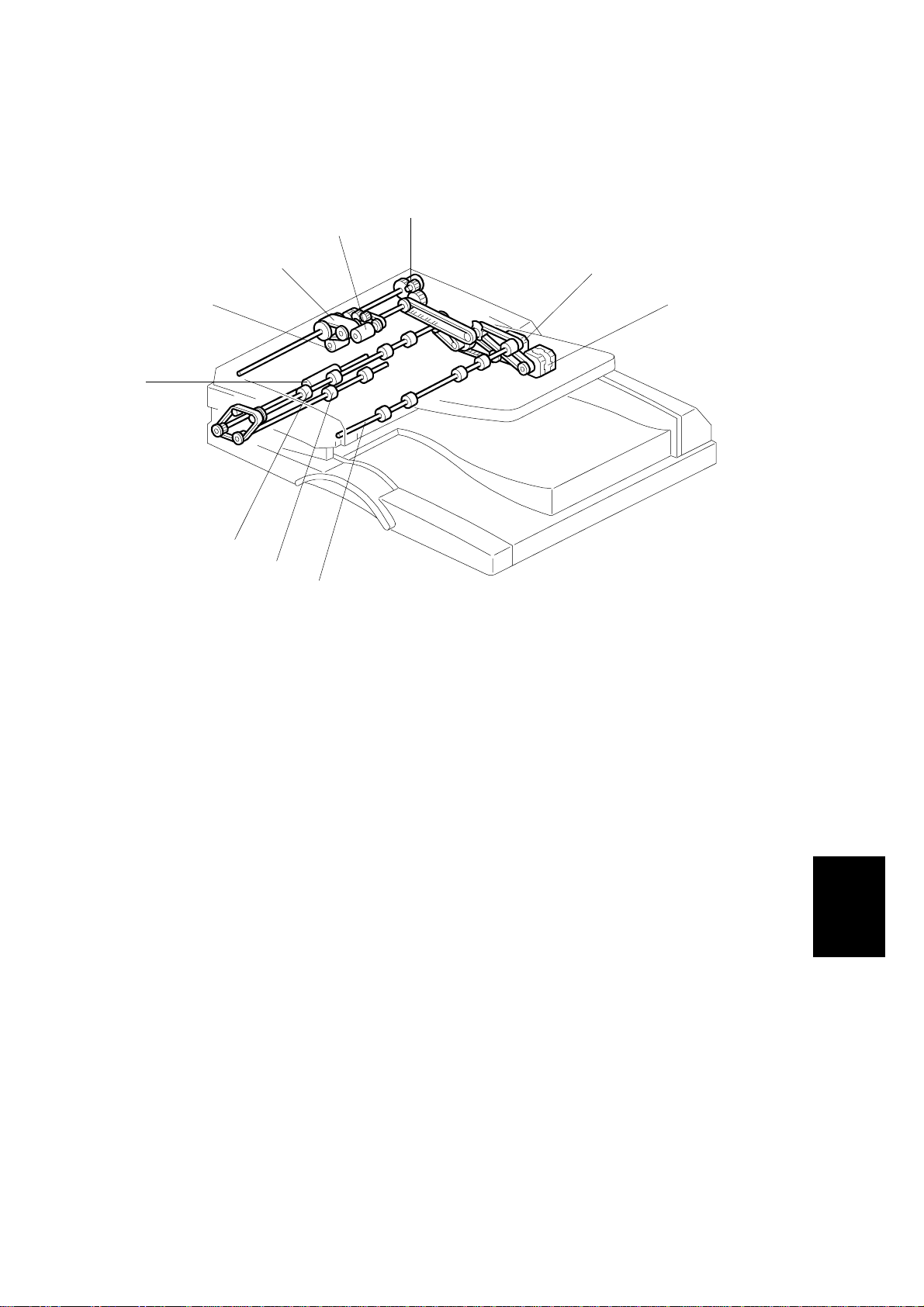

20 February, 2001 DRIVE LAYOUT

1.3 DRIVE LAYOUT

4

3

1

10

9

1. Separation Roller

2. Original Feed Belt

3. Pick-up Roller

4. DF Feed Clutch

5. DF Transport Motor

2

5

6

8

7

B379D203.WMF

6. DF Feed Motor

7. Reverse Table Roller

8. 2nd Transport Roller

9. Exit Roller

10. 1st Transport Roller

B379-3

Peripherals

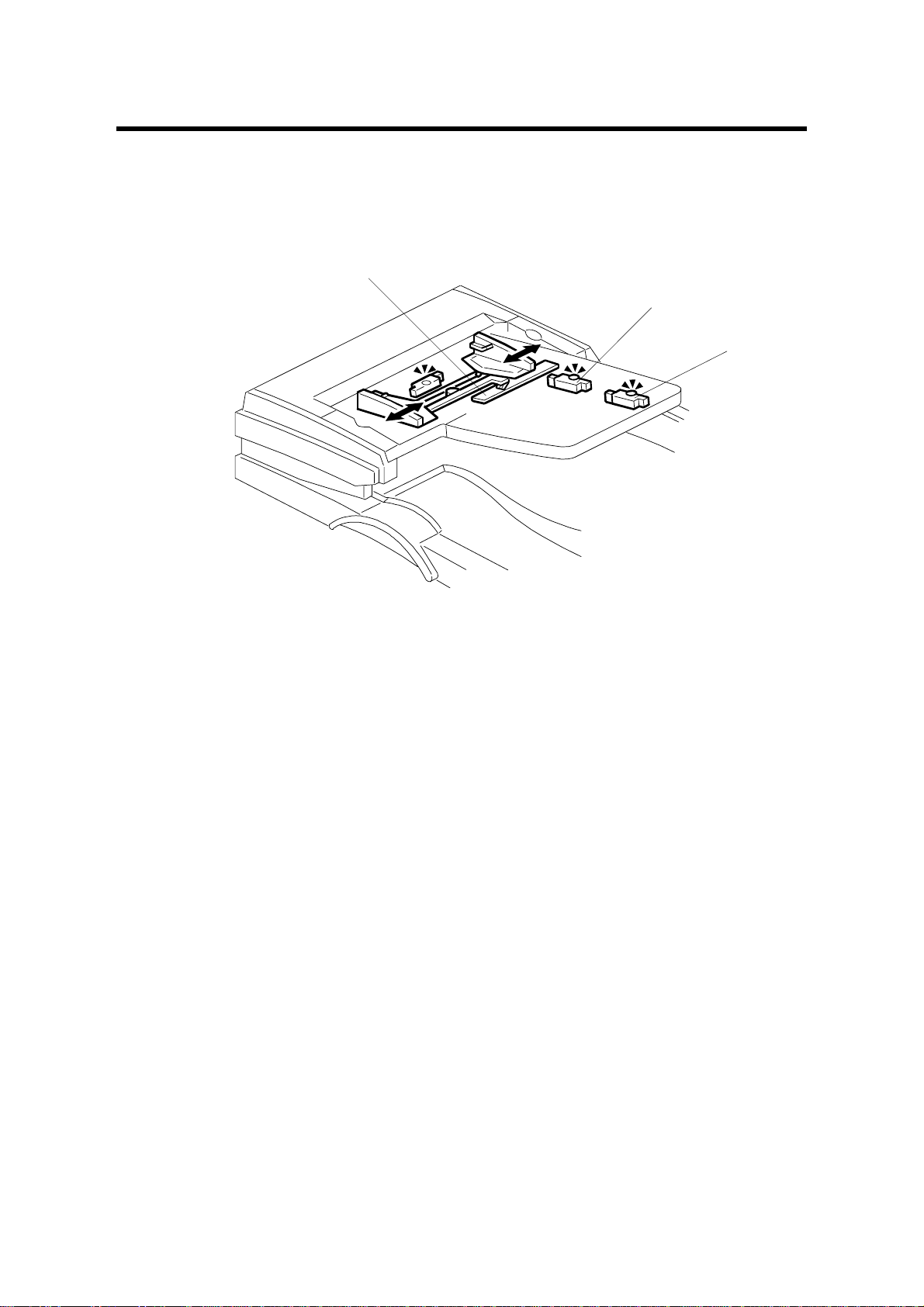

ORIGINAL SIZE DETECTION 20 February, 2001

2. DETAILED SECTION DESCRIPTIONS

2.1 ORIGINAL SIZE DETECTION

[A]

[B]

[C]

B379D503.WMF

The original size detection mechanism consists of the original width sensor board

[A] and two original length sensors-1 [B] and -2 [C]. Based on the combined output

of the length sensors and the width sensor board, the machine can detect the size

of the original. This integrated detection mechanism is detailed in the table on the

next page.

Note that the width sensor’s terminal plate is attached to the original guide, so the

widths of the originals must all be the same.

B379-4

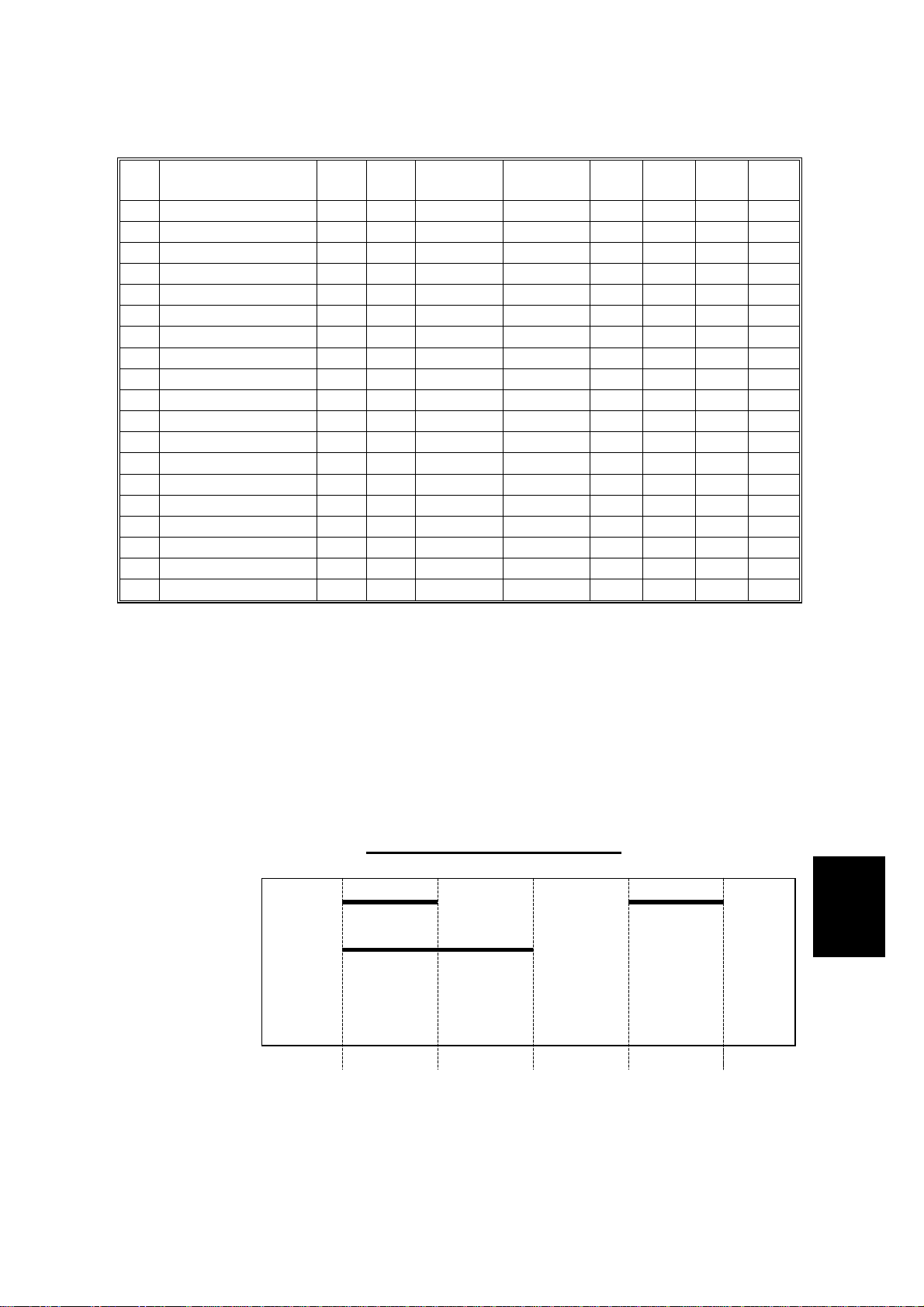

20 February, 2001 ORIGINAL SIZE DETECTION

1 A3 (297 x 420)

2 B4 (257 x 364)

3 A4 SEF (210 x 297)

4 A4 LEF (297 x 210)

5 B5 SEF (182 x 257)

6 B5 LEF (257 x 182)

7 A5 SEF (148 x 210)

8 A5 LEF (210 x 148)

9 11" x 17"

10 11" x 15"

11 10" x 14"

1/2

12 8

13 8

1/2

" x 14"

" x 13"

14 8" x 13"

1/2

15 8

16 11" x 8

" x 11" SEF

1/2

" LEF

17 8" x 10" SEF

18 5

19 8

1/2

1/2

" x 8

" x 5

1/2

1/2

" SEF

" LEF

NA EU

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

1 ✗

❍

1

#

✗

❍✗

2 ✗

❍

#

4

4

✗❍

2

#

❍

3 ✗

❍✗

3

#

✗

❍✗

❍✗

Original

Length 1

ON ON - - - ON

ON ON - - ON ON - - ON - -

-----ON

ON - ON - - -

----ON-

--ON---

---ON-ON ON - - - ON

ON ON - - - ON

ON ON - - ON ON ON - ON - ON ON - ON - ON ON - ON - ON - - ON - -

-----ON

ON - - ON - -

--ON---

---ON--

Original

Length 2

P1 P2 P3 P4

NA: America (North, Middle, South) EU: Europe, Asia, China, Taiwan

✗: No ❍: Yes ON: Paper present

❍1, #1: In NA, original size 11" x 15" is detected as 11" x 17"

❍2, #2: In NA, original size 8" x 13" is detected as 8

❍3, #3: In NA, original size 8" x 10" is detected as 8

❍4, #4: In EU, original size 8" x 13" is detected as 8

1/2

1/2

1/2

" x 14"

" x 11"

" x 13"

Original Width Sensor Board

Original Width 1

Original Width 2

Original Side

Guide Position

B5SEF/

A5SEF

A4SEF/

A5LEF

B4/B5LEF A3/A4LEF

Peripherals

P4P3P2P1

B379D501.WMF

B379-5

PICK-UP AND SEPARATION 20 February, 2001

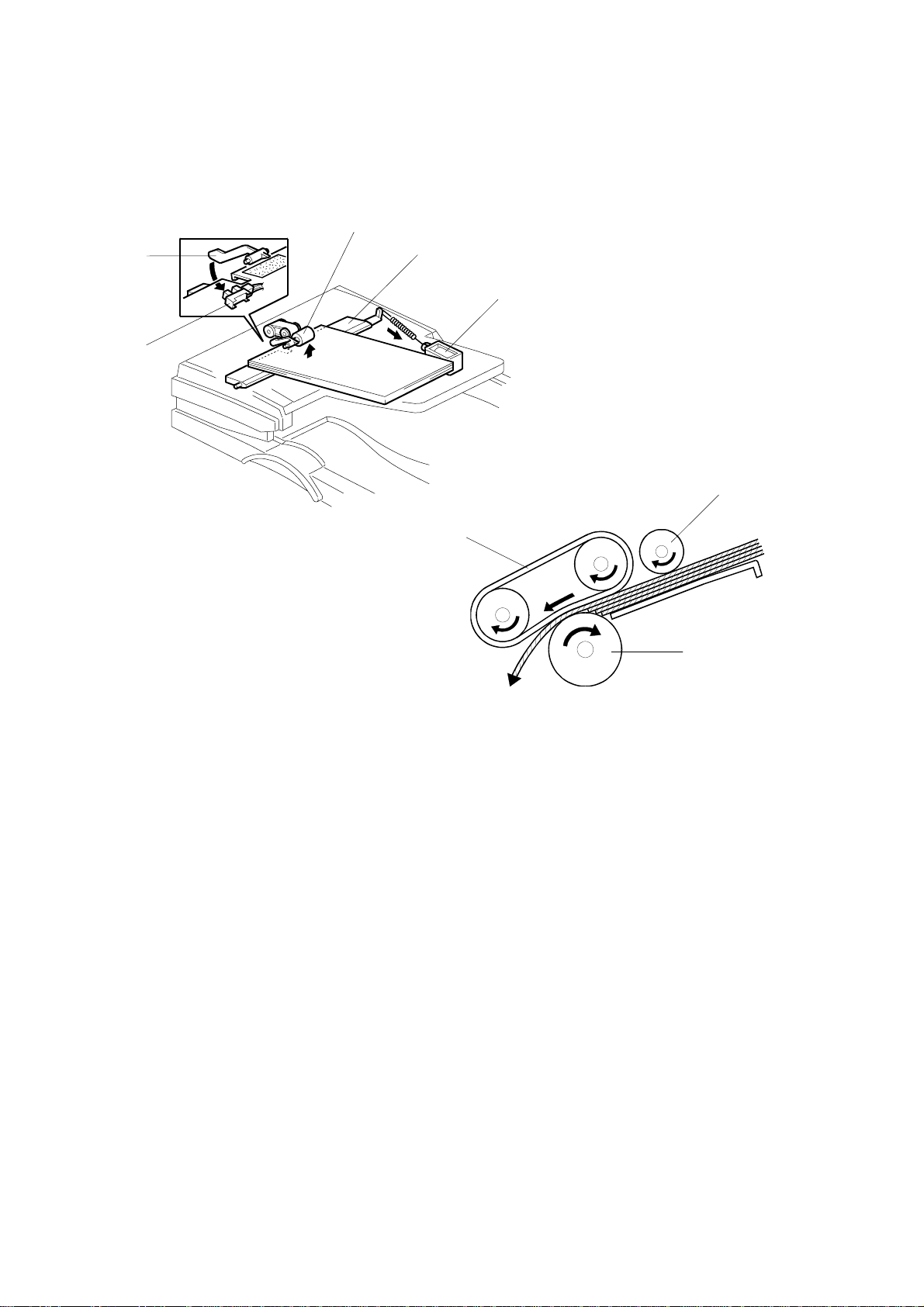

2.2 PICK-UP AND SEPARATION

[B]

[A]

[E]

B379D504.WMF

[C]

[D]

[B]

[F]

[G]

B379D505.WMF

The original is set with the image facing up. The original pushes actuator [A] and

the original set sensor [E] is activated.

After pressing the start button, the pick-up solenoid [D] is activated and the lift plate

[C] lifts the original up until it comes in contact with the pick-up roller [B]. The pickup roller then feeds the top sheet of paper.

After being fed from the pick-up roller, the topmost sheet is separated from the

stack by the separation roller and sent to the first transport roller.

The mechanism is an FRR system, consisting of the original feed belt [F] and

separation roller [G].

B379-6

20 February, 2001 ORIGINAL TRANSPORT AND EXIT

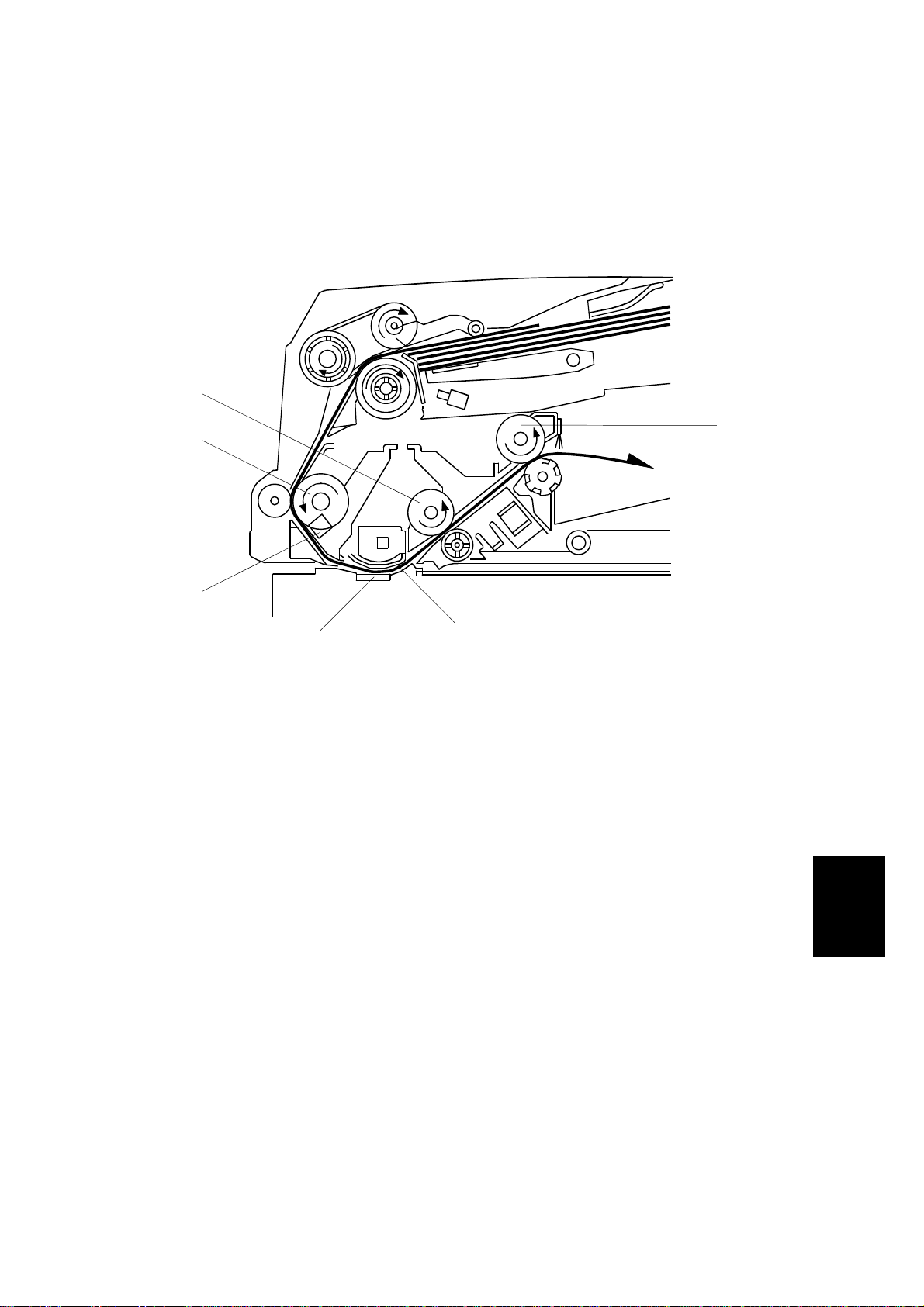

2.3 ORIGINAL TRANSPORT AND EXIT

2.3.1 SINGLE-SIDED ORIGINALS

[E]

[A]

[F]

[B]

[C]

[D]

B379D506.WMF

The DF feed motor feeds the separated original to the first transport roller [A] at

maximum speed. When the registration sensor [B] detects the leading edge, the

motor stops for a short while. Then the feed and transport motors turn on again,

and feed the original through the scanning area at a lower speed (the scanning

area contains the original exposure guide [D] and DF exposure glass [C]). After

scanning, the original is fed out by the second transport roller [E] and exit roller [F].

B379-7

Peripherals

ORIGINAL TRANSPORT AND EXIT 20 February, 2001

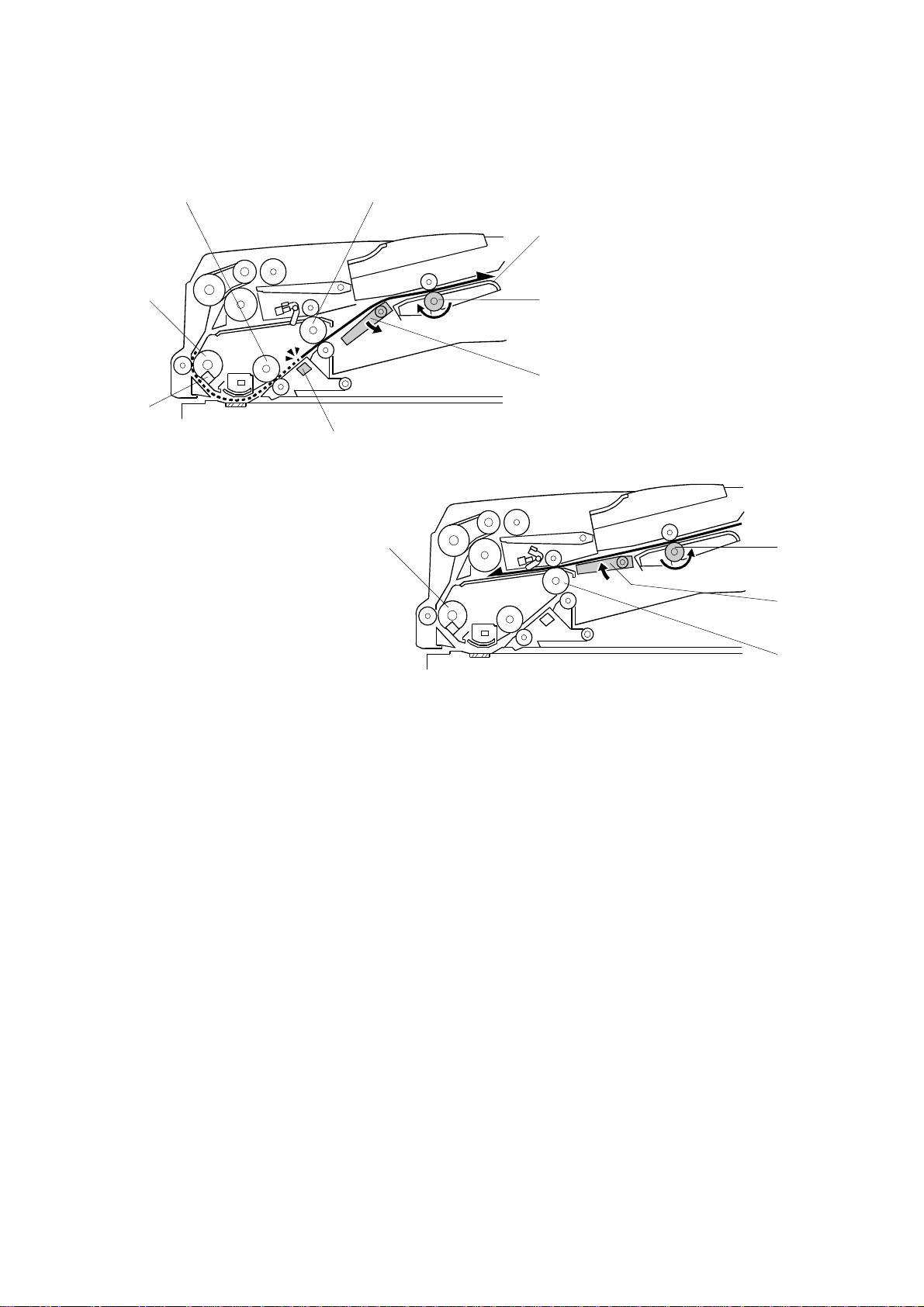

2.3.2 DOUBLE-SIDED ORIGINALS

[A]

[B]

[G]

B379D204.WMF

[C]

[F]

[A]

[H]

[E]

[D]

[E]

[D]

[F]

A858D205.WMF

When the re gistration senso r [B] detects the leading edge of t he original, the DF

feed motor (which drives the feed roller) and transport motor (which drives the

transport roller) both switch off. After a brief interval, the transport motor alone

reactivates to drive the first transport roller [A] and second transport roller [G] and

the exit roller [F]. The front side of the original is then scanned.

When the original exit sensor [C] detects the leading edge of the original, the

junction gate solenoid is activated and the junction gate [D] opens. The original is

then transported towards the reverse table [H].

Soon after the trailing edge of the original passes the exit sensor [C], the junction

gate solenoid switches off and the junction gate [D] is closed. When the original

has been fed onto the reverse table, the DF feed motor switches on in reverse. The

original is then fed by the reverse roller [E] and then by the exit roller [F] and first

transport roller [A] to the scanning area (where the reverse side will be scanned).

B379-8

Loading...

Loading...