Page 1

AUTO REVERSE DOCUMENT

FEEDER (A661)

Page 2

30 November 1996 OVERALL MACHINE I NFO R M ATI O N

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Original Size: Standard Size

Single-sided Mode: A3 to A5, DLT to HLT

Double-sided Mode: A3 to A4, DLT to LT

Non-standard Size (Single-sided Mode only)

Max. width 297 mm

Min. width 105 mm

Max. length 1260 mm

Min. length 128 mm

Original Weight : 45 kg to 90 kg

Table Capacity : 30 sheets (70 kg)

Original Standard Position: Rear left corner

Separation: FRR

Original Transport: Roller transport

Original Feed Order: From the top original

Reproduction Range: 37 to 150%

Power Source: 24 & 5 Vdc from the copier

Power Consumption: 50 W

Dimensions (W x D x H): 550 x 470 x 130 mm

Weight: 11 kg

A661-1

Options

Page 3

OVERALL MACHINE INFORMATION 30 November 1996

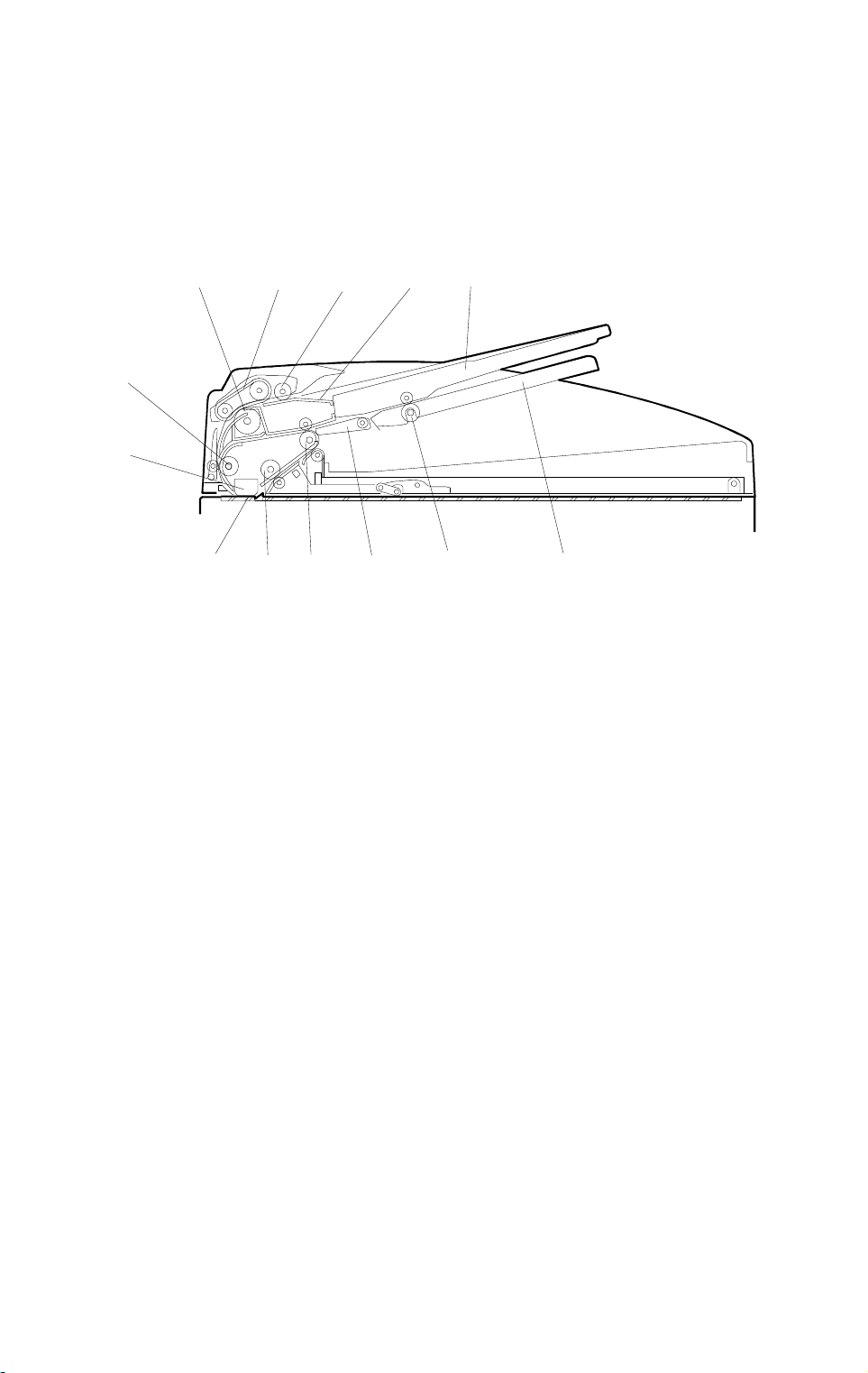

1.2 MECHANICAL COMPONENT LAYOUT

1

13

12

11

1. Separation Roller

2. Paper Feed Belt

2

3

910

4

8

5

7

6

A661V500.wmf

8. Junction Gate

9. Original Exit Roller

3. Pick-up Roller

4. Original Entrance Guide

5. Original Table

6. Reverse Table

7. Reverse Roller

10. 2nd Transport Roller

11. DF Exposure Glass

12. Original Exposure Guide

13. 1st Transport Roller

A661-2

Page 4

30 November 1996 OVERALL MACHINE I NFO R M ATI O N

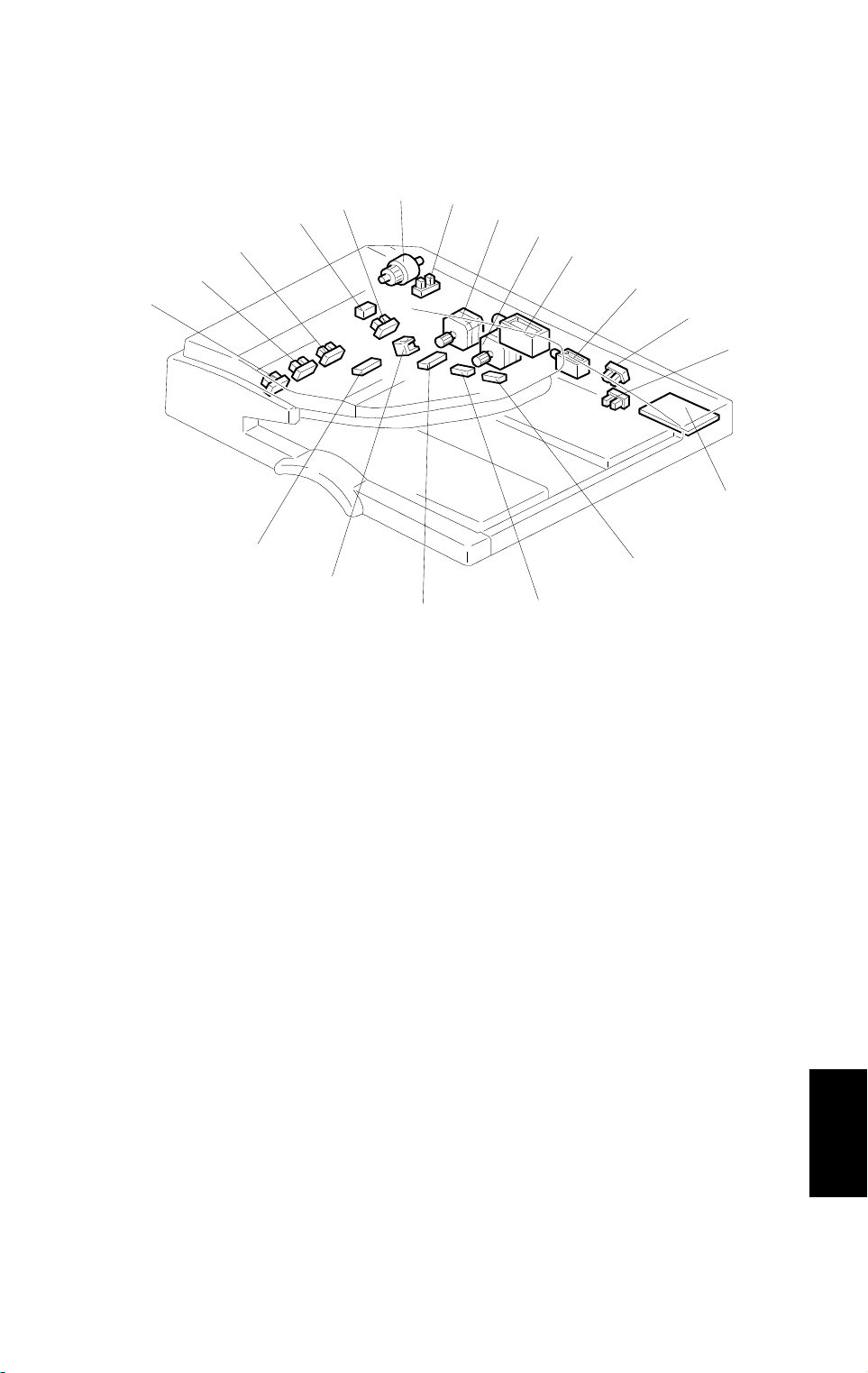

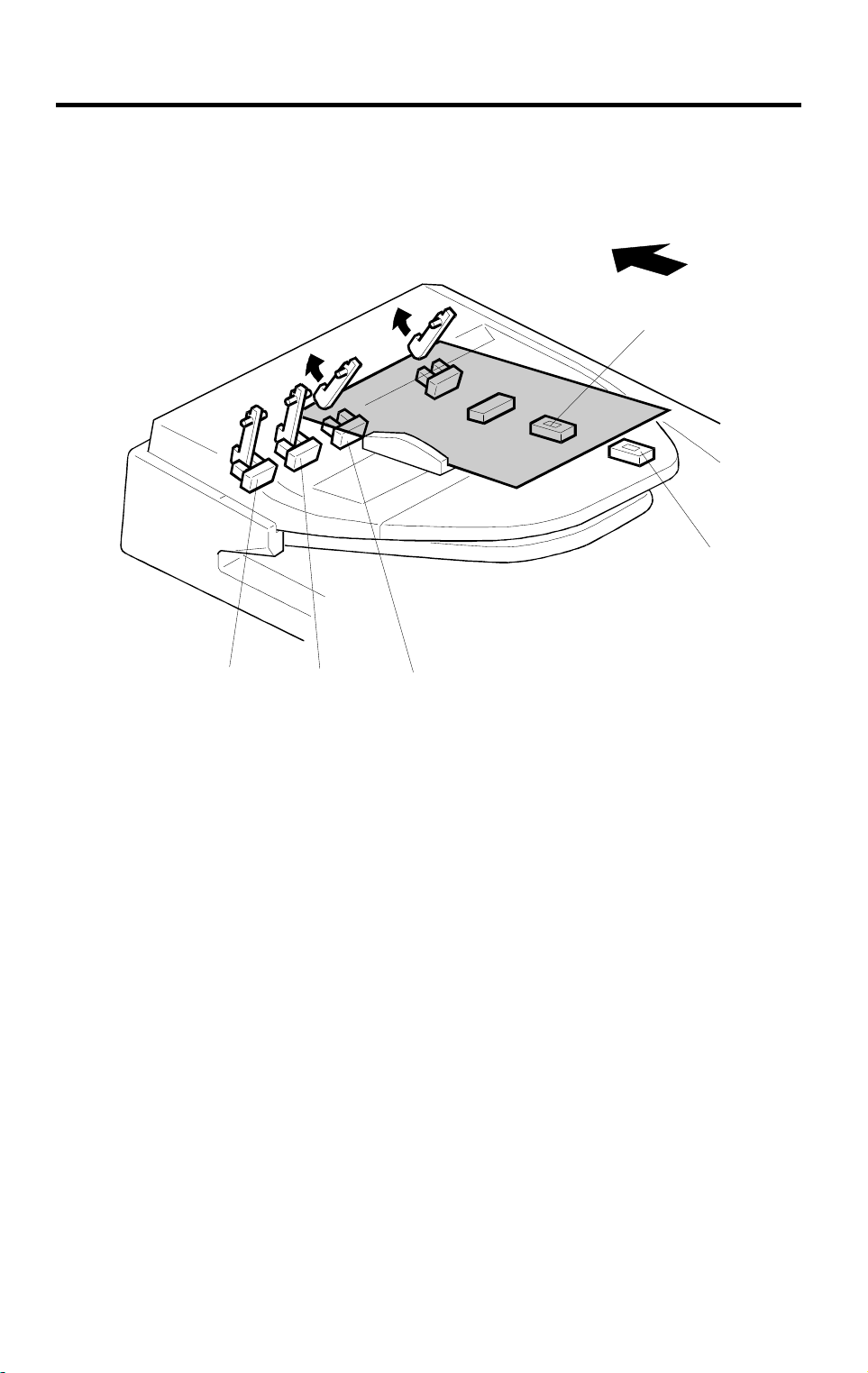

1.3 ELECTRICAL COMPONENT LAYOUT

1

18

19

17

16

15

2

3

4

5

6

7

8

9

14

13

1. DF Feed Clutch

2. Feed Cover Open Sensor

3. DF Transport Motor

4. DF Feed Motor

5. DF Pick-up Solenoid

6. Junction Gate Solenoid

7. DF Position Sensor

8. APS Start Sensor

9. DF Drive PCB

10. Original Length Sensor 2

10

12

11

A661V501.wmf

11. Original Length Sensor 1

12. Reverse Table Sensor

13. Stamper Solenoid

14. Original Exit Sensor

15. Original Width Sensor 3

16. Original Width Sensor 2

17. Original Width Sensor 1

18. Original Set Sensor

19. Registration Sensor

A661-3

Options

Page 5

OVERALL MACHINE INFORMATION 30 November 1996

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index

No.

Motors

M1 DF Feed Drives the feed bel t , separation, pic k- up, and

reverse table rollers.

M2 DF Transport Drives the transport and exit roll ers 3

Sensors

S1 APS Start Informs the CPU when the DF is opened and

closed (for platen mode) so that ori gi nal size

sensors in the copi er can check the ori gi nal size.

S2 DF Position Detects whether the DF is lifted or not. 7

S3 Registration Detects the leadi ng edge of the original to turn off

the DF feed and tran sport motors, det ect s t h e

original exposure timing, and checks for orig i nal

misfeeds.

S4 Feed Cover Open

Sensor

S5 Original Wi dt h - 1 Detects the original width. 17

S6 Original Wi dt h - 2 Detects the original width. 16

S7 Original Wi dt h - 3 Detects the original width. 15

S8 Original Lengt h - 1 Detects the original length. 11

S9 Original Lengt h - 2 Detects the original length. 10

S10 Original Set Detects if an origi nal is on the feed tabl e. 18

S11 Original Exit Detects the leading edge of the original to turn on

S12 Reverse Table Detects the trail i ng edge of the original to turn on

Solenoids

SOL1 DF Pick-up Controls the up-down movement of the origina l

SOL2 Stamper Energizes the stamper to mark the origin al . 13

SOL3 Junction Gate Opens and close s the junction gate. 6

Clutches

MC1 DF Feed Transfers trans por t motor drive to the pick-up

PCBs

PCB1 DF D rive Interfac es the sensor signal s with the copier, and

Detects whether the feed-in cov er is o pened or

not.

the junction gate solenoid and checks for original

misfeeds.

Detects the trail i ng edge of the original to turn off

the transport and feed motor and jun ct i on gate

solenoid.

the DF feed clutc h fo r next original an d checks

for original m i sf eeds.

table.

roller and feed belt.

transfers the magnetic clutch, solenoid and motor

drive signals from the copier.

4

8

19

2

14

12

5

1

9

A661-4

Page 6

30 November 1996 OVERALL MACHINE I NFO R M ATI O N

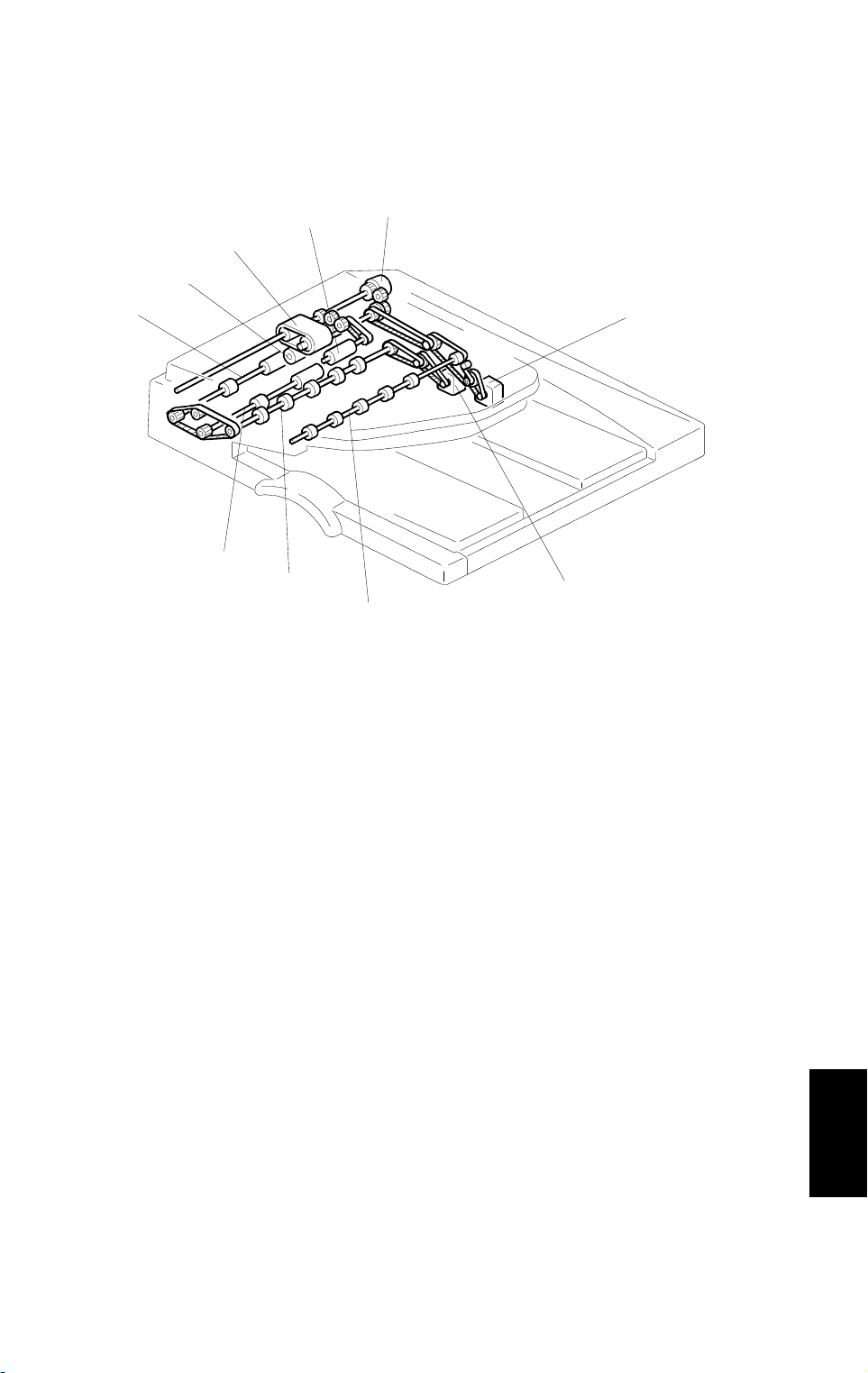

1.5 DRIVE LAYOUT

10

1

9

8

7

2

6

5

3

4

A661V502.wmf

1. DF Feed Clutch

2. DF Feed Motor

3. DF Transport Motor

4. Reverse Table Roller

5. Exit Roller

6. 2nd Transport Roller

7. 1st Transport Roller

8. Separation Roller

9. Original Feed Belt

10. Pick-up Roller

Options

A661-5

Page 7

DETAILED DESCRIPTIONS 30 November 1996

2. DETAILED DESCRIPTIONS

2.1 ORIGINAL SIZE DETECTION

[D]

[E]

A661D500.wmf

[C]

[B] [A]

The DF has three width sensors (- 1 [A], - 2 [B], and - 3[C]) to detect the

original width and two original length sensors (-1 [D] and -2 [E]) to detect the

original length. The DF detects the original size through the combination of

those five sensors as shown in the table on the next page.

When using an original of a non-standard size, the user needs to input the

original length at the operation panel.

A661-6

Page 8

30 November 1996 DETAILED DESCRIPTIONS

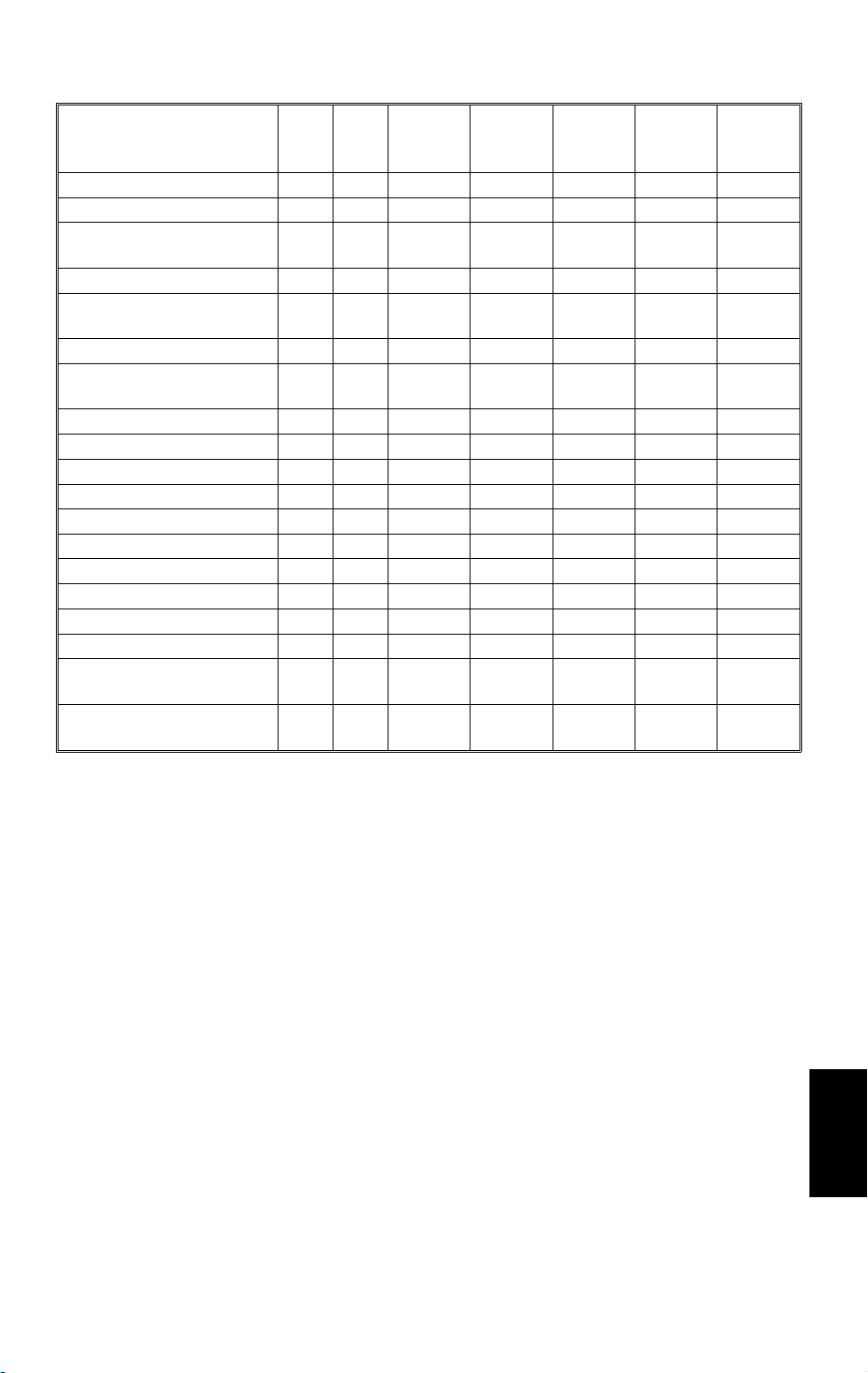

A3 (297 x 420)

B4 (257 x 364)

A4 (Lengthwise)

(210 x 297)

A4 (297 x 210) (Si dew ays)

B5 (182 x 257)

(Lengthwis e)

B5 (257 x 182) (Si dew ays)

A5 (148 x 210)

(Lengthwis e)

A5 (210 x 148) (Si dew ays)

11" x 17" (DLT)

11" x 15"

10" x 14"

8.5" x 14" (LG)

8.5" x 13" (F4)

8" x 13" (F)

8.5" x 11" (Lengt hwi se)

8.5" x 11" (Sideways)

10" x 8" (Lengthwi se)

5.5" x 8.5" (Len gt hw ise)

(HLT)

5.5" x 8.5" (Sidew ays)

(HLT)

NA EU Original

Width-1

✗❍

✗❍

✗❍

✗❍

✗❍

✗❍

✗✗

✗❍

❍✗

❍✗

❍✗

❍✗

✗❍

❍❍

❍✗

❍✗

❍✗

❍✗

❍✗

ON ON ON ON ON

ON ON – ON ON

ON – – ON –

ON ON ON – –

–––ON–

ON ON – – –

–––––

ON––––

ON ON ON ON ON

ON ON ON ON ON

ON ON – ON ON

ON – – ON ON

ON – – ON ON

ON – – ON ON

ON – – ON –

ON ON ON – –

ON – – ON –

–––––

ON––––

Original

Width-2

Original

Width-3

Original

Length-1

Original

Length-2

Key

✗: No, ❍: Yes

ON: Paper present

Options

A661-7

Page 9

DETAILED DESCRIPTIONS 30 November 1996

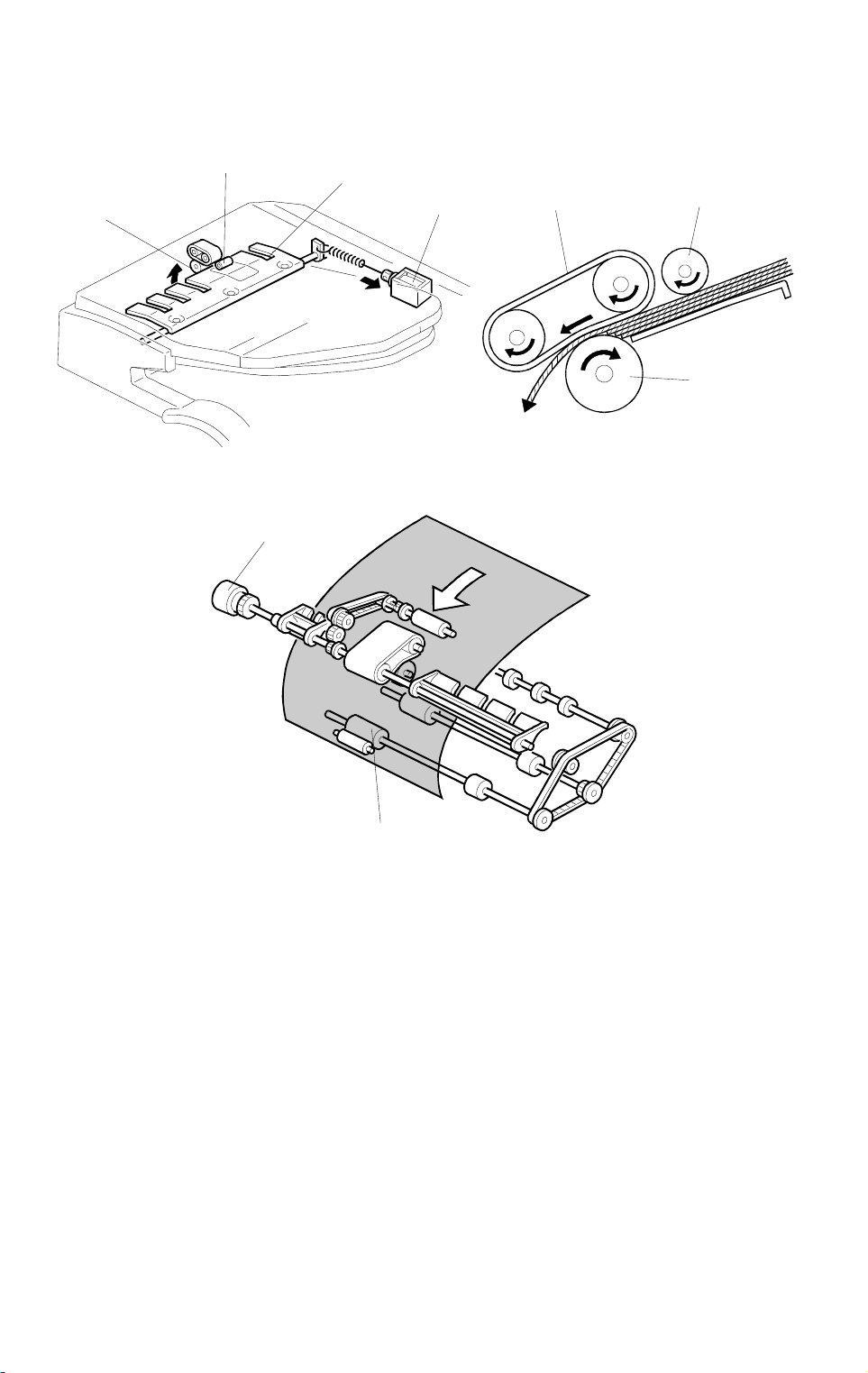

2.2 PICK-OFF AND SEPARATION MECHANISM

[F]

[B]

[D]

[C]

A661D502.wmf

[A]

[E]

[B]

[F]

A661R515.wmf

[G]

A661D501.wmf

When the print key is pressed, the DF pick-up solenoid [A] turns on and the

originals are lifted up to the pick-up roller [B] by the entrance guide [C]. At the

same time, the DF feed clutch [D] turns on.

At 200 ms after this, the DF feed motor turns on. The original is fed to the

paper feed belt [E] from the top page. The pages are separated by the

separation roller [F] and the top sheet of the original is fed to the 1st transport

roller [G]. The original separation system uses the FRR system.

A661-8

Page 10

30 November 1996 DETAILED DESCRIPTIONS

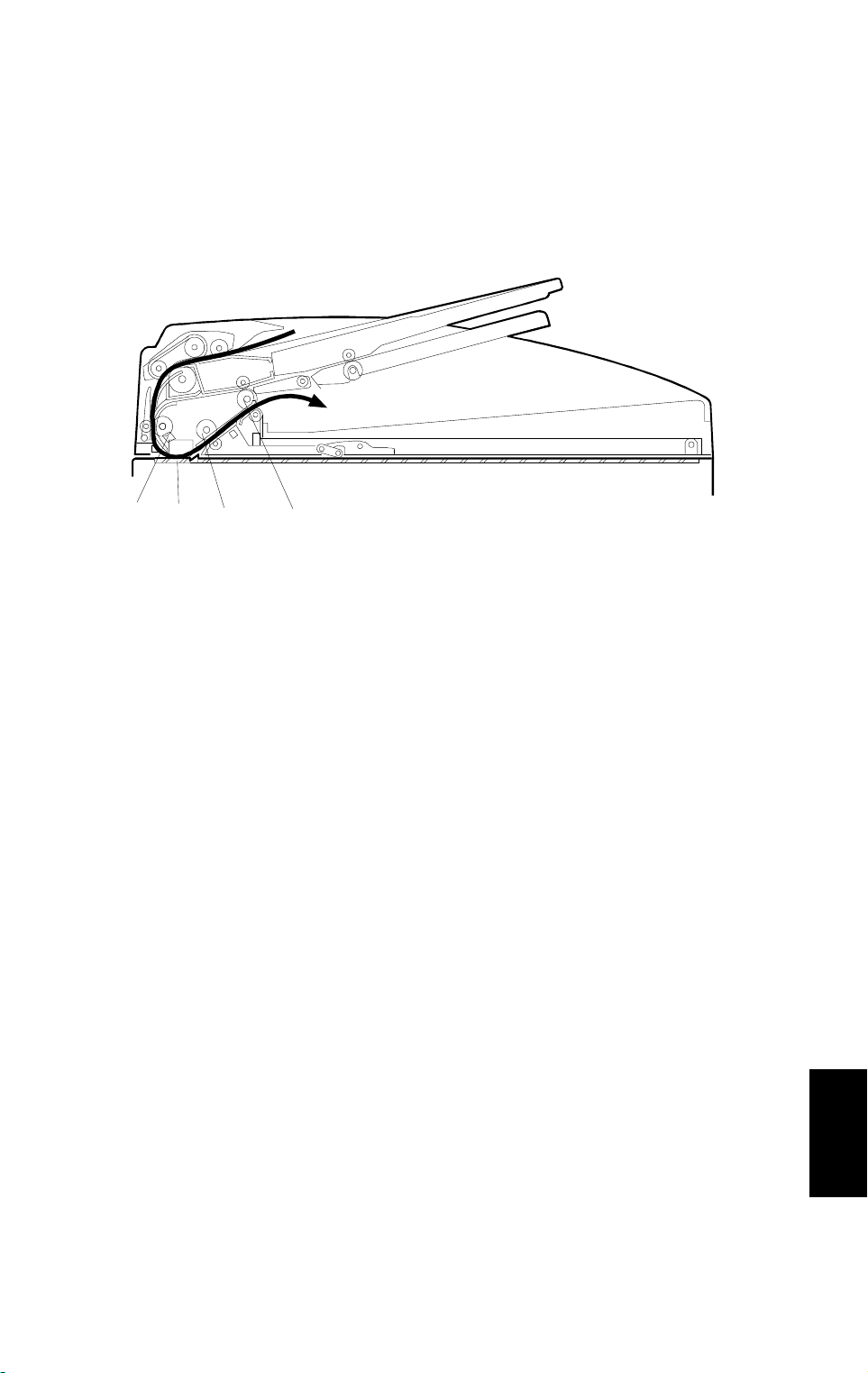

2.3 ORIGINAL TRANSPORT AND EXIT MECHANISM

2.3.1 Single-sided Original

[A]

[B]

[C]

[D]

A661D503.wmf

When the leading edge of the original reaches the registration sensor [A], the

DF feed and transport motors turn off. After a short time the DF feed and

transport motors turn on again. The original is fed to the DF exposure glass

[B] and it is scanned in this area.

The original is fed through to the 2nd transport roller [C] and fed out by the

exit roller [D].

The DF feed motor speed while feeding the original to the registration sensor

is 59.4 mm/s. However, when the motor turns on again to feed the original to

the exposure glass, the speed depends on the selected reproduction ratio. At

100%, it is 90 mm/s.

Options

A661-9

Page 11

DETAILED DESCRIPTIONS 30 November 1996

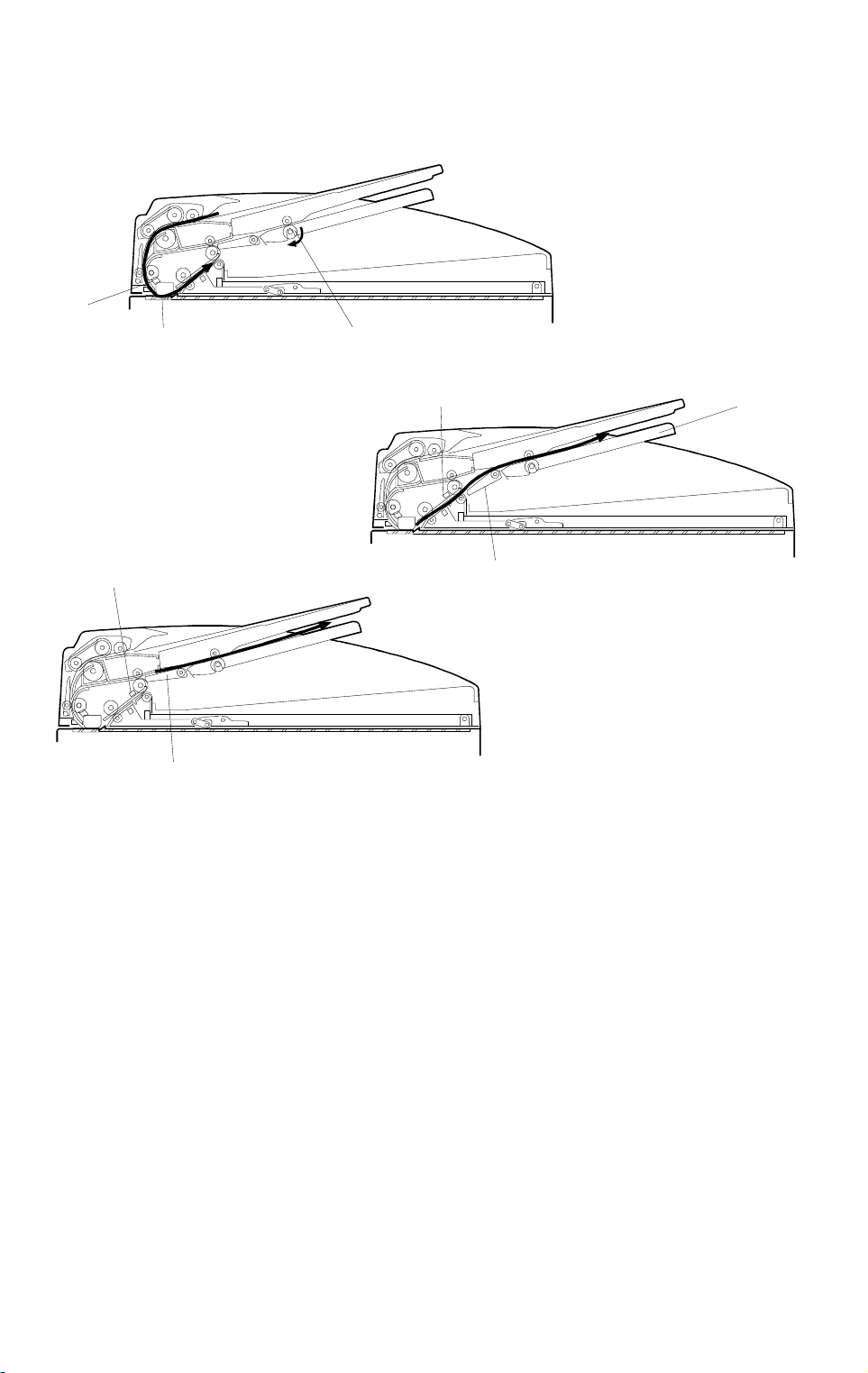

2.3.2 Double-sided Original

[A]

[B][C]

[D]

A661D516.wmf

[D]

[C]

[F]

A661D517.wmf

[E]

A661D518.wmf

1. When the leading edge of the original reaches the registration sensor [A]

the DF feed and transport motors turn off. After a short time, the DF feed

motor turns on and the DF transport motor turns on in reverse to drive the

reverse table roller [B]. The original is fed to the DF exposure glass [C]

and it is scanned in this area.

2. When the leading edge of the original reaches the exit sensor [D], the

junction gate solenoid turns on and the junction gate [E] is opened. The

original is transported to the reverse table [F] to reverse the original.

3. 33 mm after the trailing edge of the original reaches the exit sensor [D],

the junction gate solenoid turns off and the junction gate [E] closes. At the

same time, the DF feed and transport motors turn off.

A661-10

Page 12

30 November 1996 DETAILED DESCRIPTIONS

[A]

A661D519.wmf

A661D520.wmf

4. After a short time, both motors turn on in the same direction and the

original is fed to the 1st transport roller [A].

5. The original is fed and exposed in the same way as in steps 1, 2 and 3, to

copy the reverse side.

6. The original is fed out to the original exit tray.

A661-11

Options

Page 13

DETAILED DESCRIPTIONS 30 November 1996

2.4 STAMP

[C]

[A]

[B]

A661D504.wmf

This function is only for fax mode.

There is a stamp [A] between the 2nd transport roller [B] and the exit roller

[C], and its solenoid is controlled by the copier directly.

When the original reaches the stamp position, the DF feed motor stops. At

300 milliseconds after stopping the DF feed motor, the stamper solenoid

turns on if the page was sent successfully (immediate transmission) or stored

successfully (memory transmission). After stamping, the DF feed motor starts

again for feeding out the document, and its speed is about 1.3 times the

normal speed.

The stamping position on the original can be changed by adjusting SP6-010.

A661-12

Page 14

30 November 1996 DETAILED DESCRIPTIONS

2.5 TIMING CHARTS

2.5.1 LT Sideways (Single-sided Original Mode)

Feed Motor

Transport Motor

DF

Pick-up Solenoid

DF Feed Clutch

Original Set

Sensor

Registration

Sensor

Original Exit

Sensor

Reverse Table

Sensor

F Gate

Junction Gate

Solenoid

200ms

JAM 1

JAM 3,4

JAM5,6

700ms

Jam conditions: Refer to Sectio n 2. 6 for details

.

F Gate: This signal goes high whe n the laser starts to wr i t e a page to the drum.

A661-13

A661D505.wmf

Options

Page 15

DETAILED DESCRIPTIONS 30 November 1996

2.5.2 LT Sideways-Stamper Mode (Single-sided Original Mode)

Feed Motor

Transport Motor

DF Feed Clutch

DF

Pick-up Solenoid

Original Set

Sensor

Registration

Sensor

Original Exit

Sensor

Reverse Table

Sensor

F Gate

Junction Gate

Solenoid

Stamper Solenoid

200ms

JAM 1

JAM 3,4

JAM5,6

300ms

100ms

700ms

420ms

300ms 100ms 300ms

A661D506.wmf

Jam conditions: Refer to Sectio n 2. 6 for details

.

F Gate: This signal goes high whe n the laser starts to wr i t e a page to the drum.

A661-14

Page 16

30 November 1996 DETAILED DESCRIPTIONS

2.5.3 LT Sideways (Double-sided Original Mode)

260ms

580ms

JAM 2,7

JAM 8

370ms 370ms

JAM5,6

JAM 3,4

JAM 1

200ms

Original Exit

Feed Motor

Transport Motor

DF Feed Clutch

DF

Pick-up Solenoid

Original Set

Jam conditions: Refer to Sectio n 2. 6 for details

Sensor

.

Registration

Sensor

Sensor

Sensor

F Gate

Reverse Table

Junction Gate

Solenoid

F Gate: This signal goes high whe n the laser starts to wr i t e a page to the drum.

Stamper Solenoid

A661D507.wmf

Options

A661-15

Page 17

DETAILED DESCRIPTIONS 30 November 1996

2.5.4 LT Sideways-Stamper Mode (Double-sid ed Original Mo de)

260ms

580ms

JAM 2,7

JAM 8

JAM 1

200ms

Feed Motor

Transport Motor

DF Feed Clutch

DF

Pick-up Solenoid

Original Set

Sensor

Jam condition s: Refer to Section 2.6 for details

JAM 3,4

Registration

Sensor

.

JAM5,6

Original Exit

Sensor

370ms

Reverse Table

Sensor

420ms

F Gate

Junction Gate

Solenoid

F Gate: This sig nal goes high when the laser starts to write a page to the drum.

100ms

300ms

Stamper Solenoid

A661D508.wmf

A661-16

Page 18

30 November 1996 DETAILED DESCRIPTIONS

2.6 JAM DETECTION

JAM 1:

JAM 2:

JAM 3:

JAM 4:

JAM 5:

JAM 6:

If the registration sensor does not turn on before the CPU judges that

the original was fed 255 mm since the DF feed motor turned on,

when the original was fed from the original tray.

If the registration sensor does not turn on before the CPU judges that

the original was fed 190 mm since the DF feed motor turned on,

when the original was fed from the reverse tray.

If the registration sensor does not turn off before the CPU judges that

the original was fed X1 mm since the registration sensor turned on.

Standard sizes : X1 = Original Size x 1.4

Non-standard sizes : X1 = 1765

If the original exit sensor does not turn on before the CPU judges

that the original was fed 140 mm since the registration sensor turned

on.

If the original exit sensor does not turn off before the CPU judges

that the original was fed X1 mm since the original exit sensor turned

on.

If the reverse table sensor does not turn on before the CPU judges

that the original was fed 180 mm since the original exit sensor turned

on.

JAM 7:

JAM 8:

If the reverse table sensor does not turn off before the CPU judges

that the original was fed X2 mm since the DF feed motor turned on

again.

X2 = Original Size x 1.4

If the reverse table sensor is off when the DF feed motor turns on

again.

Options

A661-17

Page 19

DETAILED DESCRIPTIONS 30 November 1996

2.7 OVERALL ELECTRICAL CIRCUIT

Copier IOCSS

Board

DF Drive Board

Driver

DF Connection

5 V

DF Feed/

Transport

Motor

M

Sensors

Clutch

and

Solenoids

A661D509.wmf

The DF pick-up solenoid, junction gate solenoid, stamper solenoid, and DF

feed clutch are directly controlled by the copier through the DF drive board.

The sensor signals are directly sent to the copier through the DF drive board.

The DF drive board has a driver for the DF feed and transport motors and

thier drive signals are sent from the copier.

When the DF connector is connected to the copier IOCSS board, the DF

connection signal to the copier goes to 5 V. Then the copier detects that the

ARDF is connected.

A661-18

Page 20

30 November 1996 INSTALLATION

3. INSTALLATION

[A]

[B]

[F]

A661I500.wmf

[E]

[C]

[H]

[G]

A661I501.wmf

[D]

[I]

[J]

[I]

A661I504.wmf

CAUTION

+

Unplug the copier power cord before starting the following procedure.

NOTE:

When installing the DF, use the tool [A] in the accessory bag or a

usual screw driver.

1. Unplug the document feeder. Then, remove all tapes.

2. Remove the left scale [B] (2 screws).

3. Place the DF exposure glass [C] on the glass holder. The white mark [D]

must be at the rear side facing down.

4. Peel off the backing [E] of the dou ble side ta pe a ttached to the rear si de of

the scale guide [F], the n instal l the sca le guide (2 scr ews remove d in step 2).

5. Affix the original size decal [G] on the scale guide.

NOTE:

Place the decal along the rear edge, and the left side flush with

the scale paper guide [H], as shown.

6. Install stud screws [I] and grounding plate [J] for the DF on the copier.

Options

A661-19

Page 21

INSTALLATION 30 November 1996

[A]

[B]

A661I502.wmf

[D]

[C]

A661I503.wmf

7. Install the DF unit [A].

8. Slide the DF to the left, then secure the DF unit with 2 screws (M4 x 10).

9. Connect the I/F harness [B] to the copier.

10. Affix the original direction decal [C] on the DF table as shown.

11. Affix the glass cleaning decal [D] on the DF cover as shown

if necessary

12. Turn the ac and main switches on. Then, check if the document feeder

works properly.

A661-20

.

Page 22

30 November 1996 PREVENTIVE MAINTENANCE

4. PREVENTIVE MAINTENANCE

EM 60K 120K 185K 240K NOTE

AUTO REVERSE DOCUMENT FEEDER

Transport Belt C R R R R Al cohol

Separation Roller C R R R R Alc ohol

Pick-up Roller C R R R R Alcohol

Stamper I Replace if ne cessary

White Plate C Alcohol

DF Exposure Glass C Alcohol

Platen Cover C Alcohol

(for originals)

A661-21

Options

Page 23

REPLACEMENT AND ADJUSTMENT 30 November 1996

5. REPLACEMENT AND ADJUSTMENT

5.1 ORIGINAL FEED UNIT REMOVAL

[A]

[B]

1. Open the DF feed cover.

2. Push the original feed unit to the front [A].

3. Release the rear joint of the original feed unit [B].

4. Remove the original feed unit.

A628O015.wmf

A661-22

Page 24

30 November 1996 REPLACEMENT AND ADJUSTMENT

5.2 SEPARATION ROLLER REPLACEMENT

[B]

[A]

[D]

[C]

1. Remove the original feed unit.

2. Open the entrance guide [A].

3. Remove the support guide [B] (1 screw).

4. Remove the snap ring [C].

5. Replace the separation roller [D].

A661R501.wmf

Options

A661-23

Page 25

REPLACEMENT AND ADJUSTMENT 30 November 1996

5.3 PICK-UP ROLLER REPLACEMENT

[B]

[A]

[C]

[A]

1. Remove the original feed unit.

2. Remove the two snap rings [A].

3. Pull out the pick-up roller shaft [B].

4. Replace the pick-up roller [C].

A661R502.wmf

A661-24

Page 26

30 November 1996 REPLACEMENT AND ADJUSTMENT

5.4 FEED BELT REPLACEMENT

[A]

[C]

[B]

[C]

[D]

A661R503.wmf

[G]

[E]

[I]

[F]

A661R504.wmf

[H]

[I]

[G]

[J]

A661R505.wmf

1. Remove the original feed unit.

2. Remove the front bushing [A], spring [B], and washers [C] (1 E-ring).

3. Remove the original guide [D] (1 E-ring).

4. Remove the snap ring [E] and the pick-up roller unit [F].

5. Release the idle roller holder [G] from the drive roller shaft.

6. Remove the idle roller [H], idle roller holder [G], and 2 springs [I].

7. Replace the feed belt [J].

Options

A661-25

Page 27

REPLACEMENT AND ADJUSTMENT 30 November 1996

5.5 ORIGINAL SET SENSOR AND WIDTH SENSOR

REPLACEMENT

[A]

[C]

[D]

[E]

1. Open the DF feed cover.

2. Remove the entrance guide [A] (3 screws).

3. Replace the following sensors.

Original Set Sensor [B]

Original Width Sensor 1 [C]

Original Width Sensor 2 [D]

Original Width Sensor 3 [E]

[B]

A661R506.wmf

A661-26

Page 28

30 November 1996 REPLACEMENT AND ADJUSTMENT

5.6 DF COVER REMOVAL

[A]

1. Open the DF feed cover.

[C]

[D]

[B]

[E]

A661R507.wmf

2. Remove the front cover [A] (3 screws).

Remove the rear cover [B] (3 screws).

3. Remove the reverse table [D] (4 screws).

Remove the original table [C] (1 snap ring, 1 connector).

Remove the original exit table [E] (4 screws).

Options

A661-27

Page 29

REPLACEMENT AND ADJUSTMENT 30 November 1996

5.7 DF FEED COVER OPEN , DF POSITION, AND APS START

SENSOR REPLACEMENT

[B]

[C]

[A]

1. Remove the rear cover.

2. Replace the following sensors.

DF Feed Cover Open Sensor [A].

DF Position Sensor [B].

APS Start Sensor [C].

A661R508.wmf

A661-28

Page 30

30 November 1996 REPLACEMENT AND ADJUSTMENT

5.8 ORIGINAL LENGTH SENSOR REPLACEMENT

[D]

[A]

[B]

[C]

A661R509.wmf

1. Remove the original table.

2. Remove the original guide [A] (3 screws).

3. Replace the following sensors.

Original Length Sensor 1 [B]

Original Length Sensor 2 [C]

Reverse Table Sensor [D]

A661-29

Options

Page 31

REPLACEMENT AND ADJUSTMENT 30 November 1996

5.9 DF FEED CLUTCH, DF PICK-UP SOLENOID, AND

JUNCITON SOLENOID GATE REPLACEMENT

[C]

[B]

1. Remove the rear cover.

2. Replace the following clutch and solenoids.

DF Feed Clutch [A] (2 E-rings, 1 connector)

DF Pick-up Solenoid [B] (2 screws, 1 snap ring, 1 connector)

Junction Gate Solenoid [C] (2 screws, 1 snap ring, 1 connector)

[A]

A661R510.wmf

A661-30

Page 32

30 November 1996 REPLACEMENT AND ADJUSTMENT

5.10 REGISTRATION SENSOR REPLACEMENT

[D]

[F]

[E]

[G]

A661R511.wmf

[B]

[A]

[C]

1. Remove the front and rear cover.

2. Remove the original feed unit [A].

3. Remove the DF feed cover [B] (1 screw).

4. Remove the upper transport guide [C] (2 screws).

5. Remove the lower transport guide [D] (2 screws).

6. Remove the idle roller unit [E] (4 screws).

7. Remove the original exposure guide [F] (1 screw).

8. Replace the registration sensor [G] (1 screw, 1 connector).

A661R512.wmf

A661-31

Options

Page 33

REPLACEMENT AND ADJUSTMENT 30 November 1996

5.11 ORIGINAL EXIT SENSOR REPLACEMENT

[B]

[A]

[C]

[D]

A611R513.wmf

1. Remove the front and rear cover.

2. Release the lever [A] and open the original guide [B].

3. Remove the original exposure guide [C] (1 screw).

4. Remove the upper original guide [D] (4 screws, 1 connector).

5. Replace the original exit sensor from the upper original guide (1 screw, 1

connector).

A661-32

Page 34

30 November 1996 REPLACEMENT AND ADJUSTMENT

5.12 STAMPER SOLENOID REPLACEMENT

[B]

[C]

[A]

A661R514.wmf

1. Remove the front cover, rear cover, original table, reverse table, and

original exit tray.

2. Release the lever and open the original guide [A].

3. Remove the lower original guide [B] (2 screws).

4. Replace the stamper solenoid [C] (1 screws, 1 connector).

Options

A661-33

Loading...

Loading...